Copper-based ternary hydrotalcite thin film and preparation method thereof

A technology of hydrotalcite and film, which is applied in the direction of metal material coating process, coating, solid-state chemical plating, etc., can solve the problems of human hazards, environmental pollution, and not being effectively solved, and achieves not easy to fall off, high adhesion, Great adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

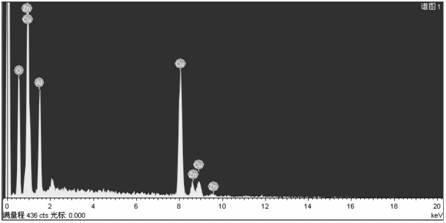

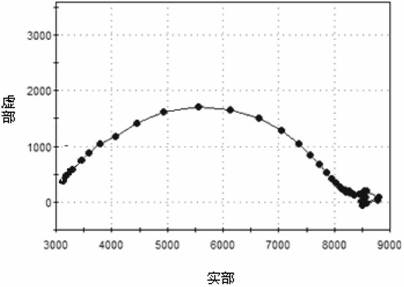

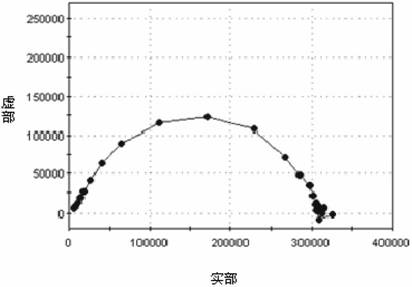

Image

Examples

Embodiment 1

[0035] A Cut copper sheets with a purity greater than 90% into 2*2cm pieces, soak them in ethanol and anhydrous sodium carbonate, then ultrasonically clean them with 1% hydrochloric acid, rinse them with deionized water, and dry them for later use.

[0036] B Add 64.76g of aluminum isopropoxide to 4L of dilute nitric acid solution with a concentration of 0.05mol / L, stir for 5-10min, heat rapidly to 80°C, reflux at constant temperature for about 6h, and form a translucent sol after cooling. The sol is centrifuged to remove the precipitate to obtain the boehmite sol.

[0037] C Weigh 11.769g of zinc nitrate, prepare 1L solution, and mix the same amount of zinc nitrate with boehmite sol. Adjust the pH value to about 7.0 with 0.1% ammonia water. Put it into the polytetrafluoroethylene reactor, put it into the treated copper sheet, put it in an oven at 60 ° C for 3 days, take out the reactor, cool it, take out the copper sheet, rinse it with deionized water and dry it. A copper-z...

Embodiment 2

[0039] A. With embodiment 1.

[0040] B Add 60g of aluminum isopropoxide to 4L of dilute nitric acid solution with a concentration of 0.05mol / L, stir for 5-10min, heat rapidly to 85°C and reflux for about 8h, and form a translucent sol after cooling. Centrifuge the sol to remove the precipitate to obtain the boehmite sol;

[0041] C Weigh 11.769g of zinc nitrate, prepare 1L solution, and mix the same amount of zinc nitrate with boehmite sol. Adjust the pH value to about 8.0 with 0.5% ammonia water. Put it into the polytetrafluoroethylene reactor, put the treated copper sheet into it, put it in an oven at 70°C for 3 days, take out the reactor, cool it, take out the copper sheet, wash it with deionized water and dry it, that is A copper-zinc-aluminum composite oxide film can be obtained on the surface of the substrate.

Embodiment 3

[0043] A. With embodiment 1.

[0044] B Add 50g of aluminum isopropoxide to 4L of dilute nitric acid solution with a concentration of 0.05mol / L, stir for 5-10min, heat rapidly to 90°C and reflux for about 12h, and form a translucent sol after cooling. The sol is centrifuged to remove the precipitate to obtain the boehmite sol.

[0045] C Weigh 23.5375g of zinc nitrate, prepare 1L solution, and mix the same amount of zinc nitrate with boehmite sol. Adjust the pH value to 7.5 with 1% ammonia water. Put it into the polytetrafluoroethylene reactor, put the treated copper sheet into it, put it in an oven at 75°C for 3 days, take out the reactor, cool it, take out the copper sheet, wash it with deionized water and dry it, that is The copper-zinc-aluminum composite oxide thin film material can be obtained on the surface of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com