Preparation method and application of strontium-incorporated hydroxyapatite

A technology of strontium hydroxyapatite and strontium oxide, which can be applied in the fields of phosphorus compound active ingredients, medical science, prosthesis, etc., can solve problems such as high price and achieve the effect of good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of strontium hydroxyapatite powder

[0037] Glass preparation process: the glass block is prepared by the melting method, and the carbonates, silicon dioxide, boric acid, etc. corresponding to various alkali metals and alkaline earth metals corresponding to the glass components are fully mixed according to the mass ratio; then The platinum crucible with mixed raw materials is placed in a silicon-molybdenum furnace at 1100-1150°C, melted for 2-3 hours, the melt is quenched on a steel plate to obtain block glass, and the glass block is ground into powder for later use.

[0038] Take the mole percentage to form 14Na 2 O·6MgO·22CaO·2SrO·18SiO 2 36B 2 o 3 ·2P 2 o 5 After being crushed, sieved to obtain irregularly shaped glass particles with a diameter of 150-300 microns, soaked in a physiological simulation solution (pH=7.2-7.4), in a closed container, under normal pressure (greater than 0.15 MPa), in the air containing carbon dioxide, react ...

Embodiment 2

[0039] Example 2: Preparation of strontium hydroxyapatite scaffold

[0040] The preparation method of the glass is the same as that in Example 1 except for the difference in composition.

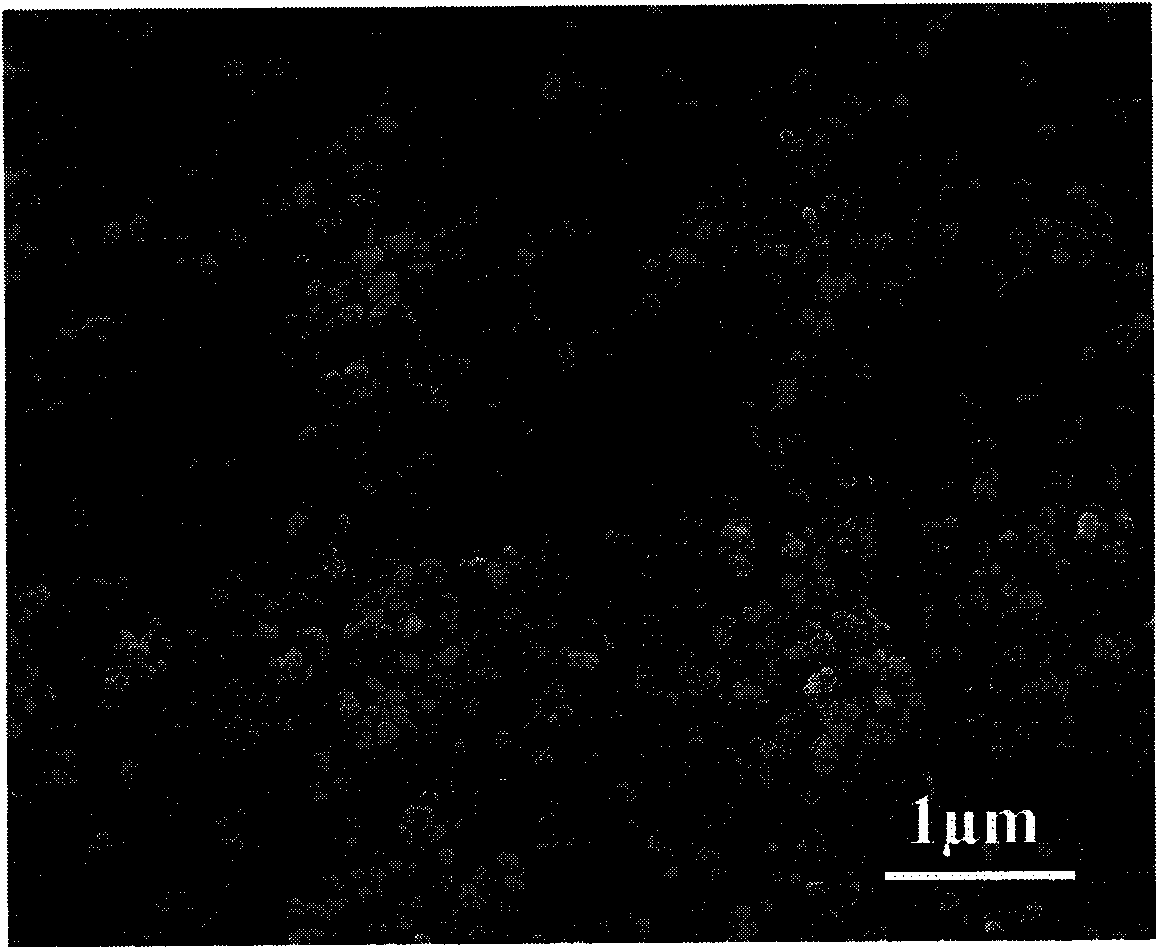

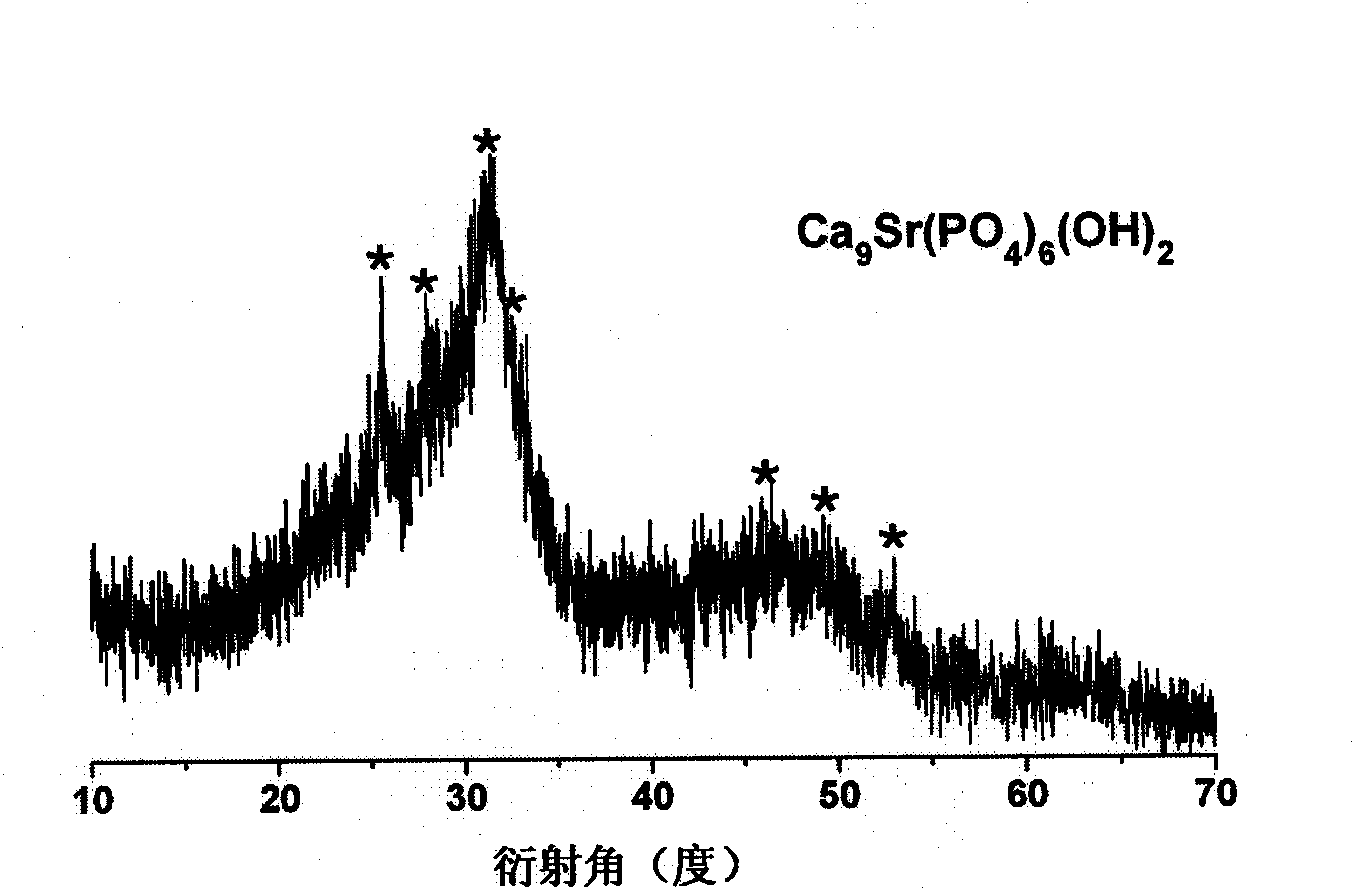

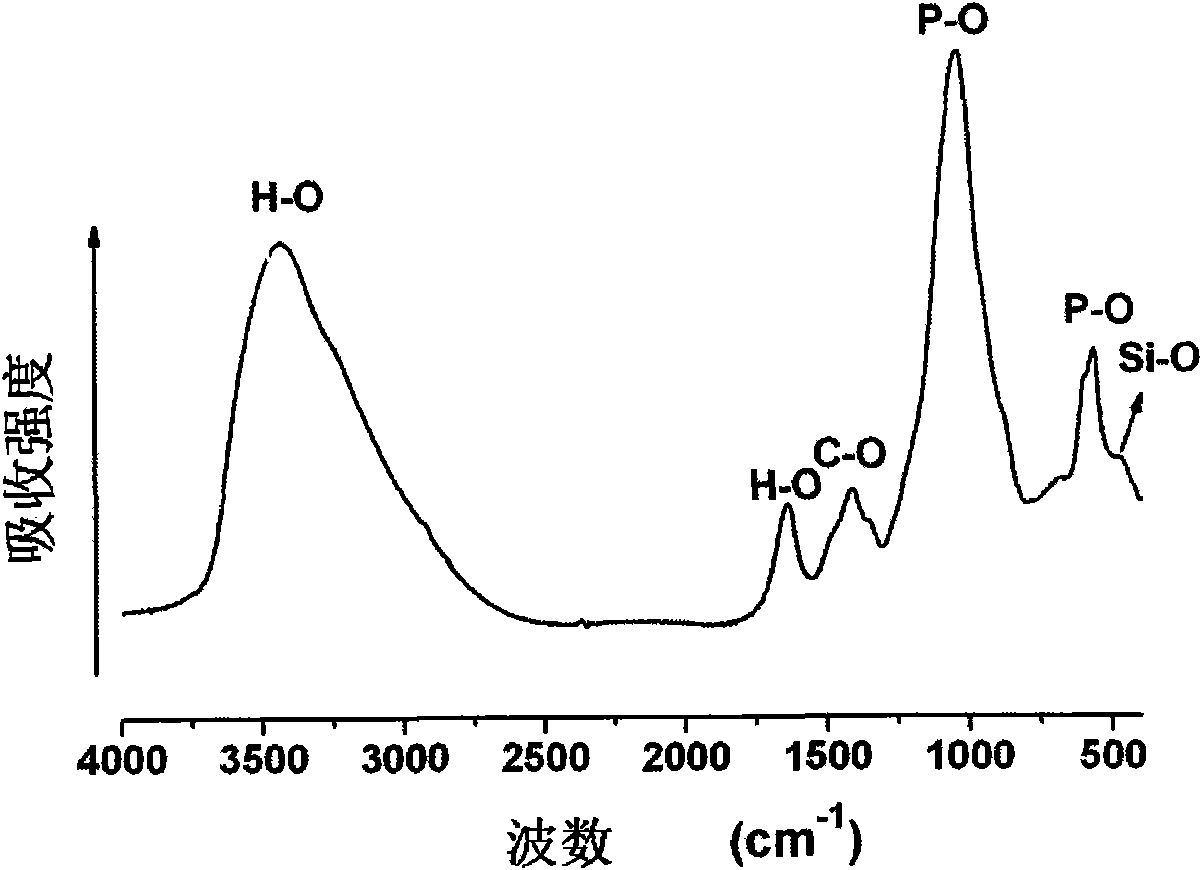

[0041] Take the mole percentage to form 14Na 2 O 4MgO 22CaO 4SrO 18SiO 2 36B 2 o 3 ·2P 2 o 5 After crushing, sieve to obtain glass particles with a diameter of less than 50 microns, prepare glass supports by template method, soak in physiological simulation fluid (SBF) (pH = 7.2 ~ 7.4), in a closed container, higher than normal pressure Under low temperature (greater than 0.15MPa), the powder is reacted with the solution in a constant temperature water bath higher than 38°C and lower than 42°C. The reaction time is 14 days. After the reaction, the product is filtered out, washed with distilled water, and dried at 90°C to obtain the shape Same size white stand. Through XRD analysis, the crystalline phase after this scaffold reaction is hydroxyapatite (see Figure 6 ), observed by SEM,...

Embodiment 3

[0042] Embodiment 3: Preparation of strontium hydroxyapatite by hydrothermal method

[0043] The preparation method of the glass is the same as that in Example 1 except for the difference in composition.

[0044] Take the mole percentage to form 14Na 2 O·2MgO·22CaO·6SrO·18SiO 2 36B 2 o 3 ·2P 2 o 5 The glass is crushed and sieved to obtain irregularly shaped glass particles with a diameter of less than 50 microns, soaked in a dipotassium hydrogen phosphate solution with a concentration of 0.2mol / L (pH=7.2~7.4), in an autoclave, at React in a thermostat at 200°C for 2 days. After the reaction, the particles are washed with distilled water and dried at 90°C to obtain white blocks with the same dimensions. Through XRD analysis, the product of this block is strontium hydroxyapatite (see Figure 8 ), observed by SEM, the surface is a fusiform crystal composed of a complete thin plate with a long diameter of about 500-600nm, a short diameter of about 300-400nm, and a plate thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com