Bioactive borophosphate glass and preparation method thereof

A technology of bioactive glass and borophosphorus, which is applied in the field of biomedicine, can solve the problems of affecting wound healing, slow degradation rate, and affecting tissue growth, etc., and achieve the effects of improving biocompatibility, promoting complexation, and increasing repair speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A boron-phosphorous bioactive glass and a preparation method thereof, the selected initial bioglass is boron-based glass, and the raw material is composed of B 2 o 3 , MgO, CaO, Na 2 O, K 2 The mass ratio of O and SrO is 45~60:2~10:15~25:3~10:10~15:1~8. The melting temperature of the initial glass is 1000-1350°C, and the holding time is 0.5-4 hours, preferably 1100-1300°C, and the holding time is 0.5-2 hours. The composition of the impregnation solution is CaCl 2 , (NH 4 ) 2 HPO 4 、K 2 HPO 4 ×3H 2 O, HCl, dissolved in 1L of ultra-pure water, the mass ratio is 5~20:15~25:60~70:0.1~2. The specific operation steps are as follows:

[0030] (1) Clean the experimental equipment used in this method, such as beakers, stirring rods, measuring cylinders, etc., with ultrapure water, and carry out disinfection and sterilization treatment;

[0031] (2) Grind and sieve the boron-based glass to obtain glass powder with a particle size of 30-45 μm, and perform disinfection ...

Embodiment 1

[0047] Embodiment 1: preparation of material and performance test result

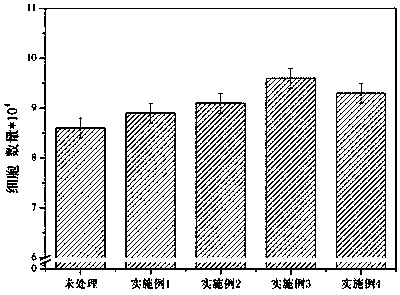

[0048] According to the proportioning of each component in Table 1, a certain amount of analytically pure raw material (B 2 o3 , MgO, CaO, Na 2 O, K 2 O and SrO), after mixing evenly, put the powder into a platinum crucible, and put it in a box-type resistance furnace for melting (melting temperature is 1350°C, holding time is 2 hours). Then pour the melt into deionized water for rapid cooling, dry to obtain glass frit, and obtain glass powder after ball milling. Weigh a certain amount of CaCl 2 , (NH 4 ) 2 HPO 4 、K 2 HPO 4 ×3H 2 O, HCl (the mass ratio is 5:23:70:2), dissolved in 1L of ultrapure water. Weigh 100g of glass powder, put it into 1L of impregnating solution, and keep stirring for 6h. After the stirring is completed, the impregnated glass powder is separated by vacuum filtration, dried and made into a biological glass dressing for later use. The dressings were used for wound heali...

Embodiment 2

[0049] Embodiment 2: preparation of material and performance test result

[0050] According to the proportioning of each component in Table 1, a certain amount of analytically pure raw material (B 2 o 3 , MgO, CaO, Na 2 O, K 2 O and SrO), after mixing evenly, put the powder into a platinum crucible, and put it in a box-type resistance furnace for melting (melting temperature is 1300°C, holding time is 2 hours). Then pour the melt into deionized water for rapid cooling, dry to obtain glass frit, and obtain glass powder after ball milling. Weigh a certain amount of CaCl 2 , (NH 4 ) 2 HPO 4 、K 2 HPO 4 ×3H 2 O, HCl (the mass ratio is 10:20:68.5:1.5), dissolved in 1L of ultrapure water. Weigh 100g of glass powder, put it into 1L of impregnating solution, and keep stirring for 6h. After the stirring is completed, the impregnated glass powder is separated by vacuum filtration, dried and made into a biological glass dressing for later use. The dressings were used for woun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com