Three-dimensional (3D) printing head for biological composite material

A composite material, 3D printing technology, applied in the field of 3D printing, to achieve the effect of improving mechanical properties and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

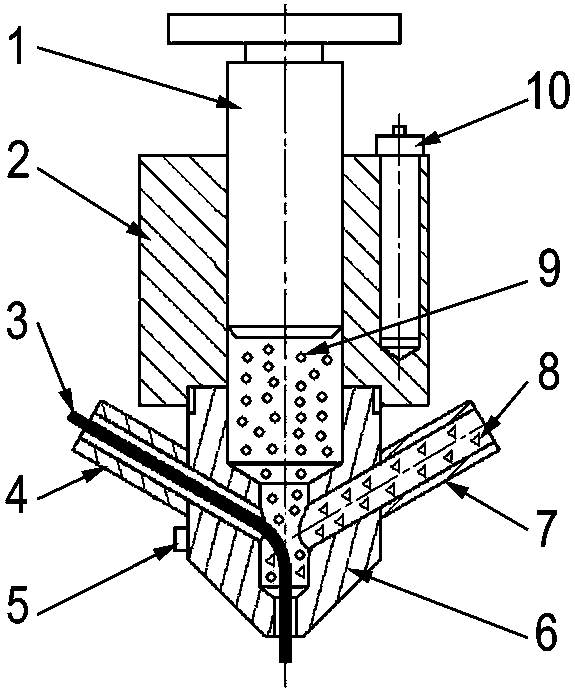

[0014] In order to facilitate the description in the invention, the description of the relative positional relationship of the devices is based on the description attached to the description. figure 2 For example, the positional relationship of up, down, left, right, front, back, inside, outside, etc. is based on the attached figure 2 determined by the layout direction.

[0015] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

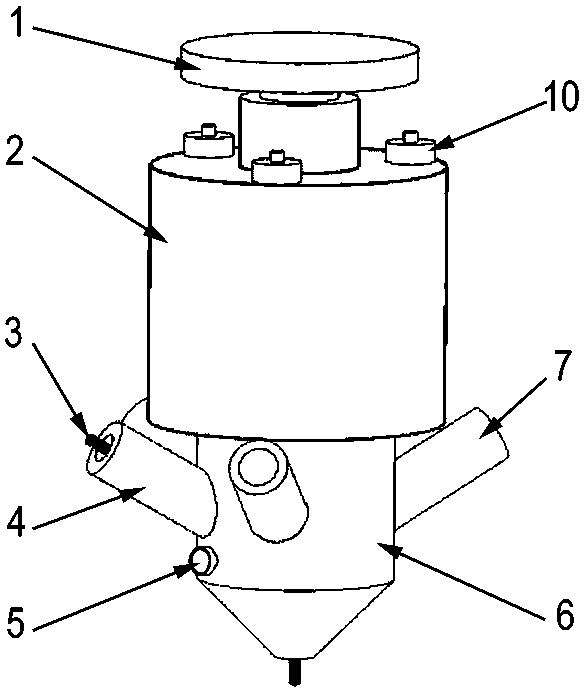

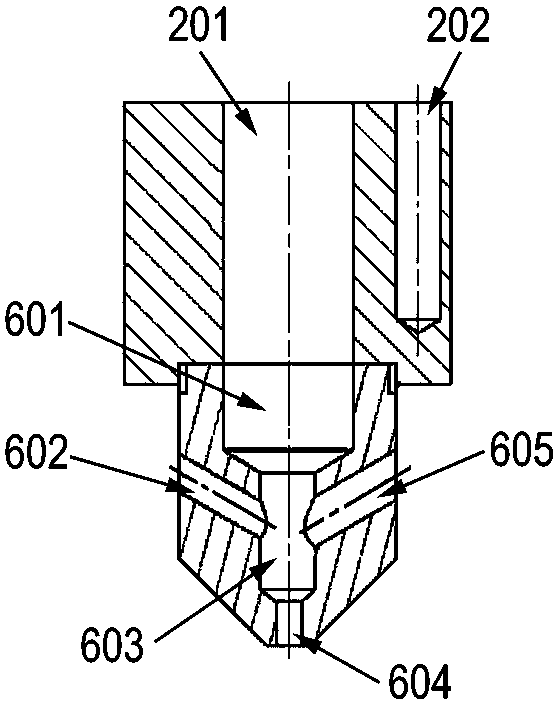

[0016] Examples, see attached figure 1 And attached figure 2 , a 3D printing nozzle for biocomposite materials, comprising: a push rod 1, a coaxial heating jacket 2, a wire feeding tube 4, a thermocouple 5, a mixing extrusion head 6, a powder feeding tube 7, and an electric heating tube 10. The mixing extrusion head 6 of the nozzle is connected with the coaxial heating jacket 2 through threads, and the push rod 1 is installed in the inner hole 201 of the feeding chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com