Injectable bone repair material with controllable magnesium ion release behavior and preparation method of material

A magnesium ion, bone repair technology, applied in pharmaceutical formulations, prostheses, drug delivery, etc., to achieve the effects of improving affinity, preventing infection, and improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

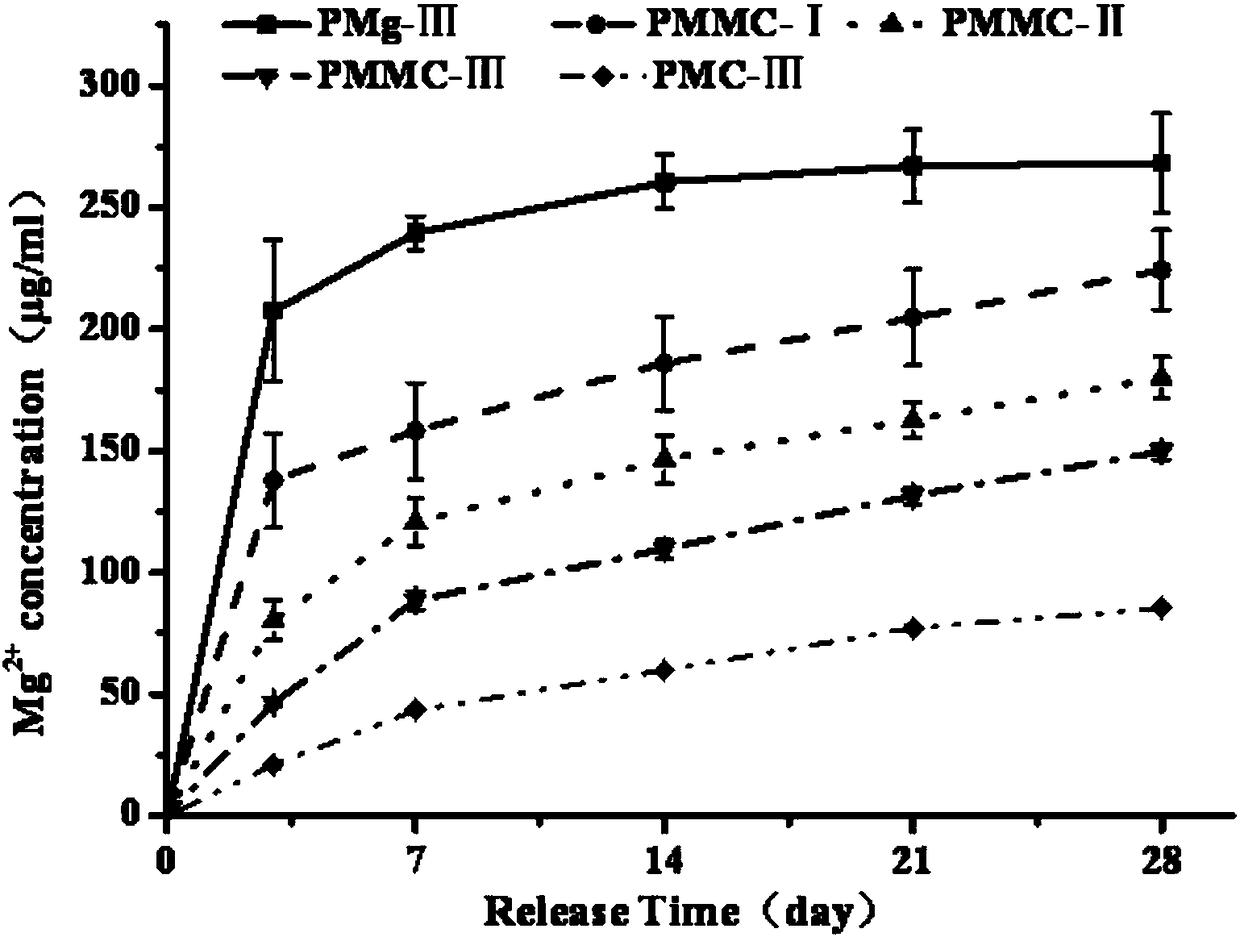

[0029] (1) 1 gram of lactide-glycolide copolymer (PLGA7525, lactide / glycolide molar ratio 75:25, molecular weight 50,000) was dissolved in 20 milliliters of dichloromethane solution, and magnetically stirred for 12 hours to obtain Solution A.

[0030] (2) Add 20 mg of Span 80 and 0.05 g, 0.1 g or 0.2 g of magnesium oxide powder to solution A, and homogenize at 12000 rpm for 5 minutes to obtain dispersion B.

[0031] (3) Dissolve 0.2 gram of Tween 60 and 2 gram of polyvinyl alcohol (PVA 1788) in 200 milliliters of deionized water to obtain solution C, and add the dispersion prepared in step (2) dropwise to this solution C under stirring at 300 rpm B. After the dropwise addition, the stirring was continued at room temperature for 8 hours to volatilize the dichloromethane solvent.

[0032] (4) Stop stirring, centrifuge at 4000rpm for 10 minutes to collect hardened microspheres, wash 3 times with deionized water, and freeze-dry for 24 hours to obtain magnesium oxide and PLGA weig...

Embodiment 2

[0034] (1) 1 gram of lactide-glycolide copolymer (PLGA7525, lactide / glycolide molar ratio 75:25, molecular weight 50,000) was dissolved in 20 milliliters of dichloromethane solution, and magnetically stirred for 12 hours to obtain Solution A.

[0035] (2) Add 20 mg of Span 80 and 0.05 g, 0.1 g or 0.2 g of magnesium carbonate powder to solution A, and homogenize at 12000 rpm for 5 minutes to obtain dispersion B.

[0036] (3) Dissolve 0.2 gram of Tween 60 and 2 gram of polyvinyl alcohol (PVA 1788) in 200 milliliters of deionized water to obtain solution C, and add the dispersion prepared in step (2) dropwise to this solution C under stirring at 300 rpm B. After the dropwise addition, the stirring was continued at room temperature for 8 hours to volatilize the dichloromethane solvent.

[0037] (4) Stop stirring, centrifuge at 4000rpm for 10 minutes to collect hardened and formed microspheres, wash 3 times with deionized water, and freeze-dry for 24 hours to obtain magnesium carb...

Embodiment 3

[0039] (1) 1 gram of lactide-glycolide copolymer (PLGA7525, lactide / glycolide molar ratio 75:25, molecular weight 50,000) was dissolved in 20 milliliters of dichloromethane solution, and magnetically stirred for 12 hours to obtain Solution A.

[0040] (2) Add 20 mg of Span 80, and 0.2 g of magnesium oxide and magnesium carbonate powder to solution A, the mass ratio of magnesium oxide to magnesium carbonate is 3:1, 1:1, 1:3, homogeneous at 12000rpm After 5 minutes, dispersion B was obtained.

[0041] (3) Dissolve 0.2 gram of Tween 60 and 2 gram of polyvinyl alcohol (PVA 1788) in 200 milliliters of deionized water to obtain solution C, and add the dispersion prepared in step (2) dropwise to this solution C under stirring at 300 rpm B. After the dropwise addition, the stirring was continued at room temperature for 8 hours to volatilize the dichloromethane solvent.

[0042] (4) Stop stirring, centrifuge at 4000rpm for 10 minutes to collect hardened microspheres, wash 3 times wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com