Total biomass composite injection moulding material and preparation method thereof

A technology of biomass and biomass polyethylene, which is applied in the field of polymer materials, can solve the problems of low strength, achieve the effects of lower prices, good performance and processing performance, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

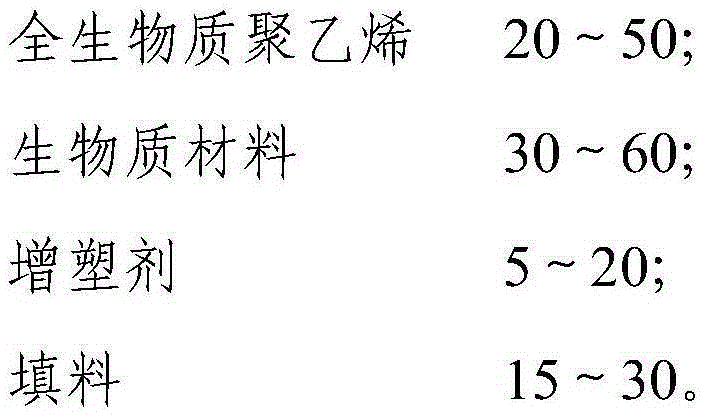

Method used

Image

Examples

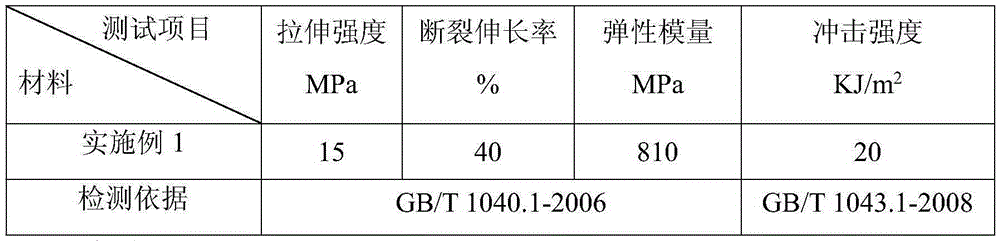

Embodiment 1

[0030] Add 20 parts by mass of whole biomass polyethylene, 60 parts by mass of starch, 5 parts by mass of glycerol, and 15 parts by mass of calcium carbonate into a high-speed mixer, stir at 120°C for 20 minutes, and mix well; then the mixture is extruded in a twin-screw Mixing and granulation at 180°C in the exiting machine can obtain the all-biomass composite injection molding material; after secondary processing on the injection molding equipment, the all-biomass composite injection molding product can be obtained.

[0031] The properties of all biomass composite injection molding materials are as follows:

[0032]

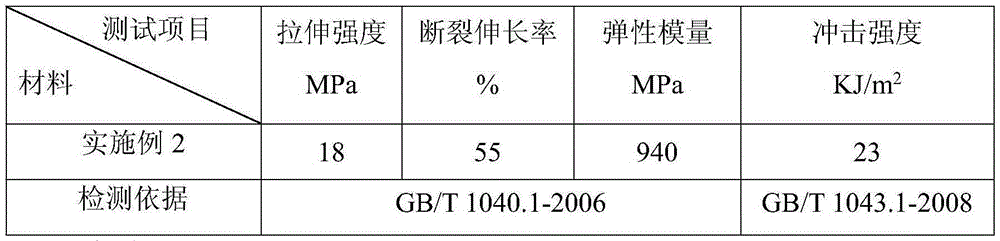

Embodiment 2

[0034] Add 45 parts by mass of whole biomass polyethylene, 40 parts by mass of starch, 10 parts by mass of ethylene glycol, and 15 parts by mass of talcum powder into a high-speed mixer, stir at 150°C for 30 minutes, and mix well; then the mixture is extruded in a twin-screw Mixing and granulation at 220°C in the exit machine can obtain the whole biomass composite plastic; after secondary processing on the blow molding equipment, the whole biomass composite plastic film bag can be obtained.

[0035] The properties of all biomass composite plastics are as follows:

[0036]

Embodiment 3

[0038] Add 50 parts by mass of whole biomass polyethylene, 30 parts by mass of cellulose (straw powder), 5 parts by mass of propylene glycol, and 15 parts by mass of calcium carbonate into a high-speed mixer, stir at 100°C for 20min, and mix well; then put the mixture in Mixing and pelletizing at 180°C in a twin-screw extruder to obtain a full-biomass composite plastic; after secondary processing on a blow molding device, a full-biomass composite plastic film bag is obtained.

[0039] The properties of all biomass composite plastics are as follows:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com