Patents

Literature

105results about How to "Good economic and environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulfurization waste water recycling and zero discharge system and method

InactiveCN103979729ALimit concentrationEfficient separationMultistage water/sewage treatmentWater dischargeWastewater

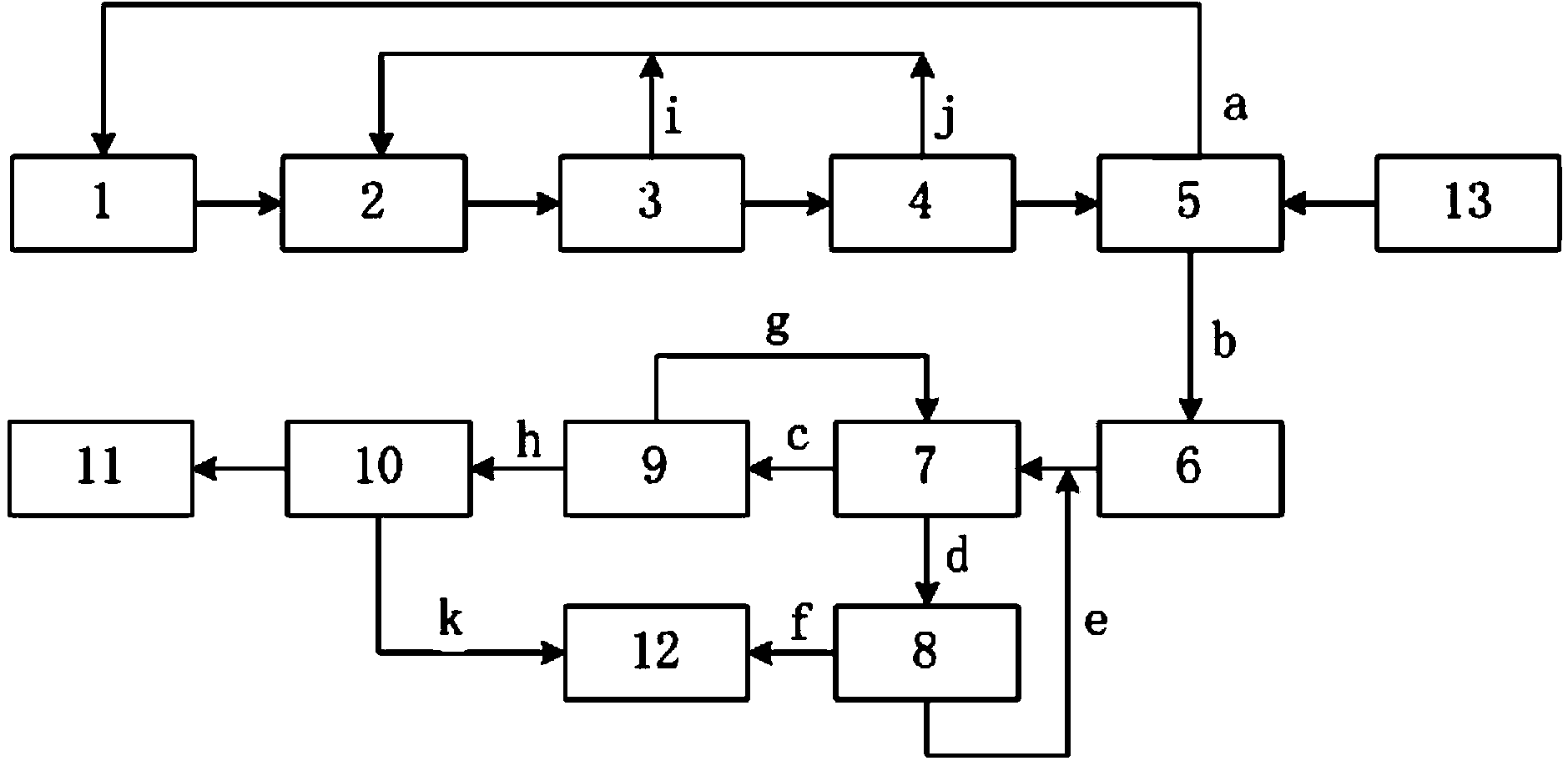

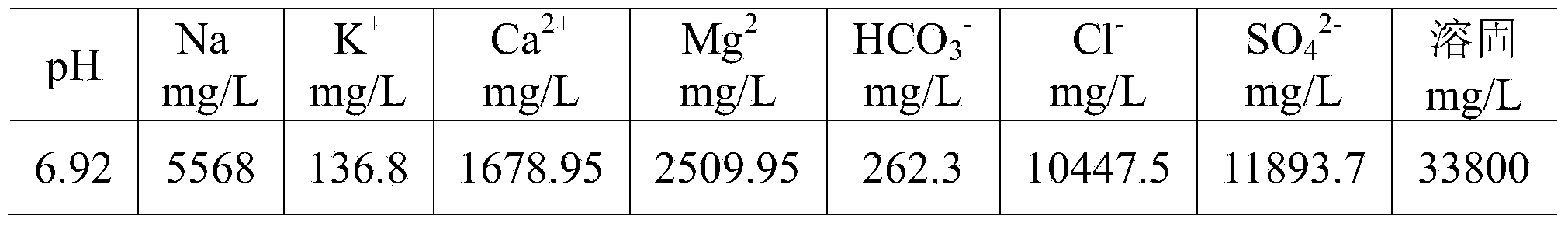

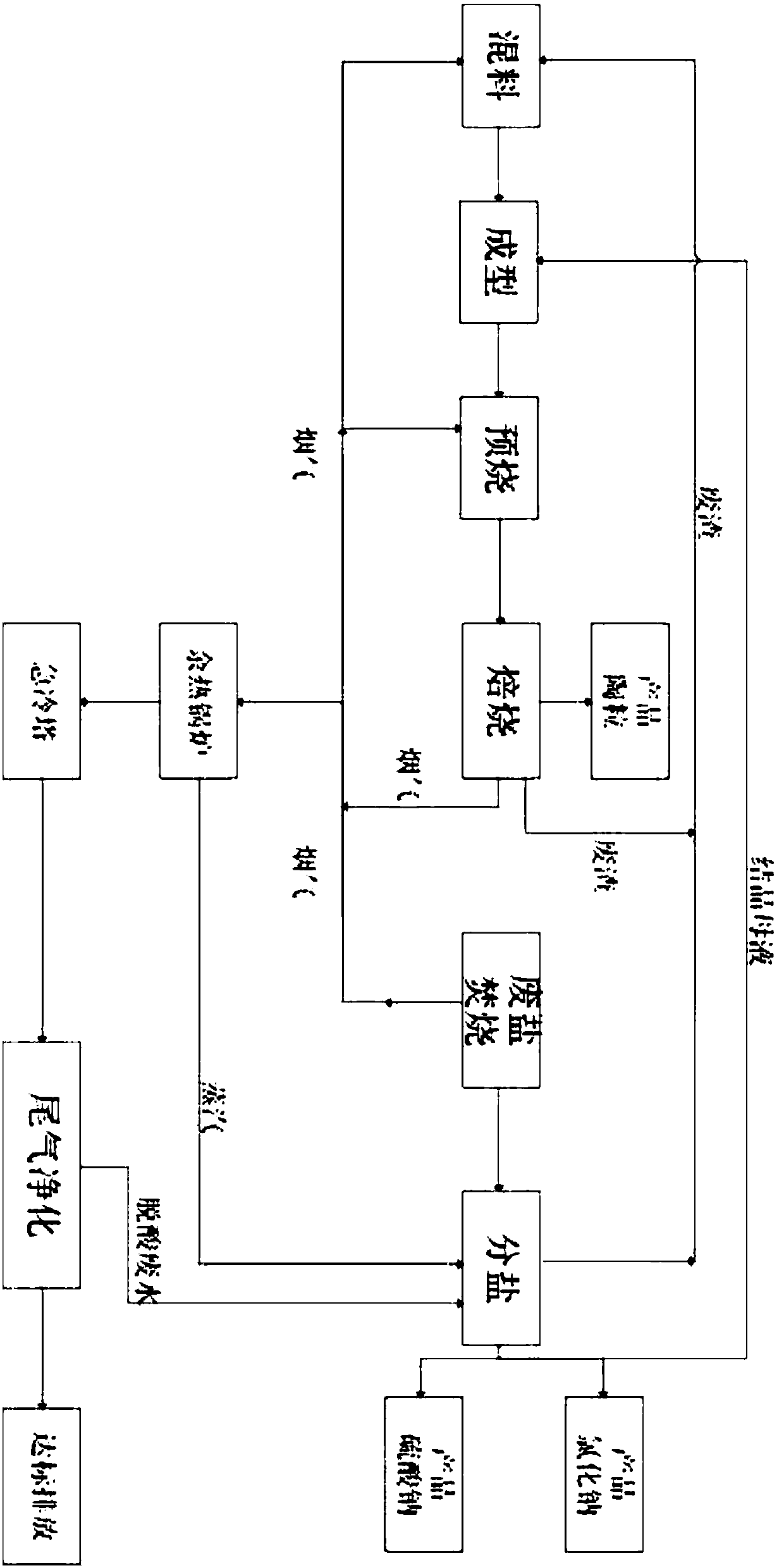

The invention relates to a desulfurization waste water recycling and zero discharge system and method. The desulfurization waste water recycling and zero discharge system comprises a desulfurization tower, a filter and a nanofiltration device which are sequentially connected, wherein a scale inhibitor dosing device is arranged at the inlet of the nanofiltration device, the concentrated water outlet of the nanofiltration device is connected with the desulfurization tower, the fresh water outlet of the nanofiltration device is connected with a saline water concentrating device, the fresh water outlet of the saline water concentrating device is connected with a fresh water tank, the concentrated water outlet of the salt water concentrating device is connected with a crystallizer, and the condensed water outlet of the crystallizer is connected with the fresh water tank; a drying encapsulating machine is arranged at the solid outlet of the crystallizer. The desulfurization waste water recycling and zero discharge system has the advantages that desulfurization waste water discharged from the desulfurization tower is filtered and then is fed into the nanofiltration device, nanofiltration concentrated water returns to the desulfurization tower, nanofiltration fresh water is treated by virtue of the salt water concentrating device and then is crystallized by virtue of the crystallizer, the obtained fresh water is recycled in the fresh water tank, and salt is separated out, dried into crystallized salt and transported outside after being encapsulated, so that zero discharge of the desulfurization waste water is realized, quality of the recycled fresh water is improved, and a chemical agent and operating cost are saved.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION +2

Flue gas low-temperature combined desulfurization and denitration technology method

InactiveCN105327612AAchieve recyclingNo entryDispersed particle separationFlue gasConcentration gradient

The invention discloses a flue gas low-temperature combined desulfurization and denitration technology method mainly including the steps: flue gas after dedusting having a purification temperature and humidity meeting desulfurization conditions is sent into a desulfurization tower to flow through a desulfurization catalyst bed, sulfur dioxide in the flue gas is oxidized into sulfur trioxide under the action of a catalyst, and sulfur trioxide acts with water in the flue gas to generate sulfuric acid; the desulfurization catalyst bed is regenerated through progressively-decreased sulfuric acid concentration gradient washing; the flue gas after desulfurization is sent into a denitration conditioning work section, is dehumidified and heated, and is adjusted to meet requirements of a denitration technology; the flue gas after dehumidification and heating is sent into a mixing tower and is mixed with injected ammonia gas, the mixed flue gas mixed with the ammonia gas is sent into a denitration tower to flow through a denitration catalyst bed, and NOx, NH3 and O2 in the mixed flue gas are converted into N2 and water under the action of a denitration catalyst. The problems that a conventional flue gas desulfurization and denitration technology is narrow in flue gas applicable scope, high in heating energy consumption, high in running cost and the like are overcome.

Owner:SICHUAN UNIV +1

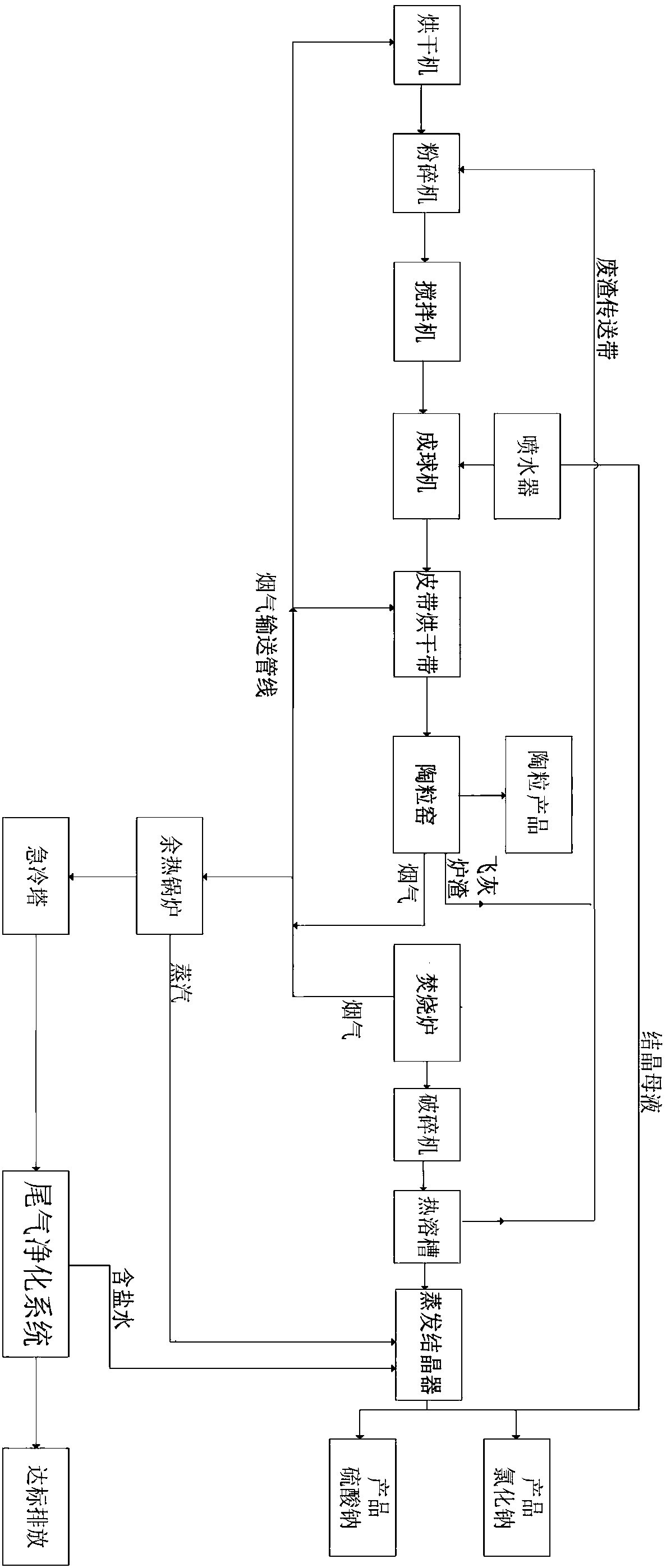

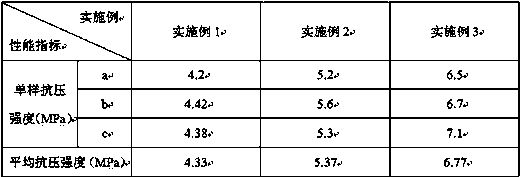

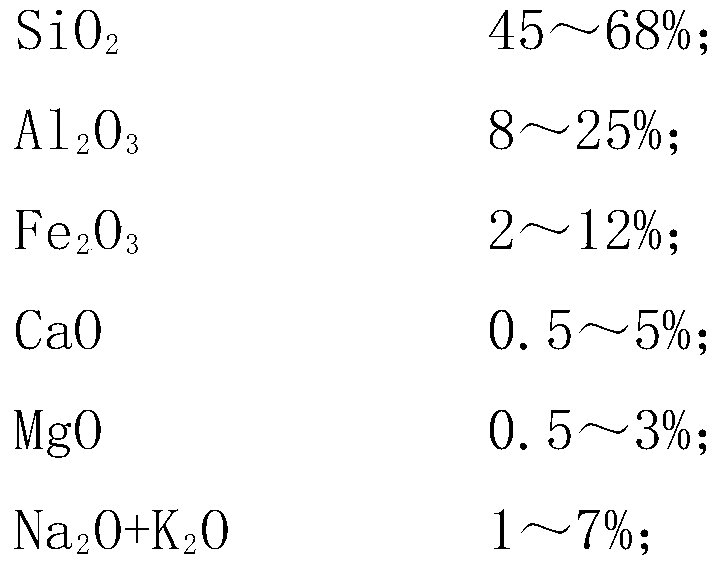

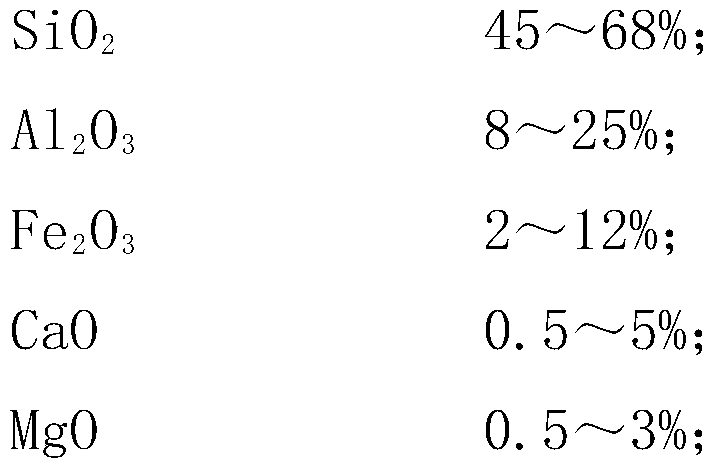

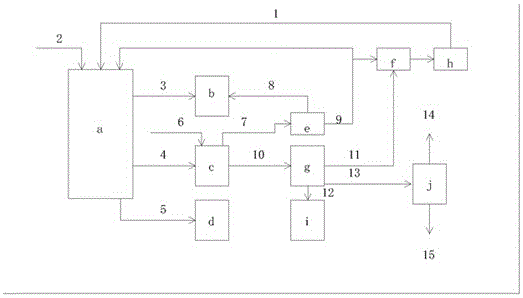

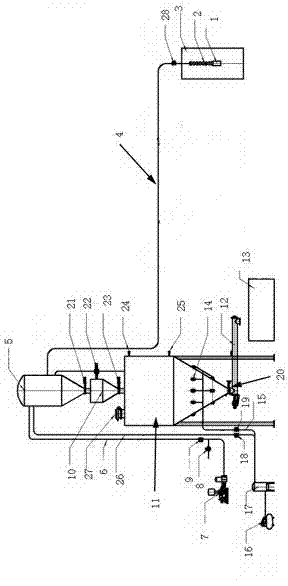

System and process of ceramsite production and co-processing of dangerous waste

PendingCN107642786AGood economic and environmental benefitsEnable co-processingIncreasing energy efficiencyIncinerator apparatusContaminated soilsCo-processing

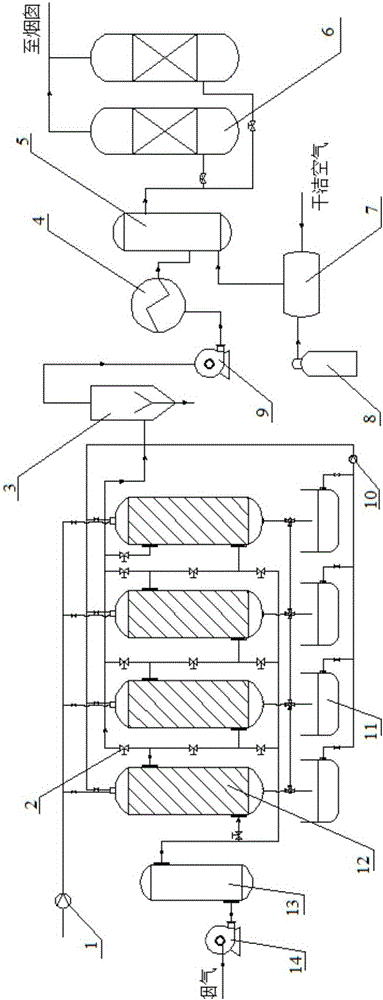

The invention belongs to the technical field of dangerous waste processing and comprehensive utilization, and provides a method for ceramsite production and co-processing of dangerous waste. The method mainly includes a ceramsite production process and a waste salt comprehensive utilization process; the ceramsite production process includes material blending, molding, pre-burning, roasting and other process steps; the waste salt comprehensive utilization process includes incineration, salt separation, waste heat utilization, tail gas purification and other process steps. By adopting the process, co-processing of the dangerous waste and various solid waste including high-salinity dangerous waste, high-heat dangerous waste, sludge, contaminated soil, slags and the like can be achieved; maximum utilization and harmless processing of the intermediate pollutants, including smoke, flying dust, slags, mother liquid and the like, which are generated in the production process, waste heat resources and all the dangerous waste raw materials can be achieved in the system, the ceramsite high in strength, sodium chloride products high in purity and sodium sulfate products high in purity are finally obtained, and the tail gas satisfies the emission standards. The process is compact and reasonable and easy to popularize and implement and has great economic benefits, environmental benefits andsocial benefits.

Owner:山东清博生态材料综合利用有限公司

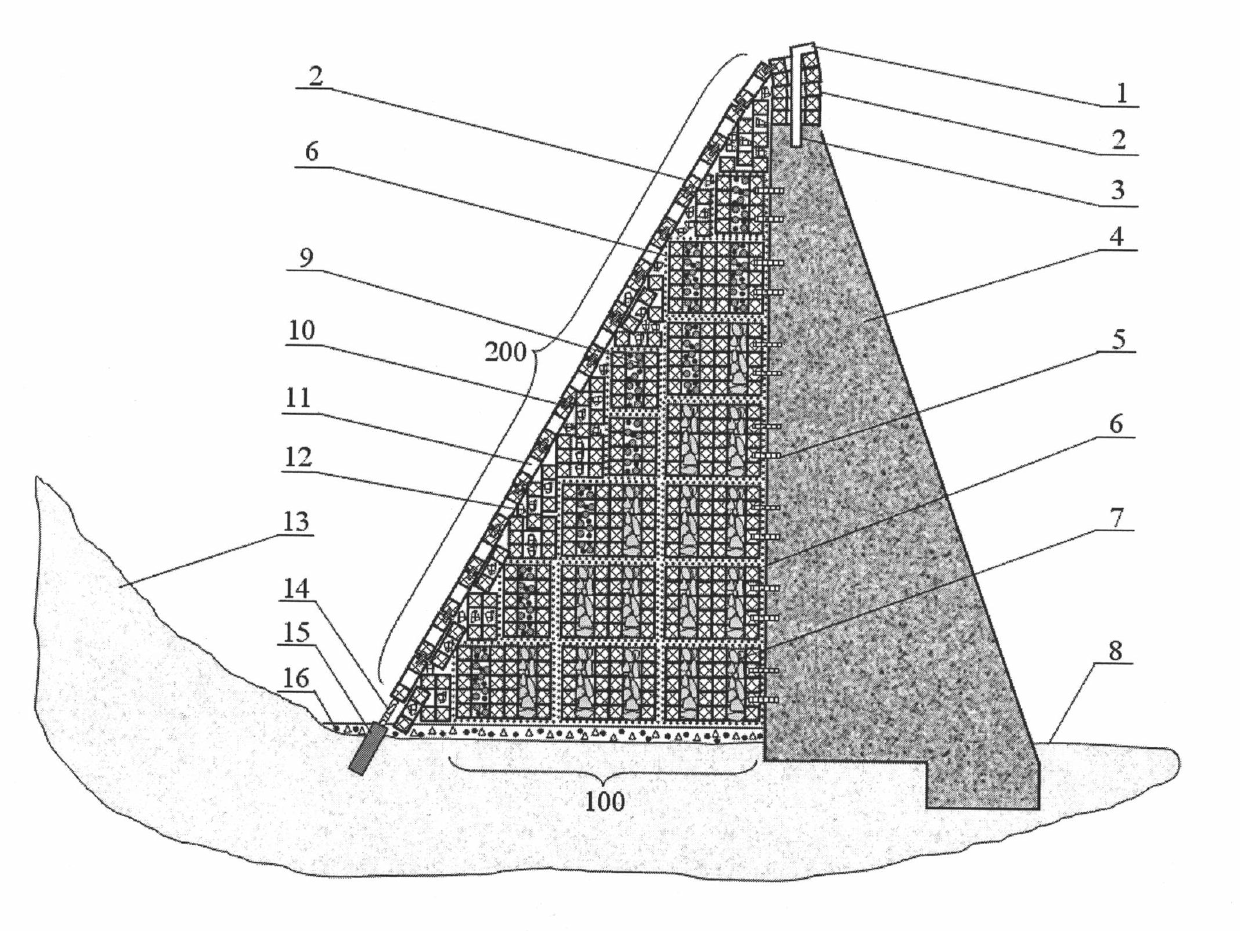

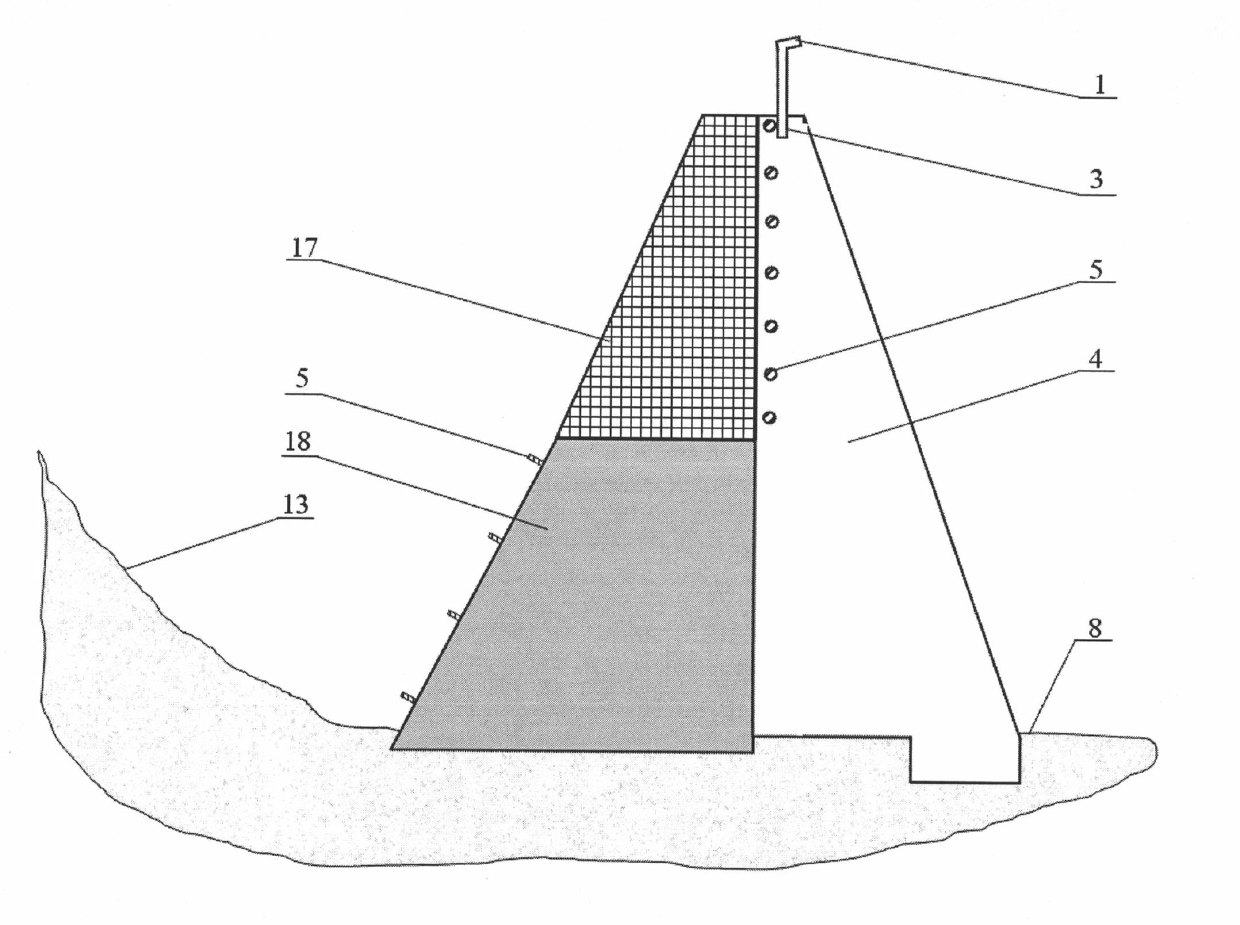

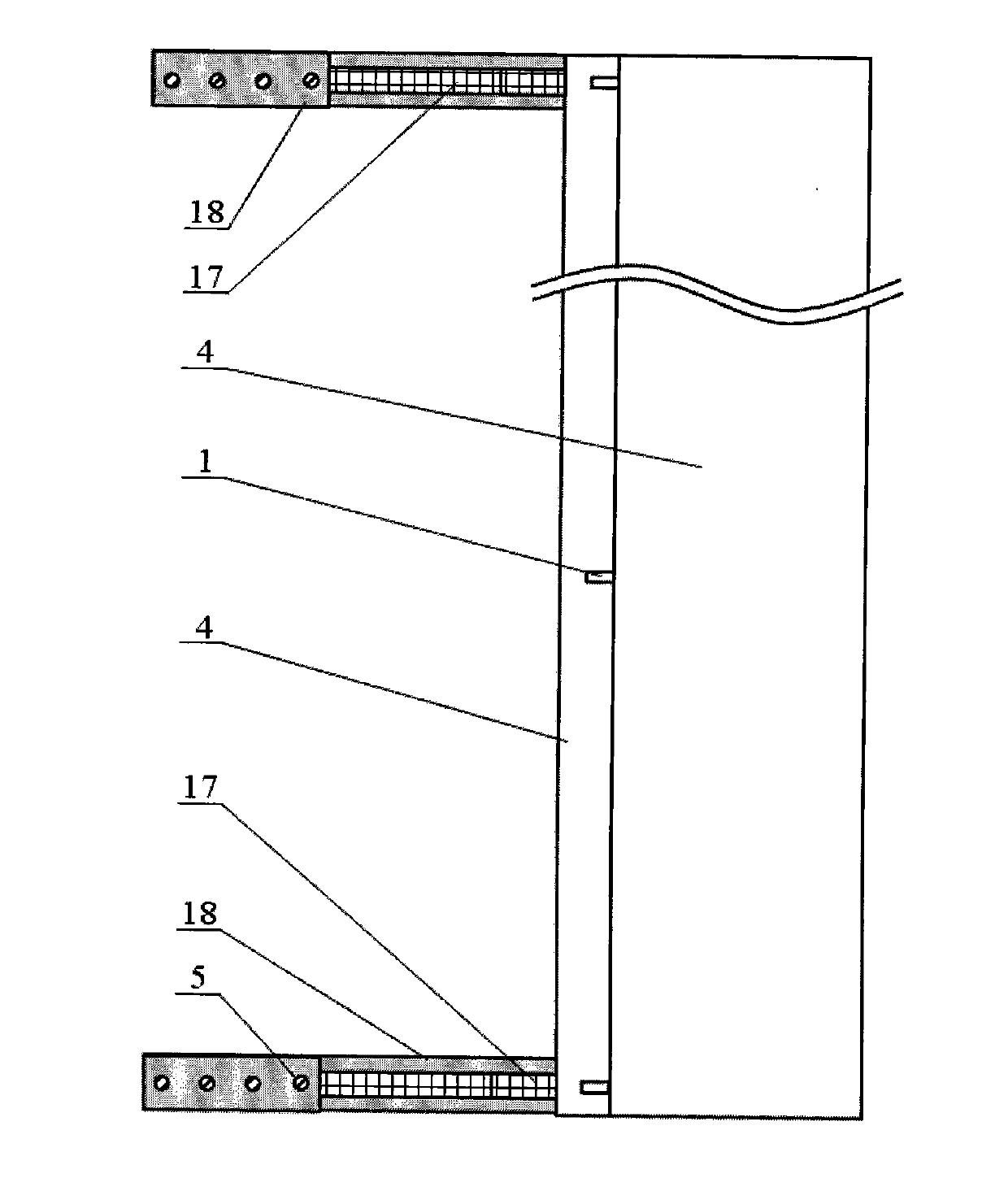

Method for preparing stone blocking dam by using waste and old rubber

InactiveCN102002917AGood economic and environmental benefitsWide range of applicationsProtective constructionPre embeddingEngineering

The invention provides a method for preparing a stone blocking dam by using waste and old rubber, which comprises the following steps of: determining construction conditions of a main body structure of the stone blocking dam, constructing a support wall and an end blocking wall of the stone blocking dam, pre-embedding fixed connectors on the walls, pre-embedding a stand column at the top of the support wall and embedding an anchor rod for fixing an anchor rope at a position of a toe; braiding tyre cages by using waste and old tyres, waste and old triangular belts and waste and old wire ropes, constructing a tyre cage energy-dissipating bank through the combination and connection of the tyre cages of different specifications, filling rock blocks, sandy soil or rubber soil into the hollow chamber of the tyre cages, fixing the tyre cage close to one side of the support wall of the stone blocking dam by using the fixed connector, and bolting other tyre cages by using the waste and old triangular belts; sleeving enough waste and old tyres on the stand column and fixing the support ropes between the adjacent stand columns by the waste and old tyres on the top; laying a layer of waste and old tyre net on the surface of the tyre cage energy-dissipating bank, wherein the support ropes between the stand columns form the upper boundary of the waste and old tyre net, the anchor rods at the position of the toes form the lower boundary of the waste and old tyre net, and the gaps between the waste and old tyre net and the tyre cage energy-dissipating bank can be filled by the waste and old tyres and waste and old rubber fragments; and constructing the dam body consisting of the support wall, the tyre cage energy-dissipating bank and the waste and old tyre net in segments step by step and constructing an end part backstop above the end part blocking wall. The method can greatly improve the rolling stone blockage performance of the stone blocking dam.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

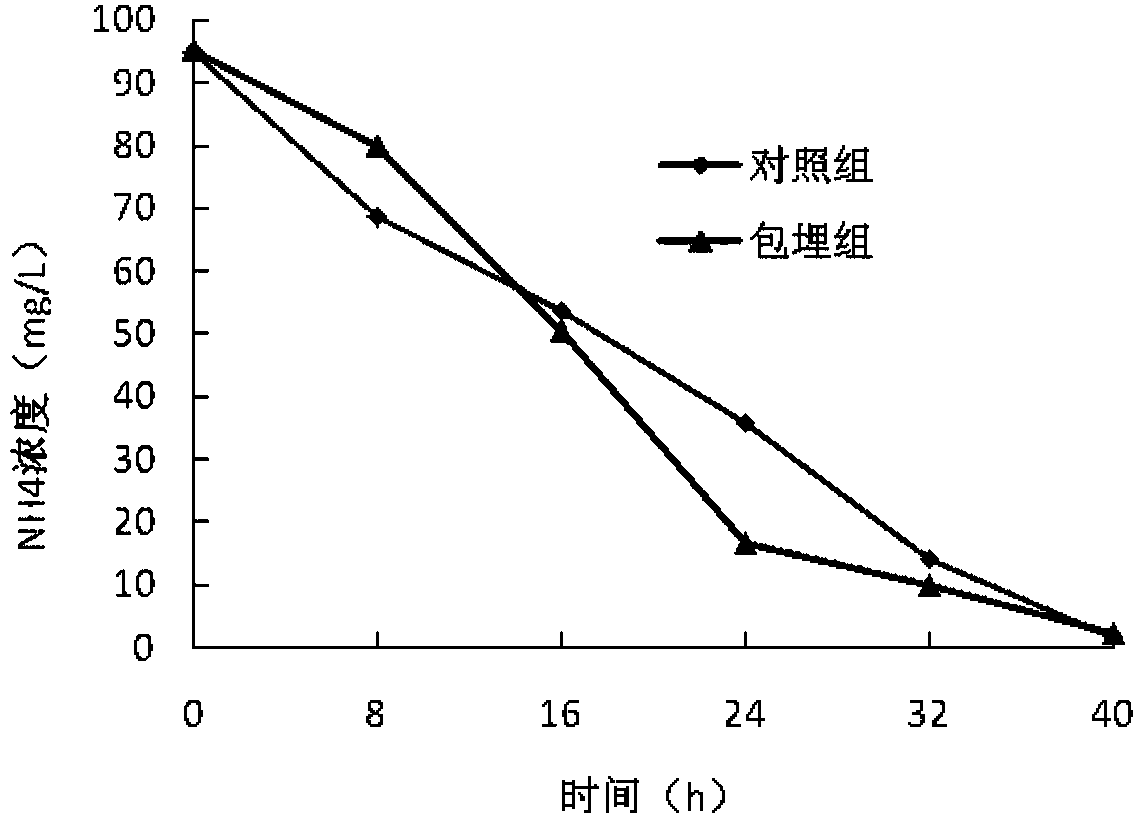

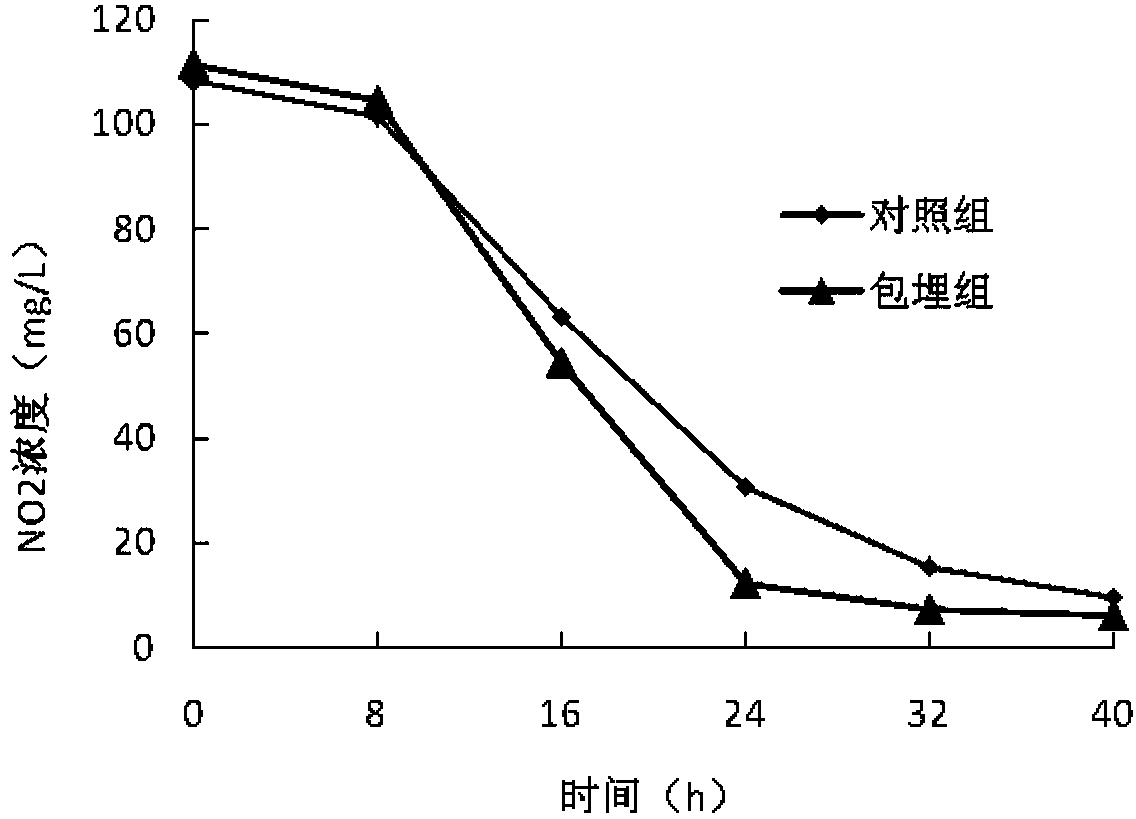

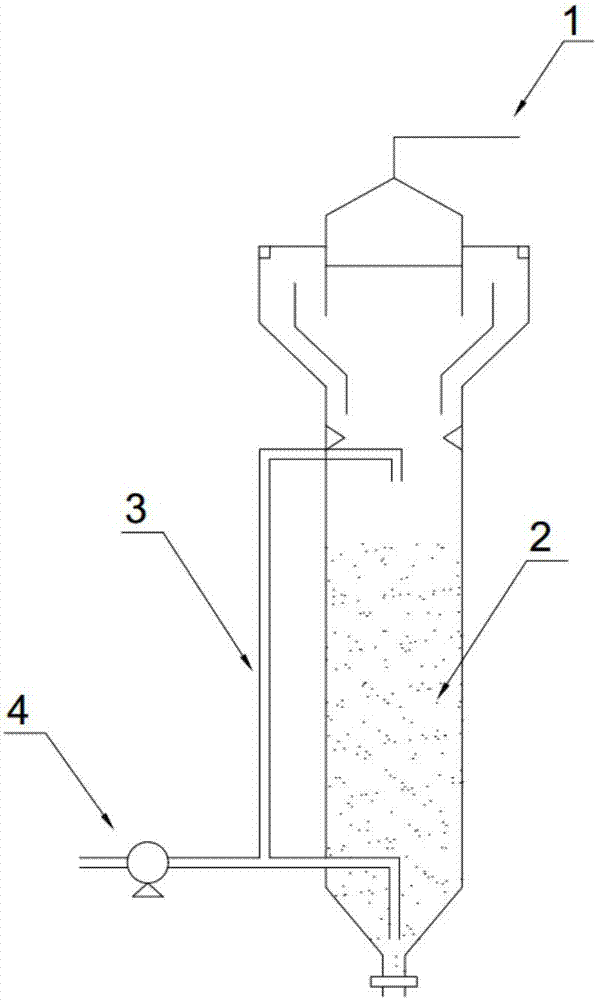

Anaerobic ammoxidation sludge embedding immobilization method

ActiveCN103408133AHigh mechanical strengthPromote swellingSludge treatmentTreatment with anaerobic digestion processesActivated carbonSludge

The invention relates to an anaerobic ammoxidation sludge embedding immobilization method belonging to the field of sewage treatment, and particularly provides a method for performing embedding immobilization on anaerobic ammoxidation sludge by adding magnetic powder and powdered activated carbon. The method comprises the following steps: preparing an embedding agent, mixing anaerobic ammoxidation sludge with the embedding agent, preparing immobilized anaerobic ammoxidation balls, activating the immobilized anaerobic ammoxidation balls and the like. The preparation of the embedding agent comprises the following steps: weighing polyvinyl alcohol (PVA), sodium alginate (SA), powdered activated carbon and magnetic powder, and preparing into a solution, wherein on the basis of percentage in mass, the concentration of the PVA is 6-10wt%, the concentration of the SA is 2-3wt%, the concentration of the powdered activated carbon is 1-2wt%, and the concentration of the magnetic powder is 2-4wt%; and uniformly stirring, thus preparing the mixed embedding agent. The method is simple in preparation process, easy to operate and low in preparation cost; and the prepared embedding immobilization anaerobic ammoxidation balls are high in activity, favorable in stability and suitable for industrial production, and can achieve favorable economic and environmental benefits.

Owner:BEIJING UNIV OF TECH

Soil stabilizer prepared from phosphogypsum and desulfurized fly ash and using method thereof

InactiveCN108467249AImprove the nature of the projectImprove mechanical propertiesBuilding constructionsOrganic fertilisersSodium BentoniteSlag

The invention relates to the technical field of construction and building materials, and in particular to a soil stabilizer prepared from phosphogypsum and desulfurized fly ash and a using method thereof. The soil stabilizer is prepared from phosphogypsum, desulfurized fly ash, metakaolin, lithiation bentonite, calcined coal gangue, lime, Portland cement clinker, steel slag powder, kieselguhr, water glass and caustic soda. The soil stabilizer can improve the soil structure and the engineering properties, and therefore the service life of a road is prolonged, the engineering project maintenancecost is saved, economic environment benefits are good, and the soil stabilizer is the current ideal option for road materials. The soil stabilizer is applicable to the fields of road foundation stabilization, slope protection, seepage-proofing in hydraulic engineering, rough roads, environmental protection projects, water and soil retention and the like.

Owner:TONGJI UNIV

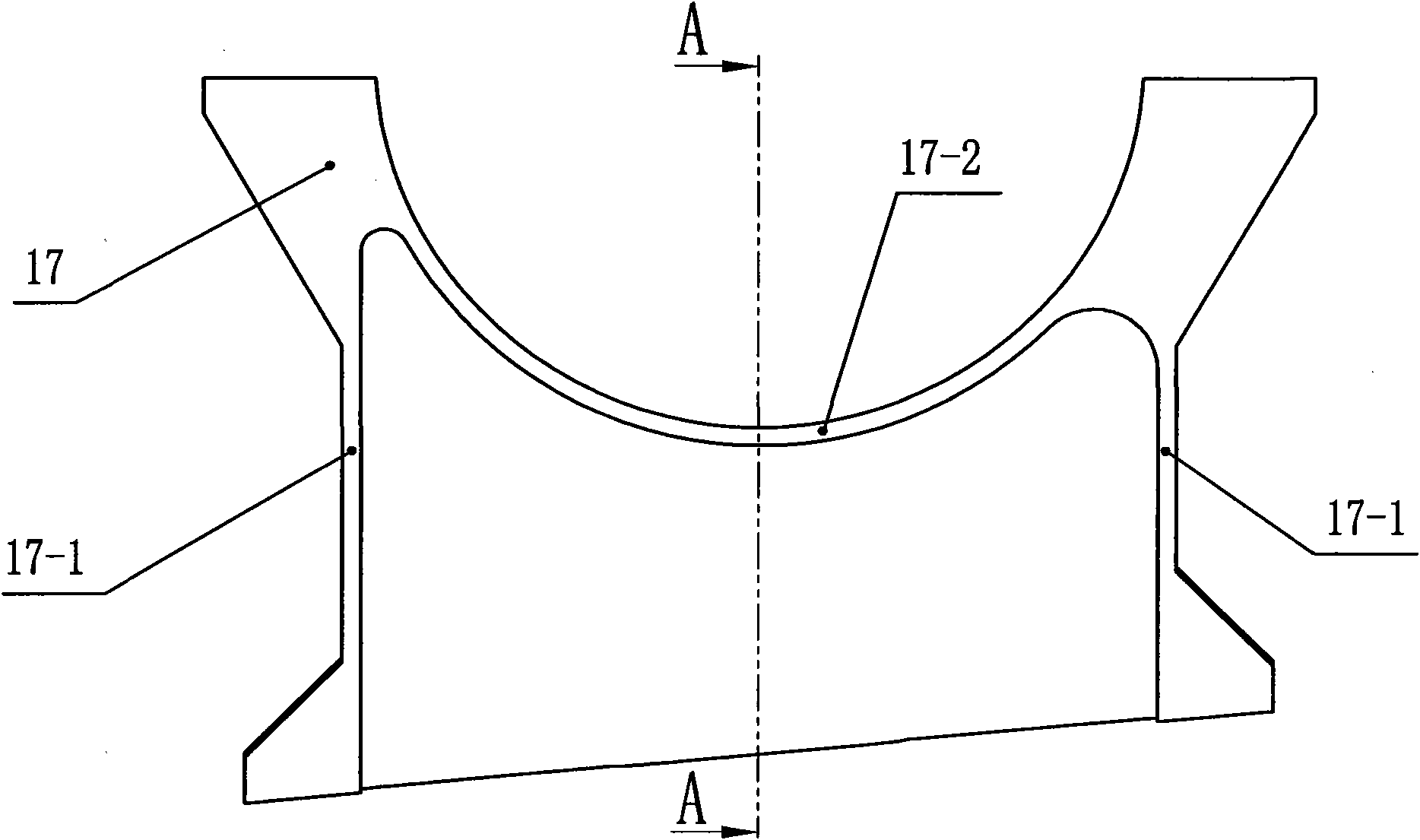

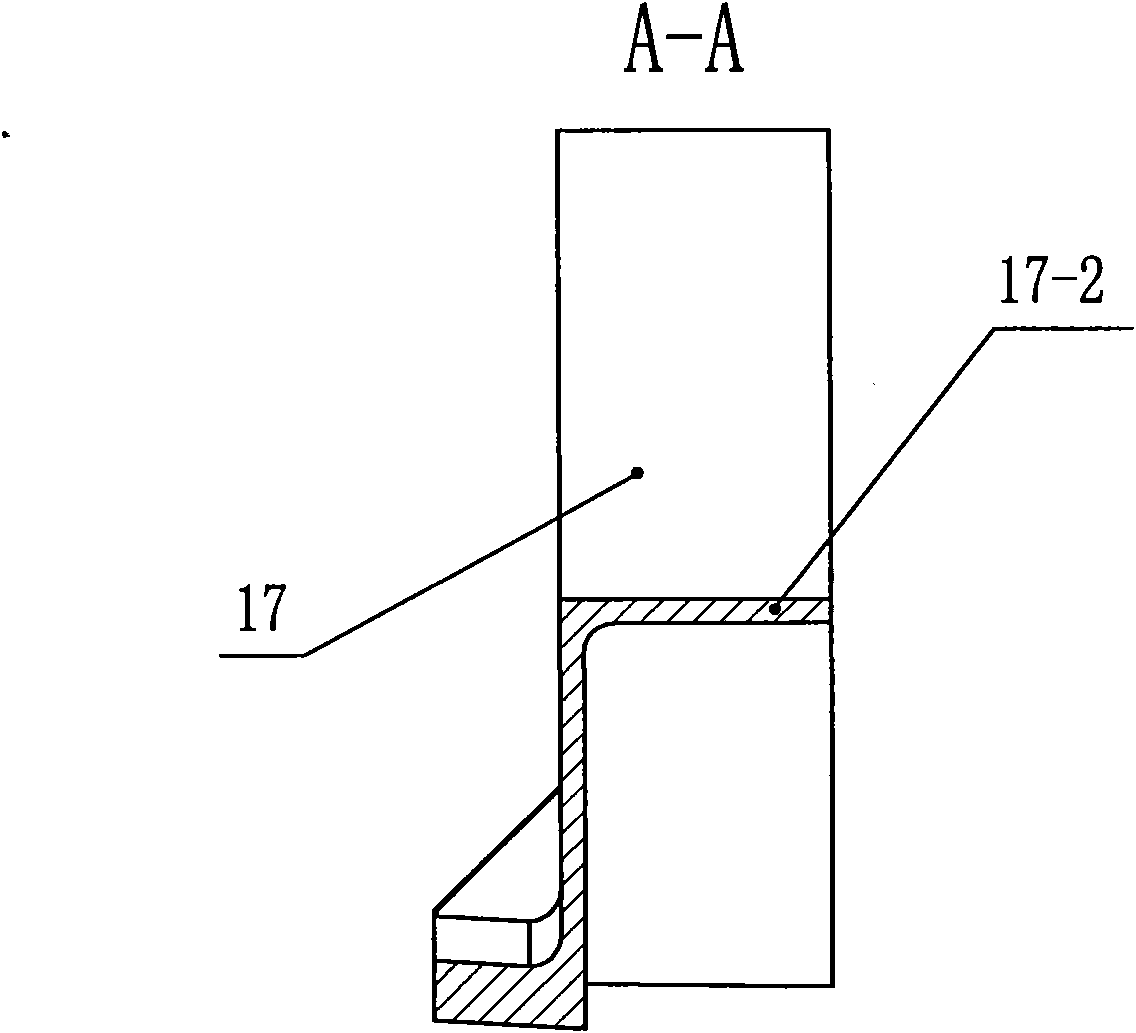

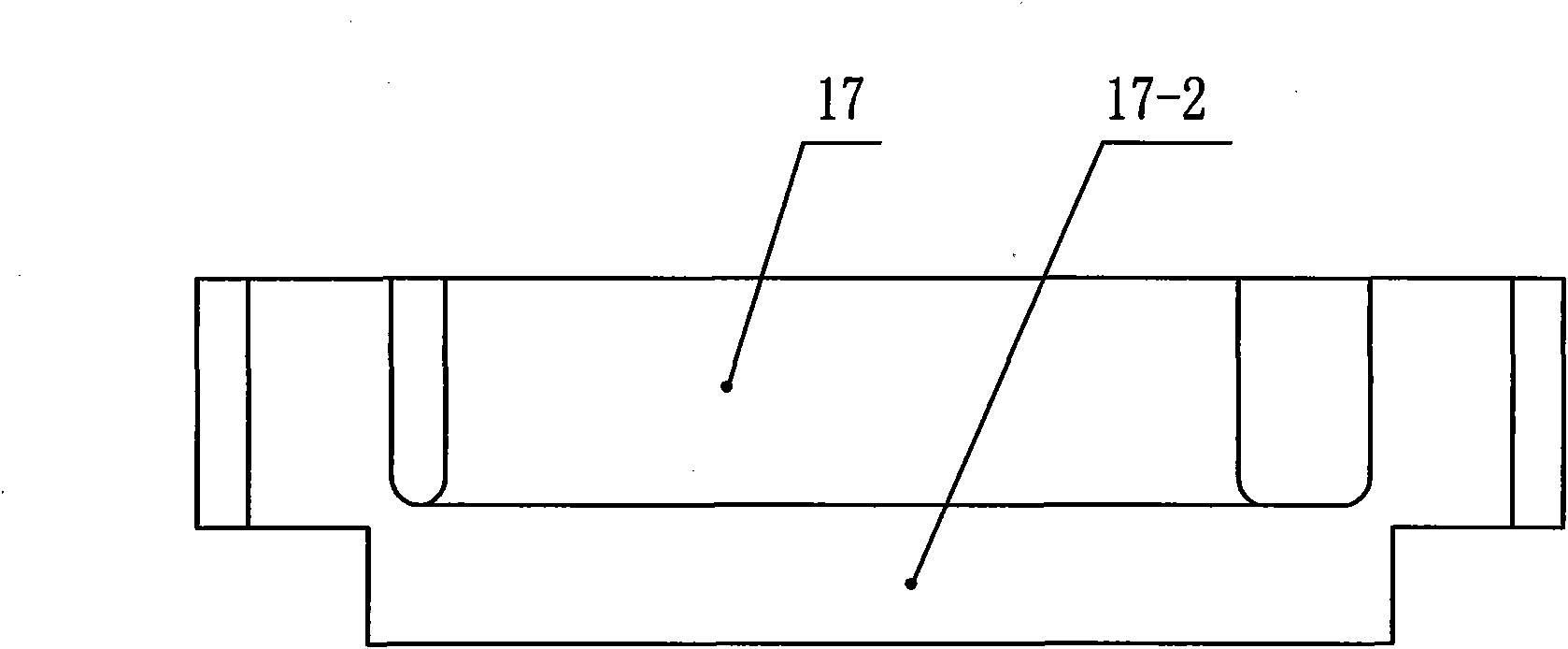

Die for controlling forming of asymmetric complex-curved rebar forge piece by using movable damping block

InactiveCN101885031AConsistent flow resistanceConsistent resistanceForging/hammering/pressing machinesEngineeringRebar

The invention relates to a die for controlling forming of an asymmetric complex-curved rebar forge piece by using a movable damping block, in particular to a forming die of an asymmetric complex-curved rebar forge piece, which solves the problem that the junction of the curved surface of an asymmetric complex-curved bar component is easily folded and not fully filled in the existing forming process. A male die (13) is provided with two pressure relief discharge openings (14), and the setting position of each pressure relief discharge opening (14) is positioned right above the corresponding side-ear connecting rib (17-1) of the asymmetric complex-curved rebar forge piece (17); the male die (13) is provided with a minor segment stepped hole (16); a movable damping block (24) is arranged in the lower end hole (16-2) of the minor segment stepped hole (16); a male die heating plate (10) is provided with a through hole (10-1) of a small punch (12) of a hydraulic press; and the through hole (10-1) of the small punch (12) of the hydraulic press corresponds to the minor segment stepped hole (16). The die is applicable to forming the asymmetric complex-curved rebar forge piece.

Owner:HARBIN INST OF TECH

Chemical copper plating waste solution treatment method

InactiveCN103224303AHigh economic and environmental benefitsGood economic and environmental benefitsMultistage water/sewage treatmentPhosphorus compoundsIonChemistry

The present invention relates to the technical field of industrial waste liquid treatments and recoveries, especially to a chemical copper plating waste solution treatment method for degrading organic pollutants in a chemical copper plating waste solution and recovering orthophosphates, wherein an oxidation method is adopted to carry out oxidative decomposition on organic pollutants in the chemical copper plating waste solution, concurrently hypophosphite and phosphate in the waste solution are oxidized into orthophosphate, the orthophosphate and copper ions in the waste solution are subjected to a chemical reaction to produce copper phosphate, the excess orthophosphate is added with metal ions so as to carry out a complete reaction of the orthophosphate and the metal ions in the waste solution to obtain the phosphate, and the obtained copper phosphate and the obtained phosphate are separated from the waste solution, and then are subjected to a drying treatment. The method has the following characteristics that: a chemical copper plating waste solution harmless treatment is achieved, resource recovery is achieved, good environmental benefits and good economic benefits are provided, and application prospects are wide.

Owner:东莞道汇环保科技股份有限公司

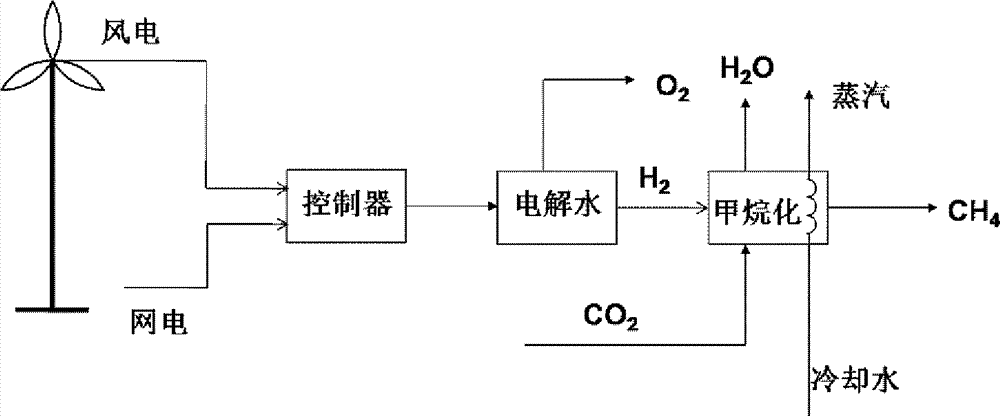

Method for recycling carbon dioxide based on non-grid-connected wind power

InactiveCN104725179AAchieve recyclingEfficient use ofElectrolysis componentsHydrocarbon from carbon oxidesElectrolysisOxygen

The invention relates to a method for recycling carbon dioxide based on non-grid-connected wind power. The method comprises the following steps: providing a power supply for water electrolysis by using complementation of non-grid-connected wind power and grid power; electrolyzing water to generate oxygen and hydrogen, wherein oxygen can be used as an oxygen source for oxygen-enriched combustion, coal gasification or other industrial purposes; feeding hydrogen and CO2 into a hydrogenation catalytic reactor, and reacting hydrogen and CO2 to generate methane (CH4) or methanol (CH3OH) according to demands; collecting catalysis reaction heat by using a heat exchanger so as to obtain steam, wherein a part of the steam is used for generating power, and the other part of steam is used for driving a compressor (for compressing H2, O2 and CH4) to do work; if CH4 is generated, separating the gas discharged from the outlet of the catalytic reactor so as to obtain high-purity methane (CH4), and compressing the high-purity methane so as to be used as an industrial and living gas, and if the catalytic product is methanol, utilizing the methanol as an industrial raw material.

Owner:江苏省宏观经济研究院

Inorganic precoated sand and preparation method thereof

InactiveCN106424535AEmission reductionImprove production environmentFoundry mouldsFoundry coresInorganic phosphateOrganic compound

The invention discloses inorganic precoated sand. The inorganic precoated sand is prepared from raw materials in parts by weight as follows: 80-90 parts of crude sand, 0.3-3 parts of a curing agent, 0.01-0.1 parts of a polyacrylamide modifying agent, 2-10 parts of a binder and 0.04-0.6 parts of calcium stearate. The invention further discloses a preparation method of the inorganic precoated sand. The method comprises steps as follows: (1) the crude sand and the curing agent are mixed; (2) the polyacrylamide modifying agent is added for a reaction; (3) the binder is added and mixed for a reaction; (4) the calcium stearate is added and mixed for a reaction. The prepared inorganic precoated sand is high in strength and good in collapsibility, according to the preparation method, inorganic phosphate of a basic metal replaces organic resin of traditional precoated sand to be used as the binder, intake of organic compounds is avoided, discharge of toxic and hazardous gases is reduced, and the production environment of workers is greatly improved.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

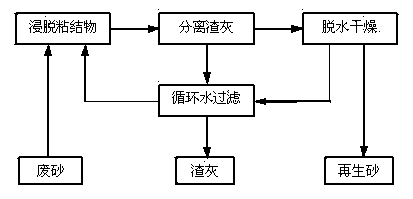

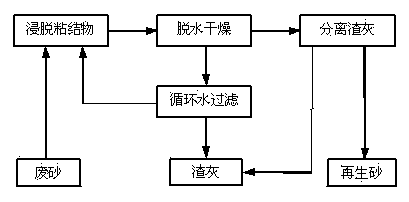

Method and device for peeling off attachments on surfaces of waste casting sands

InactiveCN104162628AGood economic and environmental benefitsRestore surface propertiesMould handling/dressing devicesSlagAqueous solution

The invention discloses a method and device for peeling off the attachments on the surfaces of waste casting sands. The method is characterized in that sands are soaked in a water solution with a certain alkalinity to remove the attachments from the surfaces of the sands without using a machinery friction method or a high temperature burning method to remove the attachments on the sand surfaces so as to completely recycle the waste casting sands, and during the process no waste is generated. The basic operations of the technology device comprise: soaking to remove the attachments, slag ash separation, dehydration drying, and circulation water filtering.

Owner:雷士文

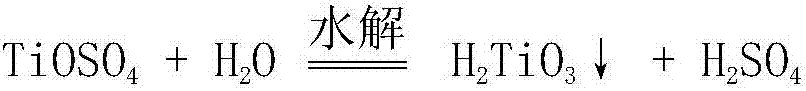

Method of using water-washing filtrate for acidolysis extraction

The invention relates to a titanium dioxide production process through a sulfuric acid method, in particular to a method of using water-washing filtrate for acidolysis extraction. The method includes following steps: A, mixing a titanium-containing raw material with concentrated sulfuric acid for acidolysis; B, adding metered water-washing filtrate into a solid-phase material; C, adding water into the solid-phase material for extraction; D, adding reduced iron powder into extract, and subjecting reduced solution to solid-liquid separation to obtain titanyl sulfate solution. The method has the advantages that the water-washing filtrate can be used for acidolysis extraction, so that sulfuric acid and titanium resources in the water-washing filtrate are recycled fully, titanyl sulfate can be effectively prevented from generating colloid in the process of adding water for extraction, and byproduct recycling and process optimizing are integrated; the water-washing filtrate does not need to be subjected to impurity removal in the method, and ingenious recycling is realized on the basis of fully combining with the titanium dioxide production process through the sulfuric acid method, so that the method has remarkable economic and environment-protection benefit.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

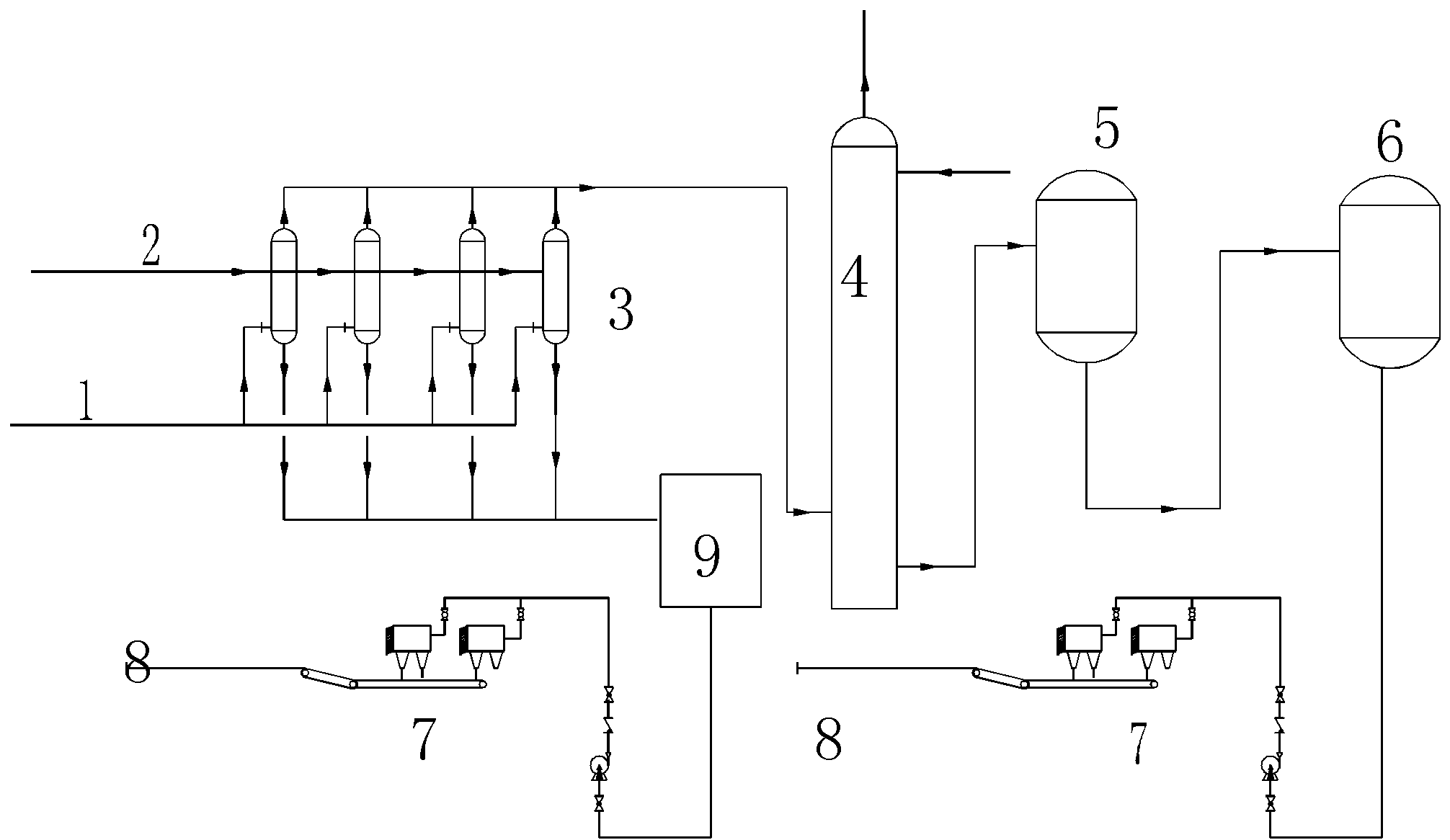

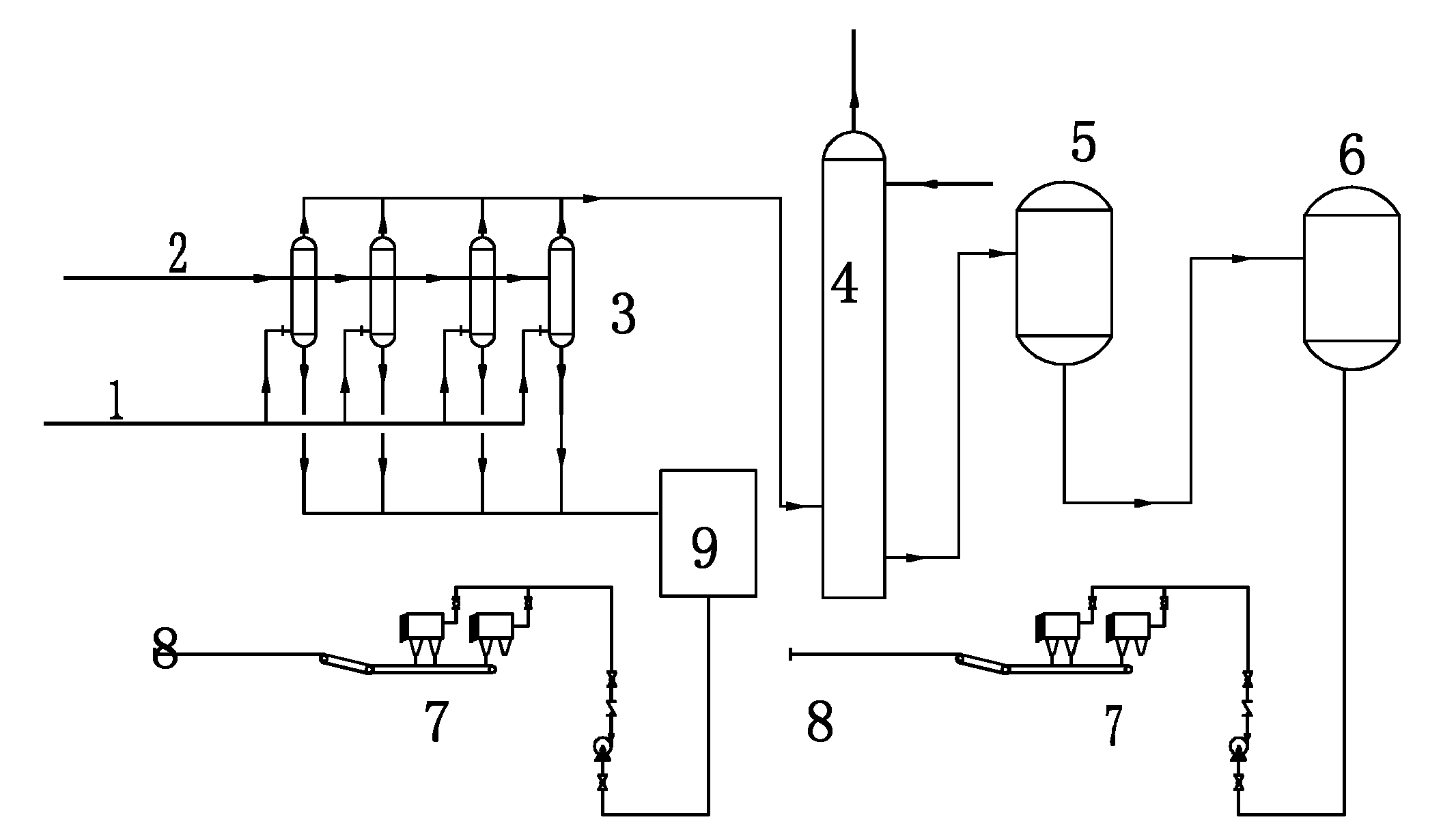

Treatment process and device of waste gas containing hydrogen sulfide and carbon dioxide

InactiveCN102059038AHigh puritySolve the problem of waste gas utilizationCalcium/strontium/barium carbonatesDispersed particle separationEnvironmental resistanceBarium sulfide

The invention discloses treatment process and device of a waste gas containing hydrogen sulfide and carbon dioxide. The treatment process comprises the following steps of: firstly decarbonizing the waste gas through a multilevel barium sulfide solution; then carrying out alkali wash through a sodium hydroxide solution, and then emptying; separating sediments generated after decarbonization to obtain a barium carbonate product; recycling mixed liquor generated after the decarbonization; and evaporating, crystallizing and separating a solution obtained by alkali wash to obtain a sodium sulfide product. The treatment process and device provided by the invention have simple process flow, cannot only directly produce the barium carbonate by utilizing CO2 contained in a mixed gas, but also produce an H2S gas needed by next step reaction through reaction, thereby not only consuming the carbon dioxide gas contained in the mixed gas, but also obtaining a hydrogen sulfide gas with very high purity; and in addition, the crystal sodium sulfide is produced by using the hydrogen sulfide, therefore, no matter the environmental protection and the benefits are optimized.

Owner:LIAOCHENG LUXI CHEM ENG DESIGN

Preparing method for hydrophobic ceramsite lightweight aggregate, hydrophobic ceramsite lightweight aggregate prepared with method and application of hydrophobic ceramsite lightweight aggregate

ActiveCN110117193AEliminates poor hydrophobic propertiesEliminate technical defects of poor sound absorption performanceCeramic materials productionClaywaresPrillFree cooling

The invention provides a preparing method for hydrophobic ceramsite lightweight aggregate, the hydrophobic ceramsite lightweight aggregate prepared with the method and application of the hydrophobic ceramsite lightweight aggregate. The method includes the following steps that a raw material is prepared and granulated, and a first particle is obtained; the first particle is pre-sintered, and a second particle is obtained; the second particle is coated with a hydrophobic function layer, and a third particle is obtained; the third particle is calcined, is cooled to 400 DEG C or below, and is taken out and naturally cooled, and the hydrophobic ceramsite lightweight aggregate is obtained; the raw material comprises solid waste, and is selected from at least one of waste incineration ash residues or manganese residues or gasification residues or aluminum-factory waste residues; according to the mass percentage content, the content of the solid waste is larger than or equal to 40%. By means of the preparing method, the more newly-developing soil waste such as the waste incineration ash residues or the manganese residues or the gasification residues or the aluminum-factory waste residues can be more effectively digested, and meanwhile the hydrophobicity and the sound insulation function of the ceramsite lightweight aggregate are improved; the preparing method has good development prospects, and therefore is more suitable for practicality.

Owner:CHINA BUILDING MATERIALS ACAD

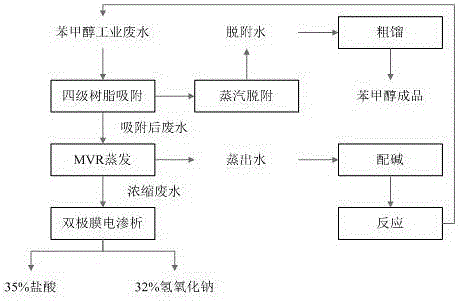

Novel process for treating industrial wastewater with benzyl alcohol

InactiveCN105692996ARealize comprehensive utilizationReduce manufacturing costChlorine/hydrogen-chloride purificationMultistage water/sewage treatmentIndustrial waste waterProcess engineering

The invention relates to a novel process for treating industrial wastewater with benzyl alcohol and salt. The novel process includes steps of (1), adsorbing and recycling the benzyl alcohol in the wastewater, and to be more specific, treating the industrial wastewater with the benzyl alcohol by the aid of macroporous resin four-stage cascade adsorption technologies; (2), comprehensively utilizing NaCl in the wastewater by means of electrodialysis, to be more specific, concentrating the adsorbed and treated wastewater by the aid of mechanical vapor recompression (MVR) to obtain high-salt wastewater, treating the high-salt wastewater by the aid of bipolar membrane electrodialysis to recycle hydrogen chloride and sodium hydroxide which are electrodialysis byproducts. The benzyl alcohol adsorption rate in the step (1) can reach 99.8% at least, and the content of the benzyl alcohol in the wastewater treated at the step (1) reaches 100 ppm. The novel process has the advantages that the environment polluting industrial wastewater with the benzyl alcohol can be treated by the aid of the novel process, the benzyl alcohol and the sodium chloride in the wastewater can be recycled, accordingly, the production cost can be obviously reduced, and the novel process has economical and environmental protection benefits.

Owner:HUBEI GREENHOME MATERIALS TECH INC +1

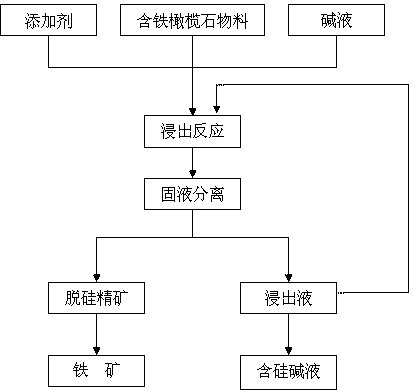

Comprehensive utilization method of ferriferous fayalite material

ActiveCN103343225AIncrease response rateEasy to separateProcess efficiency improvementFayaliteLiquid state

The invention discloses a comprehensive utilization method of a ferriferous fayalite material, relates to a processing method of the ferriferous fayalite material, and in particular relates to a method for separating and utilizing iron and silicon in fayalite. The method is characterized by comprising the following steps of: grinding the ferriferous fayalite material; mixing with alkaline liquor for leaching reaction; performing solid-liquid separation on obtained reaction slurry to obtain desilicated concentrate and silicon containing alkaline liquor; and oxidizing the desilicated concentrate in air to goethite. The method disclosed by the invention enriches, separates and extracts iron and silicon elements to form two products: goethite and silicon containing alkaline liquor through alkaline liquor leaching, wherein iron and silicon in ferriferous fayalite exist in solid and liquid states, so that the comprehensive utilization ratio of resources is high and the economic benefit is better.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

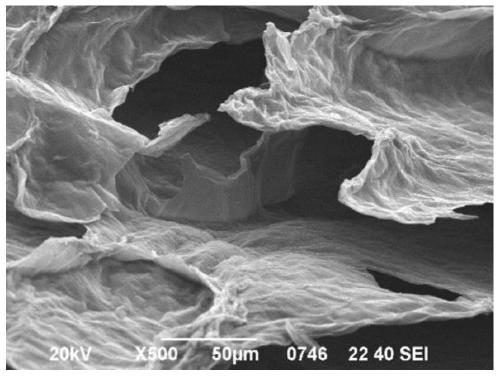

Preparation method and application of graphene oxide

ActiveCN109704322AEnhanced bioaugmentationAvoid churnCarbon compoundsTreatment with anaerobic digestion processesWater bathsIce water

The invention belongs to the technical field of sewage treatment, and relates to a preparation method and application of graphene oxide. The preparation method of graphene oxide comprises the steps:adding graphite powder to a beaker containing concentrated sulfuric acid for pre-oxidation firstly, then adding potassium permanganate to the beaker in an ice water bath, performing stirring, removingthe ice water bath, adding deionized water at room temperature, performing stirring, then adding a saturated hydrogen peroxide solution slowly until the color of the mixed liquid turns golden yellow,and performing stirring; and finally, performing washing and precipitation on the obtained mixed liquid, and performing centrifugation, dialysis and freeze drying so as to obtain the brown-yellow floc graphene oxide. The whole preparation process does not need complicated temperature control, and has easy operation and no high-temperature production stages, the production safety factor is improved, meanwhile, more energy saving is achieved, and the production cost is reduced; and the produced graphene oxide powder has good strengthening performance for anammox bacteria, and is suitable for industrial production, and good economic and environmental benefits can be achieved.

Owner:青岛绿洁坤环保科技有限公司

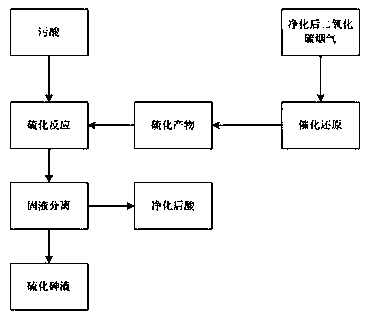

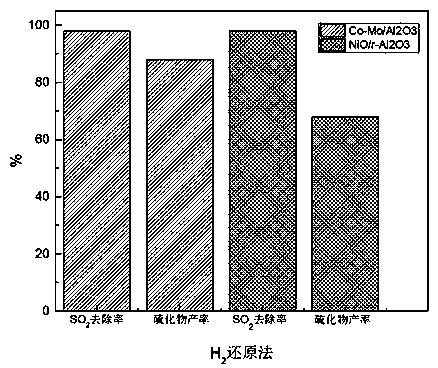

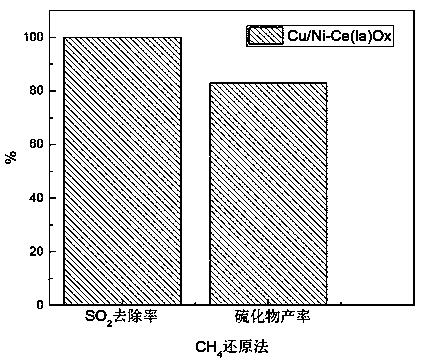

Method for treating heavy-metal contaminated acid wastewater

InactiveCN109354149AAvoid the problem of increased solid wasteReduce financial burdenGas treatmentWater contaminantsHigh concentrationReduction treatment

The invention discloses a method for treating heavy-metal contaminated acid wastewater, and belongs to the technical field of wastewater treatment. The method comprises the steps that sulfur dioxide obtained after flue gas of a smelting furnace is purified and afterwards subjected to catalytic reduction treatment to obtain a sulfur product containing hydrogen sulfide and the like; the sulfur product is introduced into contaminated acid and has a sulfide precipitation reaction with heavy metal ions and arsenic ions in the contaminated acid; a contaminated acid solution after the sulfurization reaction is subjected to solid-liquid separation, and obtained products of arsenic sulfide slag and heavy-metal sulfurized slag precipitations are recycled. By means of the method, purification equipment for a process of producing acid by using high-concentration sulfur dioxide flue gas obtained by smelting sulphide ore is relied on, with sulfur dioxide purified after sulfide flue gas acid production as a raw material, the sulfur product is prepared through catalytic reduction to treat the contaminated acid, the contaminated acid generated in the industry can be efficiently treated, and the arsenic sulfide slags can also be recycled; by means of the method, the raw material sulfur dioxide produced in enterprises is utilized for treating the contaminated acid produced in the acid productionprocess of the enterprises, the cost of treating the contaminated acid by the enterprises is reduced, and the method has obvious economic and environmental benefits.

Owner:KUNMING UNIV OF SCI & TECH

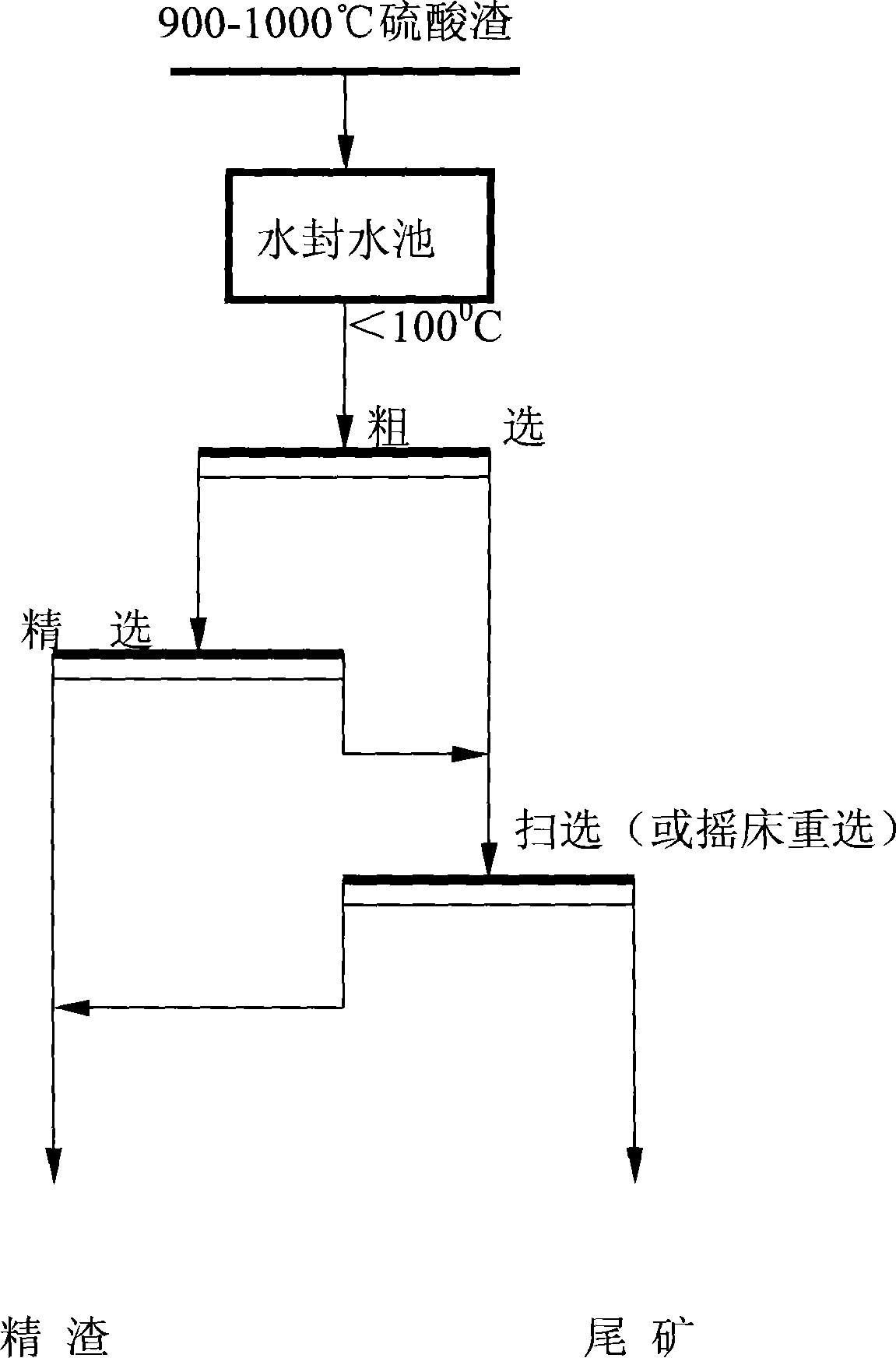

Technique for treating pyrile cinder

InactiveCN101049582AHigh recovery rateGood economic and environmental benefitsMagnetic separationWet separationCinderMagnetic separator

A process for treating the sulfuric acid dregs generated by preparing sulfuric acid from troilite concentrate includes such steps as delivering said sulfuric acid dregs via a sealed pipeline into a water sealed water pool, quick cooling, primary magnetic separating by a weak magnetic field (1100-1200 Oc), secondary magnetic separating by another weak magnetic field (1000-1100 Oc), and final separation of tailings by the third weak magnetic field (1200-1500 Oc) or a shaking table. It has high recovery rate of Fe ore.

Owner:杨建华

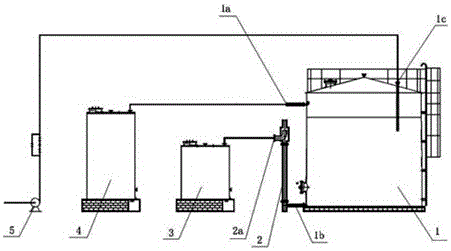

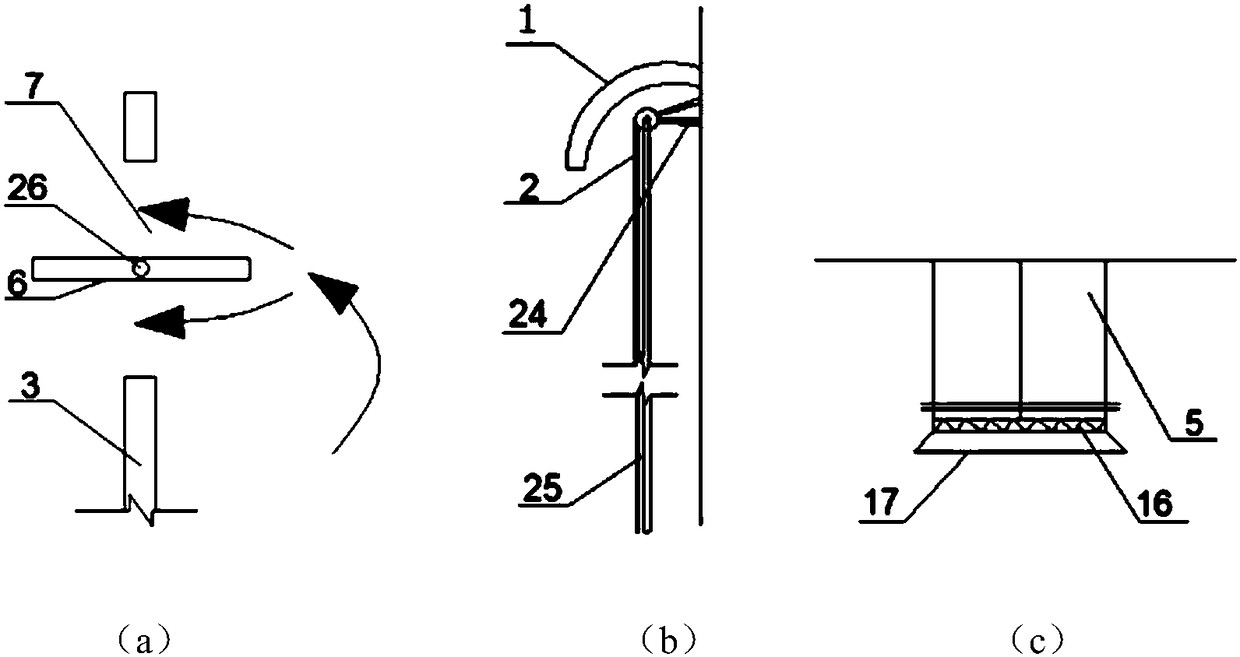

Heat preservation powder negative pressure recycling system in production of refractory material by using fusion casting method

InactiveCN103691215ARecycle thoroughlyNo pollutionDispersed particle filtrationDirt cleaningRefractoryVacuum pump

The invention relates to the technical field of refractory material production, and in particular relates to a heat preservation powder recycling system in production of a refractory material by using a fusion casting method. The system comprises a material purification system, a negative pressure vacuum system and a material recycling system, wherein a suction nozzle (1) and a soft connecting tube (2) are positioned inside a material tank (3) in the material purification system; the suction nozzle (1) is connected with a dust collector (5) through the soft connecting tube (2) and a transmission pipeline (4) in sequence; a vacuum pump (7) is connected with the dust collector (5) through a draft tube (6) in the negative pressure vacuum system; in the material recycling system, the upper part of a middle material cabin (10) is connected with the dust collector (5), and the lower part of the middle material cabin is connected with a material warehouse (11); a conveyer (12) is arranged at the bottom of the material warehouse (11) and is used for conveying a material to a material tank (13). The heat preservation powder negative pressure recycling system provided by the invention is thorough in heat preservation powder recycling, high in efficiency and free of dust pollution and simple and convenient to operate, and has good economic and environment-friendly benefits.

Owner:郑州东方安彩耐火材料有限公司

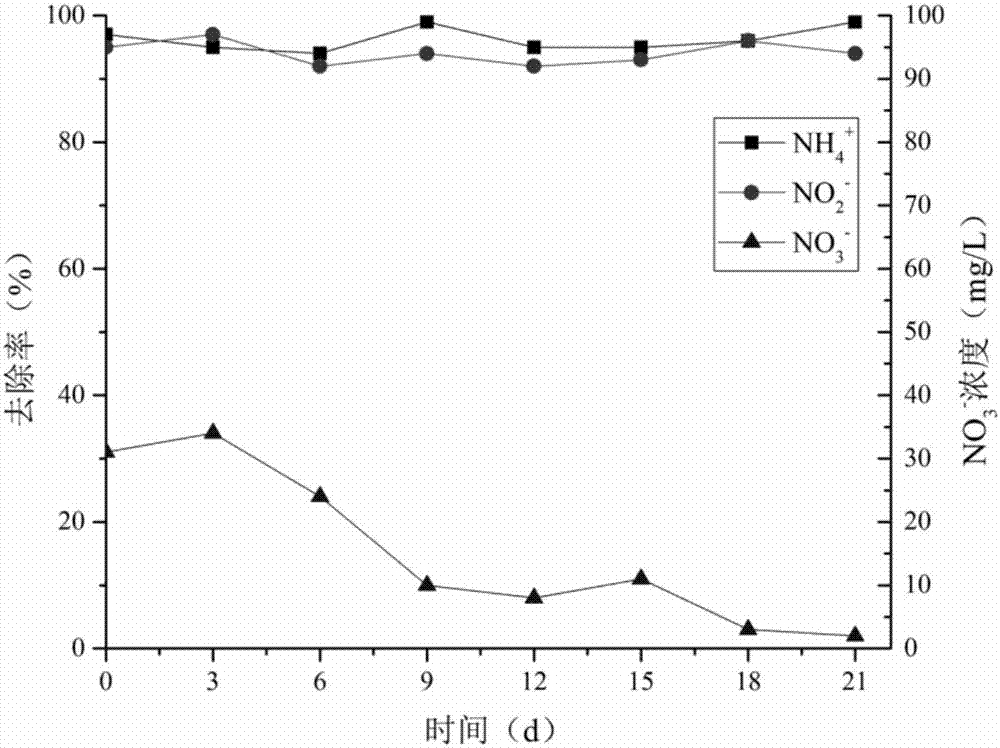

Preparation method of immobilized anammox bacterial sludge and method for sewage treatment with the same

ActiveCN107162187AImprove gel performanceGood swelling propertiesBiological treatment apparatusTreatment with anaerobic digestion processesElectron donorPolyvinyl alcohol

Belonging to the field of biological sewage treatment, the invention discloses a preparation method of immobilized anammox bacterial sludge and a method for sewage treatment with the same. According to the invention, polyvinyl alcohol, konjac glucomannan, protein powder, Fe3O4 and anammox bacterial sludge are mixed to prepare immobilized particles, then magnetic pyrite particles are added into a fluidized bed reactor, and are mixed with the immobilized particles to serve as biological filler. Through magnetic adsorption of magnetic pyrite to Fe3O4, loss of embedded particles can be avoided, anammox bacterial colonies can adhere to the filler stably, and the residence time of anammox bacteria can be increased, thus improving the removal efficiency of ammonia nitrogen and nitrite nitrogen in wastewater, at the same time sulfur in the magnetic pyrite can be used as a denitrification electron donor, nitrate nitrogen in the water can be reduced into N2 through the action of autotrophic denitrification bacteria, thus enhancing the overall nitrogen removal effect. The immobilized anammox bacterial sludge prepared by the method provided by the invention has the advantages of simple preparation, low cost, good treatment effect and strong shock resistance, and is suitable for practical production.

Owner:NANJING UNIV

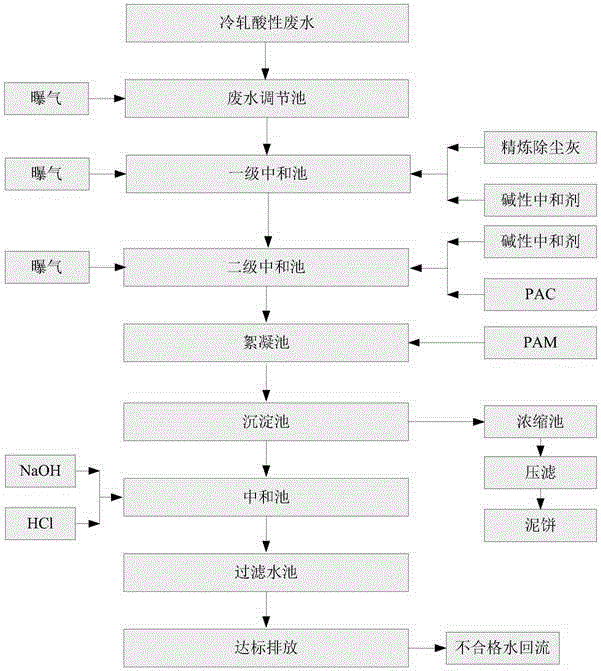

Method of comprehensive utilization of steelmaking refining precipitator dust

ActiveCN106745960AAchieve recyclingGood economic and environmental benefitsTransportation and packagingSolid waste disposalZincSludge

The invention relates to a method of comprehensive utilization of steelmaking refining precipitator dust. According to the invention, steelmaking refining precipitator dust is used to neutralize acidic cold rolling wastewater; specifically, alkaline substances such as CaO in the refining precipitator dust is used to neutralize acidic cold rolling wastewater; the wastewater is subjected to such processes as aeration, neutralization, PH adjustment and flocculating settling to meet the discharge standard; moreover, valuable elements such as Fe and Zn in the steelmaking refining precipitator dust and the acidic cold rolling wastewater enters into settled sludge; the sludge is dehydrated and filter-pressed into mud cake; and the mud cake is treated through a high temperature reduction process to obtain metallized pellets and dust rich in zinc, and such valuable elements as Fe and Zn are recovered. According to the invention, both steelmaking refining precipitator dust and acidic cold rolling wastewater can be treated simultaneously, and therefore, the problems in environmental protection are solved, and waste control by waste is achieved; in addition, such value elements as Fe, Zn and Mn in the steelmaking refining precipitator dust and the acidic cold rolling wastewater can be recovered, thereby achieving recycling of resources and providing significant economic benefits and environmental benefits.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Control method of antibiotic resistance gene of livestock residue

PendingCN108148606AGood economic and environmental benefitsEliminate potential risksOther chemical processesBiofuelsOxygen deficiencyBiomass

The invention discloses a control method of an antibiotic resistance gene of livestock residue, which includes steps of mixing livestock residue containing the antibiotic resistance gene with biomasswaste to reduce moisture content to be less than 40%; continuously delivering livestock residue to an external heating type pyrolyzing furnace through a spiral conveying method, and performing pyrolyzing treatment in the atmosphere of oxygen-free or oxygen deficiency; completely decomposing antibiotic resistance gene microorganisms in excrement to obtain a solid matter; cooling the solid matter without oxidization in the atomosphere of oxygen deficiency to obtain charcoal. In virtue of high temperature process of the pyrolytic process, the antibiotic resistance gene microorganisms in the livestock residue can be decomposed on a molecular level, thus the potential risk of the antibiotic resistance gene is completely and safely eliminated; meanwhile, massive combustible gaseous matters generated during the pyrolyzing process can be circularly burned to be pyrolyzing energy source; the antibiotic resistance gene has the advantages of clean combustion and energy-saving emission reduction,the acquired charcoal has good physicochemical property and wide application.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

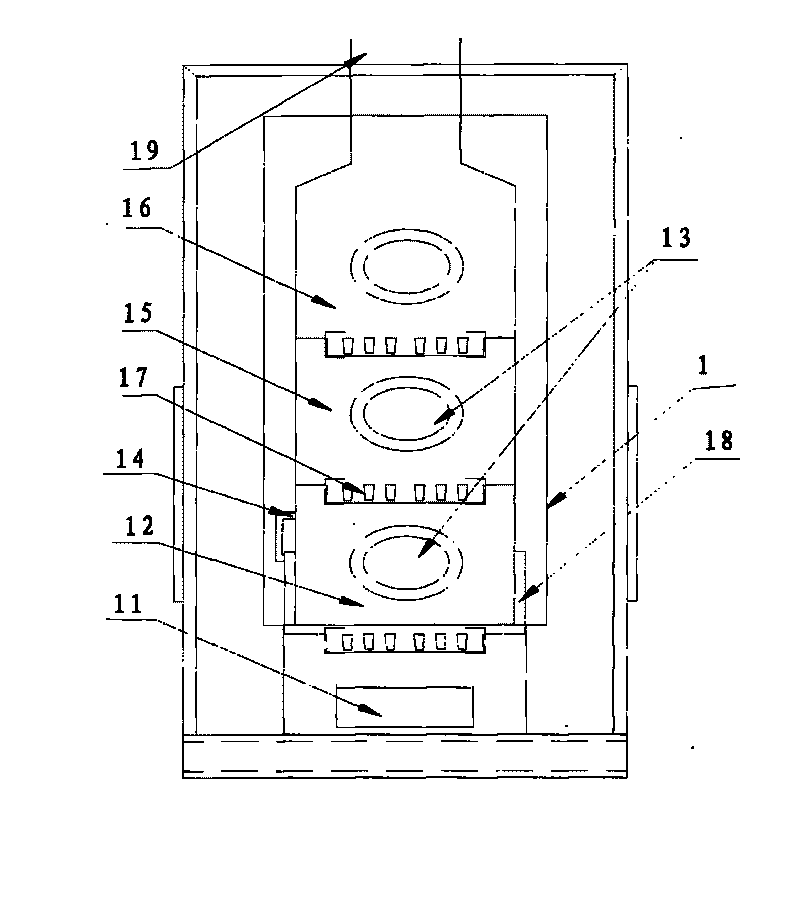

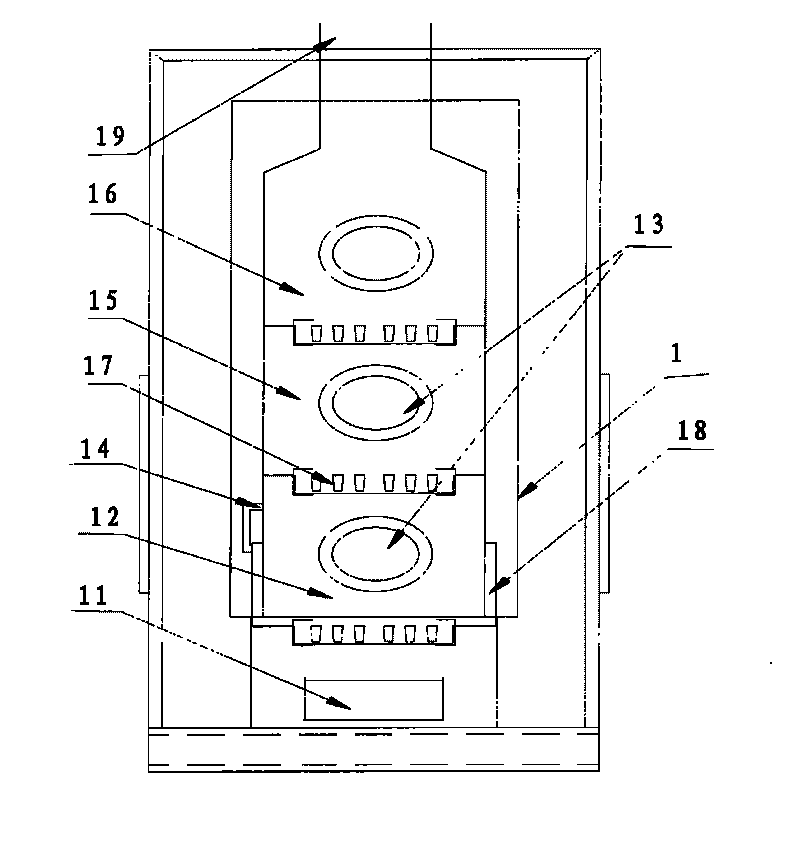

Multistage burner

InactiveCN101696797AReduce the temperatureExtended service lifeSolid fuel combustionNon-combustible gases/liquids supplySocial benefitsCombustion chamber

The invention relates to a multistage burner comprising a furnace body and a first-stage combustion chamber arranged in the furnace body. The furnace body is provided with a feed inlet and a cleaning door; at least one auxiliary combustion chamber communicated with the first-stage combustion chamber is arranged in the furnace body; and an auxiliary combustion medium in the auxiliary combustion chamber is a high temperature resistant material. The multistage burner has simple structure, energy saving and environmental protection, thereby having higher economic and social benefits and being the milestone of clean combustion of future traditional energy resources.

Owner:童书开

Method for applying slag pressing agent produced by blast furnace gun mud to converter steelmaking

ActiveCN104531938AGood economic and environmental benefitsEliminate land occupation and pollution problemsManufacturing convertersCrusherDry powder

The invention discloses a method for applying a slag pressing agent produced by blast furnace gun mud to converter steelmaking. The method comprises the following steps: firstly crushing waste blast furnace gun mud into powder particles with particle size being smaller than 1mm by using a cone crusher or a raymond mill, selecting can delivering limestone powder with particle size being smaller than 1mm to a ball-pressing production line for later use; adding the gun mud powder and the limestone powder into a stirrer according to a mass ratio of 95 to 5, uniformly stirring and mixing by using a circulation operation manner, wherein the total weight of the materials added at each time is 5 tons, and the time only used for stirring after adding the materials lasts for 35 minutes; then discharging the materials; adding the uniformly-mixed raw materials into a dry powder ball pressing machine or a fireproof material ball pressing machine to be pressed into oval balls with size of 30+ / -5mm; and drying the oval balls, then delivering the dried oval balls to a converter production line, conveying the oval balls to a high material bin for later use by using a belt conveyor system, adding the oval balls in the process of pressing slag by the converter according to a process of normally using the slag pressing agent, defoaming and pressing slag.

Owner:XINJIANG BAYI IRON & STEEL

Method for adsorbing and degrading perchlorate in water

InactiveCN102502911AShort adsorption timeGood economic and environmental benefitsWater contaminantsWater/sewage treatment by sorptionChemistryChlorate

The invention belongs to the technical field of water treatment, and relates to a method for adsorbing and degrading perchlorate in water. The method comprises the following steps of: (1) adding an adsorbent into water to be treated; (2) adsorbing and degrading perchlorate in water with an adsorbent at a certain rotating speed and certain temperature; and (3) after adsorbing, intercepting, separating and treating the adsorbent in water. In the method, perchlorate in water is adsorbed and degraded by using patina, the effects of synchronous adsorption and degradation of perchlorate into harmless chlorine ions are represented, adsorption time is short, over 90 percent of perchlorate can be adsorbed within 6 hours, degradation rate is over 75 percent, and good economic benefit and environmental benefit are achieved.

Owner:TONGJI UNIV

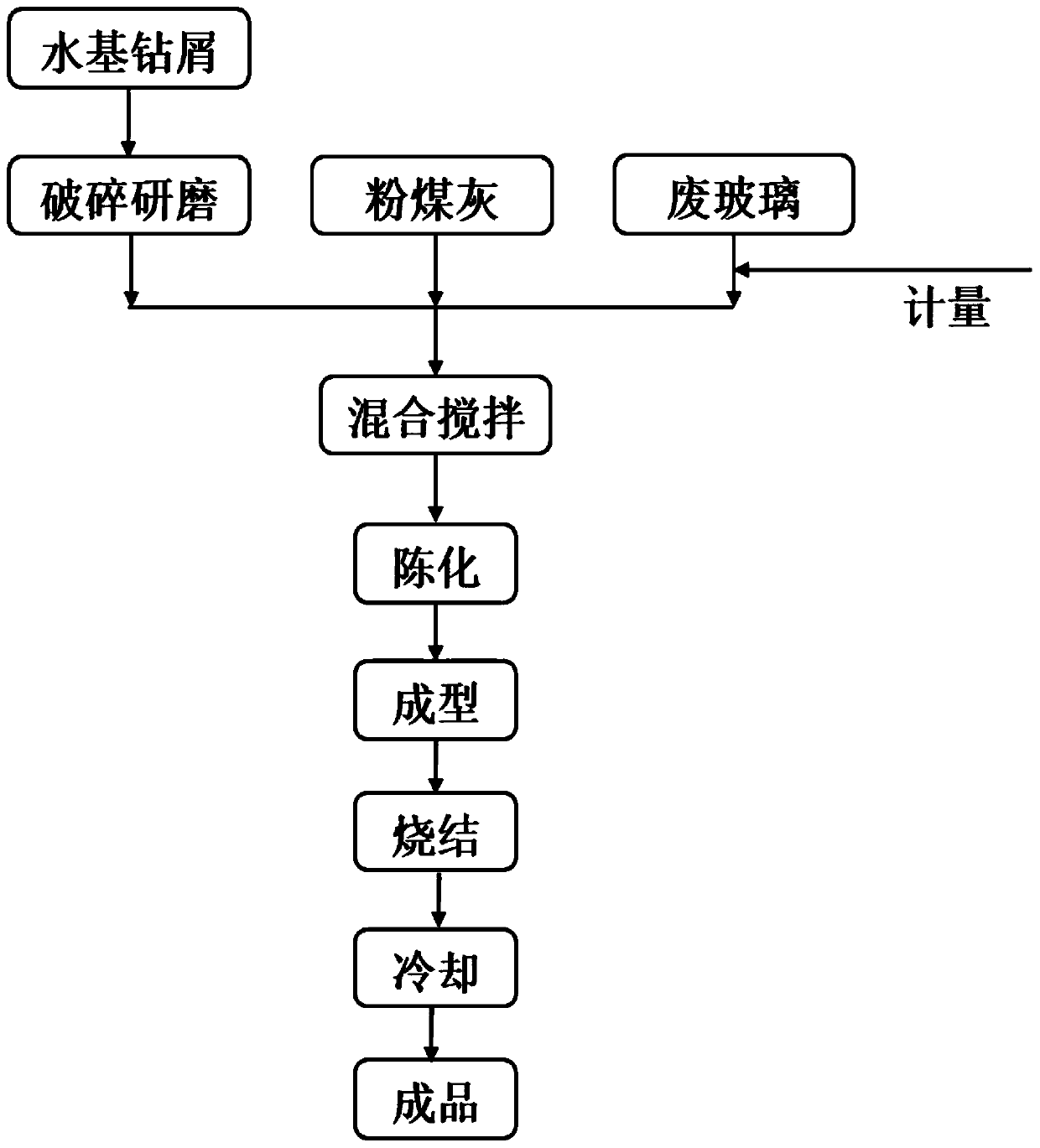

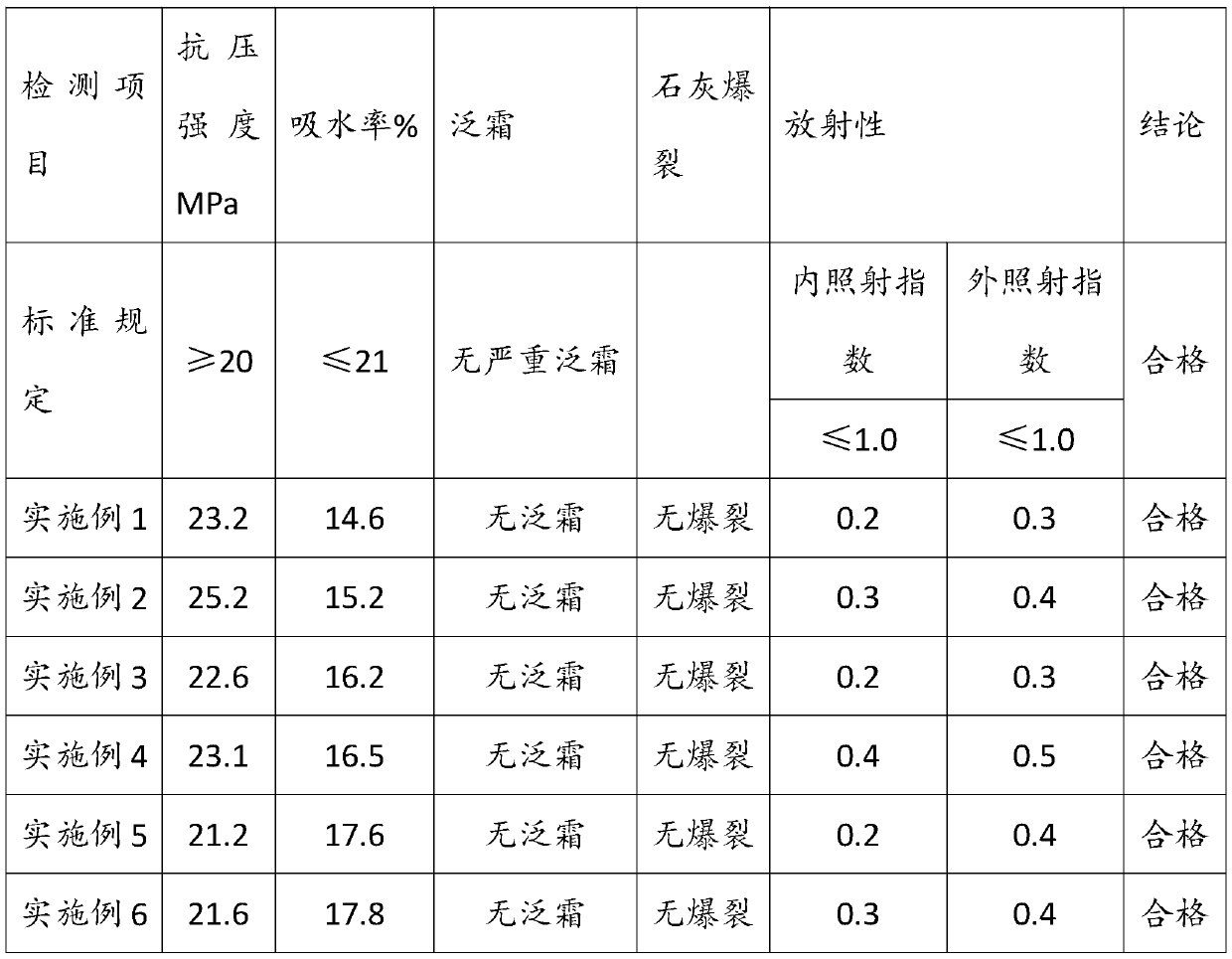

Method for preparing sintered brick from shale gas water-based drilling waste

InactiveCN110683836AReduce governance costsGood economic and environmental benefitsCeramic materials productionClaywaresShale gasDrill cuttings

The invention discloses a method for preparing a sintered brick from shale gas water-based drilling waste. The method comprises the following steps: crushing, grinding and sieving water-based drillingcuttings to obtain water-based drilling cutting powder with fineness of lower than 2 mm; uniformly mixing the water-based drilling cutting powder, fly ash and waste glass in proportion under stirringto obtain a mixed material; adding water into the mixed material, uniformly stirring the material, carrying out ageing for 24 h, and pressing the aged material into a green brick; and drying the molded green brick at 105 + / -5 DEG C for 4 h, heating the green brick to 850-900 DEG C at a heating rate of 1-4 DEG C / min, carrying out high-temperature sintering, carrying out heat preservation for 2 h,and then performing cooling and drawing to obtain a finished sintered brick product. According to the invention, the waste glass is used for tempering the water-based drilling cuttings, so the contentof silicon dioxide in the water-based drilling cuttings can be increased, the content of calcium oxide and the content of SO3 are reduced, the raw materials are allowed to meet the component requirements of the sintered brick, and therefore the phenomena of frosting, cracking and the like of a brick body are avoided.

Owner:SOUTHWEST PETROLEUM UNIV

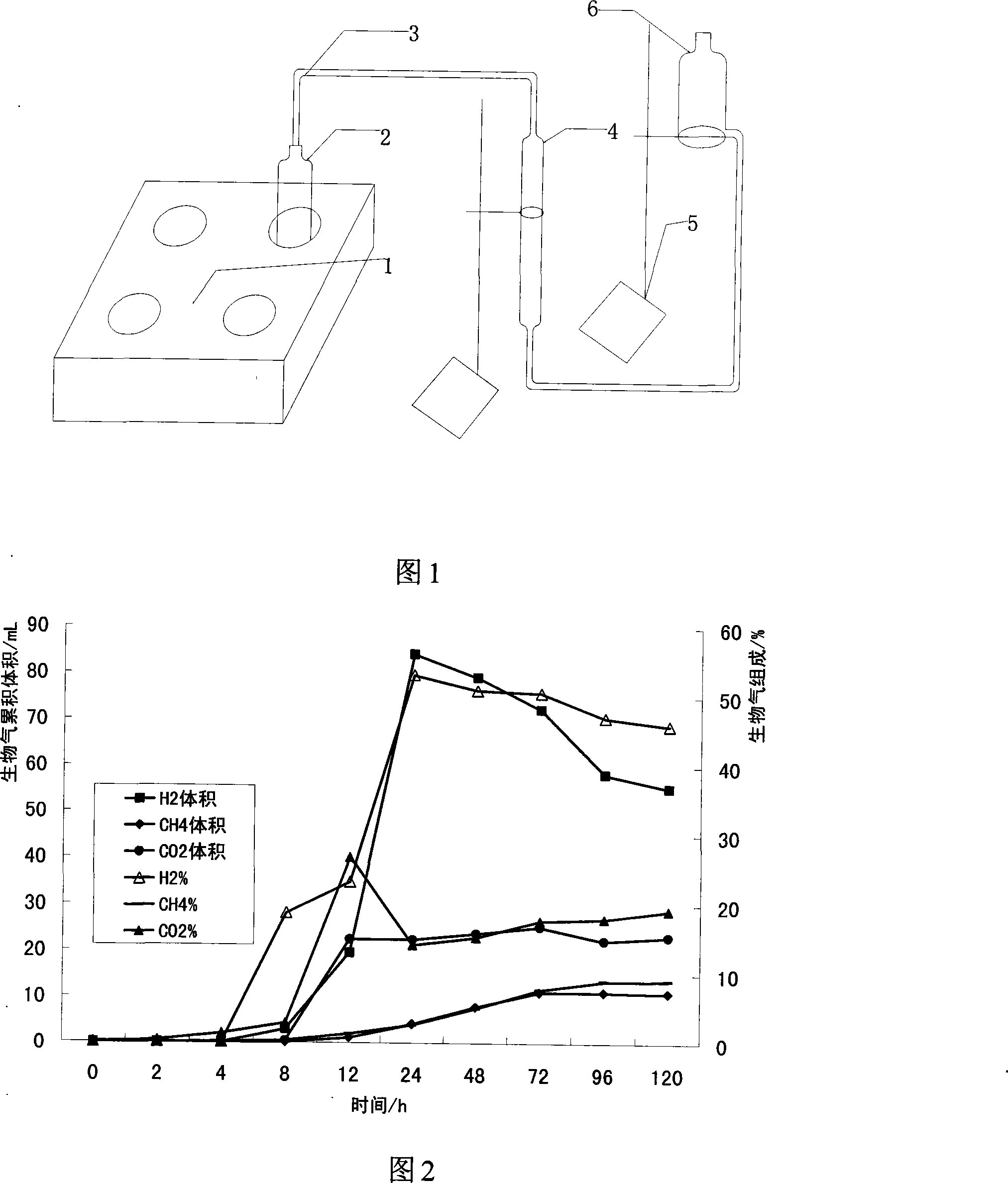

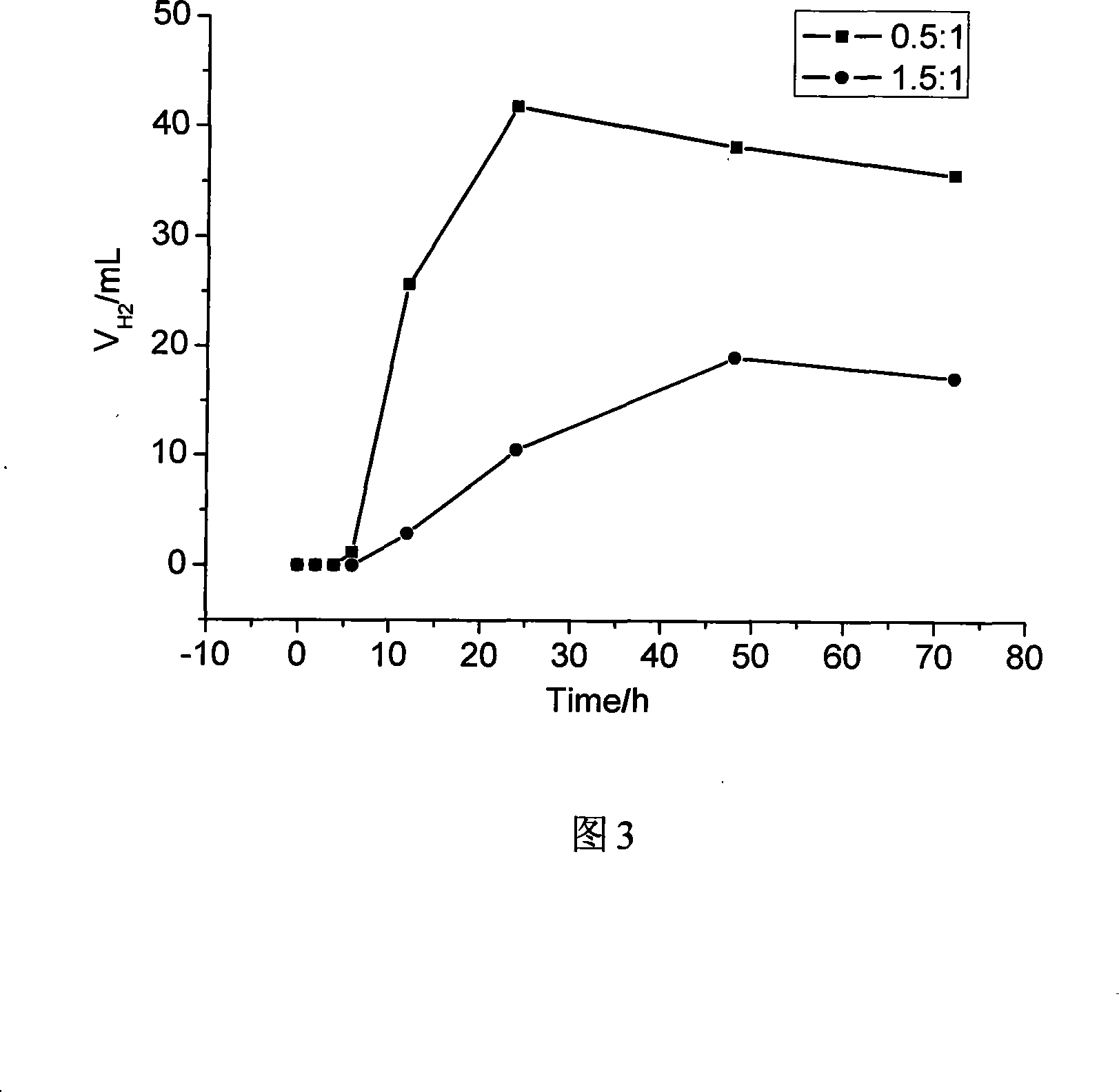

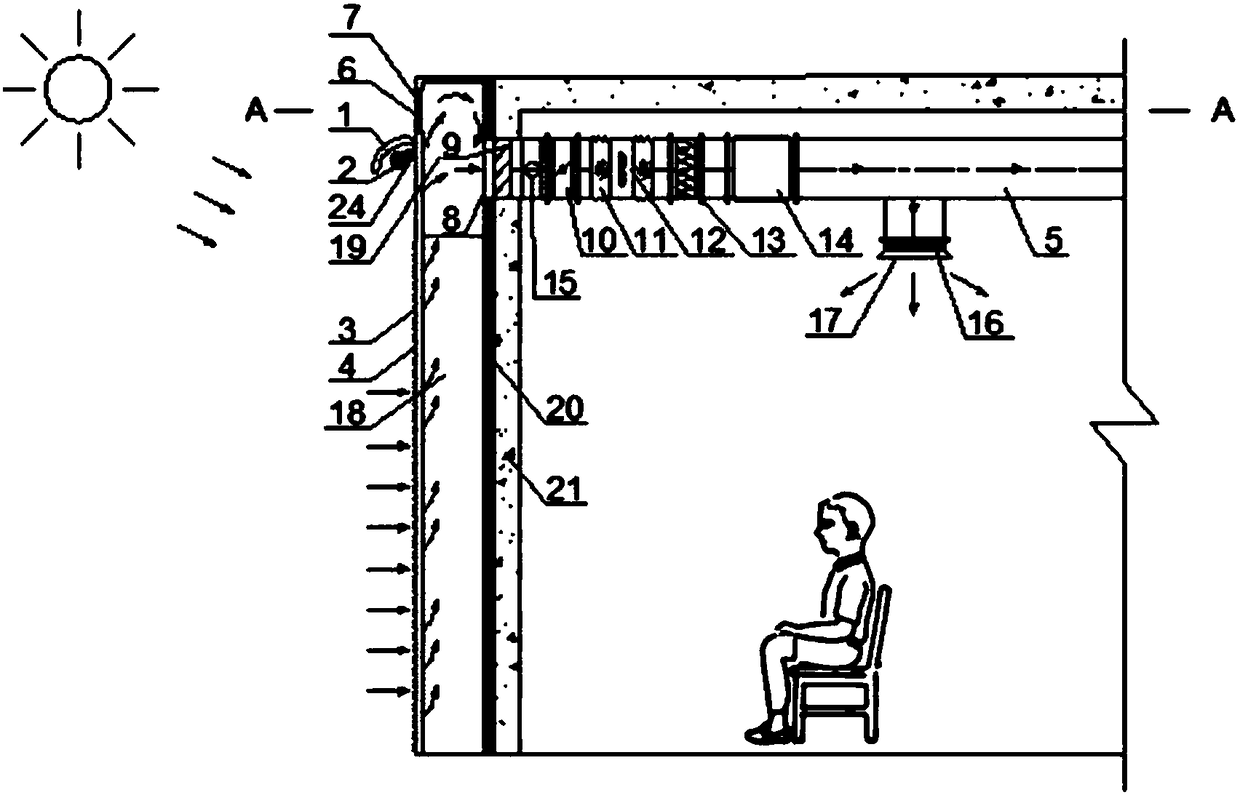

Biological method for producing hydrogen by mixing sludge and organic garbage

InactiveCN101186931AAchieve reductionGood economic and environmental benefitsGas production bioreactorsFermentationNutrientOrganic acid

The invention discloses a biological process for producing hydrogen by the mixed sludge and organic refuse. With the process, the sludge which contains nutrient elements of nitrogen, phosphorus, potassium and the like and the organic refuse are evenly mixed according the proportion of 0.5-1.5: 1 (w / w), and nutrient solution which contains trace elements, including Ca, Mg, Zn and Fe, which are the essential elements for the growth of anaerobe at the volumetric ratio of 30-40: 1 of the mixed sludge and organic refuse to substrate, and then the mixed material is introduced to an enclosure mixing hydrogen production device, the carbohydrate in the mixing material is decomposed to be H2, low molecular organic acids and alcohol materials by the anaerobe existed in the mixed material, and the temperature for the fermentation of the anaerobe is controlled to be 37+- 1 DEG C. The invention can successfully realize the bio-hydrogen production under the strictly anaerobic environment and has important engineering value.

Owner:SOUTH CHINA UNIV OF TECH

Fluorine-containing heavy-metal-ion-containing waste water processing agent and fluorine-containing heavy-metal-ion-containing waste water processing method

ActiveCN105347505AReduce heavy metal emissionsGood economic and environmental benefitsWater contaminantsWaste water treatment from metallurgical processActivated carbonEnvironmental chemistry

The invention relates to a fluorine-containing heavy-metal-ion-containing waste water processing agent and a fluorine-containing heavy-metal-ion-containing waste water processing method. The processing agent has a formula as follows: by weight, 8%-79% of one or several selected from iron powder, ferrous sulphate, sodium sulfite and ferrous chloride, 0.1%-6% of sodium borohydride and / or potassium borohydride, 0.2%-1% of biological flocculants, 0.1%-0.8% of non-ionic polyacrylamide, 10%-40% of active carbon, 5%-30% of calcium fluoride, and 5%-30% of calcium chloride. The total nickel content in fluorine-containing heavy-metal-ion-containing waste water after processing in electroplate and printing and dyeing industries can be lowered greatly, heavy metal discharge is reduced, and the total nickel content in fluorine-containing heavy-metal-ion-containing waste water after processing of the provided processing agent is less than 0.006mg / L.

Owner:太仓中化环保化工有限公司

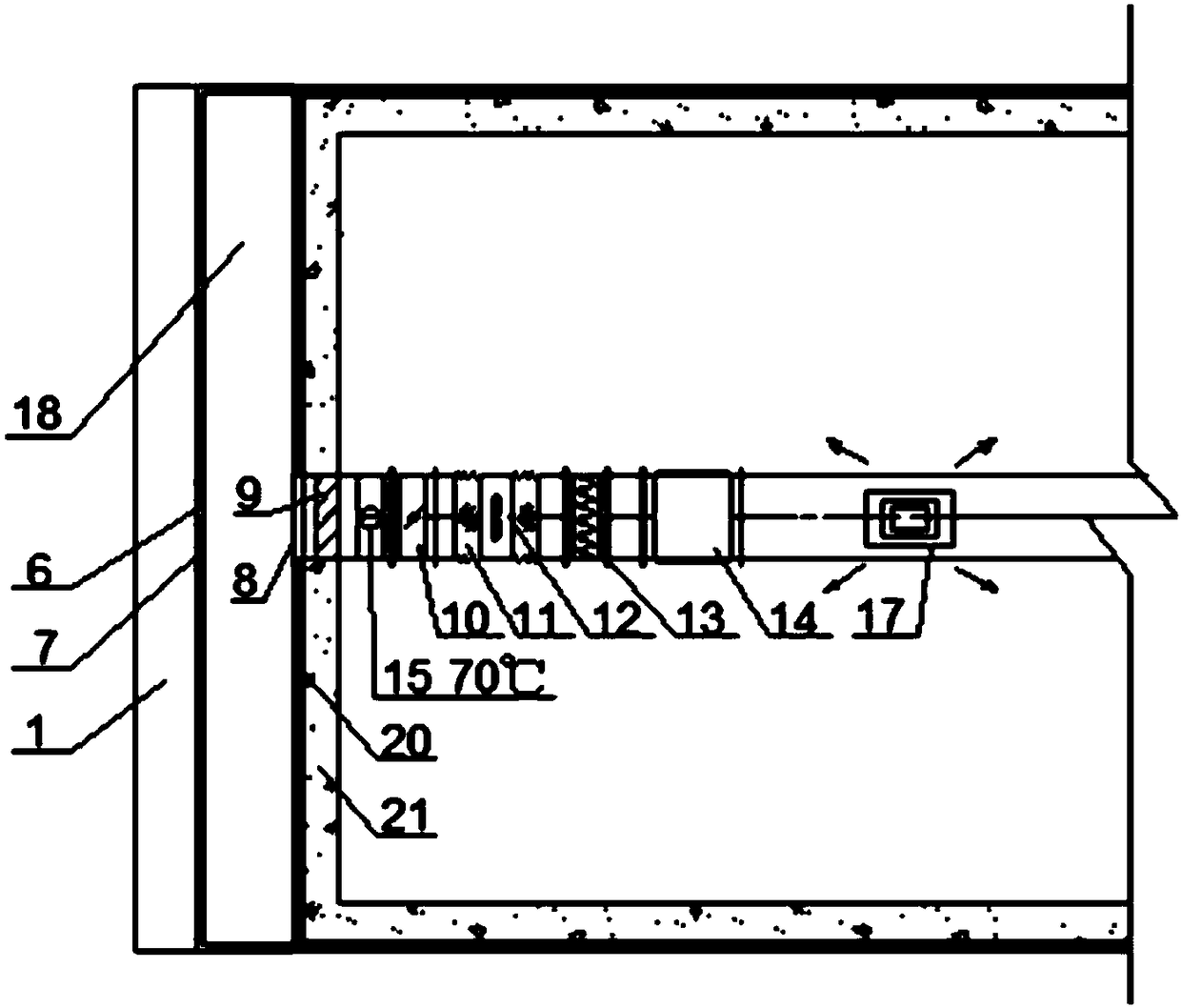

Micro-hole permeation-type fresh air preheating solar wall

ActiveCN108104300AQuality improvementGuaranteed comfortSolar heating energyLighting and heating apparatusIndoor air qualityFresh air

The invention discloses a micro-hole permeation-type fresh air preheating solar wall which comprises a heat collecting and storing system and an air flow conveying system. The heat collecting and storing system comprises a solar wallboard, and an air interlayer is reserved between the solar wallboard and a building outer wall. An air cabin communicating with the air interlayer is arranged above the solar wallboard, and an exhaust opening is formed in the outer wall of the air cabin. A flow guiding board for adjusting the opening degree of the exhaust opening is movably mounted on the exhaust opening. Air inlet holes are distributed in the solar wallboard, and a heat absorbing coating is arranged on the outer wall of the solar wallboard. A sun-shading device is arranged on the outer wall ofthe solar wallboard, and the air flow conveying system comprises a fresh air pipeline. An air valve and an axial flow fan are mounted on the fresh air pipeline, and an air supply opening is formed inthe side wall of the fresh air pipeline. One end of the fresh air pipeline communicates with the air cabin. According to the micro-hole permeation-type fresh air preheating solar wall, fresh air canbe obtained in winter, the appropriate indoor temperature can be kept, and the requirements for energy conservation and the indoor air quality can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com