Preparation method and application of graphene oxide

A graphene and pre-oxidation technology, applied in chemical instruments and methods, anaerobic digestion, inorganic chemistry, etc., can solve problems such as complex temperature control, high cost of graphene oxide, complex graphene oxide process, etc., to achieve prolonged reaction Time, easy operation, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

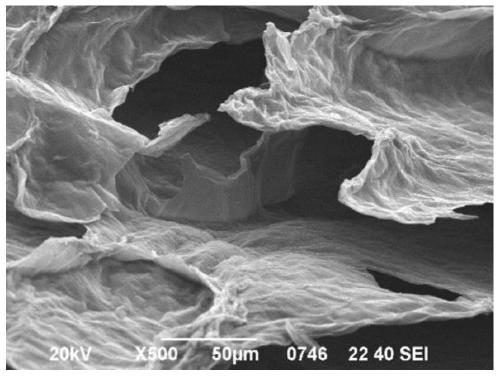

[0018] The concrete process that the embodiment of the present invention prepares graphene oxide is as follows:

[0019] (1) Pre-oxidation: get 5 grams of high-grade pure graphite powder and add it to a beaker with 500 milliliters of concentrated sulfuric acid with a mass concentration of 98%, and mechanically stir for 24 hours to obtain a mixed solution A;

[0020] (2) Oxidation: Move the beaker containing the mixed solution A to an ice-water bath below 4°C, then slowly add 25 grams of potassium permanganate (KMnO4) into the beaker, stir mechanically for 24 hours, remove the ice-water bath, and place at room temperature After slowly adding 500 ml of deionized water, stir mechanically for 24 hours to obtain mixed solution B; then slowly add saturated hydrogen peroxide solution into mixed solution B until the color of the mixed solution turns golden yellow and there is no color change within 1 minute Stir for 5h;

[0021] (3) Washing and precipitation: Fill the beaker with wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com