Method for preparing stone blocking dam by using waste and old rubber

A rock-block dam and obsolete technology, which is applied in construction, protective equipment, etc., can solve problems such as high construction costs, easy corrosion of steel bars, and insufficient long-term stability of energy-dissipating embankments, and achieve strong site adaptability, wide application range, and economical Significant effect on benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

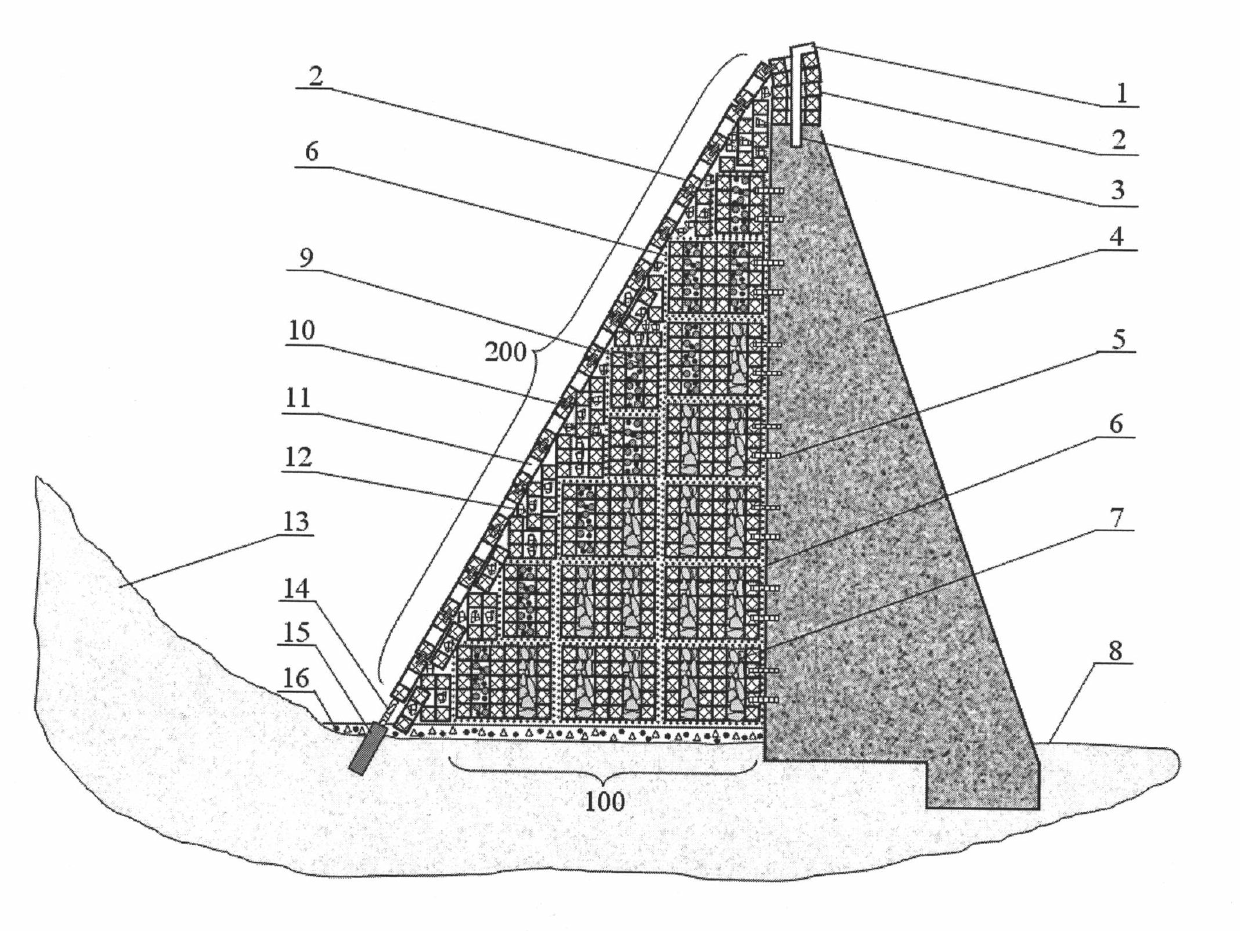

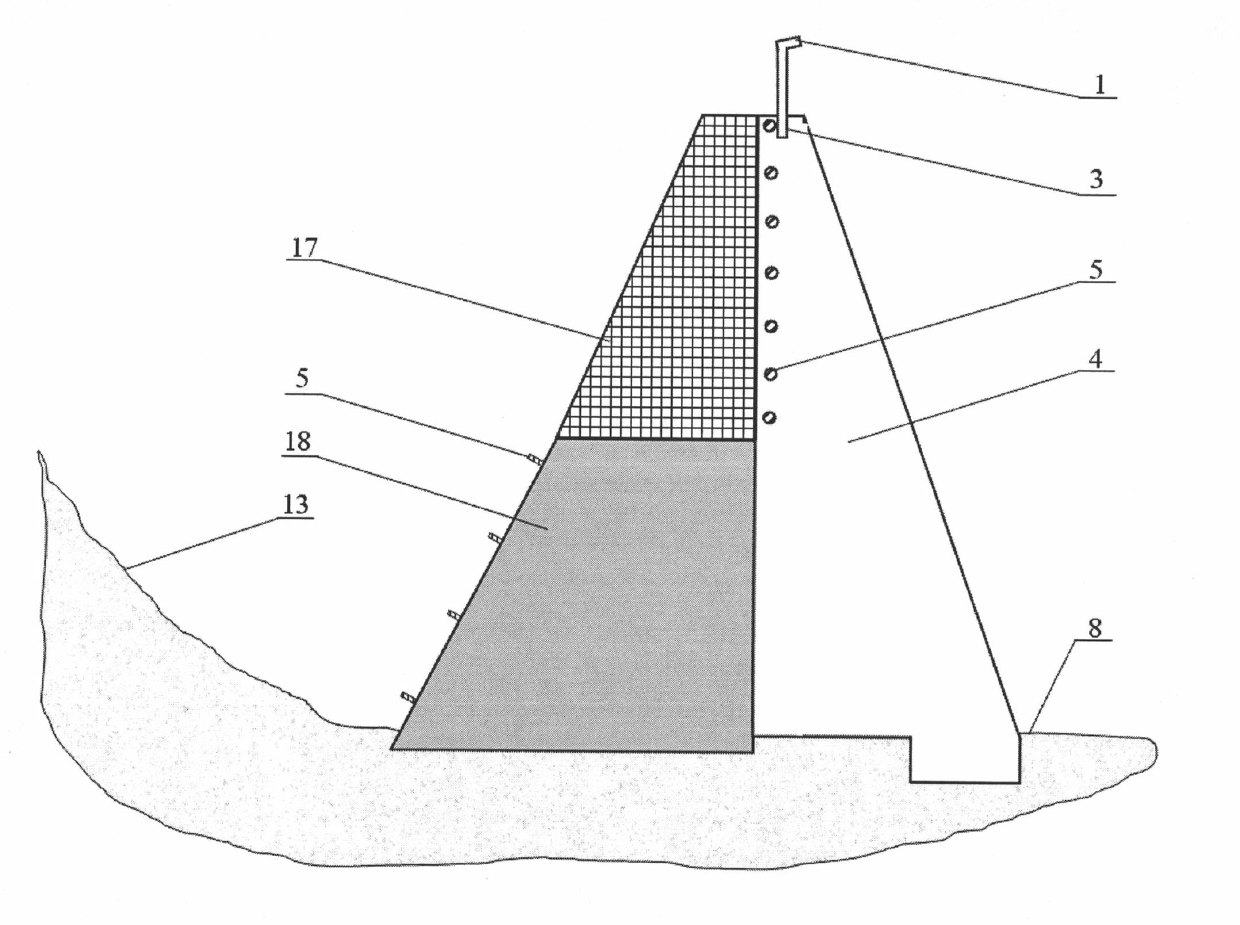

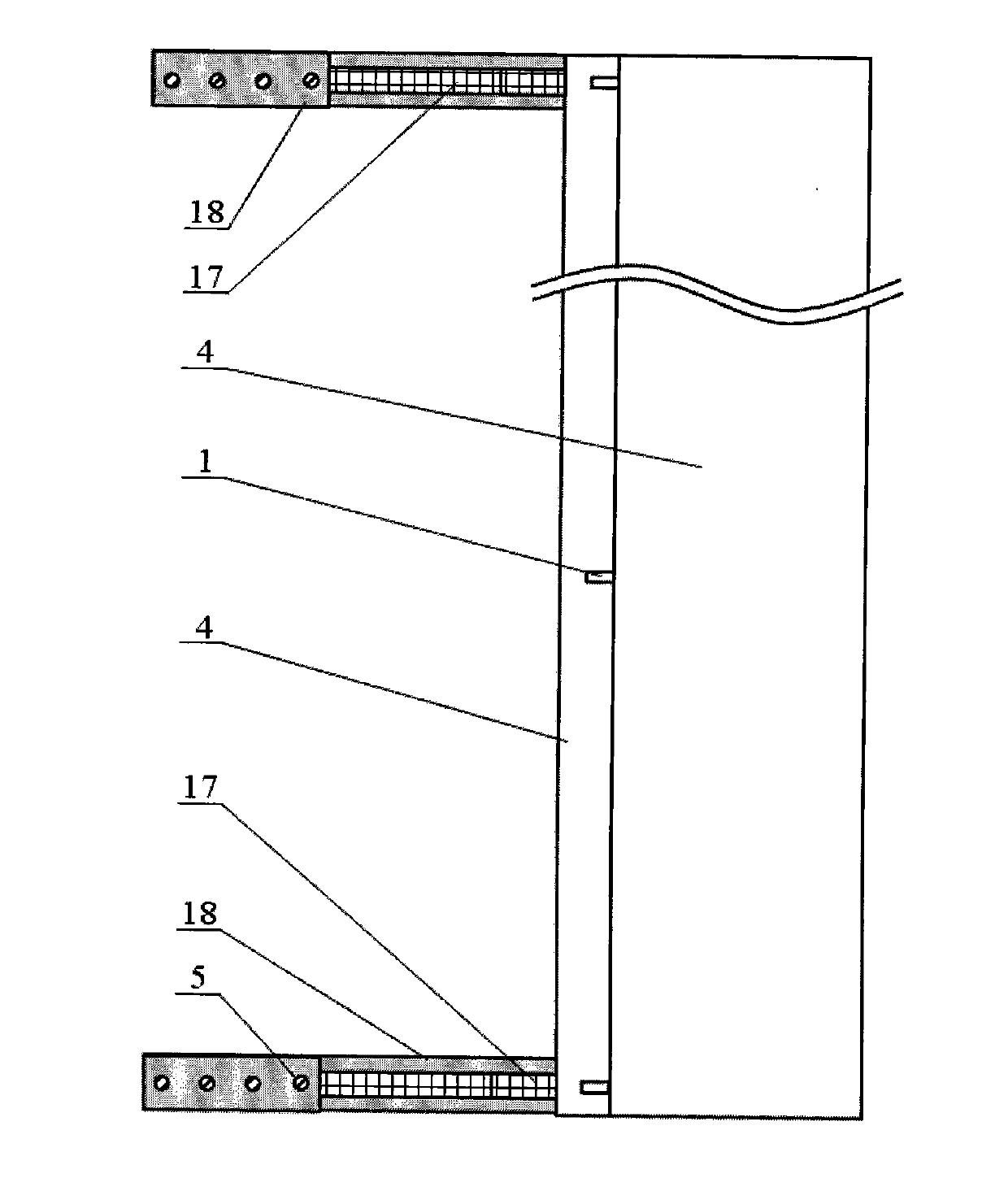

[0060] Such as figure 1 , figure 2 and image 3 As shown, the construction conditions should be determined first, and the construction preparation should be completed; the construction conditions include determining the scope, strength and cushioning performance of the rolling stone protection, selecting the support wall 4, the tire cage energy dissipation embankment 100, the waste tire net 200, the end retaining wall 20 and The form and specifications of the end retaining net 19 determine the specifications, arrangement, connection and fixing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com