Method for preparing sintered brick from shale gas water-based drilling waste

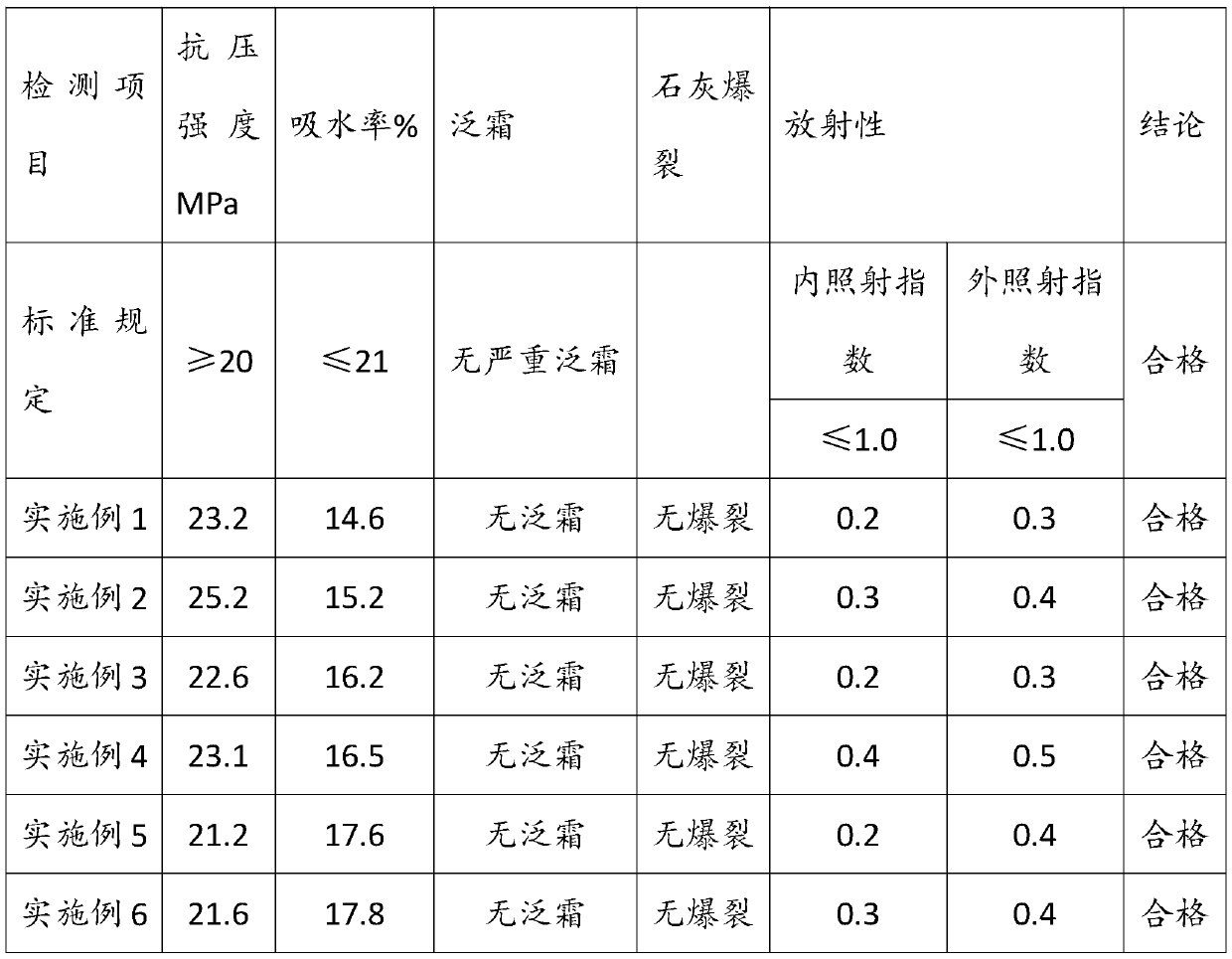

A technology for drilling waste and shale gas, applied in clay products, applications, household appliances, etc., can solve the problems of low compressive strength and high sintering temperature, achieve low water absorption, improve the performance of building materials, and reduce treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

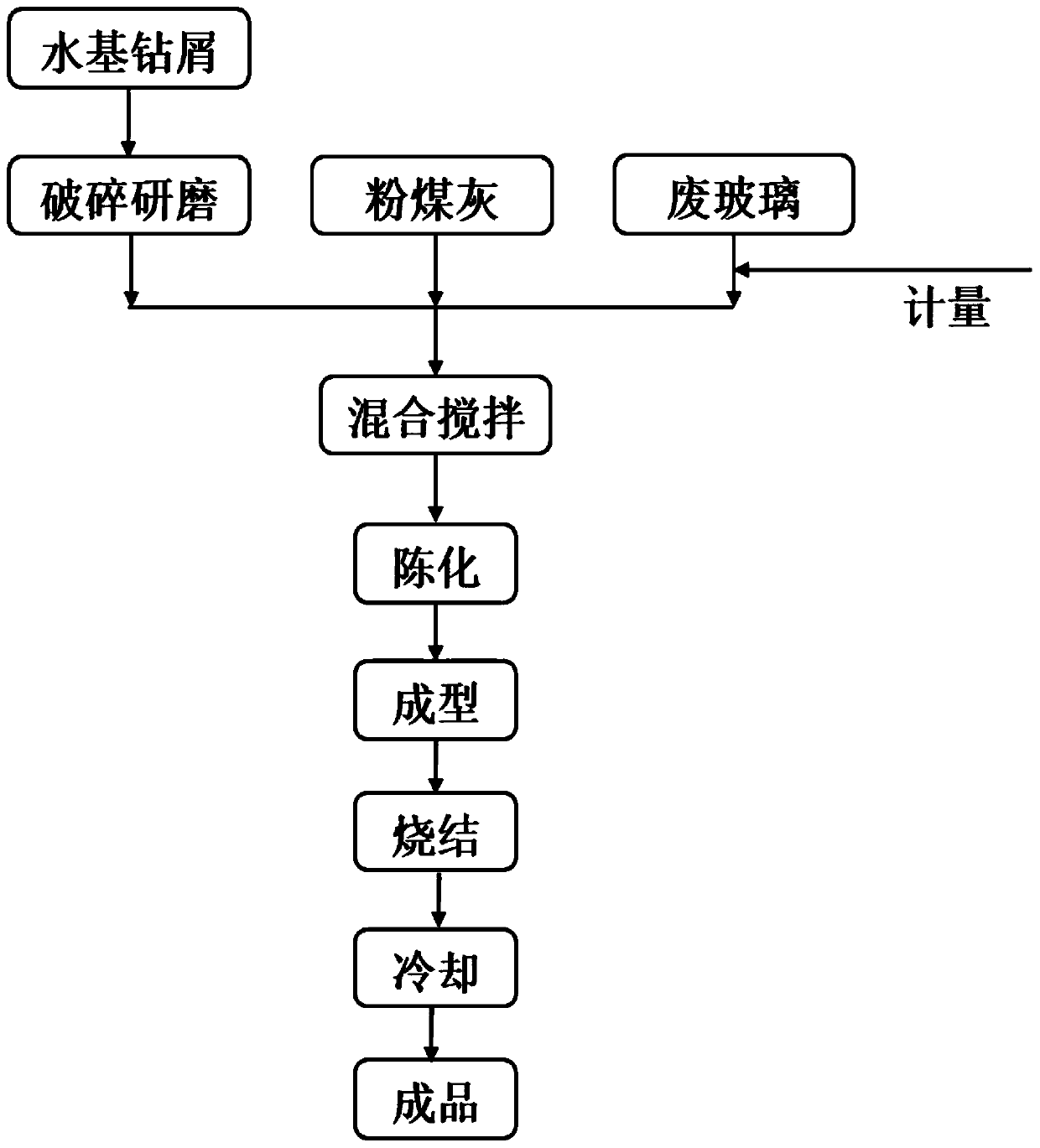

[0026] like figure 1 Shown, a kind of shale gas water-based drilling waste of the present invention prepares the method for sintered brick, comprises the following steps:

[0027] (1) Put the solidified water-based drill cuttings retrieved from the site into a jaw crusher for crushing until the particle size is less than 5mm, and then use a planetary ball mill to grind the crushed water-based drill cuttings. 10-mesh sieve to obtain water-based cuttings powder with a fineness of less than 2mm;

[0028] (2) Mix and stir the water-based cuttings powder with fly ash and waste glass powder evenly, and the mass ratio of each raw material component is water-based cuttings: waste glass: fly ash=2:2:6 to obtain the mixed material ;

[0029] (3) Add water with 10% mass of the mixed material to the evenly stirred mixed material, stir evenly and age for 24 hours, then use a pressure testing machine to carry out compression molding of the aged material with a pressure of 15 MPa and keep ...

Embodiment 2

[0032] like figure 1 Shown, a kind of shale gas water-based drilling waste of the present invention prepares the method for sintered brick, comprises the following steps:

[0033] (1) Put the solidified water-based drill cuttings retrieved from the site into a jaw crusher for crushing until the particle size is less than 5mm, and then use a planetary ball mill to grind the crushed water-based drill cuttings. 10-mesh sieve to obtain powder with a fineness below 2mm;

[0034] (2) Mix and stir powdered water-based cuttings with fly ash and waste glass powder evenly, and the mass ratio of each raw material component is water-based cuttings: waste glass: fly ash=2:2:6 to obtain a mixture material;

[0035] (3) Add water with 15% of the mass of the mixed material to the evenly stirred mixed material, stir evenly and age for 24 hours, then use a pressure testing machine to perform compression molding of the aged material at a pressure of 20 MPa and keep it for 1 minute;

[0036] (...

Embodiment 3

[0038] like figure 1 Shown, a kind of shale gas water-based drilling waste of the present invention prepares the method for sintered brick, comprises the following steps:

[0039] (1) Put the solidified water-based drill cuttings retrieved from the site into a jaw crusher for crushing until the particle size is less than 5mm, and then use a planetary ball mill to grind the crushed water-based drill cuttings. 10-mesh sieve to obtain powder with a fineness below 2mm;

[0040] (2) Mix and stir the powdered water-based cuttings with fly ash and waste glass powder evenly, and the mass ratio of each raw material component is water-based cuttings: waste glass: fly ash=3:2:5, and the mixture is obtained material;

[0041] (3) Add water with a mass of 12% of the mixed material to the evenly stirred mixed material, stir evenly and age for 24 hours, then use a pressure testing machine to perform compression molding of the aged material at a pressure of 17 MPa and keep it for 1 minute; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com