Magnetic separation purifying treatment technology for removing heavy metal pollution of soil

A heavy metal and soil technology, applied in the field of environmental materials and resources and environment, can solve the problems of non-magnetic and limited application of magnetic separation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

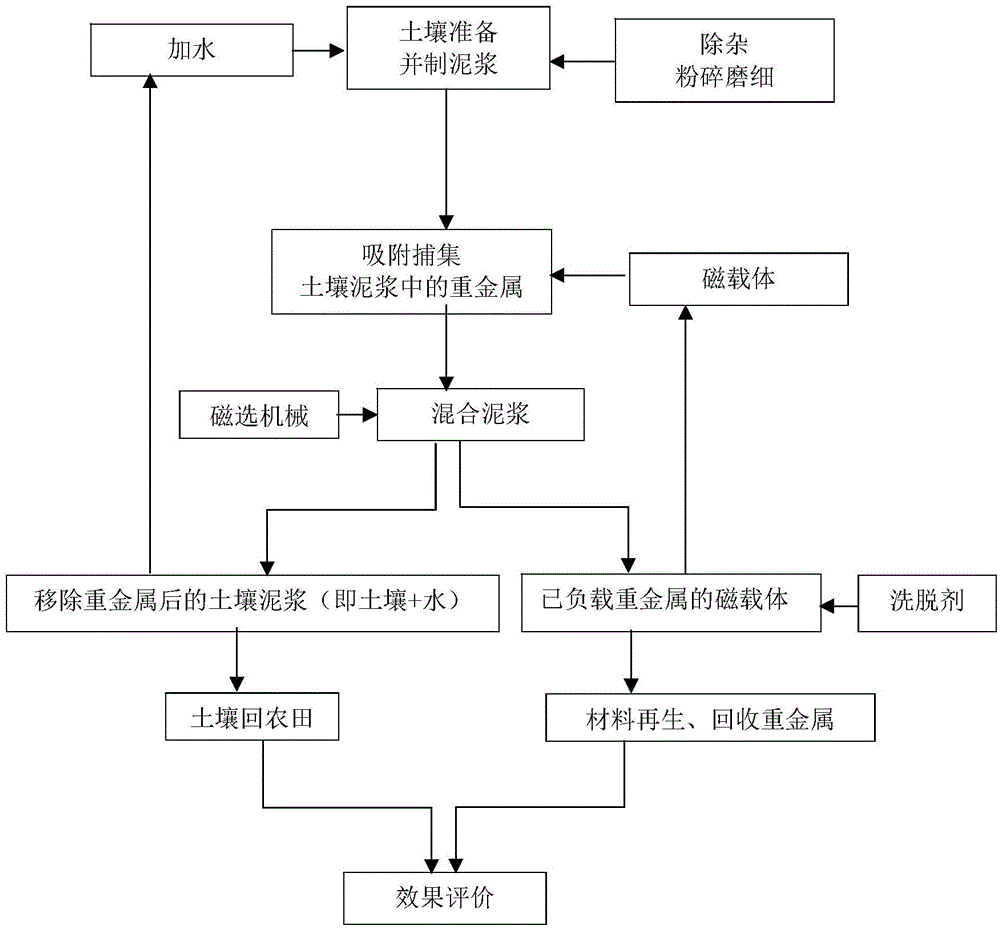

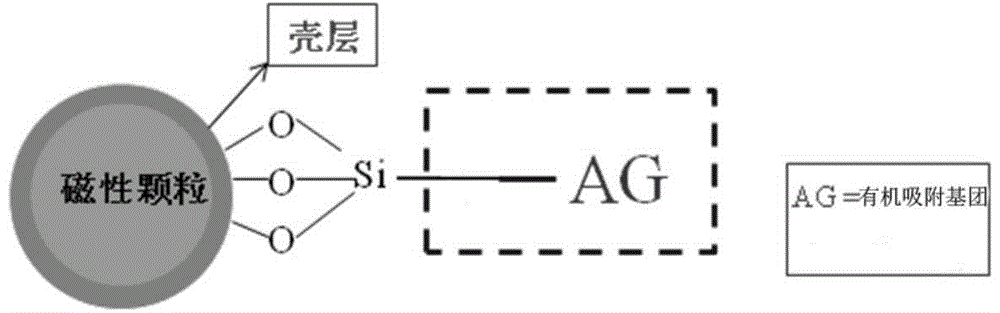

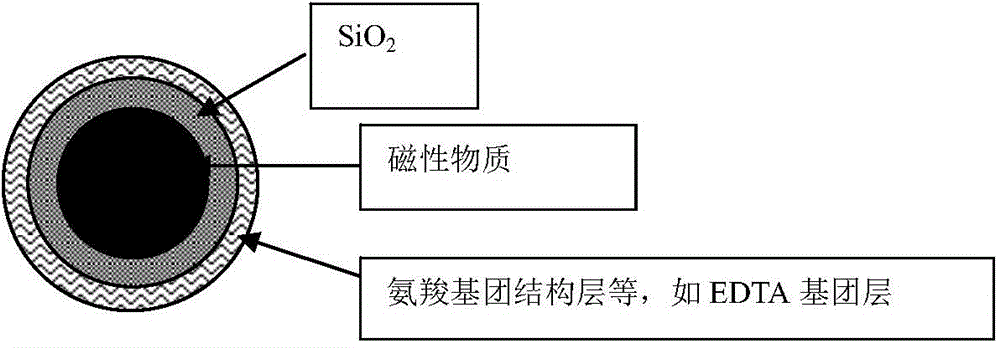

[0050] A magnetic separation, separation, purification and treatment process for removing heavy metal pollution in soil. The core-shell structure magnetic solid ammonia carboxyl adsorbent granular material FS-[ammonia carboxyl AG] is used as a magnetic carrier to adsorb and capture heavy metals in soil, and then magnetic Election is separated from soil, comprises the following steps successively:

[0051] ①Soil preparation and mud making steps: Take 1000g of Cd-contaminated farmland soil in a certain place, screen out crop stalks, gravel, etc., use a general-purpose magnetic separator to remove magnetic substances such as iron wire and nails, etc.; then use a pulverizer and a mill The soil is ground to about 60-100 mesh, and water is added to make the soil a slurry with a mud content of 20% (mass percentage);

[0052] ②The step of magnetic carrier trapping heavy metals: adding 10g of FS-[aminocarboxy AG] granular material to the slurry obtained in step ①, and fully mixing for ...

Embodiment 2

[0063] The difference between embodiment 2 and embodiment 1 is that the magnetic carrier is a regenerated magnetic carrier, and the regenerated magnetic carrier is the reactive magnetic carrier obtained in step ④ of embodiment 1 after elution of heavy metals.

[0064] According to the magnetic separation separation and purification treatment process of this embodiment, the cadmium in the weakly acid-dissolved state and iron-manganese oxide-bound state and part of the organic-bound cadmium in the soil can be removed from the soil, and the removal rate of cadmium can reach more than 74%.

Embodiment 3

[0066] A magnetic separation, separation, purification and treatment process for removing heavy metal pollution from soil. Natural magnetic mineral powder is used as a magnetic carrier to absorb and capture heavy metals in soil, and then magnetic separation and soil separation are carried out. The specific steps are as follows:

[0067] ①Soil preparation and mud making steps: take 1000g of cadmium and arsenic compound polluted farmland soil in a certain place, screen out crop stalks, gravel, etc., and use a general magnetic separator to remove magnetic substances such as iron wire and nails; then use a pulverizer and The mill grinds the soil to about 60-100 mesh, and water is added to make the soil a mud with a mud content of 30% (mass percentage);

[0068] ②The step of magnetic carrier trapping heavy metals: adding 10 g of natural magnetic mineral powder to the slurry obtained in step ①, and fully mixing for 10 hours to obtain a mixed slurry of magnetic carrier loaded with cad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com