Patents

Literature

665 results about "Magnetic carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic recording medium

InactiveUS20050260459A1Increased durabilityStorage stabilityMagnetic materials for record carriersBase layers for recording layersPolyesterNon magnetic

A magnetic recording medium comprising: a nonmagnetic support having a first surface and a second surface; and a magnetic layer containing ferromagnetic powder and a binder, so that the magnetic layer, the first surface and the second surface are in this order, wherein the nonmagnetic support contains polyester, a difference between largest ratio and smallest ratio among peak intensity ratios of gauche / trans on the first and second surfaces of the support in a machine direction and a transverse direction obtained by ATR-FT-IR method is 0.030 or less in an absolute value, and a shrinkage factor of the magnetic recording medium after preservation at 70° C. 5% RH for one week is 0.040% or less.

Owner:FUJIFILM CORP +1

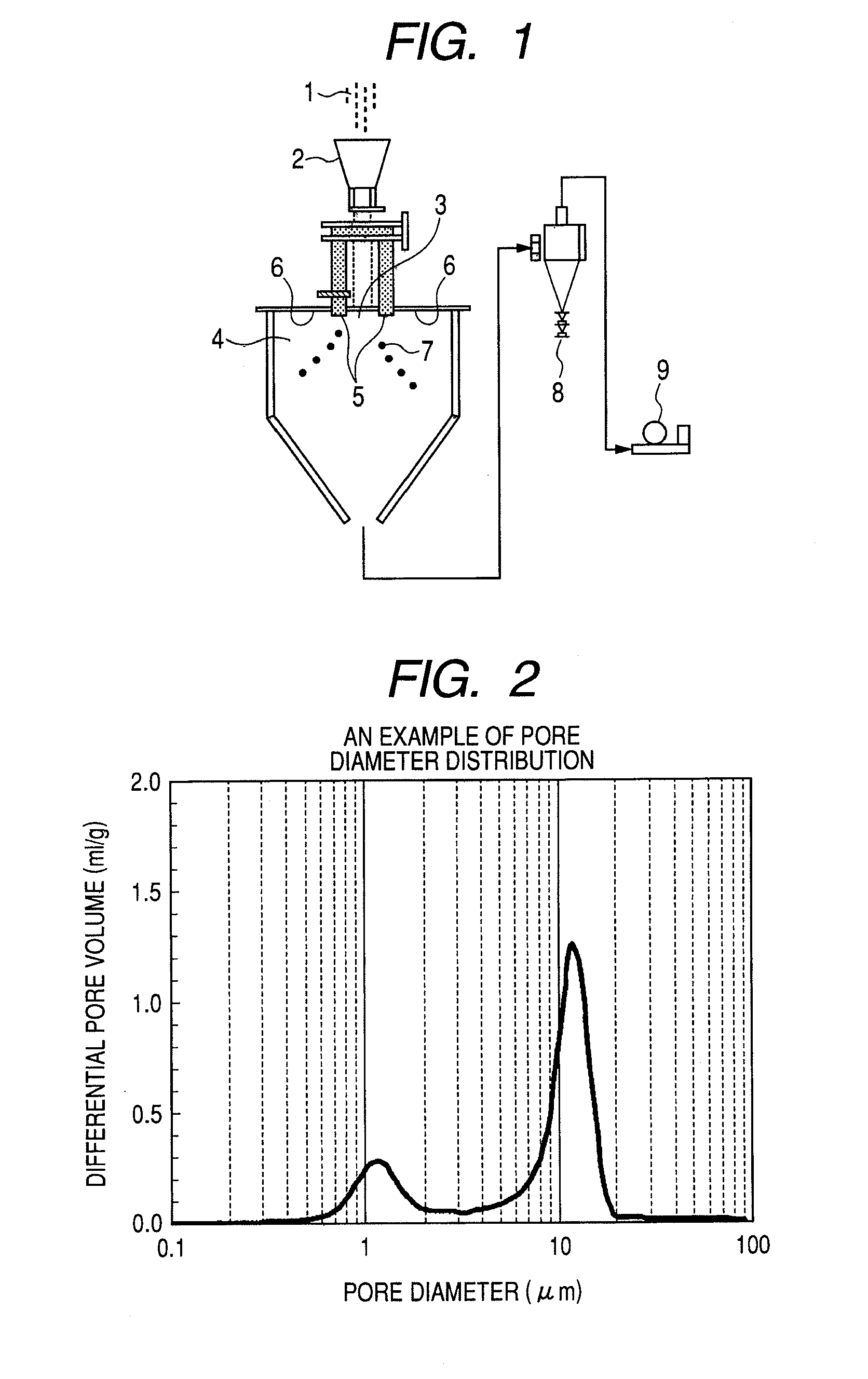

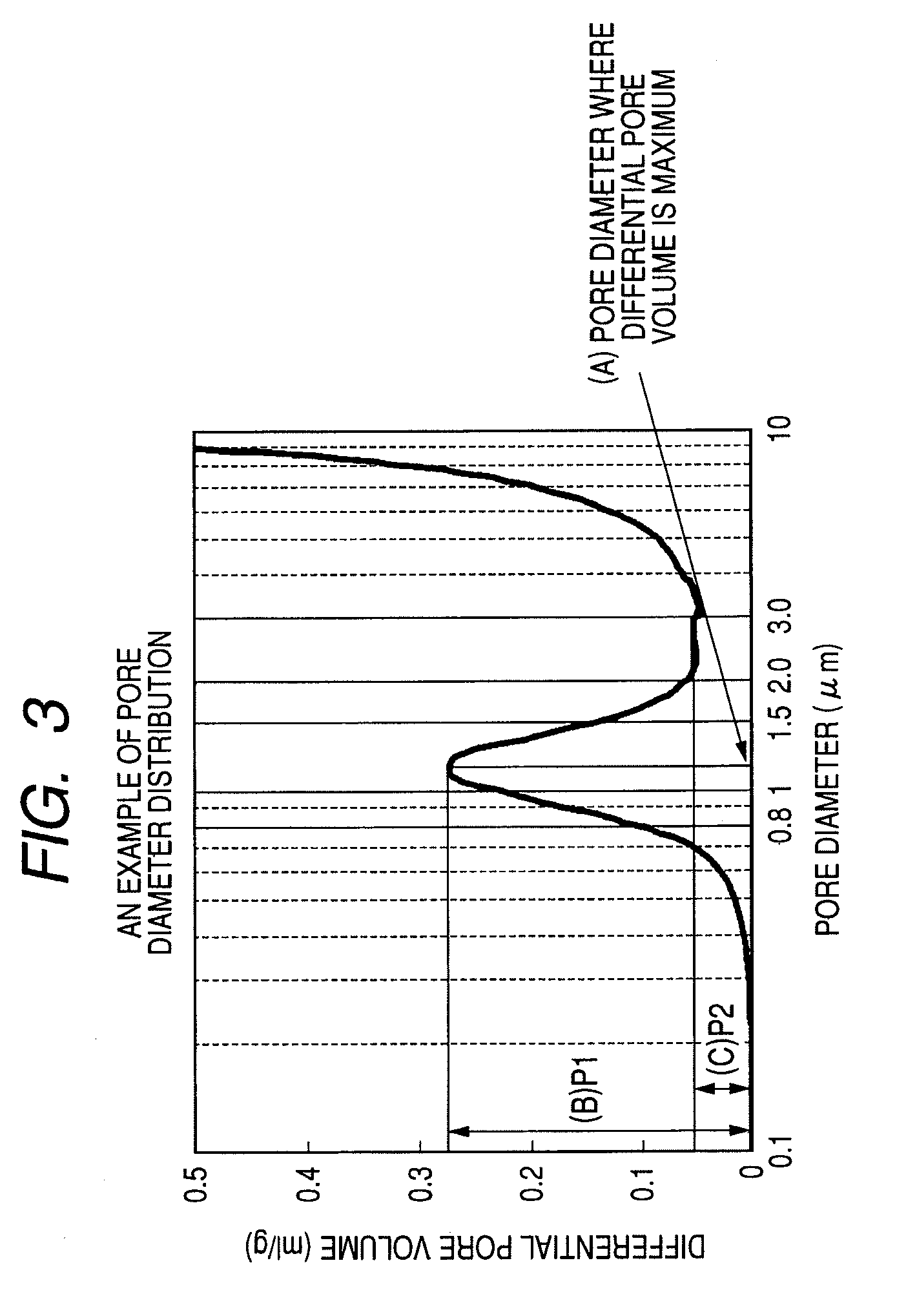

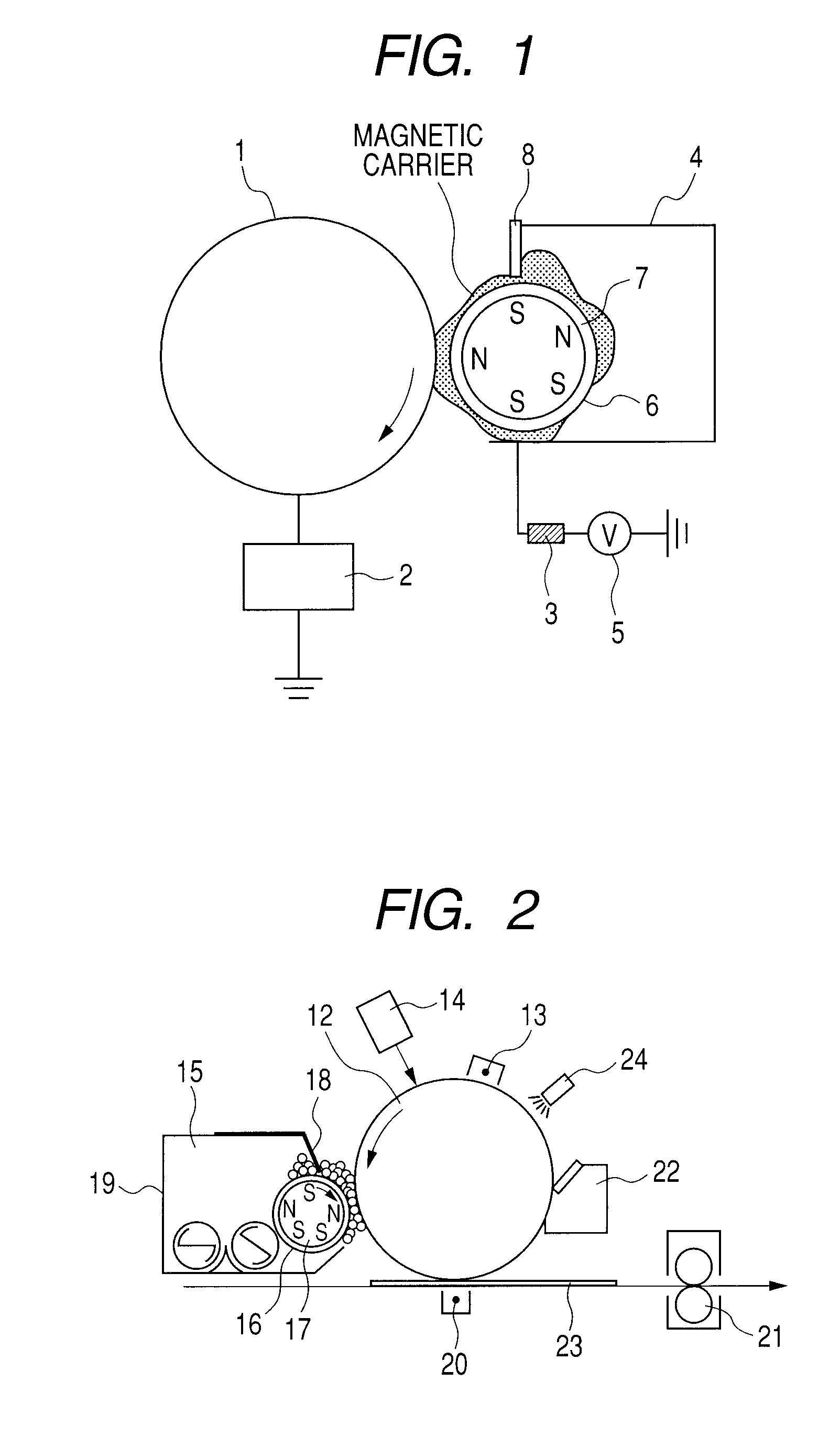

Magnetic carrier and two-component developer

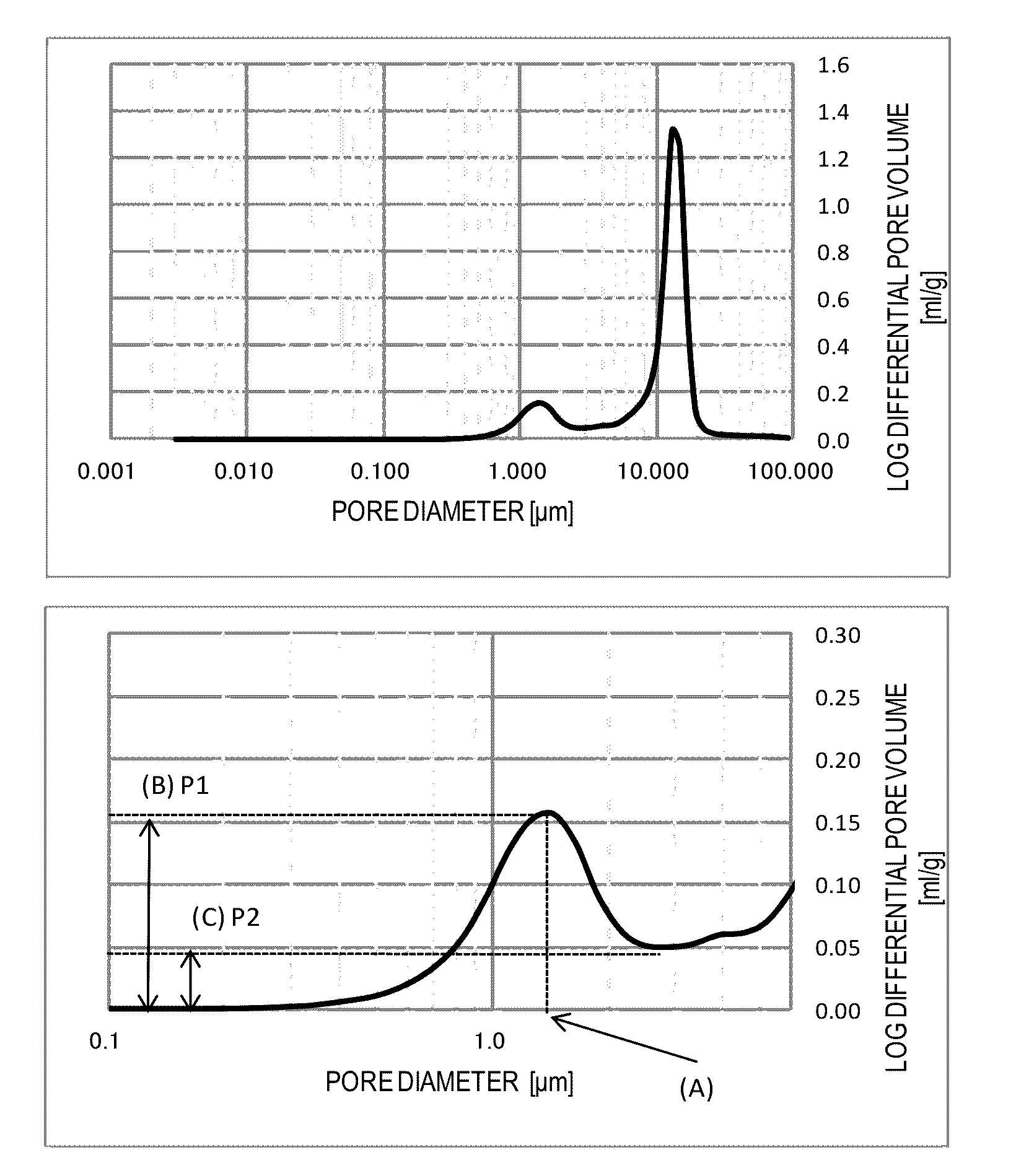

A magnetic carrier and two-component developer are provided alleviating coarse images, fogging when printing is done after a copier body is left standing for one week in a high temperature and high humidity environment and carrier adhesion after extensive operation in a low image ratio. The magnetic carrier includes magnetic carrier particles including porous magnetic core particles and a resin, wherein in a mercury intrusion method applied to the porous magnetic core particles, a pore diameter in which a differential pore volume in the specific pore diameter range becomes maximum is in a specific range, and when the maximum value of a differential pore volume in the specific pore diameter range is defined as P1 and the maximum value of a differential pore volume in the specific pore diameter range is defined as P2, P1 is in a specific range and the ratio P2 / P1 is in a specific range.

Owner:CANON KK

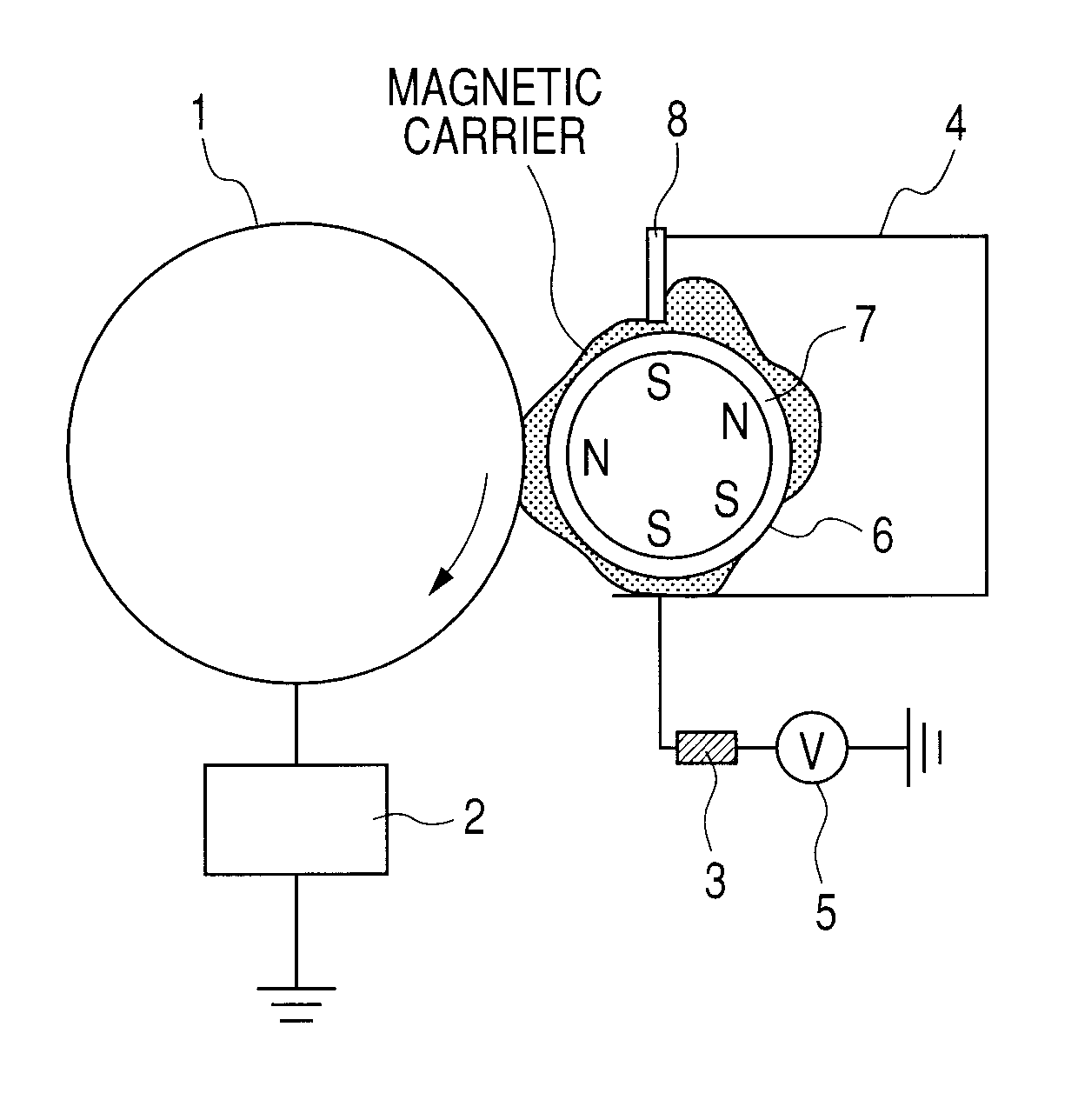

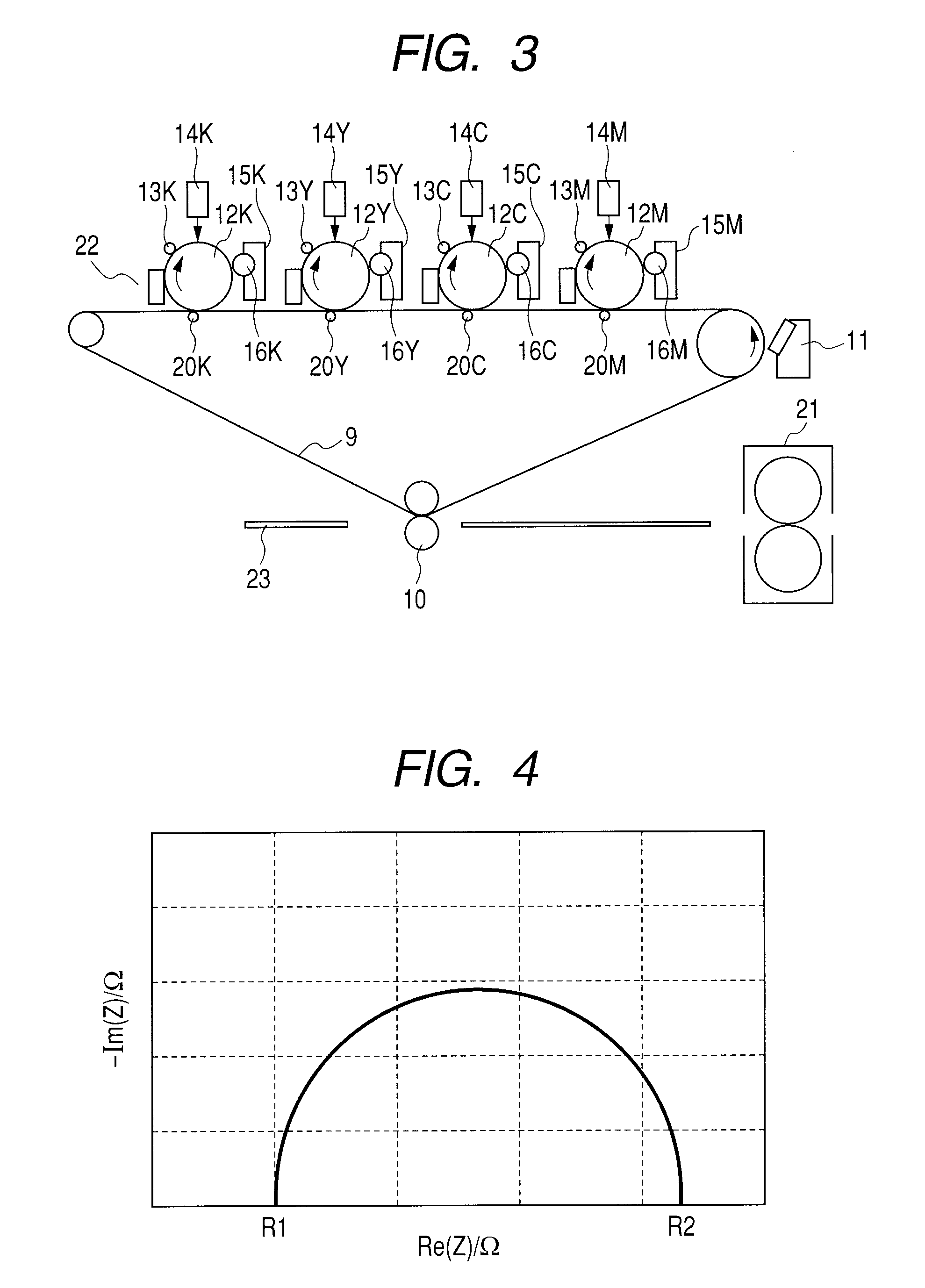

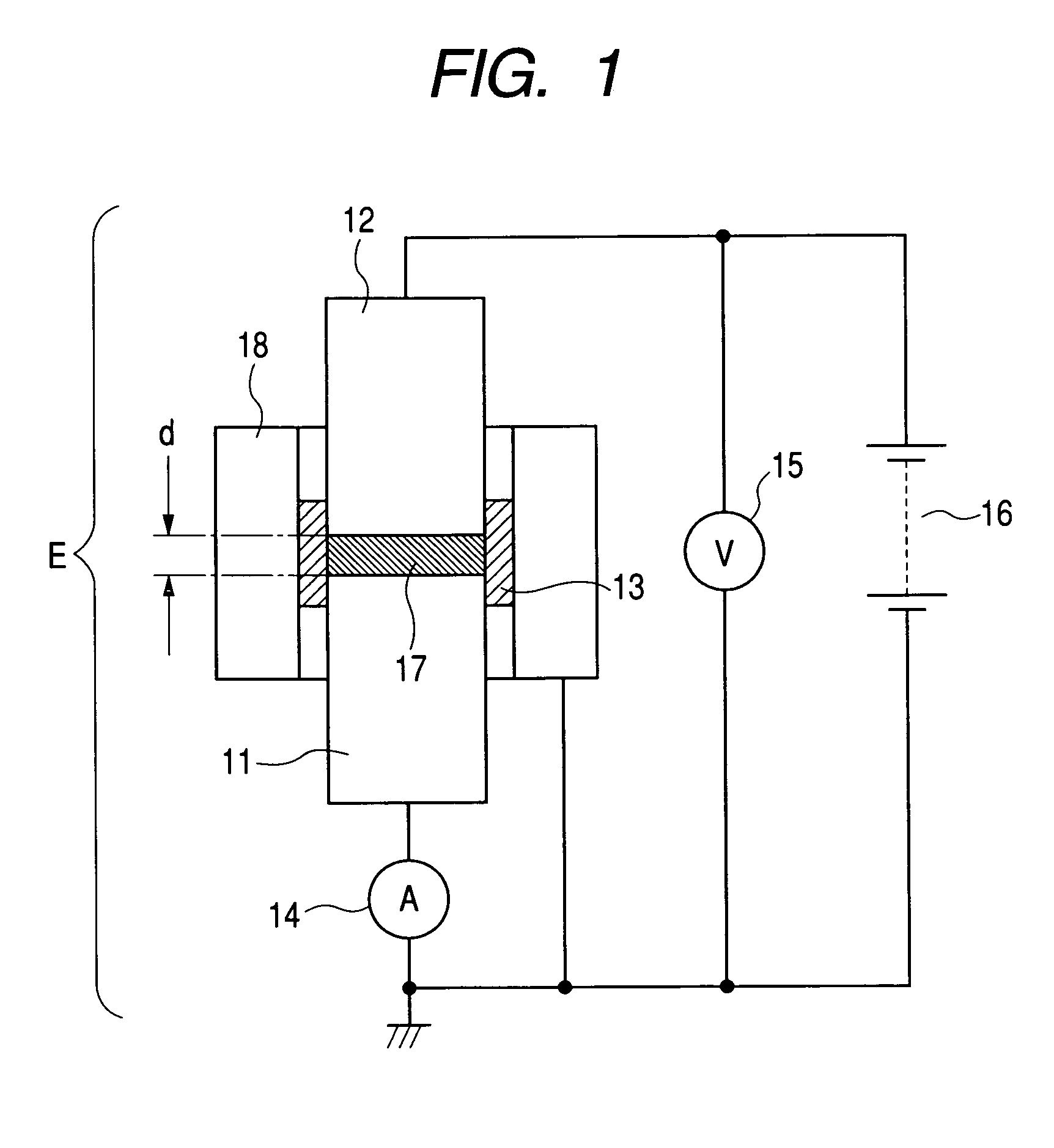

Magnetic carrier, two-component developer and image forming method

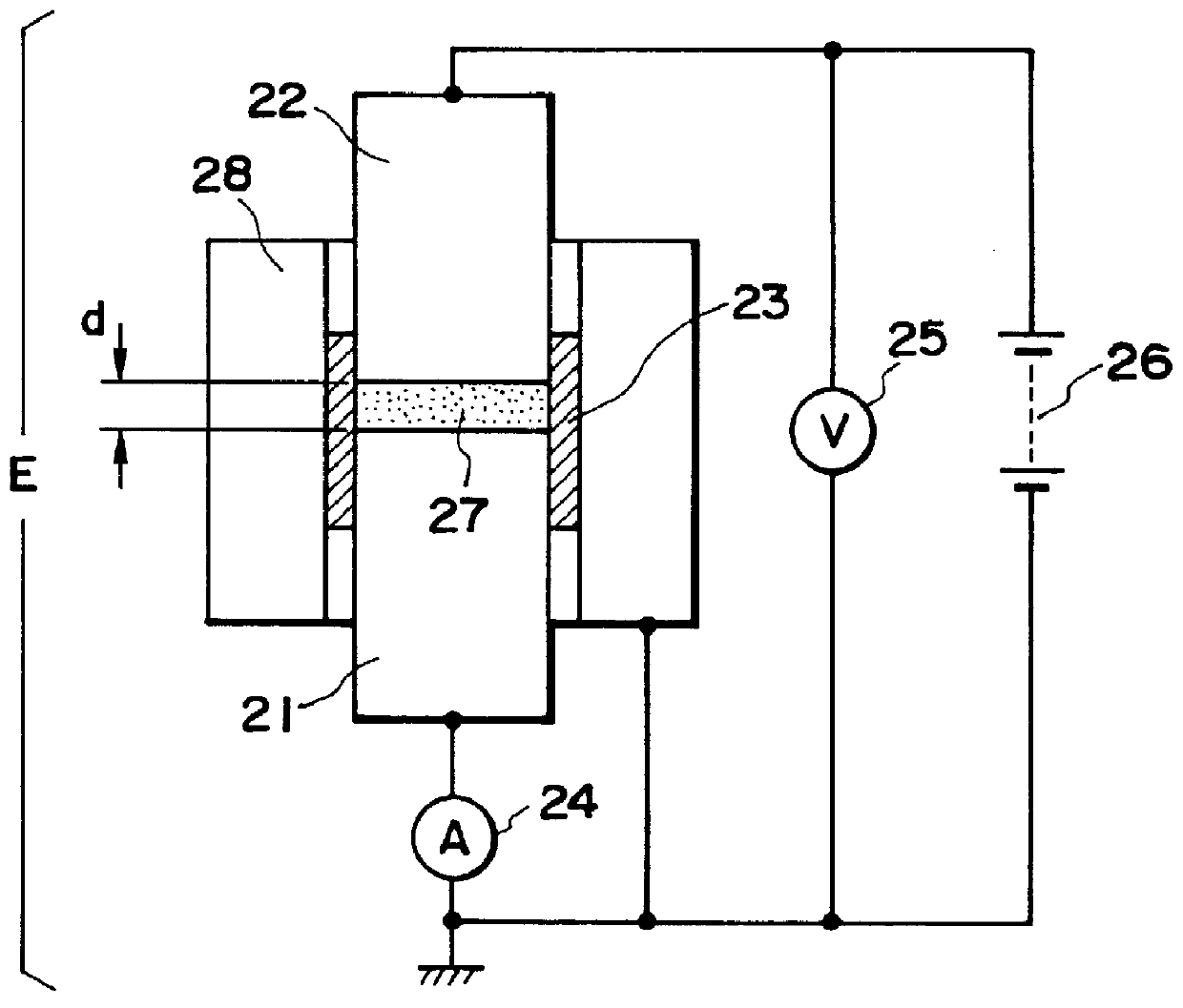

InactiveUS20100183971A1High quality imagingImprove development performanceDevelopersElectrographic processes using charge patternDynamic impedanceElectric resistivity

A magnetic carrier having magnetic carrier particles each containing at least a magnetic core particle and a resin; the magnetic carrier having a resistivity of from 1.0×106 Ω·cm or more to 1.0×1010 Ω·cm or less at an electric-field intensity of 1.0×103 V / cm as found by measuring dynamic impedance; electric-field intensity E(109) at which the resistivity of the magnetic carrier comes to 1.0×109 Ω·cm being 2.0×104 V / cm or less, and electric-field intensity E(108) at which the resistivity of the magnetic carrier comes to 1.0×108 Ω·cm being from 5.0×103 V / cm or more to 2.8×104 V / cm or less; and the electric-field intensity E(108) and the electric-field intensity E(109) being in a ratio, E(108) / E(109), of from 1.0 or more to 5.0 or less.

Owner:CANON KK

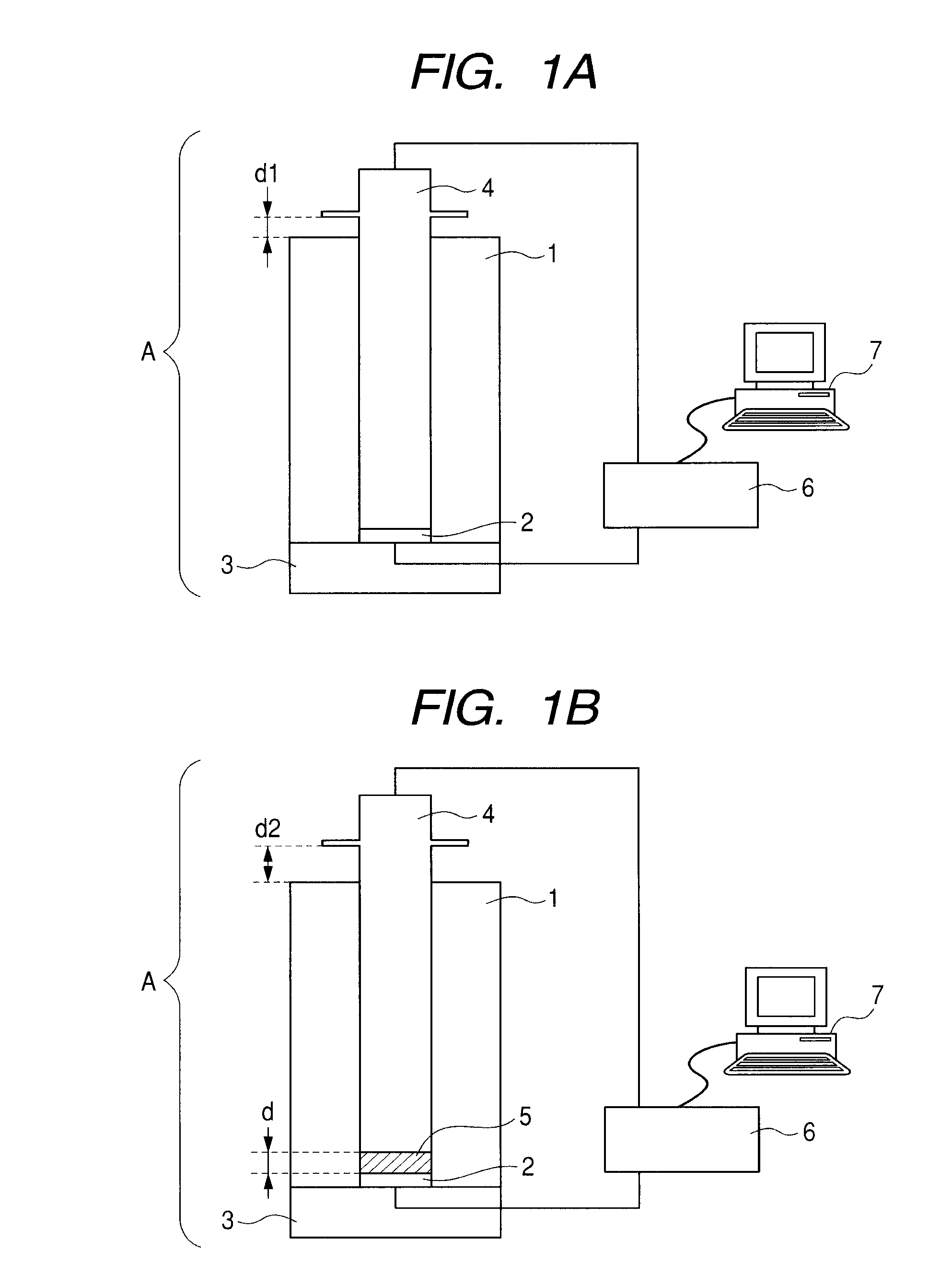

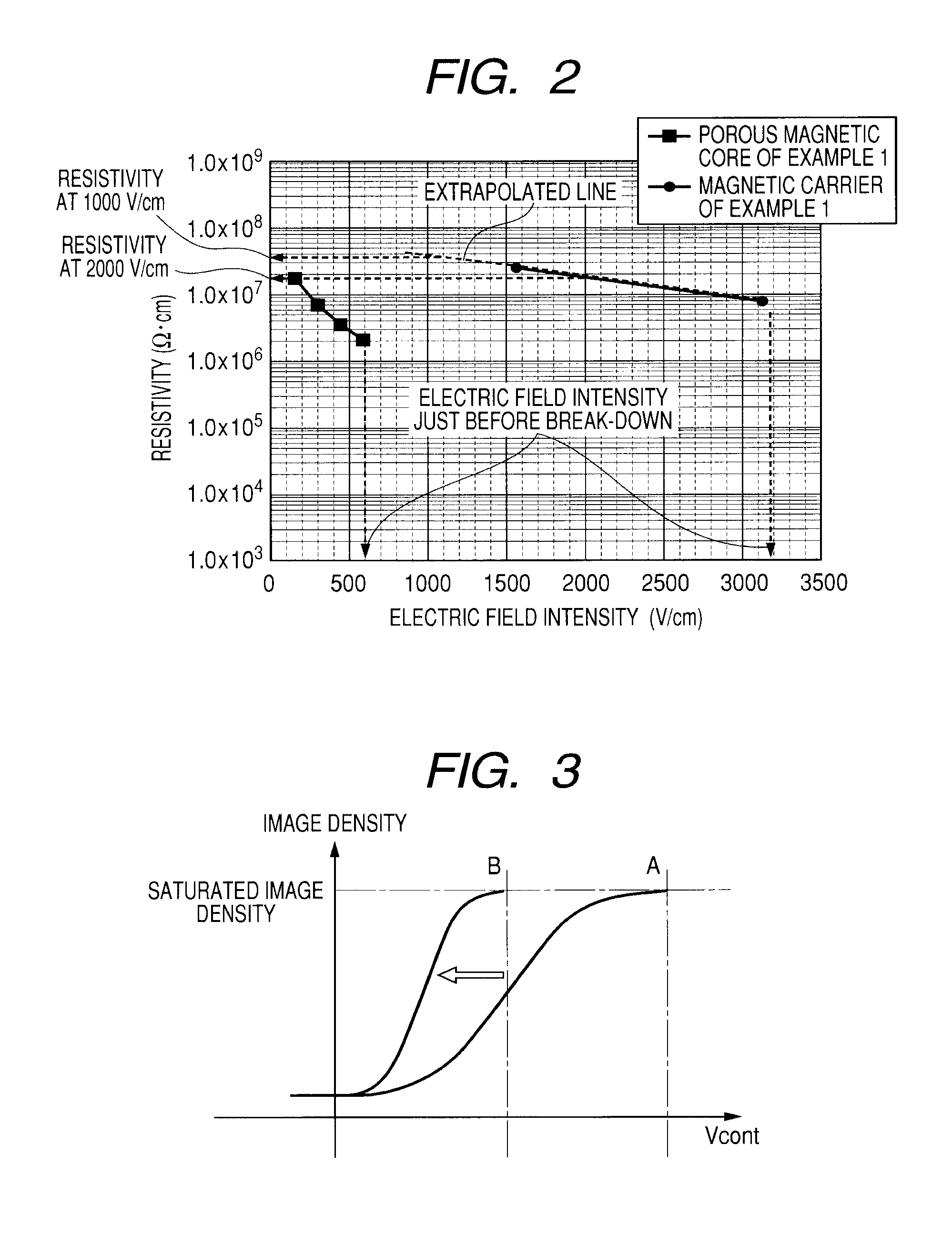

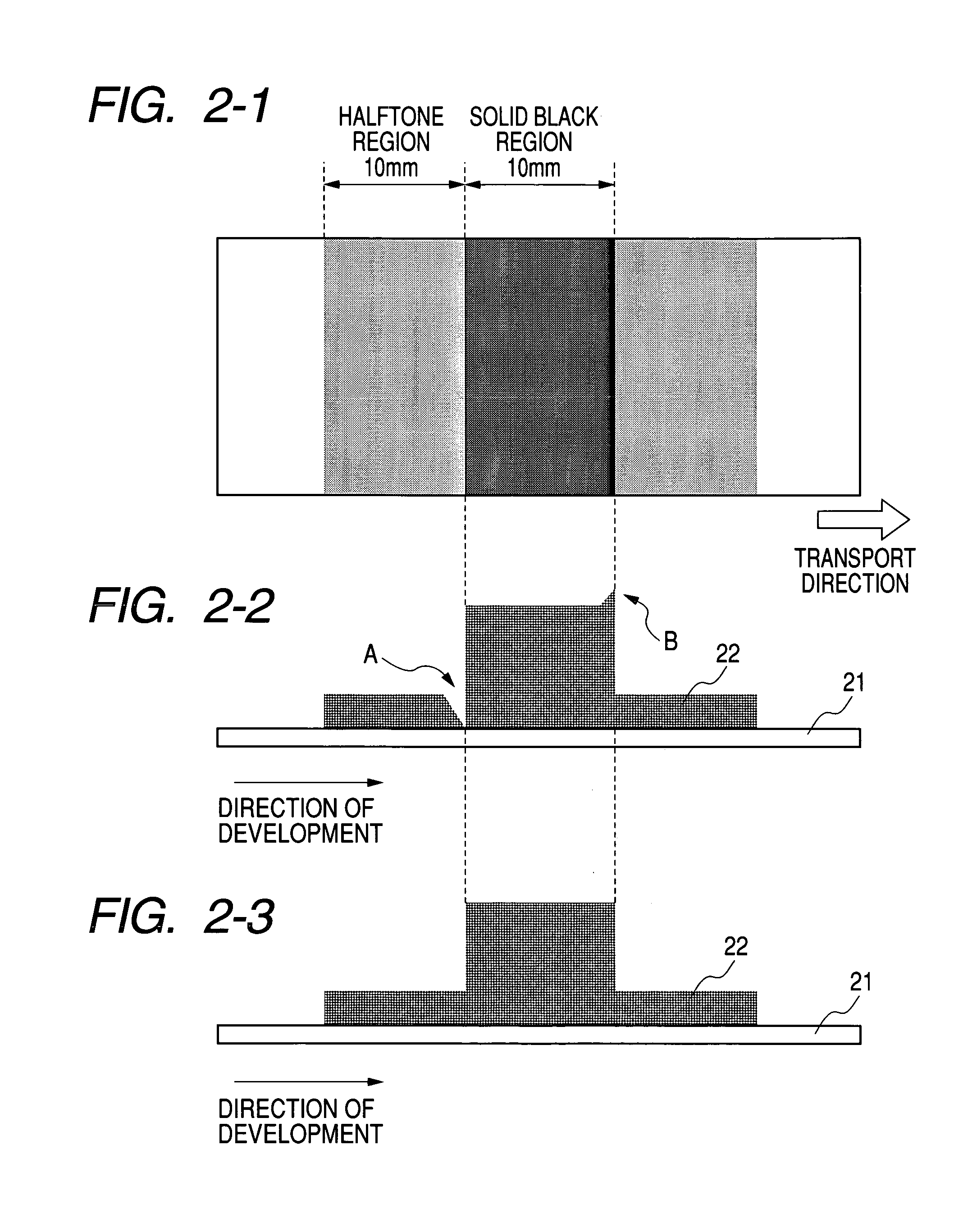

Magnetic carrier, two-component developer and image forming method

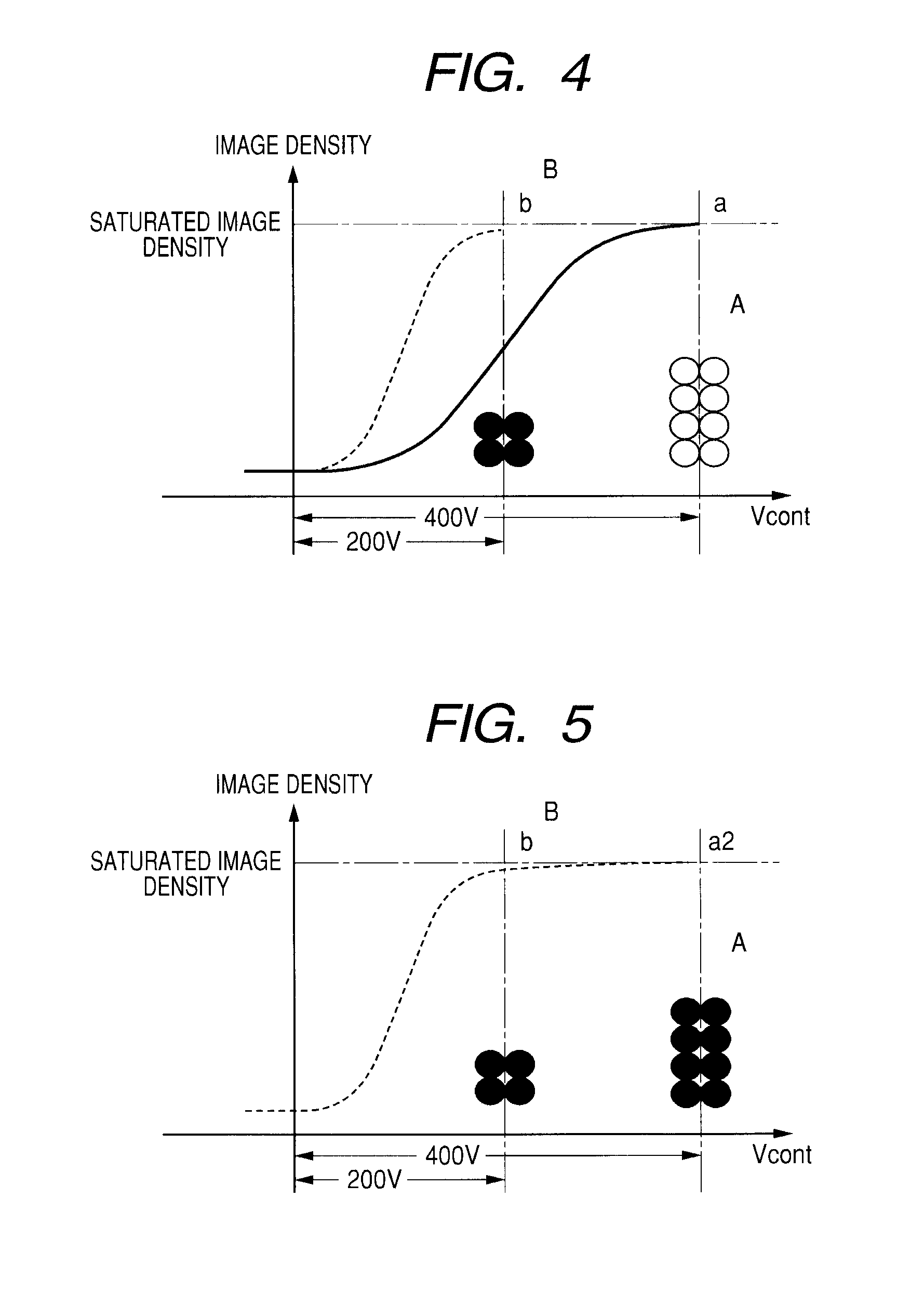

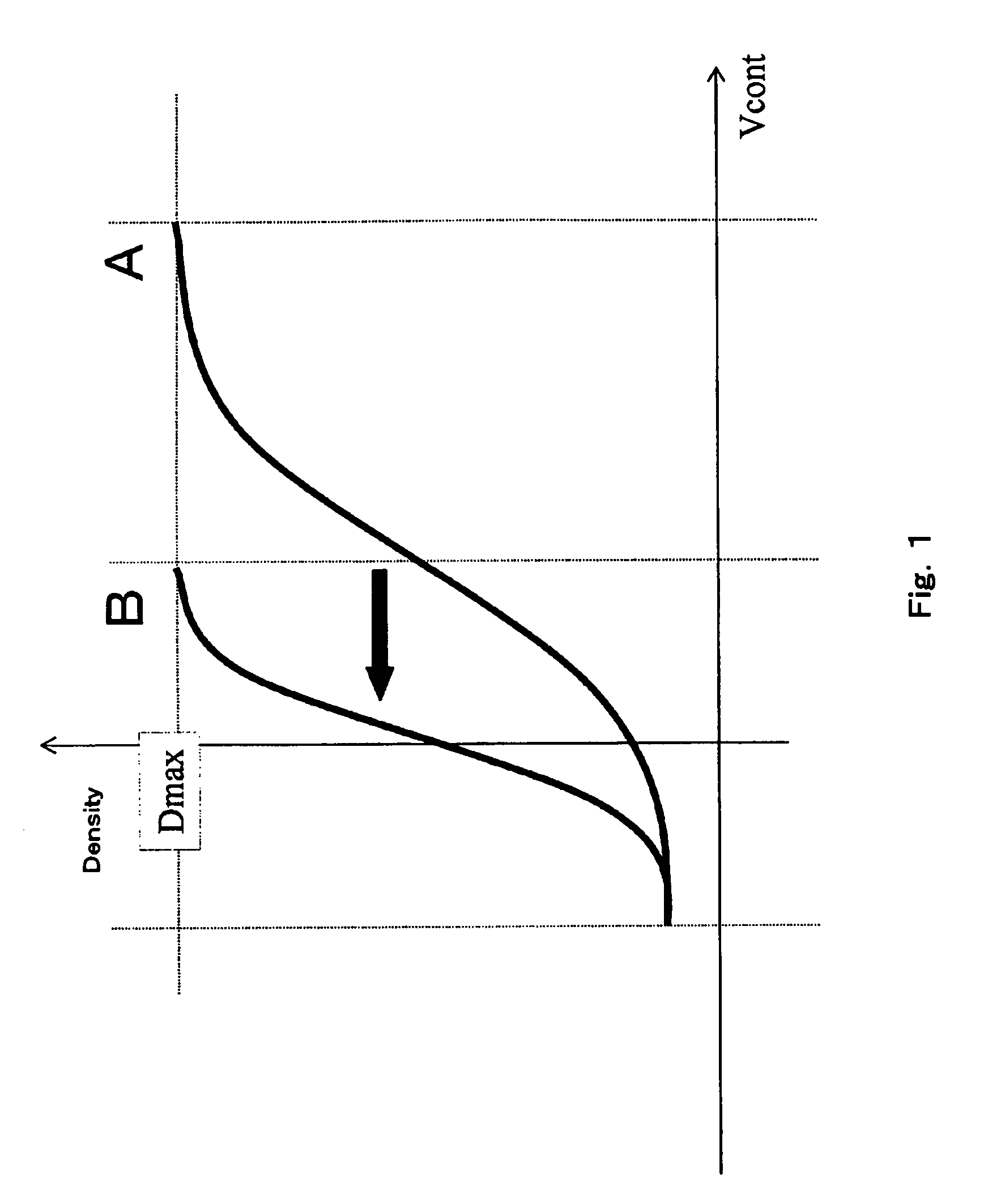

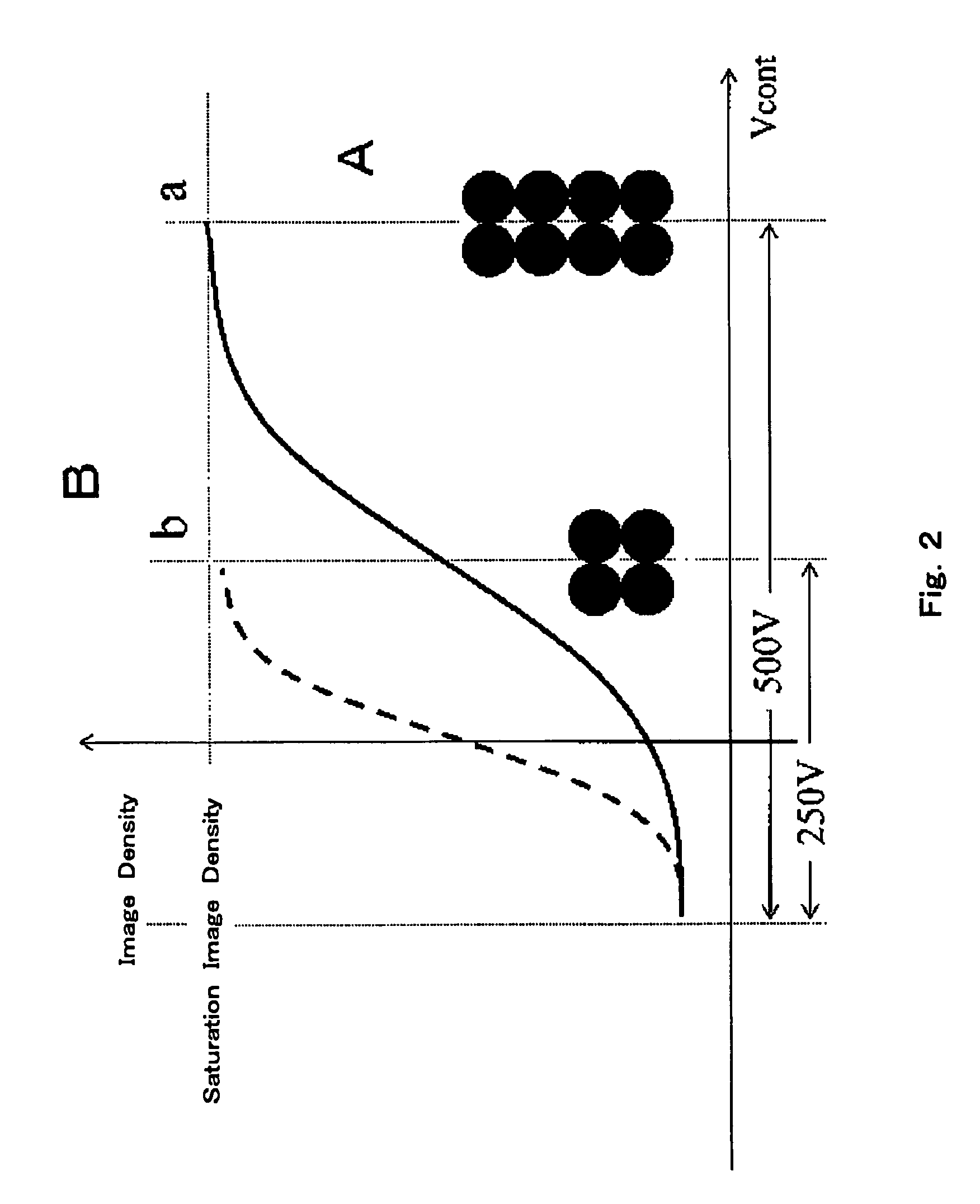

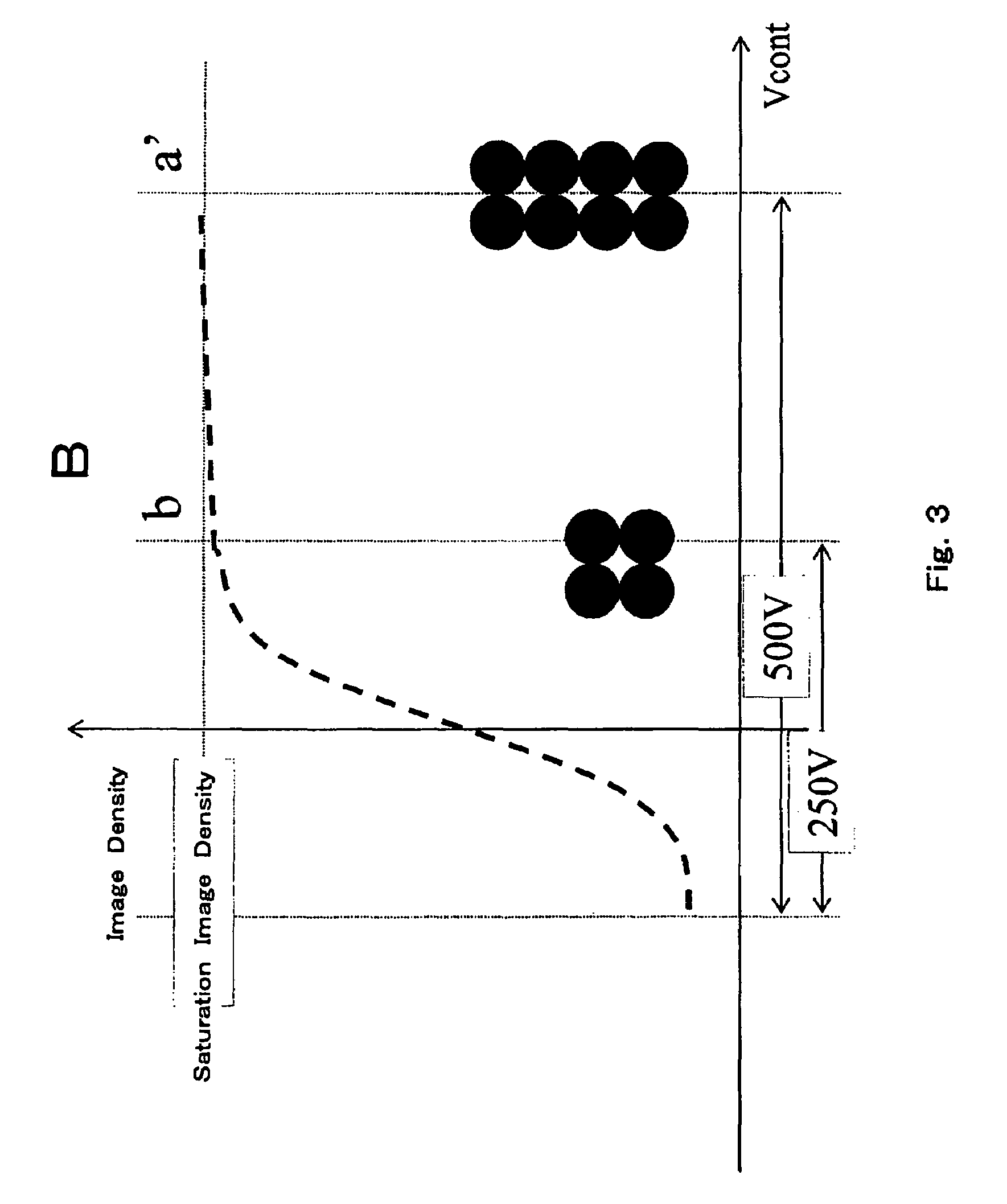

InactiveUS8137886B2High-quality image formationSolve the lack of densityDevelopersElectrographic processes using charge patternElectrical field strengthUltimate tensile strength

A magnetic carrier is provided which uses a toner having high coloring power and enables development to be performed at low electric field intensity and can form high quality images while keeping gradation characteristics. The magnetic carrier includes magnetic carrier particles including at least porous magnetic core particles and a resin. The electric field intensity just before the break-down of the magnetic carrier is 1,300 V / cm or more and 5,000 V / cm or less.

Owner:CANON KK

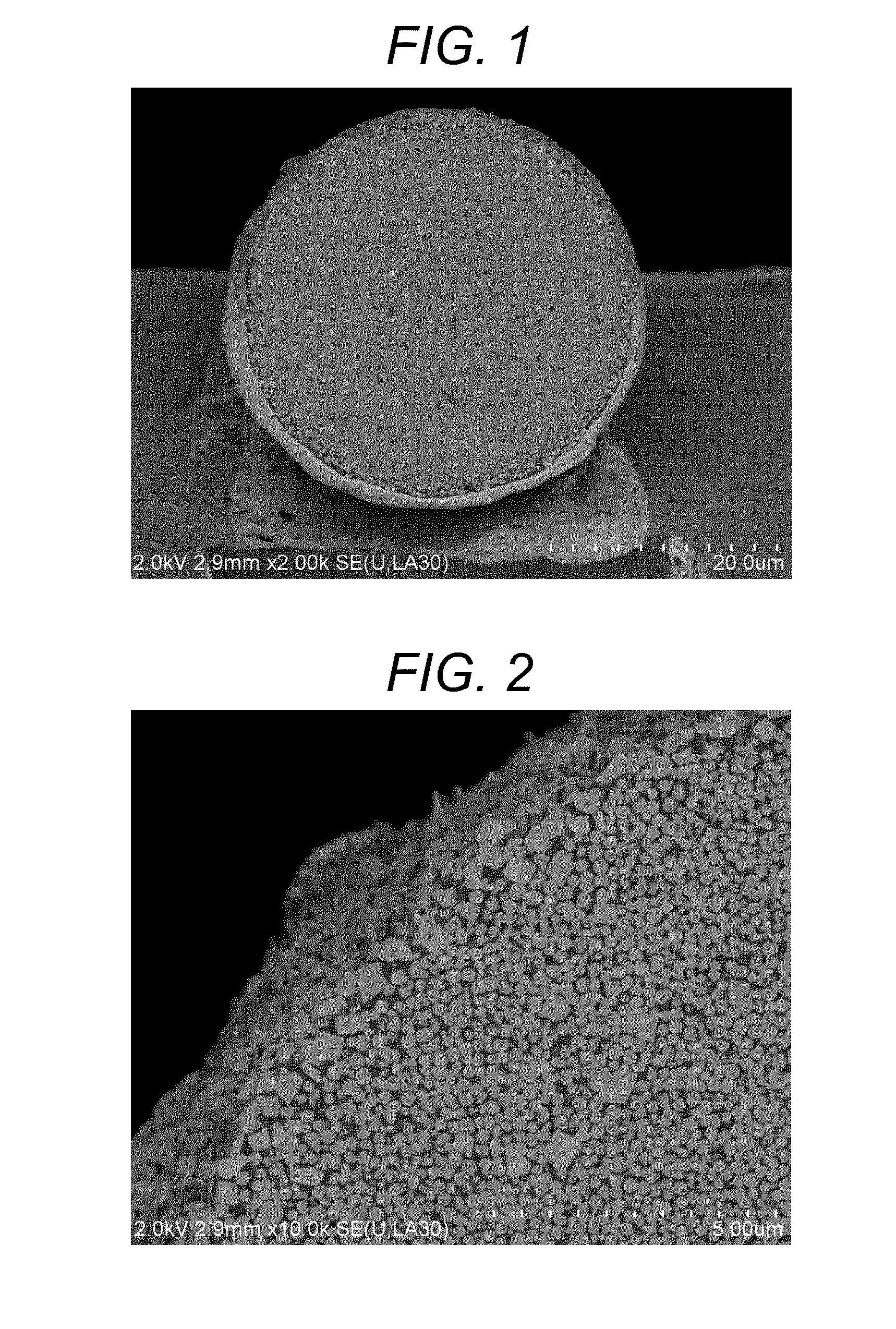

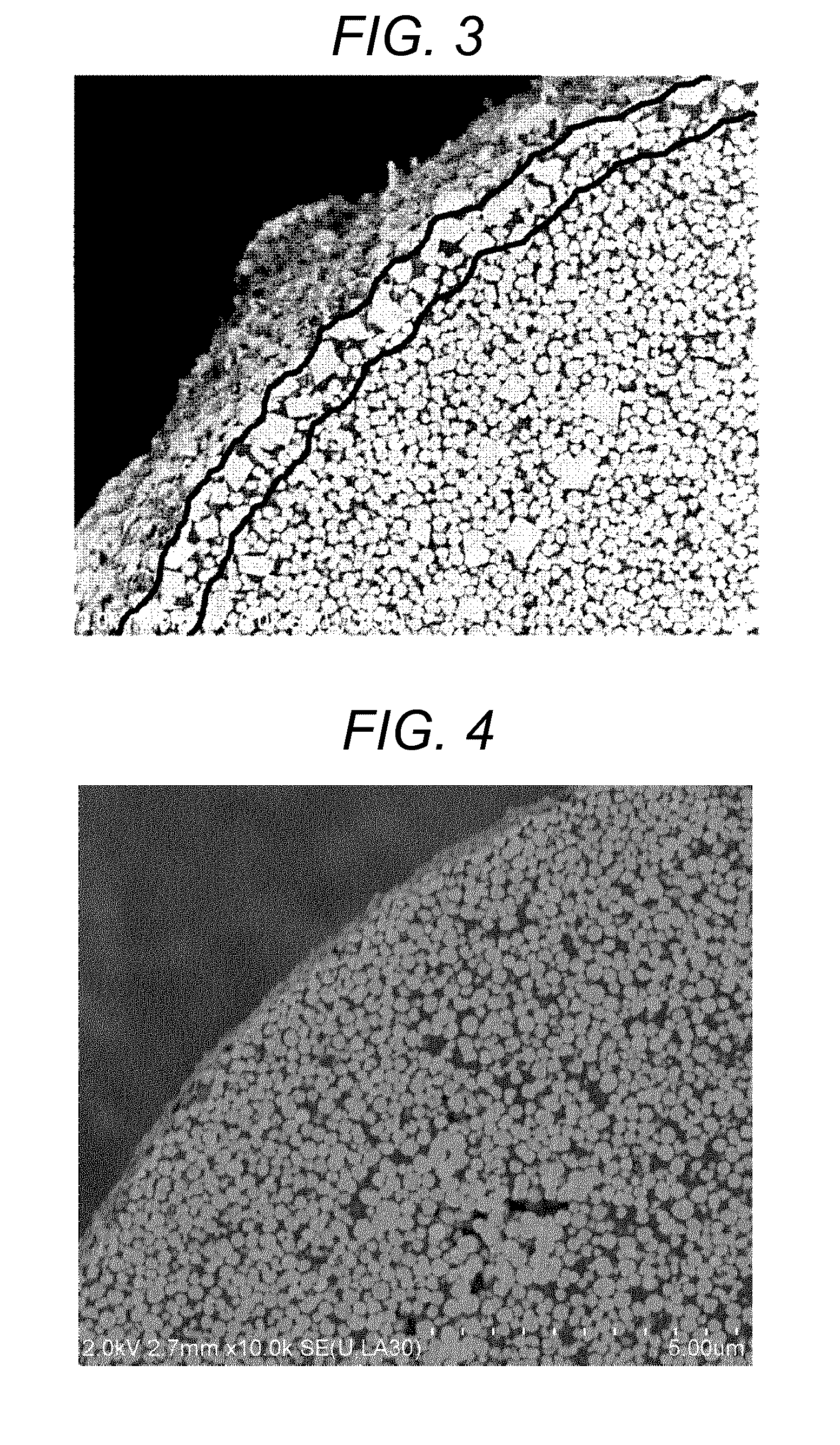

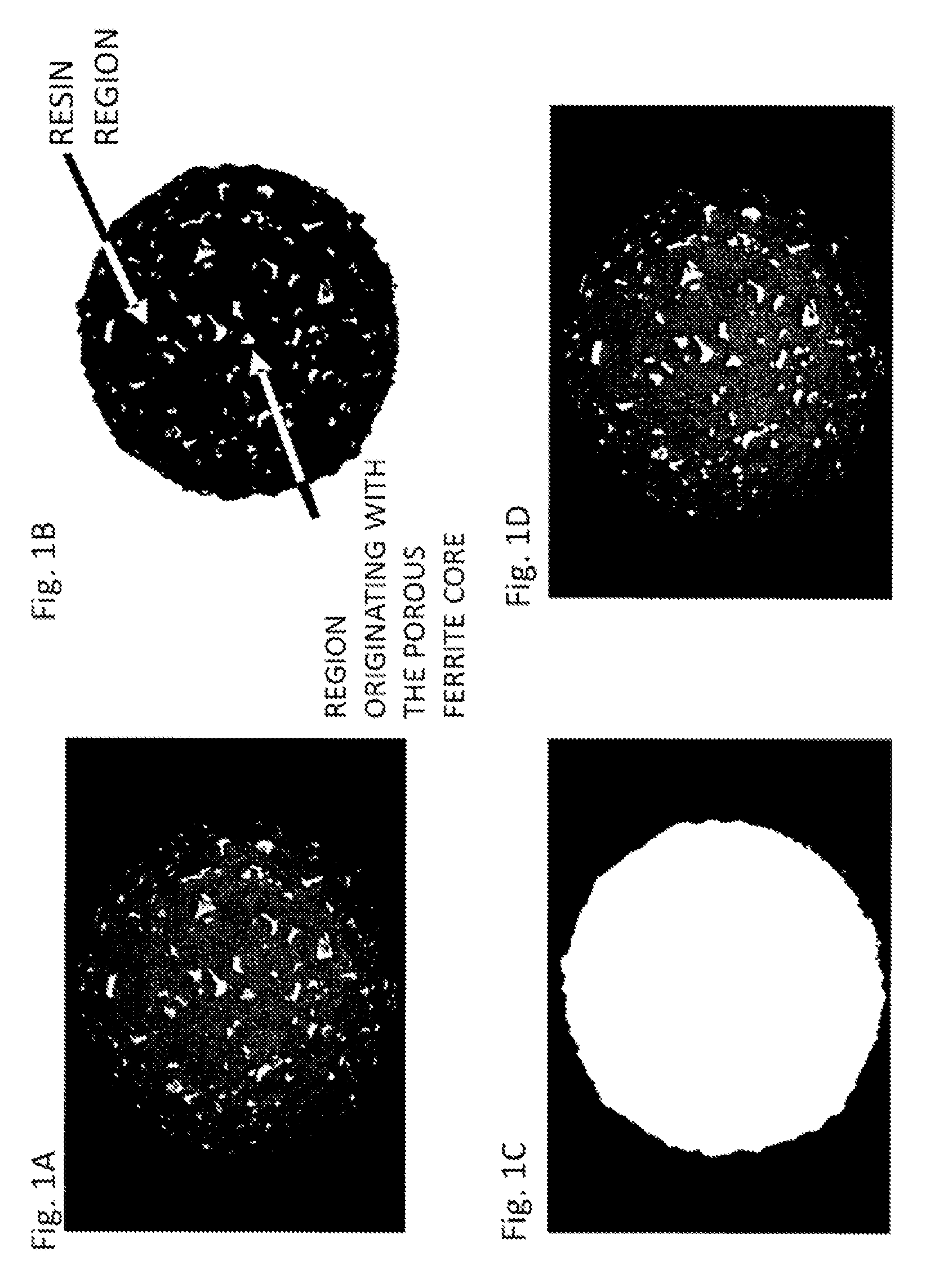

Magnetic carrier and two-component developer

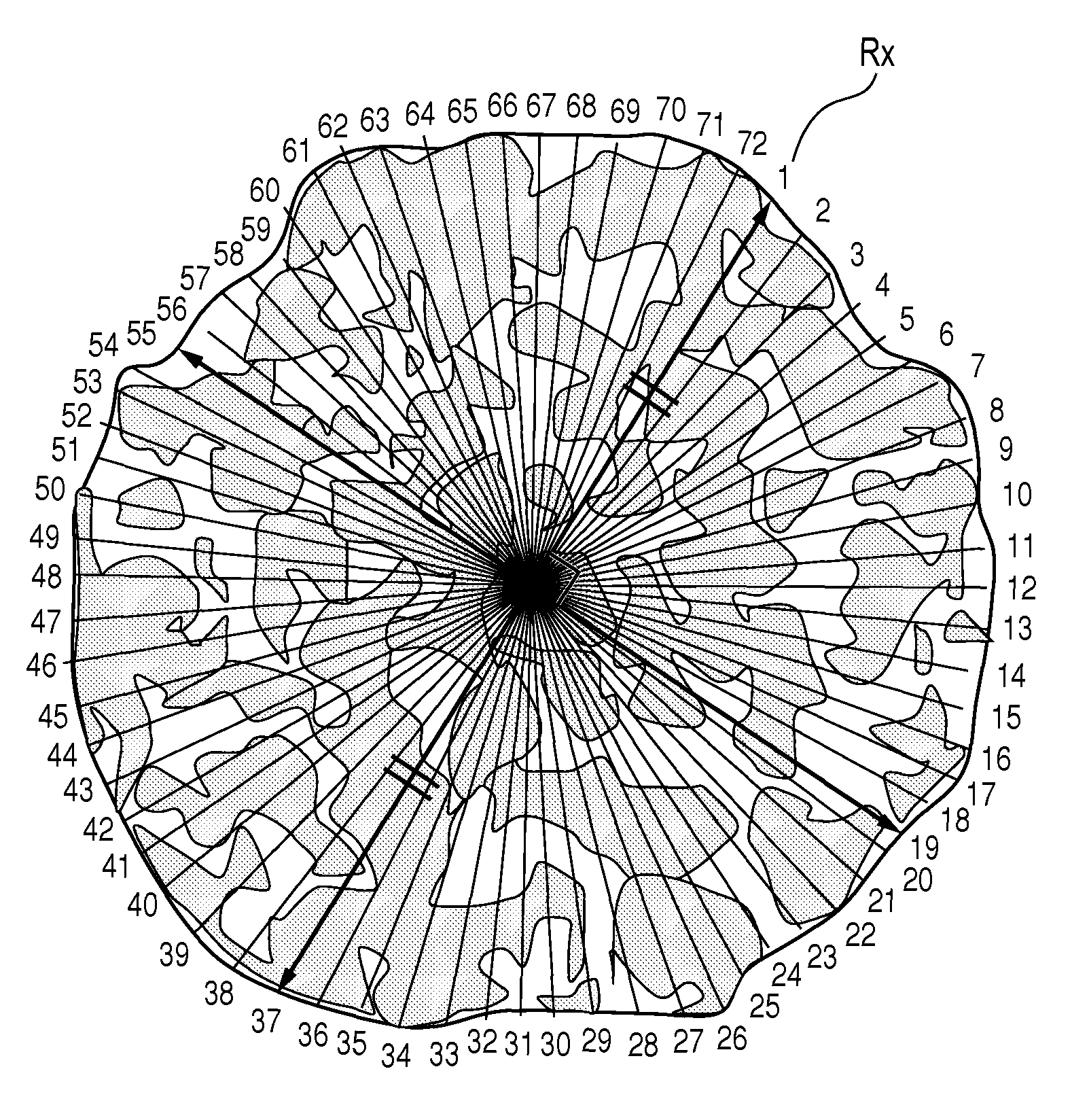

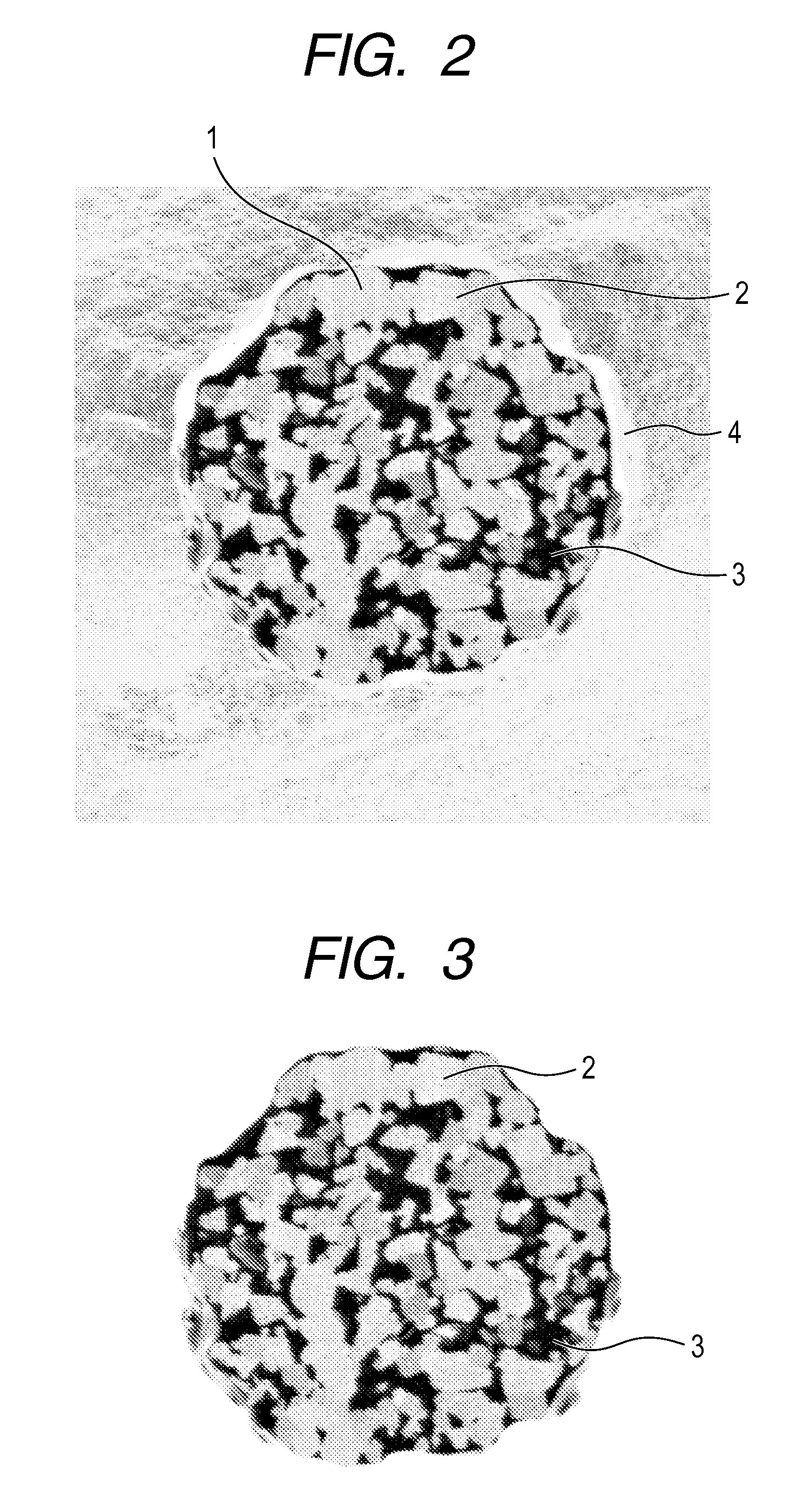

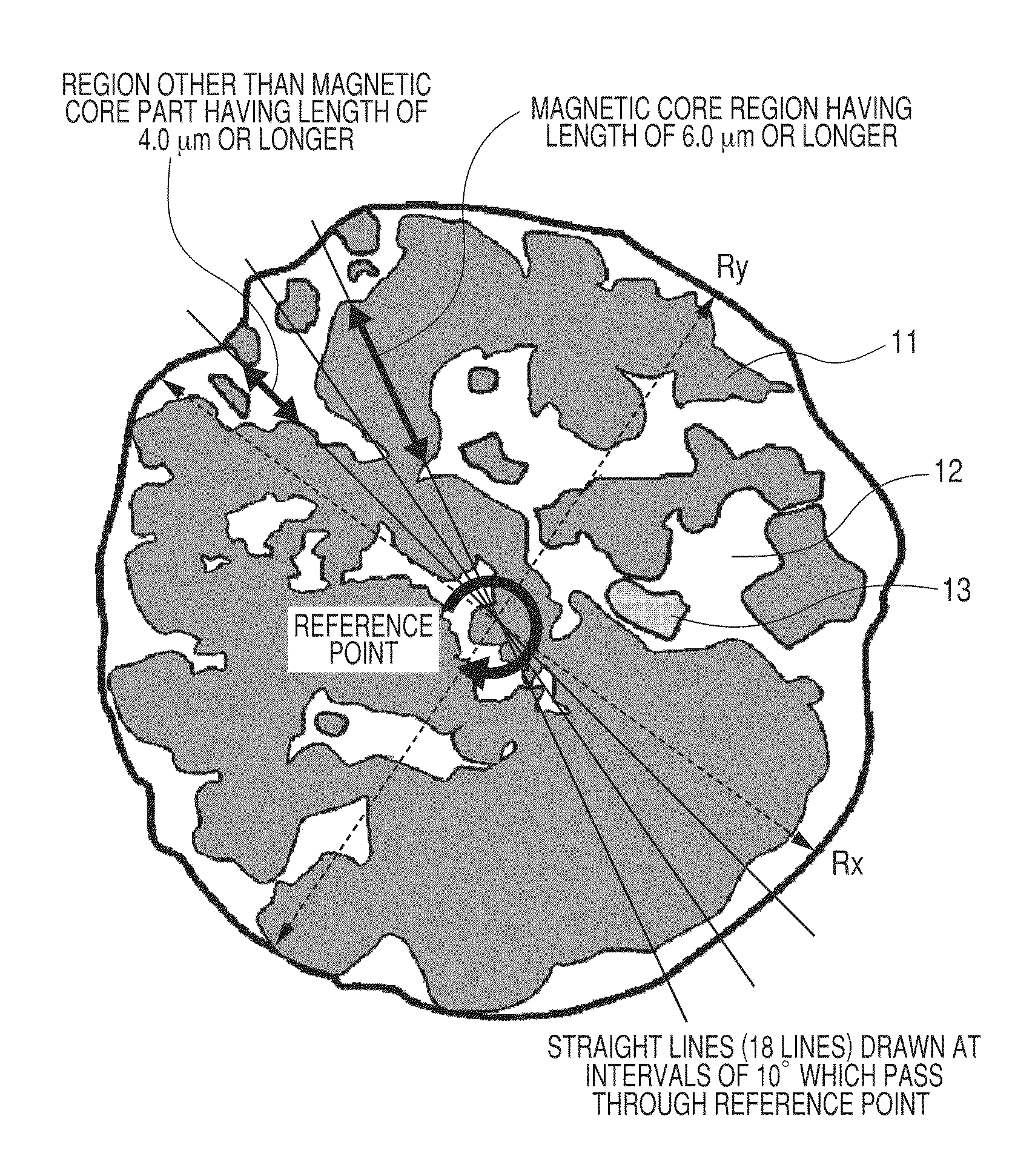

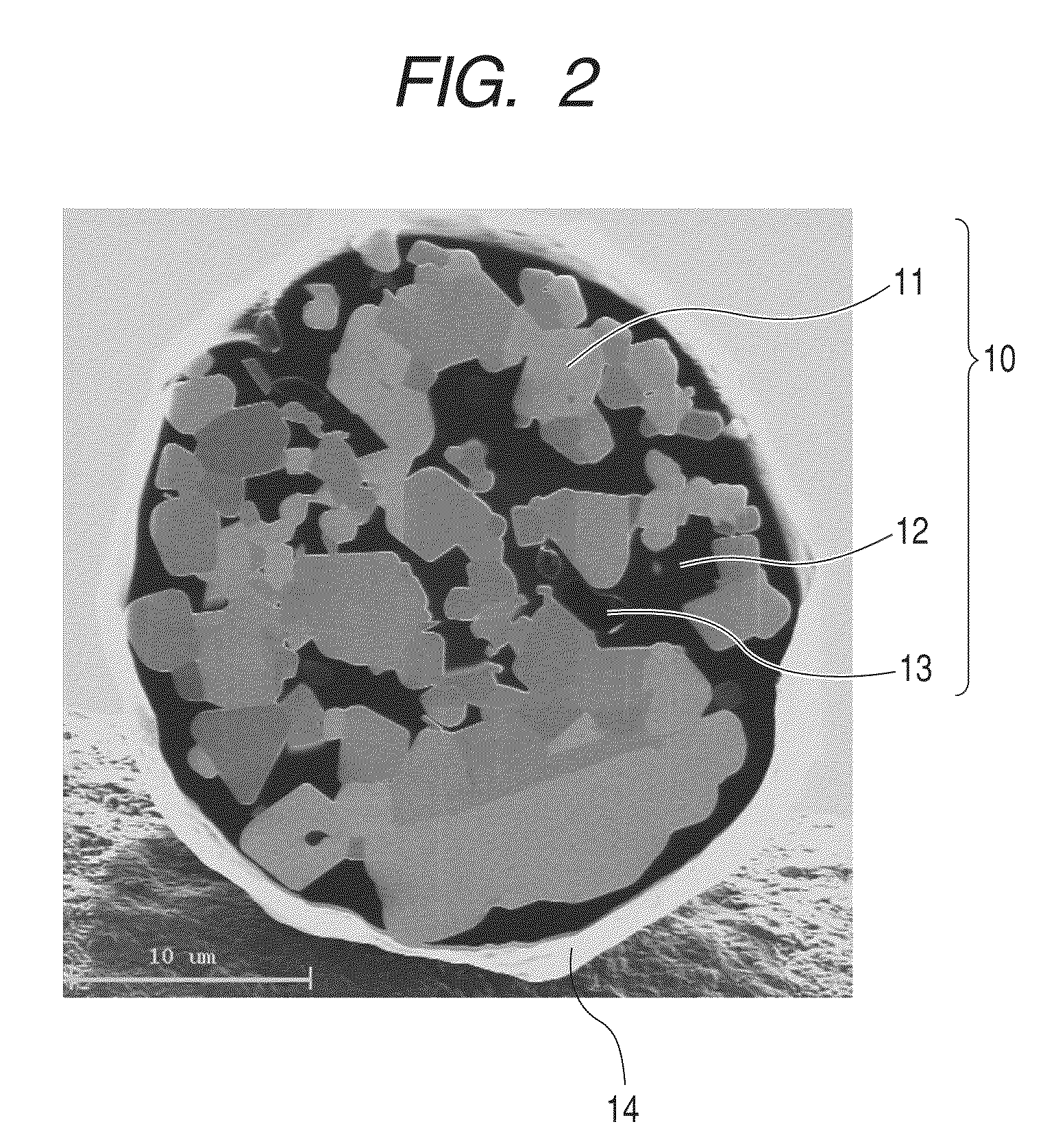

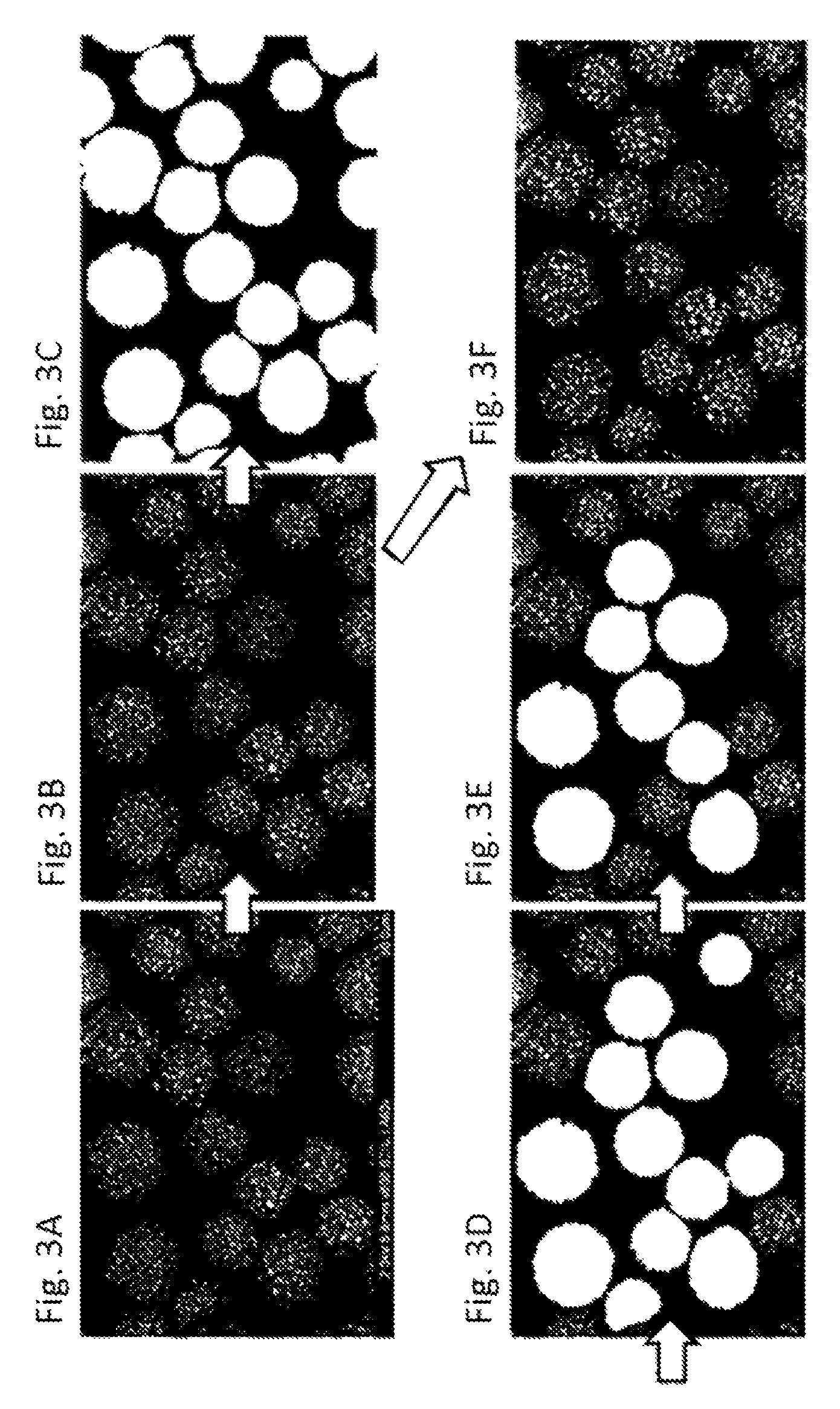

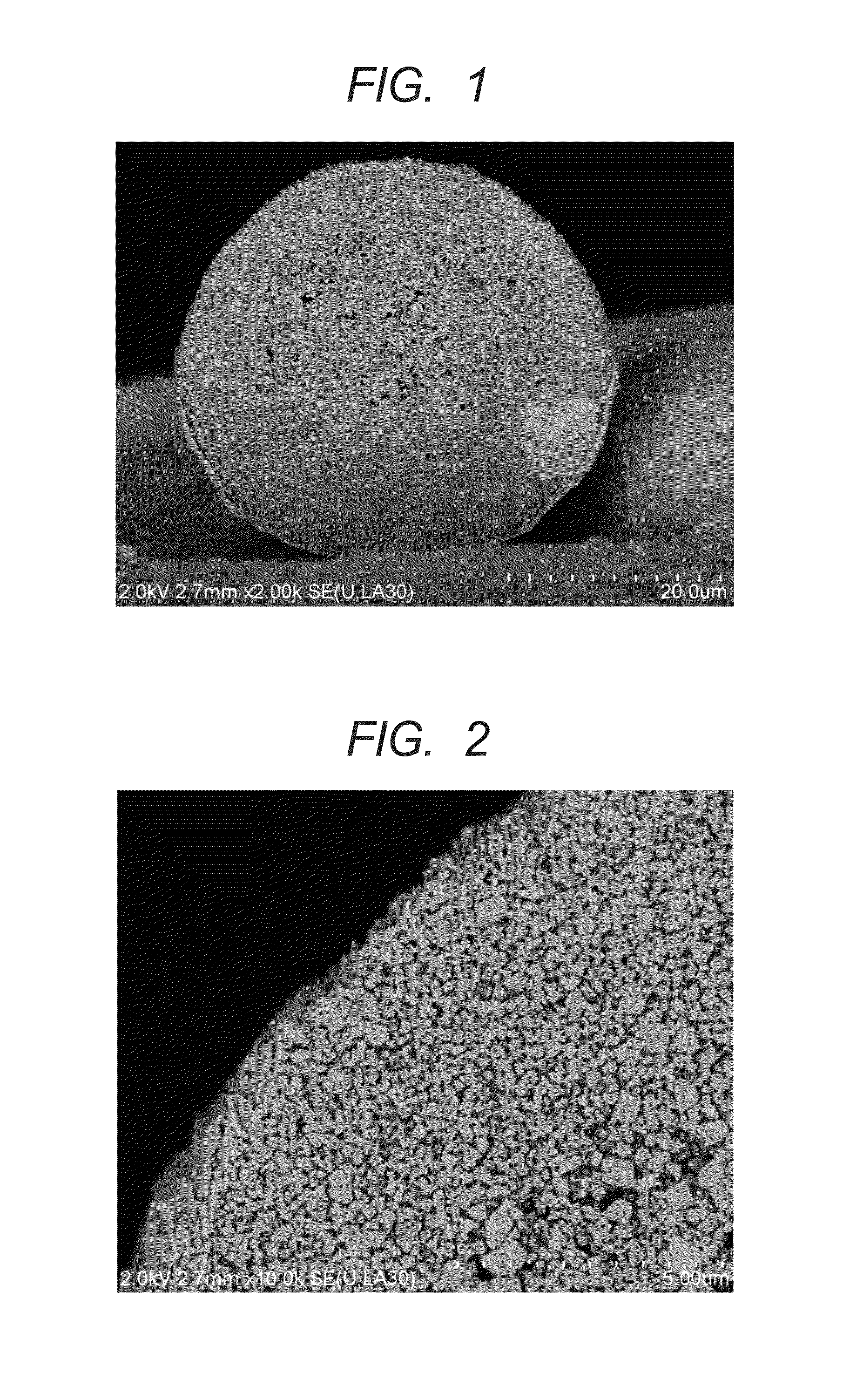

ActiveUS7939233B2Reduce variationDevelopersScanning tunneling microscopeScanning electron microscope

A magnetic carrier and a two-component developer are provided which have remedied blank areas, fog after leaving, carrier sticking during running, and image density variations before and after running. The magnetic carrier has magnetic carrier particles having at least porous magnetic core particles and a resin. The magnetic carrier particles satisfying the specific conditions (a), (b) and (c) where, in a reflected electron image of cross sections of the magnetic carrier particles as photographed with a scanning electron microscope, straight lines that divide a cross section of a magnetic carrier particle into 72 at intervals of 5° are drawn from a reference point of the cross section thereof toward the surface of the magnetic carrier particle; the magnetic carrier particles being contained in an amount of 60% by number or more.

Owner:CANON KK

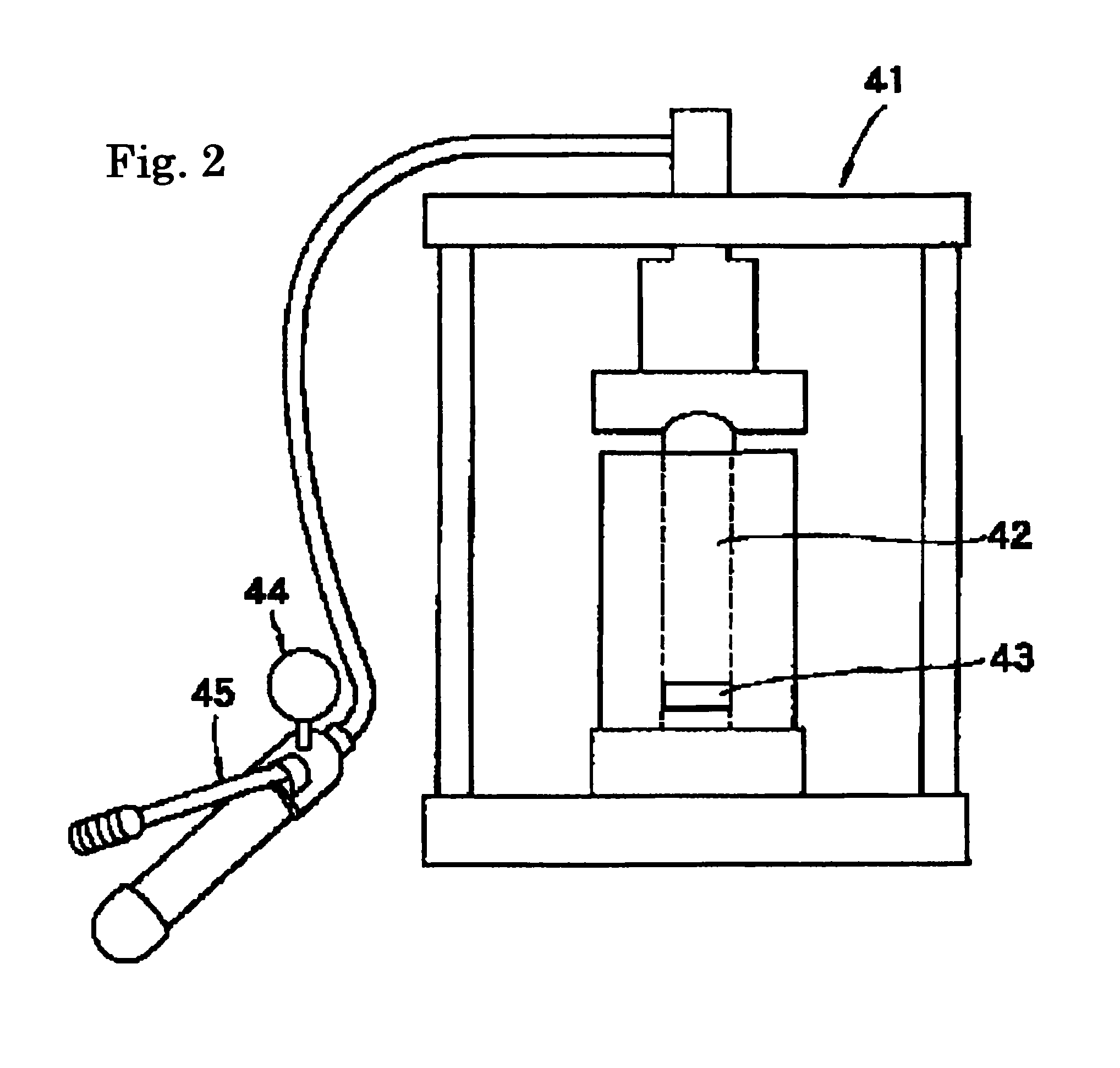

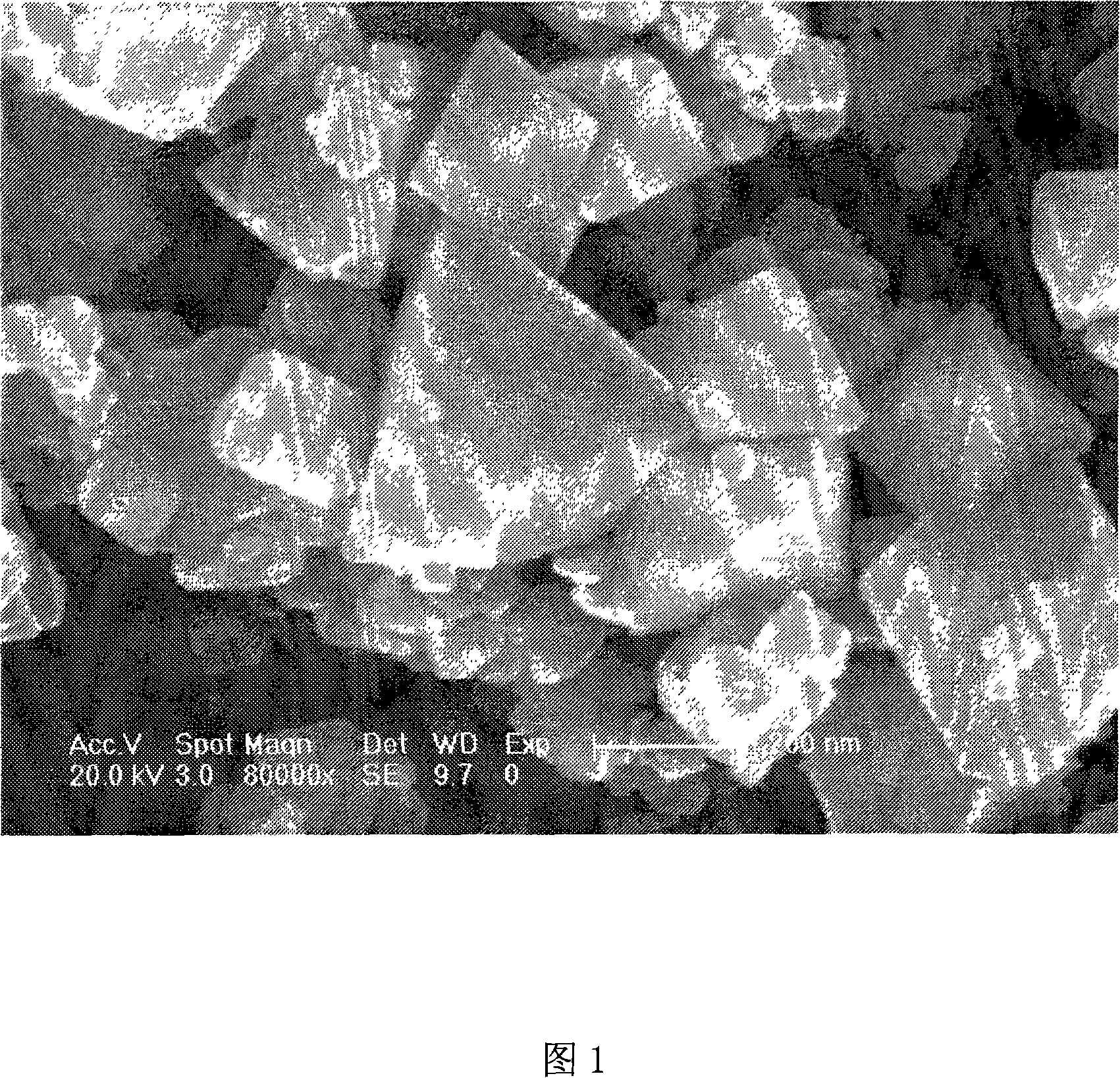

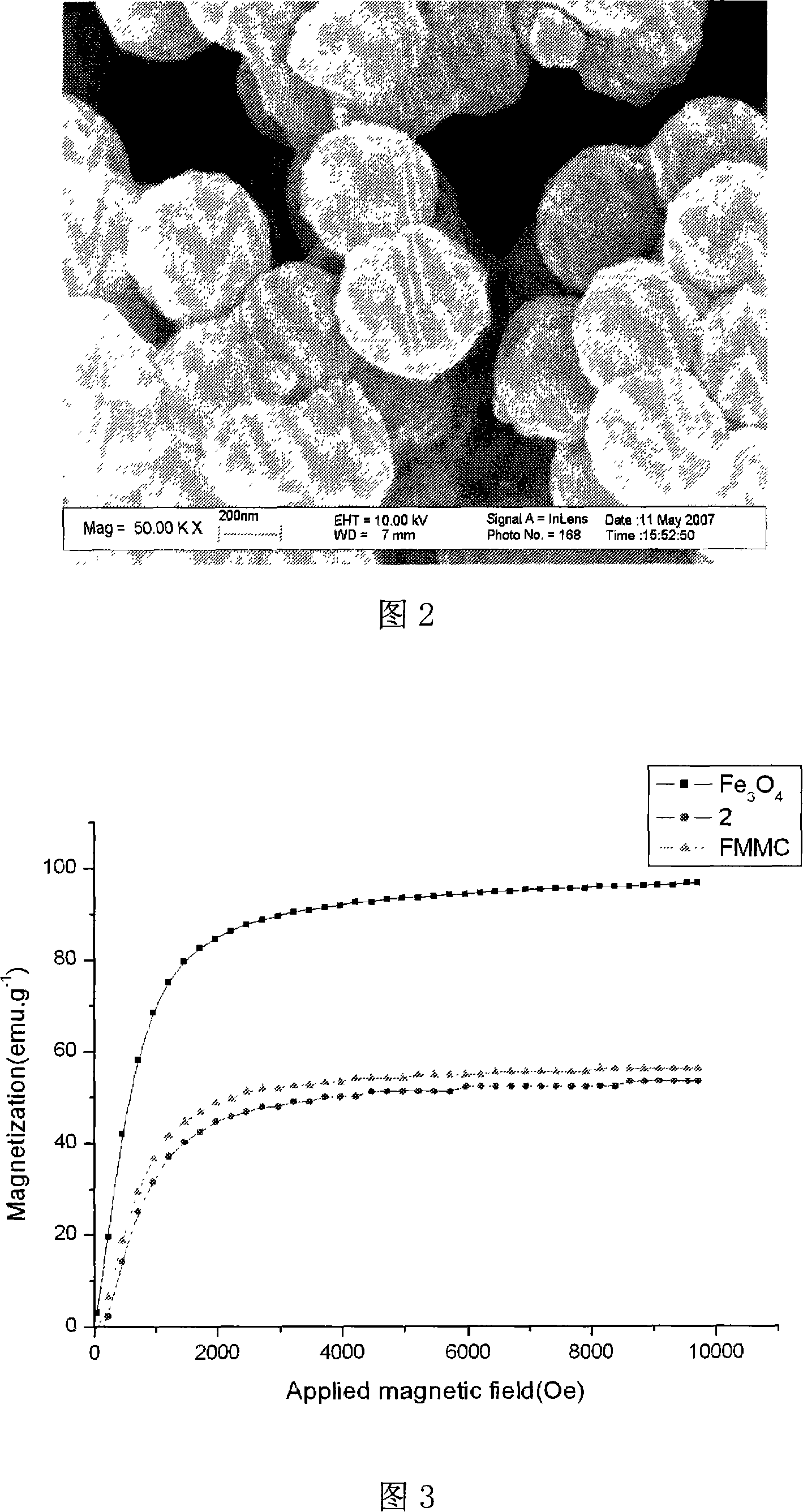

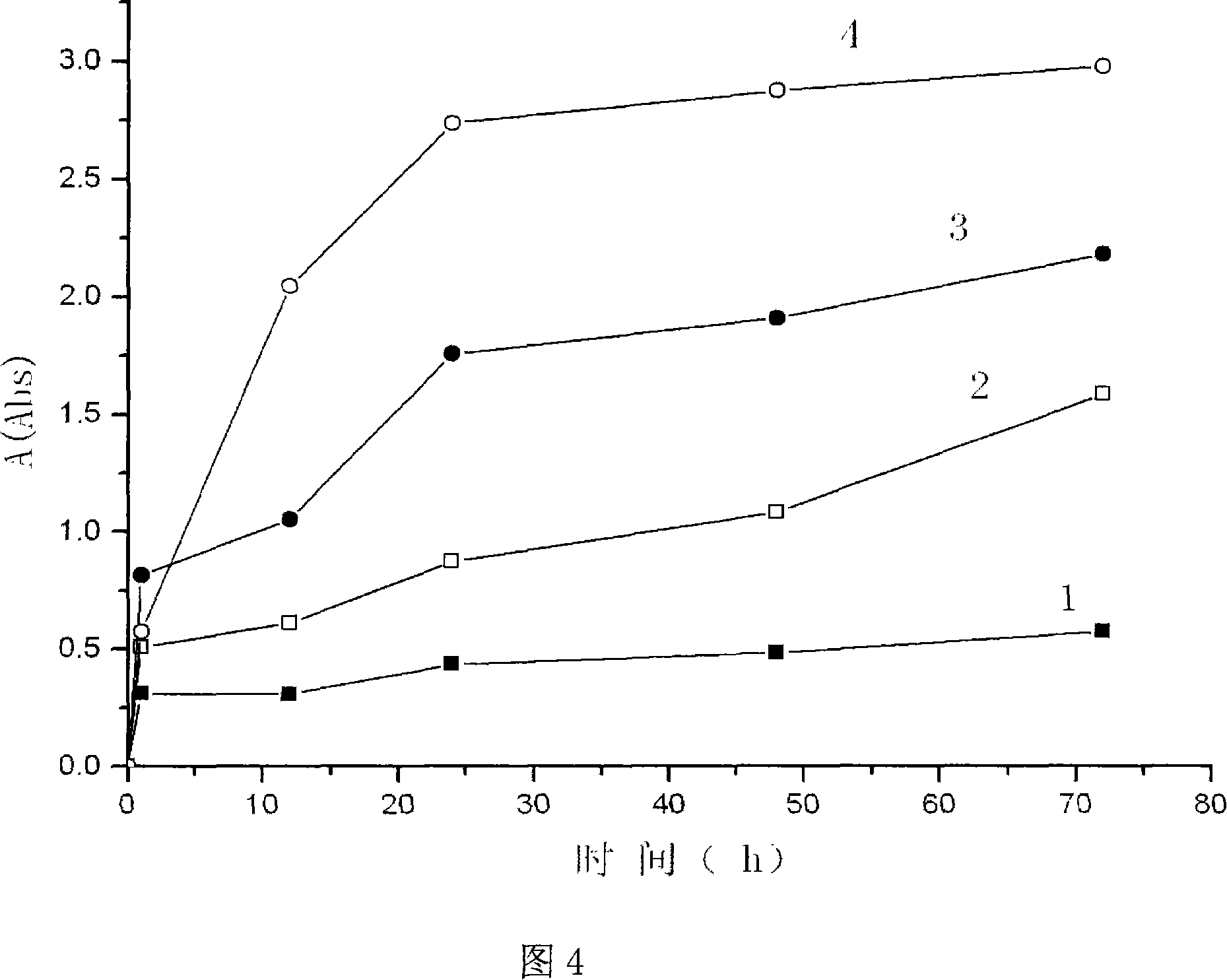

Magnetic composite microsphere with nucleocapsid structure and method for producing the same

InactiveCN101220187AHigh magnetic contentNarrow particle size distributionInorganic material magnetismMicrosphereMagnet

The invention belongs to the technical field of bioseparation material, in particular to a magnetic composite microsphere with nucleocapsid structure and a preparation method thereof. Nano ferroferric oxide decorated by oleic acid is firstly used as raw material, and is polymerized through template fine emulsion so as to prepare the monodisperse magnetic composite microsphere with high magnet content; and then the monodisperse micosphere is polymerized through seed emulsion and is added with different amount of shell monomer to prepare the magnetic composite microsphere with the nucleocapsid structure and the magnet content of 20wt percent to 80wt percent. The grain size of nucleocapsid composite microsphere is in narrow distribution, and the magnet content of the microsphere is controllable and the surface has functional reactive group; therefore, the microsphere of the invention can be surface-modified into a magnetic carrier of biological active molecule by chemical crosslinking to be applied in the biomedicine field. The method of the invention can be simply operated and the process of which can be controlled, thus having industrialized prospect.

Owner:FUDAN UNIV

Magnetic carrier and two-component developer

Owner:CANON KK

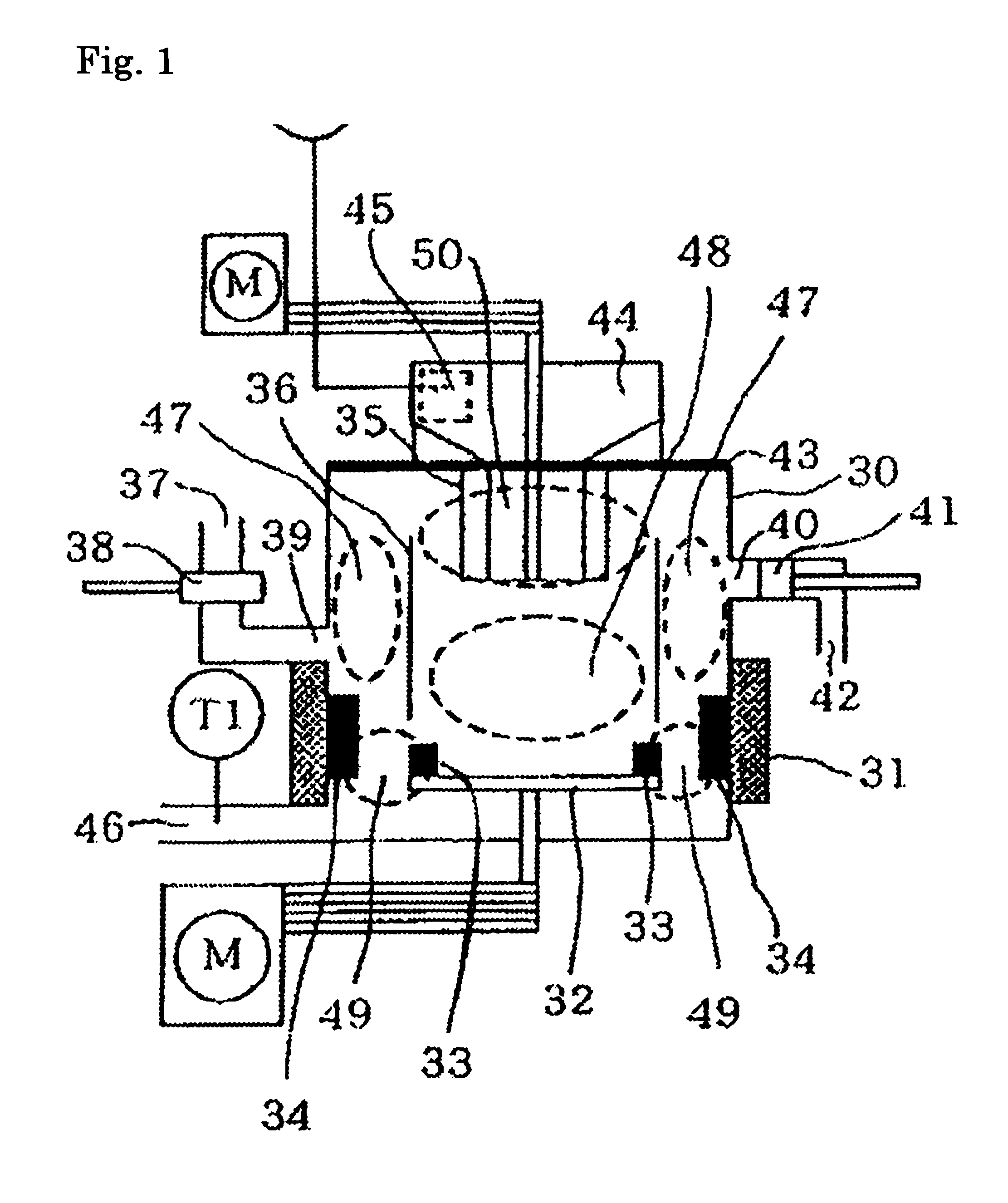

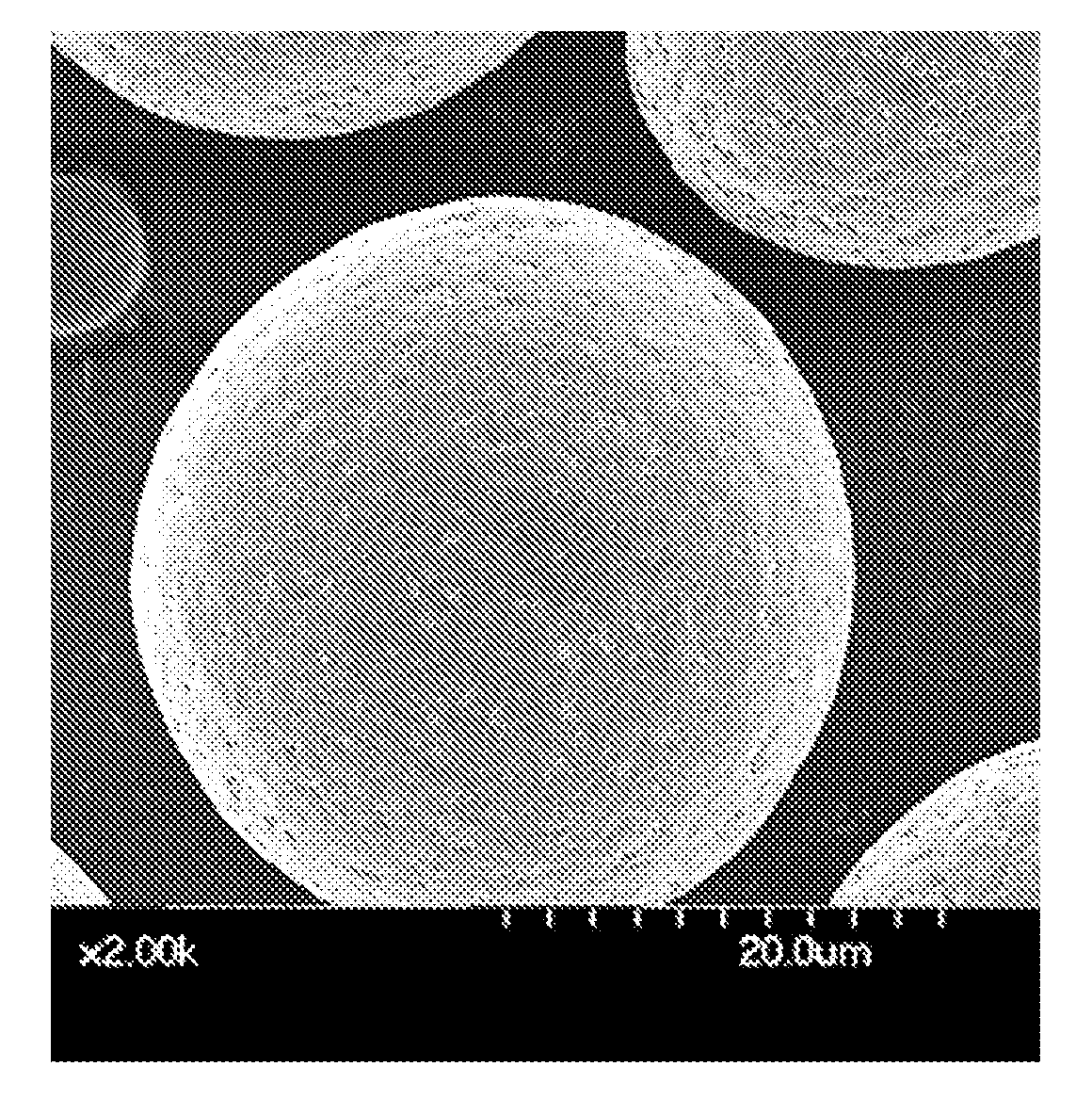

Magnetic carrier and two component developer

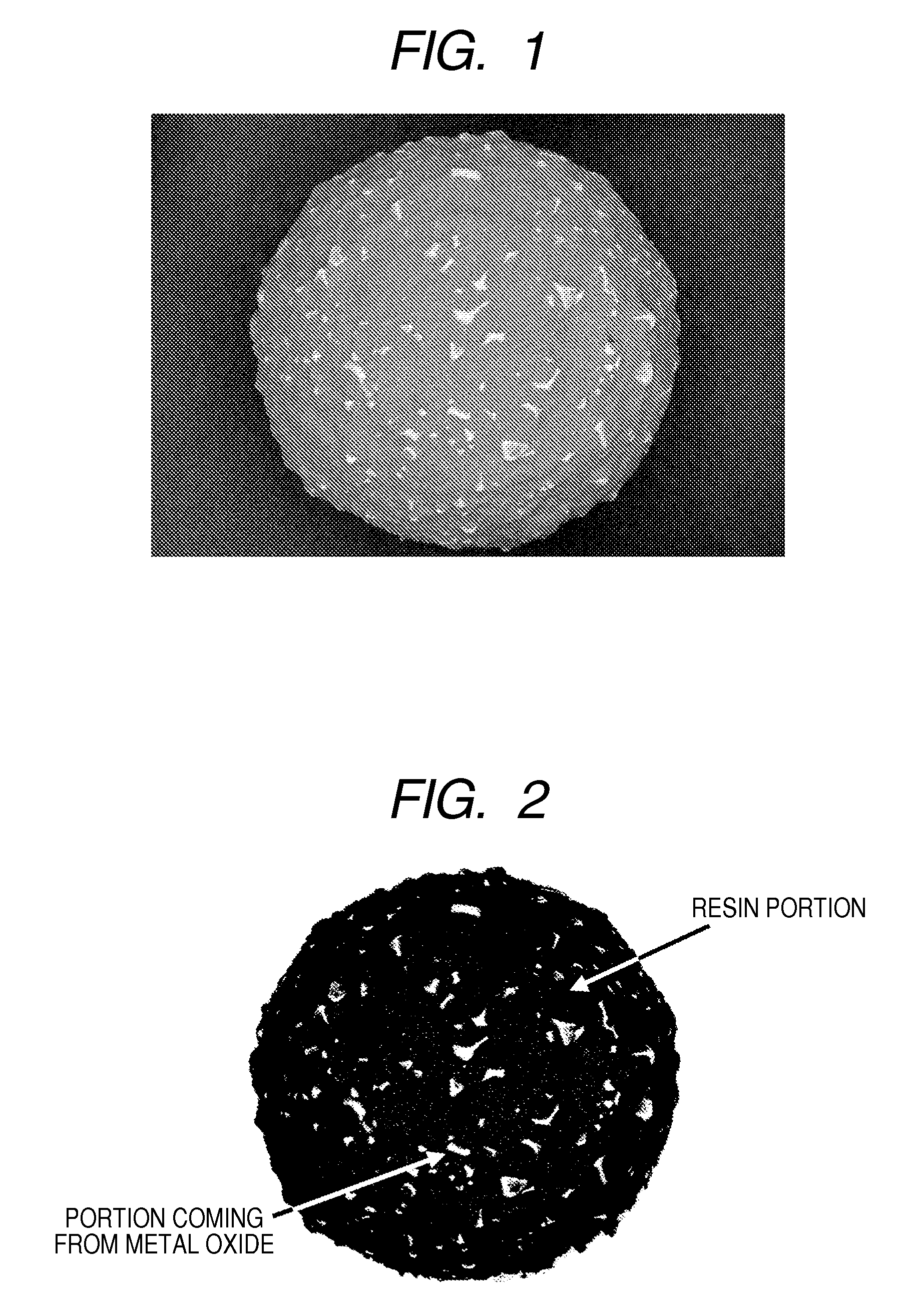

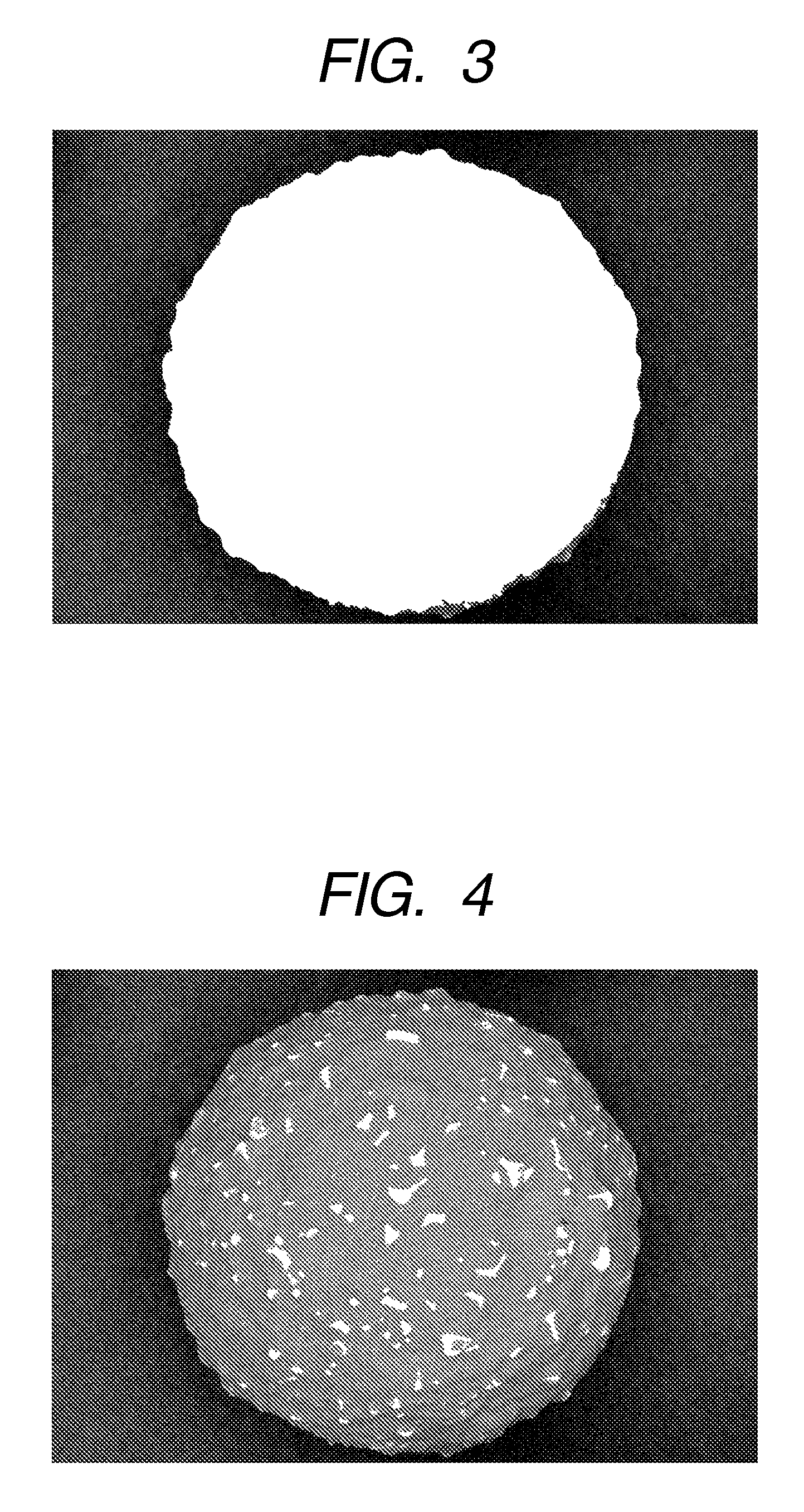

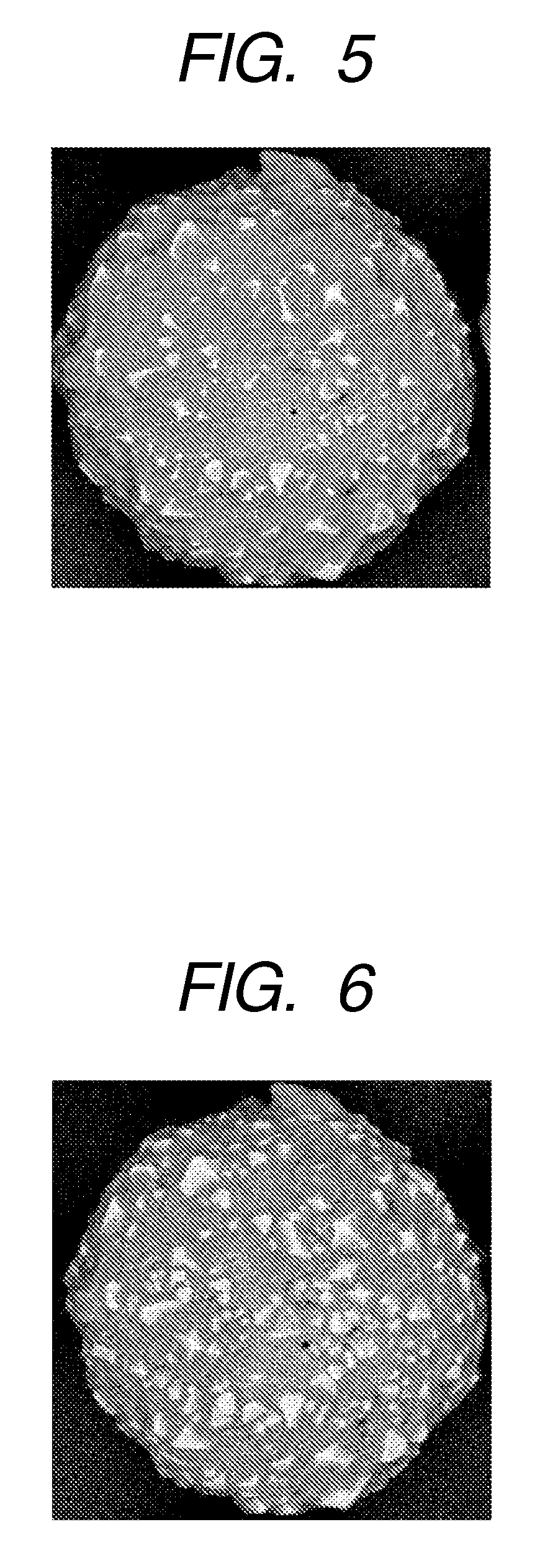

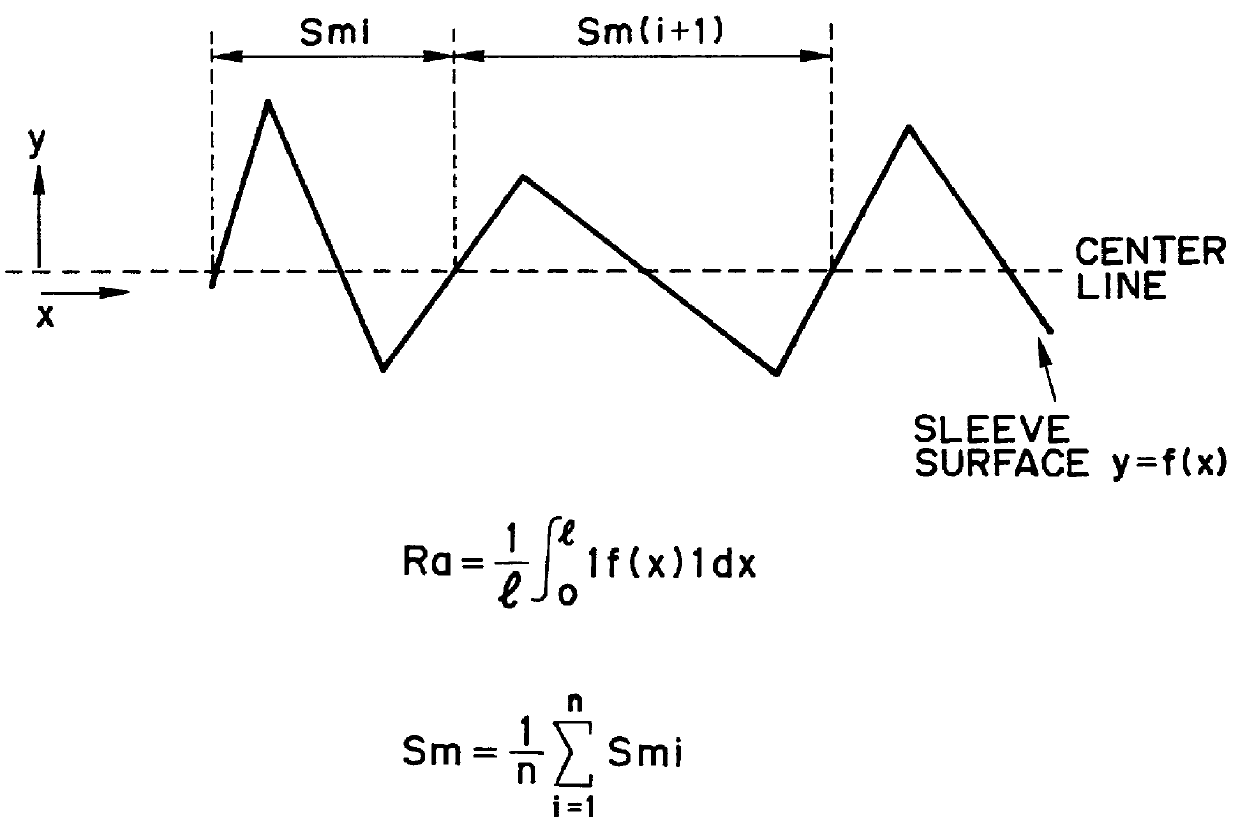

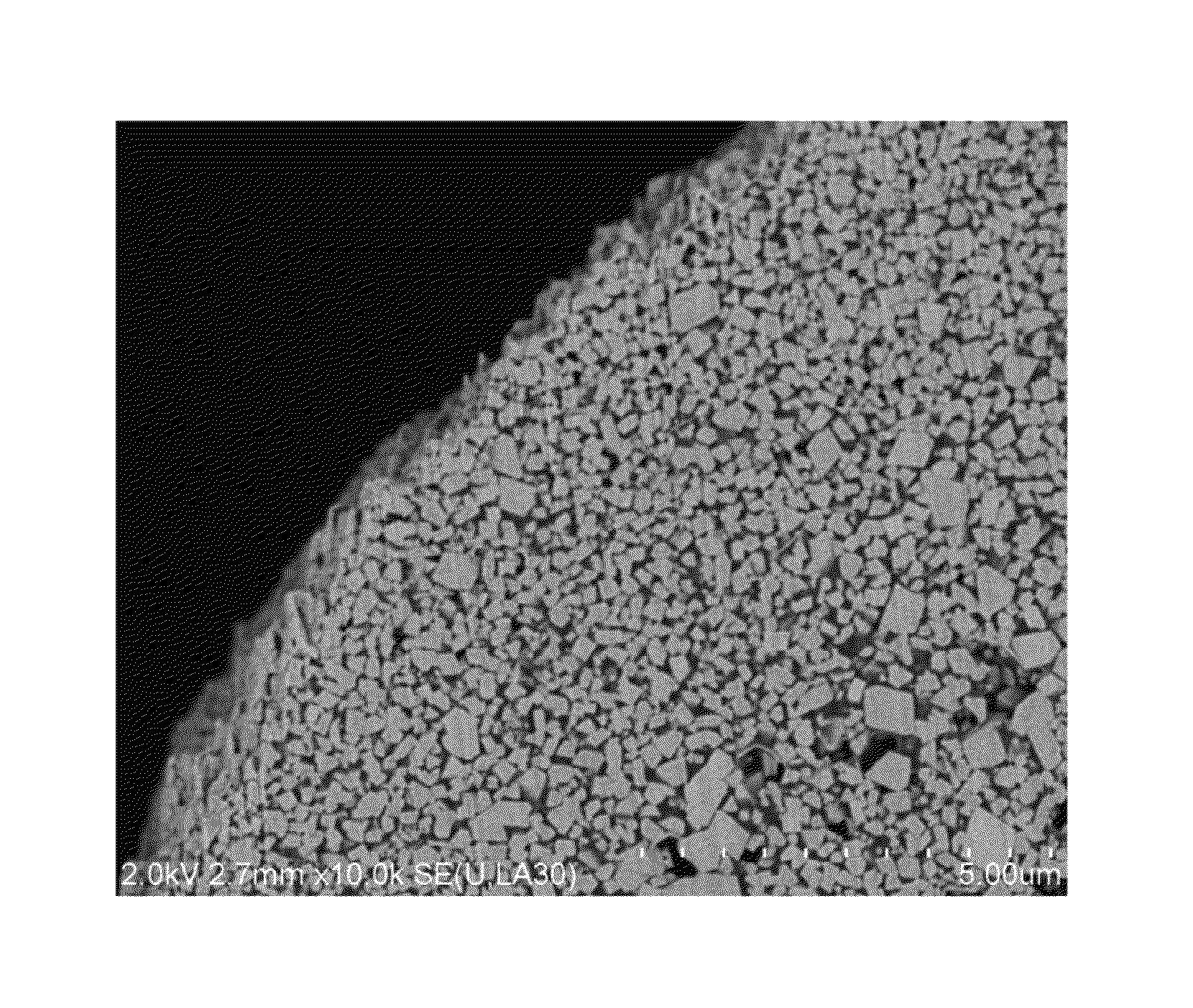

ActiveUS7927775B2Quality improvementGood reproducibilityDevelopersScanning electron microscopeVolumetric Mass Density

Provided is a magnetic carrier giving a high quality image free of density variation without the occurrence of fogging or carrier adhesion and having excellent dot reproducibility even during long-term use. The magnetic carrier has magnetic carrier particles produced by filling pores of porous magnetic core particles with a resin. The magnetic carrier contains 80% by number or more of the magnetic carrier particles satisfying the specific conditions (a) and (b) when 18 straight lines passing through a reference point of a cross section of the magnetic carrier particle are drawn at intervals of 10° in a reflected electron image of the cross section of the magnetic carrier particle photographed by a scanning electron microscope.

Owner:CANON KK

Magnetic carrier and two-component developer

InactiveUS7279262B2High image densityGood reproducibilityDevelopersMolecular geometryElectrical and Electronics engineering

A magnetic carrier composed of carrier particles is provided in which each carrier particle has a carrier core including magnetic fine particles and a binder resin with the carrier core surface being coated with a coat material containing a coat resin. In the magnetic carrier, Fatom / Catom and (Fatom / Catom) / (Fcalc / Ccalc) are respectively in specific ranges, wherein Fatom and Catom represent respectively a fluorine element abundance ratio and a carbon element abundance ratio at the magnetic carrier particle surface, and Fcalc and Ccalc represent respectively a fluorine element abundance ratio and a carbon element abundance ratio which are calculable from the molecular structure of the coat resin.In addition, a two-component developer is provoded including the magnetic carrier and a toner having a specific contact angle against water.

Owner:CANON KK

Magnetic coated carrier two-component type developer and developing method

InactiveUS6165663AImprove liquidityIncreased durabilityDevelopersElectrographic processes using charge patternCoated surfaceParticulate metal

A magnetic coated carrier suitable for constituting a two-component type developer for use in electrophotography is composed of magnetic coated carrier particles comprising magnetic coated carrier particles comprising magnetic carrier core particles each comprising a binder resin and metal oxide particles, and a coating layer surface-coating each carrier core particle. The metal oxide particles have been subjected to a surface lipophilicity-imparting treatment. The magnetic carrier core particles have a resistivity of at least 1x1010 ohm.cm, and the magnetic coated carrier has a resistivity of at least 1x1012 ohm.cm. The magnetic coated carrier has a particle size distribution such that (i) it has a number-average particle size Dn of 5-100 mu m, (ii) it satisfies a relationship of Dn / sigma > / =3.5, wherein sigma denotes a standard deviation of number-basis particle size distribution of the carrier, and (iii) it contains at most 25% by number of particles having particle sizes of at most Dnx+E,fra 2 / 3+EE .

Owner:CANON KK

Developer for replenishment and image forming method

ActiveUS8142972B2Small sizeSimple processDevelopersElectrographic processes using charge patternEngineeringCoefficient of variation

Provided is a developer for replenishment capable of forming a high-quality image even upon duration. The developer for replenishment includes at least a toner and a magnetic carrier, and in the developer for replenishment, 1 part by mass of the magnetic carrier is blended with 2 to 50 parts by mass of the toner, and the magnetic carrier contains a ferrite core and a resin component, has a true specific gravity of 2.5 to 4.2 g / cm3, has a 50% particle diameter on a volume basis (D50) of 15 to 70 μm, and has an average circularity of 0.850 to 0.950, the average circularity having a coefficient of variation of 1.0 to 10.0%.

Owner:CANON KK

Two-component developer

InactiveUS20130244159A1High quality imagingImprove development performanceDevelopersMetal catalystTitanium

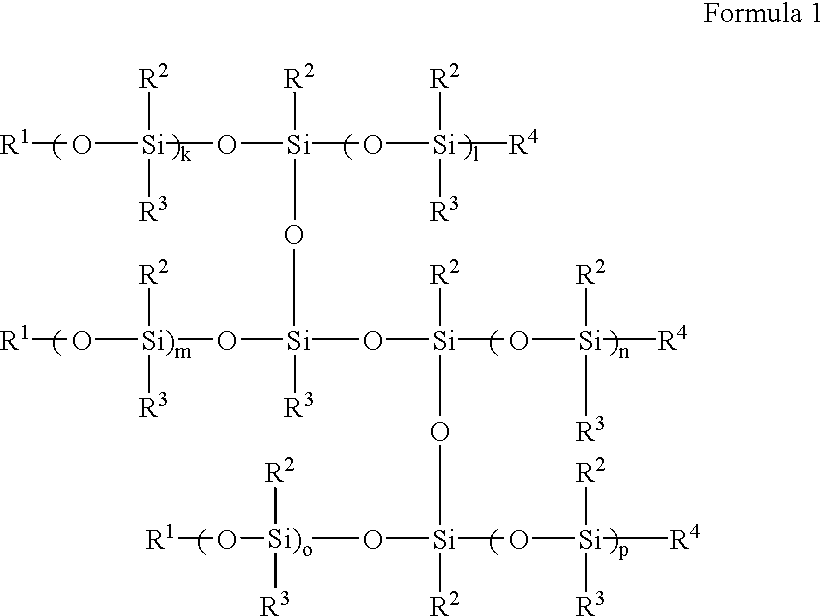

Provided is a two-component developer having excellent developing performance and little change in image concentration, and achieving long-term suppression of image defects such as transfer failure and fogging.Provided is a two-component developer containing a magnetic carrier and a toner, wherein the magnetic carrier has magnetic carrier particles comprising a silicone resin B coated on the surfaces of filled core particles in which pores of porous magnetic core particles are filled with a silicone resin A, the silicone resin A is a silicone resin cured in the presence of a non-metal catalyst or without a catalyst, while the silicone resin B is a silicone resin cured in the presence of a metal catalyst having titanium or zirconium, and the toner contains a binder resin, a release agent and a colorant, and has an average circularity of 0.940 or more.

Owner:CANON KK

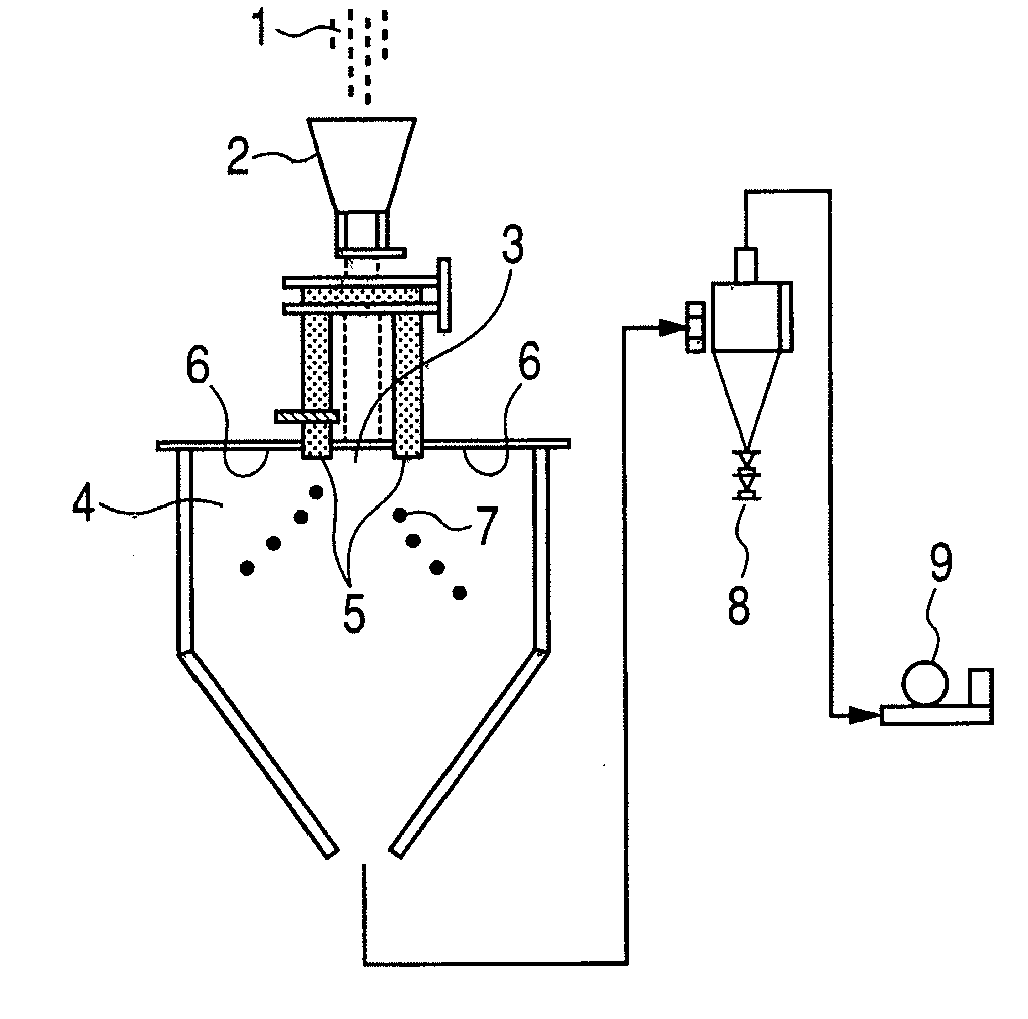

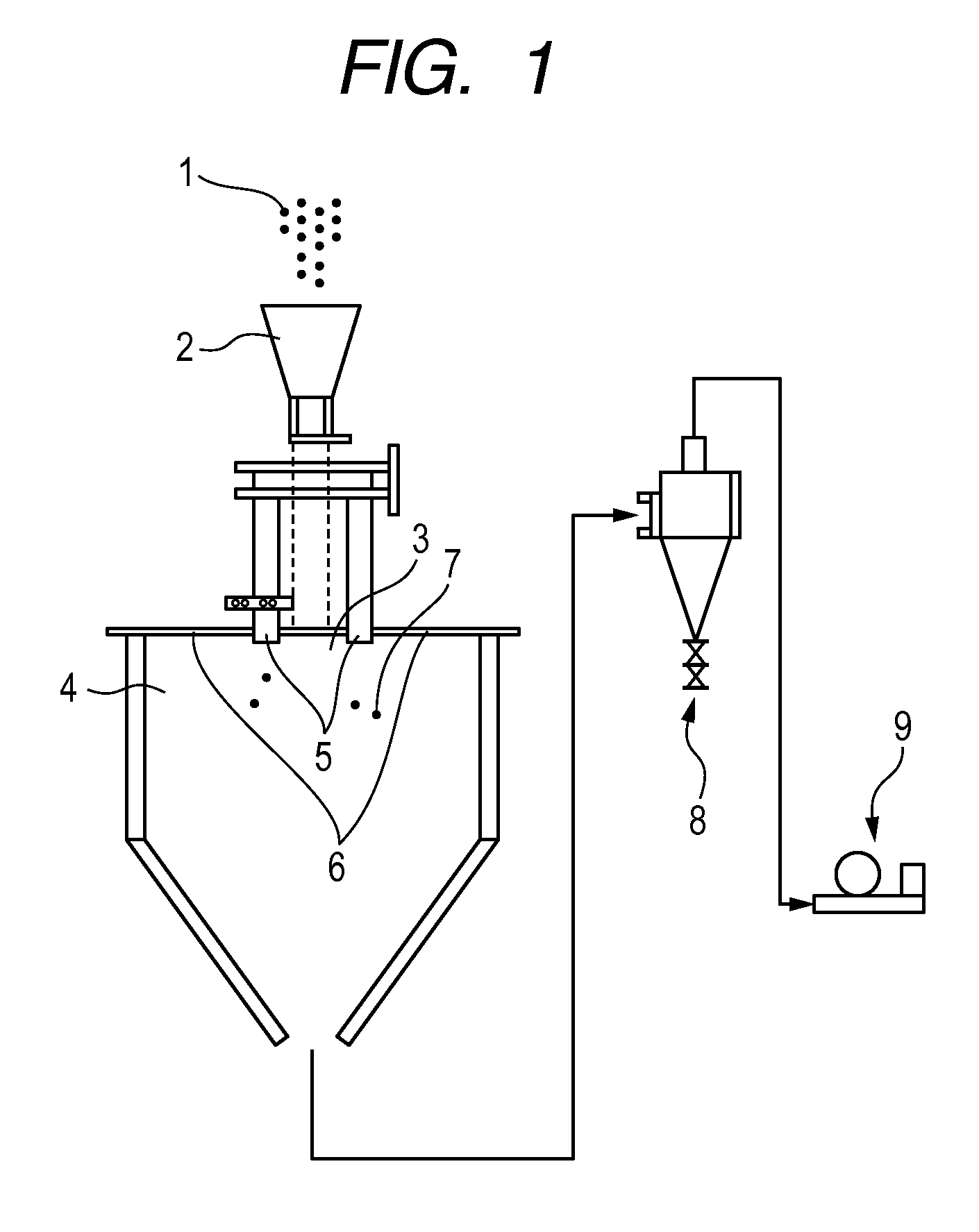

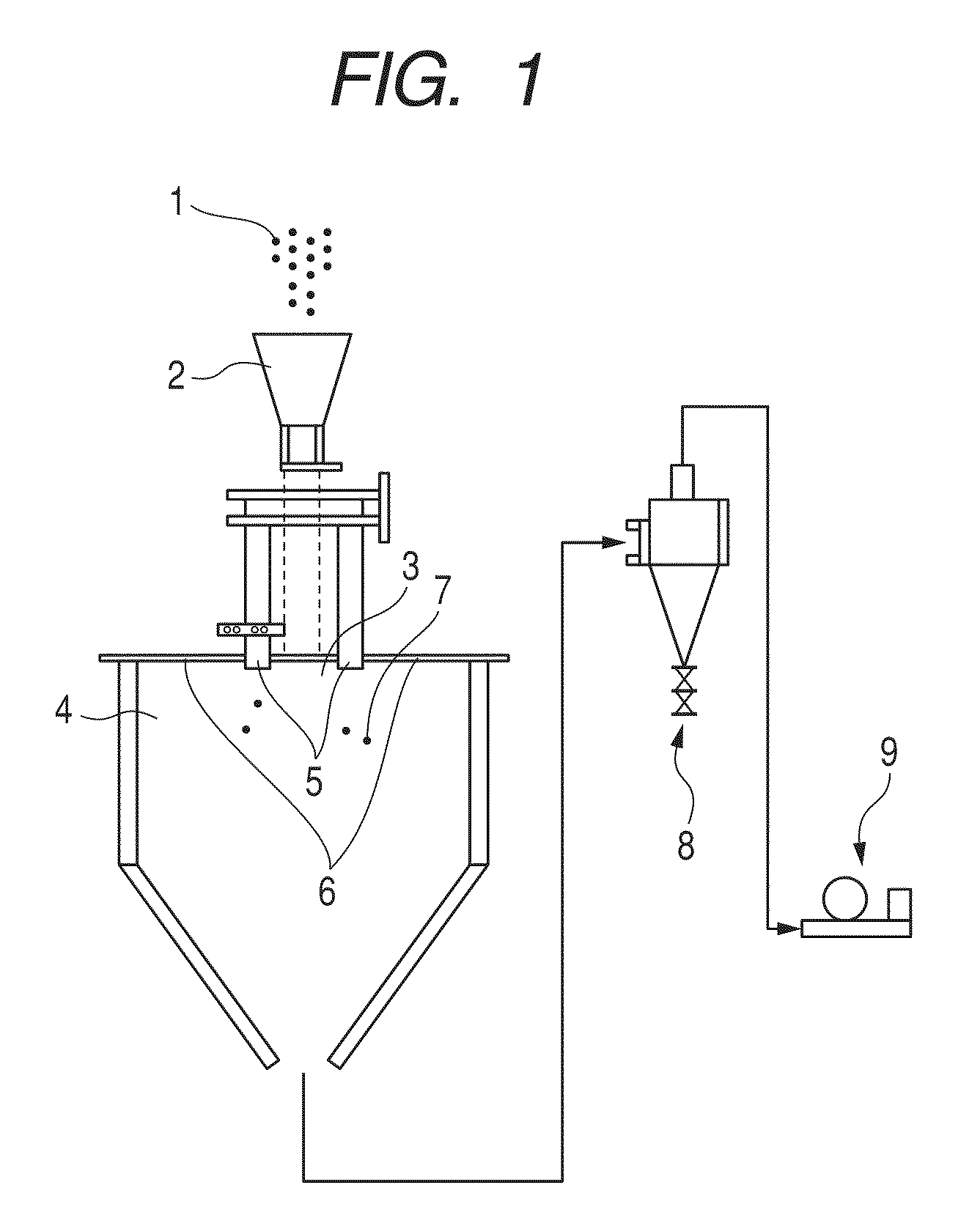

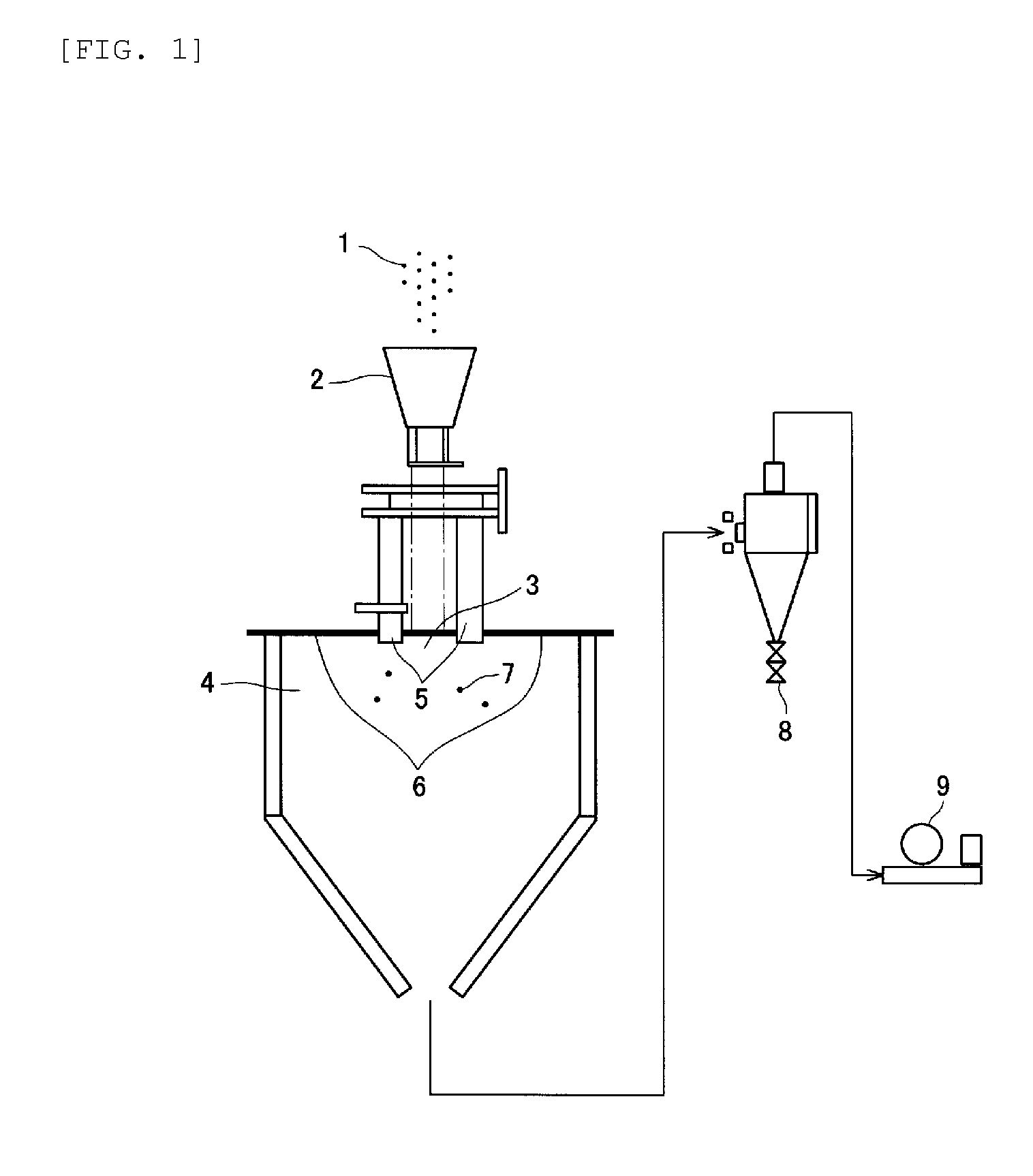

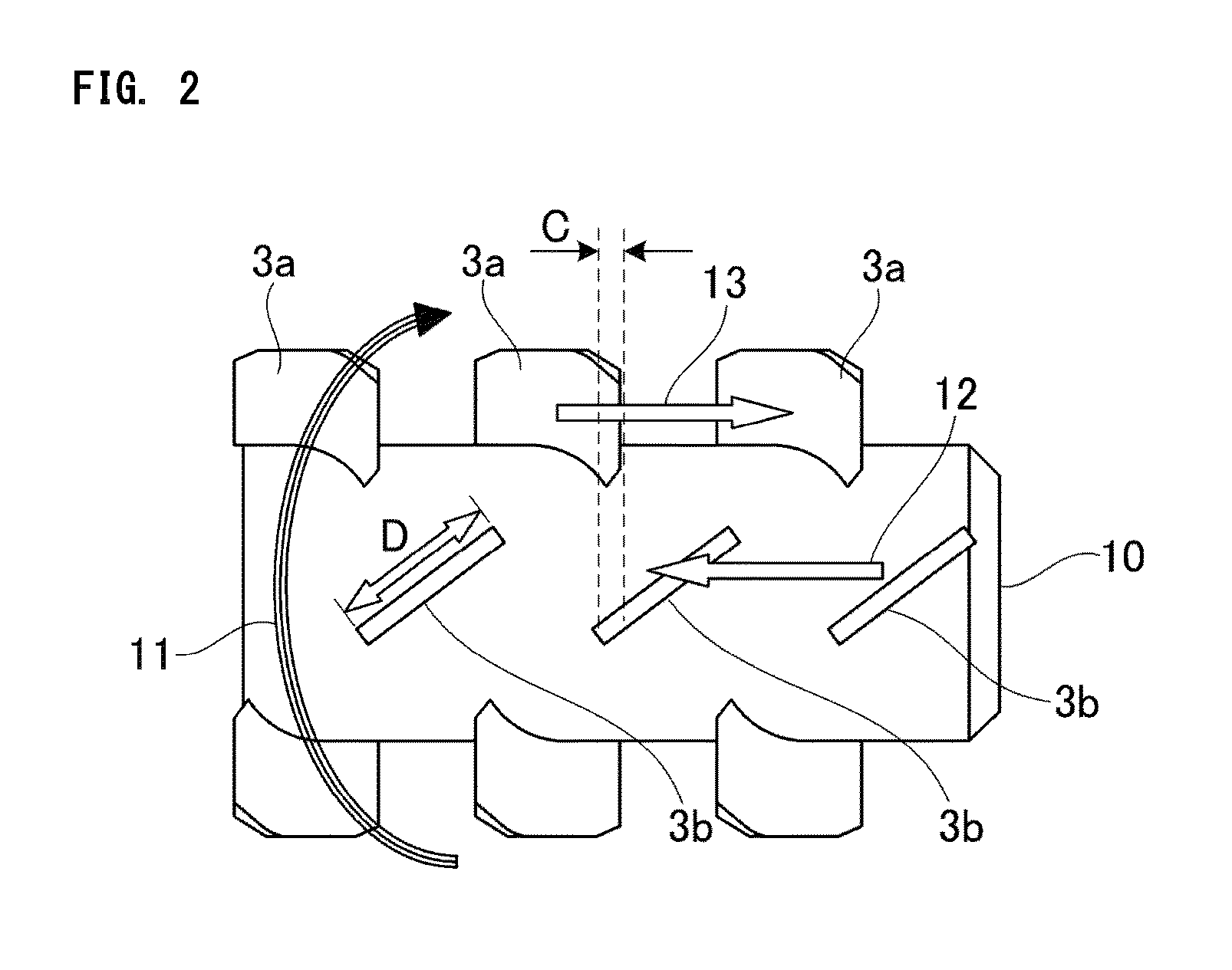

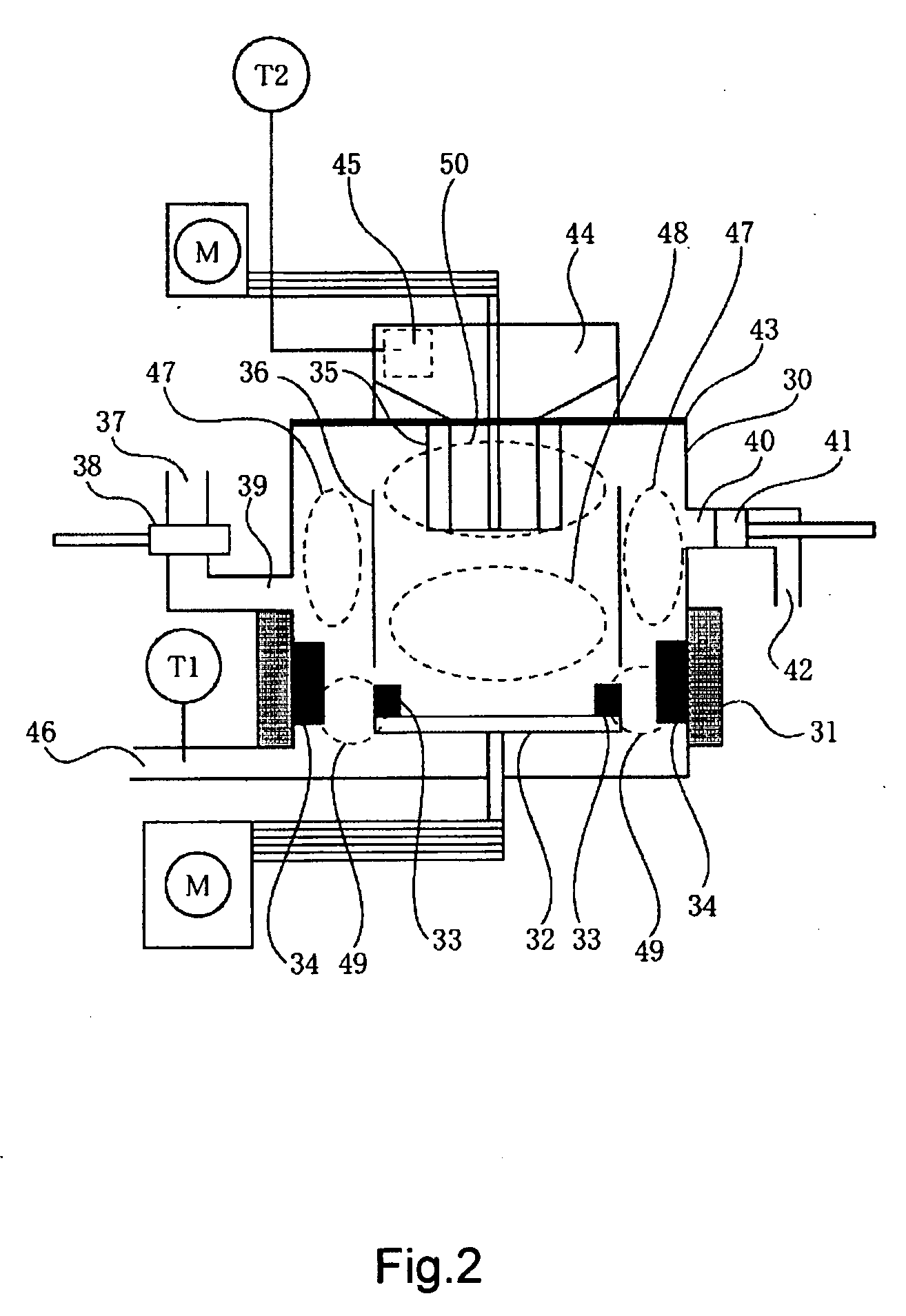

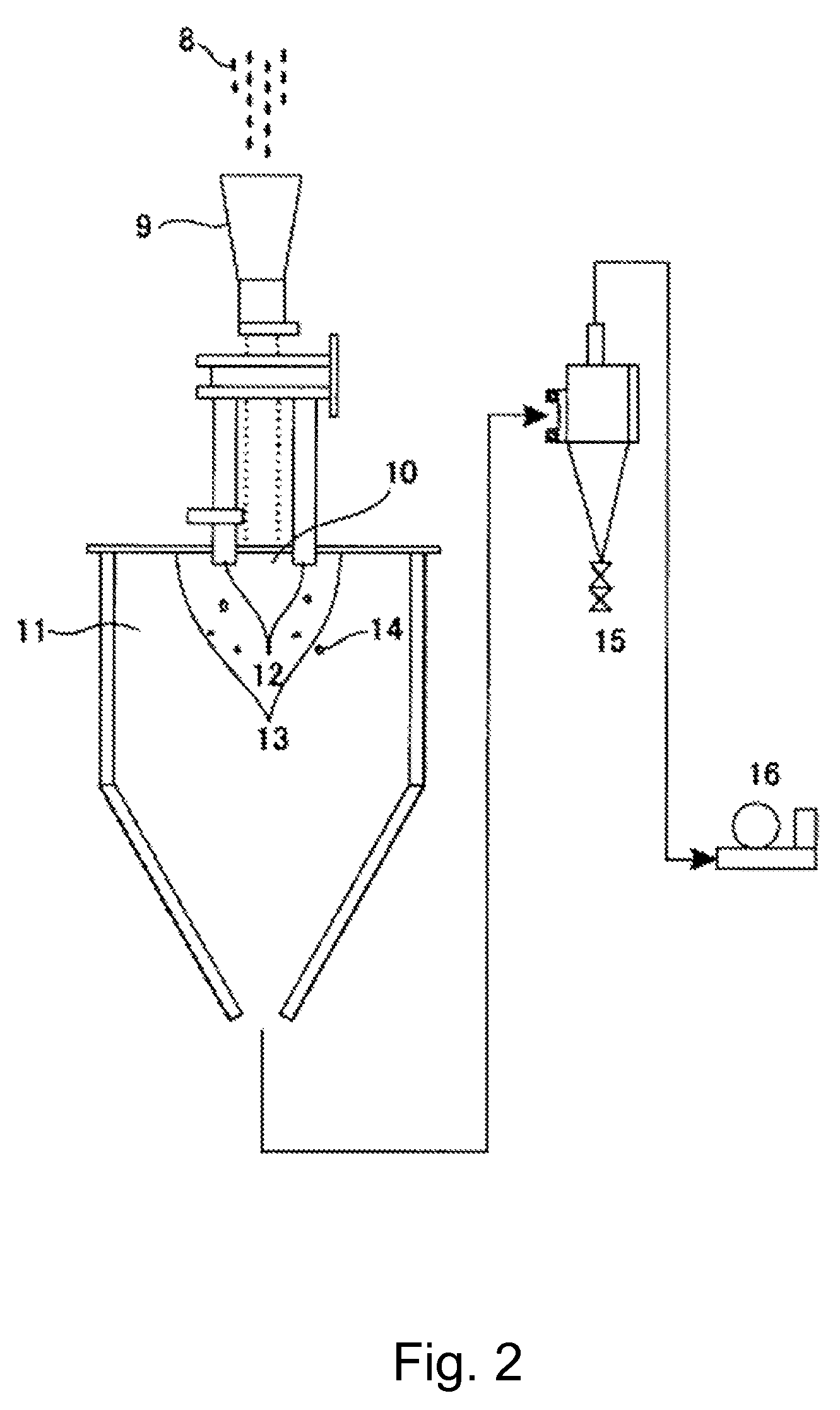

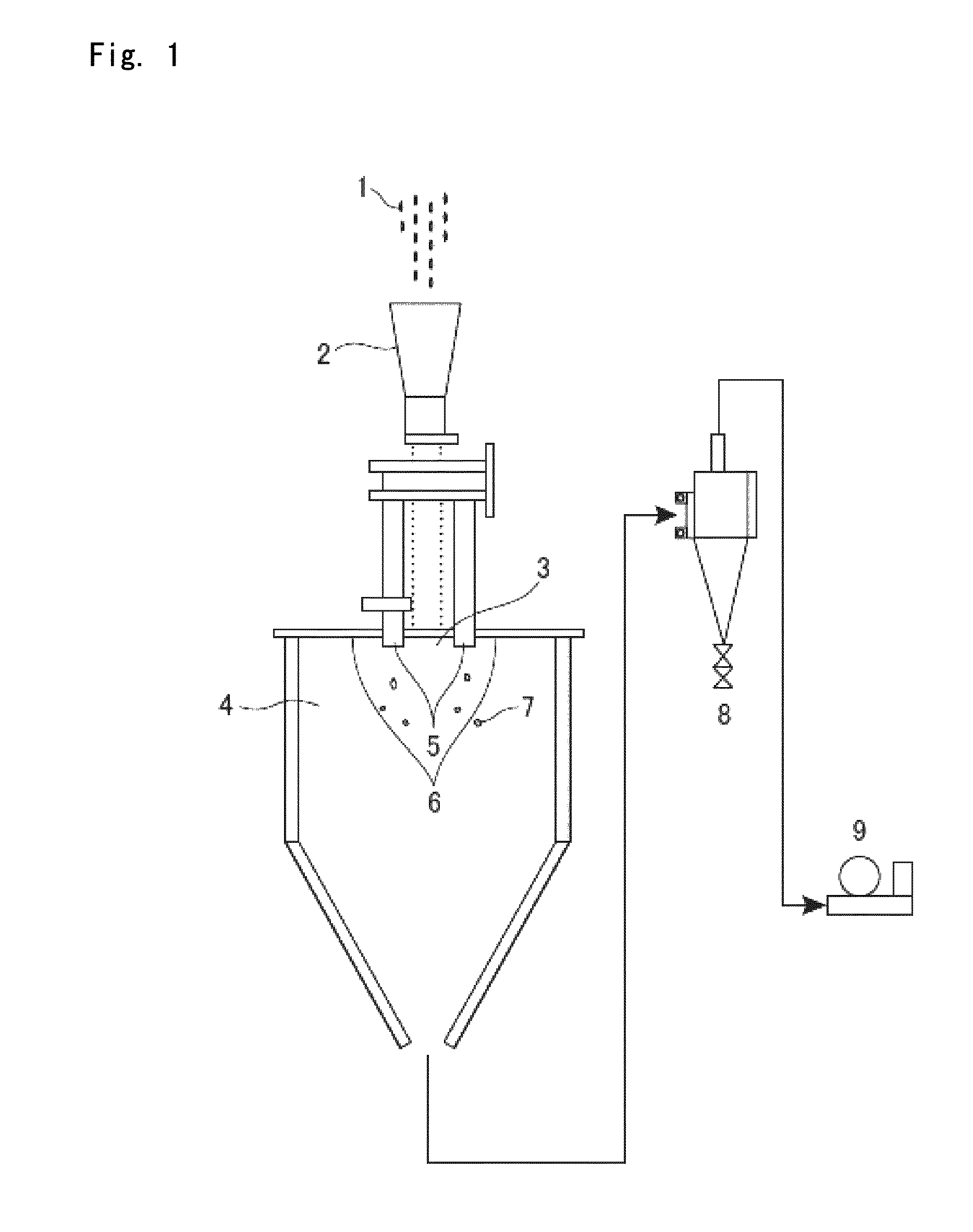

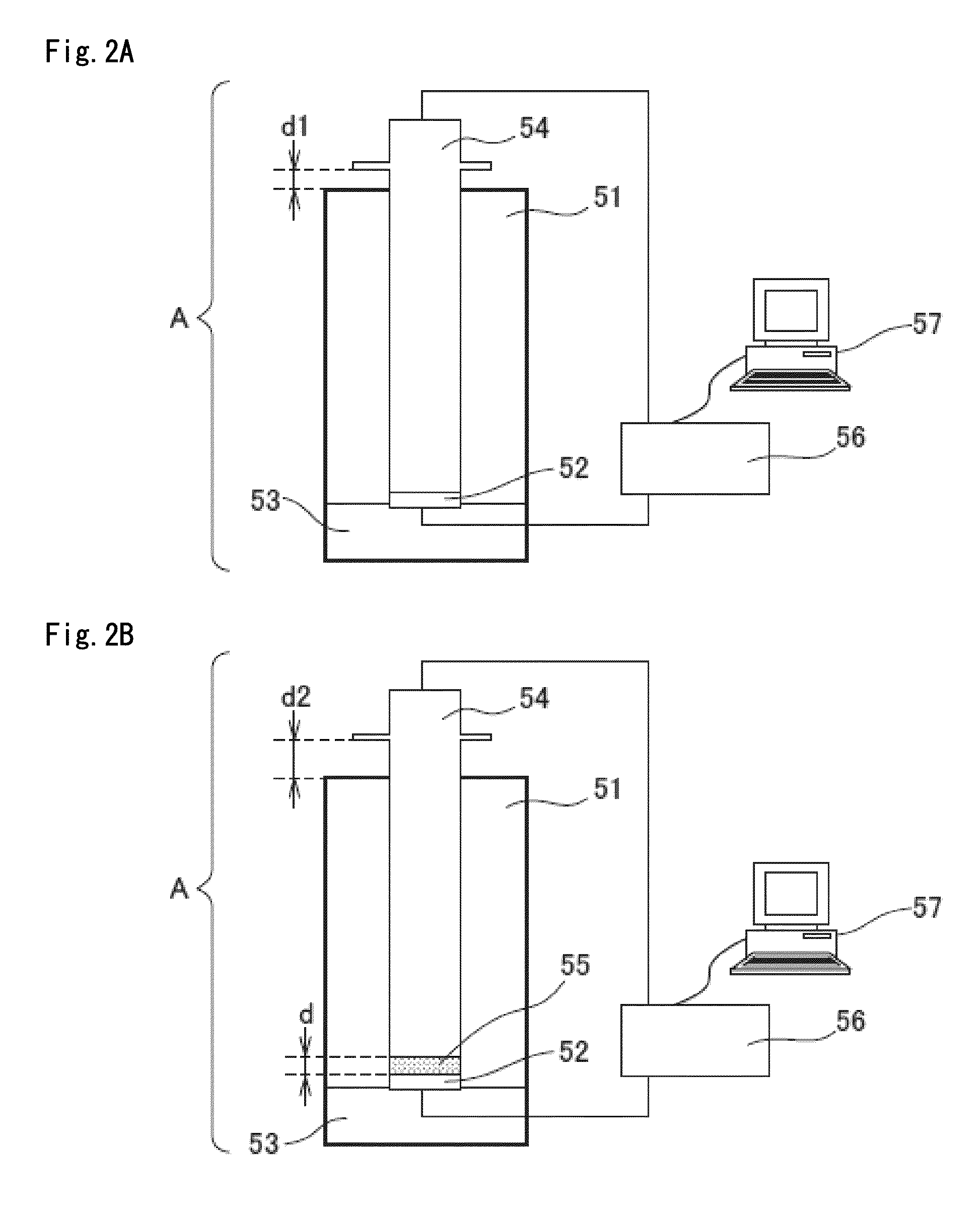

Method of producing magnetic carrier and magnetic carrier that uses this production method

ActiveUS8927188B2Good time stabilityReduce the amount requiredDevelopersVitrificationPhysical chemistry

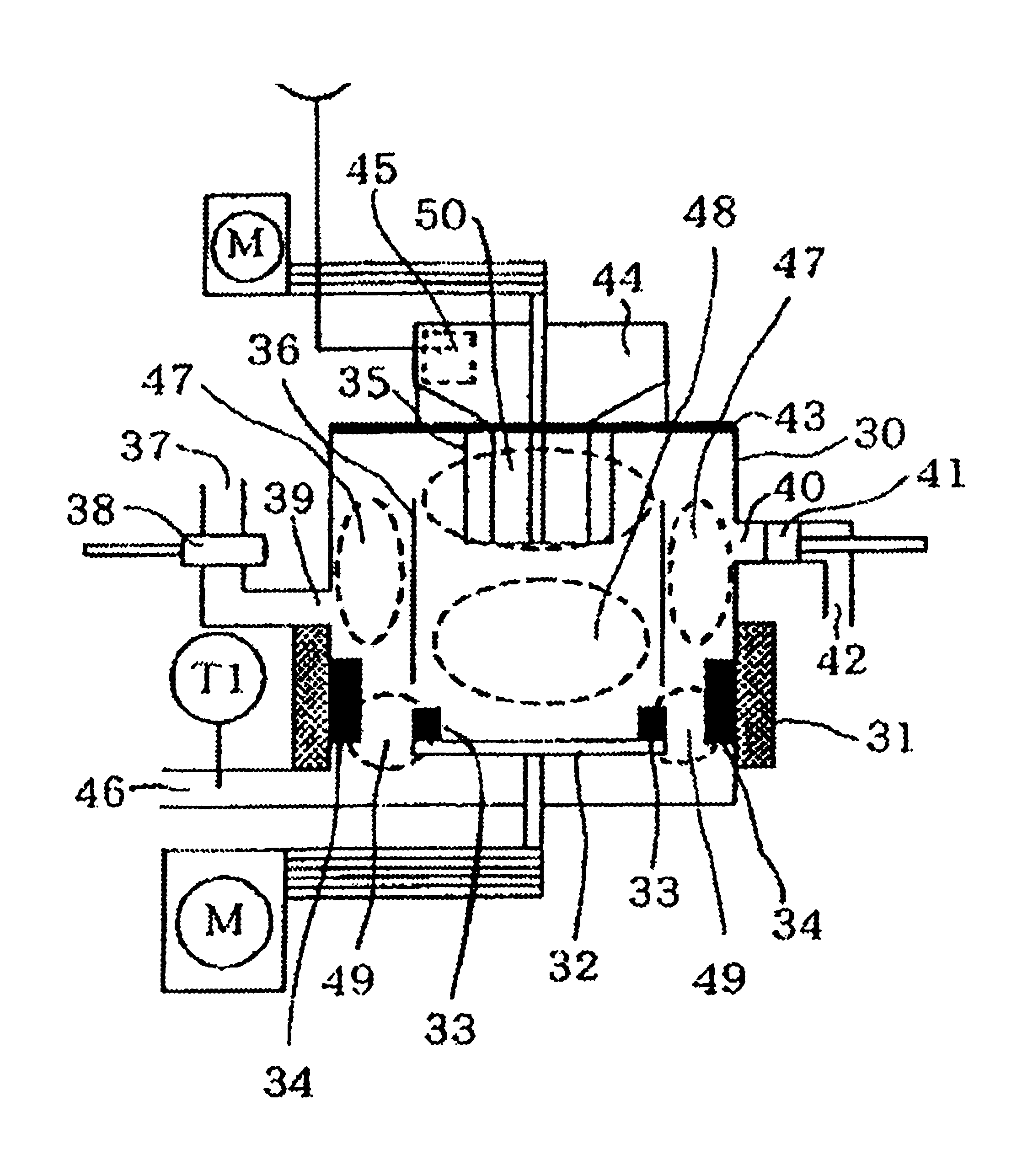

A method of producing a magnetic carrier, having a coating process step in which a surface of a magnetic carrier core is coated with particles of a resin composition by a mechanical impact force. The coating process step has a first coating process step of mixing, dispersing, and fixing the particles on the surface of the core, and a second coating process step, which is performed after the first coating process step, of carrying out a film-forming coating process on the particles. In the first and second coating process steps, the peripheral velocity of the outermost end of stirring members, the coating process time, the product temperature at the end of the coating process, and the glass-transition temperature of the resin component satisfy specific relationships.

Owner:CANON KK

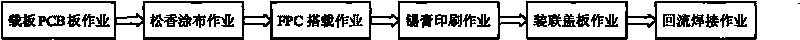

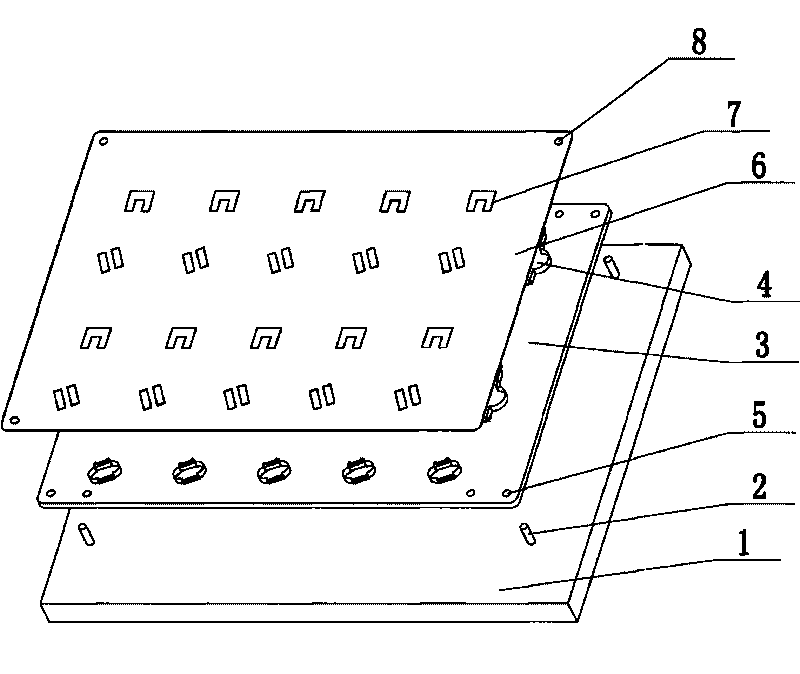

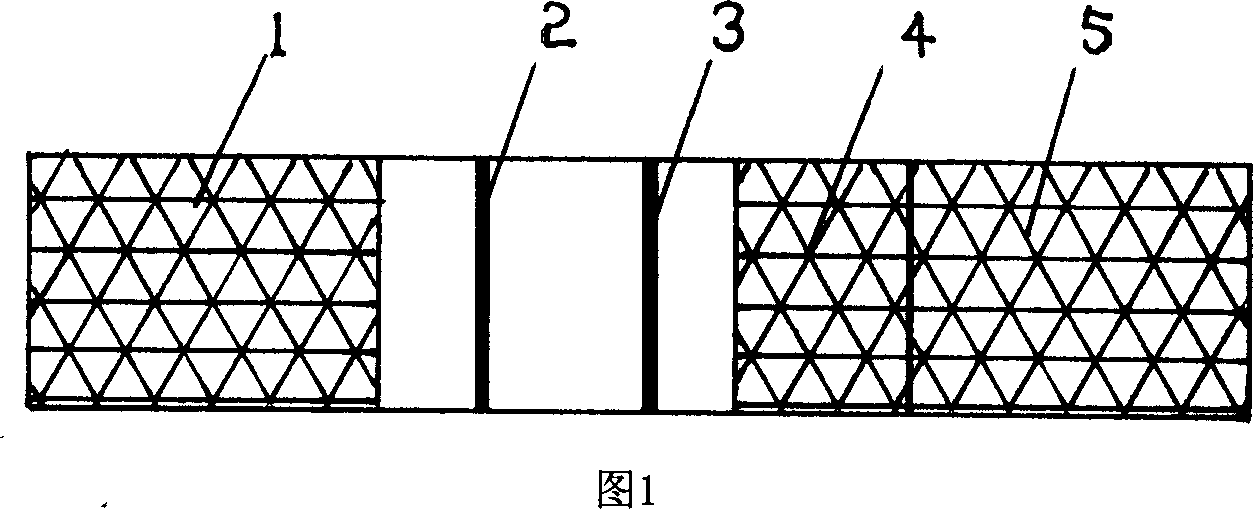

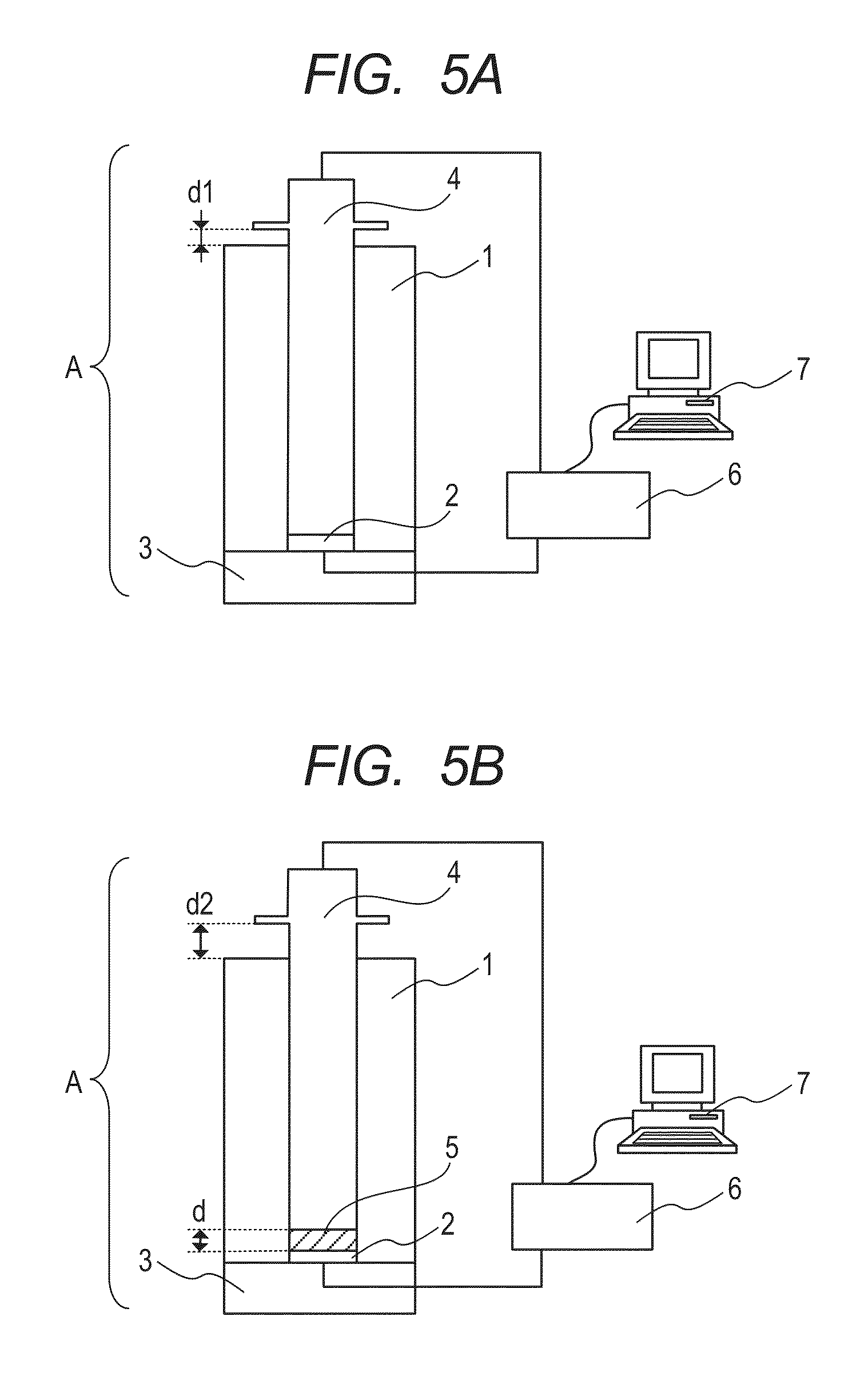

Method for assembly and reflow soldering of PCB and FPC and special positioning fixture thereof

InactiveCN101720172AIncrease productivitySimplify the initial positioning methodPrinted circuit assemblingPrinted element electric connection formationEngineeringProcessing cost

The invention discloses a method for the assembly and the reflow soldering of a PCB and an FPC and a special positioning fixture thereof, which mainly solve the problems of inaccurate positioning, low efficiency of welding efficiency, difficulty for ensuring product quality and the like of manual assembly in the processes of assembling and soldering the PCB and the FPC. The method comprises the following steps: firstly, supporting, positioning and fixing the PCB by using a magnetic carrier board; secondly, carrying the FPC; next, preliminarily positioning the PCB and the FPC with a bonding agent; thirdly, printing a solder paster on a solder pad at the junction of the FPC and the PCB; and finally, pressing a magnetic cover board on the magnetic carrier board, fixing the positions of the FPC and the PCB, and performing the reflow soldering on the FPC and the PCB through a reflow oven. The method for the assembly and the reflow soldering of the PCB and the FPC and the special positioning fixture thereof have the advantages of simple operation, good reliability, great improvement on the production efficiency and the production quality of the FPC and the PCB in the processes of assembling and soldering, and processing cost reduction.

Owner:HUIZHOUSRTY INFORMATION ELECTRONICS

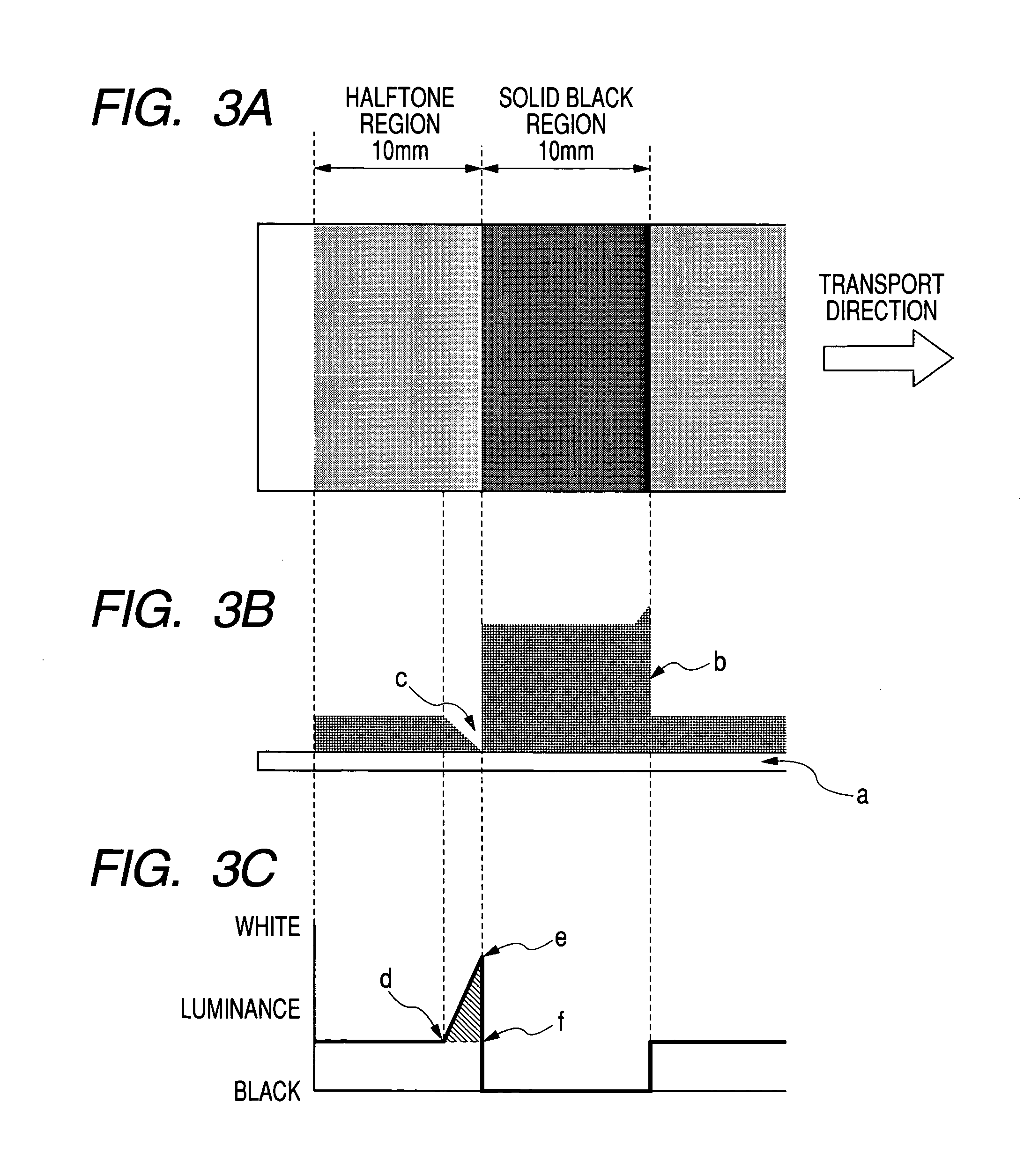

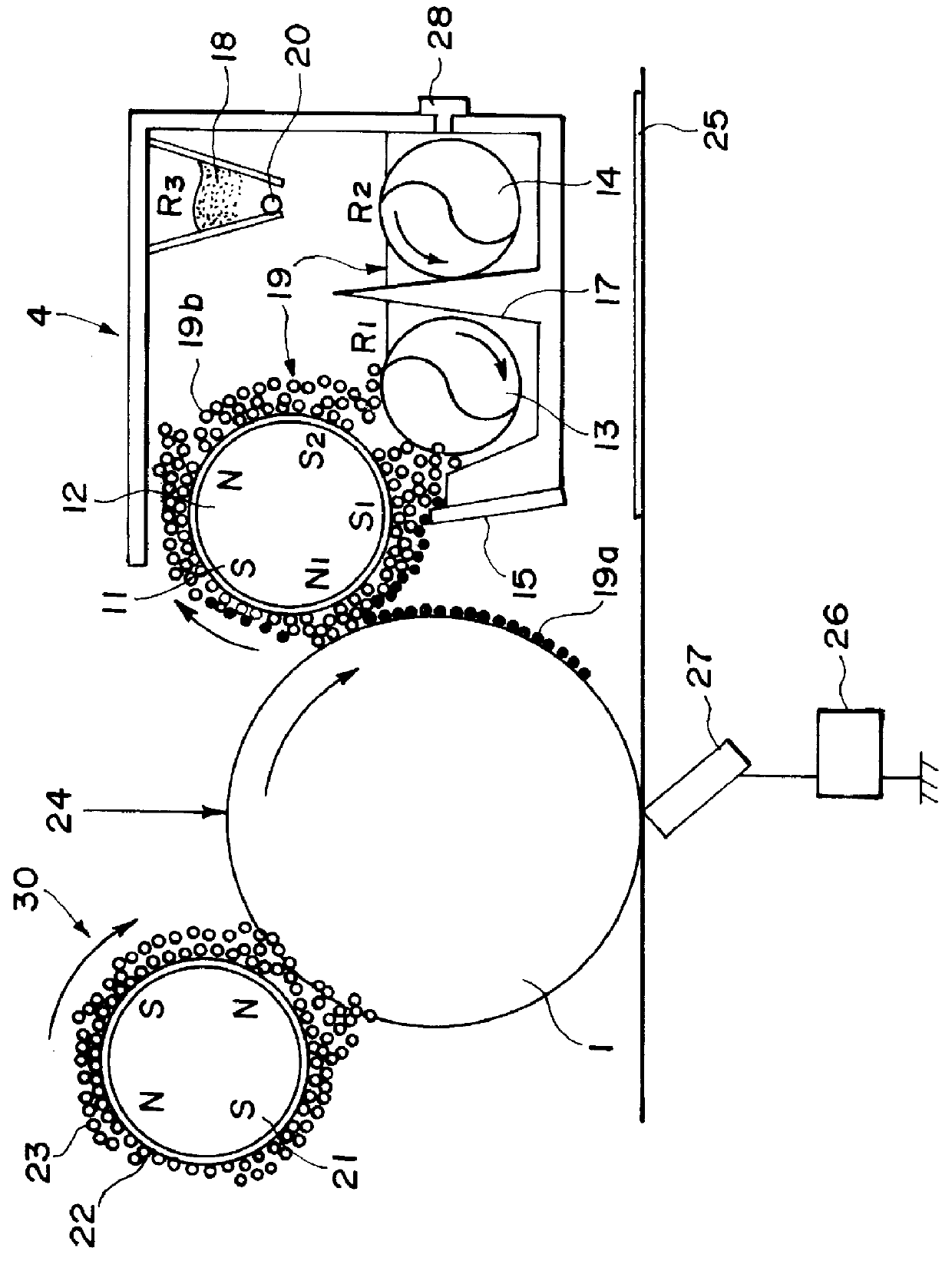

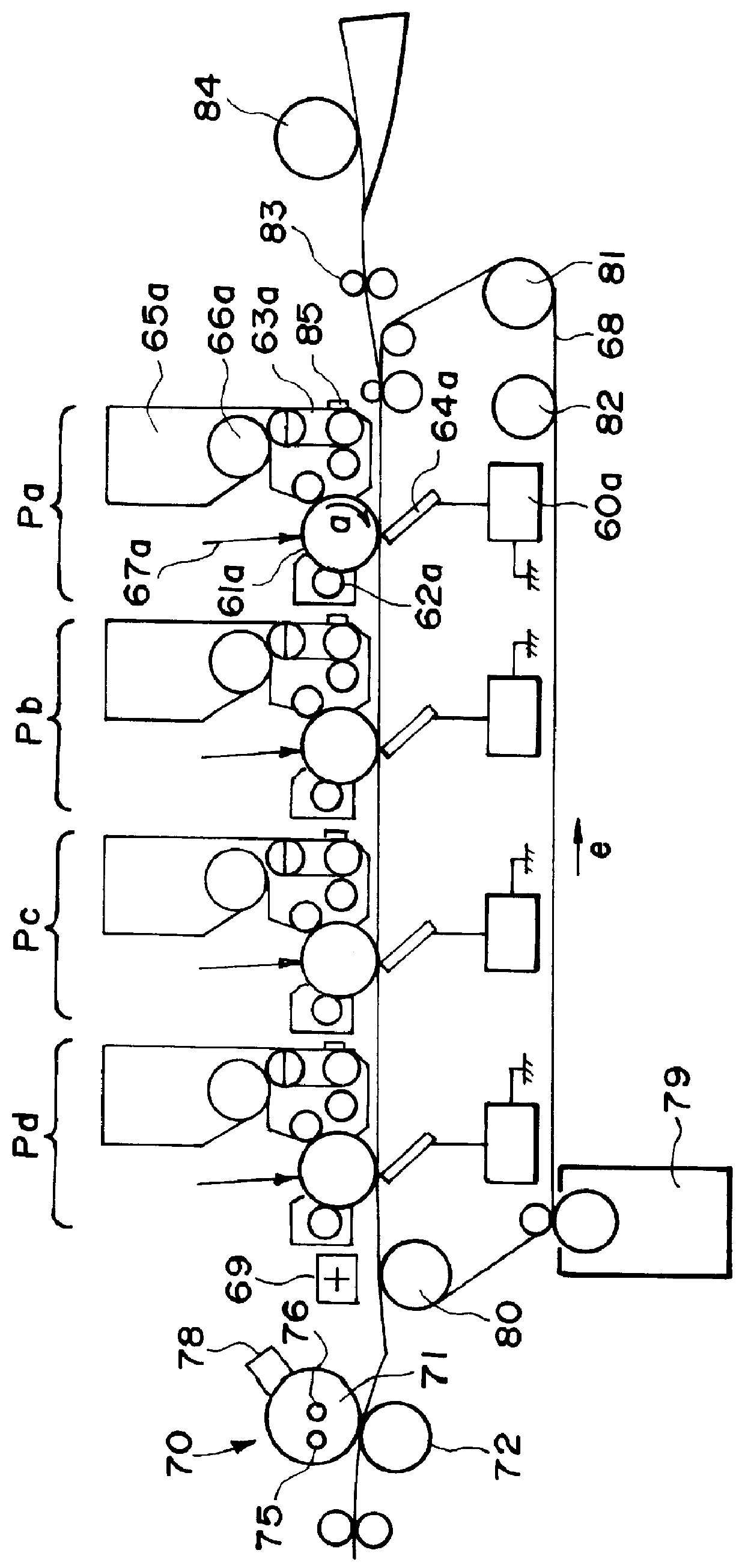

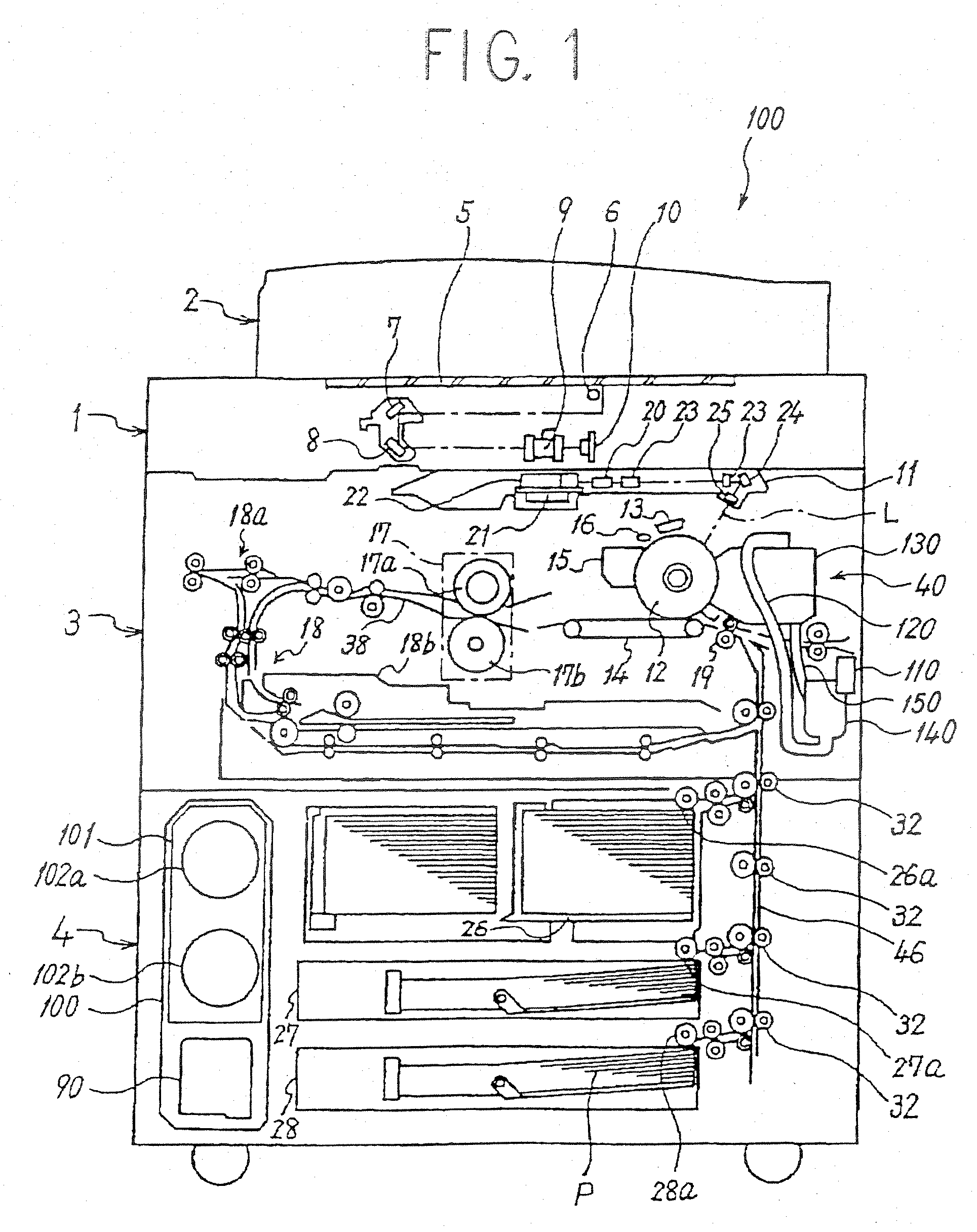

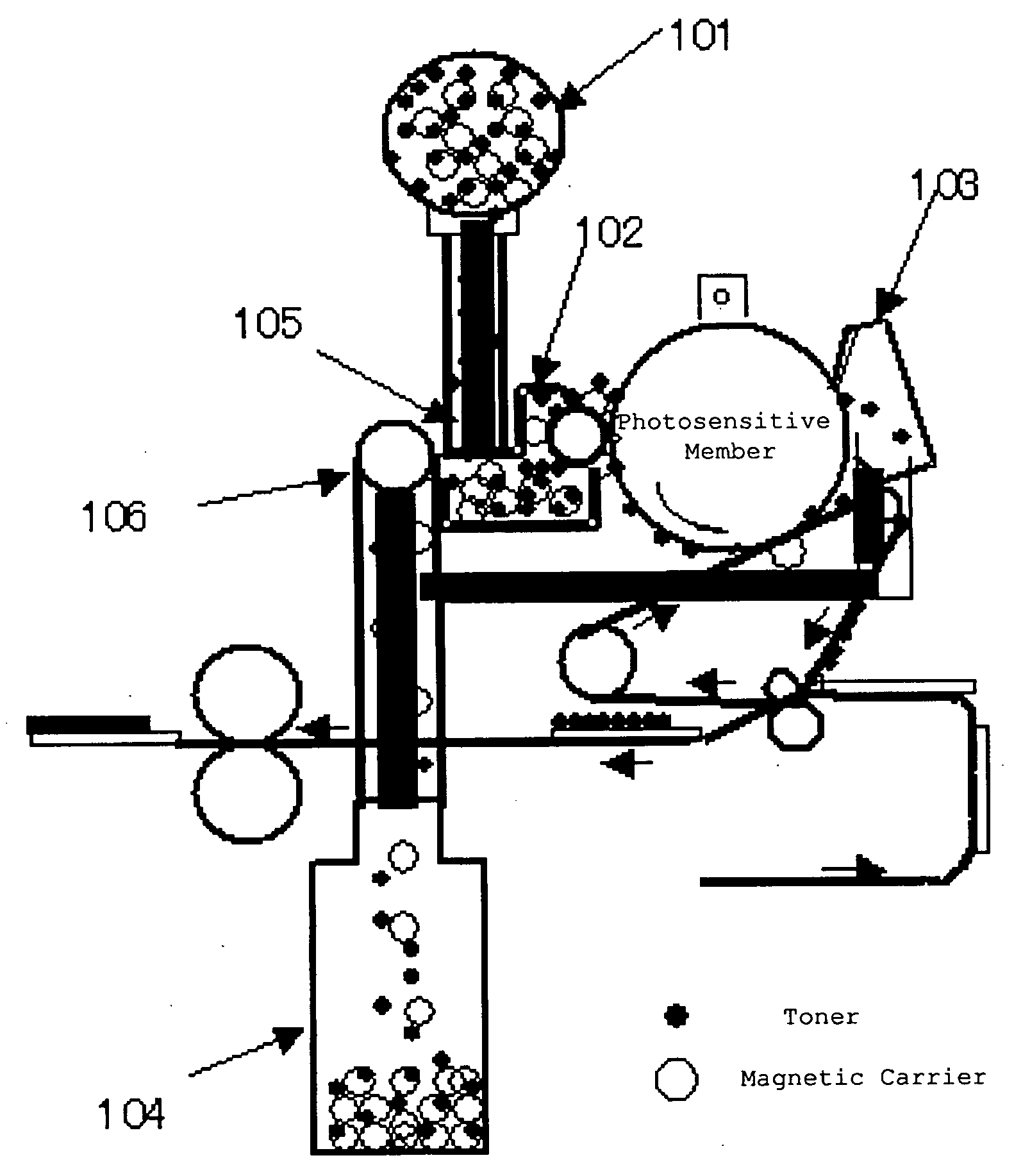

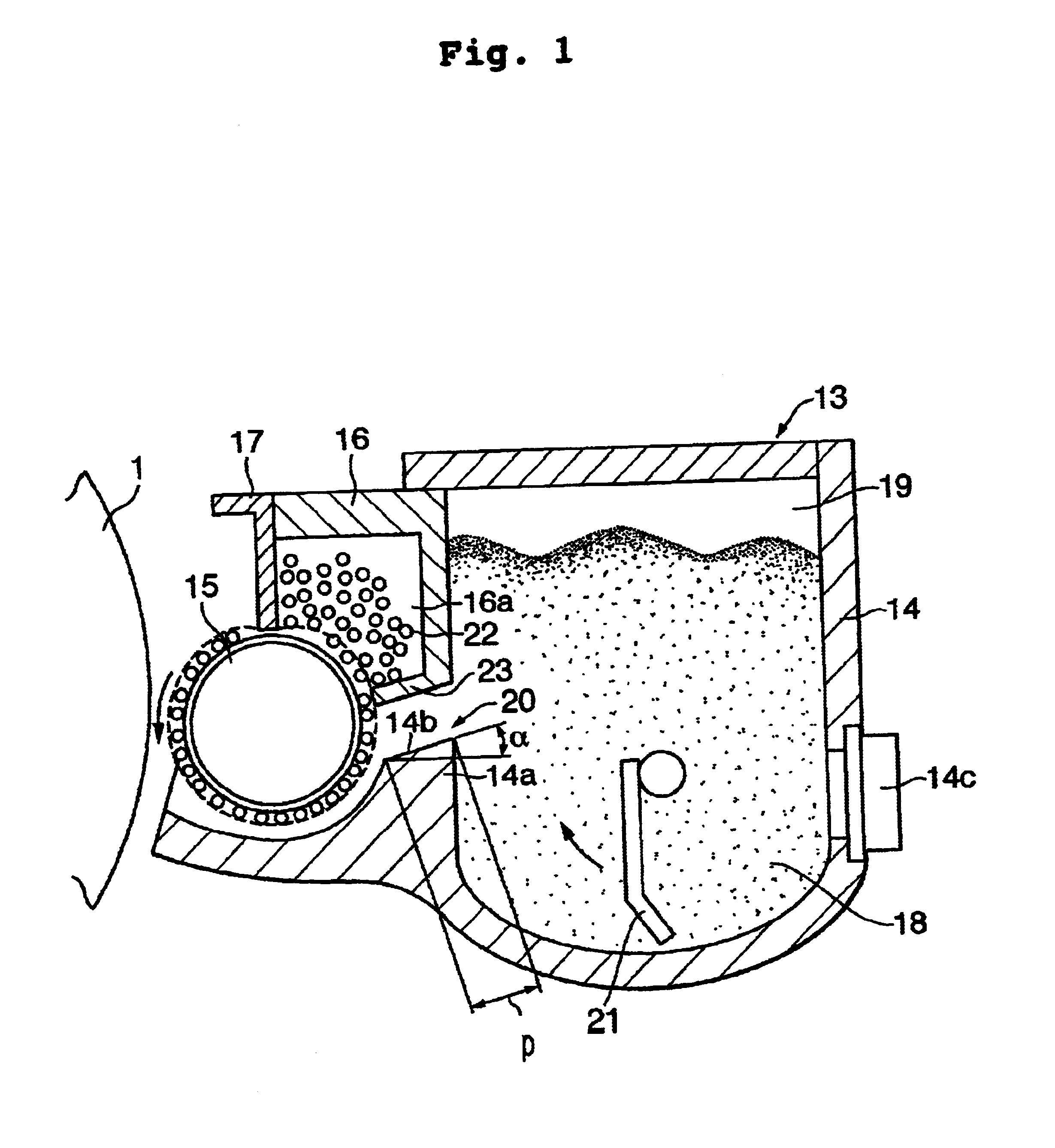

Image formation apparatus using a dry two-component developer for development

An image formation apparatus develops an electrostatic latent image with a two-component developer consisting of magnetic carriers and toners by using a development apparatus and a latent image supporter including a filler in an outermost layer thereof, the development apparatus having a developer supporter, which has an internally fixed magnetic body and rotates while supporting a developer on a surface thereof, and a developer quantity controller controlling a quantity of the developer which is supported by the developer supporter facing the magnetic body and controlling a height of magnetic brushes and consisting of materials having rigidity or rigidity and magnetic properties, wherein a ratio (Gp / Gd) of a development gap to a doctor gap between the developer supporter and the controller is from 0.7 to 1.0, and a weight-averaged particle diameter of a developer carrier is from 20 to 60 mum.

Owner:RICOH KK

Magnetic carrier, two-component developer and image forming method

InactiveUS6124067AHigh-quality tonerHigh image densityElectrographic process apparatusDevelopersEngineeringPolymer

A magnetic carrier constituting a two-component developer for use in an electrophotographic image forming method is formed of a carrier core comprising a first resin and magnetic fine particles dispersed in the first resin, and a second resin surface-coating the carrier core. (a) The magnetic carrier has a true specific gravity of 2.5-4.5, a magnetization sigma 1000 as measured in a magnetic field of 1000x(103 / 4 pi )xA / m (1000 oersted) of 15-60 Am2 / kg (emu / g), a residual magnetization sigma r of 0.1-20 Am2 / kg (emu / g) and a resistivity of 5x1011-5x1015 ohm.cm. (b) The first resin has a polymer chain including a methylene unit (-CH2-). (c) The second resin has at least a fluoro-alkyl unit, a methylene unit (-CH2-) and an ester unit. (d) The carrier core is surface-coated with (i) a mixture of the second resin and a coupling agent having at least an amino group and a methylene unit, or (ii) a coupling agent having at least an amino group and a methylene unit, and then with the second resin.

Owner:CANON KK

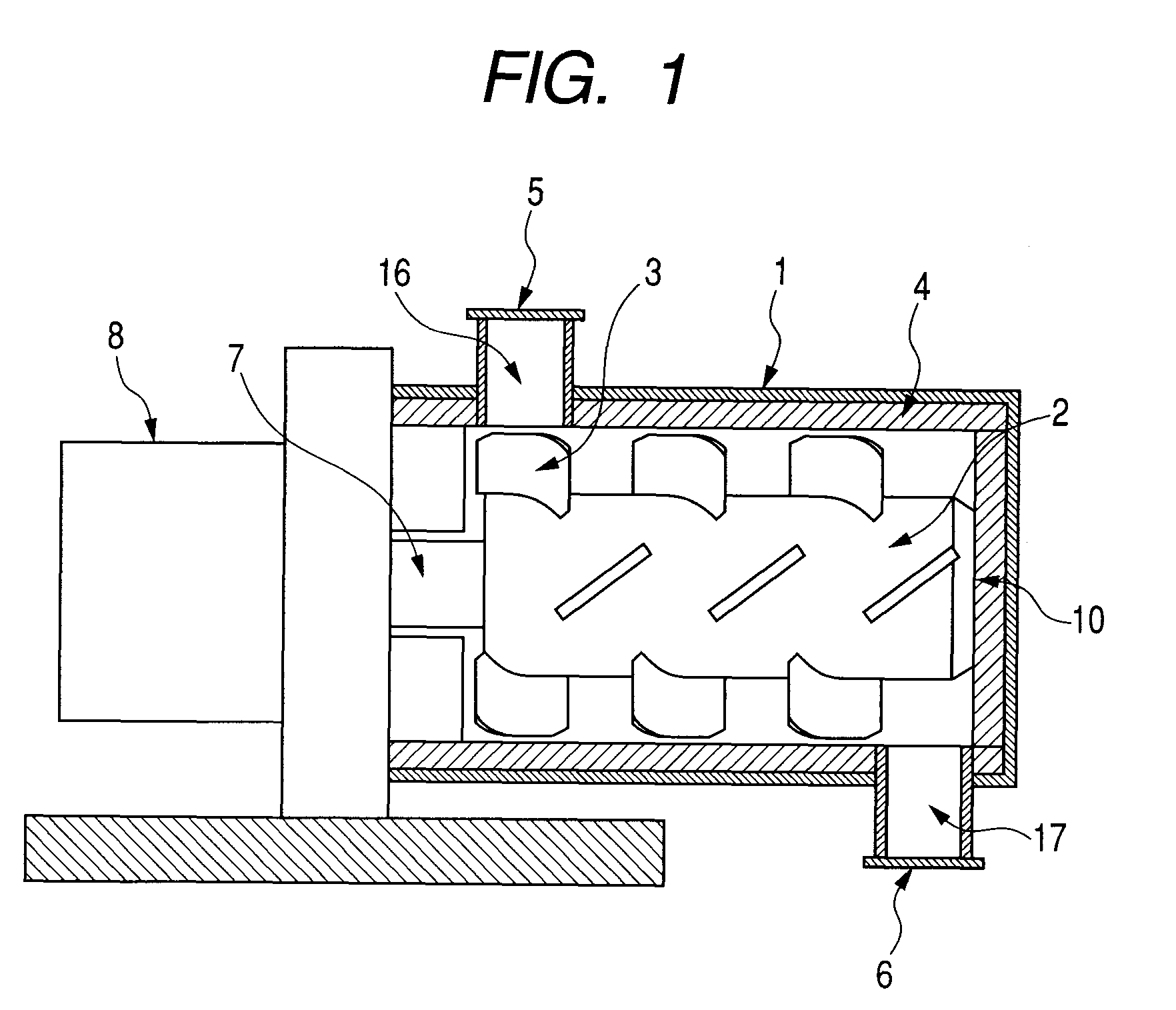

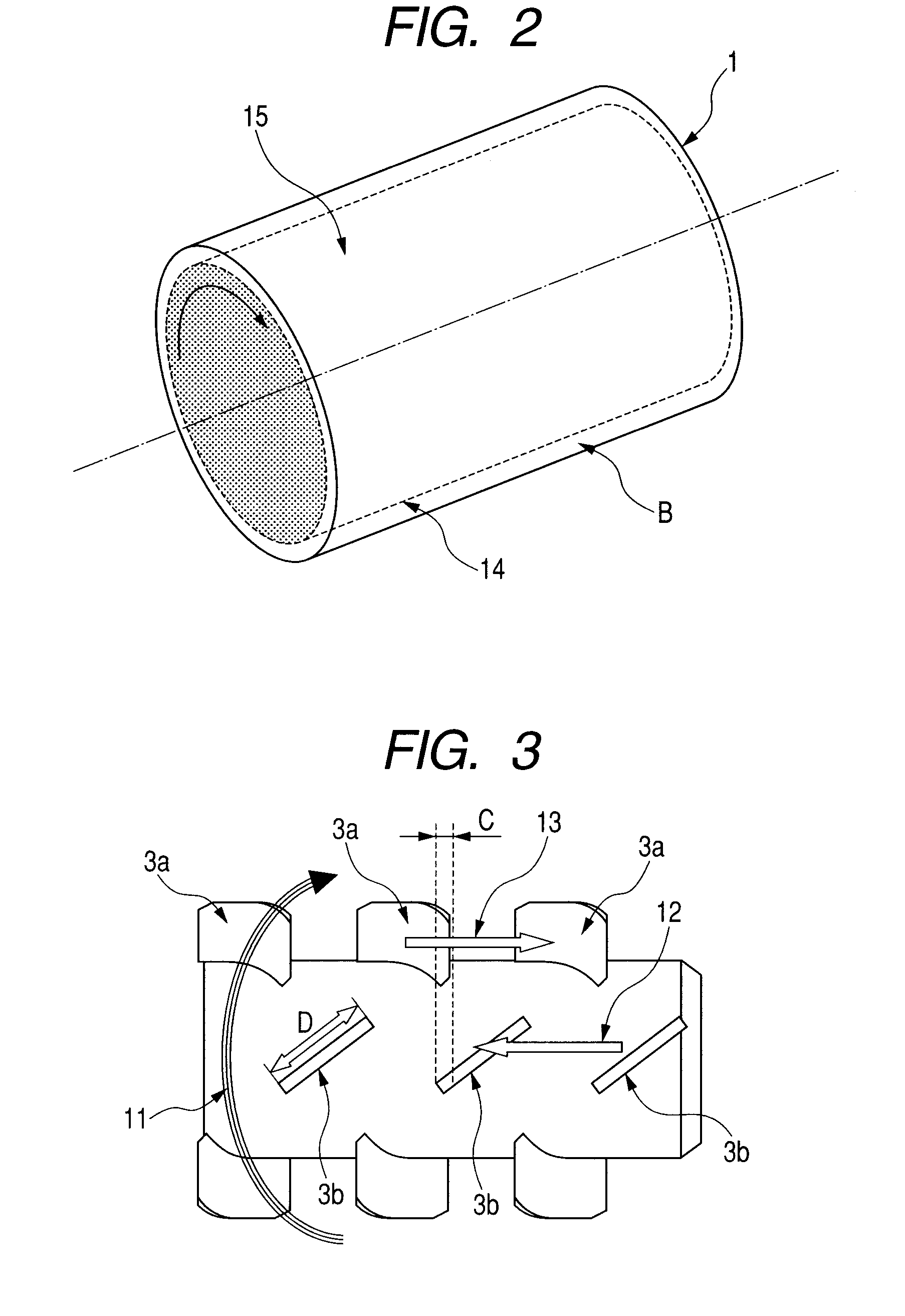

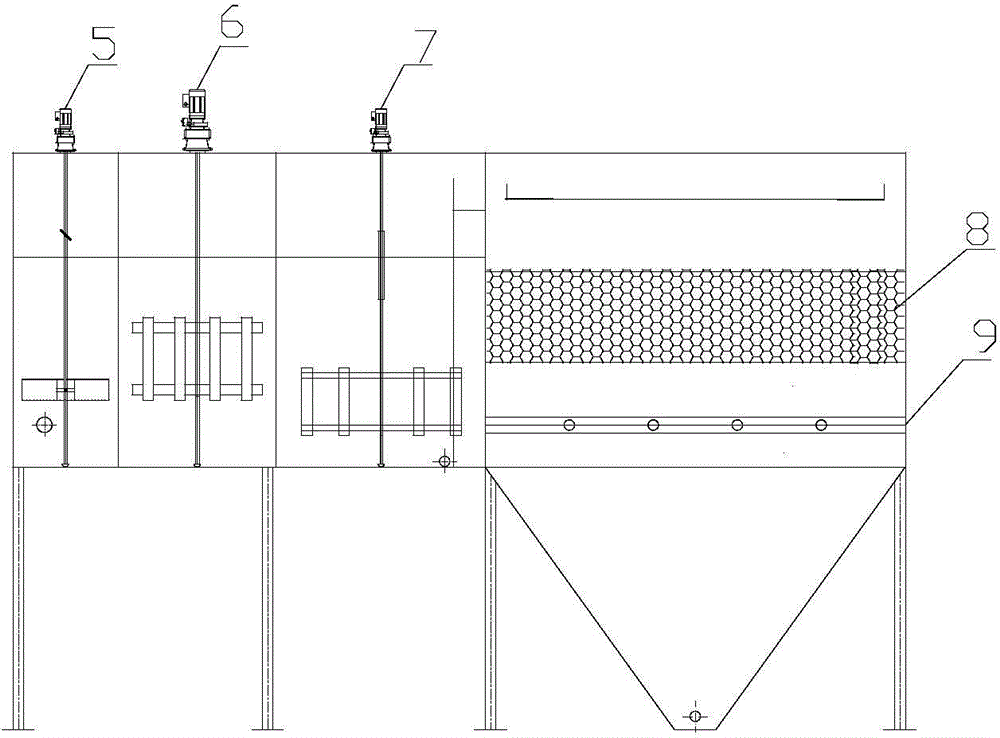

Developing apparatus and image forming apparatus using same

ActiveUS20070166079A1Pollution suppressionSuppressing toner scatteringElectrographic process apparatusImage formationMagnetic flux

A developing apparatus using a two-component developer constituted by a magnetic carrier and a toner, and an image forming apparatus comprising the developing apparatus. A developing unit and a stirring unit are provided, and in order to suppress toner scattering that may occur after a development operation has been halted for a long time, and thereby suppress contamination of the apparatus interior, the developer in a developing machine is transferred to a stirrer serving as a developer storage unit on the exterior of the developing machine when the development operation ends. Further, to extend the life of the developer, a range in which an angle of a restricting member upstream side central angle α, which is a central angle of the surface of a developing roller serving as a developer carrier on the upstream side of a restricting member opposing position opposing a doctor blade serving as a developer amount restricting member in a surface motion direction of the developing roller, is not less than 0[°] and not more than 60[°] is set as a low magnetic flux density area γ in which the maximum value of a normal direction magnetic flux density on the surface of the developing roller is not more than 30 [mT].

Owner:RICOH KK

Two-component developer, replenishing developer, and image-forming method using the developers

InactiveUS20090246675A1Avoid stickingGood reproducibilityDevelopersElectrographic processes using charge patternLatent imageEngineering

An object of the present invention is to suppress the adhesion of a carrier to an image bearing member and the generation of a flaw in the surface layer of the image bearing member, and to improve the dot reproducibility of an electrostatic latent image, and so on. The object is achieved by a two-component developer containing a magnetic carrier, which contains resin-containing magnetic particles, in which the packed bulk density ρ1 is 0.80 to 2.40 and ρ1 / ρ2 (ρ2 represents true density) is 0.20 to 0.42 of the porous magnetic core particles, and a specific resistance of the porous magnetic core particles, an average breaking strength of the magnetic carrier and a toner surface tension constant in a 45-vol % aqueous solution of methanol measured by a capillary suction time method fall into the specific range, respectively.

Owner:CANON KK

Two-component developer, replenishing developer, and image-forming method

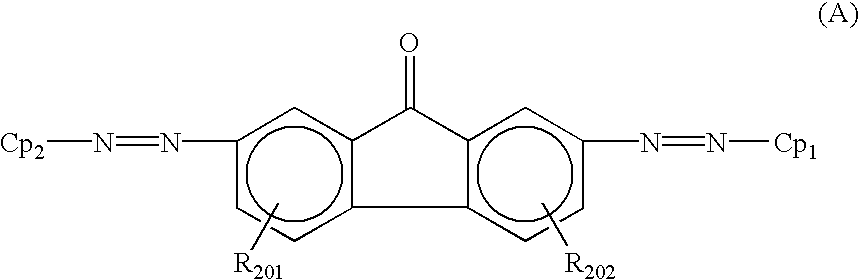

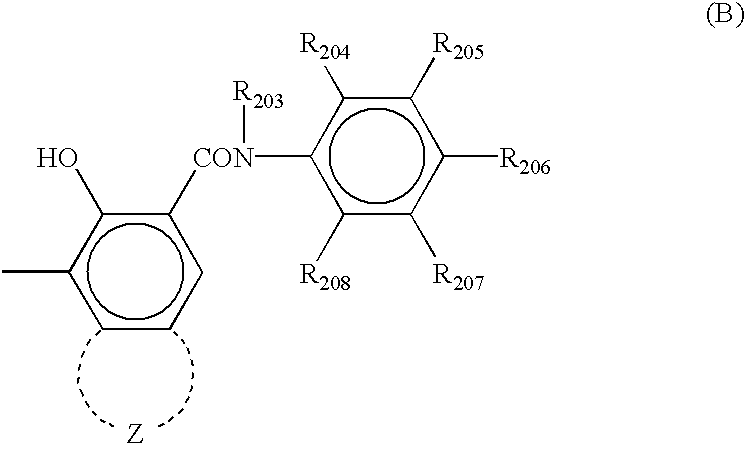

InactiveUS7767370B2Small toner laid-on levelColor stableDevelopersElectrographic process apparatusImage formationLength wave

A two-component developer containing a magenta toner and a magnetic carrier, wherein the magenta toner has the characteristics: (i) when the concentration of the magenta toner in a solution of the magenta toner in chloroform is represented by Cm (mg / ml) and the absorbance of the solution at a wavelength of 538 nm is represented by A538, a relationship between Cm and A538 satisfies the relationship of 2.00<A538 / Cm<6.55; (ii) the lightness L* and chroma C* of the magenta toner determined in a powder state satisfy the relationships of 35≦̸L*≦̸45 and 60≦̸C*≦̸72; and (iii) the absolute value for the triboelectric charge quantity of the magenta toner measured by a two-component method using the magenta toner and the magnetic carrier is 50 mC / kg or more and 120 mC / kg or less.

Owner:CANON KK

Immuno magnetic bead and producing method, and method and test plate for detection

An immune bead is made up of the magnetic carrier micro ball which combines at least one immune matching base. The micro ball is composed of the magnetic nm particle and the high molecular framework material which the core is the metal particle; the out of the core is high molecular framework, the out layer is the functional layer which can combines functional gene of different immune matching base. The manufacture method includes: the bead pretreatment, the bead activation, manufacture of the coupling antibody, closing the antibody with the confining liquid and purifying the immune bead. The detecting method is to detect the different things by the immunological response sandwich, the competition and the indirect method and set the control system on the testing board. The board is made up of the encrusting test paper, the coupling mat, the sample mat, the water suction mat, the coving film and the testing board outside calipers. It has the high sensitivity and accurate quantity; the regent is simple and cost low.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

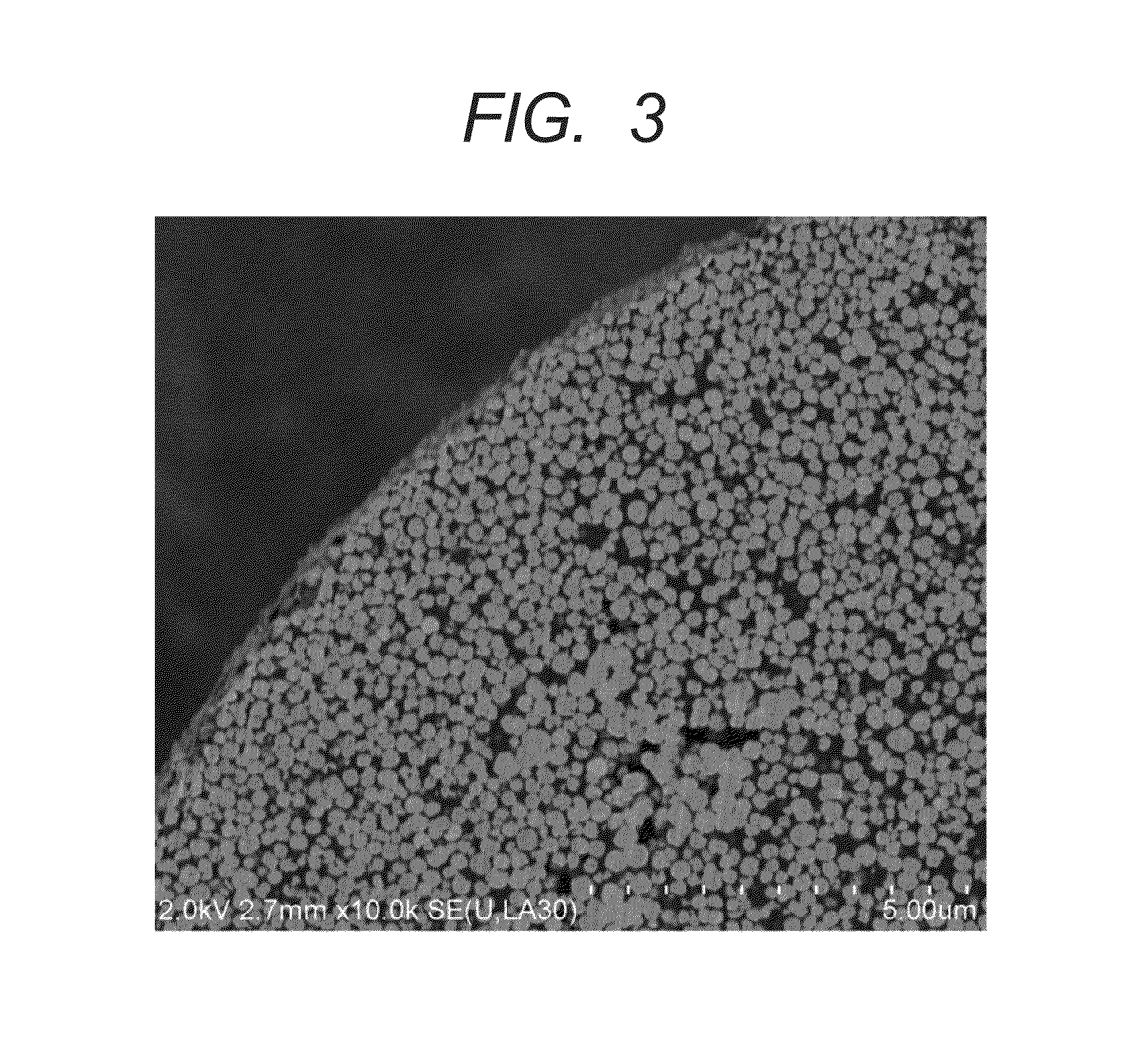

Magnetic carrier and two-component developer

InactiveUS20140134535A1Suppressing white spotsSatisfactory imageDevelopersScanning electron microscopeEngineering

Provided is a magnetic carrier satisfying leakage, white spots, charging property and high developing performance in a low electric field and having excellent durability. The magnetic carrier is a magnetic carrier comprising a magnetic substance-dispersed resin carrier core containing a magnetic substance and a binder resin, and a coating resin on a surface thereof, wherein the magnetic substance comprises a magnetic substance A having a shape without vertexes and a magnetic substance B having a shape with vertexes, the magnetic substance B has a number average particle diameter of 0.40-2.00 μm, and in a reflection electron image of a section of the magnetic substance-dispersed resin carrier core taken by a scanning electron microscope, an area proportion of the magnetic substance B is larger than an area proportion of the magnetic substance A within a region from the surface of the magnetic substance-dispersed resin carrier core to a depth of 1.0 μm.

Owner:CANON KK

Functionalized silicon coating mesoporous magnetic carrier and preparation method and application thereof

InactiveCN101139127AHigh magnetic contentStrong magnetismOn/in inorganic carrierWater/sewage treatment by sorptionChemisorptionSilicon membrane

The present invention discloses a functionalized silicon coating mesoporous magnetic carrier. The carrier is a compound magnetic carrier having a core-shell structure formed by coating the magnetic ferroferric oxide with the silicon dioxide and an active amido or mercapto is bonded on the surface of the magnetic carrier and the active amido or mercapto can apply the selective chemisorption effect to the target chemical. The present invention simultaneously discloses a preparation method for the carrier, which in particular is that the thickness and uniformity of the silicon film are increased through two times of silicon coating processes so as to effectively protect the magnetic carrier from being corroded by acid and base in the application; the template agent on the surface of the carrier is detracted with high temperature under the inert atmosphere and the porecreating processing is applied to the surface of the carrier so as to increase the effective surface area of the carrier and enhance the processing performance. The fixed active bacterium for the funtionalized silicon coating mesoporous magnetic carrier can be applied in the treatment of the urban domestic sewage delivers good treatment effect and has important meaning to the environment protection.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Two-component developer, image forming apparatus, and image forming method

InactiveUS6790575B2Enhance the imageNo toner scatteringDevelopersElectrographic process apparatusMagnetizationImage formation

Owner:RICOH KK

Magnetic carrier and two-component developer

The present invention provides a magnetic carrier that can stably impart charge to a toner on a long term basis and that exhibits an excellent toner separation property and thus exhibits an excellent developing performance. This magnetic carrier is a magnetic carrier in which a vinyl resin coats the surface of a resin-filled core in which a resin is filled in pores of a porous ferrite particle, wherein the resistivity, Mg content, and total content of Sr and Ca oxides of the porous ferrite particle exhibit prescribed values and the magnetic carrier has a total area—in the backscattered electron projection image obtained by observation using a scanning electron microscope at an acceleration voltage of 2.0 kV—for a region originating with the porous ferrite particle of from at least 0.2 area % to not more than 5.0 area % with reference to the projected area of the magnetic carrier.

Owner:CANON KK

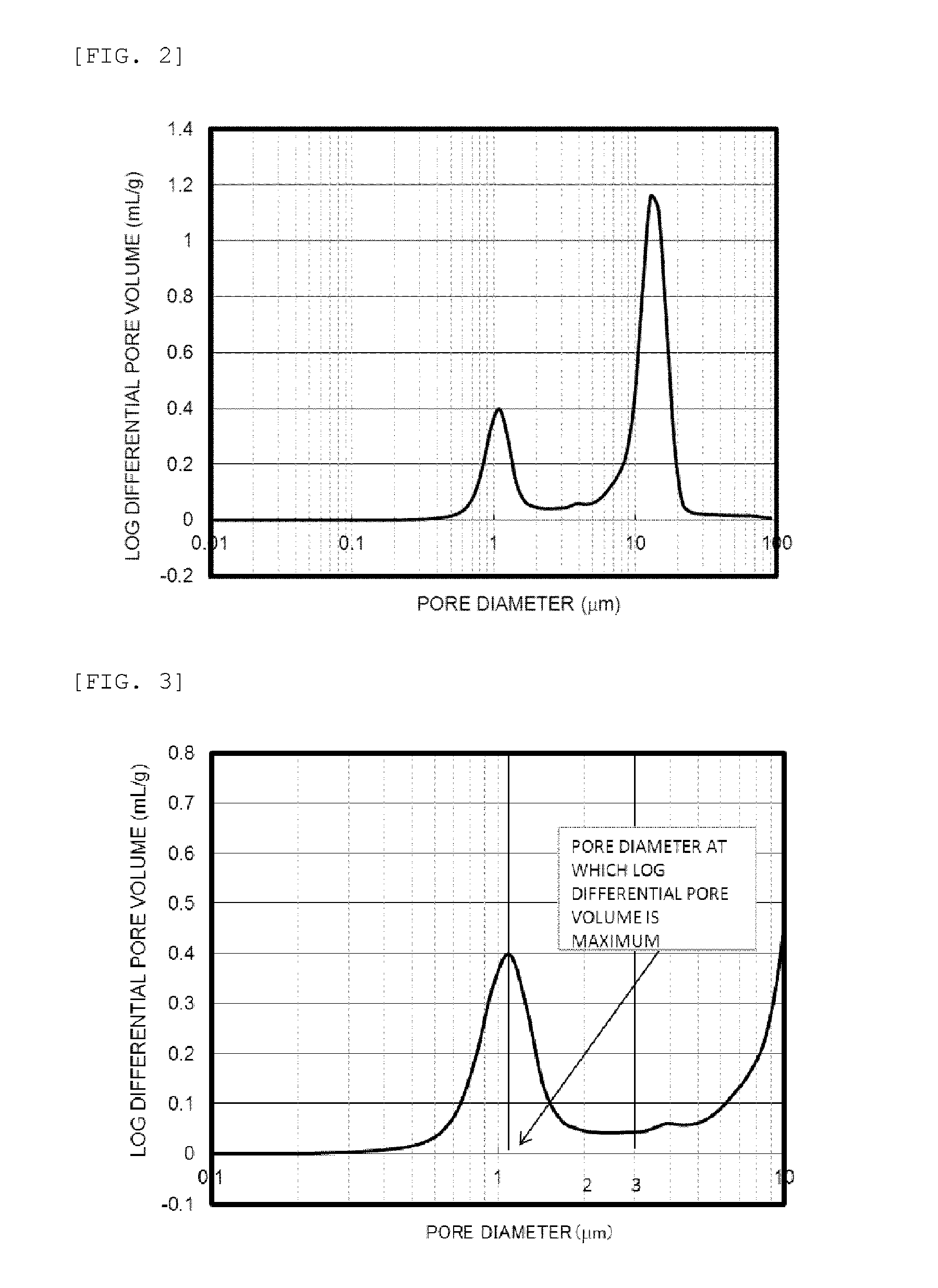

Magnetic carrier and two-component developer

ActiveUS9058924B2Improve charging effectAvoid it happening againInorganic material magnetismDevelopersPore diameterMetal

A magnetic carrier having a resin-containing ferrite particles each containing a porous ferrite core and a resin in pores of the porous ferrite core, wherein the porous ferrite core has a particular pore diameter corresponding to the maximum logarithmic differential pore volume in a pore diameter range from at least 0.10 μm to not more than 3.00 μm, the resistivity of the porous ferrite core is in a particular range, and the porous ferrite core contains an oxide of Mg in a particular amount and contains a particular amount of a oxide of at least one metal selected from the group consisting of Mn, Sr, and Ca.

Owner:CANON KK

Magnetic carrier and two-component developer

ActiveUS8921023B2Improve development performanceInhibit adhesionDevelopersElectric fieldSubstance of very high concern

Provided is a magnetic carrier excellent in leakage, uniformity of a solid image having satisfactory charging stability and developing performance at low electric field. The magnetic carrier is a magnetic carrier comprising: a magnetic substance-dispersed resin carrier core, which contains a magnetic substance and a binding resin, and a coating resin on a surface thereof, wherein: the carrier core has resistivity at 1000 V / cm of 5.0×106-8.0×107 Ω·cm, the magnetic substance has a number average particle diameter of 0.20-0.35 μm; and comprises magnetic-substance particles having vertexes and a particle diameter of 0.53 μm or more in an amount of 10.0-32.0 vol % based on a total amount of the magnetic substance; and wherein: the carrier core has Fe2O3 content of 98.00% by mass or more; and ZnO content of 0.06-0.50% by mass.

Owner:CANON KK

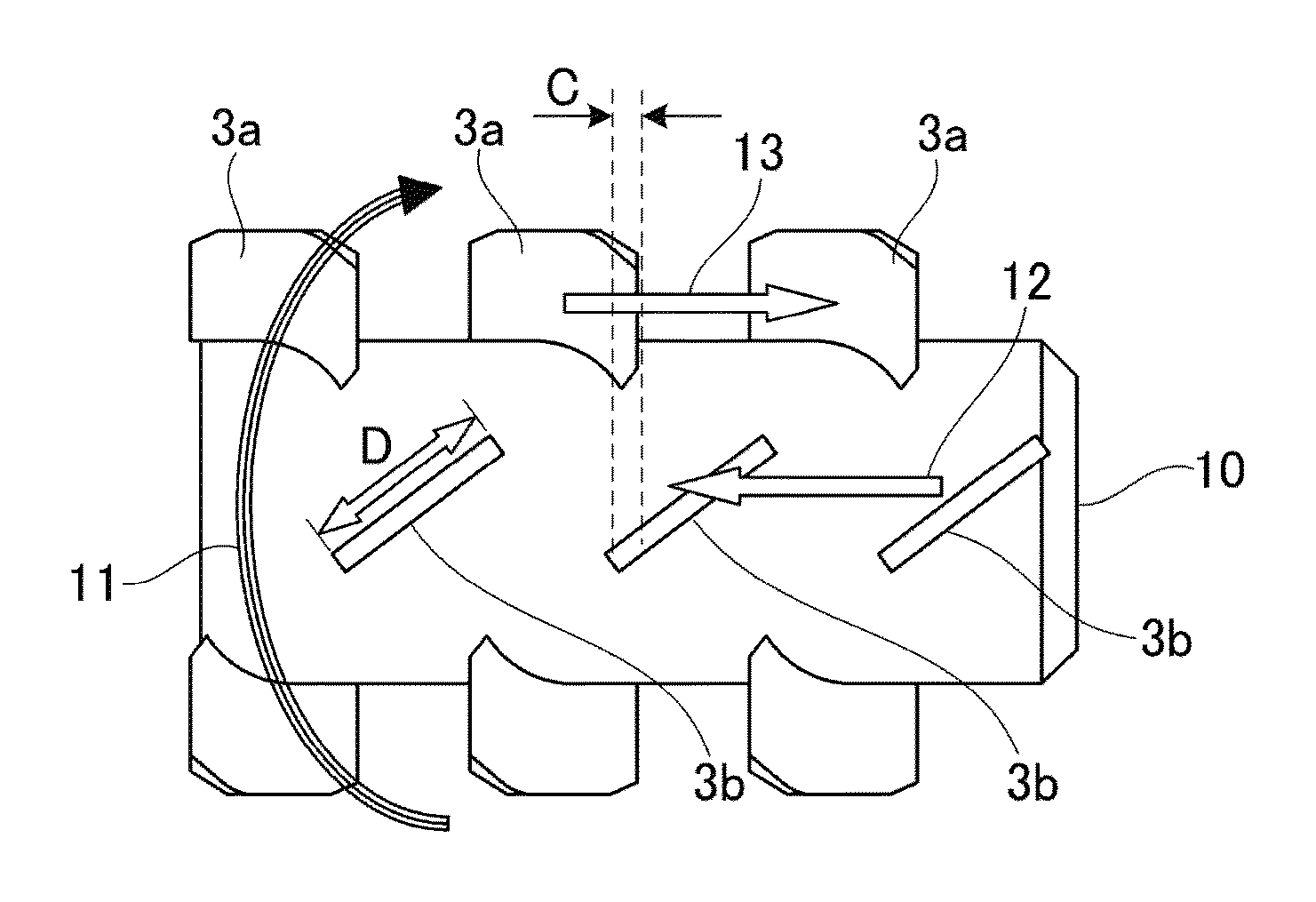

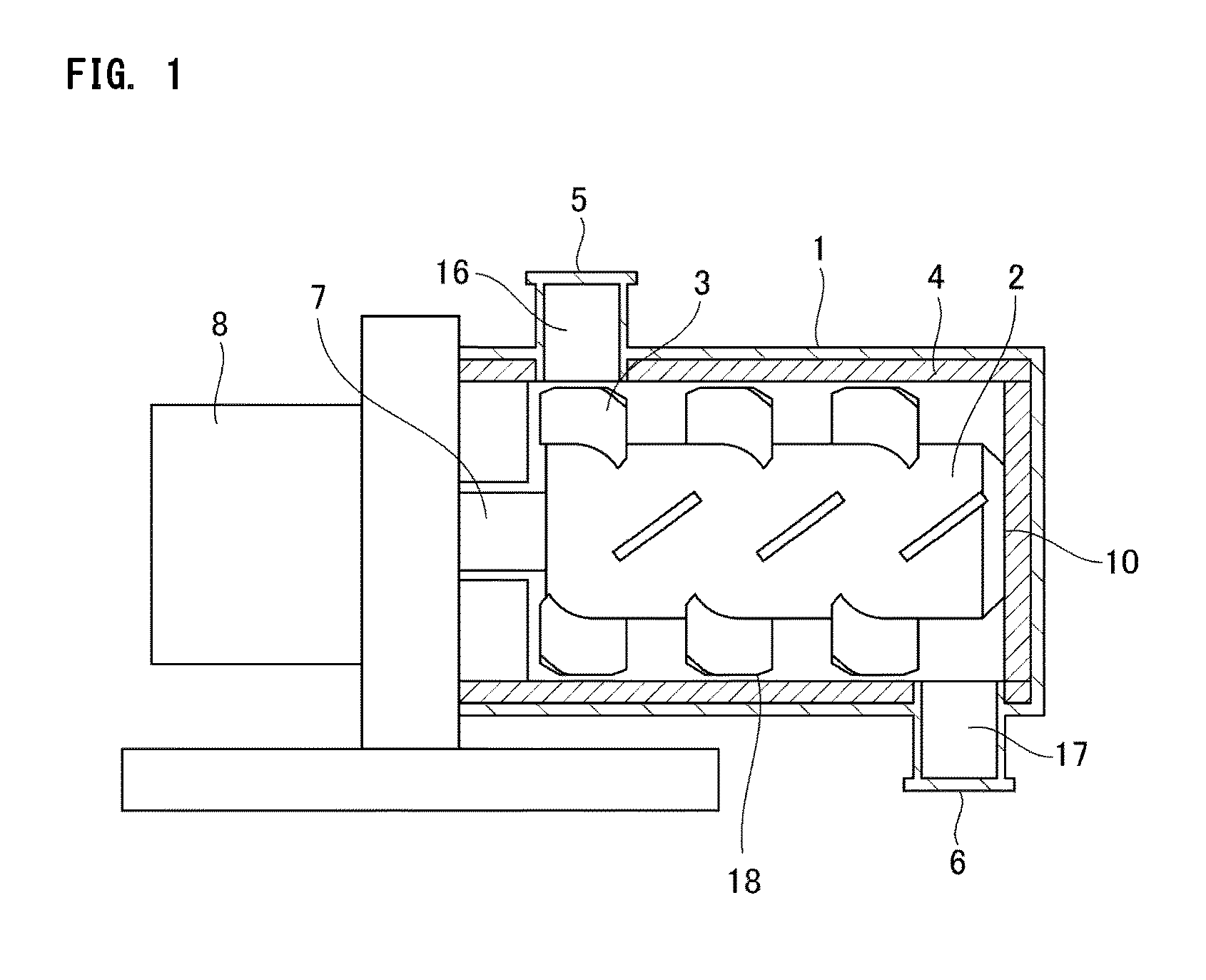

Production method of magnetic carrier and magnetic carrier produced therewith

InactiveUS8323726B2Reduce compositionImprove stabilityInorganic material magnetismDevelopersCore ParticleElectrical and Electronics engineering

When a surface of magnetic carrier core particles is coated with coating resin composition particles, the coating is conducted so that a surface of the magnetic carrier is free from cracks and chips and has fewer residual resin composition particles and a coating is uniform. In the method, a rotor having a plurality of stirring members on a surface thereof is rotated to coat the surface of magnetic carrier core particles with the resin composition particles. When the coating is conducted, while repeatedly conducting transportation in a direction of a driver and transportation in an anti-driver direction, the surface of the magnetic carrier core particles is coated with the resin composition. The resin composition particles has a 50% particle diameter (D50) based on volume of 0.2 μm or more to 6.0 μm or less and the proportion of particles of 10.0 μm or more is 2.0% by volume or less.

Owner:CANON KK

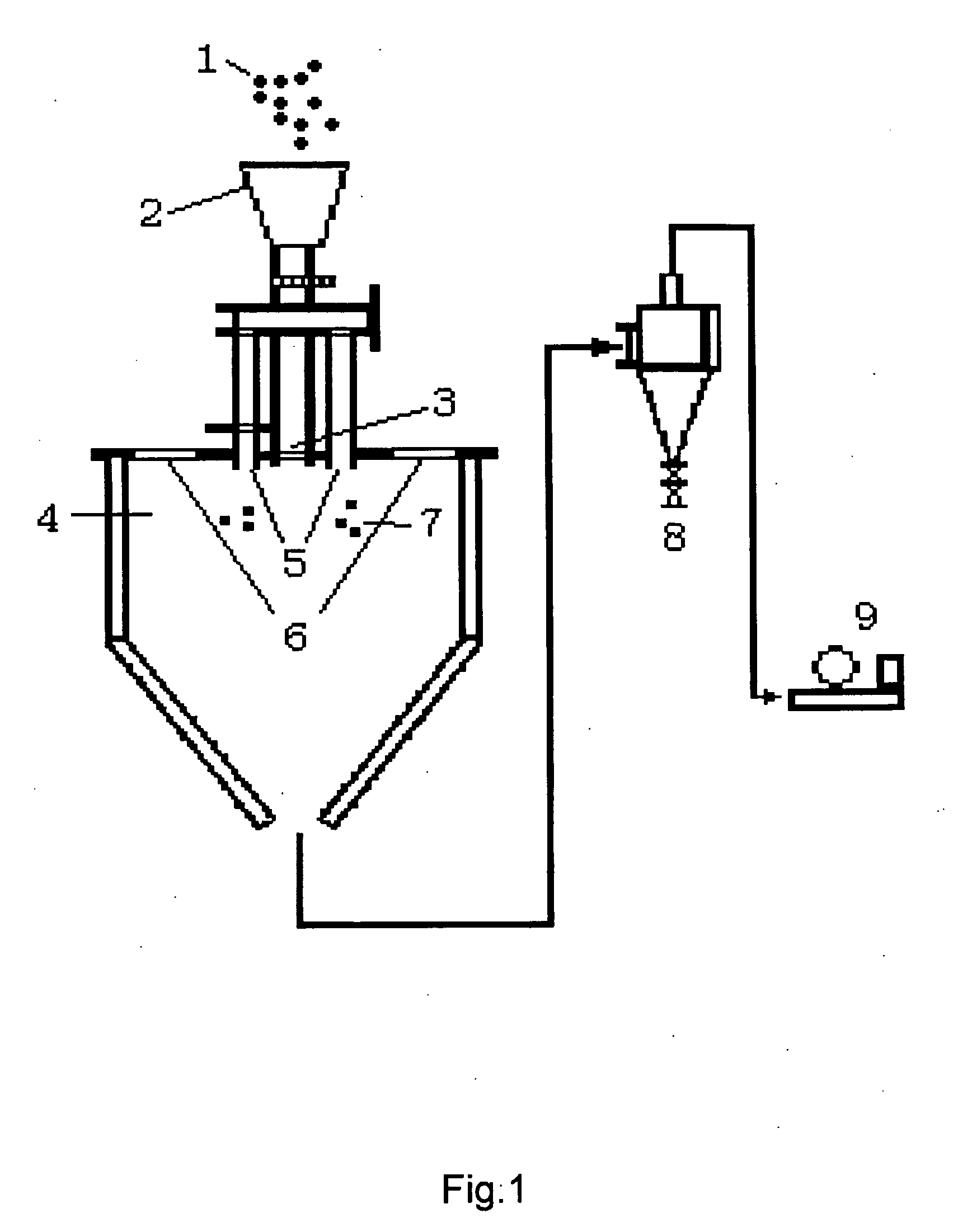

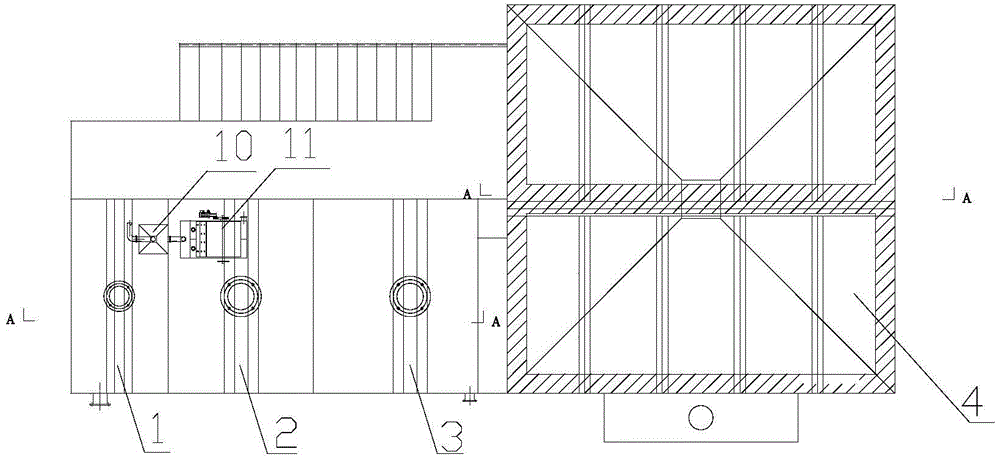

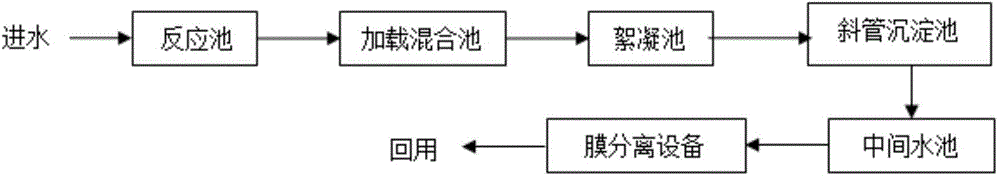

Wastewater reuse method combining magnetic loading coagulation clarification and membrane separation

ActiveCN103819045AAvoid or reduce pollutionLow costMultistage water/sewage treatmentParticulatesSolubility

The invention discloses a wastewater reuse method combining magnetic loading coagulation clarification and membrane separation. The method comprises the following steps: (1) a coagulant is added into a reaction tank to form small flocs; (2) the small flocs enter a loading and mixing tank to generate magnetic coagulation cores with magnetic carriers; (3) after the magnetic coagulation cores enter a flocculation tank, a flocculant is added to generate large-particle magnetic floccules; (4) after the magnetic floccules are stirred and dispersed strongly by a high-speed dispersion machine, magnetic carriers which are recycled via a magnetic drum separator return to the step (2), supernatant liquor enters a middle water tank via the collection by a water collecting pipe, after being pressurized by a water pump, the supernatant liquor enters membrane separating equipment for fine filtration, and filtered water is discharged for reusing. The method is used for removing particulate matters, colloid and a part of dissolved organic matters in advance before membrane filtration, so that membrane pollution degrees can be effectively avoided or reduced, and the cleaning period and the service life of membrane components are increased. The method can be used for the resource reutilization of the wastewater in industries of printing and dyeing, electroplating, paper-making and the like, as well as the upgrading and reconstruction and the tail water reuse of sewage treatment plants.

Owner:浙江立丰环保设备有限公司

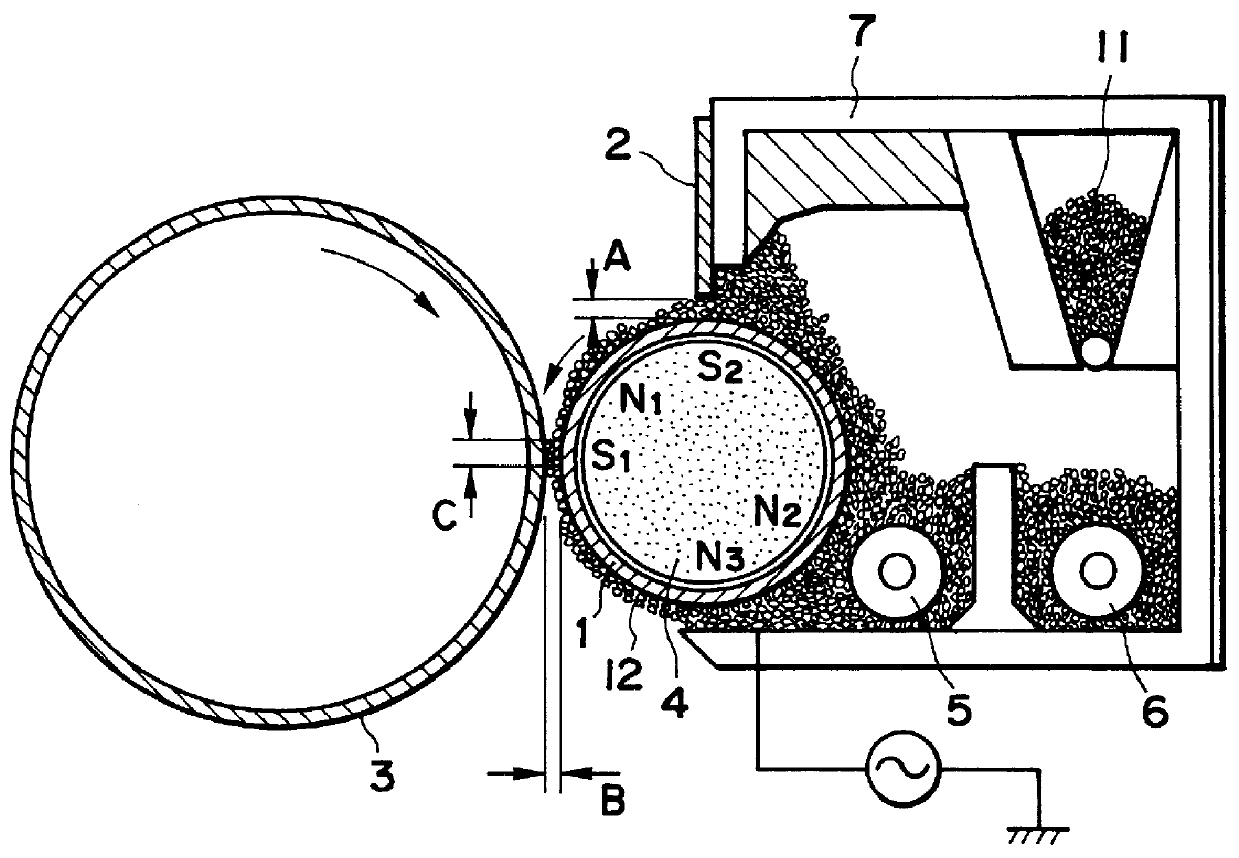

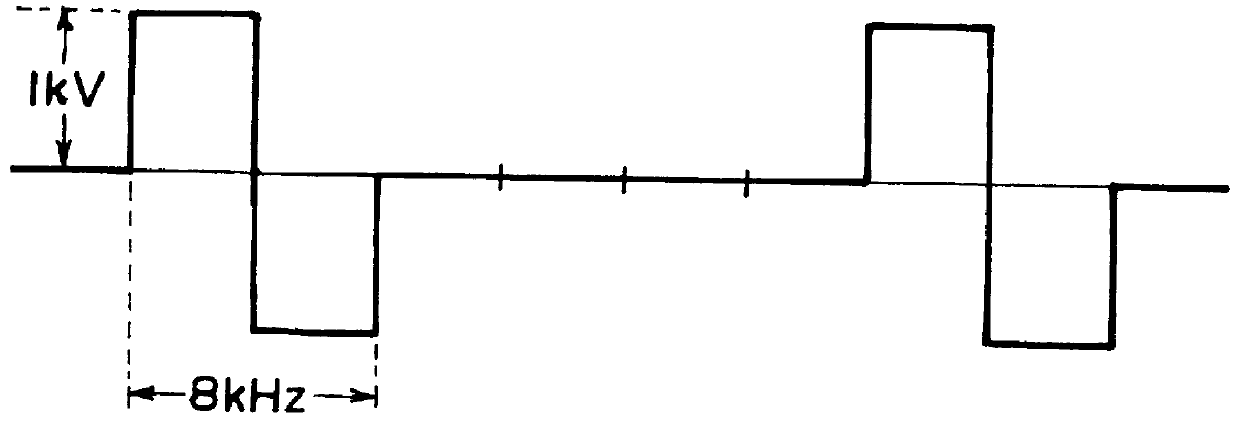

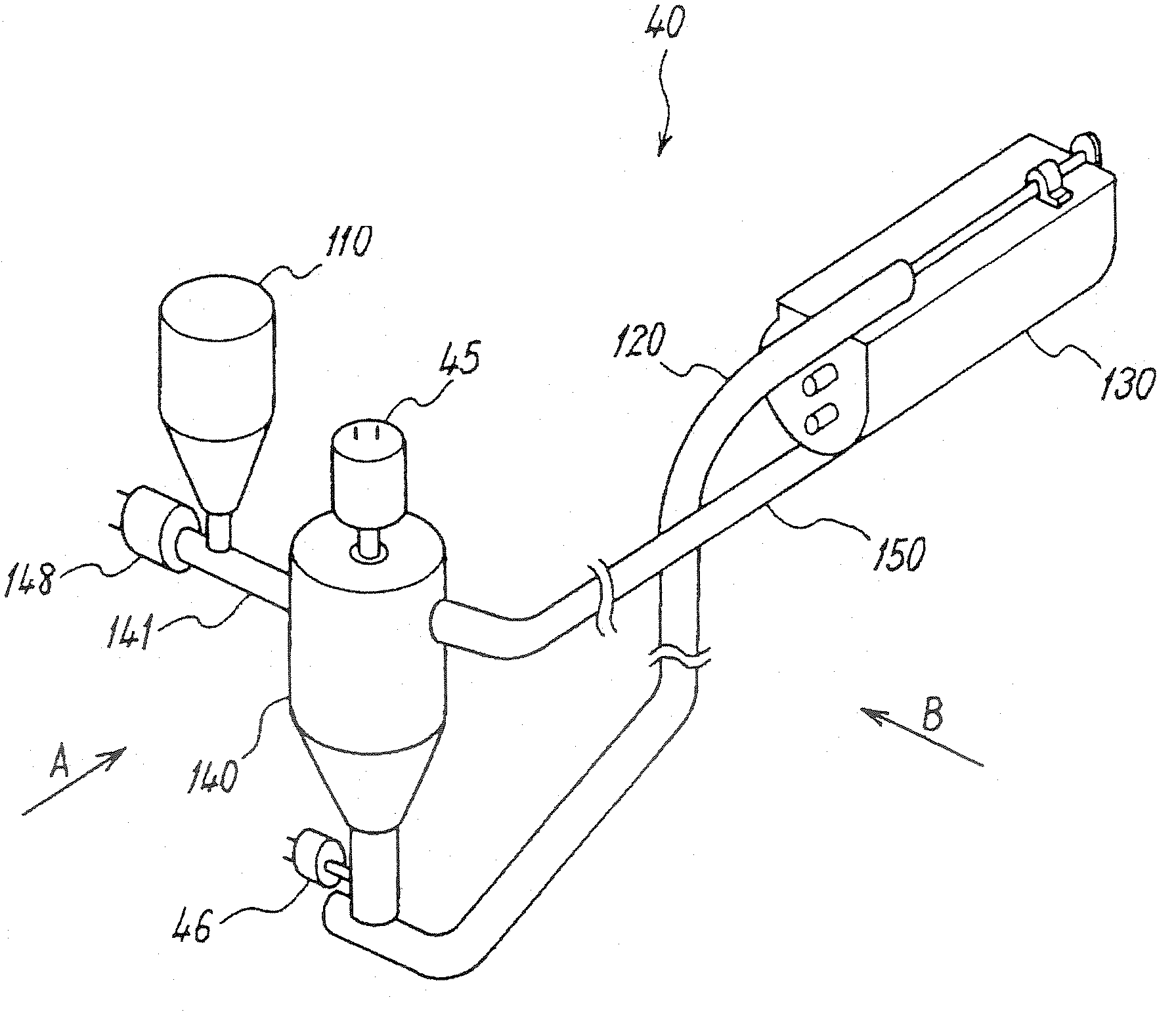

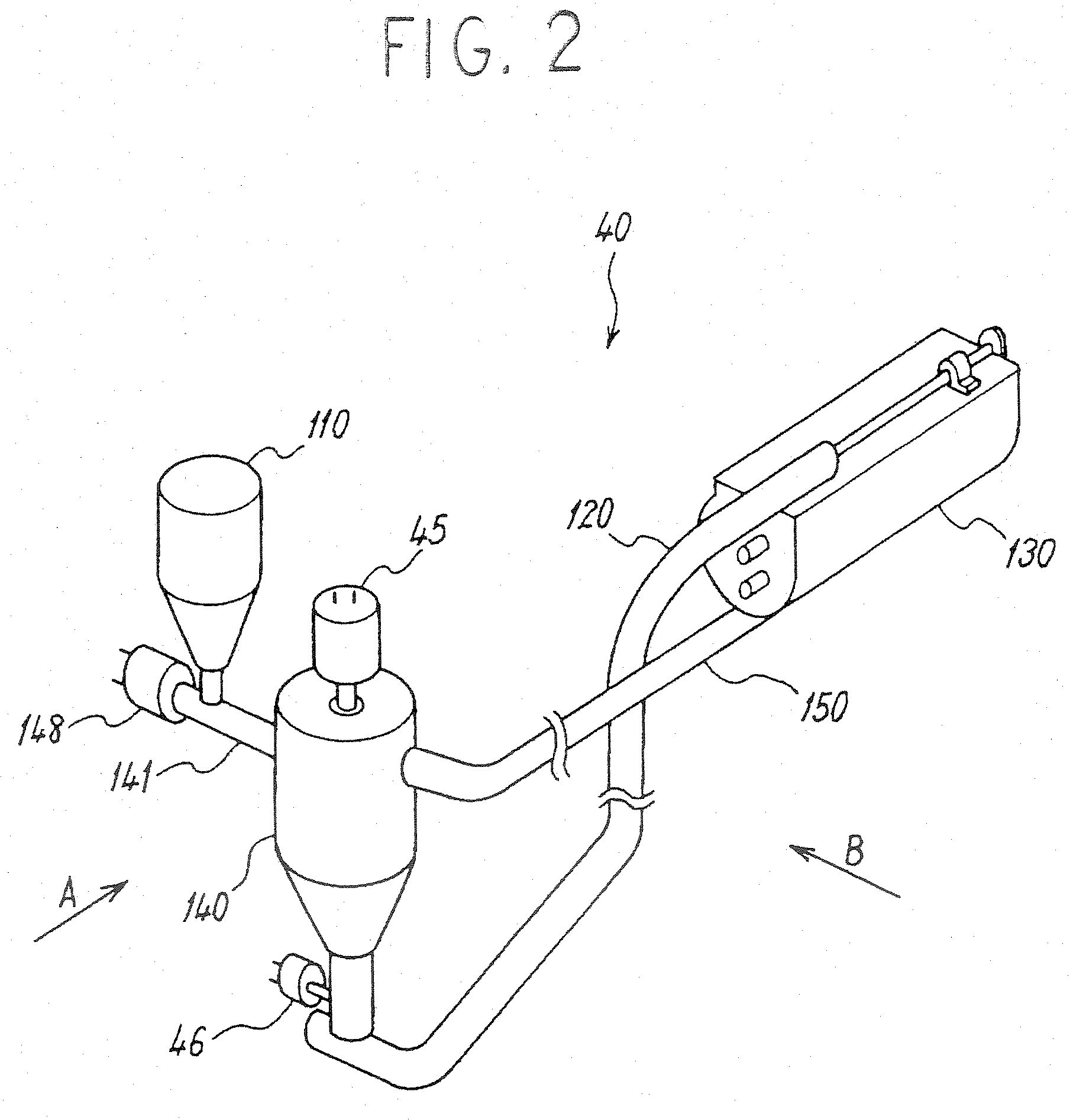

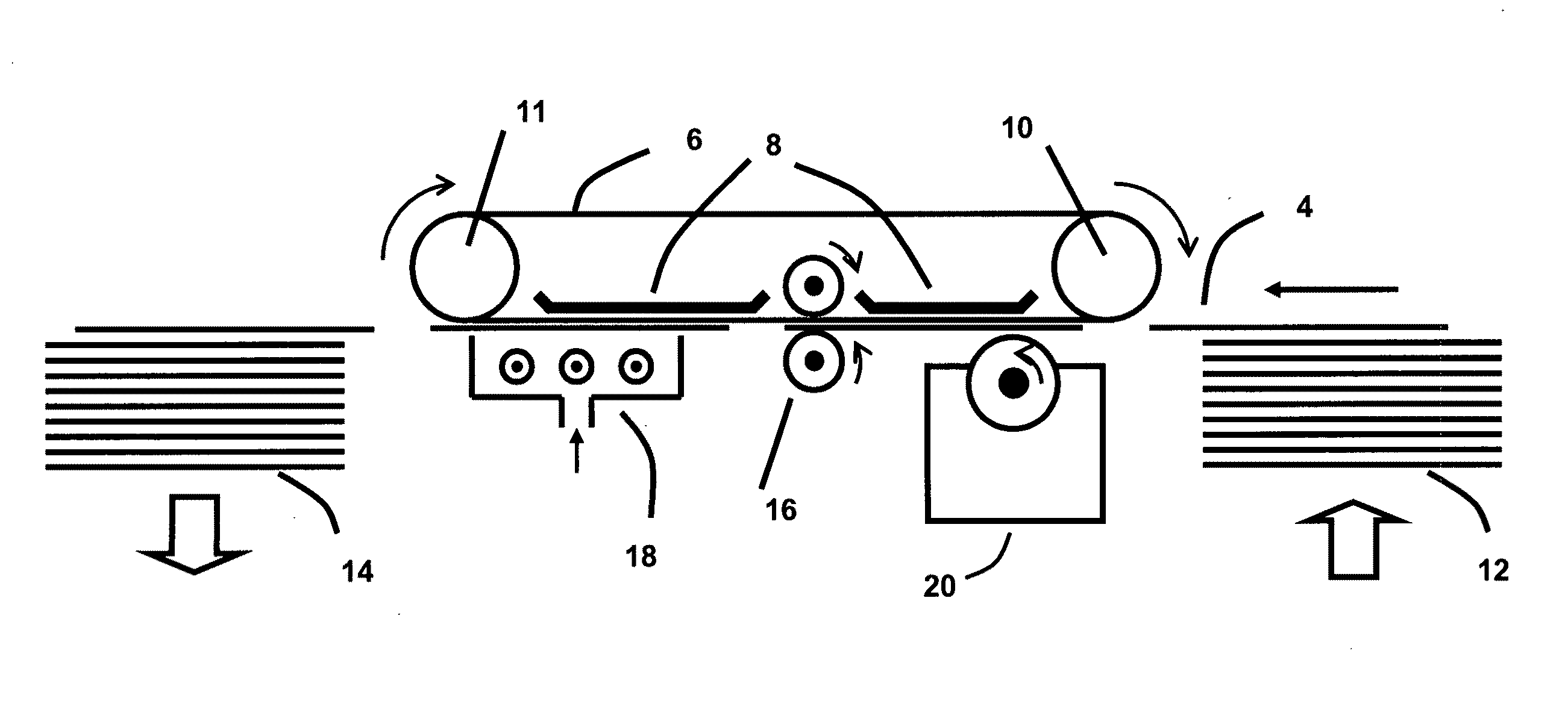

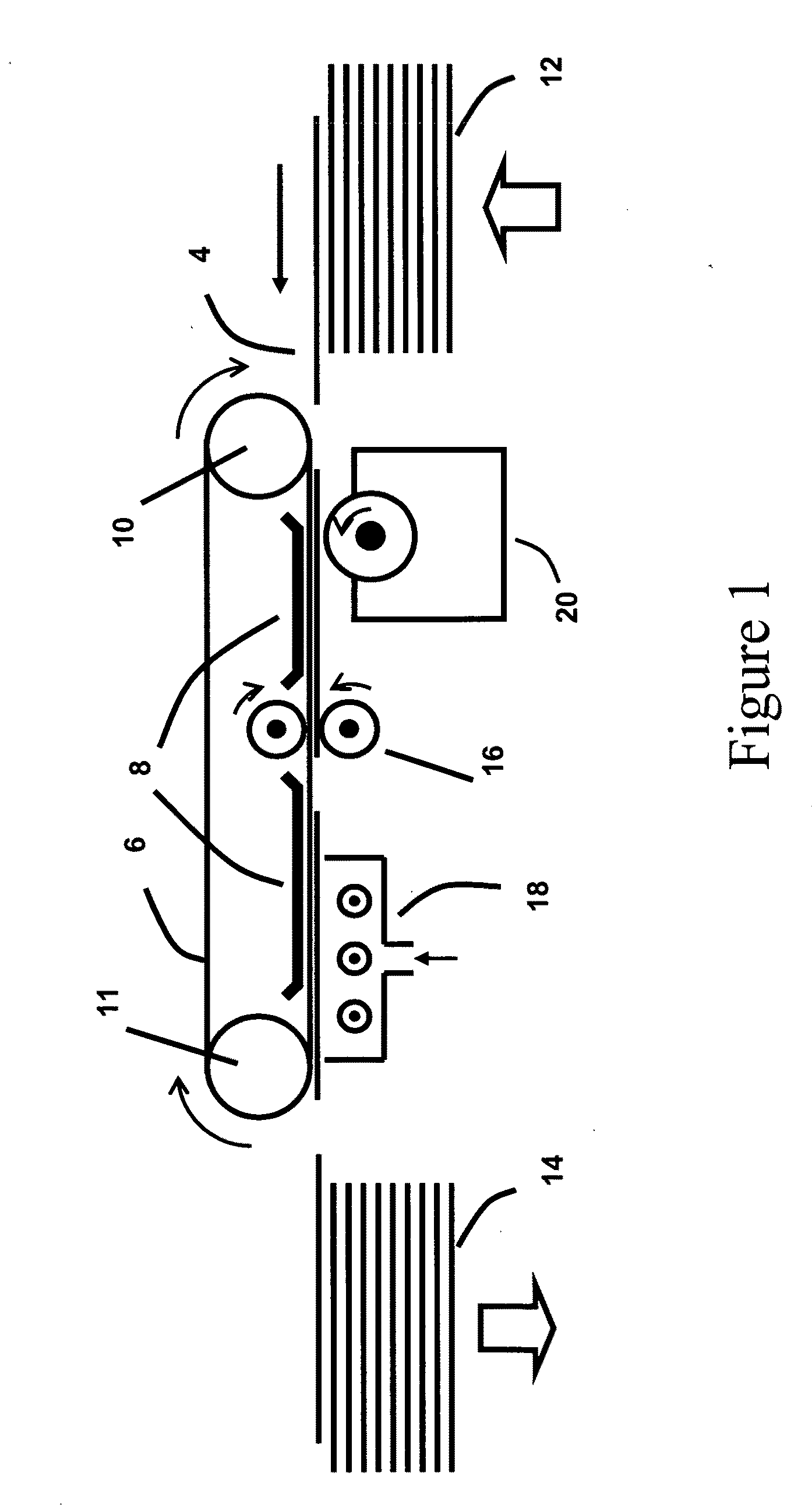

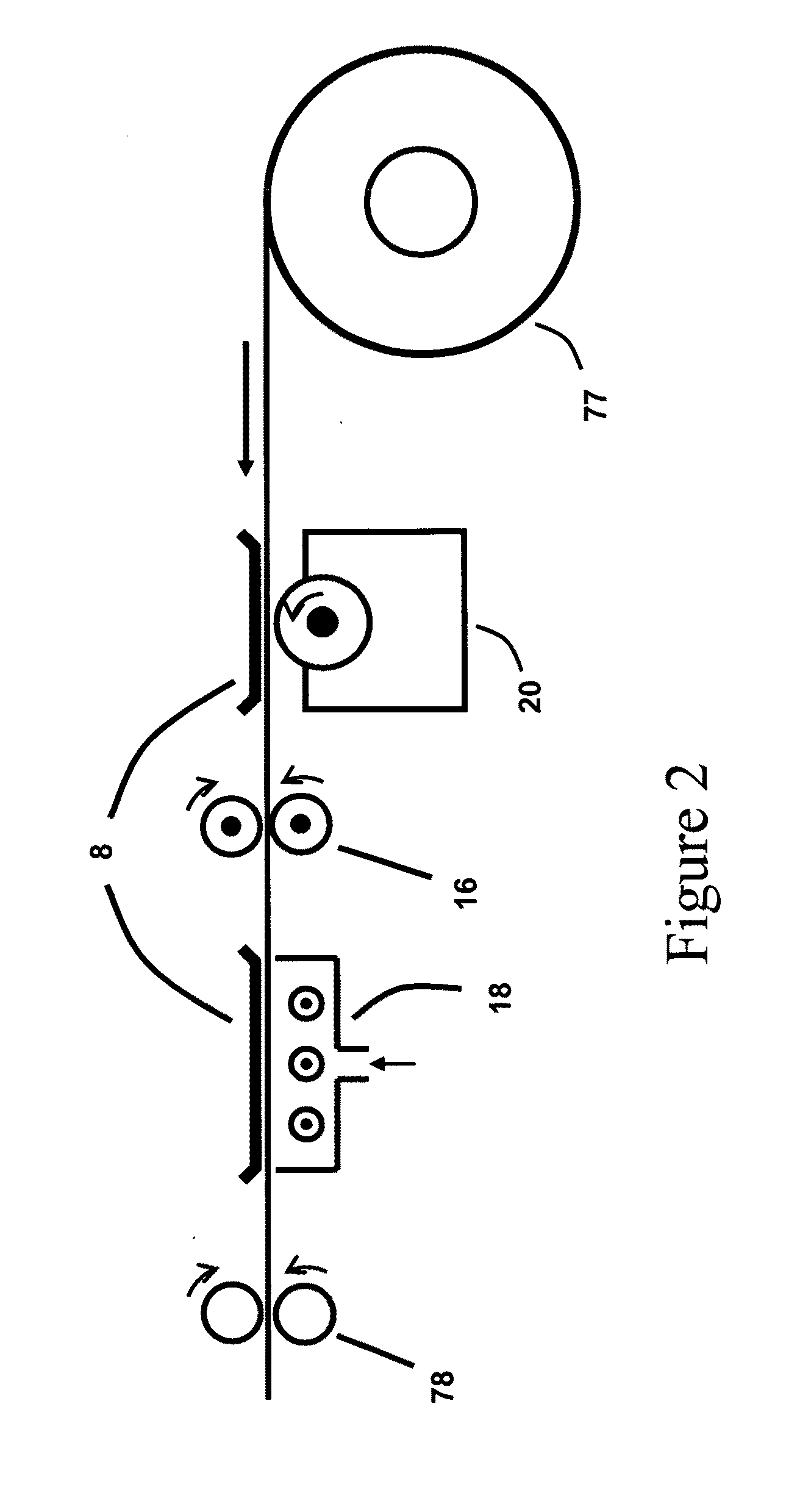

Non-interactive electrostatic deposition of induction charged conductive powder

A method for manufacturing electrodes using an electrostatic deposition unit. In the first step of the process a mixture of magnetic carrier beads and a conductive powder is prepared in the sump of the deposition unit; the mixture forms a magnetic brush on the sleeve of the deposition unit. In the second step of the process, the substrate is positioned away from the magnetic brush to form an air gap. In the third step of the process, a voltage is applied between the substrate and the sleeve of the deposition unit in order to produce a large asymmetry between the magnetic brush and said substrate such that the electric field at the magnetic brush is at least 3.0 times as great as the electric field at the substrate. In the fourth step of the process, conductive powder is deposited onto the substrate.

Owner:XACTIV

Wastewater treatment method using magnetism biological carrier and magnetic separation technique

InactiveCN101244884AEasy to handleSimple methodWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentTherapeutic effectVolumetric Mass Density

The invention relates to a sewage treatment method of adopting magnetic biological carrier and magnetic separation technique, belonging to the technical field of environmental protection, which comprises the following steps: magnetic biological carrier with density 1.0 to 1.4g / cm<3> and particle diameter 0.043 to 0.315mm is put into an aeration tank, the generated remained sewage can realize mud and water separation by magnetic separation technique, and then is put into a carrier de-molding separator, so as to realize the separation between mud and magnetic carrier, after magnetic separation, the magnetic carrier renews to be placed into the reactor, so as to realize recovery and reutilization of magnetic carrier. When the carrier additive is between 4 and 13g / L, the aeration amount is 50 to 100L / h, air apparent flow rate is 1.8 to 3.5m<3>(m<2> x h), waterpower retaining time is 1-5h, reflux ratio of the mixed liquid is 1-6, after checking, the removal ratio of effluent COD can reach 92.0 to 98.2%. When used for sewage treatment, the method in the invention has advantages of good treatment effect, simple method, strong controllability, and facility for industrial production; while obviously reducing effluent COD, the investment can be reduced and running cost can be lowered.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com