Functionalized silicon coating mesoporous magnetic carrier and preparation method and application thereof

A magnetic carrier, silicon coating technology, applied in chemical instruments and methods, fixed on or in inorganic carriers, adsorbed water/sewage treatment, etc. , to achieve the effect of good treatment of sewage, protection of acid and alkali corrosion, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

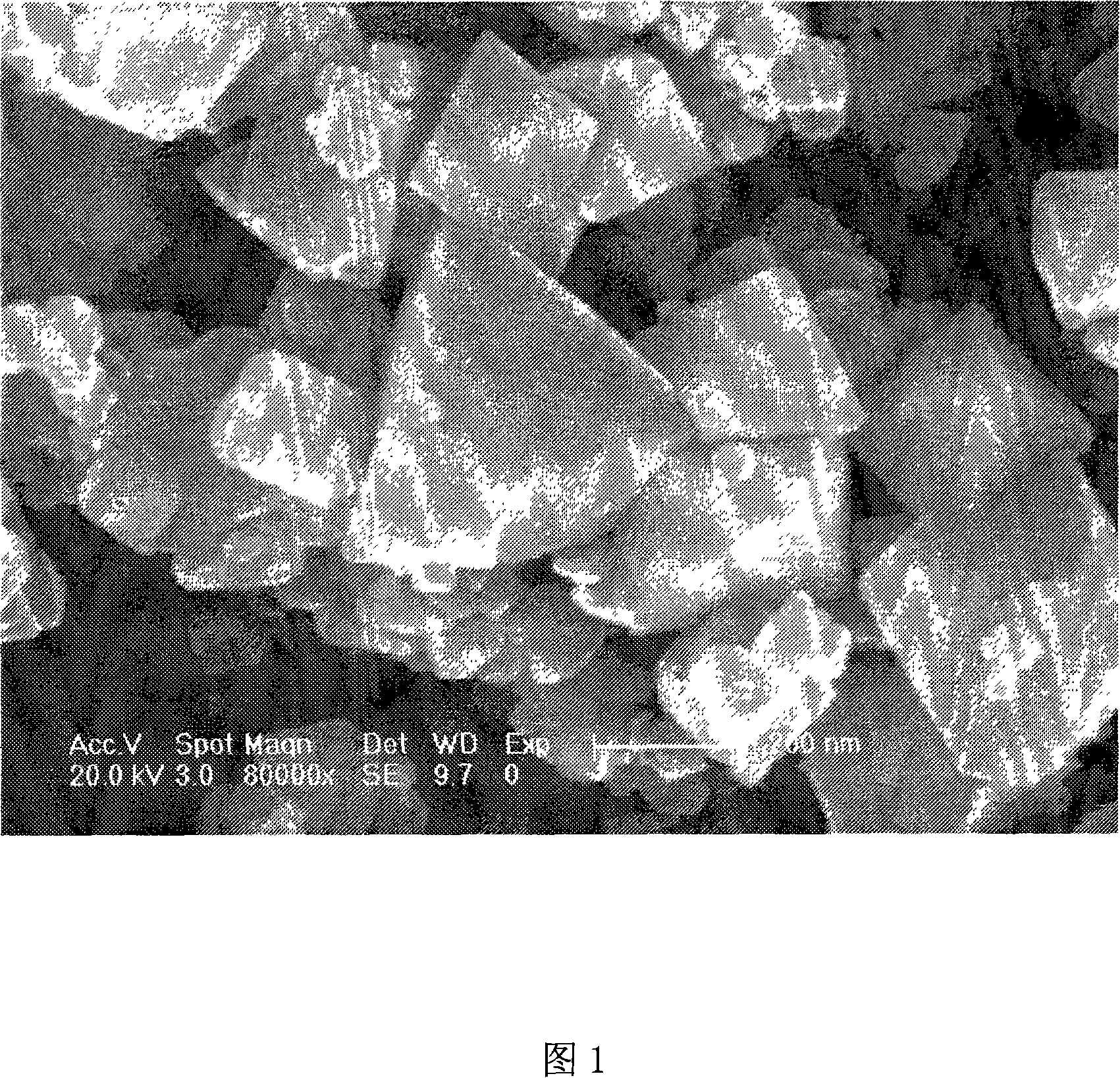

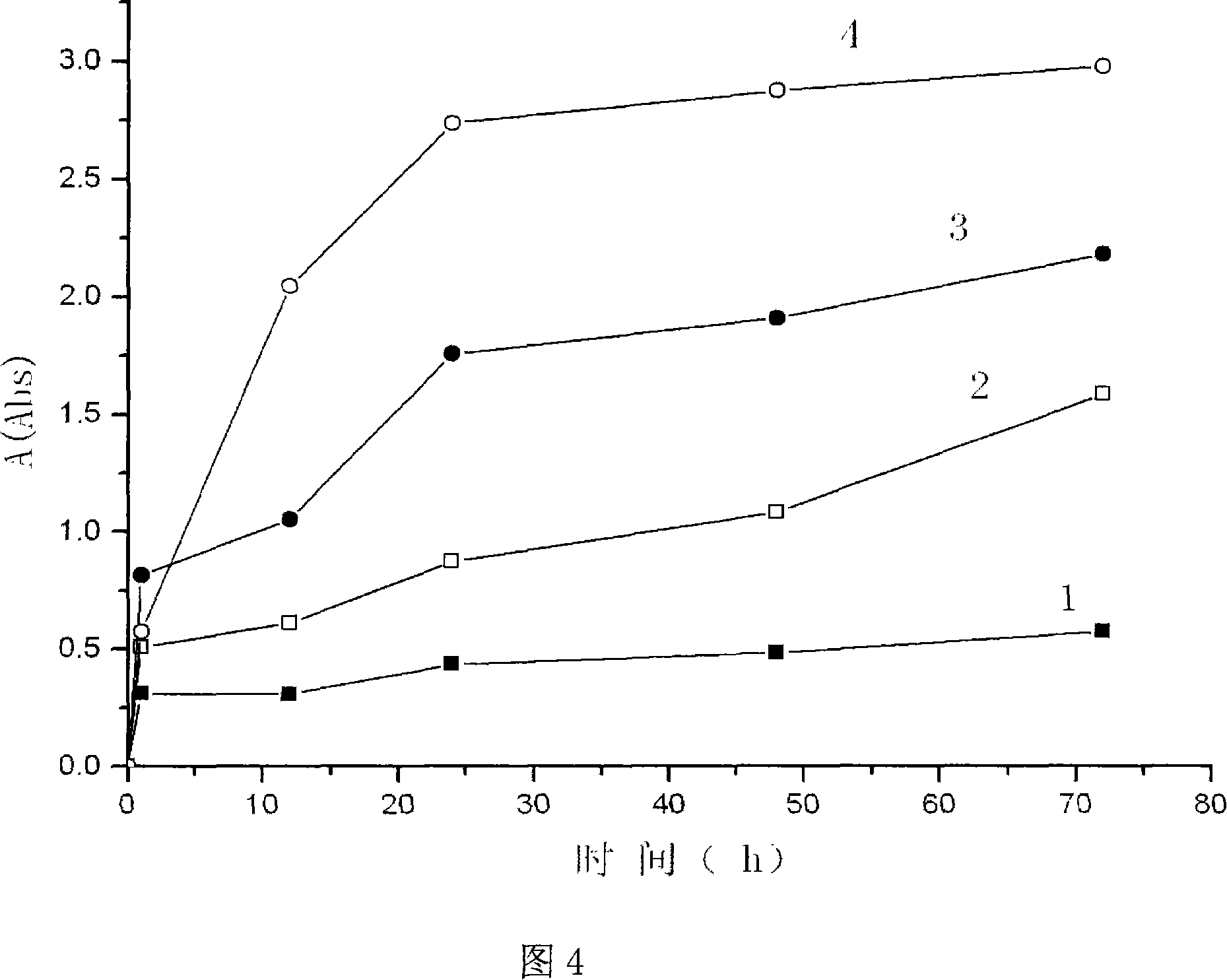

[0049] (1) Silicon coating by saturated solution method: add 3.0g Fe to 100ml deionized water 3 o 4 After the particles were ultrasonically dispersed for 30 minutes, slowly add 10ml of 0.5moL·dm -3 , sodium silicate solution, and use dilute sulfuric acid to adjust the pH of the solution to about 3.0, keep the reaction at 40±3°C for 3 hours, then raise the temperature to 95±3°C for 1 hour, separate, wash with water and dry to obtain a one-step silicon-coated magnetic carrier;

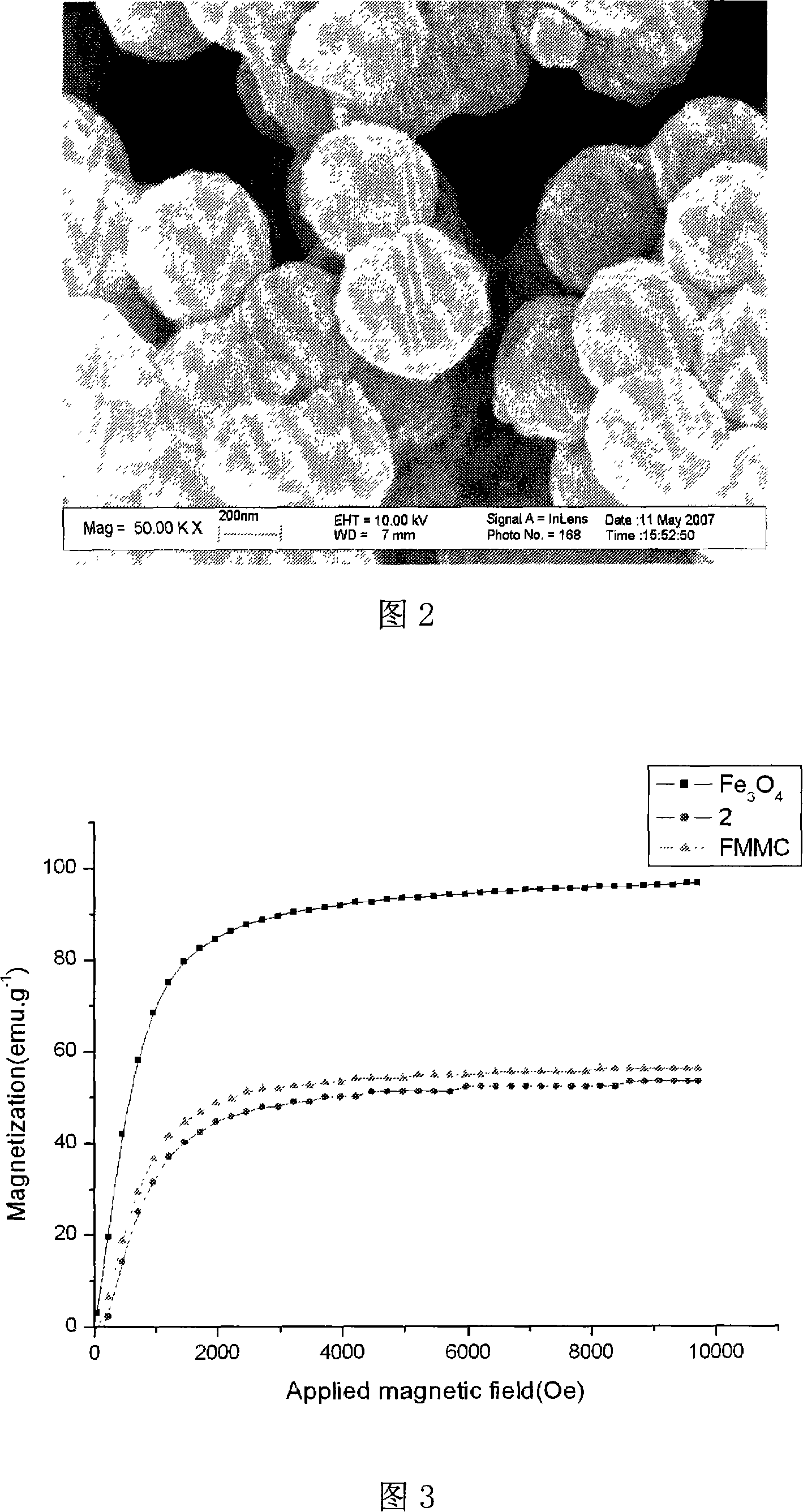

[0050] (2) Molecular templating: take 3.0 g of the product of step (1) and add it into 100 ml of deionized water for ultrasonic dispersion for 20 minutes, add 2.9 wt% cetyltrimethylammonium bromide solution CTAB under stirring, and separate it after 30 minutes of reaction product;

[0051] (3) Sol-gel method of silicon coating: the product of step (2) was added to 100ml of 95% ethanol, slowly added 10ml of ethyl orthosilicate TEOS, and reacted for 3 hours under the condition of an appropriate amount o...

Embodiment 2

[0055] (1) Silicon coating by saturated solution method: add 8.0g Fe to 150ml deionized water 3 o 4 After the particles are ultrasonically dispersed for 60 minutes, slowly add 25ml of 0.6moL.dm under stirring condition -3 Sodium silicate solution, adjust the pH of the solution to about 3.5 with dilute sulfuric acid, keep it warm at 40±3°C for 3.5 hours, then raise the temperature to 95±3°C for 2 hours, separate, wash with water and dry to obtain a one-step silicon-coated magnetic carrier ;

[0056] (2) Molecular templating: Take 3.0 g of the product of step (1) and add it to 100 ml of deionized water for ultrasonic dispersion for 30 minutes, add 5.7 wt% cetyltrimethylammonium bromide solution CTAB under stirring, and separate after 40 minutes of reaction to obtain product;

[0057] (3) Sol-gel method of silicon coating: add 100ml of 95% ethanol to the product of step (2), slowly add 25ml of ethyl orthosilicate TEOS, react for 4 hours, separate and wash with ethanol, and vac...

Embodiment 3

[0061] (1) Silicon coating by saturated solution method: add 9.0g Fe to 200ml deionized water 3 o 4 After the particles were ultrasonically dispersed for 120 minutes, add 12.5ml of 1.0moL·dm under stirring condition -3 Sodium silicate solution, adjust the pH of the solution to about 4.0 with dilute sulfuric acid, keep it warm at 40±3°C for 3.5 hours, then raise the temperature to 95±3°C for 1.5 hours, separate, wash with water and dry to obtain a one-step silicon-coated magnetic carrier ;

[0062] (2) Molecular templating: Take 3.0 g of the product of step (1) and add it into 100 ml of deionized water for ultrasonic dispersion for 60 minutes, add 2.97 wt% cetyltrimethylammonium bromide solution CTAB under stirring, and separate after 60 minutes of reaction to obtain product;

[0063] (3) sol-gel method silicon coating: add 100ml 98% ethanol to the product of step (2), add 8ml ethyl orthosilicate (TEOS), react 4 hours under the condition that an amount of ammonia is made cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com