Patents

Literature

216results about How to "Inhibit adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

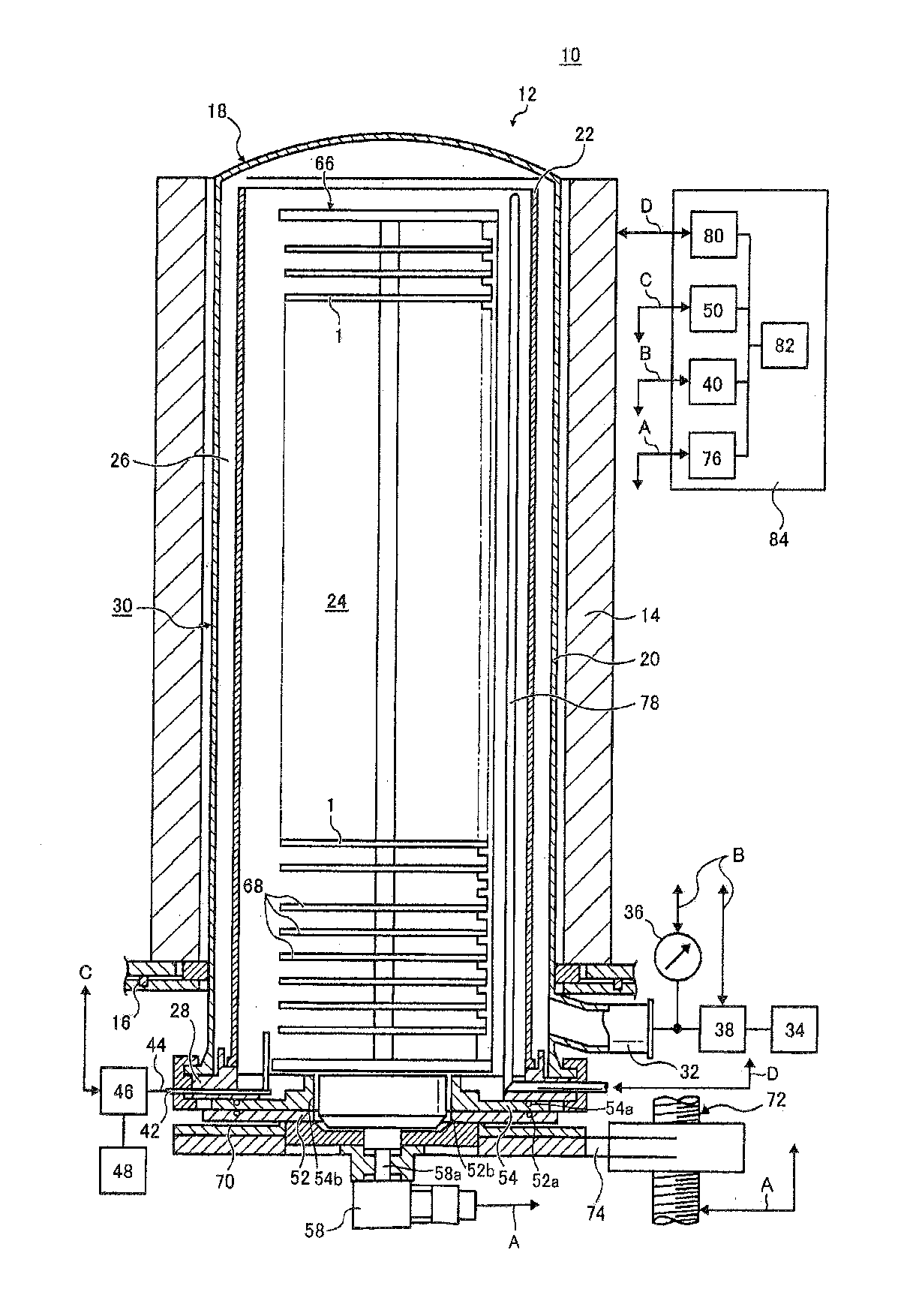

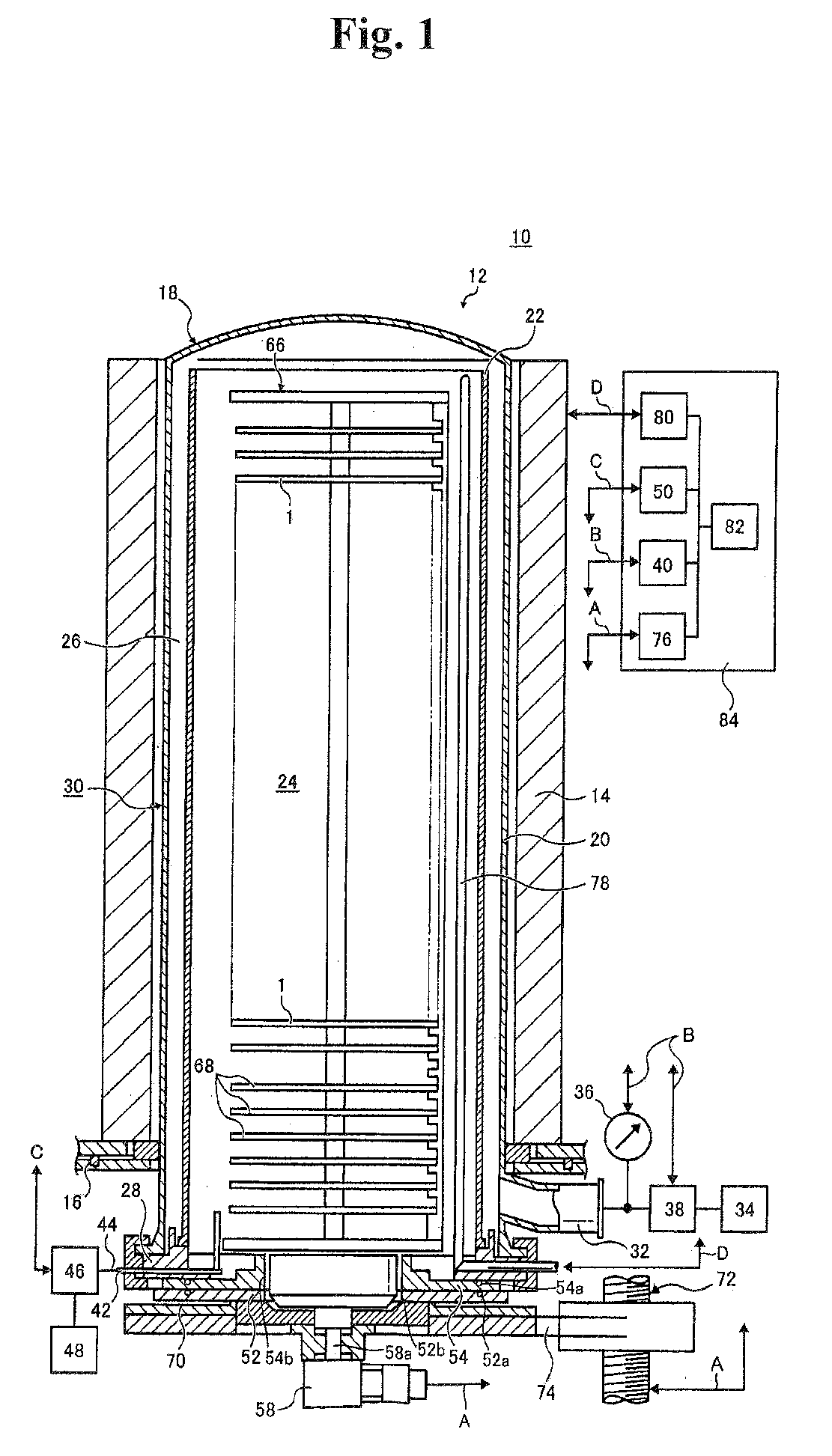

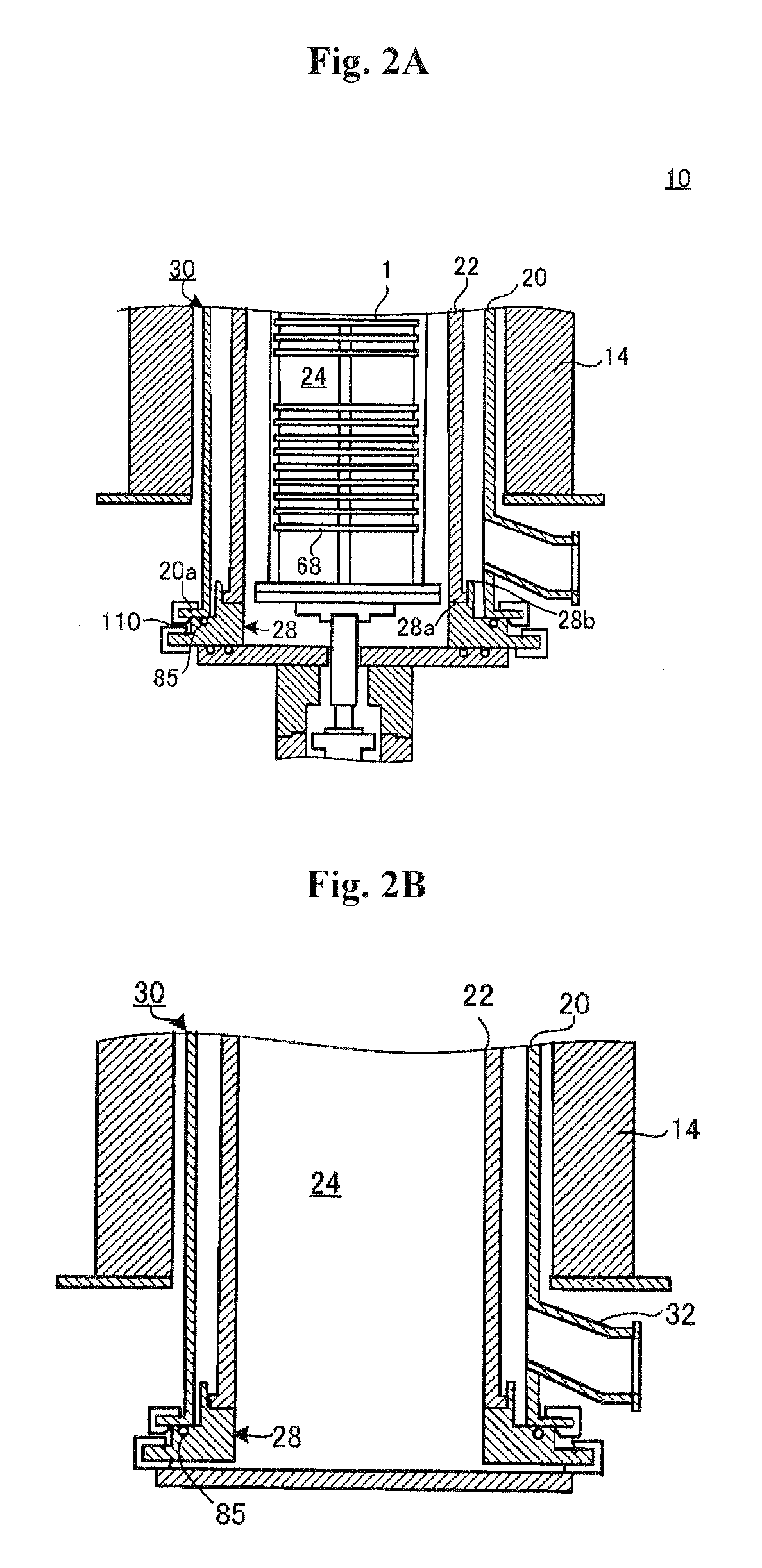

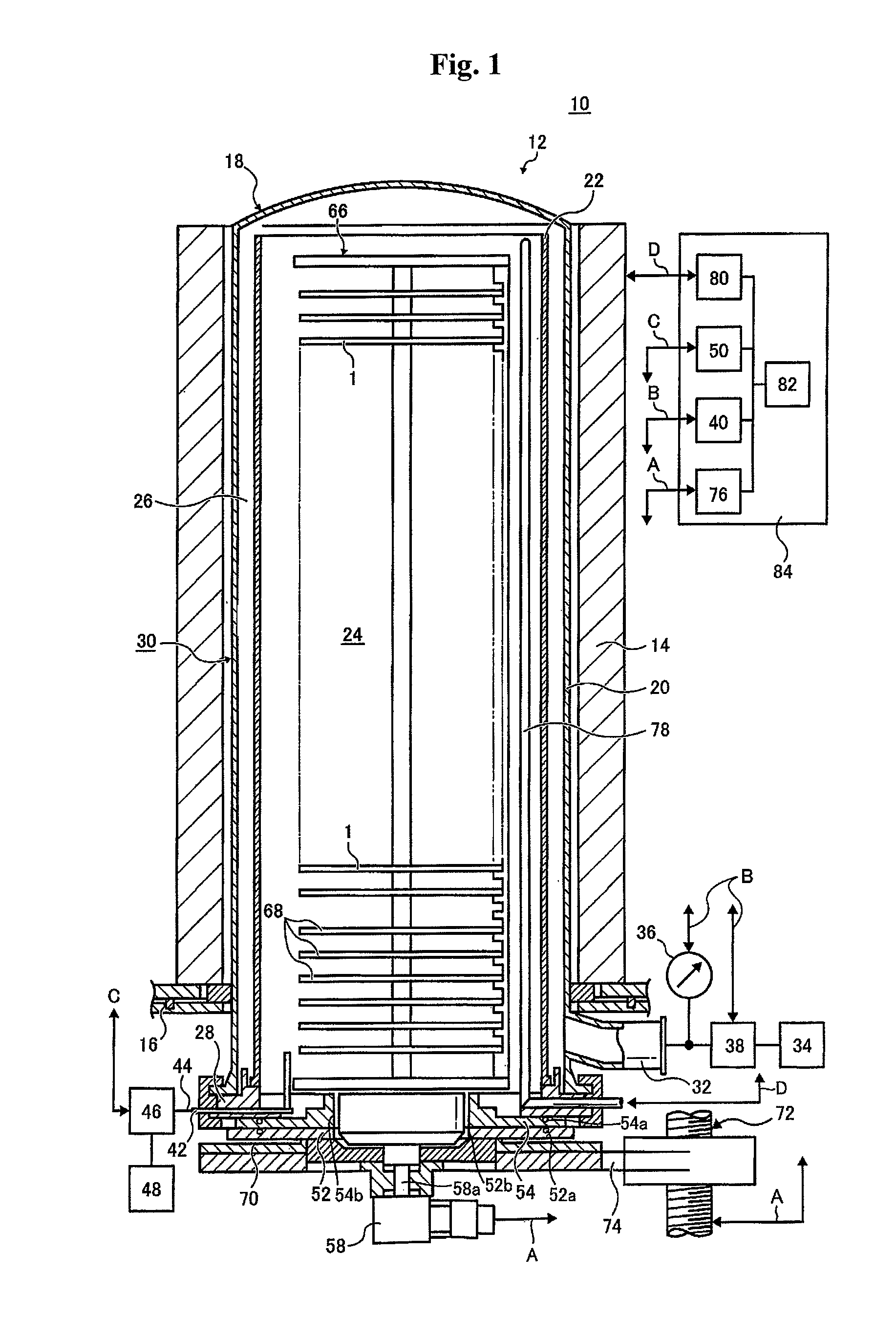

Substrate processing apparatus and method of manufacturing semiconductor device

ActiveUS20100051597A1Suppress metal contaminationSuppress adhesionDrying solid materials with heatMuffle furnacesEngineeringMetallic materials

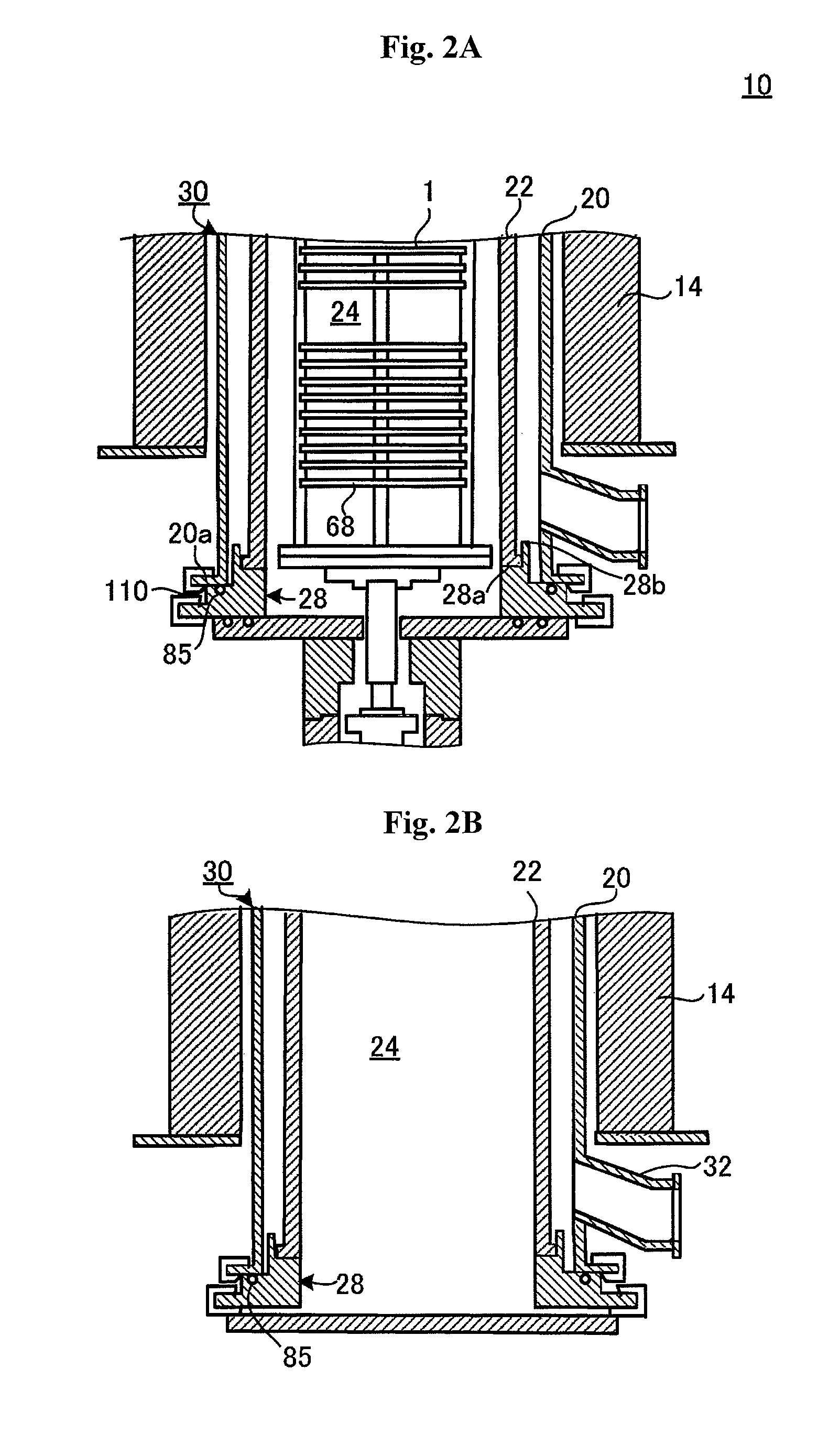

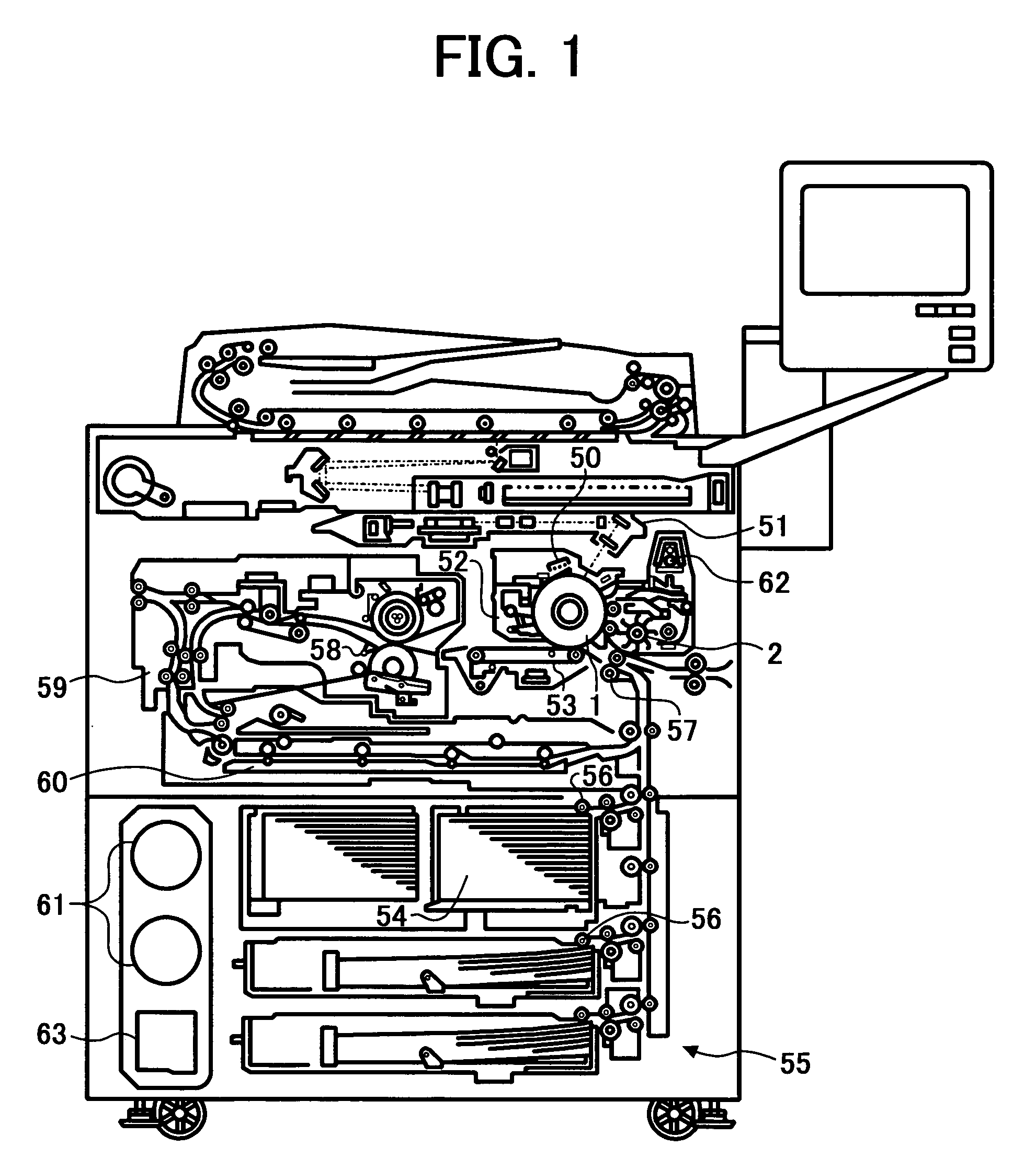

A substrate processing apparatus comprises: an outer tube; a manifold connected to the outer tube and made of a non-metal material; an inner tube disposed in the manifold at a more inner side than the outer tube and configured to process a substrate therein; a heating device installed at a more outer side than the outer tube and configured to heat the inside of the outer tube; a lid configured to open and close an opening of the manifold, with a seal member intervened therebetween; and a heat absorption member installed in the manifold, with a bottom end of the inner tube intervened therebetween, and configured to absorb heat from the heating device, the heat absorption member being made of a non-metal material.

Owner:NTT MOBILE COMM NETWORK INC

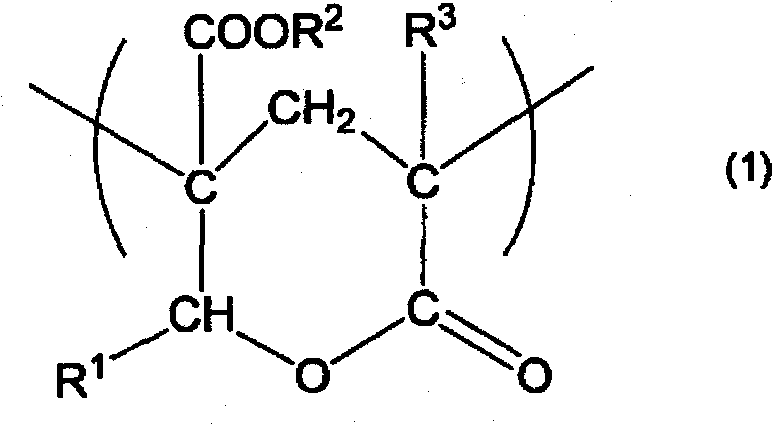

Polarizer-protecting film, and polarizing plate and image display device each comprising polarizer-protecting film

InactiveCN102112899AInhibit adhesionGood coiling effectSynthetic resin layered productsPolarising elementsColloidal silicaAcrylic resin

Disclosed is a polarizer-protecting film which rarely causes blocking during the take-up of the film and thereby has excellent take-up properties. The polarizer-protecting film comprises a (meth)acrylic resin film and a highly adhesive layer composed of a highly adhesive agent composition comprising a urethane resin and microparticles. Preferably, the microparticles comprise colloidal silica.

Owner:NITTO DENKO CORP +1

Oil agent for carbon fiber precursor fiber, carbon fiber and method for producing carbon fiber

InactiveCN101091010AInhibit thermal bondingInhibit adhesionMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentFiberCarbon fibers

By using an oil agent for precursor fiber of carbon fiber containing a base compound and a liquid fine particle, and said liquid fine particle contains a liquid of which kinematic viscosity at 150 DEG C is 15000 cSt or more, it is possible to suppress an uneven stabilization in stabilizing process, and it becomes possible to provide a carbon fiber of high performance and uniform quality.

Owner:TORAY IND INC

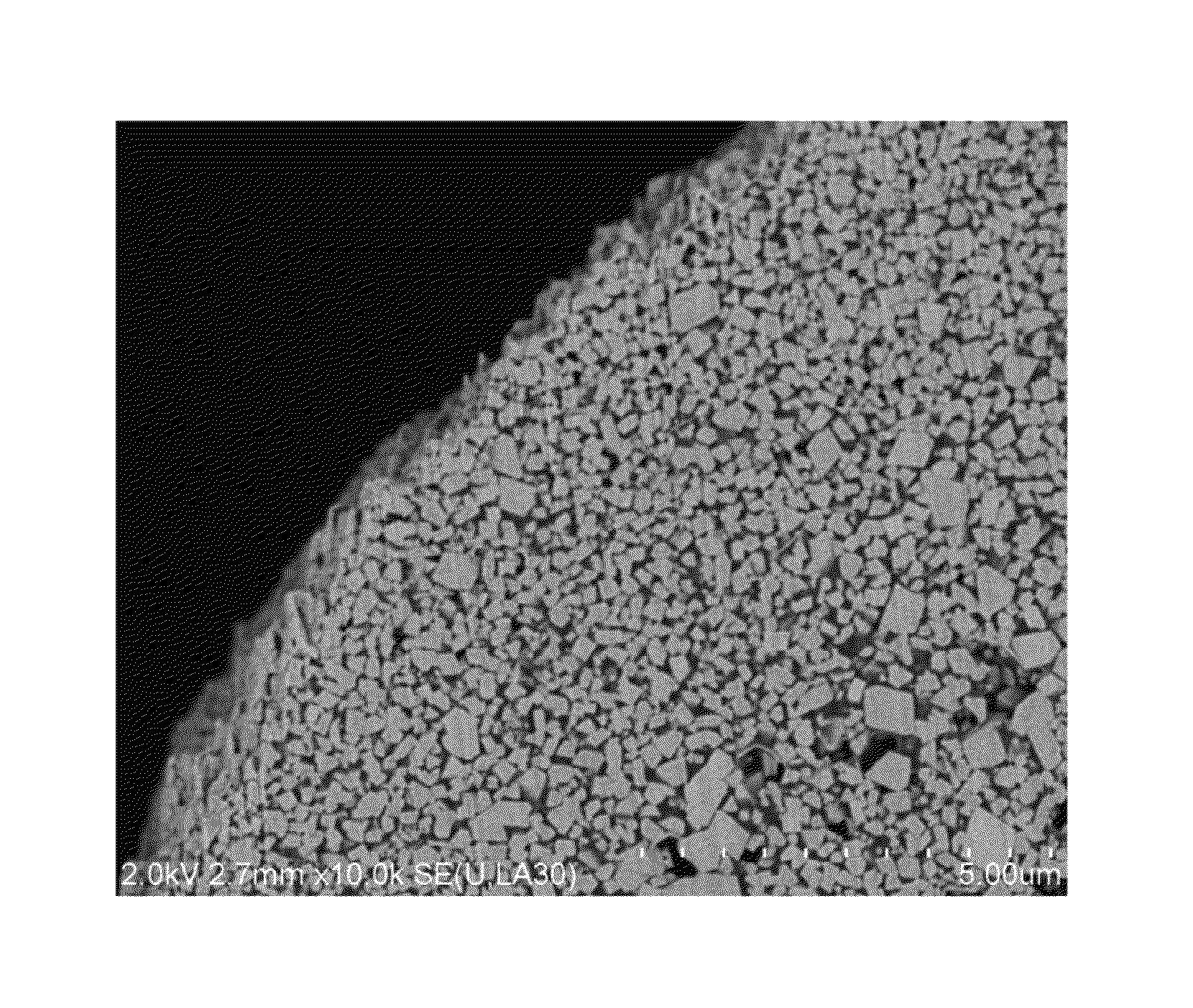

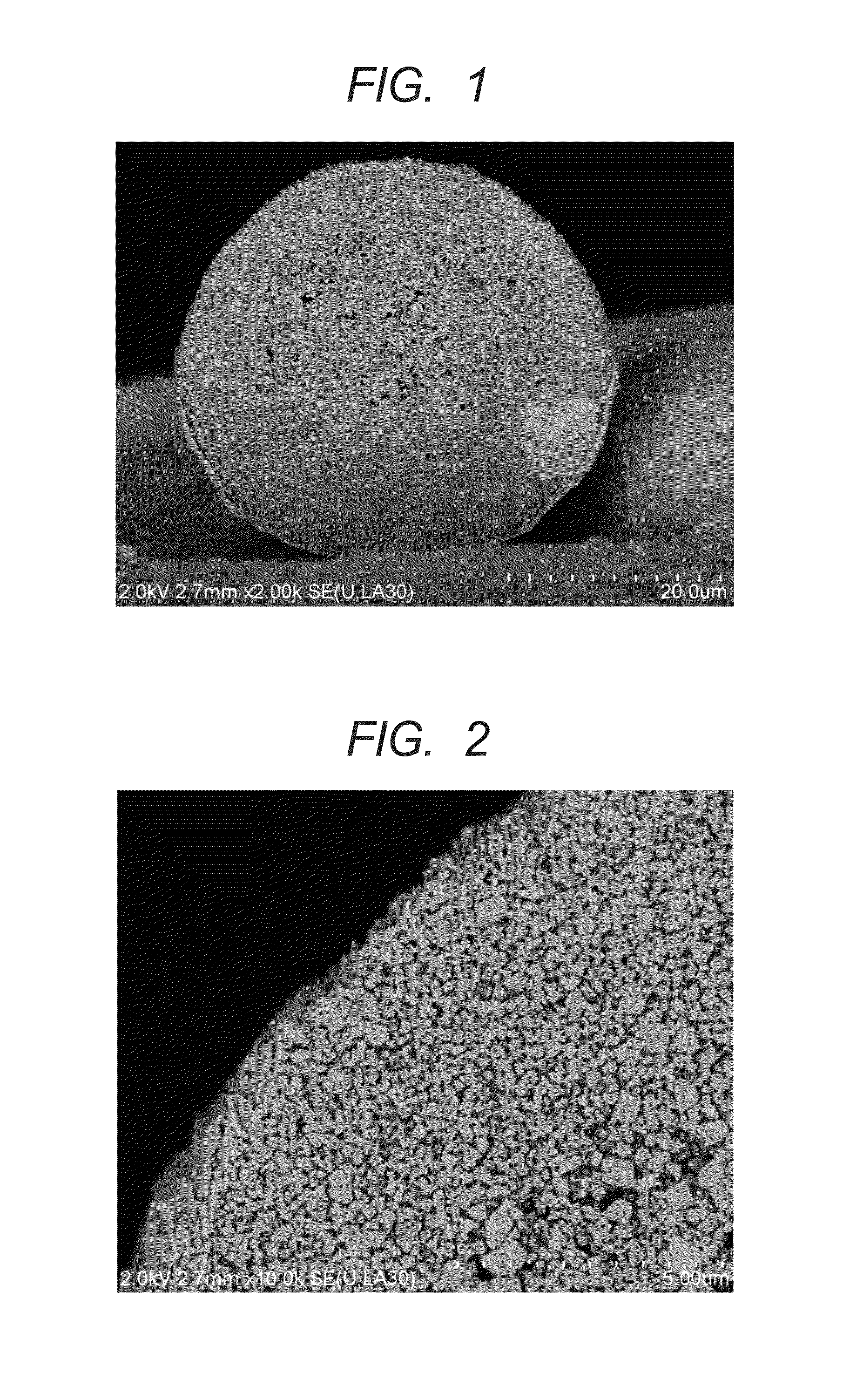

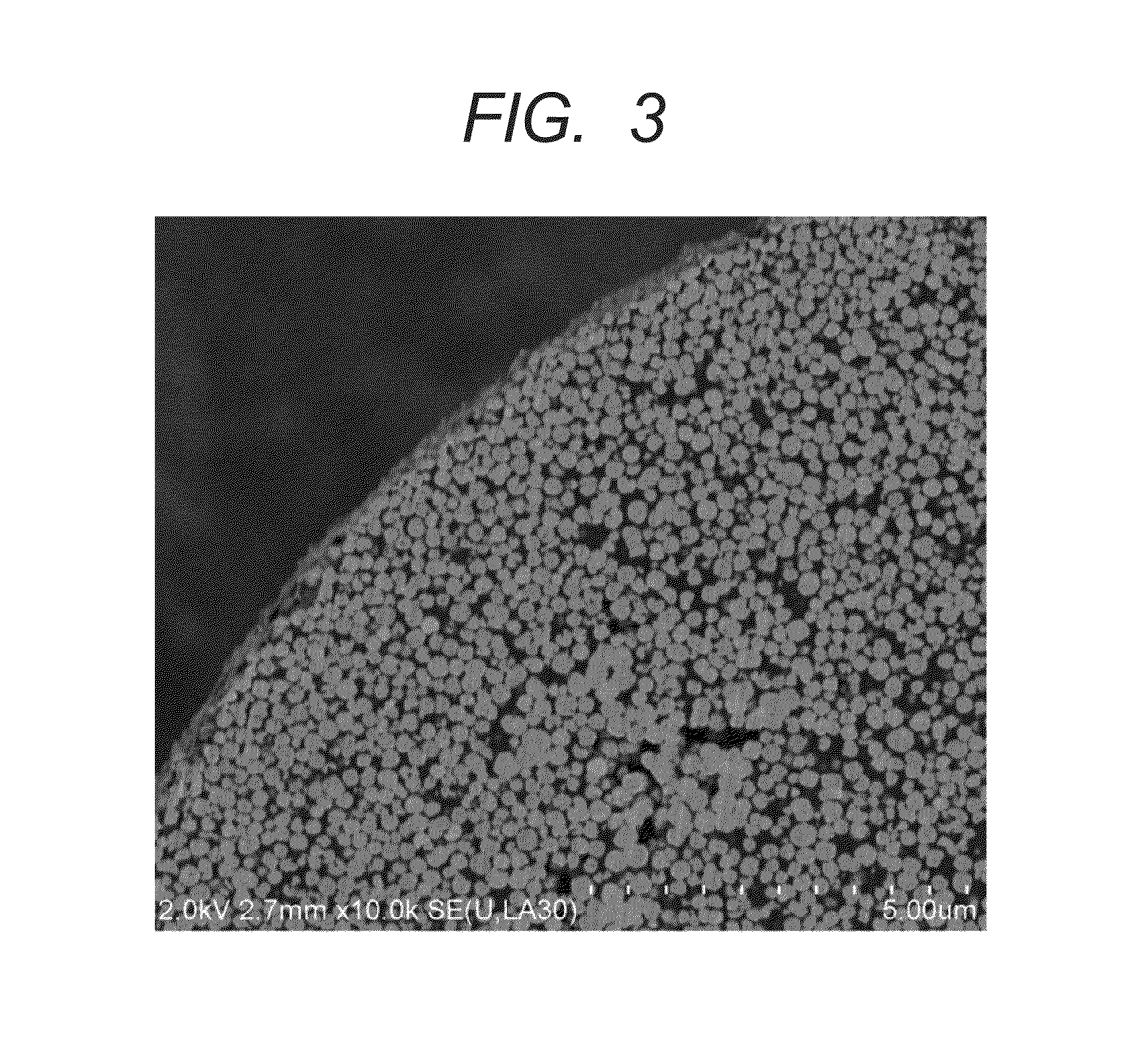

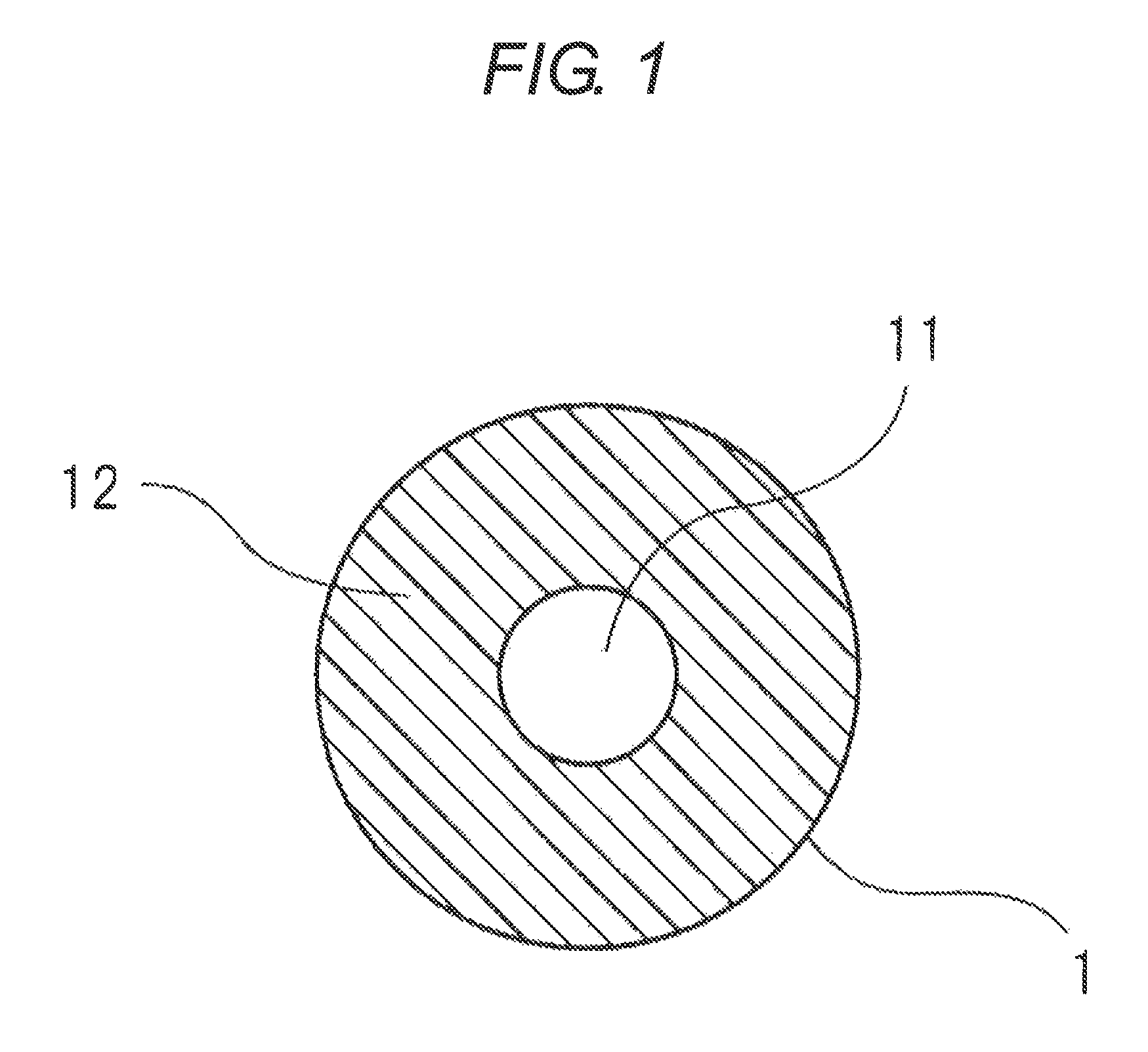

Magnetic carrier and two-component developer

ActiveUS8921023B2Improve development performanceInhibit adhesionDevelopersElectric fieldSubstance of very high concern

Provided is a magnetic carrier excellent in leakage, uniformity of a solid image having satisfactory charging stability and developing performance at low electric field. The magnetic carrier is a magnetic carrier comprising: a magnetic substance-dispersed resin carrier core, which contains a magnetic substance and a binding resin, and a coating resin on a surface thereof, wherein: the carrier core has resistivity at 1000 V / cm of 5.0×106-8.0×107 Ω·cm, the magnetic substance has a number average particle diameter of 0.20-0.35 μm; and comprises magnetic-substance particles having vertexes and a particle diameter of 0.53 μm or more in an amount of 10.0-32.0 vol % based on a total amount of the magnetic substance; and wherein: the carrier core has Fe2O3 content of 98.00% by mass or more; and ZnO content of 0.06-0.50% by mass.

Owner:CANON KK

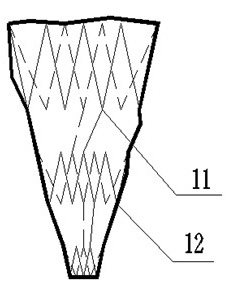

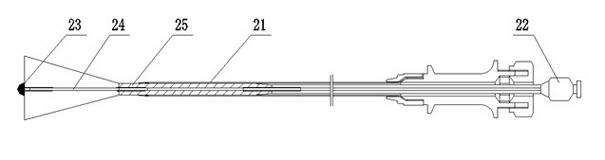

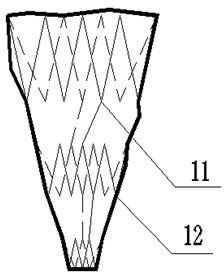

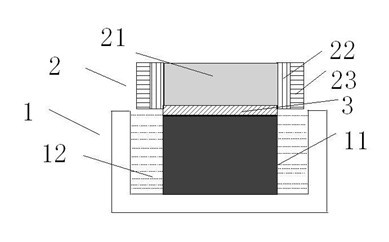

Medicinal stent-graft for preventing and treating intrauterine adhesion

The invention provides a medicinal stent-graft for preventing and treating intrauterine adhesion. The stent provided by the invention is a uterus-shaped mesh basket weaved by nickel-titanium alloy wires, wherein the mesh basket is coated by a biocompatible film, a sustained-release medicine-loading layer is sprayed outside the film, and the medicament comprises estrogen and progesterone. The medicinal film coated uterus-shaped mesh basket is placed in uterine cavity through a conduit conveyer to release; the mesh basket with the film is retracted in the conduit of the conduit conveyer in advance; a push rod is arranged at the end close to the conduit; and after the conduit conveyer is fed into the uterine cavity, the push rod does not move, an outer sleeve is withdrawn, the mesh basket with the film is gradually released, and the mesh basket automatically extends to be closely adhered to the uterine cavity, so that direct contact of endometria is isolated to achieve the purpose of preventing and treating the intrauterine adhesion. The medicinal stent-graft for preventing and treating the intrauterine adhesion has the advantage of wide application prospect.

Owner:SOUTHEAST UNIV

Polyacrylonitrile temperature-regulating fiber, and its manufacturing method

InactiveCN1851072AGood heat absorptionGood mechanical strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureIonMelt spinning

The invention relates to the polyacrylonitrile and the producing process. The weight percent of the adjusting temperature is showed below: the acrylonitrile 30.0-92.5%; the second monomer 2.5-20.0%; the chain transferring reagent 0.03-0.3%; the solicitation reagent 0.05-0.4%; phase changing material tiny capsule 5.0-50.0%. the producing process adopts the said adjusting fiber material, the solicitation reagent is used to bring the second monomer and the existing possibly third monomer and the water phase deposit of the chain transferring reagent to converge in the phase changing material tiny capsule hanging chaotic liquid, the polymer produced form the action contains the said percentage of the phase changing material tiny capsule, the mixing hybrid of the acrylonitrile sharing material and the phase changing material tiny capsule is gained; the gained equal hybrid is cleaned by the secondary or thrice ion water and dried under the temperature of 45-95 degree, the filature is melted under the temperature of 10-40 degree above the melting point of the acrylonitrile gathering material in the screw extruding engine to produce the said adjusting temperature fiber. The said adjusting temperature fiber has many merits such as the good function of absorbing or releasing the heat energy, the high machine intension and the low cost.

Owner:TIANJIN POLYTECHNIC UNIV

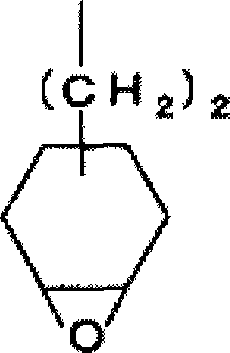

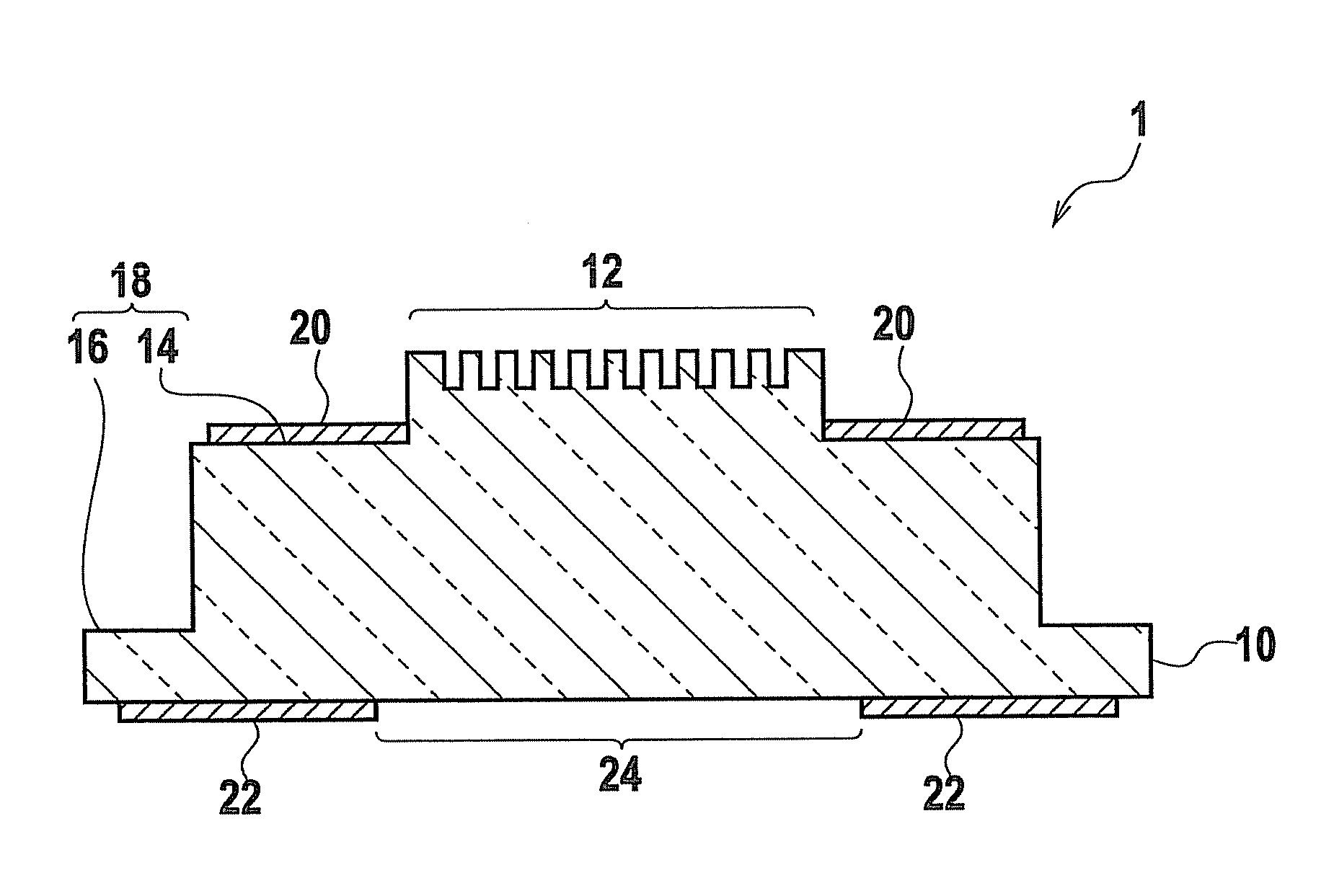

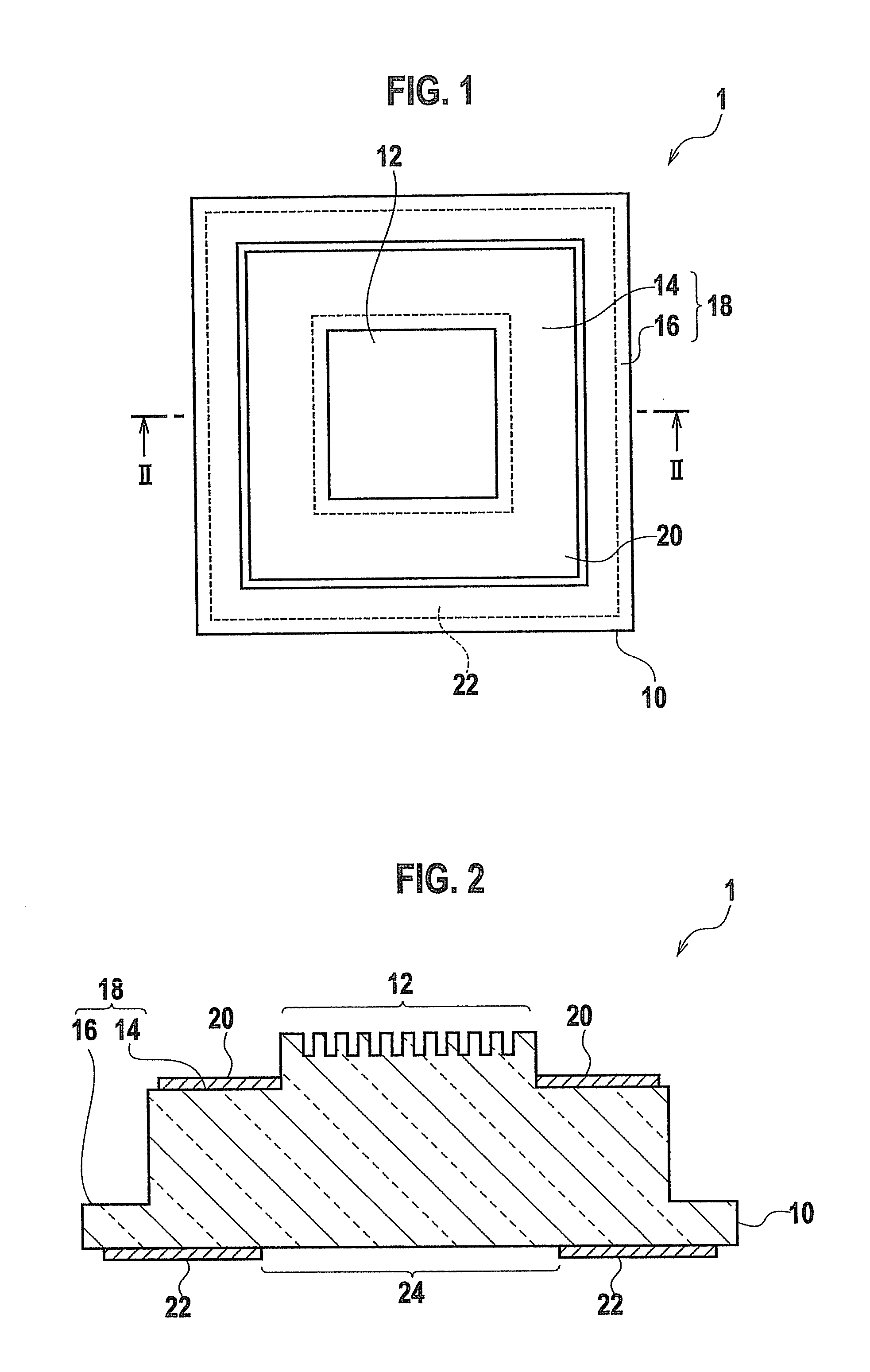

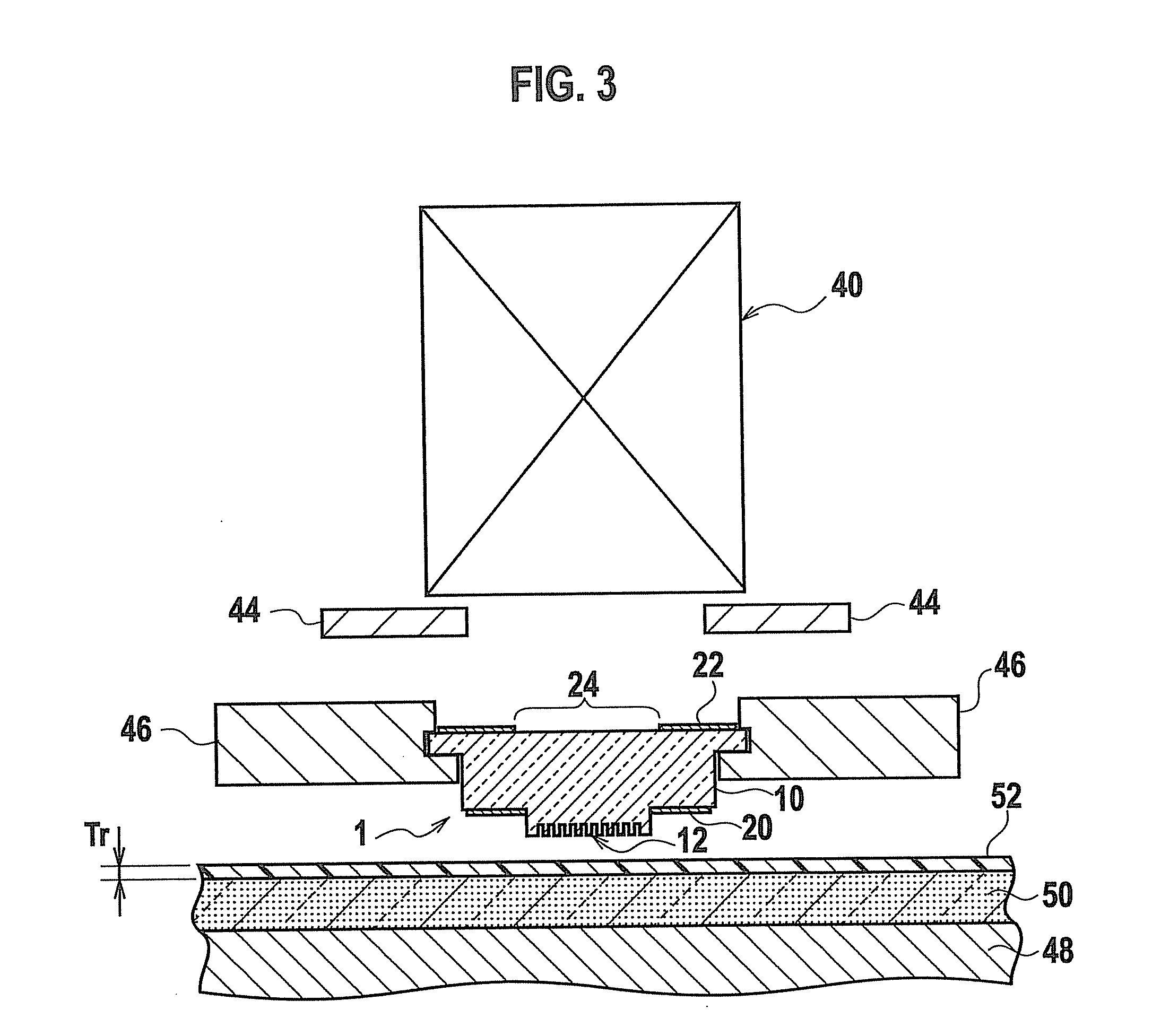

Imprint mold

An imprint mold including a substrate of transparent material having a first principal surface having a pattern region and a second principal surface; a first light shielding film provided on the first principal surface, along a periphery of the pattern region; and a second light shielding film provided on the second principal surface, having an opening including an opposite region to the pattern region, a part of the second light shielding film opposite to the first light shielding film. In a cross section perpendicular to the substrate, the maximum incident angle of the light for curing a transfer layer to the second principal surface is less than an angle between a perpendicular line of the second principal surface and a line connecting an end of the second light shielding film on a side of the opening and a farthest end of the first light shielding film from the pattern region.

Owner:DAI NIPPON PRINTING CO LTD

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

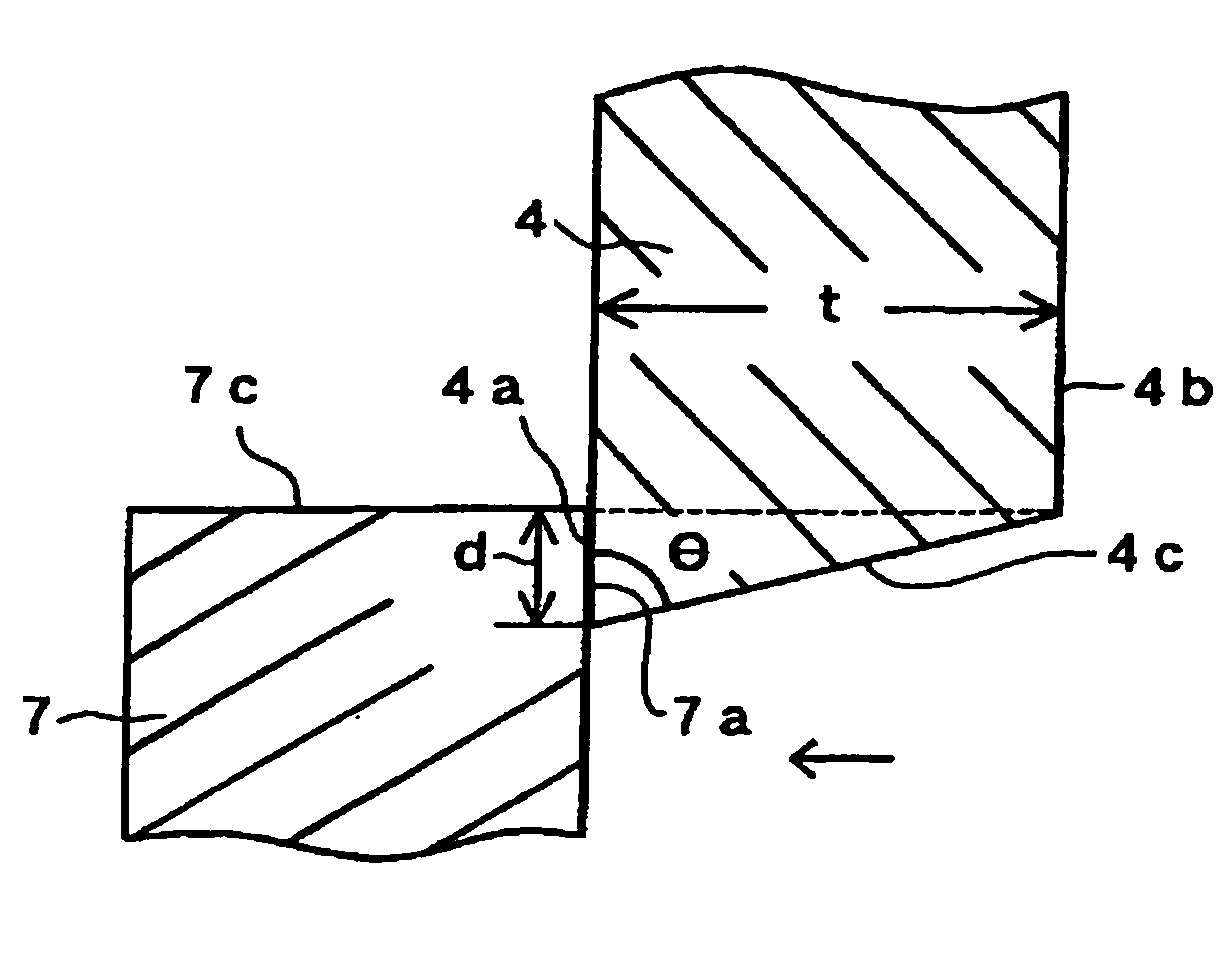

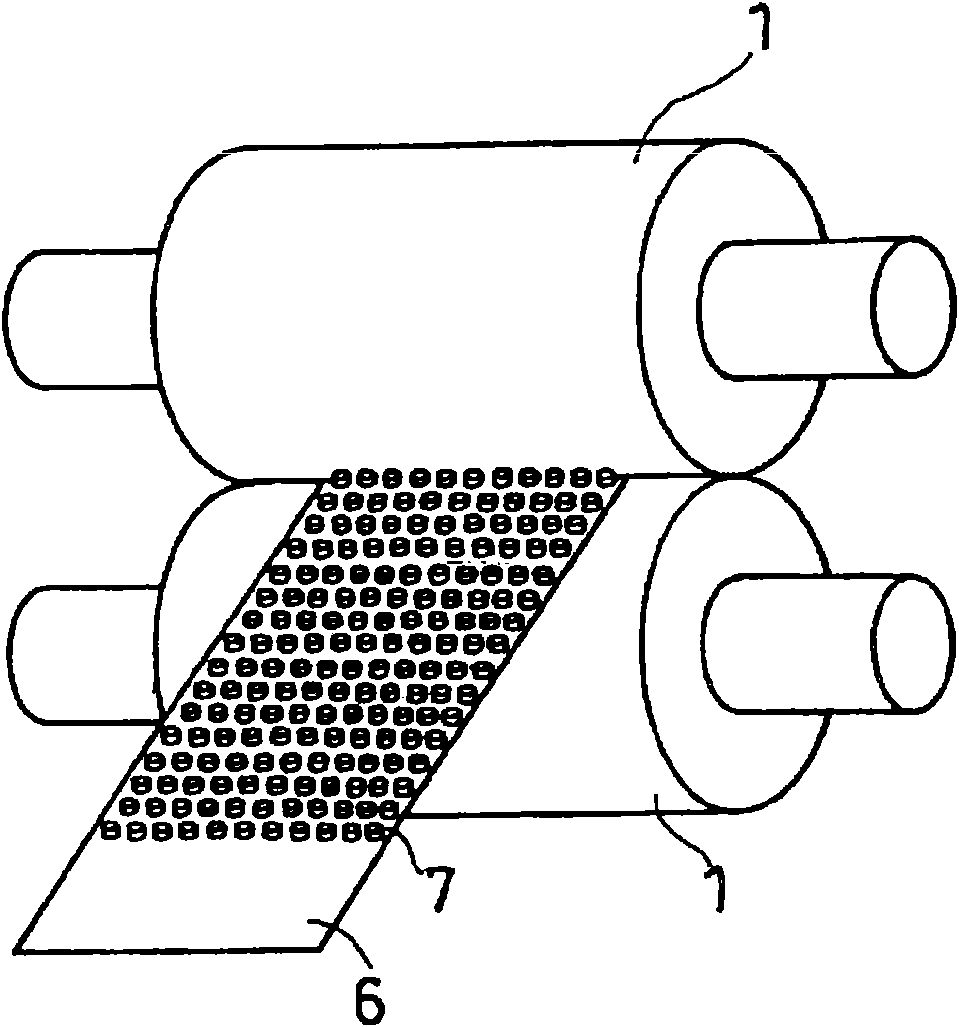

Slitter apparatus and production method of electrode

ActiveUS20060016308A1Inhibit productionAvoid stickingMilk preservationDough treatmentSurface roughnessEngineering

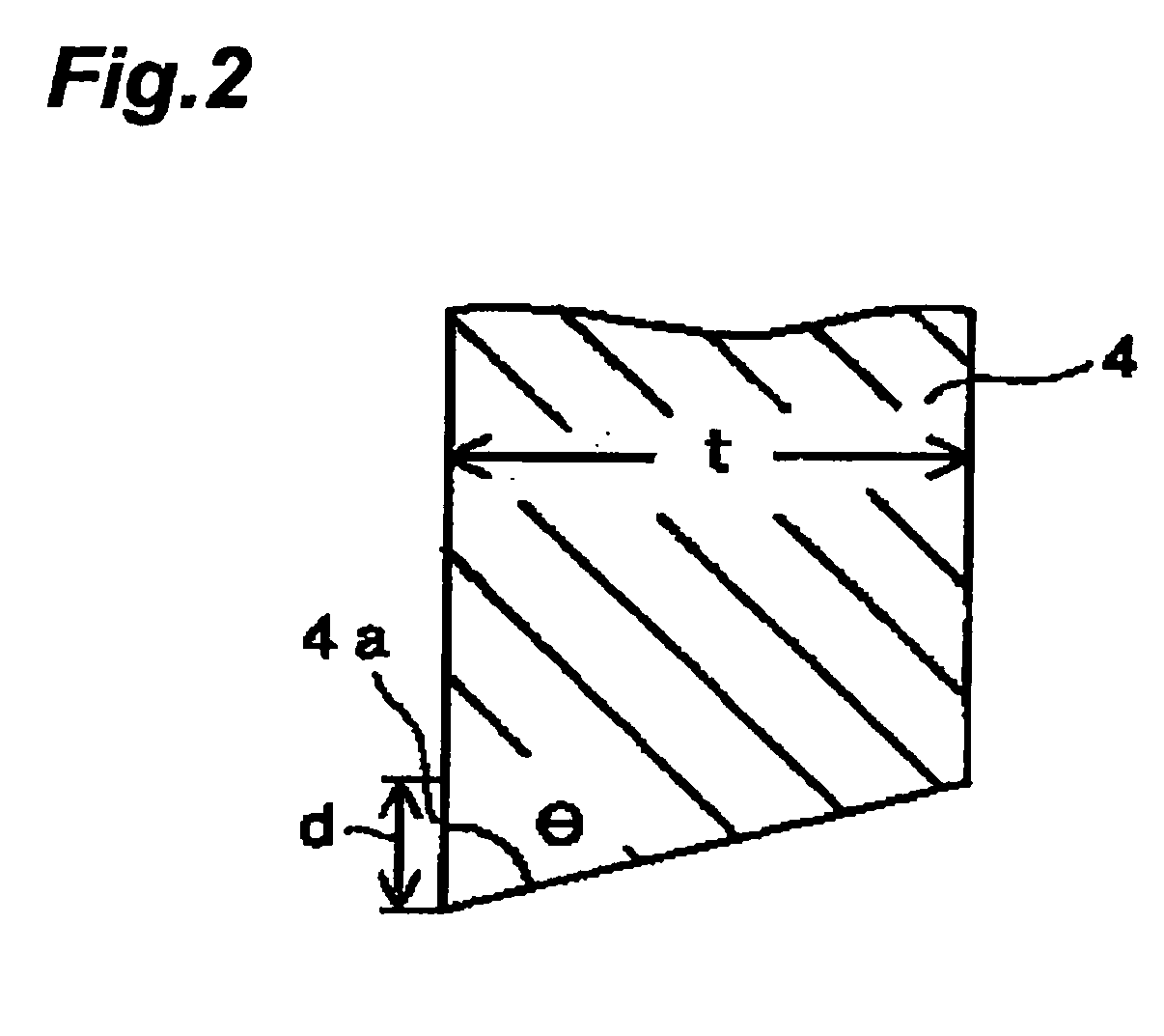

A slitter apparatus has a rotary shaft provided with one or more upper blades, and a rotary shaft provided with one or more lower blades, the rotary shafts being arranged in parallel with each other and at such a spacing as to achieve a predetermined engagement depth with contact between side face of peripheral part of upper blades and side face of peripheral part of lower blades, wherein a thickness of upper blades is not less than 1 mm, an included angle of upper blades is in a range of 75 to 88°, hardnesses of upper blades and lower blades are in a range of 6.9×103 to 8.8×103 N / mm2, a difference between the hardness of upper blades and the hardness of lower blades is not more than 4.9×102 N / mm2, surface roughnesses of upper blades and lower blades are not more than 4 μm, and a difference between the surface roughness of upper blades and the surface roughness of lower blades is not more than 2 μm.

Owner:TDK CORPARATION

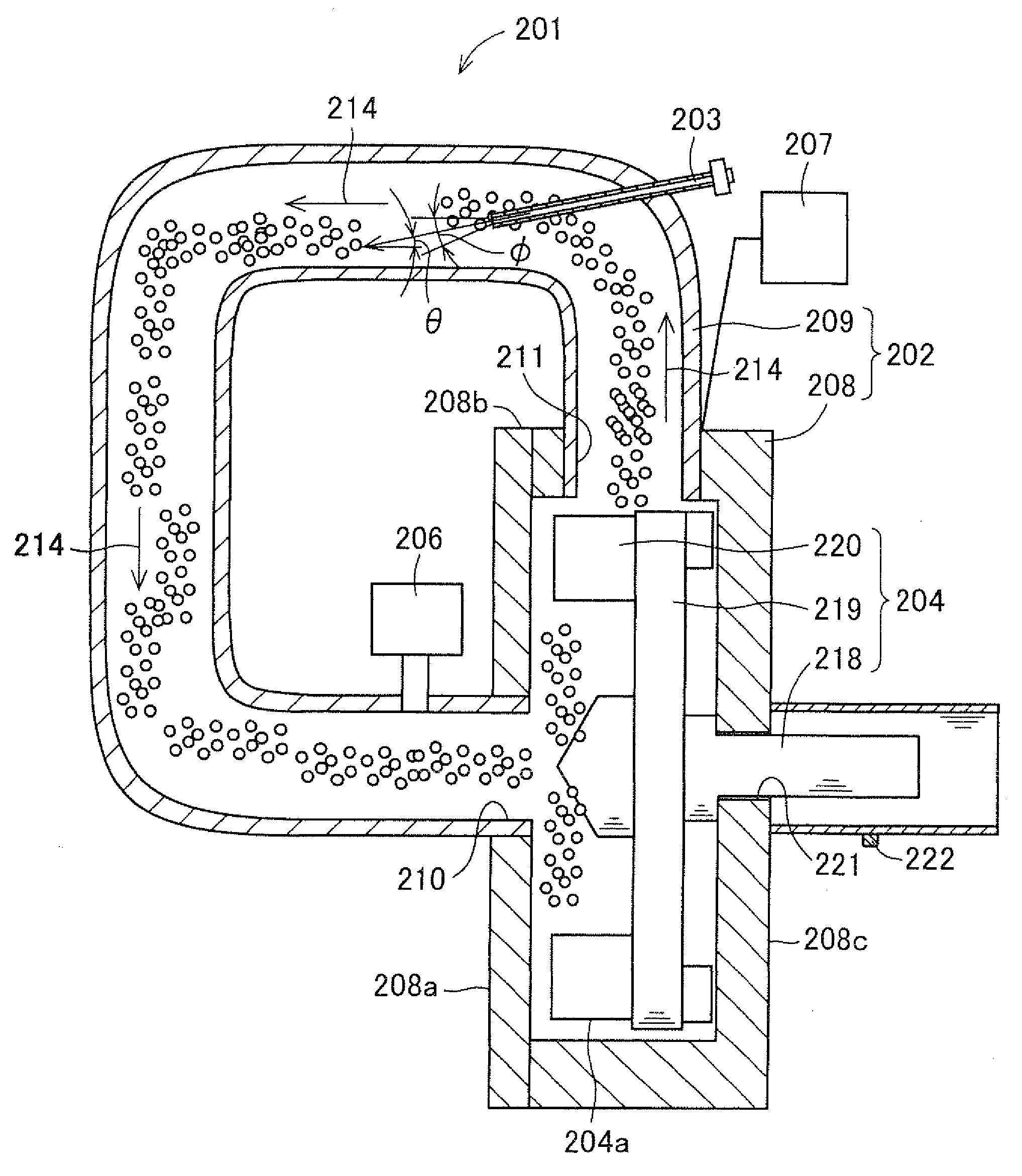

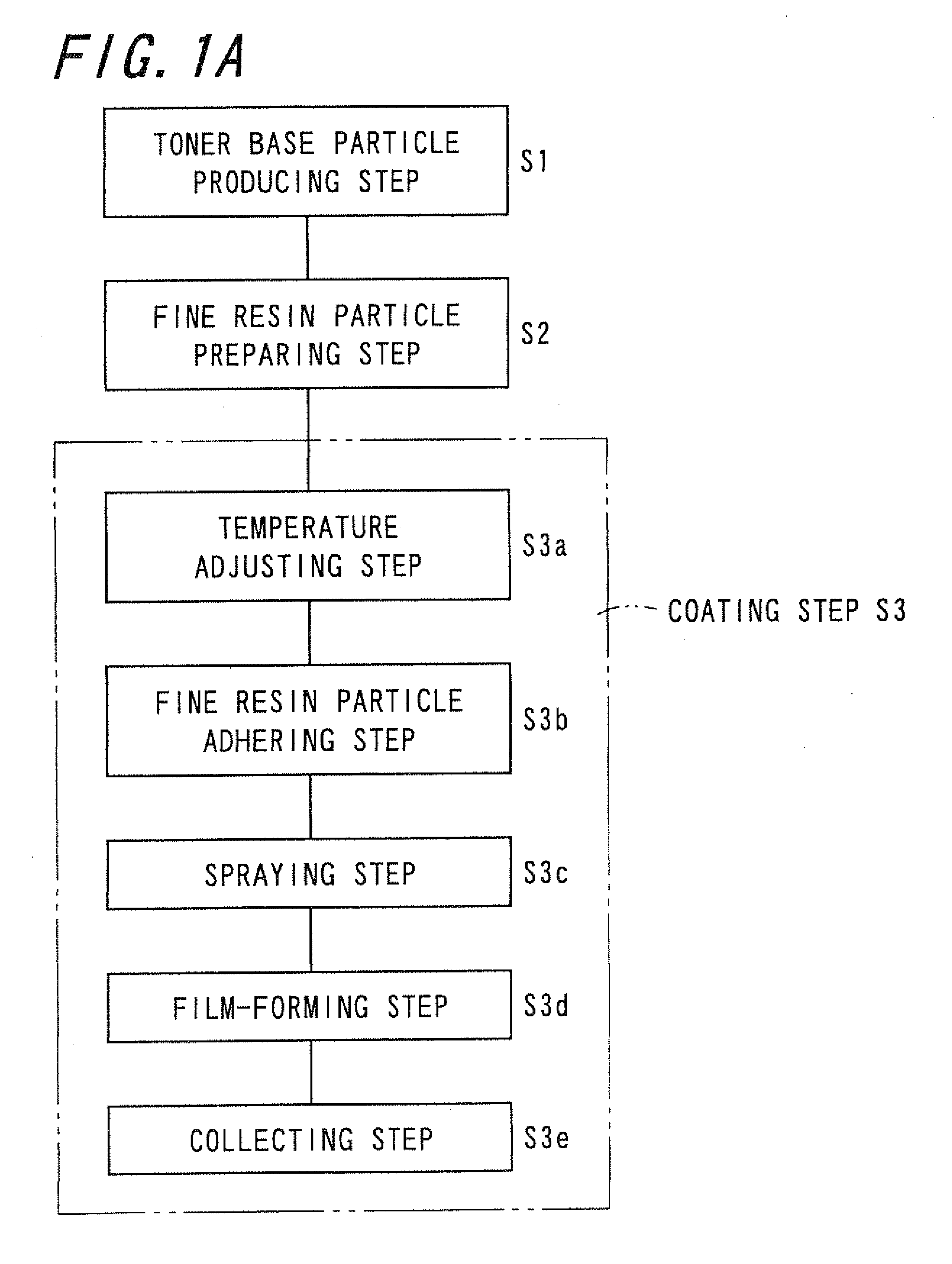

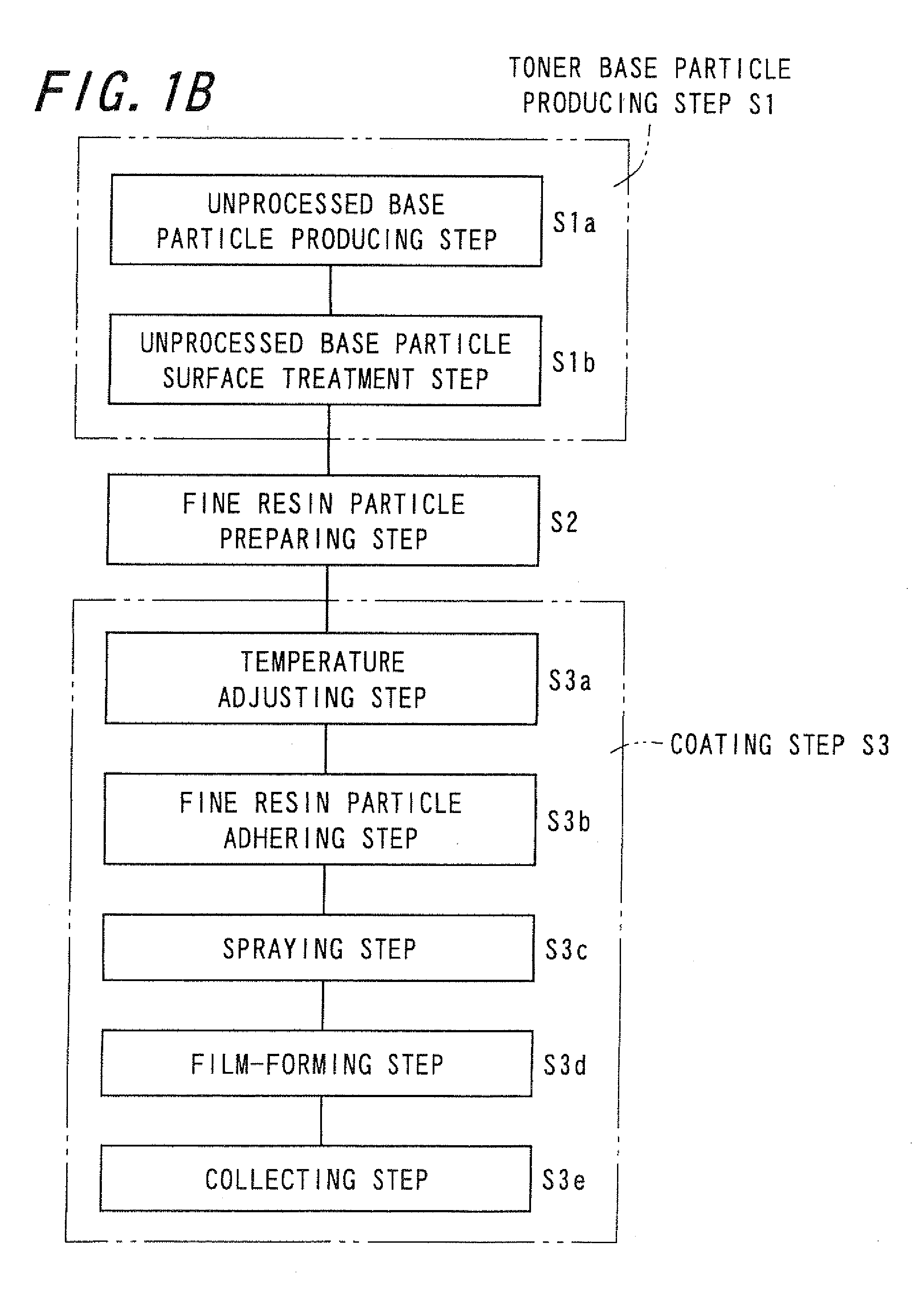

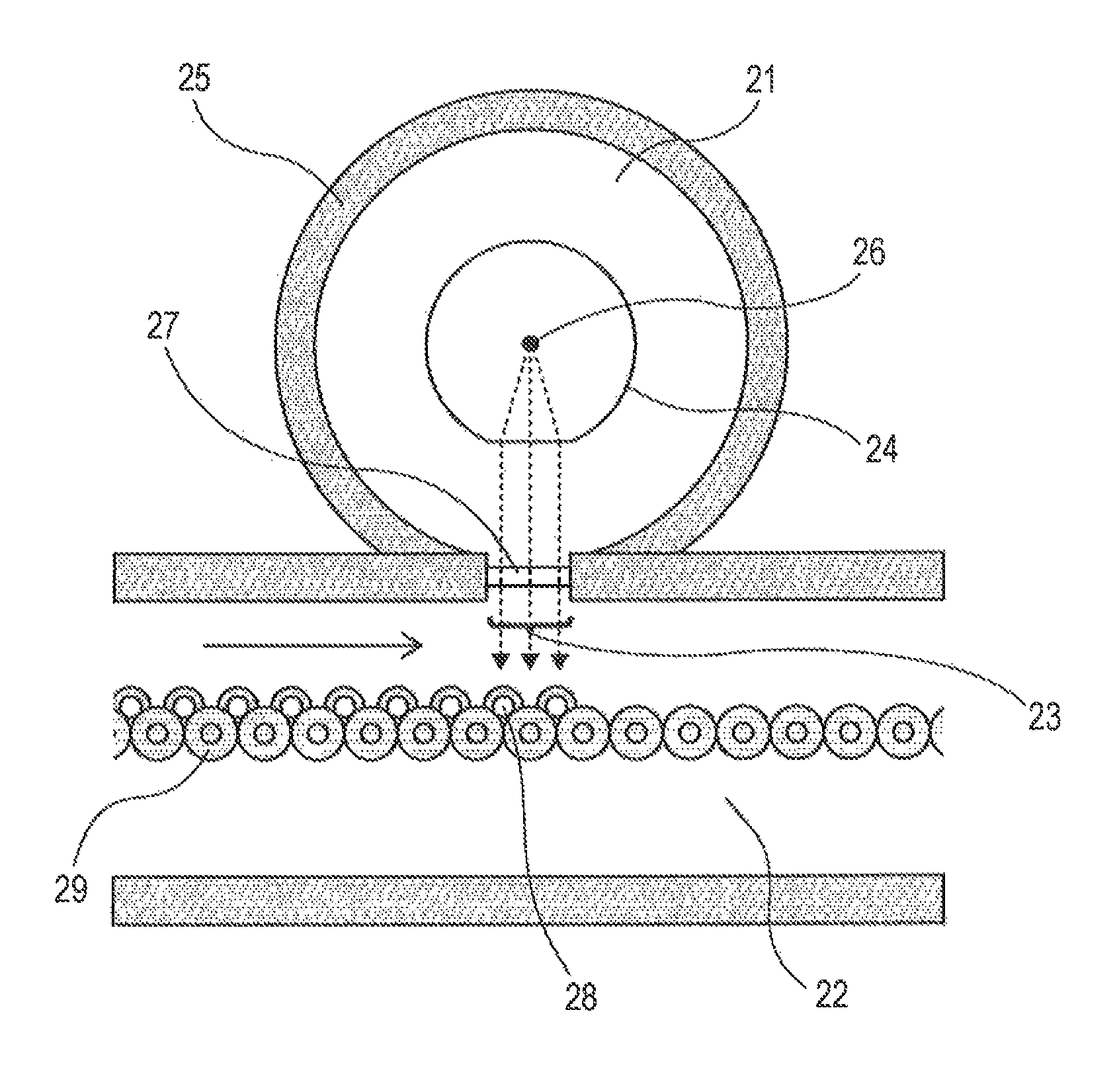

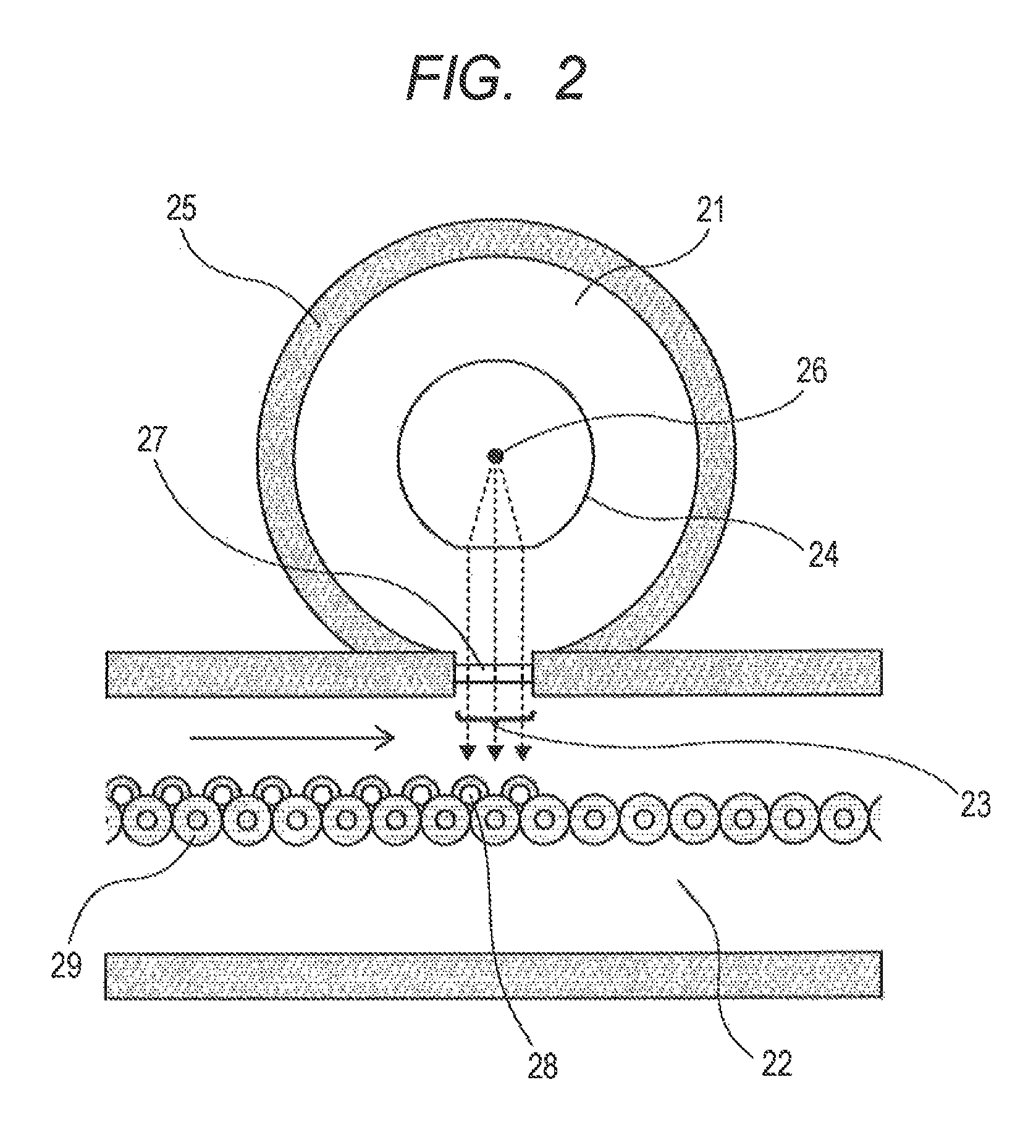

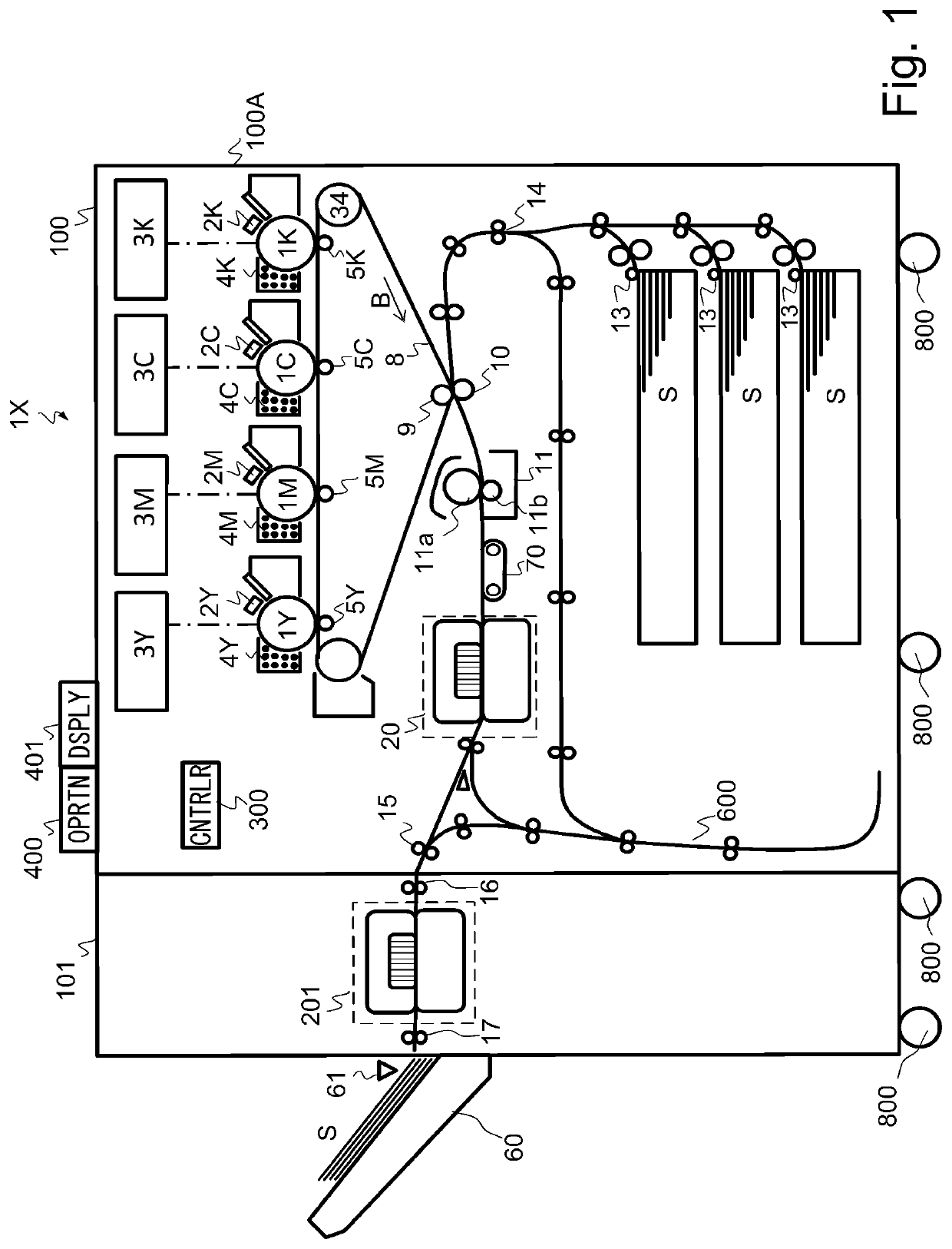

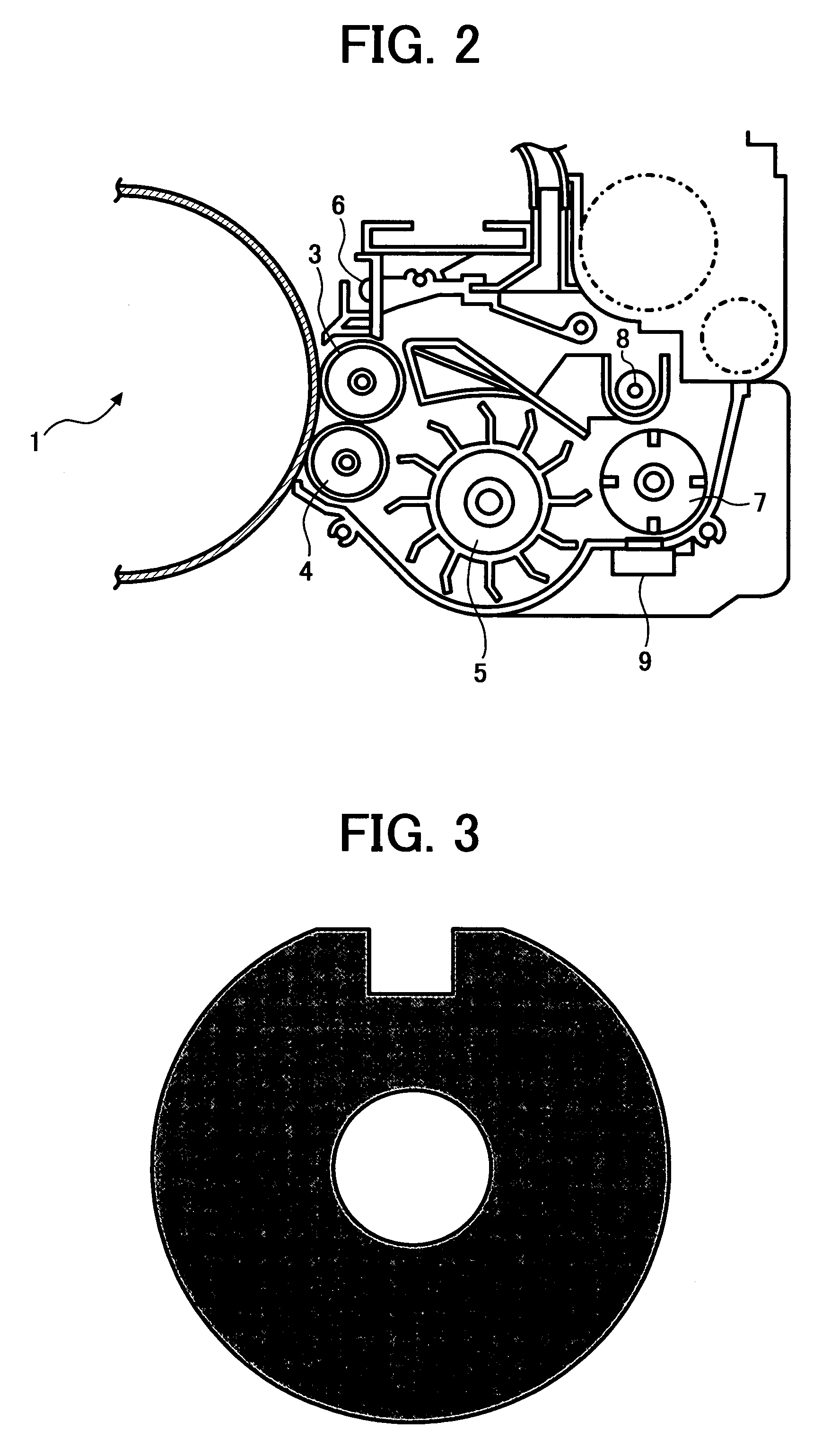

Method for manufacturing toner, toner, developer, developing device, and image forming apparatus

ActiveUS20090297224A1High definitionImage stabilizationElectrographic process apparatusDevelopersRotating discEngineering

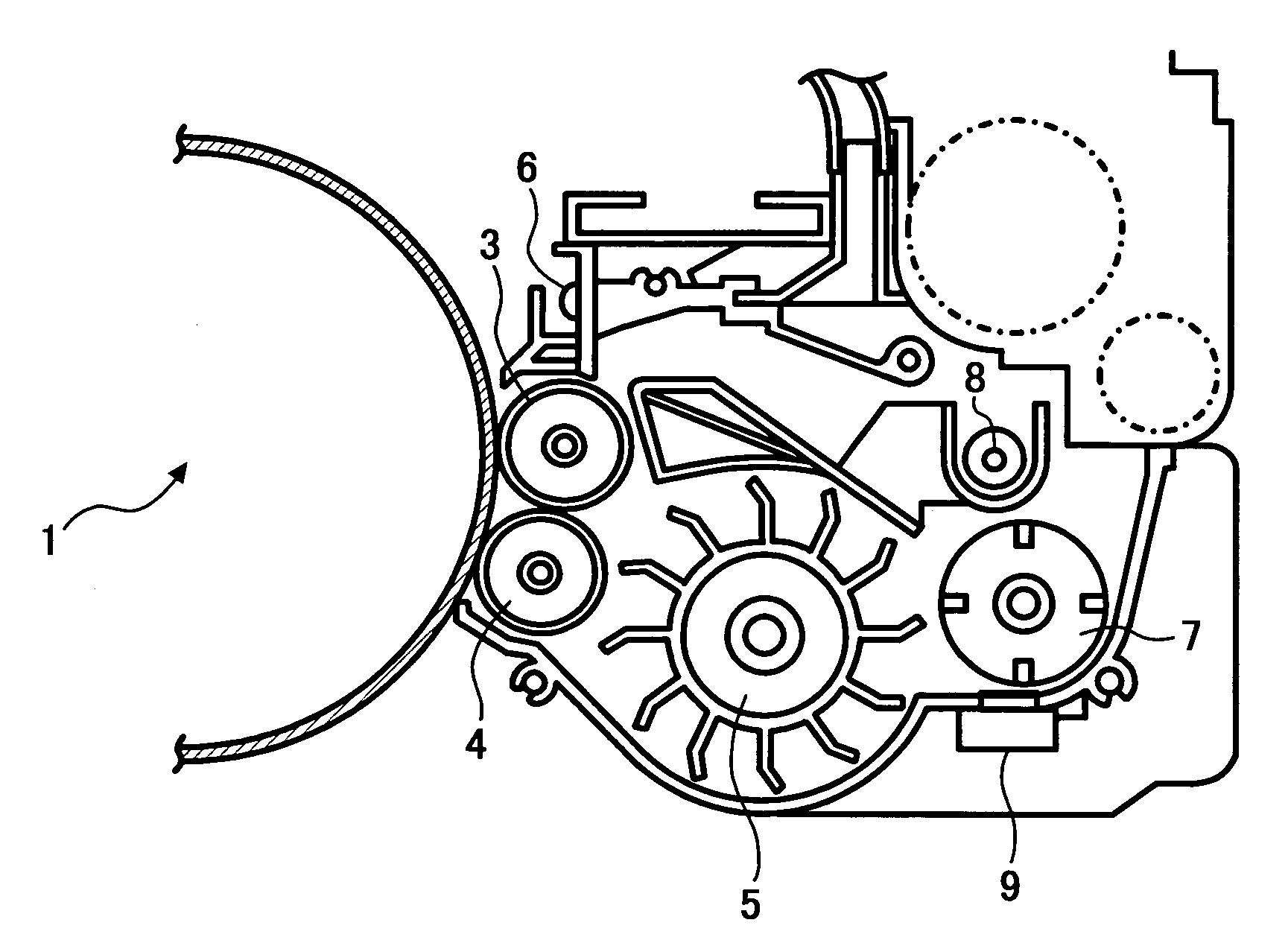

A method for manufacturing a toner is provided. The method for manufacturing a toner uses a rotary stirring apparatus that includes a circulating section for repeatedly performing circulation in a powder passage having a rotary stirring chamber and a circulation tube to return to the rotary stirring chamber by a rotary stirring section having a rotary disc around which rotary blades are installed and a rotary shaft, and a temperature adjusting section provided at least on a part of the powder passage for adjusting temperatures in the powder passage and of the rotary stirring section to a predetermined temperature, and includes a temperature adjusting step; a fine resin particle adhering step; a spraying step; and a film-forming step. The temperature in the powder passage is adjusted to the predetermined temperature by the temperature adjusting section at the fine resin particle adhering step, the spraying step, and the film-forming step.

Owner:SHARP KK

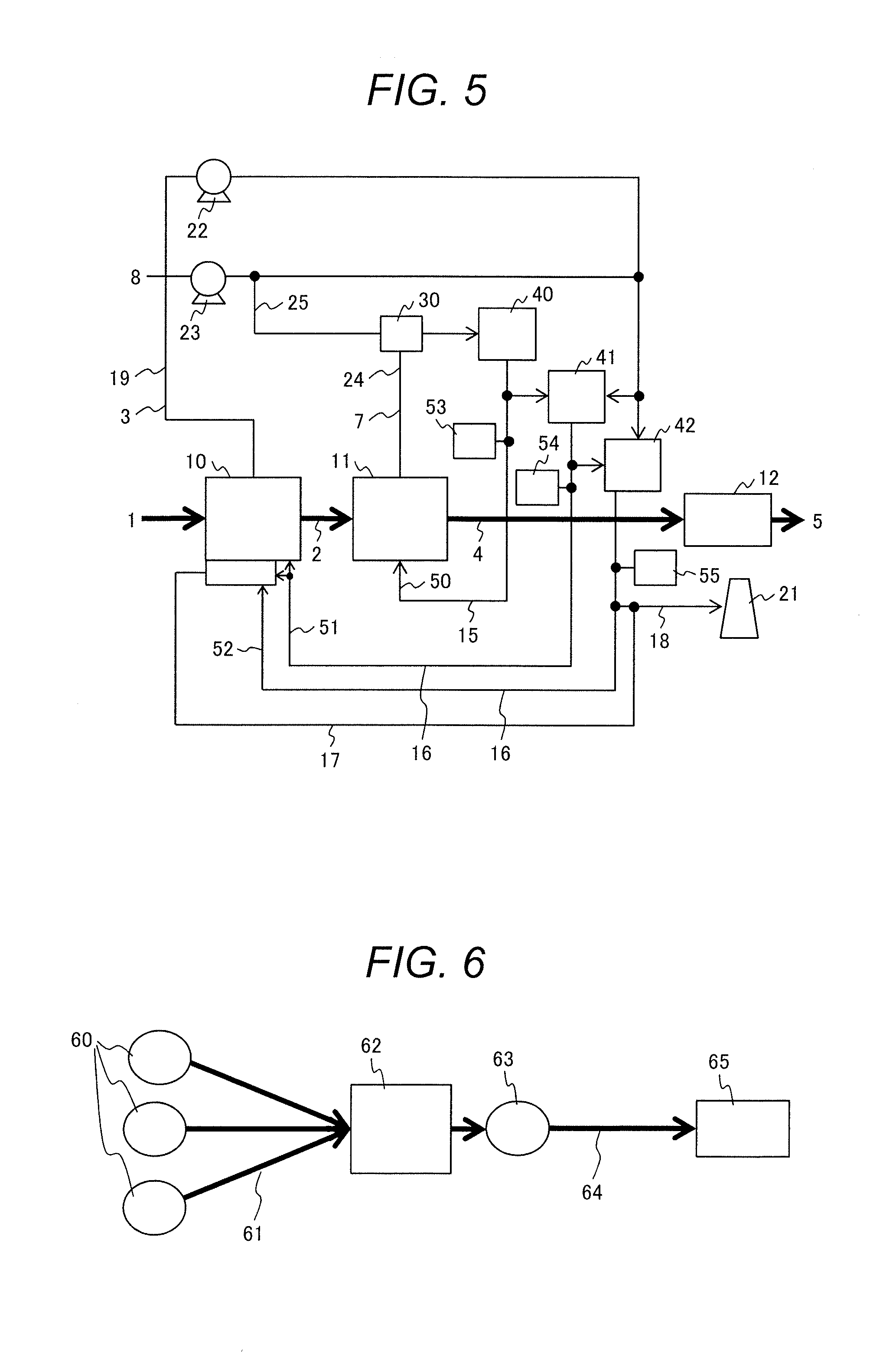

A license plate recognition method based on deep learning

ActiveCN109165643AInhibit adhesionInhibition of fractureCharacter and pattern recognitionNeural architecturesMinimum bounding rectangleLicense

The invention discloses a license plate recognition method based on deep learning, which comprises the following steps: step 1, training a deep convolutional neural network model M for license plate character detection; constructing a license plate character label set B; step 2, inputting the positioned license plate image I to a license plate character detection network M, and outputting a candidate license plate character set H; step 3, reordering the candidate license plate character set H obtained in the step 2 according to the abscissa hi.x of the upper left corner of the smallest circumscribed rectangle of the candidate license plate character from small to large to obtain a set C; step 4, further executing screening operation on the set C obtained in the step 3; step 6, sequentiallytraversing the set E obtained in the step 5; step 7, returning that license plate recognition result L obtained in the step 6. The method has the beneficial effects of effectively inhibiting the influence of license plate character adhesion, fracture, deformation, license plate dirt, license plate inclination, residual shadow on the license plate and the like.

Owner:ZHEJIANG UNIV OF TECH

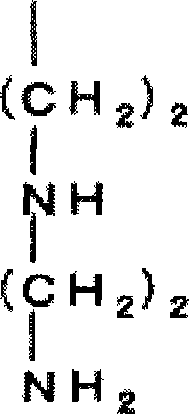

Charging member, manufacturing method for charging member, electrophotographic apparatus, and process cartridge

ActiveUS9372429B2Inhibit adhesionSuppressing generation of a C set imageElectrographic process apparatusEnergy based chemical/physical/physico-chemical processesSurface layerYoung's modulus

Owner:CANON KK

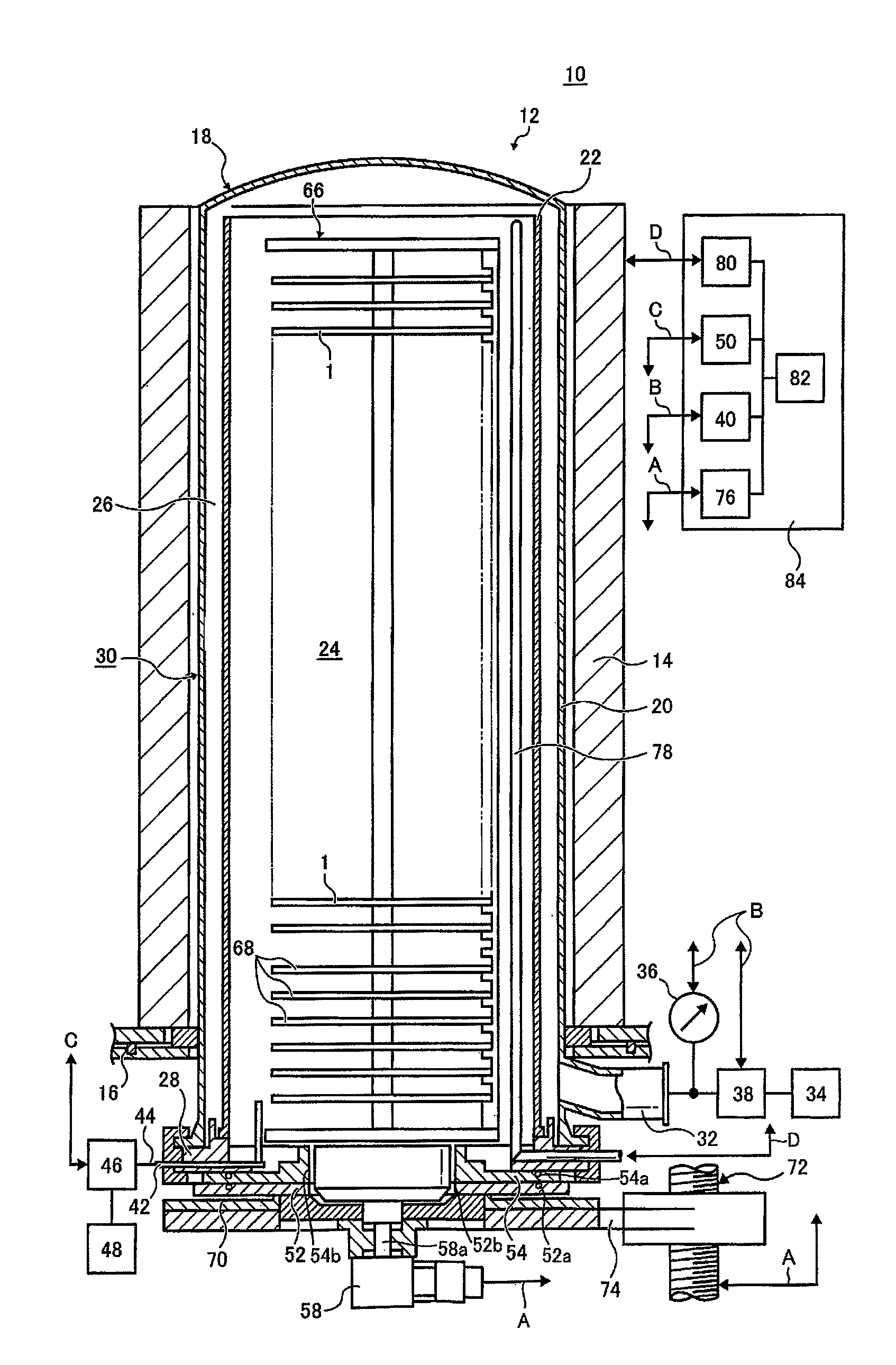

Substrate processing apparatus and method of manufacturing semiconductor device

ActiveUS8076615B2Suppressing metal contaminationSuppressing collapse of an inner tubeDrying solid materials with heatMuffle furnacesDevice materialEngineering

Owner:KOKUSA ELECTRIC CO LTD

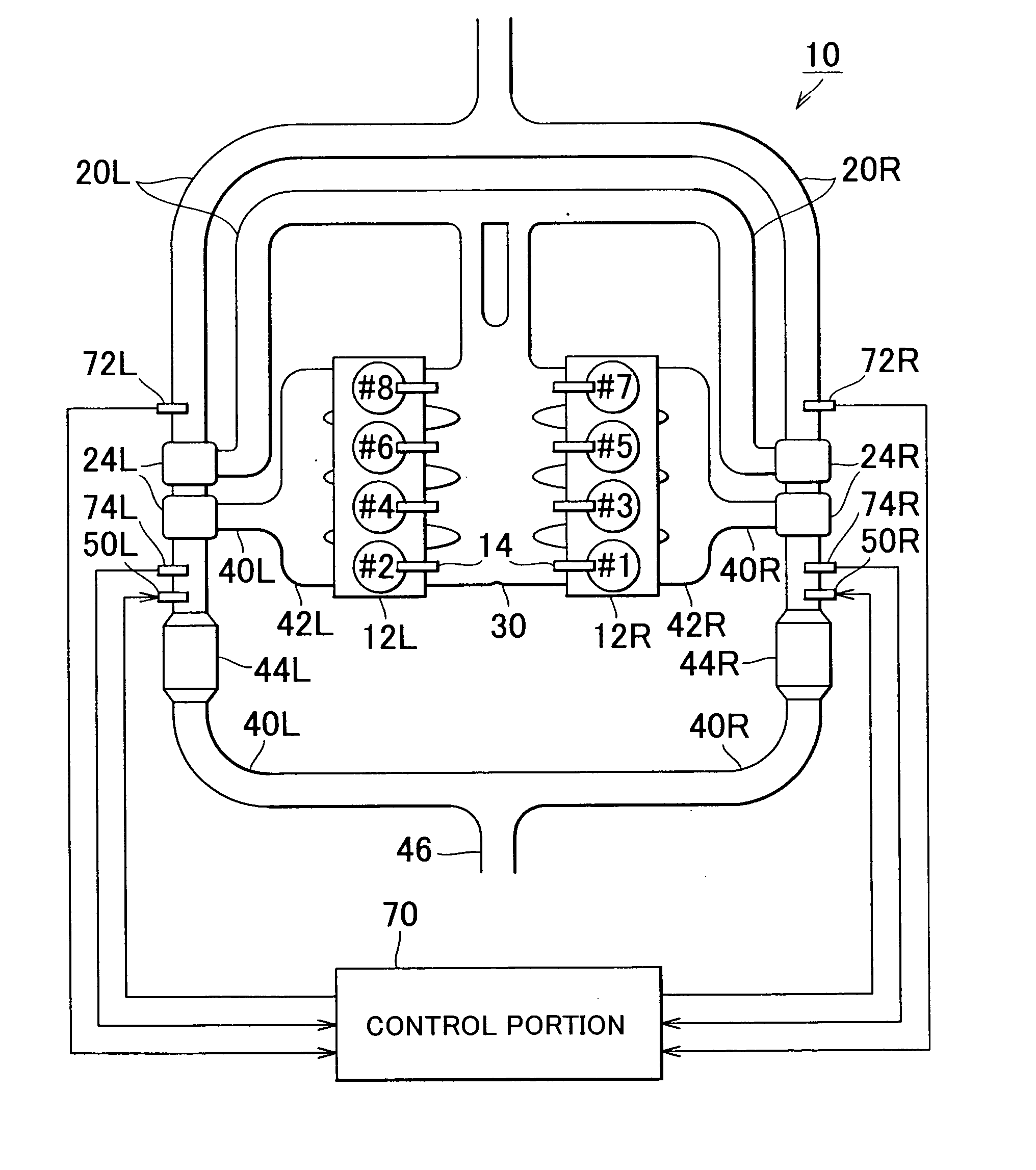

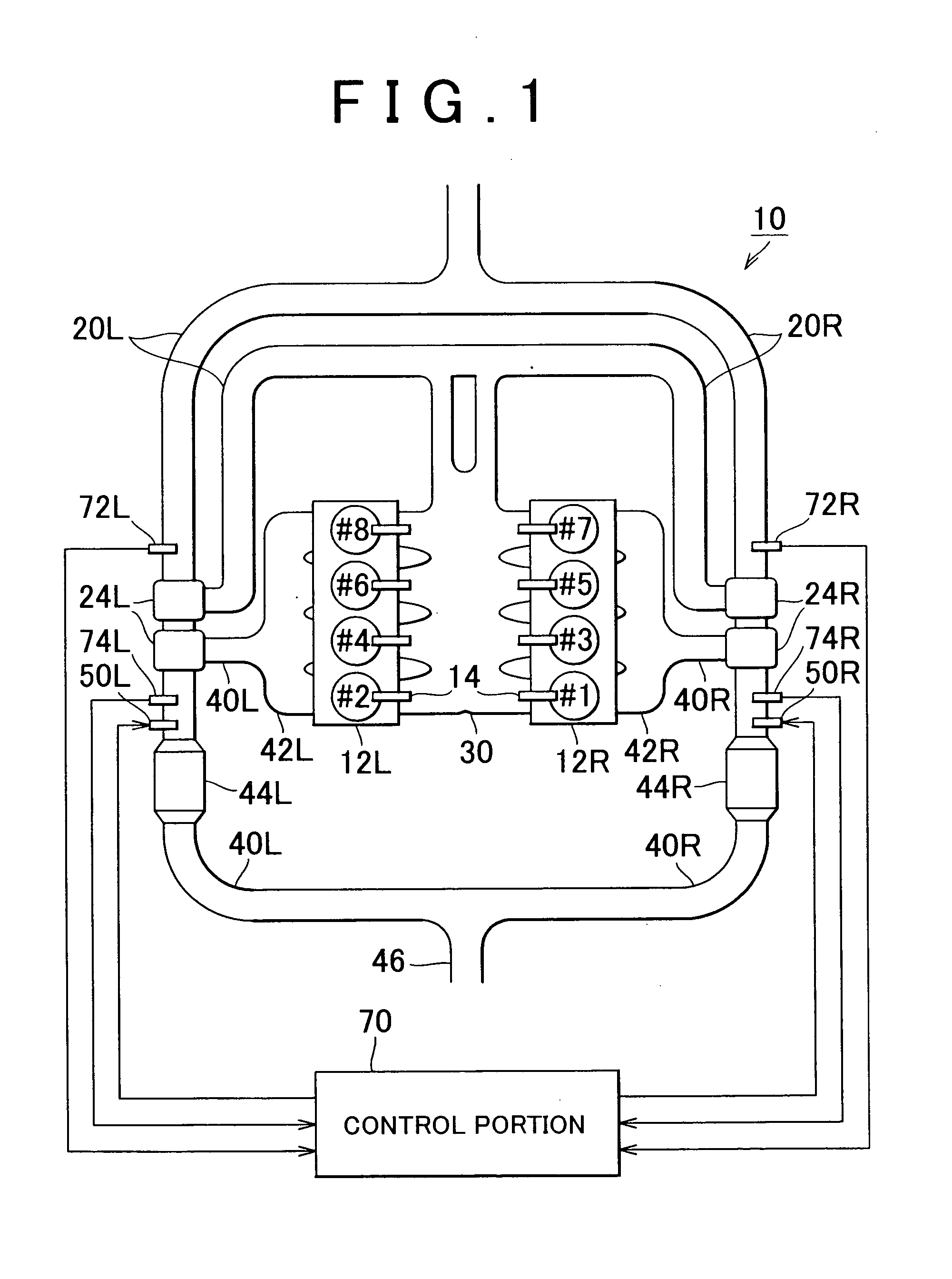

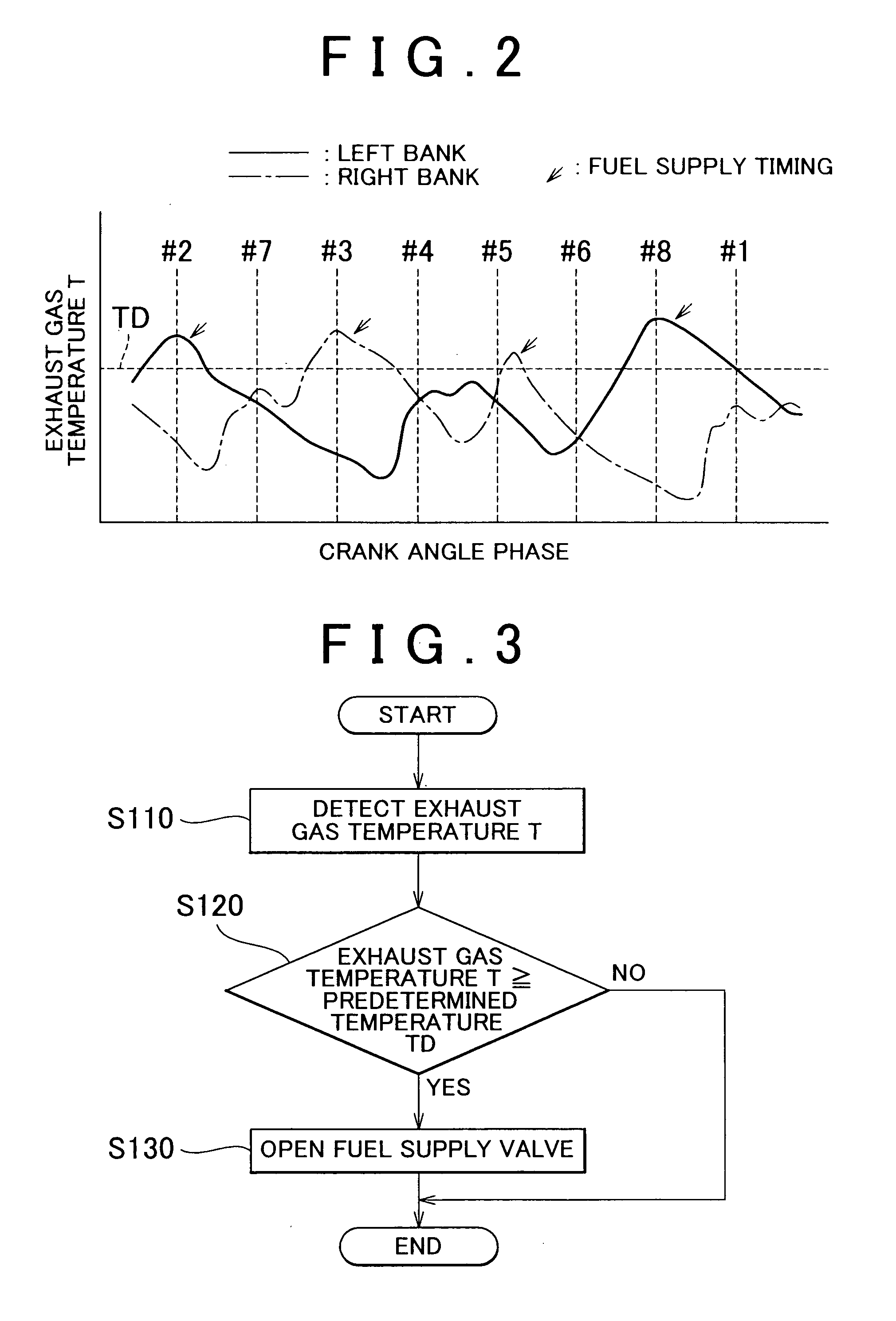

Exhaust gas control apparatus and exhaust gas control method for internal combustion engine

InactiveUS20050274106A1Appropriate flowInhibit adhesionElectrical controlPiston ringsExhaust fumesInternal combustion engine

In an exhaust gas control apparatus and exhaust gas control method for an internal combustion engine, in which fuel is supplied to a purification mechanism provided in an exhaust passage so that a function of the purification mechanism is recovered. A flow rate of exhaust gas flowing in the exhaust passage or a value correlated with the flow rate is detected, and fuel supply timing is controlled based on a result of the detection. Accordingly, even when the flow rate of the exhaust gas flowing in the exhaust passage is variously changed based on the engine operating state, the fuel supply timing can be set based on the flow rate that is appropriately detected. Thus, it is possible to appropriately convey the supplied fuel to the purification mechanism using force of the exhaust gas.

Owner:TOYOTA JIDOSHA KK +1

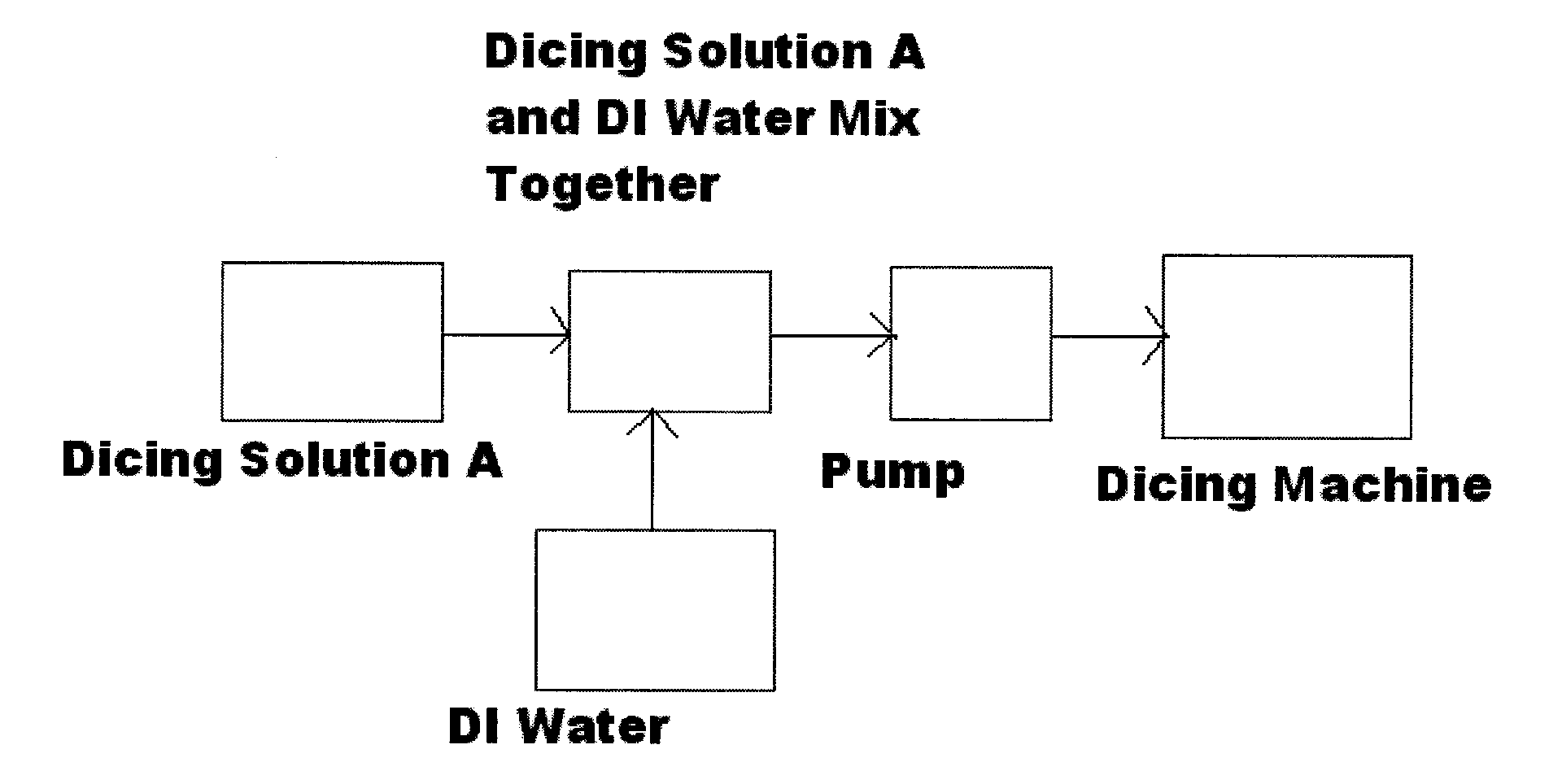

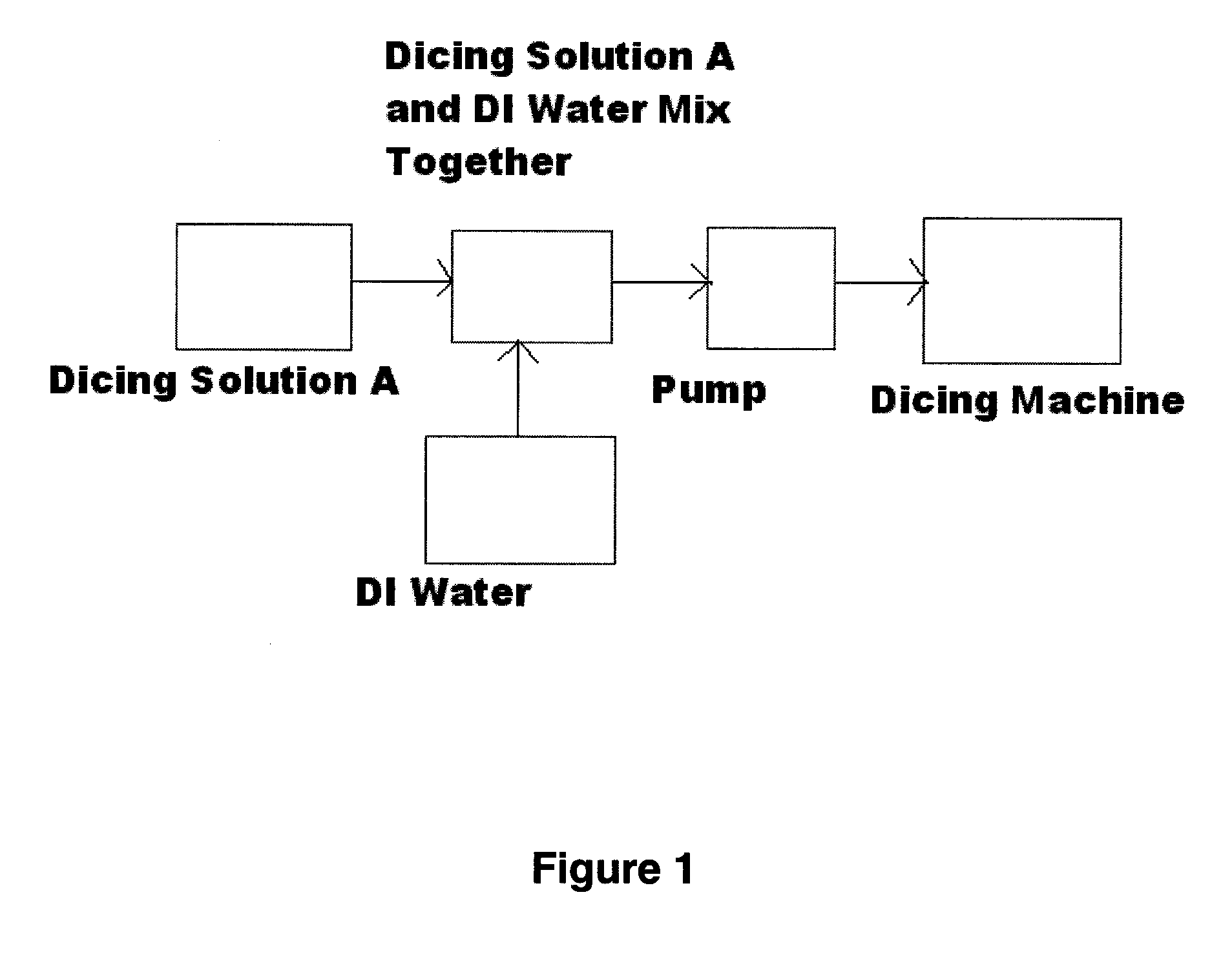

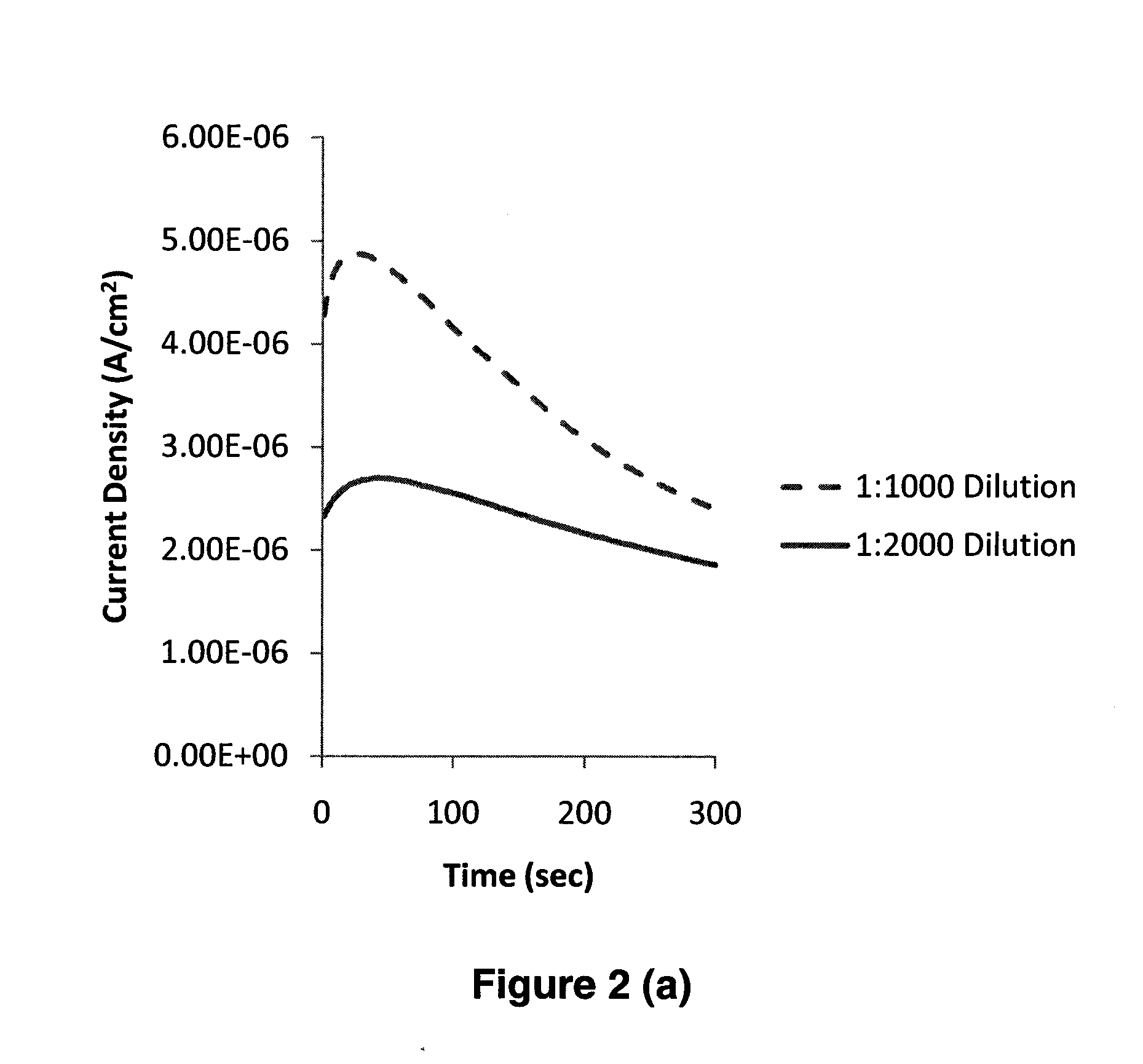

Method for Wafer Dicing and Composition Useful Thereof

ActiveUS20120009762A1Inhibit adhesionAvoid stickingOrganic detergent compounding agentsOther chemical processesIonOrganic acid

A solution for semiconductor wafer dicing is disclosed. The solution suppresses the adherence of contamination residues or particles, and reduces or eliminates the corrosion of the exposed metallization areas, during the process of dicing a wafer by sawing. The solution comprises at least one organic acid and / or salt thereof; at least a surfactant and / or at least a base; and deionized water, the composition has a pH is equal or greater than 4. The solution can further comprise, a chelating agent, a defoaming agent, or a dispersing agent.

Owner:VERSUM MATERIALS US LLC

Medicine for treating osteoarthrosis caused by wind, cold and damp and its prepn

InactiveCN101066348AInhibit adhesionRecovery functionAnthropod material medical ingredientsAntipyreticDiseaseSciatica

The present invention relates to one kind of externally applied plaster for treating osteoarthrosis caused by wind, cold and damp. The plaster is prepared with clematis root, spatholubus stem, yam rhizome, large-leaf gentian root, ledebouriella root and other Chinese medicinal materials, and through alcohol extraction to obtain extracted solution, adding matrix and other steps. It has the functions of relaxing muscles and tendons, promoting blood circulation, dispersing blood clots, dispelling cold, eliminating wind and damp, etc. It is used in treating arthritis, protrusion of cervical intervertebral disc, protrusion of lumbar intervertebral disc, spur, sciatica, etc. and has high curative effect.

Owner:钱智

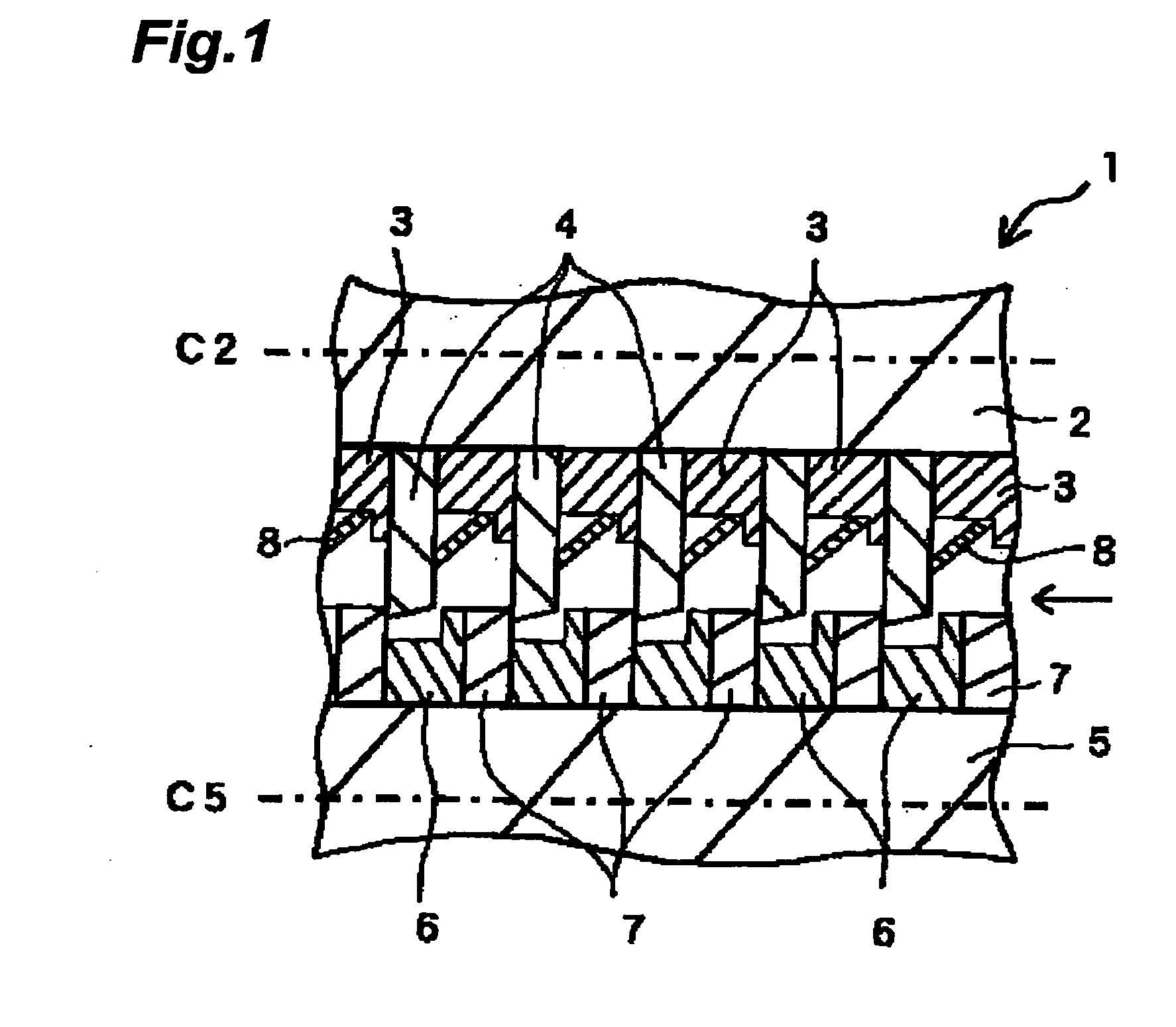

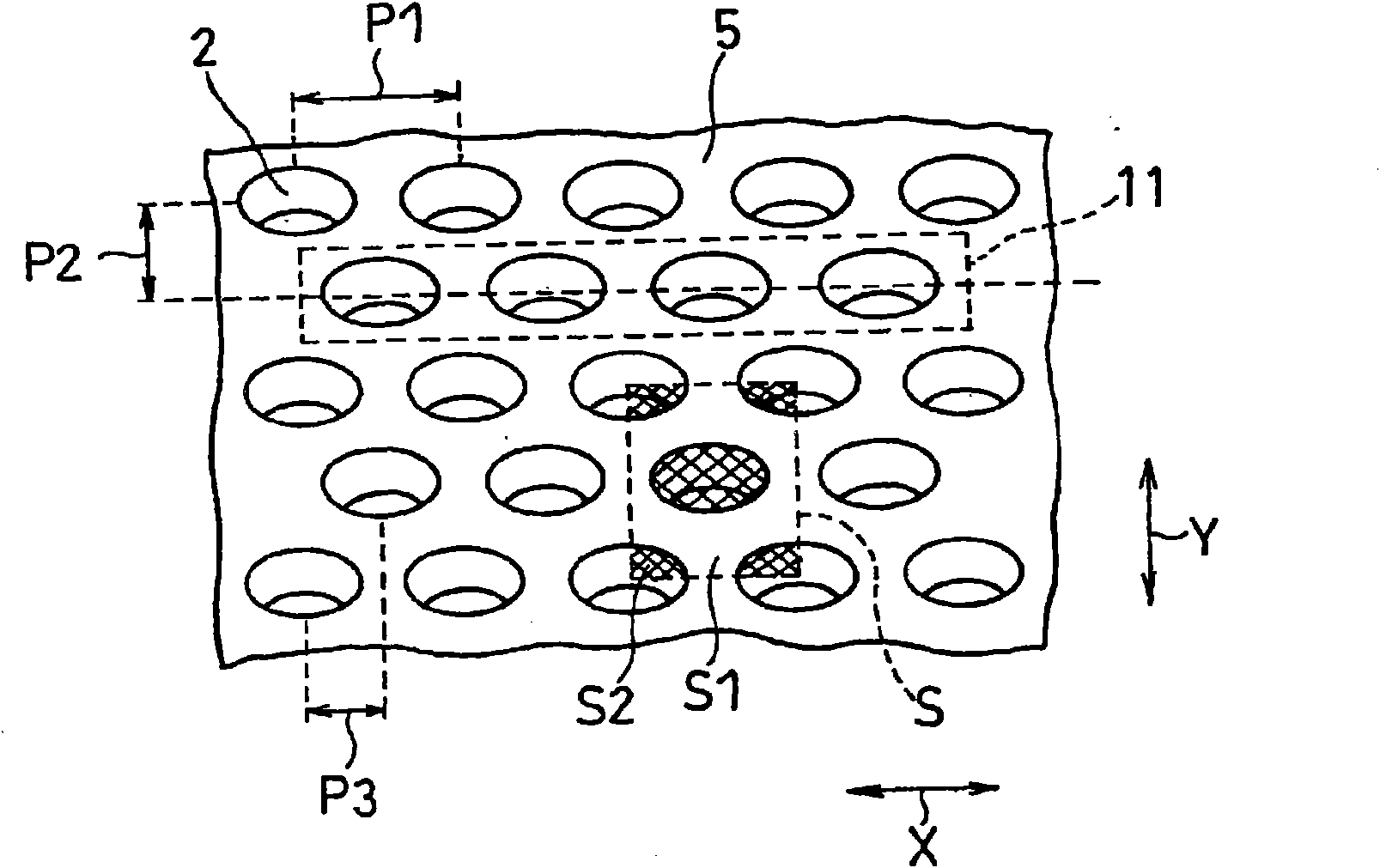

Battery current collector, its manufacturing method, and nonaqueous secondary battery

InactiveCN101652886AInhibit adhesionElectrode manufacturing processesElectrode carriers/collectorsMetal foilSurface roughness

Provided is a battery current collector made of a metal foil and carrying at least an active substance for an anode or an active substance for a cathode. On at least one face of the metal foil, a compressed base face is formed, and incompressive protrusions are formed, accordingly as the base face is formed, and are arranged at a predetermined spacing. The base face has its surface roughness madedifferent from that of the protrusions and set preferably to an arithmetic average roughness of 0.8 ¢mu!m or less.

Owner:PANASONIC CORP

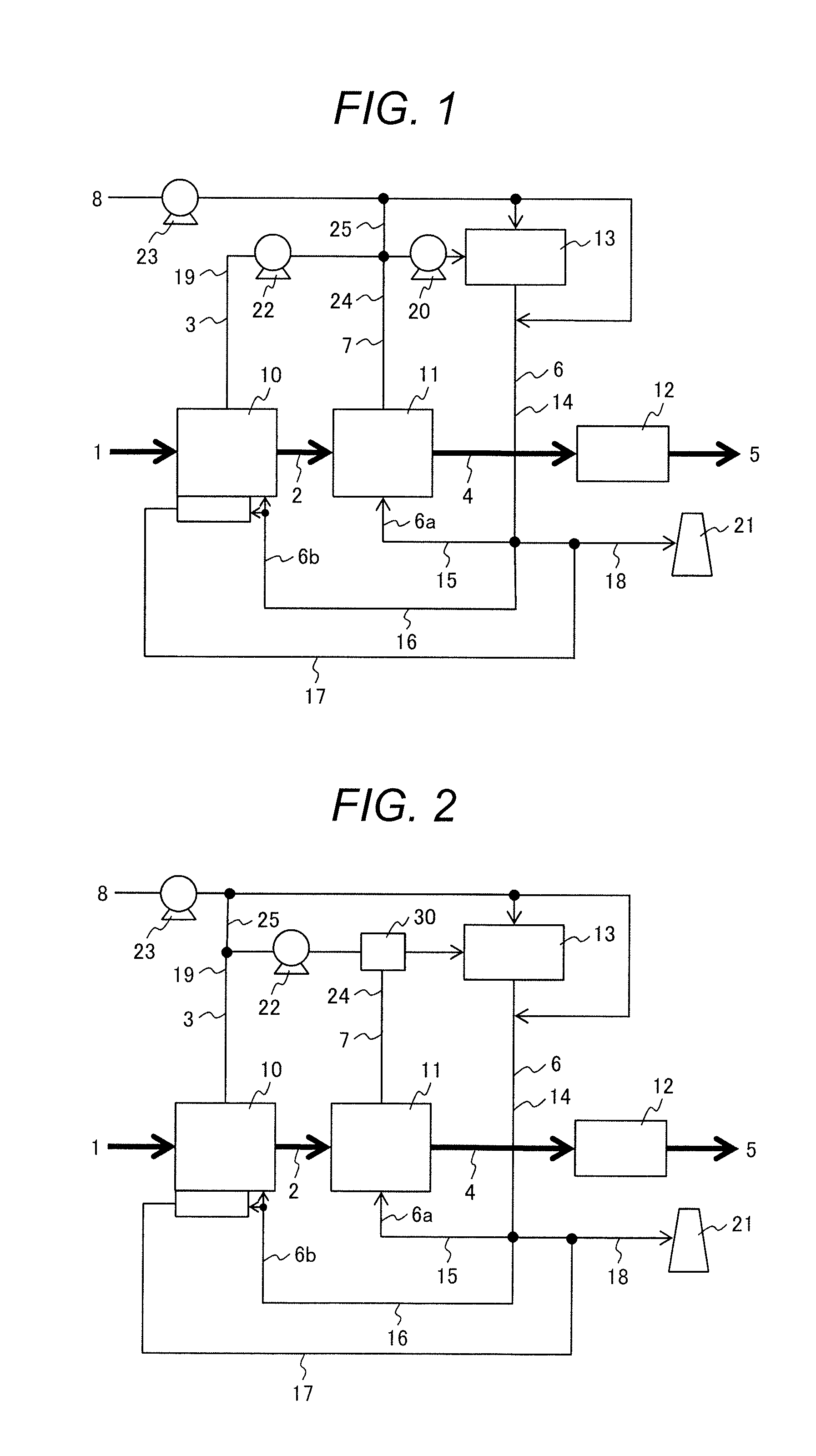

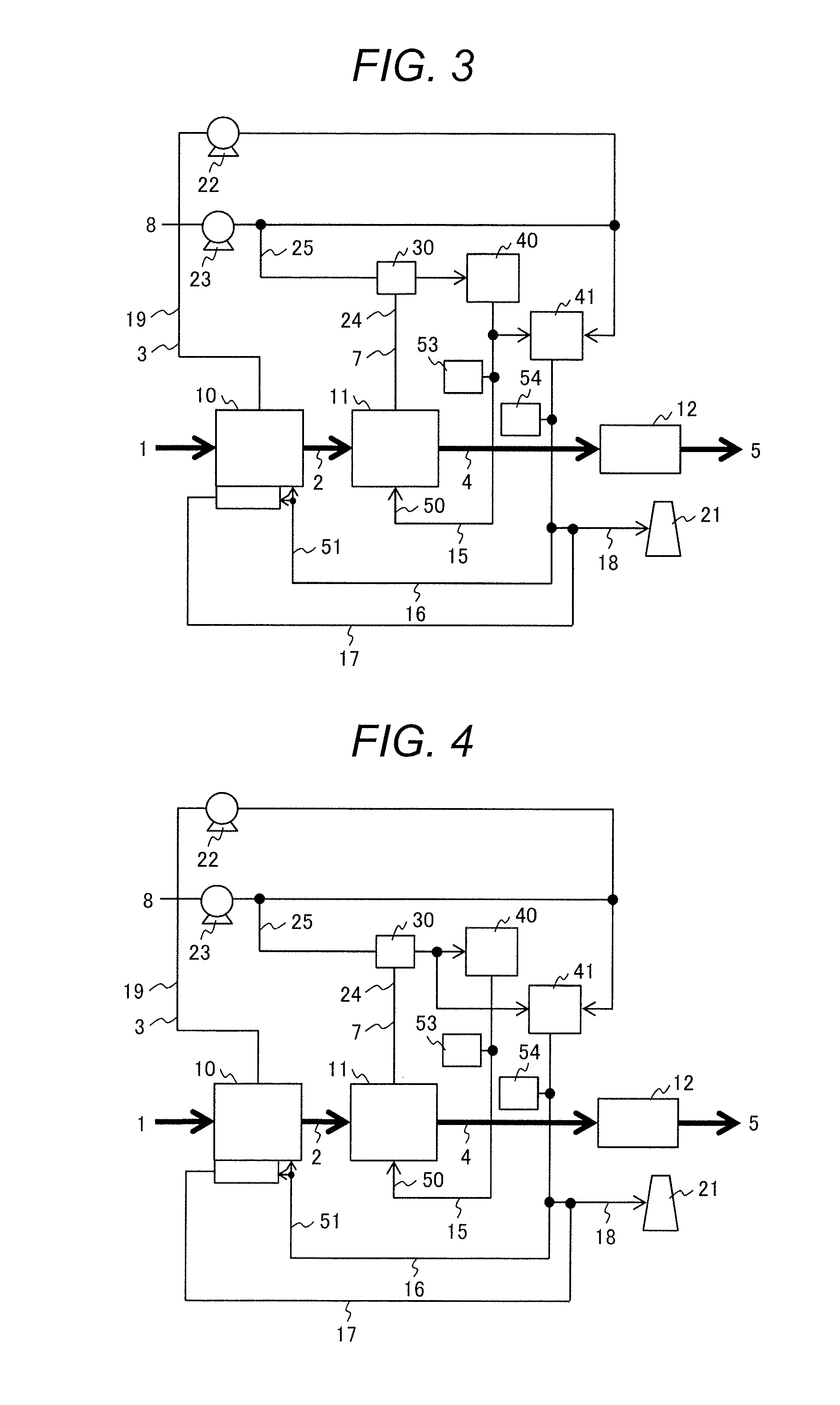

Device and Method for Manufacturing Semi-Carbonized Fuel of Biomass, and Power Generation System Using Semi-Carbonized Fuel

ActiveUS20140026791A1Inhibit adhesionImprove scaleDirect heating destructive distillationBiofuelsCombustionExhaust fumes

Provided are a device and a method for manufacturing a semi-carbonized fuel of a biomass that does not require an external heat source and is capable of suppressing adhesion of tar, condensed water, or the like to a pipe. The device includes a drying device for heating and drying a biomass, a pyrolysis device for decomposing the dried biomass, and a combustion device for supplying heat to the drying device and the pyrolysis device. The pyrolysis device is supplied with a part of a combustion exhaust gas generated in the combustion device, directly mixes the supplied combustion exhaust gas and the biomass to heat and pyrolytically decompose the biomass, and supplies a mixed gas of a generated pyrolysis gas and the combustion exhaust gas to the combustion device. The combustion device is supplied with an air for combustion, combust the supplied mixed gas, and generate the combustion exhaust gas.

Owner:MITSUBISHI POWER LTD

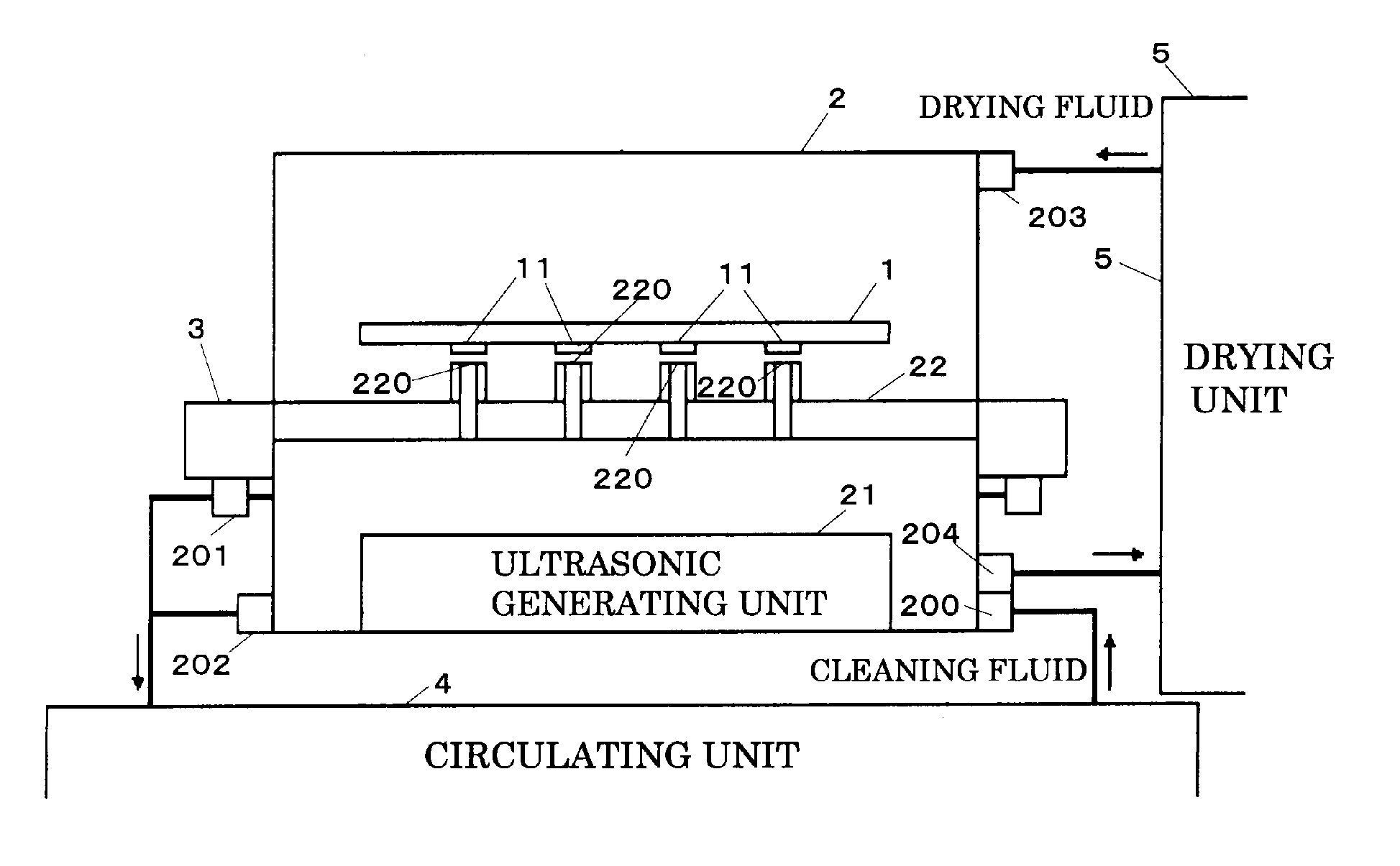

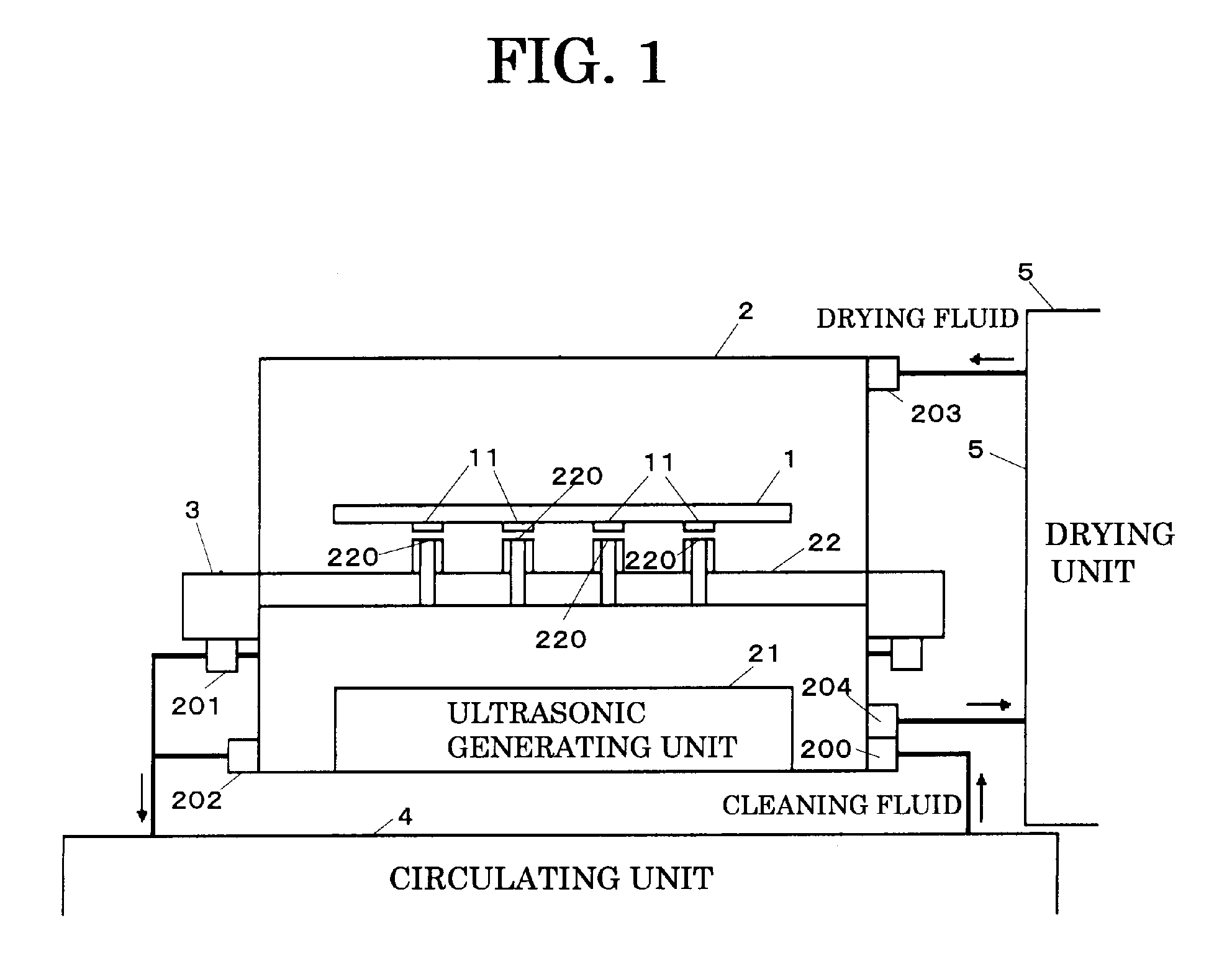

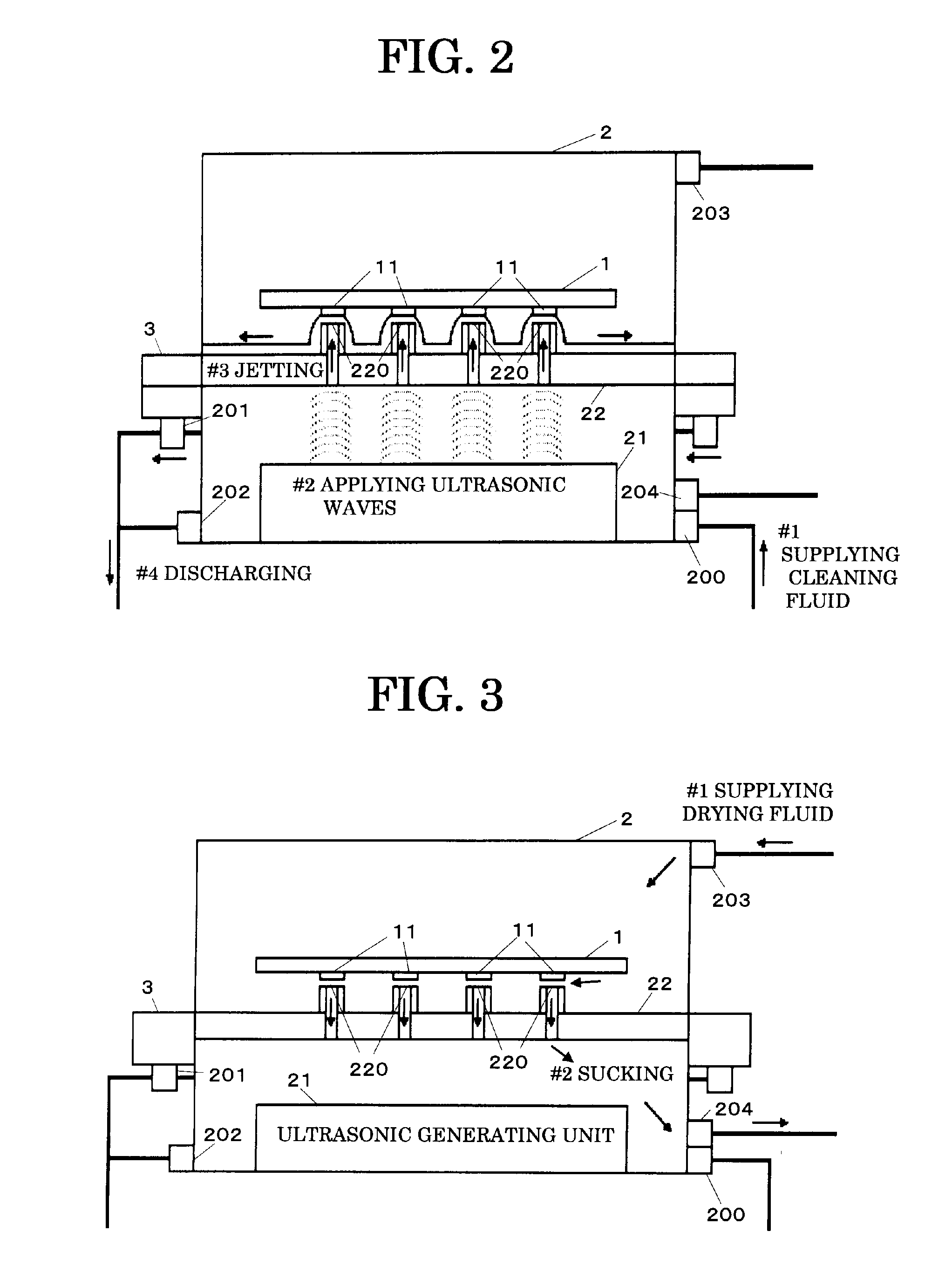

Cleaning apparatus, cleaning tank, cleaning method, and method for manufacturing article

InactiveUS20090223536A1Short timeInhibit adhesionElectrostatic cleaningCleaning using liquidsCleaning methodsEngineering

Ultrasonic generating unit of a cleaning tank in a cleaning apparatus applies ultrasonic waves to cleaning fluid supplied into the cleaning tank from a supply port and fluid jetting unit having openings at locations corresponding to areas to be cleaned of an article to be cleaned jets the ultrasonic-applied cleaning fluid from the openings to the areas to be cleaned of the article to be cleaned.

Owner:FUJITSU LTD +1

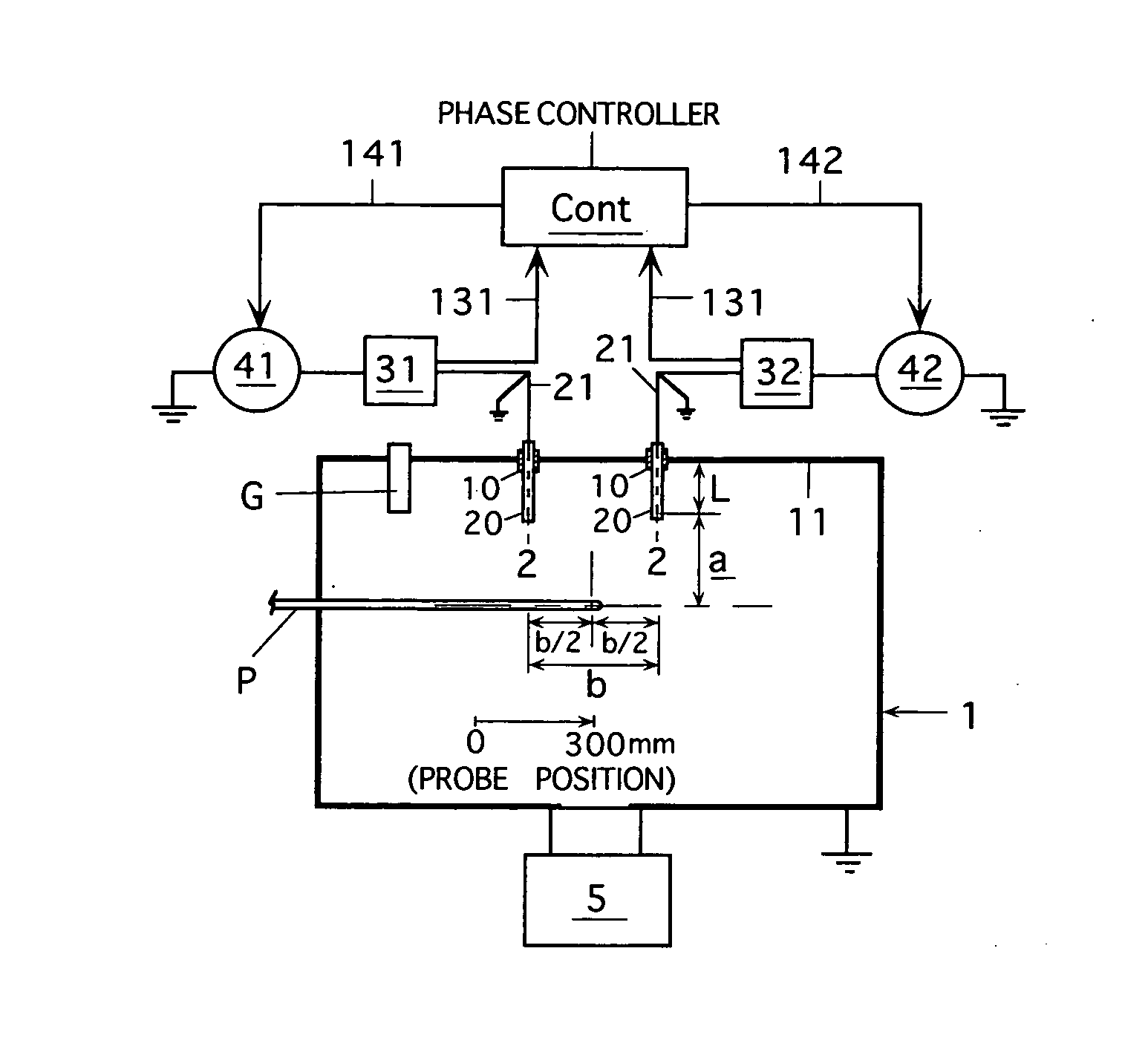

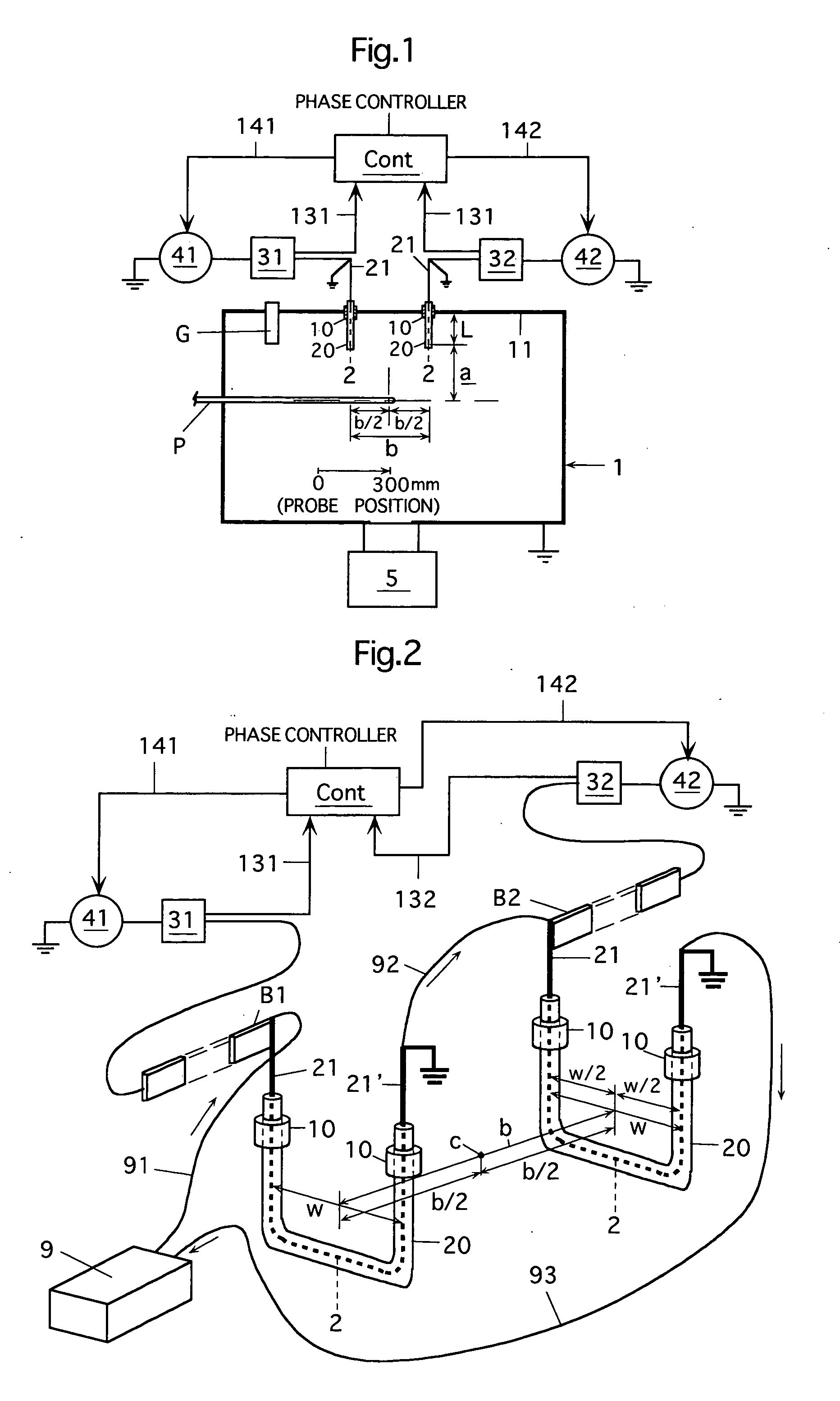

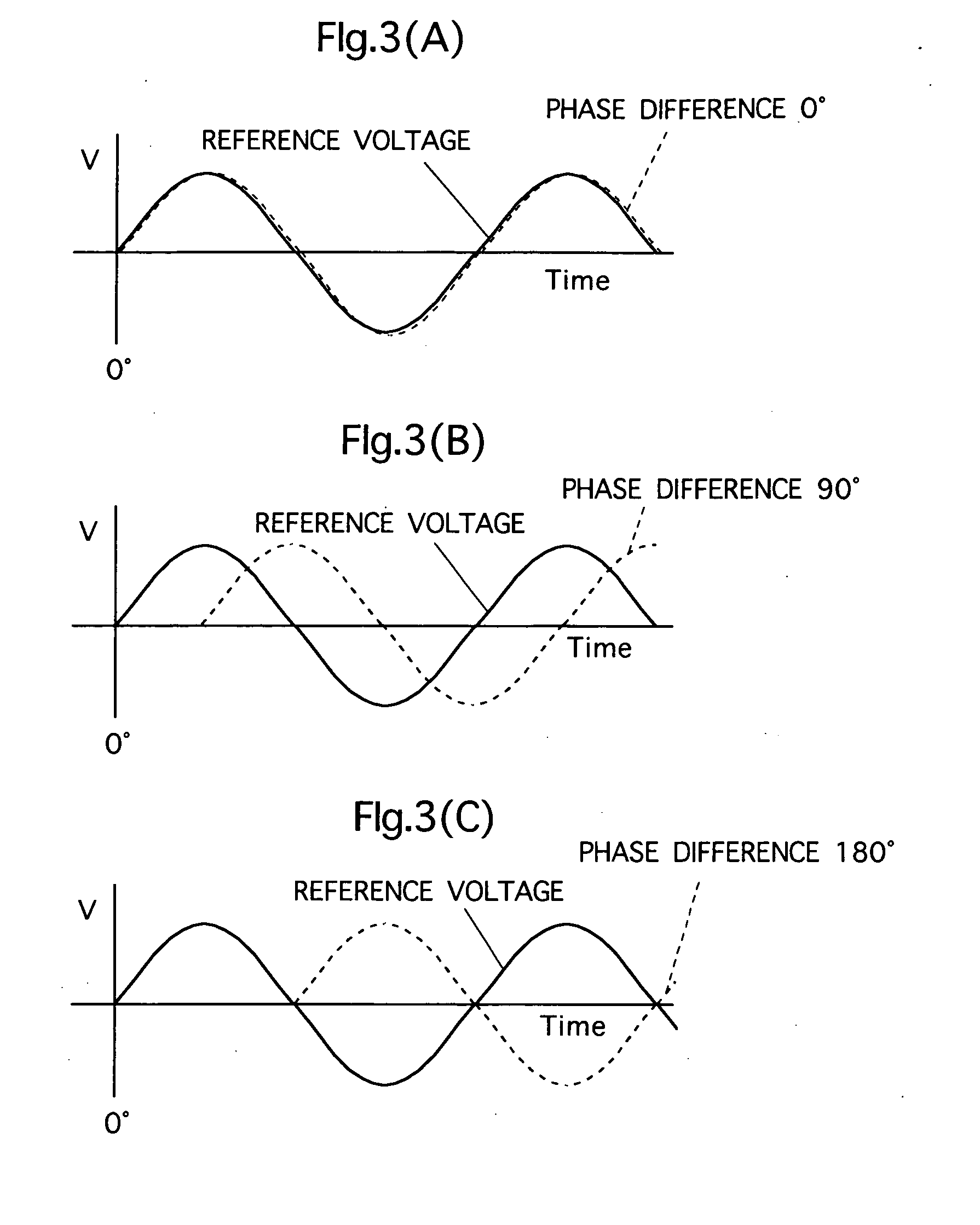

Plasma producing method and apparatus as well as plasma processing apparatus

InactiveUS20070095287A1Low electron temperatureReduce the temperatureElectric discharge tubesElectric arc lampsElectron temperatureHigh frequency power

Plasma producing method and apparatus wherein a plurality of high-frequency antennas are arranged in a plasma producing chamber, and a high-frequency power supplied from a high-frequency power supply device (including a power source, a phase controller and the like) is applied to a gas in the chamber from the antennas to produce inductively coupled plasma. At least some of the plurality of high-frequency antennas are arranged in a fashion of such parallel arrangement that the antennas successively neighbor to each other and each of the antennas is opposed to the neighboring antenna. The high-frequency power supply device controls a phase of a high-frequency voltage applied to each antenna, and thereby controls an electron temperature of the inductively coupled plasma.

Owner:NISSIN ELECTRIC CO LTD +1

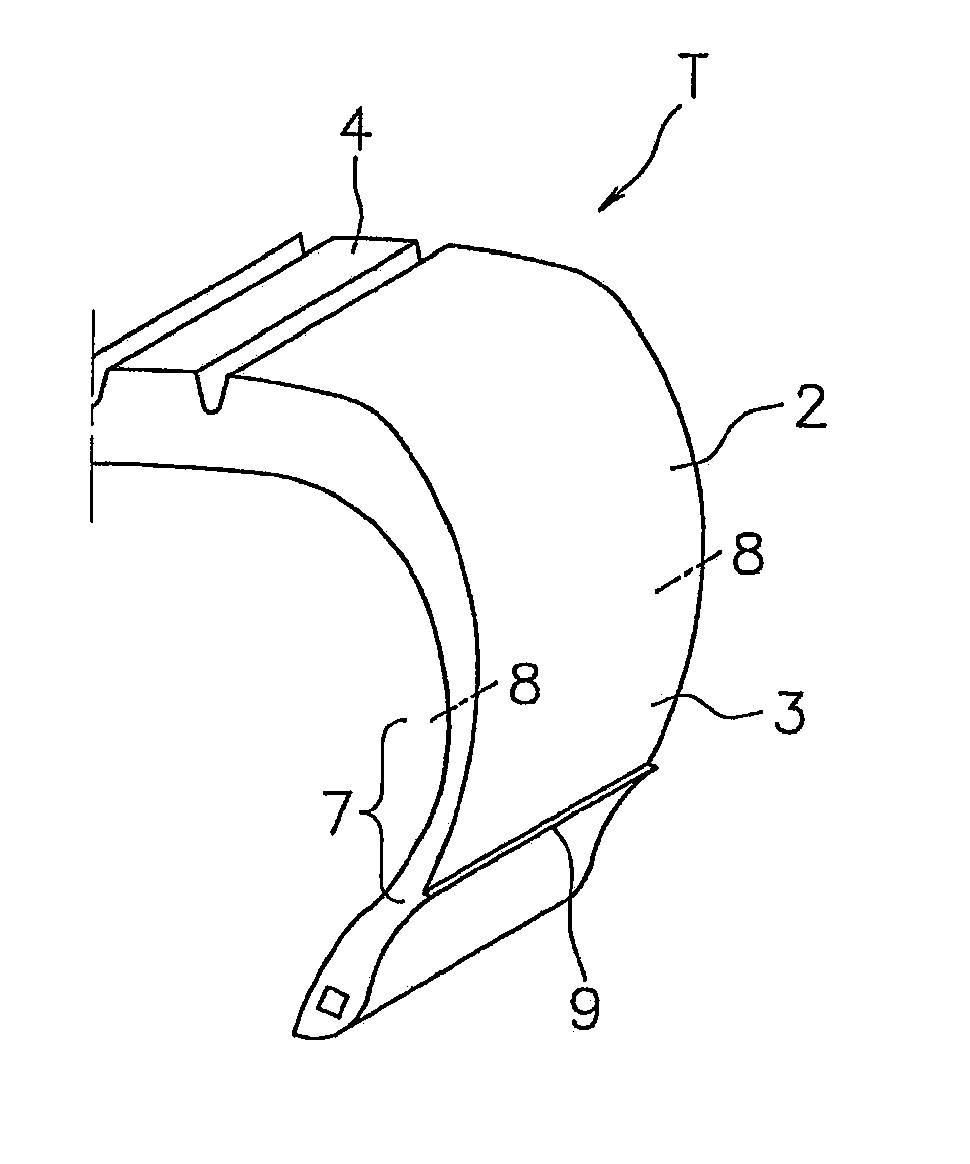

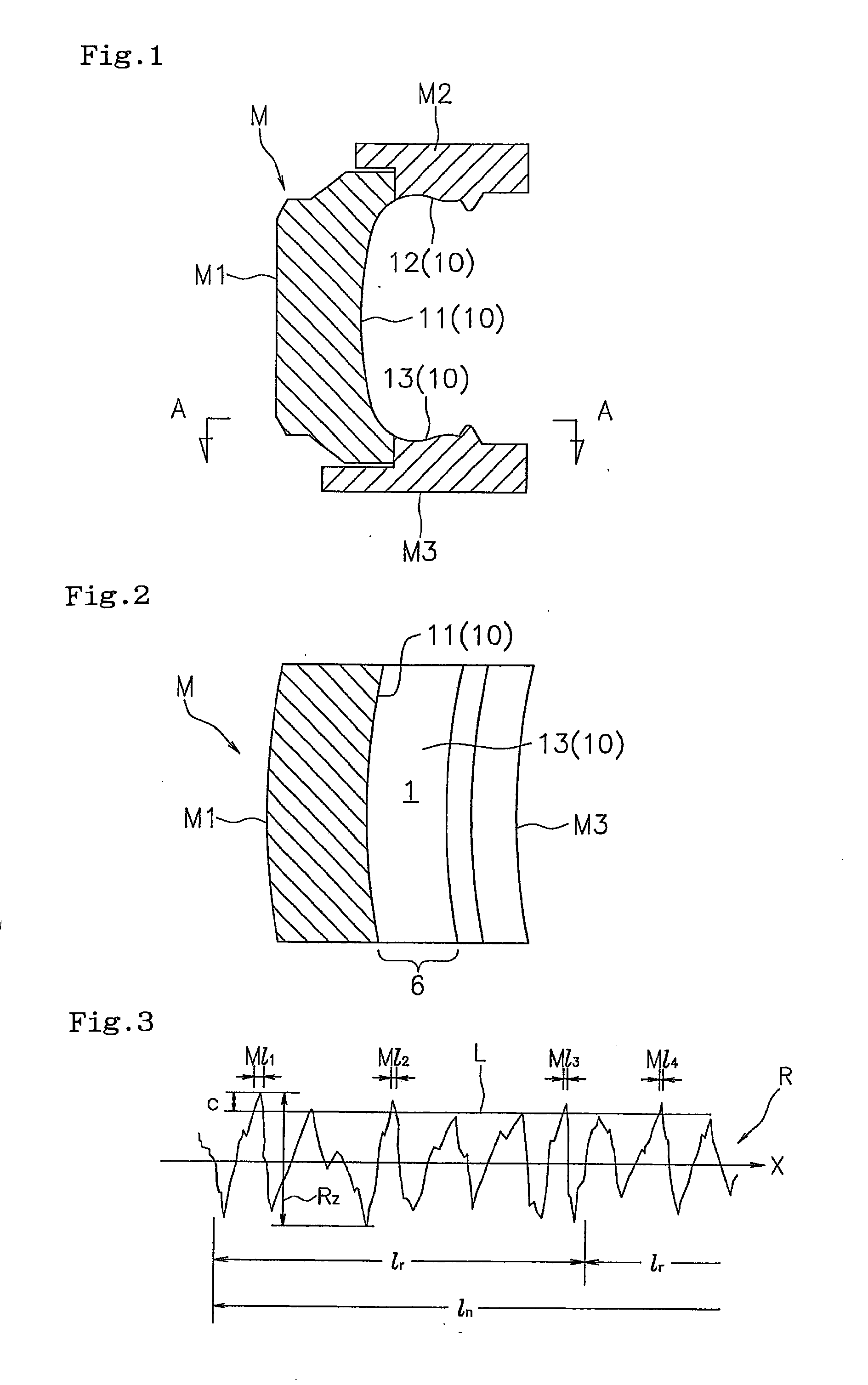

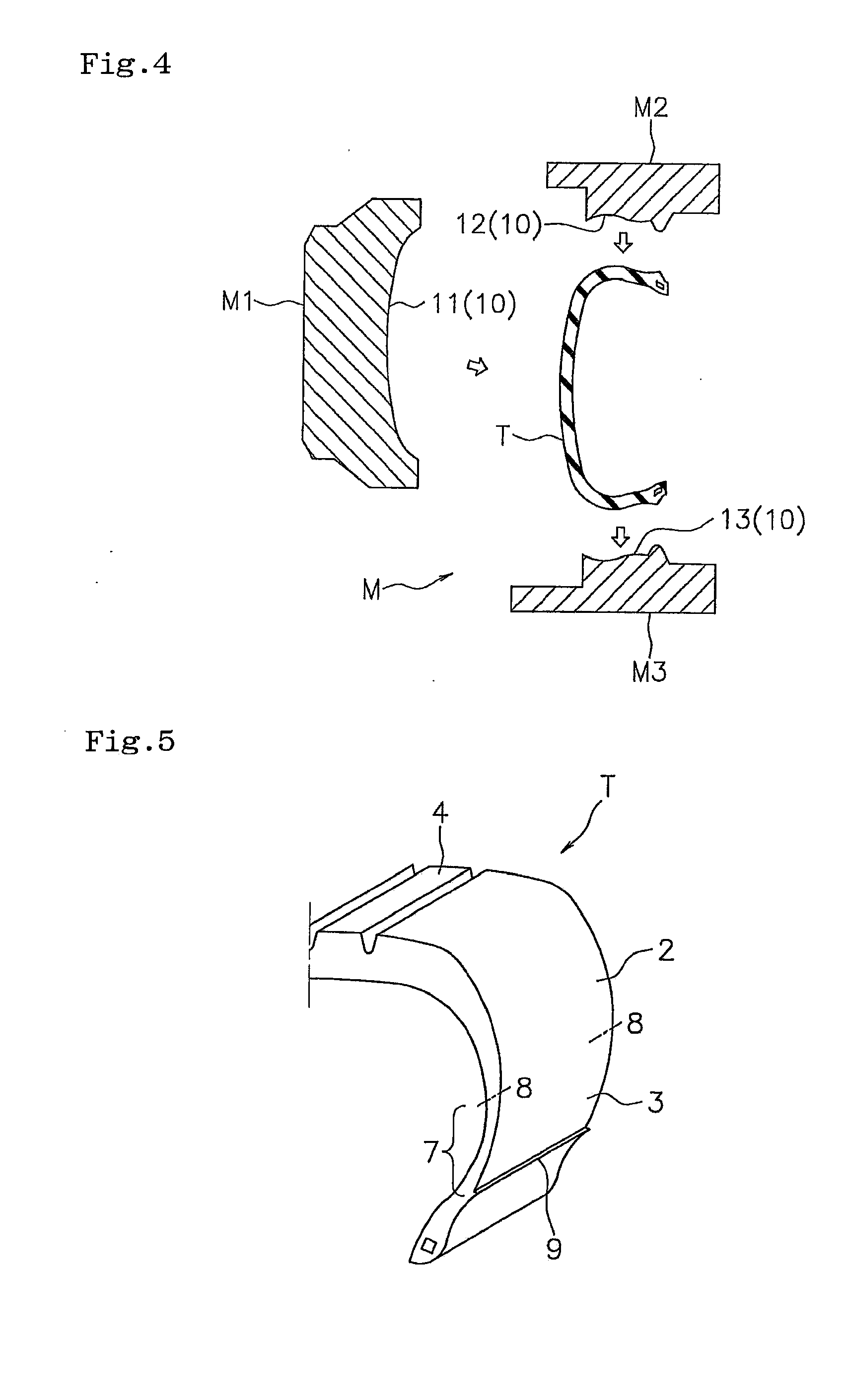

Tire mold, method of manufacturing pneumatic tire and pneumatic tire

ActiveUS20110297288A1Avoid crackingInhibit adhesionConfectioneryCeramic shaping apparatusRough surfaceAutomotive engineering

A tire mold has a tire molding surface and a rough surface molding portion provided in the tire molding surface. In the rough surface molding portion, a maximum height Rz is not less than 4 μm, a material ratio Rmr(c) in a case where 20% of the maximum height Rz is set to a cutting level c is not less than 3.5%, and a material ratio Rmr(c) in a case where 30% of the maximum height Rz is set to the cutting level c is not more than 25%.

Owner:TOYO TIRE & RUBBER CO LTD

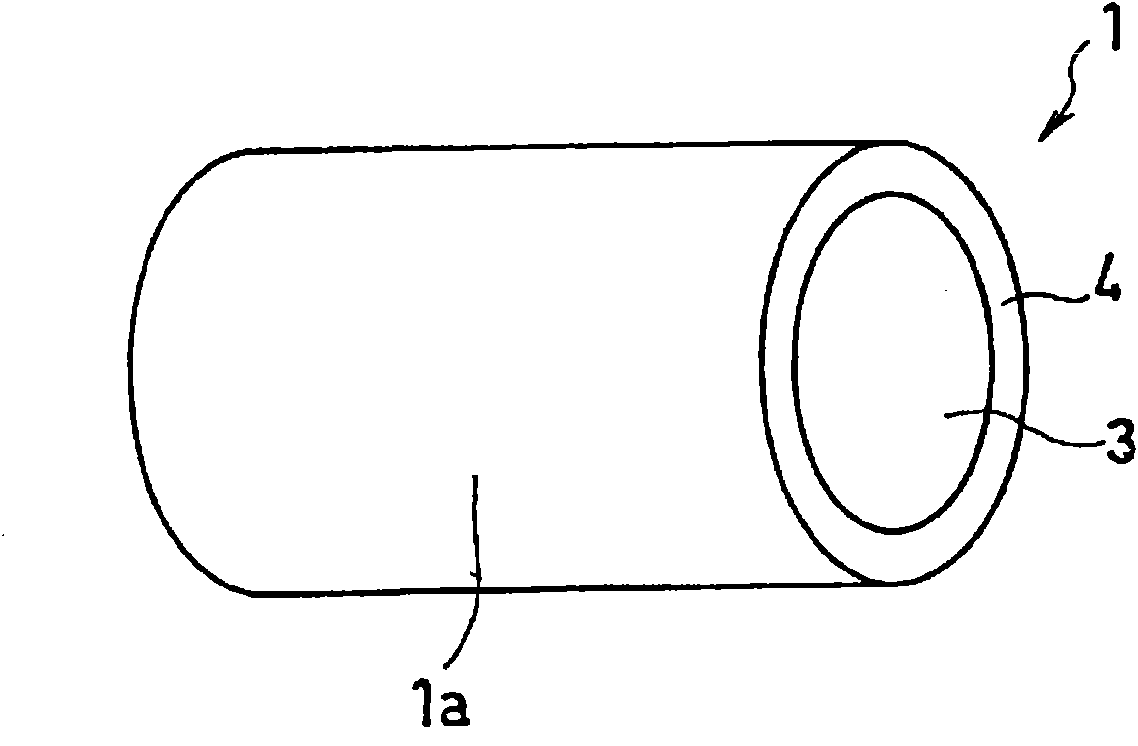

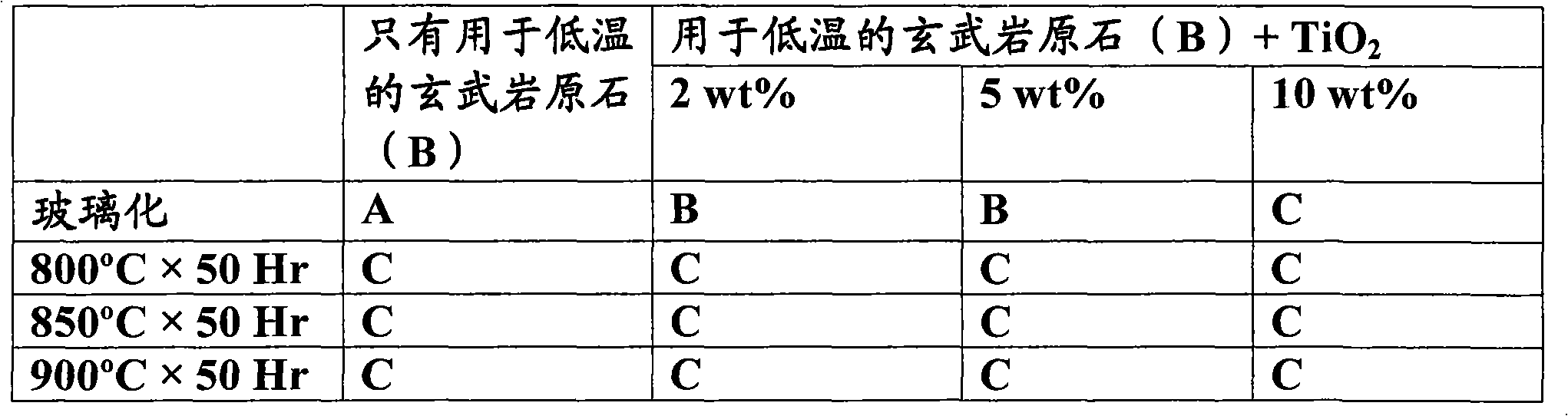

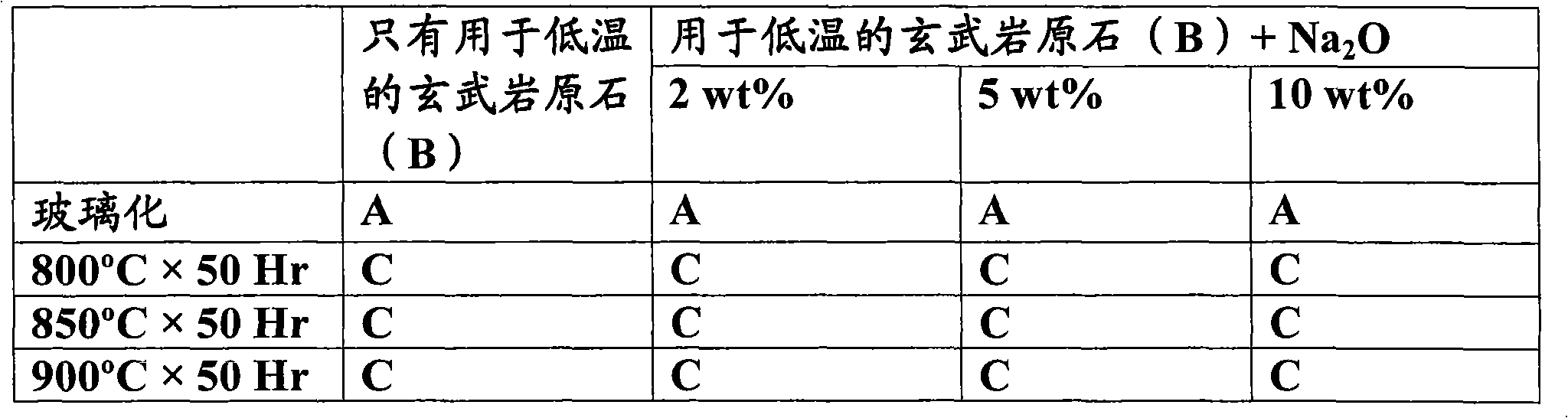

Sub-muffler

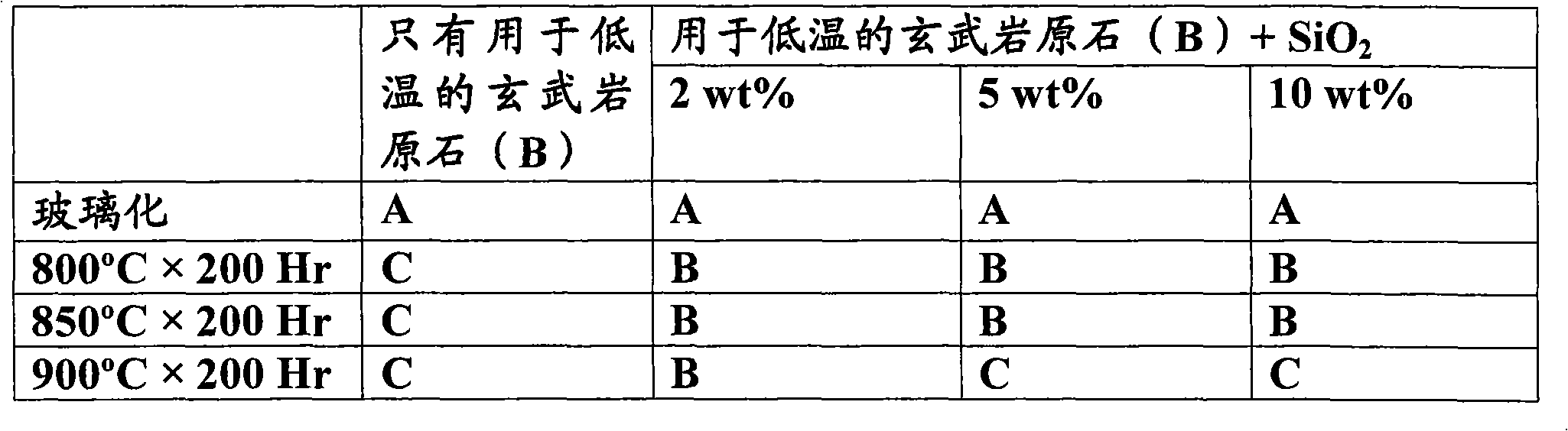

InactiveCN101313130APrevent crystallizationInhibit adhesionSilencing apparatusMachines/enginesEngineeringBasalt fiber

Provided is a sub-muffler which needs no heat resistant material such as SUS, and which can keep its durability and sound absorbing performance even when the sub-muffler is exposed to various corrosive components in the exhaust gas. At the same time, accomplished is a low-cost manufacture, which is a challenge that sub-mufflers and sound absorbing materials commonly face. Disclosed is a sub-muffler in which a perforated exhaust pipe is arranged, and caps and an out pipe are arranged outside the perforated pipe. Sound absorbing materials are filled in the space between the perforated exhaust pipe, and the caps and the out pipe. The sub-muffler is characterized in that, among the sound absorbing materials, at least part of the sound absorbing material of the perforated pipe side is a basalt fiber for high temperature.

Owner:TOYOTA JIDOSHA KK +1

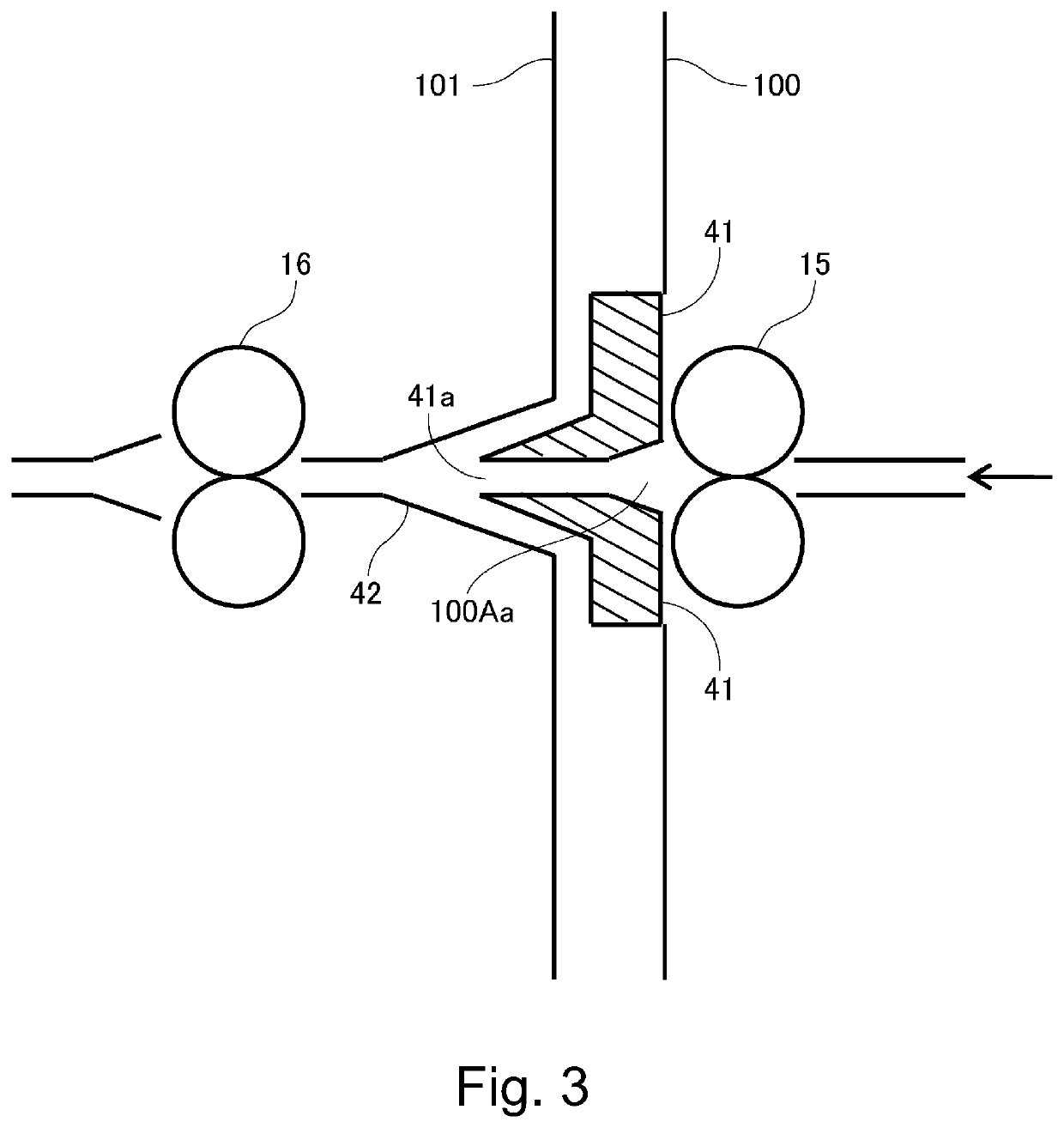

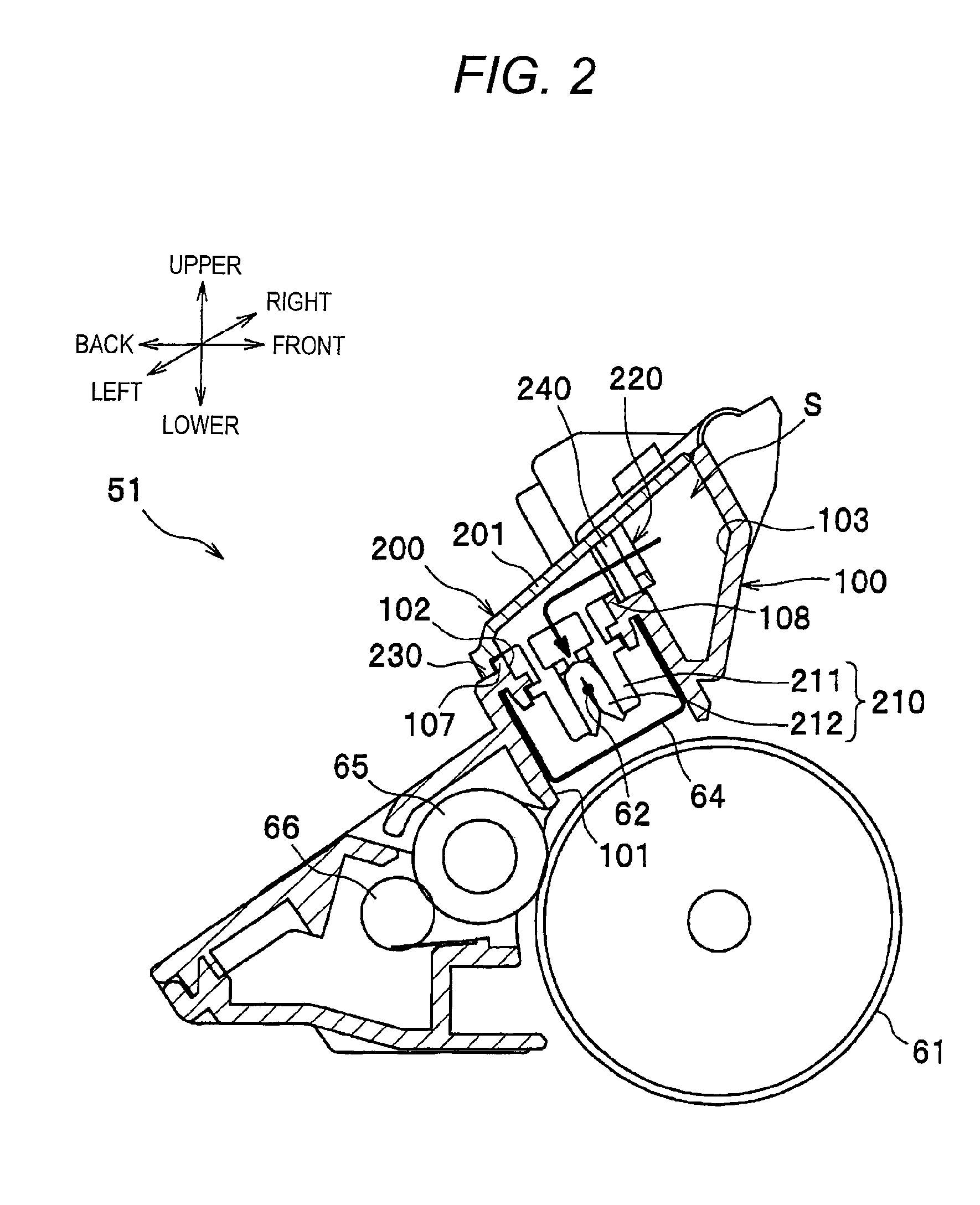

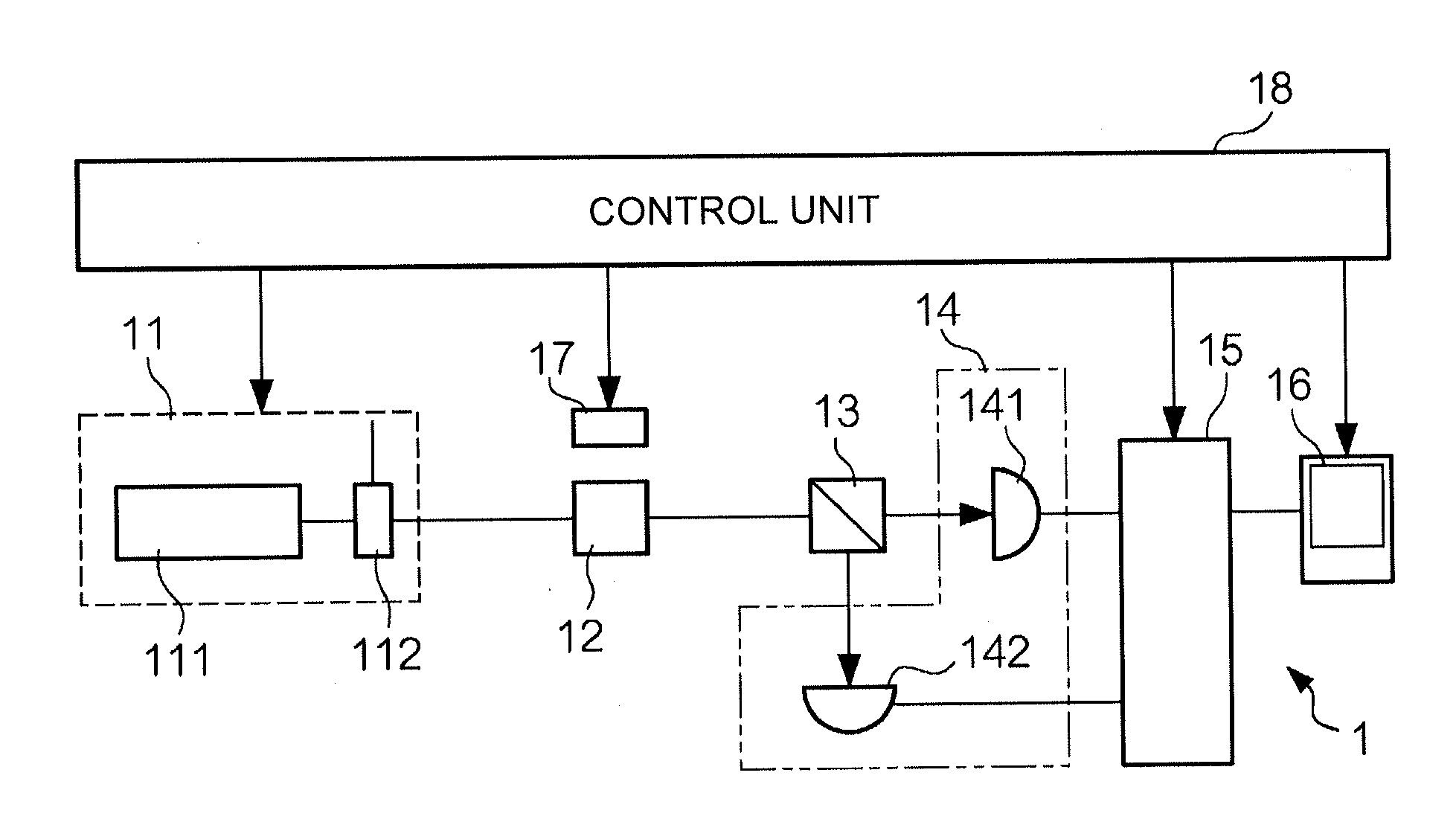

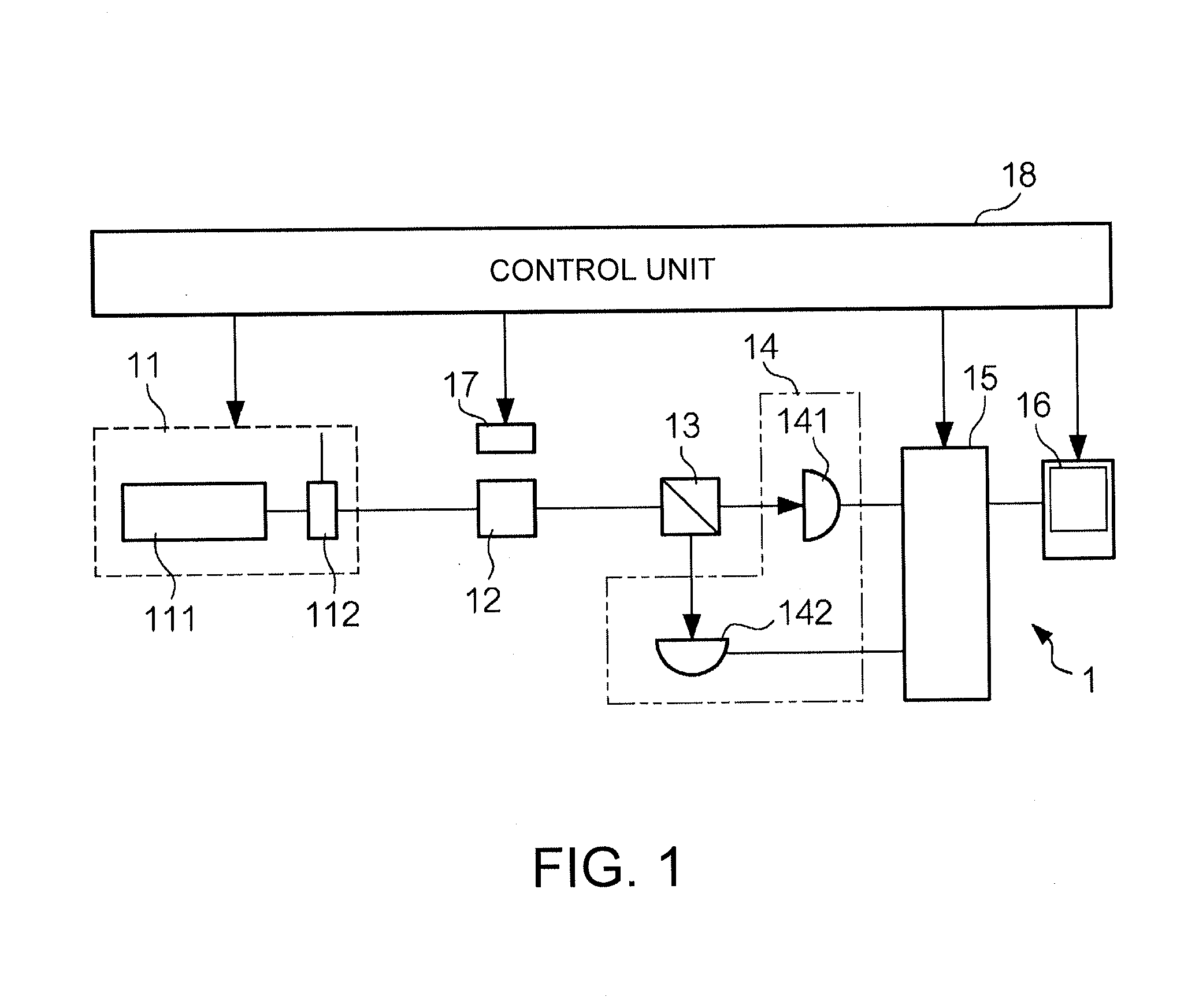

Cooling device and image forming system

ActiveUS20210072699A1Inhibit adhesionImprove imaging effectElectrographic process apparatusPictoral communicationImage formationEngineering

An external cooling device 101 is connectable to an image forming apparatus 100. The external cooling device 101 improves cooling power of a recording material S after toner image fixation. In this case, even when a heating amount of the fixing device 11 is increased, a temperature of the recording material S stacked on a stacking unit 60 can be lowered to not more than a predetermined temperature at which sticking does not occur. Further, the number of sheets stackable on said stacking unit 60 can be increased. By this, a user is capable of adjusting glossiness without concern for the sticking of the recording materials S on the stacking unit 60. Further, the user is not required to frequently carry out the recording material S of the stacking unit 60. That is, it is possible to provide an image forming system 1X capable of flexibly meeting the recording materials S of various kinds.

Owner:CANON KK

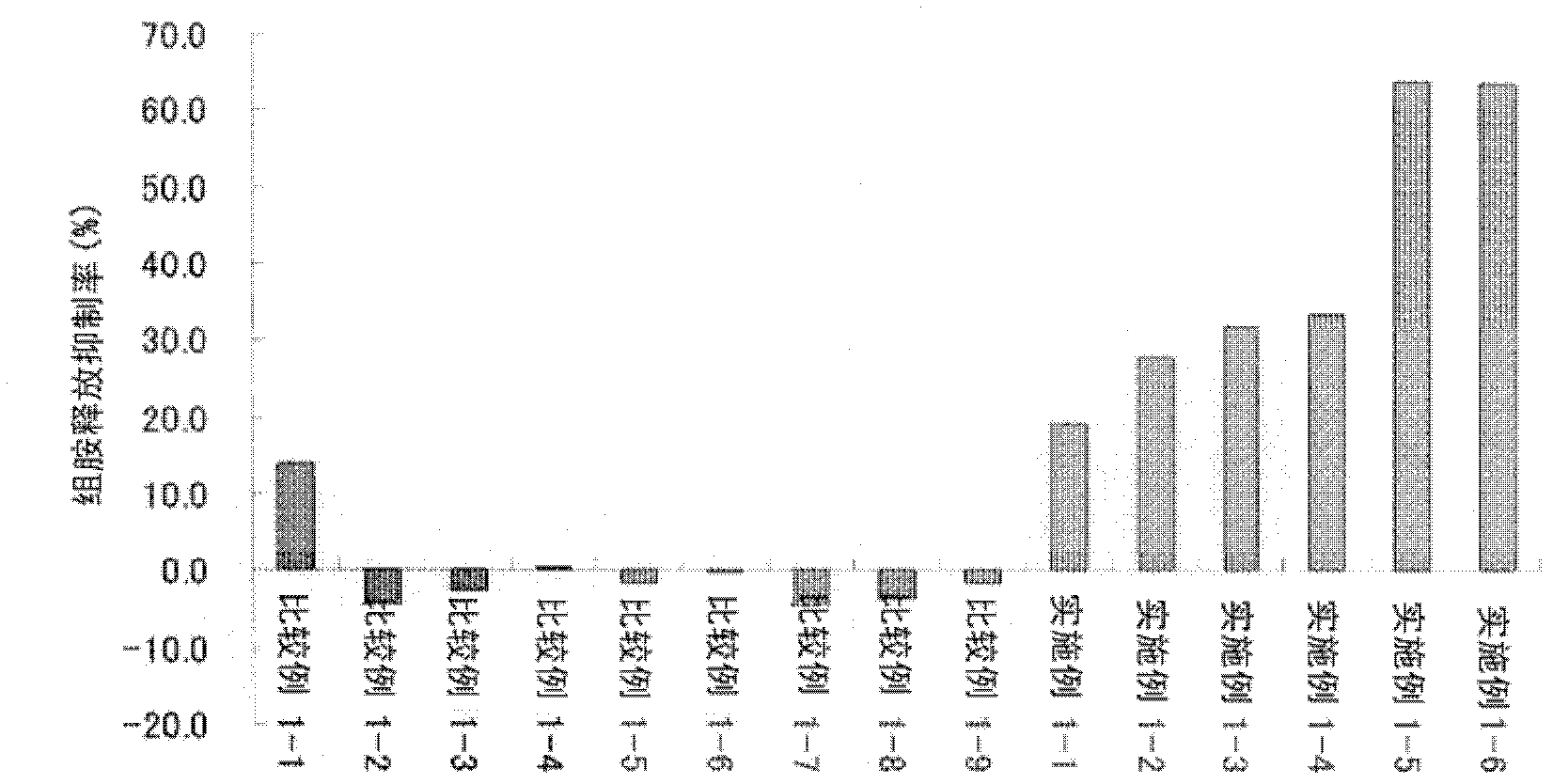

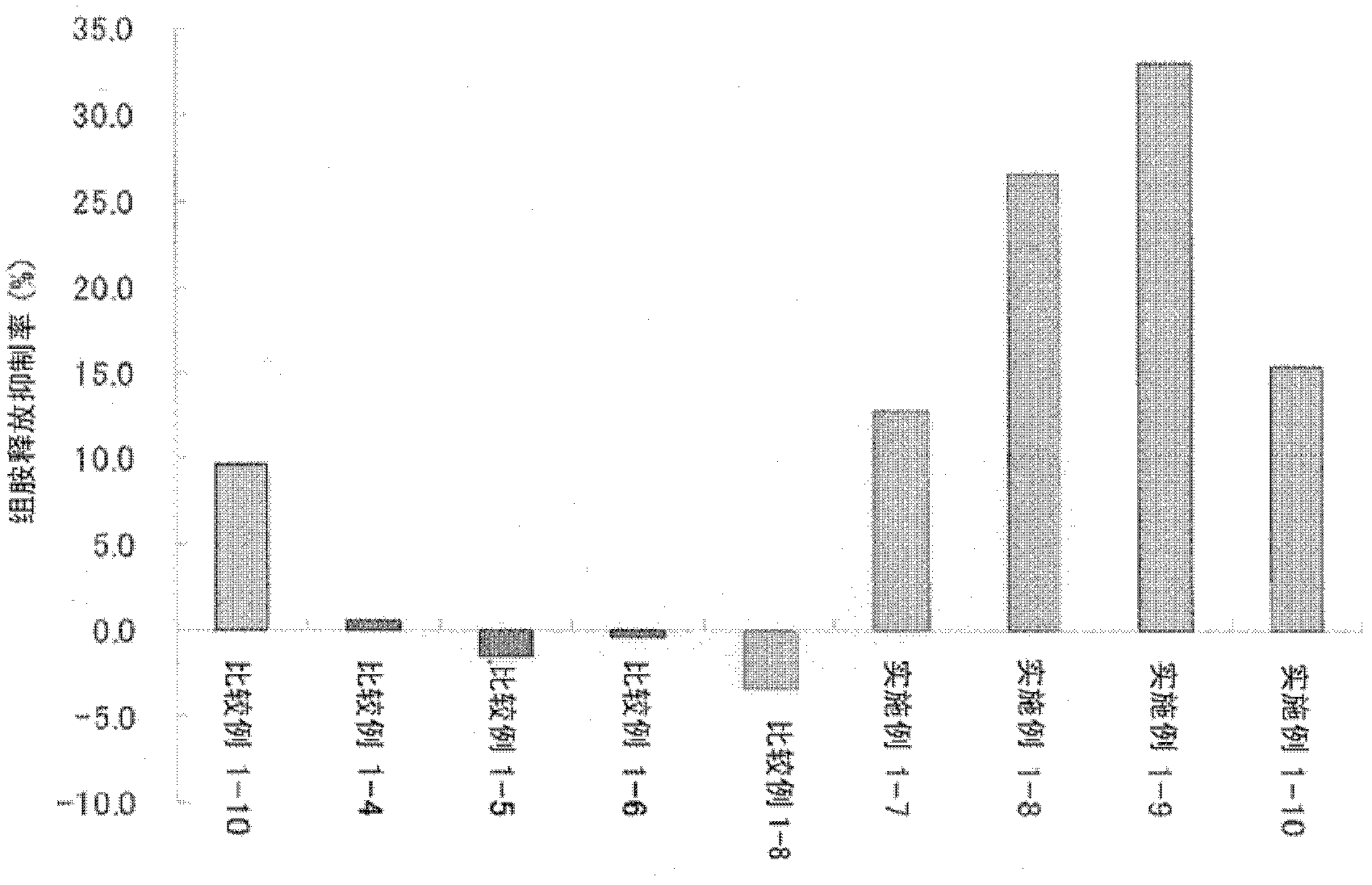

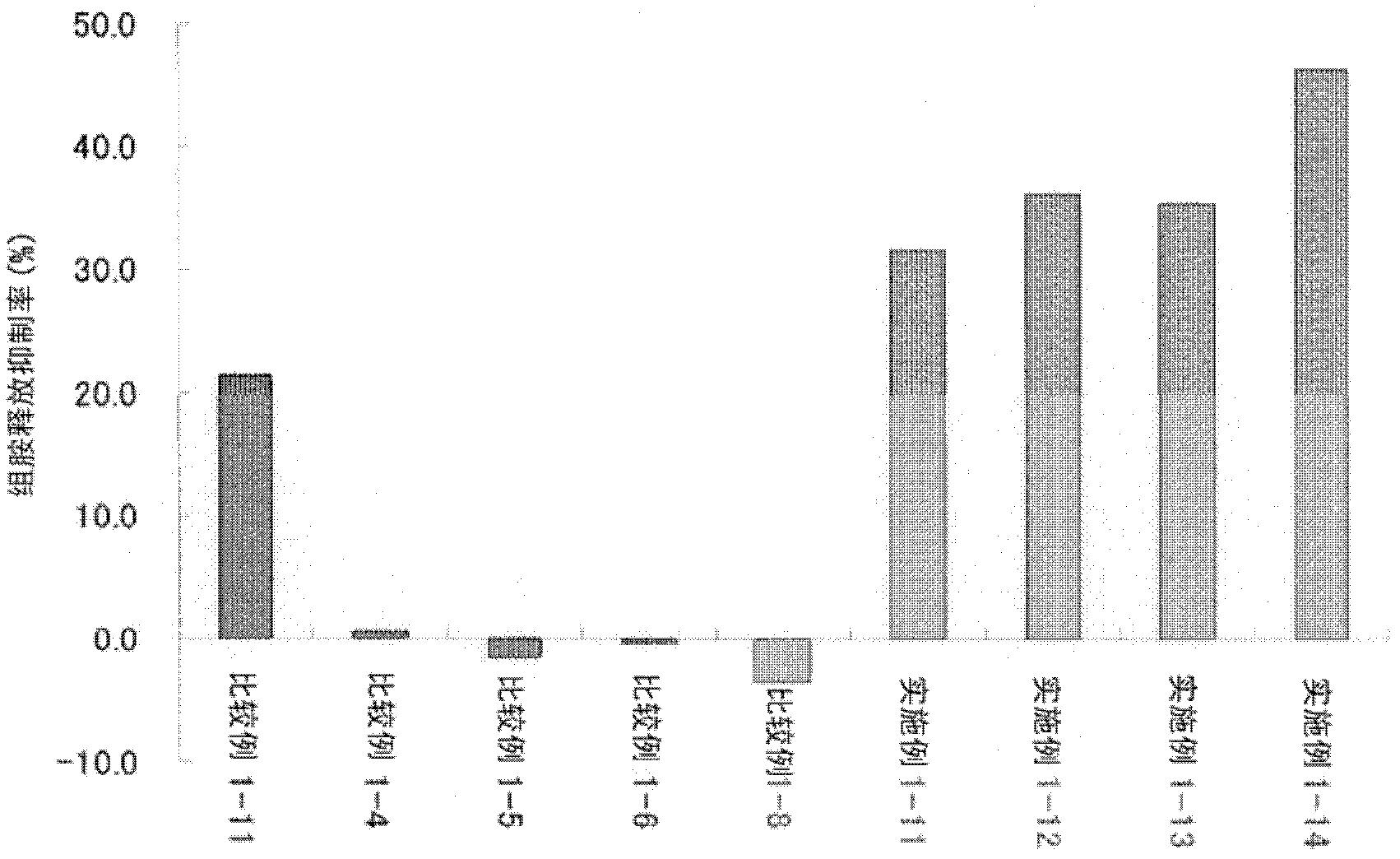

Ophthalmic composition

ActiveCN102548562AExcellent histamine release inhibitory effectSuppress discomfortAntibacterial agentsSenses disorderMentholSide chain

Disclosed are: an ophthalmic composition according to a non-conventional novel preparation, which has histamine release inhibitory action; and an ophthalmic composition for a silicone hydrogel contact lens, which is capable of suppressing adsorption of terpenoid to a silicone hydrogel contact lens. Specifically, the ophthalmic composition is prepared using (A) 0.001-2 w / v% of a polymer that has a phosphorylcholine analogous group in a side chain in combination with (B-1) 0.001-0.02 w / v% of menthol. Meanwhile, the ophthalmic composition for a silicone hydrogel contact lens is prepared using (A) a polymer that has a phosphorylcholine analogous group in a side chain in combination with (B-2) terpenoid.

Owner:ROHTO PHARM CO LTD

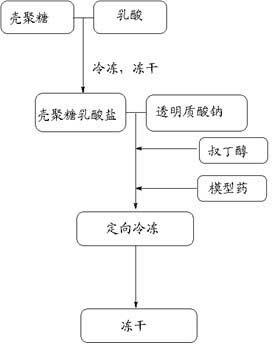

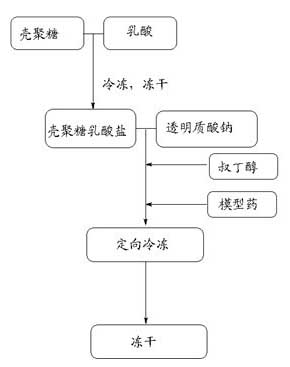

High-ventilated degradable medicine-carrying skin wound dressing as well as preparation method and device thereof

ActiveCN102210885AHigh air permeabilityImprove water absorptionDomestic cooling apparatusLighting and heating apparatusMoisture retentionSodium hyaluronate

The invention discloses a high-ventilated degradable medicine-carrying skin wound dressing as well as a preparation method and device thereof, and belongs to the technical field of medical new materials. The high-ventilated degradable medicine-carrying skin wound dressing comprises the following components in percentage by weight: 45-50% of chitosan lactate; 45-50% of sodium hyaluronate and 5-10%of antibiotic. In the porous bioactivity dressing provided by the invention, a composite material of the chitosan lactate and the sodium hyaluronate is utilized as a substrate, and the antibiotic is loaded on the substrate. The dressing based on a special refrigerating process has the advantages of vertical pore ducts, high ventilation property, high hydroscopicity and moisture retention, therebyincreasing the permeability of the wound surface; the redundant exudate can be immediately absorbed while the moisture on the surface of the wound cannot be excessively evaporated. The dressing has long-term and effective effect on treating the surface of the wound so as to avoid the pain of the patient caused by frequent dressing change.

Owner:PKU HKUST SHENZHEN HONGKONG INSTITUTION +1

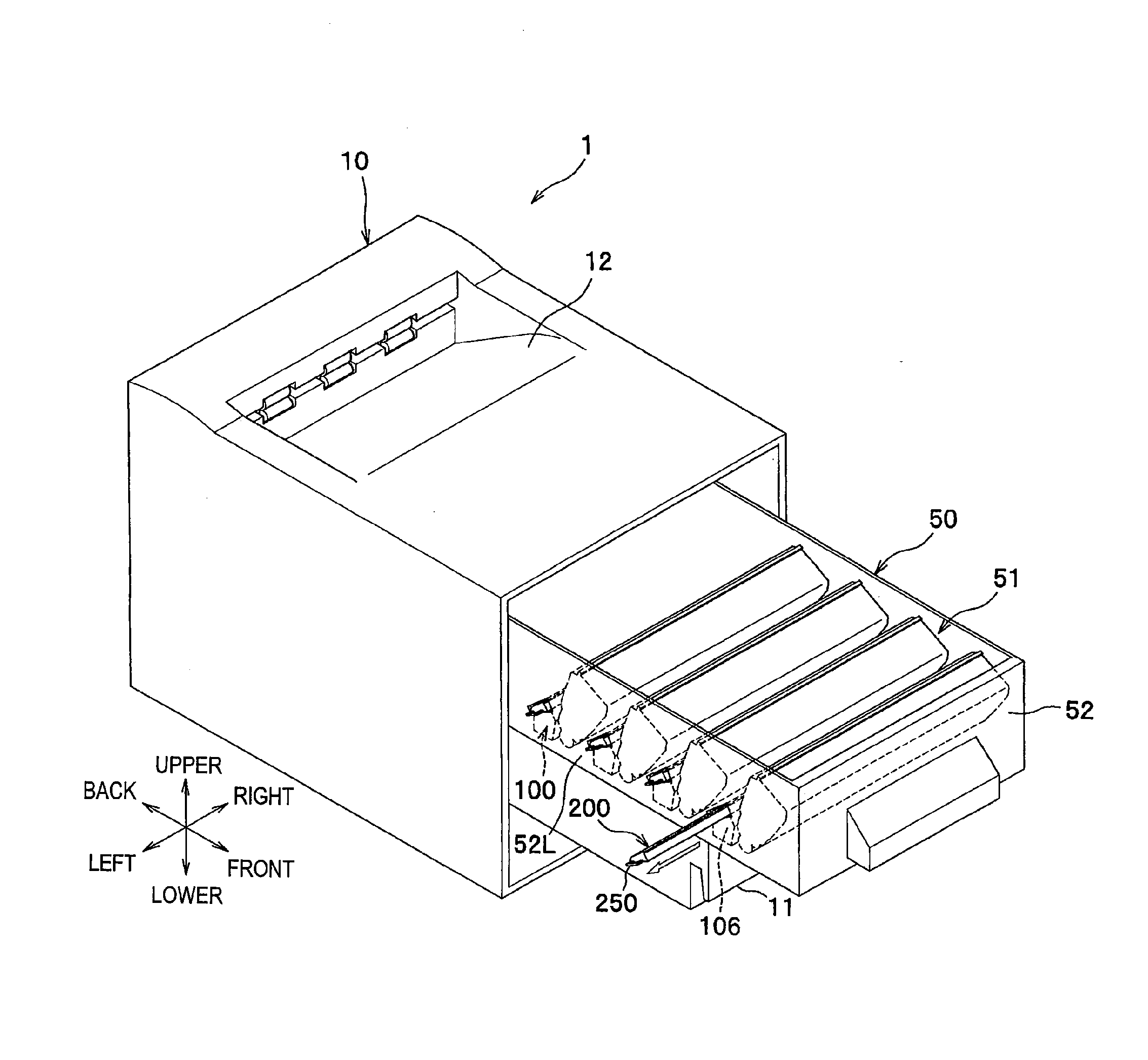

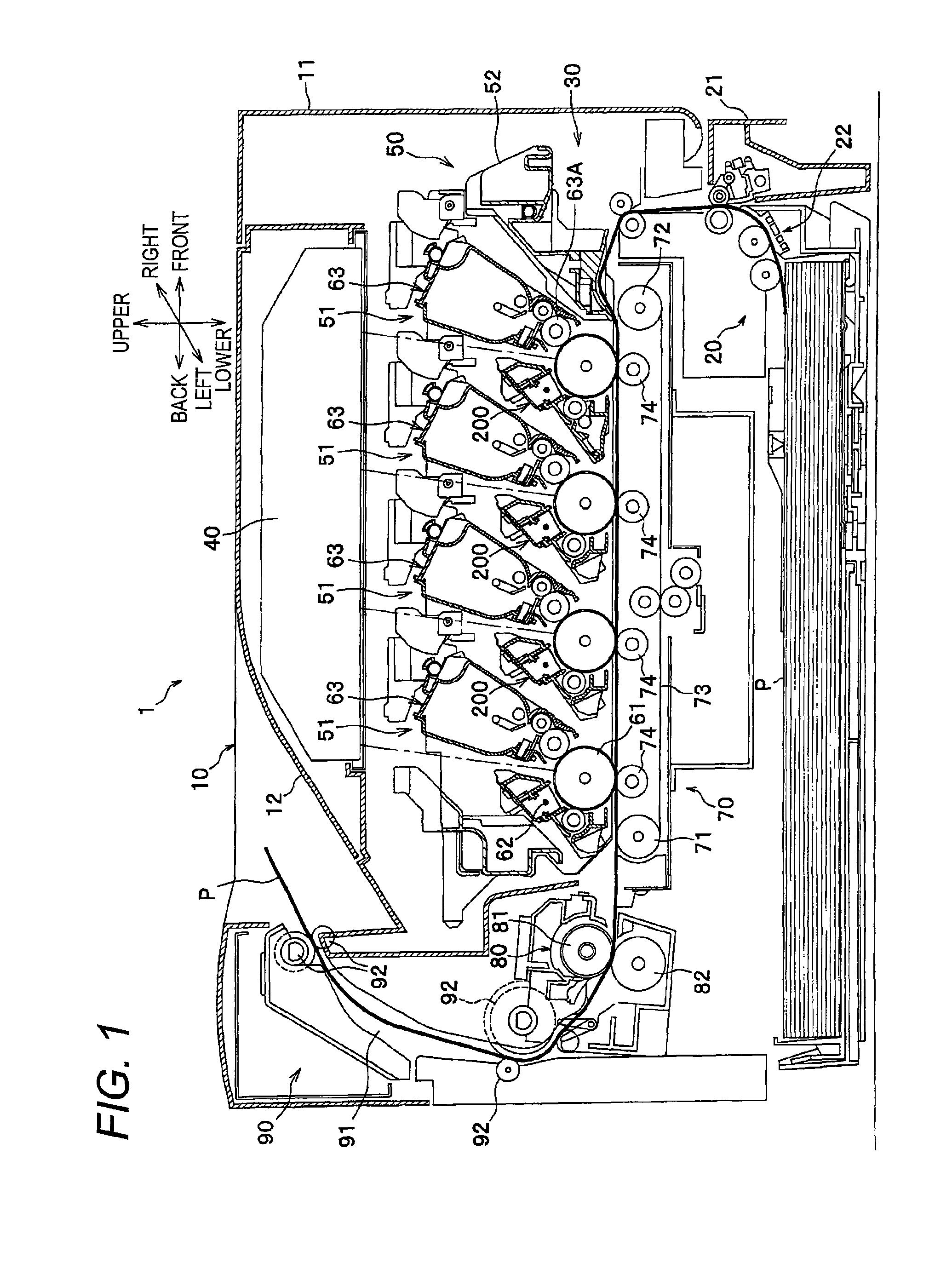

Image forming apparatus and image forming unit

ActiveUS8369734B2Easy to operateInhibit adhesionElectrographic process apparatusCorona dischargeElectric dischargeImage formation

An image forming apparatus comprises a photosensitive drum, a charged wire which extends in a shaft direction of the photosensitive drum and charges the photosensitive drum by electric discharge, a frame disposed so as to surround the charged wire, the frame in which a cover side opening is formed in the side opposite to the photosensitive drum with respect to the charged wire, and a cover member disposed so as to cover the cover side opening while forming a blow path in communication with the cover side opening between the frame and the cover member. The cover member moves along the charged wire and is constructed detachably from a side surface of the frame and also a cleaning member for cleaning the charged wire is disposed.

Owner:BROTHER KOGYO KK

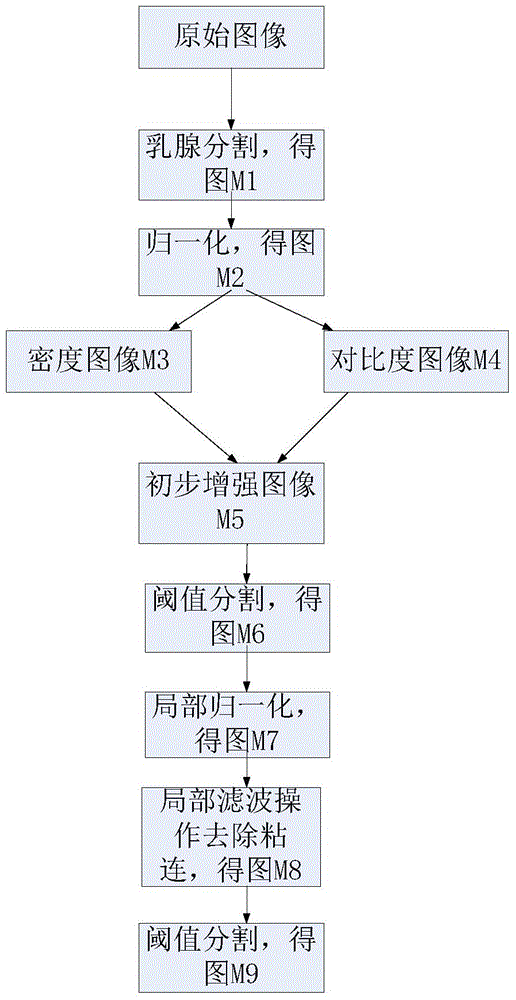

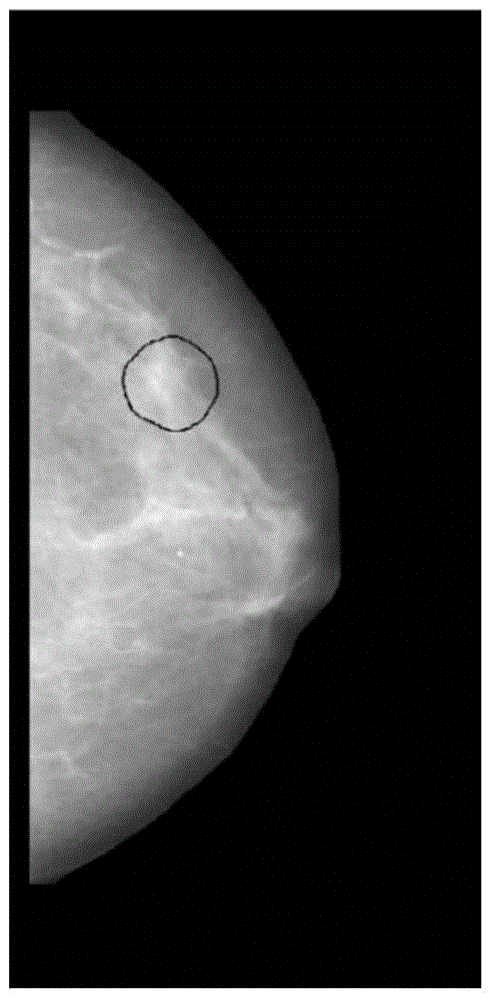

Mammary X-ray image enhancement method

InactiveCN104952044AEnhance image informationIncrease contrastImage enhancementRadiation diagnosticsX ray imageComputer science

The invention provides a mammary X-ray image enhancement method comprising the steps that a mammary X-ray image is provided; and local normalization is performed on the local part in the mammary X-ray image so that image information corresponding to the local part can be enhanced. Local information is enhanced via local normalization so that implicit local information in the global image can be effectively enhanced, i.e. low intensity lesions can be effectively enhanced. Furthermore, local filtering is adopted after local normalization so that local contrast can be enhanced, adhesion between local objects can be suppressed and adhesion of the lesions and background tissues can be effectively suppressed.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

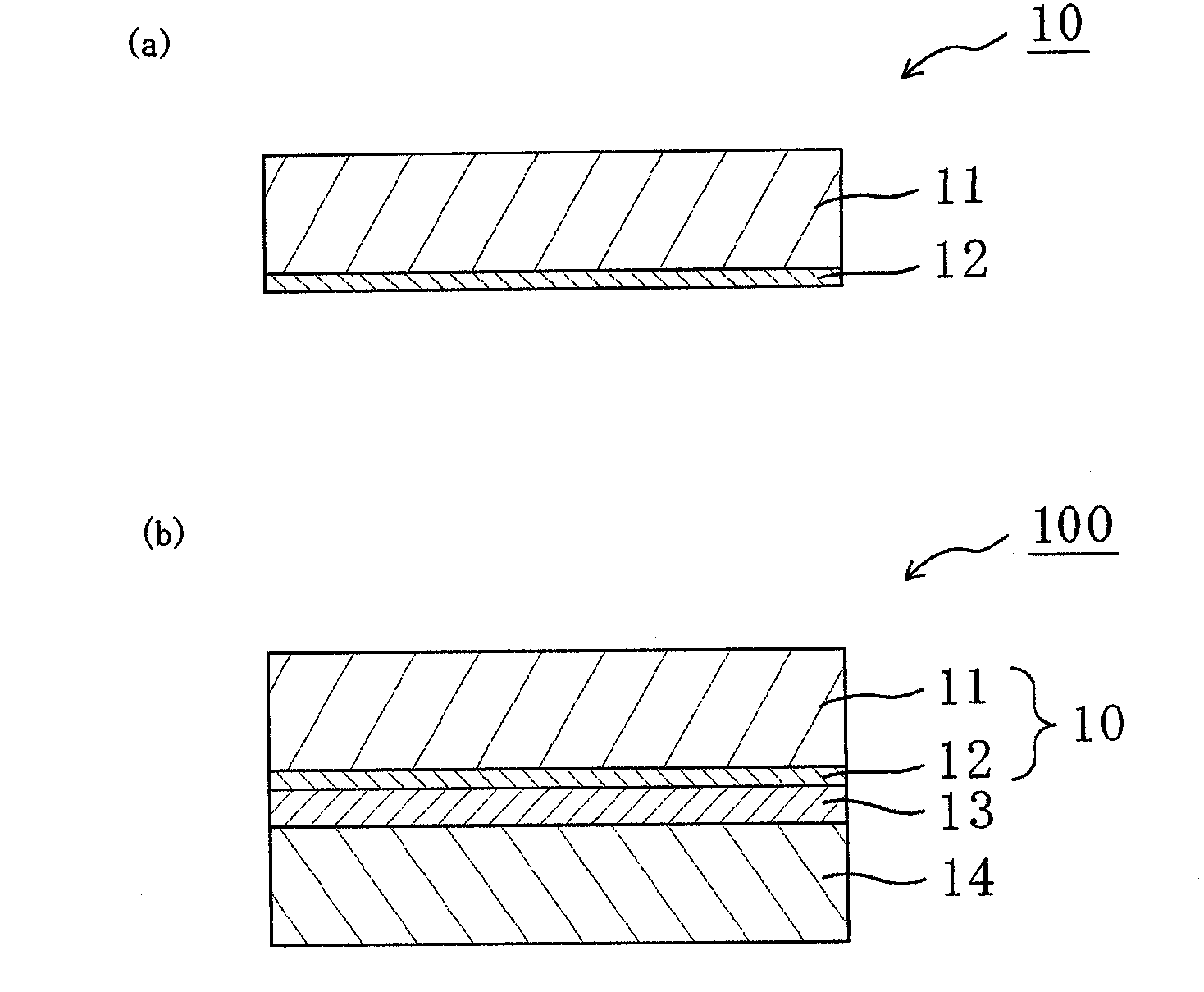

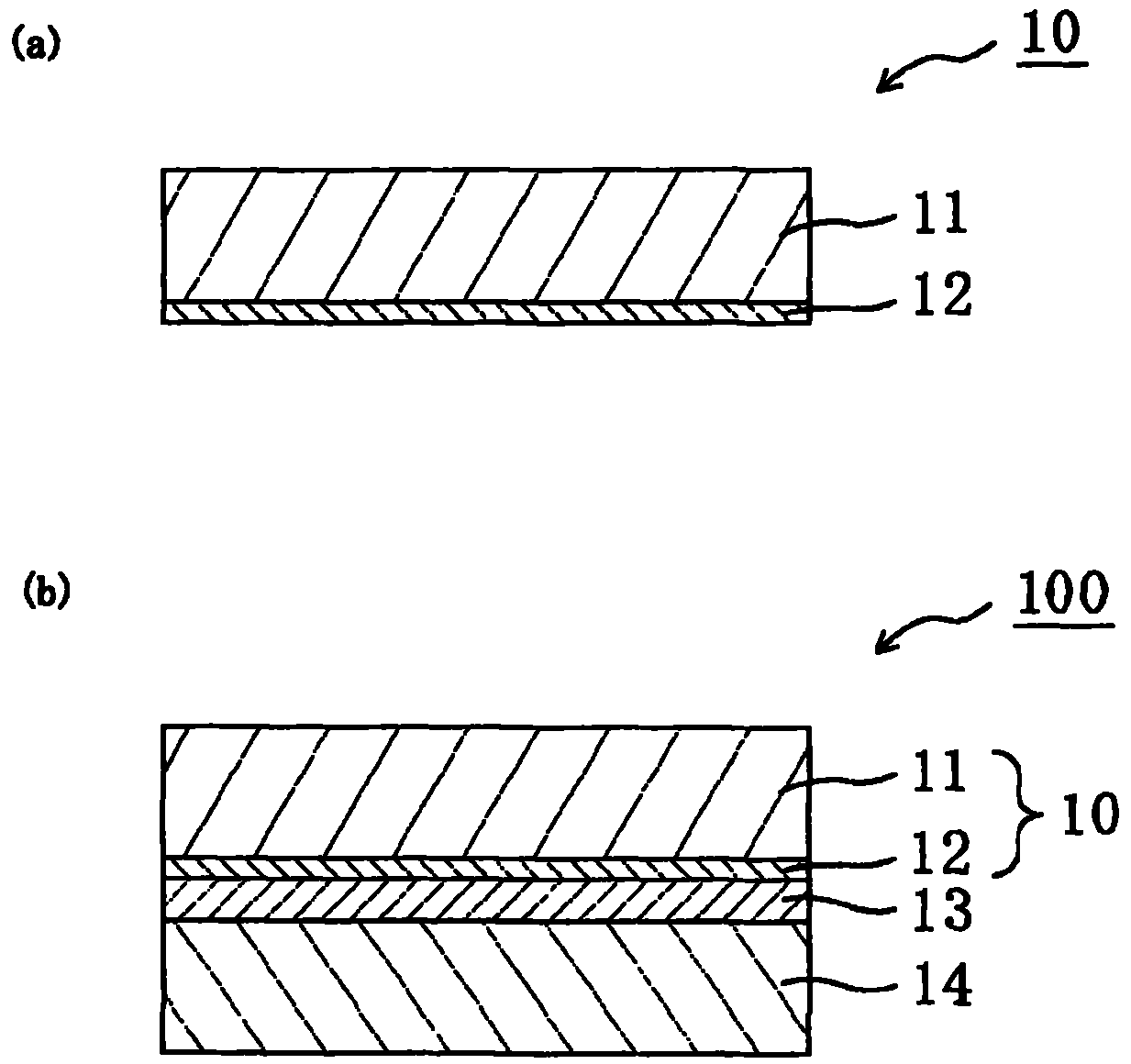

Optical film with adhesive and production method thereof, and method for producing image display device

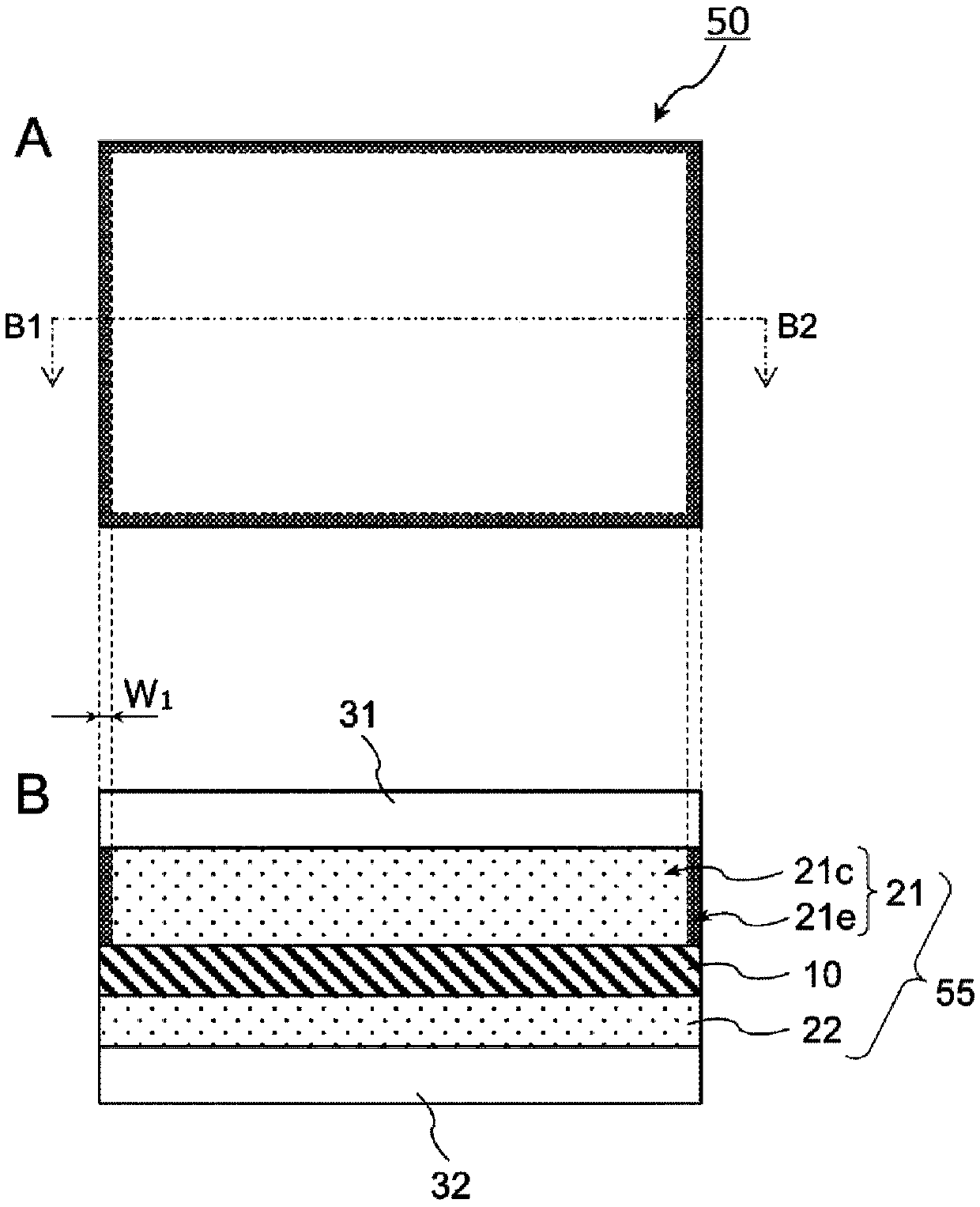

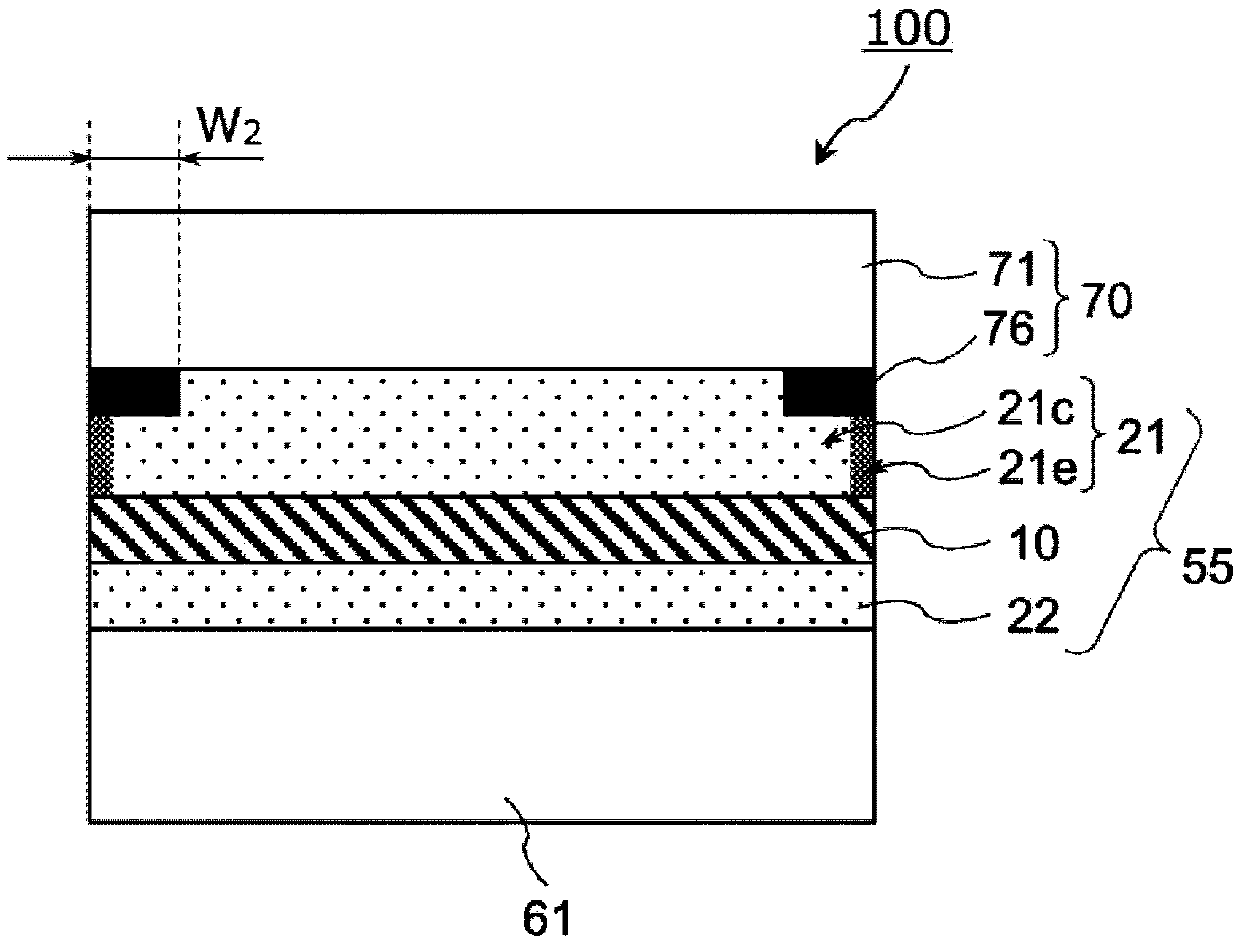

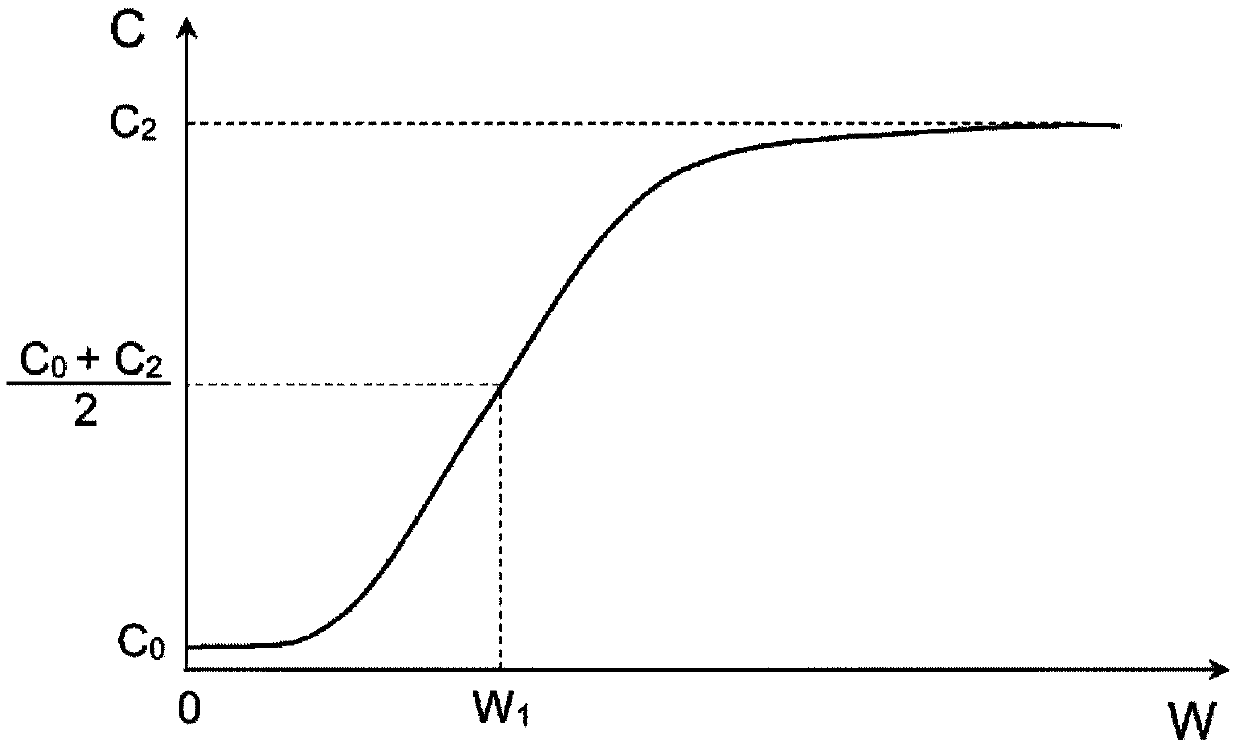

The invention relates to an optical film with an adhesive and a production method thereof, and a method for producing an image display device. The invention provides an adhesive sheet which can suppress display uneveness of the image display device when the optical film is disposed between a front transparent plate or a touch panel and an image display panel and has the adhesive protrude from an end face, and the optical film with the adhesive sheet, and the image display device. In the adhesive sheet with the adhesive, a main face of the optical film (10) comprising a polarization board includes an adhesive layer (21) for adhesion to the front transparent plate or the touch panel. The adhesive layer (21) has a thickness more than 30 [mu]m, and fluidity of the adhesive (21e) at an end surface is lower than a fluidity of the adhesive (21c) at an in-plane central part. The optical film with the adhesive is configured as the optical film (10), the second main face of which has an optical film with a double-face adhesive of an adhesive layer (22) for adhesion to the image display unit.

Owner:NITTO DENKO CORP

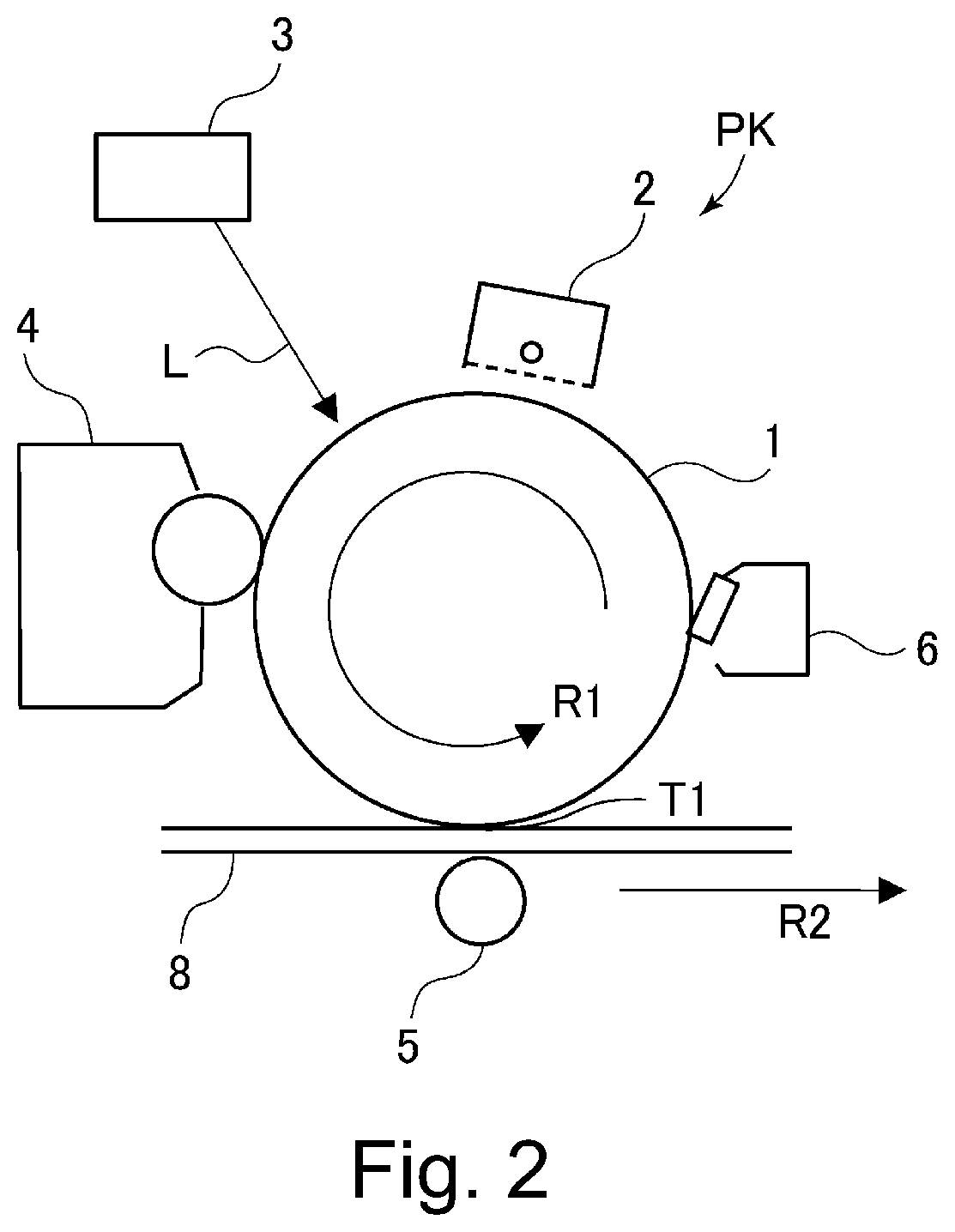

Development magnet roller, development device, process cartridge and image forming apparatus

ActiveUS7352983B2Improvement in trailing edge omissionInhibit adhesionPermanent magnetsElectrographic process apparatusImage formationPeak value

A development magnet roller for use in a development roller of an electrophotographic image forming apparatus is provided. The development magnet roller has a development pole to form a magnetic field causing a developer born on a surface of the development roller including the development magnet roller to rise in a form of a series of ears in a development area of the image forming apparatus where the development roller opposes an image bearing member, and in a magnetic flux density distribution in a normal line direction of the development pole, a peak magnetic flux density is 120 mT or greater, a zero gauss region width is 70° or greater, and a half-value region width is 40° or smaller.

Owner:RICOH KK

Gas cell and magnetic measuring apparatus

InactiveUS20160025822A1Avoid stickingInhibit adhesionMagnetic field measurement using magneto-optic devicesMeasurements using magnetic resonanceInterior spaceEngineering

A gas cell includes: a cell main body; a first wall portion defining an interior space serving as a main chamber in the cell main body; an auxiliary chamber storing an alkali metal; a second wall portion defining the auxiliary chamber connected with the main chamber in the cell main body; and a heater covering the first wall portion and vaporizing the alkali metal. The second wall portion is thicker than the first wall portion.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com