Battery current collector, its manufacturing method, and nonaqueous secondary battery

A manufacturing method and current collector technology, which are applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve problems such as decreased production efficiency, abnormal formation of protrusions, and tearing of the part where the metal foil and burrs are adhered. To achieve the effect of inhibiting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0110] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

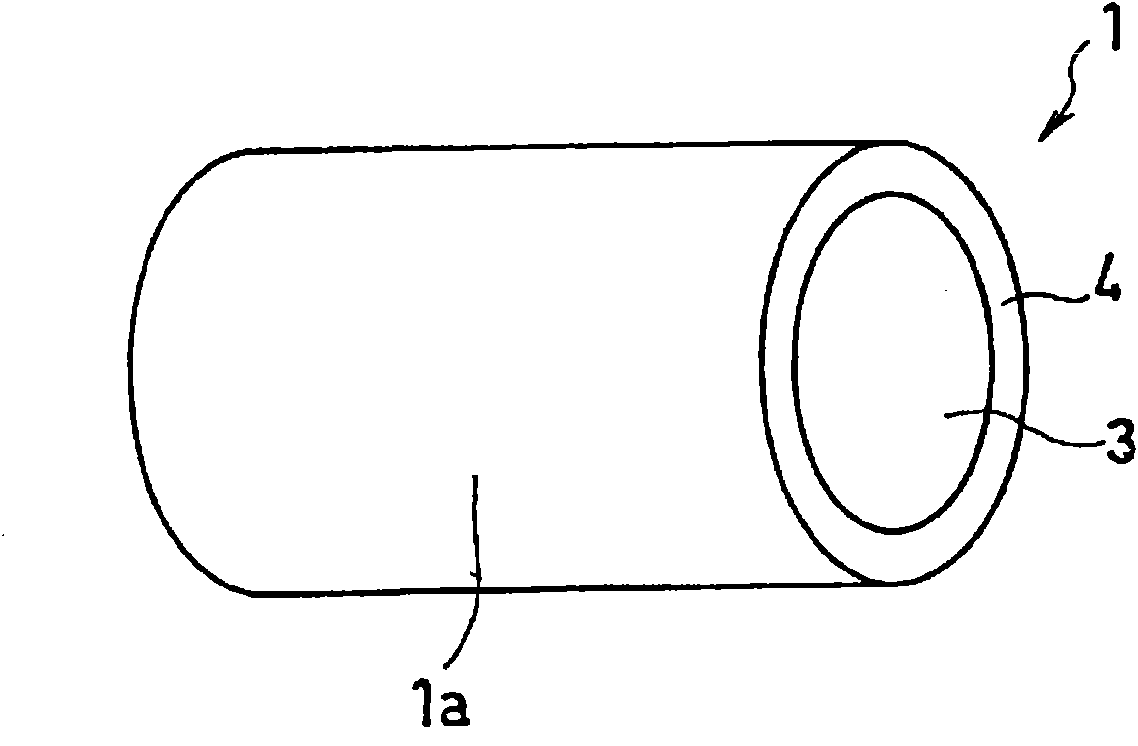

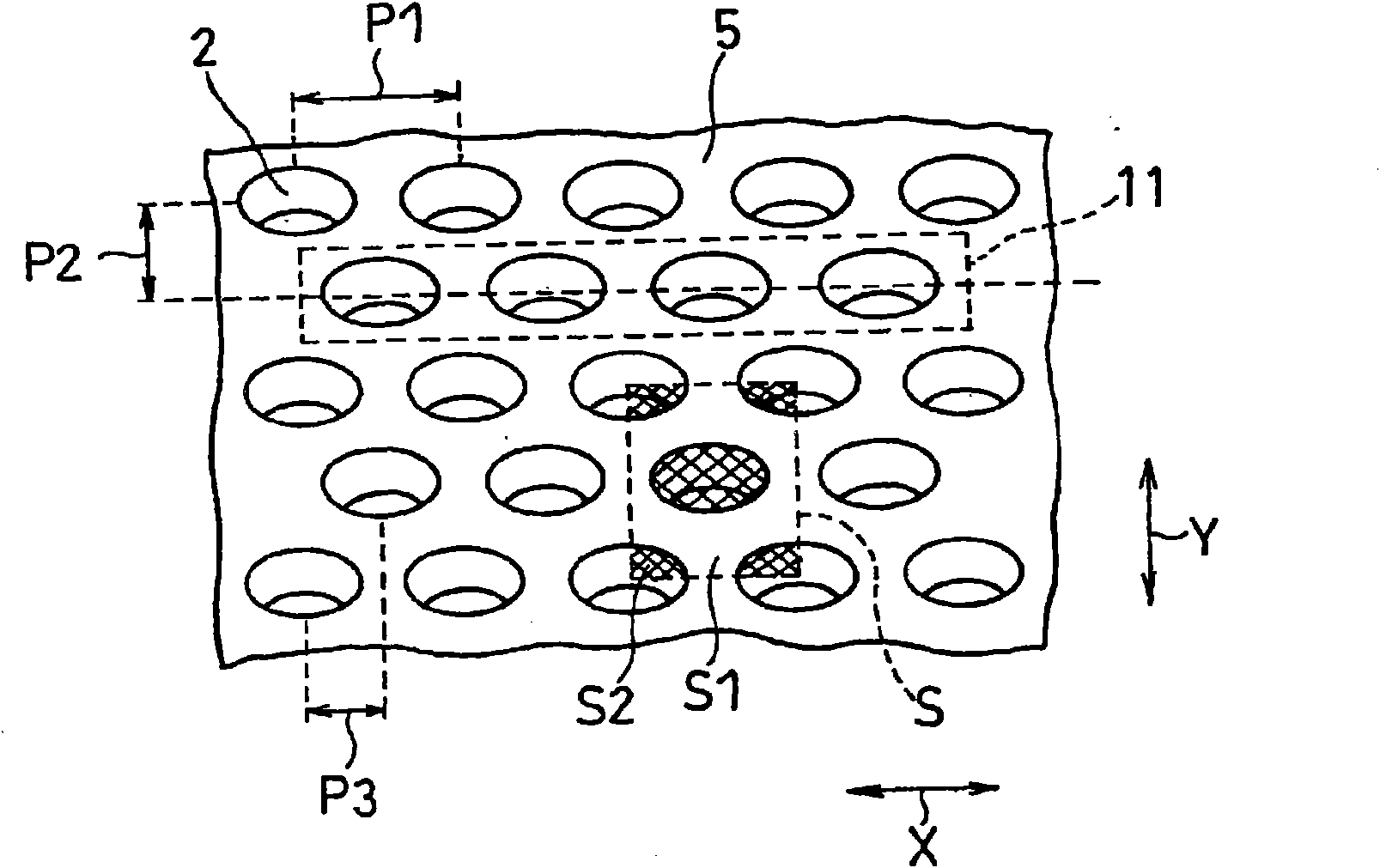

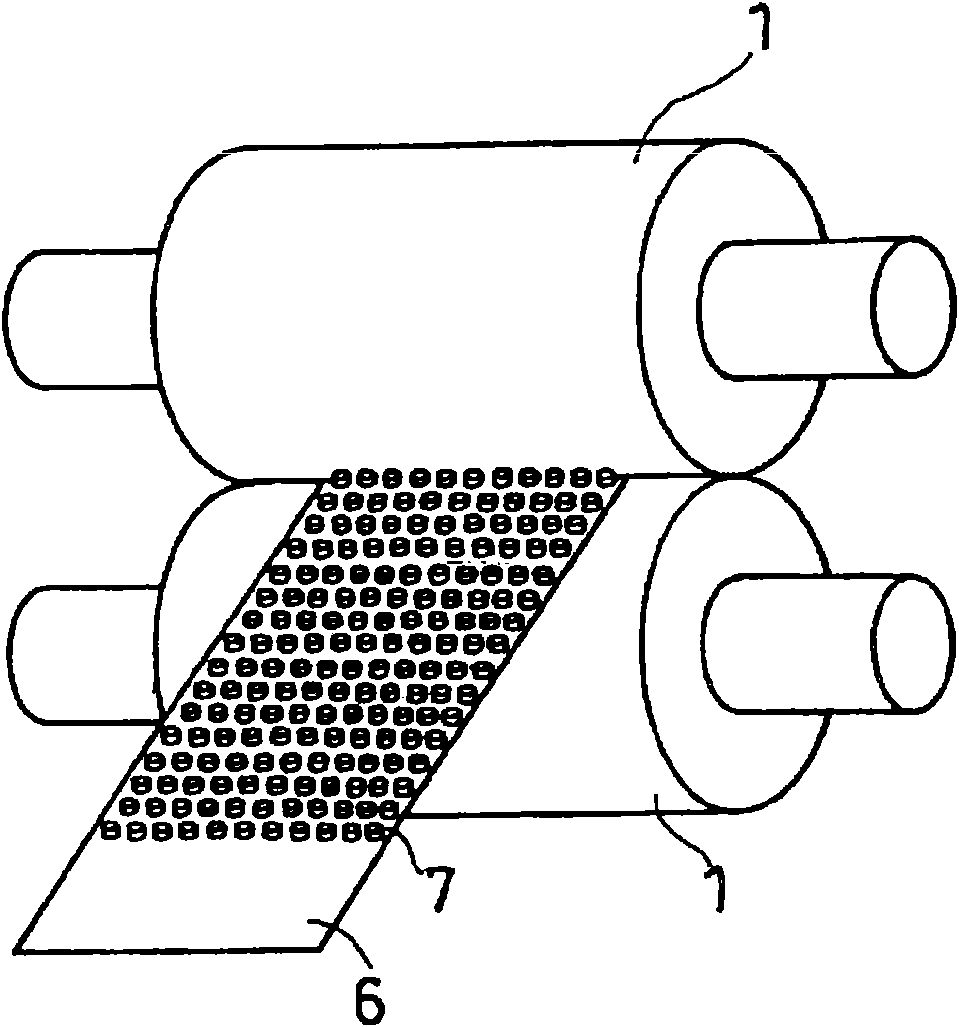

[0111] Figure 1A A schematic configuration of a roller as a processing tool used in the method of manufacturing a battery current collector according to Embodiment 1 of the present invention is shown. Figure 1B It is an enlarged perspective view of a part of its peripheral surface.

[0112] The roller 1 is constituted by forming a plurality of recesses 2 and a pressing flat surface 5 surrounding them on a peripheral surface 1a which is a processing surface. The pressing plane 5 is preferably formed such that the surface roughness (arithmetic mean roughness Ra, hereinafter the same) is 0.8 μm or less. In addition, the concave portion 2 can be formed so as to have a depth of 1 to 15 μm. In addition, the roller 1 is comprised by the core part 3 and the outer peripheral part 4 of mutually different materials as mentioned later in detail. again, in Figure 1A In , the r...

Embodiment 1

[0156] As for the roller, quenched alloy steel of die steel SKD11 was used as the core portion 3 , and an outer peripheral portion in which the peripheral surface 1 a was finished by spraying cemented carbide was used as the outer peripheral portion 4 . Furthermore, by laser processing on the peripheral surface of the roller according to Figure 1B The configuration shown forms a recess 2 . Then, the peripheral surface 1 a of the roller 1 is ground with a plurality of diamond particles having an average particle diameter of 0.5 to 30 μm to remove burrs or bulges formed on the edges of the recesses 2 . This is to prevent the surface roughness of the peripheral surface of the roller from becoming partially rough due to the above-mentioned burrs or bulges. In this way, the pressing flat surface 5, which is the portion other than the concave portion 2, on the peripheral surface of the roller was finished so that the surface roughness (arithmetic mean roughness Ra, the same applie...

Embodiment 2

[0161] The surface roughness of the pressing plane 5 of the above-mentioned upper roll was finished to 0.2 μm. Using this roll, a current collector for a positive electrode having a surface roughness of the base plane 8 of 0.2 μm was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com