Sub-muffler

一种消声器、吸声材料的技术,应用在吸声、消音装置、机器/发动机等方向,能够解决没有指明使用何种类型玄武岩纤维等问题,达到保持耐久性和吸声性能、降低制造成本的效果

Inactive Publication Date: 2008-11-26

TOYOTA JIDOSHA KK +1

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the above publication, it is not indicated at all what type of basalt fiber is used

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

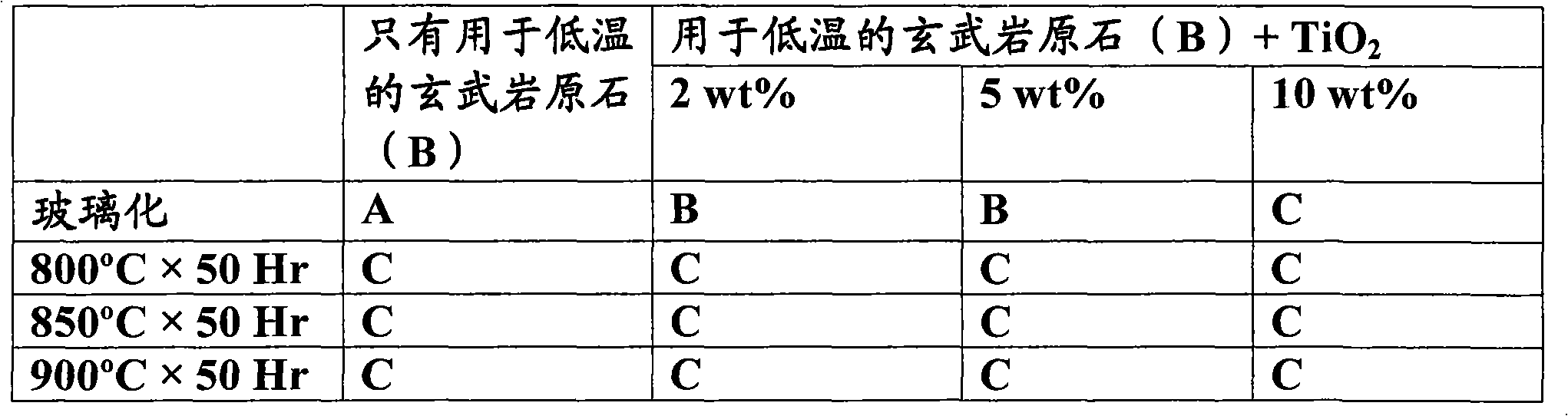

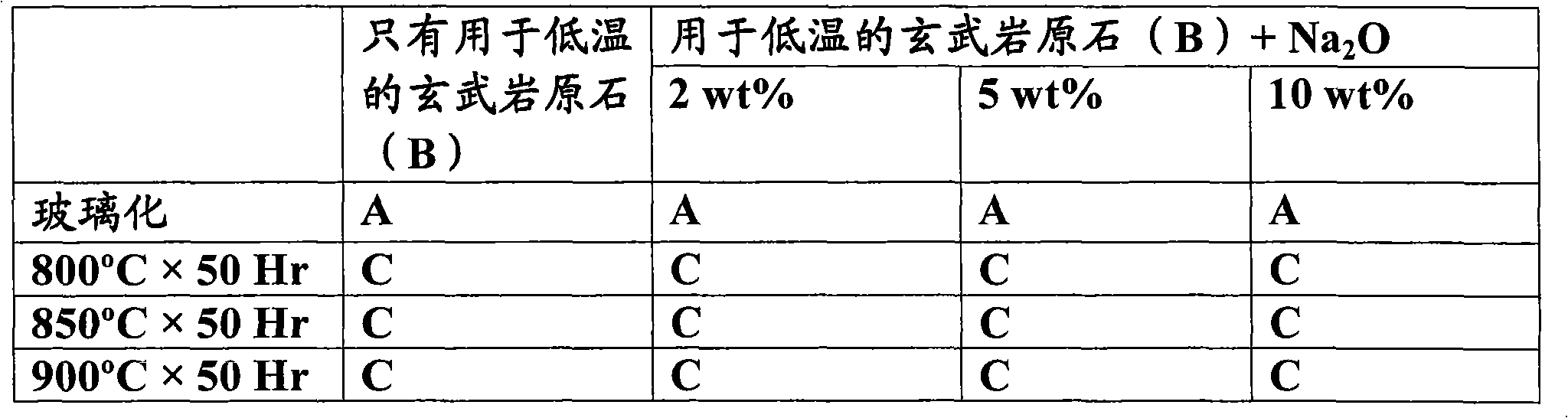

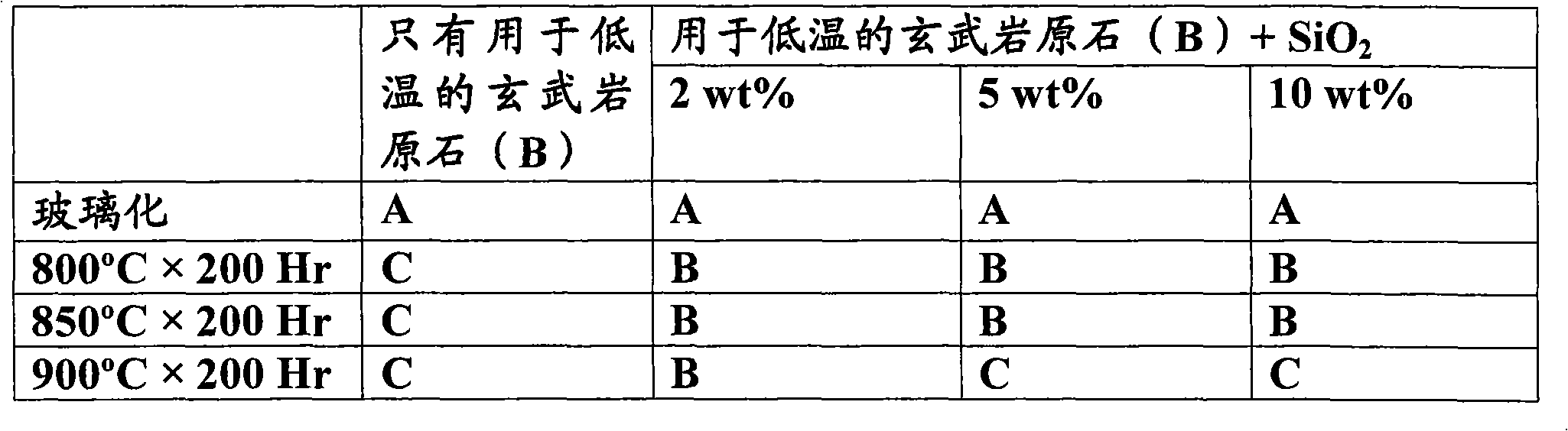

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Provided is a sub-muffler which needs no heat resistant material such as SUS, and which can keep its durability and sound absorbing performance even when the sub-muffler is exposed to various corrosive components in the exhaust gas. At the same time, accomplished is a low-cost manufacture, which is a challenge that sub-mufflers and sound absorbing materials commonly face. Disclosed is a sub-muffler in which a perforated exhaust pipe is arranged, and caps and an out pipe are arranged outside the perforated pipe. Sound absorbing materials are filled in the space between the perforated exhaust pipe, and the caps and the out pipe. The sub-muffler is characterized in that, among the sound absorbing materials, at least part of the sound absorbing material of the perforated pipe side is a basalt fiber for high temperature.

Description

Second muffler technical field The present invention relates to a sub-muffler (sub-muffler) using basalt fiber. As a sound-absorbing material, the basalt fiber has excellent sound-absorbing performance and excellent heat resistance. Background technique Automobile mufflers are used as components to absorb exhaust noise. Fiberglass is currently used as the sound-absorbing material for mufflers. Recently, the need for energy saving and stricter control of exhaust emissions have brought about an increase in the temperature of automobile engines, which is accompanied by an increase in the exhaust temperature at the muffler section to over 800°C. For this reason, there is an urgent need to develop a sound absorbing material for mufflers with higher heat resistance (capable of withstanding temperatures from 750°C to 900°C). For example, exposure to high temperature (up to 800°C) gases discharged from the exhaust systems of various types of engines has resulted in commercially...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F01N1/00F01N1/24F01N13/16F01N13/18

CPCF01N1/003F01N1/24C03C13/06F01N2310/02F01N1/00

Inventor 神谷纯生若月一稔笹木宏格中川敬章

Owner TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com