Patents

Literature

34results about How to "Appropriate flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

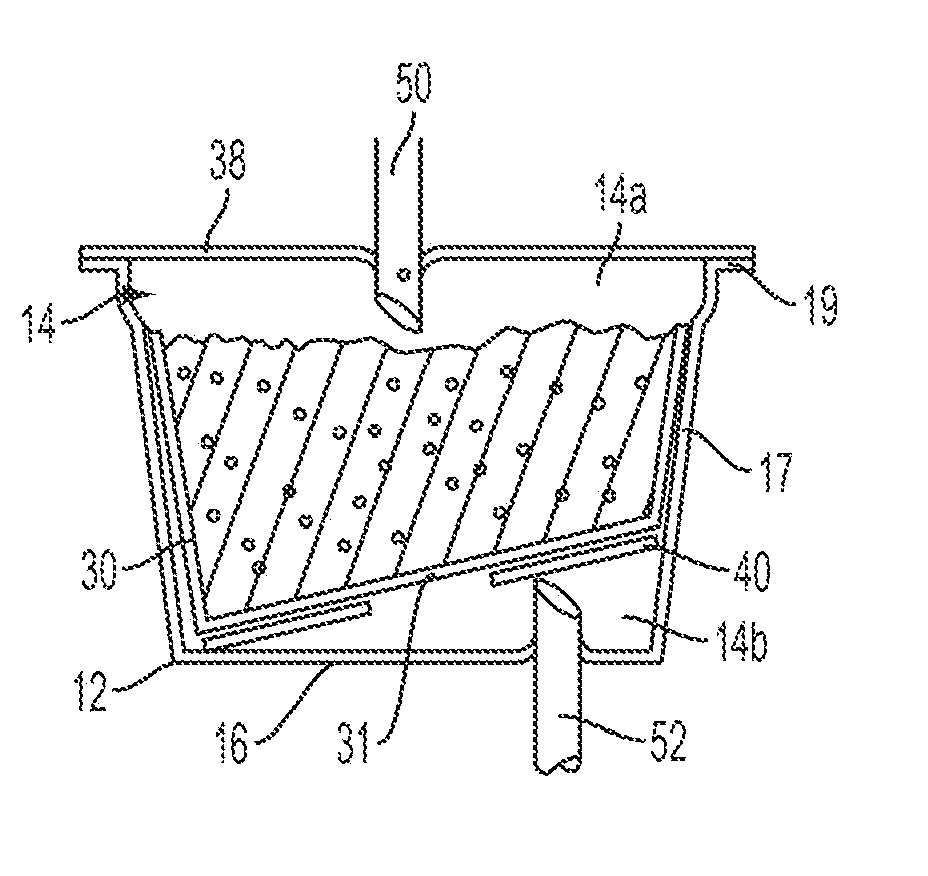

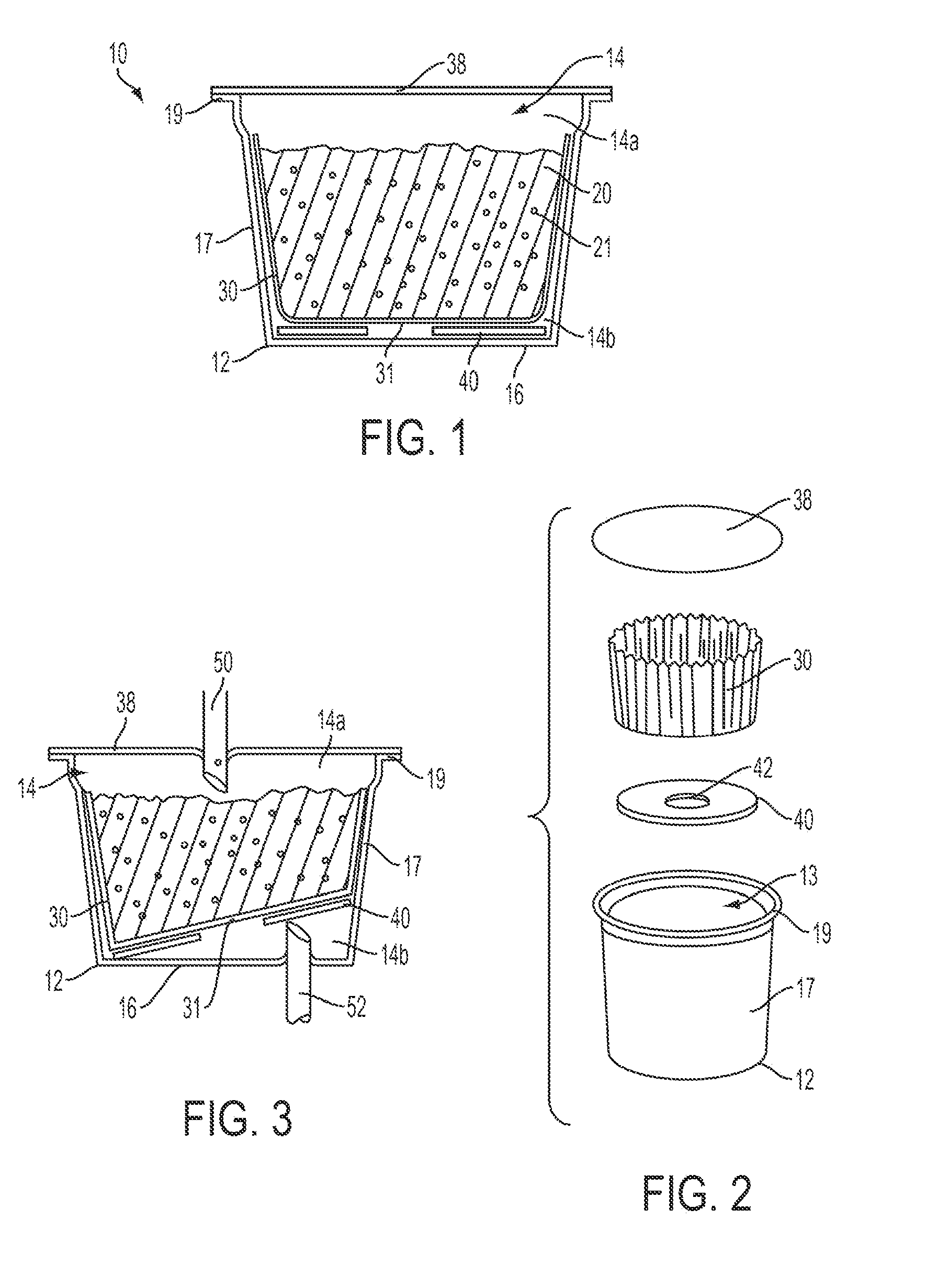

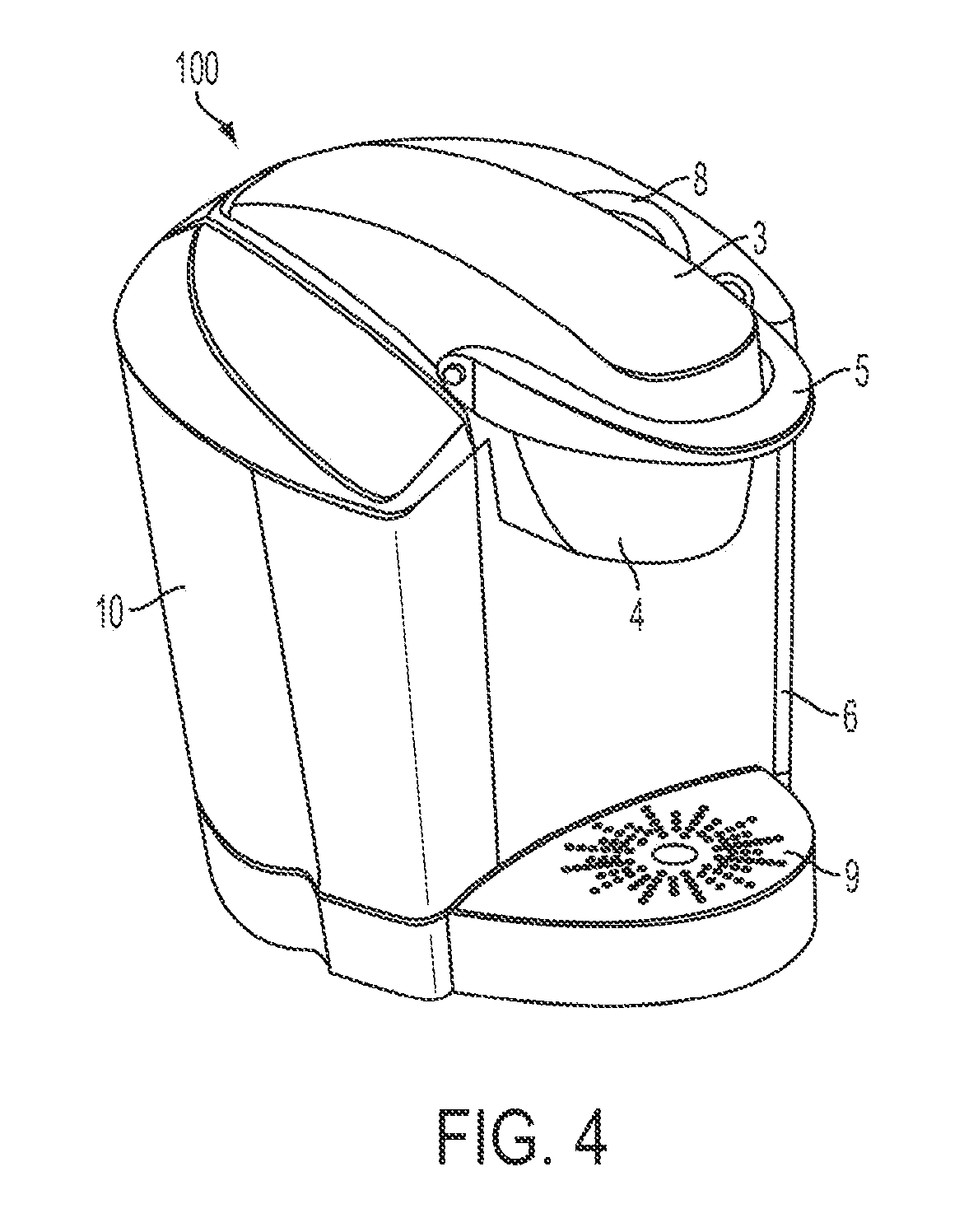

Beverage cartridge and method for beverage formation using filter aid

InactiveUS20110076361A1Speed up circulationReduce cloggingTea extractionBeverage vesselsParticulatesCellulose

A method and apparatus for forming a beverage involves the use of a filter aid, e.g., that is provided in a beverage cartridge with a beverage medium in a dry state. In one embodiment, a cartridge including a dried fruit material may also include a filter aid, such as perlite, diatomaceous earth or cellulose, that is mixed together with the fruit material. The filter aid may assist in flow through the beverage medium or through a filter, e.g., by helping prevent the clogging of pores of a filter used to remove particulate from a beverage formed by interaction of the beverage medium with water introduced into the cartridge. Thus, the filter aid may permit the use of some beverage media that would otherwise clog a filter and / or prevent proper dissolution of materials in the beverage media without the filter aid.

Owner:GREEN MOUNTAIN COFFEE ROASTERS INC

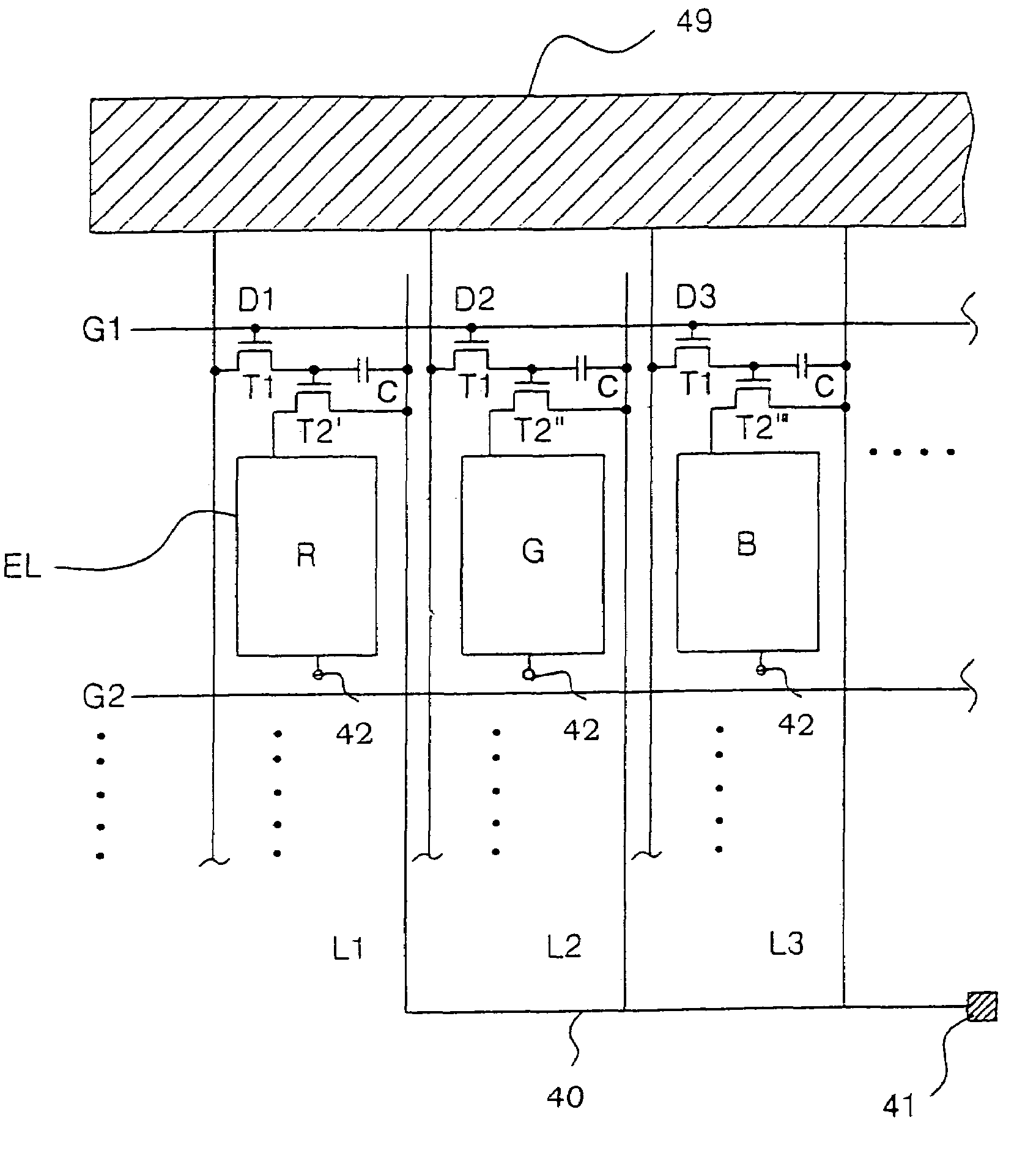

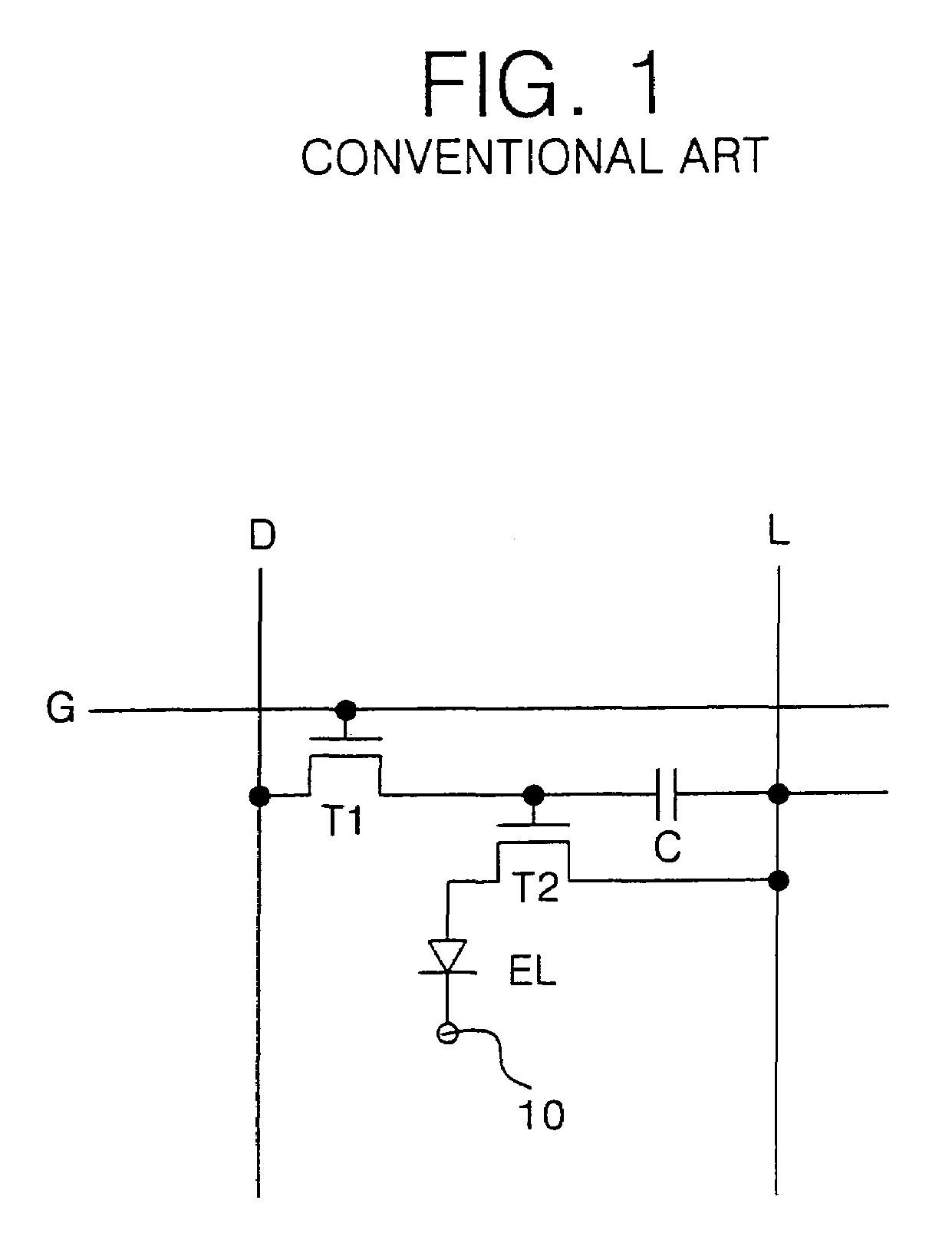

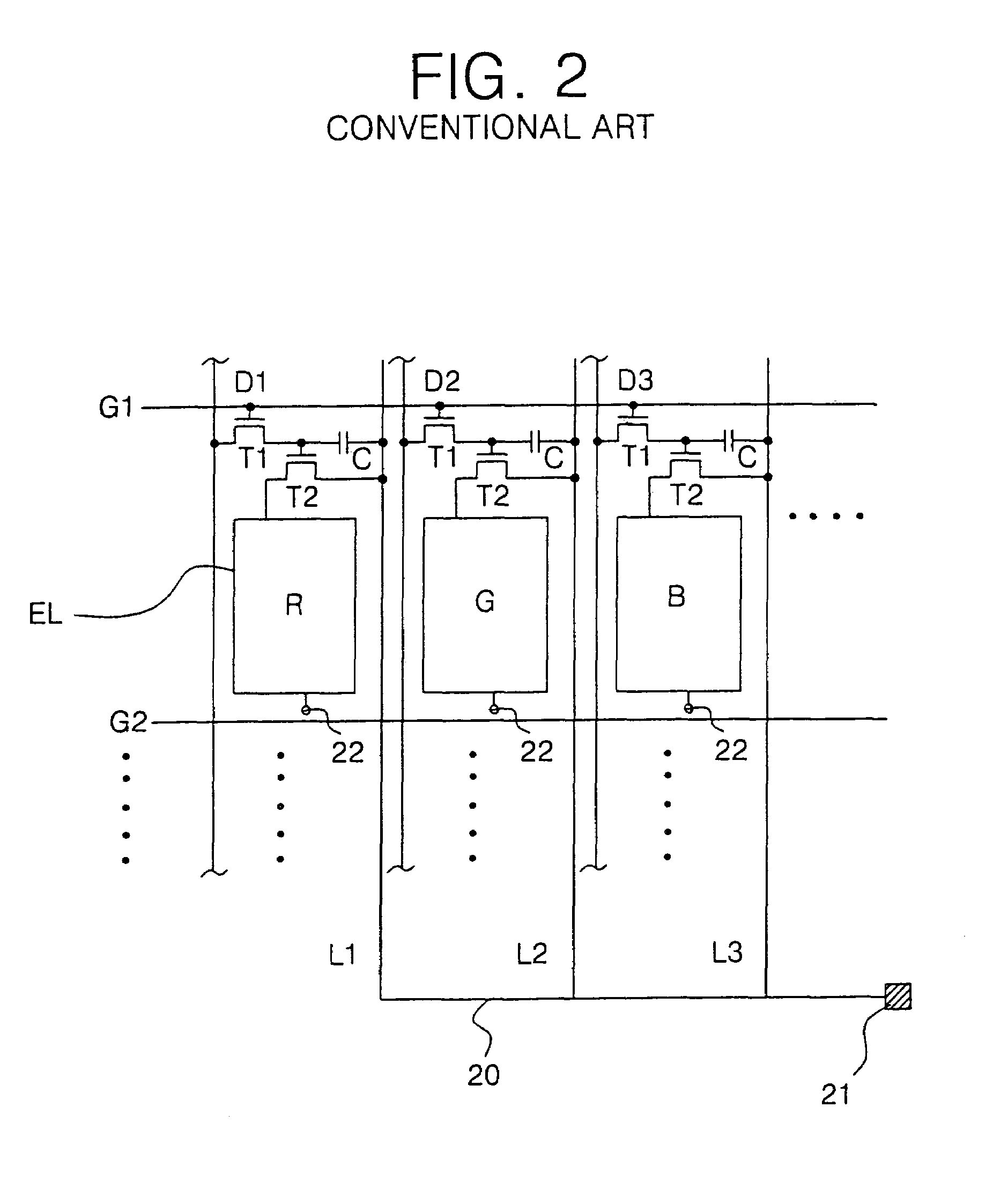

Electro-luminescence display and drving method thereof

InactiveUS7221337B1Appropriate flowStatic indicating devicesElectroluminescent light sourcesChannel widthElectricity

An electro-luminescence display which obtains proper color realization even though identical data driving waveforms are applied to each group of R, G and B pixel cells. In the display, a plurality of data lines cross a plurality of gate lines to define a plurality of pixel cell areas. A plurality of power supply lines pass through the pixel cell areas. A switching device is provided in each pixel cell area in such a manner to be electrically connected to the gate line and the data line. A plurality of driving devices are patterned based on a ratio of channel width to channel length in accordance with the type of pixel cell area. Each driving device having a gate connected to one electrode of the switching device and a source connected to the power supply line at each of the pixel cell areas. A plurality of EL diodes are connected to the plurality of driving devices, respectively. A wiring is commonly connected to the plurality of power supply lines. The R, G and B pixel cells are independently driven using different currents, although a common voltage is received by the driving devices.

Owner:LG DISPLAY CO LTD

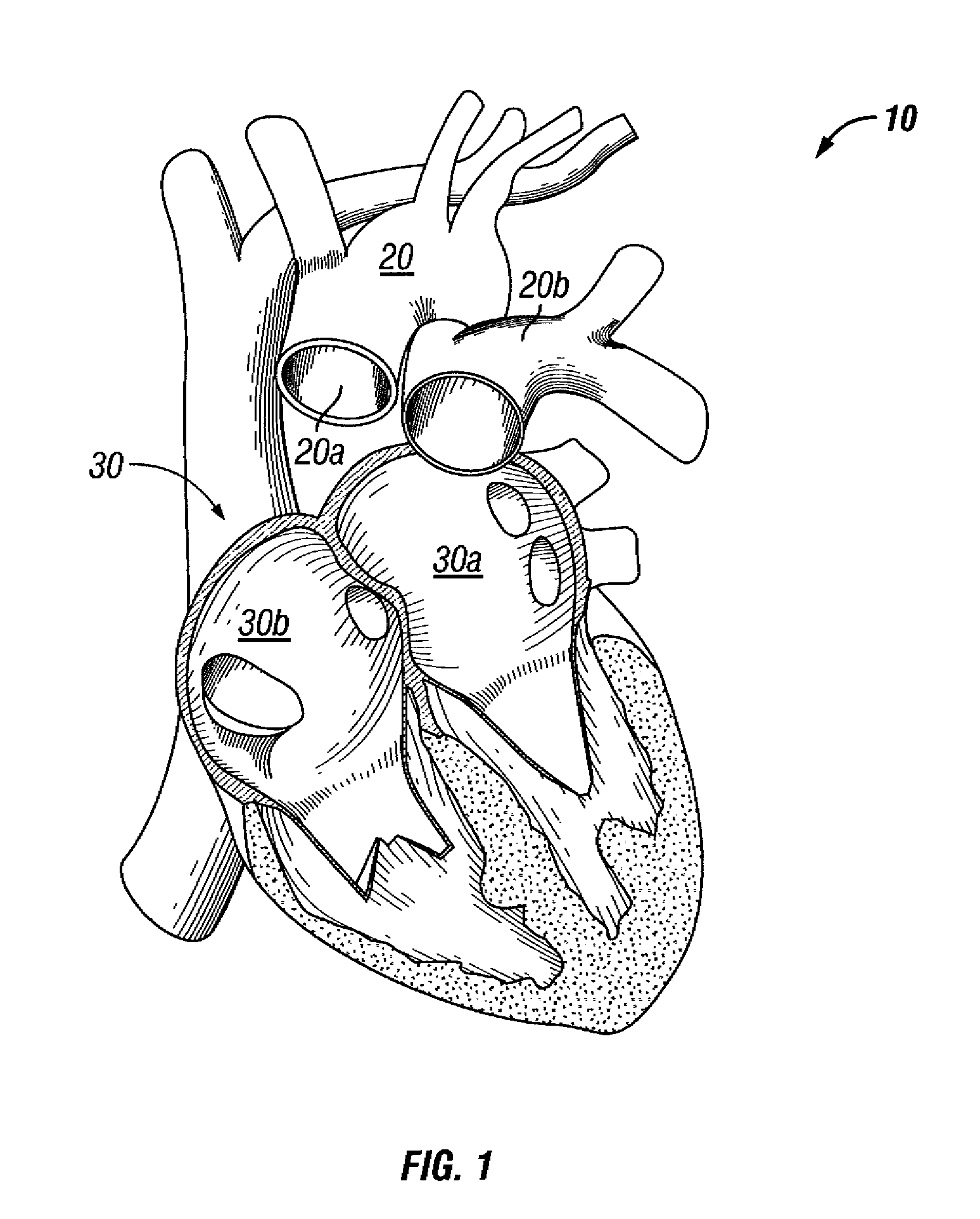

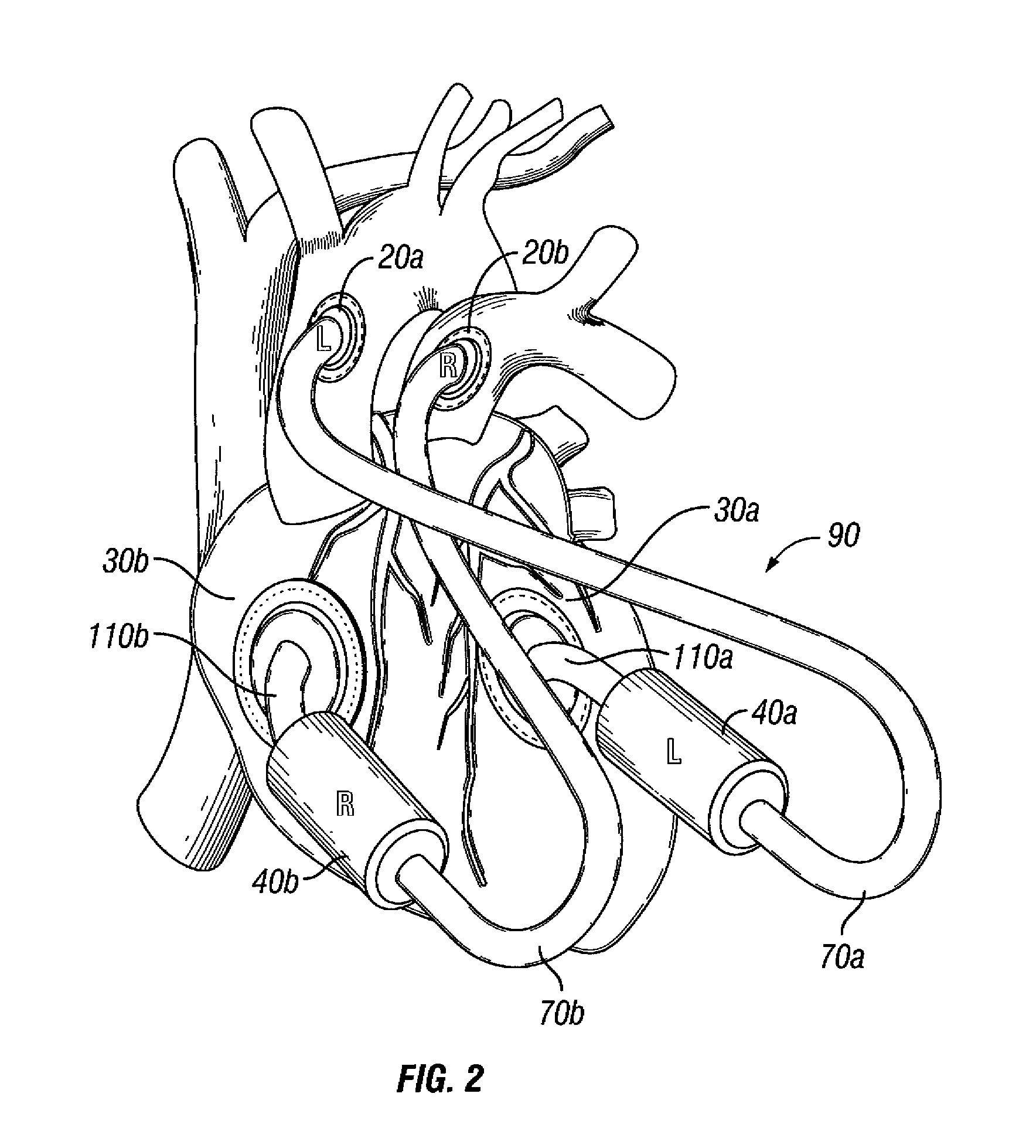

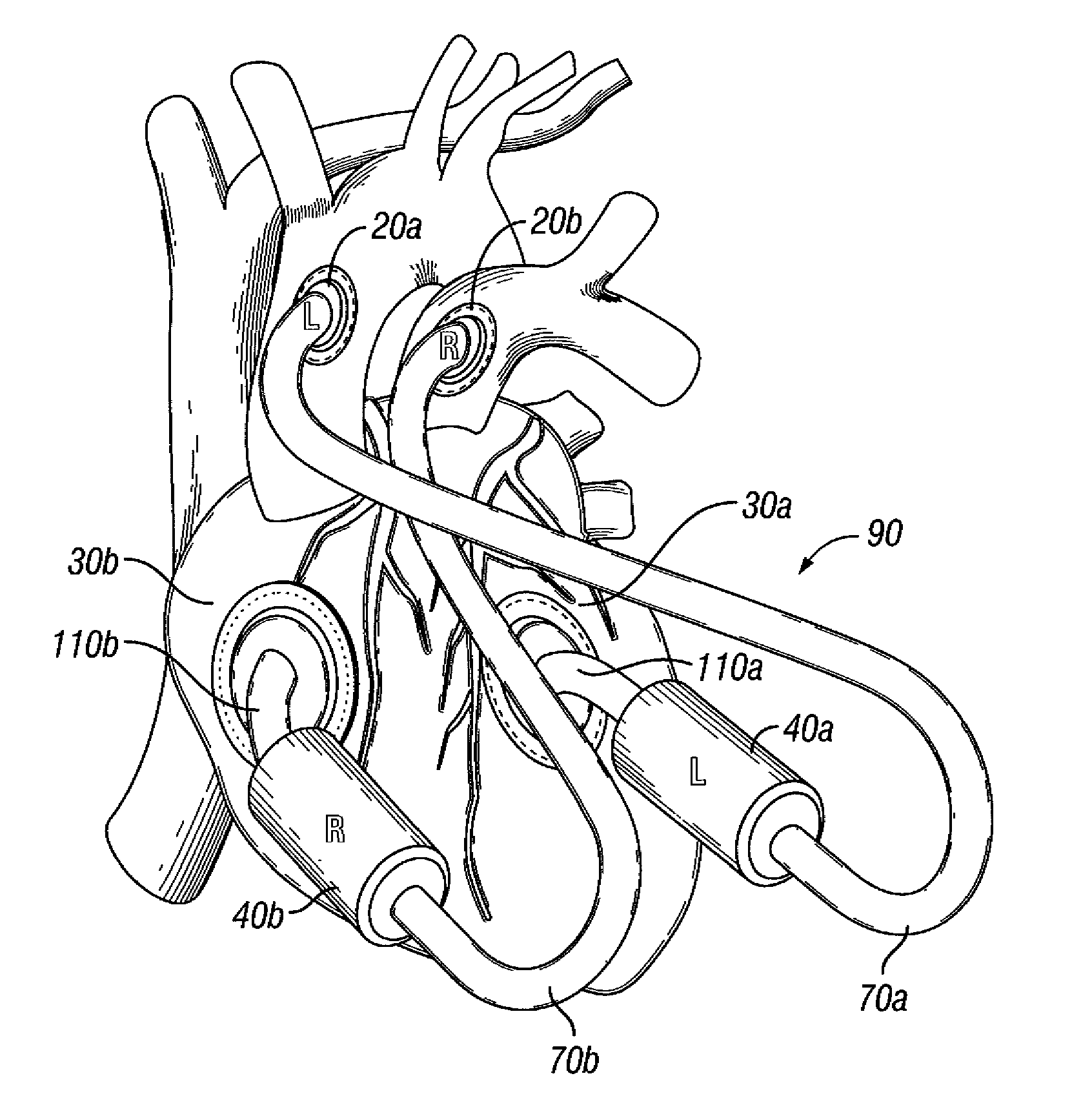

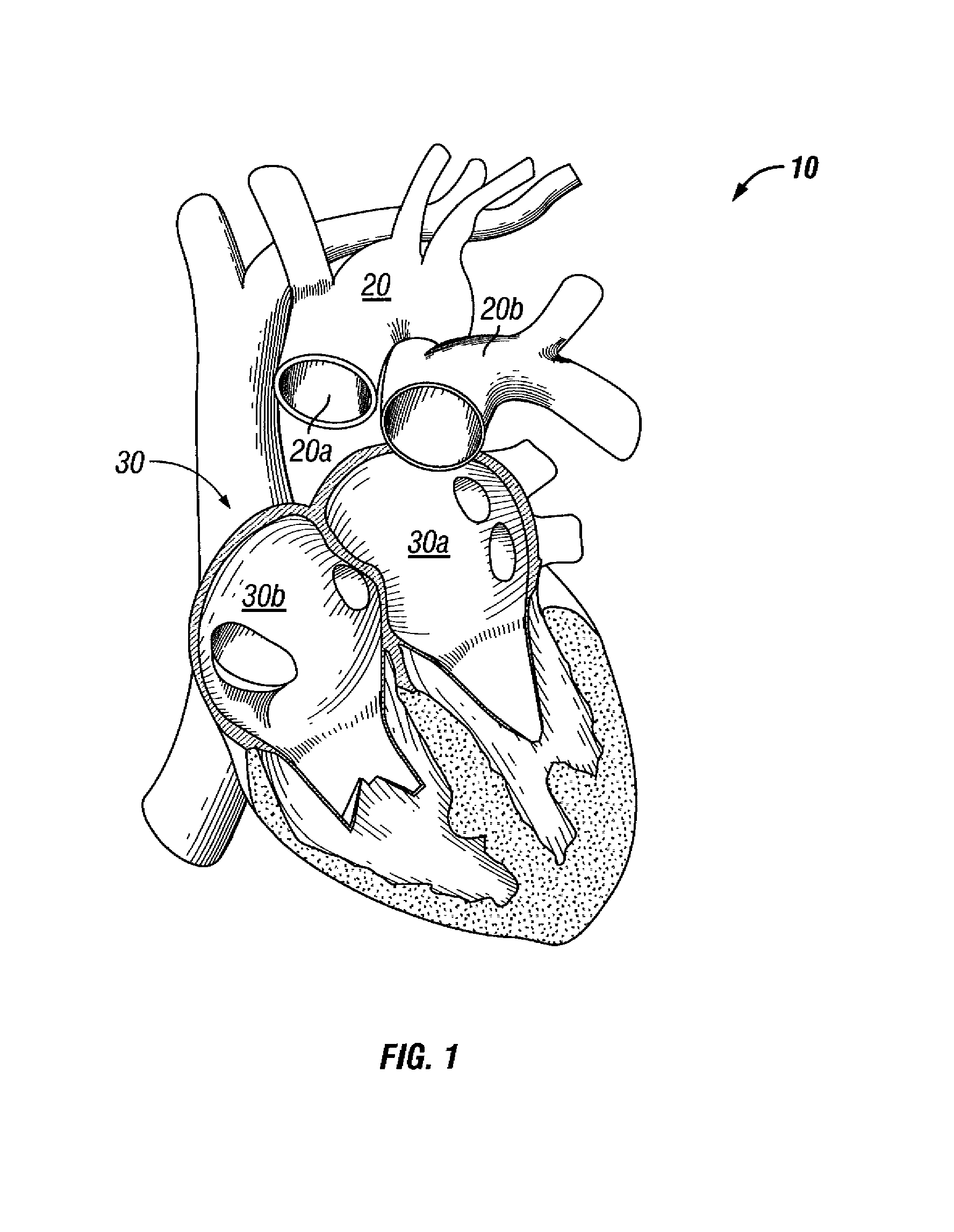

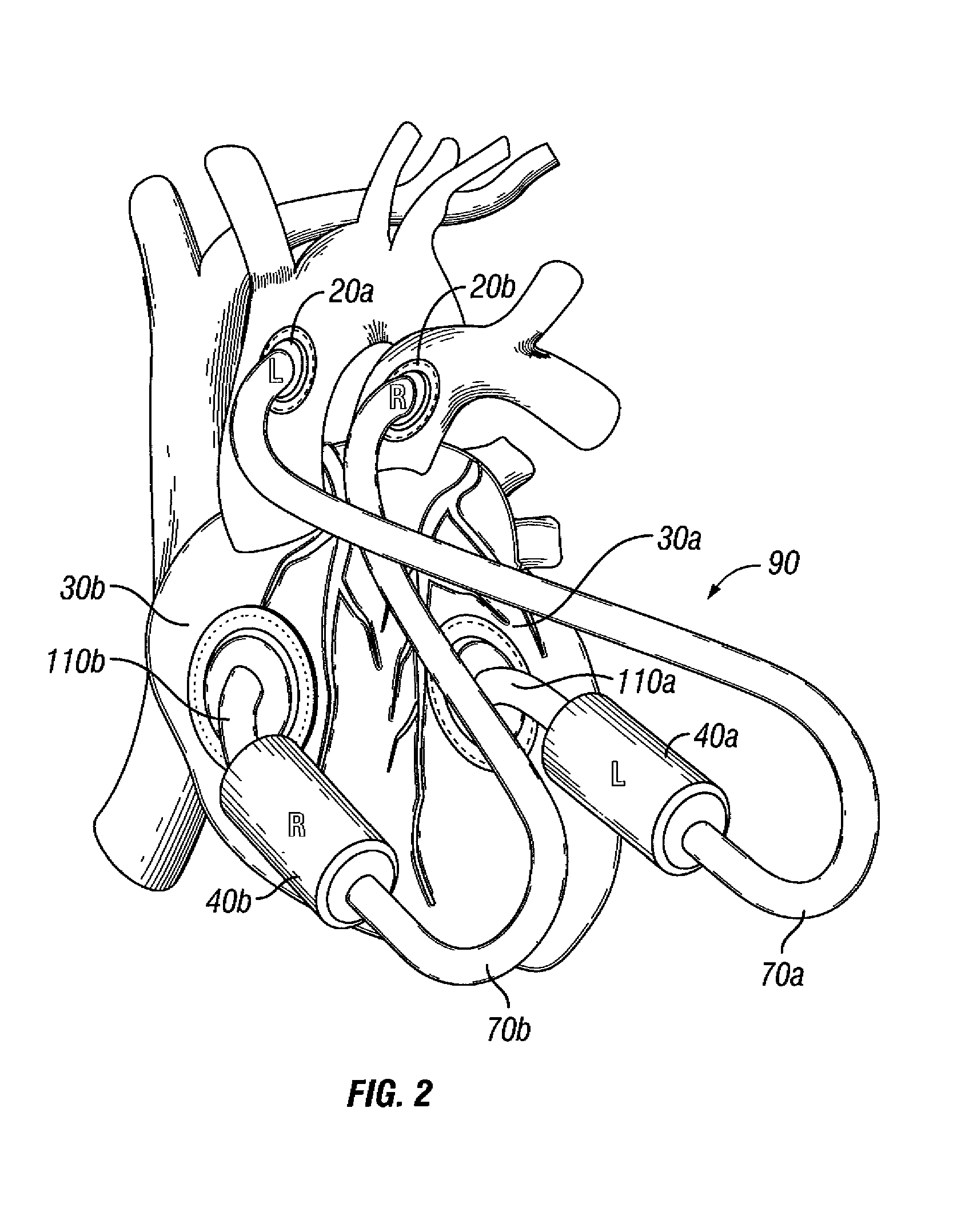

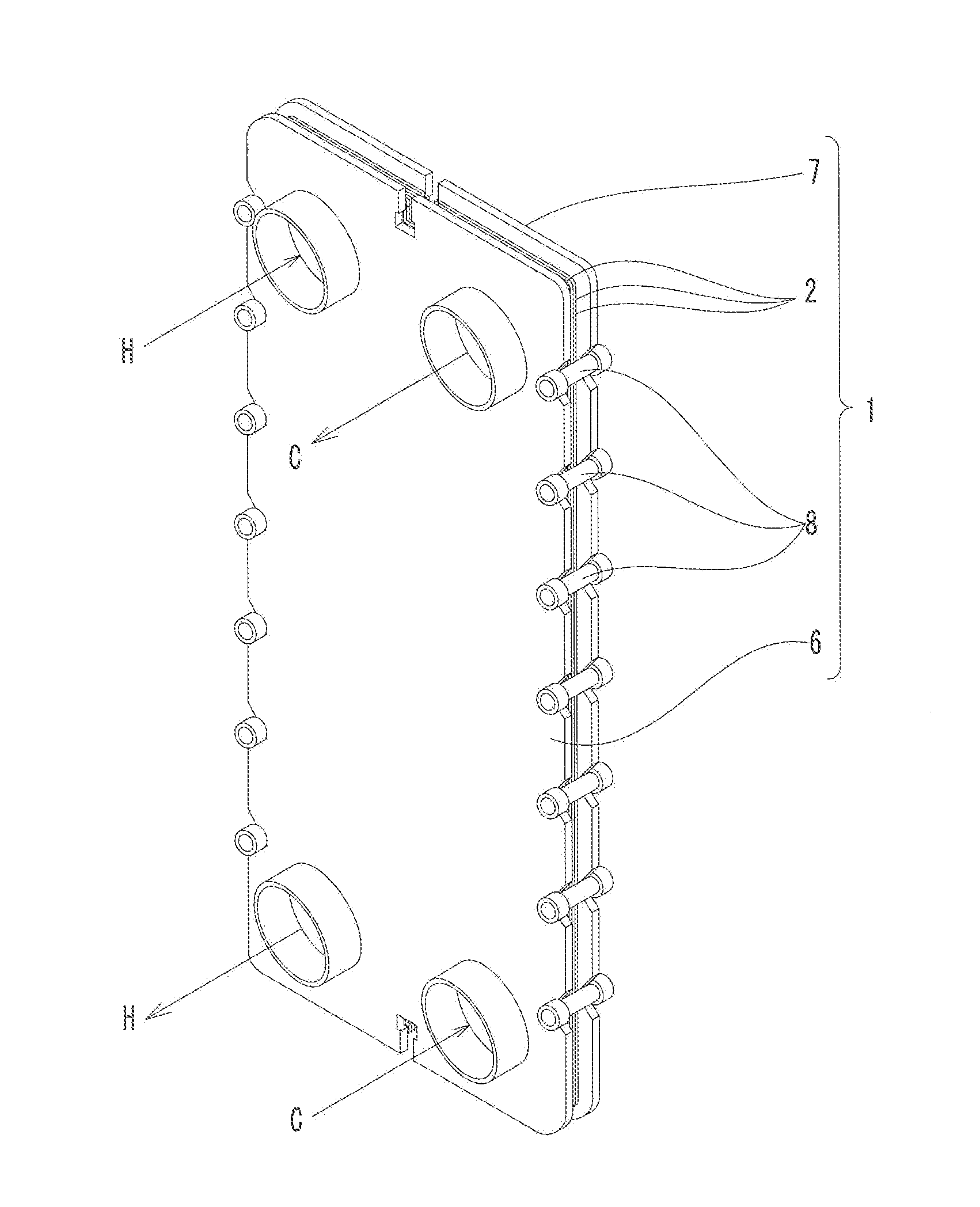

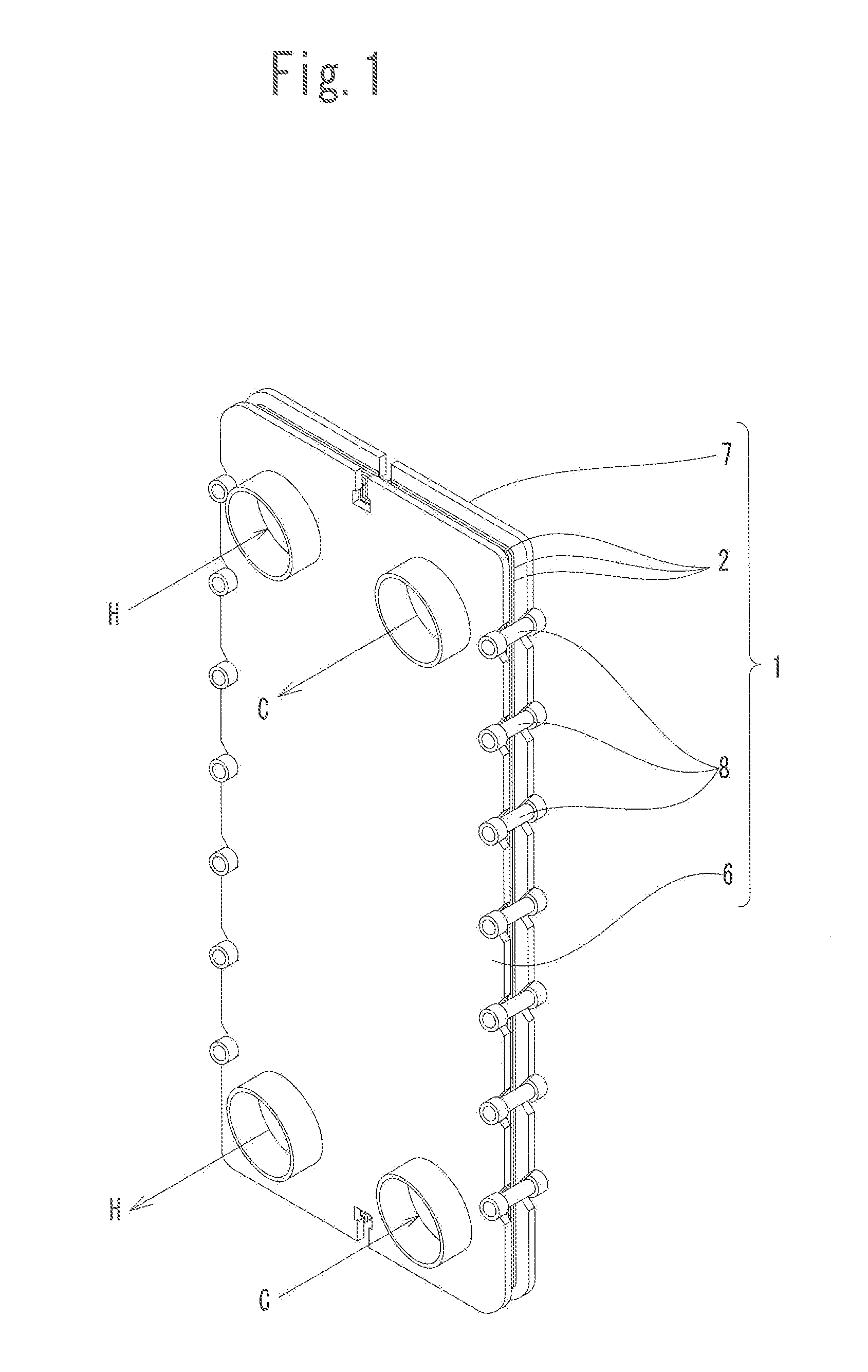

Total artificial heart system for auto-regulating flow and pressure

InactiveUS8226712B1Reduce resistanceMinimizing pressure gradientControl devicesBlood pumpsWhole bodyContinuous flow

The present invention is TAH system for auto-regulating blood flow and maintaining the asymmetric pressure balance in the mammalian cardiovascular system by decreasing the resistance in blood flow and minimizing the pressure gradients to exploit the in-flow pressure sensitivities of continuous flow pumps. The system further includes laminar flow generating manifolds connected to the atrium at one end and attached to pumps linked to the great vessels at the other, such that the in-let flow sensitivities of the pumps are maximized to auto-regulate blood flow, providing adequate pulmonary and systemic arterial flow to support normal metabolism and end-organ function and maintain the appropriate asymmetric physiologic pressure balance between the systemic and pulmonary systems of the mammalian cardiovascular system.

Owner:ALPHA DEV

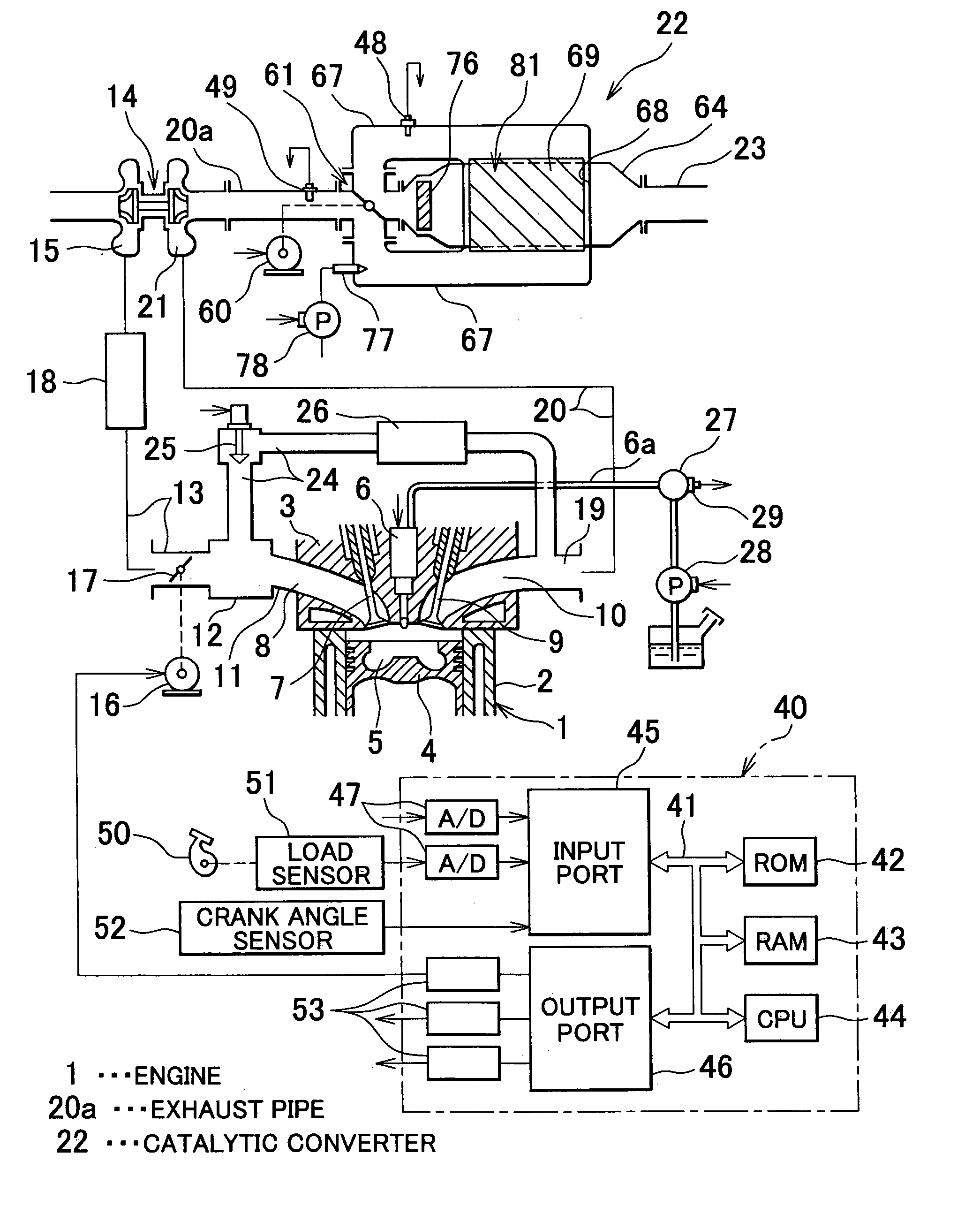

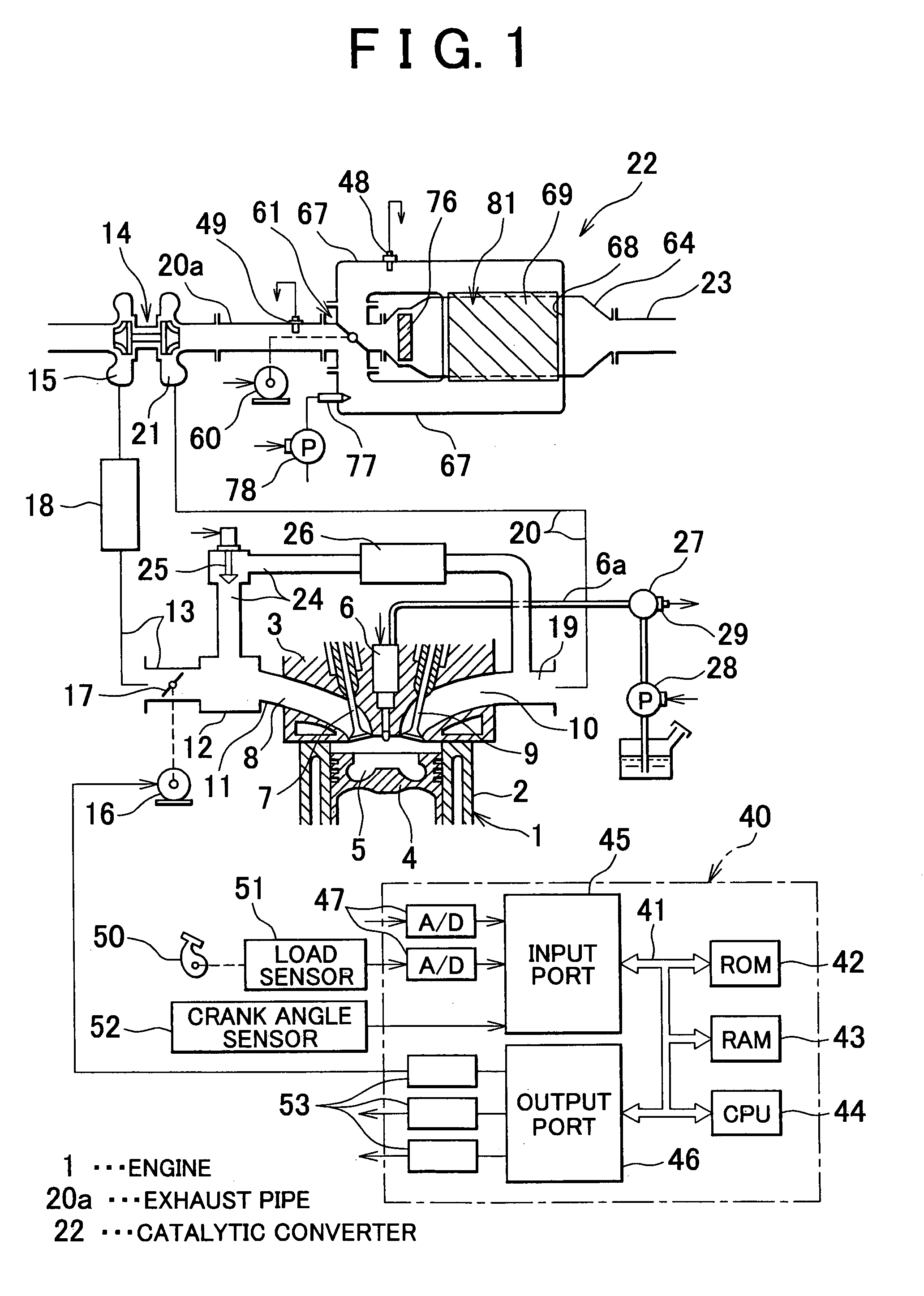

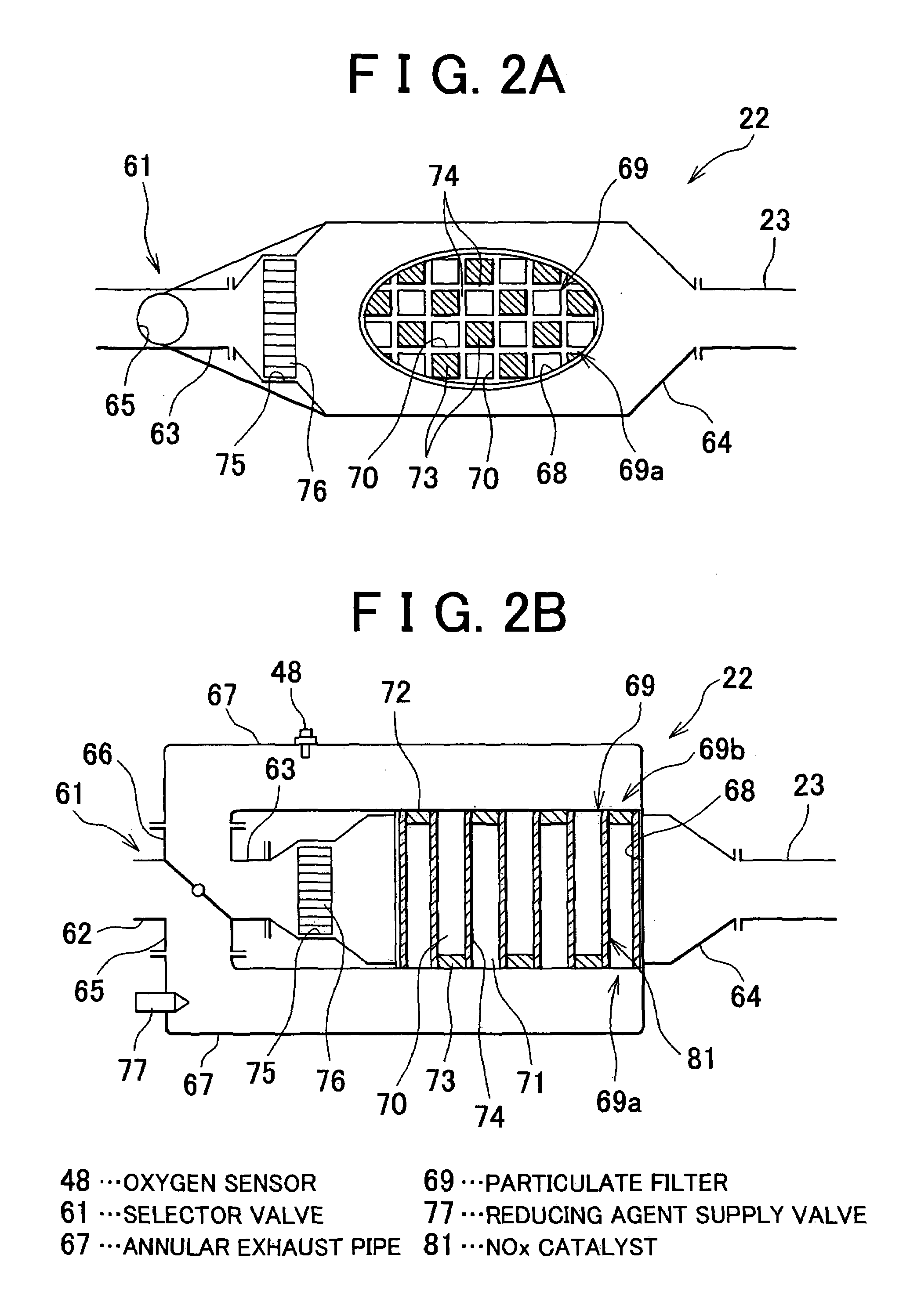

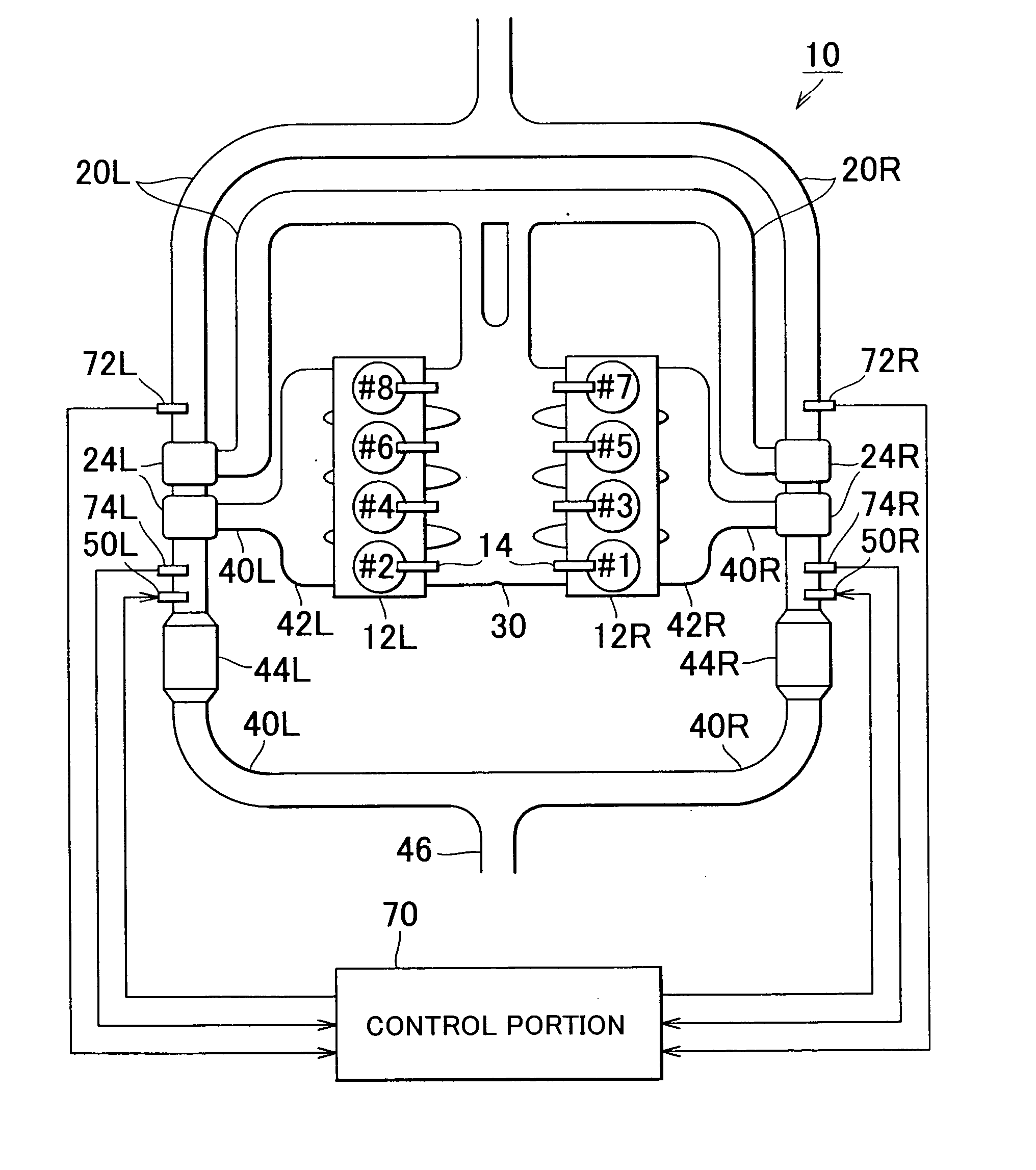

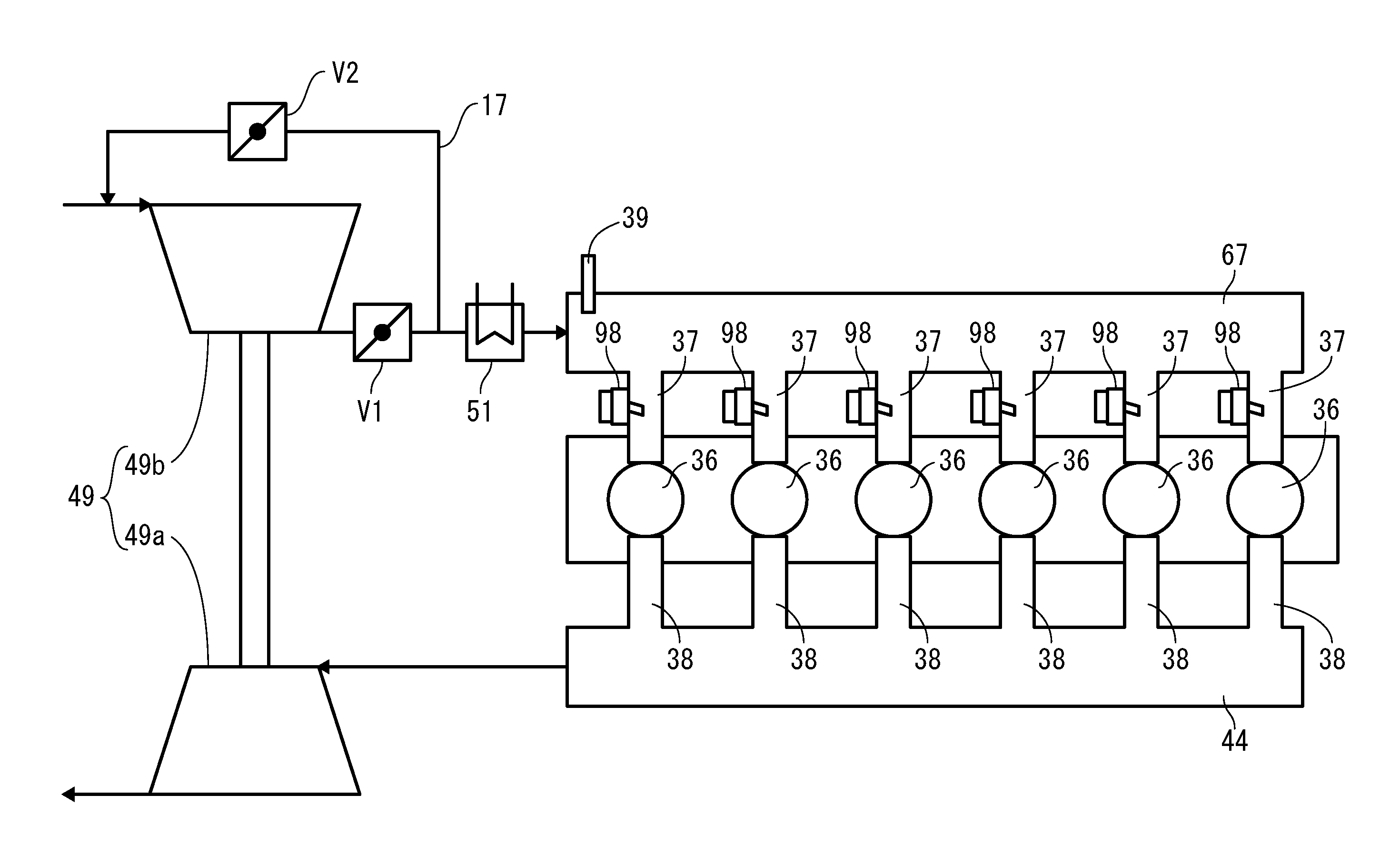

Exhaust emission control apparatus of internal combustion engine and method thereof

InactiveUS7219491B2Appropriate flowReduce flow rateExhaust apparatusDispersed particle separationPtru catalystOxygen sensor

An exhaust emission control apparatus includes a NOX catalyst provided within an exhaust passage of an internal combustion engine where fuel combustion is continuously performed at a lean air / fuel ratio, and a reducing agent supply valve within the exhaust passage upstream of the NOX catalyst. If the NOX stored in the NOX catalyst is required to be decreased, a selector valve position is selected between a forward and a reverse flow positions so as to decrease a flow rate of the exhaust gas flowing through the NOX catalyst. Then a reducing agent is supplied upon elapse of a predetermined time period from the timing when the signal instructing to select the position of the selector valve. An oxygen sensor detects an oxygen concentration of the exhaust gas discharged from the NOX catalyst upon supply of the reducing agent. The elapsing time is corrected such that a peak value of the detected oxygen concentration accords with the target value.

Owner:TOYOTA JIDOSHA KK

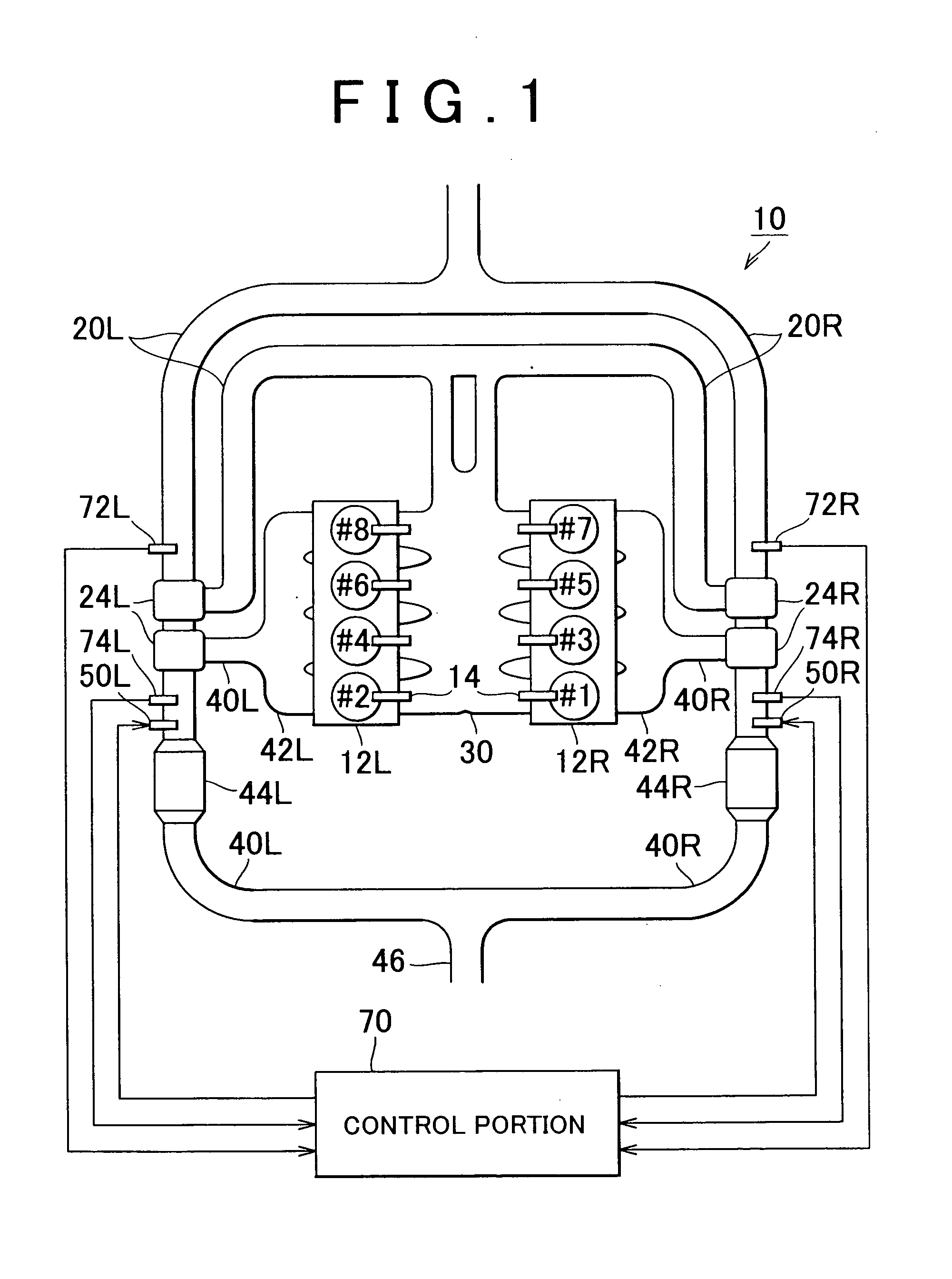

Exhaust gas control apparatus and exhaust gas control method for internal combustion engine

InactiveUS20050274106A1Appropriate flowInhibit adhesionElectrical controlPiston ringsExhaust fumesInternal combustion engine

In an exhaust gas control apparatus and exhaust gas control method for an internal combustion engine, in which fuel is supplied to a purification mechanism provided in an exhaust passage so that a function of the purification mechanism is recovered. A flow rate of exhaust gas flowing in the exhaust passage or a value correlated with the flow rate is detected, and fuel supply timing is controlled based on a result of the detection. Accordingly, even when the flow rate of the exhaust gas flowing in the exhaust passage is variously changed based on the engine operating state, the fuel supply timing can be set based on the flow rate that is appropriately detected. Thus, it is possible to appropriately convey the supplied fuel to the purification mechanism using force of the exhaust gas.

Owner:TOYOTA JIDOSHA KK +1

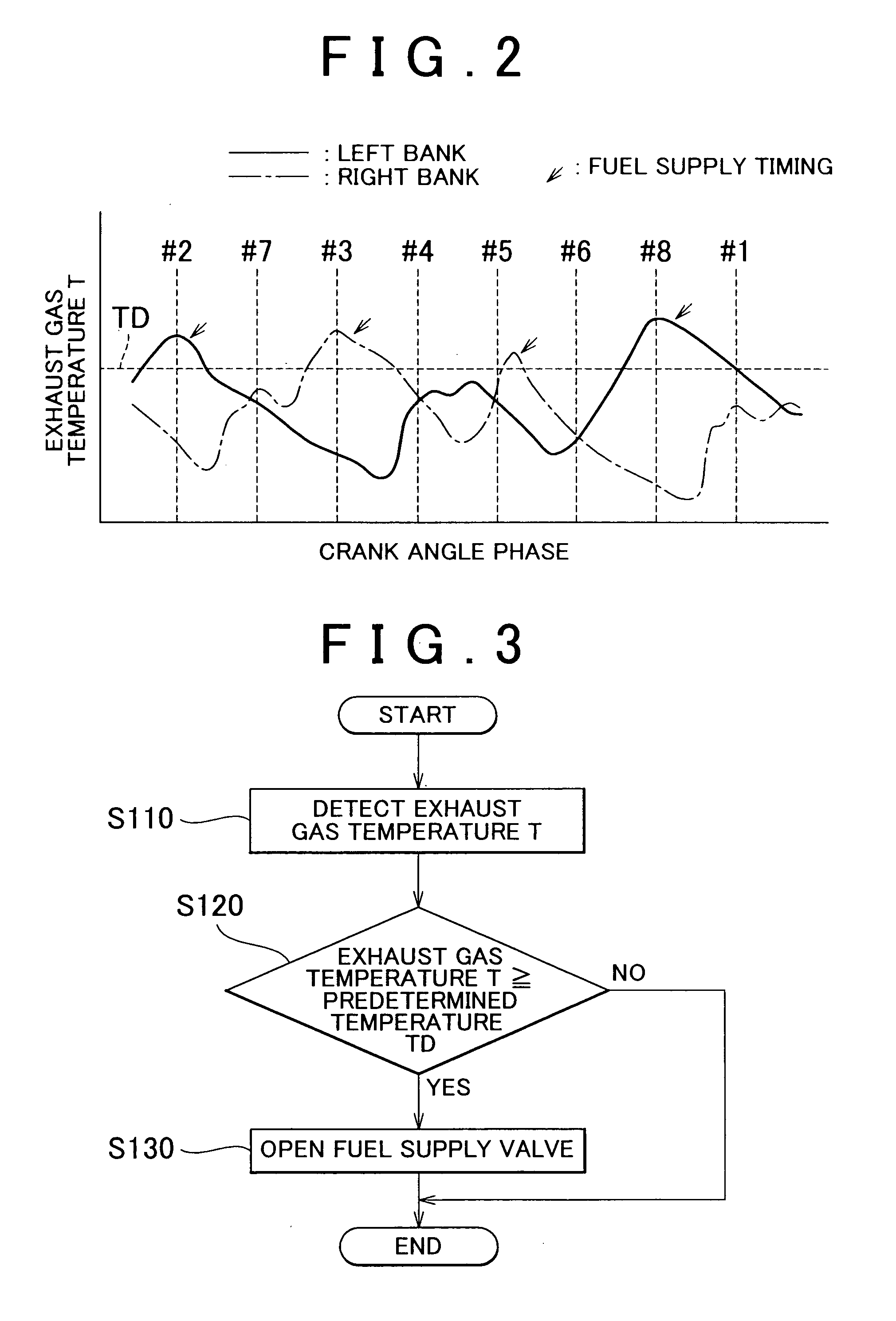

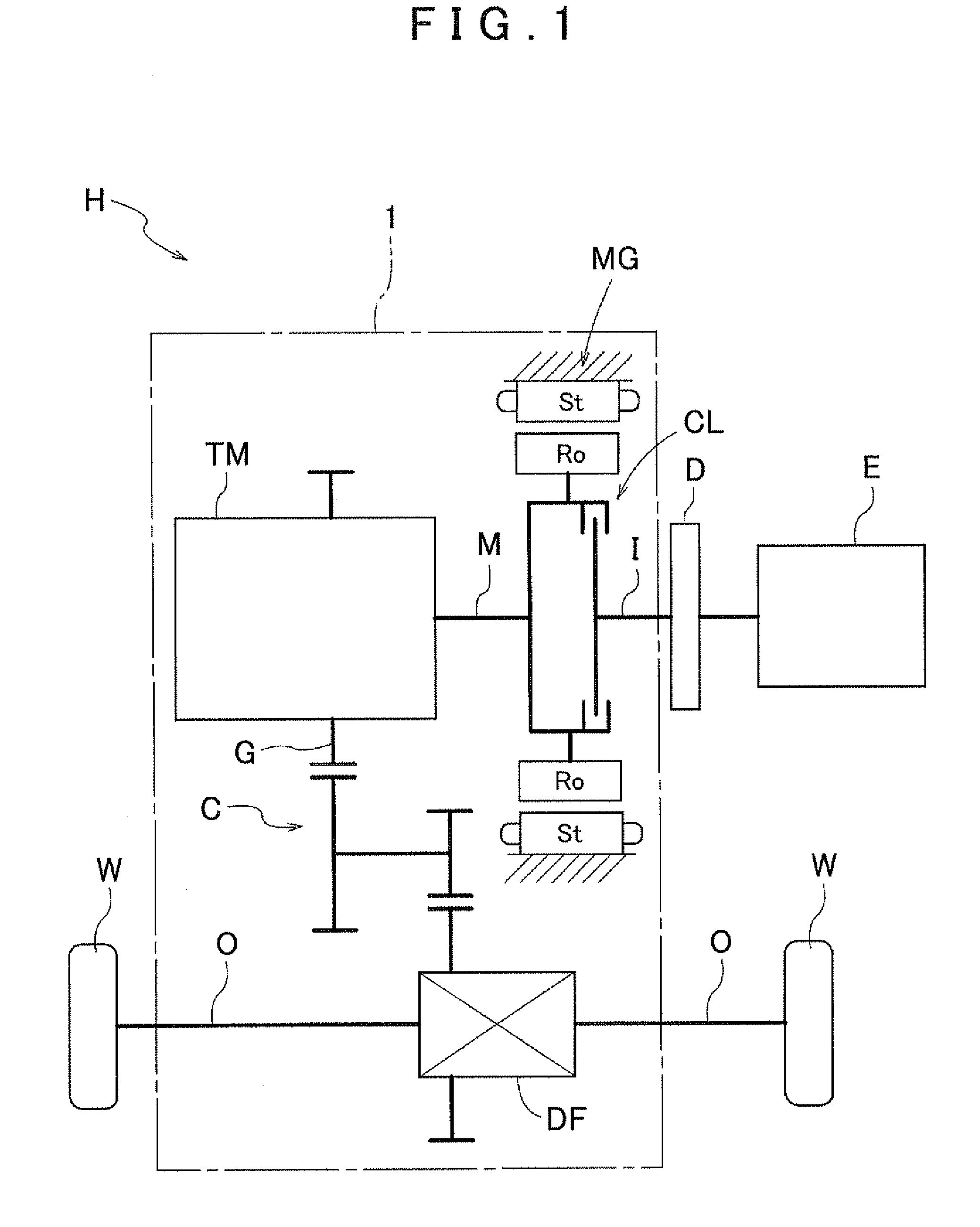

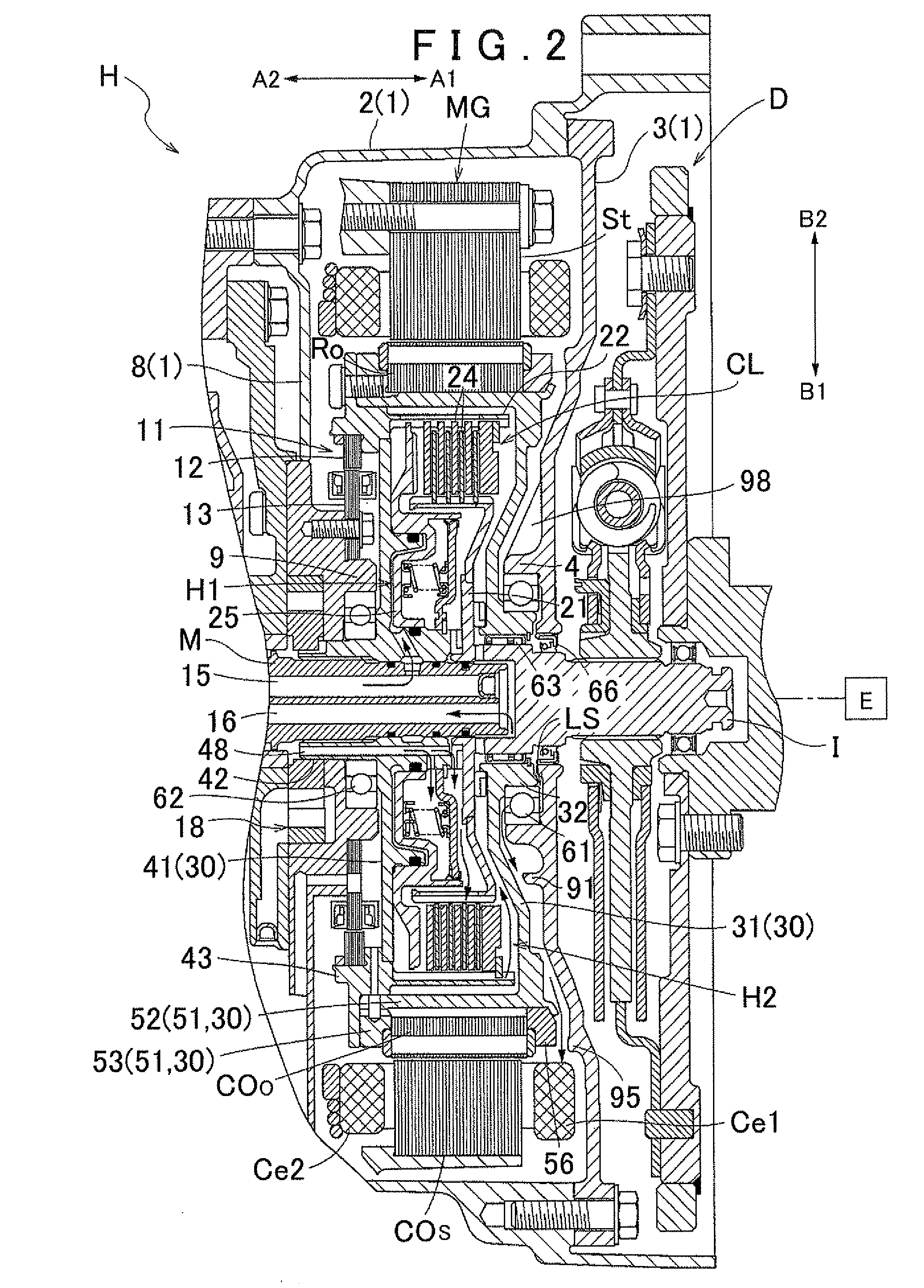

Vehicle drive system

InactiveUS20120217825A1Smooth oil flowImpedes flow of oilFluid actuated clutchesMechanical energy handlingEngineeringMechanical engineering

A vehicle drive system includes a rotor support that is more radially inward than the stator and supports the rotor; a supply that supplies oil to the rotor support bearing, the rotor support bearing includes a discharge that discharges oil supplied from the supply, the rotor support includes an opposing surface that opposes the discharge-side surface, and an opposing extension surface that extends radially from the opposing surface. The stator includes a coil end that protrudes from the stator core toward the first axial direction. A radial outer end of the opposing extension surface is more radially inward than, and overlaps with, the coil end, with a radial space between the radial outer end and the coil end. The discharge-side surface is disposed more toward the second axial direction than the radial outer end of the opposing extension surface.

Owner:AISIN AW CO LTD

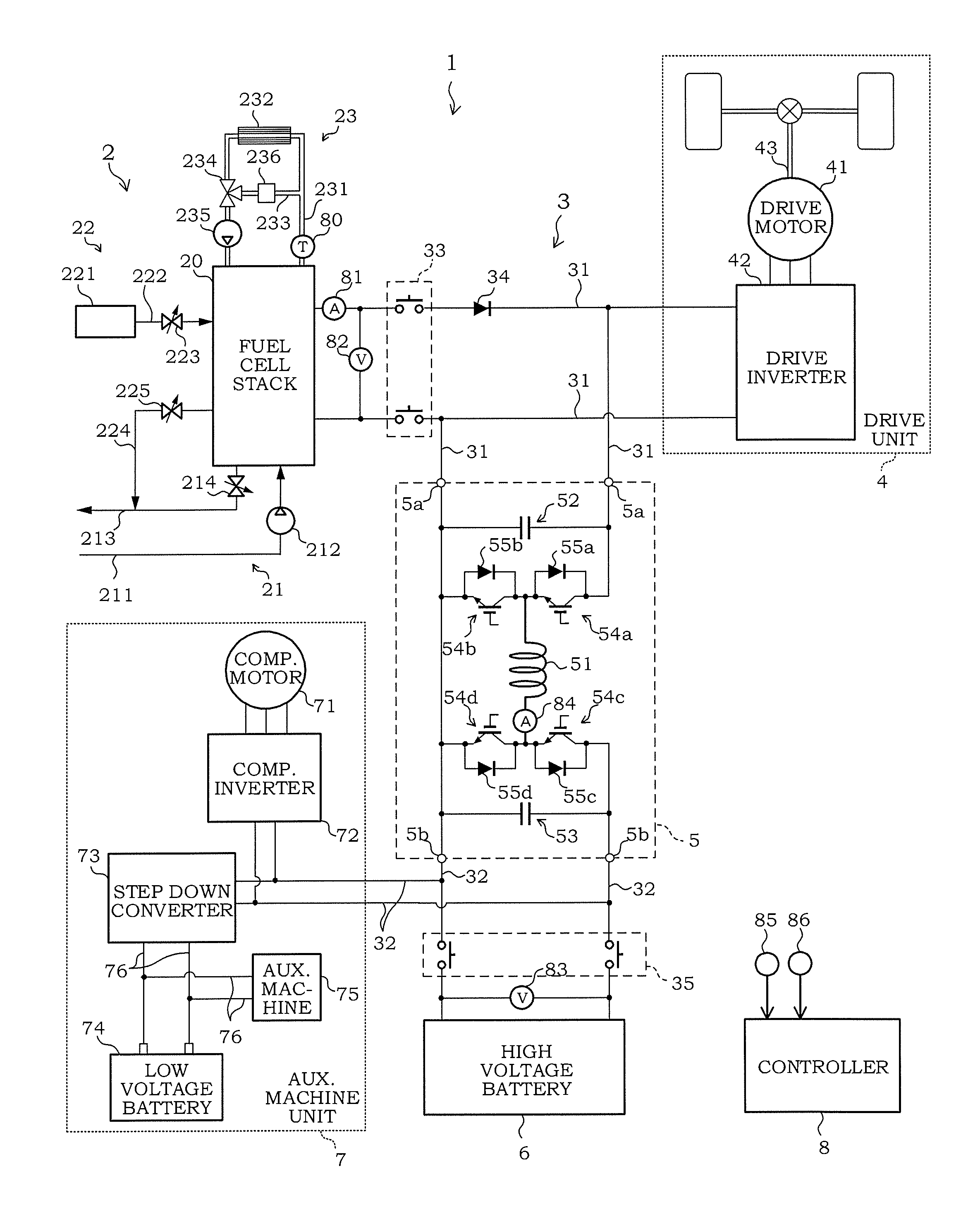

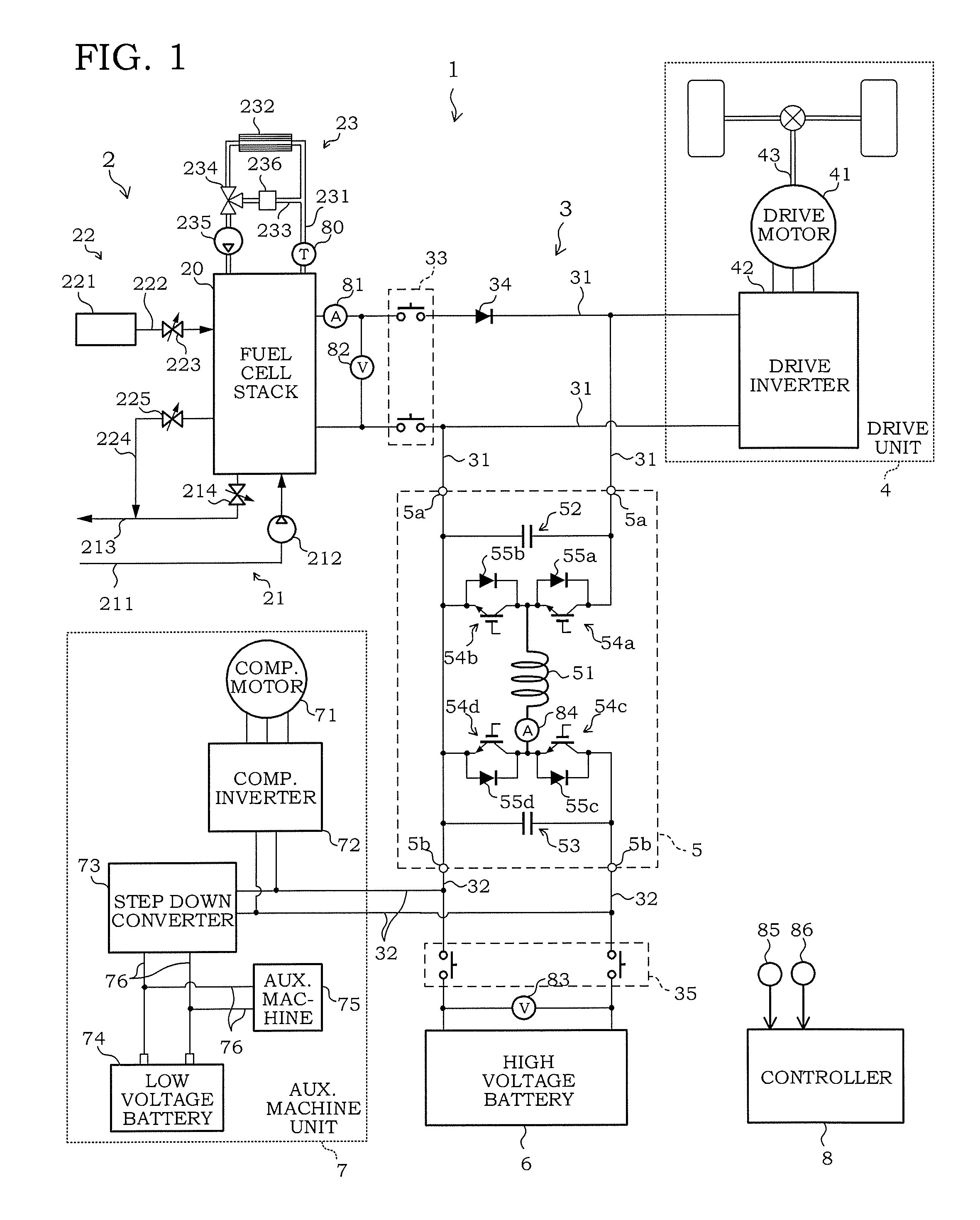

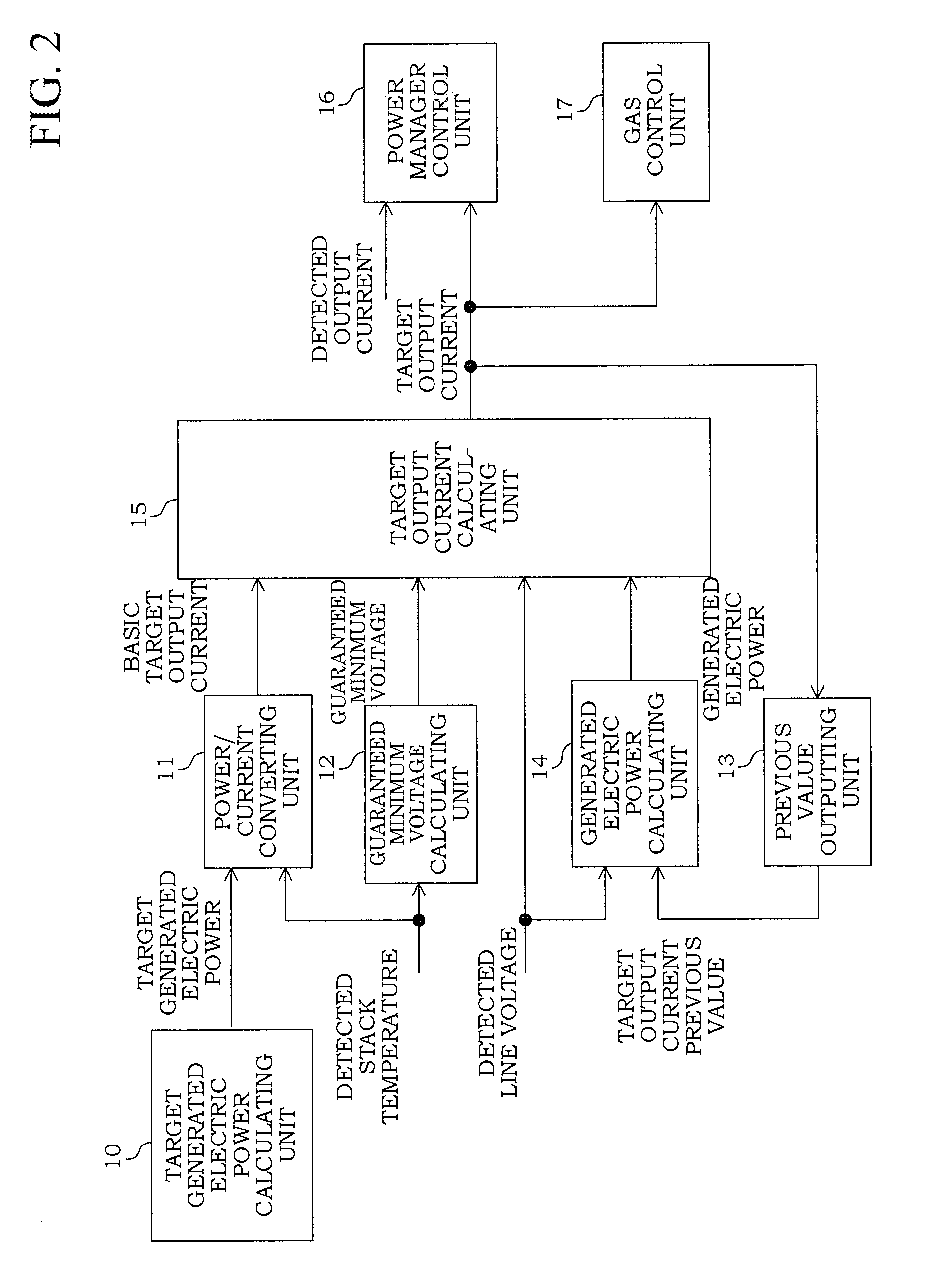

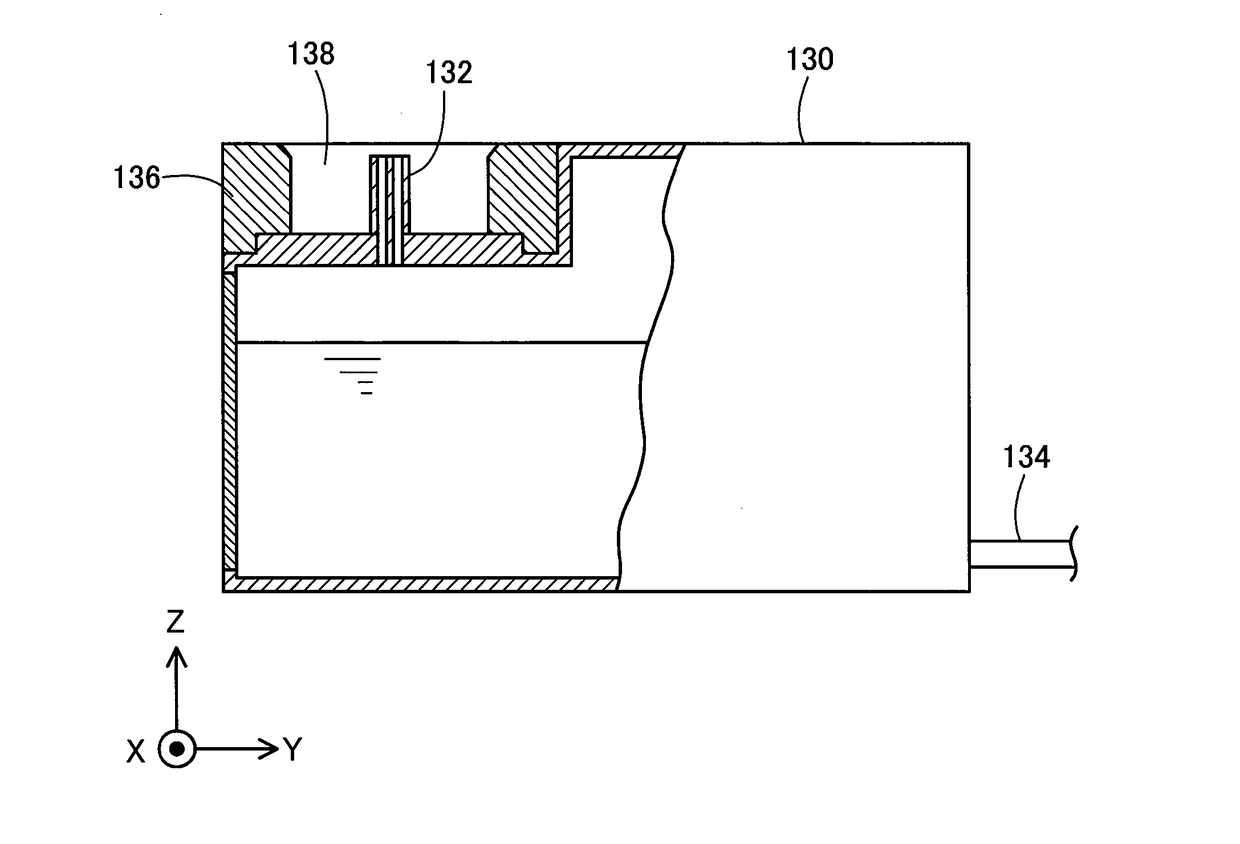

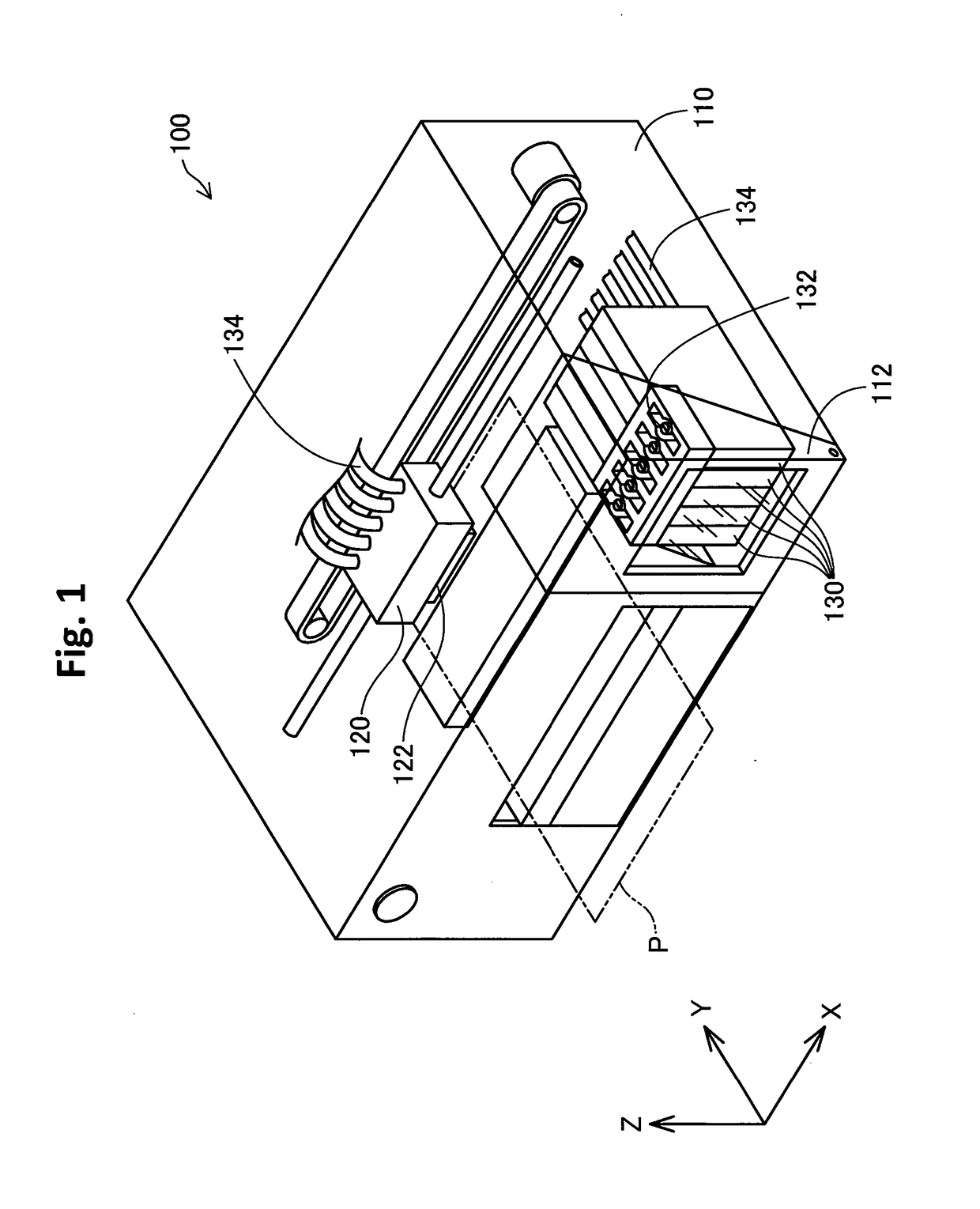

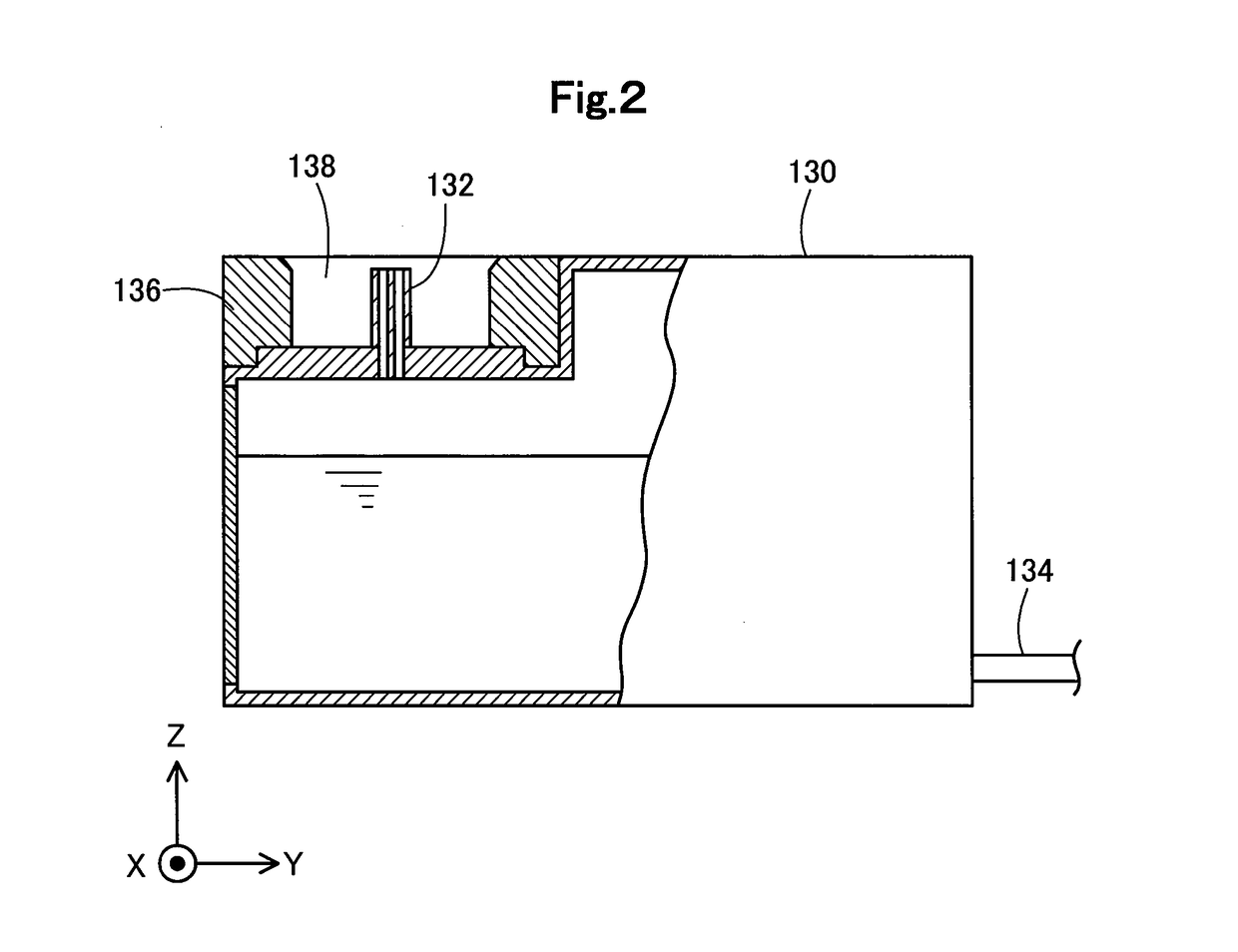

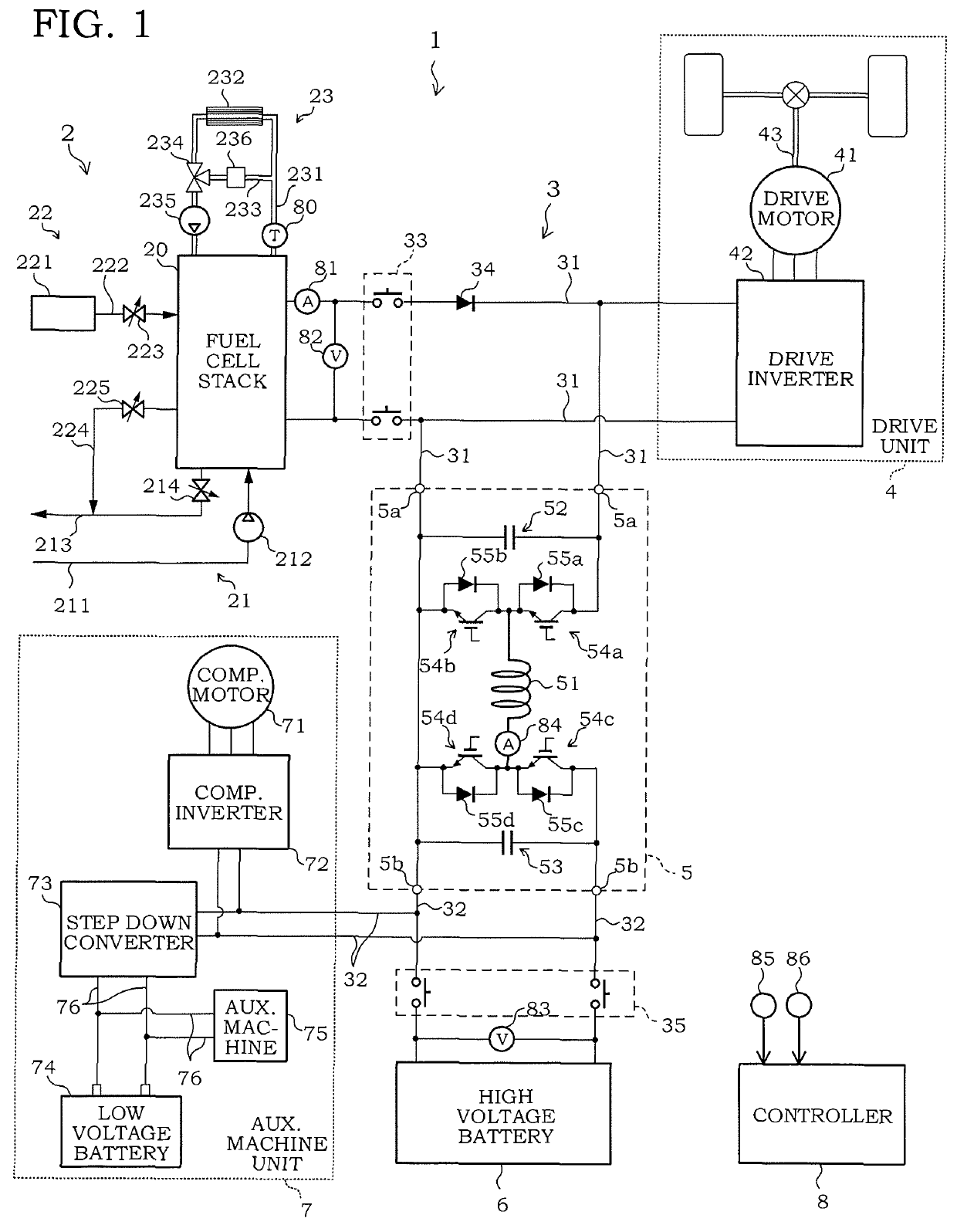

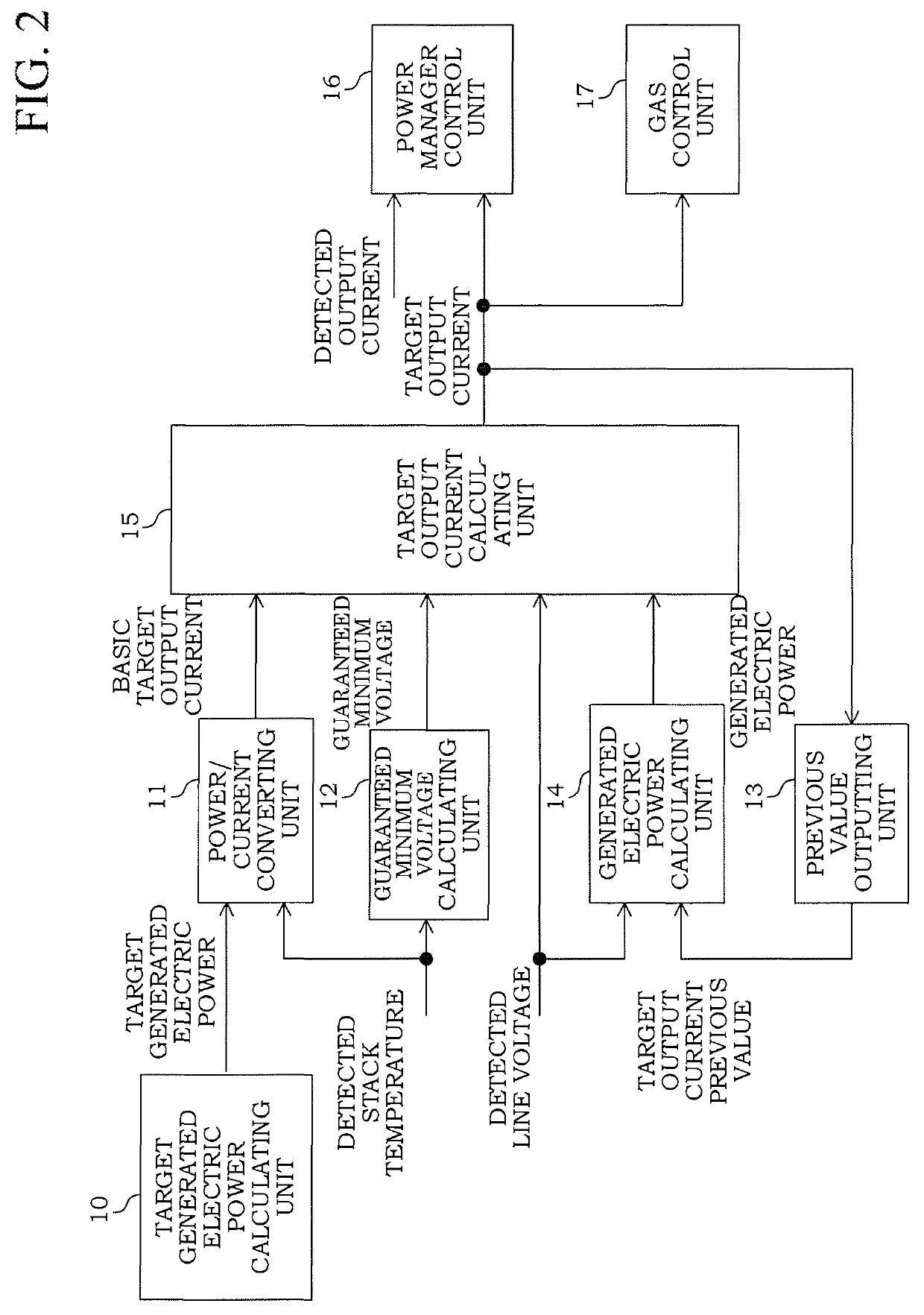

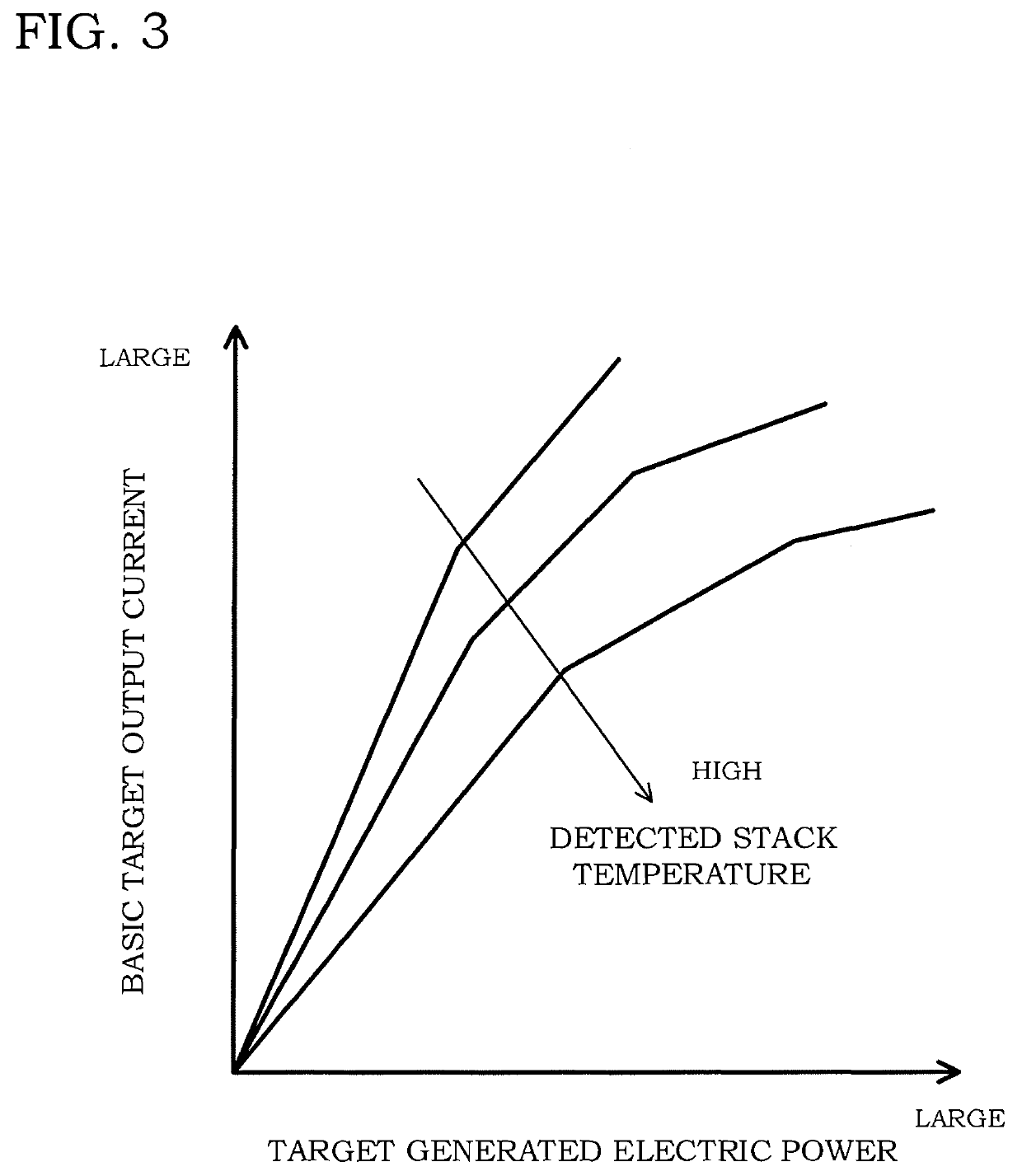

Fuel cell system

ActiveUS20160248107A1Ensure performanceAppropriate flowDc network circuit arrangementsElectrical testingElectricityPower flow

A fuel cell system configured to generate an electric power by supplying an anode gas and a cathode gas to a fuel cell includes: a connection line configured to connect the fuel cell to an electric load; a converter connected to the connection line and a battery, the converter being configured to adjust a voltage of the connection line; a target output current calculating unit configured to calculate a target output current of the fuel cell in accordance with a load of the electric load; a converter control unit configured to carry out a switching control for the converter in accordance with the target output current; and a flow rate control unit configured to control a flow rate of the cathode gas to be supplied to the fuel cell in accordance with the target output current. The target output current calculating unit sets up an upper limit to the target output current on the basis of a generated electric power of the fuel cell and a guaranteed minimum voltage of the connection line for ensuring performance of the fuel cell and the electric load.

Owner:NISSAN MOTOR CO LTD

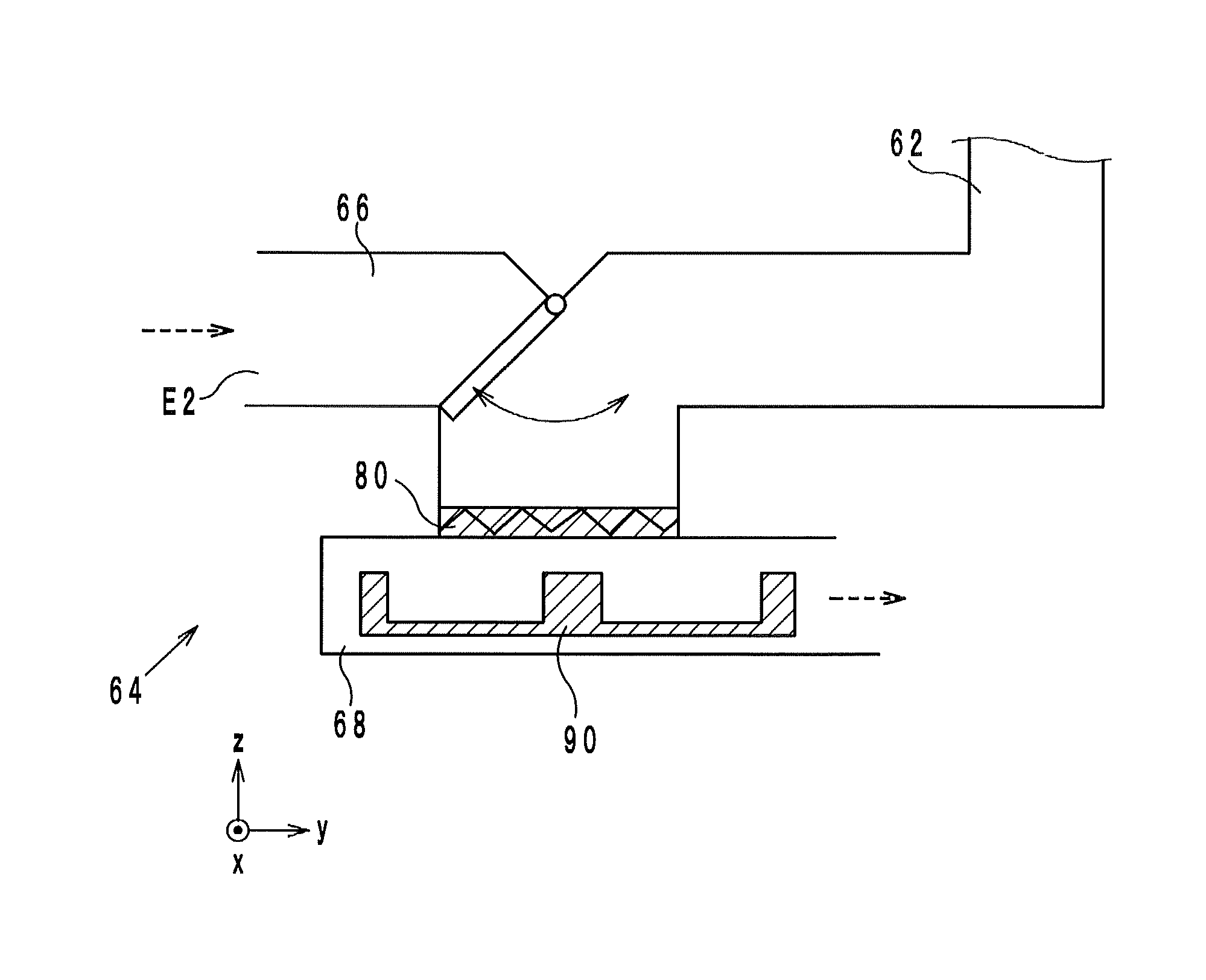

Ink replenish adjunctive device and ink replenish device

InactiveUS20170355196A1Reduce leakageAppropriate flowPrintingEngineeringElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

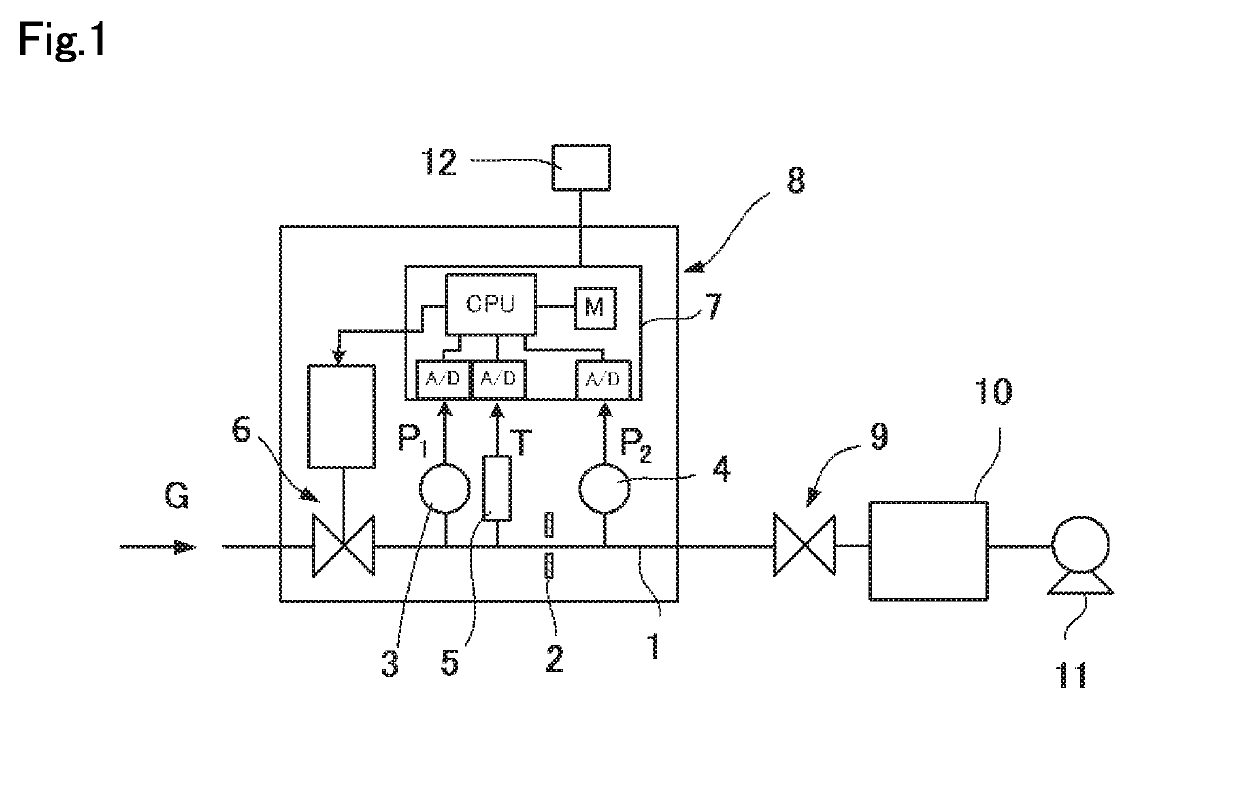

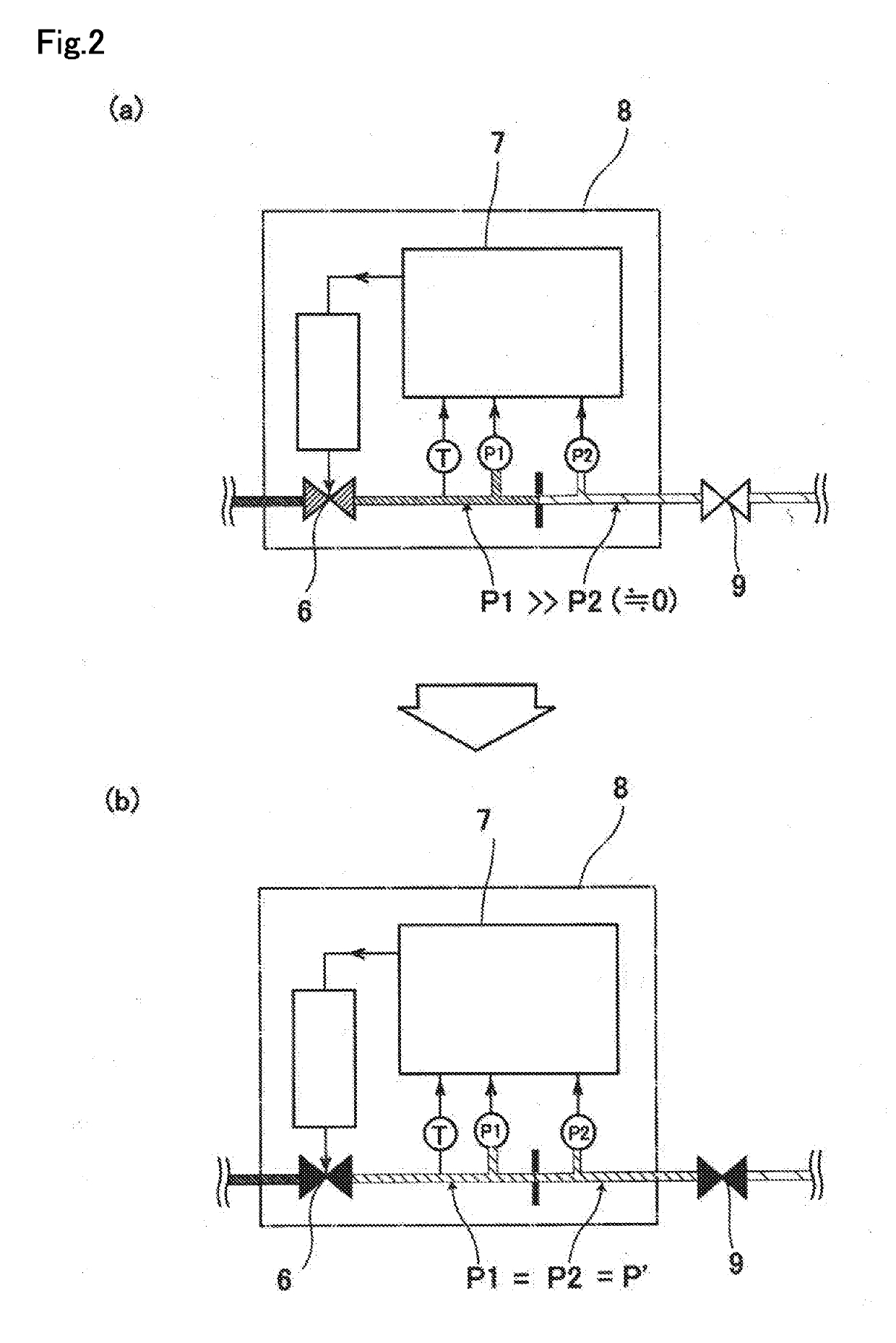

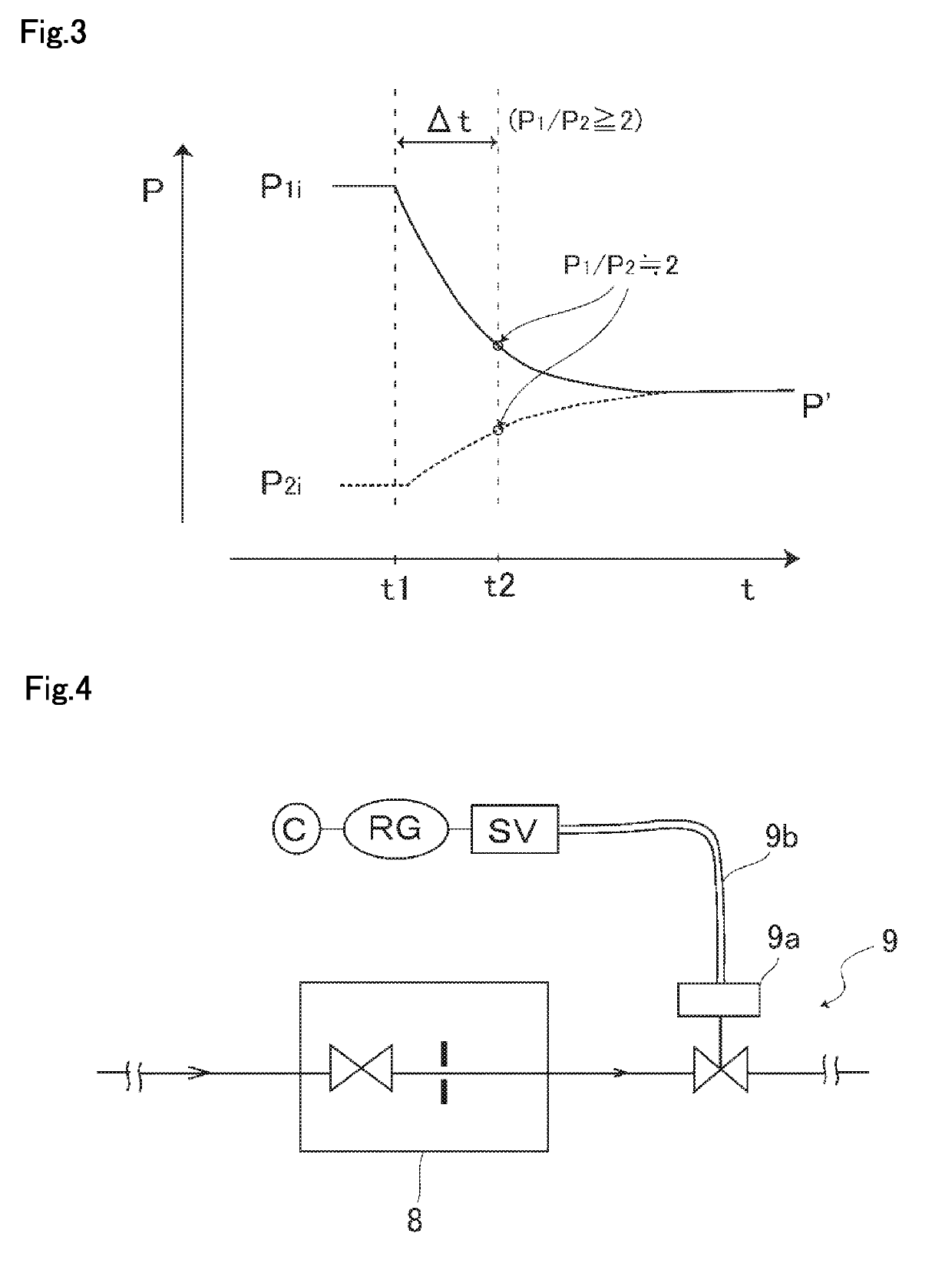

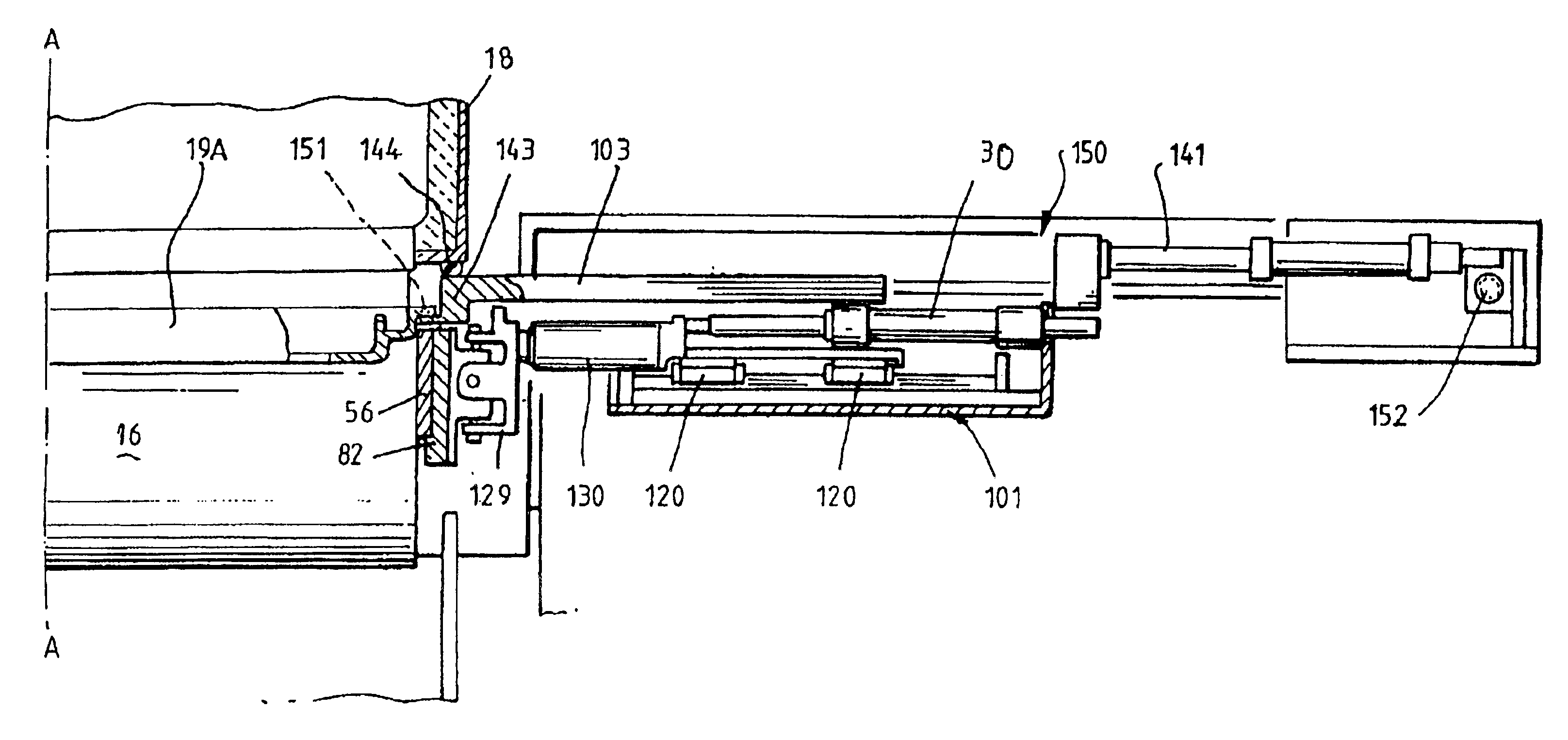

Pressure-type flow rate control device and flow rate self-diagnosis method

ActiveUS20190094847A1Data being droppedAppropriate flowFlow control using electric meansElectric testing/monitoringSelf-diagnosisFlux control

A pressure-type flow rate control device includes a restriction part, a control valve disposed upstream of the restriction part, an upstream pressure sensor, a downstream pressure sensor, and a controller that diagnoses flow rate control by using pressure drop data on a flow passage between the control valve and the restriction part and reference pressure drop data, wherein a close command is issued to the control valve and a shutoff valve provided downstream of the downstream pressure sensor, and the controller determines whether a predetermined critical expansion condition is satisfied by using outputs of the upstream pressure sensor and the downstream pressure sensor after the control valve is closed, and diagnoses flow rate control by using the pressure drop data acquired during a period in which the predetermined critical expansion condition is satisfied.

Owner:FUJIKIN INC

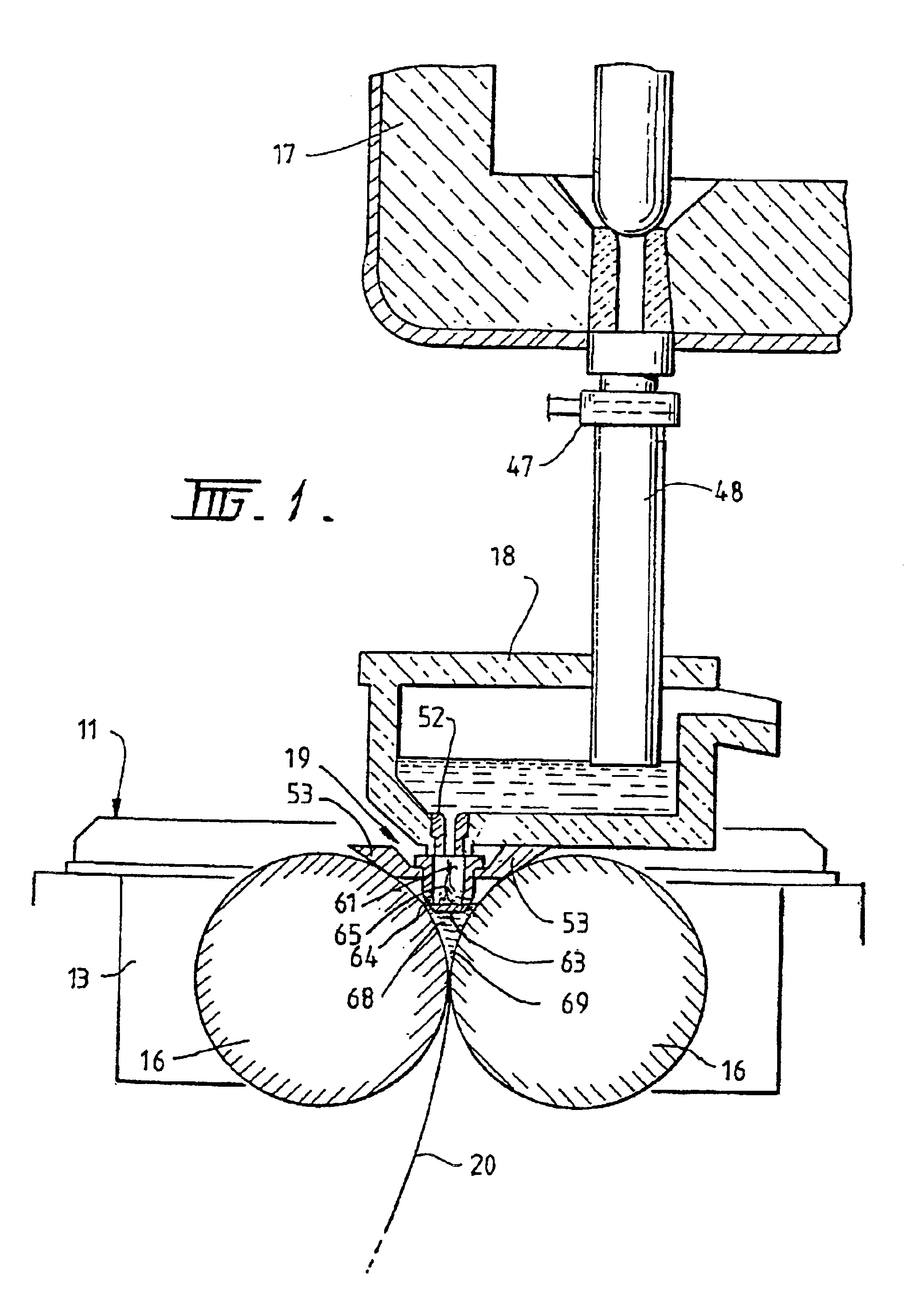

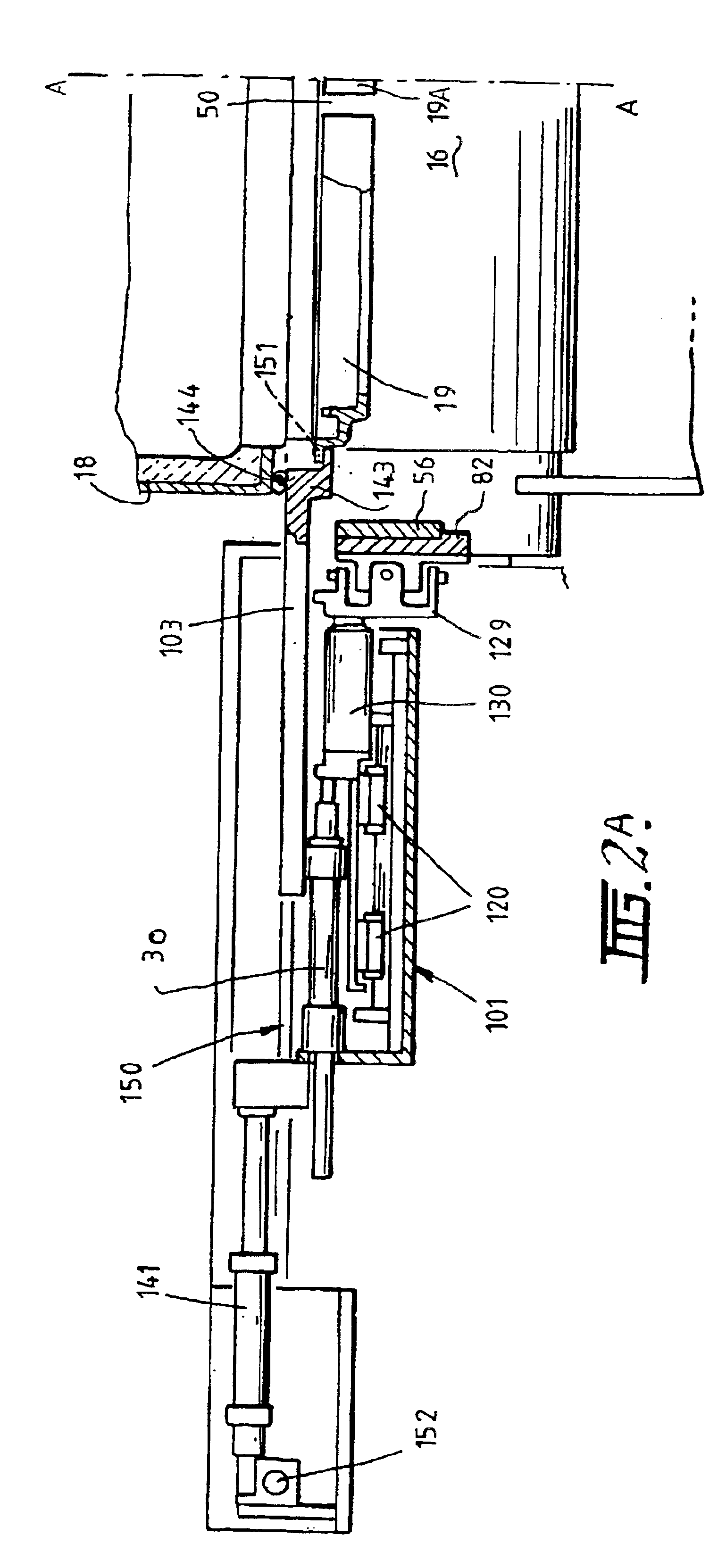

Strip casting apparatus

Owner:NUCOR CORP

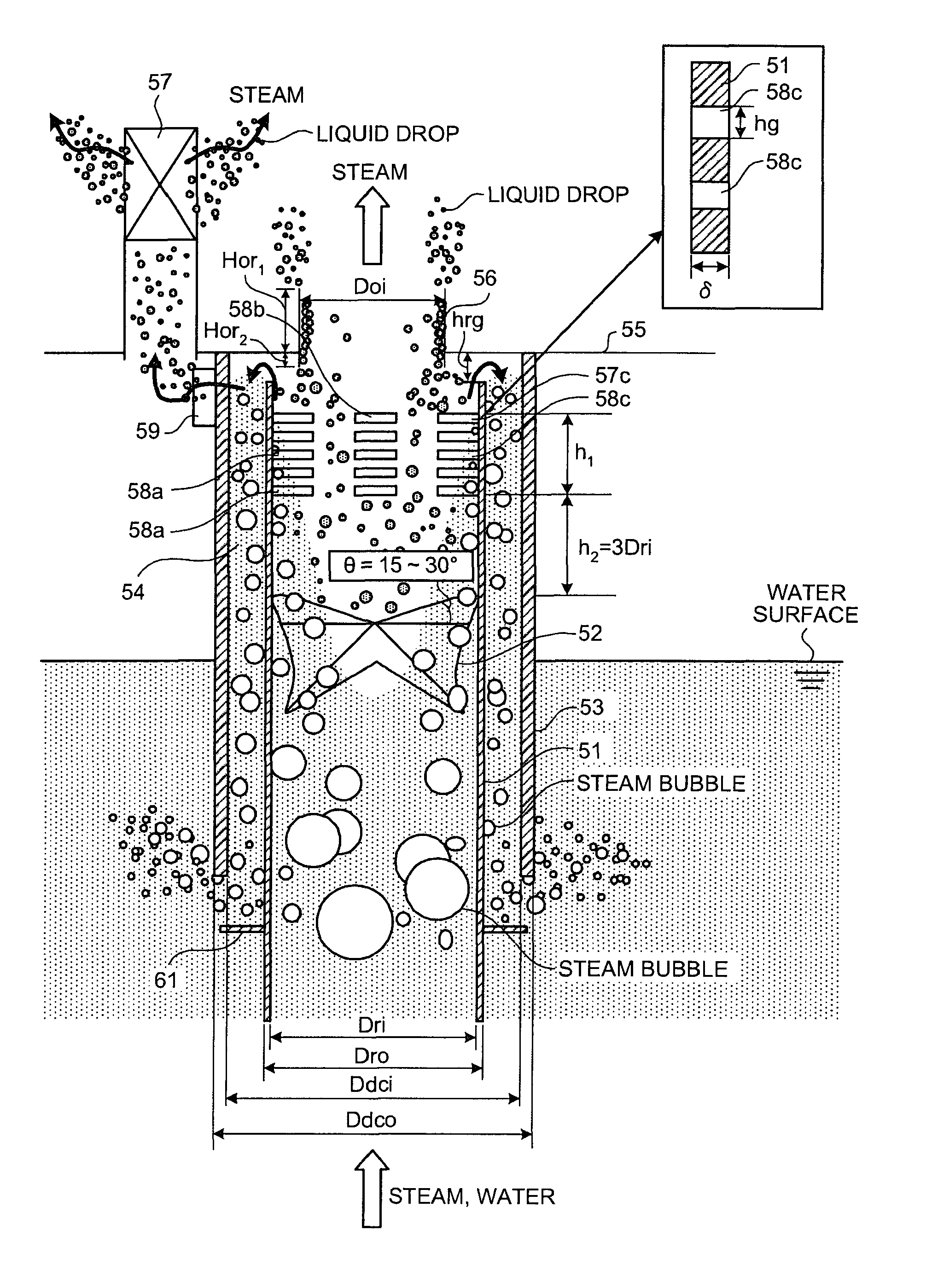

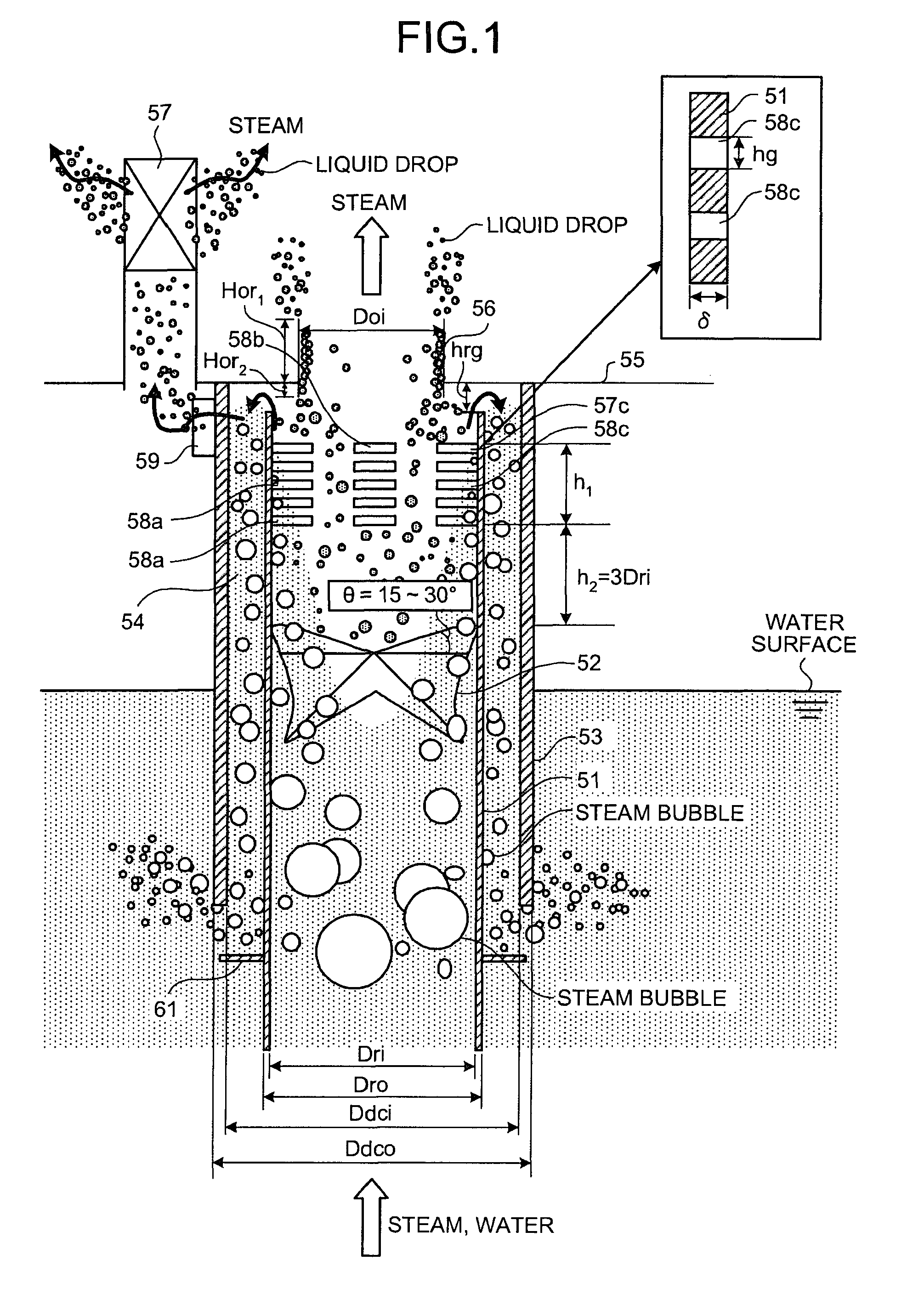

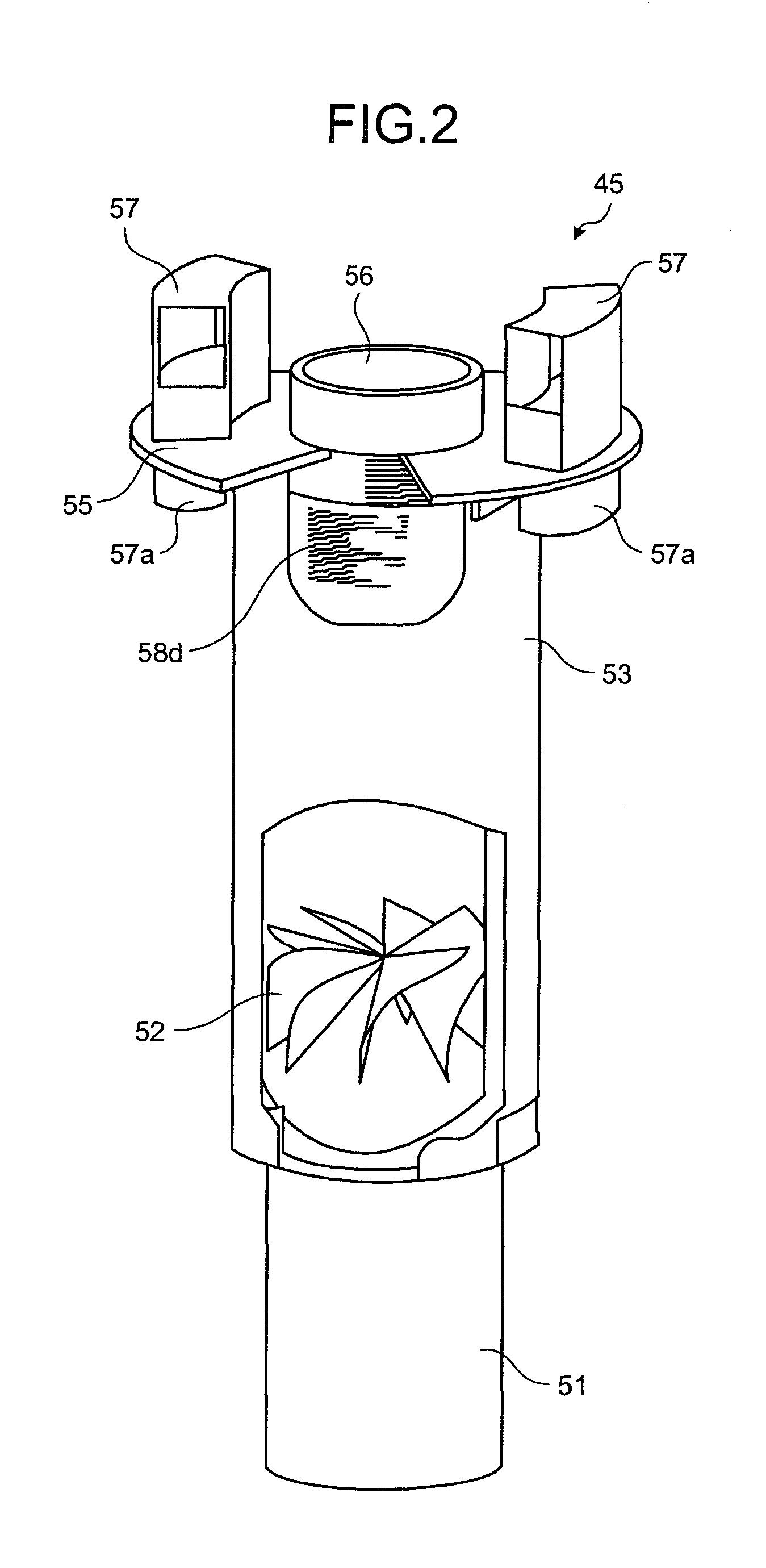

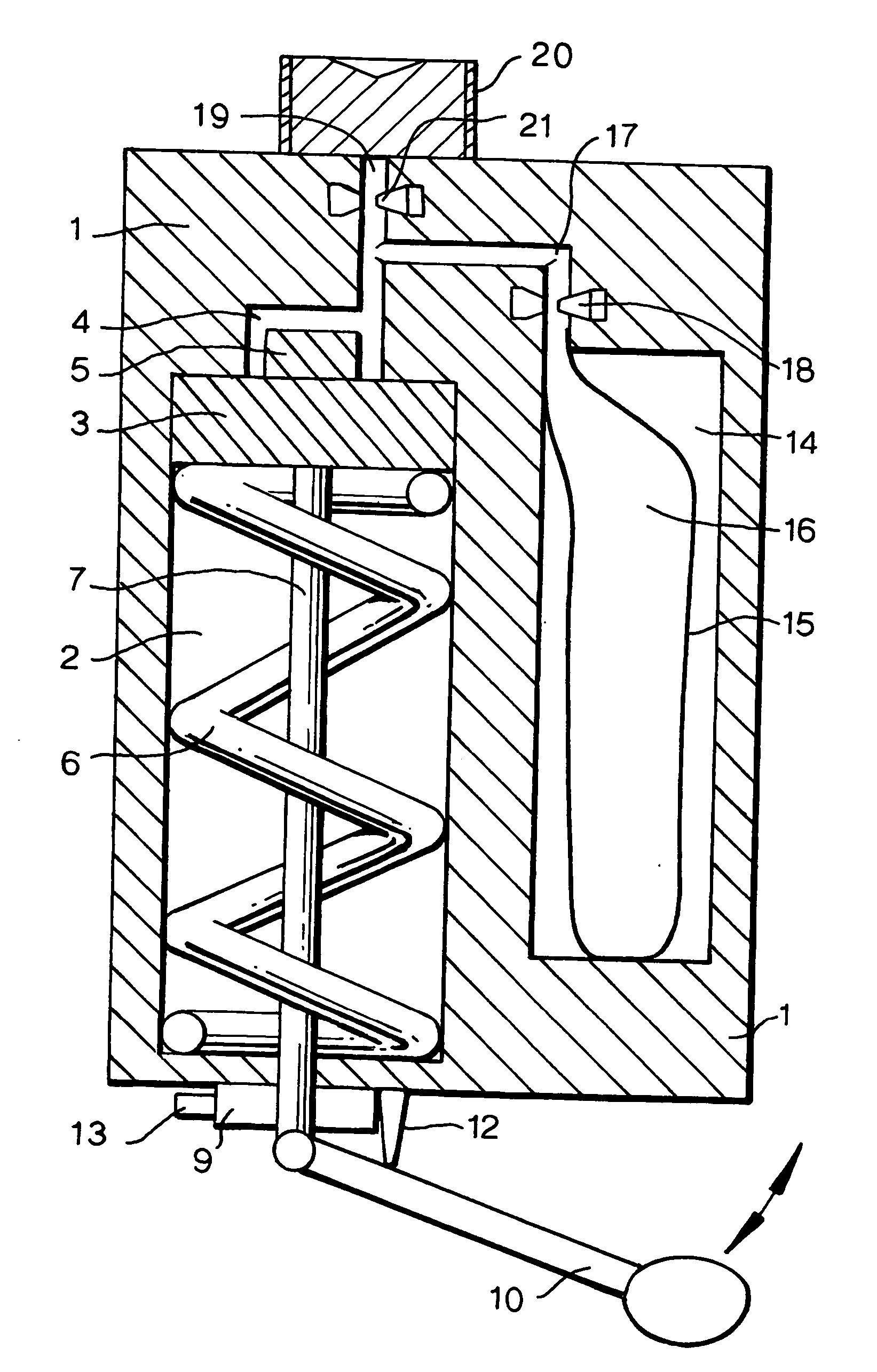

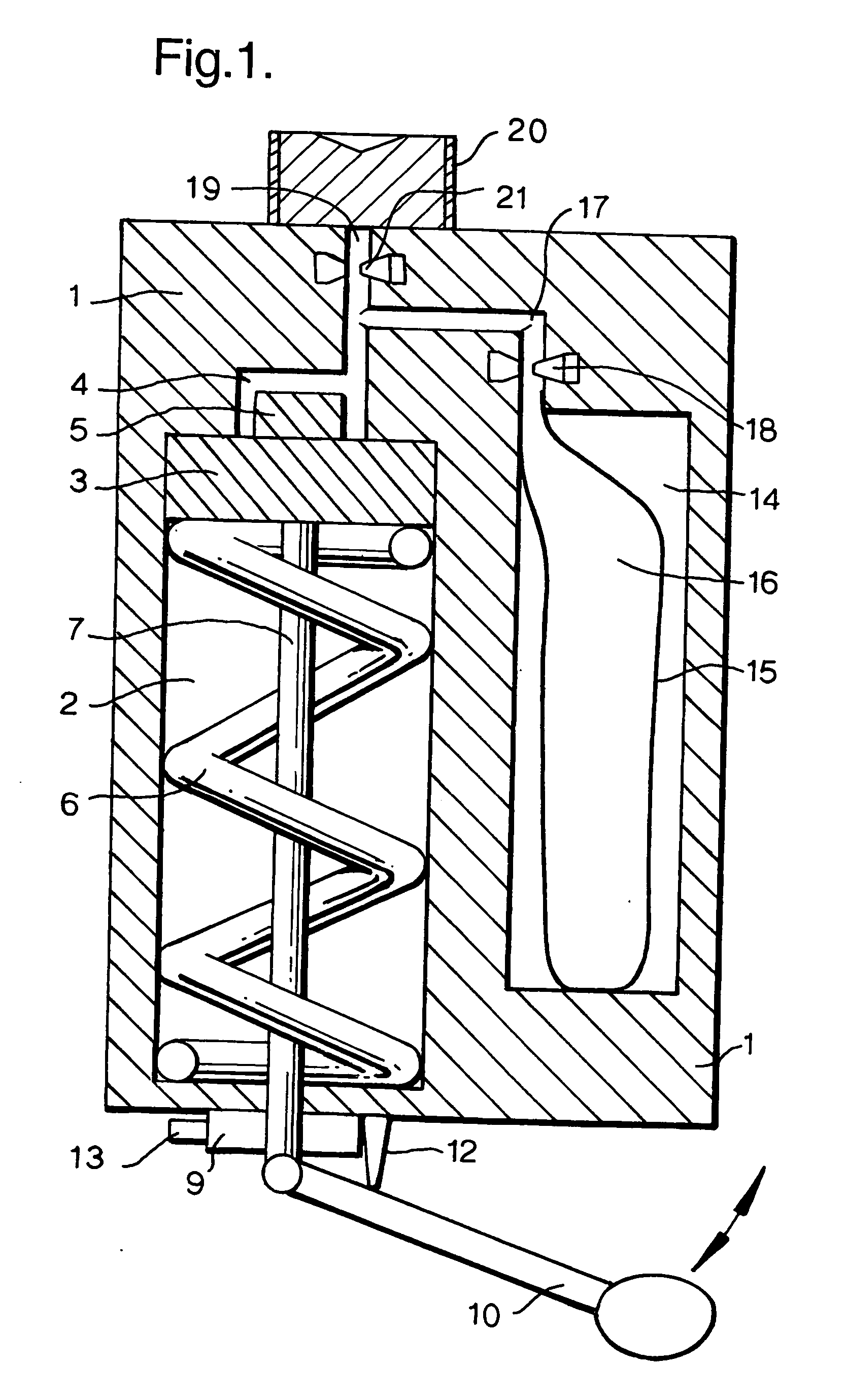

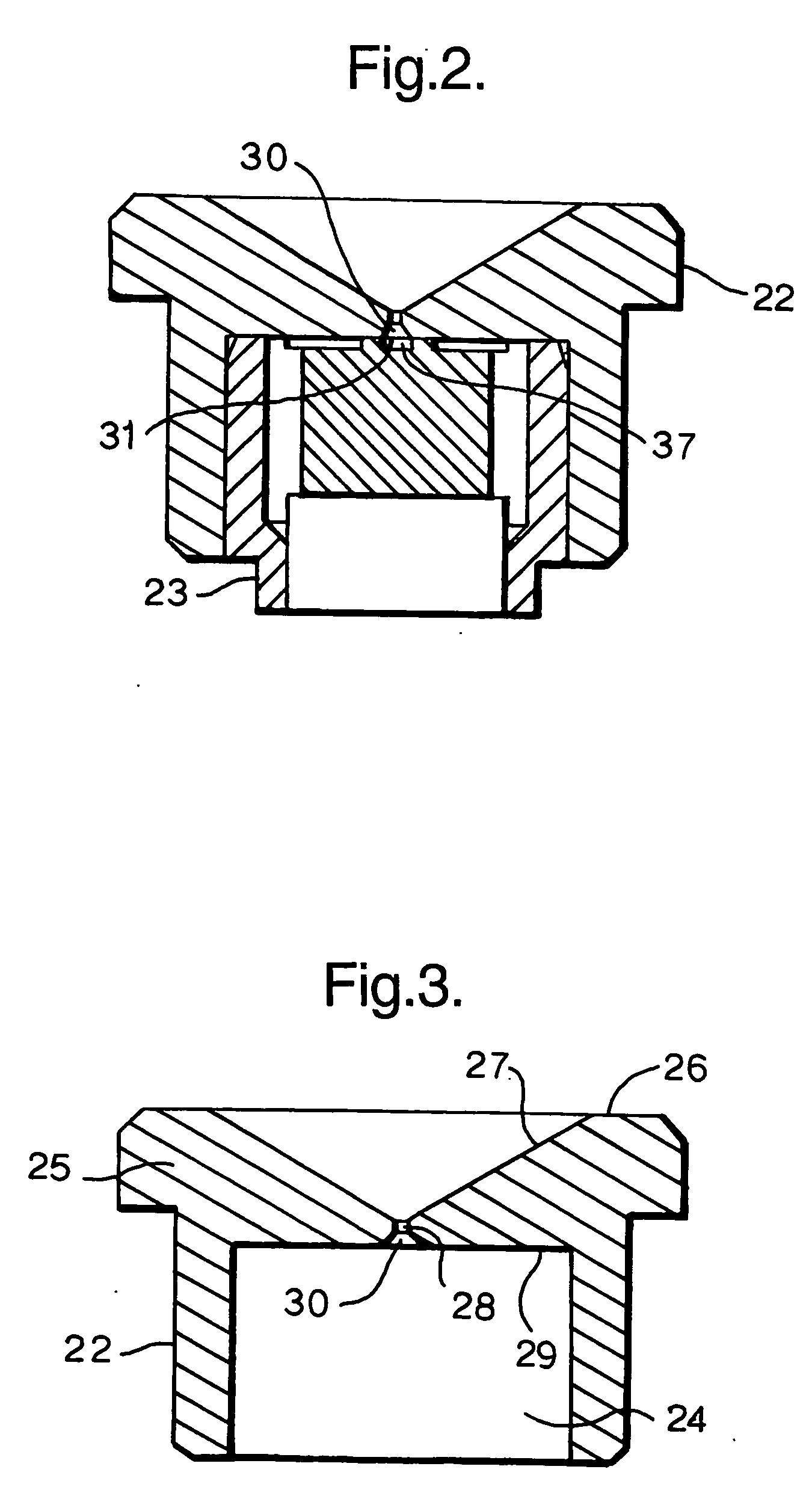

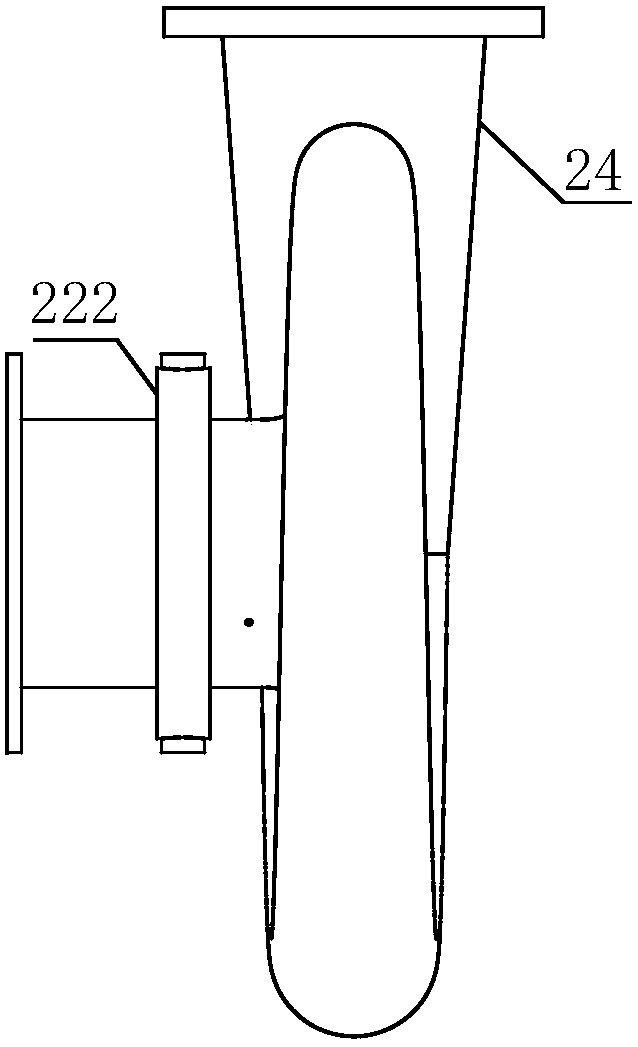

Steam-water separator

ActiveUS8002866B2Easy to separateAppropriate flowCombination devicesLiquid degasificationEngineeringAperture ratio

Owner:MITSUBISHI HEAVY IND LTD

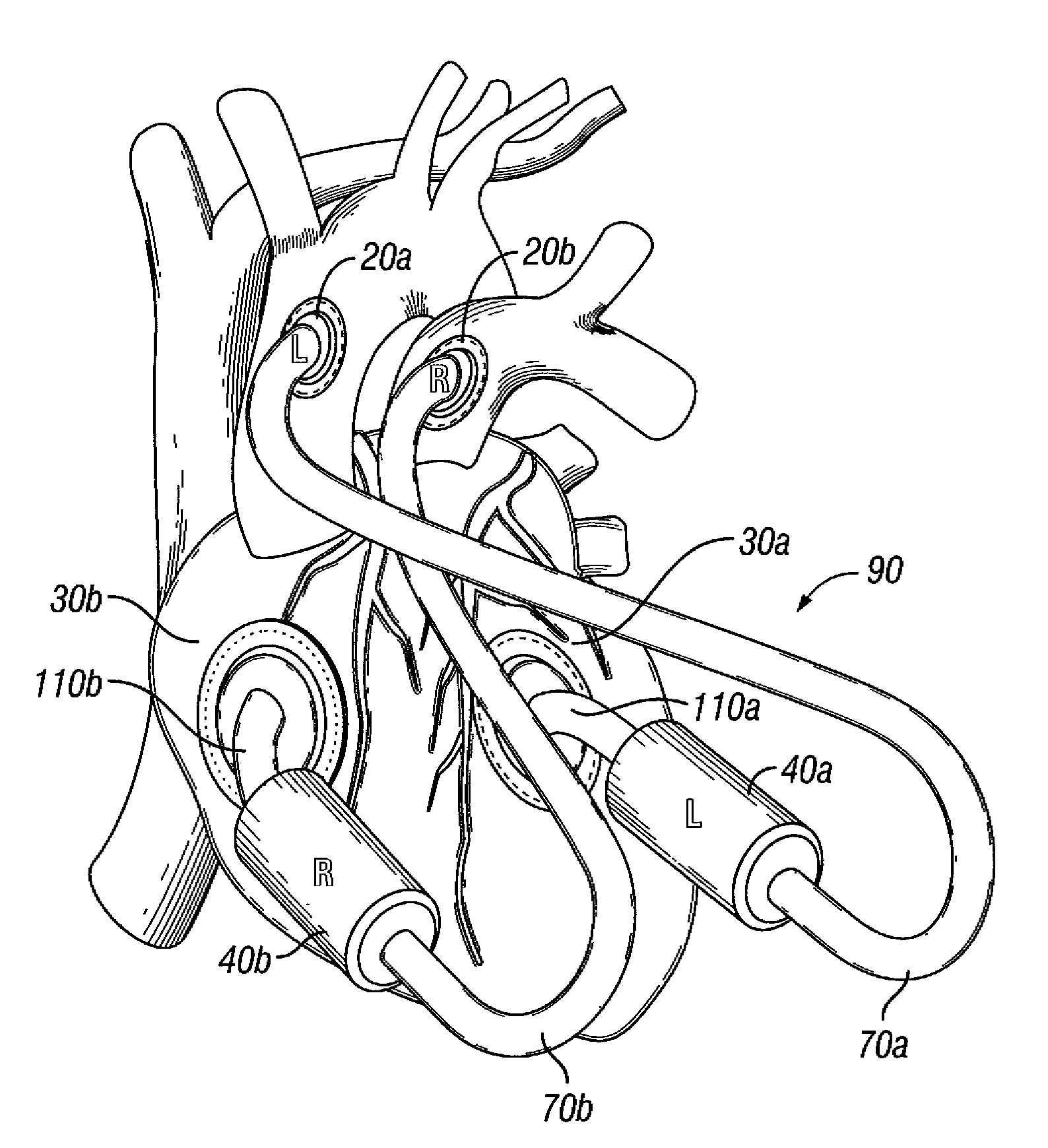

Total artificial heart system for auto-regulating flow and pressure

InactiveUS8870951B1Reduce resistanceMinimizing pressure gradientControl devicesBlood pumpsWhole bodyContinuous flow

The present invention is TAH system for auto-regulating blood flow and maintaining the asymmetric pressure balance in the mammalian cardiovascular system by decreasing the resistance in blood flow and minimizing the pressure gradients to exploit the in-flow pressure sensitivities of continuous flow pumps. The system further includes laminar flow generating manifolds connected to the atrium at one end and attached to pumps linked to the great vessels at the other, such that the in-let flow sensitivities of the pumps are maximized to auto-regulate blood flow, providing adequate pulmonary and systemic arterial flow to support normal metabolism and end-organ function and maintain the appropriate asymmetric physiologic pressure balance between the systemic and pulmonary systems of the mammalian cardiovascular system.

Owner:ALPHA DEV

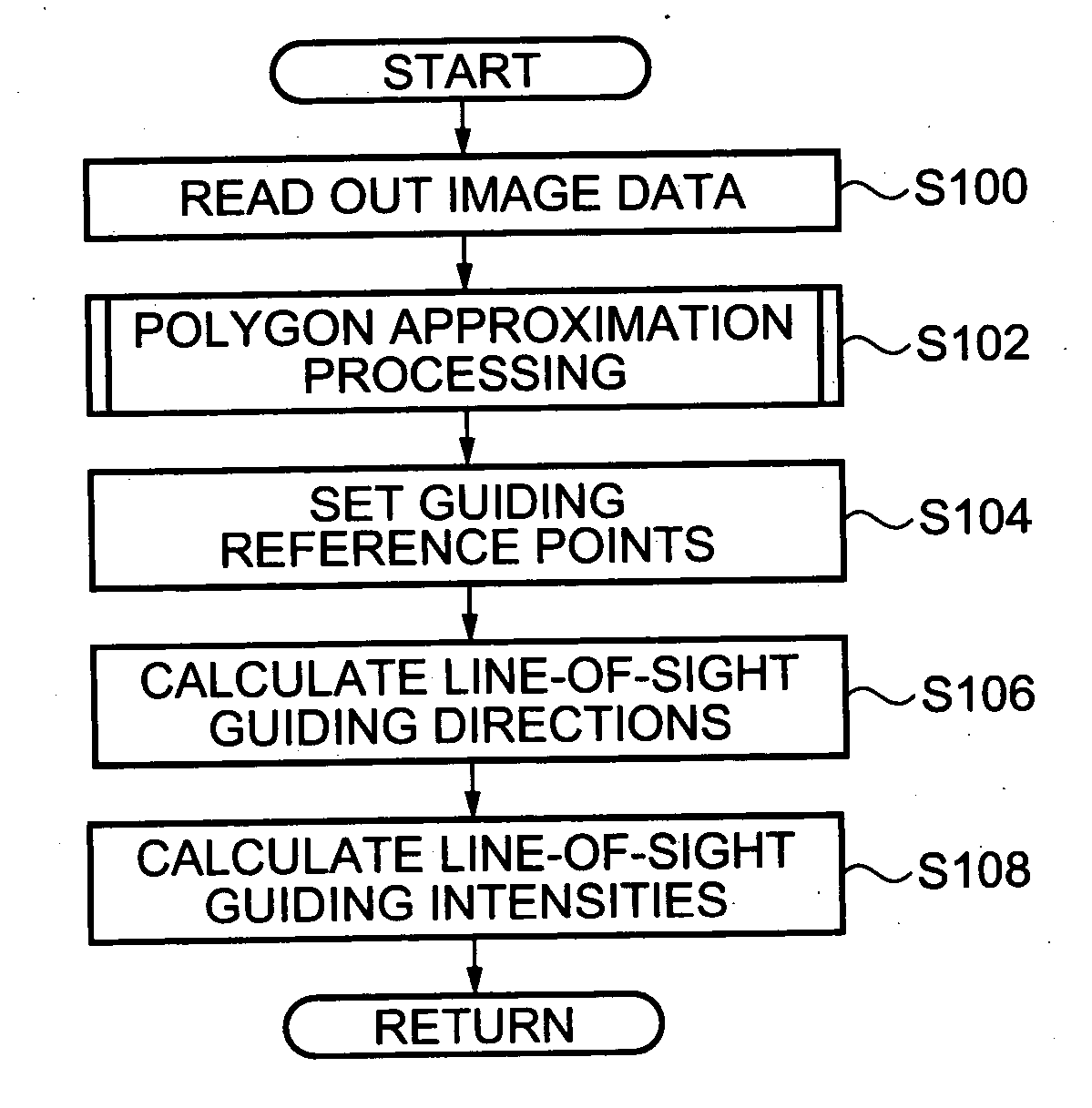

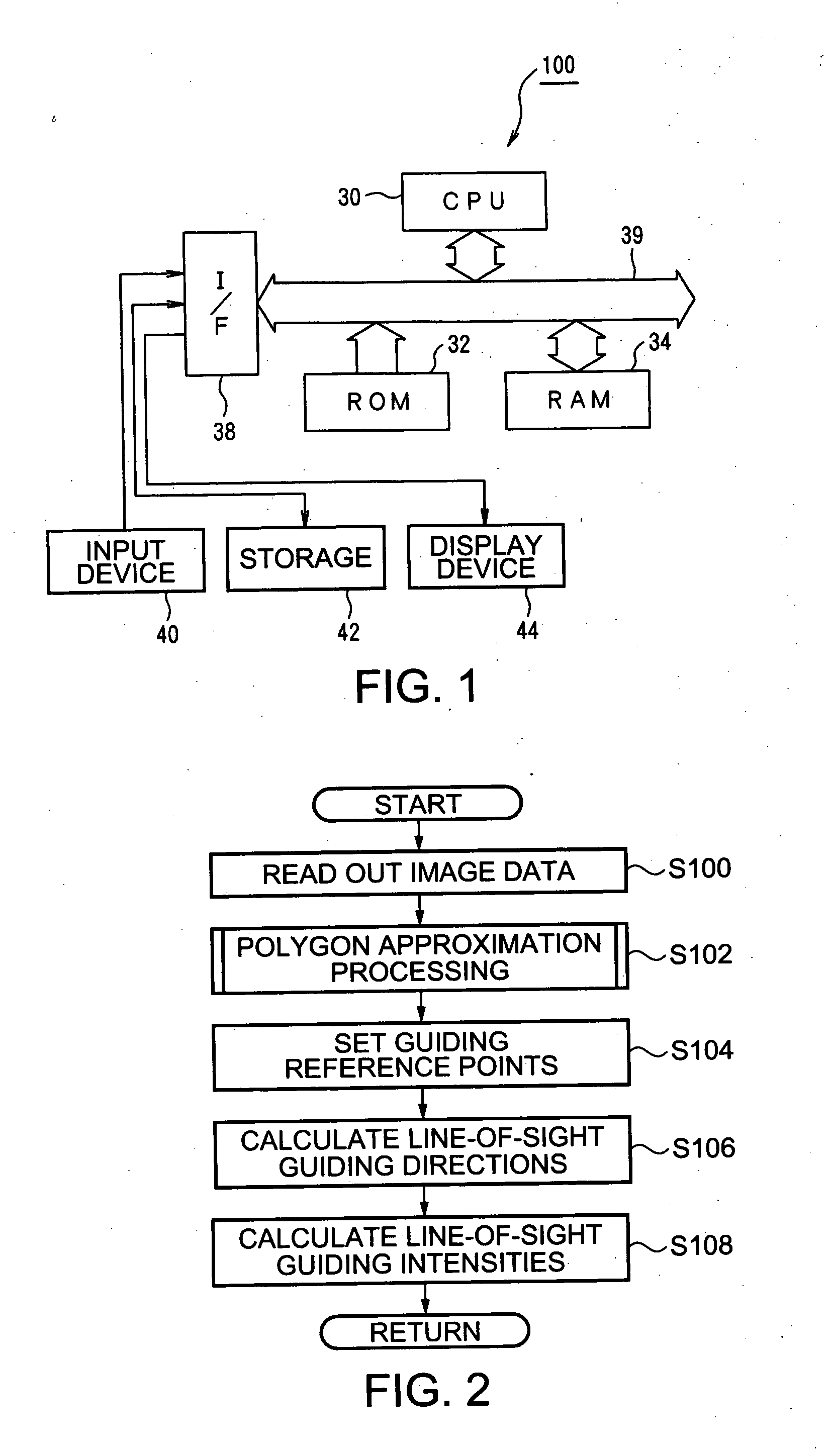

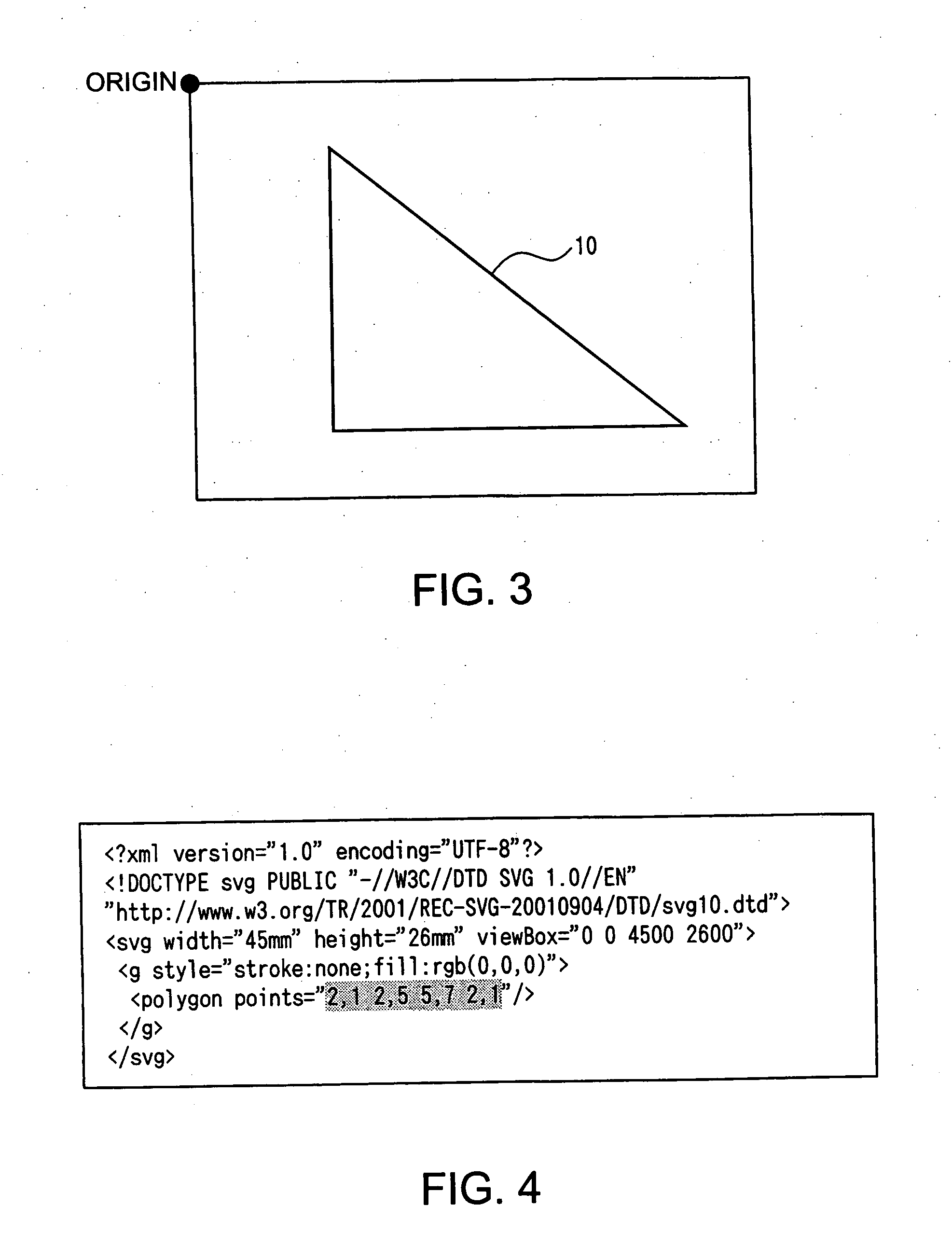

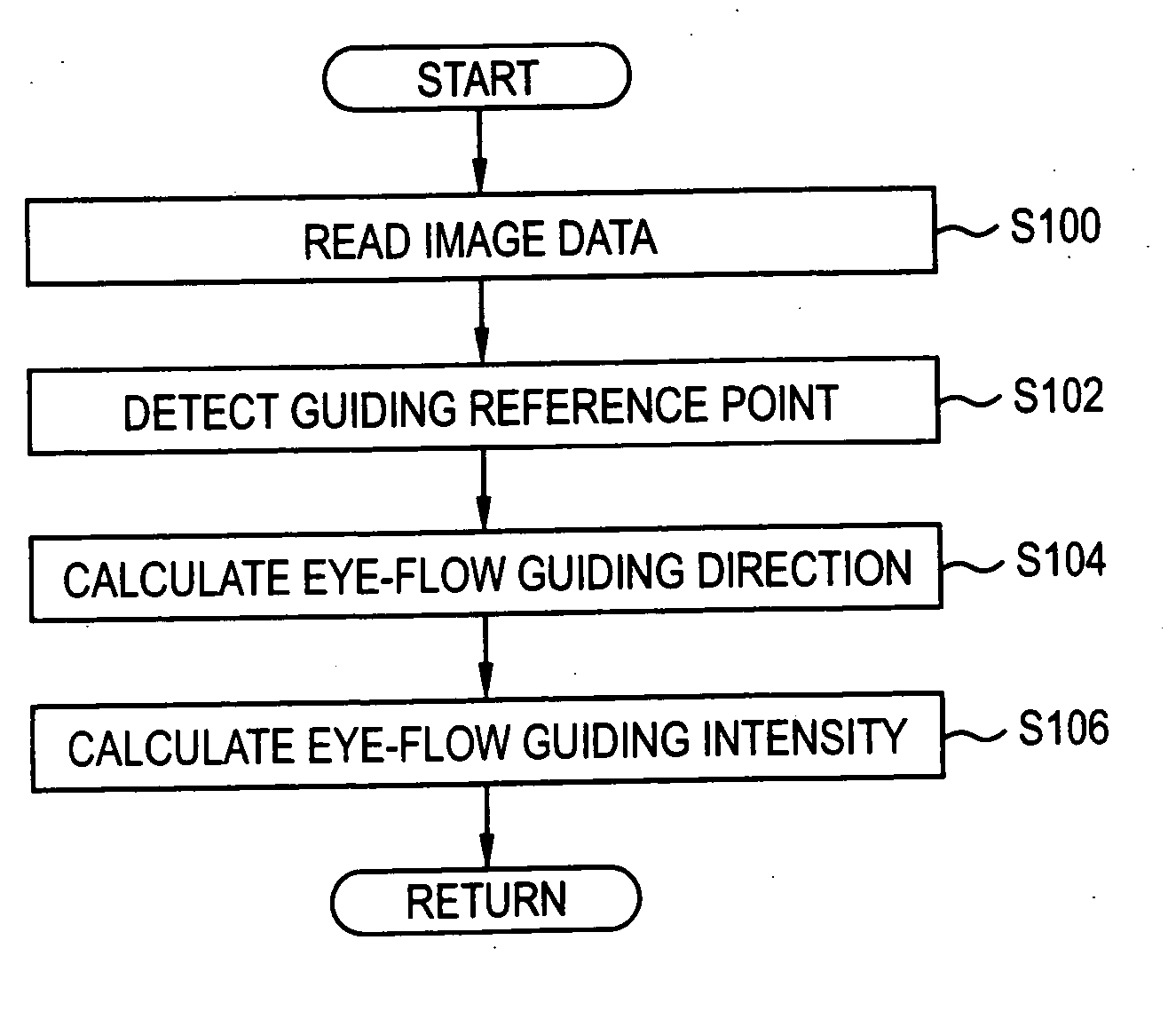

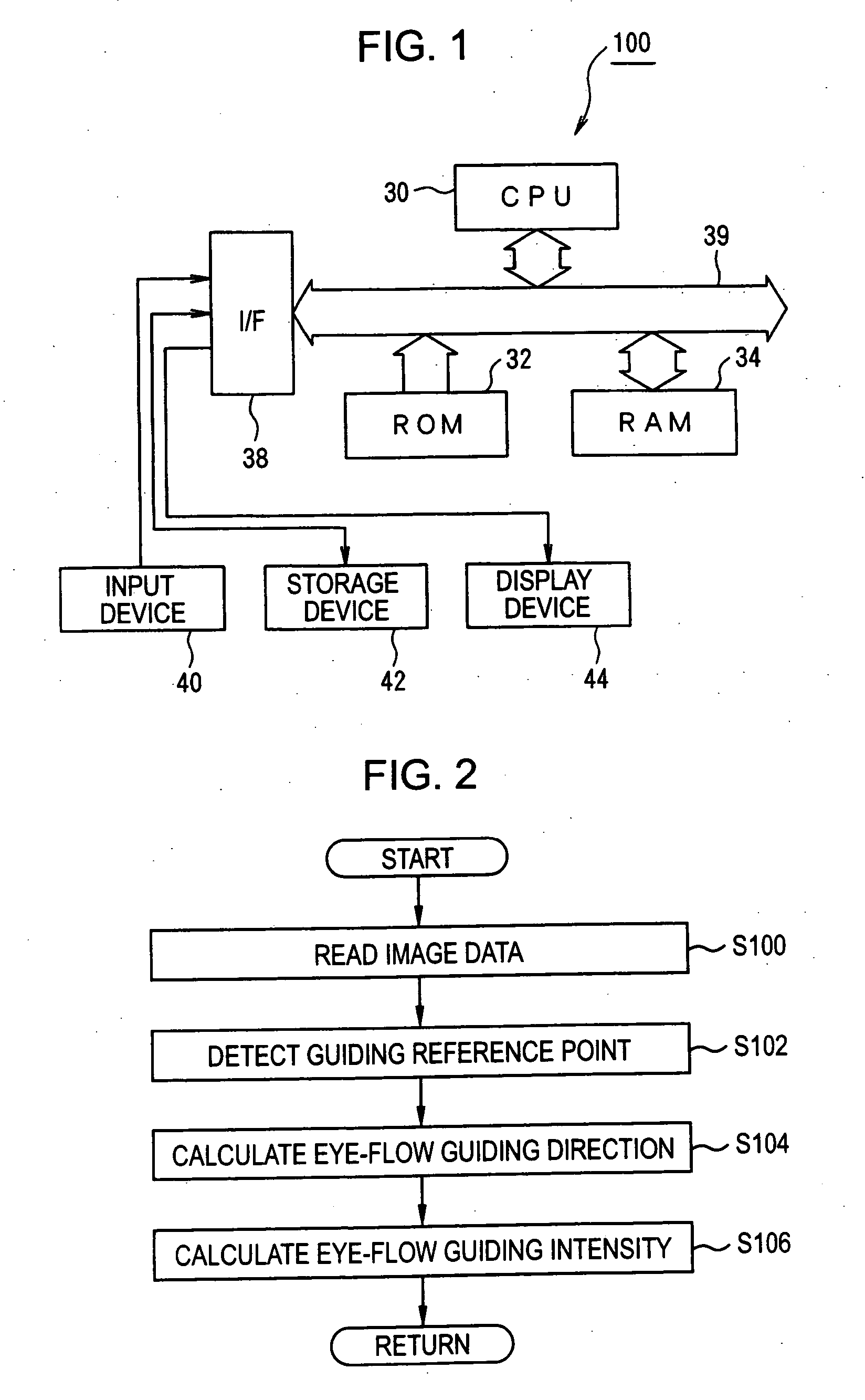

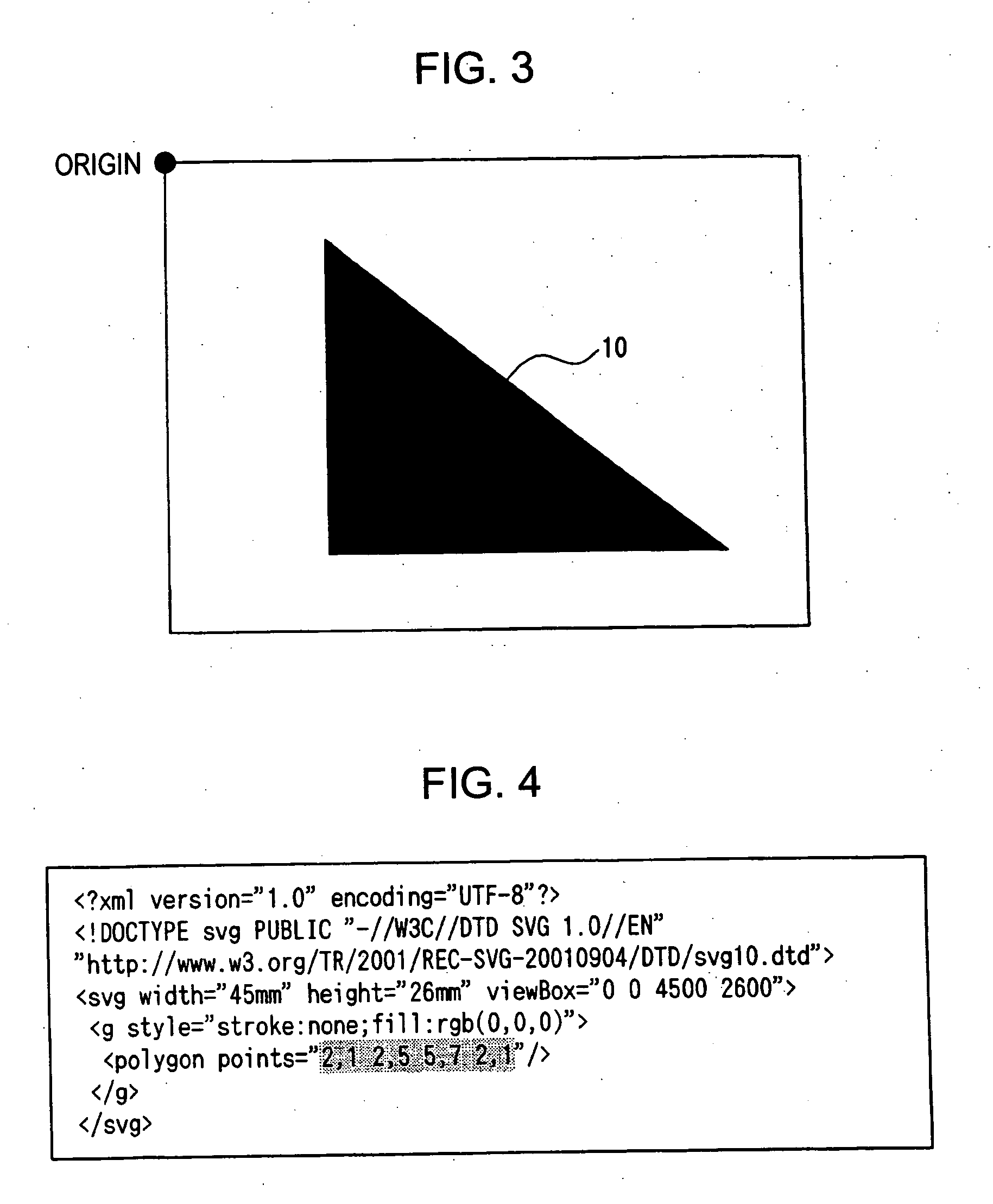

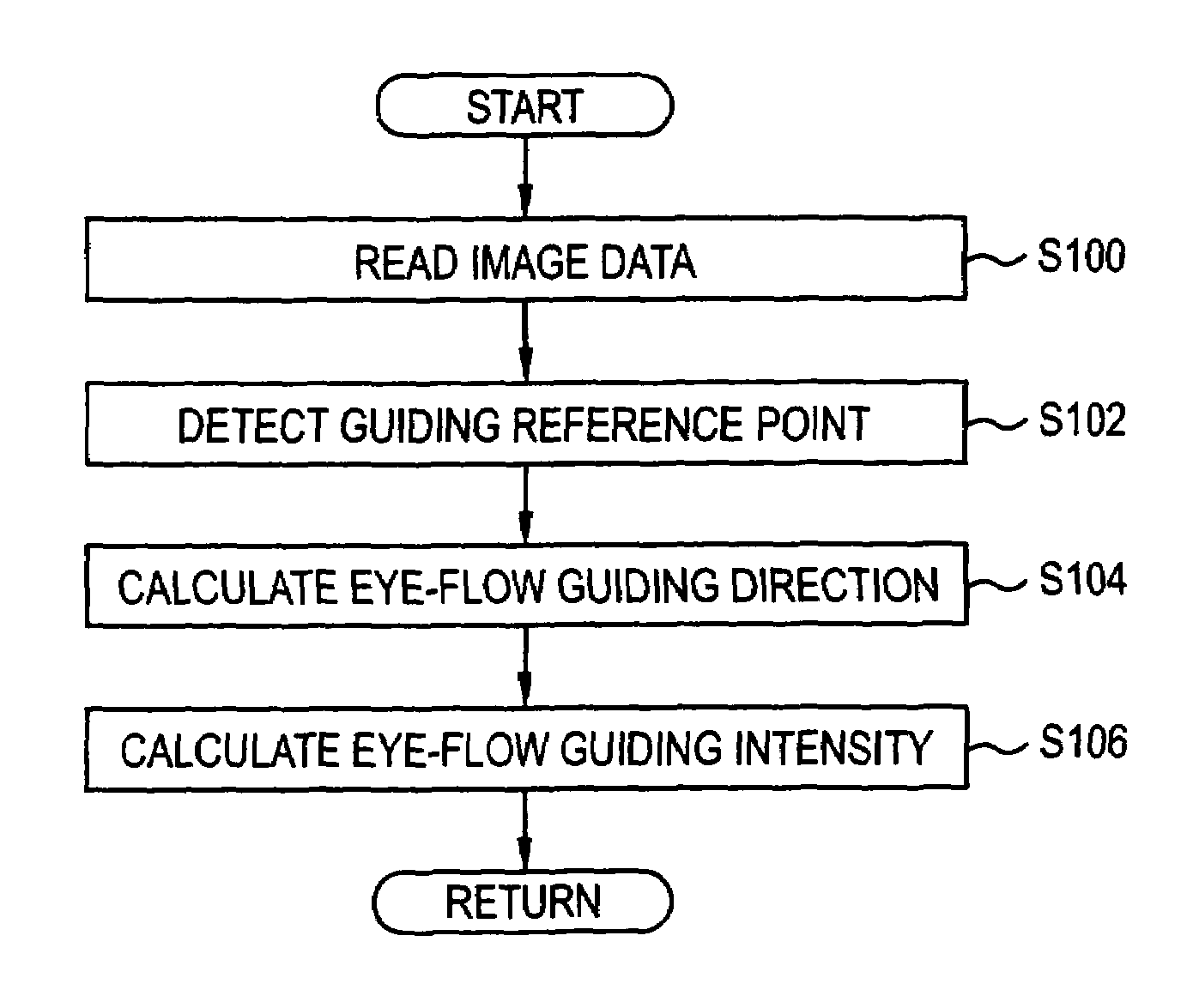

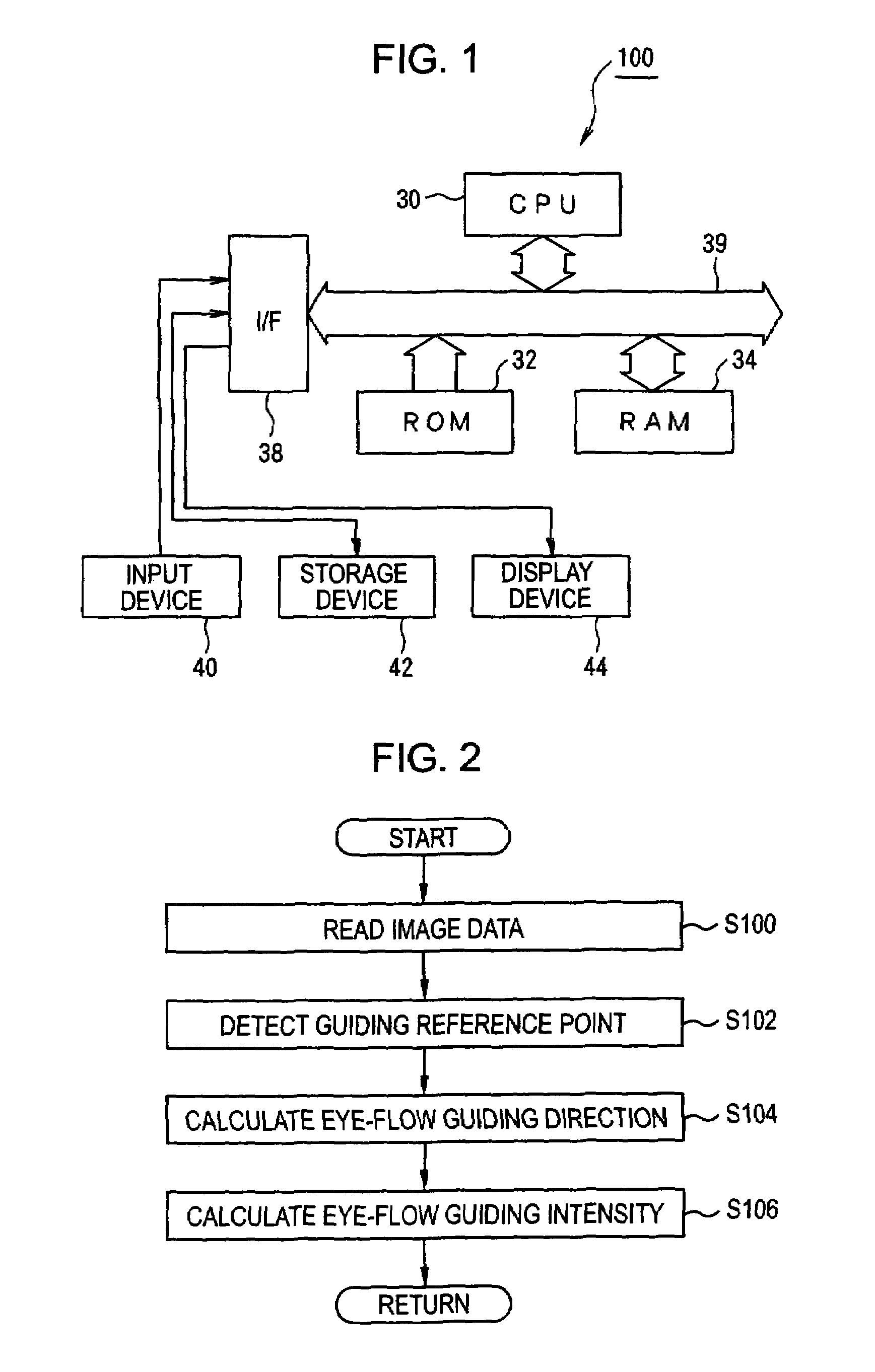

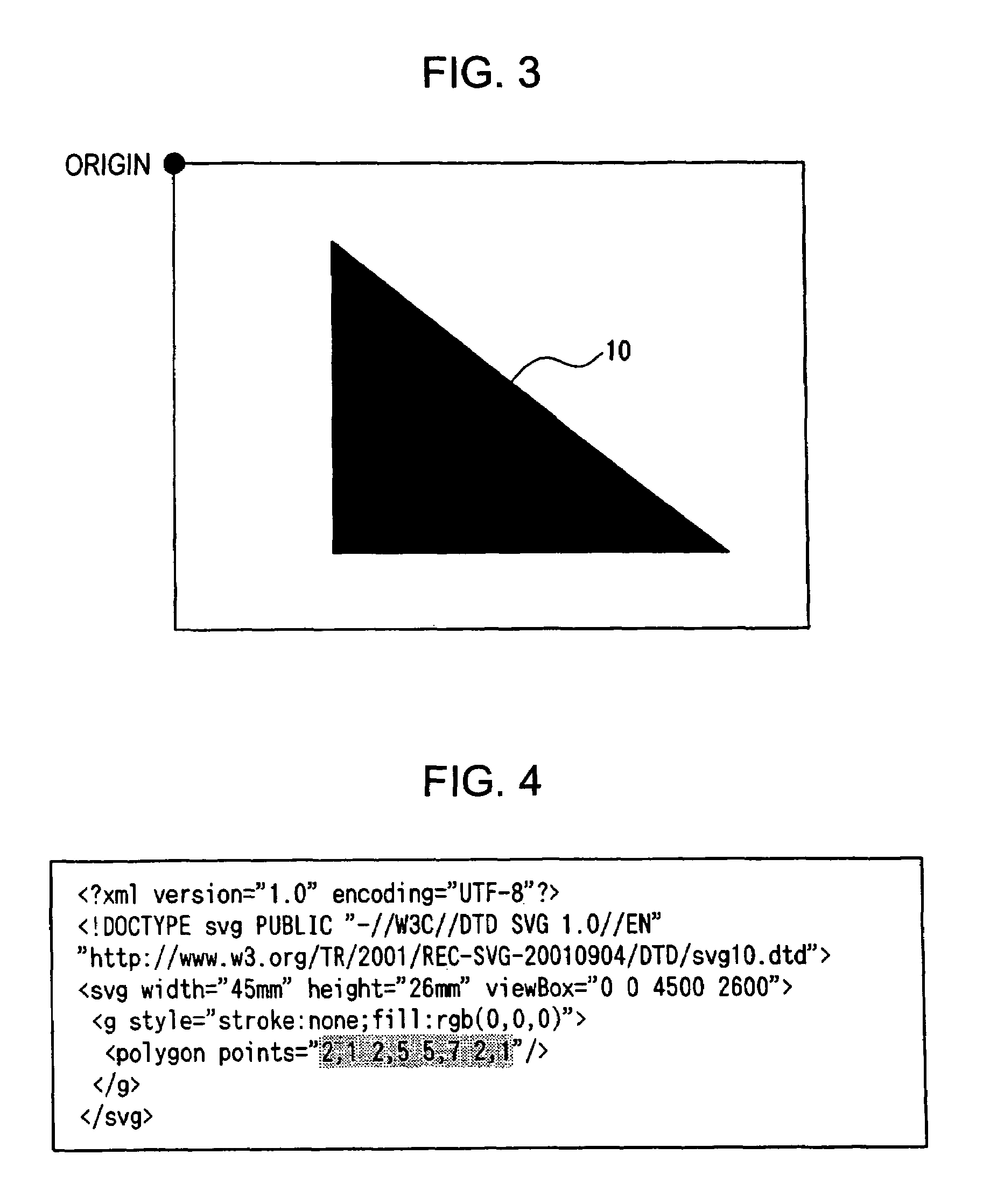

Line-of-sight guiding degree calculation system and line-of-sight guiding degree calculation program as well as line-of-sight guiding degree calculation method

InactiveUS20050138549A1Small sizeLow costEye diagnosticsSpecial data processing applicationsImage objectComputing systems

Exemplary embodiments provide a line-of-sight guiding degree calculation system that can realize reduction in size and reduction in cost of an apparatus and can obtain an appropriate eye flow surely. First, a layout apparatus approximates an image object to a polygon on the basis of vector image data and detects respective apexes of the approximated image object as guiding reference points. Then, for each of the guiding reference points, the layout apparatus forms two auxiliary lines crossing the guiding reference point imaginarily along a contour of the image object and calculates a direction in which a bisector of an obtuse angle among angles formed by the imaginary auxiliary lines extends outward from the guiding reference point as a line-of-sight guiding direction. In addition, for each of the guiding reference points, the layout apparatus calculates a distance from a center of gravity G of the image object to the guiding reference point as a line-of-sight guiding intensity. Consequently, it can be calculated quantitatively and appropriately in which direction the image object tends to guide a line-of-sight.

Owner:SEIKO EPSON CORP

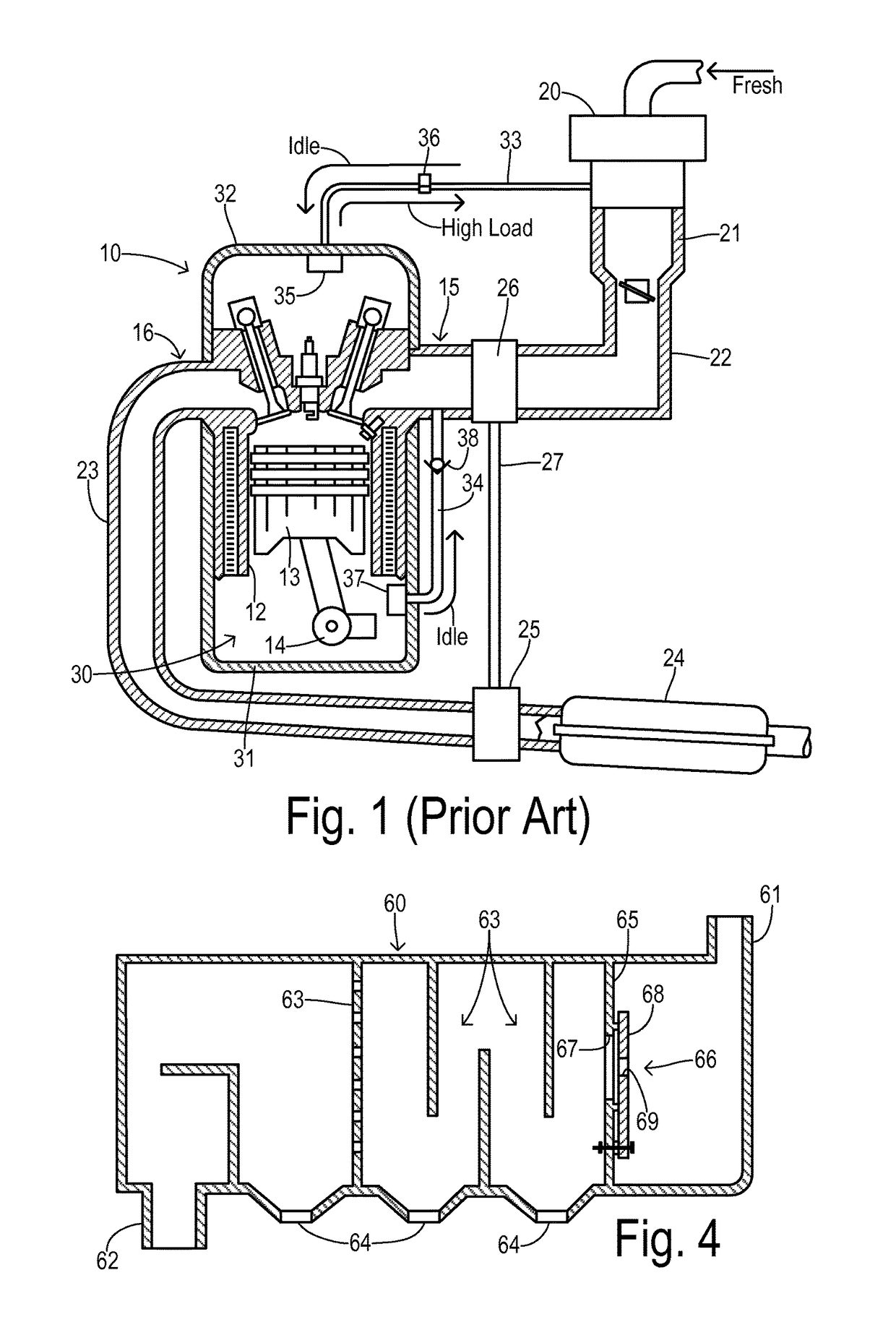

Crankcase ventilation pressure management for turbocharged engine

ActiveUS9909470B2Appropriate flowCombustion enginesCrankcase ventillationPressure managementInlet manifold

A crankcase ventilation system for a turbocharged engine has full bi-directional flow for an idle state and a boosted state. A PCV valve provides air flow from the crankcase to the intake manifold in the idle state. A restriction in a first vent line limits fresh air into the crankcase in the idle state. A PCV bypass permits a one-way flow into the crankcase via a second vent line bypassing the PCV valve in the boosted state. A pressure relief valve in communication with the first vent line is configured to bypass the restriction in the boosted state when a pressure in the crankcase exceeds a threshold pressure. In a preferred embodiment, the PCV bypass is configured to bypass both the PCV valve and a pull separator (i.e., oil separator at the second vent line) in the boosted state.

Owner:FORD GLOBAL TECH LLC

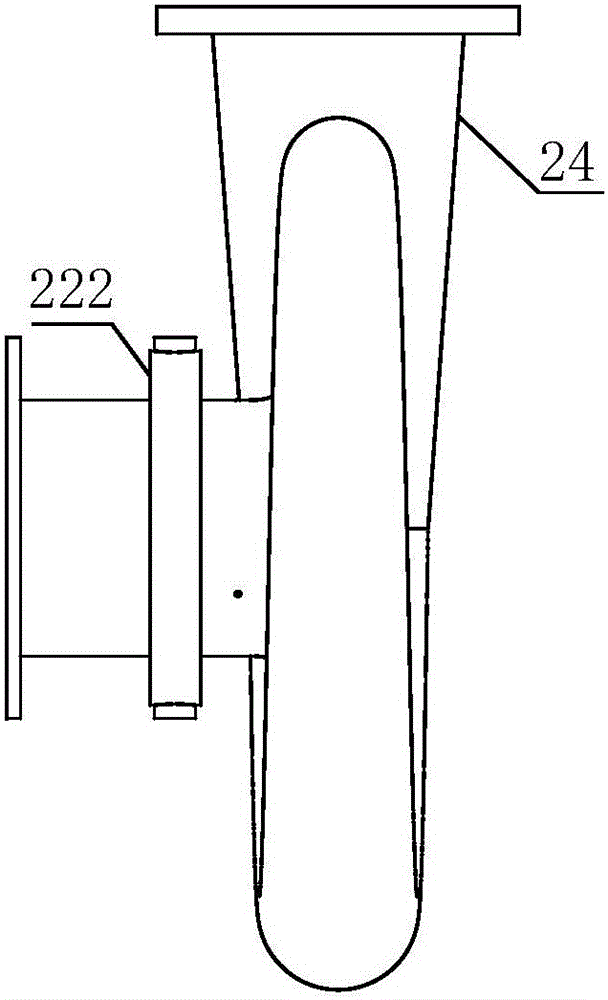

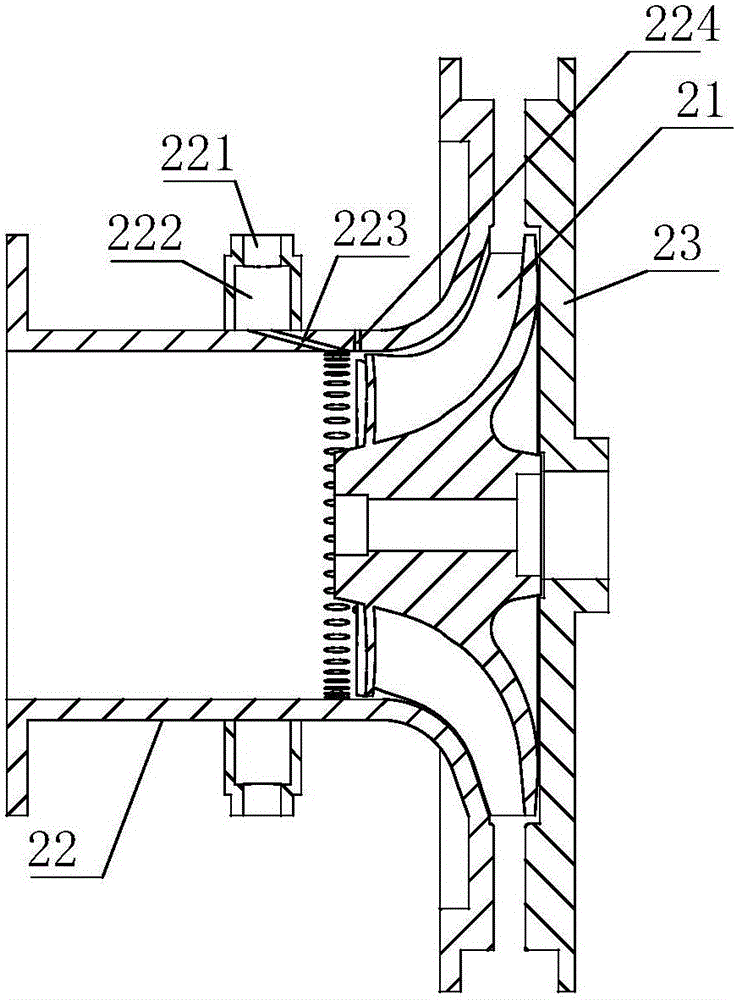

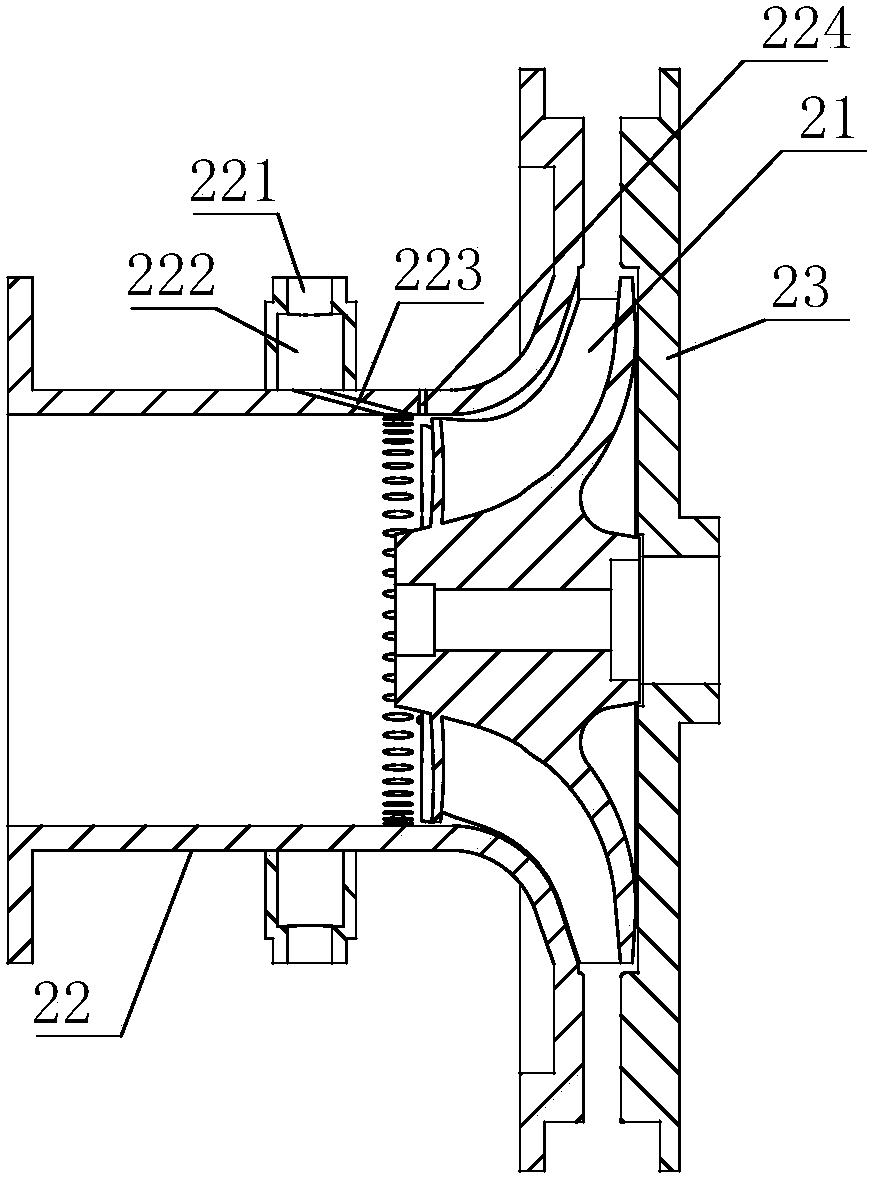

System for suppressing forced vibration of centrifugal impeller and control method for system

ActiveCN105952688AAvoid complex disadvantagesAvoid fatigue damagePump componentsPump controlFatigue damageInlet channel

The invention mainly relates to a system for suppressing forced vibration of a centrifugal impeller. The system comprises a centrifugal compressor. A housing cover plate is disposed in front of an impeller of the centrifugal compressor and forms an air suction channel. An annular air accumulation chamber is disposed on an external peripheral surface of the air suction channel, and provided with a jet air stream inlet communicating with an air inlet channel. A plurality of jet holes communicating with the air accumulation chamber and used for jetting a jet air stream to a position in front of the impeller to inhibit the vibration of the impeller are uniformly formed in the air suction channel in a peripheral direction with each jet hole axially facing the impeller. The system for suppressing forced vibration of a centrifugal impeller is provided with the annular air accumulation chamber on the housing cover plate; a jet air stream enters the annular air accumulation chamber via the jet air stream inlet and then is uniformly jetted via the jet holes to a region in front of the impeller; the jet air stream forms a local flow field for blocking the vibration of the impeller under appropriate pressure and at an appropriate angle of attack, thereby achieving an aerodynamic damping effect and allowing effective suppression of the fatigue damage of the centrifugal impeller caused by air stream excitation under complicated operating conditions.

Owner:HEFEI GENERAL MACHINERY RES INST

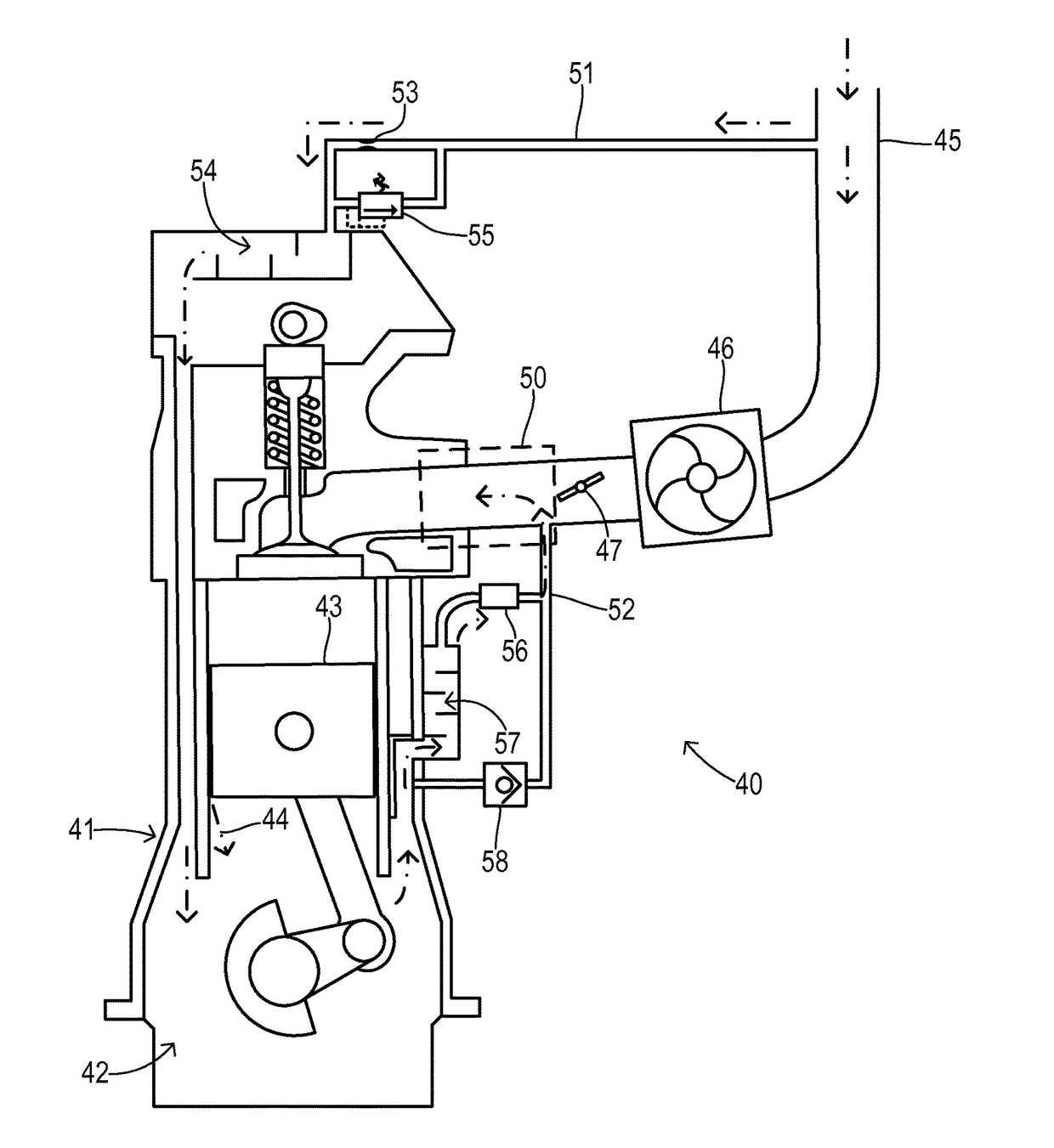

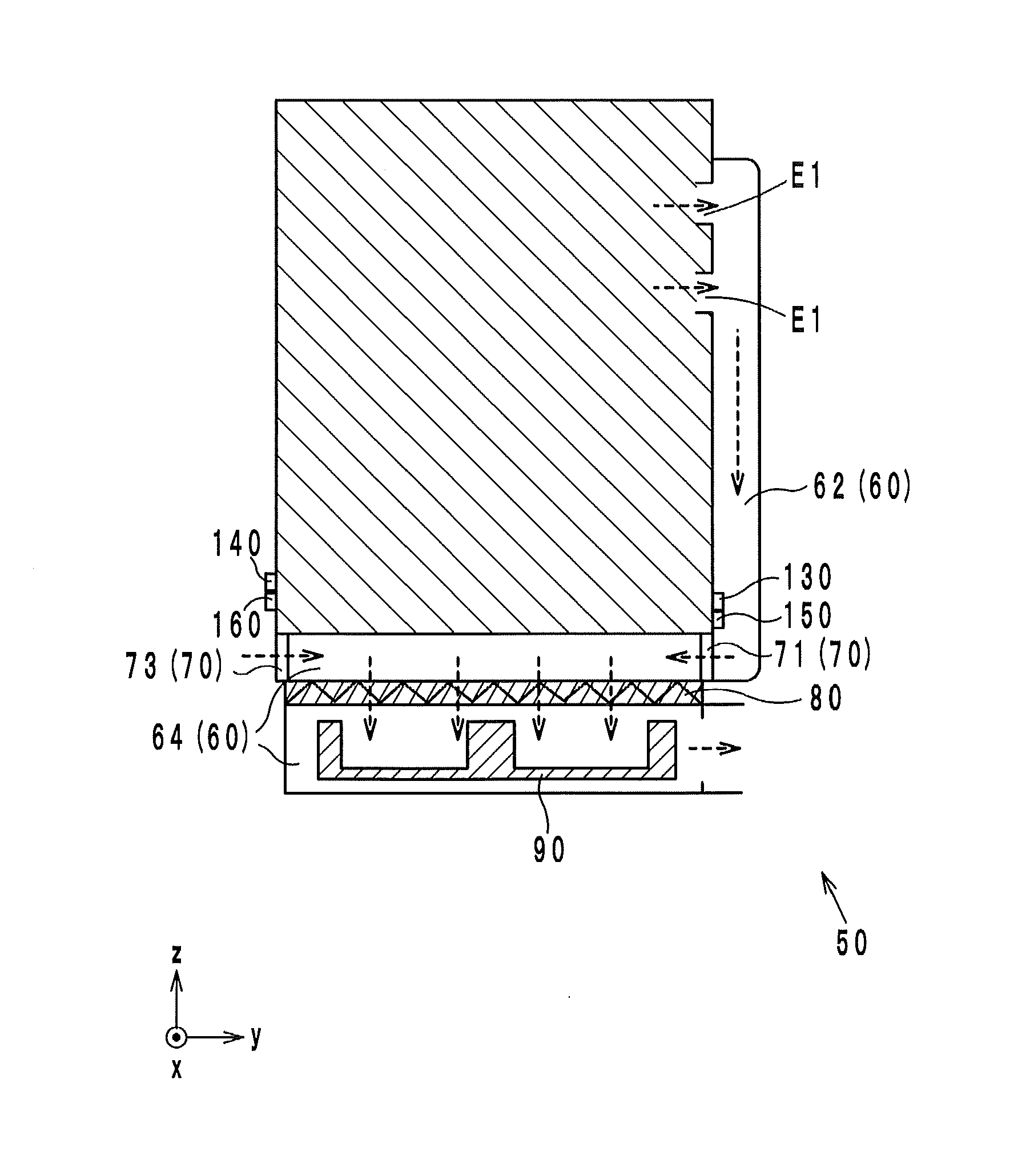

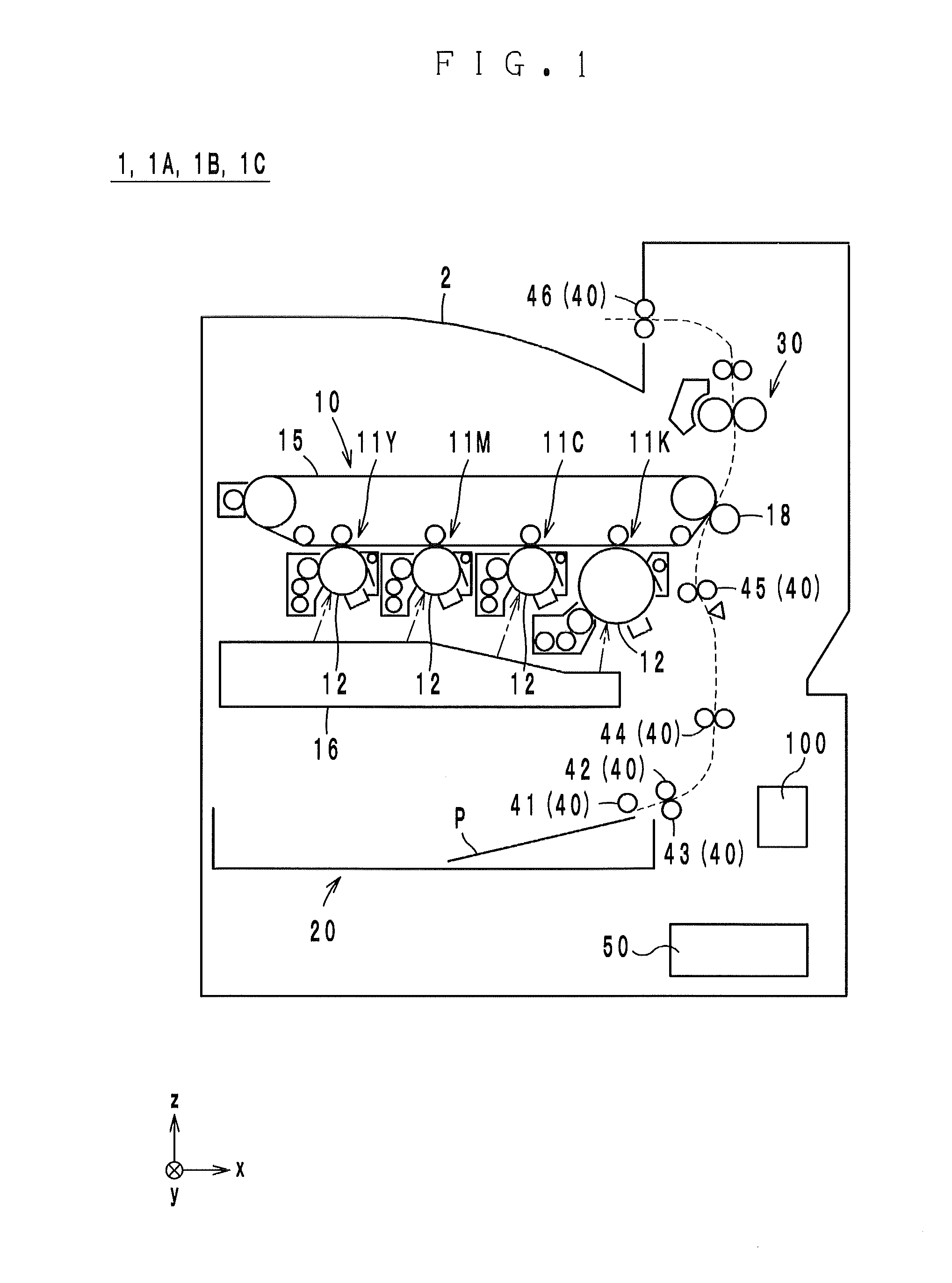

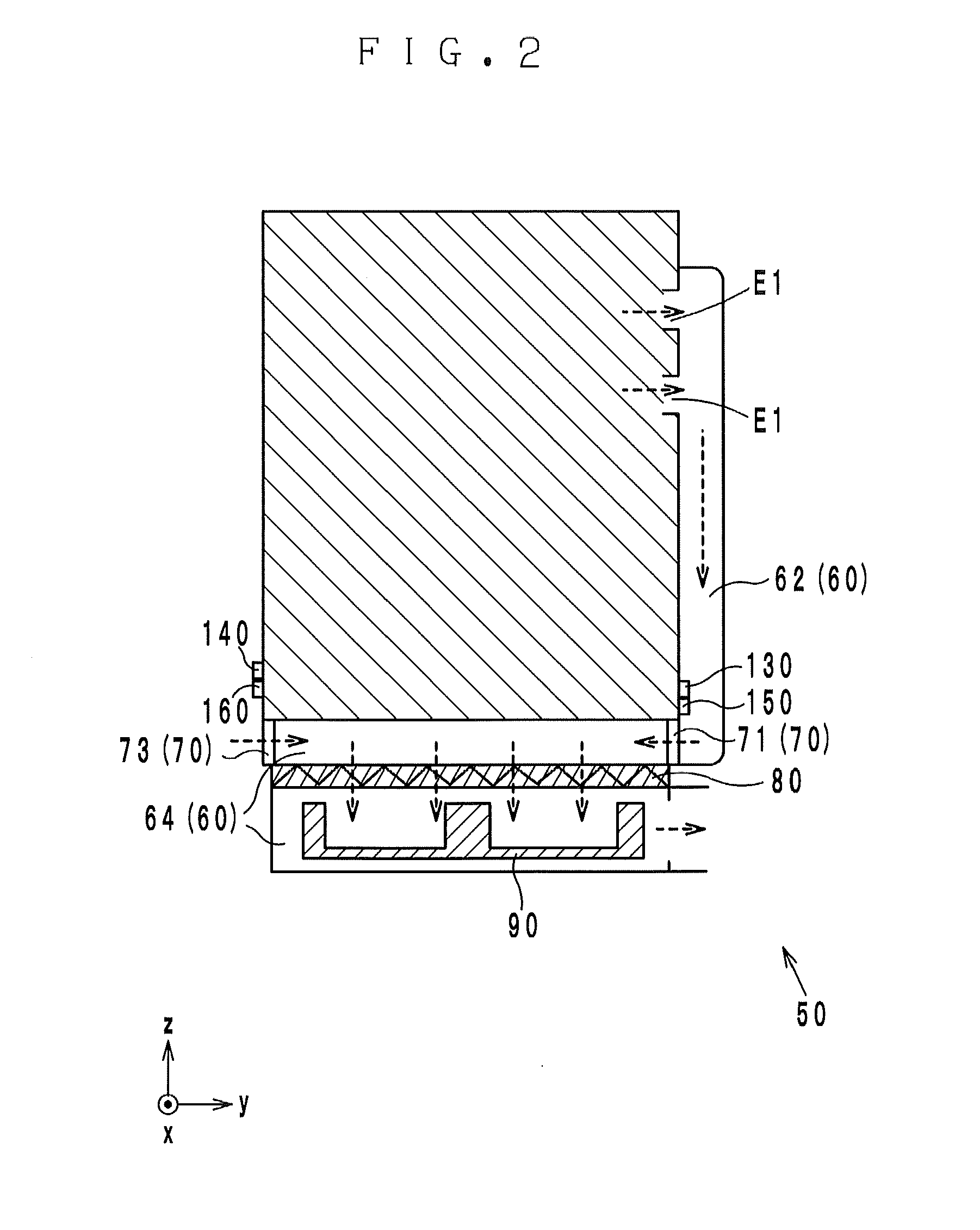

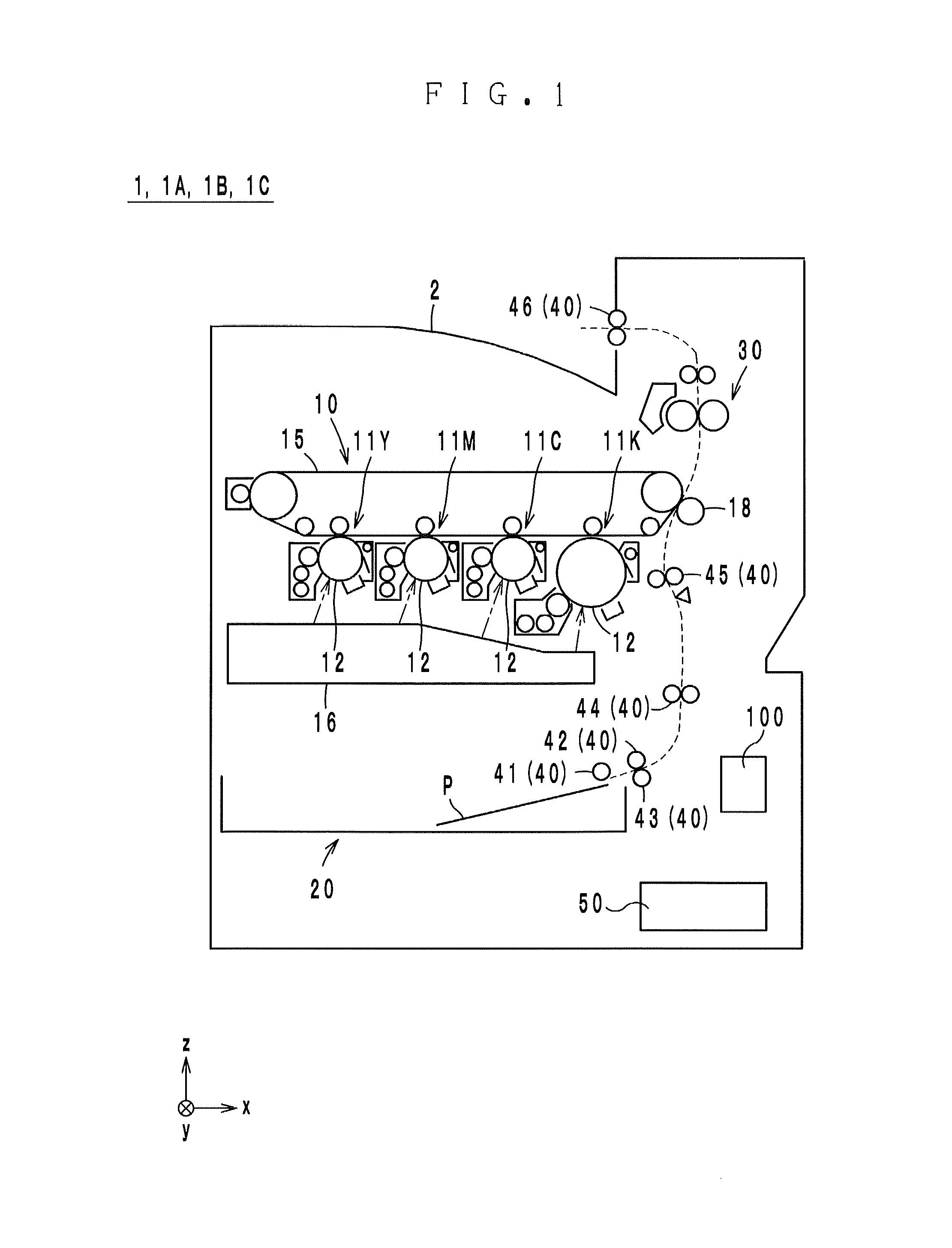

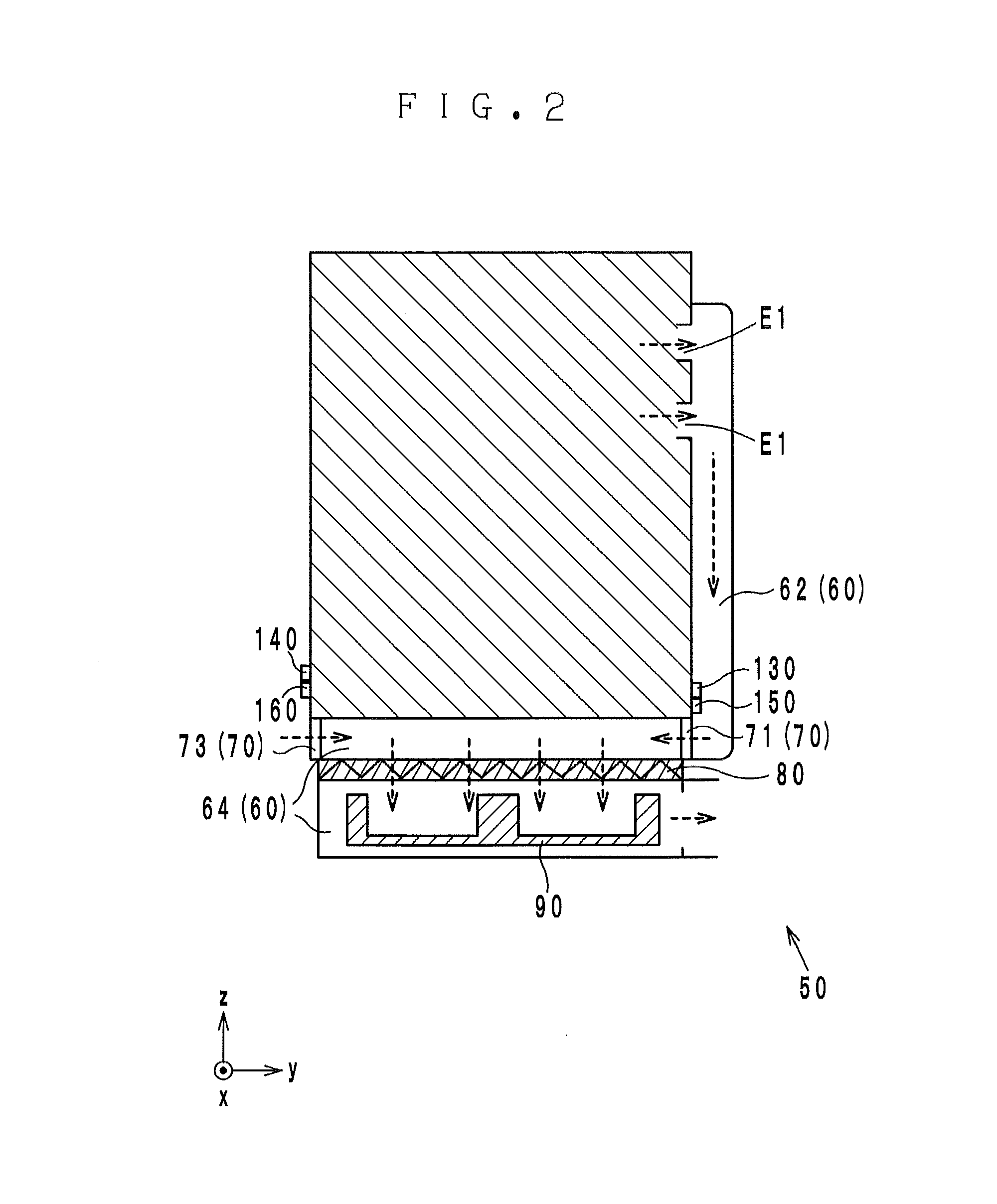

Image forming apparatus

ActiveUS20150277372A1Preventing increase in size of apparatusAppropriate flowElectrographic process apparatusAir cleaningAerospace engineering

An image forming apparatus has: an exhaust air duct capable of forming a first air flow path for an exhaust air cleaning function and a second air flow path for a room air cleaning function, the exhaust air duct having a common use space used in common for the exhaust air cleaning function and the room air cleaning function; a switching member configured to switch a flow path in the exhaust air duct, depending on which of the cleaning functions is activated; a fan configured to discharge air from the common use space in an active state of the exhaust air cleaning function and in an active state of the room air cleaning function; and a control unit configured to control the switching member and to adjust a rotation speed of the fan, depending on which of the cleaning functions is activated.

Owner:KONICA MINOLTA INC

Method of creating a cosmetic spray

InactiveUS20060275220A1Maintain good propertiesImprove spray qualityCosmetic preparationsDispensing apparatusFree flowNozzle

A method of spraying a liquid cosmetic composition onto the surface of the human body comprising: (i) mechanically pressurising a free-flowing liquid cosmetic composition to a pressure of from 1.0 to less than 5.0 MPa; (ii) passing said composition through a swirl chamber, and (iii) expelling said composition through a 100 to 200 micron outlet nozzle onto the surface of the human body.

Owner:THOMPSON GUY RICHARD +2

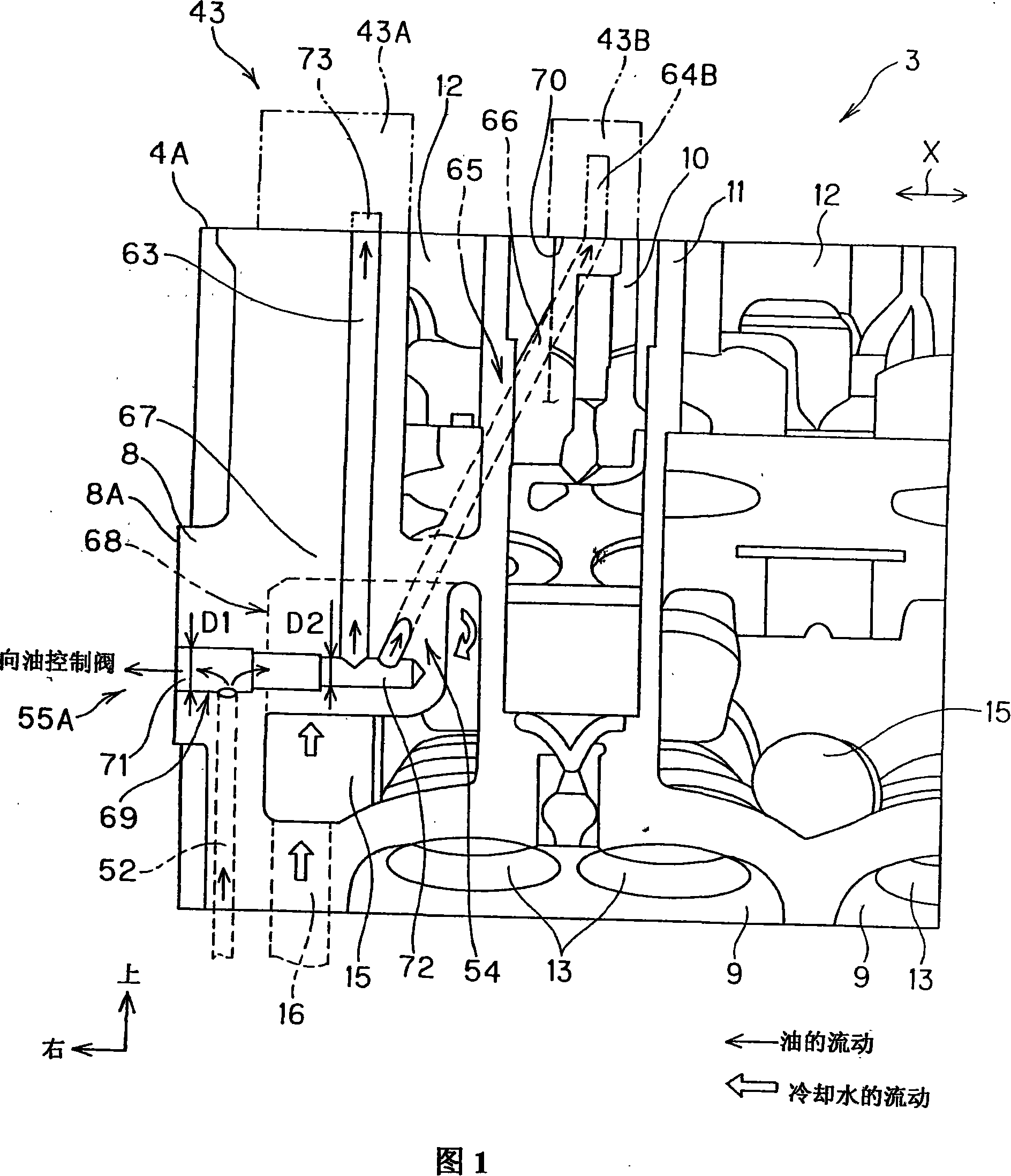

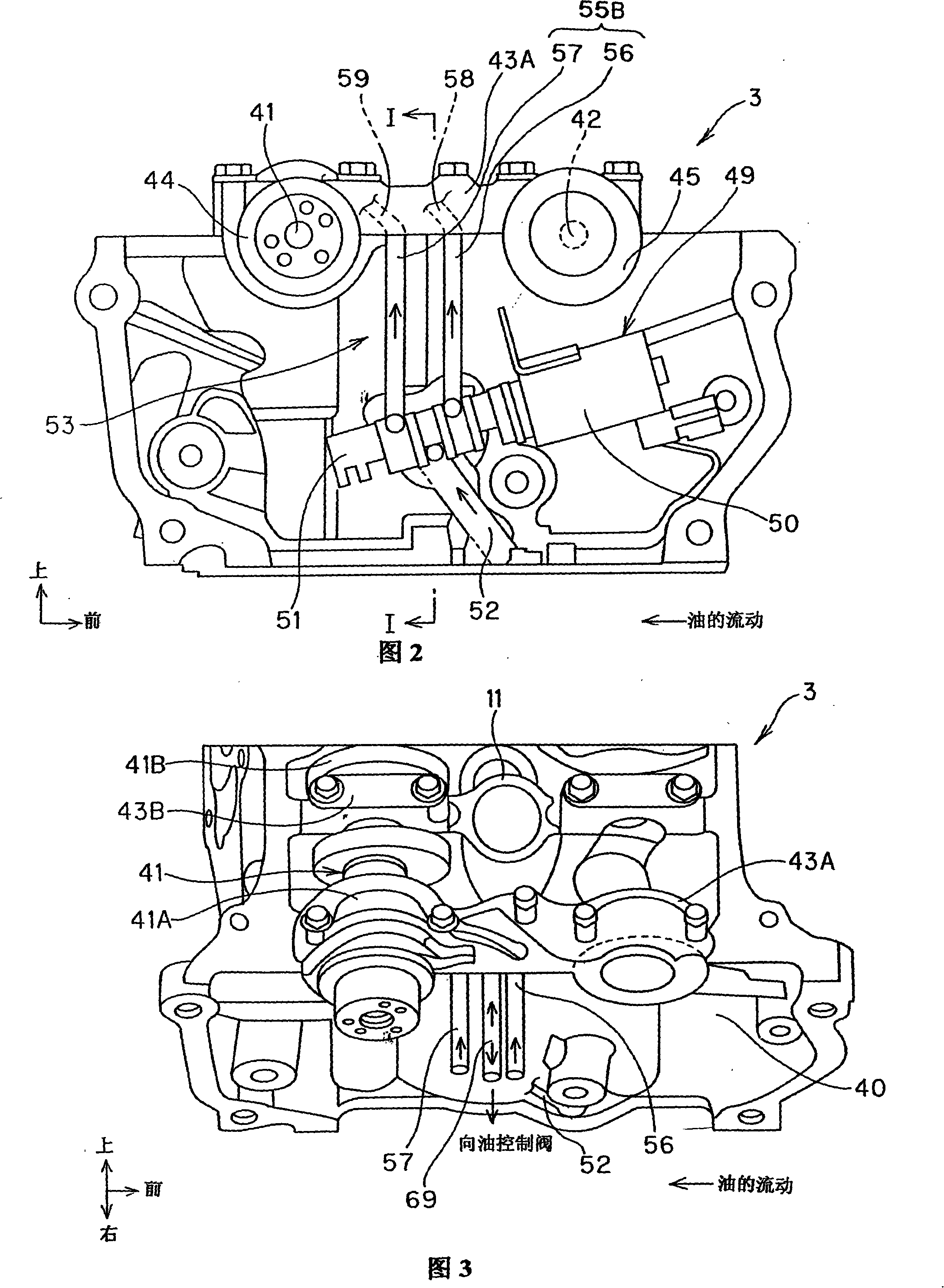

Engine cylinder head structure

InactiveCN101169057AAppropriate flowReduced parts countCylinder headsCylindersCylinder headEngineering

In a cylinder head structure of an engine, a structure of an oil passage is simplified to downside the engine and to provide proper flow of cooling water in the cylinder head. A partition wall is disposed in the cylinder head to separate an upward valve operating chamber from a downward water jacket. A boss section is formed at a position lower than the partition wall in an edge wall of the cylinder head, and has one end joined to a chain case and the other end protruding into the water jacket. A branch oil passage is formed in the boss section. The branch oil passage has a valve upstream-side passage section specified by a section toward the chain case with respect to a junction with a cylinder head-side oil passage. The linear communication passage section communicates between an end portion of the branch oil passage protruding into the water jacket and a camshaft cap coupling surface of a second camshaft bearing section.

Owner:SUZUKI MOTOR CORP

Flow Rate Regulating Device and Control Method of Flow Rate Regulating Device

ActiveUS20210254752A1Accurate supervisionAvoid it happening againSpindle sealingsDiaphragm valvesControl cellEngineering

Provided is a flow rate regulating device including a valve body section having a flat valve body surface; a main body section including a valve chamber, an inflow channel, an outflow channel, and a communication channel; a valve seat section having a flat valve seat surface provided around an inflow opening; a regulation mechanism that moves the valve body section along an axis to regulate a distance between the valve body surface and the valve seat surface; and a control unit that controls the regulation mechanism so that the valve body section moves in a movement range in which the valve body surface and the valve seat surface maintain a non-contact state, wherein a channel cross-sectional area of the communication channel is smaller than each of a channel cross-sectional area of the inflow channel and a channel cross-sectional area of the outflow channel.

Owner:SURPASS IND

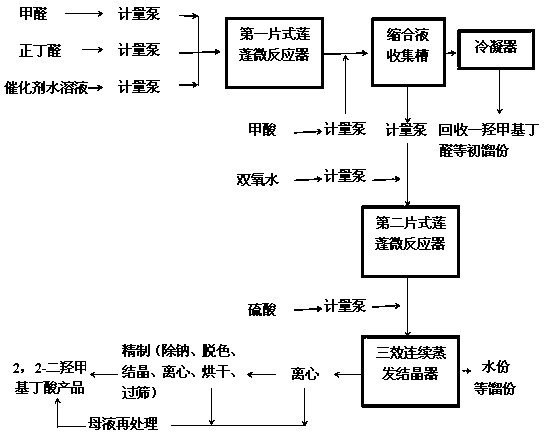

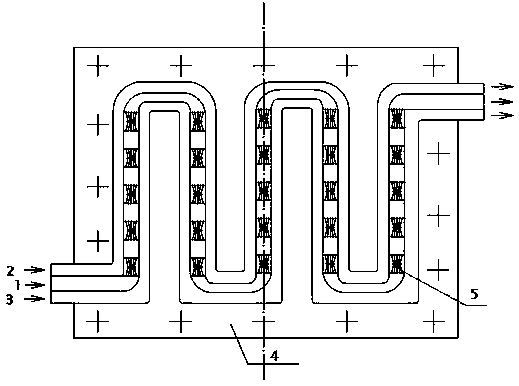

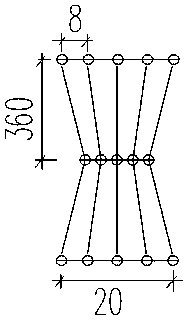

Device and technology for continuously producing 2,2-dimethylolbutanoic acid

InactiveCN108658754AIncrease flow rateWell mixedSequential/parallel process reactionsOrganic compound preparationSmall footprintSolvent

The invention relates to a device and technology for continuously producing 2,2-dimethylolbutanoic acid. The technology comprises the following steps: carrying out continuous catalytic condensation onn-butylaldehyde and formaldehyde through a first sheet-type shower nozzle micro-reactor; after neutralizing a condensed product through formic acid, carrying out continuous oxidization on the condensed product and hydrogen peroxide in a second sheet-type shower nozzle micro-reactor; acidifying an oxidized product through dilute sulfuric acid, carrying out refining treatment of carrying out crystallization after triple-effect concentration, centrifuging and separating, removing sodium sulfate through methanol, de-coloring, carrying out re-crystallization after a solvent is recycled, re-centrifuging, drying, sieving and the like, so as to obtain a 2,2-dimethylolbutanoic acid product. According to the device and the technology, provided by the invention, the first sheet-type shower nozzle micro-reactor is formed by connecting 5 to 6 sets of sheet-type shower nozzle micro-reactors in series and the second sheet-type shower nozzle micro-reactor is formed by connecting 6 to 8 sets of the sheet-type shower nozzle micro-reactors in series; condensation and oxidization are continuous reaction; a production device occupies a small area, the technology is stable and easy to control and the conversion rate of the product is high; the energy consumption is low, the emission amount of pollutants is small, the labor intensity is low, the production is safe and the production cost is low.

Owner:李先明

Image forming apparatus

ActiveUS9261858B2Increase in sizeAppropriate flowElectrographic process apparatusAir cleaningImage formation

An image forming apparatus has: an exhaust air duct capable of forming a first air flow path for an exhaust air cleaning function and a second air flow path for a room air cleaning function, the exhaust air duct having a common use space used in common for the exhaust air cleaning function and the room air cleaning function; a switching member configured to switch a flow path in the exhaust air duct, depending on which of the cleaning functions is activated; a fan configured to discharge air from the common use space in an active state of the exhaust air cleaning function and in an active state of the room air cleaning function; and a control unit configured to control the switching member and to adjust a rotation speed of the fan, depending on which of the cleaning functions is activated.

Owner:KONICA MINOLTA INC

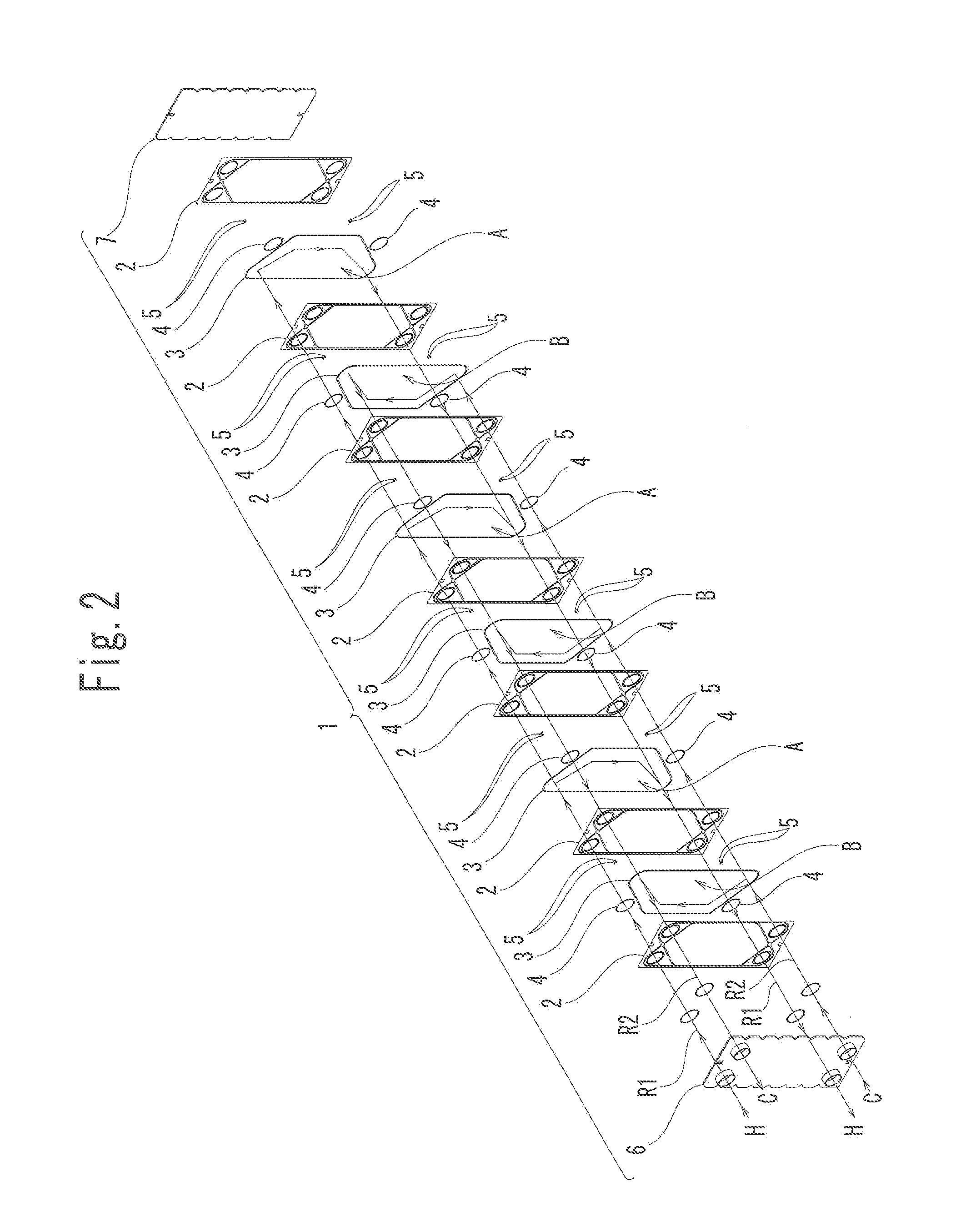

Plate heat exchanger

ActiveUS20160010925A1Avoid positioningAppropriate flowLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

Provided is a plate heat exchanger that includes a plurality of heat transfer plates stacked to each other, a gasket interposed between each adjacent heat transfer plates, and a regulating member formed to be able to support at least partially the gasket. Each heat transfer plate has a fitting recessed portion formed in recessed manner on the side on which the gasket fitting groove is formed. The fitting recessed portion crosses the recessed strip while extending along the gasket fitting groove. The support part is arranged along the gasket fitting groove when the regulating member is held in fitting engagement with the fitting recessed portion. The support part is arranged along the gasket fitting groove when the regulating member is held in fitting engagement with the fitting recessed portion.

Owner:HISAKA WORKS +1

Fuel cell system

ActiveUS10511040B2Ensure performanceAppropriate flowDc network circuit arrangementsElectrical testingElectricityFuel cells

Owner:NISSAN MOTOR CO LTD

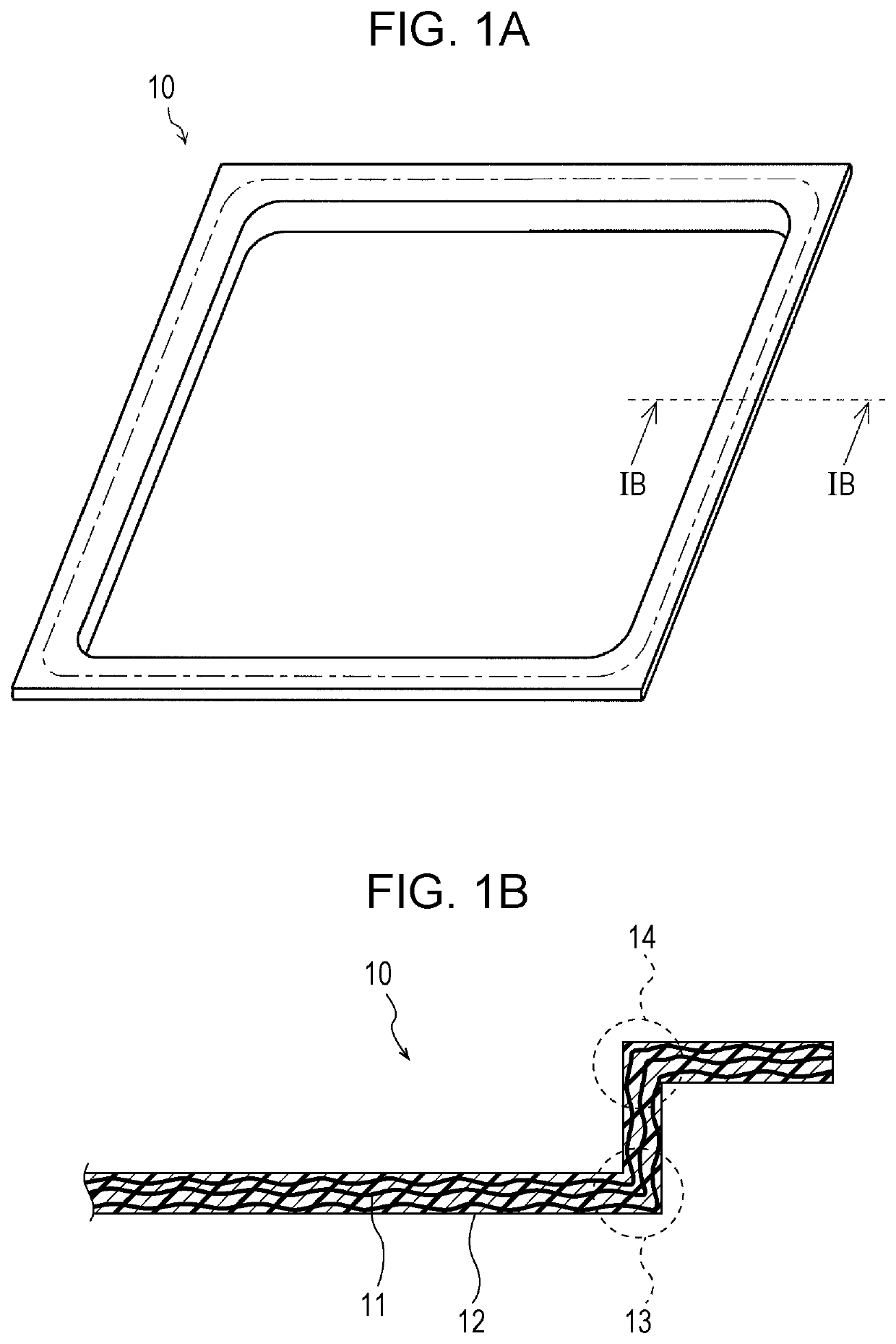

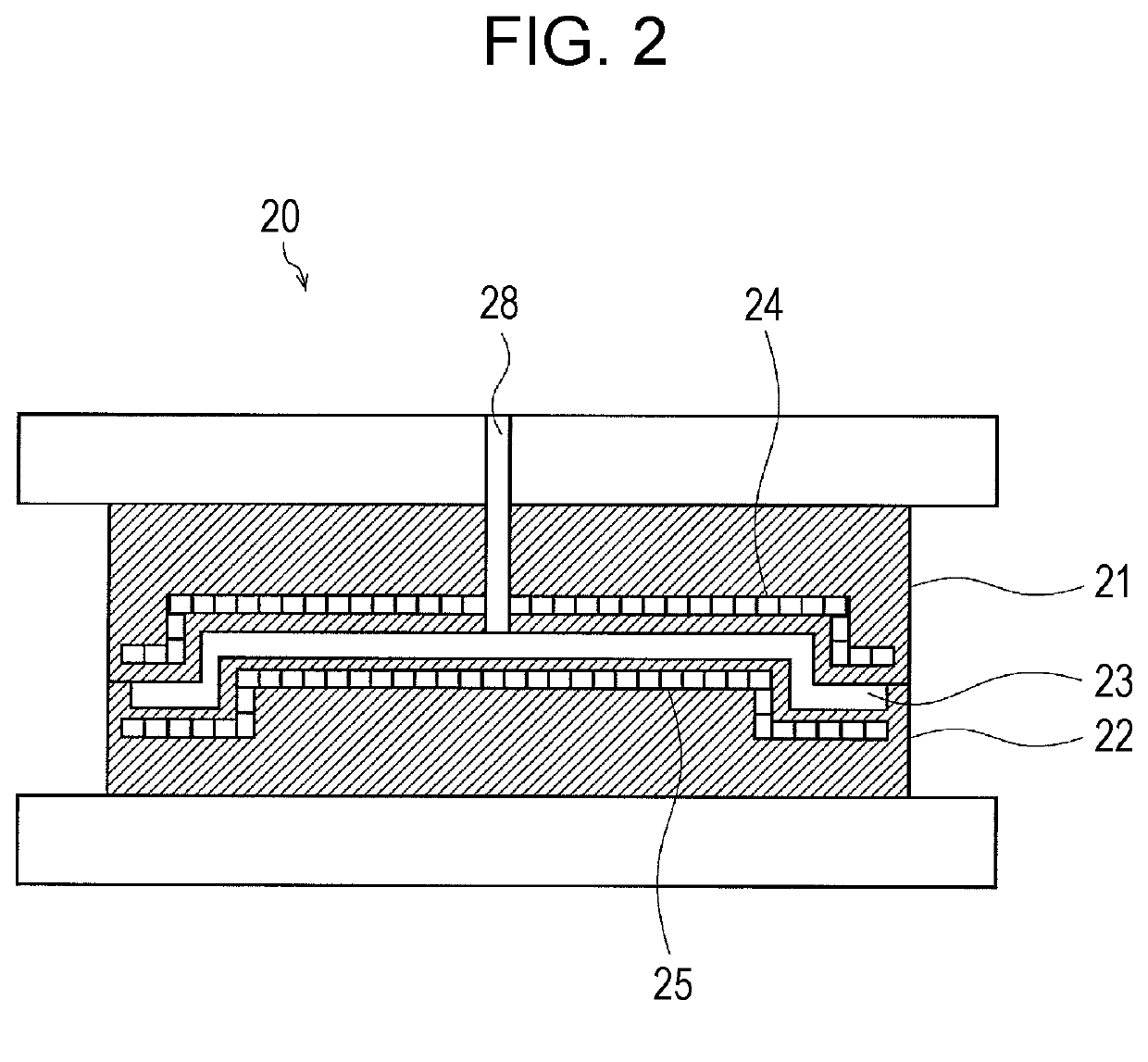

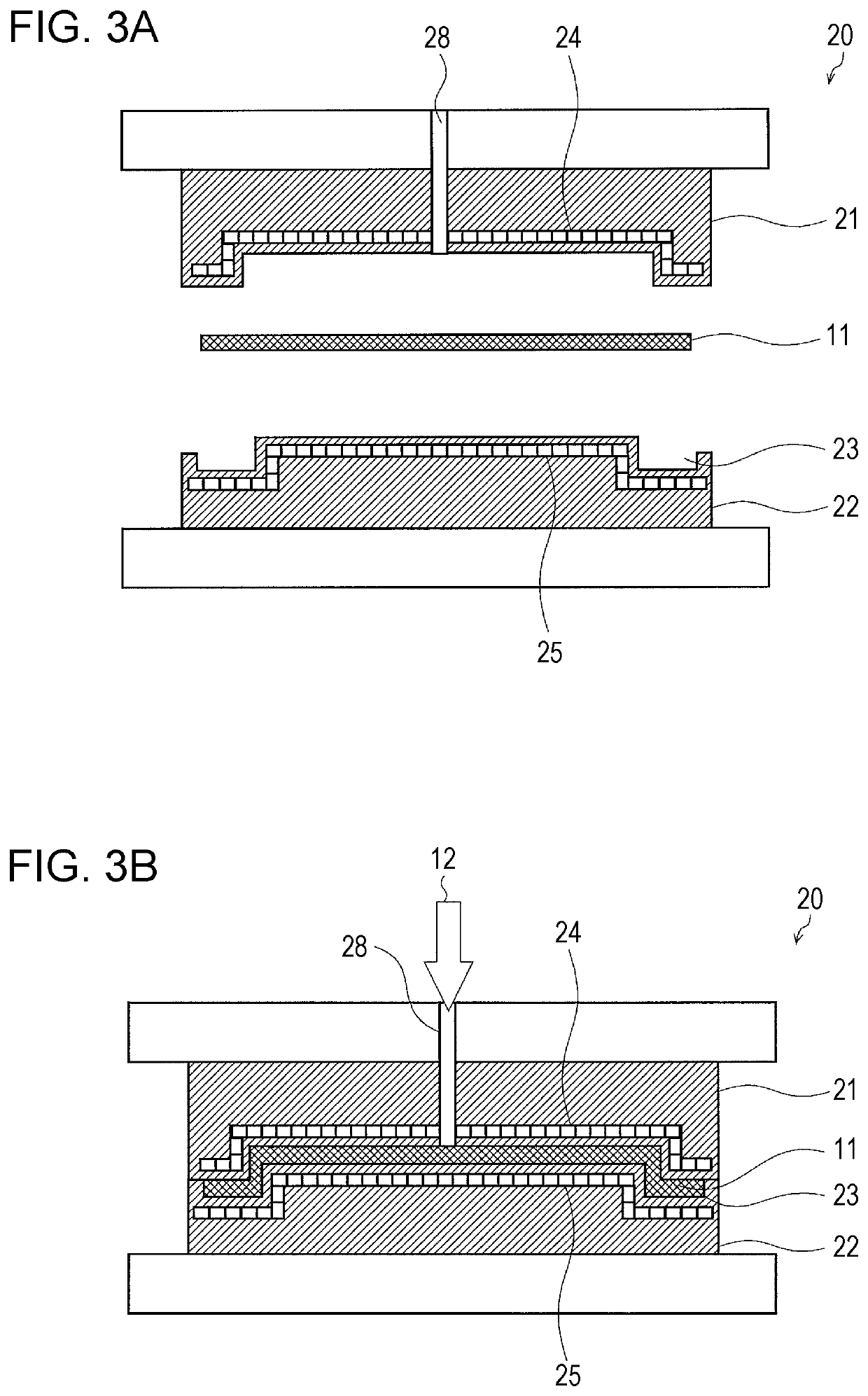

Method for producing fiber-reinforced composite material and forming mold used for the method

In a method for producing a fiber-reinforced composite material, the fiber-reinforced composite material is formed by impregnating a reinforcing fiber sheet with a resin and curing the resin. The method includes: storing the reinforcing fiber sheet in a cavity of a forming mold; and impregnating the reinforcing fiber sheet with the resin by injecting the resin into the cavity of the forming mold, and curing the resin. In the impregnating and curing, the resin containing a magnetic powder is injected into the cavity, and a magnetic field is generated in the cavity to cause the resin containing the magnetic powder to flow.

Owner:SUBARU CORP

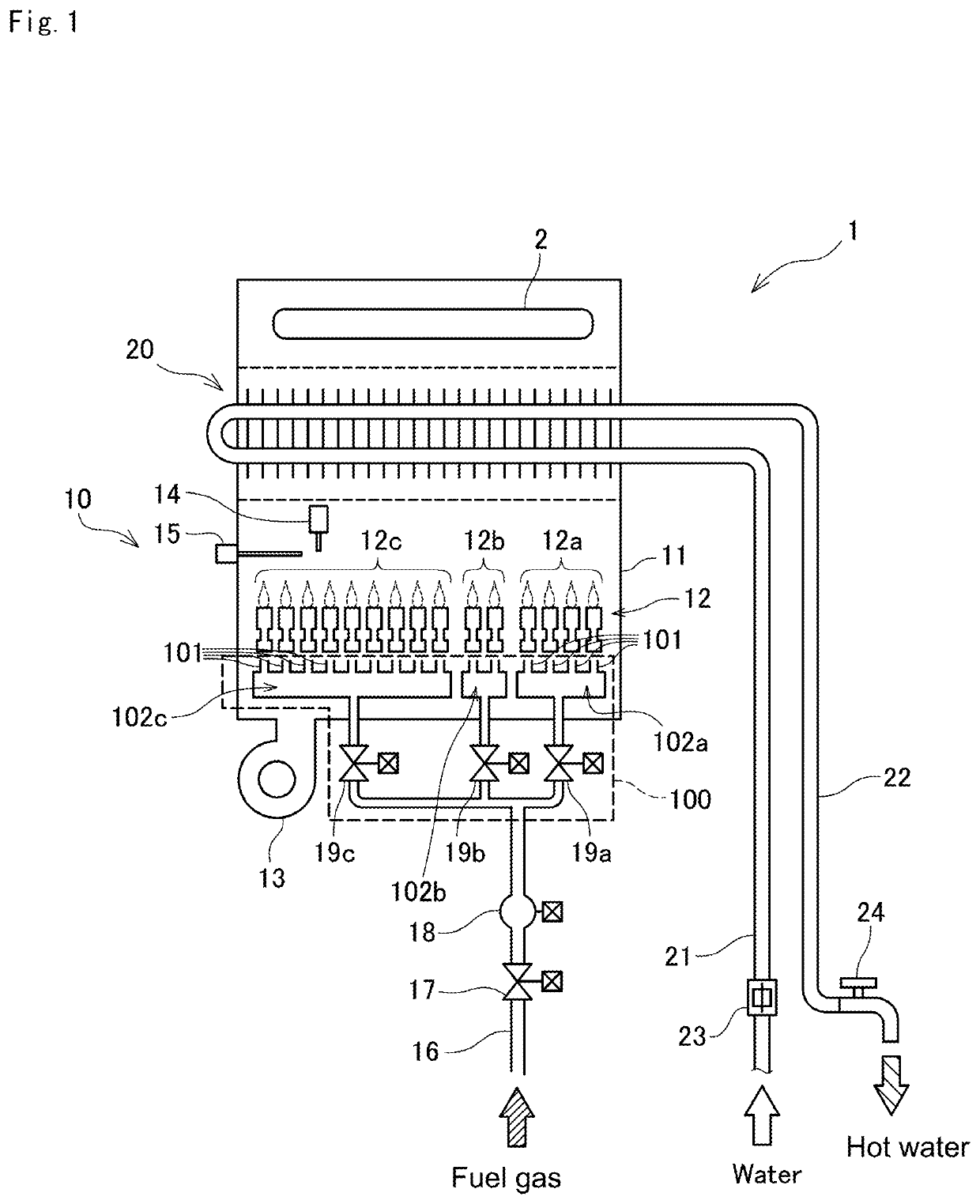

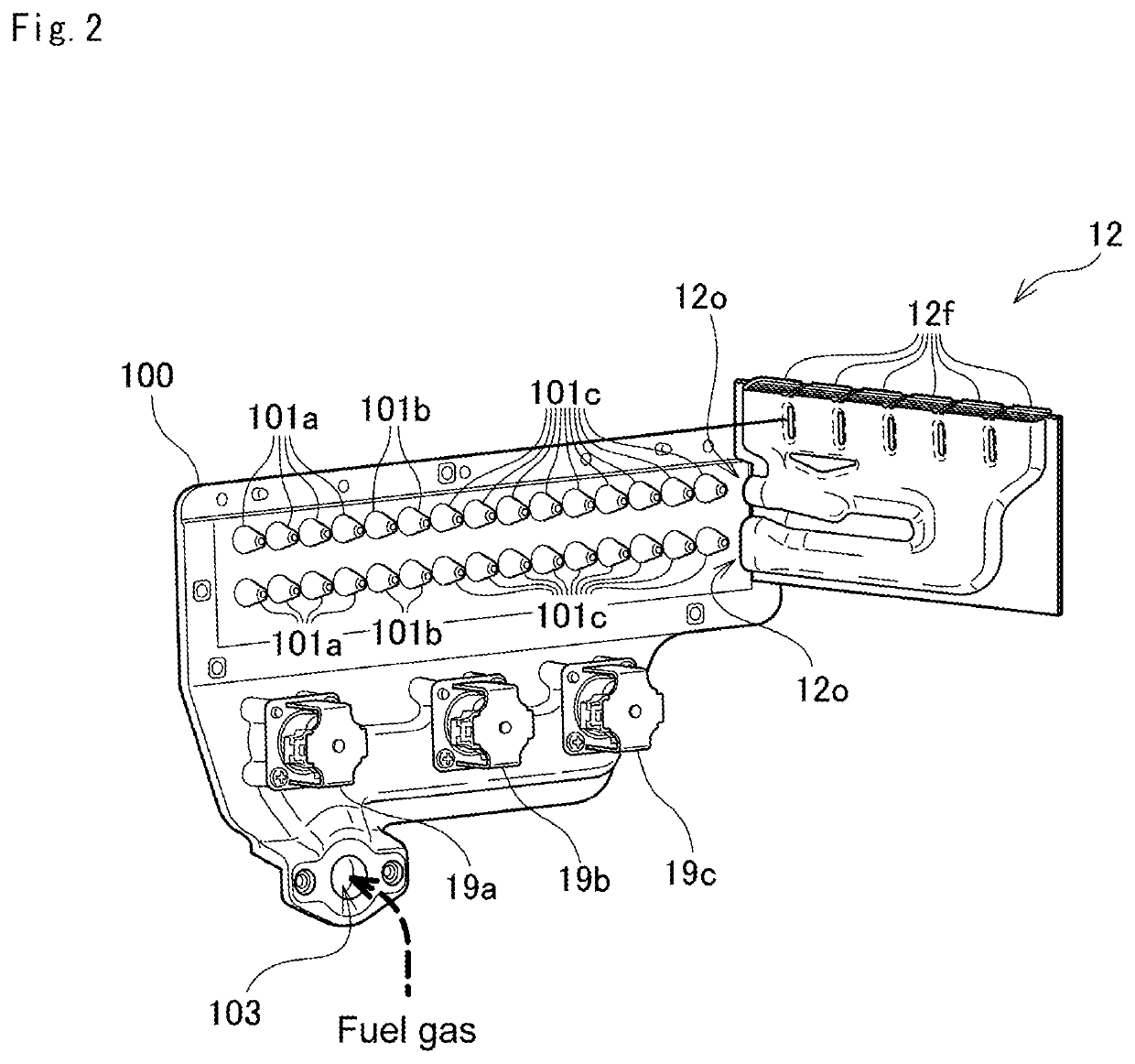

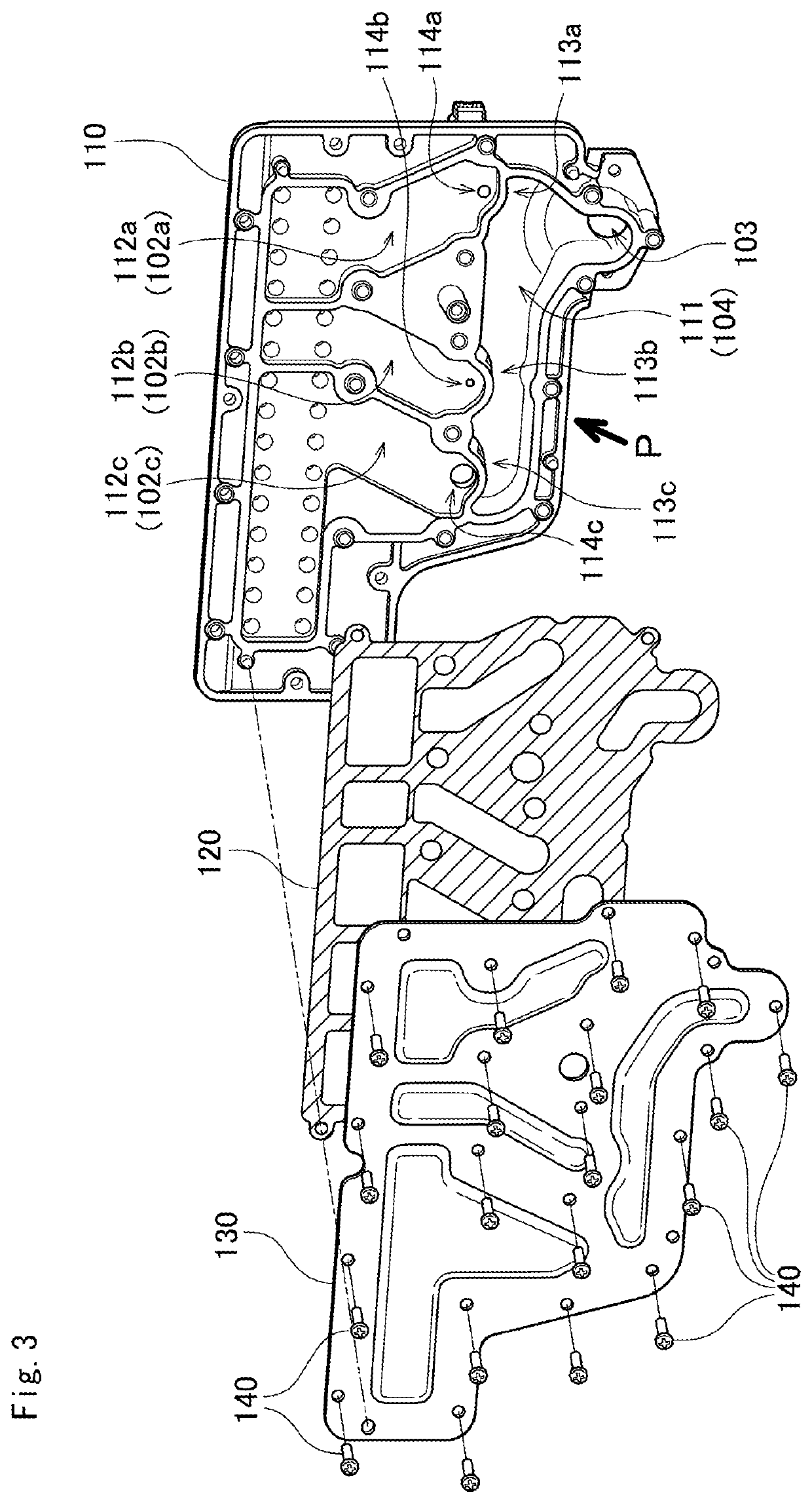

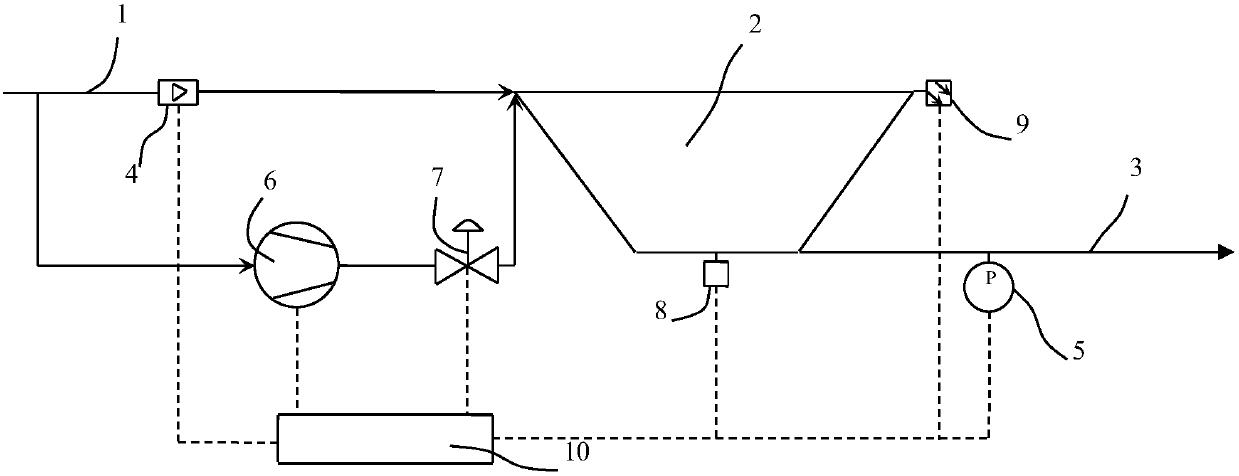

Gas manifold

PendingUS20210293183A1Increase the differenceAccurate supervisionTurbine/propulsion fuel flow conduitsTurbine/propulsion fuel valvesEngineeringFuel gas

A gas manifold allows each distribution chamber to be fed with fuel gas at an appropriate flow rate irrespective of an increase in the number of distribution chambers included in the gas manifold. Fuel gas flowing through in an inlet is distributed to a plurality of distribution chambers through a main channel. A bypass channel parallel with the main channel also feeds fuel gas to a maximum distribution chamber. This can prevent the feeding of the fuel gas to the maximum distribution chamber from being affected by and reduced by the feeding of the fuel gas to the bypassed distribution chambers. This also prevent the feeding of the fuel gas to the other distribution chambers from being affected by and reduced by the feeding of the fuel gas to the maximum distribution chamber. The plurality of distribution chambers are thus fed with fuel gas at appropriate flow rates.

Owner:RINNAI CORP

A Centrifugal Impeller Forced Vibration Suppression System and Control Method

ActiveCN105952688BAvoid complex disadvantagesAvoid fatigue damagePump componentsPump controlFatigue damageInlet channel

The invention mainly relates to a system for suppressing forced vibration of a centrifugal impeller. The system comprises a centrifugal compressor. A housing cover plate is disposed in front of an impeller of the centrifugal compressor and forms an air suction channel. An annular air accumulation chamber is disposed on an external peripheral surface of the air suction channel, and provided with a jet air stream inlet communicating with an air inlet channel. A plurality of jet holes communicating with the air accumulation chamber and used for jetting a jet air stream to a position in front of the impeller to inhibit the vibration of the impeller are uniformly formed in the air suction channel in a peripheral direction with each jet hole axially facing the impeller. The system for suppressing forced vibration of a centrifugal impeller is provided with the annular air accumulation chamber on the housing cover plate; a jet air stream enters the annular air accumulation chamber via the jet air stream inlet and then is uniformly jetted via the jet holes to a region in front of the impeller; the jet air stream forms a local flow field for blocking the vibration of the impeller under appropriate pressure and at an appropriate angle of attack, thereby achieving an aerodynamic damping effect and allowing effective suppression of the fatigue damage of the centrifugal impeller caused by air stream excitation under complicated operating conditions.

Owner:HEFEI GENERAL MACHINERY RES INST

Eye-flow guiding level calculating system, eye-flow guiding level calculating program, and eye-flow guiding level calculating method

InactiveUS20050131653A1Low costMiniaturizing system devicesImage analysisDigital computer detailsMiniaturizationComputing systems

Exemplary embodiments of the invention provide an eye-flow guiding level calculating system which can plan miniaturization and low cost of a device and surely obtain a suitable eye flow. A layout device, first, detects each vertex of an image object as guiding reference points, based on vector image data. And then, for every guiding reference point, two auxiliary lines are virtually formed to intersect the guiding reference point along an outline of the image object. Subsequently, the direction in which a bisector line of an obtuse angle among angles, made by the virtual auxiliary lines, extends outward from the guiding reference point is calculated as an eye-flow guiding direction. Further, for every guiding reference point, the distance from the center G of the image object up to the guiding reference point is calculated as an eye-flow guiding intensity. According to this construction, it is possible to quantitatively calculate in which direction the image object tends to guide the eye-flow.

Owner:SEIKO EPSON CORP

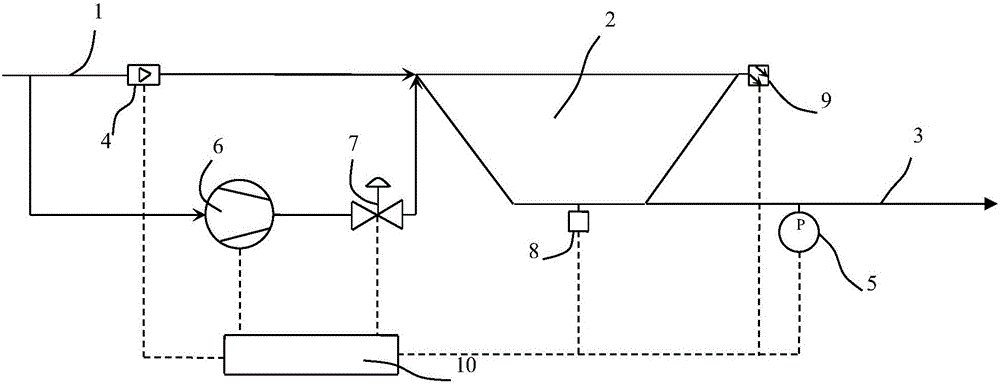

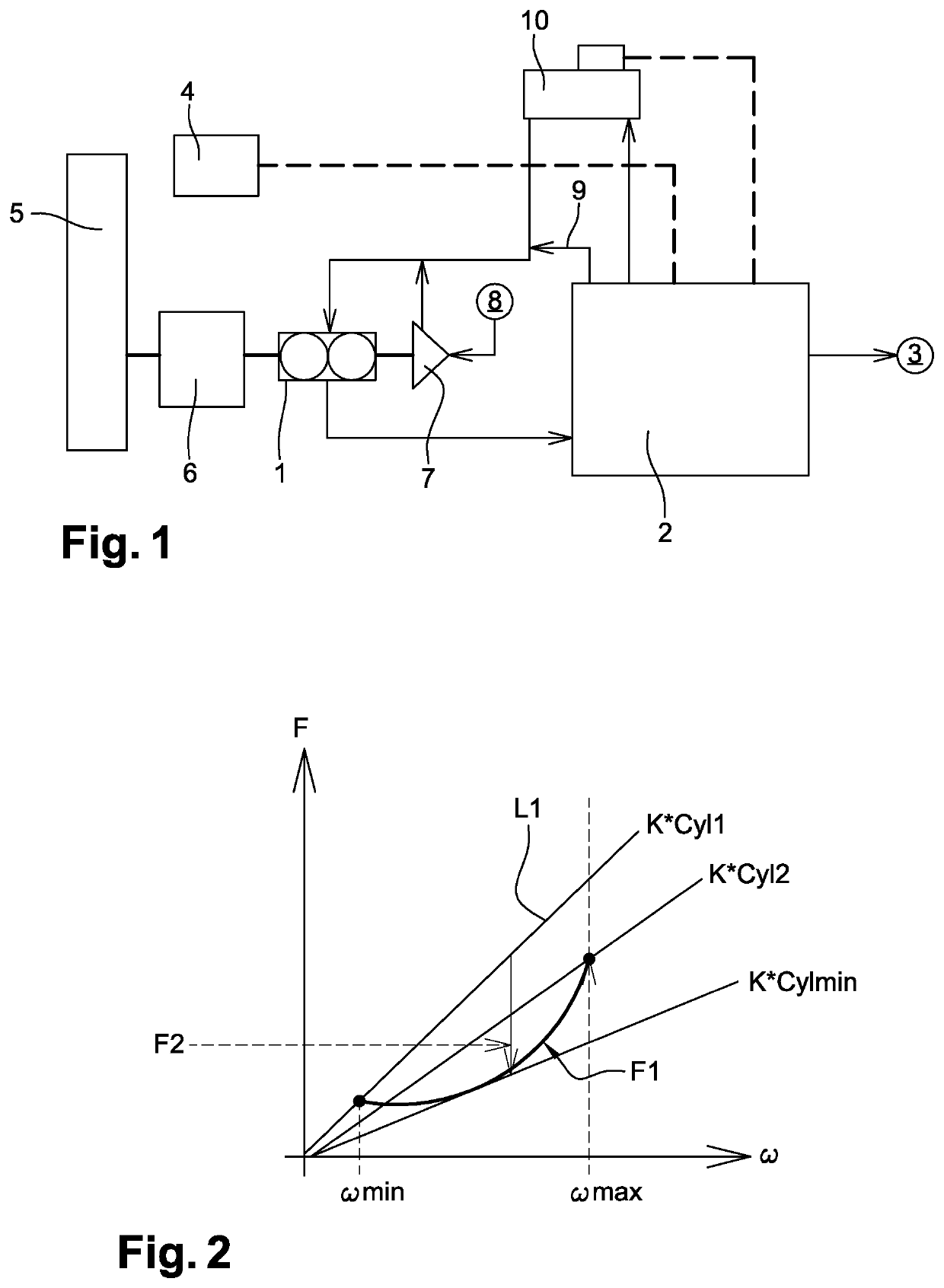

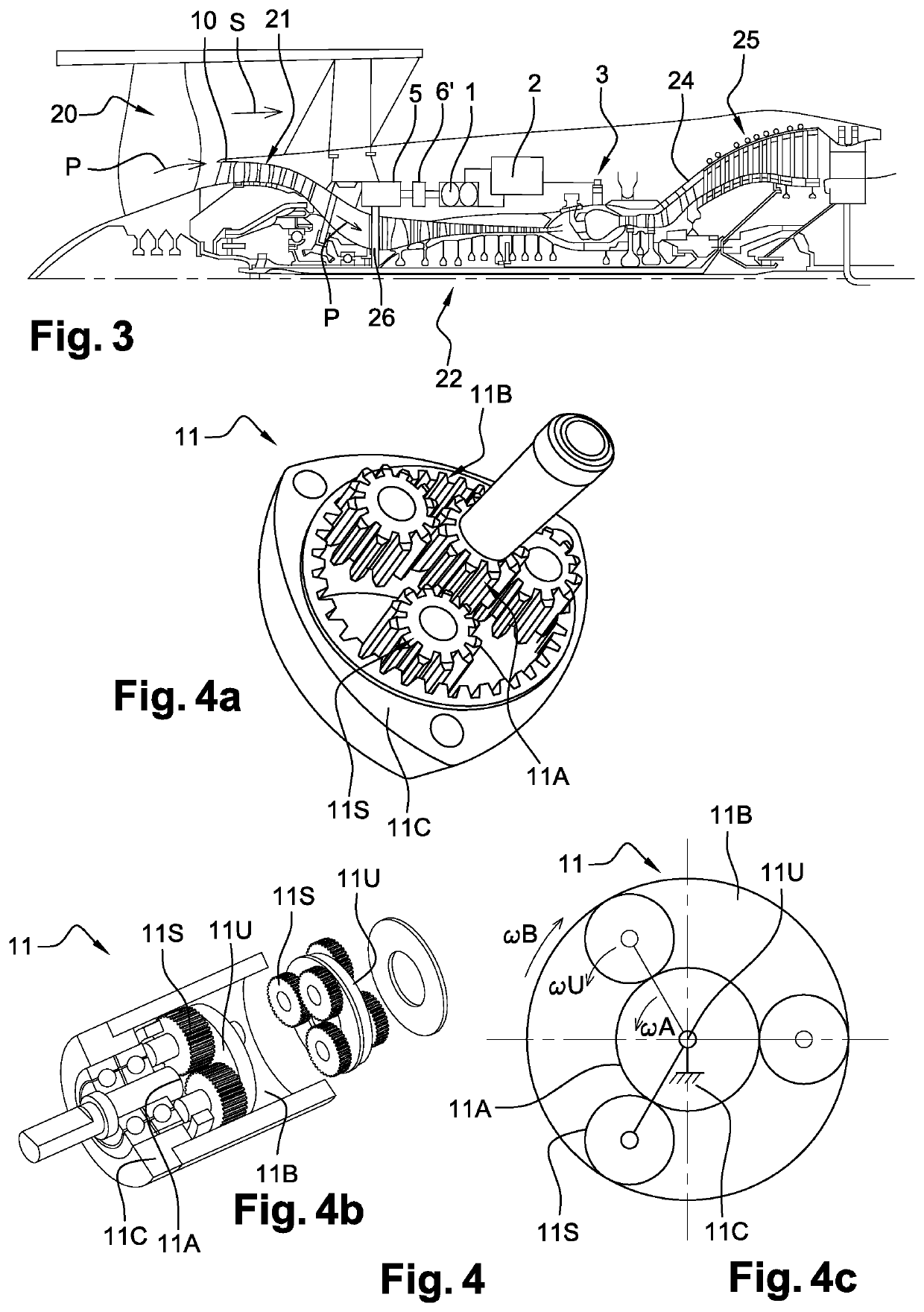

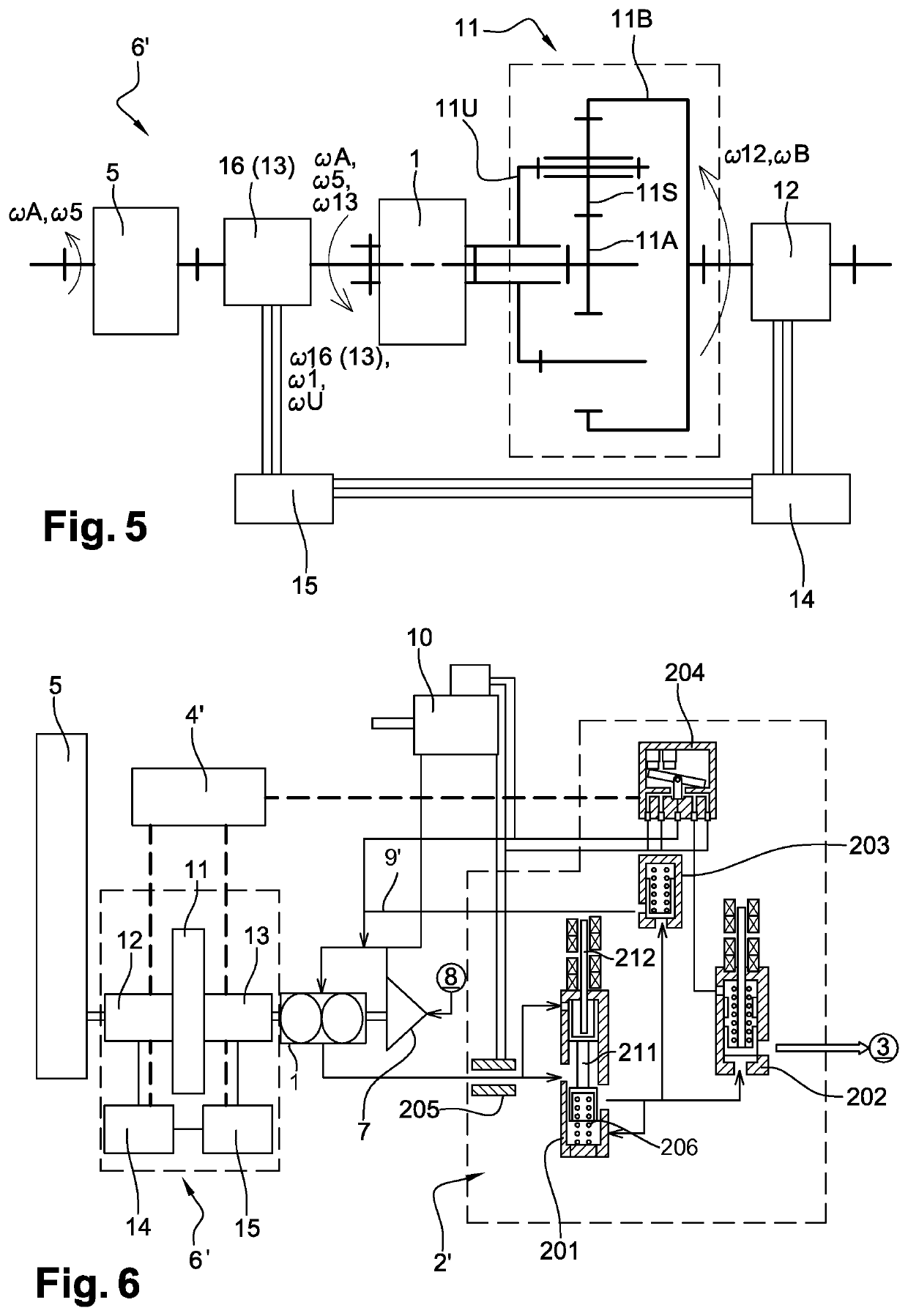

System for supplying fuel to a turbomachine

PendingUS20200003123A1Minimizing total power drawnAppropriate flowEngine fuctionsTurbine/propulsion fuel deliveryFlow transducerControl engineering

The present disclosure relates to a system for supplying fuel to a turbomachine. In some embodiments, a fuel circuit includes a pressurisation valve at an outlet of the system and a pump. The circuit may include a flow rate sensor arranged between the outlet of the pump and the pressurisation valve. In some embodiments, the flow rate sensor may include a sliding drawer, a restoring spring, and a sensor for detecting the position of said drawer in order to indicate the flow passing through the flow rate sensor. The system may include a device arranged to drive the pump with a controllable rotational speed and a control configured to control the device on the basis of a measurement supplied by the flow rate sensor, in such a way as to adapt the rotational speed of the pump shaft.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

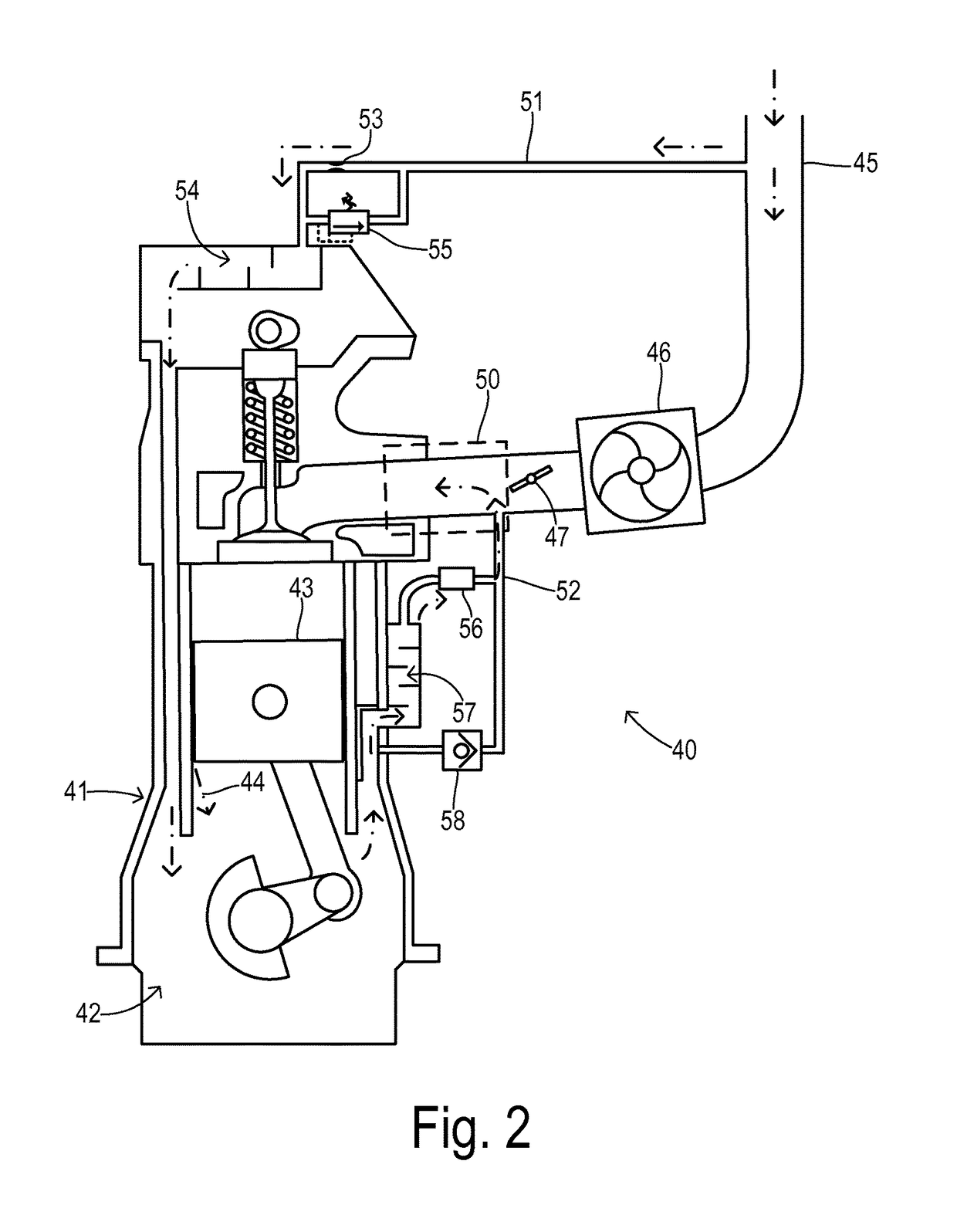

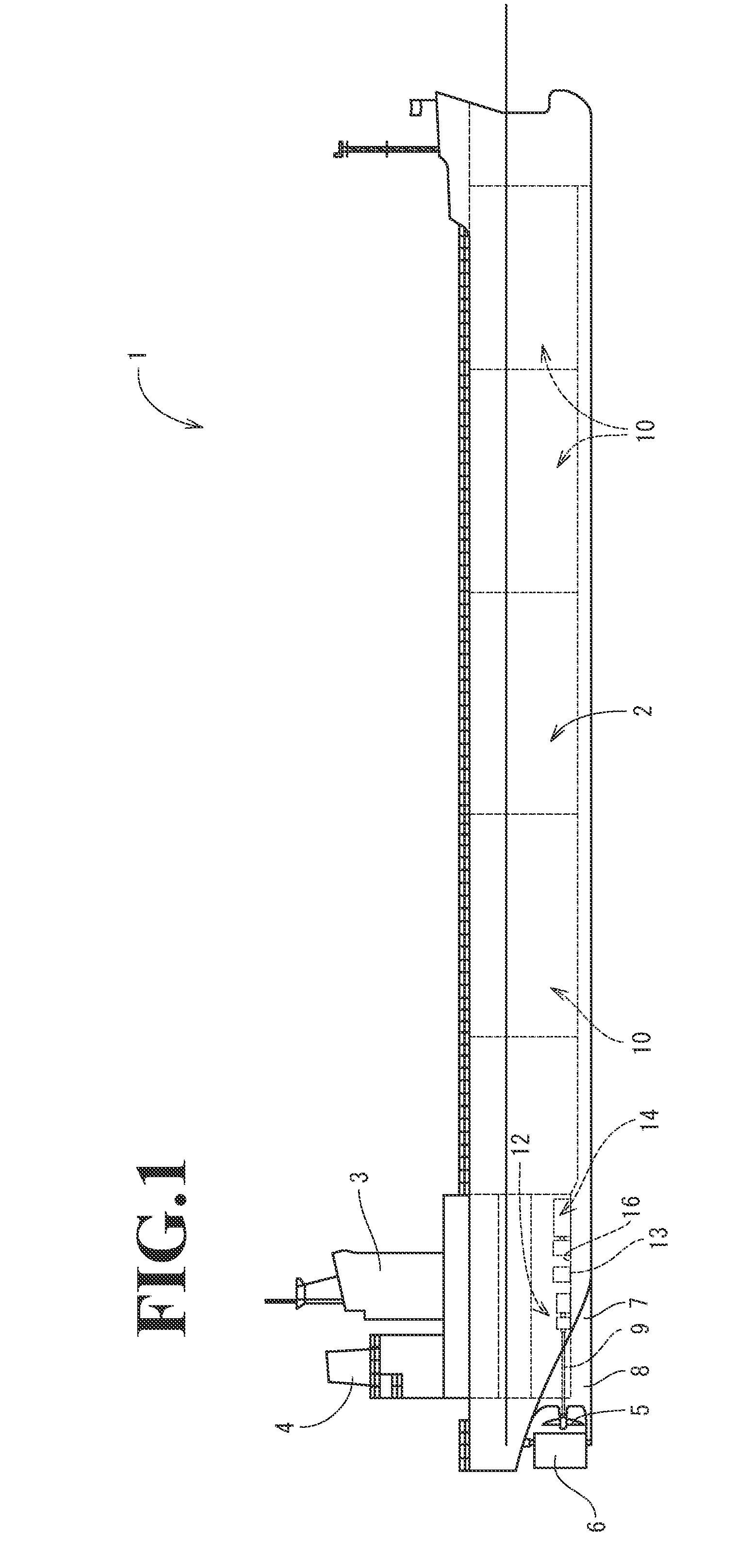

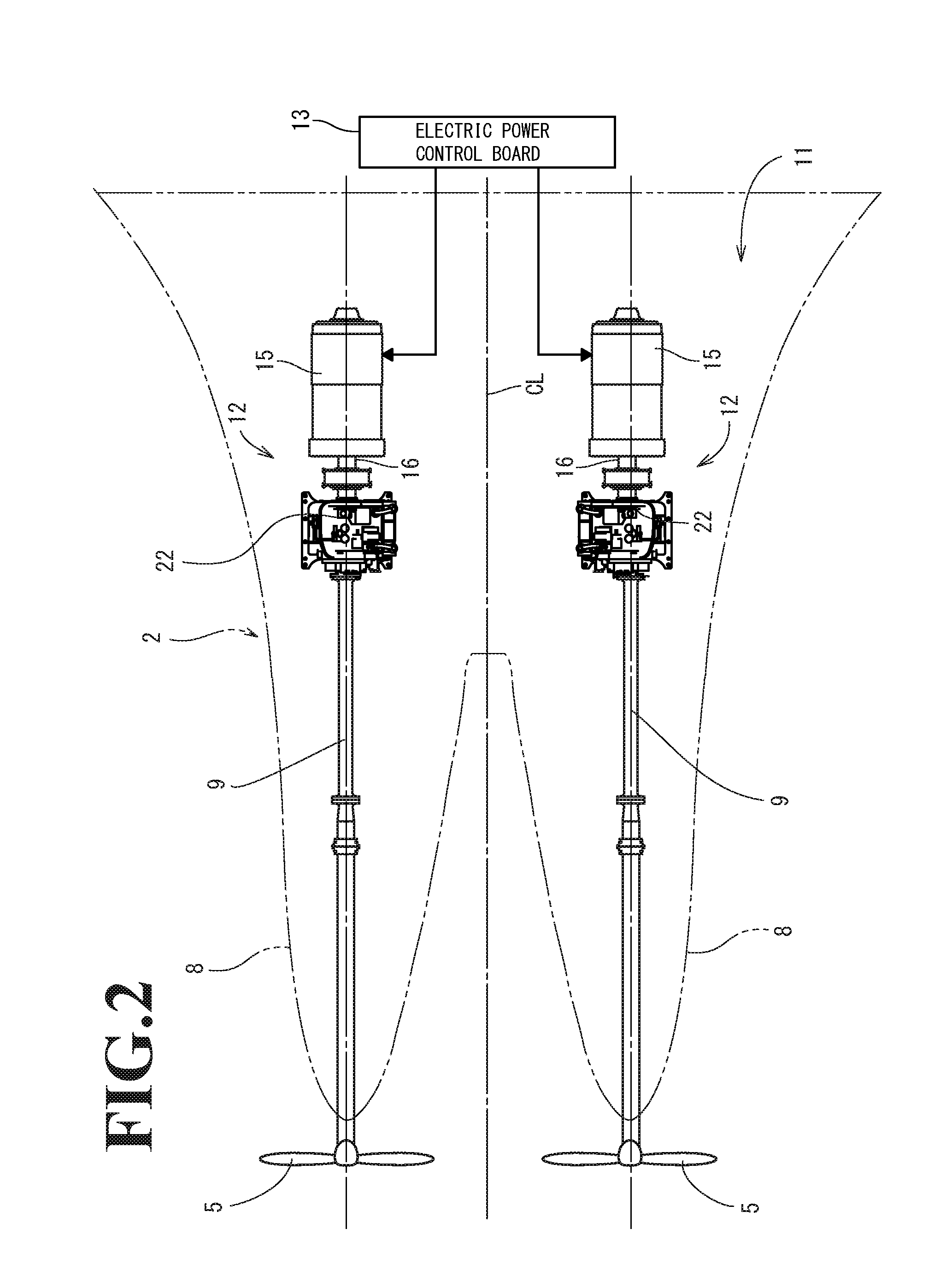

Engine device

InactiveUS20160363065A1Improve responseOptimal air-to-fuel ratioMechanical controlElectrical controlLow loadHigh load

An engine device executes the control of the opening degree of a main throttle valve when engine load is in a low load area. In contrast, when the engine load is in a medium-to-high load area, the engine device sets the main throttle valve to a predetermined opening degree and executes the control of the opening degree of an air supply bypass valve.

Owner:JAPAN SHIP MACHINERY & EQUIPMENT ASSOCIATION +1

Eye-flow guiding level calculating system, eye-flow guiding level calculating program, and eye-flow guiding level calculating method

InactiveUS7407288B2Low costAppropriate flowImage analysisDigital computer detailsOphthalmologyMiniaturization

Exemplary embodiments of the invention provide an eye-flow guiding level calculating system which can plan miniaturization and low cost of a device and surely obtain a suitable eye flow. A layout device, first, detects each vertex of an image object as guiding reference points, based on vector image data. And then, for every guiding reference point, two auxiliary lines are virtually formed to intersect the guiding reference point along an outline of the image object. Subsequently, the direction in which a bisector line of an obtuse angle among angles, made by the virtual auxiliary lines, extends outward from the guiding reference point is calculated as an eye-flow guiding direction. Further, for every guiding reference point, the distance from the center G of the image object up to the guiding reference point is calculated as an eye-flow guiding intensity. According to this construction, it is possible to quantitatively calculate in which direction the image object tends to guide the eye-flow.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com