Patents

Literature

328results about "Mechanical control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

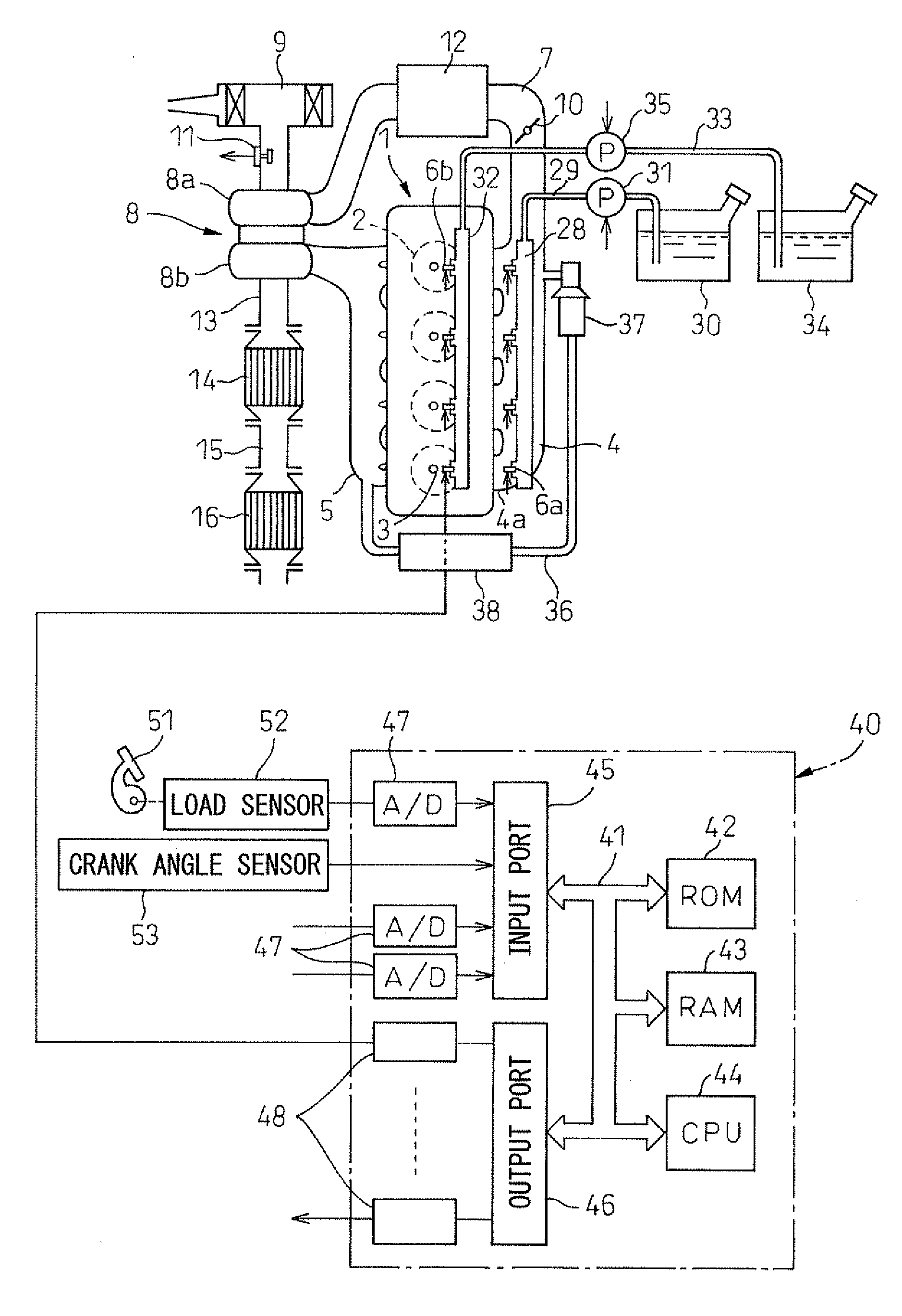

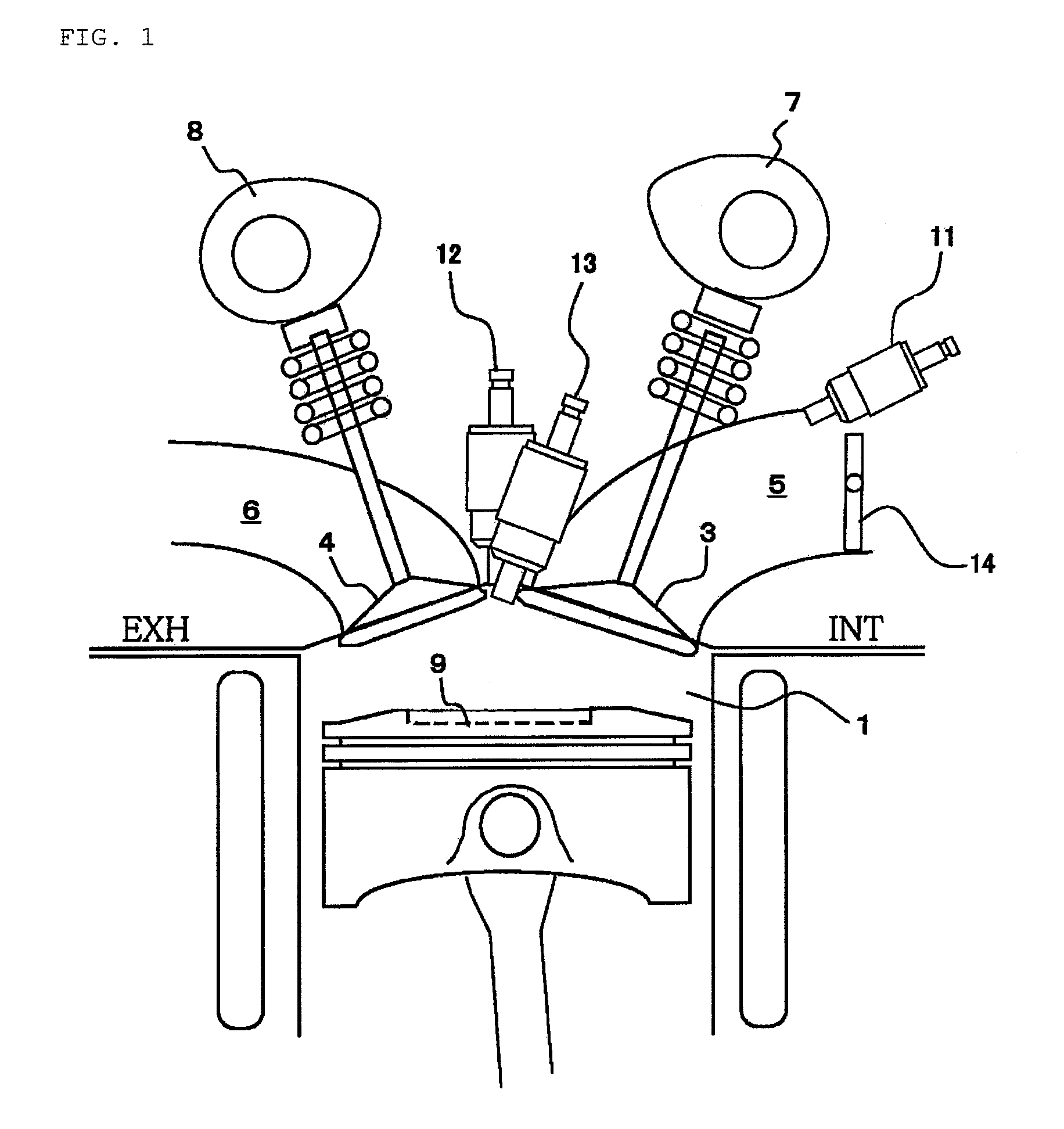

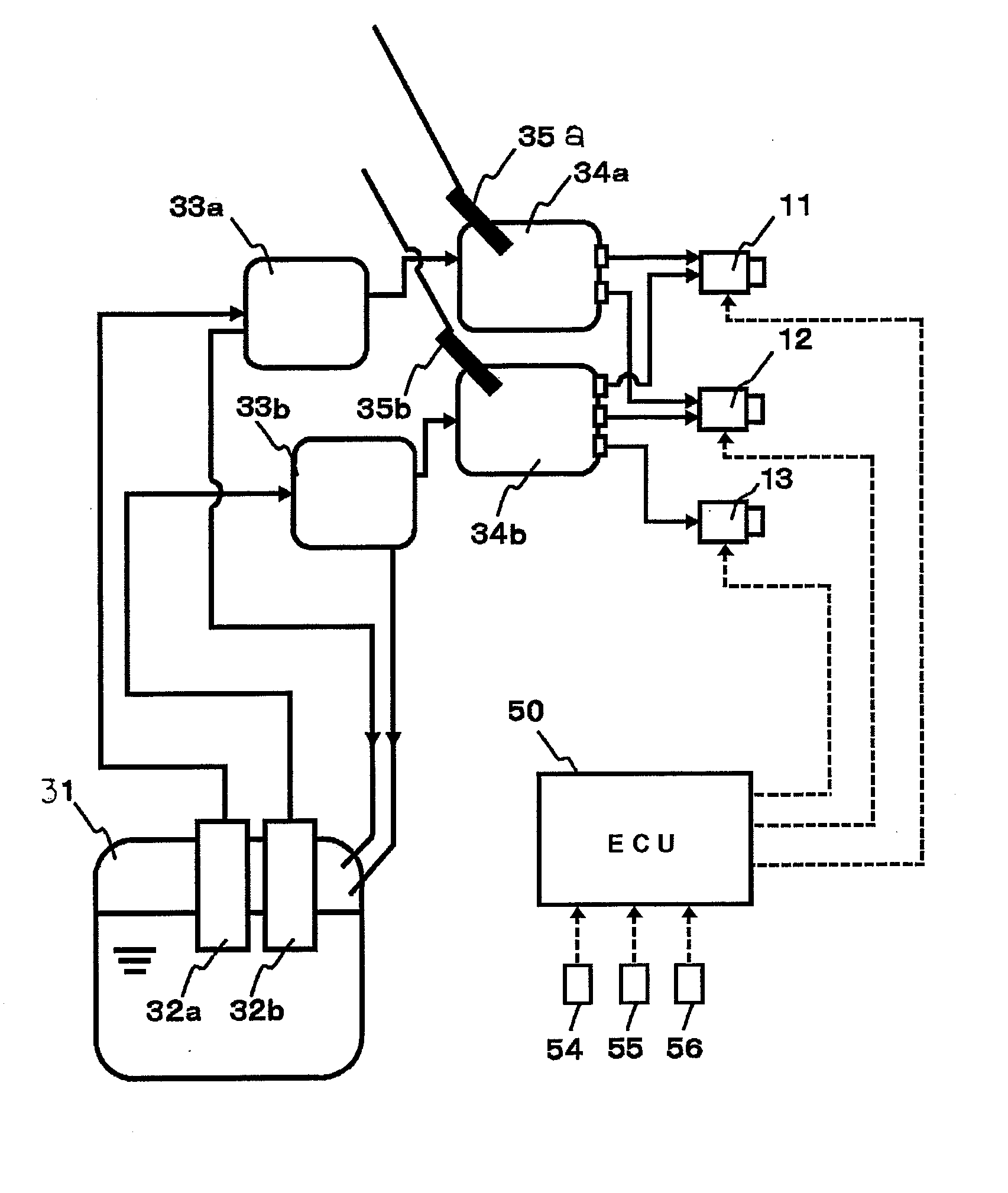

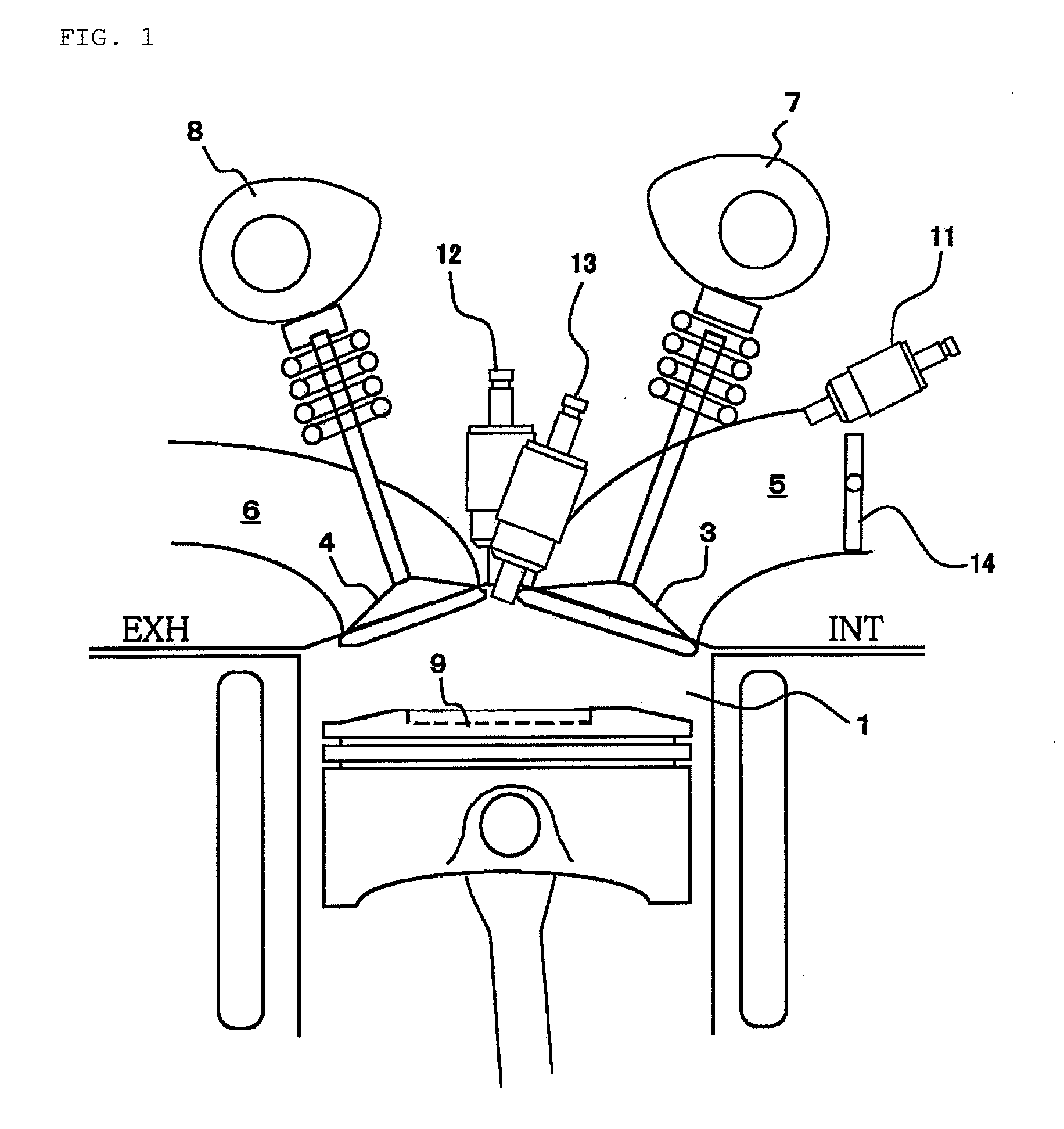

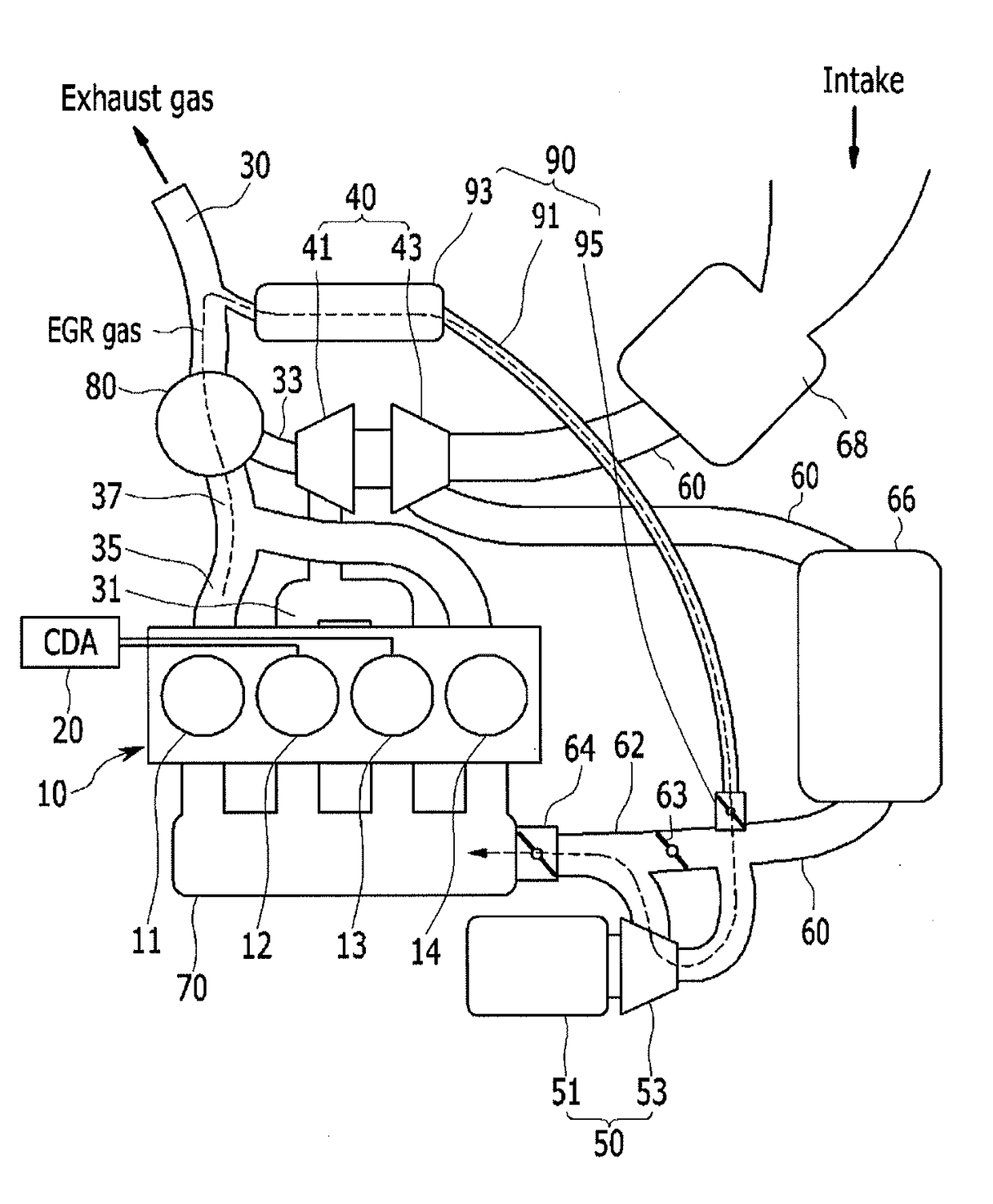

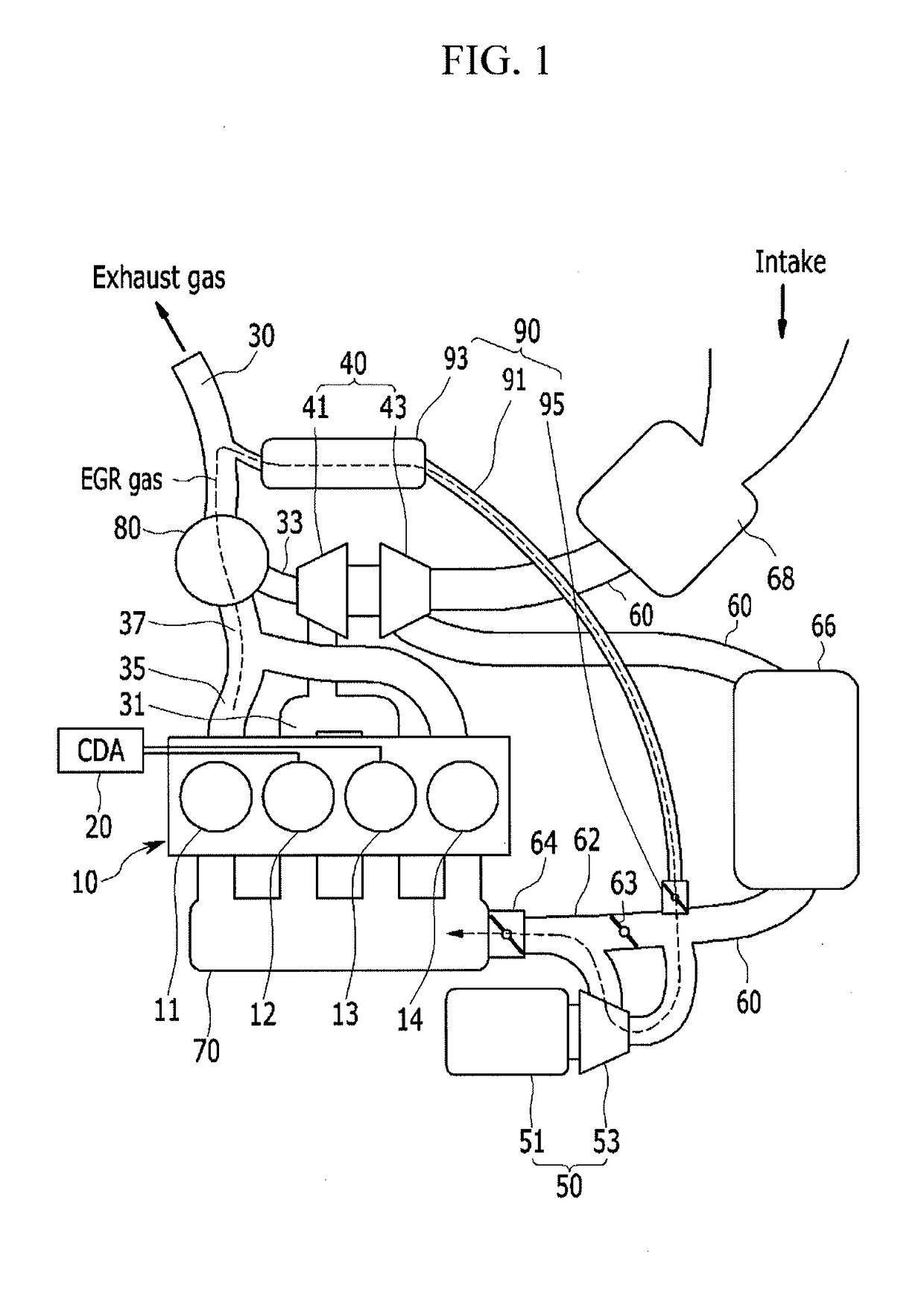

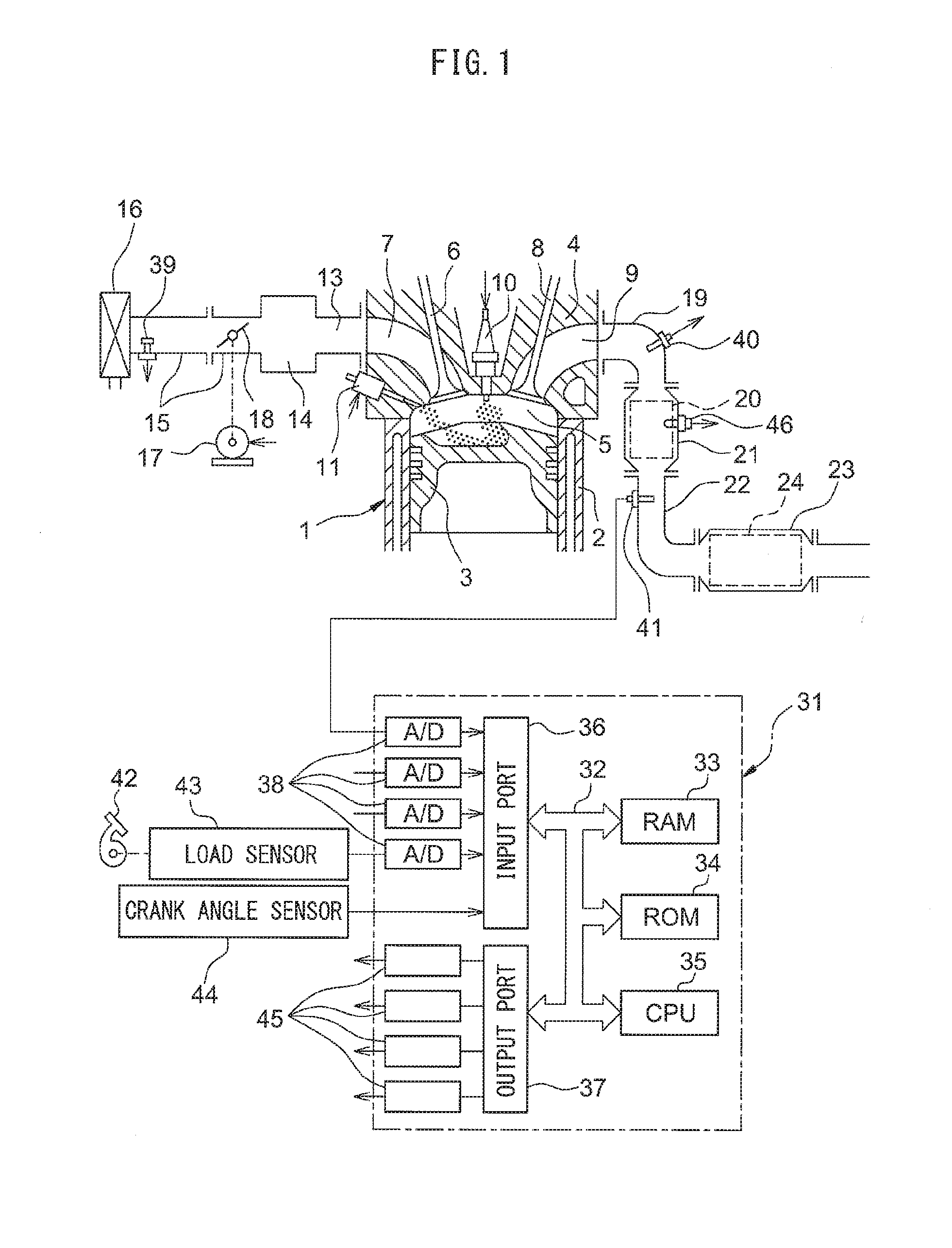

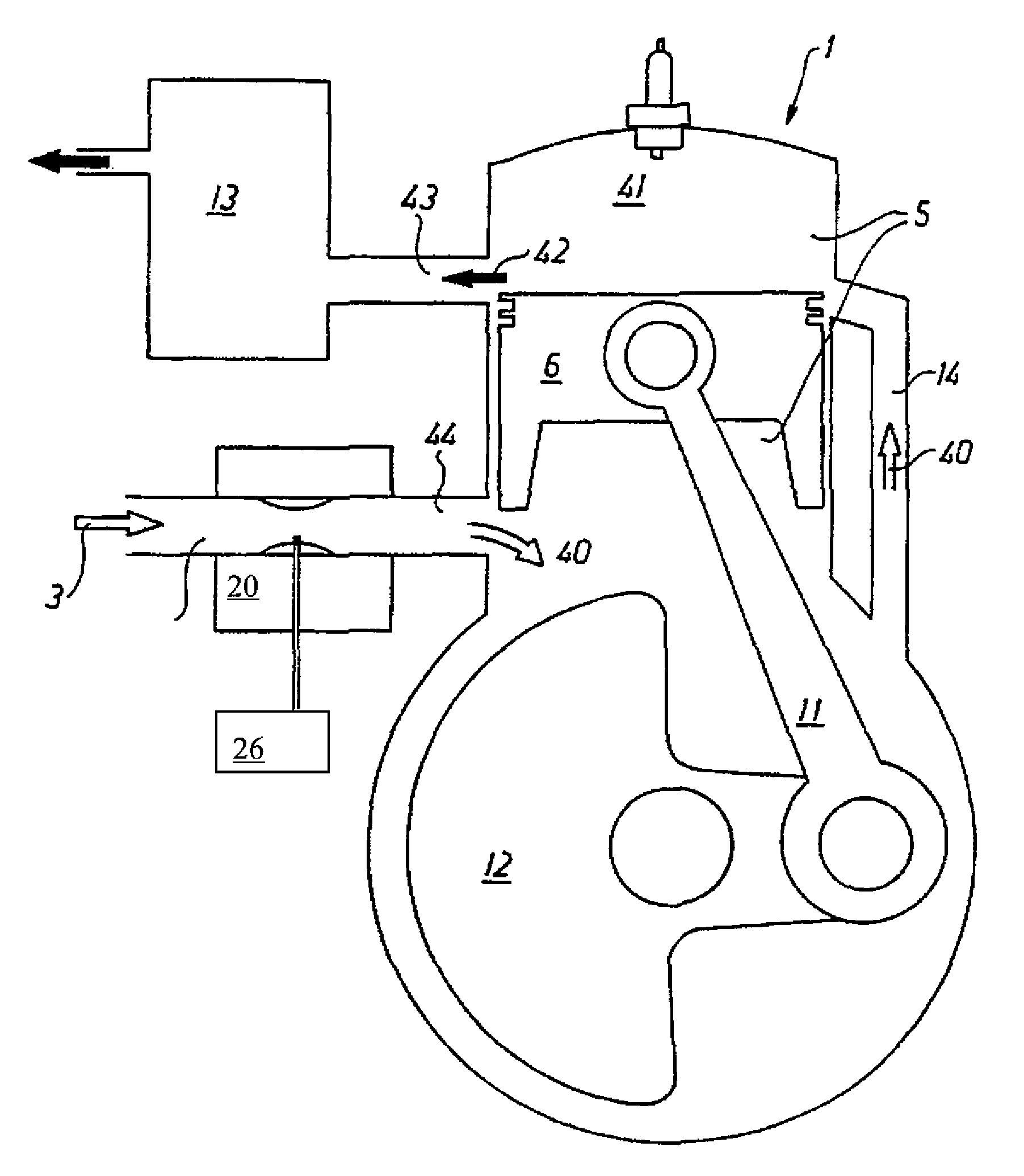

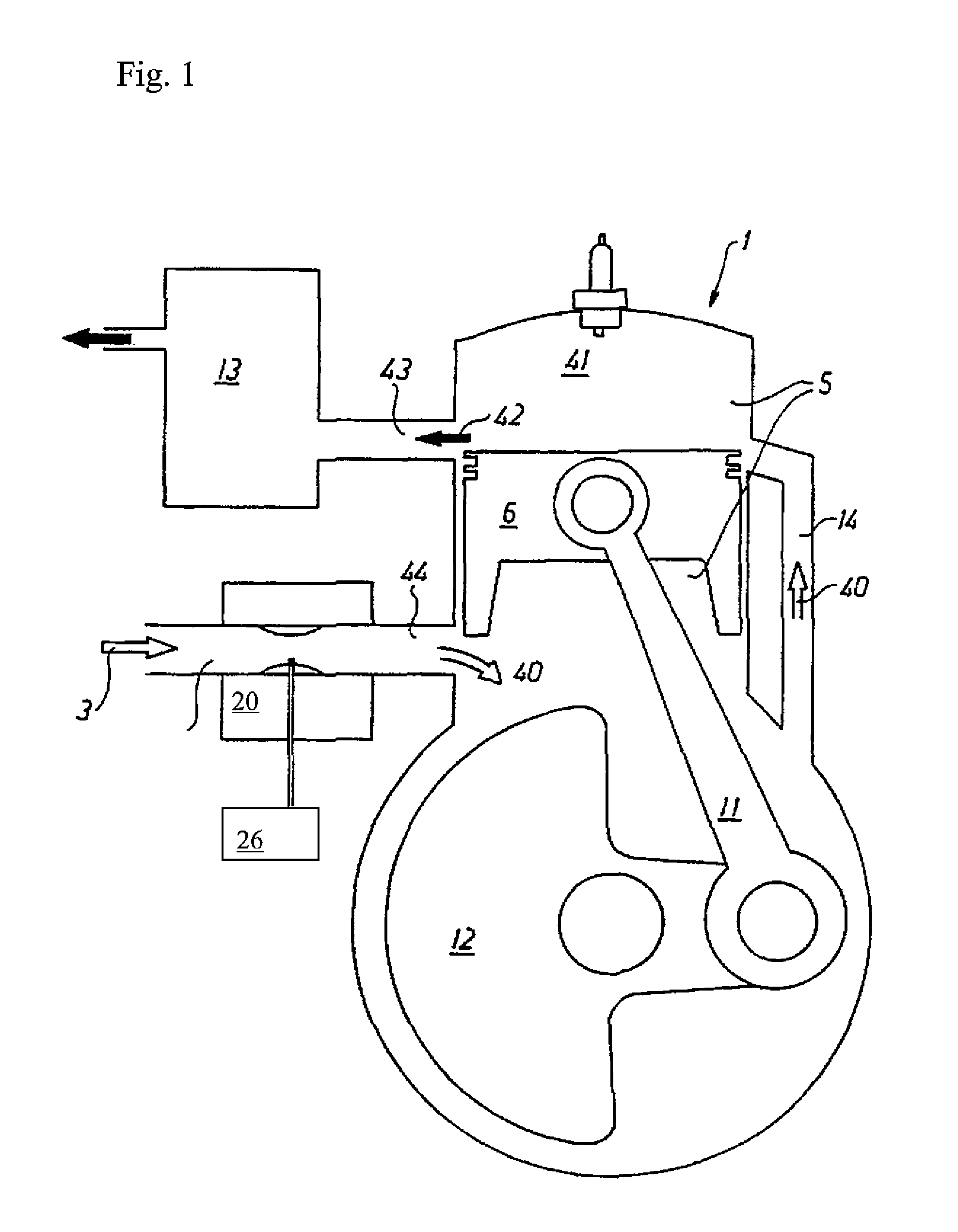

Ammonia burning internal combustion engine

InactiveUS20110259290A1Suppress drop in combustibilityMechanical controlElectrical controlCombustion chamberEngineering

An ammonia burning internal combustion engine can feed ammonia and a highly combustible substance burning easier than ammonia to a combustion chamber. When the amount of ammonia fed into the combustion chamber is increased or when the ratio of the amount of the ammonia to the total amount of the ammonia and the highly combustible substance fed into the combustion chamber is increased, the operating parameters of the internal combustion engine are controlled so the air-fuel mixture fed into the combustion chamber is made easier to burn. As a result, an ammonia burning internal combustion engine designed to suppress a drop in combustibility of auxiliary fuel due to ammonia, can be provided.

Owner:TOYOTA JIDOSHA KK

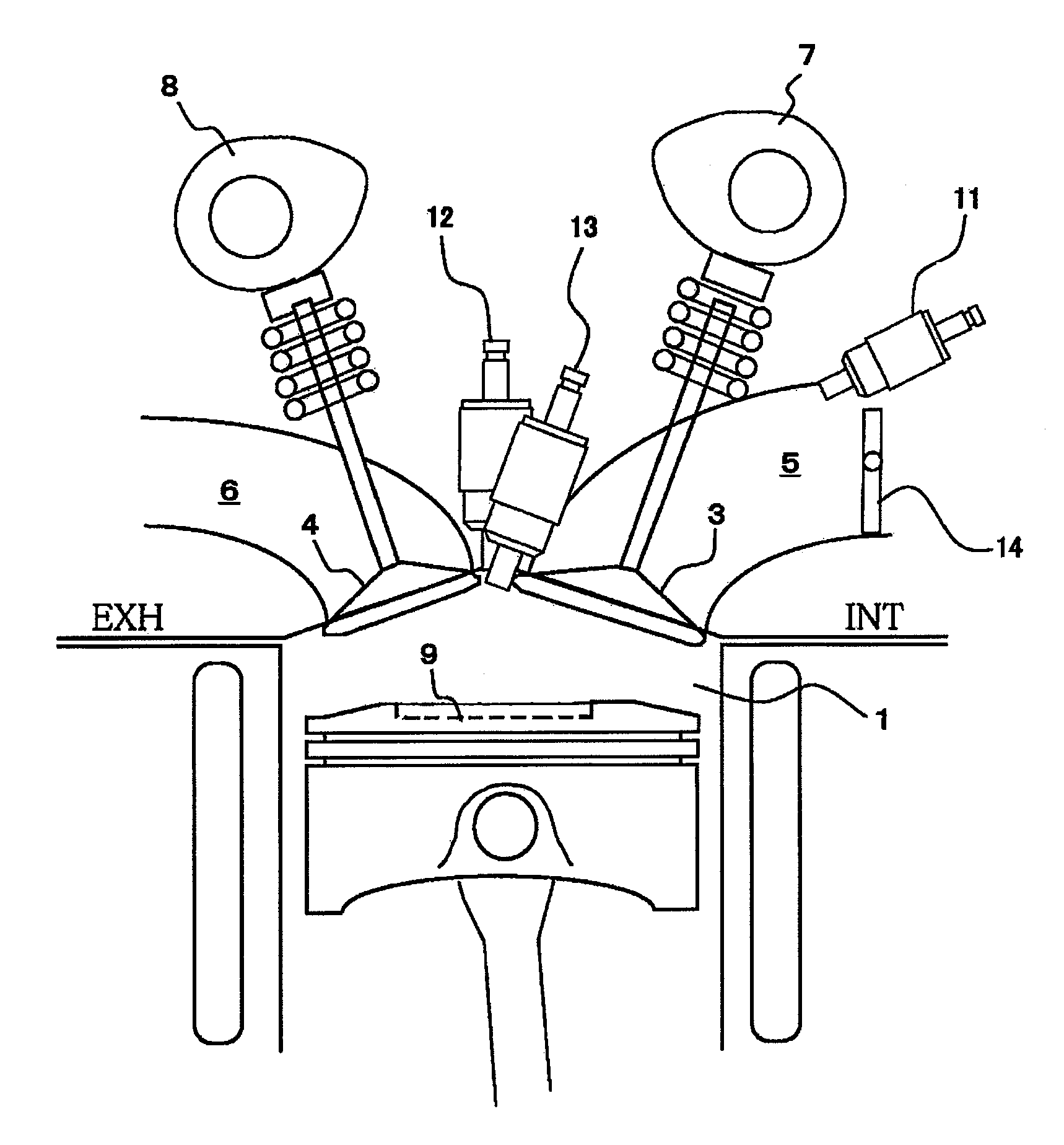

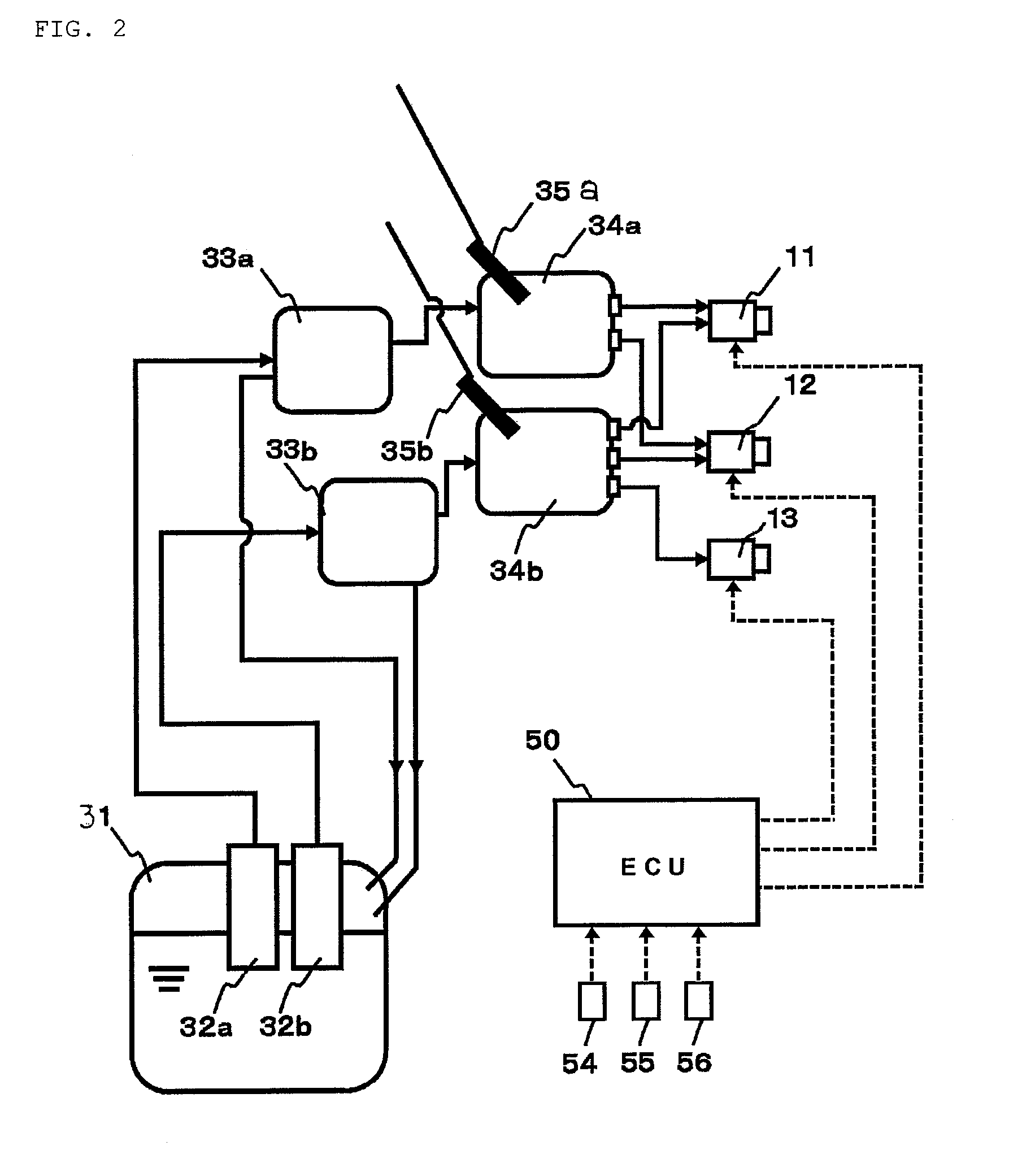

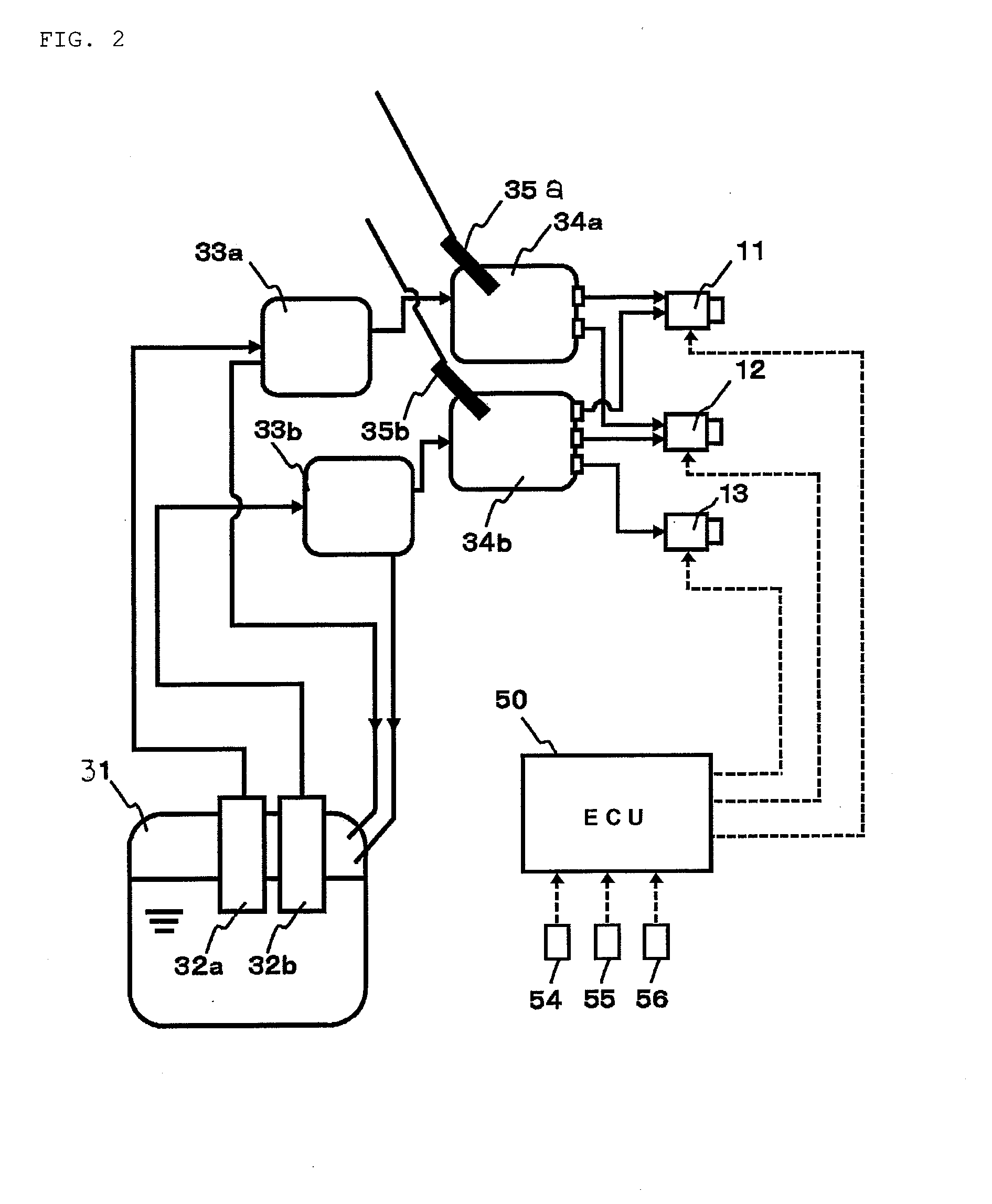

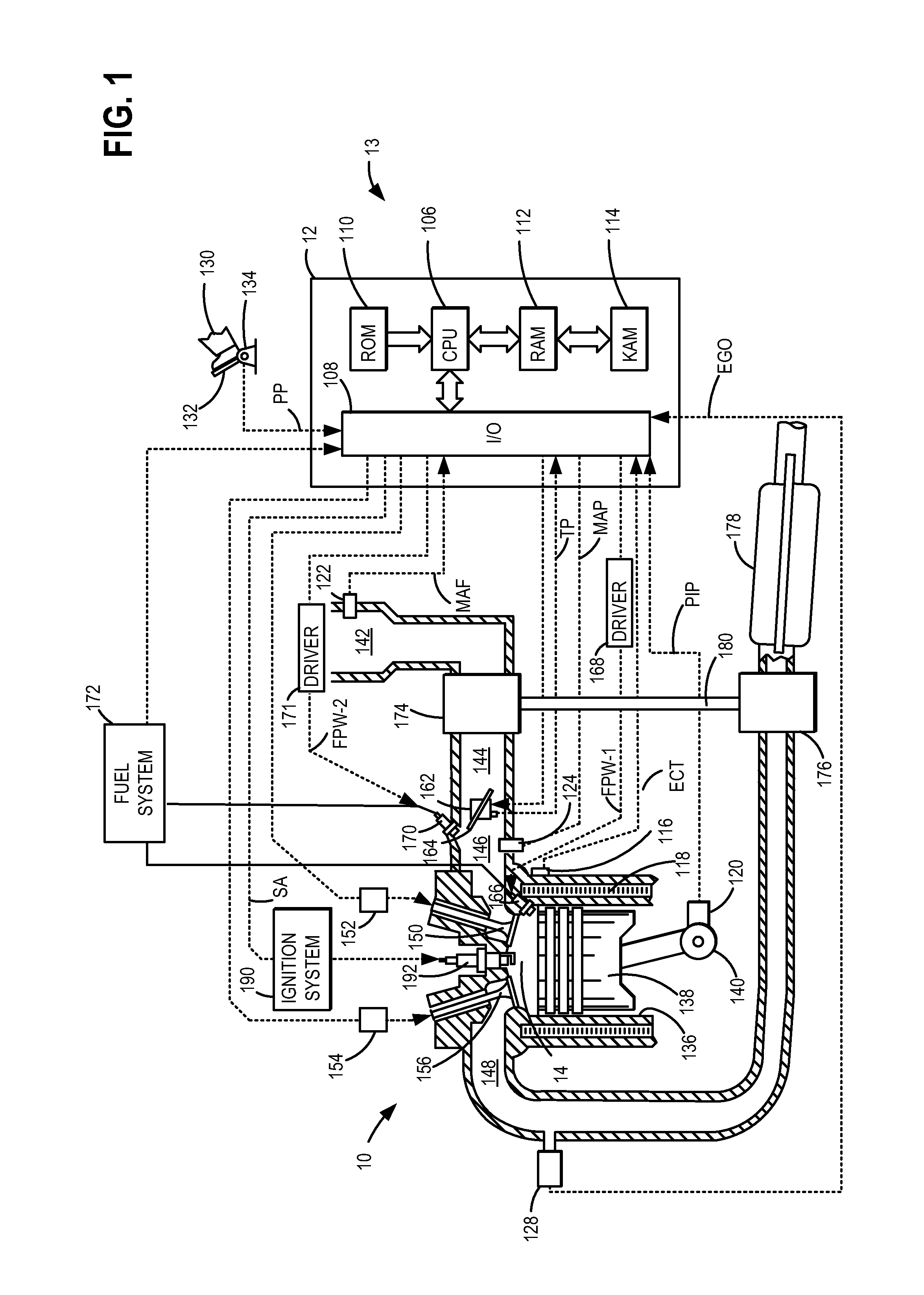

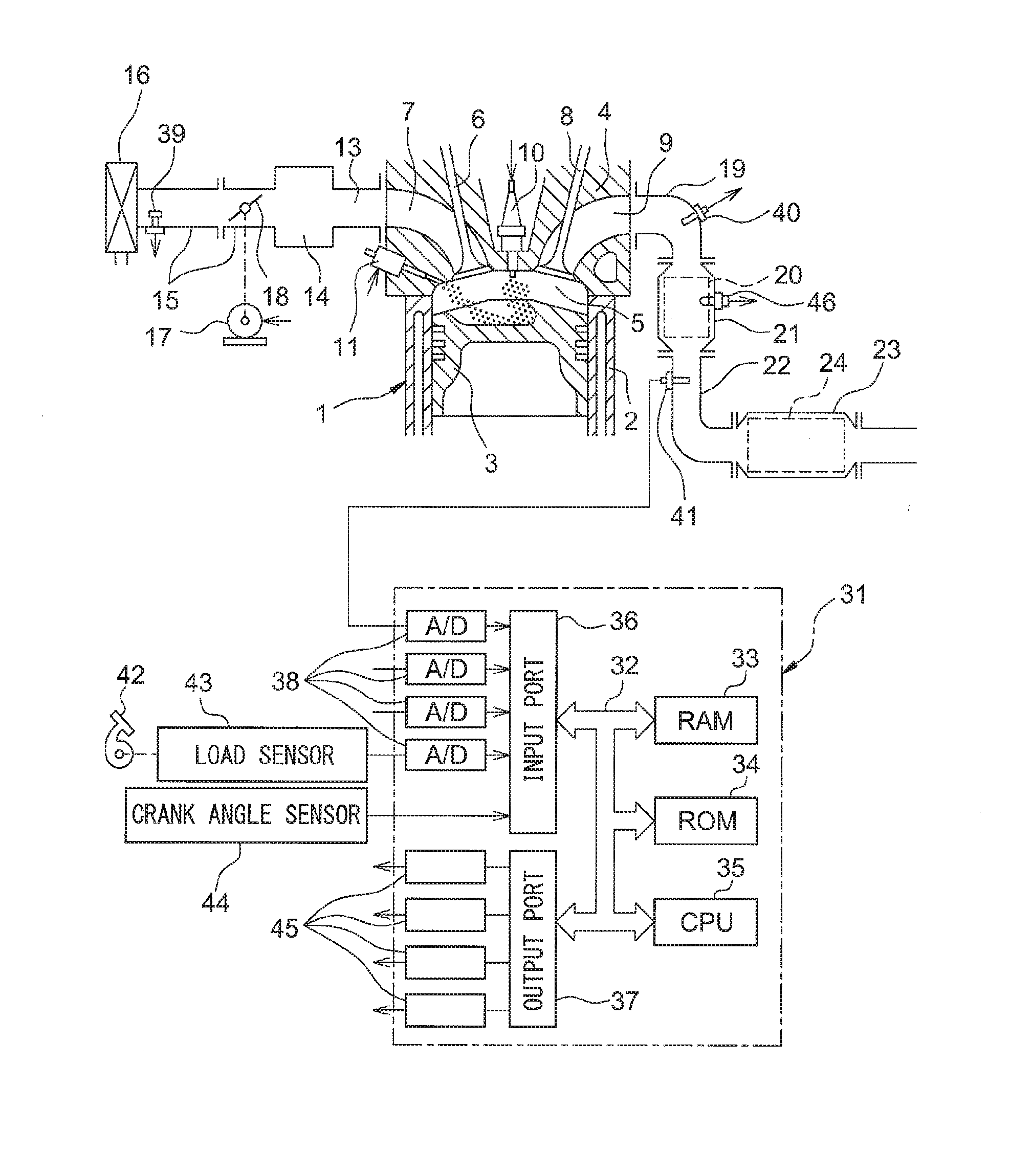

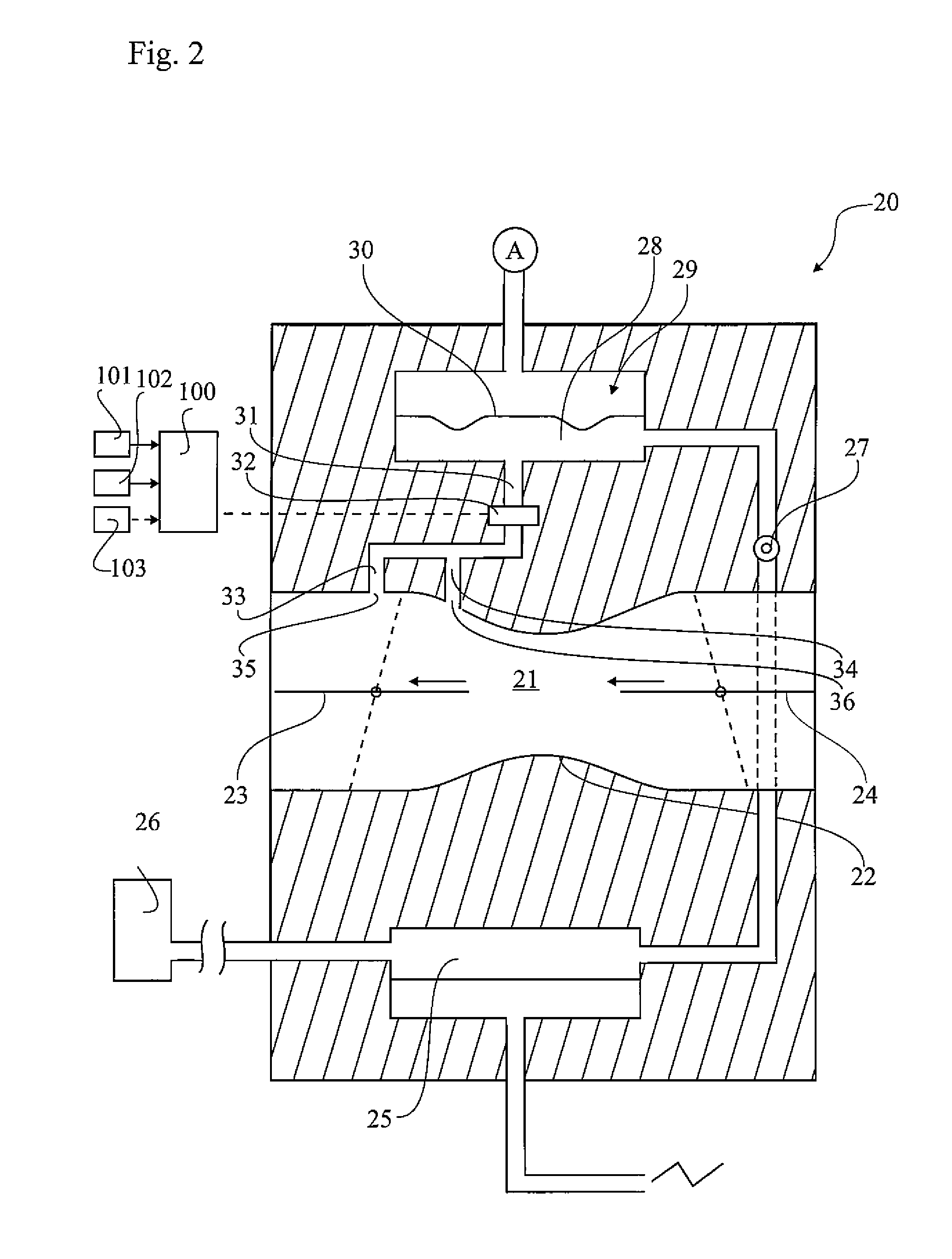

Combustion control system for internal combustion engine

InactiveUS7721703B2Reduce fuel consumption costsIncrease productionMechanical controlElectrical controlCombustionCombustion chamber

In an embodiment, the invention provides an internal combustion engine, including a first fuel injector that supplies a first fuel to a first predetermined region in a combustion chamber, and a second fuel injector that supplies a second fuel to a second predetermined region in the combustion chamber. The second fuel has an octane number that is different than an octane number of the first fuel, and the second predetermined region is different from the first predetermined region. An ignition device is configured to start ignition of one of the first and second fuels based on an ignition signal. An operation condition detector detects at least one engine operating condition. A controller is configured to provide the ignition signal to the ignition device and to determine which one of the first and second fuels to ignite by the ignition device based on the engine operation condition.

Owner:NISSAN MOTOR CO LTD

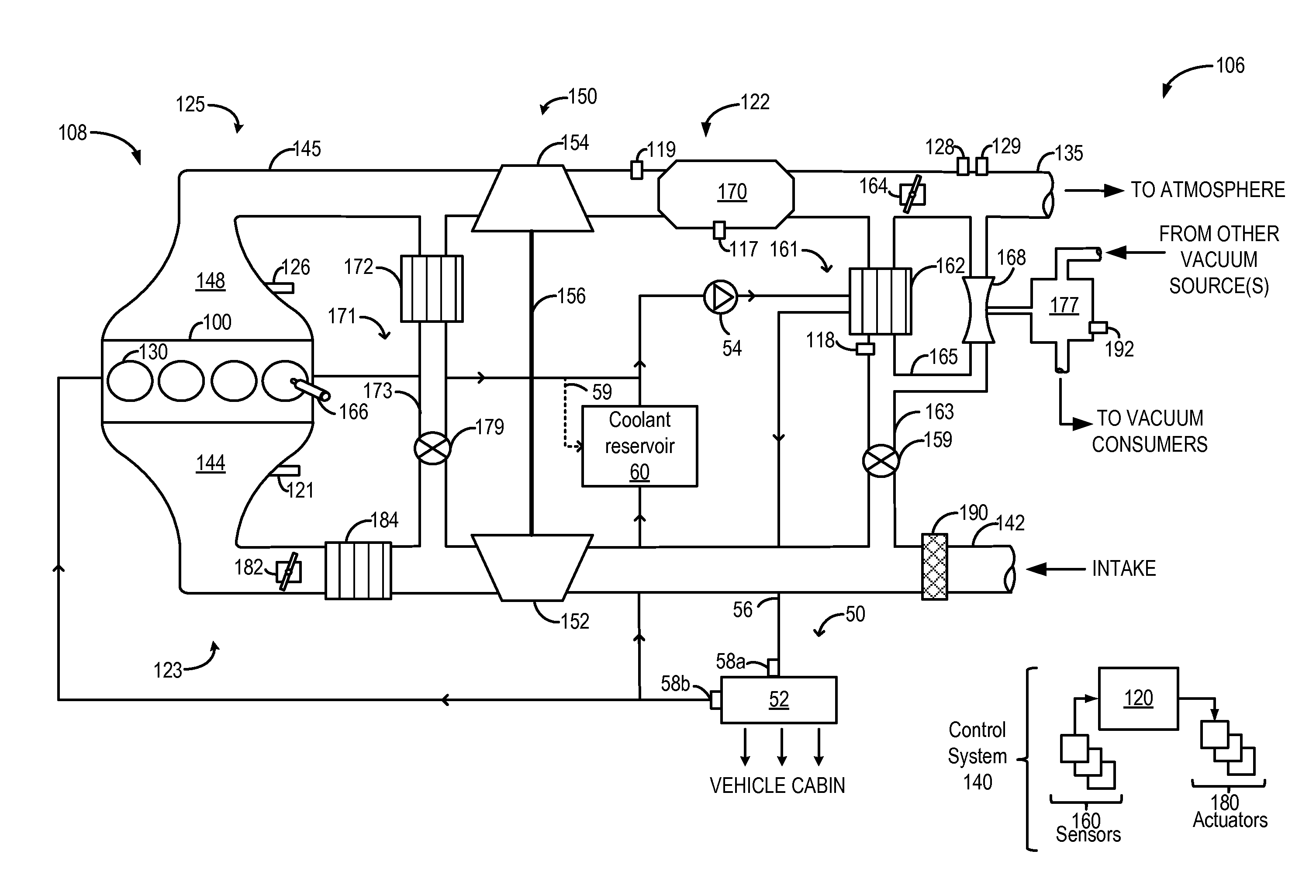

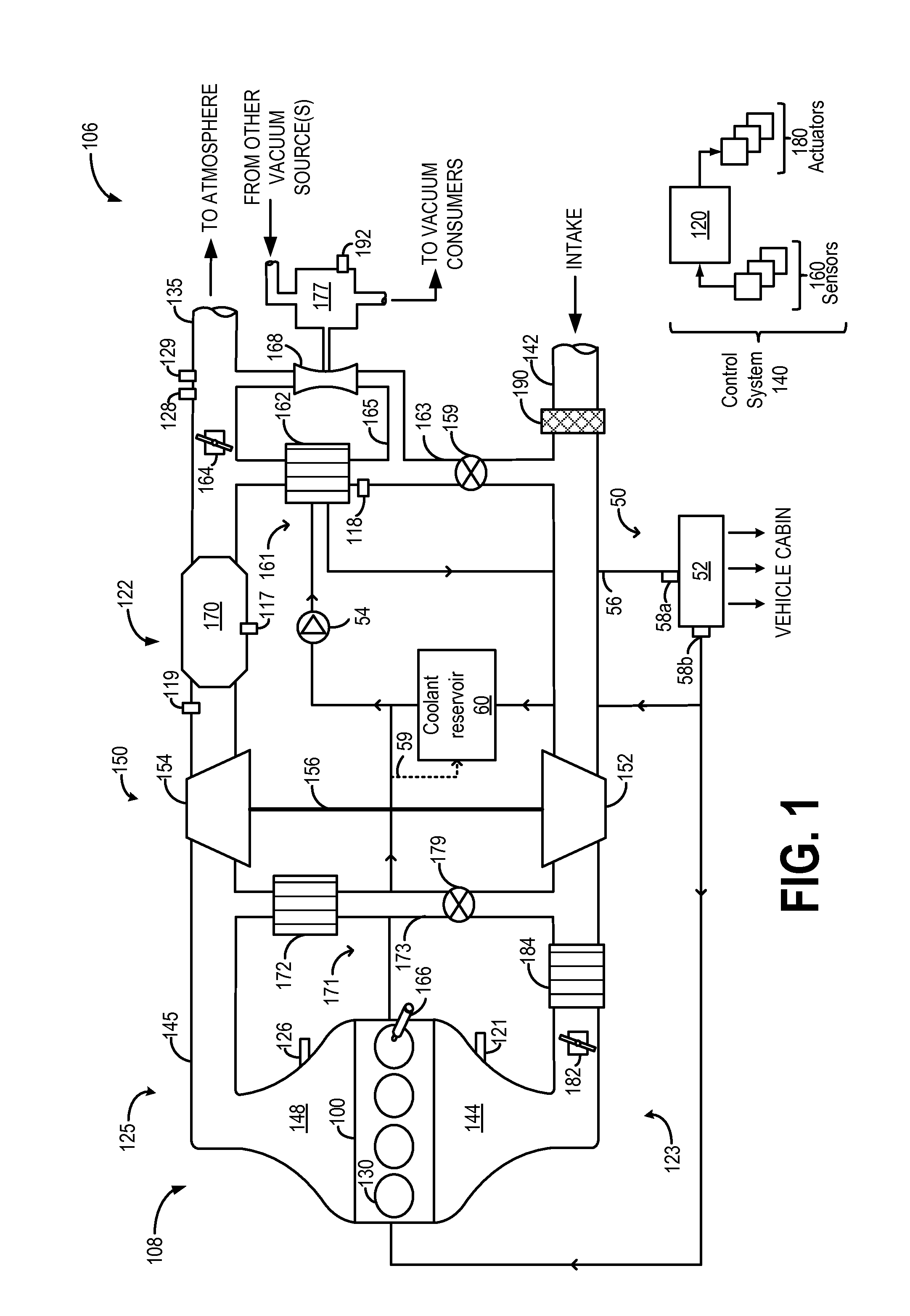

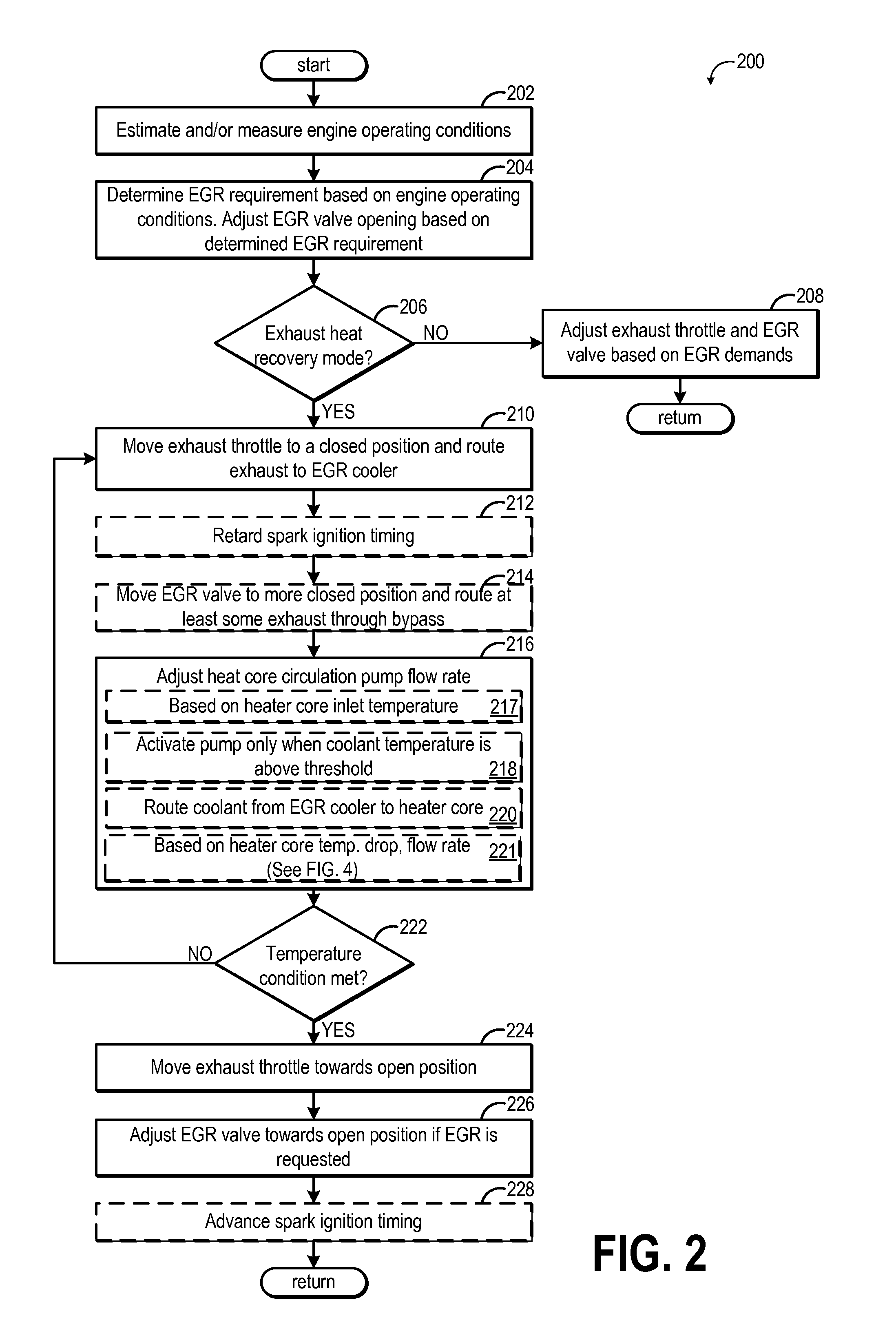

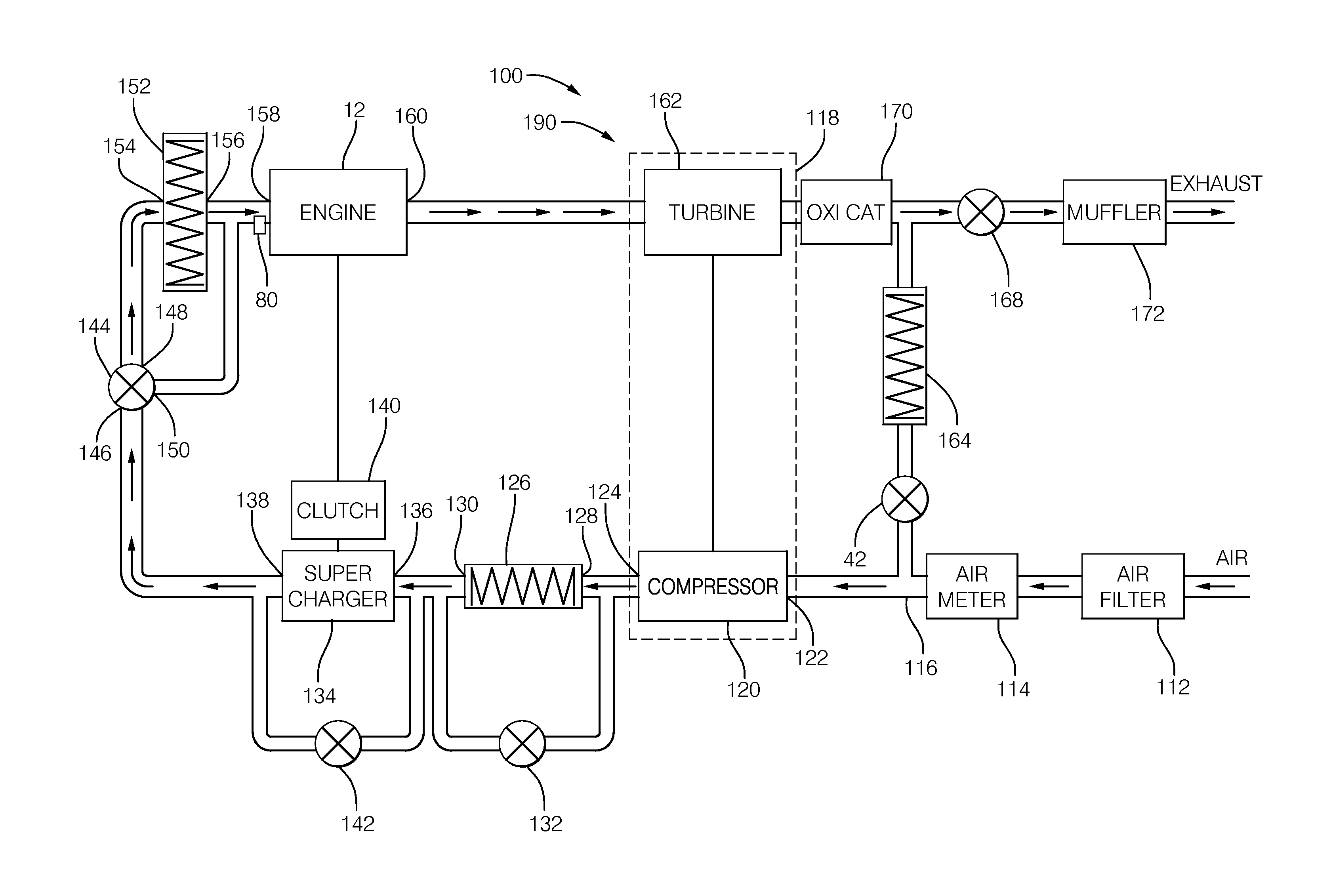

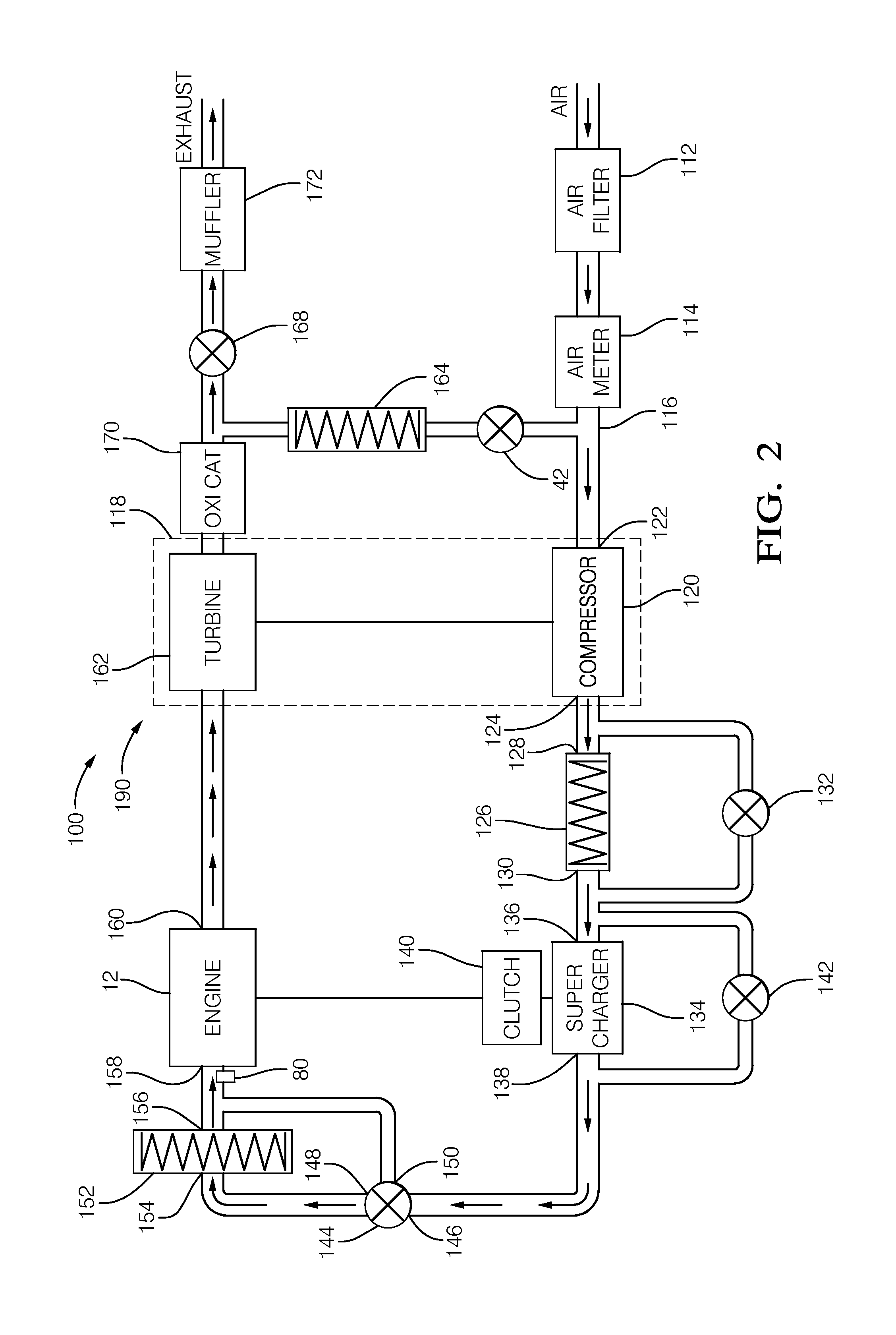

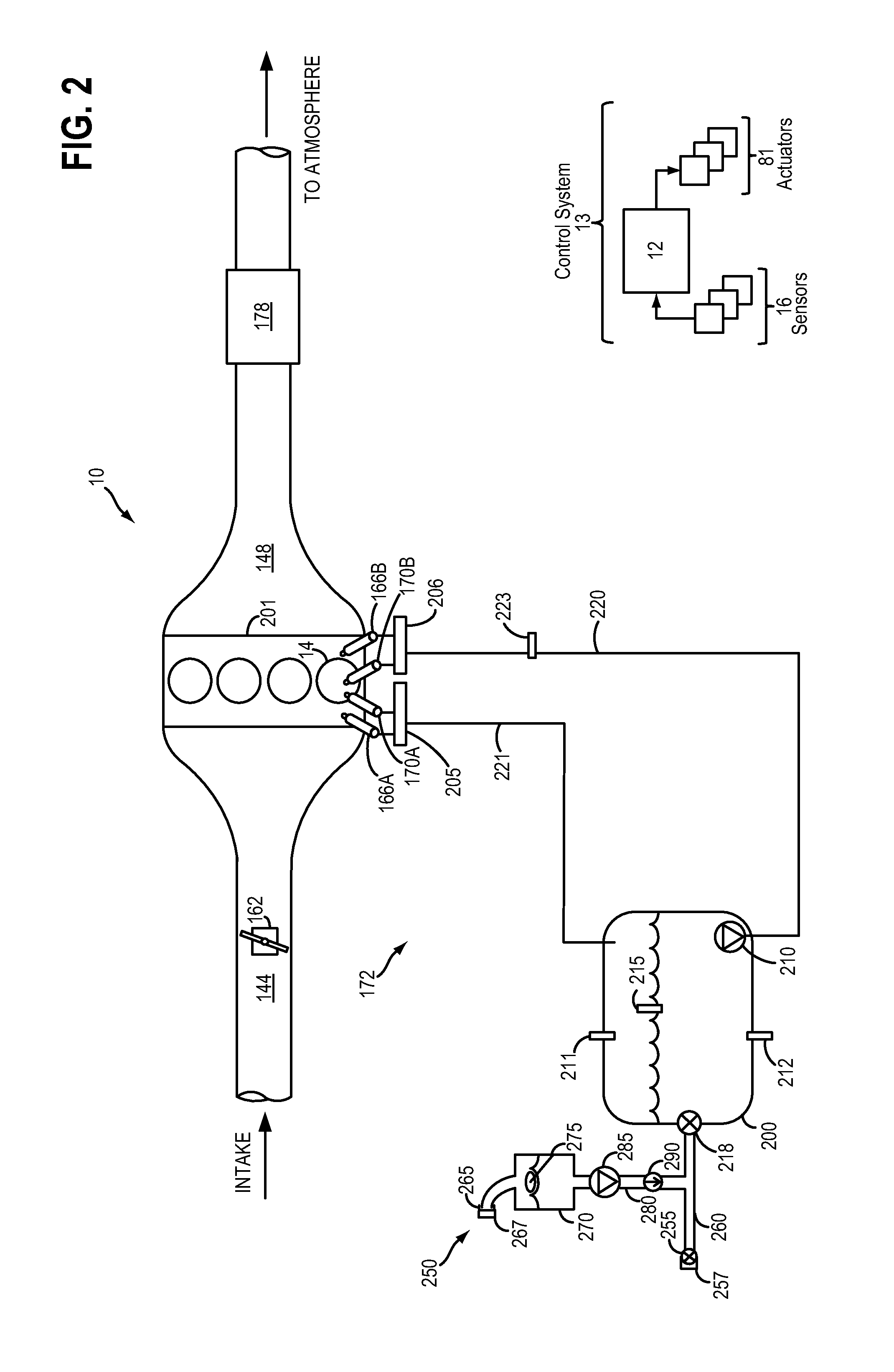

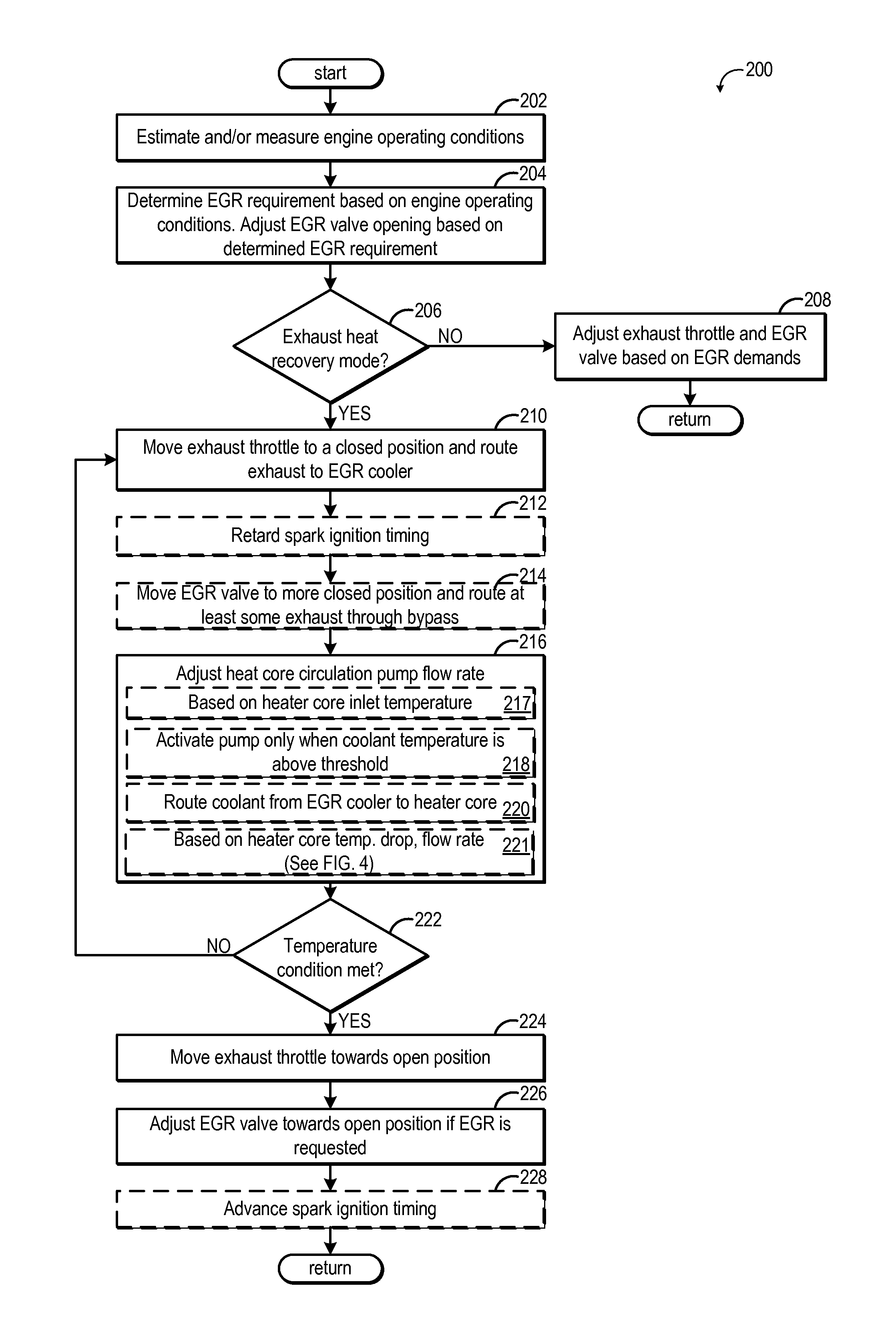

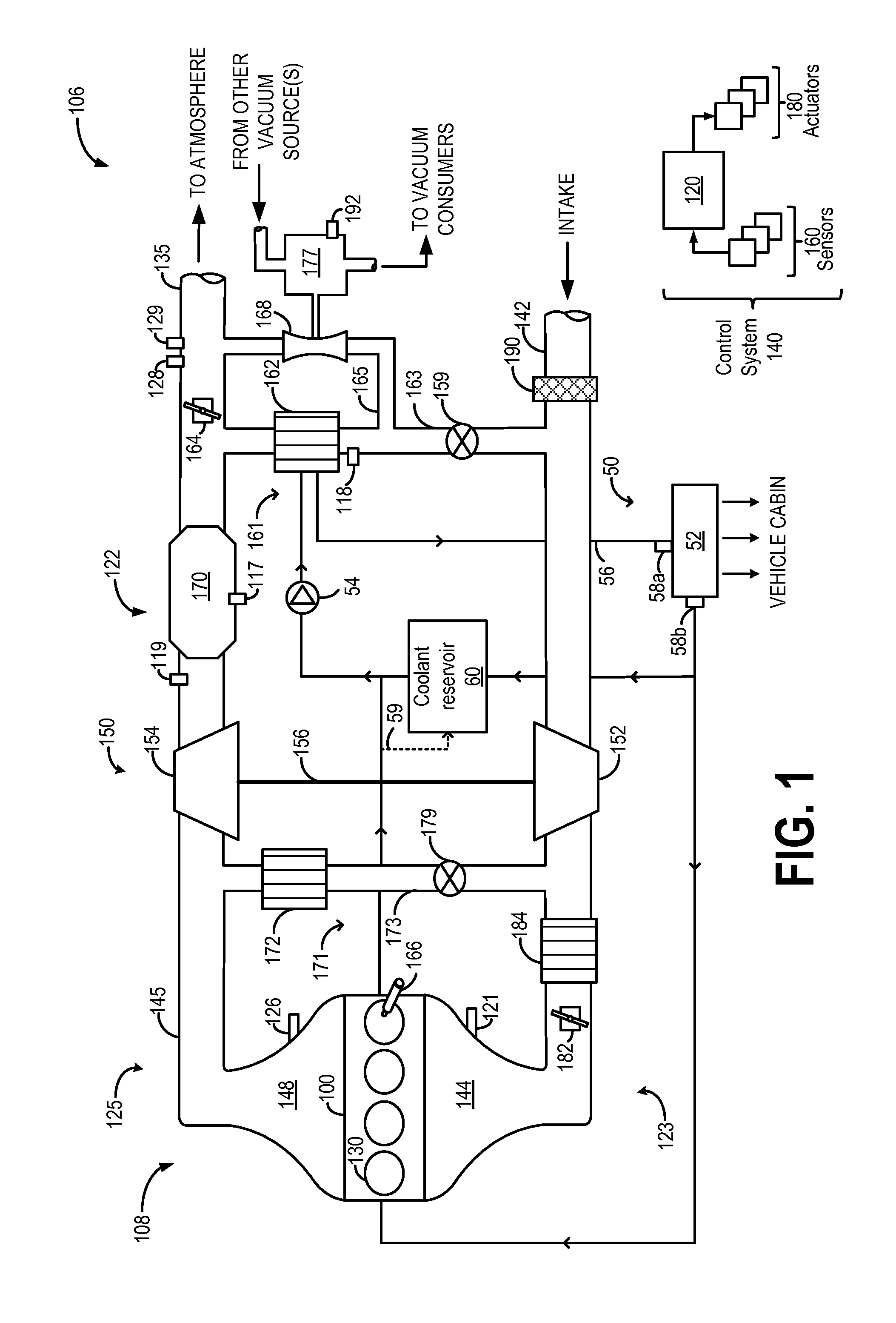

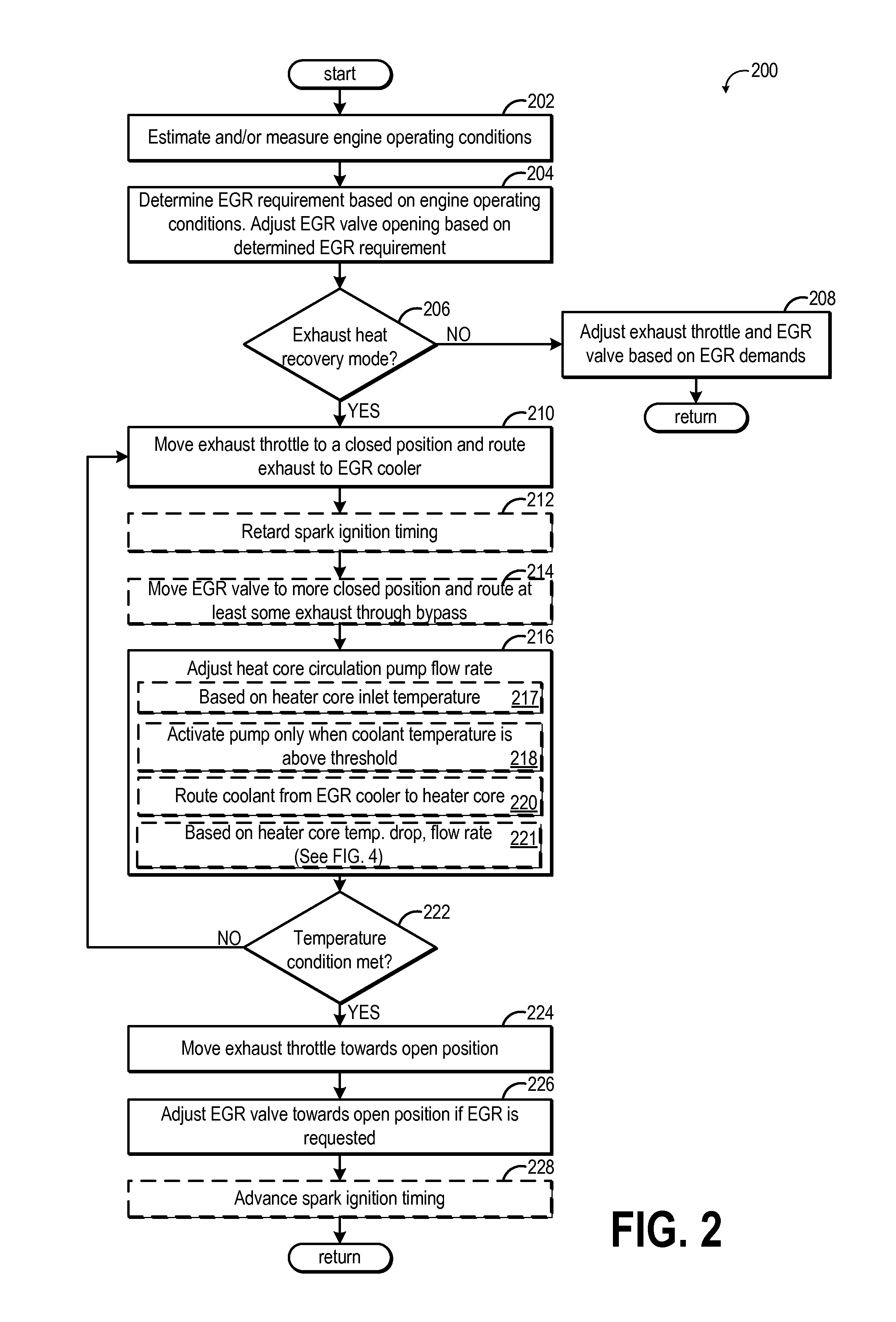

Exhaust throttling for cabin heating

ActiveUS20150121847A1Improve fuel economyReduce energy useMechanical controlElectrical controlExhaust gas recirculationHeating system

Embodiments for heating a vehicle cabin are disclosed. In one example, a method for heating a vehicle cabin comprises closing an exhaust throttle while diverting at least a portion of throttled exhaust gas through an exhaust gas recirculation (EGR) cooler coupled upstream of the throttle, and transferring heat from the EGR cooler to a heater core configured to provide heat to the vehicle cabin. In this way, exhaust heat may be directly routed to the cabin heating system.

Owner:FORD GLOBAL TECH LLC

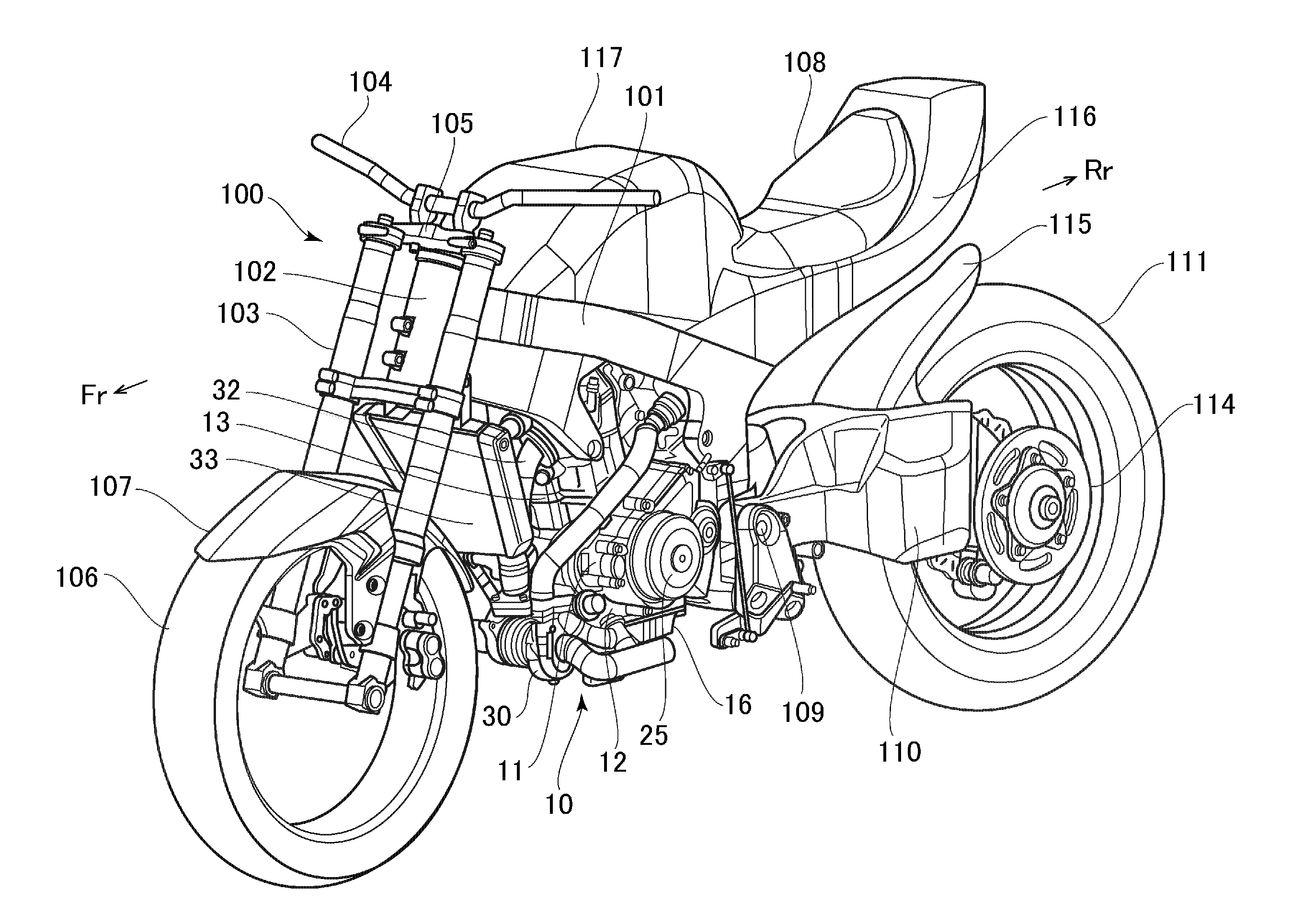

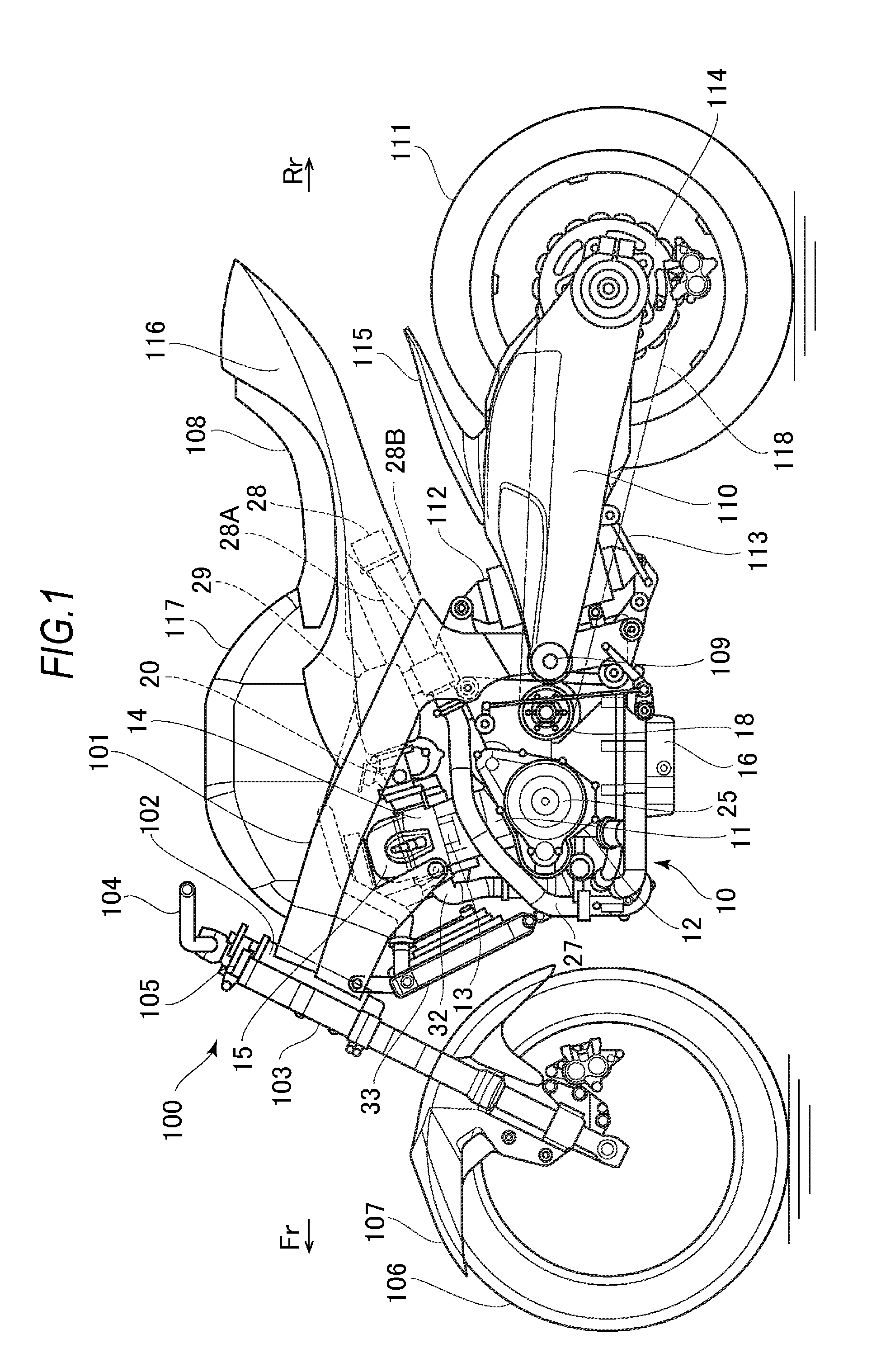

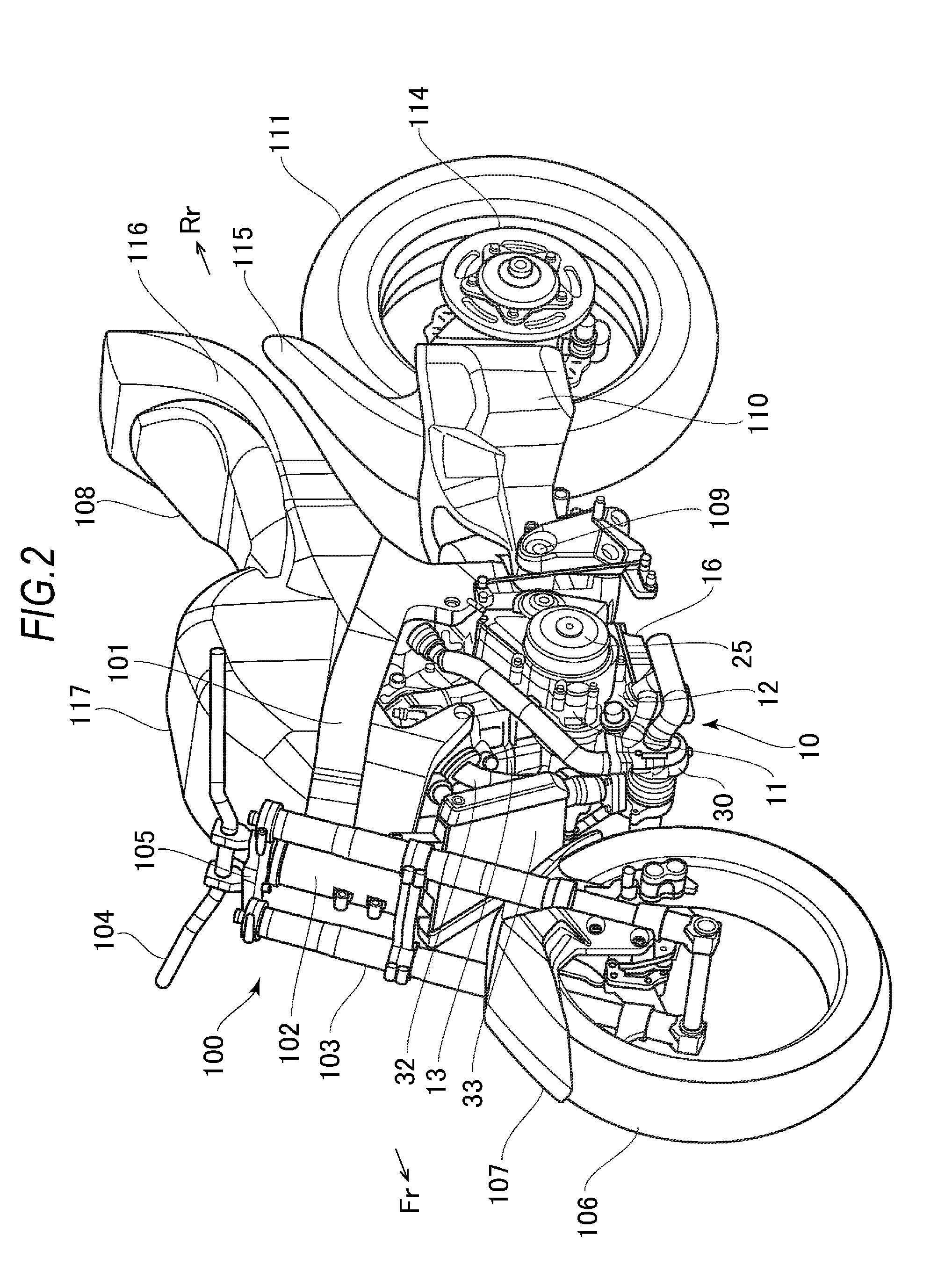

Motorcycle

ActiveUS20150083513A1Effective arrangement structureEffective structureMechanical controlInternal combustion piston enginesSurge tankCylinder head

One or more throttle bodies and a surge tank are disposed behind a cylinder head, and an intercooler is disposed by being adjacent to the surge tank at a position behind the cylinder head and the one or more throttle bodies. A supercharger is provided in front of the intercooler.

Owner:SUZUKI MOTOR CORP

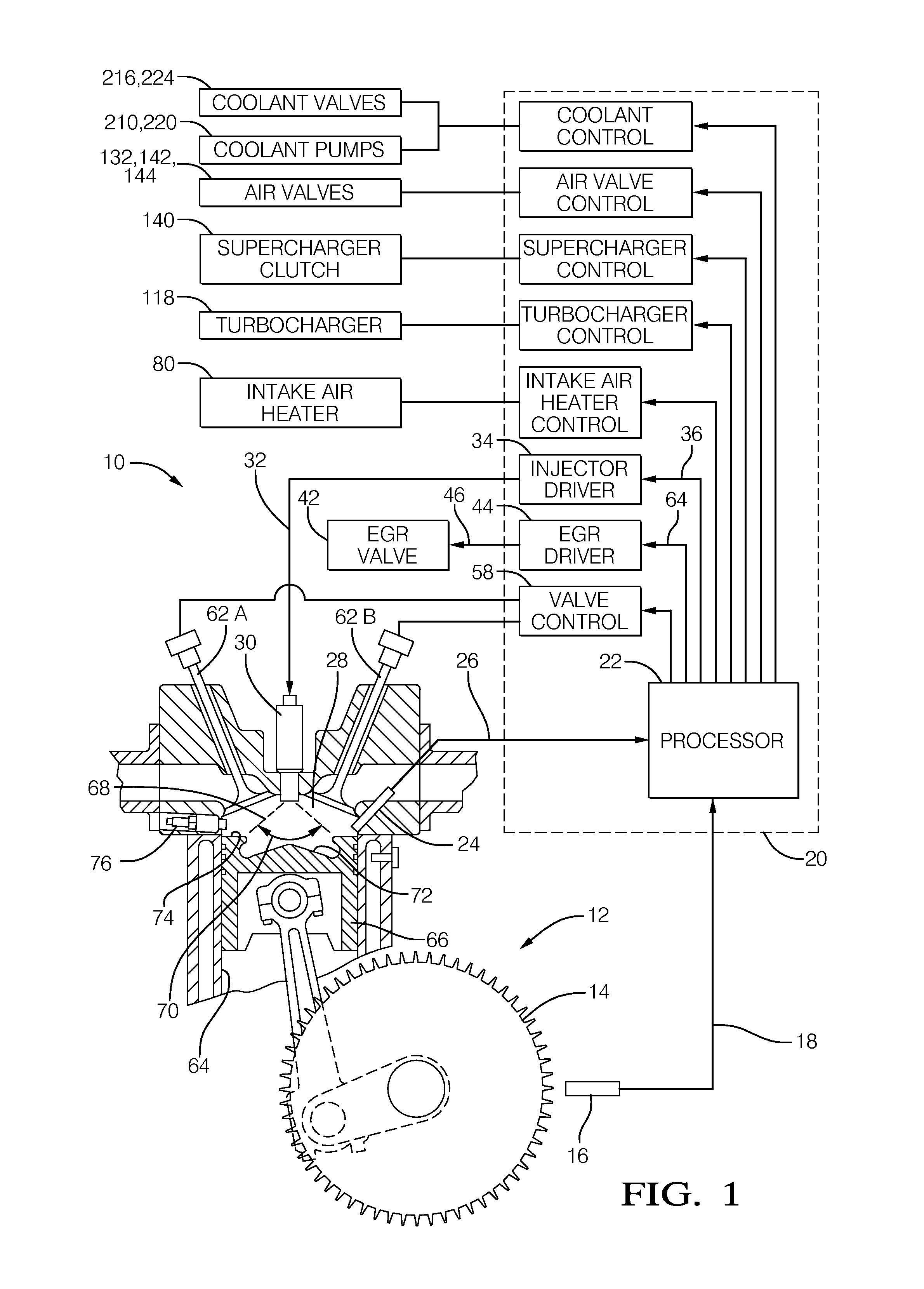

Cold start strategy and system for gasoline direct injection compression ignition engine

InactiveUS20150114339A1Increase temperatureIncrease pressureMechanical controlValve arrangementsExhaust valveGasoline direct injection

A method for starting a compression ignition engine having at least one cylinder with a reciprocating piston located therein, an intake valve configured to control the intake of air to an intake port of the cylinder and an exhaust valve configured to control the expulsion of gas from an exhaust port of the cylinder. The method includes the steps of: cranking the engine, conditioning intake air at the intake port of the cylinder to raise the temperature of air in the cylinder, controlling a valve timing the intake valve and / or the exhaust valve to allow the piston to compress the air within the cylinder, thereby increasing the temperature of the air within the cylinder, and injecting fuel into the cylinder when the air within the cylinder has been heated to a temperature sufficient to support compression ignition of a gasoline and air mixture within the cylinder.

Owner:DELPHI TECH IP LTD

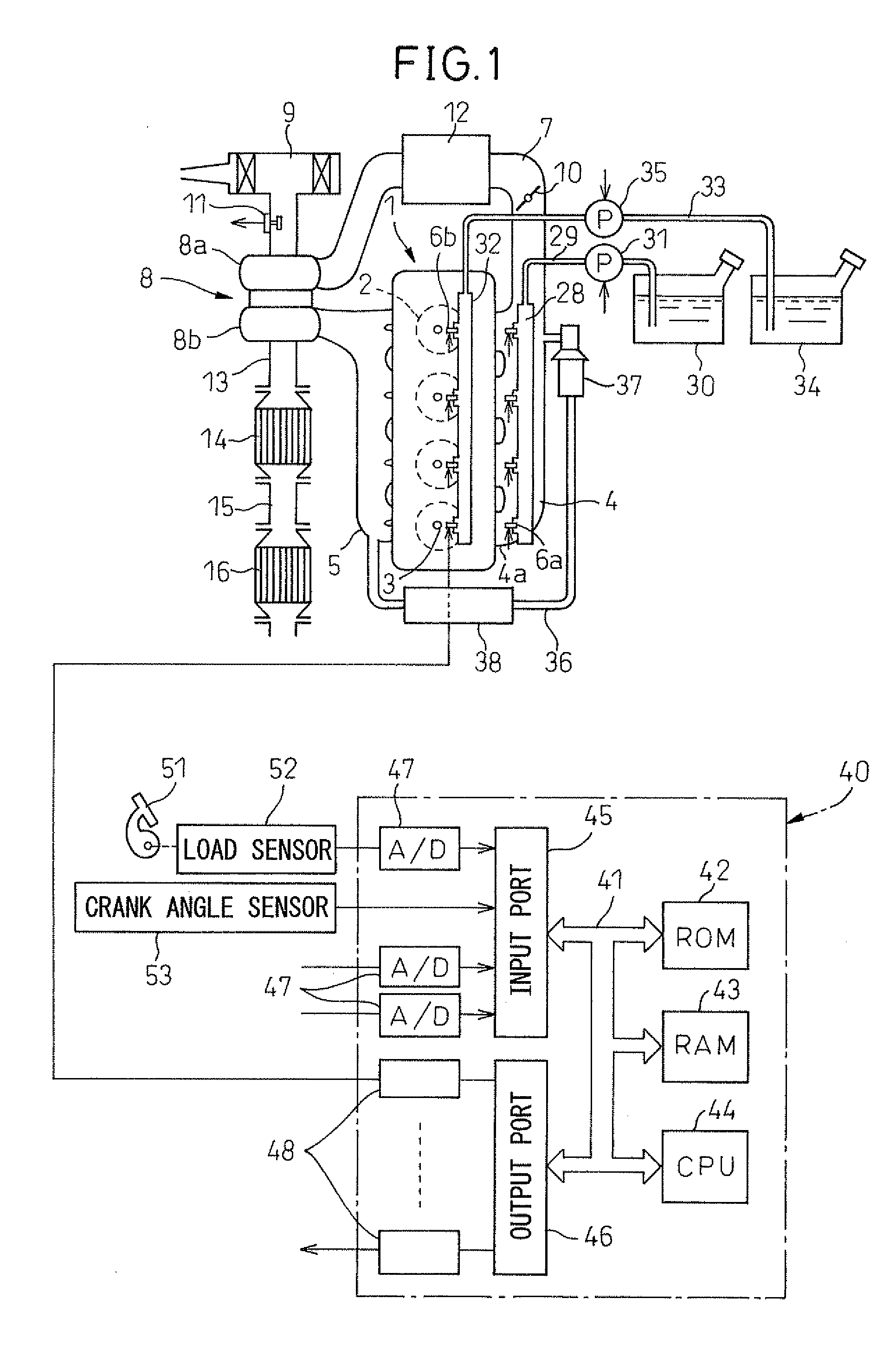

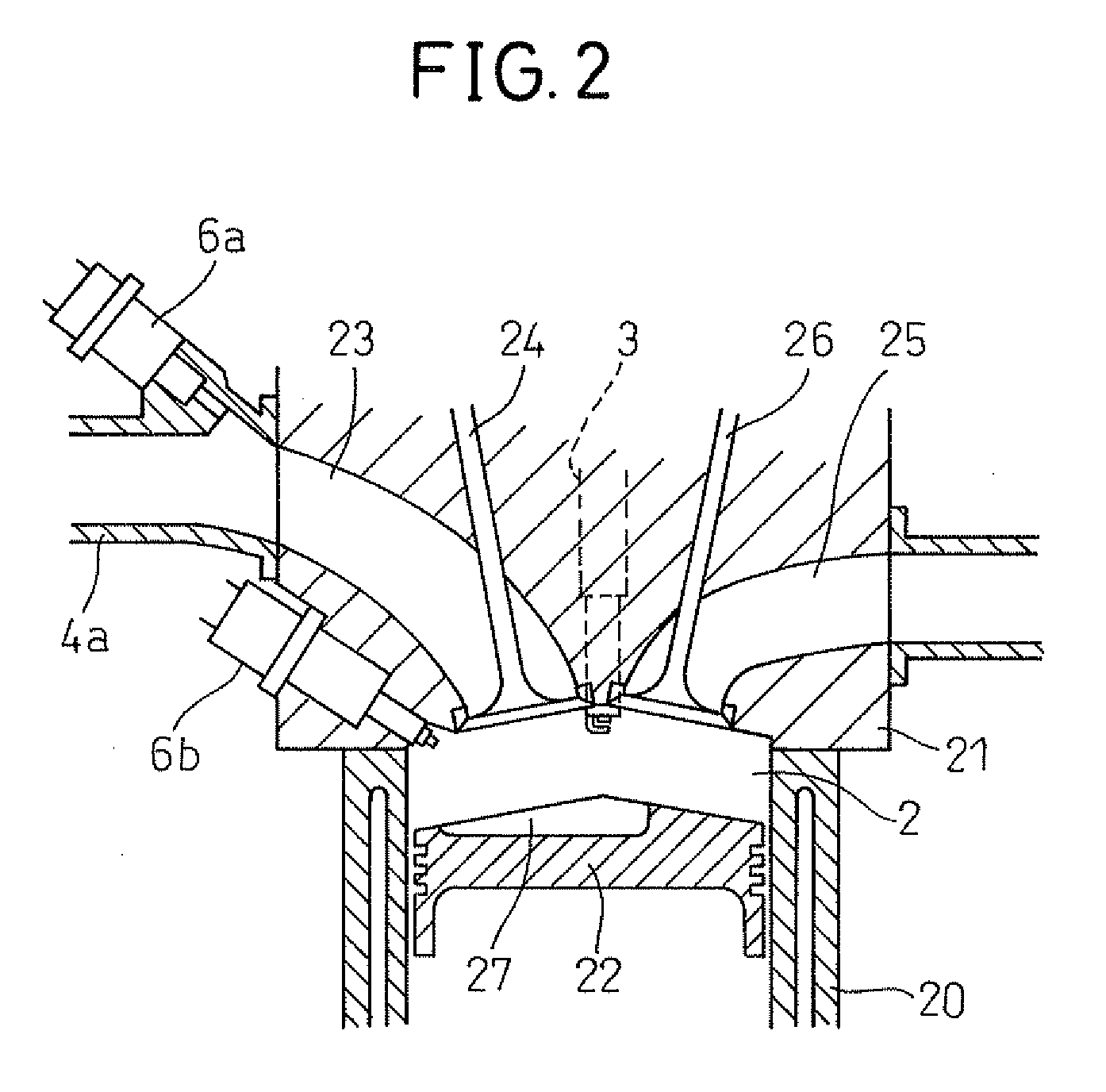

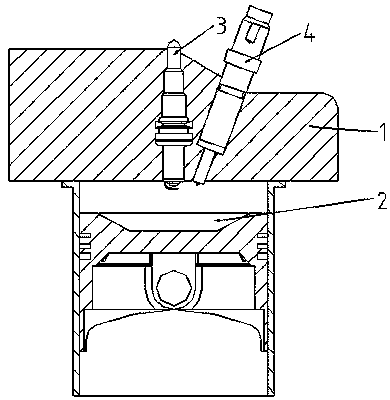

Combustion control system for internal combustion engine

InactiveUS20080236546A1Reduce fuel consumption costsIncrease productionMechanical controlElectrical controlCombustion chamberControl system

In an embodiment, the invention provides an internal combustion engine, including a first fuel injector that supplies a first fuel to a first predetermined region in a combustion chamber, and a second fuel injector that supplies a second fuel to a second predetermined region in the combustion chamber. The second fuel has an octane number that is different than an octane number of the first fuel, and the second predetermined region is different from the first predetermined region. An ignition device is configured to start ignition of one of the first and second fuels based on an ignition signal. An operation condition detector detects at least one engine operating condition. A controller is configured to provide the ignition signal to the ignition device and to determine which one of the first and second fuels to ignite by the ignition device based on the engine operation condition.

Owner:NISSAN MOTOR CO LTD

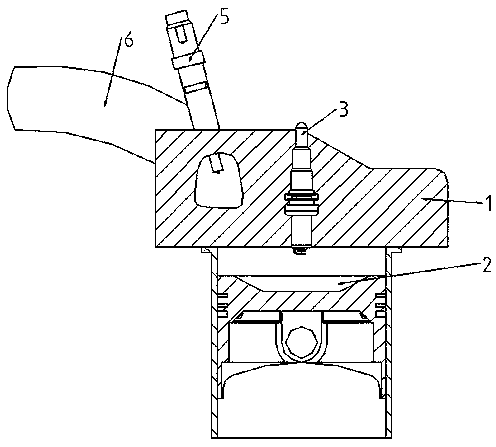

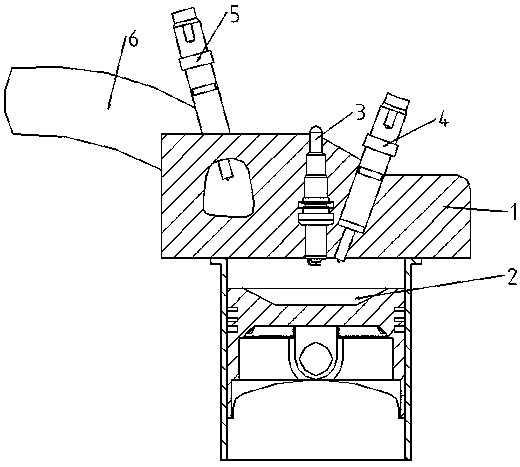

Sparking plug ignition-type premixing compression ignition system of internal combustion engine

ActiveCN107781026AReduce the effective compression ratioReduce the temperatureMechanical controlElectrical controlSpontaneous combustionExternal combustion engine

The invention discloses a sparking plug ignition-type premixing compression ignition system of an internal combustion engine, and belongs to the technical field of combustion of internal combustion engines. According to the premixing compression ignition system, a high-energy sparking plug is adopted for igniting diesel oil or igniting mixtures of the diesel oil and other fuels, wherein the dieseloil or the mixtures serve as the fuels for premixing and are jetted out in a gas feeding process or a compression process to generate premixing gas in a combustion chamber. By adopting an effective compression ratio under which the premixing gas cannot be ignited, the premixing gas in a cylinder cannot burn spontaneously; by using the high-energy sparking plug for ignition close to a compressionupper limit point, the mixed gas nearby the sparking plug is ignited to make the temperature and the pressure in the cylinder quickly rise, the other remaining premixing gas in the cylinder satisfiesthe conditions for spontaneous combustion, large-scale multi-point spontaneous combustion happens, and fast combustion of the premixing gas is achieved. By adopting a high expansion ratio, the heat efficiency is further improved.

Owner:DALIAN UNIV OF TECH

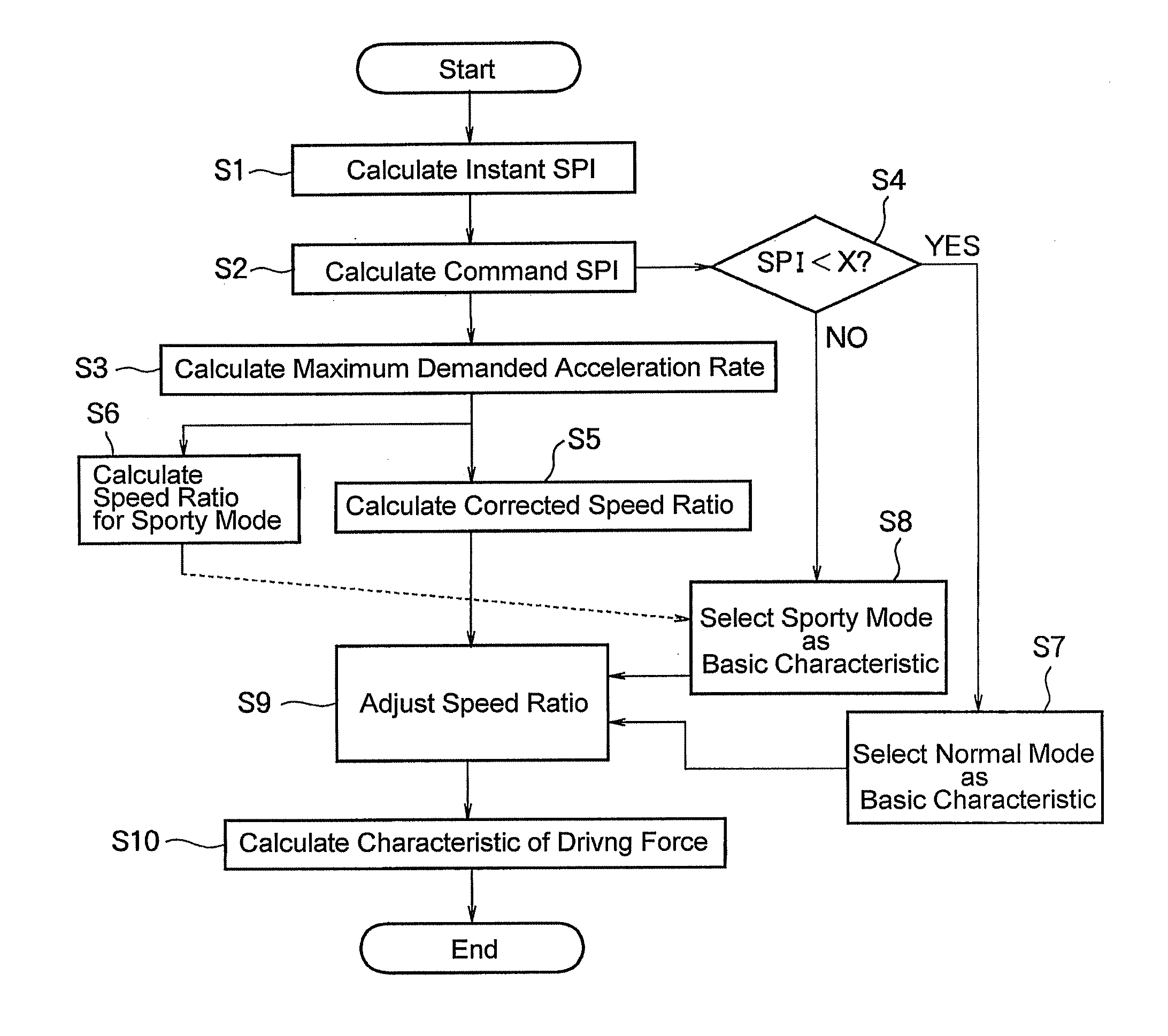

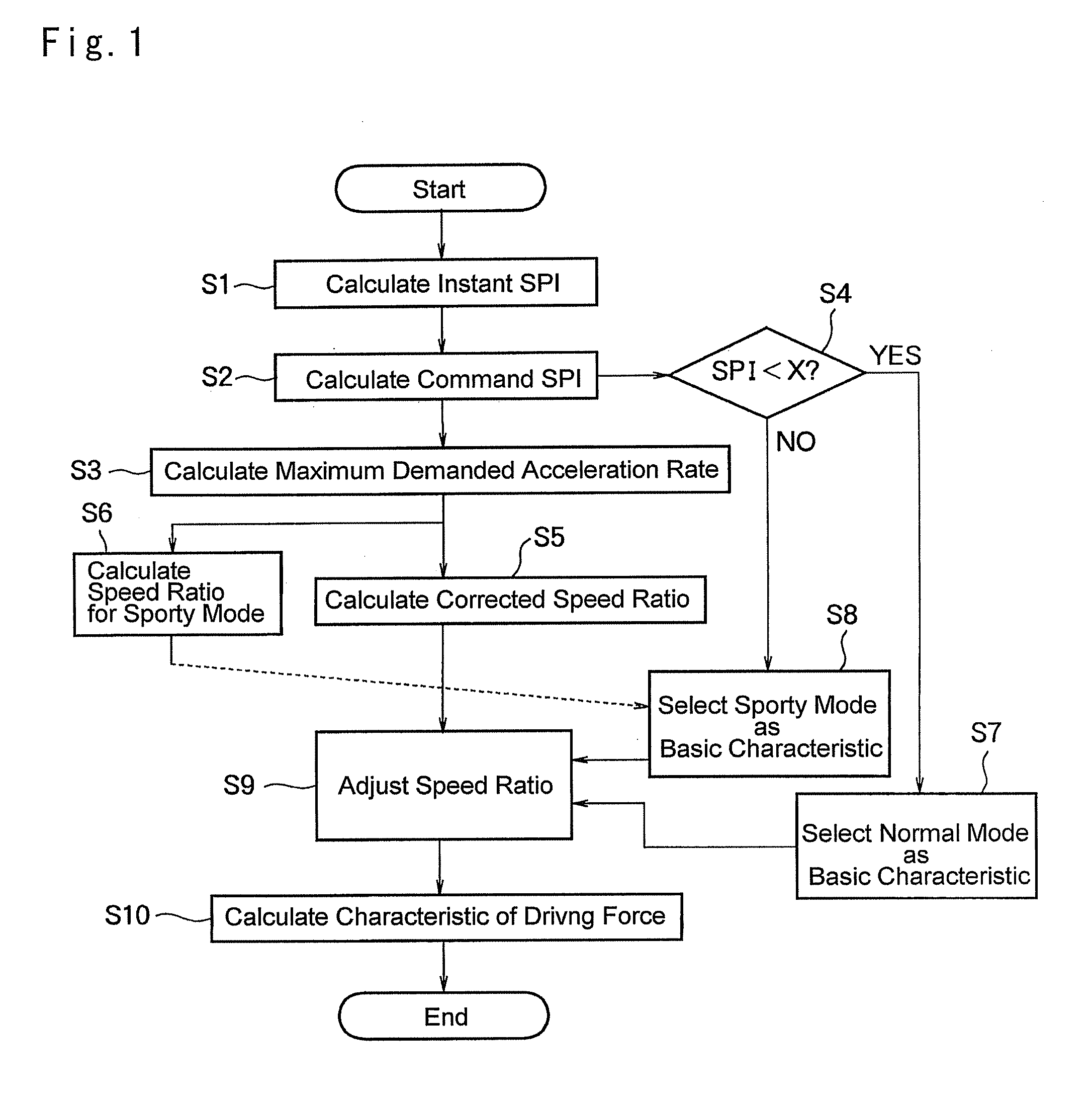

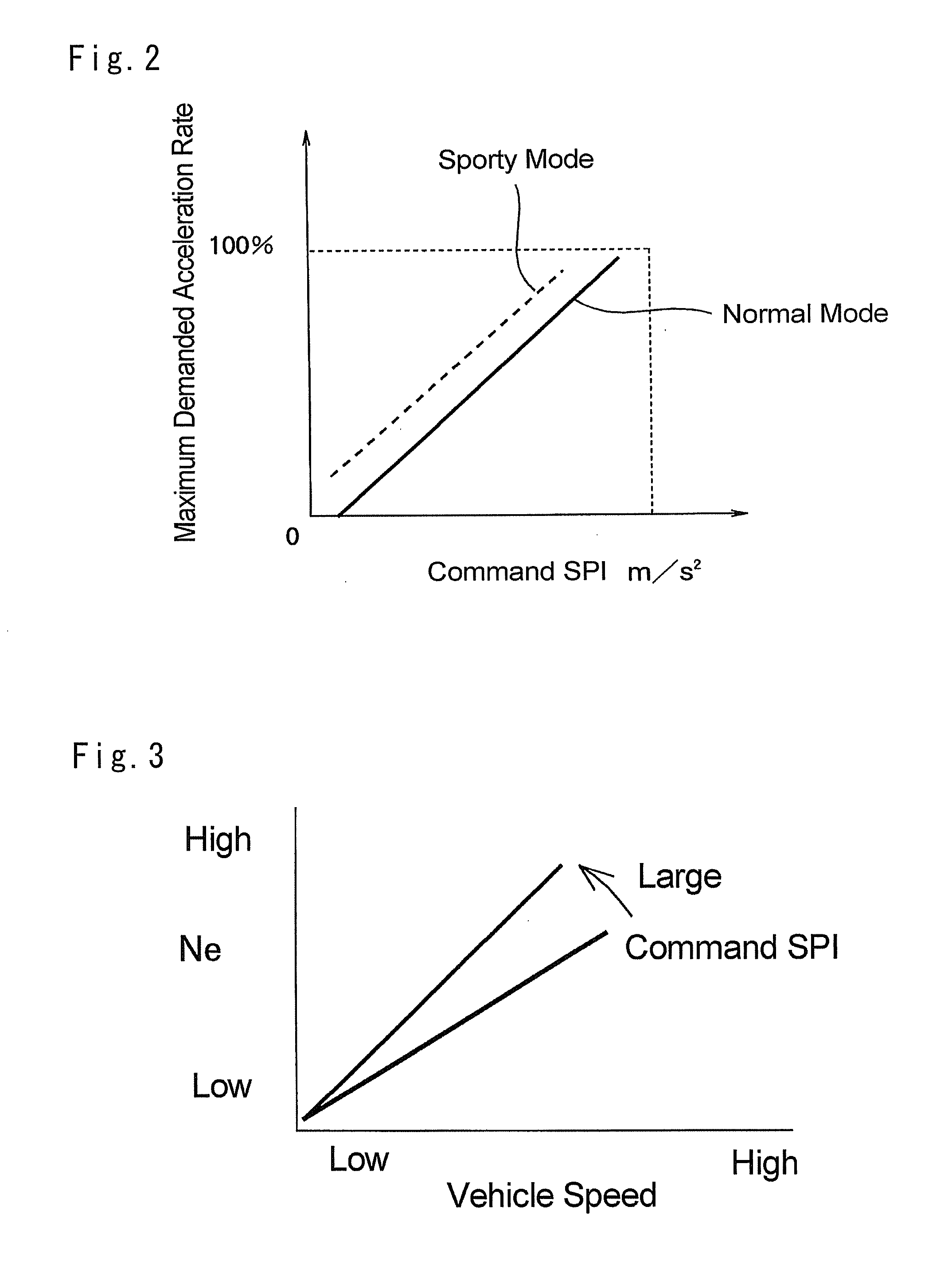

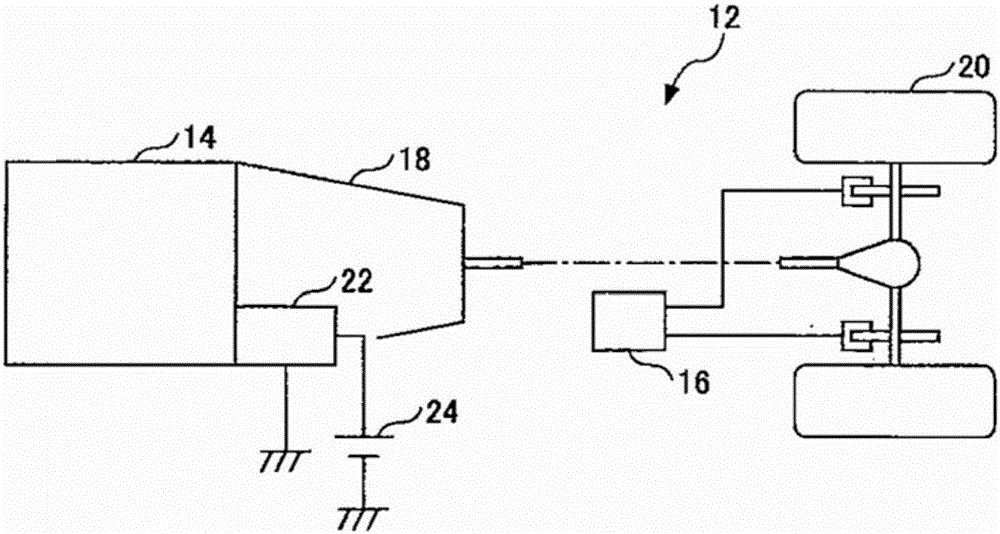

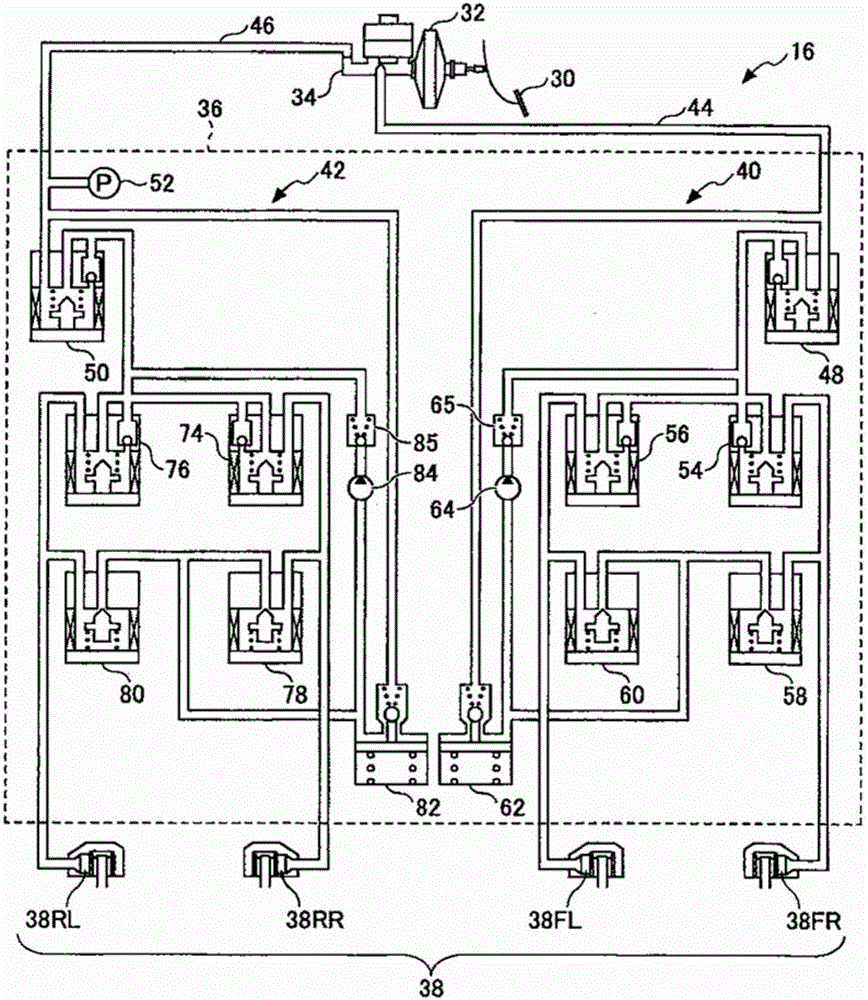

Driving force control system for vehicle

InactiveUS20150127200A1Improve fuel economyImprove agilityHybrid vehiclesMechanical controlVehicle behaviorControl system

A driving force control system for a vehicle having a mechanism for changing an engine speed continuously. The driving force control system basically controls said mechanism in a manner such that the engine speed is adjusted to optimize fuel economy. The driving force control system is configured to determine an index representing a demand to enhance agility of behavior of the vehicle based on an actual behavior of the vehicle or an amount of operation carried out by a driver to cause said behavior. An upper limit value of the engine speed of the case in which a drive demand is increased is determined on the basis of the index, and the upper limit value is set to the higher value with an increase in the index representing the demand to enhance agility of behavior of the vehicle.

Owner:TOYOTA JIDOSHA KK

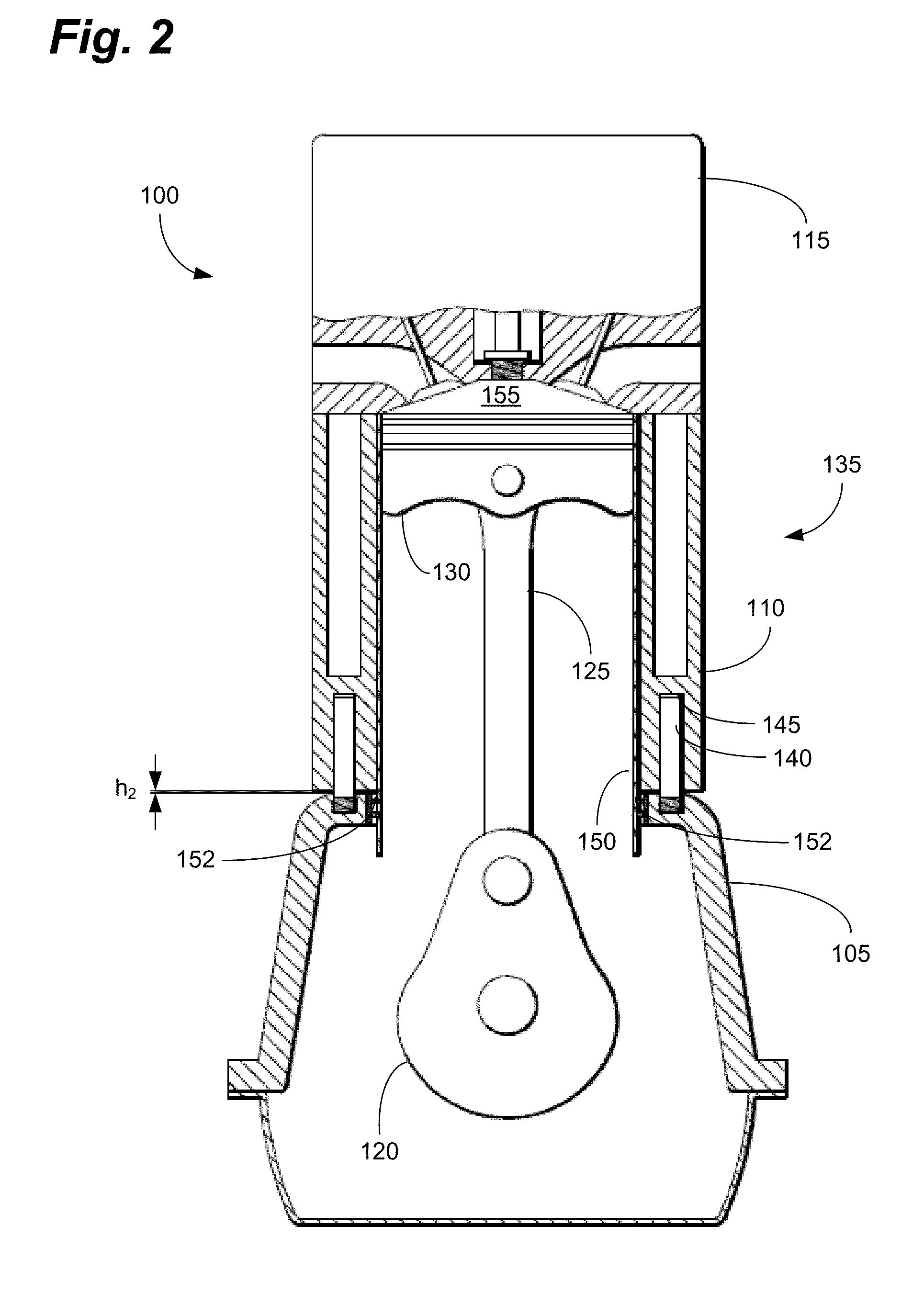

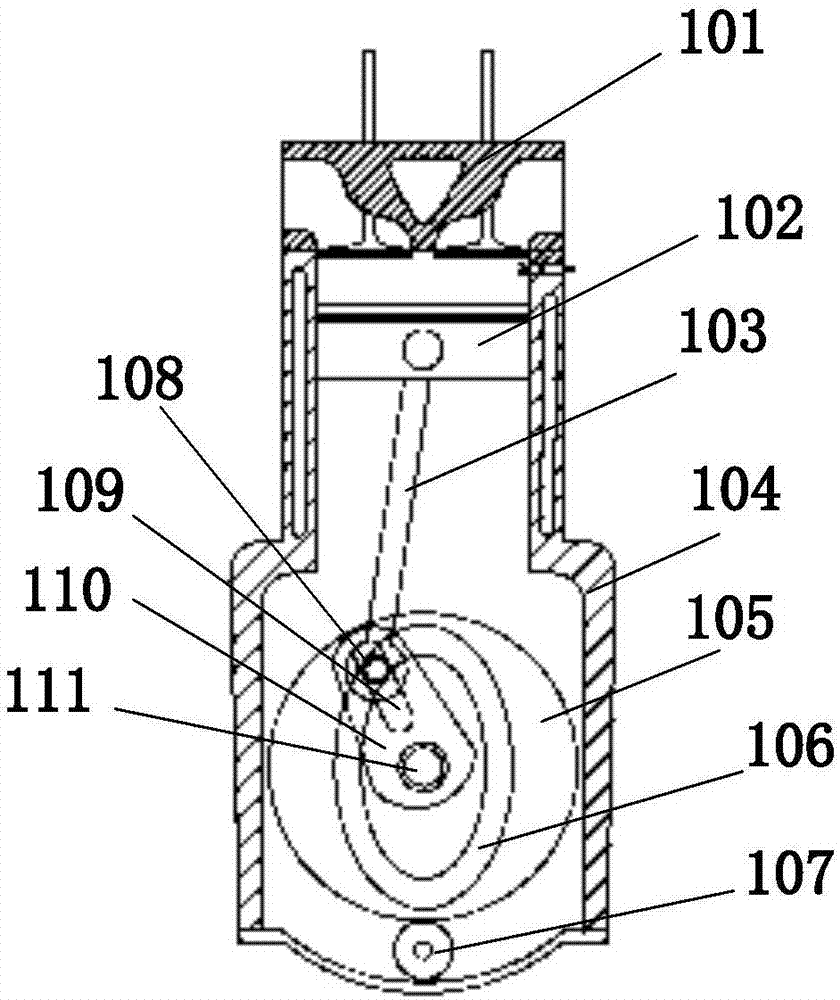

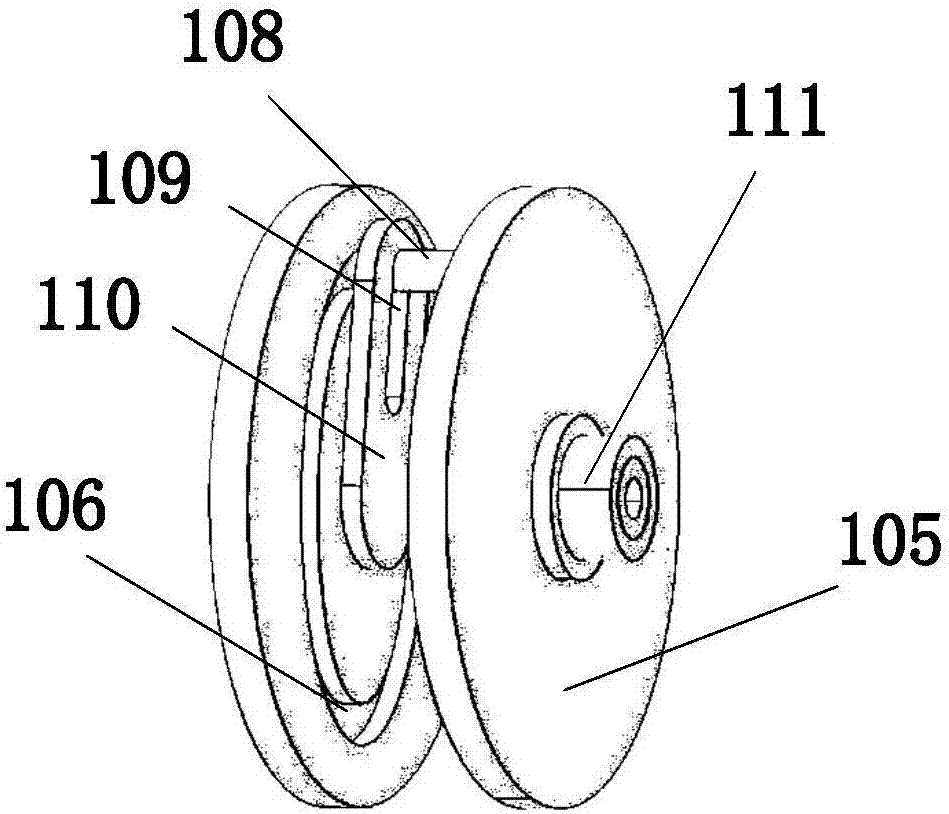

Piston with variable lift compression ratio

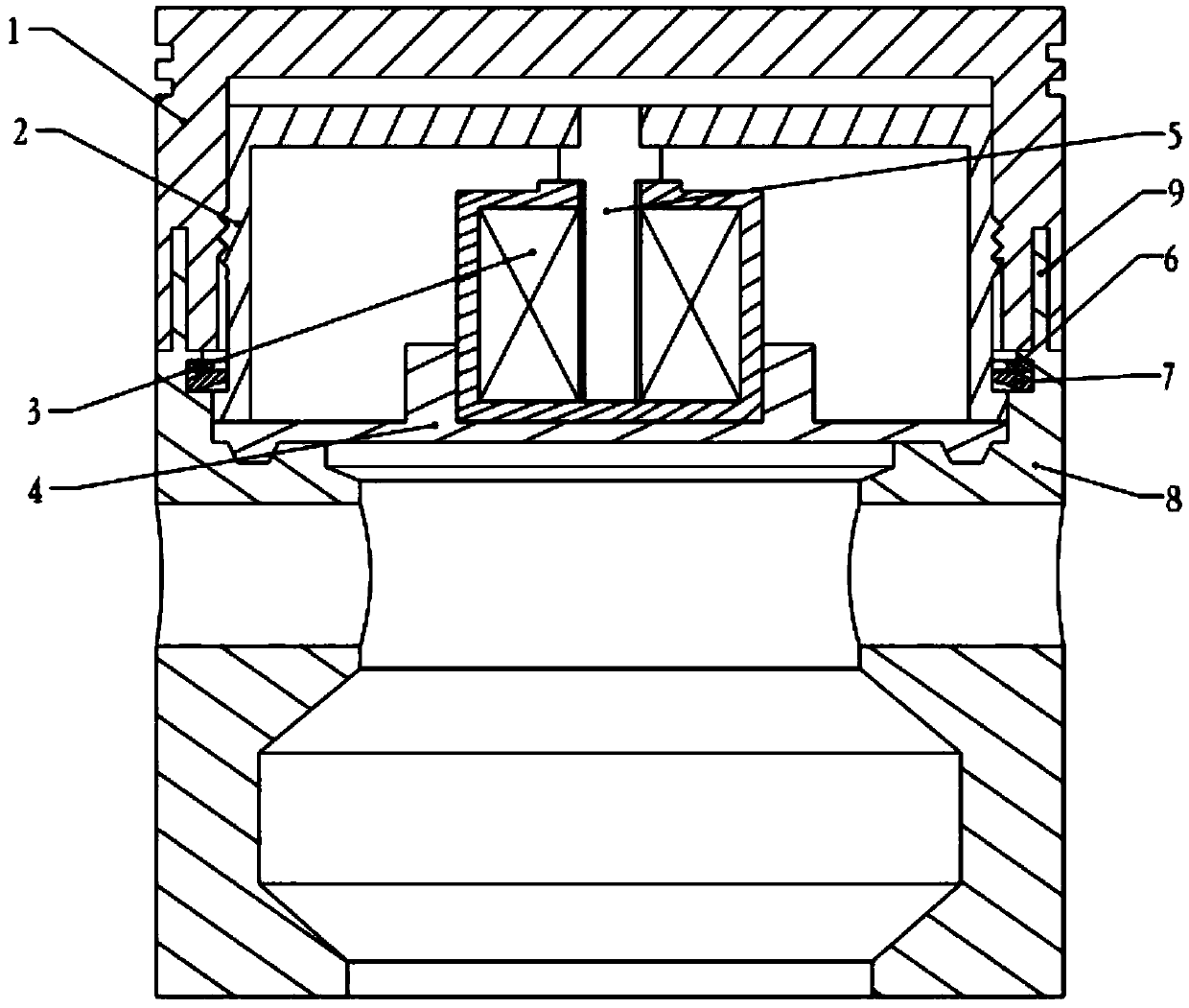

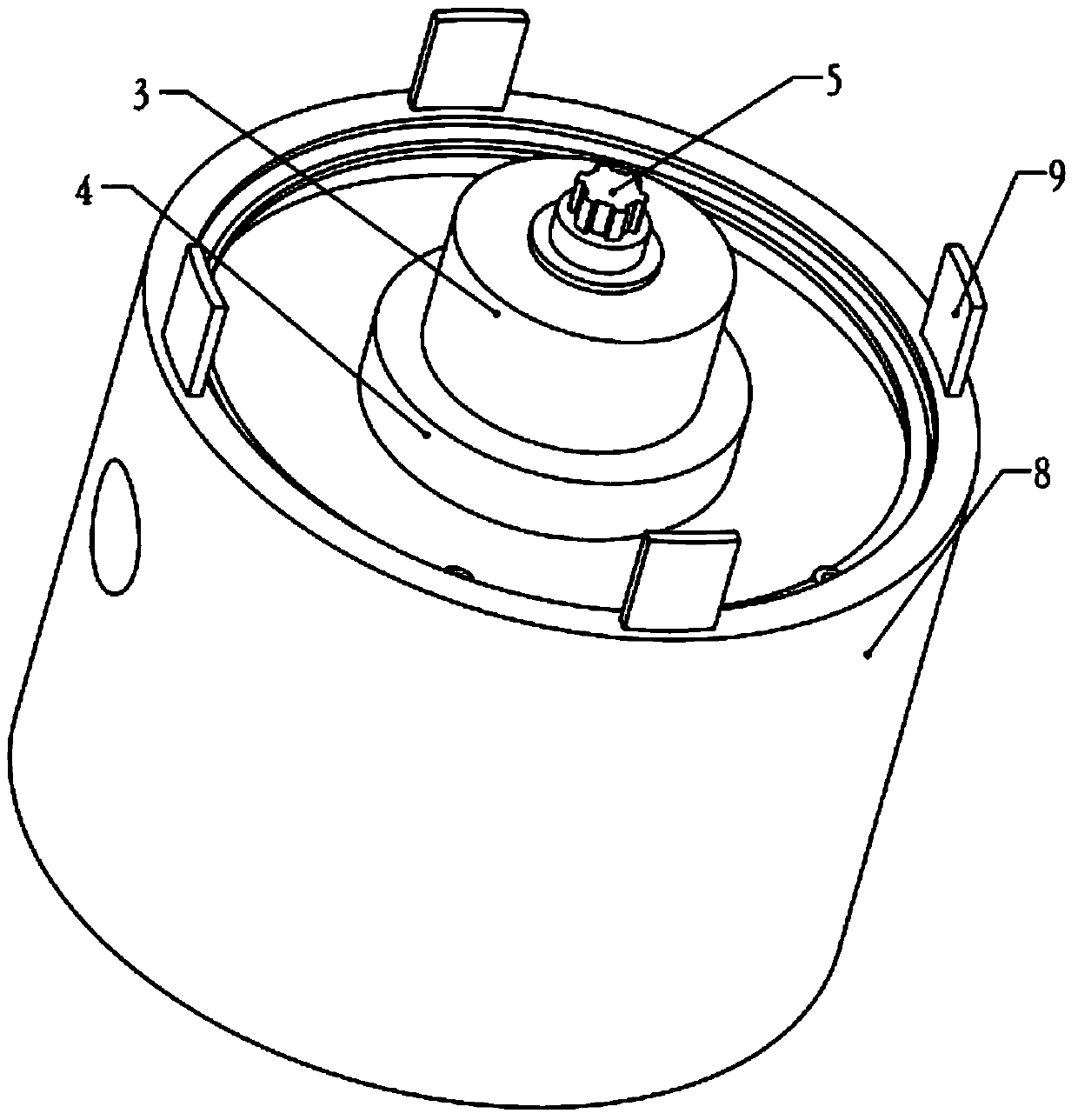

InactiveCN105370417AImprove reliabilityEasy to installMechanical controlMachines/enginesEngineeringPiston

The invention discloses a piston with a variable lift compression ratio, aiming to solve the problems of complex mechanical structure, various parts and poor sealing performance of the prior art. The piston comprises an upper piston body part, an inner sleeve, a motor stator, a motor rotor, a motor base, a snap ring, a pressure spring and a lower piston body part, wherein the motor base is fixedly connected into an inner hole in the top end of the lower piston body part, and the motor stator is fixedly connected into a circular ring body at the center of the motor base; the bottom end surface of the motor stator is connected with the motor base in the circular ring body in a contacting manner, and the motor rotor is mounted in the center hole of the motor stator; the inner sleeve is mounted around the motor rotor and the motor stator in a sleeving manner, and a splined hole in the inner sleeve is matched with a spline shaft at the top end of the motor rotor; the pressure spring and the snap ring are mounted in the annular groove in the top end of the lower piston body part from bottom to top, and the upper piston body part is mounted at the top end of the lower piston body part; the upper piston body part is in threaded connection with the inner sleeve and connected with the lower piston body part in a sliding manner.

Owner:JILIN UNIV

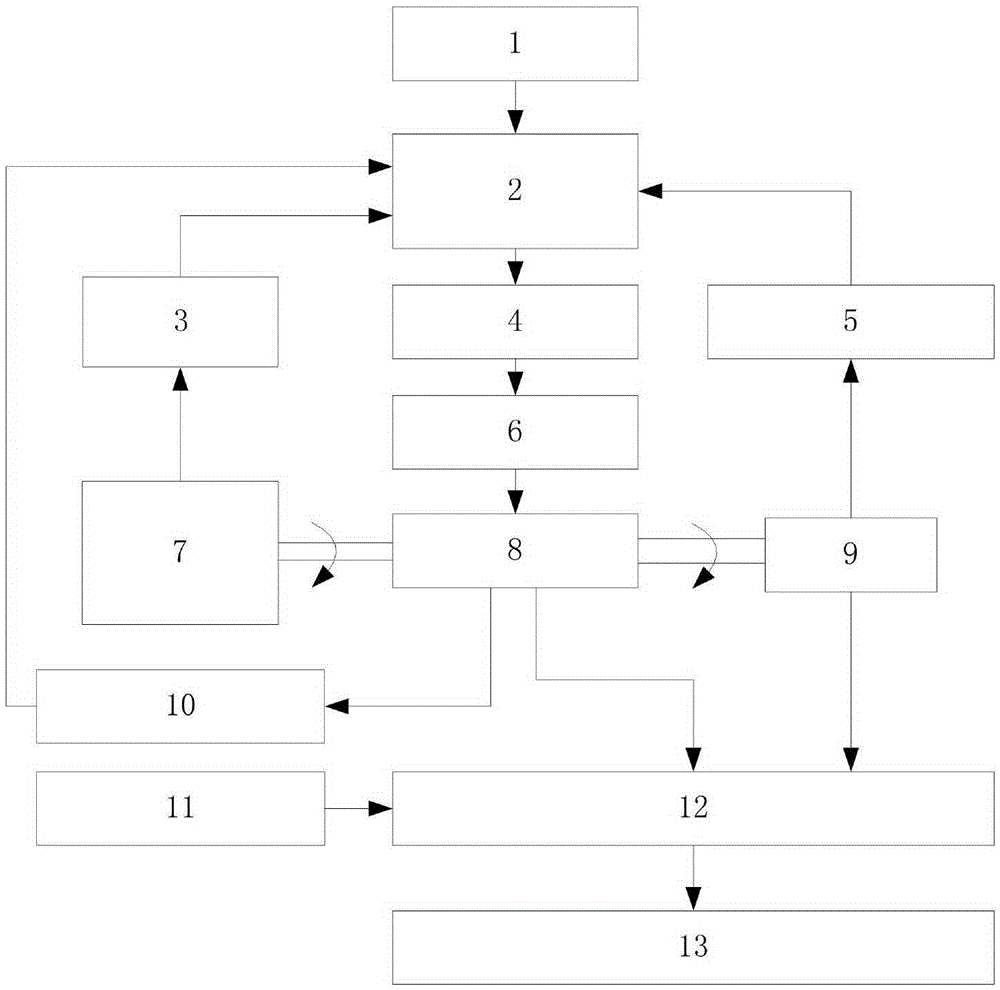

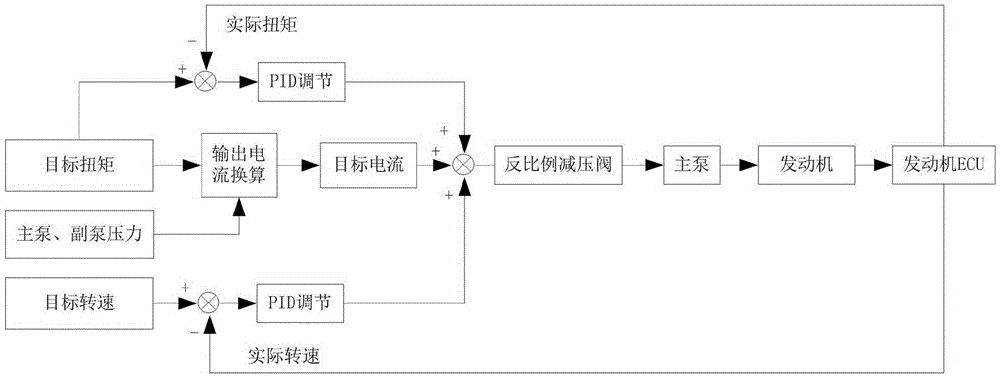

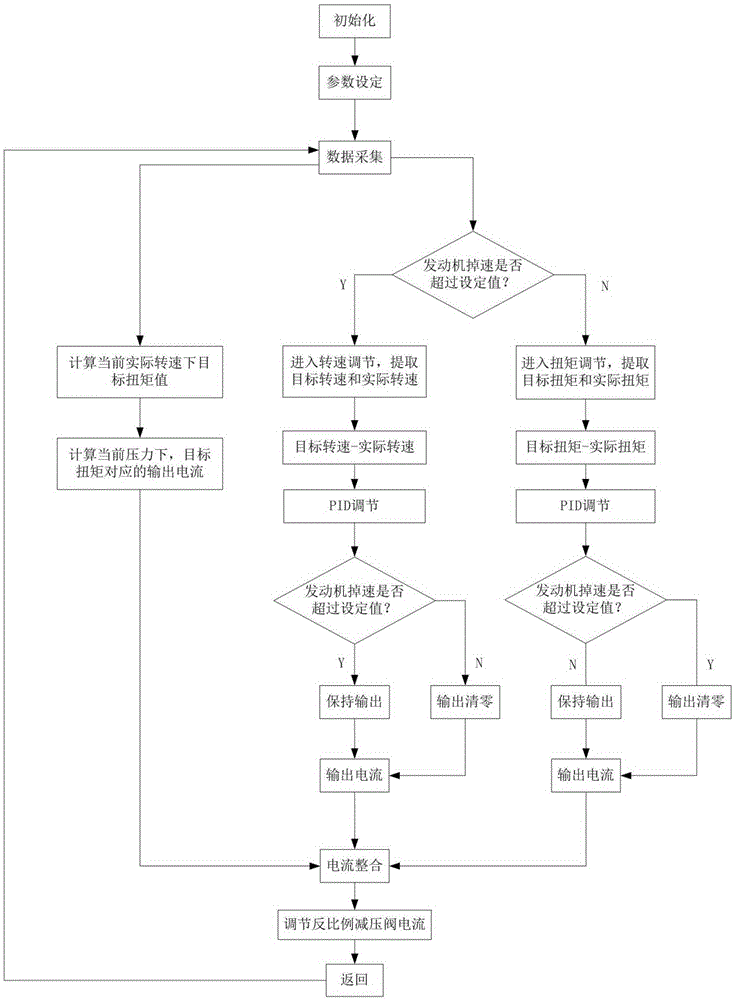

Power matching method based on torque and rotation speed compound control for rotary drilling rig

ActiveCN105402039AReal-time control of input powerAvoid severe slowdownMechanical controlMachines/enginesControl systemComputer module

The invention discloses a power matching method based on torque and rotation speed compound control for a rotary drilling rig. The power matching method comprises the following steps: calculating target current according to pressure of a primary pump and a secondary pump and set target torque percentage; setting a speed drop value during interconversion of a rotation speed regulating module and a torque regulating module; when a real-time speed drop value of an engine is smaller than a set value, adopting the torque regulating module to carry out compensation regulation on target current; when the real-time speed drop value of the engine is greater than the set value, adopting the rotation speed regulating module to carry out compensation regulation on the target current; and outputting a final current value to an inverse proportion pressure-reducing valve to control a displacement regulator to change displacement of the primary pump, thereby controlling input power of the primary pump in real time. The power matching method is simple, reliable and high in practicability, has the characteristics of rotation speed control rapidity and torque control predictability, can effectively avoid severe speed drop of the engine, avoids a shut-down phenomenon, improves operation efficiency of the rotary drilling rig and guarantees operation stability of a control system.

Owner:徐州惠力机械制造有限公司

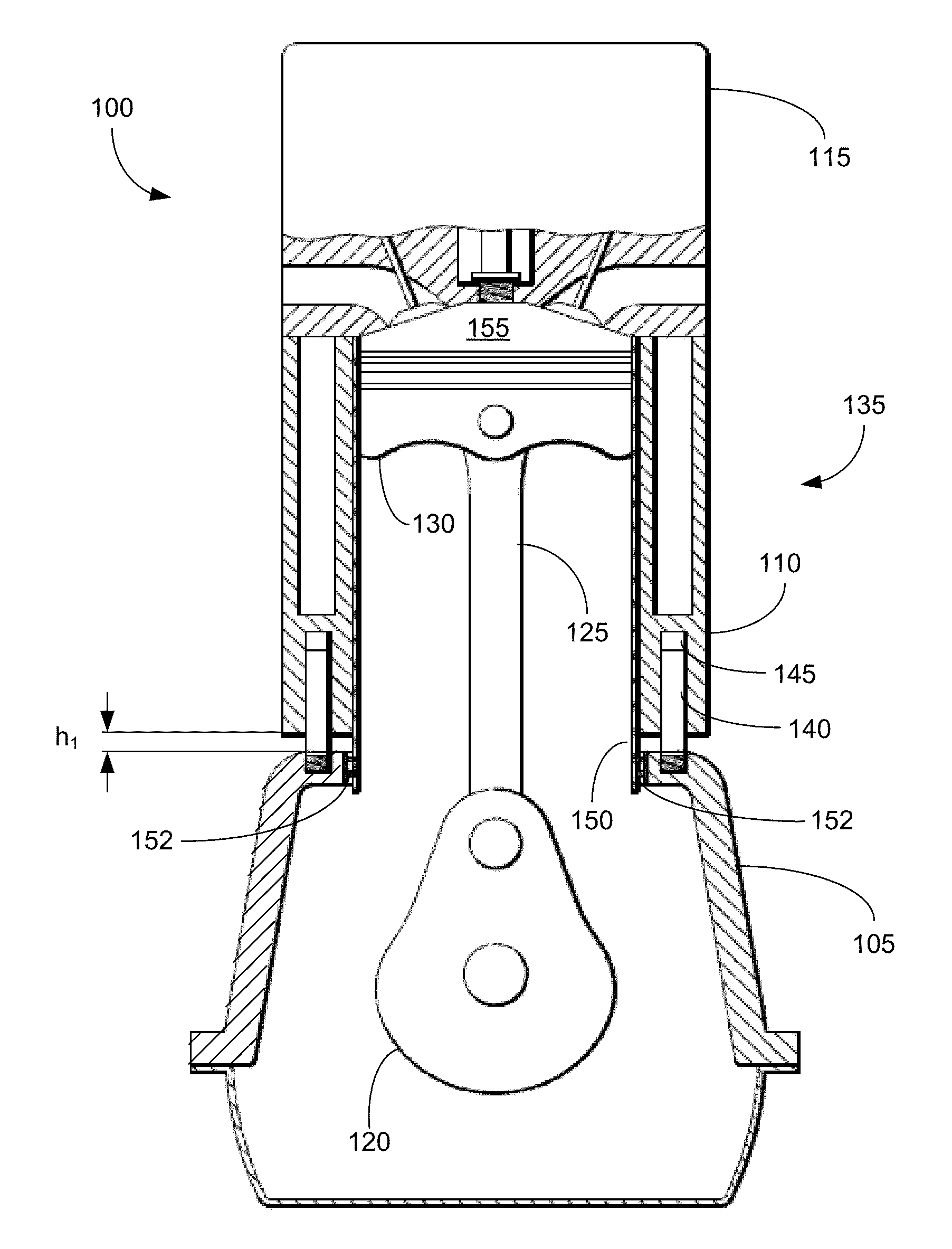

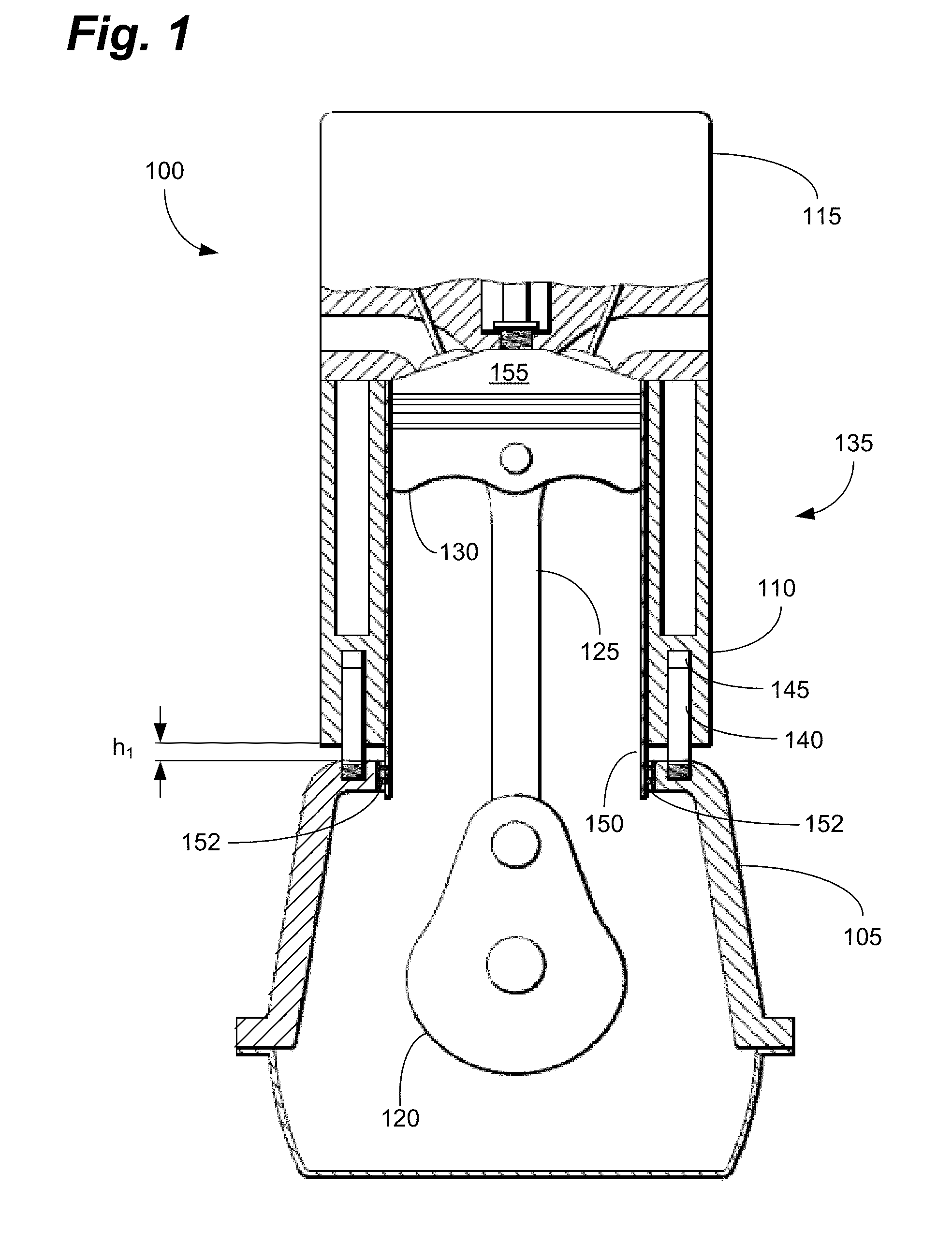

Variable compression ratio engine

ActiveUS20140116395A1Prevent movementIncrease the compression ratioMechanical controlMachines/enginesGear driveCylinder head

A system and method for providing a variable compression ratio internal combustion engine is disclosed. The system can include a frame affixed to the engine crankcase and a complementary frame affixed to the block / cylinder head assembly. The system can further comprise an actuating system to enable the block / head assembly to be moved up and down with respect to the crankcase, varying the compression ratio of the engine. A number of mechanisms can be used to achieve this movement, including a rack and pinion, a hydraulic or pneumatic actuator, and a gear drive. The compression ratio can be varied continuously during use. The frames substantially limit movement of the engine components to the y-axis, thus reducing, or eliminating, unwanted movement and stresses in other directions.

Owner:BLACKSTOCK SCOTT

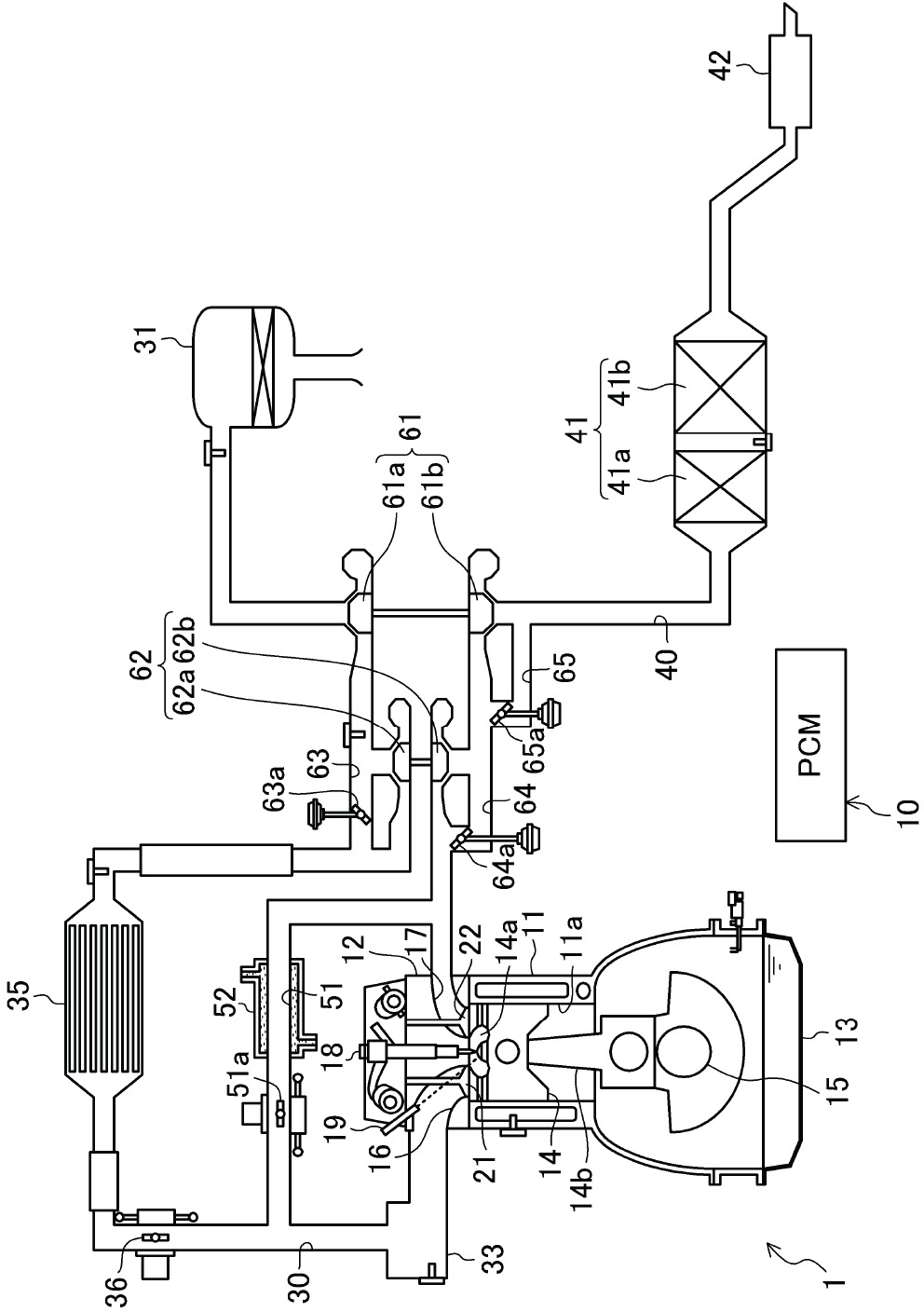

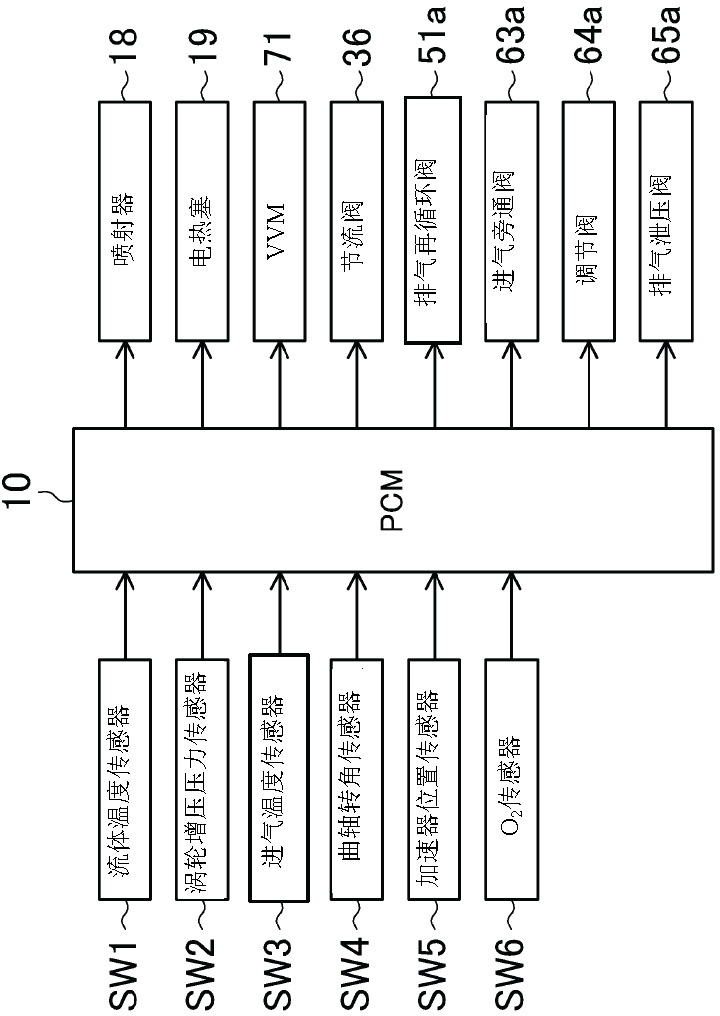

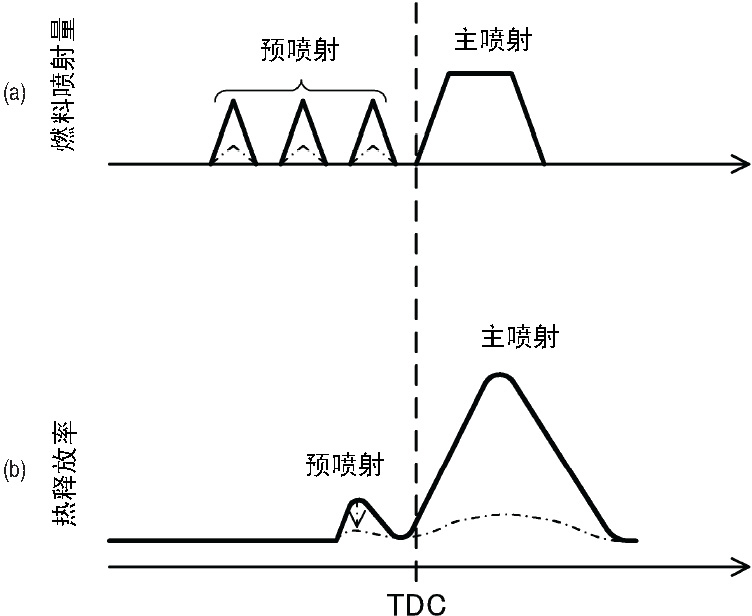

Diesel engine for vehicle

A diesel engine for a vehicle comprises an engine body mounted in the vehicle having a plurality of cylinders that is supplied with fuel, a plurality of fuel injection valves for directly injecting the fuel into the cylinders, and an injection control module for controlling a mode of injecting the fuel into the cylinders through the fuel injection valves. The injection control module sets a fuel injection amount per cylinder at least according to a load on the engine body, performs a main injection, and performs at least one pre-injection where fuel is injected prior to the main injection. The injection control module further executes a cylinder-cutoff operation mode where the fuel supplies to the cylinder or the cylinders are stopped when the engine body is under a low load condition where the fuel injection amount per cylinder is below a predetermined amount.

Owner:MAZDA MOTOR CORP

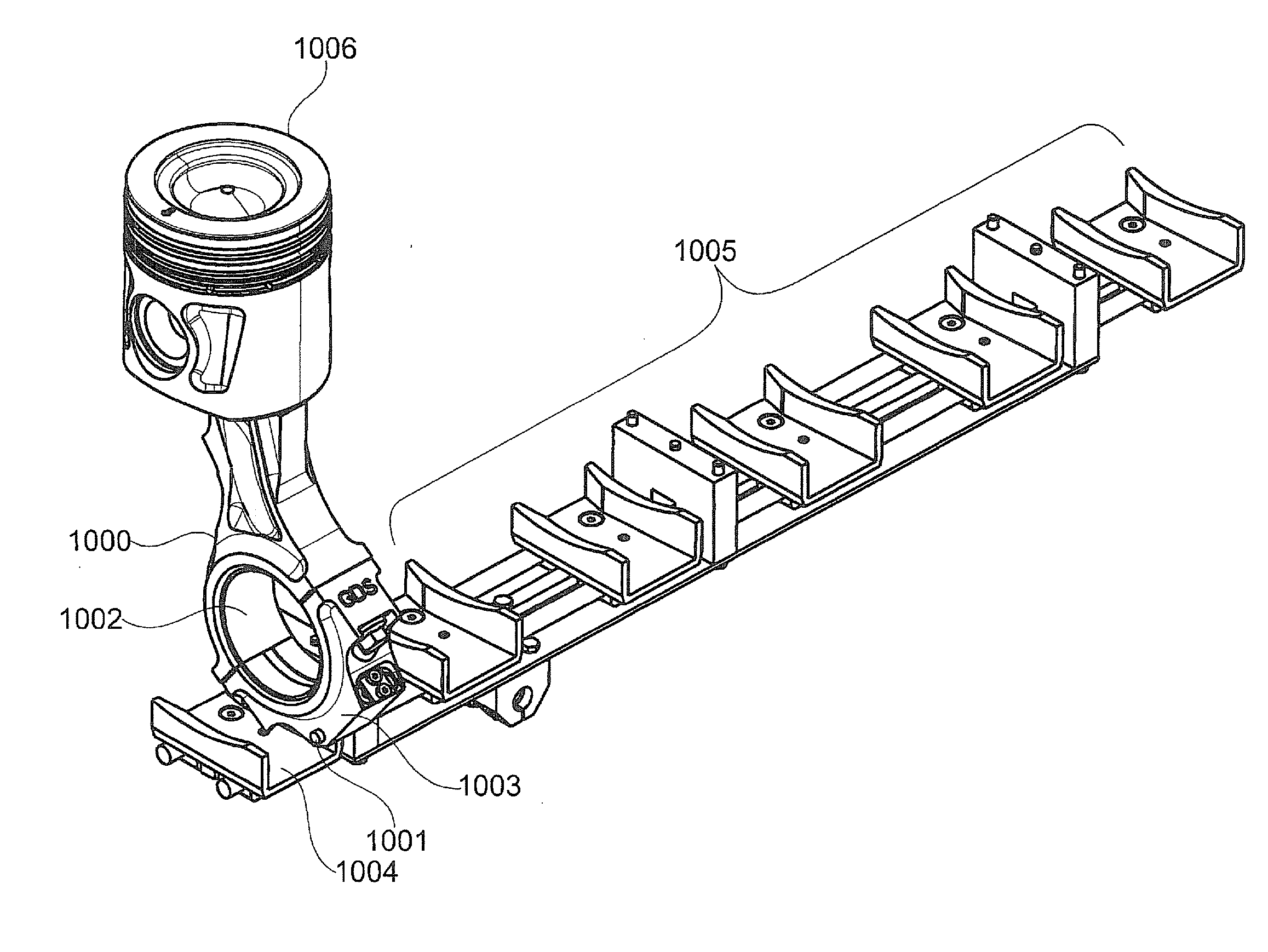

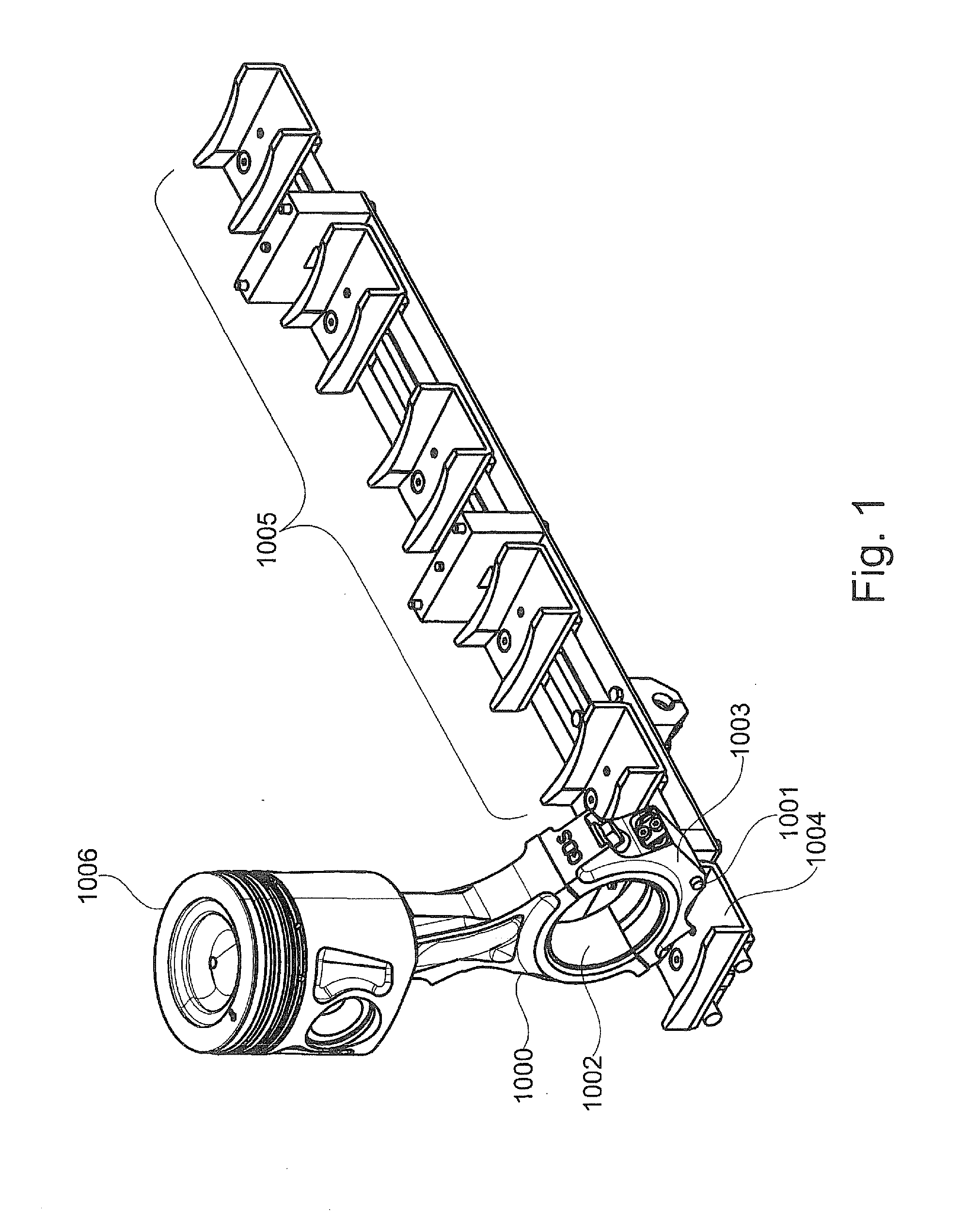

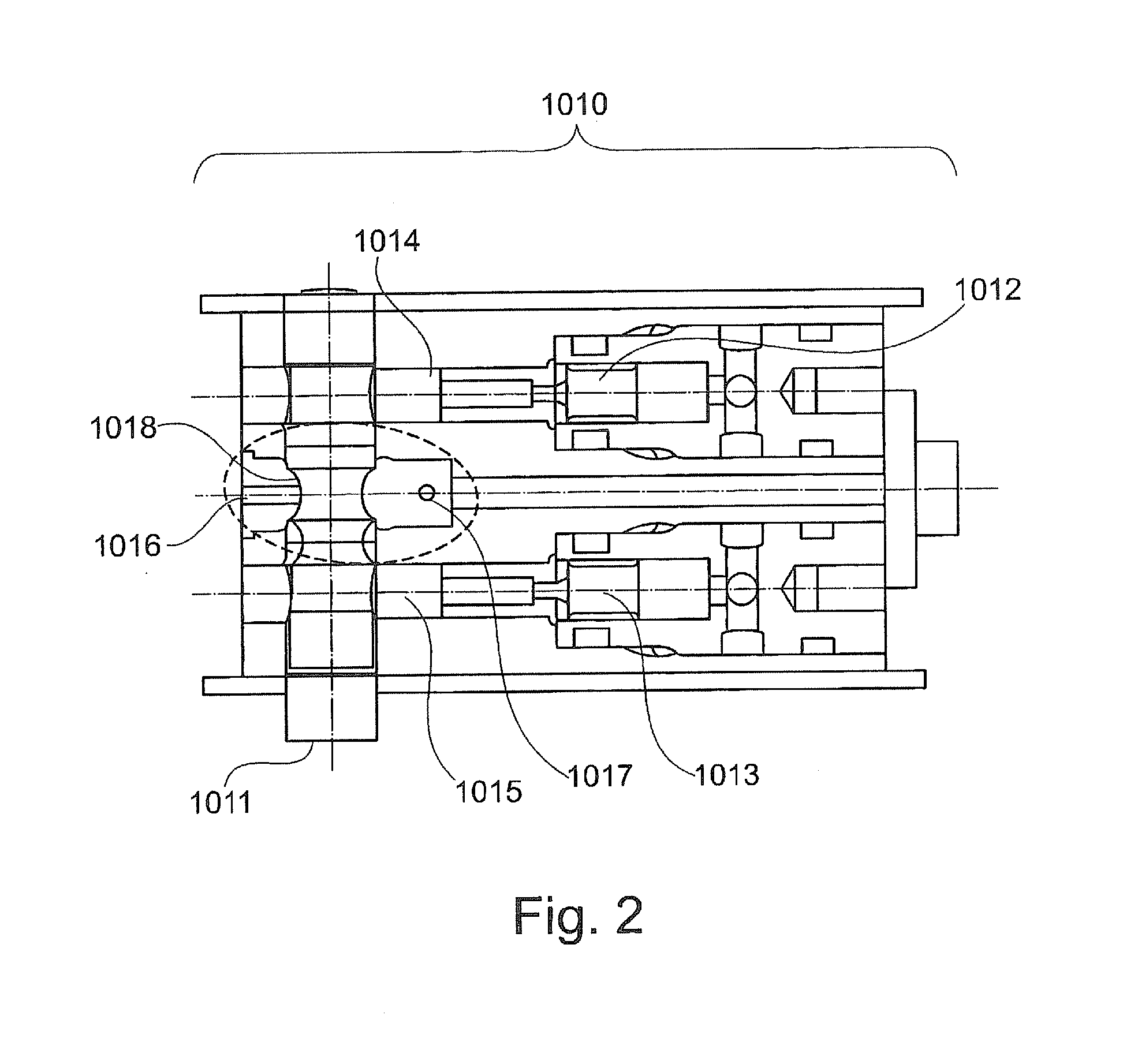

Actuating unit for variable power plant components

InactiveUS20150260109A1High strengthSimplify the assembly processMechanical controlConnecting rodsInternal combustion engineVariable length

The invention relates to a reciprocating-piston internal combustion engine with variable compression, having an actuating unit for changing a variable compression of the reciprocating-piston internal combustion engine, wherein, to change the variable compression, the actuating unit actuates a variable engine component of the reciprocating piston internal combustion engine in the form of a connecting rod with variable length, a piston with variable compression height and / or a crankshaft with variable crankshaft radius, and the actuating unit is arranged at a lower level than the reciprocating-piston internal combustion engine. Also proposed are a method and also an actuating unit for the same.

Owner:FEV

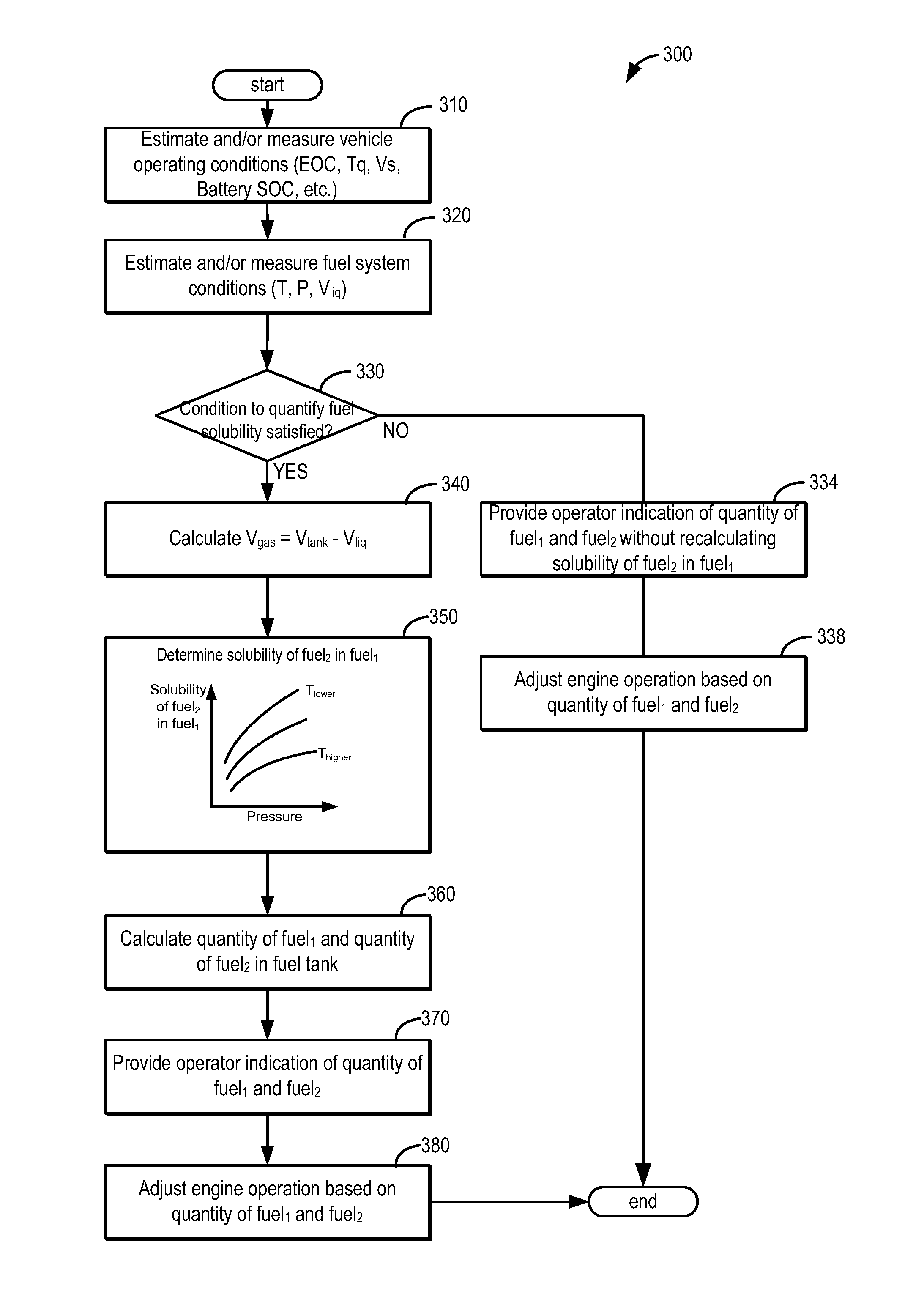

Systems and methods for determining amount of liquid and gaseous fuel

InactiveUS20150192450A1Emission reductionImprove fuel economyVehicle testingAnalogue computers for vehiclesSolubilityNuclear engineering

A method may comprise, on board a vehicle, identifying a volume of gaseous fuel in a tank based on a volume of liquid fuel in the tank, the liquid fuel comprising a first fuel and a second fuel, the gaseous fuel comprising essentially the second fuel, and identifying quantities of the first fuel and the second fuel in the tank based on a solubility of the second fuel in the first fuel.

Owner:FORD GLOBAL TECH LLC

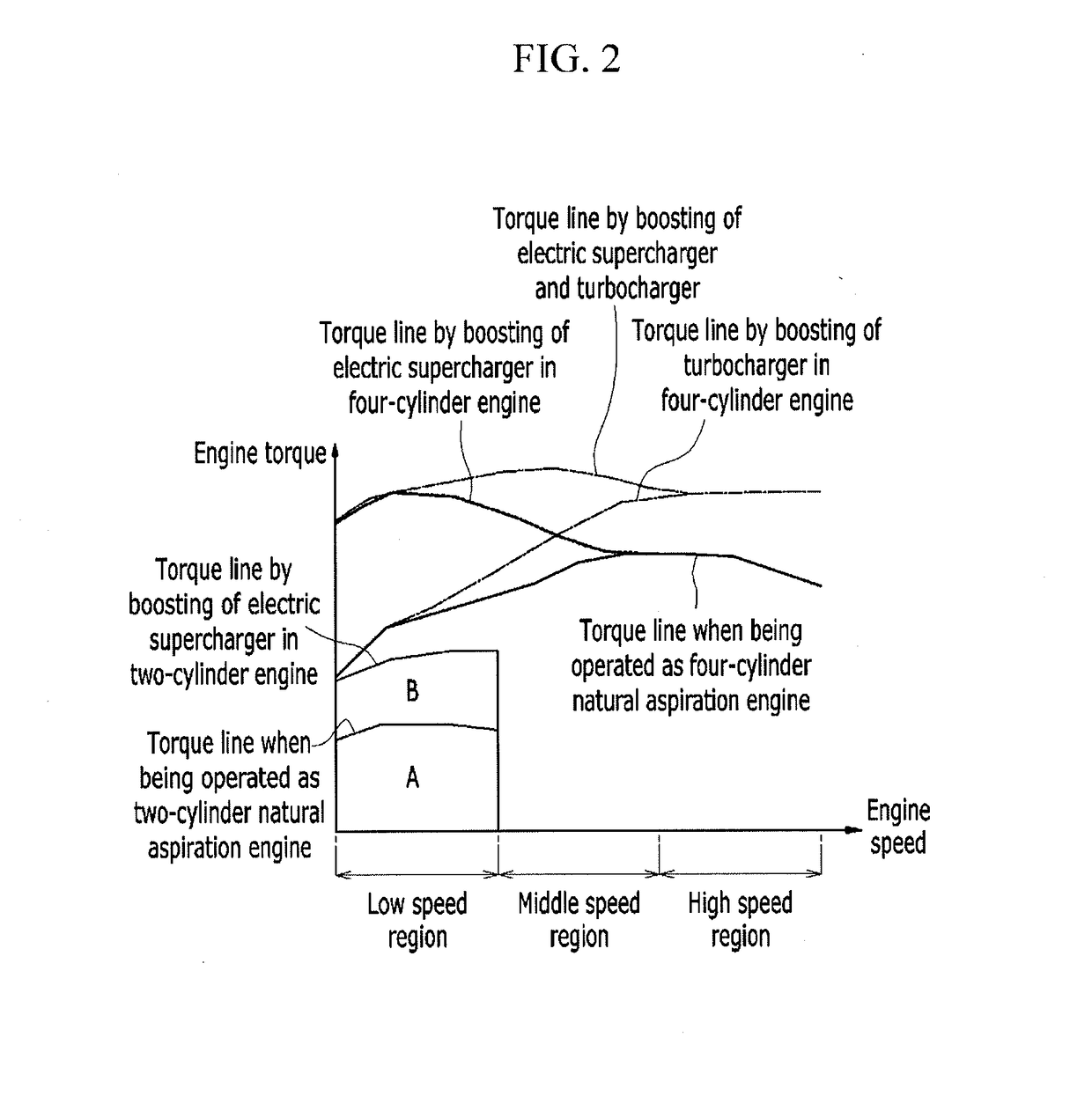

Engine system

ActiveUS20180030934A1Minimize recirculationMechanical controlElectrical controlCombustion chamberExhaust gas recirculation

An engine system may include an engine having an intake line flowing an intake gas supplied to the combustion chambers; an intake manifold; a throttle valve provided at a front of the intake manifold and controlling an air amount supplied to the combustion chamber; an electric supercharger provided at the throttle valve and including a motor and an electric compressor operated by the motor to supply the supercharged air to the combustion chamber; an exhaust gas processing device purifying an exhaust gas generated in the combustion chamber; and an exhaust gas recirculation device including a recirculation line branched from the downstream portion of the exhaust gas processing device and joined to the intake line of the upstream portion of the electric compressor, an EGR cooler mounted at the recirculation line, and an EGR valve mounted at a part where the recirculation line and the intake line are joined.

Owner:HYUNDAI MOTOR CO LTD

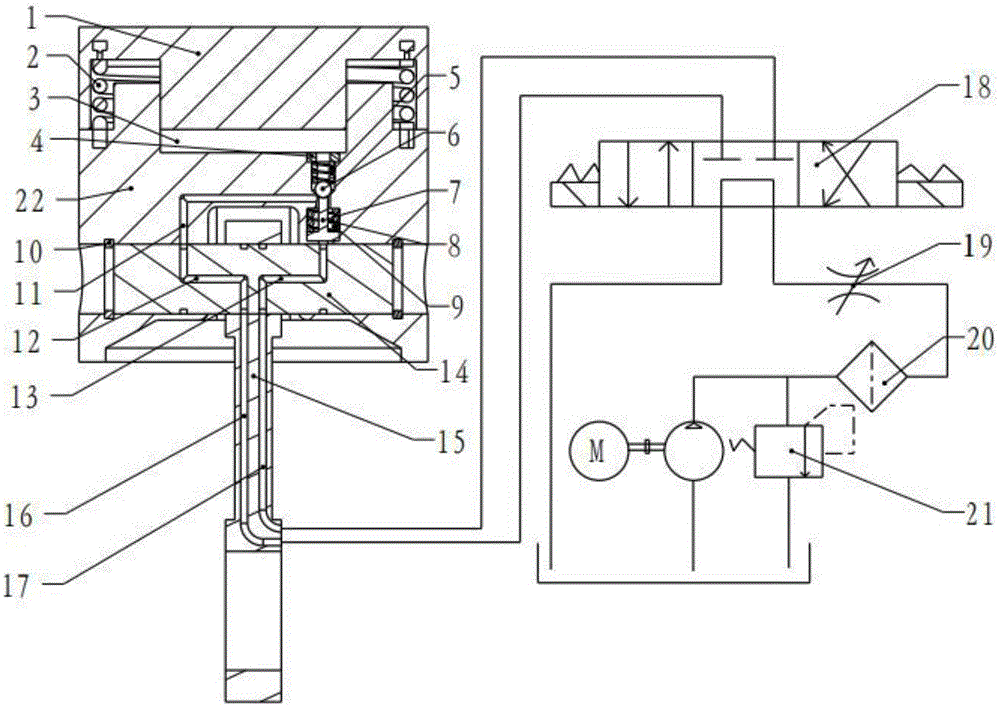

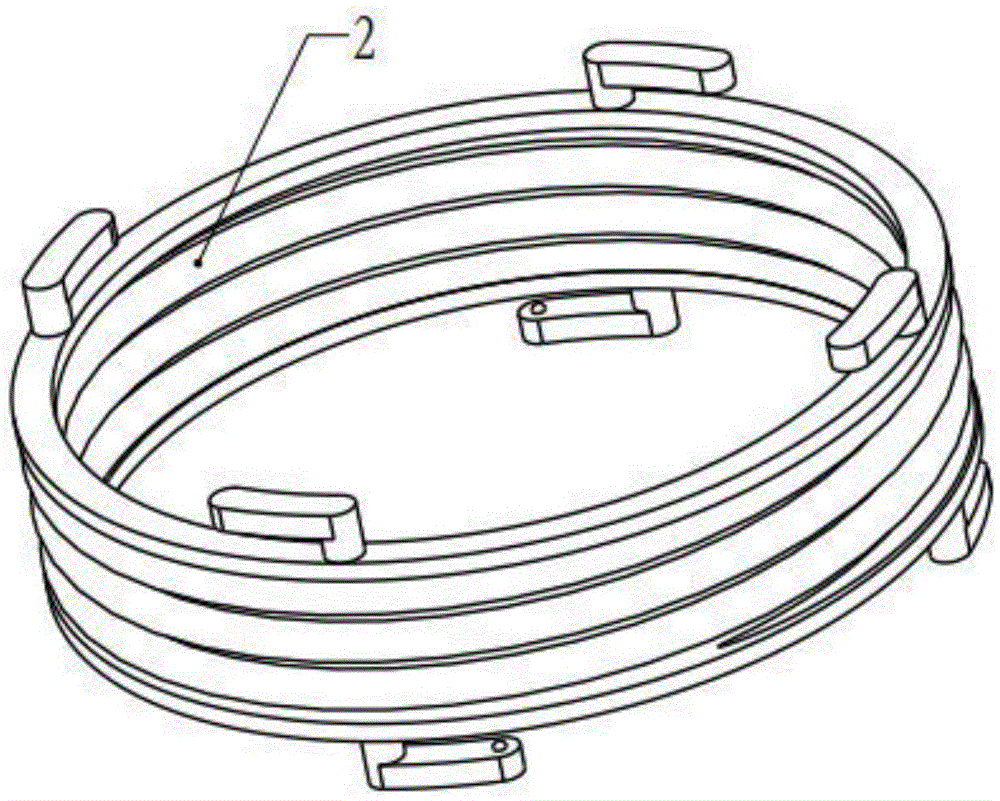

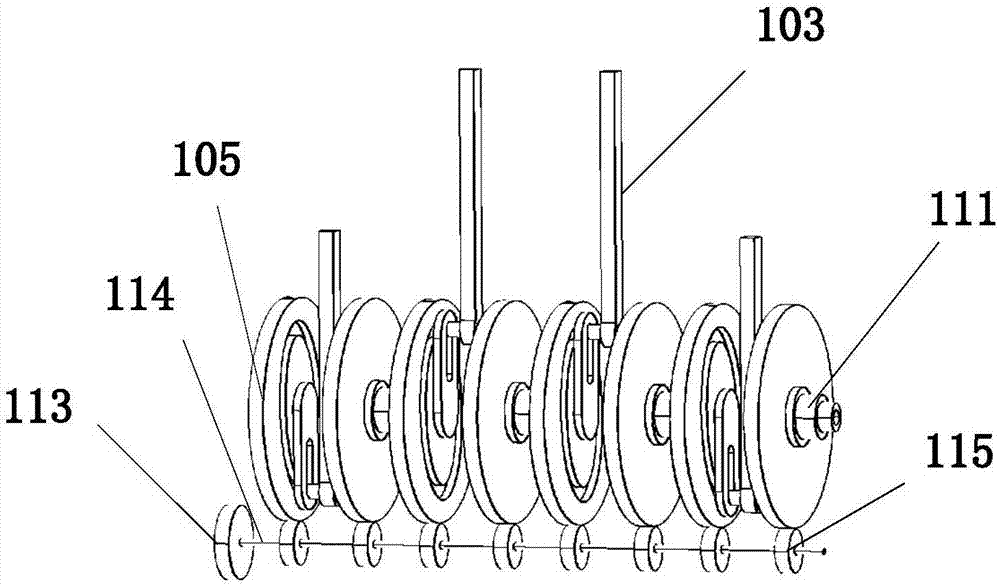

Hydraulic-drive type variable-compression-ratio piston connection rod assembly

InactiveCN105626258AChange the compression ratioWork reliablyMechanical controlConnecting rodsHydraulic pumpEngineering

The invention discloses a hydraulic-drive type variable-compression-ratio piston connection rod assembly in order to solve the problems that in the prior art, a mechanism is complex, abrasion is large and control precision is low. The hydraulic-drive type variable-compression-ratio piston connection rod assembly comprises a piston, an extension spring, a piston pin, a connection rod, a three-position four-way electromagnetic valve, a hydraulic pump, a one-way valve and other hydraulic elements. Engine oil is pumped out by the hydraulic pump, after the direction of the engine oil is changed through the three-position four-way electromagnetic valve, the engine oil sequentially flows in an oil way of the connection rod and an oil way of the piston pin, and finally a push rod ejects a small ball in the one-way valve so that the size of a main oil cavity is reduced and the compression ratio of an engine is reduced. By means of the mode that the pressure of the engine oil in the oil way on the lower portion of the piston is increased and the small ball of the one-way valve is ejected, the size of the main oil cavity is increased, and accordingly the compression ratio of the engine is increased. The compression ratio piston uses a hydraulic mechanism mode, is quick in response, high in precision and high in reliability, and meets requirements of the engine for dynamic performance and fuel economy under various working conditions.

Owner:JILIN UNIV

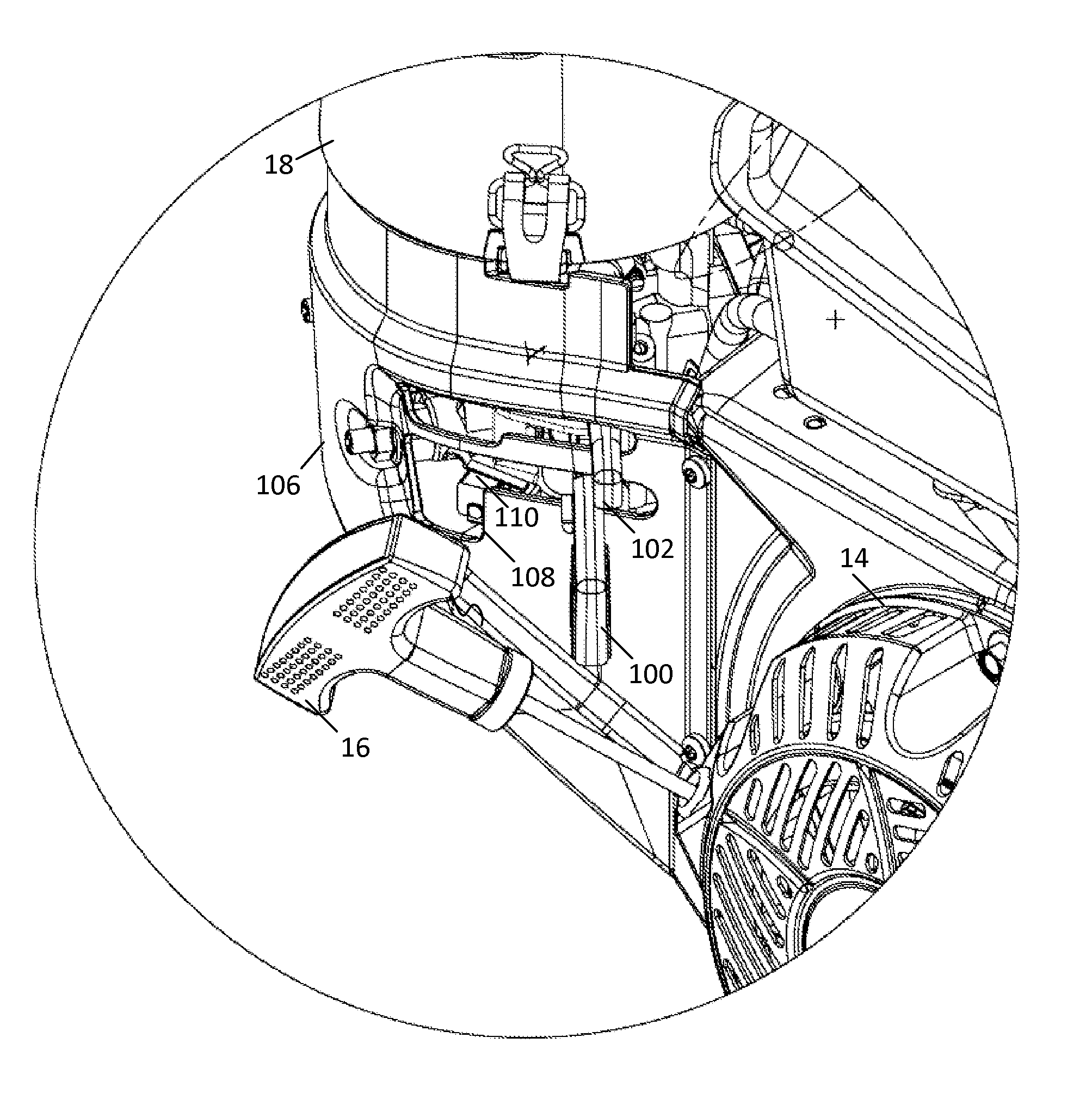

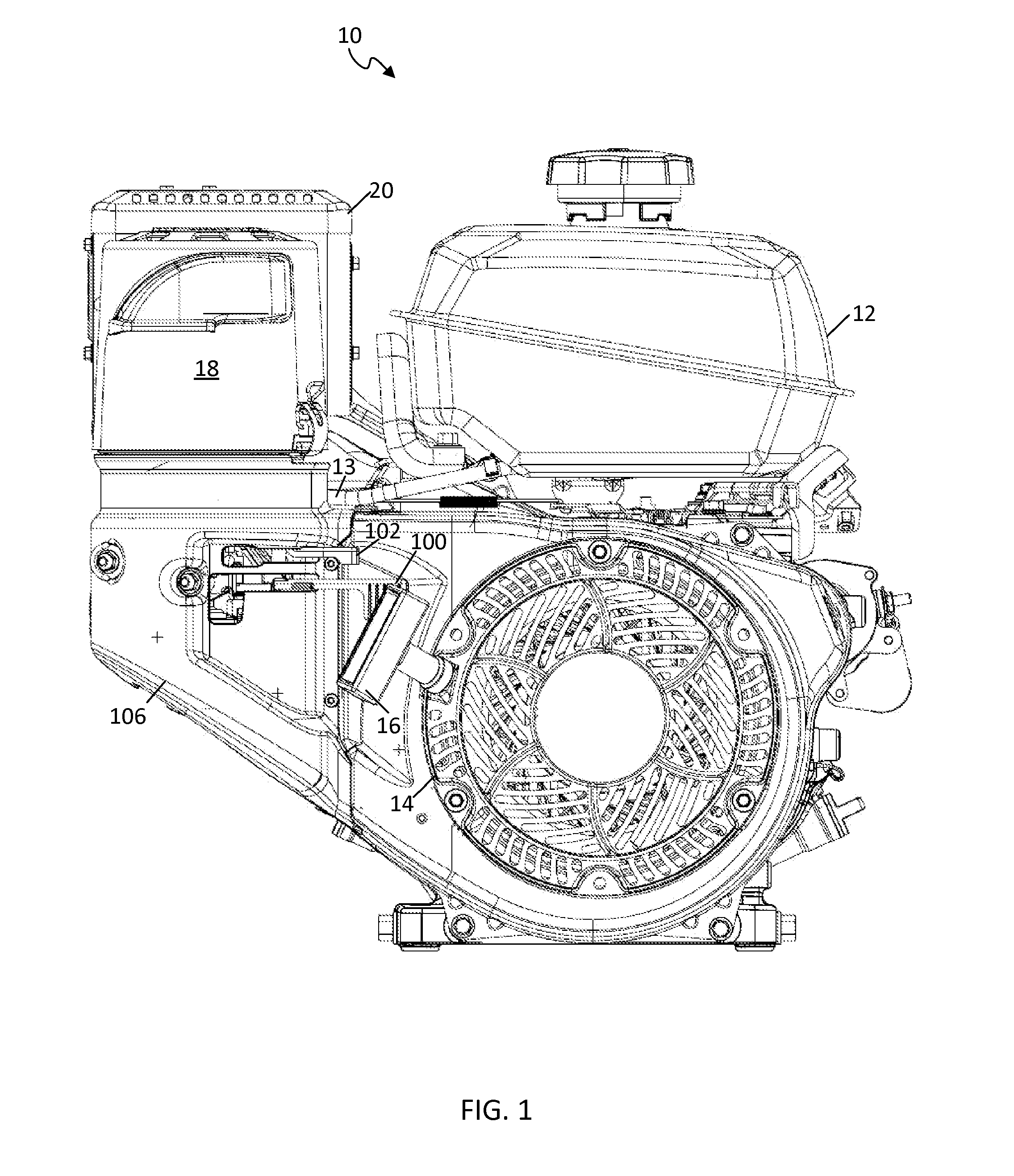

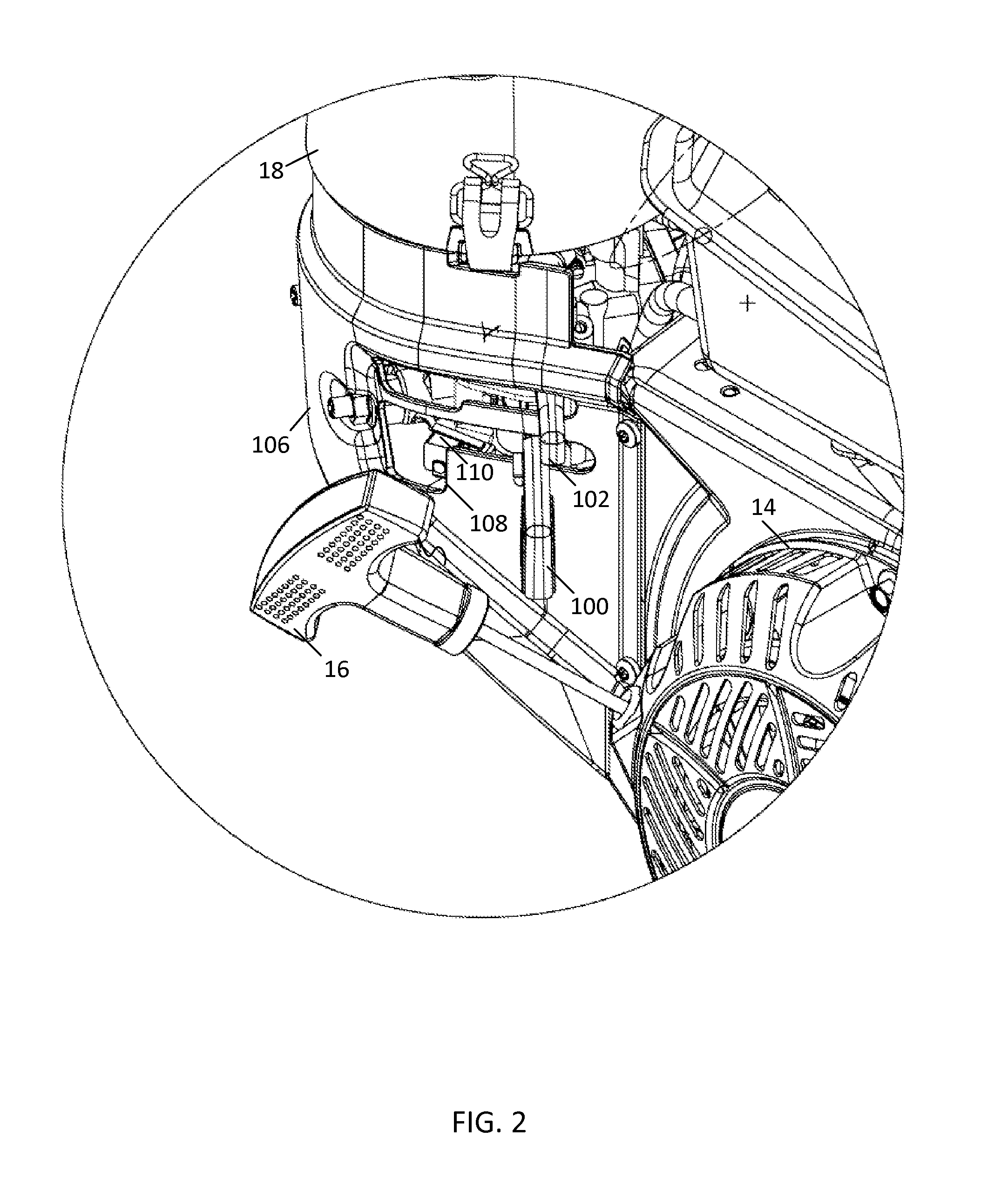

Automatic Fuel Shutoff

A combination lever for a carburetor is an integrated shutoff lever and fuel valve. The combination lever includes a longitudinal portion for a handle and a cylindrical portion including a fuel path for the fuel valve. A carburetor casing is shaped to form a valve chamber and a carburetor chamber. The valve chamber supports the cylindrical portion. A directional cavity formed in the cylindrical portion of the combination lever regulates a flow of fuel to the carburetor chamber according to a rotation of the combination lever. At one position the directional cavity opens the fuel path so that fuel flows into the carburetor chamber. At another position the directional cavity closes the fuel path so that the flow of fuel is blocked. The combination lever may also include an abutment portion to engage a switch for completing an electrical shutoff path to an engine coupled to the carburetor.

Owner:KOHLER CO

Exhaust throttling for cabin heating

ActiveUS9404409B2Reduce energy useImprove fuel economyMechanical controlElectrical controlExhaust gas recirculationHeating system

Embodiments for heating a vehicle cabin are disclosed. In one example, a method for heating a vehicle cabin comprises closing an exhaust throttle while diverting at least a portion of throttled exhaust gas through an exhaust gas recirculation (EGR) cooler coupled upstream of the throttle, and transferring heat from the EGR cooler to a heater core configured to provide heat to the vehicle cabin. In this way, exhaust heat may be directly routed to the cabin heating system.

Owner:FORD GLOBAL TECH LLC

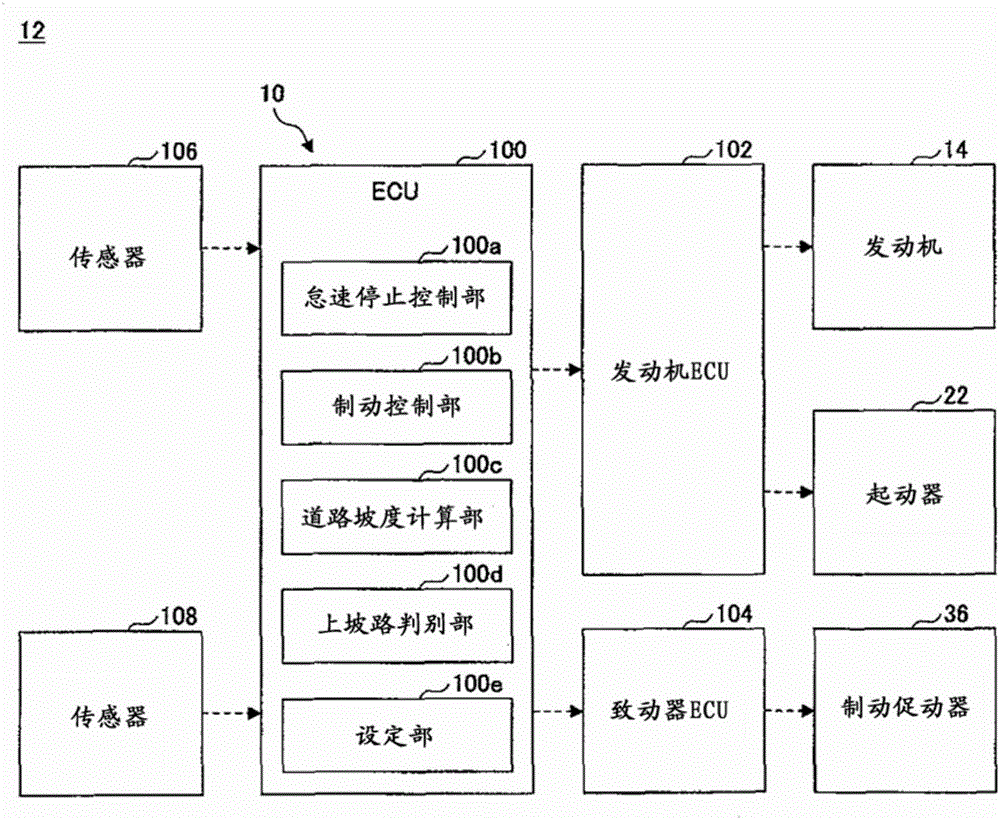

Vehicle control apparatus

InactiveCN106285973APrevent slidingMechanical controlElectric motor startersVehicle controlBrake control

The invention relates to a vehicle control apparatus. It is possible to suppress the downward movement of the vehicle on the uphill road when the engine is automatically stopped based on the idling stop control and the braking operation is released and the engine is restarted. The vehicle control apparatus includes a vehicle speed detection part, an idle stopping control part for making the engine automatically stop if the engine stopping condition including braking operation and a vehicle speed being less than or equal to a first speed is satisfied and making the engine automatically start if a condition is satisfied, including a condition that, after the engine is automatically stopped, a braking stopping operation is performed; and an uphill road determination part determining that the vehicle is on an upslope; and a brake control part automatically generating a braking force if it is determined that the vehicle is on an upslope, during a period from when the engine starting condition is satisfied to the engine starting is completed as a result of the braking stopping operation before the vehicle is stopped after the engine is automatically stopped.

Owner:TOYOTA JIDOSHA KK

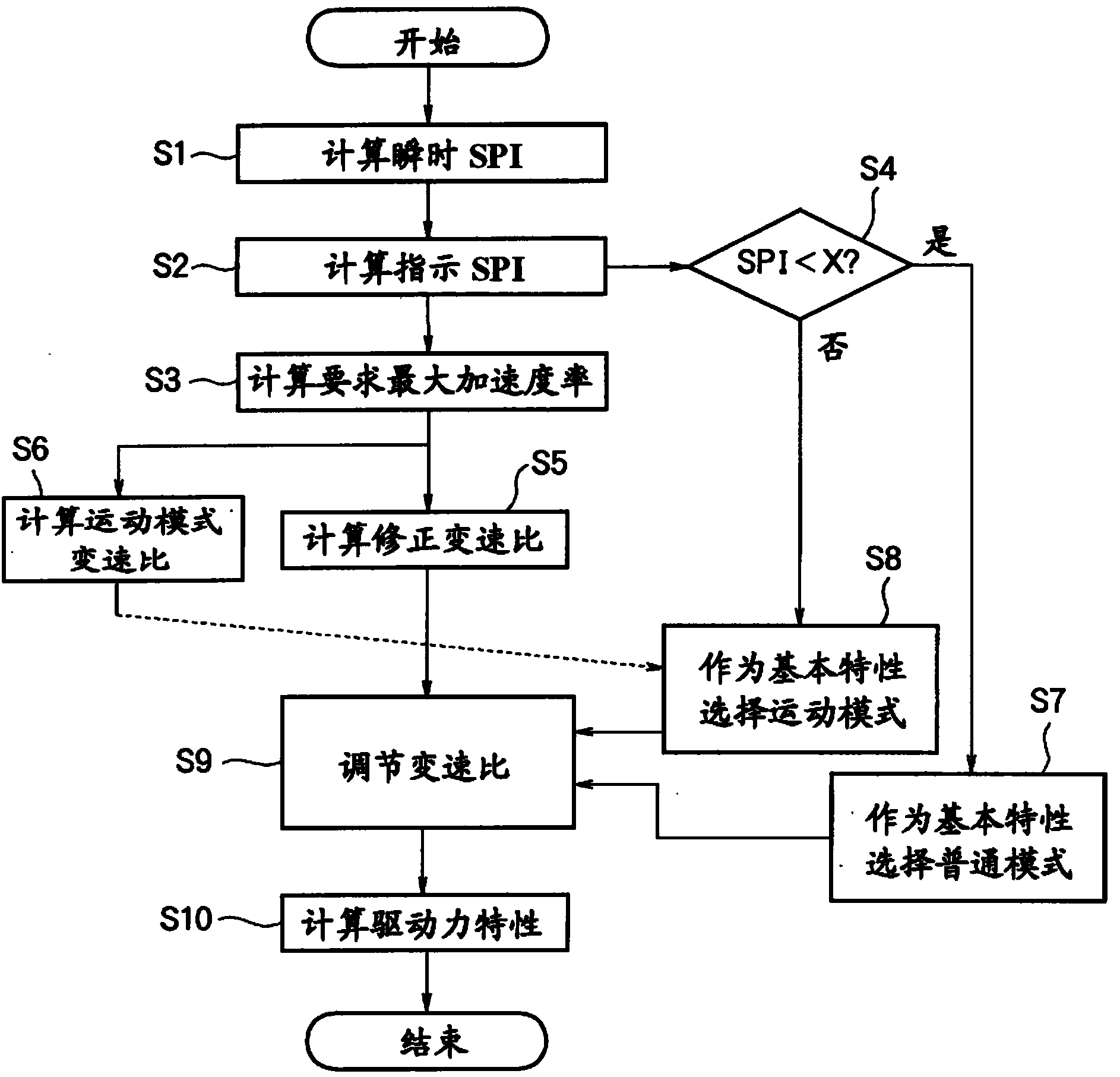

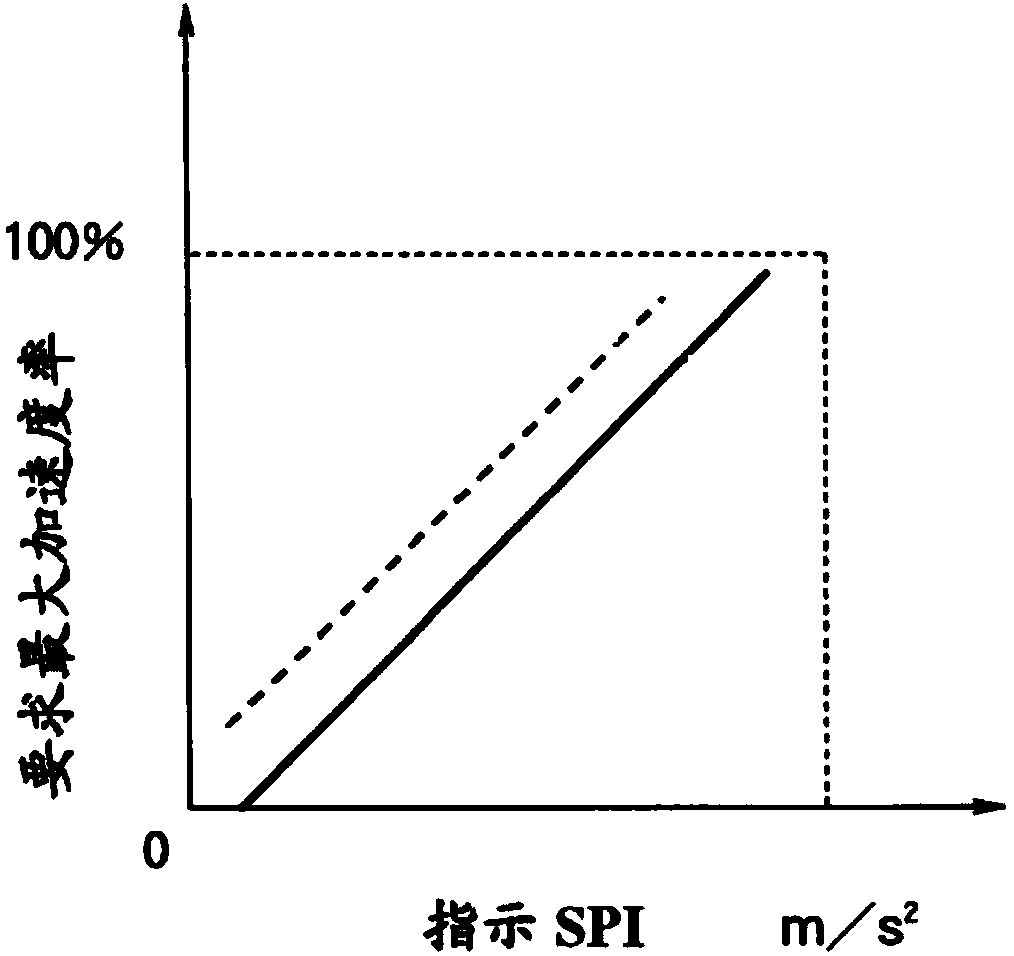

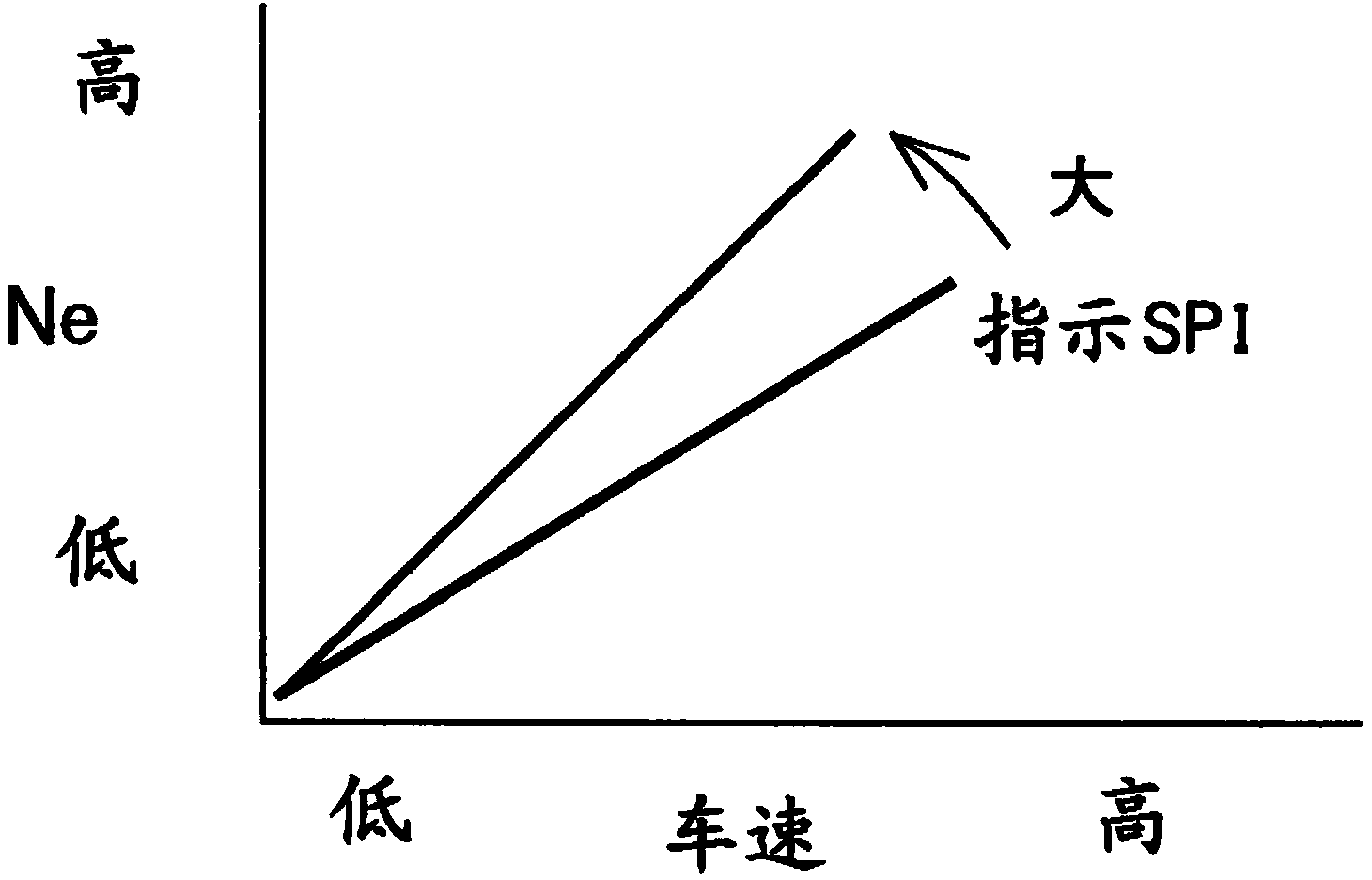

Vehicle drive force control apparatus

InactiveCN103826950AIncrease speedDriving comfortHybrid vehiclesMechanical controlFuel efficiencyLimit value

A vehicle drive force control apparatus is provided with a mechanism for continuously varying the rotation speed of an engine and with basic control characteristics for controlling the mechanism such that the engine rotation speed becomes a rotation speed with good fuel efficiency. An index that indicates a request for sharper behavior of the vehicle is determined on the basis of the actual behavior of the vehicle or the amount of an operation for causing such behavior by the driver. An upper limit value for the engine rotation speed in the case where a drive request amount is increased is set in accordance with the index. The upper limit value is increased as the value of the index is such that the sharpness of the behavior of the vehicle is increased.

Owner:TOYOTA JIDOSHA KK

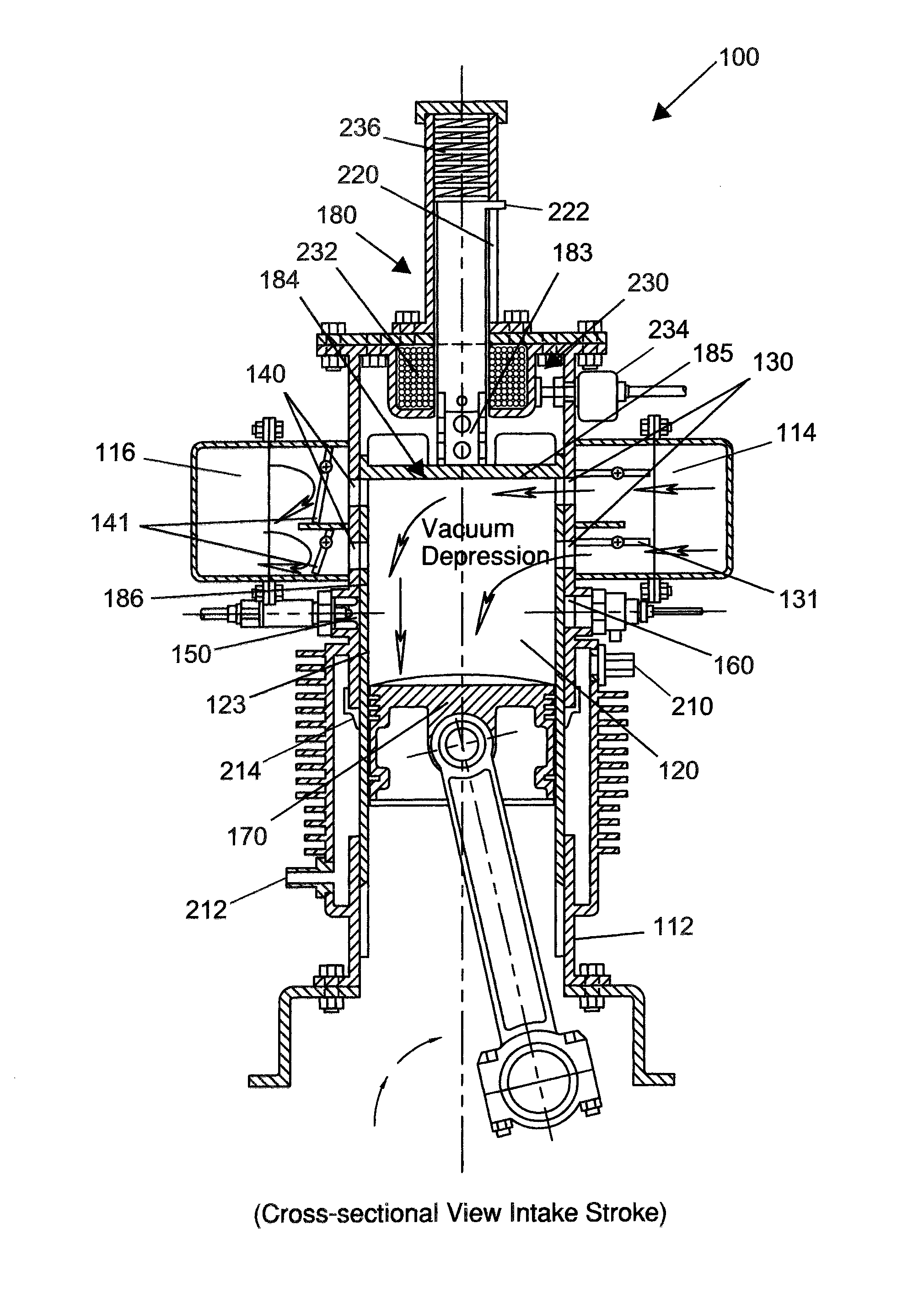

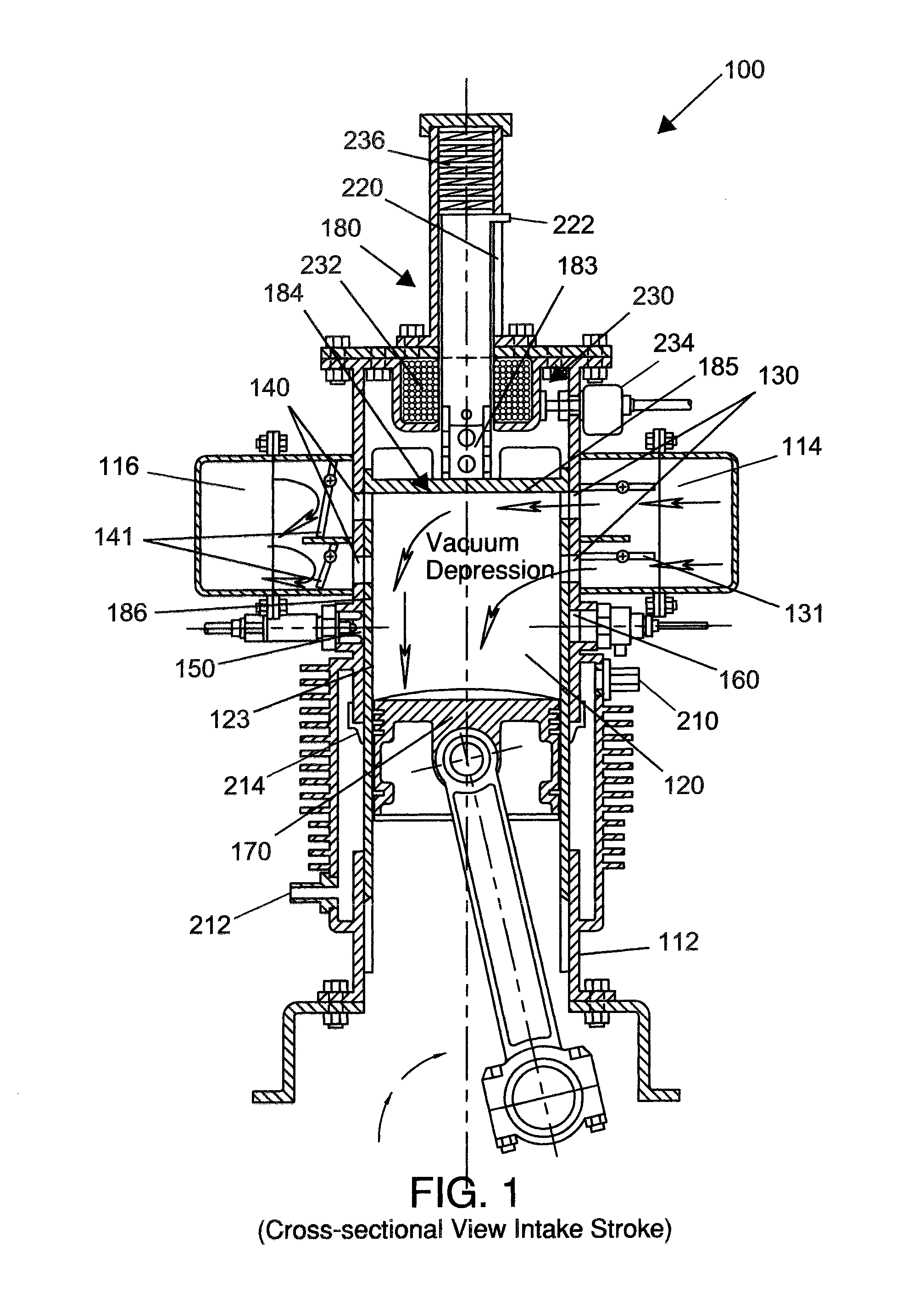

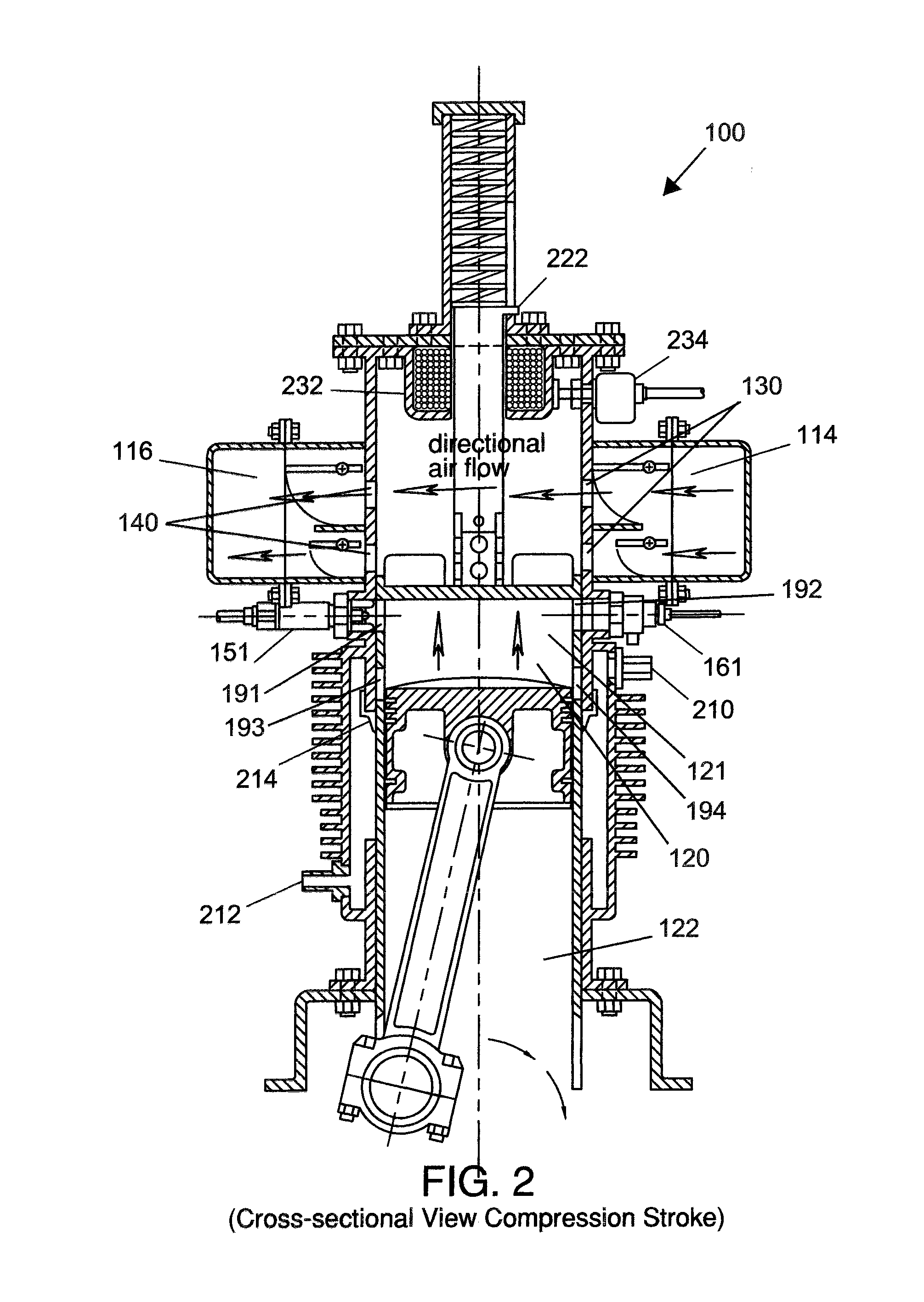

Variable volume combustion chamber system

InactiveUS9239003B1Mechanical controlInternal combustion piston enginesExternal combustion engineEngineering

A variable volume combustion chamber system for a four-cycle internal combustion engine features an engine having a cylindrical combustion chamber inside. An intake port and an exhaust port are located on a chamber side wall. An ignition plug port and a tangentially-mounted fuel injection port are also located on the chamber side wall. A cylindrical piston is pivotally located on a connecting rod in the combustion chamber. The system features an adjustable volume head assembly located on a chamber top featuring a solenoid connected to a cylindrical head and sleeve component via a positioning shaft. The cylindrical head and sleeve component adjustably extends through the chamber top into the combustion chamber and is movable via actuation of the solenoid.

Owner:MANKE DONALD W

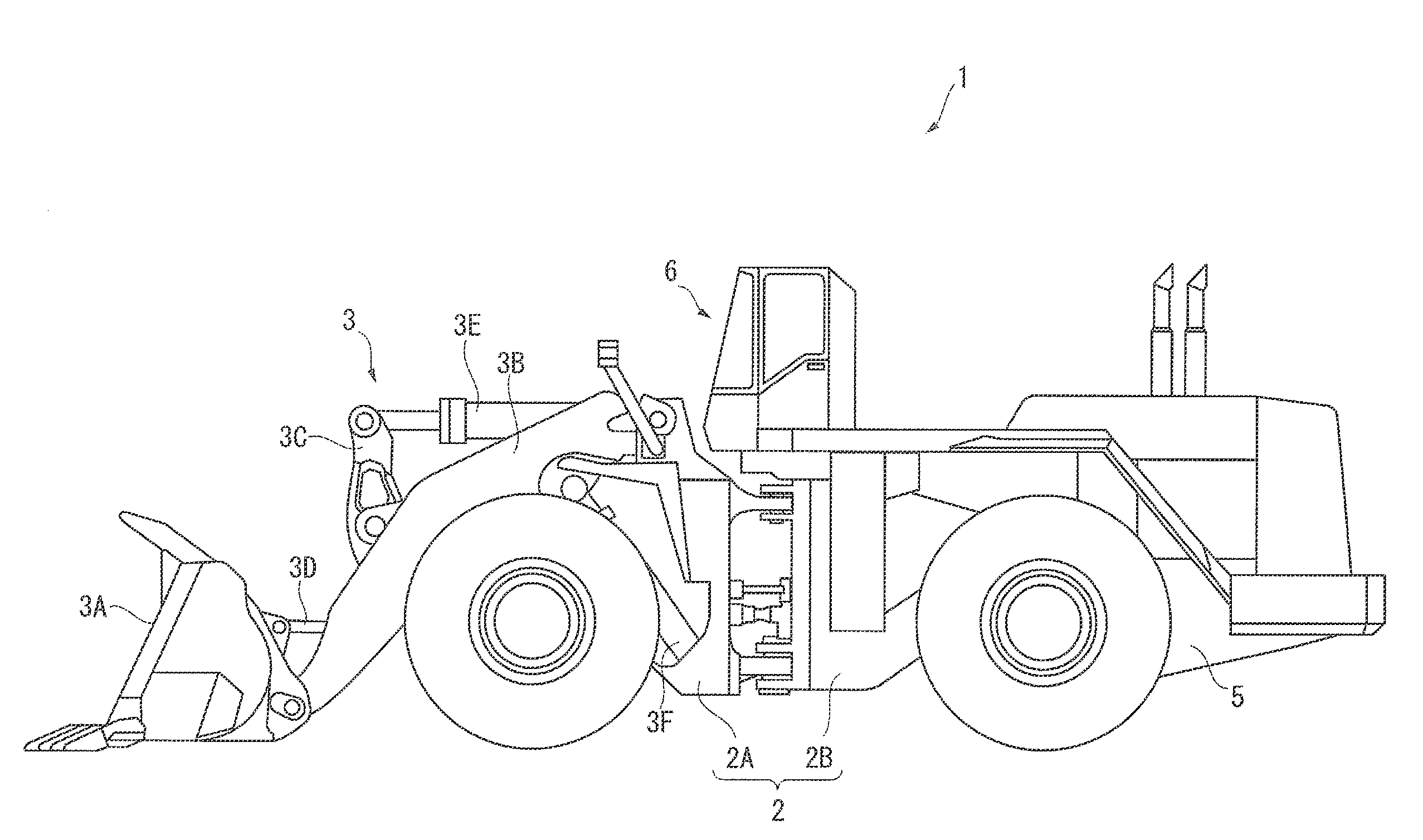

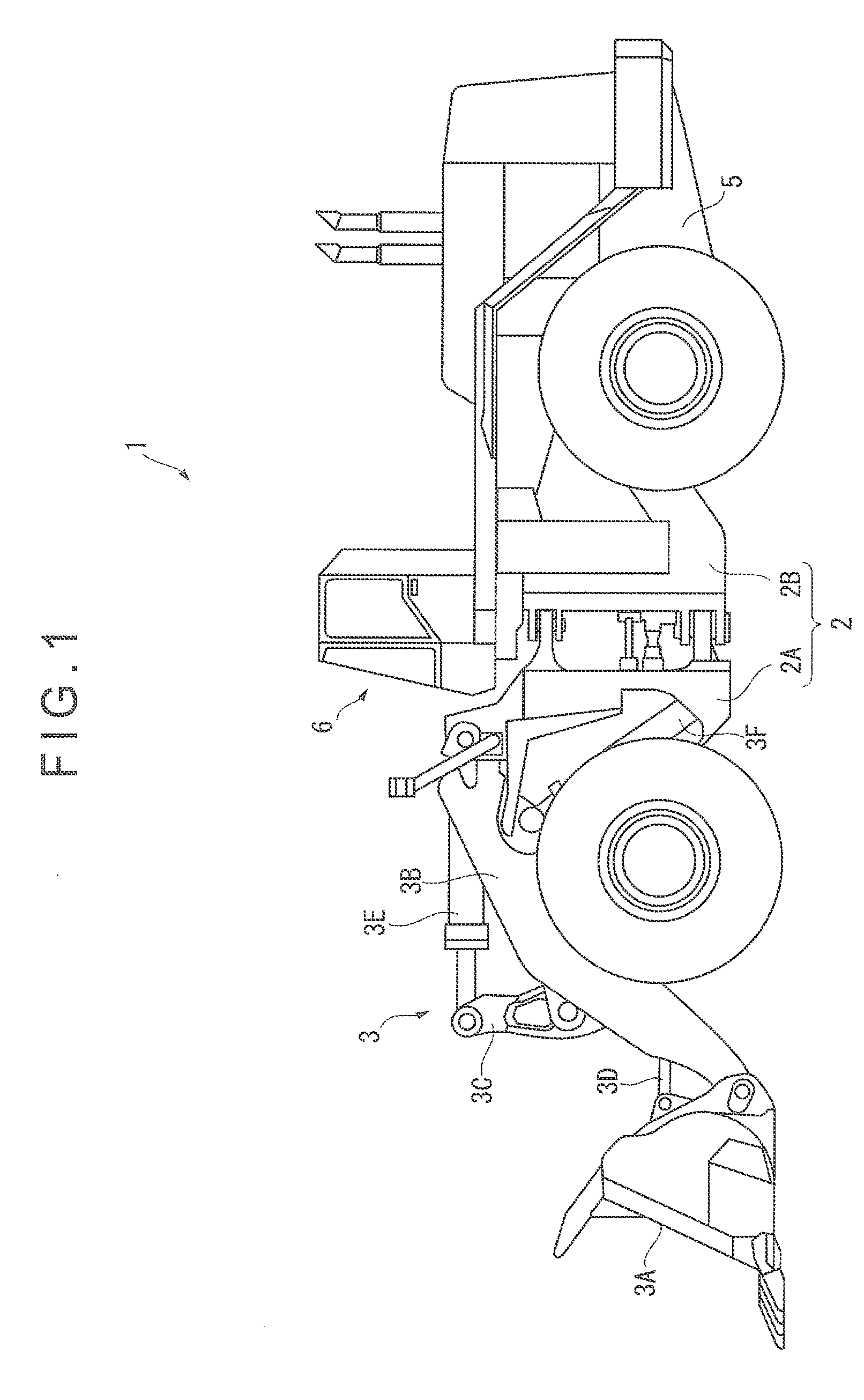

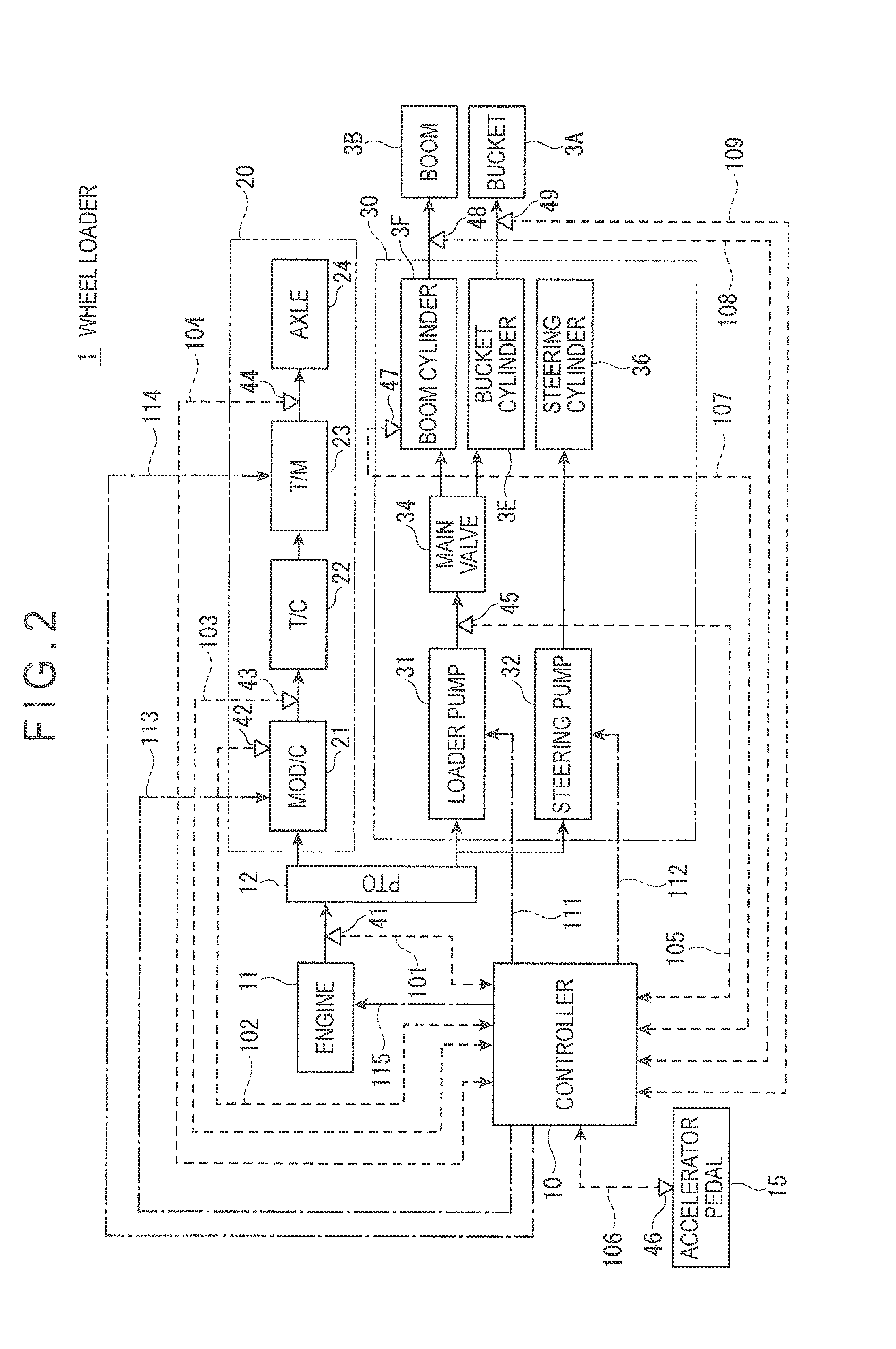

Wheel Loader and Wheel Loader Engine Control Method

A wheel loader includes detectors and a controller. The detectors include at least an accelerator pedal angle detector that detects an accelerator displacement. The controller includes: a state judging unit that judges from a detection result provided by the detectors whether or not the wheel loader is in an excavation operation; and a torque-curve selector. The torque-curve selector selects one excavation torque curve when the wheel loader is judged to be in the excavation operation by the state judging unit, and selects one of two or more non-excavation torque curves depending on the accelerator displacement when the wheel loader is judged not to be in the excavation operation.

Owner:KOMATSU LTD

Engine with compression ratio capable of being changed

ActiveCN106958488AAdapt to power needsAchieve Variable Compression RatioMechanical controlMachines/enginesCircular discCrank

The invention discloses an engine with a compression ratio capable of being changed. The engine comprises a crank case, multiple sets of changeable crankshaft and a crankshaft arm adjusting device, and the crankshaft arm adjusting device comprises a rotating shaft and multiple gears, wherein the rotating shaft is rotatably supported in the crank case, one end of the rotating shaft is provided with a locking device, the gears are fixedly arranged on the rotating shaft, and the gears are meshed with disc gears and can drive the disc gears to rotate; that is to say, the length of a crankshaft arm of the engine can be changed, the compression ratio of the engine can be changed by changing the length of the crankshaft arm, and therefore power performance and economical efficiency of the engine are effectively improved.

Owner:JILIN UNIV

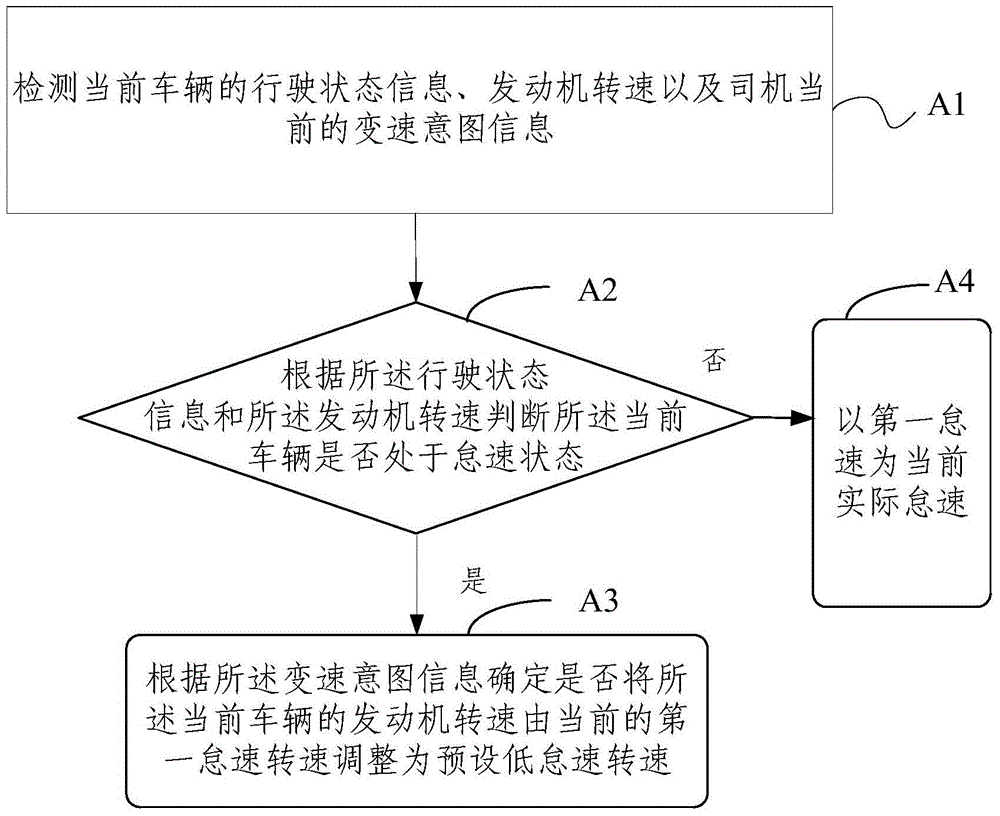

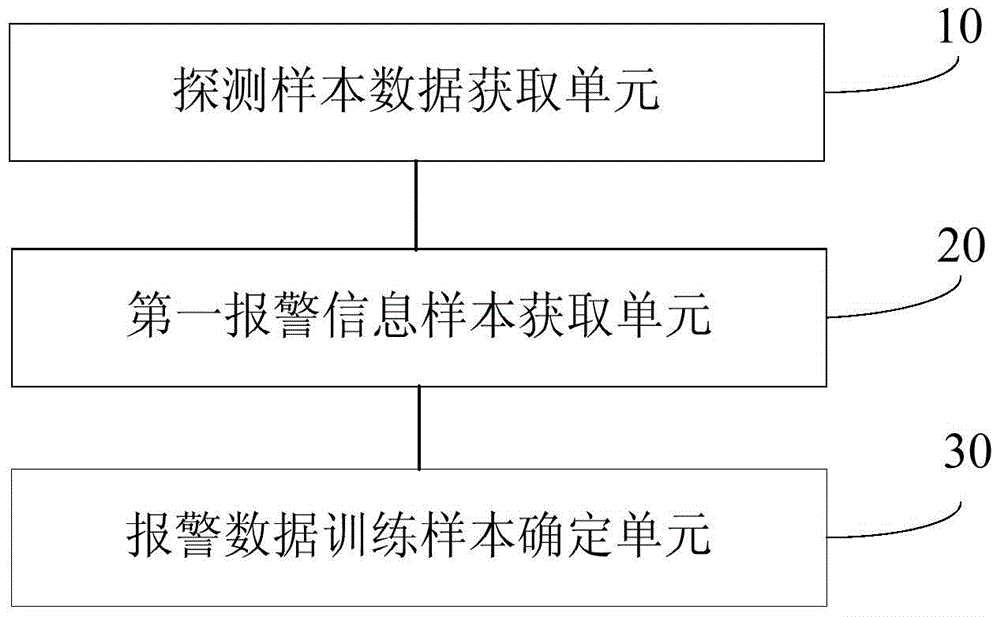

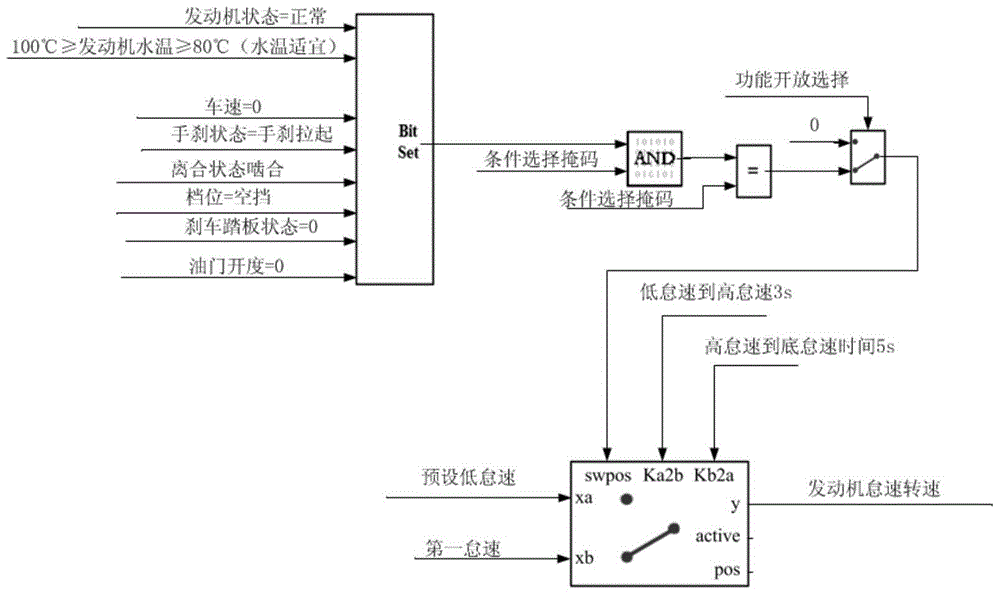

Engine idle speed reduction oil saving method and device

InactiveCN105673224AThere will be no problem of degraded experiencePlay the role of energy saving and emission reductionMechanical controlElectrical controlIdle speedEngineering

The invention relates to an engine idle speed reduction oil saving method and device. The method comprises the steps that driving state information of a current vehicle, the rotation speed of an engine and current speed changing intention information of a driver are detected; whether the current vehicle is in an idle speed state or not is judged according to the driving state information and the rotation speed of the engine; and if yes, whether the rotation speed of the engine of the current vehicle is adjusted from the current first idle speed to a preset low idle speed or not is determined according to the speed changing intention information. The scheme can be achieved only by an electric control system of the engine, the production cost of the engine does not need to be additionally increased, the problem that as the starting performance of the vehicle is reduced, the user experience is reduced is avoided, and the functions of energy conservation and emission reduction can be achieved.

Owner:WEICHAI POWER CO LTD

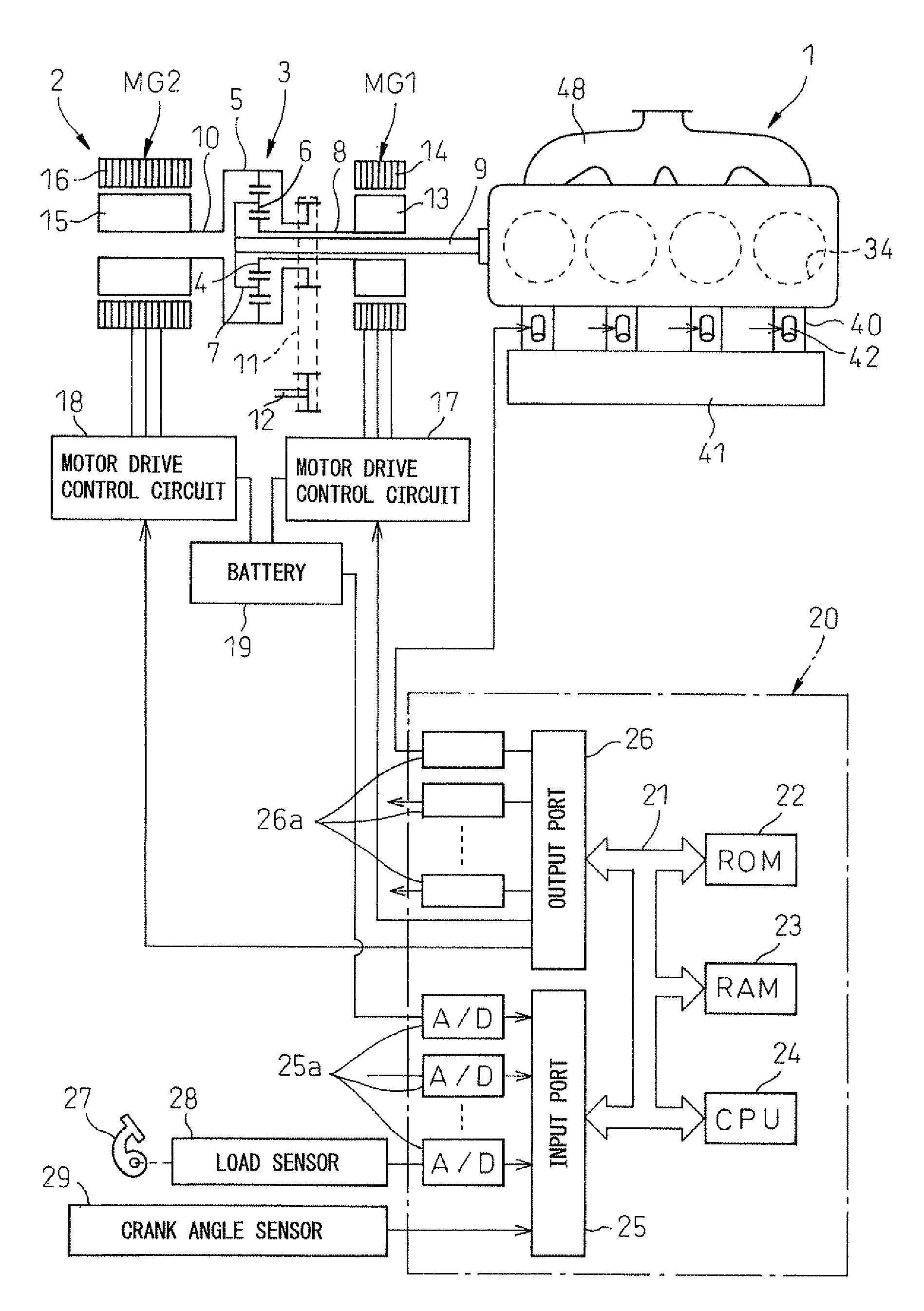

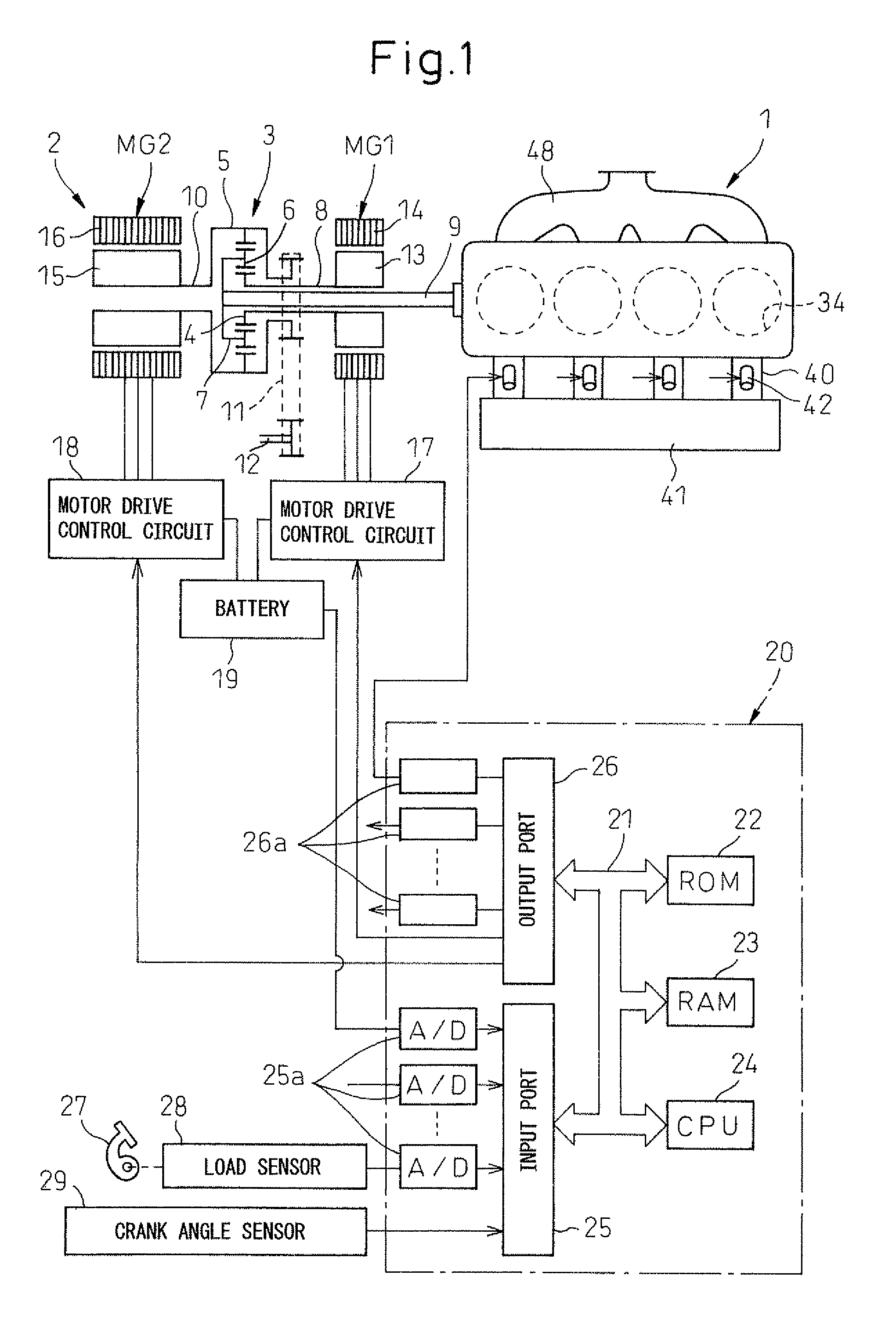

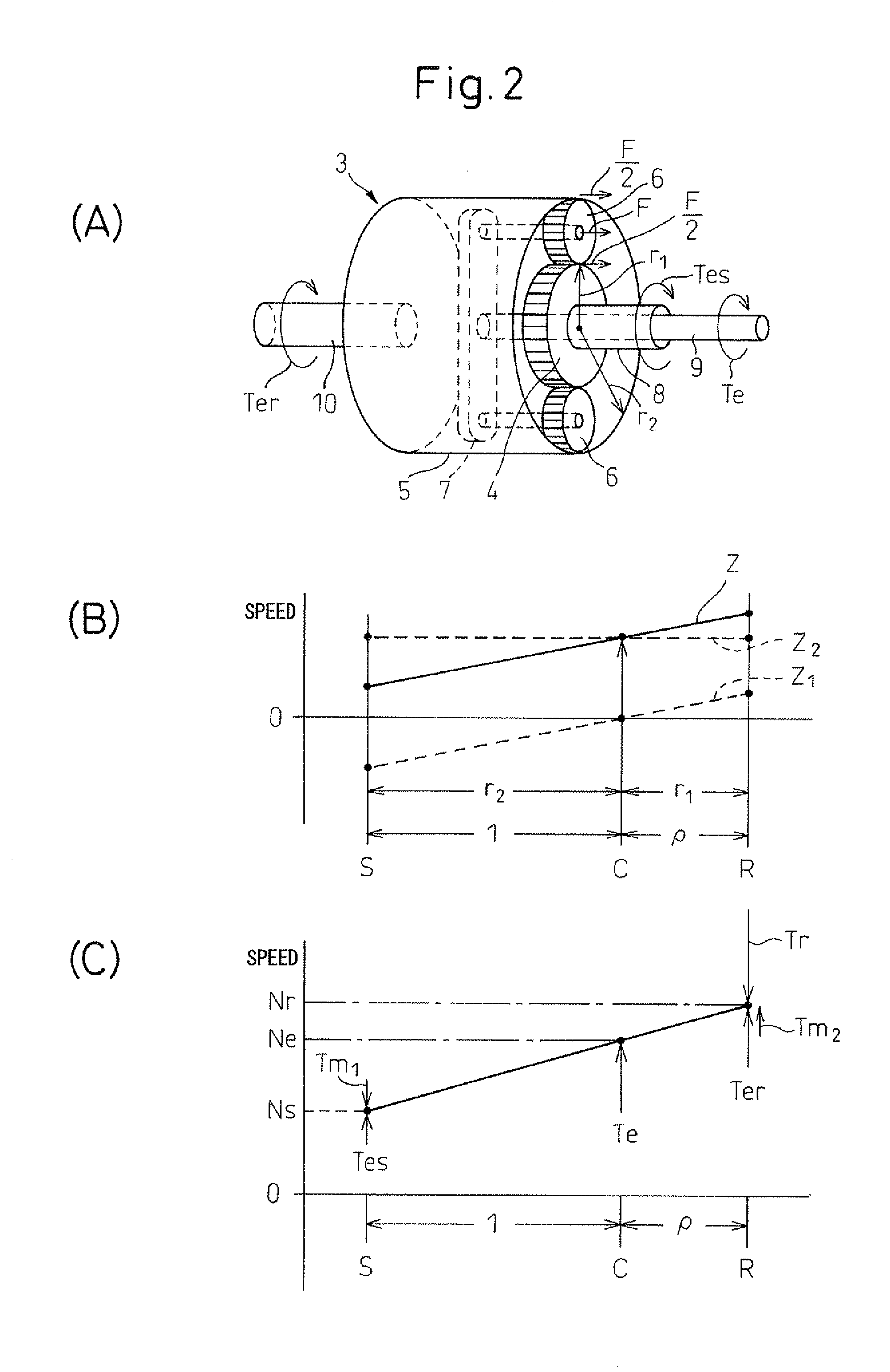

Engine control system

InactiveUS20120059543A1Improve efficiencyHybrid vehiclesAnalogue computers for vehiclesHybrid typeVariable valve timing

A hybrid type vehicle designed to use an engine and motor generators to drive the vehicle, wherein the engine is provided with a variable compression ratio mechanism and a variable valve timing mechanism. When the vehicle is backing up, one motor generator is used to generate an output for vehicle drive use. If the engine is made to operate at this time, the engine torque and the engine speed are made to change along a minimum fuel consumption rate operation line.

Owner:TOYOTA JIDOSHA KK

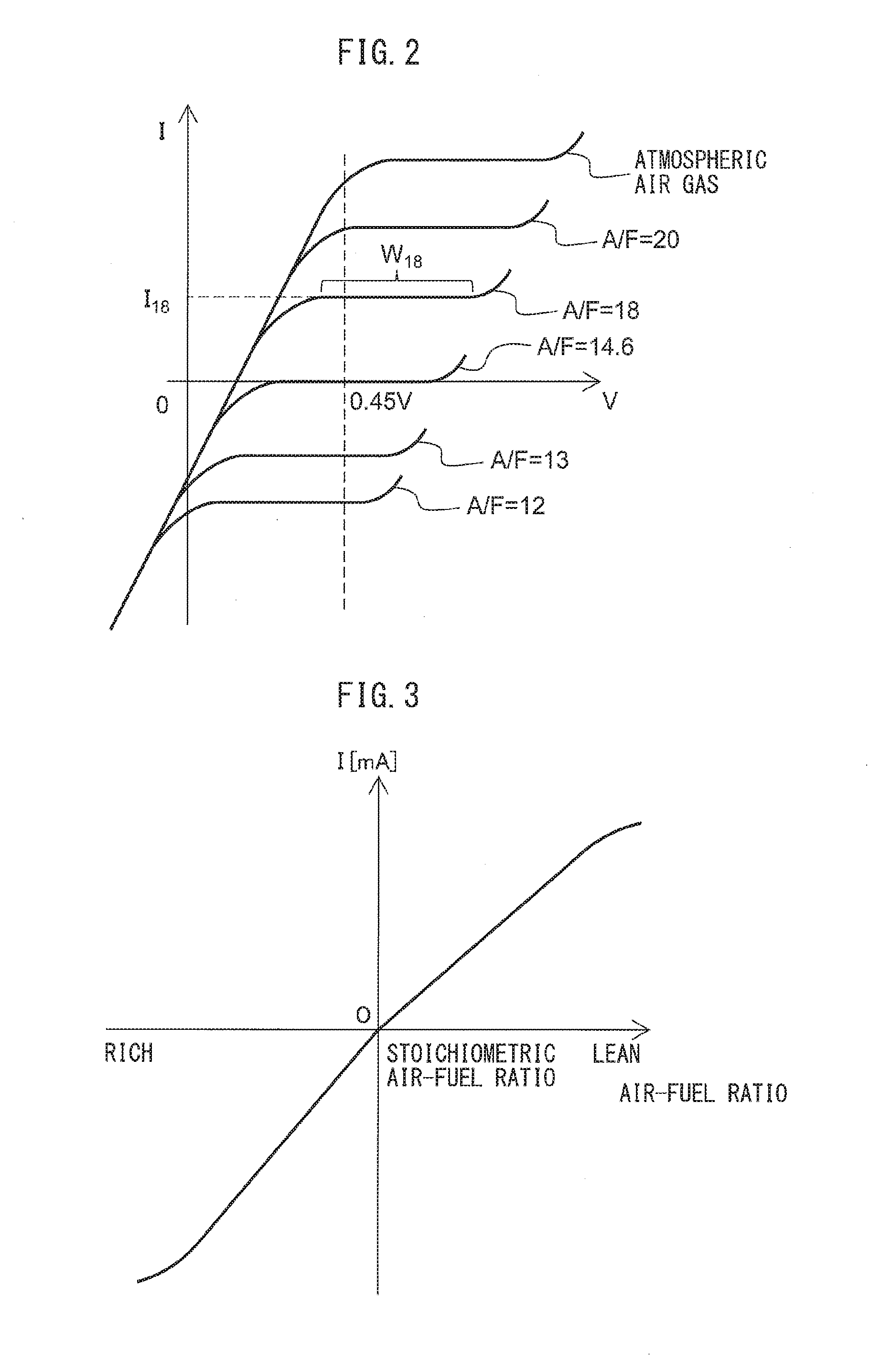

Exhaust purification system of internal combustion engine

InactiveUS20160265465A1Compensation deviationEasy to slipMechanical controlElectrical controlEngineeringOxygen

The exhaust purification system comprises an exhaust purification catalyst, downstream side air-fuel ratio sensor, and control device. The control device performs average air-fuel ratio control which alternately sets a target average air-fuel ratio between a rich air-fuel ratio and a lean air-fuel ratio and inter-cylinder air-fuel ratio control which controls the target air-fuel ratios of the cylinders so that the target air-fuel ratio becomes the rich air-fuel ratio at least at one cylinder among the plurality of cylinders even if the target average air-fuel ratio is set to the lean air-fuel ratio. The control device uses a cumulative value of a first oxygen amount from when switching the target average air-fuel ratio to the lean air-fuel ratio to when again switching it to the rich air-fuel ratio and a cumulative value of a second oxygen amount from when switching the target average air-fuel ratio to the rich air-fuel ratio to when again switching it to the lean air-fuel ratio as the basis for correcting a parameter relating to the air-fuel ratio so that the difference of these becomes smaller as learning control.

Owner:TOYOTA JIDOSHA KK

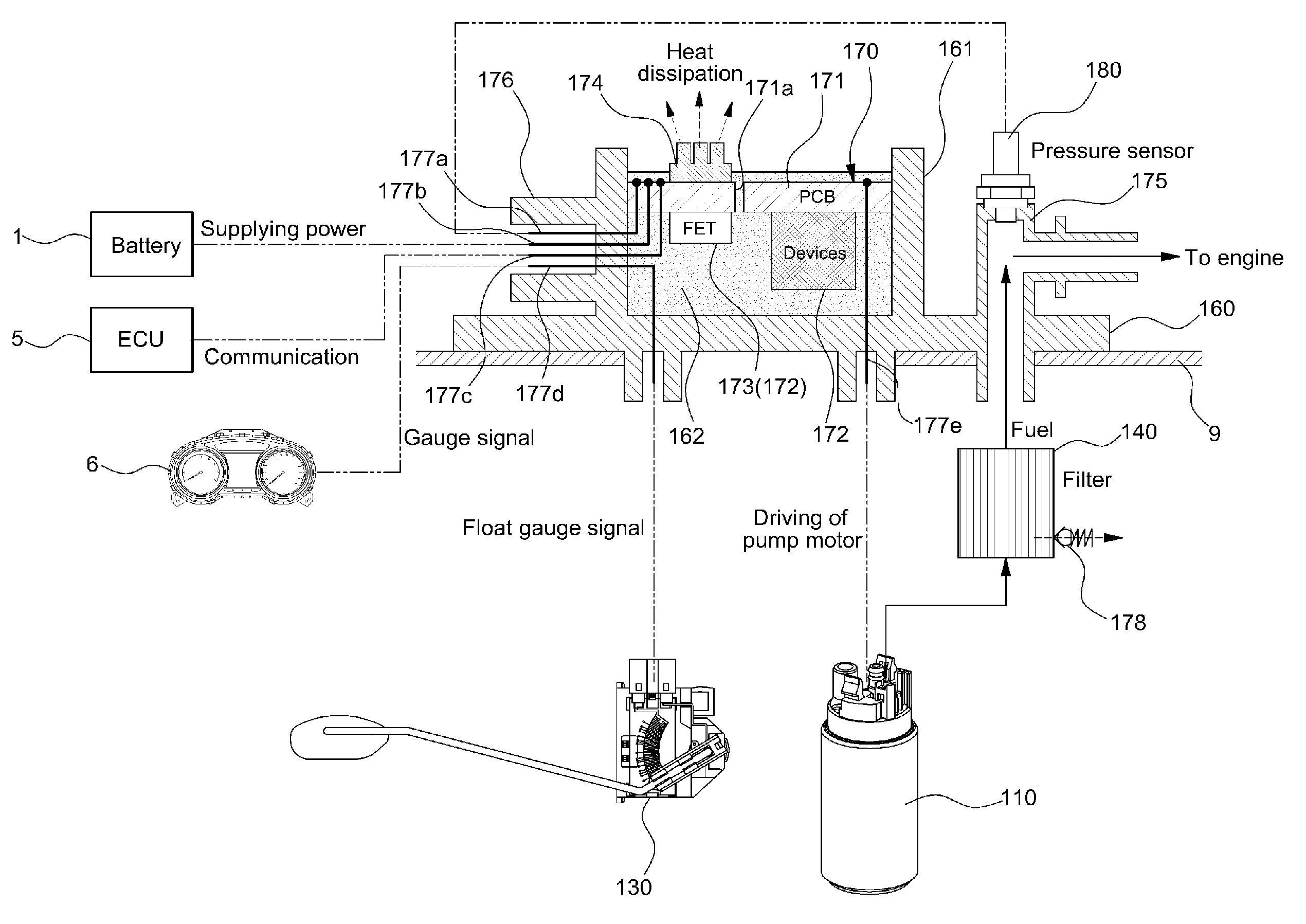

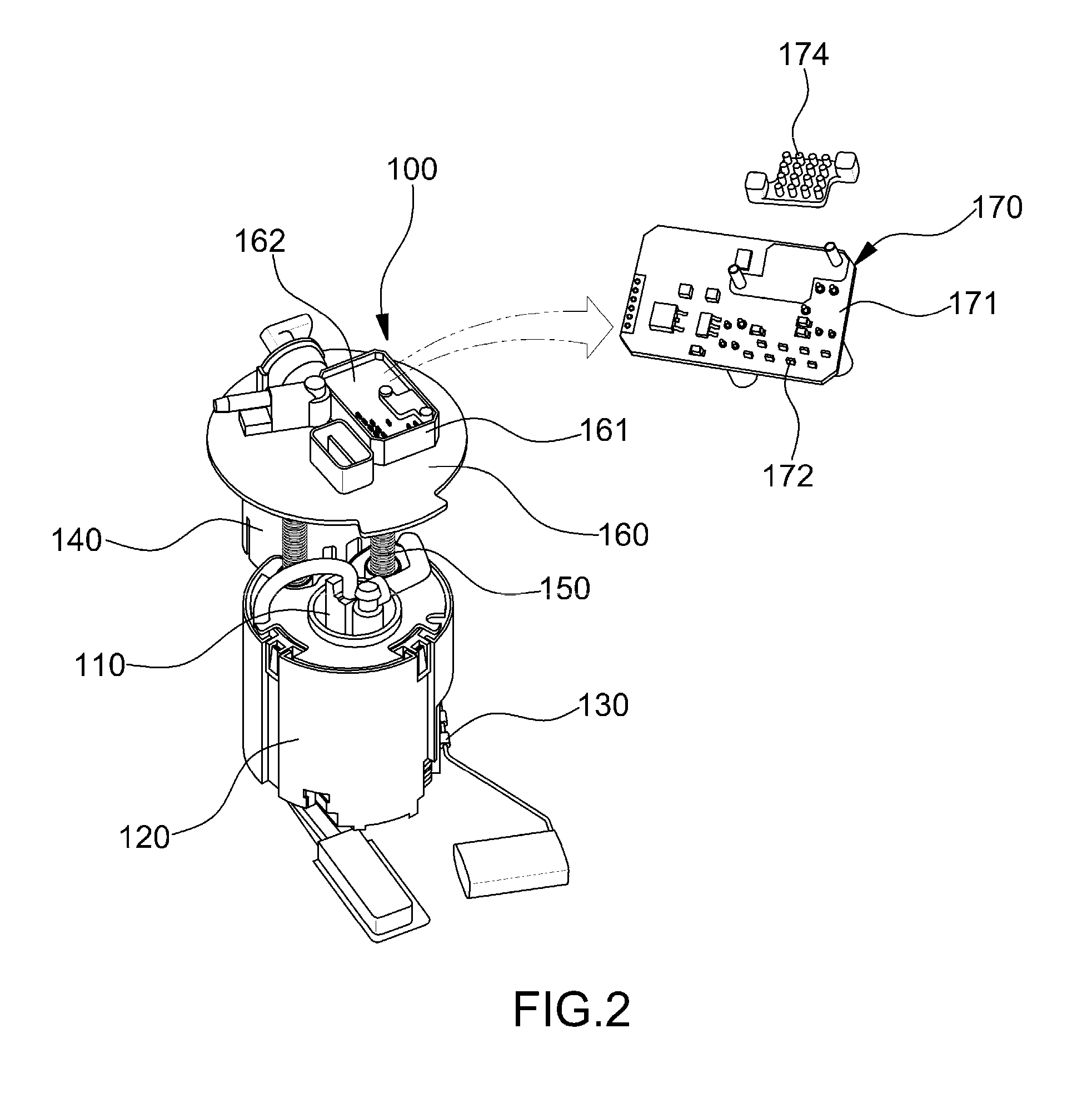

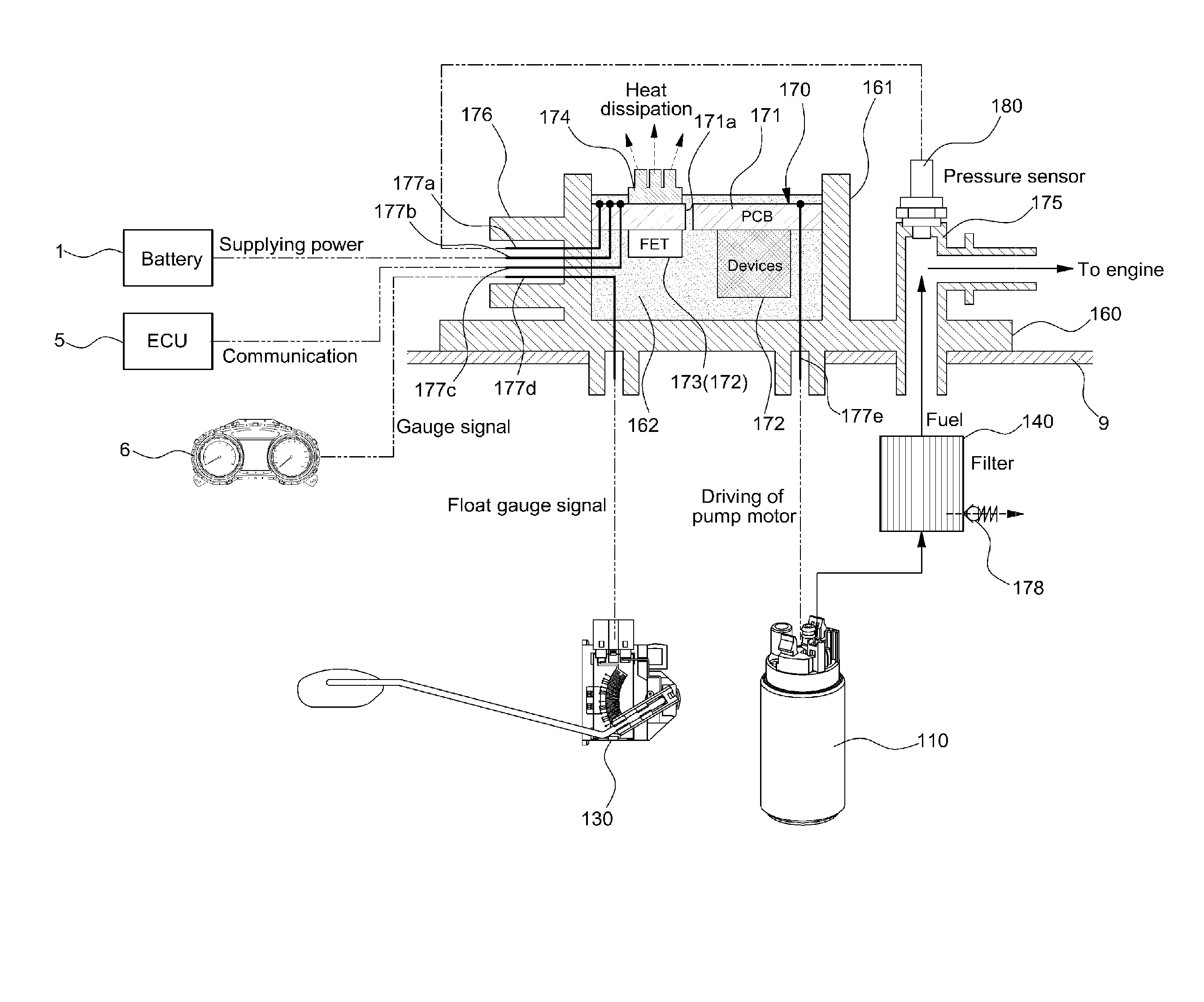

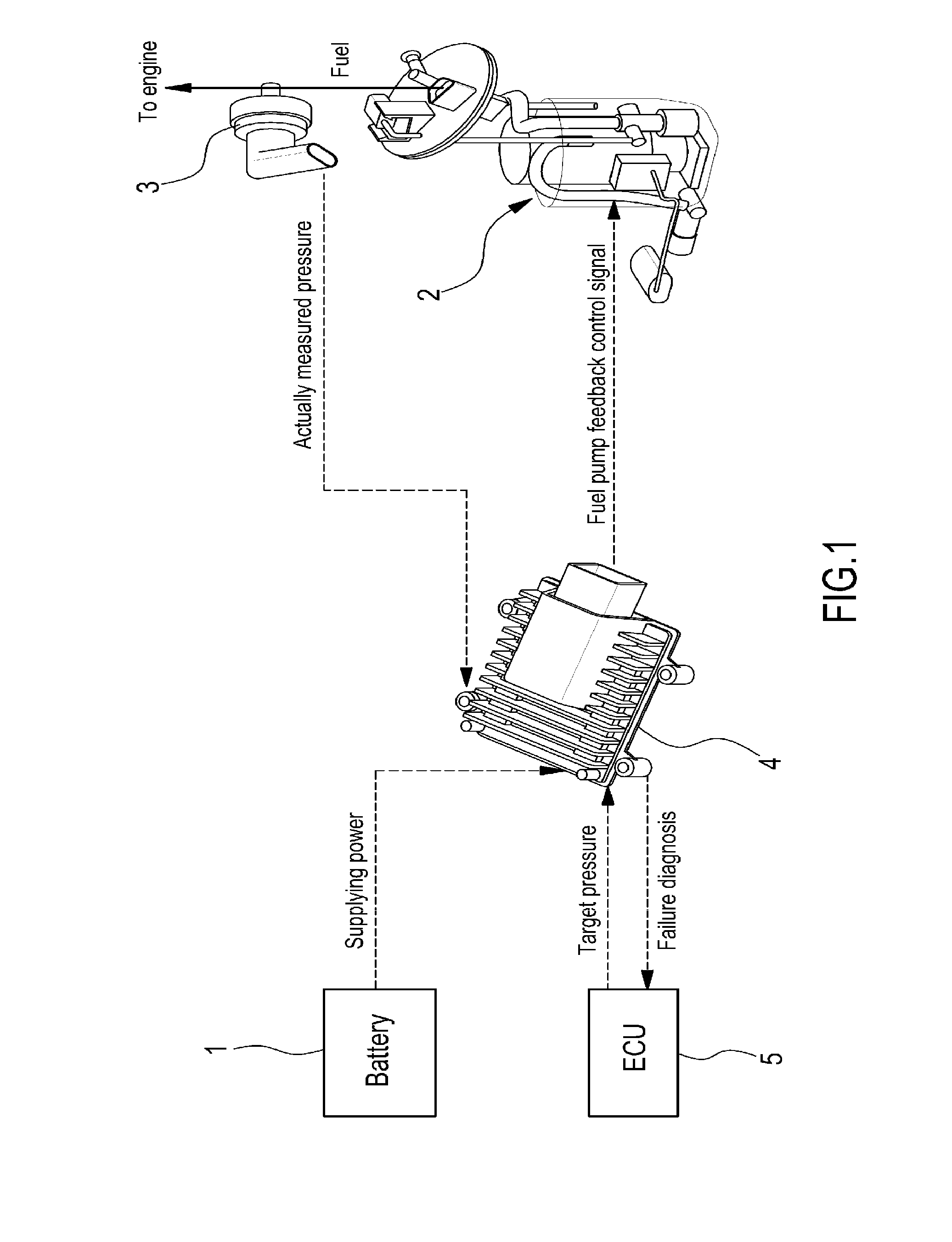

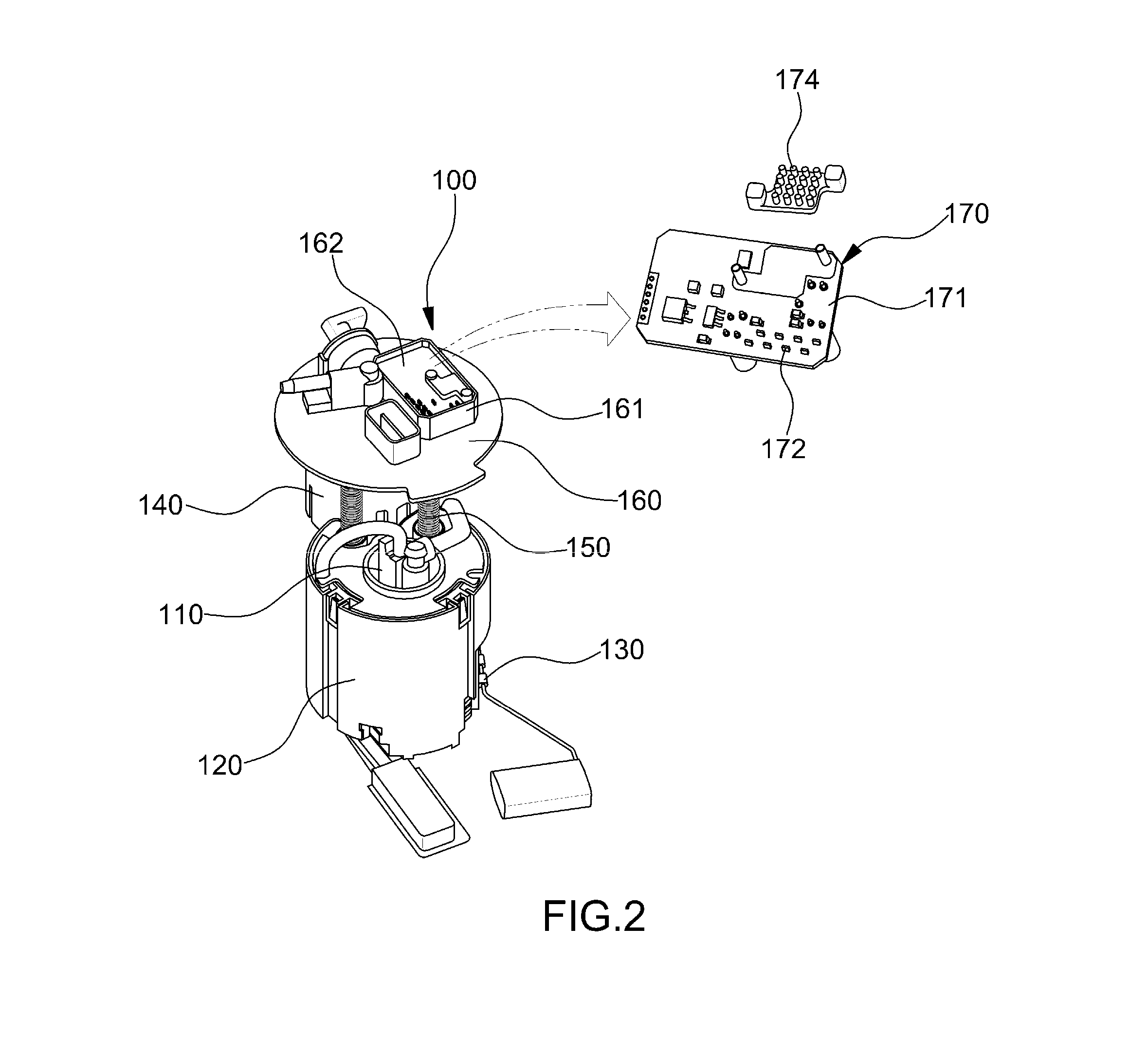

Controller integrated fuel pump module

ActiveUS9316170B2Low costReduce the numberMechanical controlElectrical controlInterior spaceFuel tank

A controller integrated fuel pump module for a vehicle, may include a reservoir cup configured to be fixed to an interior of a fuel tank, a fuel pump installed in an interior of the reservoir cup to pump fuel introduced into the interior of the reservoir cup, and a flange for fixing the reservoir cup and the fuel pump to the fuel tank, wherein a receiving part may be formed to an outer surface of the flange and may include an inner space, and wherein a printed circuit board (PCB) assembly configured to mount devices of a controller to a PCB may be molded in the receiving part, in a state in which the PCB assembly may be received in the receiving part, and a molding portion surrounds the PCB assembly in the receiving part.

Owner:HYUNDAI MOTOR CO LTD +1

Control of A/F ratio at cut-out speed

The invention concerns a method for controlling at least one of a fuel supply and an air supply to an internal combustion engine (1), in a fuel supply section thereof, such that an A / F-ratio is adjusted automatically to a desired level. Moreover, the method is activated at a speed close to a cut-out speed threshold (52) where the engine speed will fluctuate around the threshold (52) and the method comprises the steps of:receiving engine speed data on rotational speed from the engine (1),briefly changing the A / F ratio,comparing engine speed data that are essentially unaffected by the brief change to engine speed data that are affected by the brief change to evaluate the impact on the engine speed fluctuation resulting from the brief change,adjusting the A / F ratio in the same direction as the brief change if the engine speed data affected by the brief change indicates an increase in acceleration after combustion / s, andadjusting the A / F ratio in the opposite direction to the brief change if the engine speed data affected by the brief change indicates a decrease in acceleration after combustion / s.

Owner:HUSQVARNA AB

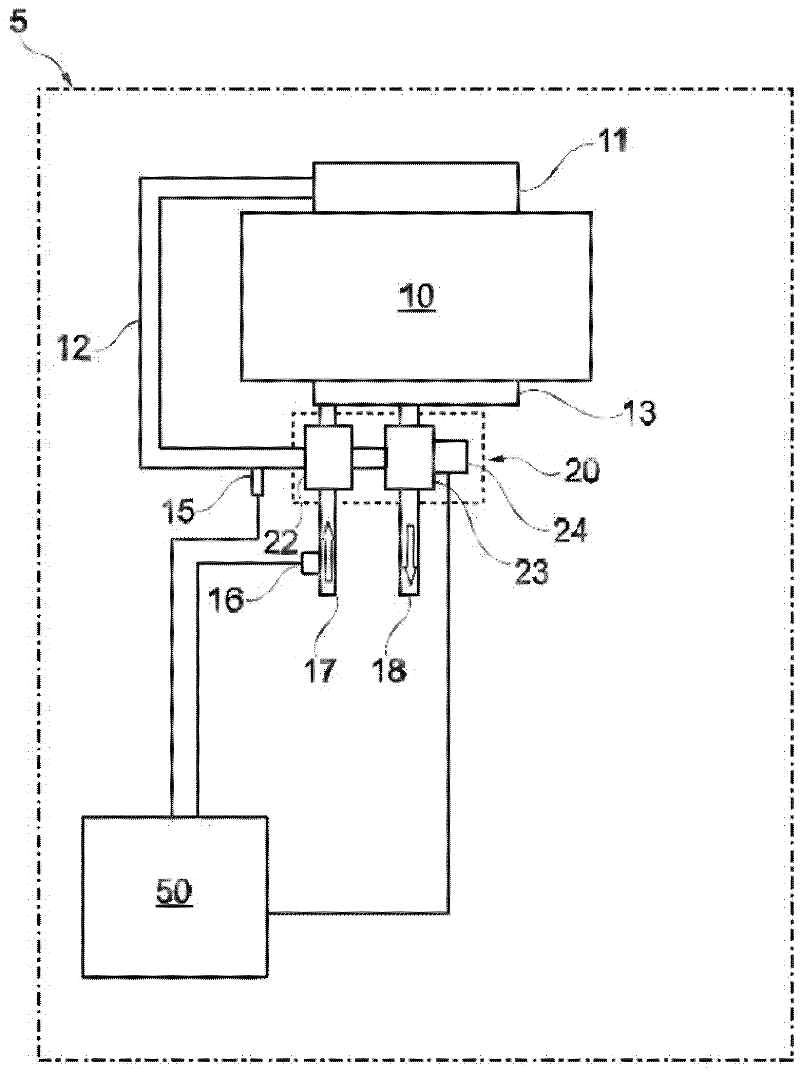

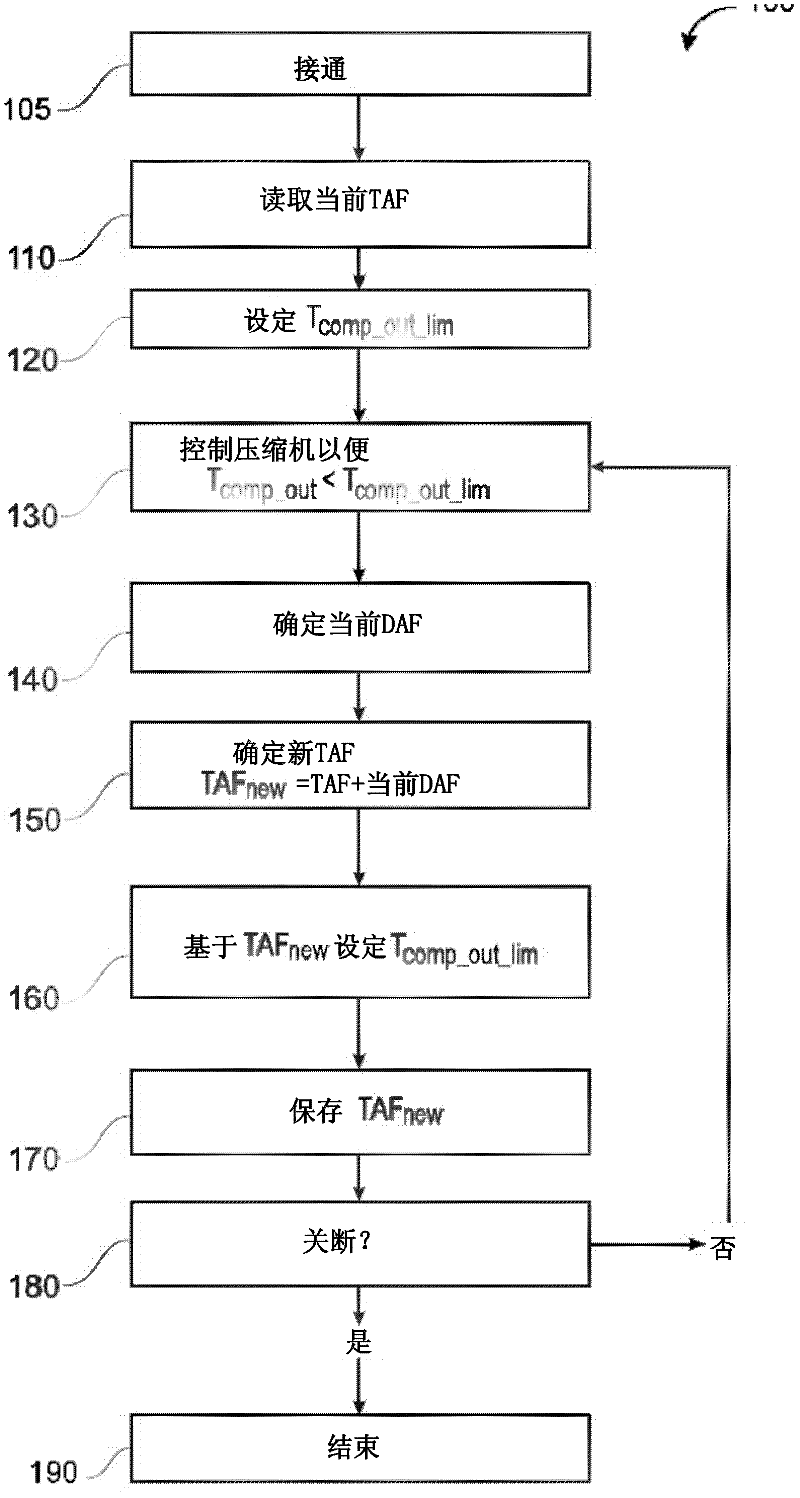

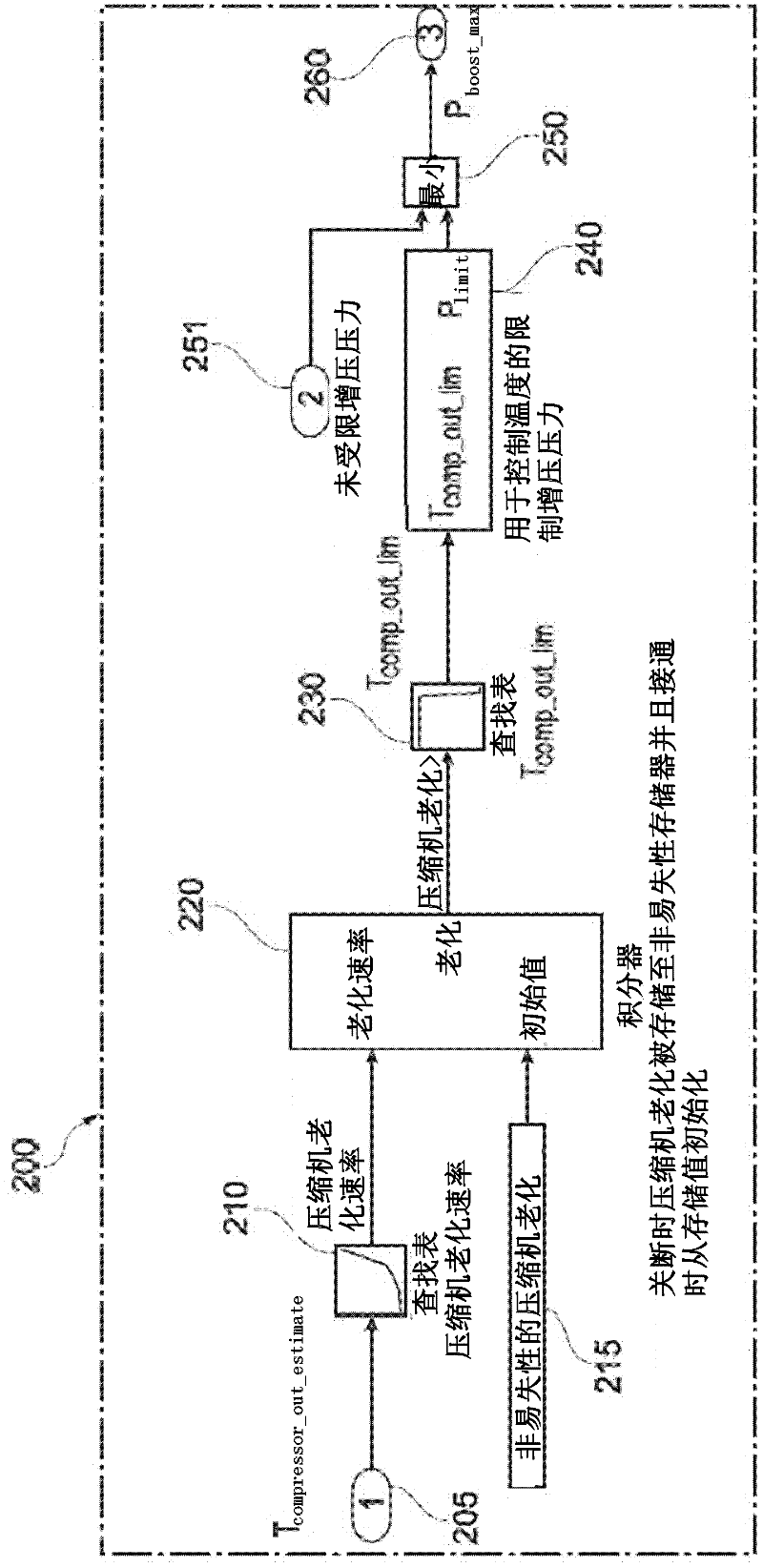

Controlling the operation of a compressor

A method and apparatus for controlling a compressor 22 of a turbocharger 20 fitted to an internal combustion engine in which the maximum permitted outlet temperature of the compressor is adjusted based upon an age factor representing an equivalent age of the compressor if the compressor 22 were to be operated at a predetermined outlet temperature. In this way a higher boost pressure can safely be used during the early life of the compressor 22 but excessive coking of the compressor 22 with a resultant loss of efficiency later in the life of the compressor 22 is avoided. The method can further comprise repetitively determining, for successive predetermined time periods, discrete age factors based on the instantaneous outlet temperature of the compressor during the predetermined time period, wherein the compressor total age factor is a summation of various discrete age factors.

Owner:FORD GLOBAL TECH LLC

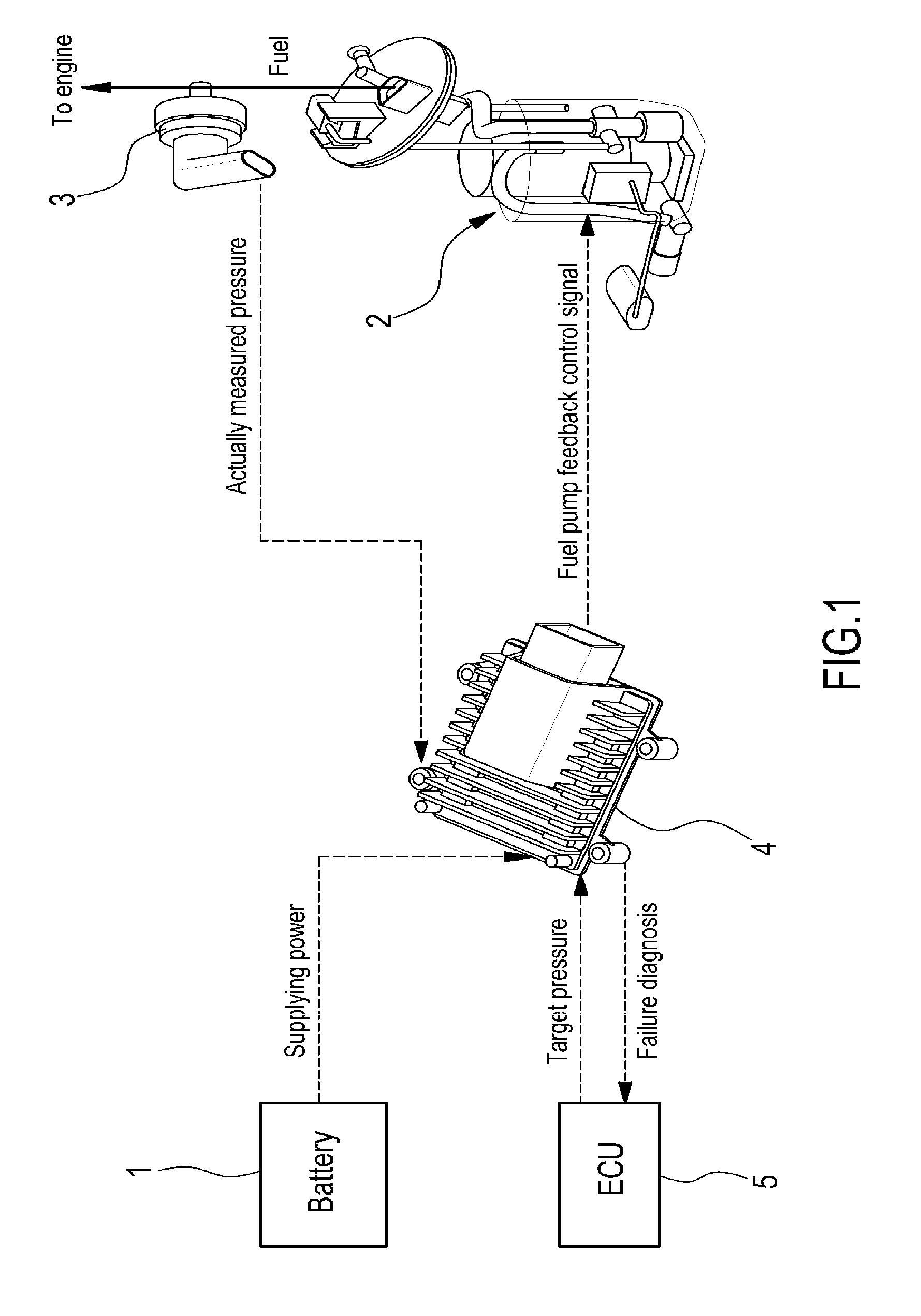

Controller integrated fuel pump module

ActiveUS20140318646A1Lower component costsLow number of componentsMechanical controlElectrical controlInterior spaceFuel tank

A controller integrated fuel pump module for a vehicle, may include a reservoir cup configured to be fixed to an interior of a fuel tank, a fuel pump installed in an interior of the reservoir cup to pump fuel introduced into the interior of the reservoir cup, and a flange for fixing the reservoir cup and the fuel pump to the fuel tank, wherein a receiving part may be formed to an outer surface of the flange and may include an inner space, and wherein a printed circuit board (PCB) assembly configured to mount devices of a controller to a PCB may be molded in the receiving part, in a state in which the PCB assembly may be received in the receiving part, and a molding portion surrounds the PCB assembly in the receiving part.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com