Piston with variable lift compression ratio

A technology of compression ratio and lift, which is applied in the direction of piston, mechanical control, machine/engine, etc., can solve the problems of numerous sealing parts, complex mechanical structure, etc., and achieve high reliability, high economic performance and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

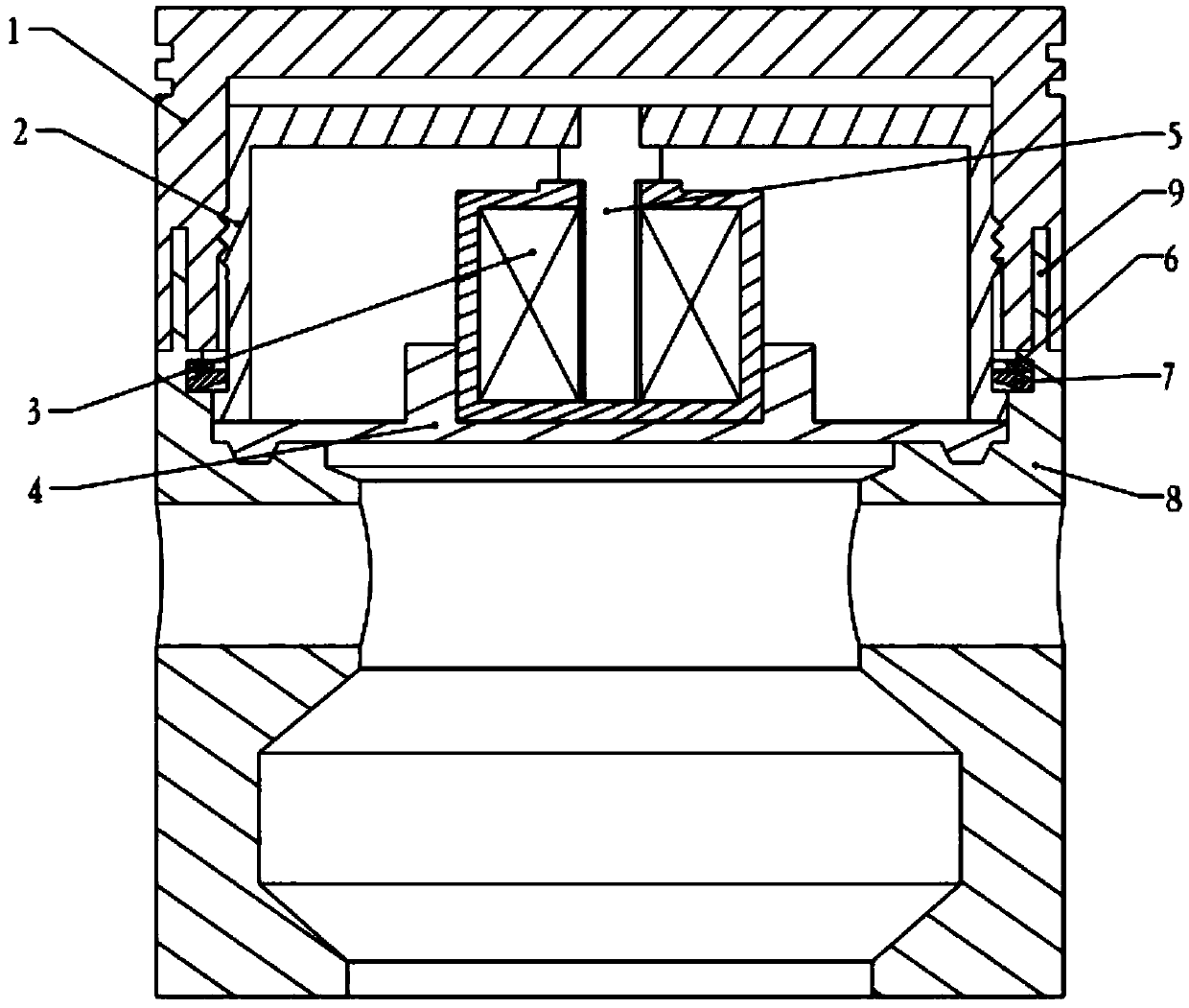

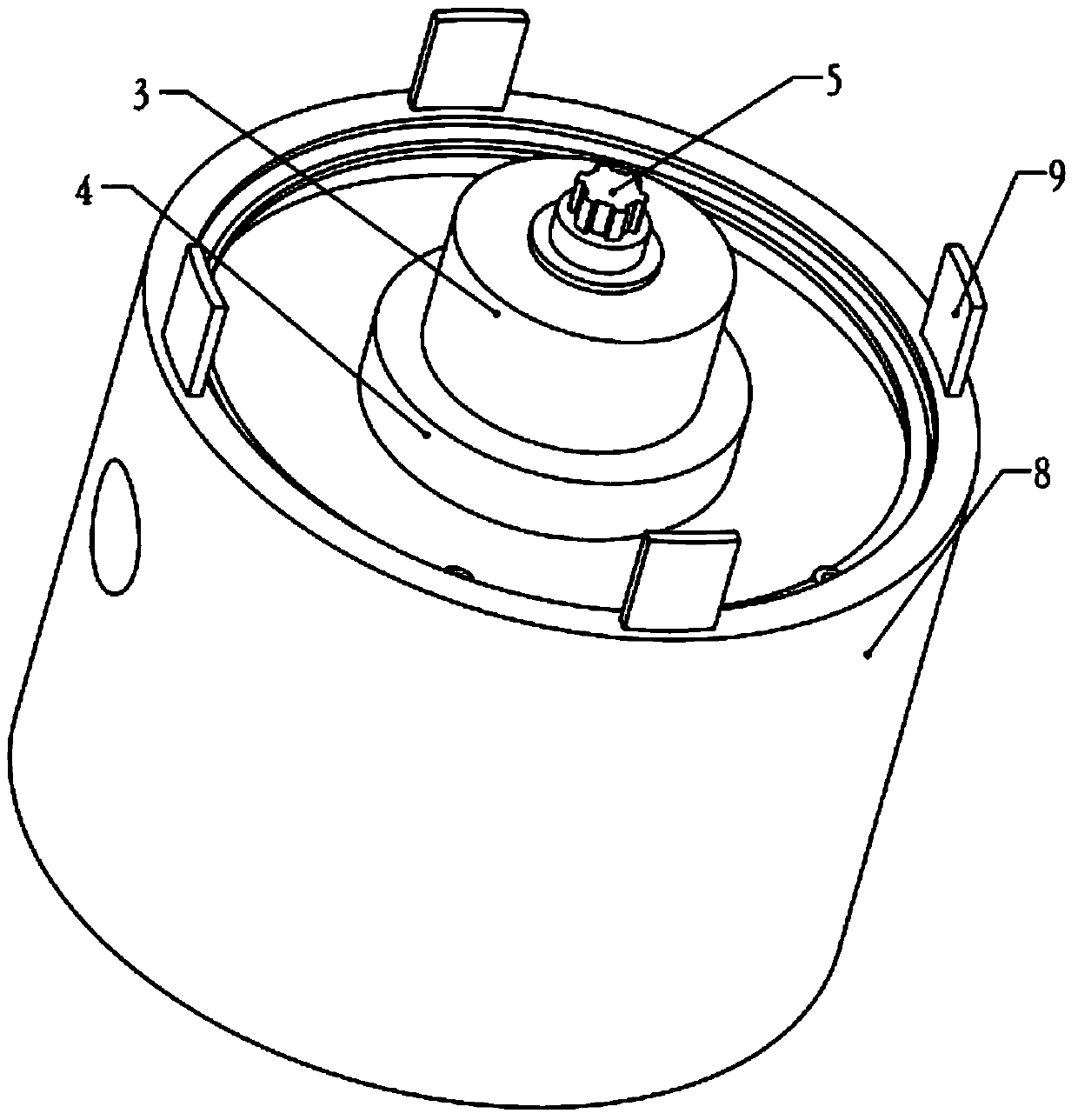

[0038] The present invention is described in detail below in conjunction with accompanying drawing:

[0039] refer to figure 1 , the variable lift compression ratio piston of the present invention comprises a piston body upper part 1, an inner sleeve 2, a motor (motor stator 3, a motor rotor 5), a motor seat 4, a snap ring 6, a compression spring 7 and a piston body lower part 8 .

[0040] refer to figure 1 and figure 2 , the whole piston is divided into two parts, the upper part 1 of the piston body and the lower part 8 of the piston body. The annular surface of the top end of the lower part 8 of the piston body is evenly distributed (cast) along the axial direction, and there are two to six sectors with the same structure in cross section. Guide plates 9, that is, the height of each guide plate is the same, the width is the same, and the thickness is the same. The center line of rotation of the circumference where guide plates 9 are distributed is collinear with the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com