Sparking plug ignition-type premixing compression ignition system of internal combustion engine

A technology of spark plugs and internal combustion engines, applied in charging systems, combustion engines, mechanical control, etc., can solve problems such as temperature and pressure rise, reduce NOx and soot emissions, and improve thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

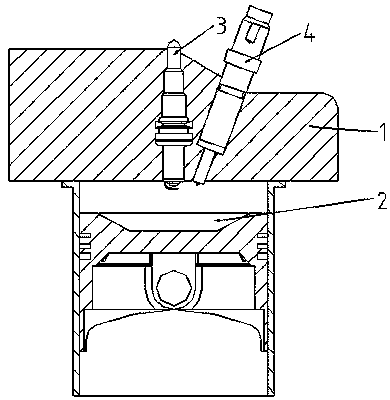

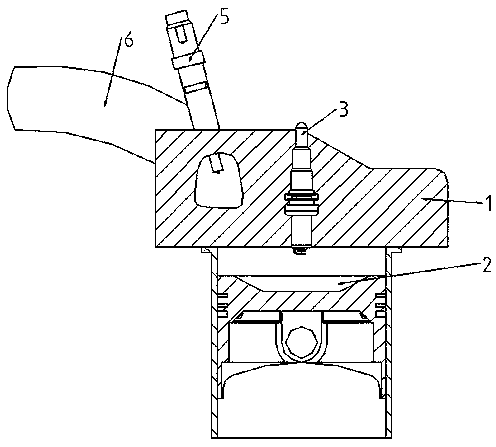

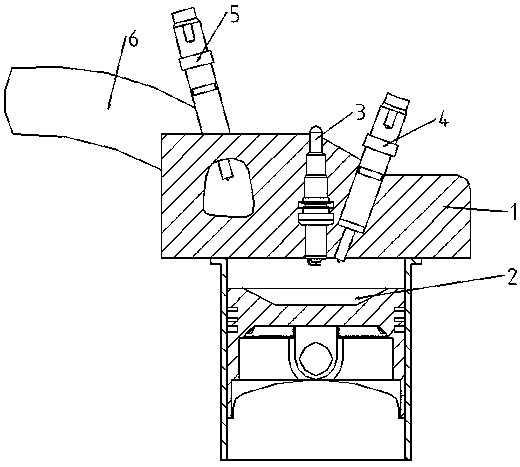

[0020] figure 1 The high-energy spark plug 3 and the direct injection fuel injector 4 of the premixed compression ignition system of the spark ignition type internal combustion engine shown are both arranged on the cylinder head 1 . The premixed compression ignition system of the spark ignition type internal combustion engine injects the premixed fuel into the combustion chamber 2 through the single or multiple pulse injections of the direct injection nozzle 4 during the intake stroke or the compression stroke to form a premixed gas; Low effective compression ratio, EGR, intake air cooling, etc. are used to prevent the pre-mixed gas in the cylinder from being compression-ignited; near the compression top dead center, the high-energy spark plug 3 is used to ignite the mixed gas near it, so that the temperature in the cylinder and The pressure rises at the same time, reaching the self-ignition condition of the pre-mixed gas, stimulating the multi-point spontaneous combustion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com