In-cylinder water spraying control method

A control method and timing technology, which is applied in the direction of engine control, adding non-fuel substances to fuel, engine components, etc., can solve the problems of slow combustion in the cylinder and high heat load of the engine, so as to increase the combustion rate, reduce the heat load, and improve the geometry. Effect of Compression Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

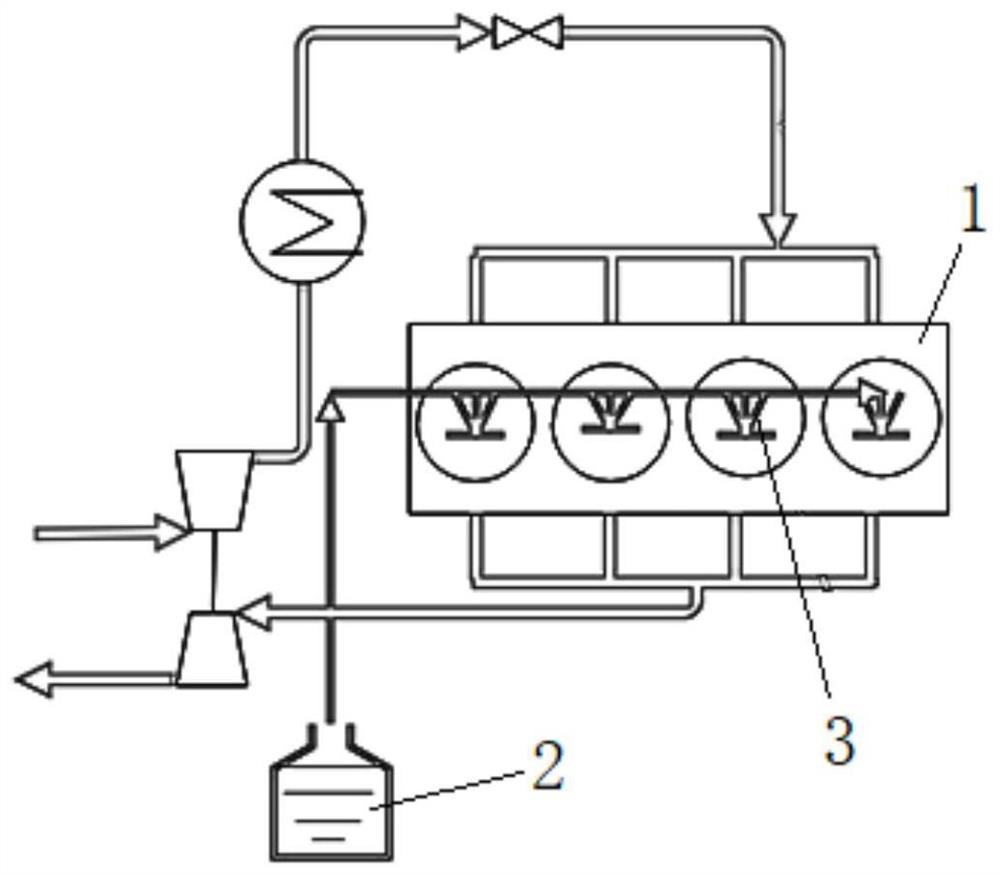

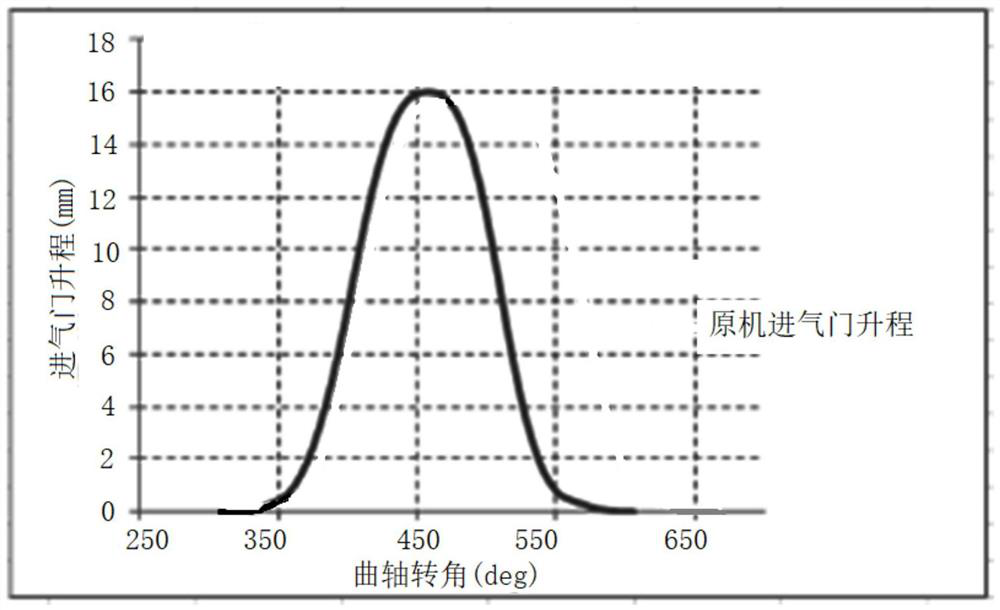

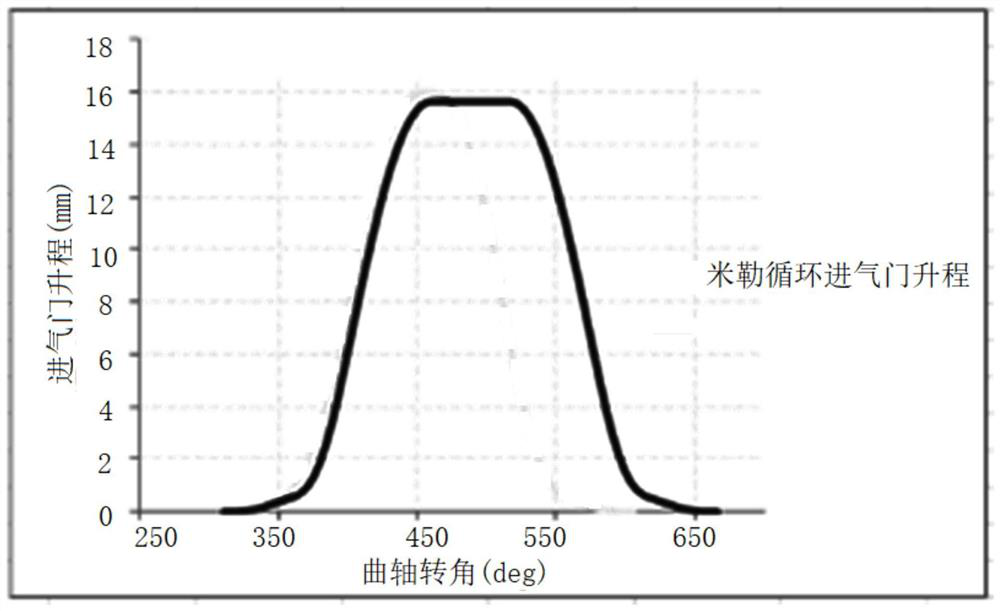

[0026] refer to Figure 1-3 , a water spray control method in a cylinder, comprising:

[0027] Set the late closing time of the intake valve;

[0028] Establish and save the water spray map table with rotation speed, load, top dead center signal, maximum burst pressure in the cylinder, exhaust temperature in front of the vortex, water spray time, and water spray duration, and the water spray map table is stored in the ECU;

[0029] The ECU obtains the current engine 1 actual speed, actual load, actual dead center signal, actual maximum explosion pressure in the cylinder, and actual exhaust temperature in front of the vortex. , The actual exhaust temperature in front of the vortex is queried from the water spray map table to obtain the best water spray time and the best water spray duration;

[0030] The ECU controls the high-pressure wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com