Patents

Literature

129results about How to "Increase the expansion ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

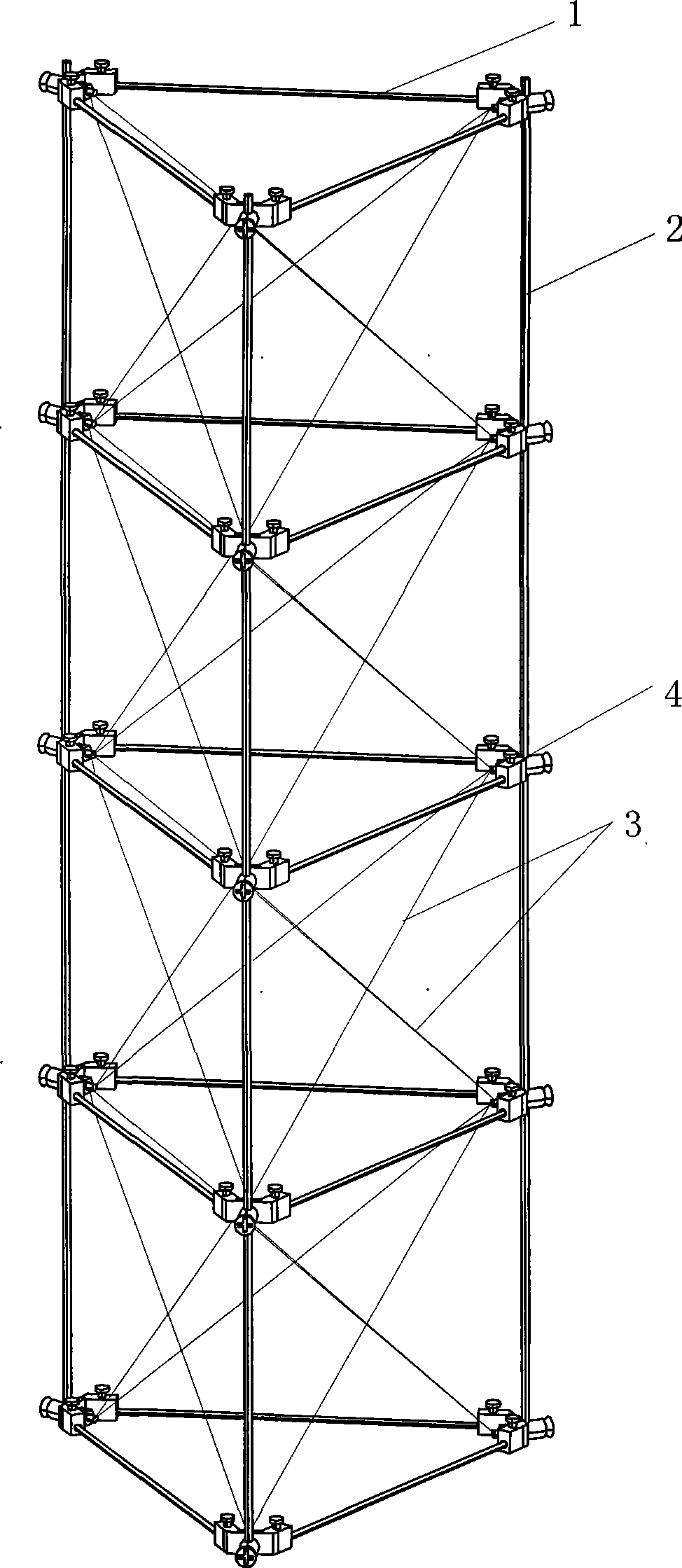

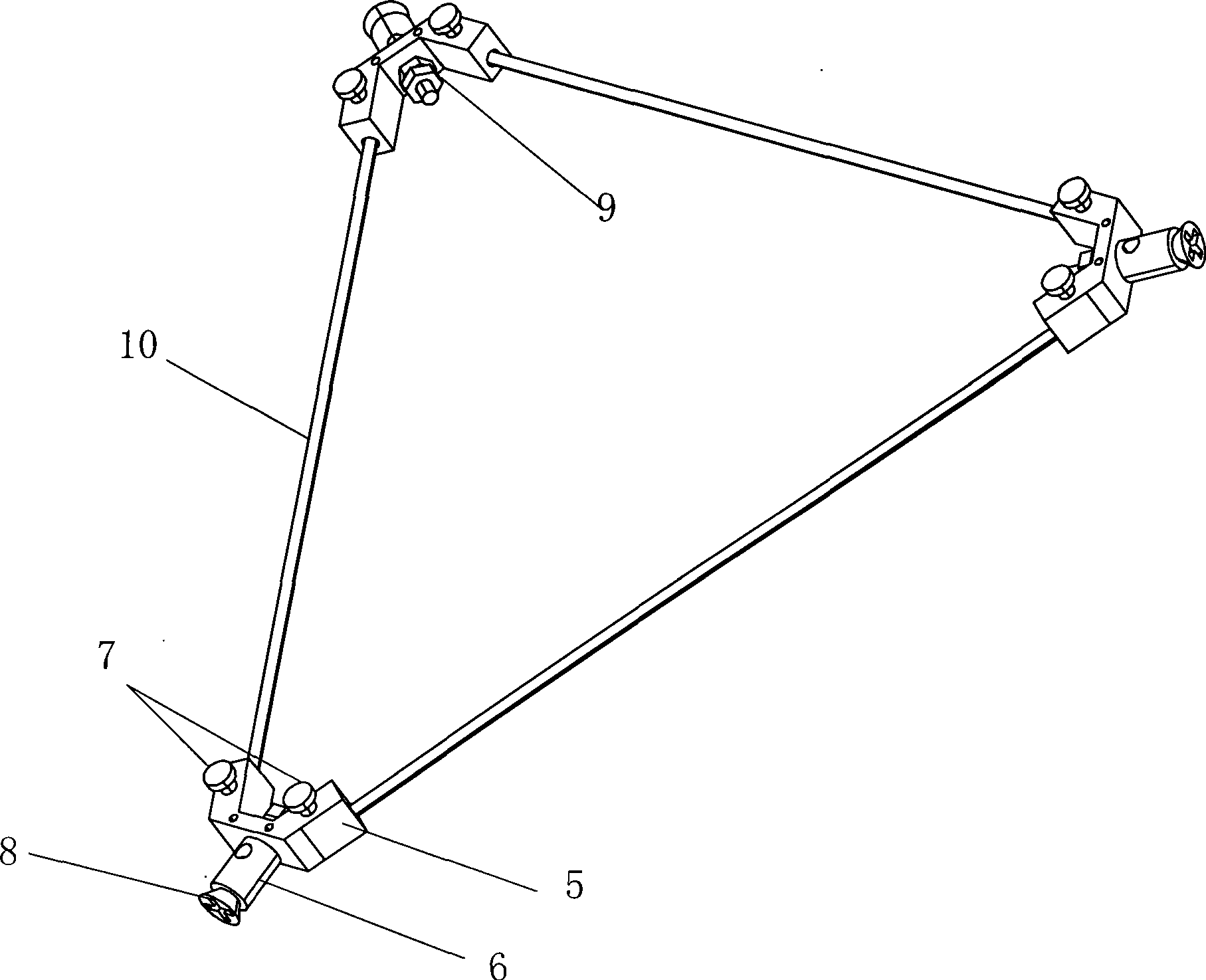

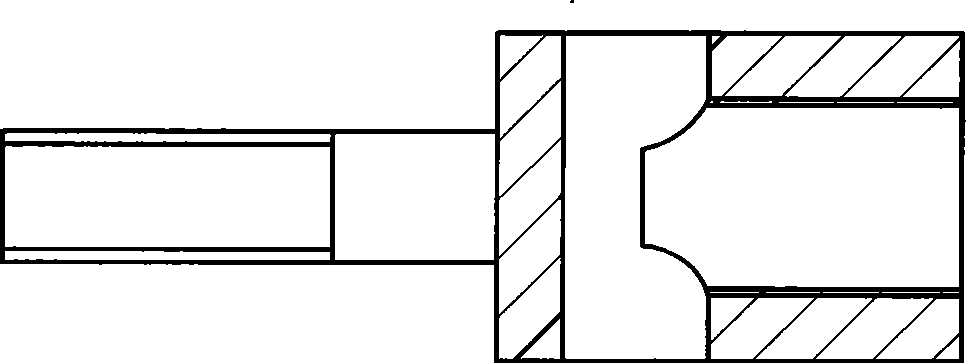

Swirl type triangle crossarm hinge space extending arm

InactiveCN101428690AIncrease the expansion ratioImprove reliabilityCosmonautic vehiclesCosmonautic partsAlloyEngineering

The invention relates to a coil type triangular horizontal framework articulate space stretch arm, which comprises a plurality of articulated triangular horizontal frameworks, three longitudinal rods and a plurality of opposite angles stiffening cables, wherein, each articulated triangular horizontal framework comprises three triangular articulation joints and three Ti-Ni alloy short rods, and provides the longitudinal rods with lateral support; each triangular articulation joint comprises a 60 DEG connector, a cylindrical joint with stairs, three bolts and two nuts; end heads of each Ti-Ni alloy short rod are fixed in the holes of the 60 DEG connectors through two M2 bolts; two holes used for fixing the opposite angles stiffening cables are further formed on each of the 60 DEG connectors; an M2 thread is arranged on the a thinner end of the cylindrical joint; the cylindrical joint is limited to make three-displacements and two-rotations relative to the connector with 60 DEG through nuts, without limiting the cylindrical joint rotate axially; and the cylindrical joint fixedly connects the longitudinal rods and the 60 DEG connectors through an axial M3 bolt. The invention can be applied in the fields of the space detection arms, the large scale solar battery arrays of spacecrafts, the main structure of space stations, and the like.

Owner:BEIHANG UNIV

Propylene-based copolymer, propylene-based copolymer composition, molded product thereof and foamed product thereof, and production process therefor

ActiveUS20140088214A1Increase in melt tensionExcellent molding processabilityExpansion ratioVacuum forming

To provide a propylene-based copolymer and a propylene-based copolymer composition, each of which has a high melt tension because it has a long-chain branched structure, exhibits excellent molding processability during molding, such as inflation molding, extrusion molding, blow molding, injection molding or vacuum forming, and is capable of favorably providing a foamed product having an excellent expansion ratio and excellent cell uniformity in the foaming stage. The propylene-based copolymer (A) of the present invention comprises 50 to 95% by mol of constituent units [i] derived from propylene, 4.9 to 49.9% by mol of constituent units [ii] derived from an α-olefin of 2 to 10 carbon atoms other than propylene and 0.1 to 10% by mol of constituent units [iii] derived from a non-conjugated polyene (with the proviso that the total amount of the constituent units [i], [ii] and [iii] is 100% by mol), and is characterized by satisfying specific requirements (a) and (c).

Owner:MITSUI CHEM INC

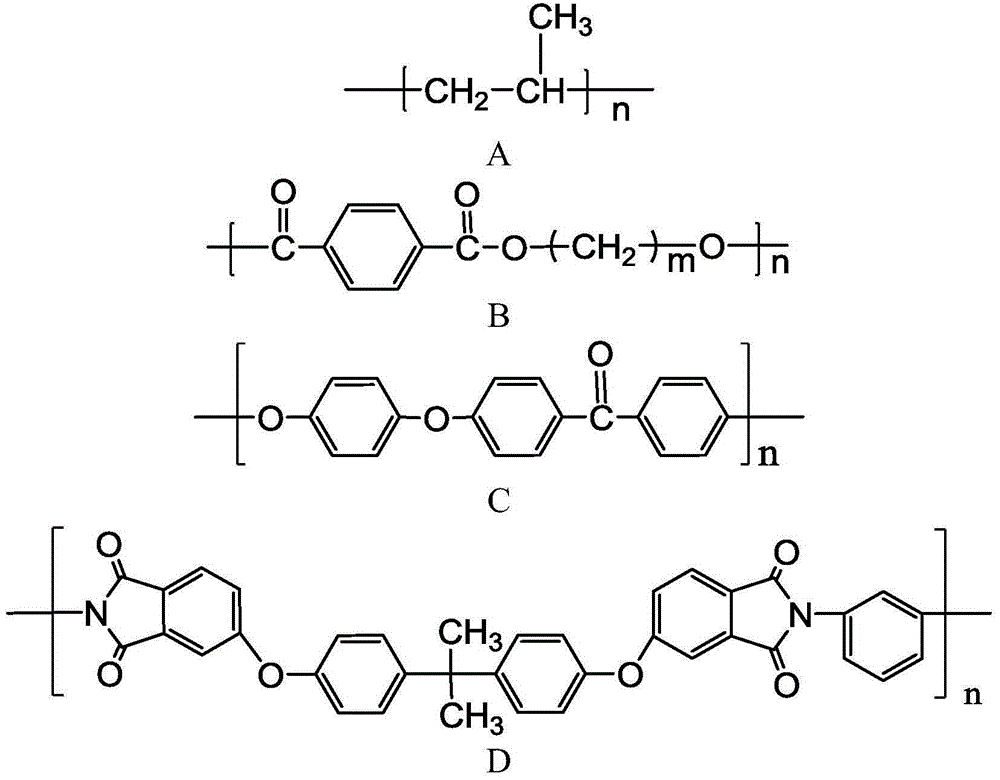

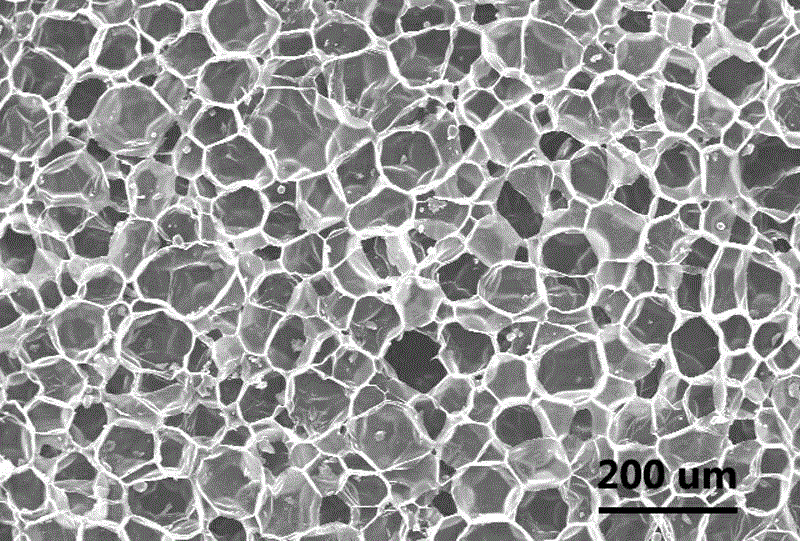

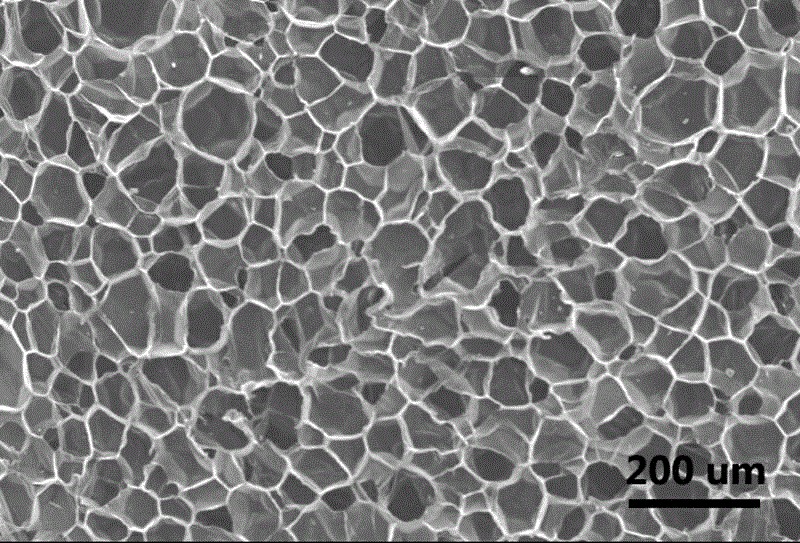

Preparation method of polymer micro-foaming film

ActiveCN104987523ASimple processImprove efficiencySynthetic resin layered productsLaminationPolyesterPolymer science

The invention discloses a preparation method of a polymer micro-foaming film. The preparation method comprises the following steps of: (1) uniformly rolling a polymer film of which the thickness is 200-500 mu m and an interval material into a coiled material; (2) putting the coiled material in a supercritical fluid reaction kettle, controlling the coiled material to be at a higher temperature and a higher pressure, so that the supercritical fluid is permeated and swelled in a polyester coiled material so as to achieve the state of saturation; (3) after achieving the state of saturation, using an ultrasonic technology in an assisting manner, enabling kernels to be uniformly formed in the inner part of a polymer film, releasing the supercritical fluid in the reaction kettle, and taking out the coiled material in which the kernels are formed; and (4) putting the coiled material in a heat source, enabling internal gas nucleus to grow, and foaming pores to form so as to prepare micro-foaming film of which the pore diameters are uniform and the foaming pores are close. The preparation method disclosed by the invention is simple in technology, is clean and pollution-free, and is higher in efficiency; the thickness of the prepared polymer micro-foaming film is between 300-1000 mu m, the density of products is between 0.25-0.65g / cm<3>, the pore diameters are between 5-20 mu m, and the density of the pores is 1010-1012cells / cm<3>; reflection of visible light can reach more than 98%.

Owner:青岛中诚高分子科技有限公司

Biodegradable polybutylene succinate (PBS) foaming material and preparation method thereof

InactiveCN102627837AThe production process is highly continuous and stableExcellent cell size distribution and mechanical propertiesMethyl formateButane

The invention provides a biodegradable polybutylene succinate (PBS) foaming material and a preparation method thereof. The biodegradable PBS foaming material is prepared by fully mixing components of 100 parts of a PBS resin, 0.1 to 10 parts of one or more chain extenders, 0.1 to 10 parts of one or more nucleating agents, 0.1 to 10 parts of one or more foaming stabilizers and 1.2 to 18 parts of a composite foaming agent by an extruder and carrying out extrusion and foaming molding, wherein the composite foaming agent comprises 1 to 10 parts of a supercutical fluid, 0.2 to 5 parts of second ingredient foaming agents and 0 to 3 parts of third ingredient foaming agents; and the second ingredient foaming agents comprise an azo-compound, sodium bicarbonate and / or citric acid, or a mixture containing polymer masterbatches of the azo-compound, sodium bicarbonate and / or citric acid; and the third ingredient foaming agents comprise ethanol, a butane, a pentane, methyl formate and / or dimethyl ether. The biodegradable PBS foaming material has good mechanical properties and biodegradable properties. The preparation method of the biodegradable PBS foaming material has high-continuity and stable production processes, is safe, does not produce environmental pollution and is suitable for large-scale industrial production.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

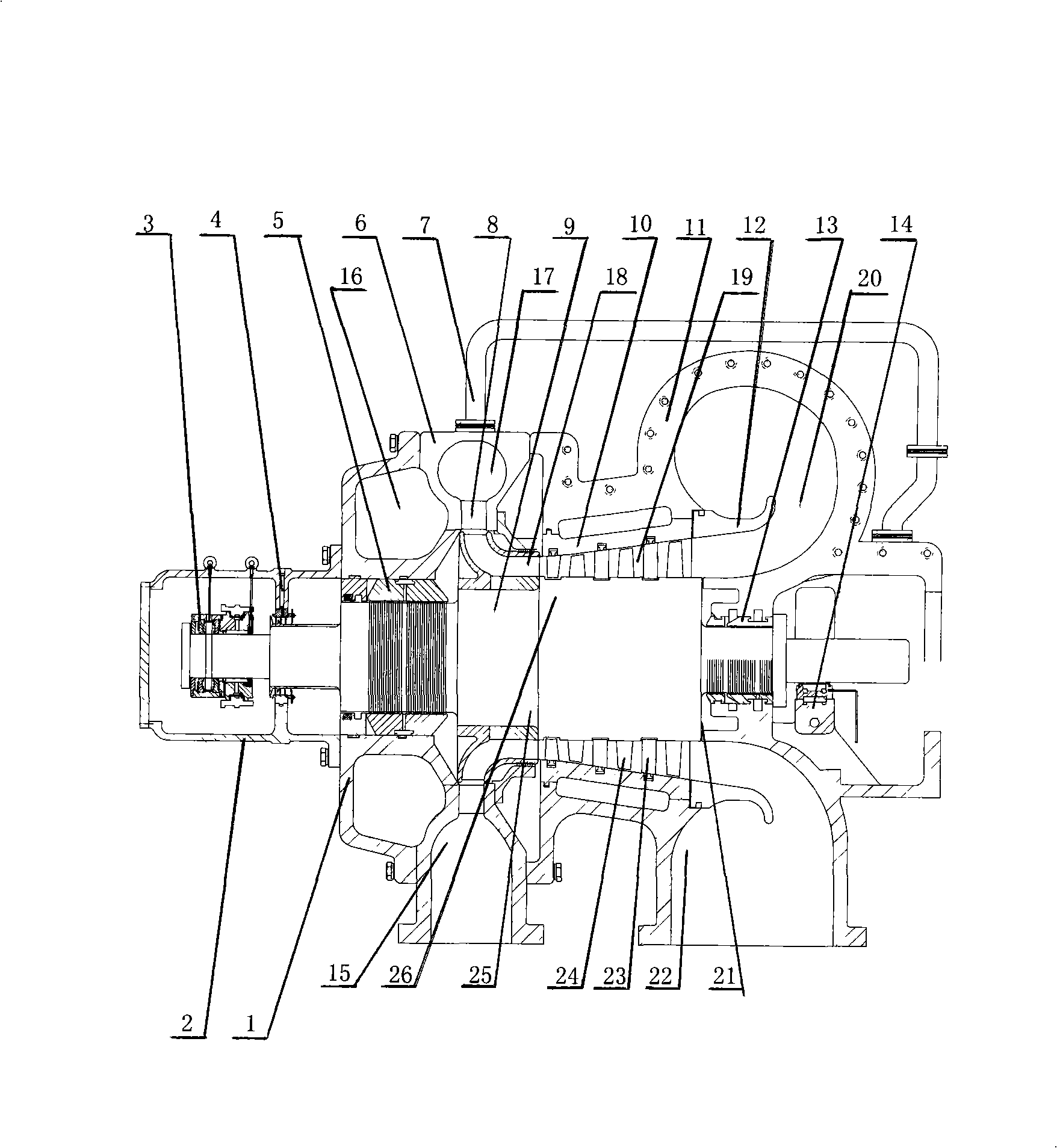

Combined turbine expansion machine

InactiveCN101265814AIncreased volume flowIncrease the expansion ratioBlade accessoriesNon-positive displacement enginesImpellerEngineering

The invention provides a composite turboexpander, which comprises a rotor. The rotor is arranged in a shell consisting of a high-pressure section casing and a low-pressure section casing; the high-pressure section casing is provided with an inlet pipe, and the inlet pipe communicates with an adjustable nozzle through a volute chamber; the high-pressure section of the rotor is provided with a radial impeller that communicates with the adjustable nozzle; the low-pressure section casing is provided with a blade carrier cylinder; the outlet of the blade carrier cylinder is provided with a flow deflecting ring, and the blade carrier cylinder is provided with a static blade; the low-pressure section casing is also provided with a volute chamber for exhausting and a vent-pipe; the low-pressure section of the rotor is provided with a moving blade; an axial flow stage comprises a first-stage static blade and a first-stage moving blade and communicates with the radial impeller and the flow deflecting ring; the pressure of the working medium decreases after going through the first-stage endocentric grade, the circumferential direction is changed into axial direction after the volume flow rate increases, and the axial flow stage is finally reached. The composite turboexpander has the advantages of simple structure, small volume flow rate for first-stage entry, high expansion rate, high expanding efficiency, convenient installation and maintenance, steady operation, etc.

Owner:冀江 +1

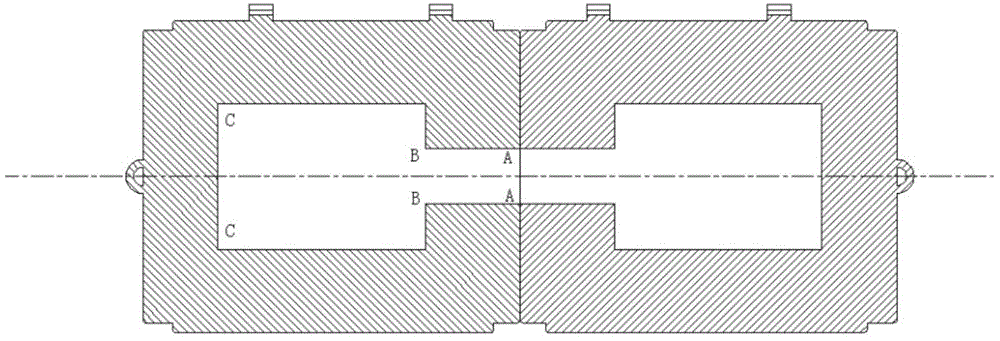

Device and method for testing power capability of composite explosives

InactiveCN104359607AHigh inert componentsAccurate measurementMaterial exposibilityMeasurement of explosion forceDetonatorTest power

The invention discloses a device and method for testing the power capability of composite explosives. The device for testing the power capability of the composite explosives is composed of winches, supports, support supporting rods, bearing bases, rotary shafts, swing arms, pendulum bobs, pendulum bob protruding teeth, a one-way limiter and angulometers. Before a test, explosive samples to be tested are prepared through special pressing molds, the samples to be tested are placed in inner cavities of the pendulum bobs and detonated through detonators, after detonation, the two pendulum bobs swing circumferentially around the rotary shafts under the limitation of the swing arms, the pendulum bobs are controlled by the one-way limiter and the pendulum bob protruding teeth to swing to the highest point and then stay still, the angulometers are used for measuring the swing angles of the pendulum bobs, and the power capability of the composite explosives after detonation is calculated and measured through the swing angles of the two pendulum bobs. According to the device and method, the improvement is made on the basis of a traditional ballistic trajectory mortar method, the conversion efficiency for converting chemical energy into mechanical energy of detonation can be improved through the two-pendulum-bob structure, and therefore the test result and the quantitative expression of the power capability of the composite explosives are more accurate.

Owner:XIAN MODERN CHEM RES INST

Preparation method of uniform-cell and high-buffer polylactic acid foamed material

The invention relates to a preparation method of a uniform-cell and high-buffer polylactic acid foamed material. The foamed material comprises a main material and an auxiliary material, and the main material comprises polylactic acid, EVA elastomer, cellulose acetate propionate, esterification modified nano-cellulose, polylactic acid grafted maleic anhydride and gelatin; and the auxiliary material comprises an antioxidant, a plasticiser and an ultraviolet resisting agent. The main material comprises, by mass, 100 parts of polylactic acid, 20-35 parts of the EVA elastomer, 8-15 parts of cellulose acetate propionate, 3-6 parts of esterification modified nano-cellulose, 4-8 parts of polylactic acid grafted maleic anhydride and 3-6 parts of gelatin. The auxiliary material comprises 2-4 parts of the antioxidant, 2-4 parts of the plasticiser and 2-4 parts of the ultraviolet resisting agent. The foamed material is prepared through a premixing, autoclave foaming and liquid nitrogen cooling technology, has the advantages of effective guaranteeing of cell uniformity, high foaming rate and good buffering performance, and can be used in the field of packaging buffering.

Owner:HUNAN UNIV OF TECH

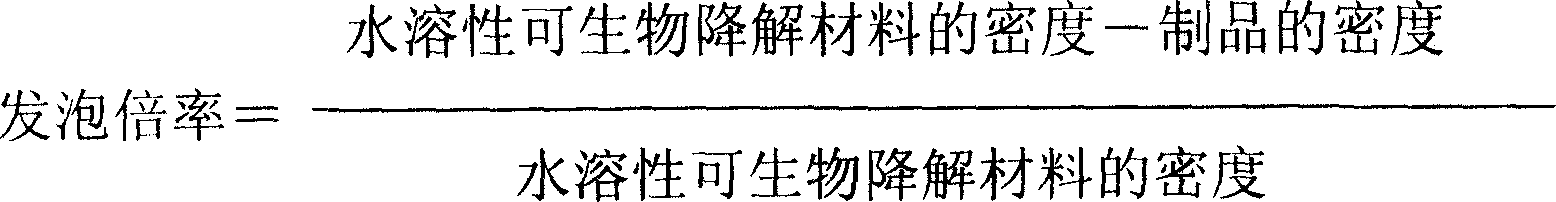

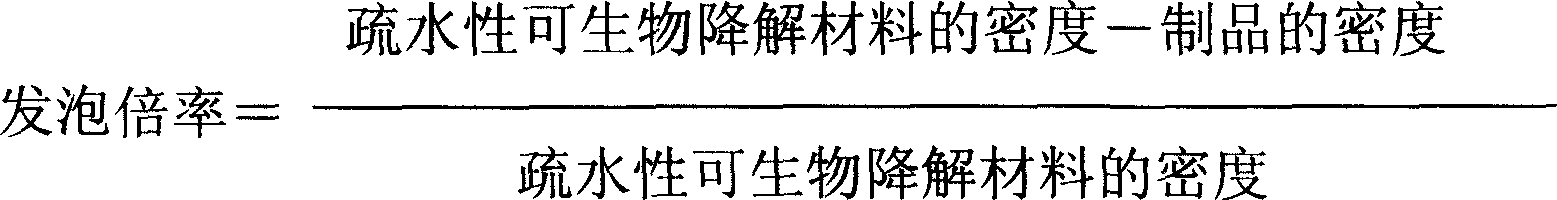

Water-soluble biodegradable material, and its preparing method and foamed product

The invention relates to water solubility biodegradable material which contains foaming agent. The material contains the outcome formed by mixture fusing which contains starch, polyhydric alcohol, and aqueous polyvinyl alcohol which has hydrophilicity. Its fusing temperature is 140-190 degree centigrade; decomposition temperature is 250-400 degree centigrade. Thus it can be used to make various foaming series products such as, tray, bowl, cut etc which have better expansion ratio and compressive strength.

Owner:BEIJING HONGHUA BIOMATERIAL

Preparation method of plant fiber cushion packaging material

InactiveCN103772733AIncrease the expansion ratioHigh densityFlexible coversWrappersFiberSodium bicarbonate

The invention discloses a preparation method of a plant fiber cushion packaging material. The preparation method comprises the steps of 1) grinding plant fiber, soaking the ground plant fiber in sodium hydroxide for 18-30 hours, filtering and collecting a filter cake, and drying the filter cake; 2) preparing a polyvinyl alcohol solution which is 5-10% in mass concentration, adding the plant fiber dried by the step 1), adding glycerol, sodium bicarbonate, azodicarbonamide and ammonium bicarbonate, and stirring the materials in a stirrer until the materials are completely and uniformly mixed to obtain a mixed sizing material, wherein the mass ratio of the polyvinyl alcohol to the plant fiber to the glycerol to the sodium bicarbonate to the azodicarbonamide to the ammonium bicarbonate is (10-15): (20-30): (3-5): (1-3): (1.2-1.8): (2-6); and 3) adding the mixed sizing agent obtained from the step 2) in a foaming mold and foaming through microwave to obtain the plant fiber cushion packaging material. The prepared foamed material is low in density and high in elastic ratio, and is specifically suitable for cushion packaging.

Owner:NANTONG TIANHE PACKING

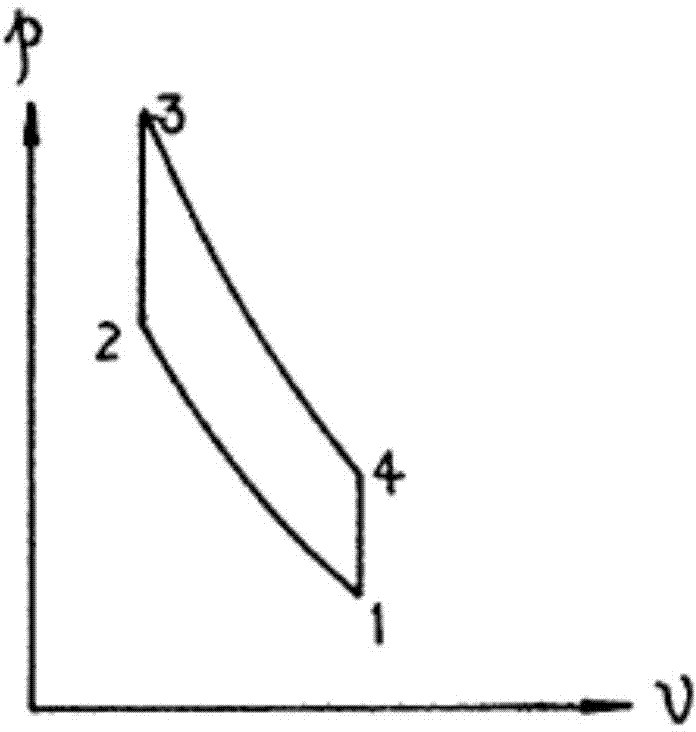

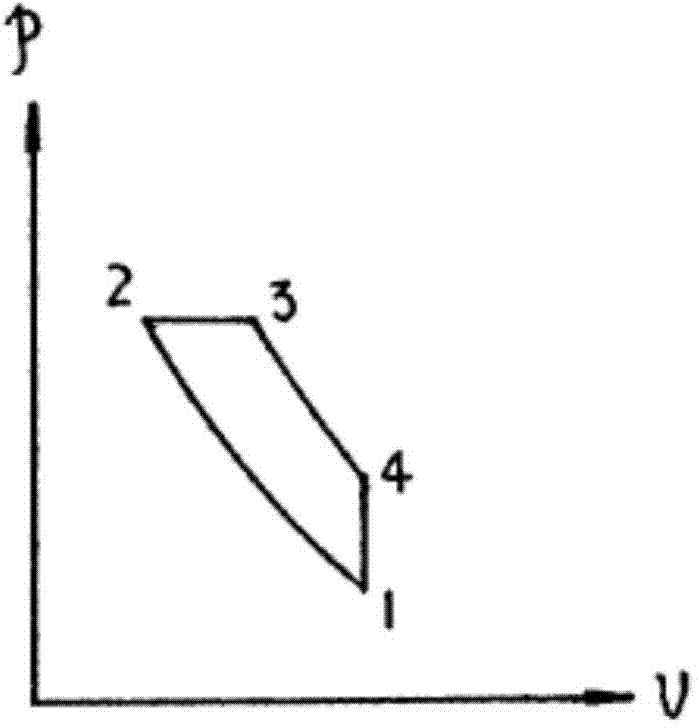

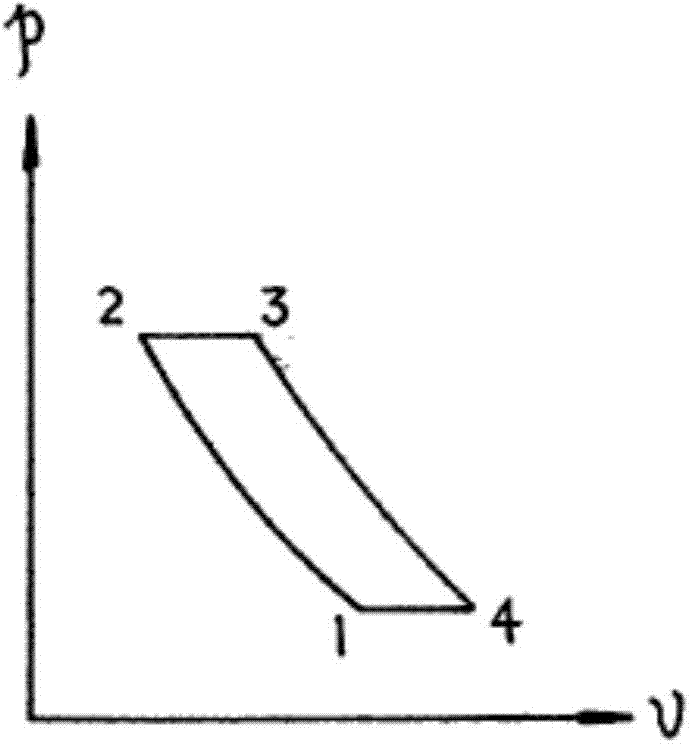

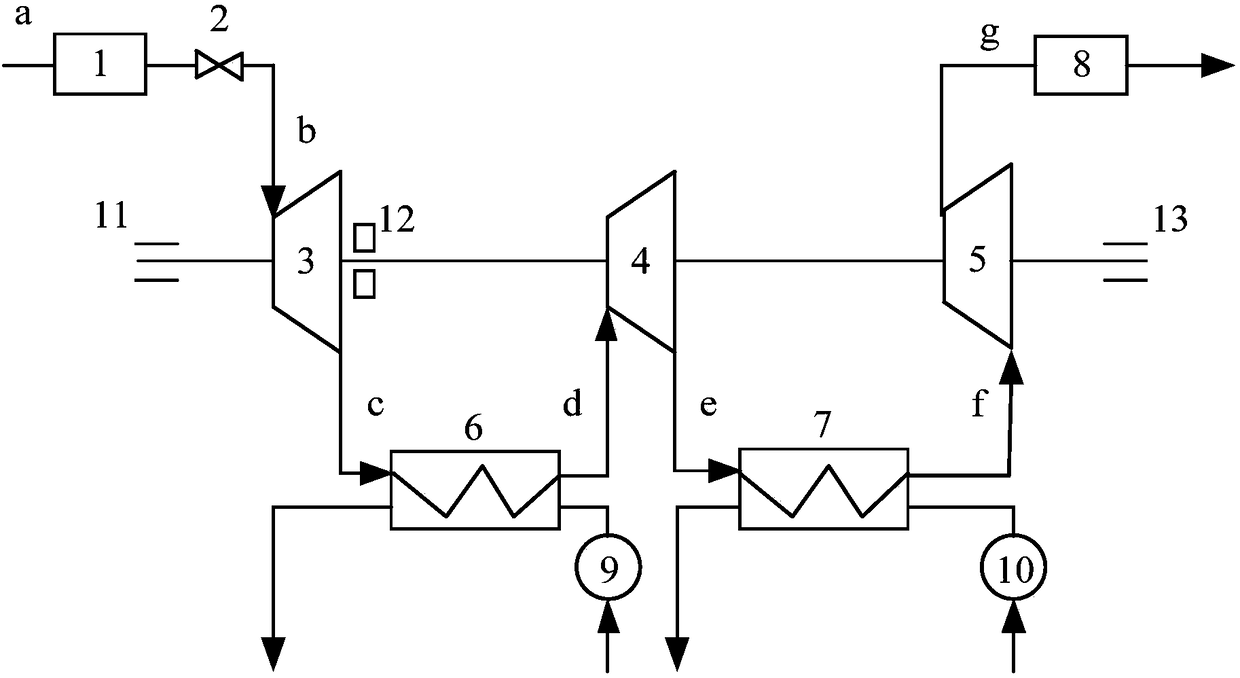

Semi-closed type timing constant-volume thermodynamic circulation method and system of prime motor

ActiveCN103883399AReduced Compression Power ConsumptionReduce fresh working fluid temperatureInternal combustion piston enginesGas turbine plantsThermal dilatationPrime mover

The invention provides a semi-closed type timing constant-volume thermodynamic circulation method and a semi-closed type timing constant-volume thermodynamic circulation system of a prime motor. The thermodynamic circulation method comprises six processes, namely multi-compression-stage intercooling, countercurrent heat exchanging, timing constant-volume burning, adiabatic expansion, aftercooling, and carbon dioxide and water removal. Heat-power conversion is achieved in the thermodynamic circulation. In the process of multi-compression-stage intercooling, compression power consumption is lowered; in the process of countercurrent heat exchanging, the enthalpy of an expanded working medium is recovered to participate in thermodynamic circulation; the process of timing constant-volume burning effectively inhibits the generation of harmful pollutants such as HC, CO, PM and NOx; in the process of adiabatic expansion, complete expansion for working is achieved; in the process of aftercooling, the working medium is further cooled to the environment temperature and the expansion ratio in the process of adiabatic expansion is enhanced; in the process of carbon dioxide and water removal, the carbon dioxide and the water generated in the process of timing constant-volume burning are removed; the remaining work mediums participate in the next thermodynamic circulation. By the method and the system, the direction is defined for designing a high-efficiency low-pollutant-emission and high-performance prime motor in the future.

Owner:GREEN ENERGY HIGH TECH GRP +5

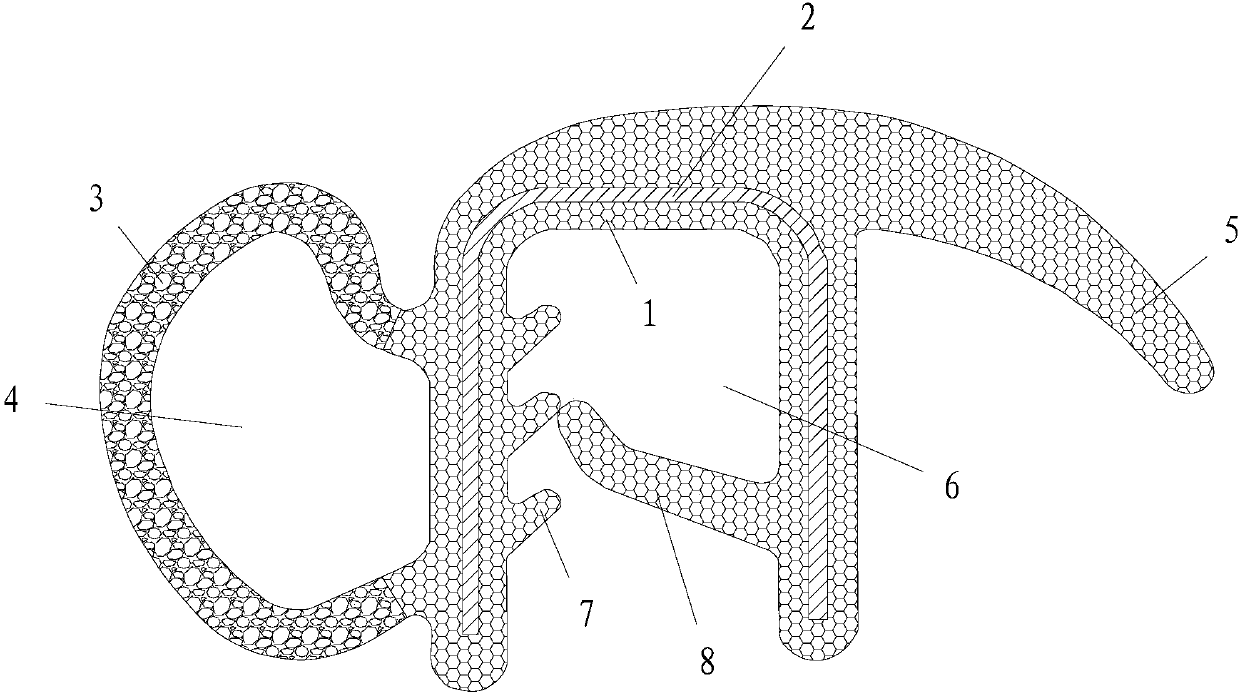

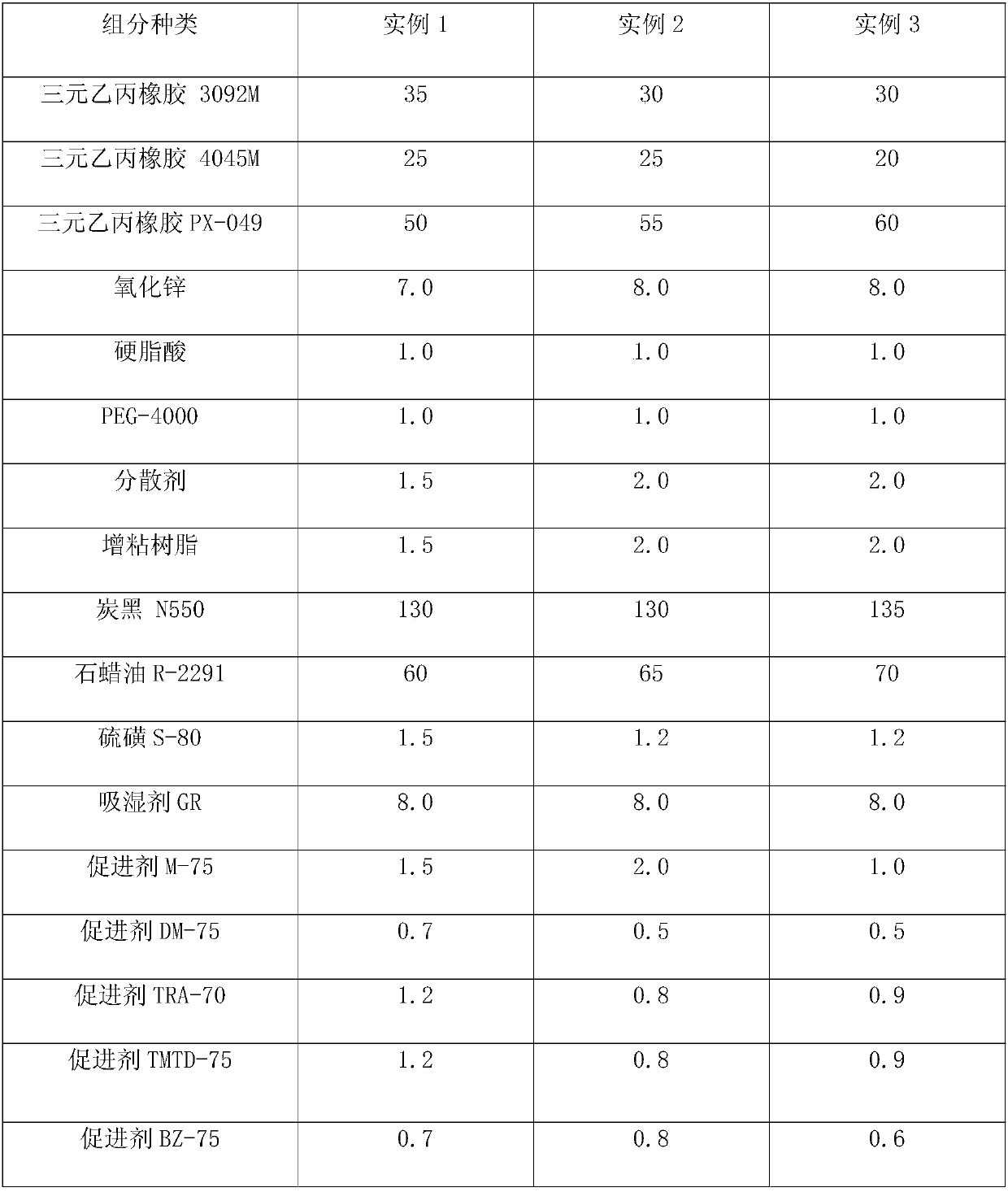

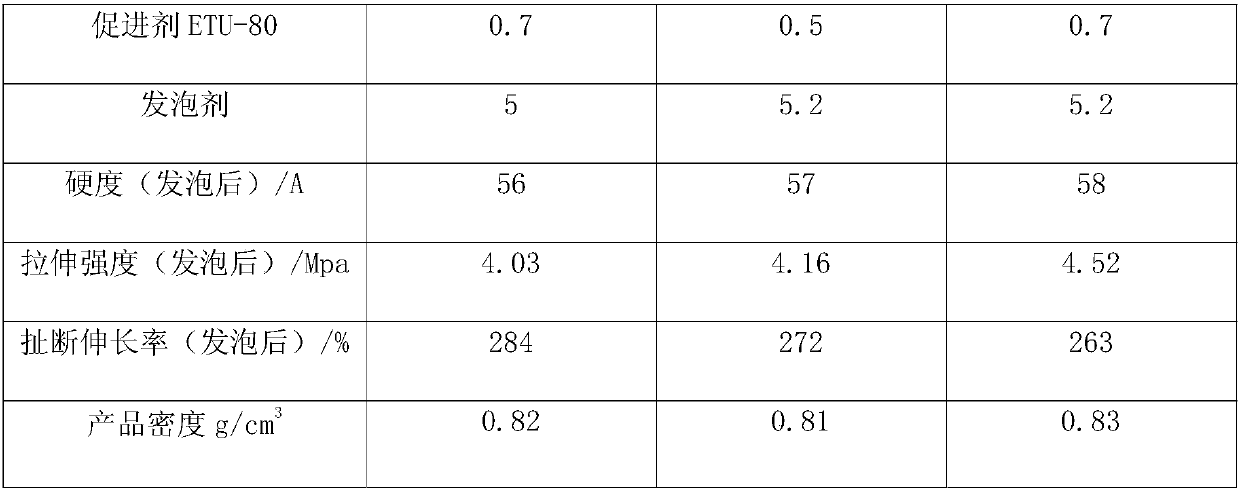

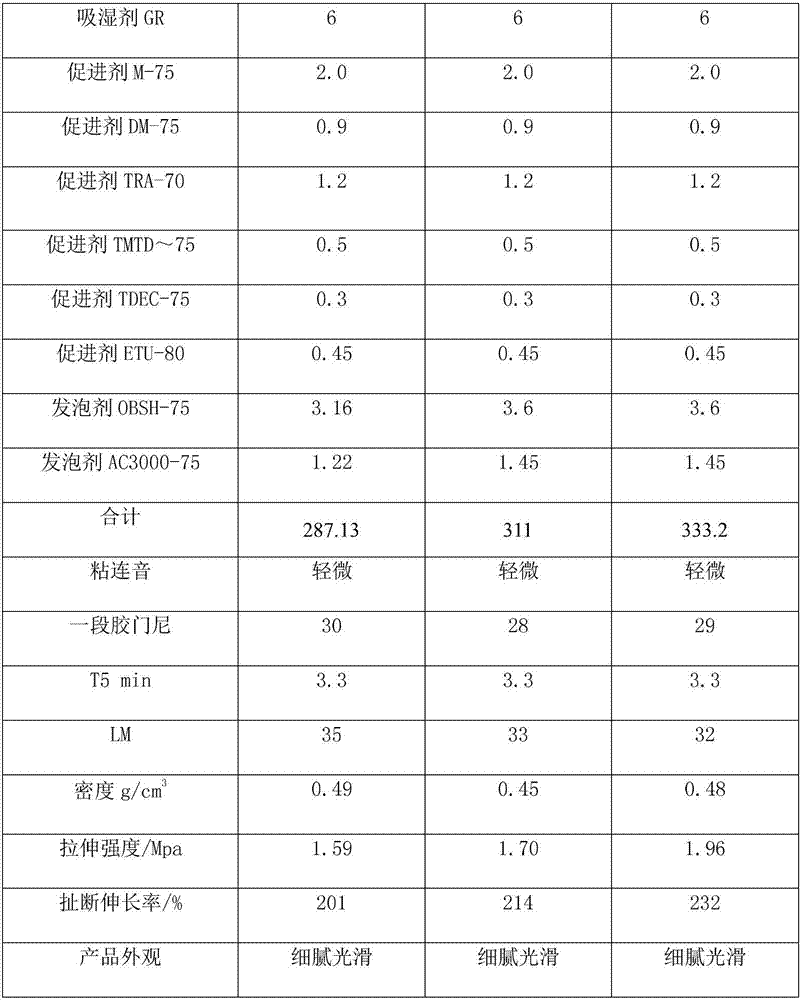

Sealing strip cladding sizing material and preparation method thereof as well as car door sealing strip and preparation method thereof

The invention provides a sealing strip cladding sizing material and a preparation method thereof as well as a car door sealing strip and a preparation method thereof. The sealing strip cladding sizingmaterial of the invention is prepared from the following components: EPDM (Ethylene-Propylene-Diene Monomer) 3092M, EPDM 4045M, EPDM PX-049, zinc oxide, stearic acid, PEG-4000, a dispersing agent, tackifying resin, paraffin oil R-2291, carbon black N550, sulfur S-80, a moisture absorbent GR, an accelerant M-75, an accelerant DM-75, an accelerant TRA-70, an accelerant TMTD-75, an accelerant BZ-75,an accelerant ETU-80, and a microsphere foaming agent EWE-60GE. The sealing strip cladding sizing material of the invention can implement the light-weight design of a sealing strip product, also hasrelatively good physical properties such as processability and surface quality, and can improve the quality of a sealing strip utilizing the sealing strip cladding sizing material.

Owner:NUOBO RUBBER PRODION

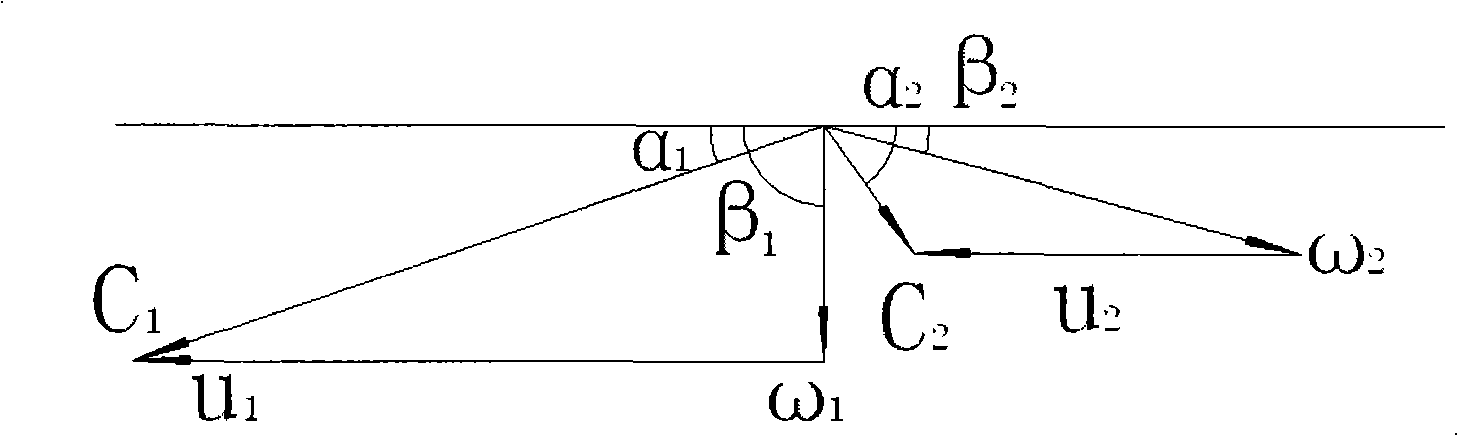

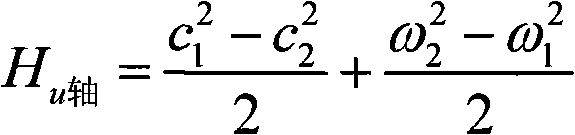

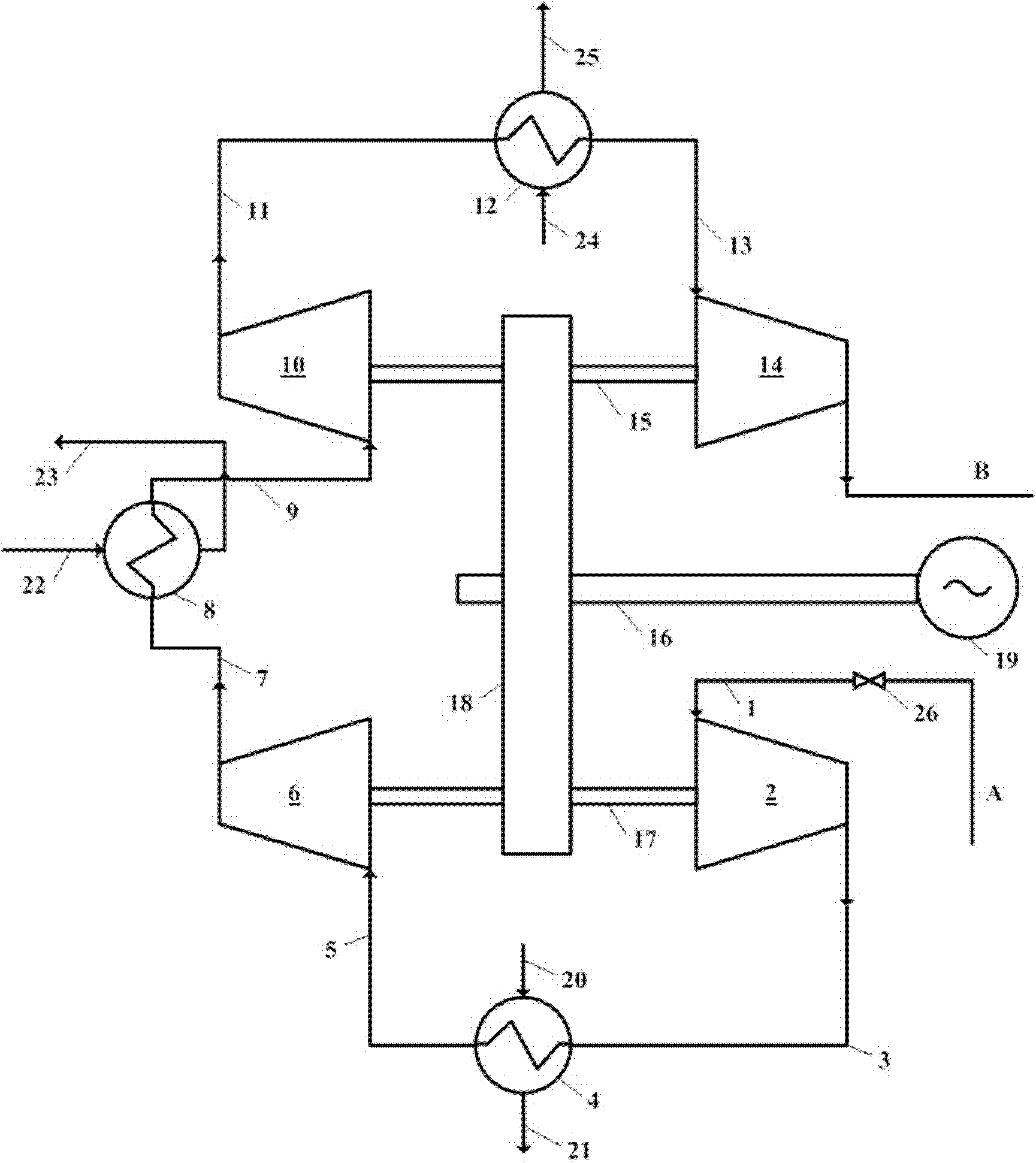

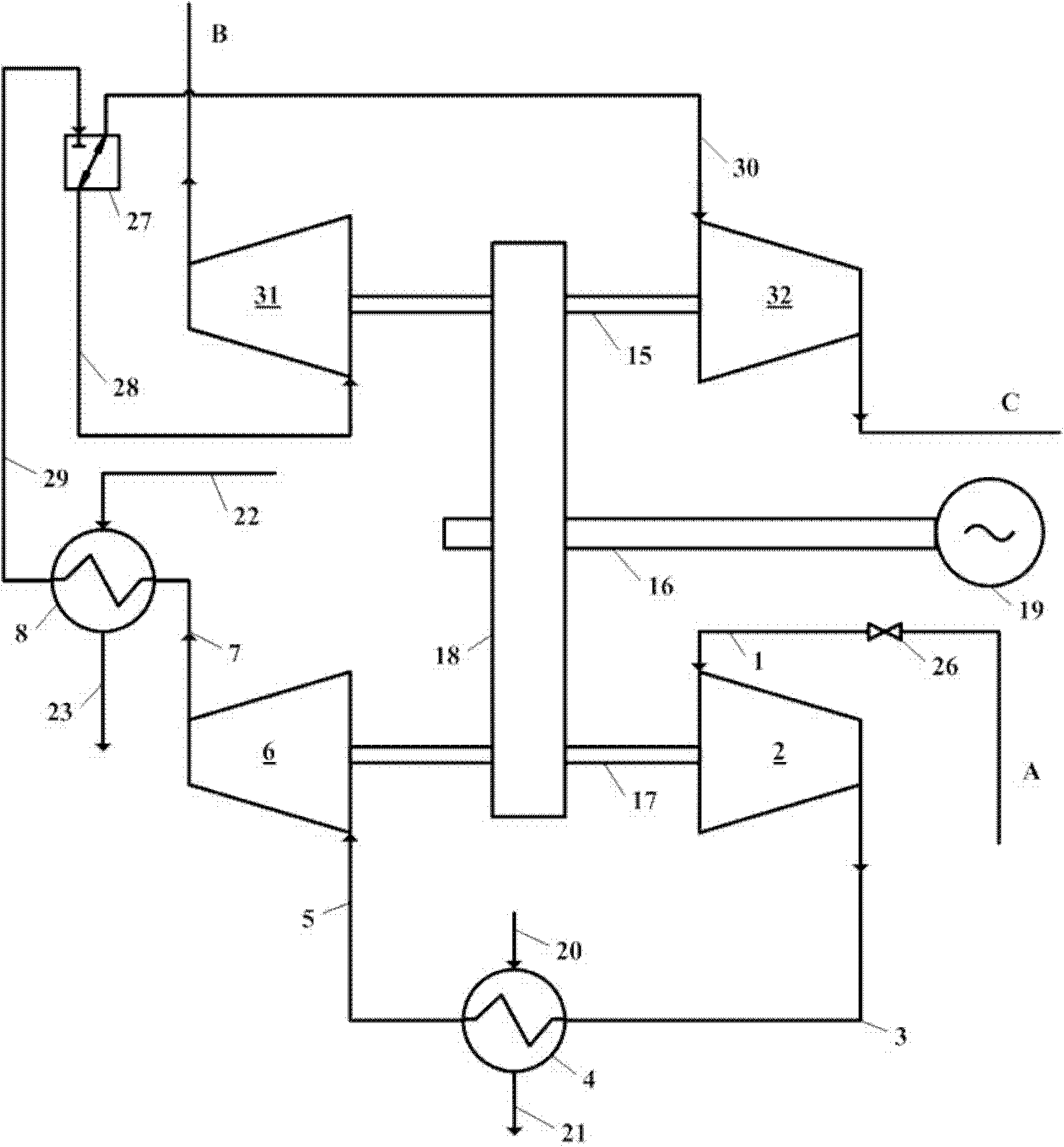

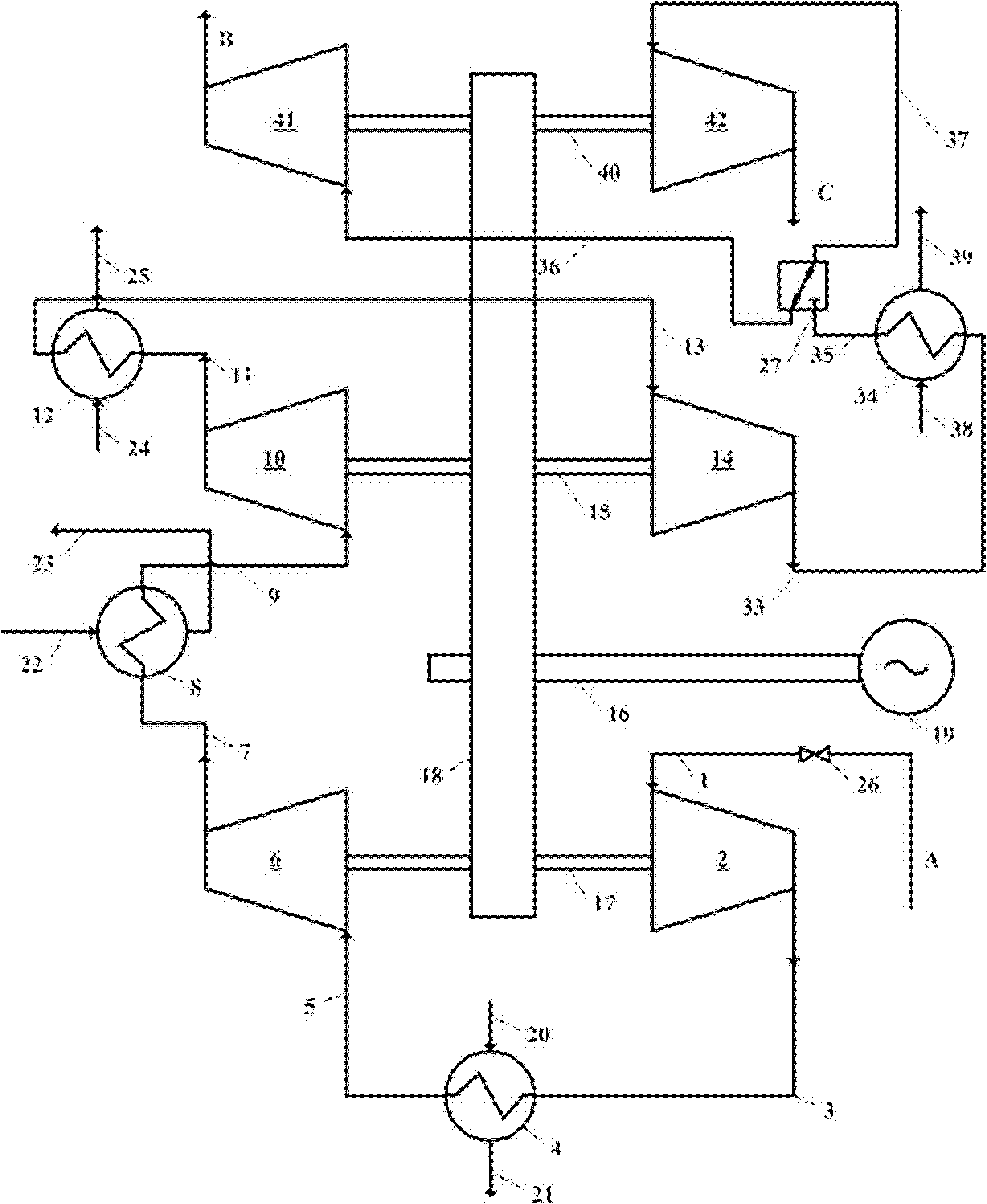

Multilevel centripetal turbine system

ActiveCN102758653AImprove efficiencyImprove operational reliabilityFrom solar energyCombination enginesRotation velocityEngineering

The invention discloses a multilevel centripetal turbine system and relates to the turbine technology. The system comprises a turbine expansion system, a reheating system and a driving system, the number of centripetal turbines of the system is even, the number of levels ranges from 2 to 8 and is determined by the expansion ratio, and each level of centripetal turbine comprises one or multiple centripetal turbines. Each two of the centripetal turbines are matched through rotating speed, has the same rotating speed and are arranged in a coaxial back-to-back form to offset axial force of a rotor. The inlet temperature of the multilevel centripetal turbine ranges from 220K to 973K, and the inlet pressure ranges from 3bar to 340bar. Heat sources of the reheating system are low-and-medium temperature (heat value) heat sources and especially are industrial residual heat and waste heat. Shaft work generated by each level of the centripetal turbines, after passing through a gearbox, is output by a main shaft to a motor or to beused as power sources for industrial production. The multilevel centripetal turbine system has the advantages of high efficiency and expansion ratio, simple and compact structure, high operating reliability, recoverability of low-and-medium temperature (heat value) waste heat and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

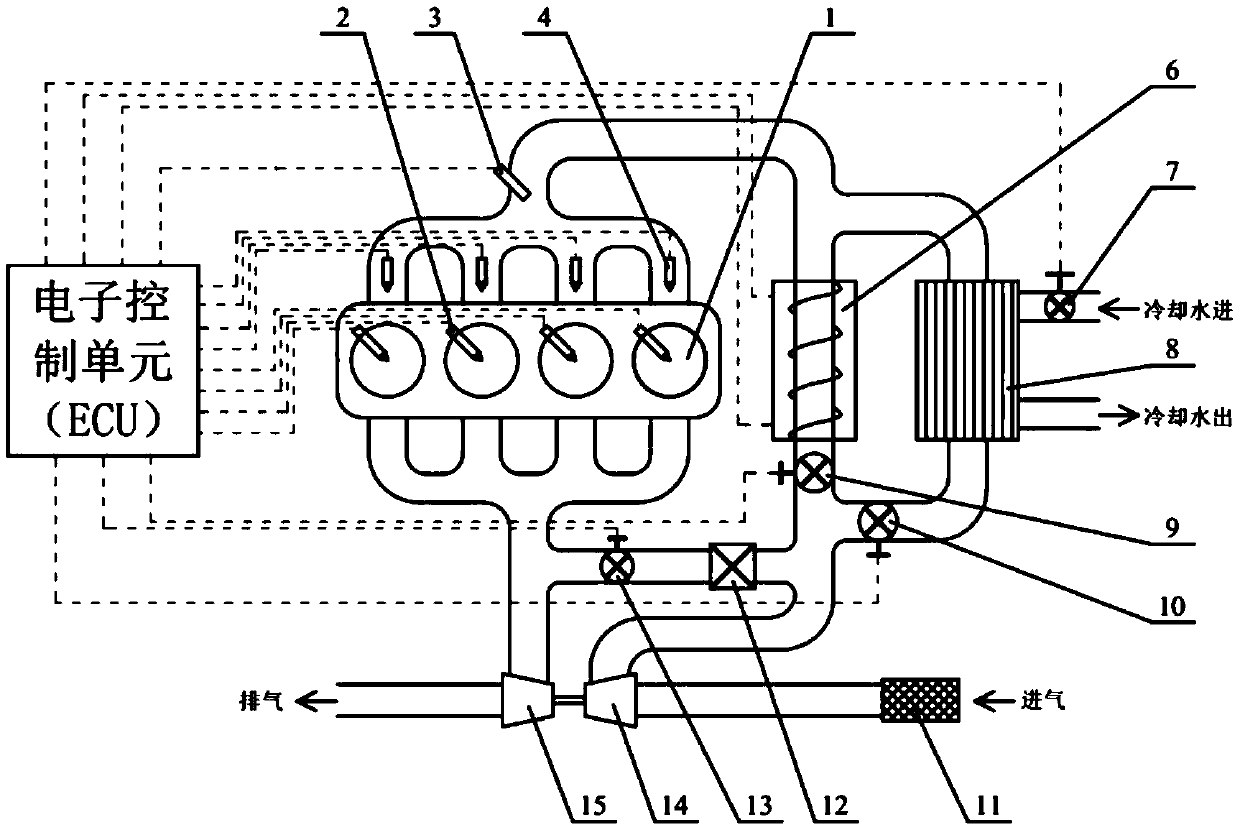

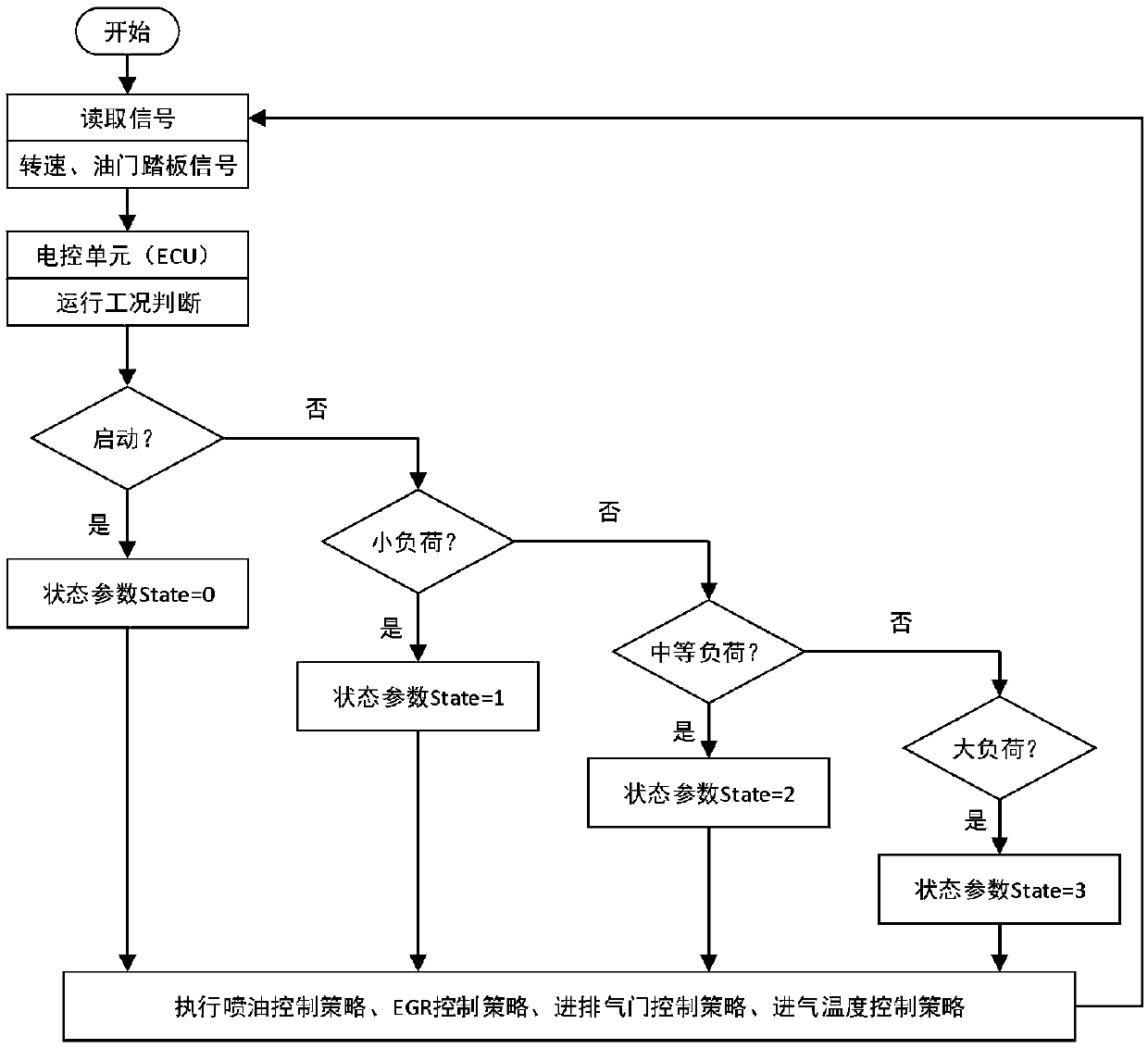

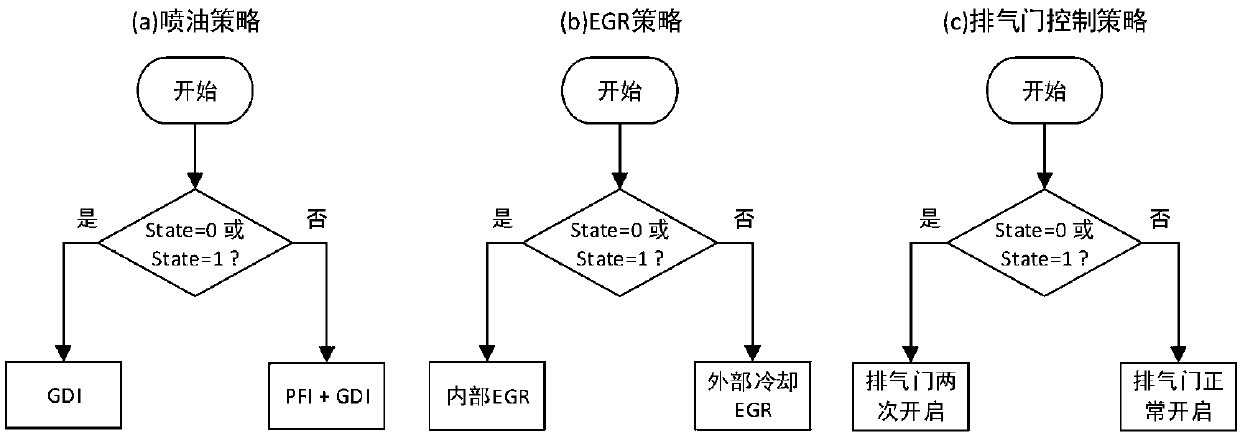

Control system and method capable of achieving efficient and clean compression ignition of gasoline in full condition range

ActiveCN109538347AImprove reliabilityEmission reductionValve arrangementsElectrical controlTemperature controlControl system

The invention discloses a control system and a method capable of achieving efficient and clean compression ignition of gasoline in a full condition range. The method comprises the steps of allowing anelectronic control unit to read an engine speed signal and an accelerator pedal position signal to judge an operation condition of an engine, if a judgment result in the first step is that the engineis under a start-up or small load condition, allowing the engine to adopt direct injection and internal EGR (exhaust gas recirculation) and execute a corresponding intake temperature control strategyand an intake valve control strategy, and if the judgment result of the first step is that the engine is under a moderate or heavy load condition, allowing the engine to employ a combined intake portinjection and direct injection strategy together with an appropriate external intercooling EGR rate and execute a corresponding intake temperature control strategy and an intake valve control strategy. The control system and the method solve the problems of high particle emission in the current direct injection technology, as well as unstable light load compression ignition and violent heavy loadcompression ignition of the gasoline.

Owner:TIANJIN UNIV

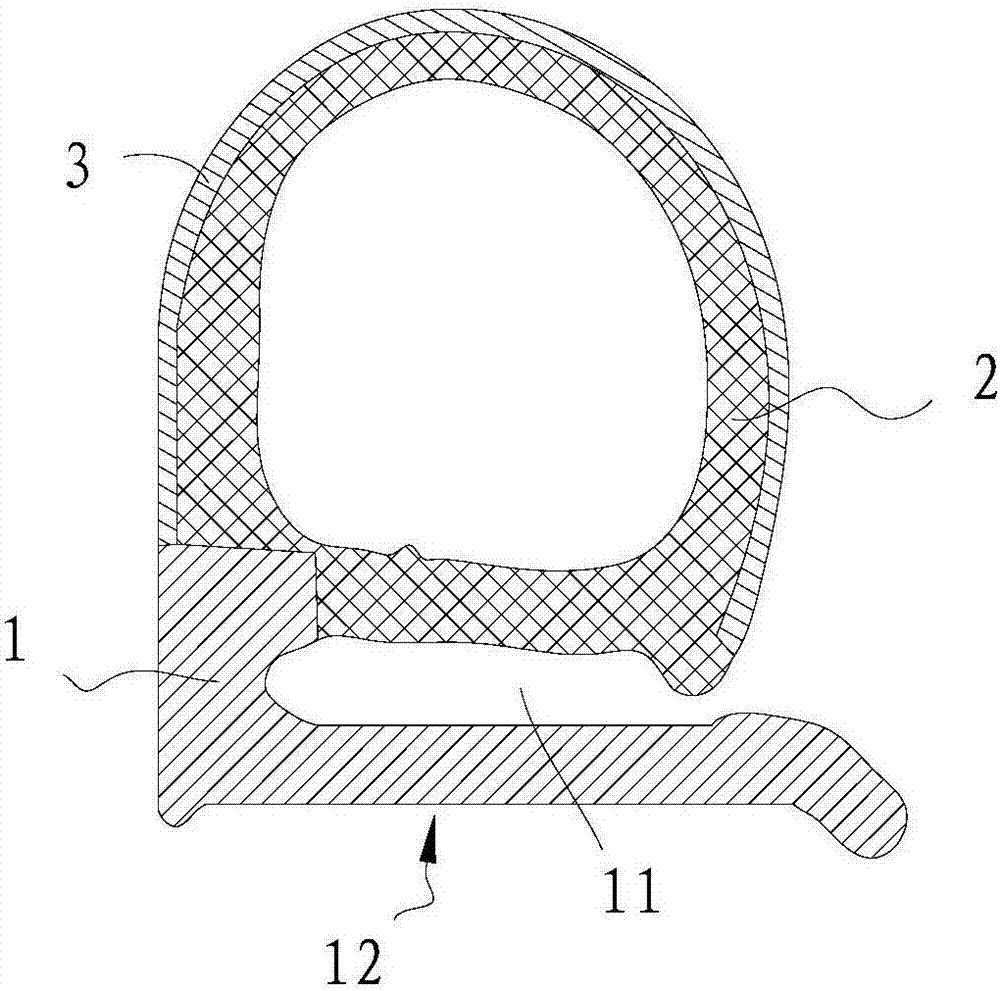

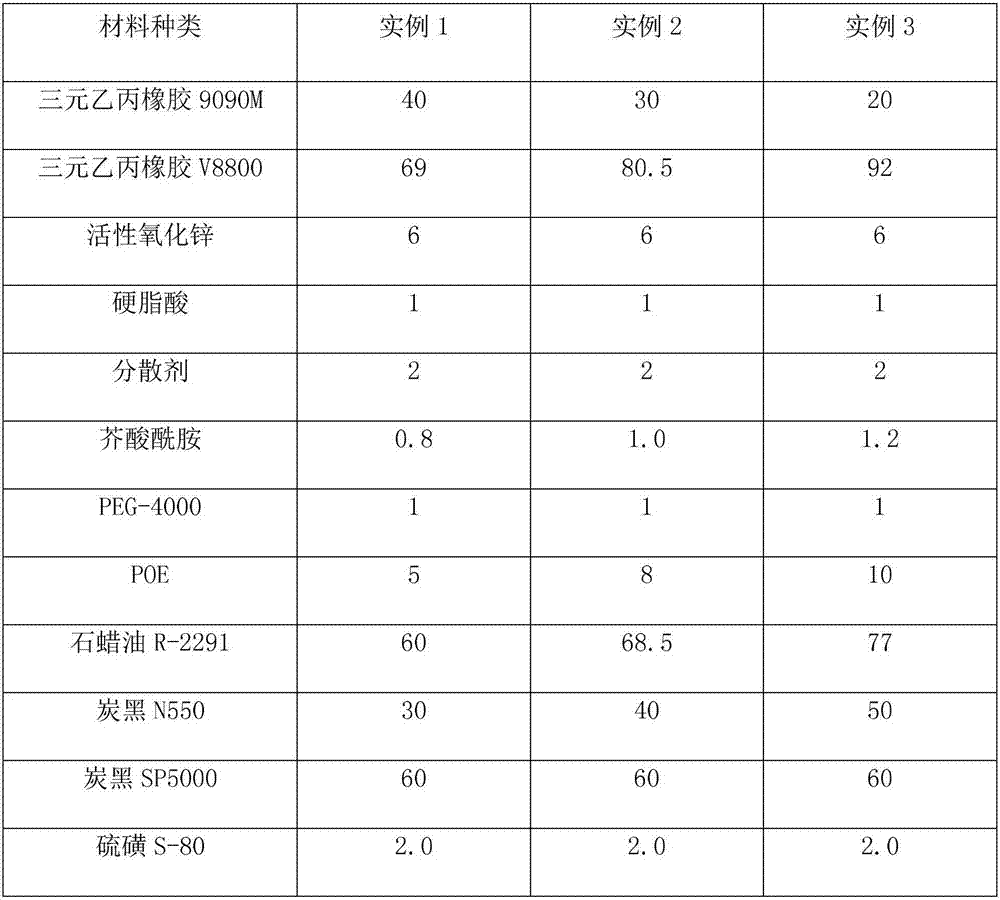

Sponge foaming rubber for car door sealing strip and preparation method thereof, car door sealing strip and preparation method thereof

InactiveCN107418061ALow viscosityConducive to lightweight designEngine sealsVehicle sealing arrangementsElastomerPolyolefin

The invention provides sponge foaming rubber for a car door sealing strip and a preparation method thereof, a car door sealing strip and a preparation method thereof. The sponge foaming rubber for the car door sealing strip, provided by the invention, is prepared from the following components in parts by weight: 20 to 40 parts of ethylene-propylene-diene monomer 9090M, 69 to 92 parts of ethylene-propylene-diene monomer V8800, 5 to 7 parts of active zinc oxide, 1 to 2 parts of stearic acid, 1 to 3 parts of a dispersant, 0.8 to 1.4 parts of erucamide, 1 to 2 parts of PEG-4000 (Polyethylene Glycol-4000), 5 to 10 parts of POE (Polyolefin Elastomer), 60 to 77 parts of paraffin oil R-2291, 30 to 50 parts of carbon black N550, 50 to 70 parts of carbon black SP5000, 1.5 to 2.5 parts of sulfur S-80, 6 to 10 parts of a moisture absorbent GR, 3 to 6.4 parts of an accelerant, 3 to 3.6 parts of a foaming agent OBSH-75 (Oxydibenzenesulfonyl Hydrazide-75) and 1.1 to 1.5 parts of a foaming agent AC3000-75. By adopting a formula of the sponge foaming rubber for the car door sealing strip, provided by the invention, the prepared sponge rubber has relatively low density and can meet a lightweight design; meanwhile, the obtained rubber also can have relatively good physical performance, so that the utilization quality of the car door sealing strip utilizing the sponge foaming rubber can also be improved.

Owner:NUOBO RUBBER PRODION

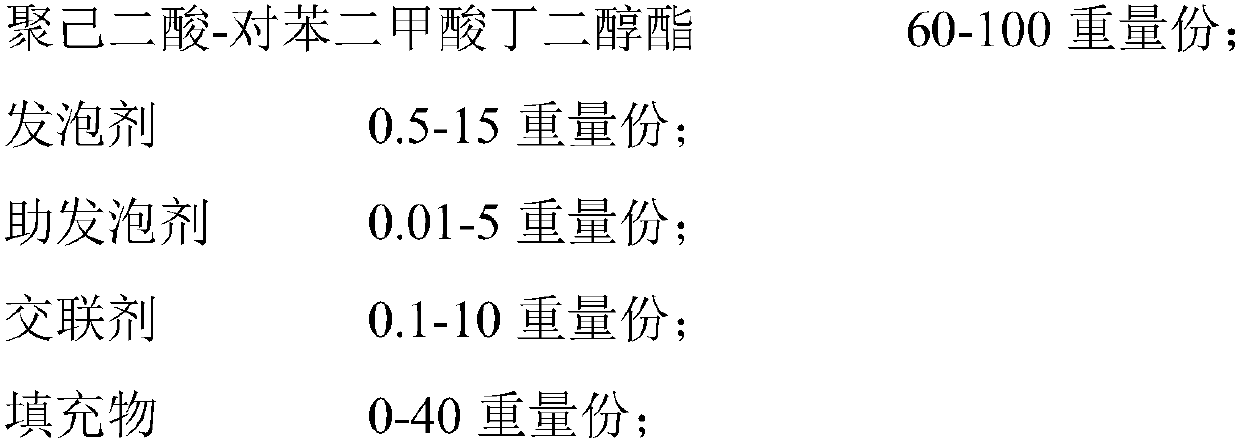

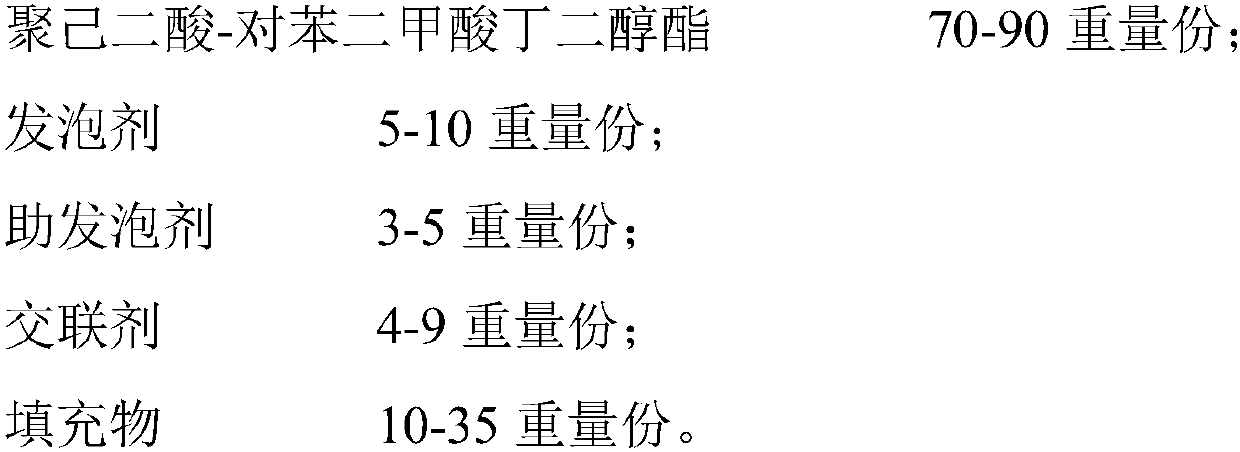

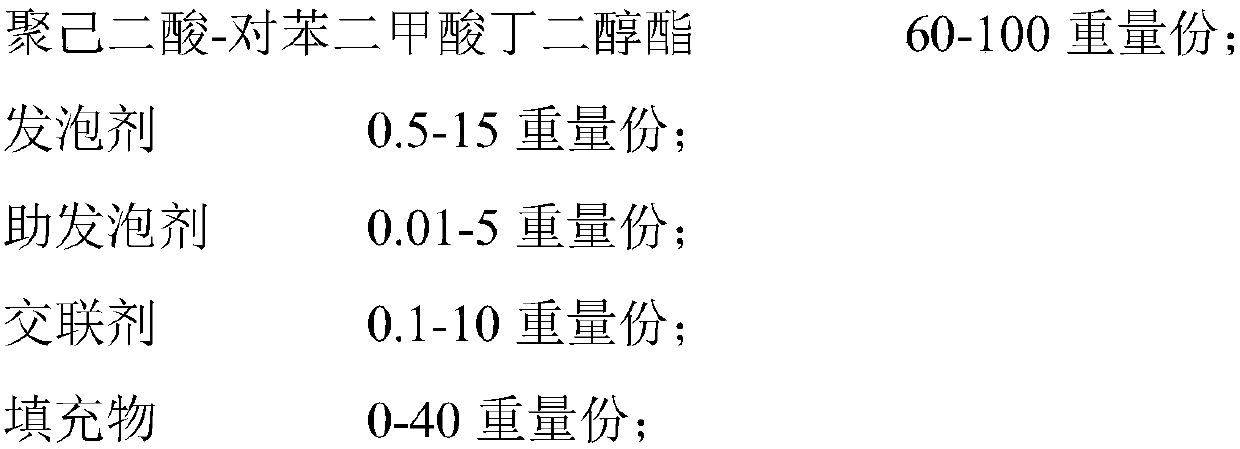

High-filling biodegradable radiation cross-link foam material and method for preparing same

The invention discloses a high-filling biodegradable radiation cross-link foam material and a method for preparing the same, and belongs to the technical field of polymers and processing of the polymers. The high-filling biodegradable radiation cross-link foam material is excellent in physical performance, good in water resistance and durability and high in foaming ratio, and the mechanical properties of the high-filling biodegradable radiation cross-link foam material can be regulated and controlled in wide ranges. The high-filling biodegradable radiation cross-link foam material comprises, by weight, 60-100 parts of poly-adipic acid-terephthalic acid butanediol ester, 0-40 parts of fillers, 0.5-15 parts of foaming agents, 0.01-5 parts of foaming auxiliaries and 0.1-10 parts of cross-linking agents. The cross-linking agents are a type of or a plurality of types of vinyltrimethylsilane, vinyltriethoxysilane and vinyl tri-(beta-methoxyethoxy) silane. The high-filling biodegradable radiation cross-link foam material and the method have the advantages that the high-filling biodegradable radiation cross-link foam material is excellent in physical performance, good in water resistance and durability and high in foaming ratio; foaming is carried out by the aid of the corresponding added fillers, and accordingly the mechanical properties of the high-filling biodegradable radiation cross-link foam material can be regulated and controlled in the wide ranges.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Quick and dynamic vacuum calibration method for vacuum gauge

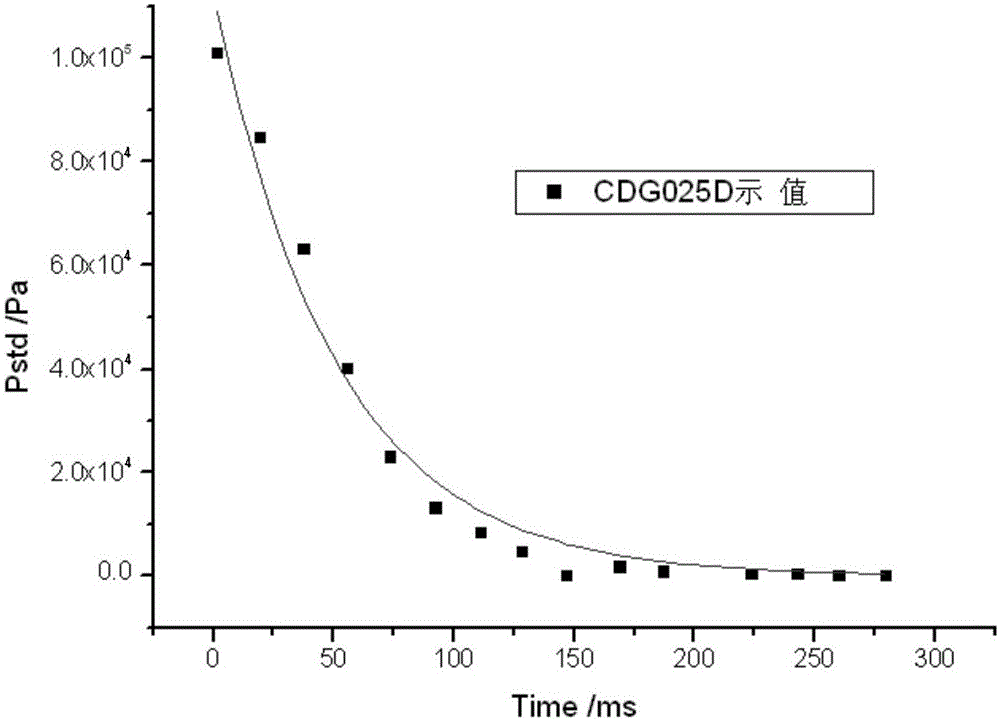

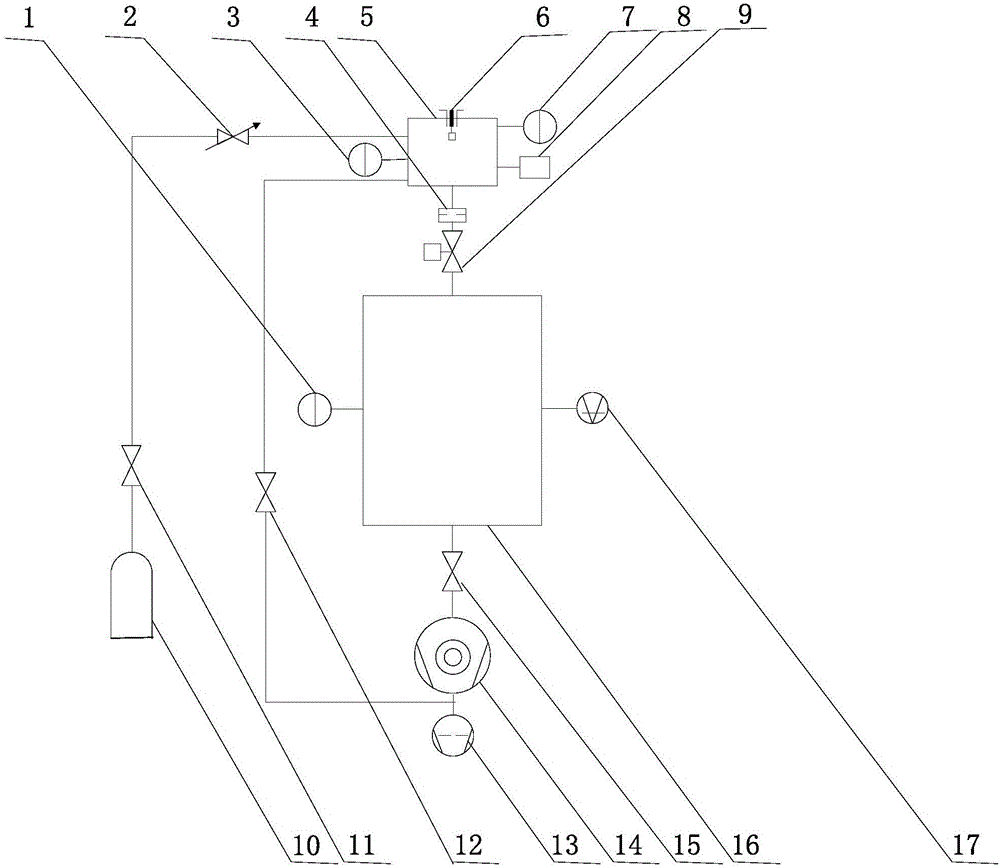

ActiveCN105004480AGuaranteed speedReduced settling timeFluid pressure measurementCalibration gasPressure curve

The invention discloses a quick and dynamic vacuum calibration method for a vacuum gauge, which can realize quick and dynamic vacuum gauge calibration with an ms-grade response time. The quick and dynamic vacuum calibration method comprises the steps of replacing a vacuum valve between an upstream chamber and a downstream chamber in a vacuum calibration device in which a static expansion method by an ultrahigh vacuum gate valve; connecting a calibrated vacuum gauge with an upstream chamber; determining whether a current limiting component is mounted and the type of the flow guiding parameter of the current limiting component according to the response time of the calibrated vacuum gauge; after calibration is started, inflating standard gas into the upstream chamber until an initial pressure is reached; opening the ultrahigh vacuum gate valve for starting a quick gas expansion process and acquiring the displayed number of the calibrated vacuum gauge; and calculating a dynamic vacuum calibration standard pressure pstd according to a formula pstd=p10exp(-t / [tao]), drawing a dynamic vacuum calibration standard pressure curve in which the pstd changes along with time t, and filling the displayed number of the calibrated vacuum gauge for obtaining a calibration result.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Method for sealing closed gas drainage hole in soft coal bed areas

ActiveCN103244073ASolve the problem of air leakageReasonable designSealing/packingFree wallCement paste

The invention relates to the technical field of mine ventilation and safety-type coal bed gas drainage, particularly to a method for sealing soft coal bed gas drainage hole areas, and solves the problem of severe air leakage of soft coal bed gas drainage hole areas. The method comprises the steps of (1), sealing gas drainage holes on a roadway lane; (2), evenly distributing 2-4 closed short holes which are 6-8m in depth within a range with the circle center of each gas drainage hole serving as the center and the radius of 1-1.5m; (3), filling each closed short hole with low-consistence high-expansion cement which permeates into coal bed fracture areas until cement paste seeps from a coal wall; (4), standing for 20-24h for solidification of cement paste to form a fracture-free wall composed of coal bodies and cement. According to the method, the design is reasonable, the hole sealing technology is improved, the defects of existing hole sealing technologies are overcome, and the problem of air leakage of coal walls is solved thoroughly.

Owner:JINCHENG MINGSHI COAL LAYER USING

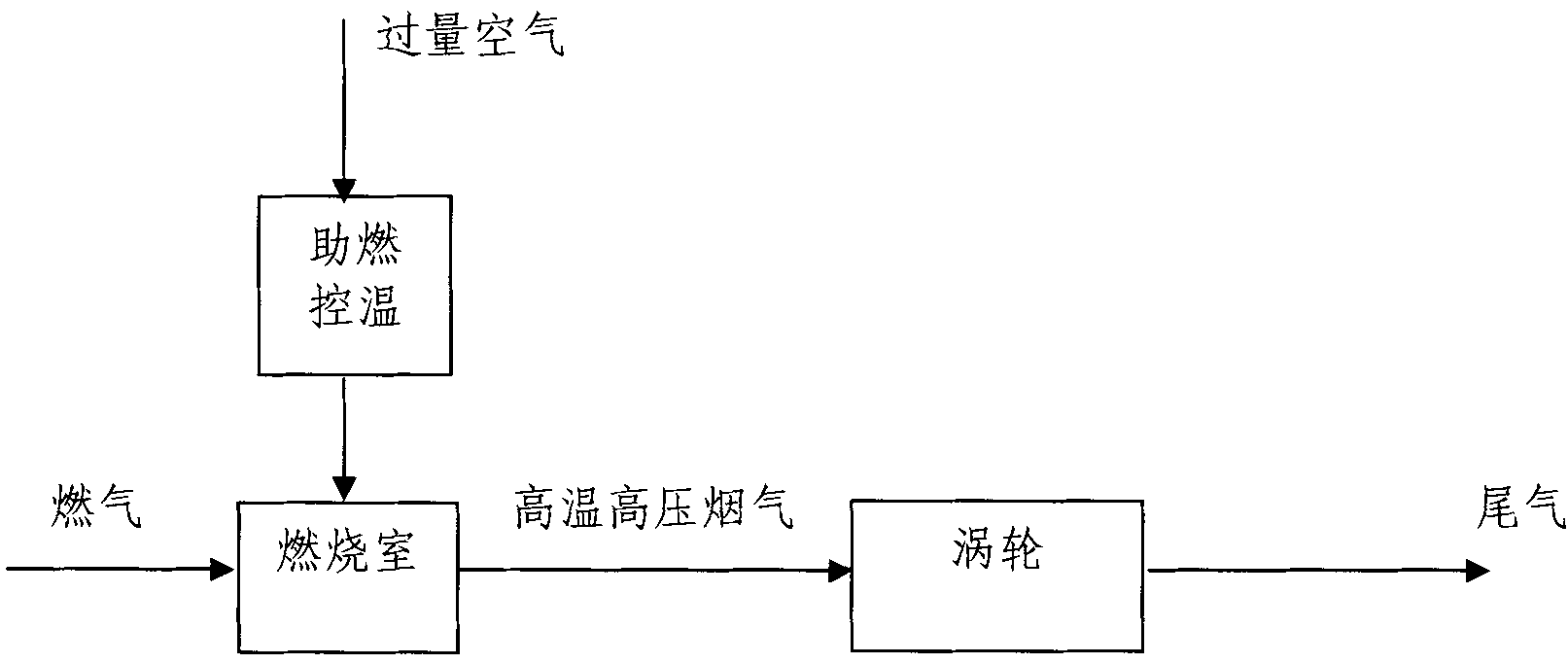

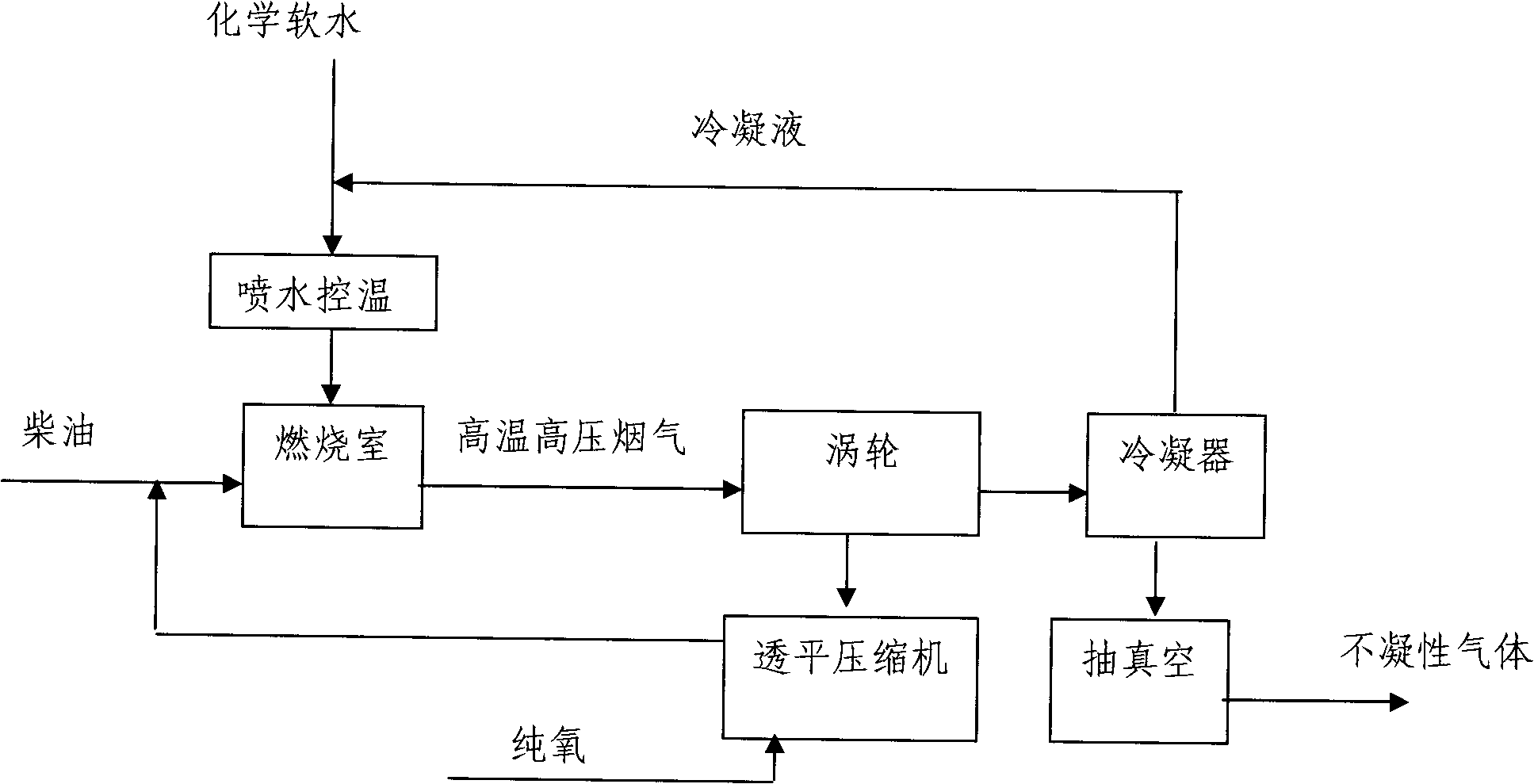

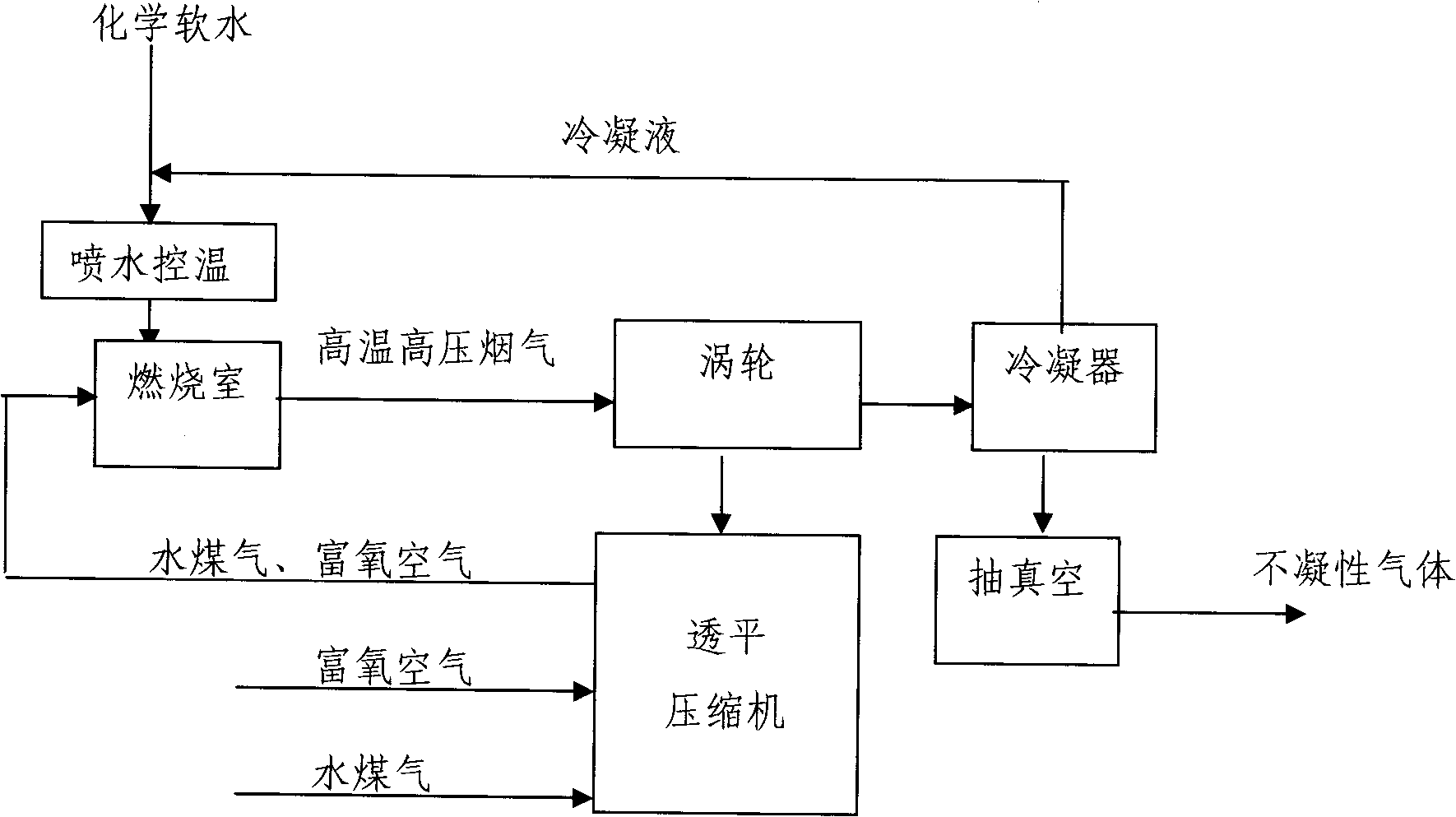

Thermal circulation process of gas turbine based on pure oxygen or oxygen-enriched combustion

InactiveCN101787930AIncrease temperatureIncrease intake pressureTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWater vapor

The invention discloses a thermal circulation process of a gas turbine based on pure oxygen or oxygen-enriched combustion, which comprises the following steps: compressing liquid fuel or gas; compressing oxygen gas or oxygen-enriched air; carrying out mixed combustion of the liquid fuel or the gas and the oxygen gas or the oxygen-enriched air; spraying water for controlling temperature; expanding high temperature and high pressure flue gas after combustion in the gas turbine for applying work; cooling most of water vapor in tail gas with circulating water in a condenser, wherein the condensed water circulates to a combustion chamber to be used for spraying water for controlling temperature, and the non-condensable gas is extracted by a vacuum pump; or exhausting gas under normal pressure without the use of the vacuum pump. By adopting direct combustion of the pure oxygen or the oxygen-enriched air and adopting the water spraying mode to replace excess air for controlling temperature, the air inflow is small, the amount of compression of a compressor is small, the restriction of the optimal pressure gas ratio is eliminated, the circulating intake pressure is improved, the non-condensable gas in the tail gas is little, and the exhaust pressure can be reduced through vacuum condensation. Because the process has high circulating intake pressure and low exhaust pressure, the expansion ratio of the gas turbine is improved, thereby improving the generating efficiency.

Owner:北京名都厚德科技有限公司

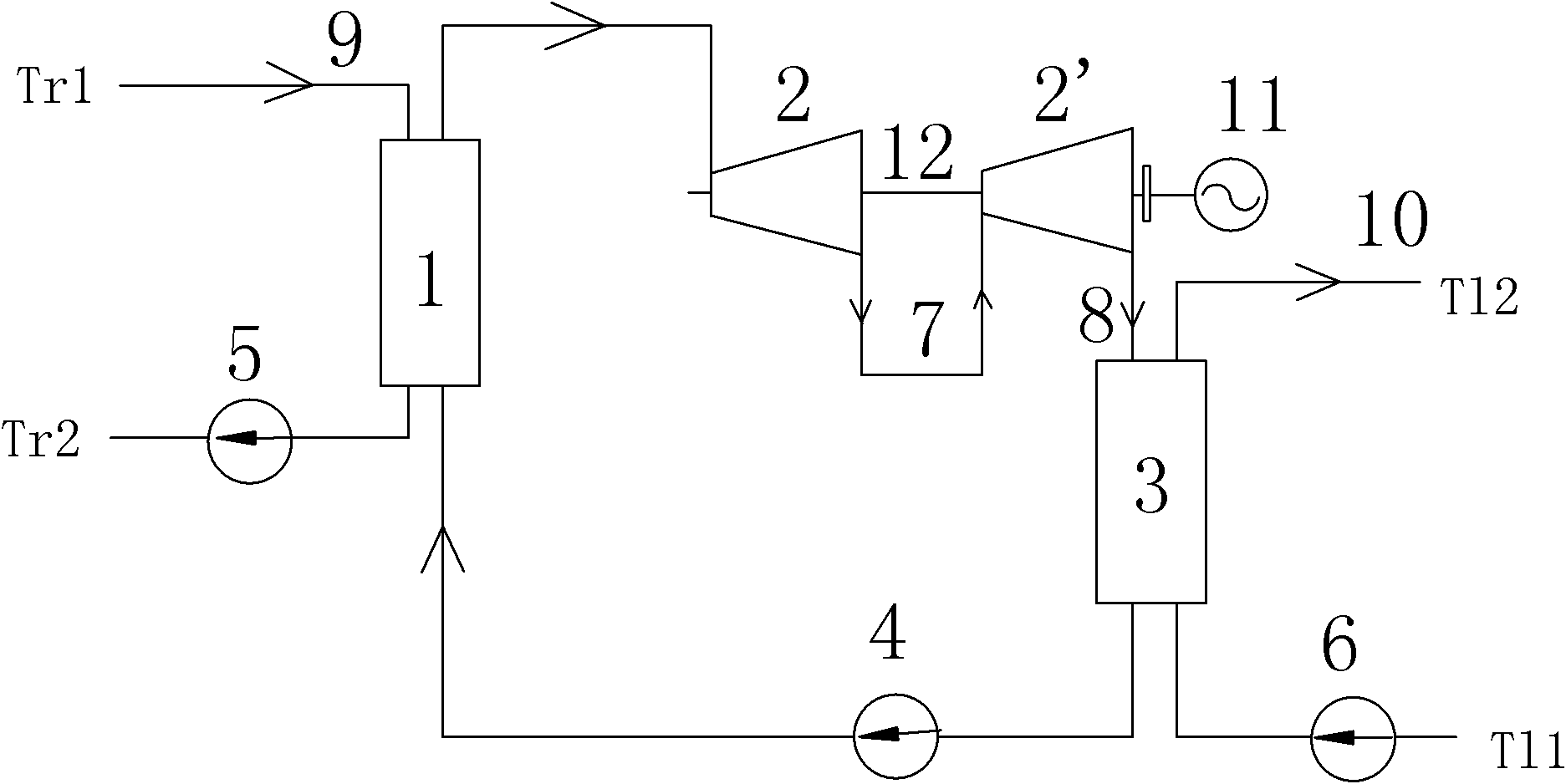

Power system of bicirculating two-level screw expander

InactiveCN102182528AZero emissionMeet the requirements of energy saving and environmental protectionGeothermal energy generationCombination enginesBoiling pointClosed loop

The invention relates to a power system of a bicirculating two-level screw expander, comprising an evaporator and a condenser, a working medium circulating passage formed between the evaporator and the condenser, a heating passage formed by the evaporator and a heat source inlet as well as a heat source outlet, and a cooling passage formed by the condenser and a cooling water inlet as well as a cooling water outlet, wherein a power device of the two-level screw expander is arranged on the working medium circulating passage between the working medium outflow side of the evaporator and the working medium inflow side of the condenser. The power system accords with energy conservation and environmental protection requirements, an organic working medium with a low boiling point adopted by the working medium circulating passage plays a role of a medium in a closed loop, and no consumption exists under a good sealing condition; the requirement on residual heat parameters is low, and no direct contact exists in heat exchange between the circulating working medium with the low boiling point and heated fluids as well as cooling water; and after the two-level screw expander is adopted, a system can obtain a greater expansion ratio, pressure drop and enthalpy drop are realized, and the heat efficiency of the system can reach 15 percent.

Owner:TIANJIN UNIV

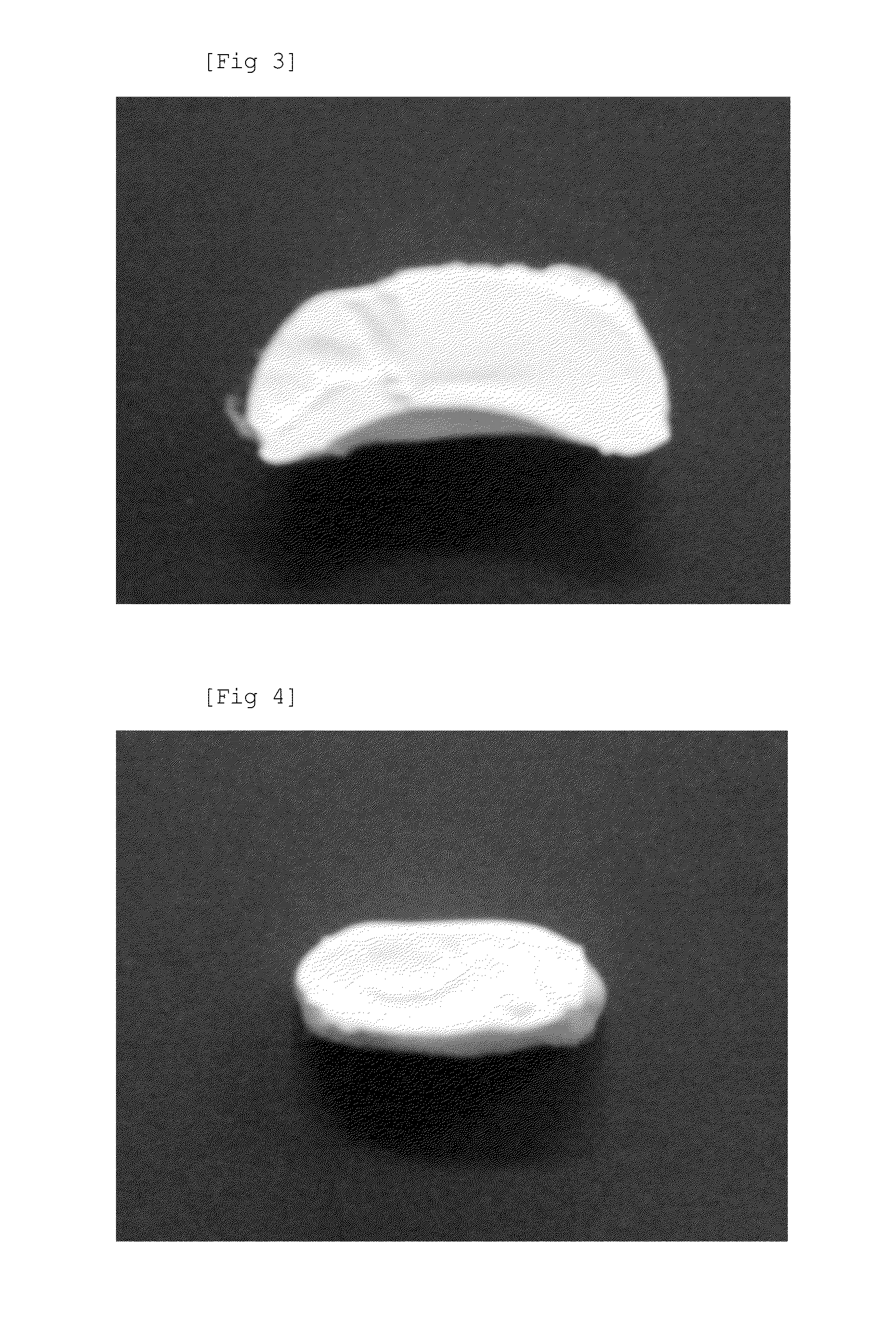

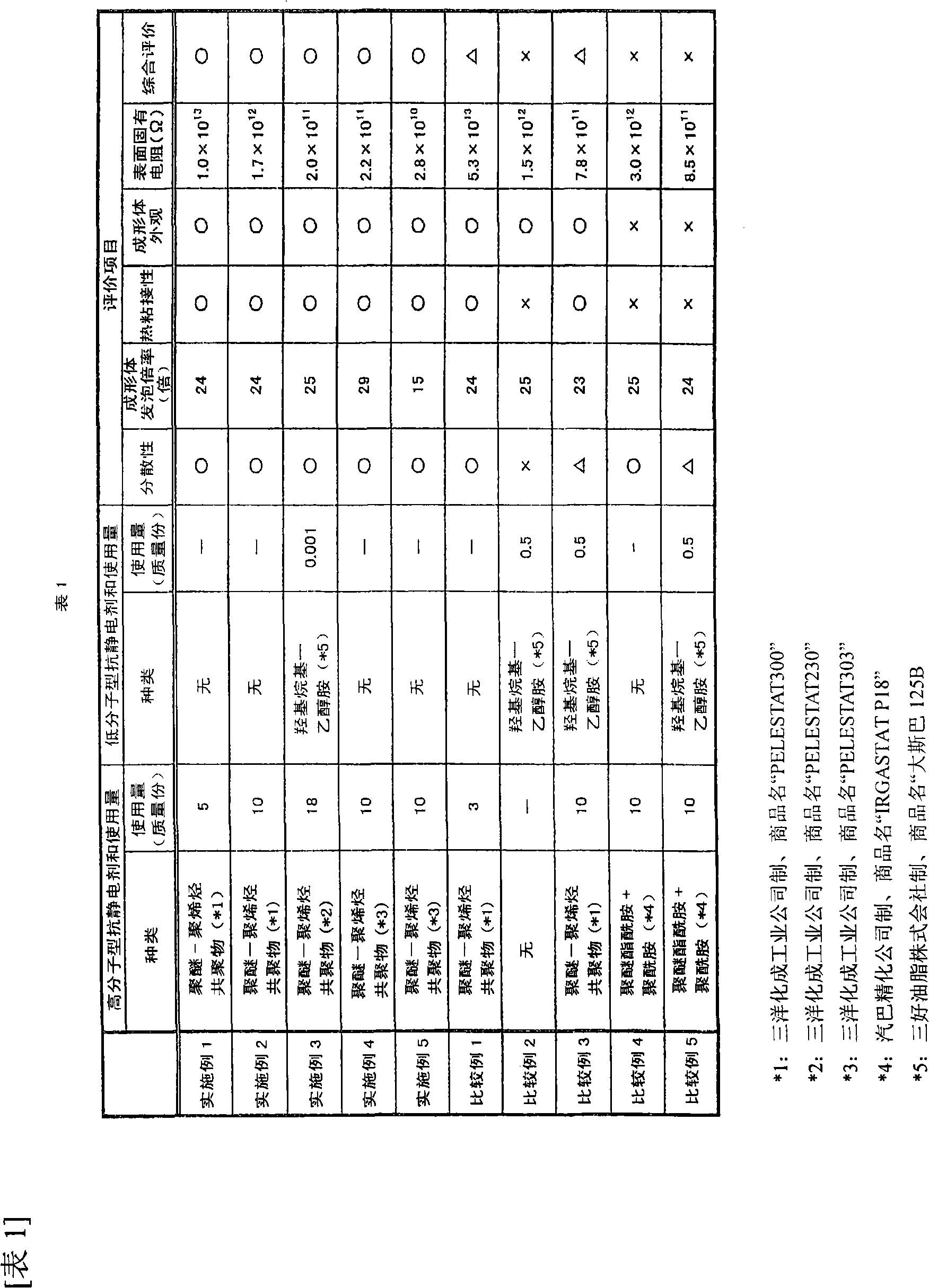

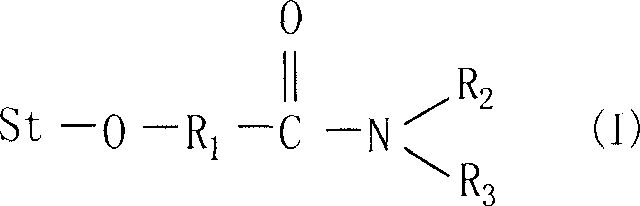

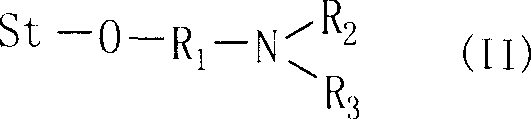

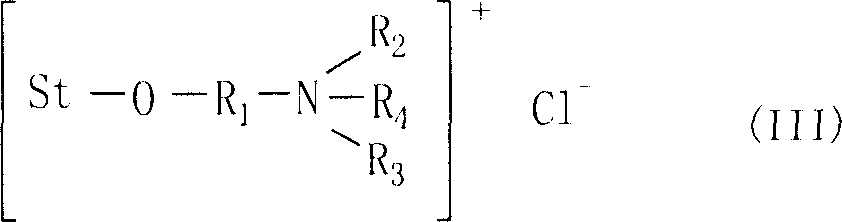

Polyolefin resin pre-foamed particle having antistatic property, and molded article produced from the particle

ActiveCN101679663AImprove anti-static effectIncrease the expansion ratioProduction ratePolymer science

Disclosed is a polyolefin resin pre-foamed particle which is produced by foaming a polyolefin resin particle formed from a polyolefin resin composition comprising 100 parts by weight of a polyolefin resin, less than 0.01 part by weight of a low-molecular-weight antistatic agent and 5 to 30 parts by weight (inclusive) of a polyether-polyolefin resin block copolymer antistatic agent. The polyolefinresin pre-foamed particle has an antistatic property. In the production of the polyolefin resin pre-foamed particle, the dispersion state of the polyolefin resin particle formed from the polyolefin resin composition in an aqueous dispersion medium is improved compared to a conventional particle. Therefore, the productivity rate of the pre-foamed particle can be improved.

Owner:KANEKA CORP

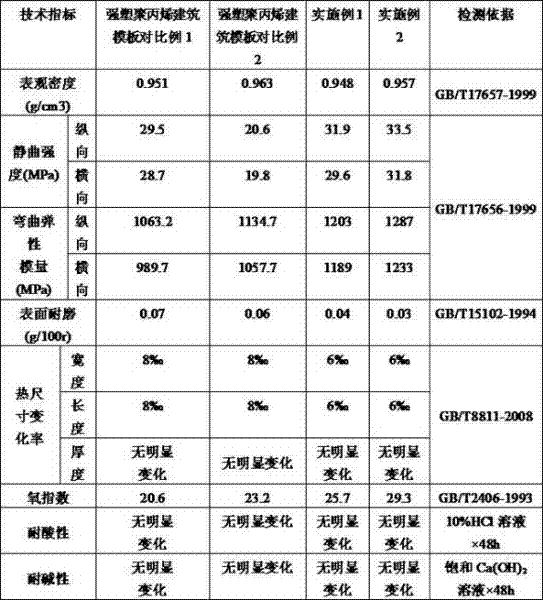

Novel environment-friendly composite reinforced polypropylene building template

InactiveCN102604205AImprove melt strengthDegree of crystallinityForming/stuttering elementsEnvironmental resistanceThermal expansion

The invention relates to a novel environment-friendly composite reinforced polypropylene building template, belonging to the technical field of building template preparation. By virtue of the interaction between fine powder of waste tires and polypropylene-styrene dibromide graft copolymer and aluminum hydroxide / polypropylene, the bonding force among the components is increased, the reinforced plastic polypropylene building template is subjected to physical blending and chemical modification, so that not only the overall properties of the reinforced plastic polypropylene building template areimproved and the flame retardant function of the reinforced plastic polypropylene building template is enhanced, but also a new field of recycling waste tires is opened. Through the composite reinforced polypropylene building template provided by the invention, the problems that the strength and rigidity of the existing composite plastic building template cannot meet the construction requirements, the thermal expansion and cold contraction coefficient is large and the electric welding dregs are likely to scald a face plate are solved, and a large amount of natural rubber and petroleum resources are saved. The composite reinforced polypropylene building template has the advantages of high strength, good flame retardant effect, easily-accessible raw materials and simplicity in production, and can be widely used as the construction template in construction engineering, hydroelectric structures, irregular design of bridges and tunnels and the like.

Owner:HUBEI XINLONG PLASTICS

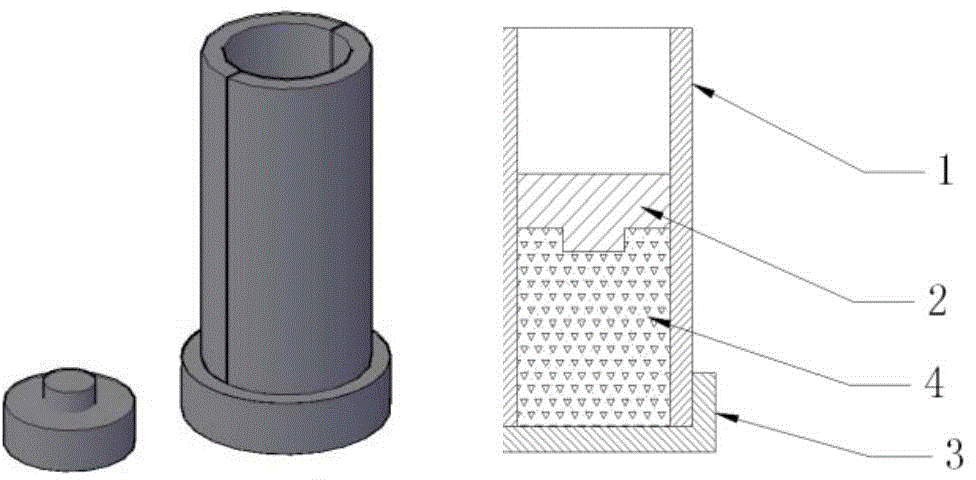

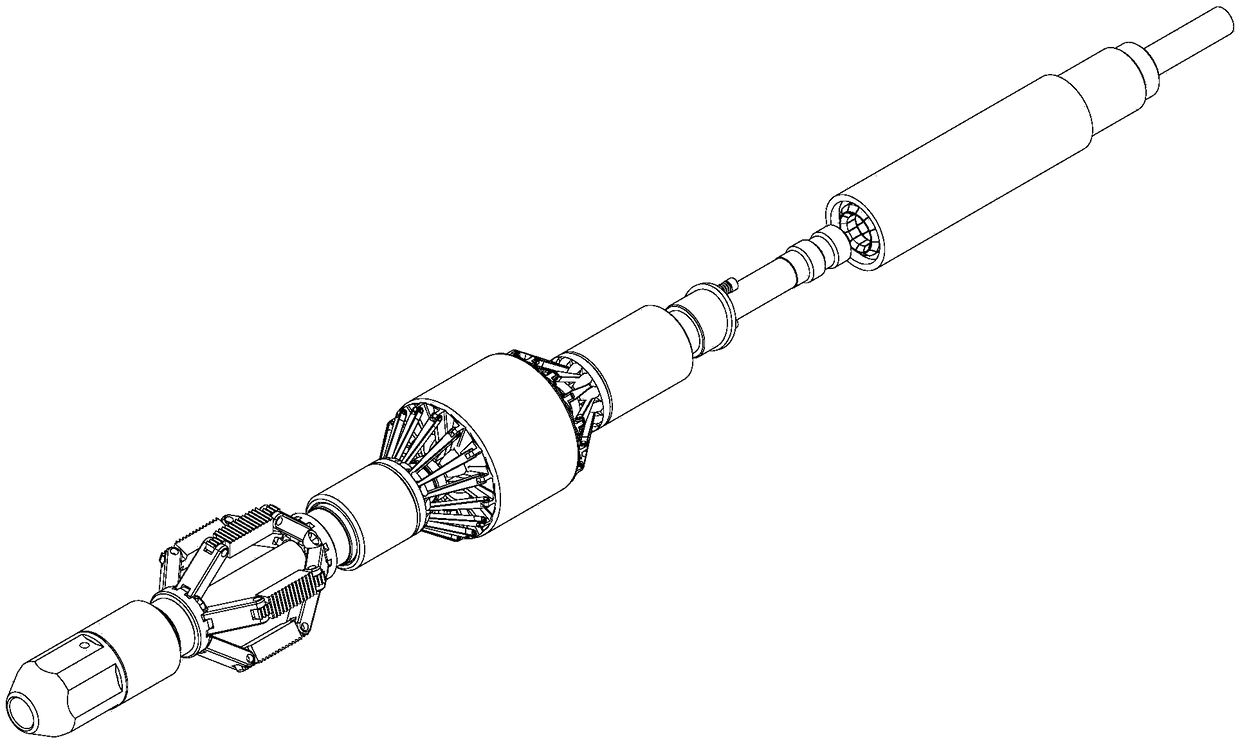

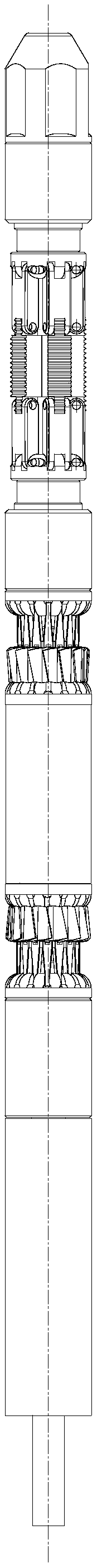

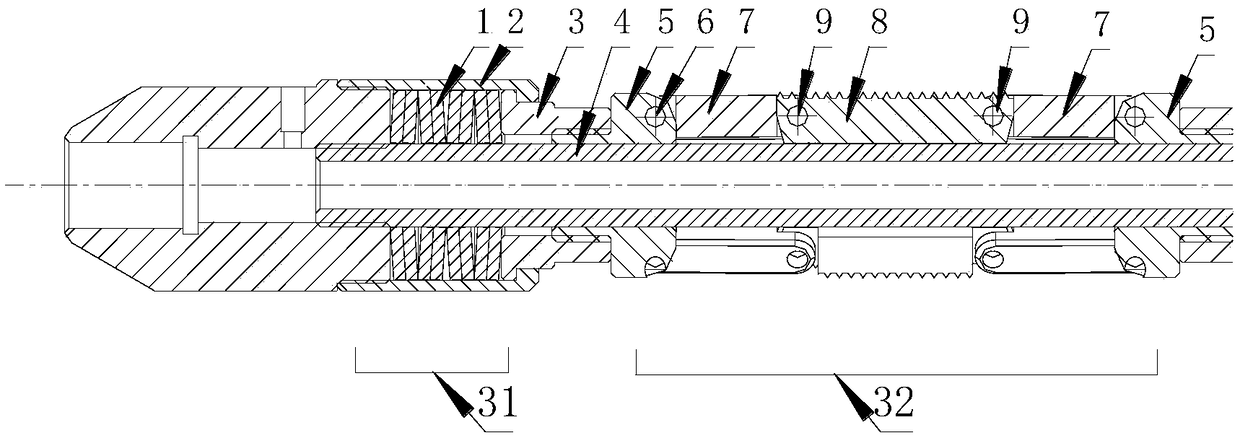

Recyclable oil pipe bridge plug with high expansion ratio

The invention relates to technological devices for well completion, oil extraction and gas production of oil and gas fields, in particular to a recyclable oil pipe bridge plug tool with a high expansion ratio. The oil pipe bridge plug comprises a first combined laminated spring assembly, a heavy hinged slip assembly, a second combined laminated spring assembly, a first joint-type and link-type anti-outburst mechanism assembly, a second joint-type and link-type anti-outburst mechanism assembly, a lock assembly and a feed-in release assembly; a central pipe is arranged in the middle of the oil pipe bridge plug; the first combined laminated spring assembly, the heavy hinged slip assembly arranged in a circular array mode, the second combined laminated spring assembly, the first joint-type andlink-type anti-outburst mechanism assembly, the second joint-type and link-type anti-outburst mechanism assembly, the lock assembly and the feed-in release assembly are mounted on the central pipe ina sleeved mode. The recyclable oil pipe bridge plug has the advantages that a piston only needs a small stroke through a crank connecting rod mechanism, and the high expansion ratio can be achieved.

Owner:弗润联科(北京)石油科技有限公司

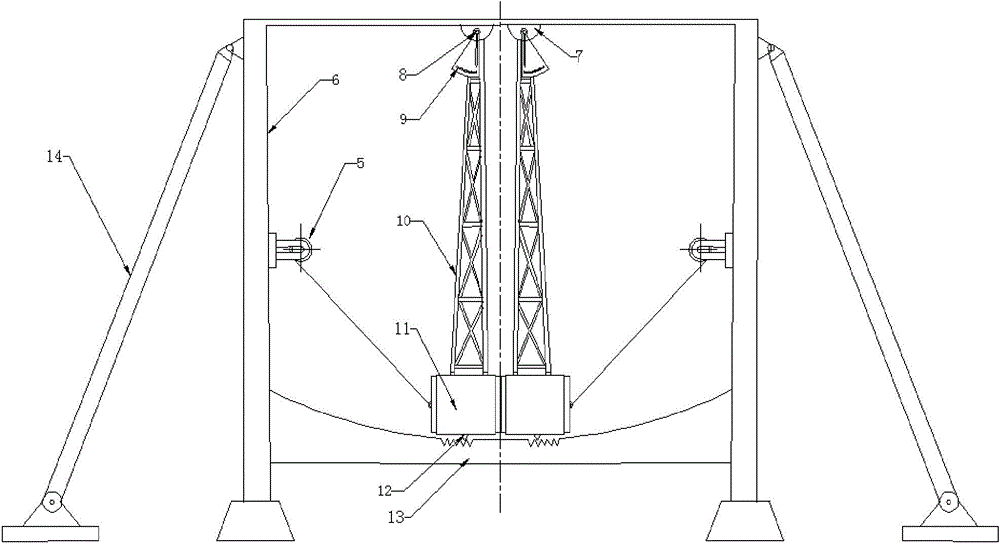

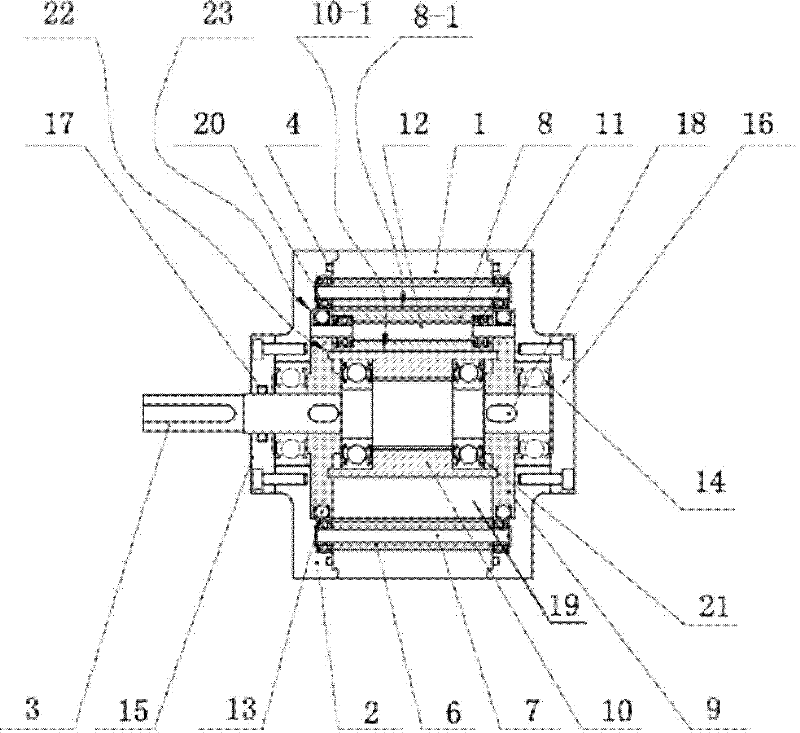

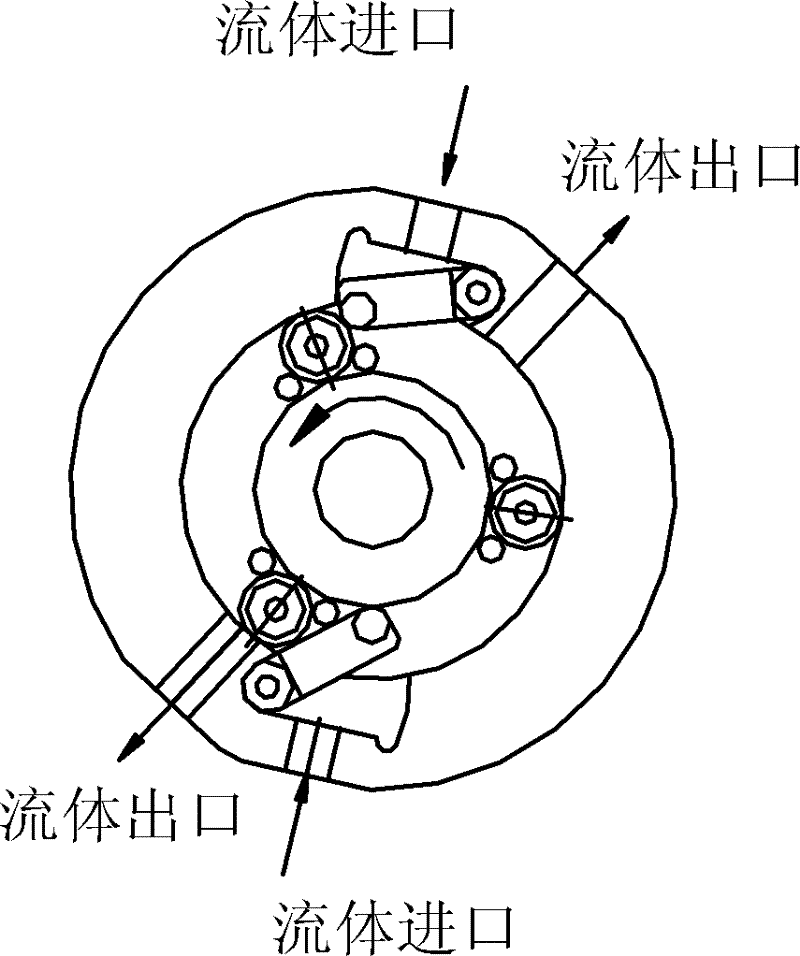

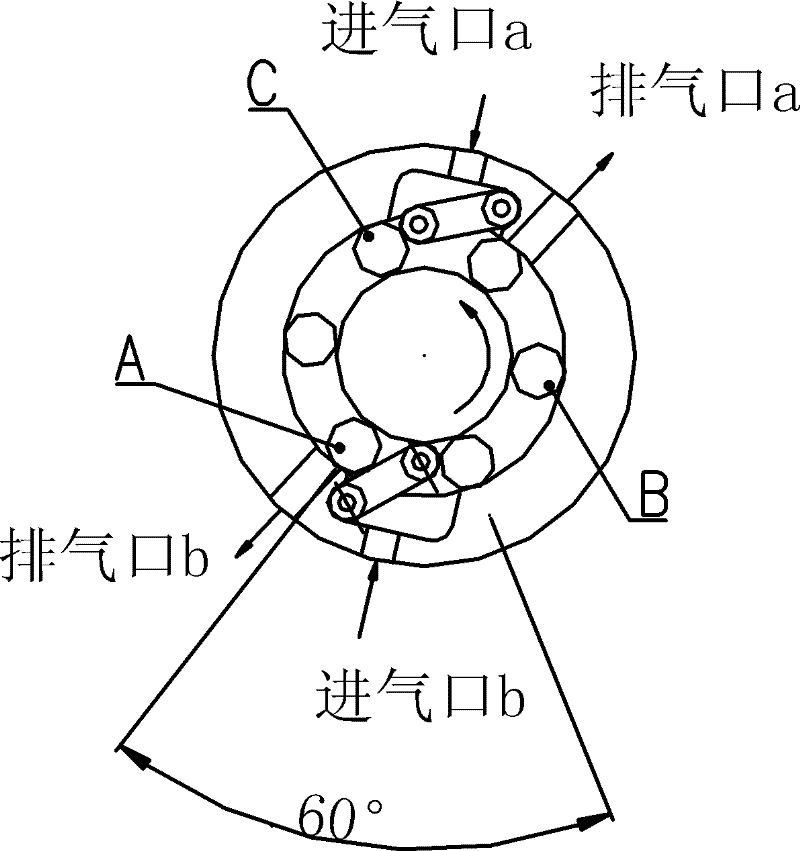

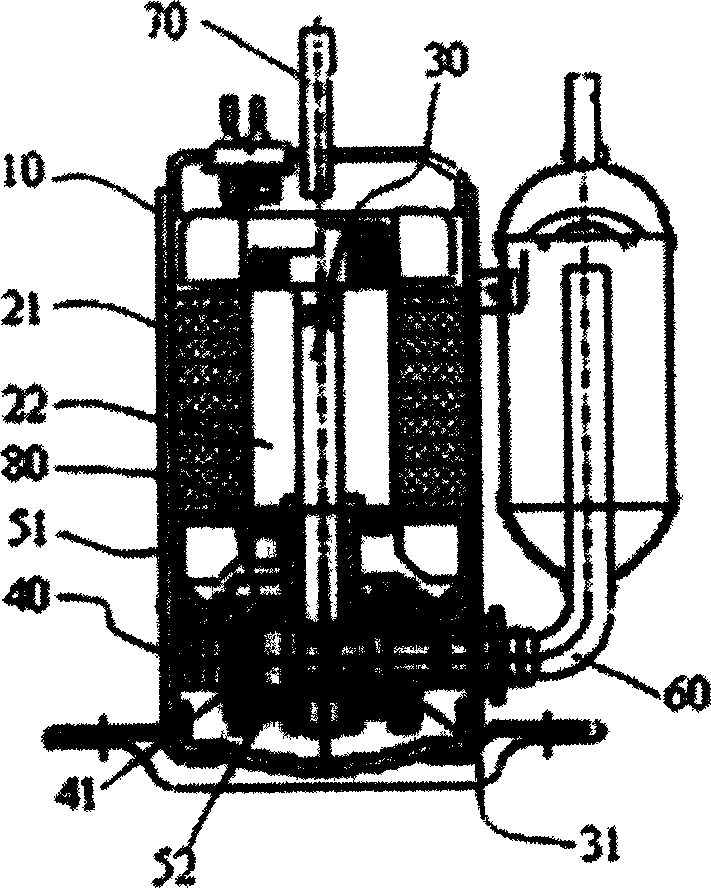

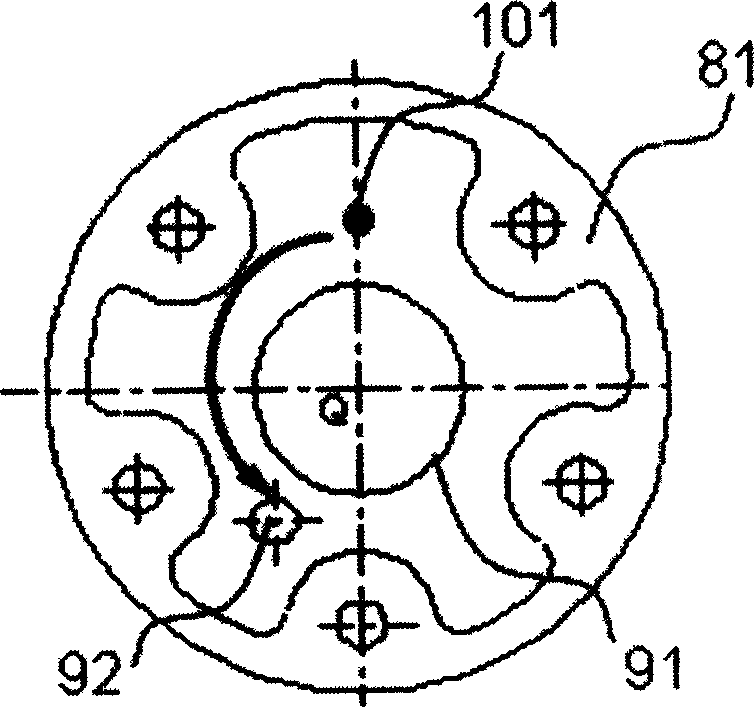

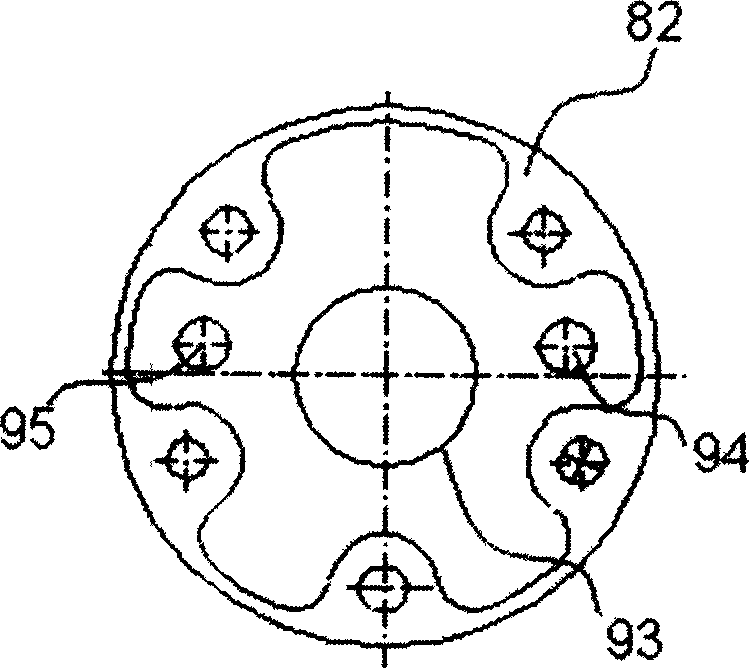

Spiraster-type rotation device, engine, pneumatic motor, and compressor

ActiveCN102678289AIncrease the expansion ratioReduce the angleInternal combustion piston enginesRotary piston pumpsPistonRotary valve

The invention discloses a spiraster-type rotation device, an engine, a pneumatic motor, and a compressor in an annular piston space with a high expansion ratio. In the present invention, a ratio of a linear diameter in the annular piston space to a diameter of a planetary piston wheel of a roller and an angle between a rotary valve sheet of a central sun gear and the diameter of the annular piston space are reasonably provided to effectively increase the expansion ratio of a working substance and reduce an angle in a critical section of the rotary valve sheet, thereby improving the energy utilization rate of the spiraster-type rotation device.

Owner:BEIJING ROSTAR TECH

Hydrophobic degradable biological material, its production and foaming products

A degradable hydrophobic biological material, its production and foaming product are disclosed. The mixture consists of polybasic alcohol and aqueous hydrophobic vinol or starch. The melt temperature of degradable hydrophobic biological material is between 130-180 degree, carbonization temperature is between 195-300 degree, melt temperature is < carbonization temperature. It has excellent water-proofing and biological degradable performances and foaming rate and compression strength.

Owner:李小鲁

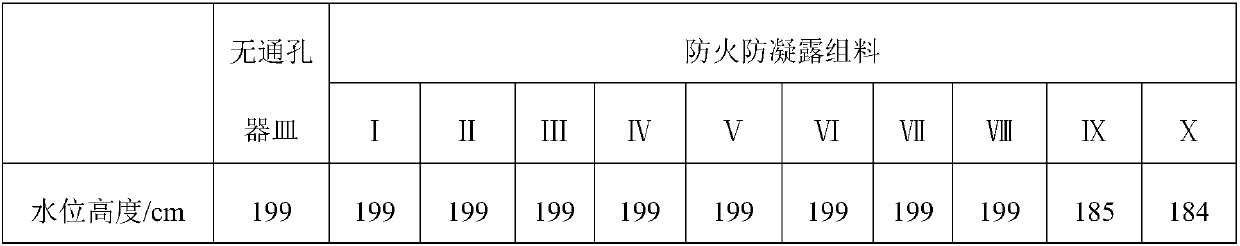

Fireproof anti-condensation combined material and preparation method thereof

The invention belongs to the technical field of cable arranging equipment, and particularly relates to a fireproof anti-condensation combined material and a preparation method thereof. The fireproof anti-condensation combined material is prepared from a component A, a component B and a component C in a mass ratio of 1 to 1 to (0.5-1), wherein the component A is prepared from polyether polyol, dichlorofluoroethane, phosphotriester and organic silicone oil; the component B is polymethylene polyphenyl polyisocyanate; and the component C is prepared from expanded graphite and ammonium polyphosphate. The preparation method for the fireproof anti-condensation combined material comprises the following steps: (1) uniformly mixing polyether polyol, dichlorofluoroethane, phosphotriester and organicsilicone oil to form the component A; (2) uniformly mixing expanded graphite and ammonium polyphosphate to form the component C; and uniformly mixing the component A, the component C and the polymethylene polyphenyl polyisocyanate. The fireproof anti-condensation combined material provided by the invention is high in foaming ratio and is less in use of sealing materials while being used for sealing a relatively long gap.

Owner:ZHEJIANG YIDIAN ELECTRIC CO LTD

Silencing device of compressor

InactiveCN1580574AExtend the flow pathChange shapeRotary/oscillating piston pump componentsLiquid fuel engine componentsSuppressorEngineering

This invention provides a sound suppressor of a compressor including a double layer of an internal sound suppressor and an external sound suppressor with exhaust outlets above the upper bearing with exhaust outlet, among which, the exhaust outlet position of the intenal sound suppressor is set at the place taking the outlet of the upper bearing as the base point rotating counter-clock-wise to the third phase to prolong the flowing path of gas in the inteal layer sound suppressor. The outer sound suppressor is a three flap for increaisng its cavity volume. The distance between two rows of gas holes of the outer suppressor is designed equalizing to the odd times of half-wavelength of the bearing eliminated noise frequency and in opposite phase to the flown sound wav from the hole.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Ethylene copolymer and process for producing the same, resin composition containing the copolymer, and uses of these

The present invention is intended to provide an ethylene copolymer having excellent mechanical properties and moldability. The copolymer comprises 40 to 99% by mol of ethylene constituent units and 1 to 60% by mol of C3-20 alpha-olefin constituent units; the ratio (Mz / Mw) of a Z average molecular weight (Mz) to a weight-average molecular weight (Mw), each molecular weight being measured by GPC, is in the range of 10 to 30, and said ratio (Mz / Mw) and the ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), each molecular weight being measured by GPC, satisfy the relation (Mz / Mw); the intrinsic viscosity is in the range of 0.5 to 4 dl / g; the ratio (n*0.01 / n*8) of a melt viscosity (eta*0.01) at a shear rate of 0.01 rad / sec, as measured at 190 DEG C., to a melt viscosity (eta*8) at a shear rate of 8 rad / sec, as measured at 190 DEG C., and the intrinsic viscosity (eta) satisfy the relation (eta*0.01 / eta*8)>=0.843x(eta)+1.0; and the absolute value of an activation energy (Ea) of a shift factor of melt viscoelasticity is not more than 4x10<4> J / mol.K.

Owner:MITSUI CHEM INC

Biodegradable composition, and its preparing method and foamed product

The invention relates to biodegradable combination which contains starch that is esterifying starch and / or etherified starch with 0.1-3 degree of substitution, poly lactic acid, polyhydric alcohol, and foaming agent. The foaming series products formed by the combination have good expansion ratio, compressive strength, high biodegradation rate, and mold degrading stage.

Owner:李小鲁

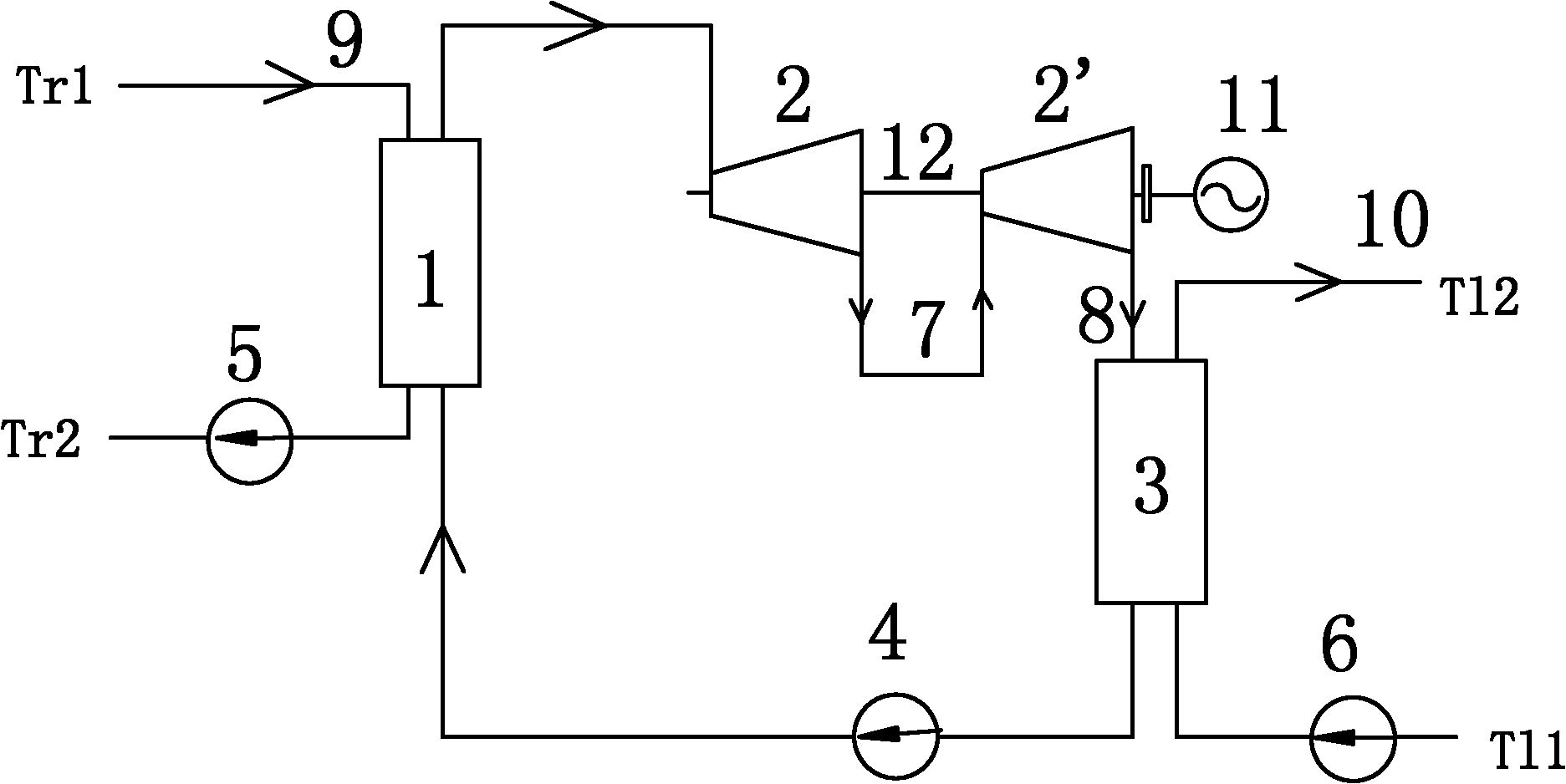

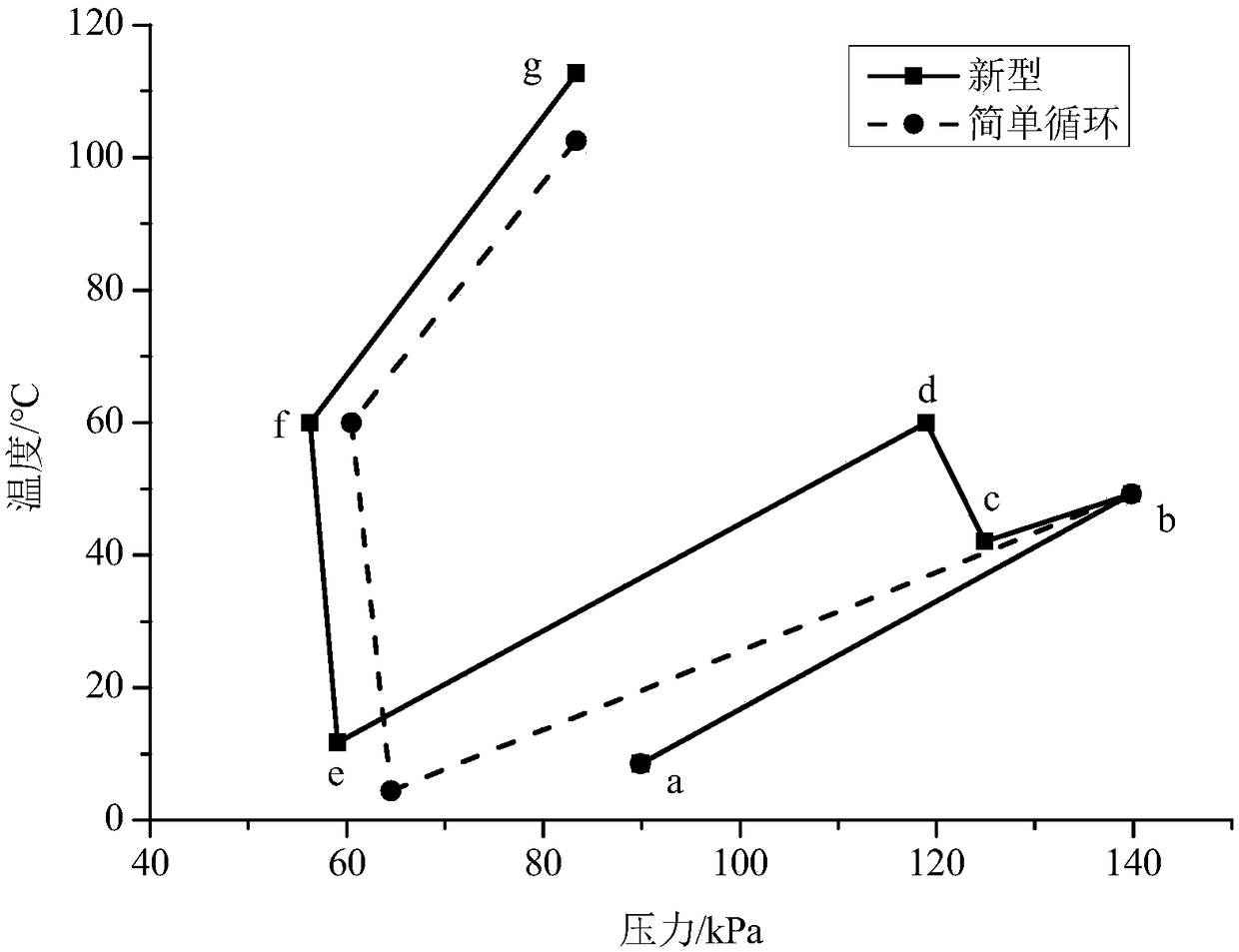

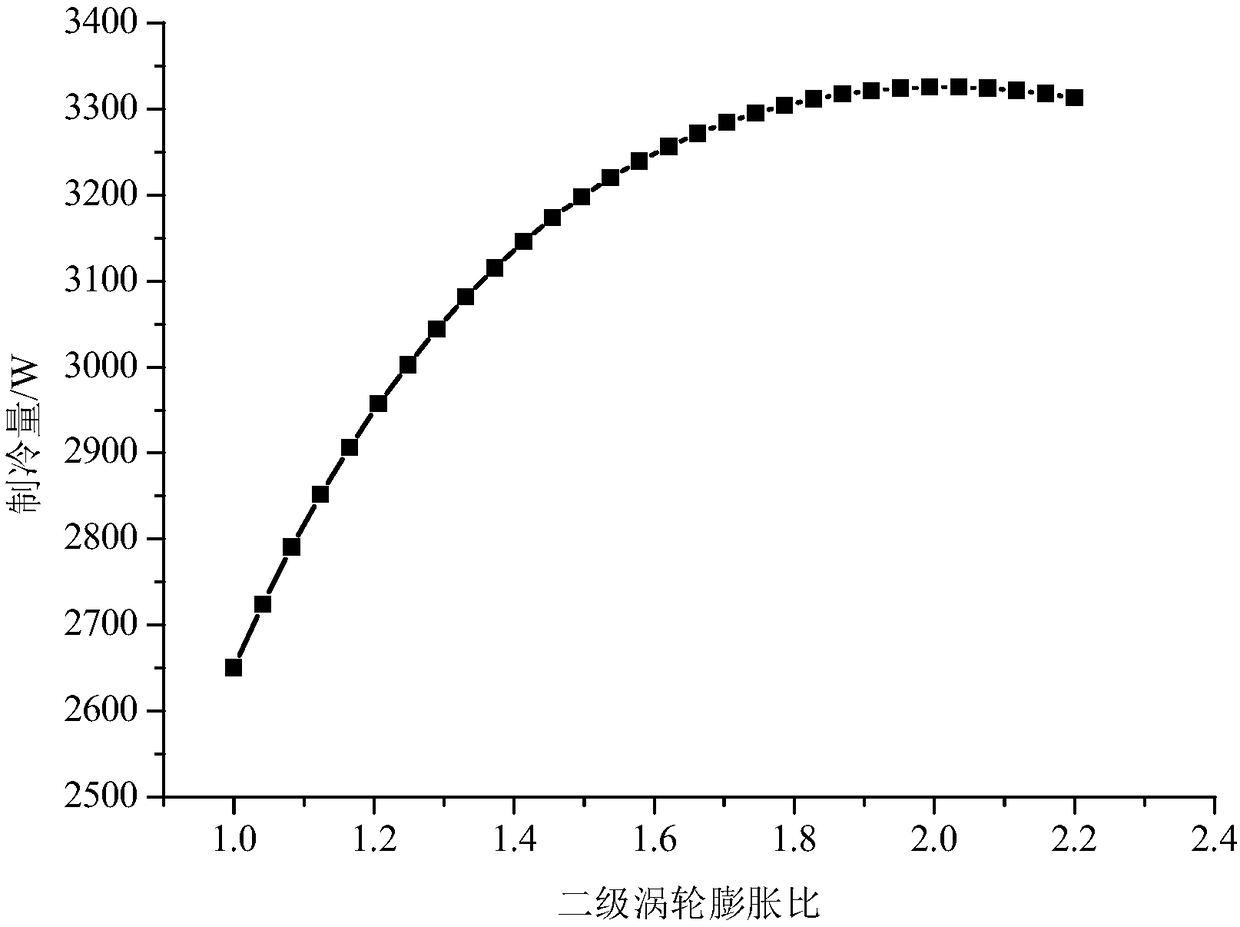

Middle reheating type turbine cooler system applied to airplane pod

InactiveCN108216642AAlleviate power tensionReduce power consumptionAir-treatment apparatus arrangementsEnergy efficient board measuresSelf weightAir compressor

The invention discloses a middle reheating type turbine cooler system applied to an airplane pod. By adopting middle reheating circulation, the system efficiency is obviously improved. The system comprises an air inlet system, a first-stage turbine, a second-stage turbine, a first-stage heat exchanger, a second-stage heat exchanger, an air compressor and an exhaust system. By means of the system,ram-air in the flying process of an airplane is used as a power source, and after two-stage turbine expansion cooling, a primary surface heat exchanger cools air in an electronic cabin. By means of the system, middle heat re-exchange circulation is adopted, and the unit flow energy heat exchange capability of a turbine cooler is obviously improved; a liquid circulation heat exchange system is notneeded, the primary surface heat exchanger is adopted to lower the weight of the heat exchangers, and the system weight is obviously lowered; the system has a very low additional power consumption amount, and energy consumption of the cooling system is obviously lowered; an air bearing system is adopted by the system, an oil lubricating system is not needed, the system self-weight is lowered, andmeanwhile, the system maintenance is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

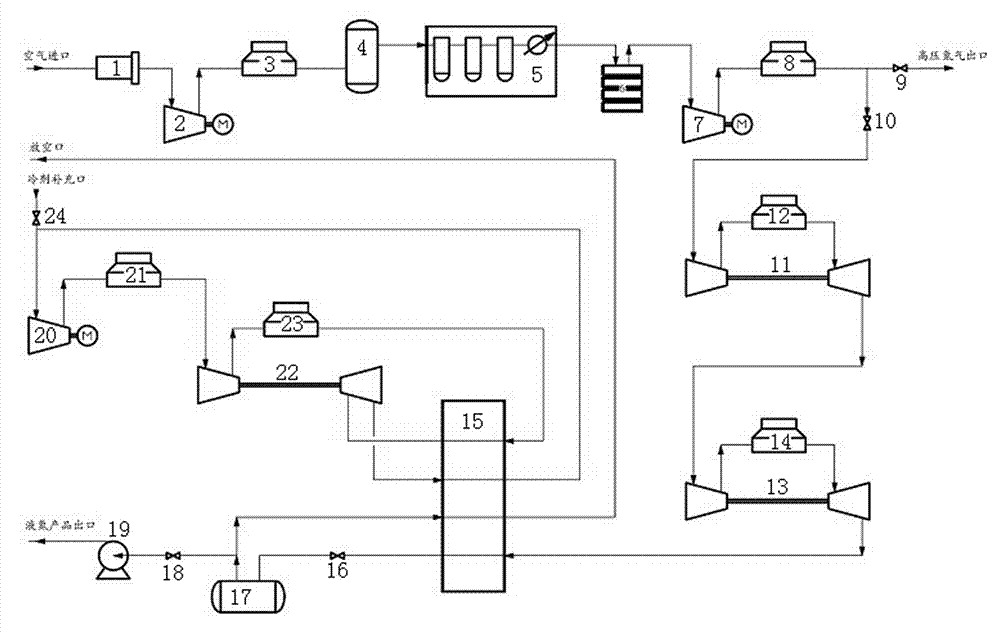

Movable oilfield nitrogen making liquefaction device

ActiveCN103486823AIncrease the expansion ratioCompact usabilitySolidificationLiquefactionNitrogenNitrogen gas

The invention relates to a movable oilfield nitrogen making liquefaction device which comprises a high-pressure nitrogen production unit and a liquid nitrogen preparation unit. High-pressure nitrogen is used for direct expansion refrigeration, parts of circulating refrigerant nitrogen media are used as refrigerants for indirect refrigeration, the nitrogen is liquefied, and energy is saved. The device is compact, convenient to adjust, continuous in operation, safe, reliable and convenient in on-site movement.

Owner:天津凯德实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com