Combined turbine expansion machine

A turboexpander, a composite technology, applied in the field of expanders, can solve the problems of difficult realization of multi-stage and power, high bearing and transmission requirements, large radial size, etc., and achieves simple structure, stable operation, and small flow loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

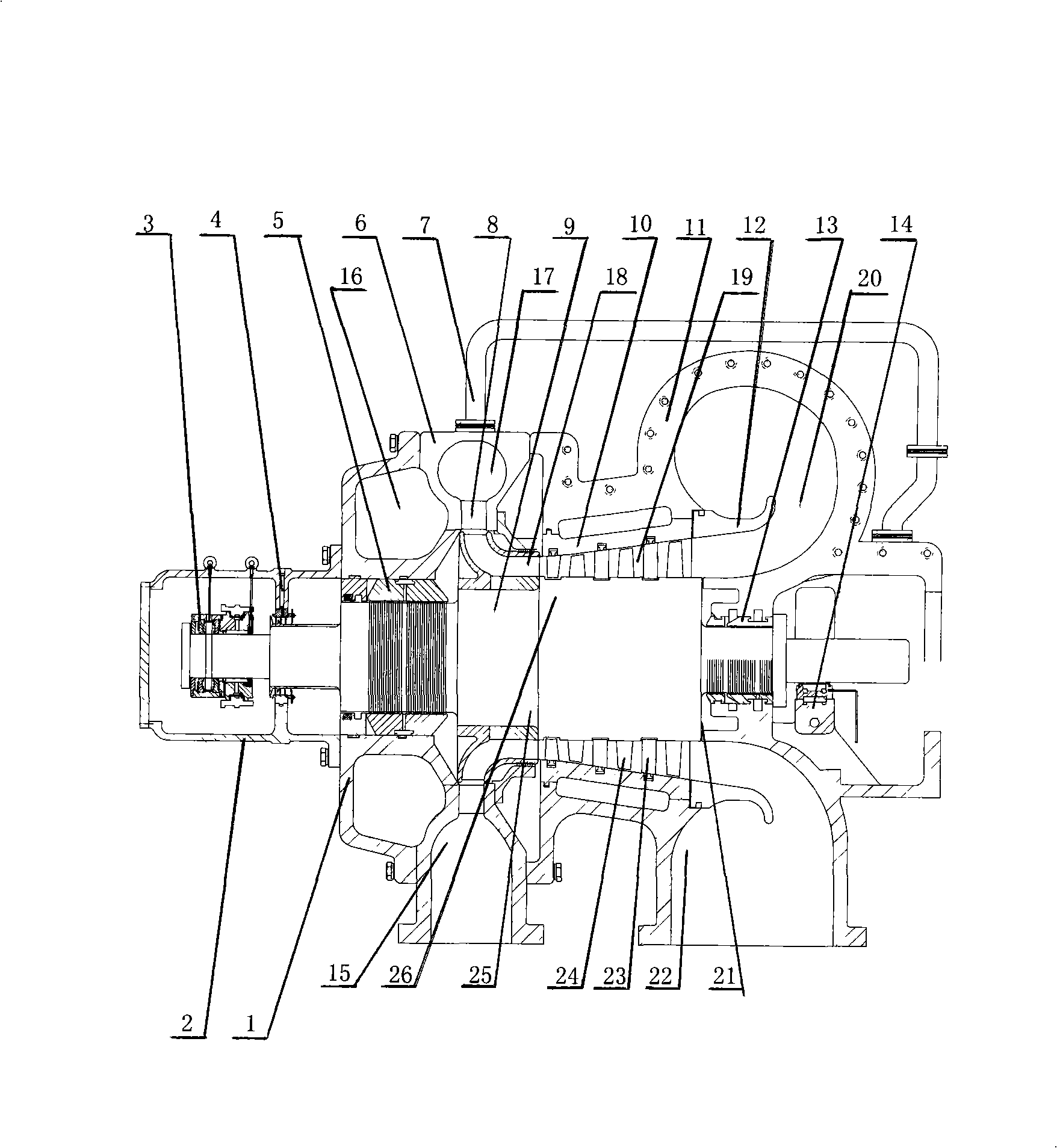

[0014] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] Referring to the accompanying drawings, a compound turboexpander includes a rotor 9, which is installed in a casing composed of a high-pressure section casing 6 and a low-pressure side casing 11, and the two ends of the rotor 9 are respectively supported by thrust bearings 3 Supported by support bearing 14, support thrust bearing 3 is installed in bearing box 2, and oil seal 4 is also arranged in bearing box 2, bearing box 2 is connected with end cover 1 through bolts, and end cover 1 is connected with high-pressure section through bolts The casing 6 is connected, and a high-pressure side shaft end seal 5 is arranged between the rotor 9 and the end cover 1. An inlet pipe 15 and an inlet volute 17 are arranged on the high-pressure section casing 6. The inlet pipe 15, the inlet volute 17 communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com