Device for introducing a gas into a fluidised bed and preparation method thereof

A gas introduction, fluidized bed technology, used in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as increased wear, high product maintenance costs, and losses

Inactive Publication Date: 2009-09-02

芬诺利特技术两合公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, on the other hand, the use of abrasive resistant (hard) fluidized bed particles also leads to increased wear of the cooling pipes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

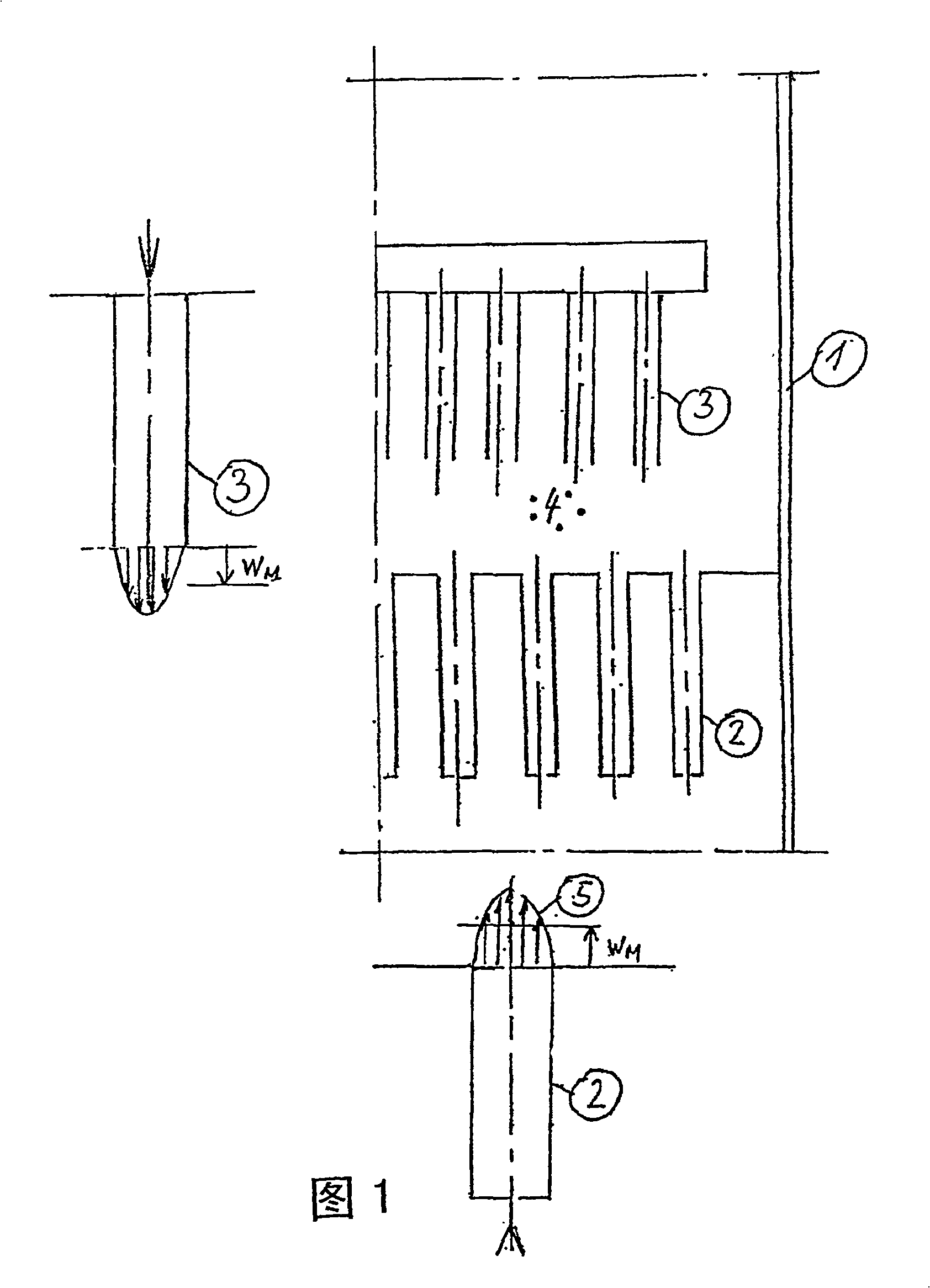

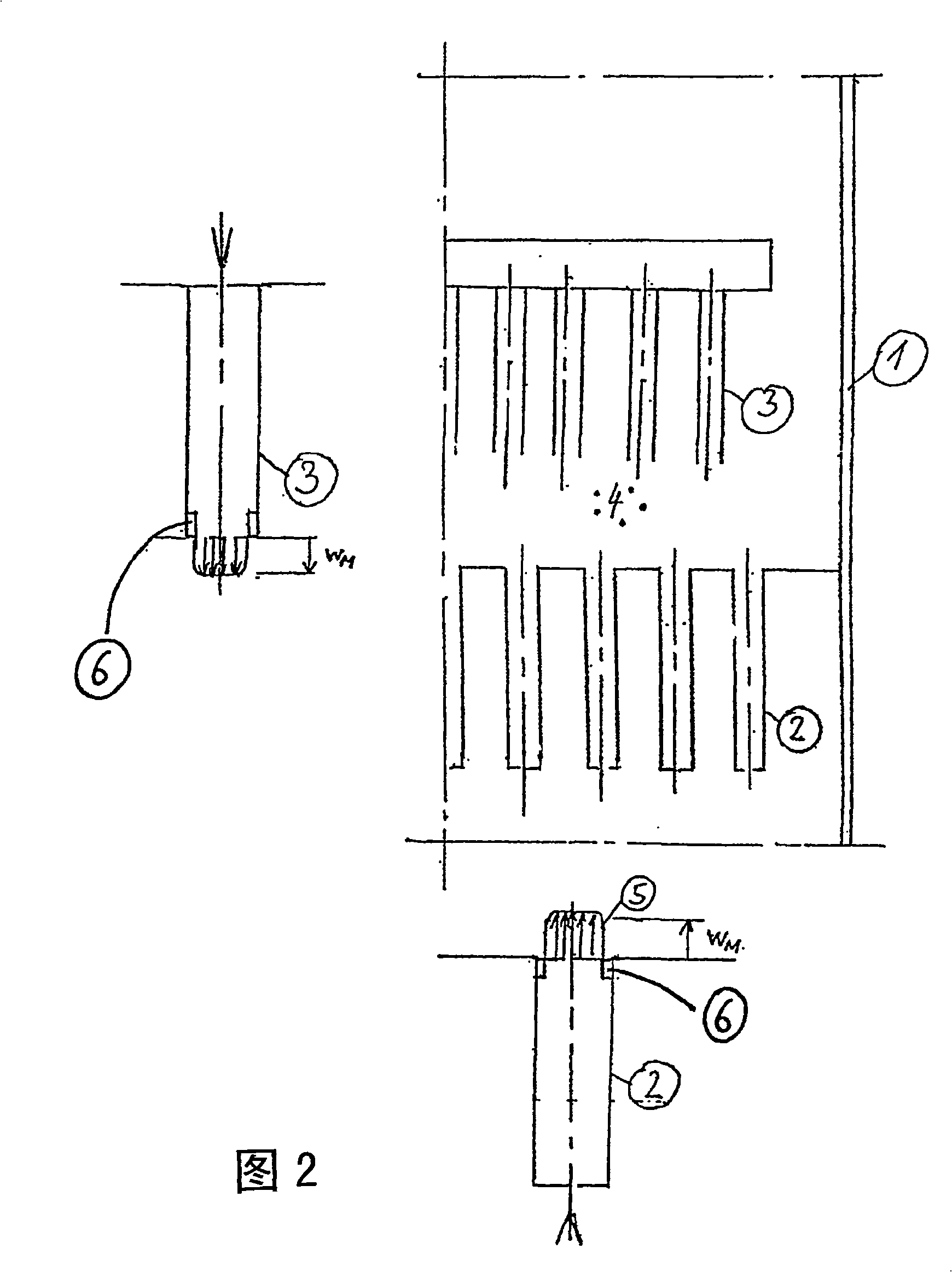

The invention relates to a device and a method for introducing gas into a fluidized bed reactor, the device having at least one gas inlet pipe (2, 3) above and/or below the fluidized bed, characterized in that the gas inlet The tubes (2, 3) have gas flow swirl means at and/or upstream of their openings.

Description

technical field [0001] The invention relates to a device for introducing gas into a fluidized bed, and to a fluidized bed reactor comprising the gas introducing device. The invention also relates to a process for the oxychlorination of ethylene to form 1,2-dichloroethane using a fluidized bed reactor according to the invention. Background technique [0002] Fluidized bed reactors generally include a catalytic bed of solid fine-grained particles, where the catalytic bed usually acts as a catalyst for the reaction to take place. The substances reacting in the reactor are generally gases, and the reaction products leaving the reactor at the top of the reactor are likewise gases. Both introduction and mixing of the reactants take place in the lower part of the reactor, in particular above and / or below the fluidized bed. The gas inlet and distribution system in which the reactants mix and come into contact with the catalyst plays an important role in the optimization of the rea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J8/18B01J8/24

CPCB01J8/1818B01J2208/00699B01J8/18B01J8/24

Inventor 克劳斯·克雷伊奇彼得·卡默霍弗因戈尔夫·米尔克乌韦·沃特英

Owner 芬诺利特技术两合公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com