Preparation method for rubber cable connector

A technology for cable joints and rubber cables, applied in the direction of connecting/terminating cable equipment, circuits, electrical components, etc., can solve the problems of complex vulcanization molding process, easy generation of bubbles in the insulating layer, uneven pressure transmission, etc., to avoid Rubber aging problem, pressure uniformity, effect of improved bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

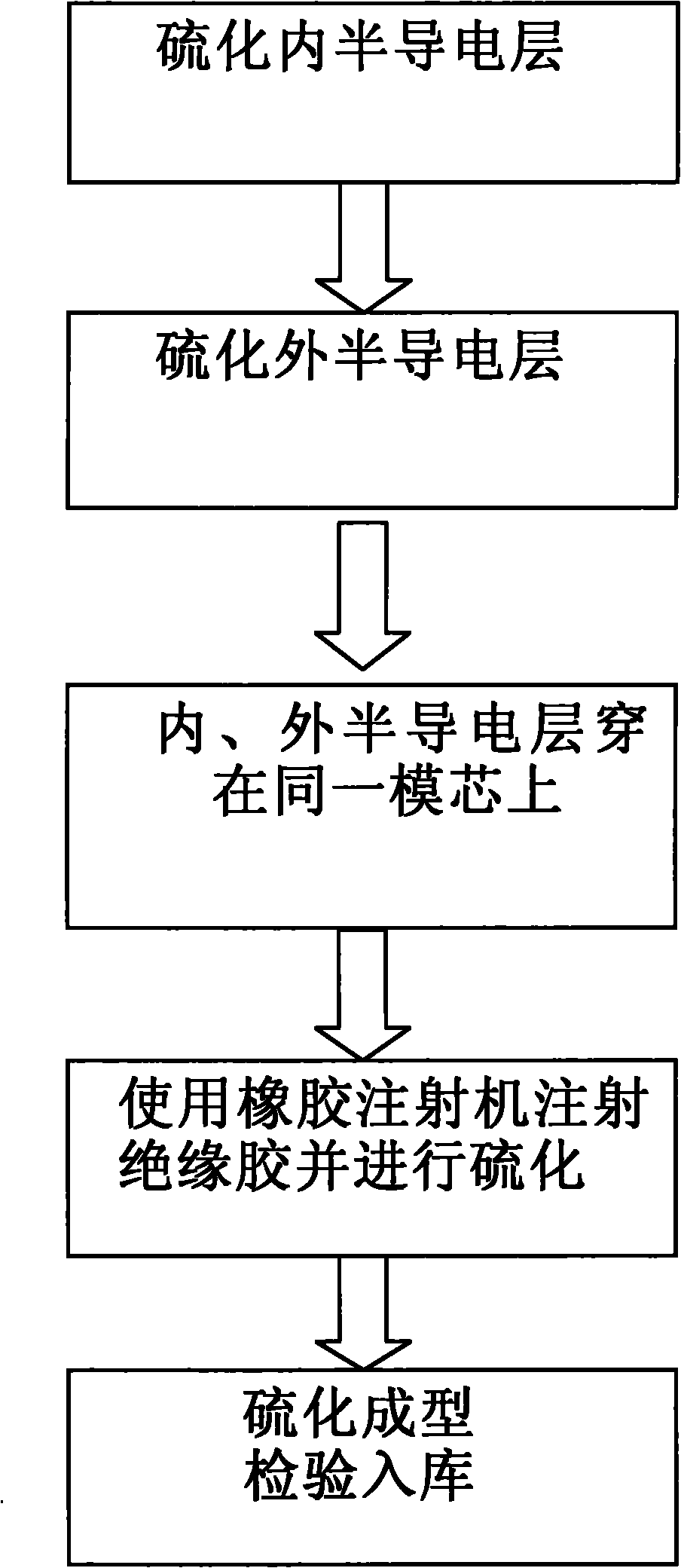

[0022] A kind of preparation method of rubber cable joint is as follows:

[0023] (1) Making the inner semiconductive layer of the rubber cable joint:

[0024] Remelt the semi-conductive mixed rubber into a 6mm thick film, cut it according to the sample, prepare the material weight 100 grams per piece, and produce 4-6 pieces for each set of molds; put the prepared rubber material into the mold of the inner semi-conductive layer, Push the mold into the rubber flat vulcanizing machine, close the mold and pressurize it, deflate it at least twice, and vulcanize it for 600 seconds at a temperature of 168°C and a pressure of 18MP;

[0025] (2) Making the outer semiconductive layer of the rubber cable joint:

[0026] Remelt the semi-conductive mixed rubber into a film with a thickness of 4mm, cut it according to the model, prepare the material weight of 240 grams per piece, and produce 2 pieces for each set of molds; put the prepared rubber material into the mold of the outer semi-c...

Embodiment 2

[0034] A kind of preparation method of rubber cable joint is as follows:

[0035] (1) Making the inner semiconductive layer of the rubber cable joint:

[0036] Remelt the semi-conductive mixed rubber into a 6.3mm thick film, cut it according to the sample, prepare the material with a weight of 100 grams per piece, and produce 4-6 pieces for each set of molds; put the prepared rubber into the mold of the inner semi-conductive layer , push the mold into the rubber flat vulcanizing machine, close the mold and pressurize it, deflate it at least twice, and vulcanize for 660 seconds at a temperature of 170°C and a pressure of 19MP;

[0037] (2) Making the outer semiconductive layer of the rubber cable joint:

[0038] Remelt the semi-conductive mixed rubber into a film with a thickness of 4mm, cut it according to the model, prepare the material weight of 240 grams per piece, and produce 2 pieces for each set of molds; put the prepared rubber material into the mold of the outer semi-...

Embodiment 3

[0046] A kind of preparation method of rubber cable joint is as follows:

[0047] (1) Making the inner semiconductive layer of the rubber cable joint:

[0048] Remelt the semi-conductive mixed rubber into a 6.5mm thick film, cut it according to the sample, prepare the material with a weight of 100 grams per piece, and produce 4-6 pieces for each set of molds; put the prepared rubber into the mold of the inner semi-conductive layer , push the mold into the rubber flat vulcanizer, close the mold and pressurize it, deflate it at least twice, and vulcanize it for 720 seconds at a temperature of 172°C and a pressure of 20MP;

[0049] (2) Making the outer semiconductive layer of the rubber cable joint:

[0050] Remelt the semi-conductive mixed rubber into a film with a thickness of 4mm, cut it according to the model, prepare the material weight of 240 grams per piece, and produce 2 pieces for each set of molds; put the prepared rubber material into the mold of the outer semi-conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com