Plant protection unmanned aerial vehicle automatic pesticide filling system

A technology for plant protection drones and drones, which is used in devices, applications, animal husbandry, etc. to capture or kill insects. Problems such as crushing and transporting, to achieve the effect of reducing the phenomenon of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

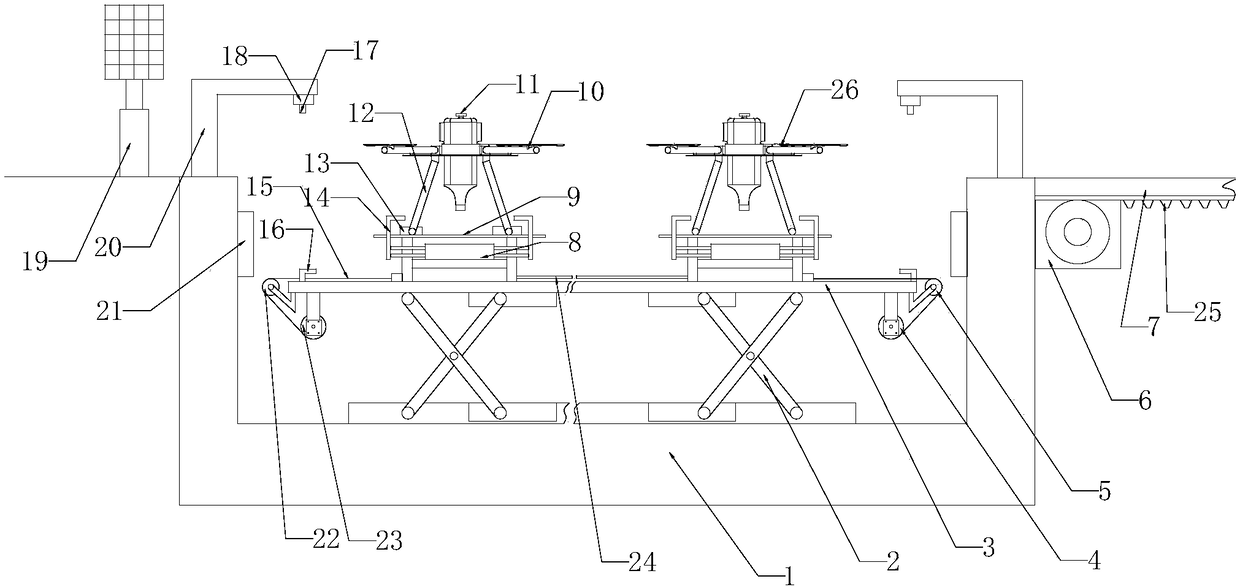

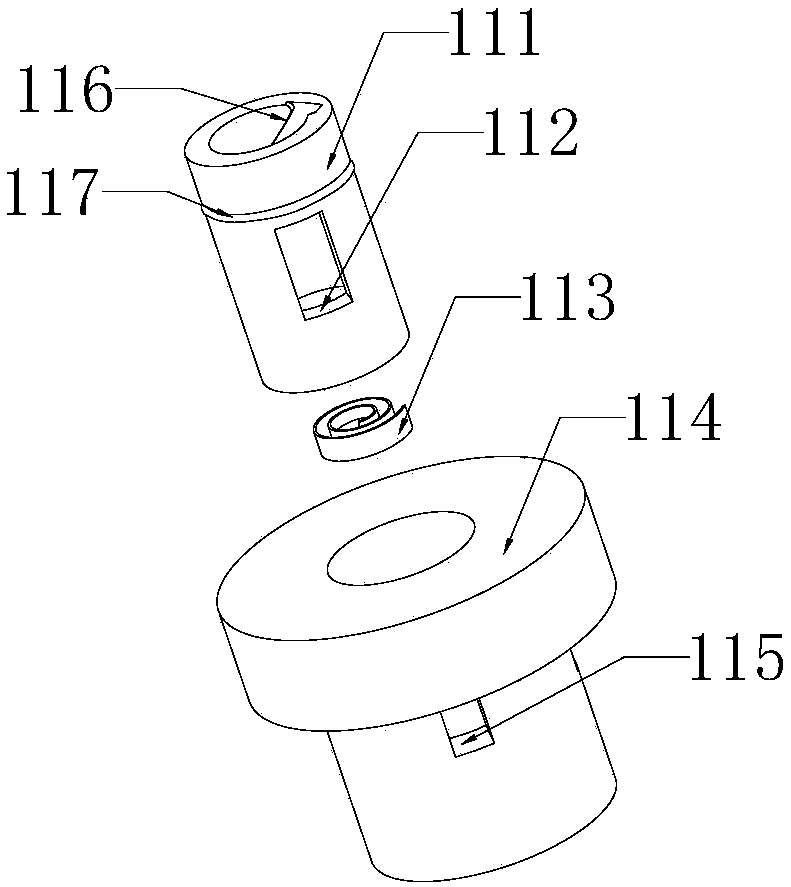

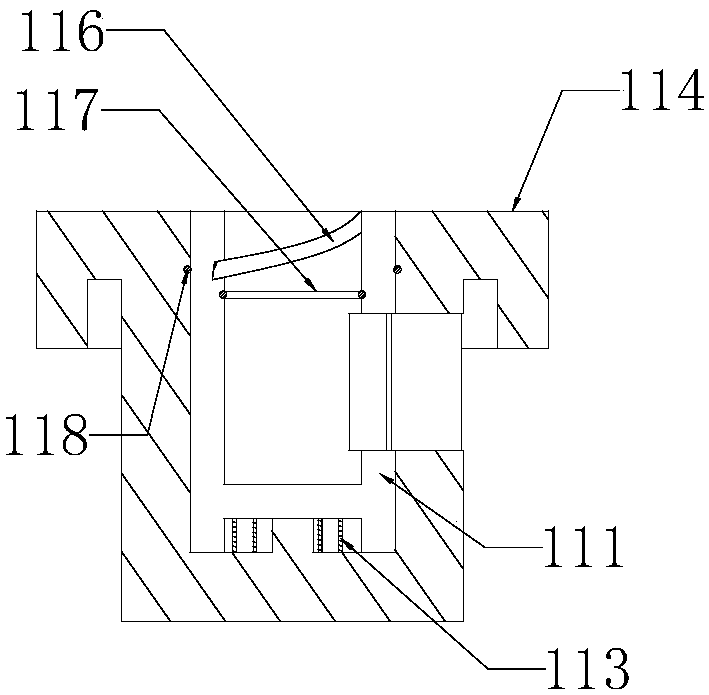

[0027] Such as Figure 1-3 Shown: the plant protection UAV automatic irrigation system in this embodiment, including a base 1, a platform for docking the UAV, a liquid injection component and a charging device set on the base 1 for filling medicinal liquid , also includes a conveying device arranged on the base 1 for driving the platform to move close to or away from the liquid injection assembly and a self-closing barrel cover 11 arranged on the upper part of the medicine barrel; the liquid injection assembly includes a catheter (not shown in the figure) logo), the liquid injection pipe 17 connected with the catheter, the cantilever beam 20 used to support the liquid injection pipe 17 and the electric water valve 18 used to control the liquid injection of the liquid injection pipe that are slidably connected to the base 1 with a single degree of freedom; The platform includes a bearing platform 9 for carrying the unmanned aerial vehicle, a weighing element (not marked in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com