Patents

Literature

358results about How to "Easy turnover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vaginal health products

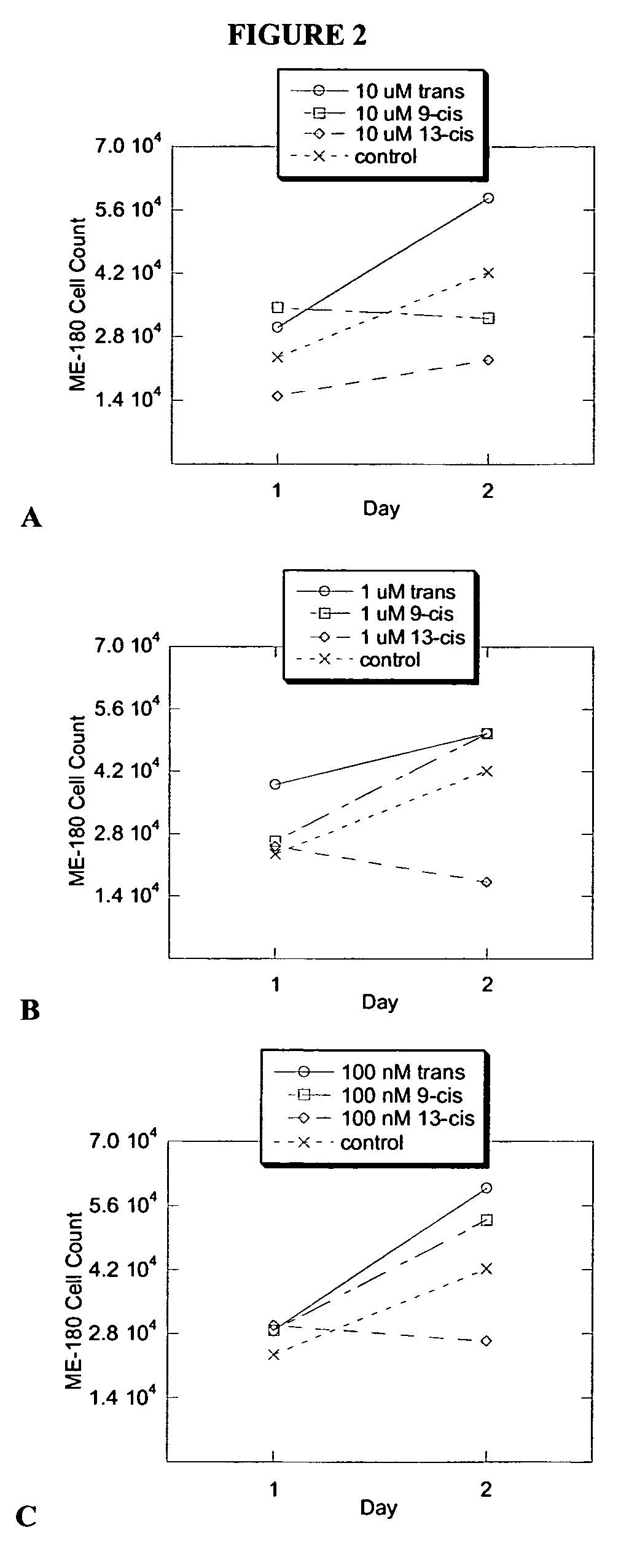

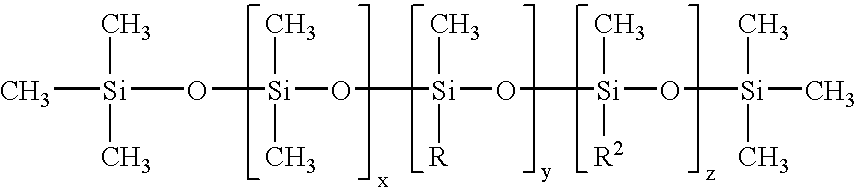

InactiveUS7485666B2Minor side effectsPromote cell growthBiocideEther/acetal active ingredientsCell turnoverMammal

Owner:KIMBERLY-CLARK WORLDWIDE INC

Humidification type dustlaying agent, preparation method, and application

InactiveCN101003721AShort storage timeEasy turnoverOther chemical processesTransportation and packagingChemistryCoal

This invention discloses a method for preparing wet dust-inhibiting agent and its application. The wet dust-inhibiting agent is composed of: polyoxyethylene nonyl phenyl ether OP-4 2-15%, OP-15 4-24%, ethylene glycol 0.5-10%, glycerol 1-10%, sodium dodecylbenzene sulfonate 0.1-5%, and tap water. The method comprises: adding tap water into a reaction kettle, heating to 40 deg.C, adding the raw materials, stirring to completely dissolve, keeping for 30 min, taking out, and packaging. When used, the wet dust-inhibiting agent is diluted with tap water at a ratio of 1 :( 1000-2000), and sprayed by spraying car or specific spraying apparatus onto dust-producing zone such as coal piles and raw material fields.

Owner:CHINA NAT OFFSHORE OIL CORP +1

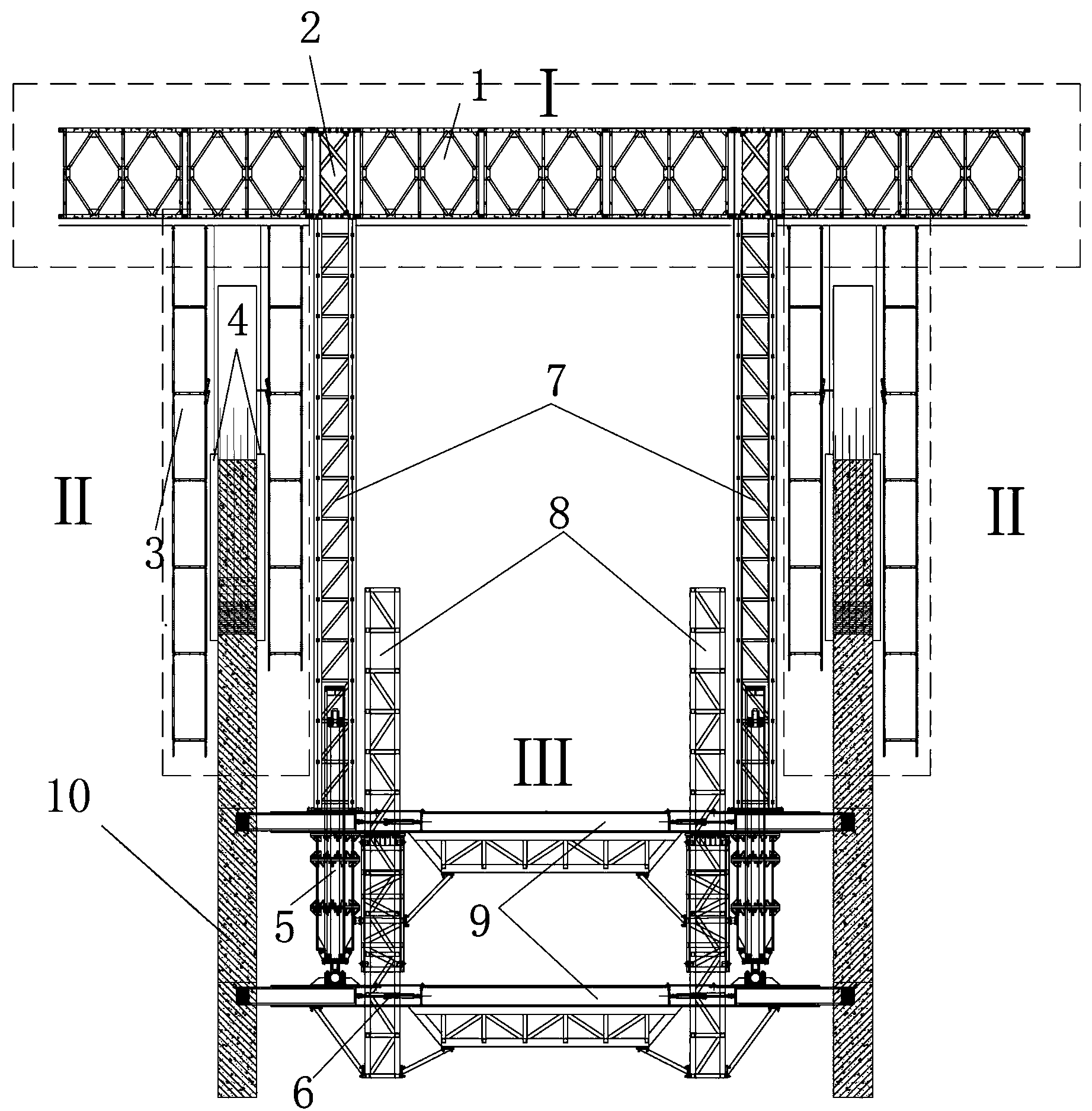

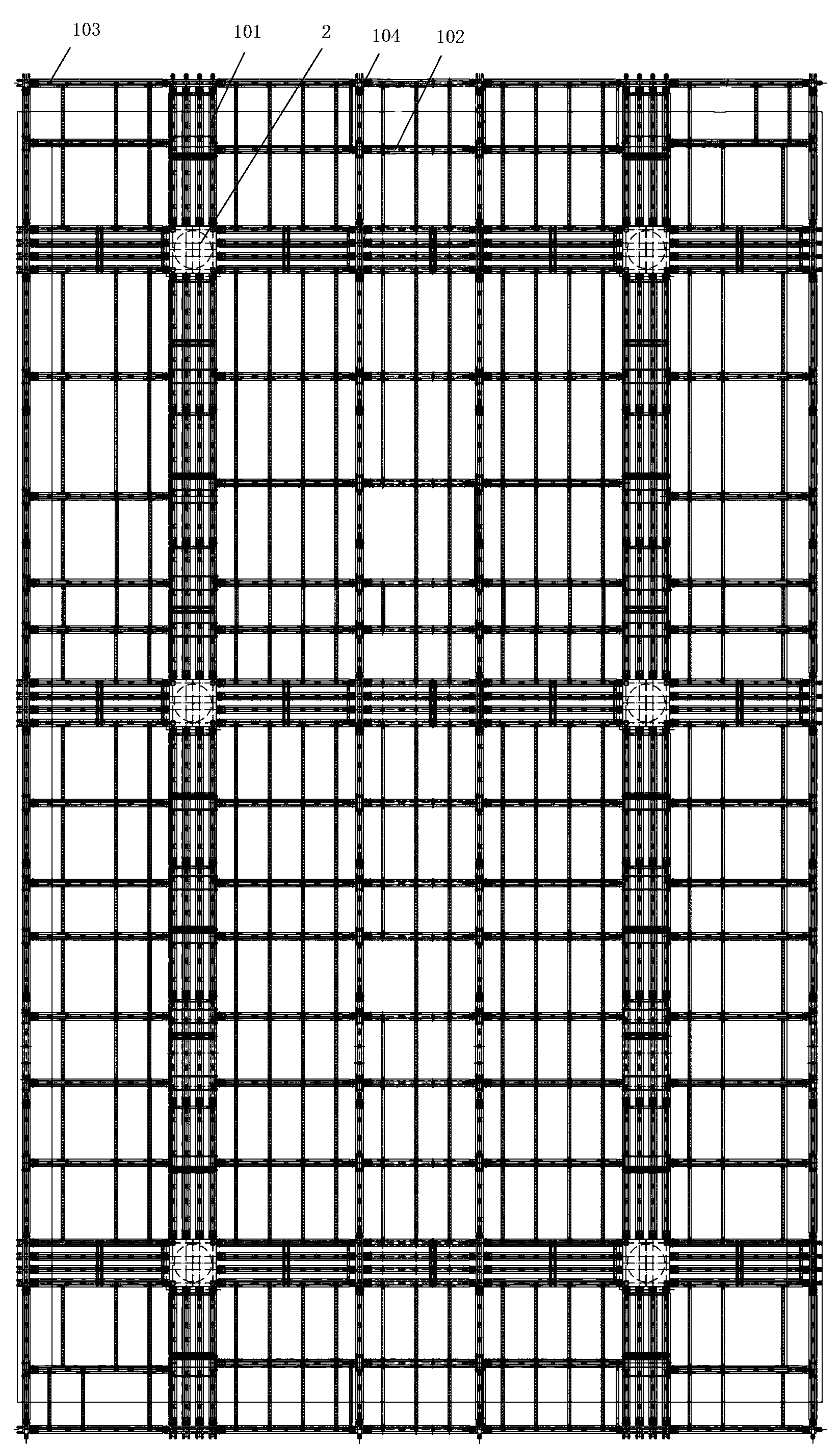

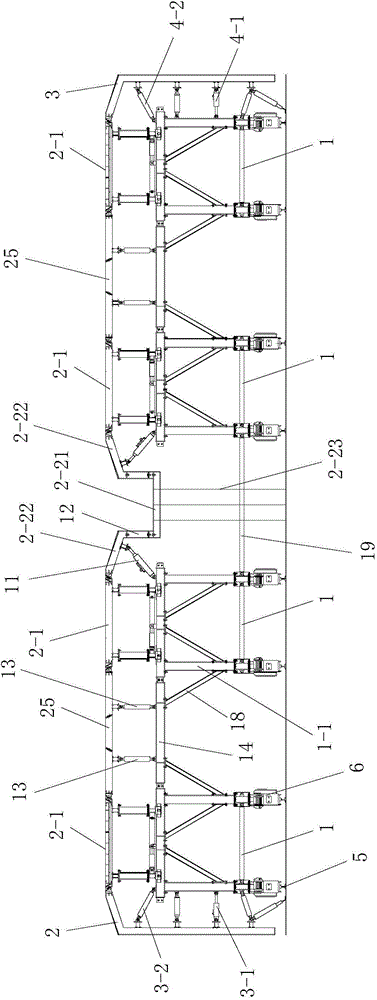

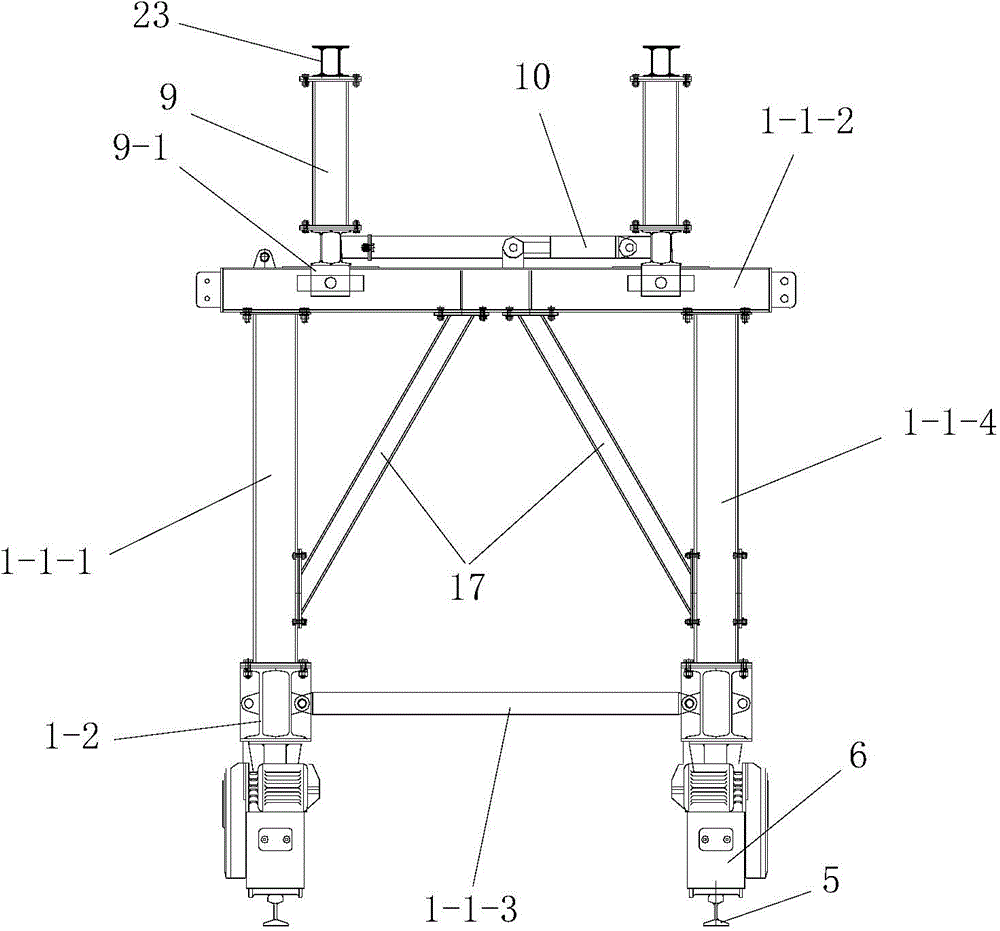

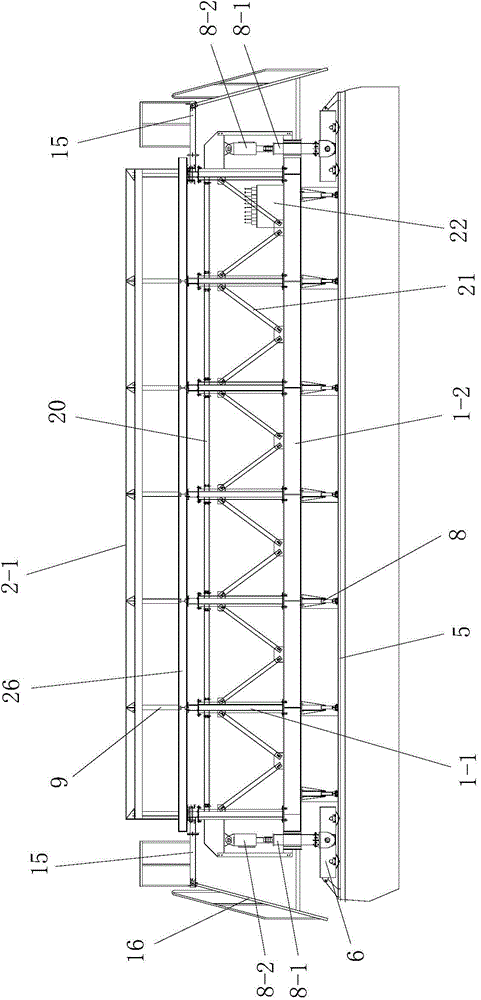

Standard Bailey truss assembling type jacking formwork system

ActiveCN103669832AEasy to assembleAdaptableForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel columnsStructural engineering

The invention relates to a standard Bailey truss assembling type jacking formwork system. The standard Bailey truss assembling type jacking formwork system is characterized in that the standard Bailey truss assembling type jacking formwork system is mainly composed of a truss platform system, a hanging system and a power supporting and jacking system, the power supporting and jacking system is fixedly supported by a core tube wall, the upper portion of the power supporting and jacking system is connected with the truss platform system through lattice supporting steel columns, the hanging system is hung on the truss platform system, the truss platform system is mainly composed of a plurality of standard Bailey trusses, the standard Bailey trusses are mutually connected to form main trusses and secondary trusses, the main trusses are connected longitudinally and transversely through Bailey truss connecting pieces to form a main framework, the Bailey trusses are connected on the periphery of the main framework to form a rectangular peripheral framework, and the Bailey truss connecting pieces are connected with the upper ends of the lattice supporting steel columns. According to the standard Bailey truss assembling type jacking formwork system, the system is composed of the standard Bailey trusses, construction and assembly are fast and convenient, repeated utilization is available, and the adaptability is high.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

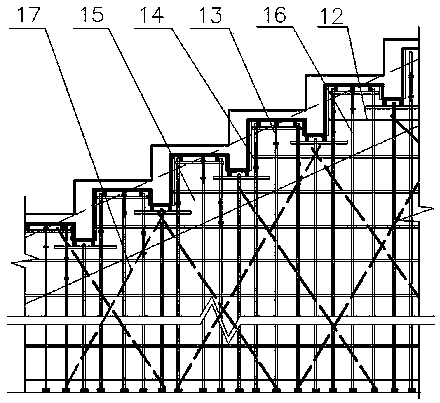

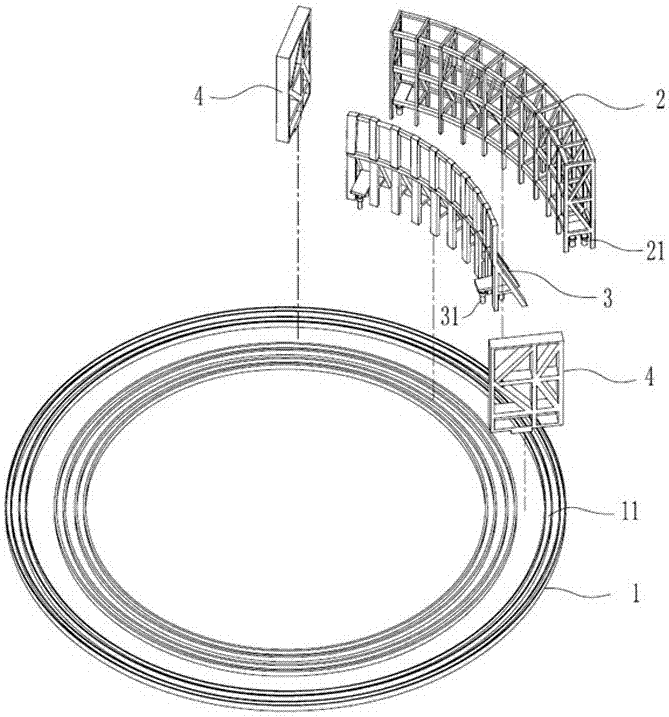

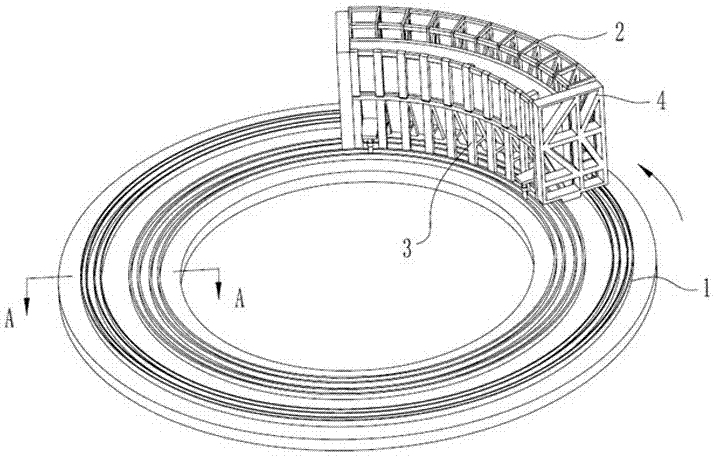

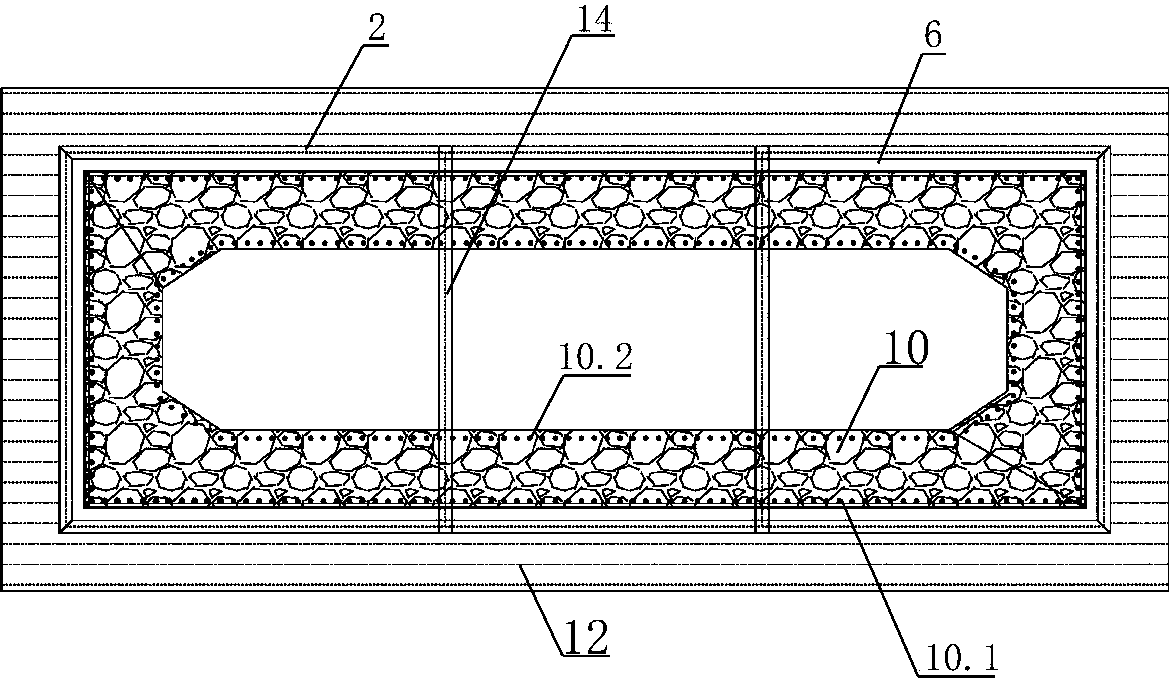

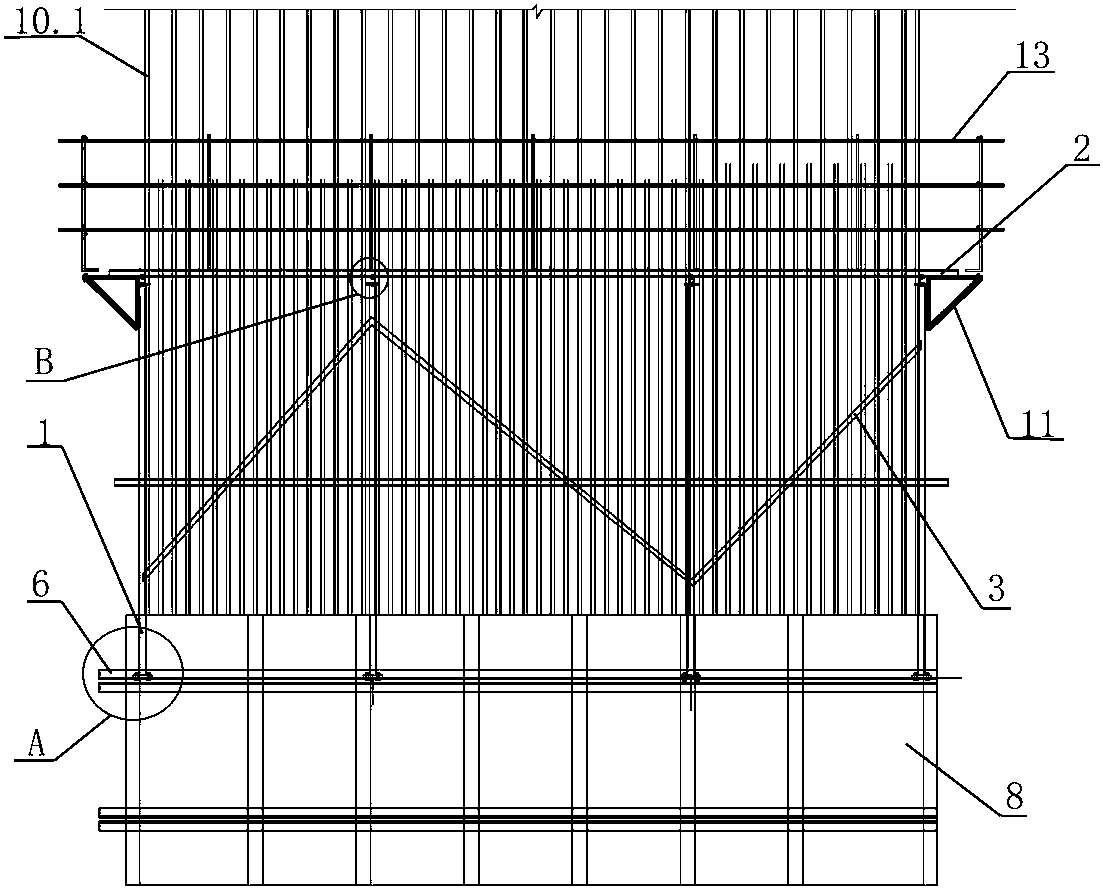

Template structure and method for template support of cast-in-place concrete arc-shaped terrace

ActiveCN103362300AMeet construction requirementsEasy constructionForms/shuttering/falseworksBuilding material handlingShaped beamEngineering

The invention discloses a template structure and a method for template support of a cast-in-place concrete arc-shaped terrace. The template structure comprises a template support frame body and a template fixing system, wherein the template fixing system comprises arc-shaped beam bottom plate templates, seat plate bottom templates, arc-shaped beam outside upper templates, arc-shaped beam outside lower templates and arc-shaped beam inside templates, wherein the arc-shaped beam outside lower templates are positioned below the arc-shaped beam outside upper templates; internal supports are arranged between the arc-shaped beam outside upper templates and the arc-shaped beam inside templates for supporting and enable the arc-shaped beam outside upper templates and the arc-shaped beam inside templates to keep set intervals; split bolts are used for connecting and fixing the arc-shaped beam outside upper templates and the arc-shaped beam inside templates; split bolts are used for connecting and fixing the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the arc-shaped beam bottom plate templates are respectively connected and fixed with the bottom ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the seat plate bottom templates are respectively connected and fixed with the upper ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

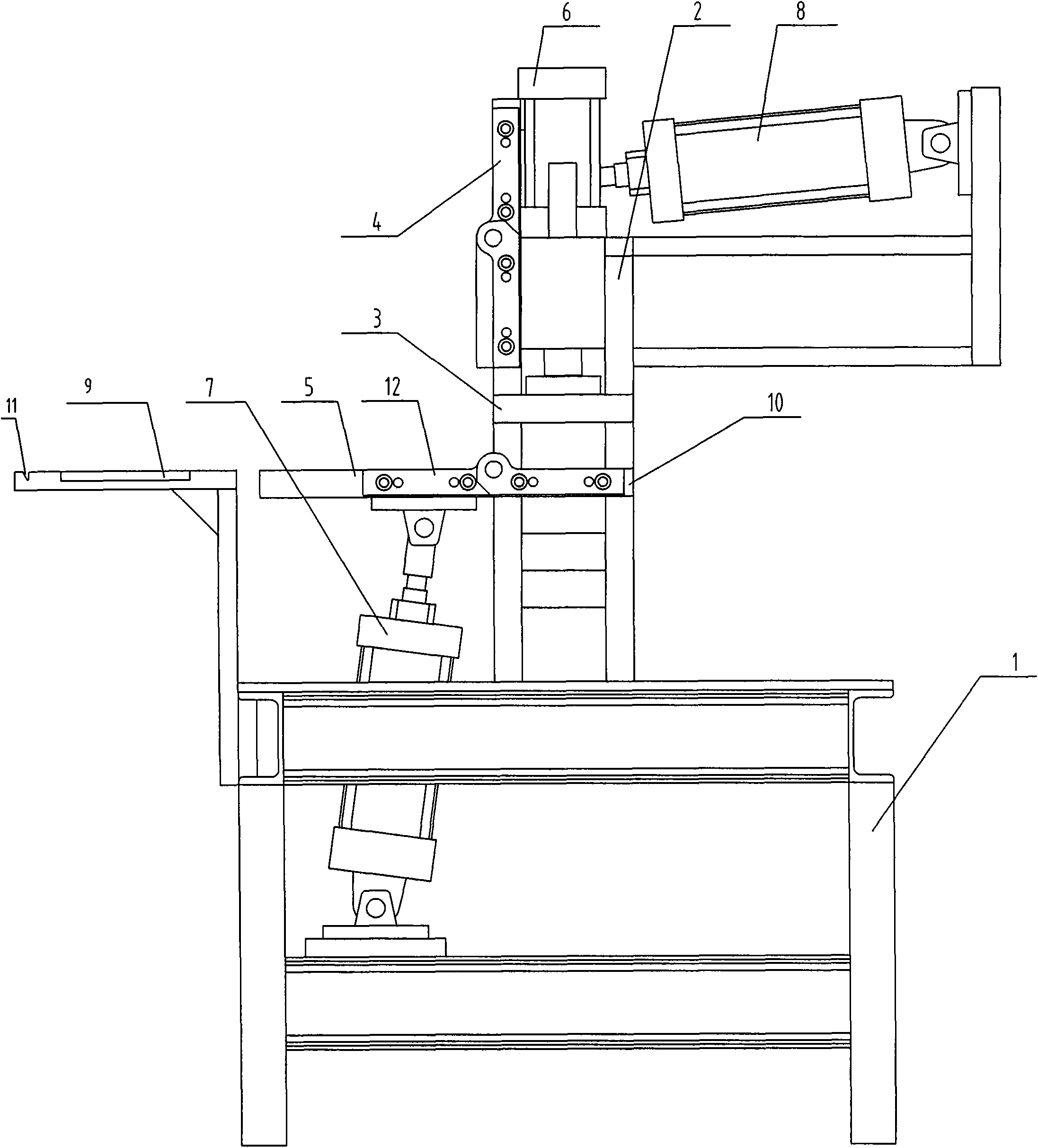

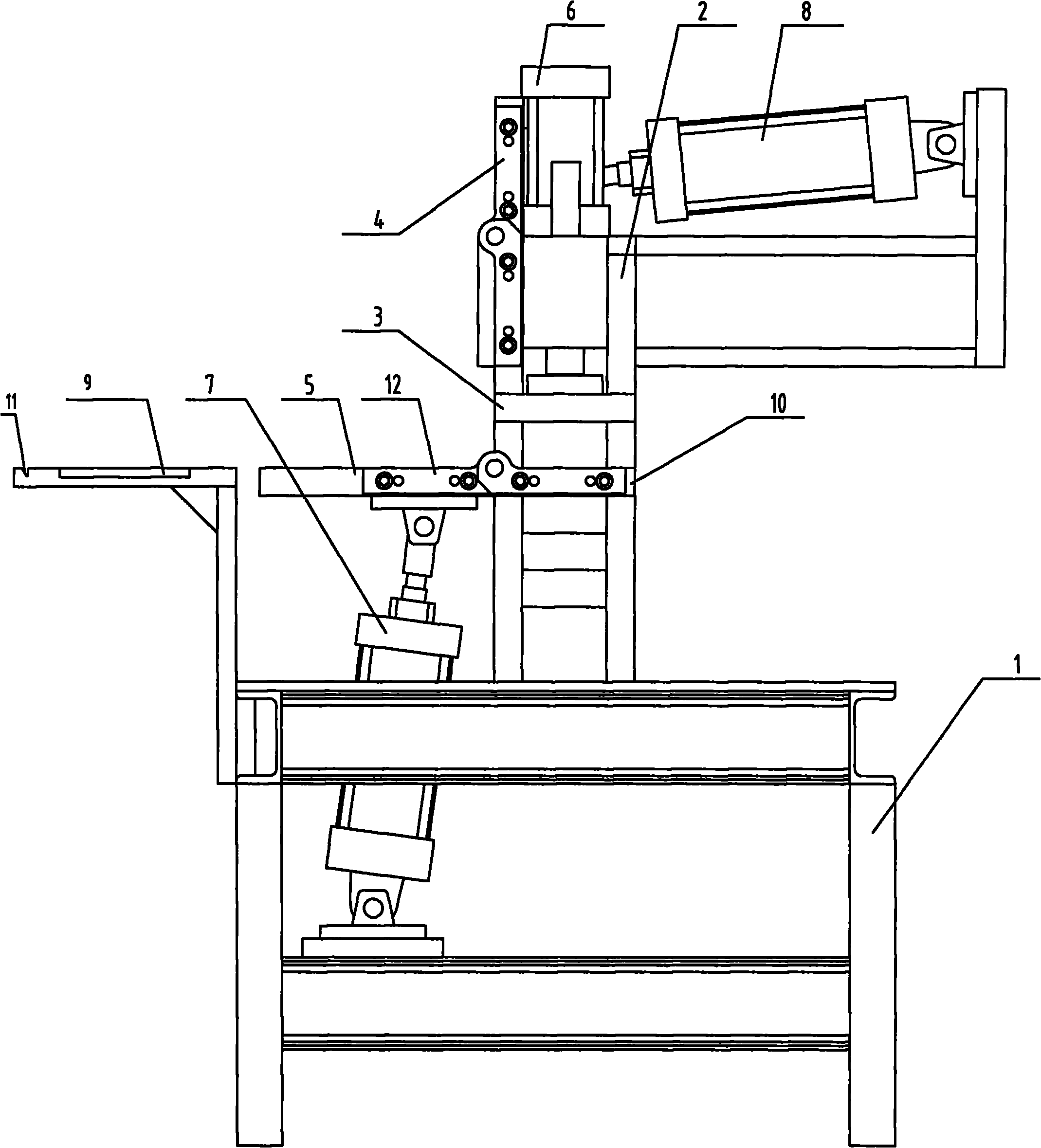

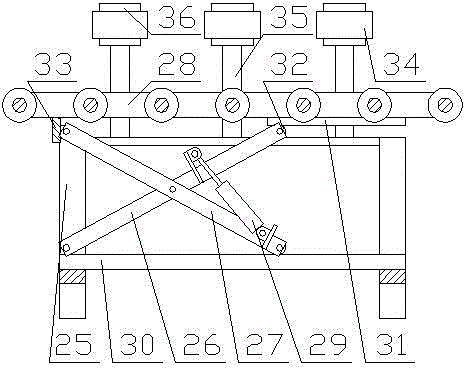

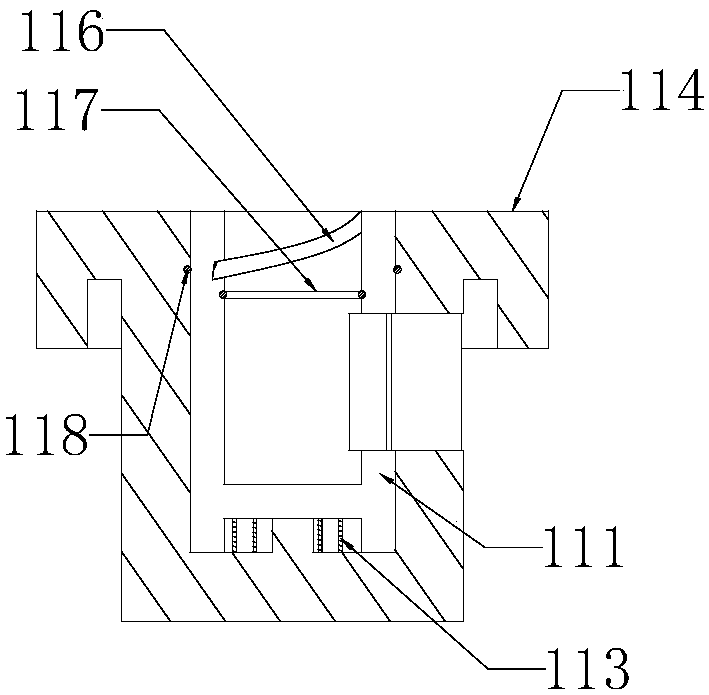

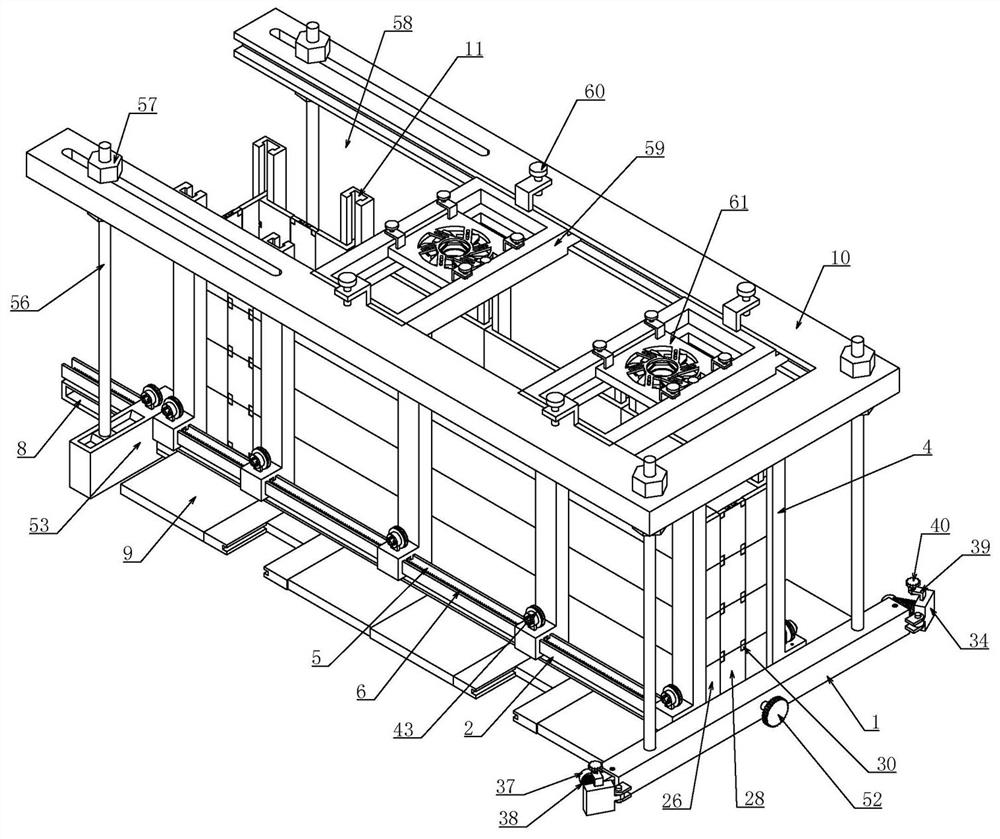

Z-shaped bending device for embossed thin aluminum sheet

The invention discloses a Z-shaped bending device for an embossed thin aluminum sheet. The Z-shaped bending device comprises a lathe bed, wherein a bottom plate is fixed on the upper surface of the lathe bed; a pressing plate which is connected with a pressing plate cylinder and can move up and down is arranged above the bottom plate; one side of the bottom plate is hinged with a lower turning plate; the lower part of the lower turning plate is connected with a lower turning plate cylinder which can turn over the lower turning plate upwards; the side of the lower turning plate is provided with a positioning device; an upper turning plate which is arranged vertically is also arranged above the pressing plate; one side edge of the upper turning plate is connected with an upper turning plate cylinder which can turn over the upper turning plate towards the other side; a wall board component is fixed on the lathe bed; and the wall board component comprises a fixed upper turning plate cylinder, the pressing plate and the pressing plate cylinder which are connected with the wall board component and the upper turning plate which is hinged and can turn over. The device has the characteristics of simple structure, convenient and reliable use, high rate of finished products, one-pass operation, high degree of automation, low labor intensity and the like.

Owner:许水林

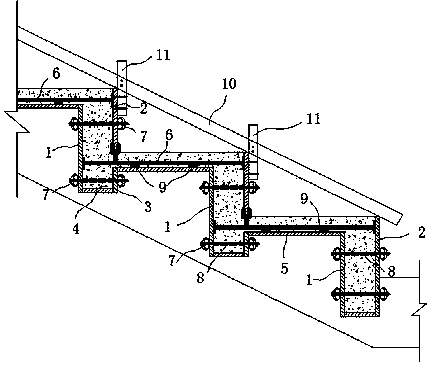

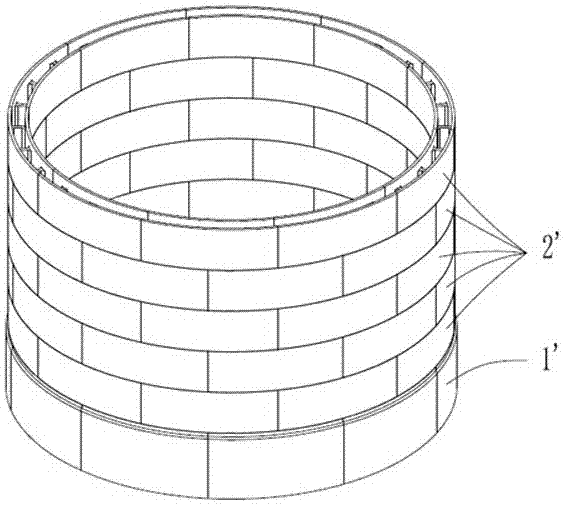

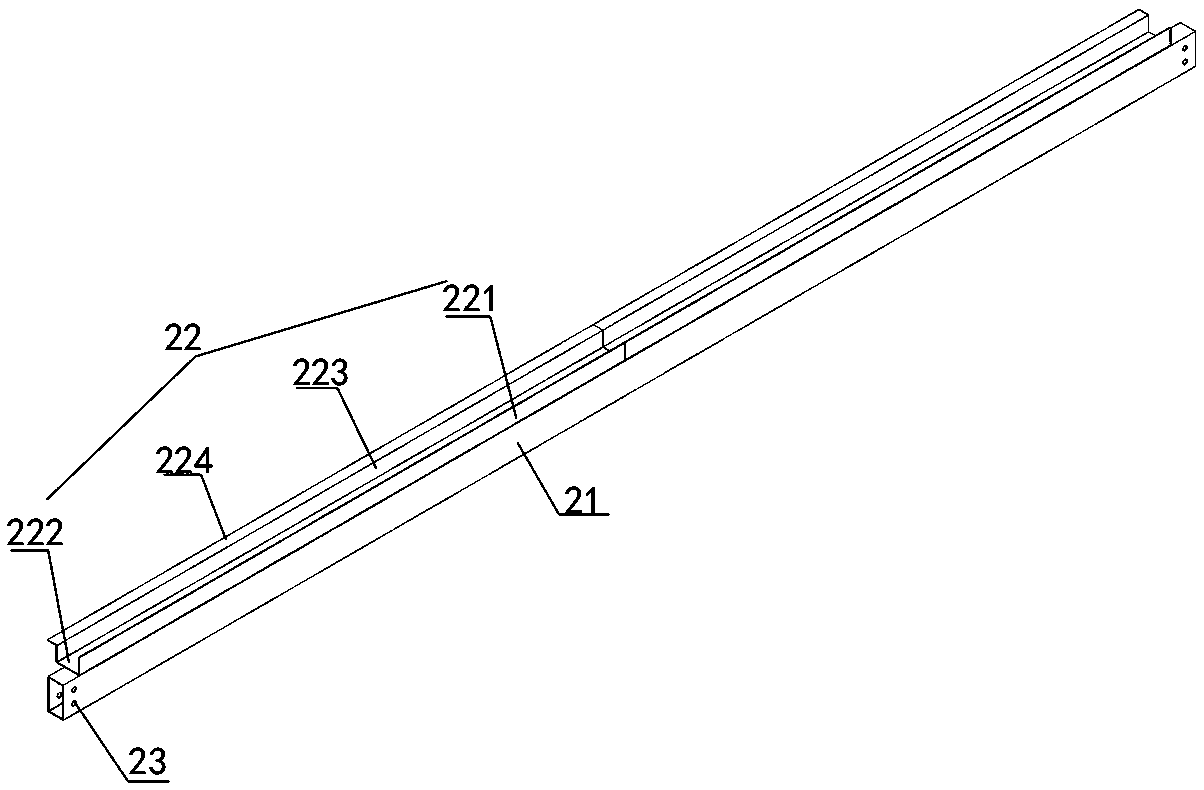

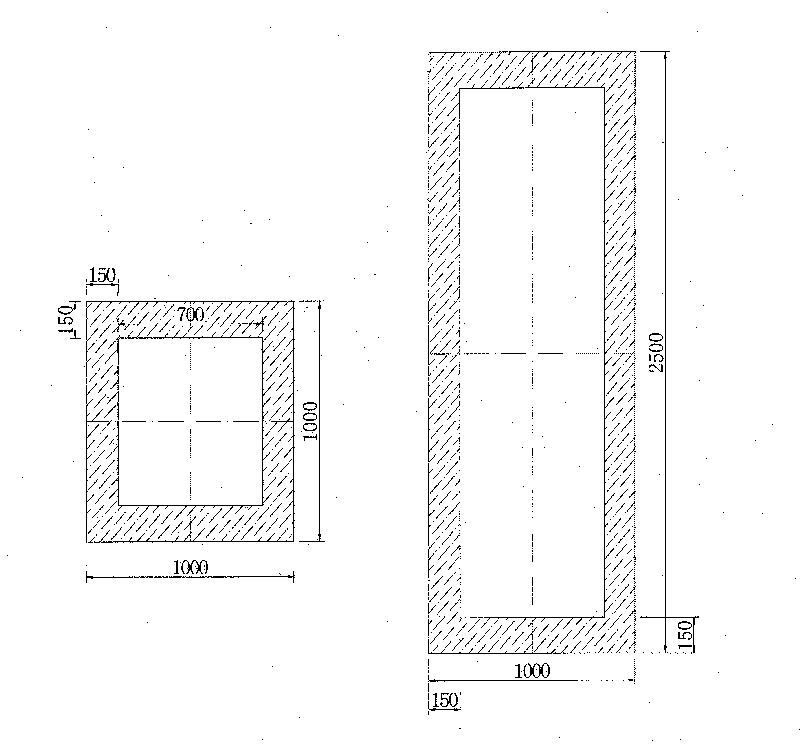

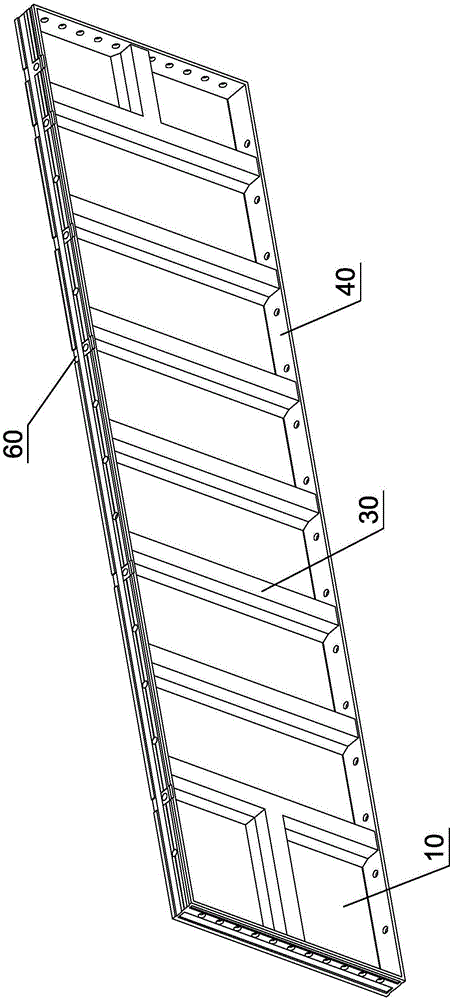

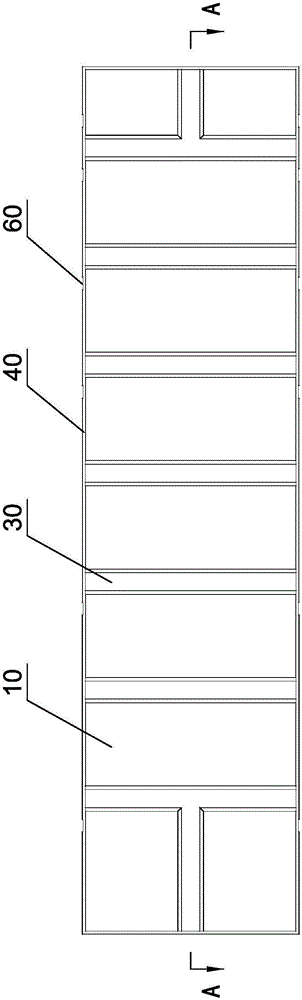

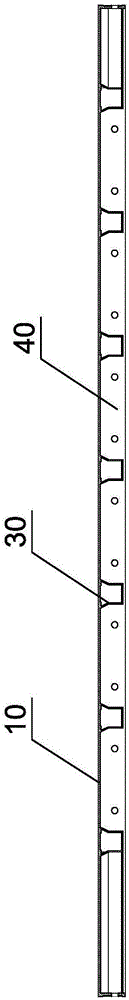

Sliding formwork component and open caisson blade foot layer sliding formwork construction method applying sliding formwork component

PendingCN107575023AGuaranteed vertical accuracyGuaranteed assembly qualityForms/shuttering/falseworksCaissonsSteel barBuilding construction

The invention discloses a sliding formwork component. The sliding formwork component comprises a sliding way, an outer template, an inner template, two side templates and a plurality of connecting fixing pieces. The sliding way is provided with a plurality of sliding grooves for installation of the outer template and the inner template. A plurality of outer stand bars are arranged at the bottom ofthe outer template. The outer stand bars are arranged on the outer side of the sliding way and can be installed and move along the sliding grooves. A plurality of inner stand bars are arranged at thebottom of the inner template. The inner stand bars are arranged on the inner side of the sliding way and can be installed and move along the sliding grooves. The side templates are arranged on the two side edges of the inner template and the two side edges of the outer template and are connected with the inner template and the outer template through the connecting fixing pieces. The invention further discloses an open caisson blade foot layer sliding formwork construction method. The method comprises the steps of field leveling, sliding way installing, steel bar bundling, template installing,concrete pouring, side template dismounting, template sliding and the like. According to the sliding formwork component and the method, the linear vertical perpendicularity after blade foot construction is finished can be ensured, and accordingly the assembling quality of upper-layer open caisson standard segments is guaranteed.

Owner:中铁科建有限公司

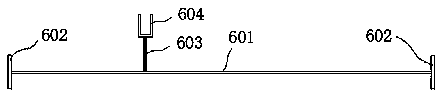

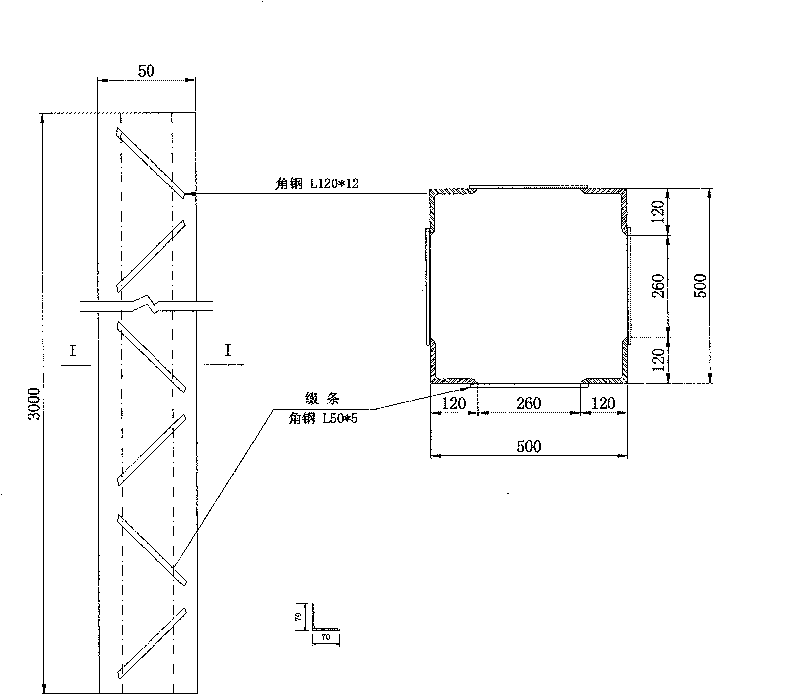

Reinforcing steel formwork supporting rack for thin-walled hollow high pier and construction method

The invention provides a reinforcing steel formwork supporting rack for a thin-walled hollow high pier and a construction method. The reinforcing steel formwork supporting rack comprises a reinforcing steel formwork supporting framework and an operation platform, wherein the reinforcing steel formwork supporting framework comprises vertical columns, a transverse bridge direction cross rod and a longitudinal bridge direction cross rod, wheel discs are arranged at the bottom ends of the vertical columns, the bottom ends of the vertical columns are in welded connection with the wheel discs, the wheel discs are fixedly connected with rollover purlins of set-shaped steel formworks through bolts, connecting steel plates are welded at the top ends of the vertical columns and connected with the longitudinal bridge direction cross rod at the top through bolts, and the transverse bridge direction cross rod is perpendicular to the longitudinal bridge direction cross rod, erected on the top surface of the longitudinal bridge direction cross rod and connected with the longitudinal bridge direction cross rod though the bolts; and operation platform comprises triangular reinforcing steel brackets and operation platform stirrups, vertical supports of the triangular reinforcing steel brackets are attached to the tops of the outer walls of the vertical rods and are in welded connection, the operation platform stirrups are uniformly distributed, and the end parts are undertook transversely on the triangular reinforcing steel brackets. The reinforcing steel formwork supporting rack for the thin-walled hollow high pier and the construction method have the advantages that thickness of a protective layer is easy to control, safety and reliability are achieved, construction cost is saved and the like.

Owner:ZHEJIANG JINZHU TRANSPORTATION CONSTR

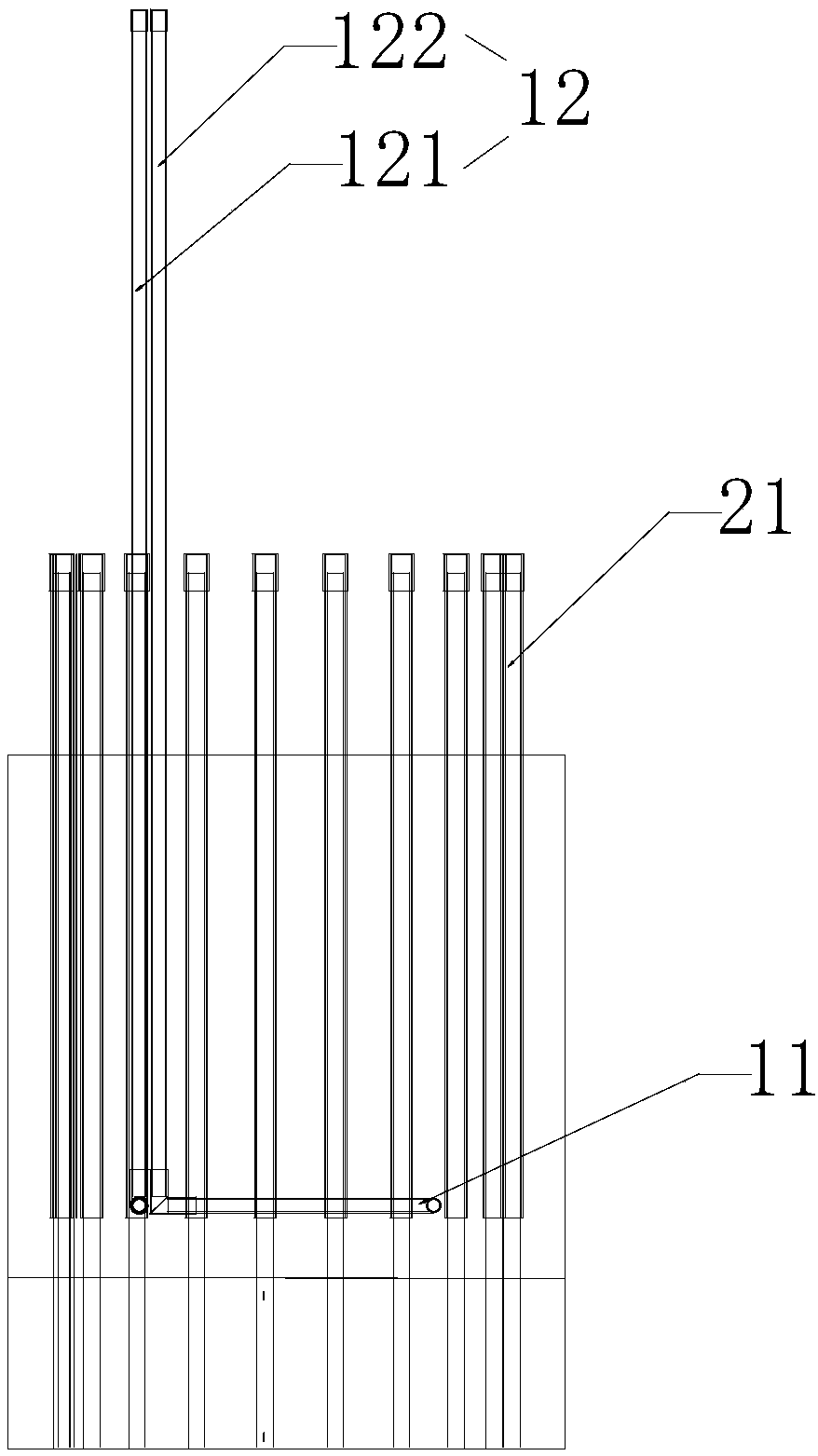

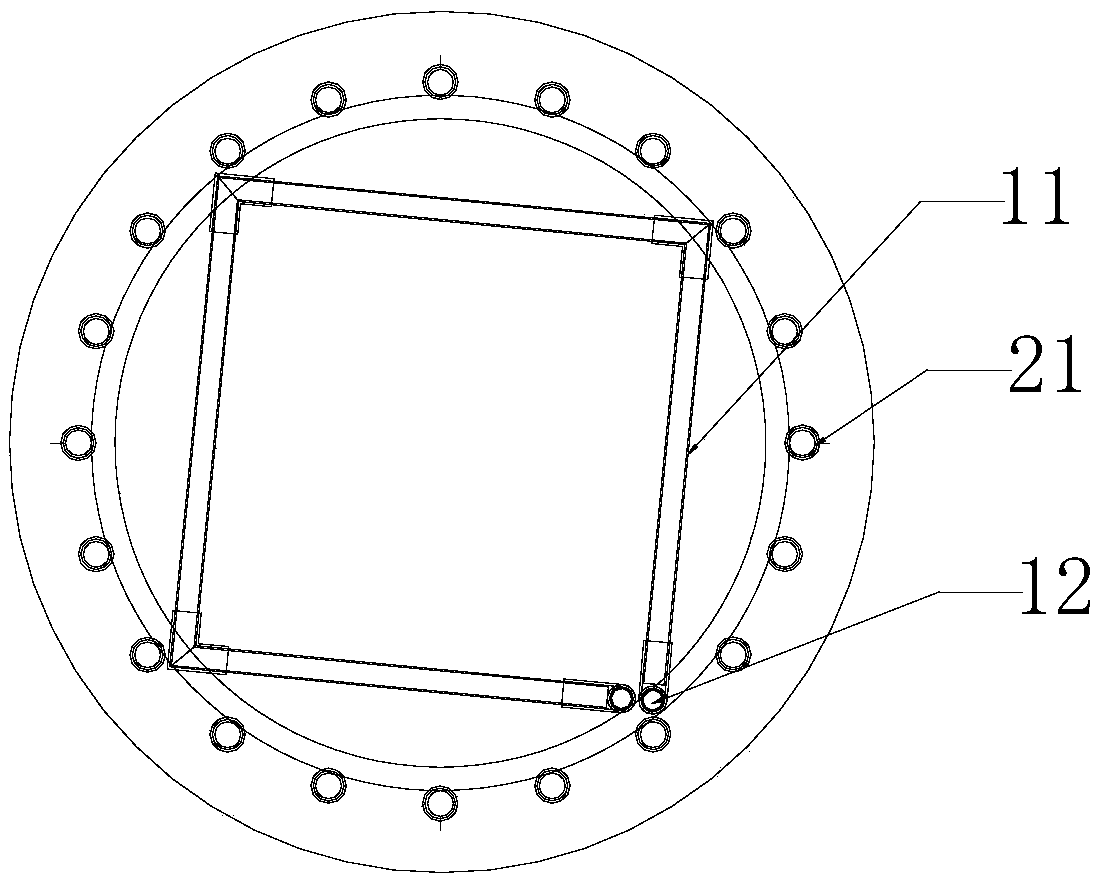

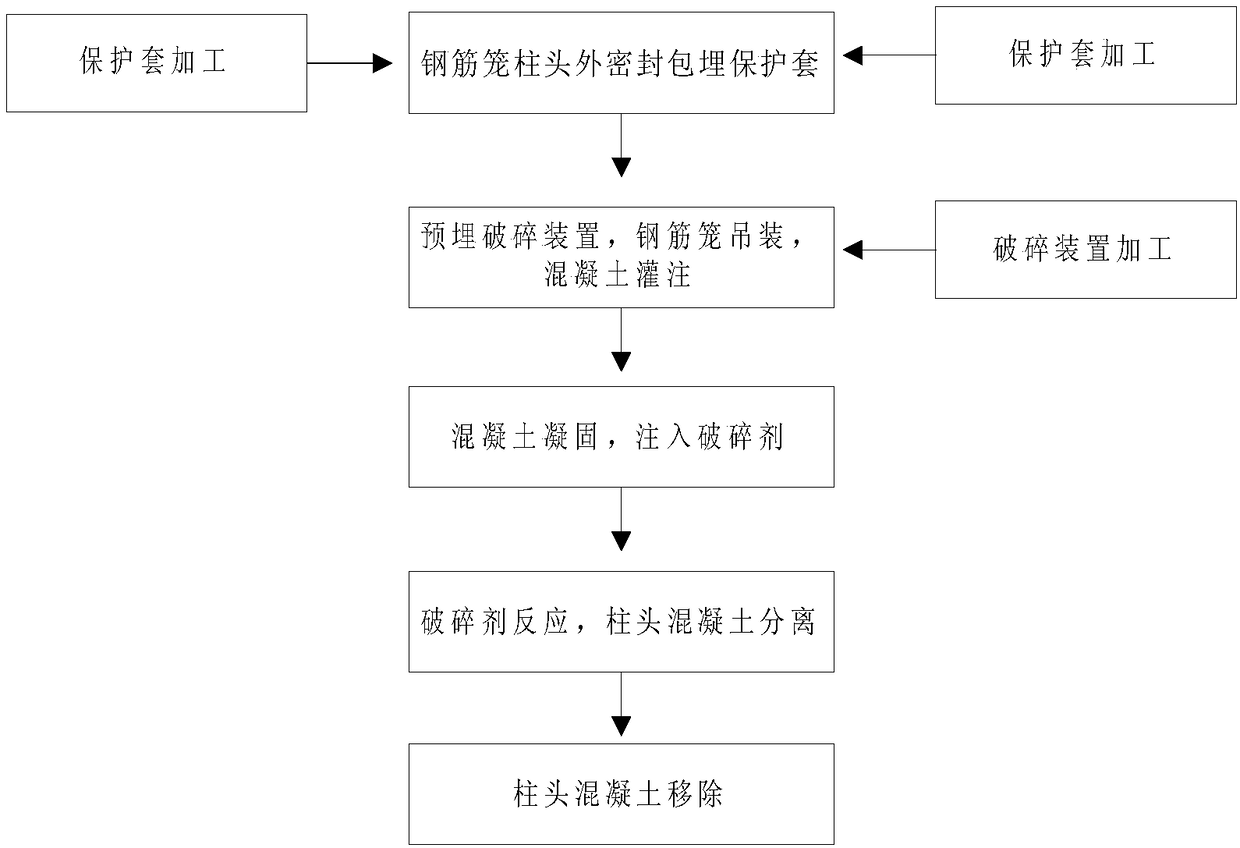

Crushing device, breaking method and application of pile head of cast-in-place bored pile

The invention discloses a crushing device, a breaking method and an application of a pile head of a cast-in-place bored pile. The crushing device of the pile head of the cast-in-place bored pile comprises the crushing device, wherein the crushing device is used for separating pile head concrete from pile body concrete through horizontal expansion force; the crushing device comprises a horizontal crushing assembly and a communicating pipe, wherein the horizontal crushing assembly is arranged at the joint position of the pile head concrete and the pile body concrete, and the horizontal crushingassembly is used for generating the horizontal expansion force to force the pile head concrete to be separated from the pile body concrete; and the communicating pipe extends out of the pile head concrete and is in communication with the inner cavity of the horizontal crushing assembly, and is used for injecting a crushing agent into the inner cavity of the horizontal crushing assembly. Accordingto the crushing device of the pile head of the cast-in-place bored pile, the structural design is simple, the crushing device of the pile head of the cast-in-place bored pile is placed at the joint position of the pile head concrete and the pile body concrete, and the separating effect can be achieved by injecting the crushing agent.

Owner:CCFEB CIVIL ENG

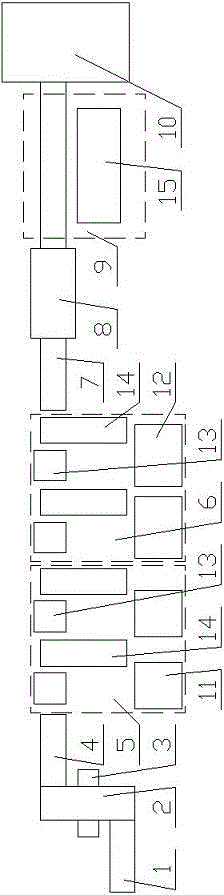

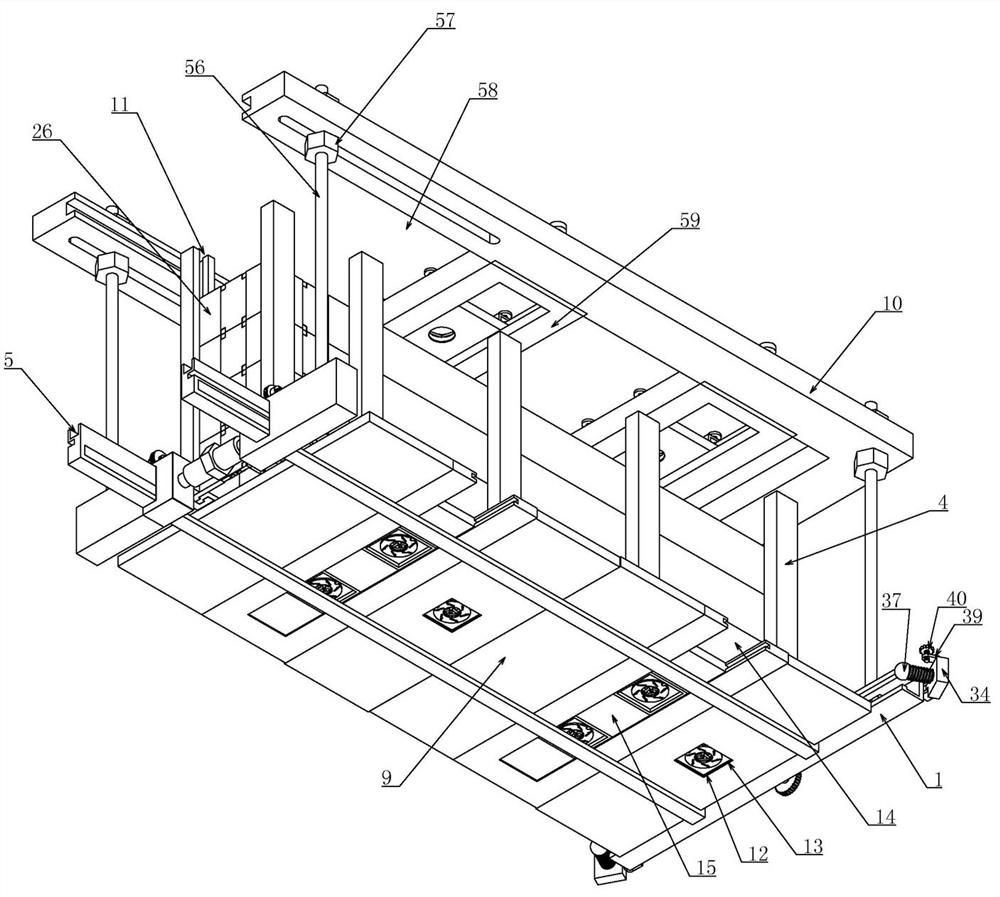

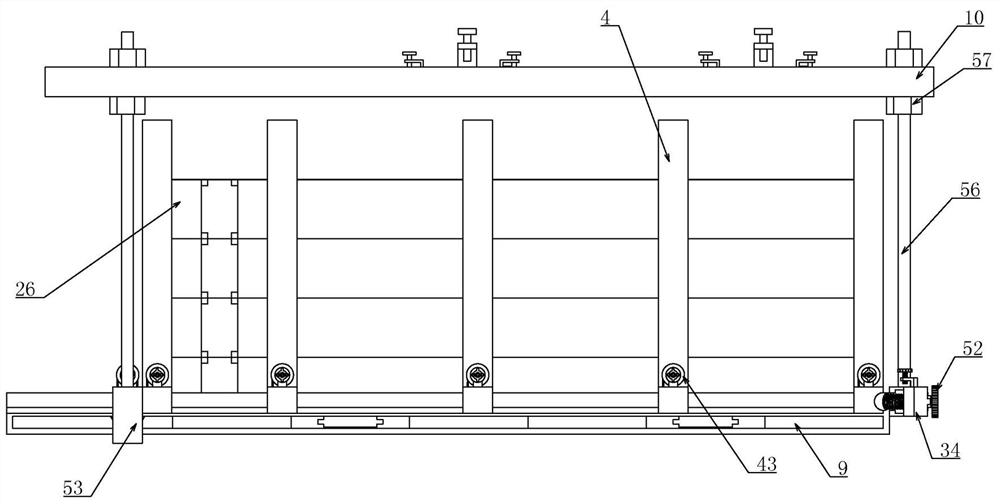

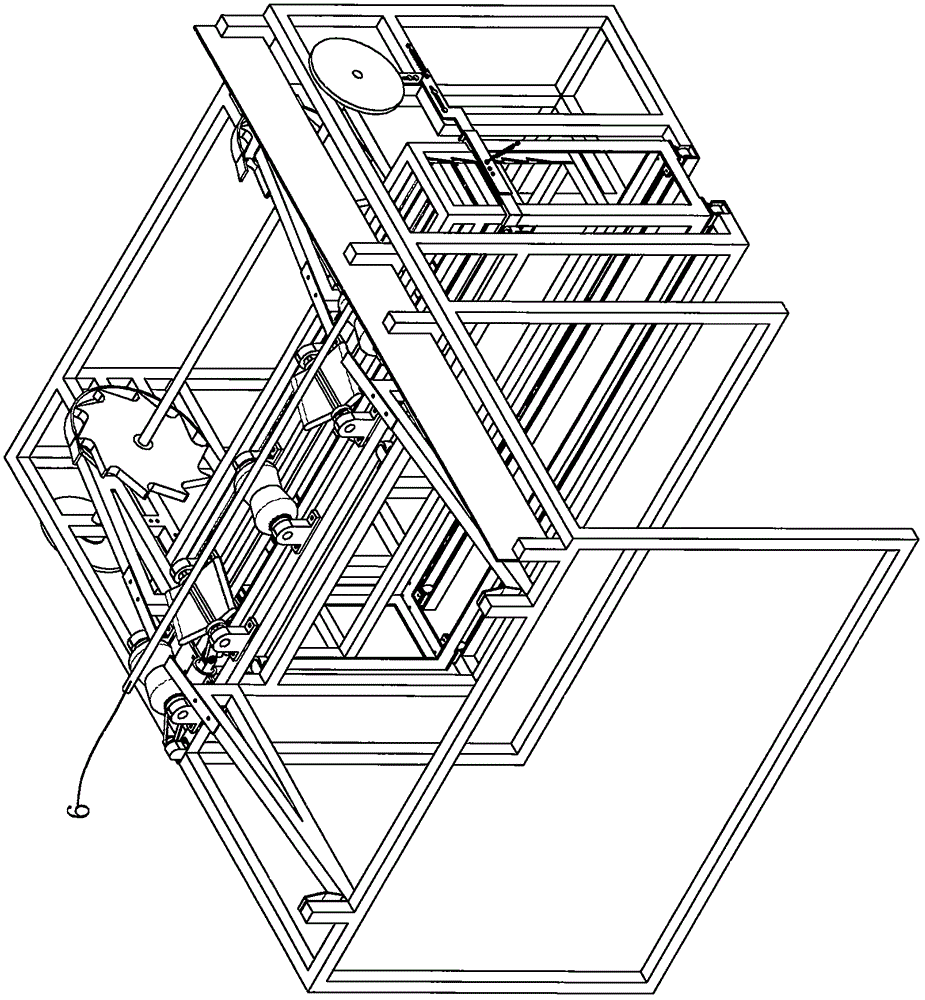

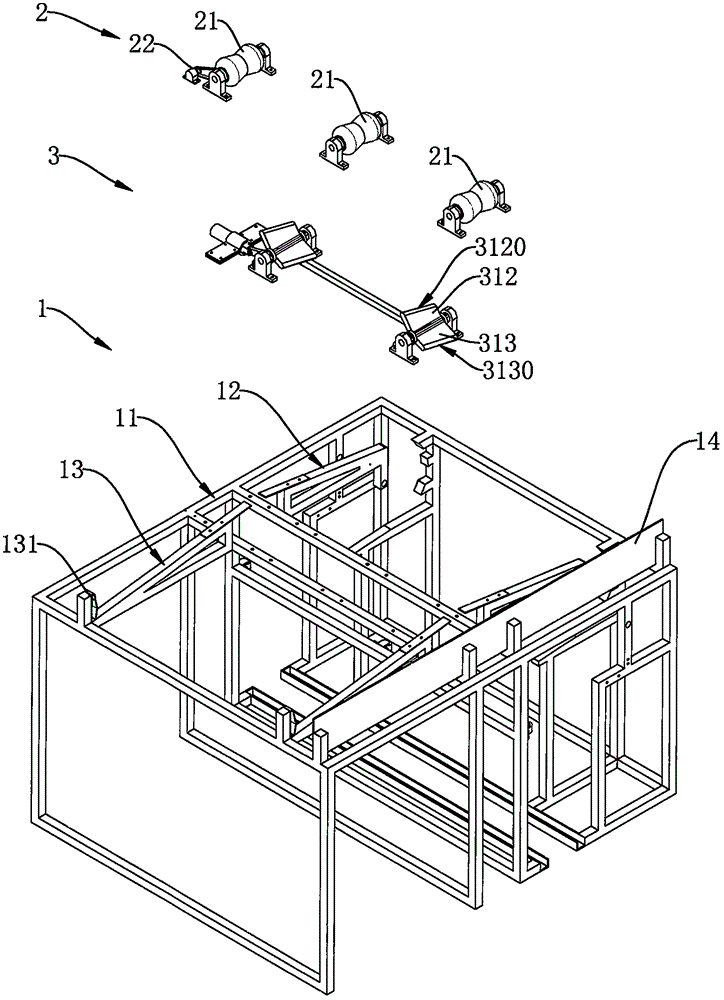

Elevator door plate production line

ActiveCN105728583AFully automatedIncrease productivityMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses an elevator door plate production line. The elevator door plate production line sequentially comprises a blank feeding device, a feeding transfer rack, a punching device, a bending device, a riveting device, a rib applying area and a blanking transfer rack. A conveying rack A is disposed between the punching device and the bending device. A conveying rack B is mounted between the bending device and the riveting device. The feeding transfer rack is disposed above the feeding device, the punching device and the conveying rack A. The conveying rack B is connected with the blanking transfer rack through the riveting device and the rib applying area. According to the structure of the elevator door plate production line, automatic production of elevator door plates is achieved, the production efficiency of the elevator door plates is improved, and the labor cost is effectively reduced.

Owner:JIANGYIN FIVE STAR WELDING COPPER

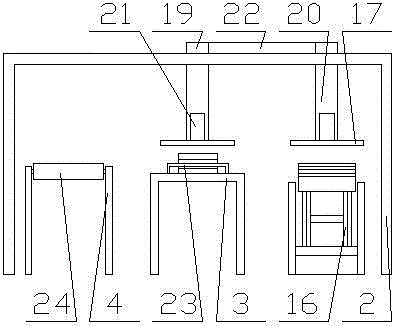

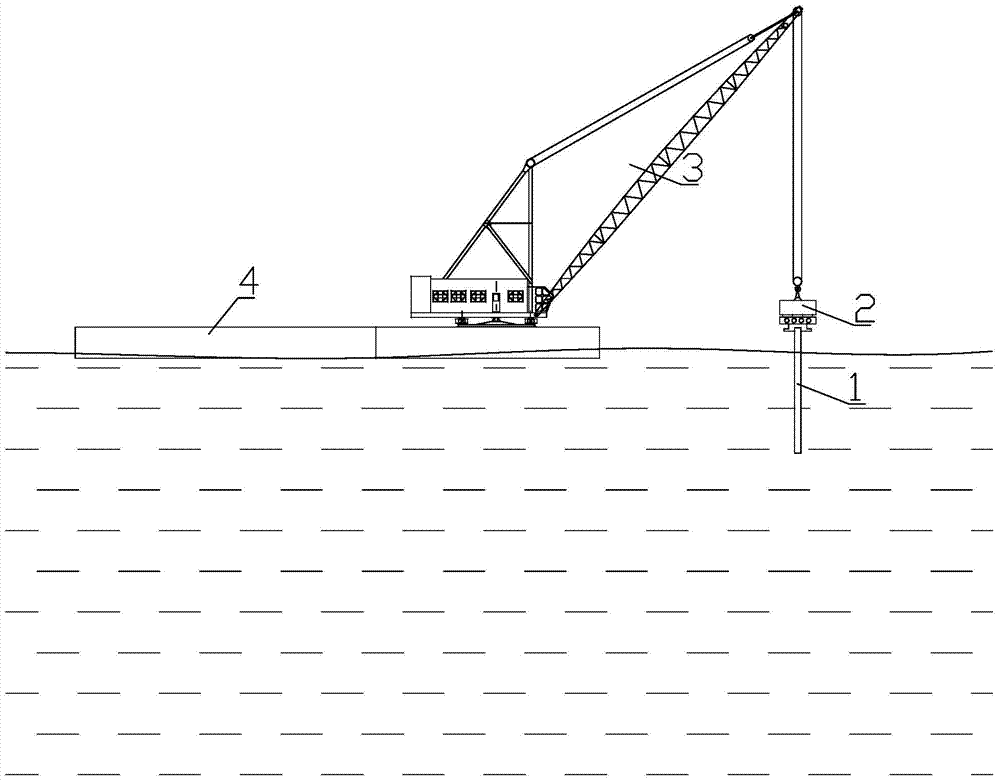

A method for pulling out underwater steel pipe piles for temporary projects of bridges

InactiveCN104196026AEasy turnoverShorter dismantling timeBulkheads/pilesOperabilityUltimate tensile strength

The invention discloses a method for pulling out underwater steel pipe piles for temporary projects of bridges. The method comprises the following steps: firstly, the model number of a vibration hammer and lifting equipment are selected through calculation, a transporting barge is prepared, and a complete set is formed and enters an operation area; then, the top of a steel pipe pile is leveled; the lifting equipment arrives at the operation area, an anchor is cast in place according to the length of a lifting arm and the operation radius, and meanwhile, the vibration hammer and the transporting barge are in place near the steel pipe pile; the vibration hammer is started to sink down the steel pipe pile, and then, the pile is pulled through vibration; after the steel pipe pile ascends, the lifting equipment directly pulls the pile until the steel pipe pile is separated from a mud surface; and finally, the steel pipe pile drops on the transporting barge, and the vibration hammer frees the pile to finish the pile pulling. In addition, a two-section pulling method is suitable for the steel pipe pile with the length more than 45 m; firstly the steel pipe pile is pulled out partially; then, the part of the steel pipe pile above a water surface is cut off; and finally, the remainder part of the steel pipe pile is pulled out. The method has the advantages of strong operability, low labor intensity, convenience for use, safety, environmental protection, quickening of construction progress and reduction of construction cost.

Owner:TIANJIN 20 CONSTR

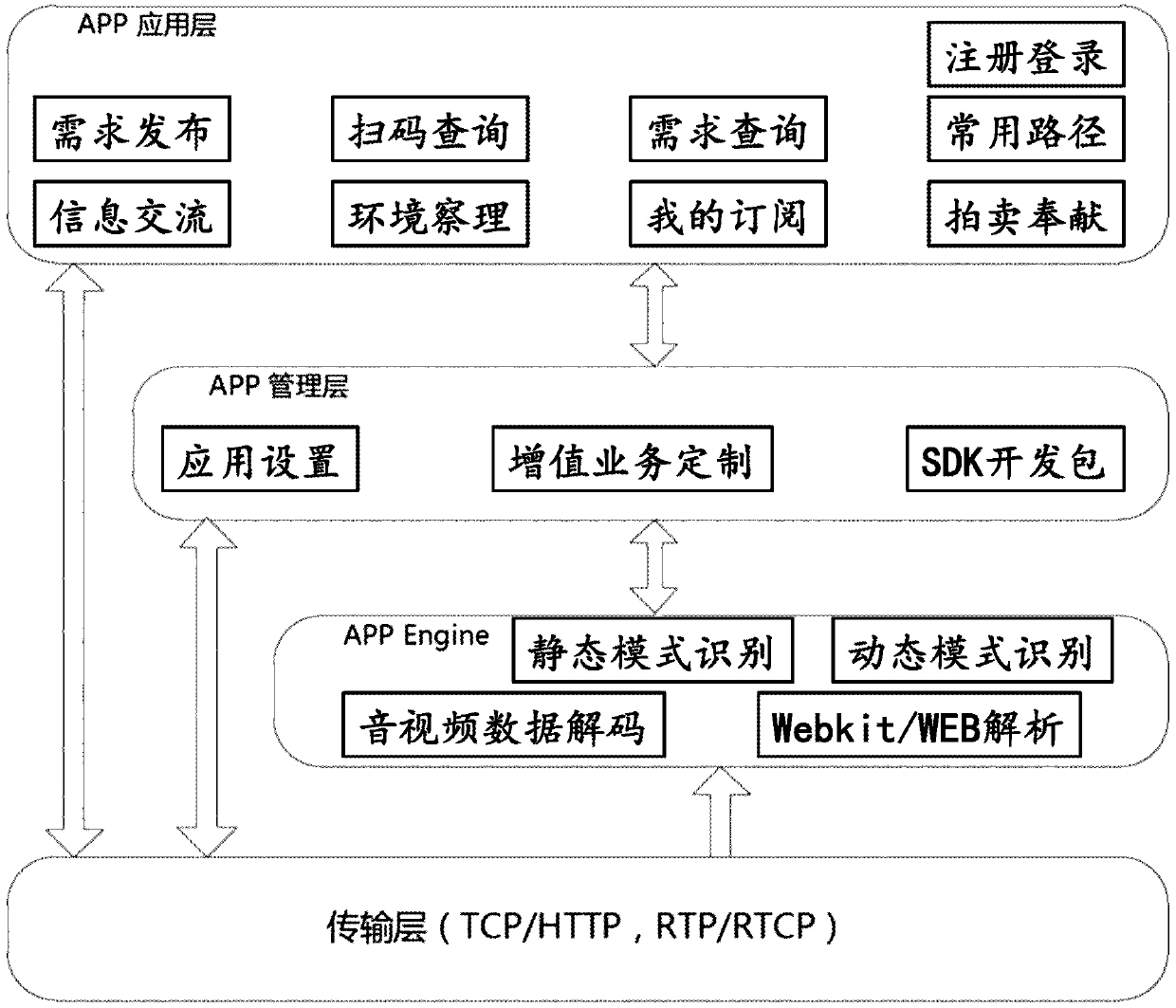

Identification code-containing device and device system and method for recycling identification code-containing device

PendingCN110135540ALow costImprove efficiencyData processing applicationsCo-operative working arrangementsRelevant informationManagement process

The invention provides an identification code-containing device and device system and a method for recycling the identification code-containing device. The invention sets articles or services to be managed in parallel with at least one device with a unique identification code or a device with a unique identification code, and scans or receives the identification code with the intelligent terminalbefore and after, and combines the relevant information in the system. The server generates a unique transaction ID in the system, and uses the unique identification code and the intelligent terminal,and its management device and system to manage the material or service data, and realizes the goods, services and exchange resources without printing the waybill or bill. The transfer and managementprocess, and the identification code form or the identifier-containing device can be recycled to the management process including the identification, classification, merging, transfer, transmission and reception, evaluation, statistics, and settlement. The program is applicable to various scenarios of commodity distribution, catering and take-out, second-hand item transfer sharing, transmission maintenance and repair, garbage classification and clearing and receiving, product life cycle management, volunteer management, and precision poverty alleviation.

Owner:北京联博达科技有限公司

Manufacturing method of metal frame for flat panel display

InactiveCN101823106AIncrease profitReduce manufacturing costMetal-working apparatusPunchingMetal framework

The invention relates to a manufacturing method of a metal frame for a flat panel display. The metal frame is manufactured by the following steps: a punch and two sets of continuous stamping dies are used to respectively punch into two|-shaped material plates and two [-shaped material plates which are ganged, and the required ster-edgefolds are formed on each|-shaped frame and each [-shaped frame; and punching shaping and the ster-edgefolds of each|-shaped frame or each [-shaped frame are formed by continuous processing with the same die on the same punch. The metal frame for the flat panel display manufactured by the method can greatly improve the utilization rate of raw materials, reduce cost, facilitate transportation, revolution and storage among various procedures during the manufacture process and simplify manufacturing process.

Owner:北京日伸电子精密部件有限公司

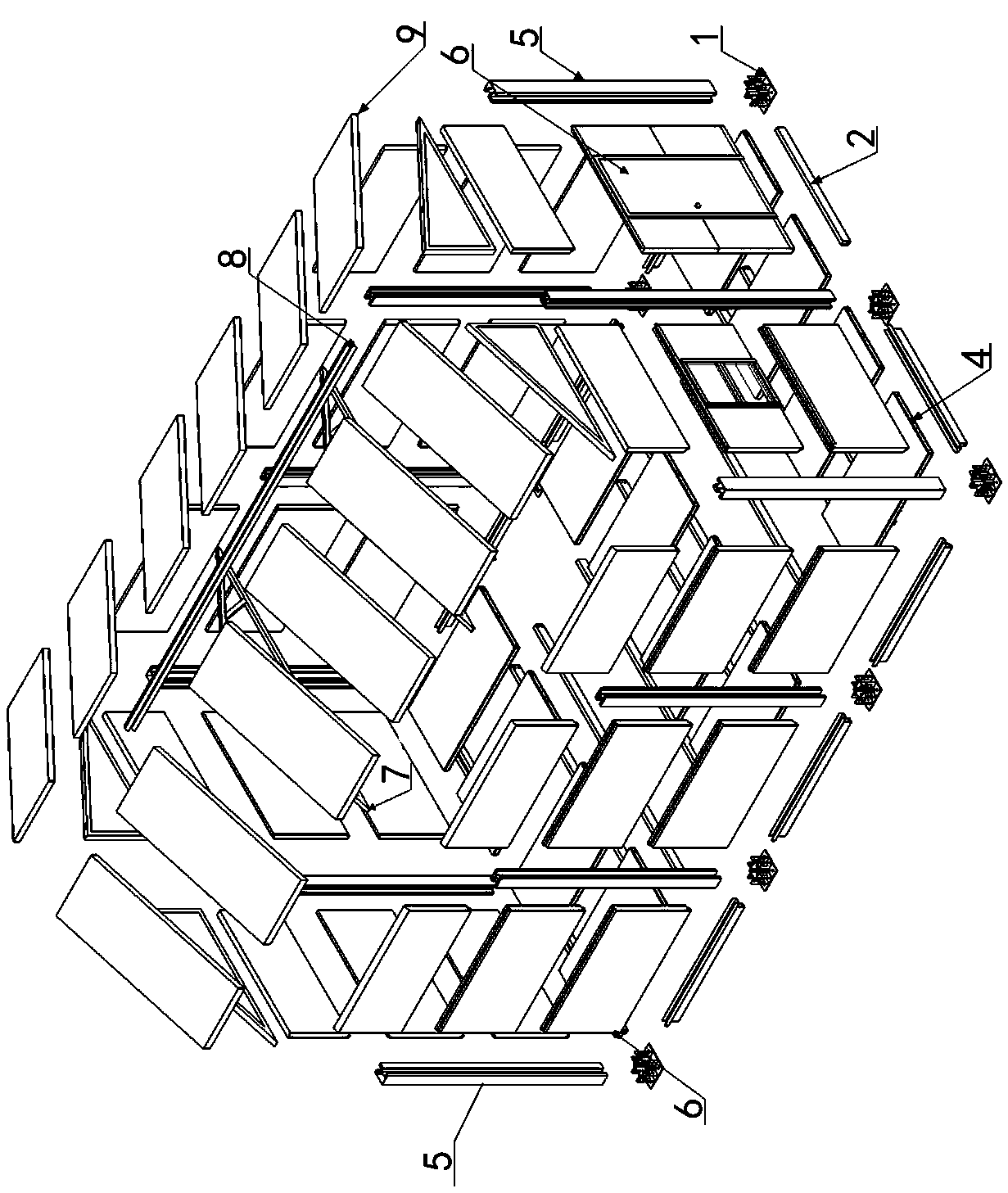

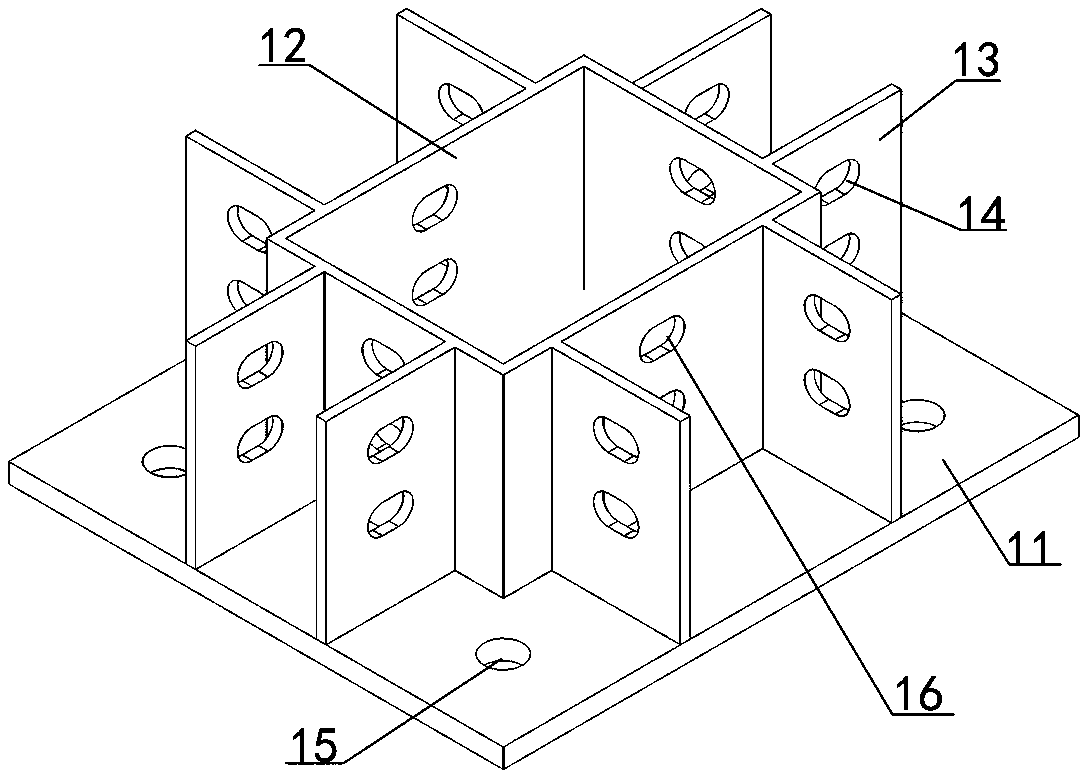

Quick disassembling and assembling type special-shaped column frame plate type support structure system and construction method thereof

PendingCN108978875AReduce weightImprove general performanceBuilding constructionsTurnover timeModular design

The invention relates to a quick disassembling and assembling type special-shaped column frame plate type support structure system and a construction method thereof, the structure system comprises atleast one unit main body structure, the unit main body structure comprises a four-way adjustable connecting support, a beam frame, a composite structure floor, a thin-wall special-shaped column, a unit wall, a lightweight triangular roof truss, a roof ridge clamping groove and a roof panel. The support and the beam frame are mounted according to modular design, modular design processing is performed, at the same time, a corresponding connection node is designed in each node, connection can be performed through a simple bolt, insertion-connection structures between the wall and the beam frame and between the wall and the column are designed, the overall mounting process realizes instrumentalization, no field welding is needed, the mounting saves both time and labor, instrumentalized quick mounting can be realized and the turnover times are high.

Owner:中建集成科技有限公司 +1

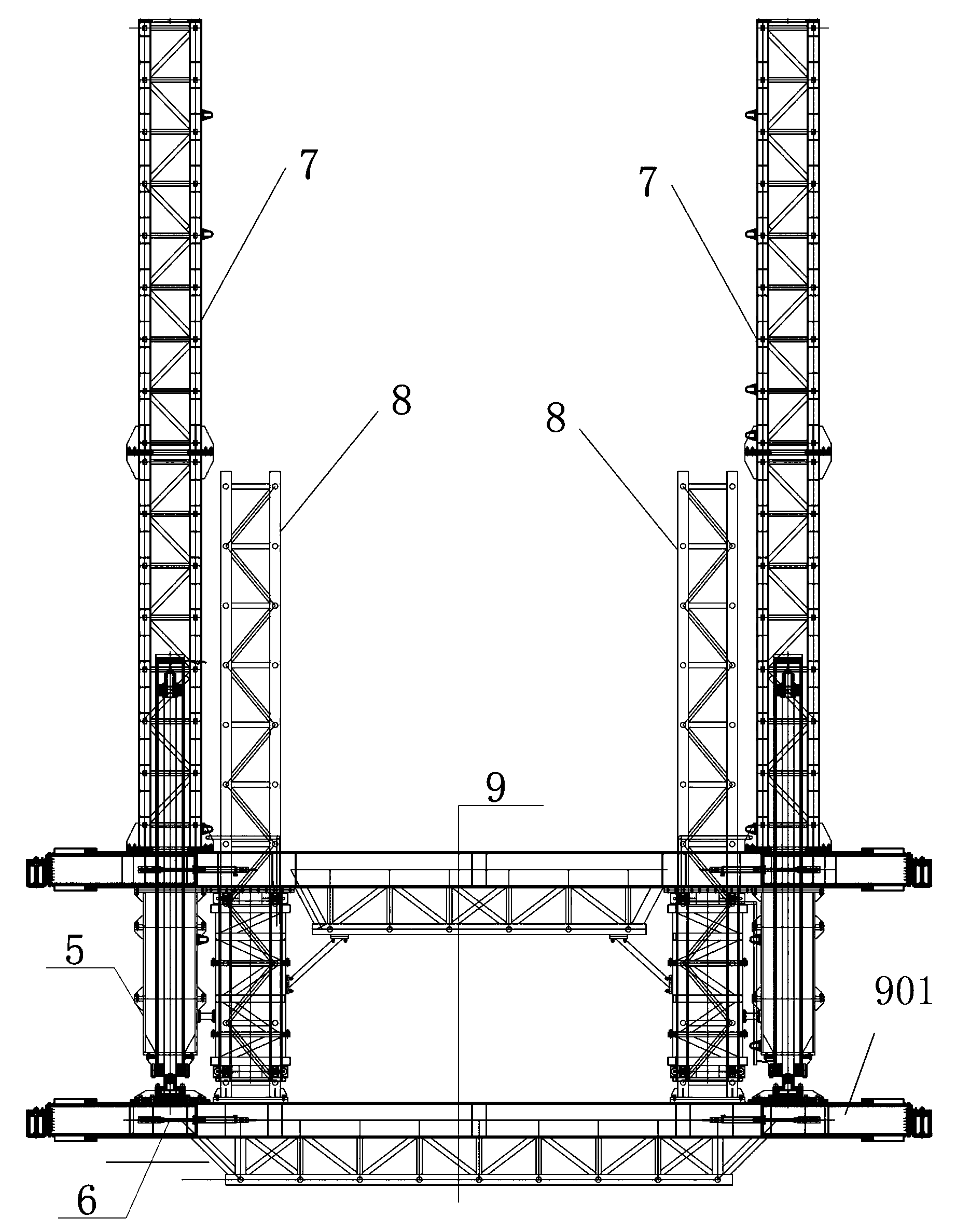

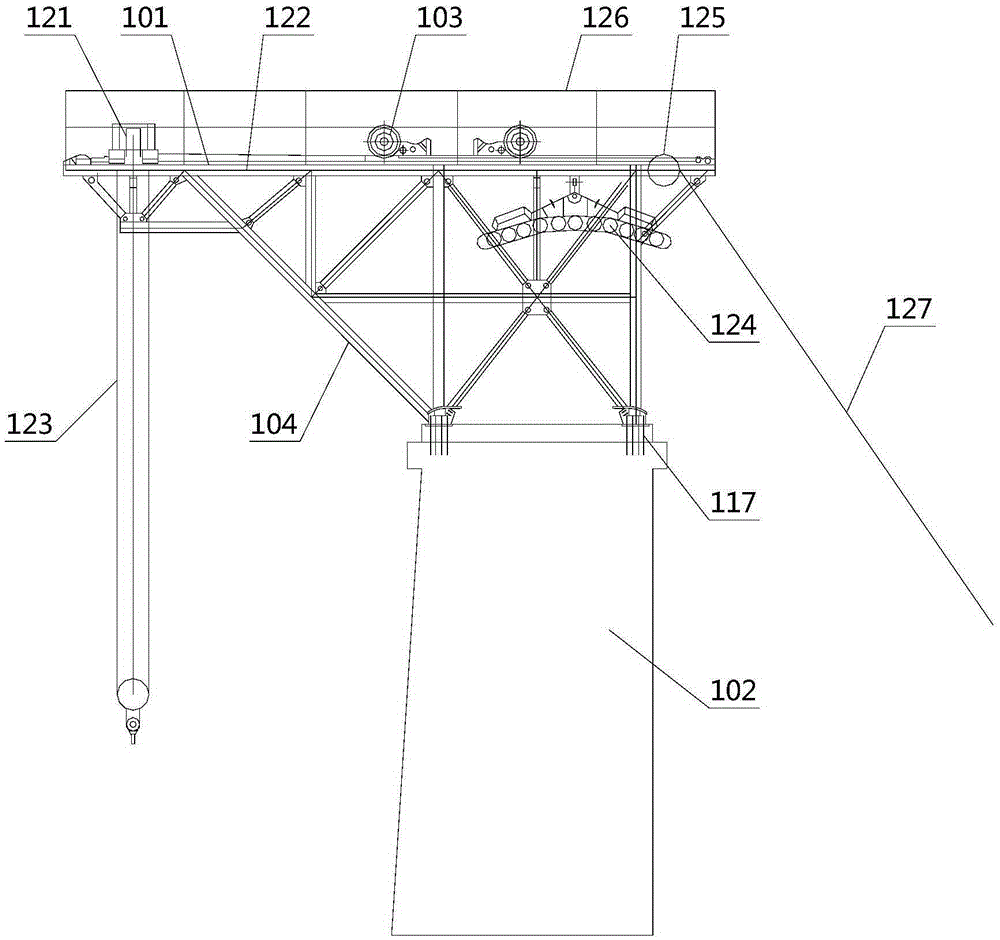

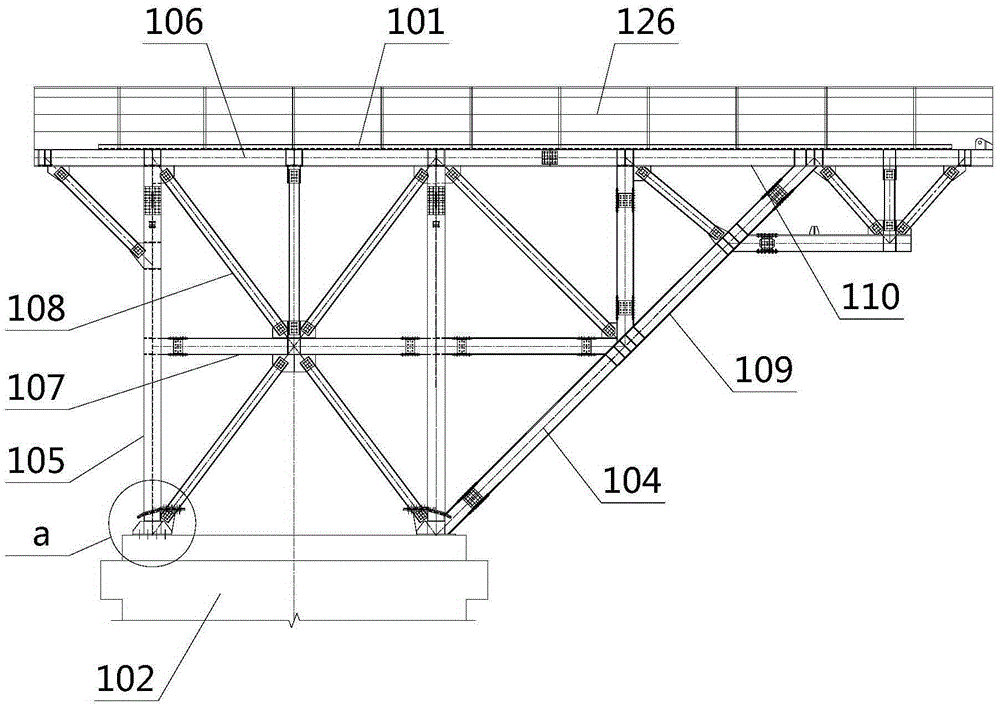

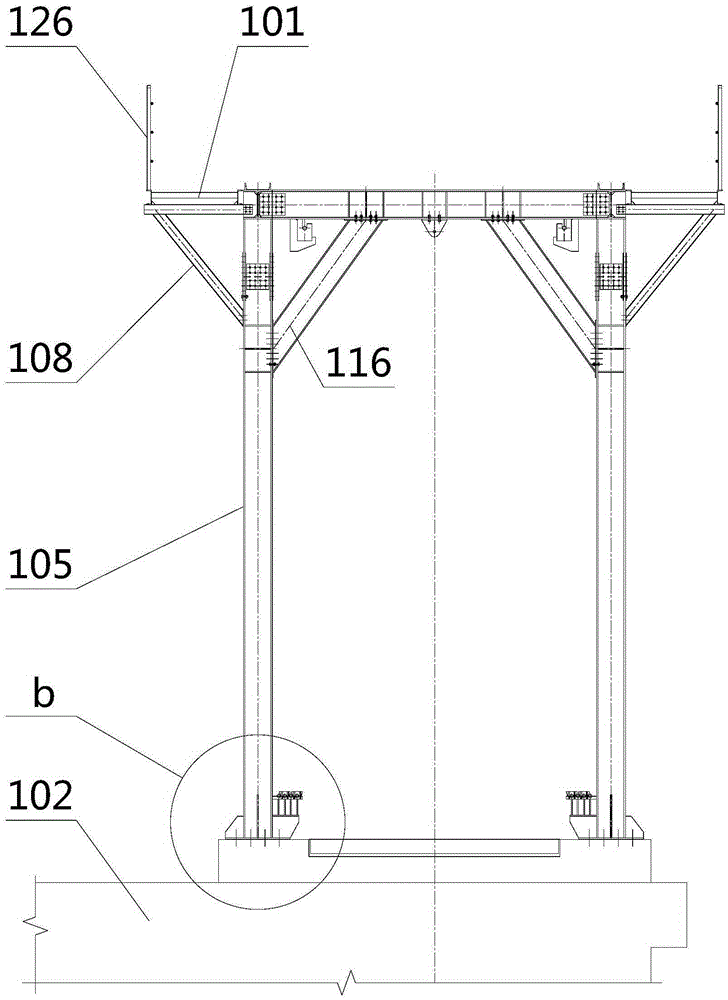

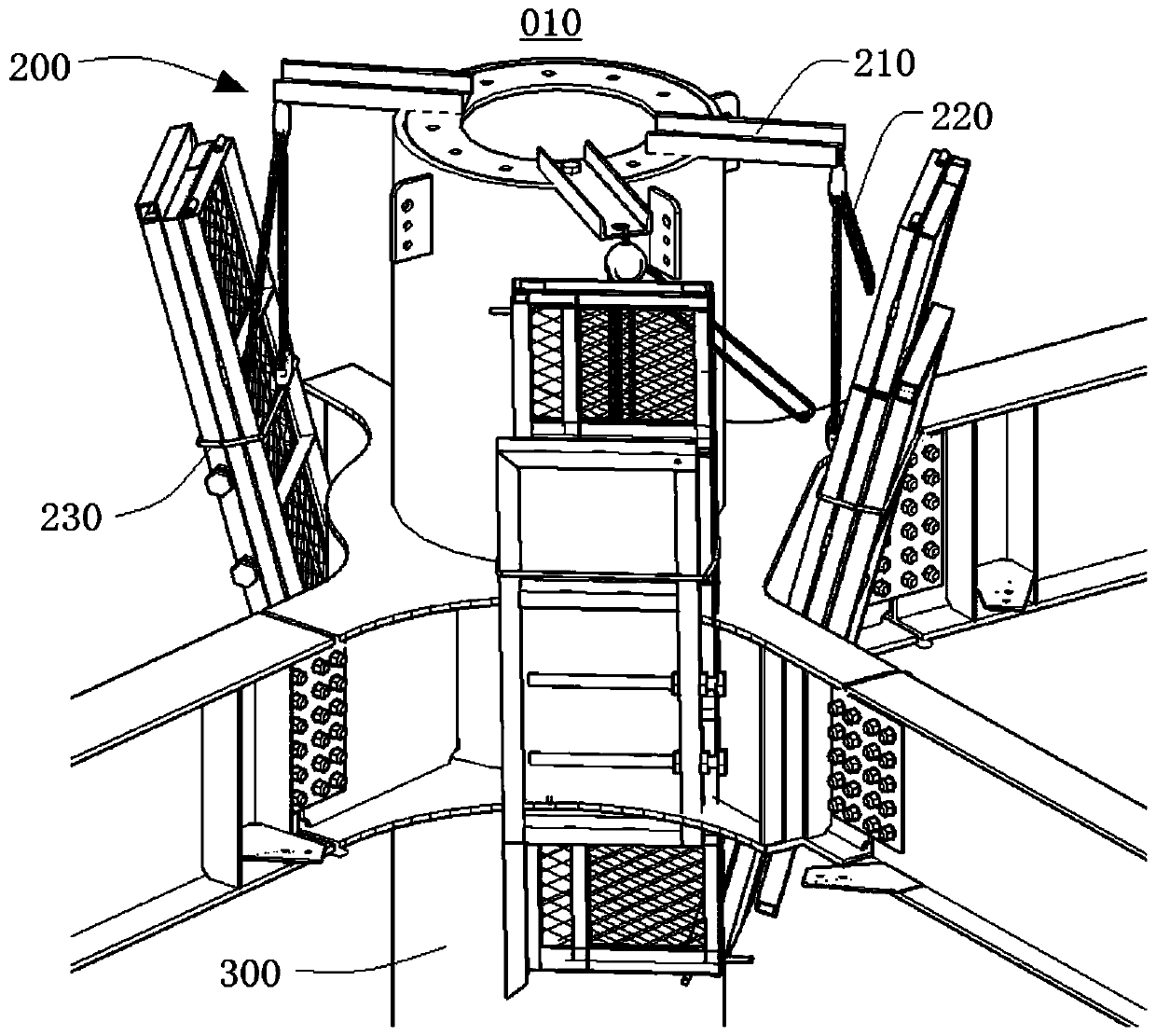

Multifunctional portal device of suspension bridge pillar top

ActiveCN105386411AStructural stress safetySimplify construction difficultyBridge erection/assemblyTraction systemTower

The invention provides a multifunctional portal device of a suspension bridge pillar top, and belongs to the field of construction devices of suspension bridges. The multifunctional portal device of the suspension bridge pillar top comprises a field mounted portal body, wherein the field mounted portal body comprises a supporting truss system, a working platform, a catwalk turning cable saddle, a lifting system and a traction system; the working platform is connected to the upper end of the supporting truss system; the lower end of the supporting truss system is anchored to the suspension bridge pillar top through an anchoring system; and the catwalk turning cable saddle, the lifting system and the traction system are respectively connected with the supporting truss system. The multifunctional portal device of the suspension bridge pillar top is provided with the field mounted portal body, a portal is divided into different blocks which are assembled on a tower top, requirements on field hoisting are met, conveying, mounting and machining can be facilitated further, construction installation is simplified, the different blocks of the portal can be combined with the catwalk turning cable saddle at the tower top, the portal is stressed safely, effects of the portal can be fully achieved in various stages of installation construction of an upper structure of the suspension bridge, and multifunction of the portal is fulfilled really.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

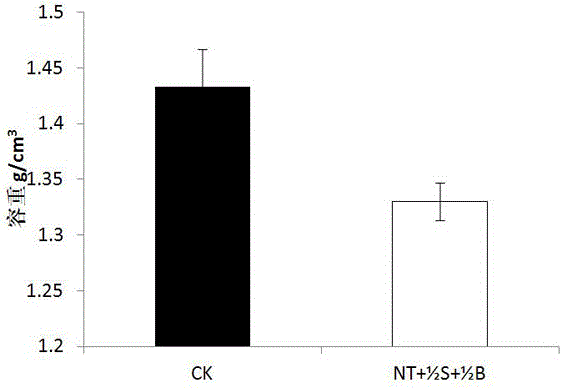

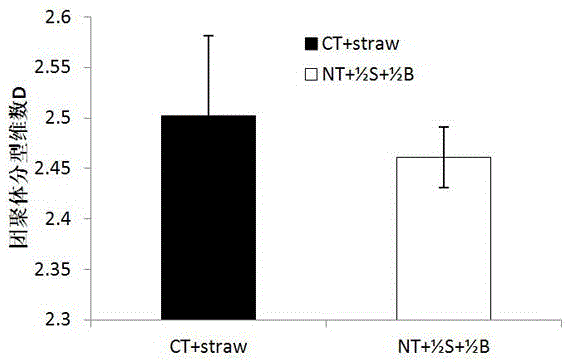

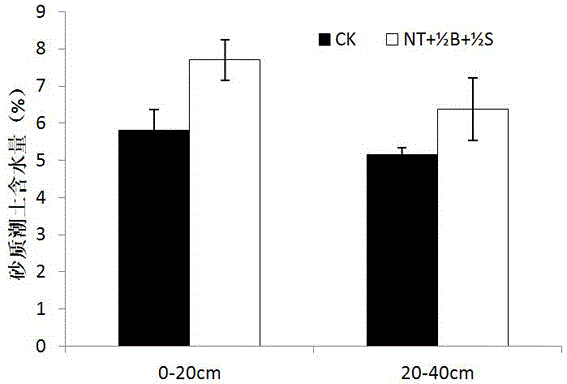

Method for improving sandy soil without tillage with straw in cooperation with biochar

InactiveCN105532110AImprove physical and chemical structureStable in natureSoil-working methodsSeederChemical structure

The invention discloses a method for improving sandy soil without tillage with straw in cooperation with biochar. The method comprises the steps that firstly, after corn is harvested, half of corn straw by mass is removed, the other half of the corn straw by mass is chopped into small sections with the length ranging from 4 cm to 6 cm to obtain corn straw fragments, small furrows with the depth being 5 cm are directly formed through a furrower for sowing wheat, and then the corn straw fragments and biochar with the carbon amount equal to that of the corn straw fragments are evenly spread; secondly, after wheat is harvested, half of wheat straw by mass is removed, the other half of the wheat straw by mass is chopped into small sections with the length ranging from 4 cm to 6 cm to obtain wheat straw fragments, the wheat straw fragments and biochar with the carbon amount equal to that of the wheat straw fragments are evenly spread, and corn is directly sown through a seeder; thirdly, the first step and the second step are repeated three times. According to the method for improving sandy soil without tillage with straw in cooperation with biochar, the total no-tillage mode is adopted, half full-dose straw and half biochar with the equal carbon amount are used for covering after seeding, and through improvement tests of six turns in three years, the physical and chemical structures of sandy soil are effectively improved, and the nutrient of sandy soil and the crop yield are increased.

Owner:HENAN AGRICULTURAL UNIVERSITY

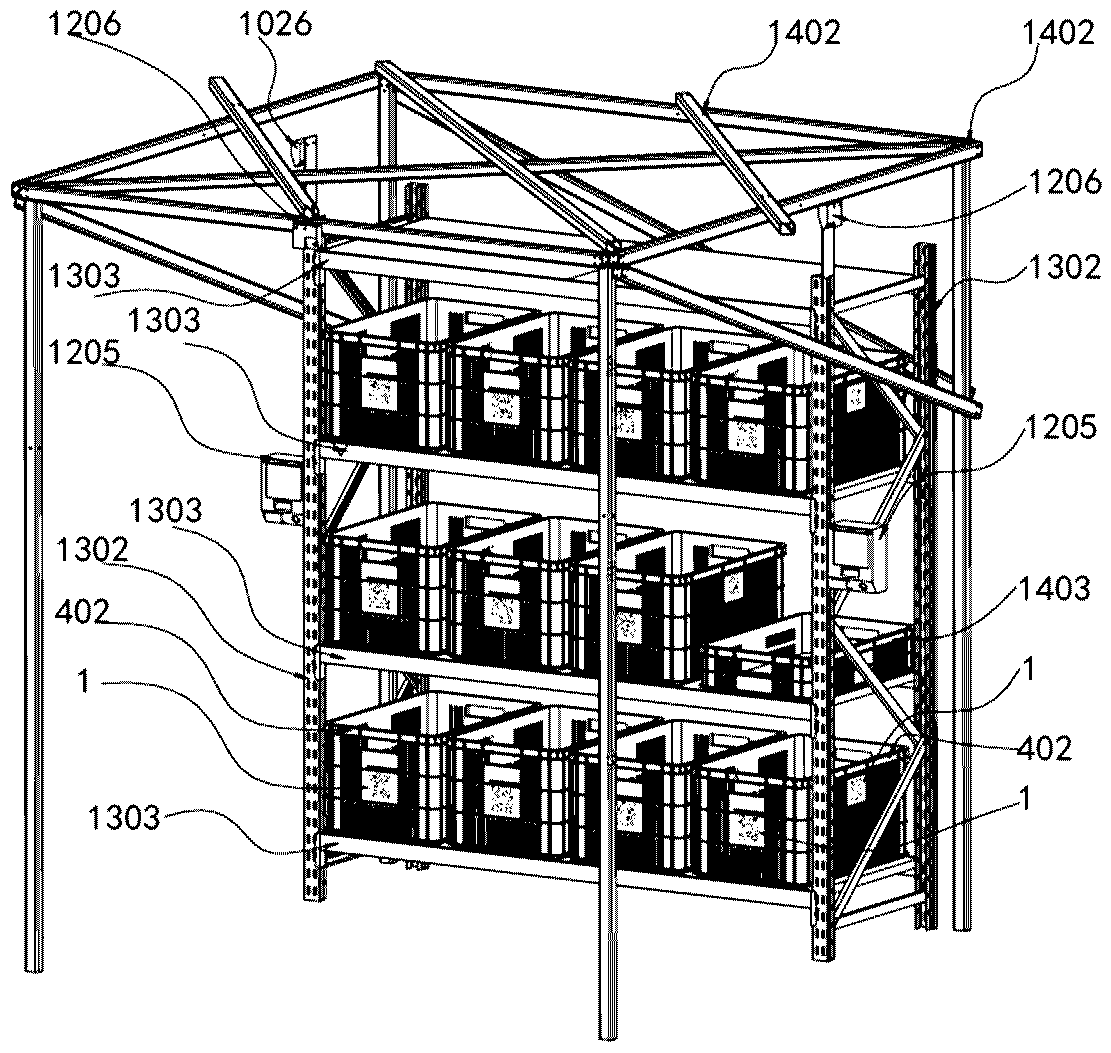

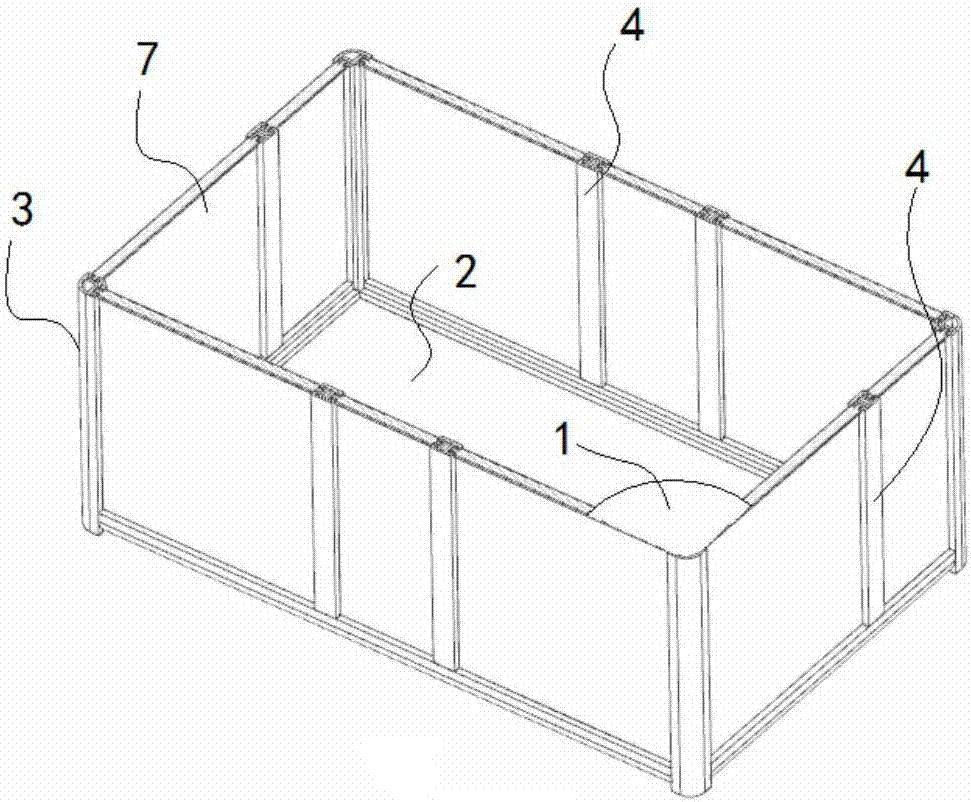

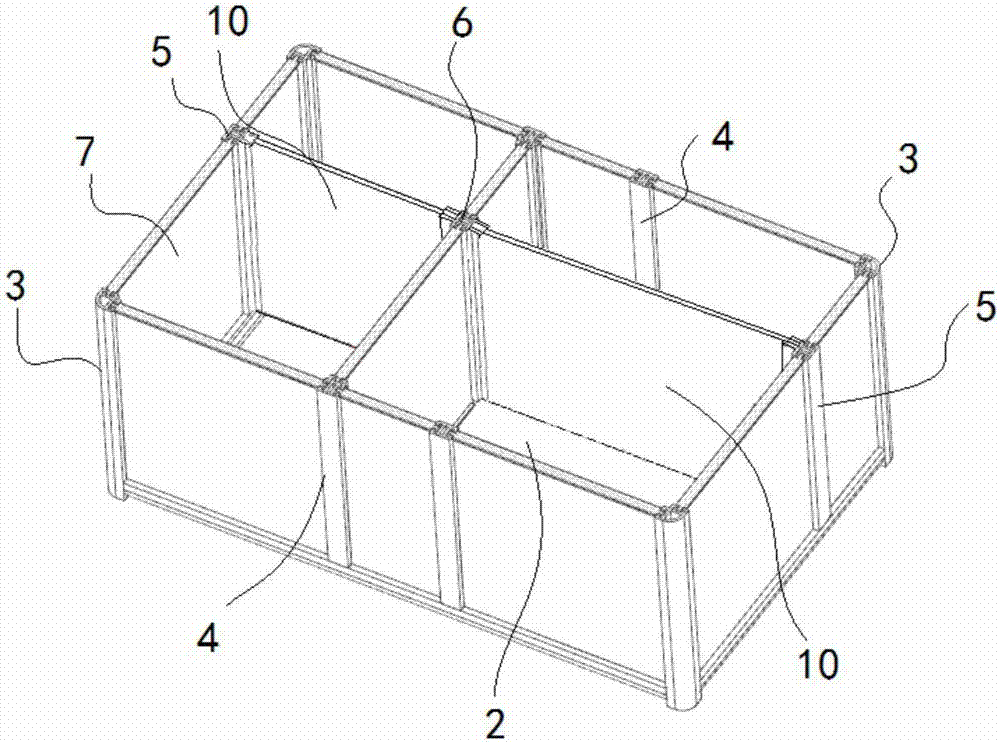

Assembling type storage, tidying and circulation packaging box for modularized building blocks

Owner:王勇

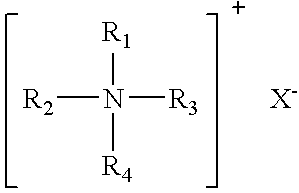

Methods for regulating the condition of mammalian keratinous tissue via topical application of vitamin B6 compositions

InactiveUS7235249B2Promoting skin desquamationPromoting exfoliationCosmetic preparationsBiocidePyridoxic AcidSugar amine

The present invention relates to methods for regulating the condition of mammalian keratinous tissue wherein the methods each comprise the step of topically applying to the keratinous tissue of a mammal needing such treatment, a safe and effective amount of a skin care composition comprising:a) a safe and effective amount of a vitamin B6 compound selected from the group consisting of pyridoxine, esters of pyridoxine, amines of pyridoxine, salts of pyridoxine and derivatives thereof, including pyridoxamine, pyridoxal, pyridoxal phosphate, and pyridoxic acid;b) a safe and effective amount of a skin care active selected from the group consisting of peptides, phytosterol, sugar amines, their derivatives, and combinations thereof; andc) a dermatologically acceptable carrier for the pyridoxine and the skin care active.

Owner:THE PROCTER & GAMBLE COMPANY

Combined lining formwork trolley for subway station

ActiveCN104453951ASimple structureReasonable designUnderground chambersTunnel liningSupporting systemEngineering

The invention discloses a combined lining formwork trolley for a subway station. The combined lining formwork trolley comprises a movable supporting system and a formwork assembly, wherein the movable supporting system is composed of a plurality of longitudinal moving trolley bodies capable of moving in the subway station under construction, the formwork assembly is arranged on the movable supporting system and conducts molding construction on secondary linings of the subway station under construction, and the longitudinal moving trolley bodies are arranged in the same horizontal plane from left to right; the formwork assembly comprises a combined top formwork and two side formworks, the two side formworks are symmetrically arranged on the left side and the right side of the combined top formwork respectively, and the combined top formwork comprises a plurality of trolley supporting top formworks mounted on the longitudinal moving trolley bodies respectively and middle connecting formworks connected between every two trolley supporting top formworks which are adjacent in a left-right mode; the middle connecting formworks are horizontal connecting formworks or groove type combined formworks. The combined lining formwork trolley is simple in structure, reasonable in design, easy and convenient to use and operate, good in usage effect and capable of solving the problems that construction is complex, the construction efficiency is low, the occupied space is large and the use effect is poor when a traditional subway station lining construction method is adopted.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

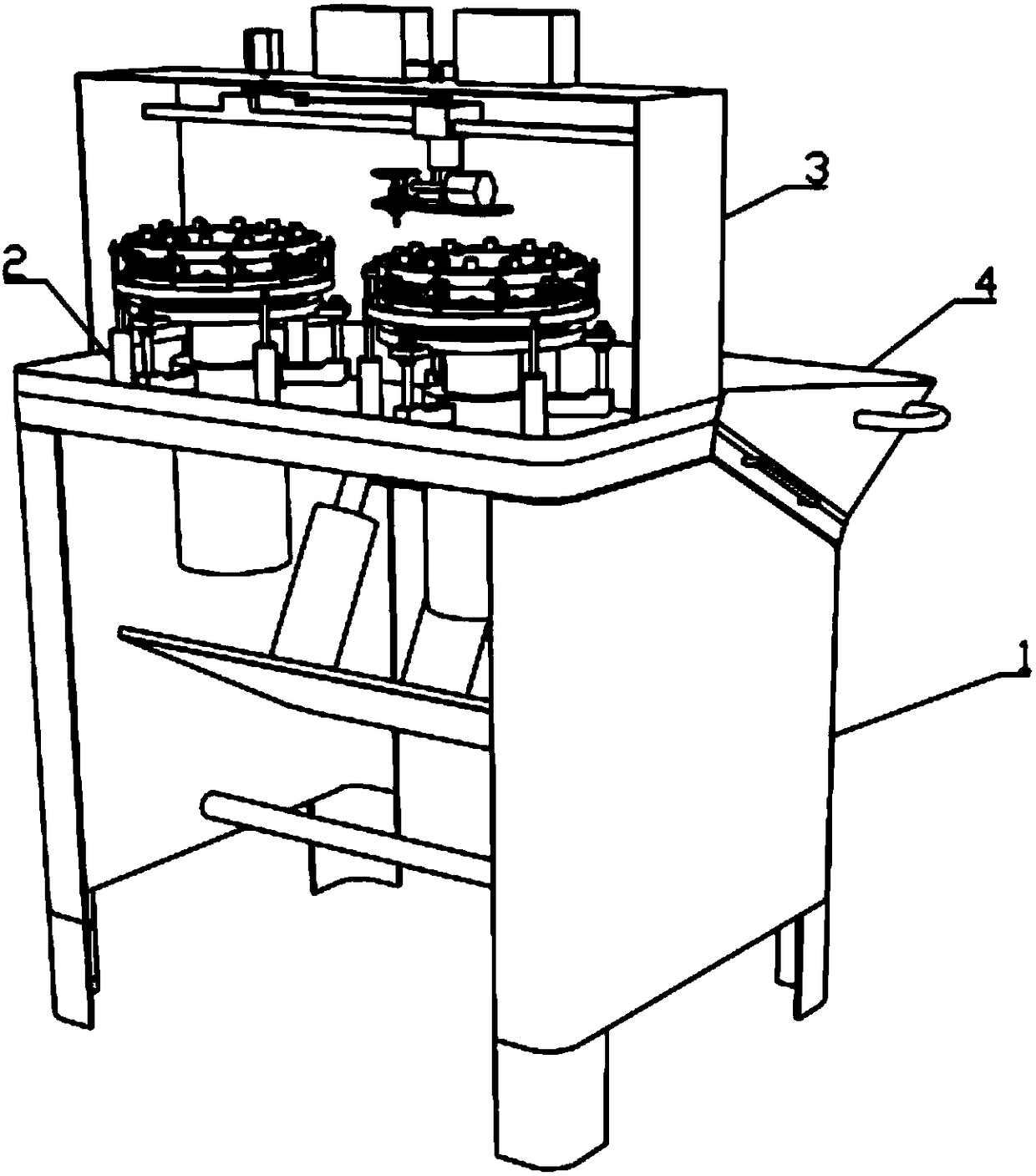

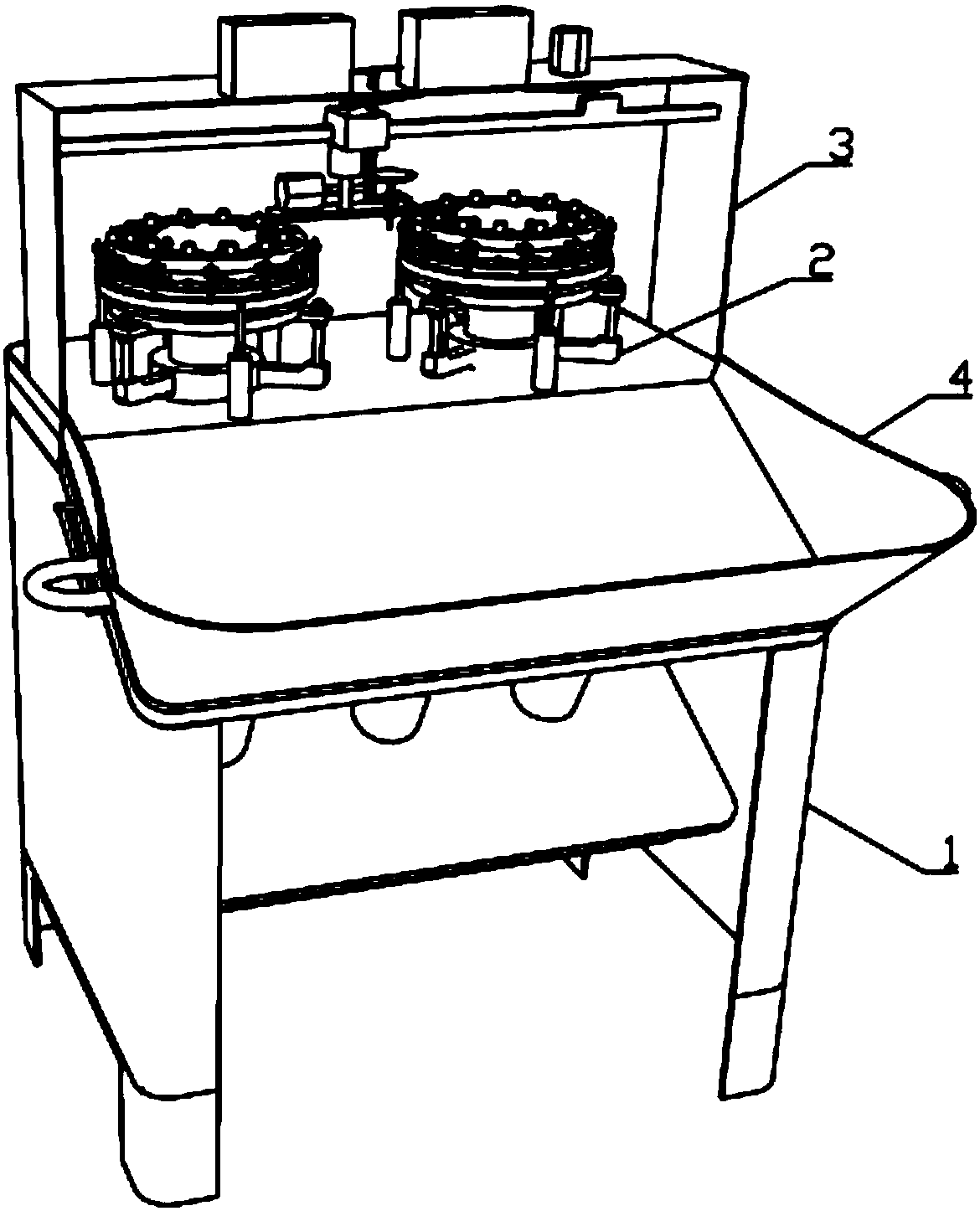

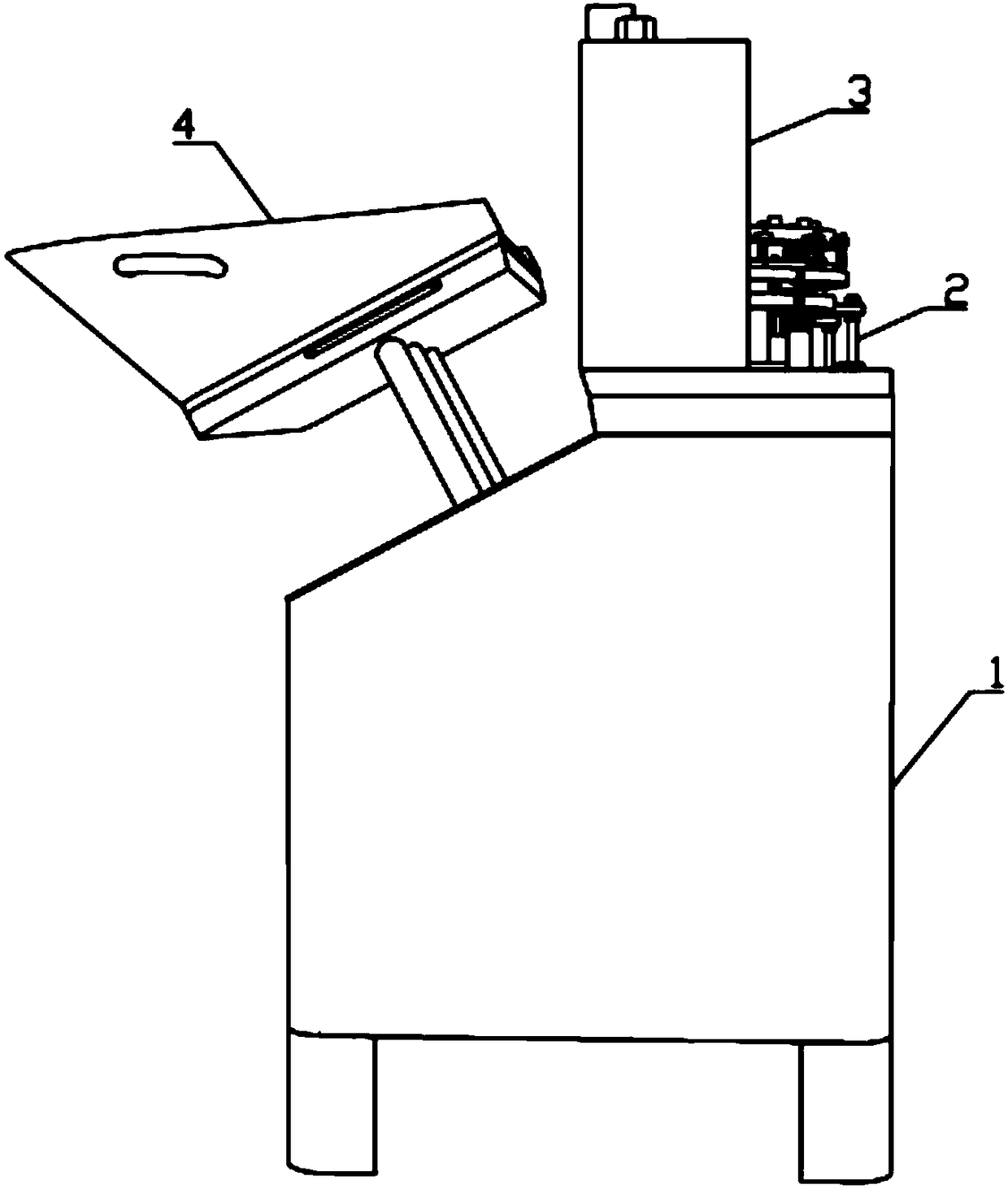

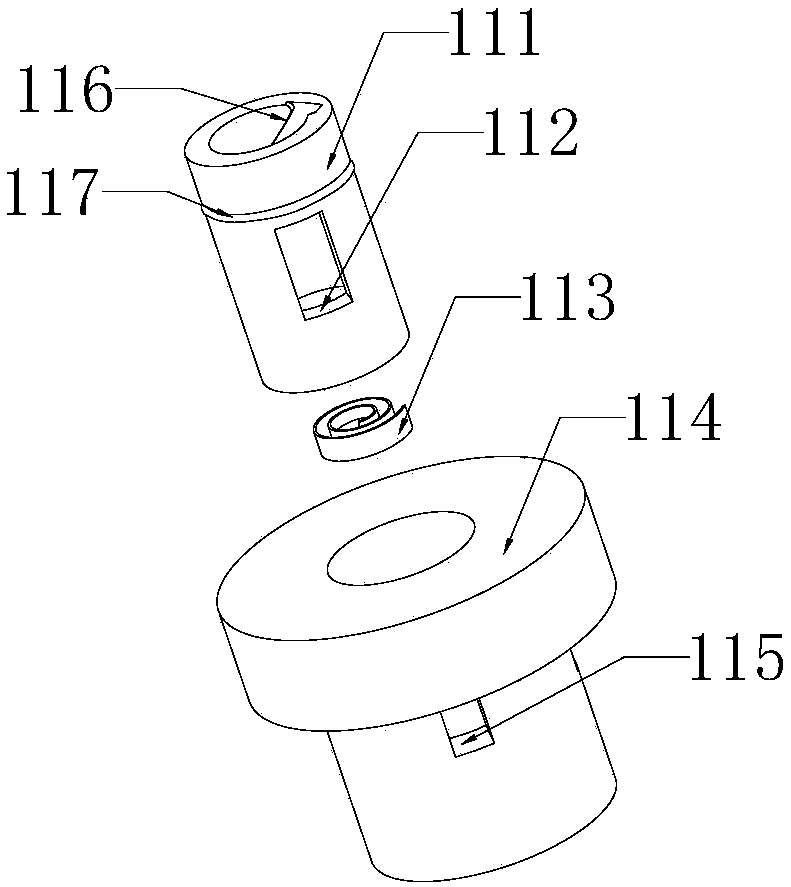

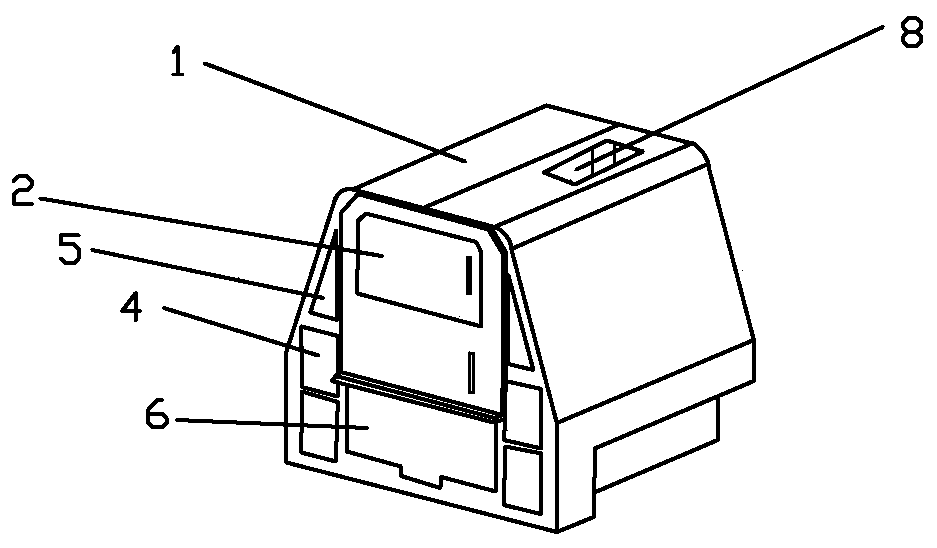

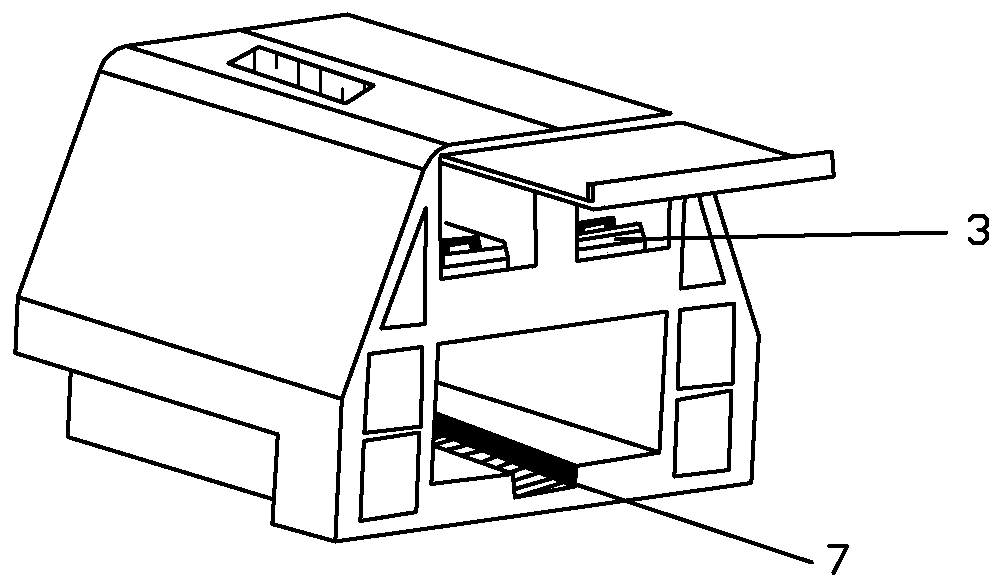

Double-set-fixture drilling machine convenient for workpiece storage and turnover

PendingCN108311726APositioning is simple and reliableEasy to installTransportation and packagingDeodrantsEngineeringDrilling machines

The invention belongs to the technical field of workpiece drilling and particularly relates to a double-set-fixture drilling machine convenient for workpiece storage and turnover. The double-set-fixture drilling machine comprises an operating platform, fixtures, a drilling mechanism and a workpiece storage mechanism, the operating platform comprises a left supporting component and a right supporting component, structures of the left supporting component and the right supporting component are symmetric left and right, the left supporting component comprises a baffle, the cross section of the baffle is in a U shape and the opening faces the right, the bottom surface of the baffle is horizontal and a front bent position and a rear bent position are fixedly provided with two support legs, themiddle front portion of the top surface of the baffle is in a horizontal shape and the middle rear portion is provided with a slope surface with the rear being low and the front being high from rear to front, an included angle between the slope surface and the horizontal bottom surface is 30-45 degrees, the top surface of the baffle is detachably provided with a sealing plate capable of sealing the top opening of the baffle, the middle front portions of the top surfaces of the left supporting component and the right supporting component are provided with a table surface plate, and the table surface plate is provided with two assembly holes.

Owner:唐莉

Processing method for anti-explosion refractory castables used by steel ladle working layers

ActiveCN103100703AExtended service lifeReduce labor intensityMelt-holding vesselsRefractoryEnergy conservation

The invention belongs to the technical field of fire resistant materials process in the ferrous metallurgy industry and discloses construction and a baking process of anti-explosion refractory castables used by steel ladle working layers. The processing method for the anti-explosion refractory castables used by the steel ladle working layers is characterized in that the purposes of improving using effect of the materials, improving production efficiency, saving energy sources and protecting environment are achieved by controlling the additive quantity of water of the refractory castables, mode of mixing and vibrating, time of vibrating, mode of demolding, time of demoulding, temperature of natural curing and time of natural curing in the pouring process of whole steel ladles and through a high-efficient rapid three-step baking process in the ladle preparing process.

Owner:北京利尔高温材料股份有限公司

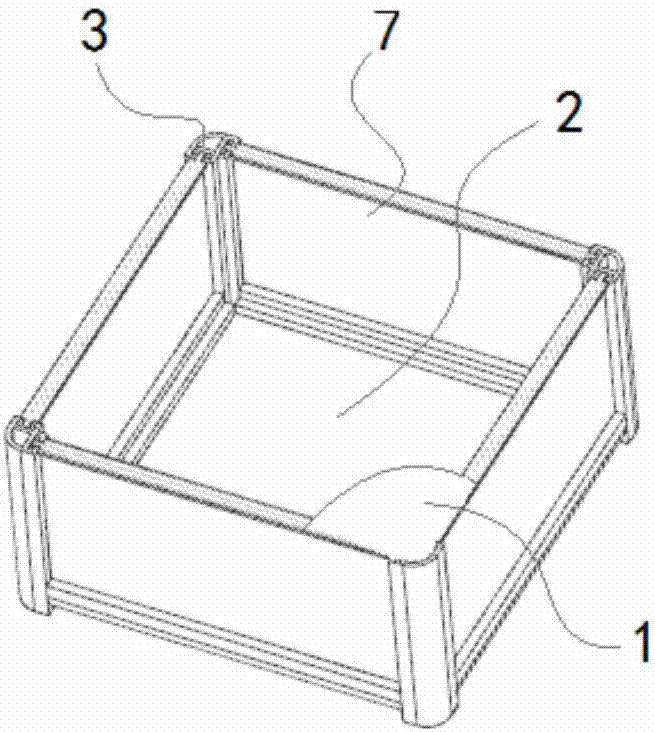

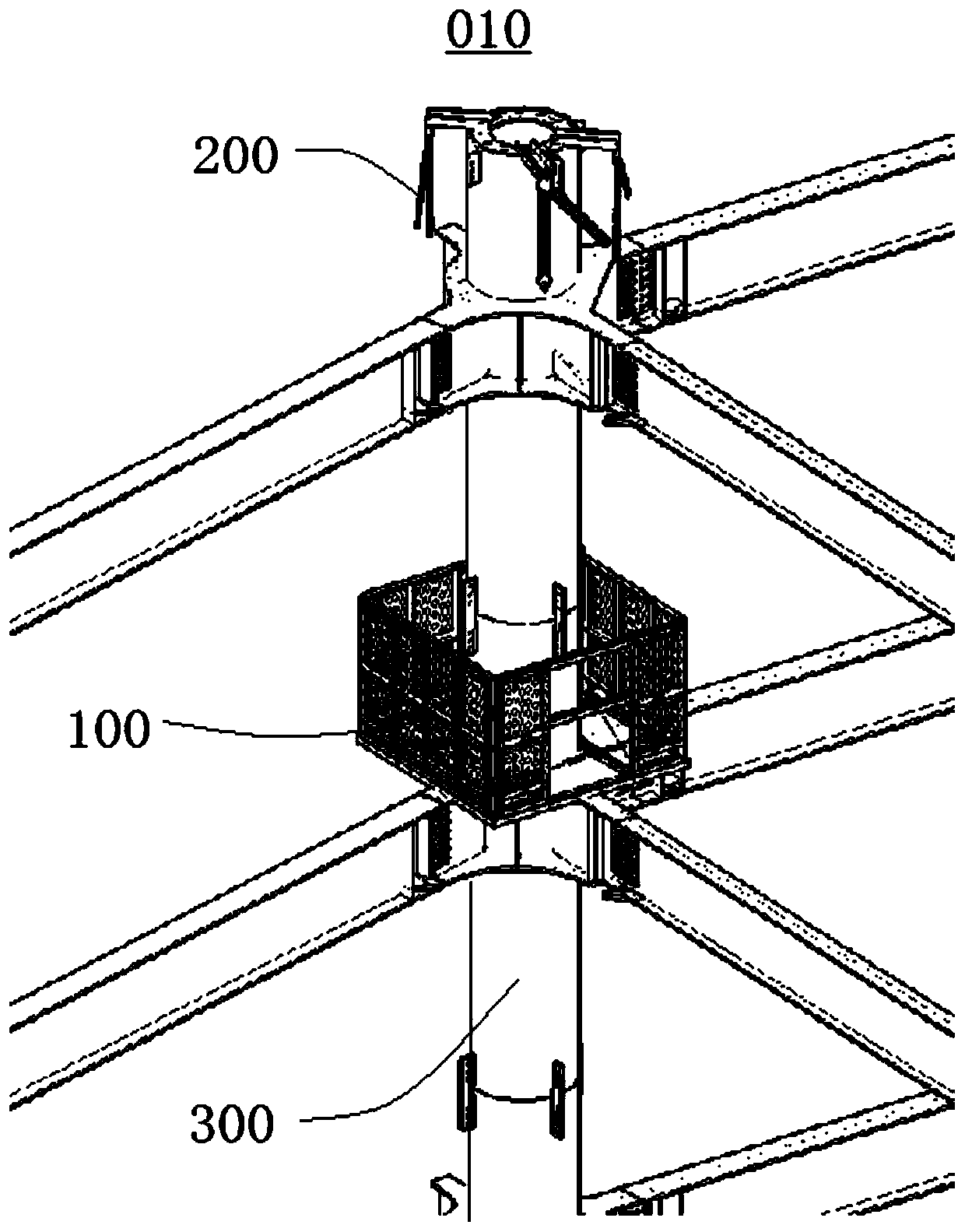

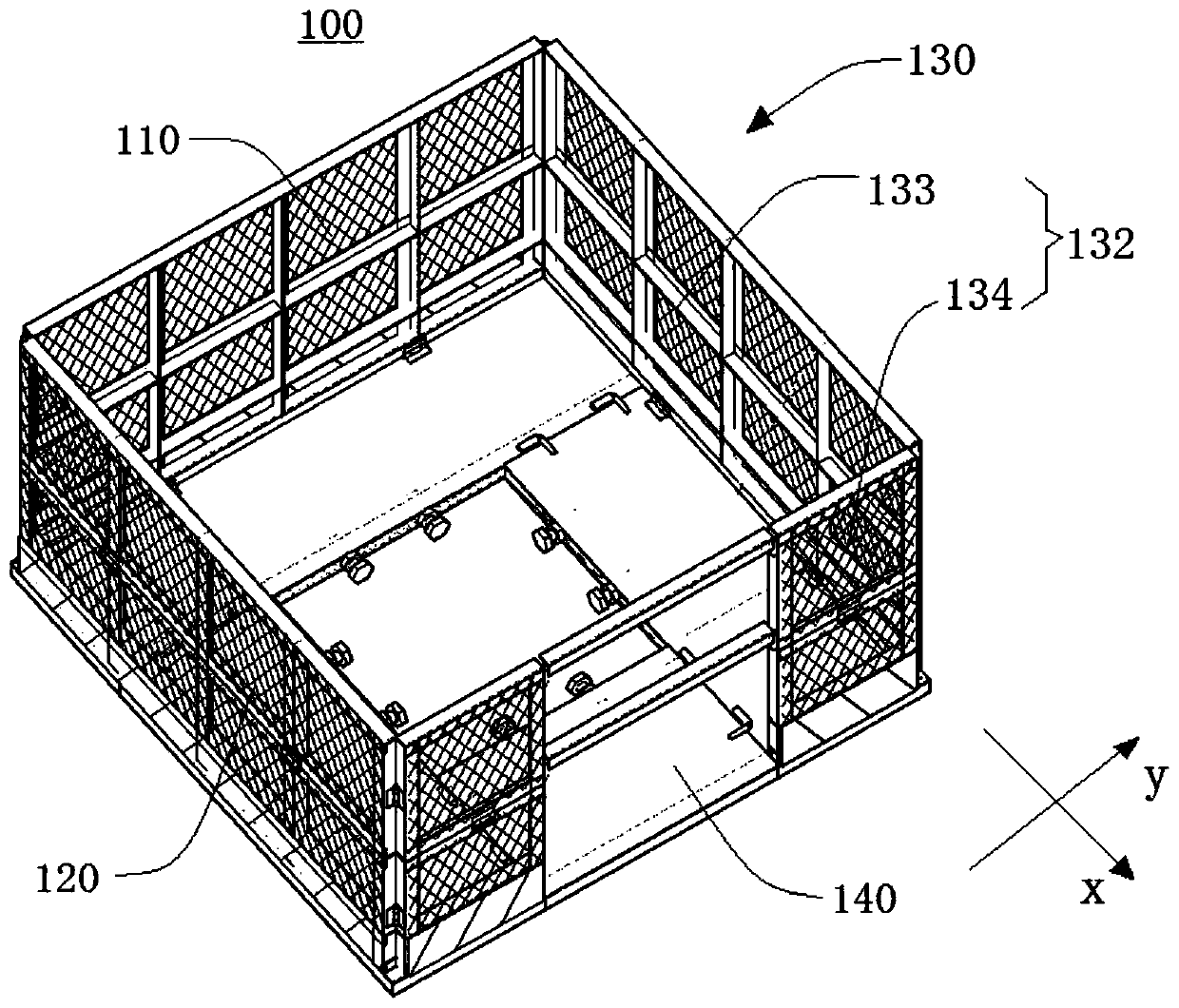

Operation platform

PendingCN110043019ASmall form factorEasy turnoverScaffold accessoriesBuilding support scaffoldsEngineeringSteel columns

The invention relates to the technical field of engineering equipment, and provides an operation platform which aims to solve the problems of difficult circulation and a complex structure of an operation platform in the prior art. The operation platform includes a platform body; the platform body comprises a plurality of assembly unit mechanisms, and the multiple assembly unit mechanisms are connected end to end and internally form a through hole penetrated by a steel column. Every two adjacent assembly unit mechanisms are detachably connected so the platform body is in an assembly or disassembly state; and at least one assembly unit mechanism includes a bottom plate assembly and a guardrail assembly, the guardrail assembly and the bottom plate assembly are connected in a rotating mode, and the assembly unit mechanisms can switch to the folding state. When the operation platform needs lifting to a next construction position along a steel column, the platform body is switched to a disassembly state to be folded, and then assembled into integration after being lifted. Therefore, rotation is convenient, and even obstacles are encountered during the process of lifting, the obstacles can be successfully overcome to achieve the lifting.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

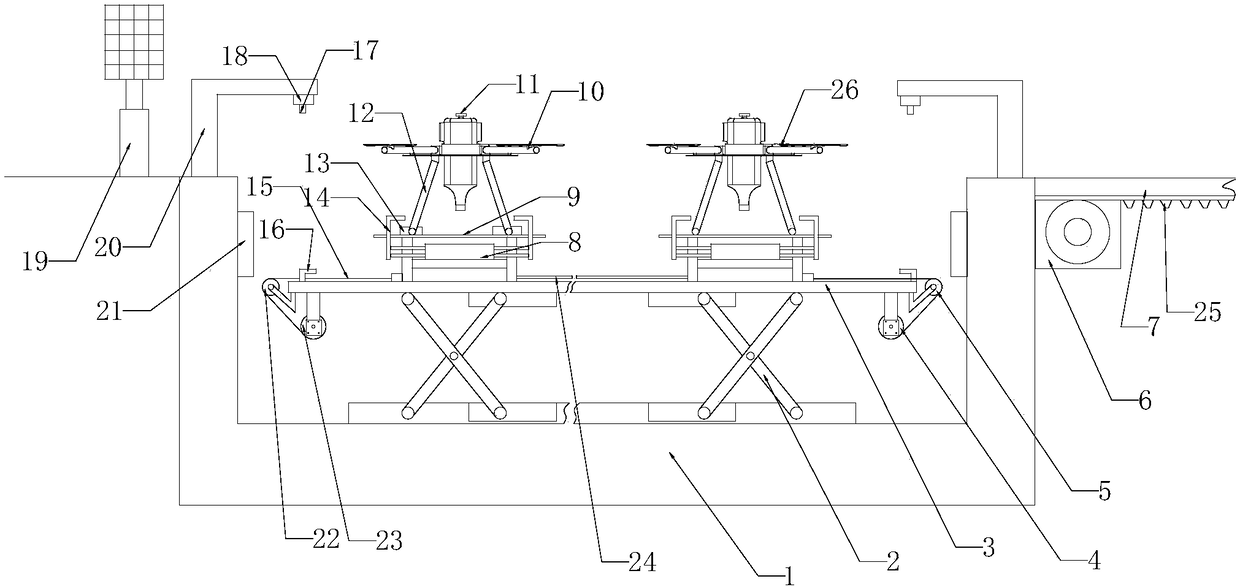

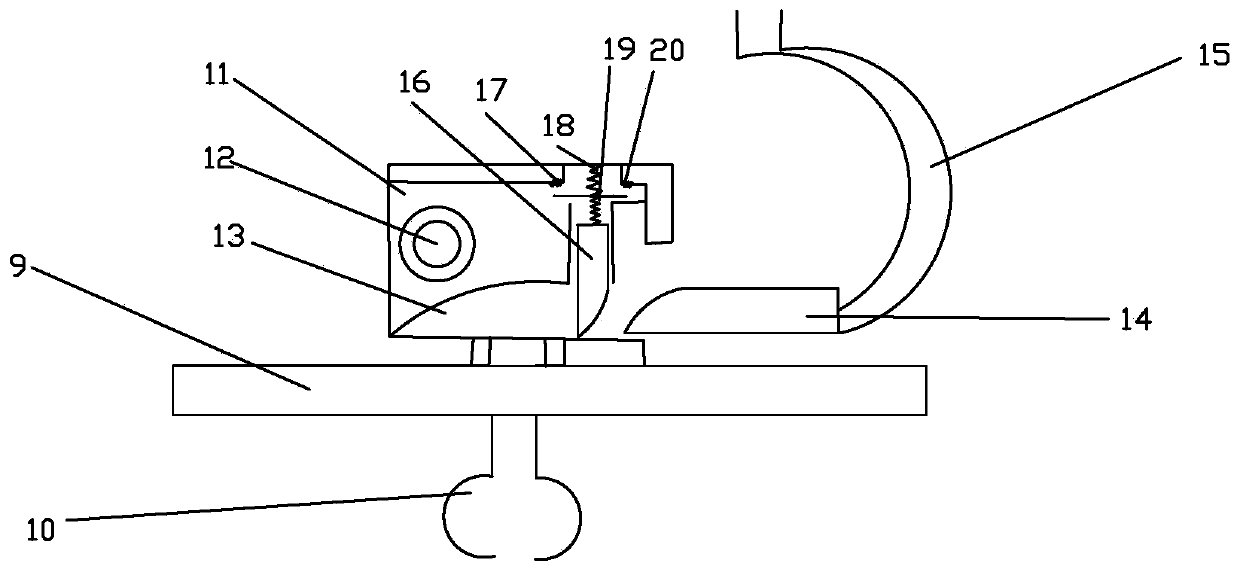

Plant protection unmanned aerial vehicle automatic pesticide filling system

PendingCN108496939AImprove plant protection efficiencyEasy turnoverInsect catchers and killersSingle degree of freedomUncrewed vehicle

The invention discloses a plant protection unmanned aerial vehicle automatic pesticide filling system. The automatic pesticide filling system comprises a base, a platform used for parking the unmannedaerial vehicle, a pesticide injection assembly which is arranged on the base and used for filling liquid pesticide and a charging device. The automatic pesticide filling system also comprises a conveying device and a self-closing type barrel cover, wherein the conveying device is arranged on the base and is used for driving the platform to move close to or far away from the pesticide injection assembly, and the self-closing type barrel cover is arranged on the upper portion of the pesticide barrel; the liquid injection assembly comprises a liquid guide pipe, a liquid injection pipe which is connected with the liquid guide pipe, a cantilever beam and an electric water valve, wherein the cantilever beam is connected with the base in the single-degree-of-freedom sliding connection and used for supporting the liquid injection pipe, and the electric water valve is used for controlling the liquid injection of the liquid injection pipe; the platform comprises a bearing platform for bearing the unmanned aerial vehicle, a weighing element and a positioning device, wherein the weighing element is arranged on the bearing platform and is used for weighing the liquid in the pesticide barrel and the positioning device is used for limiting the unmanned aerial vehicle. According to the unmanned aerial vehicle, electric energy and liquid pesticide can be timely supplied to the unmanned aerialvehicle, when the pesticide is added, the pesticide barrel changing is not needed, the whole process does not need manual participation, and time and labor are saved.

Owner:山东鸟人航空科技有限公司

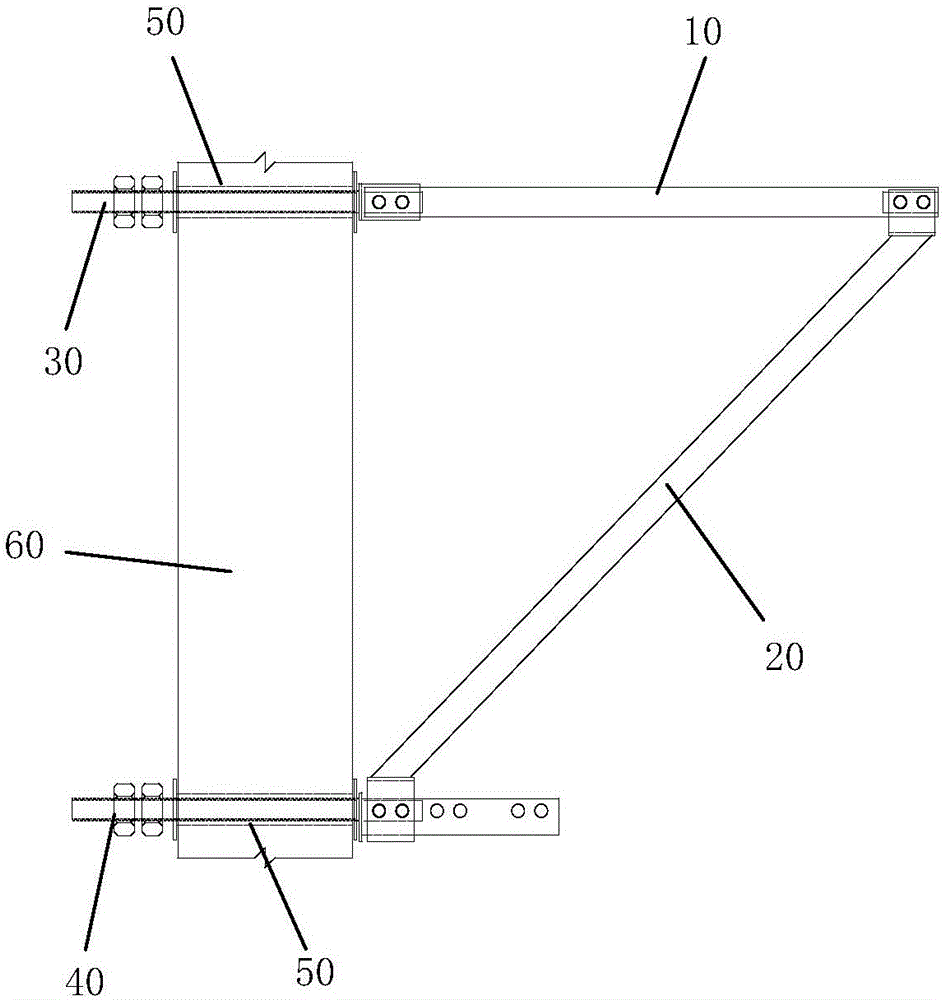

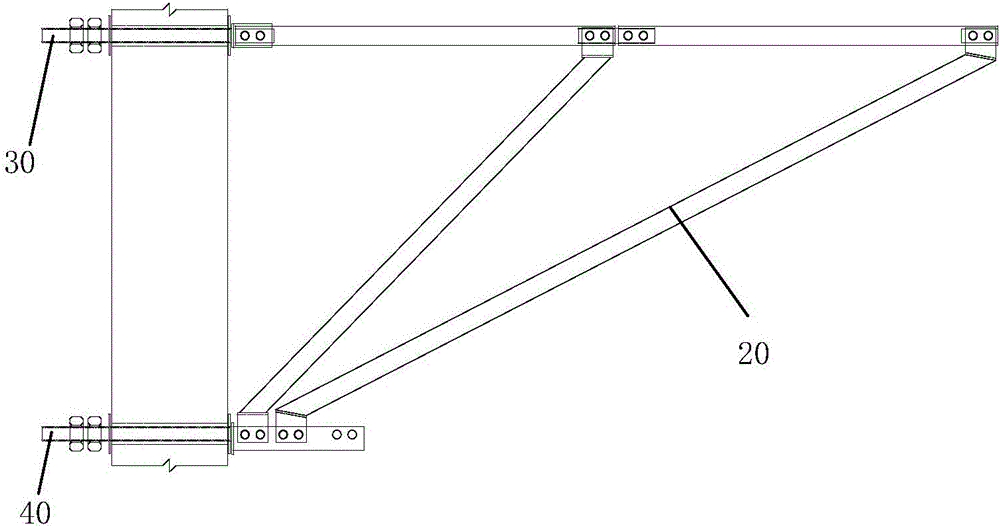

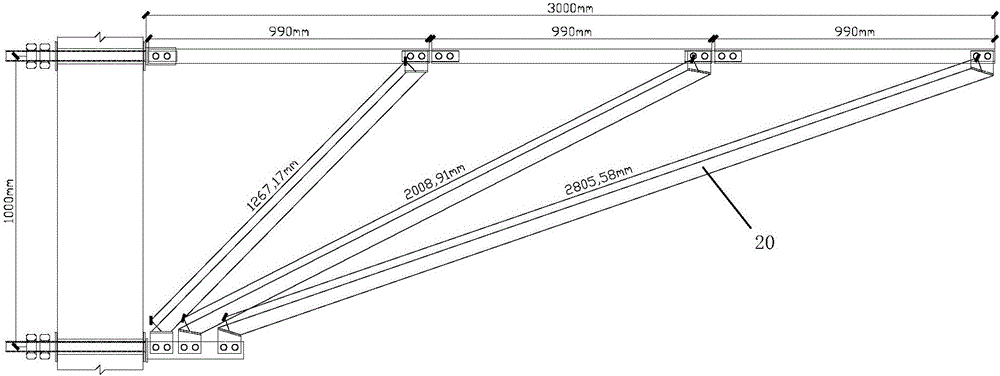

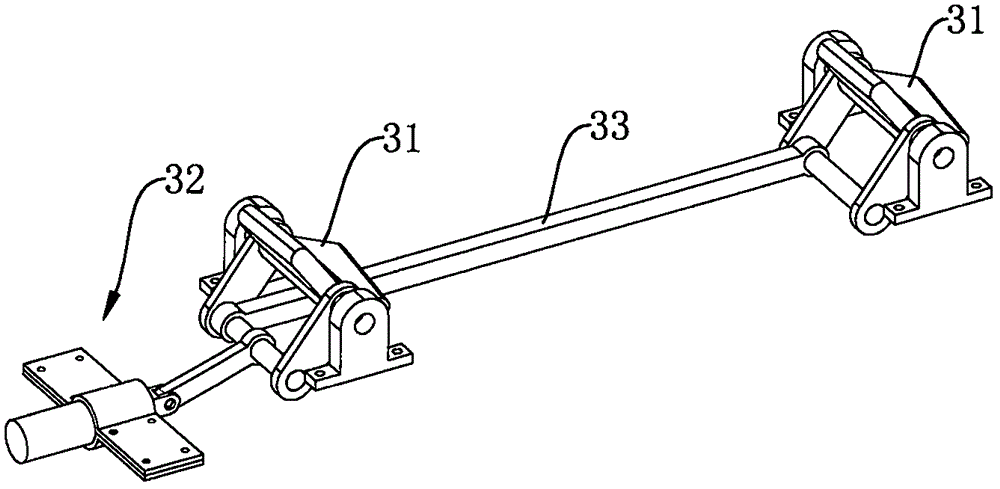

Assembled overhanging support frame

InactiveCN106351432ALow costThe installation process is simple and convenientScaffold accessoriesBuilding support scaffoldsEngineering

Owner:CHINA FIRST METALLURGICAL GROUP

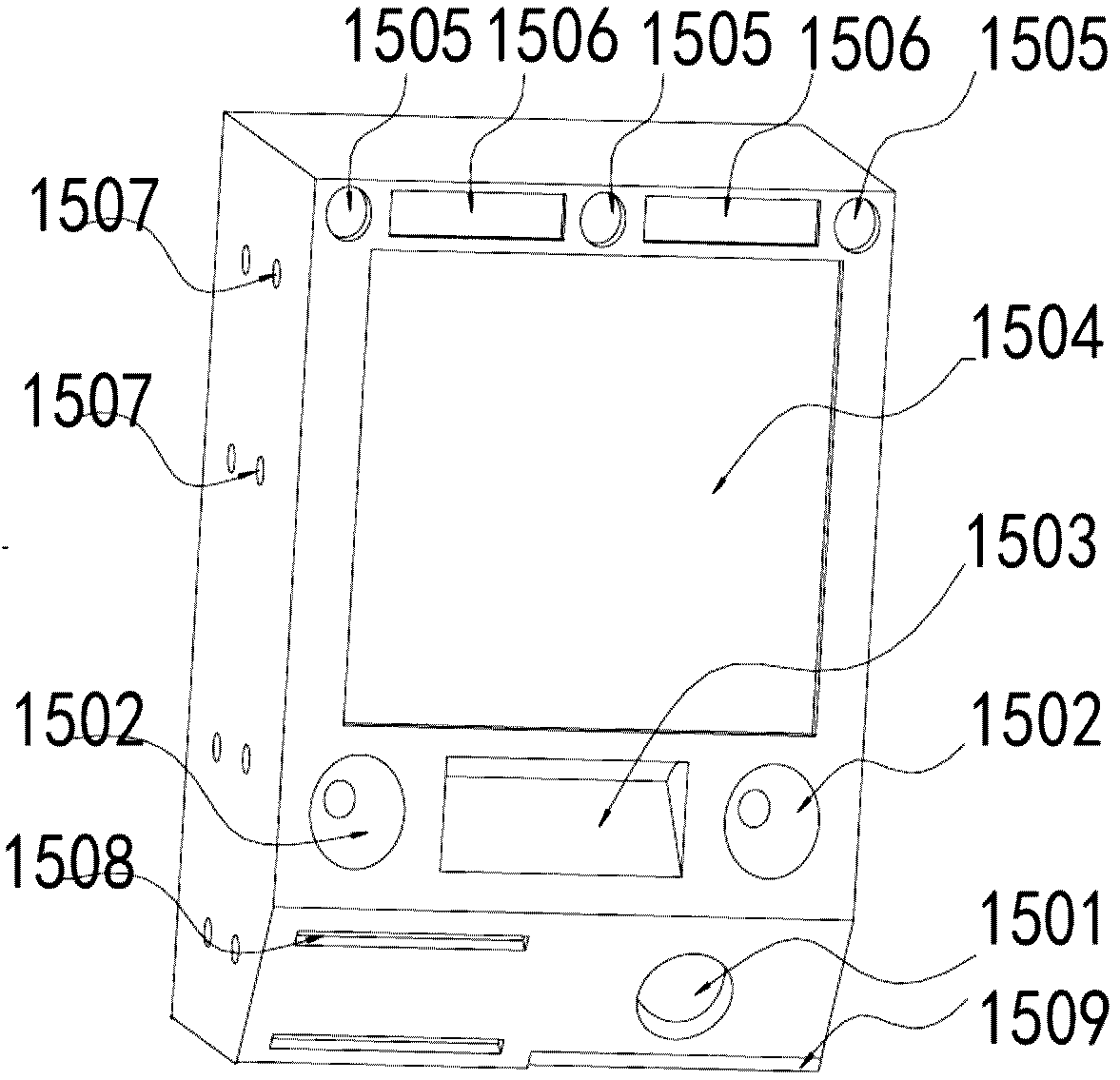

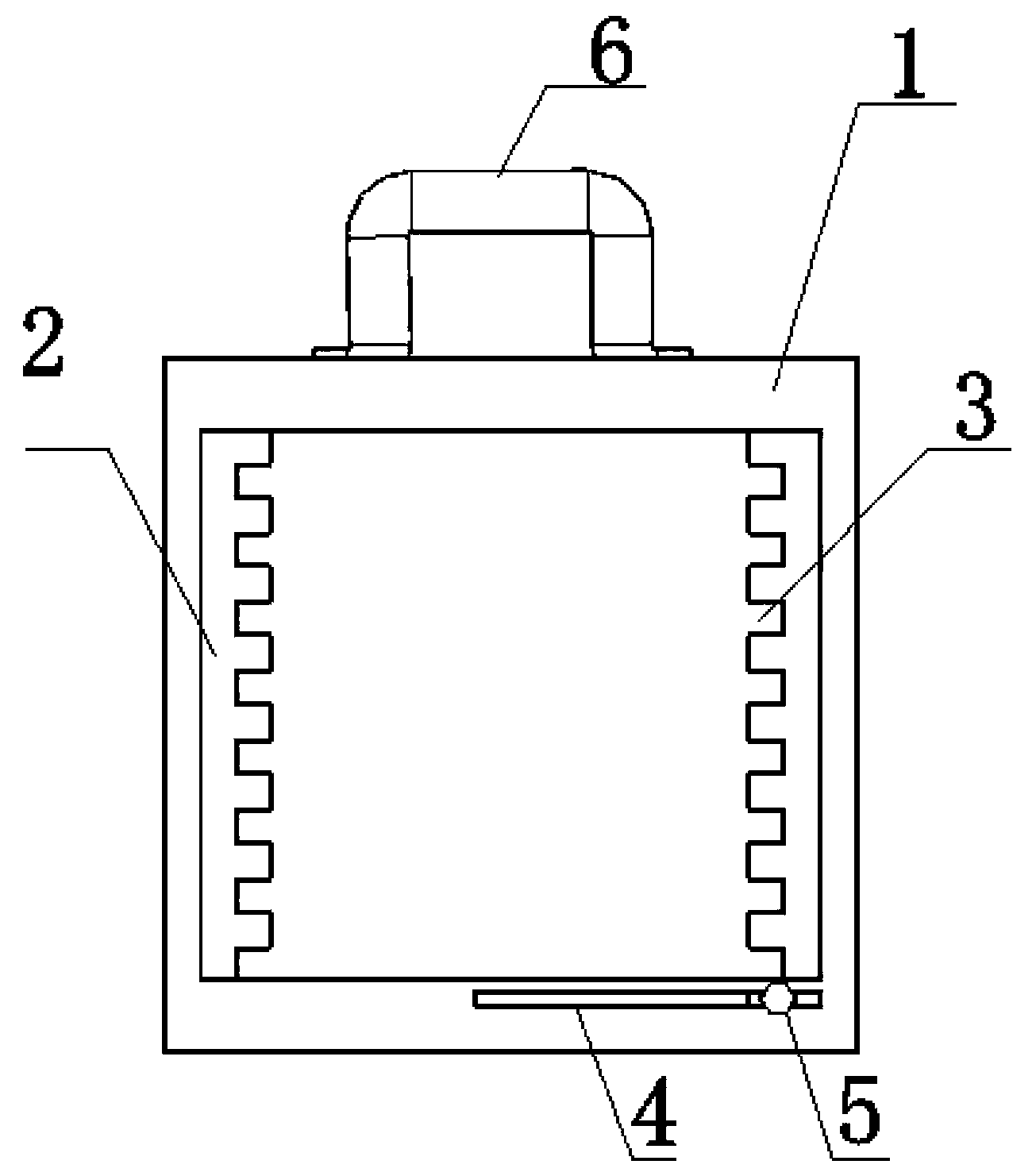

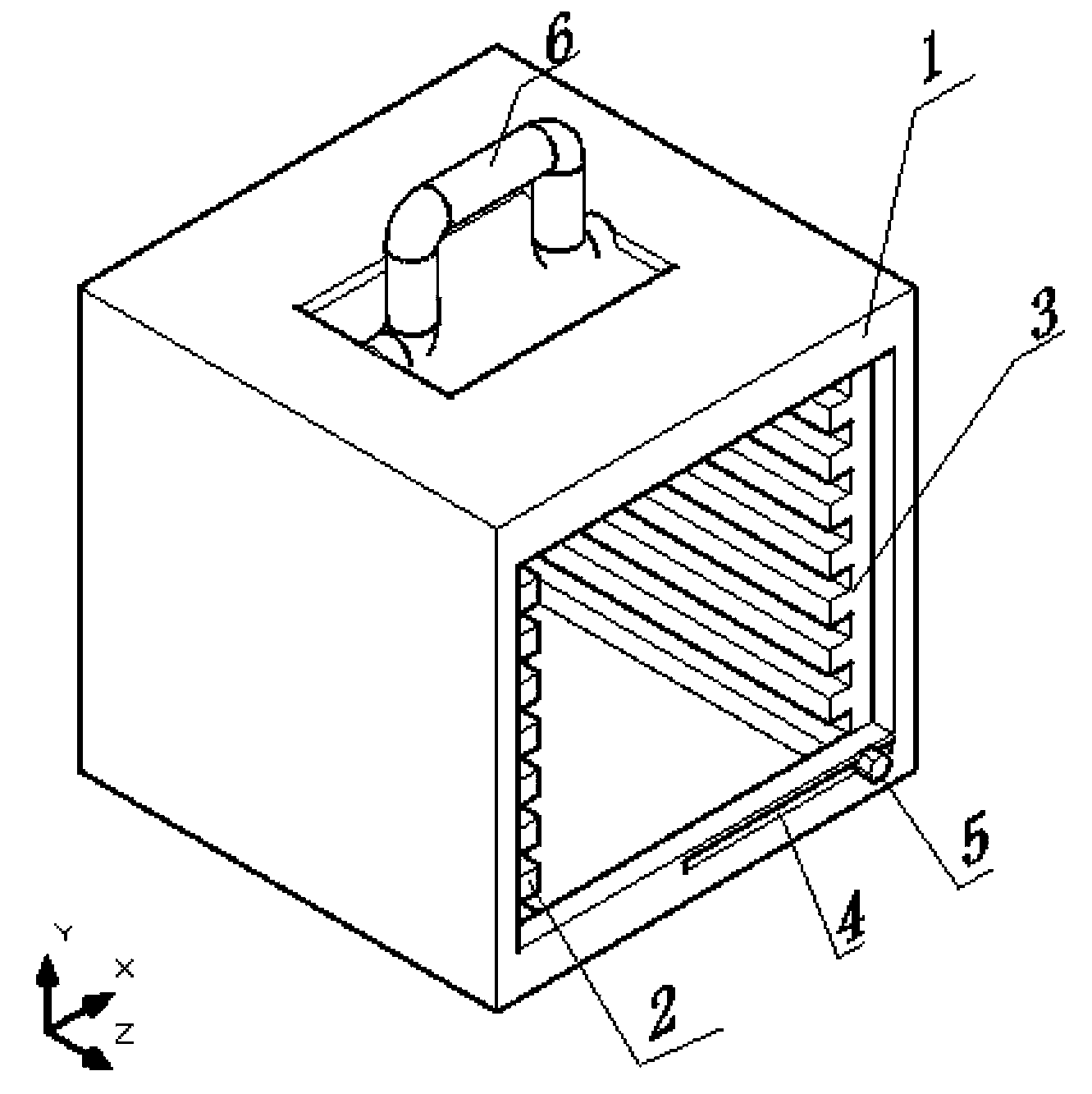

Novel PCB (printed circuit board) antistatic turnover box

InactiveCN103848115AEliminate static electricityEasy turnoverContainer handlesInternal fittingsPrinted circuit boardEngineering

The invention discloses a novel PCB (printed circuit board) antistatic turnover box, which consists of a box case, a guide rail, a handle, two side plates and screw nuts, wherein the guide rail and the handle are arranged on the box case, the two side plates are arranged on corresponding side edges, one side plate of the two side plates is fixedly arranged in the box case, one side plate can slide, the screw nuts are mainly used for regulating and fixing the movable side plates, and the side plates are prepared from antistatic plastics and are provided with mutually parallel equal-distant guide grooves. The novel PCB antistatic turnover box has the advantages that the distance between the side plates can be regulated for realizing the storage and the turnover of PCBs in different specifications, and in addition, static electricity generated on the surface of an electronic device can be eliminated.

Owner:XIAN JINGJIE ELECTRONICS TECH

Multiple unmanned aerial vehicle cooperative intelligent inspection system and method based on ubiquitous electric power Internet of Things

PendingCN111452988AEasy turnoverImprove inspection efficiencyCharging stationsVehicular energy storageGenetics algorithmsUncrewed vehicle

The invention discloses a multiple unmanned aerial vehicle cooperative intelligent inspection system and method based on ubiquitous electric power Internet of Things. The system comprises a pluralityof mobile cabins, a plurality of positioners and a server, each of the plurality of movable cabins carries a plurality of unmanned aerial vehicles; wherein the plurality of positioners are respectively installed on the unmanned aerial vehicle and the mobile cabin, the plurality of positioners are all connected with the server, and the server is used for formulating an unmanned aerial vehicle inspection route and receiving positioning information sent by the positioners. The method comprises the following steps: S1, formulating an inspection route through a genetic algorithm in combination withan inspected power grid scene; s2, numbering the nodes; s3, delivering the mobile cabin to a designated position; and S4, carrying out multi-machine simultaneous inspection according to the inspection line, and drawing a connection line between the position of the unmanned aerial vehicle and the starting point position according to the positioning information transmitted by the positioner. By extracting and formulating the inspection route, multiple unmanned aerial vehicles operate at the same time, and the inspection efficiency of a power grid line is greatly improved.

Owner:HULUNBEIER ELECTRIC POWER BUREAU OF EAST INNER MONGOLIA ELECTRIC POWER COMPANY

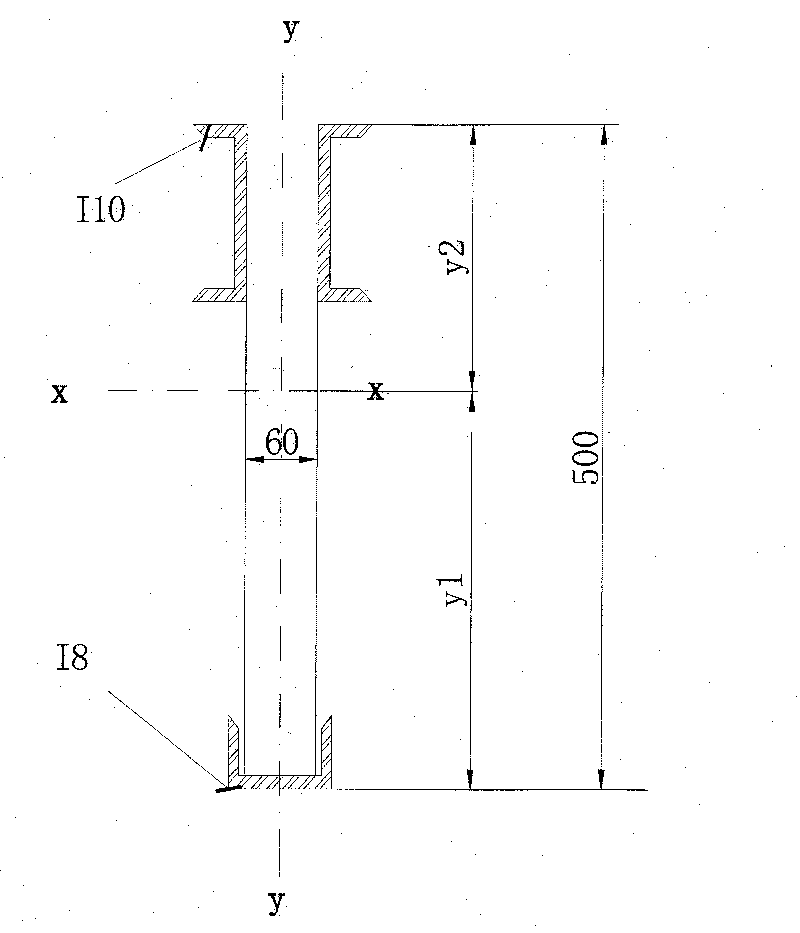

Construction process for casting large-tonnage box beam in site by support pier method

ActiveCN101736693ADeformation controllableSimple structureBridge erection/assemblyReinforced concreteOperability

The invention relates to a construction process for a cast-in-site beam, in particular to the construction process for casting a large-tonnage box beam under a condition that the height of a pier is less than 10m. The construction process is characterized in that: a support pier system formed by a reinforced concrete prefabricated hollow support pier, a steel lattice structured column, a connecting rod and the like bears the load; a height adjusting system formed by an I-shaped steel beam, a longitudinal trussed beam, an adjusting wedge, square stock wood pads arranged as required, a beam falling sand box and the like adjusts an elevation of a bottom mould, sets a camber and transfers the load; and a mould plate system ensures the casting and forming of the concrete, so that the construction process for quickly and safely casting the box beam well in site is formed. The construction process has simple structure and less connecting points, and the deformation of the support pier is easily controlled; the cross section area is big, which facilitates the foundation treatment; the operability is strong, the beam preparation period is short, and the beam is big in rigidity and reliable in stability; and the resources are saved, the cost is lowered, and the construction process is widely applied.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

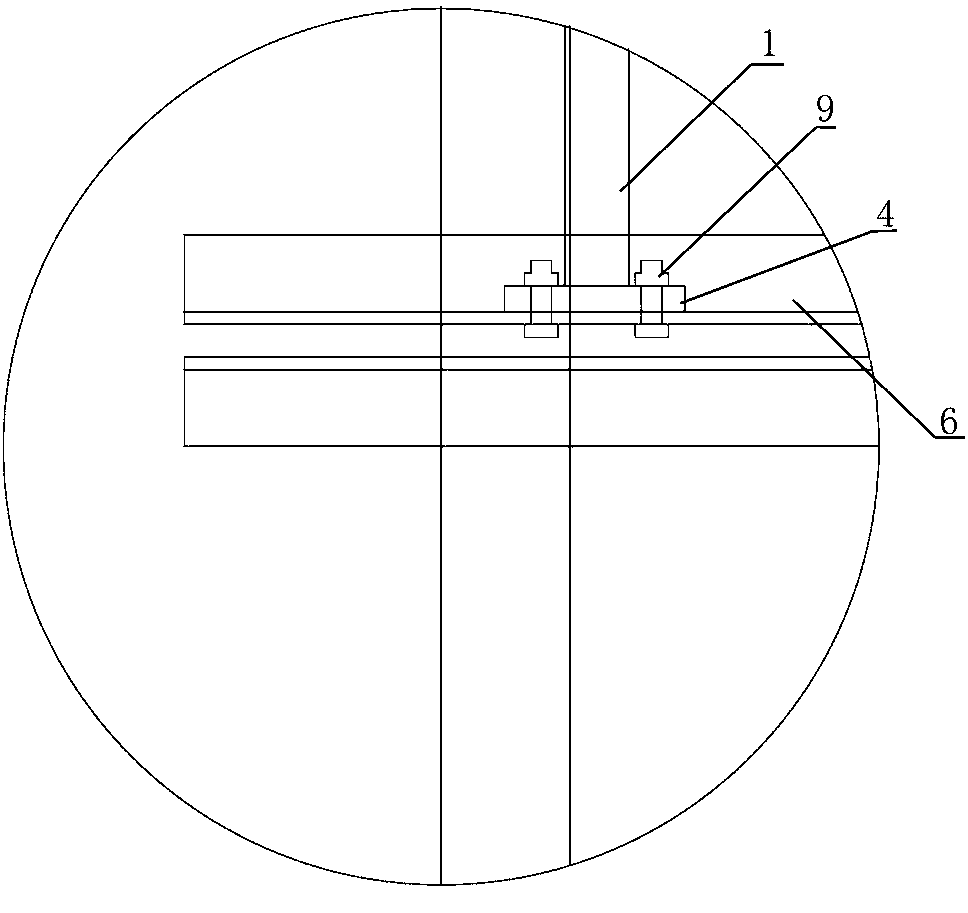

General template for pulling pieces and pulling rods and template system

ActiveCN106481064AUniform and reasonable forceCoordinated and minimal force deformationAuxillary members of forms/shuttering/falseworksForming/stuttering elementsClassical mechanicsEngineering

The invention discloses a general template for pulling pieces and pulling rods and a template system. The template system comprises the general template for the pulling pieces and the pulling rods, the pulling pieces (8), split bolt components (9) and back edge components (11), wherein the general template for the pulling pieces and the pulling rods comprises a panel (1), edge ribs (4), longitudinal reinforcing ribs (2) and horizontal reinforcing ribs (3); the bottom parts of the longitudinal reinforcing ribs (2) are fixedly connected with the panel (1); the bottom parts of the horizontal reinforcing ribs (3) are overlapped on the top parts of the longitudinal reinforcing ribs (2); pulling piece grooves (6) are arranged on the edge ribs (4); pulling rod holes (5) are arranged on the panel (1); bolt holes (7) are formed in the edge ribs (4); stress on the panel (1) is transferred to the horizontal reinforcing ribs (3) by the longitudinal reinforcing ribs (2), and then the stress is transferred to the longitudinally-arranged edge ribs (4) by the horizontal reinforcing ribs (3) so as to form a wholly-distributed two-way uniform-stressing system; the general template for the pulling pieces and the pulling rods is longitudinally arranged in a leaning manner and is fixedly connected; the pulling pieces (8) penetrate through the pulling piece grooves (6) to be oppositely pulled and fastened; the split bolt components (9) penetrate through the pulling rod holes (5) to be anchored on the back edge components (11) for oppositely pulling and fastening; and the unused pulling piece grooves (6) and the unused pulling holes (5) are sealed by adopting silica gel.

Owner:SHENZHEN RILI TECH CO LTD

Self-hardening tundish working lining material, and preparation method and construction method thereof

The invention relates to a self-hardening tundish working lining material, and a preparation method and a construction method thereof. The tundish working lining material comprises the following components, by weight: 90-93% of an aggregate of no more than 5mm and comprising magnesia and forsterite sand, 4-7% of a binder, 0.4-1% of an additive, and 1-3% of a micro powder no more than 0.074mm, wherein a total weight of the above components is 100%. The preparation method comprises the steps of: first crushing the raw materials, proportioning and stirring uniformly according to the above proportion ( except the binder and the additive), and conducting bulk packaging; and packaging and distributing the binder and the additive according to the above proportion. The construction method is as below: stirring quickly to mix the binder, the additive and materials in bulk packing according to the above proportion with a continuous mixer; continuously adding the mixture between a tundish mold tire outer wall and the permanent lining, and vibrating compactly; and standing at room temperature for 0.5-5 h, and releasing the mold to obtain the self-hardening tundish working lining material. The self-hardening tundish working lining material does not need to be baked, consumes low energy, and emits little CO2.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

Construction method for prefabricated building shear wall conversion layer

ActiveCN112627388AEasy to disassembleEasy to install and disassembleWallsForms/shuttering/falseworksRatchetArchitectural engineering

The invention relates to a construction method for a prefabricated building shear wall conversion layer. According to the construction method, a longitudinal rod, a transverse rod and a vertical rod are matched, the longitudinal rod and the transverse rod are connected through a lead screw, and therefore the longitudinal rod and the transverse rod are convenient to drive and move and convenient to disassemble; the transverse rod and the vertical rod are matched through ratchets and pawls to achieve formwork positioning, and meanwhile the vertical rod and the transverse rod are convenient to disassemble through an unlocking device; the ends are locked through a clamping device, a guide rail is arranged on the vertical rod, a formwork structure is installed in the guide rail to form a rectangular formwork frame structure, and disassembling, assembling and transferring are convenient; and meanwhile, inserting steel bar positions are positioned through sleeve positioning devices on the upper portion and the lower portion of a formwork frame, and after the upper ends and the lower ends of sleeves are locked, deviation cannot occur in the concrete pouring and vibrating process. According to the construction method, sleeve steel bars are accurately positioned and are not prone to deviation or deformation, transferring is convenient, formworks are convenient to disassemble, assemble and use, the practicability is high, and the construction method is suitable for application and popularization.

Owner:河南省第一建设集团第七建筑工程有限公司

Long screw sorting device

The invention provides a long screw sorting device. The long screw sorting device can sort detected long screws according to the fact whether the detected long screws are qualified or not and automatically store the screws quantificationally in batches. The long screw sorting device comprises a support, a screw forwarding module, a screw sorting module and a screw collecting module, wherein the support comprises an installation portion, a first guide portion and a second guide portion; the screw forwarding module and the screw sorting module are arranged on the installation portion; the first guide portion and the second guide portion are arranged on the two sides of the screw sorting module correspondingly; the detected long screws are moved to the position above the screw sorting module through the screw forwarding module; the screw sorting module drives the screws to move towards the first guide portion or the second guide portion according to the fact whether the screws are qualified or not, so that the qualified screws and the unqualified screws are separated; and the screw collecting module is arranged at the tail end of the first guide portion or the second guide portion, and used for storing the sorted screws quantificationally in batches.

Owner:JIANGSU LONGCHANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com