Quick disassembling and assembling type special-shaped column frame plate type support structure system and construction method thereof

A technology of supporting structures and special-shaped columns, which is applied in the direction of building construction and construction, can solve the problems of large welding volume, high cost, and heavy component weight, and achieve the effects of strong versatility, good turnover, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

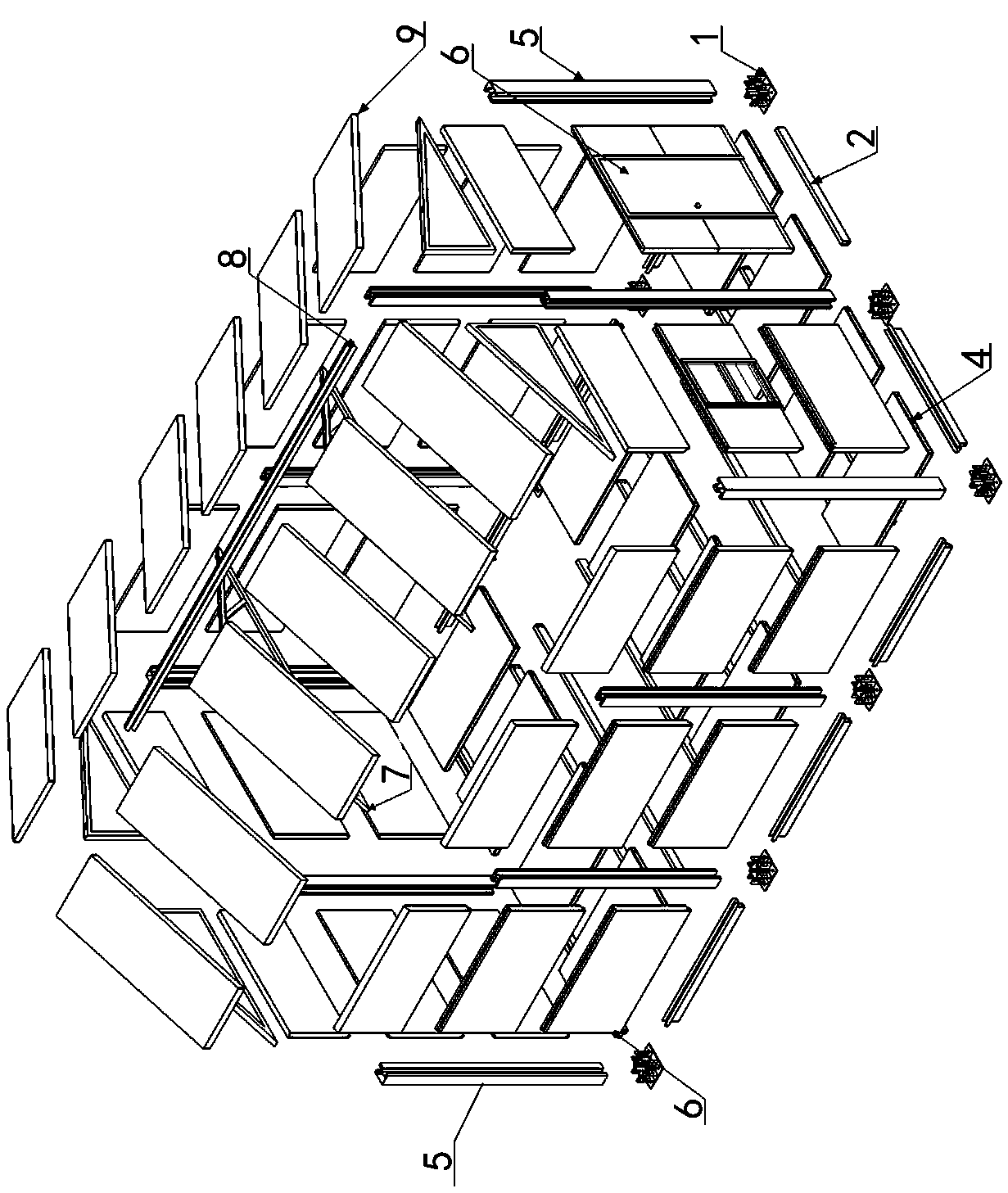

[0068] Examples see figure 1 As shown, a quick-detachable special-shaped column frame plate support structure system includes at least one unit main structure, and the unit main structure includes a four-way adjustable connection support 1, a beam frame, a composite structure floor 4, a thin-walled special-shaped Column 5, unit wall 6, lightweight triangular roof truss 7, ridge card slot 8 and roof panel 9.

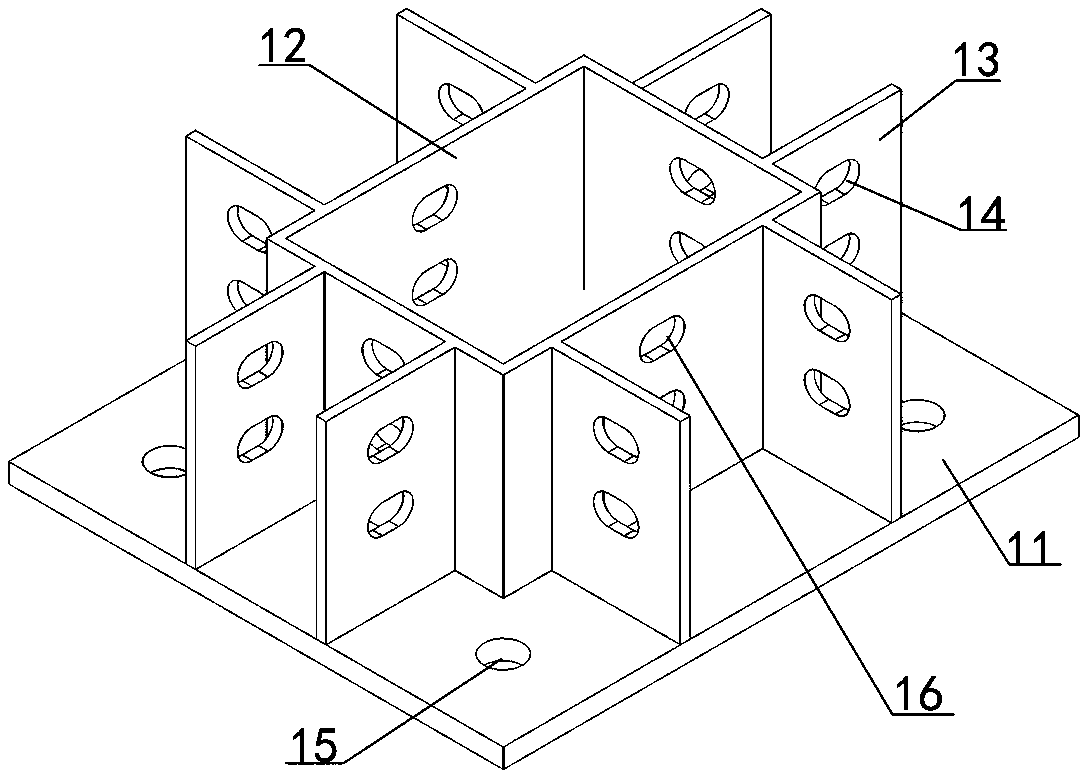

[0069] see figure 2 As shown, the bottom of the four-way adjustable connection support is fixedly connected to the ground, and the four-way adjustable connection support 1 is arranged at intervals along the unit theme structure for a circle, in rows at intervals in the horizontal direction and in rows at intervals in the longitudinal direction. The four-way adjustable connection support 1 includes a bottom plate 11 that is fixedly connected to the ground through four ground bolt holes 15 at the corners, and also includes a reinforced core frame 12 and a beam connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com