Patents

Literature

204 results about "Turnover time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Turnover time refers to the period of time during which certain materials remain within a particular system. For example, the protein that we get from food is broken down by enzymes in our bodies and then resynthesized in a different form.

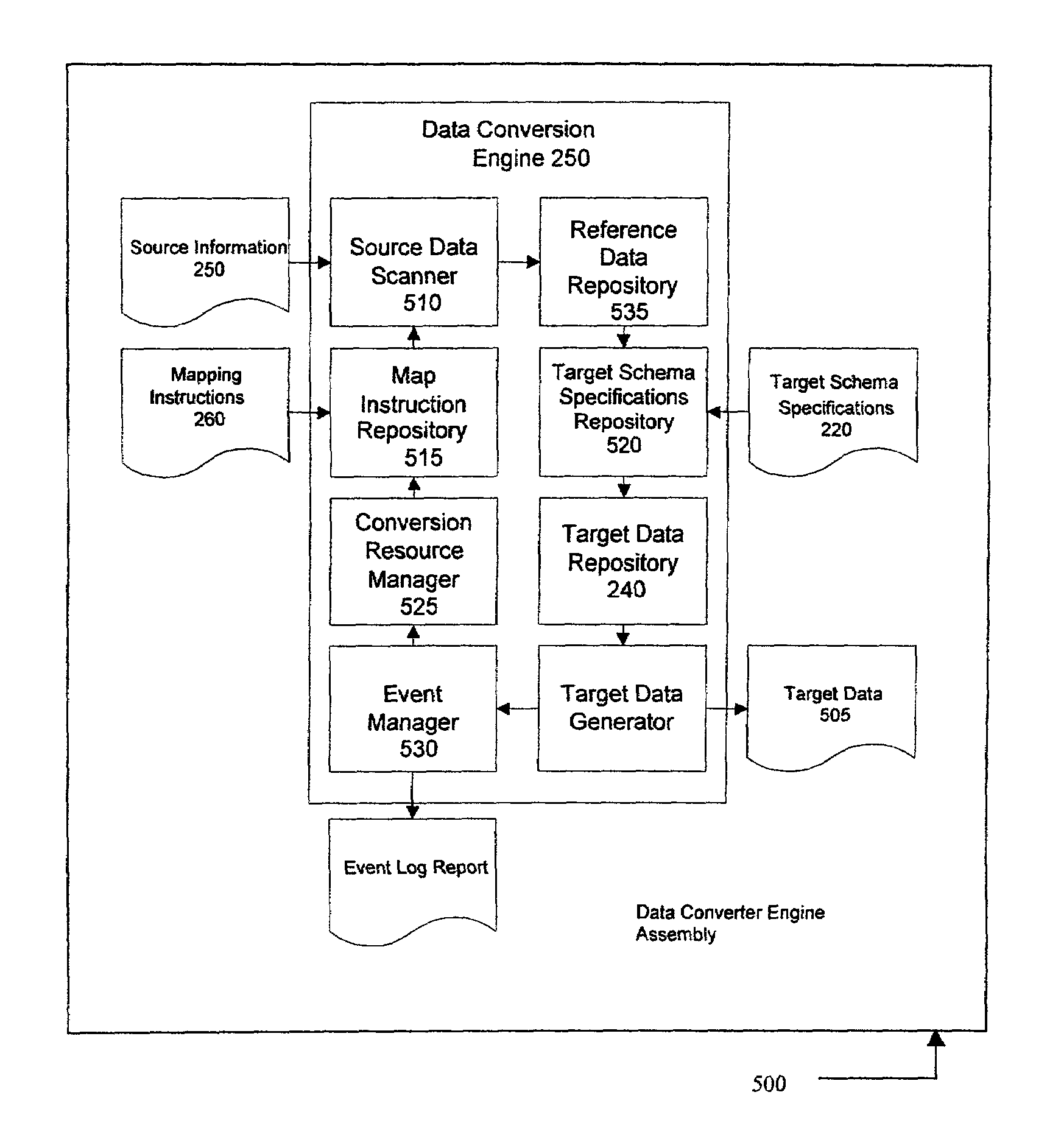

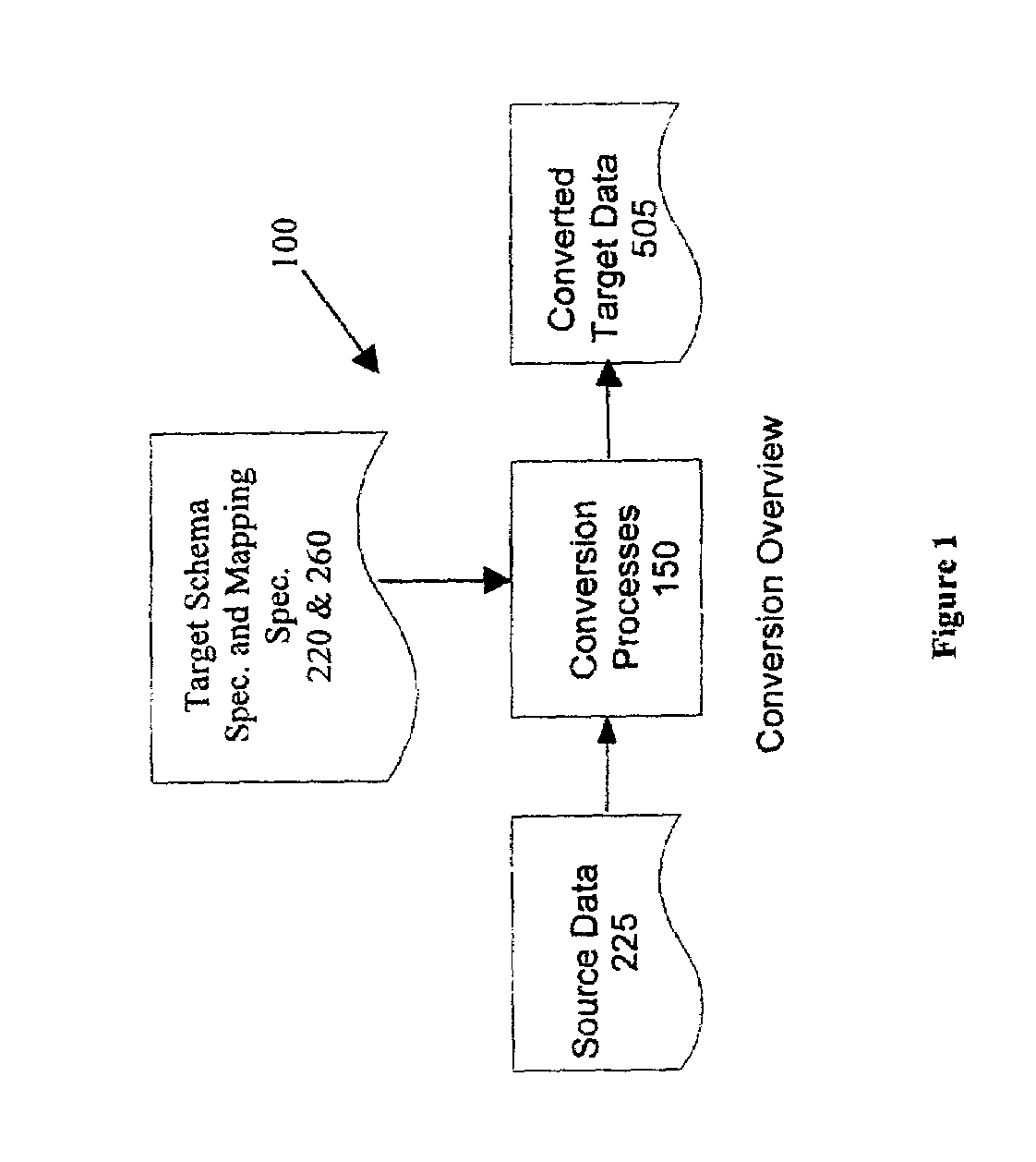

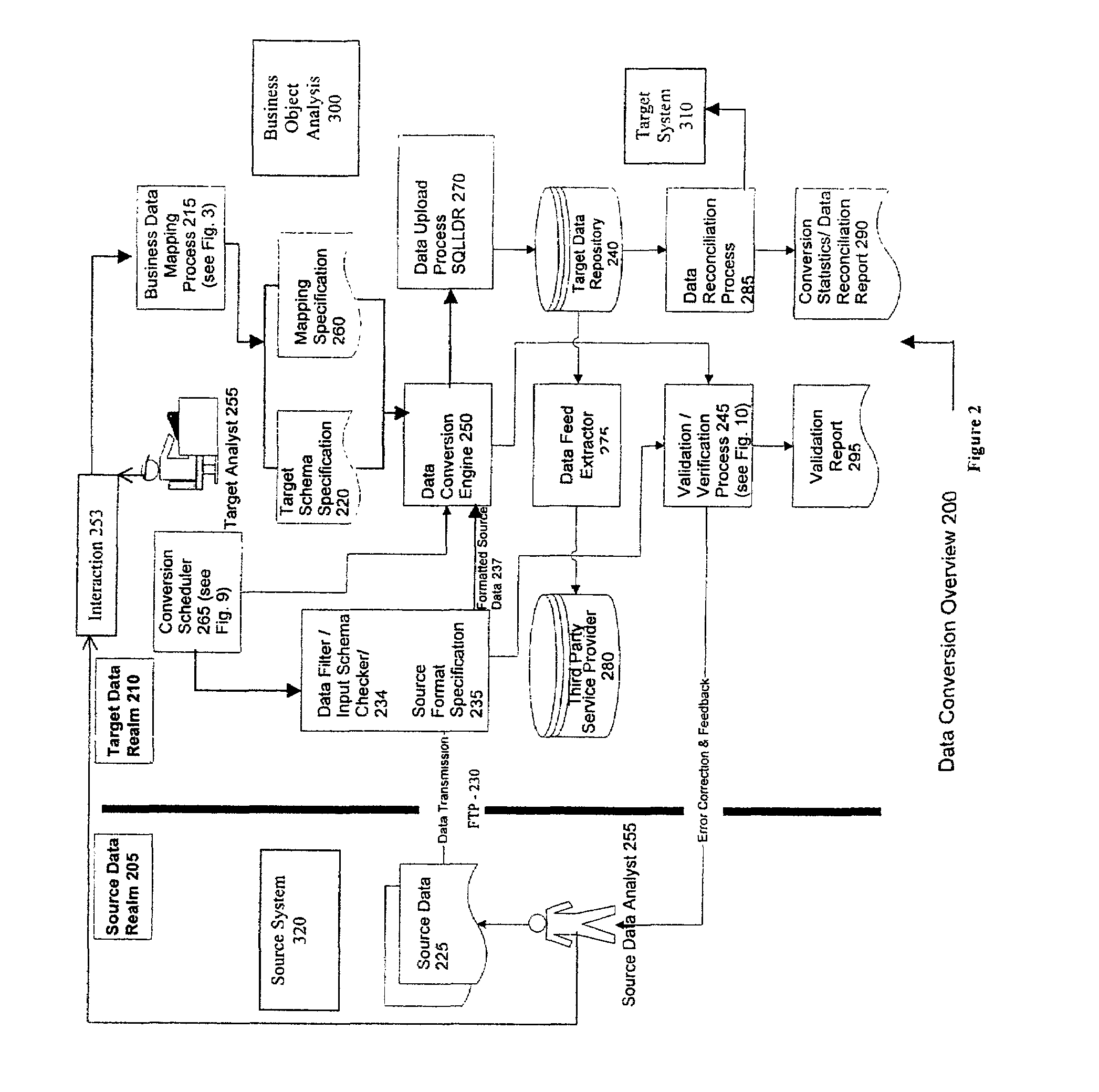

System and method for database conversion

InactiveUS6996589B1Improve performanceFlexiblyData processing applicationsDigital data information retrievalData feedExtensible markup

A database conversion engine comprising a method and system to convert business information residing on one system to another system. A generic, extensible, scalable conversion engine may perform conversion of source data to target data as per mapping instructions / specifications, target schema specifications, and a source extract format specification without the need for code changes to the engine itself for subsequent conversions. A scheduler component may implement a scalable architecture capable of voluminous data crunching operations. Multi-level validation of the incoming source, data may also be provided by the system. A mechanism may provide data feeds to third-party systems as a part of business data conversion. An English-like, XML-based (extensible markup language), user-friendly, extensible data markup language may be further provided to specify the mapping instructions directly or via a GUI (graphical user interface). The system and method employs a business-centric approach to data conversion that determines the basic business object that is the building block of a given conversion. This approach facilitates identification of basic minimum required data for conversion leading to efficiencies in volume of data, performance, validations, reusability, and conversion turnover time.

Owner:NETCRACKER TECH SOLUTIONS

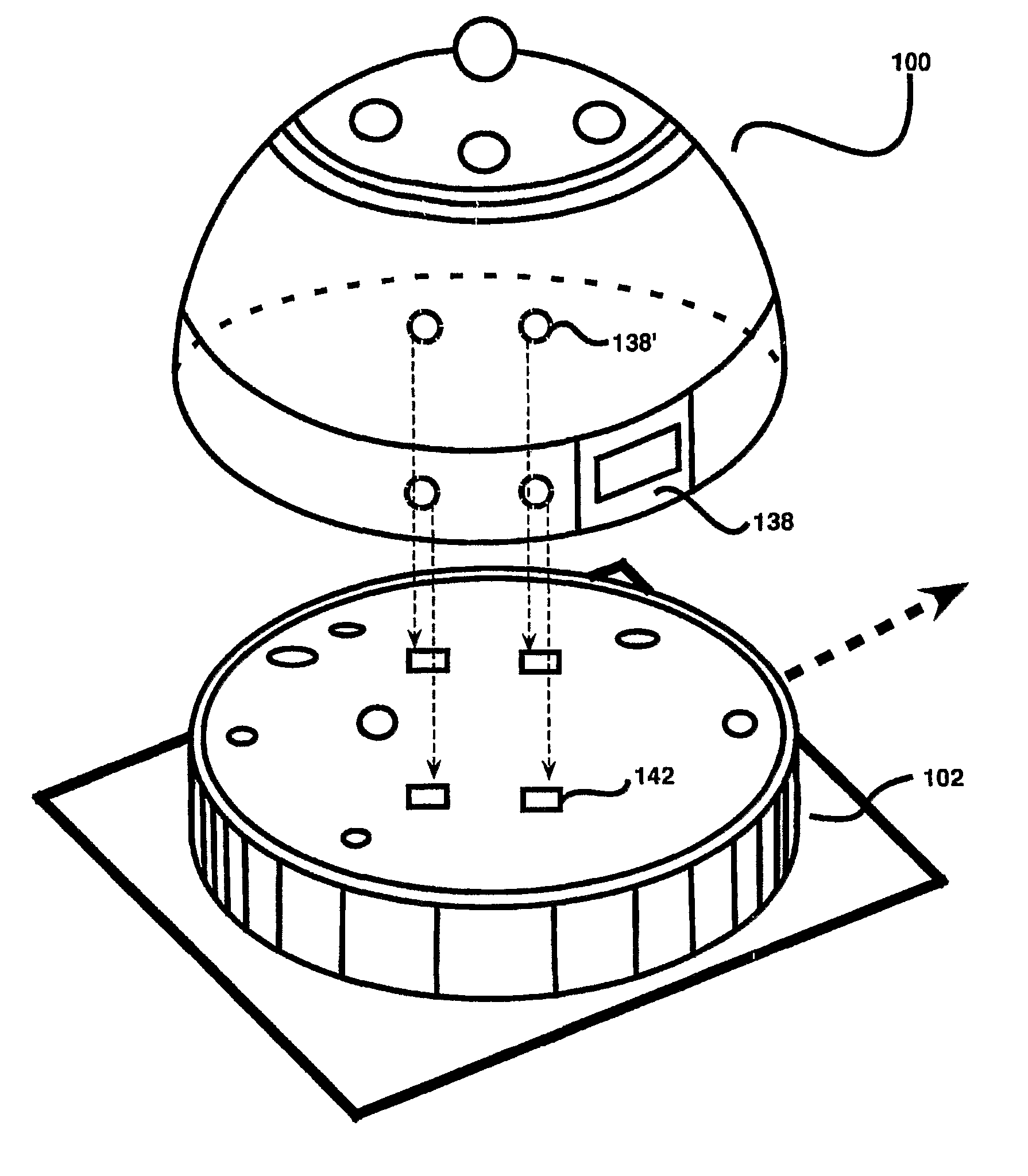

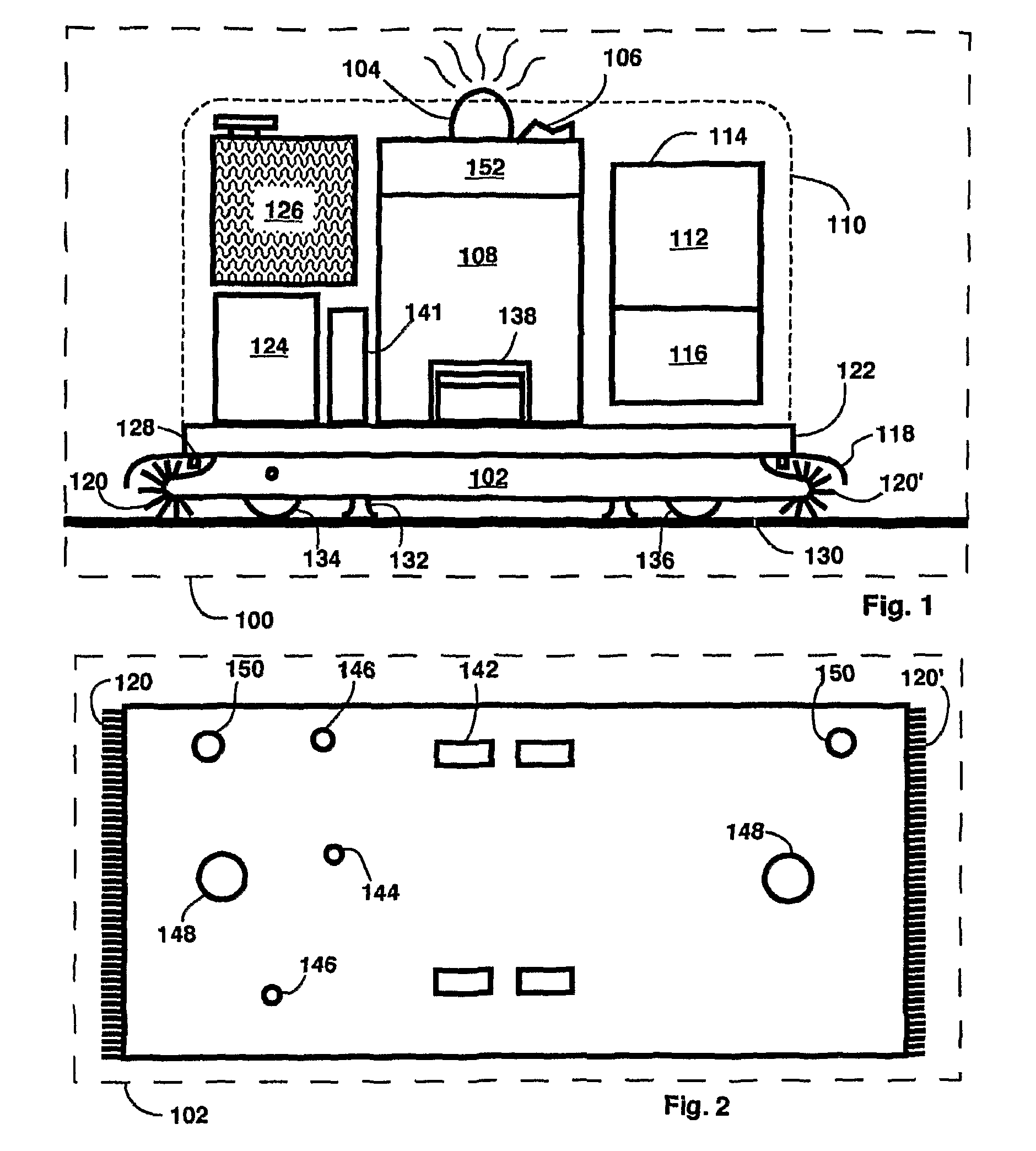

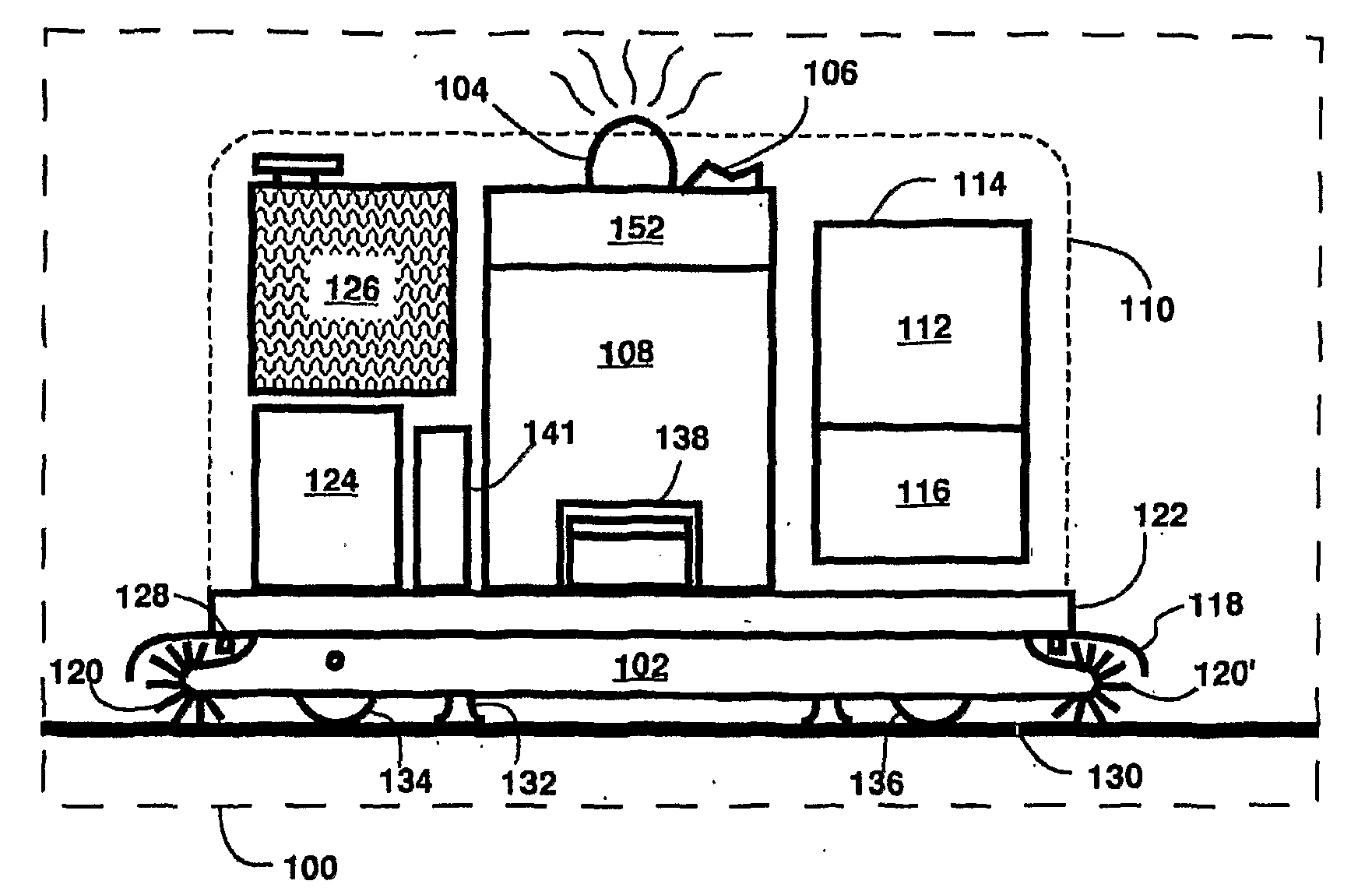

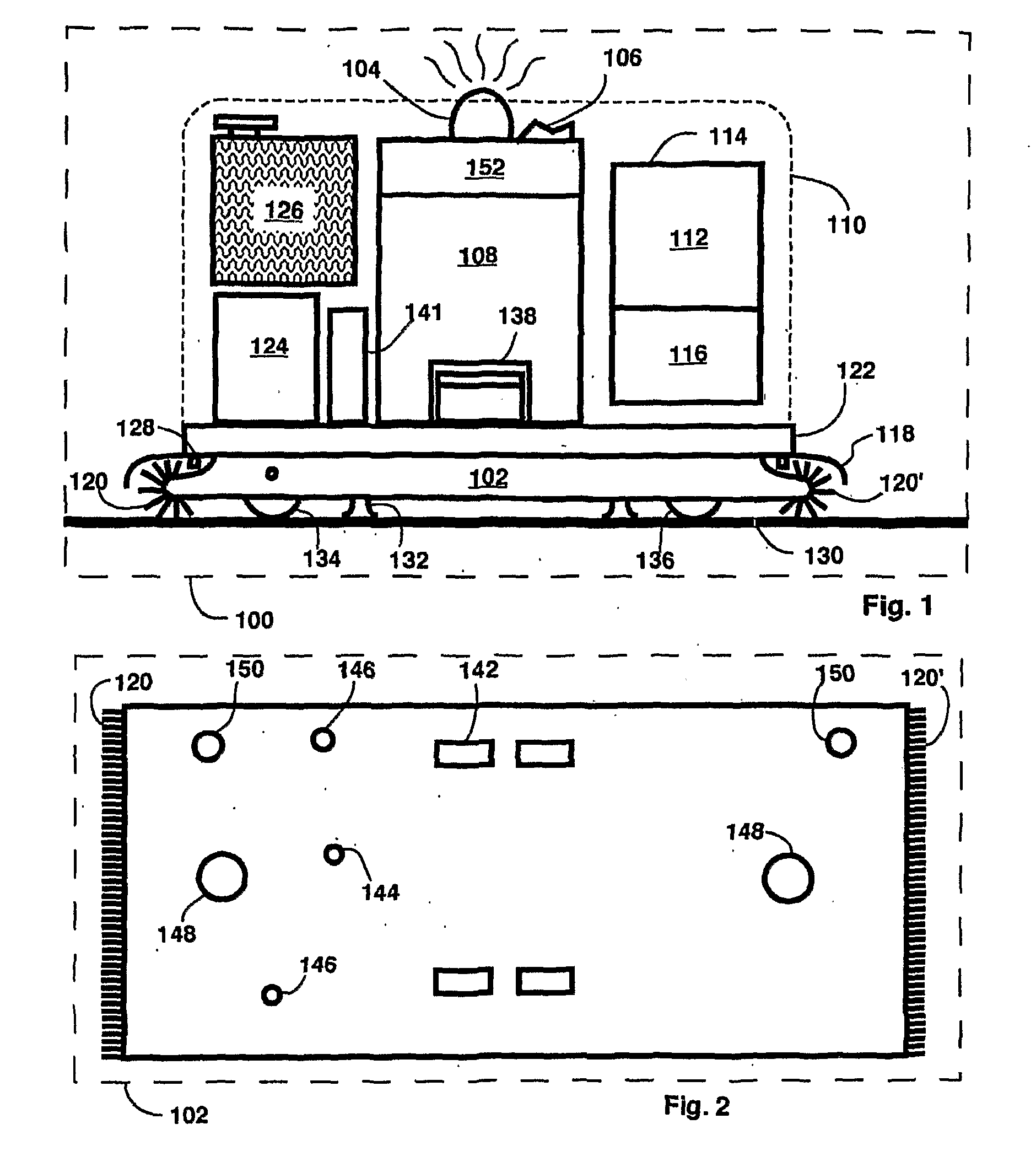

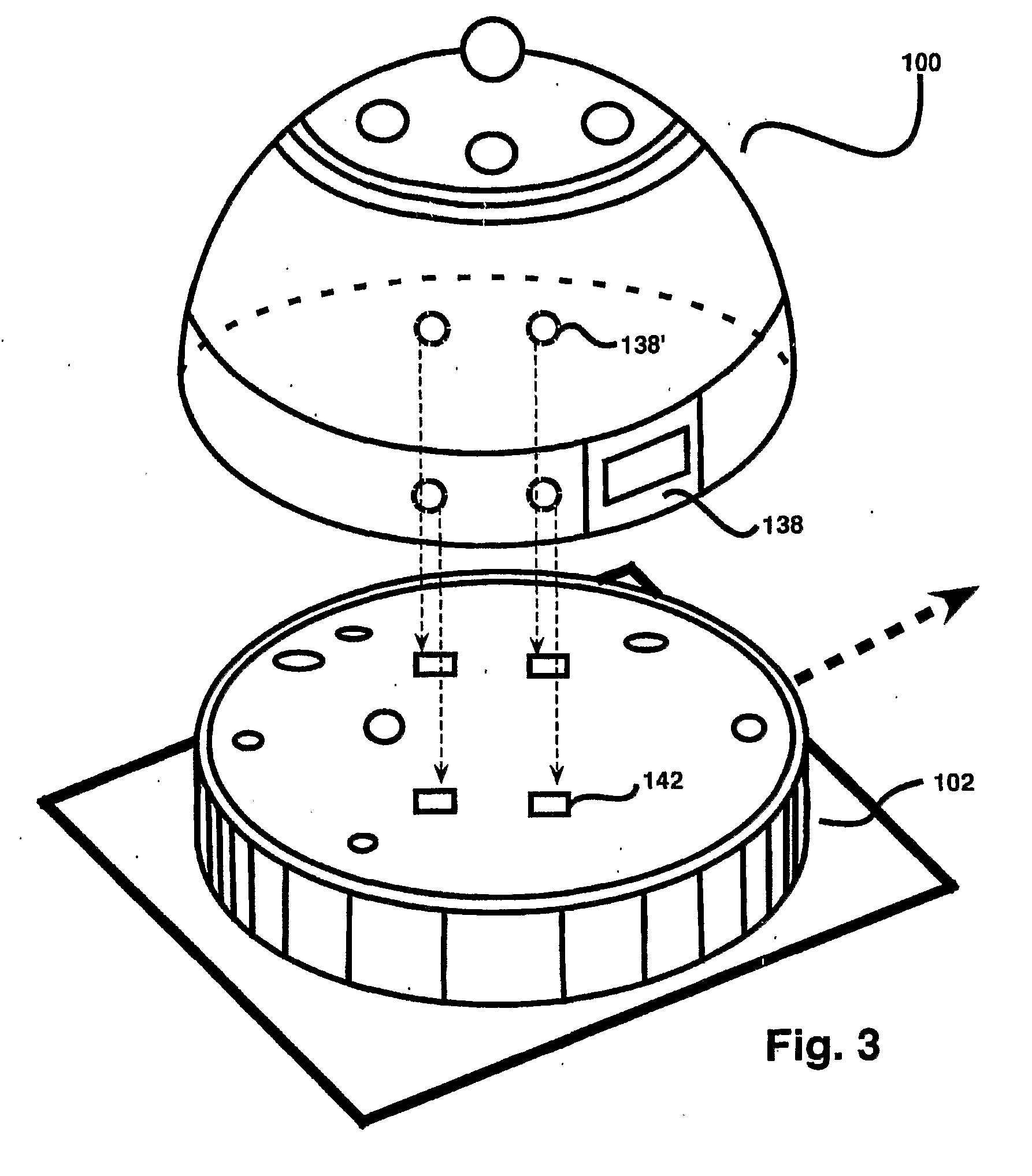

Robotic floor cleaning with sterile, disposable cartridges

An automated (robotic) floor cleaner (100) is adapted to allow sterile cleaning of sensitive environments, such as hospital room. In particular, the floor-cleaner chassis (124) is redesigned to be mounted on a deck (102) containing cleaning devices that contact the floor. The cleaning devices mounted on the deck (102) include vacuum head (132), brushes (120), cleaning fluid sprays (128), and conceivably sanitizing devices such as UV germicidal light, are provided pre-sterilized. As such, the adapted floor-cleaner chassis (124) allows the deck (102) to be mounted to the bottom of the chassis (124), the floor-cleaner (100) is then used to clean a floor, after which, the deck (102) is removed from the chassis (124) and disposed. The robotic-floor cleaner (100) and sterilization system cleans floor between or even during cases. Further, the robotic floor cleaner (100) reduces the “turnover time” required between cases, as it operates simultaneously while the staff prepares the room for the next case.

Owner:OPTIMUS LICENSING AG

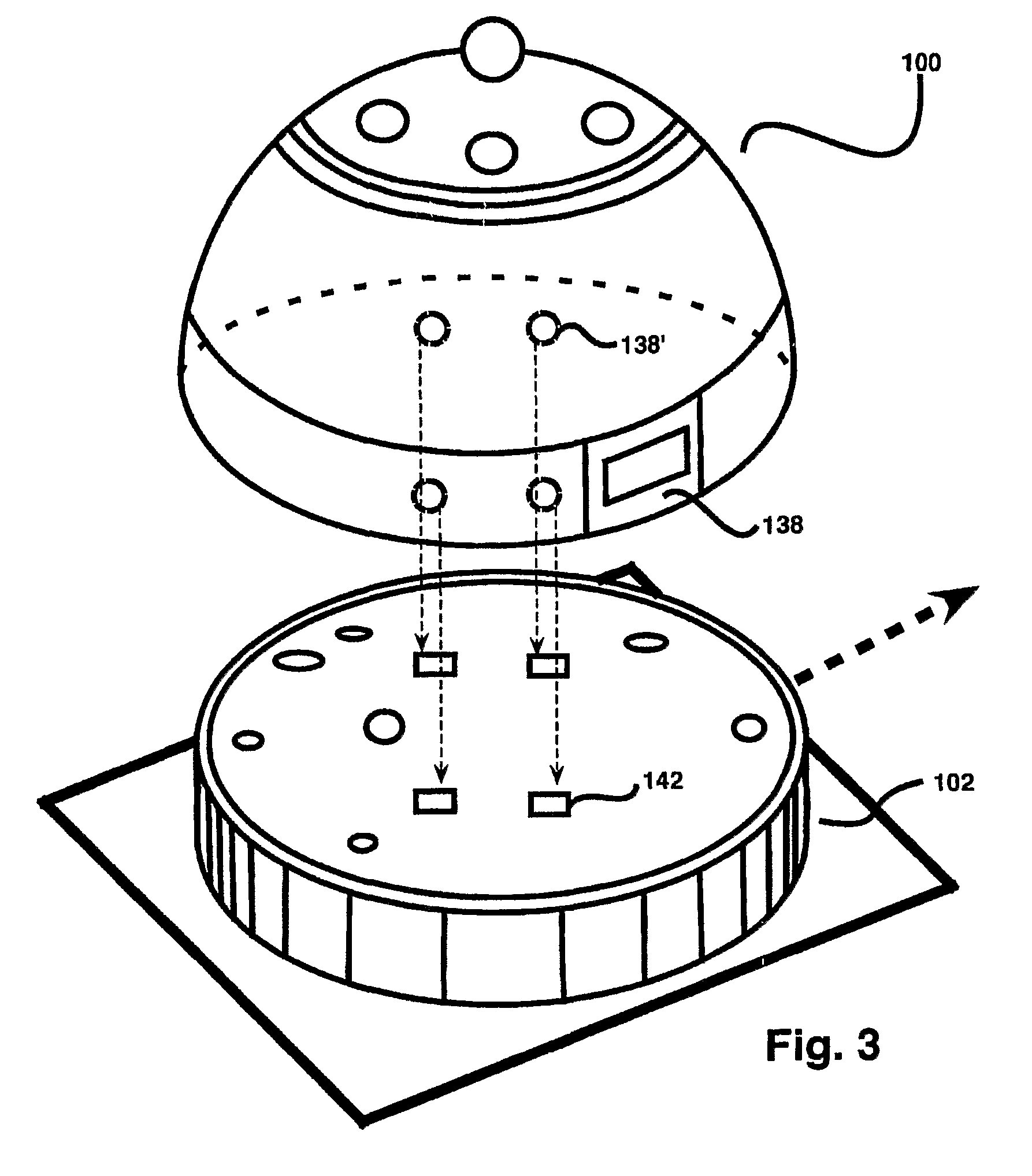

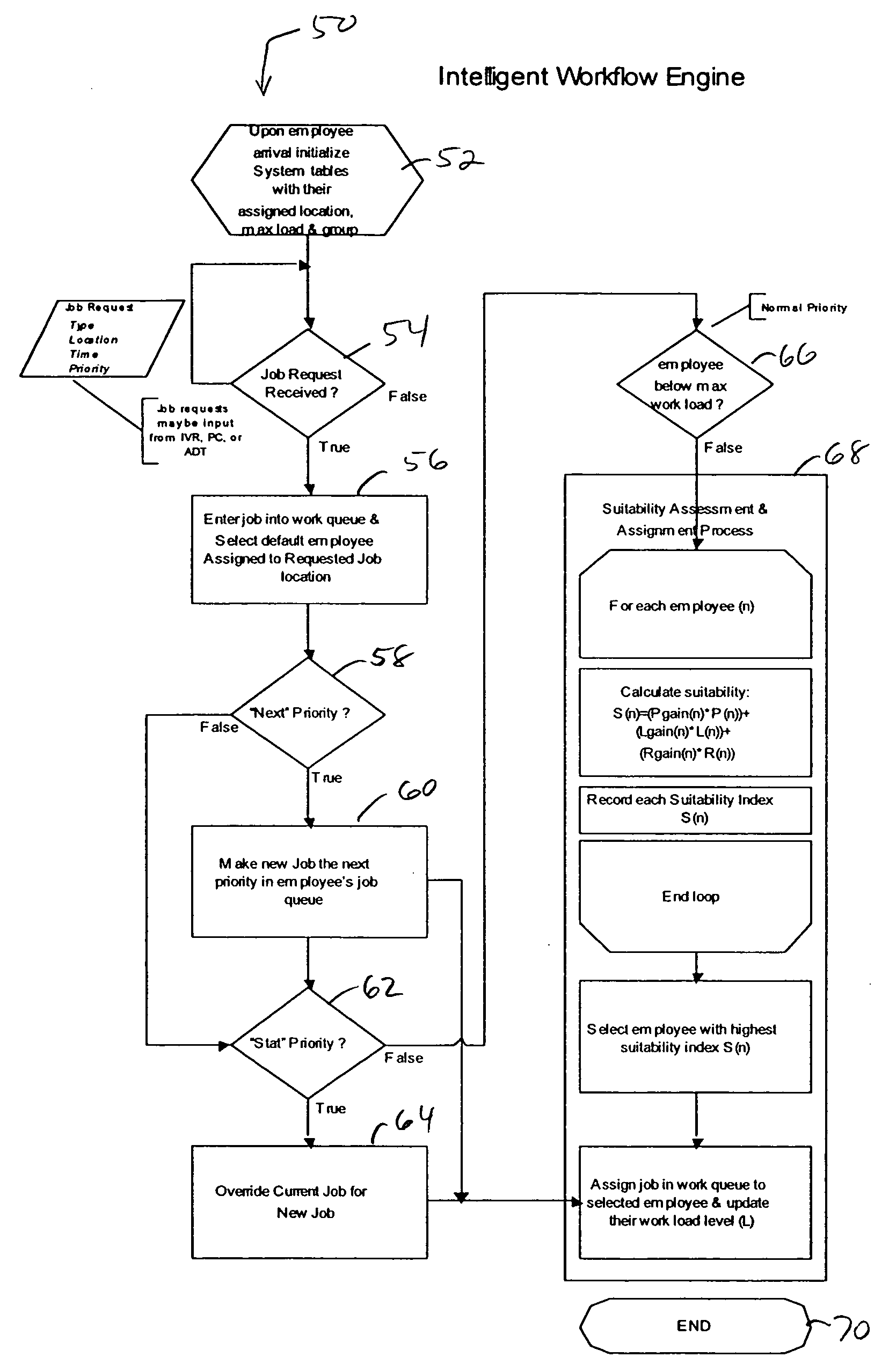

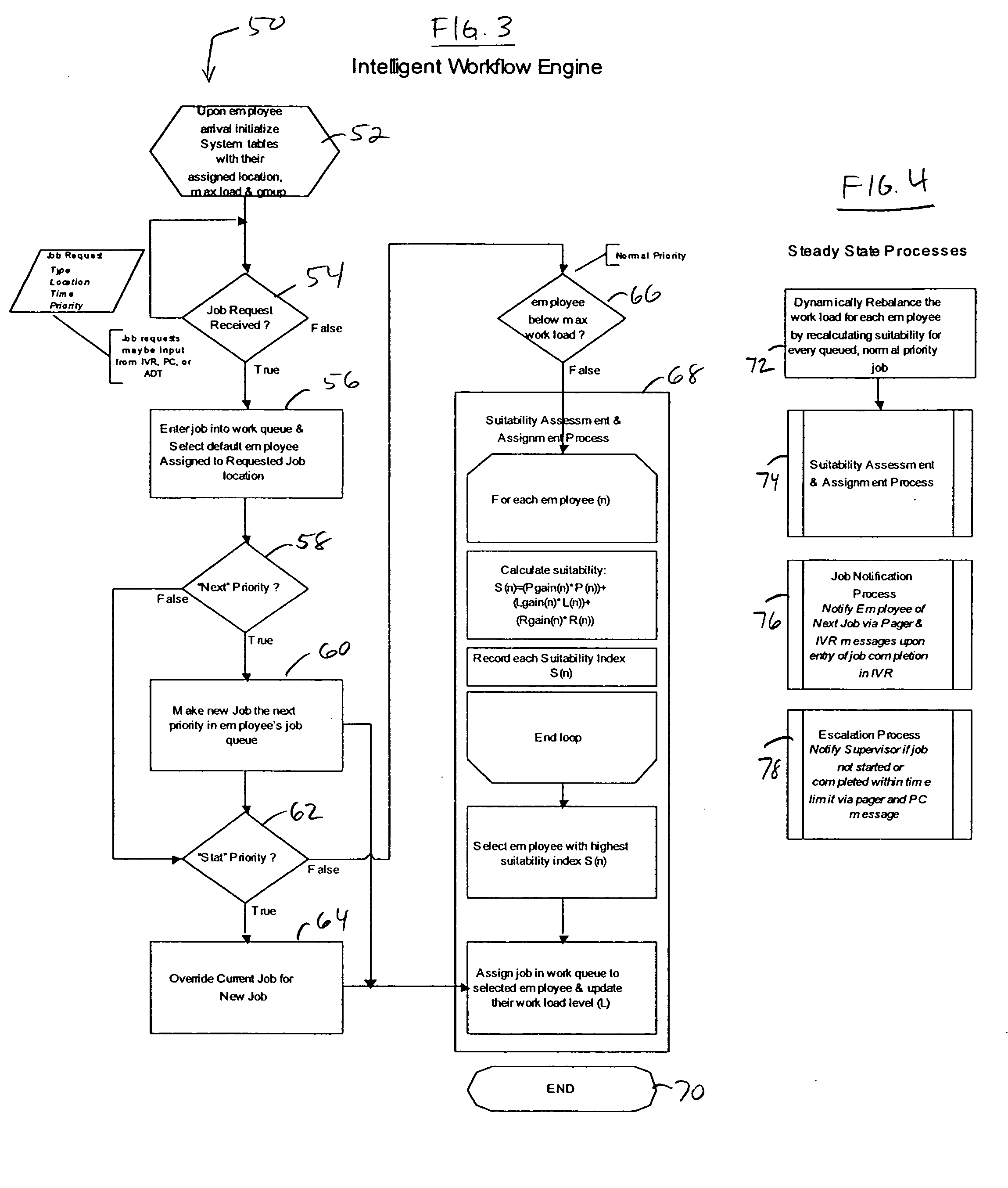

System and method for selecting a best-suited individual for performing a task from a plurality of individuals

InactiveUS20070067199A1Reduce turnover timesEffective balanceDigital computer detailsResourcesTurnover timeWorkload

The present invention provides a computer implemented system and method for selecting a best-suited individual for performing a task from a plurality of individuals. The method including identifying a plurality of individuals for performing a task, receiving a task to be assigned to an individual, assessing the suitability of each of the plurality of available individuals for performing the task, and determining a best-suited individual for performing the task. The method includes evaluating for each individual the individual's current workload, the individual's proximity to a location of the current task and the individual's responsibility for performing the current task. In a preferred embodiment, the present invention is utilized to balance the workload of a hospital's housekeeping staff assigned to dean beds in a hospital thereby decreasing the bed turnover time and increasing the patient throughput of the hospital.

Owner:ALLSCRIPTS SOFTWARE +1

Robotic Floor Cleaning with Sterile, Disposable Cartridges Cross-Reference to Related Applications

An automated (robotic) floor cleaner (100) is adapted to allow sterile cleaning of sensitive environments, such as hospital room. In particular, the floor-cleaner chassis (124) is redesigned to be mounted on a deck (102) containing cleaning devices that contact the floor. The cleaning devices mounted on the deck (102) include vacuum head (132), brushes (120), cleaning fluid sprays (128), and conceivably sanitizing devices such as UV germicidal light, are provided pre-sterilized. As such, the adapted floor-cleaner chassis (124) allows the deck (102) to be mounted to the bottom of the chassis (124), the floor-cleaner (100) is then used to clean a floor, after which, the deck (102) is removed from the chassis (124) and disposed. The robotic-floor cleaner (100) and sterilization system cleans floor between or even during cases. Further, the robotic floor cleaner (100) reduces the “turnover time” required between cases, as it operates simultaneously while the staff prepares the room for the next case.

Owner:OPTIMUS LICENSING AG

Neutral phosphorus-free rust remover used for sheet metal rust removal

The invention discloses a neutral phosphorus-free rust remover used for sheet metal rust removal. The neutral phosphorus-free rust remover is composed of, by weight: 10-35% of a complexing agent, 5-15% of an organic acid, 1-10% of a surfactant, 5-10% of an inorganic salt, 1-5% of a metal corrosion inhibitor, 3-12% of a pH regulator, and the balance deionized water. Compared with the prior art, the neutral phosphorus-free rust remover provided by the invention has the advantages of low cost, energy consumption saving in room temperature use and no environmental pollution, and can improve the workpiece's anti-rust problem caused by the workshop environment or too long process turnover time.

Owner:天津青烽永明科技发展有限公司

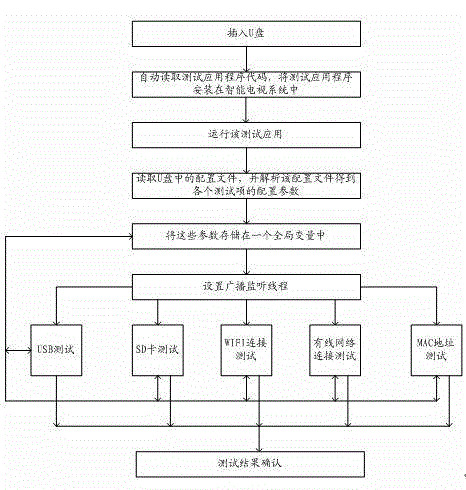

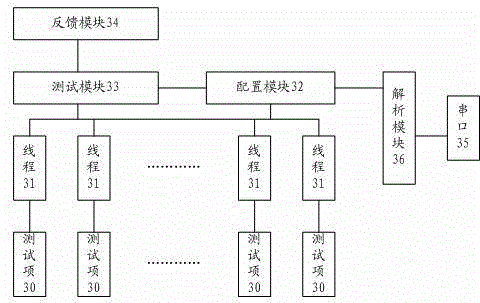

Intelligent television production test method and system

InactiveCN104683797AIncrease productivityReduce turnaround timeTelevision systemsTelevision systemTurnover time

The invention discloses an intelligent television production test method and system, and solves the technical problem that in intelligent television production, both time and labors are consumed during testing. The intelligent television production test method comprises the following steps: opening N threads in an intelligent television system, wherein the N threads are used for testing N test items respectively; reading configuration parameters corresponding to the test items; on the basis of the configuration parameters, testing the test items and feeding back test results. In production, for multiple test items, only one workstation and one tester are arranged on an assembly line, the intelligent television production test system automatically test the test items after the tester starts up the threads, and the tester receives the feedback results to judge whether the functions of the test items are abnormal or not, so that the labor is saved, the turnover time of new machines among a plurality of workstations is also eliminated, the testing time is effectively shortened, and the technical effects of saving both time and labors during the test are achieved.

Owner:QINGDAO GOERTEK

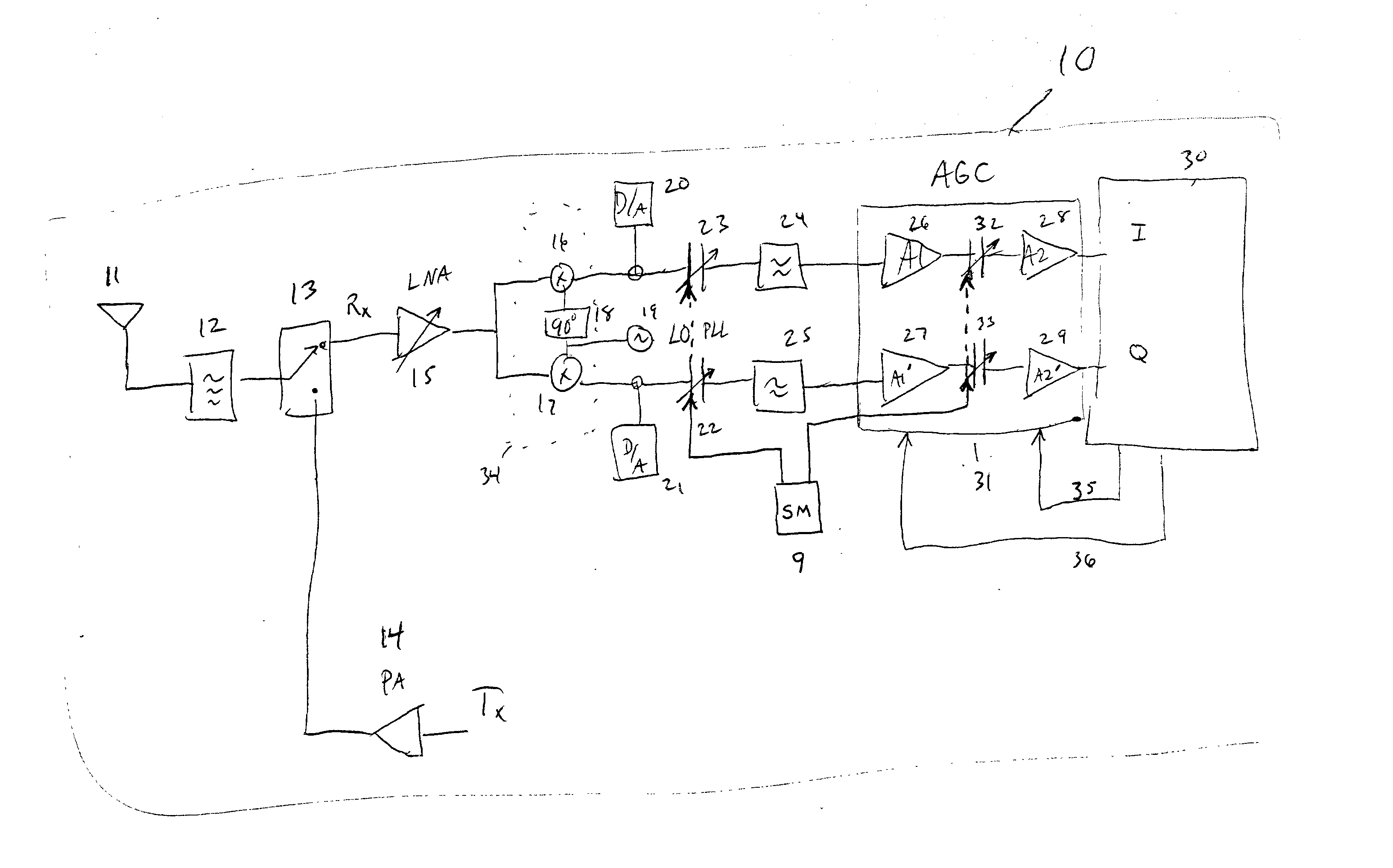

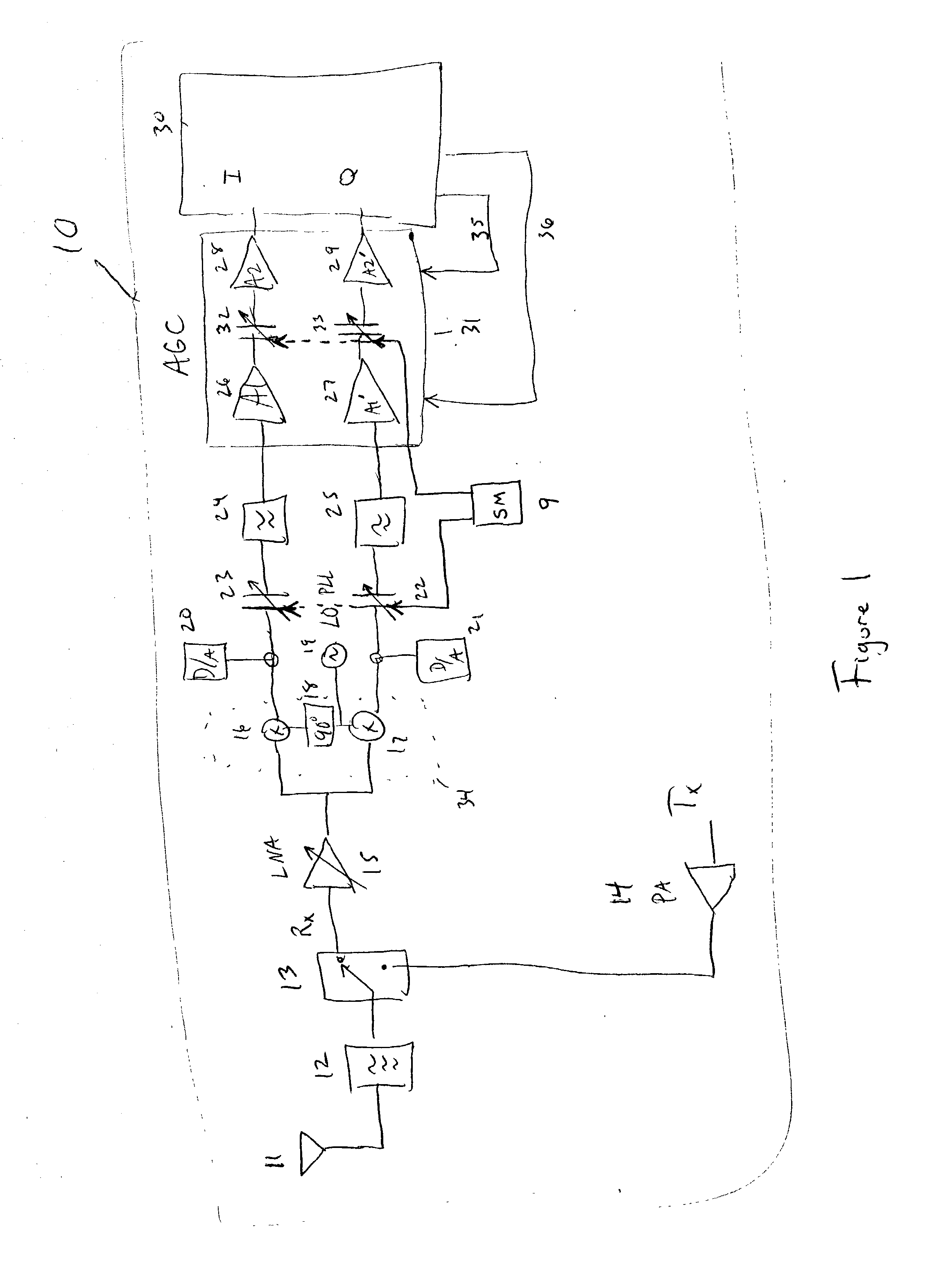

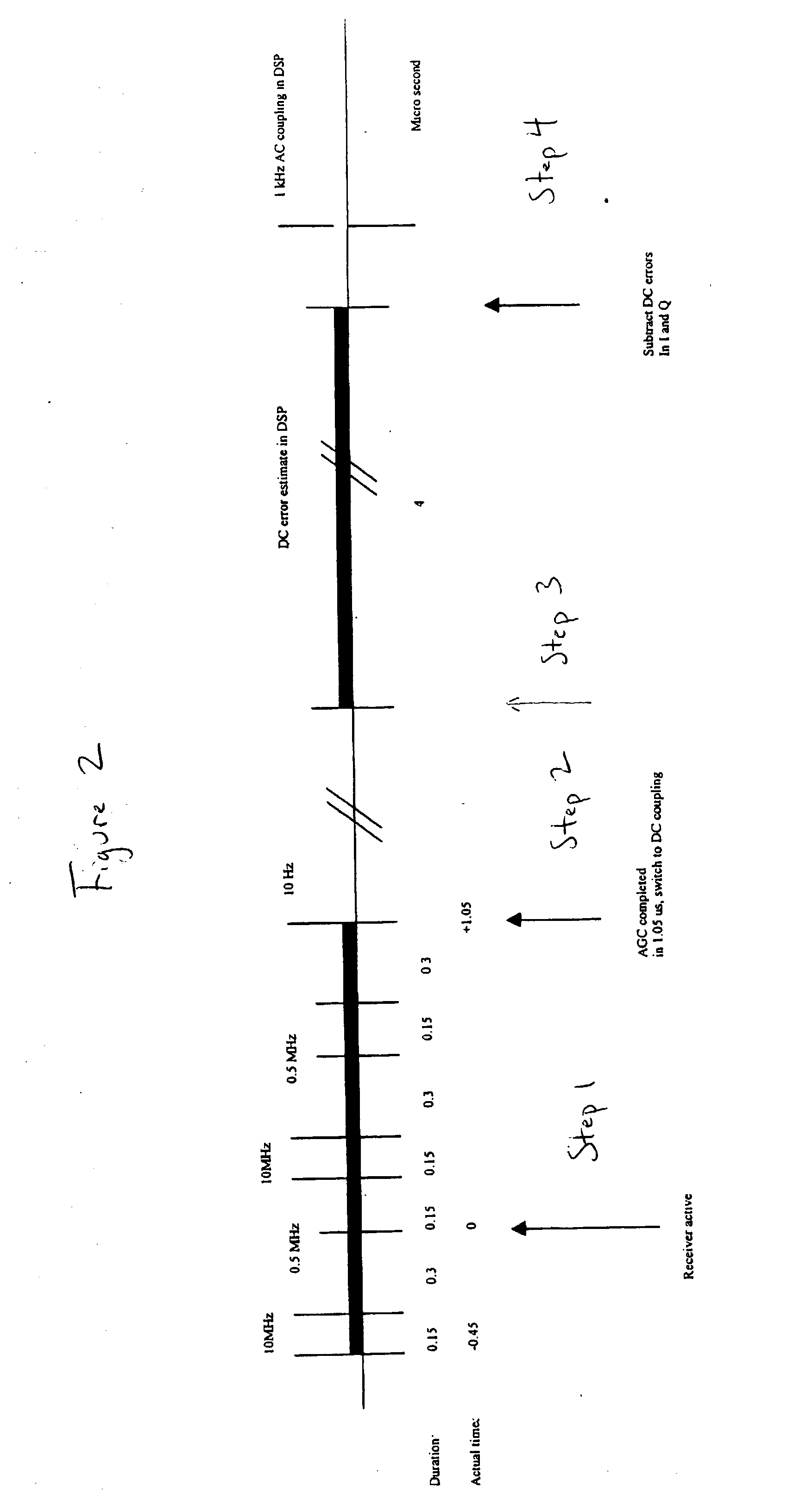

DC offset cancellation in a zero if receiver

ActiveUS20050020226A1Control offsetMinimize impactRadio transmissionDigital signal processingTransceiver

This invention describes how to quickly cancel DC offsets that are present in the two quadrature paths of a zero intermediate frequency transceiver. Previously known techniques are not suitable for the 5 GHz WLAN standards because of the very short transmit to receive turn around times and extraordinarily large dc offsets in these systems. This invention solves the above problems. The present invention uses both AC and DC coupling along with automatic gain control techniques to remove unwanted DC offsets within an acceptable time period. The invention further uses a digital signal processor to estimate and subtract out the DC offset errors using time averaged signals. The digital signal processing circuit is capable of further AC filtering and Analog to Digital conversions.

Owner:MAXIM INTEGRATED PROD INC

Welding method for vertically spliced super-thick steel plate

ActiveCN102861972AControl welding deformationReduce turning timesWelding/cutting auxillary devicesArc welding apparatusSheet steelTurnover time

A welding method for a vertically spliced super-thick steel plate is a welding method for a super-thick steel plate with the thickness ranging from 60mm to 120mm. The method is characterized by including: hoisting a primarily spliced super-thick steel plate onto a special jig frame for horizontal welding, fixing the super-thick steel plate with a waler of the jig frame by welding prior to fastening the super-thick steel plate with a ground abutting floor stand by the aid of a wedge, then using carbon dioxide arc welding for sequential symmetry horizontal welding on the front side and the back side of the super-thick steel plate respectively by even welders until spliced plate welding is finished, and finally performing postheat treatment to prevent cracks. The method has the advantages that welding deformation of the spliced super-thick steel plate can be well controlled, welding deformation correction is avoided, welding cracks are prevented, welding quality is improved, and construction requirements are met. The carbon arc air gouging process for back gouging is omitted, welding procedure is simplified, turnover times of the super-thick steel plate are decreased, workload is reduced, labor intensity is relieved, and production efficiency is improved.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

Oxidation continuous deferrization process for copper cobalt liquor

InactiveCN101117664AIncreased copper and cobalt contentPut into realizationProcess efficiency improvementAutomatic controlTurnover time

The present invention discloses an oxidation de-ironing method of copper cobalt solution. The iron removal of the copper cobalt ores lixivium adopts the interrupted de-ironing method, which can not realize the continuous input and output of material, thereby causing the long turnover time among the equipments, reducing the effective utilization rate of the equipments, at the same time increasing the production cost and the labor strength. The present invention makes a plurality of de-ironing tanks connect in series to form a multilevel continuous de-ironing system into which the copper cobalt solution containing iron is put continuously, the copper cobalt solution is performed with the oxidation treatment firstly to make ferrous iron in the solution to be oxidized completely into ferric iron, and then the copper cobalt solution carries out the multilevel continuous iron removal, and utilizes the pipeline port fall existing between the tanks to flow into the next tank from the last tank. Through adopting the present invention, the continuous input and output of the feed liquid is realized, the production continuity is good, the automatic control is realized completely, the labour force is reduced, the working intensity is lowered, and the production efficiency is high.

Owner:ZHEJIANG HUAYOU COBALT

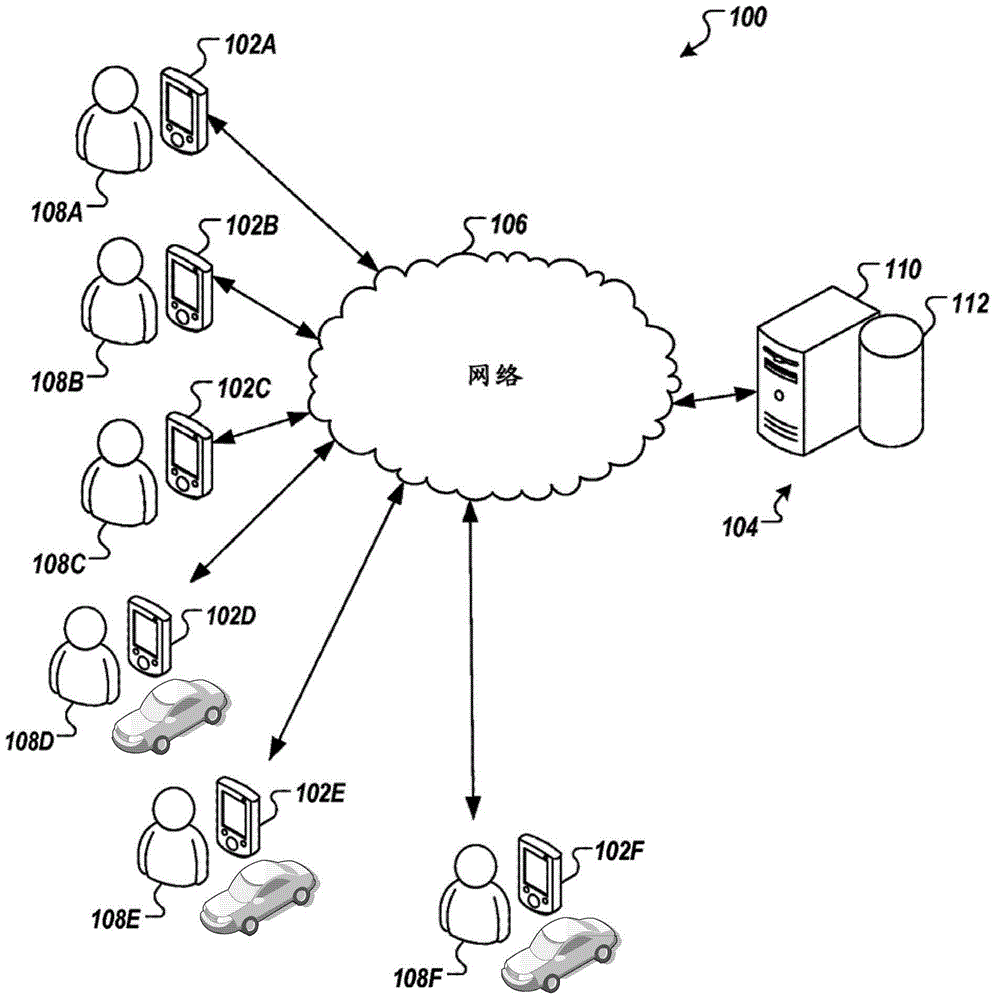

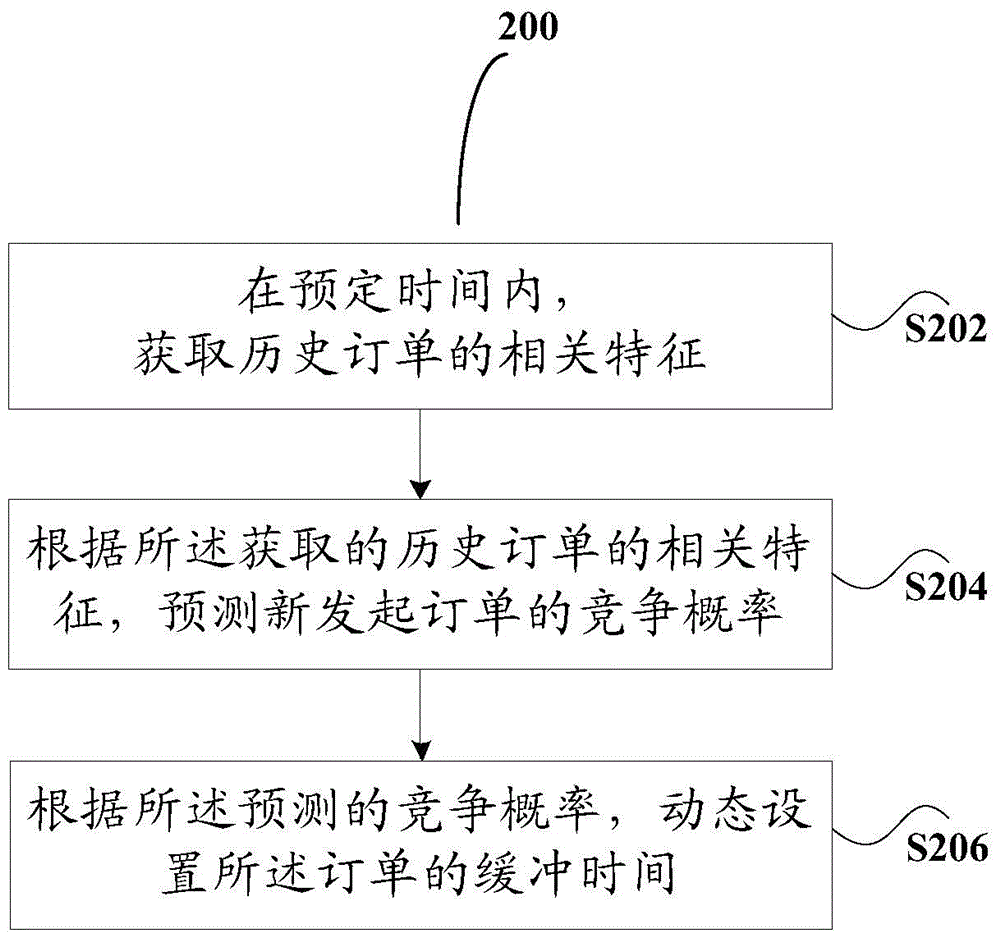

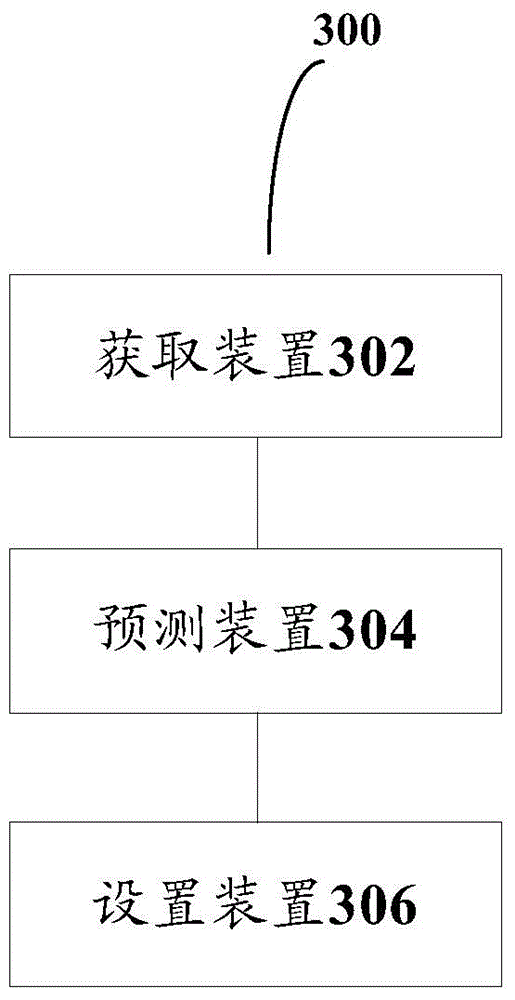

Method and equipment used for dynamically setting buffer time of order

InactiveCN104616086AReduce waiting timeSave transaction timeForecastingTurnover timeRelevant feature

The implementation mode of the invention relates to a method and equipment used for dynamically setting the buffer time of an order. The method comprises the following steps: obtaining related features of a historical order within a predetermined time; according to the obtained related features of the historical order, predicting the competitive probability of a newly initiated order; according to the competitive probability of the newly initiated order, dynamically setting the buffer time of the order. With adoption of the method and the equipment disclosed by the implementation mode of the invention, the buffer time of the order can be dynamically set, so that the waiting time of a driver and the turnover time of the order are saved and the experience of passengers can be improved.

Owner:BEIJING DIDI INFINITY TECH & DEV

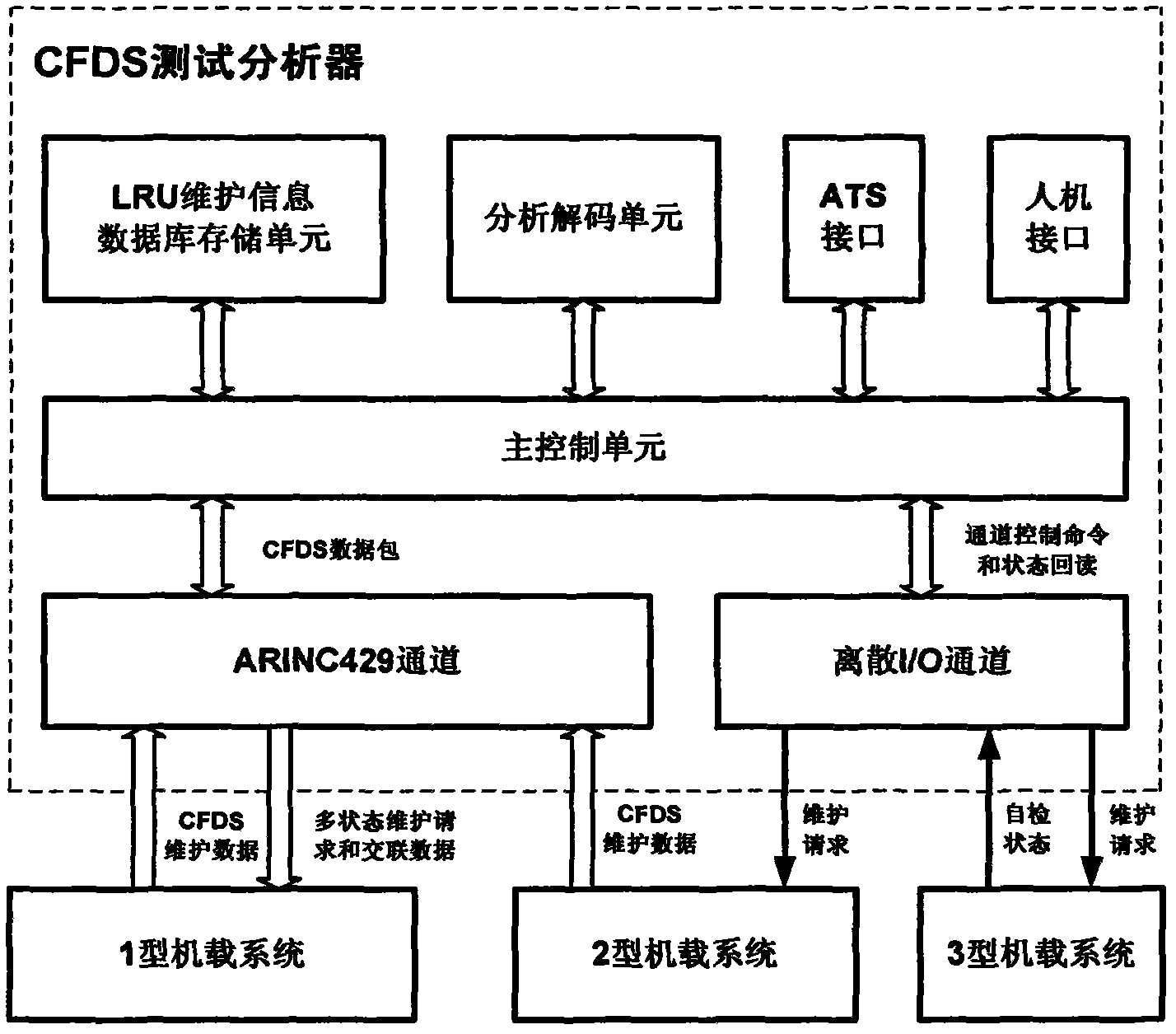

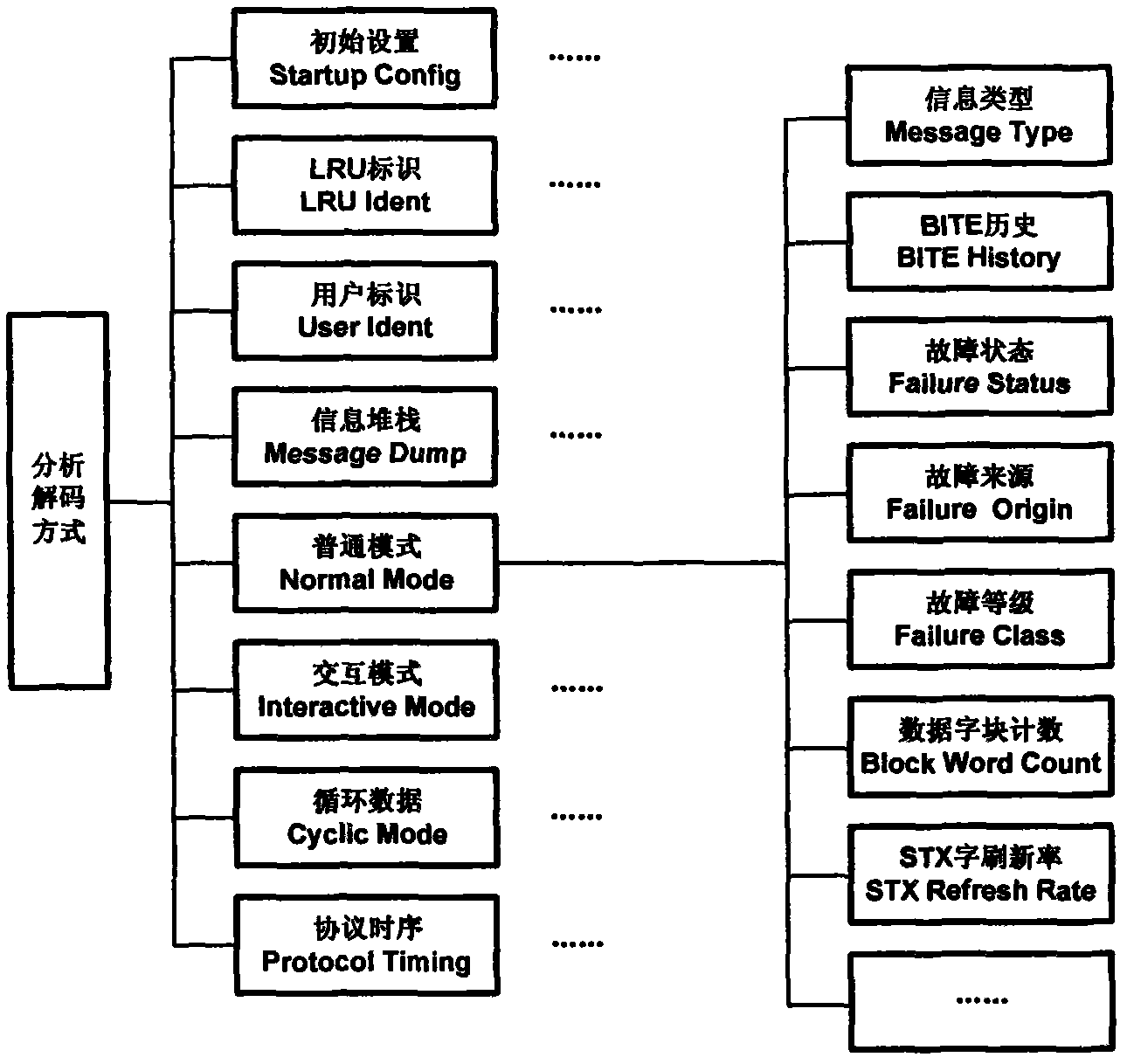

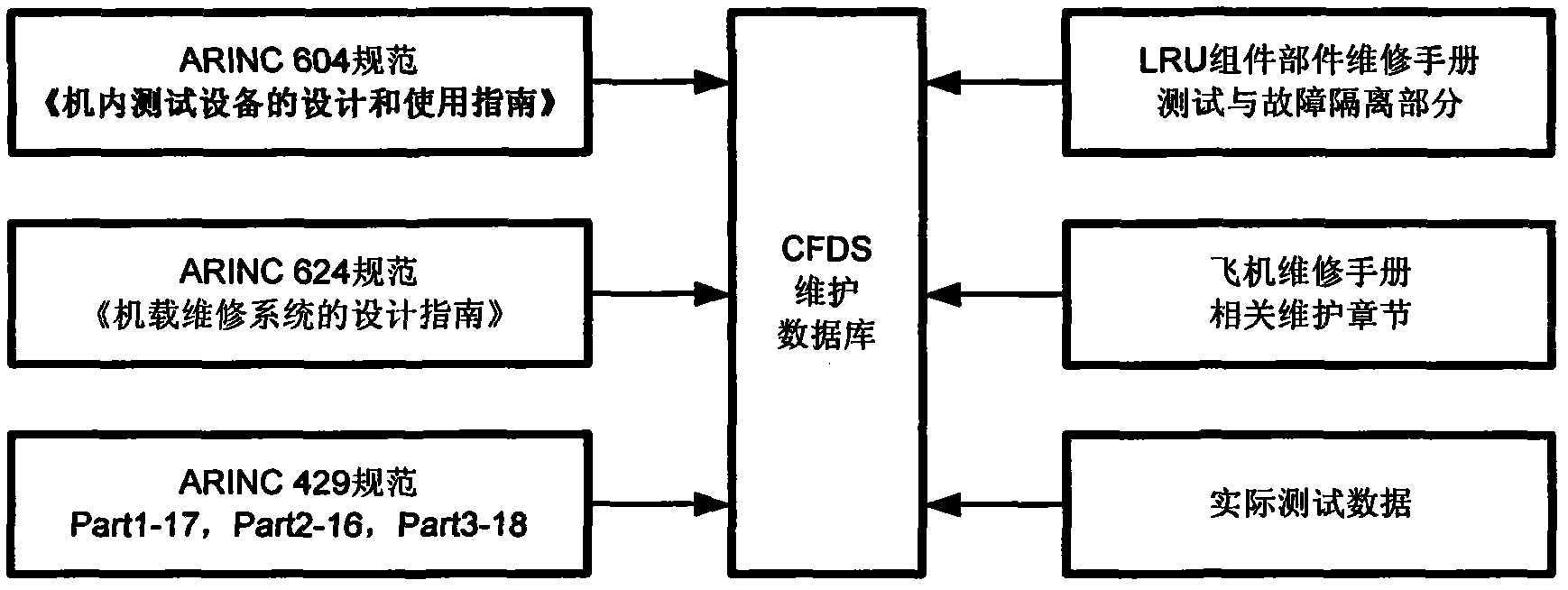

Aircraft CFDS (Centralized Fault Display System) data analyzer and implementation method thereof

ActiveCN102030111AReasonable allocation of resourcesFlexible Human-Machine InterfaceAircraft components testingMonitoring statusTurnover time

The invention relates to an aircraft CFDS (Centralized Fault Display System) data analyzer and an implementation method thereof. Firstly, the CFDS monitoring status of a line replaceable unit on an aircraft is simulated in an infield workshop; secondly, the LRU (Least Recently Used) workshop test is completed in the infield test, and after the decoding analysis and verification, the test data aretransplanted into an aircraft CFDS data analyzer which consists of an ARINC (Aeronautical Radio Inc) 429 data analyzer and an industrial control mechanism and is communicated with a tested airborne system through an ARINC 429 channel and a discrete I / O channel, and thus the aircraft CFDS analysis is realized. The price of the aircraft CFDS data analyzer is low, the aircraft CFDS data analyzer is provided with a second development interface, and thus the aircraft CFDS data analyzer is easy to independently upgrade by the technicist, and the cost for software upgrading is greatly lowered. The aircraft CFDS data analyzer complies with a modern ATS design standard and can be conveniently transplanted into different automatic test systems, the maintenance resource is saved, abroad technical monopoly is broken, the cost of return for repair and the turnover time of aeronautical materials are effectively reduced, the abroad maintenance rate of part of aircraft components is lowered, and the enterprise competitiveness is improved.

Owner:CIVIL AVIATION UNIV OF CHINA

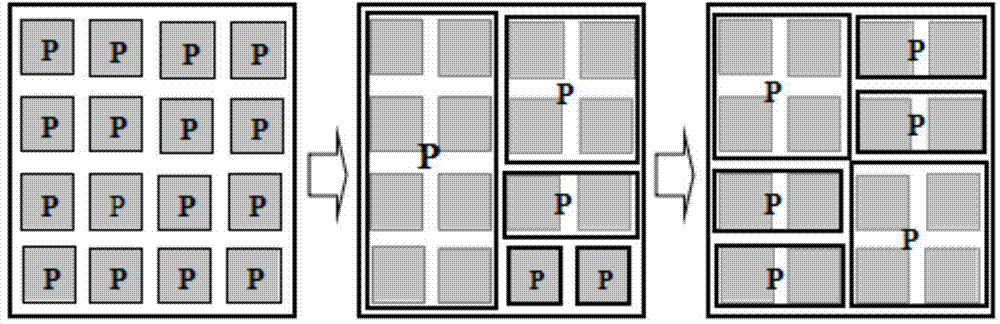

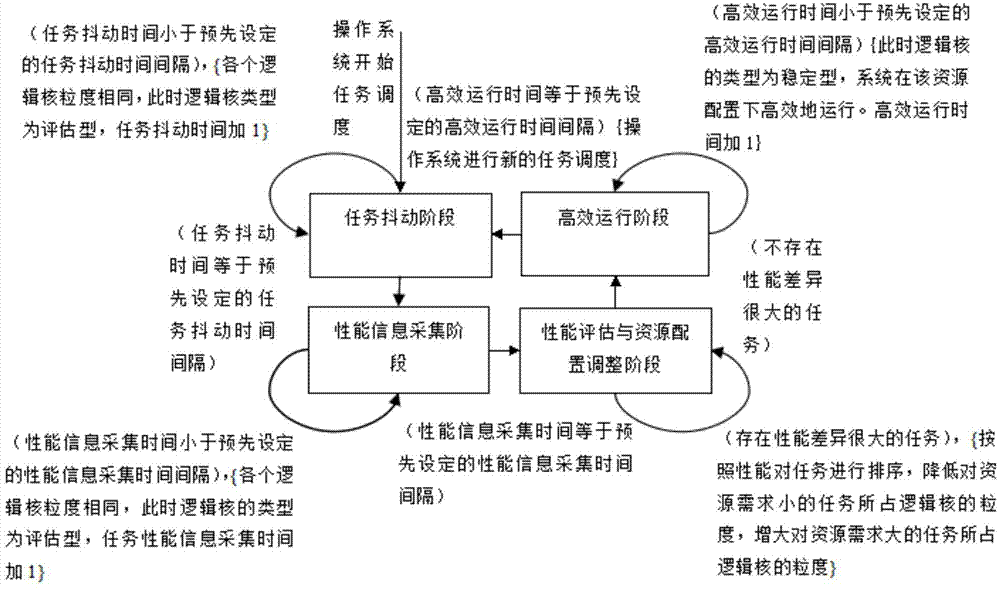

Resource distribution method for reconfigurable chip multiprocessor with task number and performance sensing functions

The invention relates to a resource distribution method for a reconfigurable chip multiprocessor with task number and performance sensing functions. The dynamic reconfigurable chip multiprocessor has the capability of dynamically reconfiguring on-chip resources during running, so as to reduce the task average turnover time, improve the system throughput rate and the chip resource utilization rate, and provide a large optimization space. The method has the advantages that in each dispatching interval of an operation system, a resource allocator is used for firstly averagely allocating a logic core according to the task number, sequencing the tasks according to the performances (for reflecting the requirement of the task on the resource) after running for a certain clock cycle, finding the task with small demand on resource, reducing the granularity of the occupied logic core, and allocating the vacant physical core from the task with small demand on resource to the task with high demand on resource, so as to increase the granularity of the logic core occupied by the task with high demand on resource; when the existing load of the system is changed or the task enters the new running phase, the resource allocator will timely make adjustments in the next operation system dispatching, so as to fully utilize the chip resources.

Owner:UNIV OF SCI & TECH OF CHINA

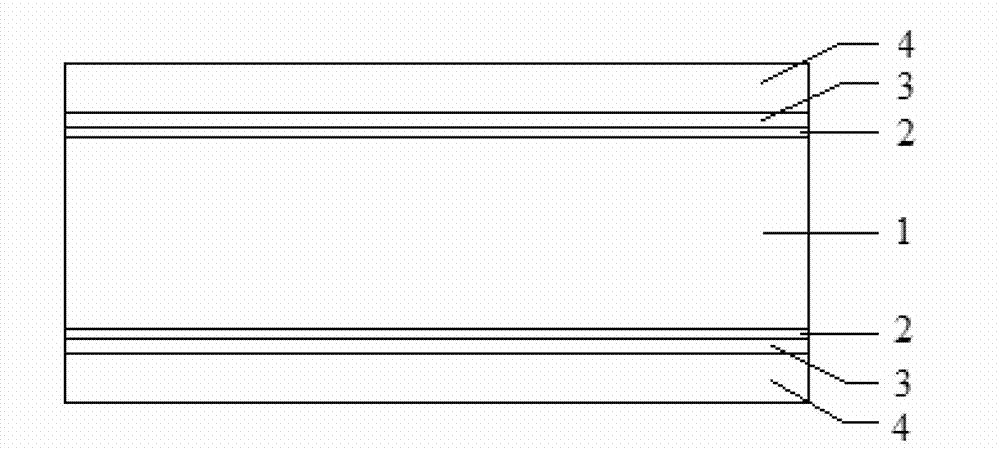

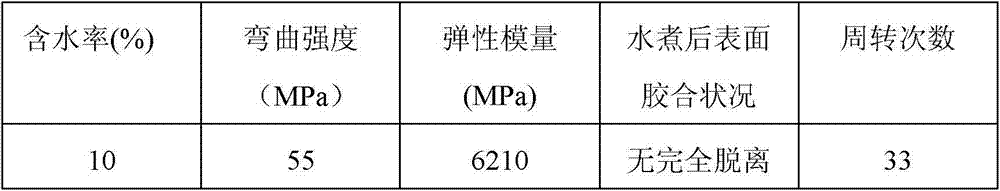

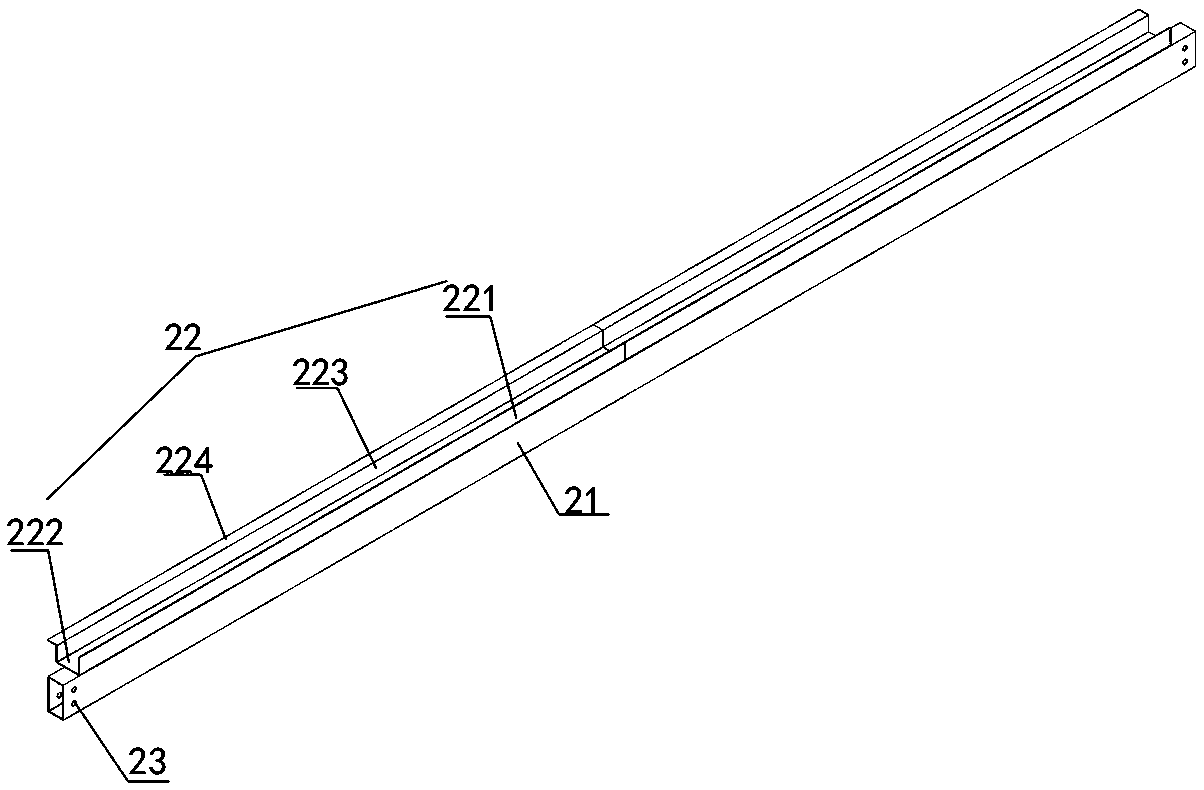

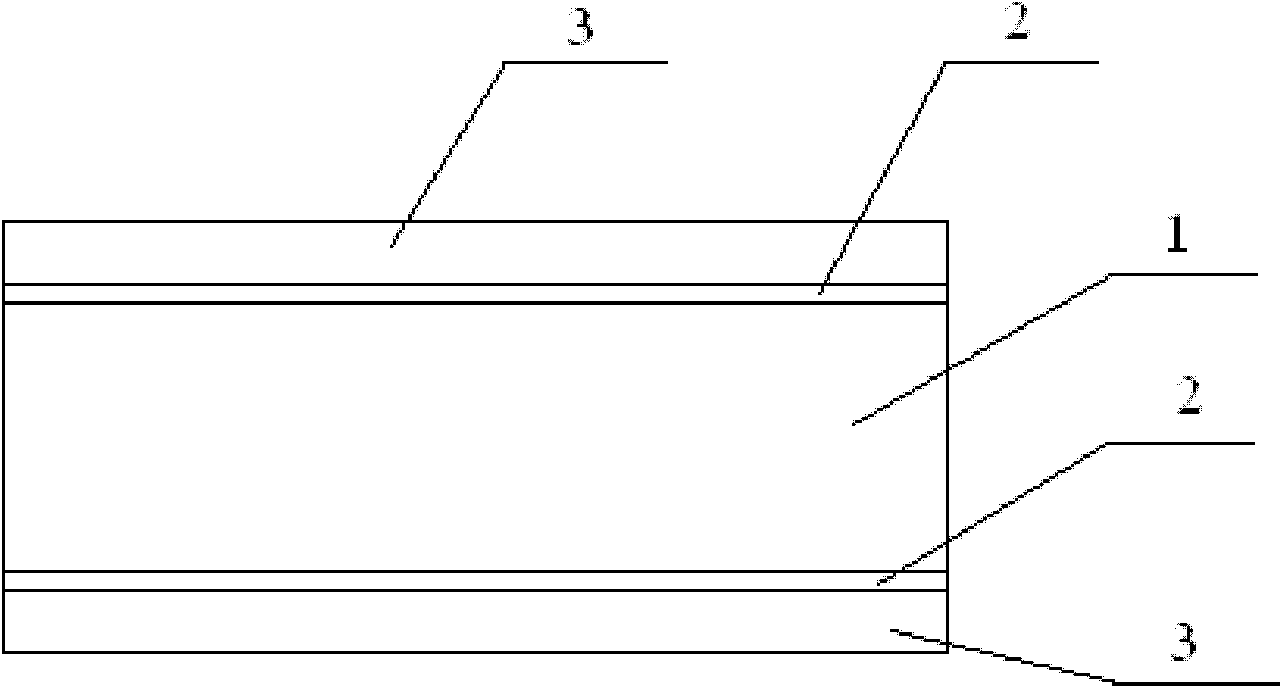

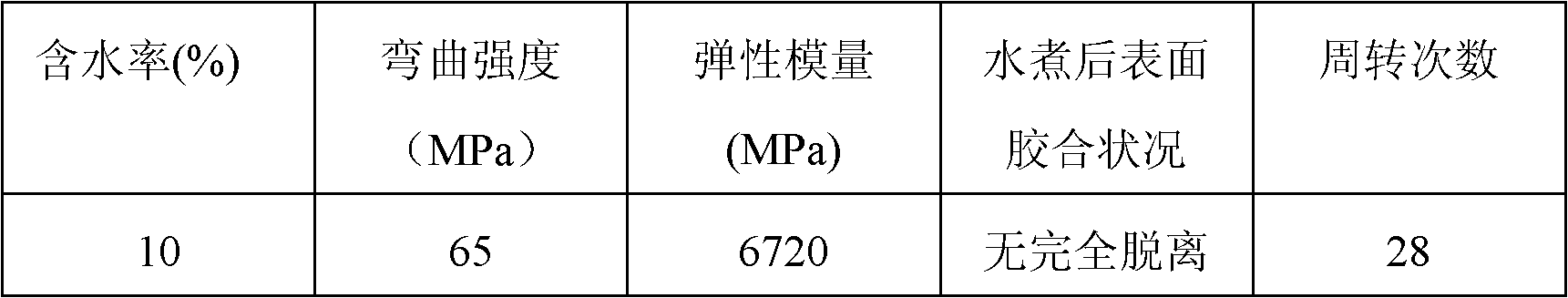

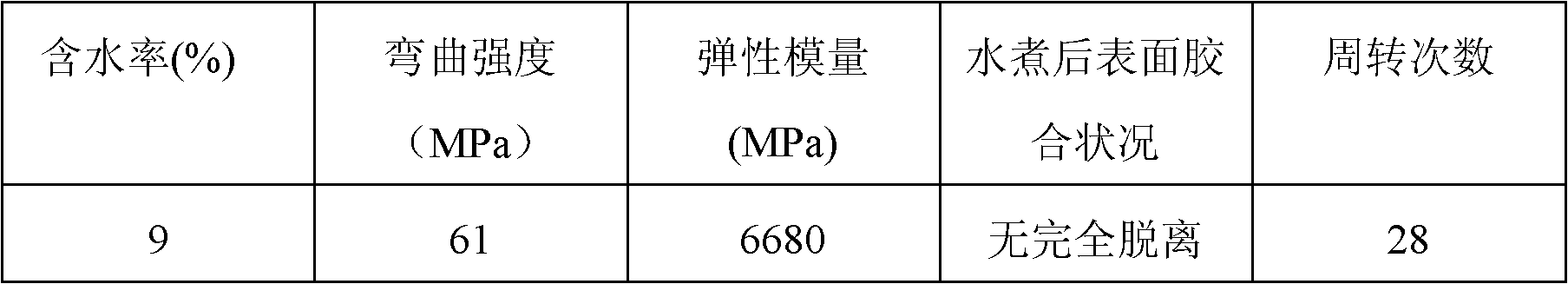

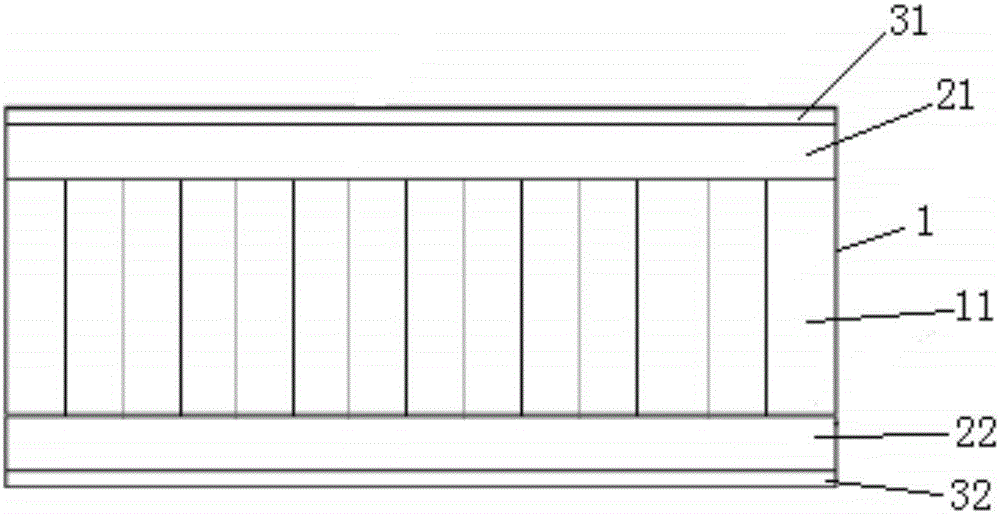

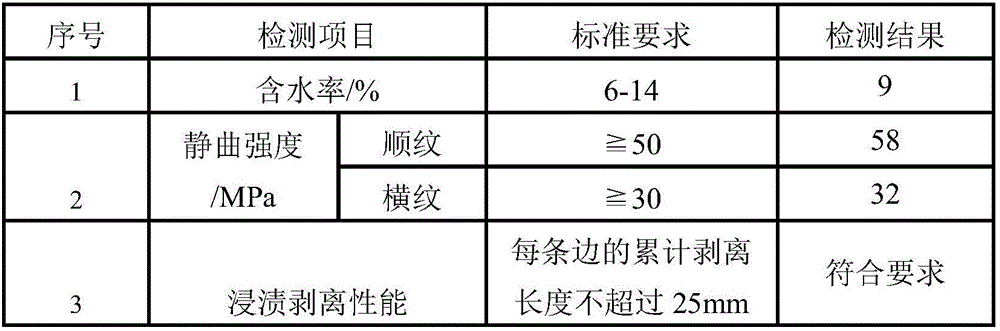

Plastic-coated wooden building template and preparation method thereof

InactiveCN103031948AEasy constructionReduce usageSynthetic resin layered productsWood layered productsPolyolefinFlexural strength

The invention discloses a plastic-coated wooden building template and a preparation method thereof, which relate to a building template and a preparation method thereof and mainly solve the problems that a high-cost performance building template prepared by the current preparation method is low in turnover times and poor in mechanical properties. The preparation method comprises the following steps: firstly, manufacturing a core plate by using a waste template; secondly, manufacturing a polyolefin veneer coated with non-woven fabric; thirdly, gluing double sides of a wood veneer, putting the wood veneer between the polyolefin veneer coated with the non-woven fabric and the core plate, with the same operation for upper and lower surfaces; and finally, pressing. The turnover times of the plastic-coated wooden building template is as high as 30-35 times, which is 10-17% higher than that of the current building template, so that the using cost of the plastic-coated wooden building template is reduced; the plastic-coated wooden building template has the bending strength of 52-55 MPa and an elasticity modulus of 6050-6210 MPa; the plastic-coated wooden building template is high in strength and good in toughness; the preparation method is simple, low in cost and easy to implement, and is applicable to large-scale popularization and application; and the plastic-coated wooden building template has relatively high economic and social benefits and can be applied to the building engineering.

Owner:安徽省崃山建材有限公司

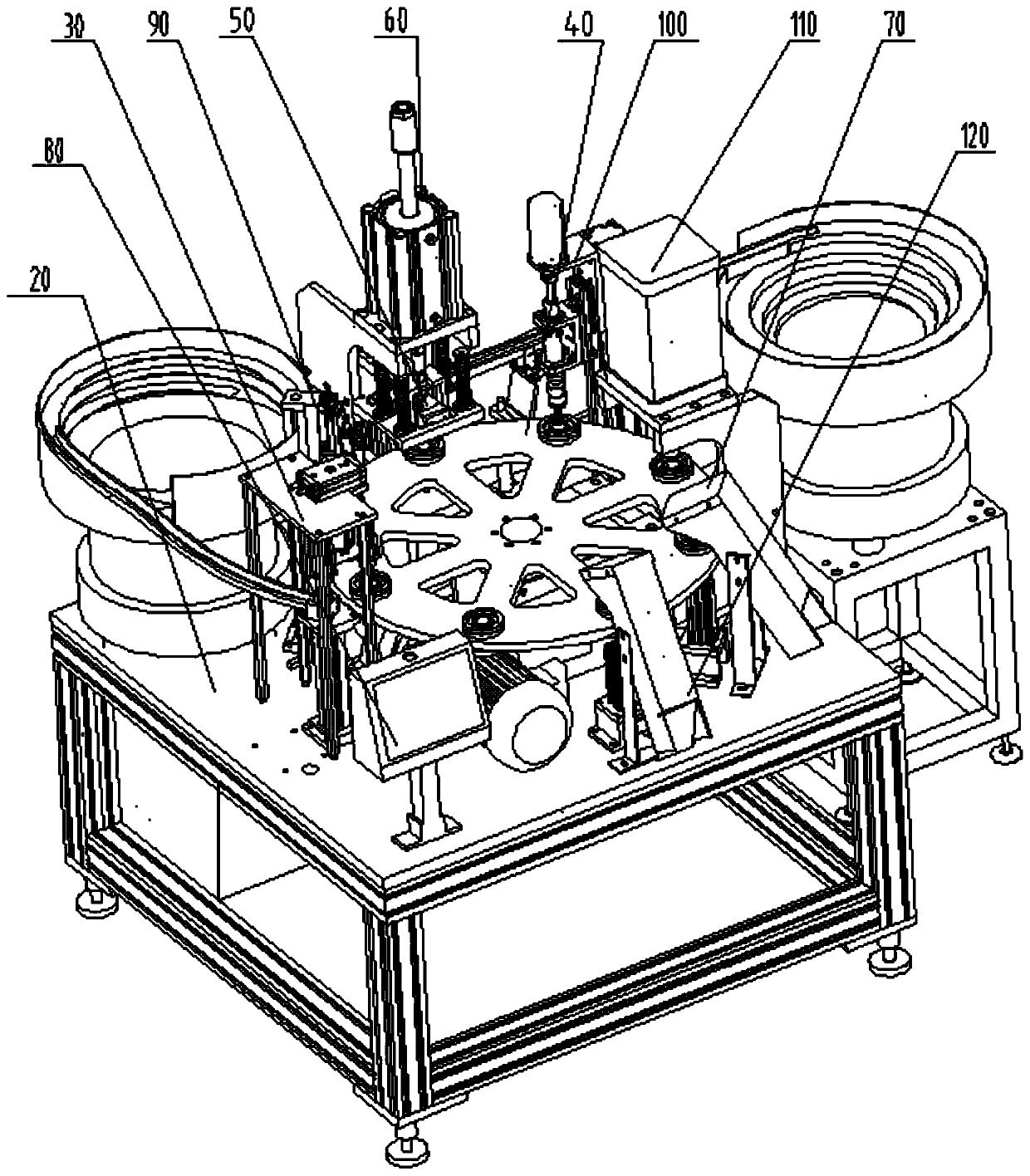

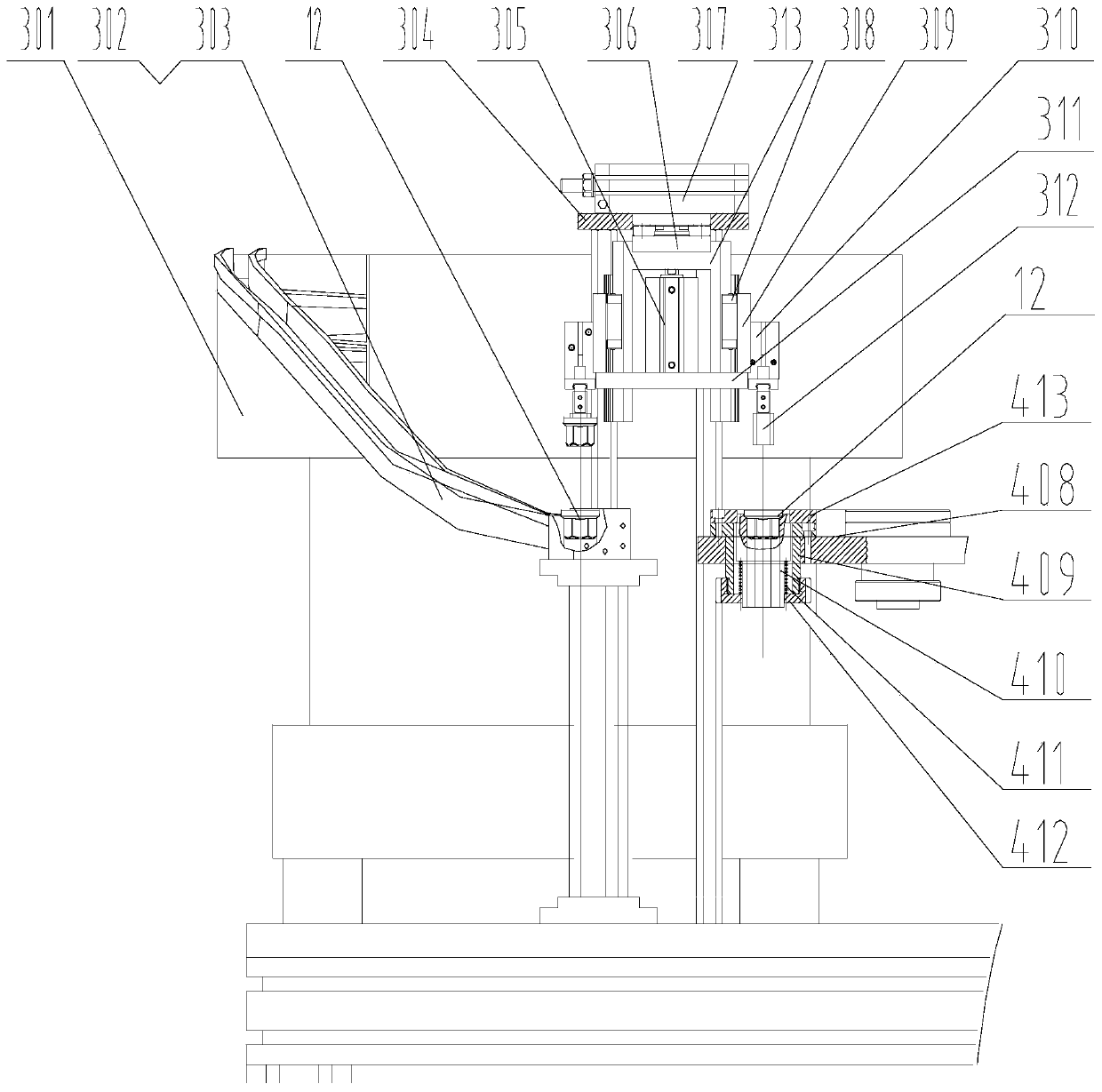

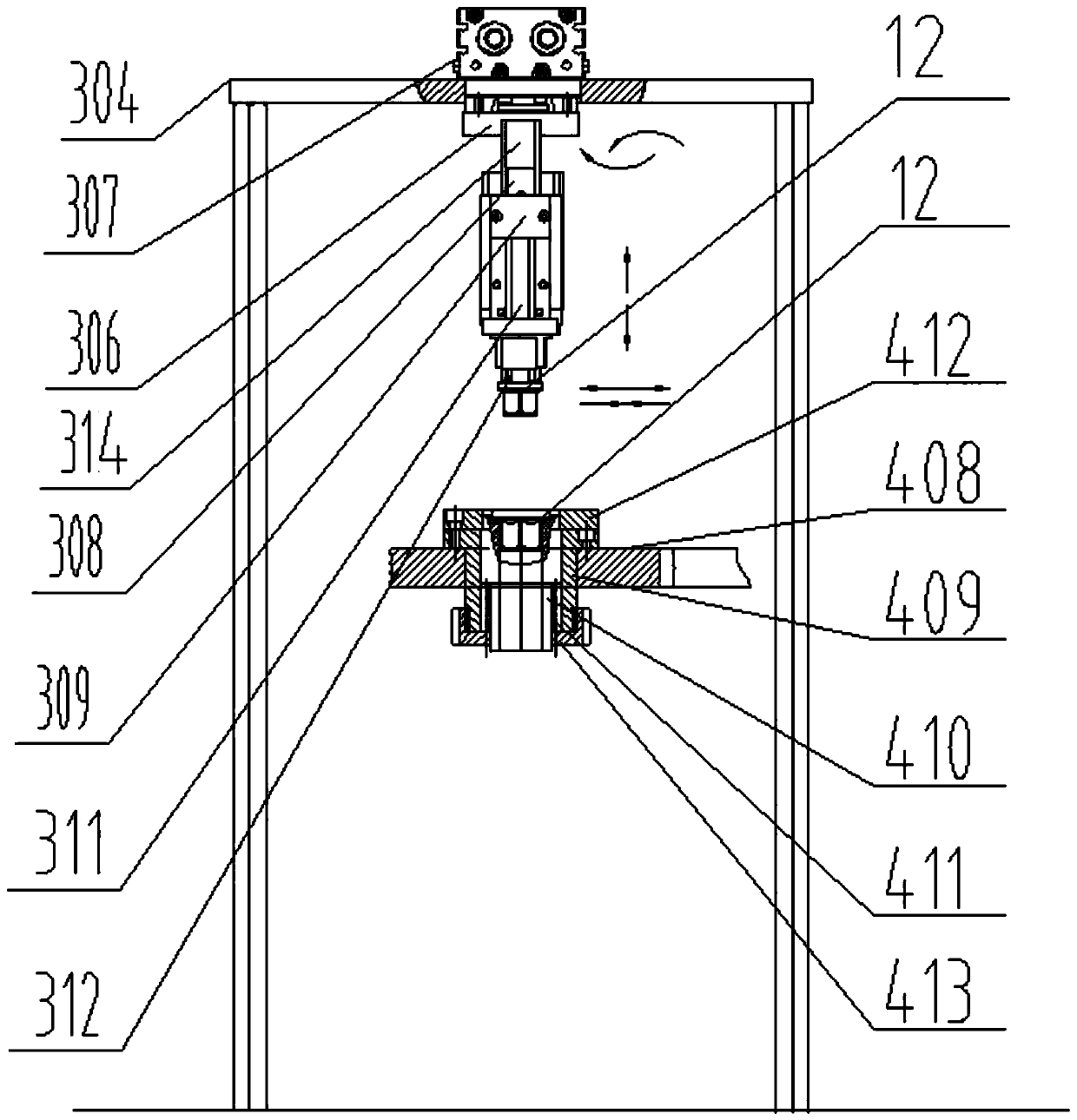

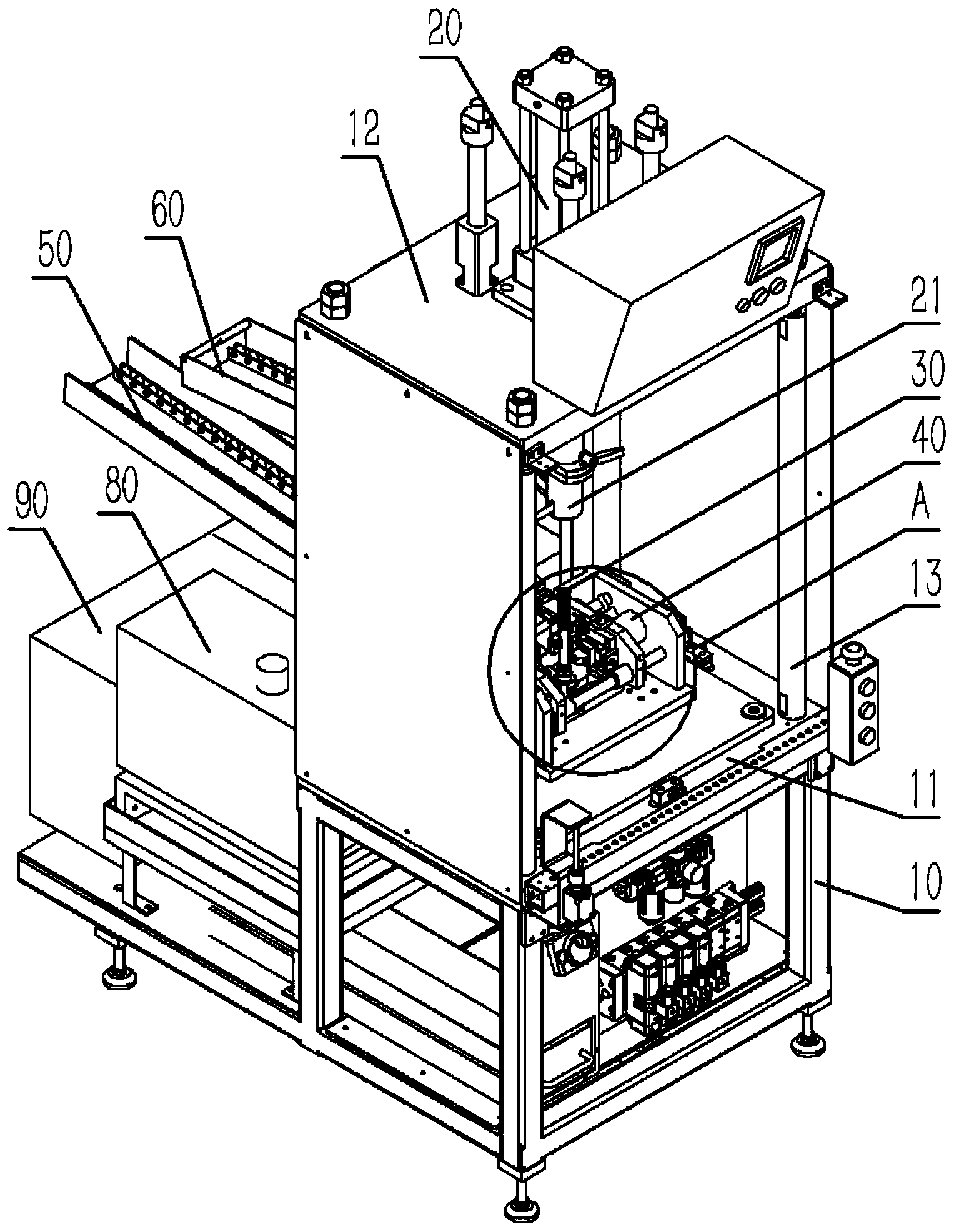

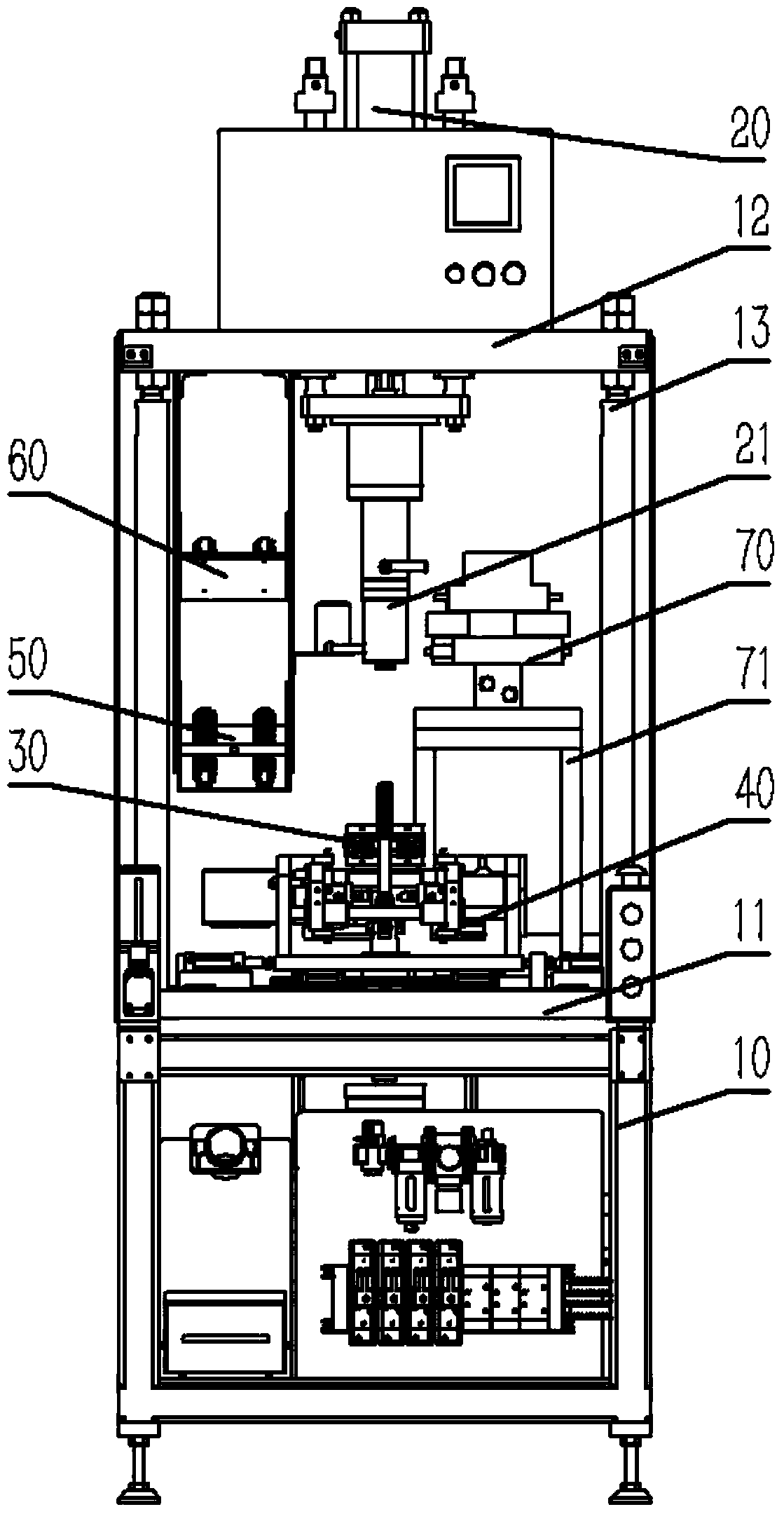

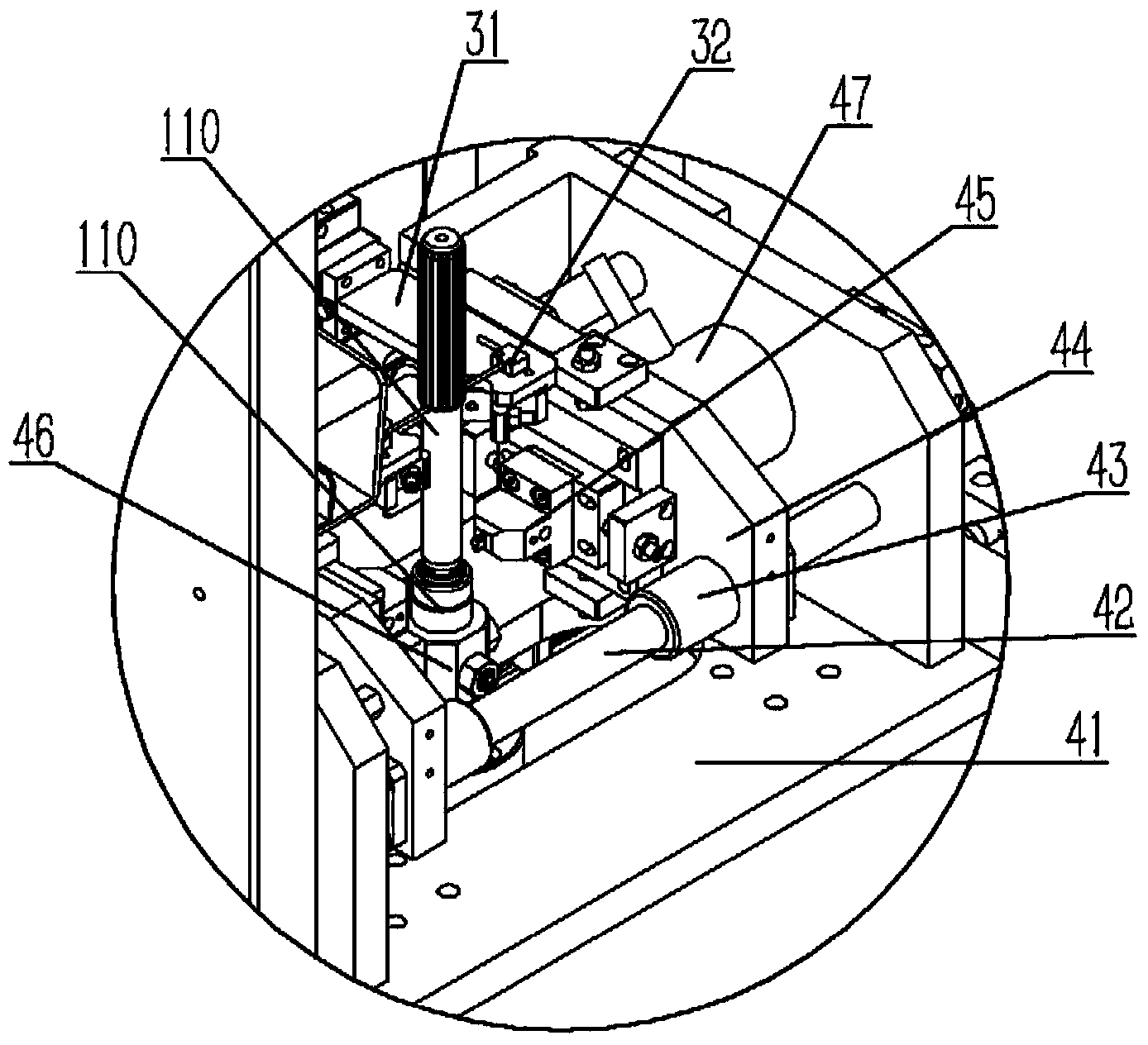

High-precision multi-station nut riveting press

PendingCN109807587ARealize riveting automationIncrease productivityOther manufacturing equipments/toolsMetal working apparatusTurnover timeEngineering

The invention provides a high-precision multi-station nut riveting press. The riveting press is used for nut riveting press. The riveting press comprises a rack, a hexagon nut cover loading device anda multi-station hexagon nut cover indexing positioning device. The rack is used for supporting; the hexagon nut cover loading device is arranged on the rack; the multi-station hexagon nut cover indexing positioning device is connected with the hexagon nut cover loading device and used for bearing hexagon nut covers loaded by the hexagon nut cover loading device. The press achieves automatic production, the circulation time and the circulation cost of different procedures can be reduced, the production period is shortened, production efficiency is improved, manpower input is reduced, and costis reduced.

Owner:宁波长华长盛汽车零部件有限公司

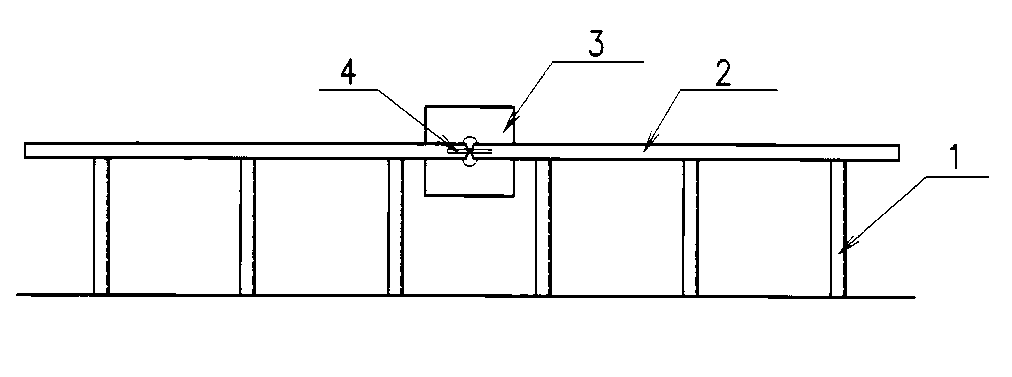

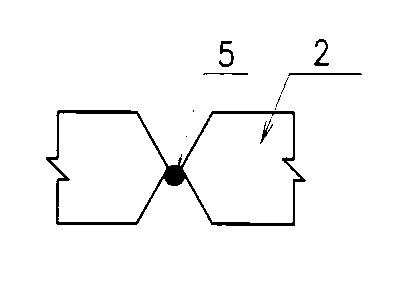

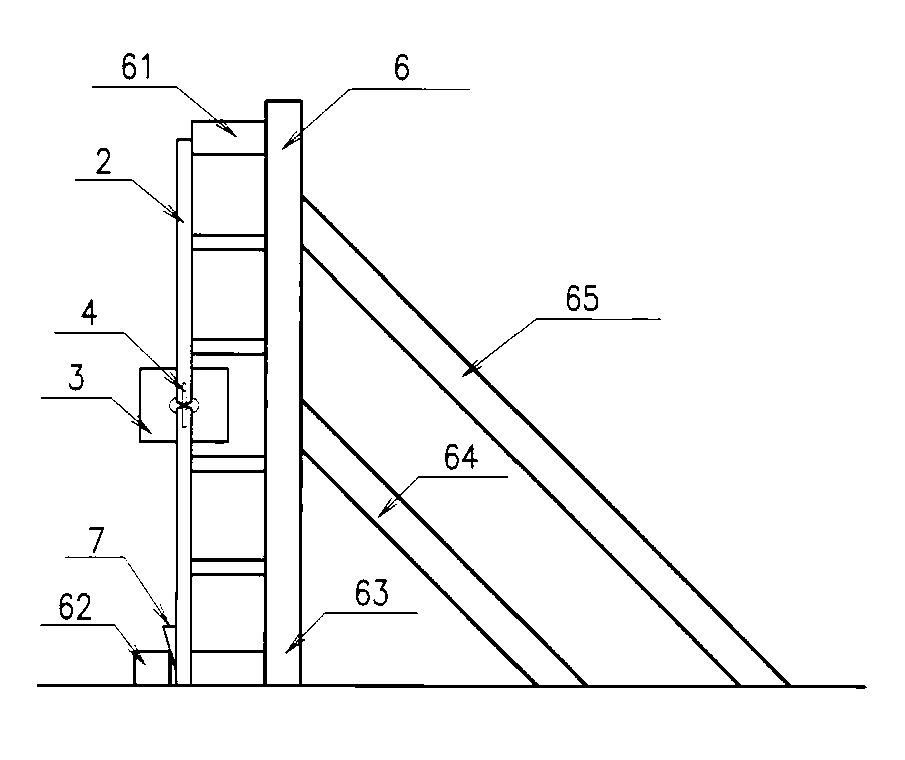

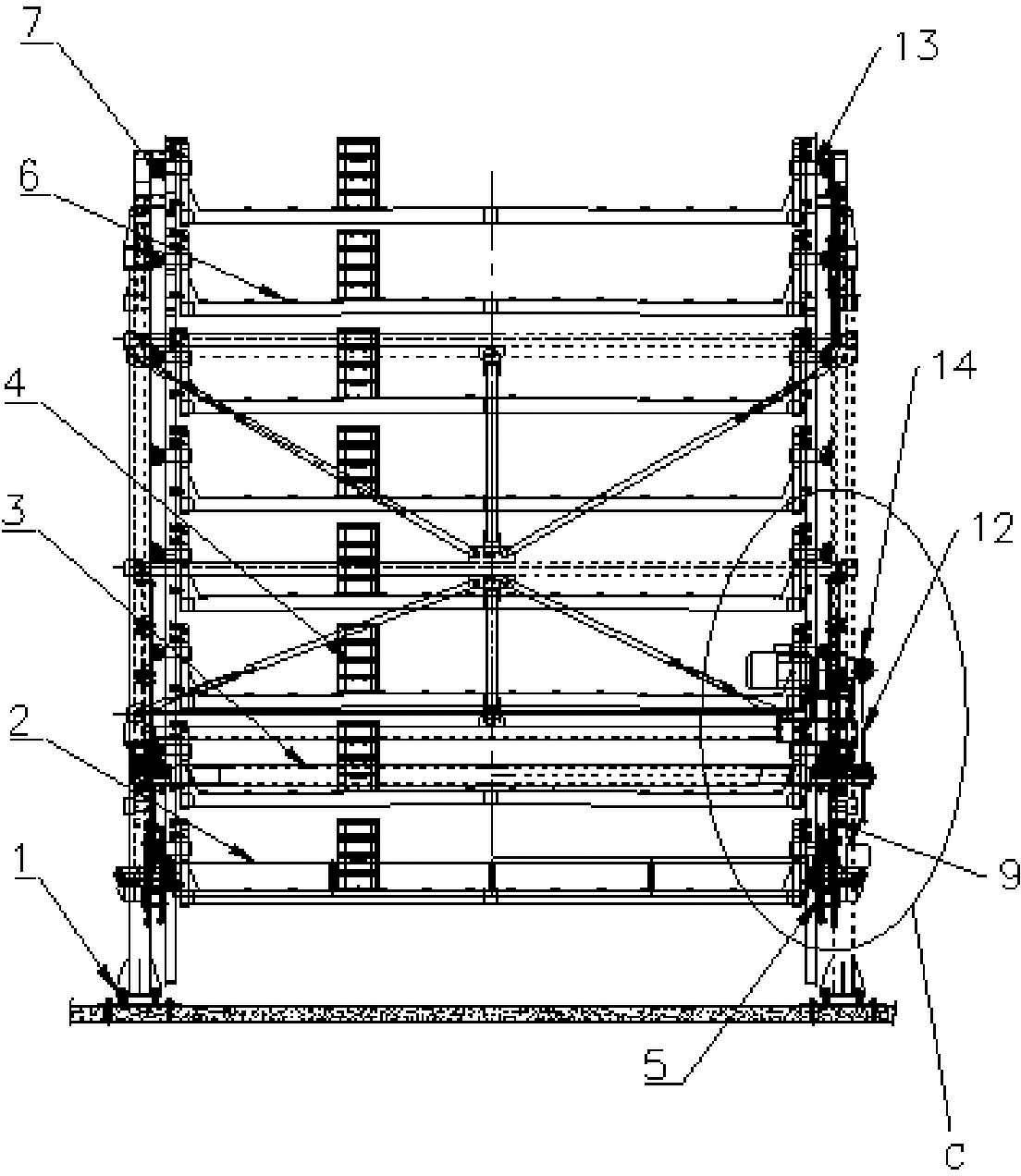

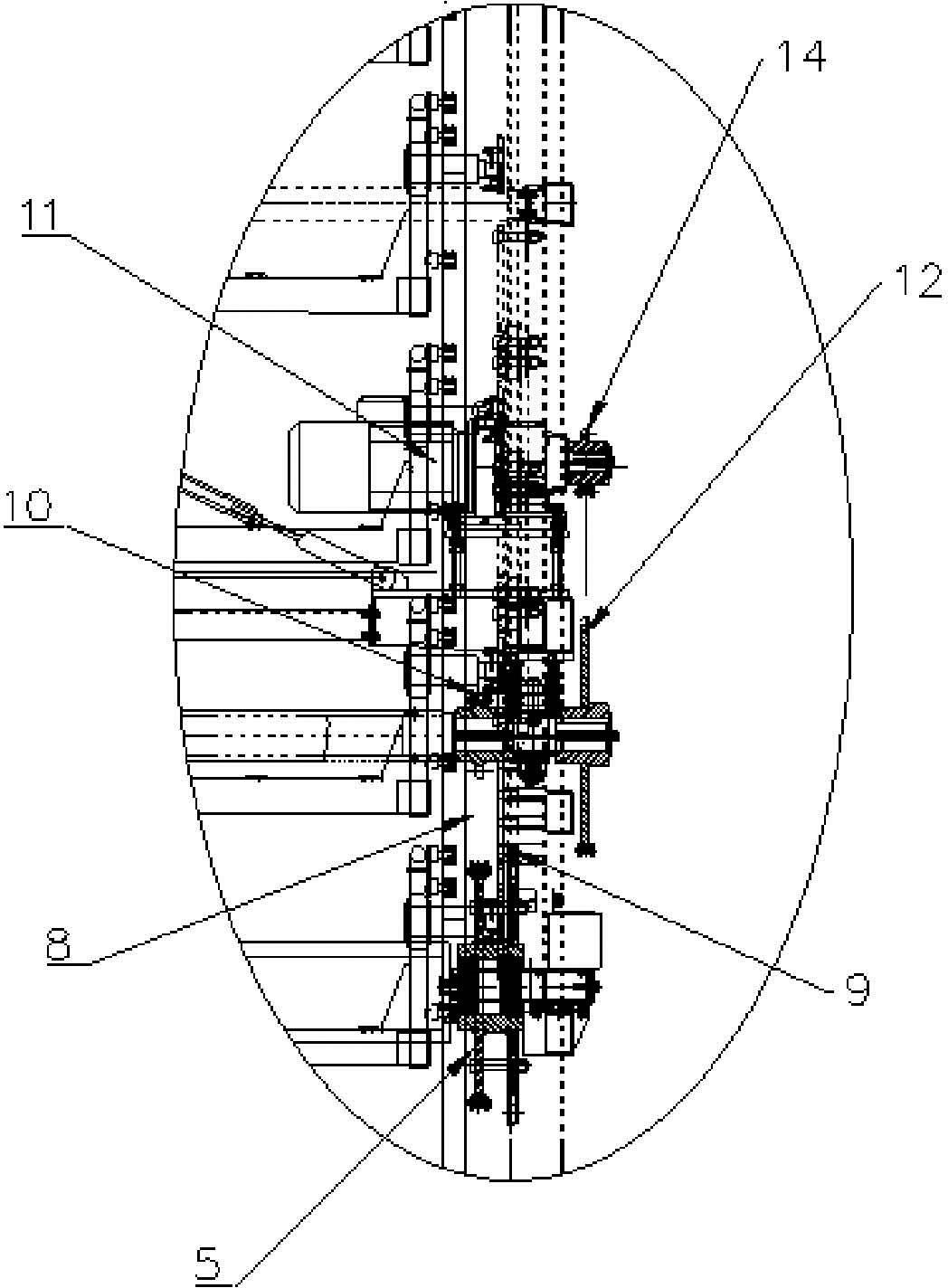

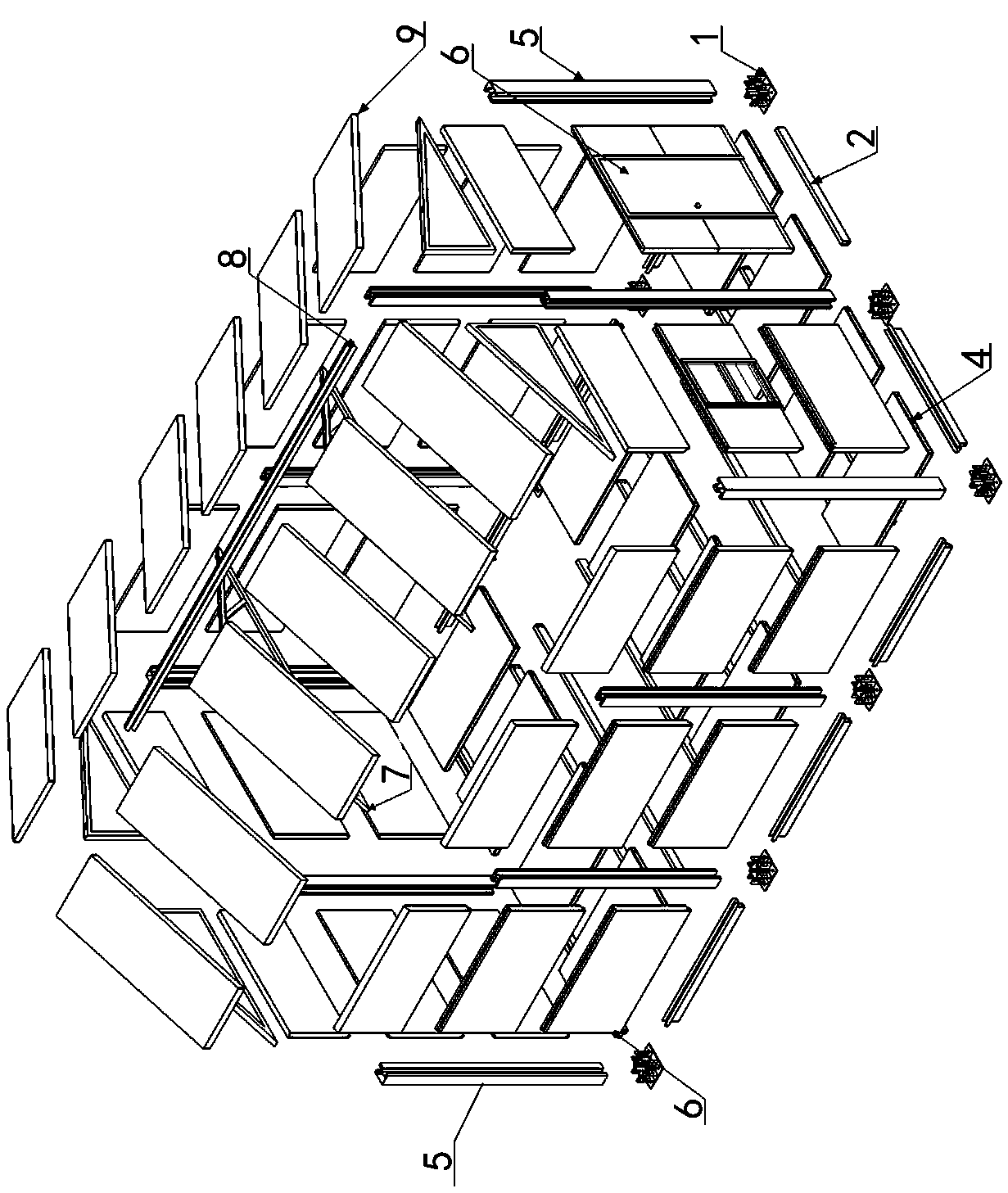

Stereoscopic perpendicular circulating warehouse

InactiveCN102602646AMeet supply needsShort turnaround timeStorage devicesProduction lineTurnover time

The invention relates to the technical field of material warehouses, in particular to a stereoscopic perpendicular circulating warehouse. The stereoscopic perpendicular circulating warehouse comprises a plurality of hanging baskets, a chain, lifting sprockets and a lifting driving mechanism, wherein the hanging baskets are used for carrying material boxes, the chain consists of a plurality of triangular chain plates, and the lifting sprocket and the lifting driving mechanism are mounted on a framework, a chain plate wheel inner rail and a chain plate wheel outer rail are mounted on the framework and form a stereoscopic perpendicular circulating rail, two chain plate wheels of each triangular chain plate are arranged in the stereoscopic perpendicular circulating rail, the lifting driving mechanism is in drive connection with the lifting sprockets, the lifting sprockets are in drive connection with the chain, and the chain drives the hanging baskets and the material boxes to rotate along the stereoscopic perpendicular circulating rail circularly. The stereoscopic perpendicular circulating warehouse can be applied to requirements of conventional warehousing and assembling production line fields, has advantages of high space utilization rate, automatic storage and delivery and energy saving and can meet the requirement of supply of massive spare parts, and turnover time of the spare parts is short, and labor and material resources can be reduced greatly.

Owner:GUANGDONG WEICHUANG WUYANG INTELLIGENT EQUIP CO LTD +1

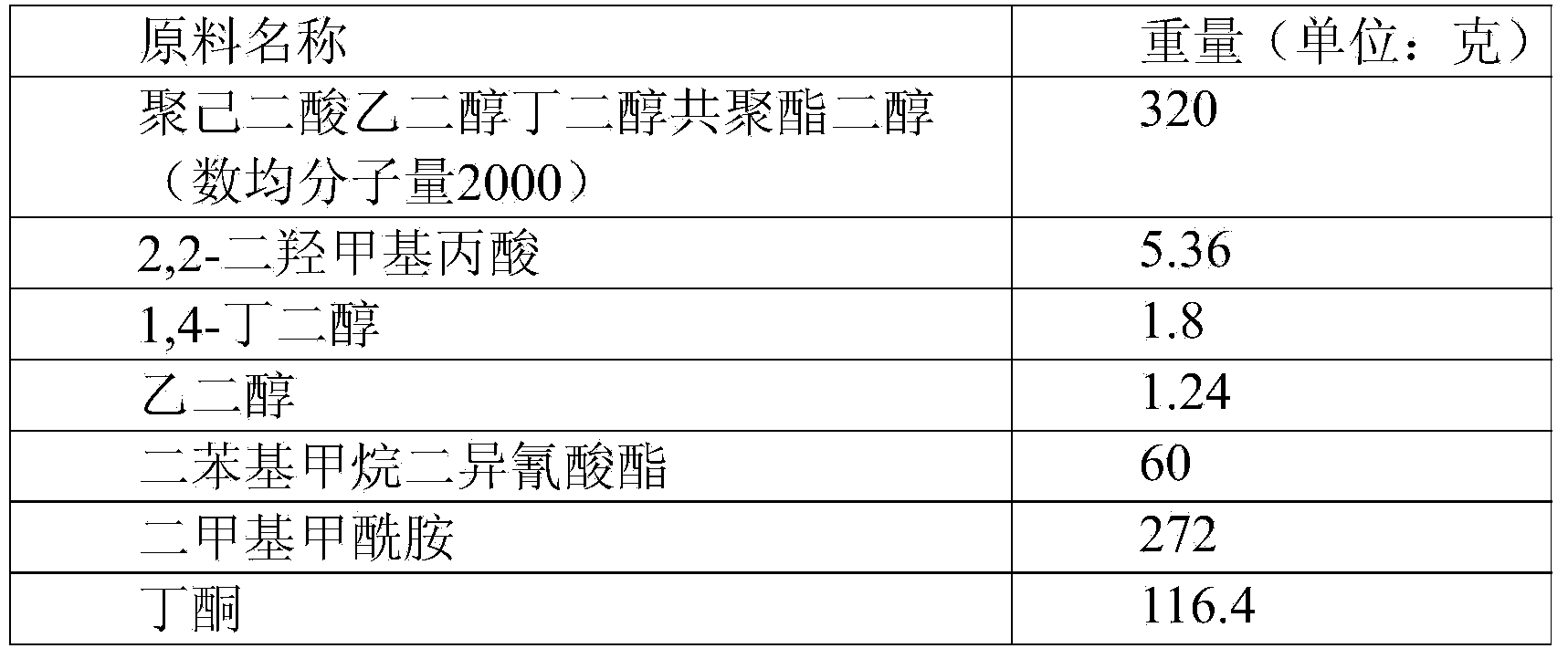

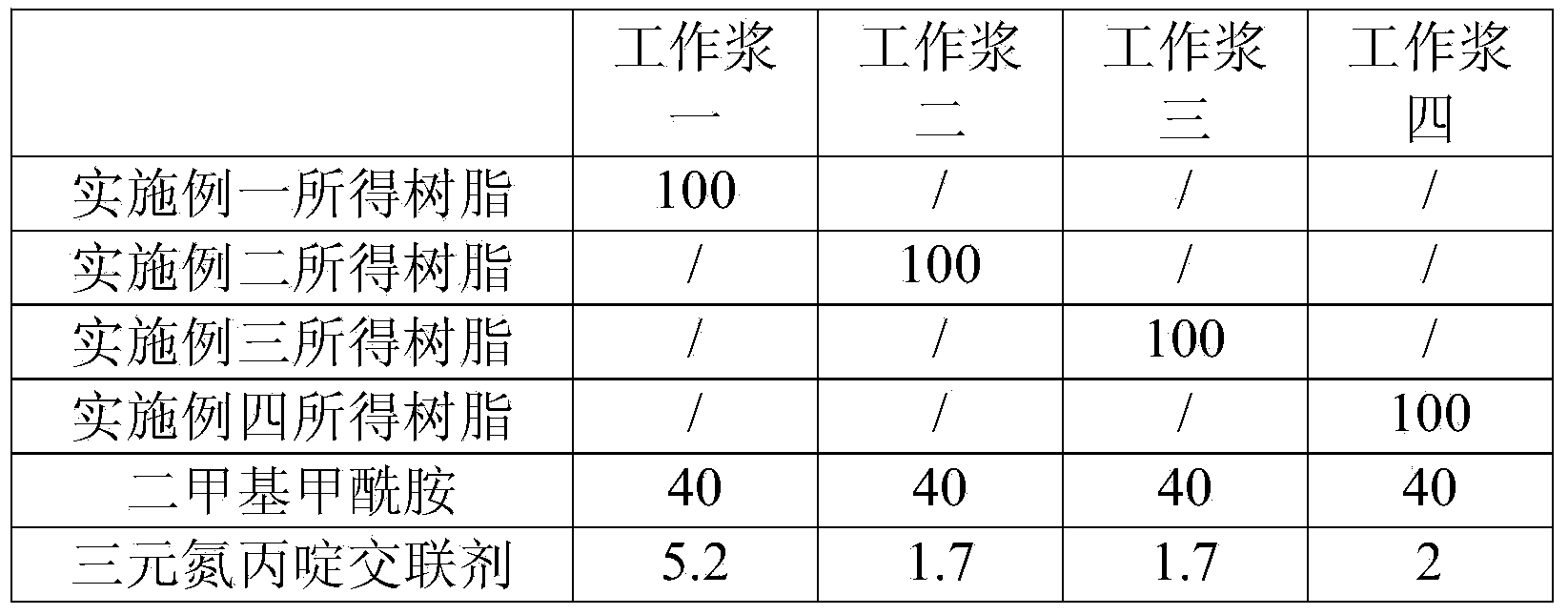

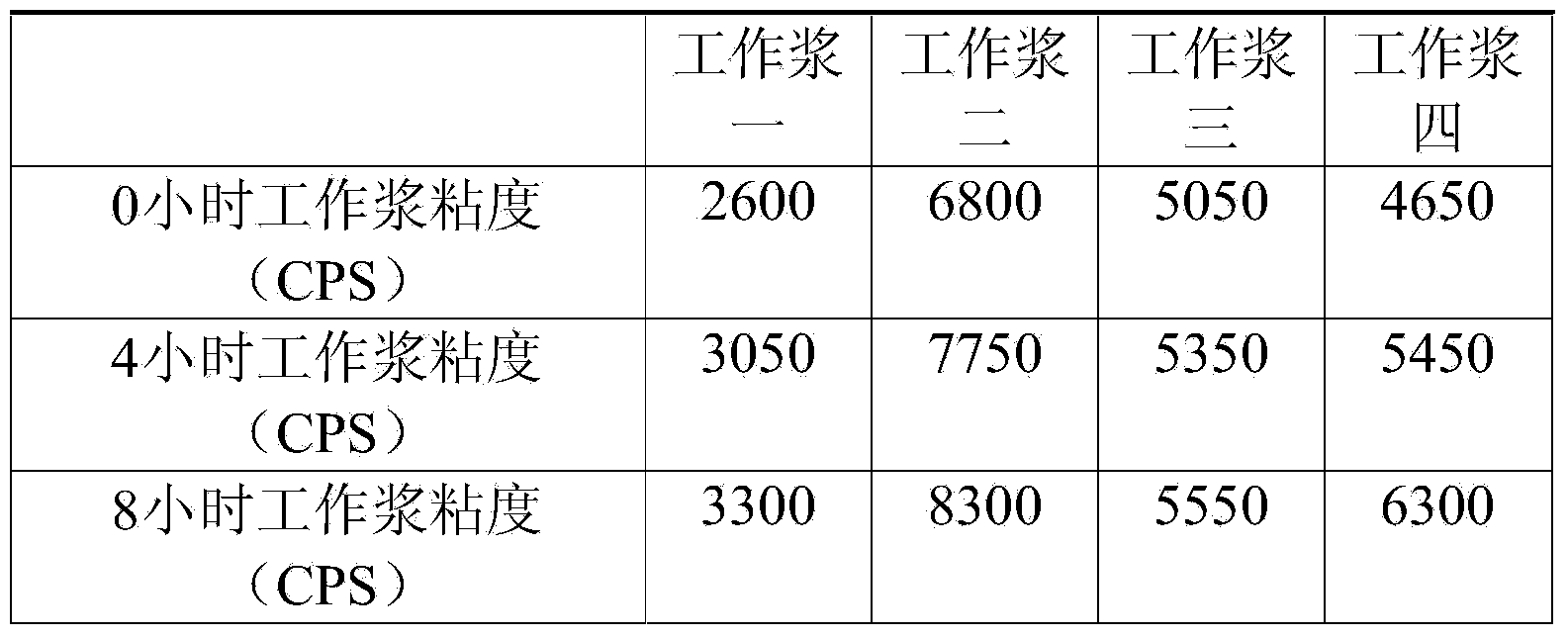

Two-component adhesive layer polyurethane resin for synthetic leather and preparation method of two-component adhesive layer polyurethane resin

The invention provides a using a two-component adhesive layer polyurethane resin for a synthetic leather and a preparation method of the two-component adhesive layer polyurethane resin. The two-component adhesive layer polyurethane resin disclosed by the invention comprises the following raw materials: polyol, chain extenders, diisocyanate and a solvent, wherein the total molar ratio of chain extenders to polyol is (0.5:1)-(3:1); the total molar ratio of diisocyanate to polyol is (1.5:1)-(4:1); the solvent accounts for 29%-71% of the total mass of polyol, chain extenders, diisocyanate and the solvent; and the chain extenders comprise a carboxyl group-containing chain extender and a carboxyl group-free chain extender, wherein the mole of the carboxyl group-containing chain extender accounts for 20%-50% of the total mole of chain extenders. Compared with the prior art, when the two-component adhesive layer polyurethane resin for the synthetic leather is adhered, the low-temperature fast curing can be achieved and thus the energy consumption of the production is reduced and the turnover times and the utilization efficiency of a release paper are both improved.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

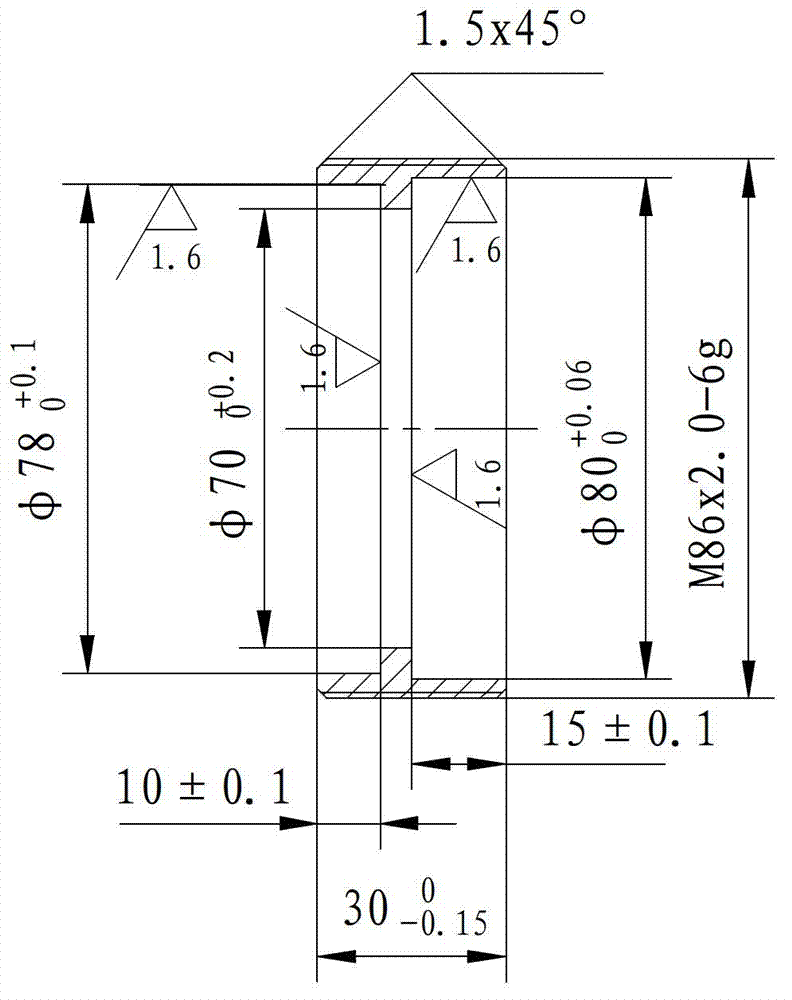

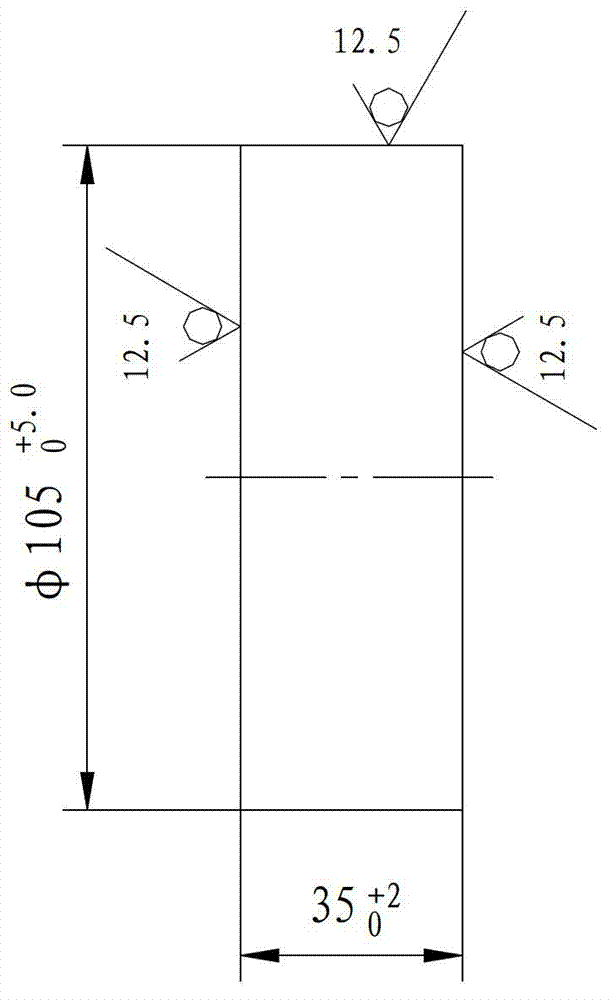

Process for processing external threads of thin-wall threaded sleeve and threaded sleeve turning clamp used for same

ActiveCN102922234AEfficient use ofLower requirementThread cutting machinesHigh volume manufacturingTurnover time

The invention discloses a process for processing external threads of a thin-wall threaded sleeve and a threaded sleeve turning clamp used for the same. The process comprises the steps of: performing rough turning, performing finish turning on an internal positioning hole, and processing the external threads of the threaded sleeve by using the threaded sleeve turning clamp. The threaded sleeve turning clamp comprises a central positioning rod, a locking nut, a hold-down gasket, a positioning reference plate and a three-paw locking disc. According to the process and the threaded sleeve turning clamp provided by the invention, (1) a material is utilized effectively and a blank material is greatly saved, (2) the principle of concentrated steps is adopted, the transfer time of a product is reduced and the discard as useless in a product transfer process is also reduced, so that the material is saved and the product processing efficiency is improved, and (3) the requirements on a cutter and an operator are low; and simultaneously, the process is suitable for large batch production, the clamping is reliable and the processing quality is stable.

Owner:GUIZHOU HANGFEI PRECISION MFG CO LTD

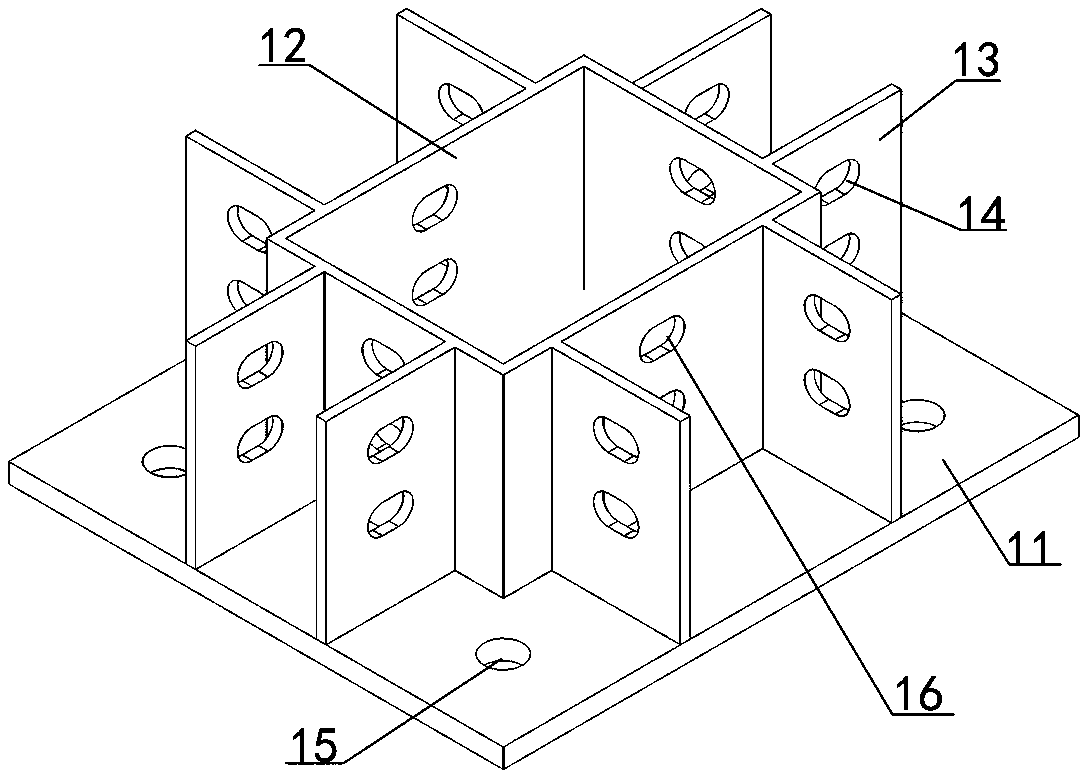

Quick disassembling and assembling type special-shaped column frame plate type support structure system and construction method thereof

PendingCN108978875AReduce weightImprove general performanceBuilding constructionsTurnover timeModular design

The invention relates to a quick disassembling and assembling type special-shaped column frame plate type support structure system and a construction method thereof, the structure system comprises atleast one unit main body structure, the unit main body structure comprises a four-way adjustable connecting support, a beam frame, a composite structure floor, a thin-wall special-shaped column, a unit wall, a lightweight triangular roof truss, a roof ridge clamping groove and a roof panel. The support and the beam frame are mounted according to modular design, modular design processing is performed, at the same time, a corresponding connection node is designed in each node, connection can be performed through a simple bolt, insertion-connection structures between the wall and the beam frame and between the wall and the column are designed, the overall mounting process realizes instrumentalization, no field welding is needed, the mounting saves both time and labor, instrumentalized quick mounting can be realized and the turnover times are high.

Owner:中建集成科技有限公司 +1

Plastic overlaid plywood building template with large turnover number and preparation method thereof

InactiveCN102425295AEasy to demouldReduce use costLaminationLamination apparatusTurnover timeAdhesive

The invention relates to a plastic overlaid plywood building template with a large turnover number and a preparation method thereof, in particular to a building template and a preparation method thereof. Due to the adoption of the plastic overlaid plywood building template with the large turnover number, the technical problems of the present wooden template or the overlaid plywood building template that a mould is difficult to remove and the turnover number is small during the application process can be solved. The plastic overlaid plywood building template with the large turnover number is characterized in that: a layer of polyolefine laminated surface is adhered on the upper surface and the lower surface of the wooden plywood template. The preparation method comprises the following steps that: after polyolefine material is extruded by a vertical-type three-roller plastic sheet machine set to obtain sheets, a layer of non-woven fabric covers the sheet to be extruded again to obtain the polyolefine laminated surface which is covered by the non-woven fabric; and adhesive is smeared onto the non-woven fabric, then the non-woven fabric which is smeared with the adhesive covers the upper surface and the lower surface of the polished wooden polywood to be pressed so as to obtain the plastic overlaid polywood building template with lage turnover number. The surface of the template is free from being adhered by the cement, the turnover times of the template are 25 to 30 times, and the template can be used for construction engineering.

Owner:卜凡华

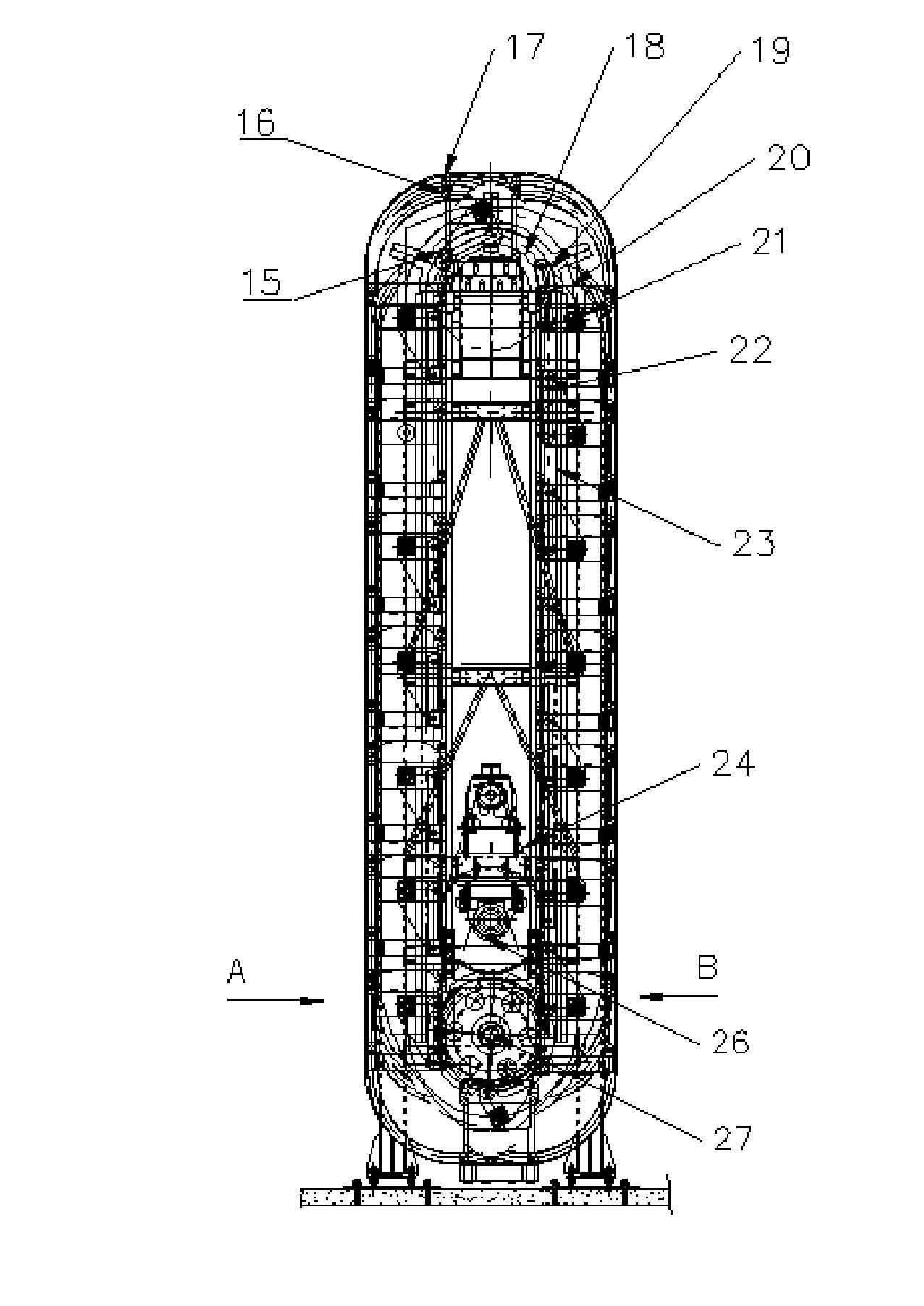

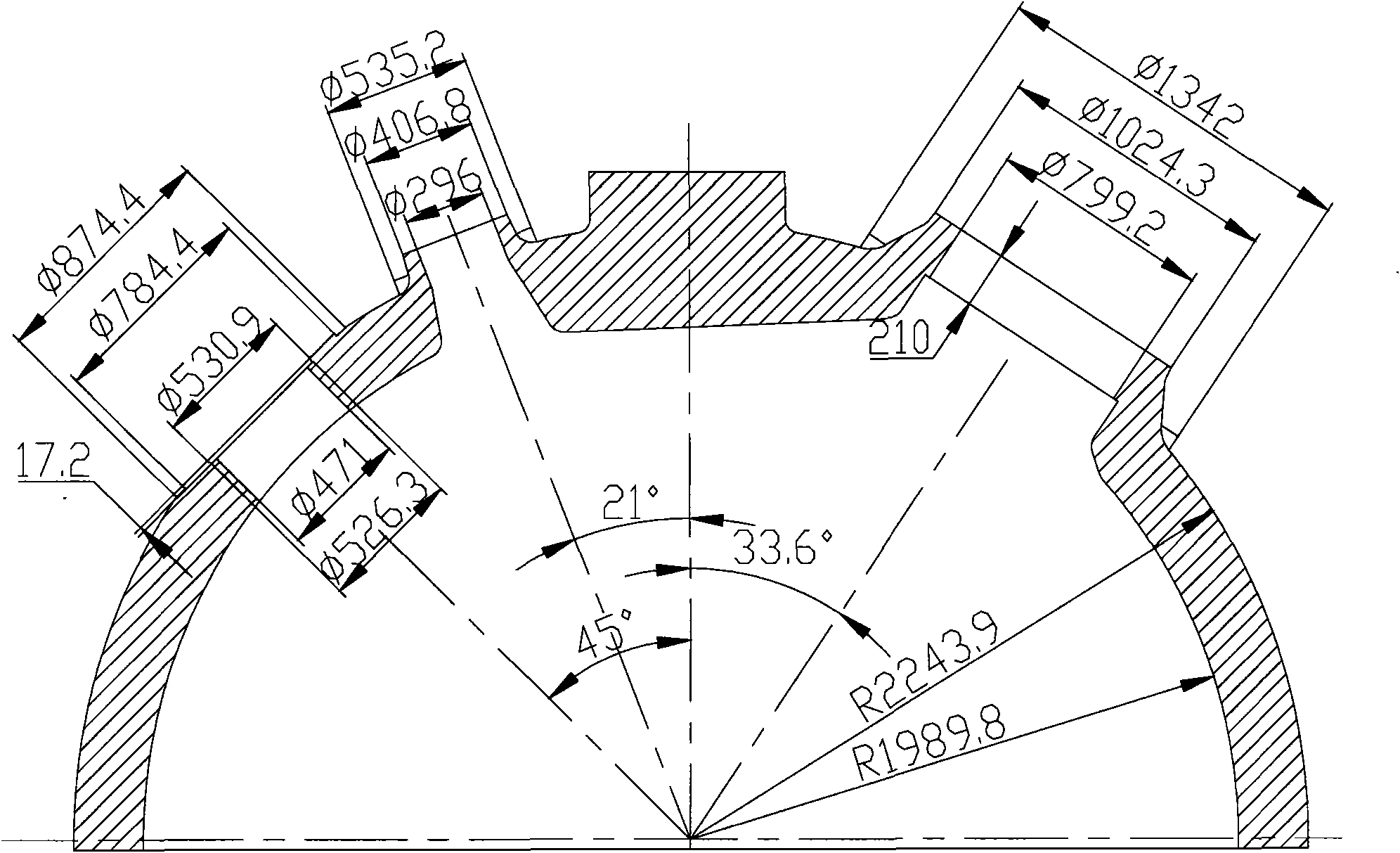

Production method for water chamber head of nuclear power equipment

ActiveCN101920452AGuaranteed machining accuracyReduce turnaround timeNuclear energy generationOther manufacturing equipments/toolsNumerical controlTurnover time

The invention discloses a method for producing a water chamber head of nuclear power equipment, a cylindrical blank work-piece is processed into a water chamber head with a plurality of inclined pipe orifices by adopting a numerical control position changer matching with a numerical control boring-milling machine in the following steps of: firstly, drawing lines; secondly, carrying out rough processing: a, clamping the work-piece; b, rotating and / or turning a working table top of the numerical control position changer to enable the inclined pipe orifices to be processed to locate at a horizontal position; and roughly processing the inner circle surfaces, the outer circle surfaces and the end surfaces of the inclined pipe orifices and related curved surfaces around the pipe orifices; c, rotating and / or turning the working table top of the position changer to another station for roughly processing the inclined pipe orifice at the another station; thirdly, detecting flaws; and fourthly, finely processing. The water chamber head with the plurality of inclined pipe orifices is processed by adopting the numerical control position changer, the inner circular surfaces, the outer circular surfaces and complicated related curved surfaces of the pipe orifices in the water chamber head can be accurately processed, the processing precision of parts is guaranteed, the unnecessary turnaroundtime of the part in the whole processing process is decreased, and the production cycle is greatly reduced.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

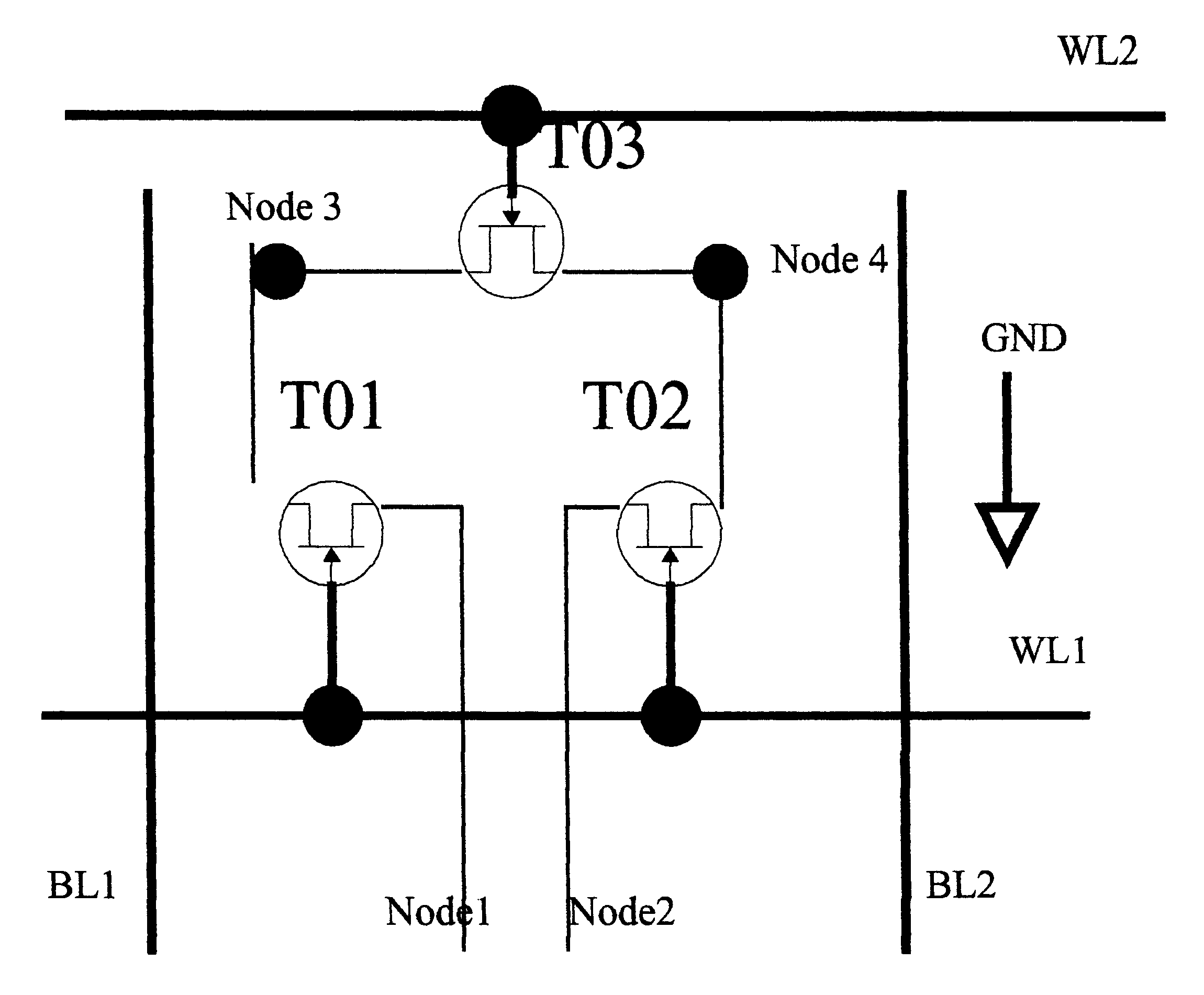

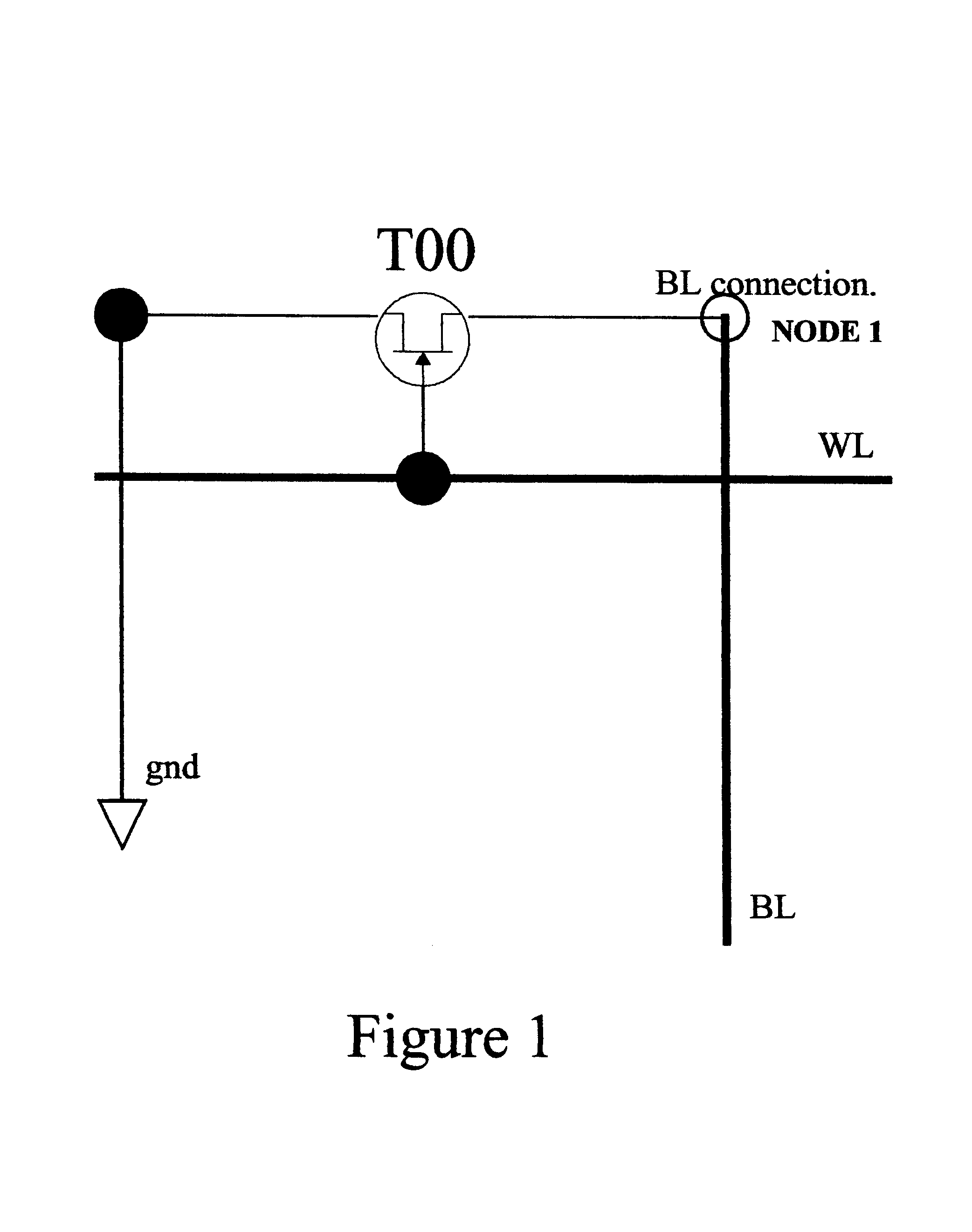

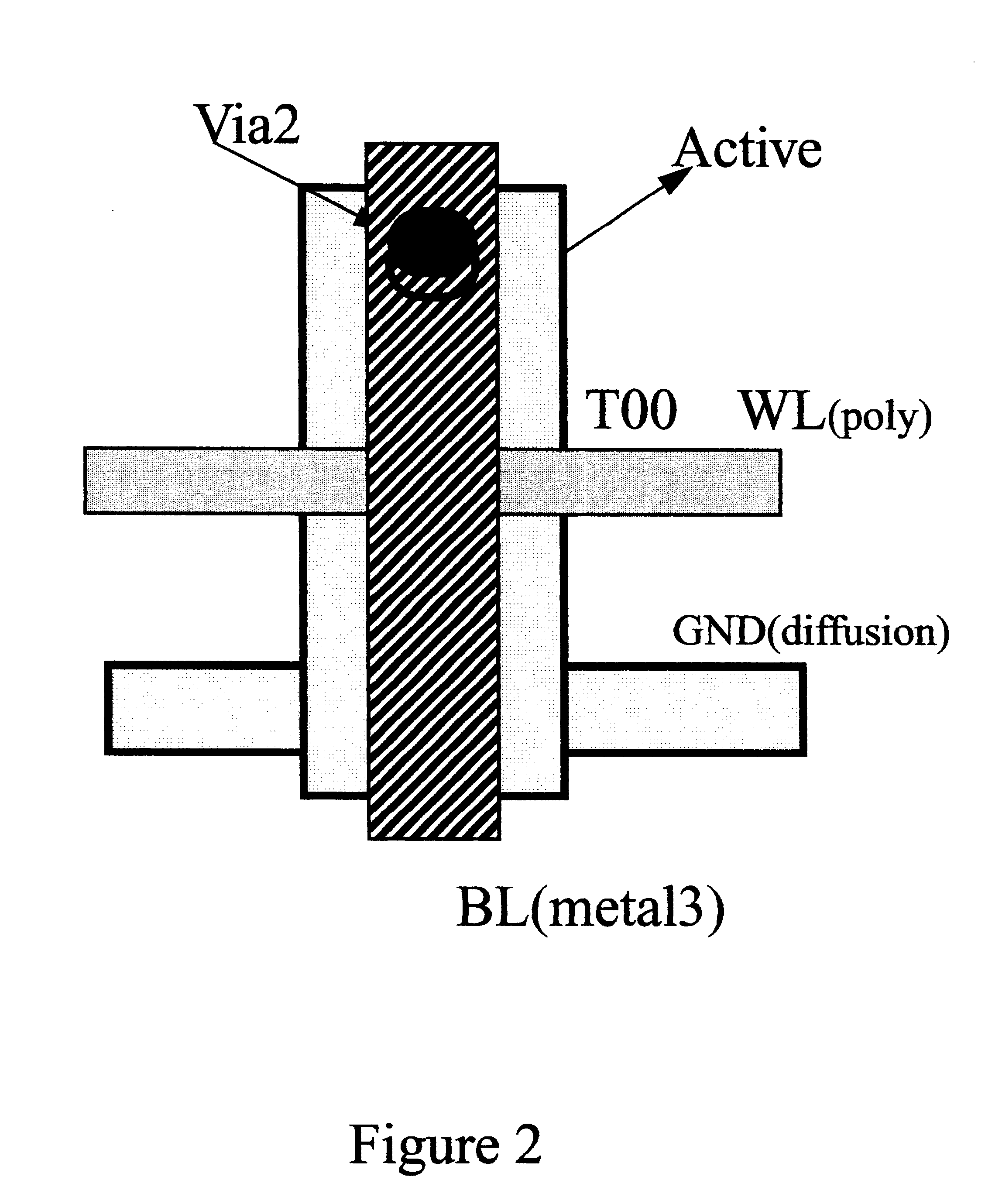

High bit density, high speed, via and metal programmable read only memory core cell architecture

InactiveUS6556468B2Increase bit densityFaster turn around timeMemory loss protectionElectric analogue storesBit lineProgrammable read-only memory

A high bit density, high speed, via and metal BE type programmable ROM core cell architecture for storing large amounts of non-volatile data and having a relatively fast turn around time is provided. The ROM core cell may include memory cells organized in rows and columns where each of the memory cells includes three transistors and two bit lines. The arrangement between the three transistors and two bit lines may be such that each of the memory cells is capable of storing four bits of data.

Owner:STMICROELECTRONICS LTD

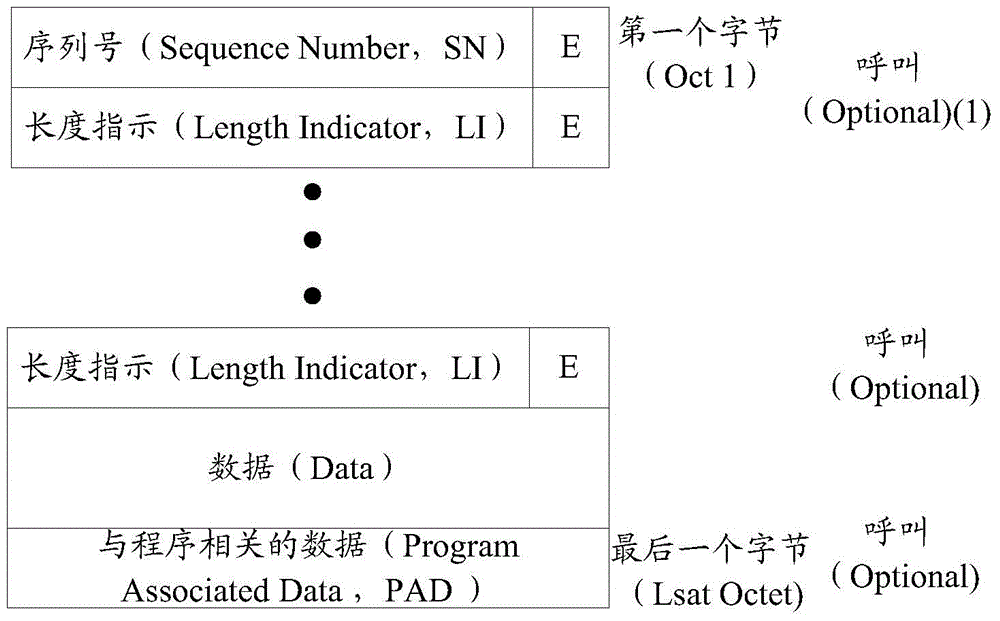

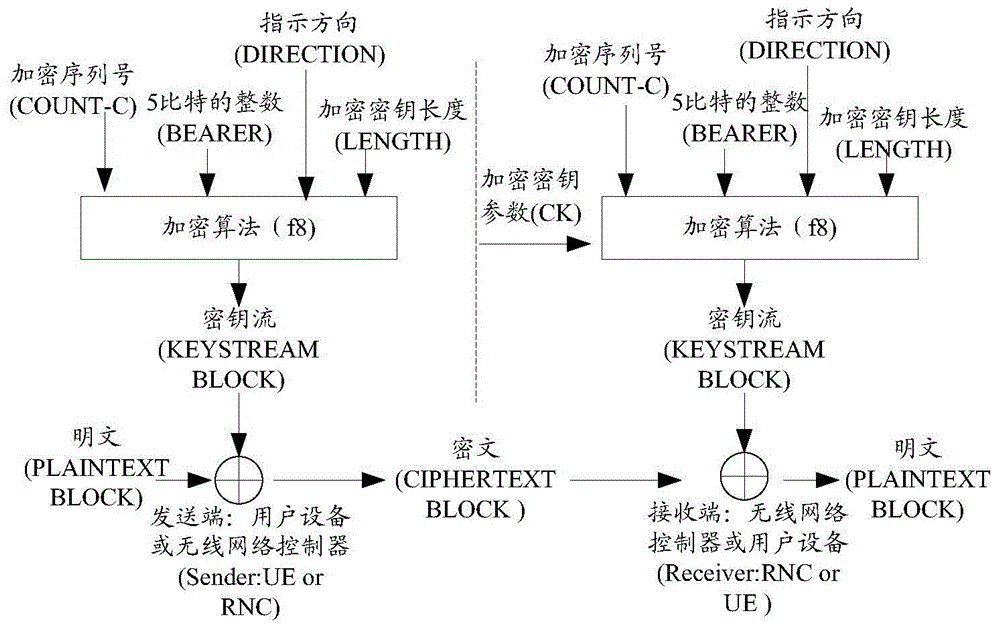

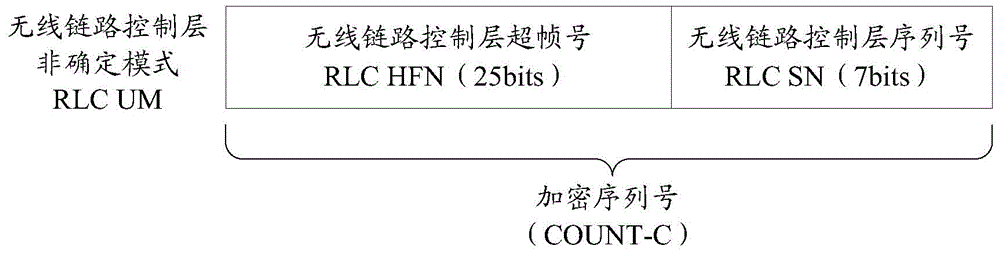

Data transmission method and device

The invention relates to a data transmission method and device. The data transmission method and device are used for achieving that a transmitting terminal and a receiving terminal can still maintain consistency of superframe numbers of data packages with the same serial number under the condition that multiple data packages are lost continuously in the RLC UM data transmission process, and then the problem of encryption and decryption exceptions caused by the continuous loss of the multiple data packages in the data transmission process is solved, the follow-up voice encryption and decryption processes can be normally conducted, and the quality of user voice is improved. The data transmission method includes the steps that the transmitting terminal determines data packages to be transmitted, wherein the data packages carry the serial numbers of the data packages and the number of turnover times corresponding to the serial numbers of the data packages, and the number of turnover times is used for representing the number of use times of the serial numbers; the transmitting terminal transmits the data packages to the receiving terminal.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Bolt component pressfit riveting machine

InactiveCN103612102AReduce turnaround timeFast assemblyMetal working apparatusTurnover timeEngineering

The invention discloses a bolt component pressfit riveting machine. A workbench is arranged on a rack, four support columns are fixed on the workbench, a top plate is fixed at the top ends of the four columns, an oil cylinder is fixed on the top plate, a press-fitting head is fixed on a piston rod of the oil cylinder, a riveting mechanism is fixed on the workbench and below the press-fitting head, and a clamping mechanism is arranged above the riveting mechanism and fixed on the rack. A feeding slide inclining frontwards and downwards is fixed on the rack on the right side of the riveting mechanism, and a waste slide inclining frontwards and upwards is arranged above the feeding slide and fixed on the rack. A hydraulic valve fixing support is fixed on the workbench on the left side of the riveting mechanism, and a hydraulic valve is fixed on the hydraulic valve fixing support. Functions of a pressfit machine and a riveting machine are realized on the same equipment, and quick linking of workpiece pressfit and riveting is completed, so that turnover time of workpieces between the pressfit machine and the riveting machine as well as part of time for feeding and taking the workpieces are saved, and production efficiency is improved.

Owner:湖州奇奇机电科技有限公司

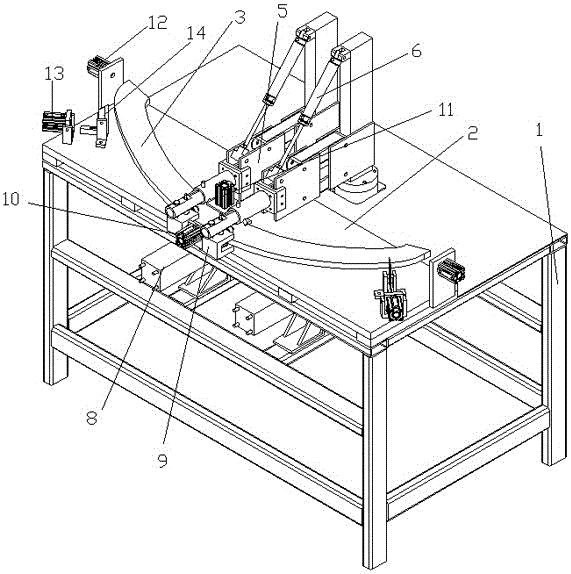

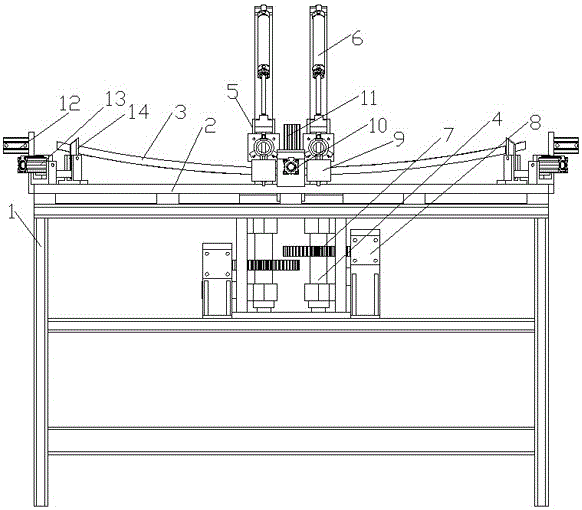

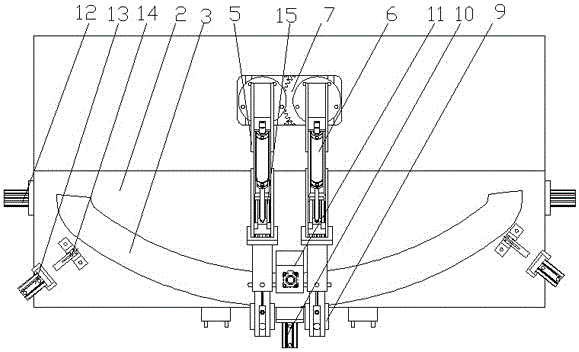

Automotive glass clamping strip bending device and forming method thereof

The invention relates to an automotive glass clamping strip bending device and a forming method thereof. The automotive glass clamping strip bending device comprises a rack, wherein a work table is arranged on the rack, and a bending mold and an end pressing cylinder are arranged on the work table; two rotating shafts with opposite rotating directions are symmetrically arranged on the rack, and a gear is arranged at the lower half part of each rotating shaft; each rotating shaft is rotationally connected with the rack, and an oil cylinder is arranged in the rack; a rack meshed with the gear is arranged at the end part of a piston rod of the oil cylinder, and a rotating arm is arranged at the upper part of each rotating shaft; the back of the rotating arm is rotationally connected with each rotating shaft, and the rotating arm is positioned above the bending mold; the front of the rotating arm is connected with each rotating shaft through a lifting cylinder, and the lifting cylinder is connected with the upper end of the rotating arm; a cylinder rod of the lifting cylinder is connected with the front of the rotating arm, and a telescopic cylinder is arranged on the rotating arm; and the tail end of the cylinder rod of the telescopic cylinder is positioned at the front side of the bending mold and is provided with a bending roller. The automotive glass clamping strip bending device and the forming method thereof provided by the invention have the advantages that the working procedure numberof forming of the automotive glass clamping strip is reduced, the time required in the product forming working procedure is shortened, and the turnover time between the working procedures is shortened.

Owner:FUJIAN FUYAO AUTOMOTIVE TRIM SYST CO LTD

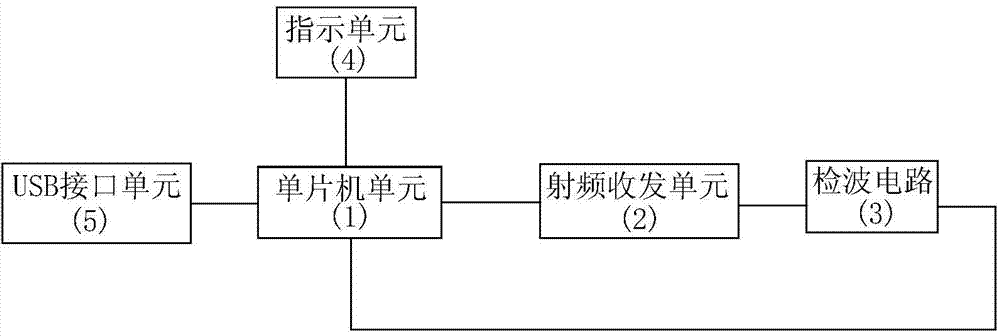

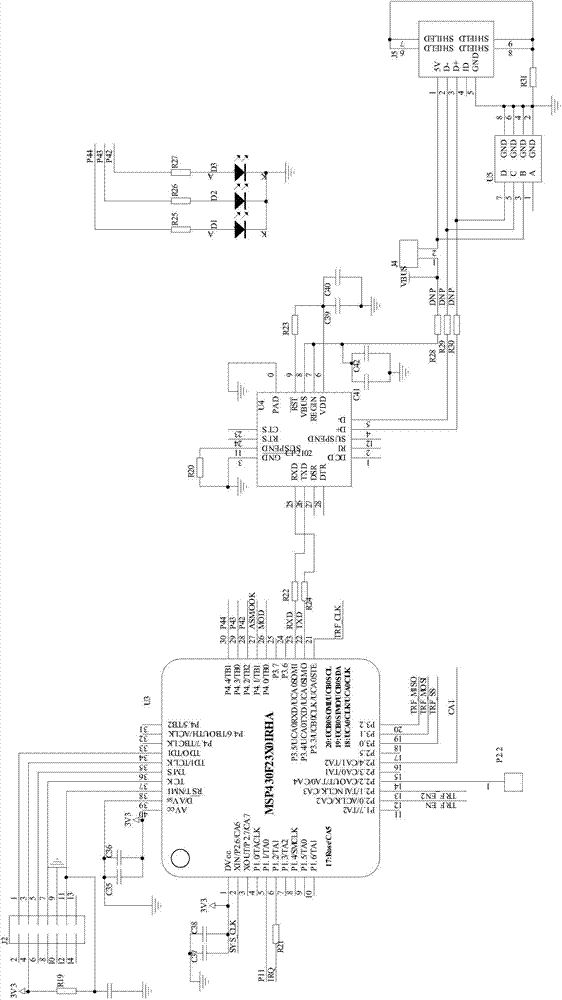

Radio frequency card detection device and radio frequency card detection method thereof

The invention relates to a radio frequency card detection device and a radio frequency card detection method thereof. The radio frequency card detection device comprises a single-chip microcomputer unit, a radio frequency receiving and transmitting unit and a detector circuit, the single-chip microcomputer unit is provided with a built-in comparator and connected with the radio frequency receiving and transmitting unit, an output end of the radio frequency receiving and transmitting unit is connected with an input end of the detector circuit, and an output end of the detector circuit is connected with an input end of the built-in comparator of the single-chip microcomputer unit. The radio frequency card detection method is characterized in that within the same starting time of the radio frequency receiving and transmitting unit, processing is performed by the aid of the detector circuit, the comparator has level turnover time, the level turnover time of a card approaching a card reader is different from that without a card approaching the card reader, whether the card approaches the card reader or not can be judged by judging the size of the level turnover time, the radio frequency card is detected, and the whole card reading process is started when the card approaches the card reader. The radio frequency card detection device is simple in structure and low in cost, fewer components are used, card searching power consumption is greatly reduced, spurious triggering caused by influence of environmental factors can be avoided, and reliability is improved.

Owner:杭州绿鲸科技有限公司

Plastic-covered plywood building formwork and preparation method thereof

InactiveCN106320695AReduce pollutionIncreased durabilitySynthetic resin layered productsStarch adhesivesTurnover timeThermal expansion

The invention relates to a plastic-covered plywood building formwork. The building formwork comprises an upper high-polymer laminating layer, an upper veneer layer, a plywood core layer, a lower veneer layer and a lower high-polymer laminating layer sequentially from top to bottom, and the thickness ratio of the upper high-polymer laminating layer, the upper veneer layer, the plywood core layer, the lower veneer layer and the lower high-polymer laminating layer is (0.2-0.6):(1.8-2.2):(9.2-10.8):(1.8-2.2):(0.2-0.6). The plywood core layer in the plywood building formwork adopts a vertical structure and is high in strength and good in toughness, and use number of building formwork supports can be reduced; the building formwork is easy to demold, not stick to concrete and is weather-resistant, anti-corrosion and high in durability, so that construction is convenient, and the project quality is guaranteed; the turnover time is 3-5 times that of traditional building formworks; the thermal expansion and cold contraction ratio is close to that of wood, the thermal conductivity coefficient is small, winter construction insulation is facilitated; the building formwork is good in water resistance and water-impermeable, and the condition that the building formwork is affected with damp and deforms with water in the concrete curing process is avoided.

Owner:CHINA SHANXI SIJIAN GRP

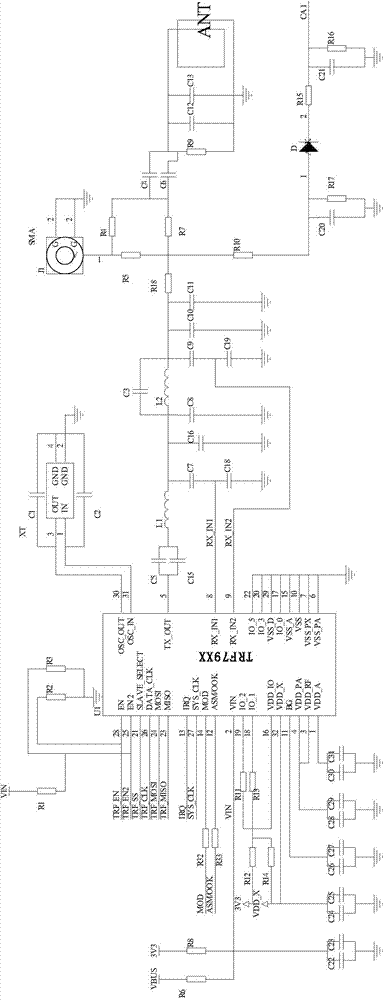

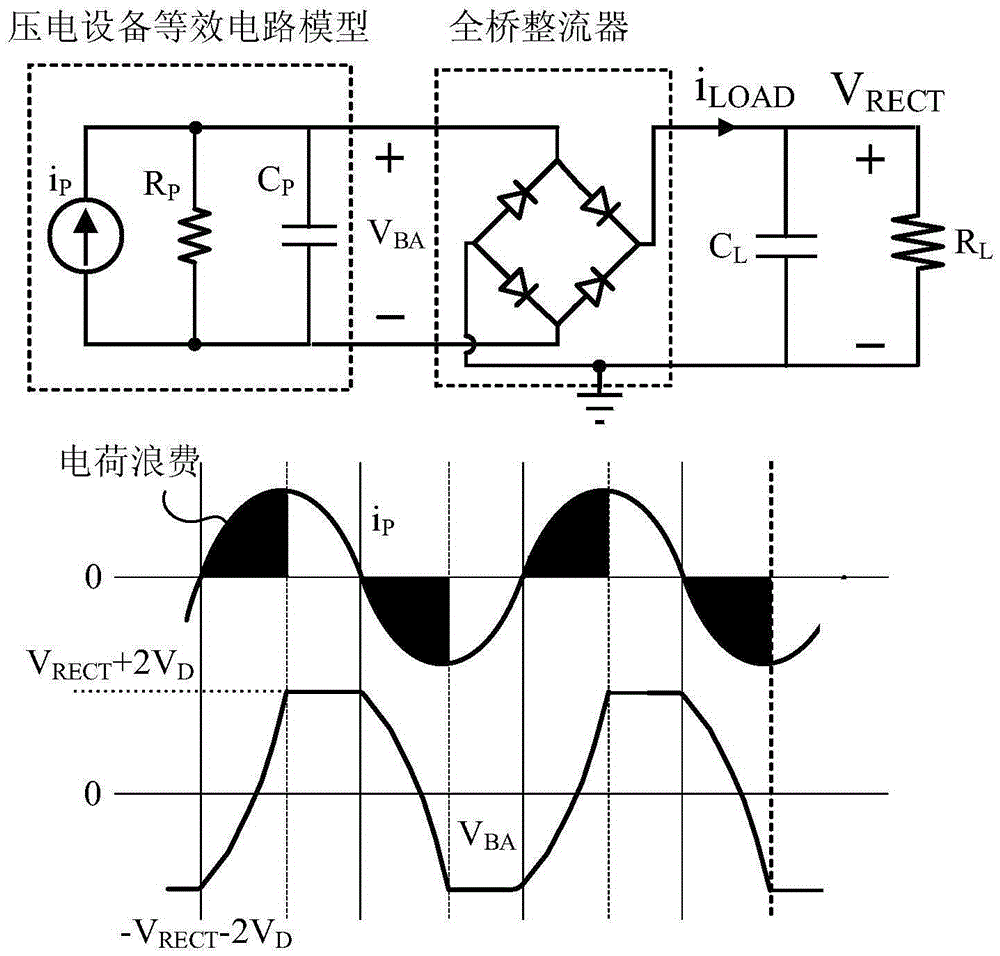

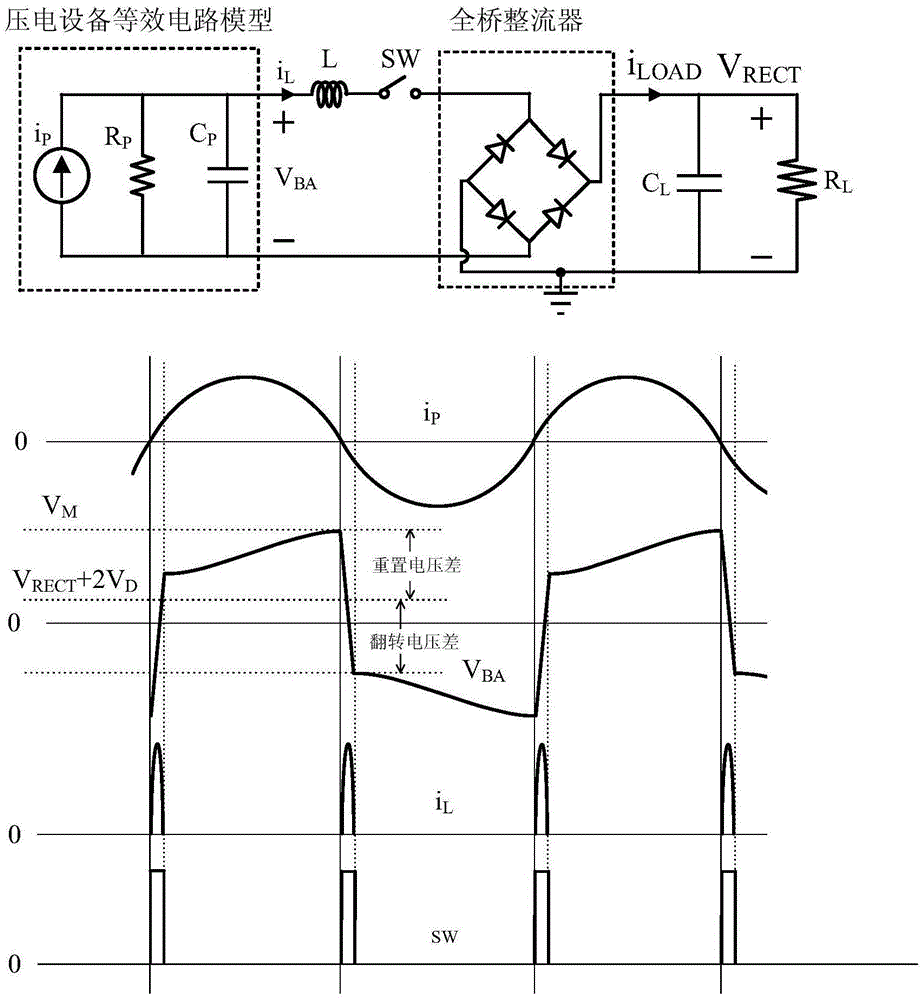

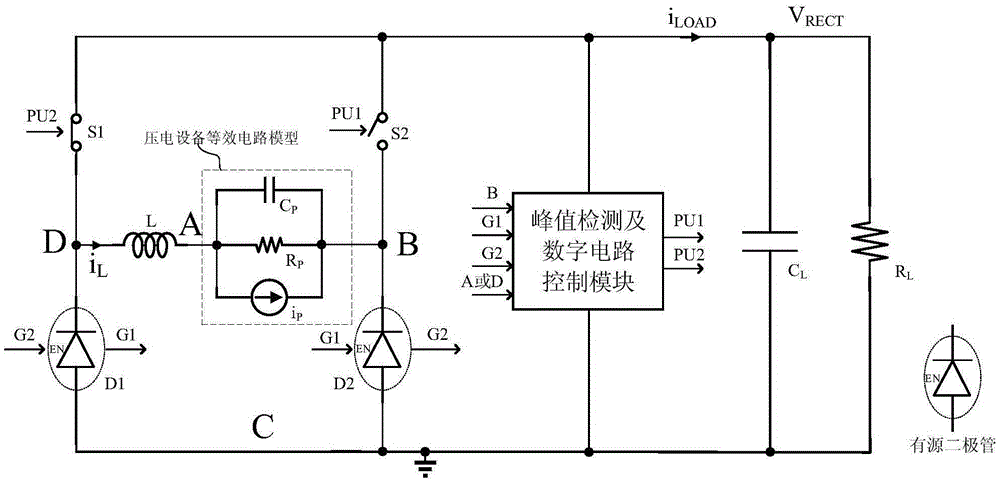

Piezoelectric energy collection rectifier for open-circuit type optimization of turnover time

InactiveCN105634300ALow costReduce forward voltage dropAc-dc conversion without reversalPiezoelectric/electrostriction/magnetostriction machinesCapacitor voltageEngineering

The invention discloses a piezoelectric energy collection rectifier for open-circuit type optimization of turnover time. The piezoelectric energy collection rectifier comprises two active diodes, two switches, an inductor and a peak detection and digital circuit control module, wherein a pair of active diodes carries out complementary conduction / stop operation; once one diode detects a zero crossing point flowing through a current from a positive electrode to a negative electrode, the diode is turned off and opposite the other diode is turned on; each active diode outputs a corresponding on-off state signal; the peak detection and digital circuit control module receives the on-off state signal of each active diode, detects a voltage peak of a cathode of the active diode and outputs a pulse signal of the optimized pulse width; the two switches receive the pulse signal of the peak detection and digital circuit control module and carry out on / off operation; and the inductor is connected with a piezoelectric device in series, and is connected to an input end of the rectifier. Under the control of the peak detection and digital circuit control module, the capacitor voltage of the piezoelectric device is optimally turned over; and meanwhile, the energy is transmitted to a load.

Owner:HUNAN UNIV

Method for manufacturing one-step formed composite foamed plastic formwork

InactiveCN101722643AReduce production energy consumptionReduce manufacturing costFlat articlesSurface layerTurnover time

The invention relates to a method for manufacturing a one-step formed composite foamed plastic formwork which comprises an upper surface layer, a lower surface layer and a core layer. The method comprises the following steps of: firstly, filling a core layer raw material into a high-speed mixing machine to perform mixing; secondly, sending the mixed core layer raw material into a double-screw extruder by a feeding machine, extruding the extruded material into a core layer extruder, and simultaneously sending surface layer raw materials into a plastic extruder; and thirdly, extruding the extruded core layer raw material, the upper surface layer raw material and the lower surface layer raw material into a confluence distributor, molding the materials in a mold, and performing three-roller press finishing or vacuum shaping, cooling and cutting to obtain a finished product. The method overcomes the defects that the plastic formwork has rigidity and tenacity; the plastic formwork can be extruded out with three layers or a plurality of layers and has a more reasonable structure; the middle part of the plastic formwork is a foam material; the weight of the plastic formwork is light; the plastic formwork plays a role in heat insulation and simultaneously reduces the abuse of large heat shrinkage rate of plastic, can be recovered for 100 percent, has more turnover times, high rigidity, cold resistance, high temperature resistance, corrosion resistance, acid and alkali resistance, easy demoulding and low production cost; besides, the plastic formwork can be customized to be made into any sizes, has fewer building wallboard seams, and has the advantages of making a wall body smoother and evener, saving more materials and the like.

Owner:靳培军

Process method for bone marrow smear digitization

InactiveCN108896363AReduce turnaround timeImprove consistencyPreparing sample for investigationSkeletal/connective tissue cellsRelevant informationTurnover time

The invention discloses a process method for bone marrow smear digitization. The process method comprises the following steps: acquiring related information of bone marrow smears, generating global images, and performing digital labeling after obtaining the to-be-digitized area as well as karyocyte collecting quantity and megakaryocyte classifying quantity; feeding the bone marrow smears into scanning equipment for performing shooting scanning: a to-be-digitized area generated by low-power lens scanning, and labeling and recognizing object observers therein; generating a spliced image in the scanning area; switching to megakaryocyte in the megakaryocyte classifying quantity generated by high-power lens scanning, and labeling and recognizing the megakaryocyte; generating the scanned megakaryocyte image; switching to karyocyte in the karyocyte collecting quantity in the to-be-digitized area generated by oil lens scanning, labeling and recognizing the karyocyte; generating the scanned karyocyte image; and generating digitalized smears of physical bone marrow smears. The artificial microscopy process is simplified; the consistency and standardization of the bone marrow examination report results are improved; and remote consultation is conveniently carried out, and the turn-round time of the physical smears is reduced.

Owner:HANGZHOU ZHIWEI INFORMATION TECH CO LTD

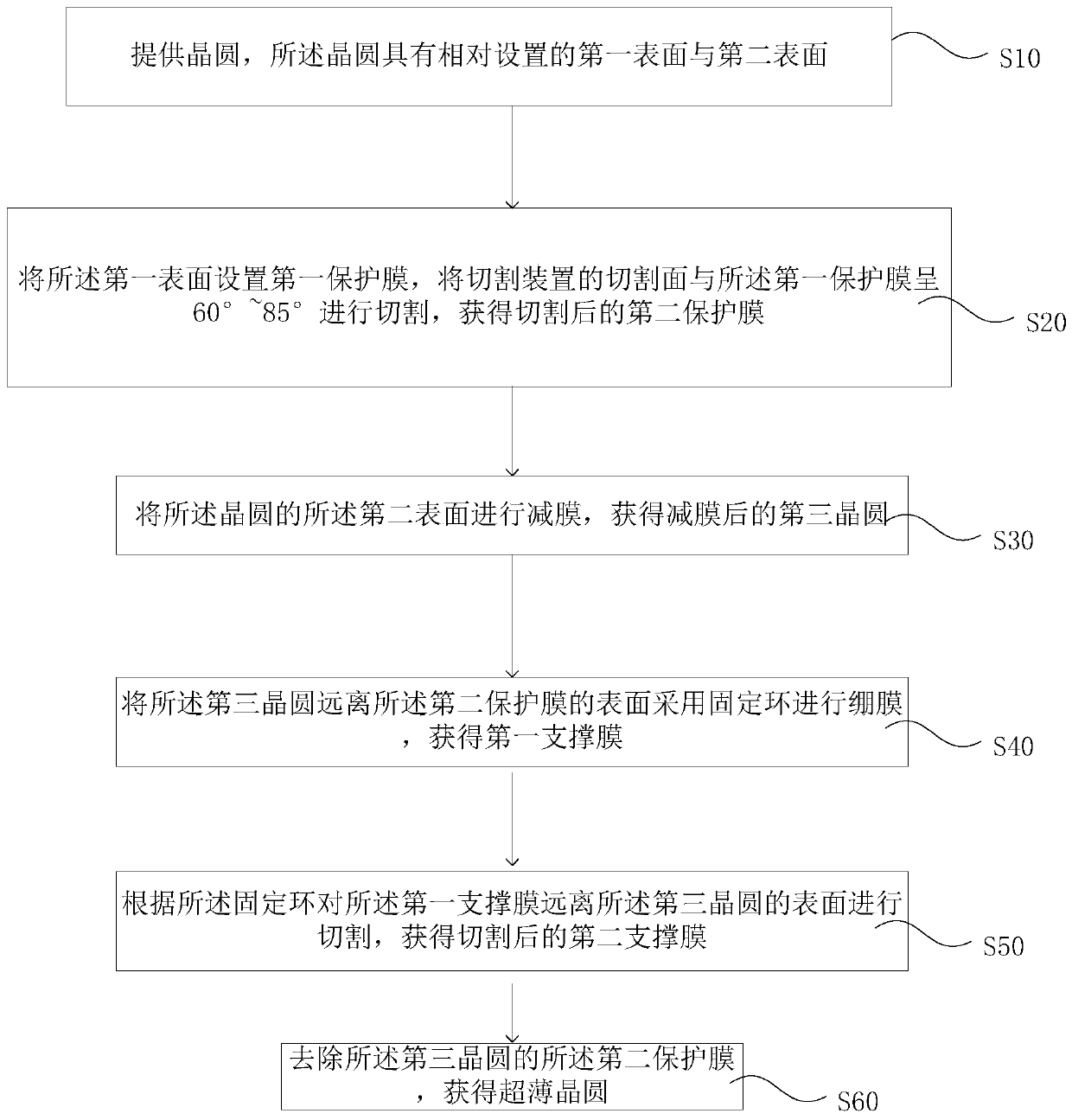

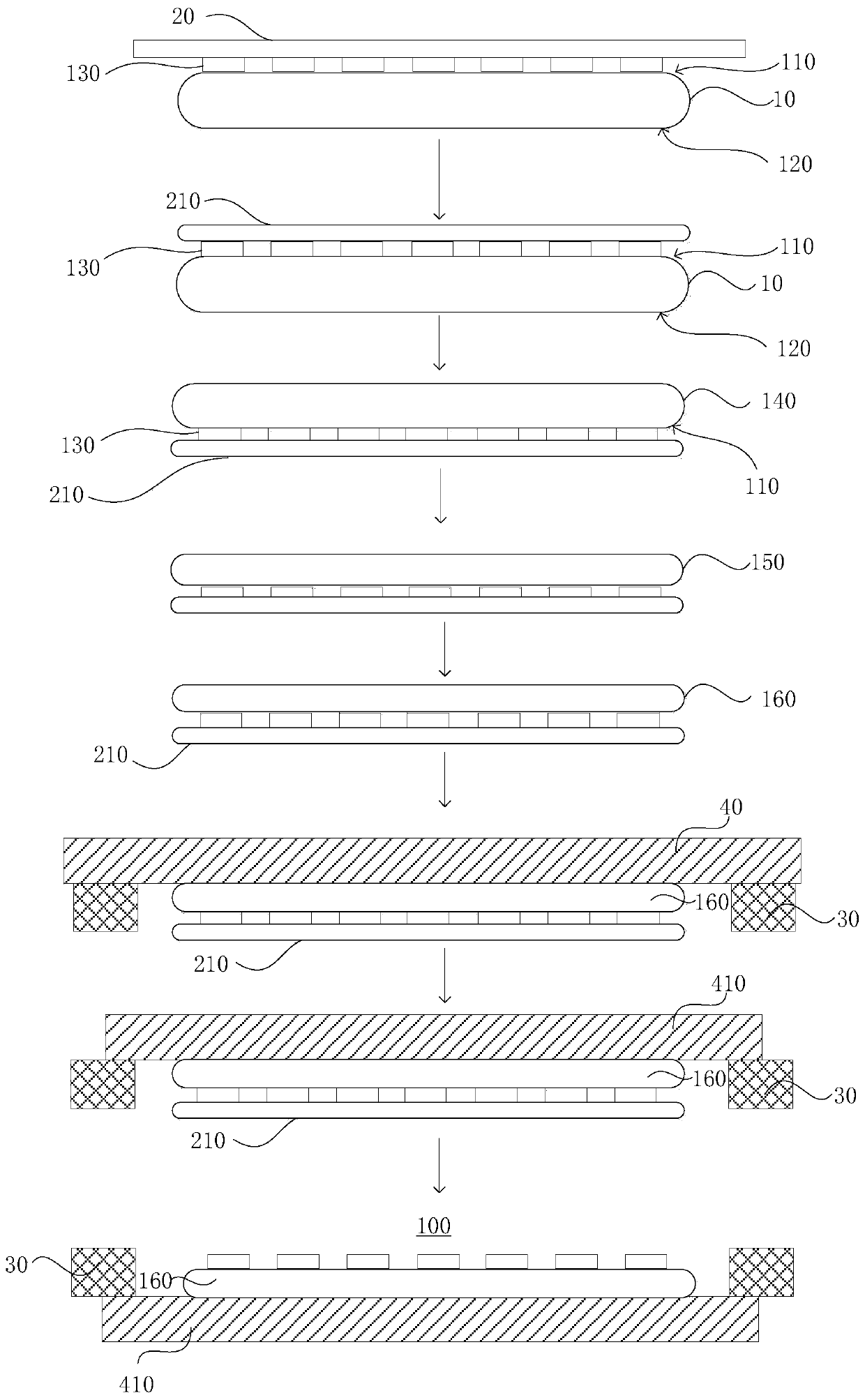

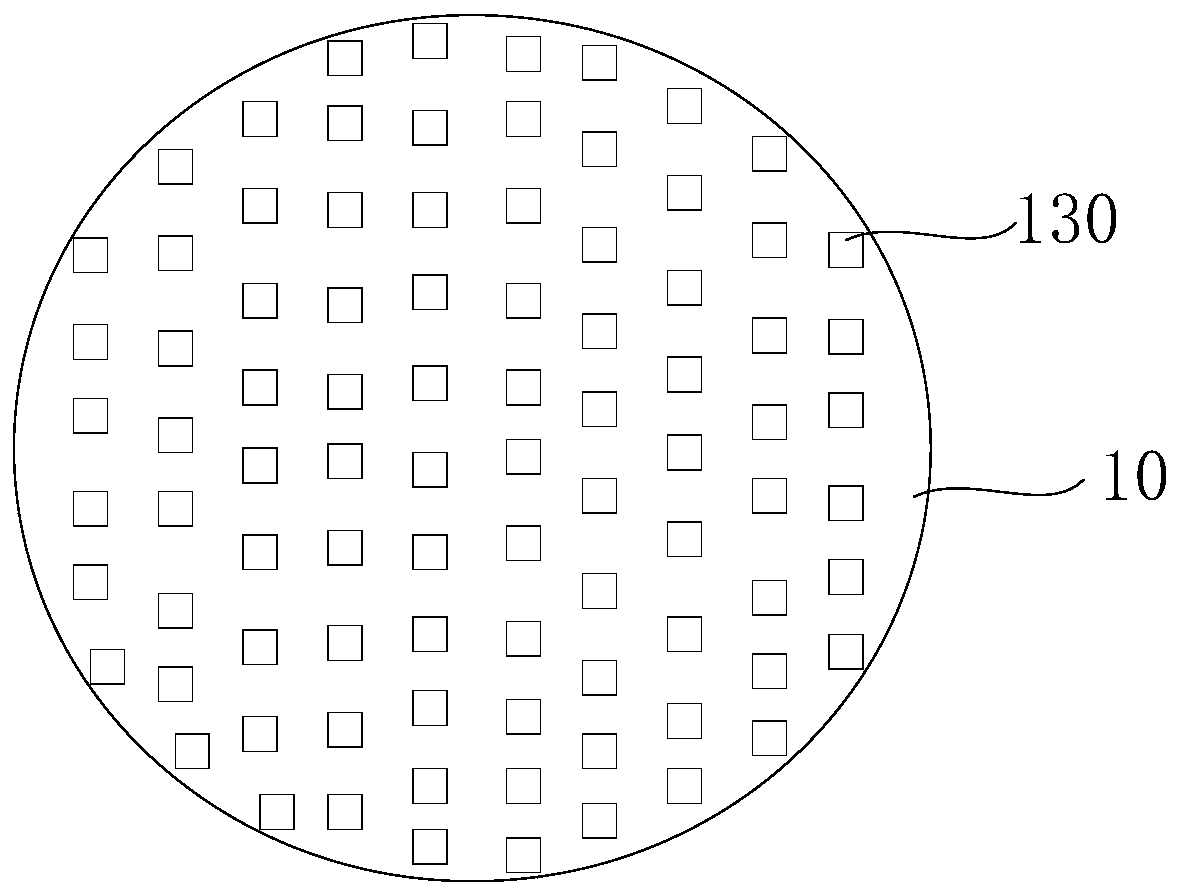

Preparation method of ultrathin wafer

PendingCN109841559AGood for controlling supportAchieve supportSemiconductor/solid-state device manufacturingTurnover timeOptoelectronics

The invention provides a preparation method of an ultrathin wafer. According to the preparation method, the technical structure is simple, the wafer is thinned directly after that first surface film pasting, turnover time of the process is short, and coarse grinding according to the first preset thickness, fine grinding according to the second preset thickness and dry-method polishing according tothe third preset thickness are carried out to control the range of thickness fluctuation. Cutting is carried out with support of a scribing iron hoop after that the wafer is thinned, a second protective film is removed, and thus, the ultrathin wafer is supported, and avoided fro, fragment and crack in the transfer process due to being too thin. The scribing iron hoop is used to stretch the film after thinning, different scribing adhesive films are selected according to requirements for chip packaging manners, and the application range is wide.

Owner:浙江荷清柔性电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com