Two-component adhesive layer polyurethane resin for synthetic leather and preparation method of two-component adhesive layer polyurethane resin

A polyurethane resin and two-component technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., to achieve the effect of increasing turnover times and utilization efficiency, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

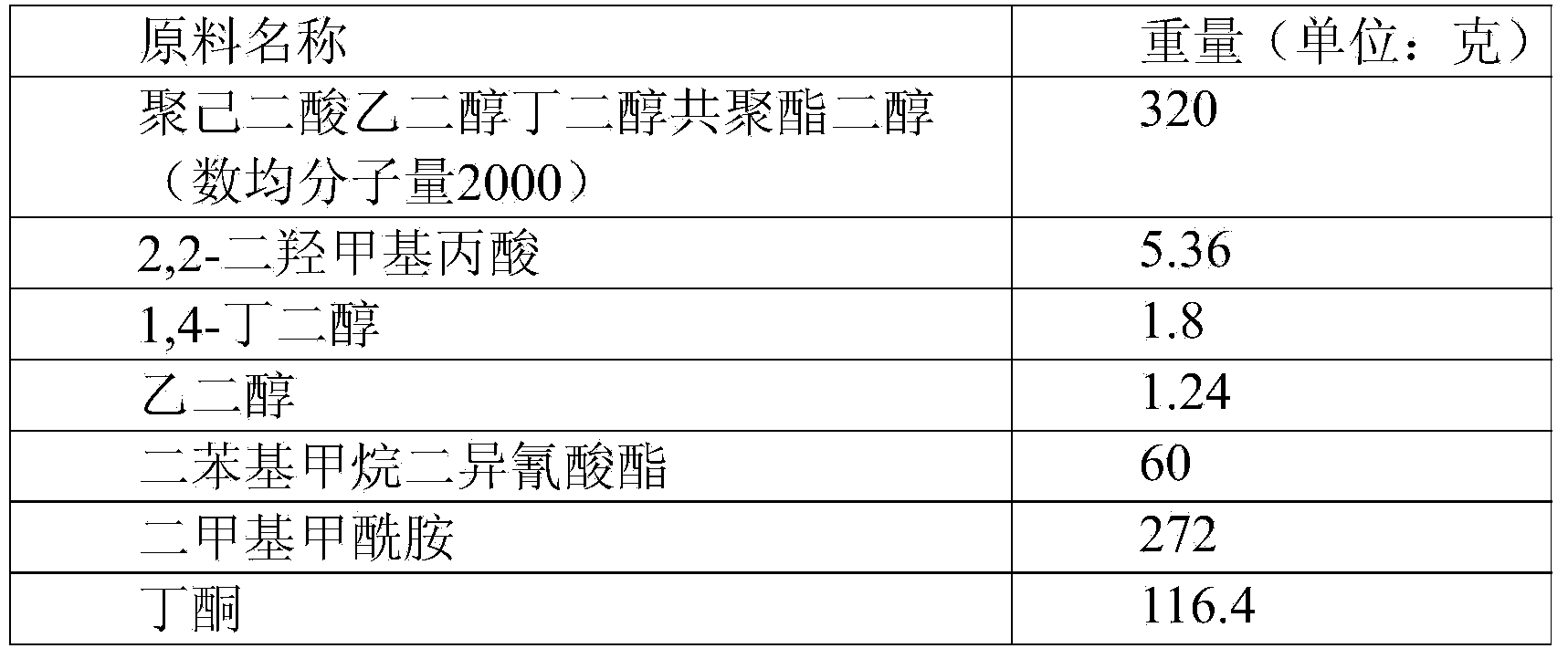

[0019] The raw materials used in this embodiment and their weight are shown in Table 1.

[0020] Table 1

[0021] raw material name

Weight (unit: g)

Polytetrahydrofuran ether glycol (number average molecular weight 2000)

320

32.16

Ethylene glycol

14.88

diphenylmethane diisocyanate

144

125.25

83.5

[0022] The preparation steps of the two-component adhesive layer polyurethane resin for synthetic leather of the present embodiment are as follows:

[0023] 1) Put 104g of dimethylformamide, 320g of polytetrahydrofuran ether glycol, 32.16g of 2,2-dimethylolpropionic acid and 14.88g of ethylene glycol into the reaction kettle, and stir evenly at 50-55°C;

[0024] 2) Put 144g of diphenylmethane diisocyanate into the reactor in batches, strictly control the reaction temperature between 65-70°C, and react under normal pressure for 7 hours, and u...

Embodiment 2

[0026] The raw materials used in this embodiment and their weight are shown in Table 2.

[0027] Table 2

[0028] raw material name

Weight (unit: g)

Polybutylene adipate diol (number average molecular weight 1000)

40

Polybutylene adipate diol (number average molecular weight 3000)

120

6.432

[0029] Ethylene glycol

11.904

diphenylmethane diisocyanate

80

506

126.5

[0030] The preparation steps of the two-component adhesive layer polyurethane resin for synthetic leather of the present embodiment are as follows:

[0031] 1) Mix 190g of dimethylformamide, 40g of polybutylene adipate diol with a number average molecular weight of 1000, 120g of polybutylene adipate diol with a number average molecular weight of 3000, 6.432g2,2 - Put dimethylolpropionic acid and 11.904g ethylene glycol into the reaction kettle, and stir...

Embodiment 3

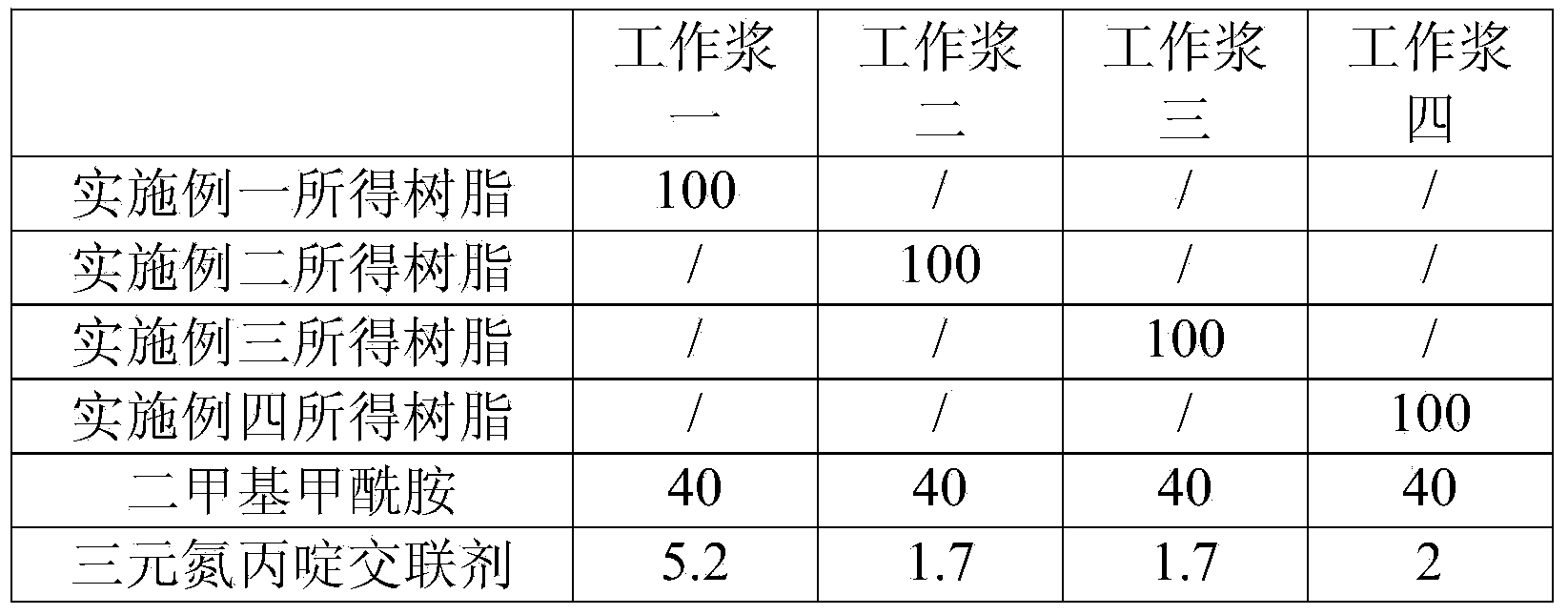

[0034] The raw materials used in this embodiment and their weight are shown in Table 3.

[0035] table 3

[0036]

[0037] The preparation steps of the two-component adhesive layer polyurethane resin for synthetic leather of the present embodiment are as follows:

[0038] 1) Mix 171g of dimethylformamide, 320g of polyethylene adipate, butanediol copolyester diol, 5.36g of 2,2-dimethylolpropionic acid, 1.8g of 1,4-butanediol and 1.24g of ethyl Put the diol into the reaction kettle, stir evenly at 55-60°C;

[0039] 2) Put 60g of diphenylmethane diisocyanate into the reaction kettle in batches, strictly control the reaction temperature between 75-80°C, and react at normal pressure for 9 hours, and according to the viscosity of the system, use the remaining dimethylformamide and butyl The ketone is diluted in stages, and the final viscosity is controlled at 60-120Pa.S25°C to obtain a two-component adhesive layer polyurethane resin for synthetic leather.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com