Plastic-covered plywood building formwork and preparation method thereof

A technology for building formwork and plywood, used in chemical instruments and methods, adhesives, adhesive types, etc., can solve problems such as difficulty in adapting to high standard requirements, less turnover, and inability to use, to avoid water and moisture deformation, Small thermal conductivity, the effect of ensuring the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

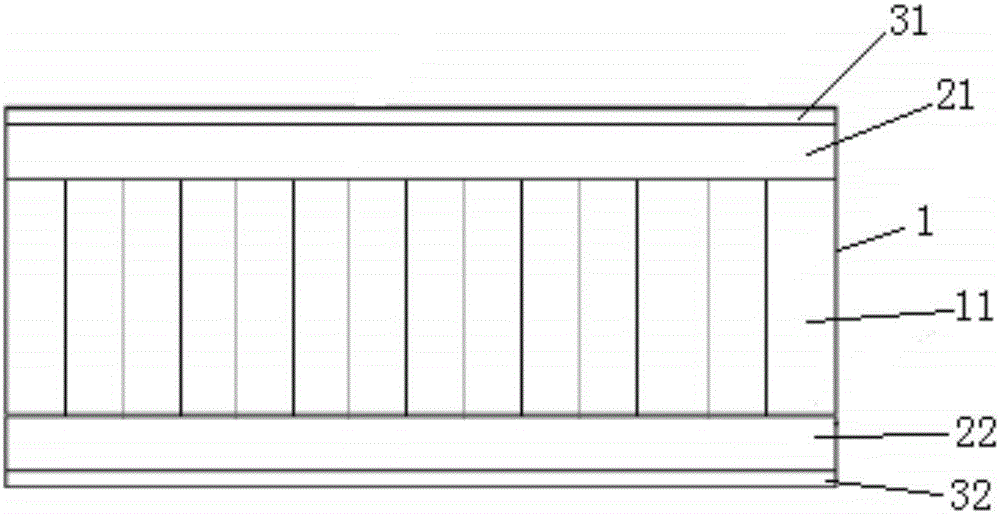

[0033] This embodiment provides a kind of plastic cladding plywood building template, such as figure 1 As shown, from top to bottom are the upper polymer coating layer 31, the upper wood skin layer 21, the plywood core layer 1, the lower wood skin layer 22 and the lower polymer coating layer 32; wherein, the upper polymer coating layer 31 The thickness is 0.2mm, and the upper veneer layer 21 is a poplar board (moisture content 11wt%) with a thickness of 2.2mm; the plywood core layer 1 is a vertical structure formed by bonding several vertically arranged wooden strips 11, The thickness of 9.2mm, the lower veneer layer 22 is the poplar board (moisture content 11wt%) of thickness 2.2mm, and the thickness of lower macromolecule coating layer 32 is 0.2mm.

[0034] Wherein, the material of the upper polymer coating layer 31 and the lower polymer coating layer 32 is the same, and both are prepared by the following method:

[0035] (S1) Weigh 120 parts by weight of polyethylene, 130 ...

Embodiment 2

[0043] This embodiment provides a plastic-clad plywood building formwork, which includes an upper polymer coating layer 31, an upper veneer layer 21, a plywood core layer 1, a lower veneer layer 22, and a lower polymer coating layer 32 from top to bottom; , the thickness of the upper polymer coating layer 31 is 0.6mm, and the upper veneer layer 21 is a eucalyptus board (moisture content 10wt%) with a thickness of 1.8mm; The vertical structure of the plywood core layer 1 is 10.8mm in thickness; the lower veneer layer 22 is a eucalyptus board (moisture content 10wt%) with a thickness of 1.8mm, and the thickness of the lower polymer coating layer 32 is 0.6mm.

[0044] Wherein, the material of the upper polymer coating layer 31 and the lower polymer coating layer 32 is the same, and both are prepared by the following method:

[0045] (S1) Weigh 150 parts by weight of polypropylene, 110 parts by weight of talcum powder, 15 parts by weight of titanate, 5 parts by weight of sodium st...

Embodiment 3

[0053] This embodiment provides a plastic-clad plywood building formwork, which includes an upper polymer film layer 31, an upper veneer layer 21, an upper non-woven fabric layer, a plywood core layer 1, a lower veneer layer 22, and a lower non-woven fabric layer from top to bottom. Cloth layer and lower polymer coating layer 32; Wherein, the thickness of upper polymer coating layer 31 is 0.4mm, and upper veneer layer 21 is the poplar board (moisture content 9wt%) of thickness 2.0mm, the upper non-woven fabric layer The specification is 60g / m 2 , thickness is 0.4mm; The plywood core layer 1 is the vertical structure that adopts some vertically arranged wooden strips 11 to bond together, the thickness of the plywood core layer 1 is 10mm, and the lower veneer layer 22 is a poplar board ( Moisture content 9wt%), the specification of the lower non-woven fabric layer is 60g / m 2 , the thickness is 0.4 mm, and the thickness of the lower polymer coating layer 32 is 0.4 mm.

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com