Patents

Literature

77results about How to "Reduce turnover times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

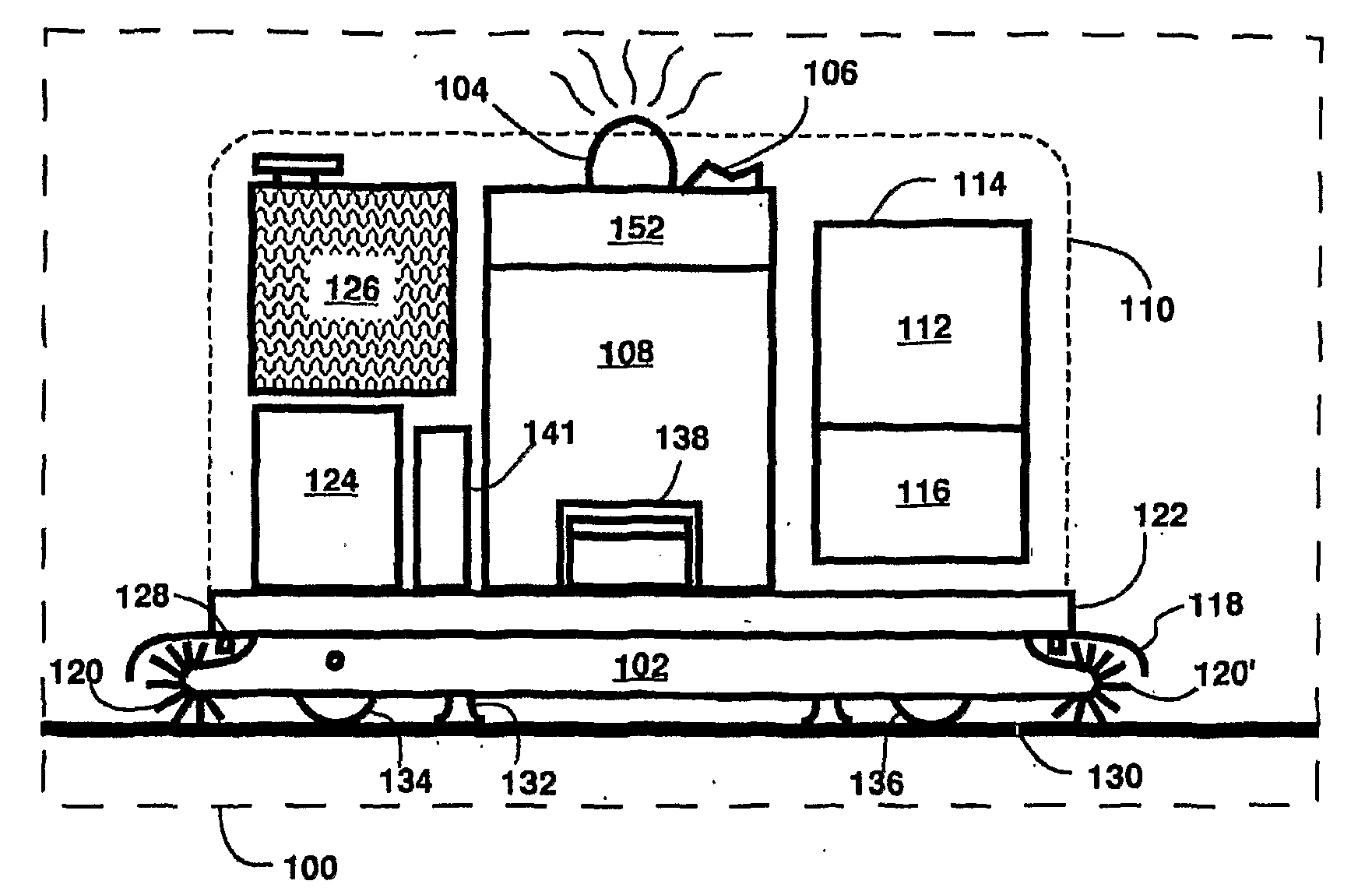

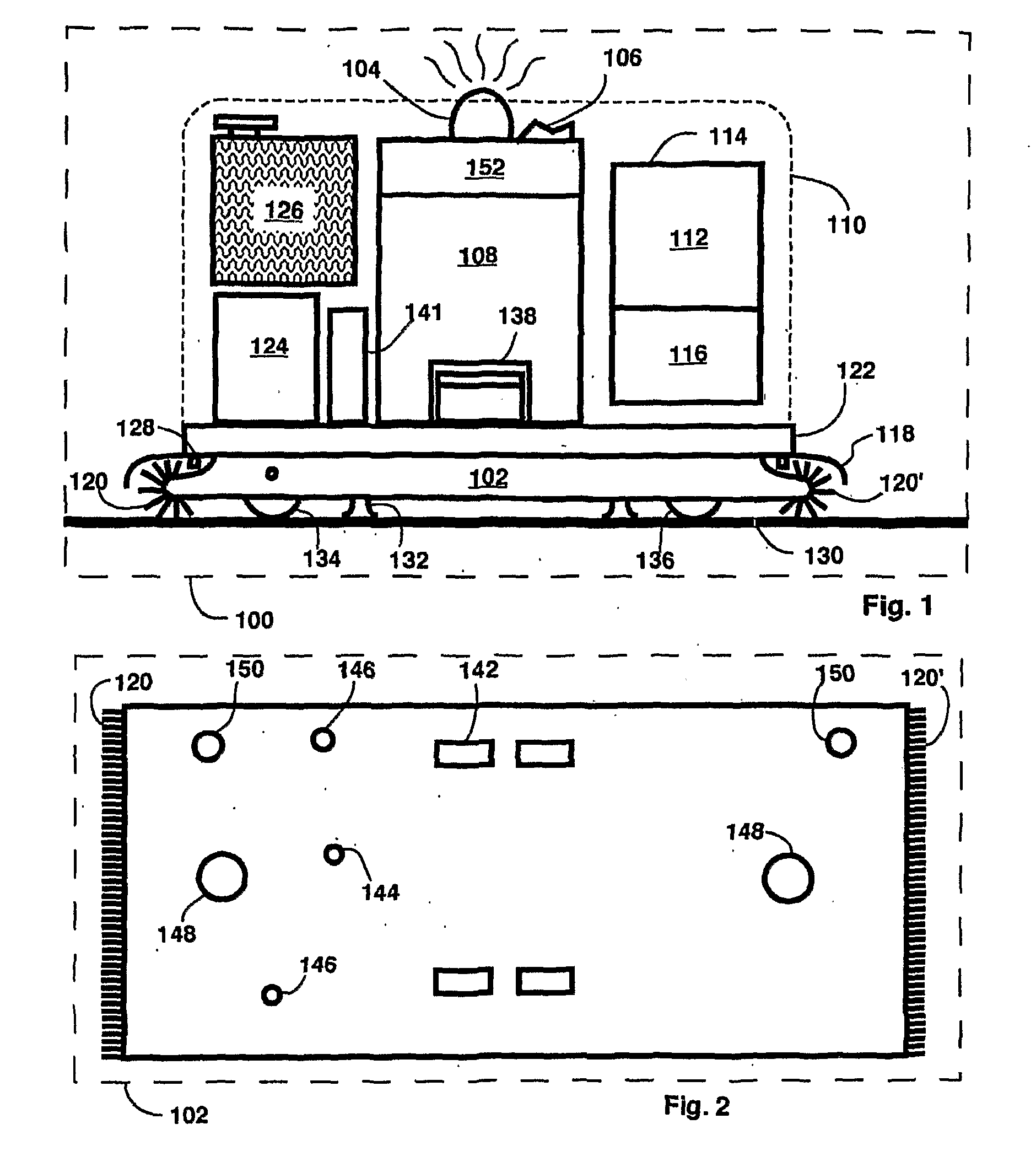

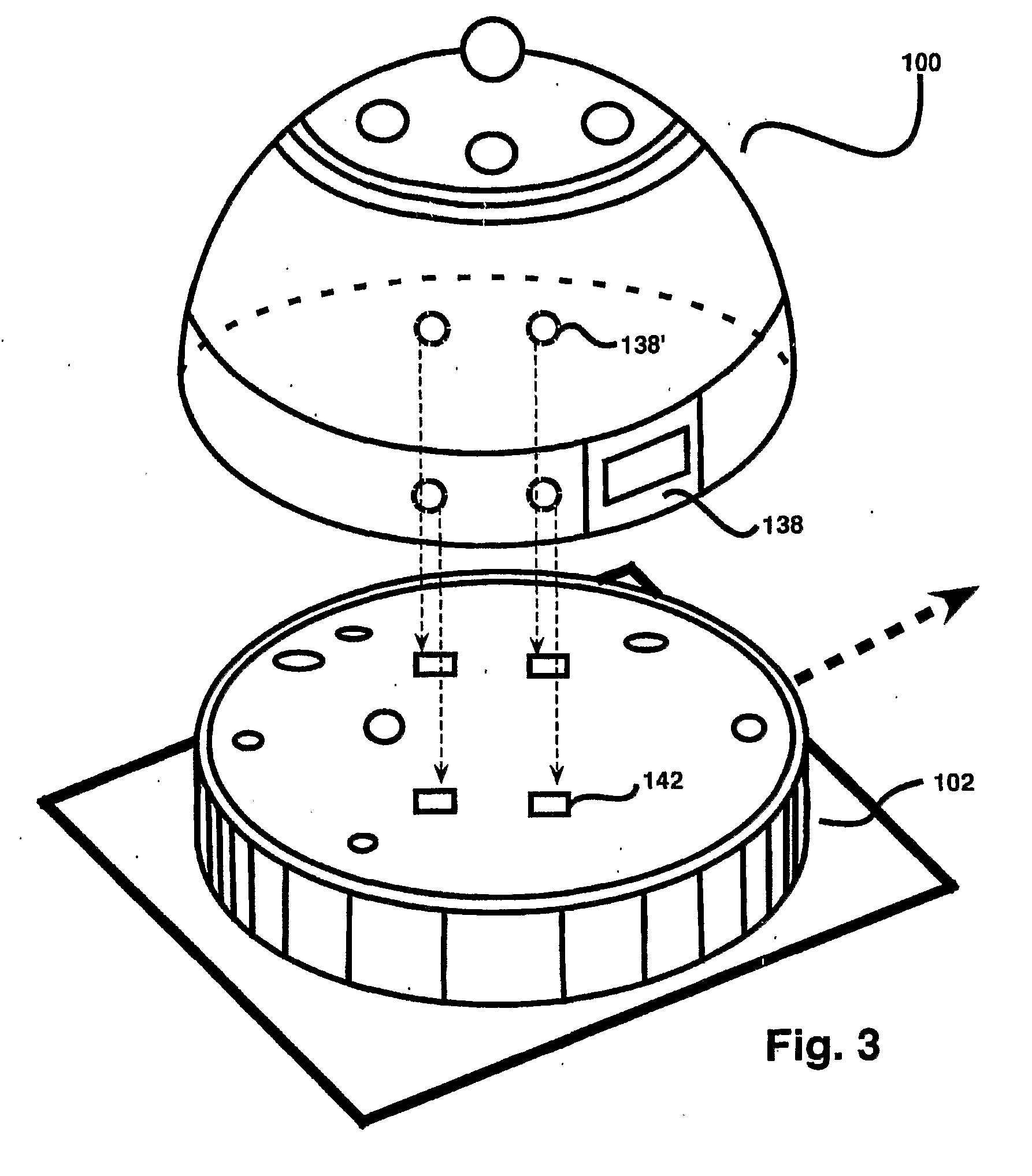

Robotic floor cleaning with sterile, disposable cartridges

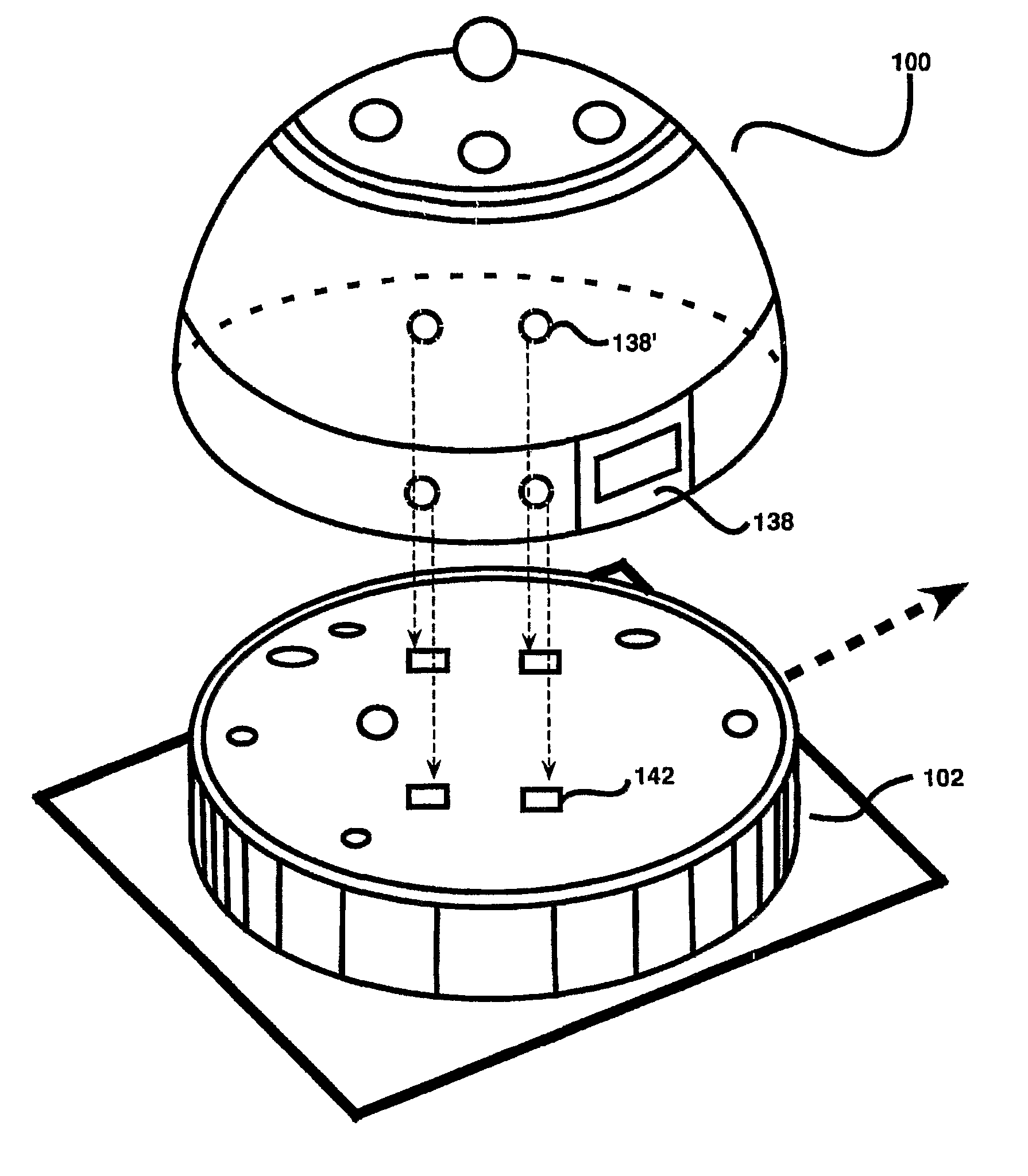

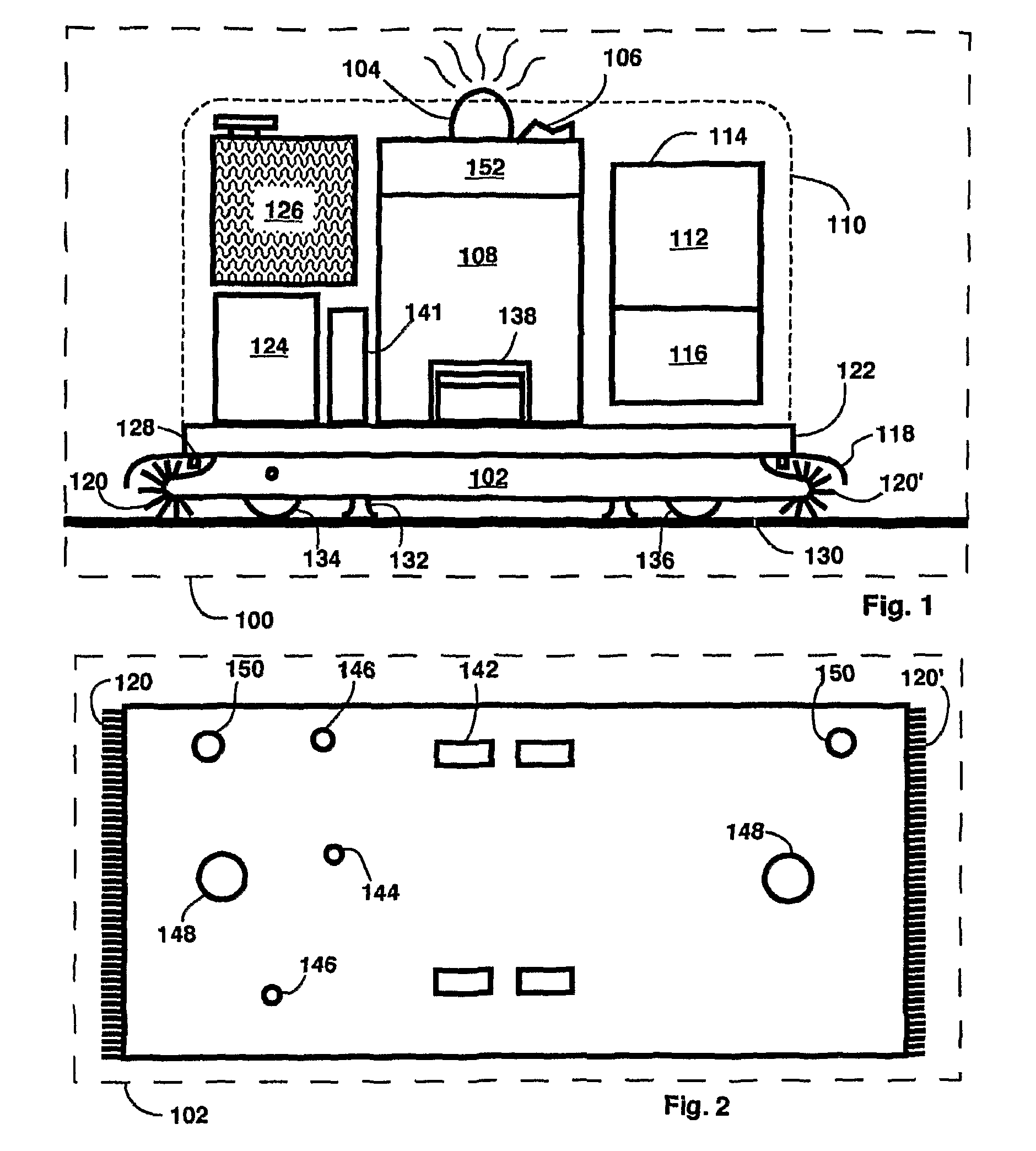

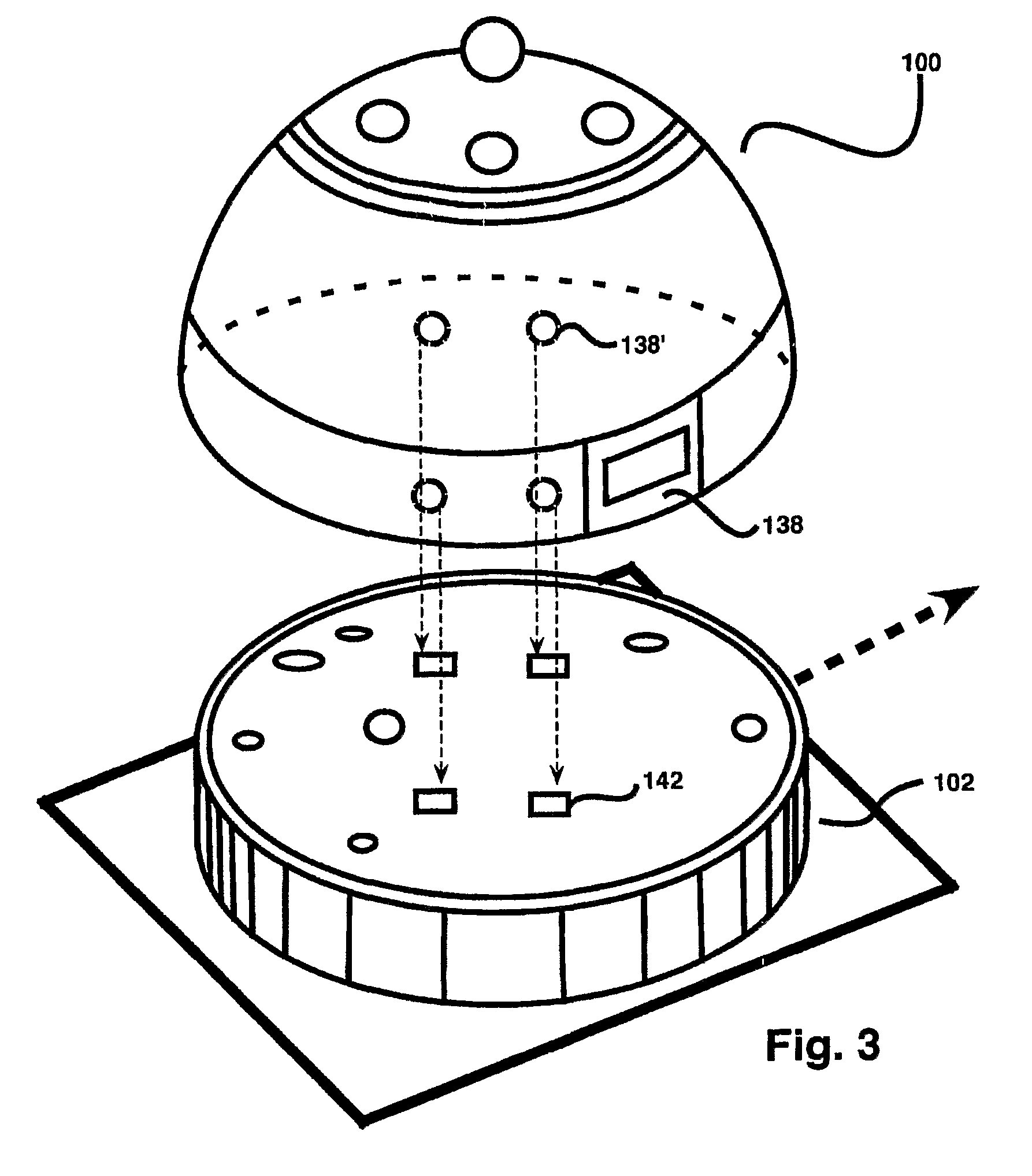

An automated (robotic) floor cleaner (100) is adapted to allow sterile cleaning of sensitive environments, such as hospital room. In particular, the floor-cleaner chassis (124) is redesigned to be mounted on a deck (102) containing cleaning devices that contact the floor. The cleaning devices mounted on the deck (102) include vacuum head (132), brushes (120), cleaning fluid sprays (128), and conceivably sanitizing devices such as UV germicidal light, are provided pre-sterilized. As such, the adapted floor-cleaner chassis (124) allows the deck (102) to be mounted to the bottom of the chassis (124), the floor-cleaner (100) is then used to clean a floor, after which, the deck (102) is removed from the chassis (124) and disposed. The robotic-floor cleaner (100) and sterilization system cleans floor between or even during cases. Further, the robotic floor cleaner (100) reduces the “turnover time” required between cases, as it operates simultaneously while the staff prepares the room for the next case.

Owner:OPTIMUS LICENSING AG

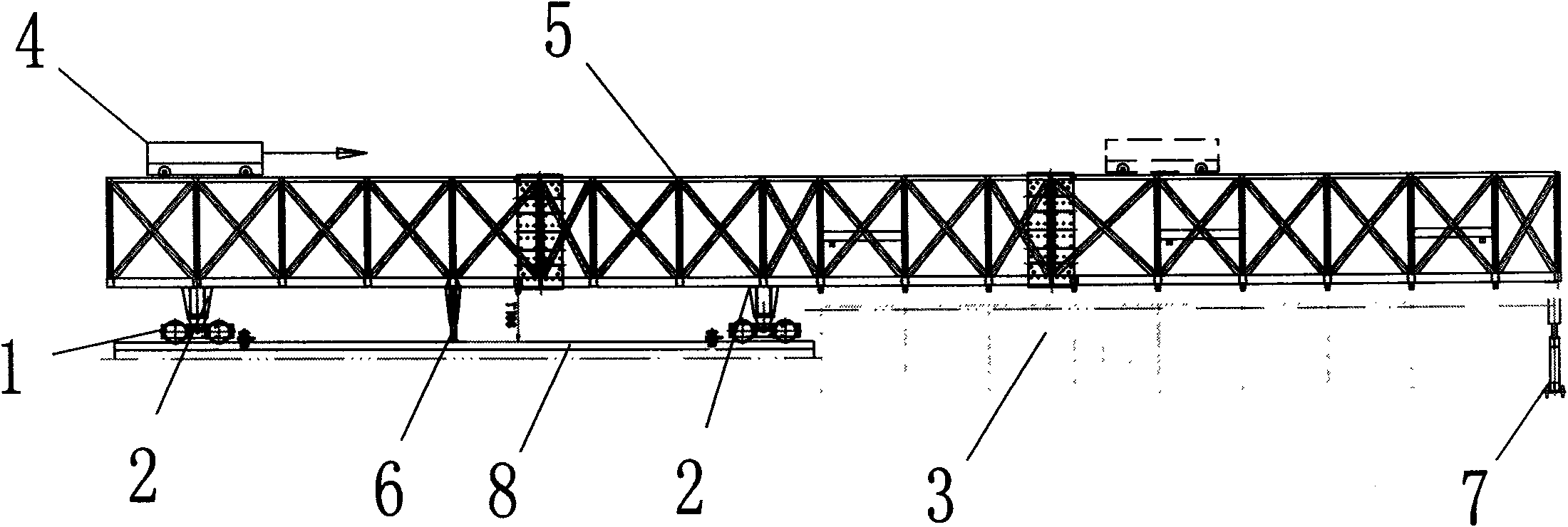

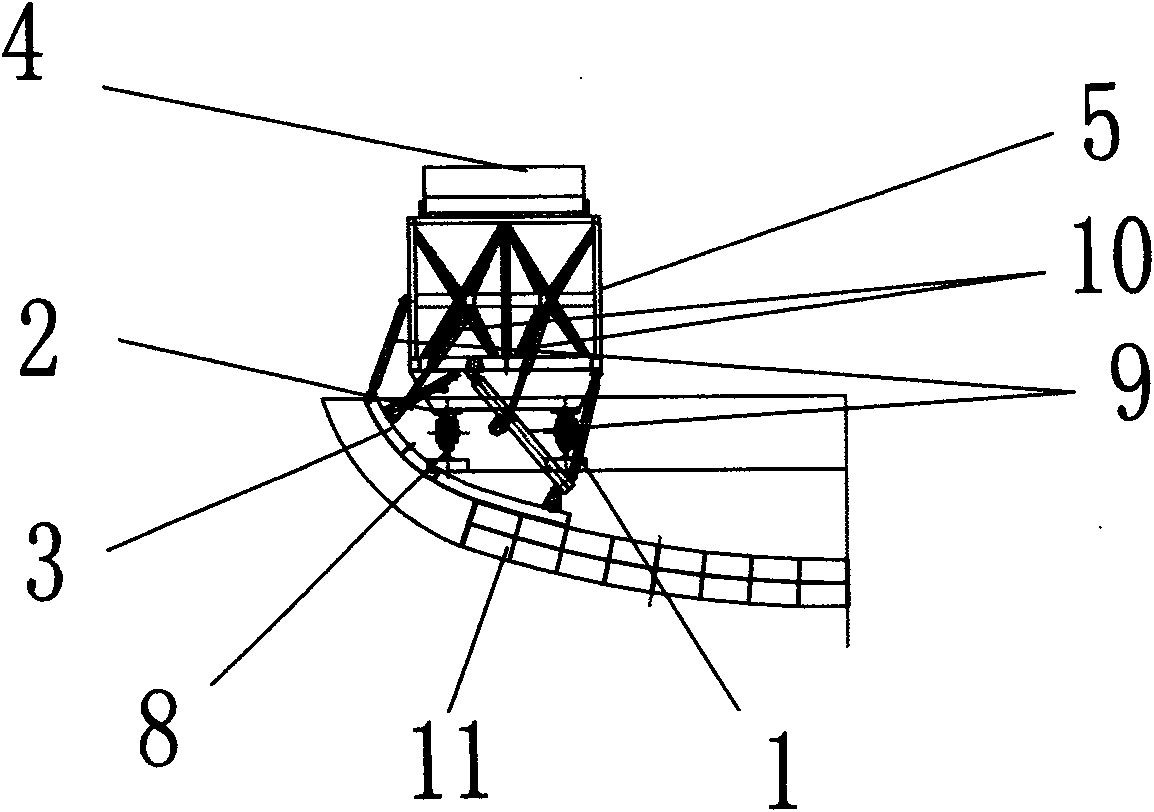

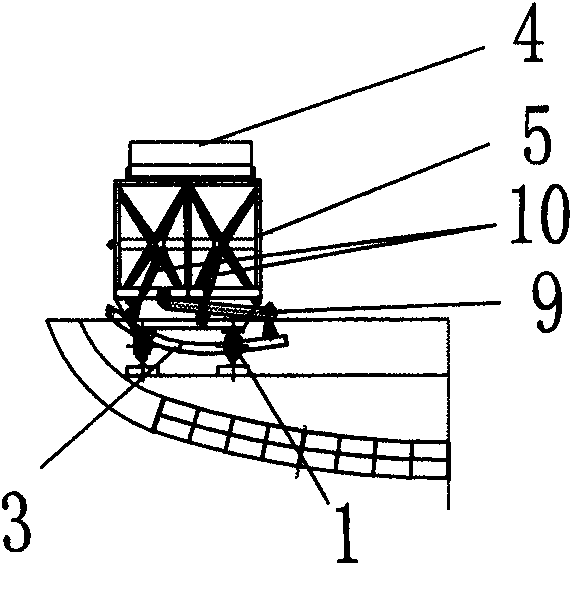

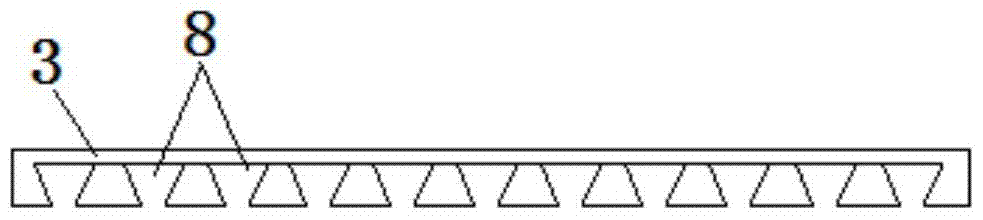

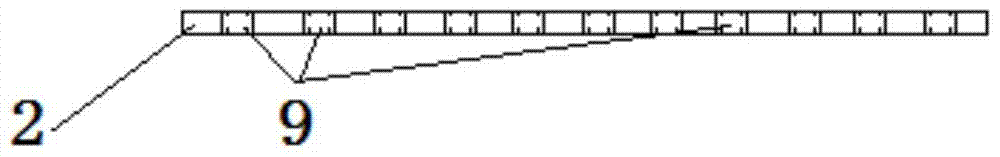

Self-propelled inverted arch template construction method

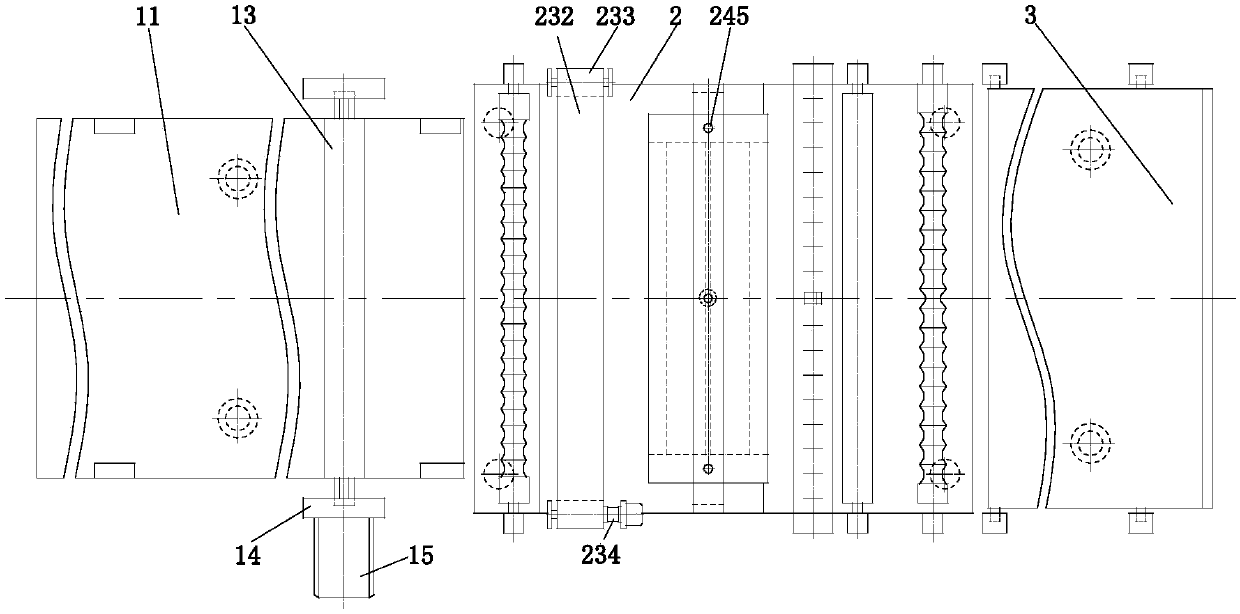

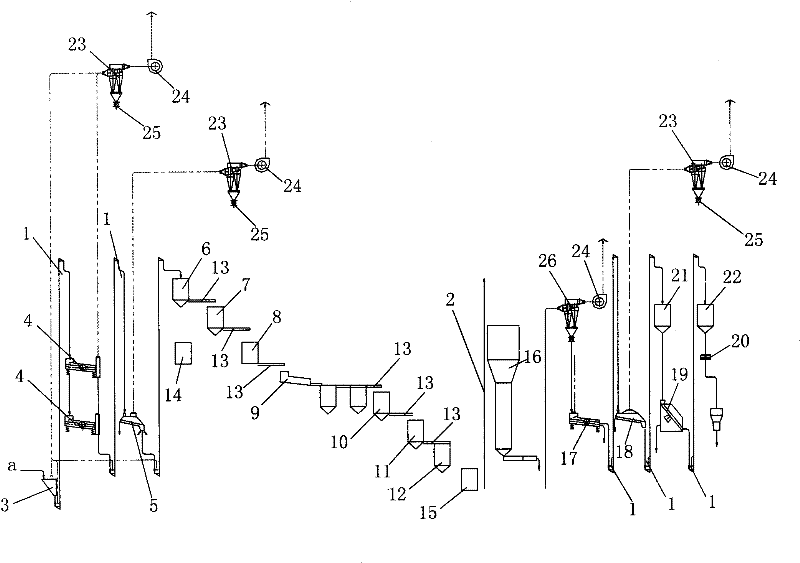

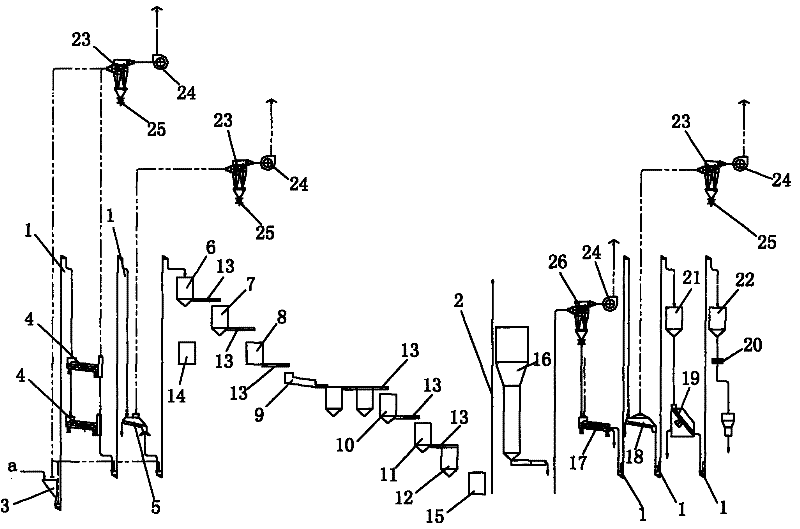

The invention discloses a self-propelled inverted arch template construction method for a tunnel, which comprises the following construction steps of: setting out a control line for an inverted arch digging section and a longitudinal construction joint according to the design requirement; performing smooth-wall blasting digging on an inverted arch of the tunnel; moving an inverted arch trestle in place; conveying inverted arch stone slag out of the tunnel by using an excavator and a conveying device and abandoning the stone slag in a slag field, and cleaning an inverted arch base; assembling an inverted arch end template; laying steel rails, and moving the inverted arch template to longitudinally move in place per se; starting a hydraulic device to lower the inverted arch template, and supporting the template firmly by using a screw jack; pouring inverted arch concrete; and curing the concrete with equal strength, folding the screw jack, withdrawing a hydraulic cylinder, and releasing a die. The construction method has low cost, is convenient to operate, and improves the construction efficiency; and the longitudinal construction joint is vibrated densely compared with common template construction, and has positive effect of improving the construction quality of tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

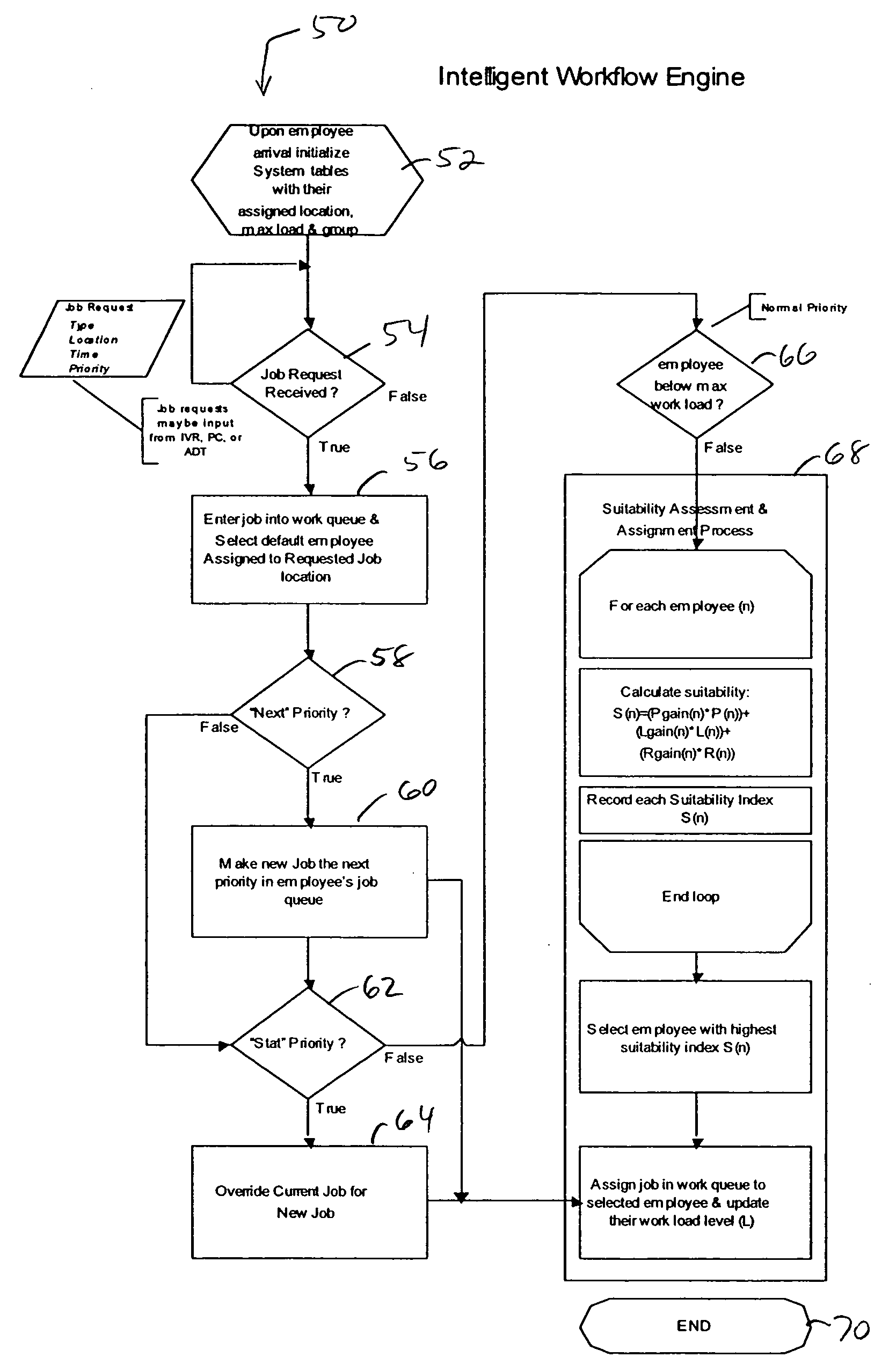

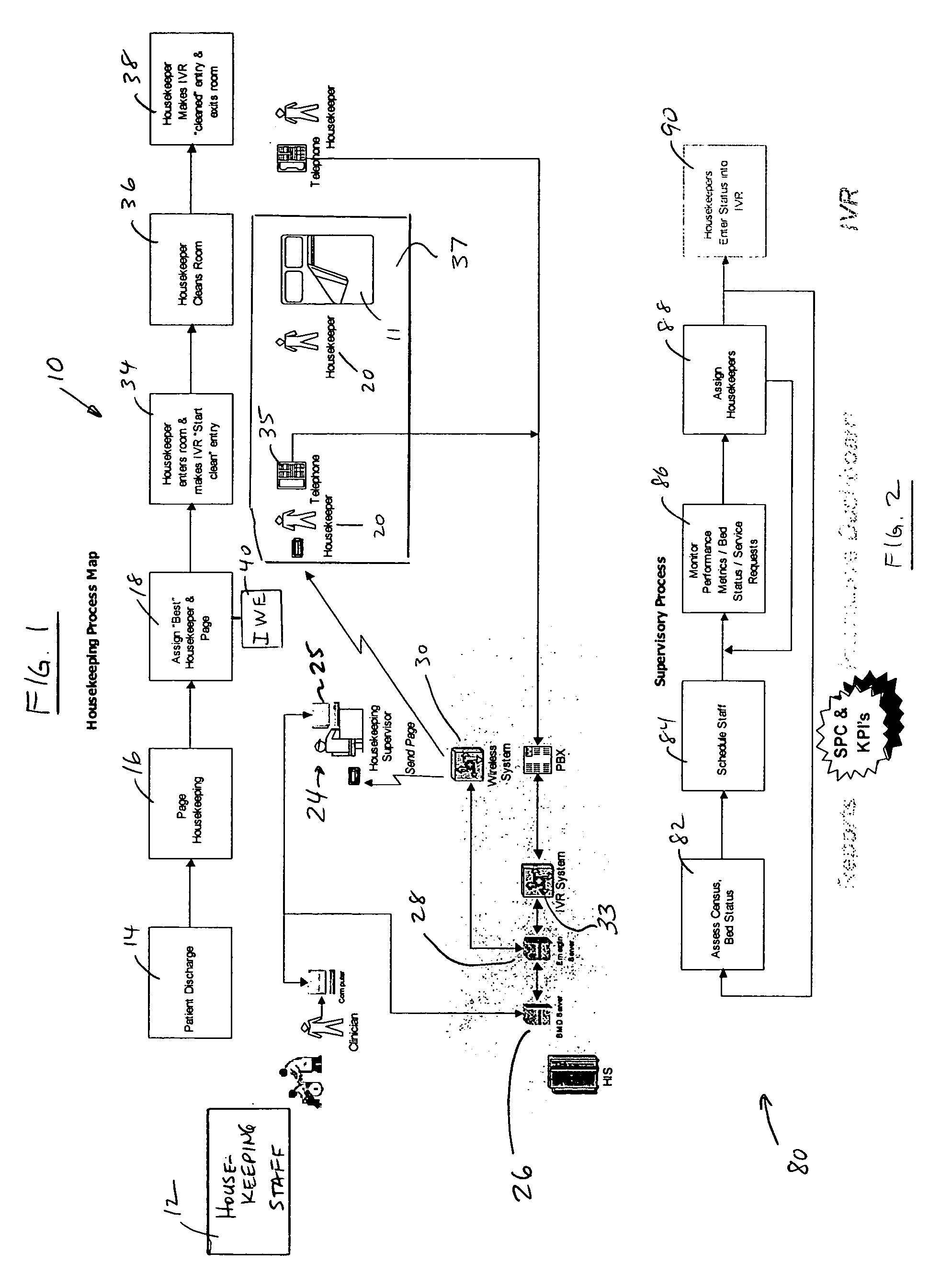

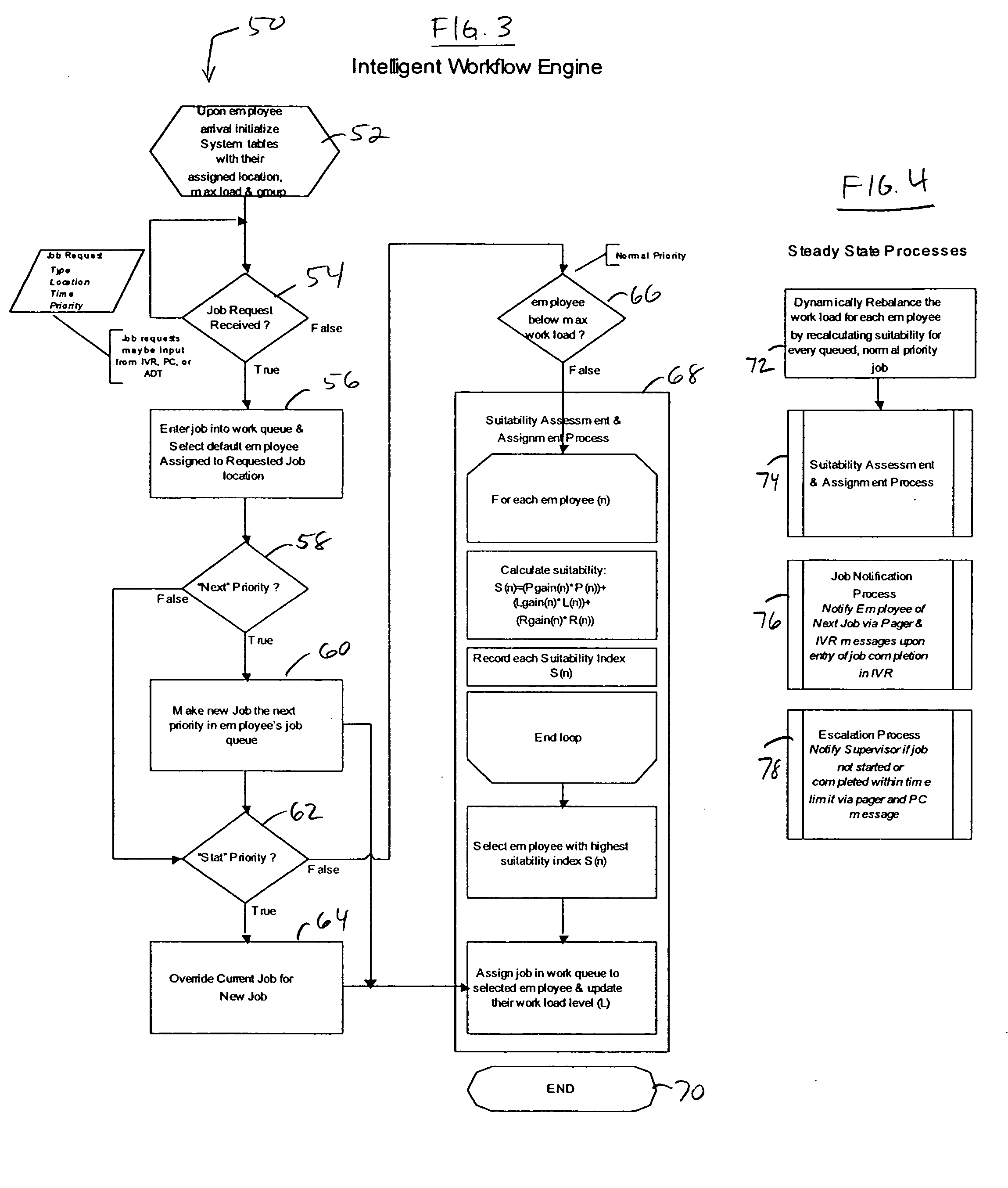

System and method for selecting a best-suited individual for performing a task from a plurality of individuals

InactiveUS20070067199A1Reduce turnover timesEffective balanceDigital computer detailsResourcesTurnover timeWorkload

The present invention provides a computer implemented system and method for selecting a best-suited individual for performing a task from a plurality of individuals. The method including identifying a plurality of individuals for performing a task, receiving a task to be assigned to an individual, assessing the suitability of each of the plurality of available individuals for performing the task, and determining a best-suited individual for performing the task. The method includes evaluating for each individual the individual's current workload, the individual's proximity to a location of the current task and the individual's responsibility for performing the current task. In a preferred embodiment, the present invention is utilized to balance the workload of a hospital's housekeeping staff assigned to dean beds in a hospital thereby decreasing the bed turnover time and increasing the patient throughput of the hospital.

Owner:ALLSCRIPTS SOFTWARE +1

Robotic Floor Cleaning with Sterile, Disposable Cartridges Cross-Reference to Related Applications

An automated (robotic) floor cleaner (100) is adapted to allow sterile cleaning of sensitive environments, such as hospital room. In particular, the floor-cleaner chassis (124) is redesigned to be mounted on a deck (102) containing cleaning devices that contact the floor. The cleaning devices mounted on the deck (102) include vacuum head (132), brushes (120), cleaning fluid sprays (128), and conceivably sanitizing devices such as UV germicidal light, are provided pre-sterilized. As such, the adapted floor-cleaner chassis (124) allows the deck (102) to be mounted to the bottom of the chassis (124), the floor-cleaner (100) is then used to clean a floor, after which, the deck (102) is removed from the chassis (124) and disposed. The robotic-floor cleaner (100) and sterilization system cleans floor between or even during cases. Further, the robotic floor cleaner (100) reduces the “turnover time” required between cases, as it operates simultaneously while the staff prepares the room for the next case.

Owner:OPTIMUS LICENSING AG

Treatment and composition for achieving skin anti-aging benefits by corneum protease activation

Novel methods and compositions for treating aged and environmentally damaged skin are disclosed which provide improvements in the skin's visual appearance, function and clinical / biophysical properties by activating at least one proteolytic enzyme in the skin's stratum corneum. The disclosed treatment methods involve topical application of a novel cosmetic composition containing a combination of a cationic surfactant such as N,N,-dimethyldodecyl amine oxide (DMDAO), an anionic surfactant such as sodium dodecyl sulfate (SDS), or monoalkyl phosphate (MAP) and a chelating agent such as ethylene diamine tetraacetate (EDTA) to stimulate a chronic increase in the replacement rate of the skin's stratum corneum by means of corneum protease activation. This chronic, low level stimulation is effective to induce repair and replacement of the stratum corneum, epidermis, and dermis of the skin and improvements in the appearance, function, and anti-aging properties of the skin.

Owner:ALLUSTRA TECH LLC

Medicinal preparation for treating nerve-root cervical spondylopathy, and preparation method and quality detection method thereof

InactiveCN104887771AMeet needsVarious dosage formsNervous disorderComponent separationClinical efficacyCervical spondylopathy

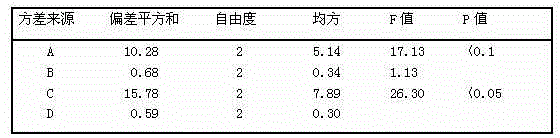

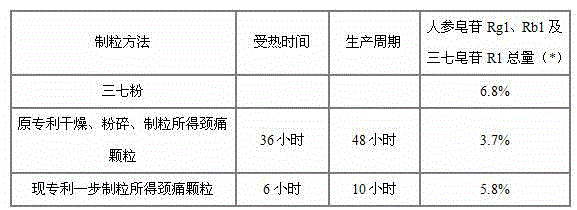

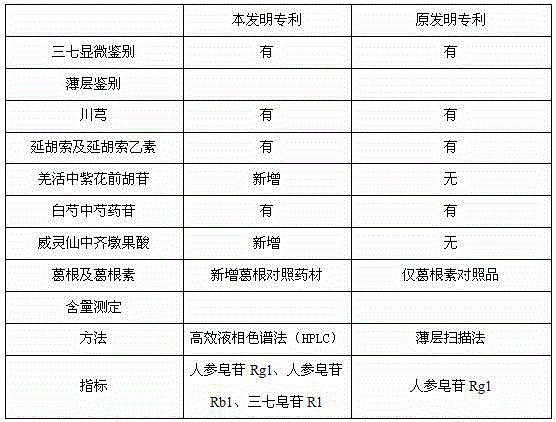

The invention relates to a medicinal preparation for treating nerve-root cervical spondylopathy, and a preparation method and a quality detection method thereof. The invention is an extension of an original invention. The medicinal preparation comprises a granule, a tablet and a capsule, the preparation method is an optimized and screened production technology based on the original invention, a modern new device, a new process and a new technique are adopted to realize industrial production; and quality standard researches are completed and improved on the basis of original standards, HPLC is adopted to simultaneously determine the content of ginsenoside Rg1, ginsenoside Rb1 and notoginsenoside R1 in a finished product, and thin layer discrimination of all medicines is carried out to comprehensively control the quality, so the clinic curative effects are guaranteed.

Owner:SHANDONG MINGREN FURUIDA PHARMA

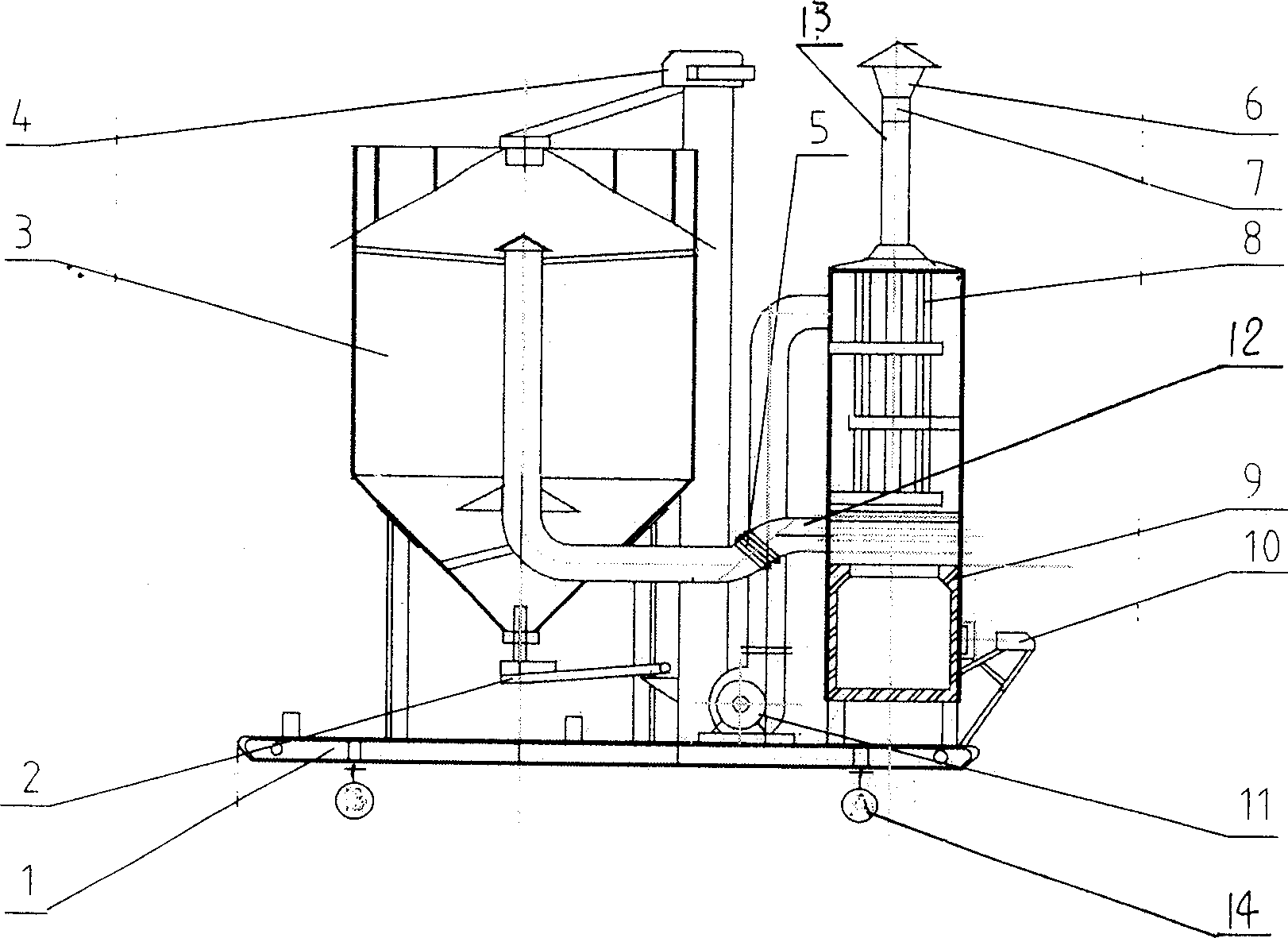

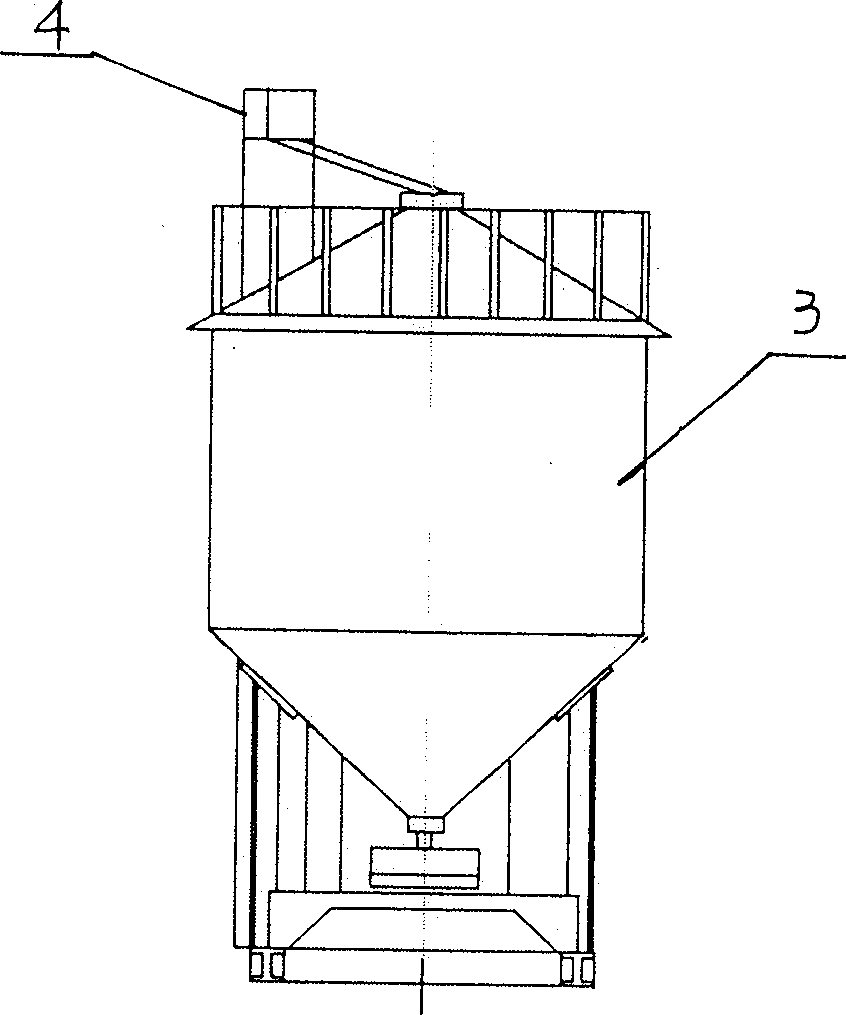

Small-sized moveable grain storing and drying barn

InactiveCN1763464AReduce turnover timesImprove qualityHeating arrangementAgricultural engineeringCoal

The invention provides a small-sized mobile grain stock drying warehouse, which consists of ventilation drying warehouse and hot air stove, wherein the ventilation drying warehouse and hot air stove are set on the same chassis; the indexable conveyor is set in the bottom outlet of ventilation drying warehouse; the grain lifter is set on one side of ventilation drying warehouse, which circulates the grain between outlet and inlet of ventilation drying warehouse; the base of hot air stove contains straw burning furnace; the heat-exchanger is set on the top of hot air stove, whose hot air outlet connects the ventilation drying warehouse through hot air pipe. The invention can dry the grain timely to improve the quality of grain and adapts the straw as fuel to reduce the coal consumption, whose ash is fertilizer for field directly.

Owner:柳芳久

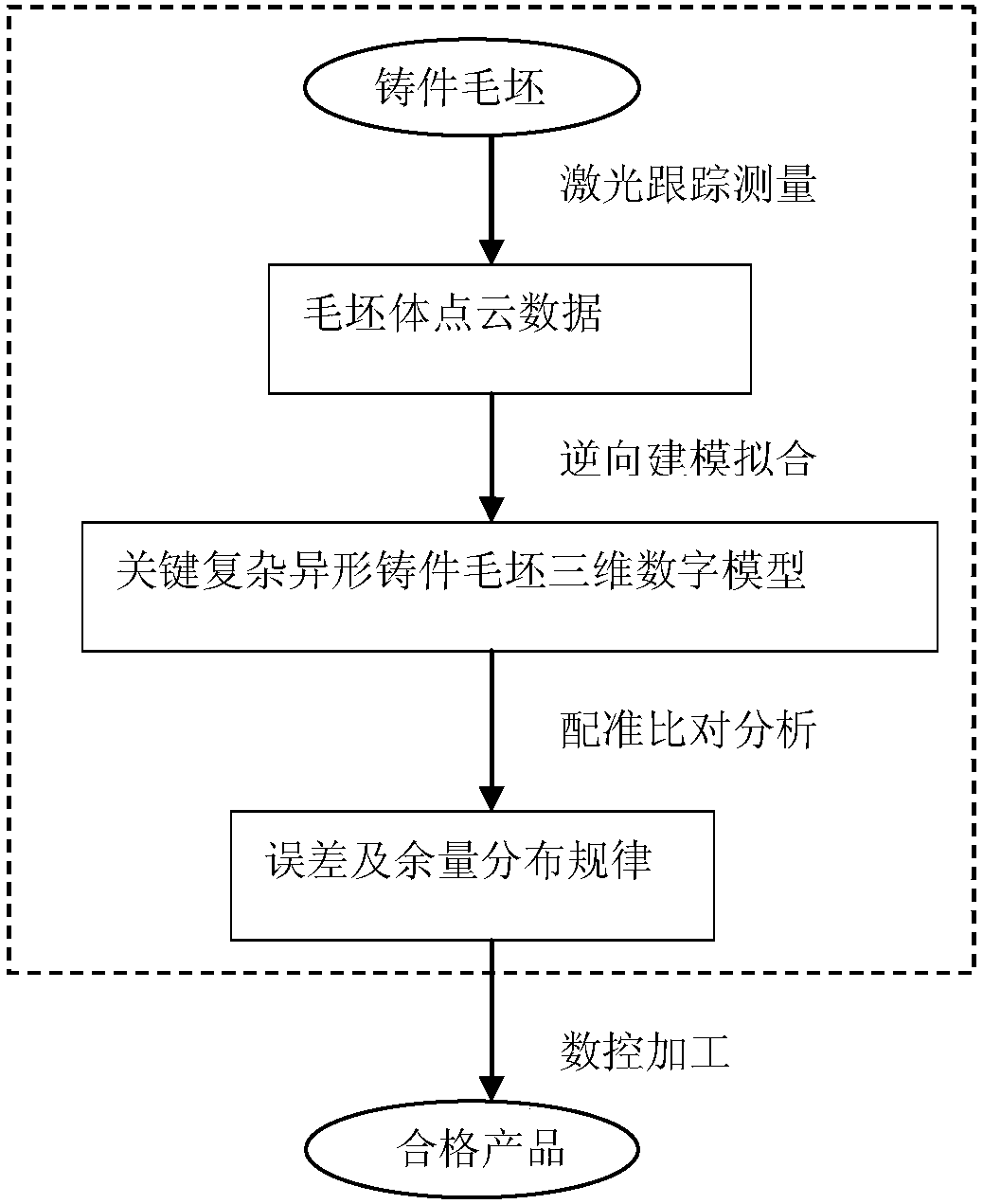

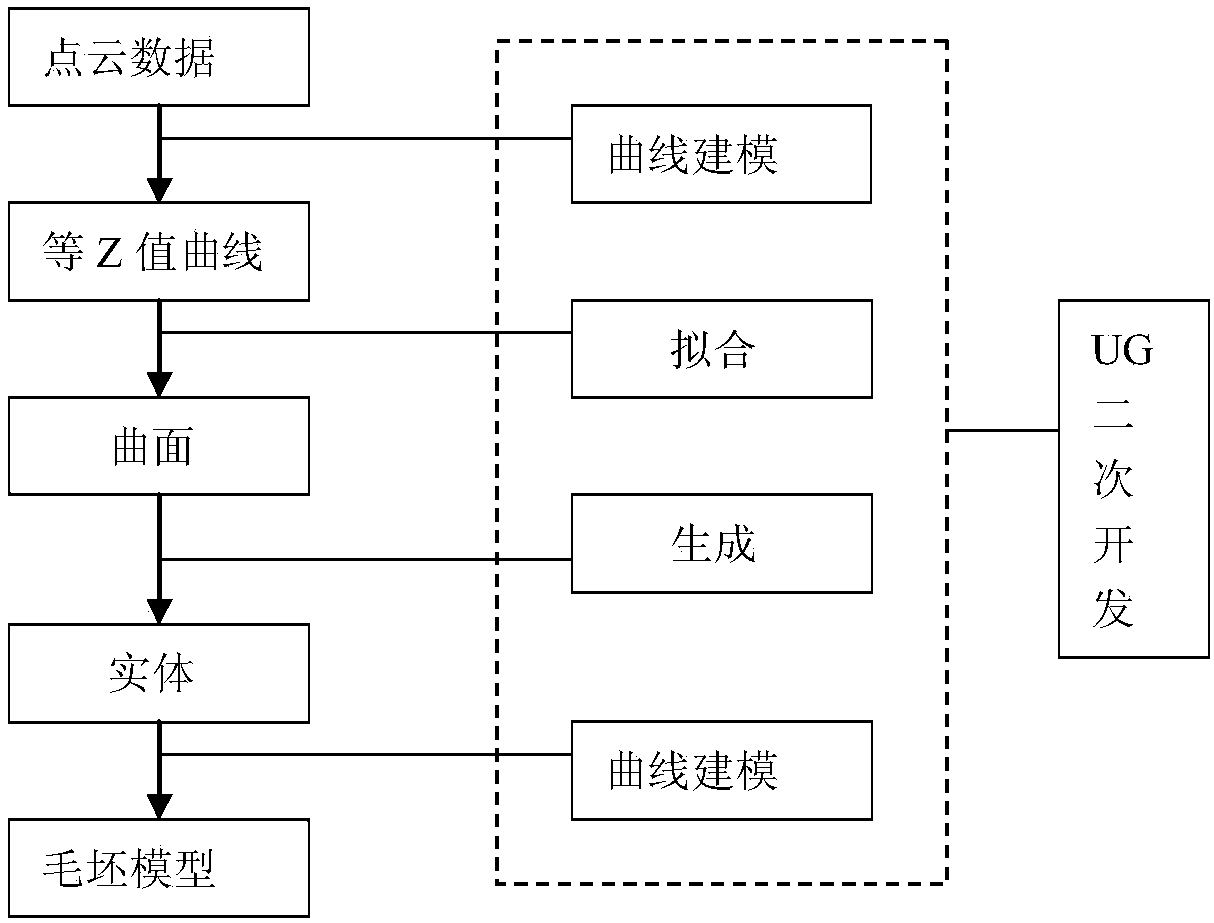

Complex special-shaped casting measurement checking method based on laser tracking measurement

InactiveCN108120373AAvoid multiple patchesReduce turnover timesUsing optical meansThree dimensional modelThin walled

The invention discloses a complex special-shaped casting measurement checking method based on laser tracking measurement, wherein the method belongs to the field of machining manufacture and settles problems such as thin wall, cutting-through and insufficient thickness caused by a blank casting error after product machining. According to the method, a measurement laser tracker or a scanner is utilized for measuring a complex special-shaped casting, and high-precision dimension scanning and measurement to the profile and inner chamber of the casting are realized, thereby obtaining cloud data ofthe profile and the inner chamber point of the complex special-shaped casting. Then through software, a solid model is generated from coordinate points, thereby realizing three-dimensional model acquisition of a blank object. Finally position registering and inclusive analysis are used as basic comparison principles, thereby obtaining a product machining allowance distribution rule, and supplyingdata supporting for subsequent numerical control machining and qualified product manufacturing.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

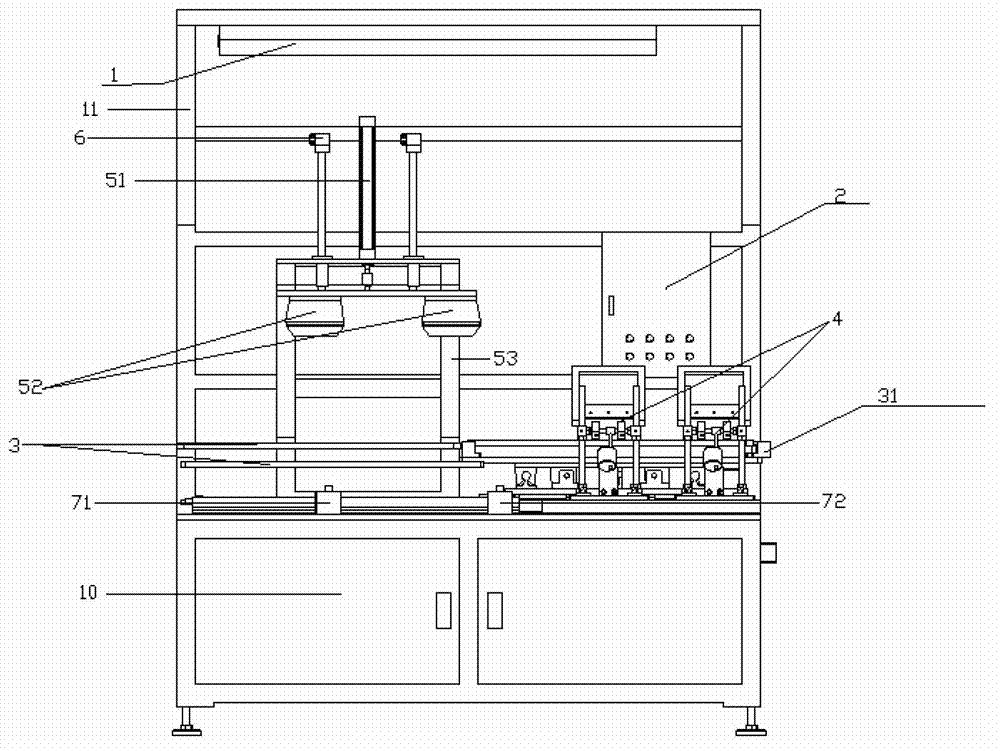

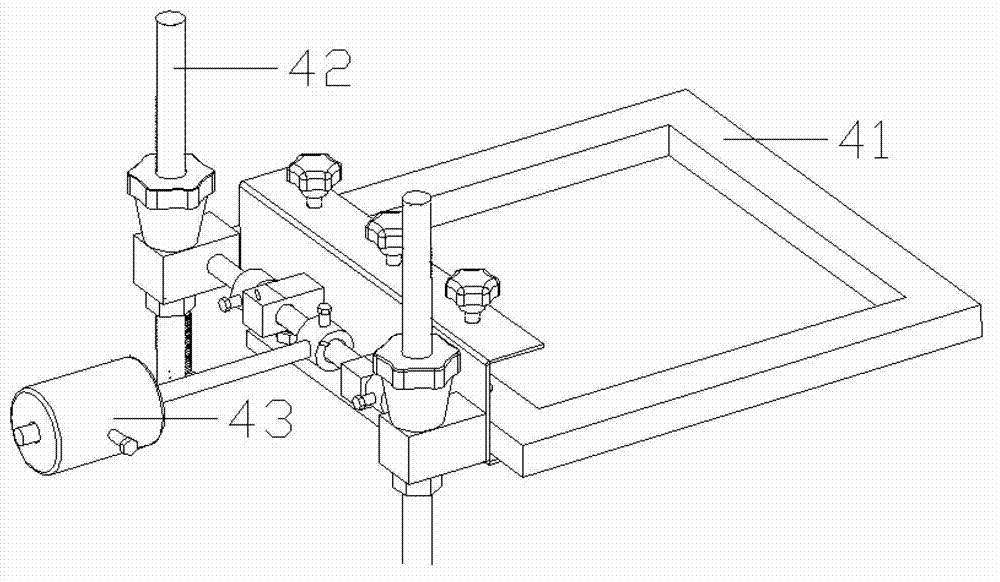

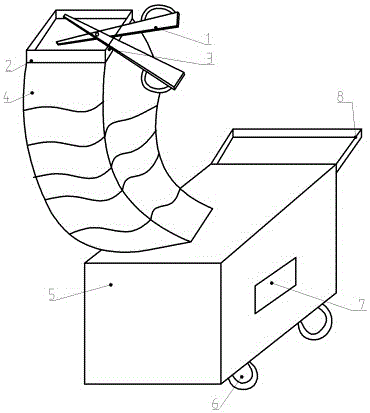

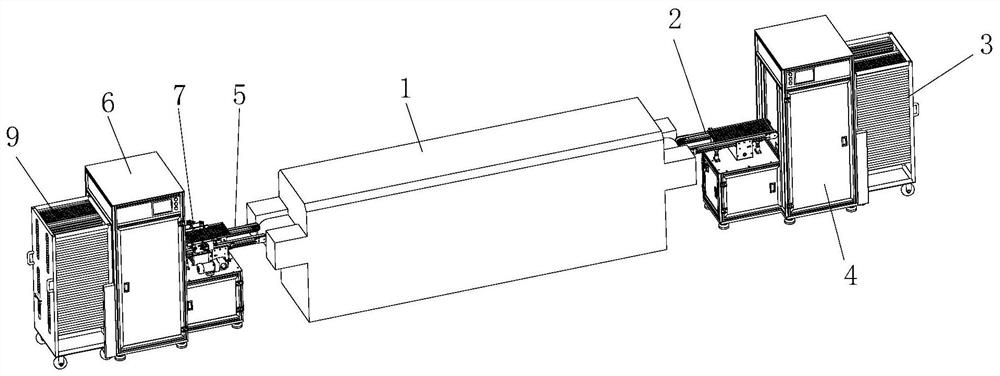

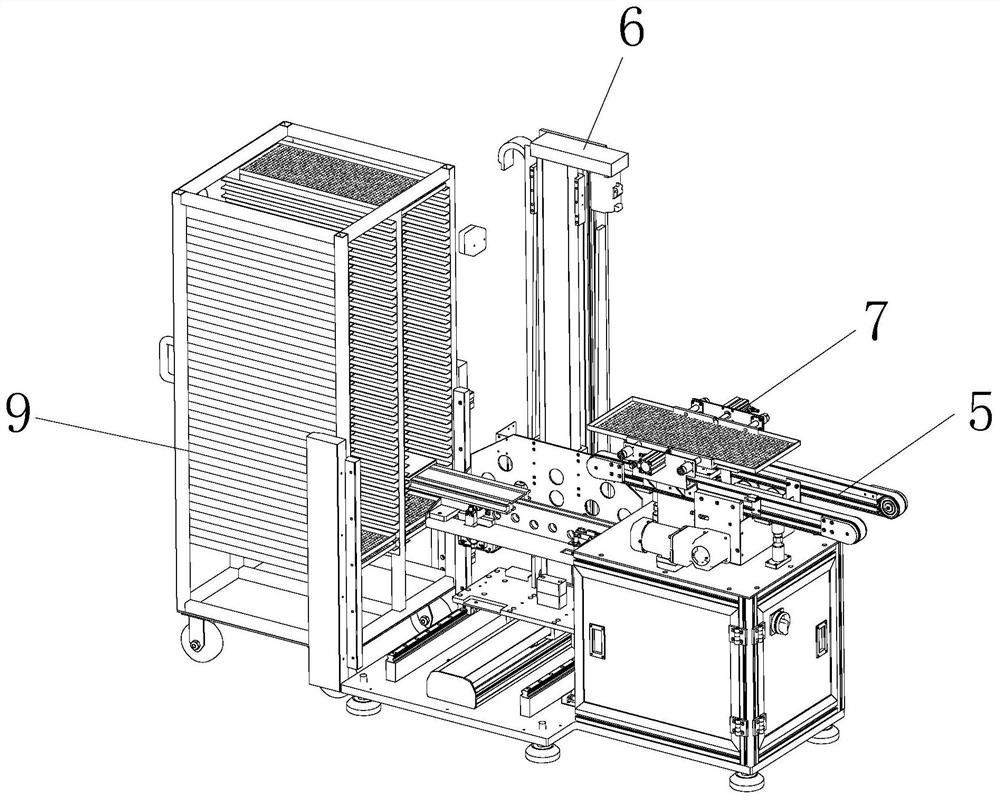

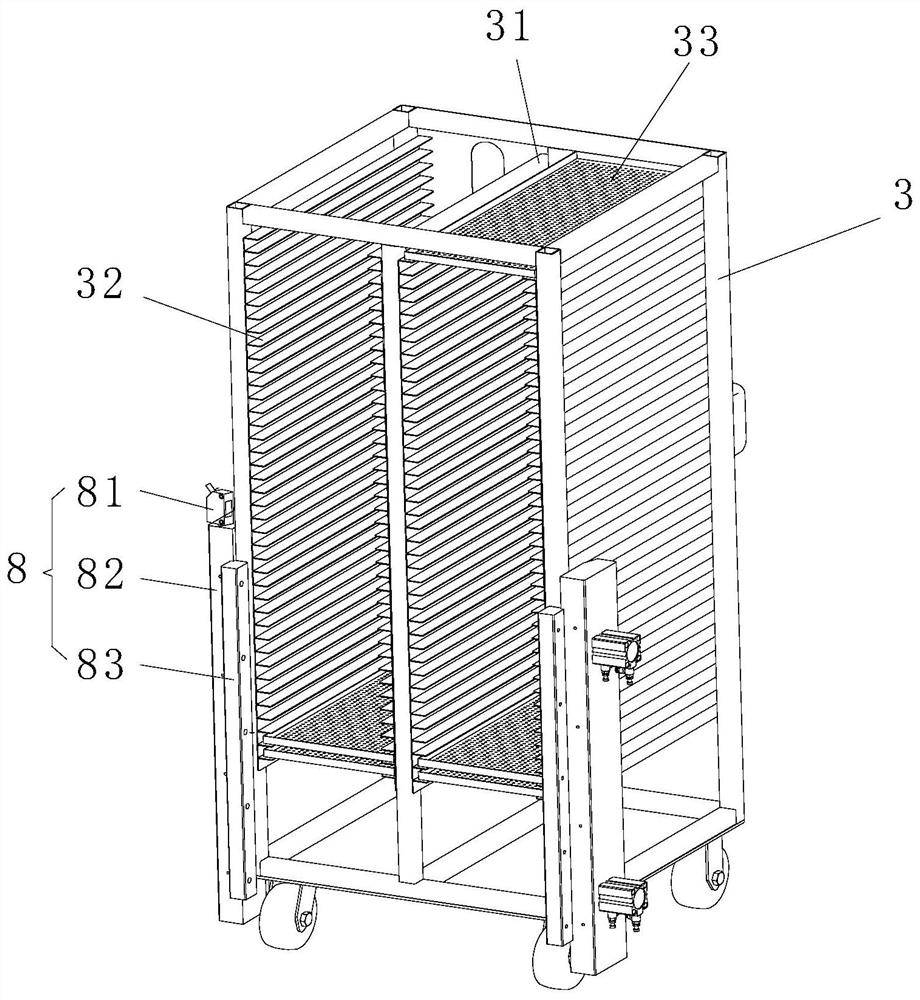

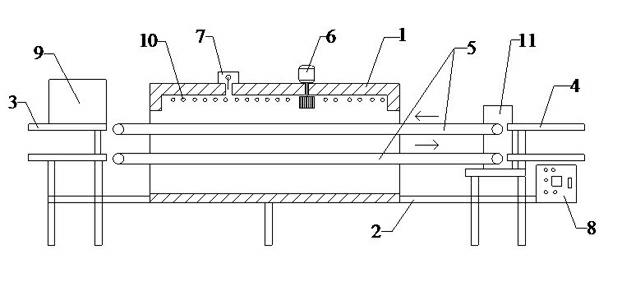

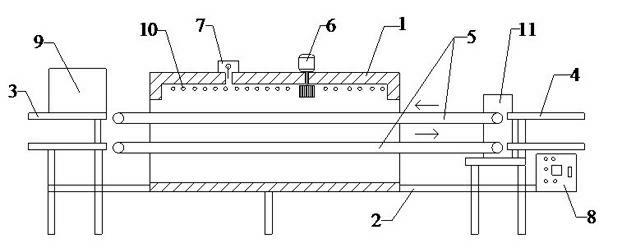

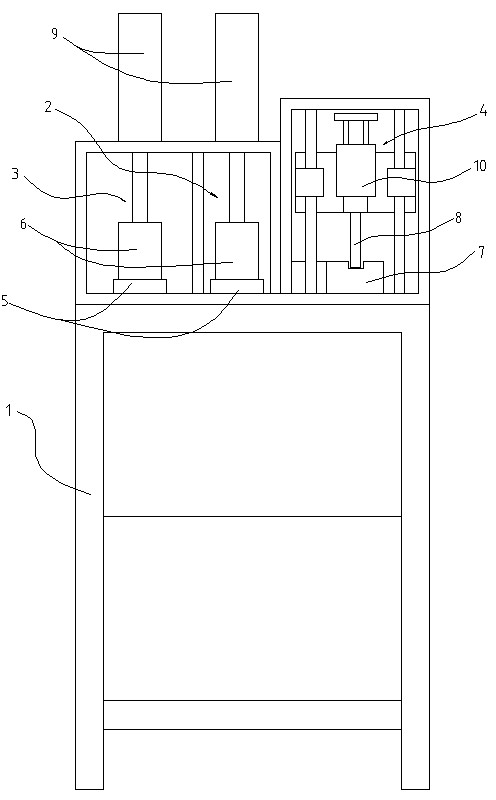

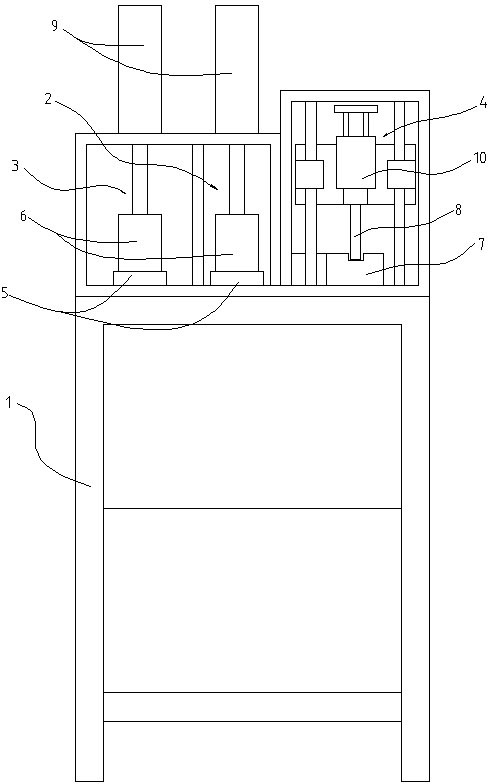

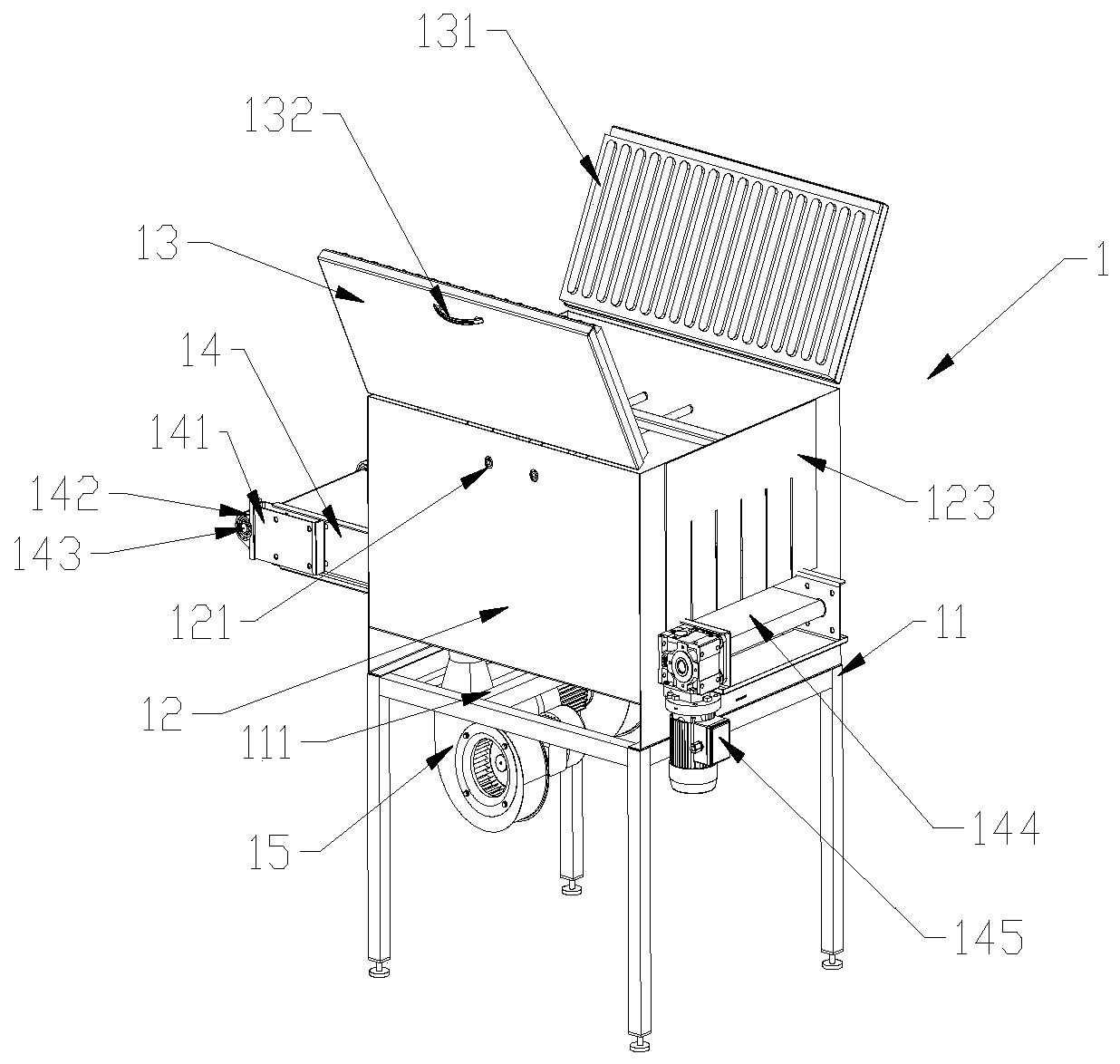

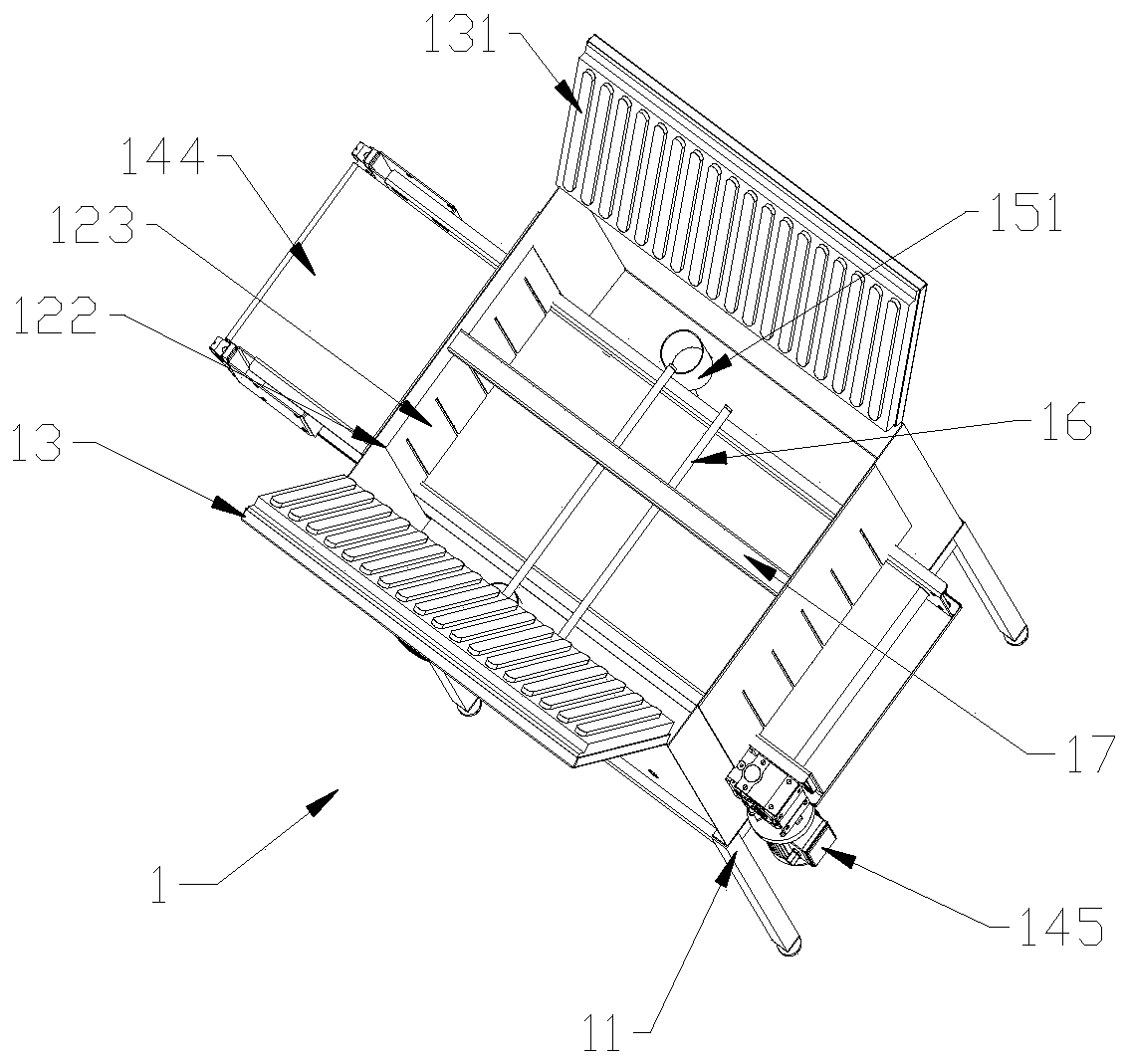

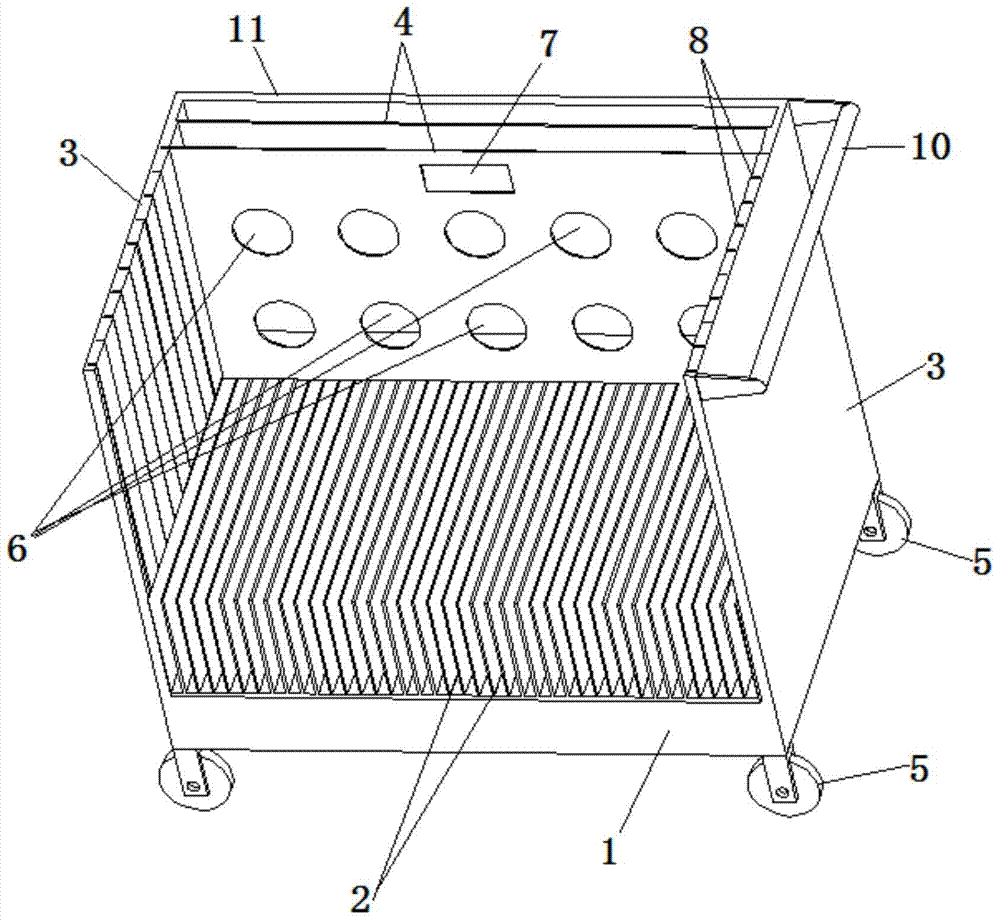

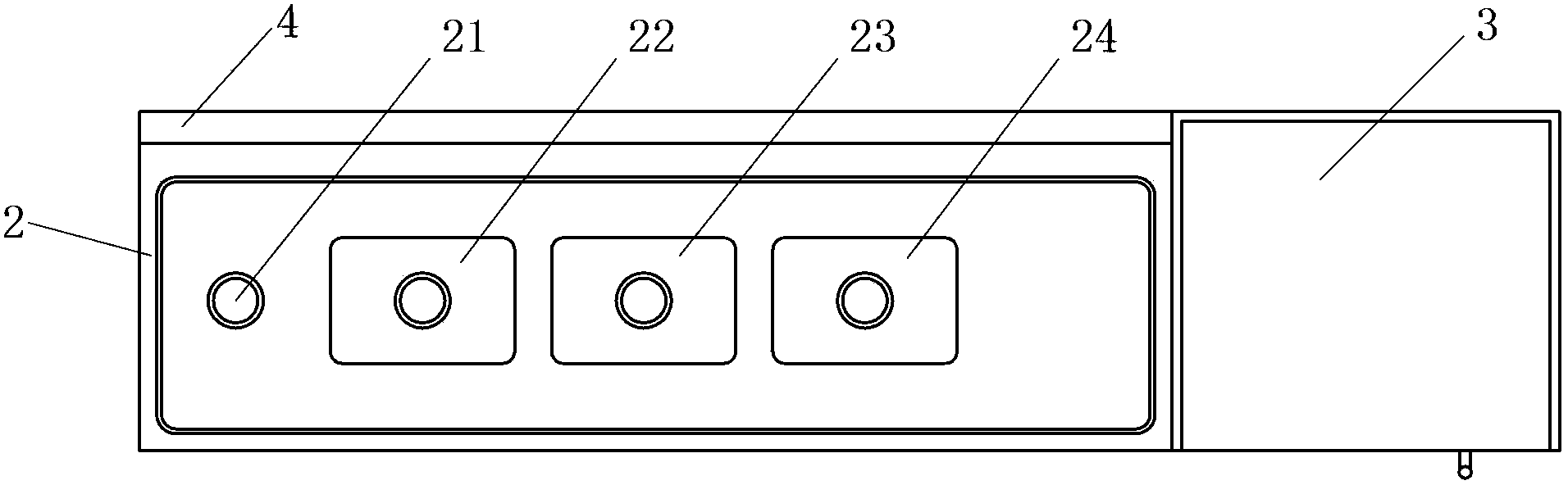

Silkscreen drying all-in-one machine

The invention provides a silkscreen drying all-in-one machine. The silkscreen drying all-in-one machine comprises an operating platform, a support, a fluorescent lamp, an intelligent electronic display board system, a drying mechanism, an electric cabinet, a screen printing device and a movable loading platform and is characterized in that the drying mechanism comprises a drying mechanism support frame, a dryer and a lifting mechanism; the screen printing device and the movable loading platform are arranged on the horizontal surface of the operating platform; the support is fixed in the vertical direction of the operating platform; the fluorescent lamp is arranged at the top end of the support, and the electric cabinet and the drying mechanism support frame are arranged in the middle of the support; the lifting mechanism and the intelligent electronic display board system are arranged on the drying mechanism support frame, and the drier is arranged at the bottom end of the lifting mechanism; the screen printing working angle of the screen printing device can be adjusted at random so that the screen printing device is very convenient to use, the operation strength is low, the operation procedure of products is greatly shortened, the production cycle of products is accelerated, manual labor and consumptive materials are saved, and the packaging frequency and the transfer frequency are reduced; the molding-machining-packaging integrated operation is implemented; and the machine platform is simple in structure and convenient to debug and jigs can be replaced conveniently.

Owner:ANHUI ECHOM SCI & TECH

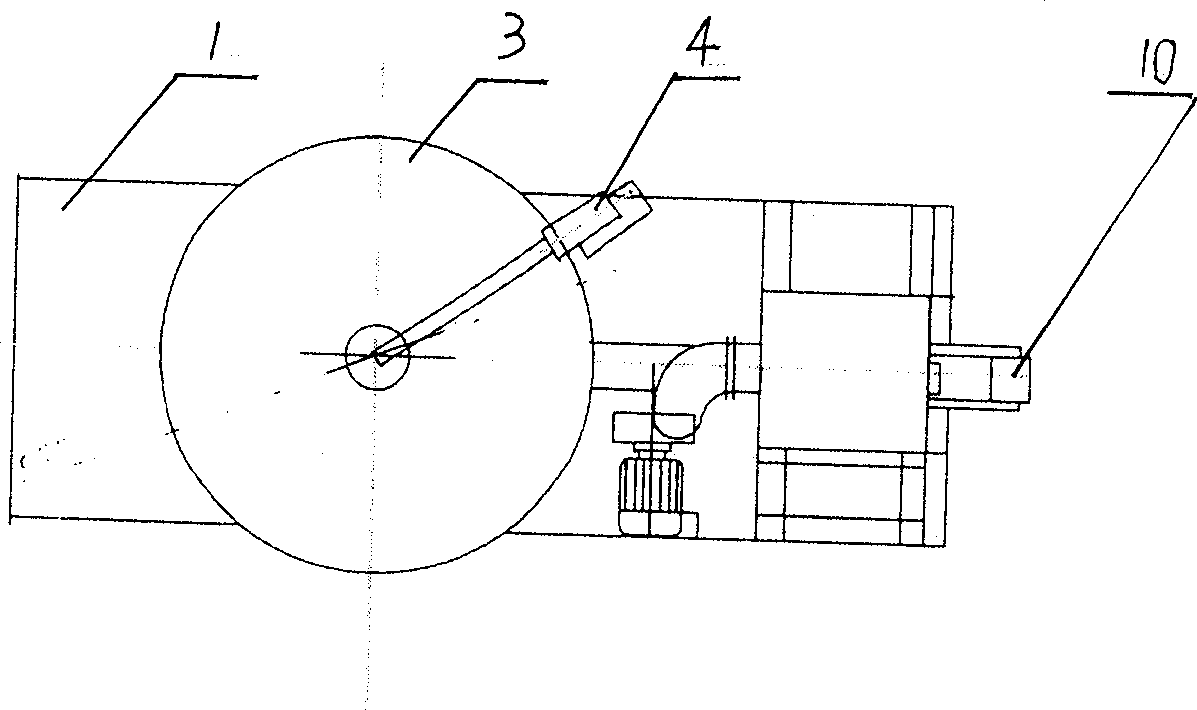

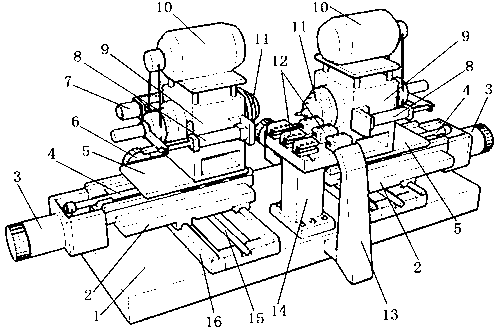

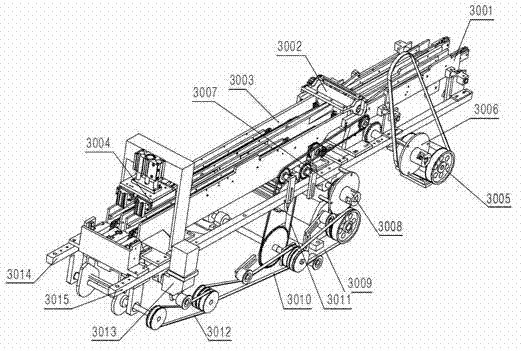

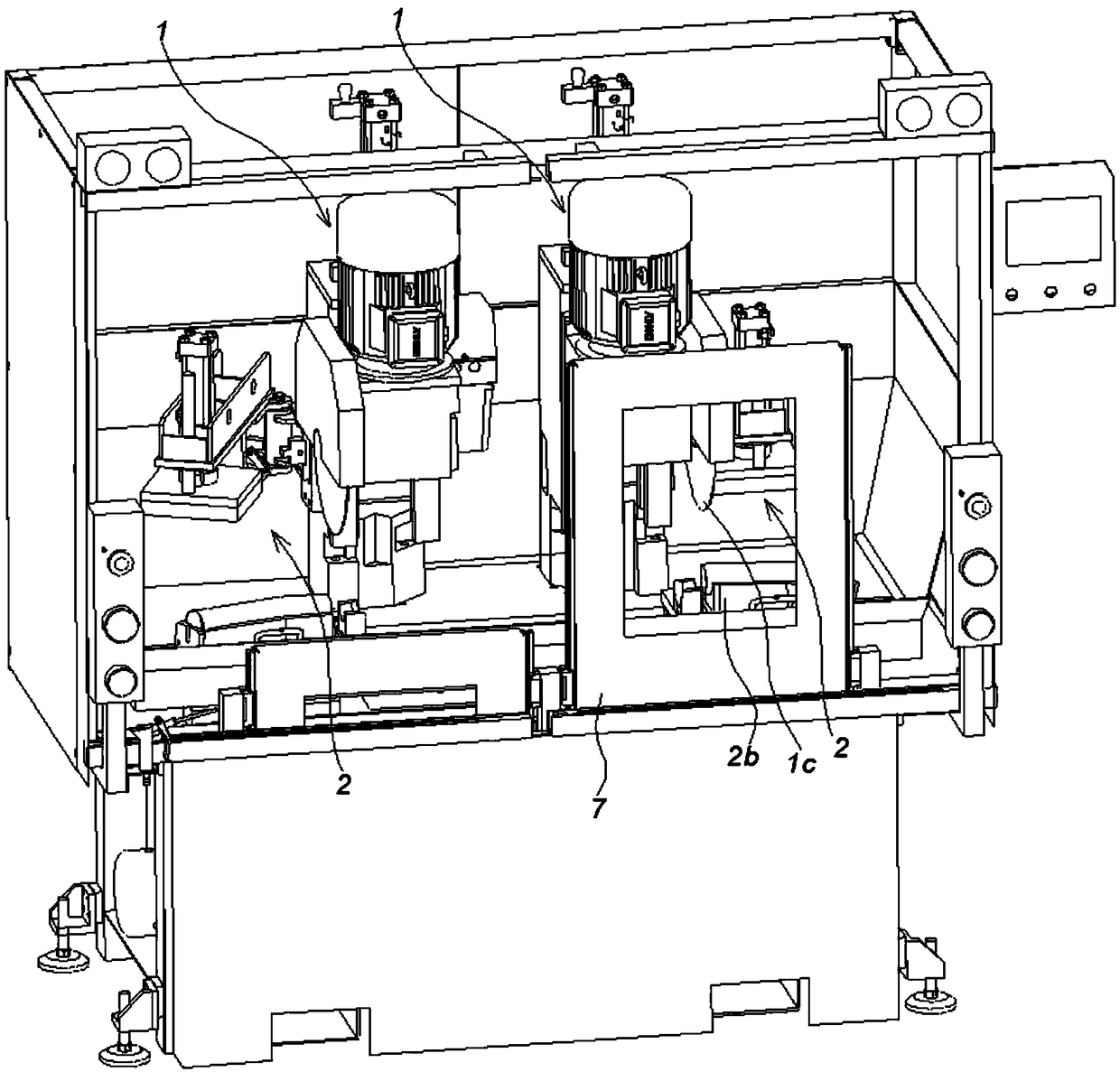

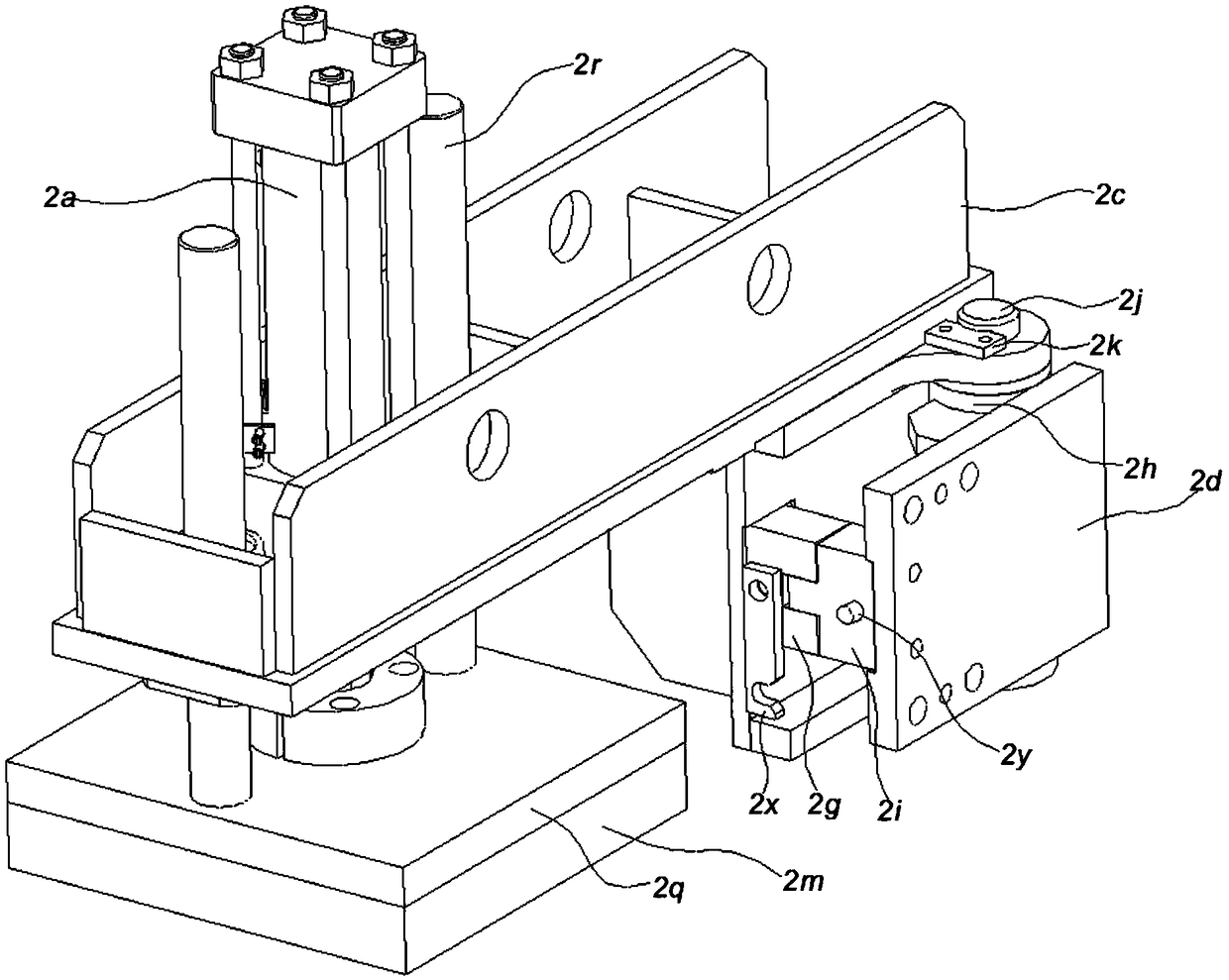

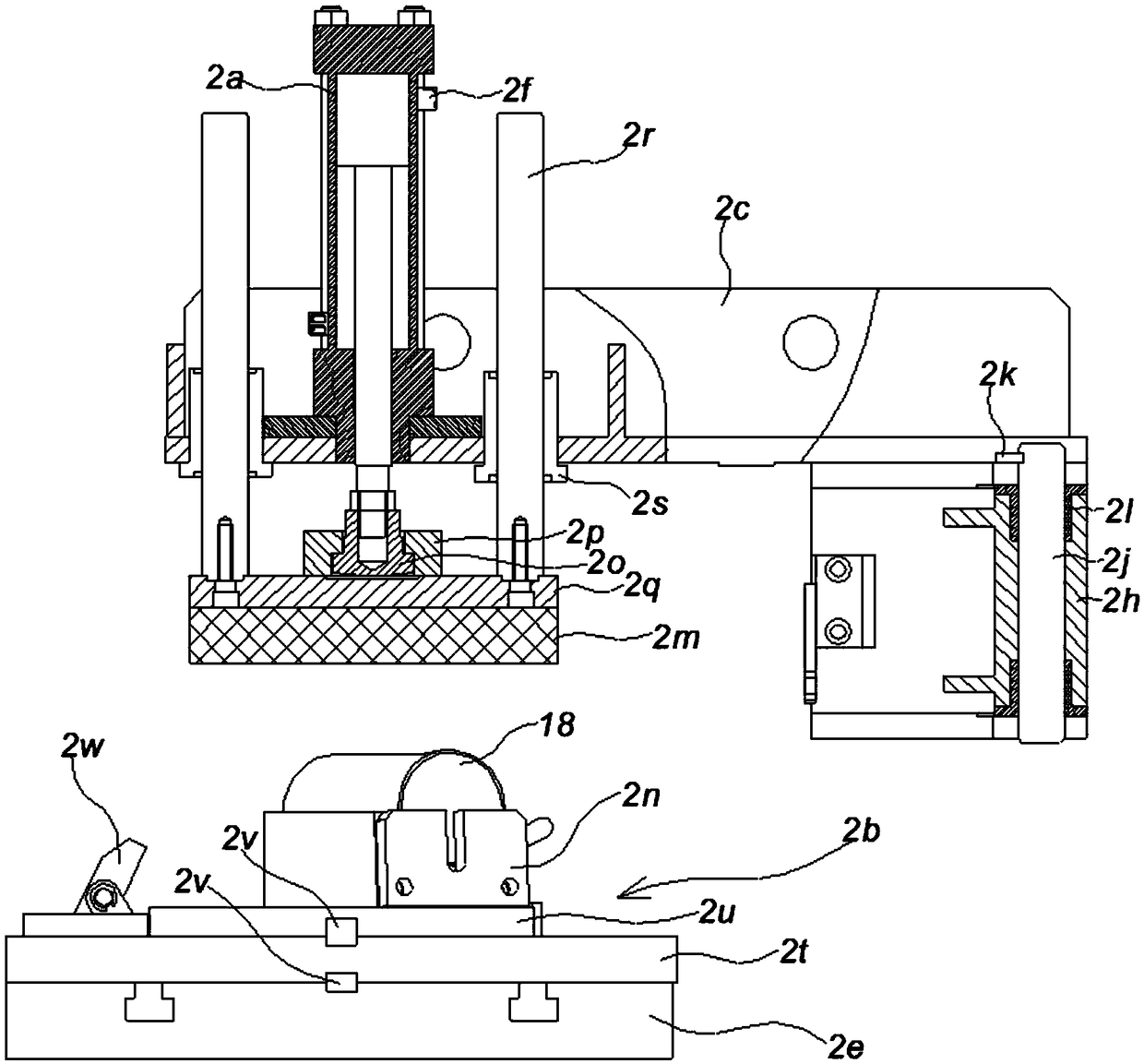

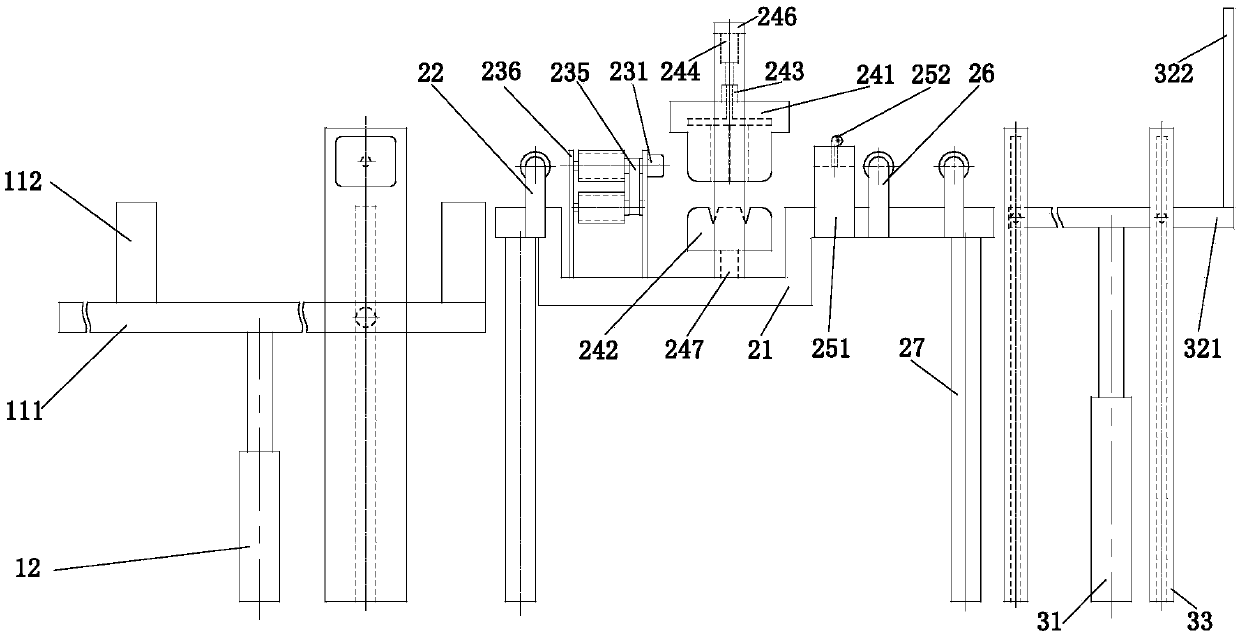

Double-lathe-head full-automatic numerically-controlled lathe

InactiveCN103170653AReduce manual loading and unloadingReduce turnover timesAutomatic/semiautomatic turning machinesMechanical equipmentEngineering

The invention discloses a double-lathe-head full-automatic numerically-controlled lathe and relates to mechanical equipment used for machining of workpieces. The double-lathe-head full-automatic numerically-controlled lathe is mainly composed of a lathe body, lathe heads, a guide rail, an X-direction moving drag plate, a Z-direction moving drag plate, a knife rest and the like. The lathe heads are of a double-lathe-head structure which allows bidirectional moving and machining at the same time, the knife rest is fixedly arranged between the two lathe heads, a double-face knife rest structure is adopted, and therefore the machining method is that the workpieces can rotate automatically and move along the X-direction and the Z-direction with the lathe heads. The structural change breaks an original structural form and machining method of a traditional lathe, machining process is simple and labor-saving, especially great convenience is brought to parts needing double-head machining, work efficiency is improved greatly, in addition, times of manual assembling and disassembling and turnover are reduced, damage on the workpieces is avoided, and machining accuracy can be effectively guaranteed.

Owner:盛焕君

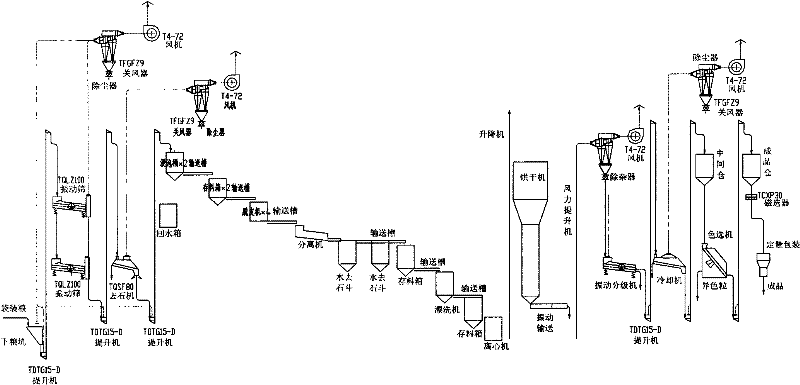

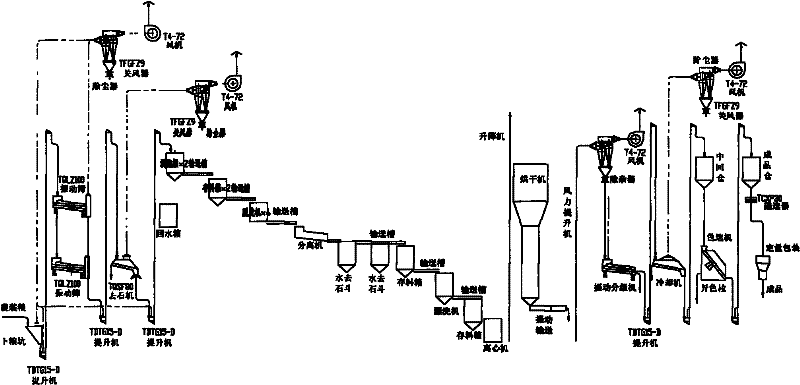

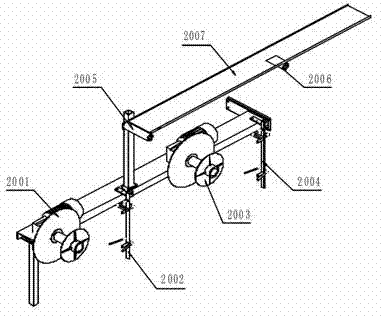

Process for washing sesame with water

InactiveCN102240653AReduce turnover timesEasy to separateCleaning processes and apparatusGeneral screeningEngineering

The invention discloses a process for washing sesame with water. The process comprises the following steps of: removing and separating impurities and stones from the sesame at first; then immersing and washing the sesame with water, stripping the sesame and separating the sesame; drying, performing color selection and magnetic separation; and finally, finishing a process of manufacturing qualified sesame meat. The whole process is extremely smooth and the transferring frequency of the sesame is low, so the production efficiency is improved greatly; various measures, such as general screening, color selection, magnetic separation and the like, are used together, so cleaning and grading can be performed simultaneously; and the later targeted deep processing of the sesame is facilitated.

Owner:NANTONG GRAIN MACHINERY

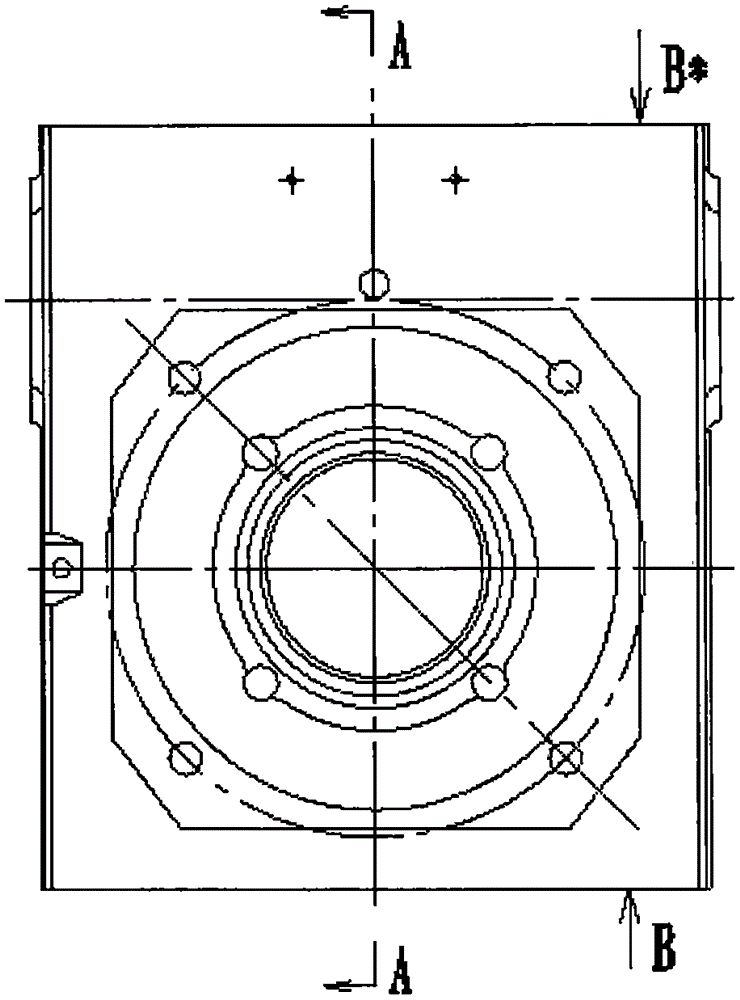

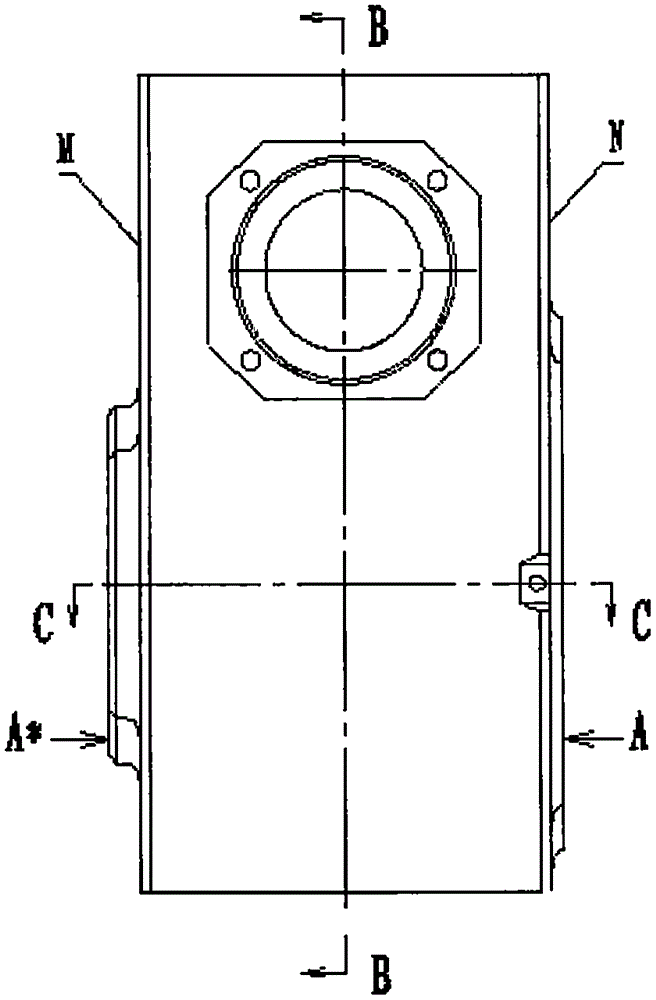

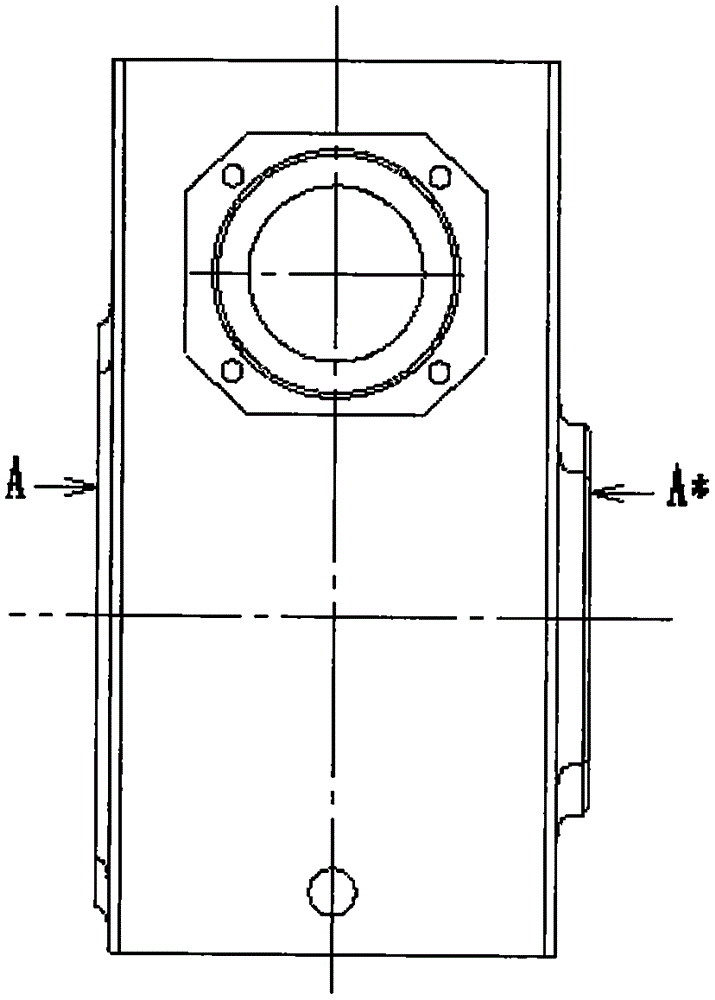

Tool for machining box and machining technology of tool

ActiveCN105479123AReduce the number of clampingGuaranteed Position Accuracy RequirementsOther manufacturing equipments/toolsPositioning apparatusEngineeringMachining

The invention discloses a tool for machining a box. The tool comprises a stand column arranged on a rotary working table of a horizontal machining center, a box tool body I and a box tool body II. The box tool body I and the box tool body II are symmetrically arranged on the two sides of the stand column. According to the box tool body I, positioning is carried out through a positioning mechanism I with the B face and the M face of a workpiece as machining standards, and the N face, the L face and the Q face of the workpiece are tightly pressed through a clamping mechanism I for fixing. According to the box tool body II, positioning is carried out in the mode that a positioning mechanism II is matched with a J hole and a K hole in the workpiece, and the M face of the workpiece is tightly pressed by a clamping mechanism II for fixing. A box machining technology in which the tool is used includes the steps that the workpiece is installed on the box tool body I and the box tool body II in sequence, a required tool is installed in a tool magazine in advance, a machining program is compiled in advance, and then a machine is started to machine the workpiece. According to the tool and the technology, box machining can be completed only through two times of clamping, the machining technology is simplified, machining quality is guaranteed, the labor intensity of an operator is reduced, and machining efficiency is improved.

Owner:SHANDONG FUYUAN TRACK MACHINERY CO LTD

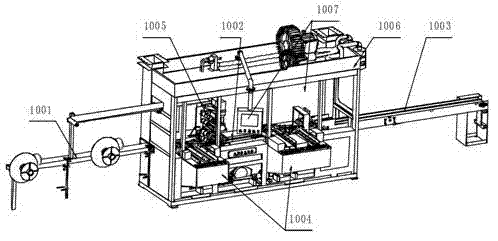

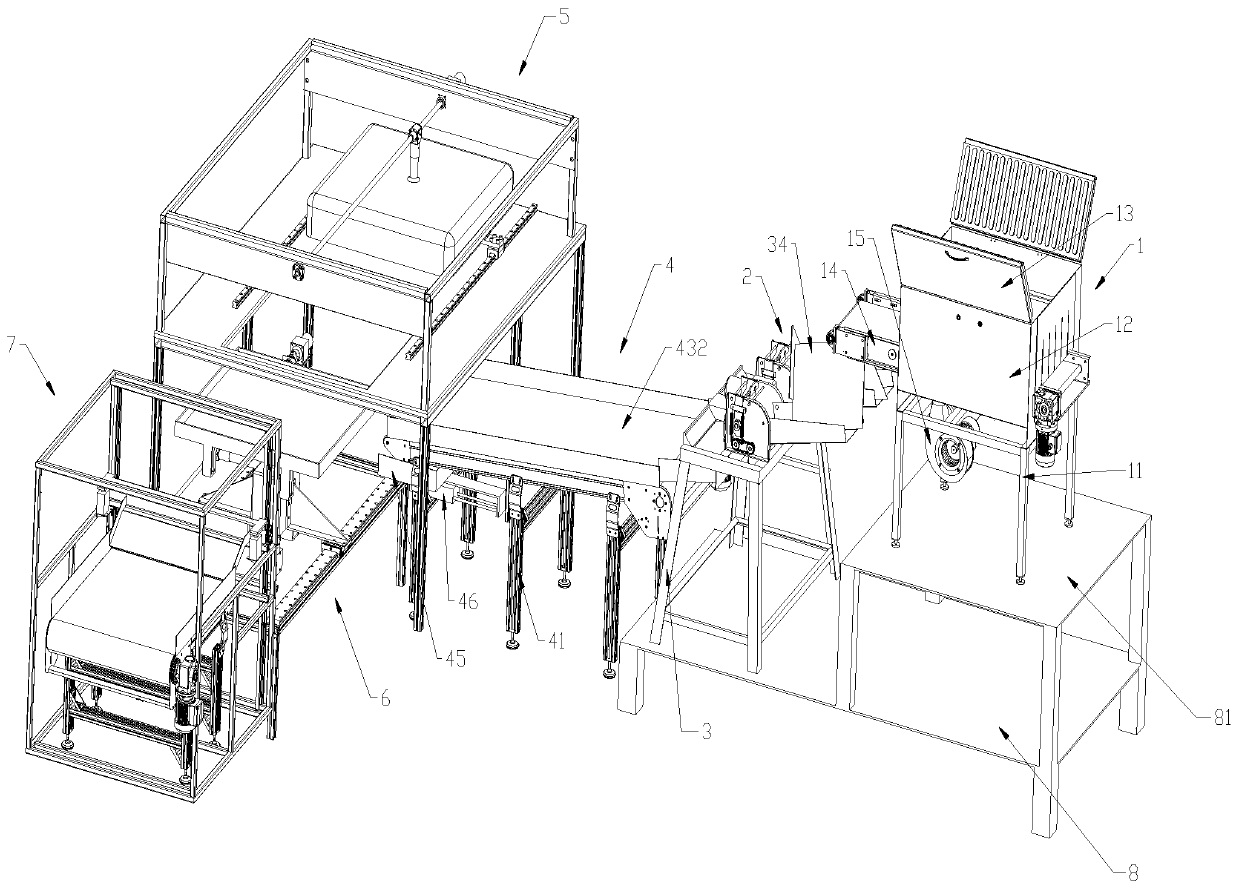

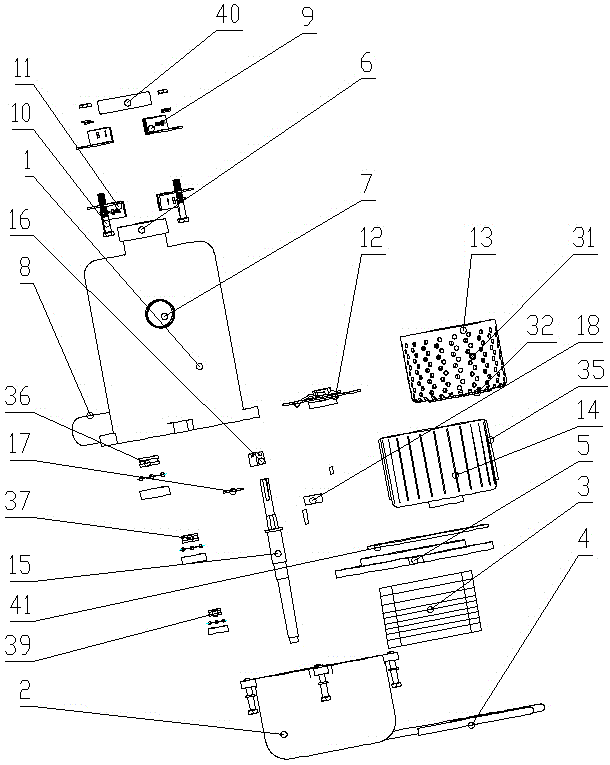

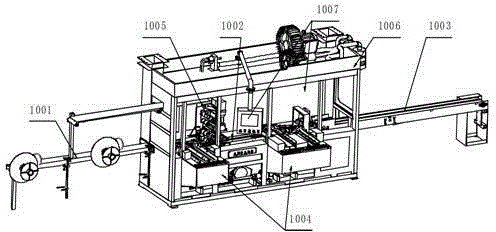

Encapsulating and matching machine of lead-acid storage battery plate

ActiveCN102891339ASimple structureReduce equipment failure rateFinal product manufactureLead-acid accumulators constructionPaper cutElectrical control

The invention relates to an automatic encapsulating and matching machine of a lead-acid storage battery plate, in particular to a device for encapsulating and matching a small-density polar plate in a production procedure of the lead-acid storage battery automatically. The encapsulating and matching machine of the lead-acid storage battery plate is an assembly line device comprising a rack, a paper feeding device, a plate feeding device, a paper cutting device, a polar plate feeding device and a collecting device which are sequentially connected, and the assembly line device automatically cooperates under the action of an electrical control system. By adopting a dual-line paper feeding device and the polar plate feeding device which are serially connected, and the plate feeding device vertically connected with the polar plate feeding device, the encapsulating and matching machine has the advantages of being simple, convenient and reasonable in structure, lowering the device failure rate and polar plate turnover times, realizing automatic encapsulation and matching of lead alloy polar plates of an automobile, completing the transformation of low-efficiency work to automatic, high-efficiency and environmental-friendly operation of the production process, greatly lowering the production strength and operation cost of manual operation, increasing the labor production efficiency, and reducing the pollution of lead dust to environment and injury to a human body.

Owner:武汉深蓝自动化设备股份有限公司

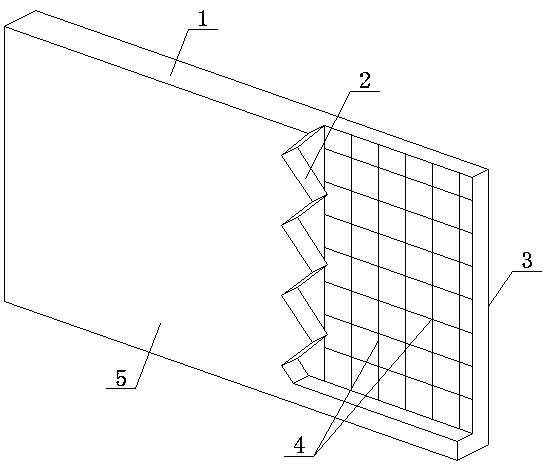

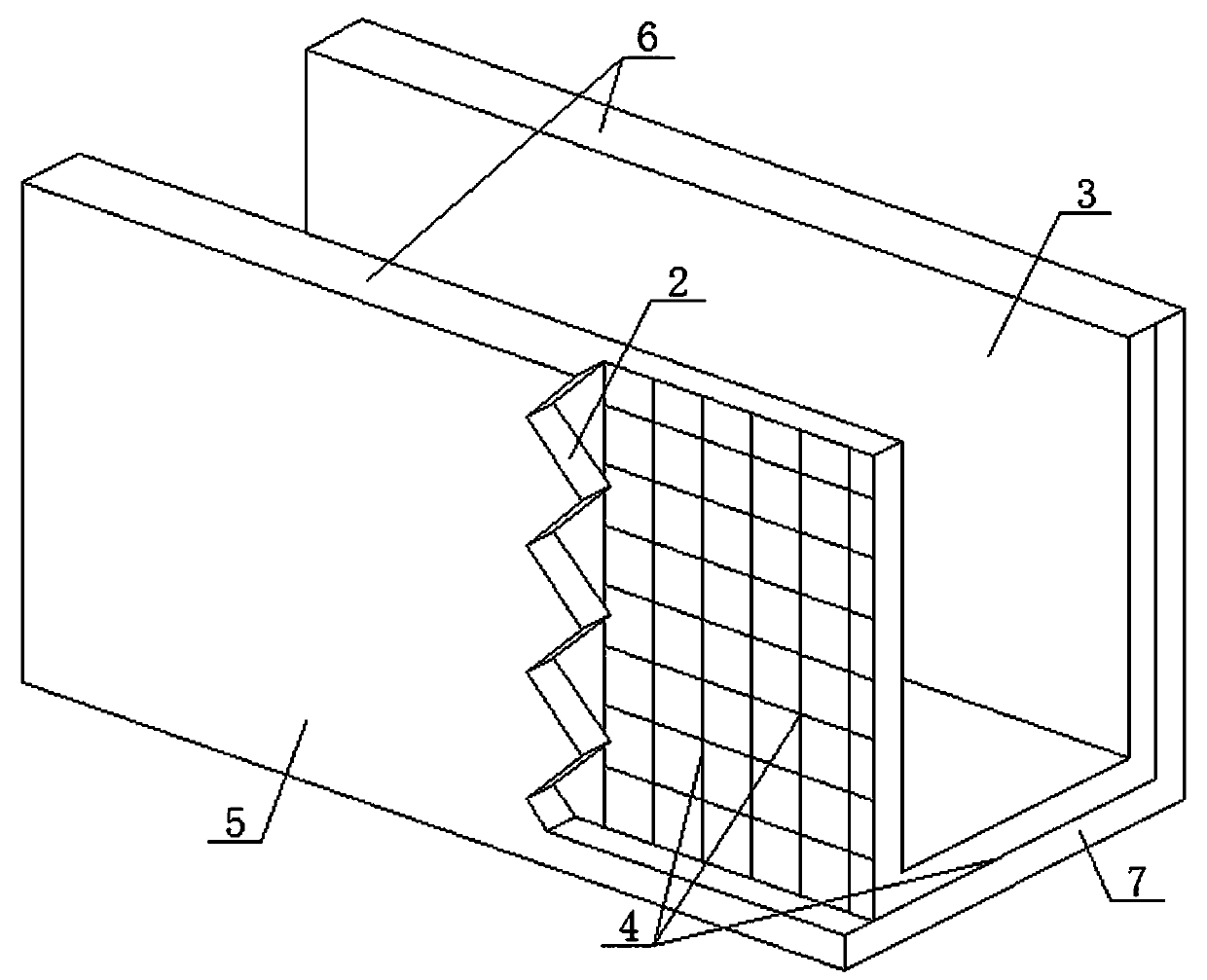

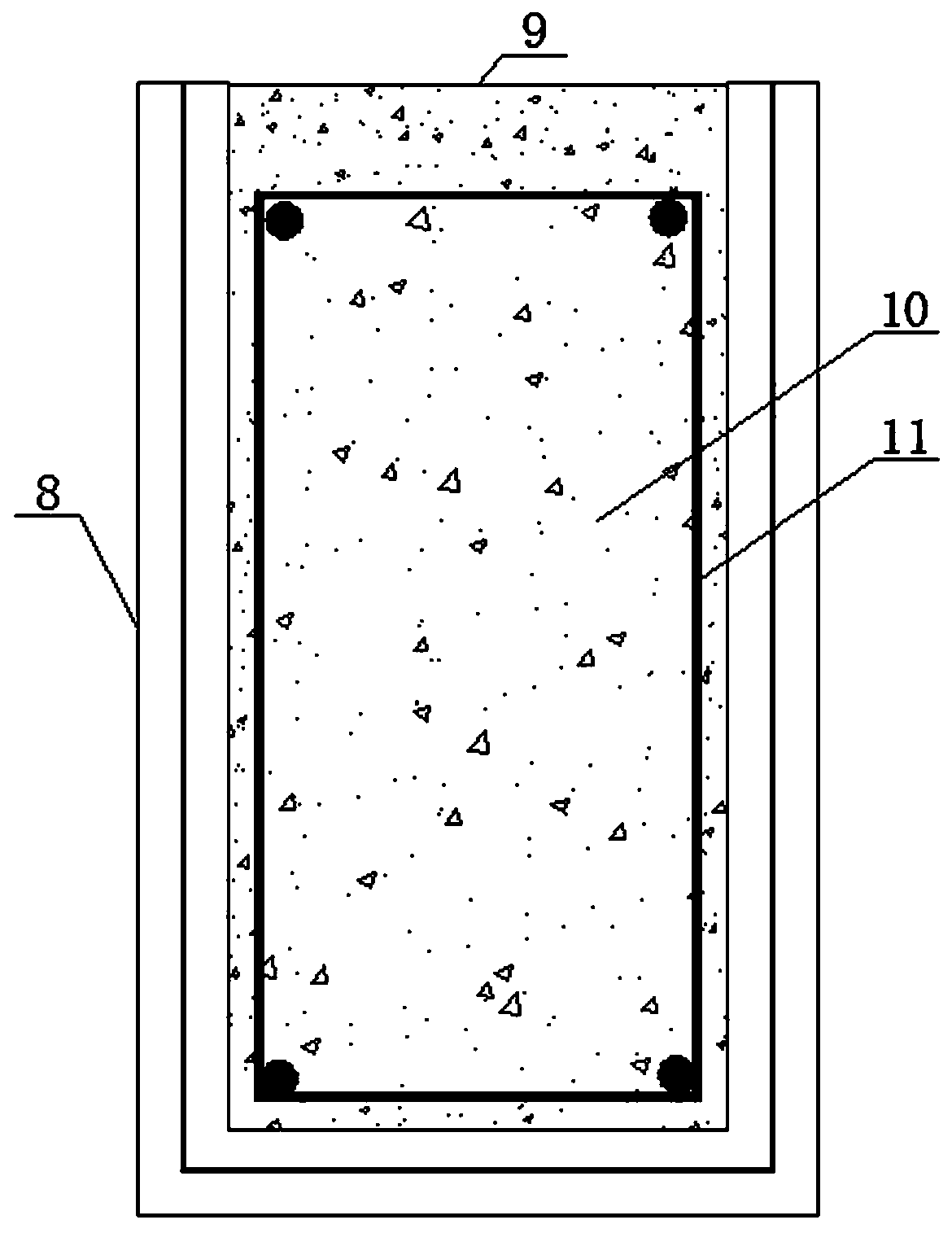

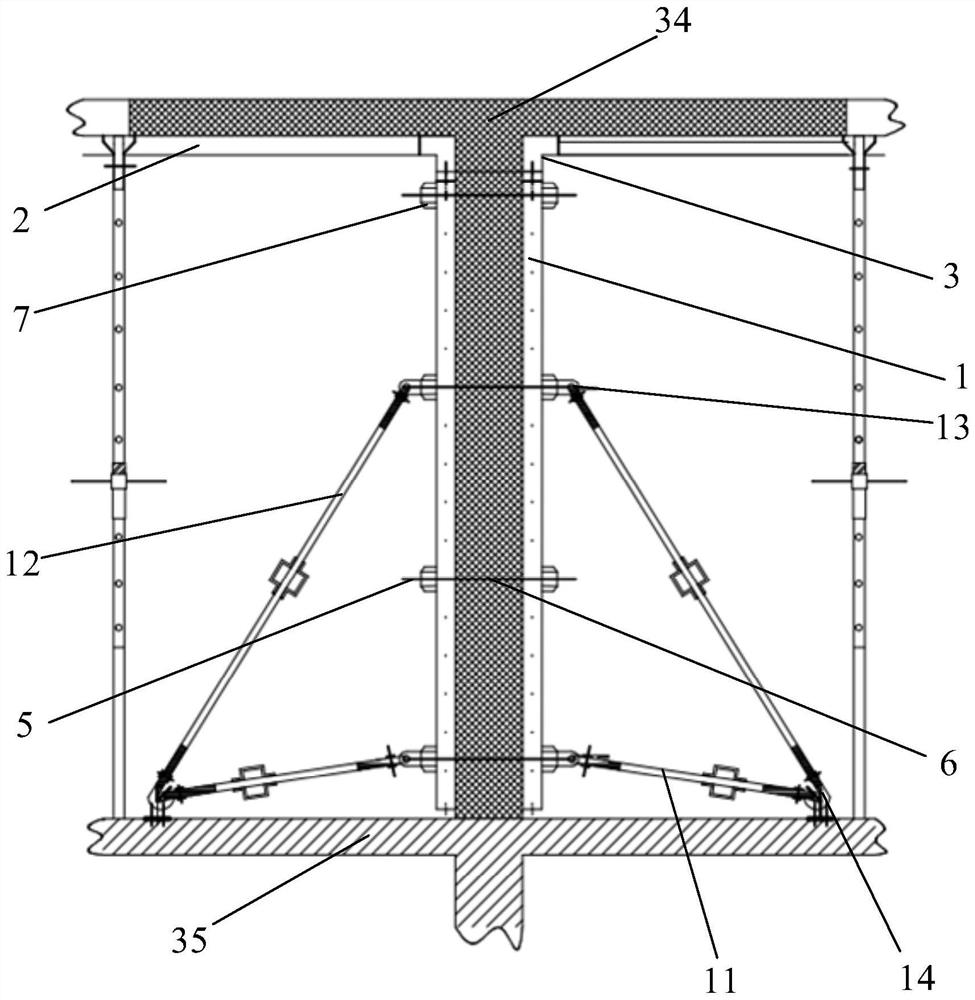

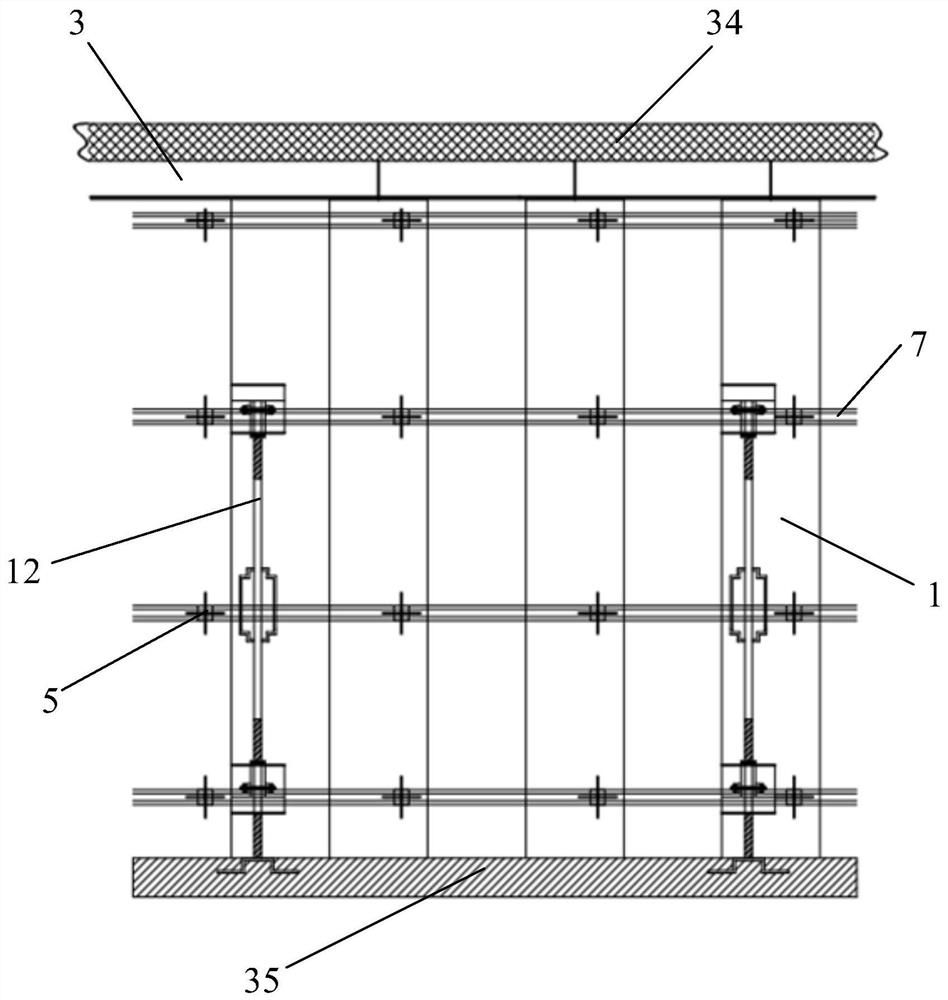

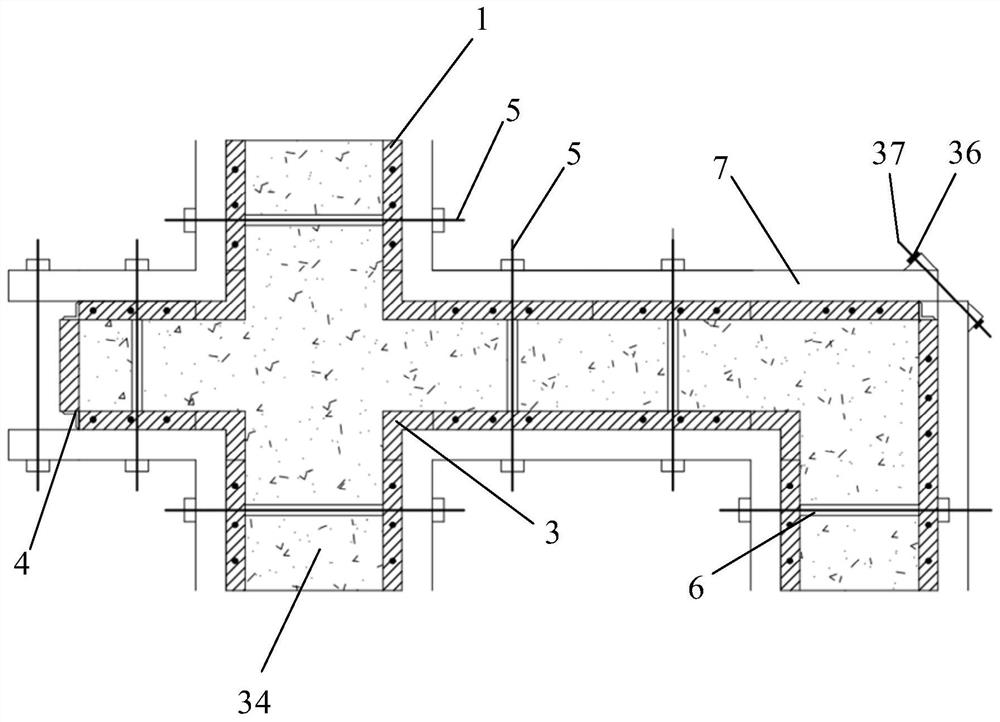

ECC non-dismantling formwork, concrete beam based on formwork and construction method thereof

PendingCN111456320ASave resourcesImprove protectionClimate change adaptationGirdersRough surfaceConcrete beams

The invention discloses an ECC non-dismantling formwork, a concrete beam based on the formwork and a construction method thereof, and belongs to the technical field of building material construction.The ECC non-dismantling formwork comprises a formwork body, the formwork body is made of cement-based composite materials, the outer side surface of the formwork body is a smooth surface, the inner side surface of the formwork body is a smooth surface, a roughened surface, a concave and convex surface or a sand blasting surface rough surface, an enhancement layer is arranged in the formwork body,and the enhancement layer is a steel strand mesh, a fiber mesh, an FRP mesh, an FRP bar or steel bar. The ECC non-dismantling formwork is not dismantled after the formwork concrete is poured, but is used as a part of a concrete structure, load is borne, some special functions, such as heat preservation, heat insulation and increasing the durability of the concrete structure are further achieved, and when the formwork is used for beam fabrication, the advantages that the construction procedures are simplified, operation is simple and convenient, labor conditions are improved, the amount of formwork support and dismantling is saved, and the construction progress is accelerated are achieved.

Owner:ZHENGZHOU UNIV

Fruit-picking device

The invention discloses a fruit-picking device, and relates to the technical field of hardware.The fruit-picking device comprises a fruit-cutting knife penetrating through a baffle provided with an opening, a telescopic channel is arranged below the baffle, and the other end of the channel is detachably connected with a loading box provided with wheels and a weightometer.Compared with the prior art, frequency of fruit carrying can be reduced, and the effort on carrying fruit with the shoulder or lifting the fruit can be reduced.

Owner:柳州市够旺贸易有限公司

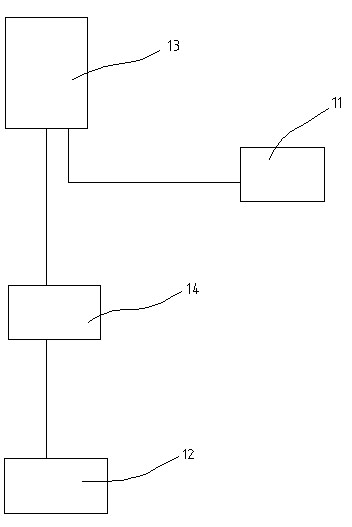

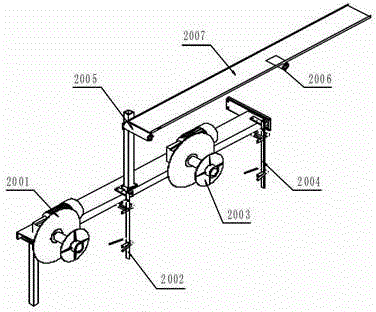

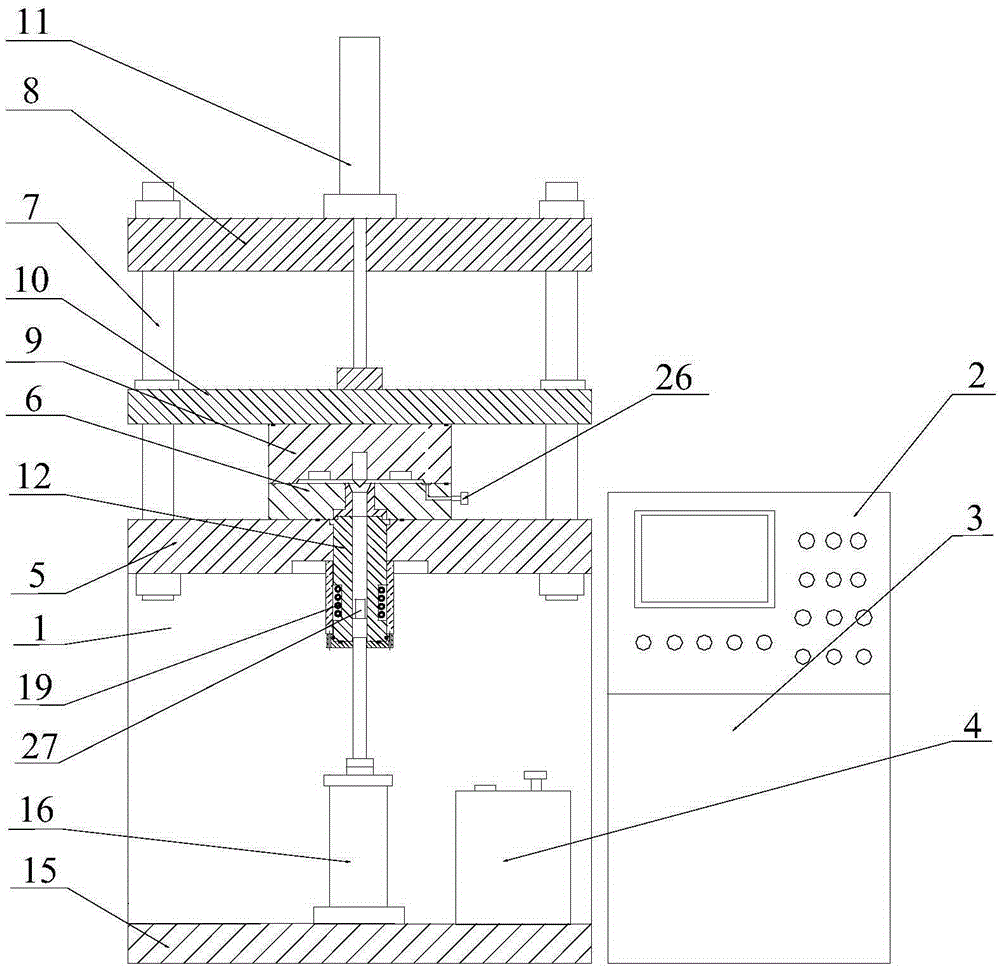

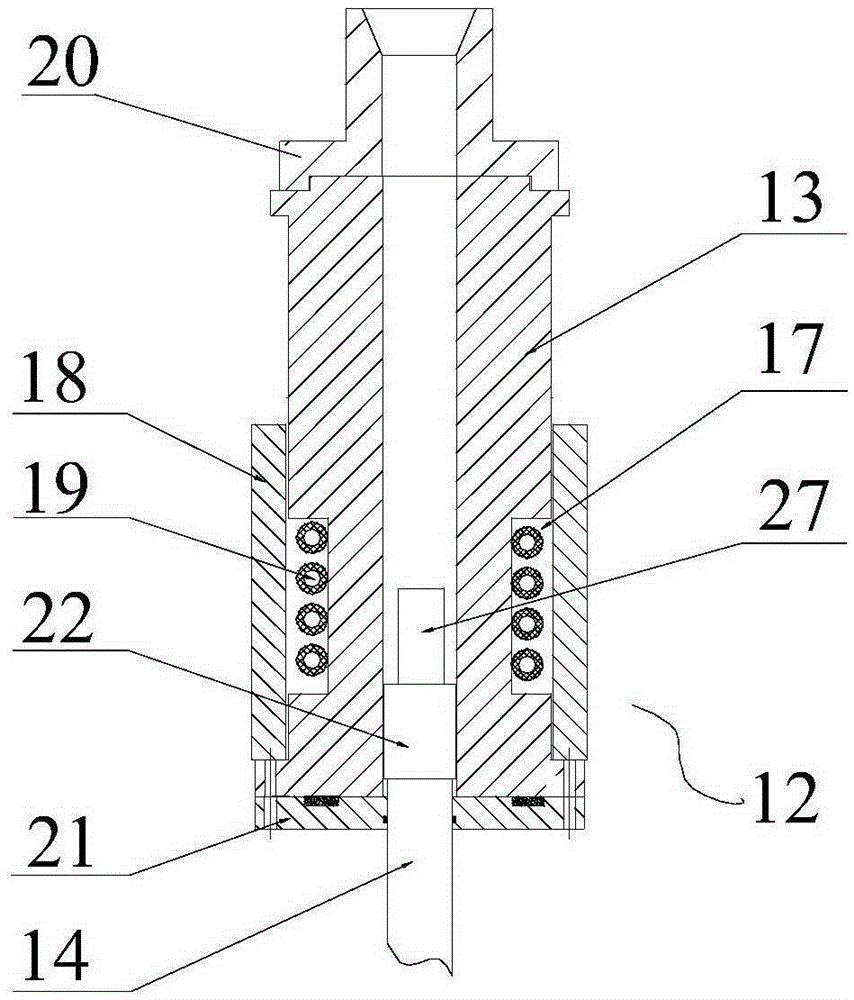

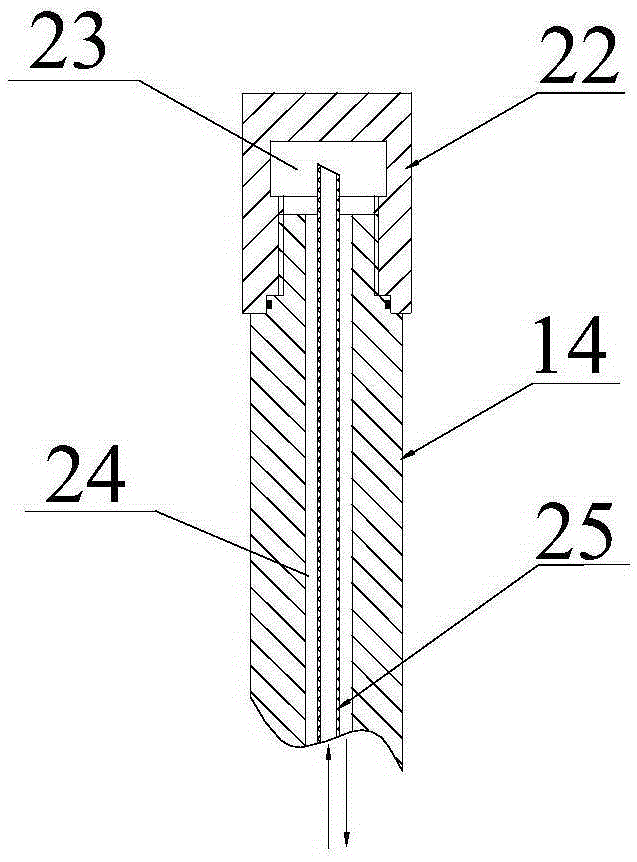

Turnover device for automatic feeding and discharging of heating furnace, and implementation method thereof

PendingCN111664711AReduce turnover timesIncrease productivityCharge manipulationThermodynamicsEngineering

The invention discloses a turnover device for automatic feeding and discharging of a heating furnace. The turnover device comprises a heating furnace body, wherein the feeding end of the heating furnace body is provided with a feeding conveyor belt, the side of the feeding conveyor belt away from the heating furnace body is provided with a feeding mechanism, the feeding mechanism is provided witha feeding turnover trolley on the side away from the feeding conveyor belt, the discharging end of the heating furnace body is provided with a discharging conveyor belt, a reclaiming positioning mechanism is arranged above the discharging conveyor belt, the discharging conveyor belt is provided with a reclaiming mechanism on the side far away from the heating furnace body, and the reclaiming mechanism is provided with a discharging turnover trolley on the side away from the discharging conveyor belt. The invention also discloses an implementation method of the turnover device for automatic feeding and discharging of the heating furnace. The invention can realize the automation of feeding and discharging, automatically take out the product holder from the turnover trolley, and put the product holder into the turnover trolley at the outlet of the heating furnace, thereby improving the production efficiency, and reducing the labor intensity and safety risks.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Energy-saving chromate planar furnace

InactiveCN102192643AReduce shipping processReduce turnover timesDrying gas arrangementsDrying machines with progressive movementsScreen printingEngineering

The invention discloses an energy-saving chromate planar furnace. The energy-saving chromate planar furnace comprises a furnace body in which a heating tube is arranged, and a bracket, and is characterized by further comprising a double-layer feeding area placement board, a double-layer discharging area placement board, two groups of conveyor belts and a power device for providing power for the conveyor belts, wherein the two groups of conveyors pass through both ends in the furnace body, are butted with the double-layer feeding area placement board and the double-layer discharging area placement board and rotate in different directions; the double-layer feeding area placement board and the double-layer discharging area placement board are arranged on the outer sides of the ports of both ends of the furnace body; and the power device is fixed on the bracket. The energy-saving chromate planar furnace has the advantages that: heat in the furnace body can be reused, so an aim that the same equipment can realize different functions is fulfilled; meanwhile, the conveying between drying and screen-printing is reduced, the production flow is optimized, the frequency of product turnover is reduced, and potential probability of unqualified products is lowered.

Owner:XINGWEI COMP KUNSHAN

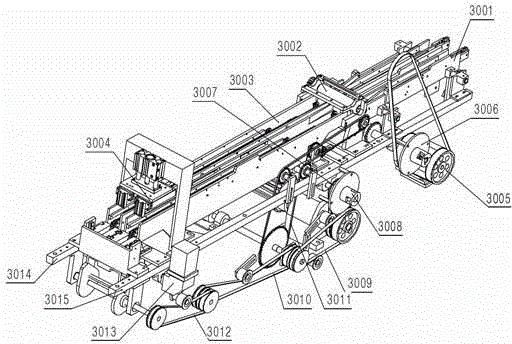

Numerically-controlled double working position cutting machine and control method thereof

PendingCN108907336AReduce turnover timesImprove processing efficiencyMetal sawing devicesMetal sawing accessoriesTurnover timeMachine control

The invention discloses a numerically-controlled double working position cutting machine. The numerically-controlled double working position cutting machine includes two cutting mechanisms and two clamp mechanisms; each cutting mechanism includes a feeding oil cylinder, a motor and a saw blade, the saw blades are mounted on the motors, and the motors are mounted on the feeding oil cylinders; eachclamp mechanism includes a clamp oil cylinder and a workpiece copying mold, the workpiece copying molds are mounted on the clamp oil cylinders, and the cutting mechanisms and the clamp mechanisms arecooperatively mounted. The invention further discloses a control method of the numerically-controlled double working position cutting machine. The control method includes the steps that a PLC receivesposition signals of a position feedback sensor and conducts judging; when a feeding position is close to the 1 / 3 position of the upper portion of a workpiece, the PLC controls the opening degree of aservo proportioning valve to increase, and the workpiece is fed and subjected to acceleration cutting; when the feeding position is close to the 1 / 3 position of the lower portion of the workpiece, the PLC controls the opening degree of a servo proportioning valve to reduce, and the workpiece is fed and subjected to reduction cutting. By adopting the numerically-controlled double working positioncutting machine and the control method thereof, the number of turnover times of the machined workpiece is reduced, and the machining efficiency is high; the numerically-controlled double working position cutting machine is small in occupied space, low in manufacturing cost, high in machining control accuracy and safety performance and convenient to maintain.

Owner:谭明

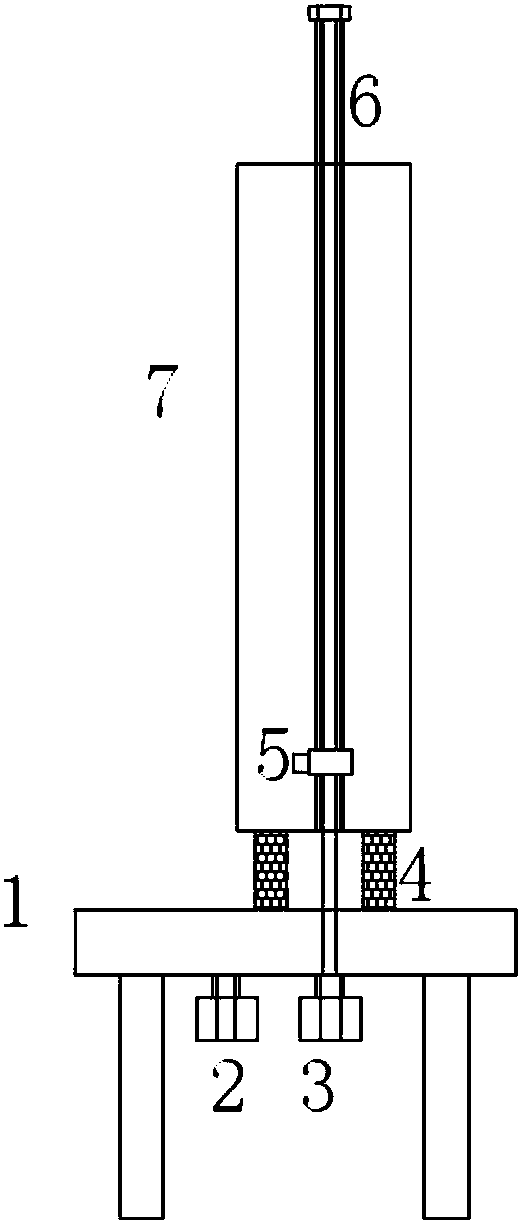

Assembly device for plastic pipe clamp

InactiveCN102615828AReduce labor intensityReduce turnover timesDomestic articlesProgrammable logic controllerPneumatic motor

The invention provides an assembly device for a plastic pipe clamp. The assembly device comprises a frame, wherein a nut mounting tool, a pin mounting tool and a bolt mounting tool are arranged on the frame side by side; the nut mounting tool and the pin mounting tool both consist of a bottom die and a pinch die, and the bolt mounting tool consists of a positioning die and a rotary die; the upper ends of the punch dies are connected with a cylinder, and the upper end of the rotary die is connected with a pneumatic motor; electromagnetic valves are arranged on the cylinder and the pneumatic motor; photoelectric sensors are respectively arranged on the bottom dies and the positioning die and connected with a PLC (Programmable Logic Controller) module; and the electromagnetic valves are connected with the PLC module through an intermediate relay. According to the assembly device, the labor intensity of workers is reduced, the turnover numbers of times of the pipe clamp are reduced, the production efficiency is improved, the cost is saved, and the consistency of product appearance quality is improved.

Owner:ERA PIPELINE (CHONGQING) CO LTD

Cleaning device for PVC pipes

ActiveCN107552500AReduce labor intensityImprove cleaning efficiencyHollow article cleaningDrying gas arrangementsEngineeringUltimate tensile strength

The invention belongs to the field of pipe cleaning equipment, and particularly relates to a cleaning device for PVC pipes. The device comprises a feeding unit, a cleaning unit and a receiving unit, wherein the feeding unit is located in front of the cleaning unit; the feeding unit conveys the PVC pipes to be cleaned layer by layer to the cleaning unit; the cleaning unit is used for cleaning the PVC pipes and continuously conveying the PVC pipes backwards; the receiving unit is located behind the cleaning unit; and the receiving unit is used for storing the cleaned PVC pipes. According to thecleaning device for the PVC pipes, an automatic cleaning mode is adopted, the pipes to be cleaned only need to be placed on a feeding platform manually, the remaining cleaning work is completely completed by the cleaning device, and the cleaning device has the characteristics of being low in labor intensity, high in efficiency and good in cleaning effect.

Owner:中山市众鑫高分子材料有限公司

Sesame washing processing device

InactiveCN102240652AReduce turnover timesEasy to separateCleaning processes and apparatusSesamum orientaleProcess engineering

The invention discloses a sesame washing processing device and belongs to the technical field of agricultural product machinery. The sesame washing processing device comprises three systems, namely a first separation system, a second washing separation system and a third drying separation system in sequence, wherein the first separation system sequentially comprises a feeding pit, an oscillating screen and a stoner, the second washing separation system sequentially comprises a soaking bucket, a material storing tank, a peeling machine, a separating machine, a second material storing tank, a rinsing machine, a third material storing tank and a centrifugal machine, and the third drying separation system sequentially comprises a drying machine, a vibration classifier, a cooling machine, a colour selection machine and a magnetic selector. All the parts in the invention are scientifically combined and reasonably arranged, thus the whole cleaning processing flow is smooth, the number of times for turning over sesame is less and the production efficiency is greatly improved; and multiple measures such as common screening, colour separation and magnetic separation are combined, and impurity removing and grading are simultaneously carried out, thus convenience is provided for targeted deep processing in a later stage of the sesame.

Owner:NANTONG GRAIN MACHINERY

Novel tobacco drying and crushing equipment

InactiveCN111588064AReduce turnover timesImprove cleanlinessTobacco preparationGrain treatmentsAgricultural engineeringStructural engineering

The invention discloses novel tobacco drying and crushing equipment. The equipment comprises a drying mechanism, the drying mechanism comprises a drying box frame, a drying box is arranged on the drying box frame, a drying box cover in mirror image distribution is arranged on the drying box, heating wires are arranged on the drying box cover, first conveying belt brackets are arranged in the drying box, a first conveying belt is arranged between the first conveying belt brackets, a draught fan is arranged below the drying box, water spraying pipe holes which are distributed in an array mannerare further formed in one side of the drying box, water spraying pipes are arranged in the water spraying pipe holes, the drying mechanism is fixed on a secondary platform arranged on the equipment platform, a flow dividing frame is further arranged on the equipment platform, a tobacco smashing mechanism is arranged on the flow dividing frame, a conveying mechanism is further arranged on one sideof the flow dividing frame, a first tobacco shred pressing mechanism is arranged above one end of the conveying mechanism, a second tobacco shred pressing mechanism is arranged below the first tobaccoshred pressing mechanism, and a slitting mechanism is jointly arranged on one side of the first tobacco shred pressing mechanism and one side of the second tobacco shred pressing mechanism. Accordingto the equipment, the turnover frequency in the tobacco production and treatment process is reduced, and the cleanliness of tobacco cigarettes is improved.

Owner:合肥经新科技有限公司

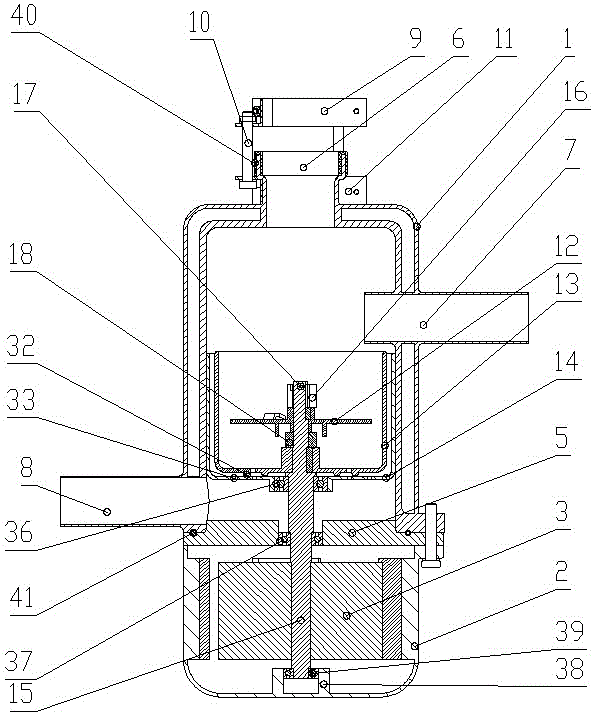

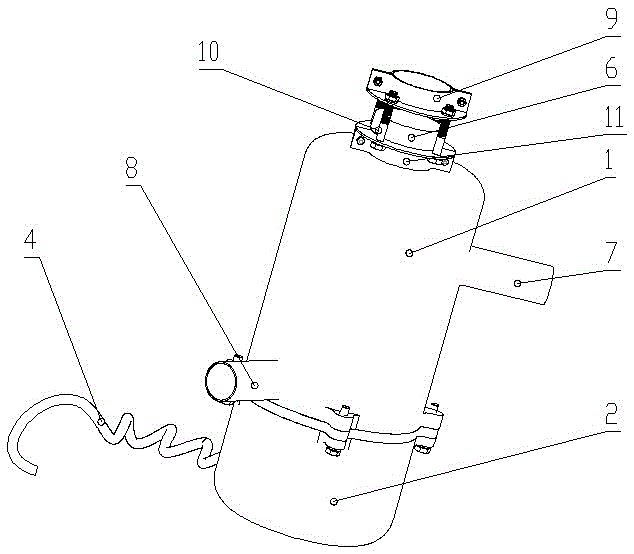

Waste processor for smashing organic substances such as bone

The invention discloses a waste processor for smashing organic substances such as bone. The waste processor comprises an upper shell and a lower shell. The lower end of the upper shell is connected with the upper end of the lower shell through a flange. A driving motor is arranged inside the lower shell. A power line connected with the driving motor is led outwards from the lower portion of the lower shell. A middle partition plate is arranged between the upper shell and the lower shell. A smashing and grinding mechanism is arranged inside the upper shell. A water inlet pipe connector is arranged at the top end of the upper shell. A feeding pipe connector and a discharging pipe connector are arranged at the lateral portion of the upper shell. An installation frame is arranged outside the water inlet pipe connector. The smashing and grinding mechanism comprises a mashing cutter disc, a grinding barrel, a fixed barrel and a rotating shaft, and the smashing cutter disc, the grinding barrel, the fixed barrel and the middle partition plate are sequentially arranged on the rotating shaft in a sleeving mode in the direction from the upper end to the lower end of the rotating shaft. The waste processor is simple in structure, reliable in work, convenient to install and easy to operate; organic substance waste such as bone can be rapidly removed, and food waste can be effectively smashed through the grading smashing function and the grading grinding function.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Steel frame plastic plate building formwork mutually combined with aluminum alloy building formwork

PendingCN112502427AGood versatilityReduce weightAuxillary members of forms/shuttering/falseworksForming/stuttering elementsAlloy steelWood glue

The invention discloses a steel frame plastic plate building formwork mutually combined with an aluminum alloy building formwork. The building formwork comprises a plurality of standard formworks; each standard formwork comprises a panel and an alloy steel frame; the panel is a hollow plastic plate or a foamed plastic plate; the panel is fixed in the alloy steel frame; and an inner transverse reinforcing rib is arranged at the inner side of the alloy steel frame. The steel frame plastic plate building formwork mutually combined with the aluminum alloy building formwork belongs to the technicalfield of buildings, and aims at solving the problems that in the prior art, wood glue formworks are small in using and turnover frequency and low in assembling and disassembling efficiency, aluminumalloy formworks are high in manufacturing cost, and plate faces are prone to being stained with dust. The steel frame plastic plate building formwork mutually combined with the aluminum alloy buildingformwork has the technical effects that the standard formwork is made of the panel and the alloy steel frame, and the panel is the hollow plastic plate or the foamed plastic plate, so that the weightof the standard formwork is reduced, workers can splice and assemble the formwork more easily and conveniently, and the assembling and disassembling efficiency is improved; the alloy steel frame is adopted for protection, so that the number of using turnover times is large; and meanwhile, compared with an aluminum alloy formwork, the manufacturing cost is greatly reduced, the plate surface is notprone to being stained with dust, and the formwork cleaning cost input is reduced.

Owner:景建华

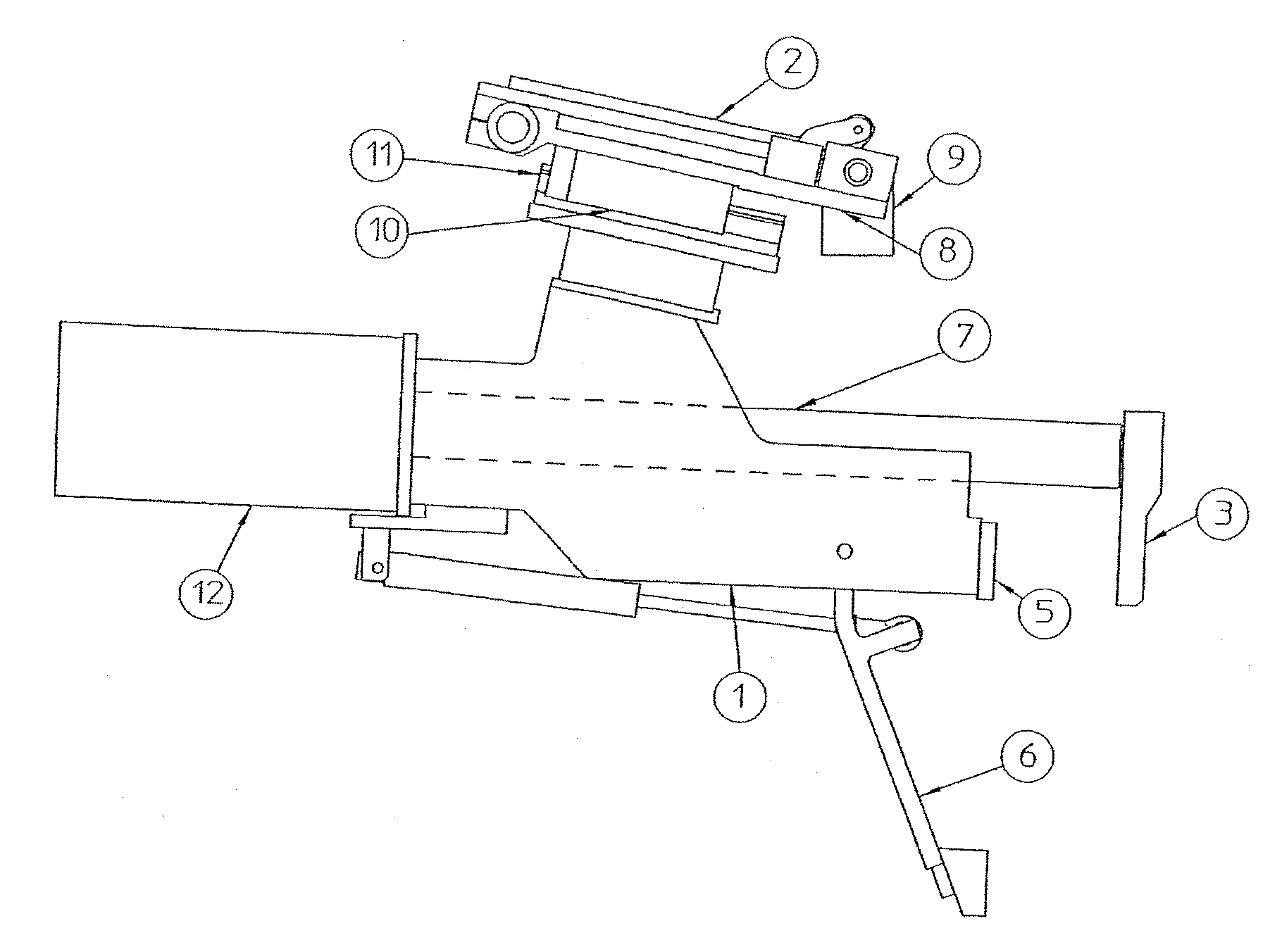

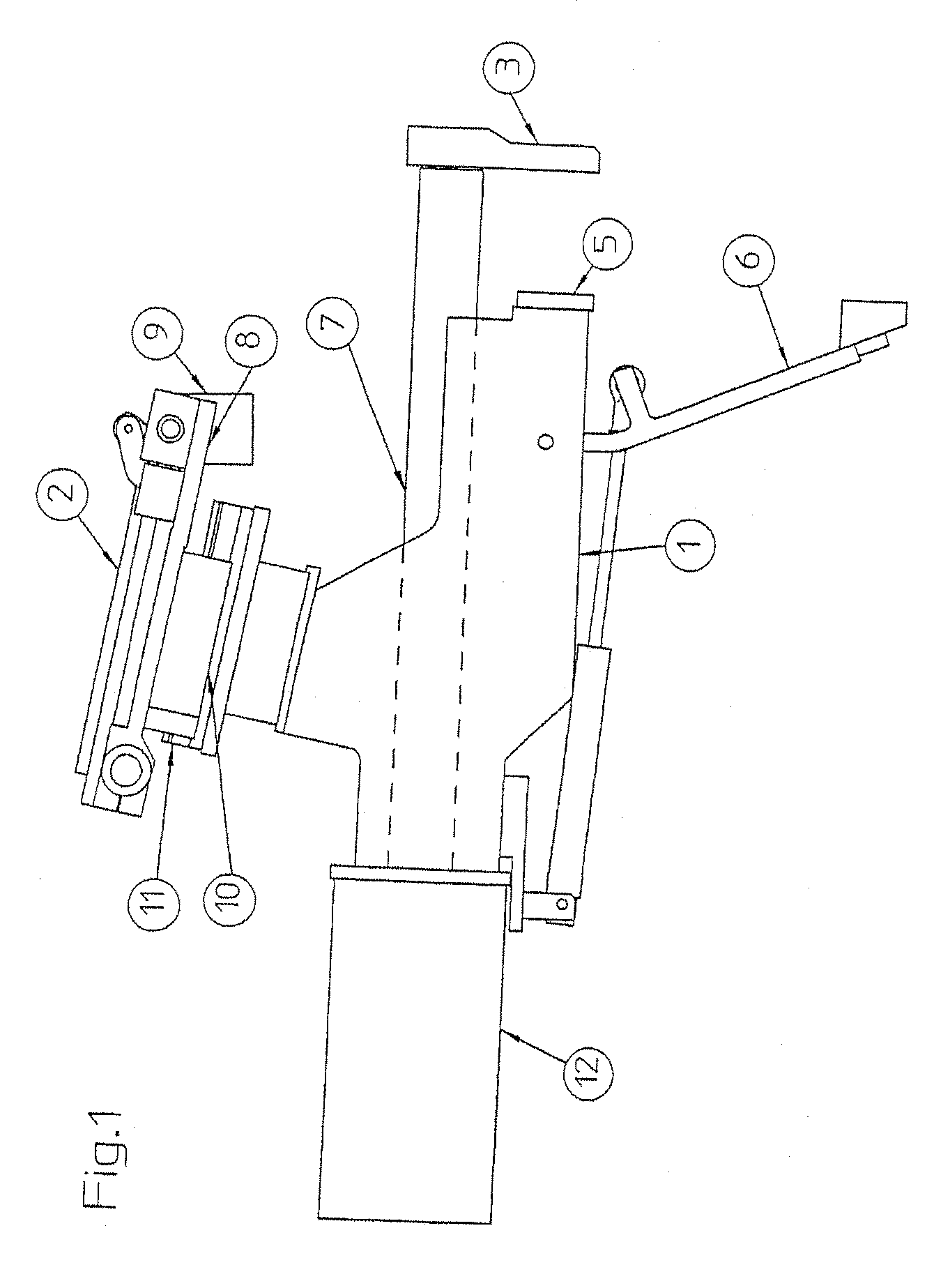

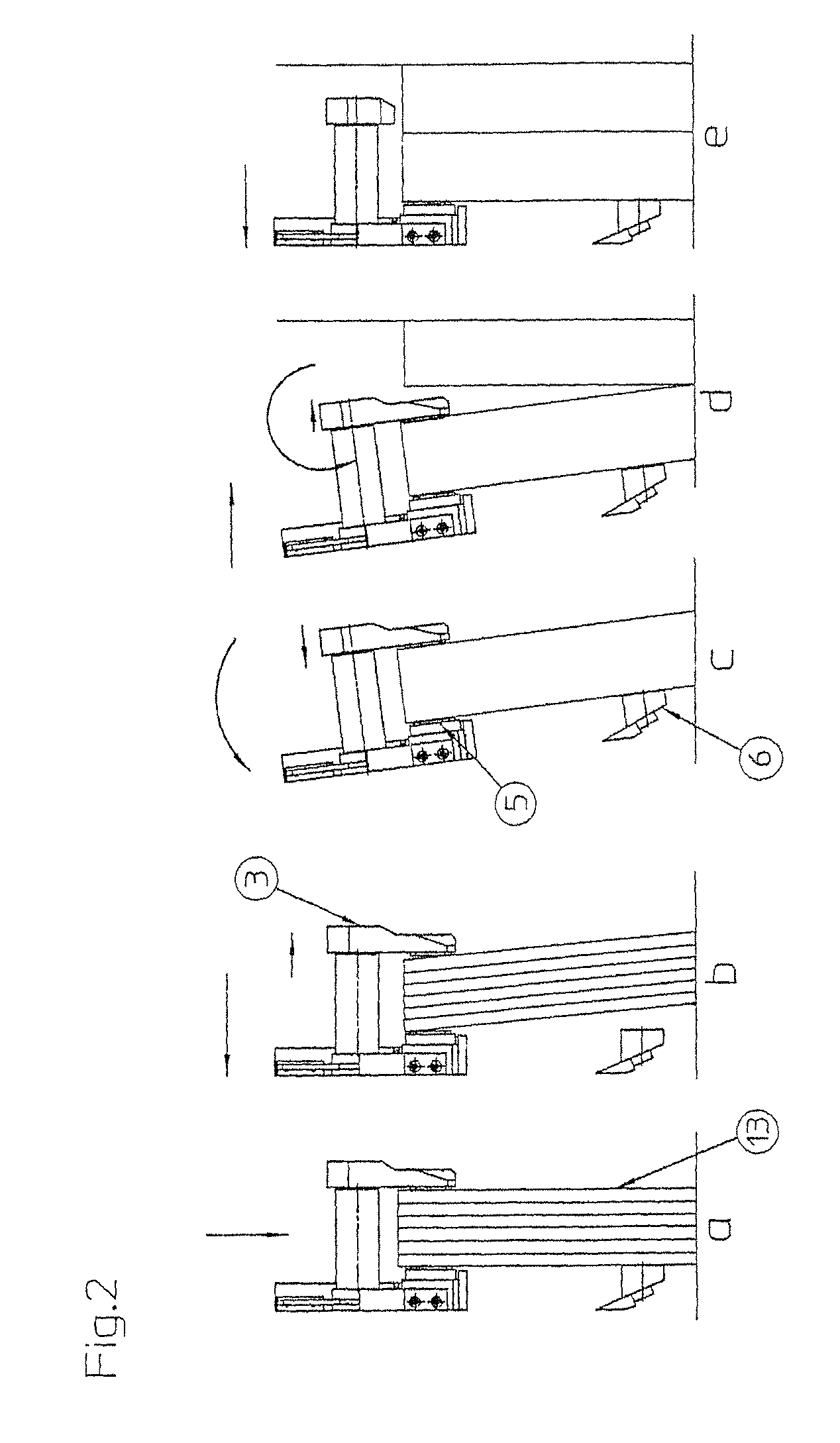

Device and method for seizing and setting down impact-sensitive sheets

ActiveUS8276960B2Easy to stackImprove productivityLoadersGripping headsRelative displacementRobotic arm

A device, method and computer readable-storage for mechanically handling impact-sensitive sheets of various formats ready for dispatch is described. The device has the following features: a) a control device in the form of a multi-axis robotic arm connected to a gripper device and means for mechanically gripping the sheets; b) the gripper device is hinged onto and suspended from the control device at a gentle incline by means of an adjustable damping device; c) the gripper device has sliding sections for the relative displacement of the means for mechanically gripping the sheets; d) the gripper device has means for determining the geometric dimensions of the sheets to be seized and for determining their set-down position; e) the gripper device has means for determining the exact positional co-ordinates of the set-down position; and f) the gripper device has means for gently feeding and depositing the sheets in the set-down position.

Owner:GRENZEBACH MASCHINENBAU GMBH

A kind of car sunroof slide rail transfer method

ActiveCN104787101BImprove transportation safetyAvoid quality problemsHand carts with multiple axesRear quarterAgricultural engineering

Owner:WUHU MOTIONTEC AUTOMOTIVE

Tissue-culture industrialized seedling production method of dendrobium officinale

InactiveCN106258981AGreat tasteReduce browningPlant tissue cultureHorticulture methodsGermplasmUndergrowth

The invention discloses a tissue-culture industrialized seedling production method of dendrobium officinale, and relates to the technical field of biology. According to the tissue-culture industrialized seedling production method of the dendrobium officinale, field cluttered germplasms are screened through a simple and easy method, and dendrobium officinale stem segments which are high in yield, disease-resistant and good in appearance and taste and of which the quality meets the standards of Chinese Pharmacopoeia are screened out to greatly shorten the variety screening time; in the culture process, a large number of elements in an MS culture medium are improved, fulvic acid calcium and a new food antioxidant of sodium erythorbate or calcium ascorbate are added in additives, the culture condition is that lighting of an led light source of which the color temperature is 4000K is used, and small seedlings of certain specifications are circularly transferred in the strong seedling production process, so that the growth rate of tissue culture seedlings is improved, and the states of small seedling browning, yellowing and undergrowth and the turnover frequency of the tissue culture seedlings are reduced in the production process to improve the industrialized production efficiency.

Owner:耿马四方生物科技开发有限责任公司

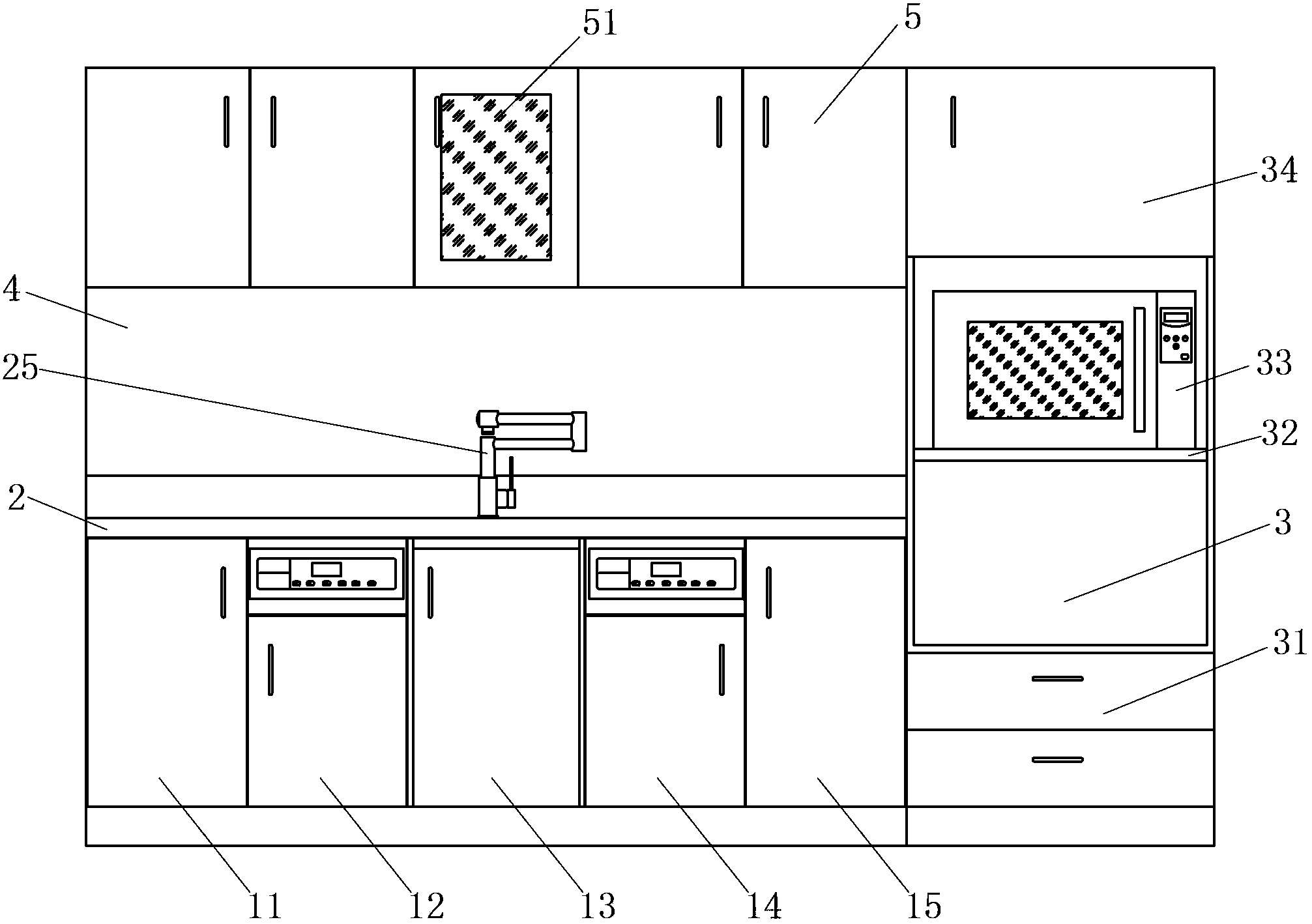

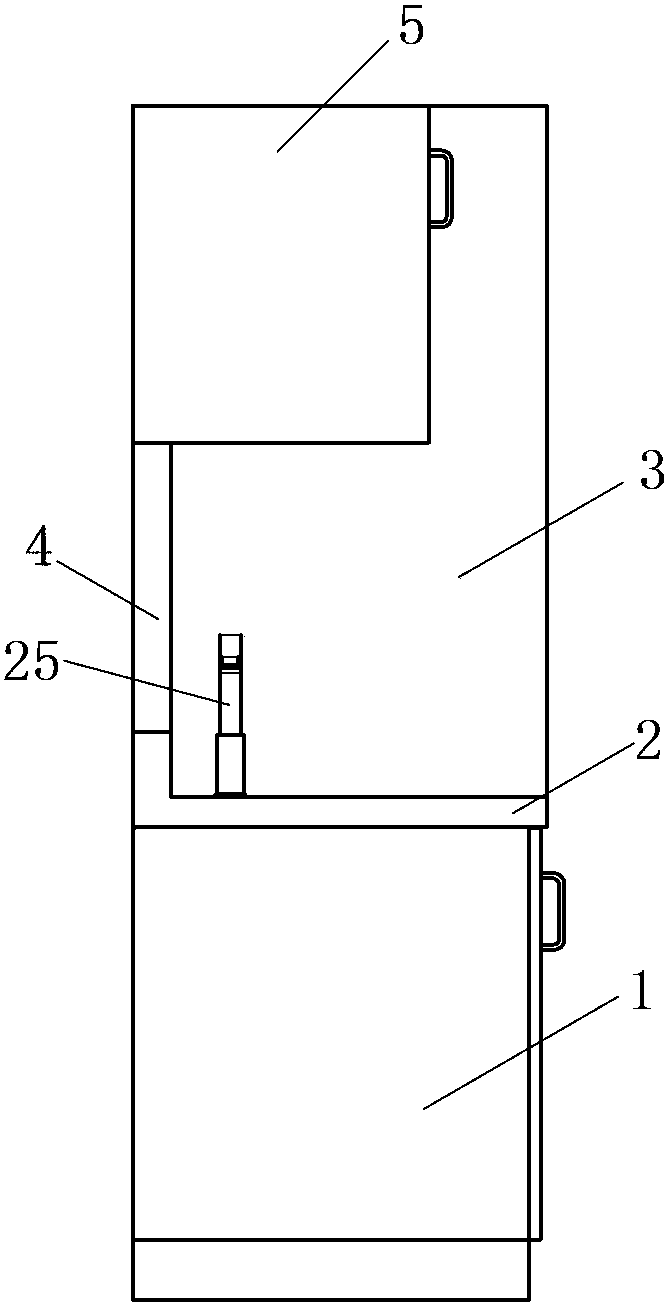

Multifunctional cleaning and disinfecting workstation for dental departments

ActiveCN102716506BSimple and elegant appearanceCompact structureCleaning using liquidsHeatMegasonic cleaningEngineering

The invention relates to a multifunctional cleaning and disinfecting workstation for dental departments, which comprises a cabinet base component, a table-board component arranged above the cabinet base component, a side cabinet component arranged on one side of the cabinet base component, a rear panel arranged at the rear part of the cabinet base component, and a top cabinet component arranged at the top of the rear panel, wherein the cabinet base component comprises a dirt pick box, an ultrasonic cleaning machine and a full-automatic cleaning and disinfecting machine; a dirt inlet positioned above the dirt pick box and communicated with the dirt pick box, an ultrasonic cleaning tank of the ultrasonic cleaning machine, a manual cleaning tank, a tap above the manual cleaning tank, and a cleaning and disinfecting tank of the full-automatic cleaning and disinfecting machine are arranged on the table-board component; and the side cabinet component comprises a partition board and a pressure stream sterilization device arranged on the partition board. The workstation integrates a plurality of cleaning and disinfecting devices, has a compact structure and is high in cleaning and disinfecting efficiency.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

Encapsulating and matching machine of lead-acid storage battery plate

ActiveCN102891339BImprove pass rateReduce turnover timesFinal product manufactureLead-acid accumulators constructionTurnover timeElectrical control

The invention relates to an automatic encapsulating and matching machine of a lead-acid storage battery plate, in particular to a device for encapsulating and matching a small-density polar plate in a production procedure of the lead-acid storage battery automatically. The encapsulating and matching machine of the lead-acid storage battery plate is an assembly line device comprising a rack, a paper feeding device, a plate feeding device, a paper cutting device, a polar plate feeding device and a collecting device which are sequentially connected, and the assembly line device automatically cooperates under the action of an electrical control system. By adopting a dual-line paper feeding device and the polar plate feeding device which are serially connected, and the plate feeding device vertically connected with the polar plate feeding device, the encapsulating and matching machine has the advantages of being simple, convenient and reasonable in structure, lowering the device failure rate and polar plate turnover times, realizing automatic encapsulation and matching of lead alloy polar plates of an automobile, completing the transformation of low-efficiency work to automatic, high-efficiency and environmental-friendly operation of the production process, greatly lowering the production strength and operation cost of manual operation, increasing the labor production efficiency, and reducing the pollution of lead dust to environment and injury to a human body.

Owner:武汉深蓝自动化设备股份有限公司

A metal vacuum melting die-casting forming equipment

Owner:DONGGUAN EONTEC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com