Numerically-controlled double working position cutting machine and control method thereof

A control method and cutting machine technology, which are applied in metal processing machinery parts, manufacturing tools, metal sawing equipment, etc., can solve the problems of reducing processing efficiency and increasing the number of workpiece turnover, so as to improve processing efficiency and reduce equipment footprint. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

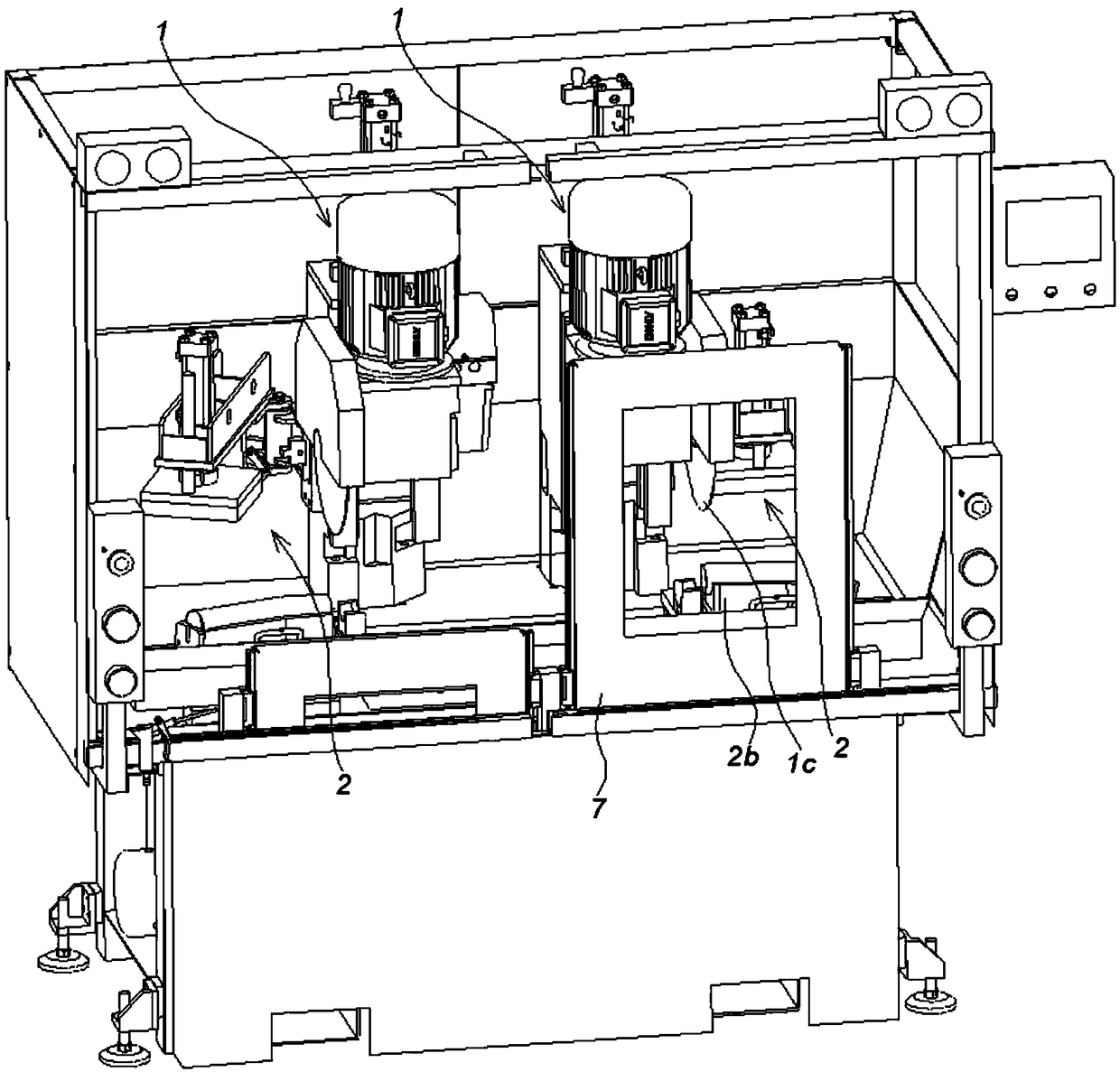

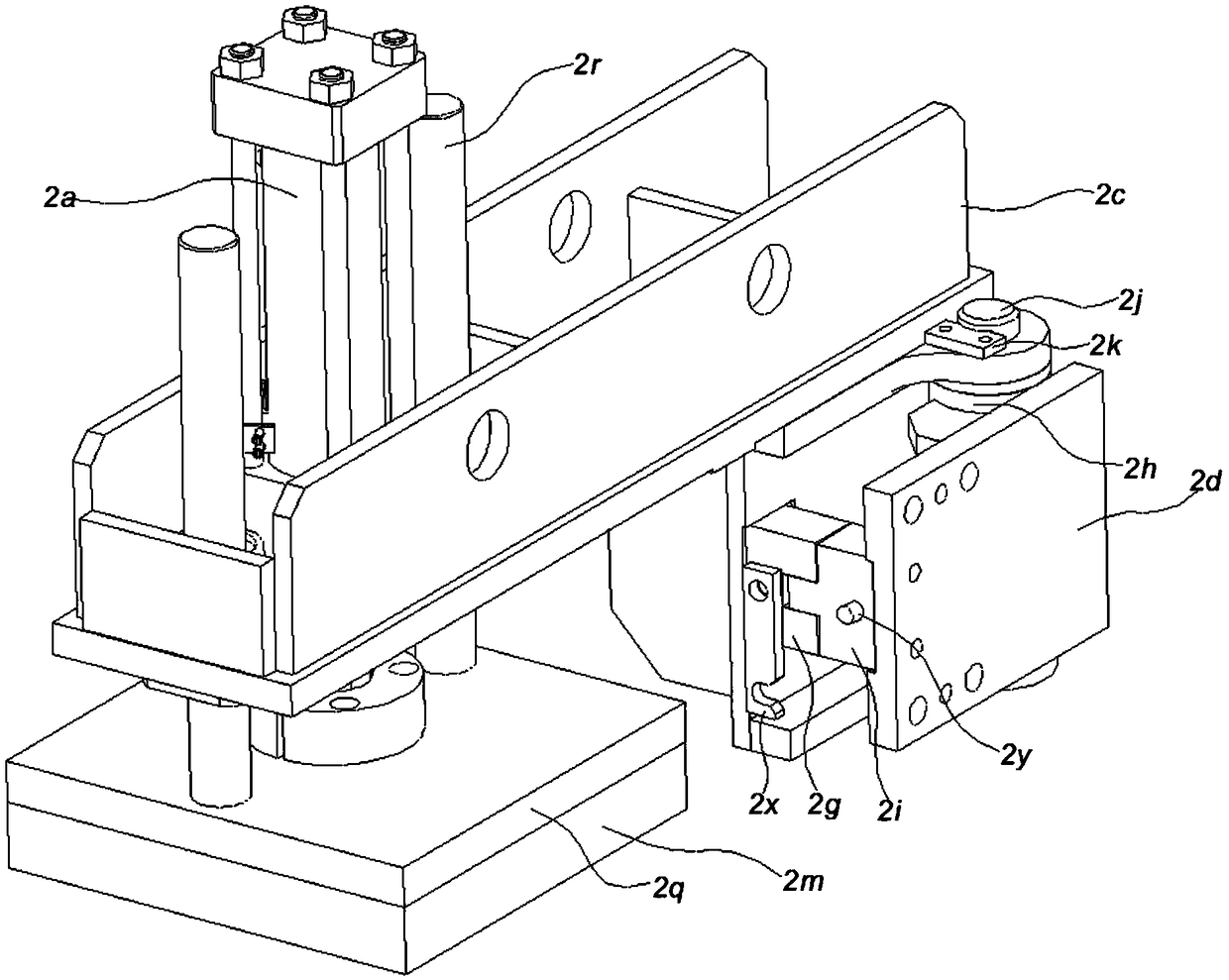

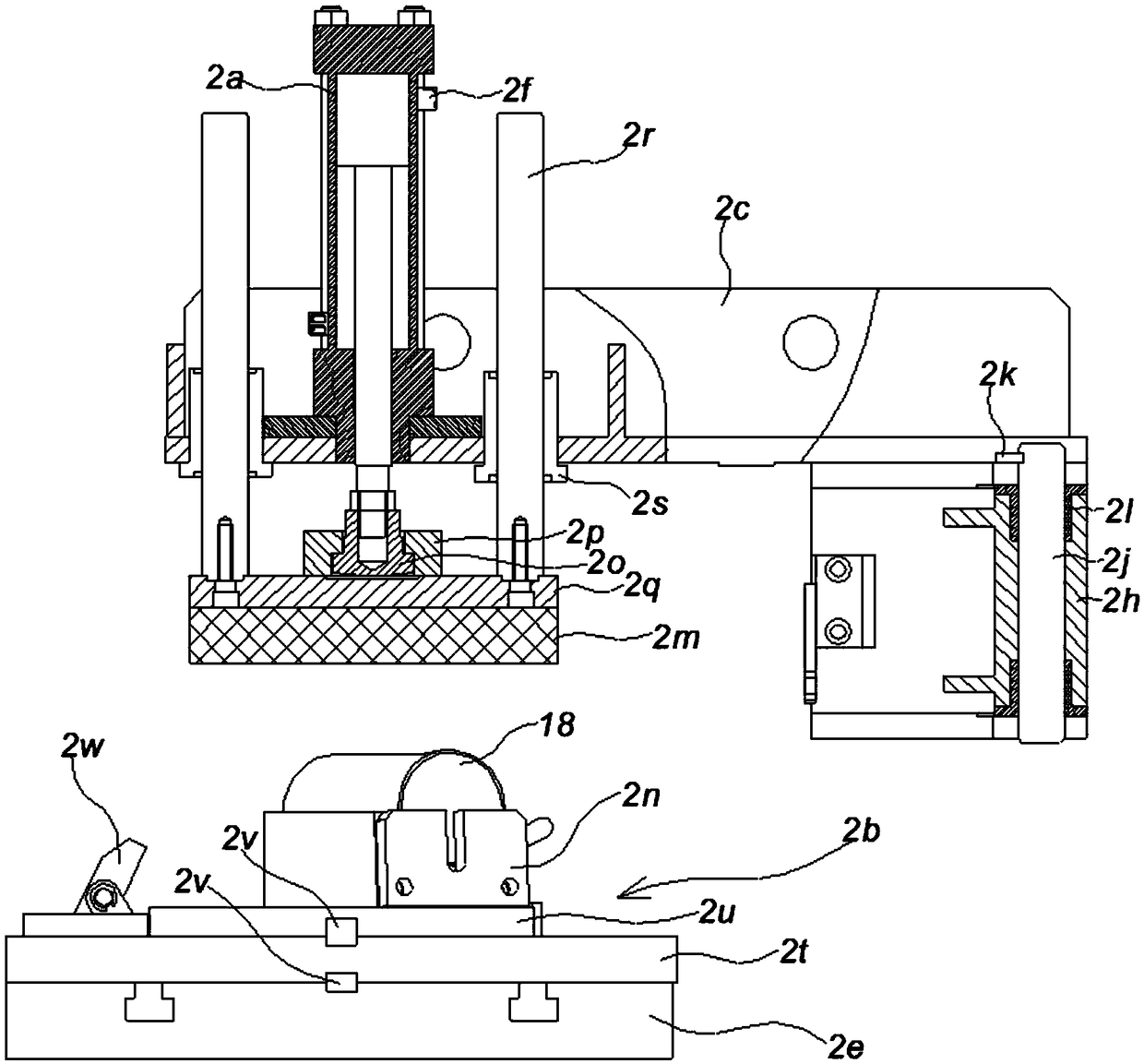

[0030] Such as figure 1 , 4 As shown, the CNC double-station cutting machine includes a cutting mechanism 1, a clamping mechanism 2, a cutting fluid container 3, a nozzle 4, a spiral magnetic separator 5, a chip collecting container 6, a safety door 7, a safety grating 8 and a PLC9. The cutting mechanism 1 is matched with the clamping mechanism 2 .

[0031] The nozzle 4 is connected to the cutting fluid container 3 through the flow regulating valve 10 and the cutting fluid pump 11 in turn. The nozzle 4 is installed facing the saw blade 1c, and the spiral magnetic separator 5 is installed under the saw blade 1c. The spiral magnetic separator 5 is produced by Taizhou Ruichuang. The model is CF-200 spiral magnetic separator. A chip collection container 6 is installed below the spiral magnetic separator 5 , and the cutting fluid container 3 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com