Self-propelled inverted arch template construction method

A construction method and self-propelled technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of waste of resources, time-consuming, non-compacting, etc., and achieve the goal of improving construction efficiency, reasonable cycle time, and shortening process time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples can explain the present invention in more detail, but the protection scope of the method is not limited to the following examples.

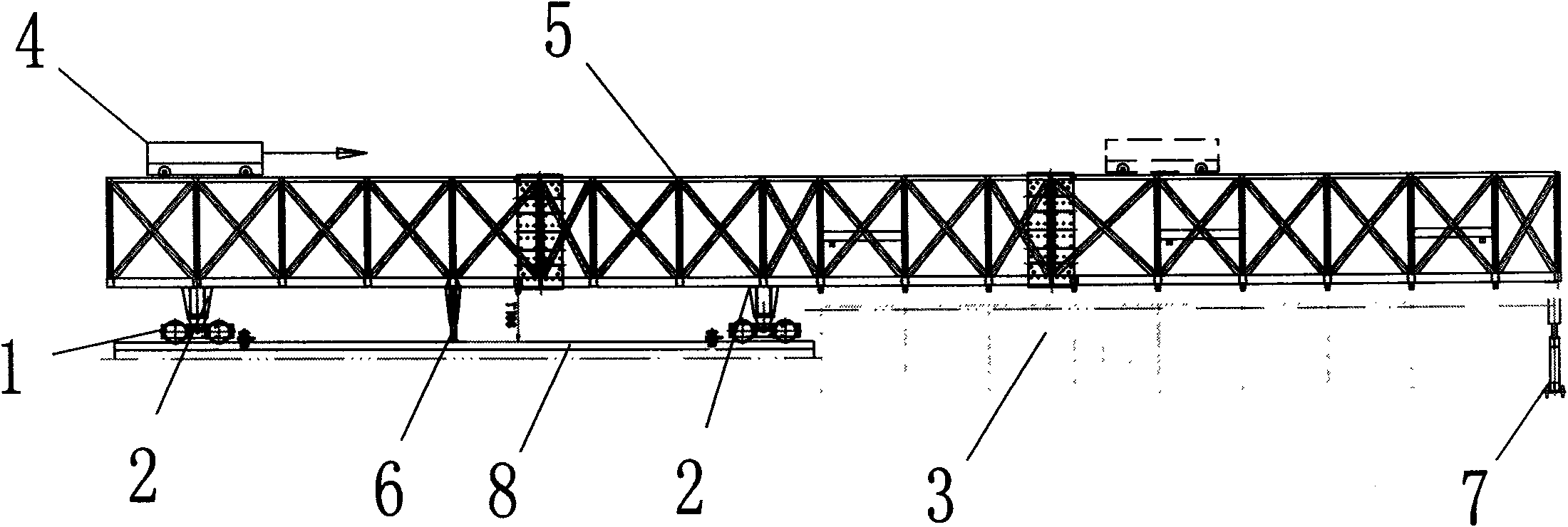

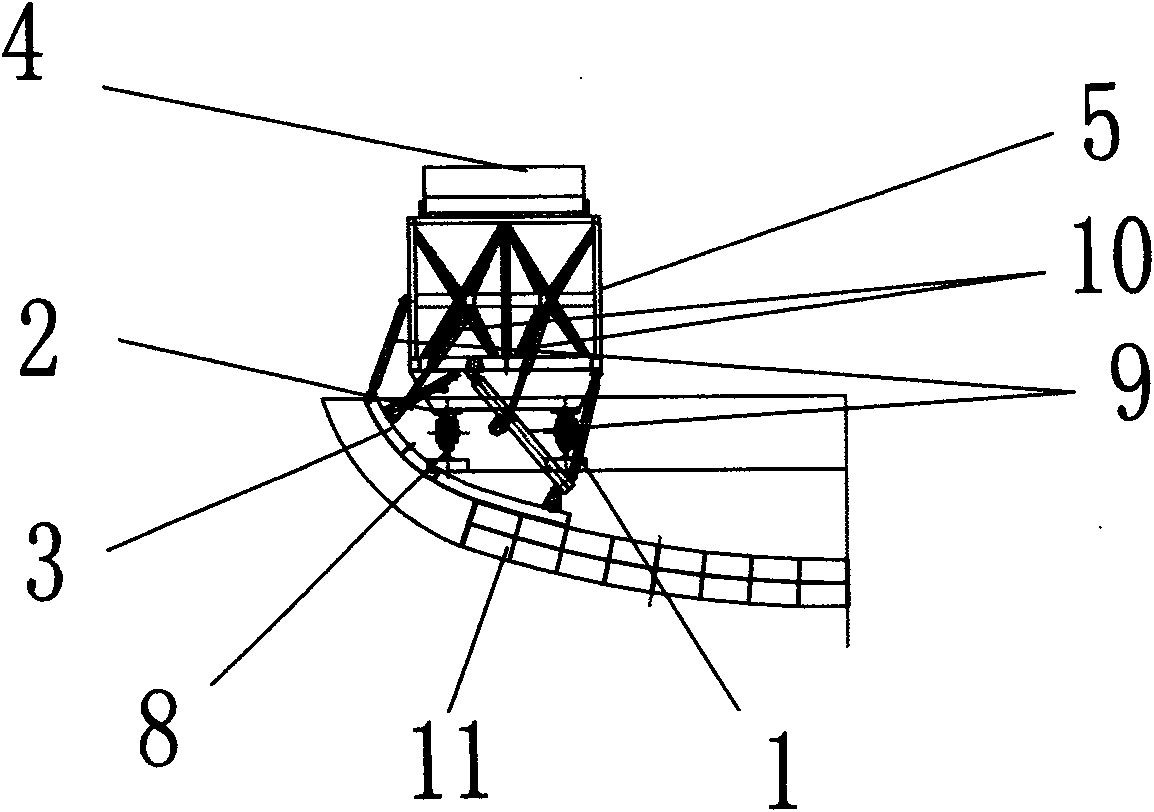

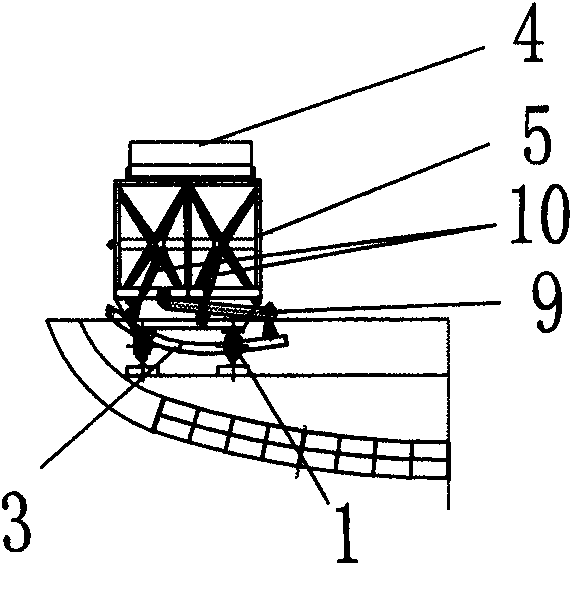

[0036] combined with Figure 1~4 , taking the construction of a tunnel invert as an example to explain the self-propelled invert formwork construction method in detail;

[0037] Project Overview

[0038] The total length of the tunnel is 14,598 meters, with 7,185 meters of grade III surrounding rock, accounting for 49.2% of the total tunnel; 7,413 meters of grade IV and V surrounding rock, accounting for 50.8% of the total tunnel. There are 13 large-scale regional fault zones in the whole tunnel, and the construction is organized at the entrance, the No. 1 horizontal guide, the No. 1 horizontal tunnel, the No. 2 horizontal tunnel and the exit. The tunnels are all designed as composite lining sections with inverted arches, the geological conditions are relatively complex, and they are located in karst areas, with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com