Complex special-shaped casting measurement checking method based on laser tracking measurement

A technology of laser tracking measurement and inspection method, which is applied in the field of mechanical processing and manufacturing, can solve problems such as blank casting errors, cut through, and meat loss, and achieve the effects of improving efficiency, simplifying process flow, and reducing turnover times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

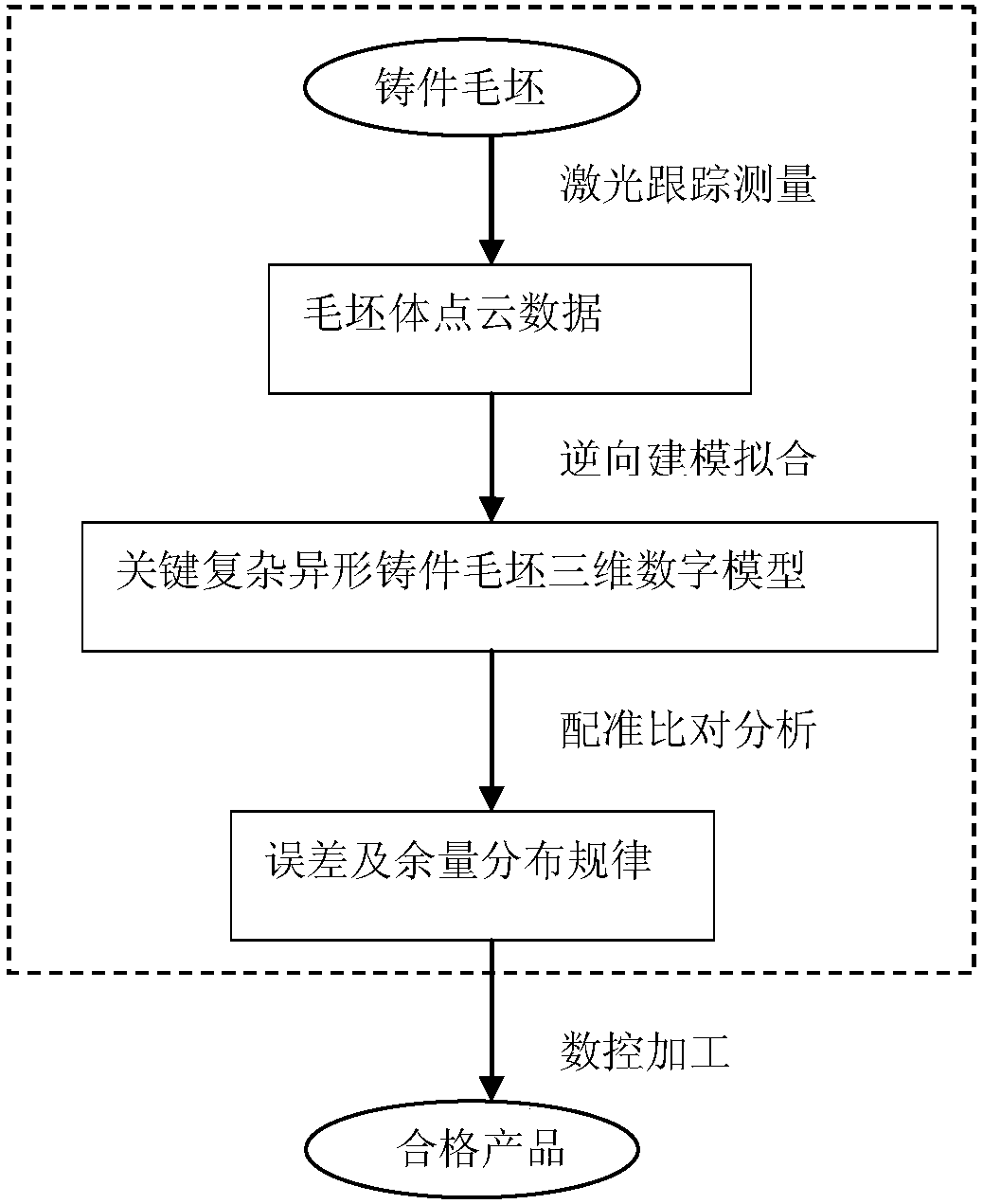

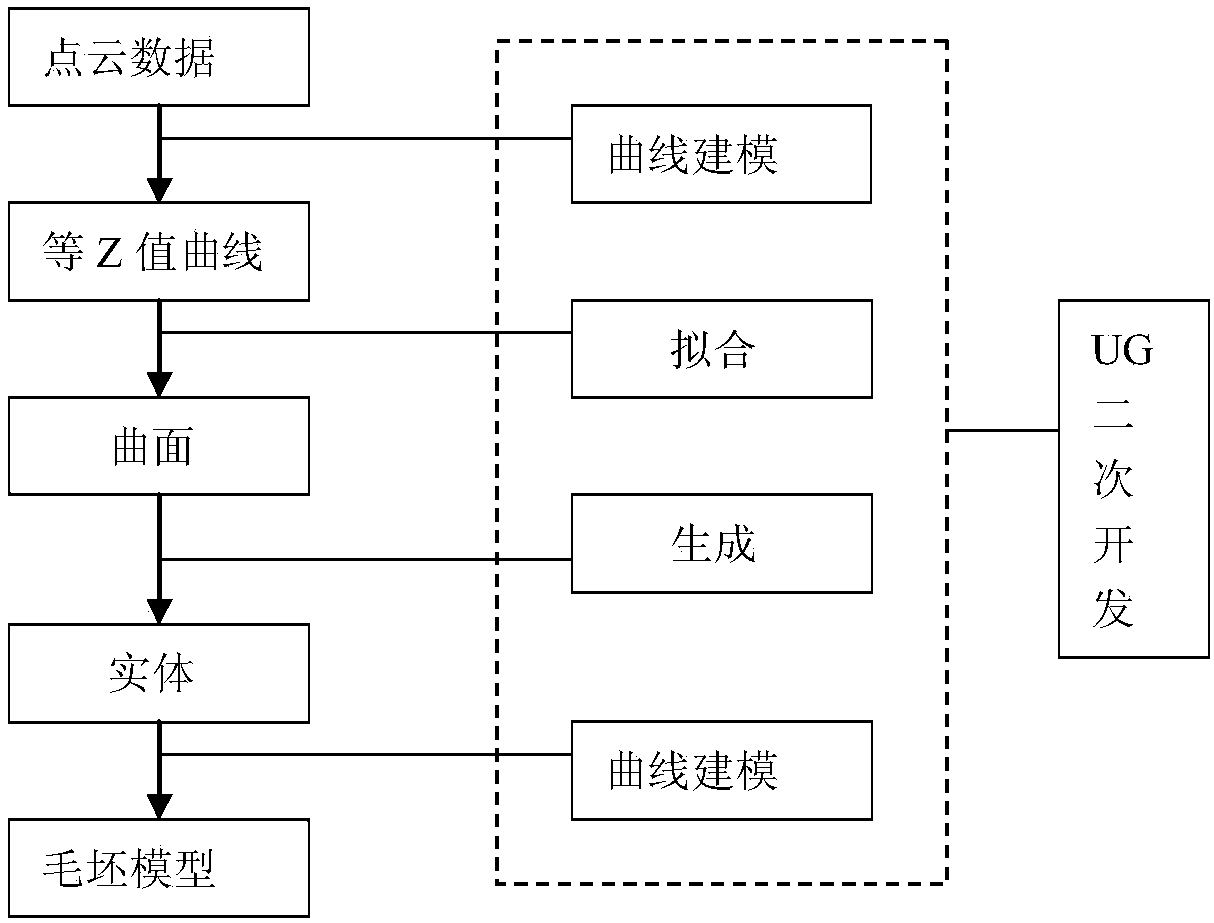

[0031] A measurement and inspection method for complex special-shaped castings based on laser tracking measurement of the present invention is as follows: figure 1 As shown, it is: use a measuring laser tracker or scanner to measure complex special-shaped castings to realize high-precision dimension scanning and measurement of the shape and inner cavity of the casting, so as to obtain the point cloud data of the shape and inner cavity of complex special-shaped castings. Then through the secondary development of software such as UG, the coordinate points are generated into a solid model, so as to realize the acquisition of the 3D model of the blank. Finally, based on the principle of position registration and inclusive analysis, the distribution law of the product machining allowance is obtained. Provide data support for subsequent CNC machining and manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com