Patents

Literature

398results about How to "Reduce manual handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

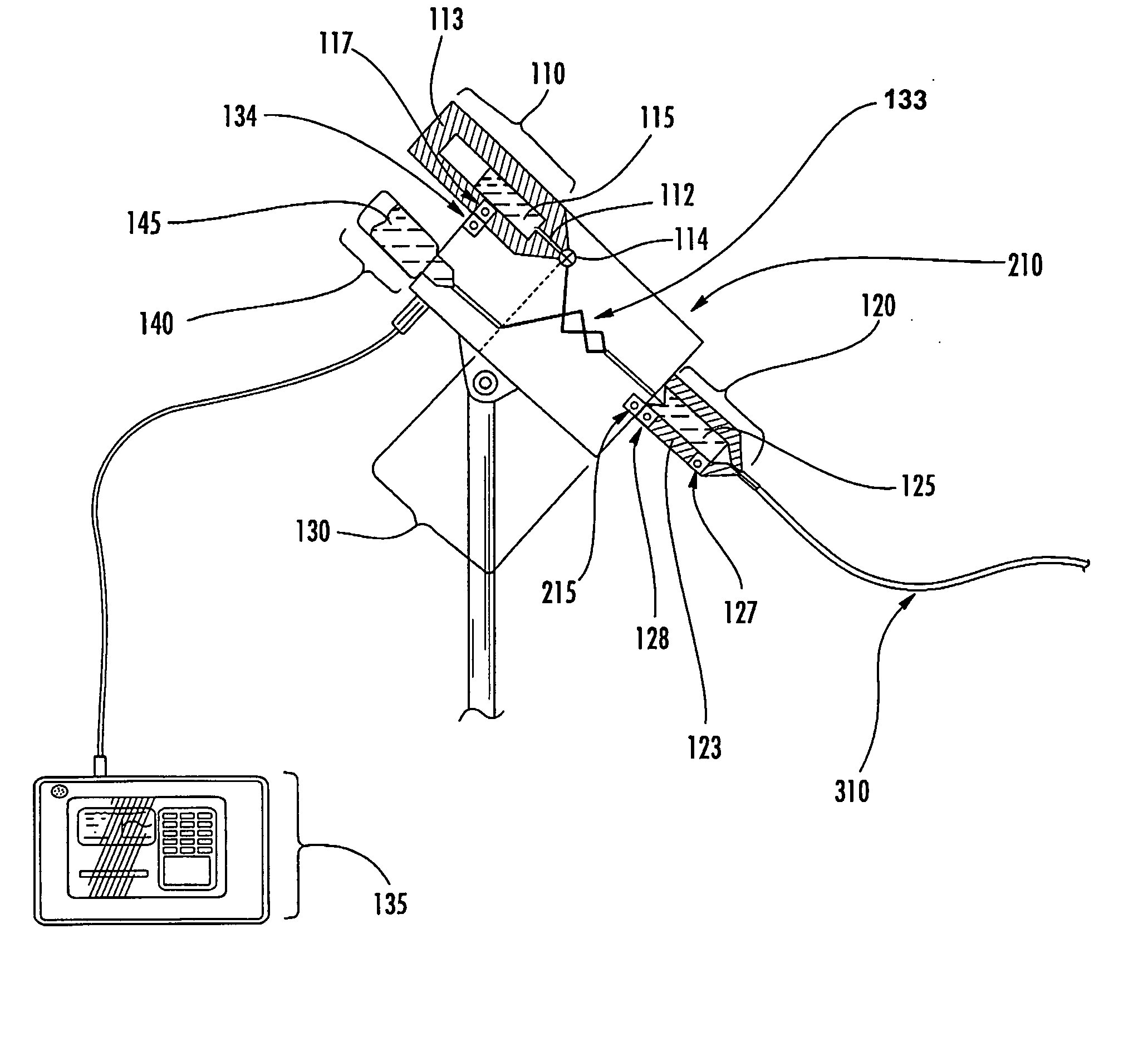

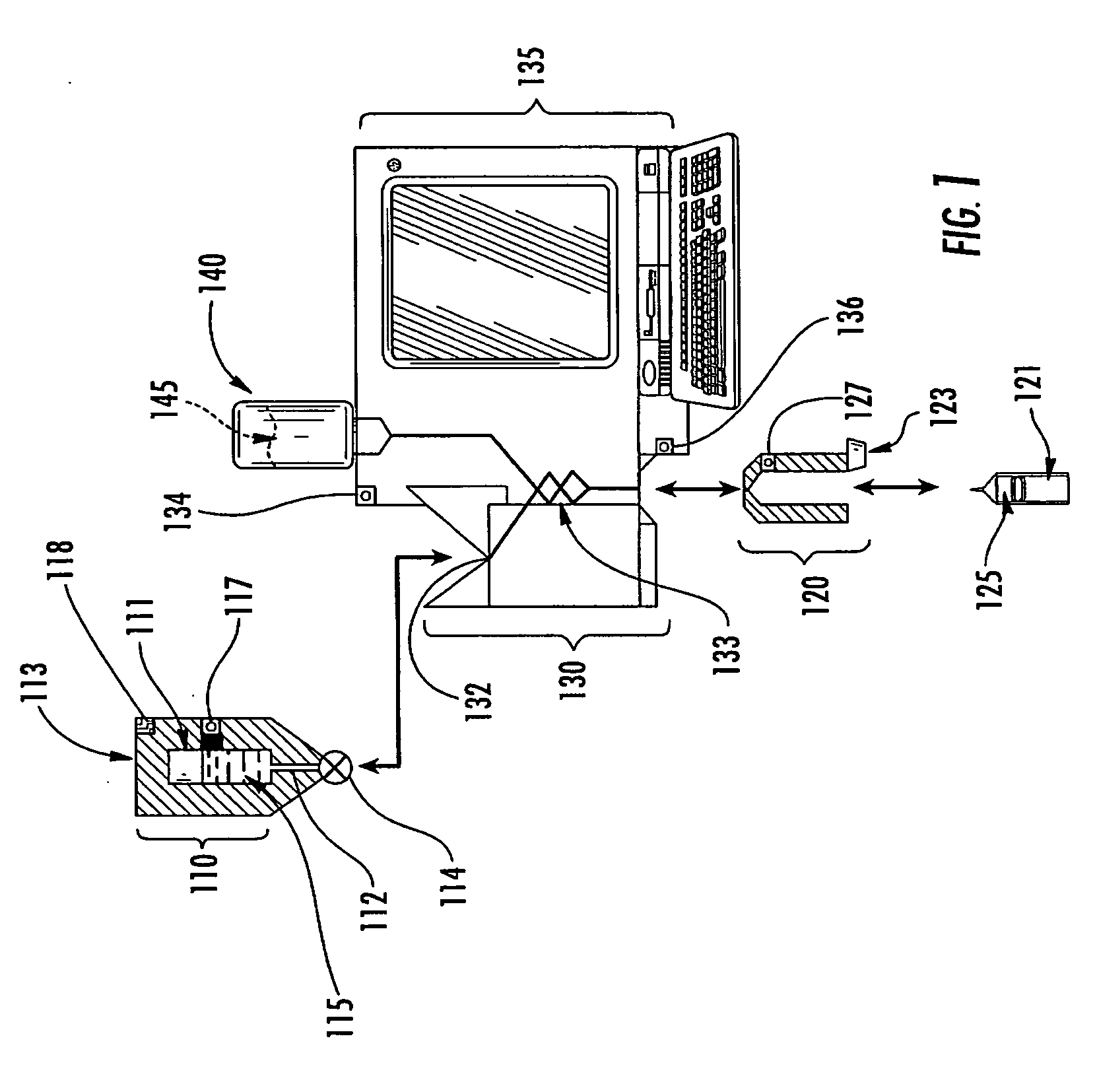

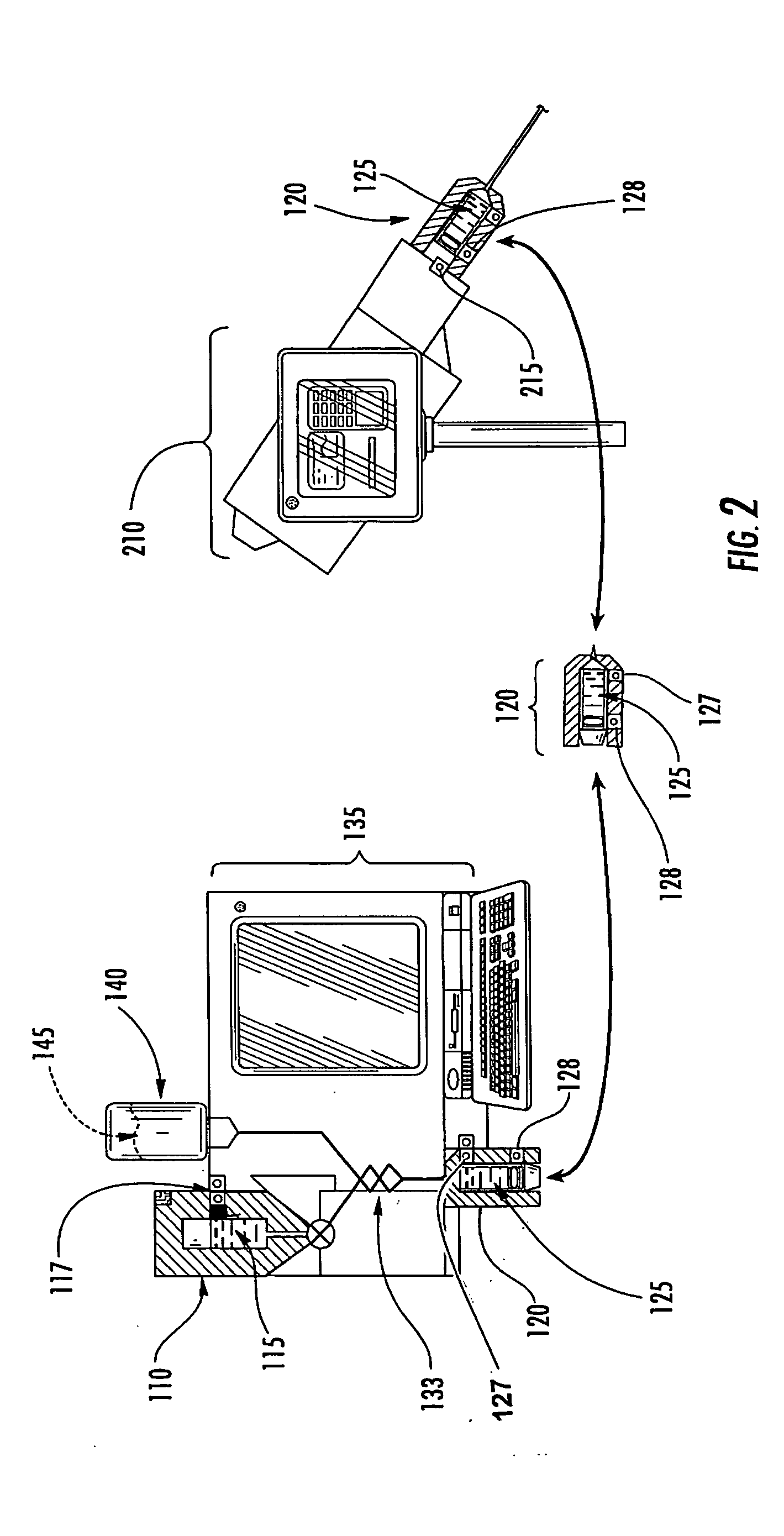

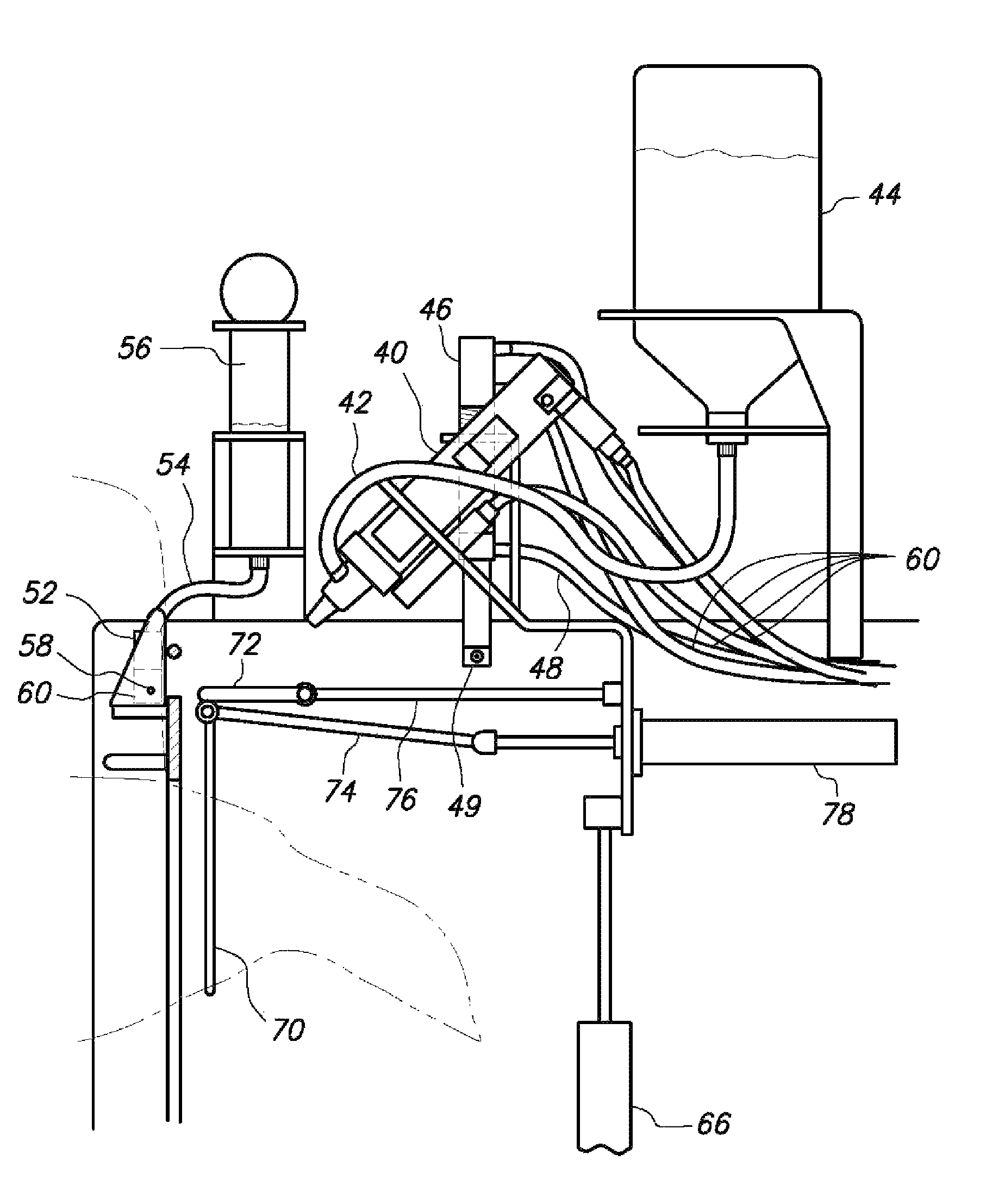

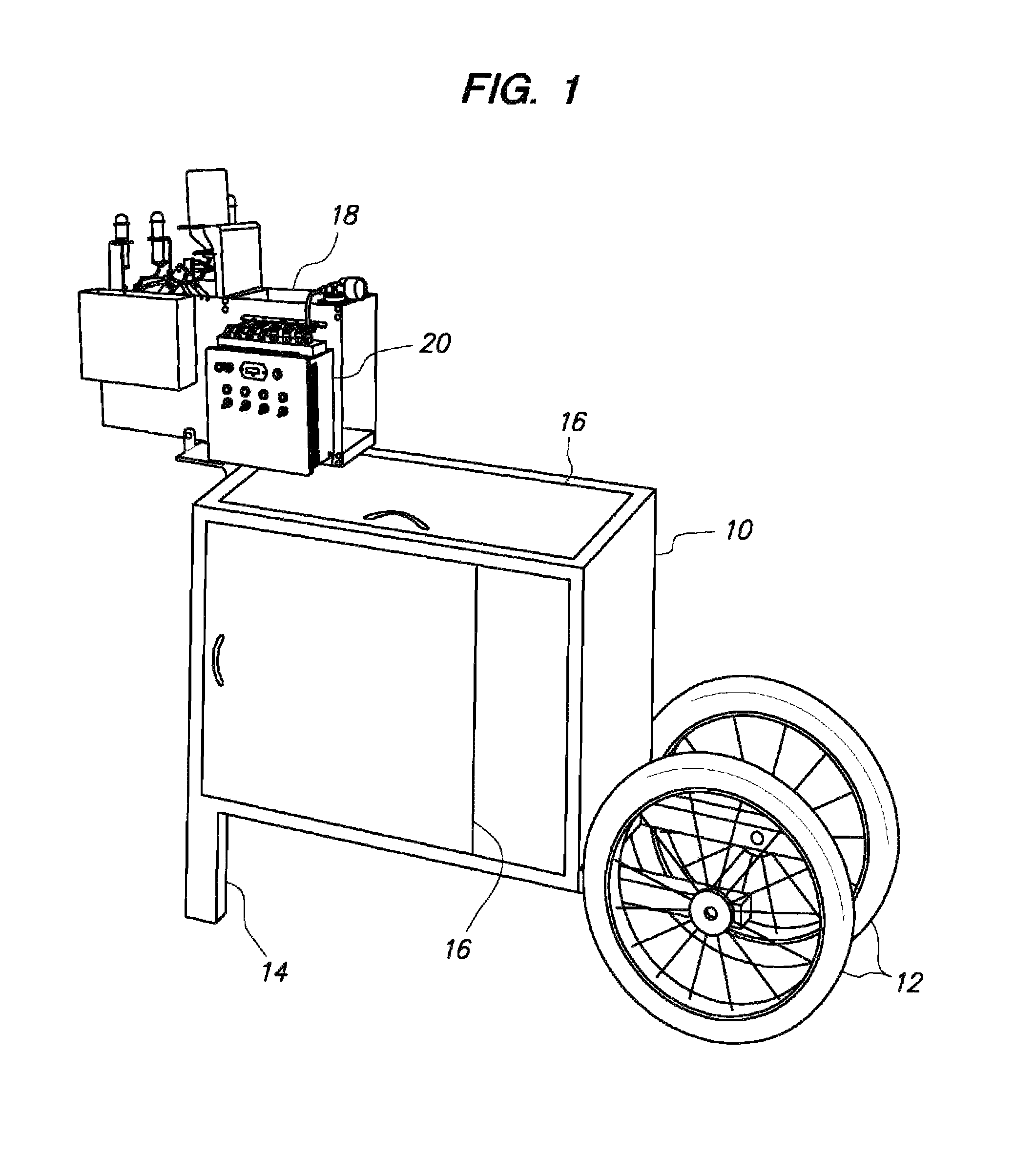

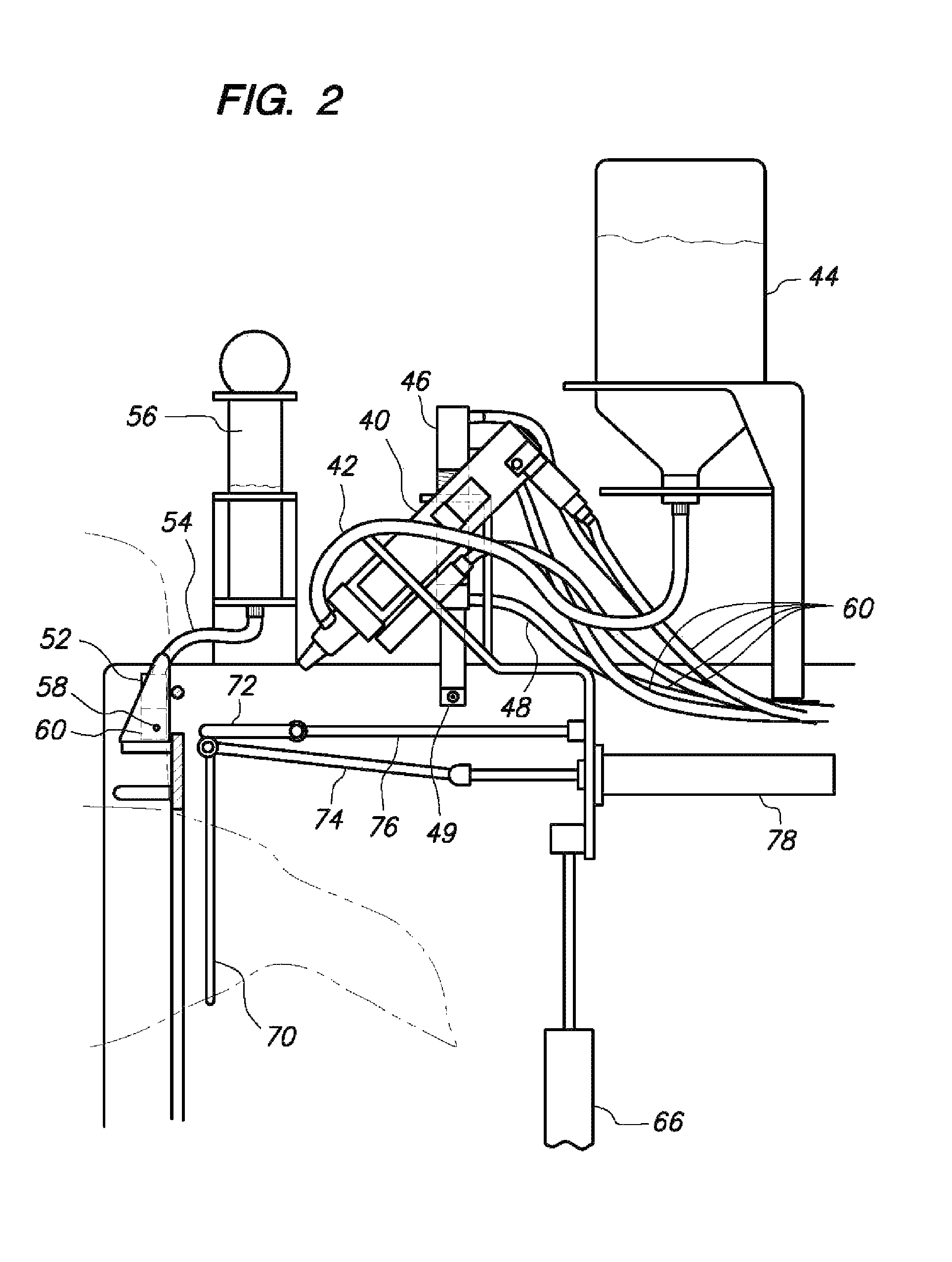

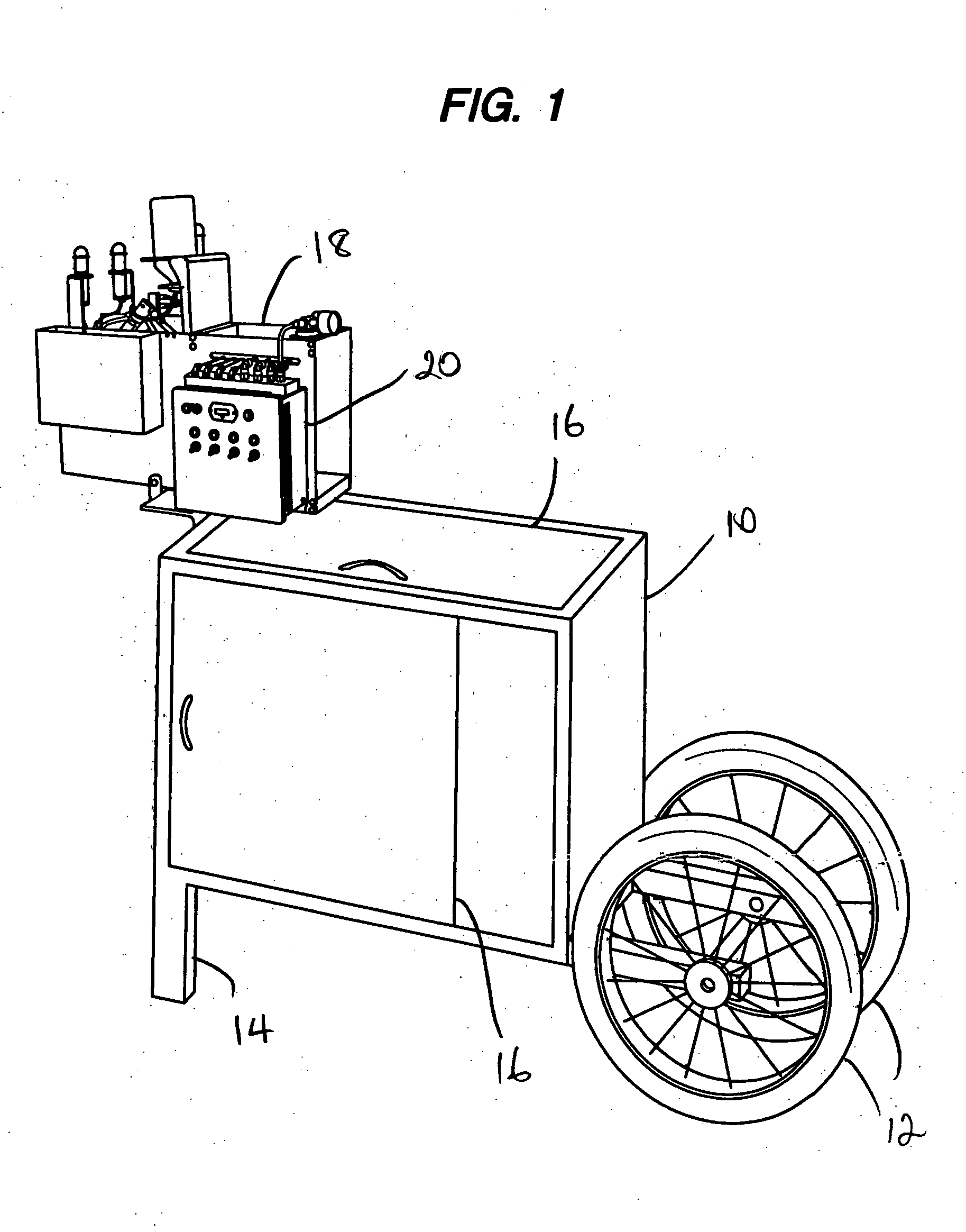

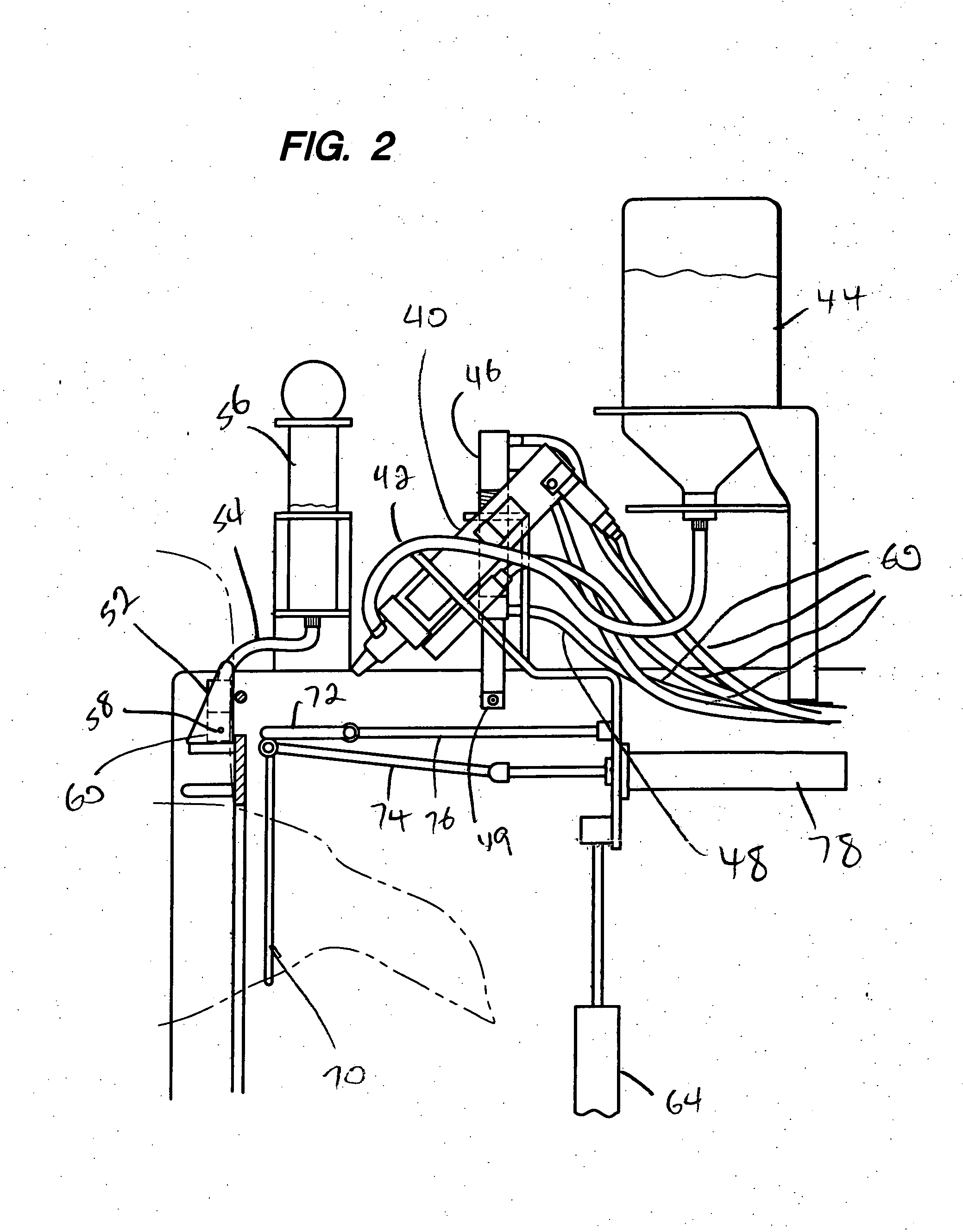

System, method, and computer program product for handling, mixing, dispensing, and injecting radiopharmaceutical agents

InactiveUS20050277833A1Reduce processingReduce manual handlingInfusion syringesMedical devicesDiluentEngineering

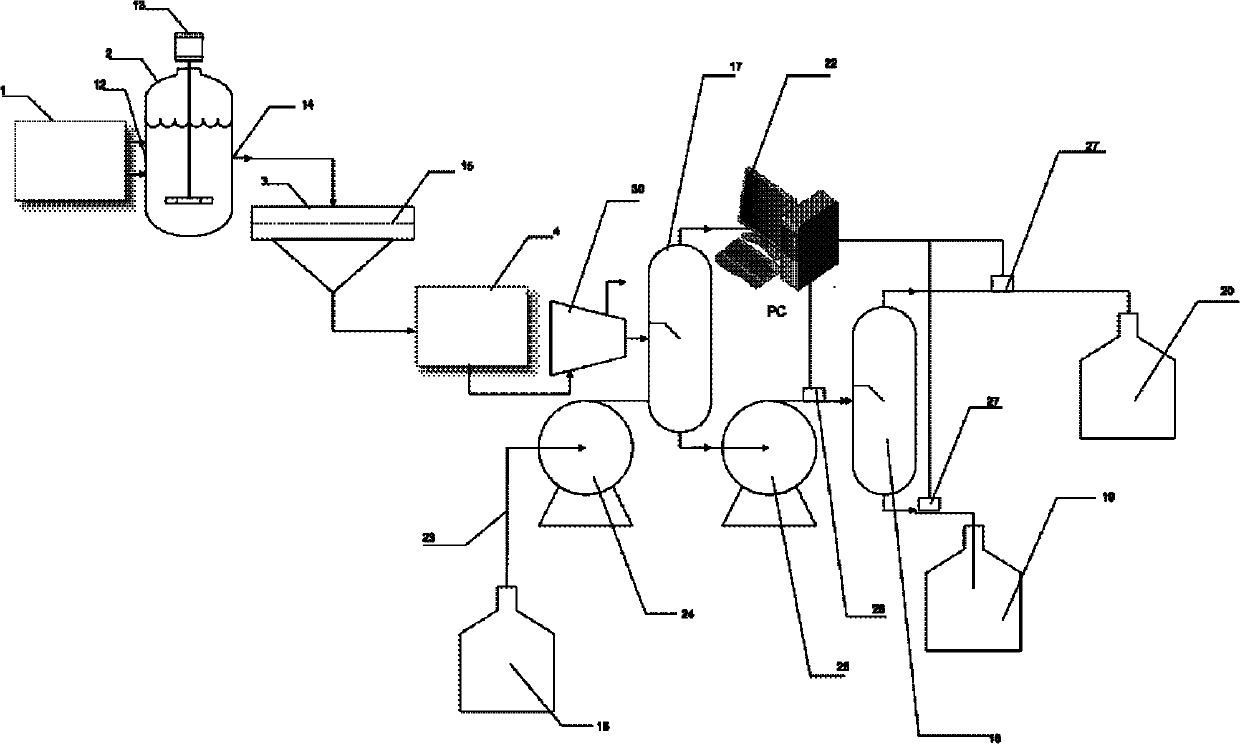

The present invention is directed to a system, method, and computer program product for handling, mixing, dispensing and / or injecting a mixture into an individual during a medical procedure. The present invention provides one or more mixing devices, containers, and dispensing devices to facilitate the handling, mixing, dispensing, and / or injecting of a mixture containing, for example, pharmaceutical agents and / or radiopharmaceutical agents. The present invention also provides a mixing device capable of diluting a radiopharmaceutical agent with, for instance, a diluent, for altering a radiation dose emitted by the radiopharmaceutical agent.

Owner:ACIST MEDICAL SYST

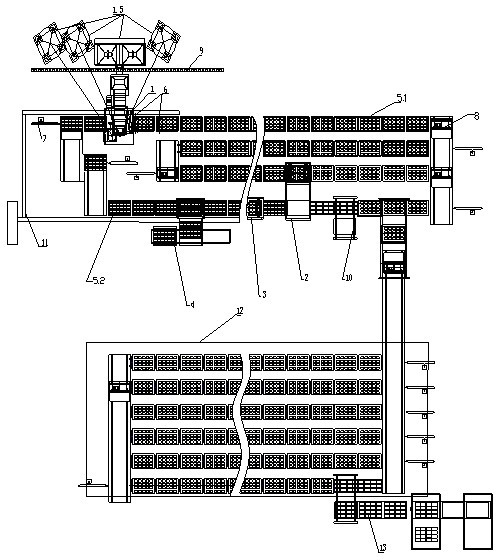

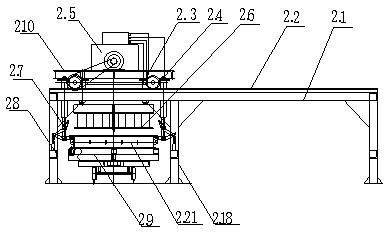

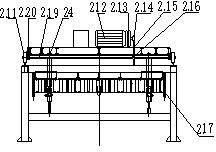

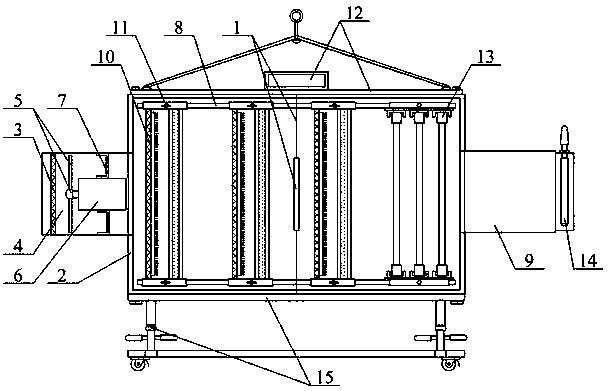

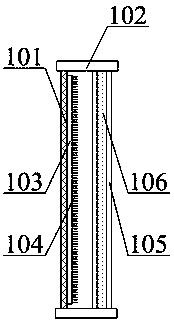

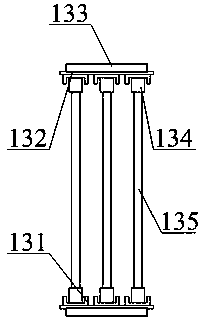

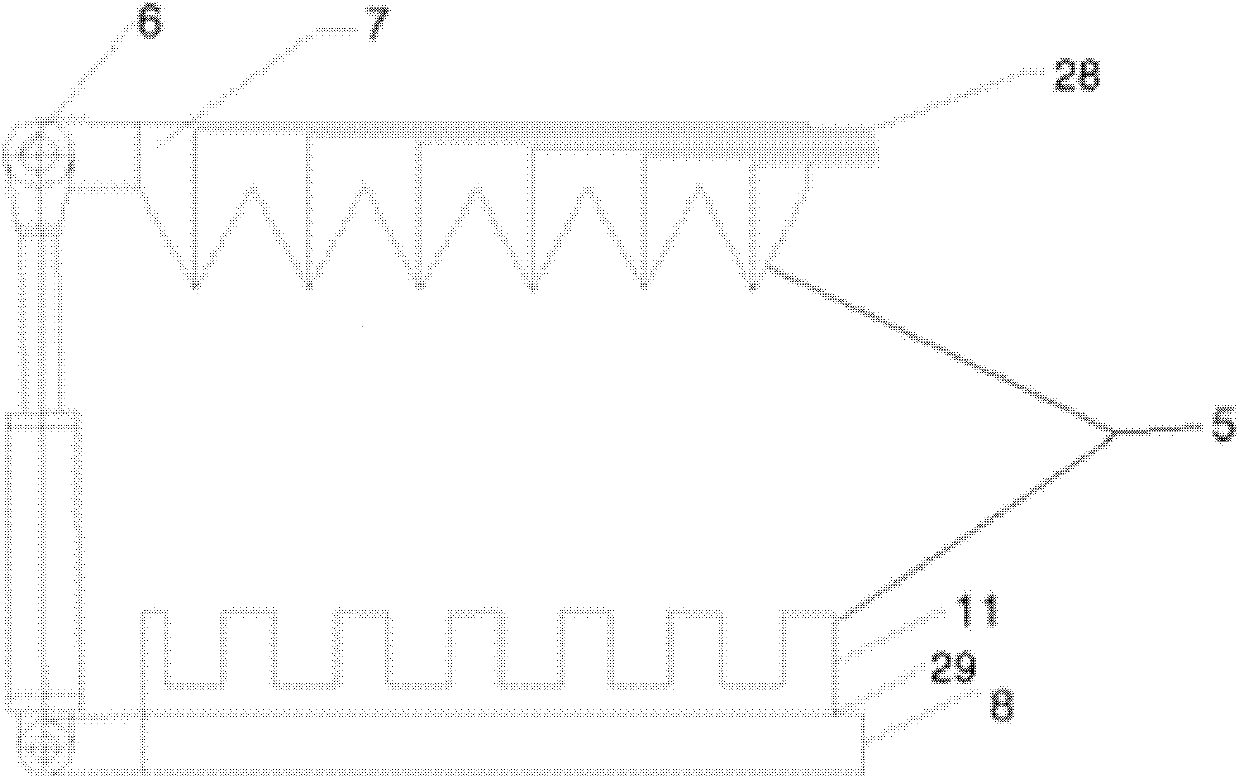

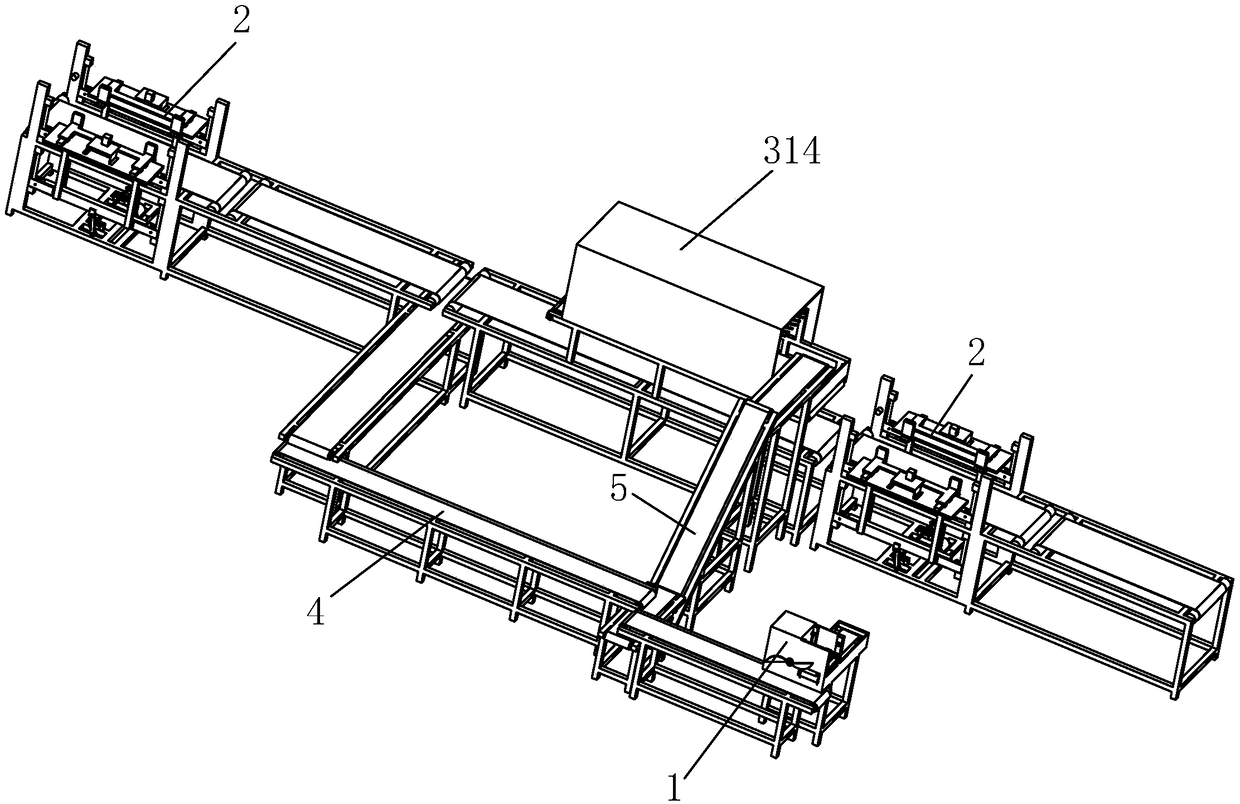

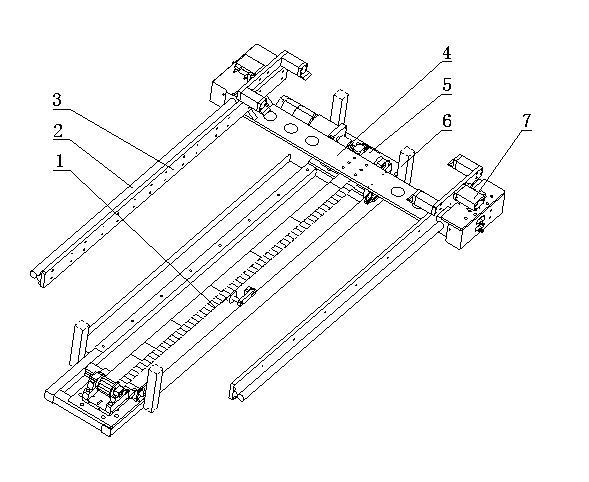

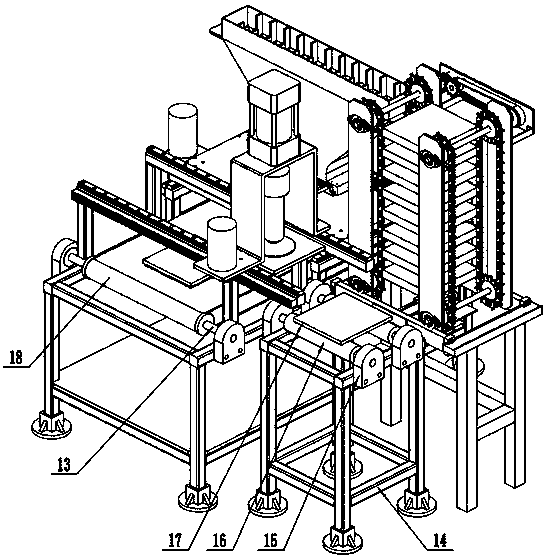

Production line for self-insulation building blocks

InactiveCN102555052AReduce occupancyReduce consumptionDischarging arrangementCeramic shaping plantsProduction lineBrick

The invention relates to a tool used in an insulation brick manufacturing process, in particular to a production line for self-insulation building blocks, which comprises a stirring machine. The production line is characterized in that automatic metering devices are arranged on a feeding port and at the bottom of the stirring machine, a production track capable of automatically conveying molds isdisposed below a distributing port of the stirring machine, a stripper is further arranged on the production track and is spaced from the stirring machine by a proper distance, a return track and a track leading into a maintenance area are respectively disposed on two sides of the other end of the stripper, the return track sequentially penetrates through a cleaning area, an oil injection area and a core setting area, a link plate machine is arranged at the other end of the maintenance area, and a manipulator is disposed at the other end of the link plate machine. The production line is high in production efficiency and annual yield, occupied land area and workshop investment are reduced, operating expense is saved, and the production line can operate continuously.

Owner:张建兴

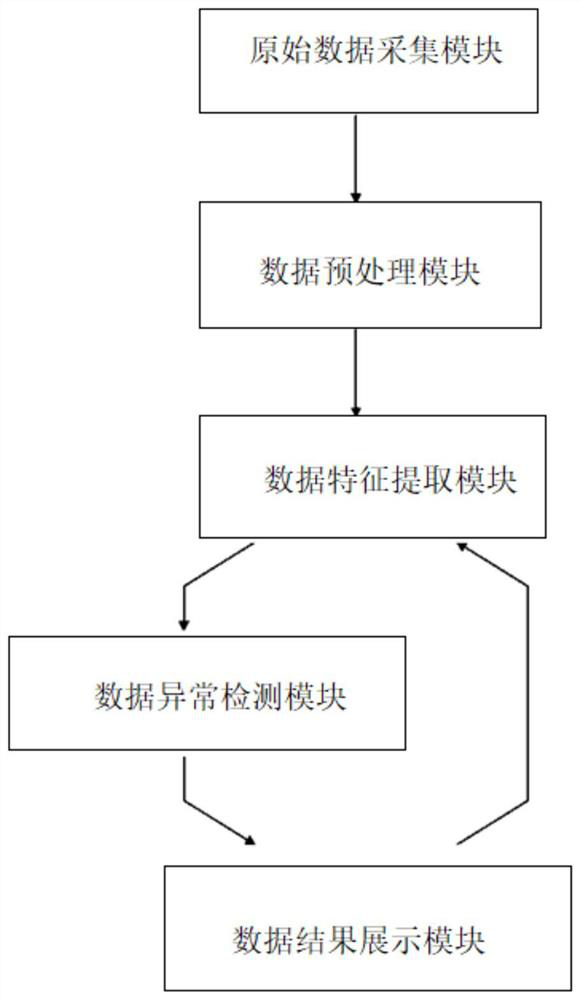

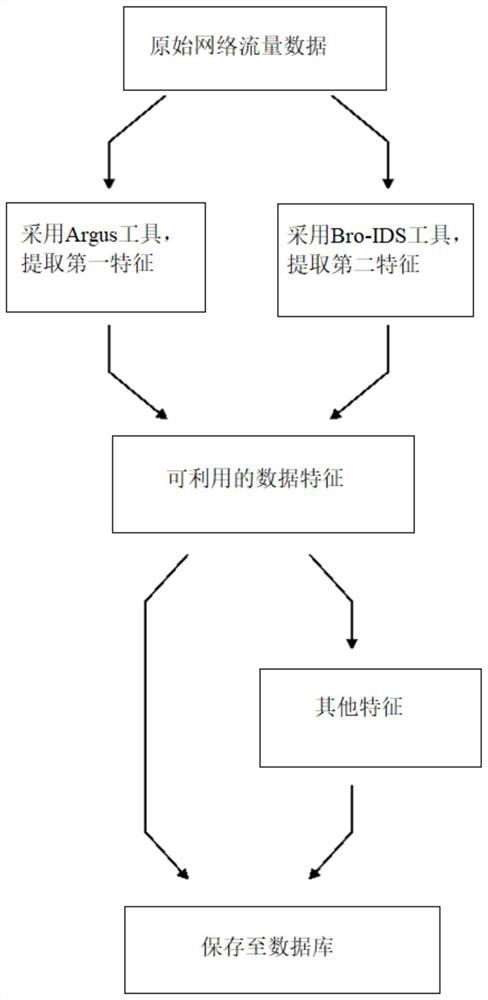

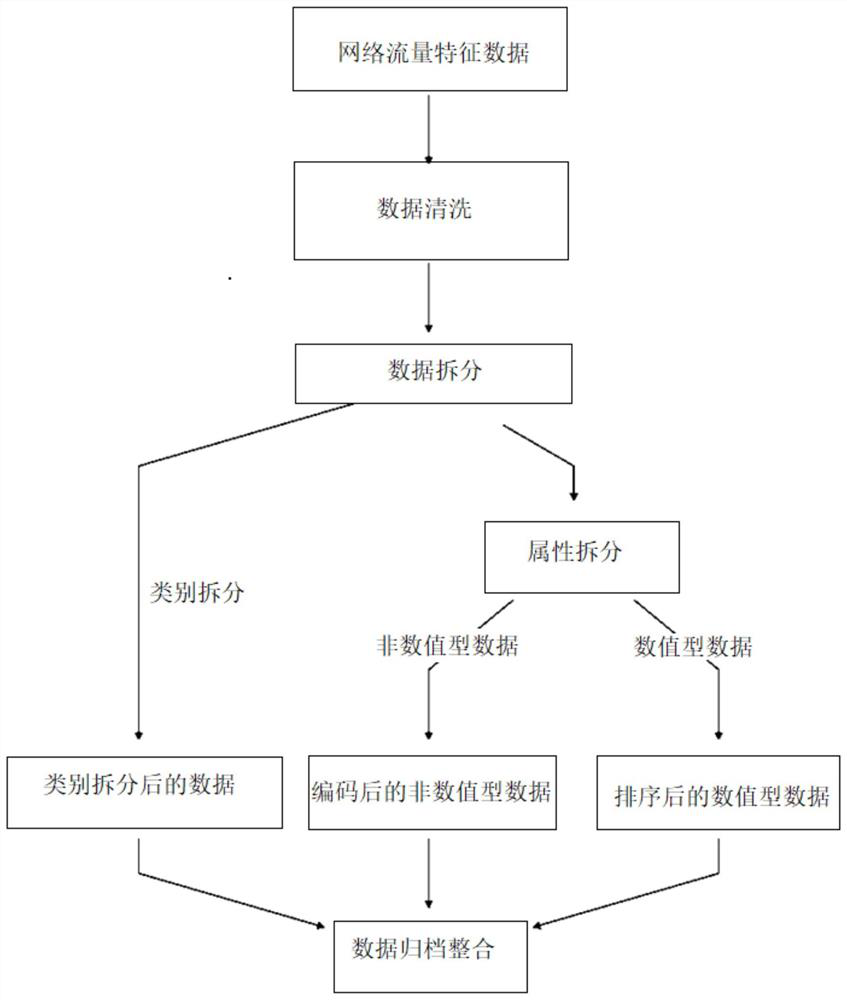

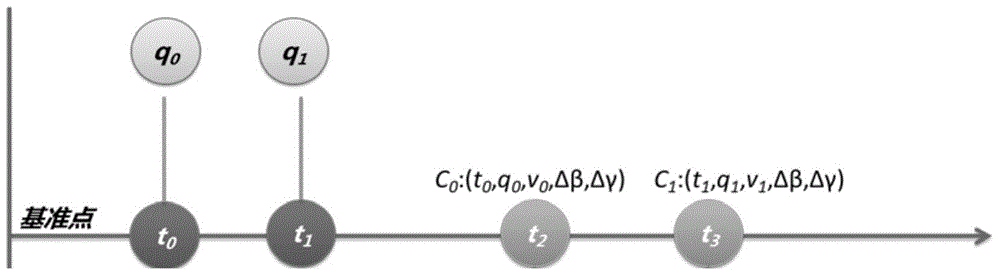

Network traffic data analysis method and system

ActiveCN112398779AReduce false alarm rateImprove robustnessData switching networksInternet trafficAnomaly detection

The invention belongs to the technical field of network flow data analysis and particularly relates to a network flow data exception detection method. The method comprises the following steps of processing original network flow data captured in real time to obtain network flow data; if the network flow data is abnormal data, outputting an exception, inputting the exception data into a pre-trainedfirst exception classifier, judging that the attack type of the exception data is a known attack type, and outputting the attack type of the exception data; if the network flow data is not abnormal data, further detecting whether the network flow data is abnormal or not by adopting an unsupervised anomaly detection method; if the network flow data is abnormal data, inputting the abnormal data intoa pre-trained second abnormal classifier, judging that the type of the abnormal data is an unknown attack type, and marking the abnormal data as the unknown attack type; and if the network flow datais not abnormal data, the output being normal.

Owner:NAT SPACE SCI CENT CAS

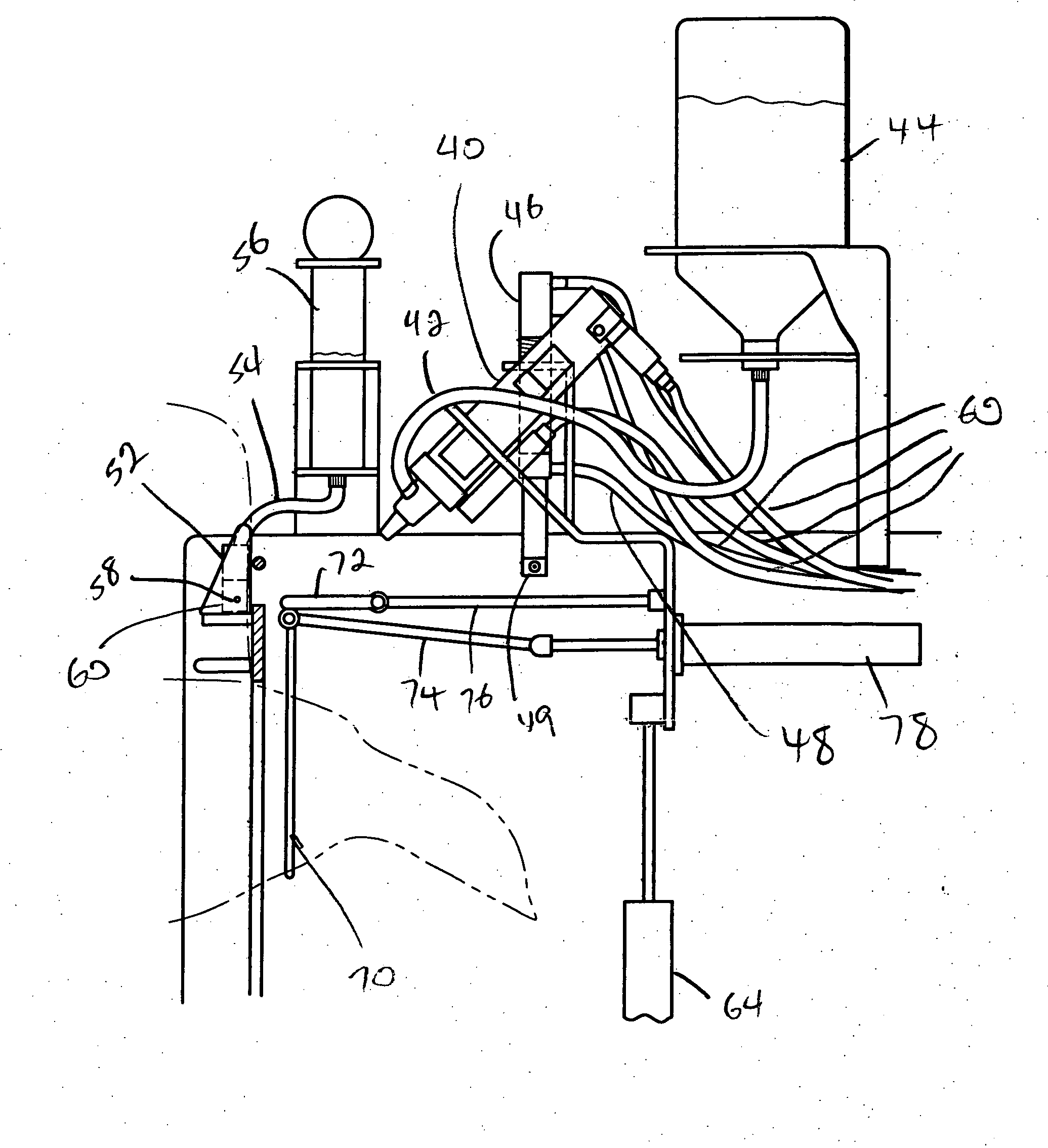

Poultry vaccination apparatus and method

Owner:ZOETIS SERVICE LLC

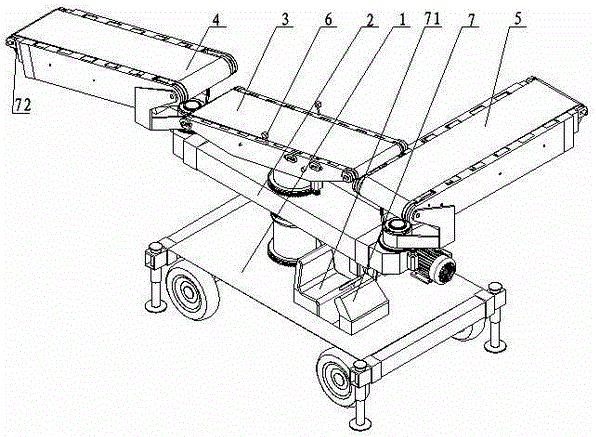

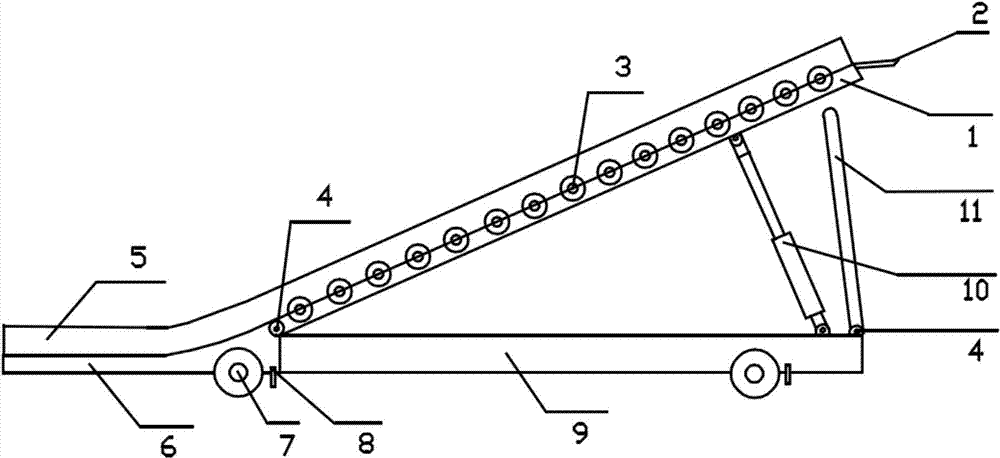

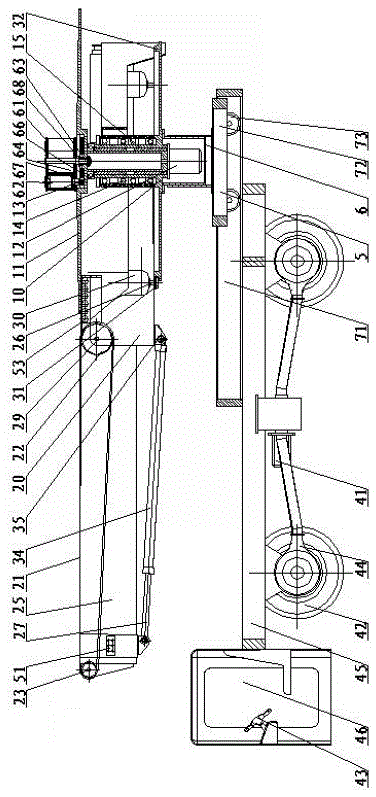

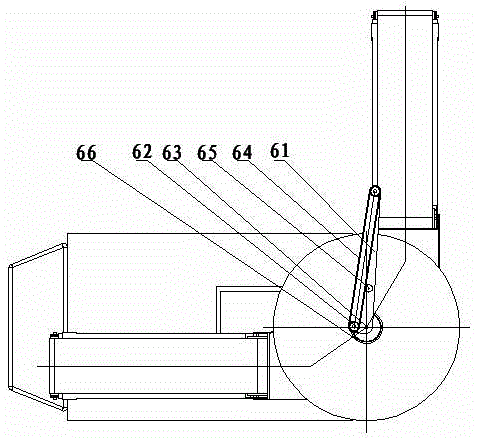

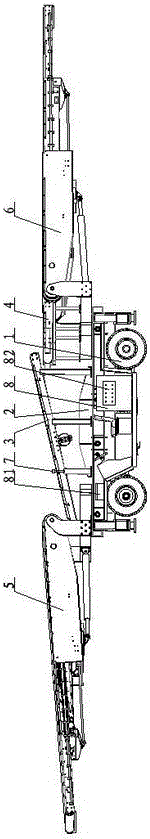

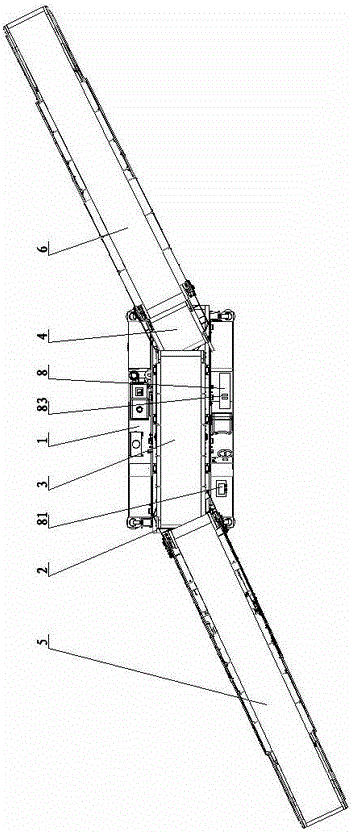

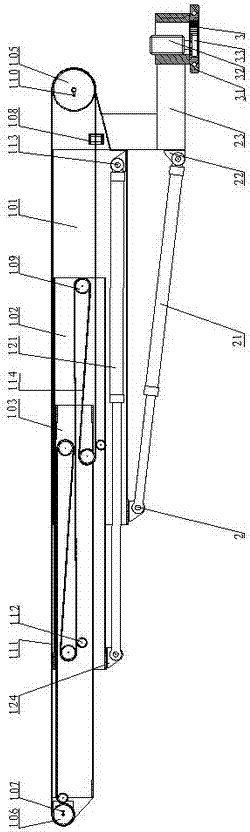

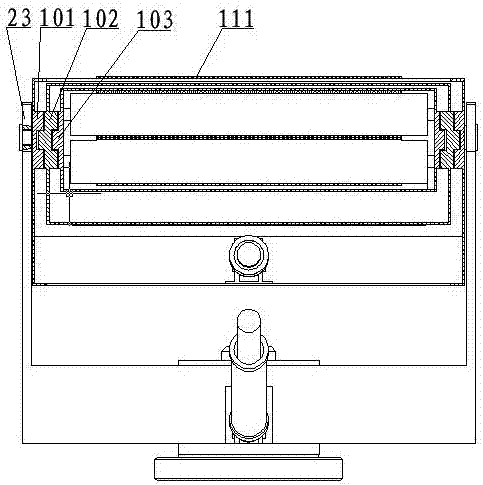

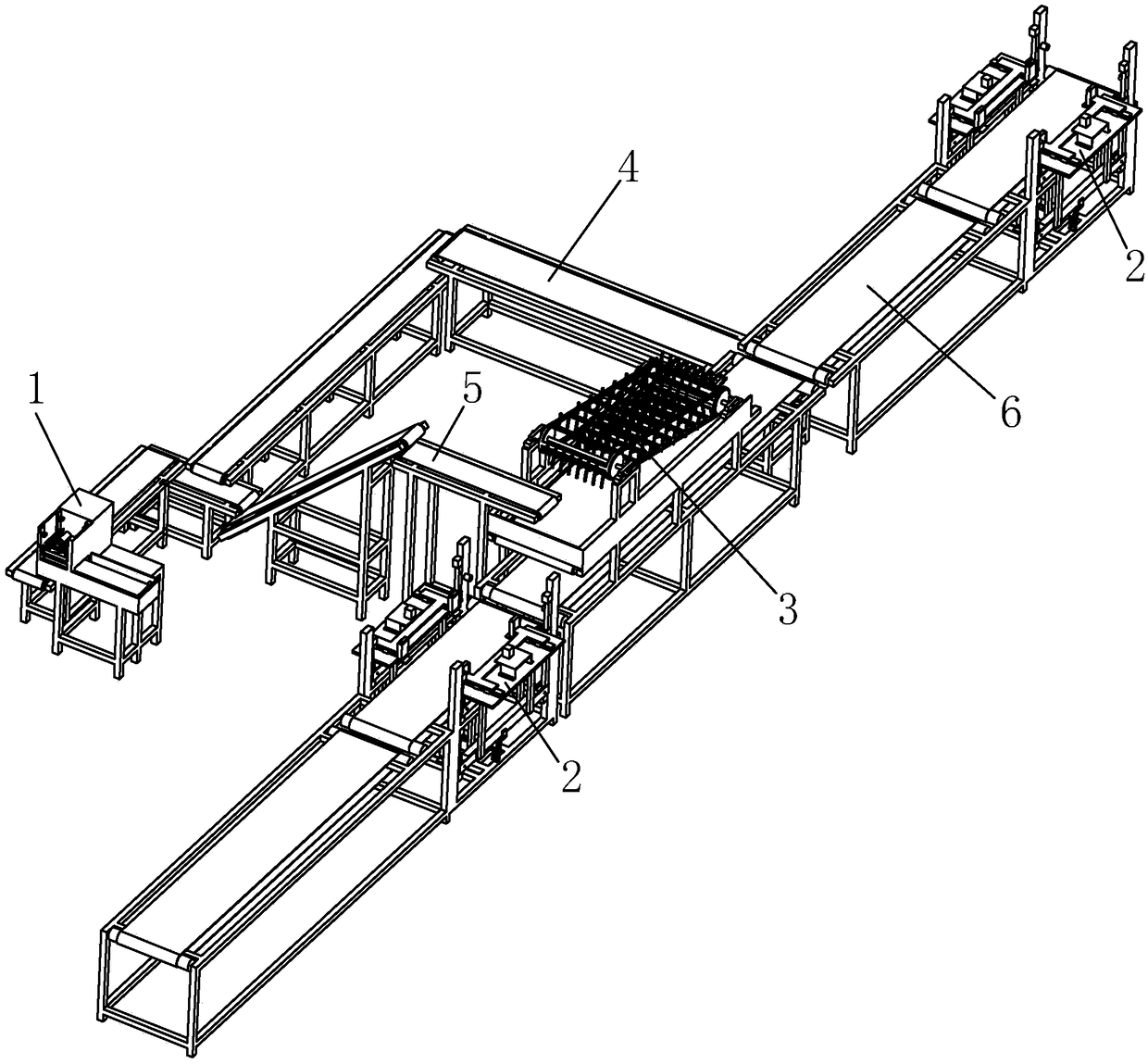

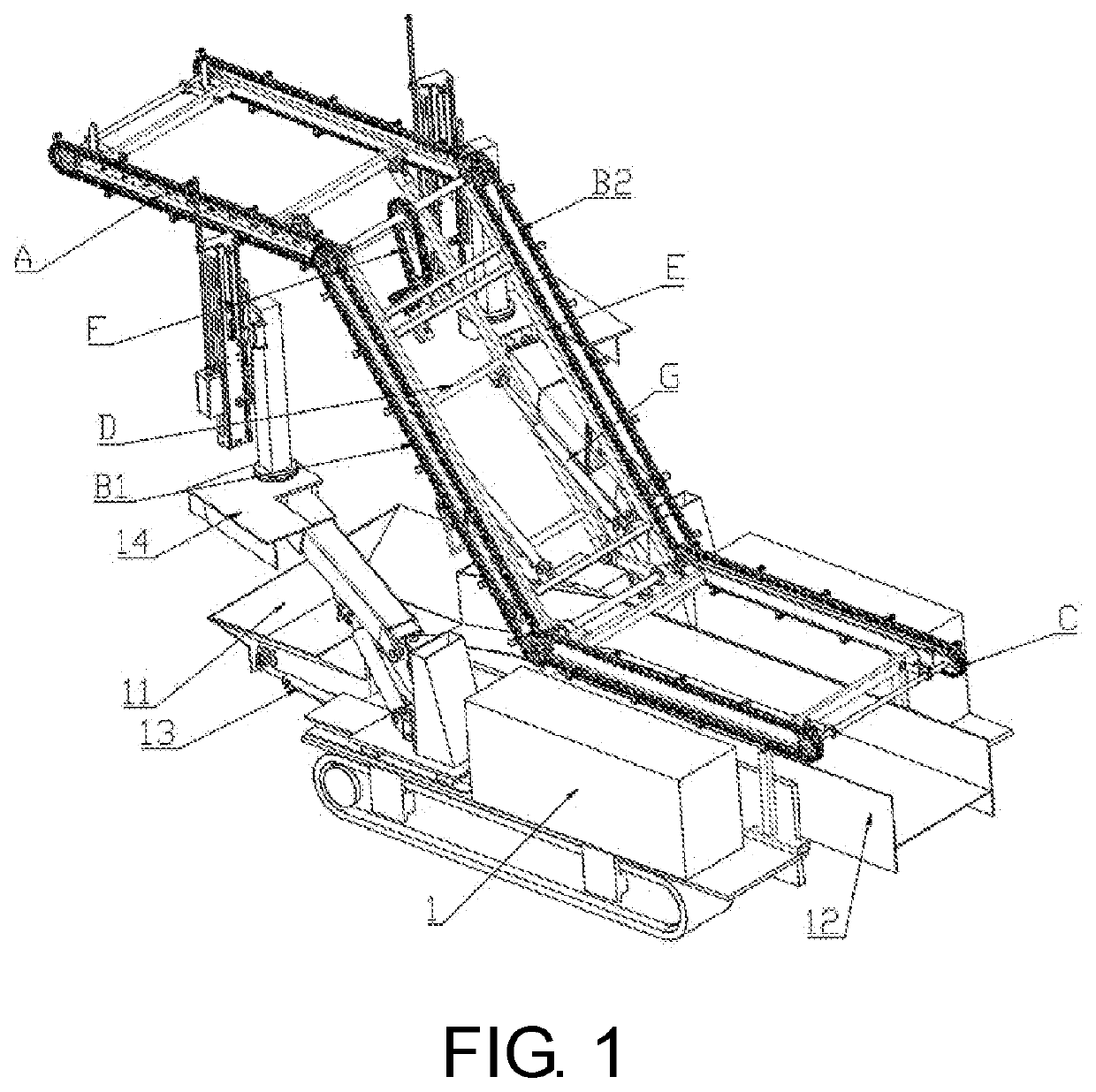

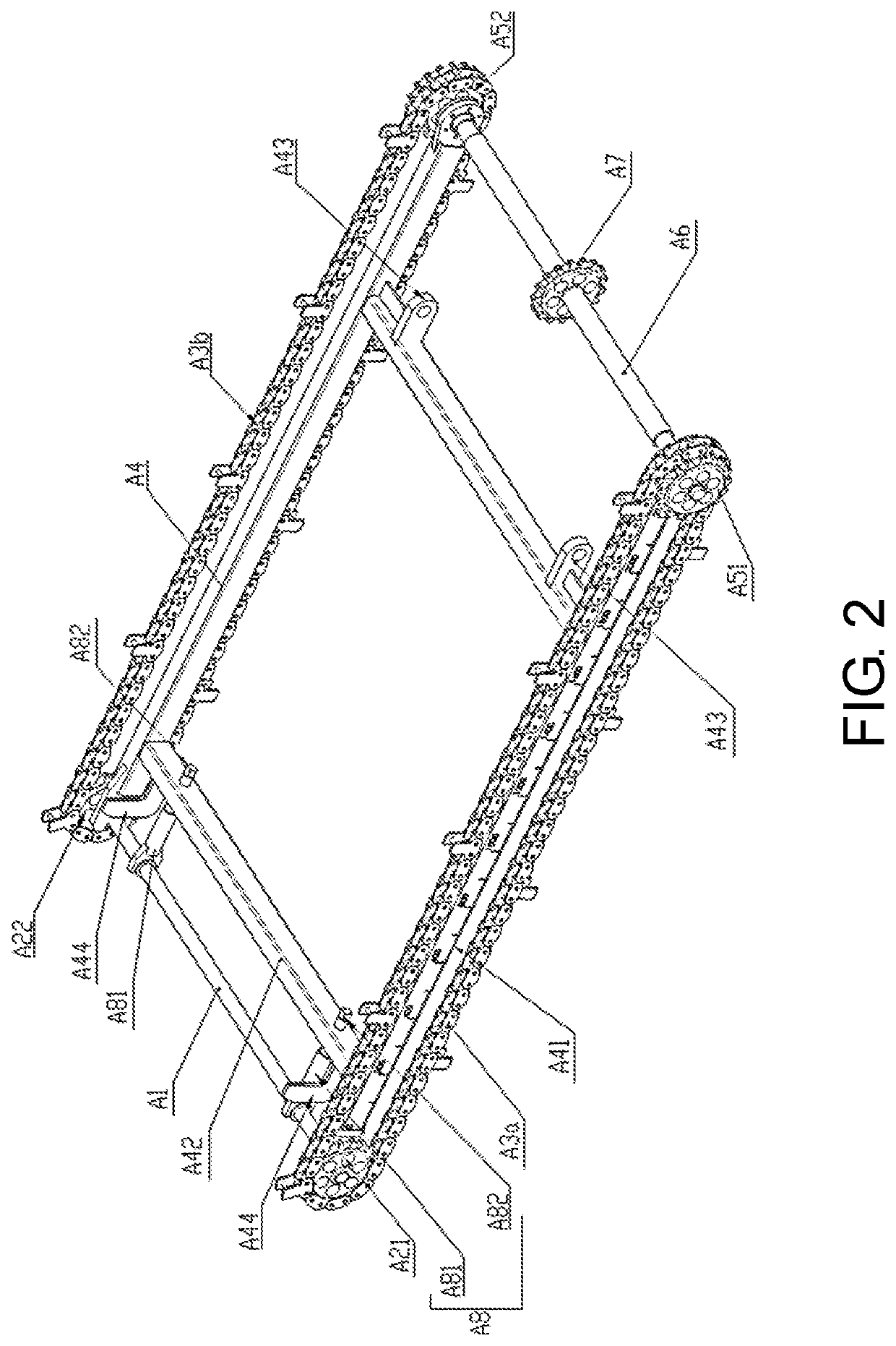

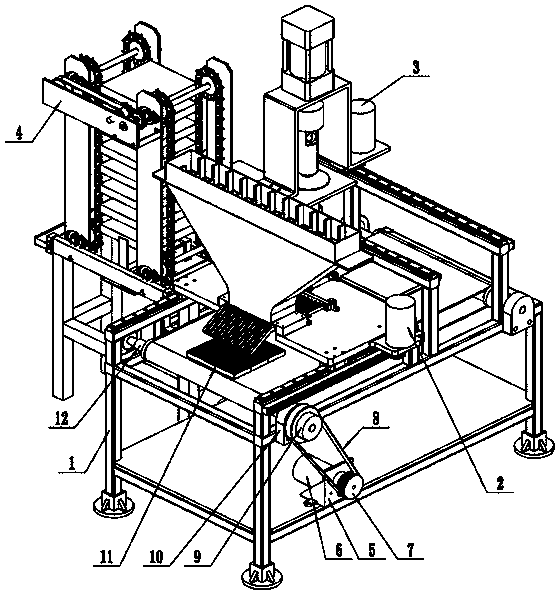

A derricking direction-changeable telescopic belt conveying bidirectional loader-unloader

InactiveCN106608551AAdjustable working heightRealize orientationConveyorsRollersControl systemStatistical analysis

The invention provides a derricking direction-changeable telescopic belt conveying bidirectional loader-unloader and relates to the field of logistics transportation cargo loading and unloading mechanical equipment. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader comprises a vehicle having bearing and walking functions, a telescopic cross arm having lifting, telescoping and swinging functions, a middle transition conveyor which has a swinging function and is capable of inclined conveying, a first belt conveyor and a second belt conveyor having derricking, swinging and telescoping functions, a metering device having metering, displaying, storing and printing functions, and an operating control system used for complete machine operation of the loader-unloader. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader has the advantages of simple structure, reliable work, convenient and rapid movement and transfer, and wide operating scope; the derricking direction-changeable telescopic belt conveying bidirectional loader-unloader can reduce manually-assisted carrying, reduce workload, shorten operating time, increase loading and unloading working efficiency, reduce the cost of loading and unloading carrying, improve working environment and work conditions, guarantee economical, rapid, convenient and safe loading and unloading and transportation, allow change of the direction of logistics conveying, and realize forward and reverse loading and unloading, automatic metering statistical analysis, and loading and unloading quantity / weight recording, displaying and storing.

Owner:襄阳忠良工程机械有限责任公司

Poultry vaccination apparatus and method

An apparatus for providing multiple vaccinations of poultry simultaneously is described. A neck injection, breast injection, two wing injections, and an eye mist or drop may be performed in one operation. The apparatus holds the bird in position for precise location of injections, thereby reducing wasted vaccine. The risk of injury to the bird during the process is minimized by greatly reducing the manual handling of the bird during vaccination. Vaccination costs are also reduced by the reduction of labor otherwise required in this process.

Owner:ZOETIS SERVICE LLC

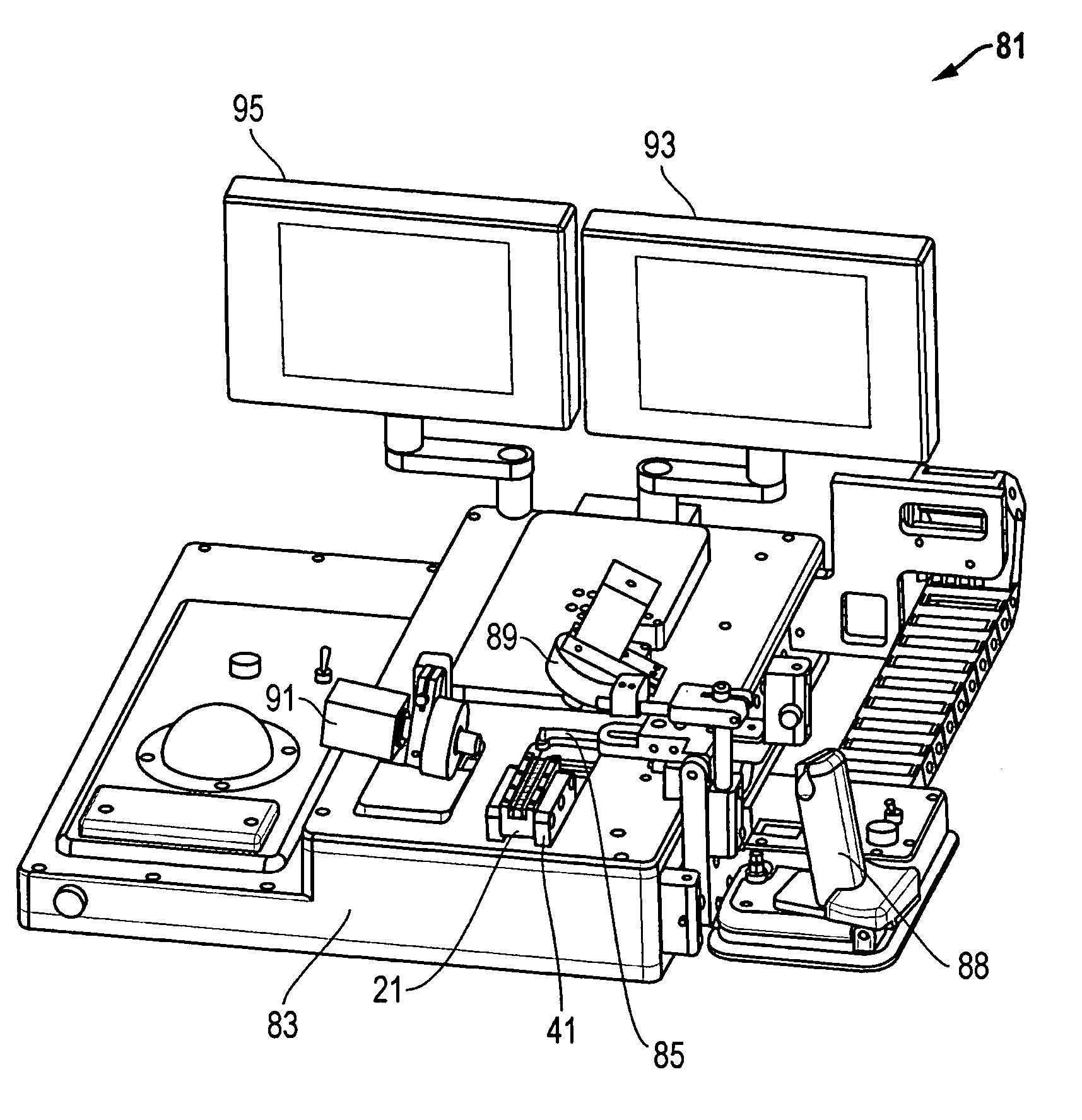

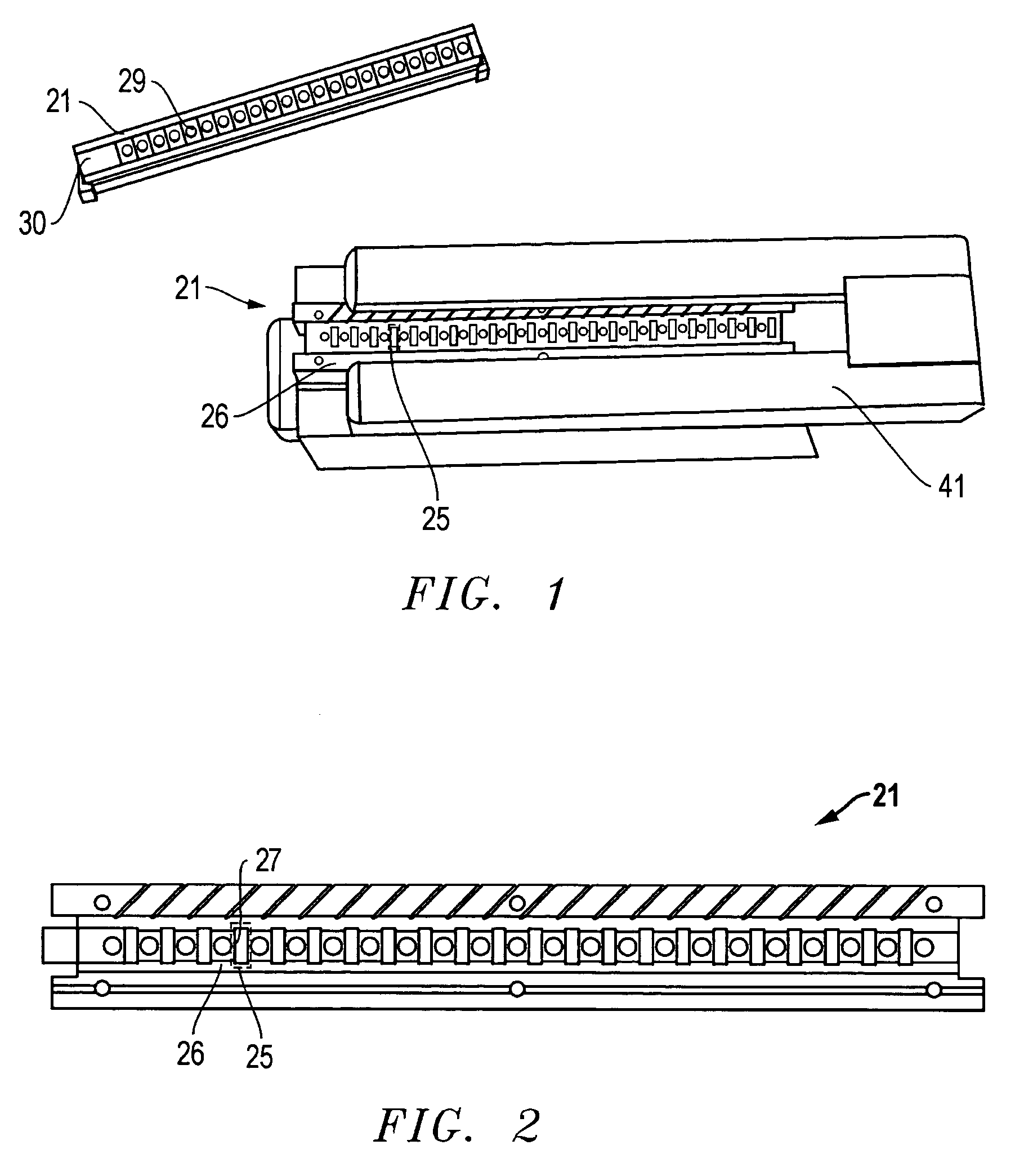

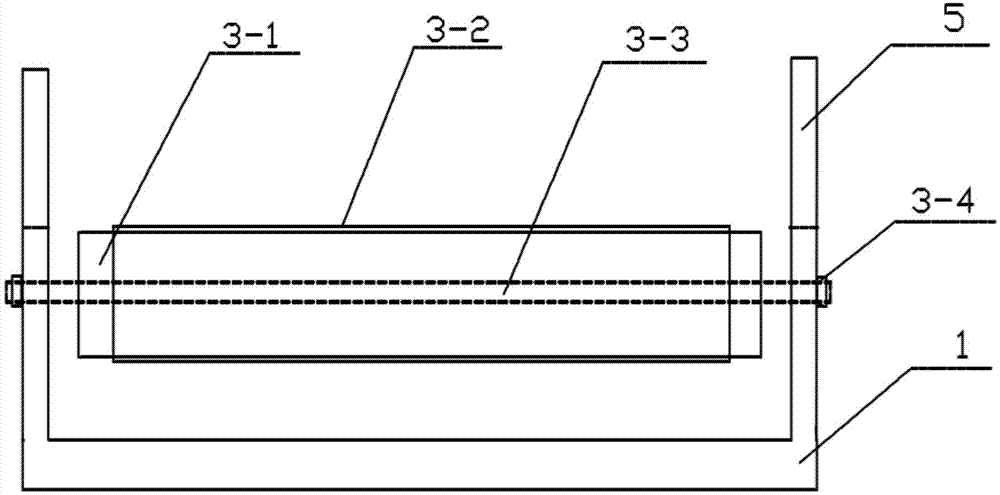

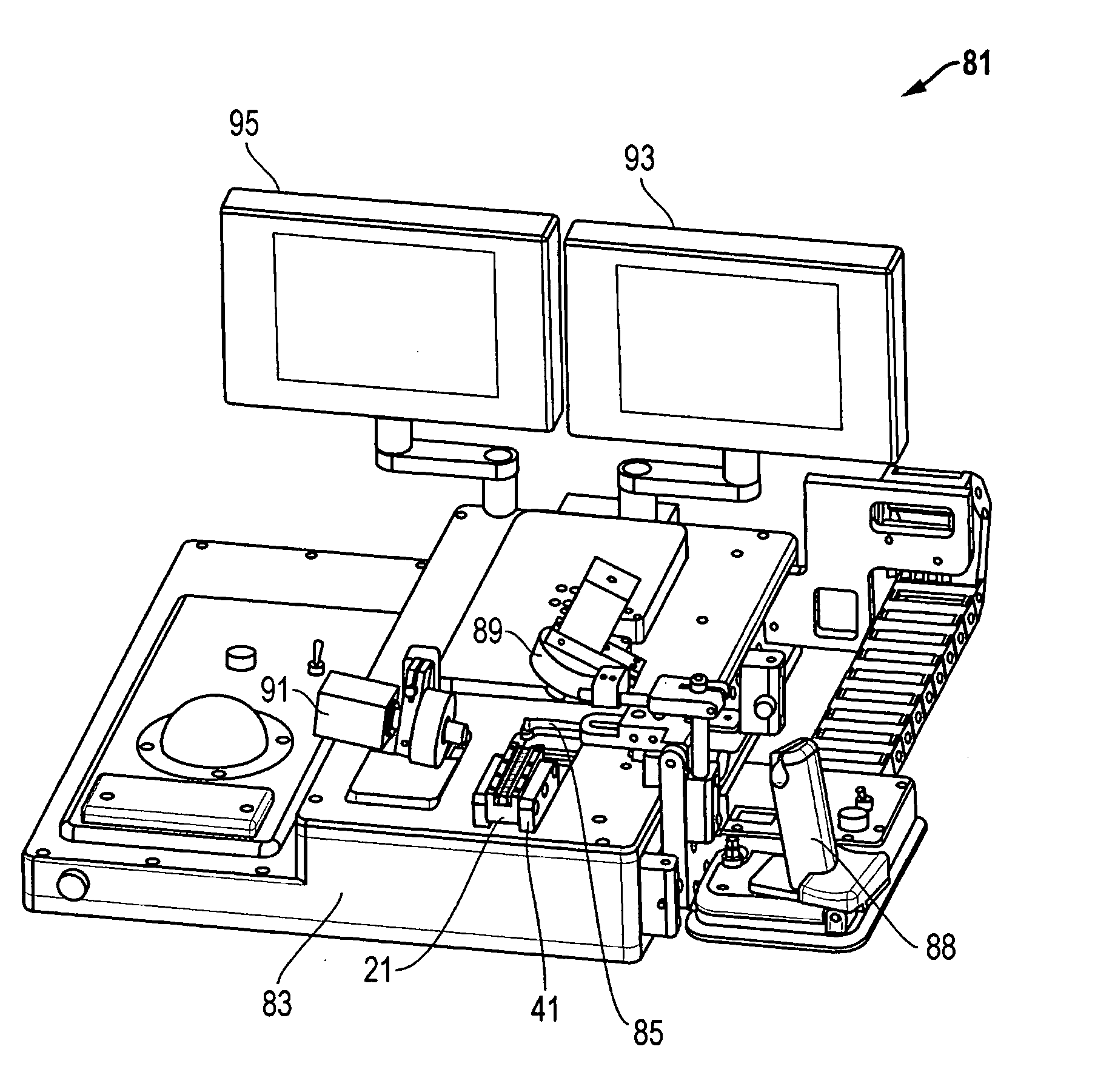

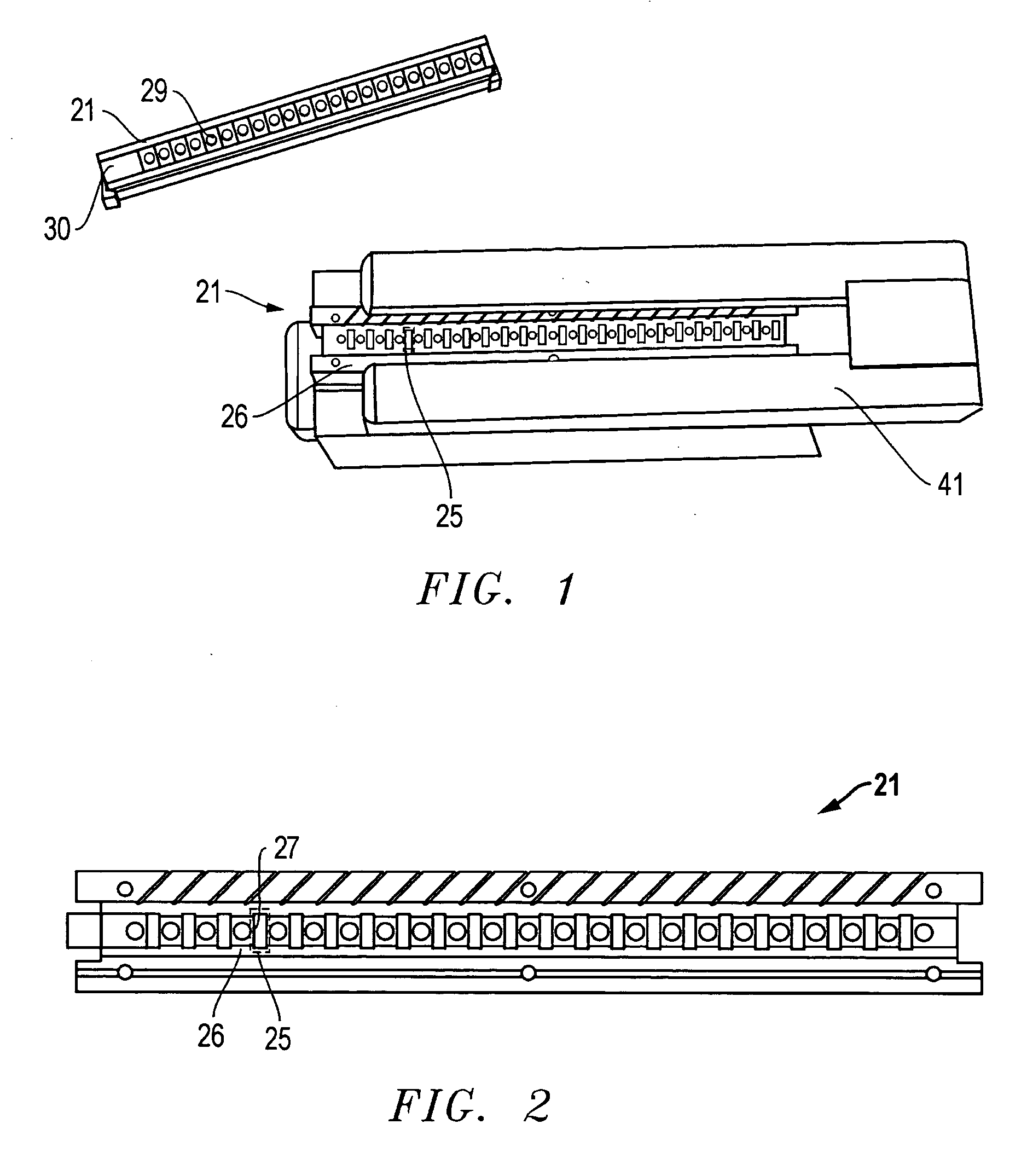

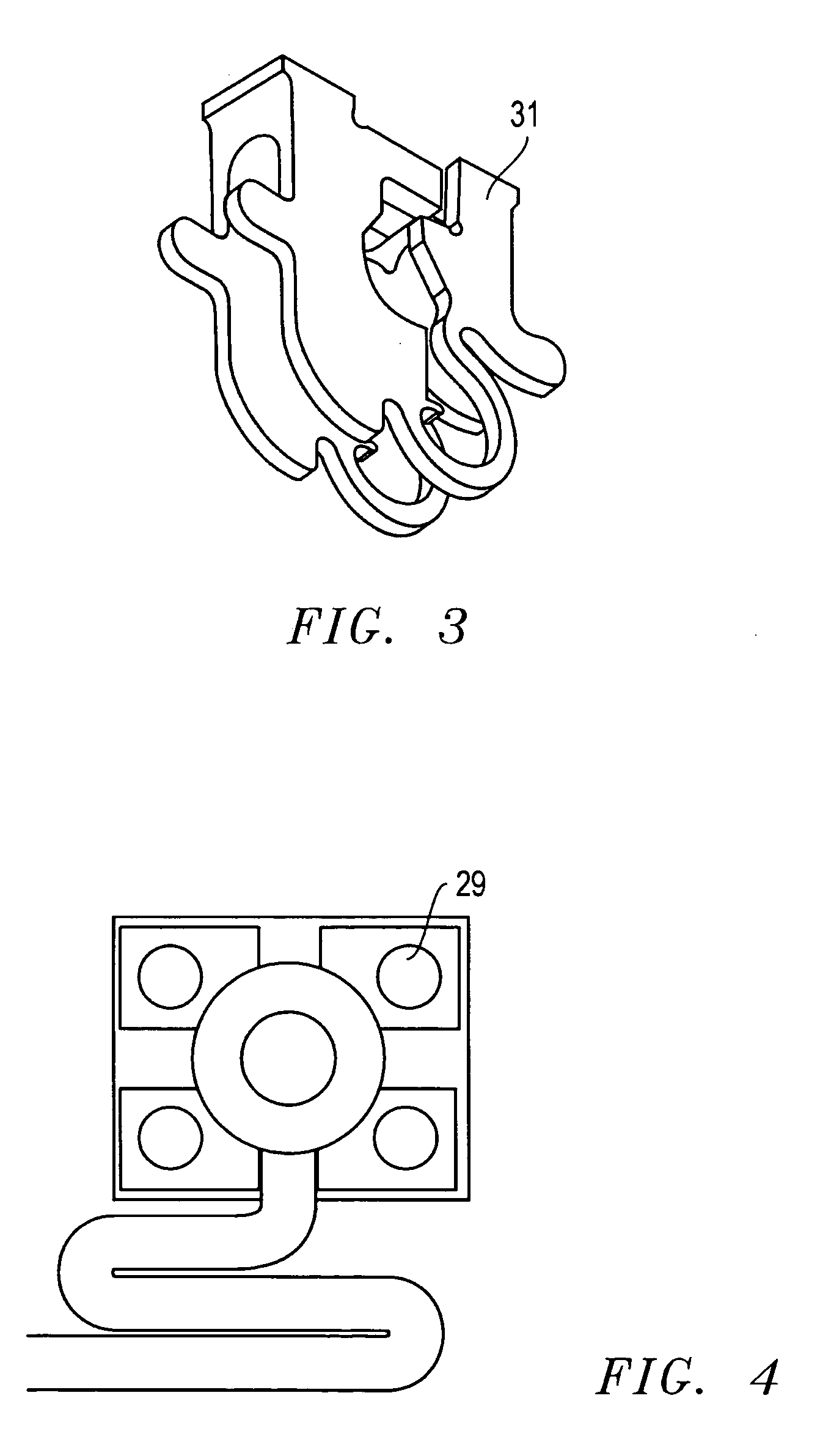

System, method, and apparatus for handling and testing individual sliders in a row-like format in single slider processing systems

InactiveUS7049809B2Avoid damageEasy dischargeElectronic circuit testingRecord information storageElectricityEngineering

A device for handling and testing individual sliders in a row-like format utilizes an elongated, row-like holder having a series of small pockets, each of which receives a single slider. After the sliders enter the holder, a clamp is moved to a closed position to retain the sliders in the holder. The holder is placed in a test fixture such that permanently mounted probes precisely engage the small pads on the sliders for multiple testing purposes. Enlarged probe pads on the test fixture are electrically interconnected with the probes to provide an operator with easy access to the slider pads. The sliders are tested in a row-like format, side by side, to reduce handling-induced electrostatic discharge and mechanical damage.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

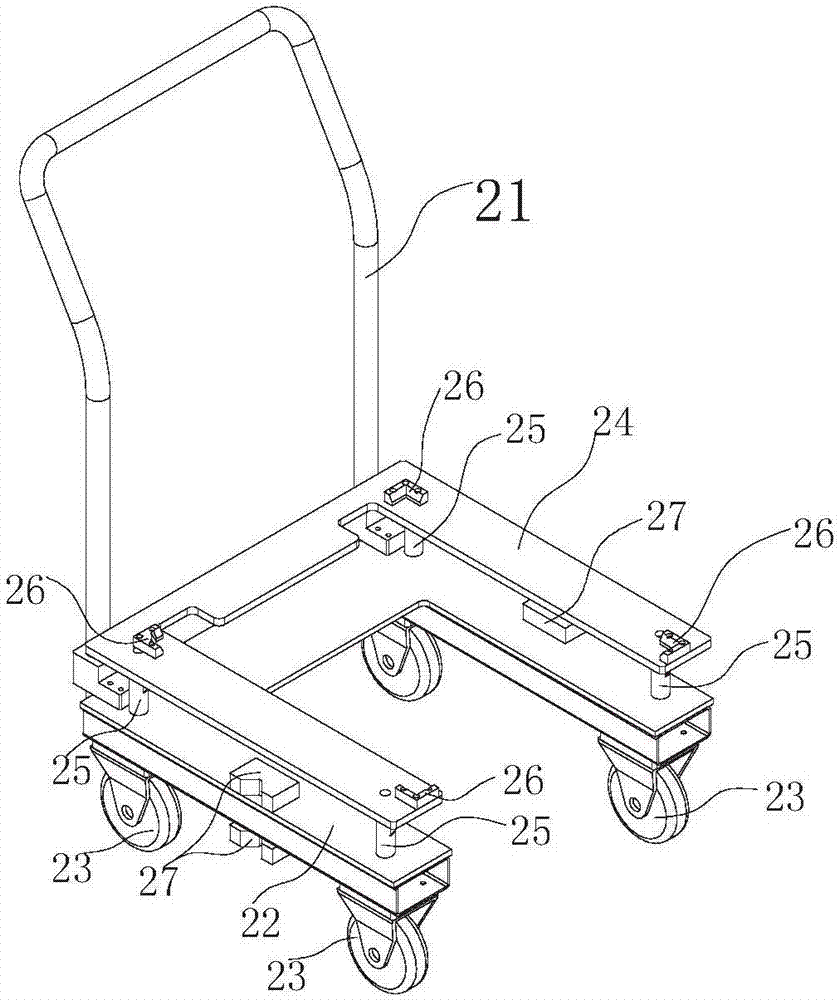

Movable and liftable unloading trolley

InactiveCN104494670AImprove work efficiencyReduce manual handlingHand carts with multiple axesEngineeringTruck

The invention relates to a movable and liftable unloading trolley which comprises a trolley body, a rail, an overlapping plate, drums, hinging parts, protective plates, a buffer platform, wheels, wheel locks, a telescopic rod and a pulling handle, wherein the wheels and the wheel locks are arranged at the bottom of the trolley body in a matched way; the tail ends of the wheel locks are connected with the trolley body in a hinging way; the pulling handle is connected to the tail of the trolley body in the hinging way; the buffer platform is arranged at the front ends of the trolley body and the rail; the front end of the rail is connected with the trolley body in the hinging way; the overlapping plate is connected to the tail of the rail; the two ends of the telescopic rod are fixed on the rail and the trolley body respectively; the protective plates are arranged on the two sides of the whole rail; the drums are arranged on the rail; threads are formed at the two ends of drum shafts; the drum shafts are fixed on the rail through nuts. The unloading trolley can freely move to a required position, the height of the drum rail is regulated through the telescopic rod, and goods are directly delivered to a tool such as a pallet from a truck or a railway platform through the drum rail. According to the unloading trolley, manual carrying and unloading links are reduced, and the unloading trolley is convenient, rapid and high in working efficiency.

Owner:GUANGXI UNIV

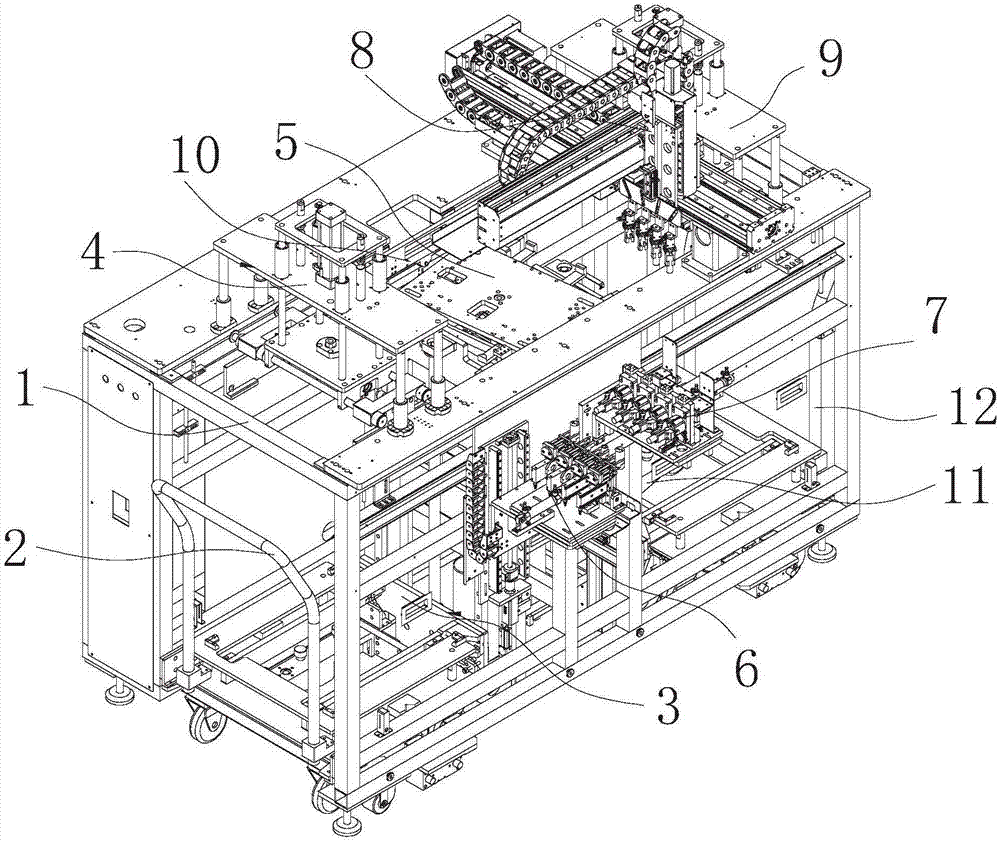

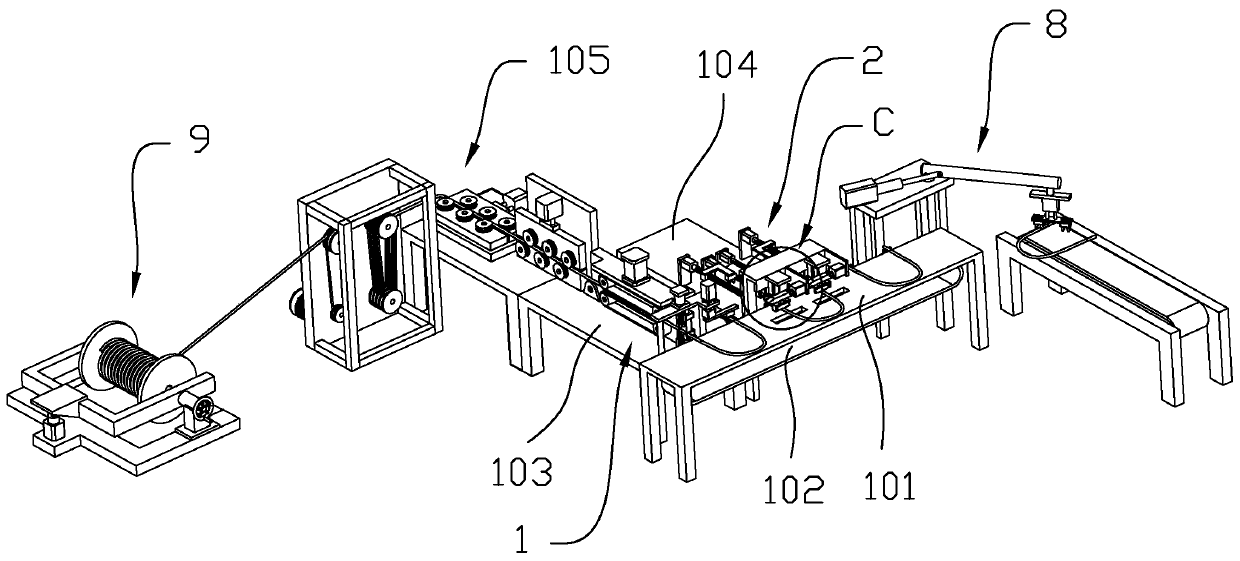

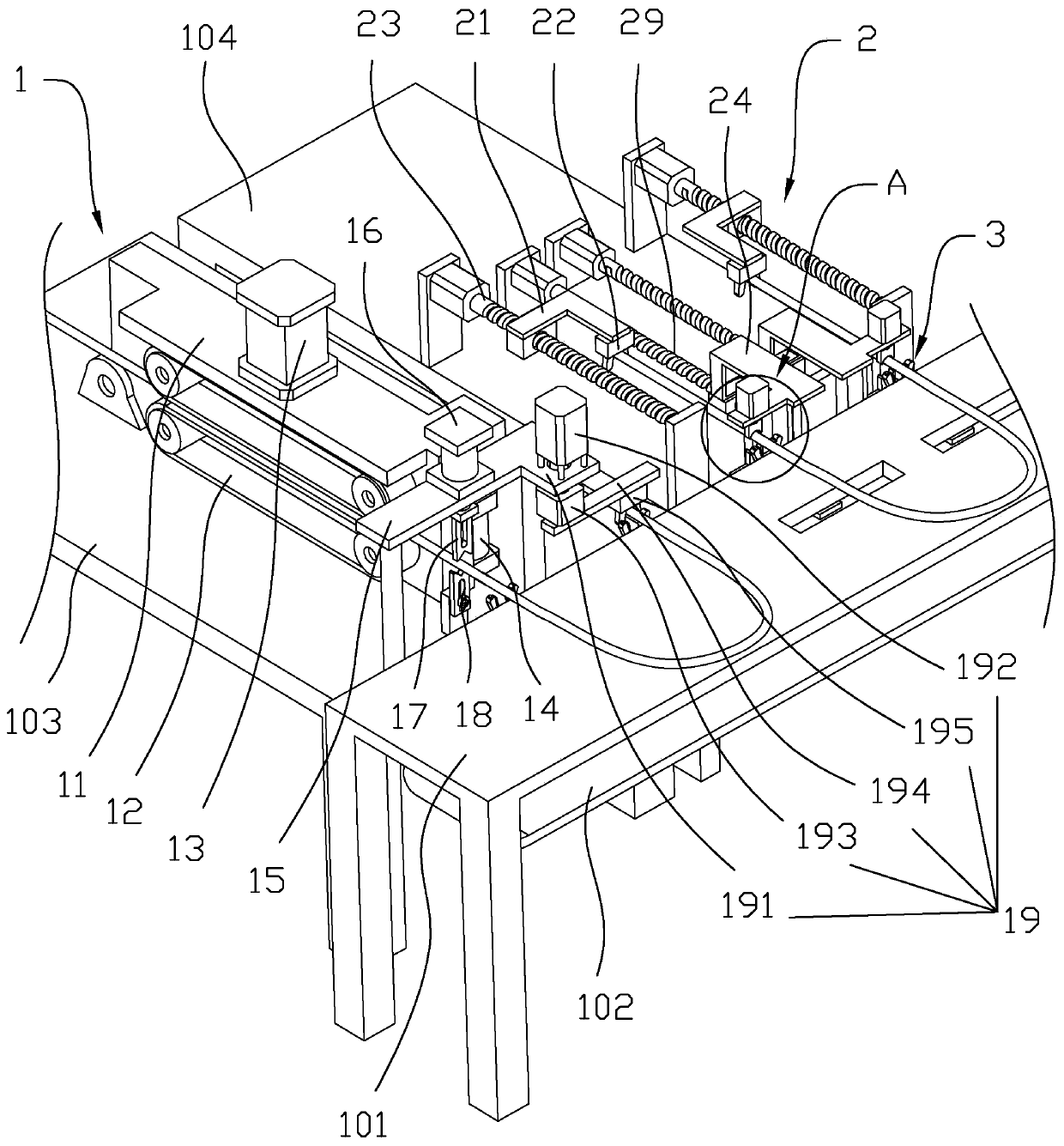

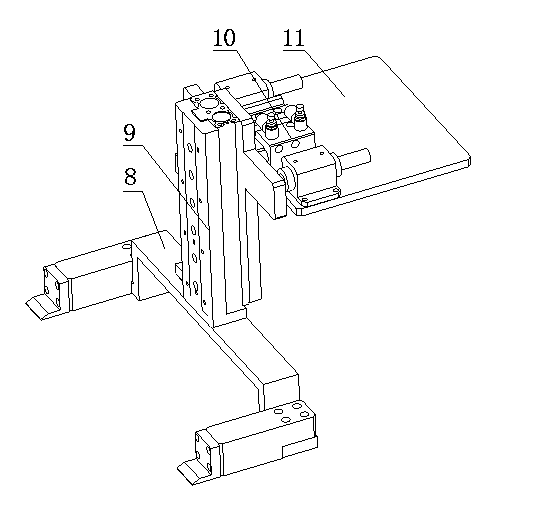

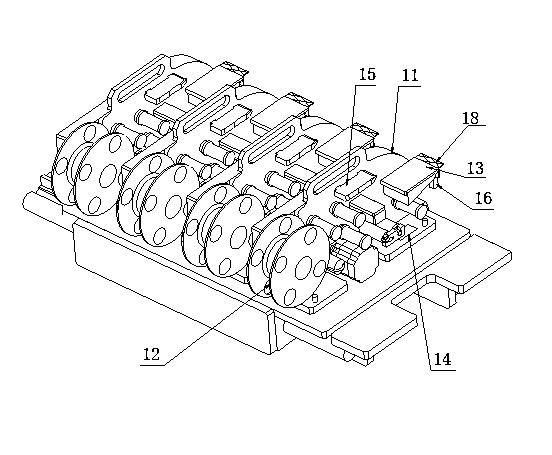

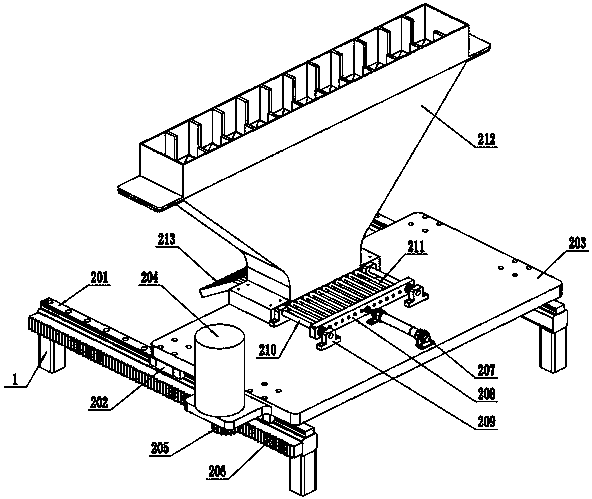

Fully-automatic tray loader for cylindrical lithium ion batteries

PendingCN107381082AImprove yield rateReduce manual handlingConveyorsIndividual articlesLithium electrodeStructural engineering

The invention provides a fully-automatic tray loader for cylindrical lithium ion batteries. The fully-automatic tray loader comprises a rack, a loading trolley, an empty tray lifting mechanism, an empty ray transfer mechanism, a tray positioning mechanism, a battery cell rotary-grabbing mechanism, a battery cell reshaping mechanism, an automatic grabbing and placing mechanism, a full-load tray transfer mechanism, a full-load tray lifting mechanism and an unloading trolley, wherein the empty tray transfer mechanism and the full-load tray transfer mechanism share a double-tray transverse moving part for transferring an empty battery cell tray at the lower end of the empty tray transfer mechanism to the tray positioning mechanism and transferring a battery cell tray which supports and is filled up with circular battery cells to the lower end of the full-load tray transfer mechanism. Through the mechanisms, the empty battery cell trays are transmitted to the tray positioning mechanism for being positioned, are automatically loaded with the reshaping battery cells, are automatically transmitted, superposed and stacked onto the unloading trolley, and are in fully-automatic butt joint with an automatic winding machine for manufacturing circular batteries or battery cells, so that multiple functions are integrated, manual tray loading is completely replaced, production efficiency is improved, and labor power is saved.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

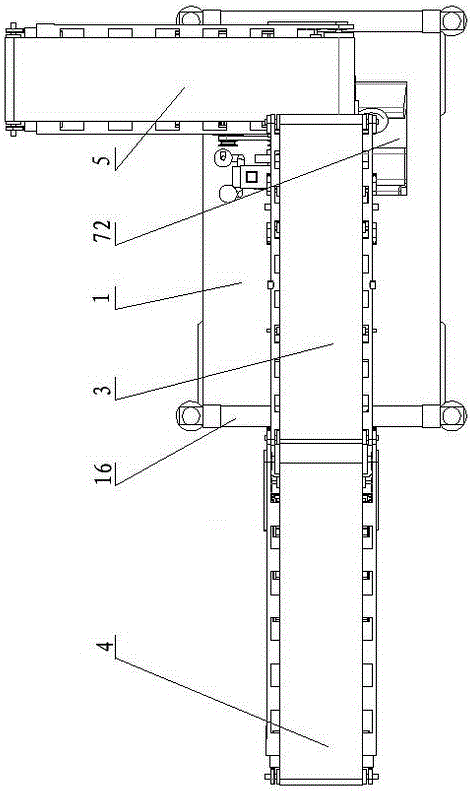

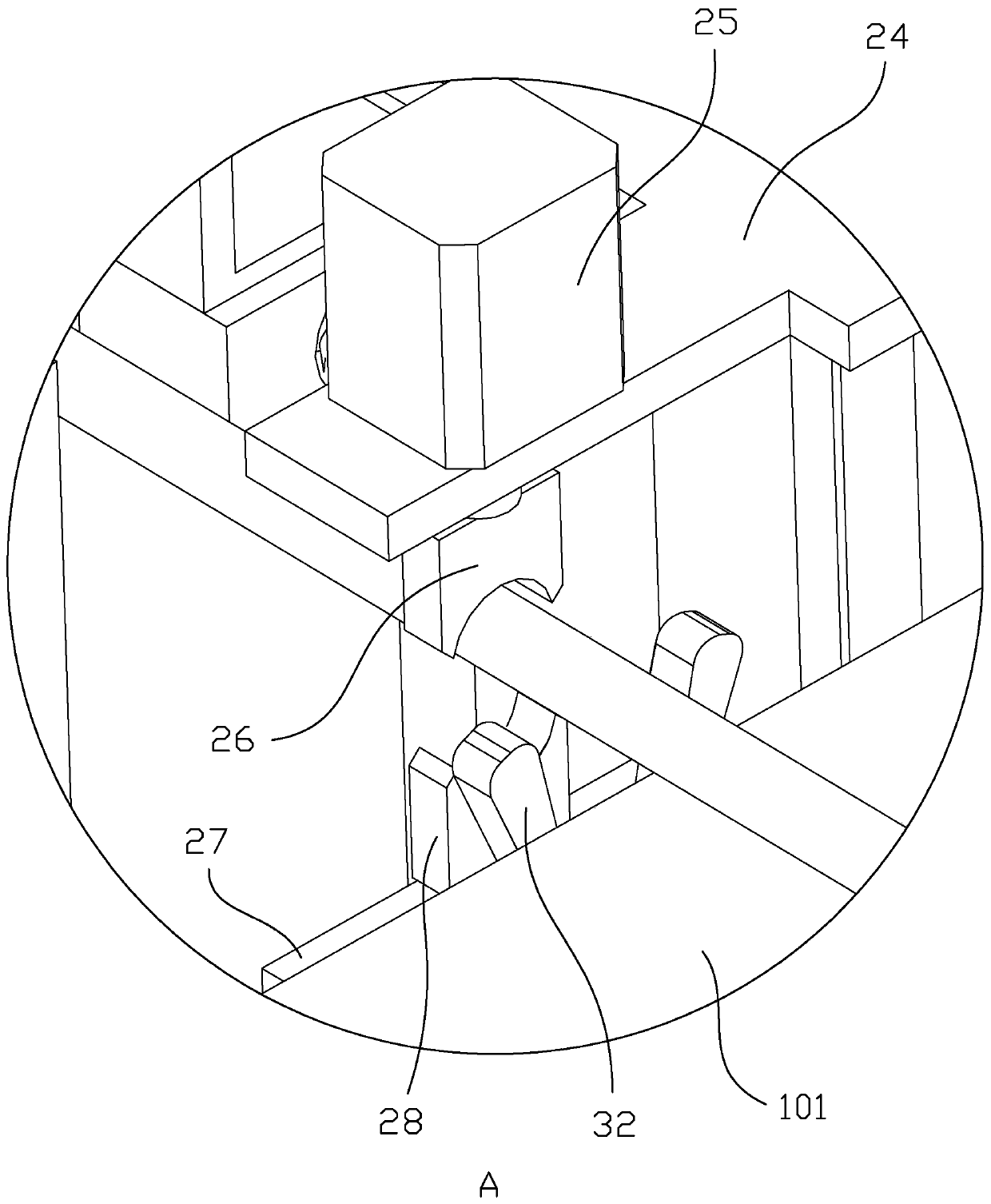

Rotating plate transition type two-way loading and unloading machine

ActiveCN105883375AReduce dropPrevent falling damageSupporting framesRotary conveyorsWorking environmentMechanical equipment

The invention discloses a rotating plate transition type two-way loading and unloading machine and relates to the field of logistics transportation goods loading and unloading mechanical equipment. The rotating plate transition type two-way loading and unloading machine is composed of a bearing trolley, a middle conveyor, two belt conveyors, a material blocking device, a slippage device, a lifting device and an operation control system of the rotating plate transition type two-way loading and unloading machine. The rotating plate transition type two-way loading and unloading machine is simple in structure, reliable in work, economical, practical, capable of saving energy and environment-friendly; the rotating plate transition type two-way loading and unloading machine is closed up during walking, the appearance size is small, and movement and field transferring are convenient and fast; the rotating plate transition type two-way loading and unloading machine is unfolded in work, the operation range is large, the logistics direction can be guided and changed, and positive and negative two-way loading and unloading are achieved; the work orientations and postures of the belt conveyors can be adjusted so that the rotating plate transition type two-way loading and unloading machine can adapt to goods loading and unloading point changes, and direct reaching of goods is achieved through one time of loading and unloading; the goods can directly enter a compartment, a goods cabinet and a container to be operated, auxiliary carrying is reduced, the labor intensity is relieved, the operation time is shortened, the loading and unloading work efficiency is improved, and the loading and unloading carrying cost is reduced; and the goods falling difference is small in the loading and unloading conveying process, transition is stable and free of impacting, dust discharge can be reduced, the work environment is improved, falling damage during transition delivery of articles is avoided, and the loading and unloading safety of the goods is guaranteed.

Owner:襄阳忠良工程机械有限责任公司

Cable processing equipment

ActiveCN111049055AReduce staff usageImprove work efficiencyApparatus for cutting/splicing cablesFilament handlingTransfer lineSupport plane

The invention relates to cable processing equipment comprising a processing table, a conveying belt which is installed below the processing table and used for conveying cables, and a first supportingframe and a second supporting frame which are located on one side of the processing table in the length direction. The first supporting frame is provided with a cutting device used for cutting a fixedlength, and the second supporting frame is provided with a wire stripping device used for stripping an insulating skin at the end of the cable after the cable is cut. The cable processing equipment has the effects that the cable can be automatically paid off, cut, stripped and taken up, manual intervention is not needed in the whole process, and the cable processing efficiency is improved.

Owner:上海裕生企业发展有限公司

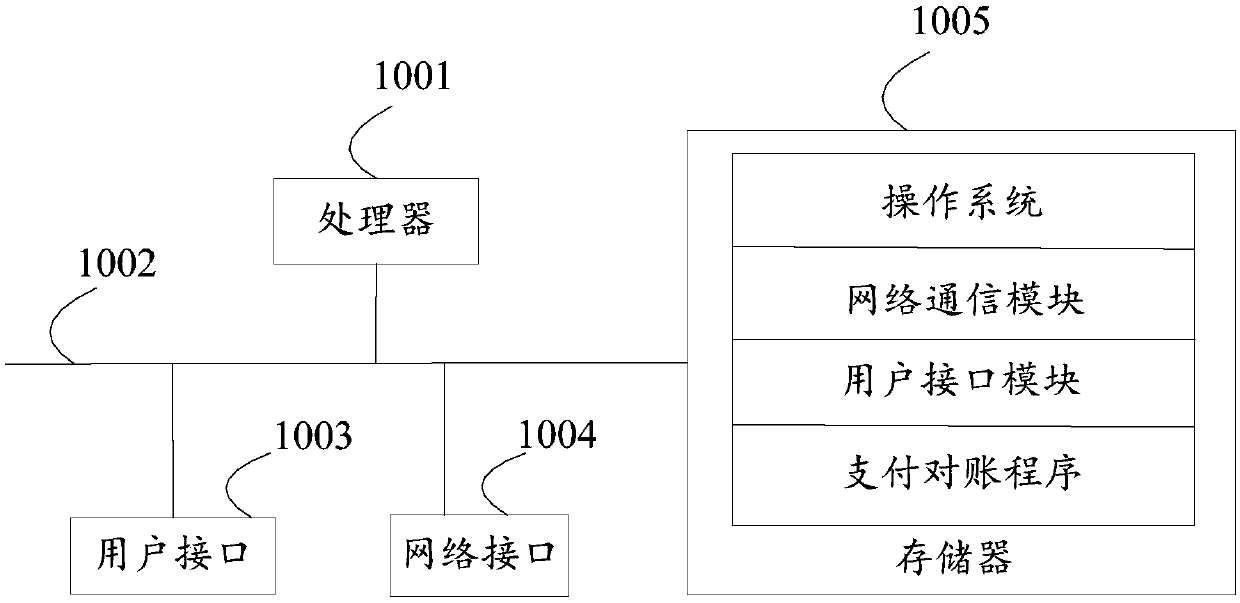

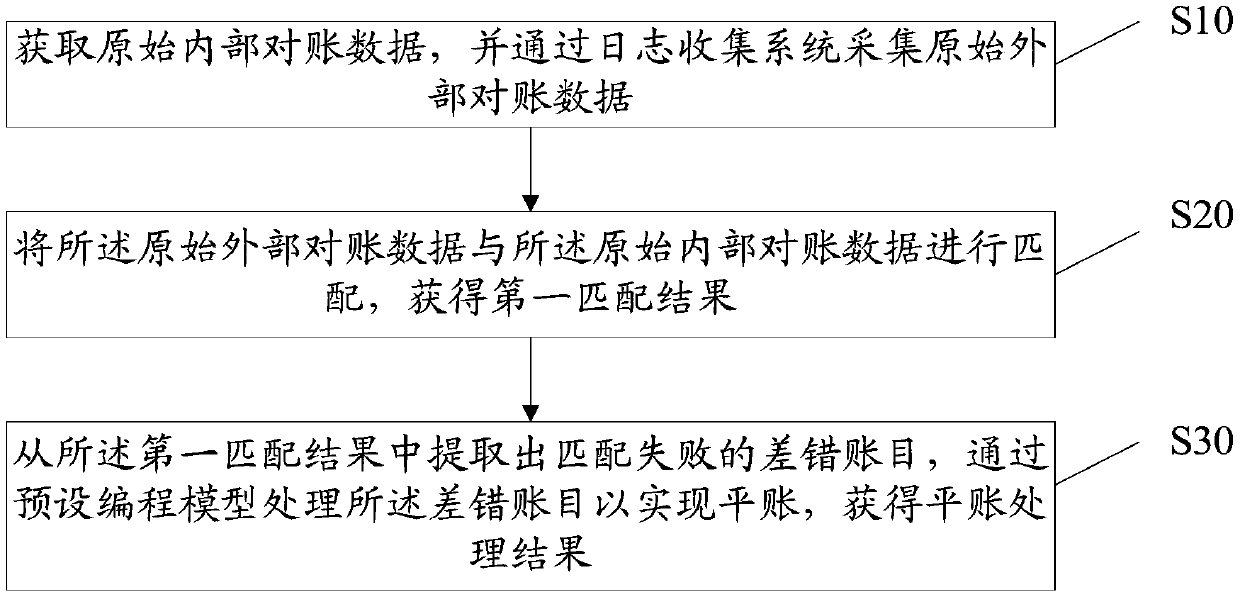

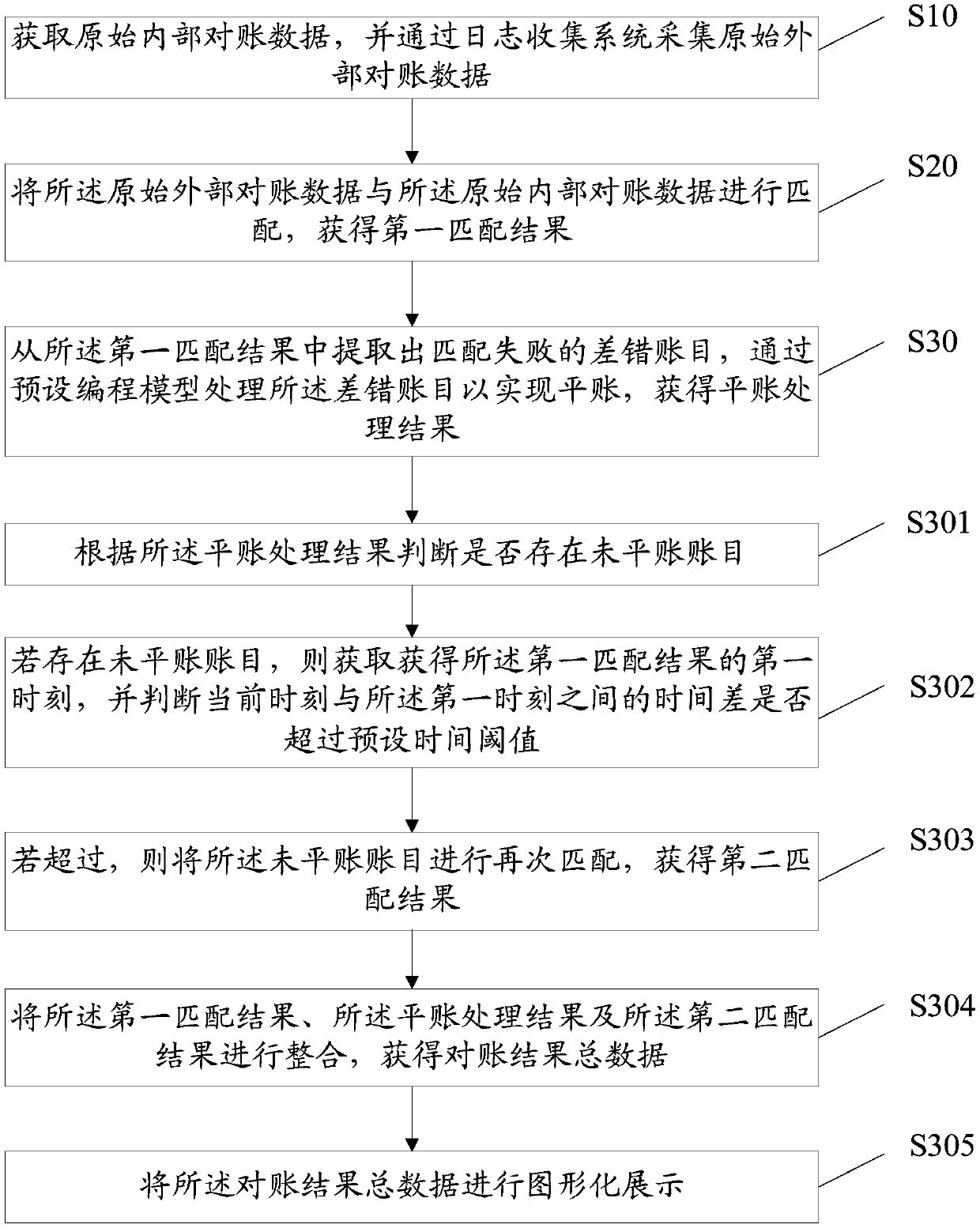

Payment reconciliation method and device, and storage medium

PendingCN109685634AImprove efficiencyImprove accuracyFinanceSpecial data processing applicationsPaymentCollection system

The invention discloses a payment reconciliation method and device, a storage medium and a device, and the method comprises the steps: obtaining original internal reconciliation data, and collecting the original external reconciliation data through a log collection system; Matching the original external reconciliation data with the original internal reconciliation data to obtain a first matching result; And extracting an error account which fails to match from the first matching result, processing the error account through a preset programming model to realize account leveling, and obtaining an account leveling processing result. Original external reconciliation data are collected through a log collection system; Compared with the prior art, the difference of channel file formats is shielded, the original external reconciliation data and the original internal reconciliation data are matched, the error account is extracted from the matching result, the error account is processed throughthe preset programming model to achieve reconciliation, manual processing in the reconciliation process is reduced, and the reconciliation efficiency and accuracy are improved.

Owner:深圳平安财富宝投资咨询有限公司

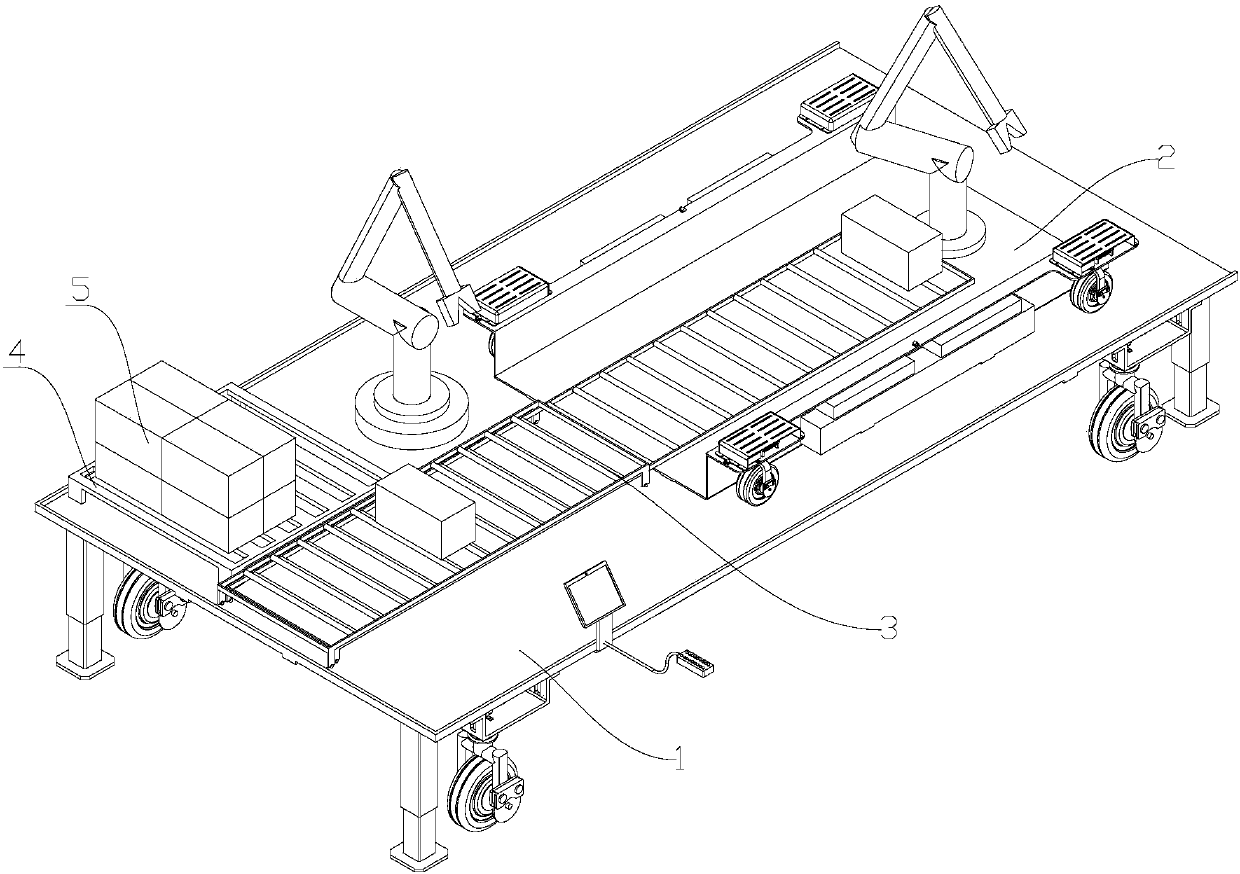

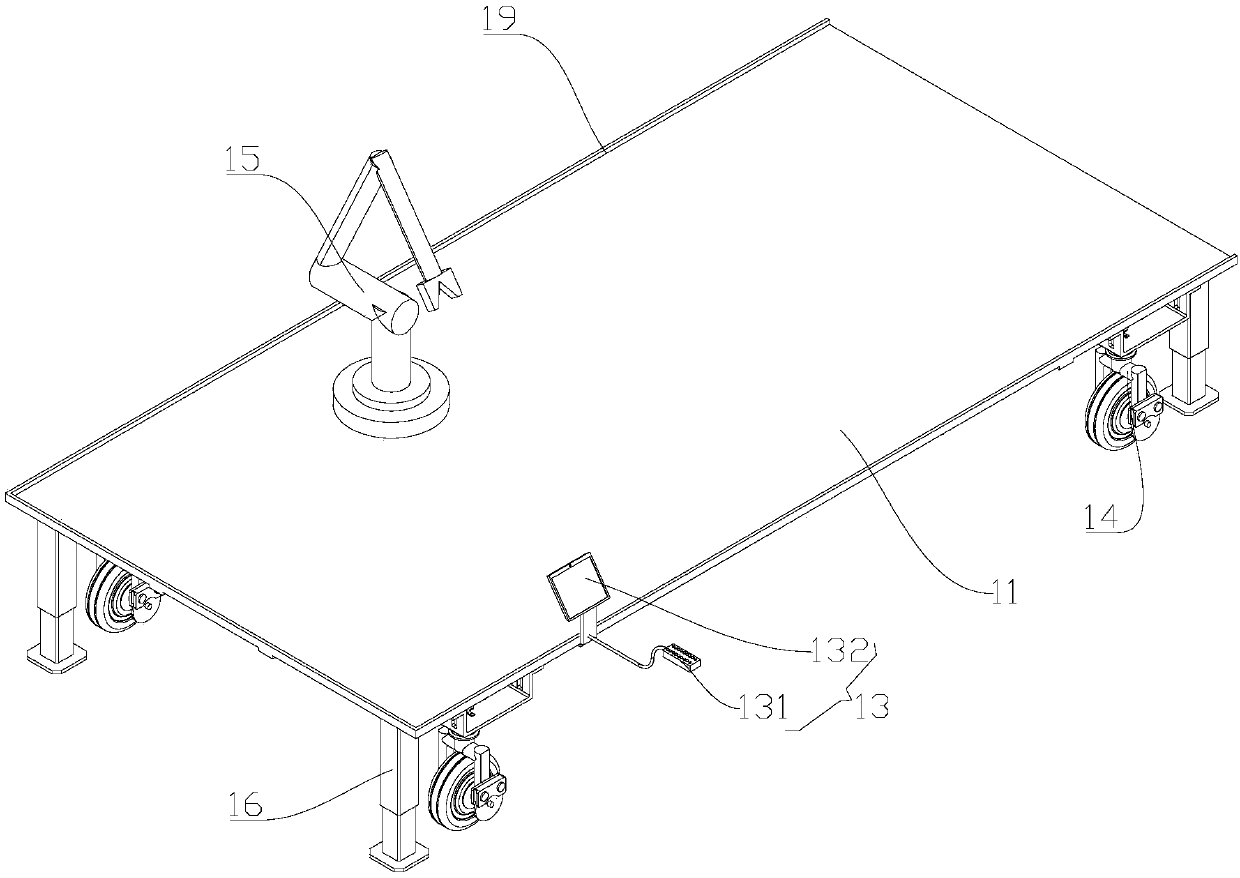

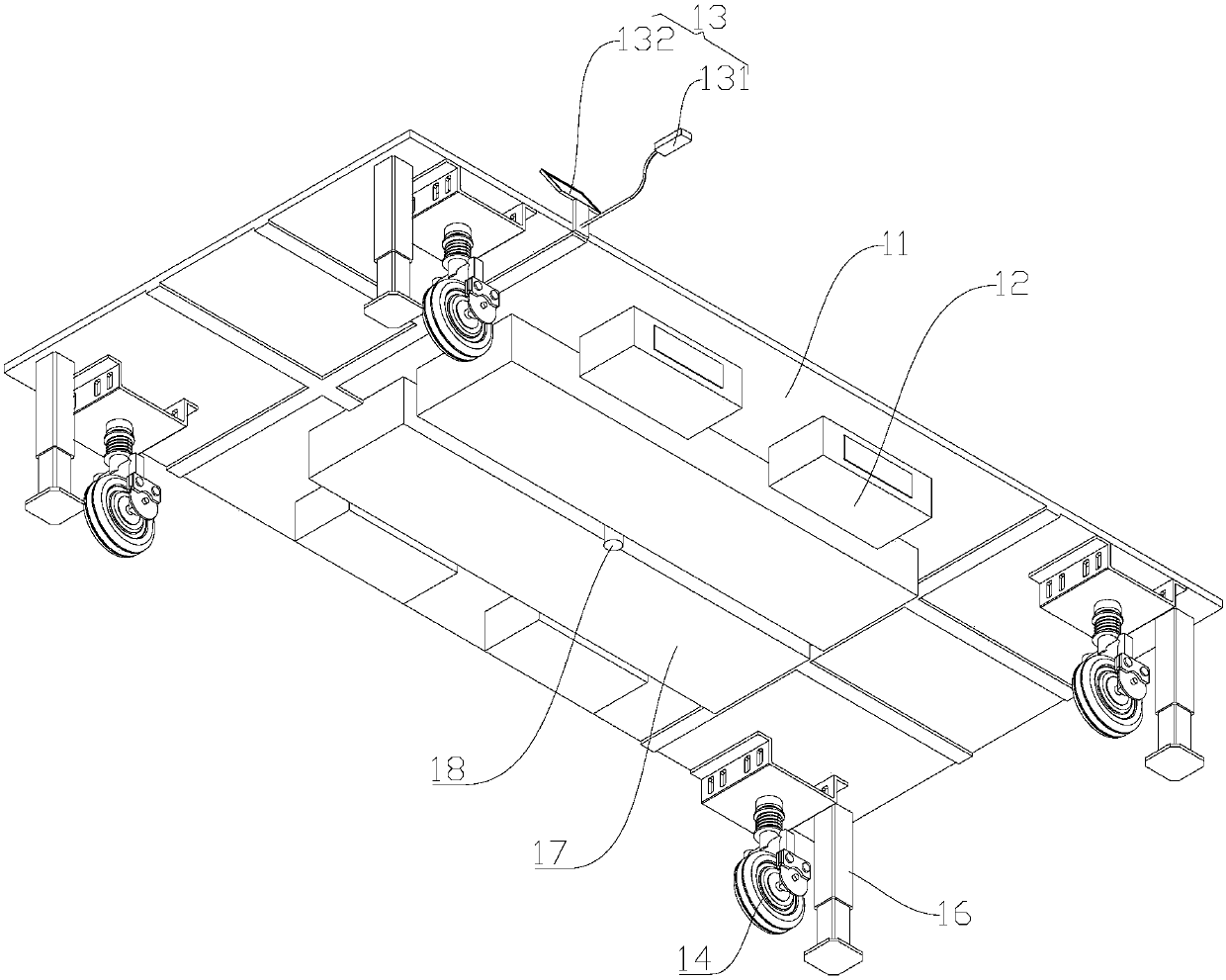

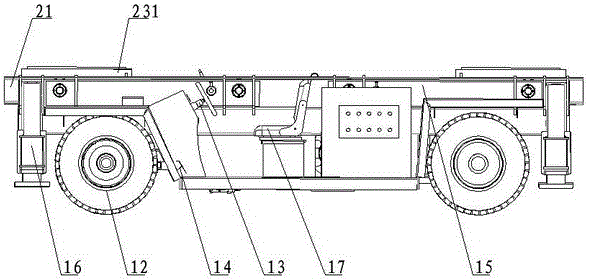

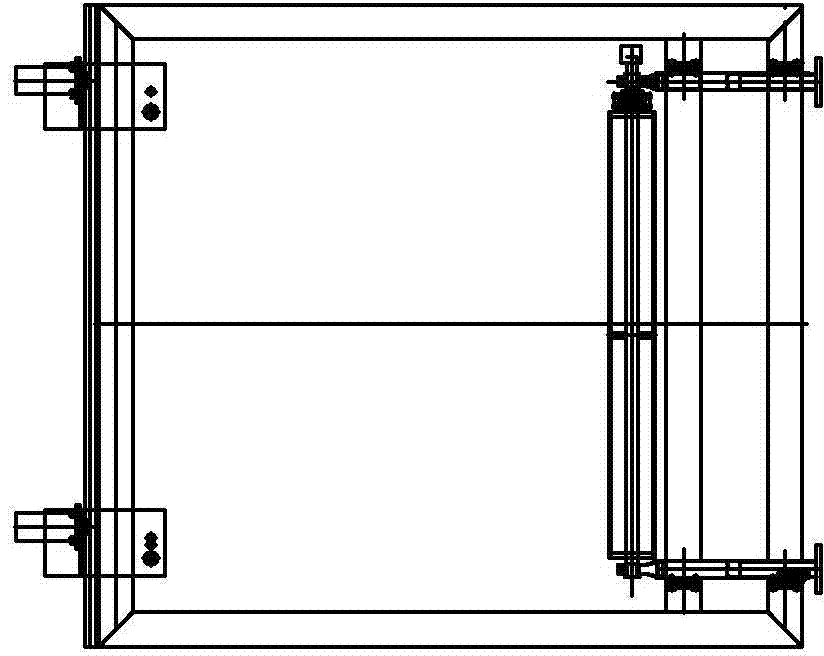

Primary-secondary electric conveying platform system

InactiveCN107585595AReduce manual handlingReduce labor costsLoading/unloadingCar drivingAutomobile platform

The invention discloses a primary-secondary electric conveying platform system. The primary-secondary electric conveying platform system comprises a primary car platform, a secondary car platform andan extensible conveying belt; the primary car platform comprises a primary car body, primary controllers, a control assembly, primary car driving devices and a primary car intelligent industrial mechanical arm, wherein the control assembly, the primary car driving devices and the primary car intelligent industrial mechanical arm are connected with the primary car controller; the secondary car platform comprises a secondary car body, secondary car controllers, secondary car driving devices and a secondary car intelligent industrial mechanical arm, wherein the secondary car driving devices and the secondary car intelligent industrial mechanical arm are connected with the secondary car controller; the secondary car controllers are connected with the primary controllers; the secondary car platform is arranged on the primary car platform and is smaller than the primary car platform; one end of the extensible conveying belt is connected to the primary car body, and the other end of the extensible conveying belt is connected to the secondary car body. In the primary-secondary electric conveying platform system, the primary car platform and the secondary car platform can finish work independently and also can work cooperatively; the aim that work is carried on in a narrow space can be achieved through the secondary car platform; cargoes can be conveyed through the extensible conveyingbelt, the labor cost is easily saved, and the efficiency is easily improved.

Owner:SHENZHEN INST OF ADVANCED TECH

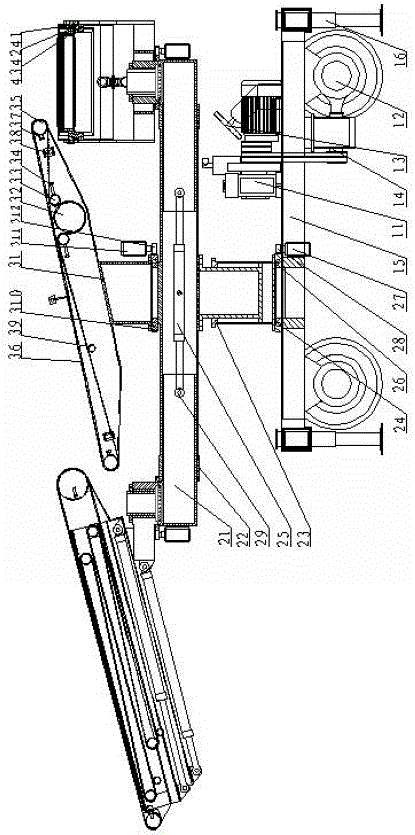

Moving belt type conveying loading and unloading machine

InactiveCN106629136AReduce wasteReduce investmentConveyorsSupporting framesWorking environmentEngineering

The invention discloses a moving belt type conveying loading and unloading machine and relates to the field of logistic transporting cargo loading, unloading and carrying equipment. The moving belt type conveying loading and unloading machine comprises a bearing vehicle, a sliding trolley, a middle conveyor, a transition conveyor, a feeding conveyor, a discharging conveyor, a metering device and an operation control system of the moving belt type conveying loading and unloading machine. The sliding trolley is arranged on the bearing vehicle. The two ends of the sliding trolley are symmetrically installed on the feeding conveyor and the discharging conveyor. The middle conveyor is installed at the middle portion of the sliding trolley. The metering device is installed on the middle conveyor. The transition conveyor is fixed to a bracket of the discharging conveyor. The moving belt type conveying loading and unloading machine is simple in structure and reliable in work, moving and field transferring are convenient and fast, the work range is large, manual auxiliary carrying can be reduced, the labor intensity is lowered, the work time is shortened, the loading and unloading work efficiency is improved, the loading and unloading carrying cost is reduced, the work environment and labor conditions are improved, it is ensured that loading and unloading transporting is economic, fast, convenient and safe, the logistic conveying direction can be changed, positive and negative bidirectional loading and unloading are achieved, and the loading and unloading number and weight are automatically metered, counted and recorded and are displayed and stored.

Owner:襄阳忠良工程机械有限责任公司

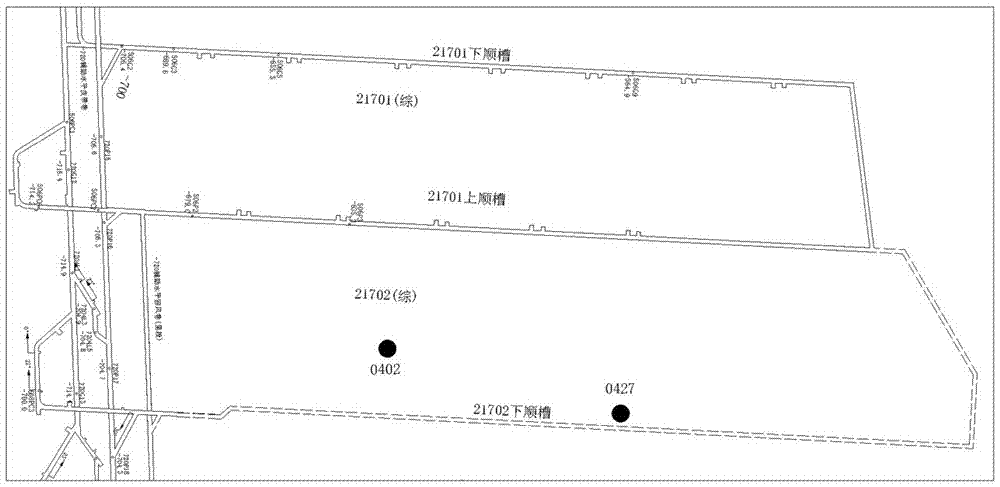

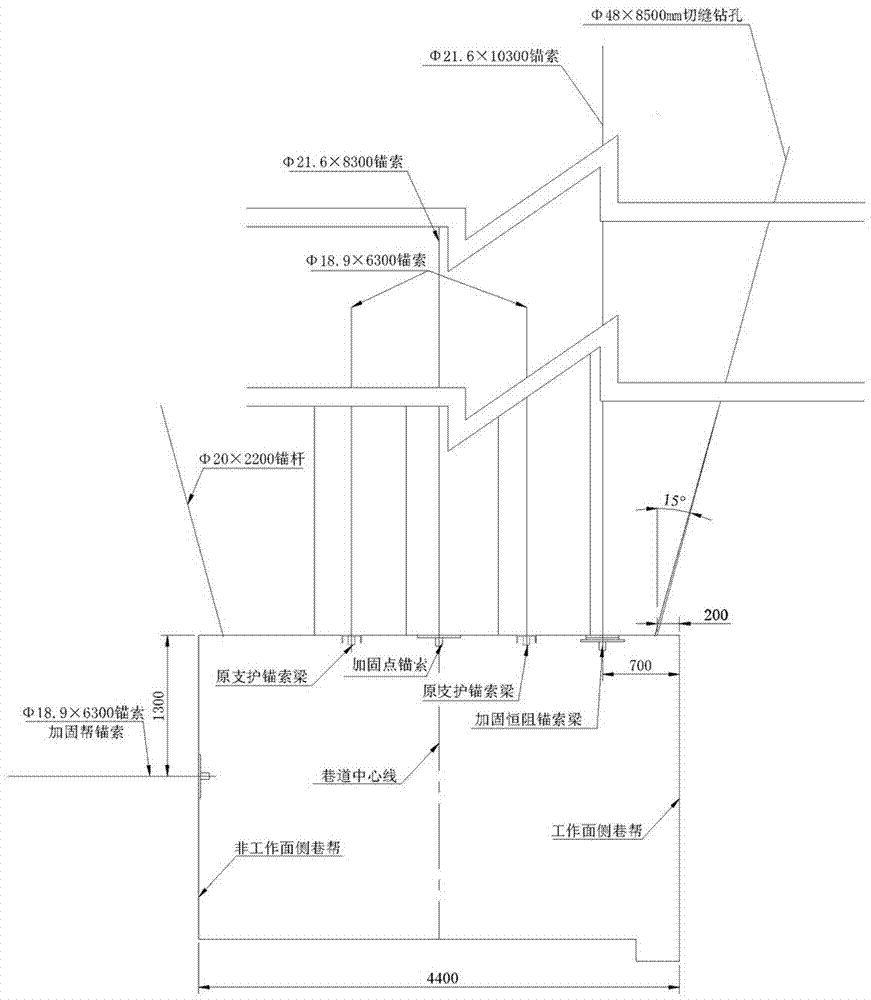

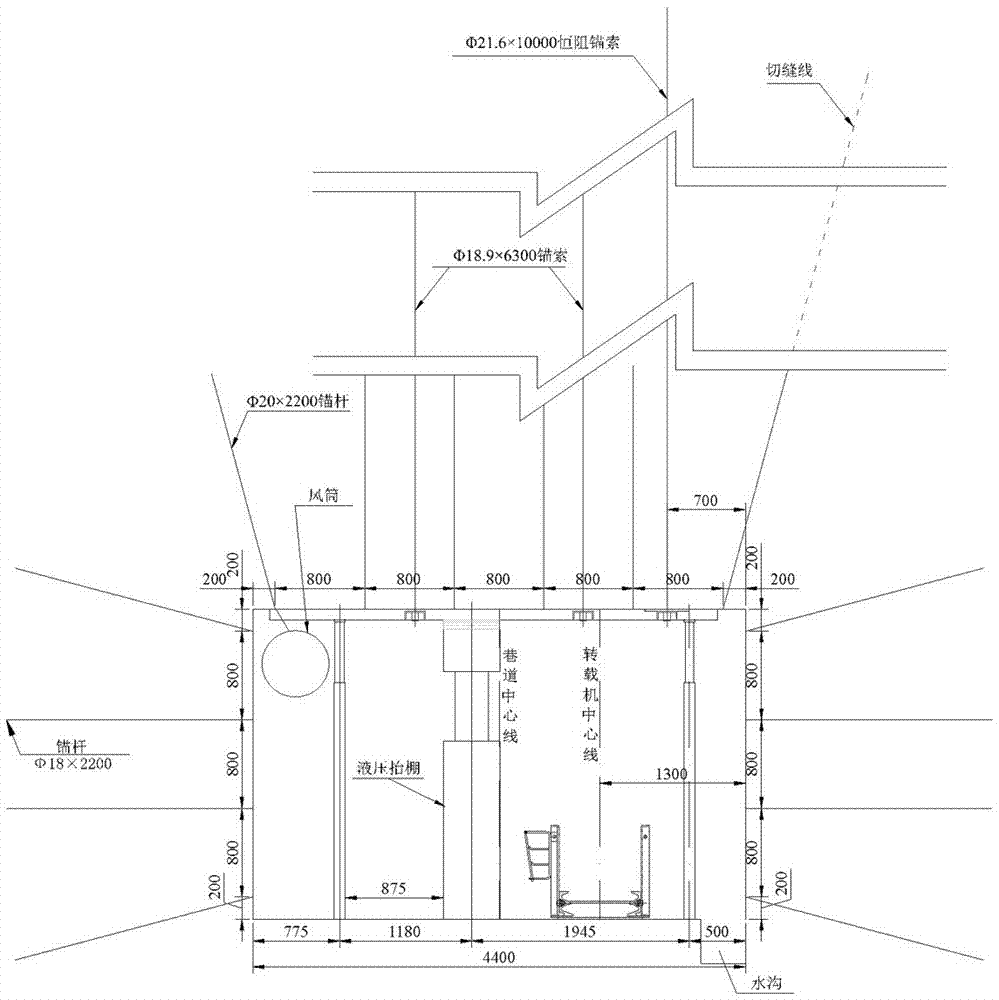

Gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method

ActiveCN107191208AImprove resource recoveryHigh recovery rateMine roof supportsMine roof capsResource recoveryStructural engineering

The invention relates to a gob-side-entry-retaining supporting method, in particular to a gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method. The method comprises the steps that a row of point-anchor rope reinforced roadway top plates are arranged in a roadway in the tunneling period, a row of point-anchor rope reinforced roadway ribs are arranged in the side roadway rib of the non-working surface, and a row of constant-resistance anchor rope beam reinforced roadway top plates are arranged on the position a certain distance away from the side roadway rib of the working surface; and according to the data changing situation of the mine pressure in a retained roadway in the period of backstopping of the working surface and the showing situation of the roadway mine pressure, an entry-in supporting area in the retained roadway is divided into an advance supporting area, a lagging supporting area, a roadway-forming to-be-stable area and a roadway-forming stable area. According to the gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method, through the successful practice of cross heading under the 21702 working surface, an excessive coal safety pillar with the width of 5 m is recycled compared with tunneling of an original gob-side entry driving, the coal resource recovery rate is improved, a solid foundation is laid for popularization of the gob-side entry retaining technology in other mining-area working surfaces of the whole mine, and a brand-new thinking is provided for the excavation-replacement layout of the whole mine.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

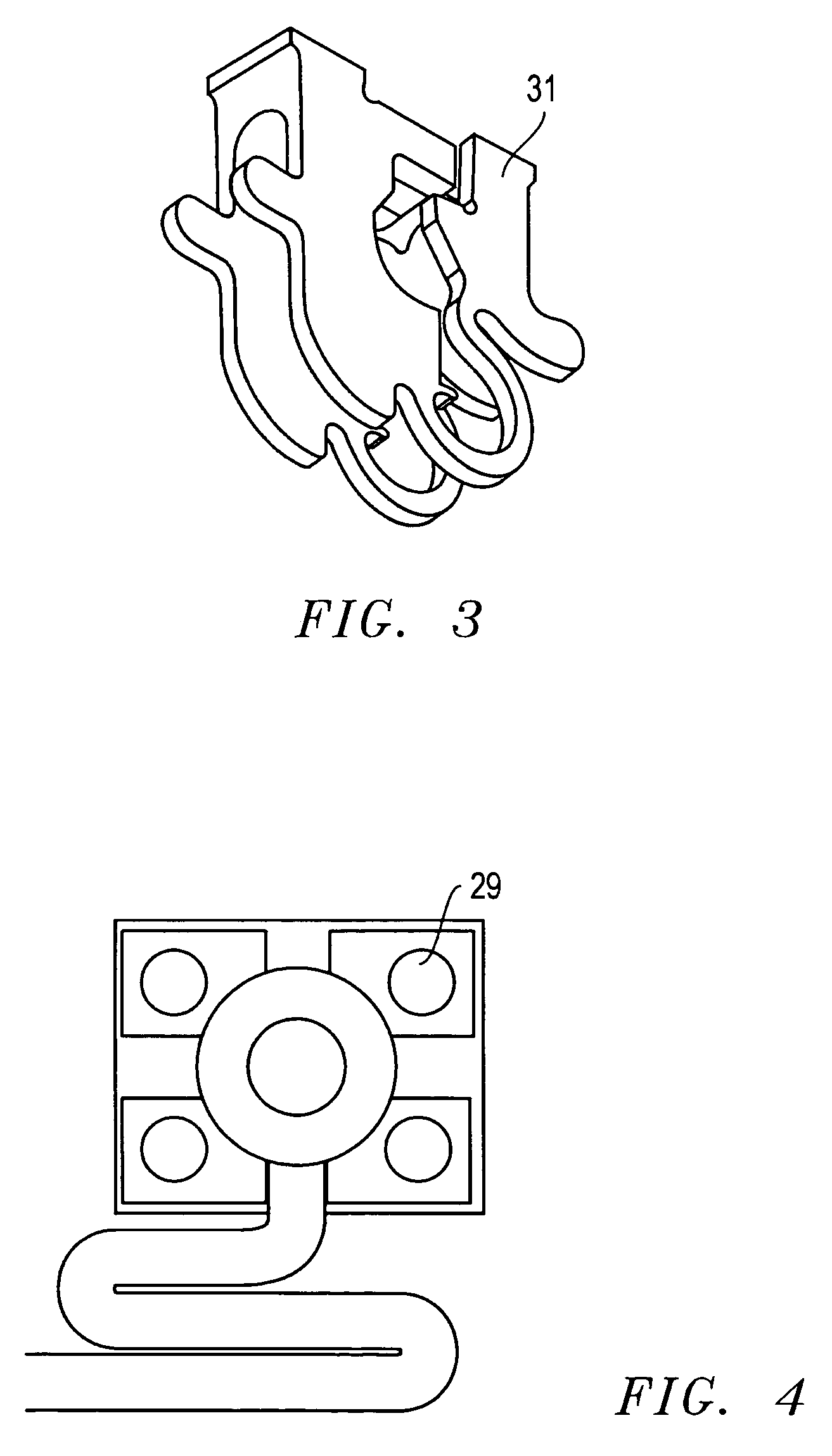

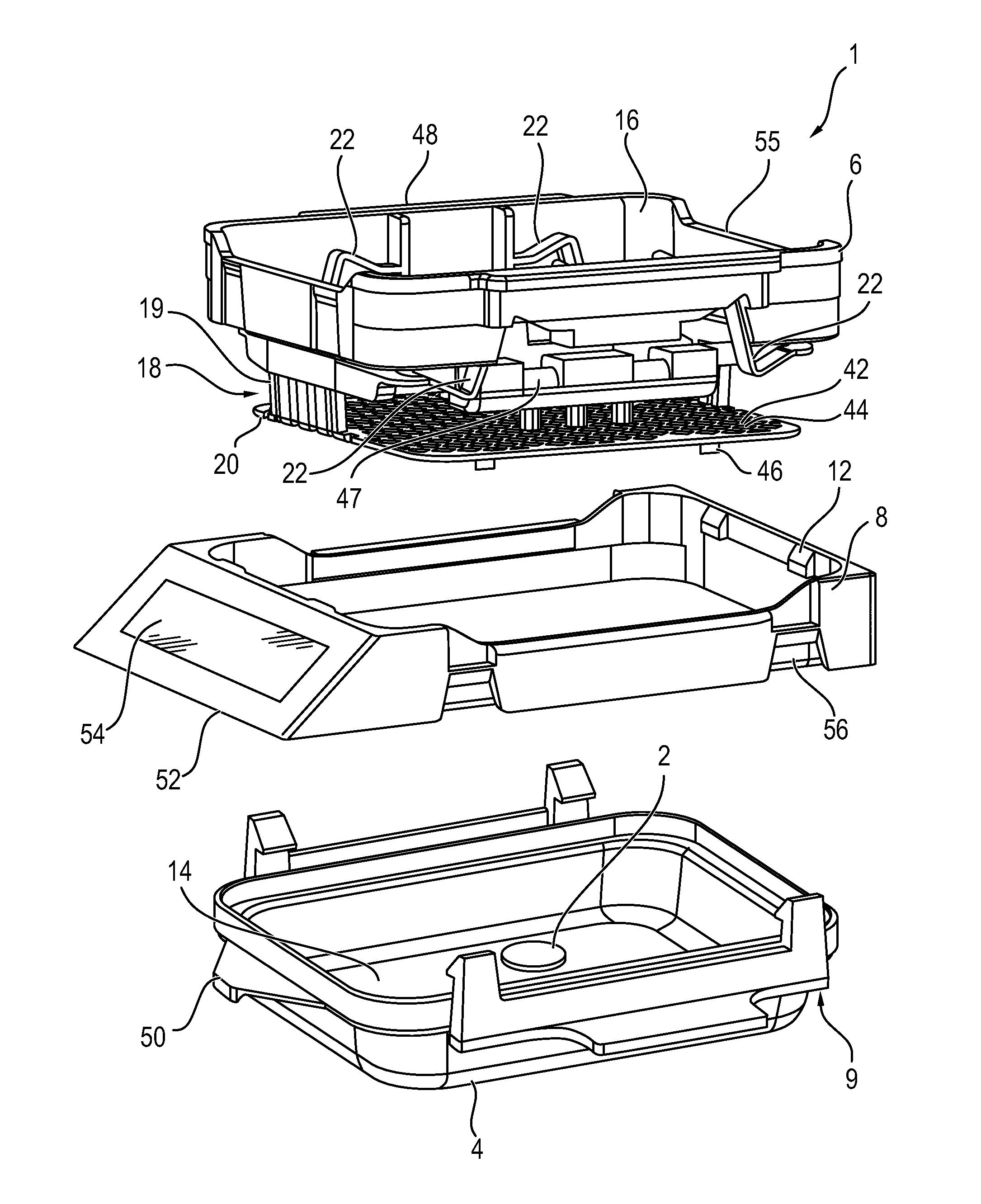

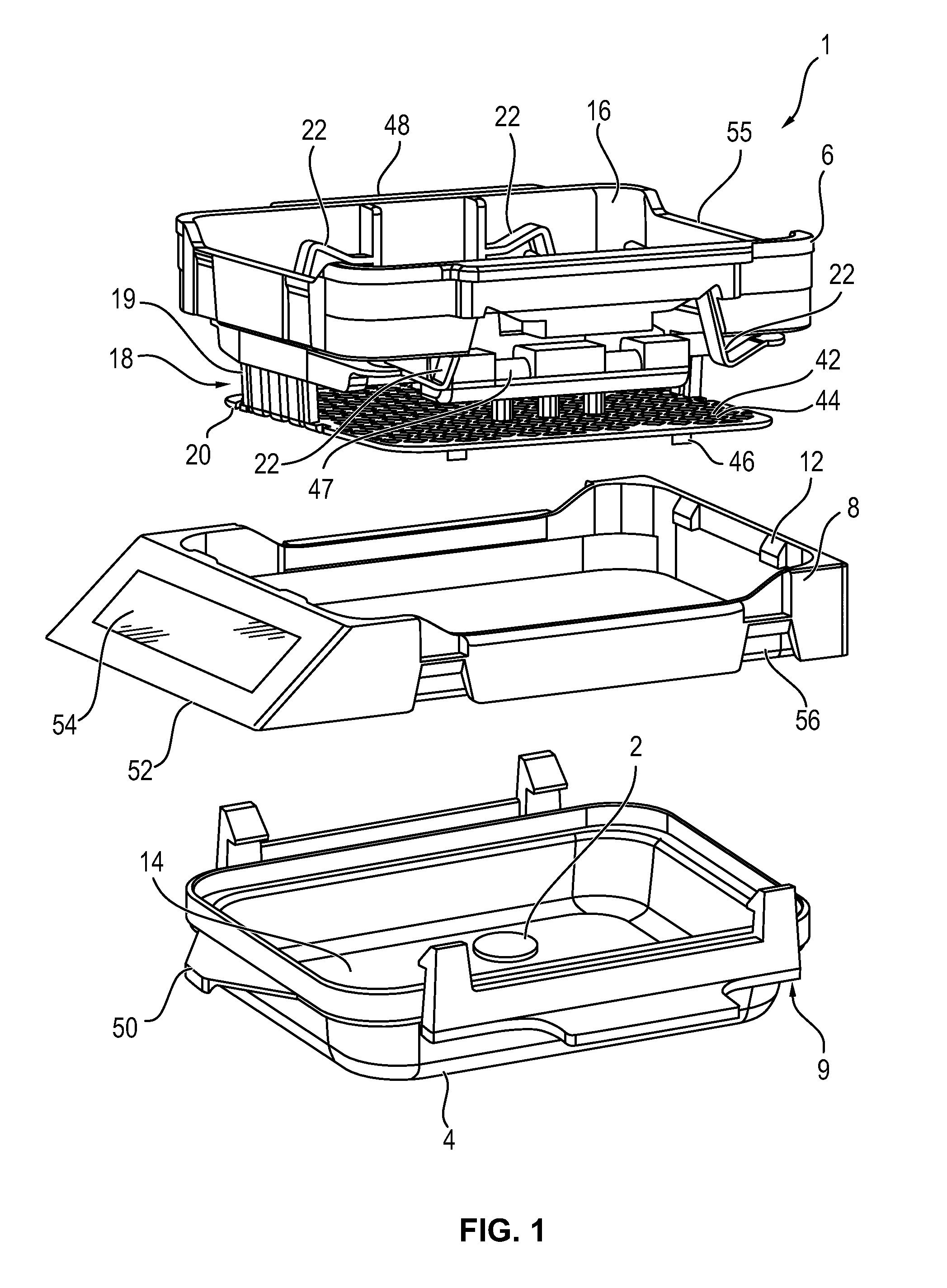

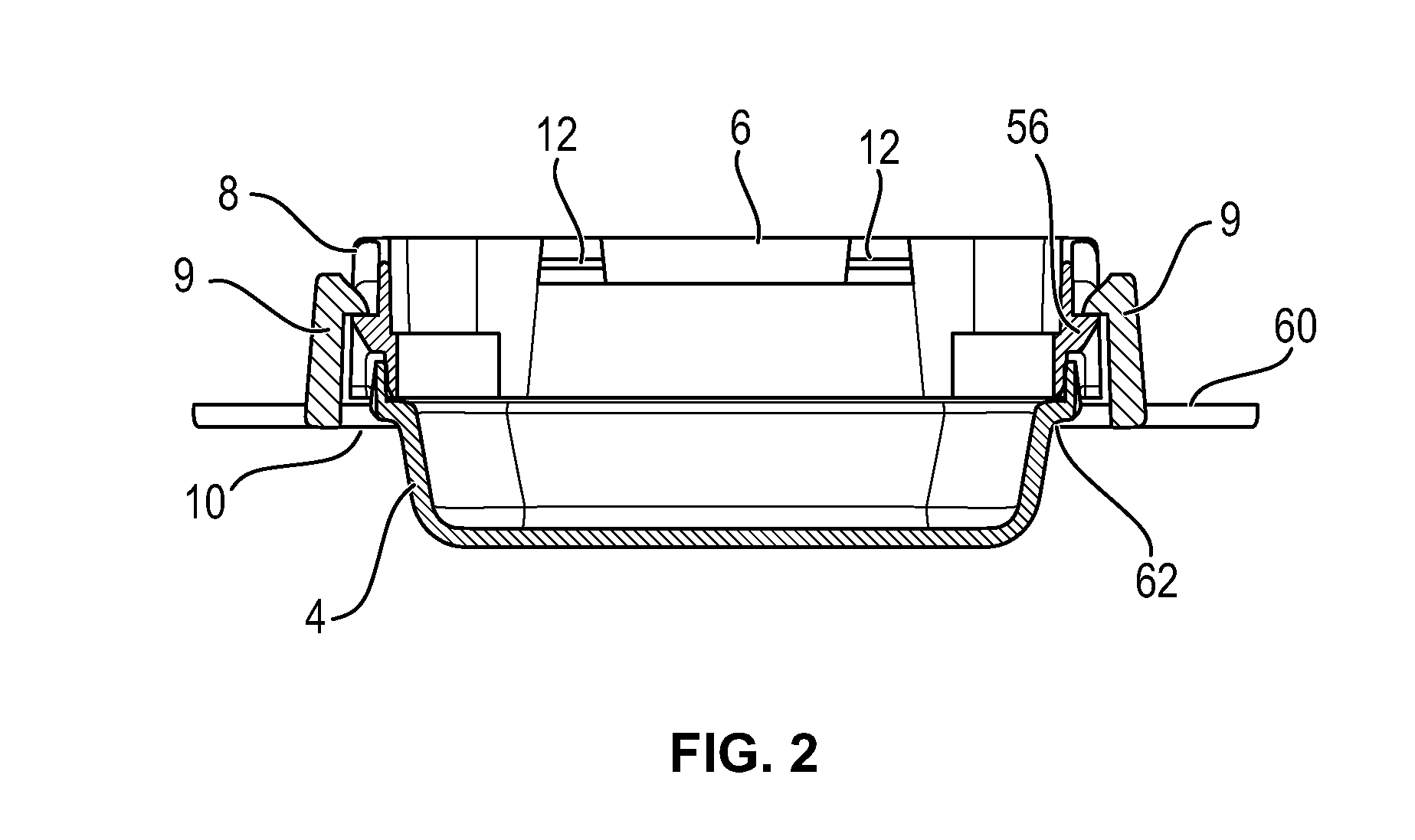

Tissue cassette with biasing element

ActiveUS9389154B2Reduce manual handlingPreparing sample for investigationLaboratory glasswaresBiomedical engineeringTissue cassette

An apparatus for holding a tissue sample including a retaining member having a first tissue engaging surface and at least one biasing element, the first tissue engaging surface being moveably attached to the retaining member by said biasing element; and a base having a second tissue engaging surface and configured to engage the retaining member to form an interior area with the first and second tissue engaging surfaces facing each other, wherein the at least one biasing element urges the first tissue engaging surface toward the second tissue engaging surface to retain the tissue sample therebetween in the interior area.

Owner:LEICA BIOSYST NUSSLOCH

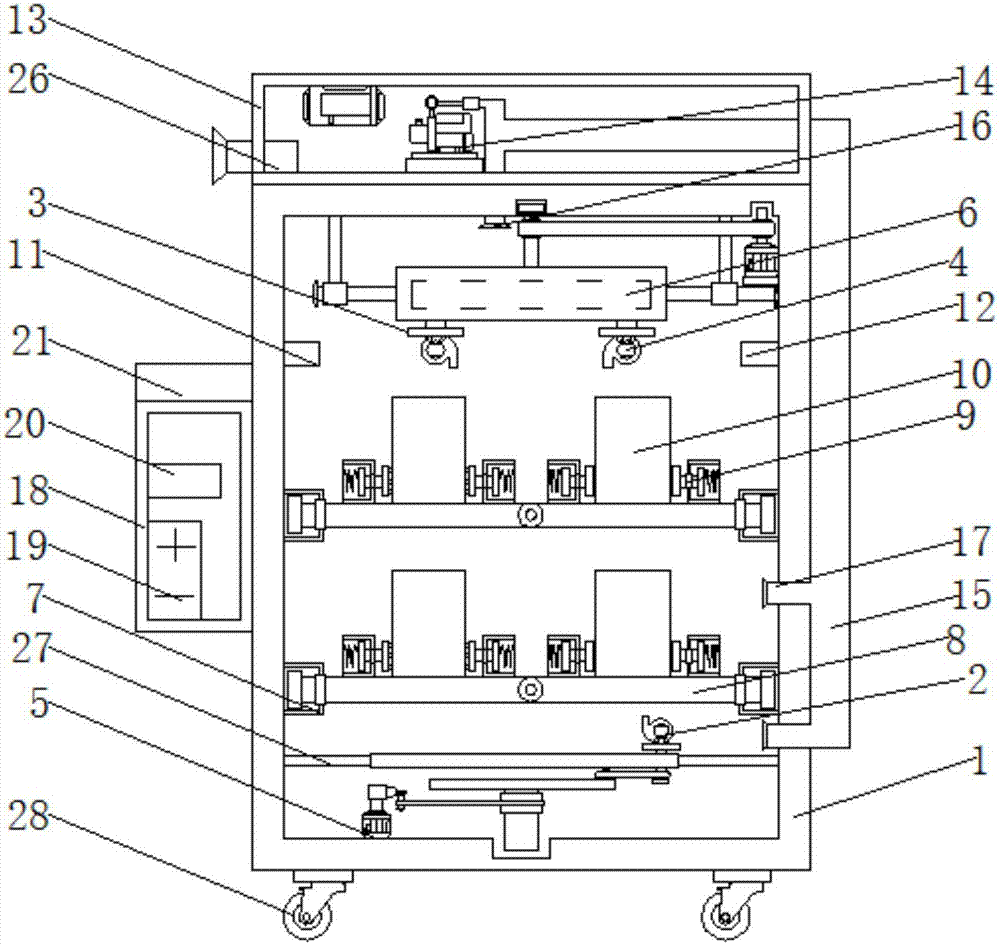

Movable multifunctional activated carbon waste gas treatment box

InactiveCN108310907ATreatment up to standardEasy to handleGas treatmentDispersed particle filtrationActivated carbonTreatment demand

The invention provides a movable multifunctional activated carbon waste gas treatment box, comprising box doors, a treatment box body, an impurity filtering screen, a gas inlet pipe, fan blades, a drive motor, a U-shaped hanging board, a sliding rail, a gas outlet pipe, an activated carbon waste gas treatment filter screen structure, a adjusting bolt, a portable lifting rope structure, a waste gastreatment sterilizing lamp structure, a waste gas emission detection rod structure and an adjustable lifting type moving wheel, wherein the box doors are respectively connected with the left part andthe right part of the front surface of the treatment box body by means of hinges; an anisotropic magnet piece is arranged in the middle of the position between the box doors. The movable multifunctional activated carbon waste gas treatment box is provided with waste gas treatment nets, absorption boards, absorbing wool and impurity absorbing sponge pieces, thus being beneficial to improvement ofwaste gas treatment effect, enabling waste gas treatment to more easily reach the standard, and realizing the absorption of impurities and fine particles in waste gas; a U-shaped sliding block, the sliding rail and the adjusting bolt are arranged, so that the position of the activated carbon waste gas treatment filter screen structure can be easily adjusted according to the waste gas treatment demand, a certain spacing is reserved, the treatment effect is further guaranteed.

Owner:杨晓丽

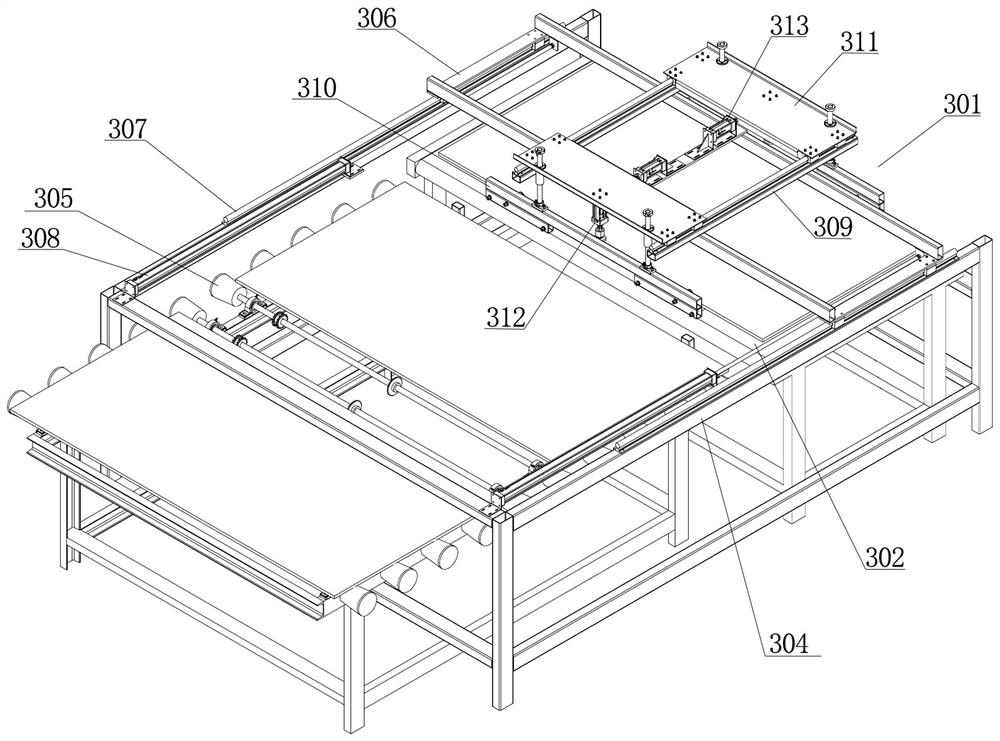

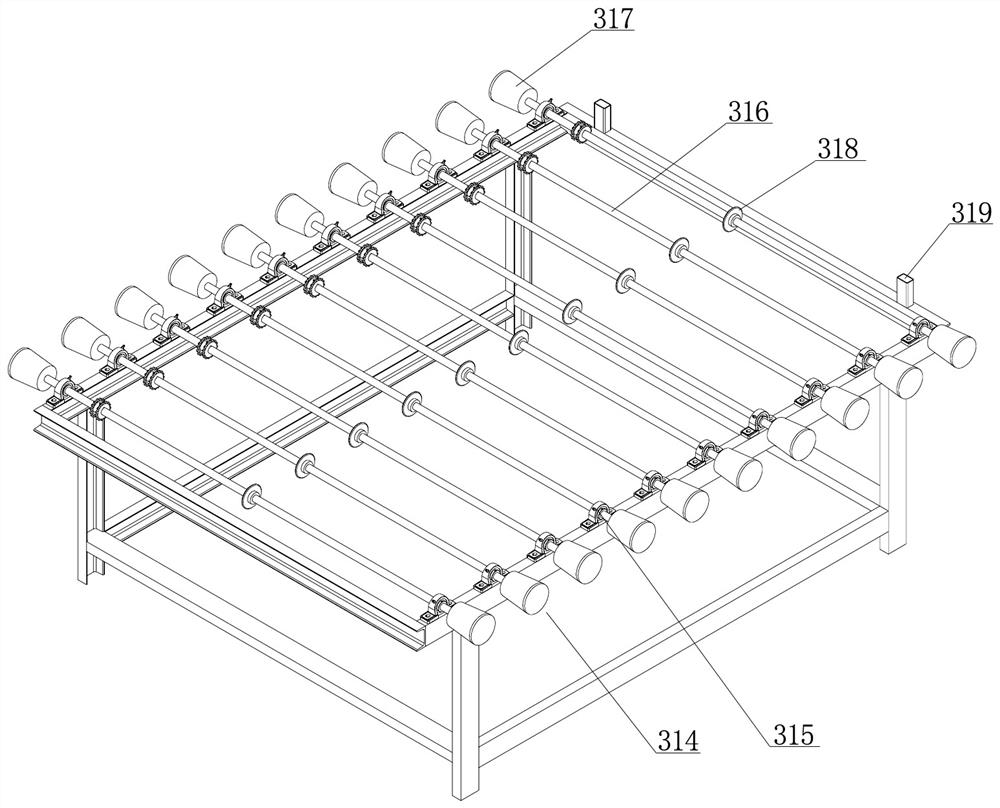

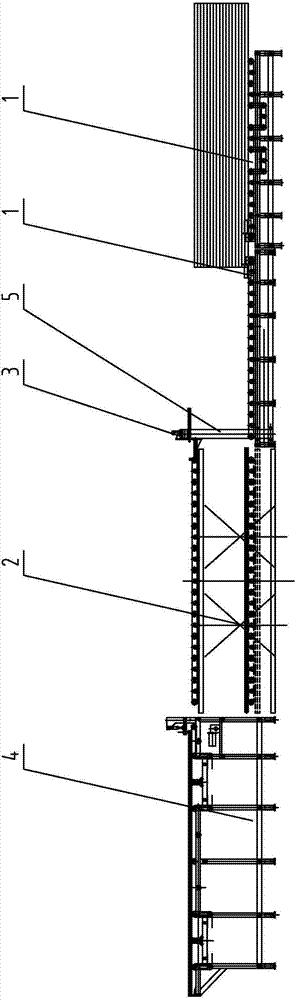

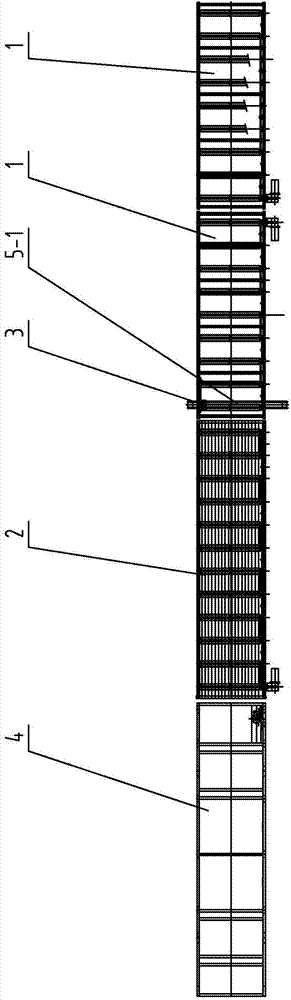

Rapid board veneering production line

PendingCN112776101ASmooth and efficient veneerPrecise veneerOther plywood/veneer working apparatusPlywood pressesProduction lineControl system

The invention discloses a rapid board veneering production line. The rapid board veneering production line comprises a veneering production line body; the veneering production line body mainly comprises a plywood feeding device, a glue coating machine, a veneer material feeding device, a cold pressing main machine, a discharged plate conveying device, a hot pressing device, a cold plate conveyor, a discharging plate conveying machine and a control system which are sequentially arranged, wherein the control system is used for controlling the working states of all the assemblies; the plywood feeding device is used for feeding conveyed and stacked plywood and conveying the plywood to the glue coating machine, the glue coating machine conducts gluing on the plywood, and the veneer material feeding device is used for attaching veneer materials to the upper outer surface and the lower outer surface of the plywood and conveying the plywood subjected to veneering to the cold pressing main machine for cold pressing; and the discharged plate conveying device is used for conveying the plywood subjected to veneering and cold pressing to the hot pressing device, the hot pressing device is used for carrying out hot pressing forming on the plywood subjected to veneering and cold pressing, and the cold plate conveyor is connected with a discharging port of the hot pressing device and cools the plywood subjected to hot pressing forming.

Owner:JIAXING QUNLUN MACHINERY

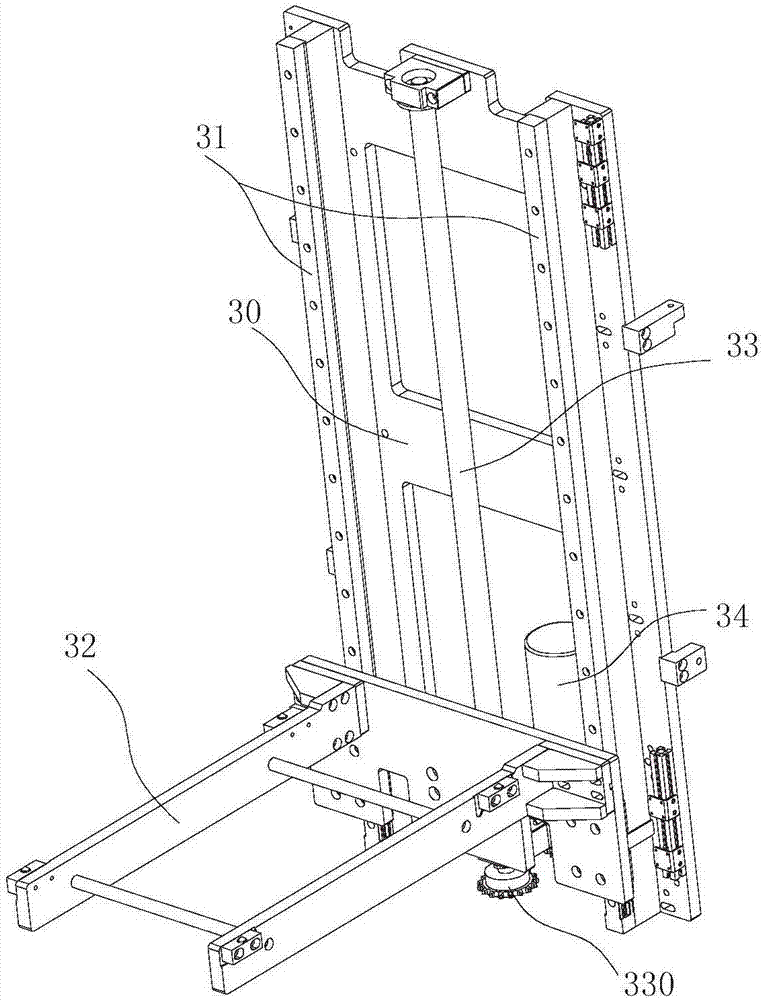

Full-automatic wood feeder

InactiveCN104493906AReduce in quantityReduce labor intensityLoading equipmentDe-stacking articlesSolid woodEngineering

The invention relates to the field of wood processing machinery, in particular to a full-automatic wood feeder, and aims to solve the problem that the wood feeding process in the existing solid-wood door / window processing field is not automated, leading to low productivity and high labor intensity for operators. The full-automatic wood feeder comprises a conveying mechanism, a lifting mechanism, a feeding mechanism, a stirring mechanism, a portal frame and a control cabinet; the conveying mechanism, the lifting mechanism and the stirring mechanism are arranged in order along the lengthwise direction; the portal frame is perpendicularly fixed to a joint of the conveying mechanism and the lifting mechanism; the feeding mechanism is disposed on a mounting beam of the portal frame; the conveying mechanism, the lifting mechanism, the feeding mechanism and the stirring mechanism are all connected with the control cabinet through power cords. The full-automatic wood feeder is used for feeding wood materials in the solid-wood door / window processing field.

Owner:HARBIN SAYYAS WINDOWS

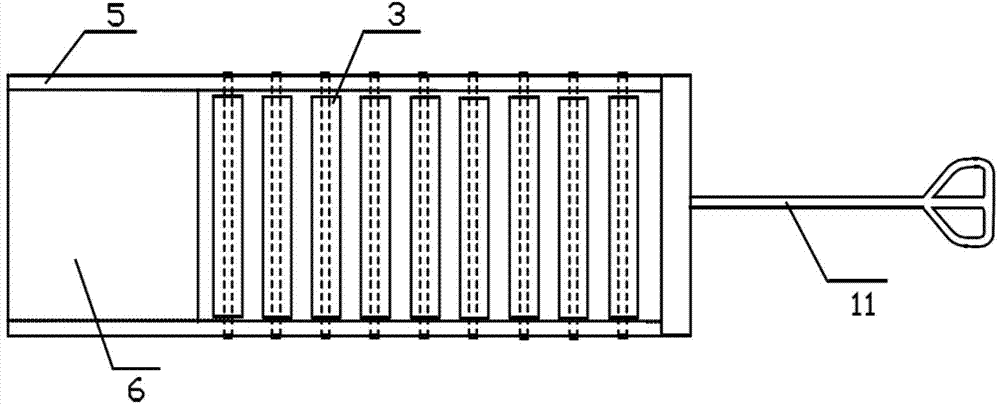

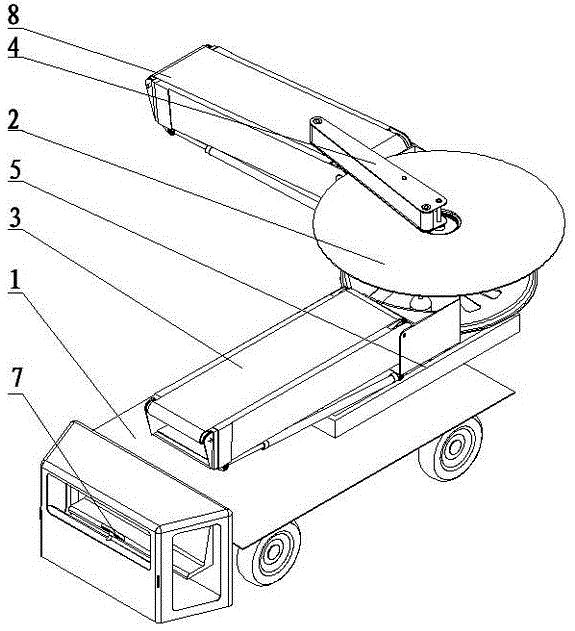

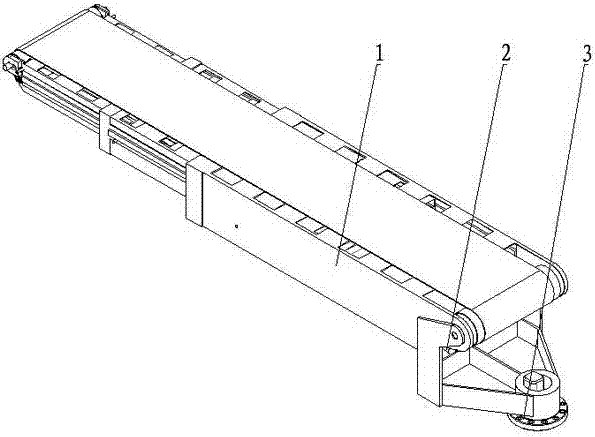

Telescopic belt conveyor changeable in amplitude and direction

ActiveCN106966116AImprove delivery rangeReduce manual handlingConveyorsClassical mechanicsLogistics management

The invention discloses a telescopic belt conveyor changeable in amplitude and direction, and relates to the field of logistics transportation cargo handling mechanical equipment. The telescopic belt conveyor is composed of a three-section two-stage telescopic belt conveyor body with a telescopic function, an amplitude change mechanism with tilting and amplitude change functions, and a swing rotating mechanism with swing rotating and direction change functions. According to the telescopic belt conveyor changeable in amplitude and direction, a sleeved telescopic machine frame structure is adopted, and the elongation and shortening function, the tilting and amplitude change functions and the swing rotating and direction change functions of the belt conveyor are added by additionally arranging the amplitude change mechanism and the swing rotating mechanism; the conveying range is widened, along with conducting of the loading, unloading and conveying processes, under the condition that loading and unloading places of materials are changed, the conveying distance, height and direction are adjusted by driving and controlling a telescopic mechanism, the amplitude change mechanism and a direction change mechanism, and thus, the telescopic belt conveyor can adapt to change of the loading and unloading places; cargoes are directly delivered to the destination through only one time of loading and unloading, manual auxiliary carrying is reduced, the labor intensity is relieved, the operation time is shortened, the loading and unloading efficiency is improved, and the loading and unloading carrying cost is reduced; and the working environment and the labor condition are effectively improved, and the effect that loading and unloading transport is economical, rapid, convenient and safe is ensured.

Owner:襄阳忠良工程机械有限责任公司

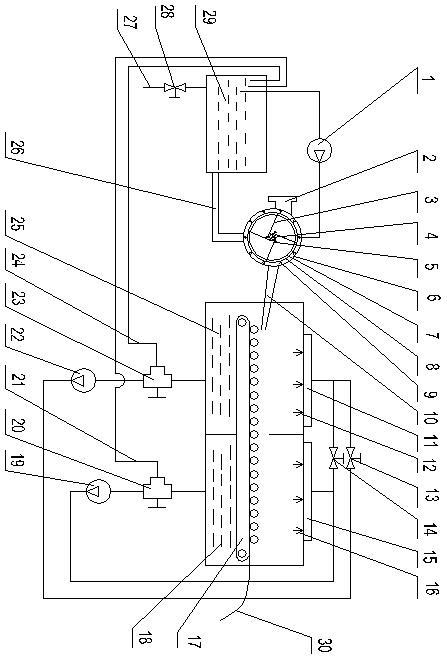

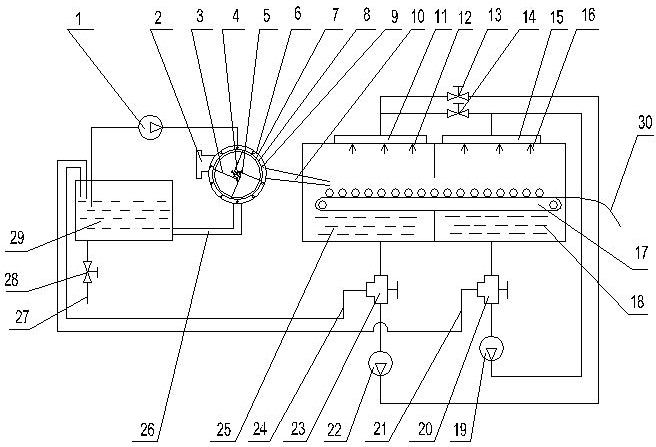

Extraction and perfusion culture system for MSCs (Mesenchymal Stem Cells)

InactiveCN103305419AKeep aliveReduce pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureLiquid waste

The invention discloses an extraction and perfusion culture system for MSCs (Mesenchymal Stem Cells), belongs to a field of medical instruments, and more specifically, provides a set of continuous and completed system design for obtaining high-purity stem cell products from a placenta organ. The device provided by the invention comprises an extraction device and a perfusion culture system, and the extraction device and the perfusion culture system are connected hermetically and aseptically, wherein the extraction device comprises a placenta cutting device, a reaction tank, a filter device, a filtrate collection device and a density gradient centrifugation device; and the perfusion culture system comprises a culture solution storer, a monitoring reactor, a cell culture bottle, a liquid waste bottle, a bottle for obtaining liquid, a biochemical criterion detection head group, an online monitoring system, a speed control fluid propeller and a pipeline device capable of controlling speed. The extraction and perfusion culture system for the MSCs (Mesenchymal Stem Cells) has benefits that the cutting efficiency is high; the operation is convenient and effective; the production efficiency can be greatly improved; the preparation technology is simple; and the quality control is simple and convenient, so as to efficiently obtain uniform and good stem cell products within a short time.

Owner:SHANGHAI ANGECON BIOTECH

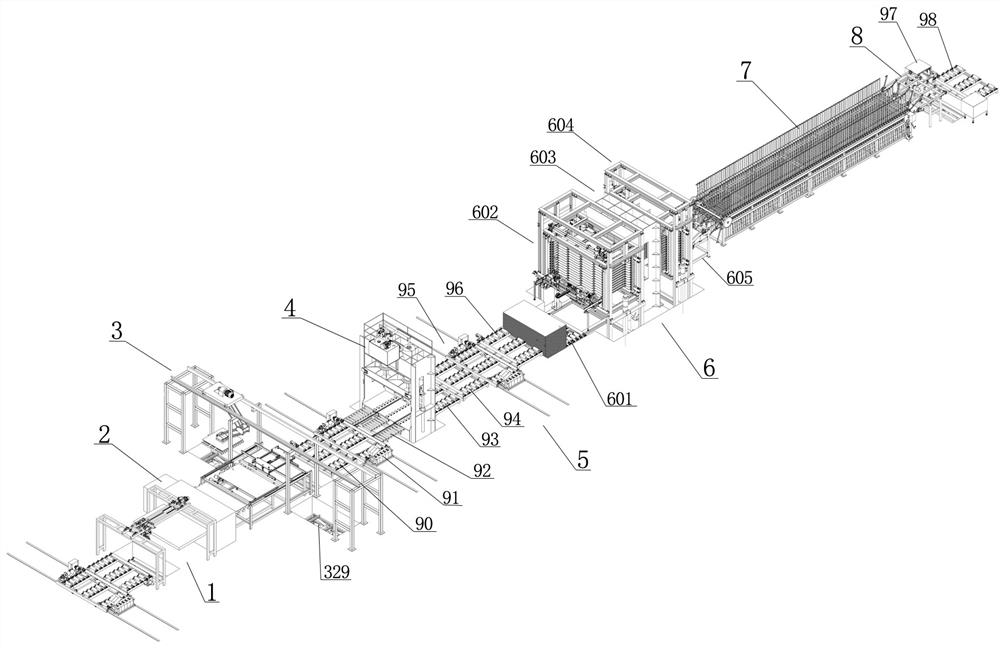

Automatic production line assembly for young silkworm feeding

PendingCN109436862AAchieve automated productionRealization of automatic silkworm feedingControl devices for conveyorsStacking articlesMicrocomputerProduction line

The invention relates to an automatic production line assembly for young silkworm feeding. The automatic production line assembly comprises an automatic leaf cutting machine, an automatic silkworm feeding system, an automatic silkworm plaque destacking and stacking machine, a control system and a power mechanism. The control system comprises an inductor and a single-chip microcomputer. The inductor is arranged on a stacking machine body, and the inductor and the power mechanism are connected with the single-chip microcomputer. Folium mori is cut through the automatic leaf cutting machine, then, the cut folium mori is conveyed into the automatic silkworm feeding system through a conveying-out belt, the folium mori falls into silkworm plaques conveyed out of a silkworm feeding machine silkworm plaque conveying belt for feeding after being evenly scraped in the automatic silkworm feeding system, and stacked silkworm plaques can be conveyed into the automatic silkworm feeding system one byone for silkworm feeding through the automatic silkworm plaque destacking and stacking machine. The automatic production line assembly achieves automatic silkworm feeding, accordingly, young silkwormfeeding automatic production is achieved, and the work efficiency is improved.

Owner:柳州蚕润丝圆蚕业机械科技有限公司

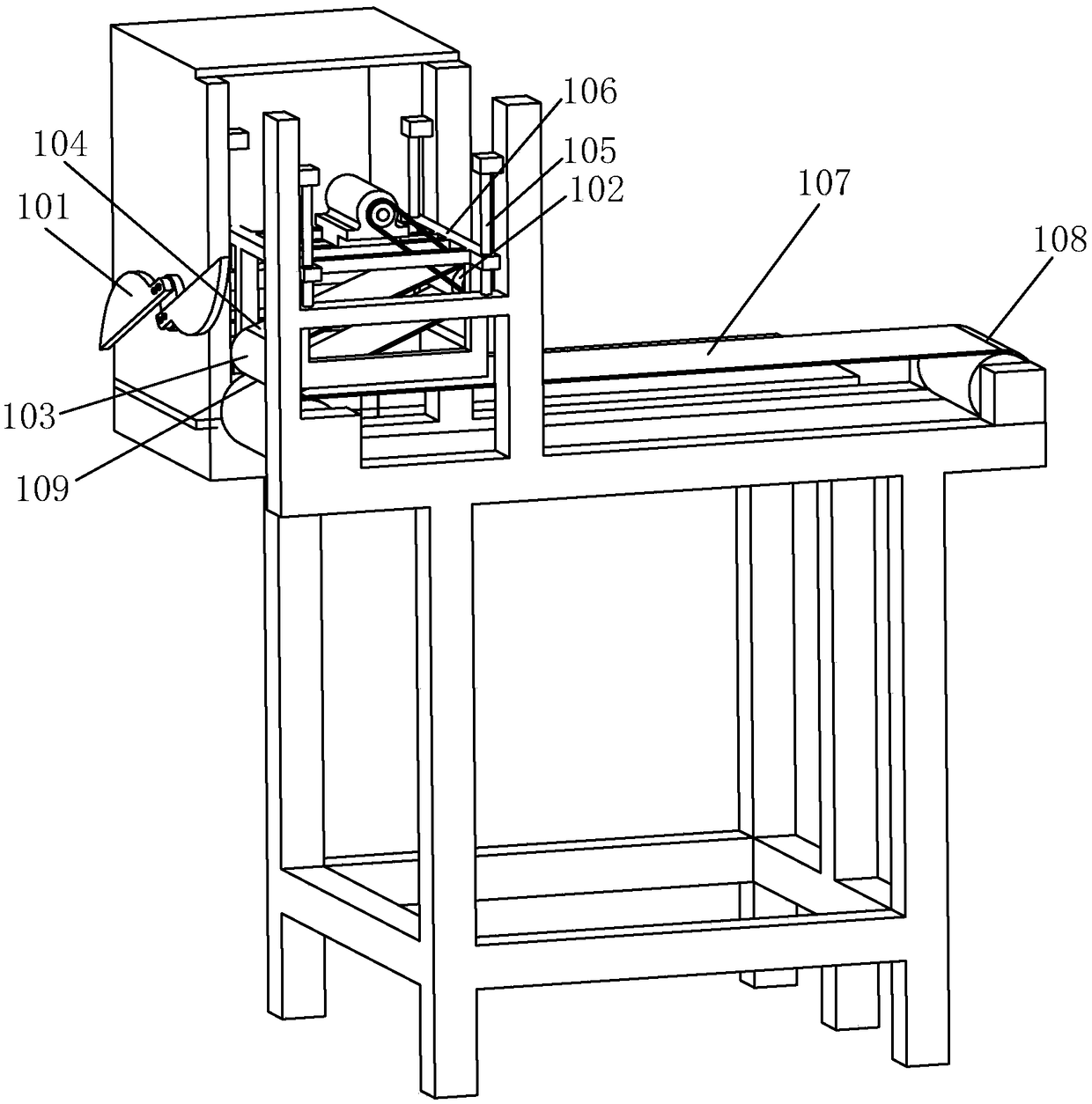

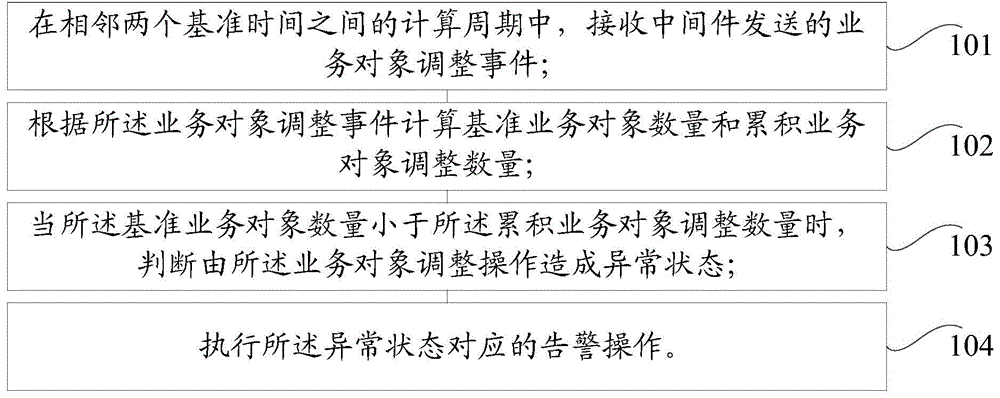

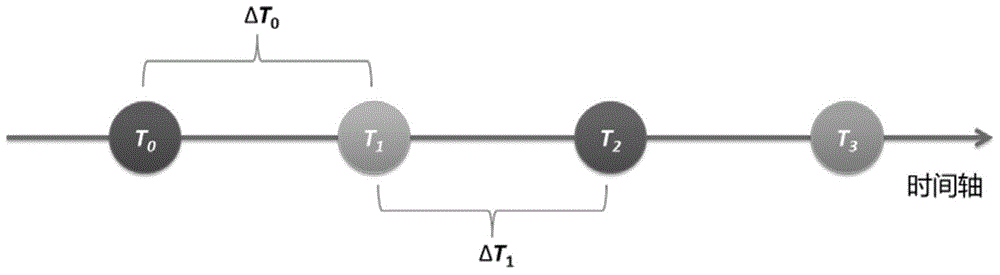

Abnormal alarm method and apparatus for business object

ActiveCN105243001AReduce manual handlingReduce labor costsHardware monitoringCommerceMiddlewareBusiness object

Embodiments of the invention provide an abnormal alarm method and apparatus for a business object. The method comprises: in a calculation cycle between adjacent reference time, receiving a business object adjustment event sent by middleware, wherein the business object adjustment event is generated when a client performs a business object adjustment operation; calculating reference business object quantity and accumulative business object adjustment quantity according to the business object adjustment event, wherein a reference storage value is business object quantity at current reference time, and the accumulative business object adjustment quantity is total business object adjustment quantity accumulated within the calculation cycle; when the reference business object quantity is less than the accumulative business object adjustment quantity, determining that the business object adjustment operation causes an abnormal state; and executing an alarm operation corresponding to the abnormal state. According to the abnormal alarm method and apparatus provided by the embodiments of the invention, real-time abnormal state monitoring of mass data is realized, manual processing is reduced, labor costs are reduced, and user loss is effectively reduced.

Owner:ALIBABA GRP HLDG LTD

Automatic labeling machine

The invention relates to an automatic labeling machine which comprises a mounting rack as well as a first shifting mechanism, a second shifting mechanism, a material identifying mechanism, a label peeling device, a controller and a production system, which are arranged on the mounting rack, wherein the first shifting mechanism is used for conveying materials; the second shifting mechanism is used for fixing and conveying the materials; the material identifying mechanism is used for identifying the materials; the label peeling device is applied to peeling and continuous working of a plurality of labels; the controller is used for receiving label information read by the material identifying mechanism, and is used for controlling the first shifting mechanism, the second shifting mechanism and the label peeling device; the production system is used for sending control instructions and data to the controller. According to the automatic labeling machine, material discs on an assembly line are shifted to machining positions by the first shifting mechanism and fixed by the second shifting mechanism, and after the labels are adhered, the material discs are conveyed to the assembly line through the second shifting mechanism. Compared with the prior art, the automatic labeling machine is high in automation degree, manual transportation is not needed, labor resource is saved, and meanwhile peeling and continuous working of the plurality of labels are realized by a plurality of label adhering units, and the working efficiency is improved.

Owner:苏州弘瀚自动化科技有限公司

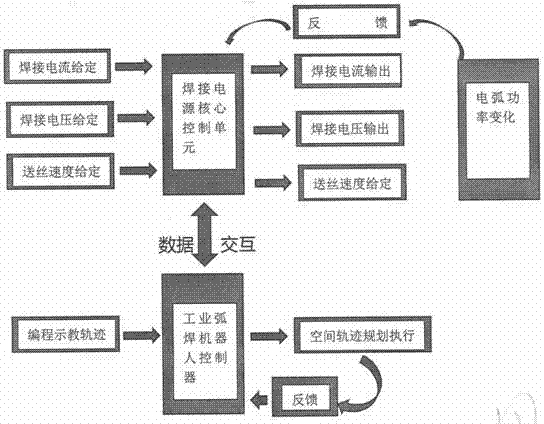

Welding power source power output change and arc welding robot motion closed-loop control method

InactiveCN106956061AEnsure consistencyReduce manual handlingArc welding apparatusLoop controlWelding power supply

The invention discloses a welding power source power output change and arc welding robot motion closed-loop control method. Welding current setting, welding voltage setting and wire feeding speed setting are all achieved through initialization panel analog quantity input setting or are provided for a welding power source by a robot upper computer controller through looped network or analog quantity IO interface initialization, are subjected to initial distribution through a welding power core processing mechanism, and are output to an electric arc load, and load power is fed back to a power core control unit when changing, the core control unit conducts processing and achieves interactive communication with an industrial arc welding robot controller, and a robot space planning track is controlled coordinately. When space speed of the robot changes, the robot and a power source achieve communication coordinately, the power source can change welding output currents, voltage and a wire feeding speed value according to the change quantity of the robot. The welding power source power output change and arc welding robot motion closed-loop control method can be widely used for the working conditions with complex robot automatic welding, and labor productivity is improved.

Owner:南通市慧冠智能科技有限公司

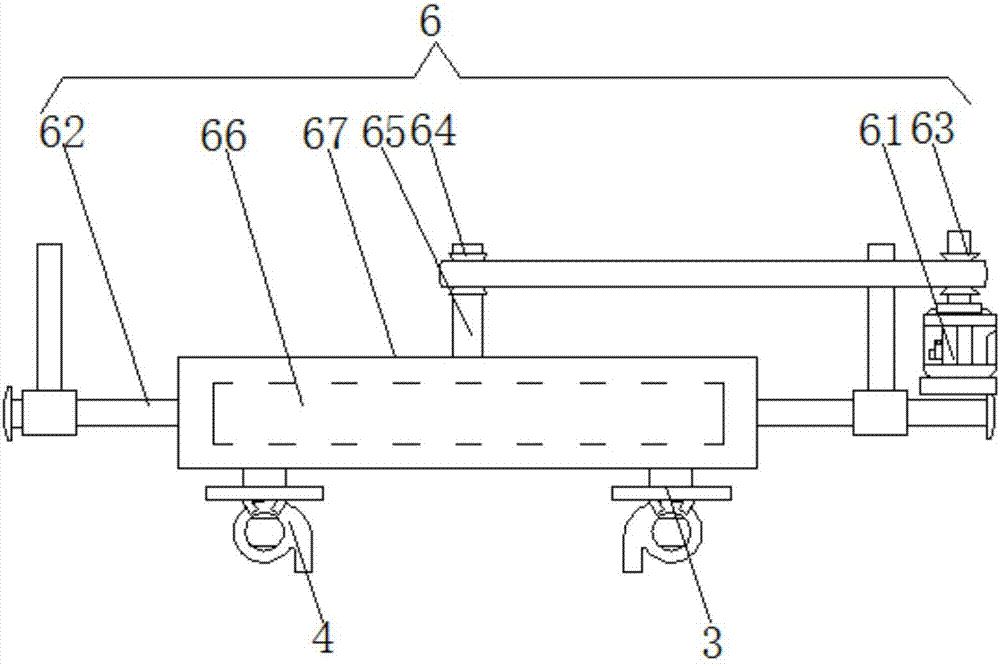

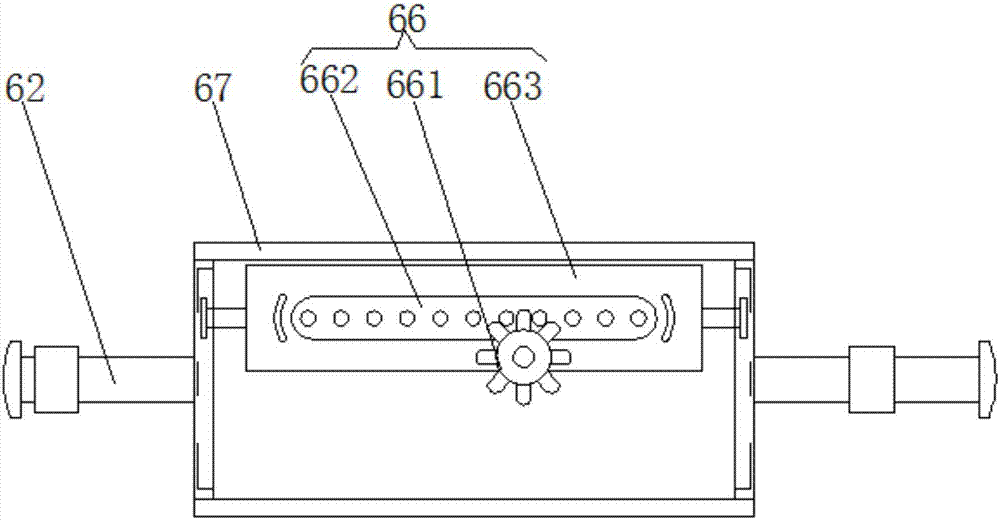

Steel belt conveying apparatus for transporting and bolting machine and transporting and bolting machine

ActiveUS20210198046A1Reduce handlingReduce installationConveyorsSupporting framesDrive shaftStructural engineering

A steel belt conveying apparatus includes upper and lower horizontal conveying portions, left and right inclined conveying chains, a connecting rod frame, an inclined frame, a drive portion, and a height adjustment cylinder. The left inclined conveying chain is separately connected to the upper and lower horizontal conveying portions. The right inclined conveying chain is separately connected to the upper and lower horizontal conveying portions. A top portion of the connecting rod frame is hingedly connected to an upper horizontal frame of the upper horizontal conveying portion. A bottom portion is hingedly connected to a lower frame of the lower horizontal conveying portion. A top portion of the inclined frame is hingedly connected to an upper horizontal drive shaft of the upper horizontal conveying portion, and a bottom portion is hingedly connected to a lower horizontal drive shaft of the lower horizontal conveying portion.

Owner:CHINA UNIV OF MINING & TECH

Electric power tool storing cabinet based on mobile internet

ActiveCN107363801APlay a protective effectNot easy to corrode and rustWork tools storageElectric power systemElectric power

The invention discloses an electric power tool storing cabinet based on mobile internet. The electric power tool storing cabinet based on mobile internet comprises a storing cabinet, a rotating device is fixedly connected with the bottom of the inner wall of the storing cabinet, and a first blower is fixedly connected with the top end of the rotating device through a base; a cooling device is movably connected with top of the inner wall of the storing cabinet through a pulling rod, and a supporting plate is fixedly connected with the bottom of the cooling device through a short rod; a second blower is fixedly connected with the bottom of the supporting plate, and guiding rails are fixedly connected with the two sides of the inner wall of the storing cabinet; the guiding rails are internally and slidably connected with panels through sliding blocks, and toolboxes are fixedly connected with the two sides of the tops of the panels. The invention relates to the technical field of electrical equipment. According to the electric power tool storing cabinet based on mobile internet, the problem that the existing storing cabinet cannot dissipate heat well is solved, dry air in the storing cabinet is guaranteed so that electric power tools are protected and are not easy to corrode and rust.

Owner:国网山东省电力公司宁津县供电公司 +2

Intelligent water color pen packaging and boxing instrument

The invention discloses an intelligent water color pen packaging and boxing instrument. The intelligent water color pen packaging and boxing instrument comprises a conveying portion, a boxing mechanism, a box cover covering mechanism, a buffering cover conveying mechanism and a cover receiving portion; the boxing mechanism and the box cover covering mechanism are fixedly installed over the conveying portion; the buffering cover conveying mechanism and the cover receiving portion are arranged on one side of the conveying portion; and the buffering cover conveying mechanism is located in front of the cover receiving portion. According to the intelligent water color pen packaging and boxing instrument, pen boxes are full of color pens through the boxing mechanism, box covers are conveyed to the box cover covering mechanism through the buffering cover conveying mechanism, the pen boxes are covered through the box cover covering mechanism, and then the automation degree and the working efficiency are improved.

Owner:王先勤

System, method, and apparatus for handling and testing individual sliders in a row-like format in single slider processing systems

InactiveUS20060012360A1Avoid damageEasy dischargeRecord information storageMagnetic property measurementsEngineeringTest fixture

A device for handling and testing individual sliders in a row-like format utilizes an elongated, row-like holder having a series of small pockets, each of which receives a single slider. After the sliders enter the holder, a clamp is moved to a closed position to retain the sliders in the holder. The holder is placed in a test fixture such that permanently mounted probes precisely engage the small pads on the sliders for multiple testing purposes. Enlarged probe pads on the test fixture are electrically interconnected with the probes to provide an operator with easy access to the slider pads. The sliders are tested in a row-like format, side by side, to reduce handling-induced electrostatic discharge and mechanical damage.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Soft capsule cleaning machine

InactiveCN102641866AExtended service lifeImprove recycling ratesCleaning using liquidsEngineeringControl valves

The invention relates to a soft capsule cleaning machine, which comprises a cylinder spray cleaning device, wherein the cylinder spray cleaning device is composed of a cavity, a barrel body, a spray cleaning water pipe, a spray cleaning pump, a spray cleaning solution tank, a plurality of first sprinklers and a plurality of second sprinklers. The soft capsule cleaning machine is characterized by further comprising an eluting device, wherein the eluting device is composed of a first eluting solution tank, a second eluting solution tank, a first eluting pipe, a second eluting pipe, a first eluting pump, a second eluting pump, a first three-way valve, a second three-way valve, a first control valve, a second control valve, a plurality of first eluting sprinklers and a plurality of second eluting sprinklers, wherein the first eluting pipe is installed on the upper portion of the first eluting solution tank, the second eluting pipe is installed on the upper portion of the second eluting solution tank, the first eluting sprinklers are evenly distributed on the first eluting pipe, the second eluting sprinklers are evenly distributed on the second eluting pipe, a revolving conveyer belt horizontally penetrates through the tanks in the middles of the first eluting solution tank and the second eluting solution tank, and a conveying board is installed at the output end of the conveyer belt. According to the soft capsule cleaning machine, the cleaning is thorough, the recycling rate of cleaning solutions are high, the cleaning is rapid, and manual handling operations can be omitted.

Owner:WEIHAI BAIHE BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com