Patents

Literature

193results about How to "Increase annual output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

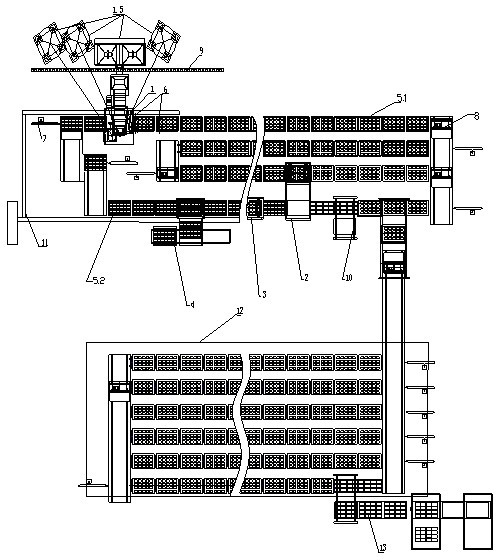

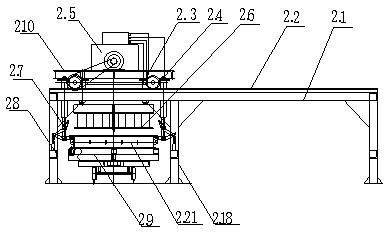

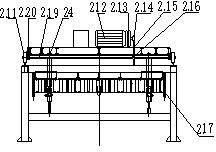

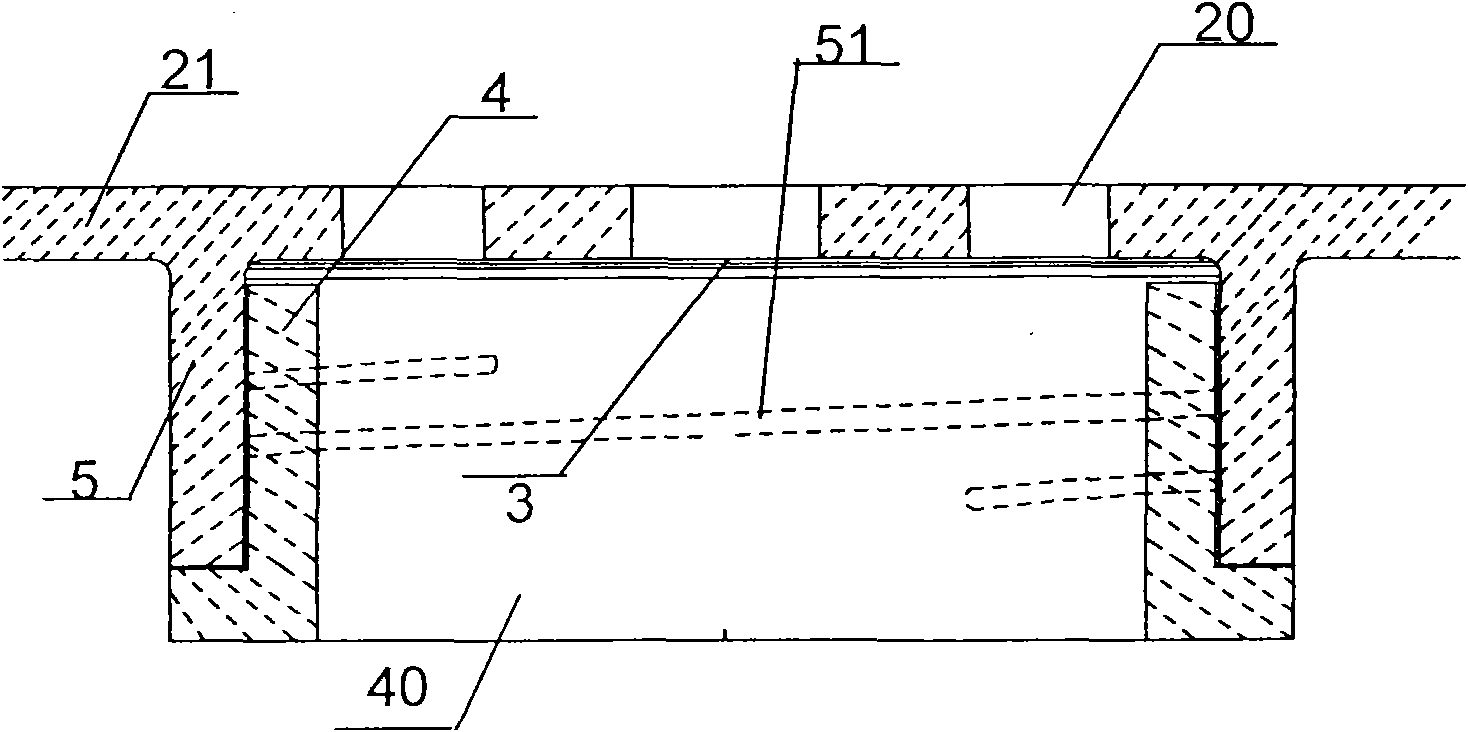

Production line for self-insulation building blocks

InactiveCN102555052AReduce occupancyReduce consumptionDischarging arrangementCeramic shaping plantsProduction lineBrick

The invention relates to a tool used in an insulation brick manufacturing process, in particular to a production line for self-insulation building blocks, which comprises a stirring machine. The production line is characterized in that automatic metering devices are arranged on a feeding port and at the bottom of the stirring machine, a production track capable of automatically conveying molds isdisposed below a distributing port of the stirring machine, a stripper is further arranged on the production track and is spaced from the stirring machine by a proper distance, a return track and a track leading into a maintenance area are respectively disposed on two sides of the other end of the stripper, the return track sequentially penetrates through a cleaning area, an oil injection area and a core setting area, a link plate machine is arranged at the other end of the maintenance area, and a manipulator is disposed at the other end of the link plate machine. The production line is high in production efficiency and annual yield, occupied land area and workshop investment are reduced, operating expense is saved, and the production line can operate continuously.

Owner:张建兴

Culture method for small and medium-sized litopenaeus vannamei

InactiveCN102893940AOvercome the shortcomings of large drainage and large irrigationGuarantee drug residueClimate change adaptationPisciculture and aquariaEnvironmental engineeringBiological organism

The invention relates to a culture method for small and medium-sized litopenaeus vannamei and belongs to the technical field of aquaculture. The culture method specifically comprises the following eight steps of: pond clearing, water introduction, disinfection, bait organism culture, water quality detection, staged shrimp seed putting, staged culture, and small and medium-sized catching and harvesting. The method adopts strict treatment such as secondary sedimentation, disinfection and secondary filtration for water for culture at each stage, one-time water introduction and sealed culture to effectively isolate the invasion of external pathogens, and does not use drugs during the whole culture process, so that the product does not have drug residues and has good quality; the staged shrimp seed putting adopts a method of pure-oxygen aeration and dry transportation by putting shrimp seed into a netting cage, with lower shrimp seed damage rate which is generally controlled below 1.0%; and a three-stage culture mode is adopted for culture and can realize 5-generation culture throughout the year, with the average yield of 750-1,000kg / mu, the culture success rate higher than that of conventional culture by 20-30%, and the output value increased by 50% compared with a conventional mode.

Owner:湛江新昶食品有限公司

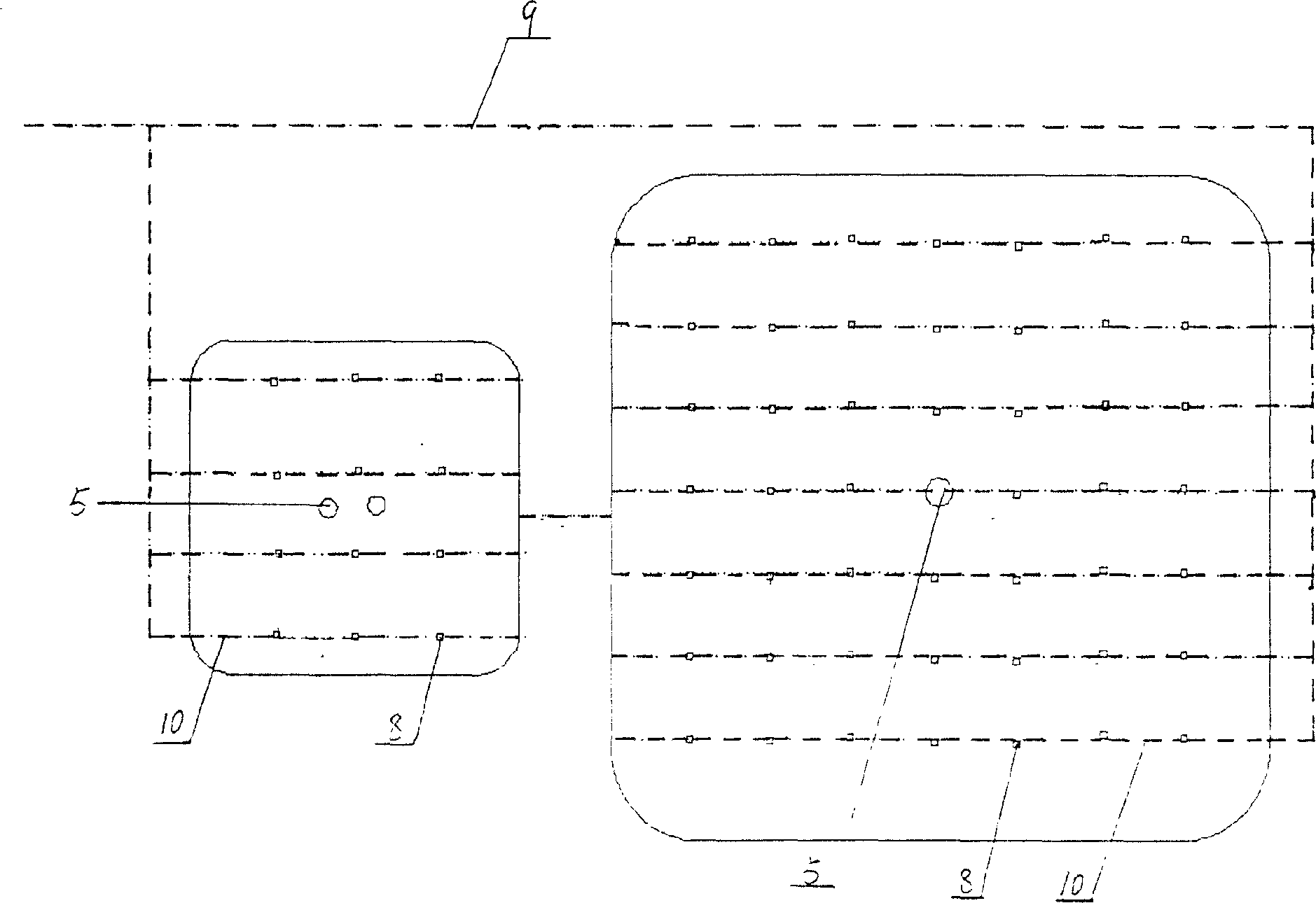

Industrial and three-crops a year type prown cutturing method, and pond therefor

InactiveCN1911003AConform to production characteristicsImprove survival rateClimate change adaptationWater aerationPrawnSeawater

An industrial culture method for prawn includes such steps as arranging the serially connected high-level culture pool and low-level culture pool, culturing the young prawn in the high-level culture pool for 30-50 days, and culturing in the low-level culture pool. Its culture pool system is composed of a primary high-level culture pool, a secondary low-level culture pool, transfer pipeline, and two drain pipes. It can output prawn three times in one year.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Pollution-free healthy culture method of grouper in pond

InactiveCN101836616AReduce the impactImprove efficiencyClimate change adaptationPisciculture and aquariaSeawaterDeep sea

The invention discloses a pollution-free healthy culture method of grouper in a pond, which comprises the following steps: (1) pond preparation: selecting sand substrates or silt substrates as pond substrates, firstly insolating and dredging, then pouring the substrates into deep sea water, applying quick lime per mu for sterilizing and improving the substrates, and discharging the quick lime after 24h; (2) working before seeding: after the pond is prepared well, pouring water, sterilizing the whole pond with chlorine dioxide, and applying special fertilizer for aquiculture and beneficial microbial agents containing bacillus after 24h; (3) seedling stocking: stocking seedlings according to the density of 700-1300 per mu; (4) bait feeding: feeding fresh sea water trash fish cream at the early stage of culture of seedlings, and feeding soft granulated feed or special commercial feed for grouper at the middle and later stages of culture of seedlings; and (5) water quality management: controlling the transparency and the pH value of pond water, and regularly applying beneficial microbes once into the pond. The culture method of grouper of the invention controls the water quality by applying beneficial microbes and organic fertilizer, reduces the use of medicines and improves the value of products.

Owner:广西红榄科技有限公司

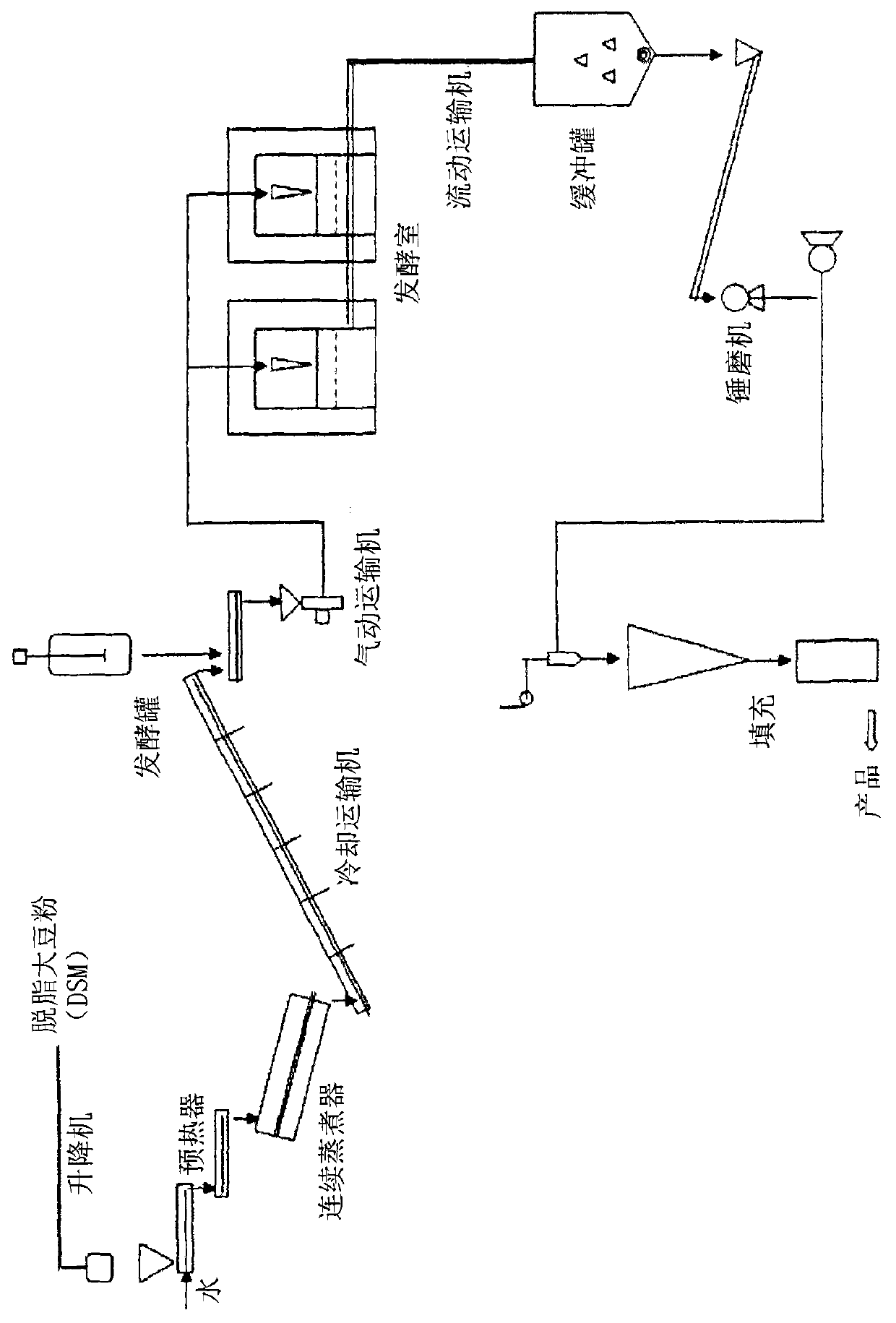

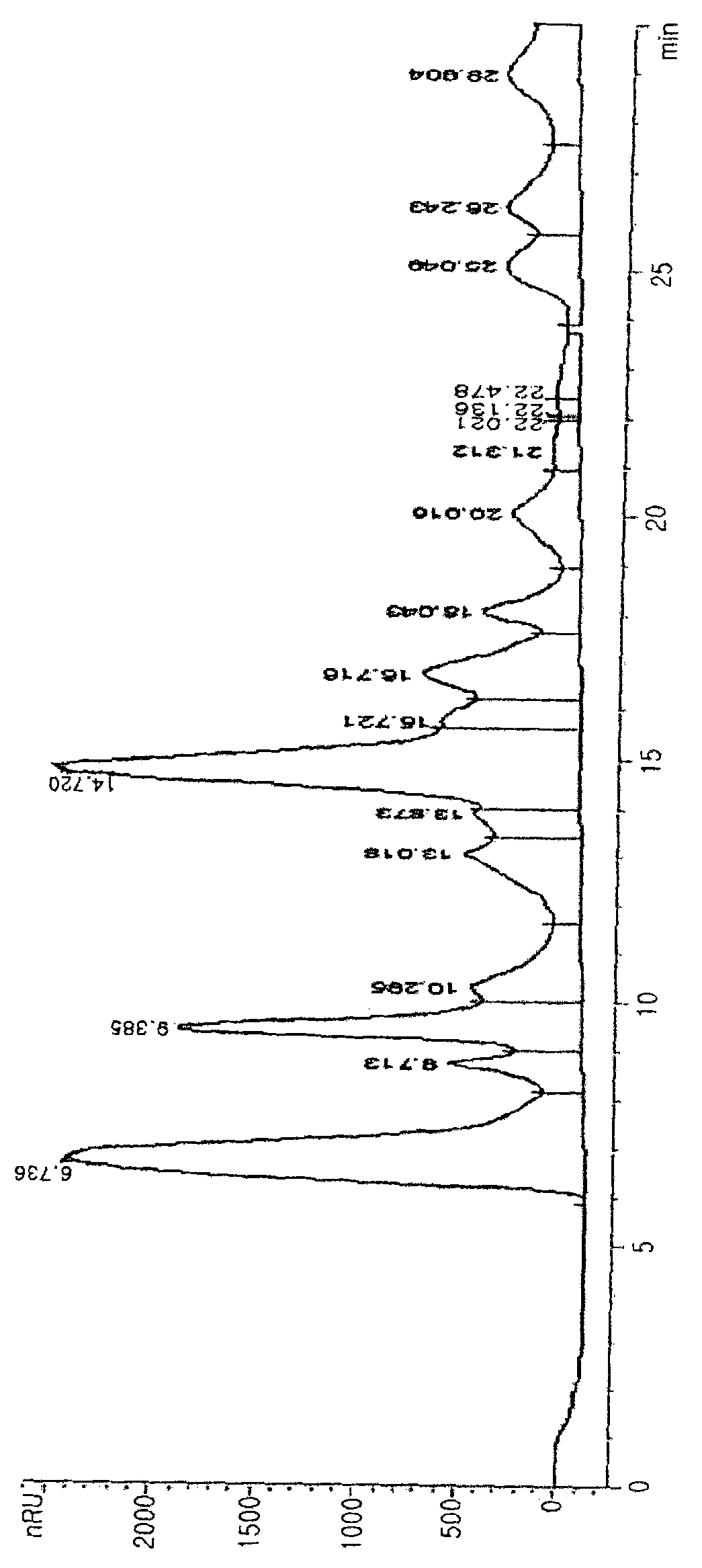

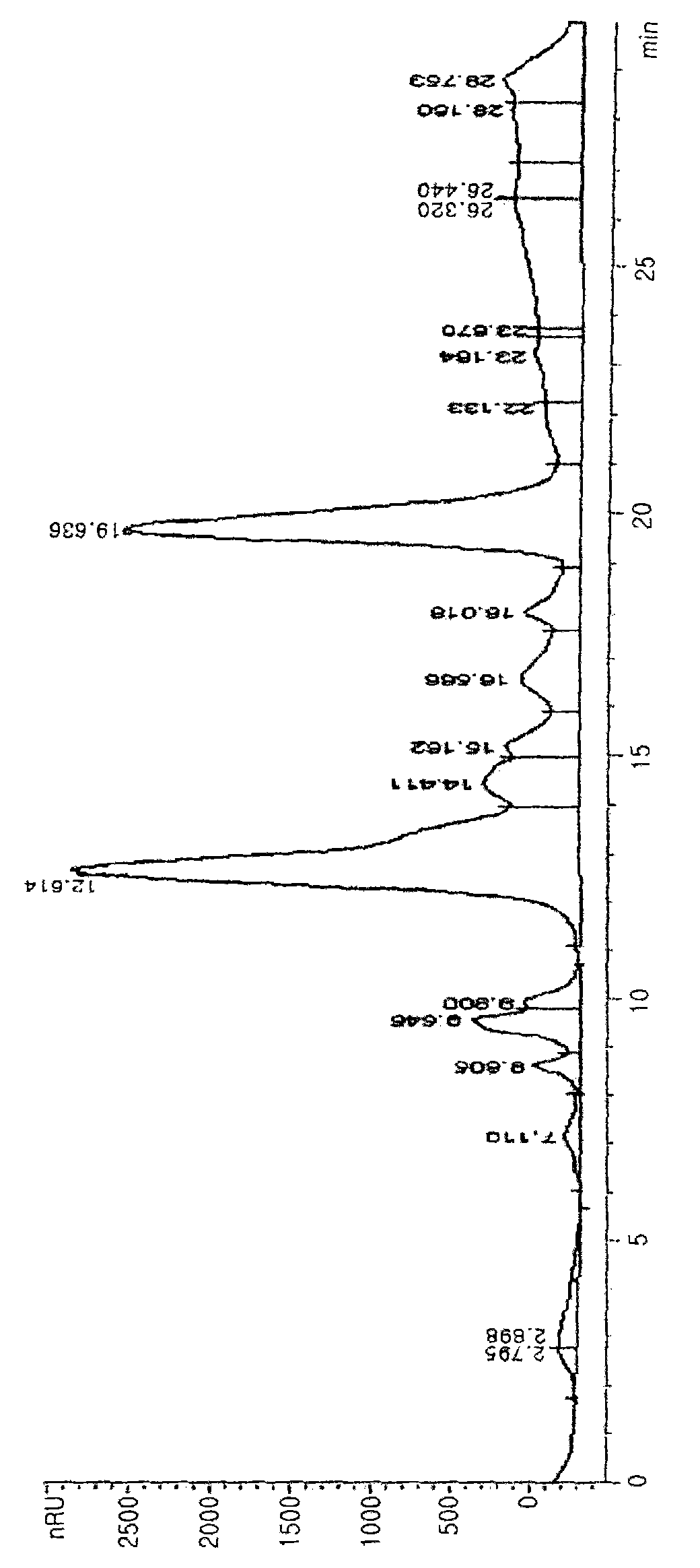

Method for preparing a fermented soybean meal using bacillus strains

ActiveCN102018096AEfficient removalImprove or improve featuresAnimal feeding stuffFood preparationTrypsin inhibitorDigestion

The present invention relates to a method for producing a fermented soybean meal, comprising the steps of: (a) adding water to a soybean meal to perform heat-treatment; (b) cooling the heat-treated soybean meal, and then inoculating a Bacillus strain thereinto; and (c) acquiring a fermented soybean meal by solid fermentation of the Bacillus-inoculated soybean meal, and to a fermented soybean meal produced by the method. The method of the present invention uses a Bacillus strain having excellent properties required for the production of fermented soybean meal, in particular, Bacillus subtilis TP6 strain as a fermentation strain. Therefore, the fermented soybean meal produced by the present invention is a high-quality plant protein source in that various anti-nutritional factors including trypsin inhibitors, soybean oligosaccharides and polysaccharides are almost all removed, its protein content is high, and digestion and absorption rates are also improved by low-molecularization of the proteins. In particular, the TP6 strain capable of removing anti-nutritional factors is used to improve the product quality equivalent to or better than those produced by the known fermented soybean meals while reducing the fermentation time, thereby remarkably increasing the annual production.

Owner:CJ CHEILJEDANG CORP

High-yield citrus planting method

InactiveCN106613666AImprove survival rateHigh activityBiocideCalcareous fertilisersSocial benefitsCitrus tree

The invention discloses a high-yield citrus planting method and belongs to the technical field of agricultural planting. The planting method includes the processes of citrus seedling selection, soil preparation, seedling planting, topdressing after planting, treatment after harvesting of citrus trees and the like. In the processes, a self-made root-inducing and sterilization solution is used for treating root systems of seedlings, a soil amendment is used for improving the soil environment of citrus tree planting, and planting a fertilizer serves as a base fertilizer of citrus trees. The planting method is scientific and reasonable, simple, easy to implement and convenient to manage, the fertilizer used in the planting process is rich in nutrient, does not contain chemical additives, does not contaminate soil and the citrus trees and is safe and reliable, the survival rate of the citrus trees in the planting process is high, the citrus yield is high, citrus production is stable, and the method is remarkable in social benefit, economic benefit and ecological benefit.

Owner:广西金神农生态农业科技开发有限公司

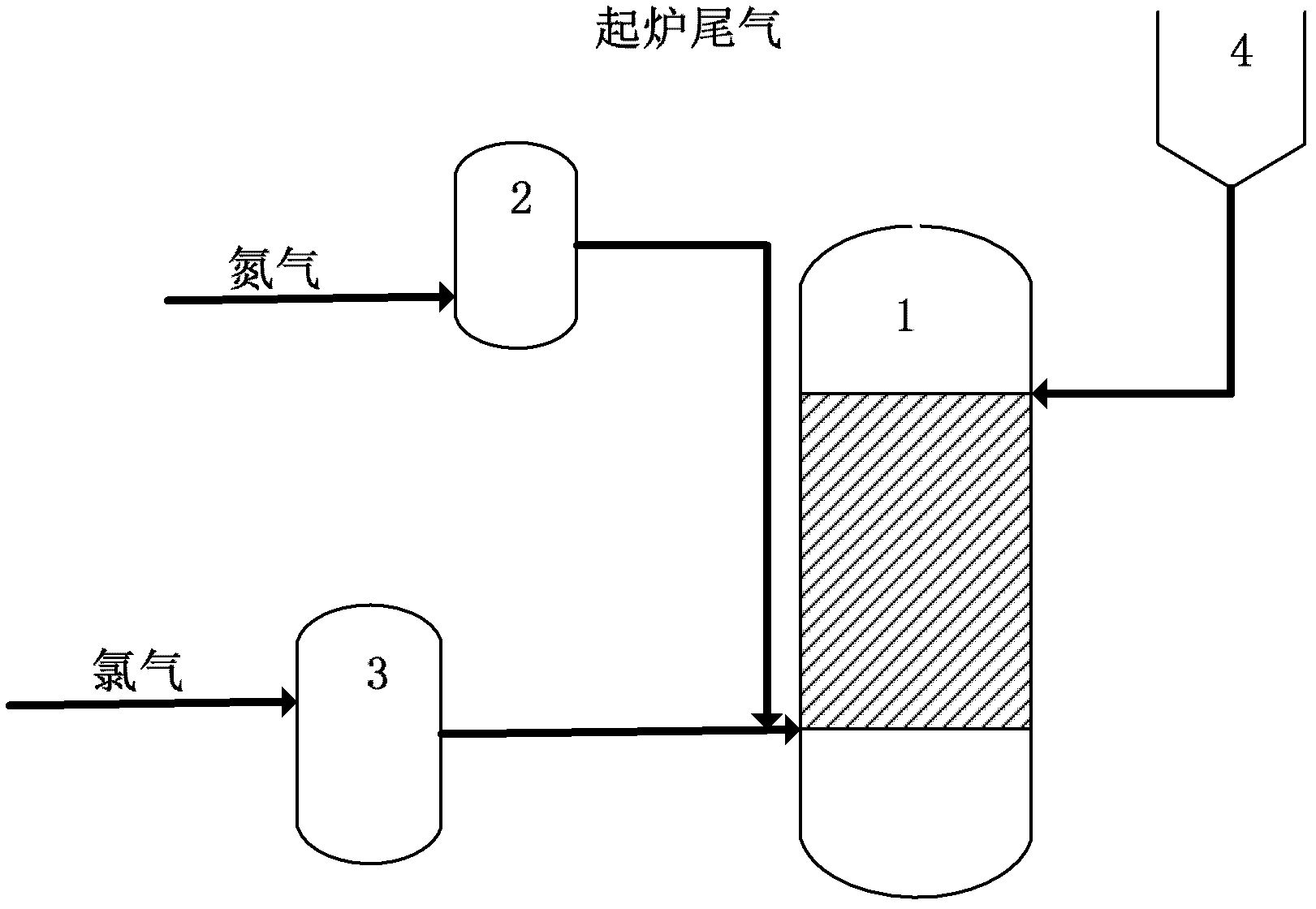

Method for stirring boiling chlorination furnace and method for preparing titanium tetrachloride

InactiveCN103121709AShort starting timeReduce startup timeTitanium halidesTitanium tetrachlorideMaterials science

The invention discloses a method for stirring a boiling chlorination furnace and a method for preparing titanium tetrachloride. The method for stirring the boiling chlorination furnace comprises the steps of: adding a titanium-containing material in the boiling chlorination furnace and introducing high-temperature non-oxide gas into the boiling chlorination furnace, wherein the temperature and the gas velocity of the high-temperature non-oxide gas enable the temperature of the added titanium-containing material to reach furnace stirring temperature, and the titanium-containing material is a titanium-containing substance for producing the titanium tetrachloride. The method for stirring the boiling chlorination furnace has the characteristics of short furnace stirring time, simple facility, operation easiness, good environment-friendly effect, and the like; and the shortened furnace stirring time is certainly beneficial to reduction of material and labor costs, increase of production time and increase of annual output.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

Layered shelf type crop rotation cultivation method of dictyophora indusiata

InactiveCN104396575AImprove economic efficiencyGood for growthCultivating equipmentsMushroom cultivationEdible mushroomDictyophora indusiata

The invention relates to the field of edible mushroom cultivation, and in particular relates to a layered shelf type crop rotation cultivation method of dictyophora indusiata, which is used for solving the problems that continuous cropping cannot be achieved, the management is rough, a great deal of land is occupied and the resource is wasted in conventional artificial dictyophora indusiata cultivation. By adopting the layered shelf type crop rotation cultivation method, anniversary, precise and intensive cultivation of dictyophora indusiata are achieved, the yield and the quality of the dictyophora indusiata are greatly improved, the benefits of planting farmers are increased, and the layered shelf type crop rotation cultivation method is simple and feasible and is easy to popularize.

Owner:CHANGNING ZHUSUN DEV INST

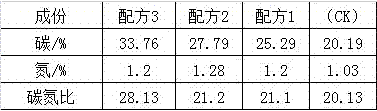

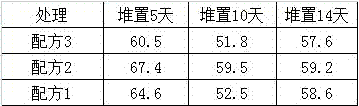

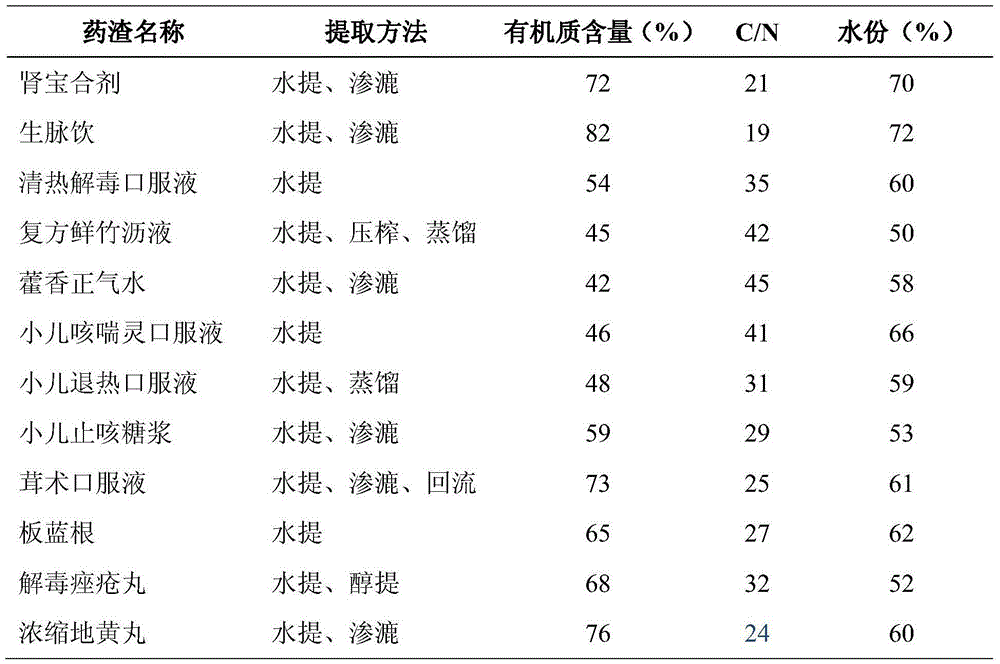

Compound substrate for hot-pepper plug seedling and preparation method thereof

InactiveCN105684779AIncrease annual outputQuality improvementGrowth substratesCulture mediaFermentationBiology

The invention discloses a compound substrate for hot-pepper plug seedling and a preparation method thereof. The basic substrate is prepared from turf, corncobs, fine sand, pond silt, traditional Chinese medicine decoction dregs, edible fungus residues, microbial fermentation bacteria and other substrates through compound fermentation, an appropriate amount of other required nutrient substances is also added in follow-up different growth periods, and high-temperature disinfection and chemical disinfection treatment are performed before usage. Compared with a traditional compound substrate for the hot-pepper plug seedling, the fertility and physicochemical properties of the substrate are remarkably improved, the seed budding time is remarkably shortened, the budding ratio is improved, the emergence rate is remarkably improved, the quality of grown hot-pepper seedlings is high, the annual output of hot peppers is also increased, the seedling quality problem caused by uniform nutrition of the substrate for traditional hot peppers is solved, the existing troubles of hot-pepper plug seedling are decreased, the annual output of the hot peppers and the quality of vegetables are greatly improved, and economic benefits are increased for vegetable growers.

Owner:赵兰

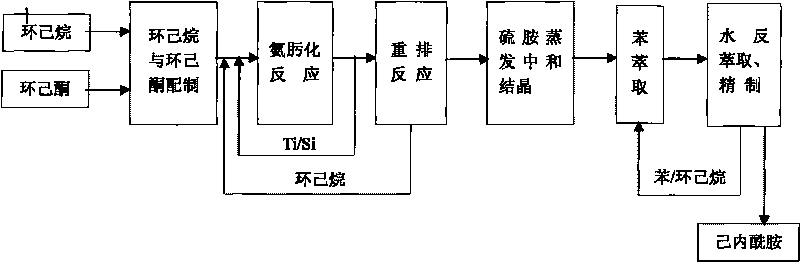

Process for preparing caprolactam

The invention discloses a process for preparing caprolactam, which comprises the following steps: after mixing cyclohexanone and cyclohexane evenly, carrying out an oxamidine reaction to obtain a cyclohexane solution of cyclohexanone oxime; enabling the cyclohexane solution of the cyclohexanone oxime and oleum to react to generate a caprolactam sulfate solution, curing the caprolactam sulfate solution, then carrying out a neutralization reaction on the cured caprolactam sulfate solution and ammonia, afterwards separating the two materials to obtain a crude product of caprolactam and then carrying out extraction and water back extraction respectively to prepare a finished product. Because of the existence of a cyclohexane inert solvent, rectification and separation do not need to be carried out after the oxamidine reaction, and only a rearrangement reaction needs to be carried out after the water phase of a catalyst is separated, thereby saving a rectification device and the steam consumption; as a result, a caprolactam enterprise with an annual yield of a hundred thousand tons can save energy worth approximately 60000000 yuan every year and can also save the one-off equipment investment totaling 60000000 yuan, the technological process of caprolactam is simplified, the procedures of water washing, extraction, distillation and the like are reduced, the production period is shortened, and the annual yield is enhanced.

Owner:河北美邦工程科技股份有限公司

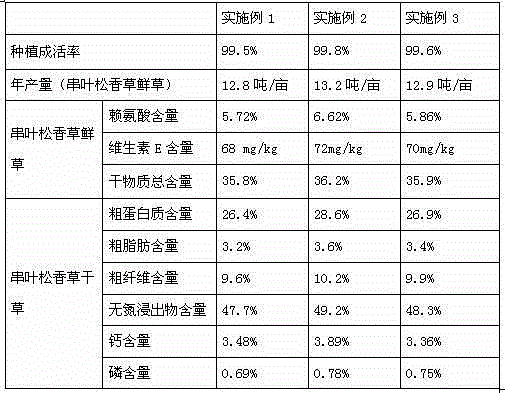

Organic matter-enriched brackish water irrigation method for saline-alkali soil and application of irrigation method in planting of silphium perfoliatum

InactiveCN105028123AIncrease annual outputImprove the survival rate of plantingClimate change adaptationWatering devicesSaline waterSilphium perfoliatum

The invention provides an organic matter-enriched brackish water irrigation method for saline-alkali soil and application of the irrigation method in planting of silphium perfoliatum. The irrigation method comprises seedling-stage irrigation, wherein irrigation is carried out in the ratio of times of rotation irrigation of the brackish water to fresh water is 1:5, and the amount of irrigation at each time is 300 to 360m<3> / hectare. The irrigation method also comprises growing-stage irrigation, wherein irrigation is carried out in the ratio of times of rotation irrigation of organic matter-enriched saline water to the fresh water is 1:2, the amount of irrigation at each time is 450 to 500m<3> / hectare, and the organic matter-enriched saline water is formed by dissolving an organic matter-enriched fertilizer into the brackish water and performing uniform mixing. The irrigation method further comprises cutting-stage irrigation, wherein irrigation is carried out in the ratio of times of rotation irrigation of the saline water to the fresh water is 1:3, and the amount of irrigation at each time is 500 to 560m<3> / hectare. According to the irrigation method, the annual output of fresh grass for planting of the silphium perfoliatum is 12.8 to 13.2 tons / acre, and the planting survival rate is 99.5 to 99.8 percent.

Owner:WEIFANG YOURONG IND

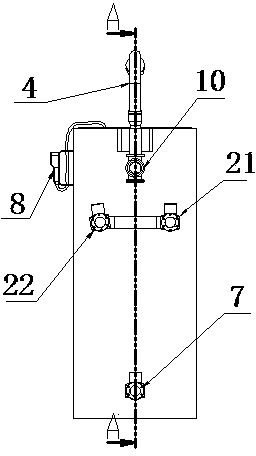

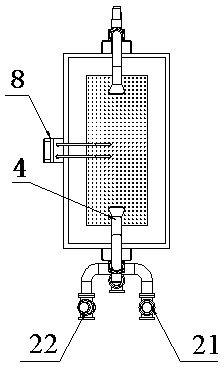

Method for culturing eurotium cristatum of loose black tea and temperature and humidity controlled incubator applied to process of culturing eurotium cristatum of loose black tea

InactiveCN104222352AIntense and delicateGreat tastePre-extraction tea treatmentVapor liquidBlack tea

The invention discloses a method for culturing eurotium cristatum of loose black tea and a temperature and humidity controlled incubator applied to a process of culturing eurotium cristatum of loose black tea. The method for culturing eurotium cristatum of loose black tea comprises the following steps: choosing raw materials, carrying out pile fermentation, spraying tea juice, steaming, culturing eurotium cristatum at controlled temperature and with controlled humidity, drying and packaging. The temperature and humidity controlled incubator comprises sprayers, a sealed interlayer, a temperature and humidity controller, an air drying layer and a culturing container, wherein a hot air inlet is formed in one side of the air drying layer; a vapor-liquid outlet is formed in one side of the sealed interlayer, and a vapor-liquid inlet is formed in the other side of the sealed interlayer; the sprayers are arranged at the upper part of the sealed interlayer; the temperature and humidity controller is mounted outside the sealed interlayer. By virtue of the adoption of the method and the temperature and humidity controlled incubator, natural culture of eurotium cristatum of loose black tea can be realized; the temperature and the humidity in a strict environment for culturing eurotium cristatum of loose black tea can be simply, effectively and accurately controlled; the eurotium cristatum culturing effect is good, and thus the quality of the loose black tea is remarkably improved.

Owner:周壮生 +1

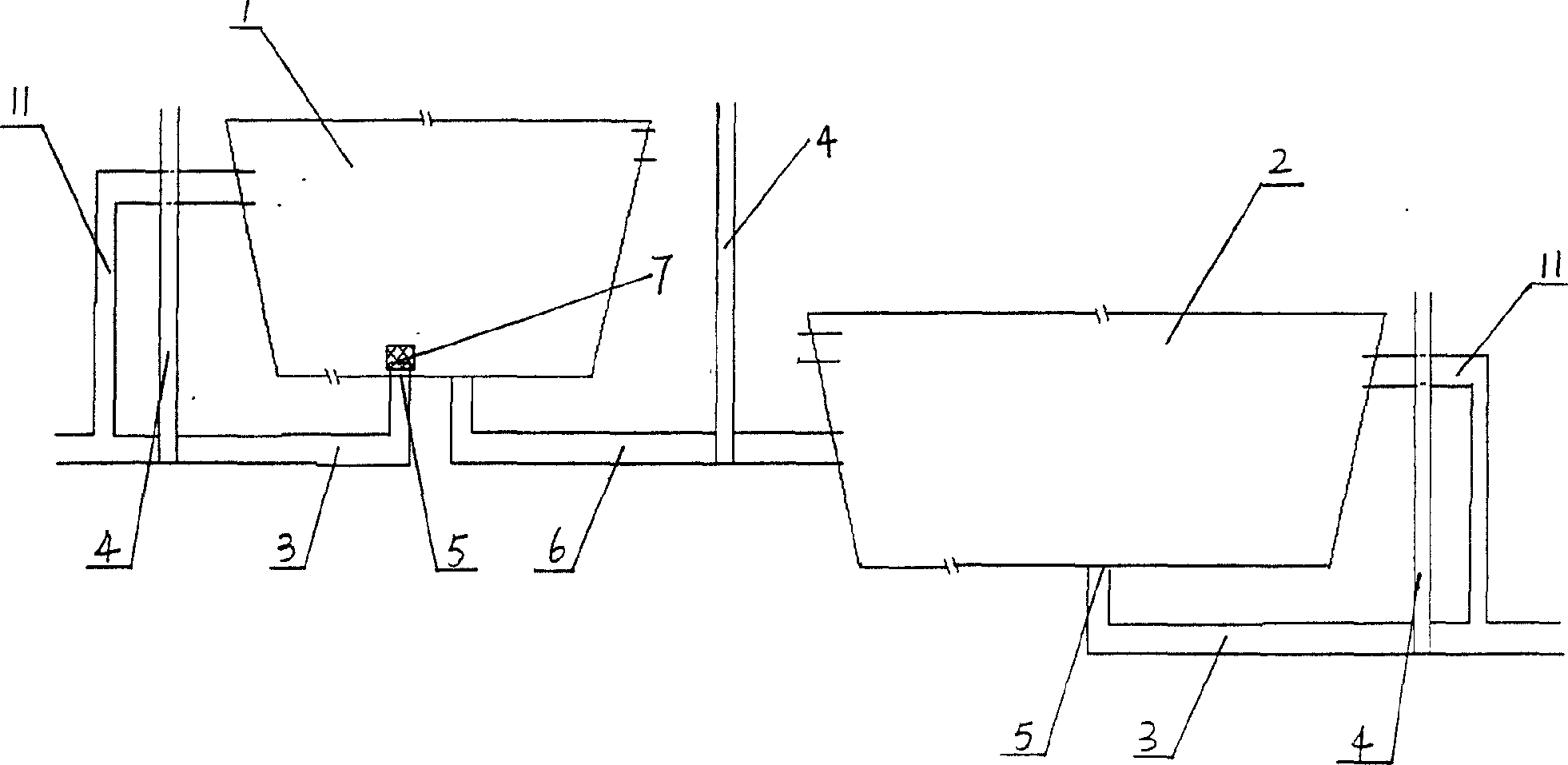

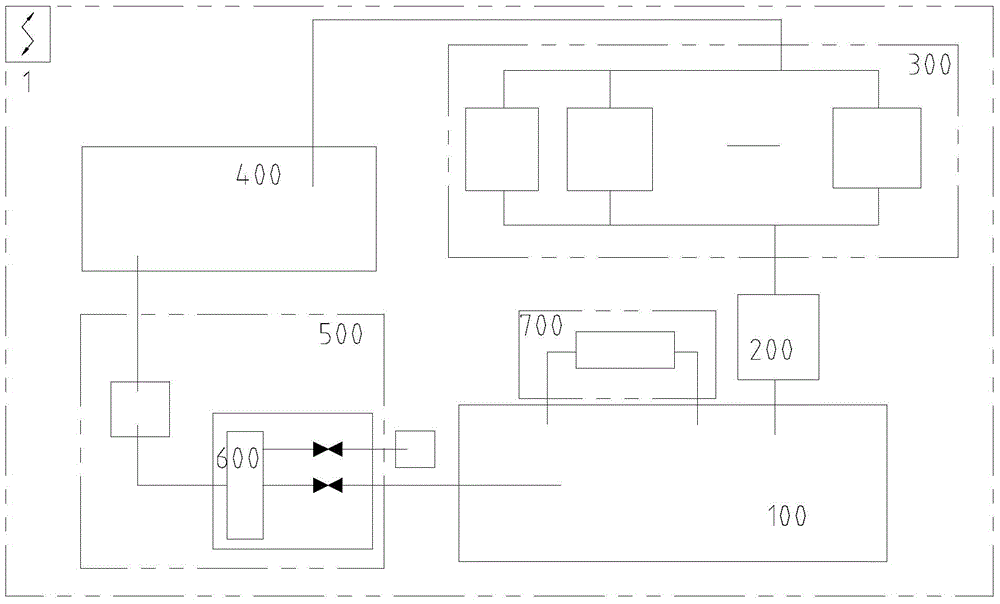

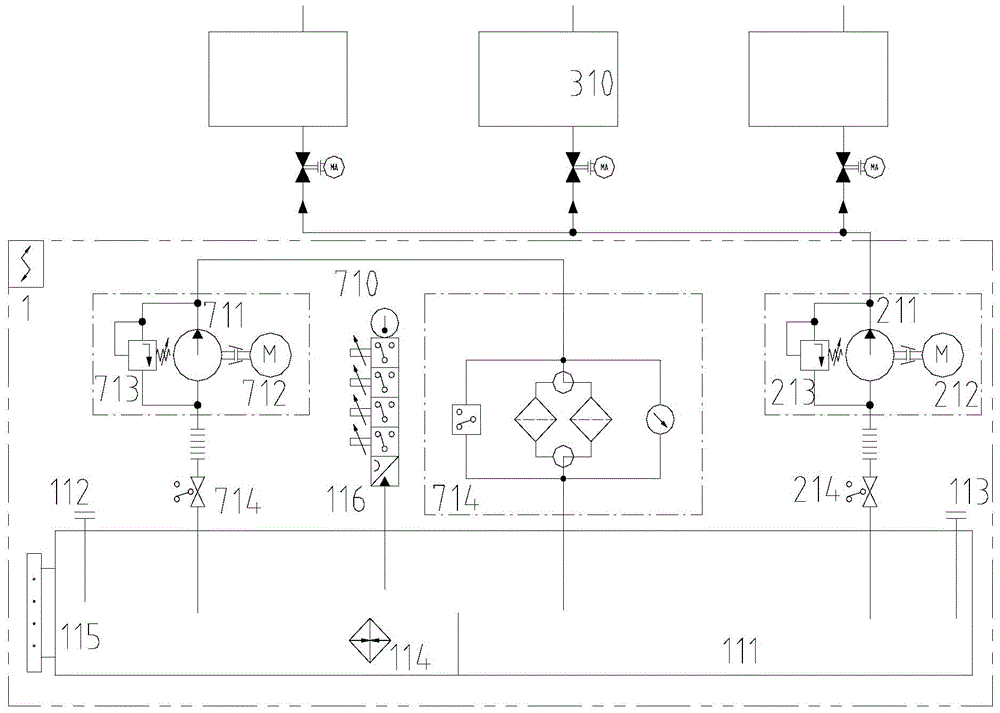

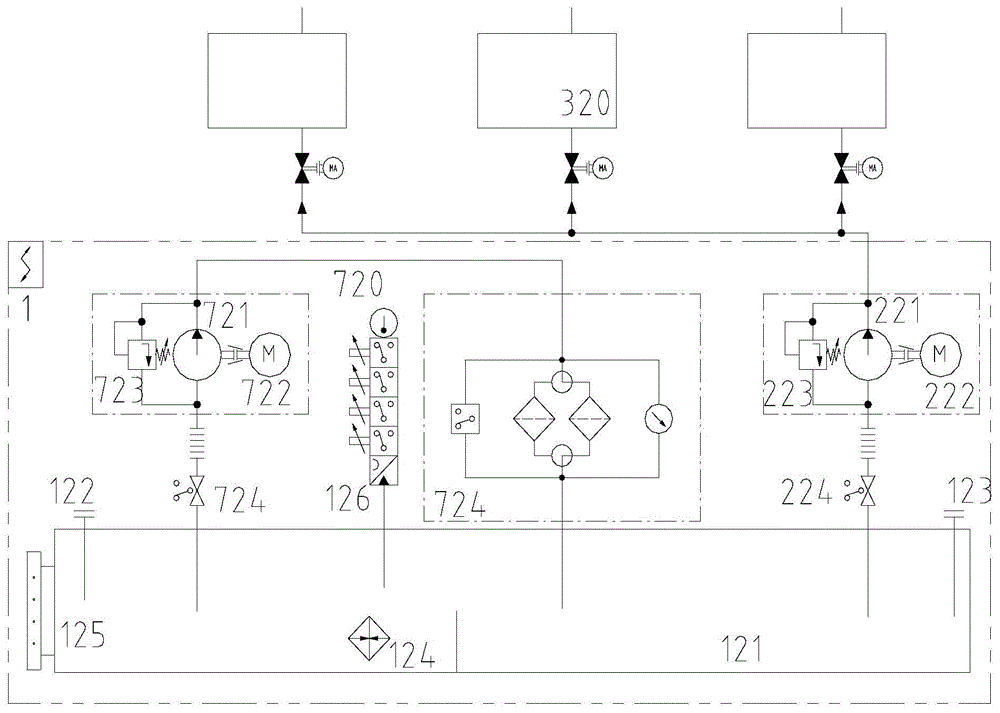

Oil supplementation system

InactiveCN104454796AAvoid pollutionReduce maintenanceLubricant transferFluid-pressure actuator componentsOil canContamination

The invention discloses an oil supplementation system. The oil supplementation system comprises an oil supplementation device and an effluent oil treatment device. The oil supplementation device comprises an oil supplementation oil tank (100) and an oil supplementation loop (200), wherein the oil supplementation oil tank (100) is connected with the oil inlet of a working oil tank (300) through the oil supplementation loop (200) and conducts oil supplementation on the working oil tank (300). The effluent oil treatment device comprises an effluent oil tank (400) and an effluent oil treatment loop (500), wherein the oil collection opening of the effluent oil tank (400) is communicated with the effluent oil opening of the working oil tank (300), the effluent oil tank (400) is used for collecting and treating effluent oil in the working oil tank (300), the oil discharge opening of the effluent oil tank (400) is connected with the effluent oil treatment loop (500), and effluent oil which is not treated or treated oil can be discharged in a classified mode through the effluent oil treatment loop (500). By means of the oil supplementation system, contamination caused by oil media is thoroughly eliminated from the source; the effluent oil in an oil system is collected in a concentrated mode, and therefore the maintenance amount of the oil system is reduced, and the oil tank cleaning time is shortened.

Owner:BERIS ENG & RES CORP

Method for wrapping and rolling composite preparation of stainless steel compound threaded rebar

InactiveCN106269856AQuality improvementImprove internal qualityTemperature control deviceMetal rolling arrangementsBond interfaceIsolation layer

The invention discloses a method for wrapping and rolling composite preparation of a stainless steel compound threaded rebar. The method comprises the following steps: raw material preparation, combination and forming of a covering material, an isolation layer and a core material, welding of a joint on the surface of the covering material, welding sealing of the end part of a compound steel blank, and heating and rolling of the compound steel blank: cleaning the surface of a raw material, forming the stainless steel covering material, pressing the carbon-steel core material and the nickel or nickel alloy isolation layer into the stainless steel covering layer to enable the covering material to be deformed and cover the core material, then welding the joint and the end part, and performing heating and rolling in sequence to obtain the compound threaded rebar. According to the technological method disclosed by the invention, the compound threaded rebar with a metallurgically bonded interface can be efficiently prepared at low cost. The compound threaded rebar prepared by the method has the characteristics of simple process, high production efficiency, high yield, low production cost, high interface bonding quality and the like.

Owner:武威市锦范工贸有限责任公司

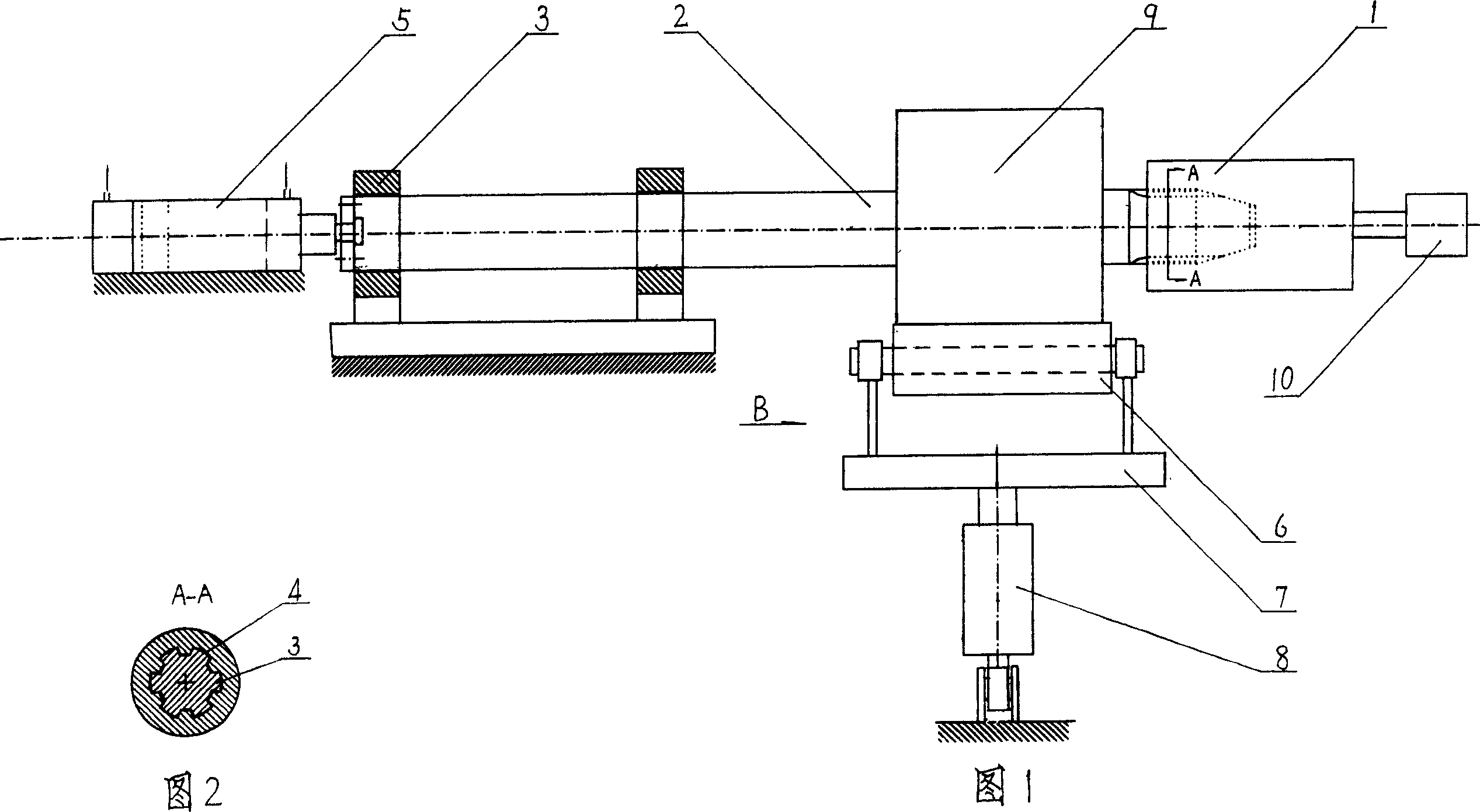

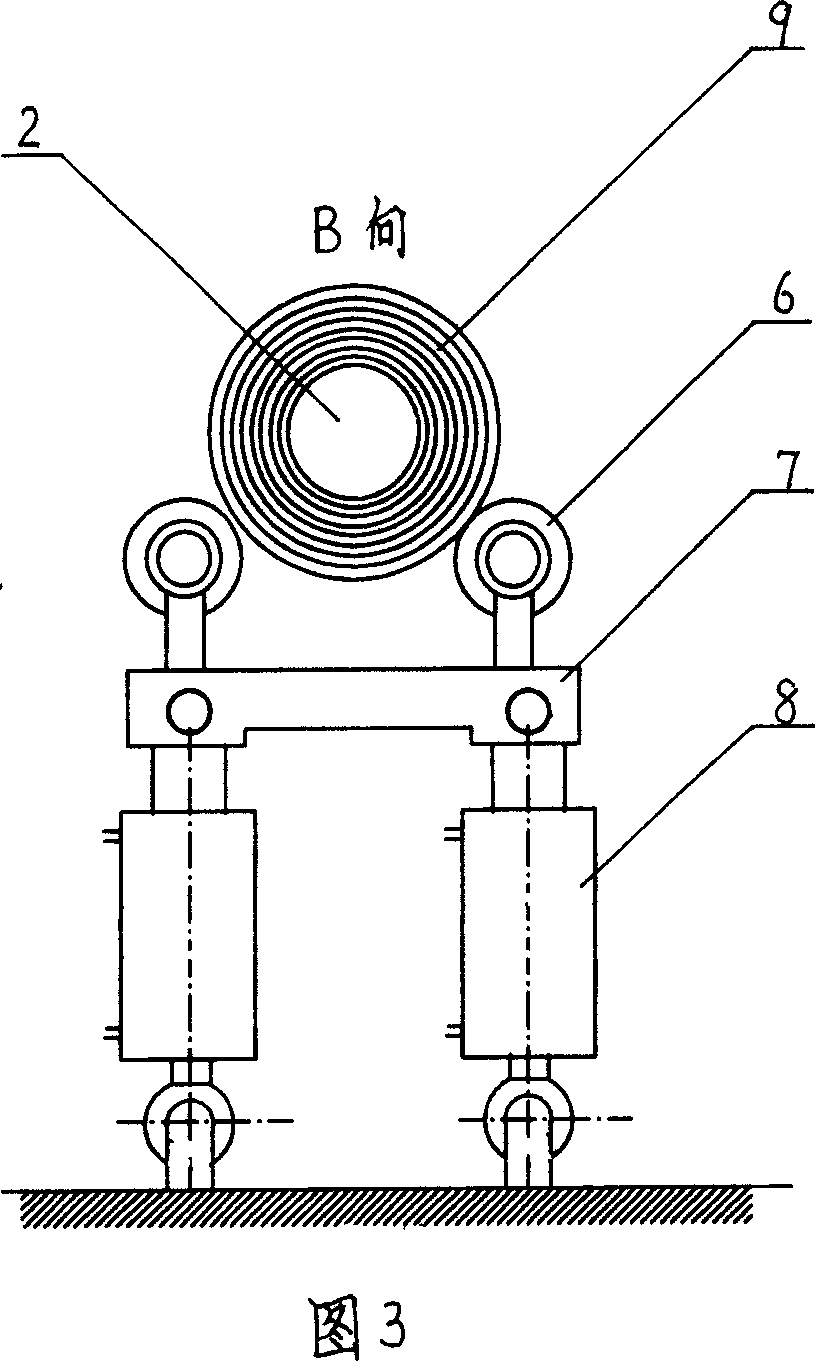

Continuous metal sheet winding apparatus

The invention discloses a continuous metal sheet coiler. It includes motor-driven roller, rolling plate axle laying one side of roller and installed on the same axial line with roller and can charge magnetism and demagnetizing, the end of said rolling plate axle which faces roller is equipped with connect key, the connect key and the key bed installed axially on the roller centre engage, and another end of rolling plate axle through frame are connected with horizontal draught device driving it move axially; rotate support device is equipped on the lower of rolling plate axle. The invention has reasonable design, easy operation and reliable work performance; it can achieve metal sheet continuous coiling operation, reduce energy consumption and improve work efficiency significantly.

Owner:宋儒钧

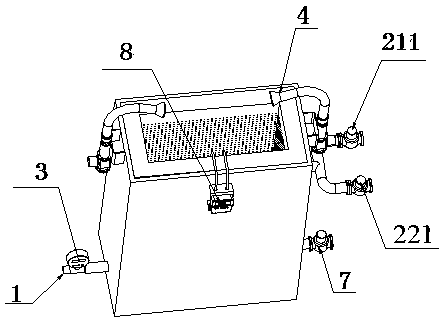

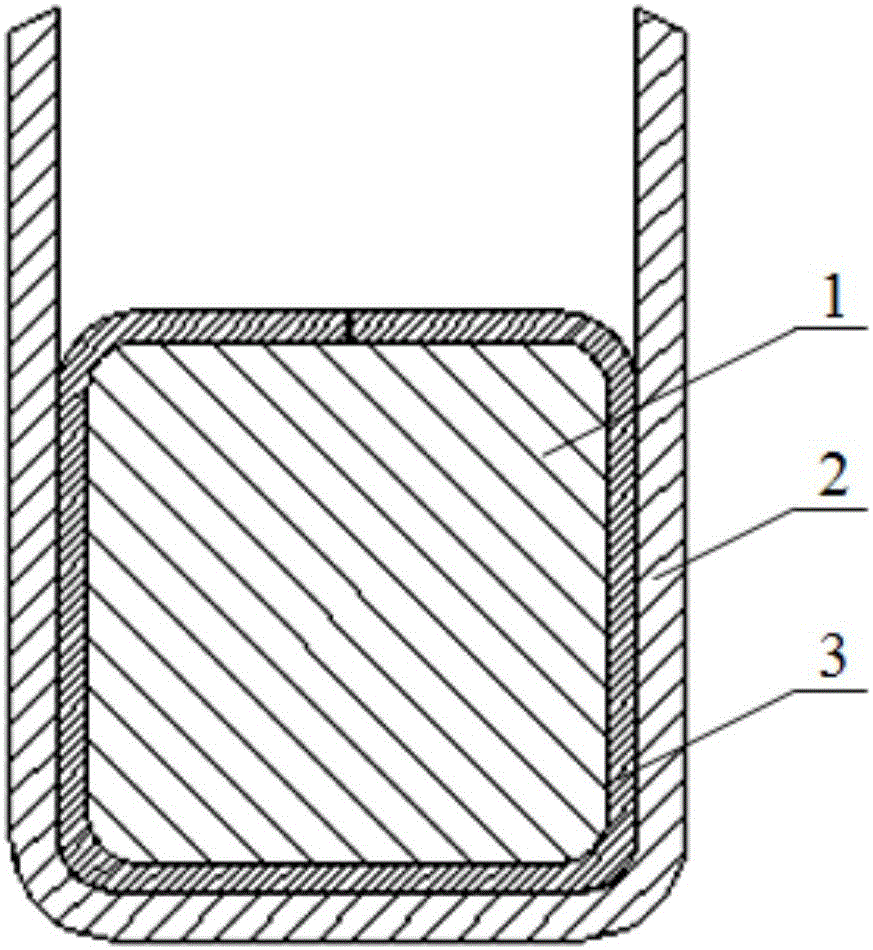

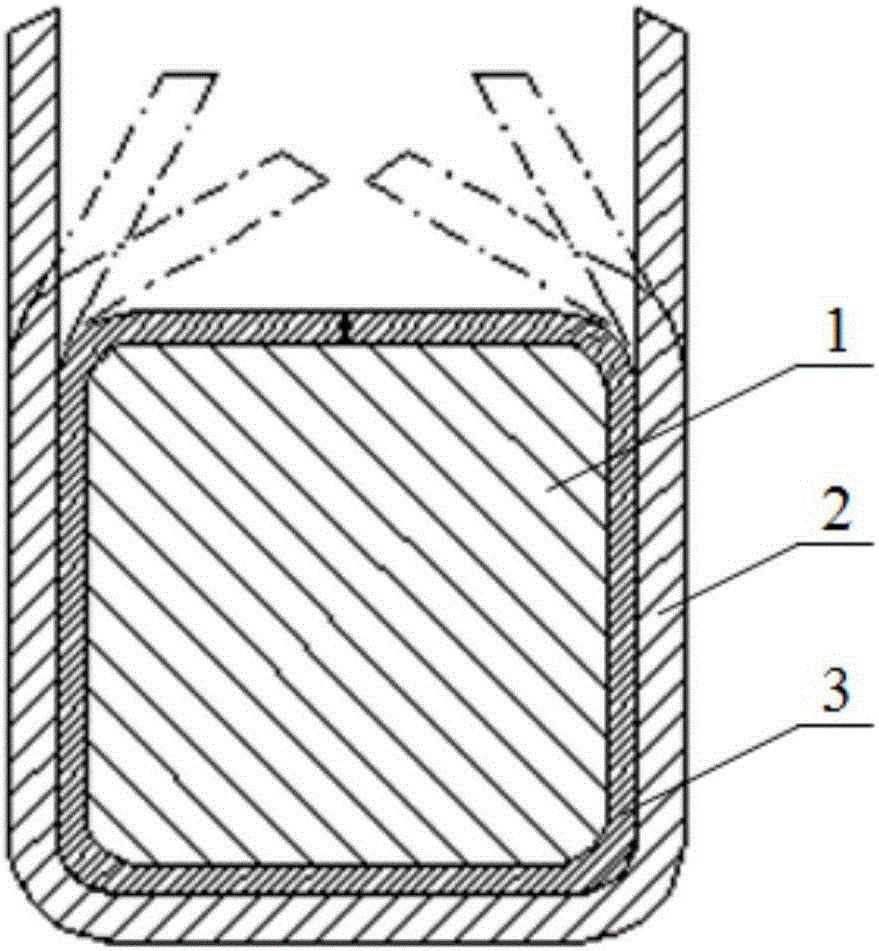

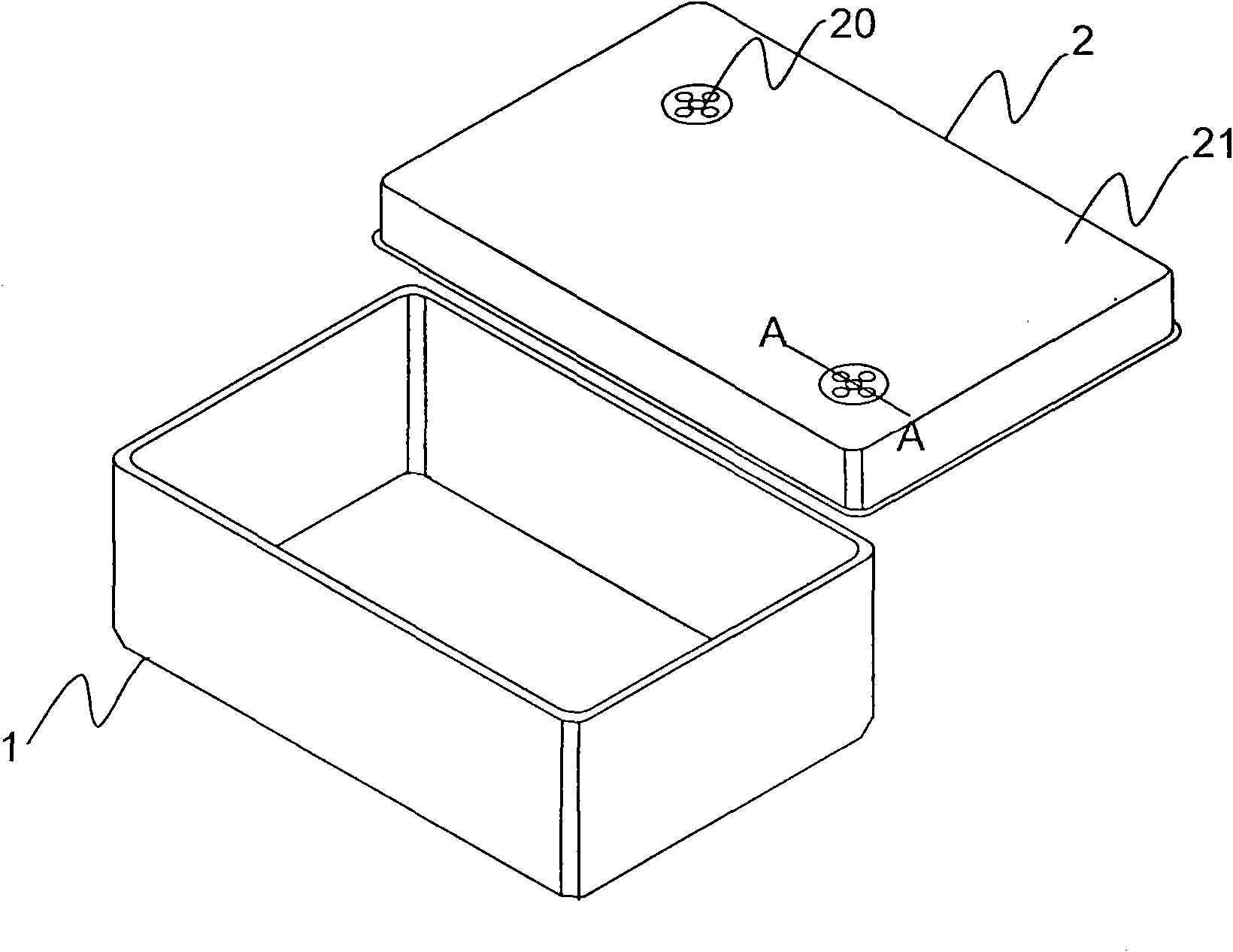

Culture utensil for large-scale cultivation of cordyceps militaris

ActiveCN101649290APromote growth and developmentHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsNutrient solutionMicrofiltration

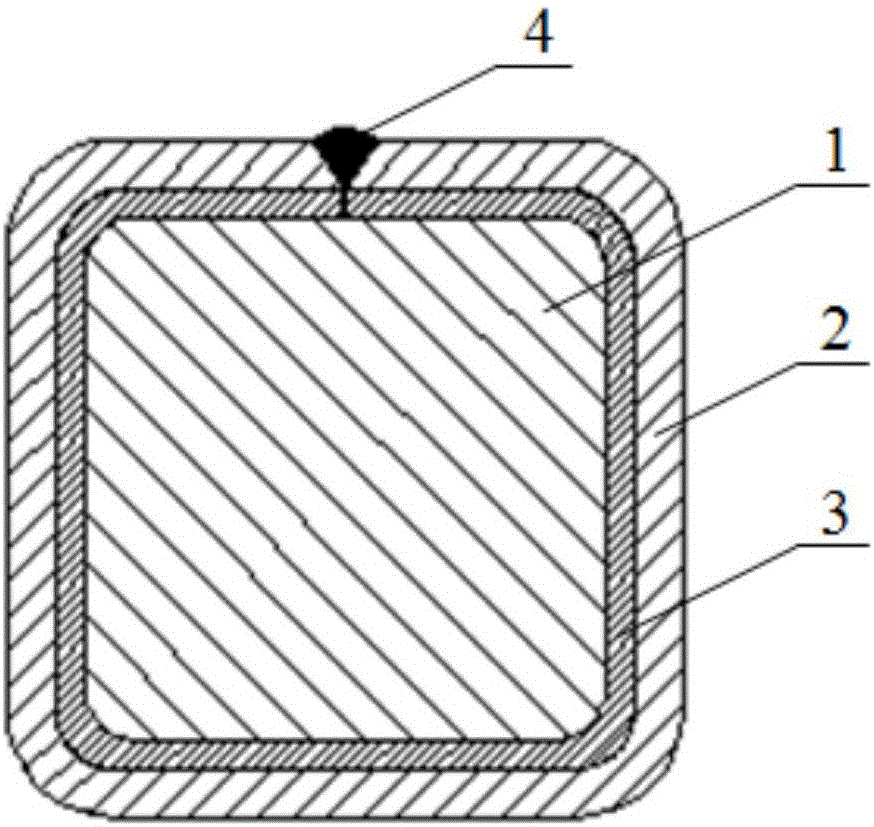

The invention relates to a culture utensil, in particular to a culture utensil for large-scale cultivation of cordyceps militaris. The culture utensil for large-scale cultivation of cordyceps militaris comprises a box body and a box lid which is matched with the box body and can integrally seal the box body. The culture utensil is characterized in that the culture utensil is provided with ventilation holes communicating the inside of the culture utensil with the outside, and a seal body which seals the ventilation holes, only allows air to freely pass in and out and performs microfiltration onthe air is also arranged on the culture utensil. The culture utensil solves the problem that as round glass bottles, round plastic bottles and small round plastic boxes cannot replenish oxygen neededduring the growth and development of the cordyceps militaris or discharge redundant moisture in culture mediums or nutrient solution because of impermeability, the air purification of the cordyceps militaris during growth in the culture utensil cannot be guaranteed, resulting in low cordyceps biotransformation rate and germination rate. The invention further improves the shape and material of theculture utensil.

Owner:唐培宸

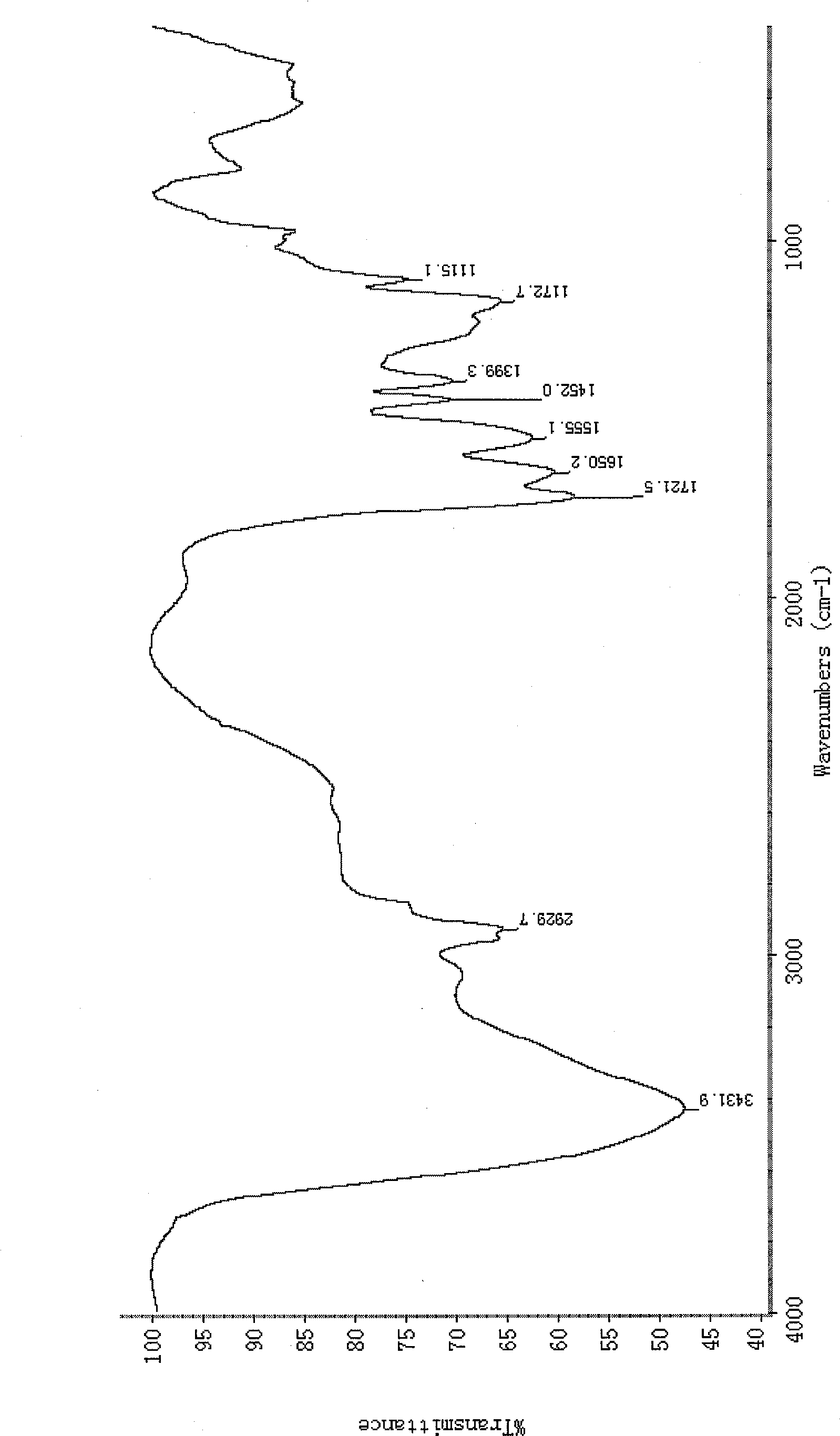

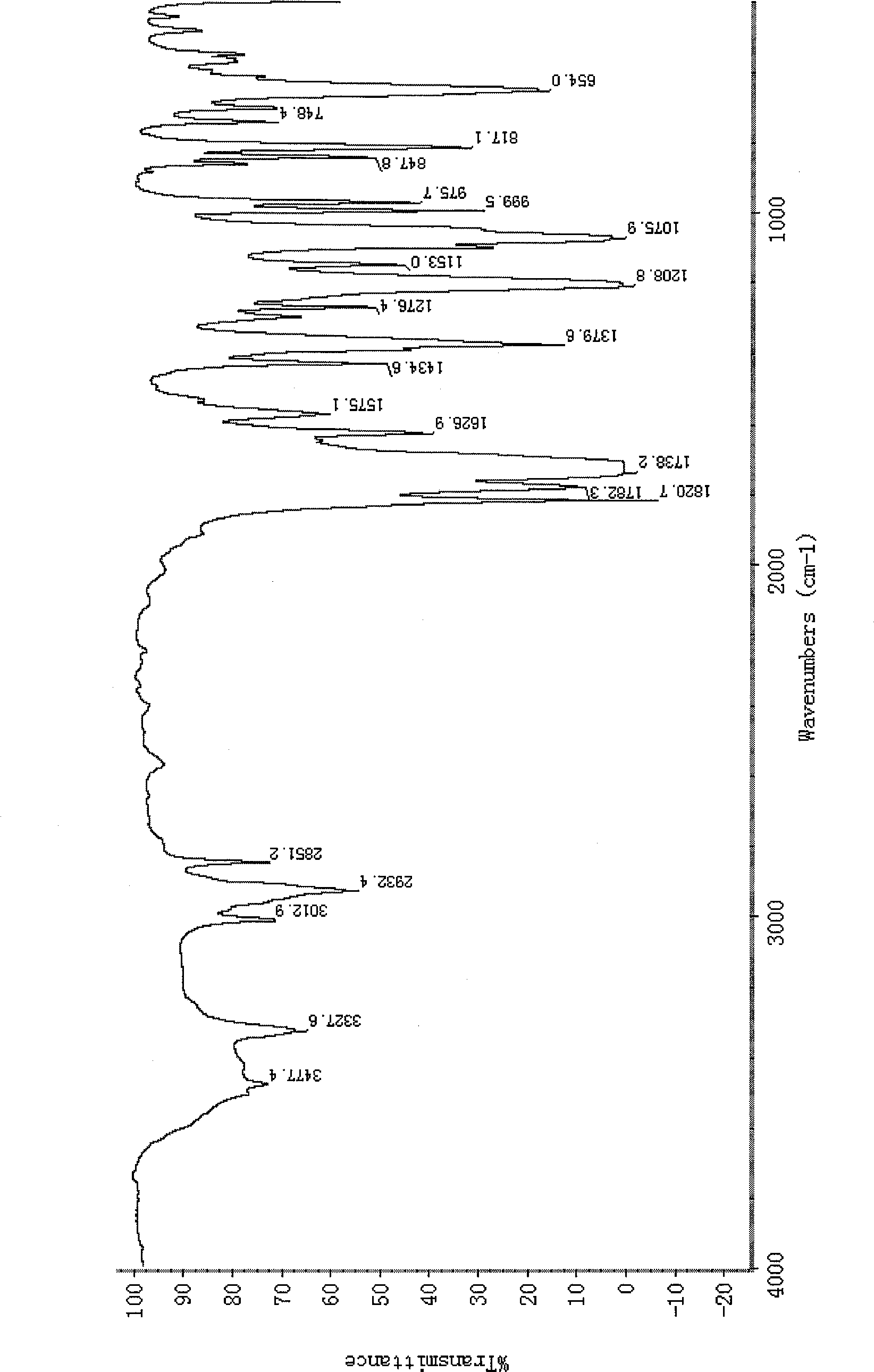

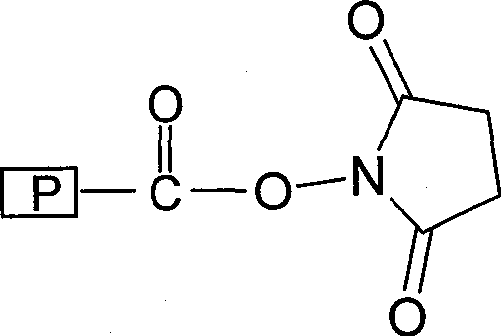

Immobilized porcine pancreatic lipase carrier, preparation method and application thereof

InactiveCN101531732AShorten the timeHigh apparent activityOn/in organic carrierCrosslinked polymersMethylene bisacrylamide

The invention discloses an immobilized porcine pancreatic lipase carrier, which is a macroporous bead crosslinked polymer containing succinimidyl ester groups and has a structure represented by the formula I. The carrier forms a high polymer with acrylic acid as a reactive monomer and N,N'-methylenebisacrylamide as a crosslinking agent, and in the meantime, incorporates the succinimidyl ester active group so that the time required for immobilizing the porcine pancreatic lipase is short, namely only 1 hour is required, and the immobilizing efficient is high and stability of activity retention of the immobilized enzyme is excellent; the apparent activity of the immobilized enzyme is high and can reach 750U / g and above. The invention also discloses a preparation method and application of the immobilized porcine pancreatic lipase carrier.

Owner:SICHUAN NORMAL UNIVERSITY

Constant-temperature three-dimensional mixed breeding method for eupolyphaga

InactiveCN104872073APromote growth and developmentIncrease productionAnimal feeding stuffFisheryInsect pest

The invention discloses a constant-temperature three-dimensional mixed breeding method for eupolyphaga, and relates to the field of breeding. The constant-temperature three-dimensional mixed breeding method for the eupolyphaga comprises the steps of construction of a constant-temperature room, building of a three-dimensional platform, preparation of feed, introduction, incubation, mixing and scientific management. According to the constant-temperature three-dimensional mixed breeding method for the eupolyphaga, a proper environment and a scientific and reasonable feed formula are provided for growth of the eupolyphagas, through mixed breeding of the eupolyphaga and earthworms, enough food are provided for the eupolyphagas while the eupolyphagas compete with one another, so that the vital force of the eupolyphagas is enhanced, the food consumption is increased, and the growth cycle is shortened; the earthworms can also be bred; meanwhile, through effective management, timely prevention and elimination of plant diseases and insect pests, the capacity for resistance of the eupolyphagas is increased, so that eupolyphaga propagation is quick, the yield is high, and the breeding cost is low.

Owner:桐城市杨清土元养殖有限公司

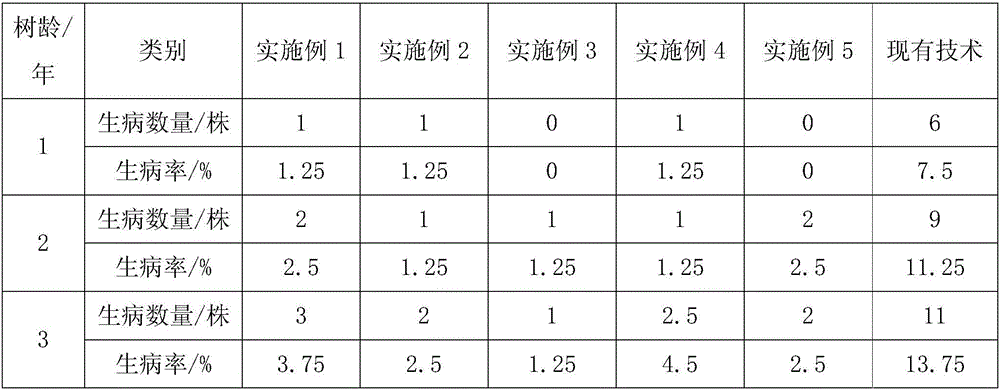

Planting method for improving orange yield

InactiveCN106718574AImprove survival rateIncrease annual outputSuperphosphatesAnimal corpse fertilisersOrange TreeSoil conditioner

The invention discloses a planting method for improving orange yield, and belongs to the technical field of agricultural planting. The planting method includes the process of orange seedling selection, land sorting, seedling planting, top dressing after planting, treatment after orange tree harvesting and the like, root systems of seedlings are treated by self-made root-inducing sterilizing solution in the process, soil is improved by soil improvement agents, and leaf fertilizers are used for topdressing in the growing and bearing process of orange trees. The planting method is scientific, reasonable, simple, easy, convenient in management, safe and reliable, and has remarkable social, economic and ecological benefits, the fertilizers used in the planting process are rich in nutrient and free from any chemical additives, pollution to the soil and the orange trees cannot be polluted, and the orange trees in the planting process are high in survival rate, high in fruit yield and stable in fruit output.

Owner:广西金神农生态农业科技开发有限公司

Biocontrol synergistic nutrient package fertilizer special for solanaceous vegetables and application method thereof

ActiveCN105330486AMeet nutrient needsIncrease annual outputFertilising methodsFertilizer mixturesMicroorganismGreenhouse

The invention relates to biocontrol synergistic nutrient package fertilizer special for solanaceous vegetables and an application method thereof. The nutrient package fertilizer is prepared from, by mass, 12%-31% of synergistic compost tea, 58%-70% of major element compound fertilizer, 9%-20% of soil conditioner and 0.1%-0.2% of medium trace element leaf fertilizer. The nutrient package fertilizer can meet the requirement of the solanaceous vegetables for nutrients at different growth and development stages, a large quantity of organic matter and microbial florae contained in the synergistic compost tea of the nutrient package fertilizer can balance the microbial ecology of soil, and soil-borne disease antagonistic bacteria are introduced for efficiently preventing soil-borne diseases of the solanaceous greenhouse vegetables.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Recovery process of caprolactam refining raffinate

InactiveCN101767860AHigh purityReduce unit consumptionOrganic chemistryWater/sewage treatment by extractionEconomic benefitsRaffinate

The invention discloses a recovery process of caprolactam refining raffinate. The caprolactam refining raffinate and oxidant are mixed according to the weight part ratio of 3.1:1-3.3:1, reacting while stirring at 32-40DEG C under normal pressure; after the reaction is carried out for 30-40 minutes, the reaction continues for 80-90 minutes while stirring at 78-82DEG C under normal pressure; the products are extracted at ambient temperature and pressure by using an extractant, and an organic extract phase which contains the caprolactam is returned to a water back-extraction system of a CPL device. The recovery process can eliminate reducing impurities and impurities with the properties which are similar to those of the caprolactam in the caprolactam refining raffinate, in particular to impurities which influence 290nm extinction value, PM value and V.B, thus recovering and preparing high-purity caprolactam. By adopting the recovery process, a company which has an annual output of 100 thousand tons of caprolactam can recover 1600-2000 tons of the caprolactam per year which is equivalent to 30 million yuan, thus improving the annual output and the economic benefit and reducing the unit consumption of the caprolactam.

Owner:河北美邦工程科技股份有限公司

Soil-free farm planting system and method based on Internet of Things

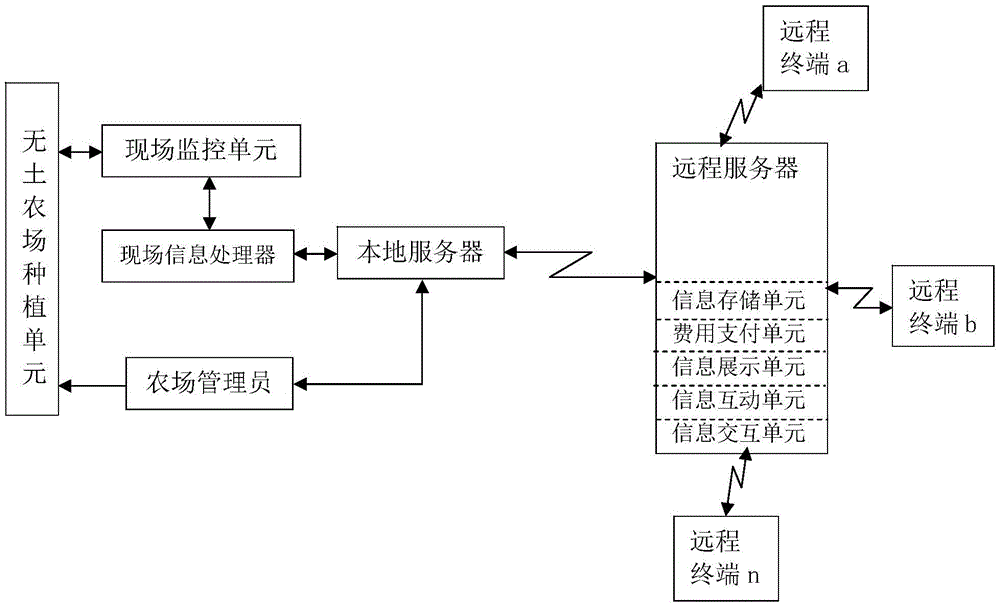

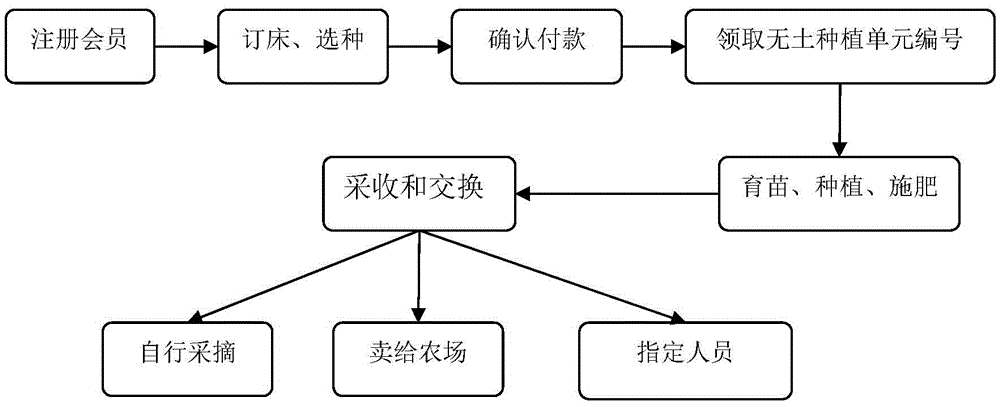

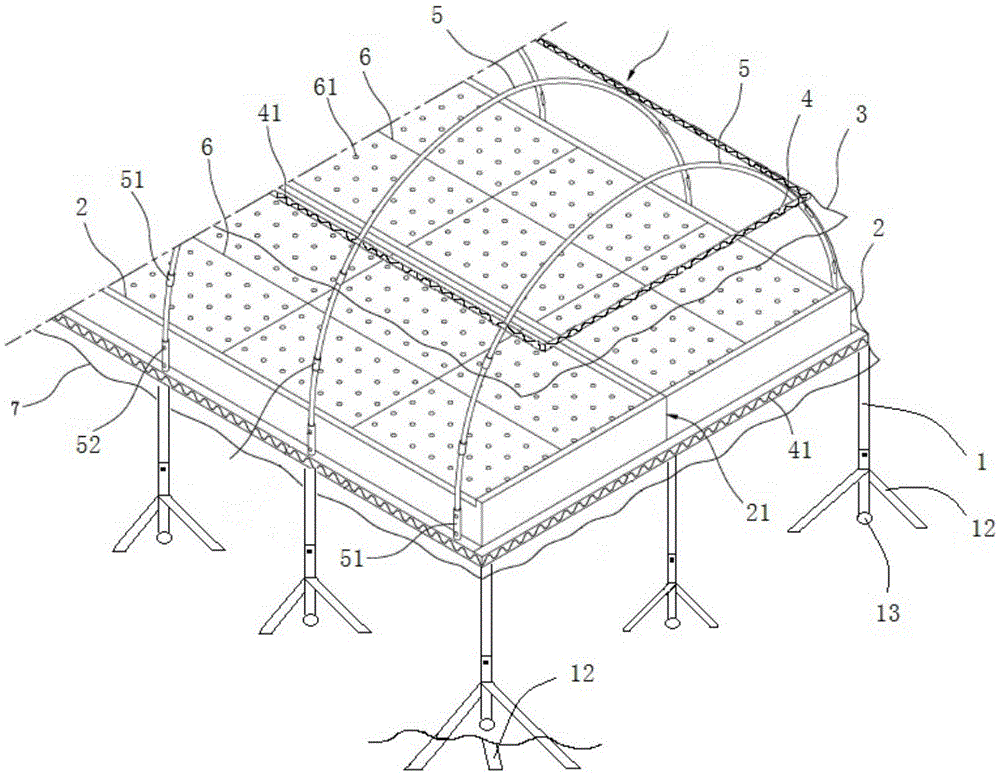

InactiveCN105532419AImprove standard production capabilitiesTo achieve the purpose of supervision and managementProgramme controlComputer controlCropping systemThe Internet

The invention belongs to the technical field of soil-free planting in farms based on the Internet of Things and particularly relates to a soil-free farm planting system and method based on the Internet of Things. The planting system comprises a soil-free farm planting unit, a field monitoring unit, a field information processor, a local server, a remote server and a remote terminal. Information, collected by the field monitoring unit, of the soil-free farm planting unit is transmitted to the remote server through the field information processor and the local server in sequence, a client logs into the remote server through the remote terminal to carry out registration and check farm information, a farm administrator obtains registration information of the client through the local server and provides maintenance and management on a soil-free planting farm according to requests in the registration information of the client. According to the soil-free farm planting system and method based on the Internet of Things, the Internet-of-Things technology is applied to soil-free farm planting, scientific production management with higher efficiency, higher convenience and higher real-time performance is achieved, the standard production capability of the farm is improved, and supervision and management on planting and selling integration can be achieved.

Owner:邹伟龙

High-yield and high-survival rate citrus planting method

InactiveCN106576848AImprove survival ratePromote growthBiocideCalcareous fertilisersSoil propertiesCitrus tree

The invention discloses a high-yield and high-survival rate citrus planting method and belongs to the technical field of agricultural planting. The planting method includes the procedures of citrus seedling selection, soil preparation, seedling planting, topdressing after planting, treatment after harvesting of citrus trees and the like. In the procedures, self-made root-inducing sterilizing solution is adopted to treat the root systems of seedlings, a soil improvement agent is used for improving the soil environment of planting of the citrus trees, a planting fertilizer serves as a base fertilizer of the citrus trees, and a soil conditioner is adopted to improve the soil properties after planting. The planting method provided by the invention is scientific, reasonable, simple and easy to implement, and management is convenient; fertilizers used during planting are rich in nutrition, no chemical additive exists, pollution to the soil and the citrus trees is avoided, and safety and reliability are achieved; and the survival rate of the citrus trees during planting is high, the fruit output is high, fruit bearing is stable, and the social benefits, economic benefits and ecological benefits are remarkable.

Owner:广西金神农生态农业科技开发有限公司

A culture material for agaricus bisporus prepared from pleurotus eryngii waste materials and a culture method

InactiveCN107306671AIncrease production timesSolve the problem of cluttering and polluting the environmentSuperphosphatesCalcareous fertilisersCaladiumAgaricus

The invention provides a culture material for agaricus bisporus prepared from pleurotus eryngii waste materials and a culture method and belongs to the field of strain planting. The culture material for agaricus bisporus prepared from pleurotus eryngii waste materials contains, by mass, 40-70 % of pleurotus eryngii waste materials, 20-30% of cow dung, 3% of bran, 1% of superphosphate, 1% of land plaster, 1% of lime, 4% of cottonseed cakes and 0-20% of wheat straw. Preferably, the culture material contains, by mass, 50 % of pleurotus eryngii waste materials, 30% of cow dung, 3% of bran, 1% of superphosphate, 1% of land plaster, 1% of lime, 4% of cottonseed cakes and 10% of wheat straw.

Owner:山东冠宇农业科技股份有限公司 +1

Compensation enlarging value determination method

InactiveCN1701903AShort cycleReduce stock trimVessel partsWorkpiece edge portionsFillet weldThick plate

This invention relates to shipbuilding technique field, particular to compensation quantity overplus value method that selects corresponding value for different welding method and thickness. The determination for compensation value of different inner frame and overplus value of welding deflection comprises following steps: the contraction compensation of welding line is same for whatever manual welding, CO2 pad welding or both sides auto welding; the compensation value for unilateral contraction value relates with plate thickness and accords the thin plate thickness when thick plate butt joins with thin plate; for manual welding, CO2 fillet welding, the compensation value varieties with thickness of fillet and plate; the compensation for cargo hold, double-layer bottom intercostal floor of engineer room, floor and its reinforcement material, keel-line, and vertical baffle plate, is minus one; the compensation value of prismatic plate, bracket welding, welding deformation of engineer room double bottom when segment and inverse-building, welding deformation of engineer room big frame, relates with parameters of B, L, and H. This invention uses compensation value instead of surplus, and decreases the amend and straightening.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology

InactiveCN104313533AReduce concentrationReduce consumptionSolid state diffusion coatingThermal fatigueHeat resistance

The invention provides an ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology. The technology comprises the following steps: oil removing, acid pickling for rust removal, washing, surface activation, auxiliary infiltration, drying, and ultrasonic frequency induction heating technology based quick aluminizing. The technology has the following advantages: concentration and consumption of a pickling solution are reduced, and a rust removal speed is greatly increased; the hot-dipping aluminizing temperature is low, and the aluminizing process is short; compared with a heating method of a traditional resistance aluminizing furnace, the induction heating method adopted enables the utilization rate of electrical energy to be improved over 20%, and enables the annual output to be increased over one time; compared with traditional diffuse type aluminizing steel material, the new aluminizing steel material prepared with the technology retains a pure aluminium layer and an iron-aluminium alloy layer under a columnar eutectic state, and has the effects of corrosion resistance, heat resistance, abrasion resistance and photo-thermal reflectivity; a fragility area on the surface is eliminated; bending performance and punch forming performance are greatly improved; resistance to heat shocks and resistance to thermal fatigue are improved over 10%.

Owner:WUHAN TIANCONG CREATIVE TECH

Process for extracting pleuromulin

InactiveCN101481308AEnables continuous extraction processReduce secondaryOrganic chemistryOrganic solventMycelium

The invention discloses a process for extracting pleuromutilin in tiamulin synthetic process. The process comprises the following steps: mixing pleuromutilin mycelium with methanol or ethanol, and continuously stirring the mixture at the temperature of 20-40 DEG C for 3-6h to prepare leach liquor; and allowing the leach liquor to pass through a closed inorganic membrane filtering system at a certain pressure, sending the obtained filtrate to a subsequent processing system, allowing part of the residual filtrate to return to a lixiviating tank and the other part thereof to run through a circulating pump for being circularly filtered by the closed inorganic membrane. The process can effectively separate and clarify the pleuromutilin leach liquor, shorten process flow by 6-10h for each day, improve the yield by 5-7% compared with a traditional plate-and-frame filtering process, and has fast filtering rate, high filtering precision and low energy consumption. The closed inorganic membrane filtering system can help reduce the loss of organic solvents caused by volatilization and realize clean production, thus lowering production cost of enterprises, greatly improving working environment, being favorable for health of operators, and having significant social and economic benefits.

Owner:河北美邦工程科技股份有限公司

Special organic-inorganic mixed fertilizer technology for gardenia asminoides ellis

InactiveCN104446785AReduce the number of turnsOmit dryingBio-organic fraction processingBioloigcal waste fertilisersNitrogenGardenia

The invention relates to a special organic-inorganic mixed fertilizer for gardenia asminoides ellis and a preparation method of the fertilizer. The method comprises the following steps: cutting up traditional Chinese medicine residues, adding strains, uniformly stirring, performing stacking fermentation for 2 weeks, performing pile-turning, performing static bag fermentation, grinding into coarse powder when the moisture content is not more than 25%, drying, and grinding into fine powder when the moisture content is not more than 20% to obtain a semi-finished fertilizer; adding an inorganic fertilizer material, wherein the inorganic fertilizer material comprises the following effective components by weight percent: 9.5-13.3% of N, 4.14-9.54% of P2O5, 8.62-19.8% of CaO, 5.16-11.93% of MgO, 7.92-10.51% of K2O, 0-0.32% of S, 0-0.66% of Zn and 0-0.11% of B; uniformly mixing organic fertilizer and inorganic fertilizer materials according to a weight ratio of 1 to 1 to obtain the finished fertilizer. The organic-inorganic mixed fertilizer has the characteristics of being simple, reasonable in ratio, easy to produce, capable of enriching and improving soil and remarkable in production and efficiency improvement effects.

Owner:JIANGXI HUIREN PHARMA CO LTD +1

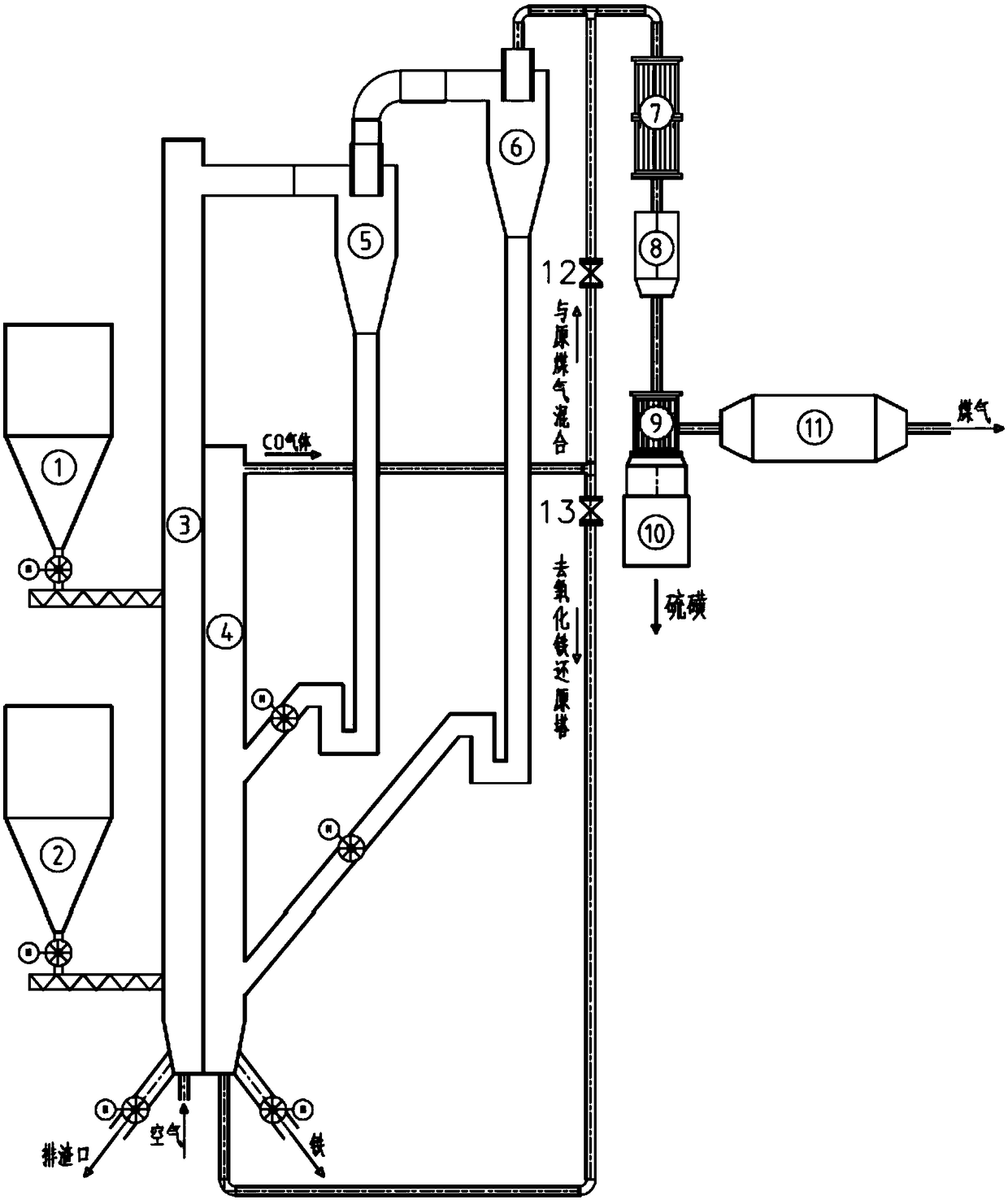

Device and method for joint production of iron, sulfur and gas in smelting process of pyrite

ActiveCN108970354AEfficient and clean utilizationAlleviate the current situation of resource shortageGas treatmentDispersed particle separationSulfur containingCoal gasification

The invention relates to a device and method for joint production of iron, sulfur and gas in the smelting process of pyrite, and belongs to the field of metal smelting. The method comprises the following steps of calcining the pyrite at the bottom part of the interior of a calcining-gasifying reaction tower, enabling pulverized coal and fly ash to generate gasifying reaction at the middle upper part, enabling the sulfur-containing flue gas to carry the high-valence oxide of iron produced by calcining at the tower bottom to the middle upper part of the reaction tower, mixing with the gas and coke produced by gasifying, and generating oxidation and reduction reaction; separating the product by an iron-based high-temperature separator and a carbon-based high-temperature separator, and sendingback into an iron oxide reduction tower; performing secondary reduction reaction on the iron oxide in the iron oxide reduction tower, and producing reduction gas, so as to obtain iron slag; purifyingthe crude gas, so as to obtain the purified gas; enabling a sulfur condenser to condense and recycle the sulfur. The method has the advantages that the joint production of iron, sulfur and gas is realized in the smelting process of the pyrite, and the pyrite can be efficiently and cleanly utilized.

Owner:SHANDONG UNIV

Planting method for regenerated rice

InactiveCN109258355AIncrease productionIncrease annual outputBiocidePlant growth regulatorsMildewSeed treatment

The invention relates to a planting method for regenerated rice. The method comprises the following steps of 1) seed selection, 2) seed treatment, 3) rice seedling bed selection, 4) field management,5) sowing and seedling cultivating, 6) first-season rice management, 7) regenerated rice management and 8) harvesting. According to the method, the conditions required by benign growth of regeneratedrice are controlled in a targeted mode, not only can the field be reasonably utilized, but also the rice yield of the area suitable for growth of the regenerate rice is increased, reasonable management is conducted in the growth processes of first-season rice and the regenerated rice, the yield of the regenerated rice is effectively increased, the yearly yield of rice is increased, and the effectsof increasing yield and saving labor are achieved. Through measures of preferable seed selection, oil preparation and the like, not only can insects in the field be prevented, but also the antibacterial ability of seeds is enhanced. Treatment liquid used for treating liquid has the germination accelerating effect on the seeds, can inhibit mycete growing on the surfaces of the seeds, and reduce insects to make the seedling survival rate high, and high yield and optimal production of the regenerated rice are ensured.

Owner:长沙顺意农业开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com