Method for wrapping and rolling composite preparation of stainless steel compound threaded rebar

A technology for rolling composite and threaded steel bars, applied in the field of steel manufacturing, can solve the problems of low interface bonding strength, low production efficiency and high preparation cost, and achieve the effects of improving interface bonding performance, high production efficiency and large annual output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

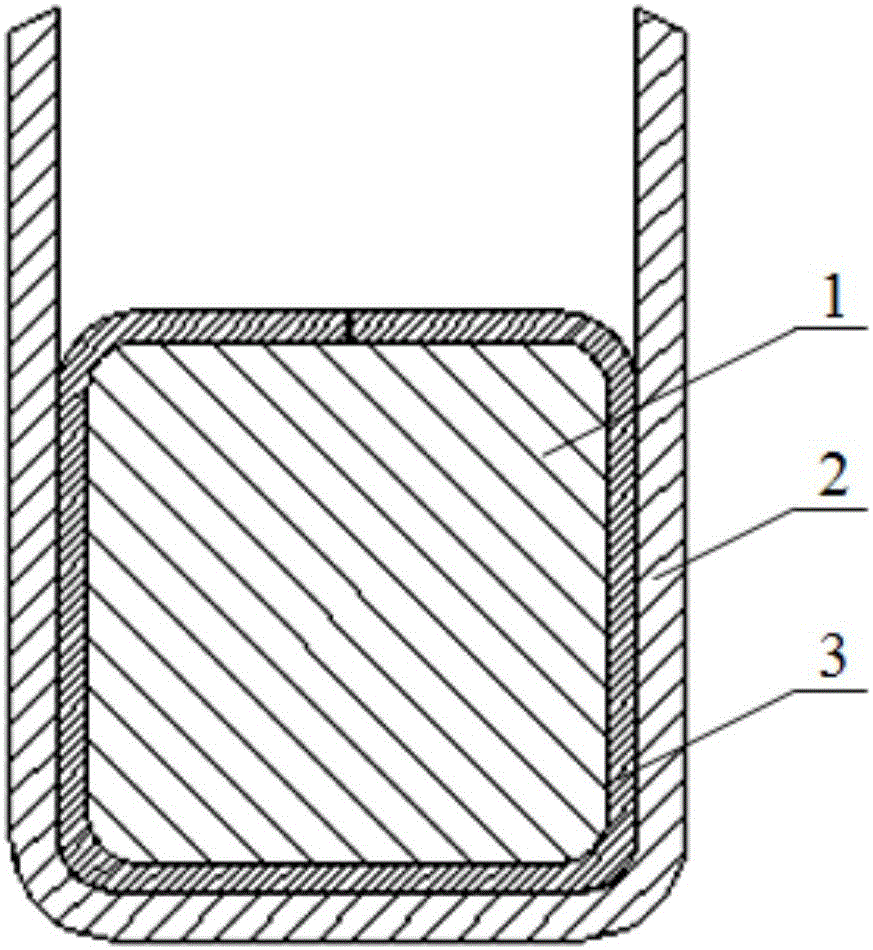

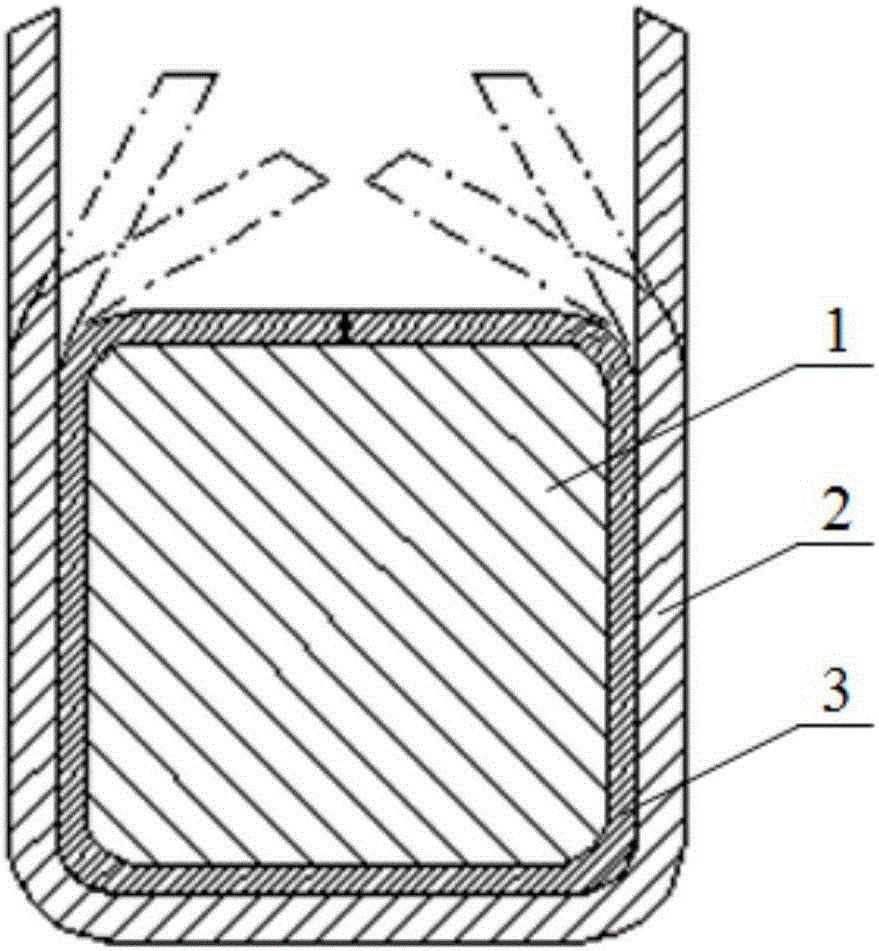

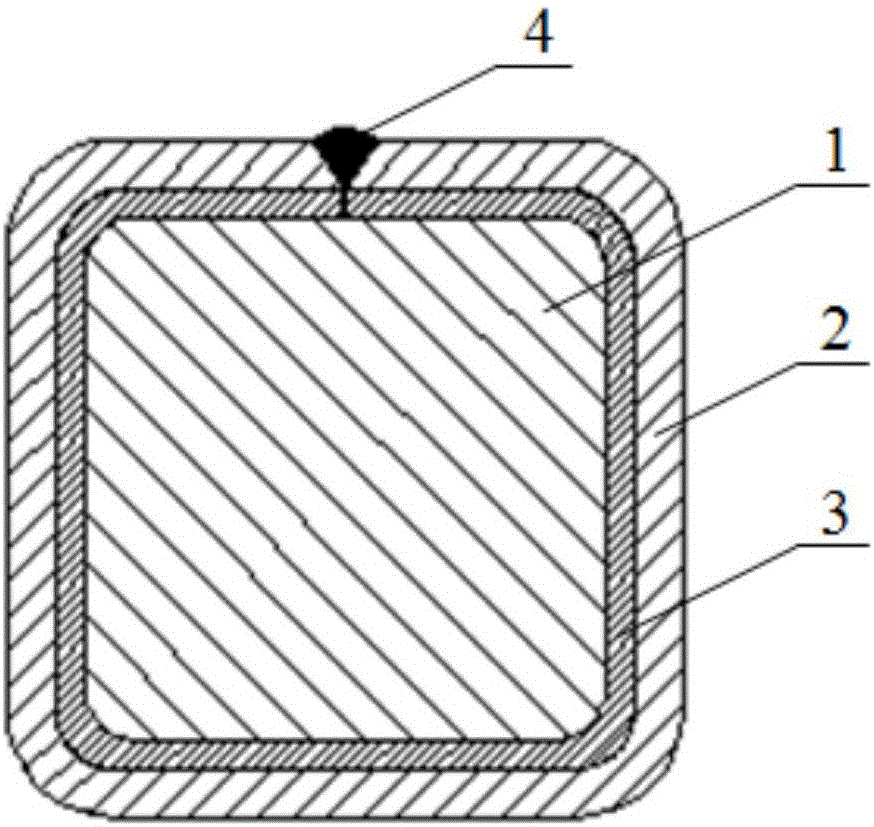

[0048] Taking a 20MnSi billet with a cross-section of 150mm×150mm as the core material and SUS304 stainless steel as the cladding material, the finished product is a φ10mm threaded steel bar (the thickness of the cladding material is 0.5mm, and the diameter of the core material is 9.0mm) as an example. The specific preparation method is as follows:

[0049] Use hydrochloric acid aqueous solution with a temperature of 60-80°C and a concentration of 8-10% to clean the iron oxide scale on the surface of the billet, then wash the residual acid with clean water, and dry it with hot air for later use; roll a 20MnSi square billet of 150mm×150mm Assuming that the rounded corner of the billet is R15mm, the total elongation coefficient reaches 350.64, the thickness of the cladding material in the finished product is 0.5mm, and the calculated thickness of the stainless steel cladding material 2 in the composite billet is 8.7mm. The side length is 167.4mm. According to the external dimens...

Embodiment 2

[0053] The 20MnSi square billet with a cross-section of 150mm×150mm is used as the core material, the electroplated nickel layer is used as the isolation layer, and the SUS304 stainless steel is used as the cladding material, and the finished product is a φ10mm threaded steel bar (the thickness of the cladding material is 0.45mm, and the thickness of the isolation layer is 0.05mm. , core material diameter is 9.0mm) as an example, the specific preparation method is as follows:

[0054] Use a high-speed rotating wire brush to clean the oxide scale on the surface of the billet; roll a 150mm×150mm 20MnSi billet into a φ10mm threaded steel bar, set the fillet of the billet as R15mm, the total elongation coefficient is 350.64, and the finished product is isolated The thickness of the layer is 0.05mm, the thickness of the cladding material is 0.45mm, the thickness of the isolation layer 3 in the composite billet is 0.86mm, the thickness of the stainless steel cladding material 2 is 7....

Embodiment 3

[0058] With the SS400MPa threaded steel billet with a cross-section of 280mm×280mm as the core material, 99.9% industrial pure nickel strip as the isolation layer, and SUS304 stainless steel as the cladding material, the finished product is a φ20mm threaded steel bar (the thickness of the cladding material is 0.9mm, The thickness of the isolation layer is 0.1mm, and the diameter of the core material is 18.0mm) as an example, the specific preparation method is as follows:

[0059] Use a high-speed rotating grinding wheel to polish the oxide scale on the surface of the billet; roll a 280mm×280mm billet into a φ20mm threaded steel bar, set the fillet of the billet as R30mm, the total elongation coefficient reaches 305.06, and the thickness of the isolation layer in the finished product is 0.1mm, and the thickness of the stainless steel cladding is 0.9mm, then the calculated thickness of the isolation layer 3 in the composite billet is 5.31mm, the thickness of the stainless steel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com