Patents

Literature

36results about How to "Alleviate the current situation of resource shortage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eugenol epoxy resin and preparing method and application thereof

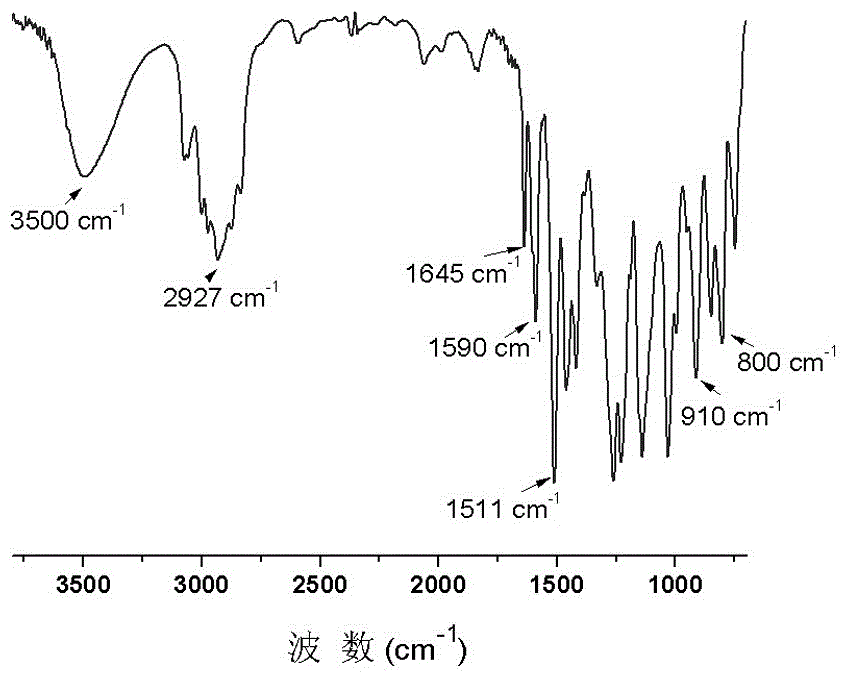

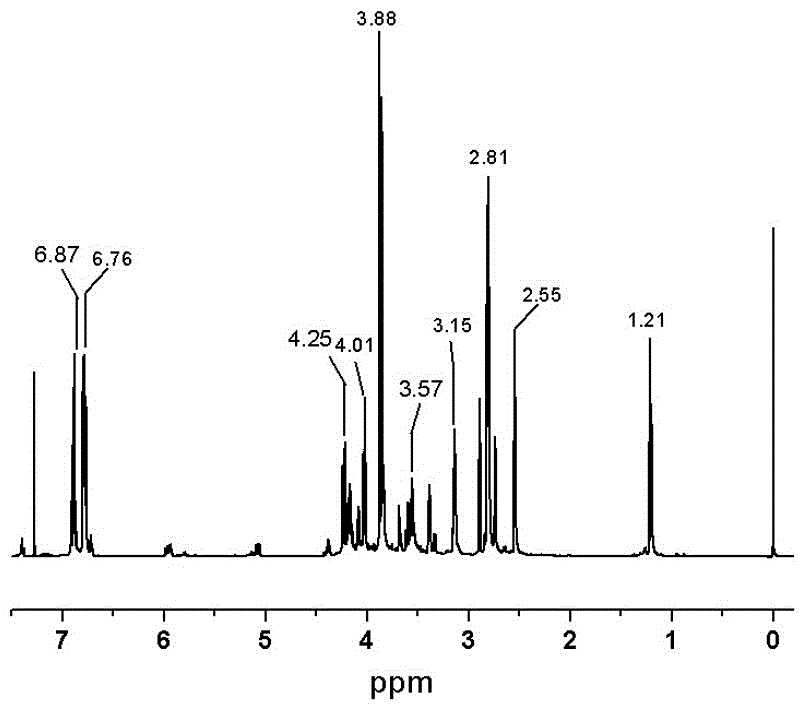

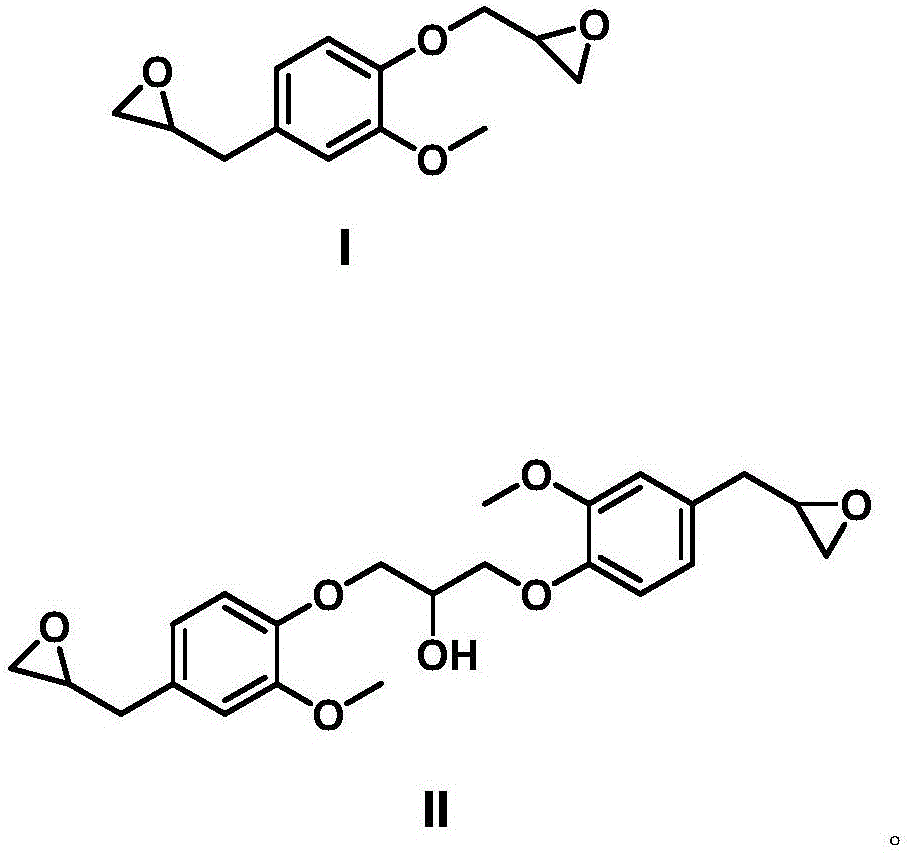

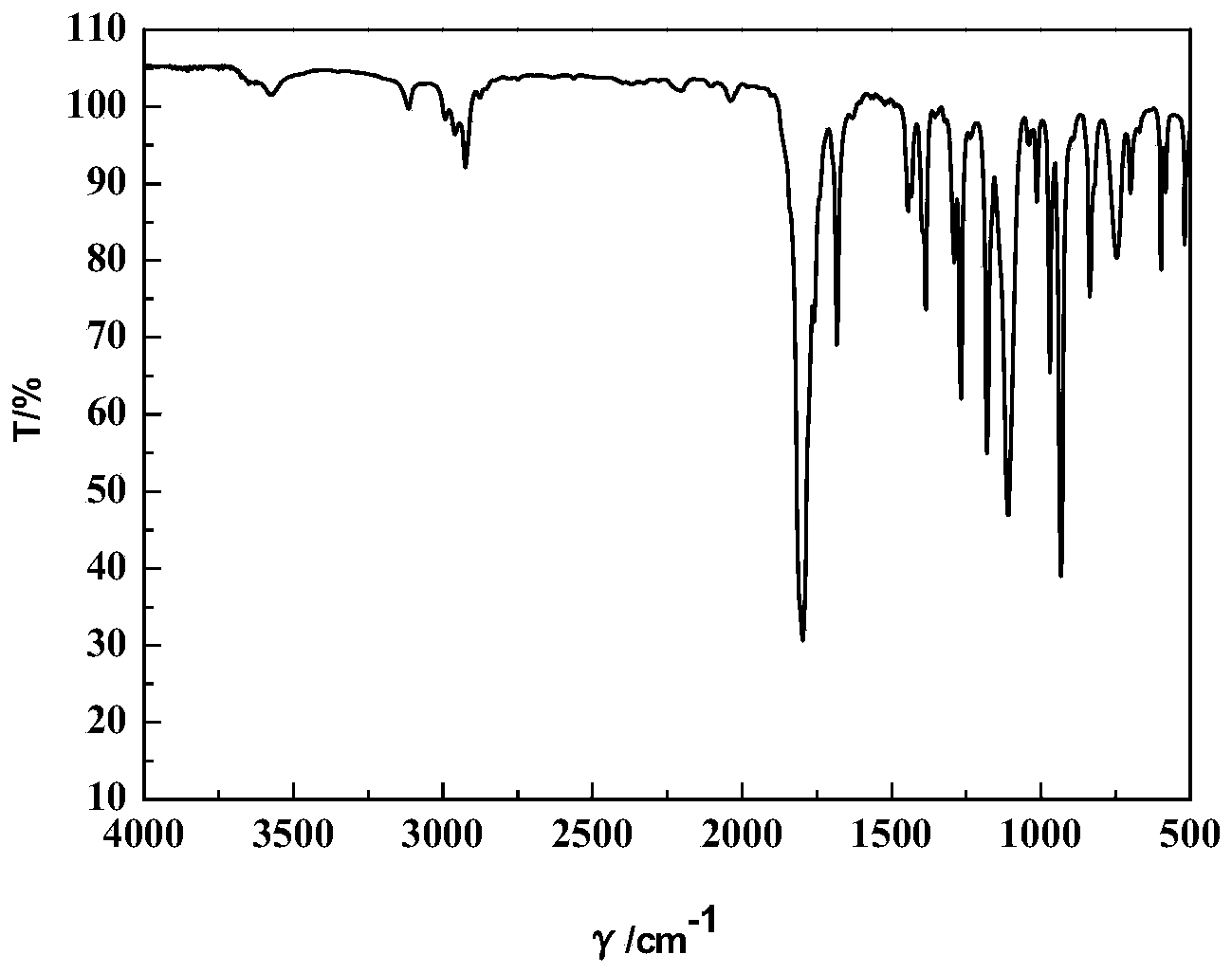

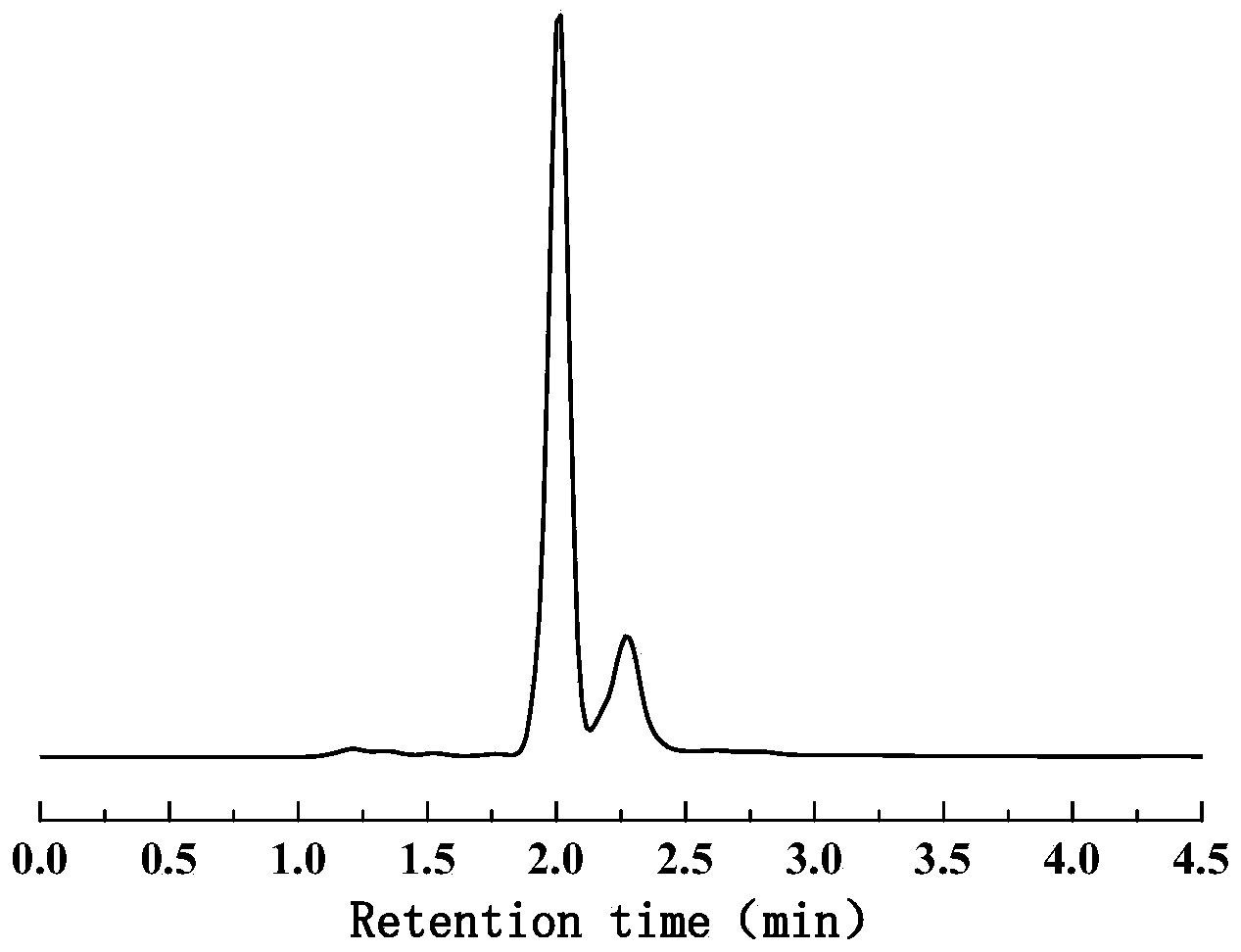

InactiveCN105924623AHigh epoxy valueReduce dependenceOrganic chemistryEpoxy resin adhesivesEpoxyAdhesive

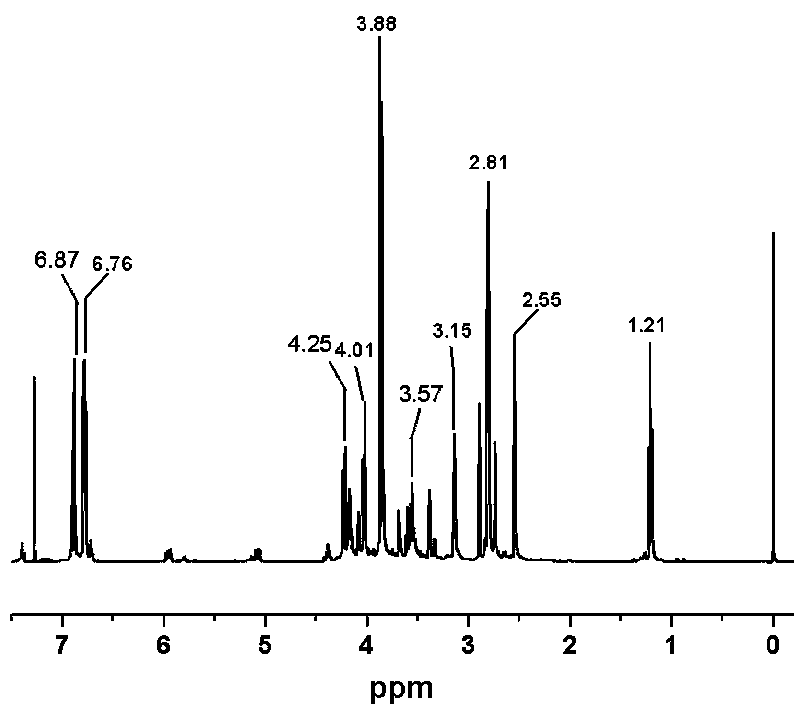

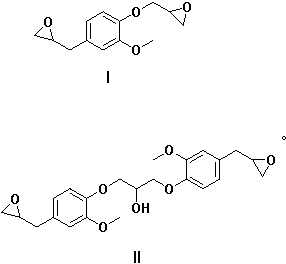

The invention provides a eugenol epoxy resin and a preparing method and application thereof. The eugenol epoxy resin is prepared from a compound shown in the formula I in the description and / or a compound shown in the formula II in the description. The epoxy resin is free of biotoxicity, the mechanical property of the epoxy resin is similar to that of traditional epoxy resin, and the eugenol epoxy resin can replace traditional petroleum-based epoxy resin. The epoxy resin is liquid at the room temperature, and is beneficial to subsequent processing and application and capable of being used for preparing composites, paint, adhesives and the like.

Owner:HEBEI UNIVERSITY

Brachymystax lenok fry high-density rearing method

InactiveCN103385192AReduce feeding costsRealize artificial breedingClimate change adaptationPisciculture and aquariaHigh densityWater flow

The invention relates to the field of fry rearing, in particular to a brachymystax lenok fry high-density rearing method. The brachymystax lenok fry high-density rearing method comprises the steps of controlling the fry rearing density, controlling the water flow, controlling types of baits, controlling the feeding quantity and controlling the illumination intensity. According to the rearing method disclosed by the invention, high-density rearing can be carried out on the premise of controlling the survival rate of fries, rearing cost of brachymystax lenok is reduced, the output is improved, manual rearing of brachymystax lenok is implemented, and the current situation of shortage of resources of brachymystax lenok in China can be relieved.

Owner:河北省海洋与水产科学研究院

Functional amino acid enzyme and preparation method thereof

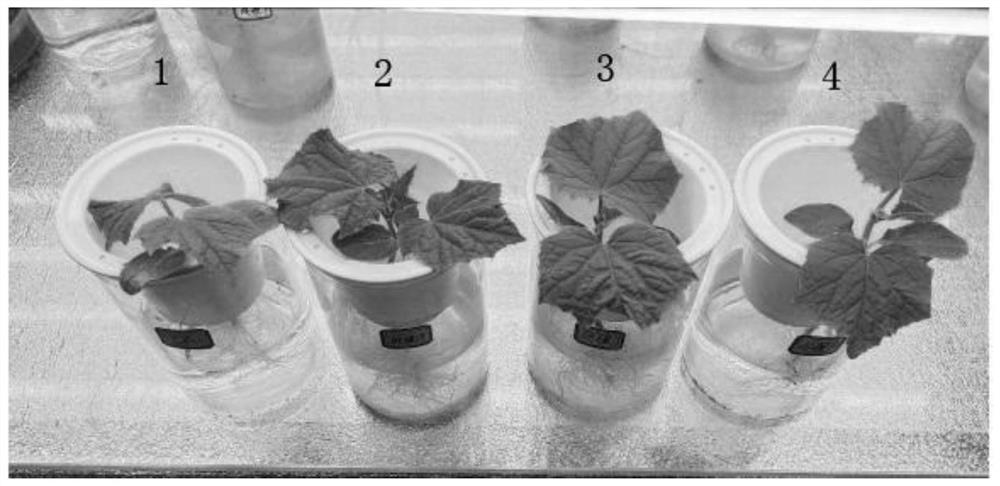

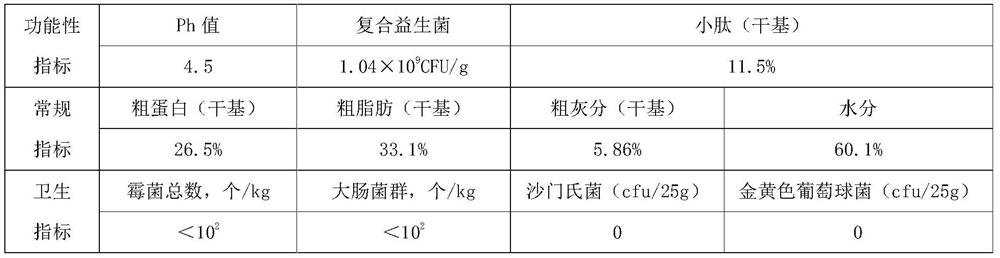

InactiveCN111838408AImprove immunityEnhance disease resistance functionBio-organic fraction processingFood processingBacillus licheniformisLactobacillus acidophilus

The invention discloses a preparation method of a functional amino acid enzyme. The method comprises the following steps: crushing an animal-derived protein raw material, and using acid protease and lipase for treatment; then carrying out aerobic fermentation by using bacillus subtilis, bacillus licheniformis and saccharomyces cerevisiae, carrying out anaerobic fermentation by using enterococcus faecalis, lactobacillus plantarum, lactobacillus acidophilus and streptococcus thermophilus after the aerobic fermentation is finished, and converting into a functional amino acid enzyme for feed or anagricultural functional amino acid enzyme fertilizer after microbial fermentation; the invention further discloses characteristics and application of the functional amino acid enzyme. According to the method, harmless treatment and resource utilization can be carried out on animals died of illness, the defects in the prior art are overcome, and the method has the advantages of being environmentally friendly, low in treatment cost, high in product additional value and wide in product application range and is a technology worthy of being popularized in the industry.

Owner:SHANDONG BAIDE BIOLOGICAL TECH

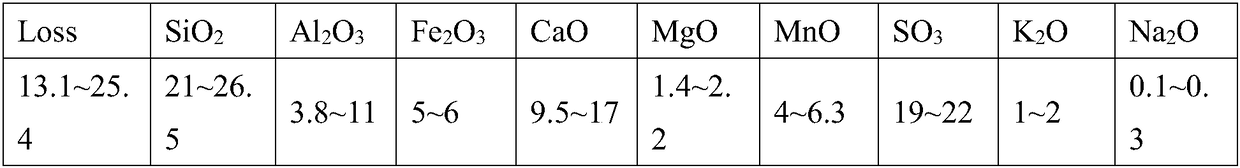

Comprehensive resource utilization method of electrolytic manganese slag and steel slag tailing mud

PendingCN108585721AReduced activityElicit activitySolid waste managementCeramicwareFoam concreteElectrolysis

The invention provides a production method for producing autoclaved aerated blocks by using raw electrolytic manganese slag and raw steel slag tailing mud. The autoclaved aerated blocks are produced from 30-50% of the electrolytic manganese slag, 10-30% of the steel slag tailing mud, 10-20% of water-quenched blast furnace slag, 5-15% of Portland cement, 5-10% of quicklime, 0.1-0.8% of an aluminumpowder paste (admixture) according to the following sequential steps: S1, performing mixed grinding; S2, proportioning; S3, slurrying; S4, stirring and pouring; S5, heating and standing; S6, cutting;S7, autoclaving; S8, aging. The aerated blocks produced by the production method can meet block standards of A1.5-A5.0, B09 and B10 classes in JC1062-2007 foam concrete block standards.

Owner:中冶武汉冶金建筑研究院有限公司

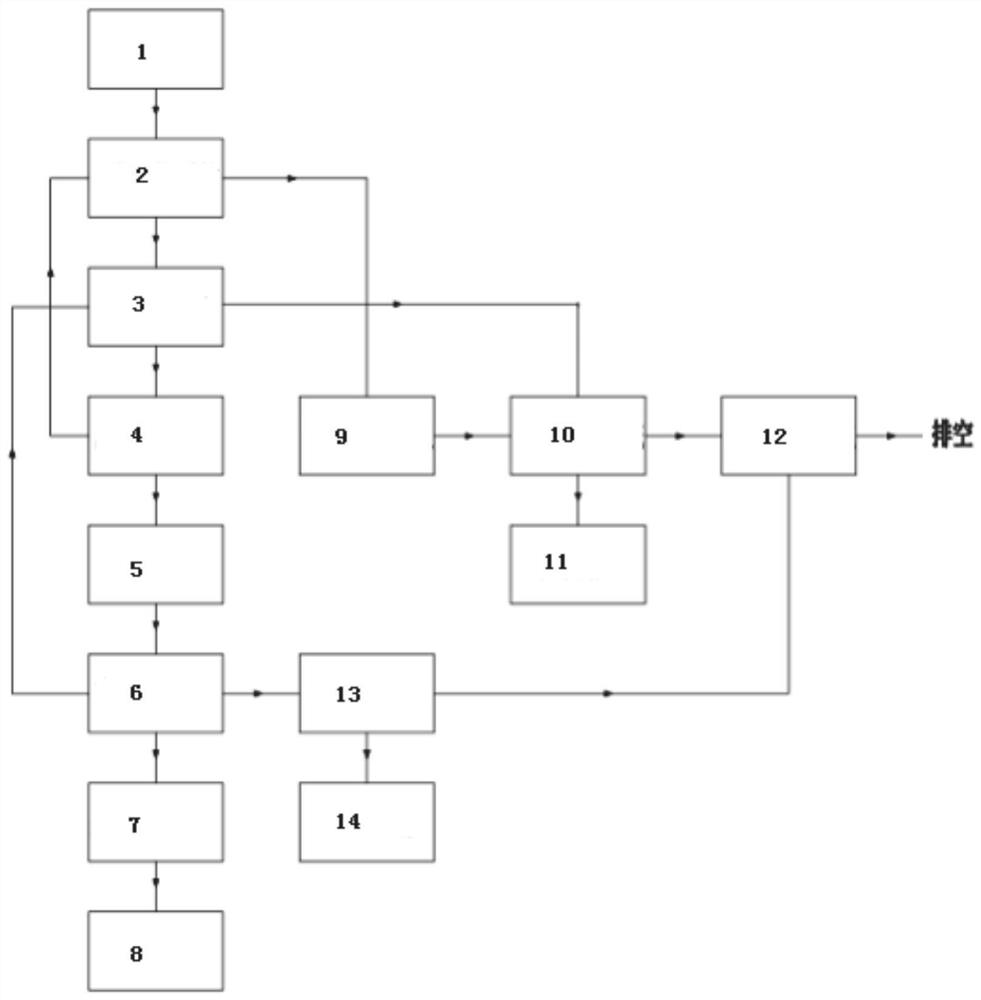

Process and system for co-production of quick lime and sulfur through gypsum reduction, oxidation and cyclic calcination

ActiveCN111995264ASolve the unavoidable situation that a small amount of CaS is generatedLower decomposition temperatureSulfur preparation/purificationCalcium/strontium/barium oxides/hydroxidesSulfur productCalcium sulfide

The invention belongs to the field of solid waste resource utilization, and particularly provides a system and process for co-production of quick lime and sulfur through gypsum reduction, oxidation and cyclic calcination. The method comprises the following steps that gypsum is subjected to reduction calcination and then subjected to oxidation calcination, the reaction temperature of reduction calcination and oxidation calcination is controlled to be 700-1200 DEG C, and the gas-air coefficient is the excess air coefficient; sulfur dioxide in the flue gas separated in the reduction calcining process is subjected to carbon thermal reduction to generate sulfur; flue gas generated in the oxidation calcining process carries an oxidation calcining material to return to the reduction calcining process for cyclic calcining until the mass fraction of collected solid materials meets the requirements of quicklime products, the problems that in the prior art, quick lime prepared by taking gypsum asa raw material contains calcium sulfide, the quality of the quick lime is greatly reduced, a sulfur product cannot be co-produced in the process of preparing the quick lime by taking gypsum as a rawmaterial, and the environment is polluted are solved.

Owner:SHANDONG UNIV

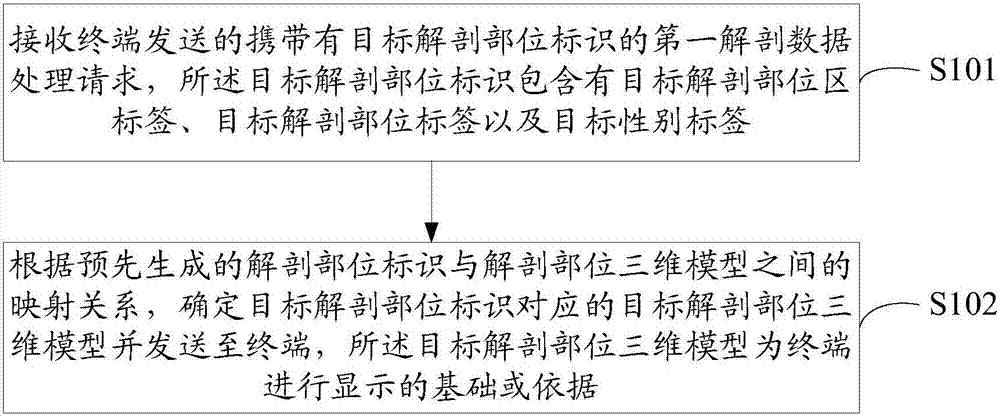

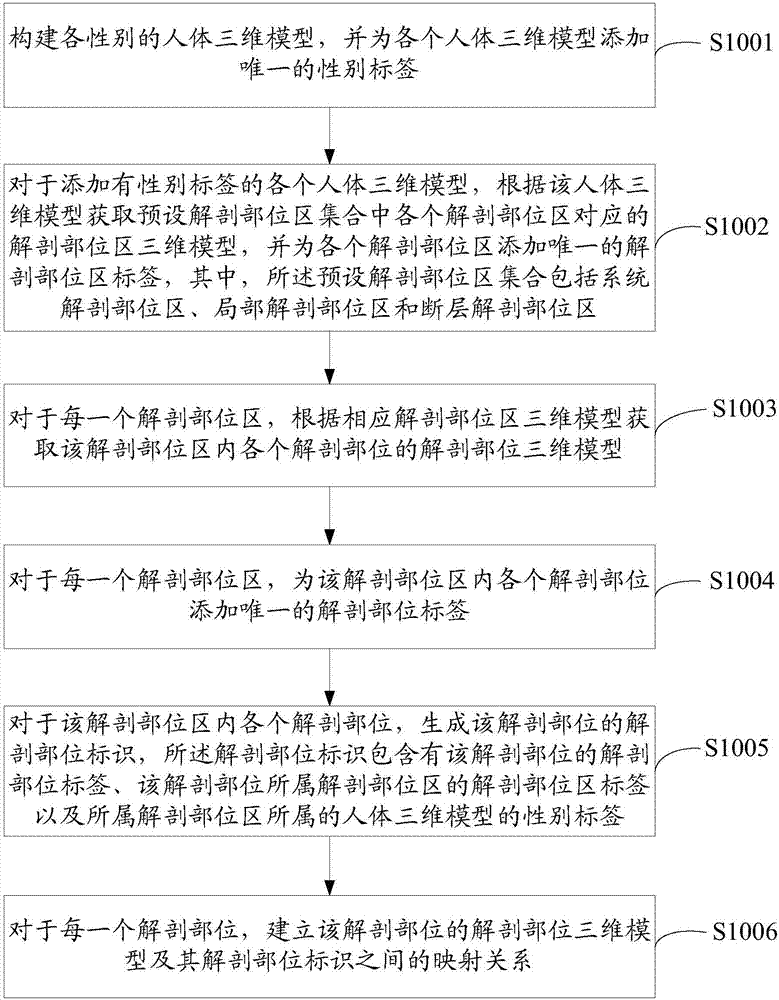

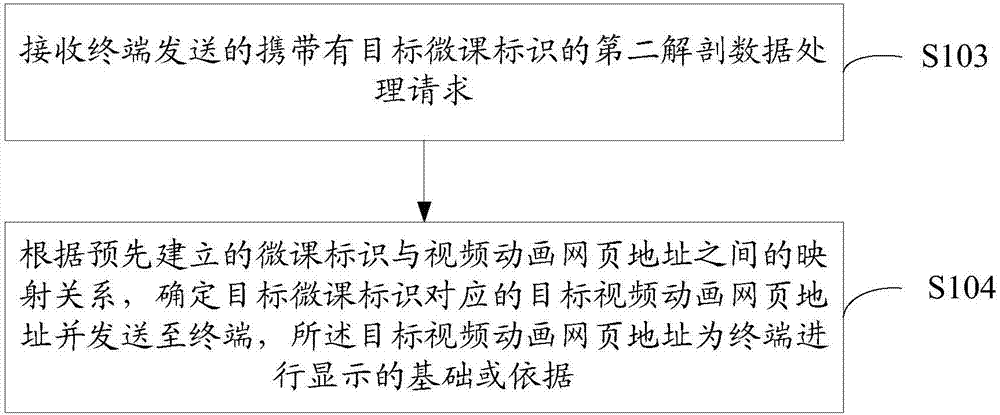

Anatomical data processing method, device and system

ActiveCN107248353AReduce usageAlleviate the current situation of resource shortageImage enhancementImage analysisData processing systemHuman body

The invention provides an anatomical data processing method, device and system. The anatomical data processing method is applied to a server in the anatomical data processing system, and comprises the steps of receiving a first anatomical data processing request which is sent by a terminal and caries a target anatomical part identifier; determining a target anatomical part three-dimensional model corresponding to the target anatomical part identifier according to a pre-generated mapping relation between anatomical part identifiers and anatomical part three-dimensional models, and sending the target anatomical part three-dimensional model to the terminal, wherein the target anatomical part three-dimensional model is a foundation or basis for the terminal to perform display. According to the method disclosed by the invention, display of the terminal for the target anatomical part three-dimensional model is realized through data interaction between a server and the terminal, and a user can watch the anatomical part effectively in real time by using the terminal, so that utilization of a human body anatomical specimen is reduced, thus the current situation that the human body anatomical specimen source is shortage is effective relieved, and further a problem that students sitting far away cannot watch when the number of learning people is great is also avoided.

Owner:山东数字人科技股份有限公司

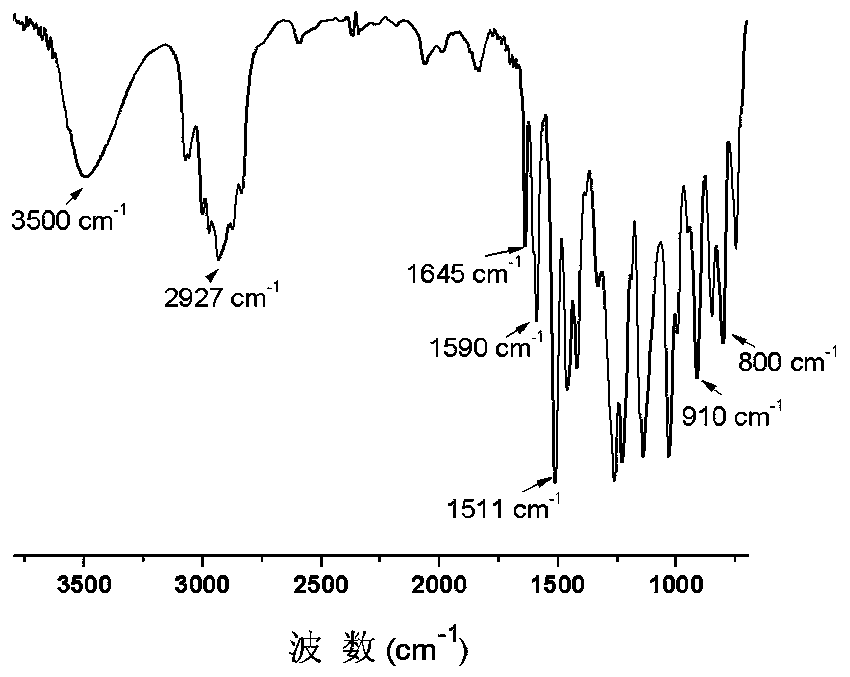

A kind of eugenol epoxy resin and its preparation method and application

InactiveCN105924623BHigh epoxy valueReduce dependenceOrganic chemistryEpoxy resin adhesivesEpoxyAdhesive

The invention provides a eugenol epoxy resin and a preparing method and application thereof. The eugenol epoxy resin is prepared from a compound shown in the formula I in the description and / or a compound shown in the formula II in the description. The epoxy resin is free of biotoxicity, the mechanical property of the epoxy resin is similar to that of traditional epoxy resin, and the eugenol epoxy resin can replace traditional petroleum-based epoxy resin. The epoxy resin is liquid at the room temperature, and is beneficial to subsequent processing and application and capable of being used for preparing composites, paint, adhesives and the like.

Owner:HEBEI UNIVERSITY

Waste polyester-cotton textile degrading and recycling process and system

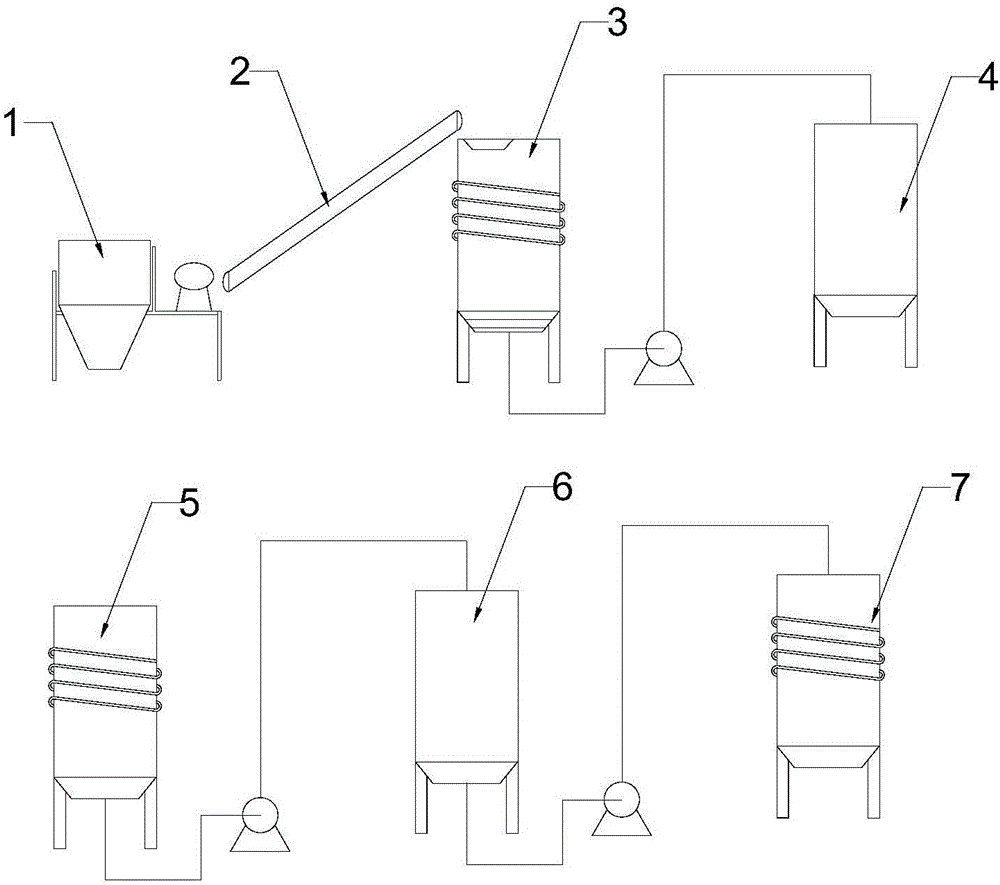

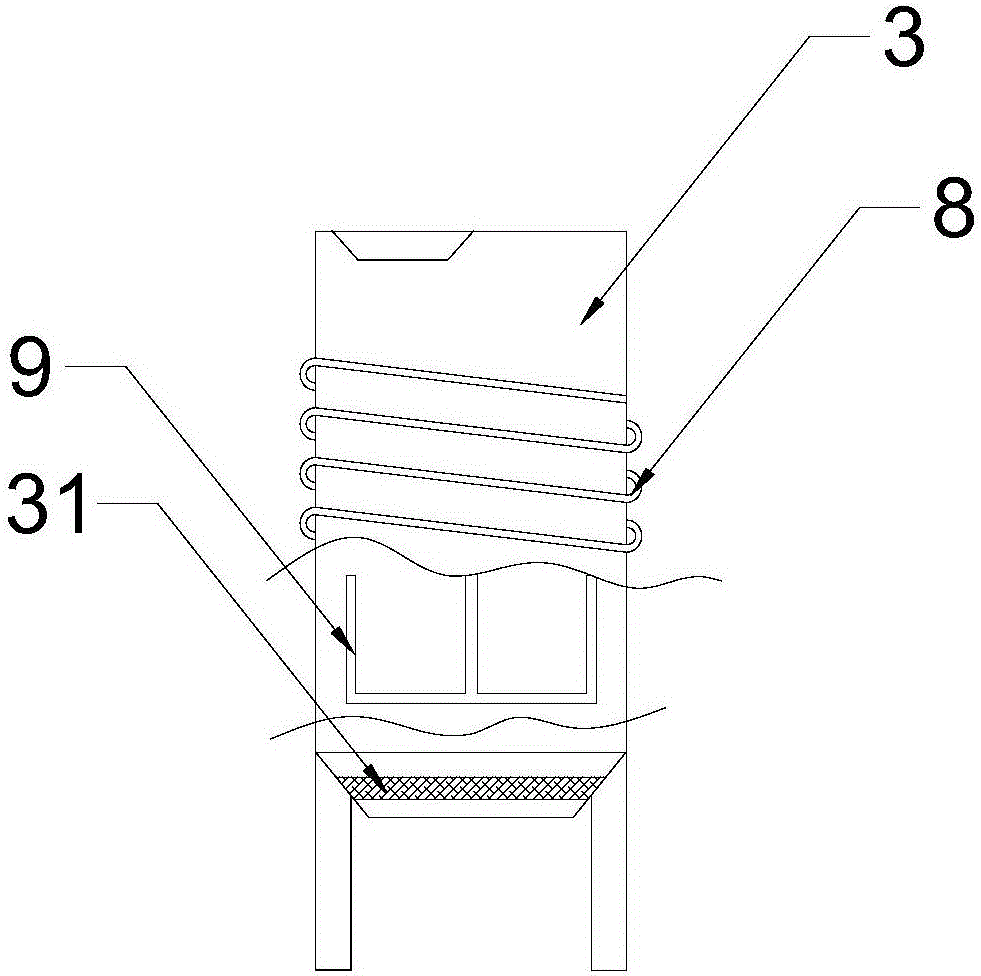

PendingCN106519293AAlleviate resource shortagesReduce pollutionPlastic recyclingChemistryWater soluble

The invention relates to a waste polyester-cotton textile degrading and recycling process and system. According to the waste polyester-cotton textile degrading and recycling process, high-concentration phosphoric acid and cotton fibers in polyester-cotton are reacted at first, water-soluble cellulose phosphate ester is generated, and primary separation of polyester and the cotton fibers is completed; then the cotton fibers are separated out through hydrolysis, and pure cotton fibers are obtained; and alkali liquor is added into reaction liquid subjected to acidolysis for alkaline hydrolysis, water-soluble sodium terephthalate is generated through sodium hydroxide and the polyester and further hydrolyzed to generate terephthalic acid, the obtained terephthalic acid is subjected to direct esterification through ethanediol, polyethylene glycol terephthalate, namely PET is obtained, and subsequent cyclic utilization is facilitated. Through the waste polyester-cotton textile degrading and recycling system, the waste polyester-cotton textile degrading and recycling process can be completely efficiently, and the cotton fibers and the polyethylene glycol terephthalate which are high in purity and facilitate subsequent cyclic utilization are obtained.

Owner:深圳恒锋资源股份有限公司

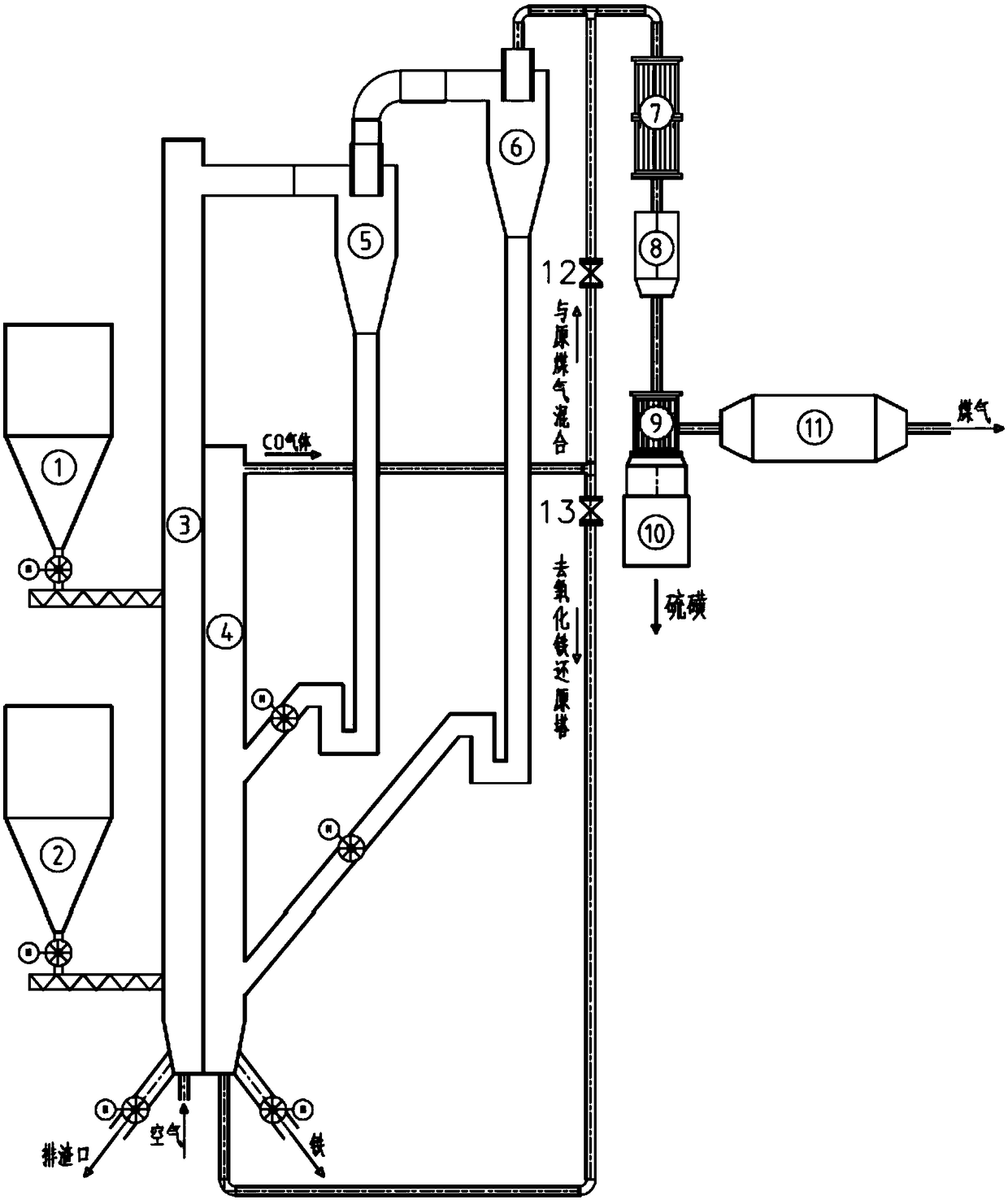

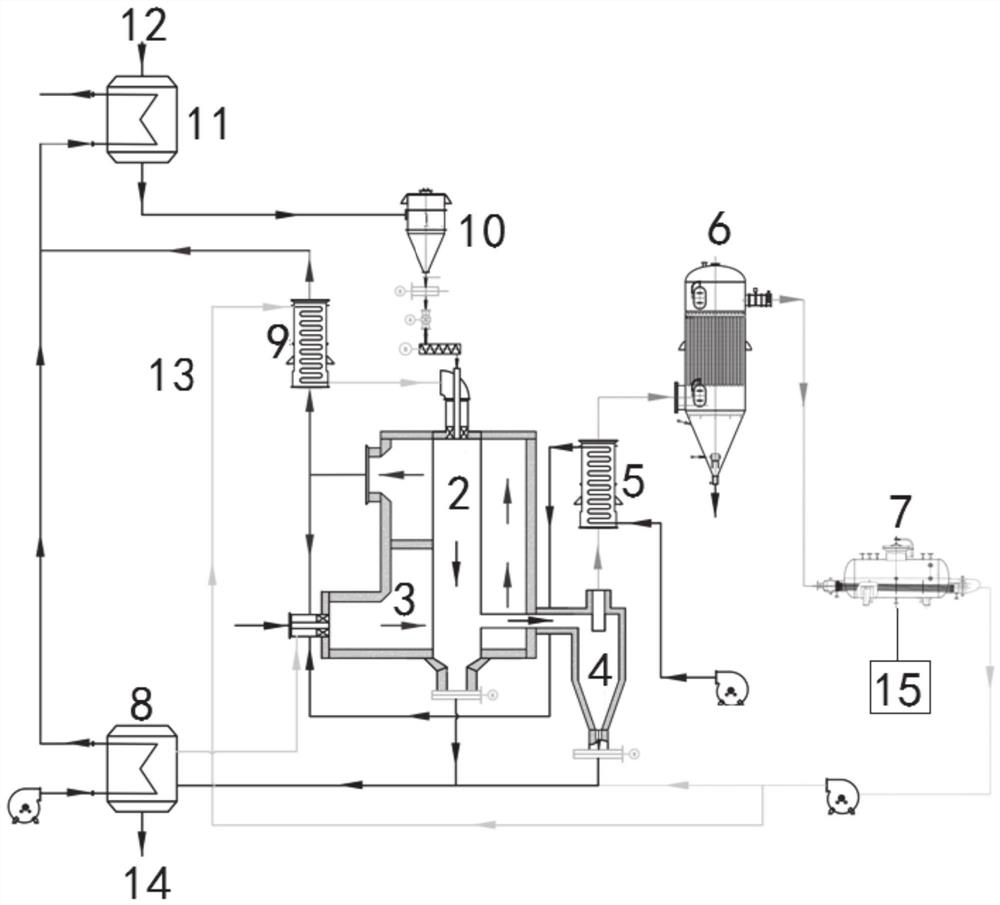

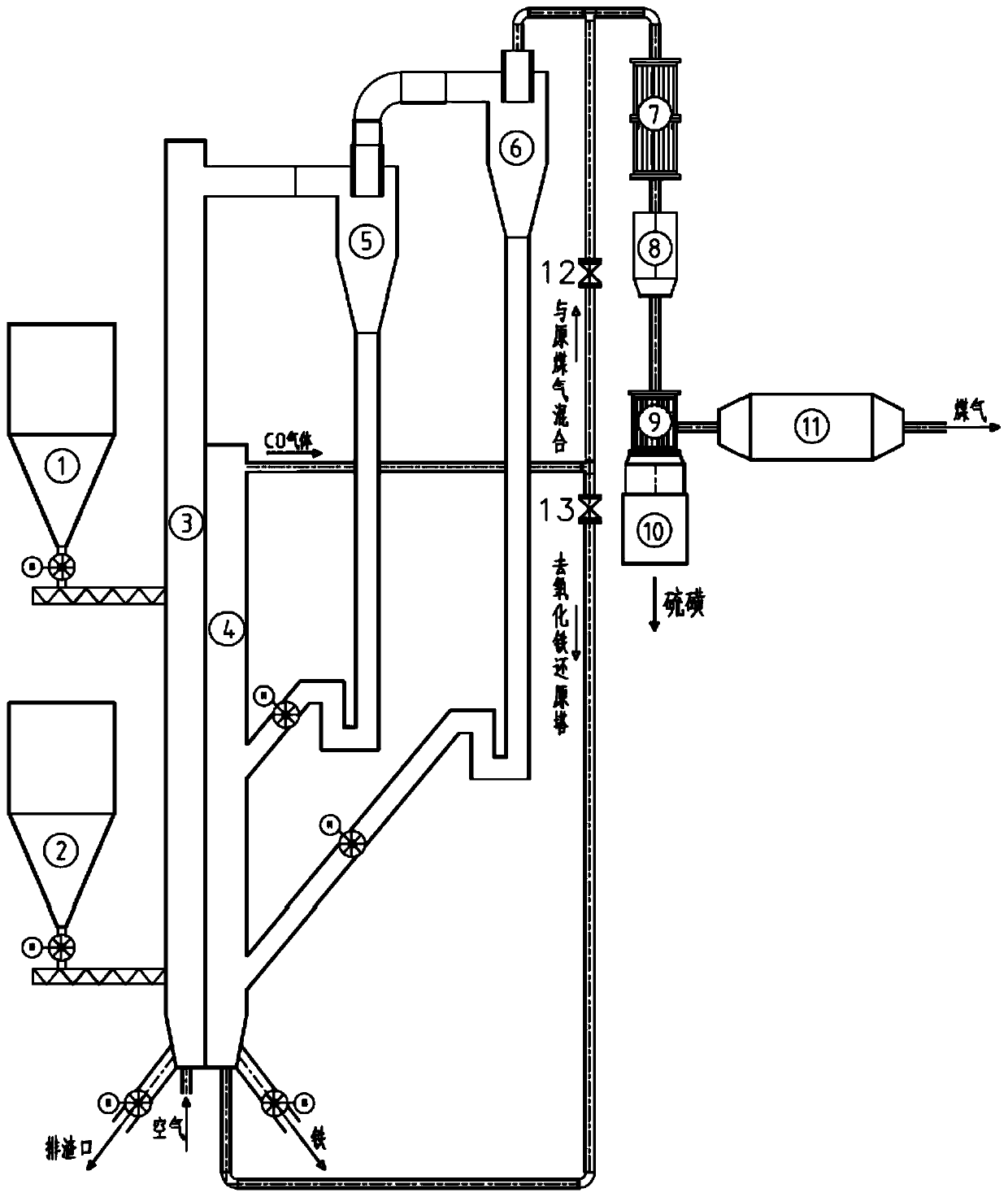

Device and method for joint production of iron, sulfur and gas in smelting process of pyrite

ActiveCN108970354AEfficient and clean utilizationAlleviate the current situation of resource shortageGas treatmentDispersed particle separationSulfur containingCoal gasification

The invention relates to a device and method for joint production of iron, sulfur and gas in the smelting process of pyrite, and belongs to the field of metal smelting. The method comprises the following steps of calcining the pyrite at the bottom part of the interior of a calcining-gasifying reaction tower, enabling pulverized coal and fly ash to generate gasifying reaction at the middle upper part, enabling the sulfur-containing flue gas to carry the high-valence oxide of iron produced by calcining at the tower bottom to the middle upper part of the reaction tower, mixing with the gas and coke produced by gasifying, and generating oxidation and reduction reaction; separating the product by an iron-based high-temperature separator and a carbon-based high-temperature separator, and sendingback into an iron oxide reduction tower; performing secondary reduction reaction on the iron oxide in the iron oxide reduction tower, and producing reduction gas, so as to obtain iron slag; purifyingthe crude gas, so as to obtain the purified gas; enabling a sulfur condenser to condense and recycle the sulfur. The method has the advantages that the joint production of iron, sulfur and gas is realized in the smelting process of the pyrite, and the pyrite can be efficiently and cleanly utilized.

Owner:SHANDONG UNIV

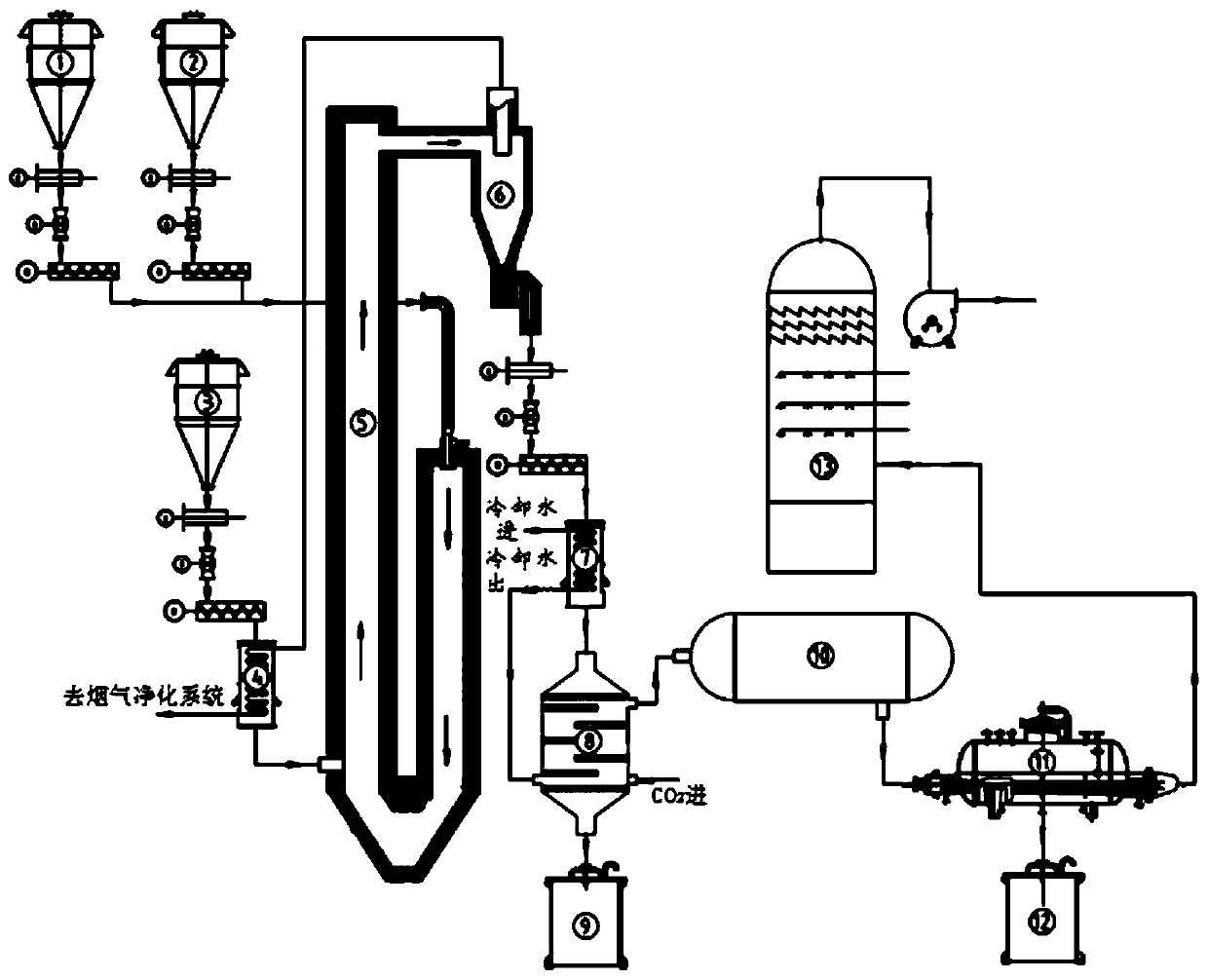

System and method for recovering calcium carbonate and sulfur by calcining gypsum

ActiveCN109928415AAvoid overheatingIncrease profitCalcium/strontium/barium carbonatesSulfur preparation/purificationFlue gasSulfur

The invention relates to a system and a method for recovering calcium carbonate and sulfur by calcining gypsum. The system comprises a coal gasification-calcination U-shaped furnace, a H2O-CO2 processor and a Klaus reactor. A coal gasification section on the right side of the coal gasification-calcination U-shaped furnace is respectively connected with a calcium-based material storage bin and a coal powder storage bin. A calcination section on the left side of the coal gasification-calcination U-shaped furnace is connected with a gypsum storage bin. The top end of the calcination section on the left side of the coal gasification-calcination U-shaped furnace is connected with a high-temperature separator. The bottom of the high-temperature separator is sequentially connected with a calciumsulfide-calcium oxide cooler, a H2O-CO2 processor and a calcium carbonate storage bin. The H2O-CO2 processor is also connected with the Klaus reactor. The Klaus reactor is sequentially connected witha sulfur recovery device and a sulfur storage bin. The sulfur recovery device is also connected with a flue gas purification system. The system and the method are used for preparing the sulfur and a byproduct, calcium carbonate powder, by using the industrial byproduct gypsum which is difficult to treat, and the byproduct calcium carbonate powder can replace limestone to be used as a desulfurization and denitrification agent for recycling and can also be used as a catalyst of a coal gasification process.

Owner:SHANDONG UNIV

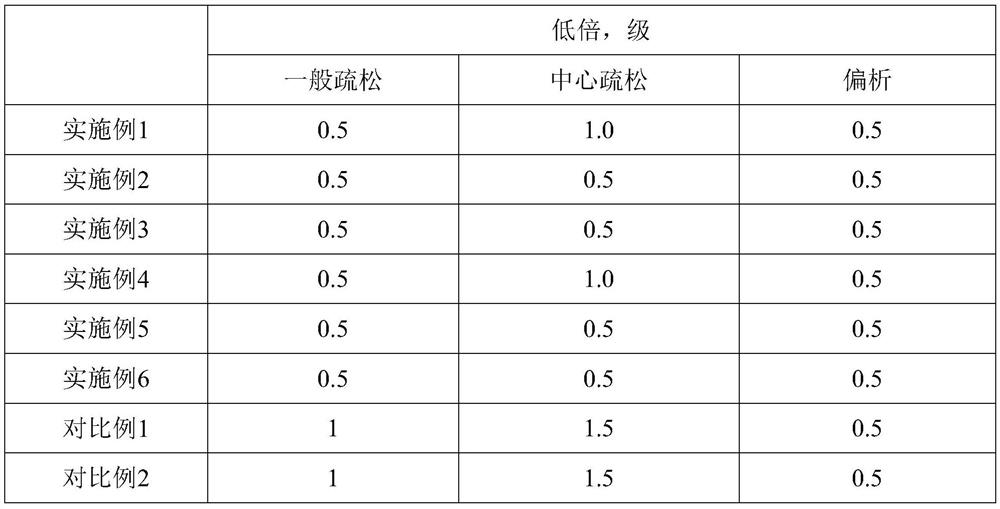

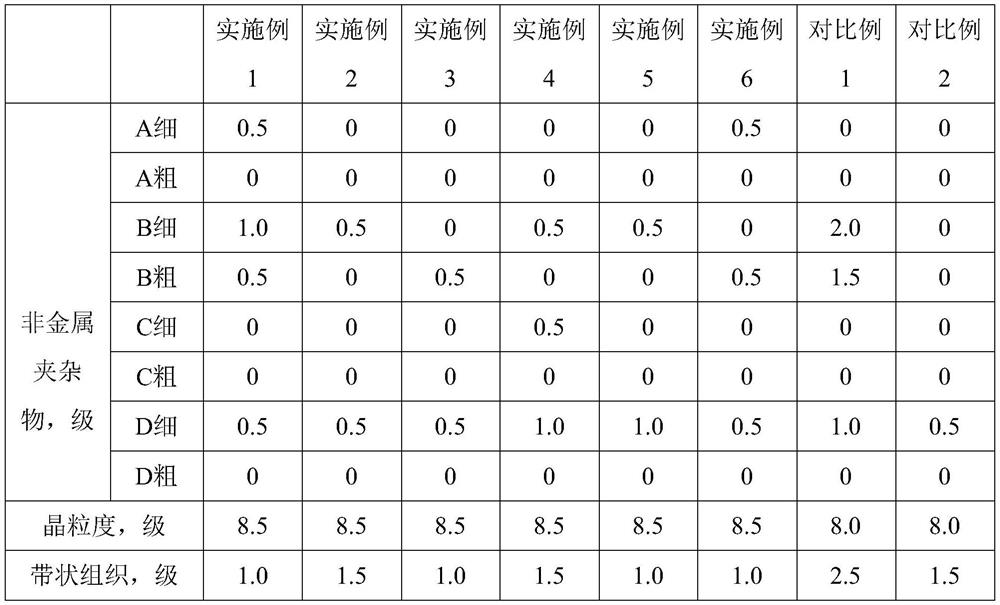

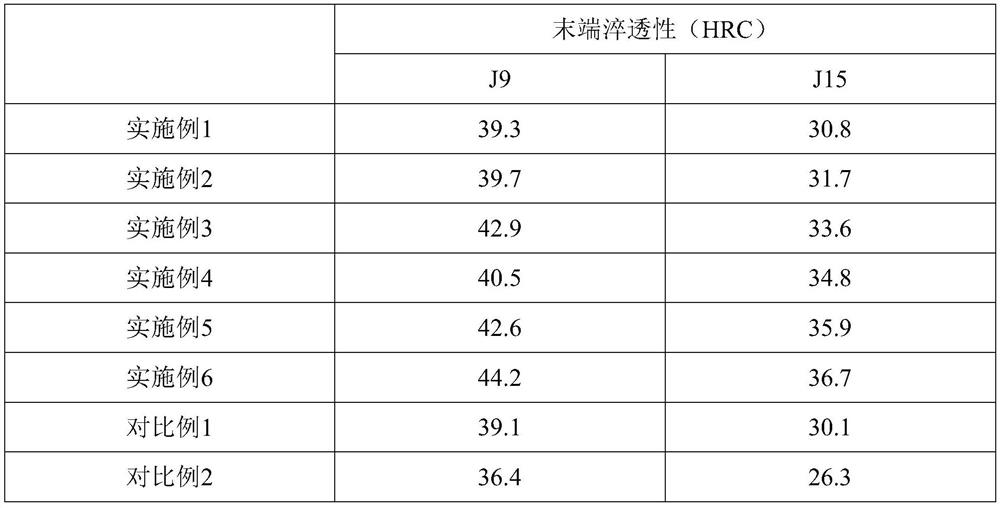

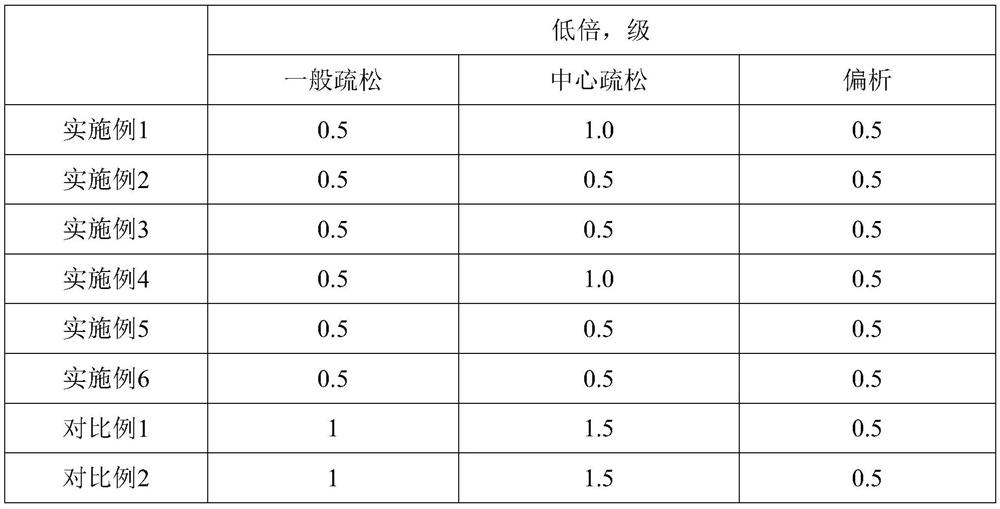

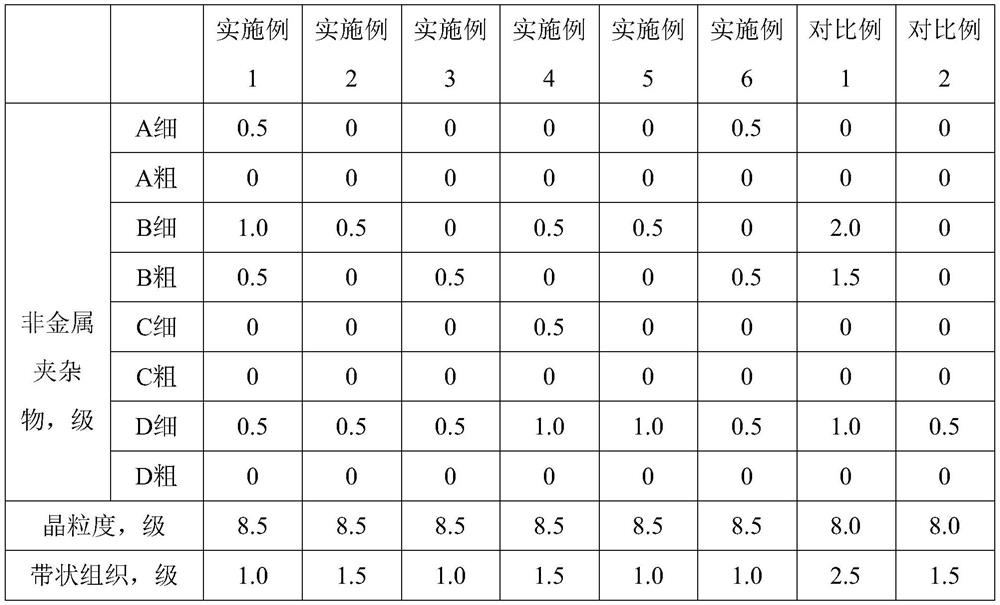

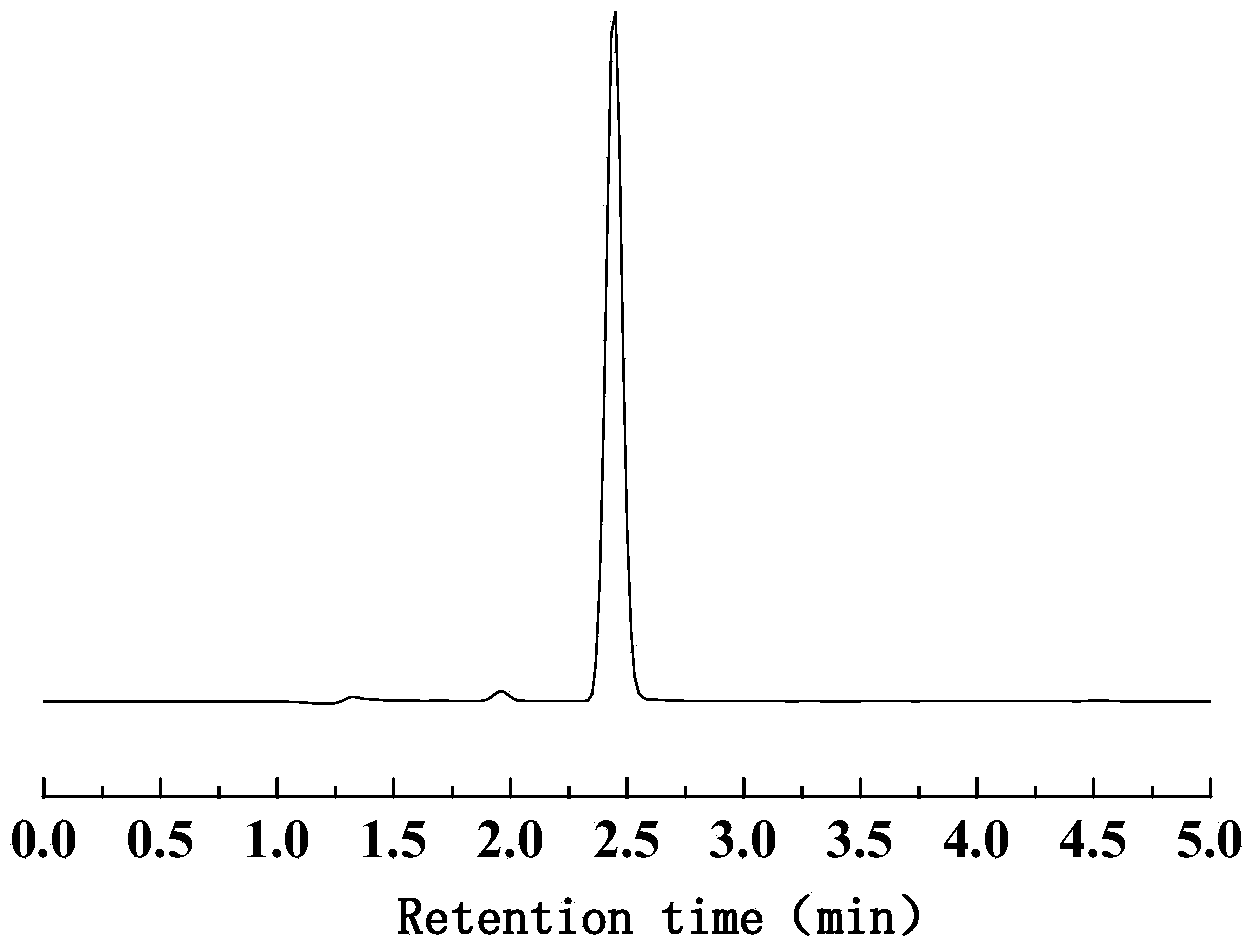

Hardenablity-retaining gear steel and preparation method thereof

The invention discloses hardenablity-retaining gear steel and a preparation method thereof. The hardenablity-retaining gear steel mainly comprises the following components in percentage by mass: 0.18-0.21% of C, 0.20-0.28% of Si, 0.75-1.05% of Mn, 0.95-1.25% of Cr, 0.035-0.055% of Ti, 0.020-0.035% of Al, 0.0008-0.0030% of B, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 20 ppm of T[O], less than or equal to 80 ppm of T[N], less than or equal to 0.10% of Ni, less than or equal to 0.20% of Cu, less than or equal to 0.10% of Mo, and the balance of Fe. The gear steel with a narrow hardenability band and an excellent fatigue life is prepared by controlling primary melting and strengthening refining, large ladle submerged nozzle argon blowing, catalyzer slag protection, plasma tundish heating and constant-temperature constant-pull-speed casting, and compound electromagnetic stirring through converter, dual-refining and continuous casting processes.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

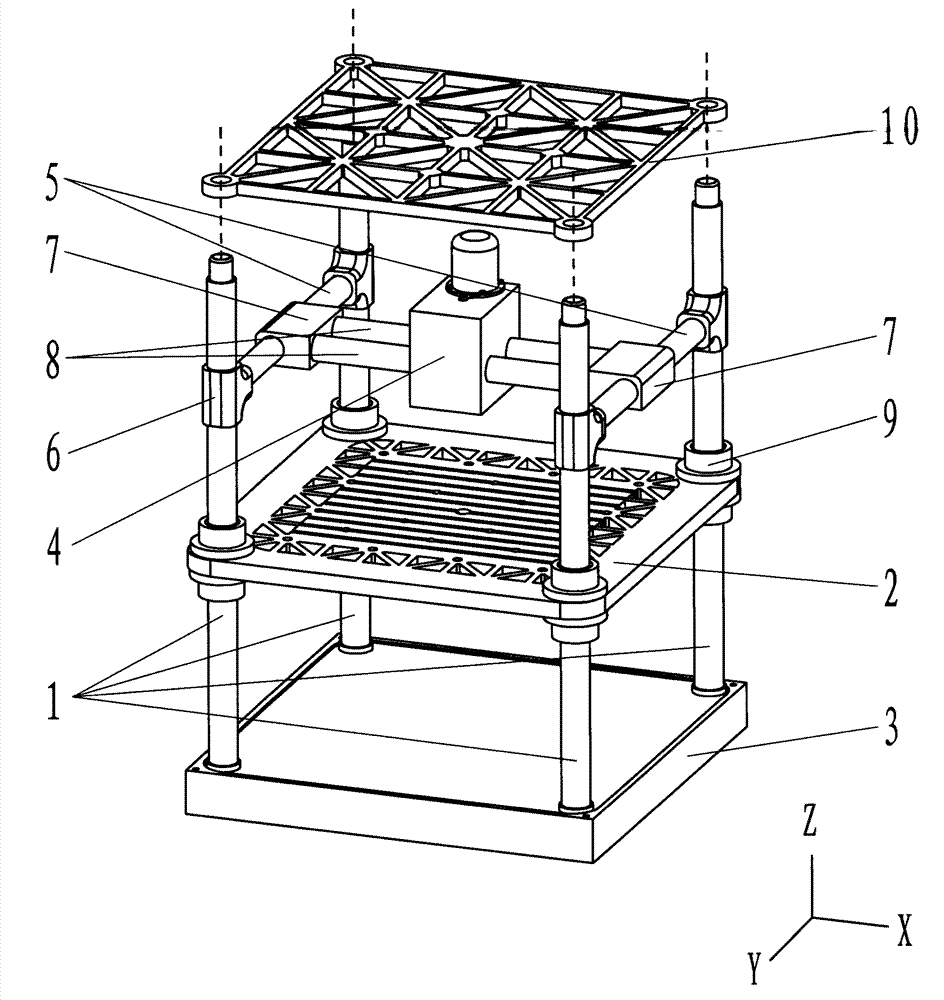

Improved structure of vertical processing machine tool

InactiveCN102773715ALose weightAlleviate the current situation of resource shortageFeeding apparatusLarge fixed membersKinematic pairEngineering

The invention discloses an improved structure of a vertical processing machine tool and aims to provide an improved structure which has relatively light weight and small volume, big processing space, simple manufacturing process, and low cost and can be independently disassembled and transpositionally assembled. The improved structure of the vertical processing machine tool comprises a pedestal, a machine body, a working platform, and a processing unit. An interlock frame style machine body composed by at least four guide rails is vertically fixed on the pedestal, and the upper part is provided with a stable frame. An X-direction kinematic pair, a Y-direction kinematic pair and the processing unit are arranged at the upper part of the machine body. The working platform is arranged on the machine body for moving in Z-direction. The routes of the guide rails in X, Y and Z directions are expanded to a maximum extent so as to obtain a larger processing space. The requirements for processing strength and precision are well guaranteed by adopting a reasonable structure and a lightweight guide rail pair with a cylndrical surface. The improved structure of the vertical processing machine tool is suitable for various ordinary and numerically controlled metal-cutting machine tools such as drill machines, drilling and milling machines, milling machines, boring and milling machines, multi-function machine tools, and vertical machining centres, is suitable for wide application, and plays a great role in saving resource.

Owner:杜双全

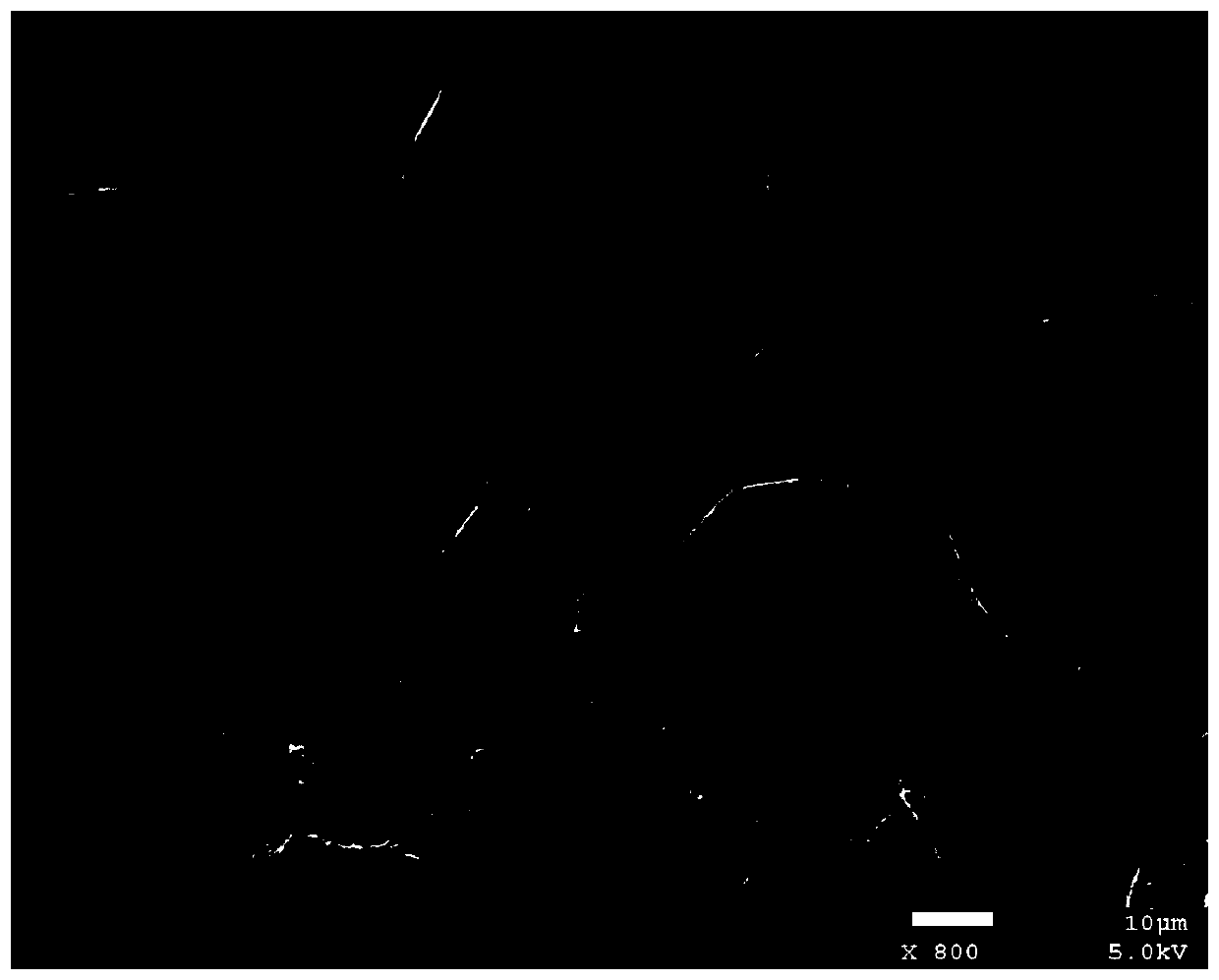

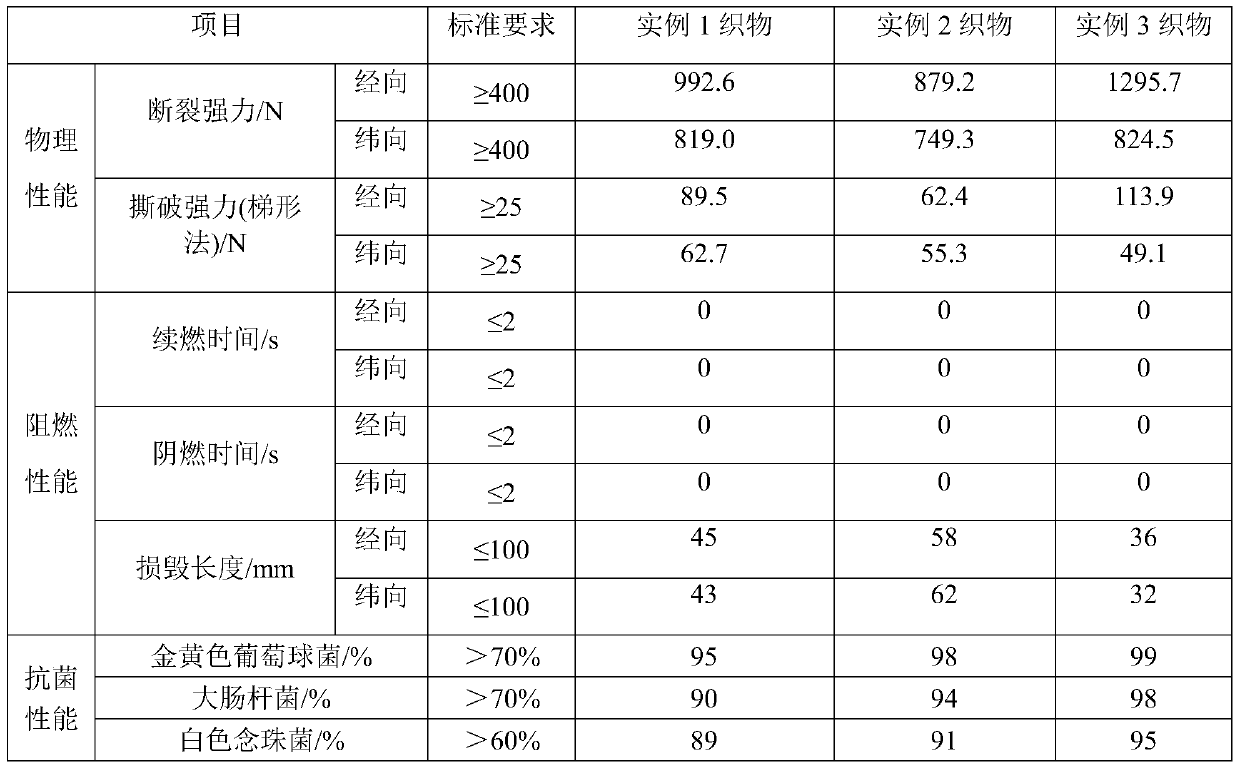

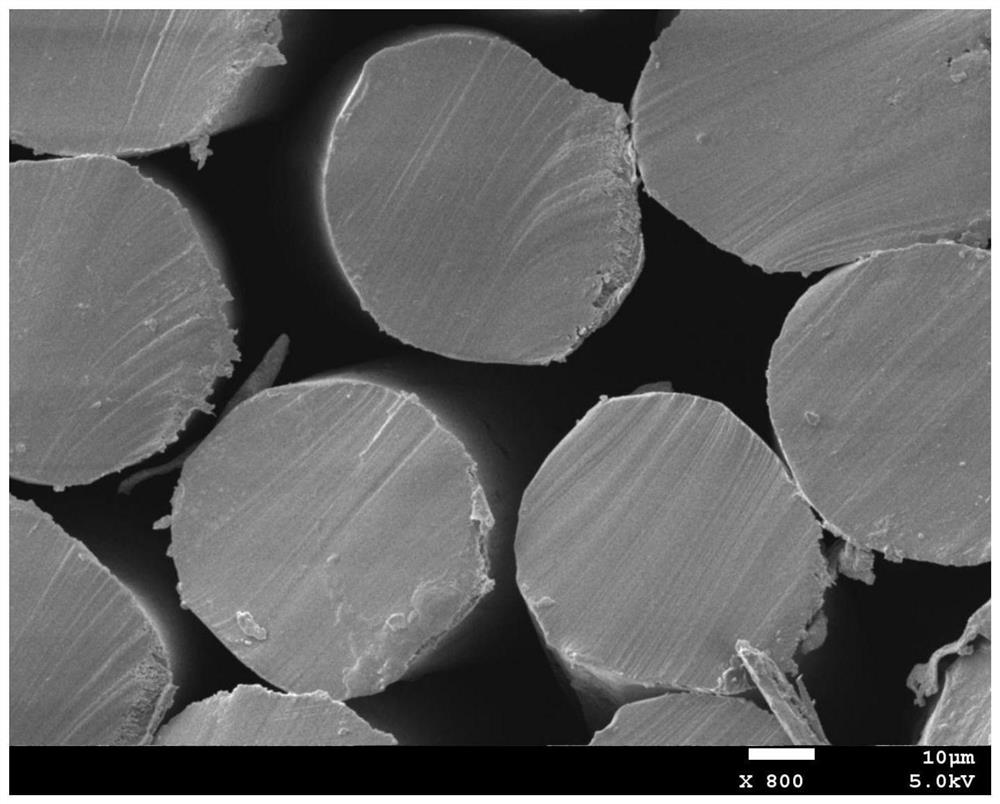

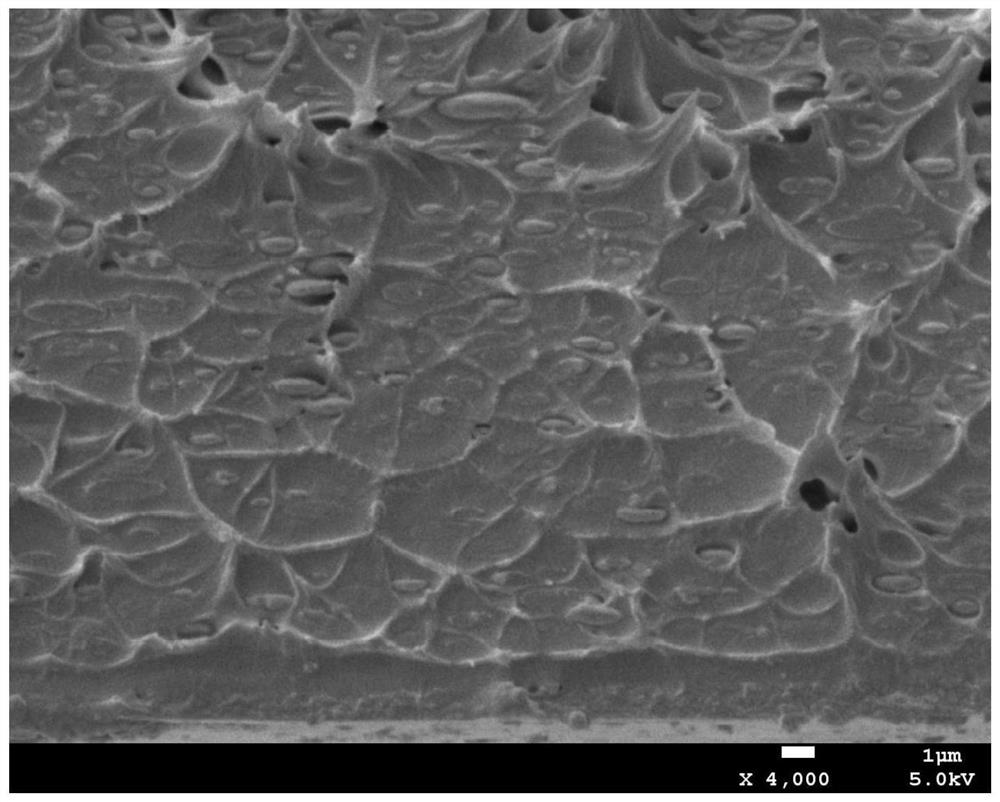

Antibacterial flame-retardant fibers and preparation method of fabric of antibacterial flame-retardant fibers

ActiveCN111020737AAlleviate the current situation of resource shortageReduce pollutionFlame-proof filament manufactureArtificial filaments from cellulose derivativesCellulosePolymer science

The invention discloses a preparation method of antibacterial flame-retardant fibers. The preparation method specifically comprises the steps that a collected raw white pure cotton waste fabric is crushed after washed and dried, then oxygen bleaching is carried out by using oxygen peroxide, drying is carried out, and then a sodium hydroxide or sodium carbonate solution is used to carry out processing and drying to obtain alkali cellulose; and the alkali cellulose / a hydroxy-containing phosphorus flame retardant and a cross-linking agent are mixed to enable the obtained mixture to subjected toan oxyamination crosslinking reaction to prepare flame-retardant cellulose, the flame-retardant cellulose is mixed with a nano antibacterial sol to prepare a cellulose solution, then spinning is carried out to obtain primary fibers, and the primary fibers are processed to obtain the antibacterial flame-retardant fibers. The invention further discloses a method for preparing an antibacterial flame-retardant fabric. According to the preparation method of the antibacterial flame-retardant fibers, the waste raw white pure cotton fabric is used to prepare the antibacterial flame-retardant fibers, resources are fully used, environmental pollution is reduced, the antibacterial flame-retardant fabric prepared by using the fibers is long-lasting and stable in antibacterial and flame retardant properties and washable, and after 50 times of washing, the antibacterial flame-retardant performance still meets the standard requirements.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

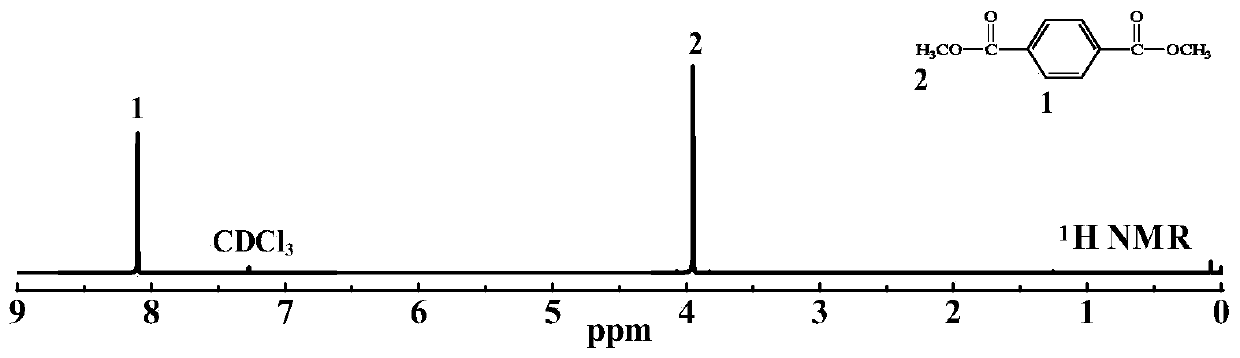

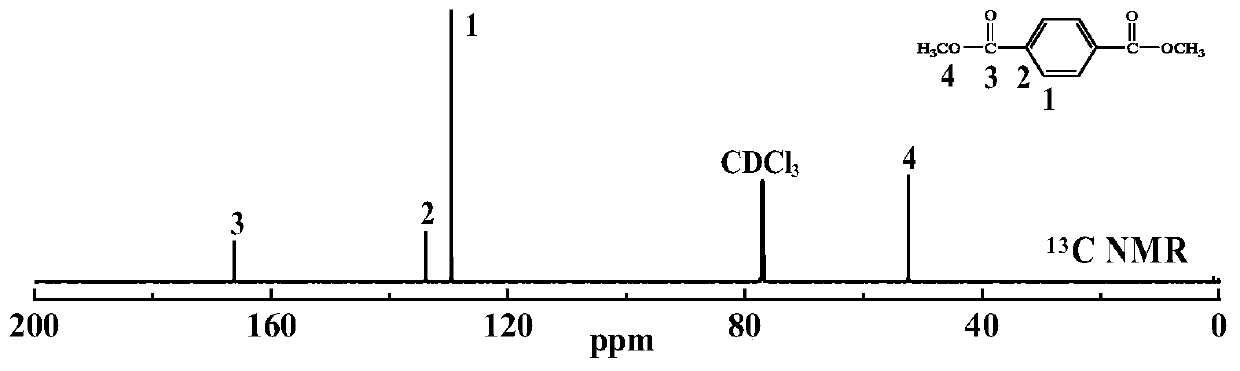

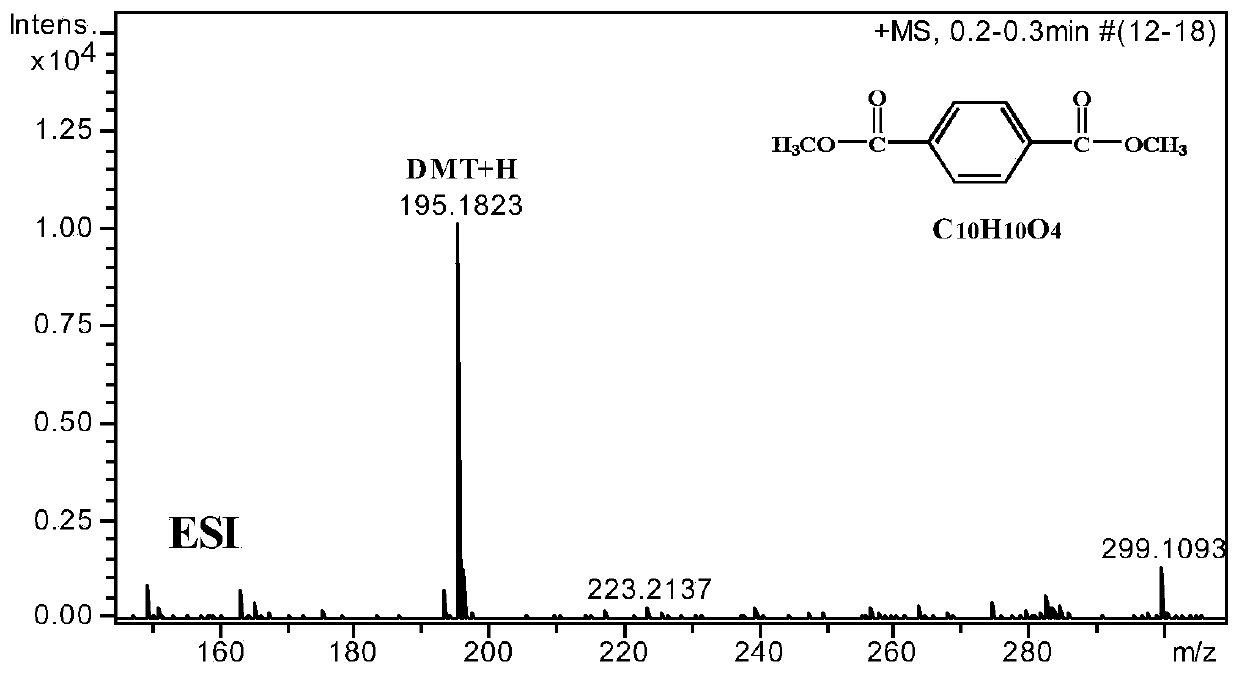

Method for catalyzing waste PET polyester methanol alcoholysis by deep eutectic solvent

The invention relates to a method for catalyzing waste PET polyester methanol alcoholysis by a novel deep eutectic solvent. The method is characterized in that waste PET polyester (including PET bottles, PET packaging sheets, PET fibers and PET textiles) is used as a raw material, a urea-based deep eutectic solvent is used as a catalyst, methanol in a mass ratio of (0.5:1)-(20:1) with PET is usedas a solvent, and methanol alcoholysis is carried out on PET under the conditions that the use amount of the catalyst is 0.1%-10% of the mass of PET, the reaction temperature is 120-200 DEG C and thereaction time is 10-360 minutes. The method for catalyzing waste PET polyester methanol alcoholysis by the novel deep eutectic solvent has the characteristics of wide raw material applicability, the cheap and easily available catalyst, the low alcoholysis temperature, the short alcoholysis time, the high PET conversion rate, the high DMT monomer yield and easiness in product separation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

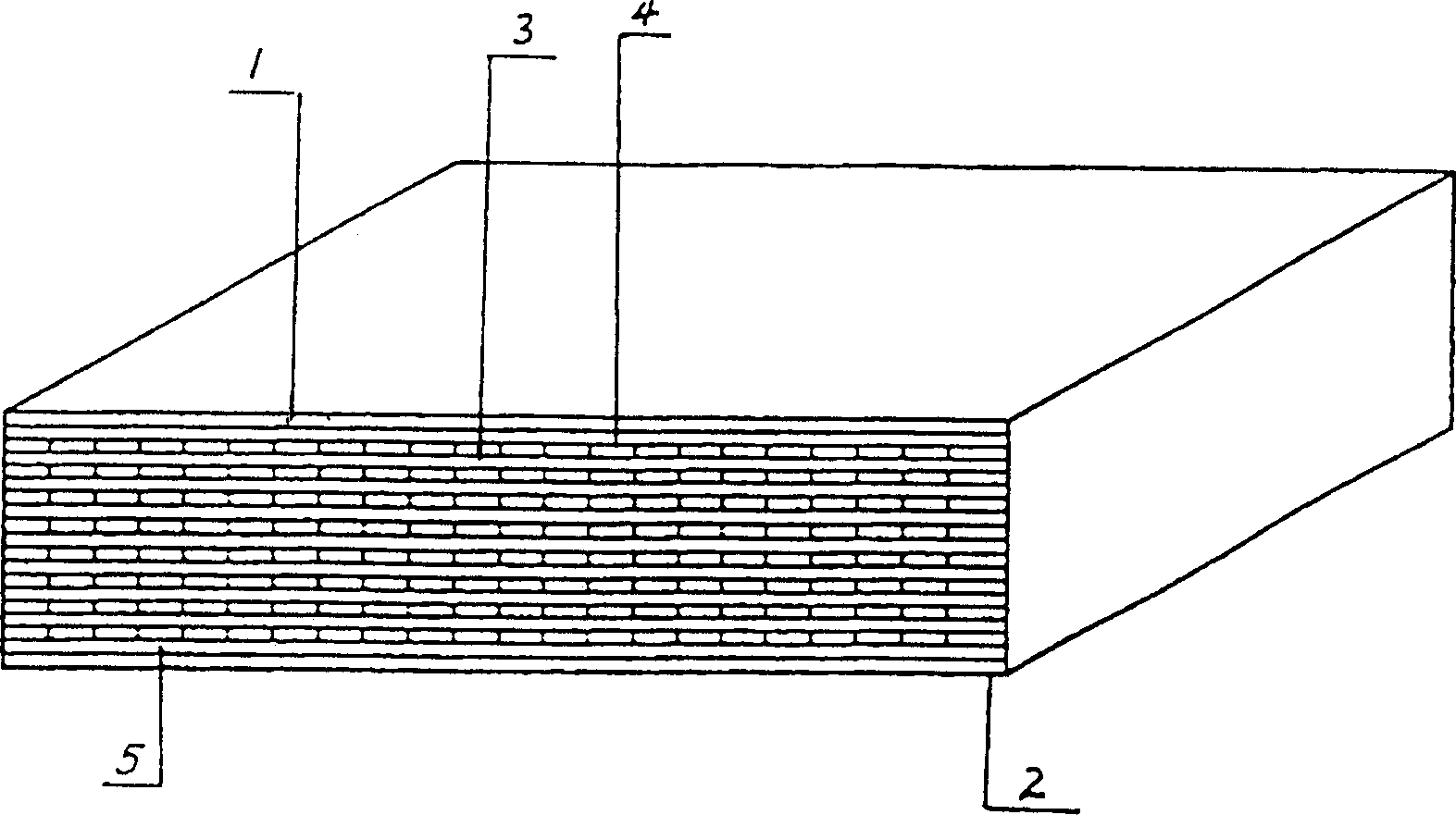

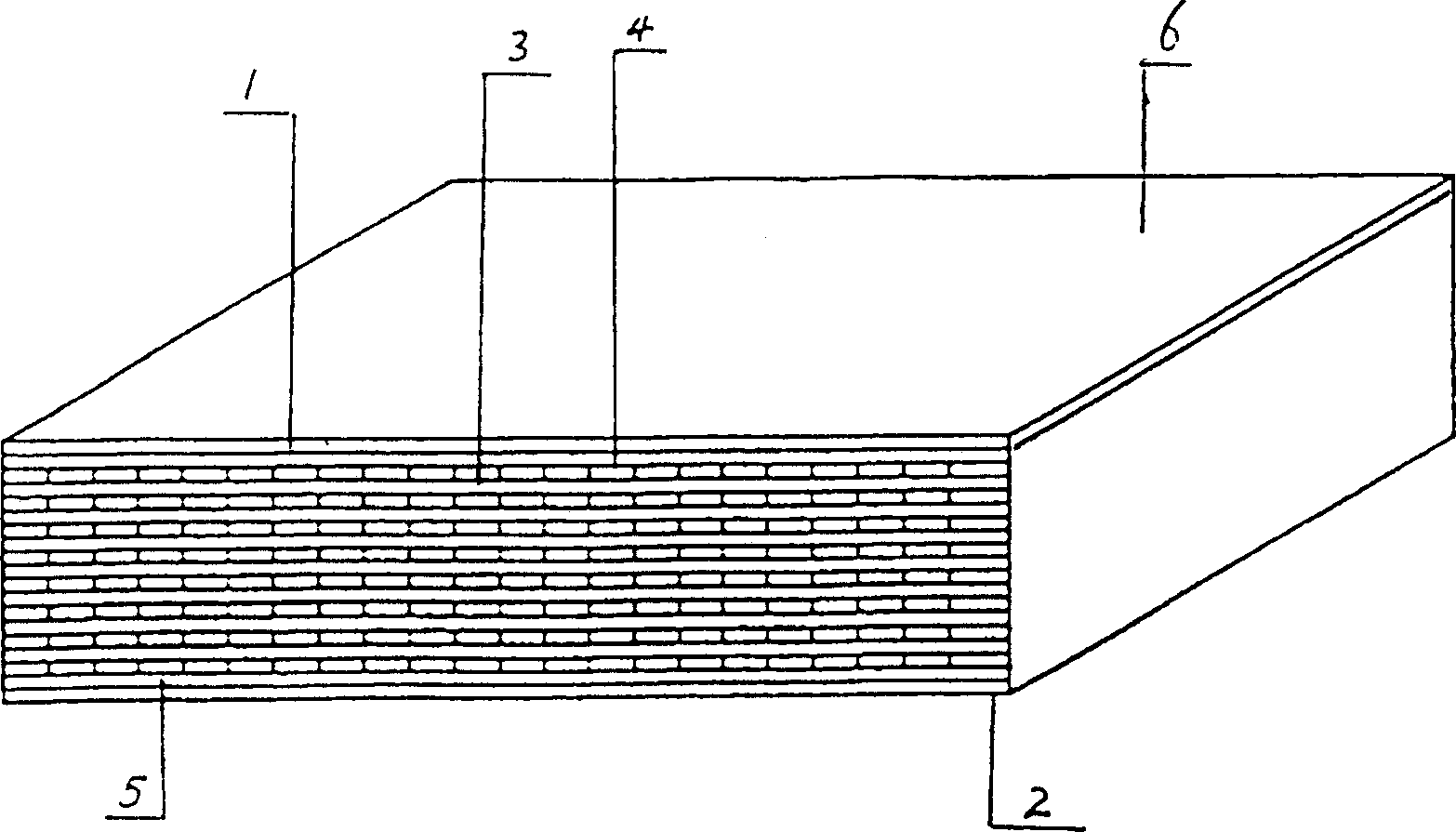

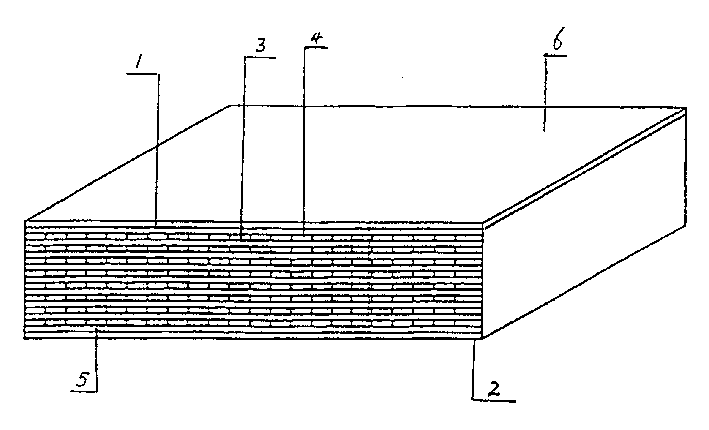

Wood base board for container of domestic material mode from leftover and its manufacturing method

InactiveCN1470439AIncrease profitHigh yieldFlexible coversWrappersMechanical engineeringIndustrial engineering

The invention discloses a kind of wood board for homemade container which is made up with leftover material and the manufacturing method. It comprises panel, bottom board, lengthways long core board,transverse double printing core board and lengthways core board. The panel and bottom clamp the three kinds of core boards. On little pressed part, it uses low intensity core board which is made up of leftover material through rough hydraulic shaping or speed-up material which hasn't been used in engineering. Pastes high intensity frigid zone hardwood on the core board.

Owner:赵显劲 +1

System and process for decomposing calcium sulfate and recovering sulfur and calcium oxide through carbon-sulfur cooperation

InactiveCN109502555ALower decomposition temperatureIncrease concentrationSulfur preparation/purificationCalcium/strontium/barium oxides/hydroxidesSulfurDecomposition

The invention discloses a system and a process for decomposing calcium sulfate and recovering sulfur and calcium oxide through carbon-sulfur cooperation. The process comprises the steps as follows: calcium sulfate, a catalytic carbon material and sulfur are heated to the temperature of not lower than 800 DEG C, so that calcium sulfate is decomposed, decomposition smoke and calcium oxide at the temperature not lower than 700 DEG C are produced, the content of SO2 in the decomposition smoke is controlled to be not smaller than 5wt% through the addition amount of sulfur, a reduction carbon material is added to the decomposition smoke for a carbon heat reduction reaction, SO2 in the decomposition smoke produces elementary sulfur, reduction smoke produced after carbon reduction of the decomposition smoke not only contains elementary sulfur, but also contains the reduction carbon material not participating in the reduction reaction, one part of reduction carbon material not participating inthe reduction reaction is used as the catalytic carbon material, and one part of elementary sulfur is used as a sulfur material for catalyzing calcium sulfate decomposition. The problem that gypsum isdifficult to treat can be relieved, gypsum can be recycled, sulfur and calcium oxide can be recovered, and the current situation of shortage of sulfur resources can be relieved.

Owner:SHANDONG UNIV

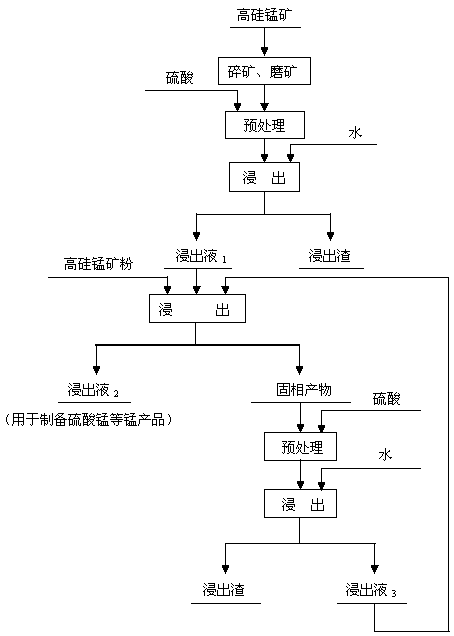

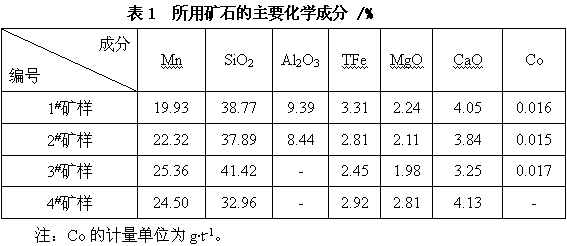

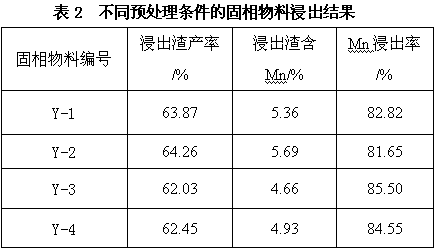

A method for extracting manganese from manganese ore containing manganese silicate minerals

ActiveCN107400790BReduce utilizationImprove leaching rateProcess efficiency improvementHydrometallurgySilicate minerals

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

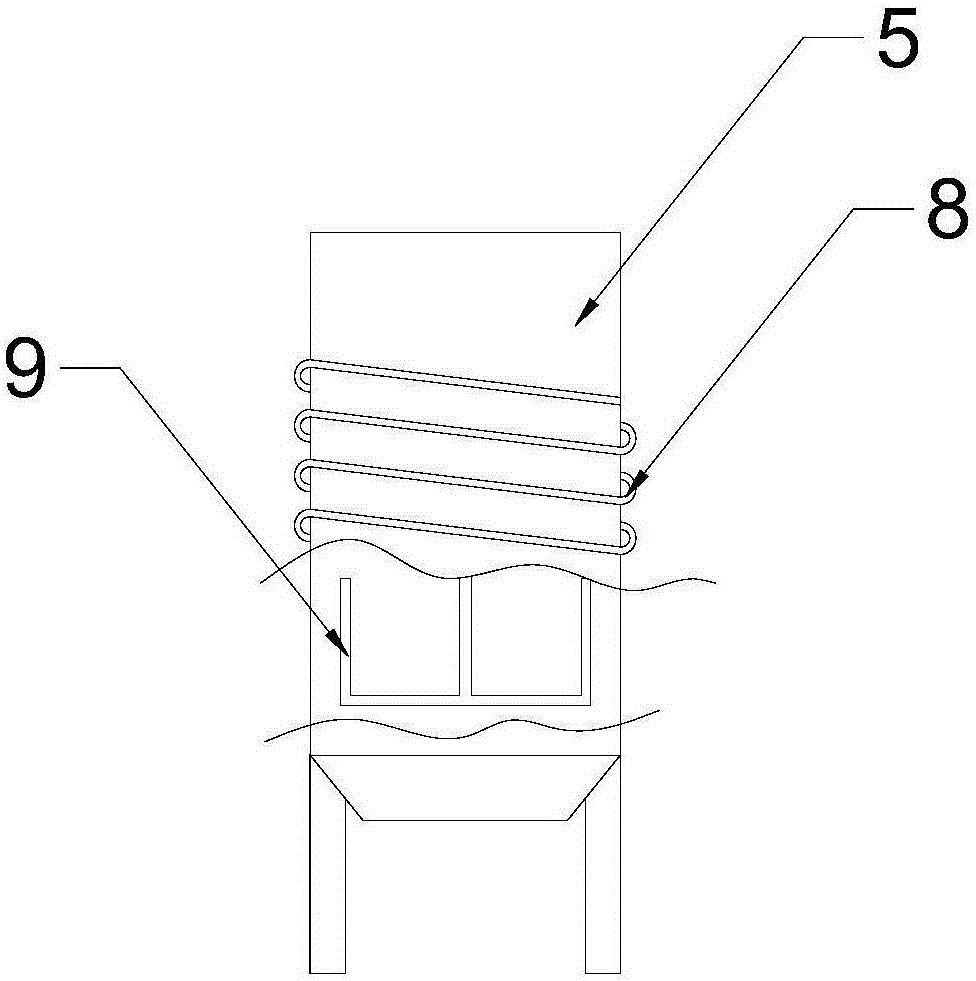

Integrated device and method for preparing sulfur by synergistic regeneration and reduction of active coke

ActiveCN114130311AShort reaction timeHigh specific surface areaEnergy inputSulfur preparation/purificationGas solidCoke

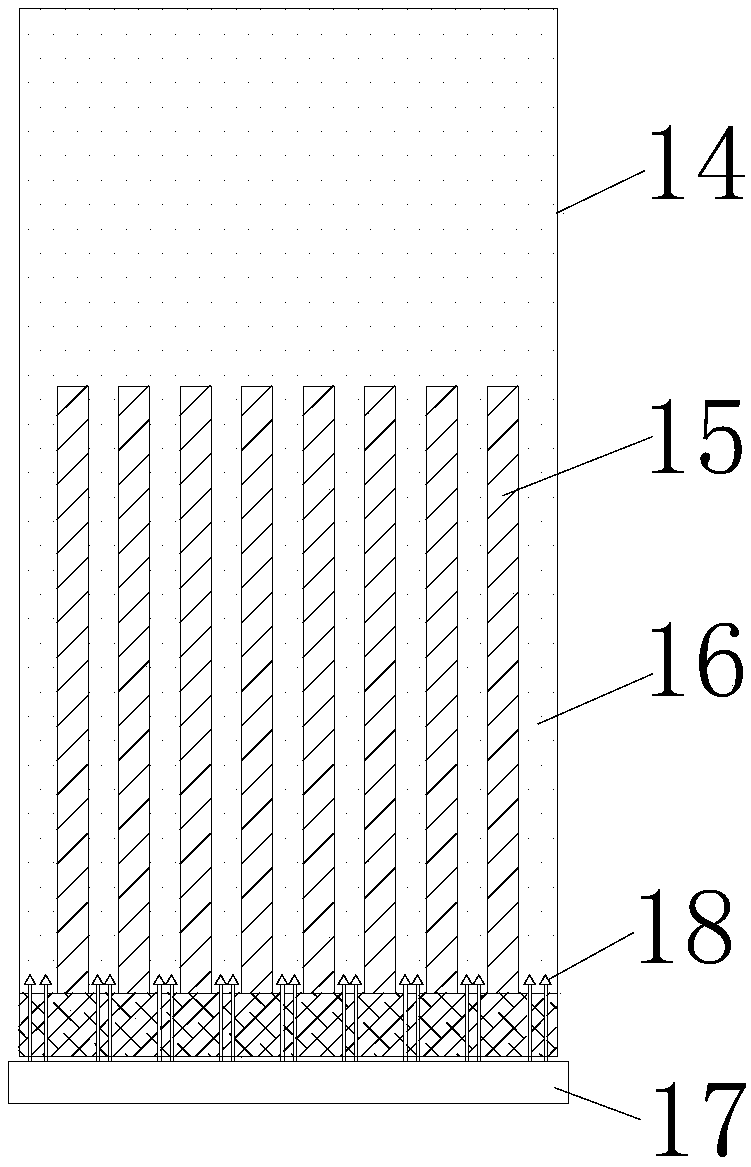

The invention relates to an integrated device and method for preparing sulfur through regeneration and reduction of active coke. Comprising a regeneration reduction furnace which is of a shell-and-tube structure and comprises a reaction inner tube and a combustion cavity on the outer side of the reaction inner tube, the reaction inner tube is vertically arranged, the top of the reaction inner tube is provided with a coke breeze feeding port, the bottom of the reaction inner tube is provided with a coke breeze discharging port, and one side of the lower portion of the reaction inner tube is provided with a gas outlet; a gas outlet of the reaction inner pipe is connected with an inlet of the gas-solid separator; the gas outlet of the gas-solid separator is connected with the inlet of the sulfur recovery device. The integration of regeneration reaction and reduction reaction is realized. The reaction time is short, the sulfur conversion rate is high, and the adsorption capacity of the regenerated active coke is large.

Owner:SHANDONG UNIV

A kind of antibacterial flame retardant fiber and preparation method thereof

ActiveCN111020737BAlleviate the current situation of resource shortageReduce pollutionFlame-proof filament manufactureArtificial filaments from cellulose derivativesCelluloseFibre treatment

The invention discloses a preparation method of an antibacterial and flame-retardant fiber, which specifically comprises: washing and drying the collected white pure cotton waste fabrics, crushing them, then using hydrogen peroxide for oxygen bleaching, drying, and then using sodium hydroxide or sodium carbonate solution Processing and drying to obtain alkali cellulose; mixing alkali cellulose / hydroxyl-containing phosphorus flame retardant and cross-linking agent to make the mixture undergo a hydroxylation cross-linking reaction to prepare flame-retardant cellulose, and combine flame-retardant cellulose with The nano antibacterial sol is mixed to prepare a cellulose solution, and then spun to obtain primary fibers, and the primary fibers are treated to obtain antibacterial and flame-retardant fibers. The invention also discloses a method for preparing the antibacterial and flame-retardant fabric. The invention discloses a method for preparing antibacterial and flame-retardant fibers. The antibacterial and flame-retardant fibers are prepared by using waste and old white pure cotton fabrics, which can make full use of resources and reduce environmental pollution. The antibacterial and flame-retardant fabrics prepared by using the fibers have long-lasting antibacterial and flame-retardant properties. Stable and washable, after 50 times, the antibacterial and flame retardant properties still meet the standard requirements.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

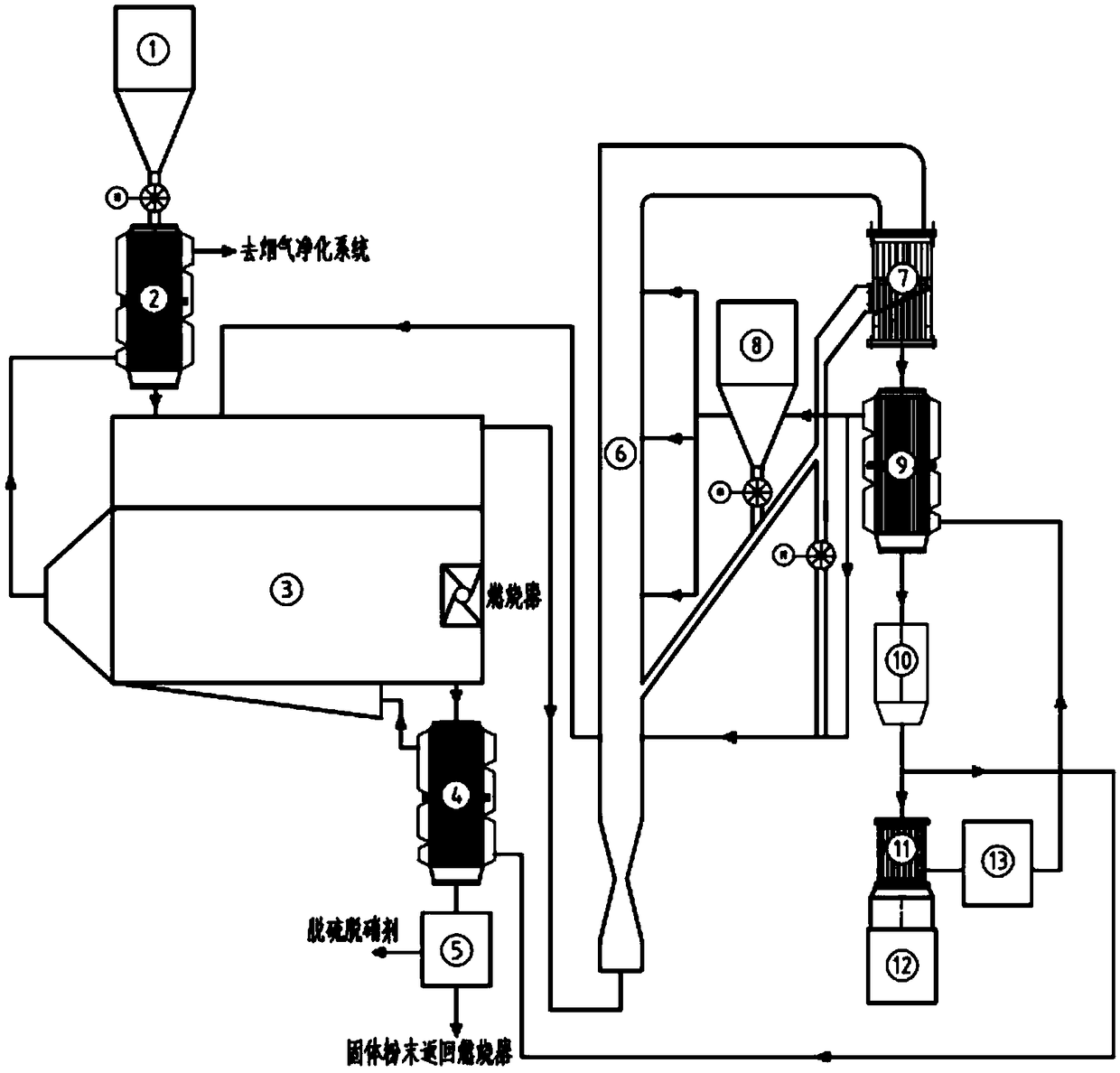

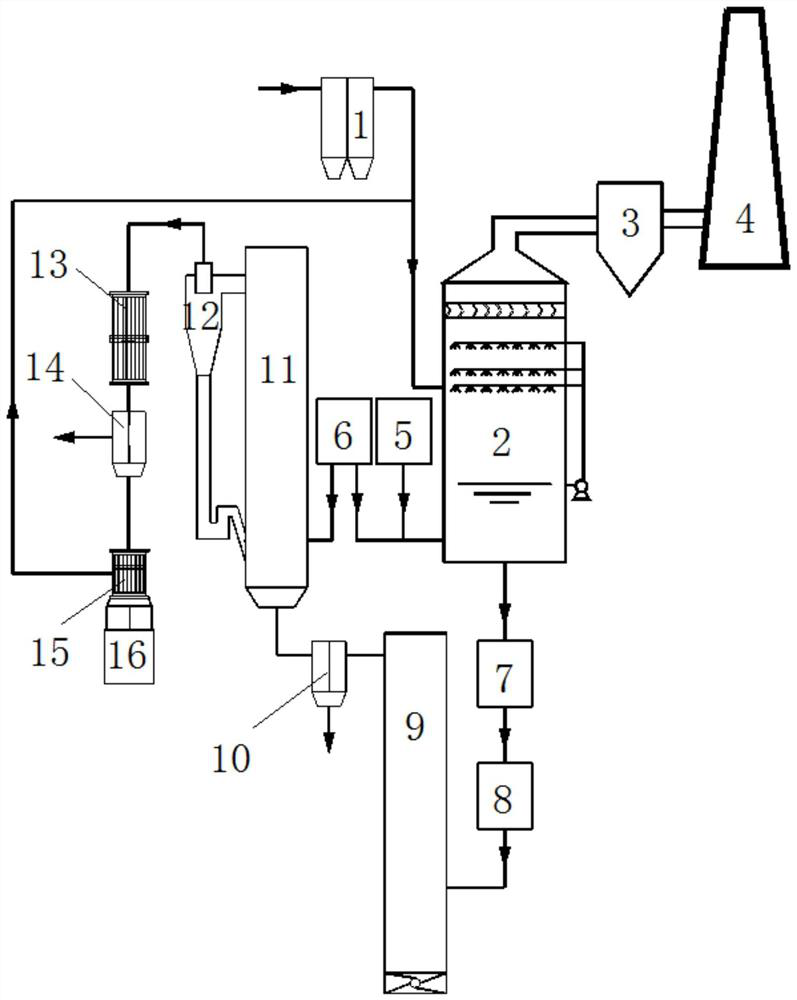

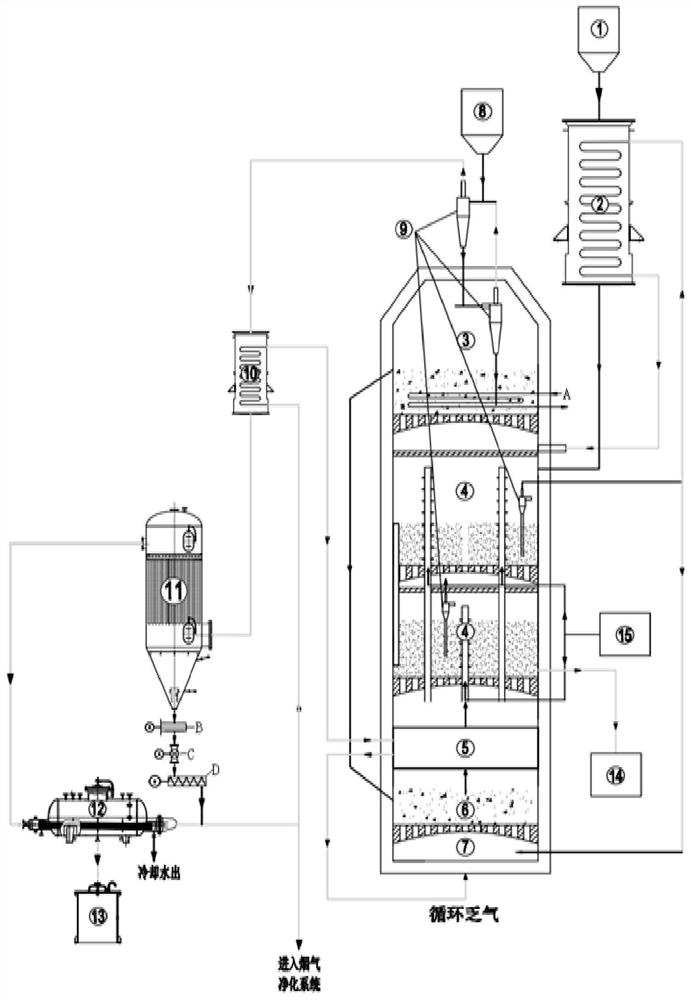

Calcium/magnesium-based wet desulfurization and calcium/magnesium sulfite resource utilization system and process

ActiveCN109499344BAlleviate the current situation of resource shortageReduce external dependenceGas treatmentDispersed particle separationMagnesium sulfiteCalcium sulfite

The invention discloses a calcium / magnesium-based wet desulfurization and calcium / magnesium sulfite resource utilization system and process. SO 2 React with calcium / magnesium-based desulfurization slurry to generate calcium / magnesium sulfite, and add oxidation inhibitors to the desulfurization slurry to inhibit the oxidation of calcium / magnesium sulfite to calcium / magnesium sulfate. For high concentrations of SO produced by calcium / magnesium sulfite roasting 2 The flue gas undergoes a reduction reaction at high temperature and is directly reduced to elemental sulfur vapor. After dust removal, temperature reduction, and fine dust removal processes, sulfur is recovered by the sulfur recovery device. Calcium / magnesium oxide is used as a desulfurizer and returned to the desulfurization tower for recycling.

Owner:SHANDONG UNIV

A kind of method that takes biomass as raw material to prepare biogasoline

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

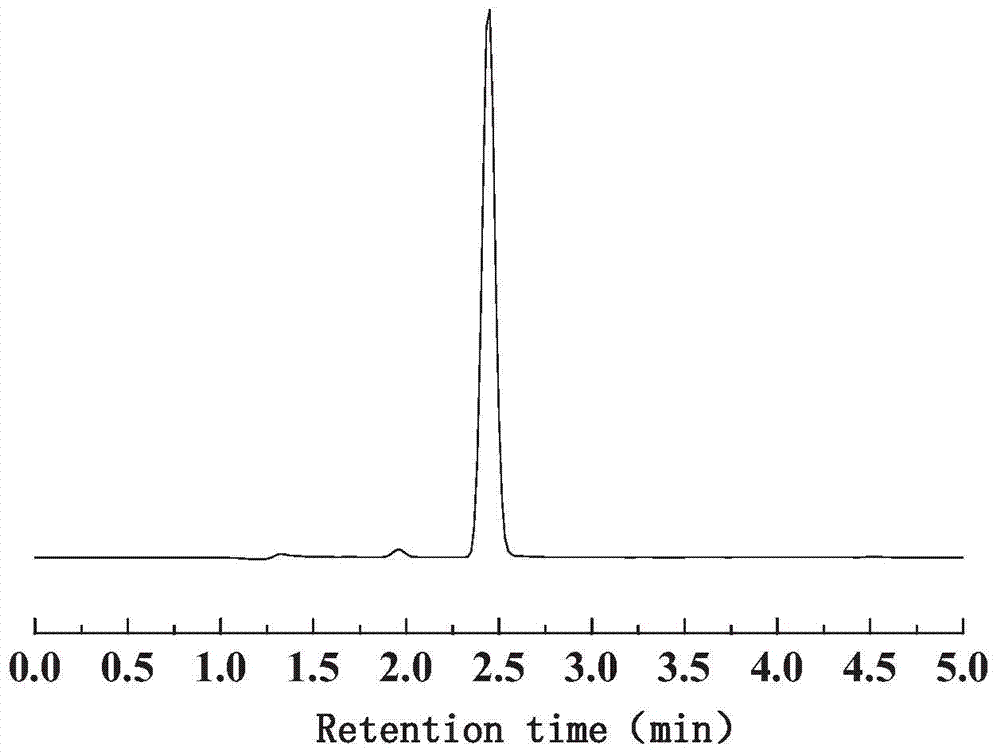

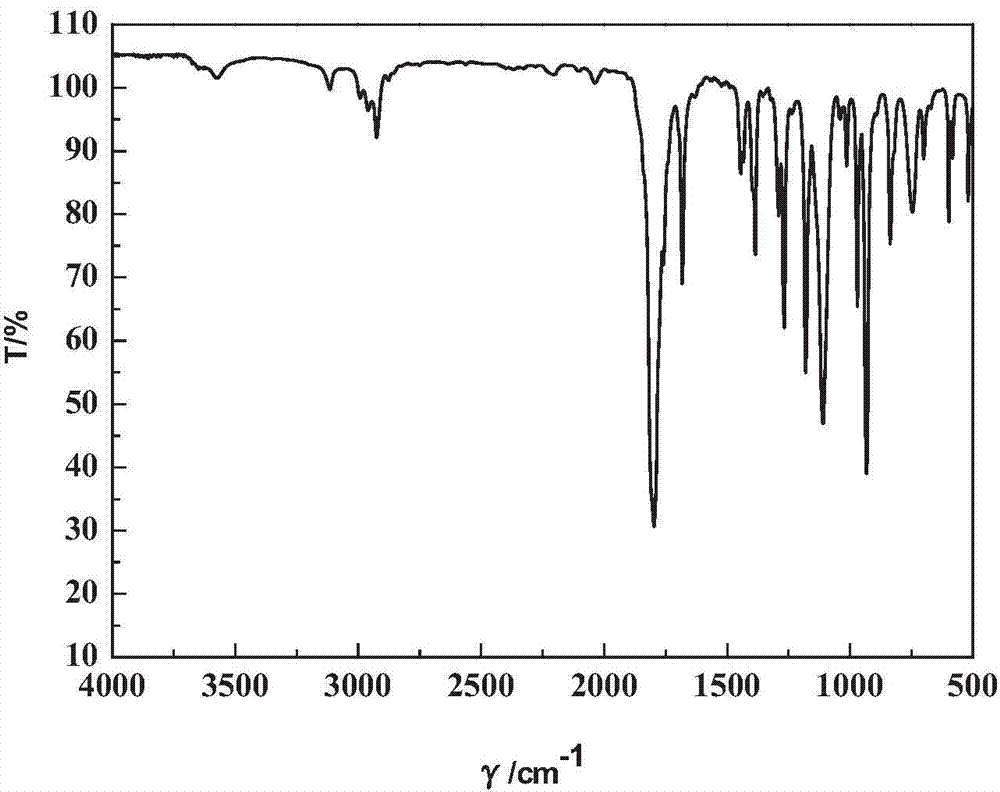

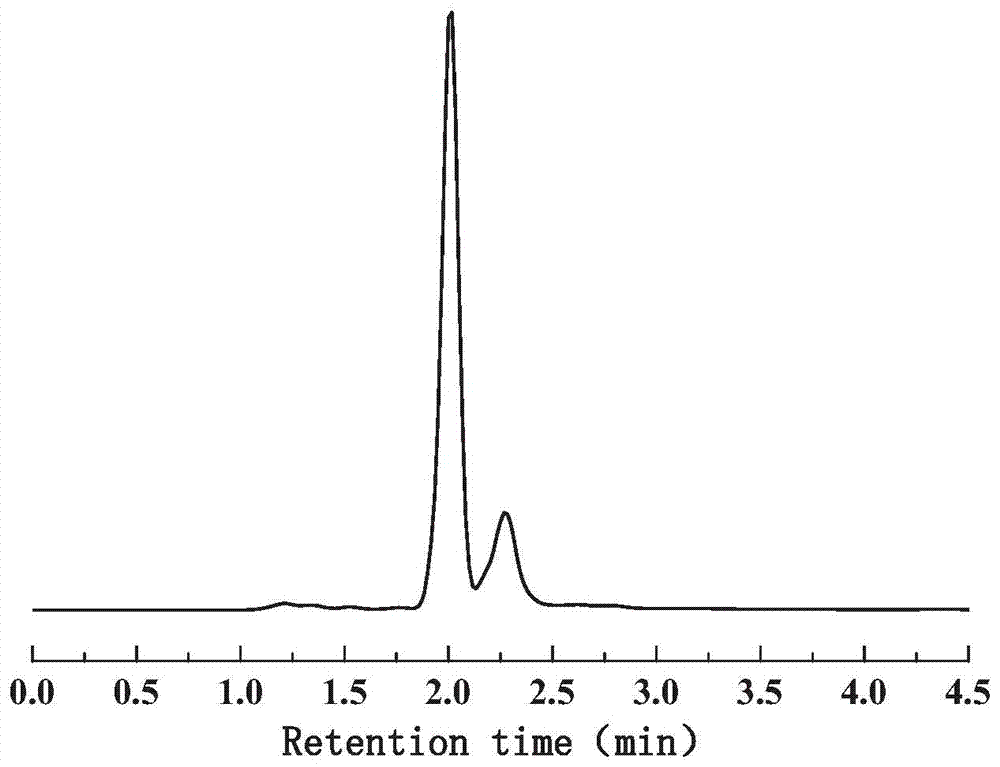

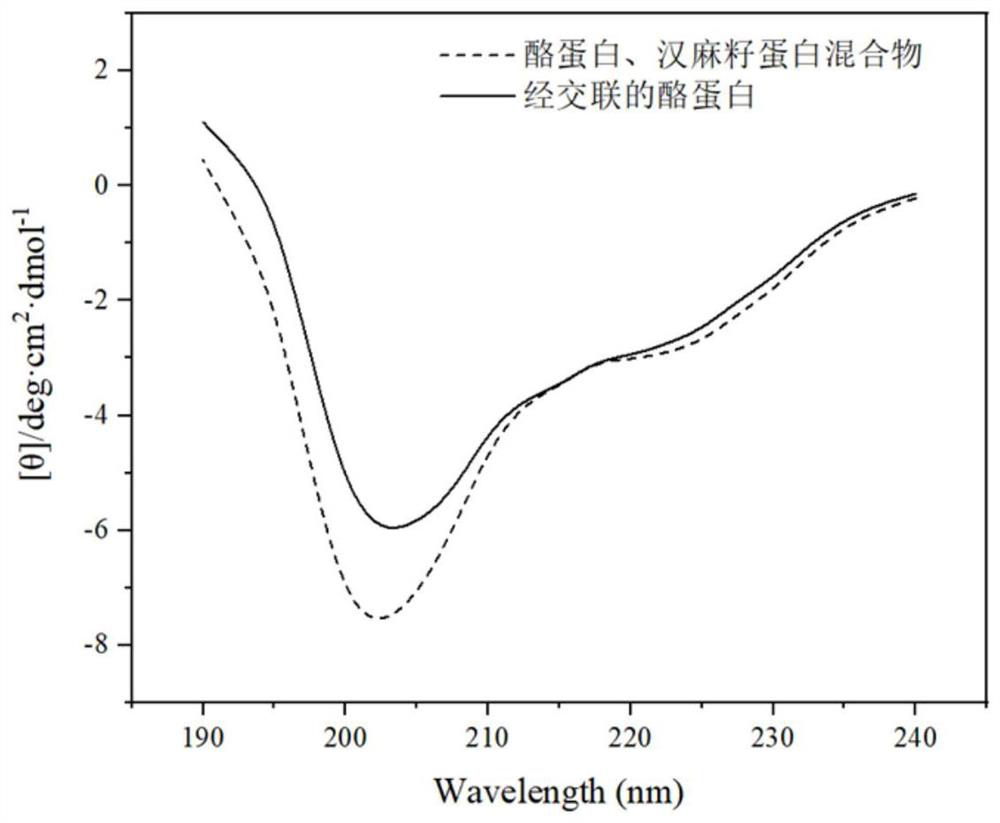

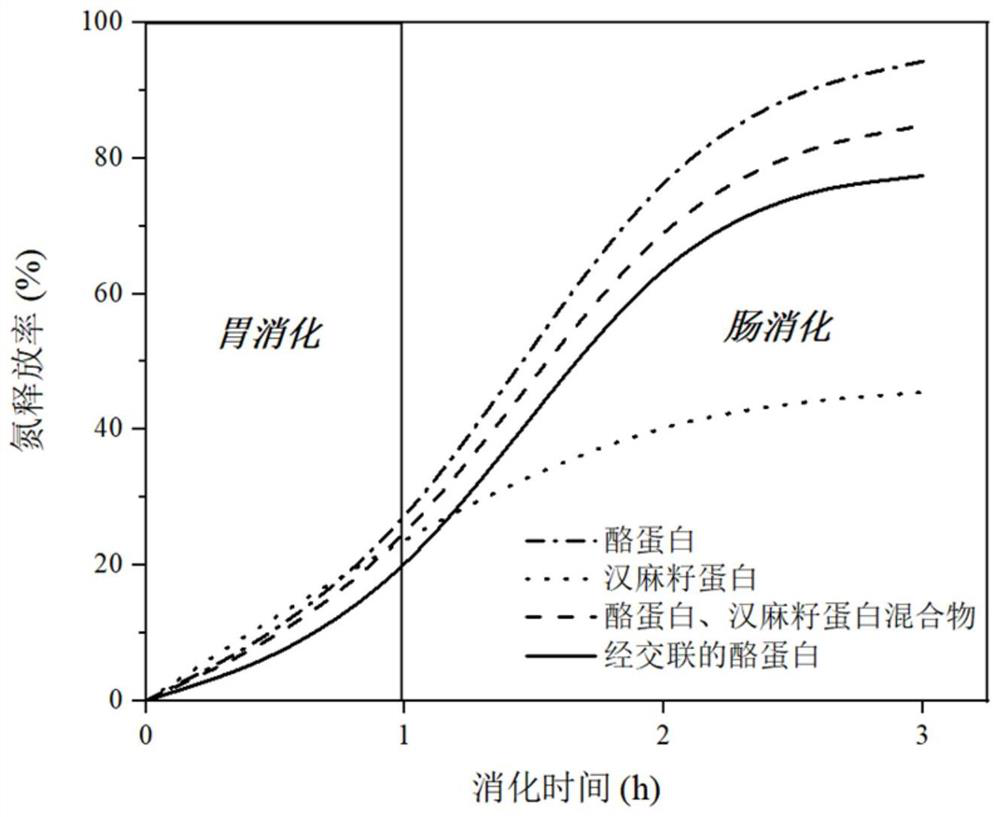

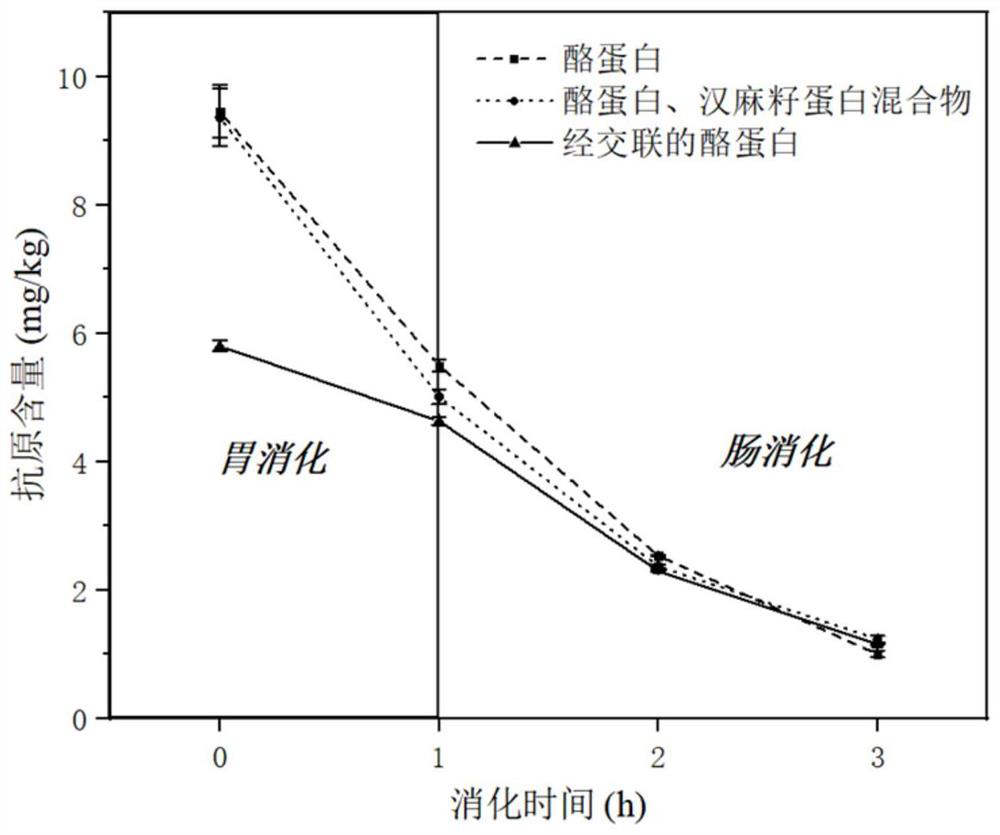

Method for improving enzymolysis resistance of casein and reducing sensitization

PendingCN114277074AImprove resistance to enzymatic hydrolysisAllergenicity reductionPeptide preparation methodsFermentationBiotechnologyNovel food

The invention relates to a method for improving enzymolysis resistance of casein and reducing sensitization, which is used for cross-linking China-hemp seed protein and casein through transglutaminase, and specifically comprises the following steps: (1) preparing a mixed solution of casein and China-hemp seed protein; (2) adding transglutaminase into the mixed solution of the casein and the hemp seed protein, and carrying out cross-linking reaction to obtain a cross-linked casein solution; and (3) placing the cross-linked casein solution in an environment of 3-5 DEG C, and terminating cross-linking. Compared with the prior art, the method has the advantages that the process steps are simple, the novel food resource, namely the hemp seed protein, is fully utilized, the casein is replaced by the hemp seed protein, the sensitization of the casein is further reduced, the enzymolysis resistance of the casein is improved, and the delivery effect of the casein on sensitive substances in the fields of food and pharmacy is improved.

Owner:SHANGHAI JIAO TONG UNIV

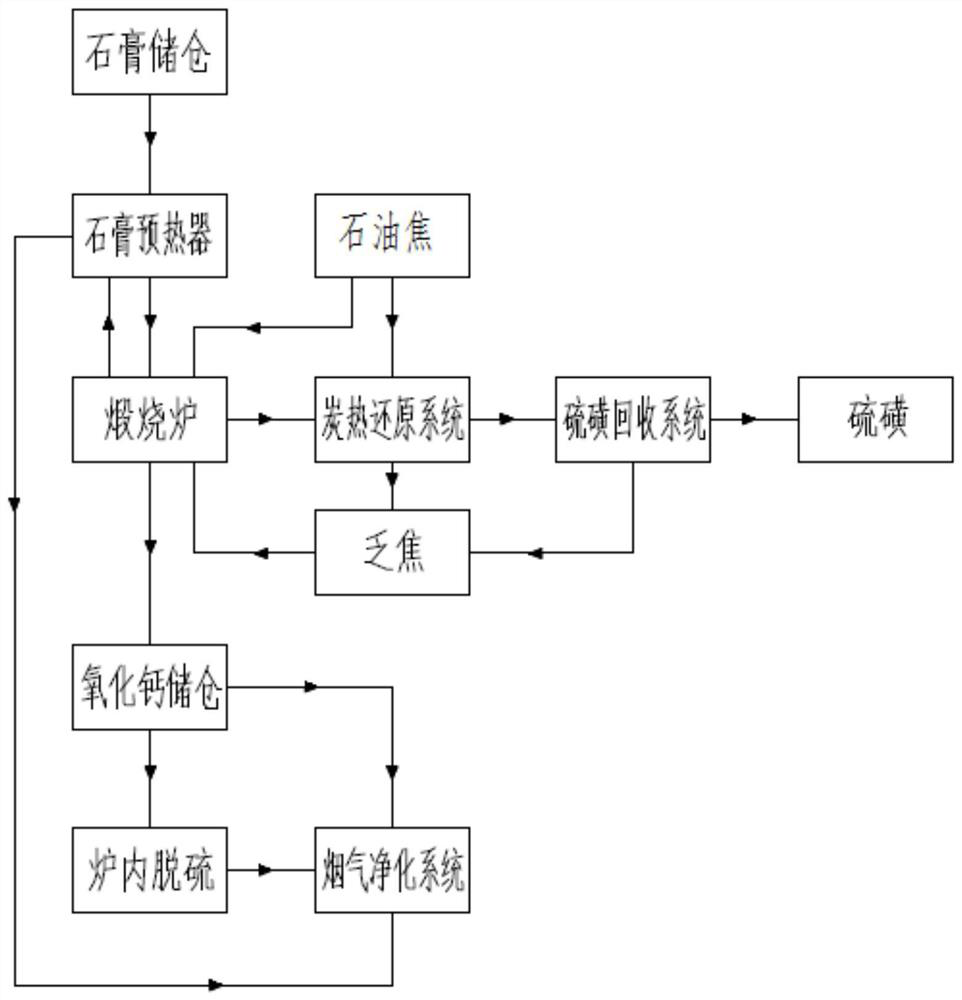

A system and method for synergistic gypsum calcination and carbon thermal reduction of petroleum coke

ActiveCN110950309BImprove desulfurization efficiencyHigh yieldSulfur preparation/purificationCalcium/strontium/barium oxides/hydroxidesThermodynamicsPetroleum coke

The invention discloses a system and method for petroleum coke synergistic gypsum calcination and charcoal thermal reduction. The system and the calcination furnace are divided into an upper section and a lower section, the upper section is an oxidation calcination area, and the lower section is a reduction calcination area. An oxygen-containing gas inlet is provided; the lower section is respectively connected with the gypsum source and the petroleum coke source; the carbon thermal reduction tower, its gas inlet is connected with the gas outlet of the calciner through a high-temperature separator, its solid inlet is connected with the petroleum coke source, and its solid outlet It is connected with the calciner; the gas inlet of the sulfur recovery device is connected with the gas outlet of the carbon thermal reduction tower. Not only can it solve the problem that low-grade industrial gypsum (mainly calcium sulfate) and high-sulfur carbon materials in China are difficult to handle, but it can also make them collaborative resource utilization and recover high-quality sulfur and calcium oxide. Alleviate the current situation of shortage of sulfur resources in our country and reduce the foreign dependence on sulfur resources. In addition, calcium oxide can replace limestone as a desulfurization agent for wet desulfurization.

Owner:SHANDONG UNIV

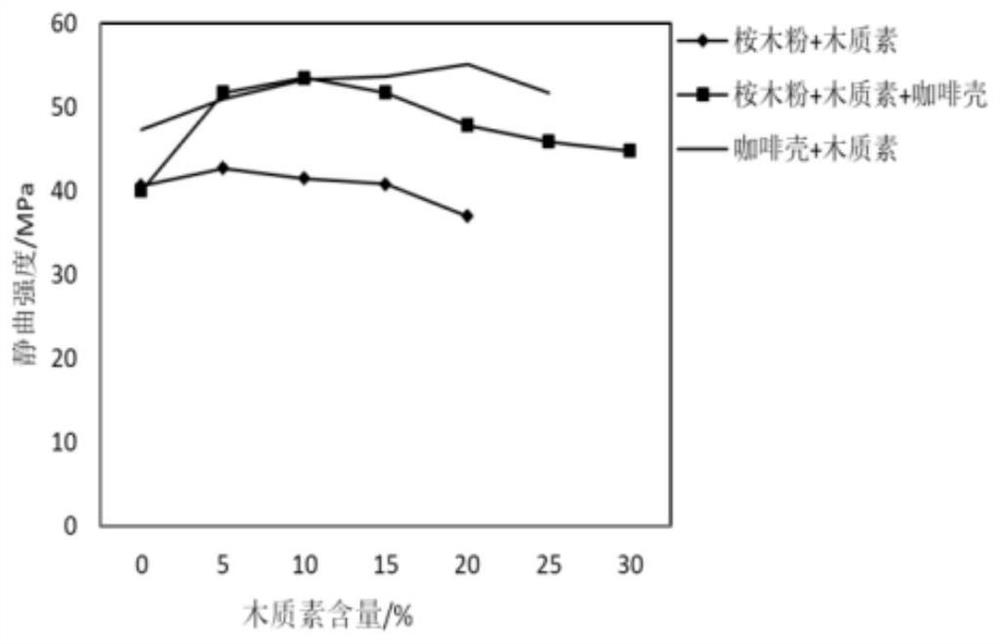

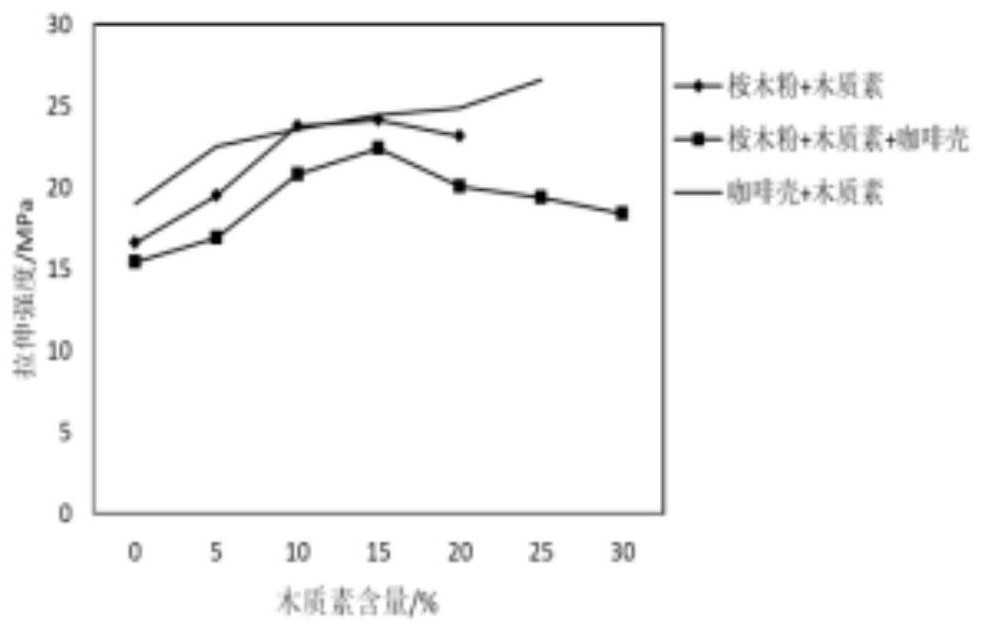

A wood-plastic composite material based on lignin and coffee shell powder and its preparation method

ActiveCN110643191BAlleviate the need for high volumeAlleviate the current situation of resource shortageLubricantWood flour

The invention discloses a wood-plastic composite material prepared from lignin and coffee husk powder and a preparation method thereof. The material includes the following raw materials in mass percentages: 5%-30% of lignin, 5%-60% of coffee husk powder, wood powder 0‑30%, density 0.90‑0.96g / cm 3 20‑30% polyethylene, 0‑10% compatibilizer, 8% filler, 1% lubricant and 1% dispersant. The multiple properties of the composite material of the present invention are greatly improved, and at the same time, the anti-fungal erosion effect of the wood-plastic composite material is also significantly improved. During the aging process of the wood-plastic composite material, its biological durability can be improved, and it has the advantages of Broad application prospects.

Owner:SOUTHWEST FORESTRY UNIVERSITY

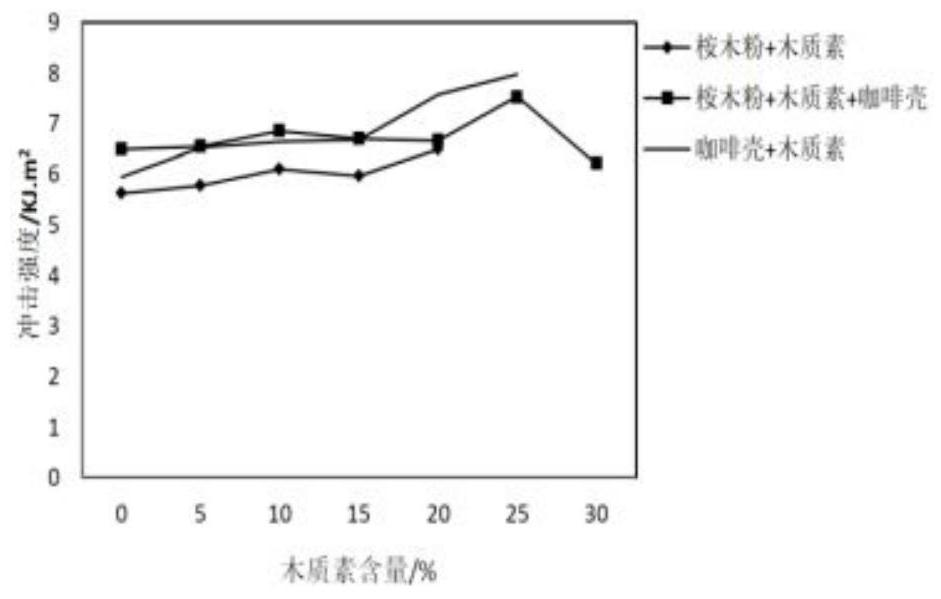

A kind of slow-release fertilizer for soil improvement and its preparation method and application

ActiveCN105367346BIncrease profitRealize secondary useBioloigcal waste fertilisersEnergy inputSoil heavy metalsPlant growth

The invention discloses slow-release fertilizer for soil improvement and a preparation method and application thereof. The method is easy to operate, cost is low, raw materials can be obtained easily, the effect is obvious, secondary pollution can be avoided, and the method is poisonless, harmless and more environmentally friendly. Ground phosphate rock is activated through high temperatures and acid liquor, the soluble phosphate content is increased, and the plant growth requirement is met. Meanwhile, crop waste is added and ferric salt is loaded, so that loose and porous charcoal is generated at the high temperature for improving soil; generated ferric oxide can adsorb and fix heavy metal at the same time, and soil improvement and slow release of fertilizer are integrated. The utilization rate of the ground phosphate rock is increased by activating the ground phosphate rock, the shortage current situation of phosphate rock resources is relieved, and secondary utilization of waste is realized by using the crop waste. The slow-release effect of slow-release fertilizer phosphorus for soil improvement is good, the requirement for the biological activity of plants is met, and phosphorus losses can be avoided. The slow-release fertilizer has the advantages of adsorbing and fixing the heavy metal of the soil, reducing soil hardening, increasing soil bulk density and the like; the grain yield is increased, and the grain safety is guaranteed.

Owner:SOUTH CHINA AGRI UNIV

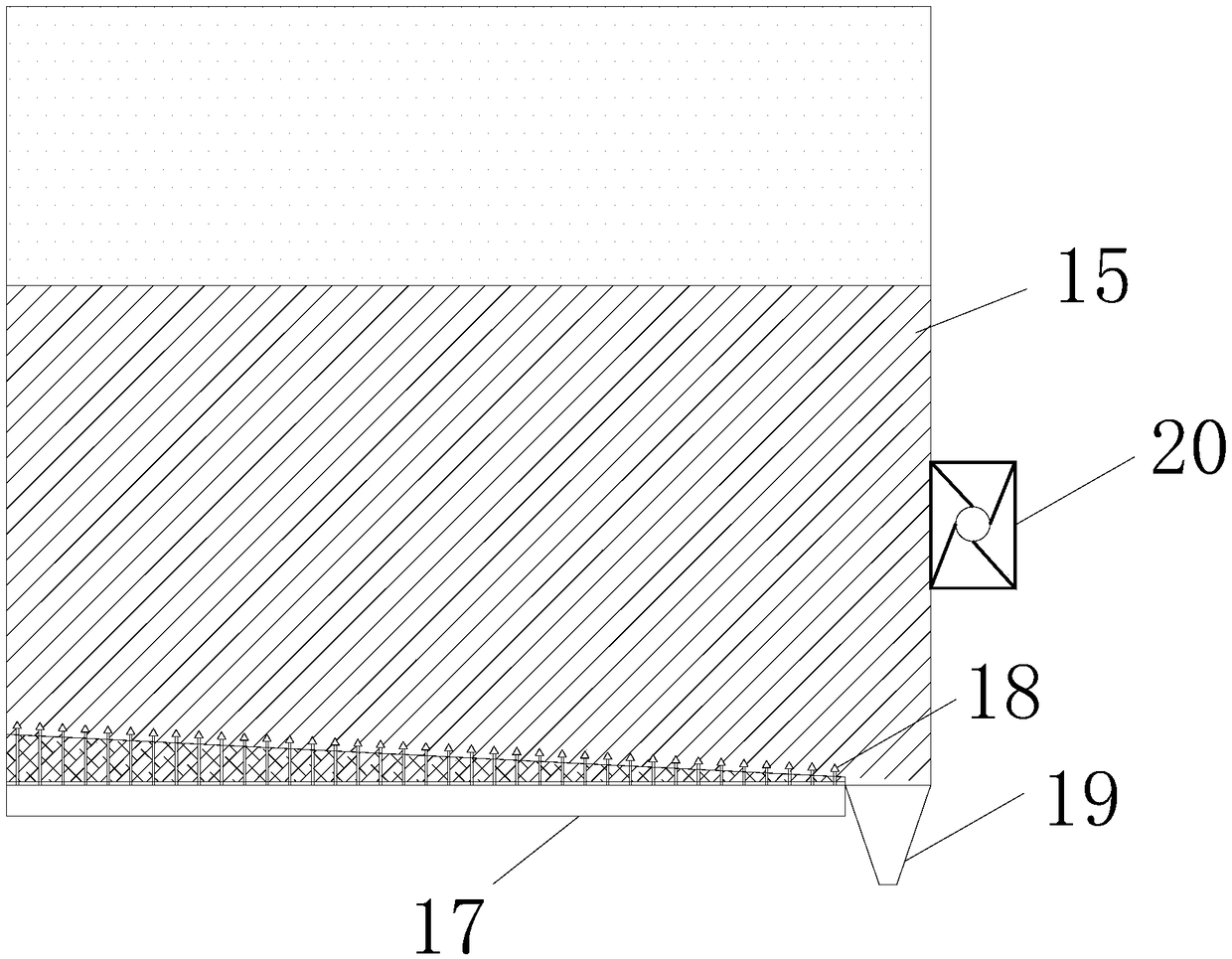

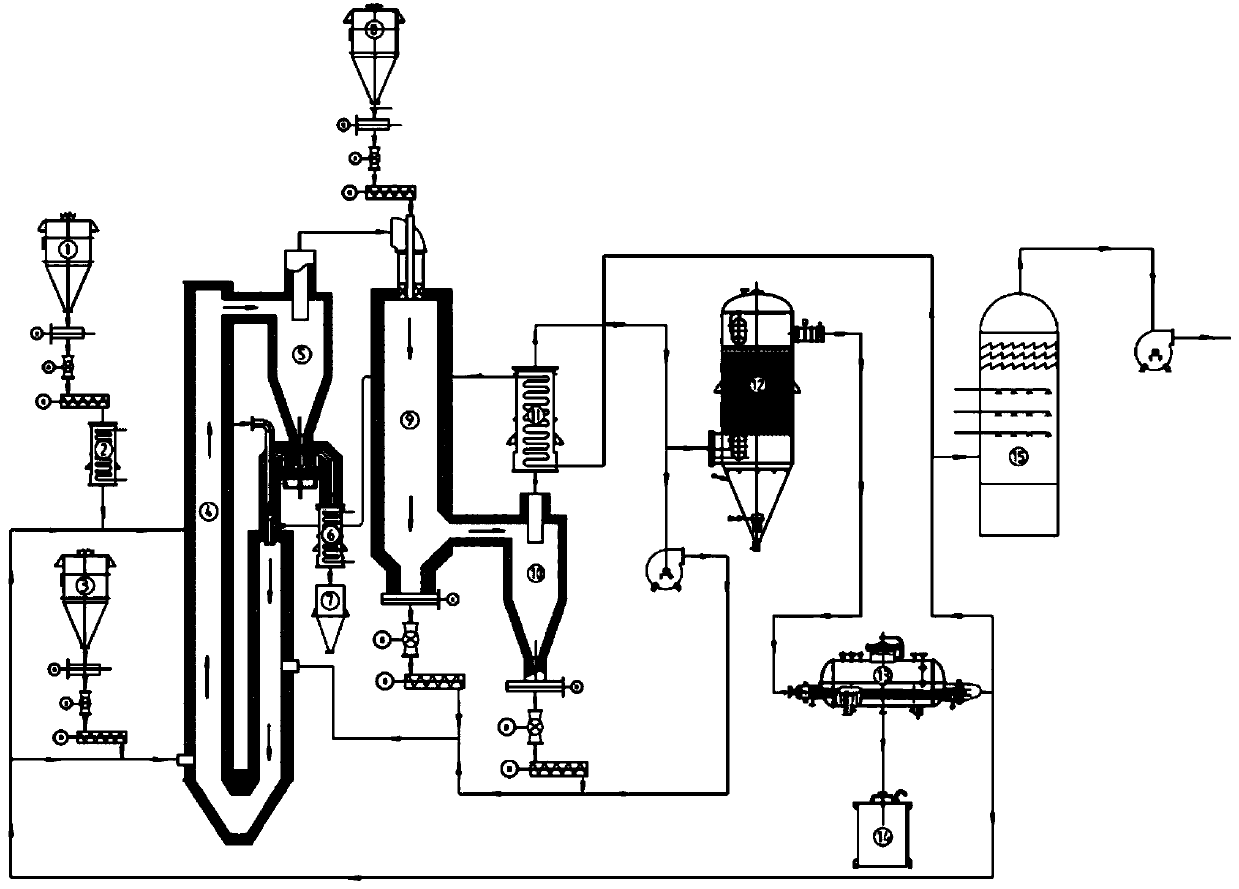

Device and method for preparing sulfur by coal gasification in conjunction with calcium sulfate calcination and carbon thermal reduction

ActiveCN109775666BReduce decompositionReduce the temperatureSulfur preparation/purificationFlue gasSulfate

The invention relates to a process and method for preparing sulfur by coal gasification in conjunction with calcium sulfate calcination and charcoal thermal reduction. For the reaction of calcium sulfate with carbon materials and sulfur at high temperature to produce high concentration of SO 2 Flue gas and metal calcium oxide, using U-shaped coal gasification calciner, charcoal thermal reduction tower, sulfur recovery device and various heat exchangers, etc., through precise control of various reaction conditions, sulfur is prepared from solid waste calcium sulfate that is difficult to handle, and at the same time Calcium oxide is a by-product, which can replace limestone as a desulfurization and denitrification agent.

Owner:SHANDONG UNIV

A kind of hardenability gear steel and preparation method thereof

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Method for preparing biological gasoline from biomass

The invention relates to a method for preparing biological gasoline from biomass, which comprises the following steps: biomass hydrolysis: hydrolyzing biomass in 0.1-10% dilute acid at 140-220 DEG C for 5-240 minutes to prepare levulinic acid; carrying out dehydration reaction on the levulinic acid at 130-180 DEG C for 60-180 minutes under the action of 0.1-5% liquid acid, acidic ionic liquid or molecular sieve to prepare angelica lactone; carrying out polymerization reaction on the angelica lactone at 60-160 DEG C for 1-180 minutes under the action of 0.1-5% inorganic alkali to prepare an angelica lactone polymer; and carrying out hydrogenation reaction on the angelica lactone polymer at 200-400 DEG C for 4-60 hours under the action of a 0.1-5% catalyst to obtain the final product biological gasoline. The method can greatly enhance the carbon utilization ratio, reduce the carbon dioxide emission, and lower the dependence on petroleum and other nonrenewable resources. The method has the advantages of short technical process and mild reaction conditions; and the product has the advantages of high yield and high quality.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Device and method for triple production of iron, sulfur and gas in pyrite smelting process

ActiveCN108970354BEfficient and clean utilizationAlleviate the current situation of resource shortageGas treatmentDispersed particle separationSmelting processFlue gas

The invention relates to a device and method for joint production of iron, sulfur and gas in the smelting process of pyrite, and belongs to the field of metal smelting. The method comprises the following steps of calcining the pyrite at the bottom part of the interior of a calcining-gasifying reaction tower, enabling pulverized coal and fly ash to generate gasifying reaction at the middle upper part, enabling the sulfur-containing flue gas to carry the high-valence oxide of iron produced by calcining at the tower bottom to the middle upper part of the reaction tower, mixing with the gas and coke produced by gasifying, and generating oxidation and reduction reaction; separating the product by an iron-based high-temperature separator and a carbon-based high-temperature separator, and sendingback into an iron oxide reduction tower; performing secondary reduction reaction on the iron oxide in the iron oxide reduction tower, and producing reduction gas, so as to obtain iron slag; purifyingthe crude gas, so as to obtain the purified gas; enabling a sulfur condenser to condense and recycle the sulfur. The method has the advantages that the joint production of iron, sulfur and gas is realized in the smelting process of the pyrite, and the pyrite can be efficiently and cleanly utilized.

Owner:SHANDONG UNIV

A process and device for gypsum calcination in conjunction with co-coupled carbon thermal reduction

ActiveCN111498811BHigh market valueLower decomposition temperatureEnergy inputSulfur preparation/purificationActivated carbonFlue gas

The invention relates to a process and device for gypsum calcination coordinated with CO coupled carbon thermal reduction. Circulating exhaust gas contains high concentration of CO 2 , react with coke to generate CO, part of CO is used to reduce gypsum and SO 2 , the other part is used for supplementary heat in the gypsum reduction and calcination process; after calcination, the flue gas contains high concentration of SO 2 ; Calcined flue gas reacts in the temperature range of 600-1000°C to generate elemental sulfur vapor under the catalysis of activated carbon materials. Sulfur is recovered after the elemental sulfur vapor is cooled and dedusted. Part of the reduced exhaust gas after sulfur recovery enters the flue gas purification system for purification and then is emptied, and the other part is returned to the system as circulating exhaust gas to provide high-concentration CO for the system. 2 . The circulating exhaust gas in the system is preheated by reducing the temperature of the reducing gas. The oxygen-enriched oxygen supplemented by the gypsum reduction and calcination process is preheated by cooling the calcined product quicklime and exothermic. The gypsum is dried and preheated by the calcination flue gas. This system realizes the energy level Utilization; in order to achieve the heat balance of the system, an external heat source is needed to supplement the heat of the system.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com