A process and device for gypsum calcination in conjunction with co-coupled carbon thermal reduction

A gypsum and calcination technology, which is applied in the process and device field of gypsum calcination and CO coupled carbon-thermal reduction, can solve problems such as ecological environment and human health impact, waste of sulfur resources, etc. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

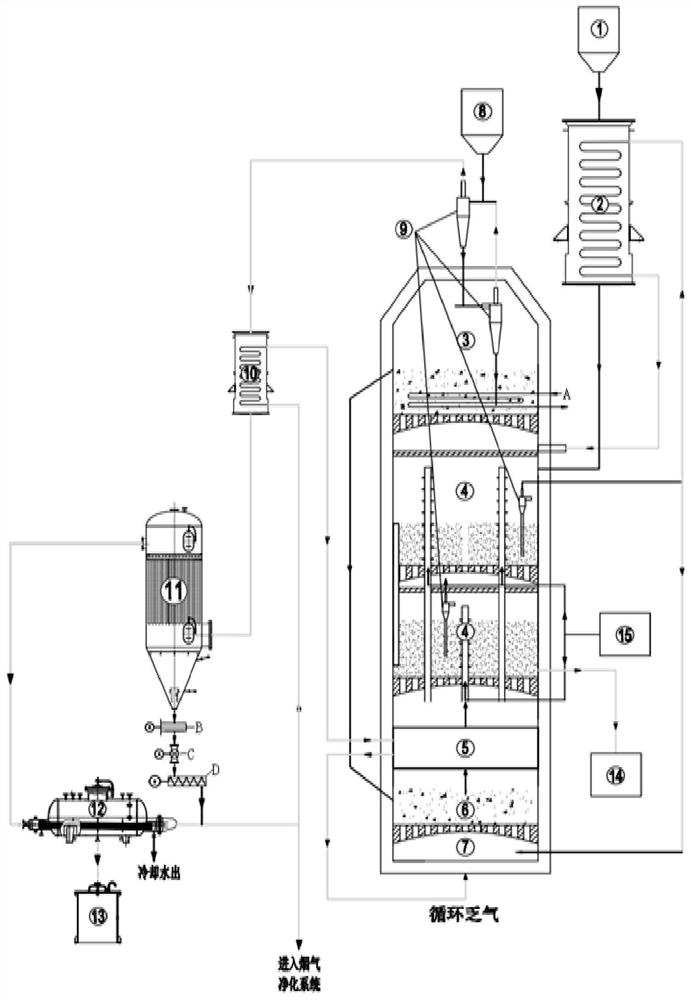

[0056] A process and device for gypsum calcination coordinated with CO coupled carbon thermal reduction, mainly including:

[0057] The gypsum is stored in the gypsum bin, and the feeding amount is precisely controlled by the feeder to be transported to the gypsum preheater for preheating and drying. The high-temperature heat source comes from the calcination flue gas discharged from the gypsum calcination section; the temperature of the gypsum after preheating and drying is 600- 1050°C, first enter the upper part of the gypsum calcining section, which is divided into upper and lower layers. During the last gypsum calcining process, it entered the lower part of the gypsum calcining section through the overflow pipe for secondary calcination to ensure sufficient solid residence time to obtain higher quicklime Yield, the temperature of the gypsum calcination section is 700-1200°C; the quicklime product produced by calcination is cooled to 20-50°C and stored in the quicklime stora...

Embodiment 2

[0059] A system for gypsum calcination coordinated with CO coupled carbon thermal reduction, including: calcination furnace, gypsum bin 1, gypsum preheater 2, carbon material bin 8, reheater 10, high-temperature filter 11, sulfur recovery device 12, quicklime storage Bin 14; the calciner is divided into SO from top to bottom 2 Reduction section 3, gypsum calcining section 4, external heat source 5, coke gasification section 6 and gas mixing section 7; the feed port of the gypsum calcining section 4 is connected to the gypsum preheater 2 and the gypsum bin 1 in sequence, and the gypsum The discharge port of the calcining section 4 is connected with the quicklime storage bin 14; the SO 2 The reduction section 3 is connected with the carbon material warehouse 8, and the SO 2 Reduction section 3 is also connected with high temperature separator 1, reheater 10, high temperature filter 11 and sulfur recovery device 12 in sequence; said reheater 10 is also connected with the air inl...

Embodiment 3

[0061]A system for gypsum calcination coordinated with CO coupled carbon thermal reduction, including: calcination furnace, gypsum bin 1, gypsum preheater 2, carbon material bin 8, reheater 10, high-temperature filter 11, sulfur recovery device 12, quicklime storage Bin 14; the calciner is divided into SO from top to bottom 2 Reduction section 3, gypsum calcining section 4, external heat source 5, coke gasification section 6 and gas mixing section 7; the feed port of the gypsum calcining section 4 is connected to the gypsum preheater 2 and the gypsum bin 1 in sequence, and the gypsum The discharge port of the calcining section 4 is connected with the quicklime storage bin 14; the SO 2 The reduction section 3 is connected with the carbon material warehouse 8, and the SO 2 Reduction section 3 is also connected with high temperature separator 1, reheater 10, high temperature filter 11 and sulfur recovery device 12 in sequence; said reheater 10 is also connected with the air inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com