Patents

Literature

117results about How to "Improve the effect of magnetic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation and purification method of electrolytic aluminum scraps

ActiveCN101818253ASolve stubborn problemsImprove the effect of magnetic separationProcess efficiency improvementPurification methodsIron fluoride

The invention discloses a separation and purification method of electrolytic aluminum scraps, characterized by comprising the following steps of: crushing electrolytic aluminum scraps in a wet type, floating and magnetically separating, firstly removing iron and silicon and separating to obtain carbon powder and another raw material A; and putting the raw material A in an electric furnace, electrifying to dissolve fluoride salt, restoring harmful impurities in the scraps into an elementary substance metal state by utilizing metal aluminum, precipitating at the bottom of the electric furnace and secondarily removing the iron and the silicon to obtain an electrolyte B. The invention has the advantages that metal aluminum particles in electrolytic aluminum scraps in the electric furnace is utilized as a low-cost reducing agent to restore and precipitate iron, silicon and other harmful impurities at the bottom of the furnace when the fluoride salt is in a dissolved state so as to solve the problem that iron fluoride with high stability is hard to remove, and the reducing agent is utilized in the floatation process to improve the magnetic separation effect. For a product obtained in an electric furnace melting system, an acid-method process is adopted to convert alumina into cryolite, thirdly remove silicon and obtain a byproduct of ammonium bicarbonate.

Owner:周俊和 +1

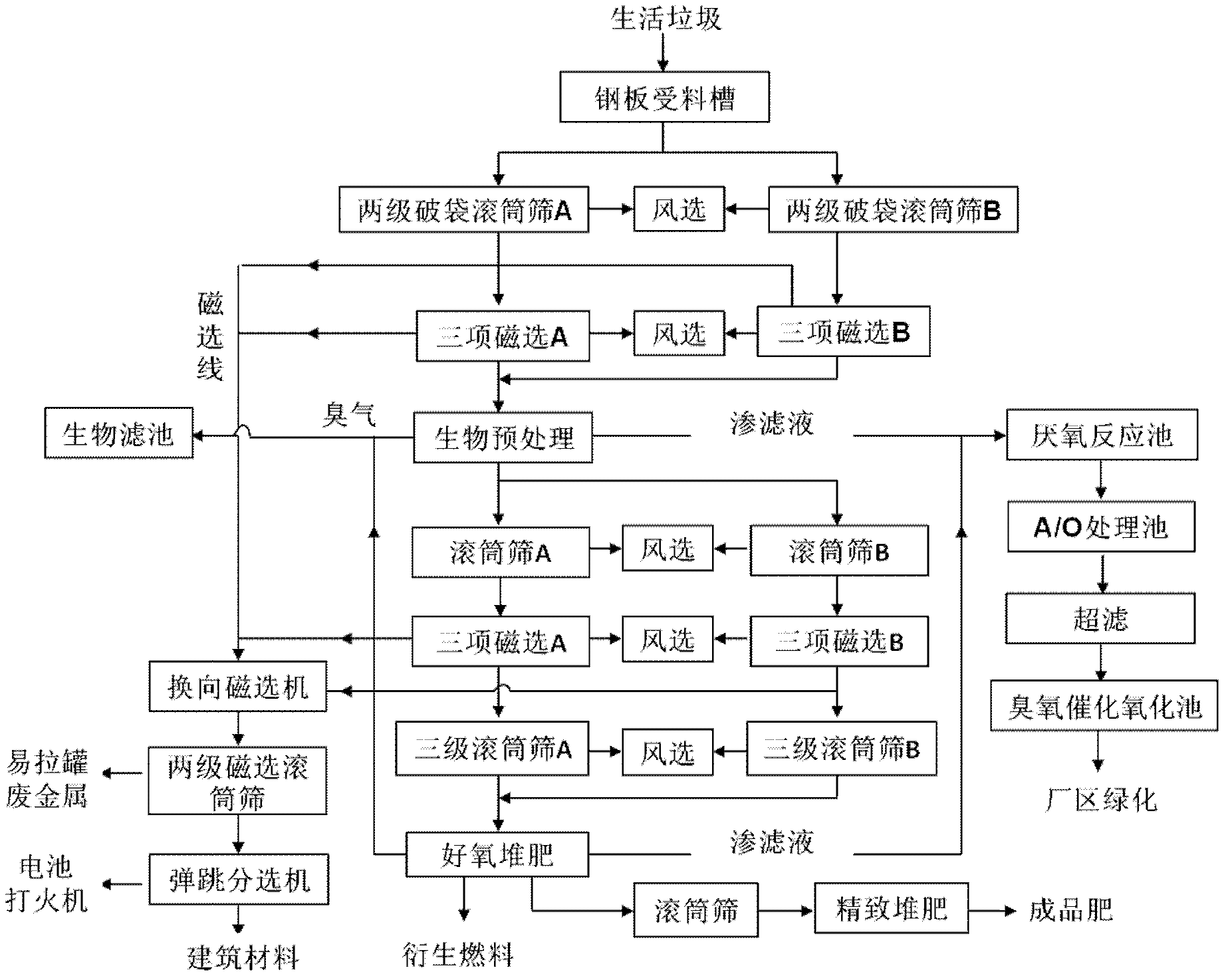

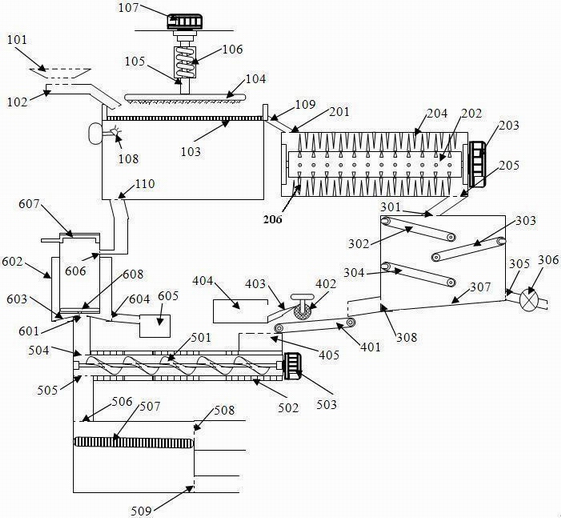

Method for comprehensive treatment of household refuses and secondary pollution control

ActiveCN103008326ACompact layoutReasonable configurationBio-organic fraction processingWaste processingRefuse-derived fuelUnit device

The invention provides a method for comprehensive treatment of household refuses and secondary pollution control. The method comprises the following procedures of: 1) coarse separation of the household refuses; 2) pretreatment of the household refuses; 3) fine separation of the household refuses; 4) aerobic composting of the household refuses; 5) biological organic fertilizer preparation; 6) fabrication of refuse derived fuels; and 7) secondary pollution control. The method employs parallel dual-separation lines which are compact in arrangement; each functional unit device is rational in configuration, easy to operate and mechanically control; the sorting efficiency and the energy source recovery effect are obviously improved; and minimization, harmless treatment, recycling and energy conversion of the household refuses can be realized.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

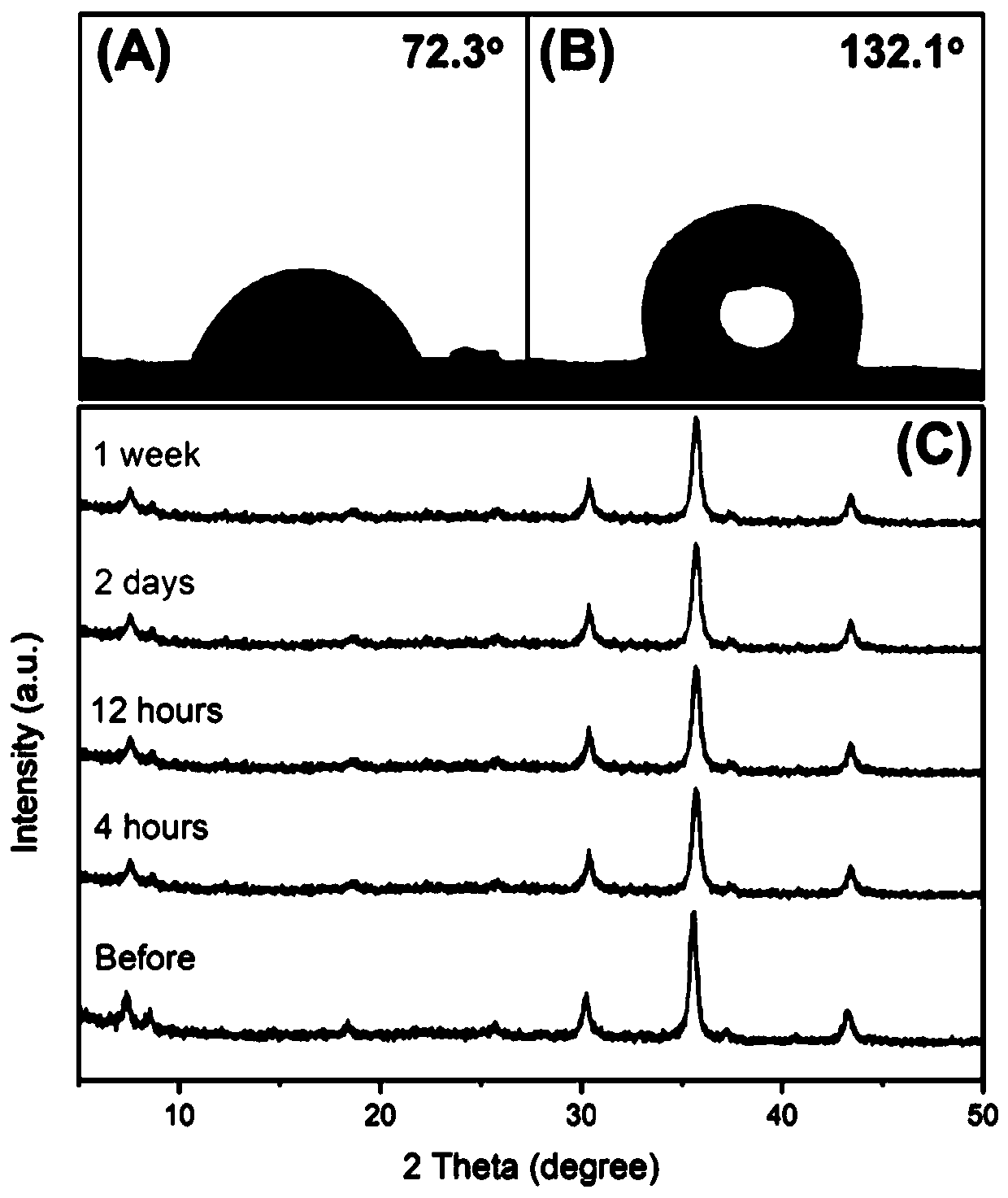

Magnetic selection method for electrolytic aluminum waste material

ActiveCN101811090AImprove the effect of magnetic separationHigh market valueAluminium fluoridesMagnetic separationMagnetiteMagnetic separator

The invention discloses a magnetic selection method for an electrolytic aluminum waste material. The electrolytic aluminum waste material is subjected to wet-type breakage and floating selection. The method is characterized by comprising the following steps of: adding a reducing agent into the electrolytic aluminum waste material; converting the surface of a hematite-contained particle in the waste material into magnetite; and removing ferrum and silicon in magnetic selecting equipment and separating to obtain carbon powder and other raw materials. The hematite (Fe2O3) on the surface of an impurity particle is converted into the magnetite (F3O4) with strong magnetism by utilizing the trace reducing agent in the process of floating selection, the effect of the magnetic selection is greatly improved, and the effect of a gradient magnetic separator can be achieved by adopting a common magnetic separator. Then, the initially separated carbon powder is subjected to alkali type dissolving, the cryolite (Na3AlF6) is separated, and the processed carbon powder (ash content being 1-2 percent) reaches the grade of high-purity carbon powder and greatly improves the market value of products.

Owner:周俊和 +1

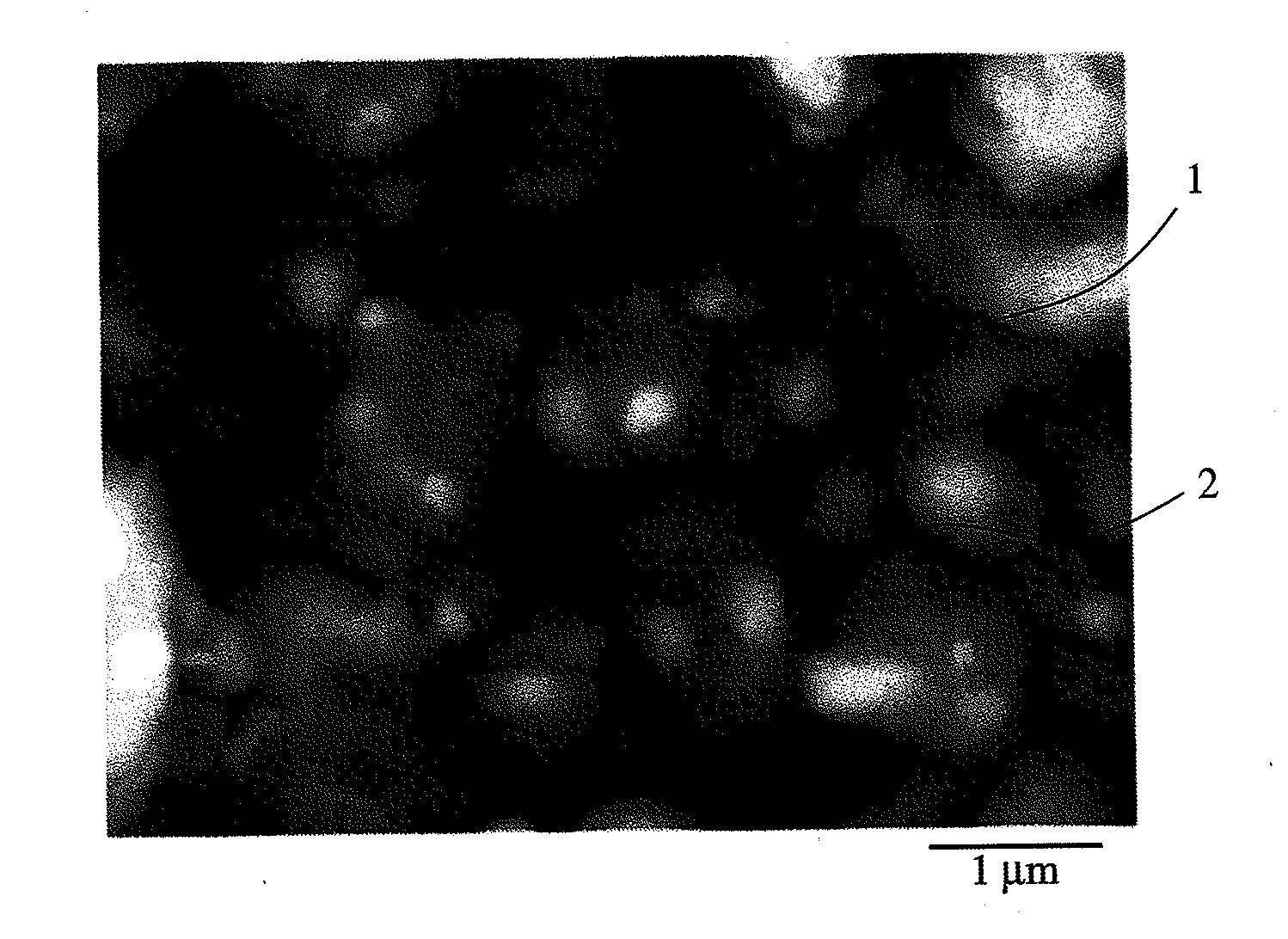

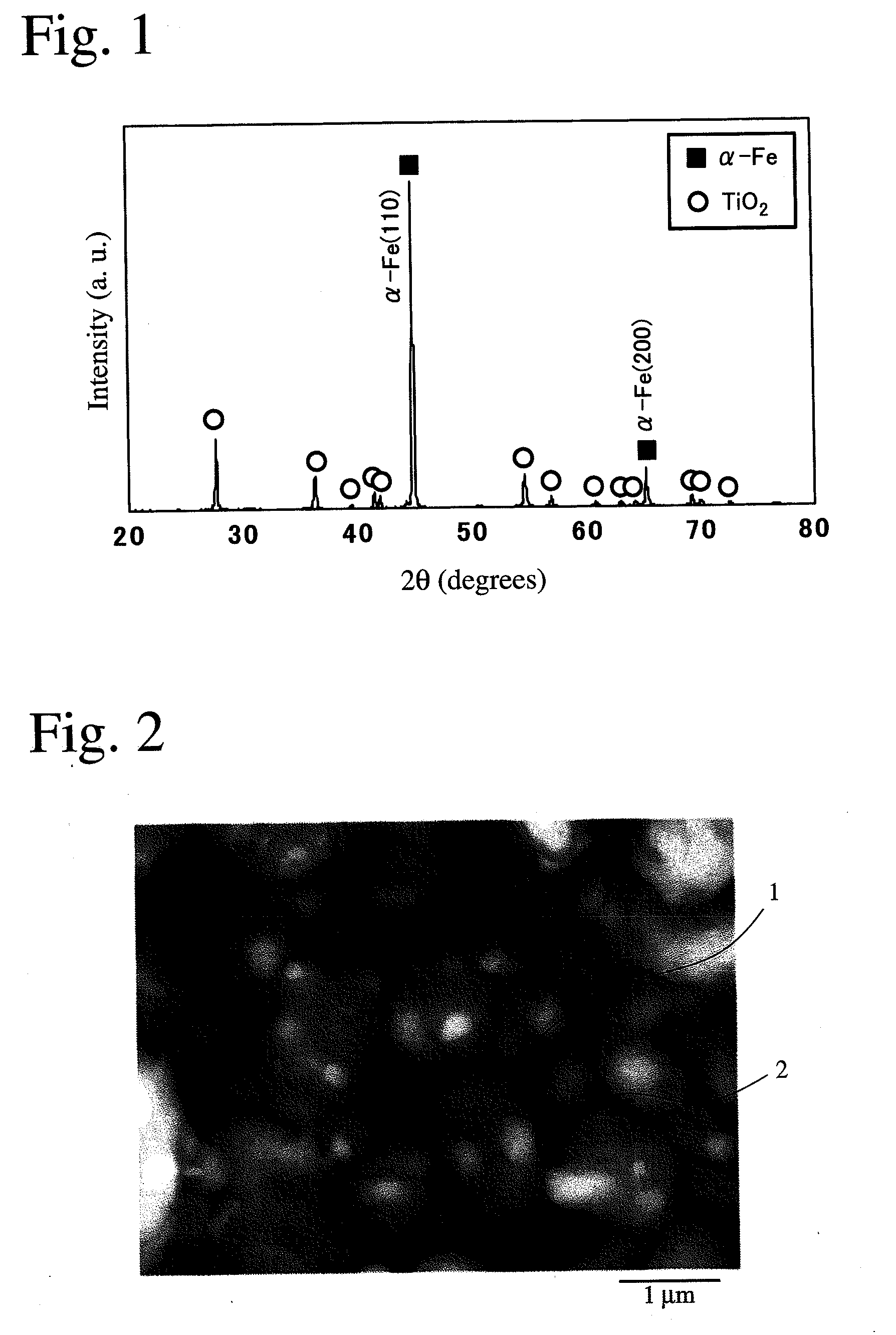

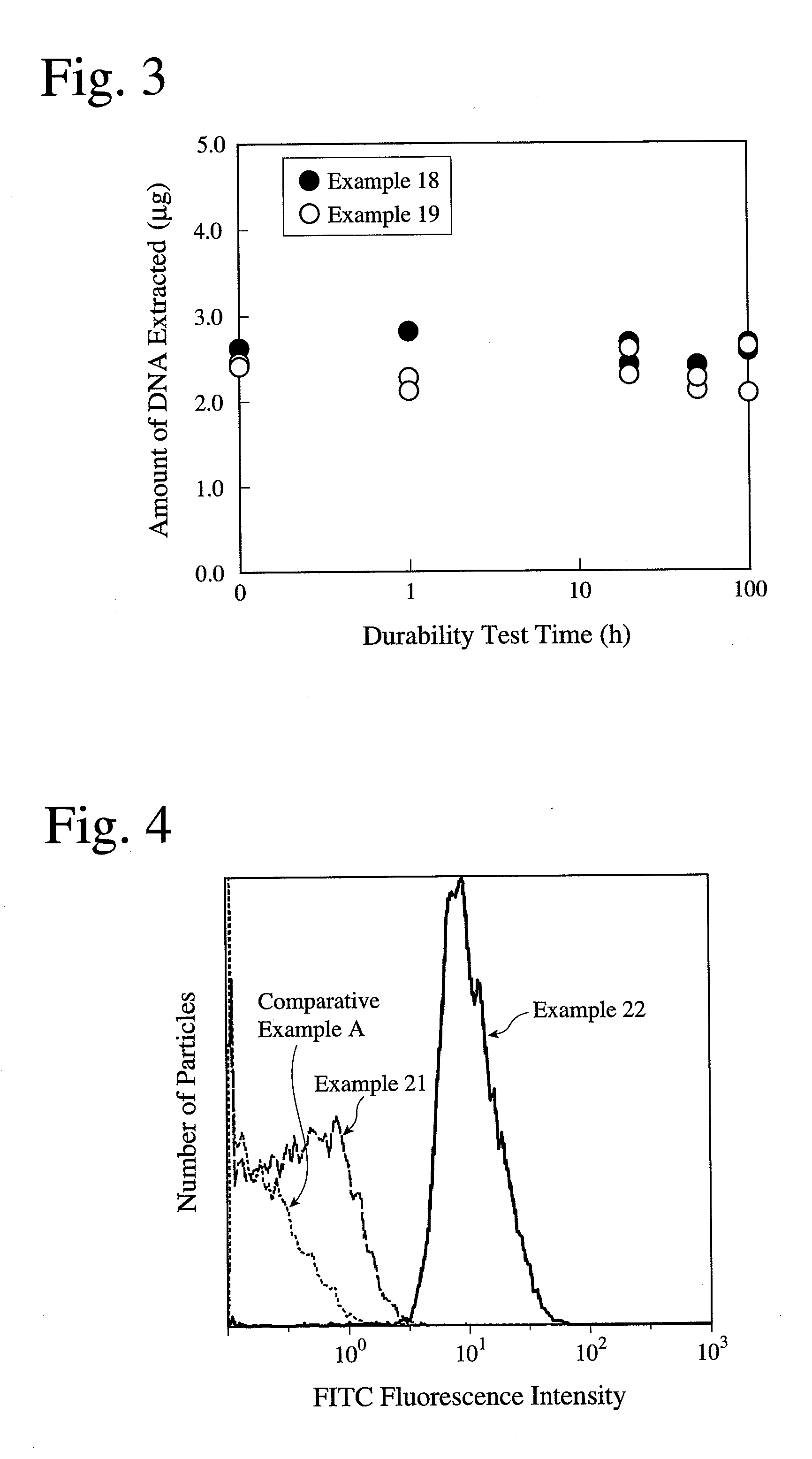

Magnetic particles having porous surfaces, method of producing the same, carrier for biochemical use, and biotin-bonding particles

InactiveUS20060223126A1Improve the effect of magnetic separationImprove bindingBiological testingThin material handlingPolymer scienceOrganosolv

Magnetic particles having porous surfaces are obtained by forming a polymer part (B) soluble in an organic solvent (S) and a polymer part (C) insoluble in the organic solvent (S) on surfaces of magnetic matrix particles (A) and causing the polymer part (B) to come into contact with the organic solvent (S).

Owner:JSR CORPORATIOON

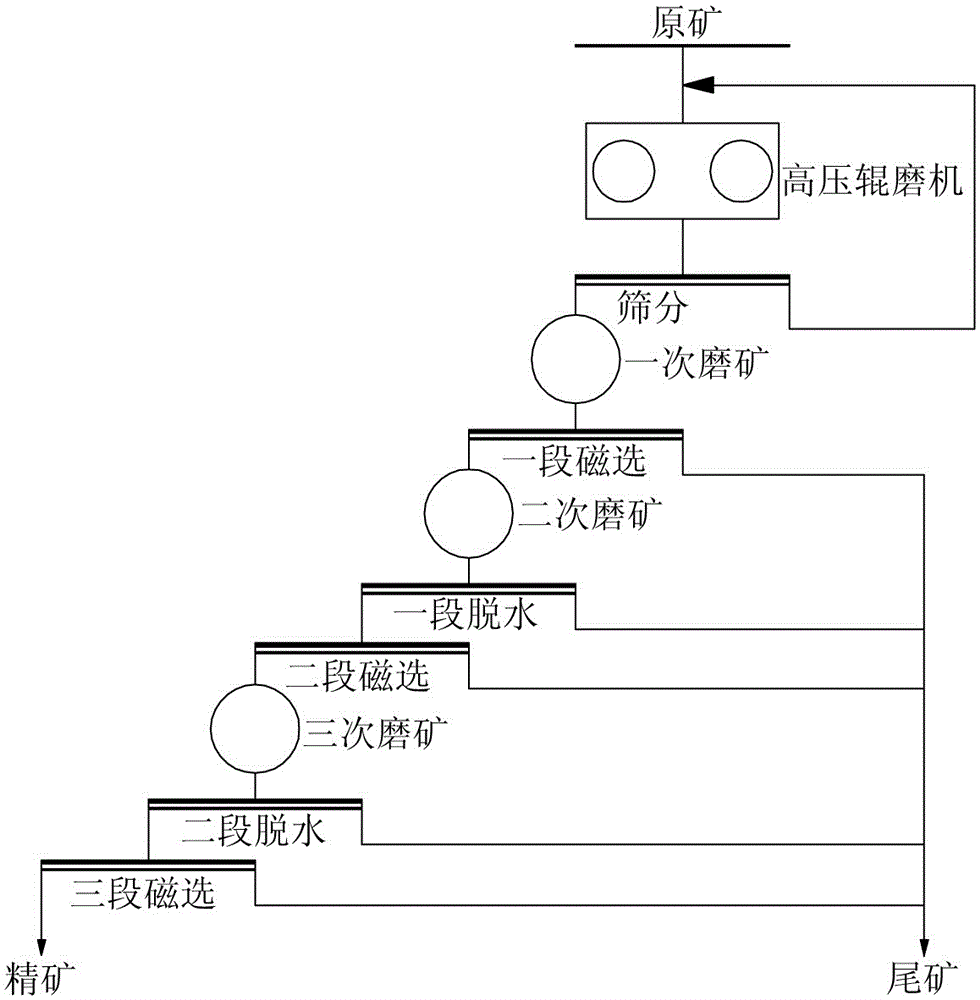

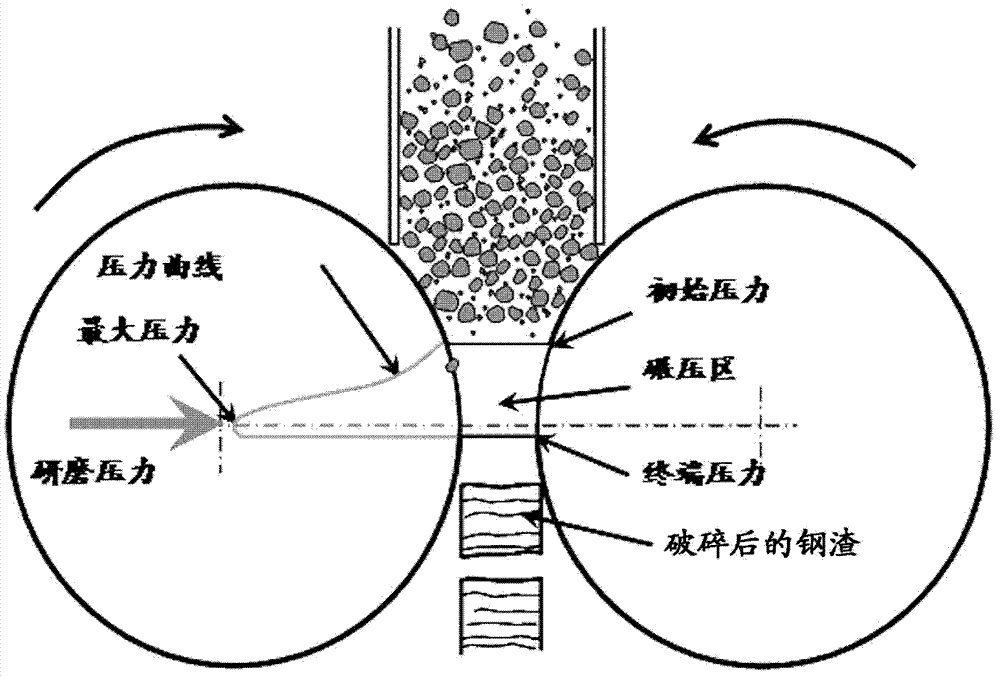

High-pressure roller selective comminuting and magnetic separating method for lean magnetite ore

The invention relates to a high-pressure roller selective comminuting and magnetic separating method for lean magnetite ore. According to the method, ultrafine crushing is conducted on raw magnetite with a grade of 28.59% by means of a high-pressure grinding roller, and three times of ore grinding, two-section dewatering and three-section magnetic separation are conducted on the crushed product to obtain concentrate with a grade of 68.23% and metal recovery rate of 82.35%. The method has the advantages that the recovery rate of the final concentrate can be increased, and efficient recovery and utilization of resources are achieved; the dissociation degree of the product is high, excessive grinding degree is low, follow-up magnetic separation effect is good, and the separation precision of equipment is improved; on the premise that the quality of the concentrate is guaranteed, concentrate recovery rate can be increased, iron ore resources can be recovered and utilized fully and reasonably, and resource waste is reduced.

Owner:ANSTEEL GRP MINING CO LTD

High-whiteness ceramic tile and preparation method thereof

The invention provides a high-whiteness ceramic tile and a preparation method thereof. The preparation method comprises the following steps: preparing raw materials, performing wet-process ball milling, adding water to dilute, magnetically separating, sieving, concentrating and regulating concentration, spray-drying and pelletizing, forming, drying, applying glaze to a glazed brick (canceled for an unglazed brick), sintering, polishing and cutting, inspecting and packaging. By adopting the novel process, the magnetically separating effect of a magnetically separating procedure is greatly improved, the content of magnetic substances in the base body is greatly reduced, and the sintering whiteness of the base body is greatly increased. After a novel process is adopted, the iron content in a base body can be reduced by 0.3-1%, and the base body sintering whiteness is greatly increased by 10-40 degrees in comparison that before magnetically separating; a low-price argillaceous sand stone raw material which is high in iron content and low in sintering whiteness can be adopted in the formula of the ceramic base body to replace raw materials with low iron content and high whiteness of each current manufacturer to produce the base body with whiteness reaching the whiteness required by a high-grade wall and floor tiles, and a ceramic product, so that the base body formula cost is greatly reduced.

Owner:陶正武

Method for recycling red mud

InactiveCN102531440APrevent proliferationEffectively electedSolid waste managementProcess efficiency improvementBrickRed mud

The invention discloses a method for recycling red mud to pulp the red mud. The method is characterized in that a reducing agent is added into the red mud, iron-containing particles in the red mud are reduced into magnetite particles, and then the magnetite particles are subjected to magnetic separation to obtain an iron-containing product A; and then the red mud subjected to the magnetic separation is used to prepare a baked brick product B. The applicant summarizes a set of method for preparing the baked brick, wherein a brick body prepared by the red mud is put into a mixed liquor of sodium silicate solution and barium sulfate, and then is blown to be dry by carbon dioxide, then a layer of barium sulfate protection film is covered on the surface of the brick body to shield the radioactivity. According to the method for recycling the red mud, the construction wastes being waste materials are added as aggregate, so that the strength of the brick body is improved, the fusion points of refractory materials can be reduced by adding a little fluoride salt, and various construction wastes and the red mud can be sintered together at a lower temperature.

Owner:贵州绿水青山环保科技有限公司

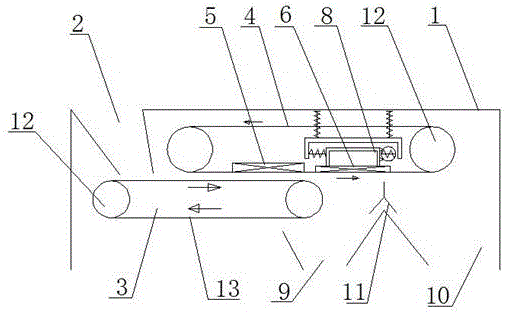

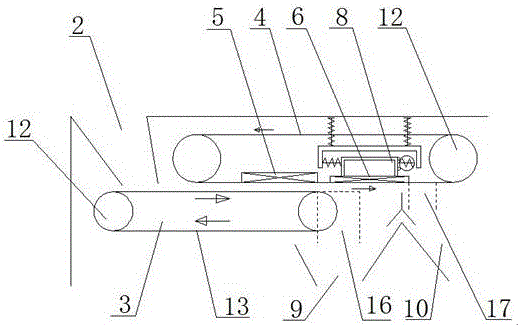

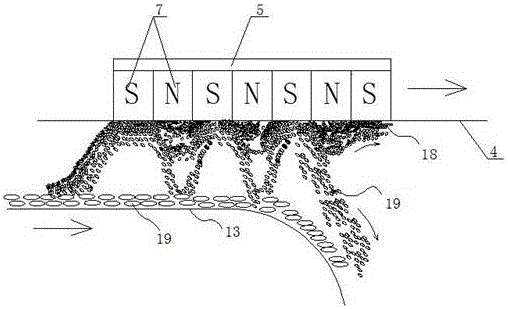

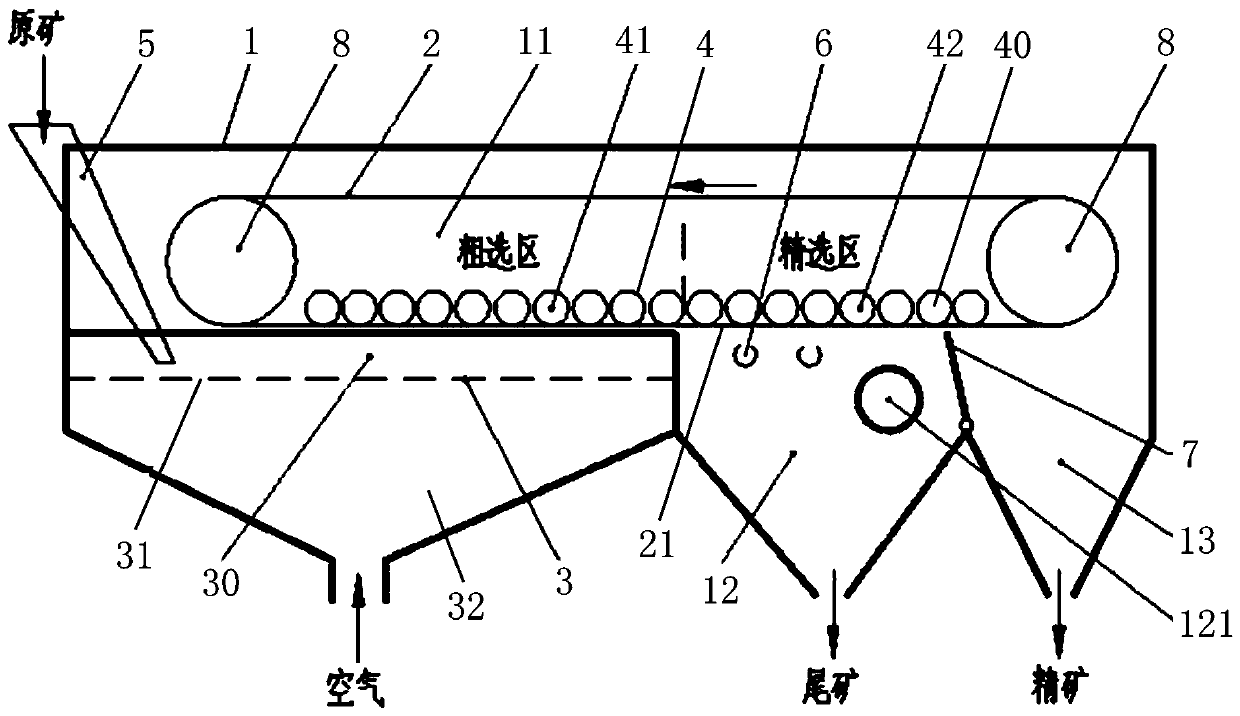

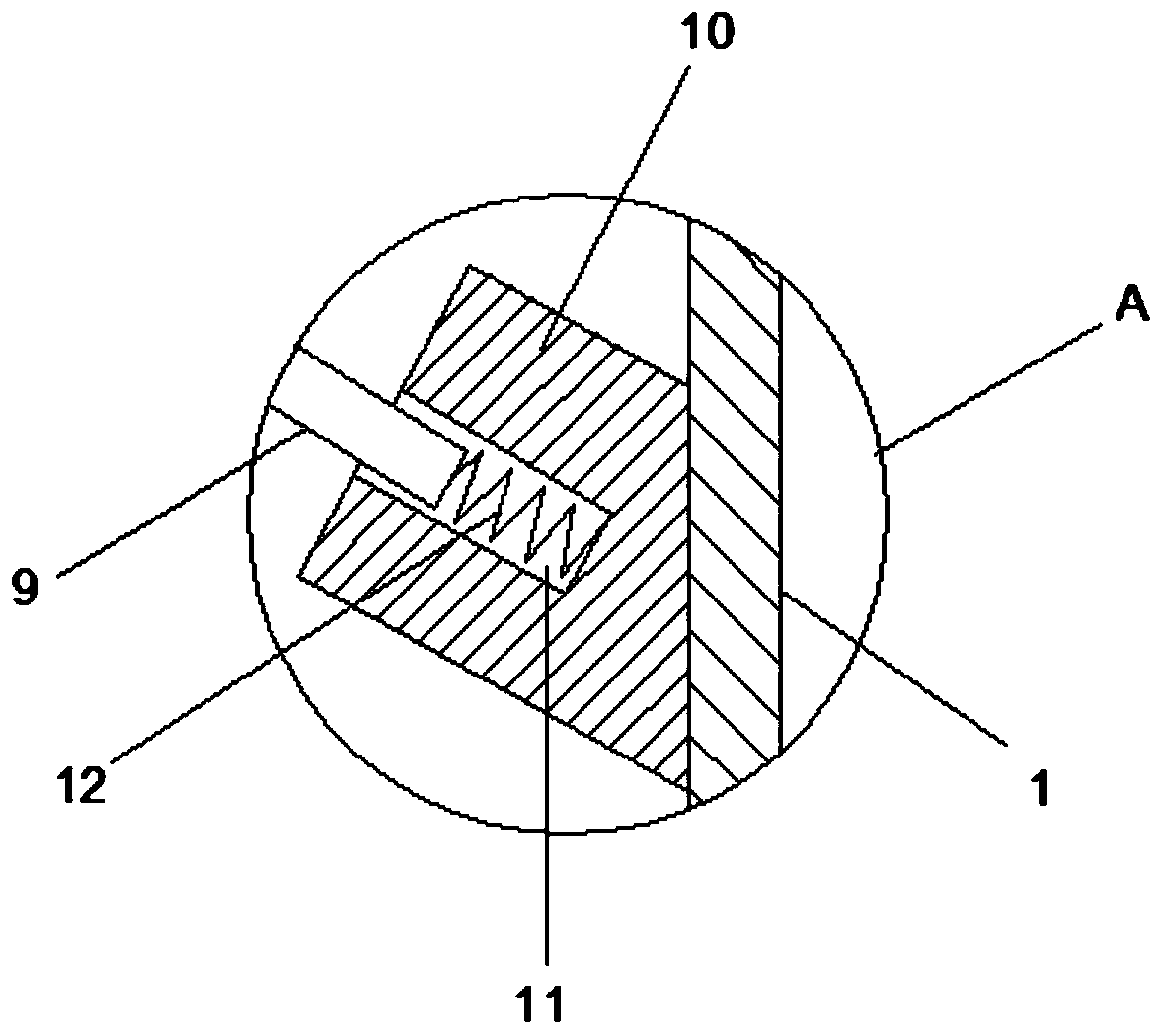

Belt-type dry magnetic separator

ActiveCN106000636AEasy to handleHigh belt speedMagnetic separationMagnetic separatorMineral particles

The invention discloses a belt-type dry magnetic separator. The belt-type dry magnetic separator comprises a housing, the upper part of the housing is provided with a feeding inlet, a feeding device is arranged below the feeding inlet, a magnetic separation device is arranged above the feeding device, the magnetic separation device comprises a magnetic separation belt, along a material conveying direction of the feeding device, a primary separation magnetic system and a refined separation magnetic system are orderly arranged in the magnetic separation belt in parallel, a conveying tail end of the feeding device is not in a magnetic material discharge range of the refined separation magnetic system, a magnetic field range of the primary separation magnetic system covers materials on the feeding device, a magnetic field of the refined separation magnetic system is an alternating magnetic field, and magnetic field ranges of the primary separation magnetic system and the refined separation magnetic system are superimposed. The belt-type dry magnetic separator continuously treats a crushed magnetic material so that a product with quality close to that of water separated products is obtained, strictly controls mine tailing magnetic object quality, has a high treatment capability and a large tailings discarding rate, has a very wide mineral particle fraction application range and reduces a later technical equipment investment and a system operation cost.

Owner:CHENGDU LEEJUN TECH CO LTD

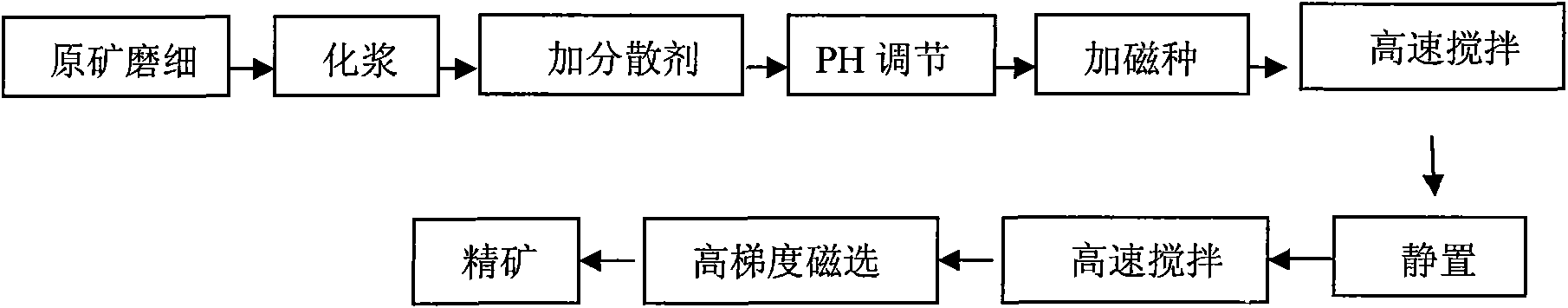

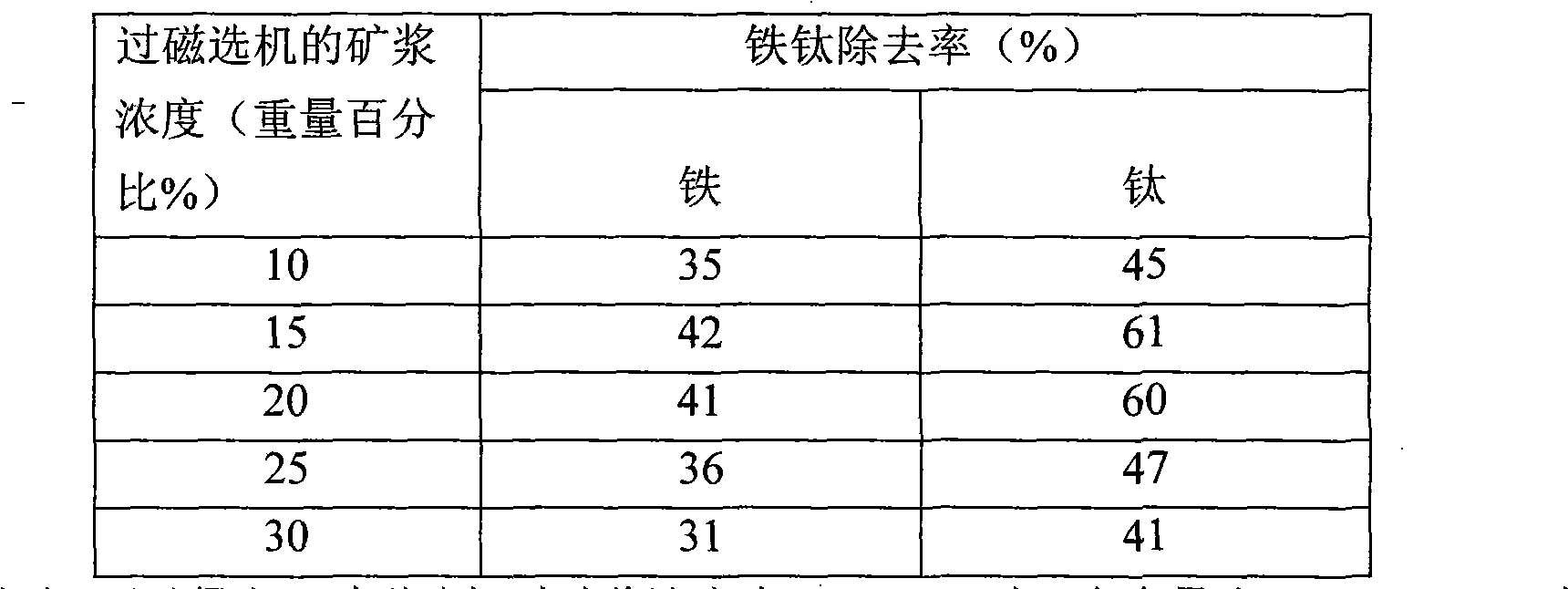

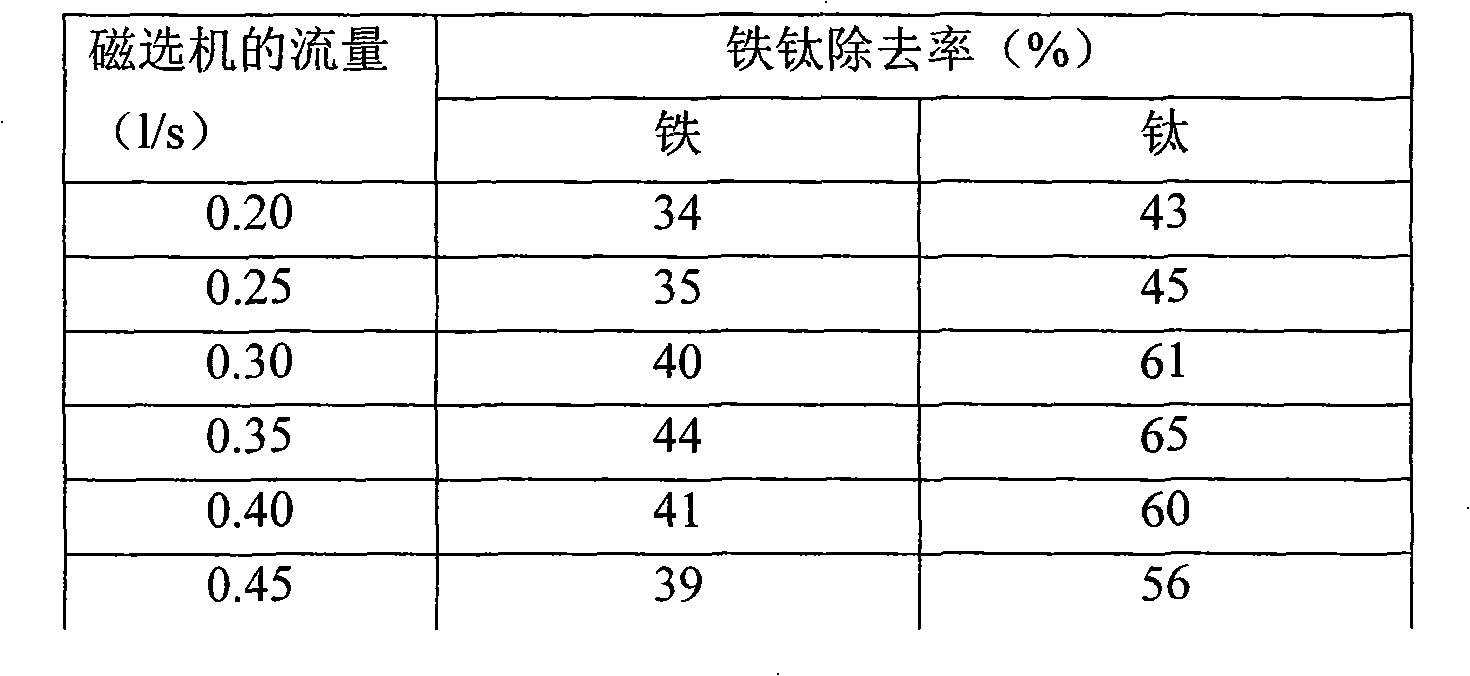

Method for removing iron titanium from non-metallic mineral raw materials

InactiveCN101618366AImprove processing efficiencyImprove efficiencyHigh gradient magnetic separatorsMagnetic separatorTitanium

The invention discloses a method for removing iron titanium from non-metallic mineral raw materials and relates to the method for removing iron titanium from the non-metallic mineral raw materials in the ceramic industry. The method comprises the steps of firstly grinding non-metallic raw ores into 250 meshes-300 meshes, preparing ore pulp with water content of 50%-70%, then adding a dispersing agent, adding a pH adjuster, regulating pH to 5.5-7.0, evenly stirring, adding magnetic seeding particles which are pre-dispersed in water, then standing for 12-24h, diluting till the water content of 80%-85% after the completion of standing, further using two permanent-magnet high-gradient magnetic separators which are connected in series for carrying out magnetic separation, collecting magnetic seeds after the ore pulp passes the magnetic separators completely, and recycling the magnetic seeds after drying. The method determines the optimum process parameters, achieves the purpose of saving energy, reducing consumption and reducing production cost under the condition of ensuring high processing efficiency of impurities of iron and titanium and has great application prospects.

Owner:SOUTH CHINA UNIV OF TECH +1

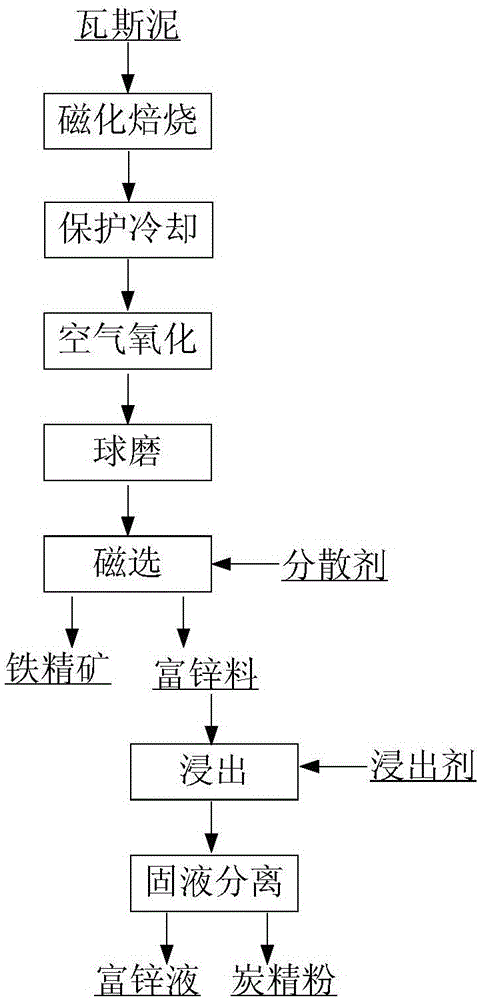

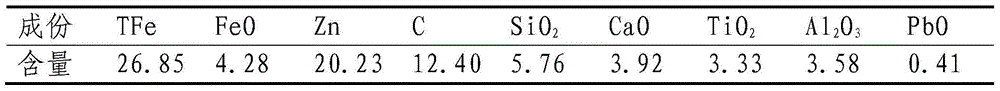

Method for separating iron, zinc and carbon in blast furnace sludge

ActiveCN105063254APromote productionEasy to separateRecycling and recovery technologiesProcess efficiency improvementSludgeTherapeutic effect

The invention discloses a method for separating iron, zinc and carbon in blast furnace sludge. The method for separating the iron, the zinc and the carbon in the blast furnace sludge comprises the steps that the blast furnace sludge is oxidized after being directly magnetically roasted; wet magnetic separation is conducted after proper ore grinding, so that iron concentrate from magnetic separation and tailing zinc-rich materials are obtained; zinc in the zinc-rich materials is extracted by means of a leaching agent, so that a zinc-rich solution and carbon powder are obtained. All products obtained by treating the blast furnace sludge through the method can be effectively utilized, and zero discharge of solid waste of the blast furnace sludge is achieved. The method for separating the iron, the zinc and the carbon in the blast furnace sludge has the advantages that the technique is simple, investment is small, energy consumption is low, and the treatment effect is good. The method for separating the iron, the zinc and the carbon in the blast furnace sludge can provide important theoretical guidance and technical support for comprehensive utilization of blast furnace sludge resources in iron and steel plants.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Coated, fine metal particles and their production method

InactiveUS20100047579A1Improve corrosion resistanceHigh magnetizationNanomagnetismMetal-working apparatusFree energiesNitrogen

A method for producing coated, fine metal particles comprising the steps of mixing powder comprising TiC and TiN with powder of an oxide of a metal M meeting the relation of ΔGM-O>ΔGTiO2, wherein ΔGM-O represents the standard free energy of formation of metal M oxide, and heat-treating the resultant mixed powder in a non-oxidizing atmosphere to reduce the oxide of the metal M with the powder comprising TiC and TiN, while coating the resultant metal M particles with Ti oxide, and coated, fine metal particles each comprising a metal core particle and a Ti oxide coating and having a carbon content of 0.2-1.4% by mass and a nitrogen content of 0.01-0.2% by mass.

Owner:HITACHI METALS LTD

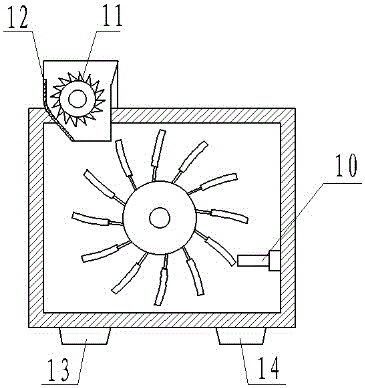

Circulating type automatic iron removing machine

InactiveCN102728460AIncrease the magnetic field strengthImprove adsorption capacityMagnetic separationSoft magnetEngineering

The present invention relates to a circulating type automatic iron removing machine. With the circulating type automatic iron removing machine, a magnetic region used for magnetic separation is designed into a structure with a closed periphery to gather magnetic induction lines and form a closed magnetic circuit of magnetic induction line circulation, circulation of the magnetic induction lines inside the magnetic region is adopted to enhance magnetic field strength, and a clean problem of a magnetic conductive media after iron impurity absorption is effectively solved. The magnetic region is formed by semi-enclosing a soft magnet, wherein the soft magnet is provided with a permanent magnet, the synonym poles of the permanent magnet are located oppositely, and a working chamber is arranged in the magnetic region. The exterior of the magnetic region is provided with a brush body. A pushing device for pushing the magnetic conductive media and a transimisson device for conveying the magnetic conductive media to generate friction between the magnetic conductive media and the brush body are mounted on the working chamber, wherein the pushing device and the working chamber form a head-tail connection. The circulating type automatic iron removing machine of the present invention has characteristics of simple structure, low cost, and high automation degree, and can be widely used in fields of dry powder iron removing and ceramic. With the circulating type automatic iron removing machine of the present invention, iron can be removed completely, and cleaning is performed completely.

Owner:廖明勇

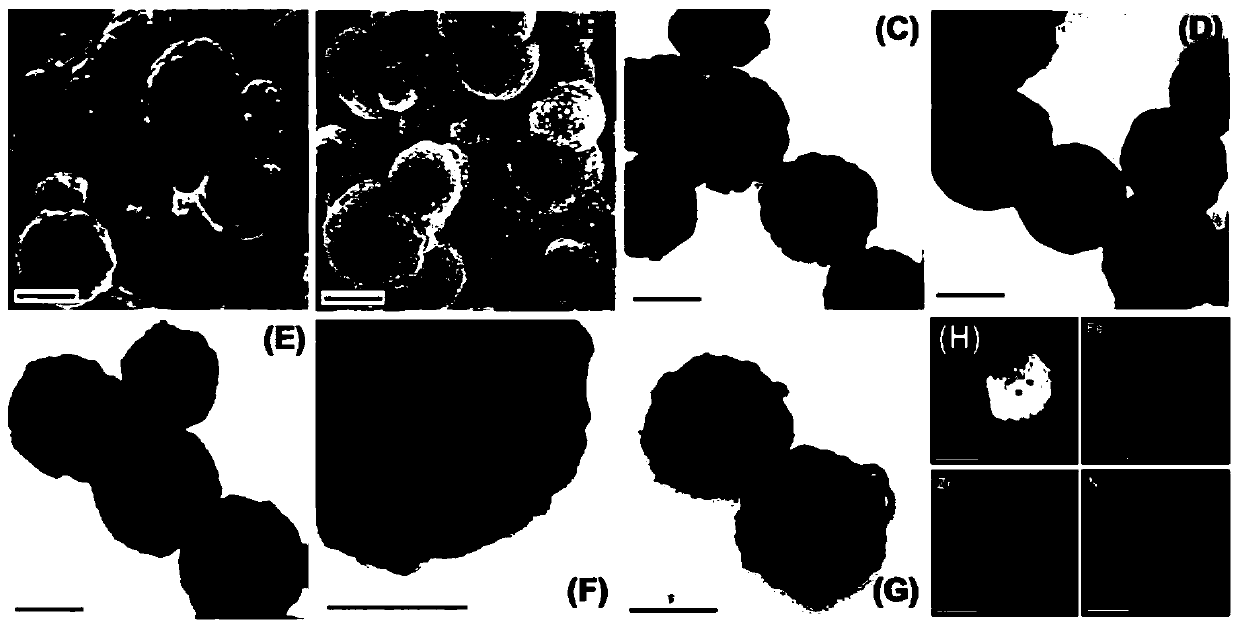

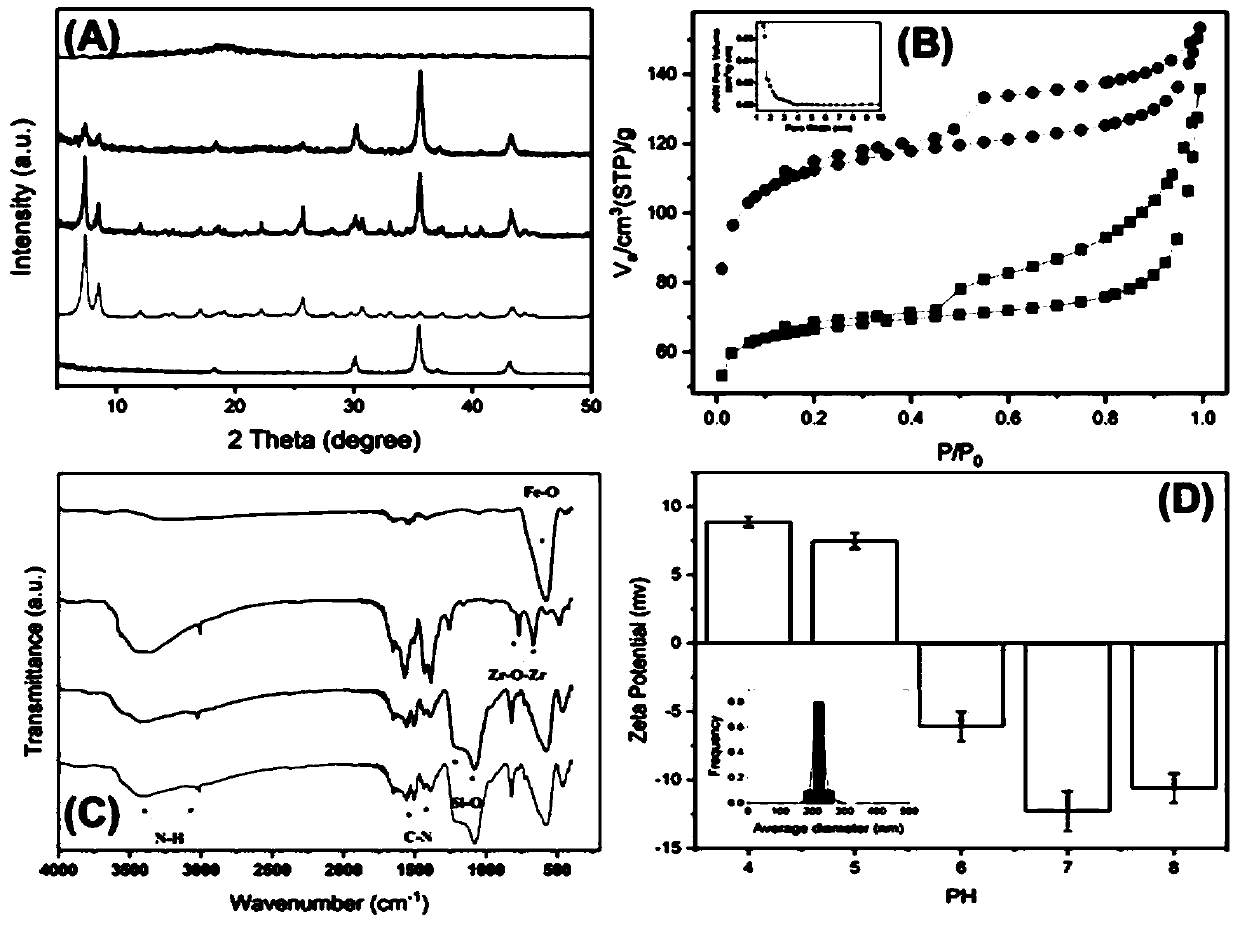

Preparation and applications of magnetic composite porous network adsorbing material

ActiveCN110586052AImprove uniformityImprove stabilityOther chemical processesAlkali metal oxides/hydroxidesOrganic solventSolid phase extraction

The invention relates to preparation and applications of a magnetic composite porous network adsorbing material, wherein the preparation method comprises: (a) preparing a magnetic porous organic framework material with strong adsorbability and large specific surface area by adopting an in-situ growth method, and (b) synthesizing a novel composite porous network adsorbing material with a core-shellstructure through a sonogashira coupling reaction so as to achieve the selective adsorption and efficient enrichment of food and environment pollutants. According to the present invention, the prepared magnetic composite porous network adsorbing material has good particle size uniformity and significantly efficient adsorption capacity on target pollutants, the separation step during solid-phase extraction is greatly simplified due to the magnetic characteristic of the material, and the microporous organic coating changes the hydrophobicity of the surface of the material, such that the material has high stability in a humid environment, can well play a role in an organic solvent, and is suitable for adsorption and enrichment of various food pollutants.

Owner:NANKAI UNIV

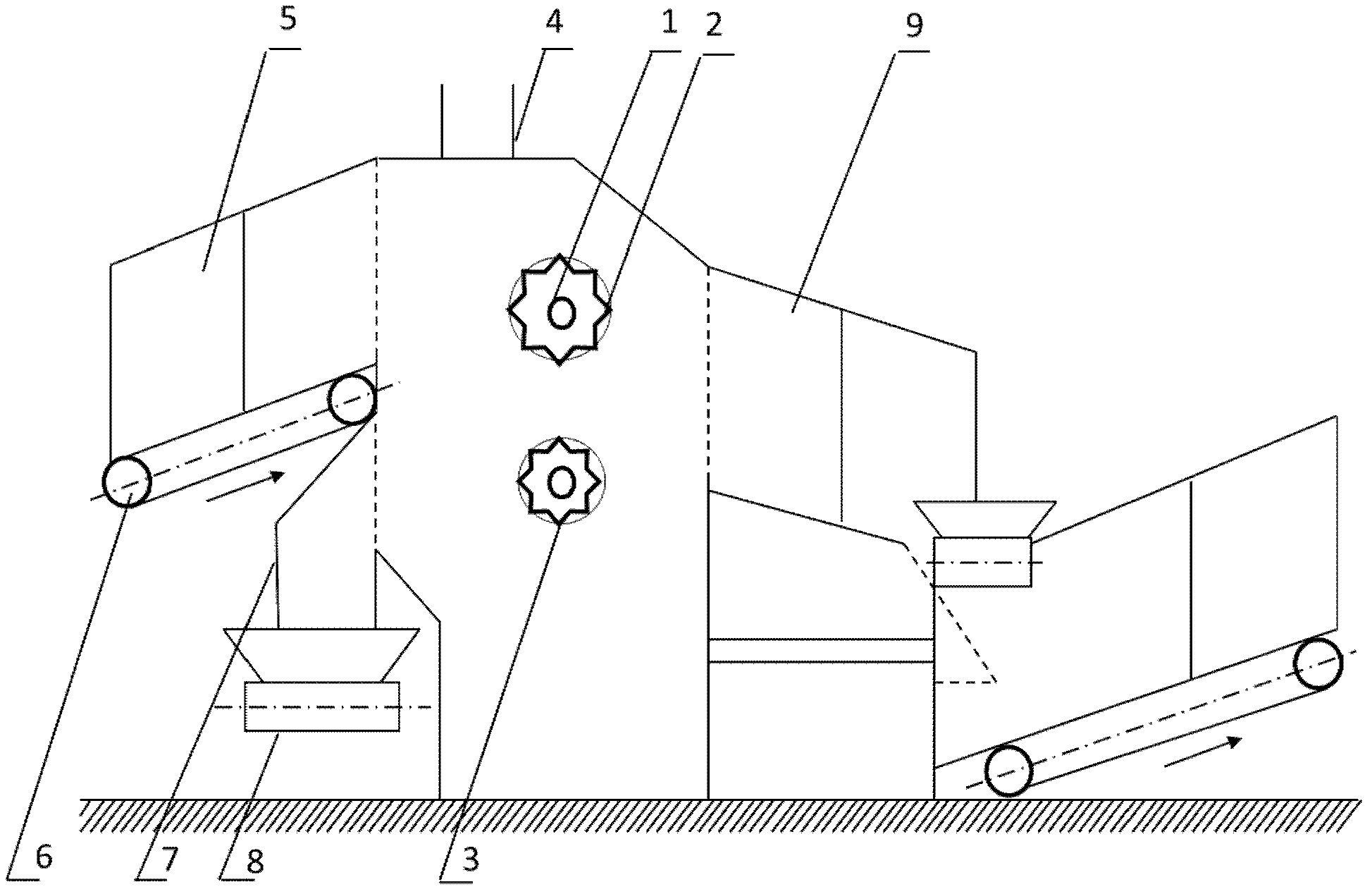

Electromagnetic separator

ActiveCN105903558ASimple structureEasy to install and maintainMagnetic separationReverse currentMagnetic separator

The invention relates to the field of electromagnetic separators, and discloses an electromagnetic separator. The electromagnetic separator comprises a body, a driving device, a crushing device and a magnetic separating device, wherein the outside of the body is connected with the driving device; the crushing device and the magnetic separating device are arranged in the body; the crushing device is arranged in a feeding opening in the body; the magnetic separating device comprises sorting equipment and reverse current equipment; and the sorting equipment is connected to the body through a shaft. The electromagnetic separator is simple in structure, speedy and convenient to mount and good in sorting effect, the electromagnetic property of a magnetic core is excellent, and the problems that an electromagnetic separator in the prior art is not ideal in magnetic separation effect and the using performance of a magnetic core is poor in actual use are solved.

Owner:温州市康尔微晶器皿有限公司

Air-suspending dispersion dry separation belt magnetic separator

PendingCN107716099AReduce self-adhesionReduce inclusionsMagnetic separationMagnetic separatorNon magnetic

An air-suspending dispersion dry separation belt magnetic separator comprises a shell with a closed inner cavity. A non-magnetic-conduction annular belt is installed in the closed inner cavity. One section on the lower portion of the non-magnetic-conduction annular belt is a magnetic separation section. A conveying tank, a non-magnetic product receiving hopper and a magnetic product receiving hopper which are located below the magnetic separation section and sequentially arranged in the operation direction of the magnetic separation section are arranged in the closed inner cavity. A conveyingpassageway for conveying materials to the non-magnetic product receiving hopper is defined by the conveying tank and the magnetic separation section. A magnetic separation magnetic system is arrangedabove the magnetic separation section and extends to the portion above the magnetic product receiving hopper from the portion above the conveying tank. A material distribution device is installed on the shell. The air-suspending dispersion dry separation belt magnetic separator further comprises an air-suspending dispersion device used for conveying the materials to the non-magnetic product receiving hopper in a dispersion and suspension state in the conveying passageway. By means of the magnetic separator, the powder dry magnetic separation efficiency, the magnetic separation effect and the product taste can be greatly improved, and the air-suspending dispersion dry separation belt magnetic separator is simple and compact in structure, stable and reliable in work, high in processing capacity and convenient to operate and control.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for treating steel slag tailings subjected to magnetic separation

InactiveCN102019286AMaximize resourcesImprove product added valueSolid waste disposalRecycling and recovery technologiesSlagFerric

The invention discloses a method for treating steel slag tailings subjected to magnetic separation. By the method, steel slag micro-powder of which the specific surface area is more than 400m<2> / kg can be produced in a treatment mode of drying the steel slag tailings, carrying out powder selection and magnetic separation, adding abrasive dust for milling and circulating repeatedly, the recovery rate of iron resources in recovered slag can be improved and the powder milling cost of the steel slag micro-powder can be effectively reduced.

Owner:TIANJIN SUMEIR ENVIRONMENTAL PROTECTION INVESTMENT

Magnetic separation equipment and magnetic separation method for quartz sand

The invention discloses magnetic separation equipment and a magnetic separation method for quartz sand. The equipment comprises a magnetic separation bin and a feeding hopper fixedly connected to thetop of the magnetic separation bin; a crushing device is arranged in the feeding hopper, and comprises a crushing motor and a crushing roller; a magnetic separation device is arranged in the magneticseparation bin; the magnetic separation device comprises a driving wheel, a driven wheel and a conveying belt connected to the driving wheel and the driven wheel; electromagnets are arranged on the upper side and the lower side in the conveying belt; the left side of the magnetic separation bin is provided with a magnetic scraping device; the magnetic scraping device comprises a magnetic scrapingplate and a base connected with the magnetic scraping plate in a sliding mode; the base is fixed on the inner side wall of the magnetic separation bin; a sliding groove is formed in the top of the base; and one end of the magnetic scraping plate is connected in the sliding groove in a sliding mode through a spring, and the other end of the magnetic scraping plate abuts against the conveying belt.The magnetic separation equipment has the advantages that the magnetic separation effect is good, magnetic substances in the quartz sand can be effectively removed, and the purity of the quartz sand is improved.

Owner:新沂市嘉新矿业有限公司

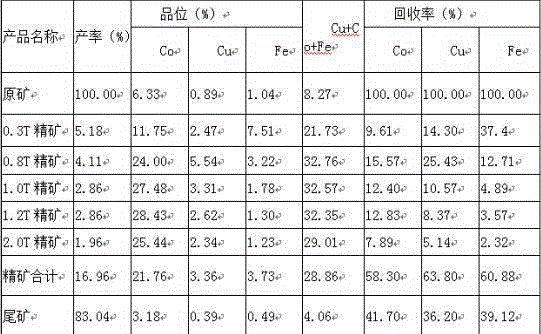

Method for detecting the magnetism of weakly-magnetic mineral

InactiveCN105259522AEasy to operateField strength selection is convenientMagnetic property measurementsSlurryField intensity

The invention discloses a method for detecting the magnetism of a weakly-magnetic mineral, wherein the method may achieve an optimum magnetic separation effect by selecting field intensity corresponding to certain ore when the certain ore is required to be subjected to magnetic separation. The method comprises flows of: (1) a sample ore preparing step of fragmenting, grinding, and screening raw ore ; (2) a slurry forming step of pouring the grinded ore into water and stirring the grinded ore in order to form ore mortar, wherein the content of the ore in the ore mortar maintains between 10 and 40 percent; (3) a magnetic separation step of uniformly mixing the ore mortar and adjusting and increasing background field intensity increased from 0.05T to a maximum value in such a manner that 0.2 or 0.3T is increased every time; and an analysis step of analyzing magnetic ore concentrate and final tailings in each field intensity in order to obtain magnetic substance mineral constituents. Accordingly, the method has characteristics of simple operation, convenient field intensity selection, and good magnetic separation effect.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

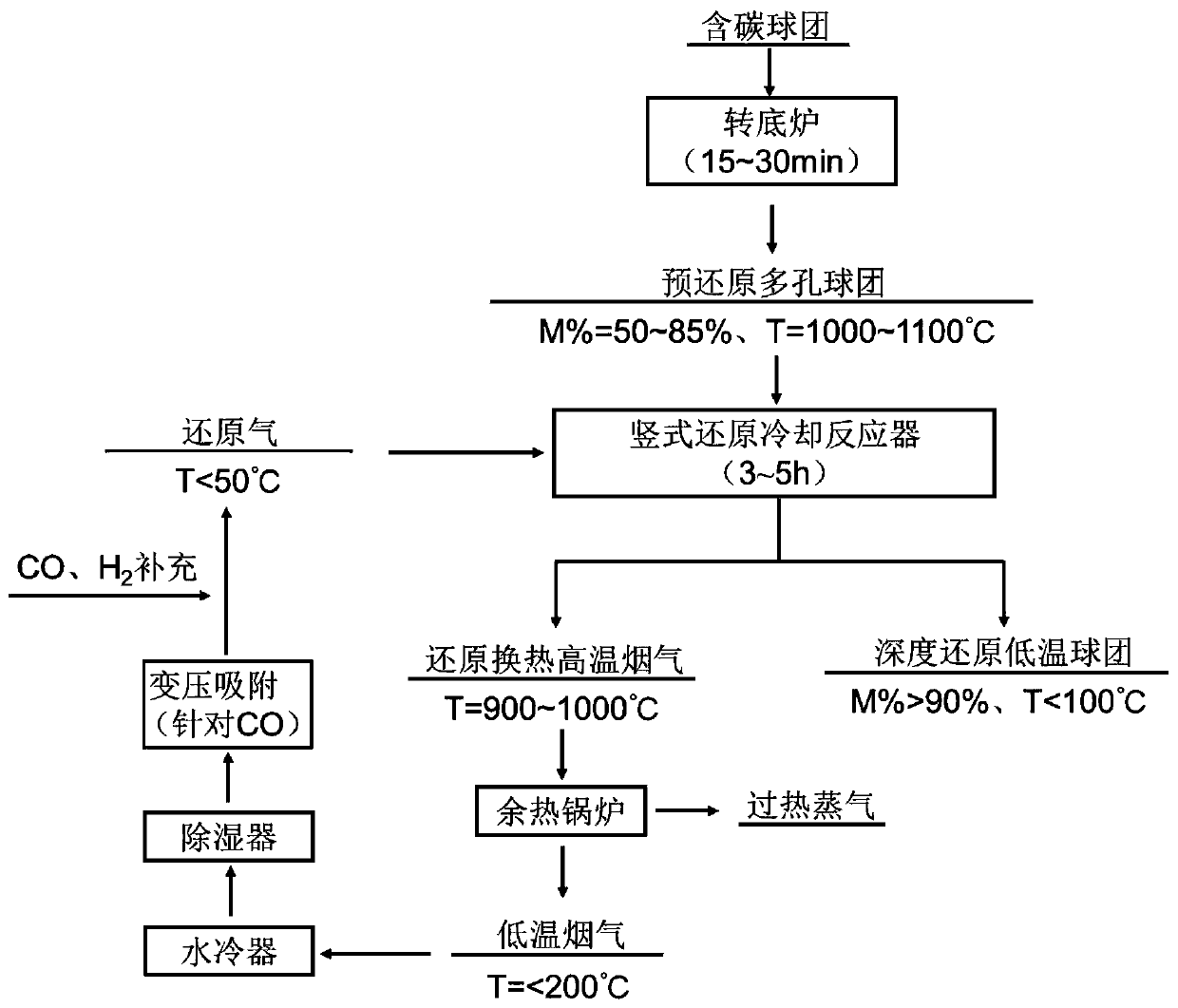

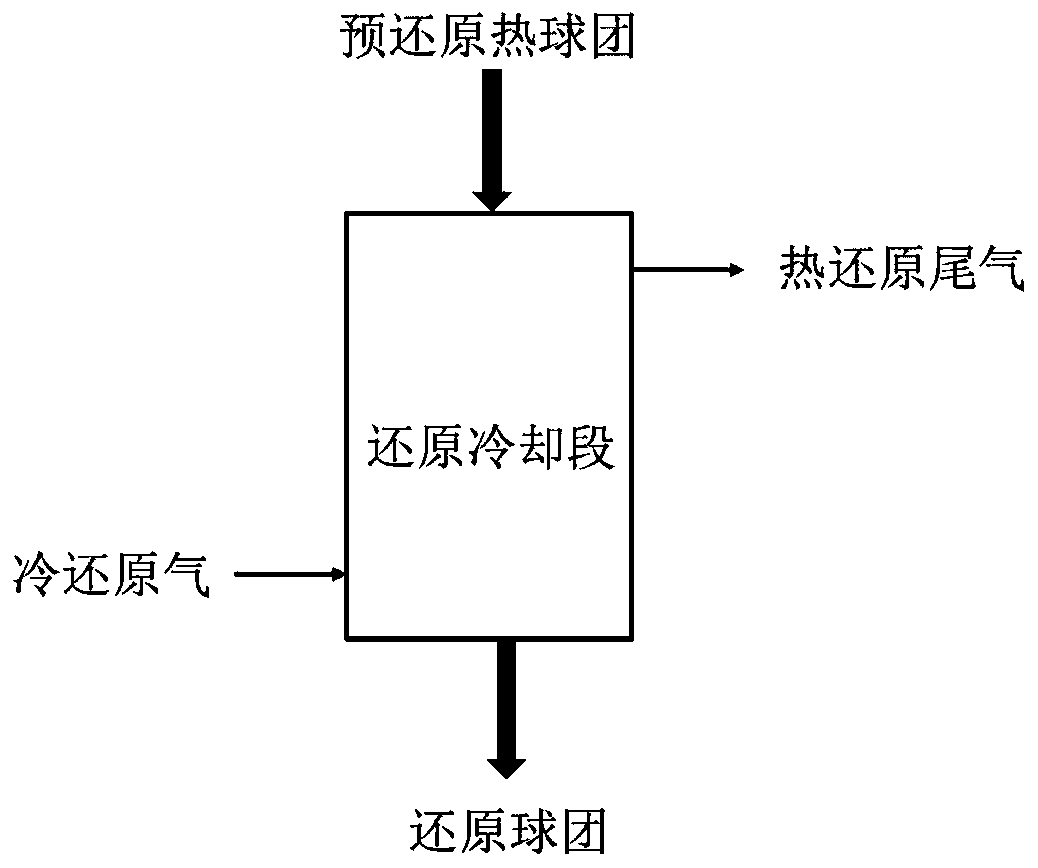

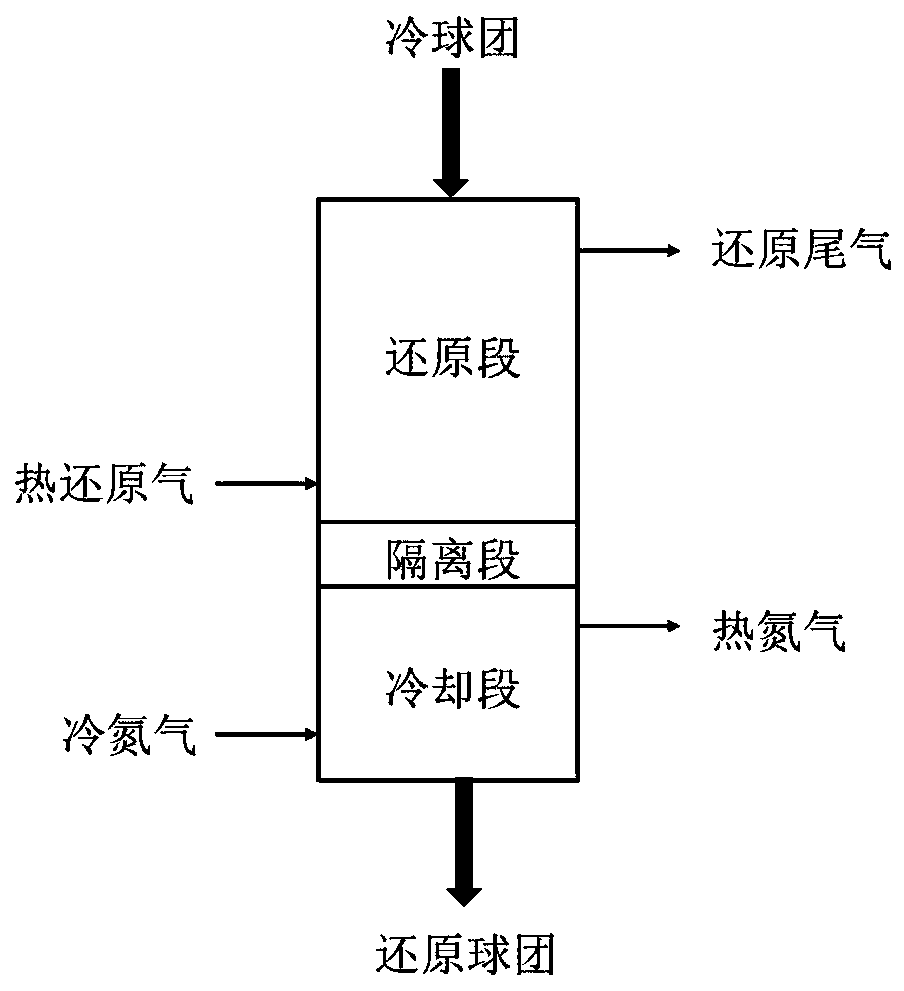

Iron-making method adopting carbothermal pre-reduction, gas-based deep reduction and synchronous cooling

PendingCN111304395AReduce restore timeCarbothermal pre-reduction rate is fastRotary drum furnacesExhaust gas handlingChemistryProcess engineering

The invention relates to an iron-making method adopting carbothermal pre-reduction, gas-based deep reduction and synchronous cooling, and belongs to the field of non-blast furnace ironmaking. The problems of low carbon thermal reduction degree, low gas-based reduction rate and long cooling time of existing pellets and complex gas source isolation control system due to different gas sources of a reduction section and a cooling section during gas-based reduction are solved. The iron-making method adopting carbothermal pre-reduction, gas-based deep reduction and synchronous cooling comprises thefollowing steps that 1, the carbon-containing pellets are subjected to pre-reducing by using a rotary hearth furnace to obtain porous pre-reduced metalized pellets; 2, the porous pre-reduced metalizedpellets are discharged into a vertical reduction cooling reactor in a hot state, and subjected to countercurrent reduction and heat exchange with cold-state reducing gas; and 3, the high-temperaturegas subjected to reduction and heat exchange is subjected to heat exchange through a waste heat boiler, physical heat is utilized, and after the cooled gas is dehumidified and subjected to impurity removal, unreacted reducing gas returns to the vertical reduction cooling reactor to be recycled. According to the method, the high reduction degree effect that the pellet metallization rate is larger than 90% within 3 h-5 h is achieved.

Owner:CENT IRON & STEEL RES INST +1

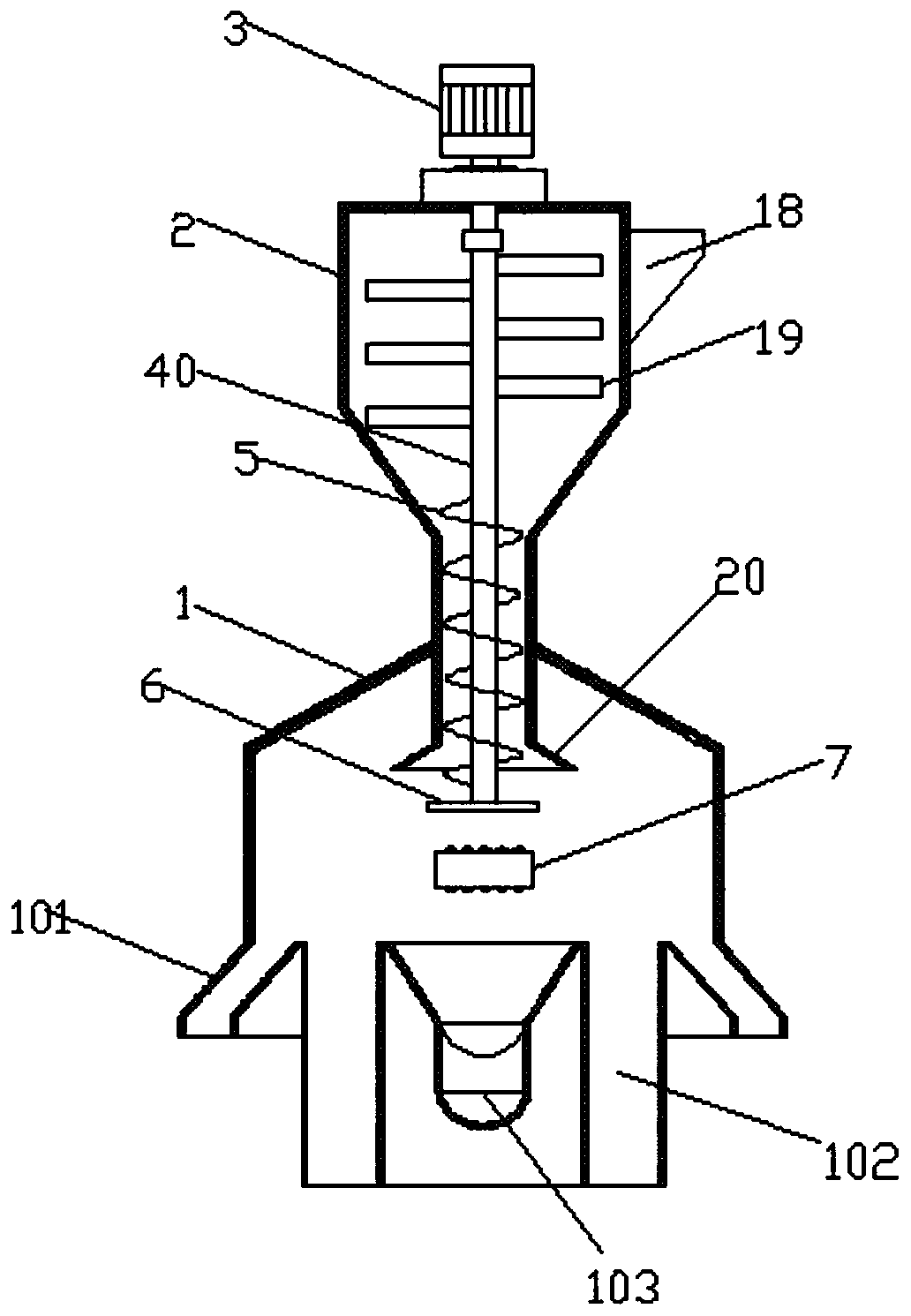

Magnetic separation equipment used in process of recycling copper and nickel salt from waste ABS electroplated parts

InactiveCN110898988AEfficient screeningImprove magnetic separation efficiencyMagnetic separationNickel saltCopper

The invention belongs to the technical field of waste electroplated part magnetic separation, and specifically relates to magnetic separation equipment used in the process of recycling copper and nickel salt from waste ABS electroplated parts. The magnetic separation equipment comprises a magnetic drum. A feeding bin is arranged above the magnetic separation cylinder. A feeding motor is fixed to the upper surface of the feeding bin, a material guiding pipe inserted into the magnetic separation barrel is arranged at the lower end of the feeding bin, an output shaft of the feeding motor extendsinto the lower end of the feeding bin to be connected with a rotating rod, a spiral blade penetrating through the material guiding pipe is arranged on the rotating rod, and a circular material throwing plate is connected to the lower end of the rotating rod. According to the magnetic separation equipment, ABS crushed materials are subjected to primary magnetic separation through centrifugal force,the crushed materials are divided into three types, then ABS inclusions are subjected to magnetic separation through secondary magnetic separation, the magnetic separation efficiency is high, and themagnetic separation effect is excellent.

Owner:怀化恒安石化有限公司

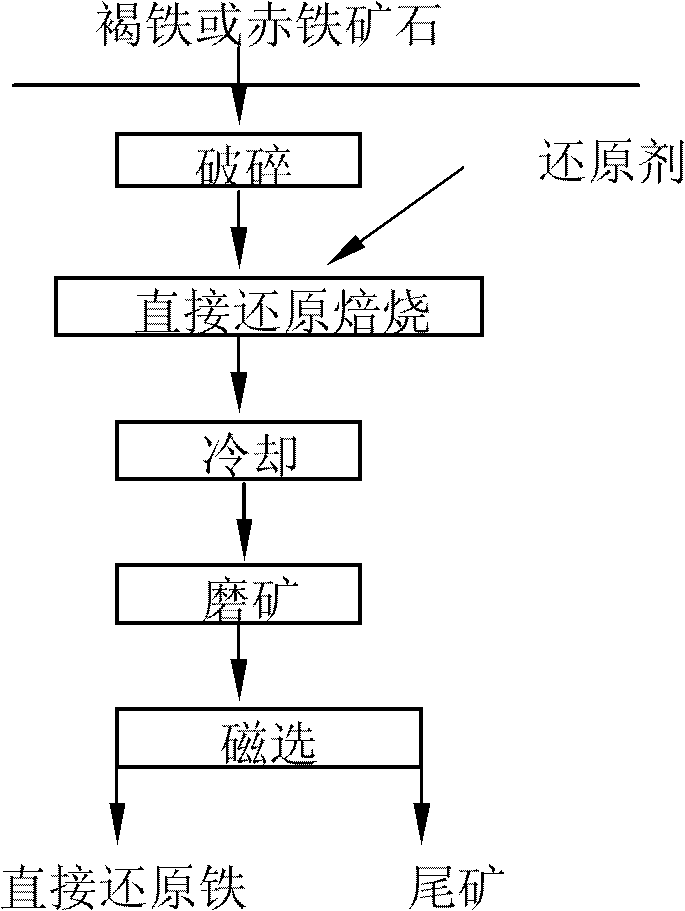

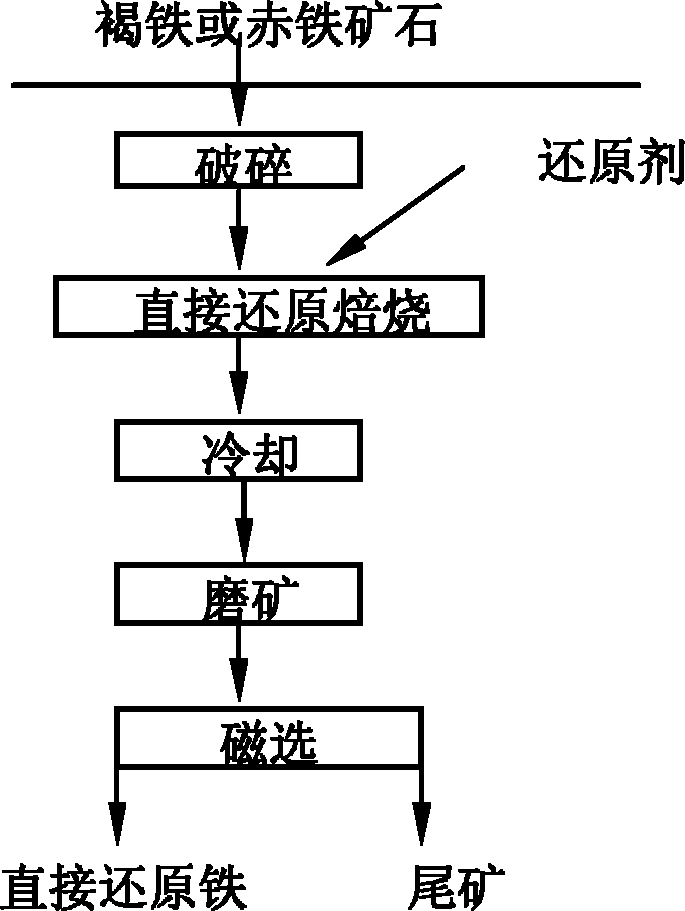

Reducing agent for carrying out direct reduction roasting on limonite and hematite to produce reduced iron

InactiveCN102168159AWell mixedTake advantage ofProcess efficiency improvementReducing atmosphereRoasting

The invention belongs to the field of ferrous metallurgy and relates to a reducing agent for carrying out direct reduction roasting on limonite and hematite to produce reduced iron. The invention is characterized in that the reducing agent is prepared by fully and evenly mixing coal, lime stone and sodium hydroxide in a certain proportion; a direct reduction roasting-magnetic method is utilized, iron, especially iron ore existing in the form of limonite and hematite is utilized as a raw material, the reducing agent provided by the invention is added so as to carry out direct reduction roasting, and then ore grinding and magnetic separation are carried out, thus obtaining directly-reduced iron product with the iron grade larger than or equal to 90 percent and the iron recovery rate larger than 80 percent; the reducing agent plays a role in generating reducing atmosphere and promoting the iron in the limonite and hematite of ore to be fully reduced into metal iron and then recycling metal iron through a magnetic method under the condition of anaerobic roasting; and the proportion of the coal to lime stone to sodium hydroxide in the reducing agent is 100:(5-4):(2.5-1). The reducing agent is less in using amount, low in cost and good in magnetic separation effect after use.

Owner:UNIV OF SCI & TECH BEIJING +1

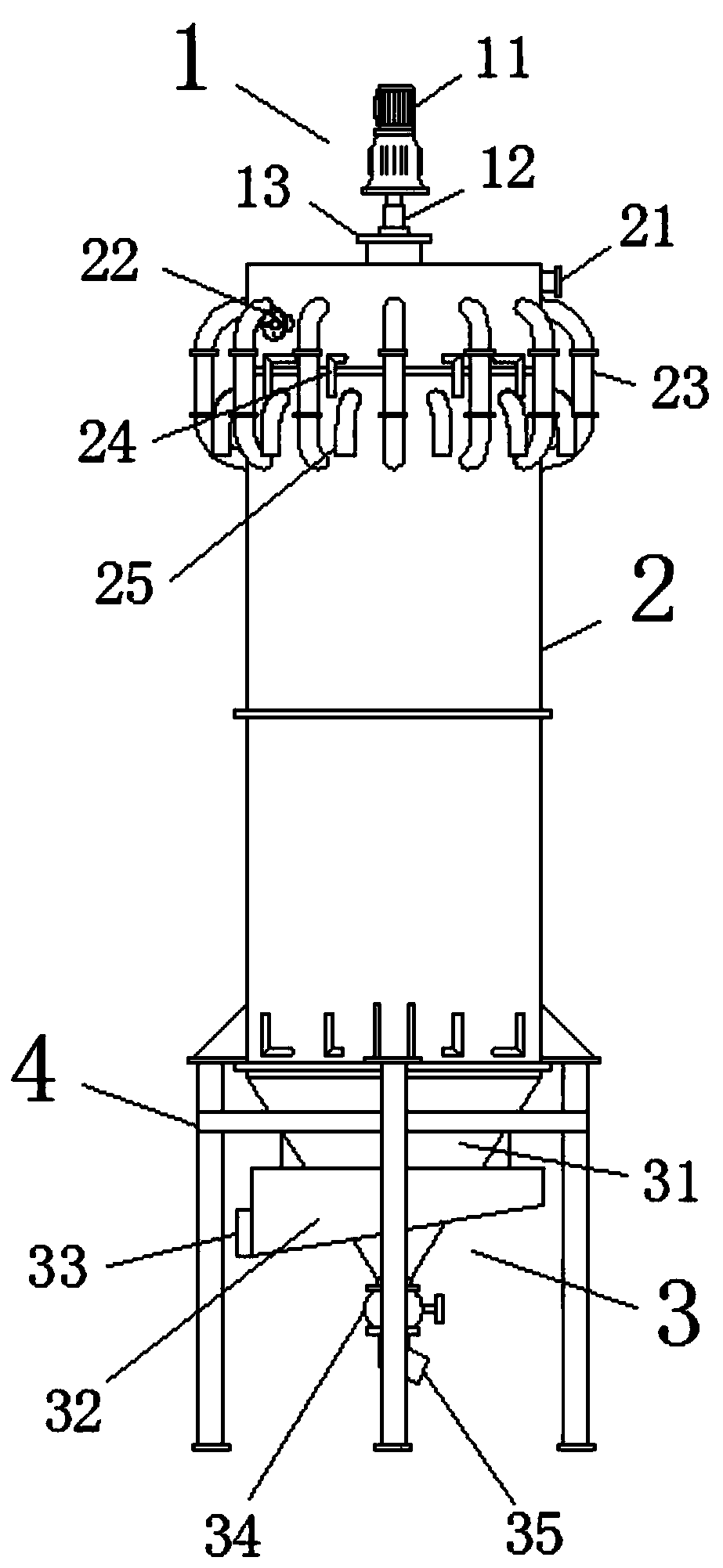

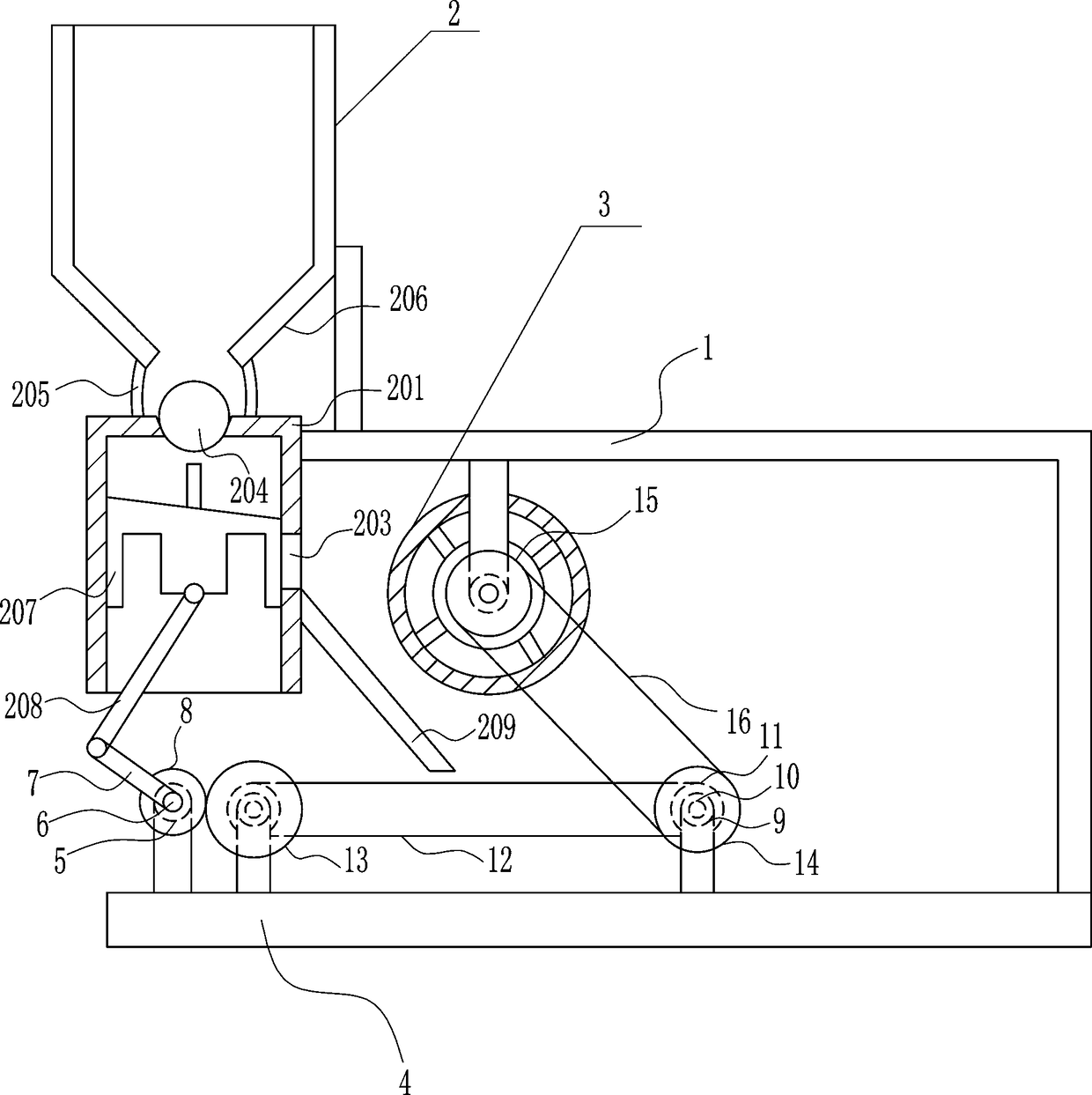

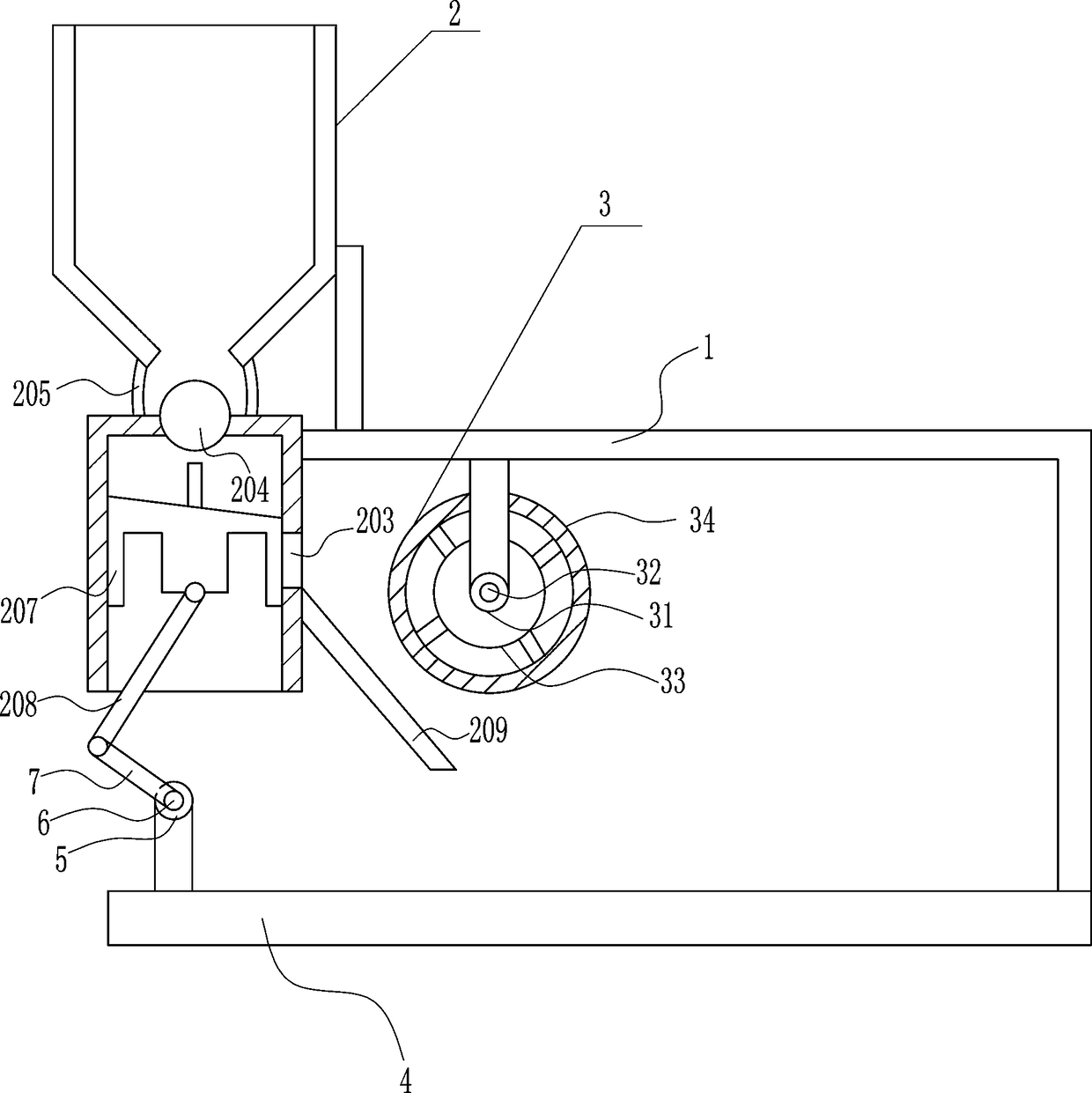

Double-cylindered magnetite fine powder grade improver

PendingCN110302898AStir wellUniform concentrationMagnetic separationWet separationEngineeringDrive motor

The embodiment of the invention discloses a double-cylindered magnetite fine powder grade improver, comprising a driving device, an outer cylinder, a discharging device, a support frame and an inner cylinder, wherein the driving device comprises a driving motor, a transmission shaft and a bearing bracket; the upper end surface of the outer cylinder is provided with an annular water distributor; the upper end of the annular water distributor is provided with an annular material distributor; and the side surfaces of the annular distributor and the annular water distributor are provided with a material inlet and a water inlet respectively. A clearance space between the outer cylinder and the inner cylinder of the double-cylindered structure increases the contact area between the magnetite material and the clean water and increases the washing speed of the slurry. A plurality of magnets are annularly arranged side by side to define a cylindrical inner cylinder permanent magnet mechanism soas to increase the magnetic separation area and increase the number of mineral rubbing and overturning times. The outer cylinder is provided therein with a scraper arranged in a spiral shape to scrape off the fine iron powder in the outer cylinder downward. The water rinses the fine iron powder from the bottom to the top to achieve efficient wet magnetic separation. The double-cylindered magnetite fine powder grade improver improves work efficiency and is easy to operate.

Owner:山西建兴机械设备有限公司

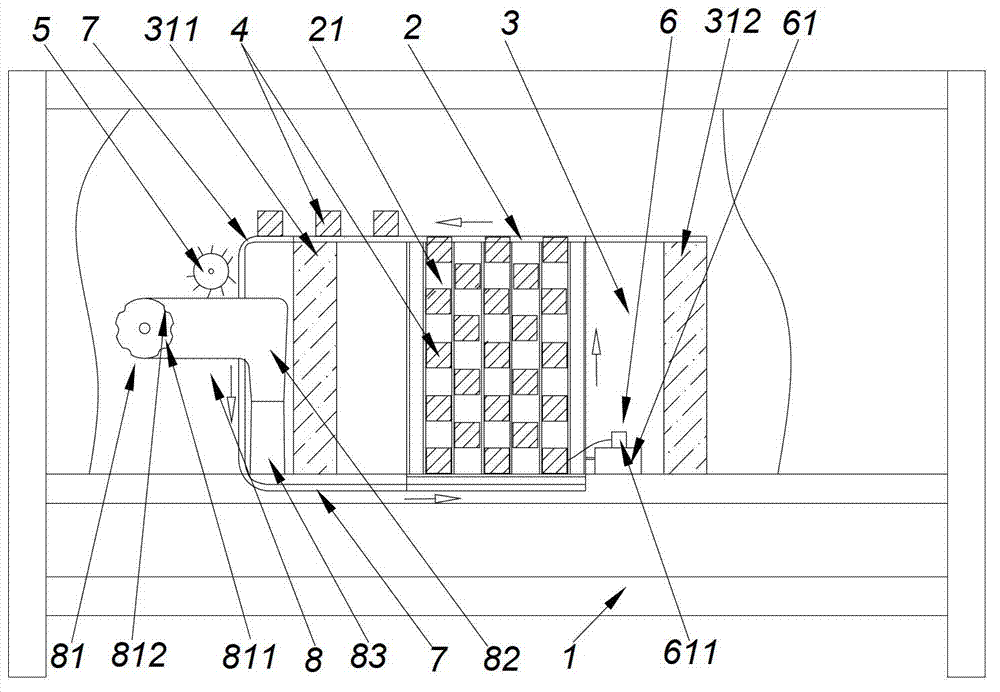

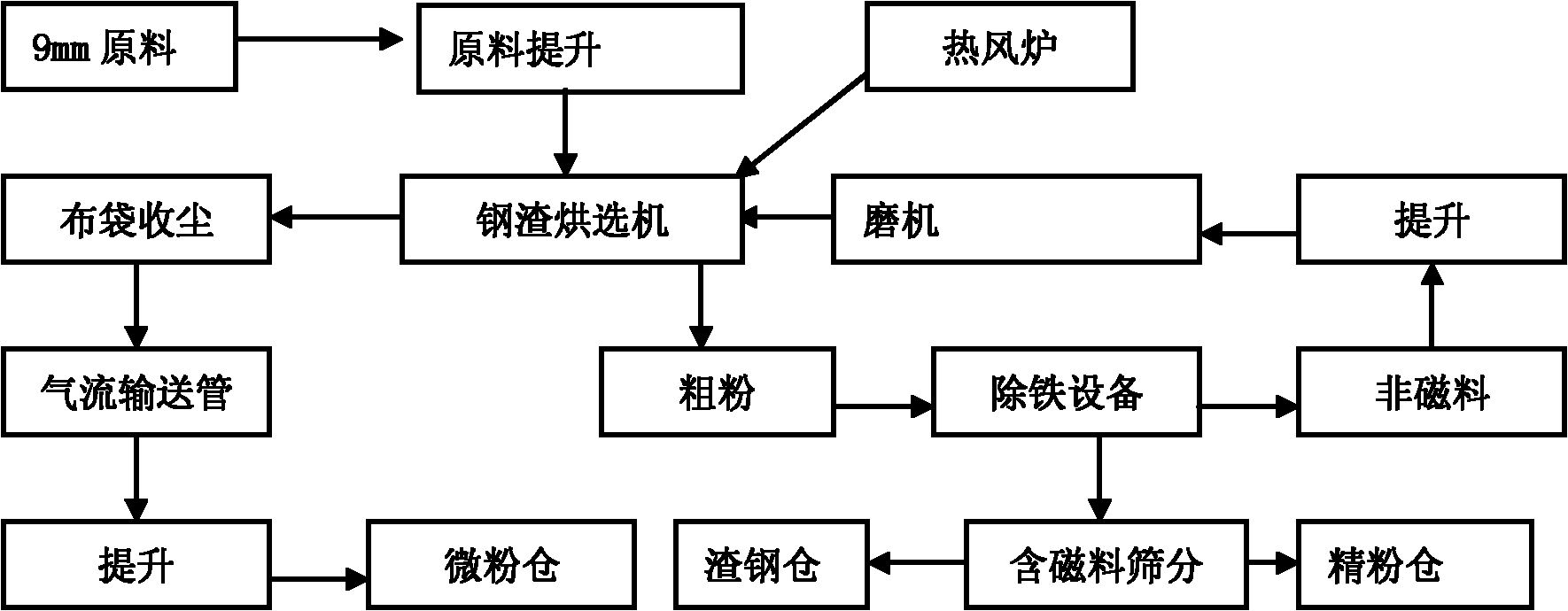

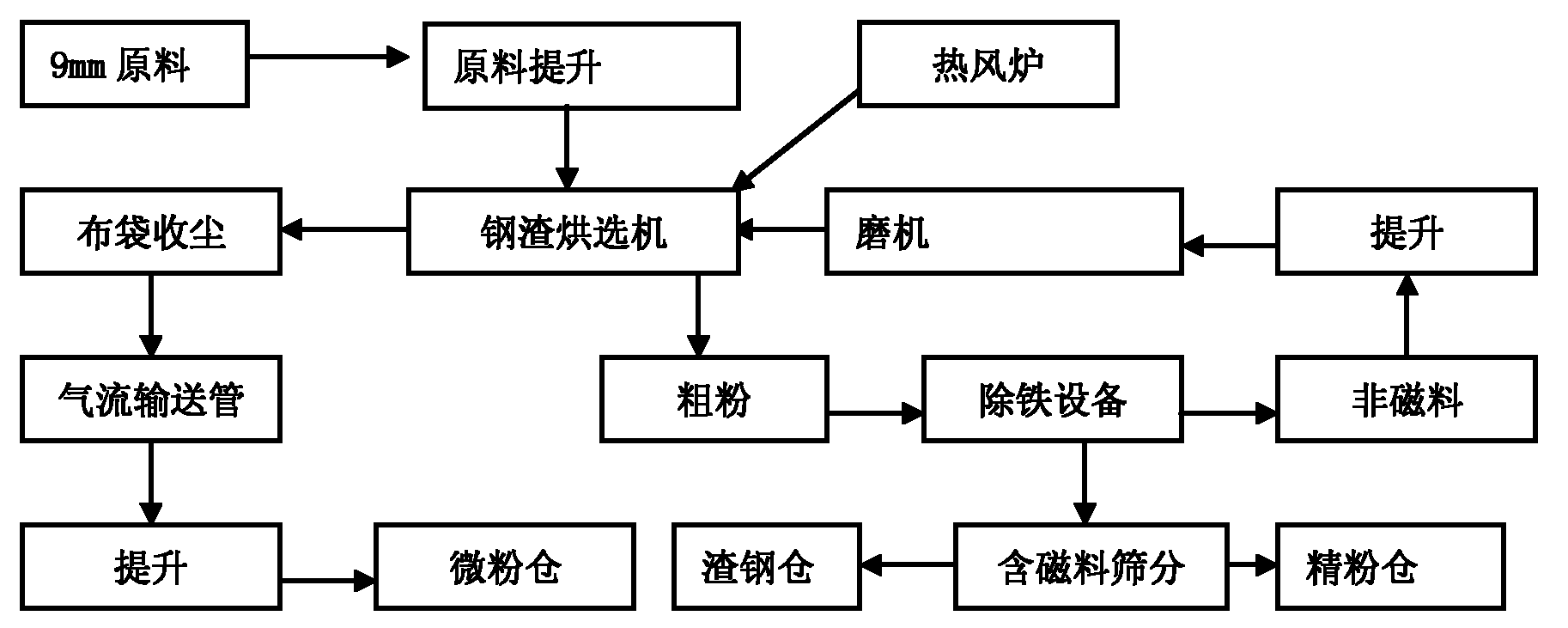

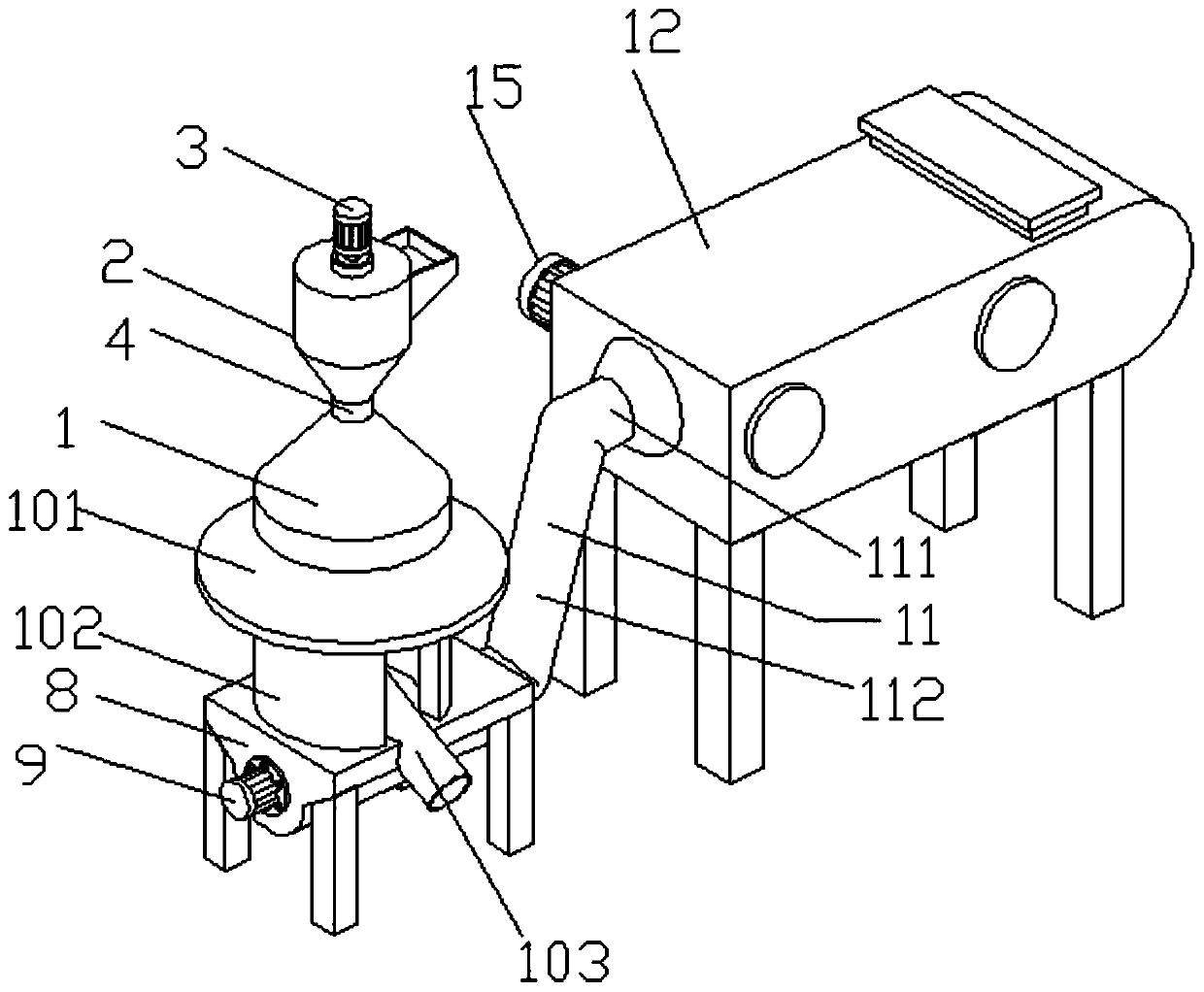

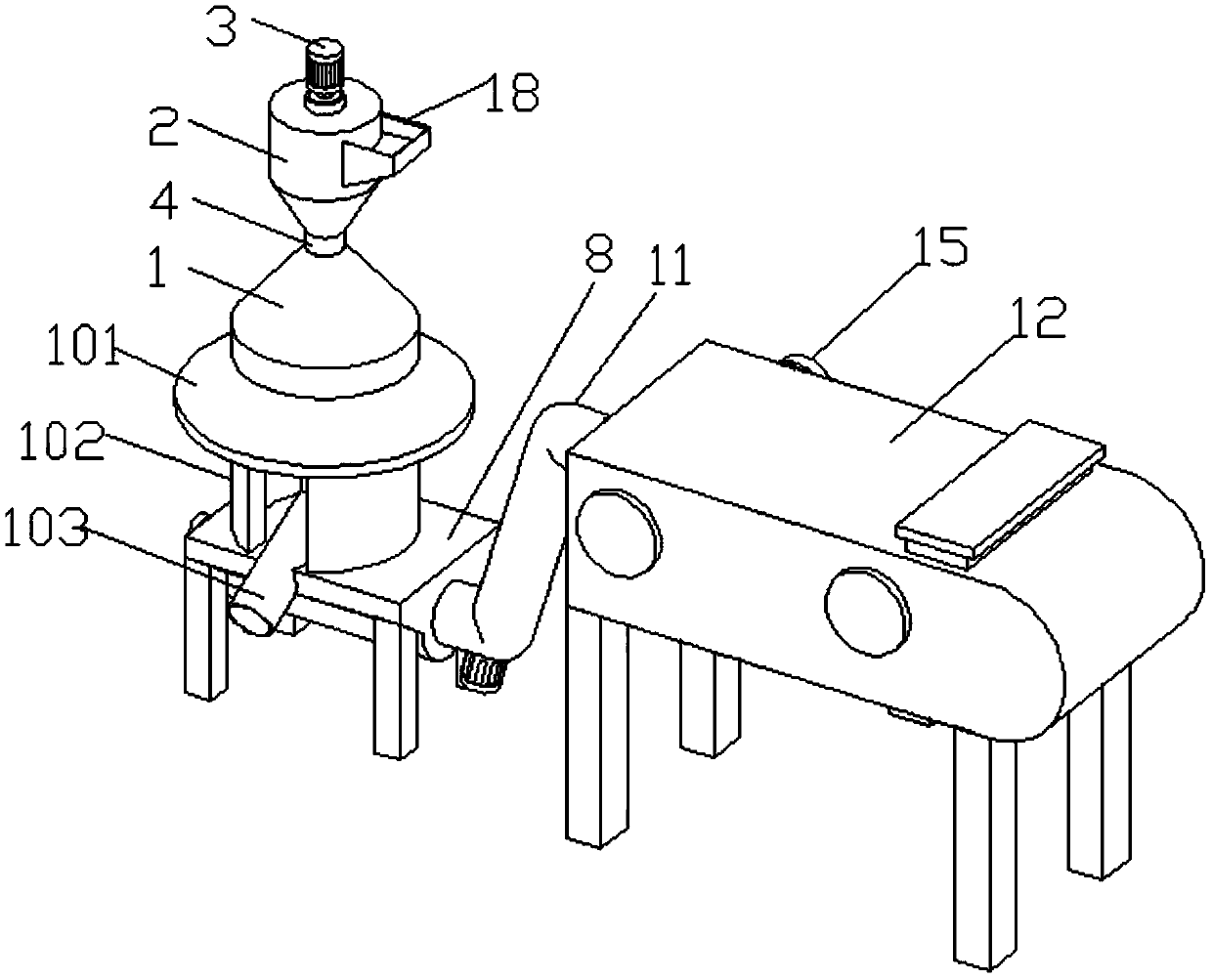

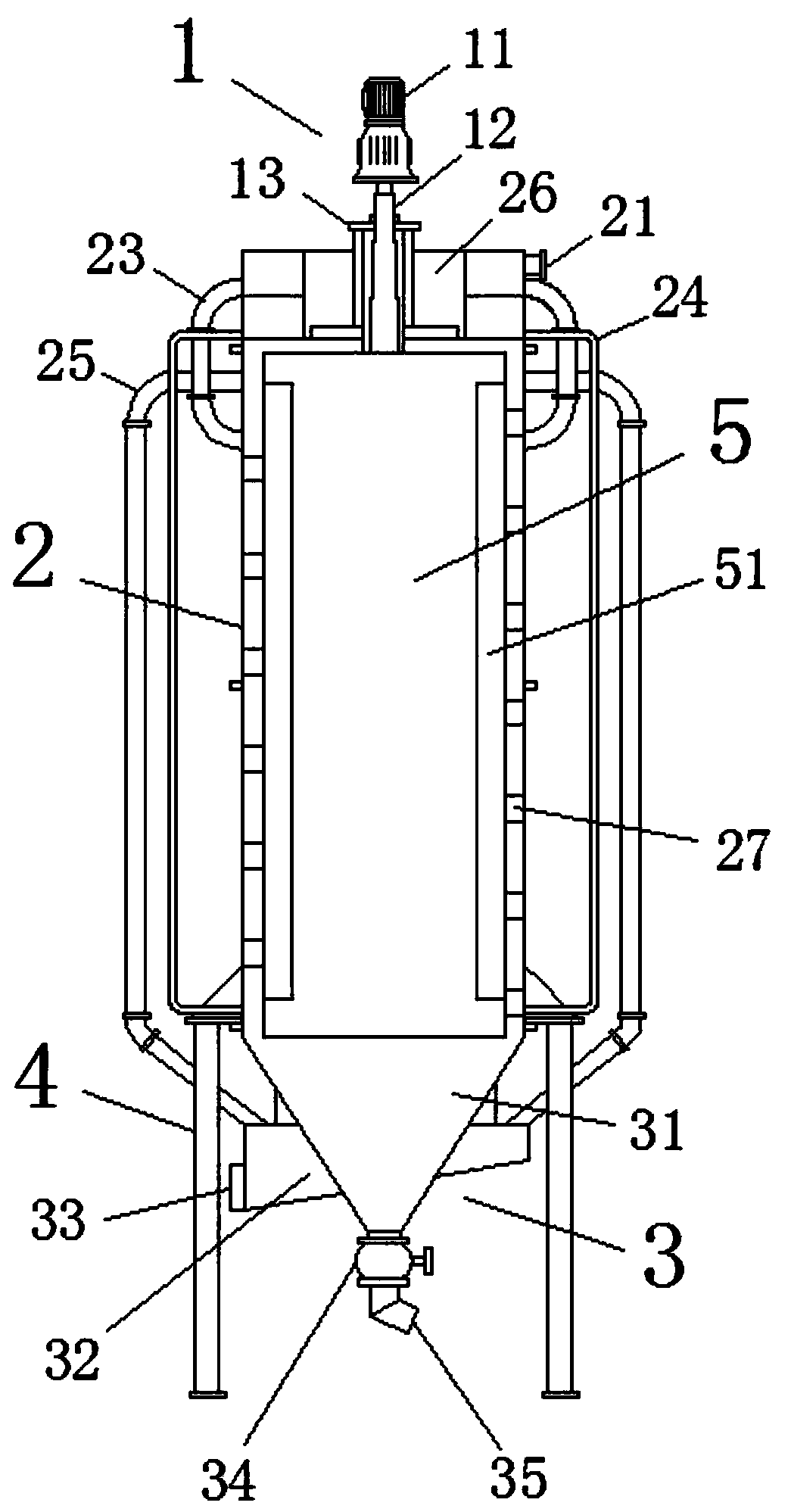

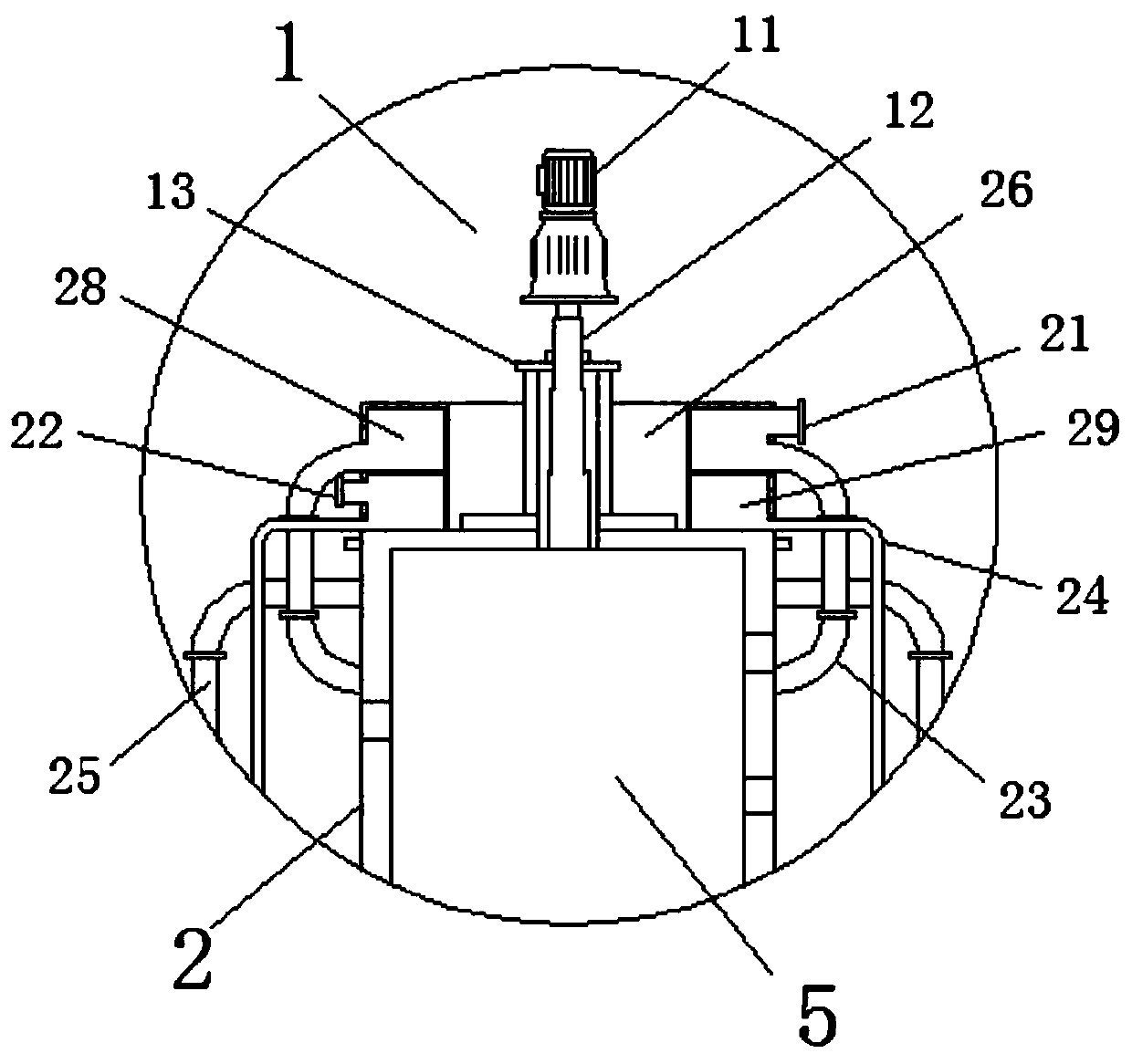

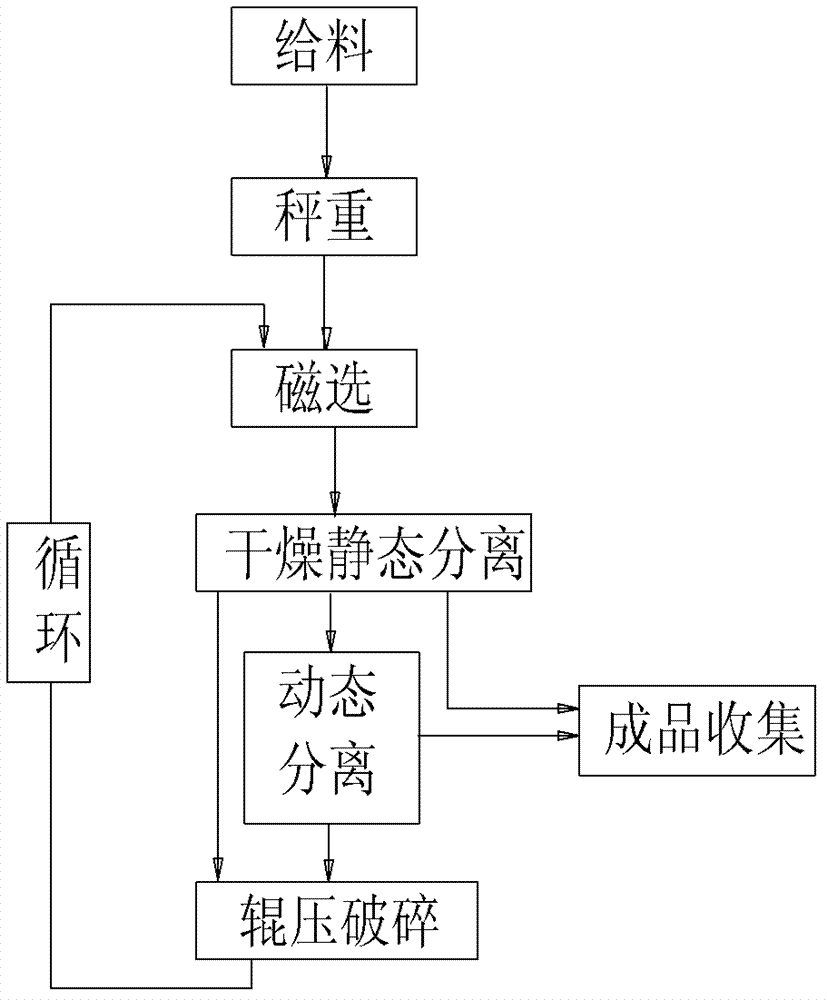

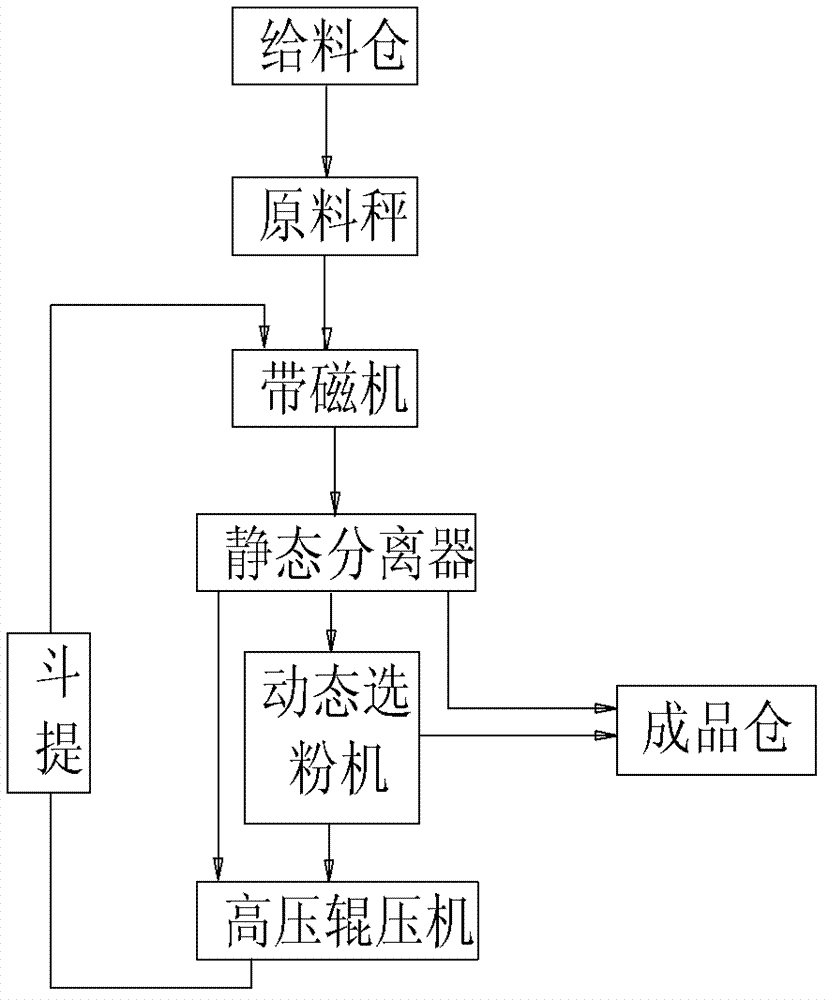

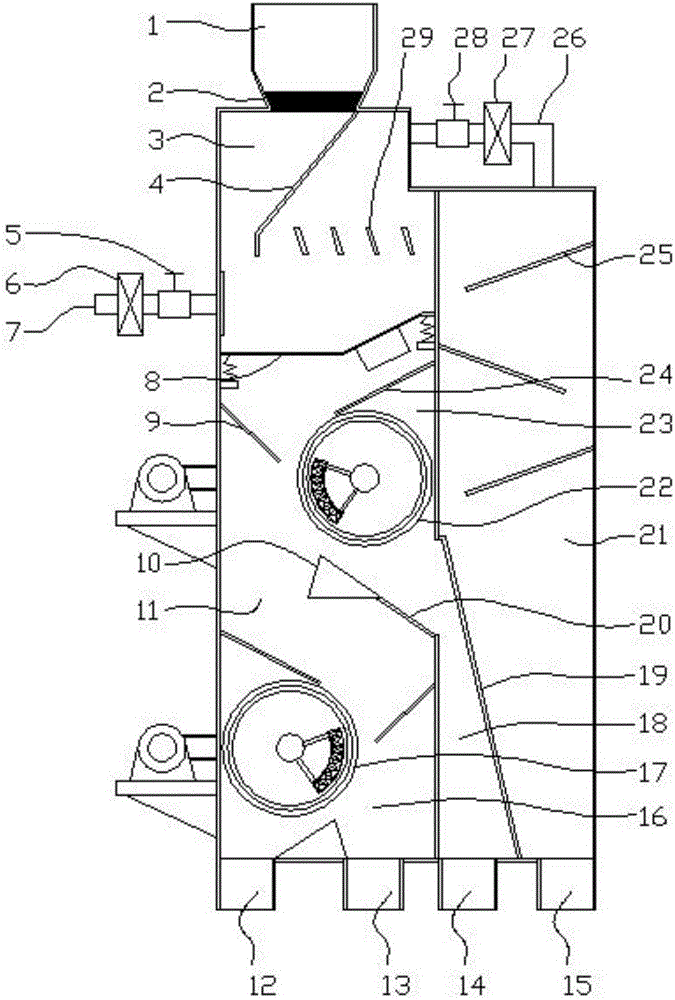

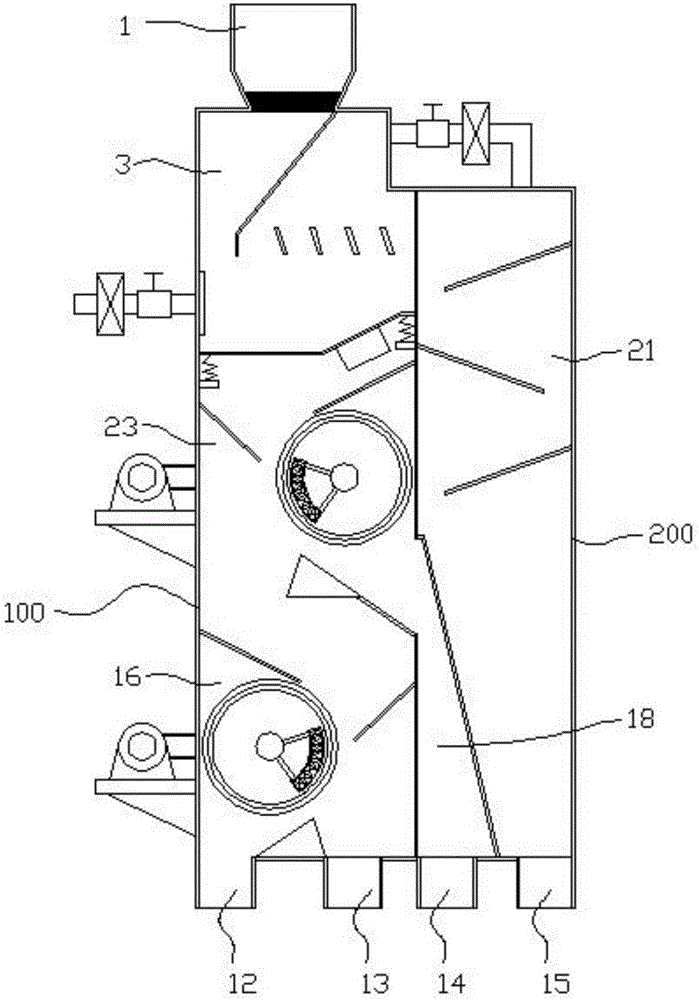

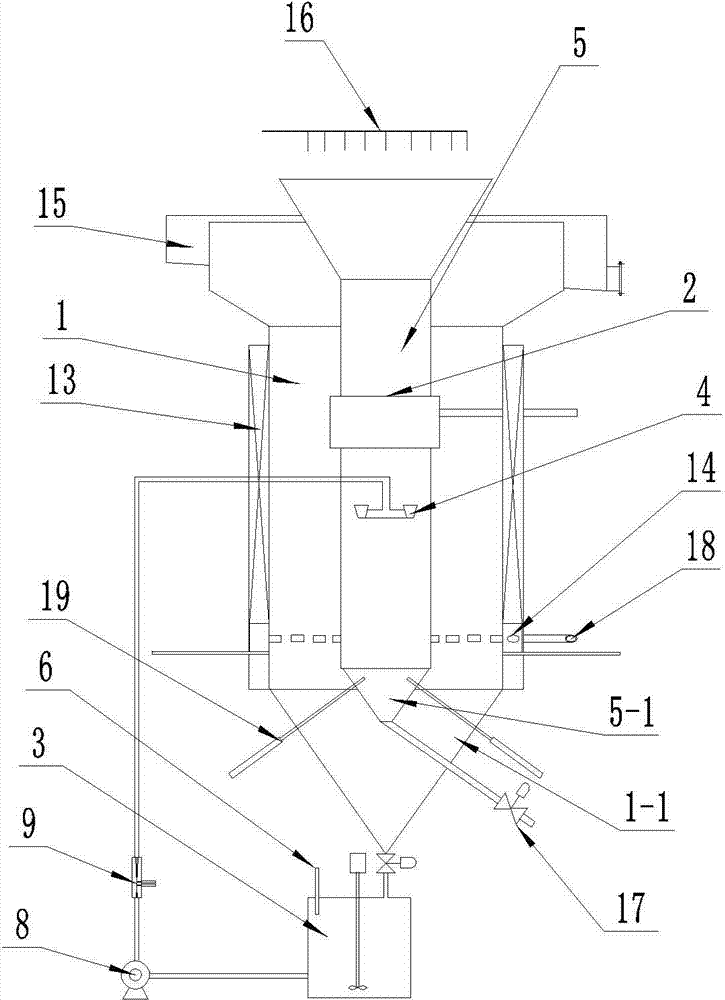

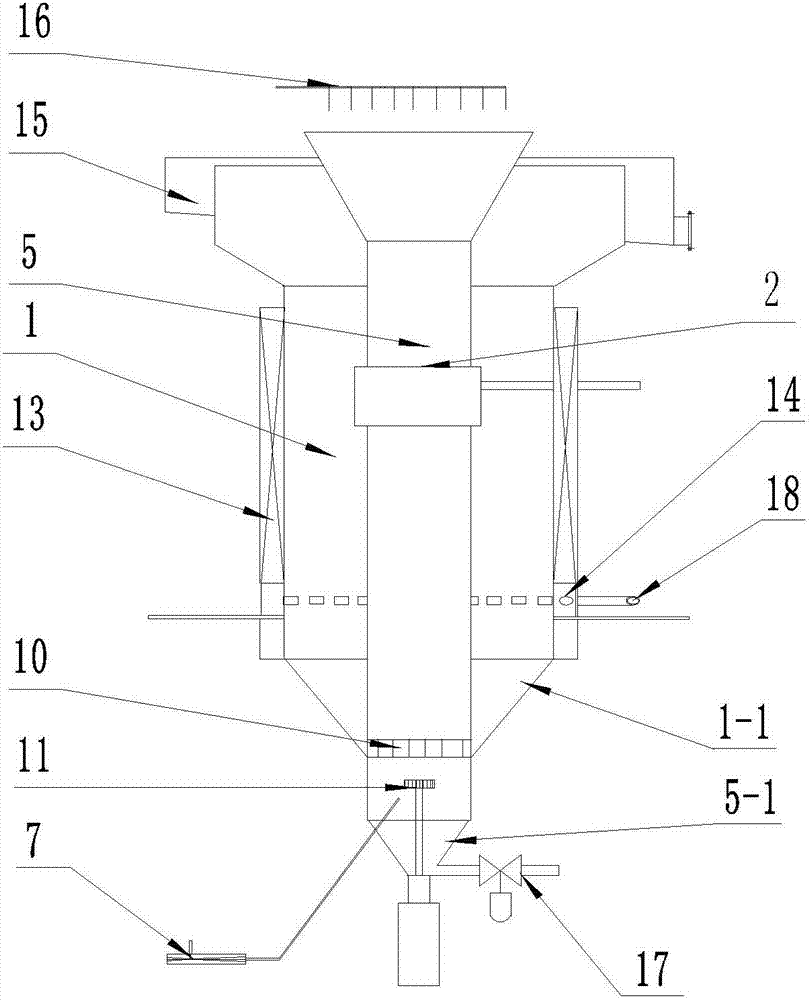

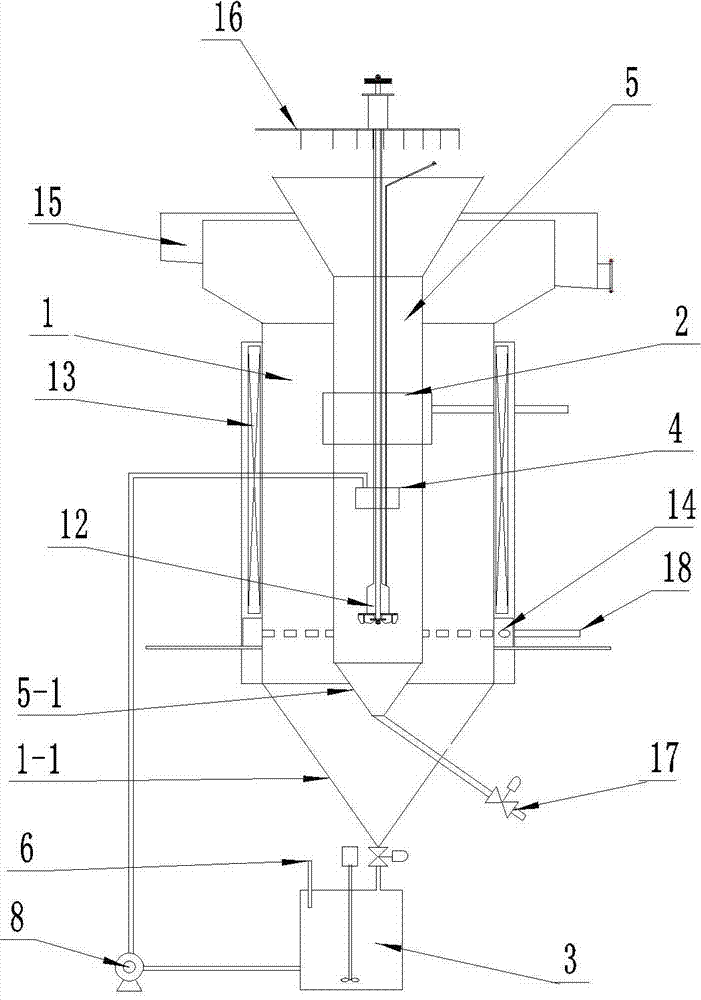

Smelting steel tailings micro-powder production method and apparatus thereof

ActiveCN103084266AImprove the effect of magnetic separationImprove powder selection efficiencyMagnetic separationGrain treatmentsWork in processHigh pressure

The present invention relates to the field of steel tailings micro-powder utilization, particularly to a smelting steel tailings micro-powder production method and an apparatus thereof. The method comprises steps such as material feeding and weighing, and is characterized in that weighed raw materials sequentially form process connections with a magnetic device, a static separator, a dynamic powder selection device, a high pressure roller press and a finished product warehouse, wherein a material outlet of the high pressure roller press is connected with a material feeding port of the magnetic device through a bucket elevator so as to achieve multiple material external circulations, multiple material magnetic separations, and efficient roller pressing crushing. Compared with the method and the apparatus in the prior art, the method and the apparatus of the present invention have the following beneficial effects that: 1) with the magnetic device, it can be effectively ensured that magnetic substances can be separated at the same quality; 2) with the static separator, half finished products are primarily separated, such that powder selection efficiency of the follow-up dynamic powder selection device is increased, and the condition that a specific surface area of the finished product is more than or equal to 450 m<2> / kg is met; 3) the high pressure roller press has characteristics of high operation rate and low power consumption so as to substantially improve steel tailings powdering efficiency; and 4) influence on the high pressure roller press service life by the magnetic substances is reduced.

Owner:鞍钢绿色资源科技有限公司 +1

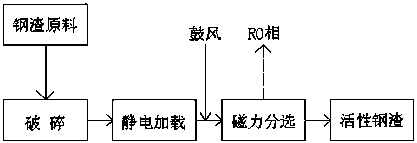

Efficient separation and recycling method for RO phase in steel slag

InactiveCN107721211AEfficient separation and recoveryObvious repulsionCement productionSlagMaterials science

The invention discloses an efficient separation and recycling method for an RO phase in steel slag. The method comprises the following steps: 1) crushing the steel slag; 2) loading electric charges; 3) carrying out RO phase separation; and 4) carrying out separation and recycling. The method disclosed by the invention has the advantages that the steel slag is taken as a treating object, firstly the steel slag is crushed and screened, particle size is less than 100 meshes, and then steel slag micro powder passes through an electric charge loading device, so that fine powder particles carry thesame electric charge and produce electrostatic repulsion mutually, and ultra-dispersed treatment is realized; then air is blasted, so that the fine powder particles pass through an electromagnetic separator in a suspension state, the RO phase is separated and removed, residual materials are recycled, utilization rate of the steel slag is improved, and the method disclosed by the invention is significant to comprehensive utilization of resources and environmental protection.

Owner:山西双良国环科技有限公司

Iron removal mineral separation device used for feldspar quarry

ActiveCN106423551AImprove product qualityAvoid pollutionVortex flow apparatusMagnetic separationParticulatesEngineering

The invention discloses an iron removal mineral separation device used for feldspar quarry. The device comprises a feeding hopper, a winnowing chamber, a feeding baffle, a first pressure adjusting valve set, an air blower, an air inlet pipeline, a vibration screening module, a magnetic separation guide plate, a triangular guide module, a second-level magnetic separation chamber, a second magnetic separation mechanism, a magnetic material channel, a partition plate, a guide block, a dust fall chamber, a first magnetic separation mechanism, a first-level magnetic separation chamber, a magnetic separation block plate, a dust fall module, an air outlet pipeline, an exhaust fan, a second pressure adjusting valve set, a windowing guide plate and the like. The characteristic that after broken feldspar quarry and ferric oxide are separated, the sizes and the weights of particulate matter are different is used for successively carrying out windowing, first-level magnetic separation and second-level magnetic separation, a flotation agent does not need to be added, the corrosion and the damage of the traditional flotation manner to the feldspar quarry are avoided, due to multi-level impurity removal, most of ferric oxide and other magnetic separation impurities are separated, the quality of feldspar quarry is improved, in addition, the device carries out degradation on dust, and environment is protected.

Owner:湘潭中韩长石矿业有限公司

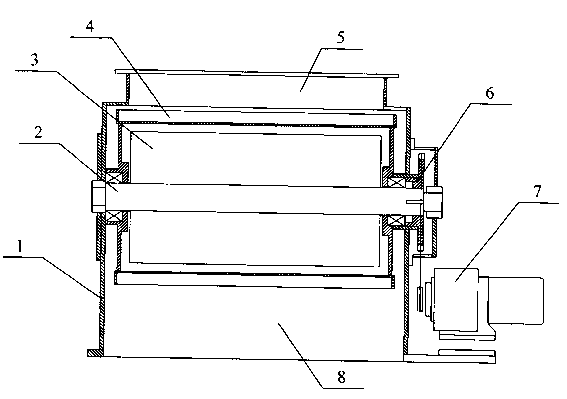

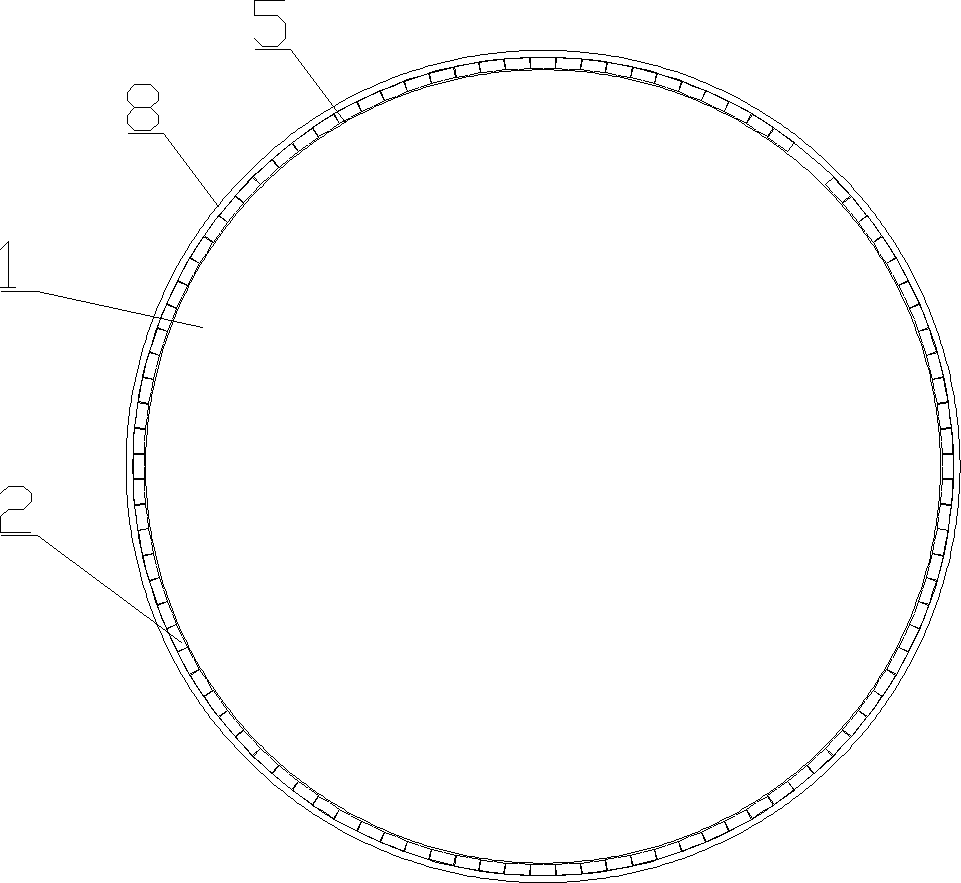

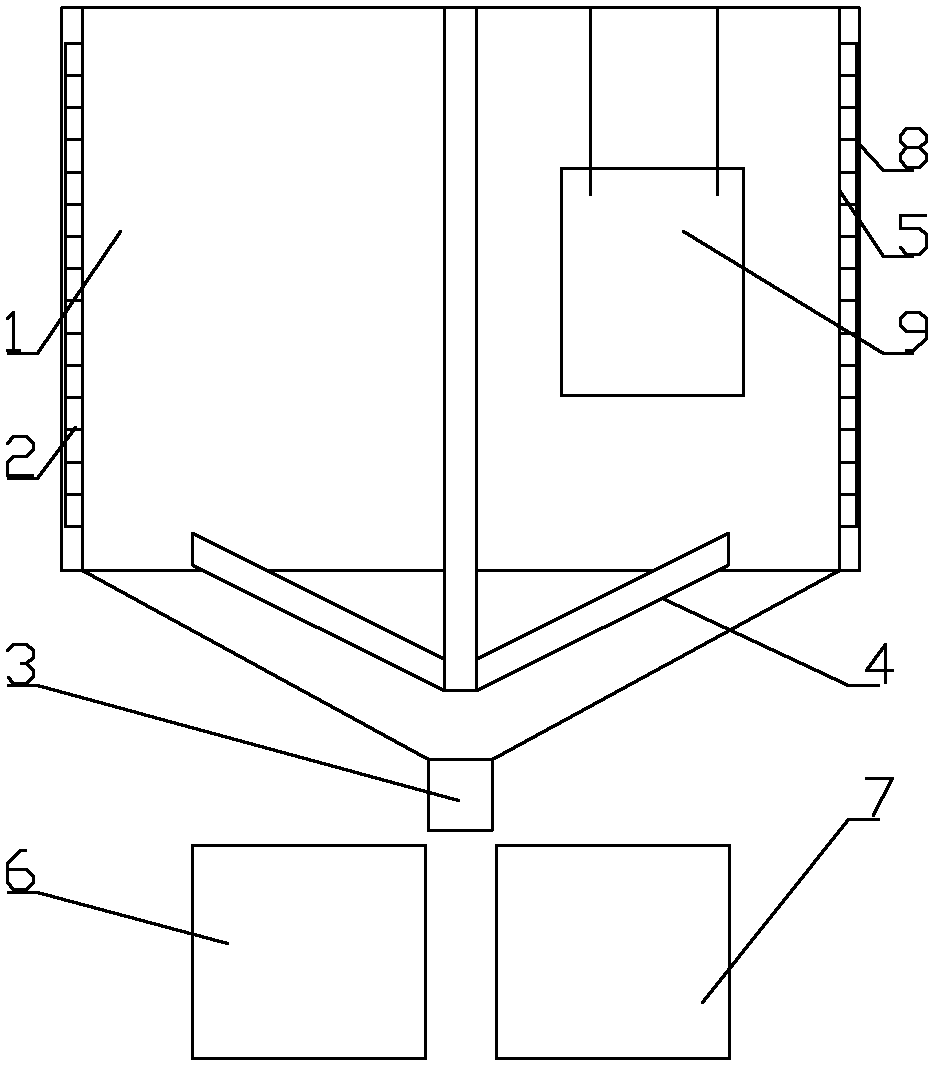

High-efficiency complex ore-dressing device and ore dressing method

ActiveCN104492589AIncrease the magnetic field strengthAdd depthWet separationEconomic benefitsEngineering

The invention belongs to the technical field of mineral separation, provides a high-efficiency complex ore-dressing device and a high-efficiency ore dressing method, and solves the technical problem that existing wash mills and magnetic flotation columns are high in space occupancy and long in technical process for iron ore dressing. The high-efficiency complex ore-dressing device structurally comprises cylinders of a wash mill and a magnetic flotation column, feeding and discharging passages and a servo mechanism, and the feeding and discharging passages are fittingly matched with the two cylinders. The high-efficiency complex ore-dressing device is characterized in that the cylinders of the wash mill and the magnetic flotation column are in a coaxial nested complex structure, and excitation coils are arranged outside the wash mill with an annular section. The high-efficiency complex ore-dressing device and the high-efficiency ore dressing method have the advantages that technical process is effectively shortened, floor area is greatly reduced, and high economic benefits can be obtained.

Owner:石家庄金垦科技有限公司

Integrated domestic solid waste treatment device

InactiveCN111774407AReduce work intensityAchieving Impact DispersionSolid waste disposalTransportation and packagingProcess engineeringSewage

The invention relates to an integrated domestic solid waste treatment device which comprises an extruding and separating component, a crushing component, a drying component, a magnetic separation component, a pyrolysis screening part and an evaporating and condensing component. Through specifically arranging all components, optimization of integrated procedures including water removal, crushing, drying, magnetic separation, pyrolysis and screening of solid waste and oil gas condensation is realized, secondary pollution free treatment of solid waste is realized, solid contents in the solid waste are recycled to the maximum, and at the same time, sewage in the solid waste is also treated to truly realize harmless disposal.

Owner:胡妤婕

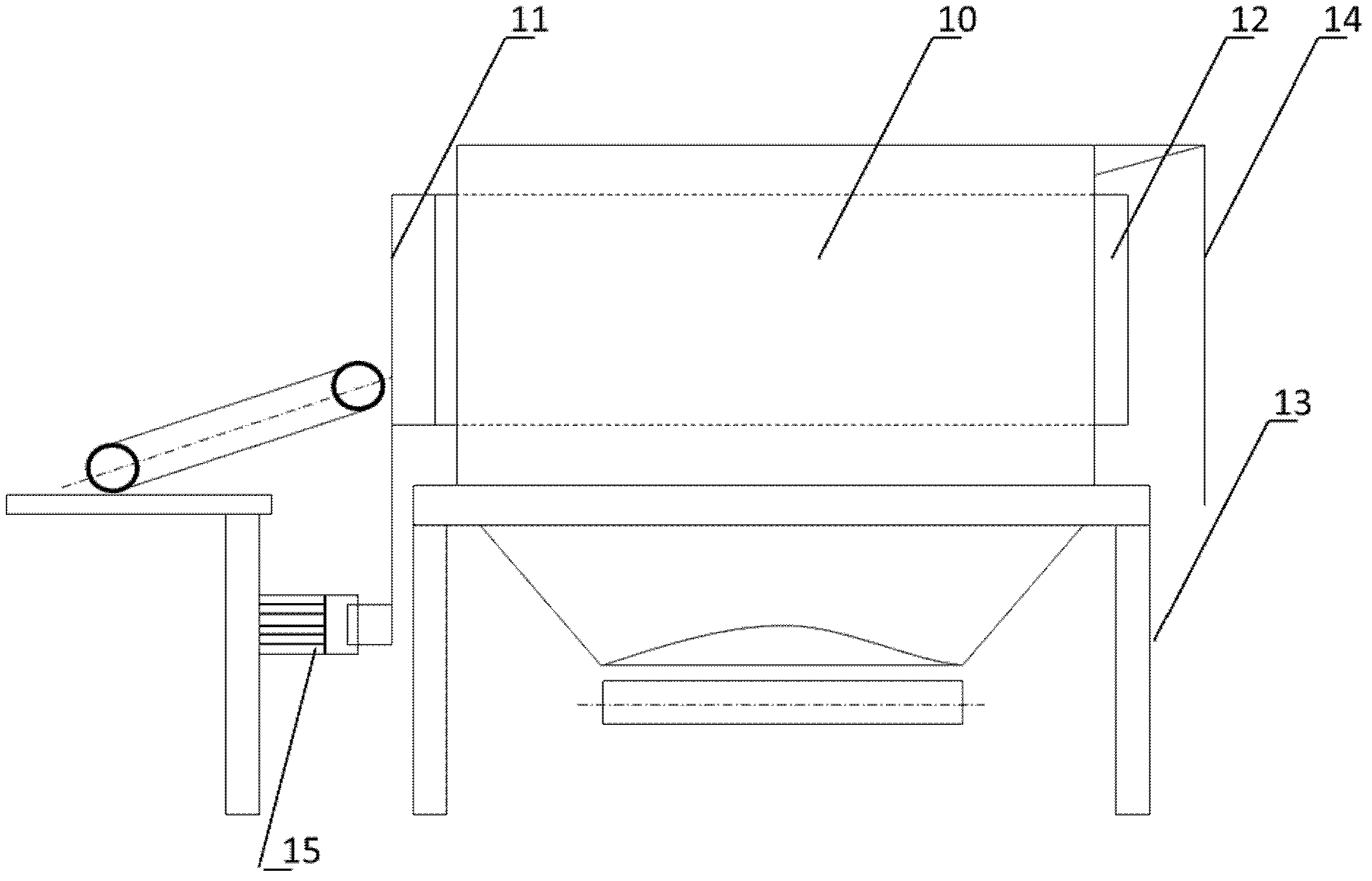

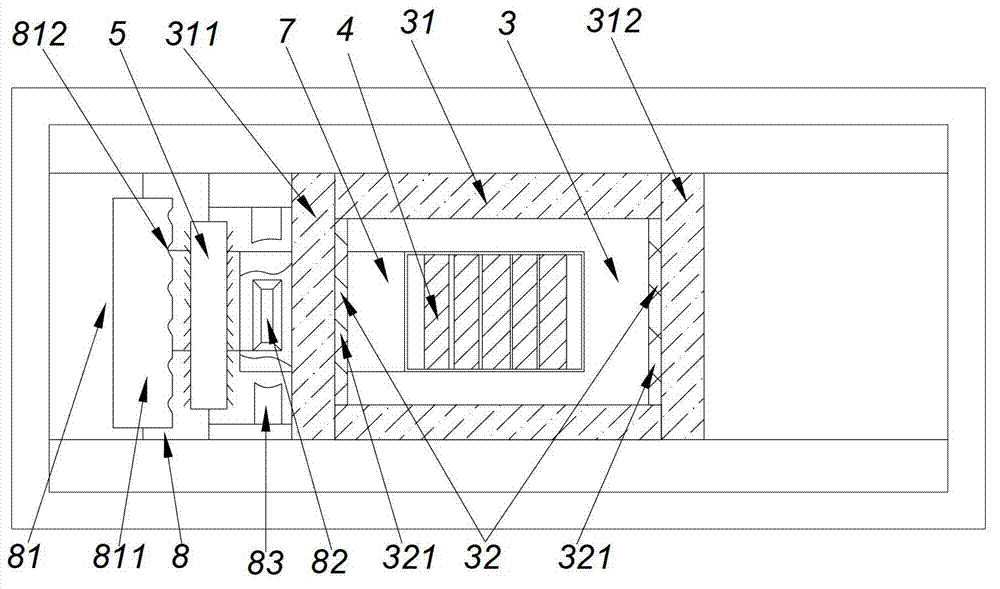

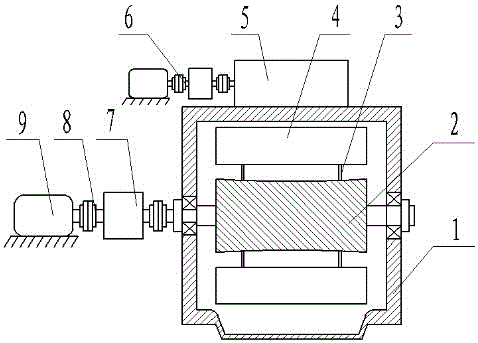

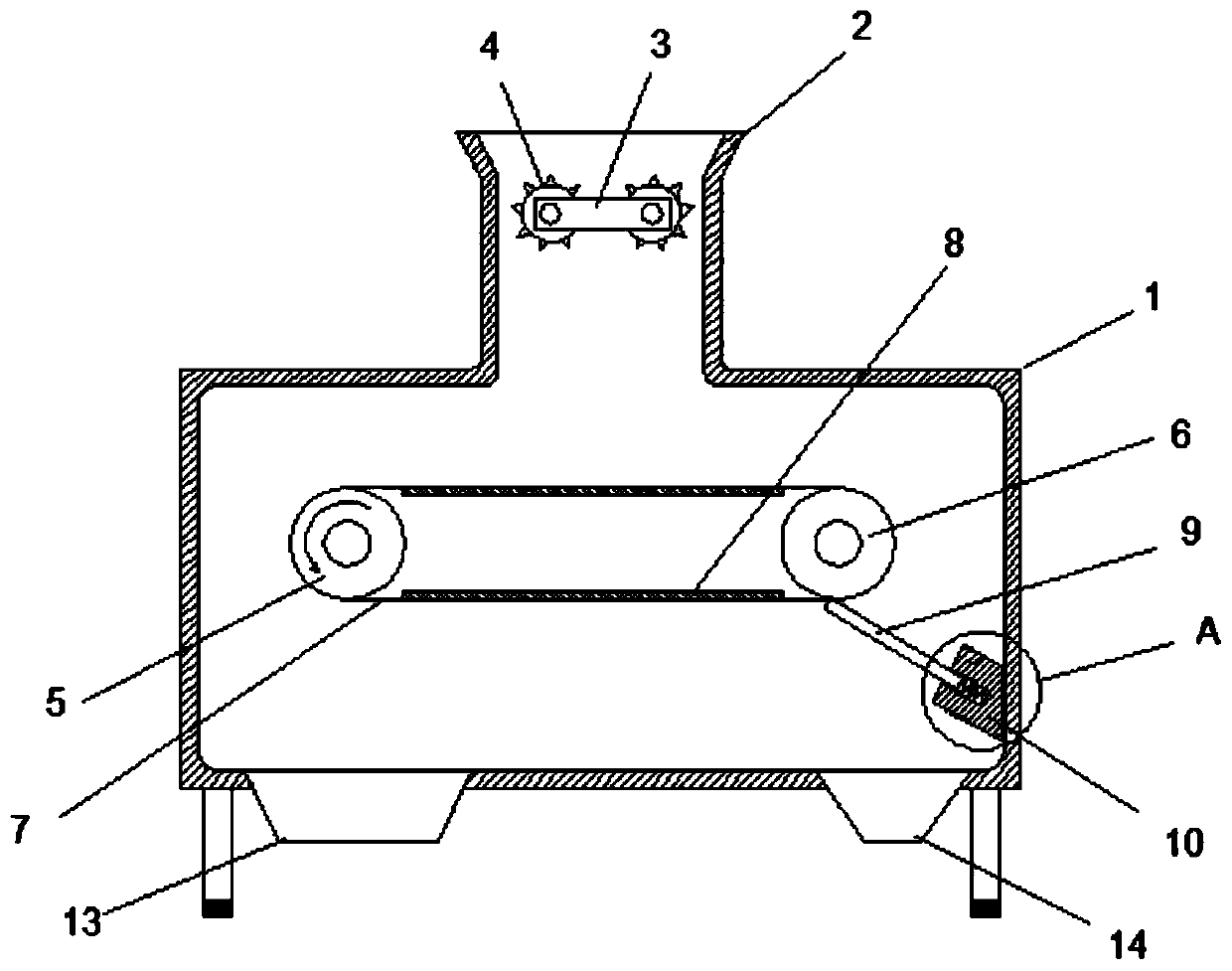

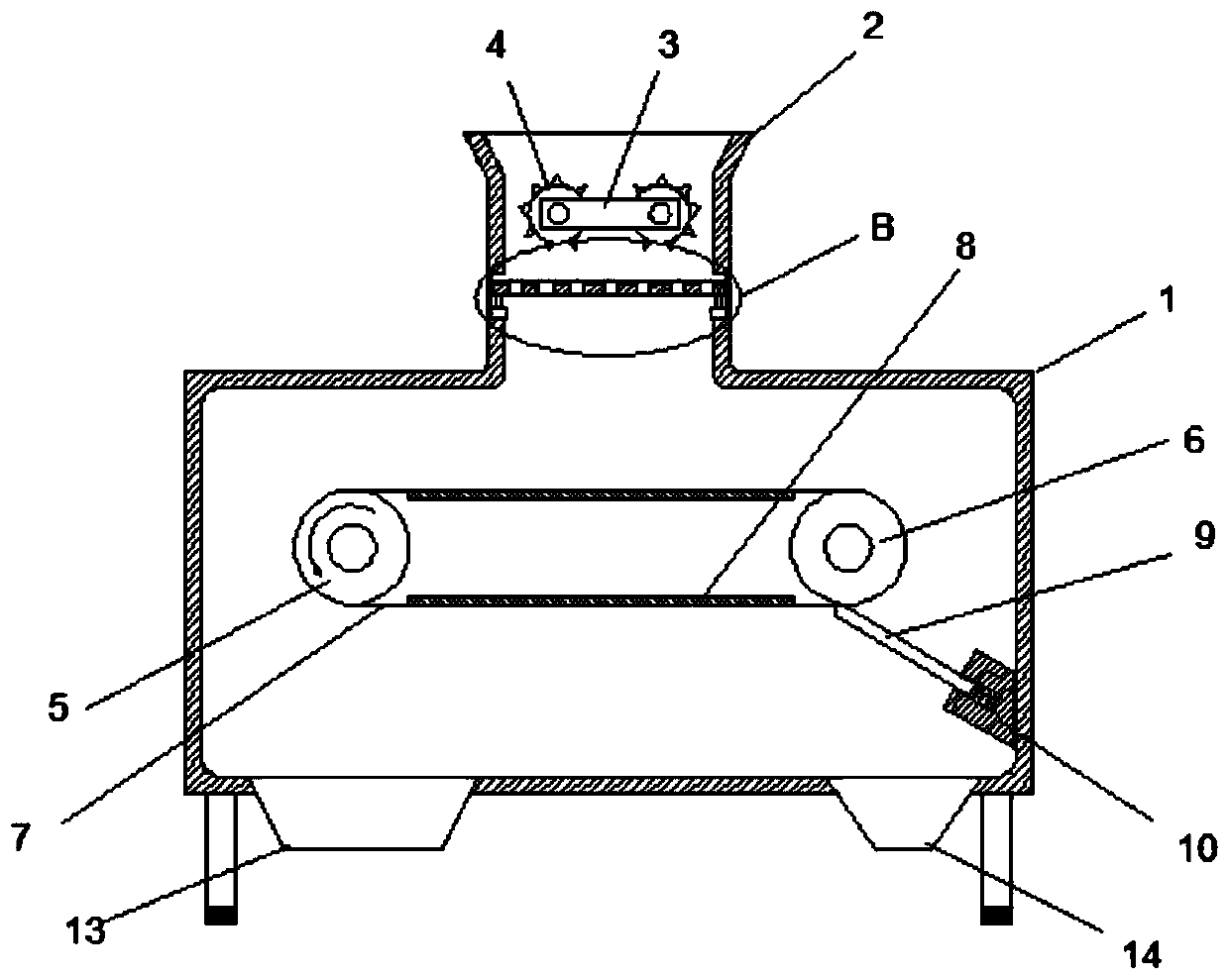

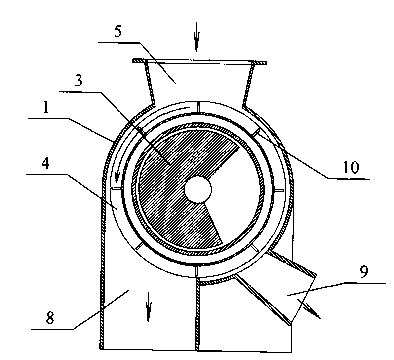

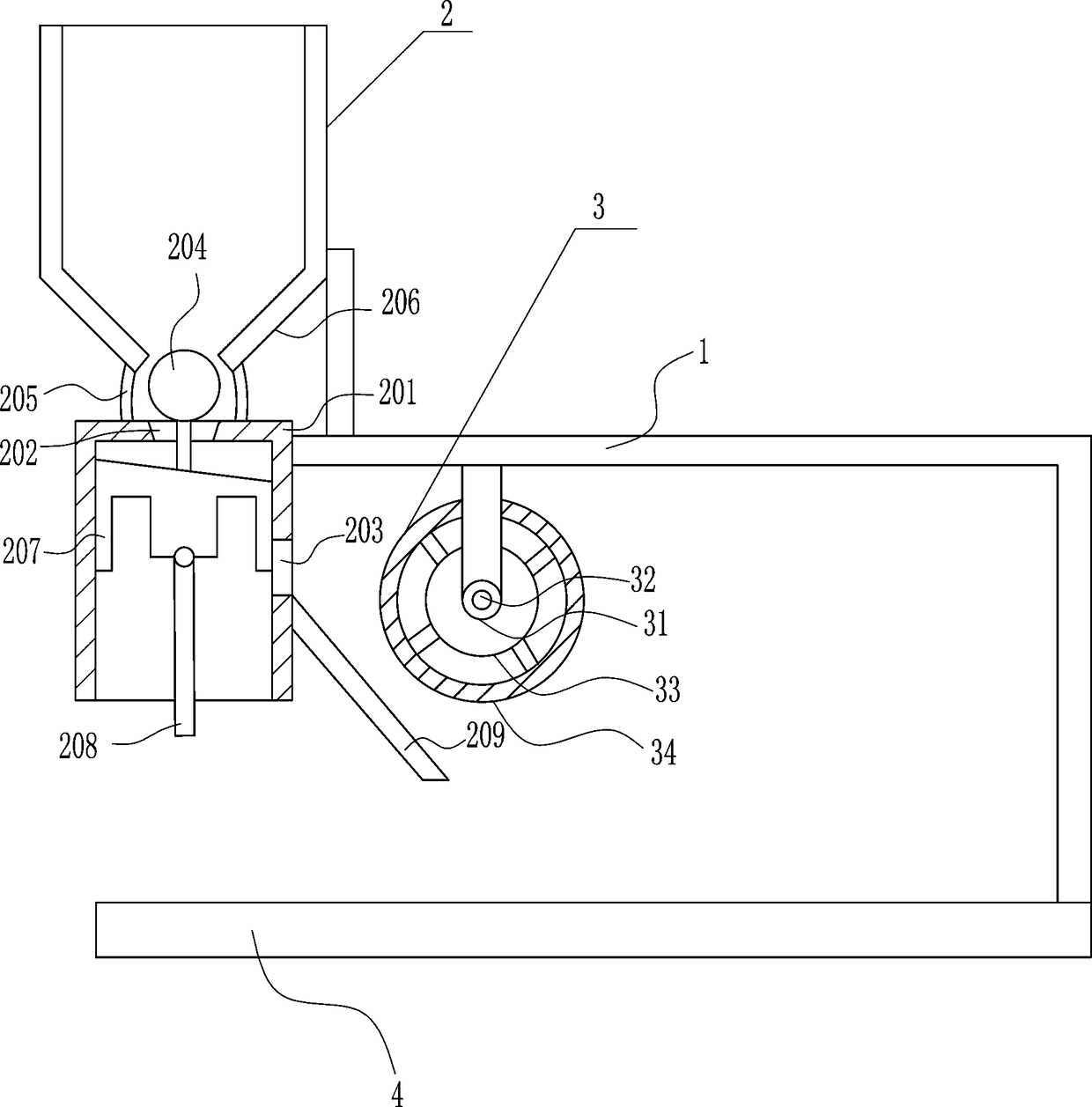

Magnetic separator

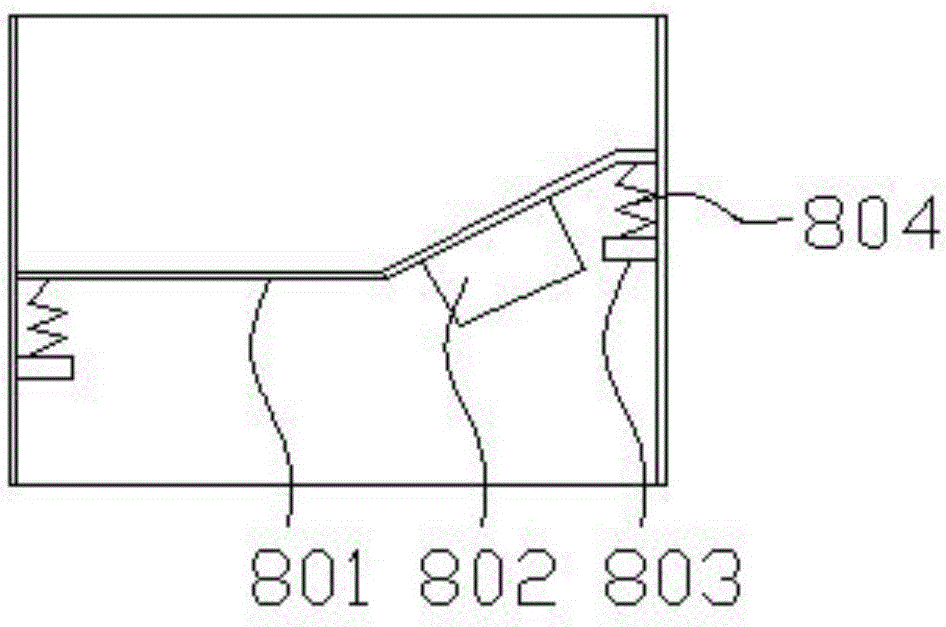

InactiveCN103008103AImprove the effect of magnetic separationEasy to cleanMagnetic separationMagnetic separatorImpurity

The invention particularly relates to a magnetic separator comprising a magnet (3), a feed port (5), a stand (1), a fixed shaft (2), the magnet (3), a rotary drum (4), the feed port (5), a motor (7), a first discharge port (8) and a second discharge port (9), wherein the feed port (5) is positioned at the top end of the stand (1); and the first discharge port (8) and the second discharge port (9) are positioned at the lower end of the stand (1). The fixed shaft (2) is fixedly connected with the stand (1), the fixed shaft (2) is connected with the rotary drum (4) by a bearing, the magnetic (3) is positioned between the rotary drum (4) and the fixed shaft (2) and is connected with the fixed shaft (2), a power output end of the motor (7) is connected with a power input end of the rotary drum (4), a section of the magnet (3) is a sector magnet extending to the first discharge port (8) from the feed port (5), and the second discharge port (9) is positioned on the rear side of the sector magnet. By utilizing the magnetic separator, iron impurities can be automatically cleared, and the magnetic separation effect is good.

Owner:溧阳市华生机械制造有限公司

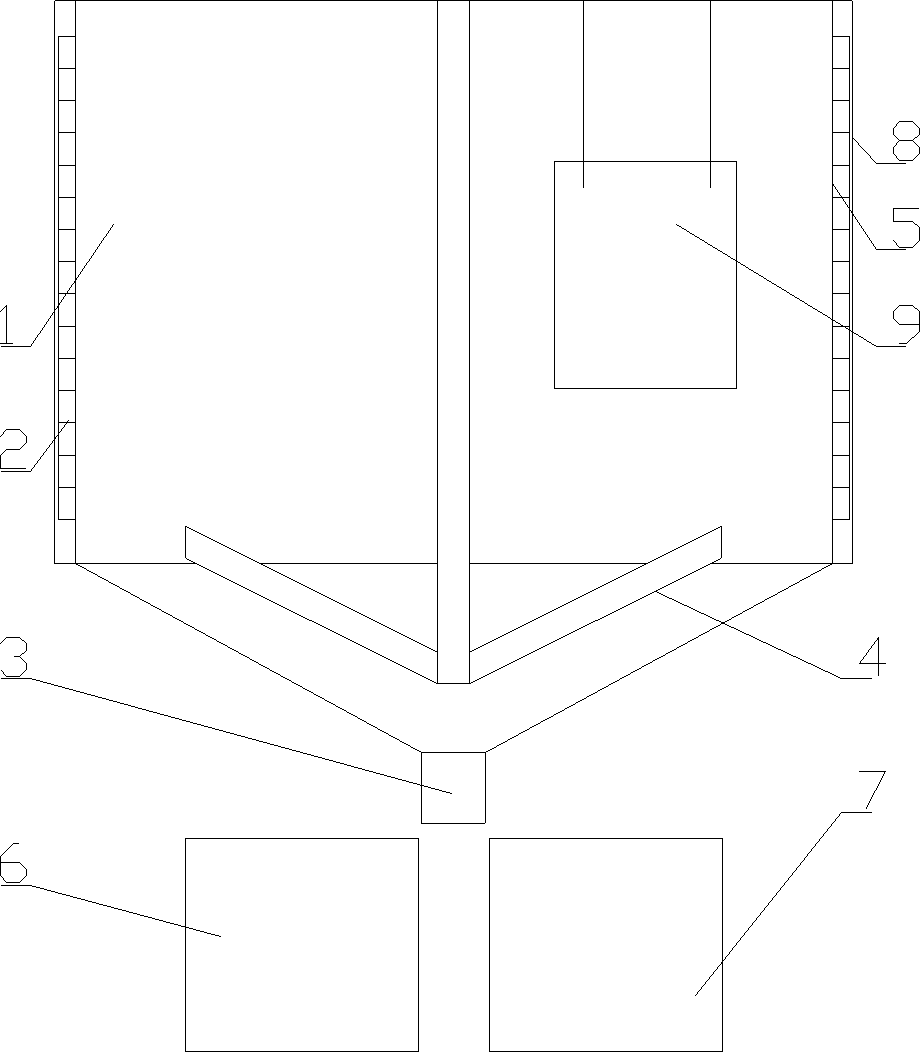

Vertical magnetic separation method and vertical magnetic separation device

InactiveCN102614981ADoes not reduce the adsorption effectReduce adsorptionMagnetic separationSlurryCentrifugal force

The invention discloses a vertical magnetic separation method and a vertical magnetic separation device. The vertical magnetic separation method is characterized in that materials are placed into a vertical barrel (1) after being crushed into slurry, and then are stirred and rotated through stirring blades (4), so that the magnetic materials are attracted by magnets (2) on the barrel (1), and the magnetic materials in the materials are separated. The magnetic separation barrel is vertically mounted and provided with the magnets, the materials are close to the magnets of the barrel under drive of the stirring blades and are attracted by the magnets when in magnetic separation, and as centrifugal force of the barrel is identical with the magnetic force in direction, rotation of the materials cannot reduce magnetic attracting effects of the magnets, and magnetic separation effects are enhanced. As applicants test, the vertical magnetic separation device can reduce the iron content to be lower than 0.2% and is higher in the magnetic separation effects than existing superconductive magnetic separation equipment. Besides, the vertical magnetic separation device is simple, low in cost and suitable for small-scale production.

Owner:周俊和 +1

Rotary magnetic separation equipment for quartz sand utilized as building material

ActiveCN108405174AConvenient for magnetic separationUniform magnetic separationMagnetic separationConveyor partsBuilding materialEngineering

The invention relates to a feeding device, in particular to rotary magnetic separation equipment for quartz sand utilized as a building material, and aims to solve technical problems in the prior art.In order to solve the above technical problems, the rotary magnetic separation equipment which is applicable to the quartz sand utilized as the building material, has the intermittent adding function, and is good in magnetic separation effect is provided. The rotary magnetic separation equipment for the quartz sand utilized as the building material comprises ab racket and the like, wherein the bracket is connected with the right side of the top of a base; a discharging mechanism is connected with the left end of the bracket; and a magnetic separation mechanism is connected with the left sideof the inner top of the bracket and positioned on the right side of the discharging mechanism. By adoption of the designed rotary magnetic separation equipment for the quartz sand utilized as the building material, the quartz sand can be quantitatively and intermittently added; the manual adding operation is not needed; more convenience is brought; and through the arrangement of a motor, a secondrotating rod and a third rotating rod, the automatic, quantitative and intermittent adding operation can be achieved without manually moving a connecting rod.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com