Method for treating steel slag tailings subjected to magnetic separation

A treatment method and steel slag technology, which is applied in the field of comprehensive utilization of solid waste resources in the metallurgical industry, can solve the problems of restricting the use of steel slag tailings, the loss of iron resources in slag, and the high consumption of grinding bodies, so as to increase the added value of products and reduce grinding costs. , Improve the efficiency of powder selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

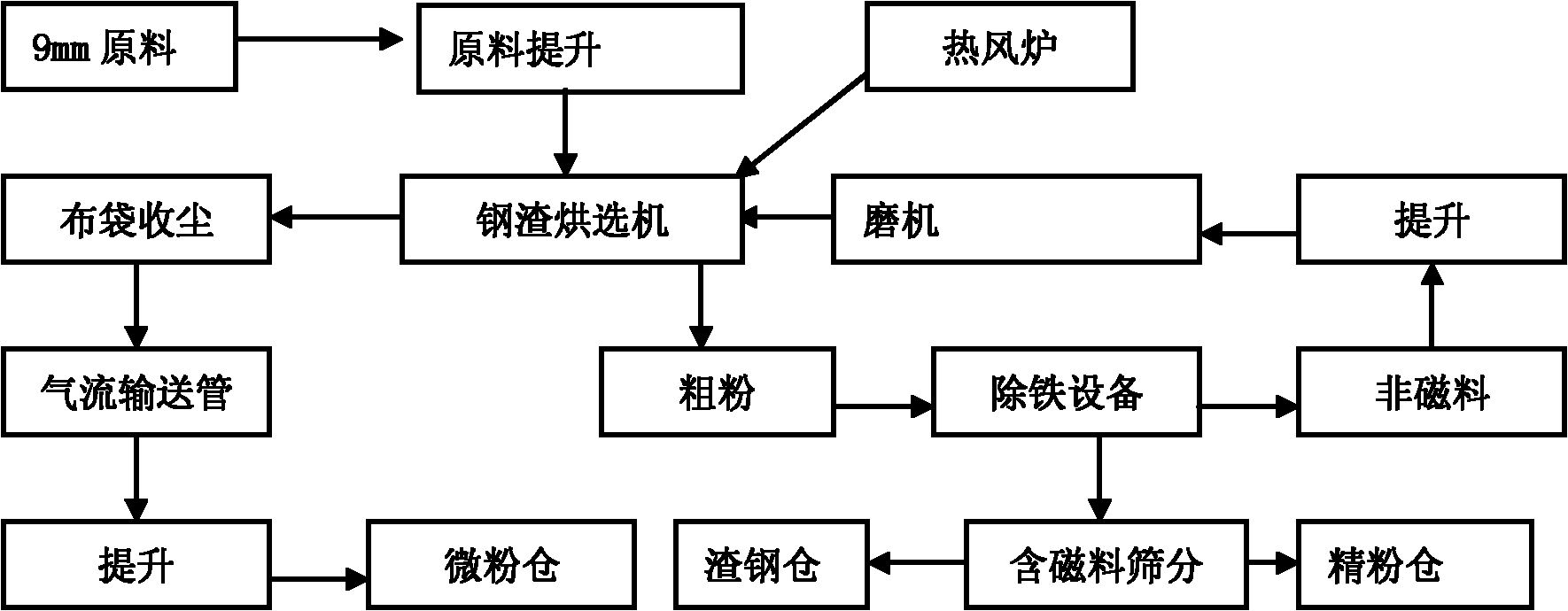

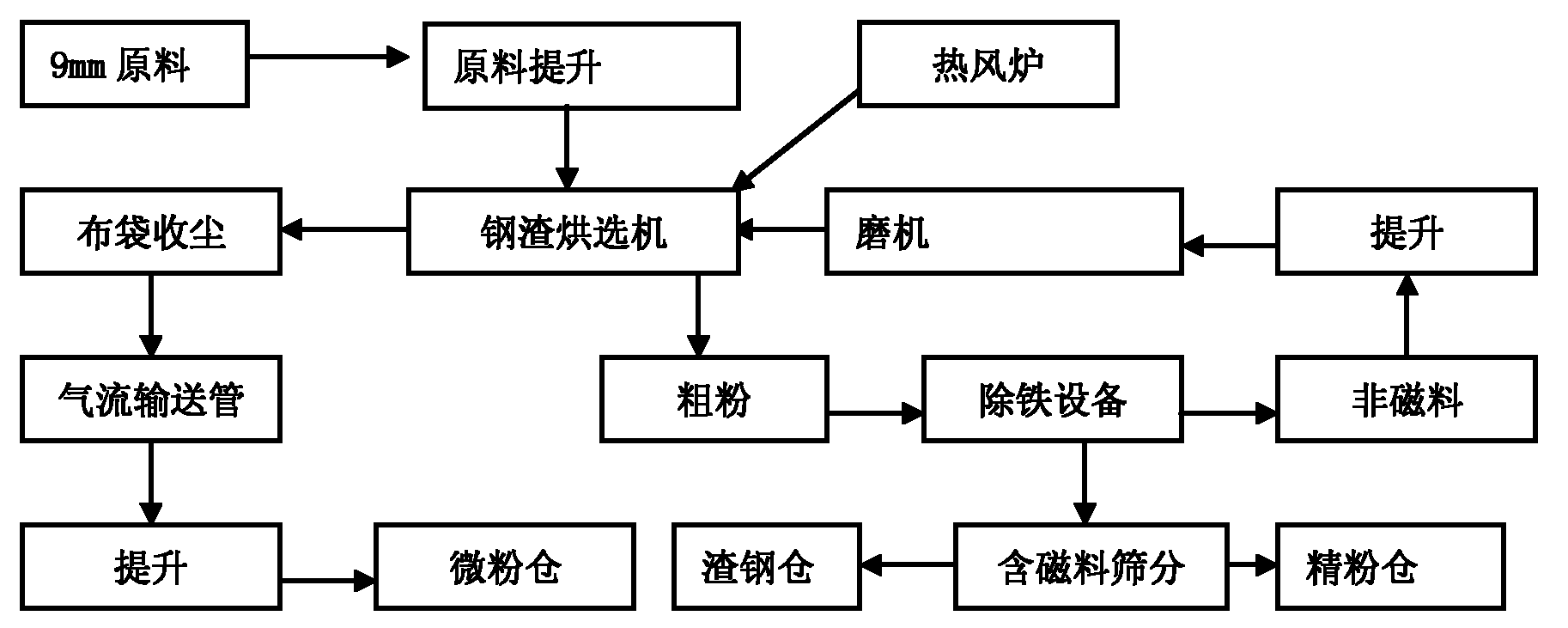

[0021] The steel slag tailings with a metal iron content of 1-3% and a particle size of 0-20 mm are lifted into the drying and sorting device, and the material is constantly vibrating and jumping in the device with the hot air of 200-800 °C blown by the hot blast stove Mixing to produce fluidization, the fine powder mixed with hot air will produce flash evaporation, and the qualified fine powder will be dried in a few seconds, the dried fine powder will rise with the flue gas, and enter the cloth bag after classification The dust collector is collected, and then transported into the finished product warehouse. After the coarse powder is magnetically separated, the slag steel and slag fine powder in the powder are recovered. The non-magnetic coarse powder after magnetic separation enters the mill to be ground, and the ground material is mixed with steel slag and tailings raw materials, and then baked and separated magnetically, and the cycle continues.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com