Patents

Literature

330results about How to "Reduce grinding costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

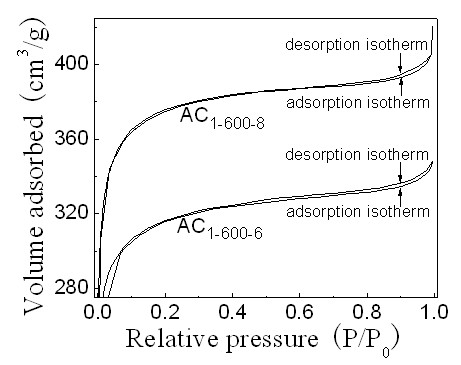

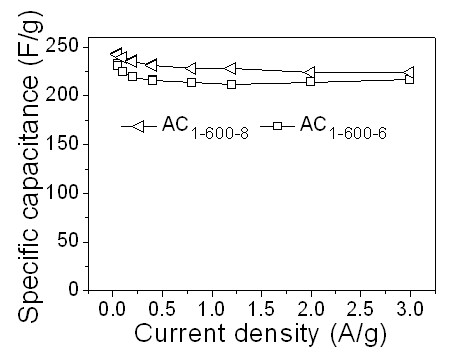

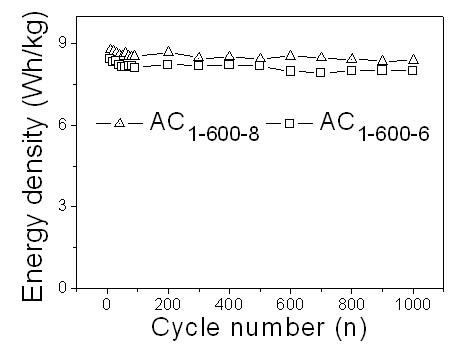

Preparation method of activated carbon material for electrochemical capacitor

The invention discloses a preparation method of an activated carbon material for an electrochemical capacitor and belongs to the technical field of carbon material and microwave chemistry. The preparation method comprises the following steps of: using peanut shells as a raw material, processing the peanut shells by using a KOH solution and a potassium hydroxide alkali solution, transferring the peanut shells processed by the potassium hydroxide alkali solution into a corundum crucible, placing the corundum crucible into a microwave reactor for microwave heating and activation to obtain the activated carbon material for an electrochemical capacitor. According to the method, with peanut shells as a carbon source and potassium hydroxide as an activator, the activated carbon material is prepared by microwave-assisted heating of the potassium hydroxide activated peanut shells. The activated carbon material prepared by the preparation method is characterized in that its specific surface area is 990-1277m<2> / g, total pore volume is 0.47-0.63cm<3> / g, and the yield is 14.2-24.4%. The activated carbon material, which is prepared as an electrode material for an electrochemical capacitor, hasgood stability and excellent comprehensive performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

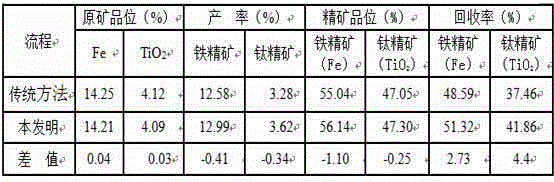

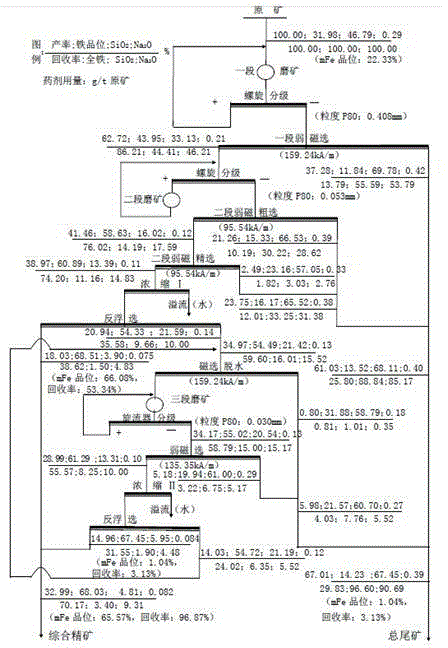

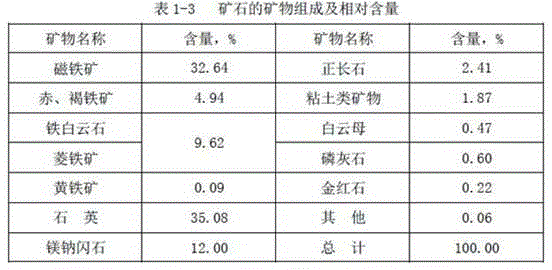

Low-cost high-recovery environment-friendly mineral separation method of low-grade vanadium titano-magnetite

ActiveCN105107616AIncrease production capacityReduce unit energy consumptionWet separationMagnetiteHigh pressure

The invention discloses a low-cost high-recovery environment-friendly mineral separation method of low-grade vanadium titano-magnetite. Medium-intensity magnetic primary iron separation, large-particle strong-magnetic tail throwing, subsequent ore grinding magnetic separation iron separation, strong-magnetic flotation titanium separation are conducted after three segments of crushing including rough crushing, medium crushing and high-pressure roller grinding are conducted, the iron and titanium ore concentrate quality and yield are higher, energy consumption per unit is lower, tailings discharge pressure is smaller, and the production capacity is greatly improved. According to the method, qualified tailings are thrown out in advance through the method that medium-intensity magnetic primary iron separation and strong-magnetic tail throwing are conducted after fine crushing is conducted, so that the subsequent ore grinding amount is reduced, the grade of iron and titanium generated in the subsequent grinding and separation processes is increased, and thus the product cost is reduced. The method is simple in technological process, easy to operate, low in cost and high in ore separation efficiency, the produced product is stable in performance, the production environment is more environmentally friendly, chemical matter generated in the flotation titanium separation production process is greatly reduced, and the pollution is low. The method is not limited by the production scale, the iron and titanium ore concentrate quality and yield are increased while large-particle qualified tailings can serve as by products to increase benefits, so that the enterprise profits can be maximized, and the method has wide application prospects on the aspect of vanadium titano-magnetite separation.

Owner:赣州金环磁选科技装备股份有限公司

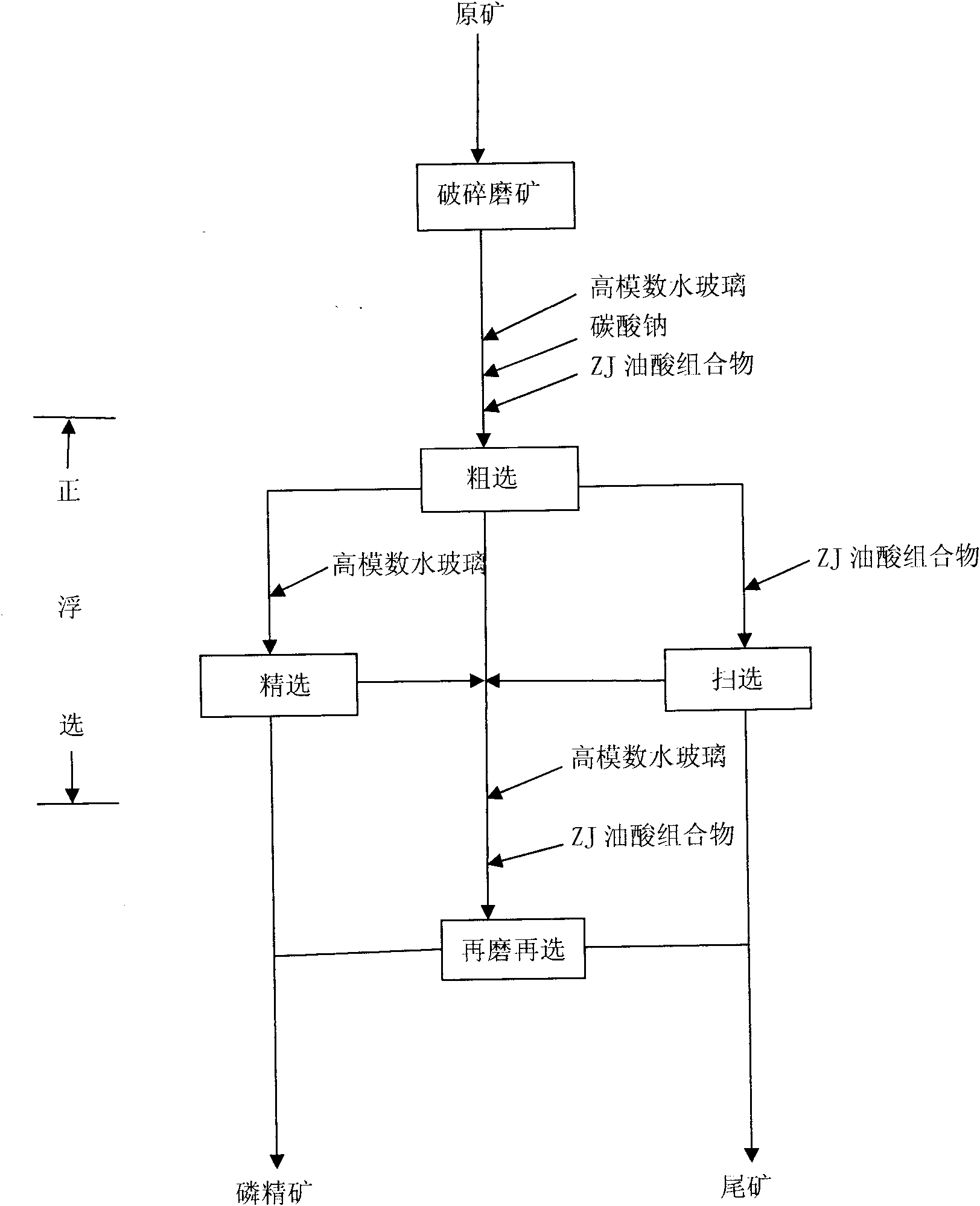

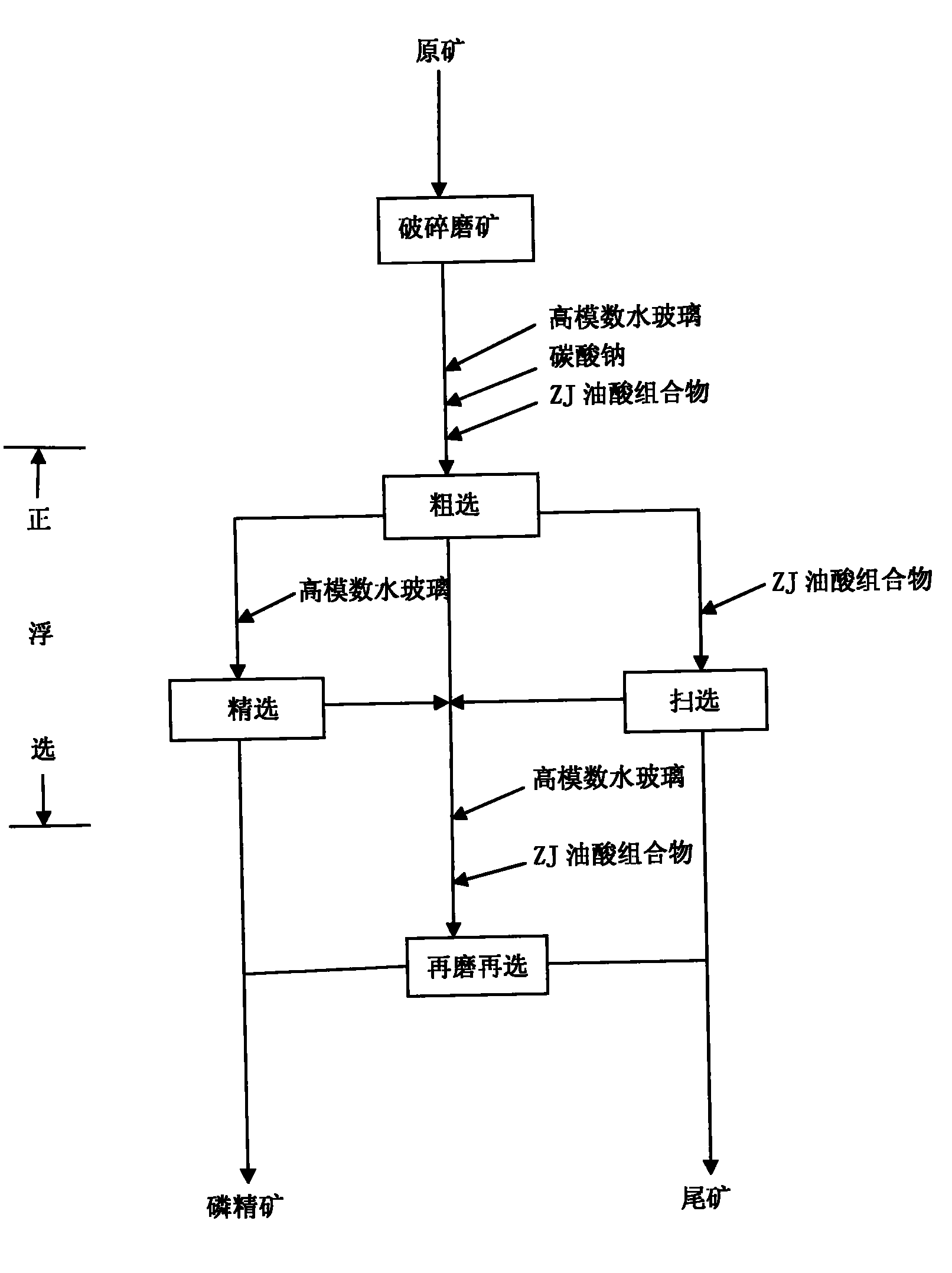

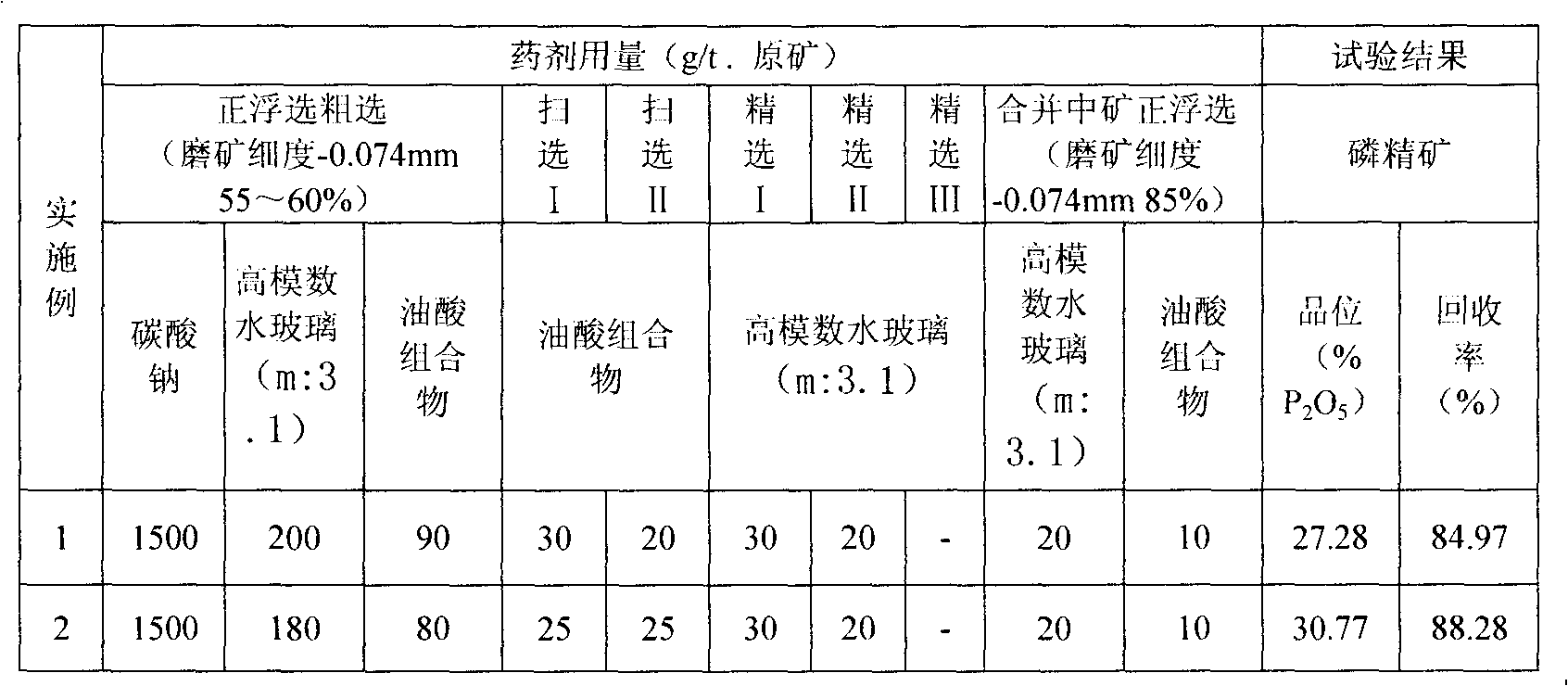

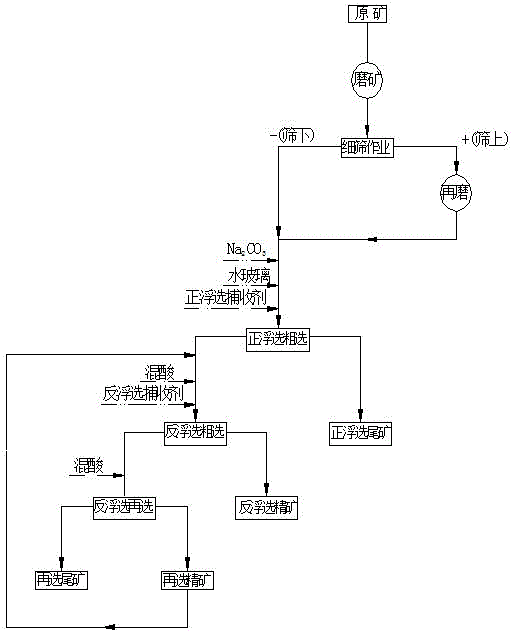

Positive flotation method of low grade refractory phosphate ores

The invention relates to a positive flotation method of low grade refractory phosphate ores. The method comprises the following specific steps: 1. crushing and grinding ores: grinding raw ore according to the grinding density of 1:1 to -0.074mm of 55-60% tailings discarding fineness; 2. performing positive flotation: firstly, roughing, namely adding depressant sodium carbonate, big modulus sodiumsilicate and collector ZJ oleic acid composite, stirring to obtain roughing concentrate, roughing middlings and roughing tailings; secondly, concentrating, namely adding big modulus sodium silicate in the roughing concentrate to perform 3-4 times of concentrations and obtain concentrating middlings and phosphorus product concentrate; thirdly, scavenging, namely adding ZJ oleic acid composite in the roughing tailings to perform 2-3 times of scavengings and obtain scavenging middlings and tailings; and 3. regrinding and reprocessing, namely further dissociating ores, and reprocessing to obtain tailings and residual phosphorus concentrate. The invention is characterized in that the ore grinding cost is low, the dosage of reagents is low, the ZJ oleic acid composite is easy to prepare and is convenient to use, the separating effect of phosphorus ores and gangue mineral is obvious, the separation indexes are good, etc; and the method is especially suitable to be used in the flotation of silicon-poor deposition-calcium phosphorite type phosphate ores with a concentration of P2O5 of less than 20%.

Owner:ZIJIN MINING GROUP

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

Sintering grinding medium and preparation thereof

InactiveCN101434828AChange the internal structure of the particleChange the grinding performanceOther chemical processesAdhesiveGranularity

The invention provides an abrasive which is prepared by the steps as follows: 0.5-2.5Mu meter of corundum (95-98 percent) sold in the market, silicon carbide, diamond or cubic boron nitride abrasive micro-powder are mixed with 2-5 percent of ceramic adhesive, thermally disposed under high temperature of 840-1200 DEG C and combined with the abrasive micro-powder by the ceramic combination phase to form the abrasive with microcrystalline structure, wherein, according to the weight percentage, the raw material of the ceramic adhesive comprises 5-20 percent of NaO, 10-25 percent of B2O3, 45-70 percent of SiO2, 13-17 percent 4-5 components of Li2O, MgO, K2O, CaO and ZnO; all raw materials are sequentially mixed, screened, smelted, quenched, dried, crushed, screened to prepare the sintered abrasive, the granularity, classification and application of which are consistent to that of the corundum, carborundum, diamond or cubic boron nitride abrasive. The abrasive changes the internal structure of the abrasive grains, thus changing the processing performance of the abrasive, improving the processing precision, processing quality, processing efficiency, prolonging the service life of the grinder, and reducing the processing cost of the grinding.

Owner:TIANJIN UNIV

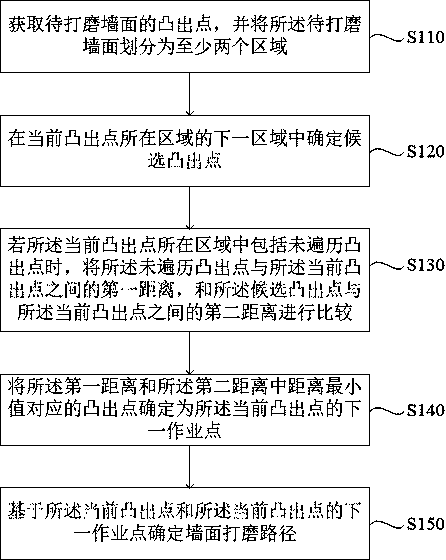

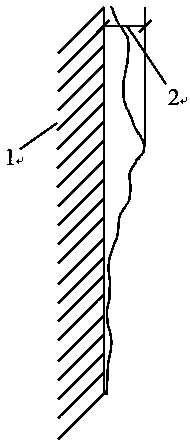

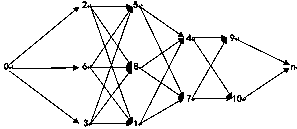

Wall surface grinding path planning method, device and equipment and medium

ActiveCN111203766AEasy to planReduce grinding distanceProgramme controlProgramme-controlled manipulatorSurface grindingMechanical engineering

The embodiment of the invention discloses a wall surface grinding path planning method, device and equipment and a medium. The method comprises the steps that protruding points of a to-be-ground wallsurface are obtained, and the to-be-ground wall surface is divided into at least two areas; candidate protruding points are determined in the next area of the area where the current protruding point is positioned; if the area where the current protruding point is positioned comprises non-traversal protruding points, the first distance between the non-traversal protruding points and the current protruding point is compared with the second distance between the candidate protruding points and the current protruding point; the protruding point corresponding to the minimum distance value in the first distance and the second distance is determined as the next operation point of the current protruding point; and a wall surface grinding path is determined based on the current protruding point andthe next operation point of the current protruding point. According to the technical scheme, the problem that the grinding path of the grinding equipment covers the area which does not need to be ground at the present stage is solved, and the effects of optimizing the operation path of the grinding equipment, improving the grinding efficiency and reducing the grinding cost are achieved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Vitrified bond cubic boron nitride (CBN) grinding wheel for grinding titanium alloy

ActiveCN103223644AHigh grinding temperatureHigh thermal conductivityAbrasion apparatusBoron nitrideTitanium alloy

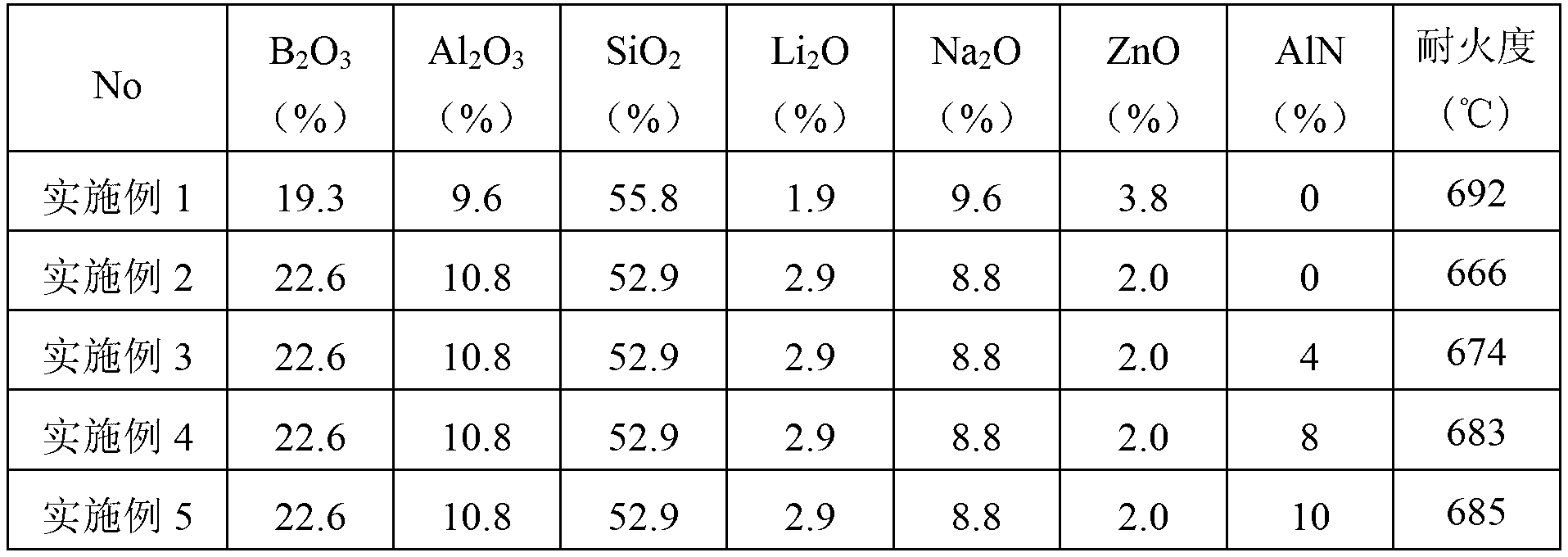

The invention discloses a vitrified bonded cubic boron nitride (CBN) grinding wheel for grinding titanium alloy, which comprises a basal body, grinding wheel blocks and bonding layers, wherein the grinding wheel blocks comprise the following raw materials in weight percentage: 40-80 percent of cubic boron nitride grinding material, 0-30 percentage of silicon carbide, 14-35 percent of ceramic binder and 6 percent of temporary binder; and the ceramic binder comprises the following raw materials in weight percentage: 15-25 percent of B2O3, 8-15 percent of Al2O3, 46-60 percent of SiO2, 2-8 percent of Li2O, 2-10 percent of Na2O, 2-10 percent of ZnO and 2-10 percent of AlN, and the refractoriness of the ceramic binder is lower than 700 DEG C. The vitrified bound cubic boron nitride grinding wheel can effectively overcome the defects of strong grinding force, high grinding temperature, serious grinding wheel bonding and the like caused during grinding the titanium alloy, and has the advantages of high thermal conductivity, good self-sharpening performance, high grinding efficiency, long service life, low cost and simple process.

Owner:TIANJIN UNIV

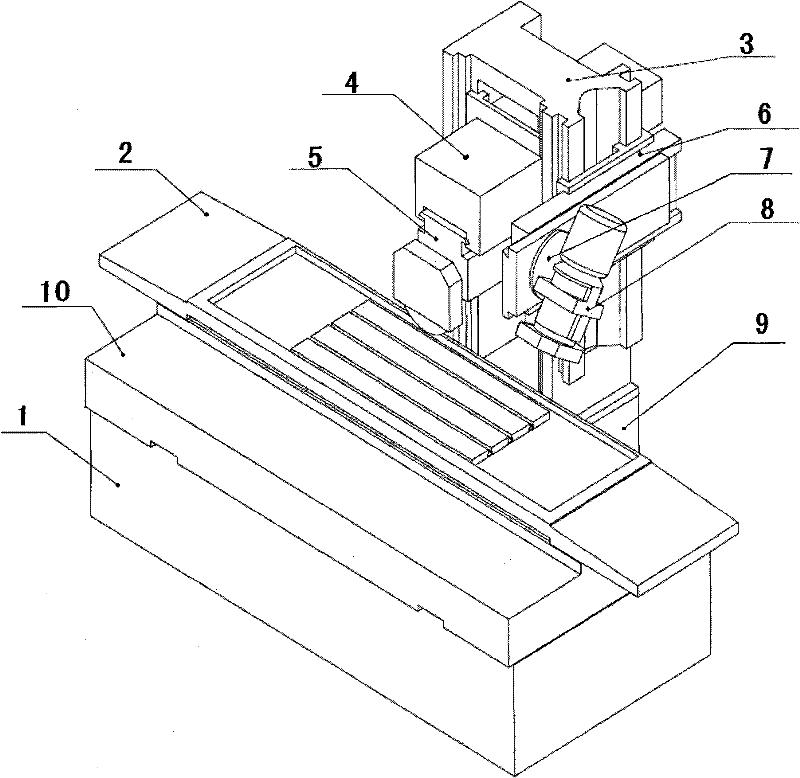

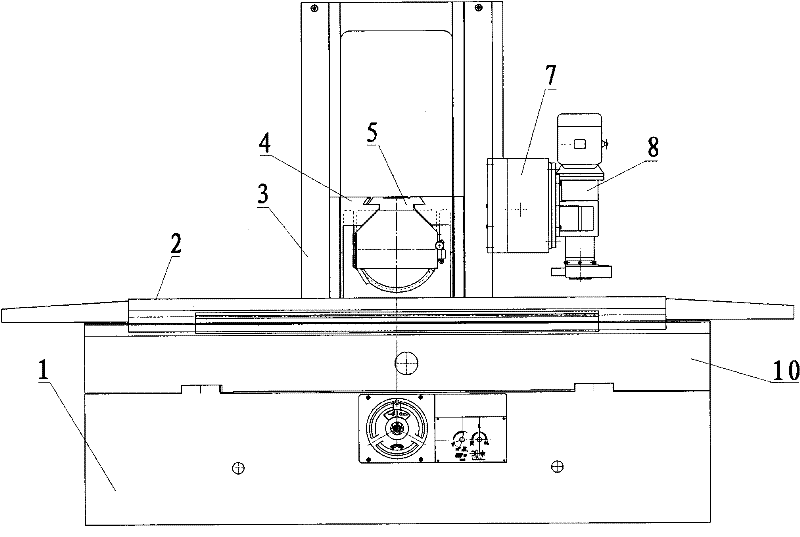

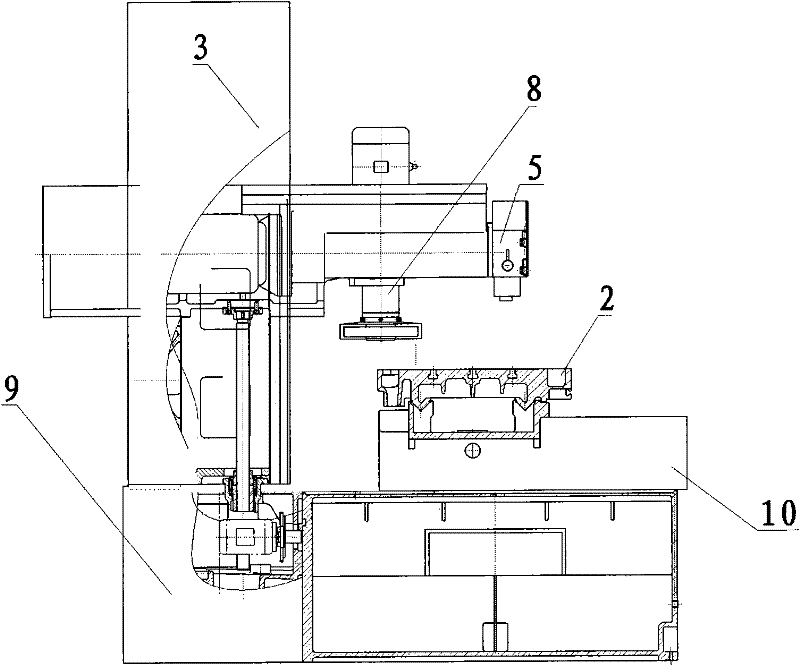

Grinding Center

InactiveCN102259282ACompact structureImprove transmission efficiencyRevolution surface grinding machinesControl systemEngineering

A grinding processing center, in order to solve the problem of single function of the existing grinding machine, it includes a bed, a large carriage, a workbench, a column, a horizontal grinding head assembly and a vertical grinding head assembly, a lubrication system, and a control system. The control system includes The computer numerical control system and servo system mainly adopt the vertical and horizontal double grinding head structure with external memory, which can realize six-axis linkage, compact structure and high transmission efficiency, which can meet various grinding processing needs.

Owner:XIANGTAN SANFENG CNC MACHINE TOOL

Comprehensive utilization method of graphite tailings

InactiveCN102399080AHigh strengthImprove compactnessSolid waste disposalGraphiteUltimate tensile strength

The invention discloses a comprehensive utilization method of graphite tailings. According to the invention, graphite tailings, quartz powder, and kaolin are adopted as raw materials, and are mixed according to a certain mass ratio. The mixture is grinded, water is added to the mixture, and the mixture is mixed; the mixture is aged, and is processed through pressure-molding; the molded material is processed through high-temperature calcining, such that feldspar-quality daily-use ceramics are produced. The required mass ratio of graphite tailings to quartz powder to kaolin is 50-75:5-35:15-45.The daily-use ceramics are characterized by high strength, good compactness, low water absorption, and small shrinkage. The ceramics are not easy to deform.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Preparation method of metallographic samples

InactiveCN108896339AAvoid it happening againEasy to observeWithdrawing sample devicesPreparing sample for investigationColloidMaterials science

The invention discloses a preparation method of metallographic samples. The preparation method includes the following steps: S1, a step of sampling, namely a step of cutting samples at the edge and center of a sample object; S2, a step of inlaying, namely a step of slowly guiding flows of colloid into an inlaying die through galvanized iron wires for curing; S3, a step of grinding; S4, a step of polishing; and S5, a step of corrosion, namely a step of corroding a metallographic detected surface with a corrosion solution. The method can effectively prevent bubbles from forming in the metallographic samples, improve the polishing effect, shorten the polishing time, facilitate metallographic observation of the metallographic detection surface, and improve the detection accuracy.

Owner:JIANGSU SCIENCE TEST TECHNOLOGY SERVICE CO LTD

Metal plate polishing device

InactiveCN102029557AReduce wear rateImprove stabilityGrinding drivesPlane surface grinding machinesEngineeringUltimate tensile strength

The invention discloses a metal plate polishing device. The device is characterized by comprising a base frame, a motor, a bearing mechanism and a transmission mechanism, wherein a polishing table face for arranging a metal plate is arranged on the upper end face of the base frame; the motor is arranged on the base frame and can rotate clockwise and anticlockwise; the bearing mechanism can be arranged on the polishing table face in a way of moving back and forth; sanding paper is detachably arranged on the bottom face; and the transmission mechanism is provided with a power input end connected with the motor and a power output end connected with the bearing mechanism. Compared with the prior art, the metal plate polishing device has the advantages that: the clockwise and anticlockwise rotation of the motor is converted into the back and forth movement of the bearing mechanism, so that the sanding paper on the bearing mechanism polishes the metal plate; the structure is simple; the automation degree is high; the polishing efficiency is improved; the whole polishing operation does not need manual operation substantially, so that the labor intensity is greatly reduced and human factors are reduced; and the uniformity and quality stability of the polished product are obviously better than those of the product polished by manual operation.

Owner:NINGBO SOKEN CHEM

Numerical control fine-grinding quality control method of rail welding joint

InactiveCN102535279AImprove straightnessImprove pass rateRailway track constructionNumerical controlProgrammable logic controller

The invention relates to a numerical control fine-grinding quality control method of a rail welding joint; longitudinal temperature and flatness data of a welding joint region are obtained through on-line actual measurement, a flatness curve measured actually is converted into the flatness curve corrected by temperature and removing temperature effect according to the relation of temperature change and rail flatness variation, and the parameters such as grinding position, range, feed rate and the like can be calculated by the corrected flatness curve, the fine-grinding process can be automatically and flexibly controlled by a programmable logic controller according to the calculated fine-grinding parameters, and the corrected flatness curve of the rail joint after each fine-grinding is measured again, the fine-grinding parameters are reset to perform next round of fine-grinding, until the measured corrected flatness curve meets the standard requirements. The method can perform automatic whole-course fine-grinding to the rail welding joint ground coarsely, the fine-grinding process has high automation degree and low fine-grinding cost, the welding joint ground finely has smooth appearance and good flatness, and no depressed joint can be ground; the method is convenient for data traceability, analysis and responsibility.

Owner:SOUTHWEST JIAOTONG UNIV

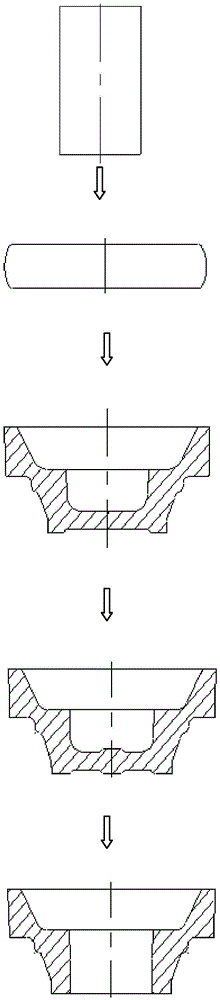

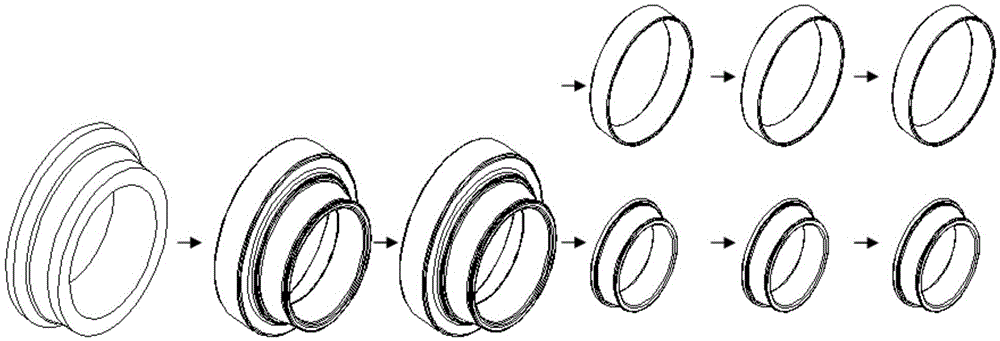

Machining method for inner ring and outer ring of conical roller bearing

The invention discloses a machining method for an inner ring and an outer ring of a conical roller bearing, and relates to a bearing machining method. The method is used for solving the problems that in existing bearing machining, detection omission is prone to occurrence in steel material detection, deformation is large after thermal treatment, grinding amount increase exists, grinding efficiency is reduced, product quality can be not ensured easily, and manufacturing cost is increased. The method includes the steps of firstly, conducting nondestructive examination of steel materials; secondly, cutting off examined steel materials; thirdly, forging an inner and outer one-piece sleeve ring; fourthly, conducting annealing; fifthly, lathing the inner and outer one-piece sleeve ring; sixthly, quenching the lathed inner and outer one-piece sleeve ring; seventhly, separating the sleeve ring into an inner ring and an outer ring; eighthly, conducting chamfering; ninthly, grinding the inner ring and the outer ring. The thermal treatment deformation is greatly reduced, the grinding residual amount is decreased, and grinding efficiency is improved; the method is suitable for machining the inner ring and the outer ring of the bearing.

Owner:哈尔滨汽车轴承有限公司

A method for direct reduction of industrial waste slag in rotary hearth furnace

InactiveCN102277461ALow mechanical strength requirementIncrease flexibilityProcess efficiency improvementHearthProcess conditions

The invention relates to a direct reduction method for treating industrial waste slag in a rotary hearth furnace, belonging to a new direct reduction ironmaking process in the metallurgical industry. The main process is: ingredients - mixing - pellets - drying - preheating - reduction - metallized pellets. Metallized pellets with a metallization rate of over 80% can be obtained after reduction in a rotary hearth furnace. The present invention comprehensively recycles and utilizes valuable elements in iron-containing industrial waste residues, economically obtains reducing agent resources, and solves the problem of low falling strength of cold solidified carbon-containing pellets prepared in the process of comprehensive recycling of industrial waste residues It has the advantages of high metallization rate, simple operation, easy control of process conditions, less equipment investment, low production cost, easy to meet raw material conditions, etc., and the overall process is more energy-saving than the furnace smelting process. It is also more environmentally friendly, and more importantly, the method can comprehensively recycle industrial waste, reduce its pollution to the environment, and save energy and protect the environment.

Owner:UNIV OF SCI & TECH BEIJING

Method for performing fine sieving, regrinding and bulk flotation on low-level silicon calcium collophanite

The invention discloses a method for performing fine sieving, regrinding and bulk flotation on low-level silicon calcium collophanite. The method comprises the following steps: finely grinding the low-level silicon calcium collophanite, adding water to prepare original ore pulp; sieving the grinded original ore pulp by a fine sieve; regrinding materials on the sieve, then adding water to prepare original ore pulp, putting the original ore pulp into a floatation device together with materials under the sieve, performing direct rough floatation so as to obtain under-sieve product direct floatation roughing concentrate and tailings; performing reverse floatation on the under-sieve product roughing concentrate so as to obtain under-sieve reverse floatation recleaning concentrate and tailings. Compared with a two-section continuous ore grinding technology, the method provided by the invention can be used for improving the floatation condition, and reducing the recovery loss caused by fine fraction mechanical entrapment in the floatation operation on one hand, and can be used for reducing the energy consumption of two-section ore grinding and further reducing the ore separation cost on the other hand. The method provided by the invention can play a favorable floatation effect, and can achieve the industrial production of purification of low-level silicon calcium collophanite easily.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

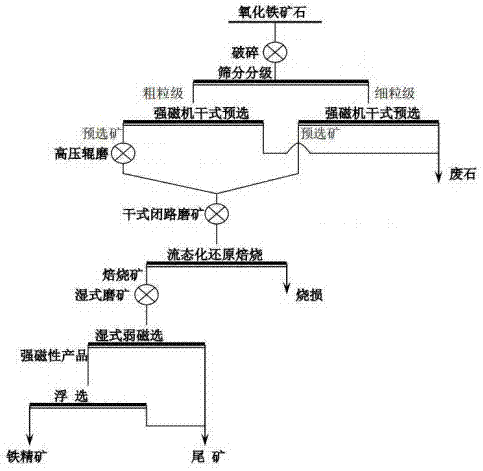

Combined mineral separation technology for ferric oxide mineral

InactiveCN107185686AThrow out earlyReduce transportationMagnetic separationGrain treatmentsIronstoneOxide minerals

The invention discloses an iron oxide ore joint beneficiation process, which comprises the following steps: (1) dry selection and discarding of iron oxide ore to obtain pre-selected coarse-grained ore, pre-selected fine-grained ore and waste rock; (2) high-pressure Roller mill crushing: the pre-selected coarse-grained ore obtained in step (1) is fed into a high-pressure roller mill for crushing; (3) dry grinding: the crushed product in step (2) and the pre-selected fine-grained ore in step (1) Combined for dry closed-circuit grinding; (4) Fluidized reduction roasting: a. Put the ground product obtained in step (3) into the fluidized reduction roaster; b. Preheating; c. Heating; d. Magnetization roasting; e . Cool to below 200°C to obtain roasted ore with a magnetite content greater than 90%; (5) beneficiation of roasted ore to obtain iron concentrate products with a grade of 57%-65%. The present invention can effectively solve the current iron oxide ore beneficiation There are technical problems such as low resource utilization rate, poor concentrate quality and high energy consumption in the process.

Owner:JIUQUAN IRON & STEEL GRP

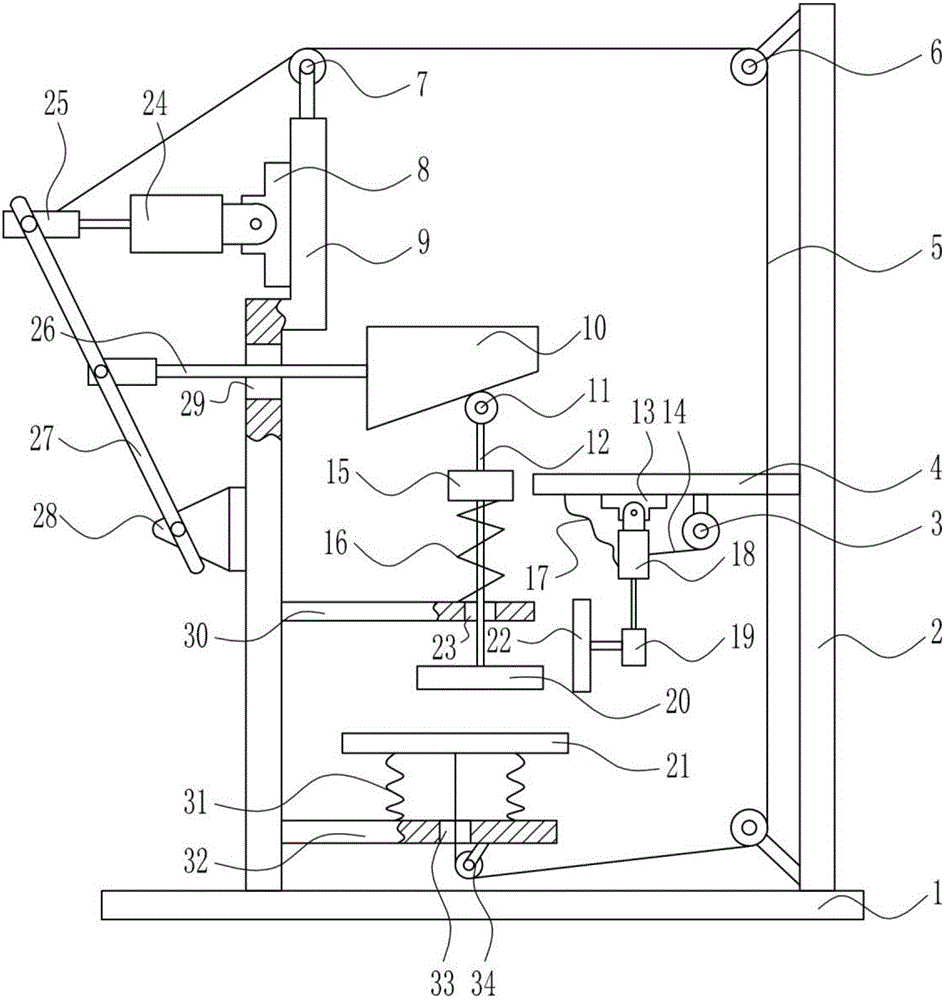

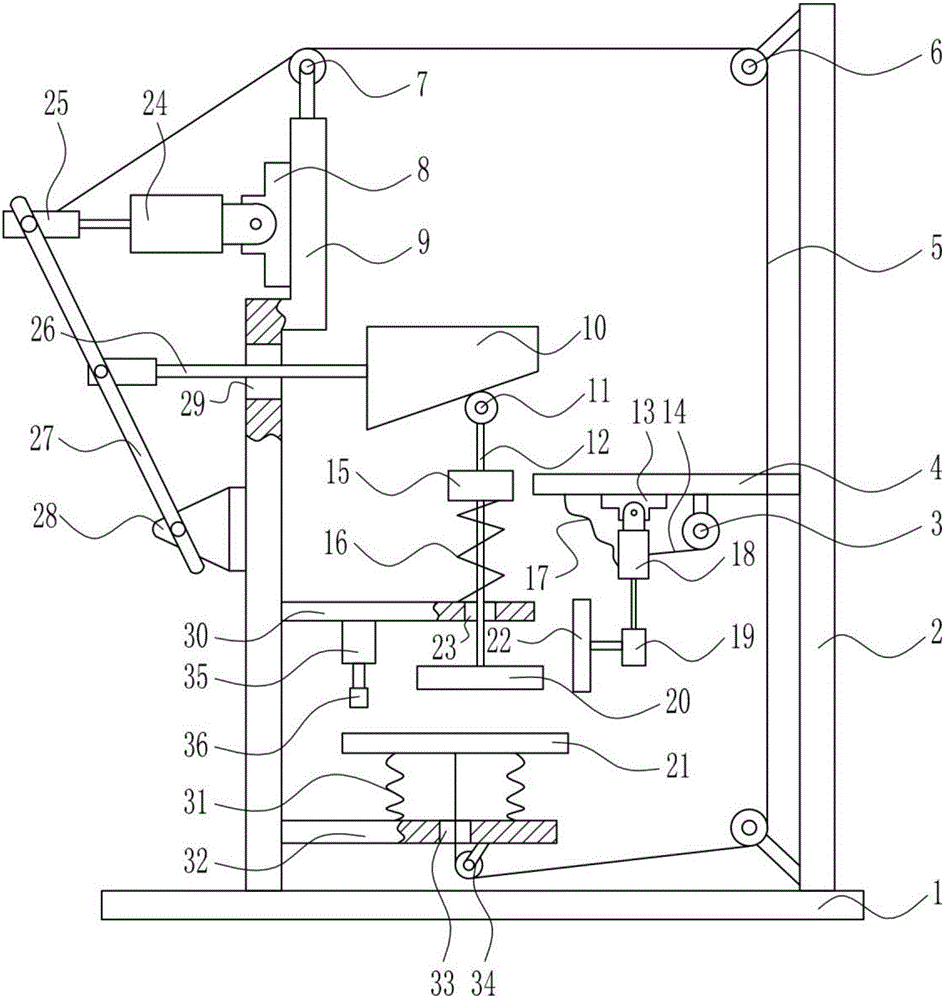

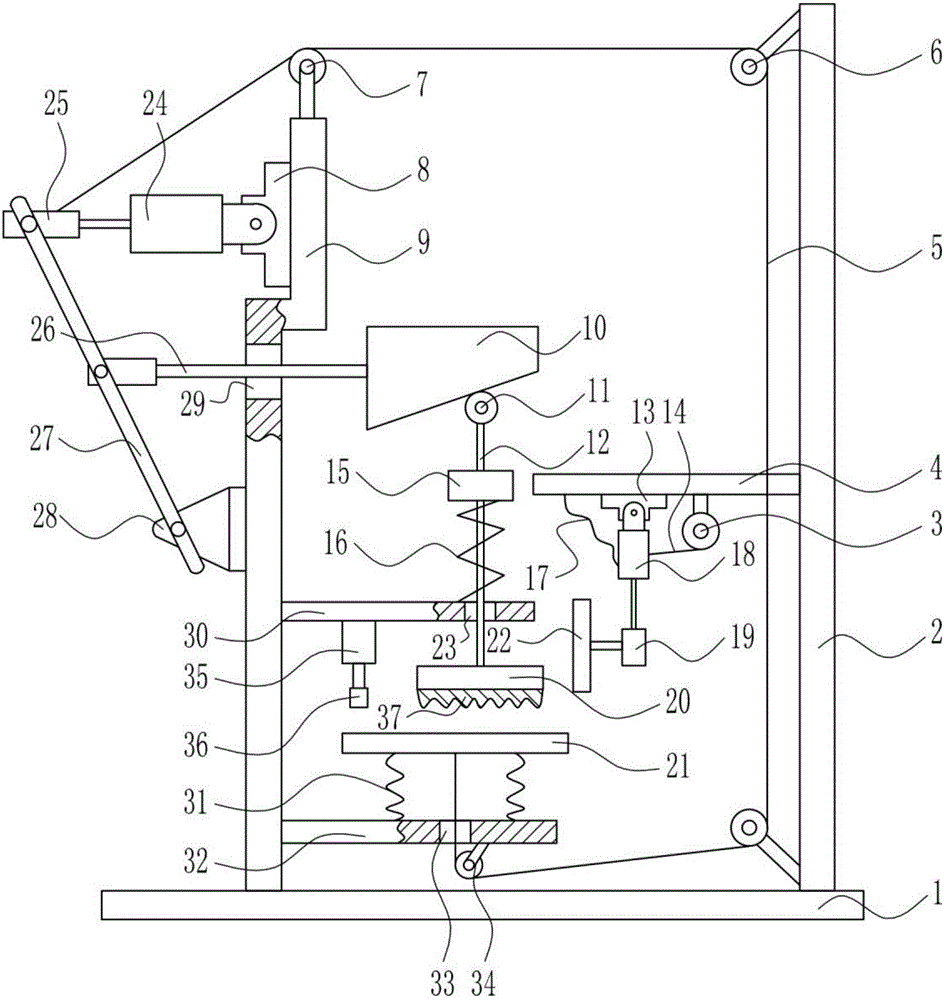

Uniform side and corner polishing device for mosaic tiles

InactiveCN106271953APrevent movementIncrease frictionEdge grinding machinesGrinding carriagesEngineeringLinear actuator

The invention relates to a polishing device, in particular to a uniform side and corner polishing device for mosaic tiles. The technical aim of the uniform side and corner polishing device for the mosaic tiles is to enable side and corner polishing to be uniform. In order to achieve the above technical aim, the uniform side and corner polishing device for the mosaic tiles is provided and comprises a base plate, a right support, an electric wheel, a fixing plate, a first pull wire, a first fixed pulley, a second fixed pulley, a first swing base, a left support, a wedge block, a contact idler wheel, a lifting rod, a second swing base, a second pull wire, a fixing block, a third spring, a first spring, a second linear actuator, a rotation motor, a pressing plate, a containing plate and the like. The left end and the right end of the top of the base plate are provided with the left support and the right support correspondingly. By means of the uniform side and corner polishing device, the effect of being uniform in side and corner polishing is achieved; when the uniform side and corner polishing device is used for side and corner polishing of the mosaic tiles, the polishing angle can be adjusted, and polishing can be more comprehensive; and meanwhile, the manpower for polishing is saved.

Owner:CHONGQING RYAN PAINT CO LTD

Polishing equipment and method

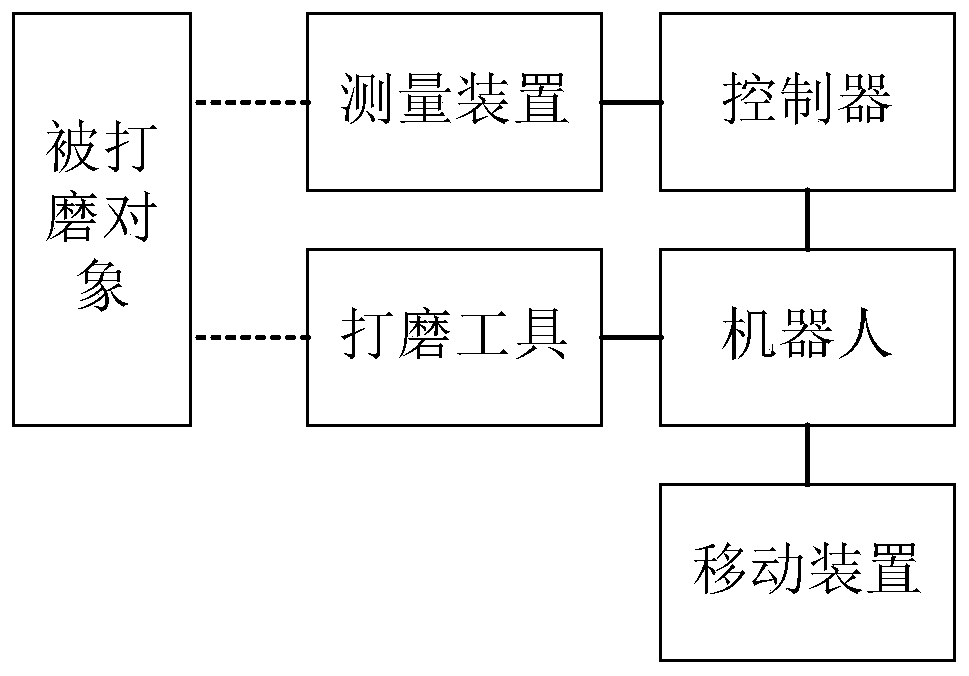

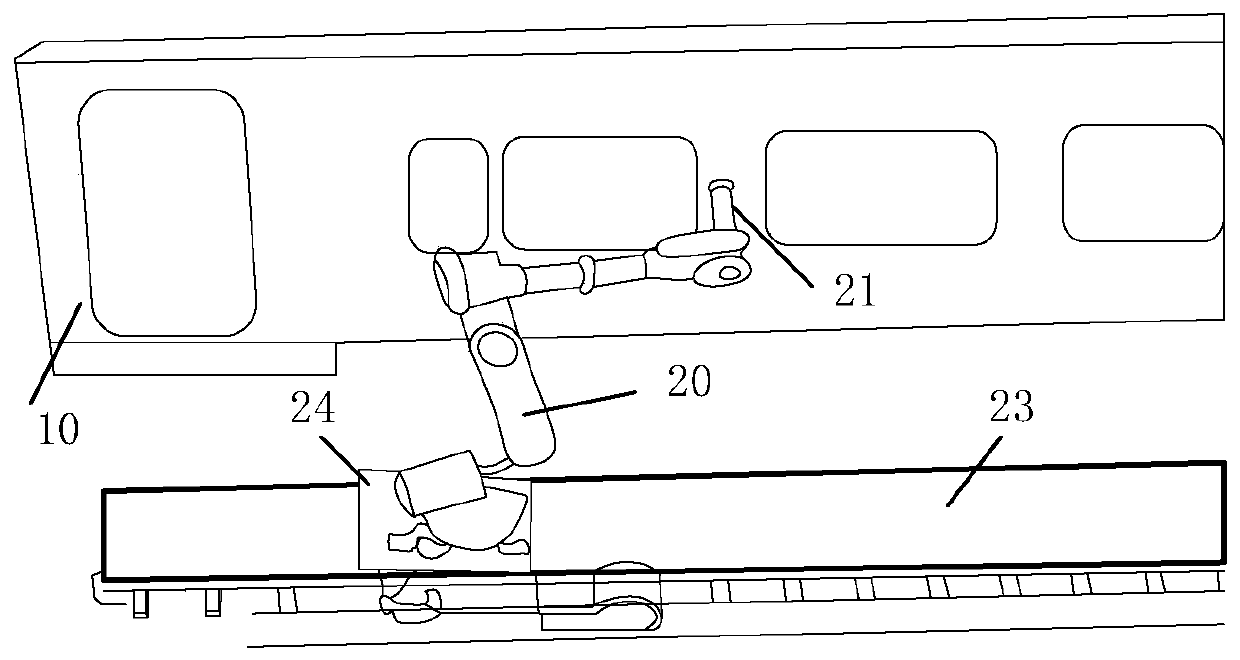

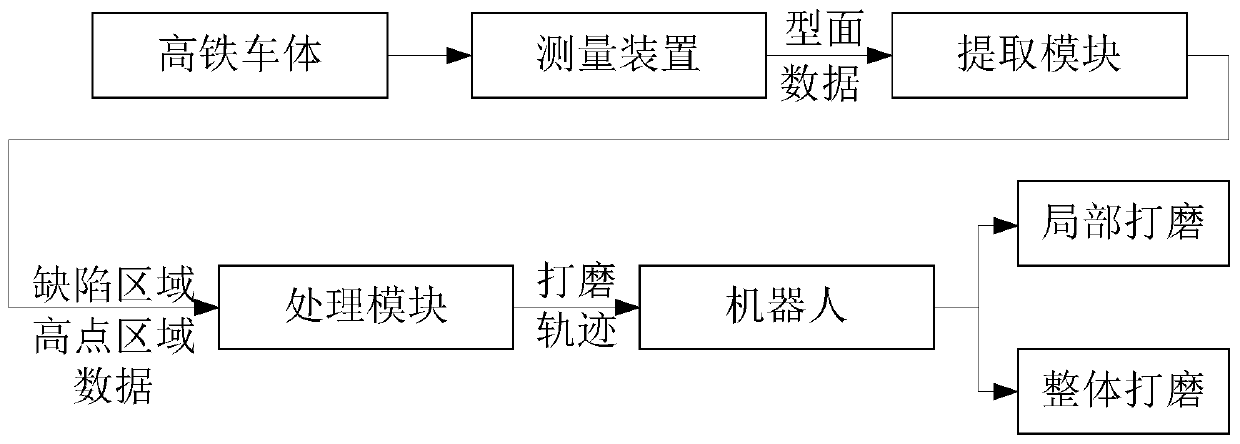

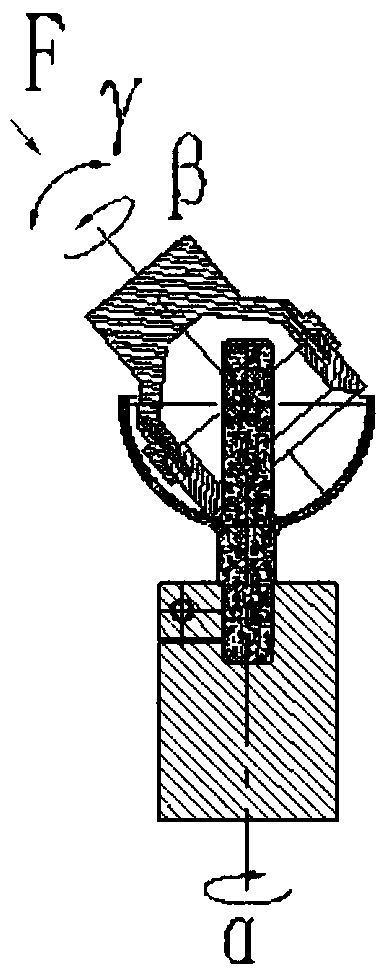

InactiveCN110625491ATo achieve the purpose of automatic grindingImprove grinding efficiencyProgramme-controlled manipulatorGrinding feed controlMeasurement deviceSimulation

The invention discloses polishing equipment and method. The polishing equipment comprises a measuring device, a robot and a controller. The measuring device is used for collecting data of a polished object. The robot is mounted on a movable device, a polishing tool is mounted at one end of the robot. The controller is in communication with the measuring device and the robot and is used for analyzing the received data to obtain high spot area data, and the robot is controlled to execute the action of high spot polishing based on the high spot area data. According to the polishing equipment andmethod, the technical problem that due to the fact that in the prior art, a manual operation mode is adopted for polishing the polished object, the polishing efficiency is low is solved.

Owner:CRRC QINGDAO SIFANG CO LTD

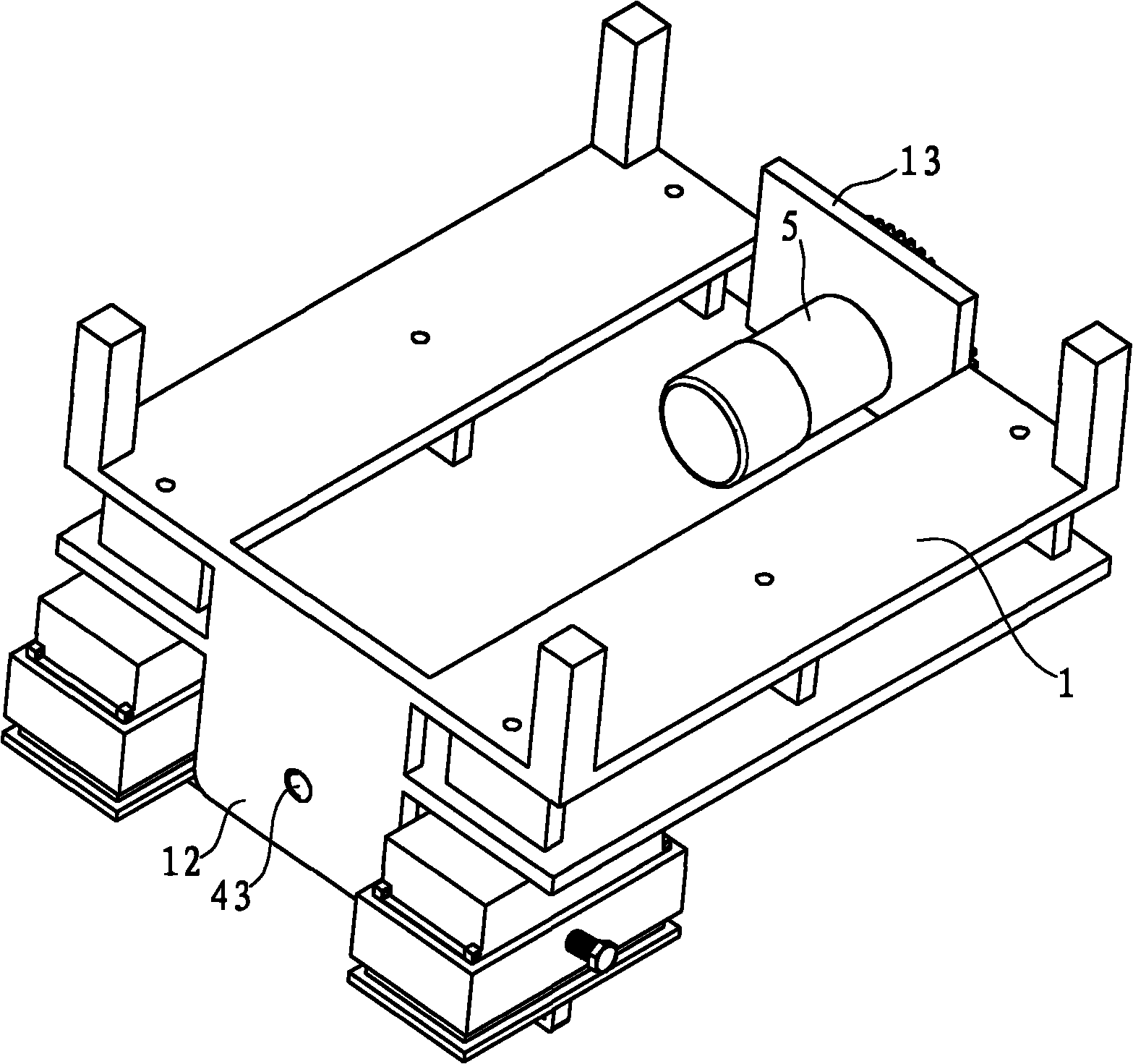

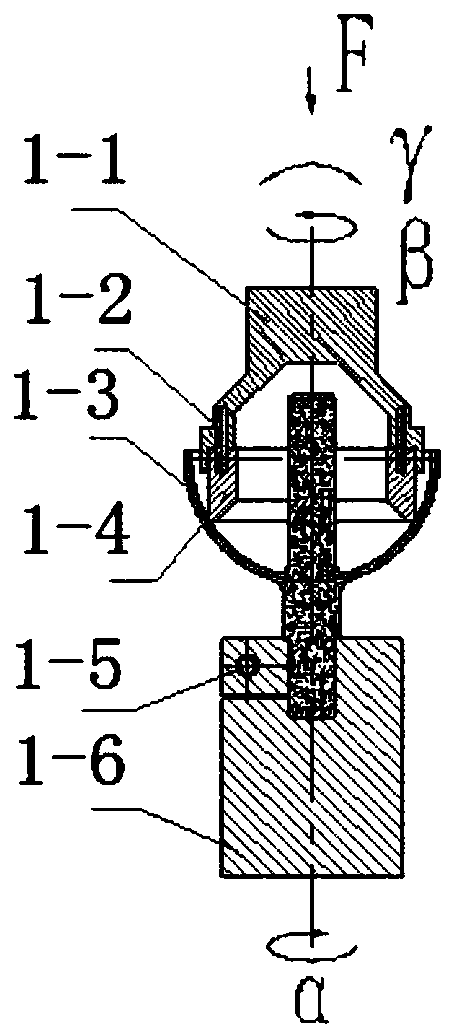

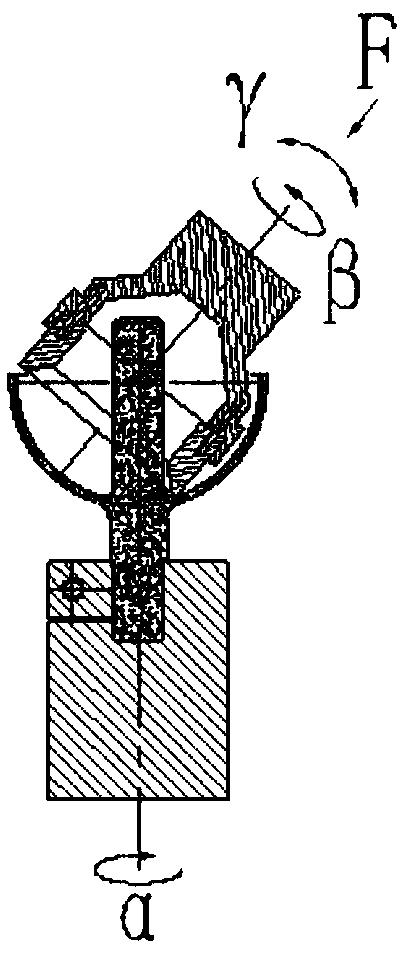

Ultra-precision spherical surface processing device and method for hemispherical shell resonator

PendingCN109483394AUltra-precision machining with high precisionIncrease stiffnessLapping machinesDesign methodsResonator

The invention provides an ultra-precision spherical surface processing device and method for a hemispherical shell resonator. The ultra-precision spherical surface processing device comprises hemispherical shell resonator inner spherical surface ultra-precision processing device, hemispherical shell resonator outer spherical surface ultra-precision processing device, a hemispherical shell resonator filling sealing method and related device, a spherical shell port inverted inner spherical surface angle device, an outer spherical surface chamfering indicator, an inner spherical chamfering indicator, and a supporting rod adaptive elastic grinding head device. The ultra-precision spherical surface processing method includes the following steps of first, a precision spherical surface processingmethod; second, a various parameter combination sequence method; third, a precision spherical surface processing grinding head design method and an abradant material and particle size control method;fourth, micro-stressed spherical surface precision processing elastic loading force control method; fifth, hemispherical shell resonator filling sealing method; sixth, hemispherical shell resonator precision measurement method, specifically, a true sphericity measurement method and a coaxial measurement method are included; seventh, a spherical shell port chamfering and supporting rod R roundingmethod; and eighth, a supporting rod adaptive elastic grinding head use method.

Owner:西安航晨机电科技股份有限公司

Method for leaching low-grade phosphate ore from ferrous oxide thiobacillus

InactiveCN101838737AHigh activityImprove enduranceBacteriaMicroorganism based processesNutrient solutionBacterial strain

The invention relates to the technology of microbial leaching, in particular to a method for leaching low-grade phosphate ore from ferrous oxide thiobacillus obtained by sampling and separating in the acid puddle of Hubei Tonglushan copper ore. The method comprises the following steps: (1) sampling; (2) enrichment and separation and acclimatization of bacterial strains; and (3) phosphate leaching. The method has the advantages that 1. the bacterial strains has high activity and good endurance, and the phosphate leaching rate is high; 2. the cost is low, the cost for making up nutrient solution by a large number of expensive drugs is reduced, and a phosphorus compound does not need to be additionally added to the liquid nutrient medium; 3. the self-associated iron pyrite of the phosphate ore and phosphorus in the phosphate ore are sufficiently used as the energy substances and the nutrients for bacteria growth, which is beneficial to the circulation and the high-efficiency utilization of the associated resources in the phosphate ore; and 4. the method is friendly to the environment: the usage amount of the acid bacterial liquid is low, which is beneficial to reducing environmental pollution.

Owner:WESTERN MINING CO LTD

Slag and steel slag grinding-assisted activating agent

The invention discloses a slag and steel slag grinding-assisted activating agent. The slag and steel slag grinding-assisted activating agent is prepared from the following raw materials in percentage by mass: 7 to 15 percent of lactose, 6 to 14 percent of propylene glycol, 5 to 15 percent of glycol, 4 to 10 percent of polyamide, 3 to 7 percent of oleic acid, 6 to 13 percent of anhydrous sodium sulfate, 5 to 12 percent of caustic soda, 2 to 4 percent of composite aid and the balance of water. The slag and steel slag grinding-assisted activating agent is used for grinding slag and steel slag, can increase the hourly output of a grinding machine by 10 to 16 percent and reduce the grinding power consumption by 7 to 13 percent, and also can increase the activity index of the slag and the steel slag by above 8 percent.

Owner:CNBM HEFEI POWDER TECH EQUIP CO LTD

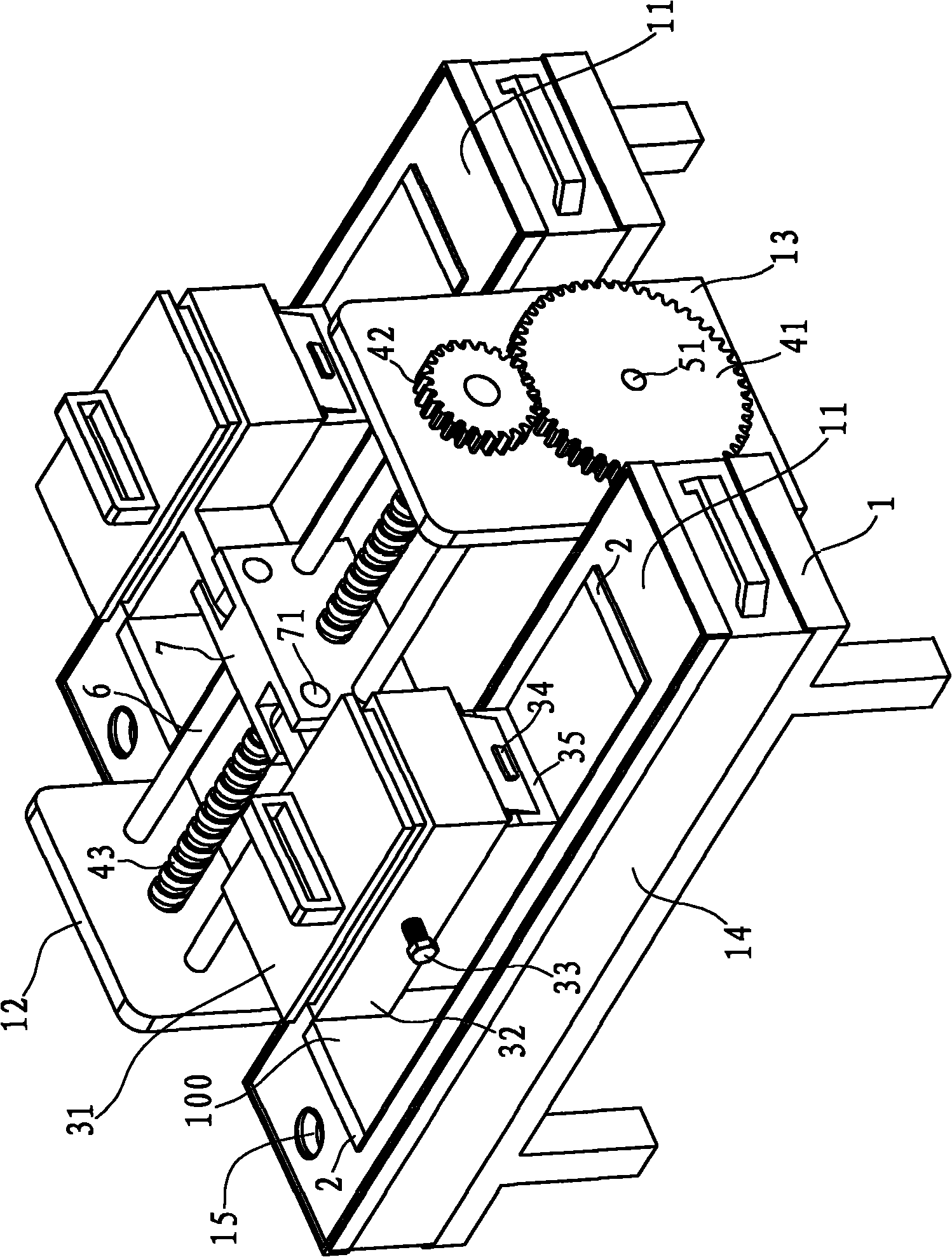

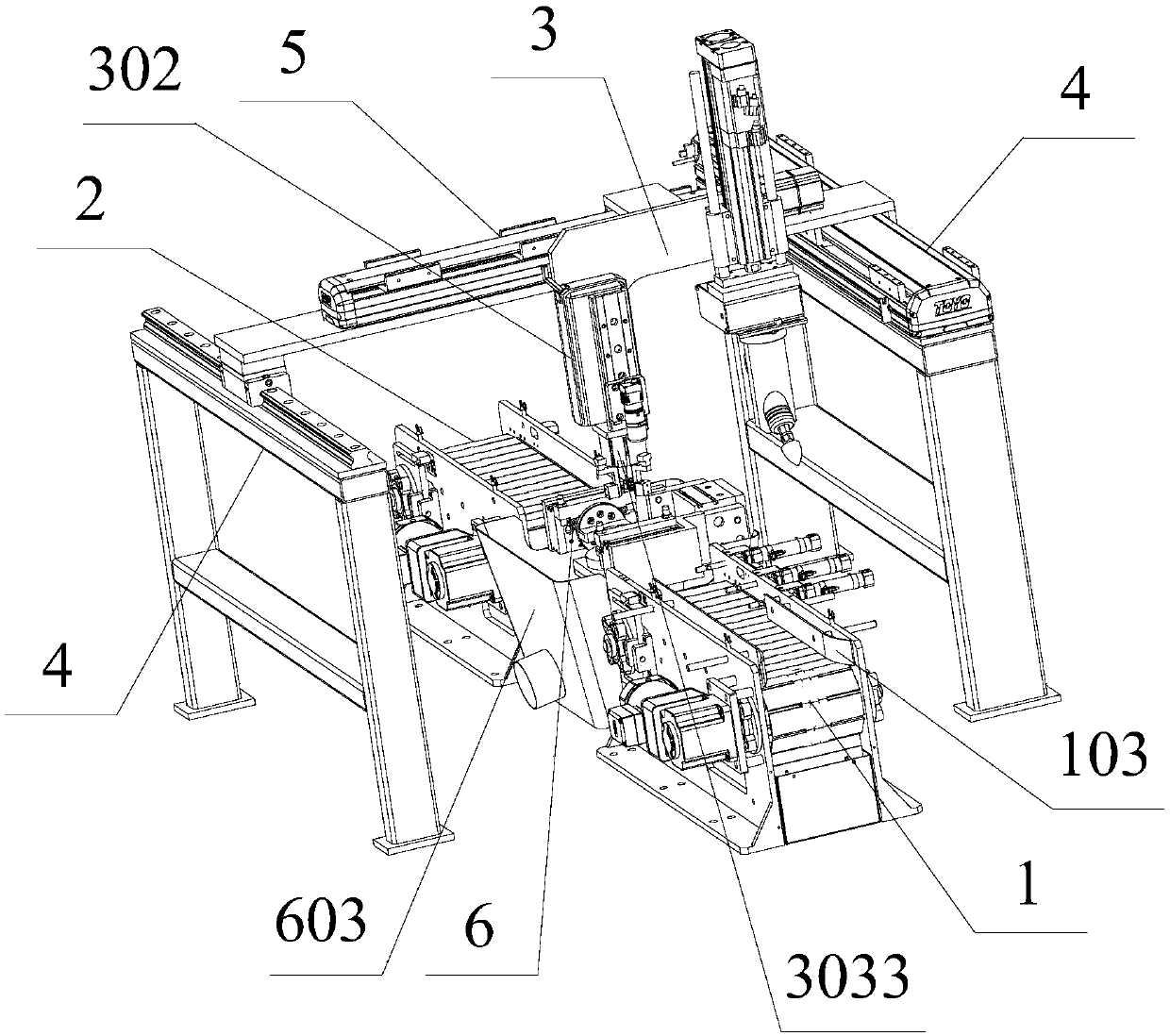

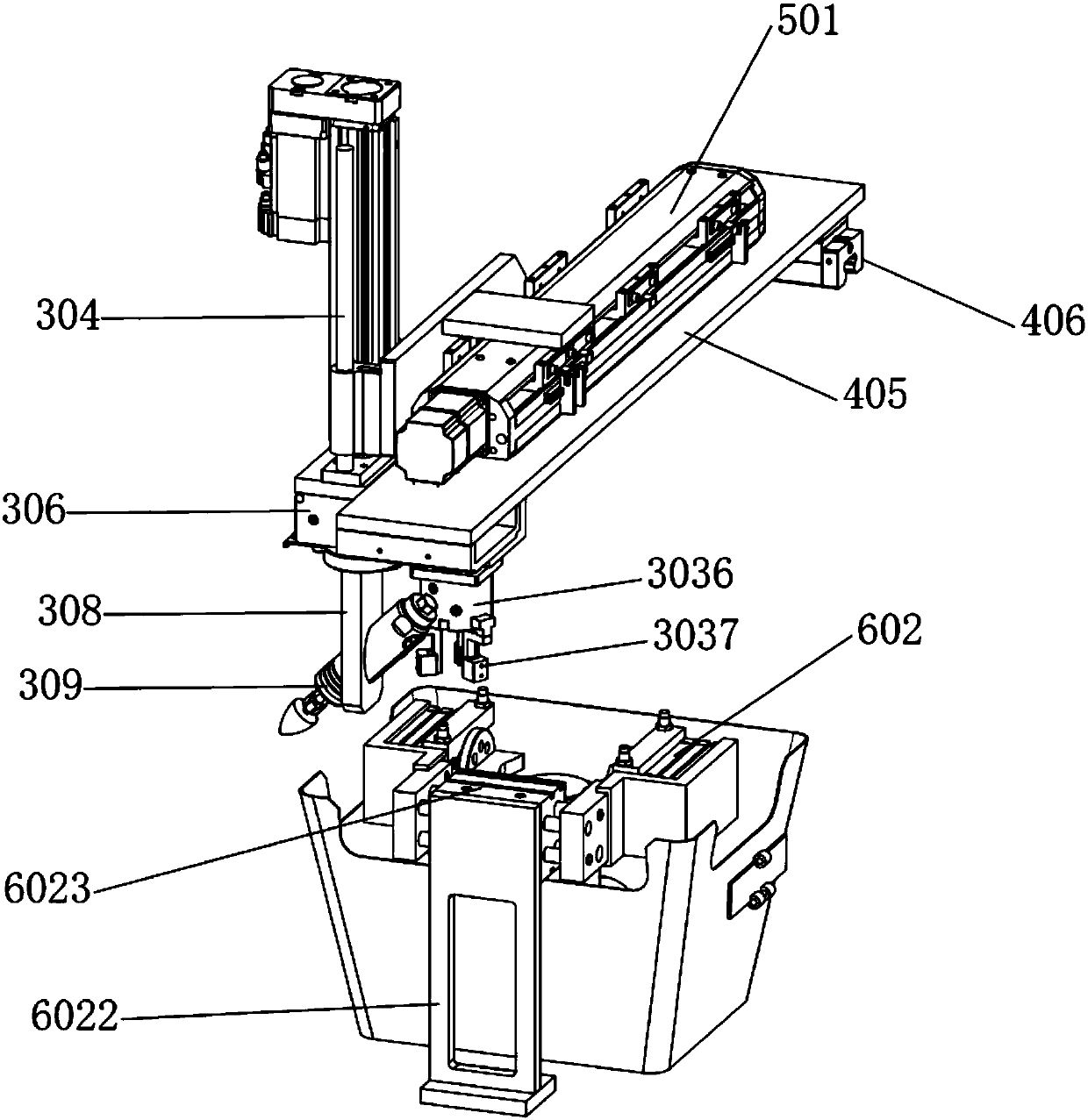

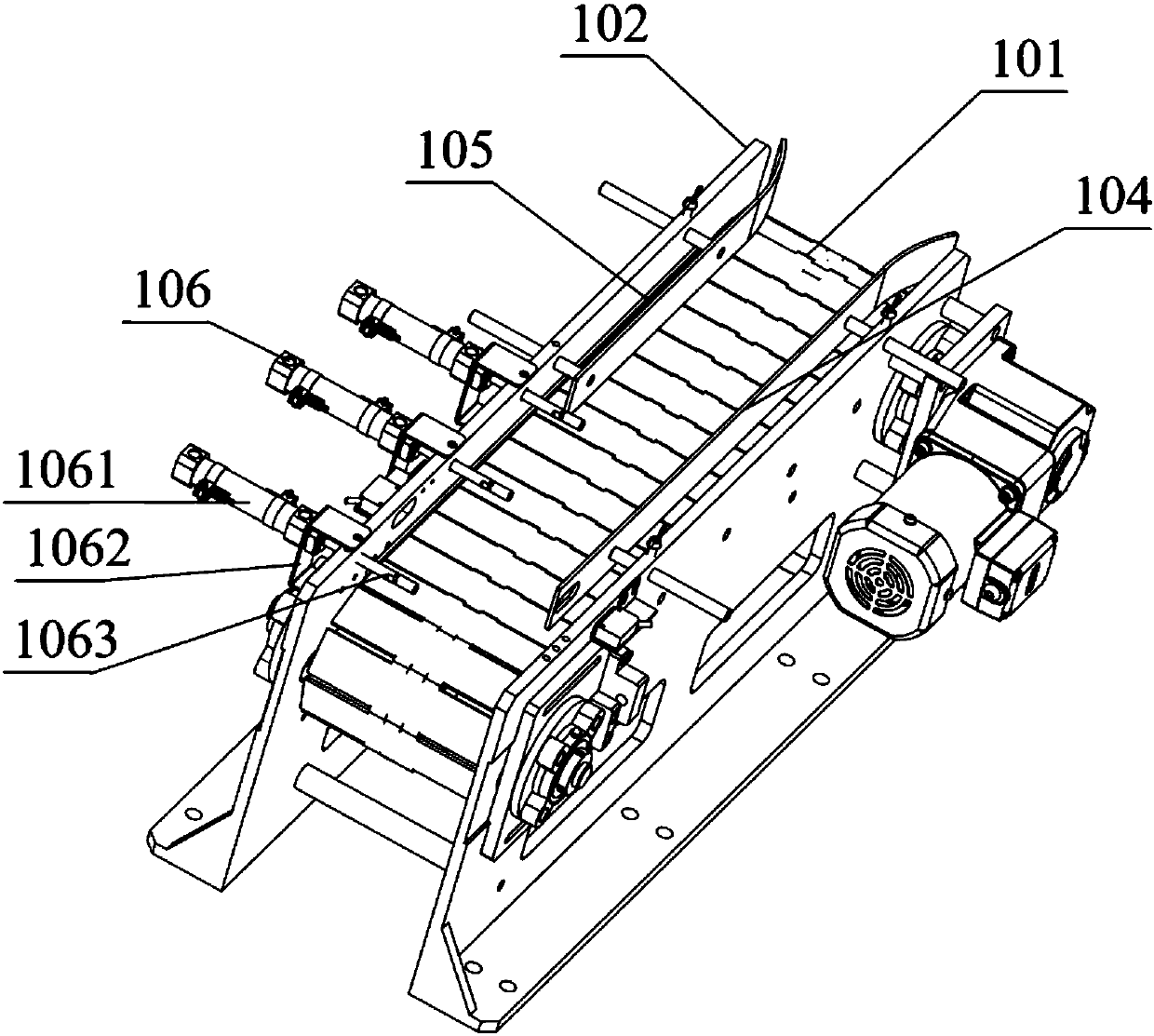

Pneumatic grinding equipment for automobile universal joint

InactiveCN107838778ARealize all-round angle grindingReduced impact on grinding and grinding efficiencyGrinding carriagesGrinding drivesUniversal jointEngineering

The invention provides a pneumatic grinding device for automobile universal joints, which includes a feeding device, a grinding device and a discharging device. The grinding device includes a biaxial drive mechanism, a positioning grinding mechanism and a grinding rotation mechanism. The grinding rotation mechanism is arranged between the feeding device and the grinding rotation mechanism. Between the discharge devices, the dual-axis drive mechanism includes an X-axis drive mechanism and a Y-axis drive mechanism. The Y-axis drive mechanism is connected to the X-axis drive mechanism. The positioning and grinding mechanism is set on the Y-axis drive mechanism, and the X-axis drive mechanism drives the Y-axis The driving mechanism moves back and forth, and the Y-axis driving mechanism drives the positioning and grinding mechanism to move left and right. Under the control of the control system, the present invention performs precise grinding in a three-in-one manner. With the progress of the grinding process, the surface area and angle of the workpiece will also change, and the angle of the grinding tool is continuously adjusted through rotation, lifting and translation to better It adapts to the entire grinding process of the workpiece to adapt to different curved surface structures, ensuring the accuracy of the grinding angle and product quality.

Owner:杭州同筹网络科技有限公司

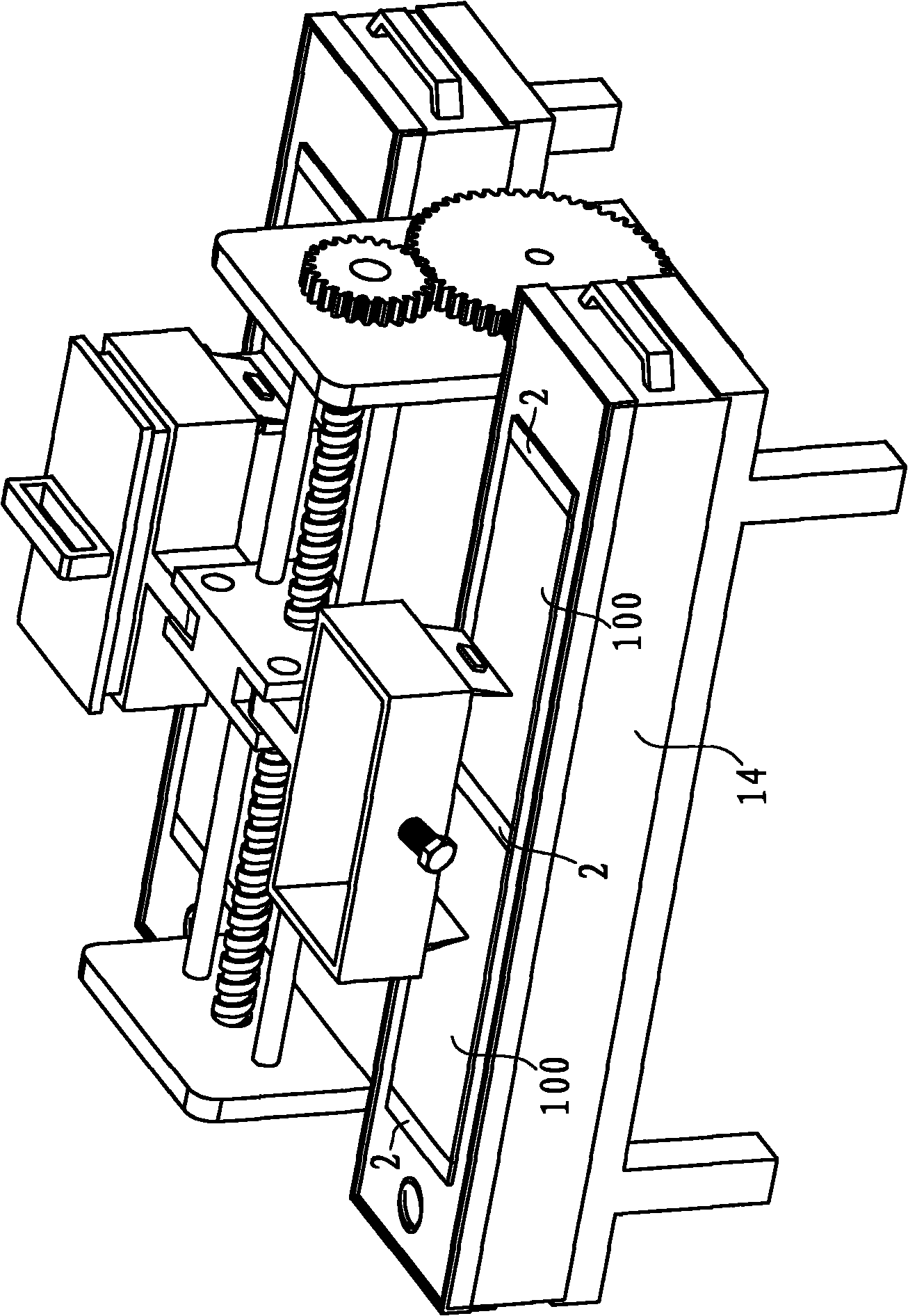

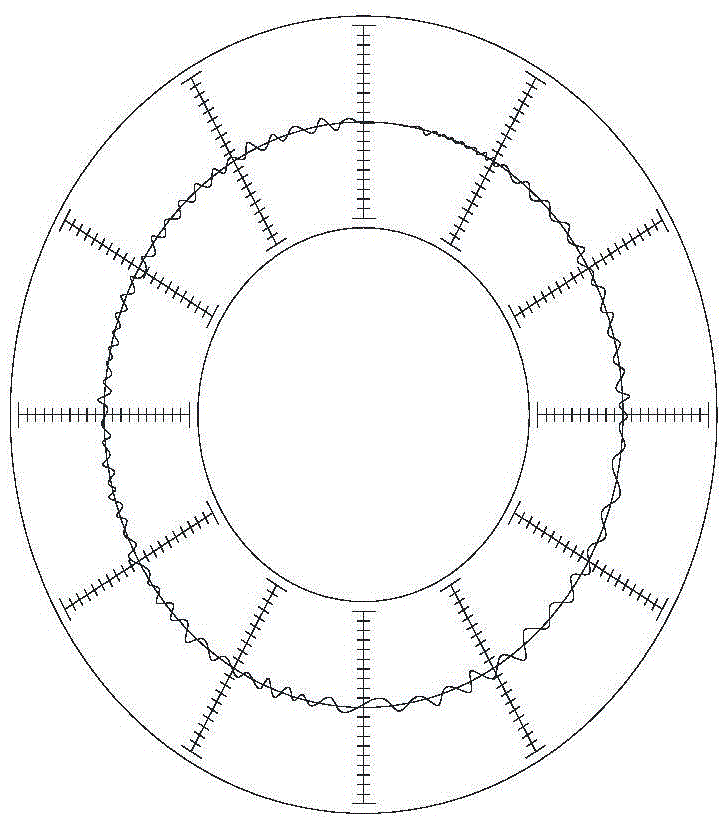

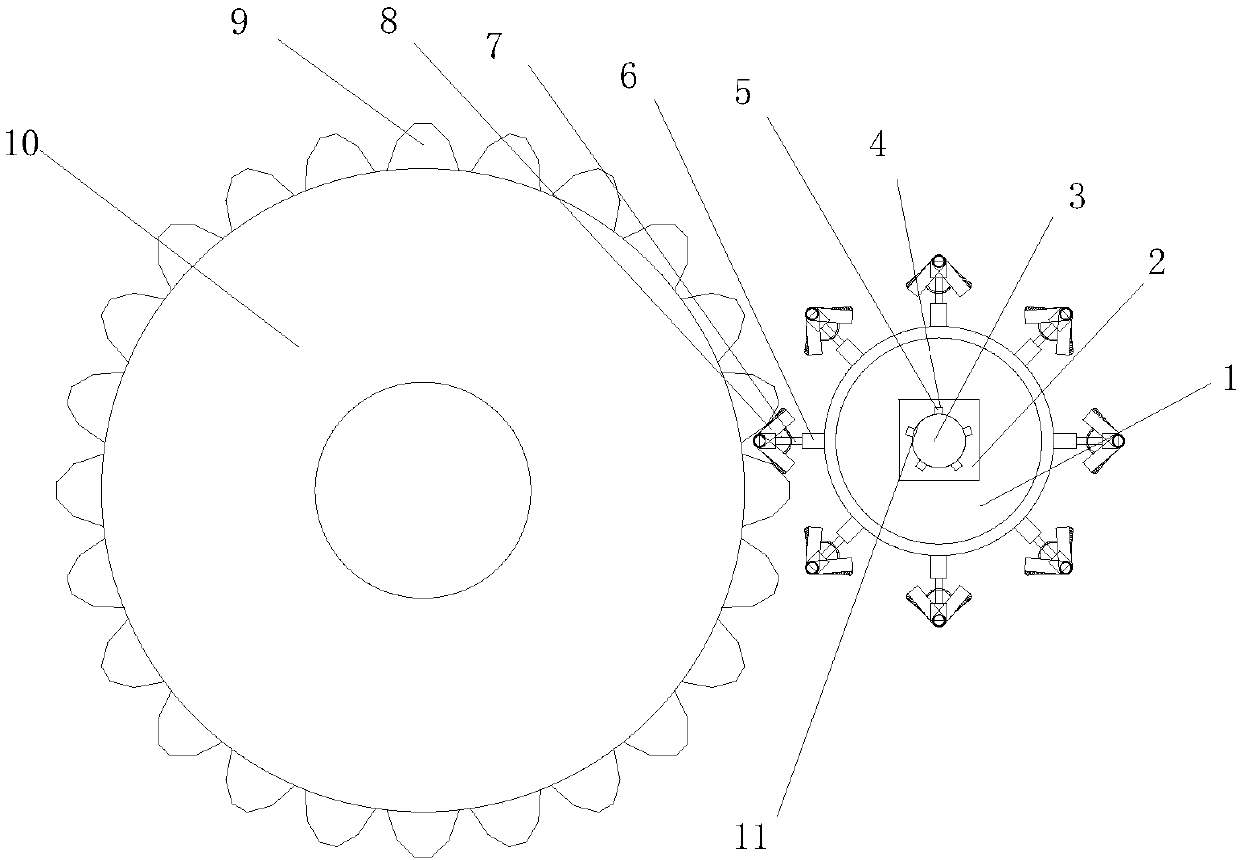

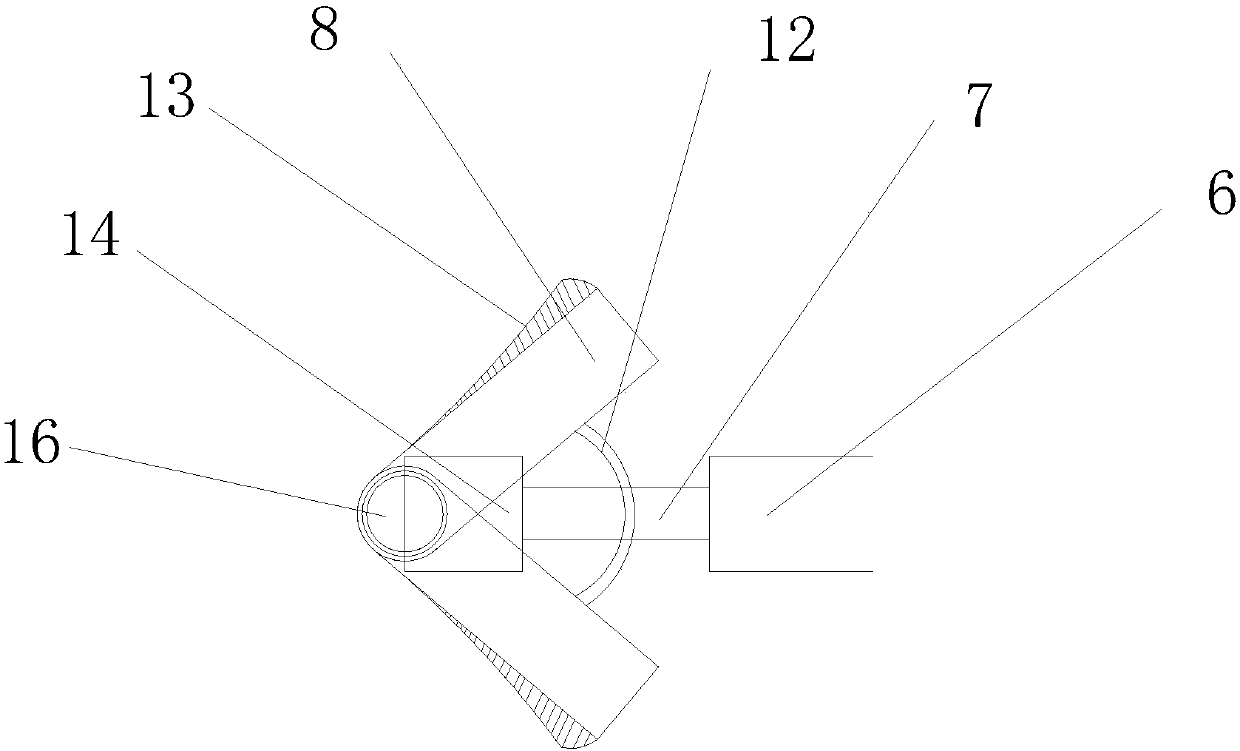

Gear tooth surface grinding mechanism

PendingCN107695459AImprove grinding efficiencyReduce manual operationsGear teethGear wheelElectric machinery

The invention aims at providing a gear tooth surface grinding mechanism. The gear tooth surface grinding mechanism comprises a gear. The gear is provided with uniform gear teeth. One side of the gearis provided with a grinding device used for accurately grinding the surfaces of the gear teeth. The grinding device comprises multiple sets of grinding heads and a rotary disk. The multiple sets of grinding heads are uniformly arranged on the periphery of the rotary disk. Connecting blocks of the grinding heads are connected with driving motors through rotary rods. The grinding heads make contactwith the side faces of the gear teeth. A connecting hole in the center of the rotary disk is connected with a connecting rod of a rotating motor. Automatic cycle all-in-one grinding is achieved. The grinding efficiency is improved. The manual operating difficulty is lowered. Meanwhile, by adopting the angle-adjustable grinding heads, the gear tooth surface grinding mechanism can effectively adaptto the gear tooth space according to the size of the gear tooth space, promote grinding blades to conduct deep grinding, improve the grinding quality and lower the grinding cost.

Owner:六安市金龙齿轮有限公司

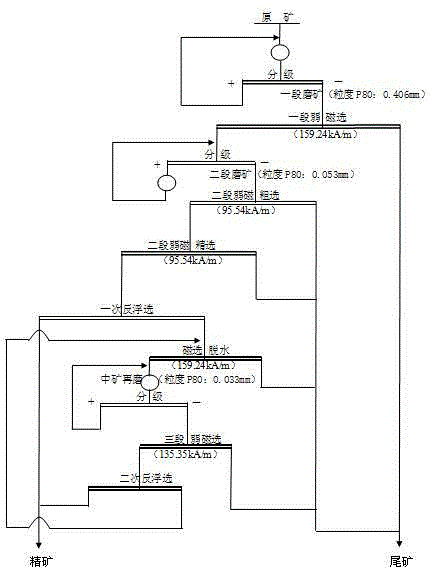

New mineral separation method suitable for separation of hard-separation micro-fine particle magnetic iron ores

InactiveCN104826728ASolve the bottleneck problem of development and utilizationHuge market potentialFlotationWet separationSingle stageThree stage

The invention discloses a new mineral separation method suitable for separation of hard-separation micro-fine particle magnetic iron ores. The new mineral separation method adopts a process comprising the steps of carrying out two-stage grinding on raw ores, carrying out low-intensity magnetic separation, obtaining ore concentrate through reverse flotation and single-stage roughing, regrinding middlings, carrying out the low-intensity magnetic separation and carrying out the reverse flotation; two-stage low-intensity magnetic separation ore concentrate is obtained through the process by adopting a method comprising the steps of stage grinding and stage low-intensity magnetic separation tailings discarding; qualified iron ore concentrate can be obtained in advance by carrying out a cationic collector reverse flotation technology on the two-stage low-intensity magnetic separation ore concentrate under the situation that the granularity is roughened; a regrinding and low-intensity magnetic separation technology is carried out on reverse flotation middlings, the cationic collector reverse flotation technology is carried out on three-stage low-intensity magnetic separation ore concentrate, and thus the iron concentrate grade is increased. According to the new mineral separation method disclosed by the invention, ore concentrate is obtained in advance as the reverse flotation is carried out by independently adopting a cationic collector under the situation that a depressor DF is not added, adding points of medicament are reduced, the manual operation difficulty is reduced, and the cost of mineral separation medicament is reduced; since the ore concentrate is obtained in advance through the reverse flotation, three-stage ball milling material amount is reduced, the ore grinding cost is greatly reduced, and the effect of extracting iron and reducing the energy can be achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Composite inhibitor and direct flotation method for low-grade refractory phosphate

The invention provides a composite inhibitor and a direct flotation method for low-grade refractory phosphate. The composite inhibitor comprises caustic starch and high-modulus water glass, and the specific configuration method is that firstly, starch and NaOH tablets are allocated according to the weight ratio of (3-5): (1-1.5) in the way that the well metered starch is dissolved in clear water of 5-7 m<3> and fully mixed, a sodium hydroxide solution with the concentration of 10-20%, which is dissolved and prepared in advance, is slowly added into the starch solution, and full stirring is performed for reaction for 25-35 min to prepare a caustic starch solution; and secondly, the caustic starch solution and the high-modulus water glass are fully mixed according to the weight ratio of 2: 3 to obtain a composite inhibitor solute. According to the invention, the effect in separating phosphate from gangue minerals is remarkable, the separation index is good, the recovery rate of phosphorus finished ore is about 10% higher than that of the traditional process, and residual phosphate in mineral tailings is low (2-3%). The effect in inhibiting iron and aluminium impurities in slurry is obvious and qualified phosphorus finished ore is provided for preparing superior MAP (monoammonium phosphate) through phosphoric acid by wet process.

Owner:YUNNAN HONGFU CHEM FERTILIZER

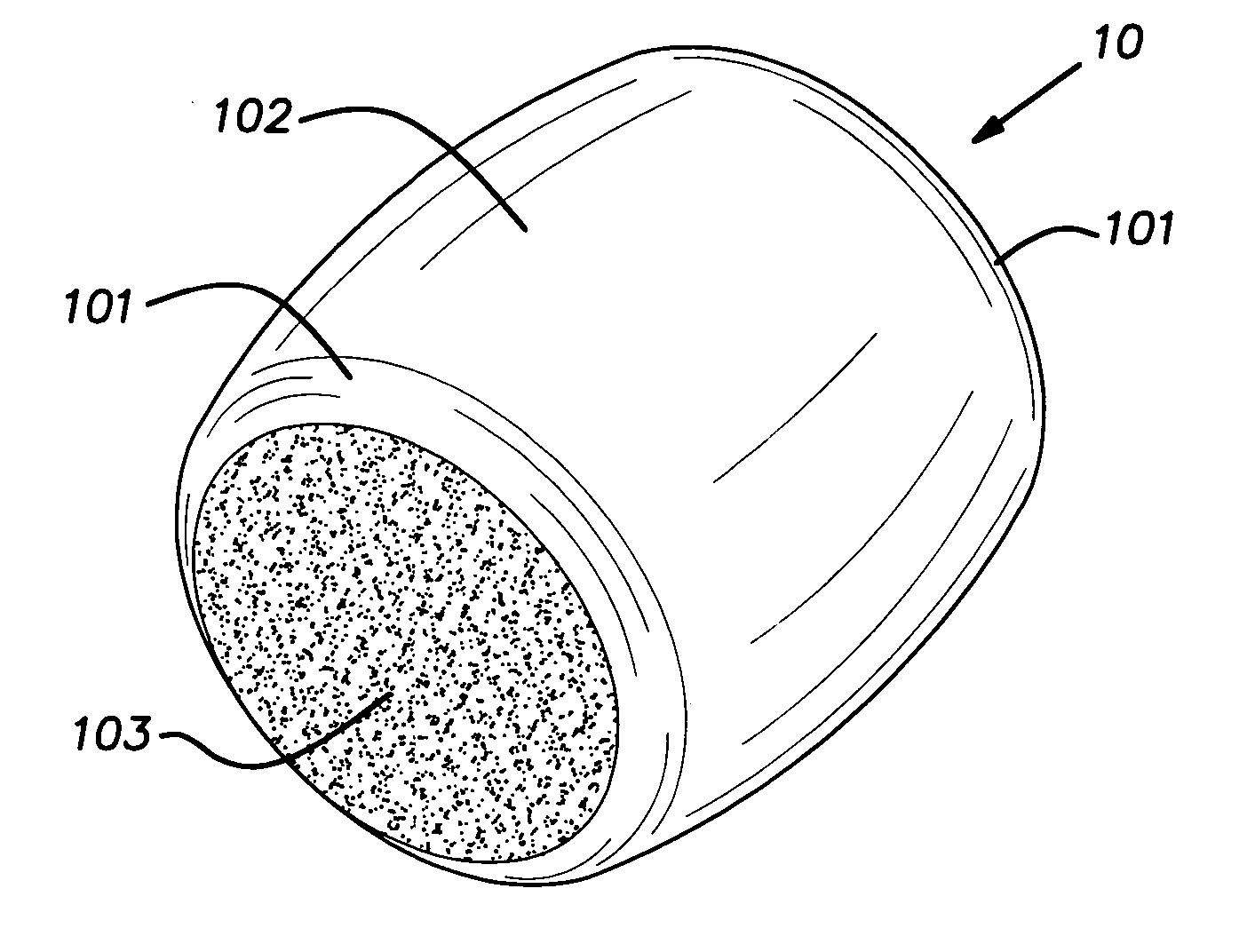

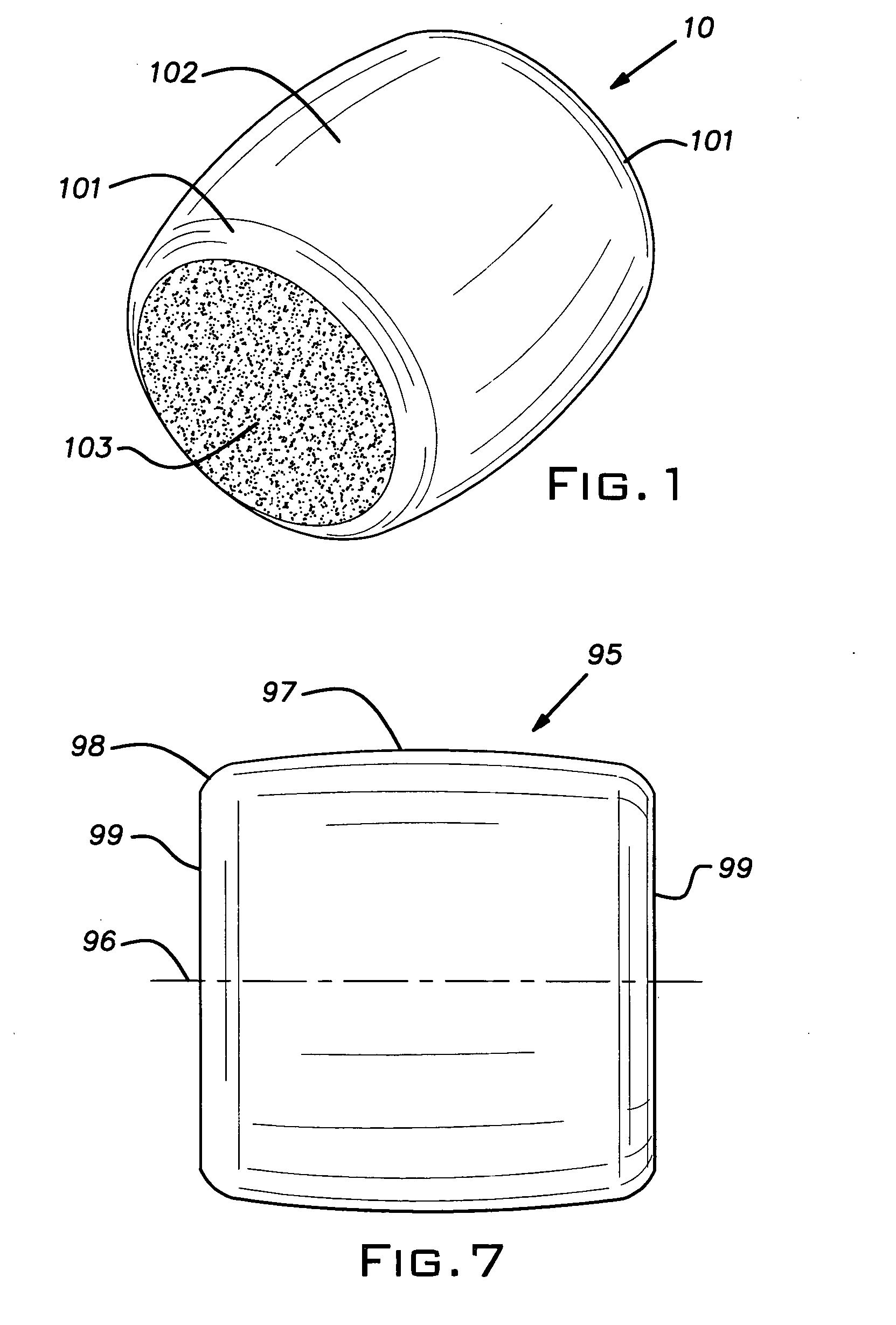

Forged roller

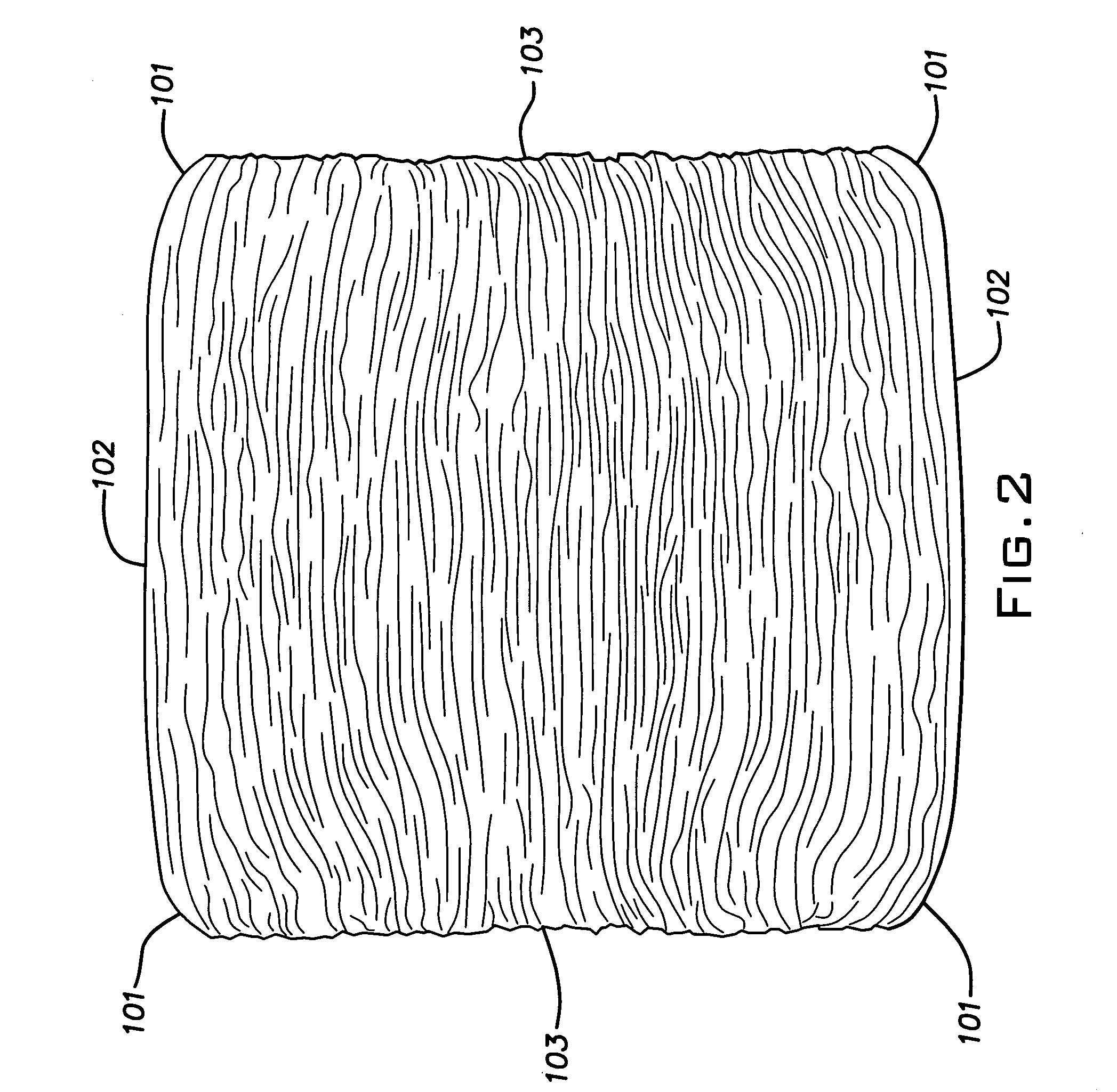

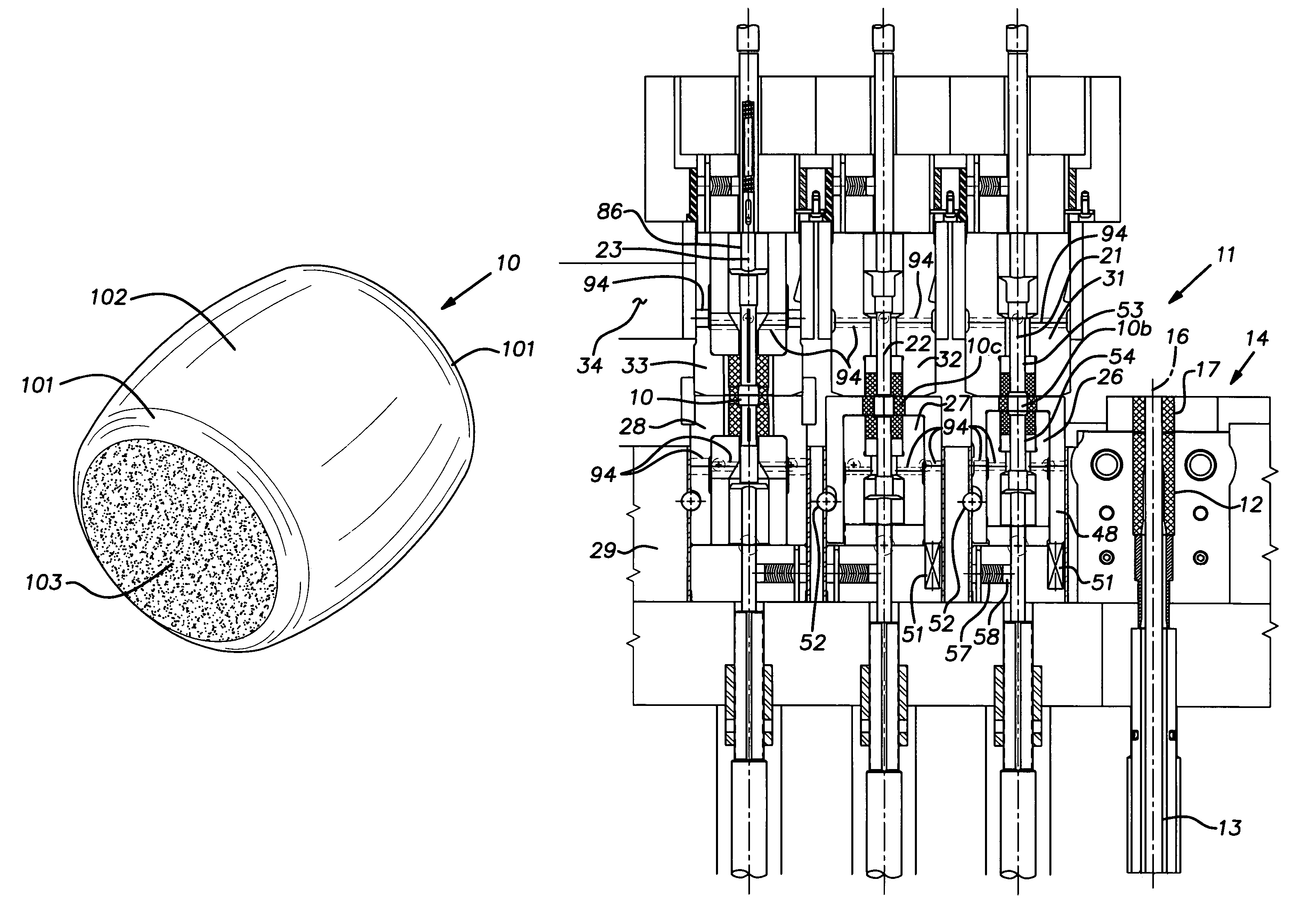

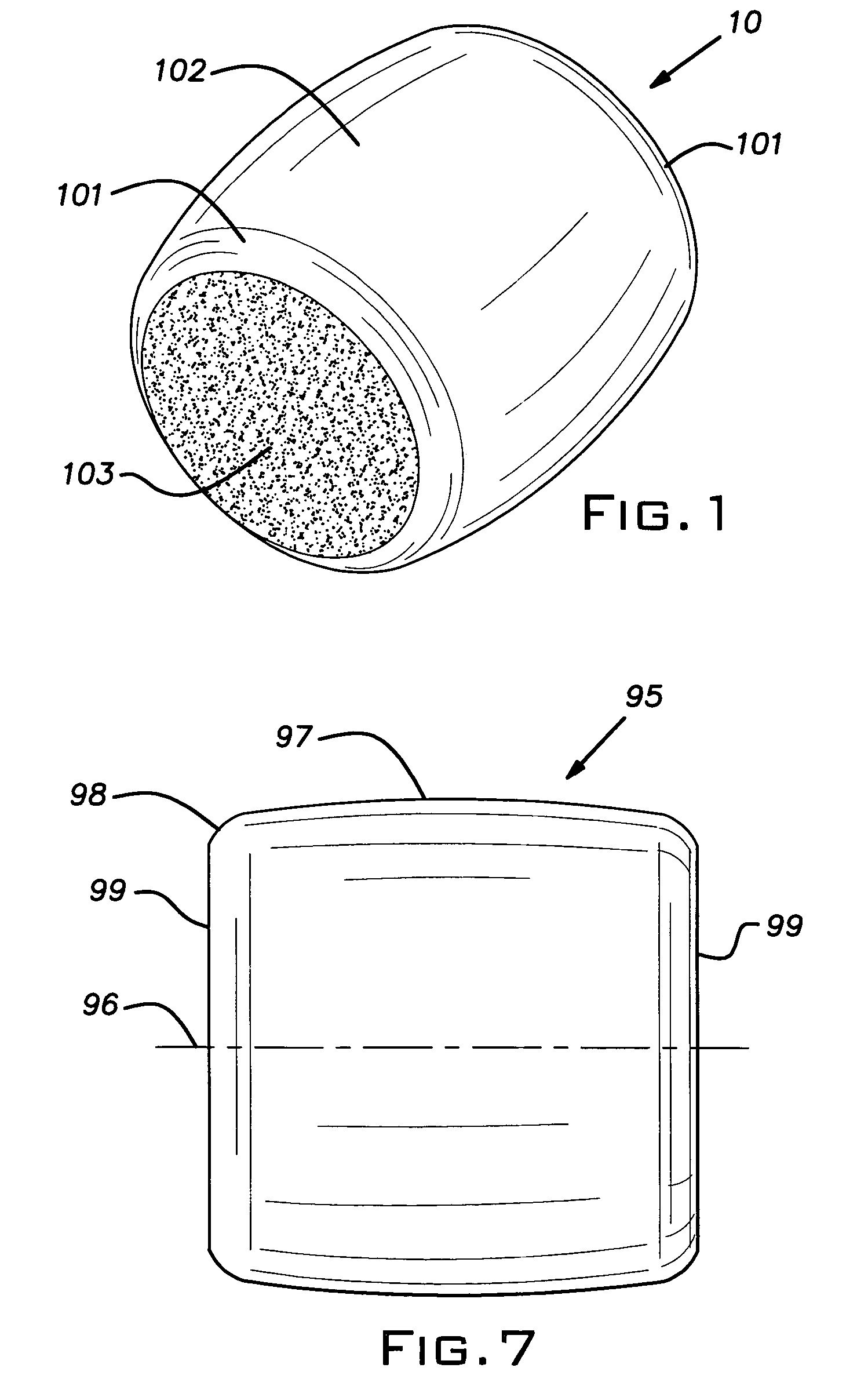

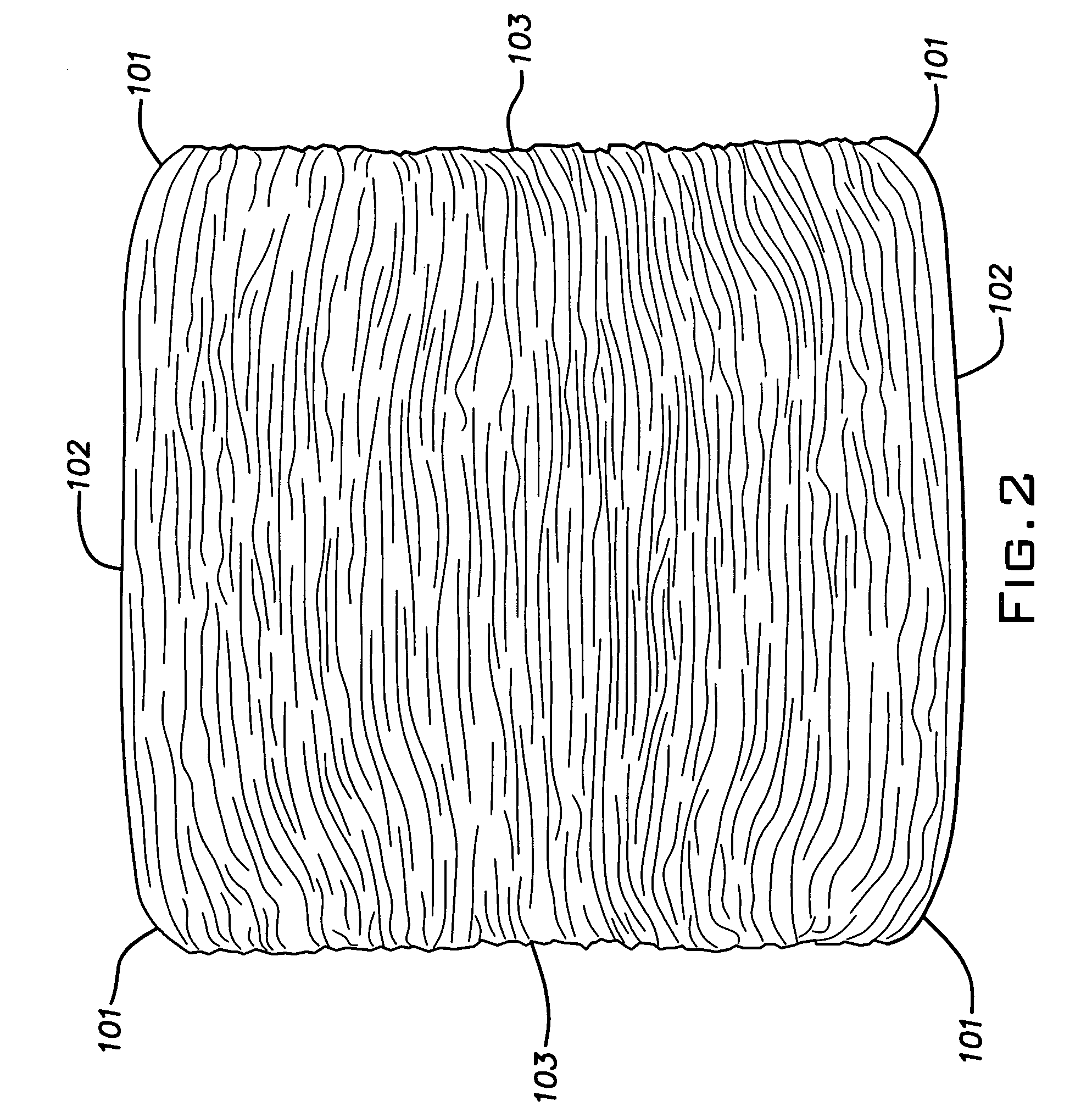

ActiveUS20060013521A1Cost reductionImprove grain structureBearing componentsForging/hammering/pressing machinesCrystalliteRoughcast

A machine, method and tooling to precision cold-form roller blanks for anti-friction bearings. The machine is a multistage progressive former using floating die cavities to enable simultaneous shaping of the ends of the roller with high accuracy and without flash. The tools and staged forming create an improved roller with an advantageous grain pattern and devoid of structural defects previously attributable to the presence of sheared end face material in the radiused corners of the blank and flash at its mid-section.

Owner:THE NAT MASCH CO

Method of cold-forming near net shape metal roller blanks for anti-friction bearings

ActiveUS7377042B2Avoid violationsReduce grinding costsBearing componentsForging/hammering/pressing machinesCold formedPulp and paper industry

A machine, method and tooling to precision cold-form roller blanks for anti-friction bearings. The machine is a multistage progressive former using floating die cavities to enable simultaneous shaping of the ends of the roller with high accuracy and without flash. The tools and staged forming create an improved roller with an advantageous grain pattern and devoid of structural defects previously attributable to the presence of sheared end face material in the radiused corners of the blank and flash at its mid-section.

Owner:THE NAT MASCH CO

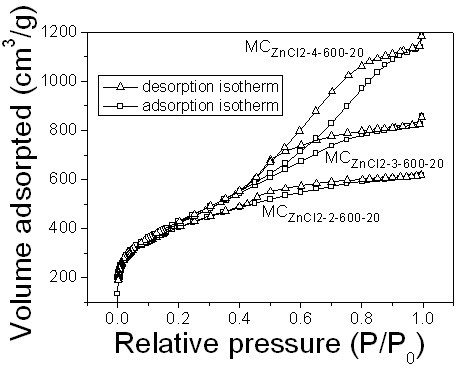

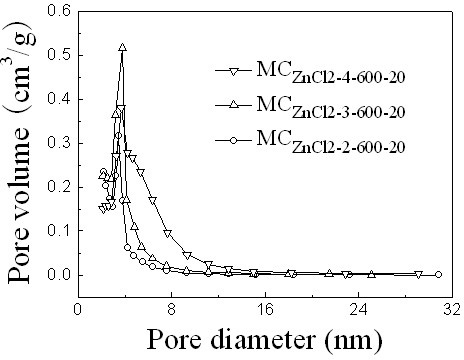

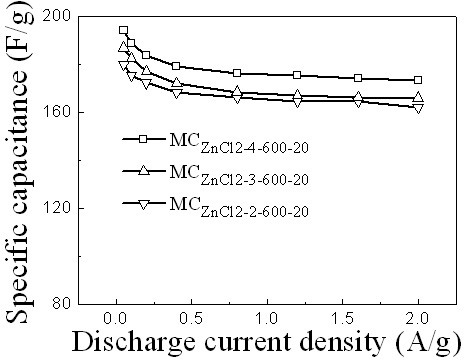

Method for preparing mesoporous carbon material for electrochemical capacitor

ActiveCN102424383ACarbon savingCarbon source is easy to getWaste processingSolid waste disposalPhosphoric acidEnergy conservation

The invention provides a method for preparing a mesoporous carbon material for an electrochemical capacitor, and belongs to the technical fields of carbon materials and microwave chemistry. In the method, peanut shells are taken as a carbon source, zinc chloride or phosphoric acid is taken as an activating agent, and the mesoporous carbon material is prepared by one step of activating the peanut shells through microwave-assisted heating; and the obtained mesoporous carbon material has the specific surface area of between 1,307 and 1,552m<2> / g, the total pore volume of between 0.67 and 1.83cm<3> / g, and the average pore size of between 2.06 and 5.02nm; non-micropore volume is 62.7 to 99.2 percent of the total pore volume; and the yield is 32.3 to 44.9 percent. The carbon source is a renewable agricultural waste, and has the characteristics of low price and high availability; the microwave heating has the advantages of uniformity, quickness and energy conservation; and the obtained mesoporous carbon serves as a material for the electrochemical capacitor, and has high stability and excellent comprehensive properties.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

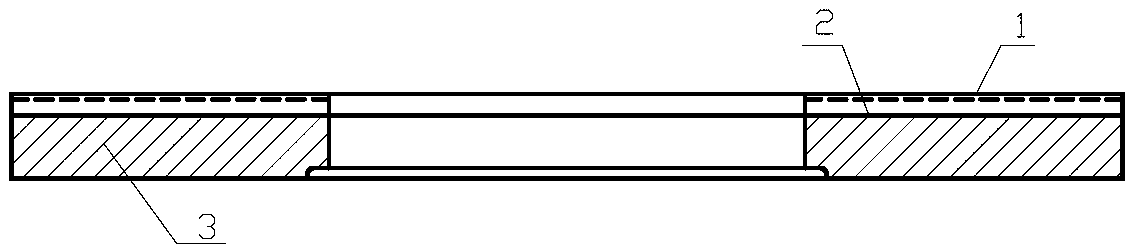

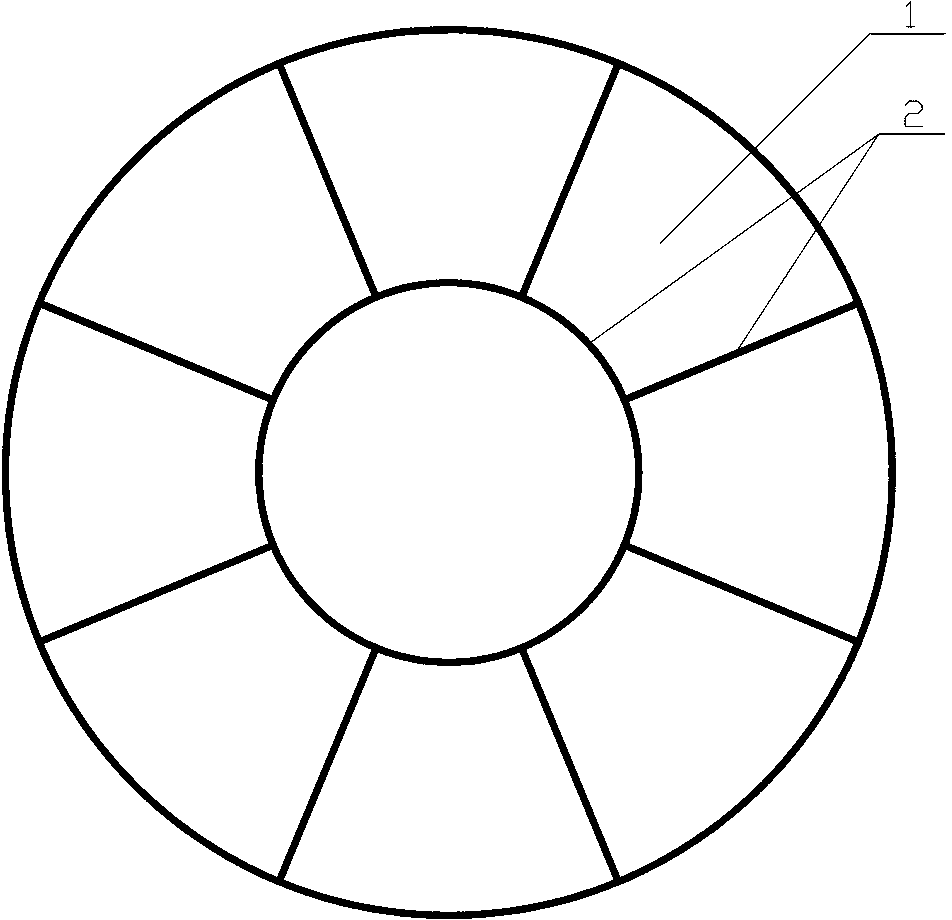

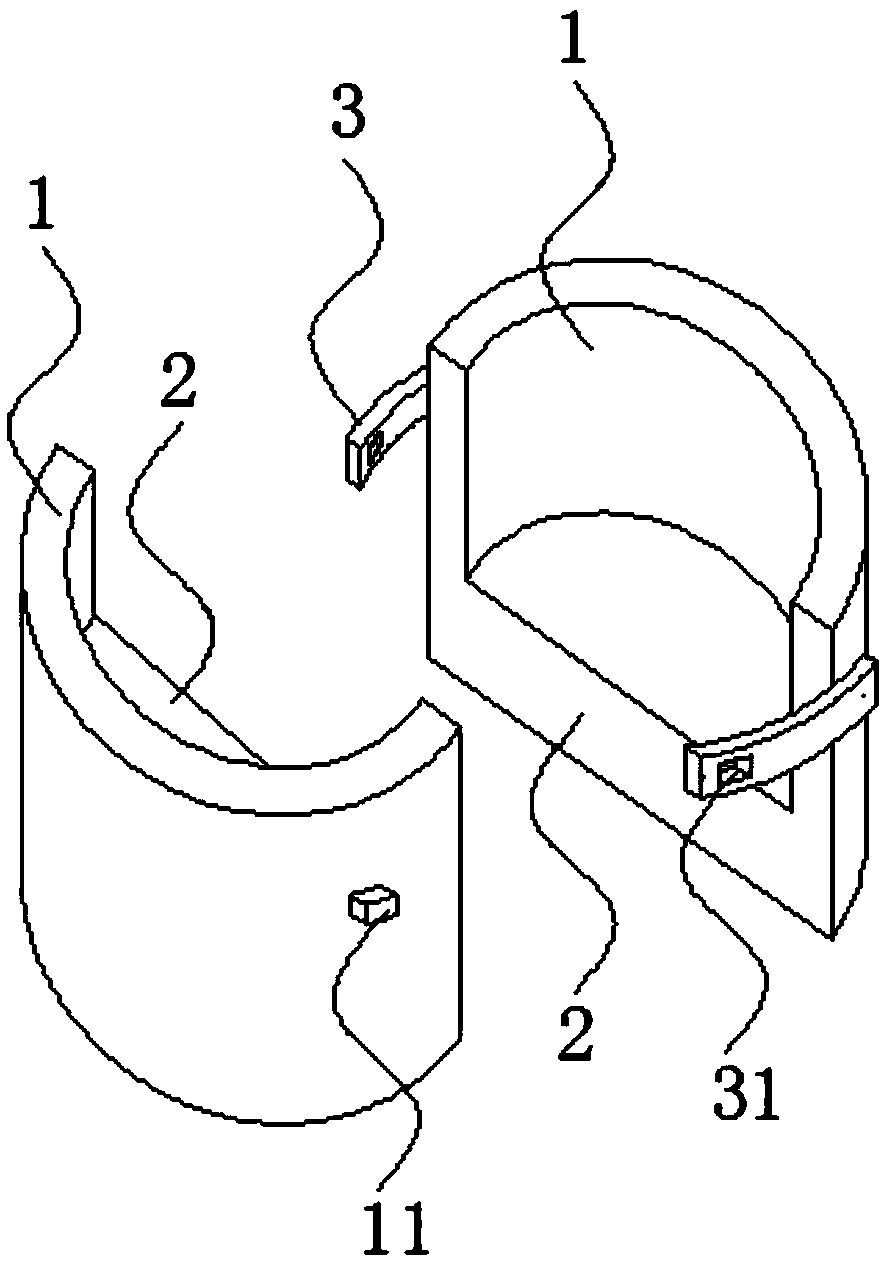

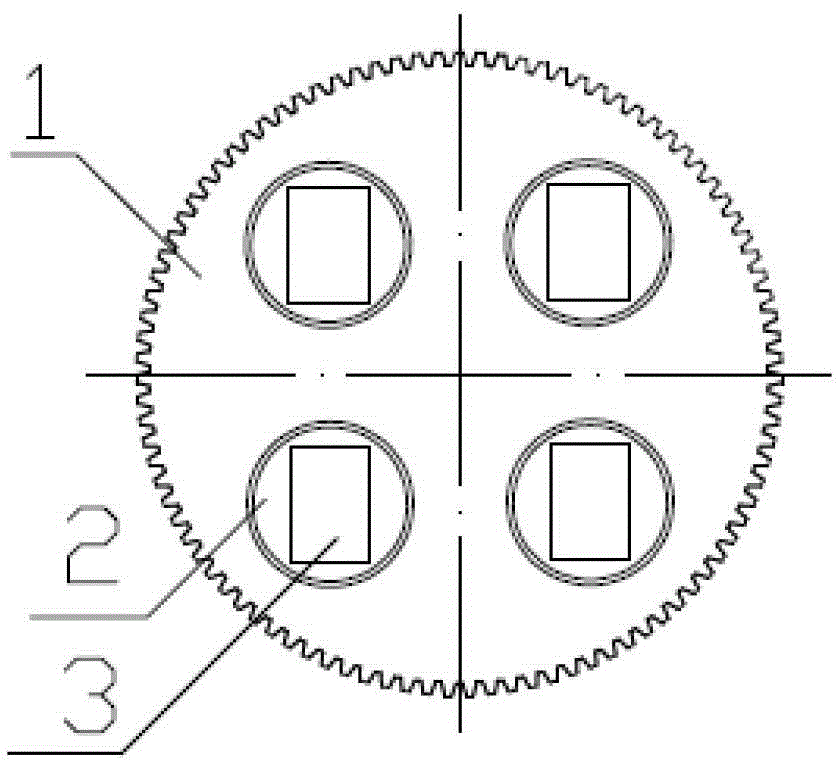

Wandering star wheel

InactiveCN102975114AIngenious and reasonable designFix issues with crafting multiple vehiclesWork carriersEngineeringTotal thickness

The invention discloses a wandering star wheel, belonging to the technical field of sapphire processing. The wandering star wheel consists of a main wheel and sub-wheels, wherein teeth matched with grinding equipment are arranged on the outer circumference of the main wheel; holes matched with the external diameters of the sub-wheels are formed in the main wheel; and other holes for the accommodation of workpieces to be processed are formed in the sub-wheels. In comparison with the prior art, during the grinding of the wandering star wheel, the sub-wheels rotate in the main wheel, so that the processed workpieces are driven to self-rotate; in such a way, the grinding is more uniform; after the grinding, the indexes such as TTV (Total Thickness Variation) and Warp for the surfaces of wafers can reach requirements; the wandering star wheel is skillful and rational in design; and in addition, the problem of manufacturing multiple diecarriers during the grinding ofn various nonstandard pieces is solved, and the grinding cost is decreased greatly.

Owner:江苏吉星新材料有限公司

Anti-cleavage suspended grinding fluid for gallium oxide wafer and preparation method thereof

ActiveCN105273638AInhibition of cleavage defectsFast removal ratePolishing compositions with abrasivesAlkaneMaterial removal

The invention discloses an anti-cleavage suspended grinding fluid for a gallium oxide wafer and a preparation method thereof. The fluid is prepared from aluminium oxide micropowder, a dispersing thixotropic agent, a surfactant, kerosene, an alkane, a pH value conditioning agent, an antifoaming agent, a bactericide and a cleaning auxiliary agent. The anti-cleavage suspended grinding fluid is preferably obtained through a large amount of experiments. The grinding fluid is good in stability, and is applicable to rough grinding and smooth grinding of the gallium oxide wafer. The material removal speed is fast, and the wafer surface is smooth and does not have obvious scratches or pits. The grinding fluid is capable of reducing mechanics expansion effect during grinding on surface micro cracks, stress damage layers and other defects left after cutting is performed , is capable of effectively inhibiting cleavage defects during grinding of the gallium oxide wafer, also is low in cost and beneficial for popularization application, and overcomes many disadvantages in the prior art.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com