Preparation method of metallographic samples

A metallographic sample and metallographic detection technology, which is applied in the field of metallographic sample preparation, can solve the problems of affecting the smoothness of the detection surface, affecting the observation clarity, and easily generating bubbles in the mounting, so as to improve the polishing effect and shorten the Polishing time, the effect of shortening the grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

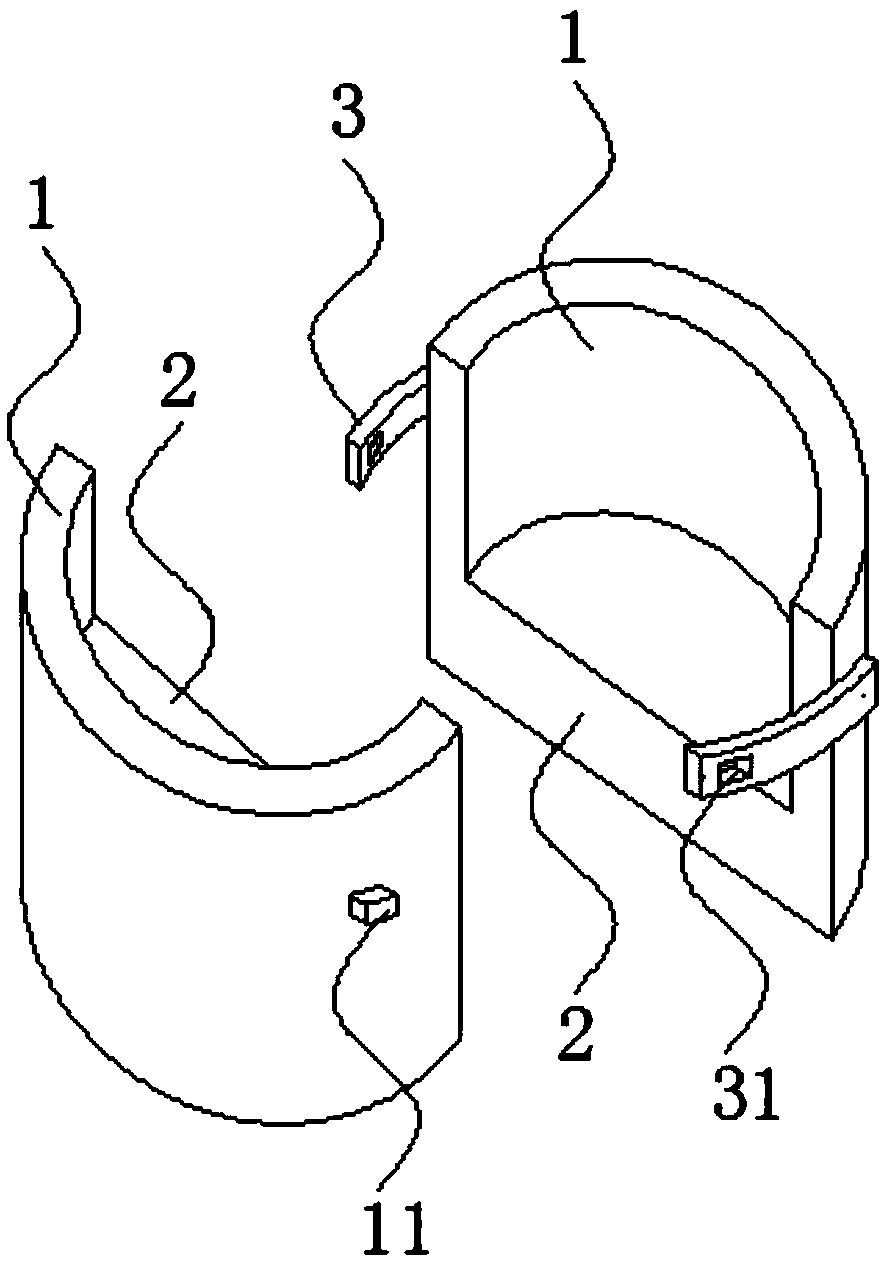

[0039] Embodiment: a kind of preparation method of metallographic sample, as figure 1 shown, including the following steps:

[0040] S1. Sampling: Cut samples at the edge of the sample and at the center of the sample respectively. The cutting direction should be parallel to the metallographic detection surface of the sample. According to the thickness of the sample, the sample should be treated as follows:

[0041] (1) When the thickness of the sample is less than 30mm, directly use the cut surface as the metallographic detection surface;

[0042] (2) When the thickness of the sample is between 30-50mm, cut the obtained sample into 2 samples at 2 / 3 of the thickness direction, and use the cut-off surface as the metallographic detection surface;

[0043] (3) When the thickness of the sample is greater than 50mm, cut the obtained sample into three equal parts in the thickness direction, and use the cut-off surface as the metallographic detection surface;

[0044] S2. Inlaying: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com