Patents

Literature

36results about How to "Easy to handle and process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing soybean protein modified adhesive formaldehyde-free medium-density fiberboard

ActiveCN104059598AResolve dependenciesReduce dependenceNon-macromolecular adhesive additivesProtein adhesivesFiberPolymer science

The invention provides a method for manufacturing a soybean protein modified adhesive formaldehyde-free medium-density fiberboard, and belongs to the technical field of density fiberboard manufacture. The method comprises the following steps: heating, stirring and mixing raw materials (soybean pulp, a denaturing agent, a crosslinking agent, a defoaming agent, a preservative and water) to react; preparing the soybean protein formaldehyde-free adhesive by virtue of a colloid mill and a homogenizer; adding a water-proofing agent, a curing agent and a buffering agent into the soybean protein formaldehyde-free adhesive, stirring and mixing at room temperature, and uniformly mixing with wood fibers; performing drying, paving and hot-pressing to prepare the soybean protein modified adhesive formaldehyde-free medium-density fiberboard. The method is environment-friendly and non-pollution; the soybean protein modified adhesive formaldehyde-free medium-density fiberboard is high in adhesion strength, good in water proofing, low in price, low in viscosity and easy to treat and process, can be subjected to hot-pressing and cold-pressing in application, and is not easy to crack. The soybean protein modified adhesive formaldehyde-free medium-density fiberboard can be adhered to fibers and the like, and the processing process can be controlled, and an environment-friendly fiberboard can be manufactured.

Owner:DONGYING ARTIFICIAL BOARD FACTORY

Preparation method of metallographic samples

InactiveCN108896339AAvoid it happening againEasy to observeWithdrawing sample devicesPreparing sample for investigationColloidMaterials science

The invention discloses a preparation method of metallographic samples. The preparation method includes the following steps: S1, a step of sampling, namely a step of cutting samples at the edge and center of a sample object; S2, a step of inlaying, namely a step of slowly guiding flows of colloid into an inlaying die through galvanized iron wires for curing; S3, a step of grinding; S4, a step of polishing; and S5, a step of corrosion, namely a step of corroding a metallographic detected surface with a corrosion solution. The method can effectively prevent bubbles from forming in the metallographic samples, improve the polishing effect, shorten the polishing time, facilitate metallographic observation of the metallographic detection surface, and improve the detection accuracy.

Owner:JIANGSU SCIENCE TEST TECHNOLOGY SERVICE CO LTD

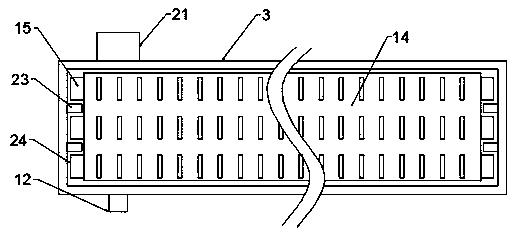

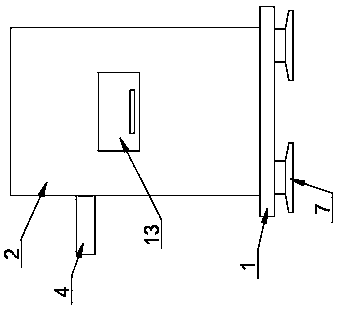

Glass overturning mechanism used for glass processing

InactiveCN104925520ASimple structureInnovative designCharge manipulationConveyor partsReducerGlass production

The invention relates to the technical field of glass production and discloses a glass overturning mechanism used for glass processing. The glass overturning mechanism comprises a set of rectangular framework. Supporting legs are arranged at the four corners of the rectangular framework. The supporting leg on the right side extends out of the upper end of the rectangular framework. A set of opposite hole positions are formed in the extending section of the supporting leg on the right side. A rotary shaft is arranged between the hole positions and penetrates out of the outer sides of the hole positions. A belt wheel is arranged on one side of the rotary shaft and connected with a speed reducer through a belt. The speed reducer is arranged at the bottom of the rectangular framework. The rotary shaft is provided with multiple supporting plates. The other ends of the supporting plates are movably arranged on the rectangular framework. Each supporting plate is provided with a set of sucker frame. The sucker frames are provided with suckers. The glass overturning mechanism used for glass processing has the beneficial effects of being simple in structure, being novel in design, not only facilitating normal carrying and processing through mechanical glass overturning, but also saving time and labor, improving the working efficiency, being good in practicability and facilitating application and popularization.

Owner:肥西县三星玻璃有限公司

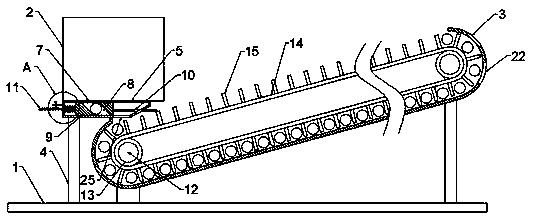

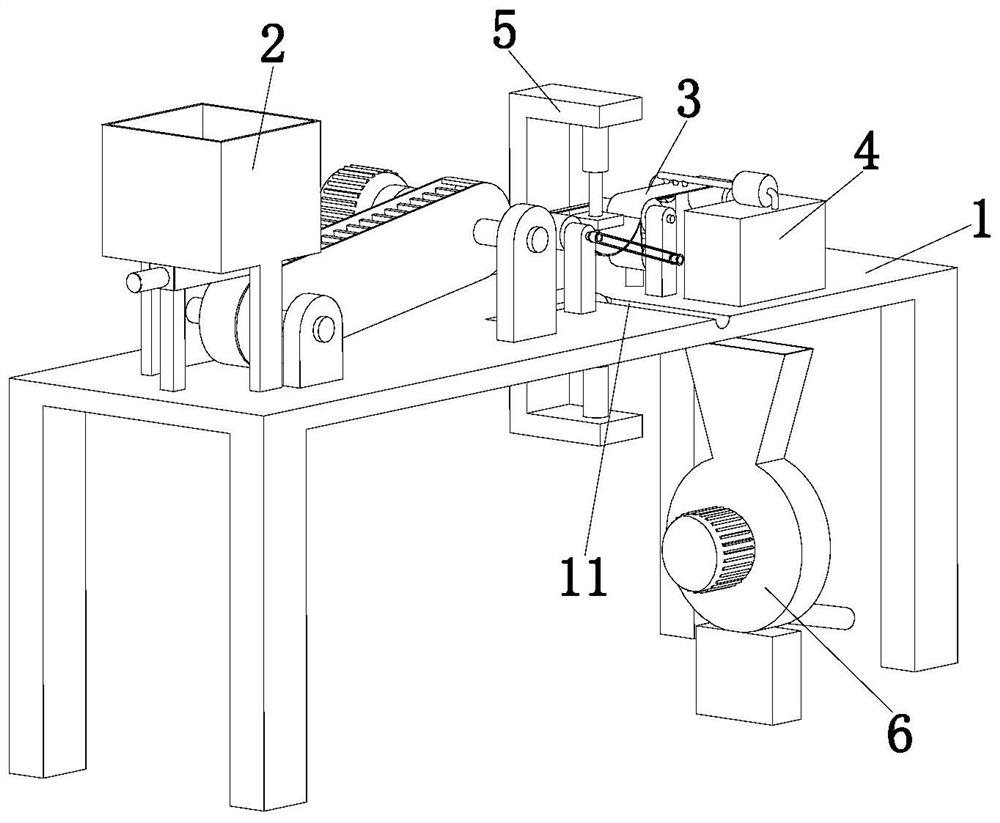

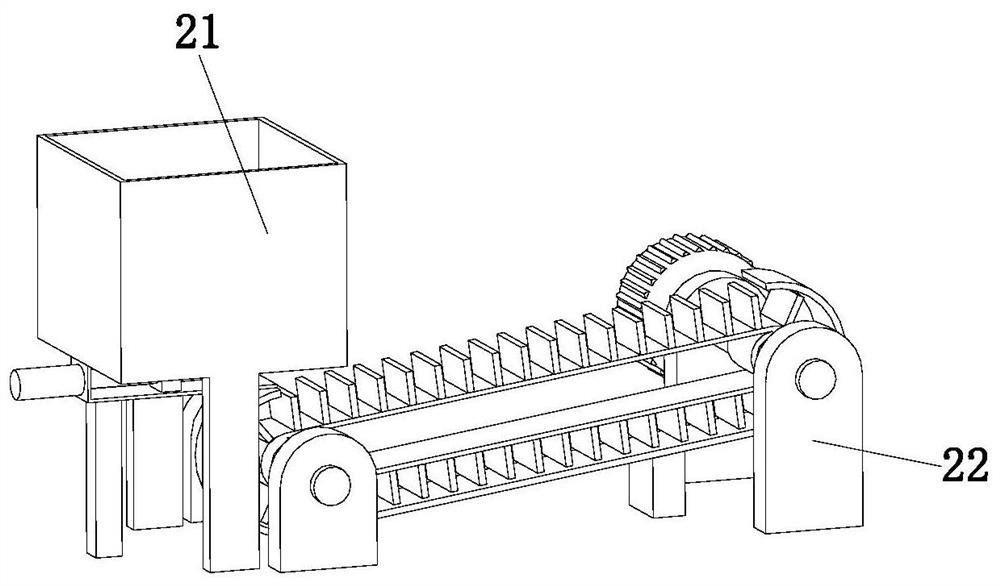

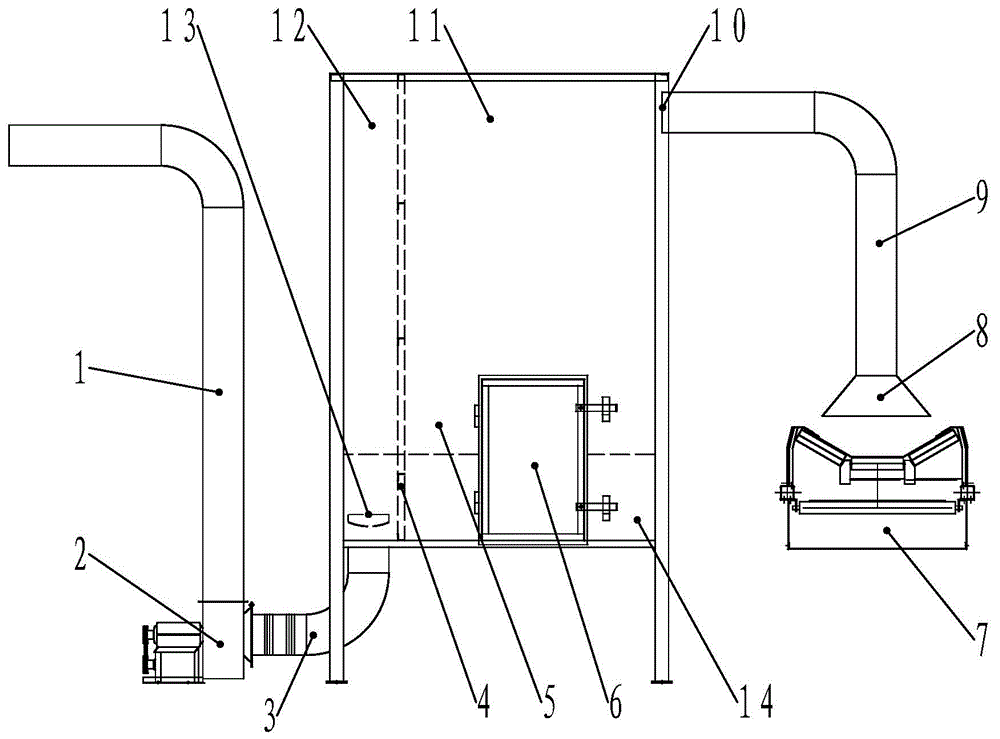

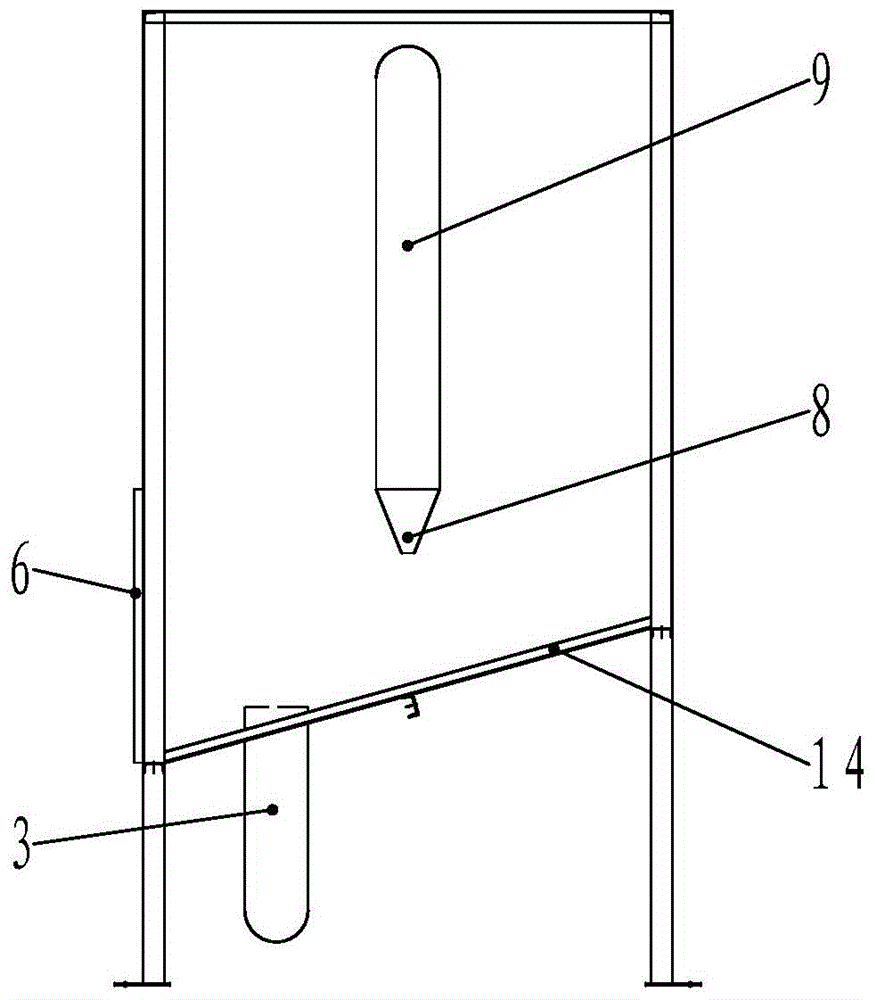

Automatic feeding device for glass bead production

InactiveCN108545410AOrderly loadingEasy to handle and processConveyorsConveyor partsConveyor beltGuide tube

The invention discloses an automatic feeding device for glass bead production. The automatic feeding device comprises a base bottom plate, a storing box and a feeding inclined guide tube. One end of arotating rod shaft is connected with a feeding motor arranged on the end side of the feeding inclined guide tube. A plurality of shifting boards which are arranged at equal intervals are arranged onthe outer side face of a conveyor belt. A ball storing gap is formed between every two adjacent shifting boards. An adjusting feeding chamber is formed in the lower side of the storing box, and an inlet port communicating with the interior of the storing box is formed in the upper end wall of the adjusting feeding chamber. A push block is arranged in the adjusting feeding chamber, and the end side, away from the feeding inclined guide tube, of the push block is connected with the inner wall of the adjusting feeding chamber through a reset spring. A feeding hole is formed in the semi-cylindrical outer arc-shaped face located at the upper end of the feeding inclined guide tube. According to the automatic feeding device, the structure is simple, automatic feeding can be achieved, manual operation is not needed, equal-quantity feeding is achieved, treatment and machining are facilitated, the efficiency is high, and the practicability is high.

Owner:山东超福钻石饰品股份有限公司

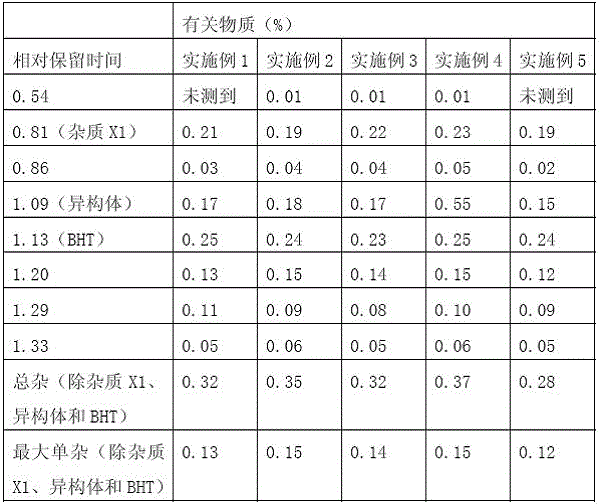

Preparation method of everolimus solid dispersion

InactiveCN106265525AAvoid oxidative degradationImprove drying efficiencyPowder deliveryOrganic active ingredientsMicrowaveEverolimus

The invention discloses a preparation method of everolimus solid dispersion. The preparation method particularly comprises the following steps that 1, everolimus, hydroxypropyl methyl cellulose and organic solvent are stirred and mixed to be uniform; 2, the organic solvent in the materials which are stirred to be uniform in the step 1 is removed through a microwave vacuum drying method, and then the everolimus solid dispersion is obtained, wherein the vacuum degree of microwave vacuum drying is lower than or equal to 0.080 MPa, and the drying temperature is lower than or equal to 55 DEG C. According to the method, the organic solvent in the preparation process of the everolimus solid dispersion is removed by adopting the microwave vacuum drying method which is conventionally applied to agricultural product and food processing, oxidative degradation of everolimus can be effectively avoided, the drying efficiency can be greatly improved, the dried materials are loose in surface, and the next processing step is easy to operate.

Owner:CHANGZHOU LANLING PHARMA +1

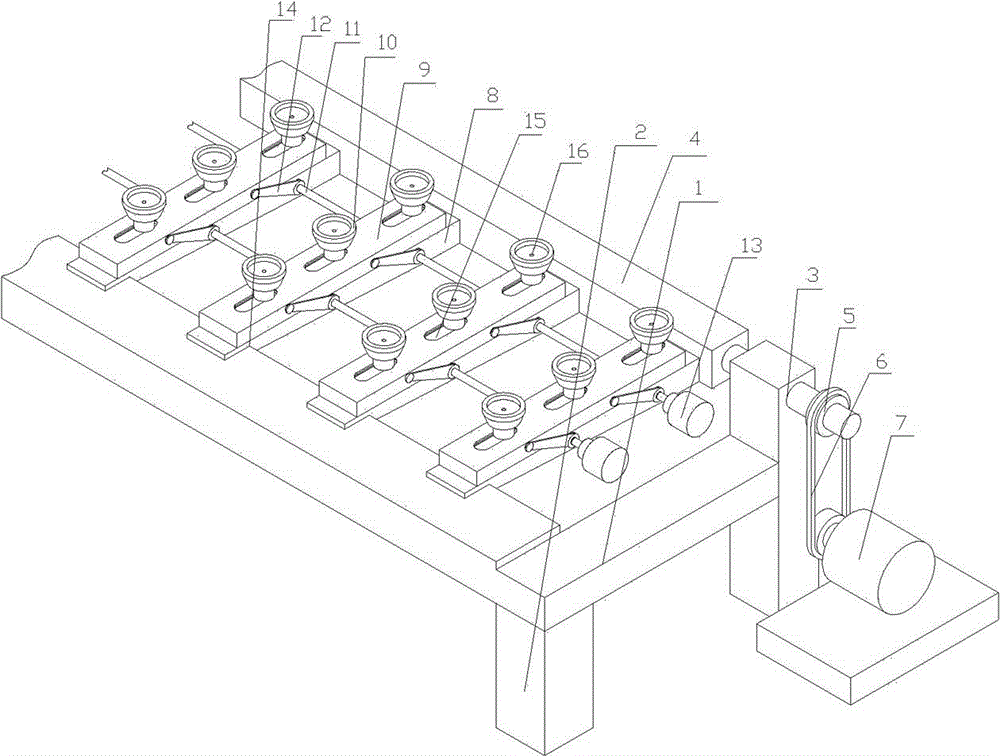

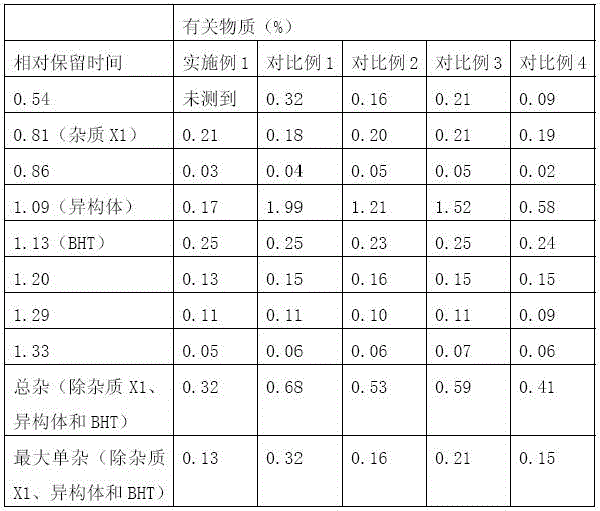

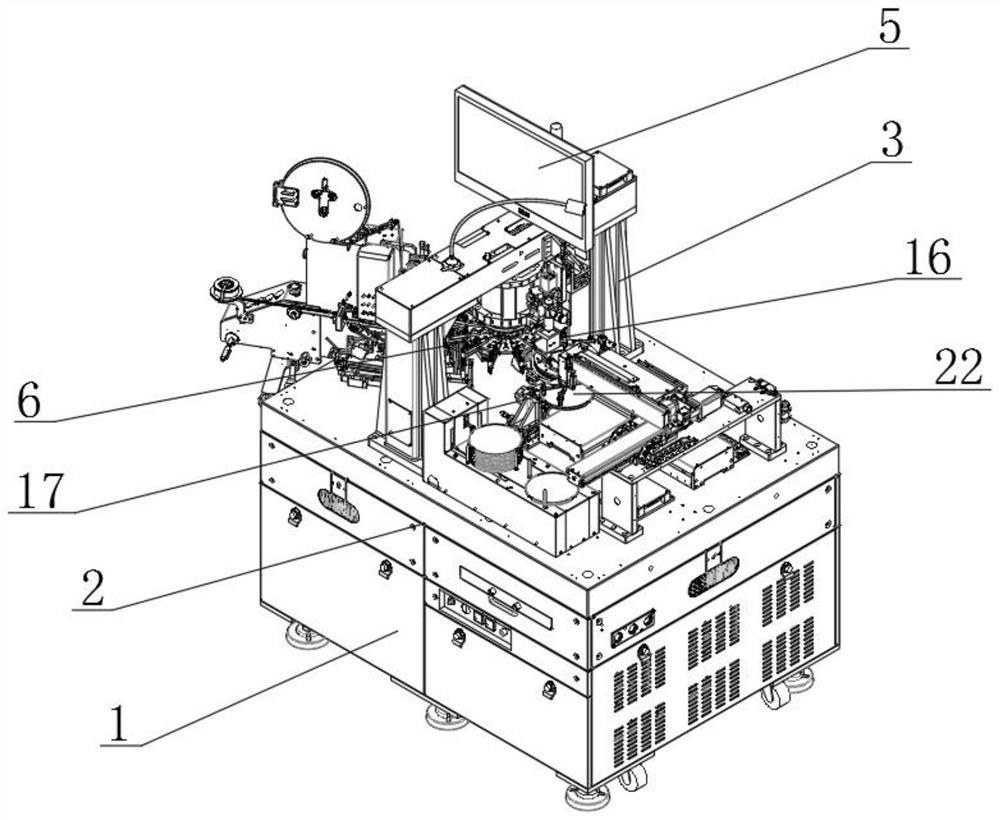

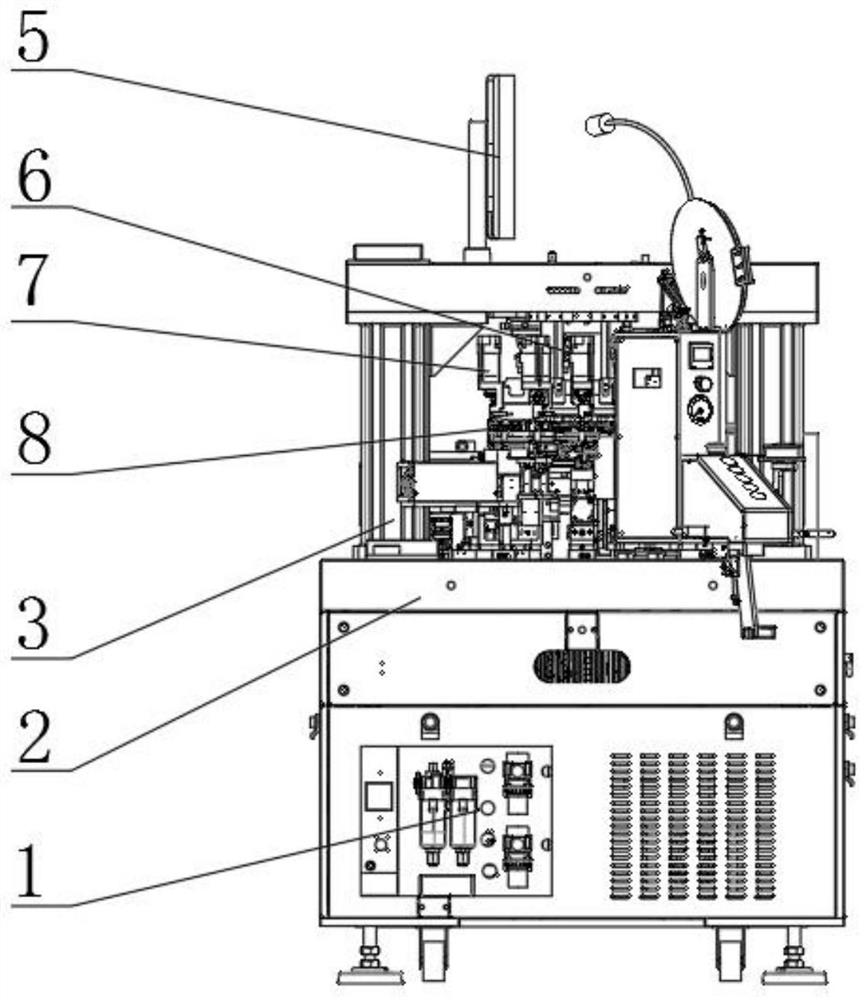

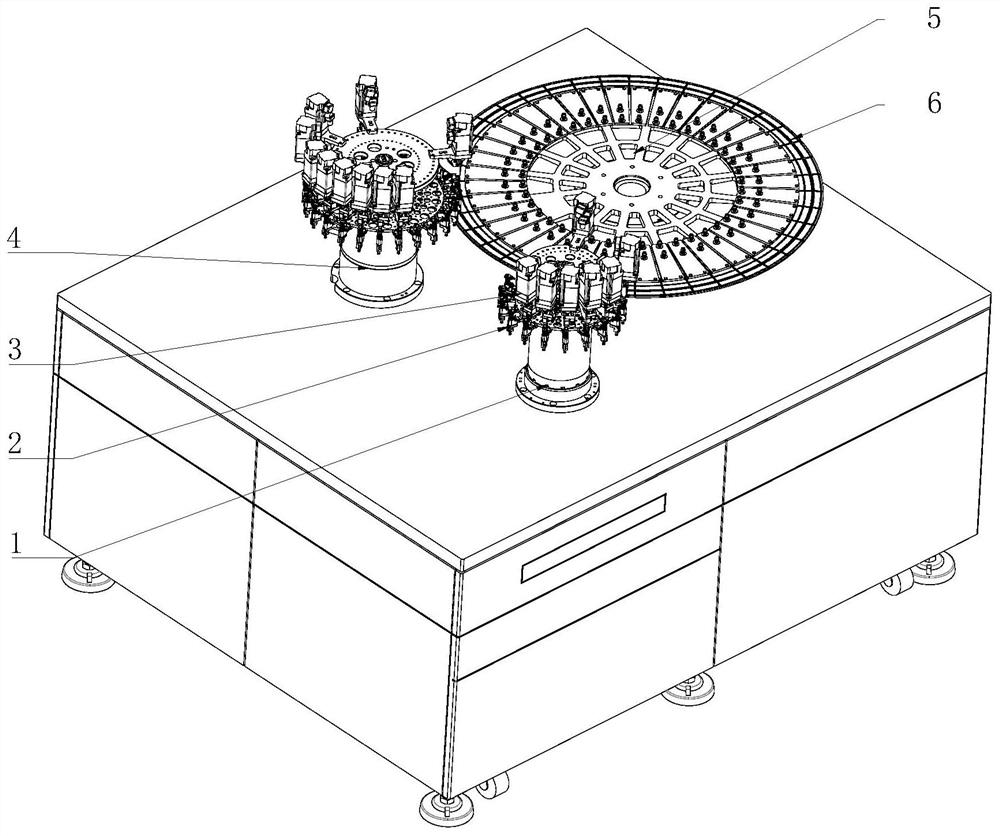

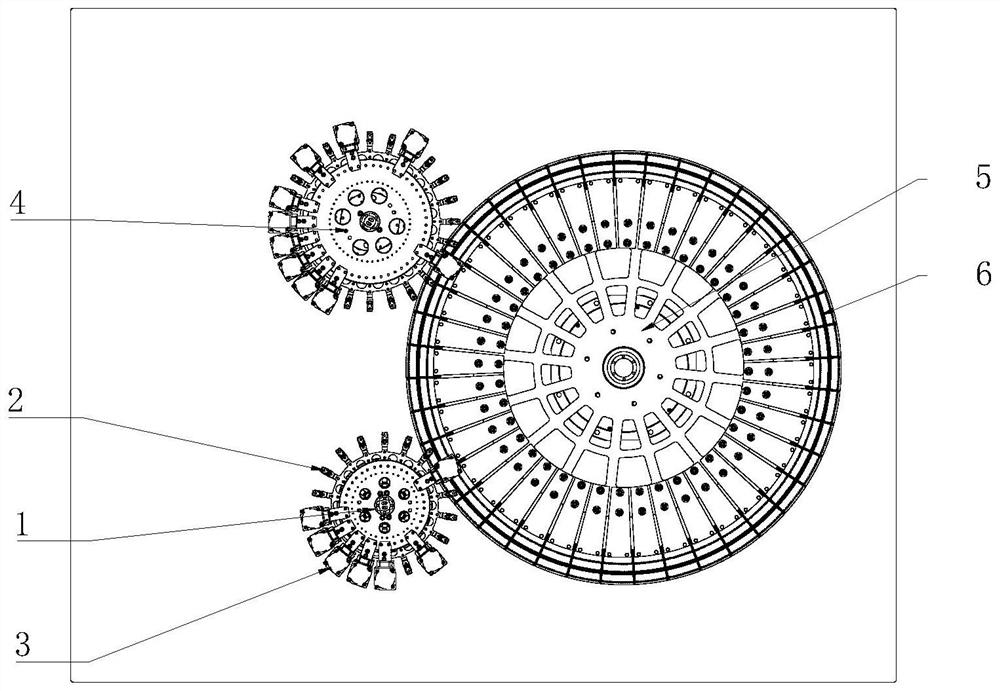

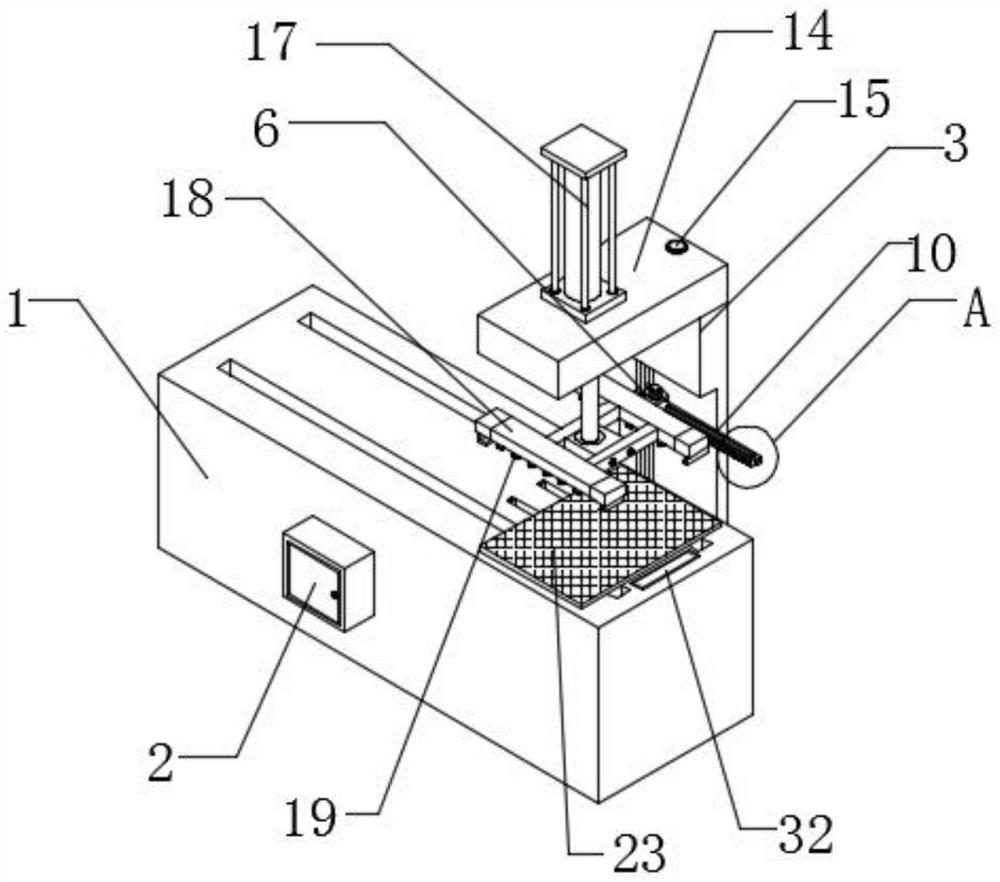

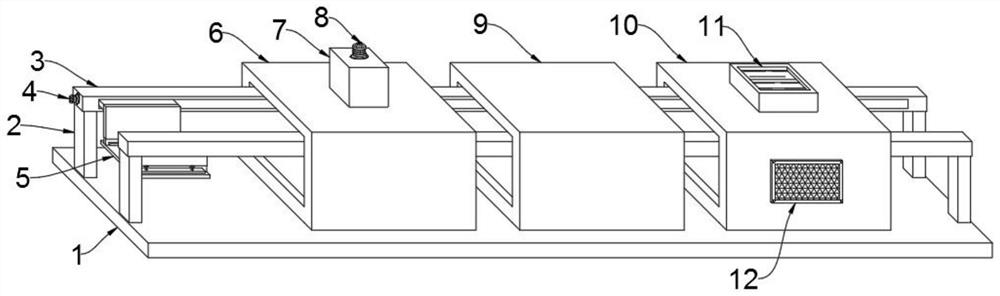

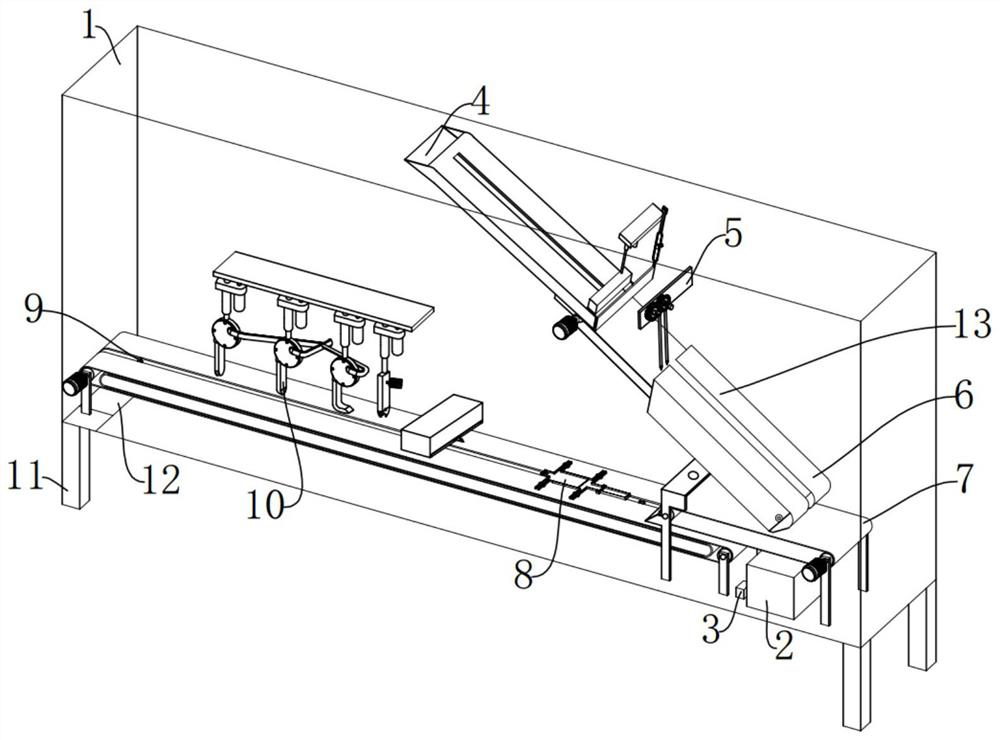

Wafer chip product testing and braiding equipment and processing method thereof

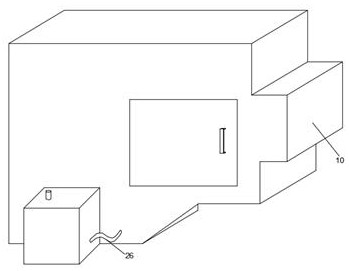

PendingCN112820683AHigh-speed spatial location transferPrecise spatial position transferSemiconductor/solid-state device manufacturingConveyor partsProduct testingWafer

The invention discloses wafer chip product testing and braiding equipment and a processing method thereof. The wafer chip product testing and braiding equipment comprises an equipment electric box cabinet used for providing power supply power for the whole equipment. The equipment electric box cabinet comprises a workbench and a gantry vertical arm mechanism, and the bottom end of the gantry vertical arm mechanism is connected to the surfaces of the two sides of the workbench through bolts, and the gantry vertical arm mechanism is used for fixing a vacuum turret module movably arranged at the bottom end of the gantry vertical arm mechanism, and the wafer disc lifting mechanism is arranged on the side, away from the gantry vertical arm mechanism, of the surface of the workbench. According to the invention, the wafer feeding system, the vacuum turret system and the chip closing processing system are reasonably arranged and formed, and through close cooperation of the wafer feeding system, the vacuum turret system and the chip closing processing system, high-speed, accurate and reliable spatial position transfer of wafer chip products can be carried out on the same equipment, rapid picking and testing of the wafer chip products from a wafer blue film are realized. The problems of dark cracks, scratches, damages and the like on wafer chip products in the process are avoided, manpower is saved, and the production efficiency is improved.

Owner:NORTECH AUTOMATION SHENZHEN CO LTD

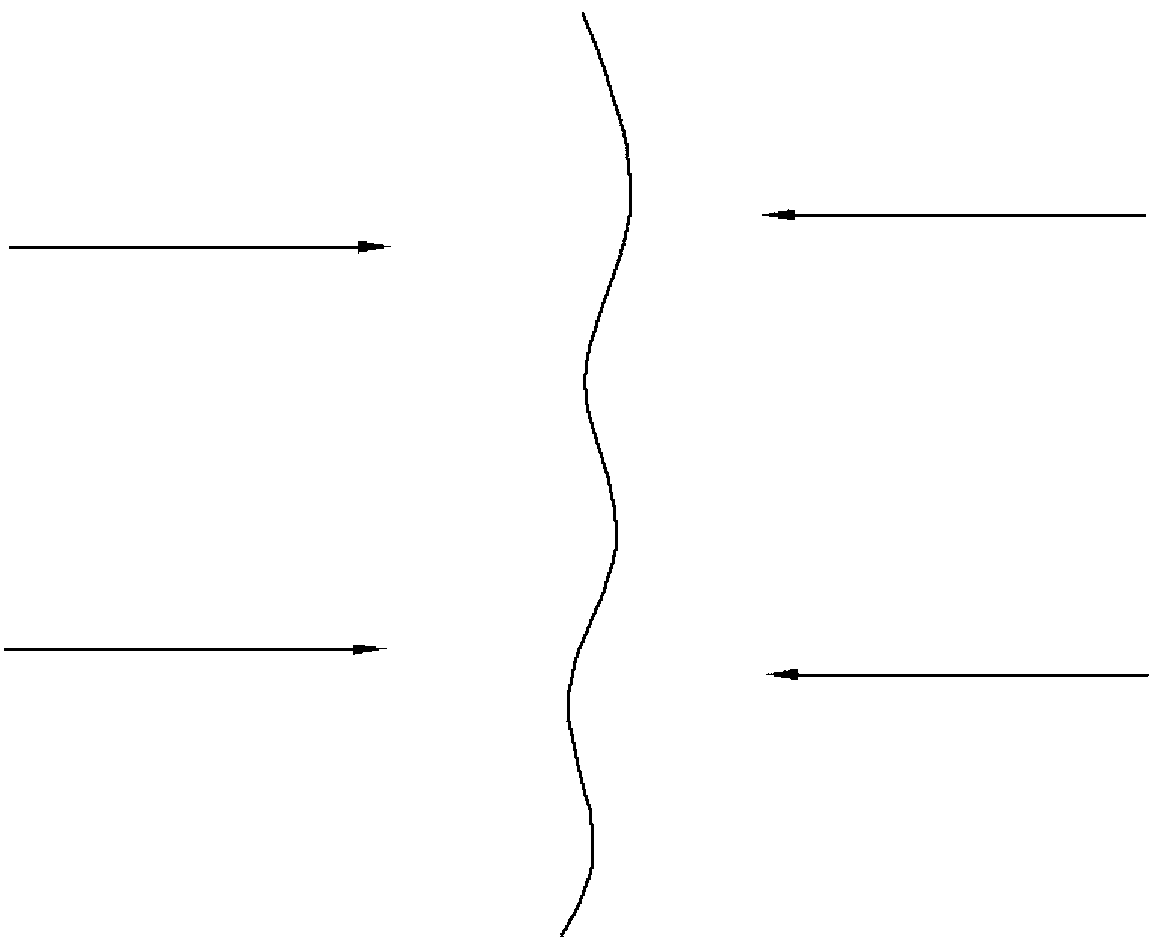

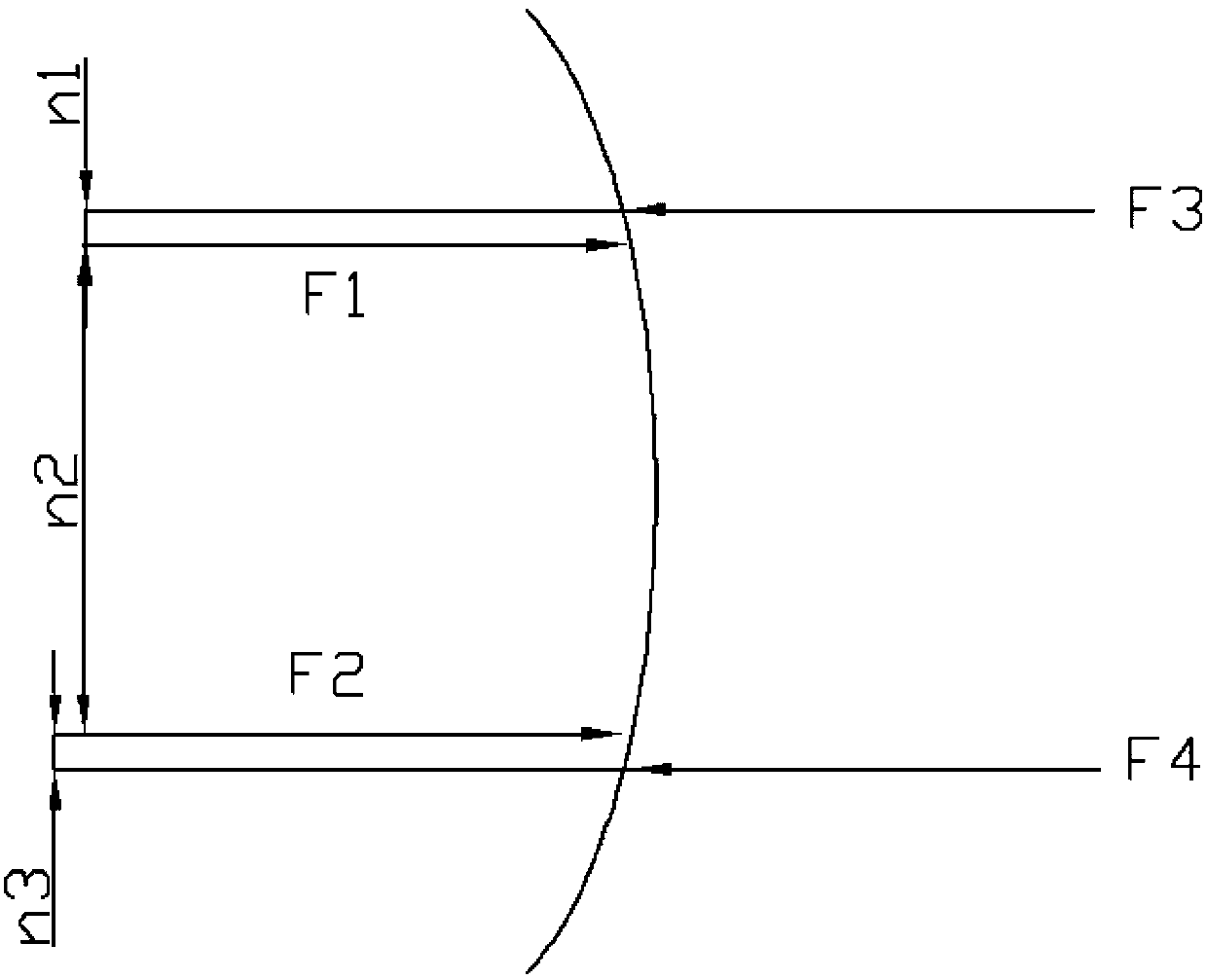

Control method of molding shape in glass base plate production

ActiveCN102992591AImprove cross-cut stabilityControl deflectionGlass forming apparatusGlass productionEngineeringSize adjustment

The invention relates to a control method of a molding shape in glass base plate production, which is characterized in that the control method comprises the following steps of: applying a first acting force (F1) and a second acting force (F2) to a glass plate from the left side of the glass plate along the horizontal direction between a stress removing zone and a cutting device zone, and simultaneously applying a third acting force (F3) and a fourth acting force (F4) to the glass plate from the right side of the glass plate along the horizontal direction. The control method used in the glass base plate production has the advantages that 1 the transection stability of the glass plate is improved so that the cutting loss is greatly reduced, and production yield is improved; 2 the form of glass plate is stable between the stress removing zone and a cutting device zone so that the warping and stress stability is greatly improved; and 3 the size adjustment of the molding shape for the form of the glass plate between the stress removing zone and a cutting device zone is favorable for the control on the deflection of the glass plate.

Owner:陕西彩虹电子玻璃有限公司

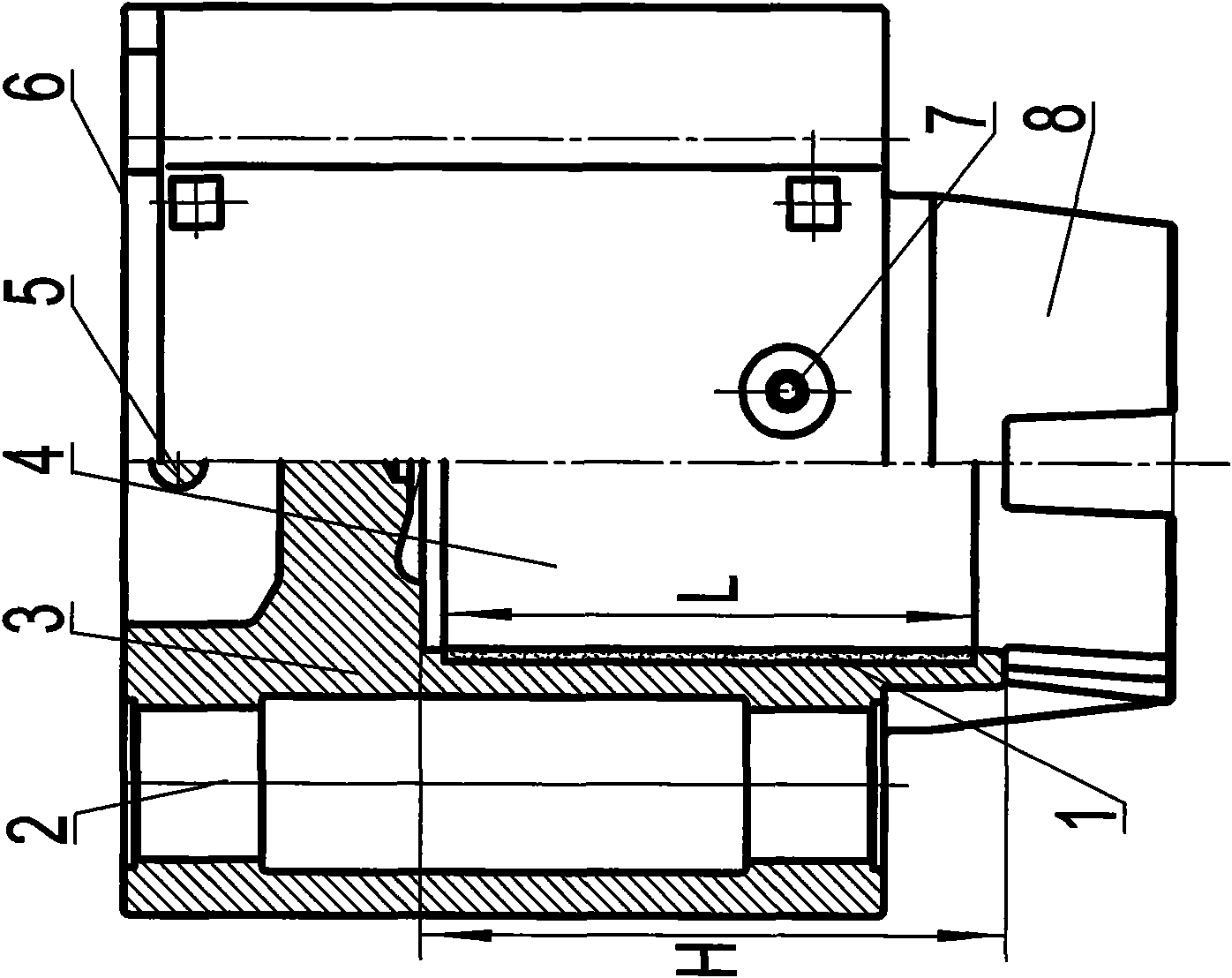

Wear-resistant cylinder hammer for guide rod type diesel pile driver and processing method thereof

InactiveCN101619577AHigh surface hardnessImprove surface wear resistanceBulkheads/pilesWear resistantEngineering

The invention discloses a wear-resistant cylinder hammer for a guide rod type diesel pile driver, which comprises a cylinder hammer body and a cylinder cavity, wherein the cylinder cavity is arranged on the cylinder hammer body; the cavity wall of the cylinder cavity is provided with a hardening layer; and the ratio of the width L of the hardening layer to the hole depth H of the cylinder cavity (4) is that L / H is between 0.8 and 1.0. To obtain the wear-resistant cylinder hammer, a processing method at least comprises the steps of: a, performing casting forming, in which a formed cylinder hammer blank with a blank hole of the cylinder cavity is cast; b, processing a cavity hole of the cylinder cavity, namely processing the cavity hole of the cylinder cavity on the formed cylinder hammer blank by a turning or / and boring processing method; c, grinding the cavity wall of the cylinder cavity, namely performing grinding processing on the cavity wall of the cylinder cavity; and d, performing surface quenching on the cavity wall of the cylinder cavity. The wear-resistant cylinder hammer has the highly hard and wear-resistant cavity wall of the cylinder cavity, and has high blow efficiency and long service life. The processing method has a reasonable process and convenient implementation.

Owner:束为林

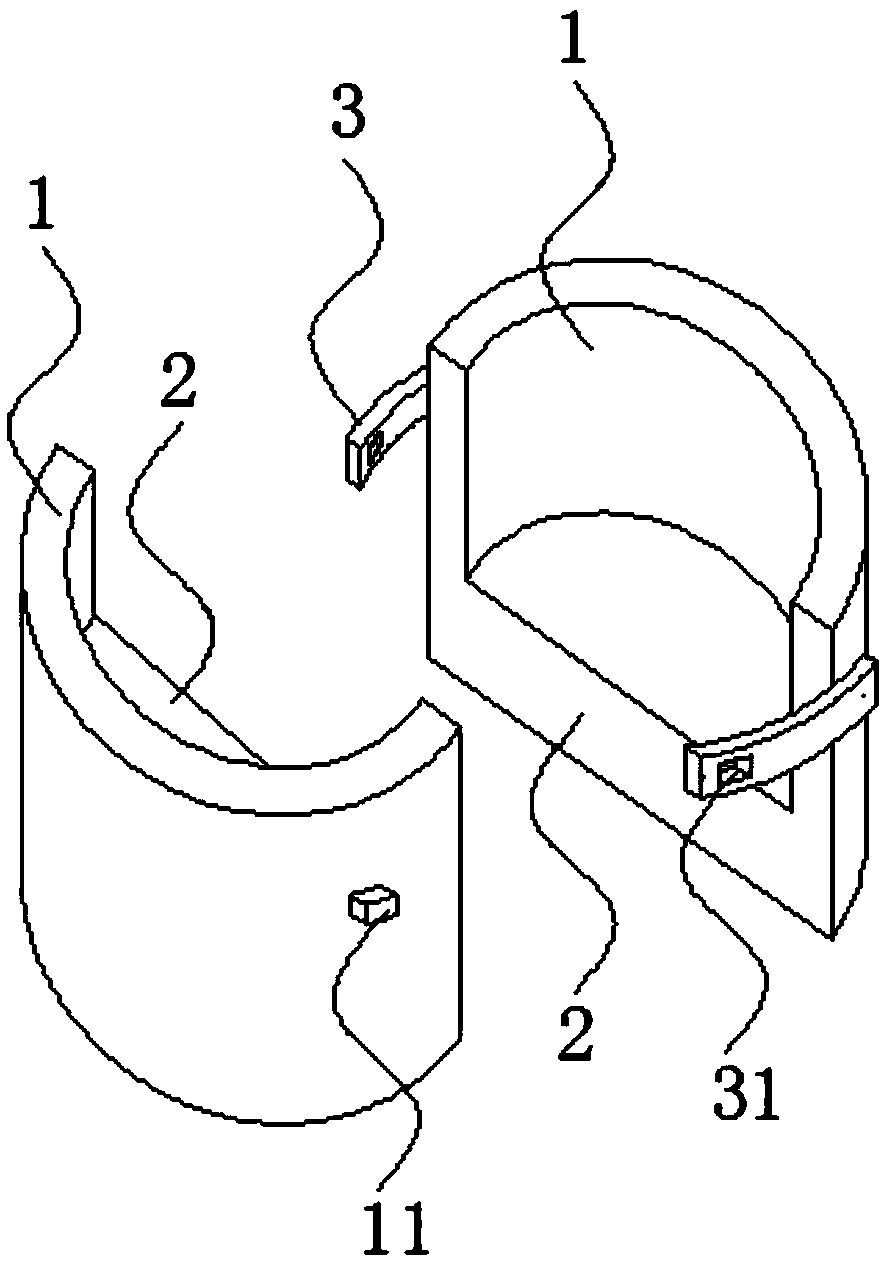

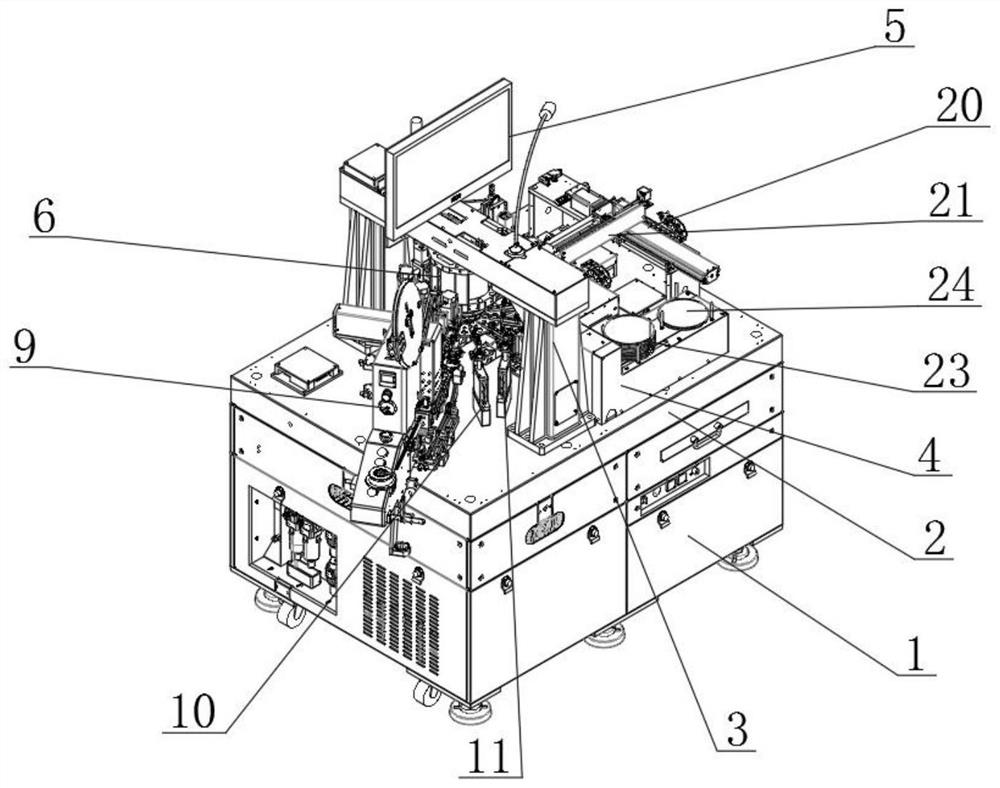

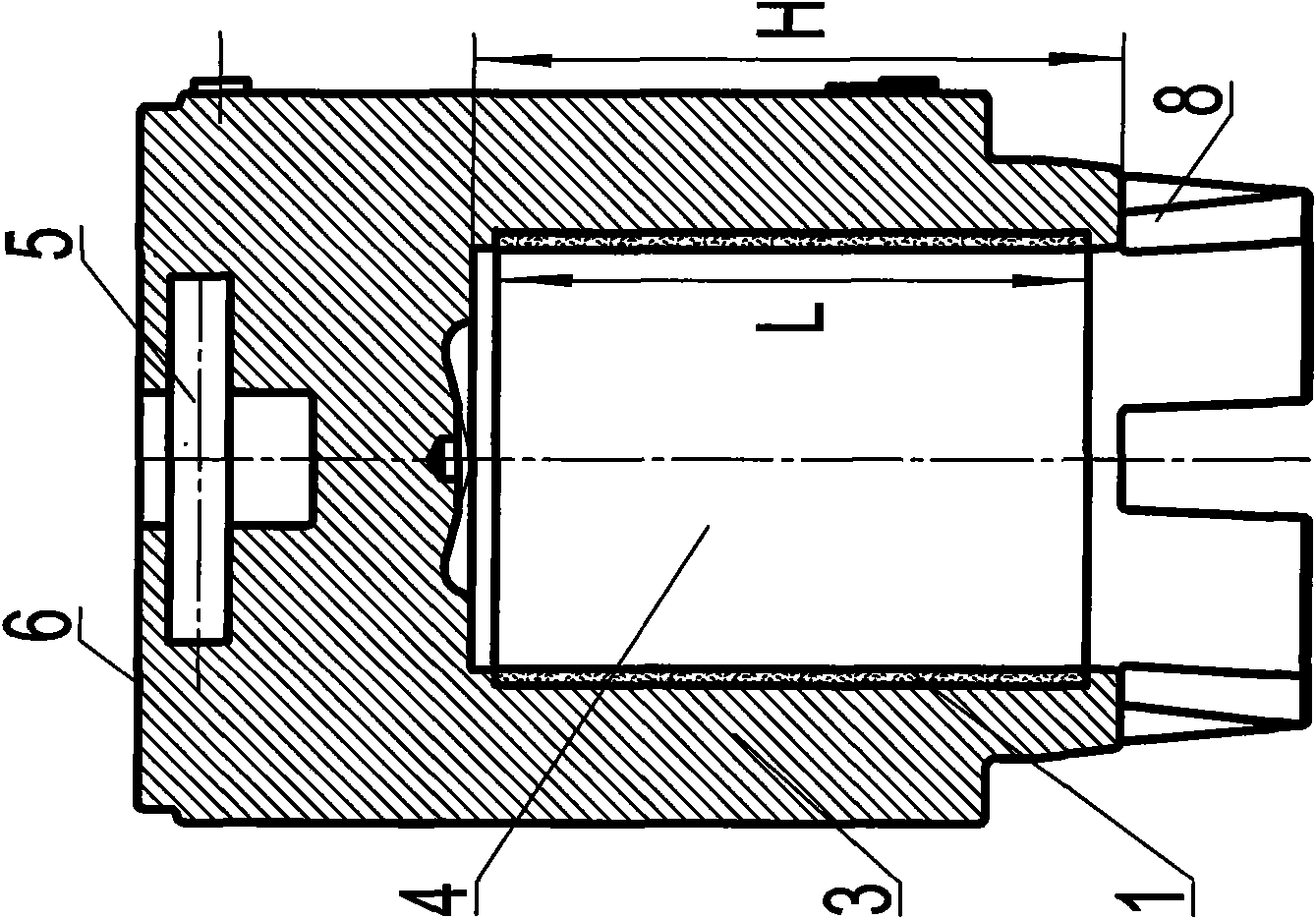

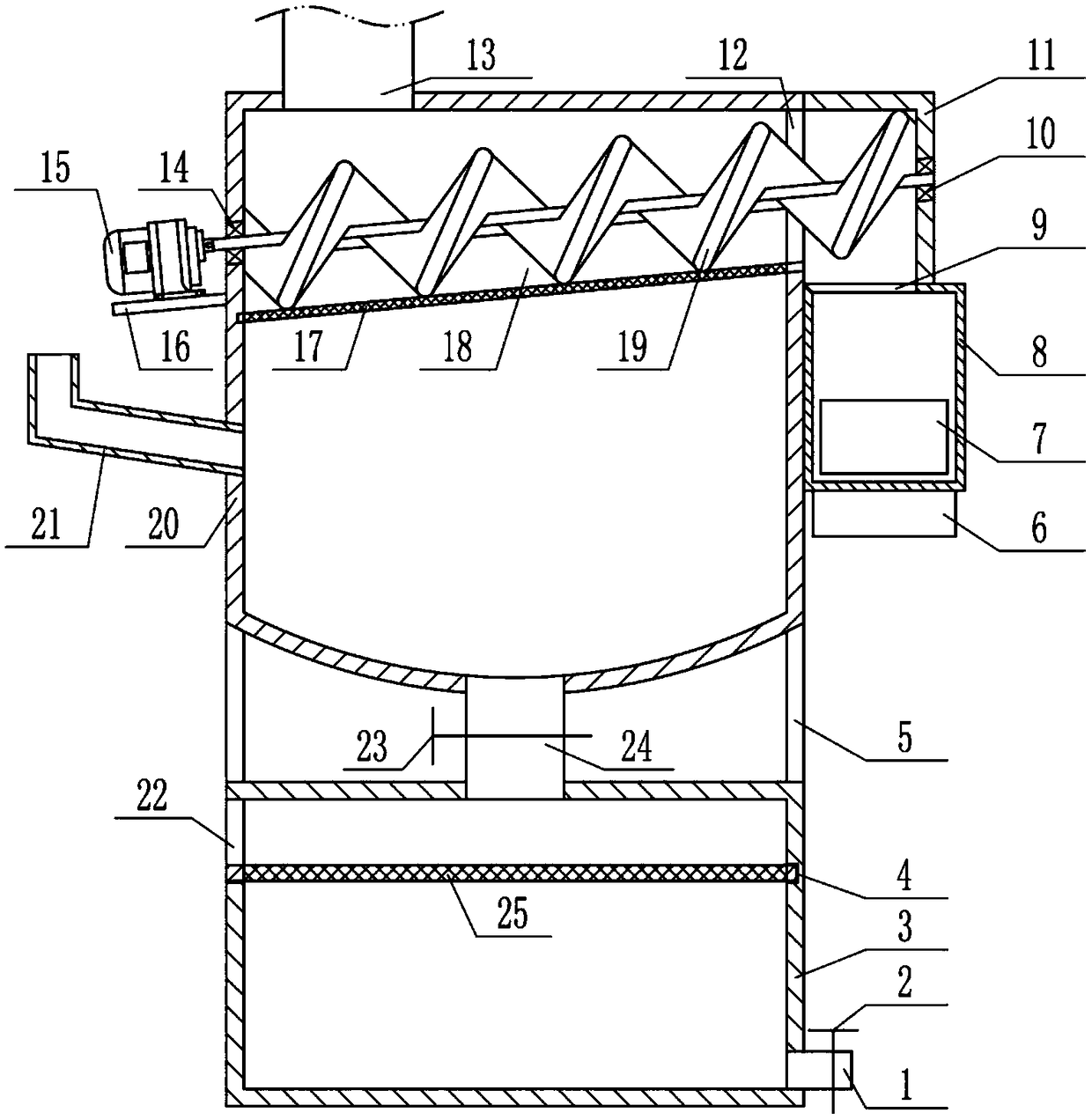

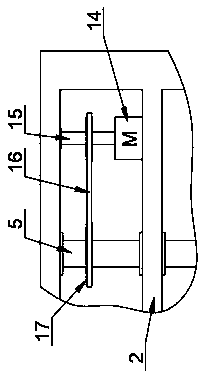

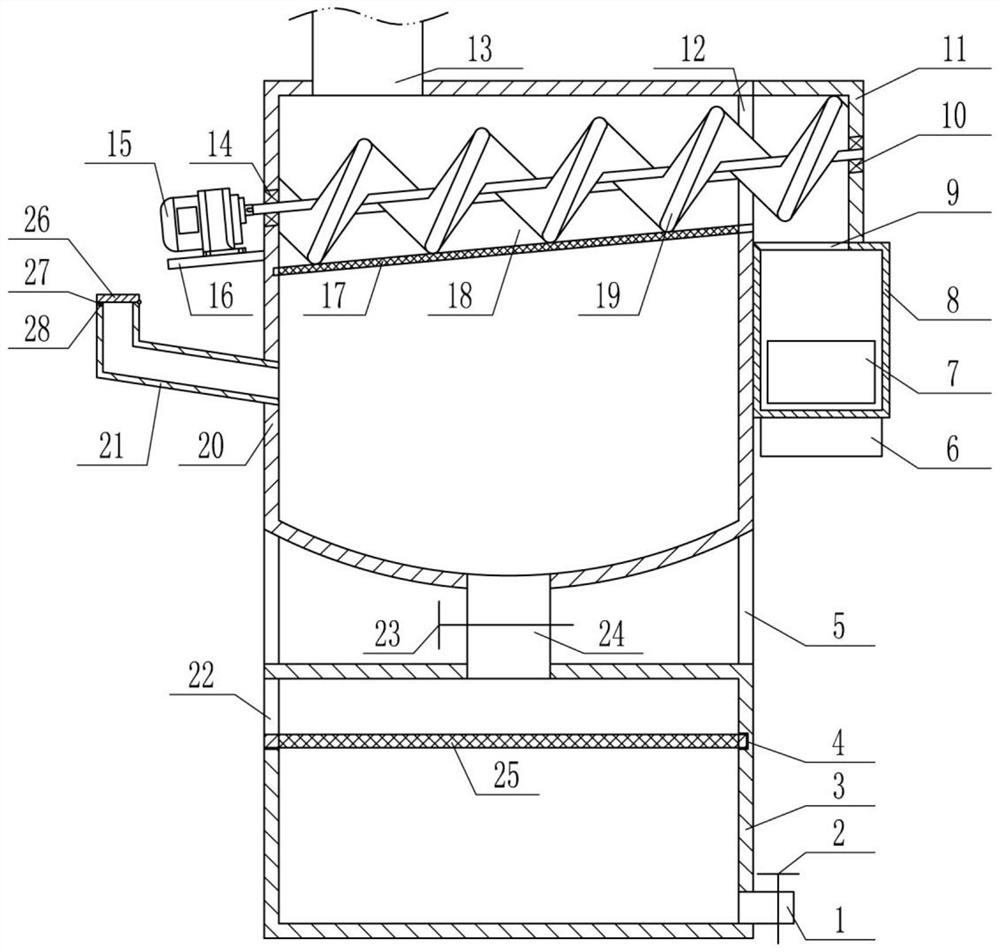

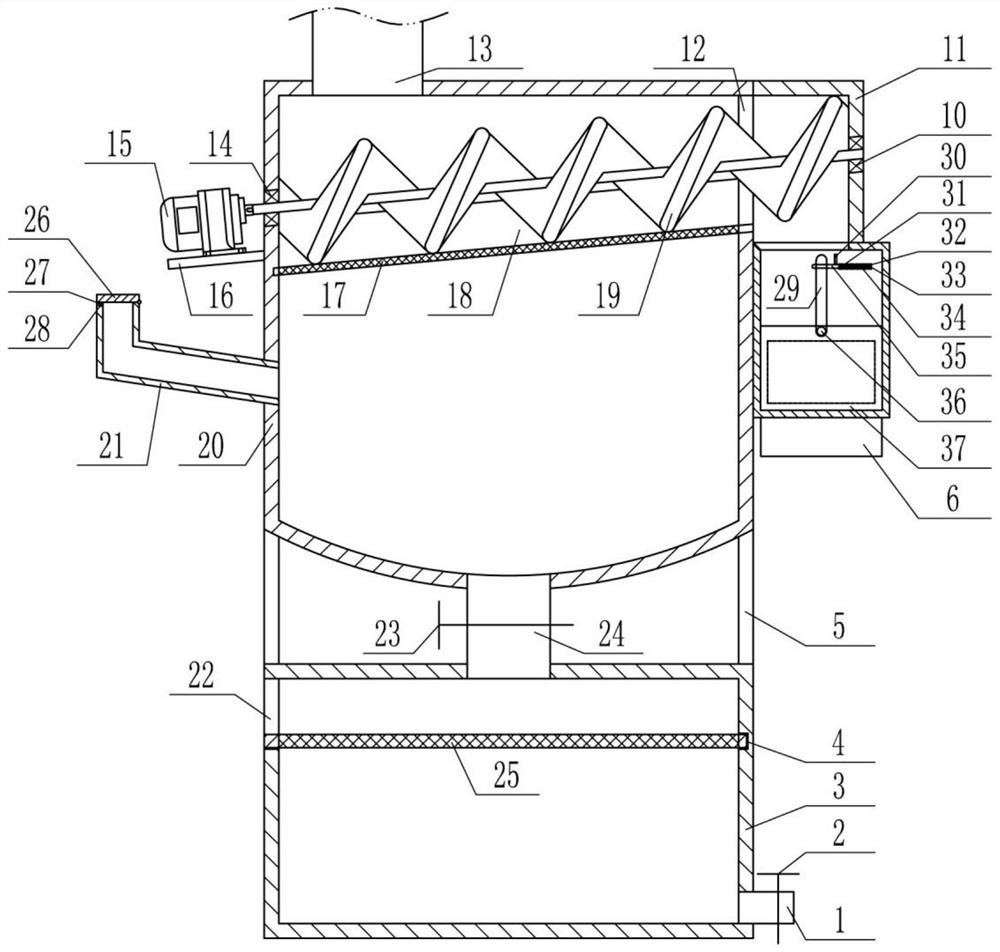

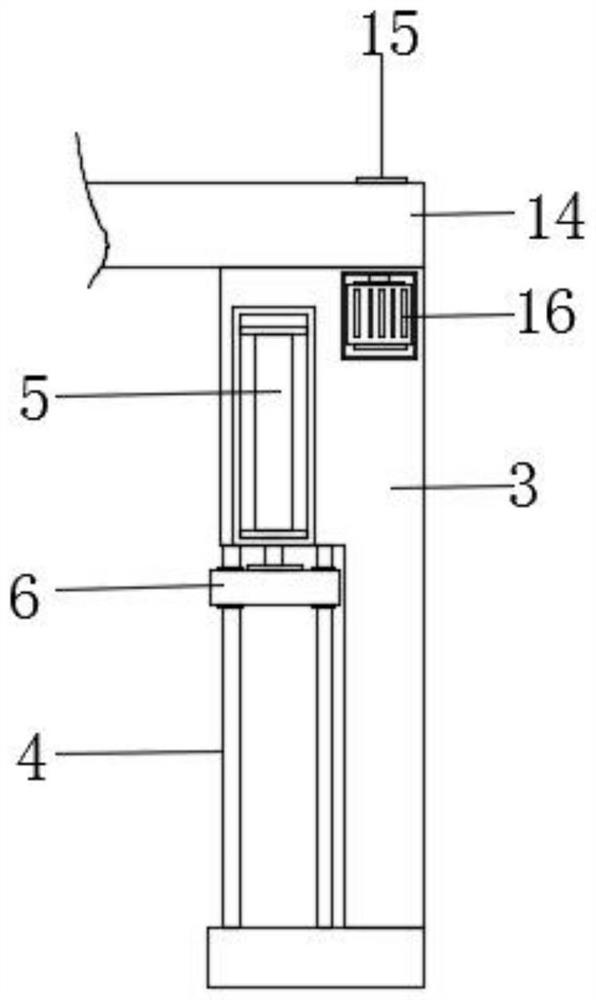

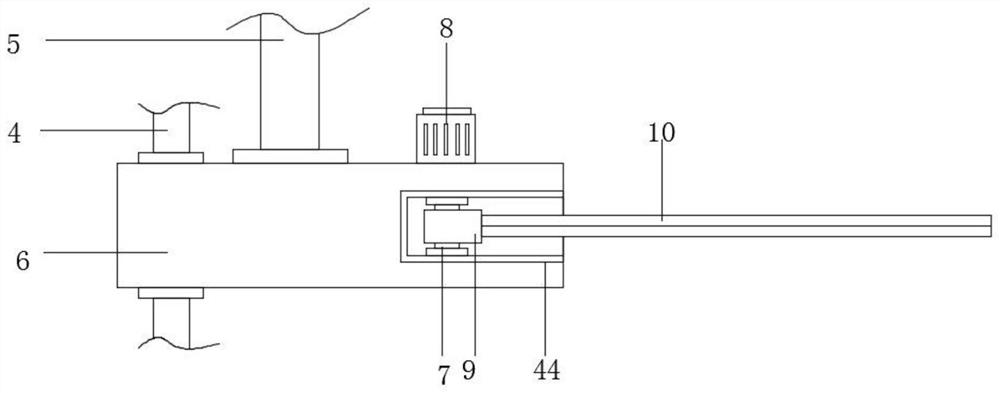

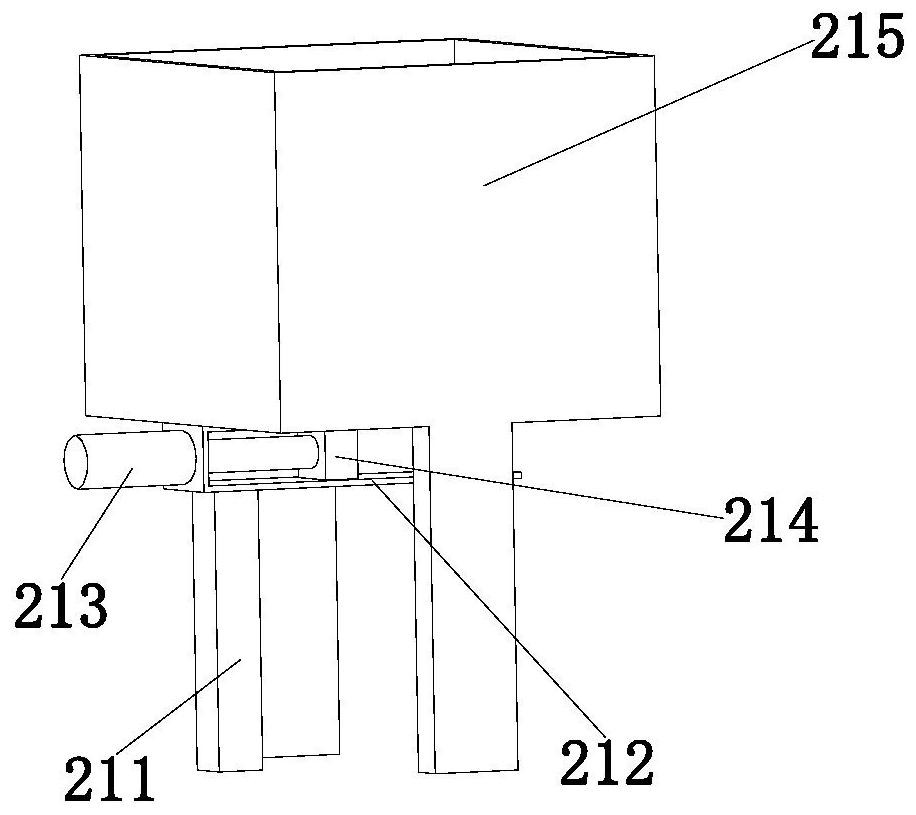

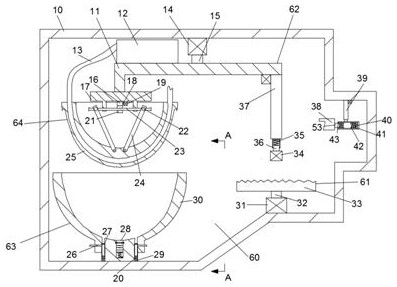

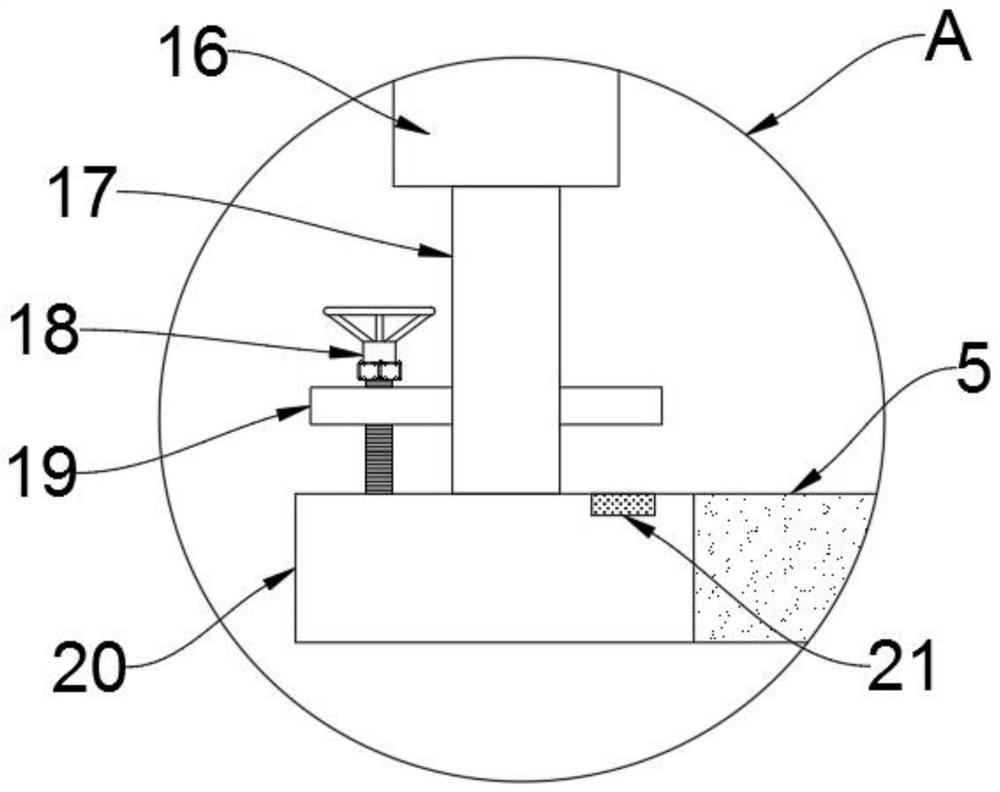

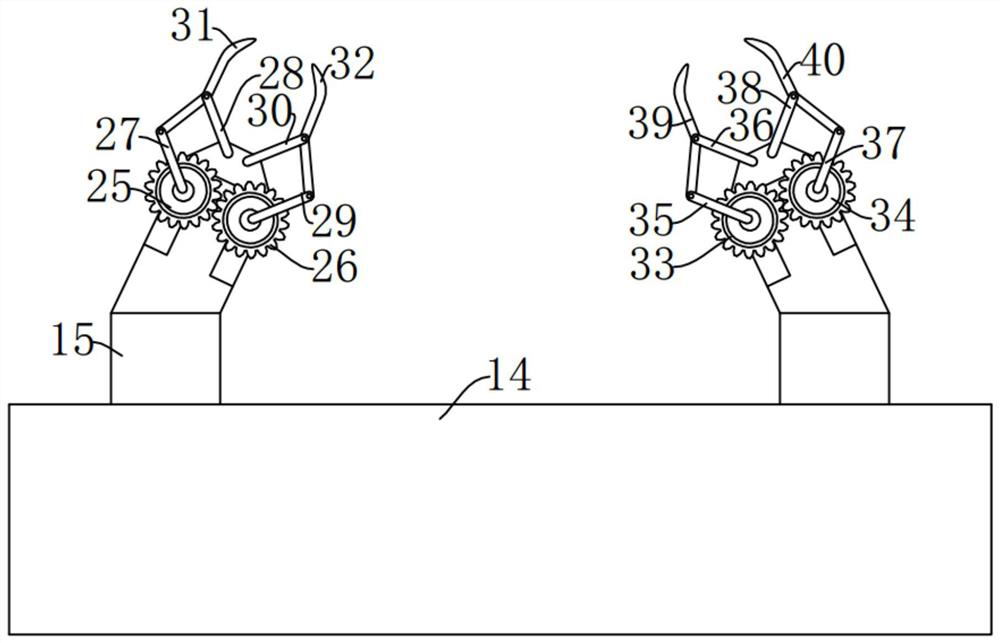

Integrated machine for killing and processing geckos

InactiveCN109315469AImprove work efficiencyEasy to handle and processElectric current slaughtering/stunningSlaughterhouse arrangementsBody measureGecko

The invention discloses an integrated machine for killing and processing geckos. The machine includes an operation box, a power supply, a central processing unit, an electric shock mechanism, a body measuring mechanism, a transmission overturning mechanism, an receiving and sliding mechanism, a support transmission mechanism, an eye-digging mechanism and a viscera clearing mechanism. The inner andouter walls of the operation box are provided with insulating film layers, the electric shock mechanism is arranged in the operation box, the transmission overturning mechanism is arranged at the tail end of the electric shock mechanism, the body measuring mechanism is arranged on the upper portion of the transmission overturning mechanism, the support transmission mechanism is arranged at the lower end of the tail end of the transmission overturning mechanism, the viscera clearing mechanism is arranged on the upper portion of the support transmission mechanism, the eye-digging mechanism is arranged in the support transmission mechanism, the power supply is arranged in the operation box, and the central processing unit is arranged in the operation box. The invention belongs to the field of gecko killing machines and particularly provides the integrated machine for killing and processing geckos, wherein the machine is high in practicability, can better guarantee the medicinal properties of the geckos, avoids damage to the tails of the geckos, and prevent the geckos from escaping and injuring people.

Owner:徐州锌浩精密机械科技有限公司

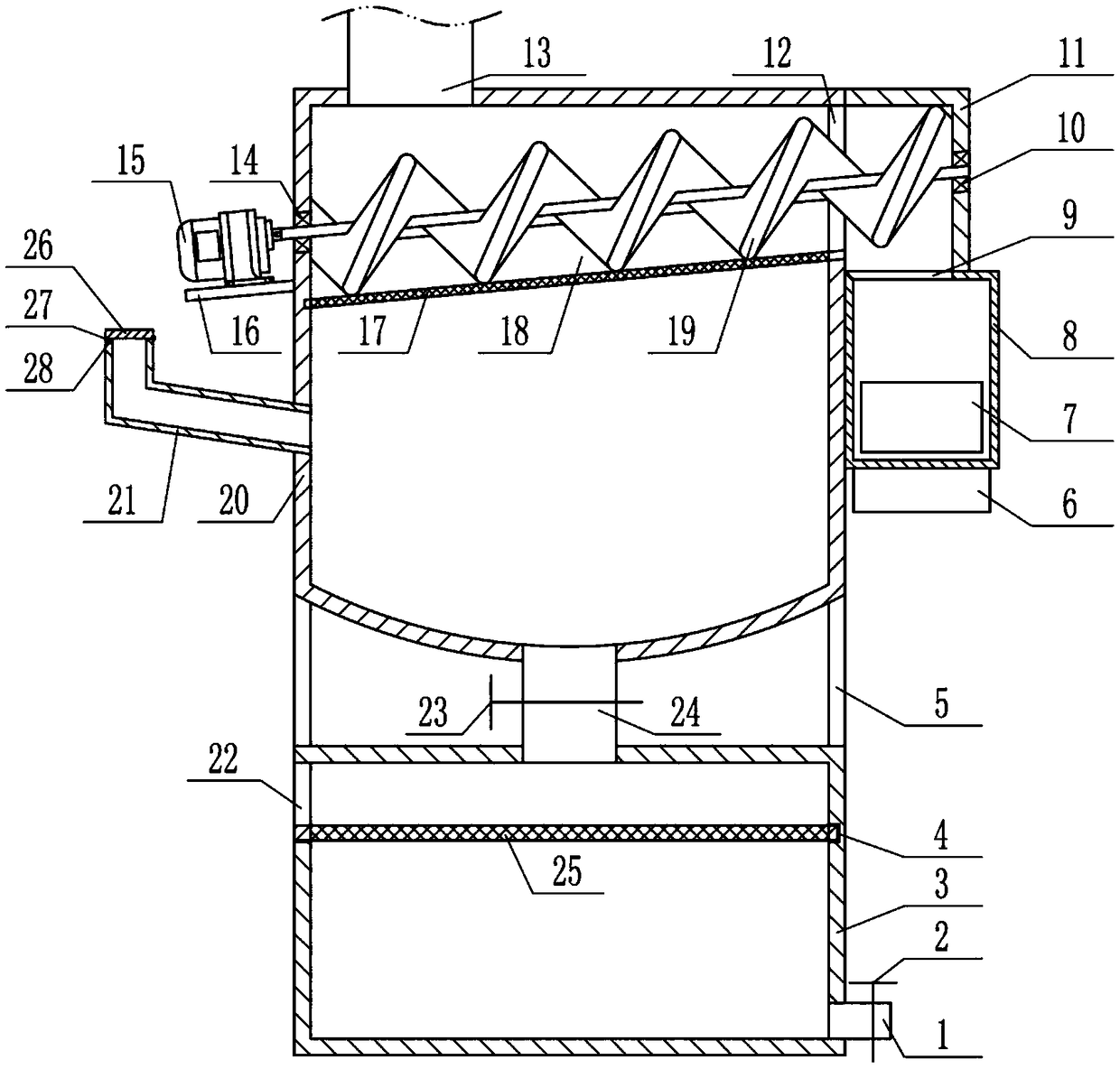

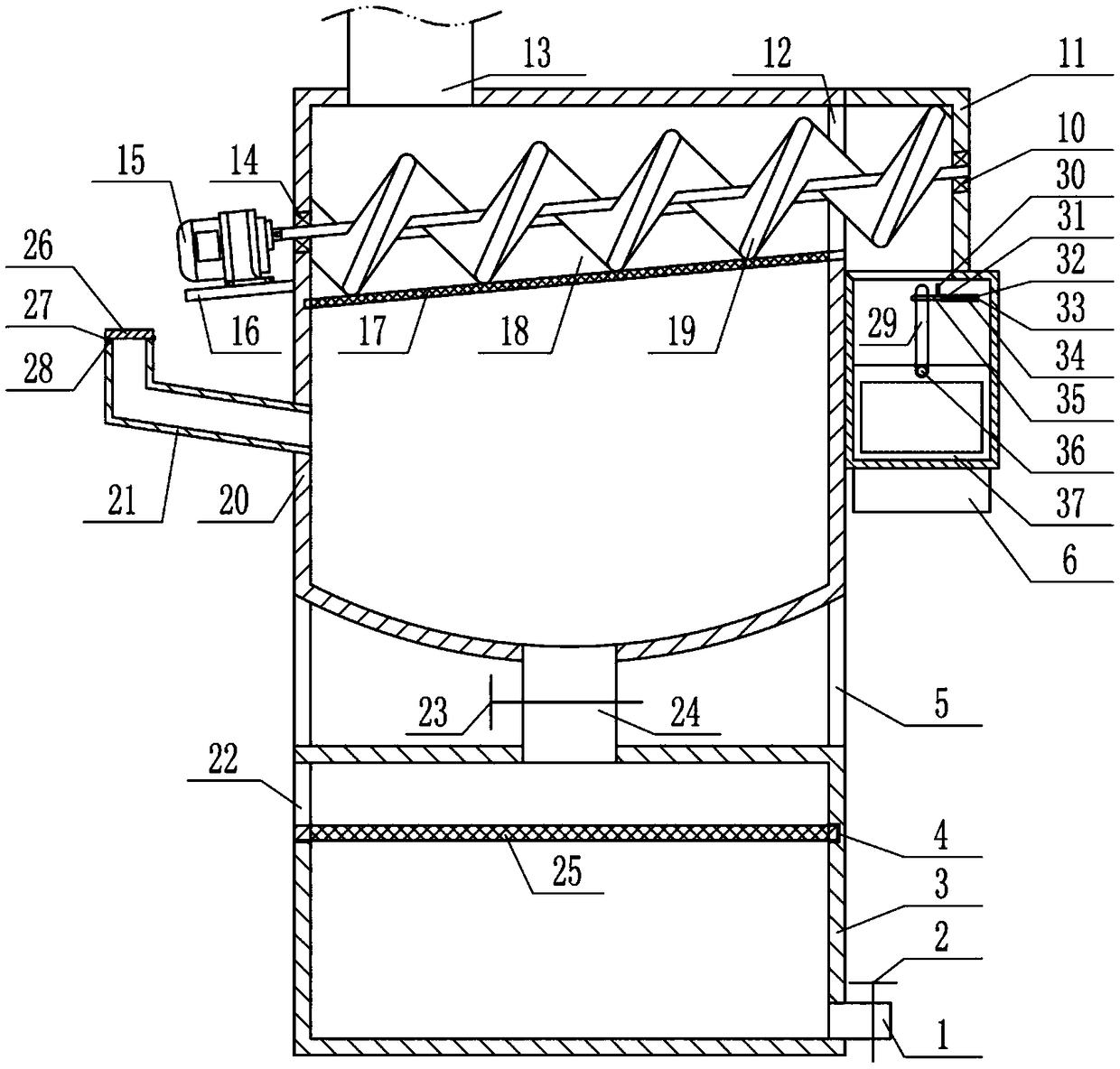

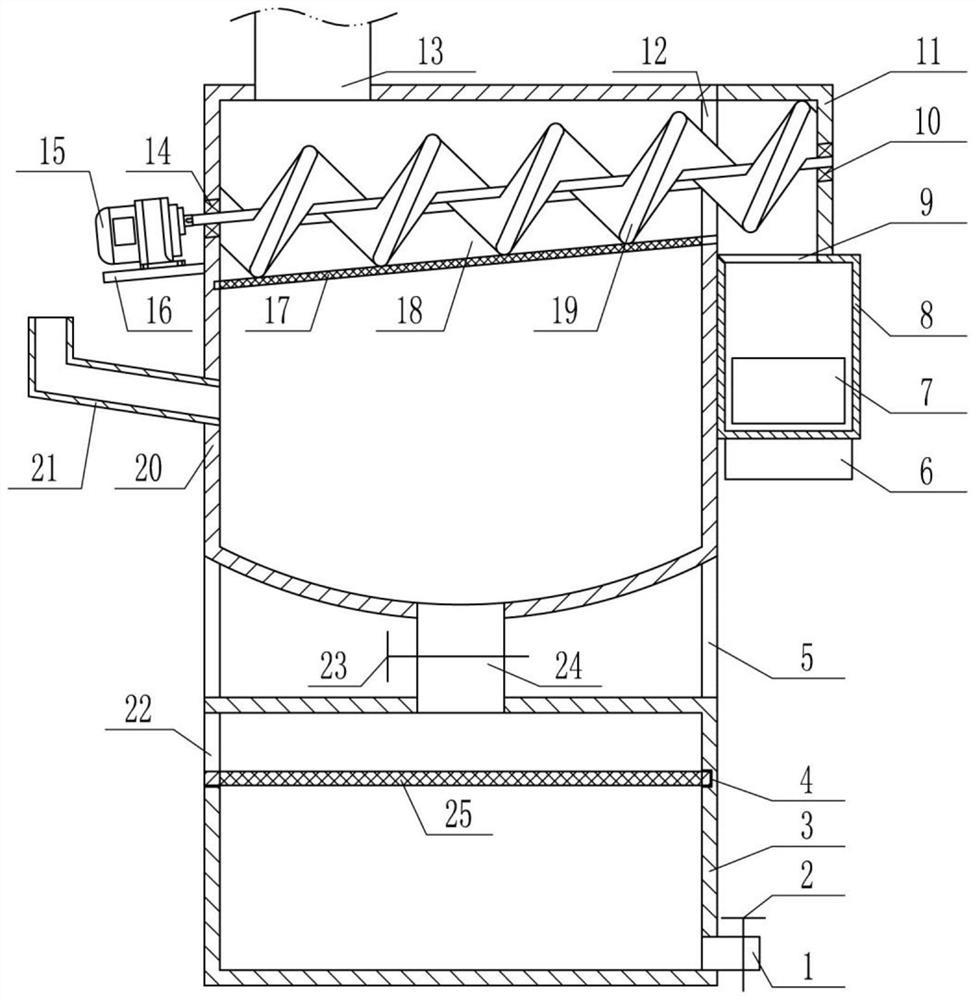

Mold processing cooling liquid recycling device

InactiveCN108889031ASave raw materialsImprove filtering effectFiltration circuitsSedimentation settling tanksScrapSludge

The invention belongs to the field of mold processing, and particularly relates to a mold processing cooling liquid recycling device. Discharged iron scrap and sludge can be conveniently and quickly treated by the mold processing cooling liquid recycling device. The mold processing cooling liquid recycling device comprises a first water outlet pipe, a first valve, a collecting tank, two first fixing rods, an oblique plate, a mounting tank, a first bearing block, a first mounting frame, a liquid inlet pipe, a second bearing block, a motor, a first fixing plate, a filter screen, an arc-shaped plate, a conveying rod, a second mounting frame, a feed hopper, a second valve, a second water outlet pipe and a filter plate. The second mounting frame is fixedly connected to the top of the collectingtank by the two first fixing rods; an end of the second water outlet pipe is communicated with the bottom of the second mounting frame. The mold processing cooling liquid recycling device has the advantage that effects of conveniently and quickly treating the discharged iron scrap and the sludge can be realized by the mold processing cooling liquid recycling device.

Owner:上海神富机械科技有限公司

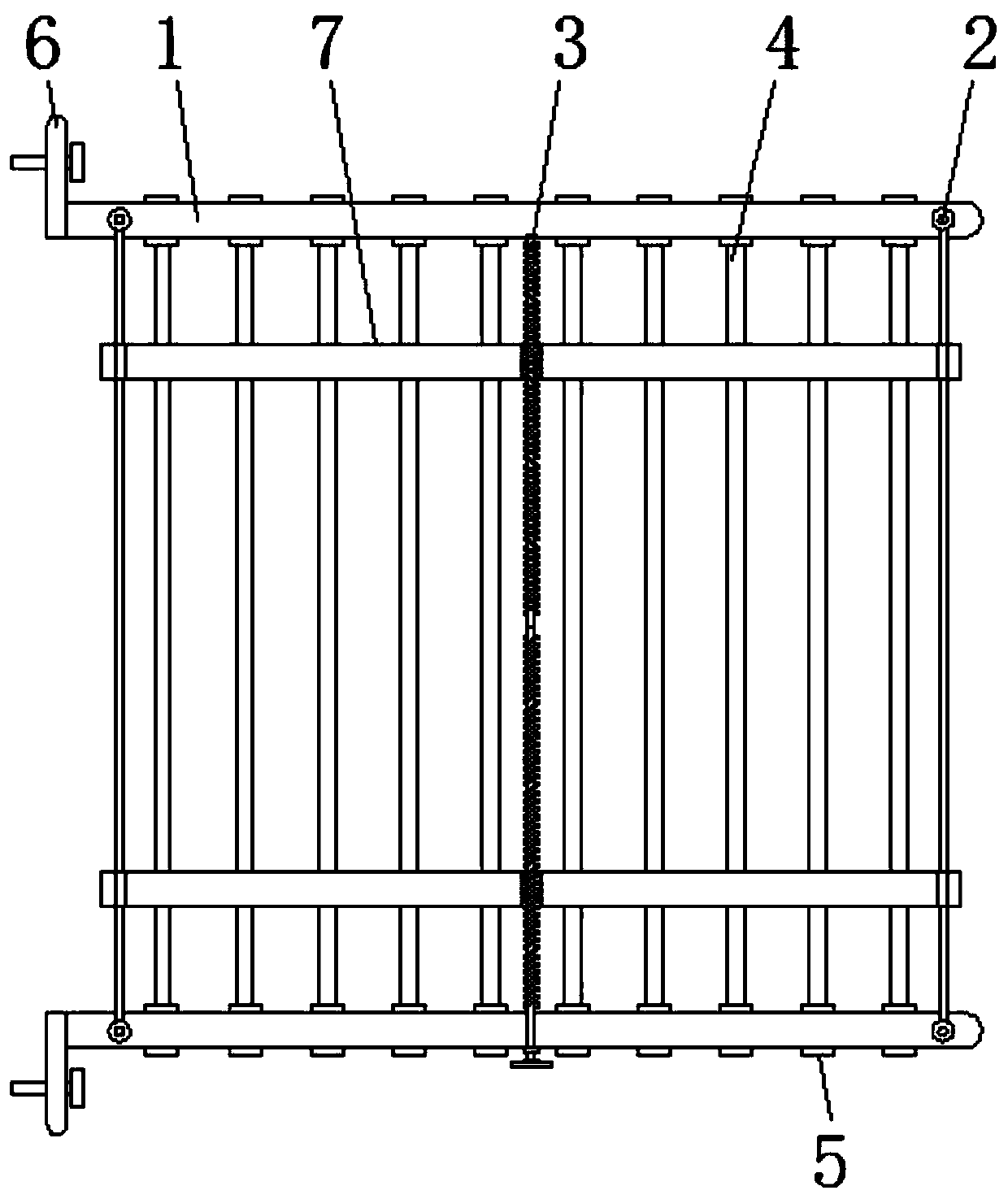

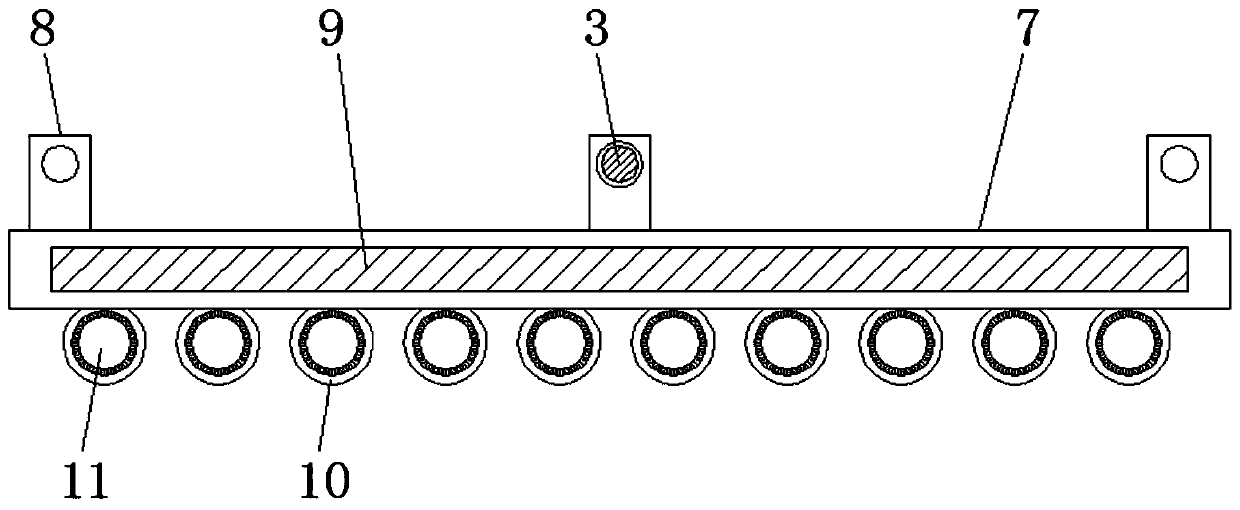

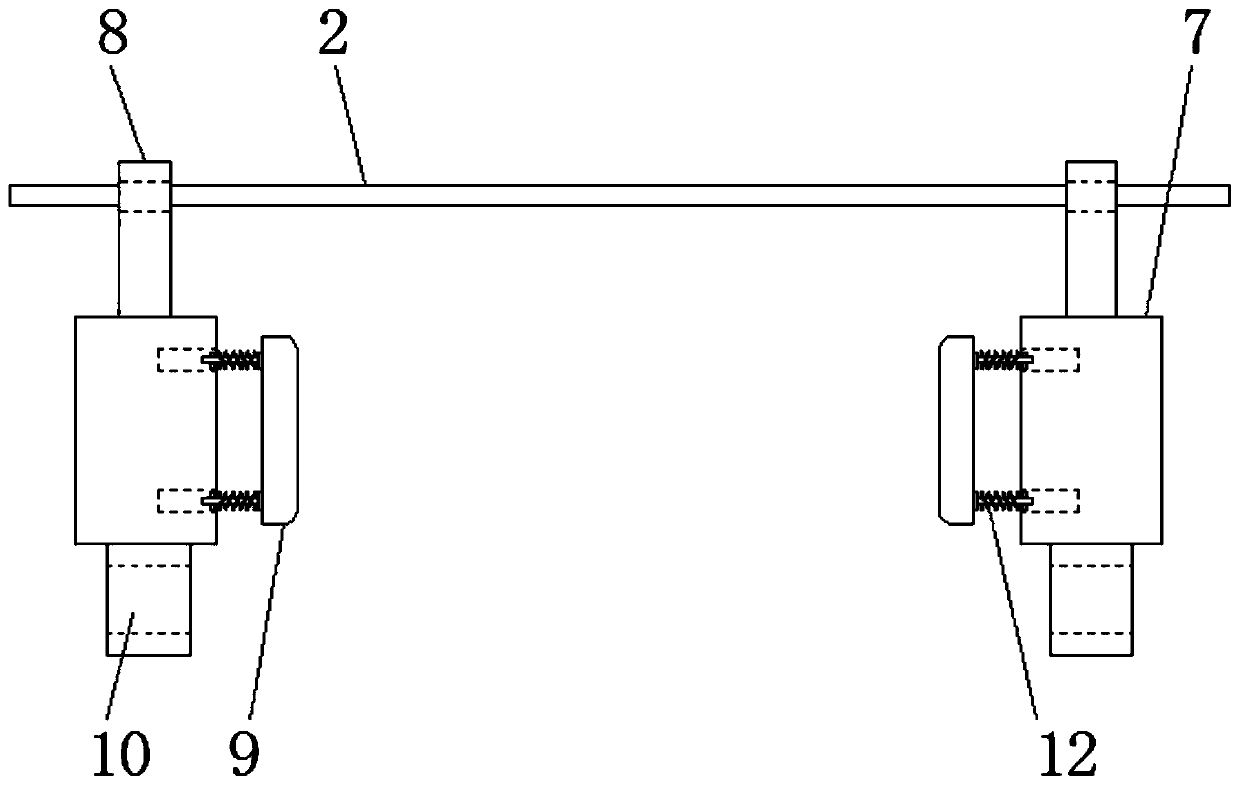

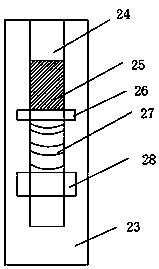

Convenient-to-clean fabric-guiding frame for circular weft knitting machine

InactiveCN111270404AEasy to cleanEasy to installWeft knittingCleaning using toolsSlide plateThreaded rod

The invention discloses a convenient-to-clean fabric-guiding frame for a circular weft knitting machine. The frame comprises a frame body, a fabric-guiding rod and a connecting frame, wherein limit rods are fixedly connected to the upper side of the left end and the upper side of the right end of the frame body respectively, a threaded rod is rotationally connected to the upper end of the middle of the frame body, the connecting frame is fixedly connected to the left end of the frame body, the fabric-guiding rod is fixedly connected into the frame body through an installing block, the limit rods and the threaded rod are provided with sliding blocks respectively in a sleeved mode, the lower end of each sliding block is fixedly connected with a sliding plate, the lower end of each sliding plate is fixedly connected with a sweeping cylinder, a sweeping brush is connected into each sweeping cylinder in a pasting mode, a rubber block is connected to the inner wall of each sliding plate in apenetrating mode, and each rubber block is provided with a spring in a sleeved mode. According to the convenient-to-clean fabric-guiding frame for the circular weft knitting machine, it is convenientto install and dismantle the fabric-guiding frame, meanwhile, it is convenient to adjust the fabric-guiding width of the fabric-guiding frame, and it is convenient to remove dust on the fabric-guiding frame.

Owner:浙江稻盛纺织面料股份有限公司

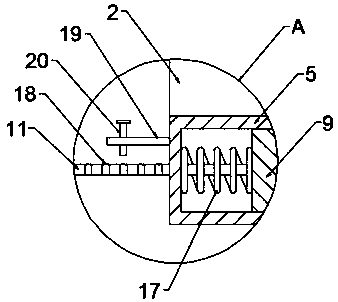

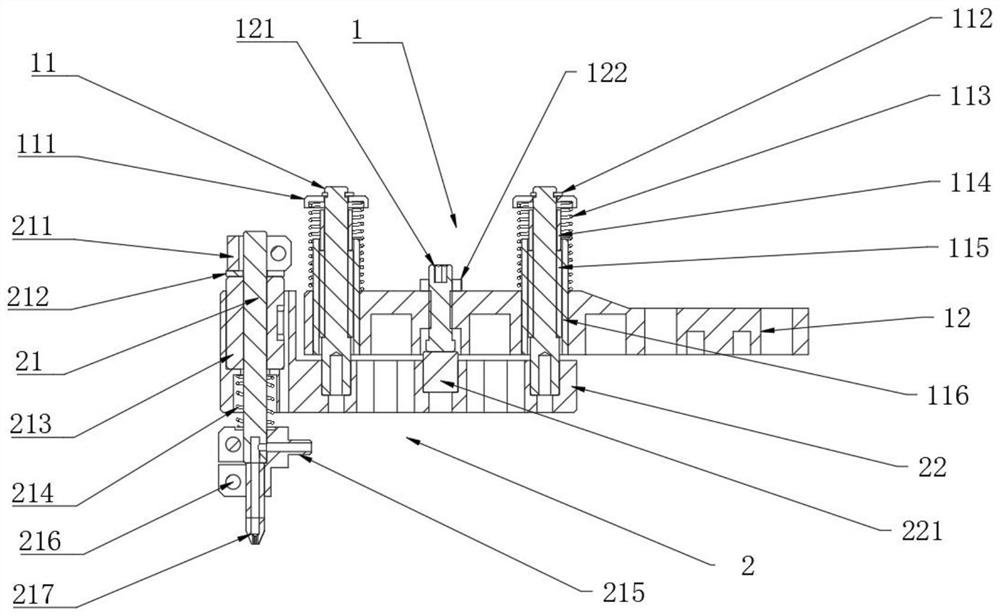

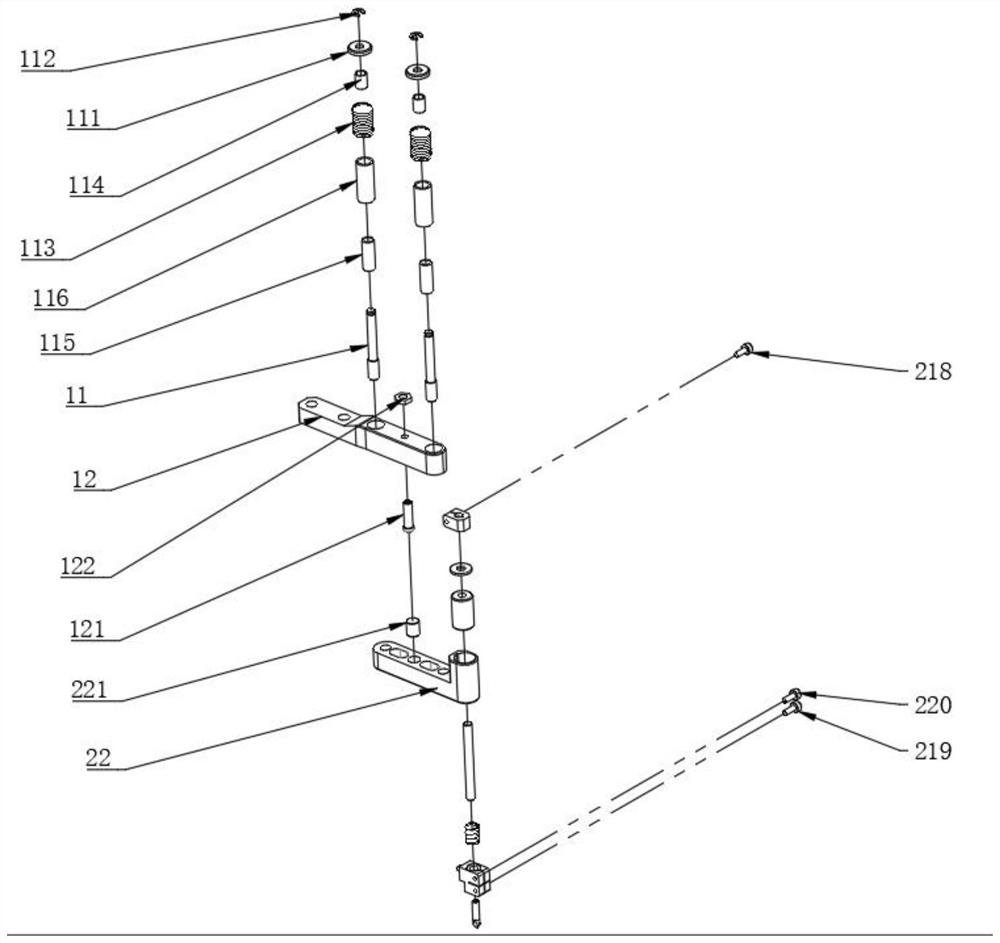

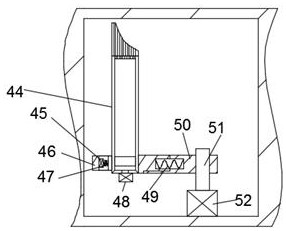

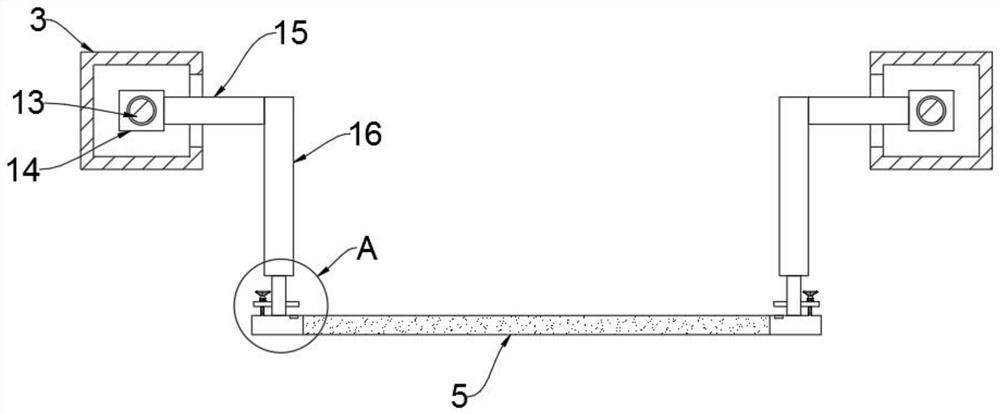

CSP chip product taking and placing mechanism and using method

PendingCN112864080AHigh-speed spatial location transferPrecise spatial position transferSemiconductor/solid-state device manufacturingConveyor partsControl theoryElectrical and Electronics engineering

The invention relates to a CSP chip product taking and placing mechanism and a using method, the CSP chip product taking and placing mechanism comprises a lining bearing linear guide mechanism, the lining bearing linear guide mechanism is located at the upper end of a device, two lining bearings and a guide rod main supporting frame are arranged in the lining bearing linear guide mechanism, and the two lining bearings are adjacently arranged at the upper end of the guide rod main supporting frame, and vertically penetrate through the guide rod main support frame to control a suction mechanism to suck and transfer a CSP chip product; a spline bearing linear guide mechanism is located at the lower end of the lining bearing linear guide mechanism and fixedly connected with the lining bearing linear guide mechanism, a spline bearing guide rod device is arranged in the spline bearing linear guide mechanism and located at the leftmost end, and a suction device is arranged on the lower portion of the spline bearing guide rod device and used for taking and placing the CSP chip product. A complex CSP chip product taking and placing mechanism and a processing grabbing mechanism can be combined, meanwhile, multiple devices can be integrated into one device, and the CSP chip product production transfer error caused by the multiple devices is reduced.

Owner:NORTECH AUTOMATION SHENZHEN CO LTD

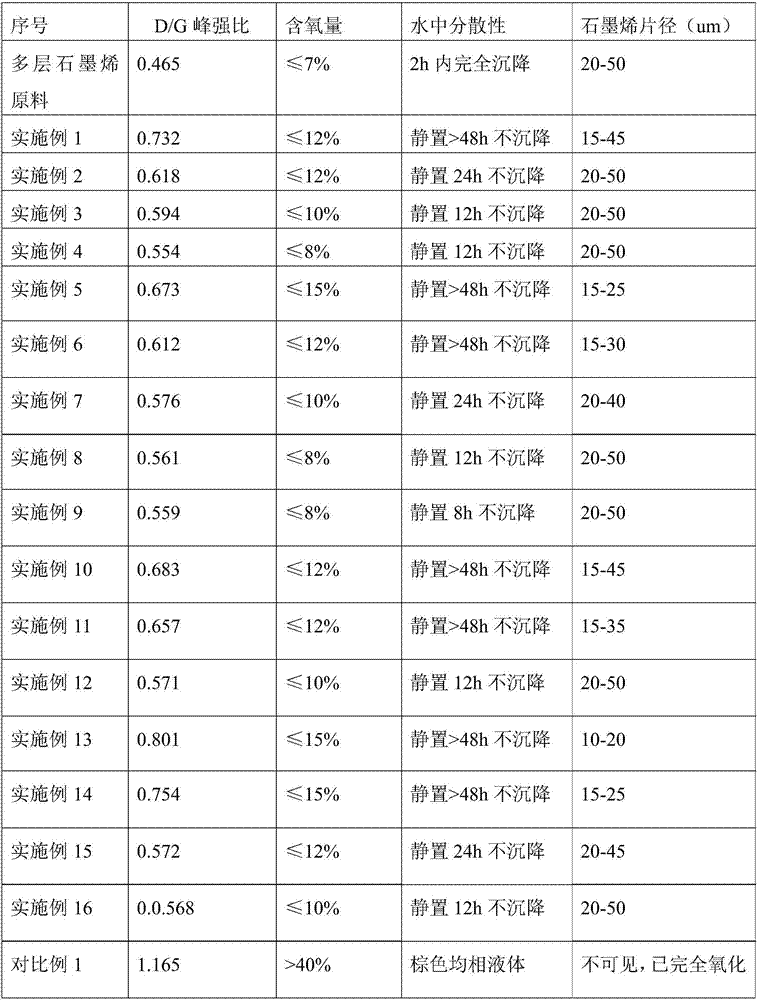

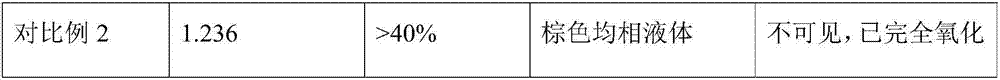

Dispersion method for multilayer graphene

ActiveCN107304047AEffective dispersionLittle impact on performanceGrapheneWater basedCrystal structure

The invention discloses a dispersion method for multilayer graphene. The method comprises the following steps: putting multilayer graphene into an acidic oxidation liquid, mixing and stirring; cleaning and disacidifying the graphene, thereby acquiring water-based graphene pulp; adding a solvent for diluting the water-based graphene pulp, thereby acquiring graphene dispersion liquid. According to the method disclosed by the invention, the efficient dispersion of the multilayer graphene can be realized, the huge energy consumption caused by high-power ultrasonic or grinding can be avoided and the cost can be greatly lowered; no surfactant (or dispersion auxiliary) is used, the influence of the impurities on the graphene performance is reduced and the subsequent material processing technology is obviously simplified; the efficient dispersion is lastly realized, the crystal structure of the graphene is protected from serious damage and the intrinsic characteristics of the graphene material can be kept.

Owner:2D CARBON CHANGZHOU TECH INC

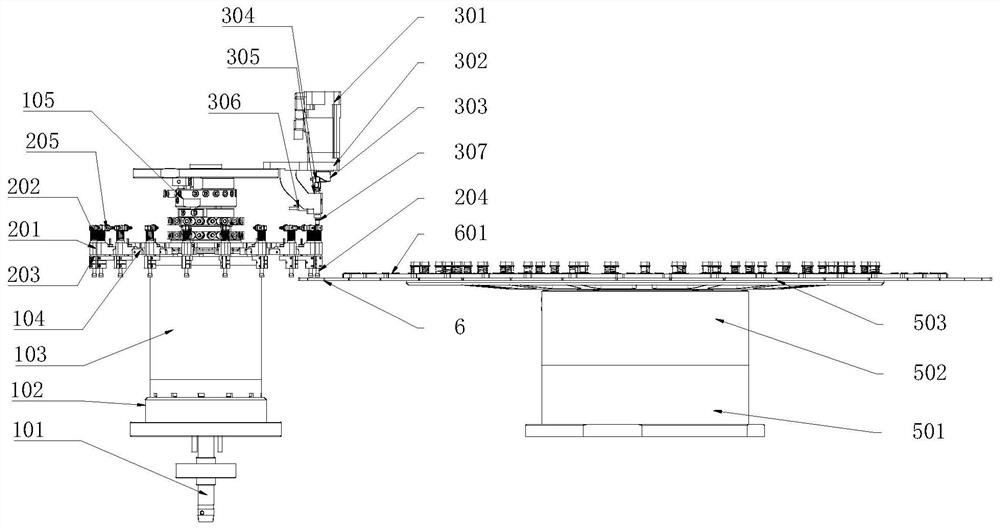

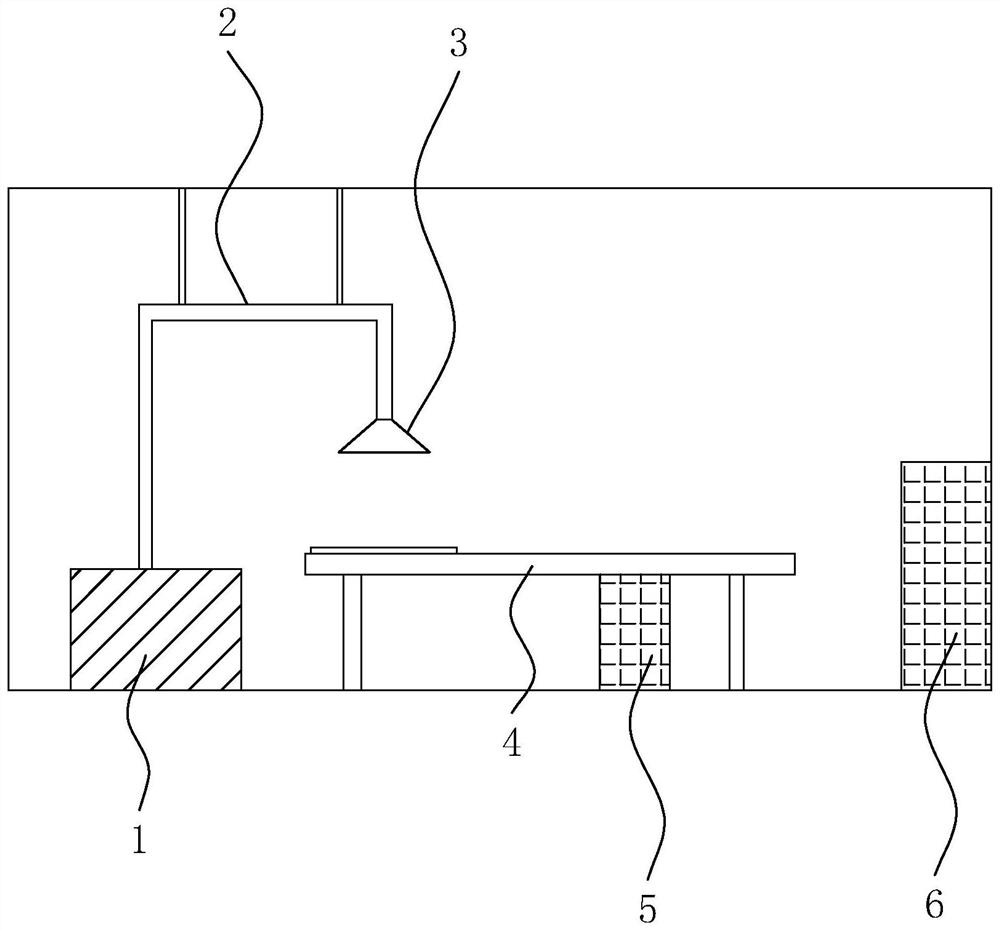

Chip transfer processing device and method

PendingCN111816597AEasy to handle and processSave human effortSemiconductor/solid-state device manufacturingConveyor partsVisual inspectionElectronic chip

The invention relates to the technical field of semiconductor processing and further discloses a chip transfer processing device and method. The device comprises a first turret module, a second turretmodule and a tray turret module, wherein a suction nozzle support mechanism is arranged on an outer surface of the first turret module, a linear pressing mechanism is arranged at an upper end of thefirst turret module, the second turret module is arranged on the side surface of the first turret module, a carrying tray turret module is arranged on the side surface of the first turret module, anda device carrying tray device is arranged at the top of the carrying tray turret module. The chip transfer processing device is advantaged in that the first turret module and the second turret moduleare arranged on a cabinet, and meanwhile, a tray turret module is arranged, positioning is conducted through a position detection sensor, expansion and compatibility of production processes such as processing, visual inspection, electrical property testing, laser printing, product classification and finished product packaging in the rear-section production and manufacturing process of electronic chip products are facilitated, manpower is saved, and production efficiency is improved.

Owner:深圳市诺泰芯装备有限公司

Precious metal recycling device

InactiveCN111282949AStable structureEasy to operateTransportation and packagingSolid waste disposalExhaust gasMetal recycling

The invention discloses a precious metal recycling device. The precious metal recycling device comprises a fixed base. The upper end of the fixed base is fixedly connected with a machining box. A rotary shaft is vertically and rotatably connected to the interior of the machining box. The lower end of the rotary shaft is fixedly connected with a stirring disk. The upper end of the machining box isprovided with a cavity. The upper end of the rotary shaft extends into the cavity and is rotatably connected with the inner top wall of the cavity. A driving mechanism is arranged in the cavity and isconnected with the rotary shaft. The sidewall of the machining box communicates with a communicating pipe. The end, far away from the machining box, of the communicating pipe communicates with a treatment box. The side, far away from the communicating pipe, of the treatment box communicates with an exhaust pipe. The precious metal recycling device is stable in structure, easy to operate, scientific and reasonable in design, short in production cycle, capable of sufficiently recycling and treating materials and free of atmosphere pollution when exhaust gas generated during machining is discharged.

Owner:新沂市达婷黄沙有限公司

Garment Processing Method Based on Solvent and Physical Temperature Control

ActiveCN109338613BGood effectEasy to produceFibre treatmentHeating/cooling textile fabricsMechanical engineeringFreezing point

The invention discloses a garment processing method based on solvent and physical temperature control, comprising the following steps: S1, preparing a coagulant, and spraying it evenly on the fabric to be processed; S2, controlling the temperature of the fabric after the coagulant is sprayed until it solidifies The coagulant coagulates and hardens the fabric; S3, transports the hardened fabric to the subsequent process; the freezing point of the coagulant is -5°C-25°C. Through the above settings, the soft fabric can have good hardness after being sprayed with coagulant and cooled. At this time, it can be transported by suction cup or other methods. At the same time, different temperatures can be adjusted to adjust the hardness. It is also more beneficial to cut and sew the fabric in the later stage, and the solidified fabric with hardness is not easy to deform or twist when cutting. Therefore, the fabric after the above-mentioned treatment is convenient to carry, is beneficial to processing, improves work efficiency, and also improves the quality and uniformity of products.

Owner:杭州恢弘科技有限公司

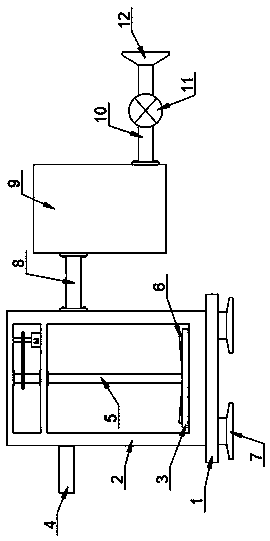

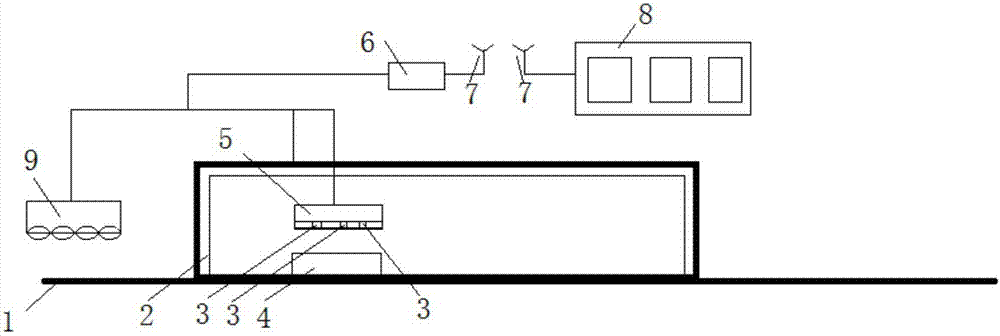

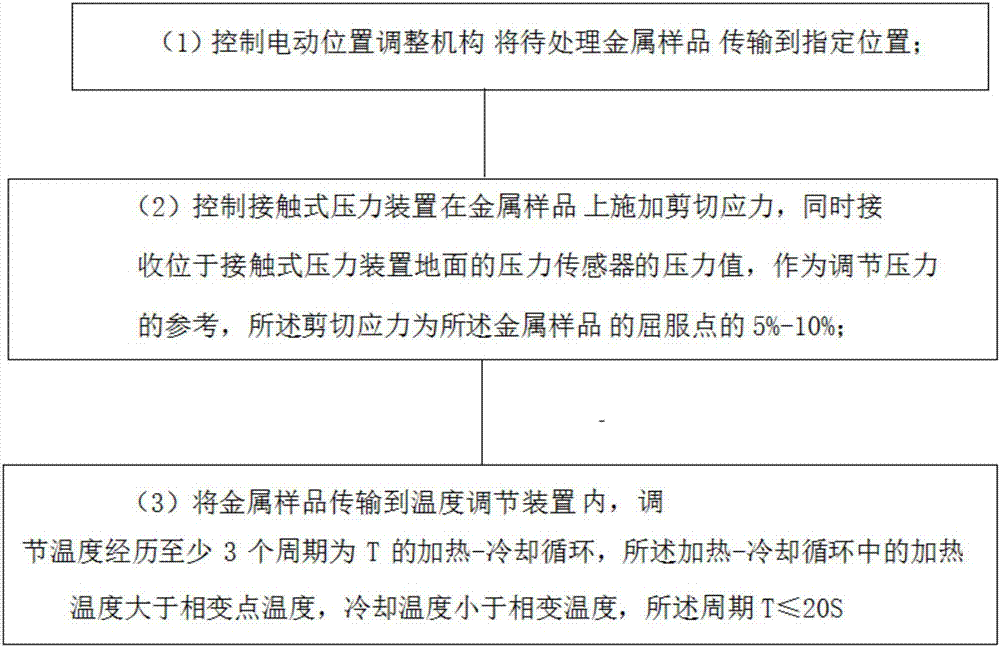

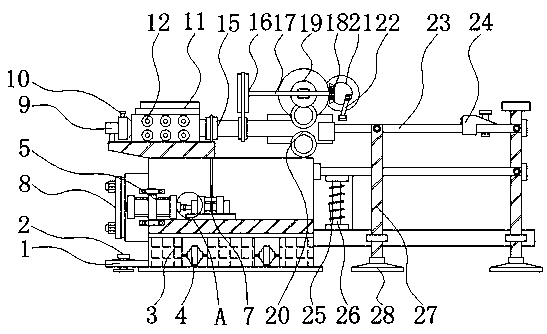

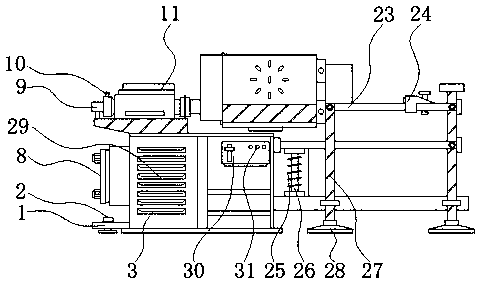

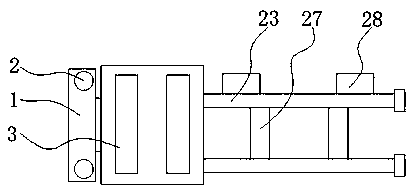

Metal toughening treatment system

InactiveCN107502720AImprove toughness and strengthToughness treatment and easy processingHeat treatment process controlCommunication unitContact pressure

The invention relates to a metal toughening treatment system for mainly solving the technical problems that in the prior art, machining is complex, and using is inconvenient. The system comprises a conveying belt, a temperature regulating device, a contact pressure device, an electric position regulating mechanism connected with the contact pressure device, a control unit which is connected with the temperature regulating device, the contact pressure device and the electric position regulating mechanism, and a remote server side which is connected with the control unit through wireless communication units. The temperature regulating device and the contact pressure device are located in the same position. The contact pressure device is provided with pressure sensors on the ground, and the pressure sensors are used for acquiring pressure values to be fed back to the control unit. The control unit comprises a first storage medium and a first processor; and the first storage medium is used for storing a metal toughening control program, and the first processor is used for executing the technical scheme of the metal toughening control program. The problems are well solved, and the metal toughening treatment system is used for metal toughening production treatment.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

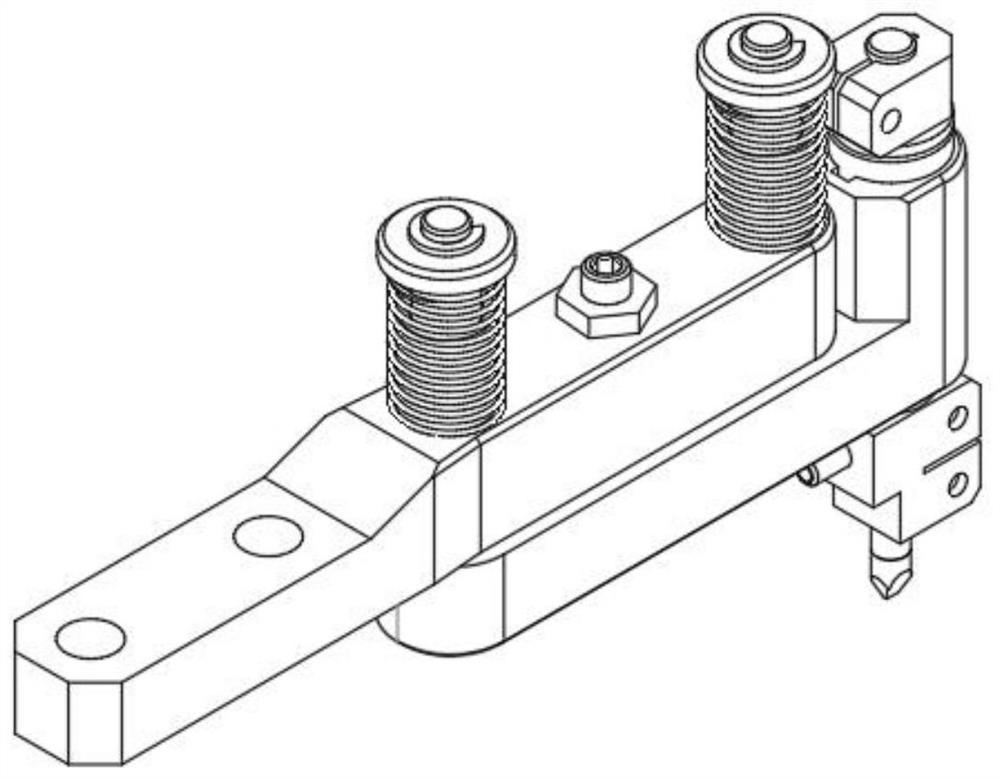

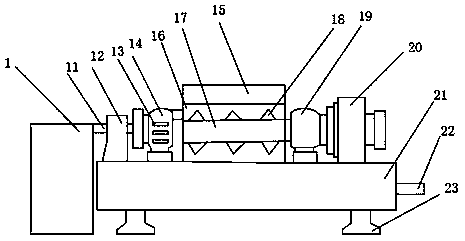

Steel bar straightening machine with adjustable compression strength

The invention discloses a steel bar straightening machine with adjustable compression strength, and relates to the technical field of powder packing. The steel bar straightening machine comprises a fixing block and a rotating shaft. A supporting block is arranged on the inner side of the fixing block, and a supporting cabinet is arranged on the right side of the supporting block. A stable block isarranged on the inner side of the supporting cabinet, and a motor is arranged above the stable block. According to the steel bar straightening machine with the adjustable compression strength, by thearrangement of the fixing block, the supporting block, the supporting cabinet, the stable block, the motor, the rotating shaft, a transmission belt and a fixing plate, a user can carry out good support for the fixing block by the fitting of the bottom of the supporting block and the ground, and the fixing block can carry out good support for the supporting cabinet, so that sideslip deviation of the device during use is prevented; the stable block can provide good stability for the device, so that excessive jitter of the device during use is prevented; and the motor drives the transmission belt to rotate through the rotating shaft, so that the top of the device can be driven greatly.

Owner:嘉兴新博信息科技有限公司

A cooling liquid recovery device for mold processing

InactiveCN108889031BImprove filtering effectEasy to transportFiltration circuitsSedimentation settling tanksSludgeElectric machinery

The invention belongs to the field of mold processing, in particular to a cooling liquid recovery device for mold processing. The technical problem to be solved by the present invention is to provide a cooling liquid recovery device for mold processing that can conveniently dispose of iron filings and sludge. A coolant recovery device for mold processing, including a first water outlet pipe, a first valve, a collection box, a first fixed rod, an inclined plate, a mounting box, a first bearing seat, a first mounting frame, a liquid inlet pipe, a first Two bearing housings, motor, first fixed plate, filter screen, arc plate, transmission rod, second installation frame, feed hopper, second valve, second water outlet pipe and filter plate; the second installation frame passes through two first The fixing rod is fixedly connected to the top of the collection box; one end of the second water outlet pipe communicates with the bottom of the second installation frame. The invention achieves the effect of being able to conveniently process iron filings and sludge.

Owner:上海神富机械科技有限公司

Unstacking and separating device for thin steel plates with good anti-sticking effect

ActiveCN114852707APrevent sticky conditionsEasy to separateCleaning using toolsDe-stacking articlesElectric machineryStructural engineering

The unstacking and separating device for the thin steel plates is good in anti-sticking effect and comprises a workbench, an anti-sticking device, a transferring device, a box body and a limiting stopper, a supporting frame is installed on the outer wall of the workbench, multiple sets of guide rods are installed on the inner wall of the supporting frame, a first telescopic rod is installed on the inner wall of the supporting frame, and a second telescopic rod is installed on the inner wall of the first telescopic rod. And an anti-sticking device is installed at one end of the first telescopic rod, one end of the guide rod penetrates through the interior of the anti-sticking device, and a driving motor is installed on the outer wall of the connecting frame. An anti-sticking device is installed to prevent a thin steel plate from sticking, when a vacuum suction cup sucks the thin steel plate, and when the thin steel plate is stuck, the output end of a first motor rotates to drive a first rotating shaft to rotate, and the first rotating shaft drives a first plate body to move when rotating; and the first plate body moves to enter the position between the two sets of sticky thin steel plates, so that the two sets of sticky thin steel plates are rapidly separated, and the situation that the thin steel plates are sticky is prevented.

Owner:江苏广泽龙谊机械科技有限公司

Automatic decal sticking equipment for glass balls

InactiveCN112319024ASimple structureRealize orderly loadingTransfer printingLoading/unloadingGlass ballEngineering

The invention discloses automatic decal sticking equipment for glass balls, and belongs to the technical field of decal sticking equipment. The equipment comprises a workbench, a feeding assembly, a decal sticking assembly, a water spraying assembly, a compacting assembly and a discharging assembly; the workbench is arranged on the ground; a sliding groove is formed in the workbench; the feeding assembly is arranged on one side of the workbench; the decal sticking assembly is arranged on one side of the feeding assembly; the water spraying assembly is arranged on the other side of the workbench; the compacting assembly is arranged in the middle of the workbench; the working end of the compacting assembly corresponds to the decal sticking assembly; and the discharging assembly is arranged below the workbench. The production efficiency of the glass ball decal sticking is greatly improved, automatic feeding of the glass balls and automatic decal tearing are realized, decals are attached to the surfaces of the glass balls and automatic discharging of the glass balls is achieved.

Owner:刘志兵

A kind of manufacturing method of soybean protein modified glue formaldehyde-free medium density fiberboard

ActiveCN104059598BResolve dependenciesReduce dependenceNon-macromolecular adhesive additivesProtein adhesivesEnvironmental resistanceFiber

The invention provides a method for making soybean protein modified glue formaldehyde-free medium density fiberboard, which belongs to the technical field of density fiberboard production. Stir and mix the reaction, and then make a soybean protein formaldehyde-free adhesive through a colloid mill and a homogenizer, and add a waterproofing agent, a curing agent and a buffer to the soybean protein formaldehyde-free adhesive. Drying, laying, hot pressing to make soybean protein modified glue formaldehyde-free medium density fiberboard. The method is environmentally friendly, pollution-free, high in bonding strength, good in water resistance, low in price, low in viscosity, easy to handle and process, can be hot-pressed or cold-pressed during use, and is not easy to crack. And bonding with fibers, etc., and controlling the processing technology, an environment-friendly fiberboard can be prepared.

Owner:DONGYING ARTIFICIAL BOARD FACTORY

Injection molding rapid forming system

InactiveCN114290600AEasy to handle and processEasy to polishEdge grinding machinesGrinding drivesEngineeringMachine

The invention discloses an injection molding rapid forming system which comprises a machine shell, a forming cavity communicated with the outside is formed in the machine shell, a starting mechanism, a smearing mechanism and a polishing mechanism are arranged in the machine shell, a relay and a magnet are arranged in the starting mechanism, injection molded plastic parts can be taken out, and therefore follow-up processing is facilitated; by means of the arranged hydraulic rod, the sliding rod slides up and down at the end of the hydraulic rod by changing stretching and retracting of a spring, the mutual movement mode of the sliding rod and the hydraulic rod is changed, the bottom and the bowl opening of a bowl can be conveniently polished, and the device can be flexibly machined and is simple in structure, the size of the device is reduced, and maintenance is easy.

Owner:陈艳芬

A garbage disposal vacuum suction machine

The invention discloses a vacuum suction machine for garbage disposal. The vacuum suction machine comprises a storage bin, a bottom plate is arranged on the lower portion of the storage bin, a vertical air and matter separation screen is arranged in the storage bin which is divided into an air suction pipe orifice area and a matter suction pipe orifice area by the air and matter separation screen, an air suction port is arranged in the bottom plate of the air suction pipe orifice area, a centrifugal fan is arranged nearby the storage bin, an air suction pipe is arranged at an inlet of the centrifugal fan to be connected with an air suction pipe outlet, and an exhaust pipe is arranged at an outlet of the centrifugal fan. A matter inlet is arranged on the upper end side wall of the matter suction pipe orifice area and connected with a matter suction barrel, and the lower end of the suction barrel is arranged on the upper end surface of a matter conveying belt. A seal door is arranged on the side wall of the matter suction pipe orifice area. According to the vacuum suction machine, impurities such as plastic and paper in separated organic matters are subjected to secondary effective separation through a vacuum suction principle, and convenience is brought for further disposal of organic matters.

Owner:SHAANXI ZIZHAO EQUIP MFG

Electrode foil directional chambering device and chambering method thereof

PendingCN113909601AImproves stability and orientationImprove production qualityElectrochemical machining apparatusEngineeringMaterials science

The invention discloses an electrode foil directional chambering device and a chambering method thereof, relates to the technical field of electrode foil, and aims to solve the problems that in the prior art, existing electrode foil is mostly placed in corrosive liquid for chambering treatment during chambering, directional chambering cannot be carried out, and the production quality of the electrode foil is affected. A chambering box is fixedly installed on the upper portion of a working base, a washing box is arranged on one side of the chambering box, and the washing box is fixedly connected with the working base through bolts. A drying box is arranged on one side of the washing box, and the drying box is fixedly connected with the working base through bolts. Supporting frames are fixedly installed on the upper portion of the working base, lead screw boxes are fixedly installed on the upper portions the supporting frames, and the lead screw boxes sequentially penetrate through the chambering box, the washing box and the drying box. A solution tank is arranged in the chambering box, a lifting frame is arranged above the solution tank, and a negative electrode carbon plate is fixedly installed in the lifting frame.

Owner:YANCHENG INST OF TECH

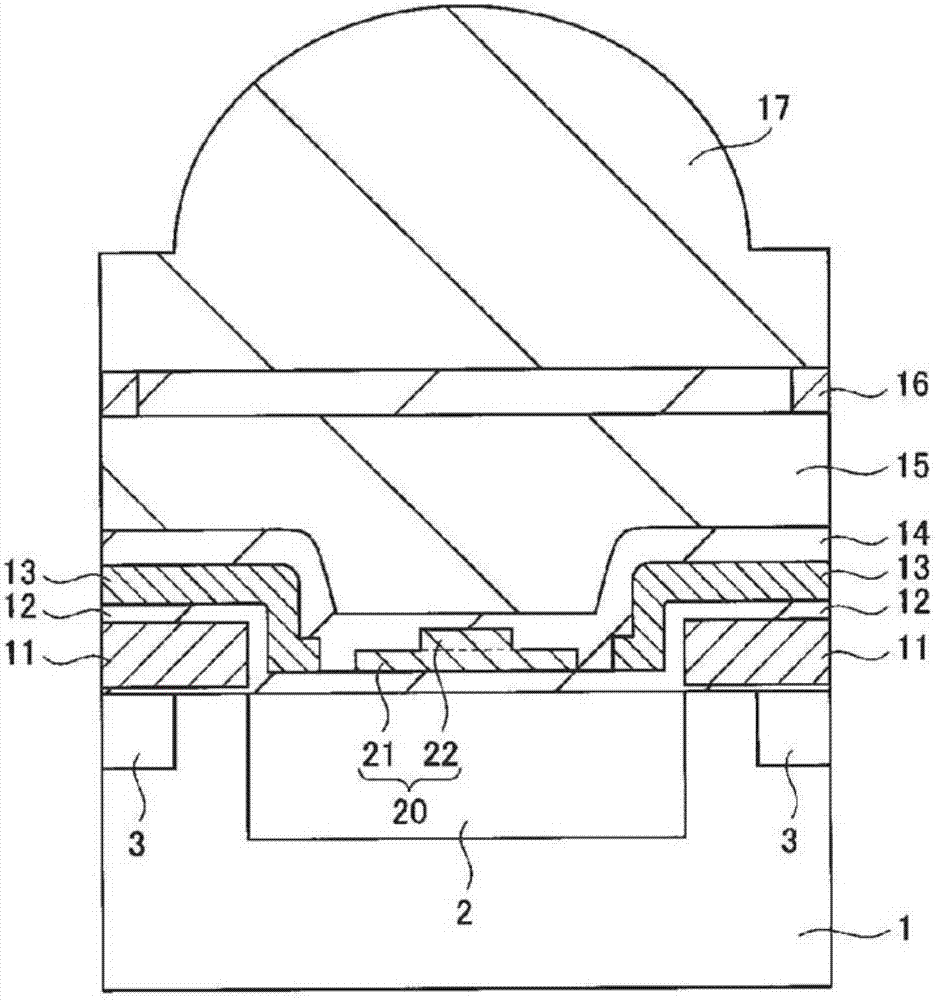

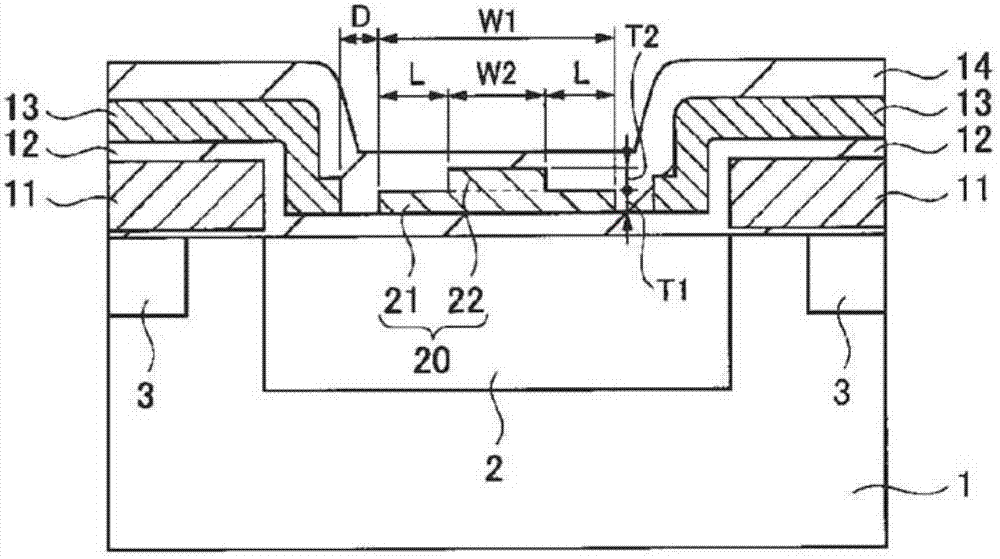

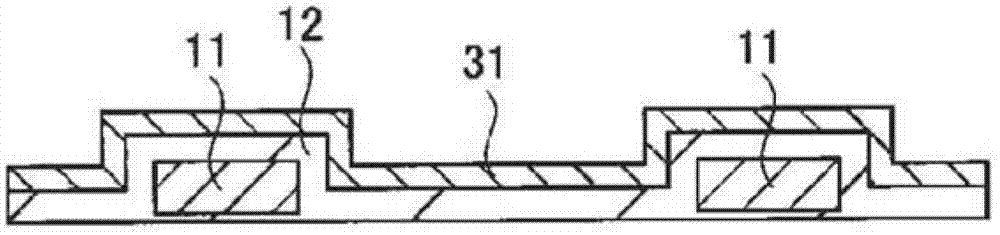

Solid-state imaging element and electronic apparatus

InactiveCN103367373AReduce smearingReduce color mixingSolid-state devicesCoatingsEngineeringSemiconductor

A solid-state imaging element includes a light receiving unit formed on a semiconductor base, and an anti-reflection film formed on the light receiving unit. The anti-reflection film has a plurality of planar layers whose planar layer in an upper layer is narrower than the planar layer in a lower layer.

Owner:SONY SEMICON SOLUTIONS CORP

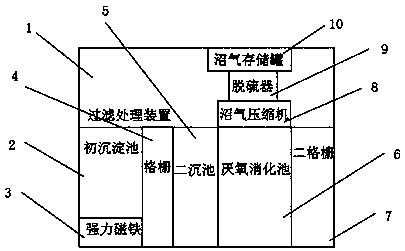

Environment-friendly equipment with multistage filtering function for sludge treatment

InactiveCN107857450AAvoid cloggingNot easy to bondSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCombustionEngineering

The invention discloses environment-friendly equipment with a multistage filtering function for sludge treatment. The environment-friendly equipment comprises a filtering treatment device, wherein a primary precipitation pool is arranged on the inner surface inside the filtering treatment device; a strong power magnet is fixedly arranged on the inner surface inside the primary precipitation pool;grids are fixedly arranged on the outer surface of one side of the primary precipitation pool. The environment-friendly equipment with the multistage filtering function for sludge treatment is provided with the strong power magnet, the two grids, a methane compressor, a methane storage tank, a combustion furnace, a rolling tube machine and a support spring; metal in the sludge can be subjected toadsorption collection, so that the heavy metal content in the sludge is reduced; the further filtering effect can be achieved, so that the sludge becomes fine and can be easily treated; the fast conveyance and recovery of the methane can be realized; the better environment-protection and energy-saving effects are achieved; the contact area between the sludge and the drying media can be increased;the sealing performance is good; the vibration of the equipment during the operation can be reduced; the abrasion among components is reduced; the service life of the equipment is prolonged.

Owner:长兴华阁耐物流装备有限公司

Method for producing hard alloy bar

InactiveCN113441721AHigh strengthHigh hardnessTurbinesOther manufacturing equipments/toolsChromium carbideTitanium carbide

The invention discloses a method for producing a hard alloy bar. The hard alloy bar is composed of the following raw materials of, in parts by weight, 86-91 parts of tungsten carbide, 1-6 parts of cobalt carbide, 1-2 parts of titanium carbide, 0.2-0.5 part of nickel carbide and 0.2-0.5 part of chromium carbide. According to the method, firstly, chromium carbide and nickel carbide are added so that the strength, hardness and abrasion resistance of the alloy bar can be remarkably improved, the attractiveness and cleanliness of the alloy bar are enhanced, and the requirement for chromium raw materials is reduced; a filter screen is placed at a discharging opening of a ball grinding machine, secondary wet grinding needs to be carried out on a mixture which does not meet the requirement, the primary wet grinding time is 30 h, and each of the later wet grinding time is reduced by half, so that the wet grinding effect of materials is improved, and the mixture can be better treated and machined in the subsequent process; and a comprehensive grinding method combining a longitudinal grinding method and a transverse grinding method is adopted in the external rounding and accurate grinding process of the profile alloy bar, the surface of the alloy bar can be effectively ground through the comprehensive grinding method, and meanwhile the working efficiency can be improved.

Owner:ZHUZHOU LIZHOU CEMENTED CARBIDE

A gecko slaughtering and processing integrated machine

InactiveCN109315469BImprove work efficiencyEasy to handle and processElectric current slaughtering/stunningEviscerating scissorsGeckoElectric shock

Owner:徐州锌浩精密机械科技有限公司

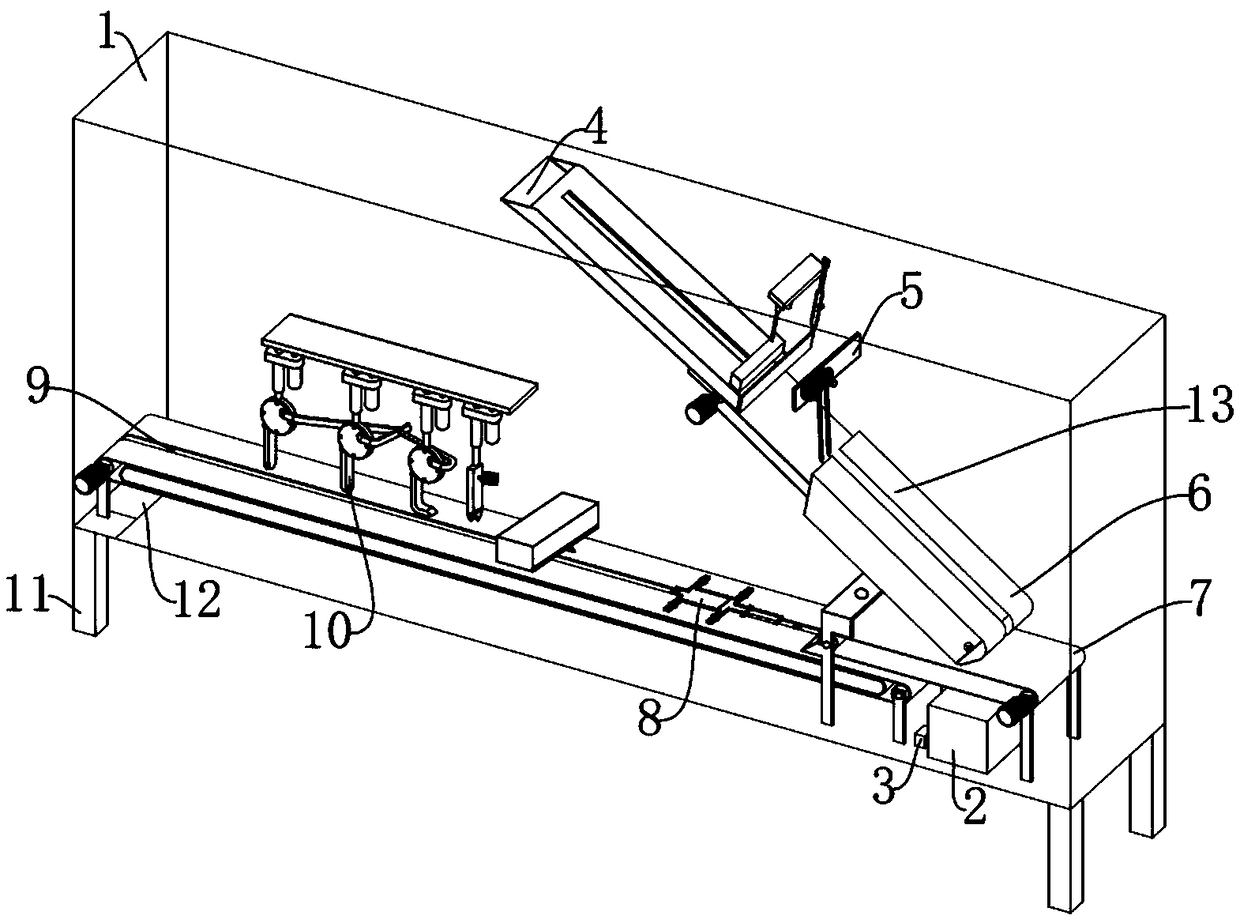

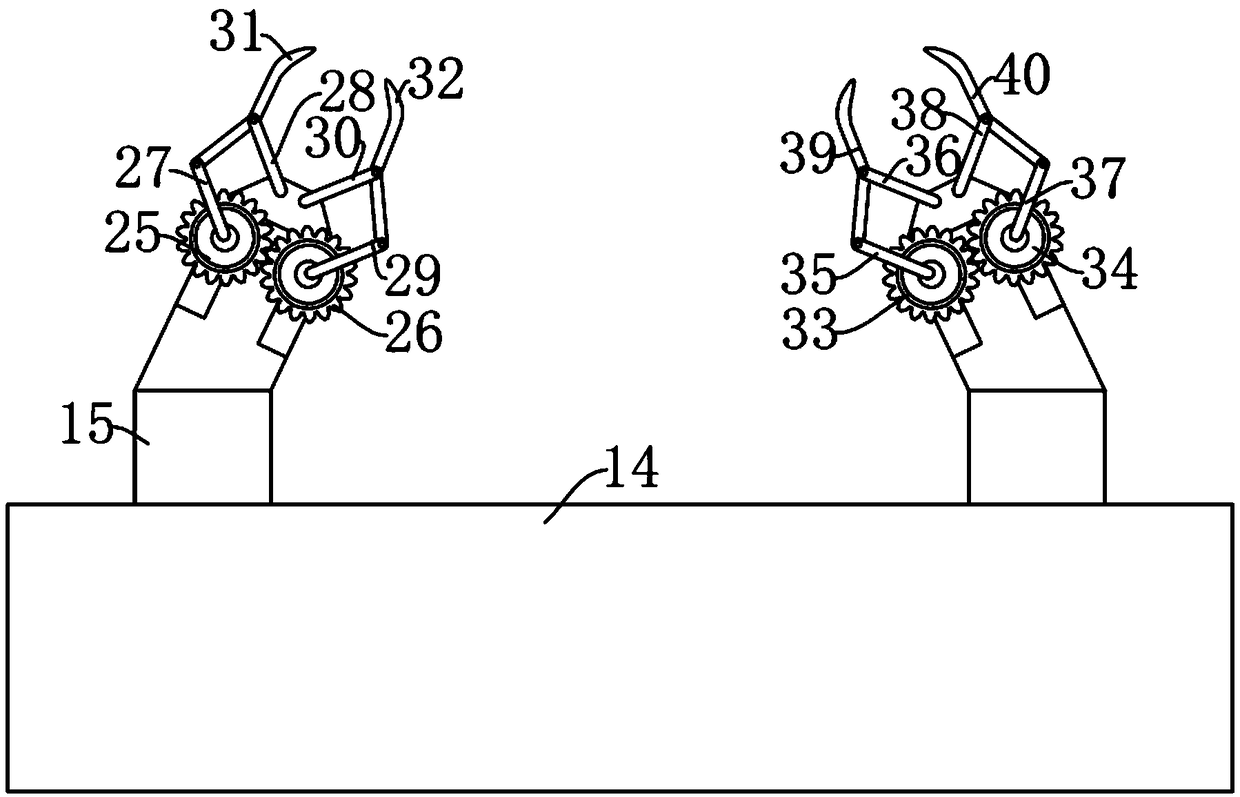

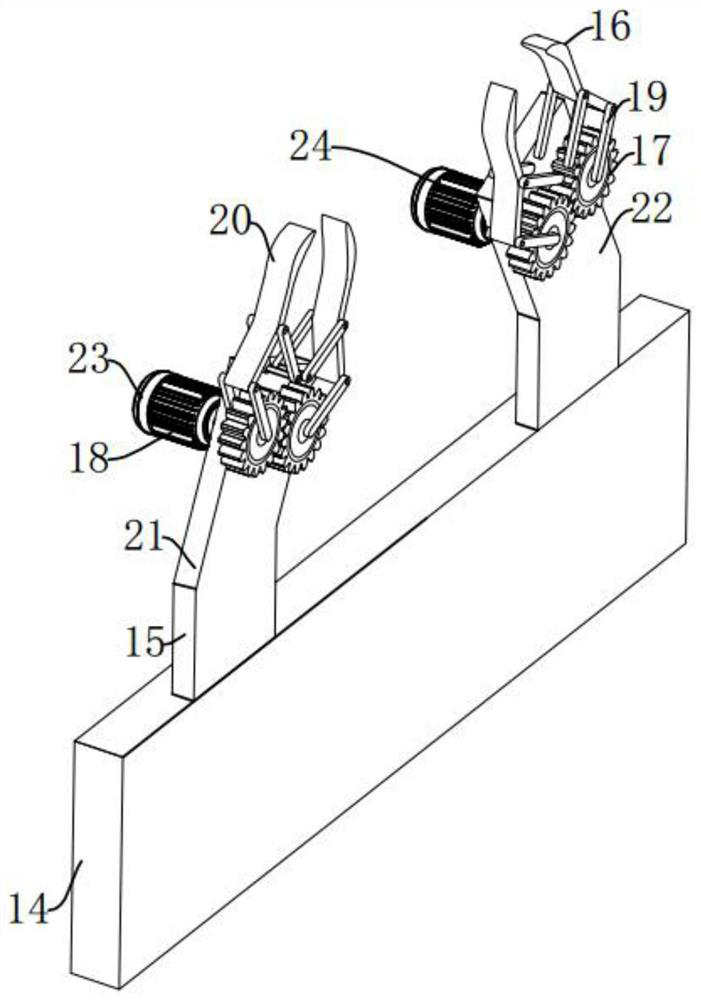

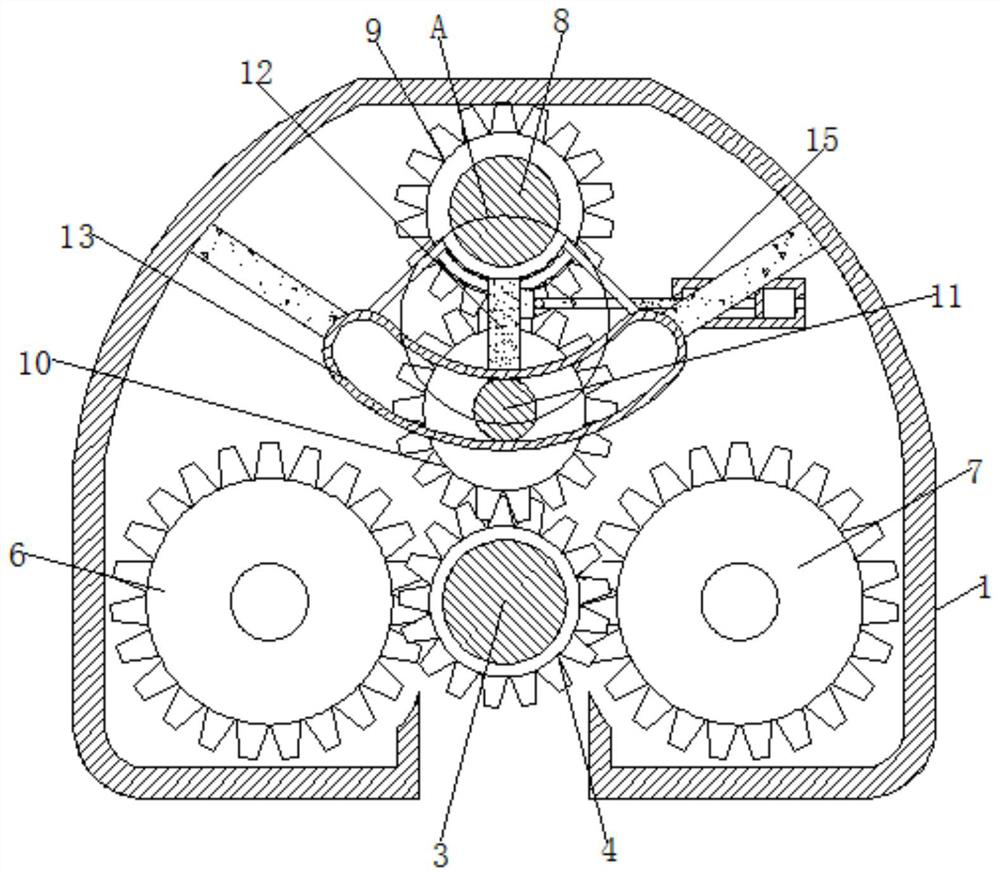

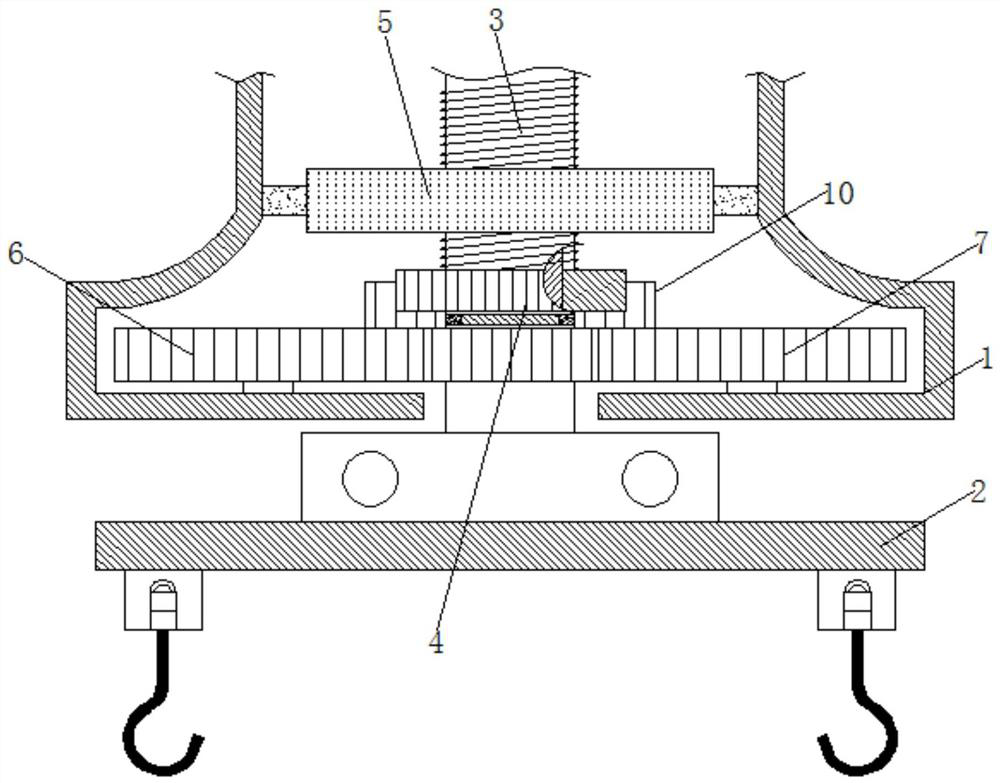

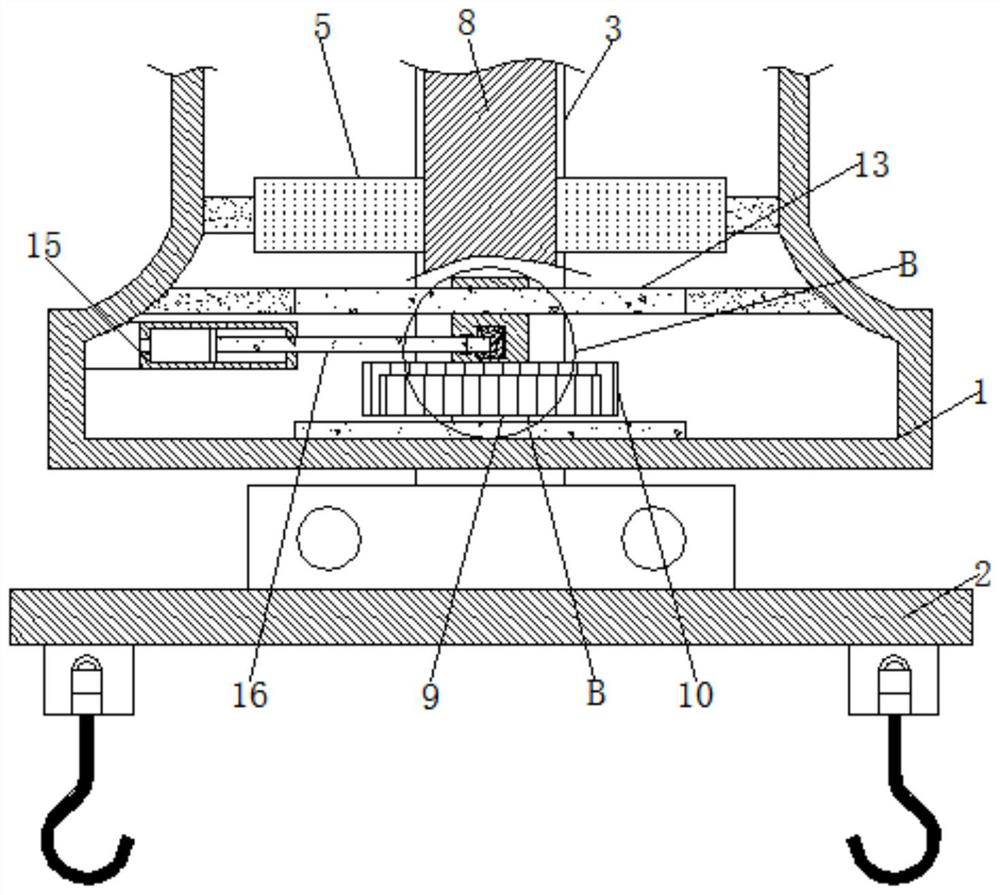

Slaughtering lifting appliance position adjusting mechanism

InactiveCN112065948AImprove the rotation effectImprove processing efficiencyToothed gearingsLifting devicesGear wheelEngineering

The invention relates to the technical field of slaughtering equipment, and discloses a slaughtering lifting appliance position adjusting mechanism. The slaughtering lifting appliance position adjusting mechanism comprises a shell, a lifting appliance is arranged on the lower portion of the shell, a supporting shaft is arranged on the surface of the lifting appliance, a driving gear is arranged onthe surface of the supporting shaft, a push ring is arranged on the surface of the supporting shaft, and a first gear, a second gear and a rotating shaft are arranged inside the shell. According to the slaughtering lifting appliance position adjusting mechanism, through cooperative use of a hydraulic device and a push rod and cooperative use of a rotating rod and an axis, the position of a transmission gear can be adjusted and changed, through cooperative use of the transmission gear and the first gear and the second gear, and cooperative use of the first gear, the second gear and the supporting shaft, the lifting appliance can be rotated and adjusted, the rotating effect of slaughtered objects is improved, workers can conveniently treat and process the slaughtered objects, and the slaughtered object treating and processing efficiency is improved.

Owner:刘玉枚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com