Patents

Literature

55results about "Eviscerating scissors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

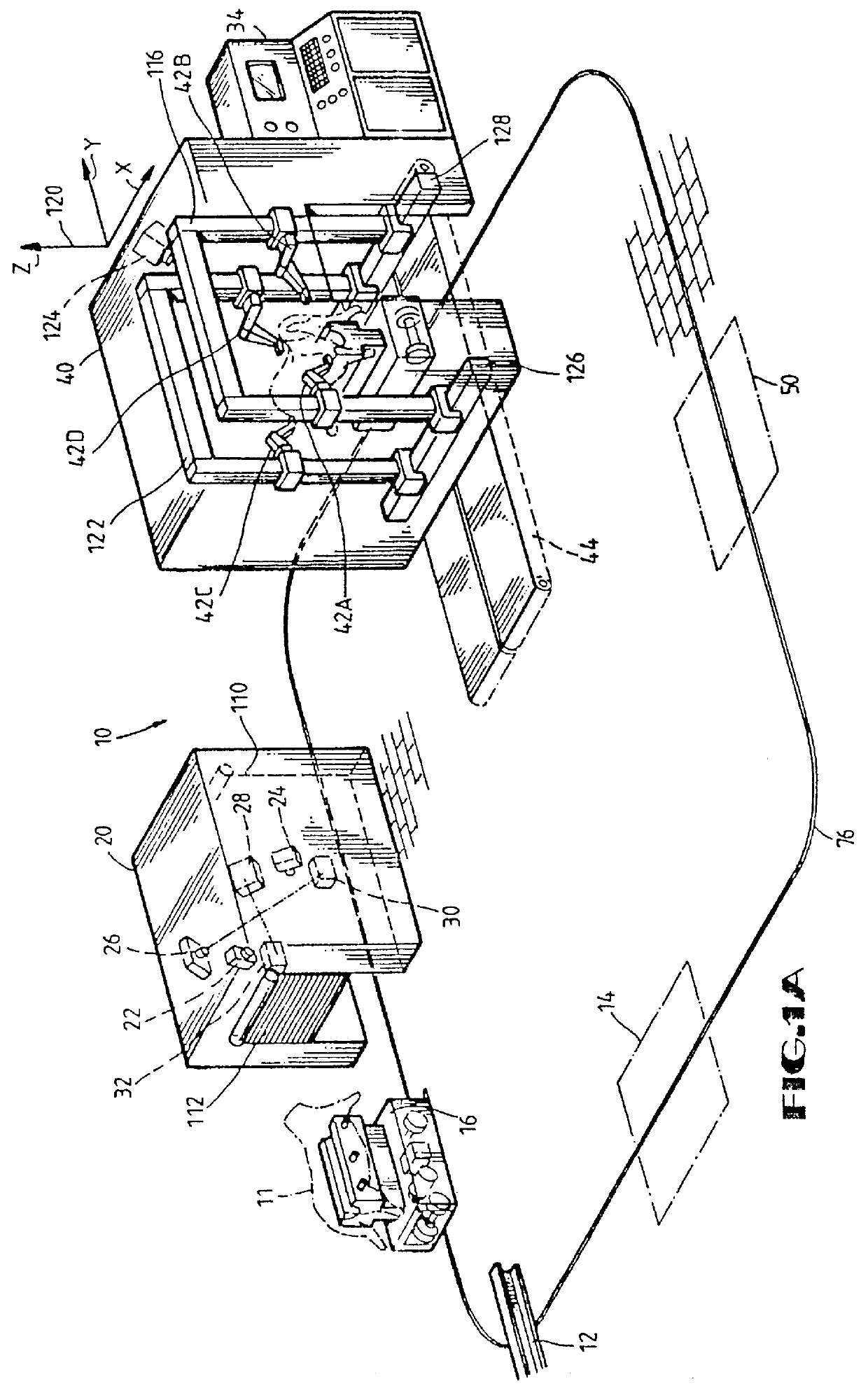

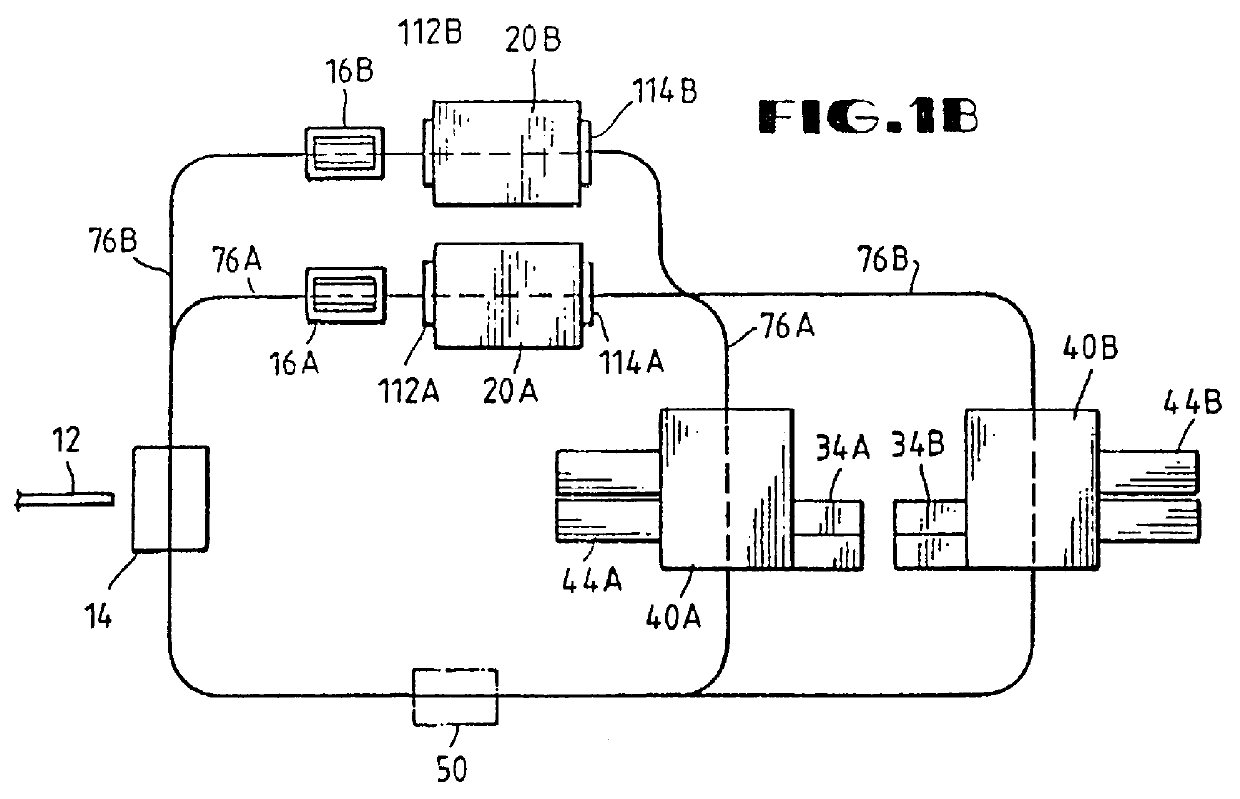

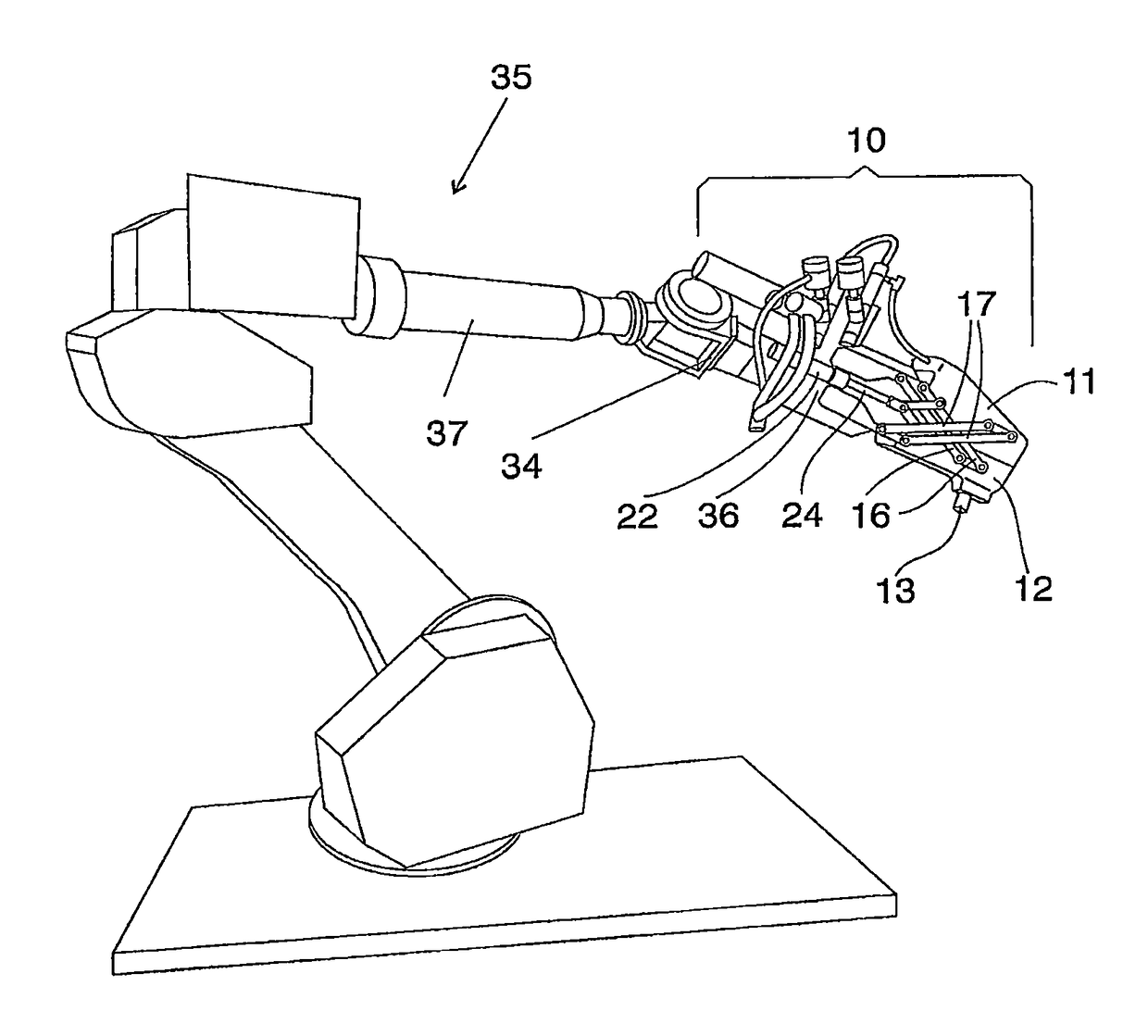

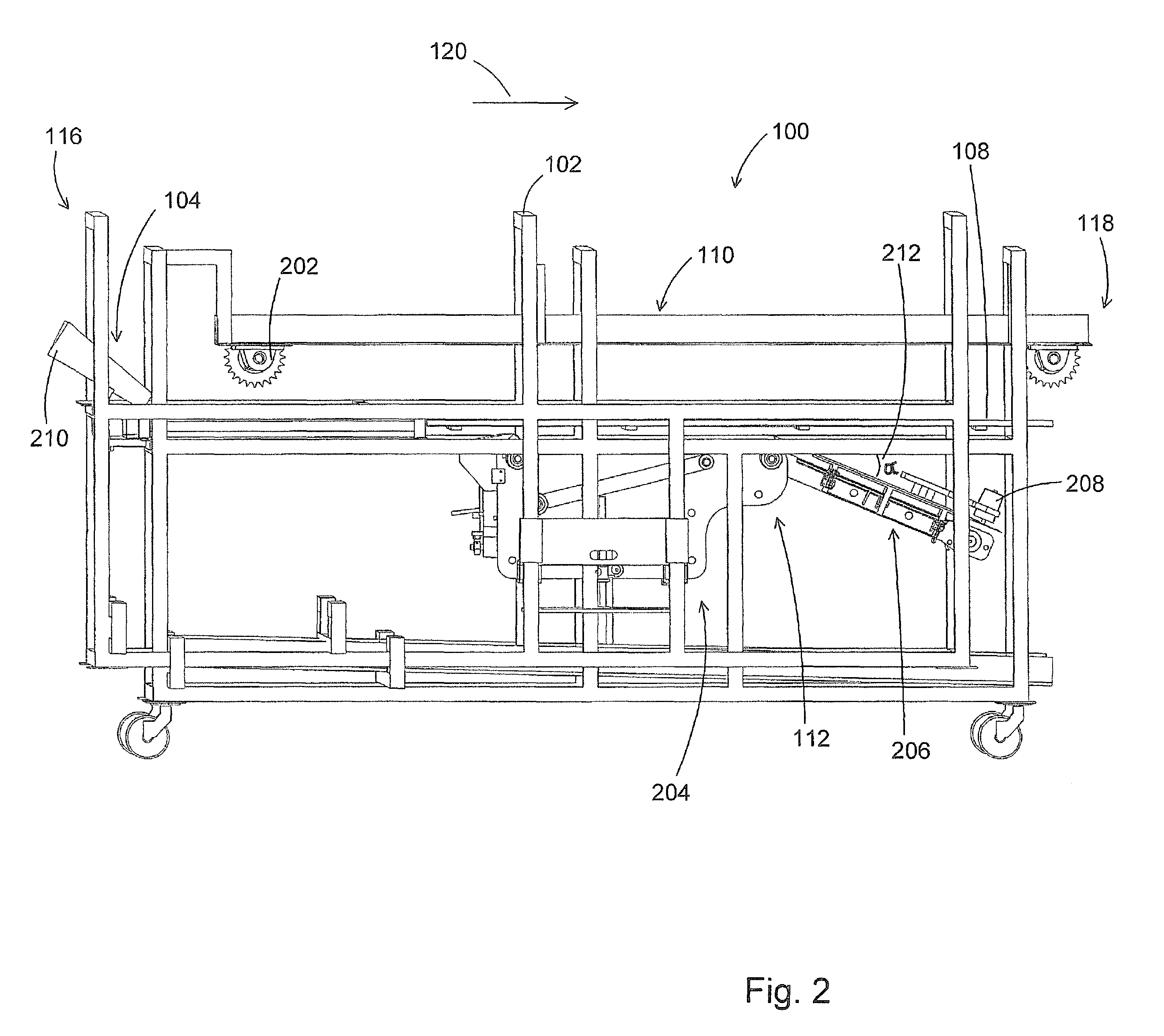

Method and apparatus for automatically segmenting animal carcasses

Manually segmenting animal carcasses into primary cuts involves an enormous amount of manual labor and attendant expense. However, known automated systems for segmenting carcasses cannot match the accuracy of expert butchers. The apparatus for segmenting animal carcasses disclosed herein provides an imaging station having a vision system that determines parameters of the interior and / or exterior of the carcass. Using these parameters, a computer determines a cutting path or a plurality of cutting paths for segmenting the carcass. A mounting vehicle, which securely holds the carcass, transports the carcass from the imaging station to a cutting station. In the cutting station, electrically controlled cutting implements, such as high-pressure water jets or lasers, segment the carcass along the determined cutting path or paths.

Owner:TEXAS BEEF GROUP +1

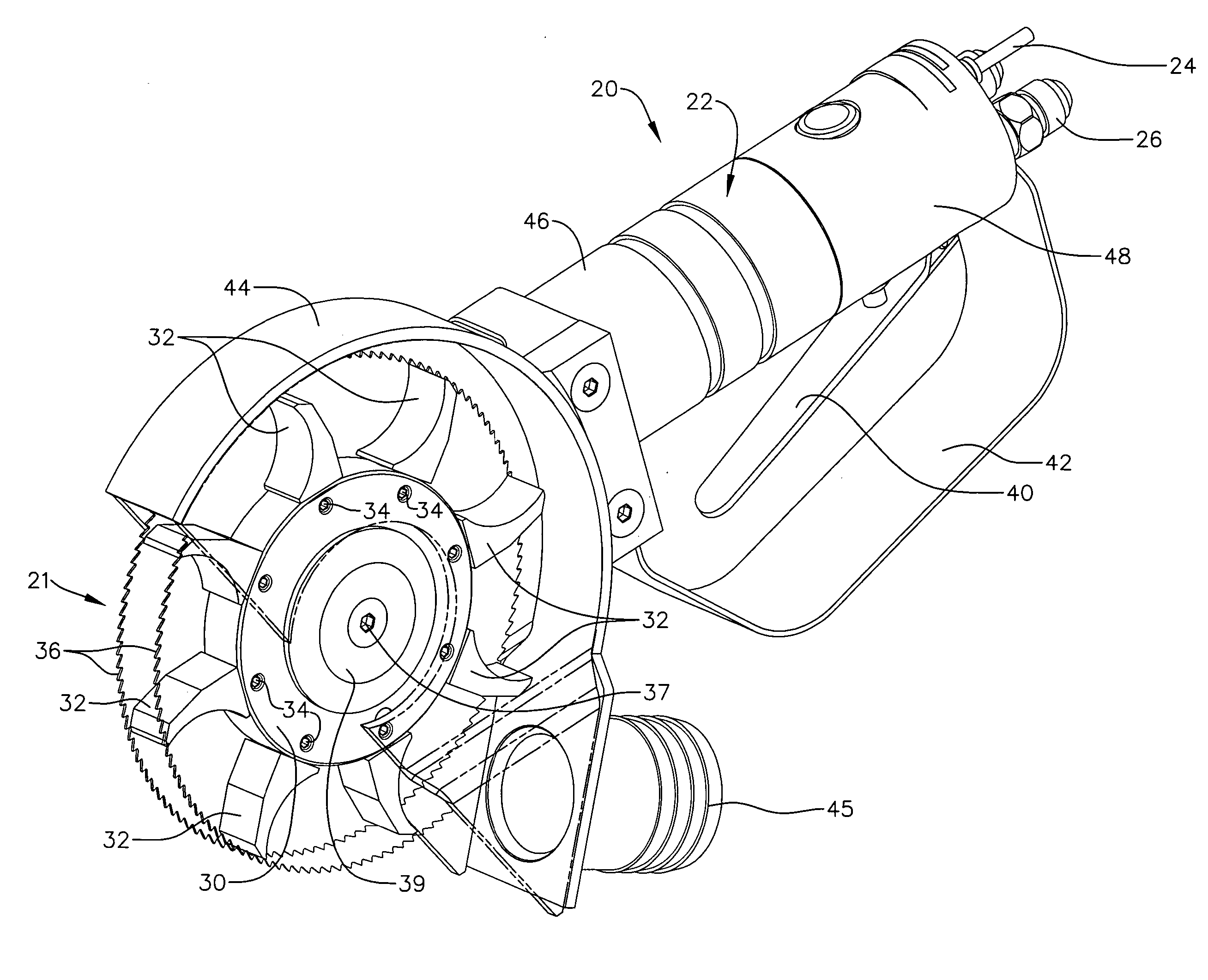

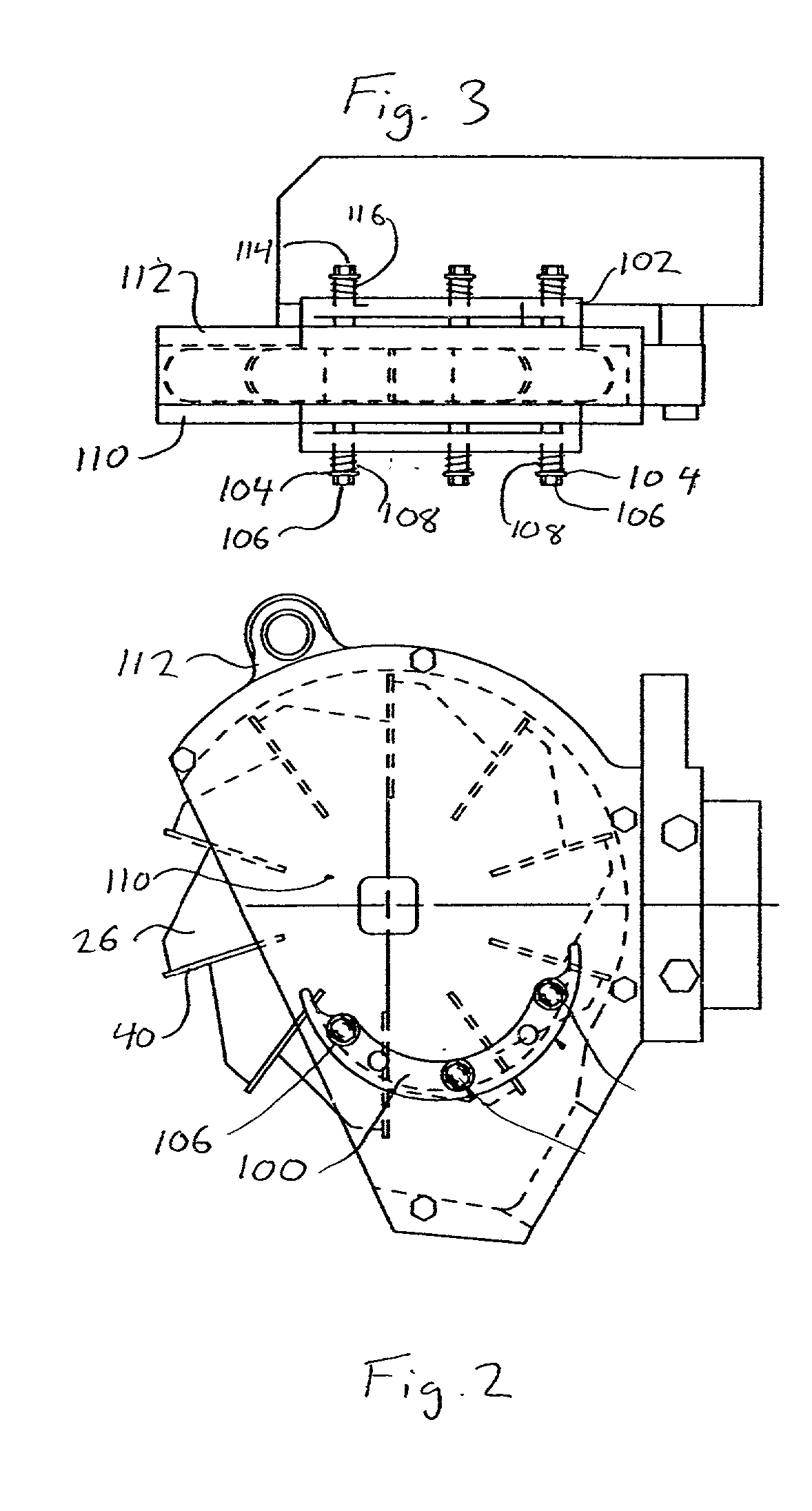

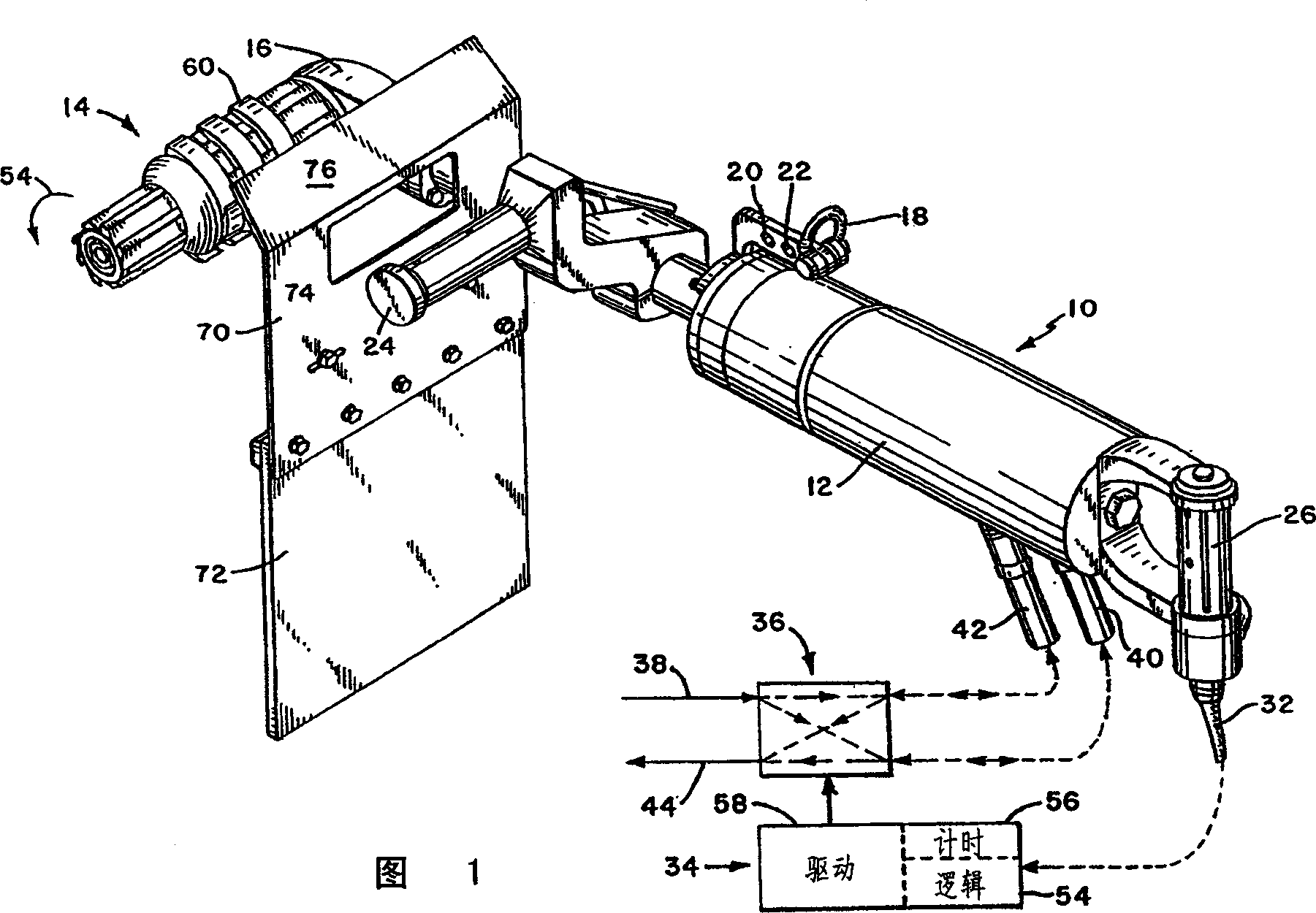

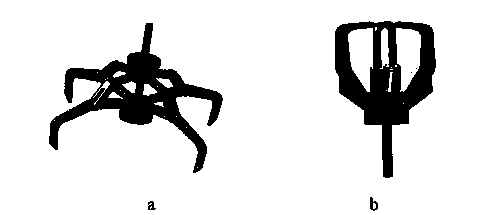

Multi-purpose cutting tool

InactiveUS20060200152A1Efficient removalMaterial removalMetal sawing devicesEviscerating scissorsSpinal cordCircular saw

A multi-purpose cutting device for removing the spinal cord and spinal meninx lining of the spinal cord of a slaughtered animal which has been longitudinally cut in two along the length of the spinal cord. The cutting device comprises a rotary cutting tool having a hub with radially outwardly projecting cutting fingers equidistantly spaced apart around the hub. The cutting fingers have blunt ends and are of substantially uniform length. A pair of circular saw blades are rigidly secured to opposite faces of the cutting tool. The saw blades have a circumference that approximately matches the effective circumference of the working ends of the cutting fingers. In use, when the cutting device is powered by a drive motor, the cutting fingers and saw blades rotate in unison. The cutting fingers rotate to remove the spinal cord and spinal meninx from the carcass while the saw blades cut into bone along opposite sides of the meninx. The saw blades assist the cutting fingers in dislodging regions of bone material in which the spinal cord or meninx materials may be lodged.

Owner:KENTMASTER MFG

Method and apparatus for harvesting livers and hearts

InactiveUS20080160892A1High yieldQuality improvementAnimal stomach clearancePoultry eviscerating devicesGizzardEngineering

A method and apparatus for harvesting livers and hearts from a giblet package comprising an infeed pinch roller assembly, a slide assembly, an indexer assembly, an intestine pull down and a liver and heart separator assembly, which teaches a novel method and apparatus for harvesting livers and hearts with an increased yield. The steps of the process include loading a load viscera pack into a feed chute that channels the pack to a pair of counter rollers. The viscera pack is captured by infeed pinch rollers thereby forcing the package into and between the rollers with only the gizzard remaining on top of the roller body. The liver and heart is isolated and separated by a pull down stripper assembly and a stripper arm assembly.

Owner:TYSON FOODS

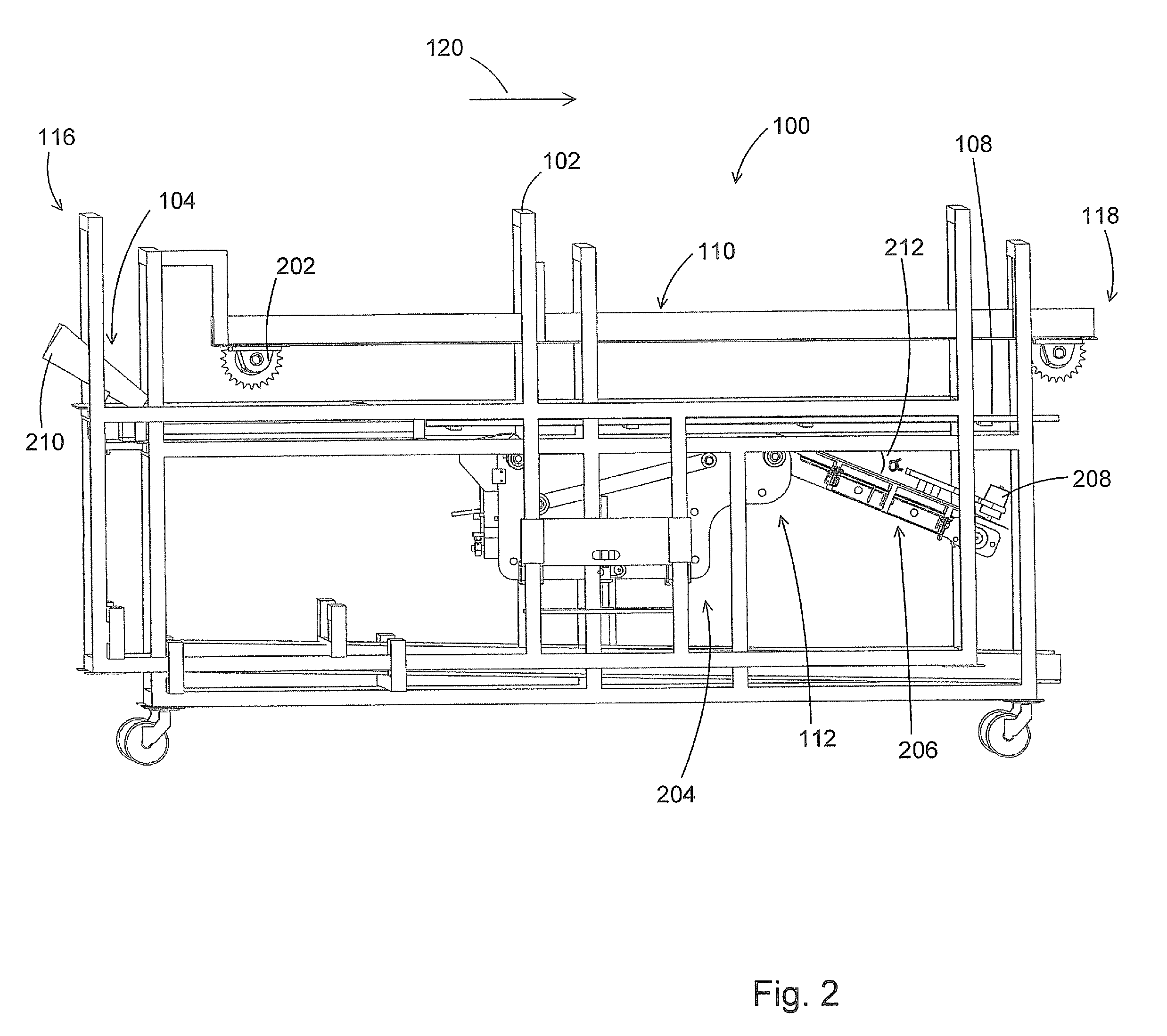

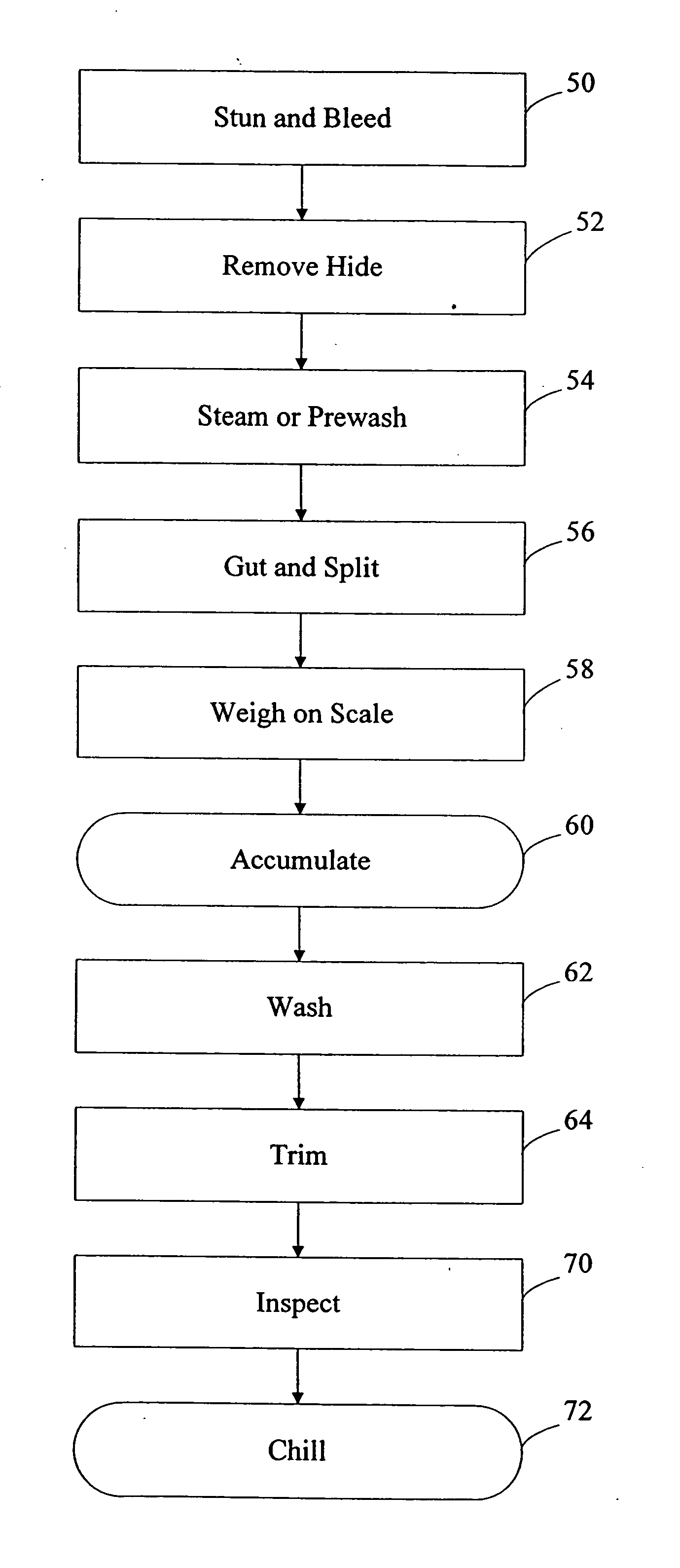

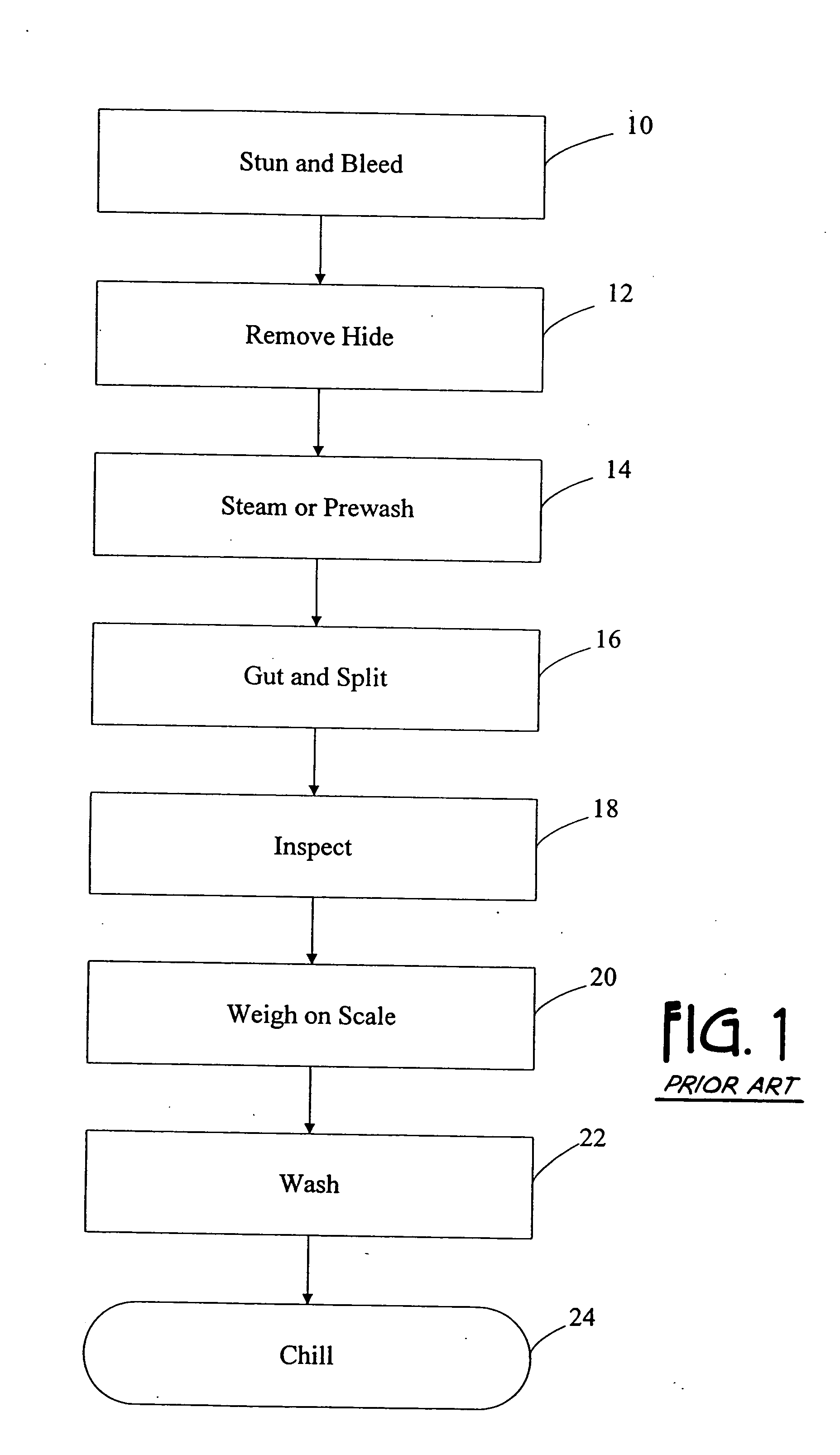

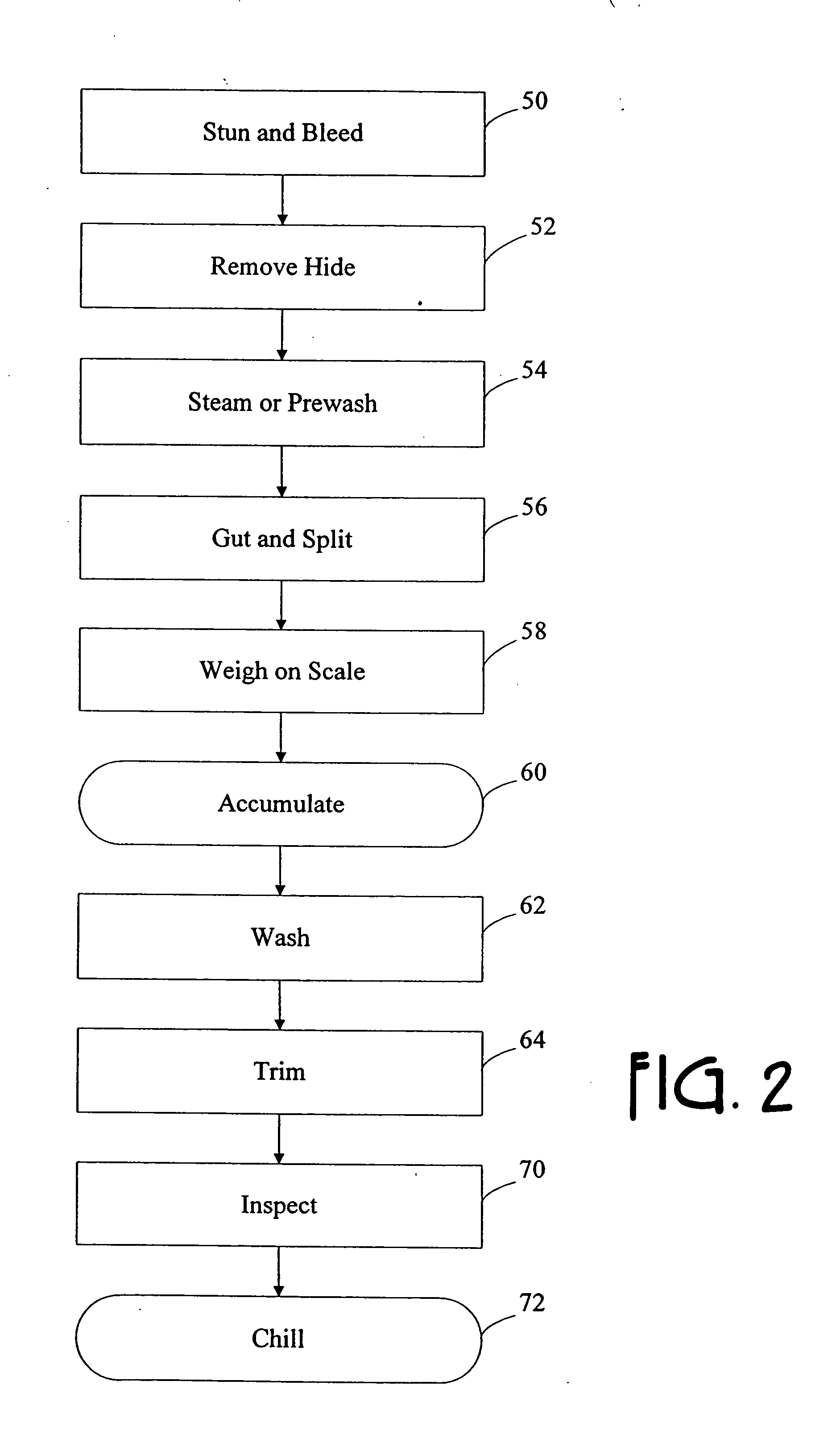

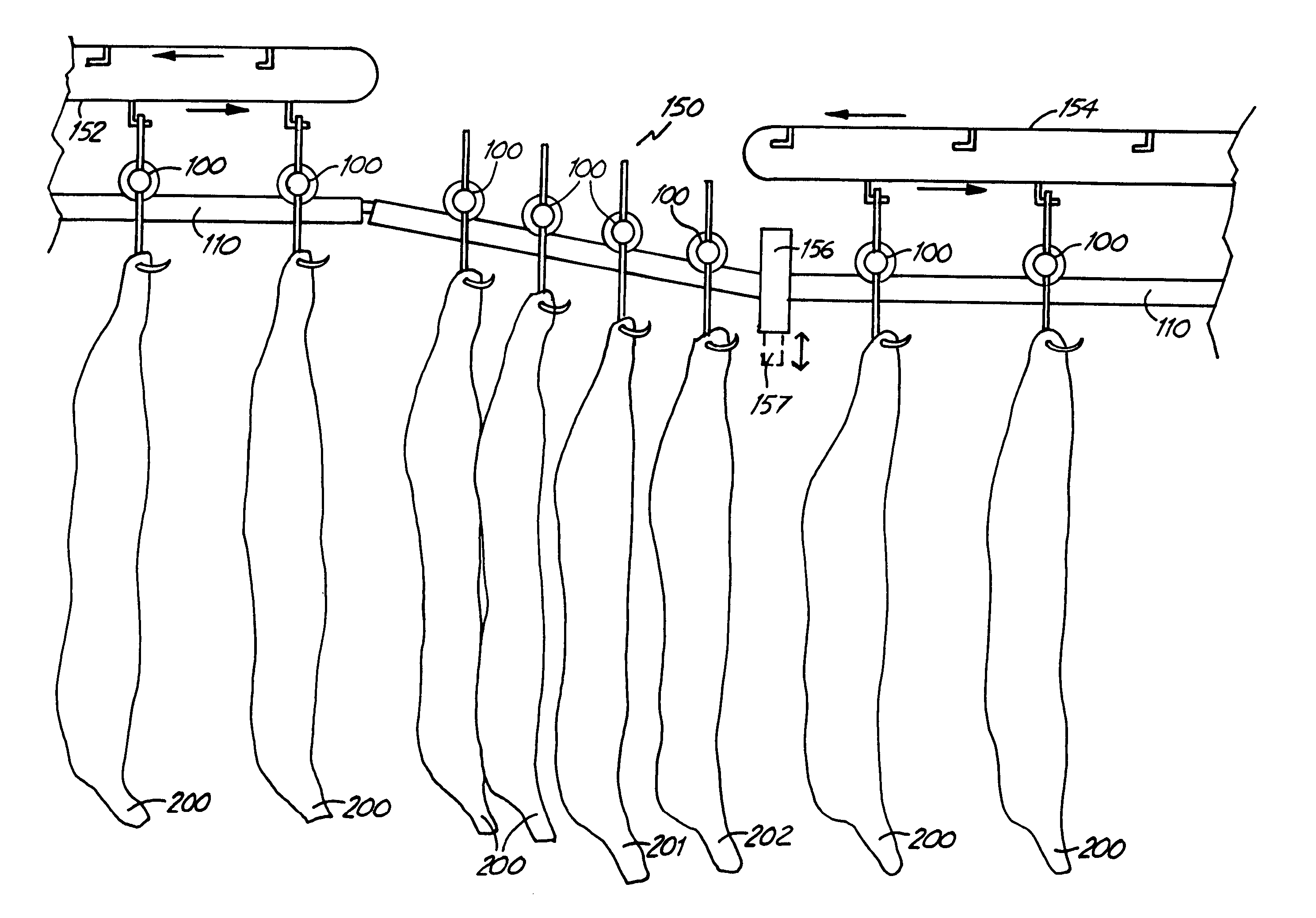

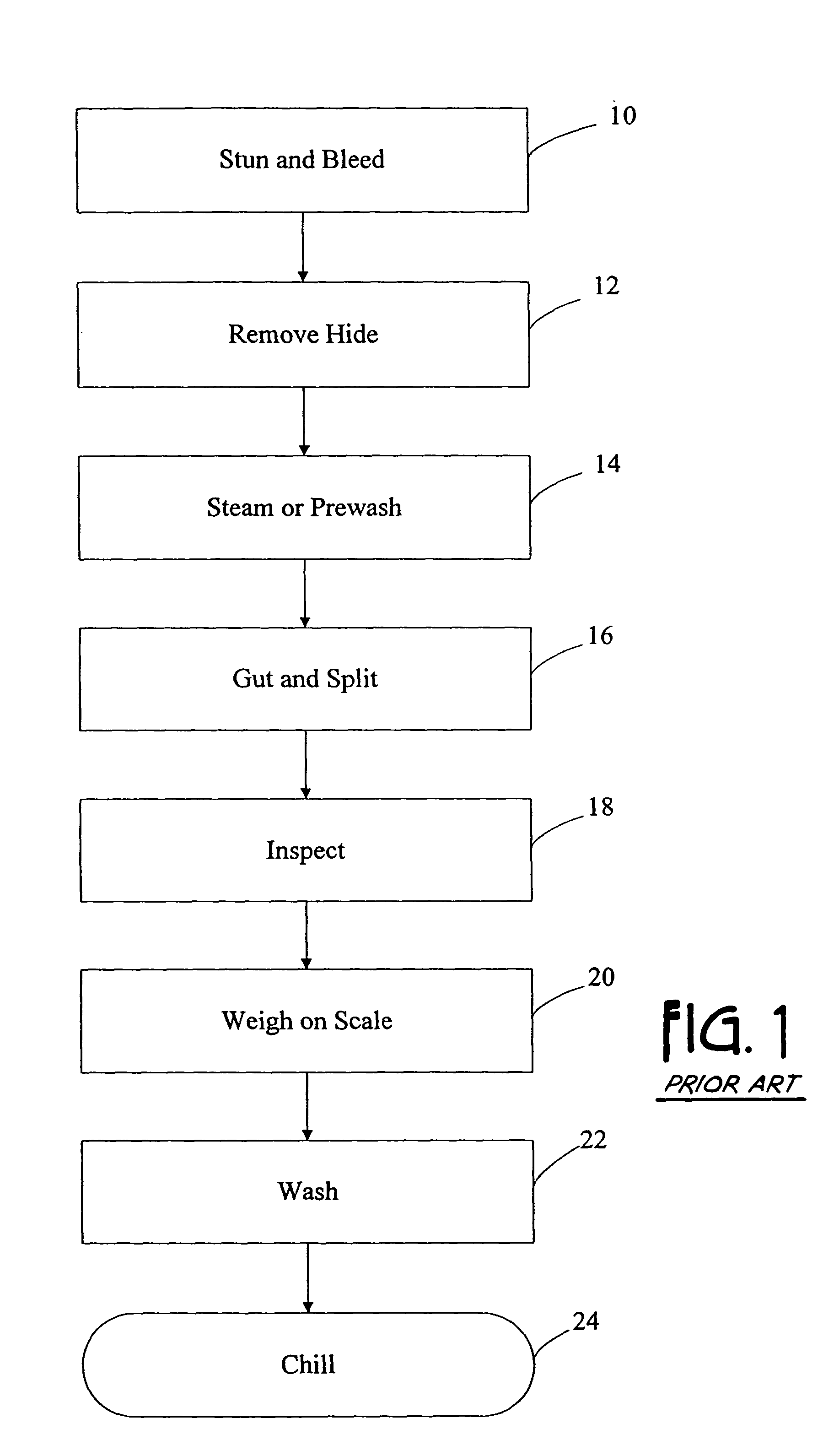

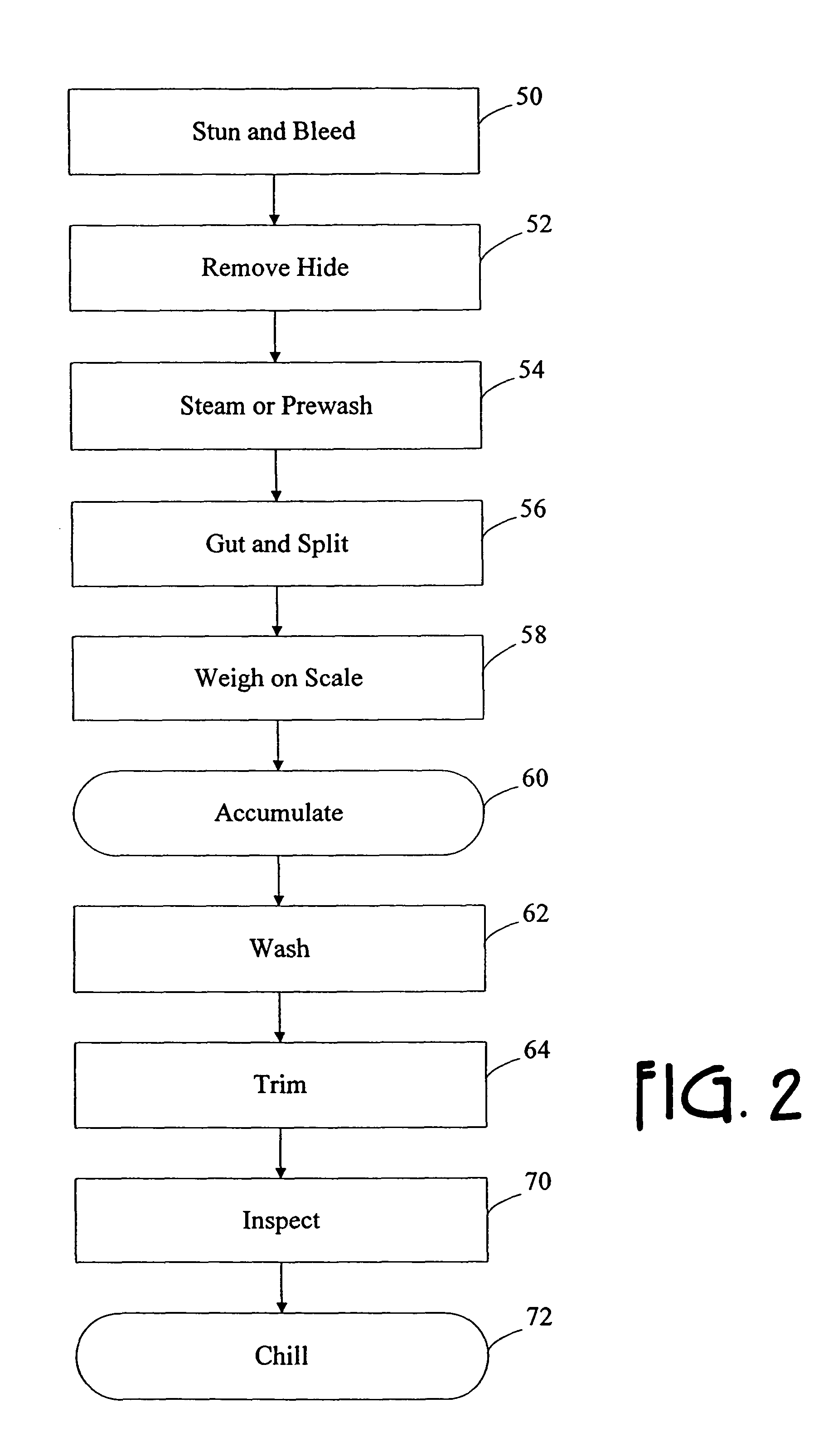

Method and apparatus for processing carcasses

InactiveUS20050042980A1Animal stomach clearanceFish washing/descalingProcess engineeringProcessed meat

A method for processing meat along a meat processing line. The method includes removing viscera from a carcass, accumulating the carcass along a dead rail stack of the meat processing line, washing the carcass, and inspecting the carcass at an inspection station following the act of washing the carcass.

Owner:CARGILL INC

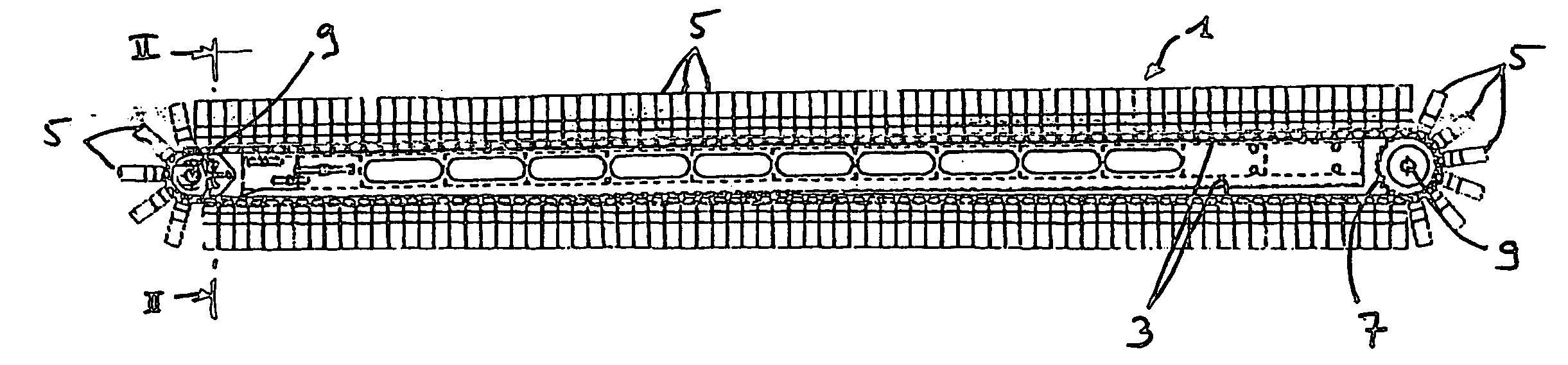

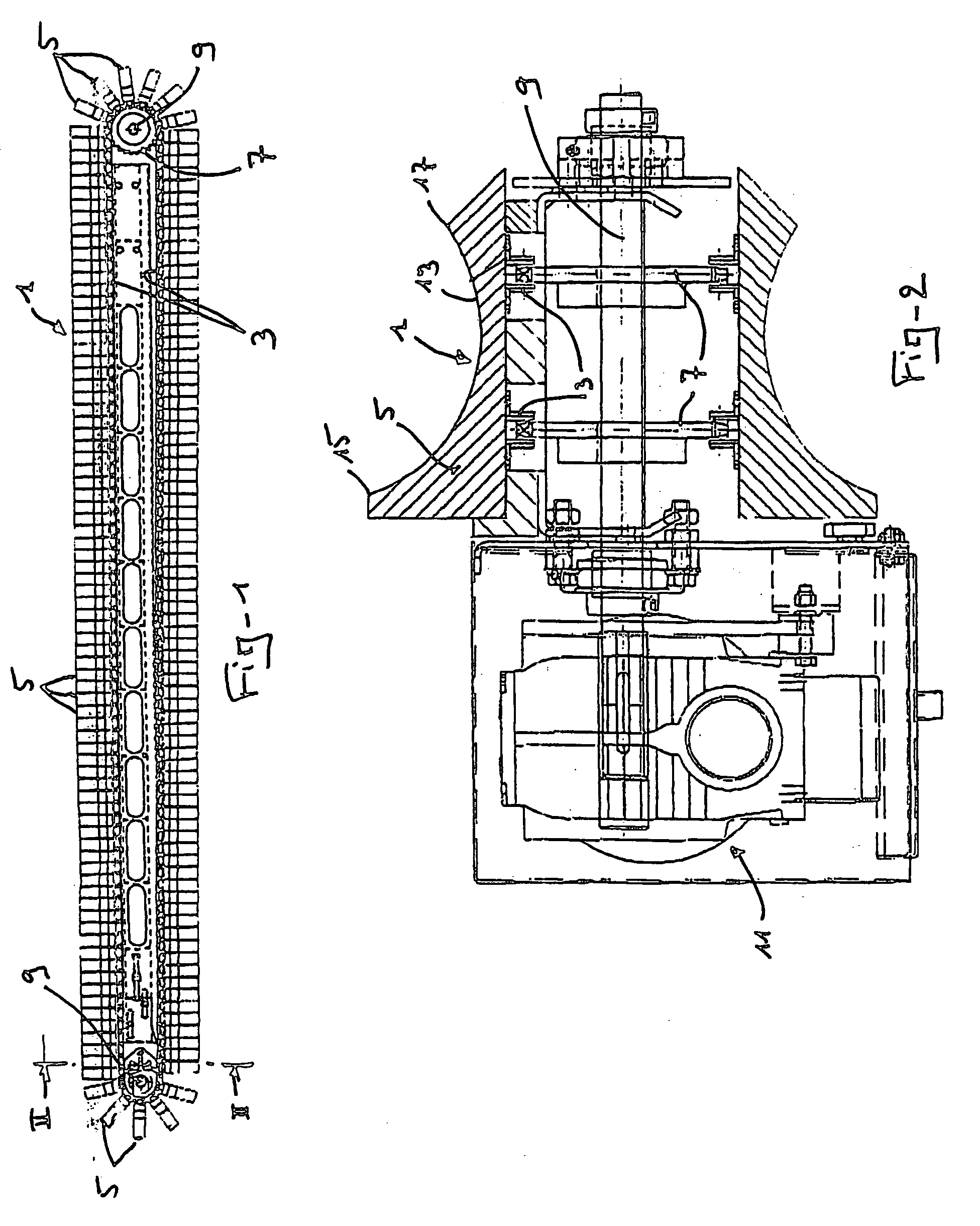

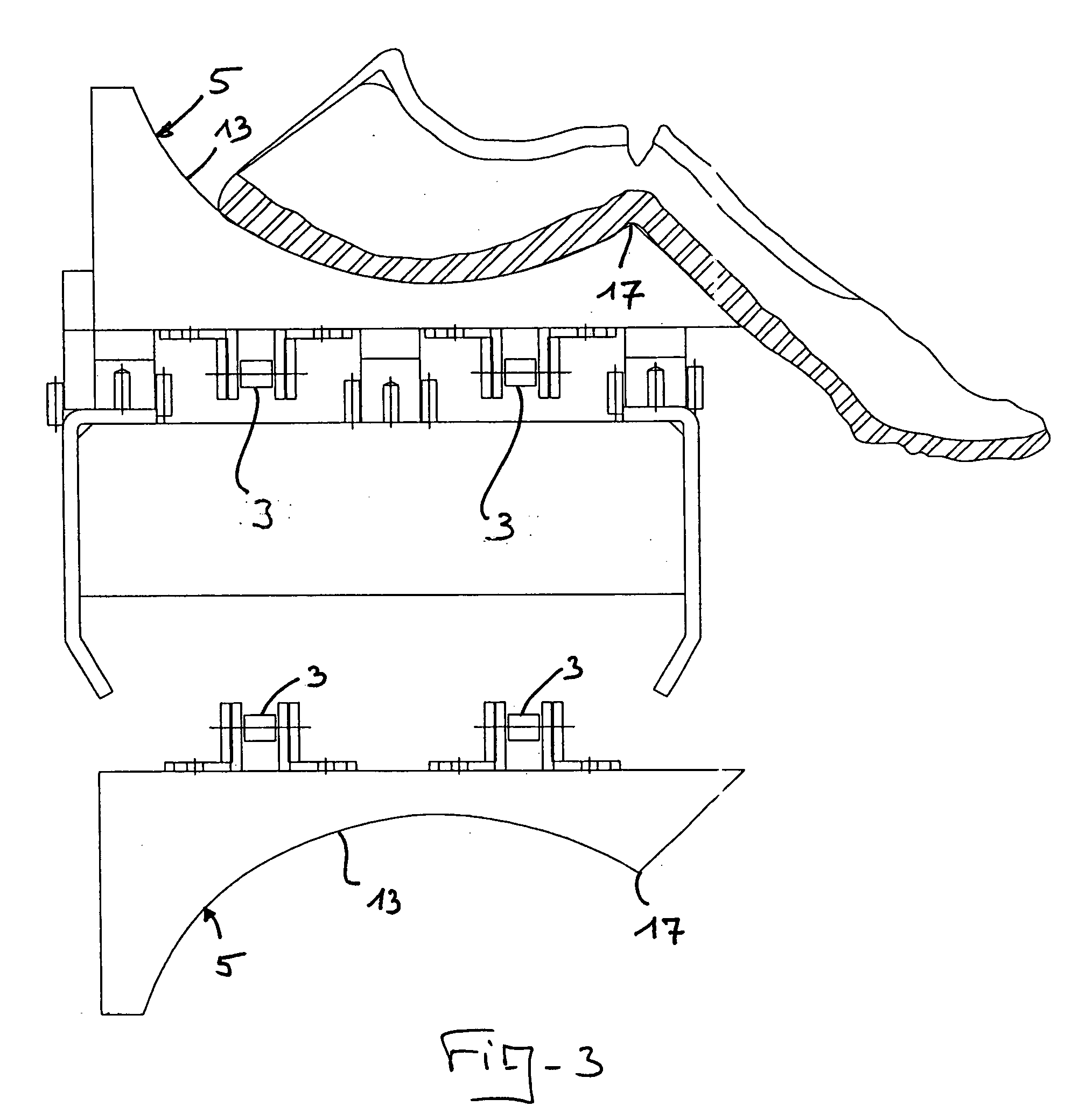

Modular belt shaped to fit the shape of a loin

InactiveUS20060030251A1Easy to getSimpler and easy to maintainConveyorsMeat processing plantsLeather beltEngineering

Disclosed is a belt for conveying loins attached to flanks in a loin puller equipment. This belt comprises one or more driving chains and a plurality of modules for supporting the loins, which are mounted in parallel relationship over all the length of the chains. These modules are in the form of blocks preferably made of rigid Nylon, which extend transversally to the chains and are provided with an upper surface that is round-shaped and recessed in order to receive and hold the parts of the loins where the fat is located. The blocks are advantageously interchangeable and then adaptable to the size of the loin to be cut. The belt is therefore easily modifiable as a function of the product to be processed. It is also easy to manufacture and install and much easier to maintain. The belt permits to convey loins that are not yet separated from the adjacent flanks without any risk of friction or scrapping, as is the case with the existing belt.

Owner:G E LEBLANC

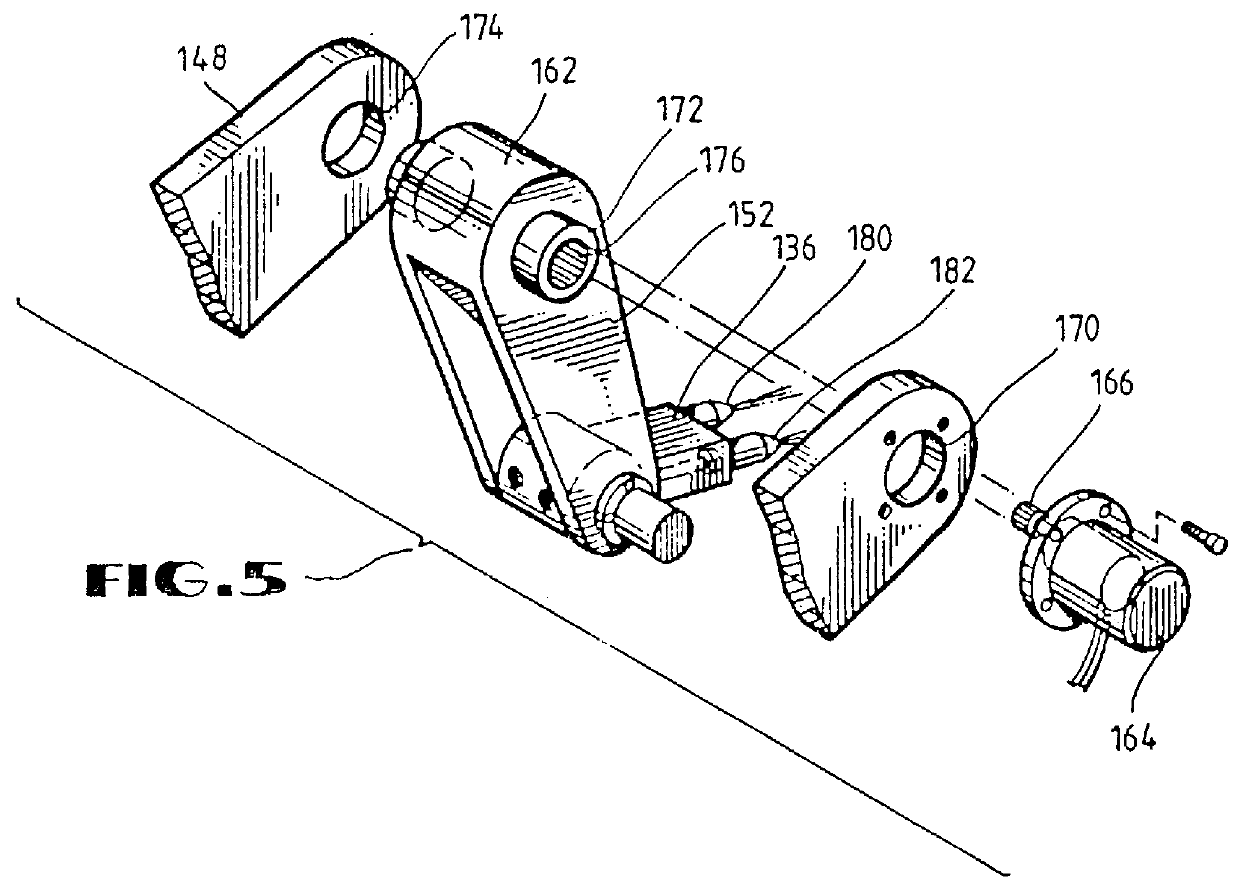

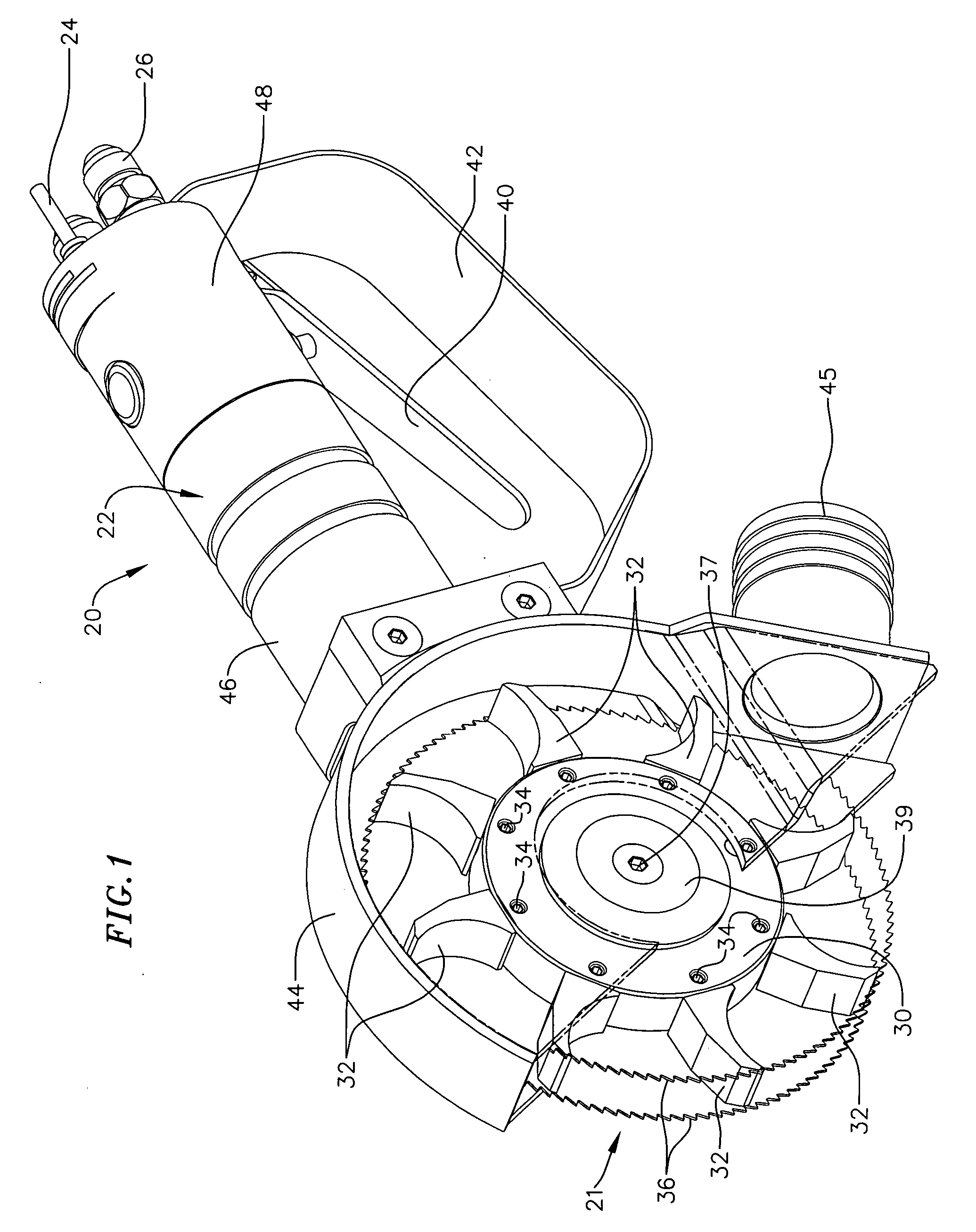

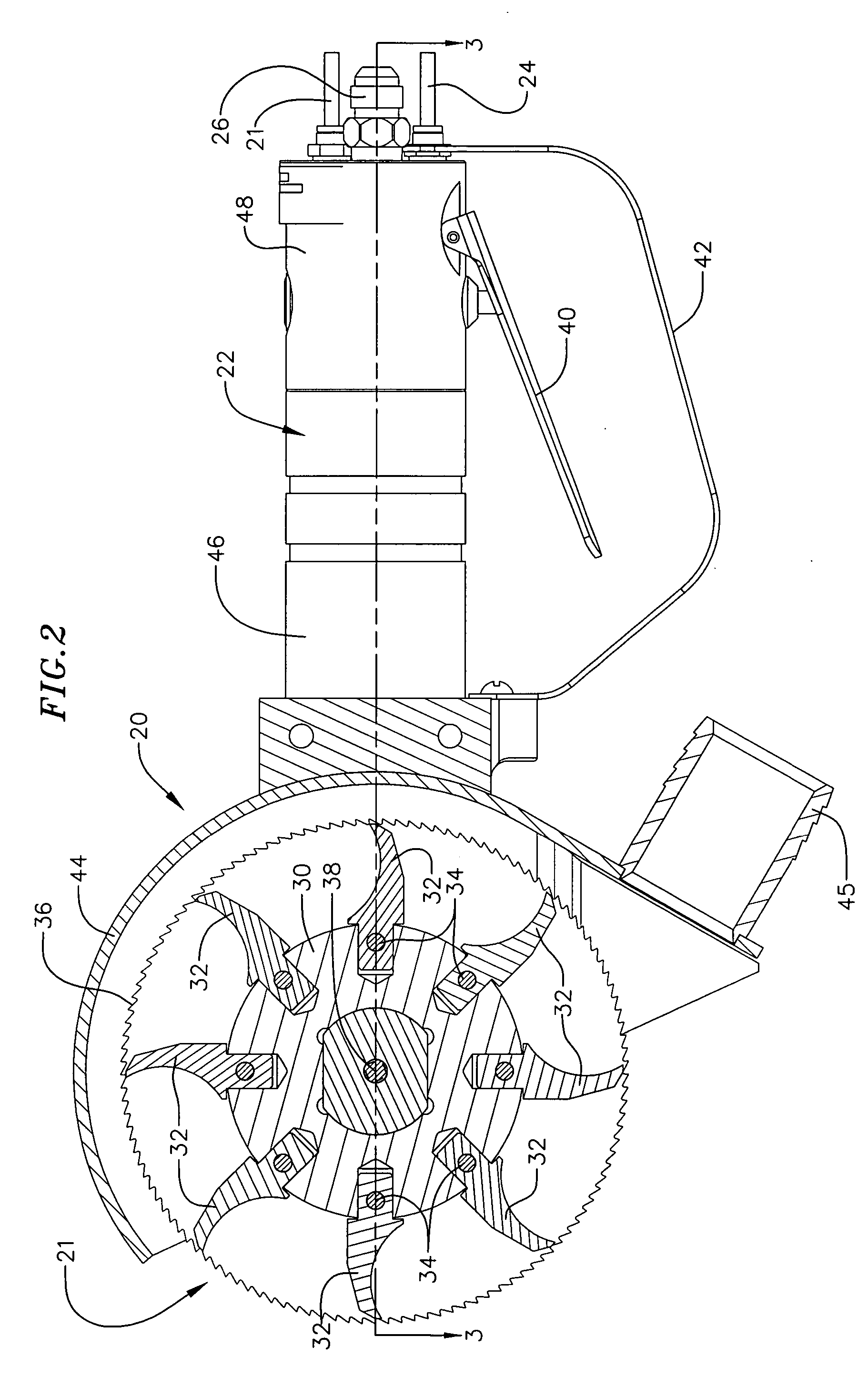

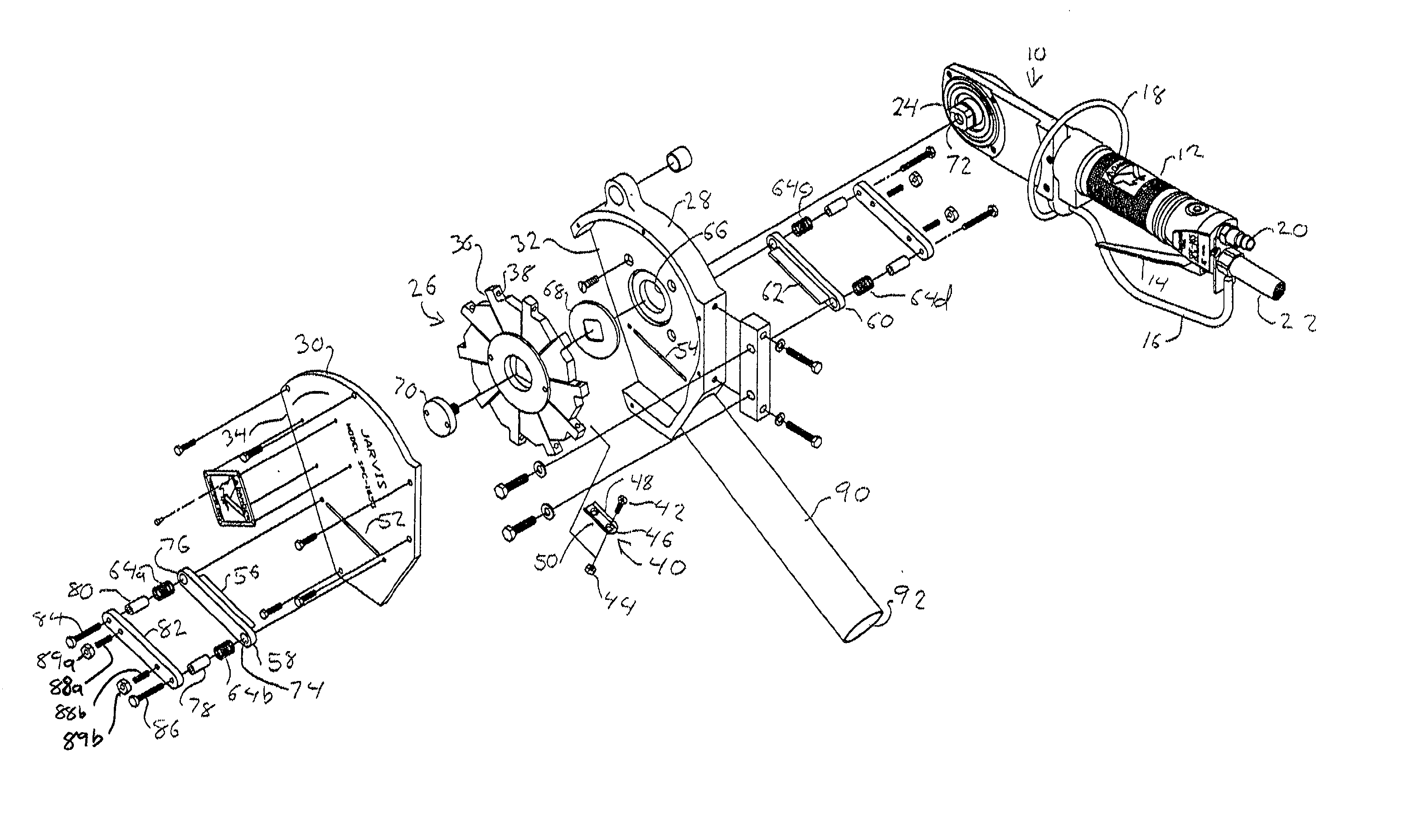

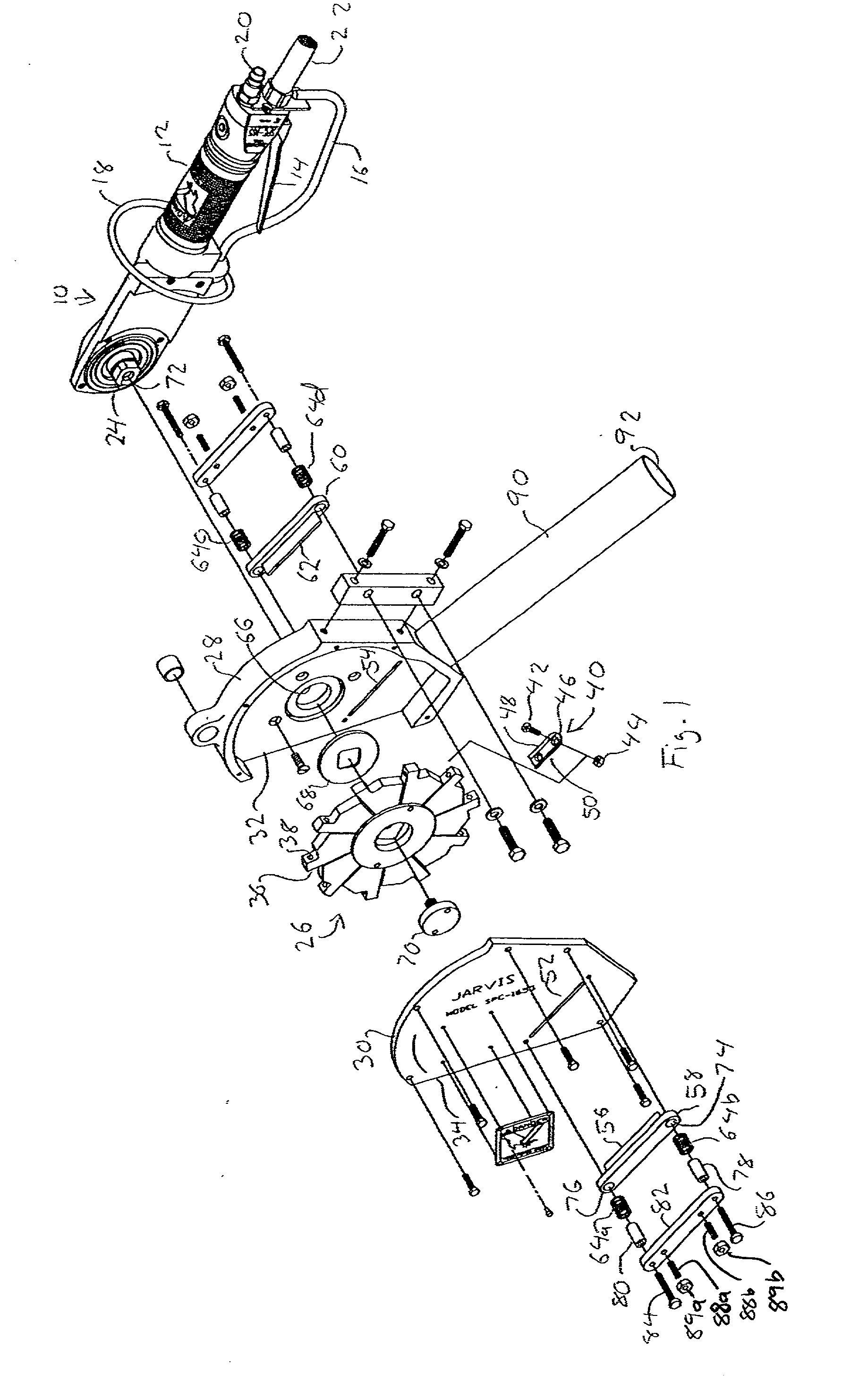

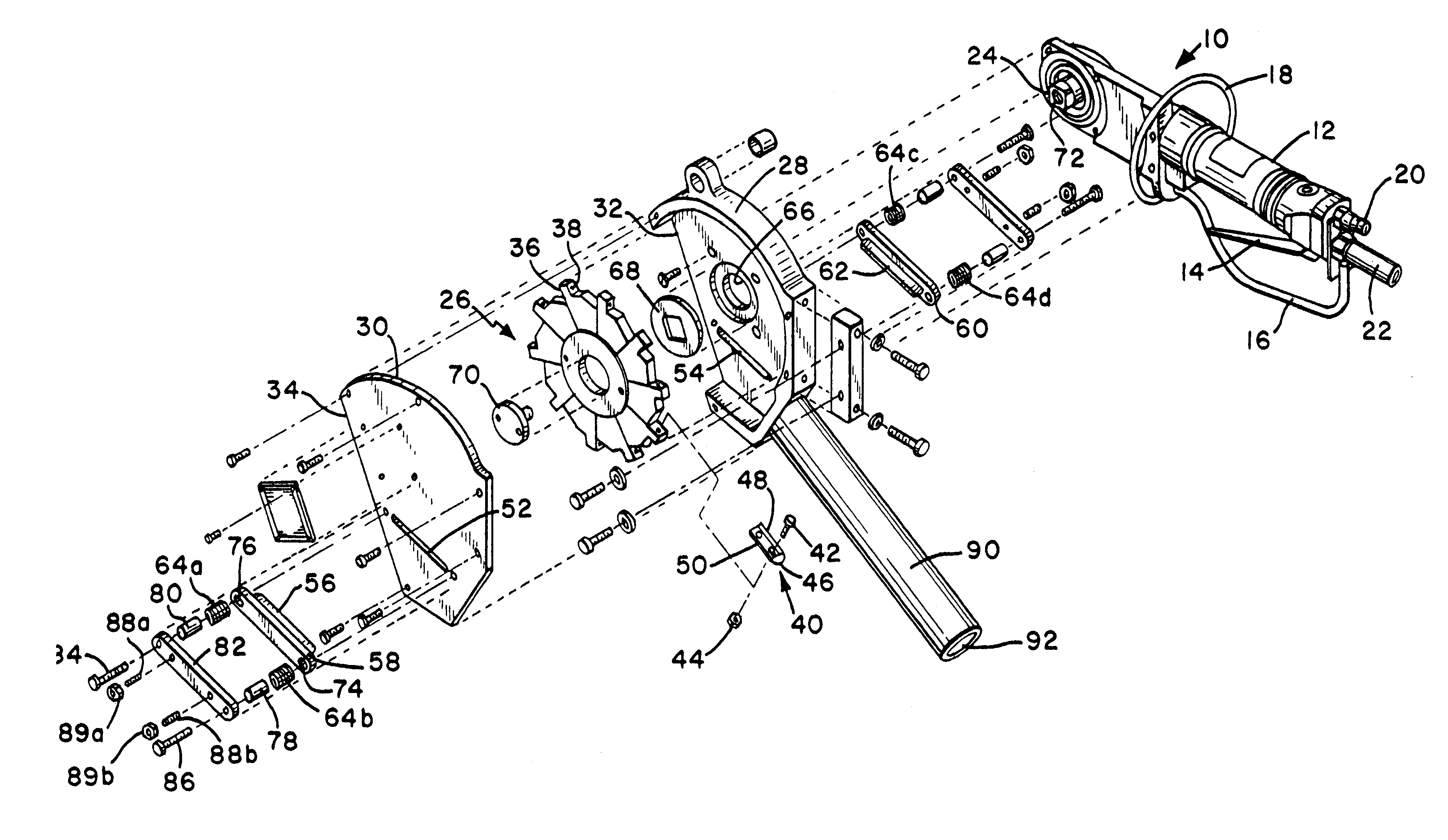

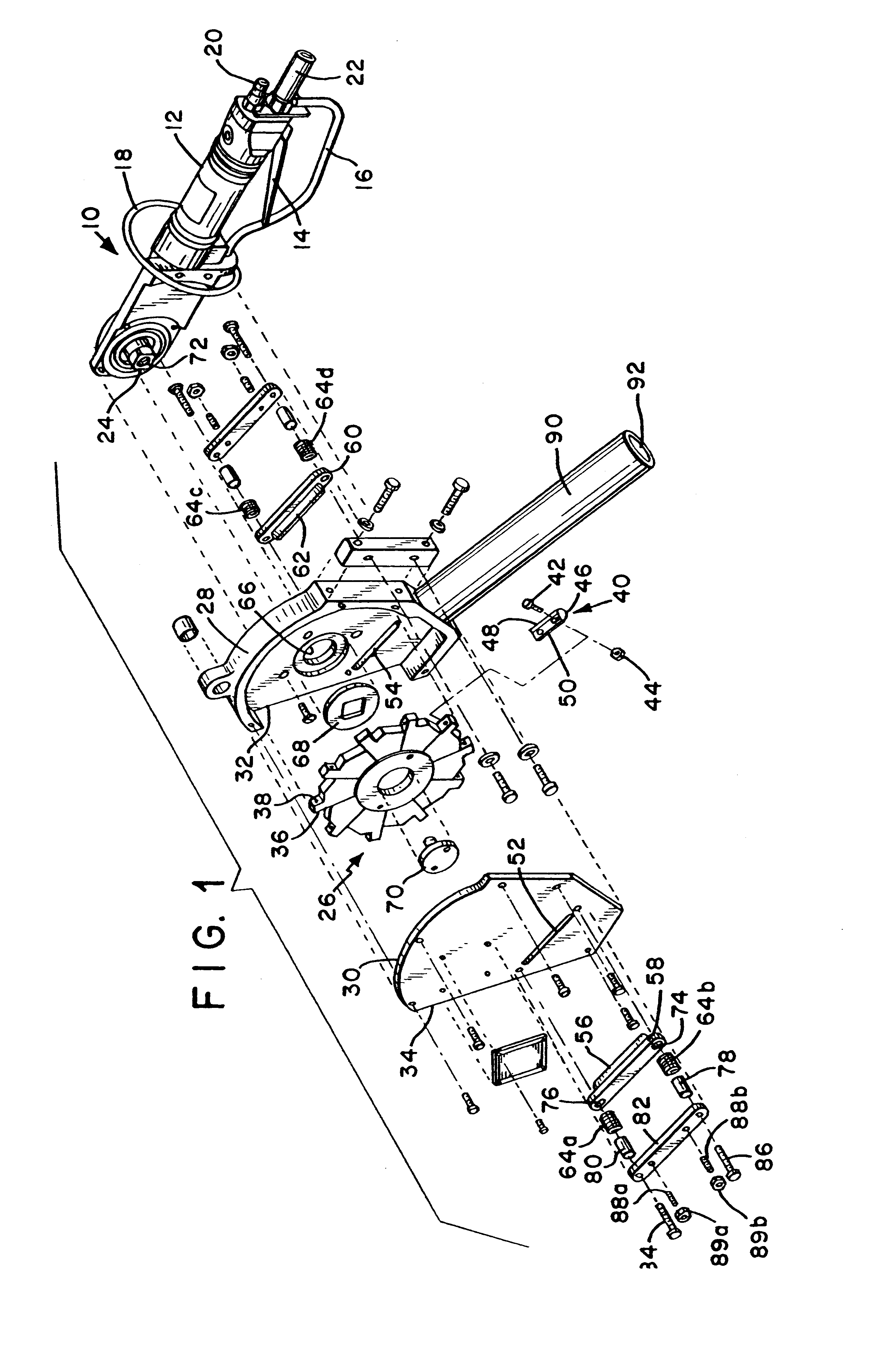

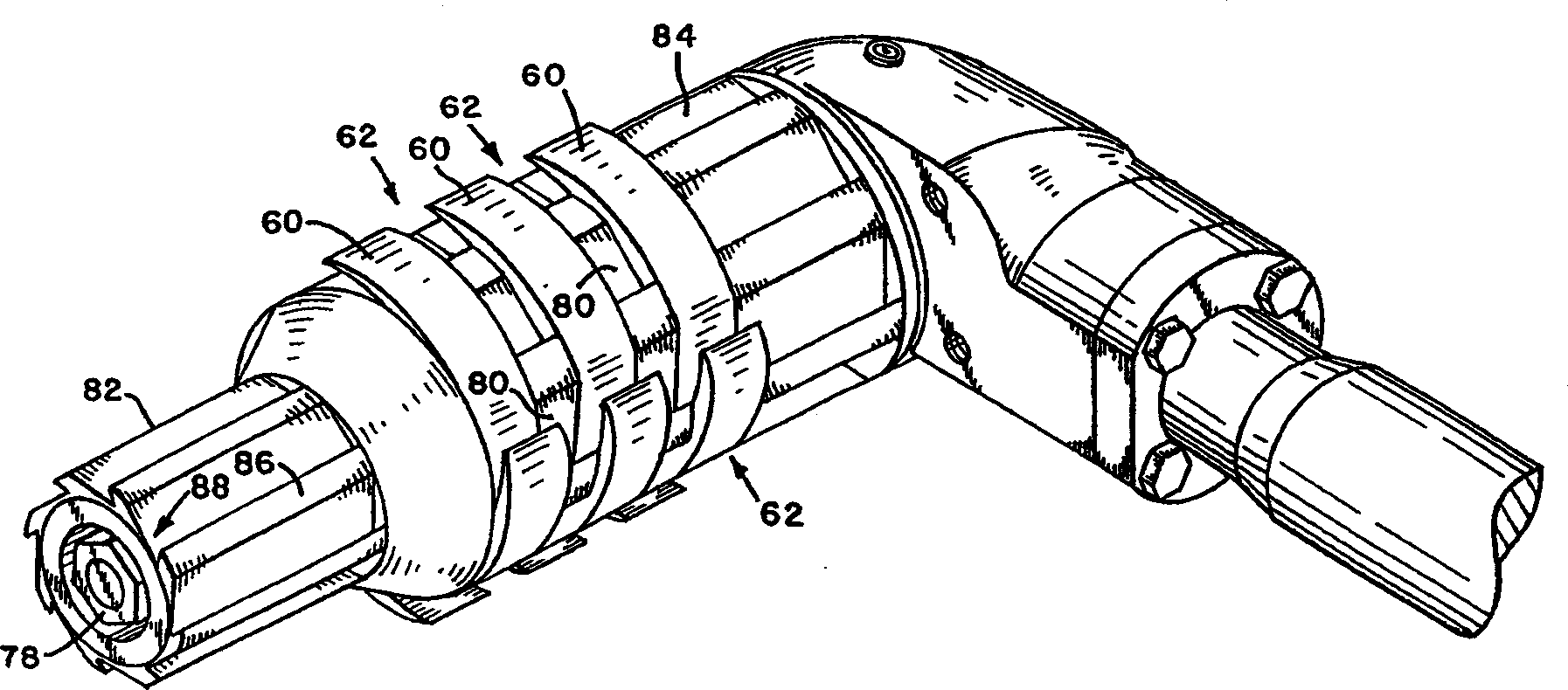

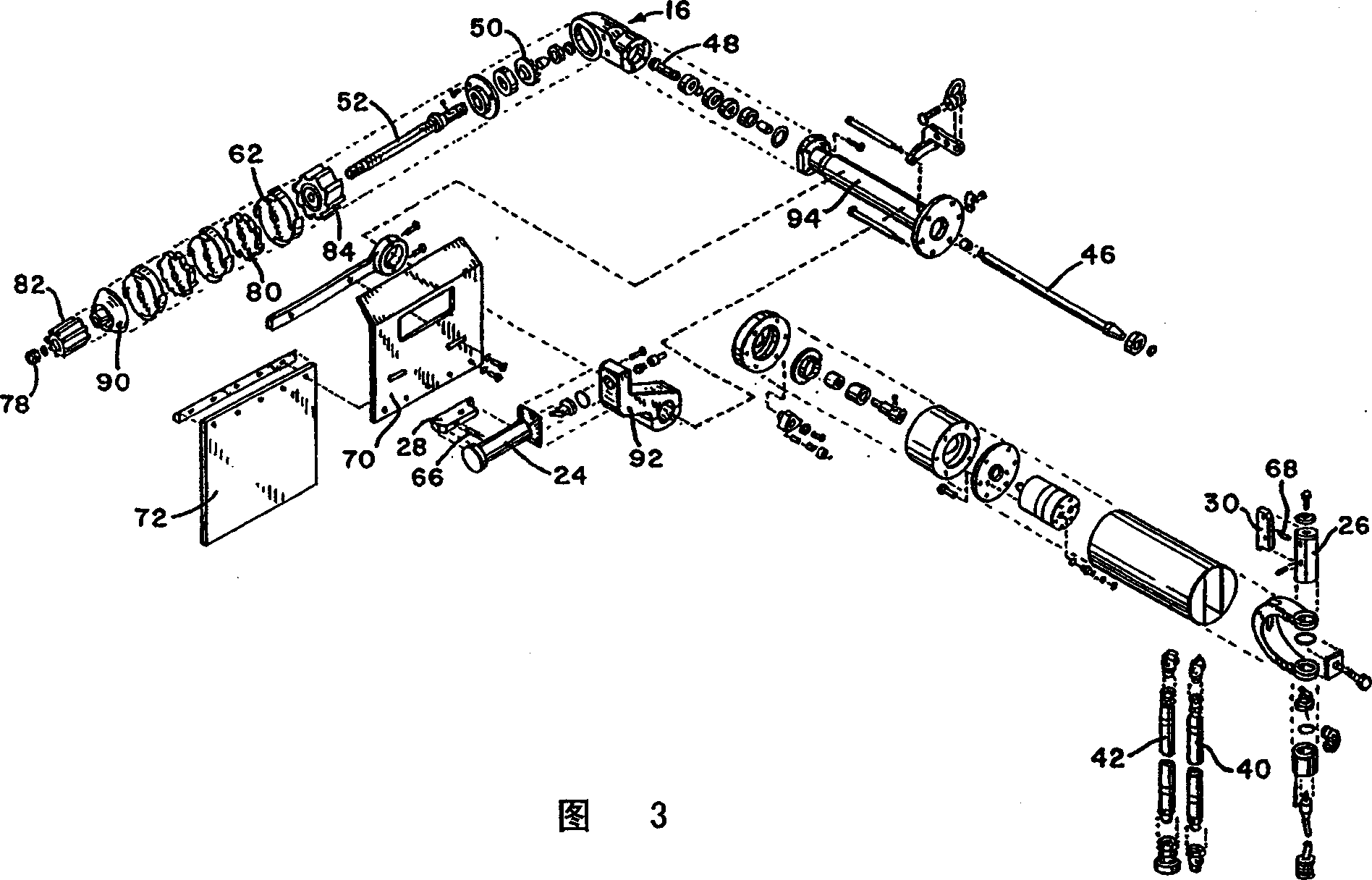

Spinal cord removal tool with adjustable blades

InactiveUS20030045882A1Increase speedSupport moreEviscerating scissorsSurgical sawsLow noiseSpinal cord

A spinal cord removal tool for removing a spinal cord and spinal cord membrane from a carcass includes a spinning blade disk having multiple removal blades mounted around its perimeter, each removal blade having a forward facing cutting edge that can enter the spinal cord channel and side cutting edges that cooperate with side blades to chop the spinal cord membrane as it is brought into the tool. The side blades are adjustably mounted to move towards and away from the removal blades and compensate for changes in the width of the removal blades due to wear or sharpening. The side blade adjustment mechanism may include a self-adjusting floating mount for the side blades or a manually adjustable mount that can be set to any desired blade clearance for higher-speed and lower noise operation.

Owner:JARVIS PROD

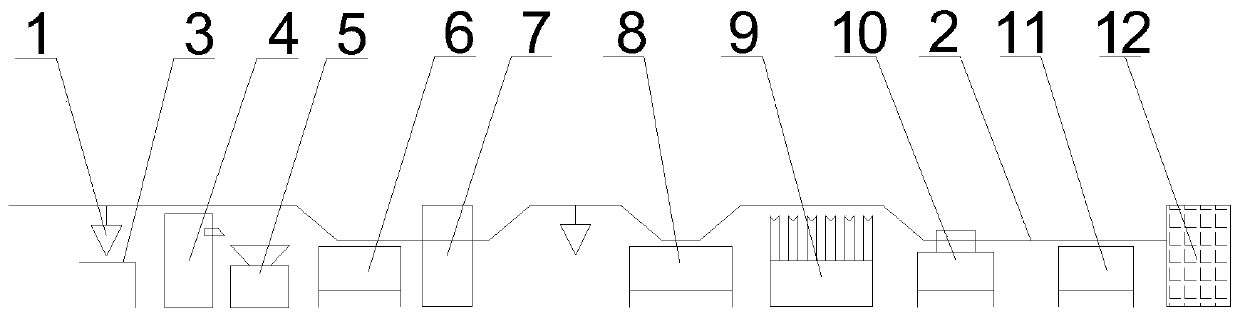

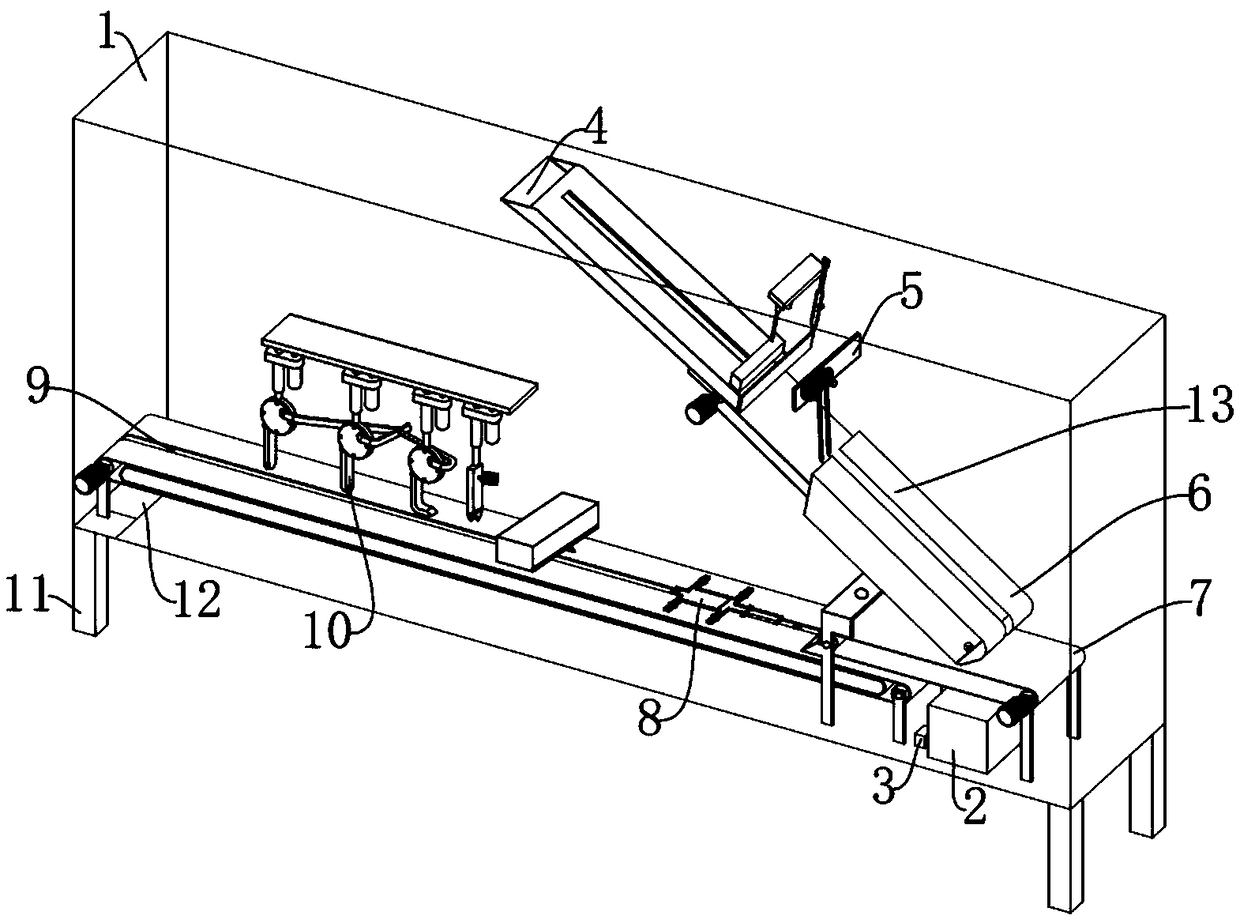

Slaughtering and processing device and slaughtering and processing method for chilled chicken

InactiveCN111418638AGreat tasteEnsure hygieneBlood collection/stirring apparatusPoultry/fish slaughtering/stunningBiotechnologyBrowning

The invention discloses a slaughtering and processing device and slaughtering and processing method for chilled chicken. The method comprises the following steps: manually fixing chicken on a hook ofa conveying device; sending the hung chicken into a stunning and killing device through the hook and the conveying device for welfare slaughtering, draining blood after slaughtering, and then performing soaking, scalding and unhairing, and sending the treated chicken into a first cleaning tank for cleaning; performing evisceration to remove internal organs after cleaning, and then performing cleaning again; and sending the chicken into a bone removing device to remove the head and feet after cleaning, sending the chicken into a cooling tank for pre-cooling, and sending the chicken into a low-temperature freezing box after per-cooling. The slaughtering and processing method is clean and rapid, ensures sanitation of slaughtering sites, reduces bacterial colony on the chicken, and avoids chicken taste deterioration caused by the huge change from the high temperature for unhairing to the freezing temperature, breeding of bacteria is prevented by a plasma electrostatic field, and the purpose of continuous insurance is achieved. Moreover, juice loss and surface browning are avoided, quality is ensured, the shelf life is prolonged, and the slaughtering and processing method has wide applicability in the field of chicken processing.

Owner:新疆帕戈郎食品有限公司

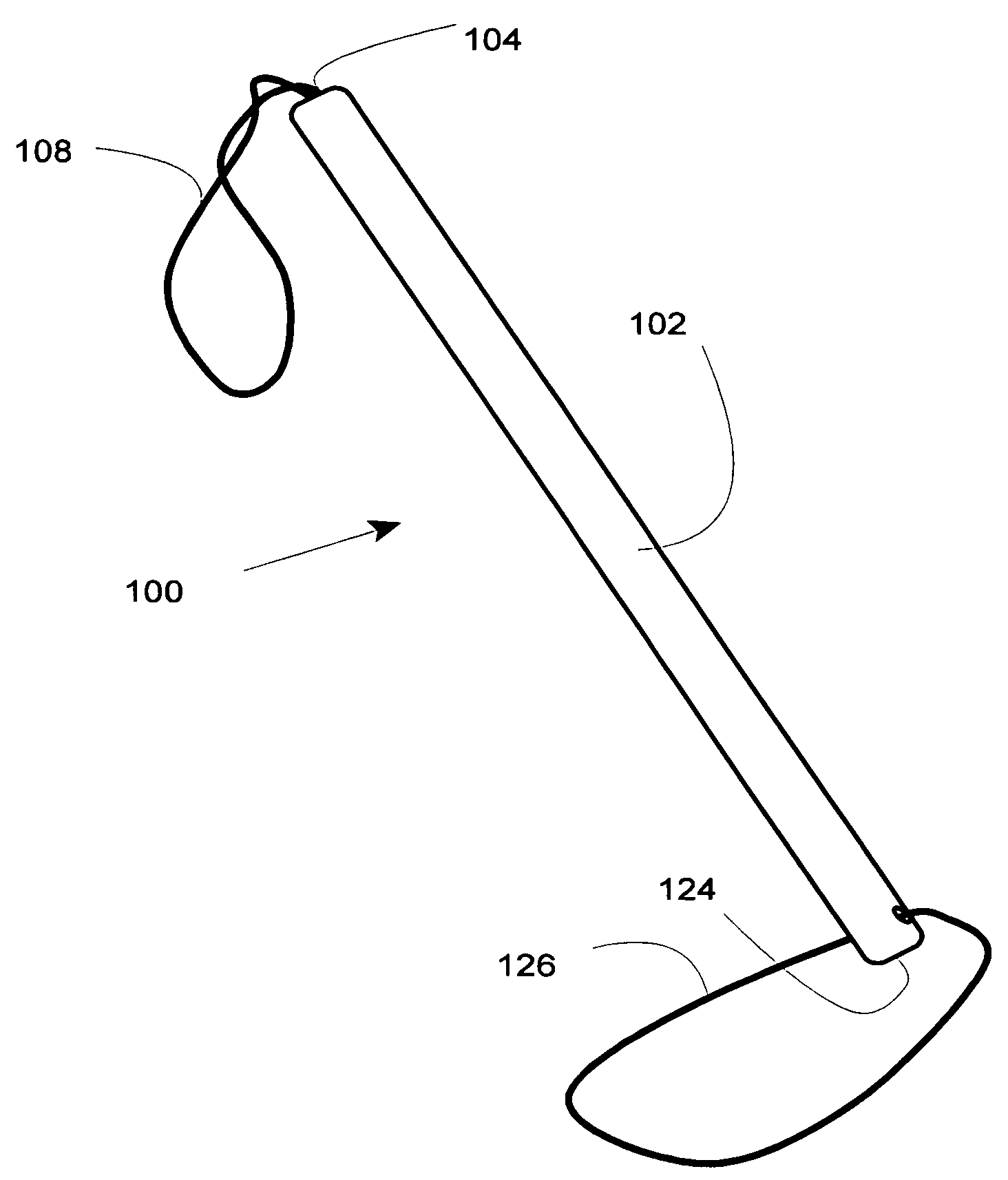

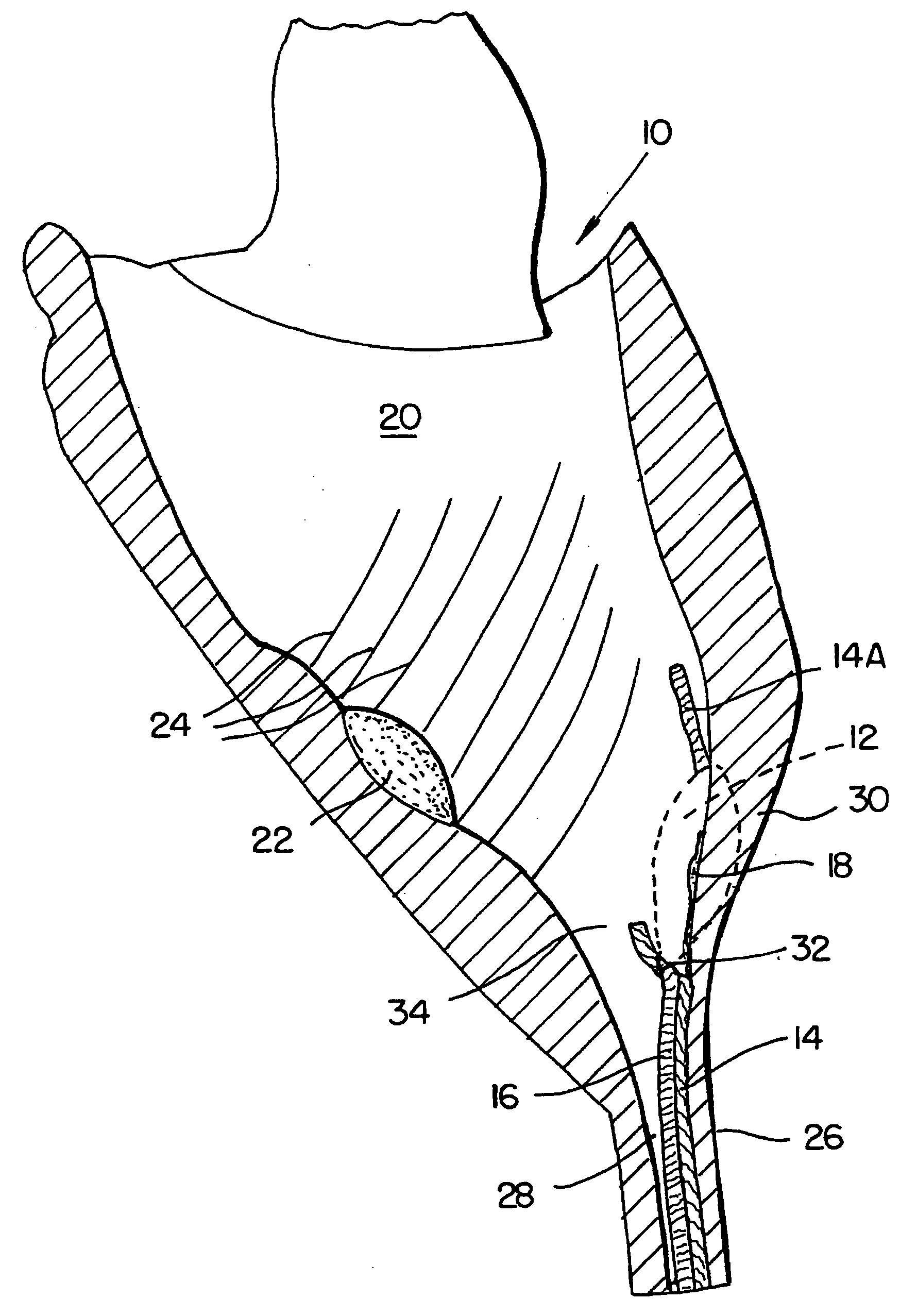

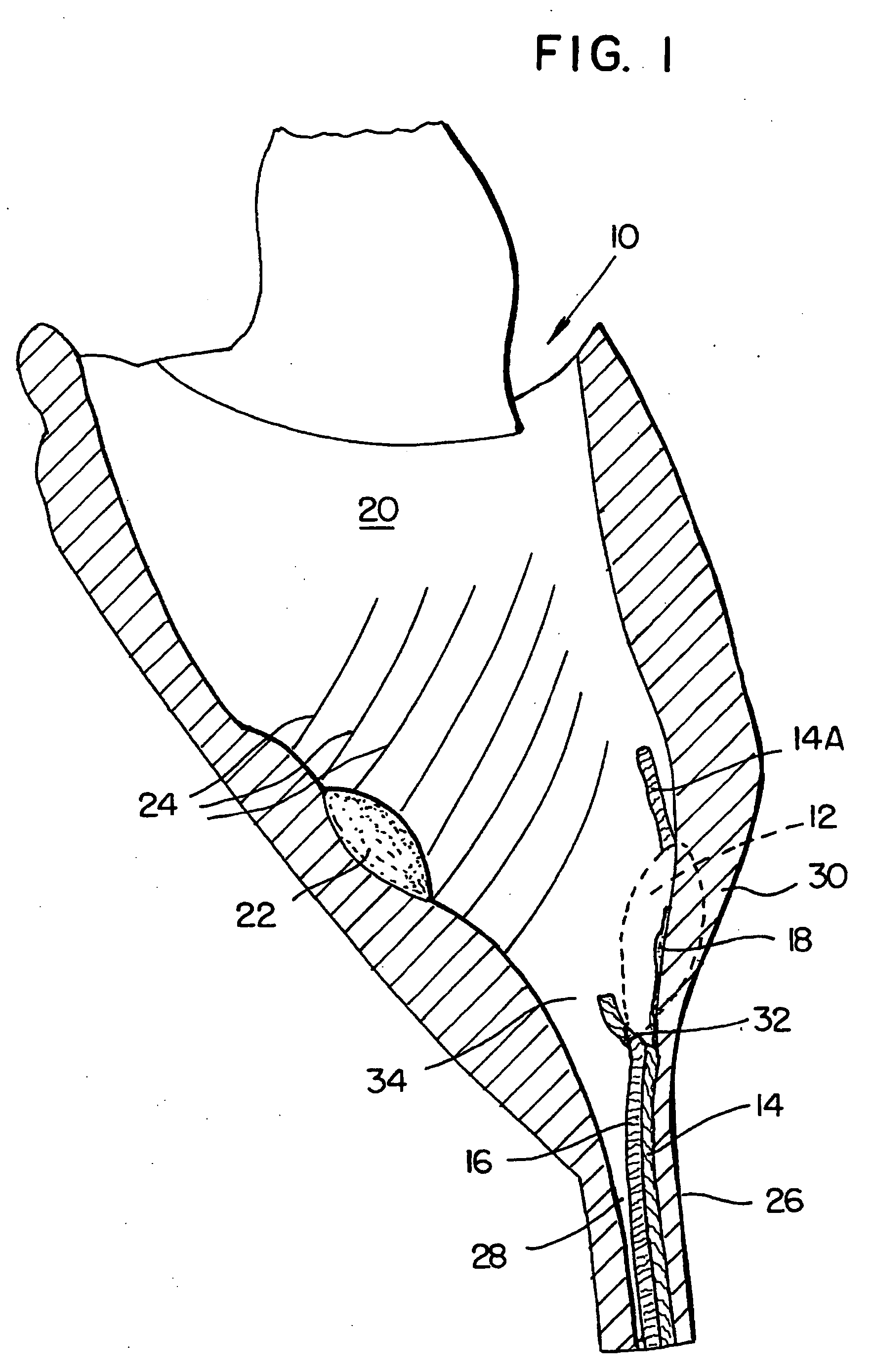

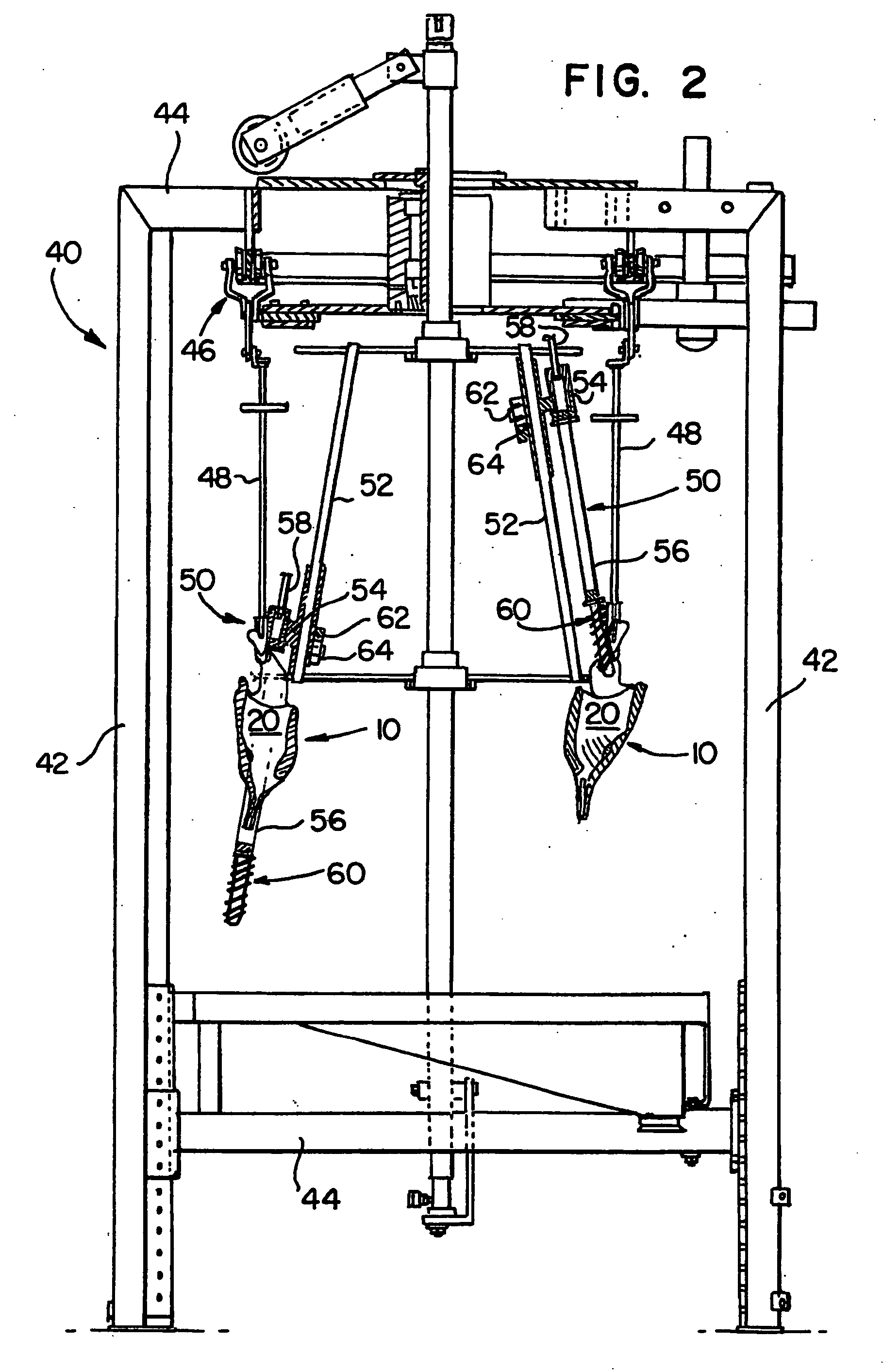

Easy big game field dressing apparatus

InactiveUS7252583B1High strengthTighter engagementFish washing/descalingPoultry plucking mechanismsEngineeringBody cavity

A big game dressing device has a handle portion having two ends: a first end with a grip attachment to aid gripping it with a hand, and a second end having a windpipe loop dimensioned and configured to engage around the windpipe of a big game animal to be gutted. The device may be extendible, may have a handle or the like at the first end, and may be made of a strong material. In use, the body cavity of the big game animal is cut open from top to bottom and the windpipe of the animal is cut across. The windpipe loop is then placed over the end of the windpipe and the device is pulled, assisting in the removal of the visceral of the animal.

Owner:JONES RONALD T

Decropping tool and wrapped cam for use in food processing machinery

InactiveUS20050186895A1Easy to manufactureHigh degree of path accuracyAnimal stomach clearancePoultry eviscerating devicesDead bodyEngineering

A tool, or probe, is provided for insertion into a avian or poultry carcass for removing the crop and / or windpipe and / or gullet and / or other undesired viscera from the neck of the bird carcass. The probe has helical threads protruding from a probe body. V-shaped voids are cut into the helical threads to provide teeth for removal of the crop and other inedible viscera from the carcass. A cam and method of manufacturing a cam for use in decropping machines and other food processing machinery is provided. The cam includes plastic guides that are pre-shaped in two dimensions and then wrapped about a three dimensional cam frame to provide a desired path for a cam follower.

Owner:JOHNSON FOOD EQUIP

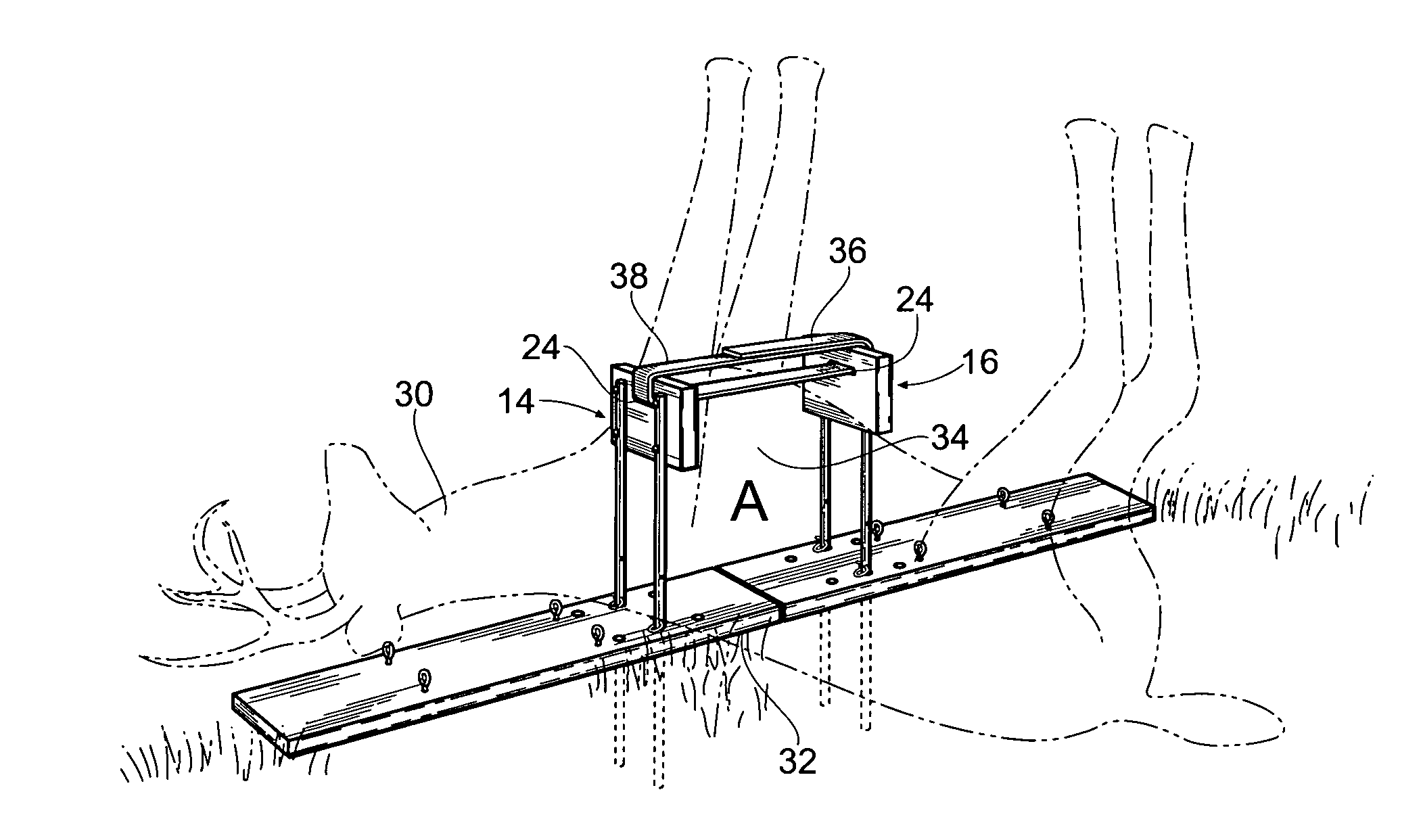

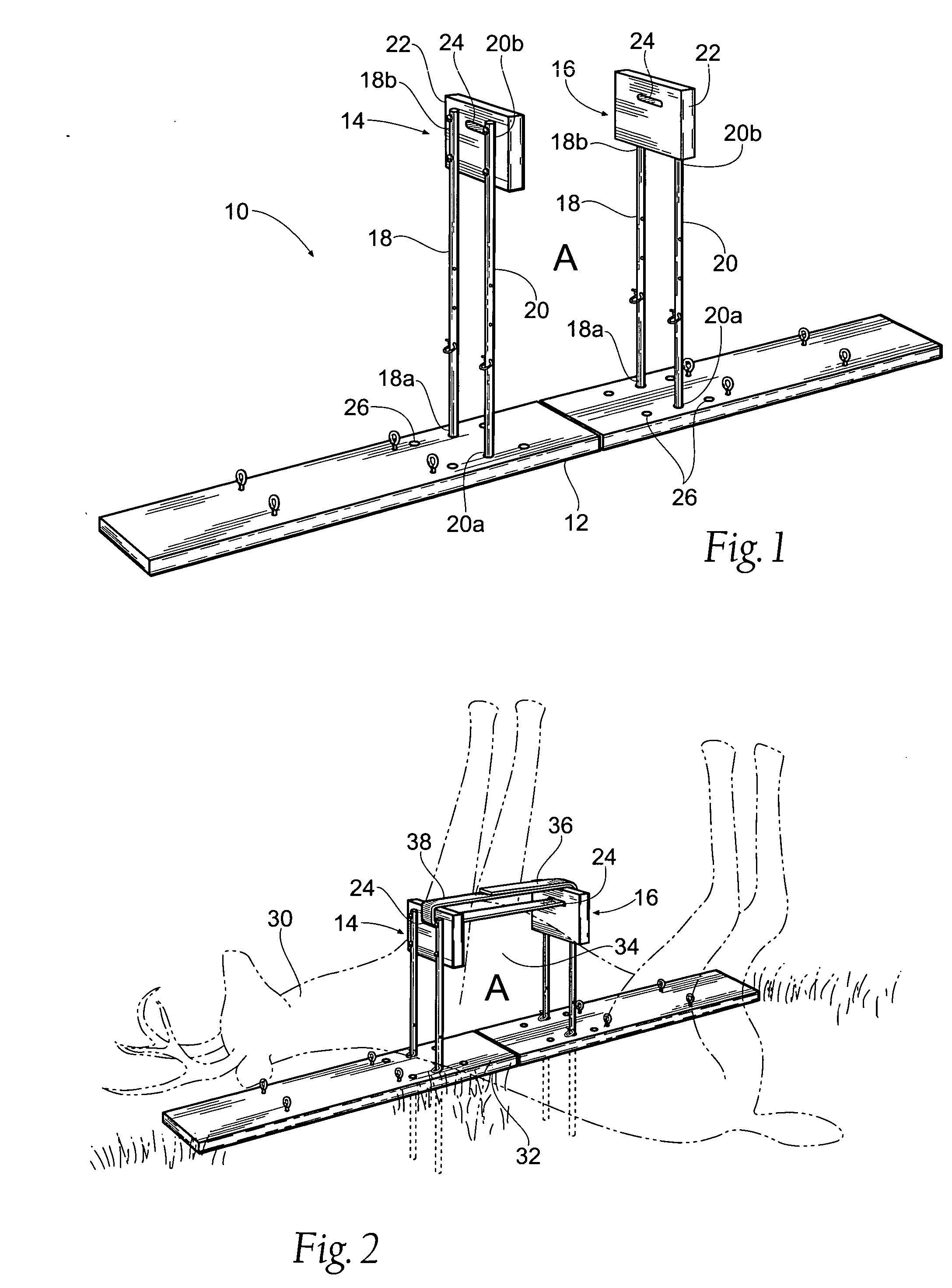

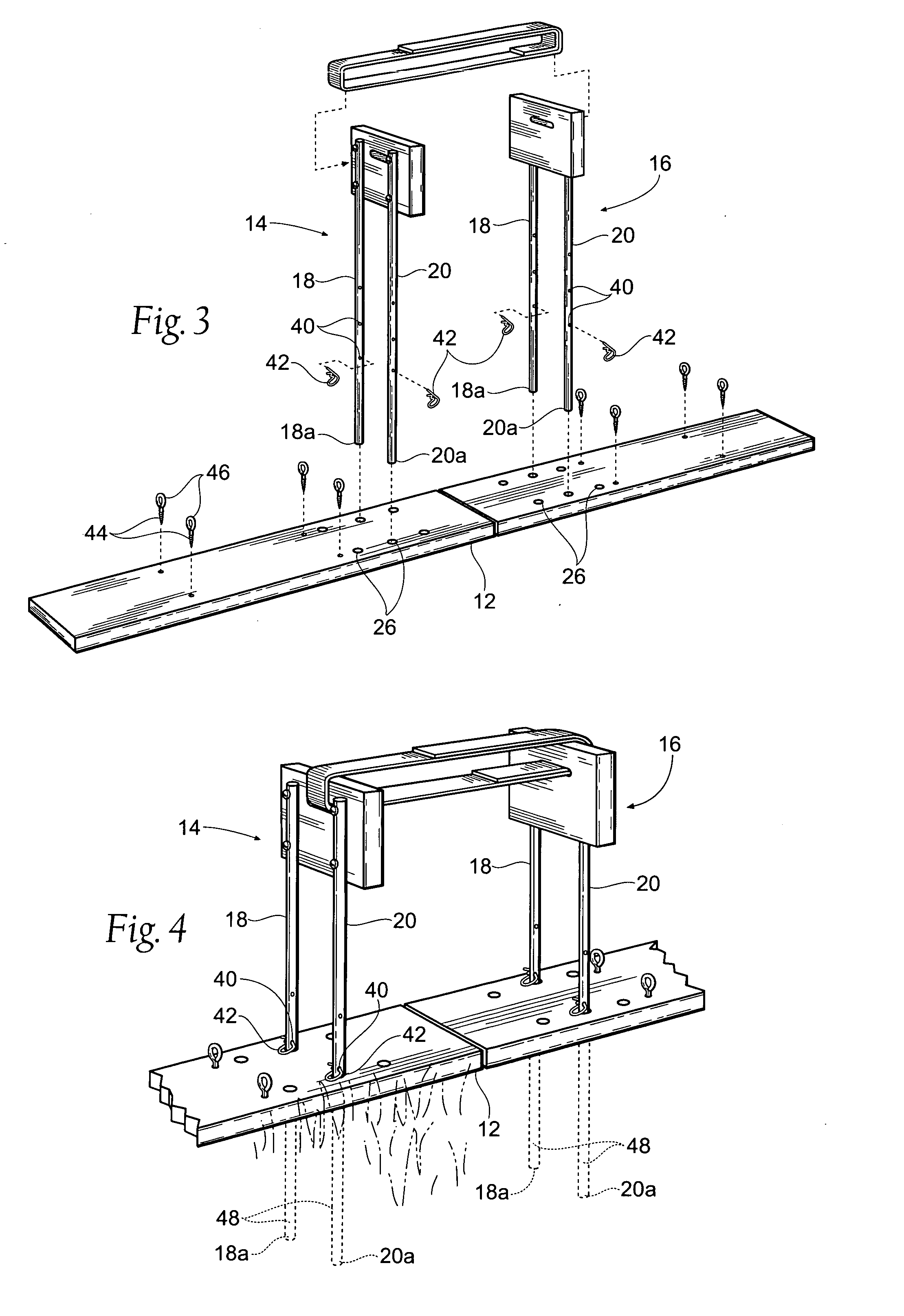

Deer evisceration apparatus

InactiveUS20060252359A1Eviscerated easily and efficiently by an individual personFish work-tablesSlaughtering stands/spreadersProne positionAbdominal evisceration

A portable apparatus for eviscerating an animal comprising a base arranged for placement on a flat surface, a first upright section, and a second upright section. The base supports the upright sections in a spaced apart manner, sufficient enough to form a cross-sectional area defined by the base and upright sections to receive the animal in a lengthwise prone position.

Owner:HELBING ORLIN H

Spinal cord removal tool

A spinal cord removal tool for removing a spinal cord and spinal cord membrane from a carcass includes a spinning blade disk having multiple removal blades mounted around its perimeter, each removal blade having a forward facing cutting edge that can enter the spinal cord channel and side cutting edges that cooperate with floating self-adjusting side blades to chop the spinal cord membrane as it is brought into the tool.

Owner:JARVIS PROD

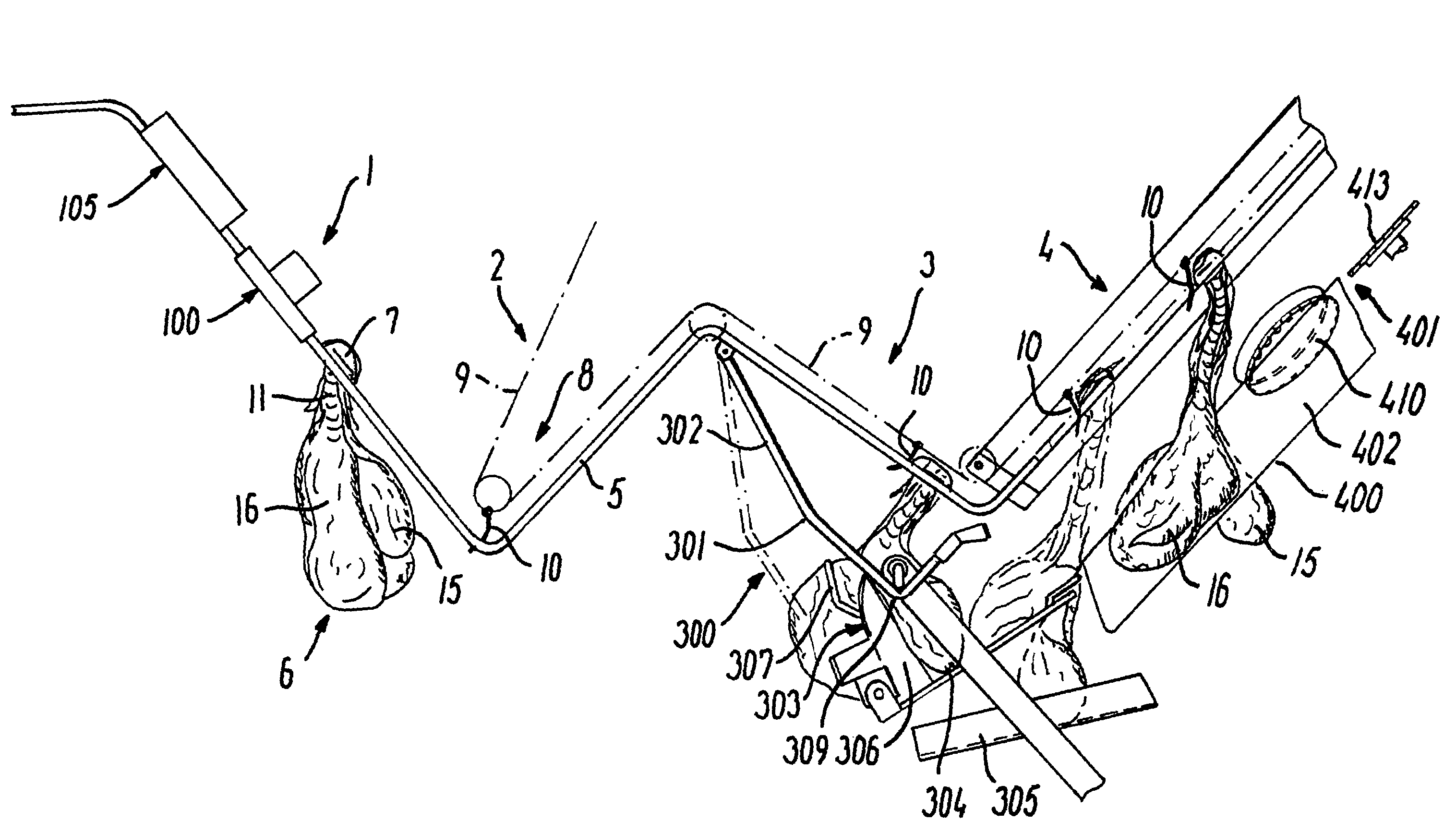

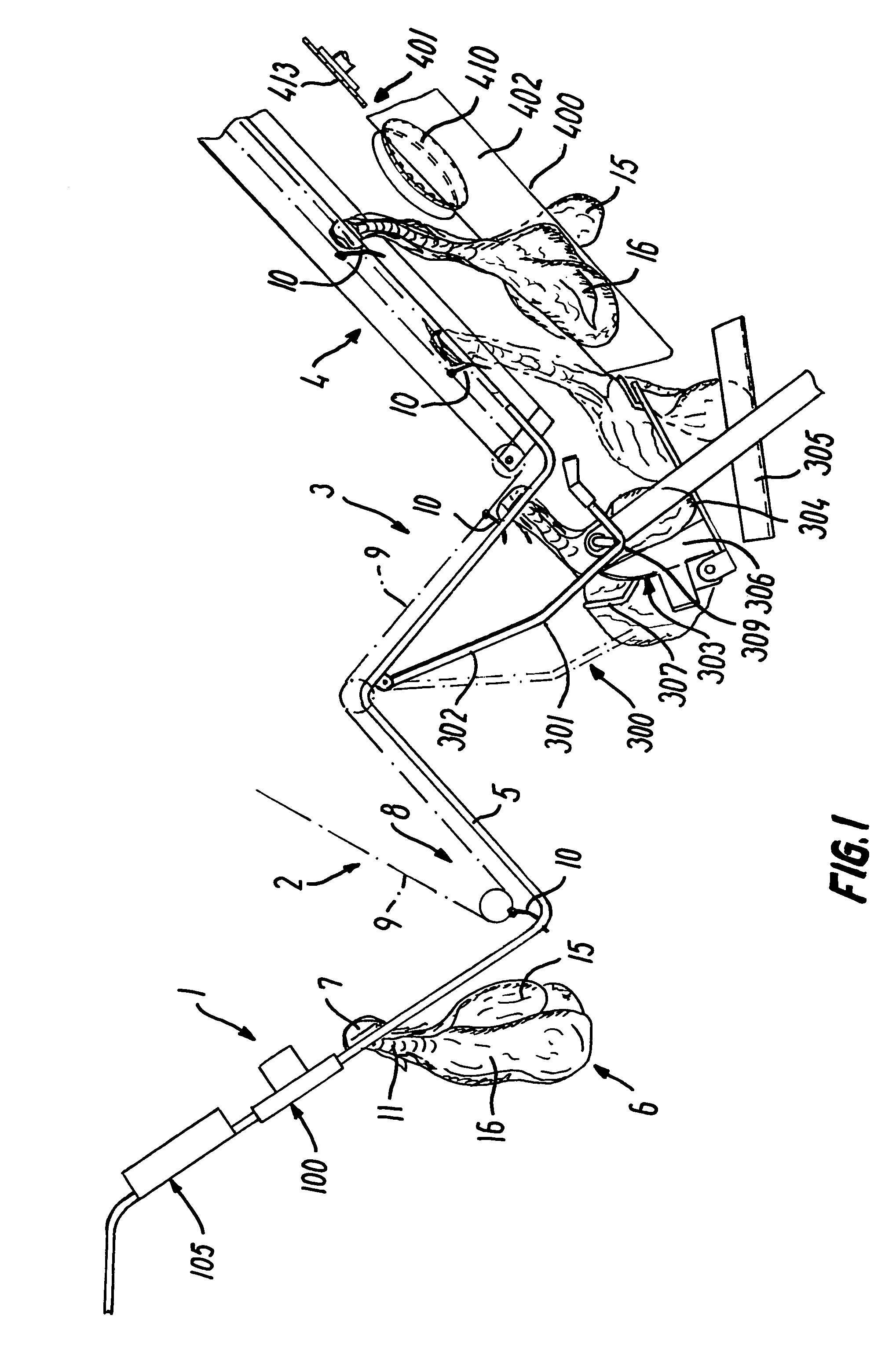

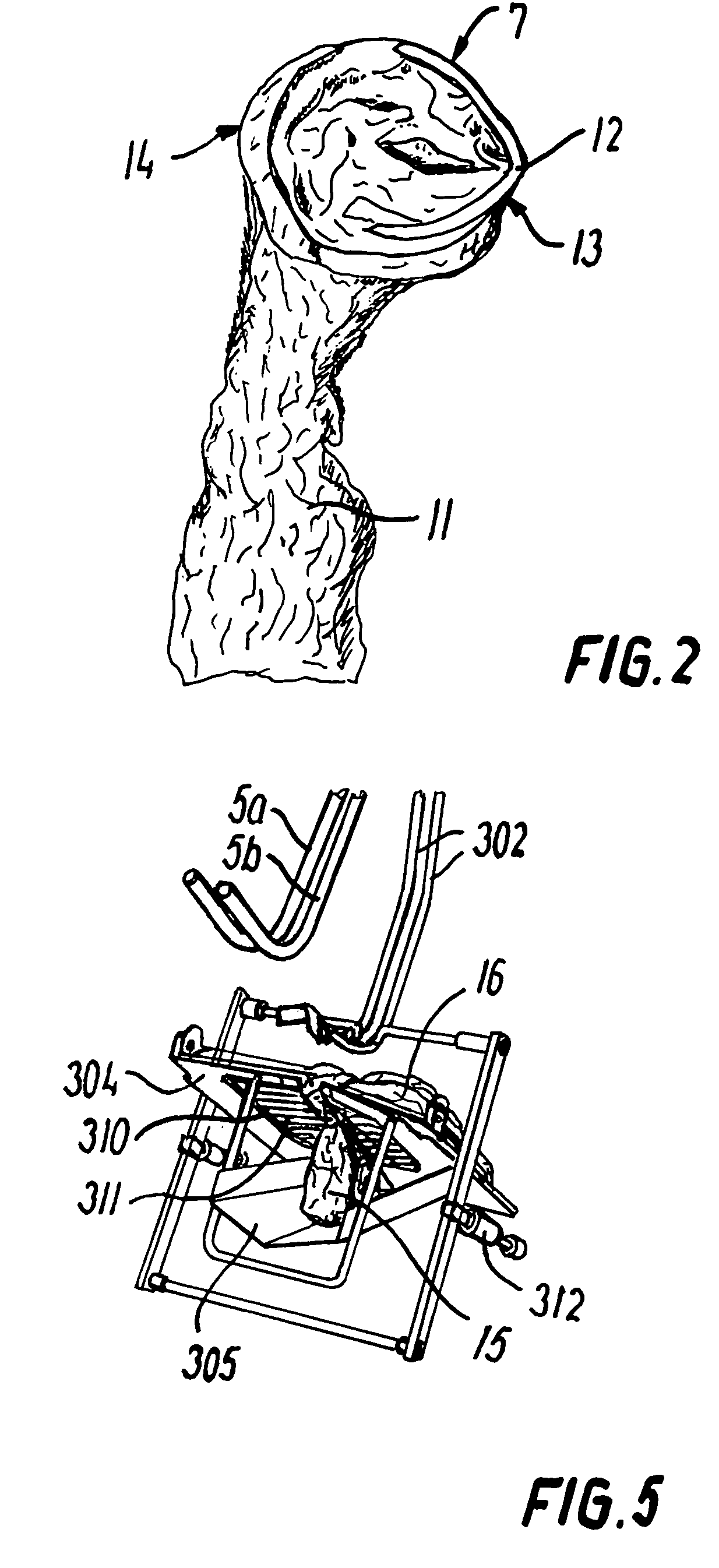

Apparatus and a method for automatic cutting of organs from a plucks set from a carcass

An apparatus for automatic cutting of organs from a plucks set from a carcass by a cutting device, the plucks set comprising larynx, gullet and windpipe, lungs and heart. The apparatus comprises a suspension device for holding the pipes, moving device for moving the plucks set relative to the cutting device, while the pipes are held in the suspension device, and a guiding device adapted to guide the plucks set to the cutting deice and keep the lungs and the heart separated from each other.

Owner:TEKNOLOGISK INST

Device for cleaning and for processing the rectum and pelvis of slaughtered pigs and operating method of said device

The invention relates to a device for cleaning and processing the rectum and pelvis of slaughtered pigs, that is mainly mechanical in nature, and its operating method and that it solves the problem of the cleaning and disinfection operations of these devices, basically of the blades and the mandrel which are inserted into the animal's rectum, this invention carries out these operations in a single operation, which allows it to successively in about 2 to 3 seconds enter the animal's rectum, cut it out and make an incision in the animal's pelvis and then simultaneously clean and sterilize by incorporating into the device a semi-enclosed chamber in which this cleaning takes place.

Owner:INNOVATIVE FOOD ROBOTICS BANSS & AIRA

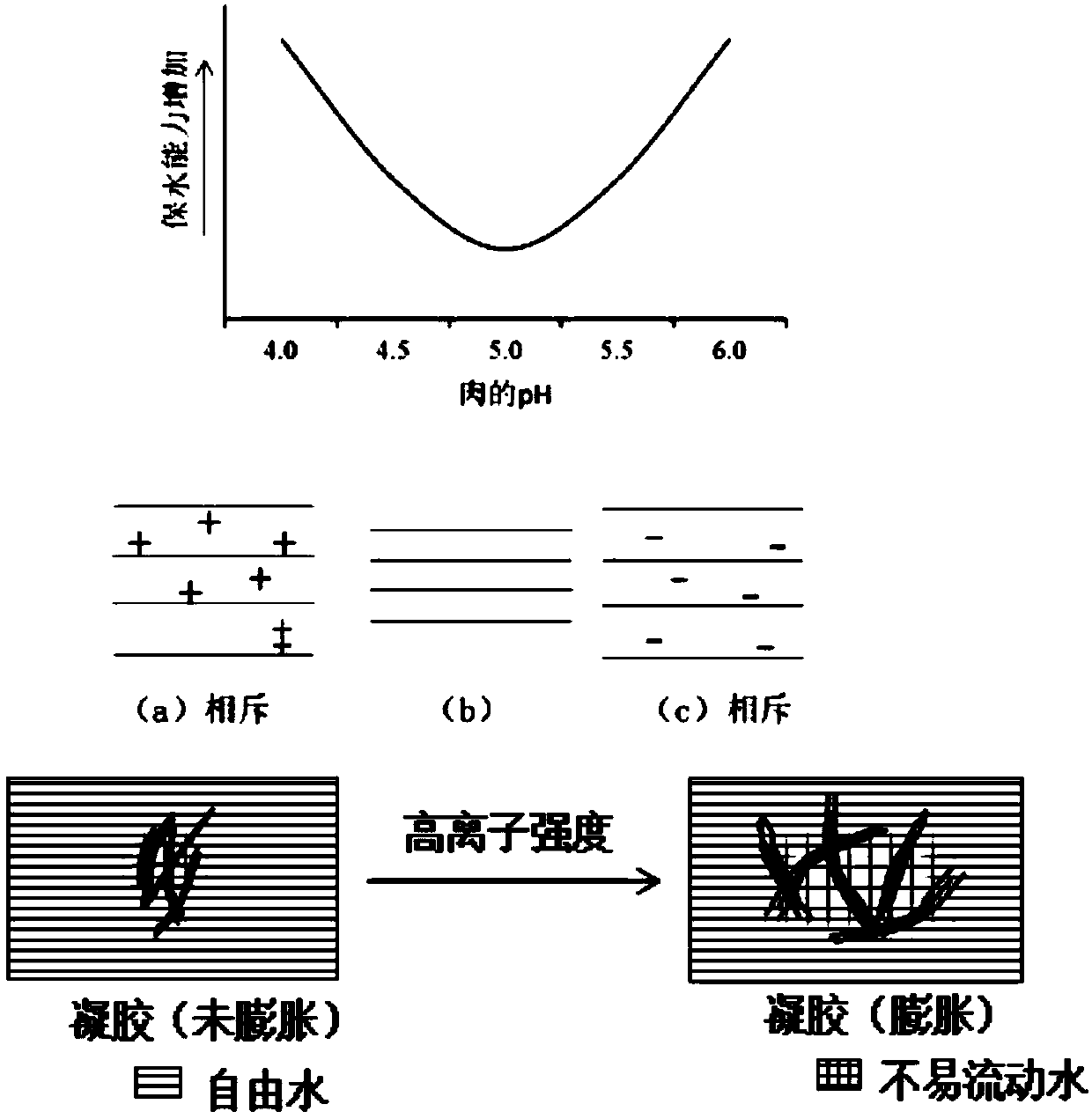

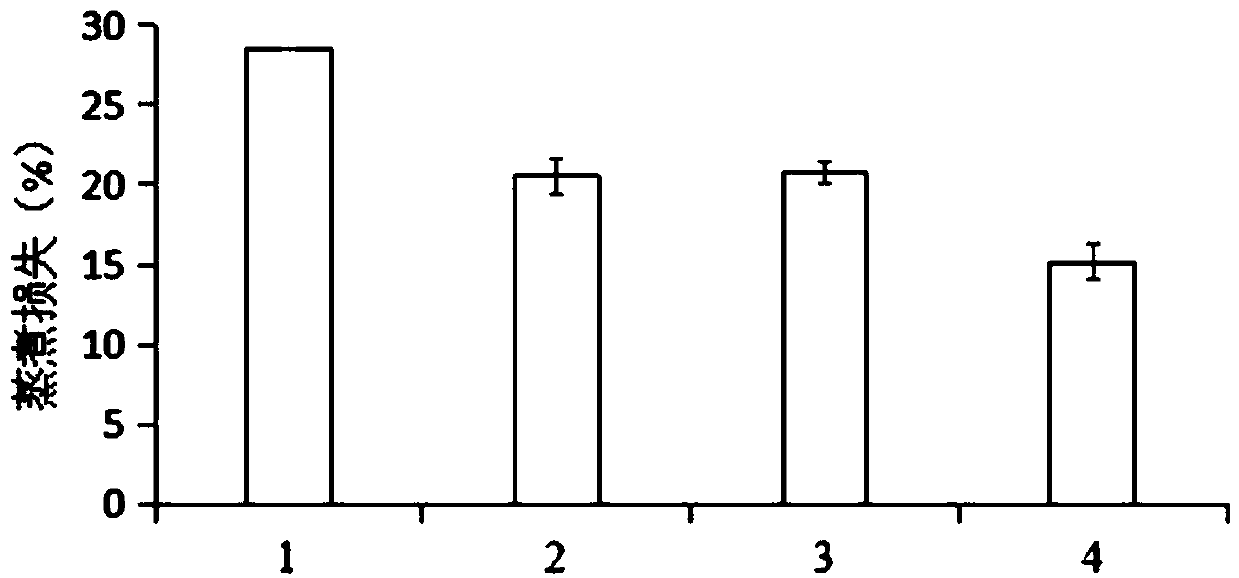

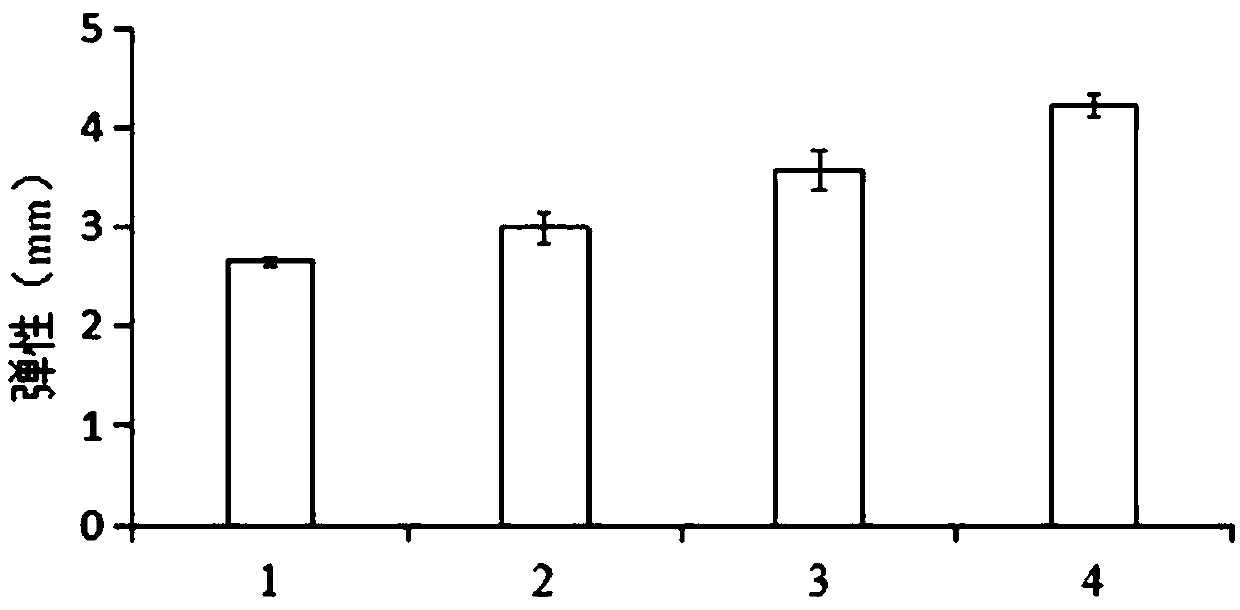

Compound water retaining agent capable of improving bullfrog quality and application method of compound water retaining agent

InactiveCN109588645AImprove water retentionImprove qualityFood ingredient as antioxidantFood ingredient as raising agentSodium bicarbonateSolubility

The invention provides a compound water retaining agent capable of improving bullfrog quality and an application method of the compound water retaining agent. Raw materials of the compound water retaining agent comprise polyphosphate and sodium bicarbonate, polyphosphate is basic, can increase pH of bullfrog and can also binds with polyvalent metal ions binding with structural protein of muscle, so that carboxyl groups get free from protein, the protein is enabled to be negatively charged, and electrostatic repulsion between the carboxyl groups is increased. Polyphosphate can provide higher ionic strength, can improve solubility of myofibrillar proteins and the like, is beneficial to transformation of muscle protein into a loose state and can also dissociate actomyosin, water retention ofmeat is improved, and tenderness of the meat is improved. Sodium bicarbonate can also provide a basic environment and improve meat bulkiness, so that the protein structure of the treated bullfrog getslooser, the water retention is improved substantially, the tenderness is improved, eating quality of the bullfrog is improved, and the market of the bullfrog is further expanded.

Owner:新派(上海)餐饮管理有限公司

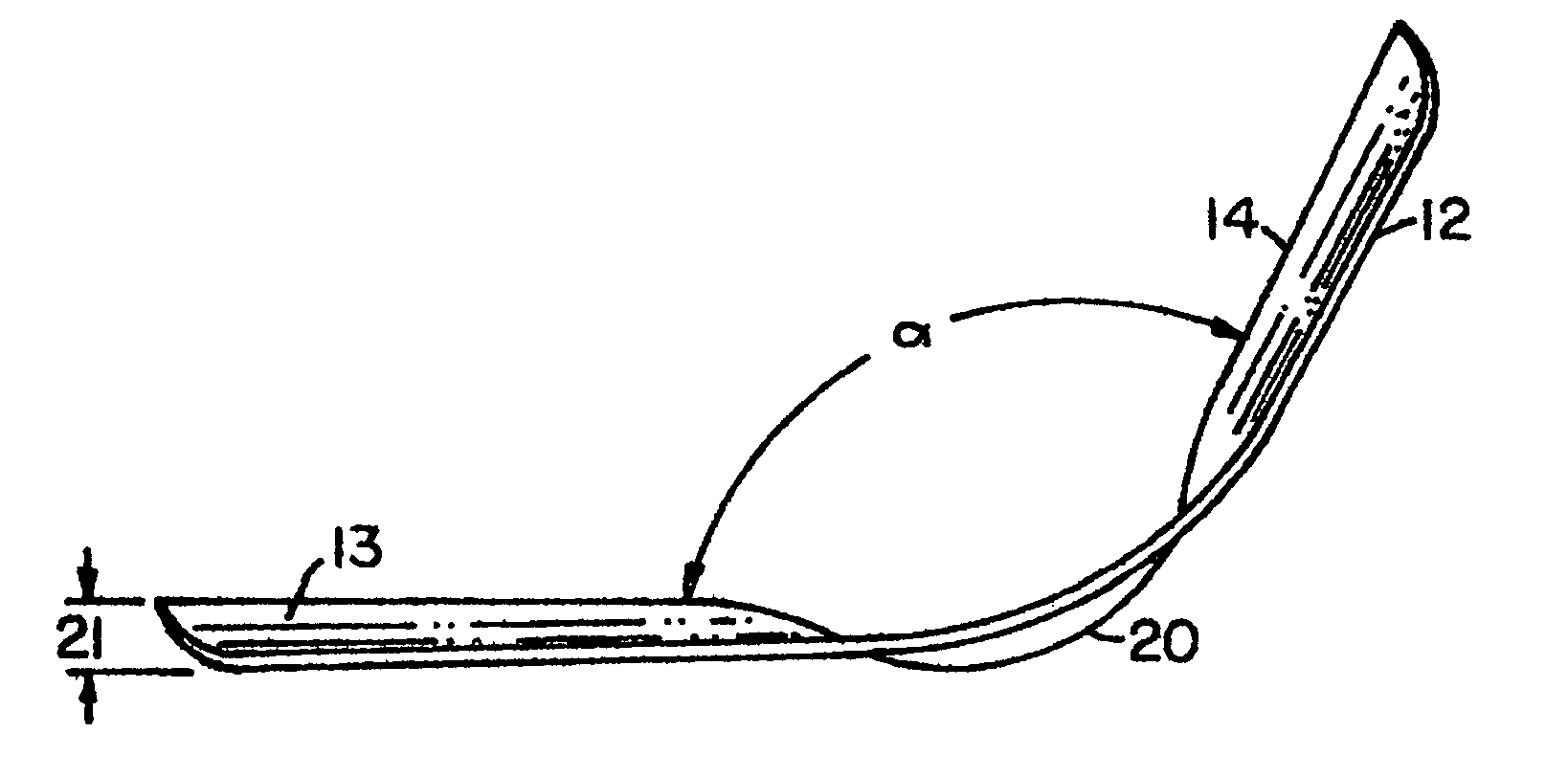

Deer eviserating protective tool and method

A protective tool for assisting in field dressing a deer, the tool having a protective shield of a convenient width and contour to be slid thru an incision made thru the belly skin of a deer just forward of the pelvic crest and hence into and thru the pelvic cavity between the inner surface of the crest and the colon, whereby the crest can then be sawed thru longitudinally along the crest without danger of the saw cutting into the colon or adjacent viscera and releasing meat damaging fluids.

Owner:MCCONNELL WILLIAM R +1

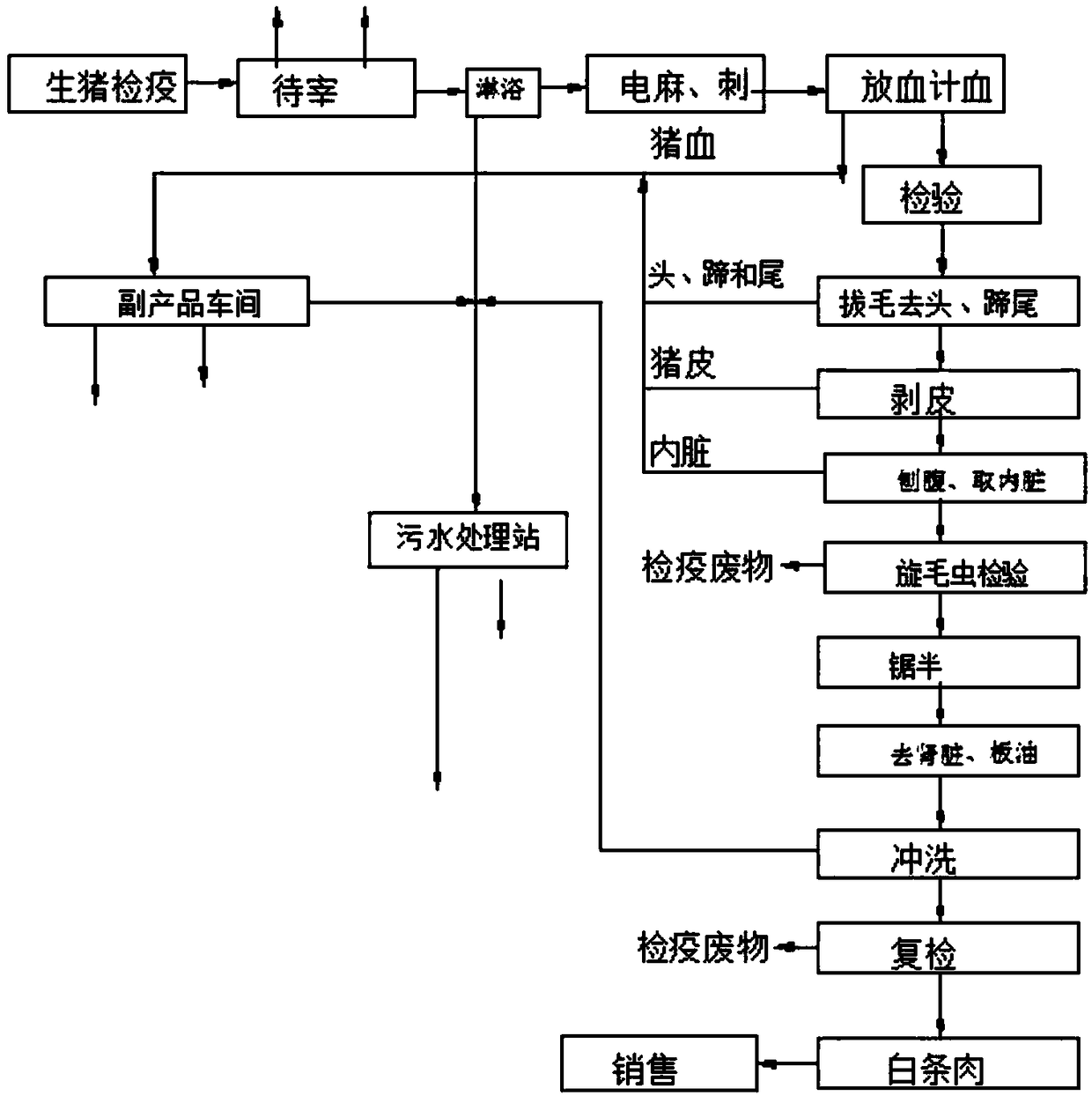

Pork slaughtering processing technological process

InactiveCN108713578AEnsure hygiene and safetyIncrease profitElectric current slaughtering/stunningSlaughterhouse arrangementsWater flowEngineering

The invention discloses a pork slaughtering processing technological process. The process comprises the steps of soaking and scalding, pig hair removing, eviscerating, head, trotter and tail removal and splitting in two, wherein after blood is completely removed, a live pig is unloaded on a receiving platform of a pig scalding pool through a pig unloading device, the pig body slips into the pig scalding pool for soaking and scalding, and the soaking and scalding mode adopts an artificial reversing scalding; after soaking and scalding, the live pig is sent into a hair removing machine, throughdehairing and rotating modes of a soft plane claw, after hair removing, the pig carcass is pushed out from the other end of the hair removing machine and put into a cleaning pool for cleaning, trottershells are removed, the pig carcass is sent to the designated position for eviscerating through a conveyor, at the designated position, the head, front trotters and tail of the pig carcass are removed, the pig carcass is split in two, carcass meat is sent to a meat airing area, secondary products are conveyed to a secondary product workshop and processed, secondary product processing treatment iscarried out on pig haslet, pig skin, pig head, pig tail, front trotters and pig blood in the secondary product workshop, the produced waste water flows into a sewage treatment station, systematized slaughtering work is conducted, the slaughtering efficiency is improved, safety and sanitation of raw pork are ensured, the secondary product processing treatment is carried out on the pig haslet, thepig skin, the pig head, the pig tail, the front trotters and the pig blood in the secondary product workshop, and utilization rate of the raw pork is improved.

Owner:重庆盛顺肉类加工有限责任公司

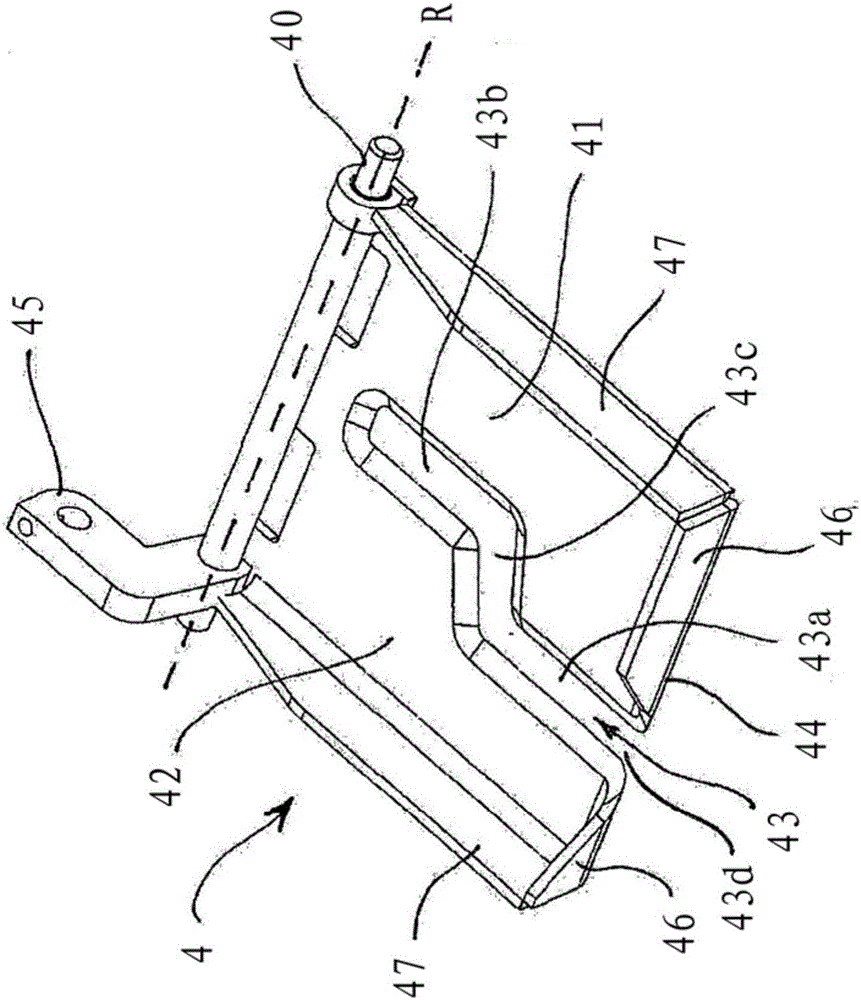

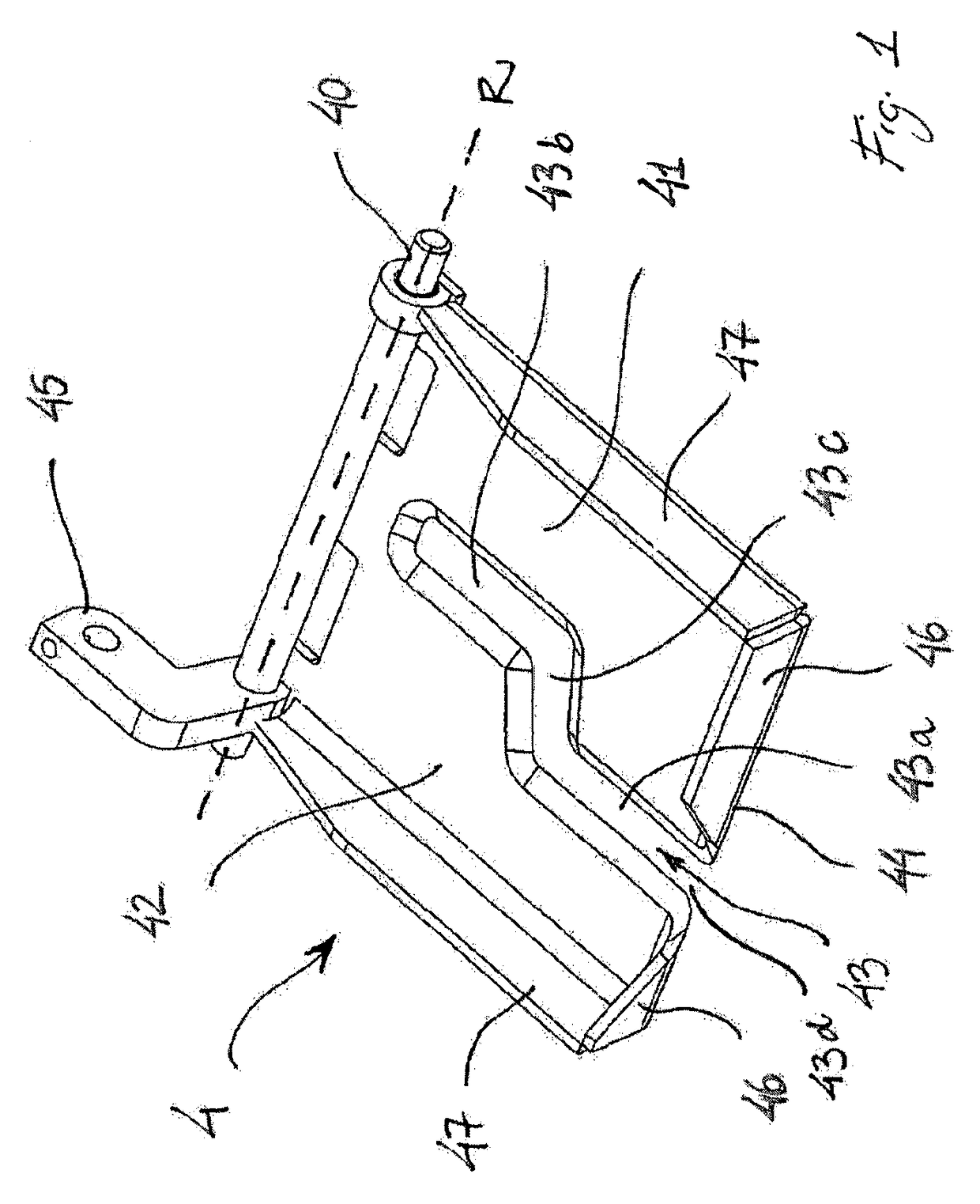

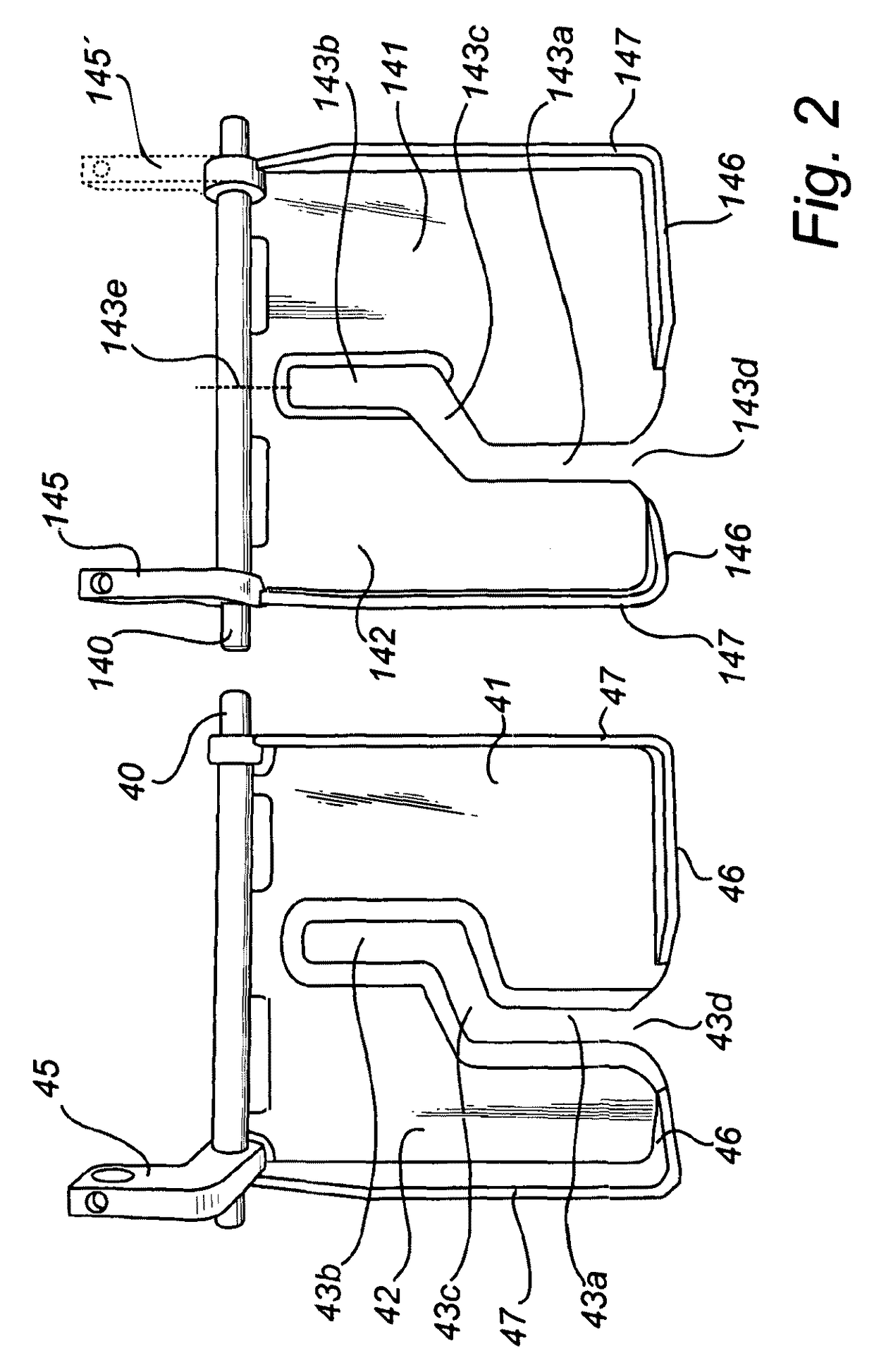

A guide member, a guide assembly, a system and a method for separating a viscera set eviscerated from slaughtered poultry

A guide member (4) for use in separating viscera sets eviscerated from slaughtered poultry comprising a separation support surface (41, 42) having an elongated opening (43) for receiving a viscera set (1) in a manner whereby at least the intestines (15) and the gallbladder (18) are suspended below said guide member (4) and the liver (16) and gizzard (17) are positioned above said guide member. The elongated opening (43) extends away from a front edge of the separation support surface and a distal section of the opening is off-set in relation to a proximal section in a direction substantially parallel to the front edge. A gripping member (3) may be arranged below said guide member for gripping a part of the intestines (15). In a method according to the invention the guide member (4) is moved into contact with the viscera set whereby the intestines and / or gallbladder enters the elongated opening.

Owner:BAADER FOOD SYST DENMARK AS

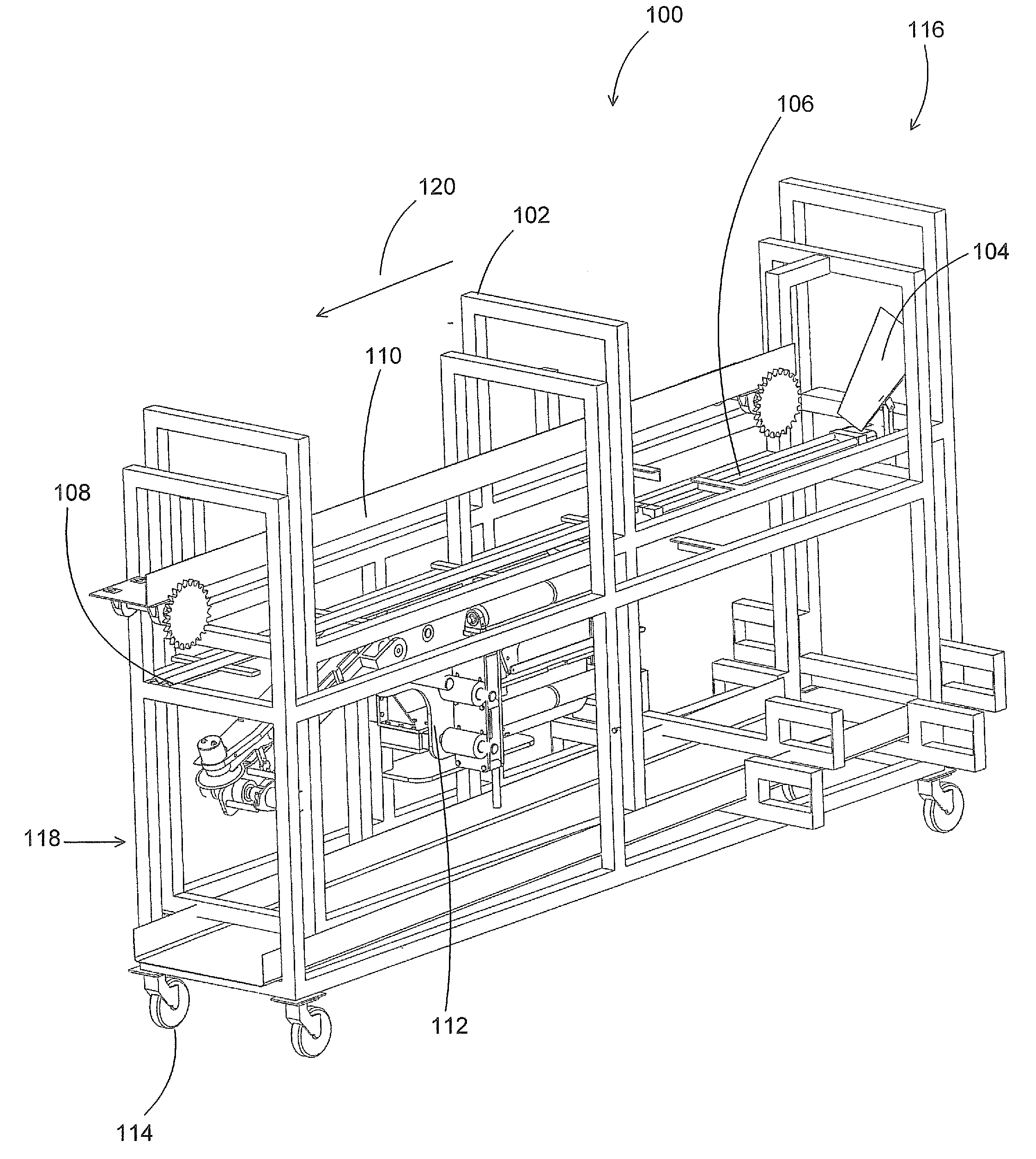

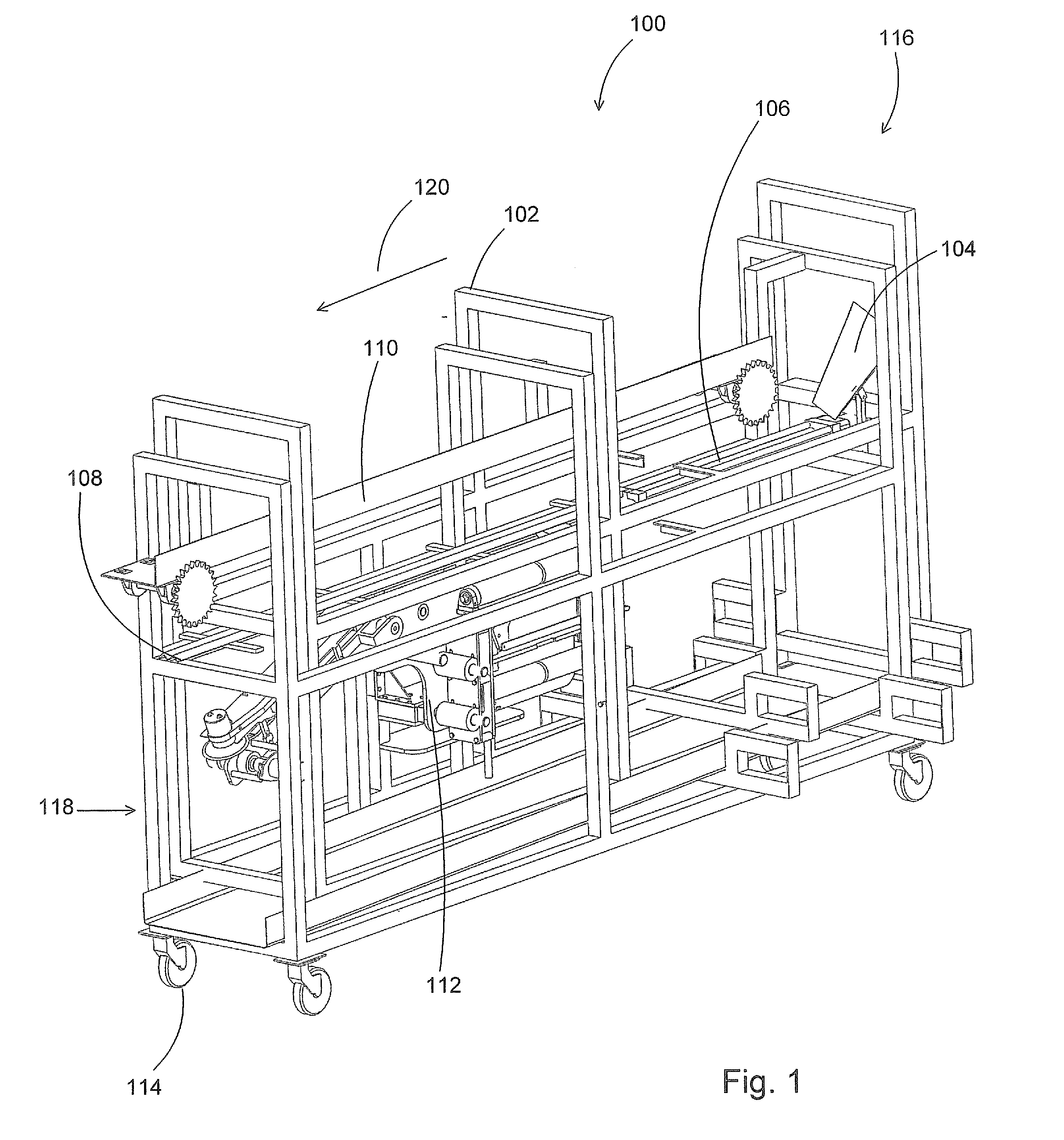

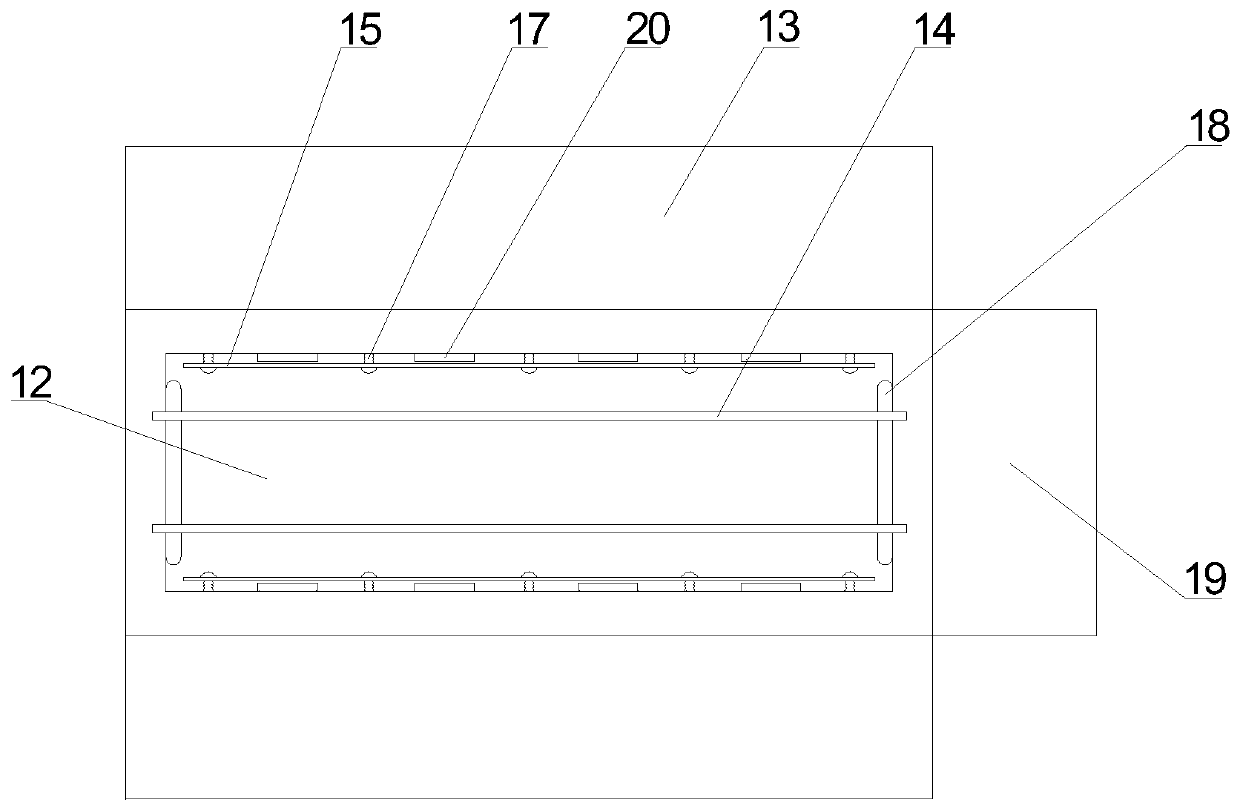

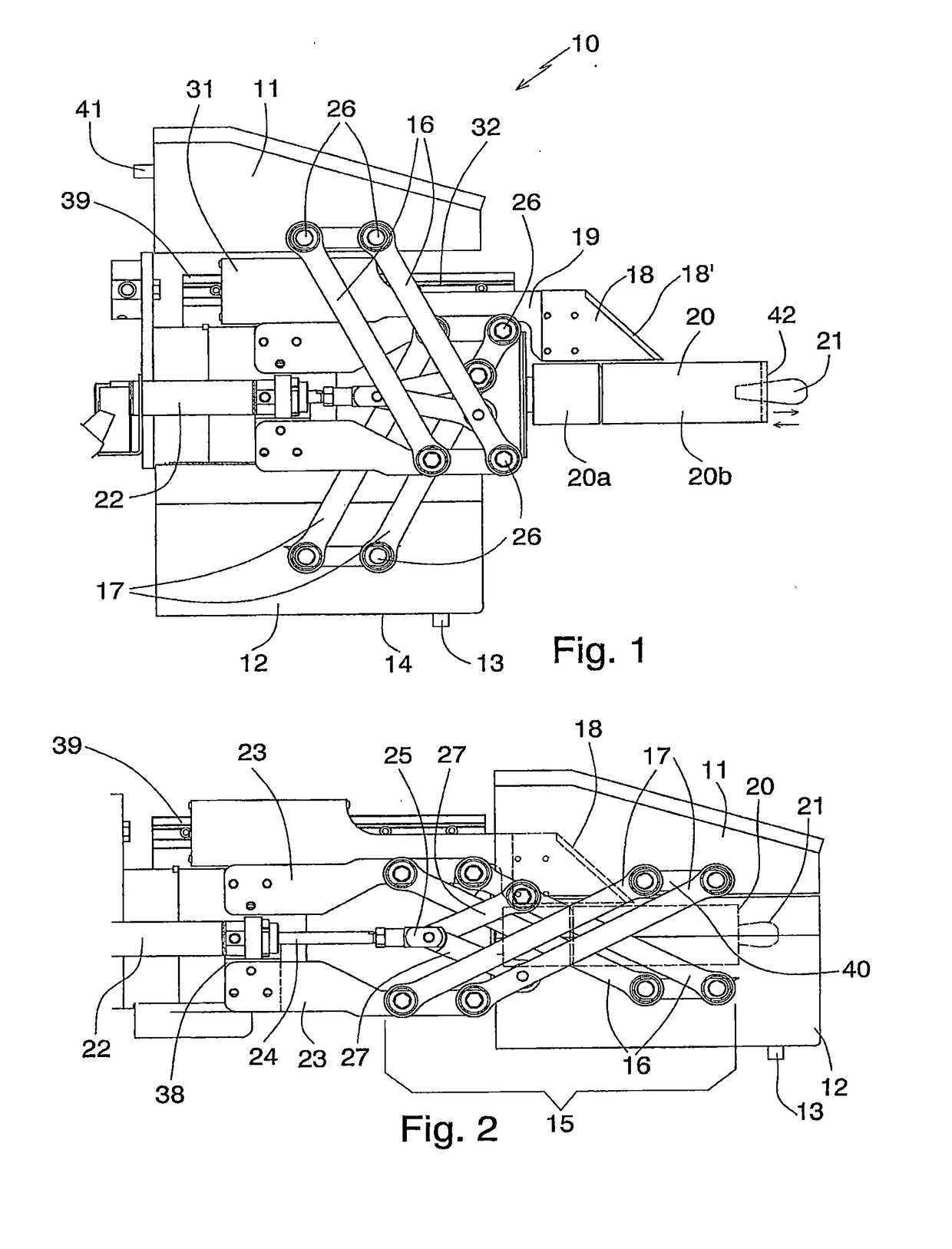

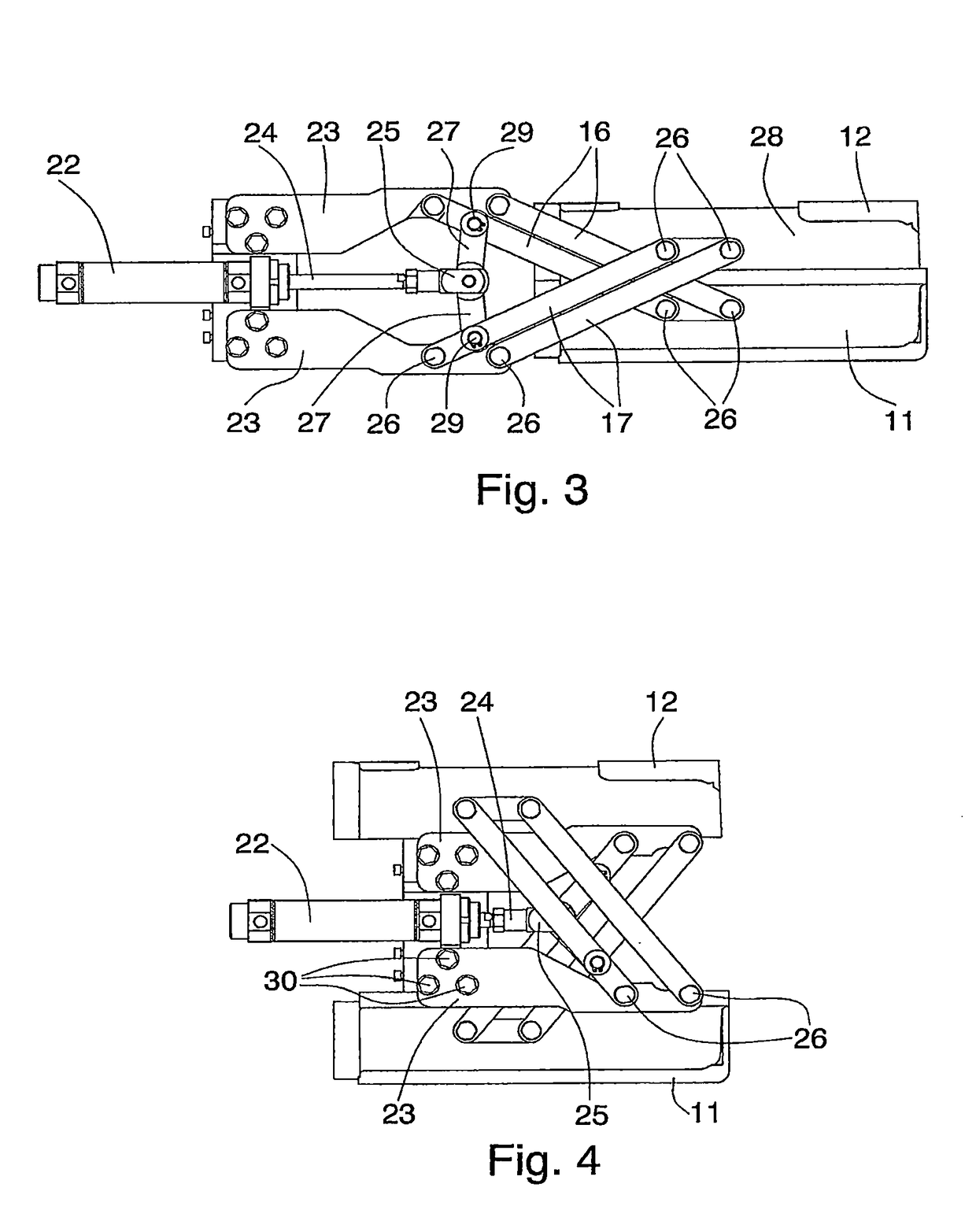

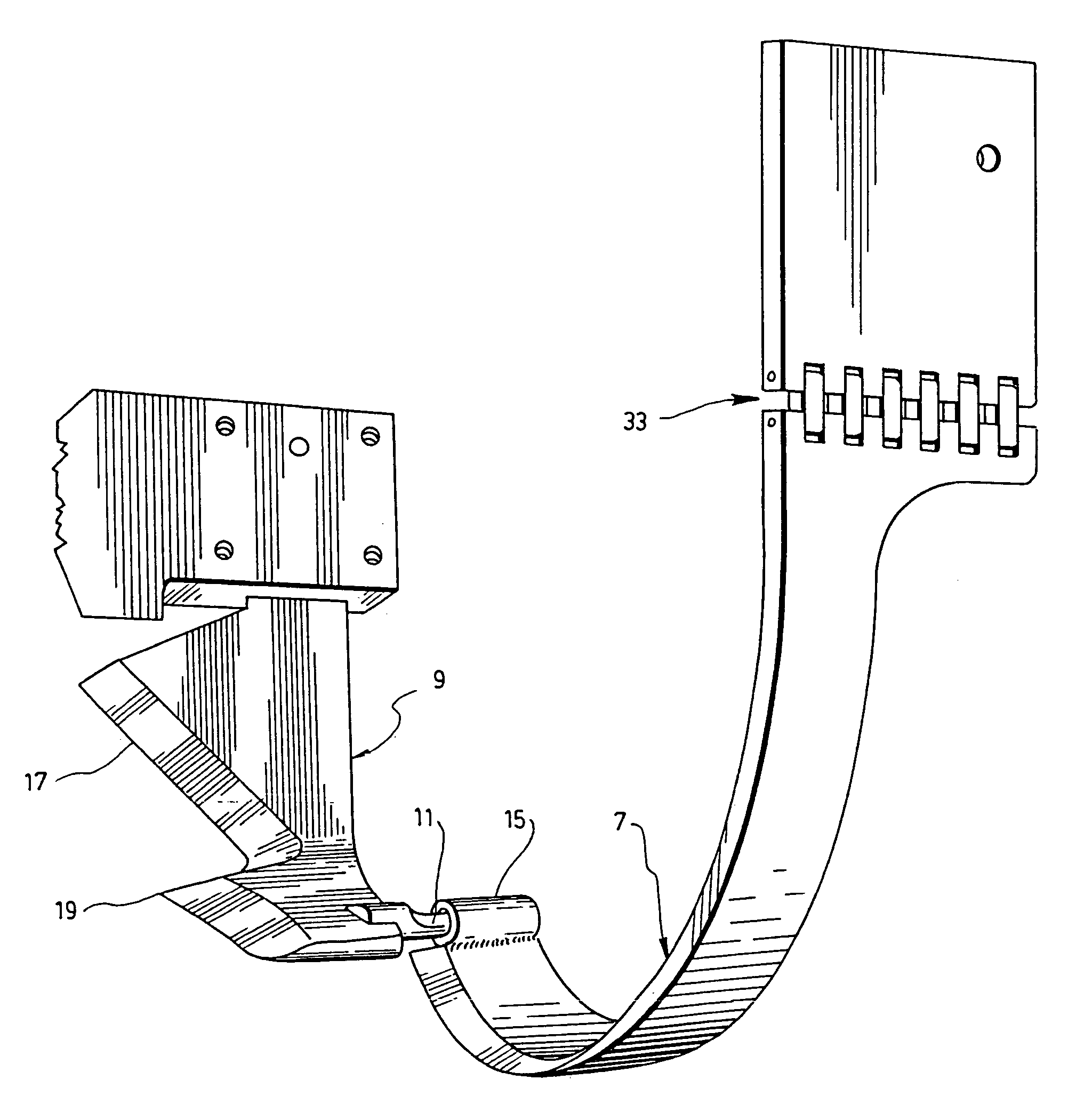

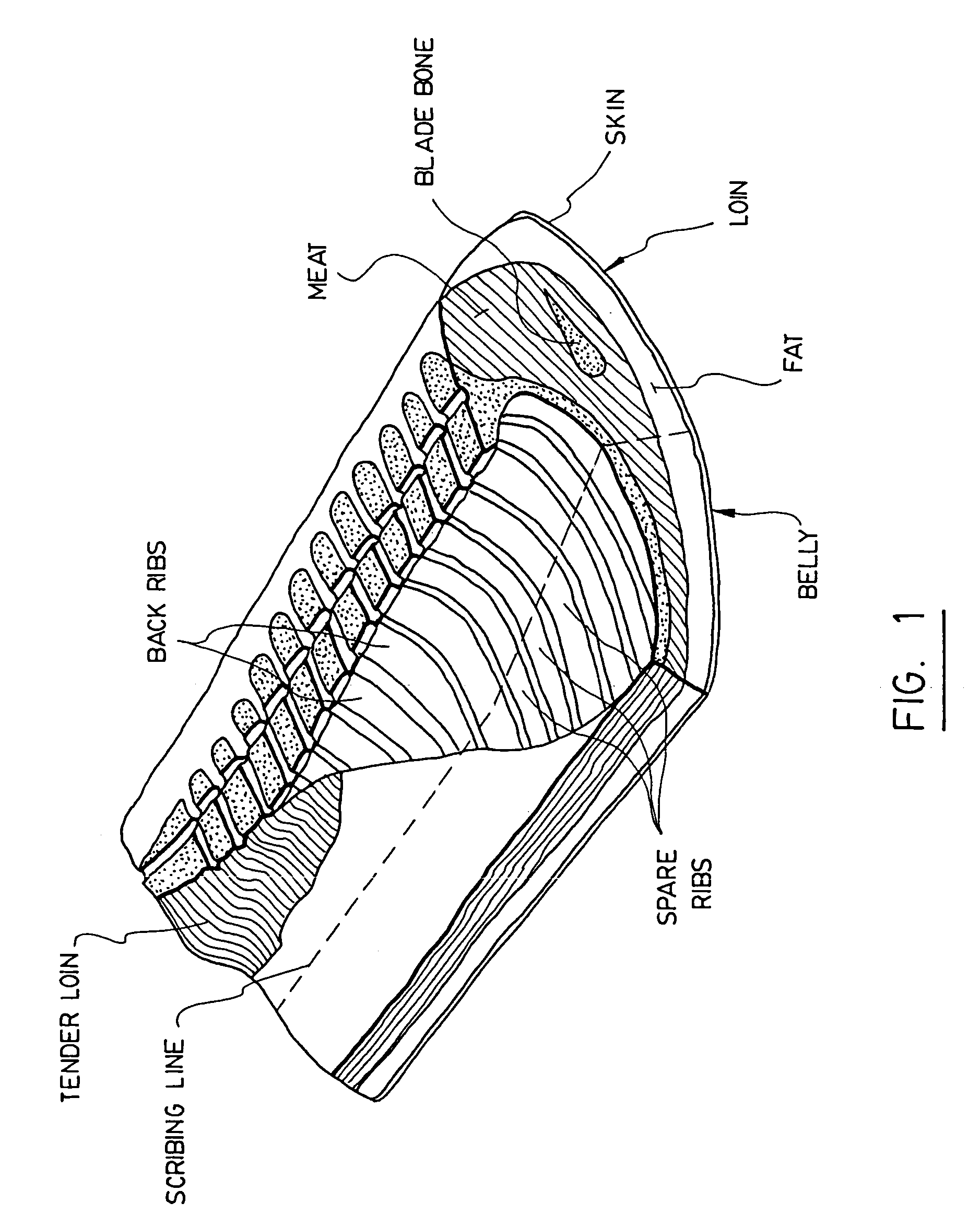

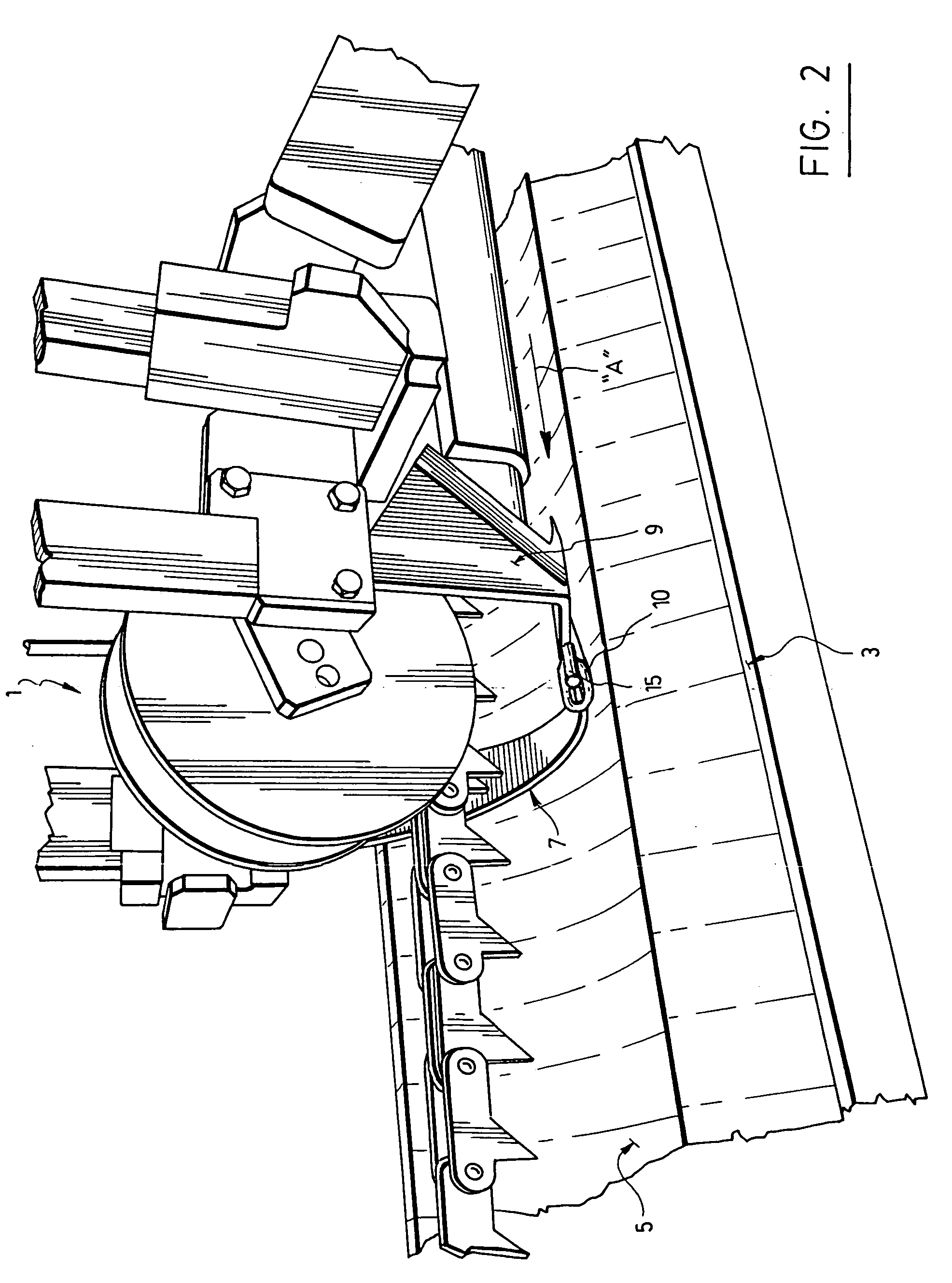

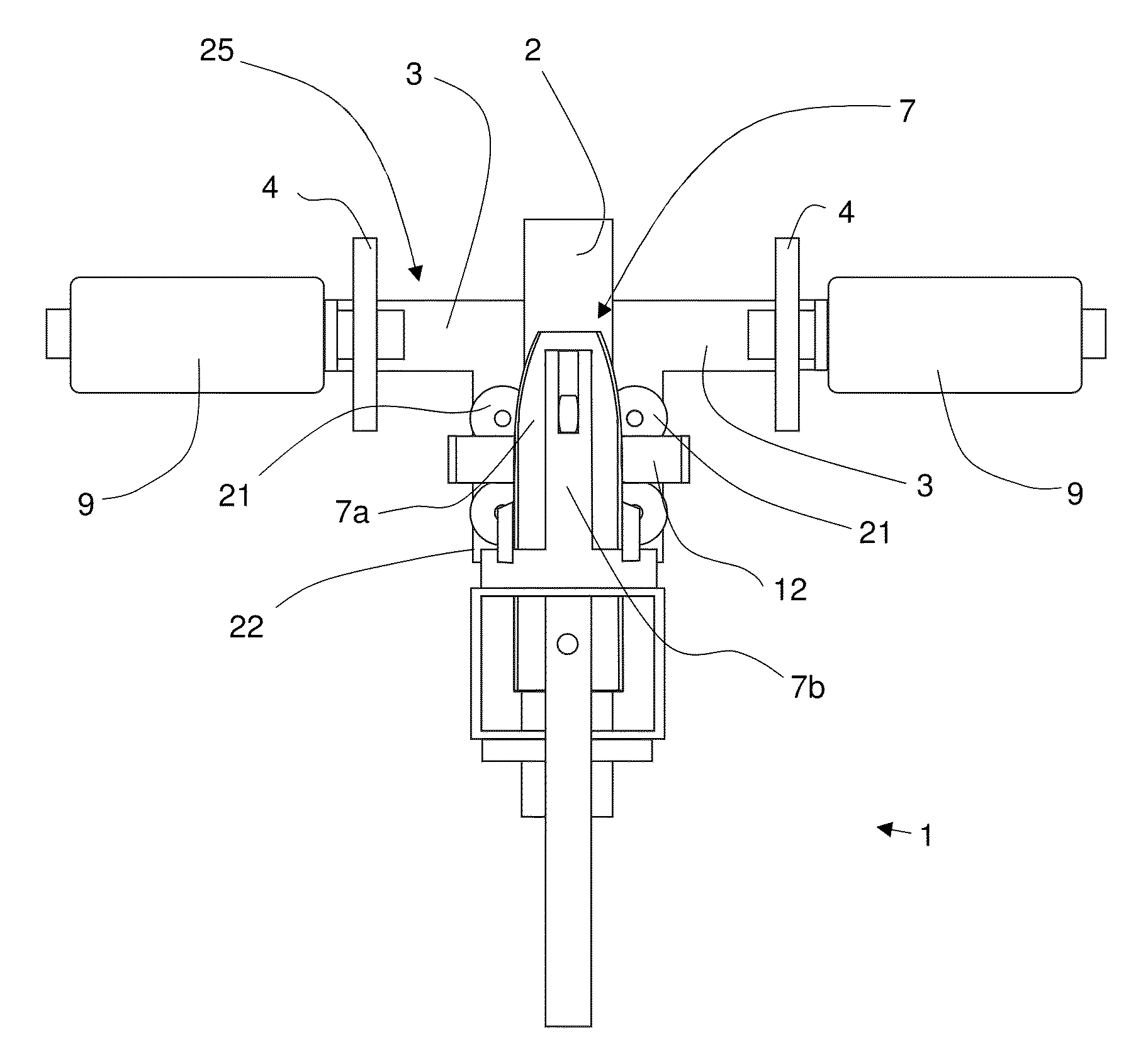

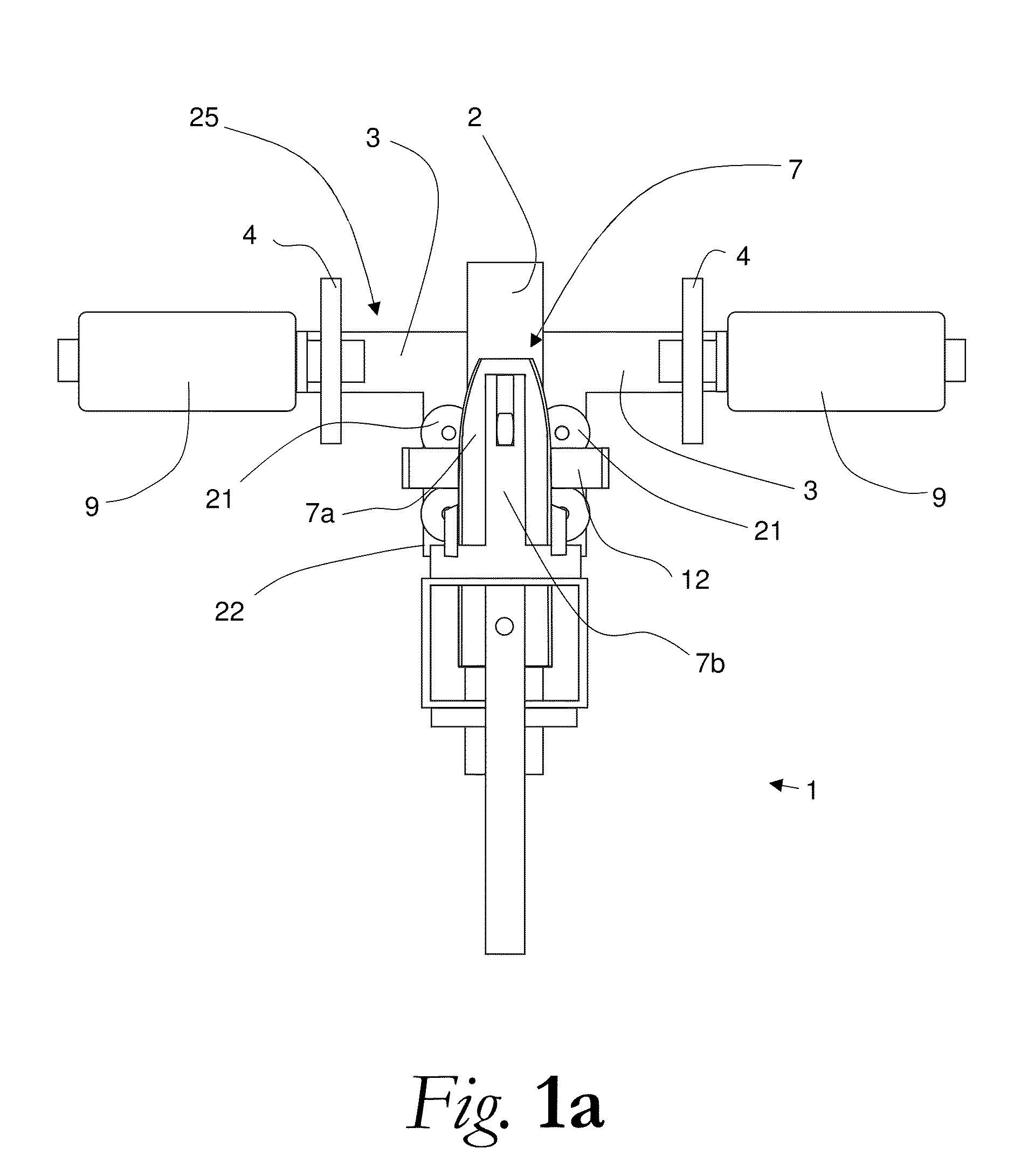

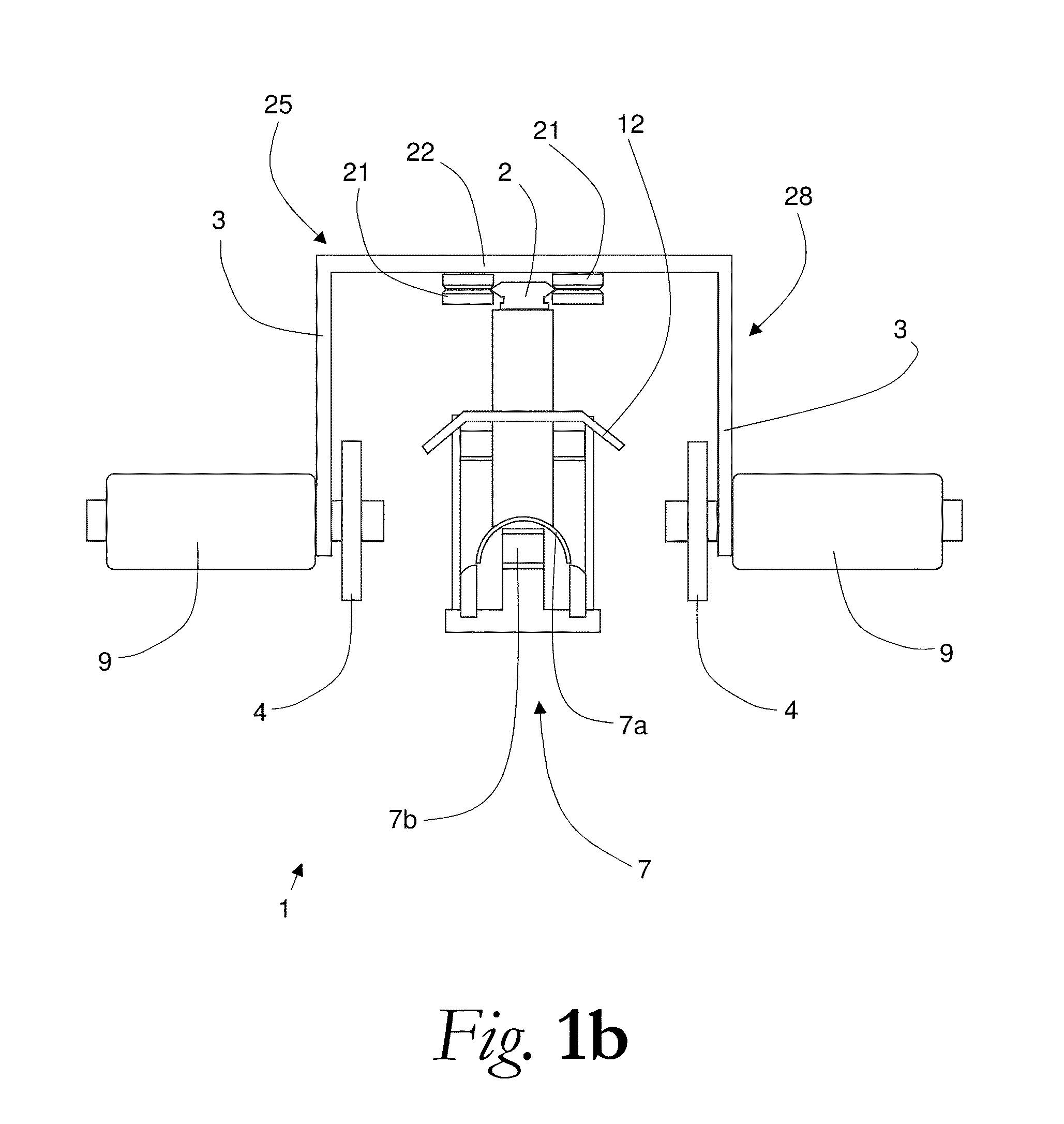

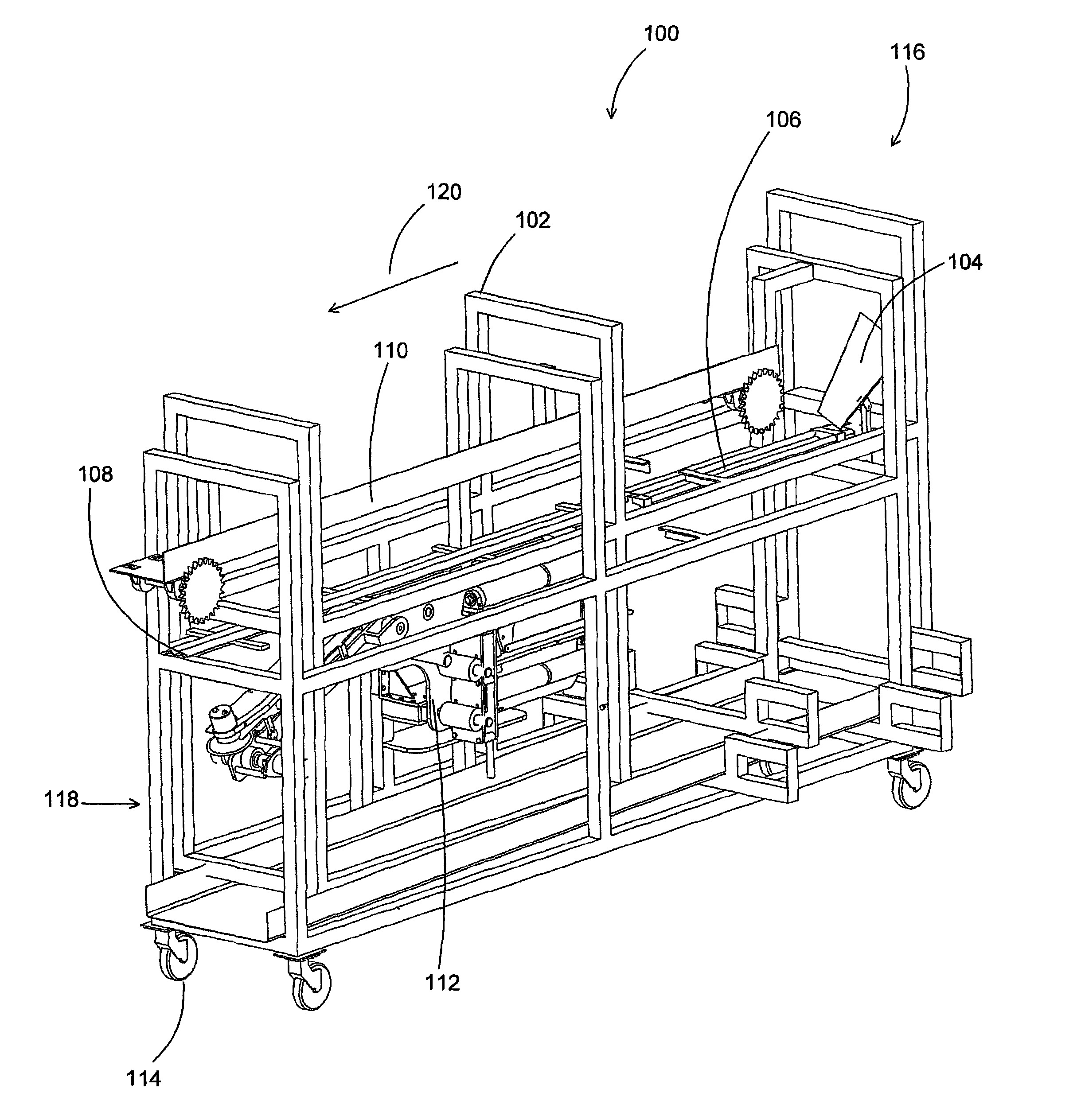

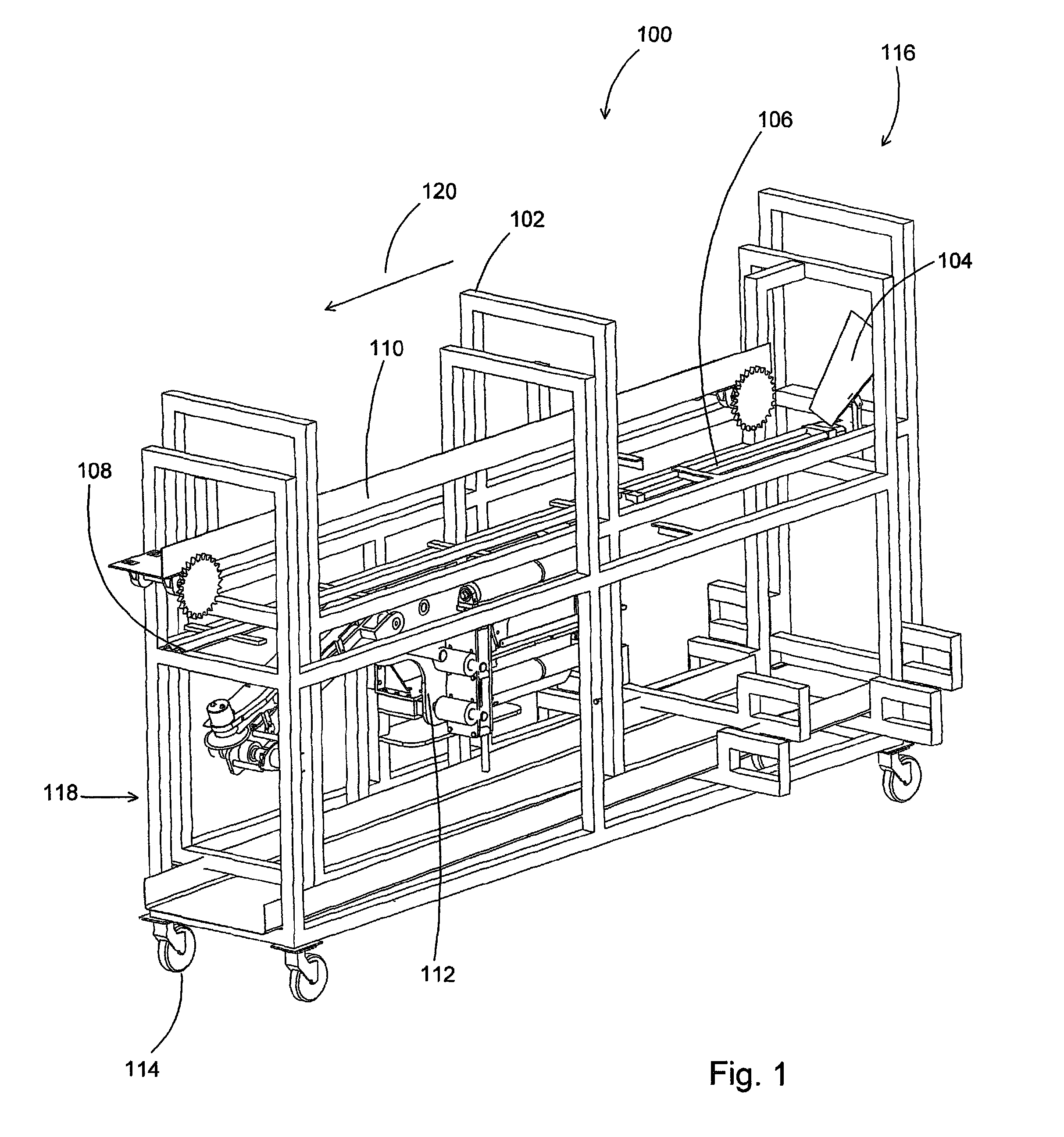

Loin puller with two separate cutting blades

ActiveUS7331850B2Cutting is improvedAvoid less flexibilityMeat processing plantsEviscerating scissorsEngineeringKnife blades

Disclosed is a loin puller for trimming off the backfat of a loin that has been scribed from a belly. This loin puller has a frame on which is mounted a conveying system for engaging the loin and moving it towards a cutting zone. In this zone, a cutting tool is mounted for engaging the loin when it is moved by the conveying system, and for cutting the backfat to be trimmed off from the loin, with the so-cut backfat remaining attached to the belly. The cutting tool has two blades that are preferably controlled independently from each other. One of these blades is arcuate and positioned onto the frame so as to engage at least one part of the loin from a side of the loin opposite to the belly, and to cut the backfat to be trimmed from the loin. The other blade is L-shaped and positioned onto the frame so as to engage another part of the loin and cut the backfat to be trimmed thereof directly from the scribing line just below the back ribs of the loin. The two blades are long enough to ensure that all the backfat of the loin be trimmed off. Advantageously, the arcuate blade has one end pivotably attached to the frame by a joint and another opposite end attached either to the frame or the L-shaped blade. The use of such a joint gives much more flexibility of the arcuate blade and makes it much more efficient.

Owner:G E LEBLANC INC

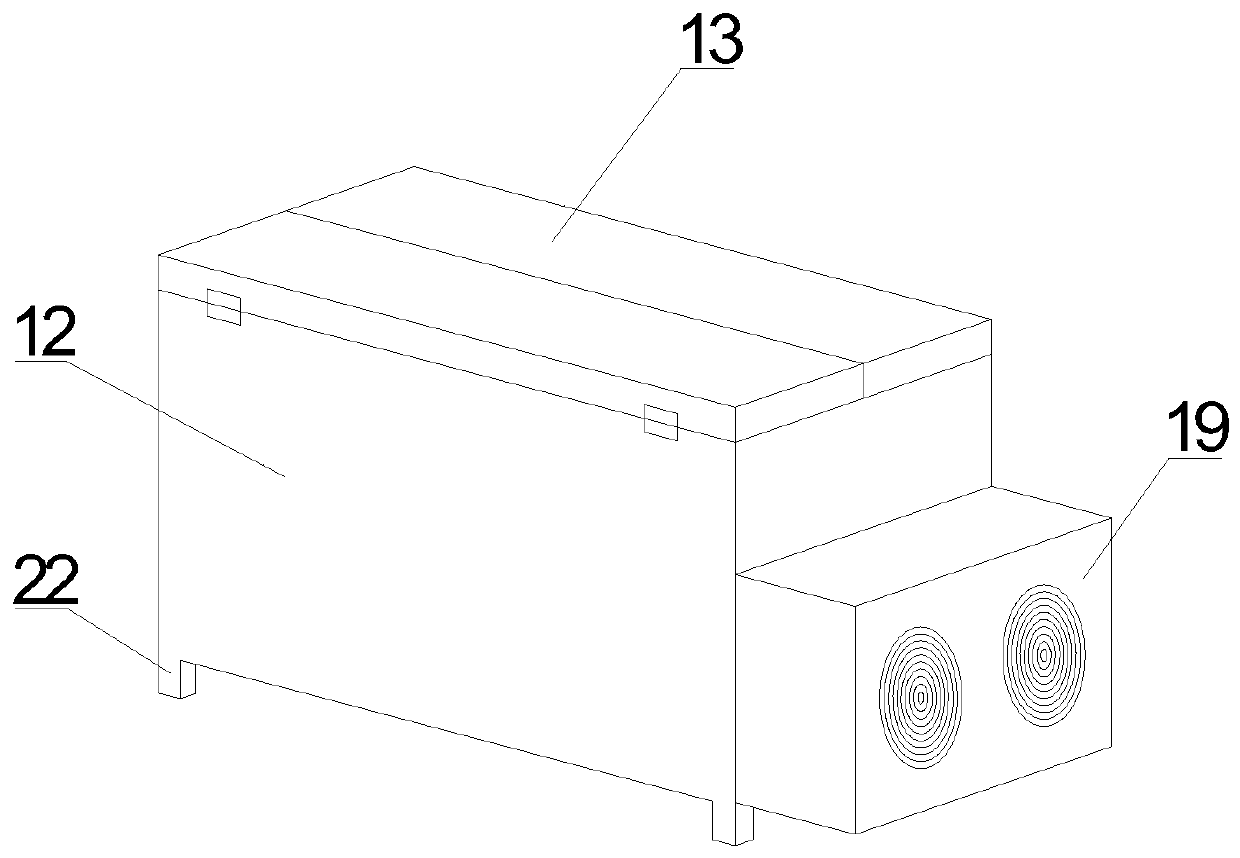

Integrated machine for killing and processing geckos

InactiveCN109315469AImprove work efficiencyEasy to handle and processElectric current slaughtering/stunningSlaughterhouse arrangementsBody measureGecko

The invention discloses an integrated machine for killing and processing geckos. The machine includes an operation box, a power supply, a central processing unit, an electric shock mechanism, a body measuring mechanism, a transmission overturning mechanism, an receiving and sliding mechanism, a support transmission mechanism, an eye-digging mechanism and a viscera clearing mechanism. The inner andouter walls of the operation box are provided with insulating film layers, the electric shock mechanism is arranged in the operation box, the transmission overturning mechanism is arranged at the tail end of the electric shock mechanism, the body measuring mechanism is arranged on the upper portion of the transmission overturning mechanism, the support transmission mechanism is arranged at the lower end of the tail end of the transmission overturning mechanism, the viscera clearing mechanism is arranged on the upper portion of the support transmission mechanism, the eye-digging mechanism is arranged in the support transmission mechanism, the power supply is arranged in the operation box, and the central processing unit is arranged in the operation box. The invention belongs to the field of gecko killing machines and particularly provides the integrated machine for killing and processing geckos, wherein the machine is high in practicability, can better guarantee the medicinal properties of the geckos, avoids damage to the tails of the geckos, and prevent the geckos from escaping and injuring people.

Owner:徐州锌浩精密机械科技有限公司

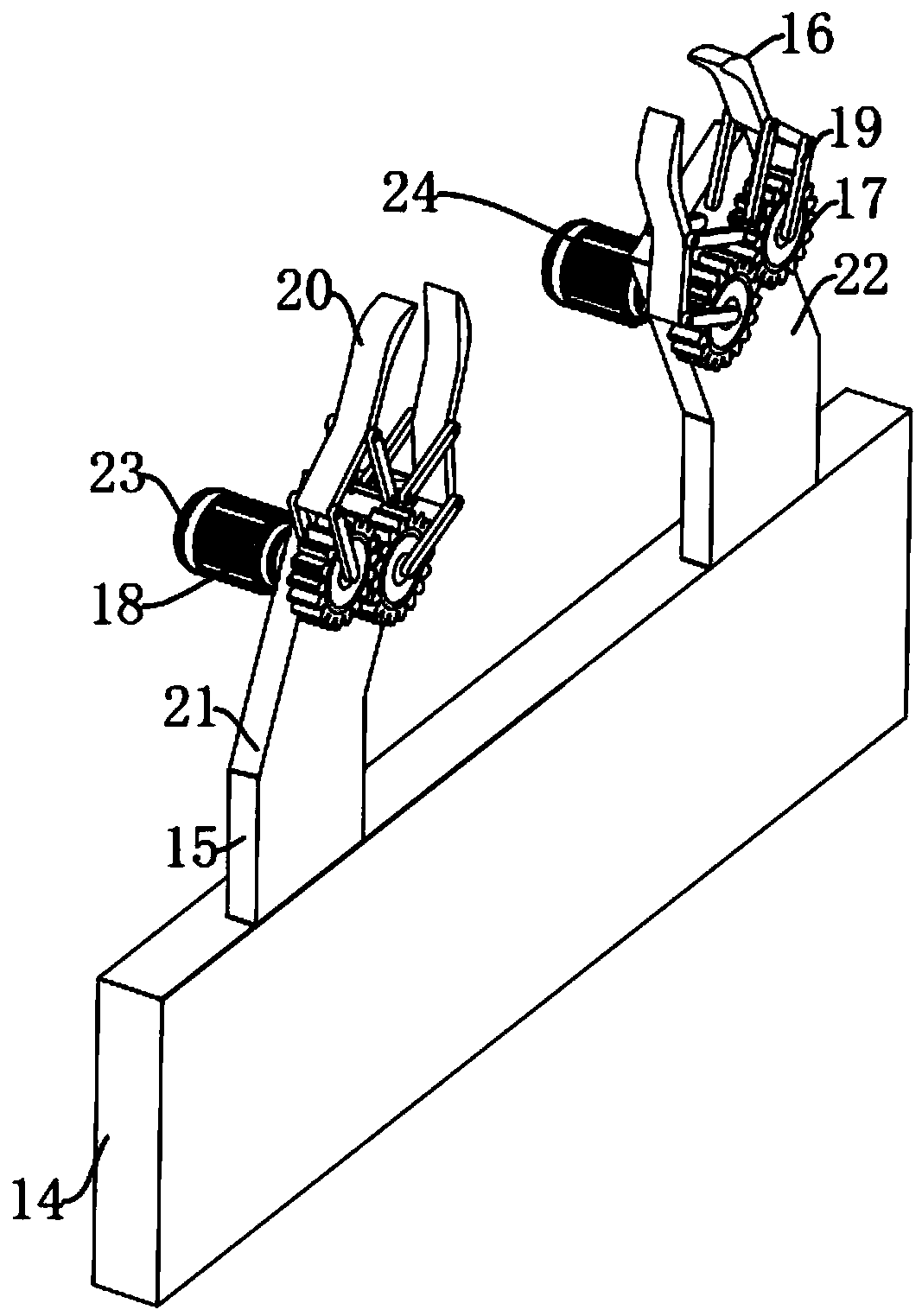

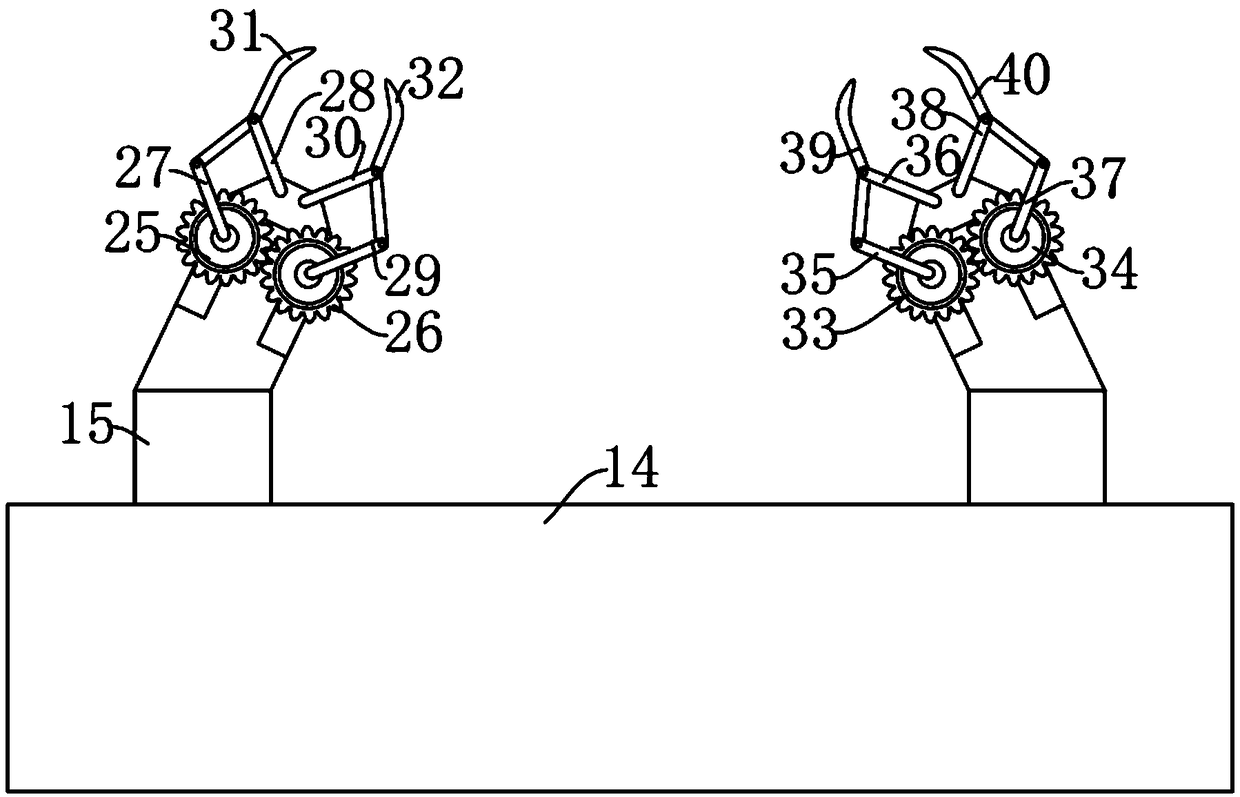

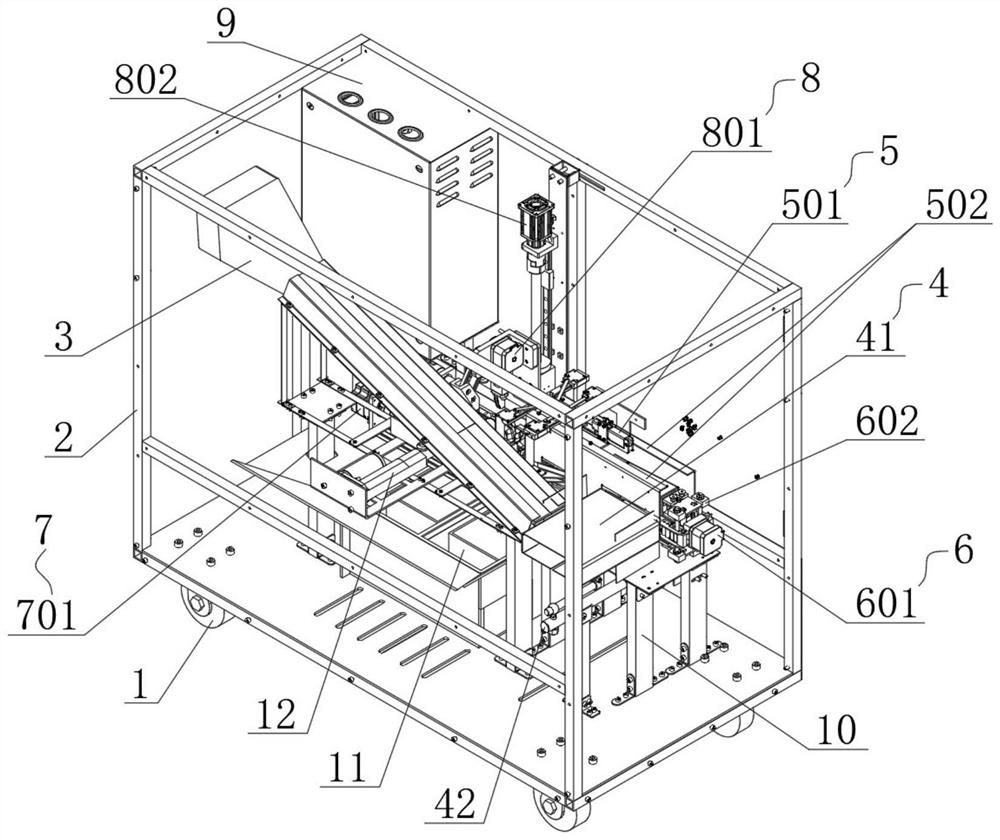

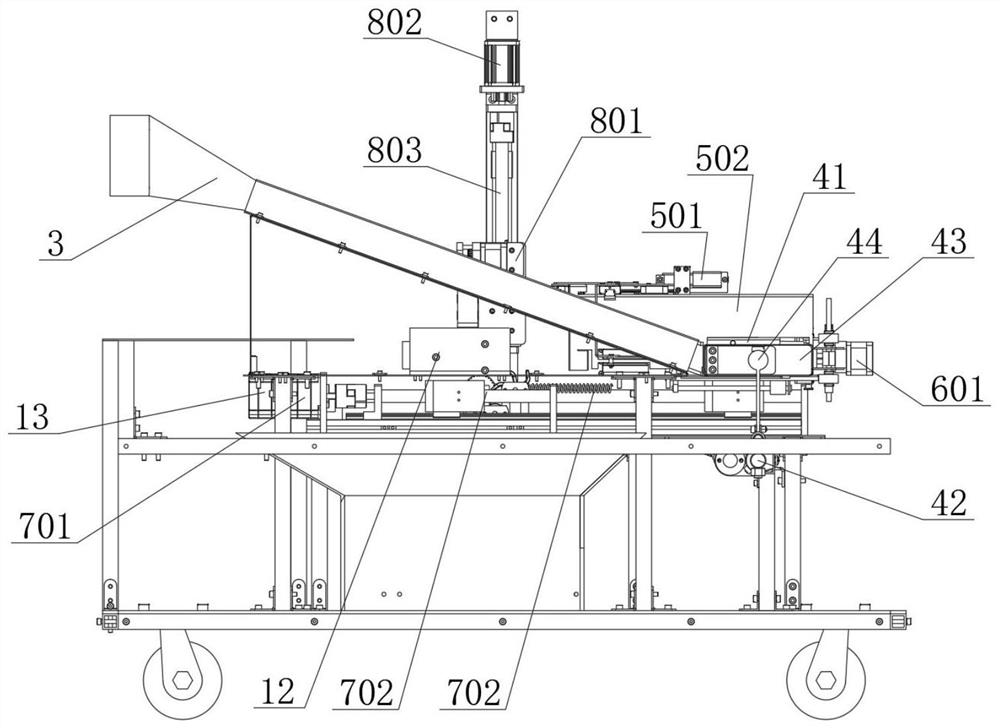

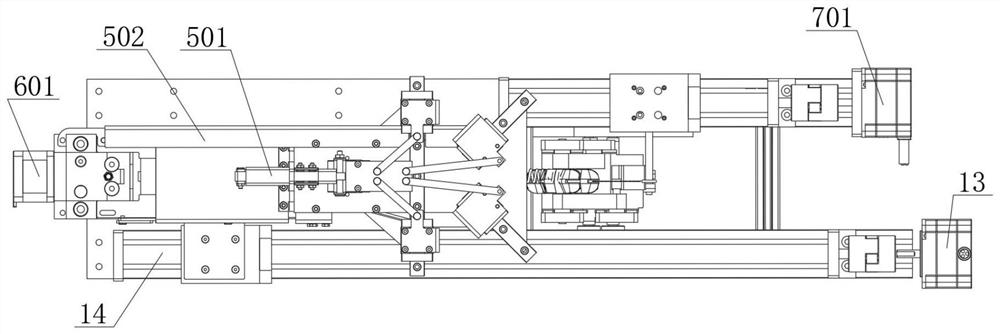

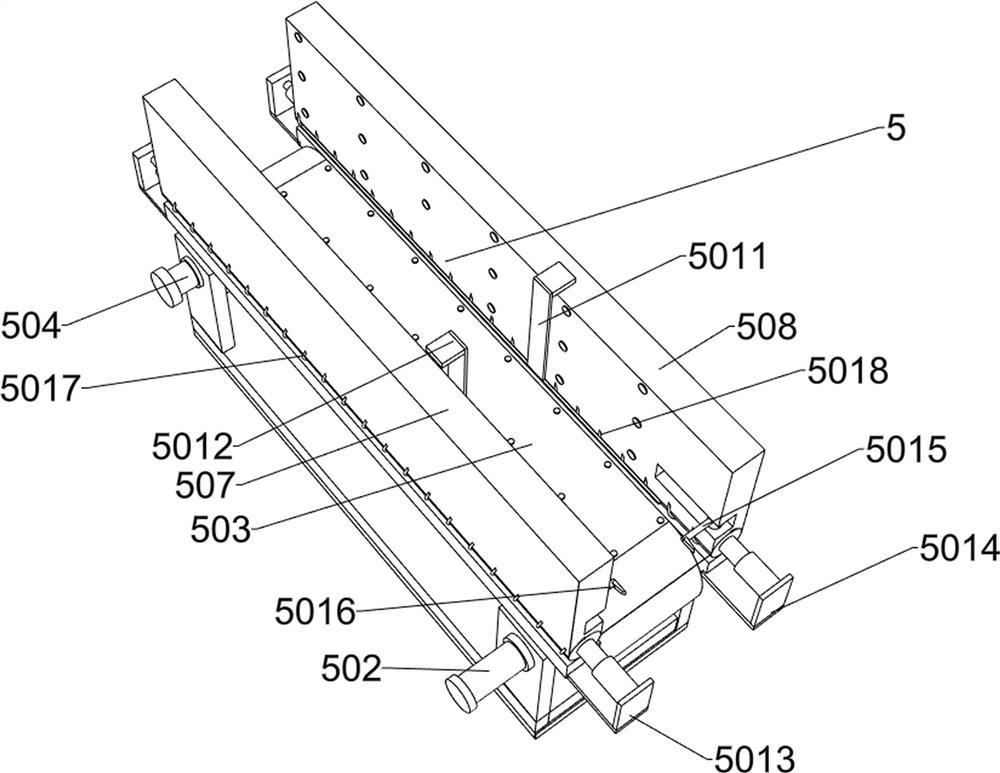

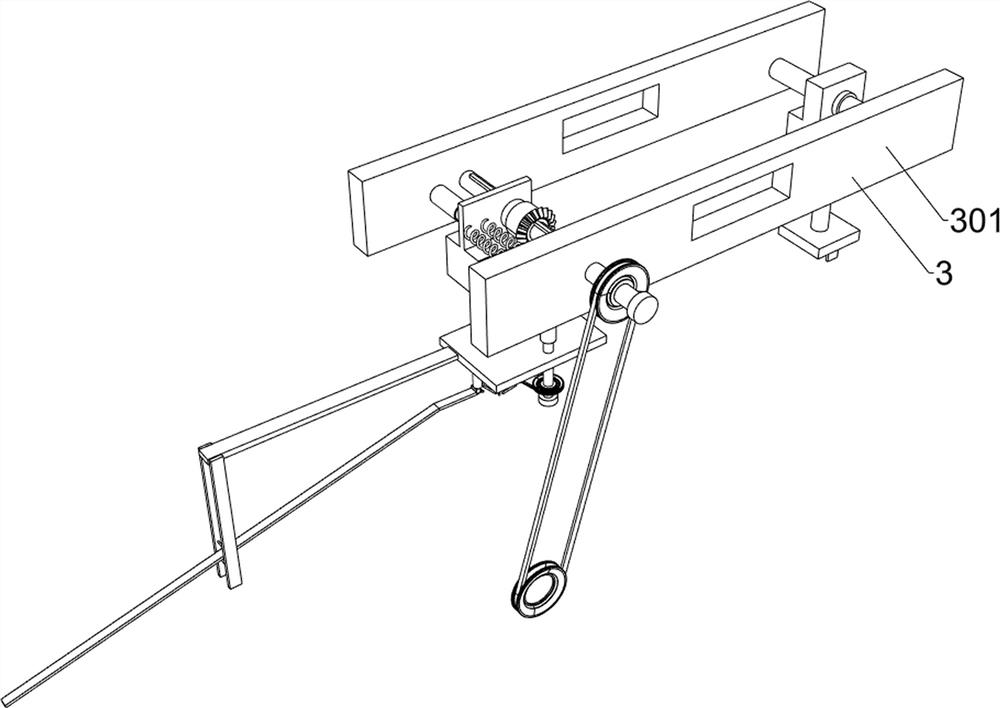

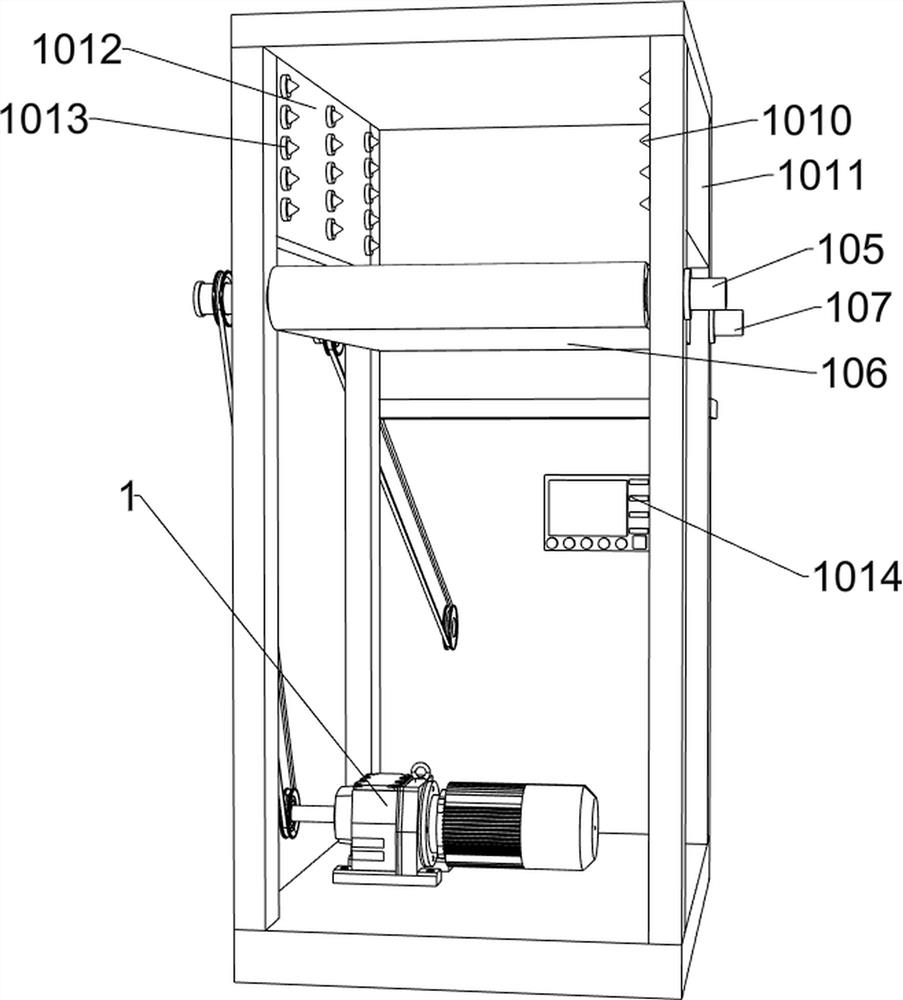

Automatic bullfrog slaughtering and processing equipment

ActiveCN114223696AImprove quality and efficiencyImprove work efficiencySkinning instrumentsSlaughtering animals fettering apparatusAnimal scienceMedicine

The invention provides automatic bullfrog slaughtering and processing equipment which comprises a straightening and positioning device (5), a clamping and cutting mechanism (6), a dissecting and digging device (7), a skin and meat separating device (8) and a processing platform (15), the straightening and positioning device (5) straightens the posture of bullfrogs on the processing platform (15), then the clamping and cutting mechanism (6) conducts neck girdling operation on the straightened bullfrogs, and the bullfrogs are separated from the skin and meat separating device (8). Then the bullfrogs subjected to ring cutting are subjected to opening and viscera removing operation through the dissecting and digging device (7), then the bullfrogs subjected to opening and viscera removing operation are subjected to peeling operation through the skin and meat separating device (8), and finally the heads of the bullfrogs subjected to peeling operation are removed through the clamping and cutting mechanism (6). The bullfrog slaughtering and processing device is used for slaughtering and processing bullfrogs, a modularized bullfrog slaughtering and processing operation mode can be formed, and the bullfrog slaughtering and processing device has the outstanding advantages of being high in automation degree, reducing labor intensity, improving bullfrog slaughtering quality and operation efficiency and the like.

Owner:HUBEI JUPENG KITCHEN EQUIP CO LTD

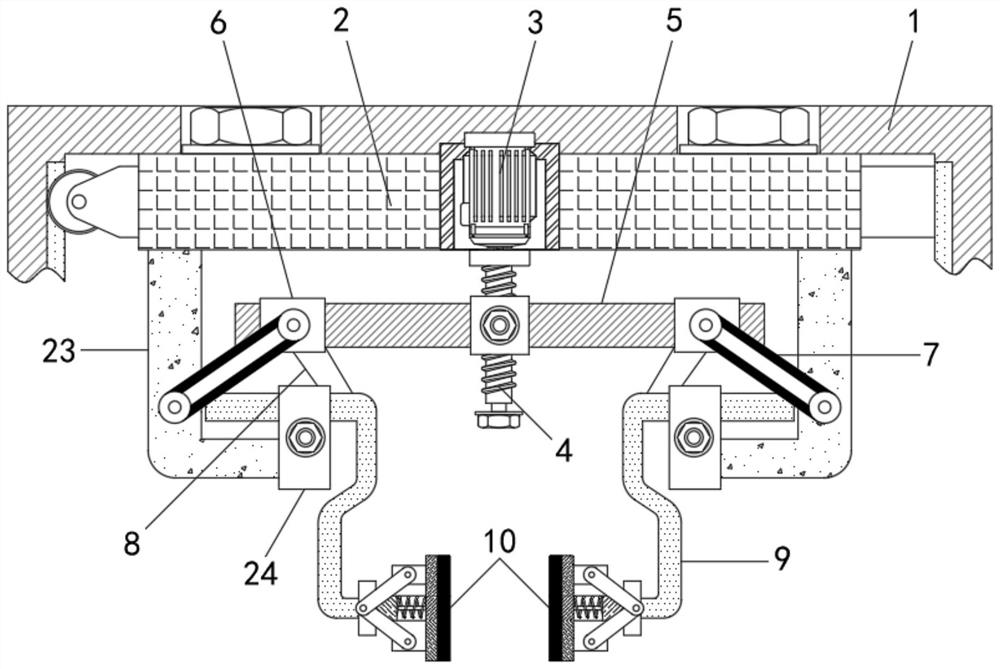

Pork lymph gland cutting device with automatic limiting function

ActiveCN113598216AEasy to operateAccurate limitSlaughterhouse arrangementsEviscerating scissorsPork meatSurgery

The invention relates to the field of pork cutting, in particular to a pork lymph gland cutting device with an automatic limiting function. According to the technical scheme, the pork lymph gland cutting device with the automatic limiting function comprises a conveying and cleaning device, a conveying supporting plate device, a lymph gland excision device and the like; the lymph gland excision device is fixedly connected with a first support frame; and the lymph gland excision device is connected with a conveying fixing device. According to the pork lymph gland cutting device, cleaning of live pigs is achieved, then overall limiting of the live pigs is matched with local limiting of the lymph gland excision device, accurate lymph gland excision is achieved, the working efficiency is greatly improved, meanwhile, limiting of the live pigs is achieved, and accurate lymph gland excision is guaranteed.

Owner:南京御品食品机械有限公司

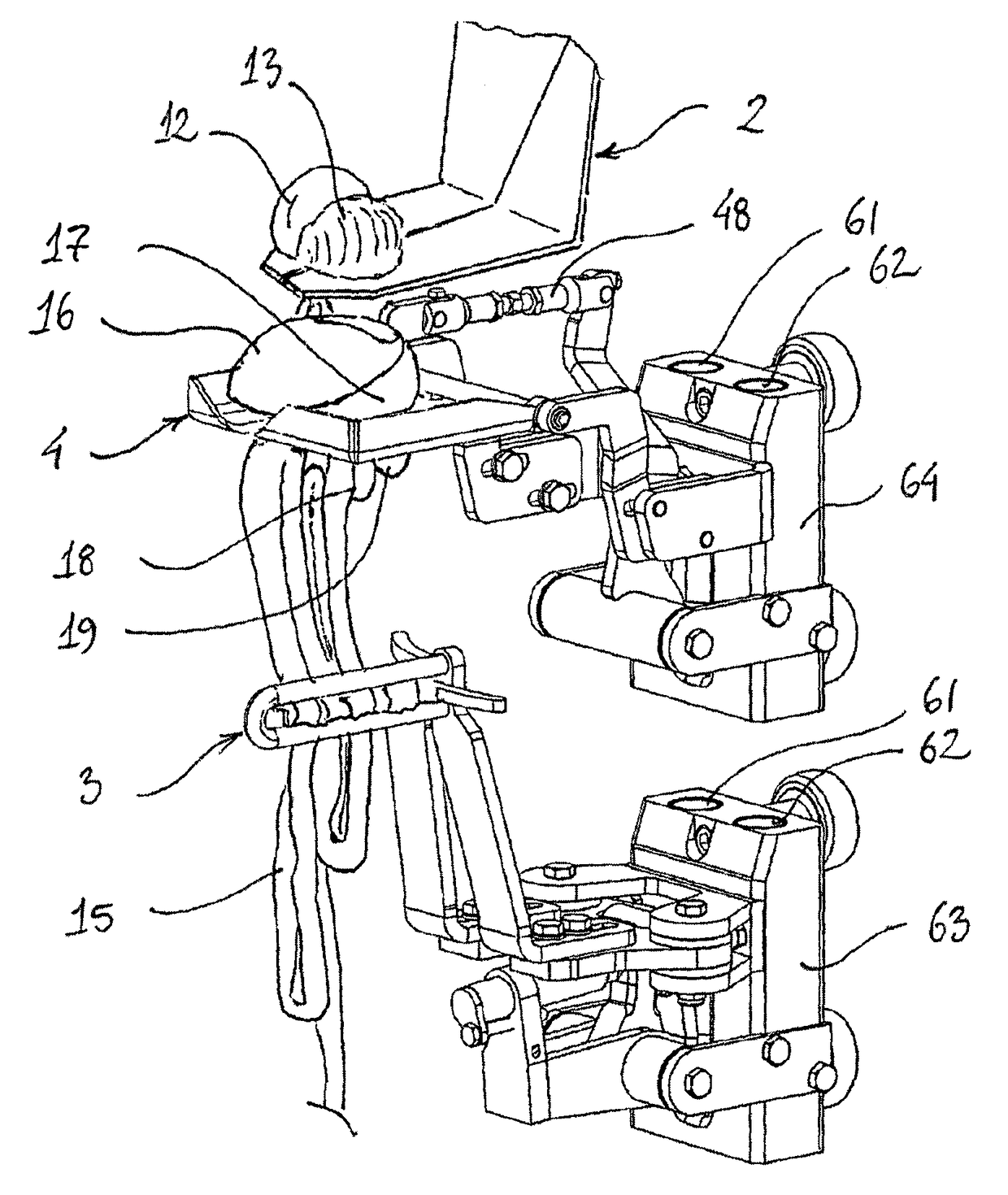

Device and a method for fixing a carcass

InactiveUS7625267B2Less prone to failureReduce the valueBlood collection/stirring apparatusSlaughtering tools/knivesBiomedical engineeringMedicine

The invention relates to a fixation device (1) and a method for fixating a carcass, e.g. during processing the carcass at a slaughterhouse, such as a carcass hanging head-down from a gambrel, wherein the device (1) comprises mouth-engaging fixation means.

Owner:TEKNOLOGISK INST

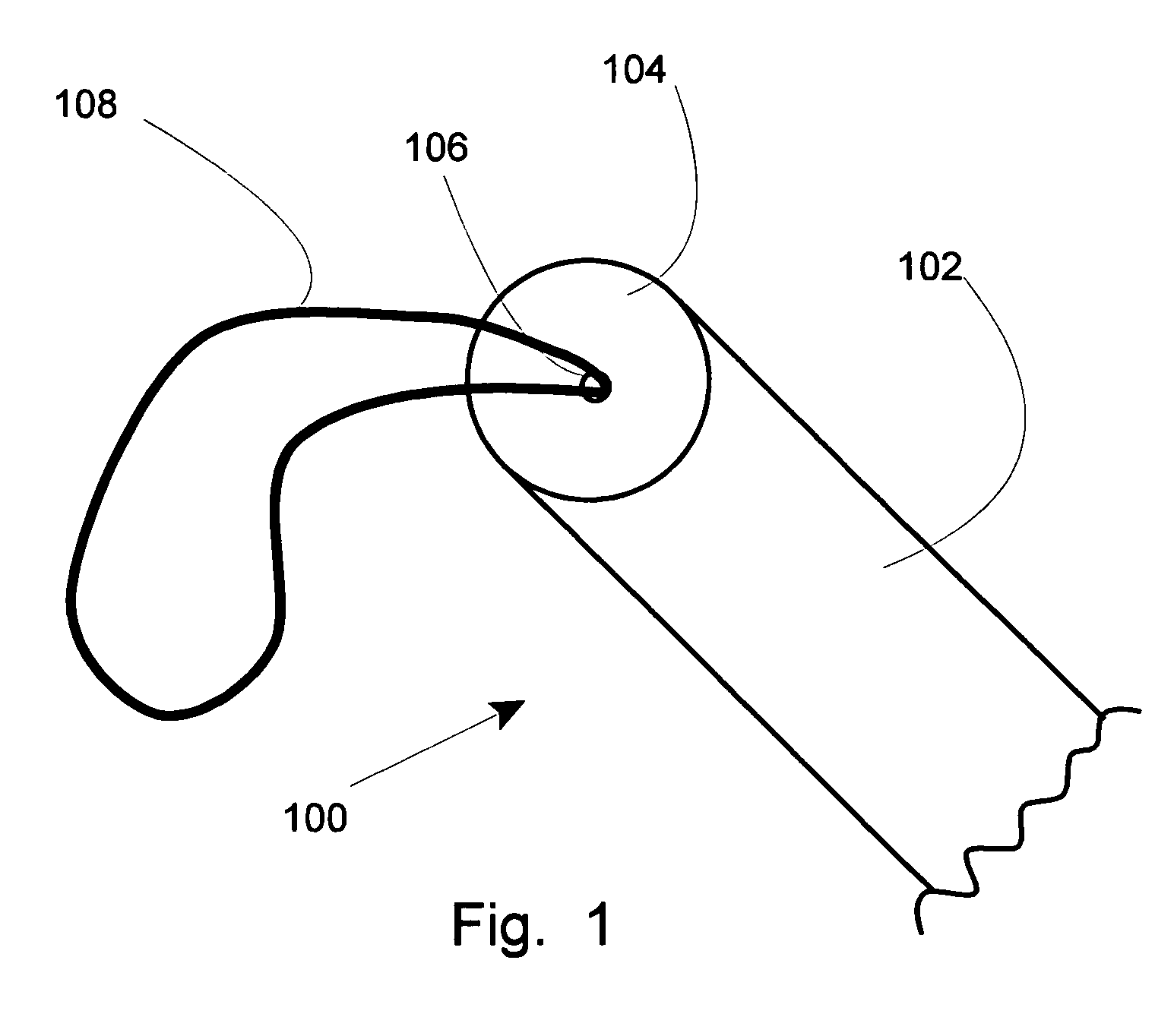

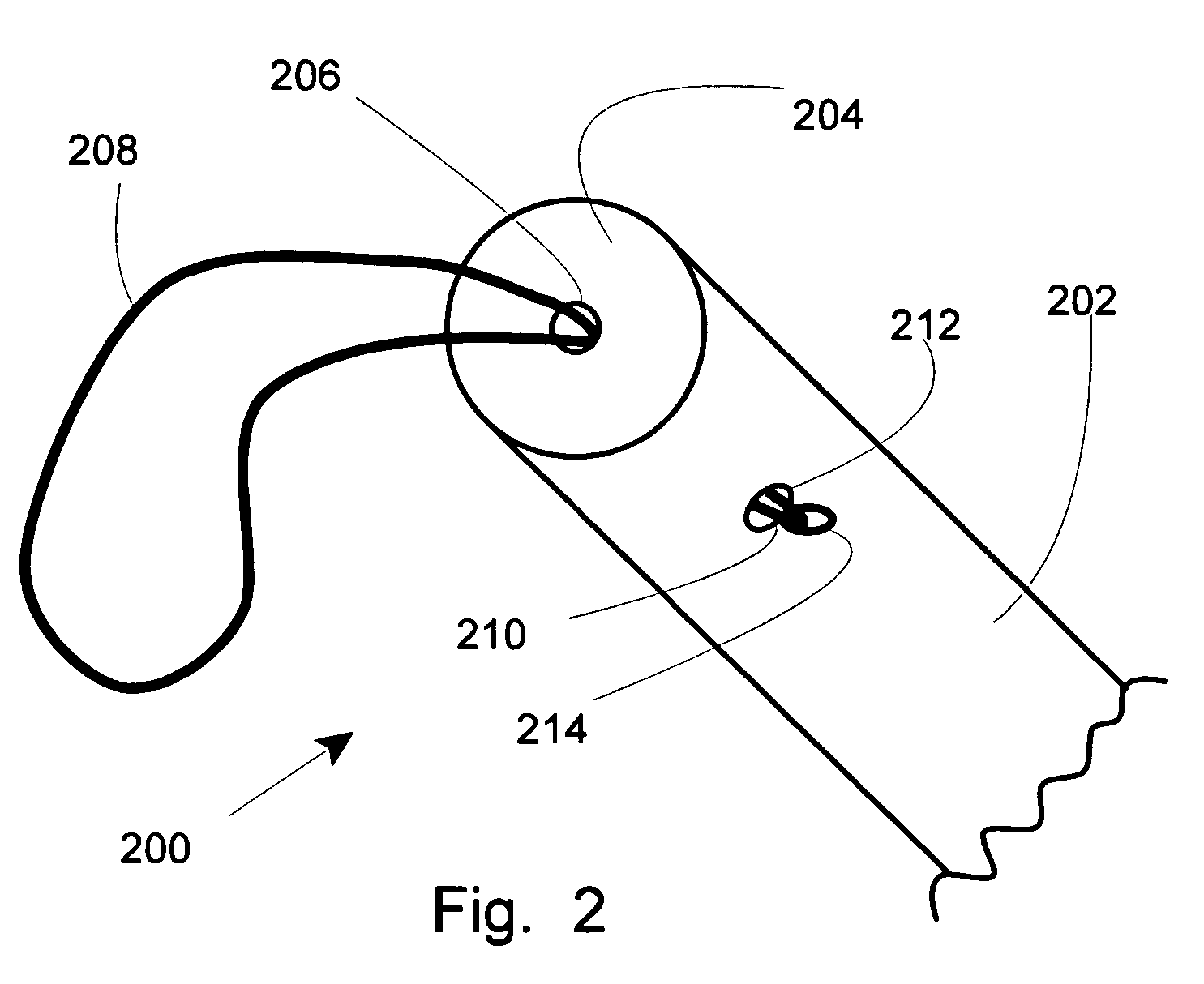

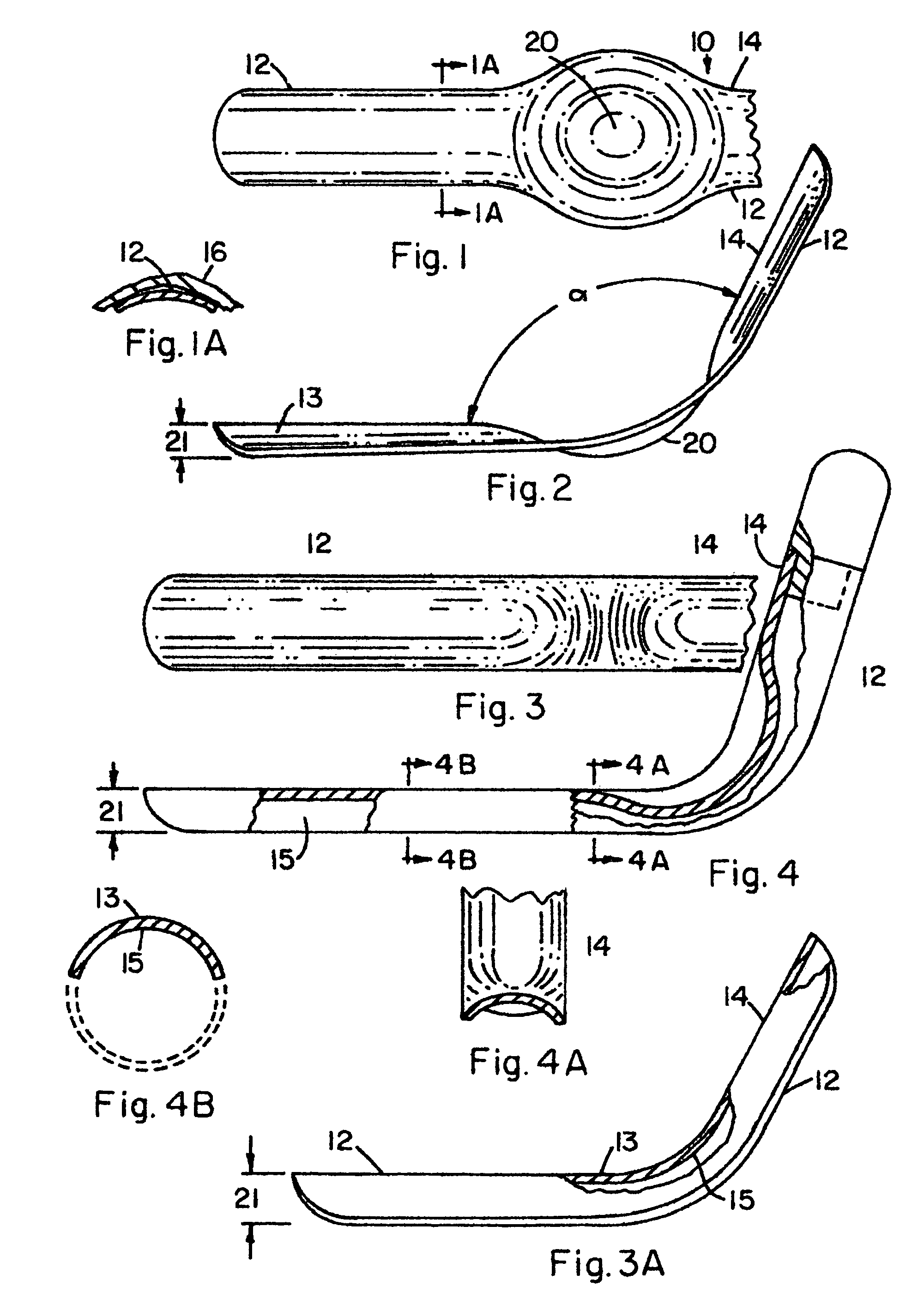

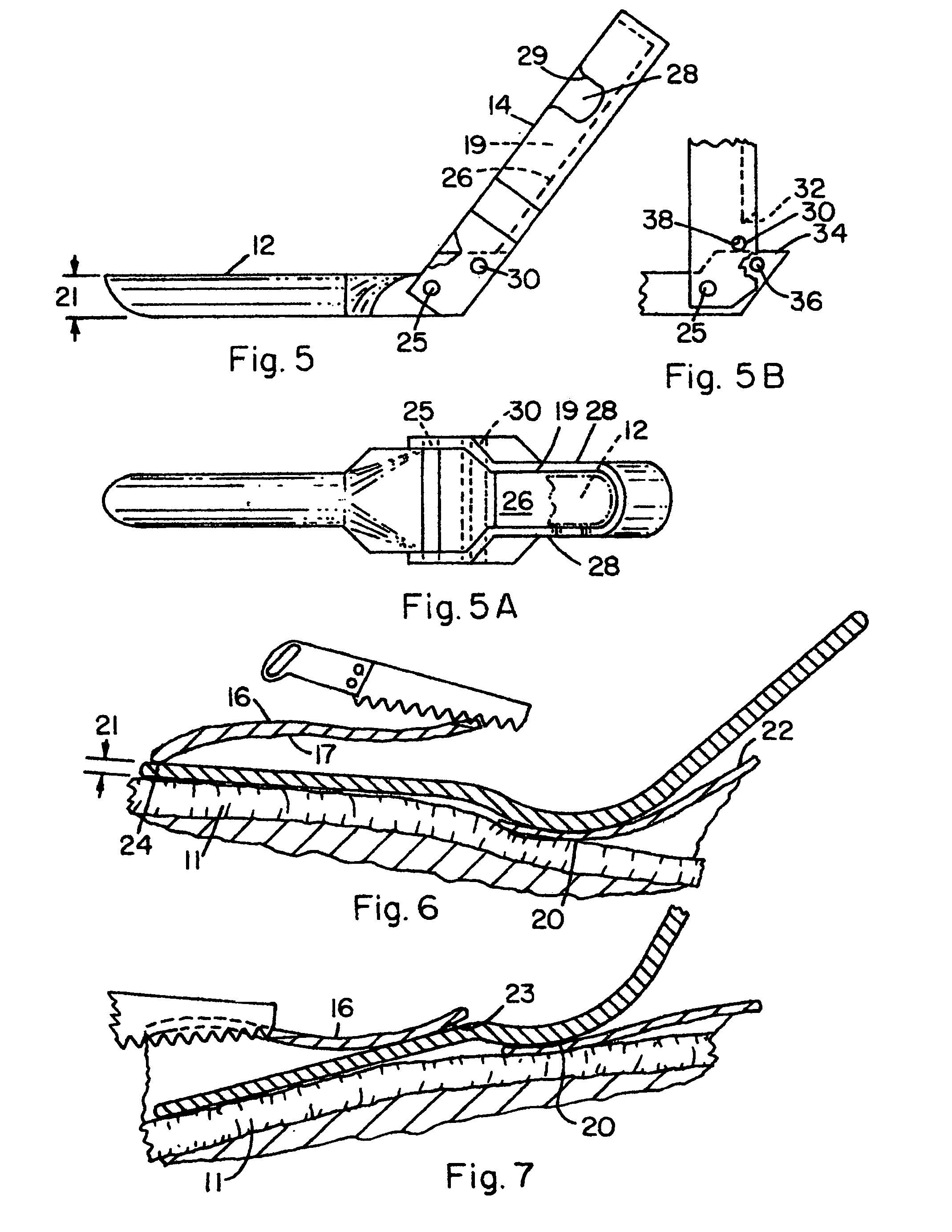

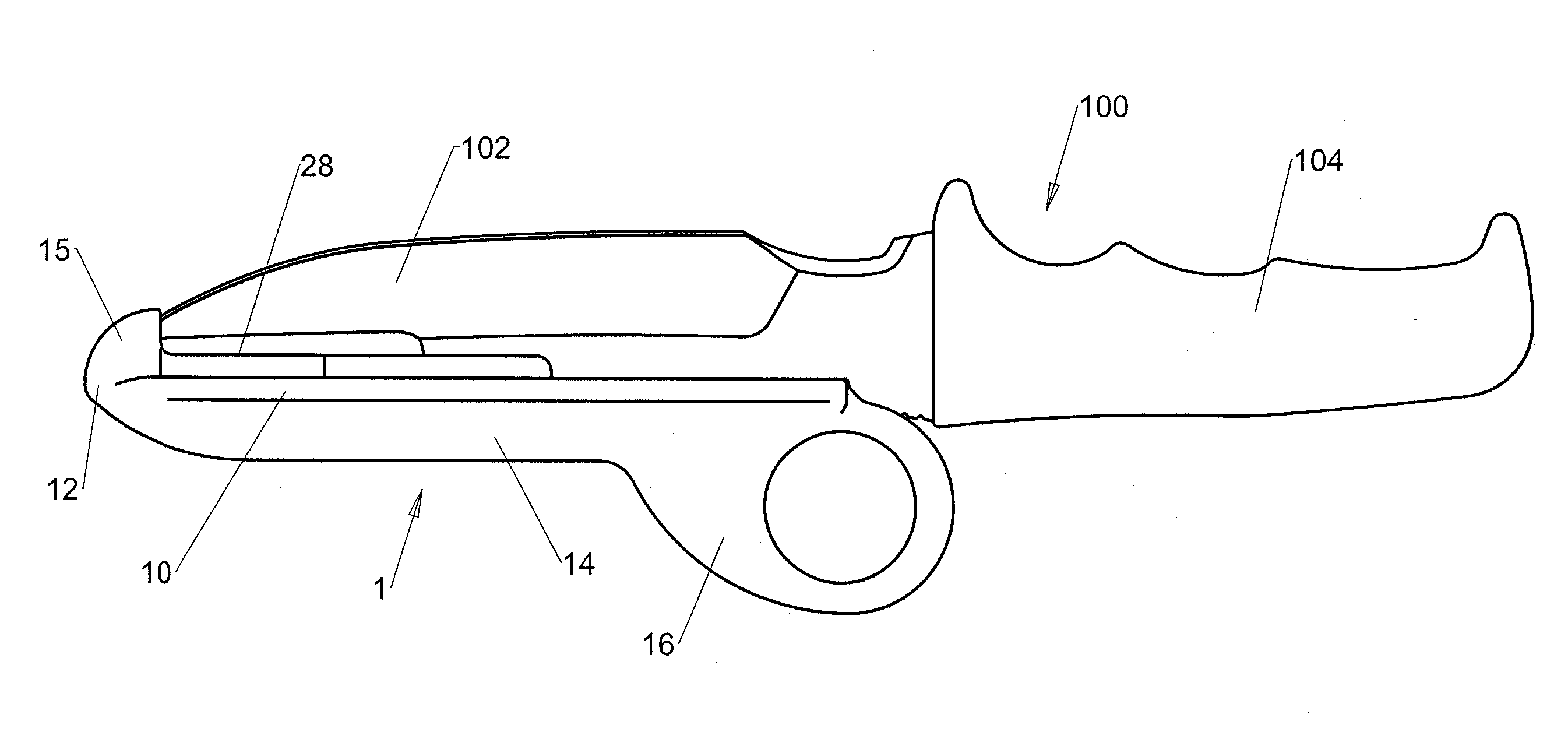

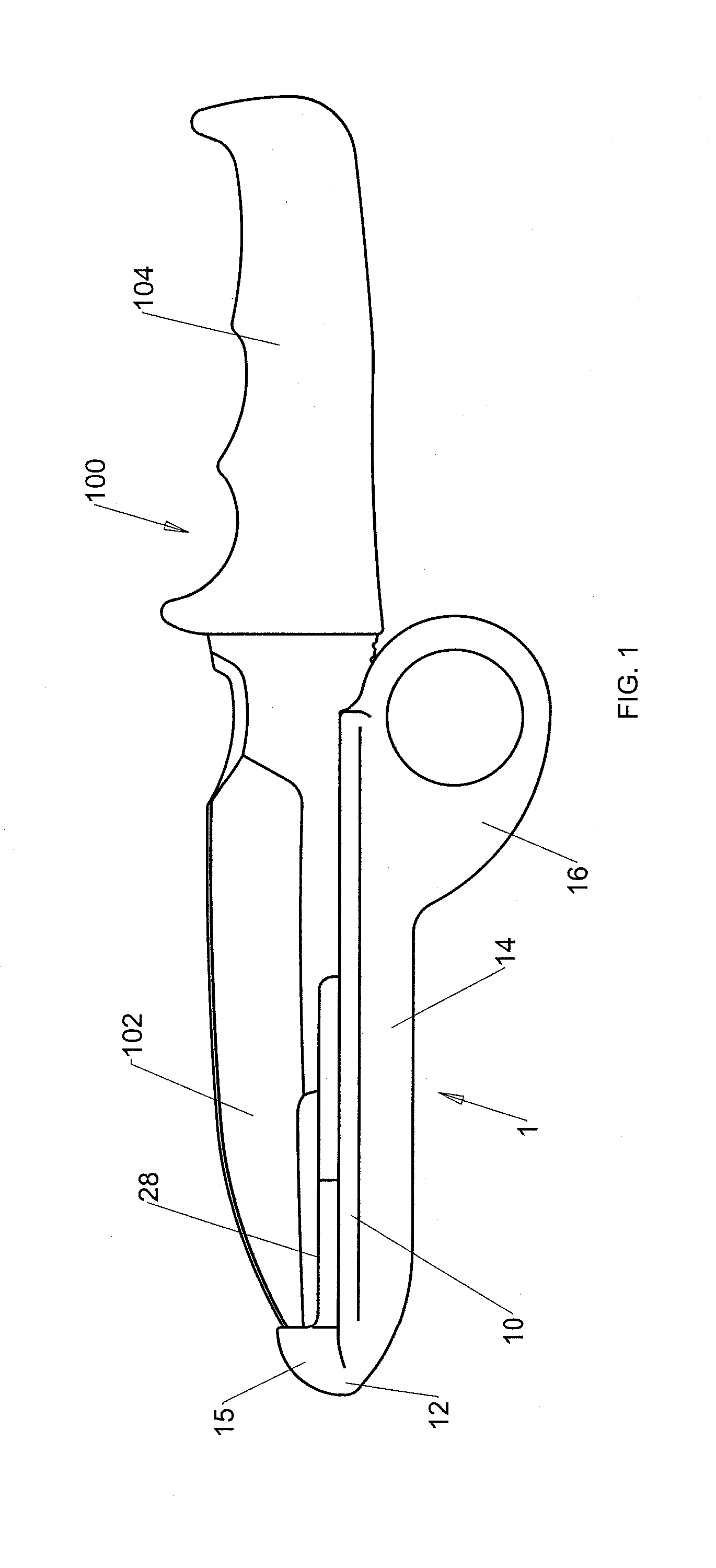

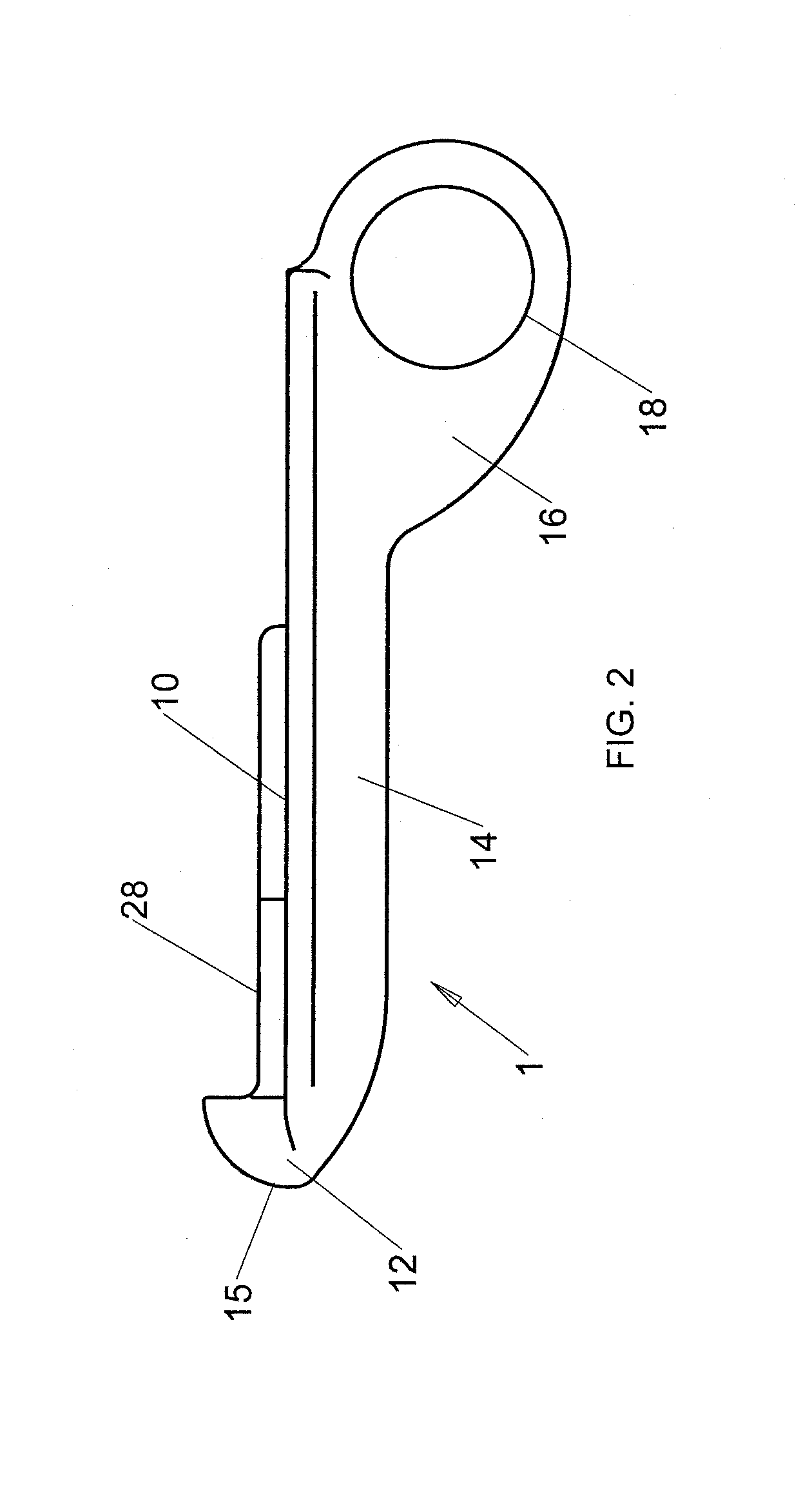

Field dressing attachment for a hunting knife

A field dressing attachment for a hunting knife preferably includes a support plate, an end hook, a bottom gusset and a finger ring. One end of the support plate is terminated with the end hook. The bottom gusset extends downward from a bottom of the support plate. The finger ring extends from the bottom gusset and is located at an opposing end of the support plate. A blade groove is formed in the support plate to receive a non-cutting edge of a knife blade. A tip cavity is formed in the end hook. A tip of the knife blade is inserted into the tip cavity. A user's finger is inserted through the finger ring and a remainder of the hand is wrapped around a handle of the knife. The forefinger is used to keep the tip of the knife blade in the tip cavity.

Owner:KITSCHA JOHN J

Method and apparatus for harvesting livers and hearts

InactiveUS8172652B2Quality improvementHigh yieldAnimal stomach clearancePoultry eviscerating devicesGizzardEngineering

Owner:TYSON FOODS

Leaf lard remover

Owner:JARVIS PROD

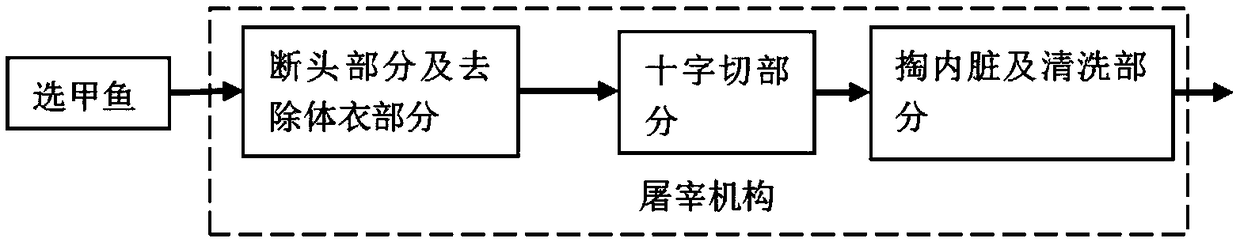

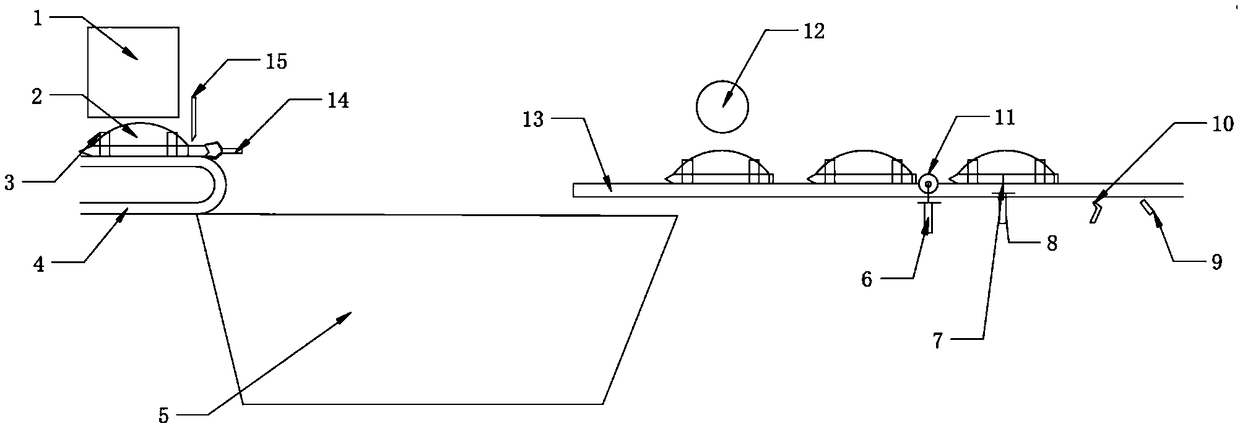

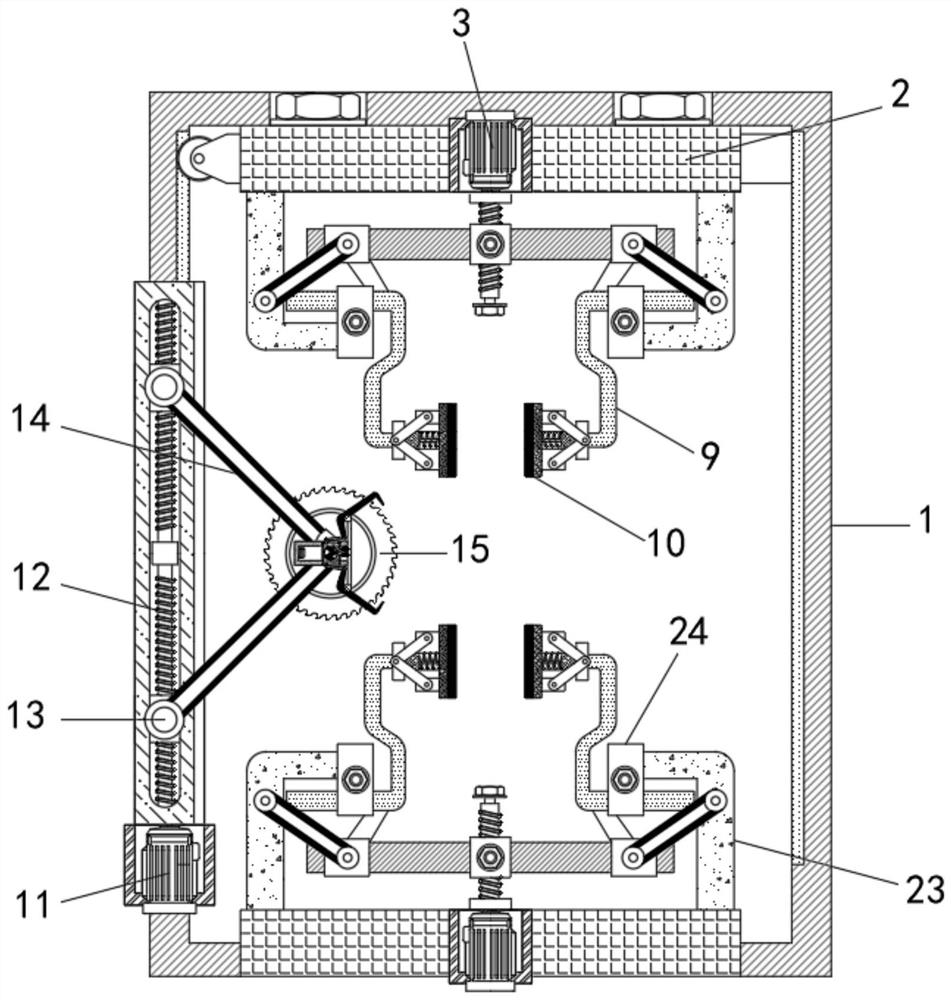

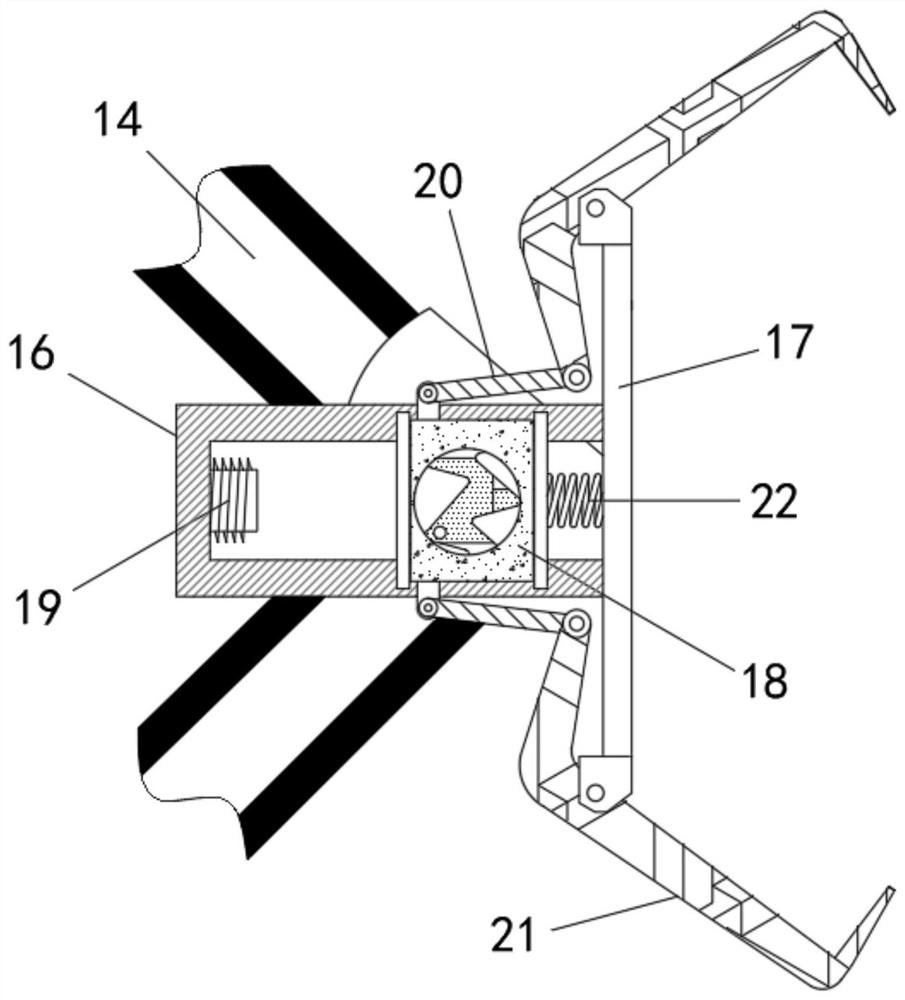

Fresh soft-shelled turtle automatic processing equipment and processing method

ActiveCN108835194AHigh degree of automationSave human effortSlaughtering/stunningEviscerating scissorsControl systemEagle

The invention discloses fresh soft-shelled turtle automatic processing equipment and a processing method. The equipment comprises a squeezing mechanism, a clamping mechanism, a first conveying mechanism, a second conveying mechanism, a flexible turtle head-imitated chuck mechanism and a control system, wherein the squeezing mechanism is located over the first conveying mechanism; the clamping mechanism can move on the first conveying mechanism and the second conveying mechanism; the flexible turtle head-imitated chuck mechanism is mounted on one side of the first conveying mechanism; a triangular head cutting edge is arranged above the flexible turtle head-imitated chuck mechanism; a constant-temperature water tank is arranged between the first conveying mechanism and the second conveyingmechanism; a roller brush is arranged above the second conveying mechanism; a longitudinal round sawblade, a transverse straight sawblade and an eagle claw-imitated hook are mounted at the middle partof the second conveying mechanism in sequence. The fresh soft-shelled turtle automatic processing equipment disclosed by the invention is relatively high in automation degree, effectively reduces thelabor for killing a soft-shelled turtle, improves the quality and consistency of a product, and realizes sterile production.

Owner:LUKA IND GUANGDONG

Slaughtering device capable of automatically eviscerating animals and removing viscera

InactiveCN112471210AAvoid cutting deviationAutomatic removalEviscerating scissorsAnimal scienceDraft animals

The invention relates to the technical field of slaughtering, and discloses a slaughtering device capable of automatically eviscerating animals and removing viscera, which comprises an equipment mainbody; wherein the upper end and the lower end of the equipment main body are fixedly connected with mounting brackets, the middle parts of the mounting brackets are provided with first motors, the output ends of the first motors are provided with first threaded rods, and a rod body of the first threaded rod is in threaded connection with a sliding rod. According to the slaughtering device, after eviscerating, the electromagnet is powered on to enhance magnetism of the electromagnet, then a metal block slides in the direction away from a supporting rod and drives an remover to contract througha third connecting rod, so that viscera are clamped, then a second motor is controlled to enable an output shaft of the second motor to rotate reversely, and a second threaded rod rotates reversely accordingly; thus, the threaded blocks get away from each other and drive the cutting knife and the sliding groove to get away from the livestock through the guide rod, and the remover synchronously moves along with the threaded blocks and removes the clamped viscera from the livestock body, and therefore the viscera of the livestock are automatically removed.

Owner:赵应文

Method and apparatus for processing carcasses

InactiveUS8002613B2Fish washing/descalingAnimal stomach clearanceProcess engineeringManufacturing line

Owner:CARGILL INC

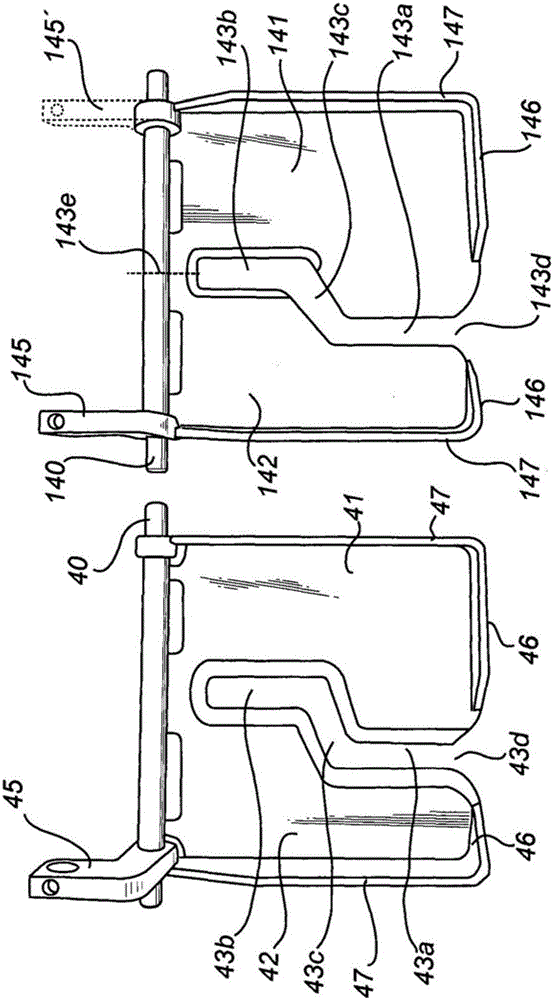

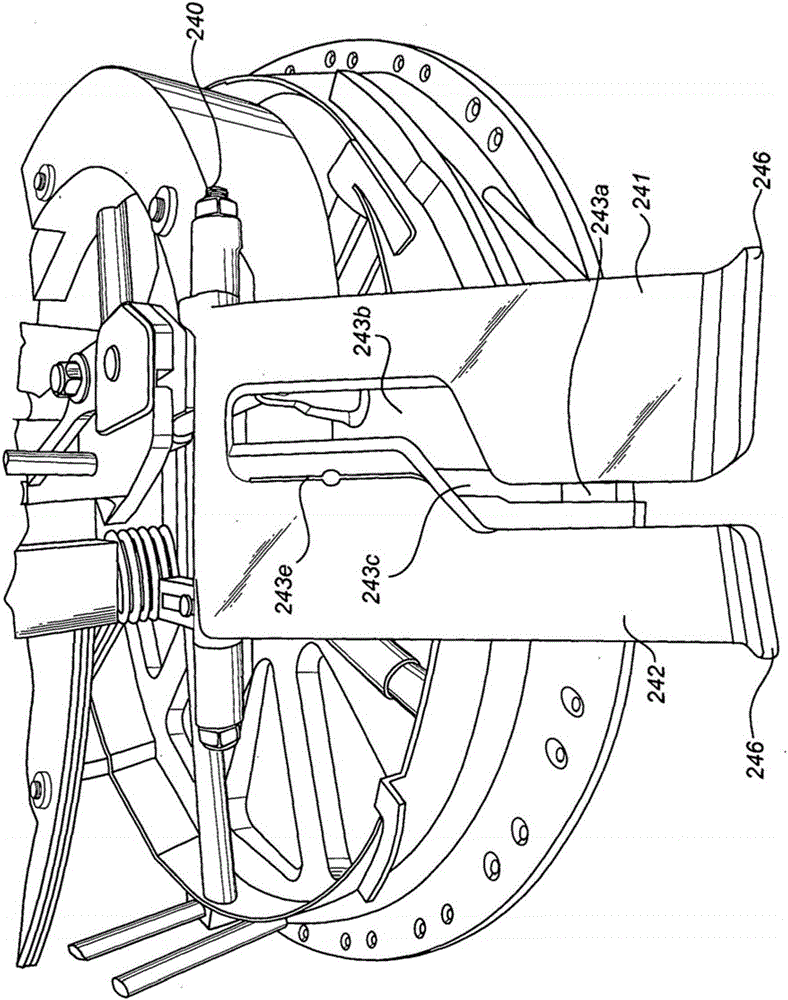

Guide member, a guide system and a method for separating a viscary set eviscerated from slaughtered poultry

ActiveUS9648887B2Avoid damagePrecise positioningPoultry eviscerating devicesEviscerating scissorsGizzardEngineering

A guide member for use in separating viscera sets eviscerated from slaughtered poultry comprising a separation support surface having an elongated opening for receiving a viscera set in a manner whereby at least the intestines and the gallbladder are suspended below said guide member and the liver and gizzard are positioned above said guide member. The elongated opening extends away from a front edge of the separation support surface and a distal section of the opening is off-set in relation to a proximal section in a direction substantially parallel to the front edge. A gripping member may be arranged below said guide member for gripping a part of the intestines. In a method according to the invention the guide member is moved into contact with the viscera set whereby the intestines and / or gallbladder enters the elongated opening.

Owner:BAADER FOOD SYST DENMARK AS

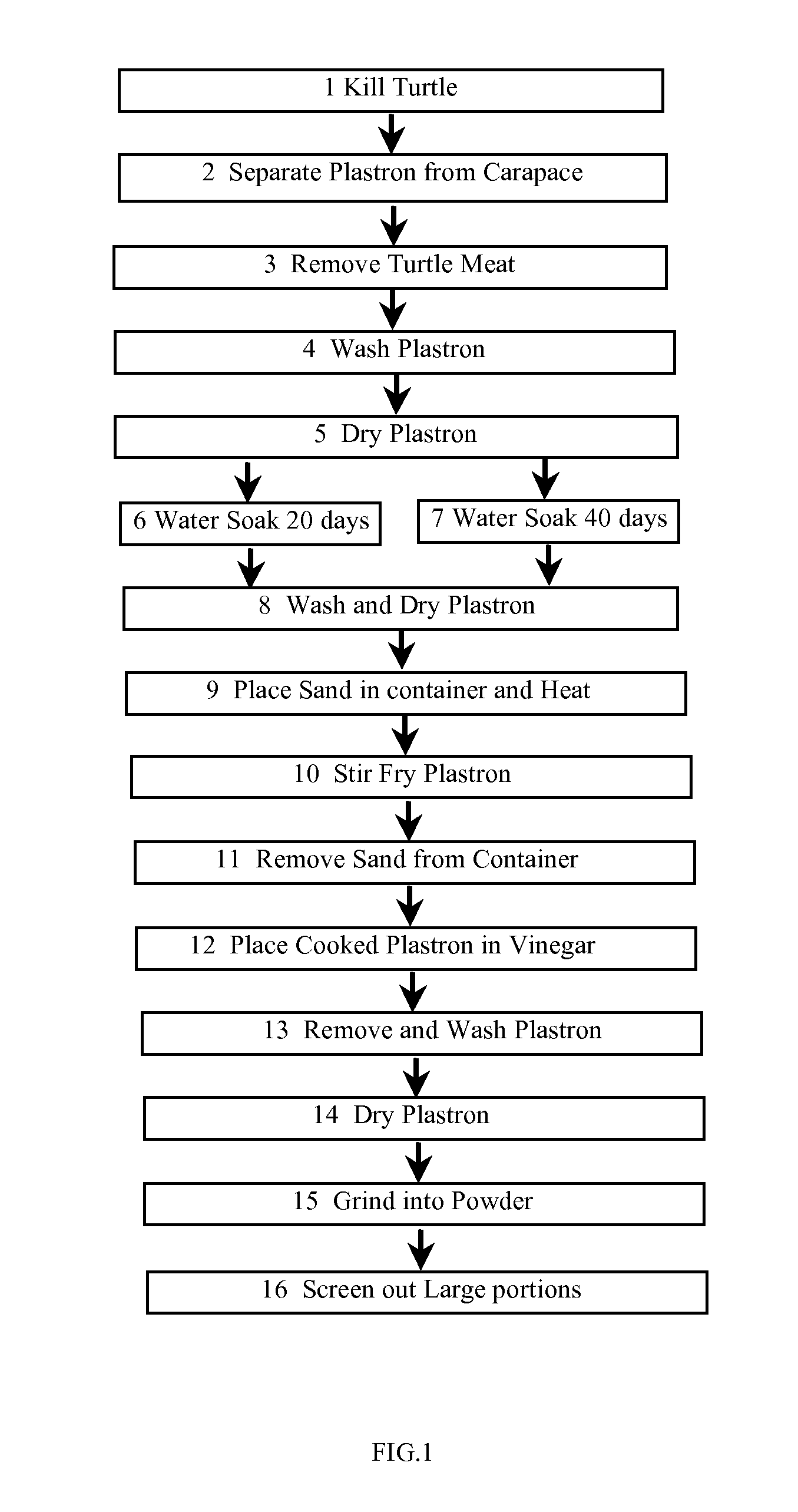

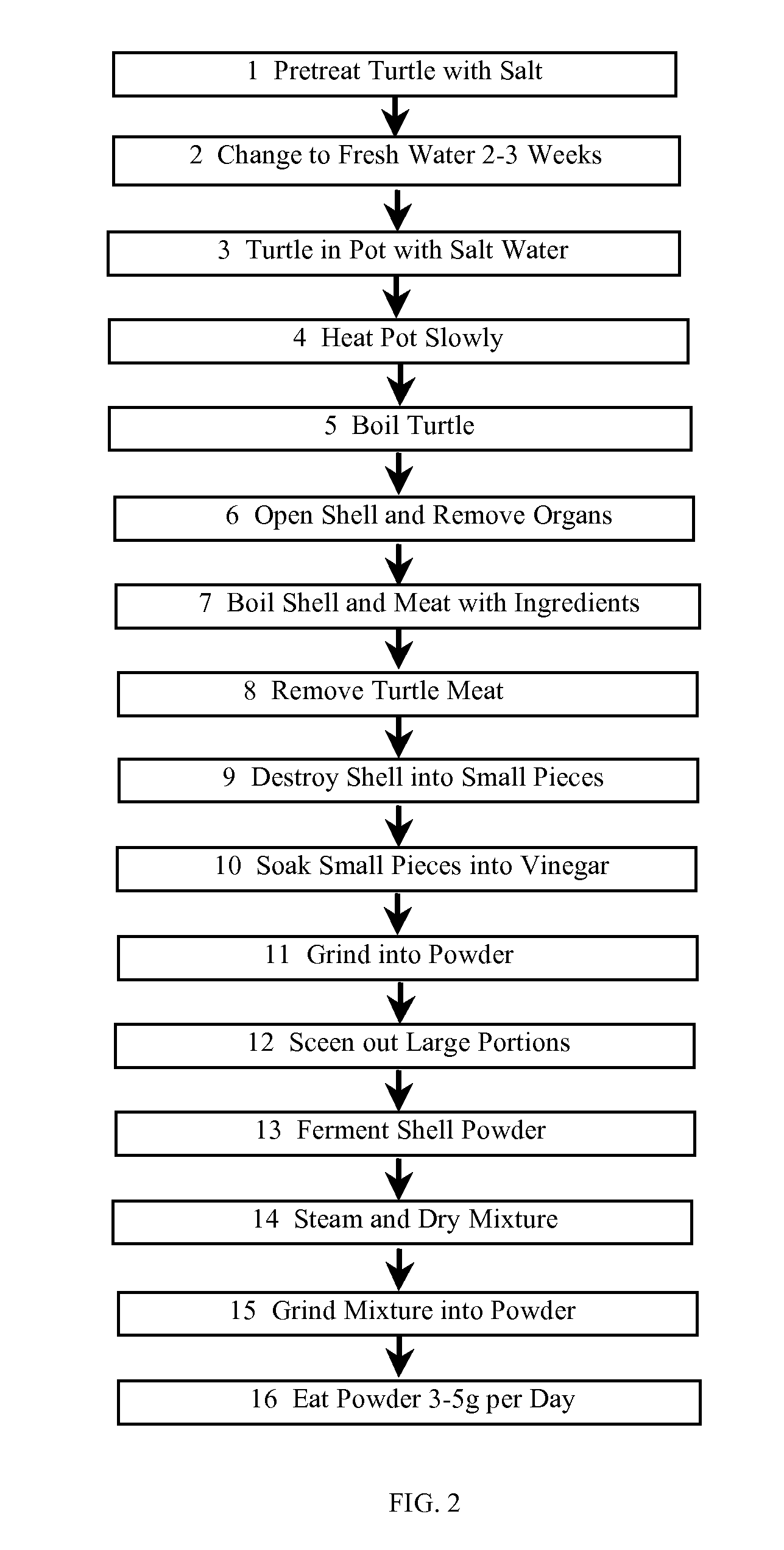

Method of Making Fermented Turtle Shell Powder Mixture

ActiveUS20150237904A1Avoid infectionGreat tasteOrganic active ingredientsAntinoxious agentsSide effectPowder mixture

This invention provides a quick and sanitary way to change inedible and almost useless shells of freshwater hard shell turtles into an edible and extremely valuable fermented turtle shell powder mixture with a salutary taste and attractive smell. The novelties taught herein maximize the retention of turtle shell nutrition and minimize any irritation that can be caused from the traditional method of making turtle shell powder. Also, this enhances the digestive absorption of the powder thereby efficiently improving human's health and looks. No negative side effects have been observed to this product. Various steps are provided that enhance the positive benefits of the powder.

Owner:LIU CANHUI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com