Slaughtering and processing device and slaughtering and processing method for chilled chicken

A processing device and processing method technology, applied in the direction of slaughtering devices, slaughtering, slaughtering accessories, etc., can solve the problems of incomplete cleaning, surface browning, juice loss, etc., to reduce chicken colonies, avoid browning, and prevent bacterial growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

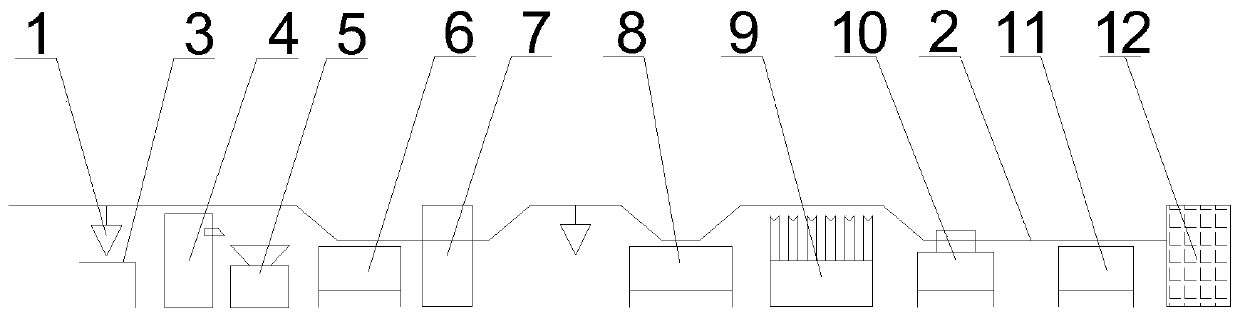

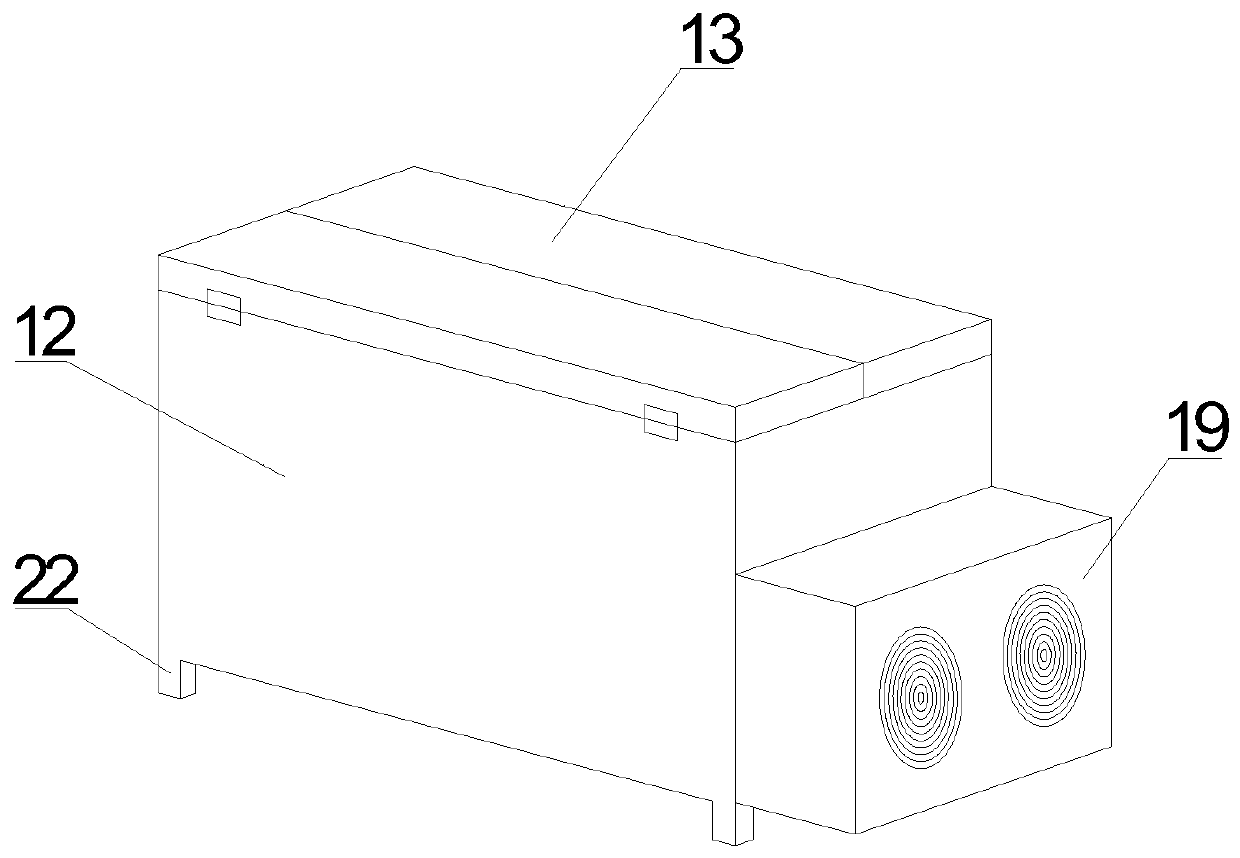

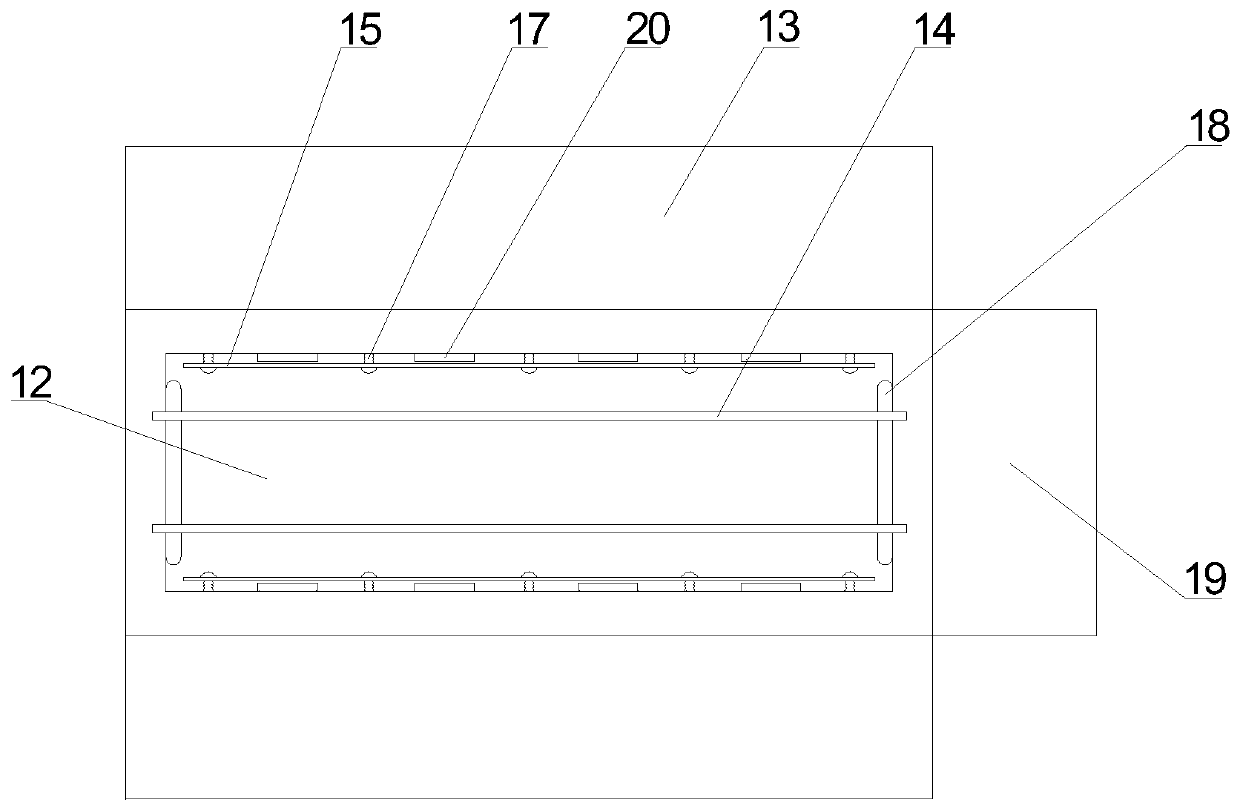

[0035] Embodiment 1: A kind of chilled chicken slaughtering and processing device

[0036] The invention provides a chilled chicken slaughtering and processing device, comprising a stunning and stabbing device 4, a bleeding device 5, a scalding and depilatory device 6, a first cleaning tank 7, a device for disemboweling and removing viscera 8, a second cleaning tank 9, A bone device 10 and a freezing mechanism. The freezing mechanism includes a cooling pool 11 and a freezing box 12. The cooling pool 11 and the freezing box 12 are connected by a transmission device 2, and a hook 1 is provided on the transmission device 2.

[0037] In the present invention, the transmission device is provided with a hook 1, the lower end of the transmission device 2 is provided with a stun and assassination device 4, and one side of the stun and assassination device 4 is provided with a bleeding device 5, and the bleeding device 5 is far away from the side of the stun and assassination device 4 ...

Embodiment 2

[0042] Embodiment two: a kind of frozen chicken slaughtering and processing method

[0043] The present invention provides a chilled chicken slaughtering and processing method suitable for the above-mentioned embodiment one providing a chilled chicken slaughtering and processing device, comprising the following steps:

[0044] (1) Manually fix the chicken on the hook 1 of the conveying device 2 .

[0045] (2) The hung chicken is sent to the stunner and assassination device 4 through the hook 1 and the transmission device 2 for welfare slaughter. After the slaughter, the chicken is drained, scalded, depilated, and then sent to the first cleaning pool 7 for cleaning.

[0046] (3) After cleaning, disembowel and remove the viscera, then send it to the second cleaning pool 9 to clean and remove blood.

[0047] (4) After cleaning, send it to the deboning device 10 to remove the head and feet, send it to the cooling pool 11 for pre-cooling, and send it to the low-temperature freezer...

Embodiment 3

[0050] Example 3: Application of a chilled chicken slaughtering and processing method and device

[0051] On the basis of the first and second embodiments above, when the method and device of the present invention are applied, the chickens are manually fixed on the hook 1 on the conveying device 2 and slaughtered in the stunning stabbing device 4, and the blood is drained after slaughter , remove hair by scalding depilatory device 6, after cleaning once, use ripping device 8 to remove viscera, wash again to remove blood and send it to deboning device 10 to remove larger bones, and then enter the freezing process. When freezing, first pass through cooling pool 11 The ketone body cools down and then enters the freezer for 12 seconds of quick freezing. During the freezing process, a plasma generator is used to sterilize. The whole process is fast and clean, with less loss of meat quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com