Patents

Literature

204results about "Poultry/fish slaughtering/stunning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

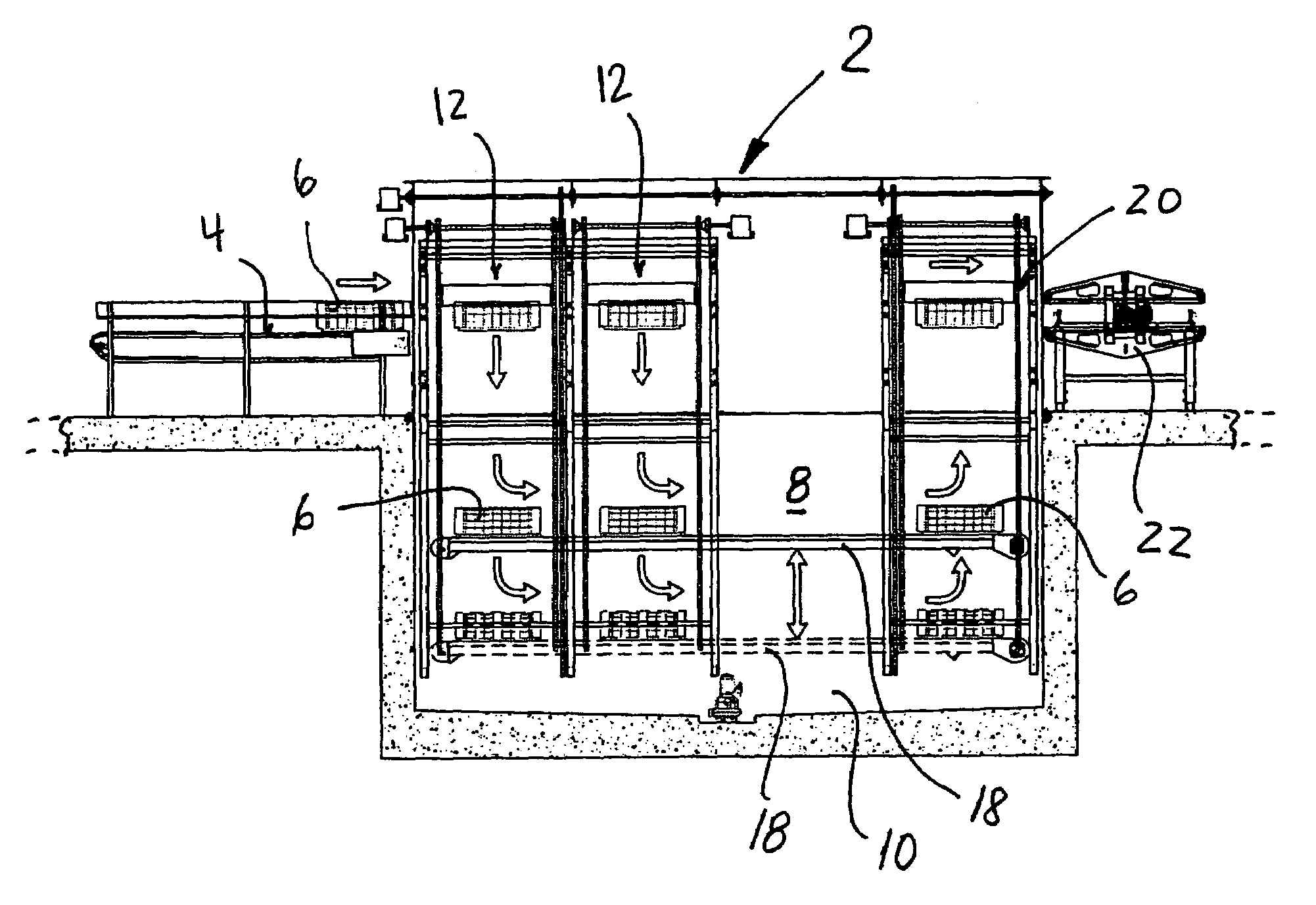

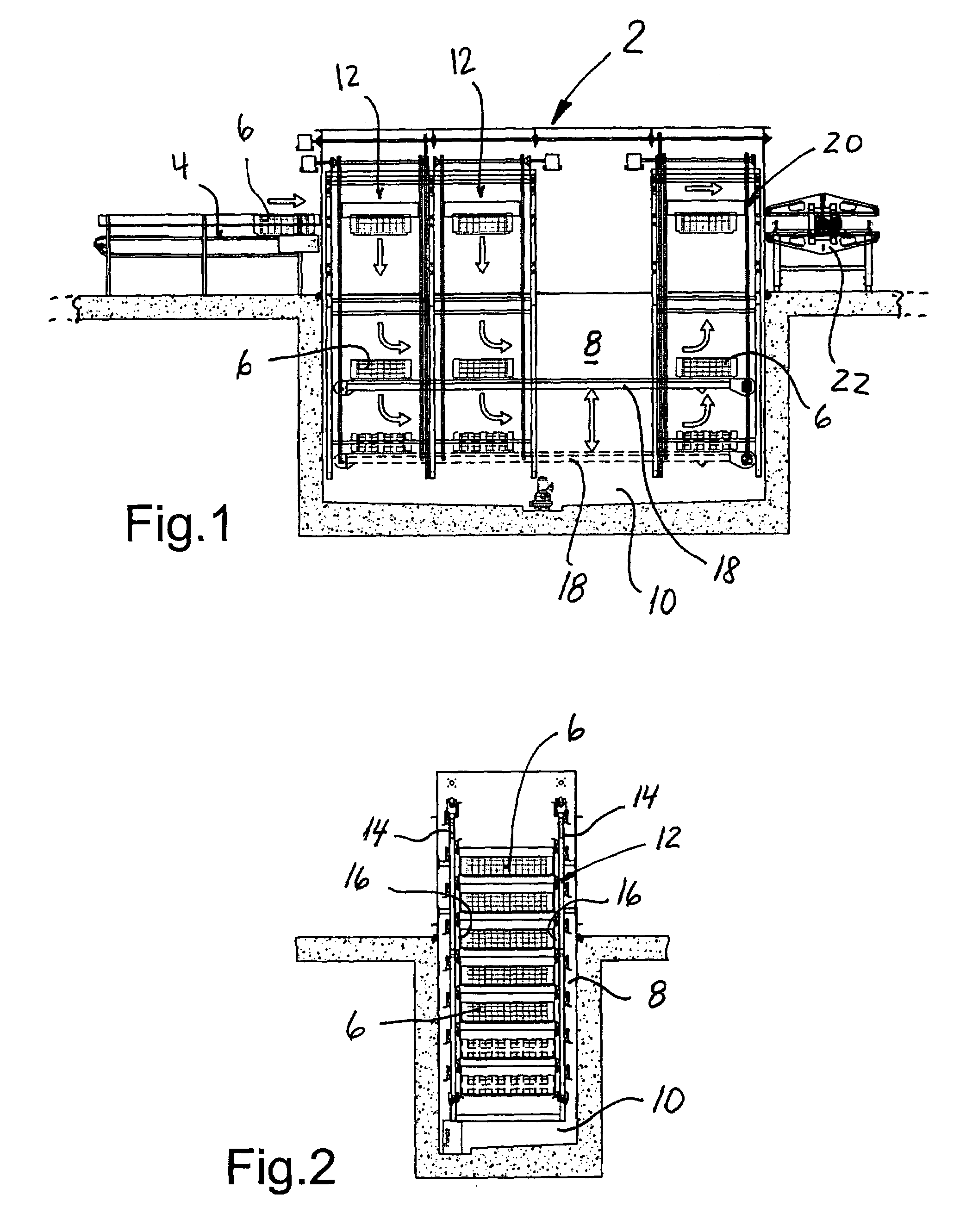

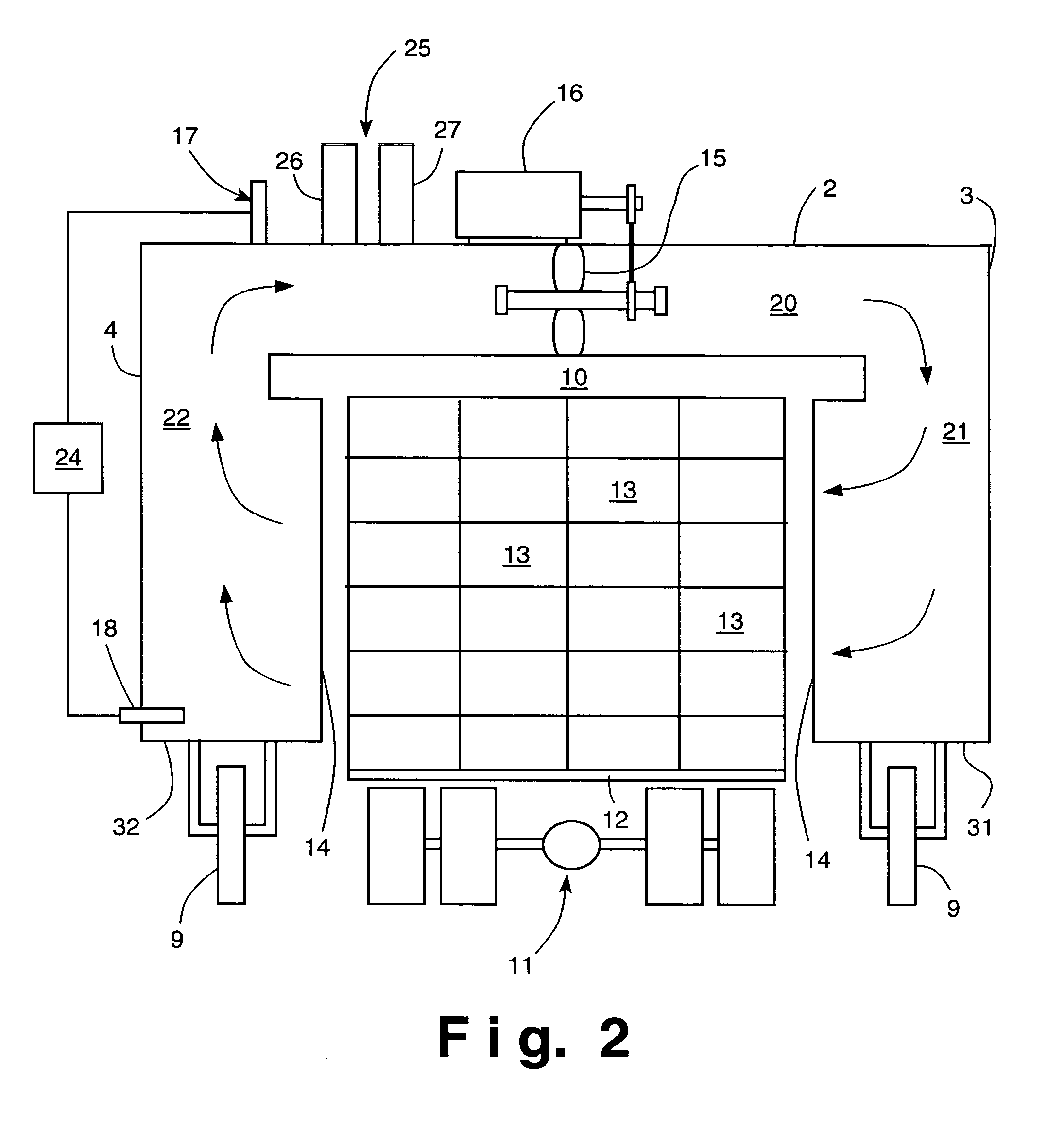

Method and system for gas stunning of poultry for slaughter

InactiveUS7097552B2Easy to optimizeEasy to prolongBlood collection/stirring apparatusGas slaughtering/stunningEngineeringCrate

Owner:LINCO FOOD SYST AS +1

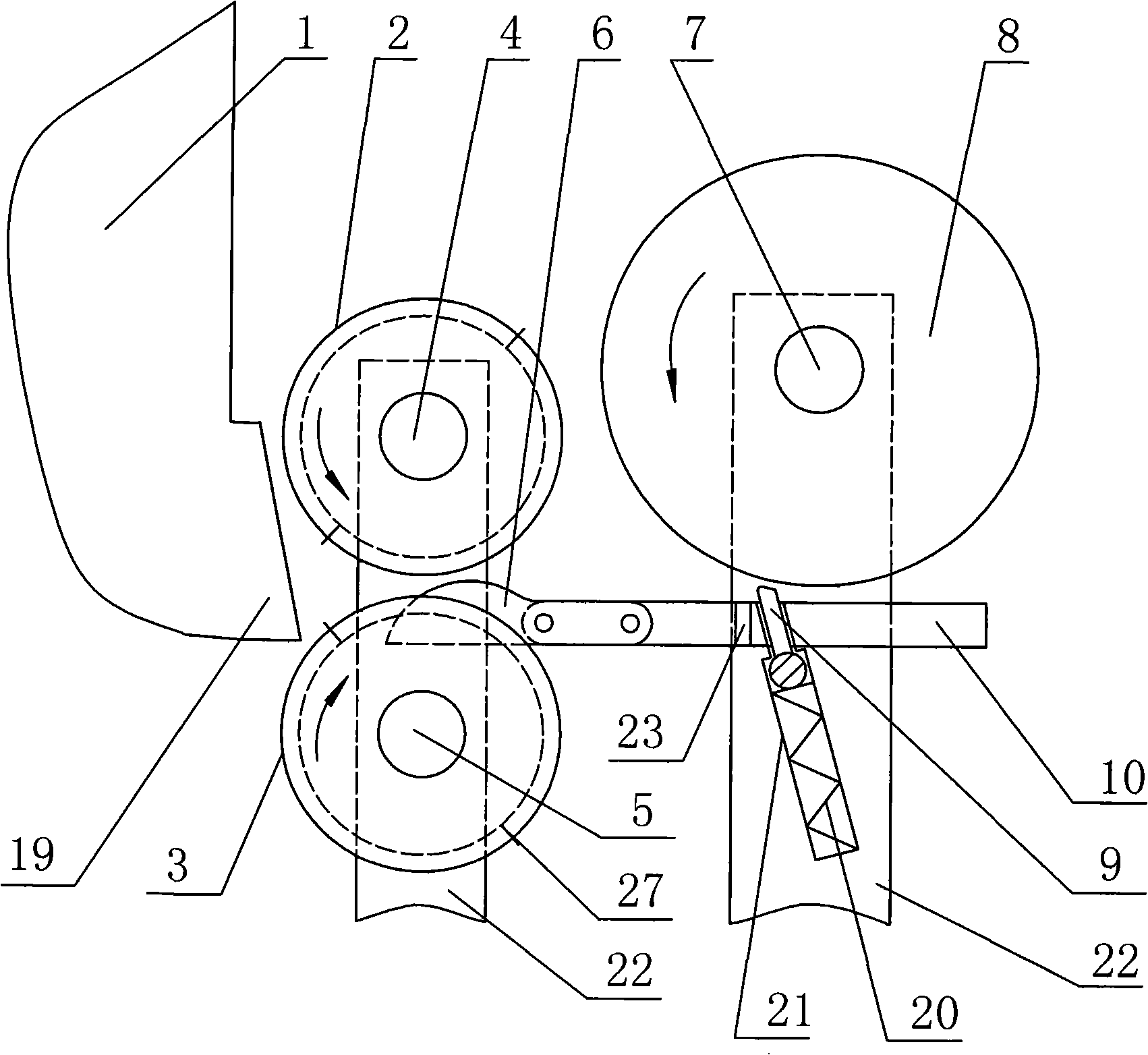

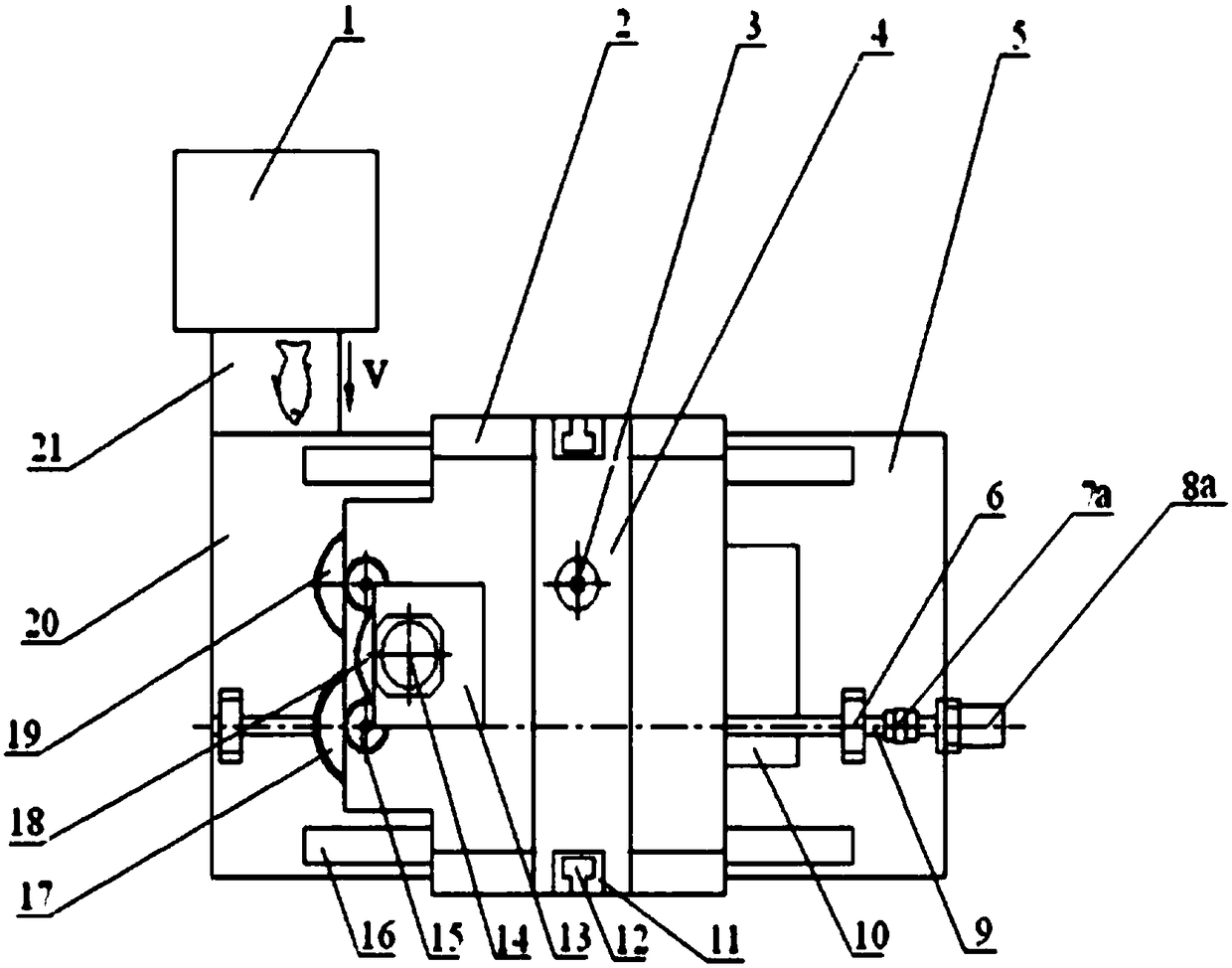

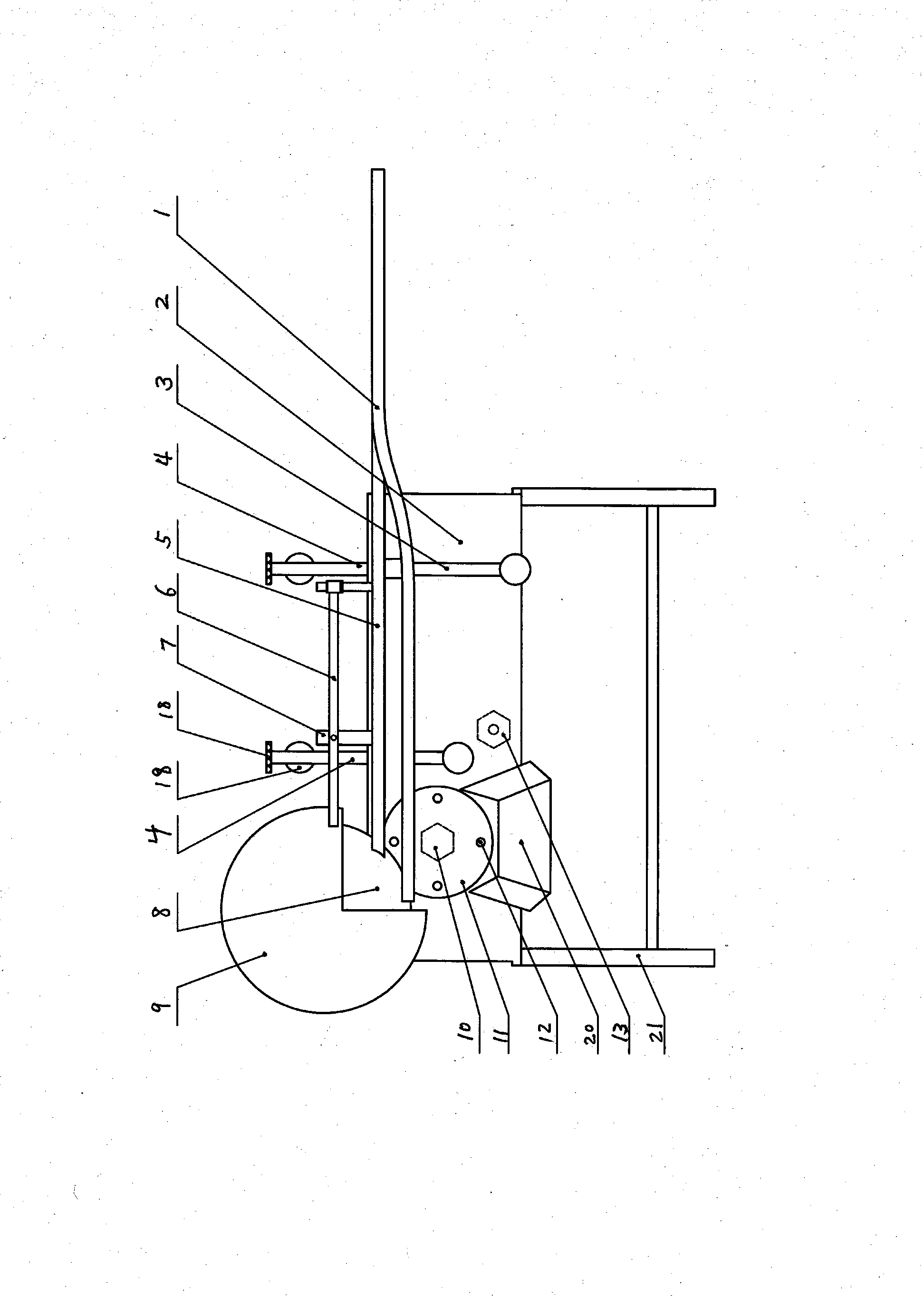

Machine for slaughtering ricefield eel

InactiveCN101273733ASlaughter fastIncrease productionPoultry/fish slaughtering/stunningFinless eelGear wheel

The invention relates to a finless eel butchering machine, belonging to the field of processing machinery of marine products. The machine comprises a charging basket, an upper pair roller, a lower pair roller, a cutting knife, a press roller, a scraper, a supporting plate, a material receiving barrel, a stander and a motor, etc., wherein, one side of the stander is provided with the charging basket, the other side thereof is provided with the upper and the lower pair rollers and the press roller, and an upper and a lower pair roll and a press roll are respectively installed on the upper and the lower pair rollers and the press roller. The lower part of the stander is provided with the motor; the same ends of the upper pair roller and the press roller and the motor are provided with pulleys, other end of the upper pair roller and the same end of the lower pair roller are provided with drive gears; the supporting plate is arranged under the press roller, and the scraper and the cutting knife are arranged on the supporting plate. The butchering machine finishes butchering finless eel by means of automatically entering or going out of a feeding hole according to the habit that the eel likes entering a hole, snatching randomly by the pair rolls, squeezing and sliding cutting, thus solving the problem that the existing butchering device has complicated structure, low working efficiency and great labor intensity by adopting manual feeding, meeting the random butchering demands of families and restaurants, etc., and being capable of being made into a production line for deep processing of finless eel.

Owner:李平

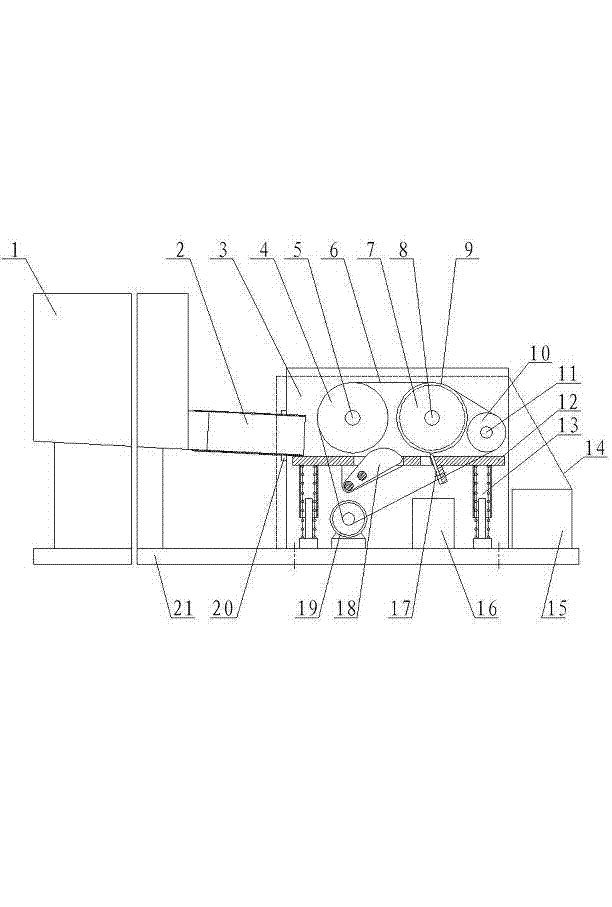

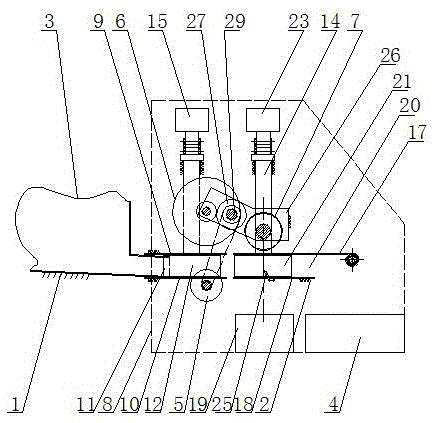

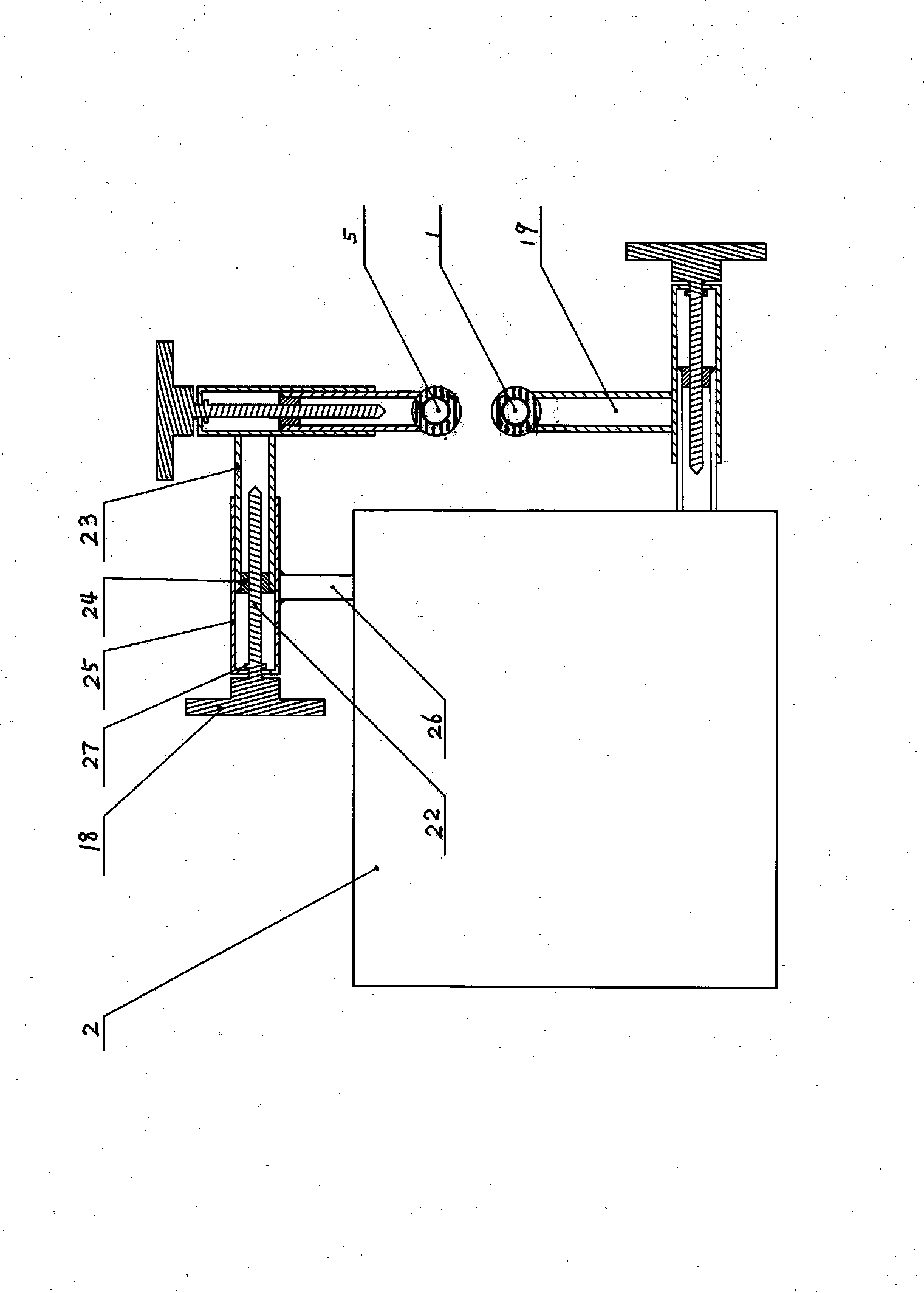

Eel and loach slaughtering machine

InactiveCN103168819ASolve the problemSolve the problem of missed killingPoultry/fish slaughtering/stunningAquatic productBack cutting

The invention relates to an eel and loach slaughtering machine which belongs to the field of an aquatic product processing machine. The eel and loach slaughtering machine is formed by a rack, a feeding barrel and a slaughtering device, wherein the feeding barrel is mounted at the one end of the rack and the slaughtering device is arranged at the other end of the rack; the feeding barrel and the slaughtering device are movably connected through a feeding hose and a hose clamp; and the slaughtering device is provided with a protection cover. The eel and loach slaughtering machine disclosed by the invention adopts a feeding roller to randomly grasp and convey eel and loach, the slaughtering speed is high, the slaughtering requirements on eel and loach with different sizes can be met, and the frequent problems that some eel and loach are not correctly slaughtered or are not slaughtered when an existing slaughtering machine is used for slaughtering eel and loach with different sizes are solved. When the eel and loach slaughtering machine disclosed by the invention is used for slaughtering eel and loach, eel and loach do not need to be classified according to specifications and sizes in advance, so that the labor intensity of workers is reduced and the working efficiency is improved; and eel and loach can be slaughtered from abdomens or from backs through the selection connection between the feeding hose and a back cutting supporting plate and between the feeding hose and an abdomen cutting supporting plate, and furthermore, the requirements on deep processing of eel and loach can be met.

Owner:李平

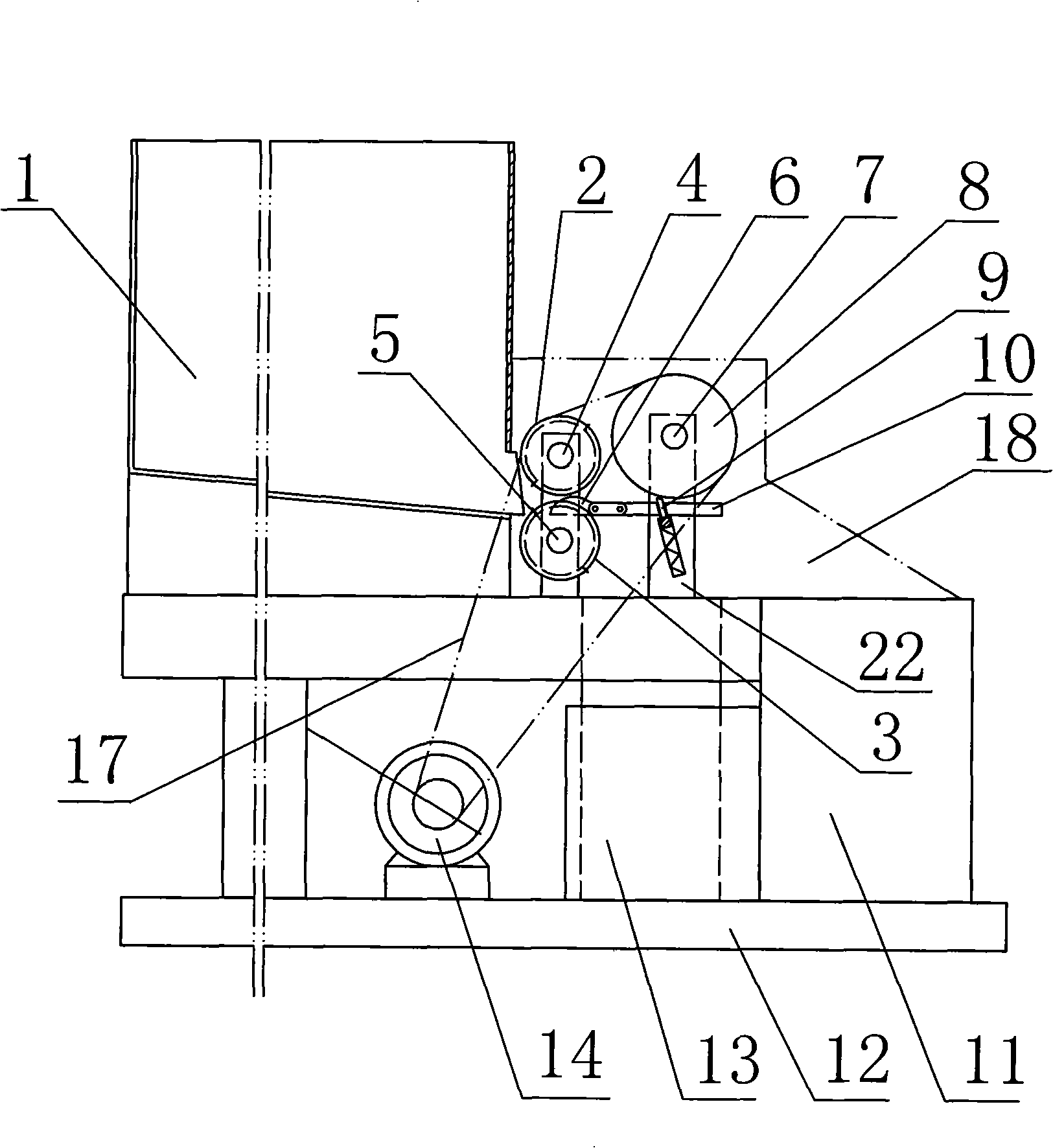

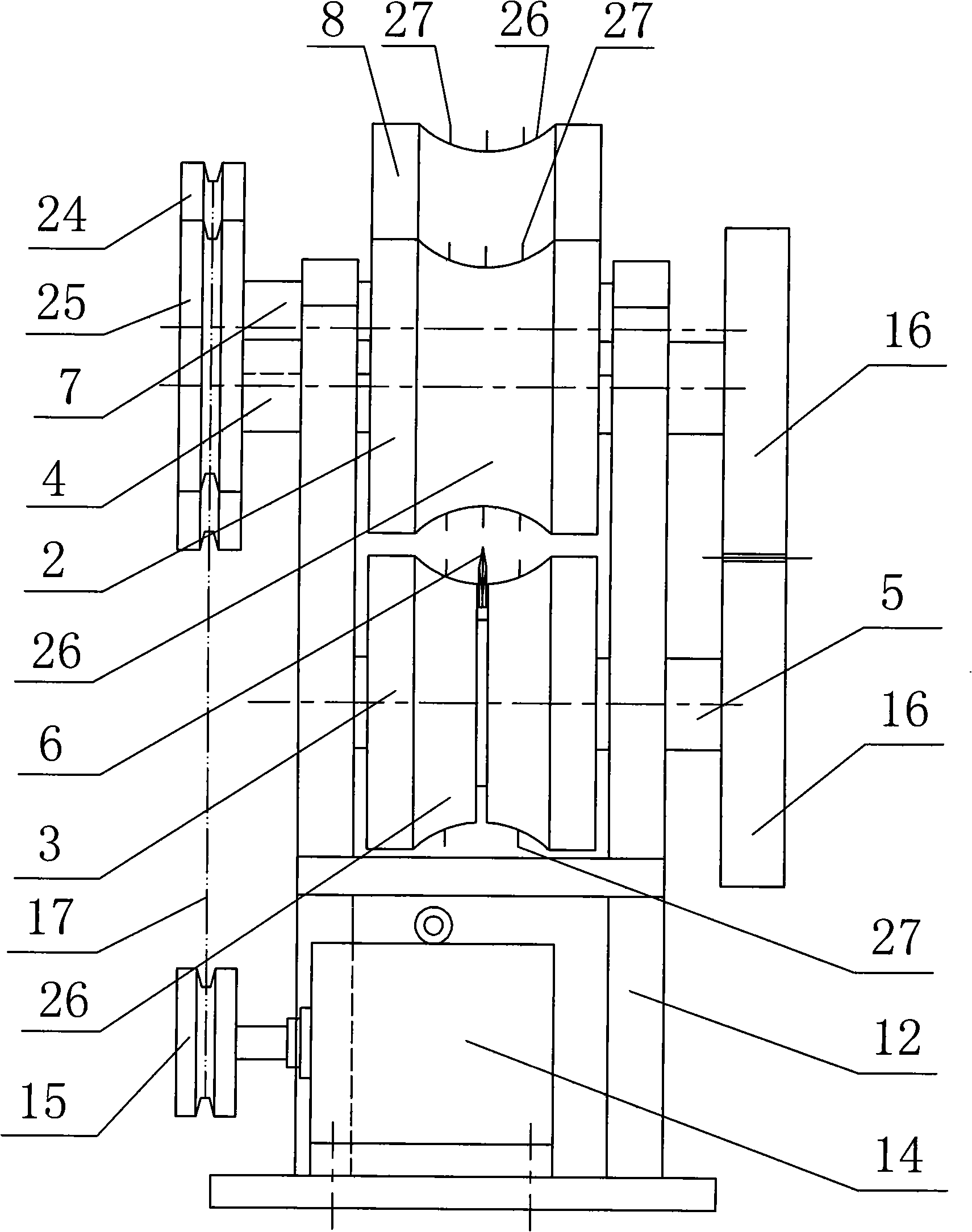

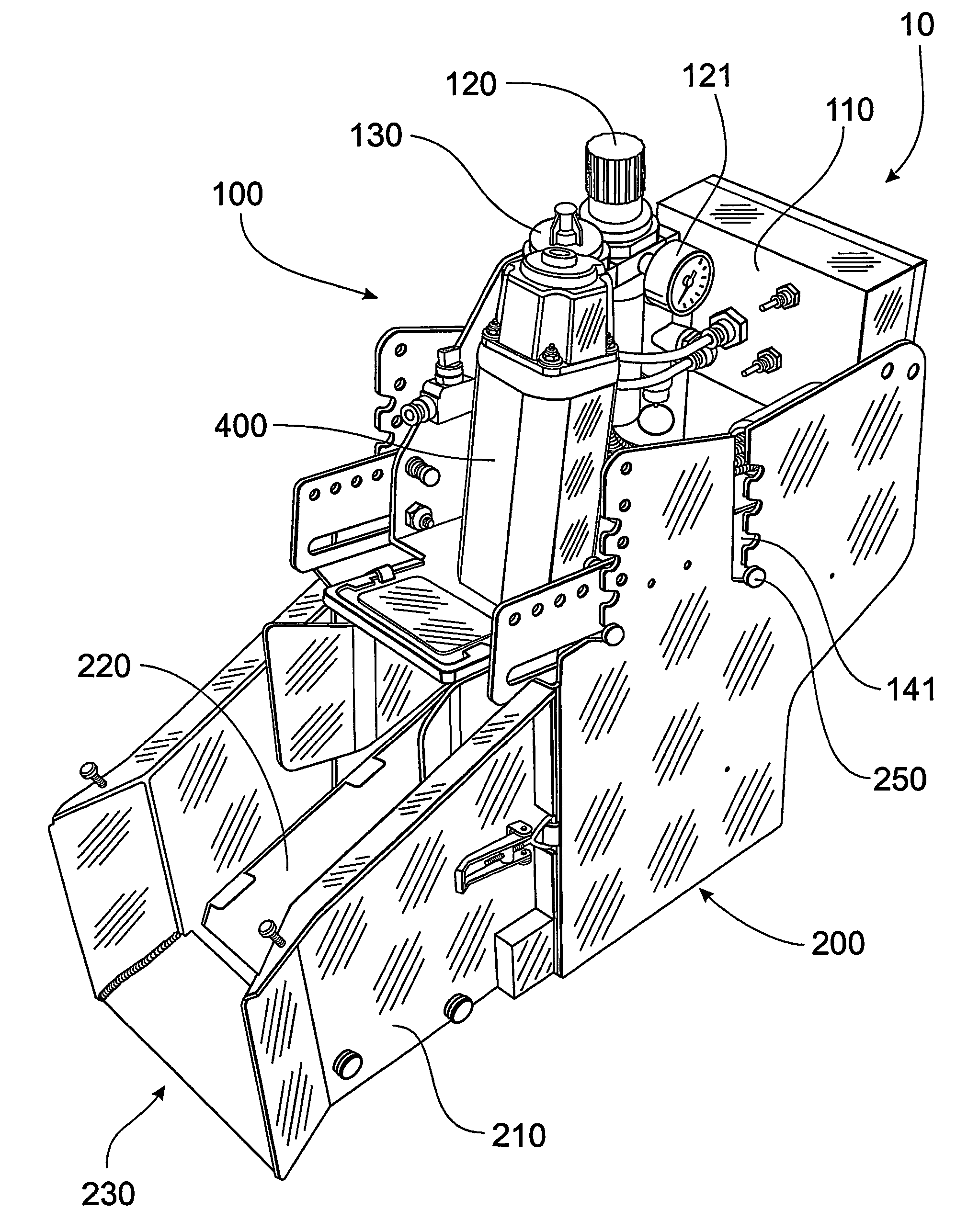

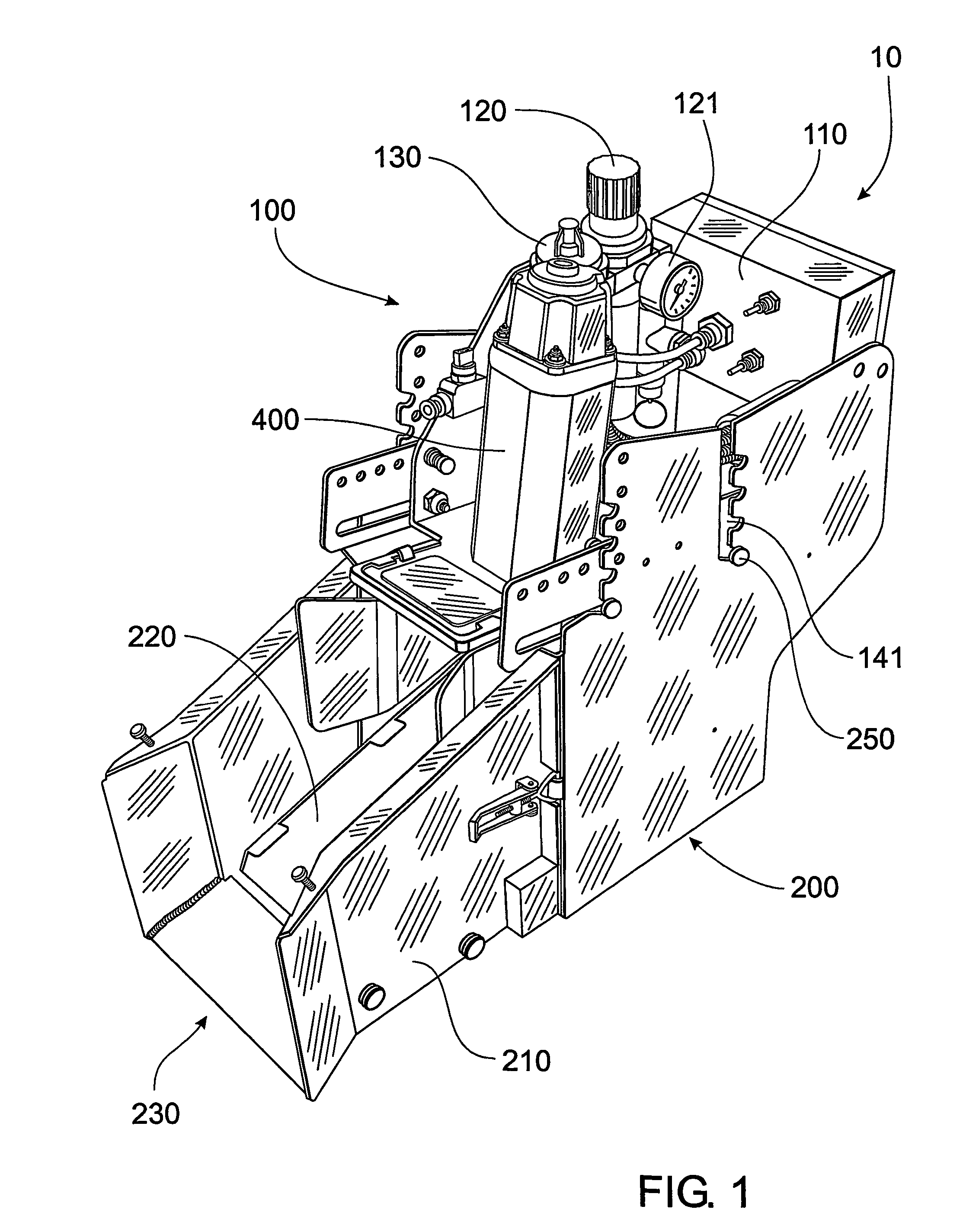

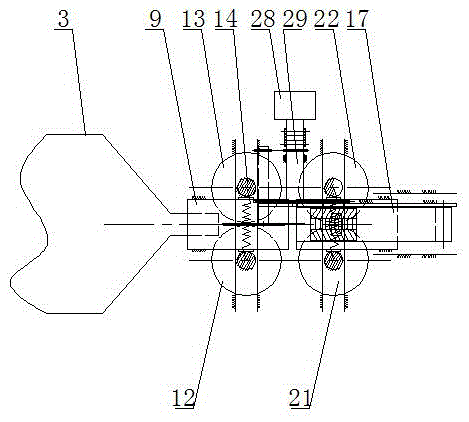

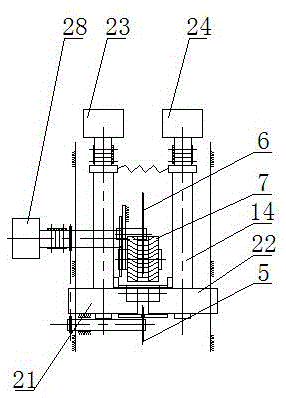

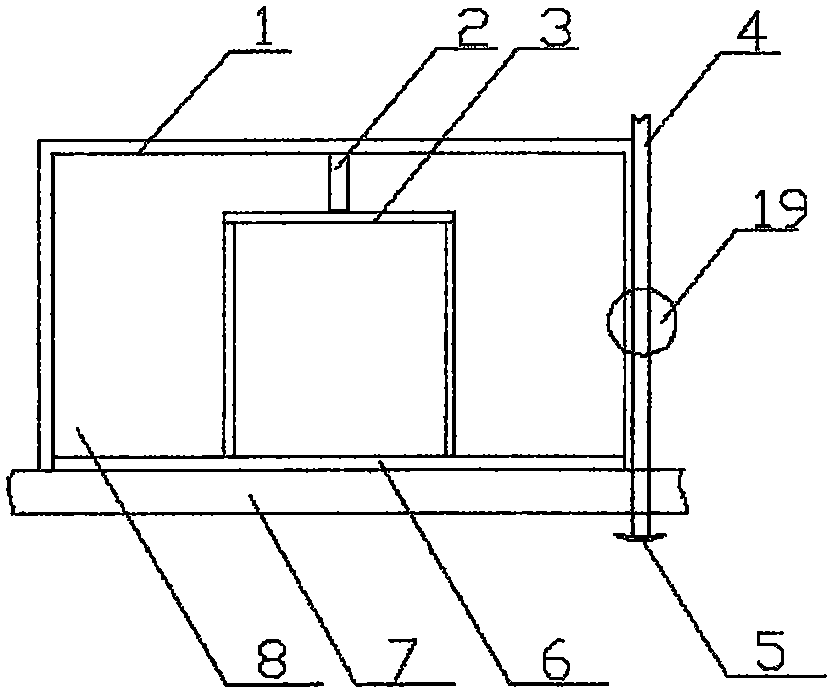

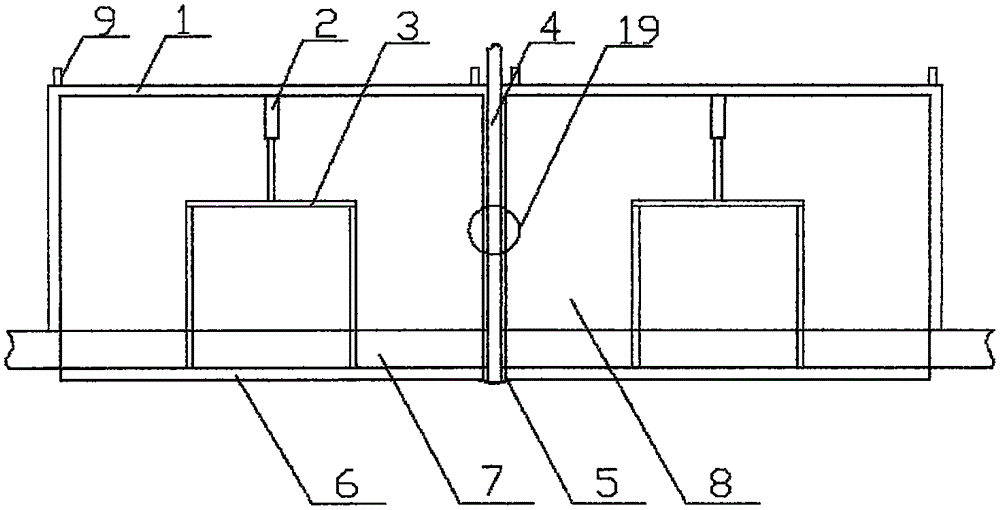

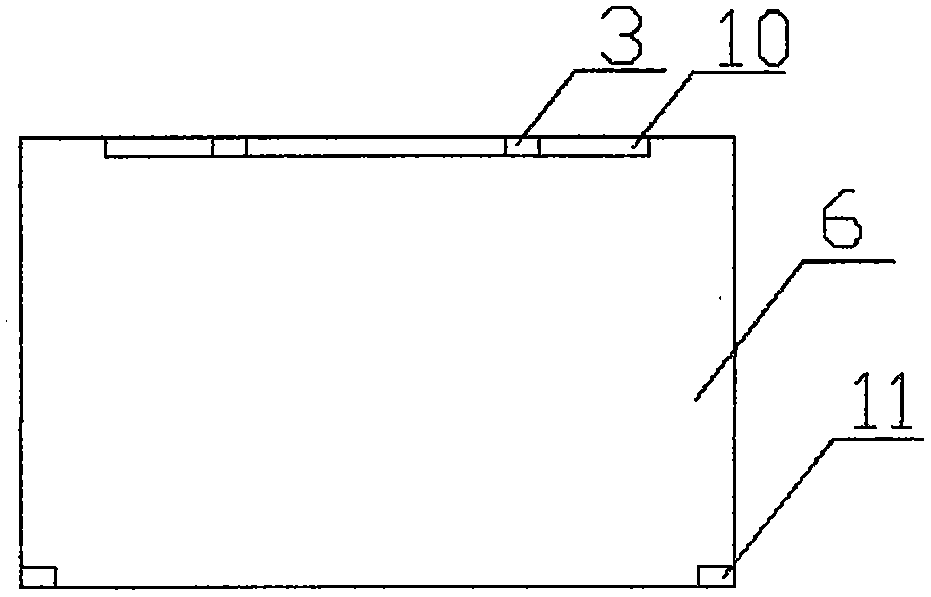

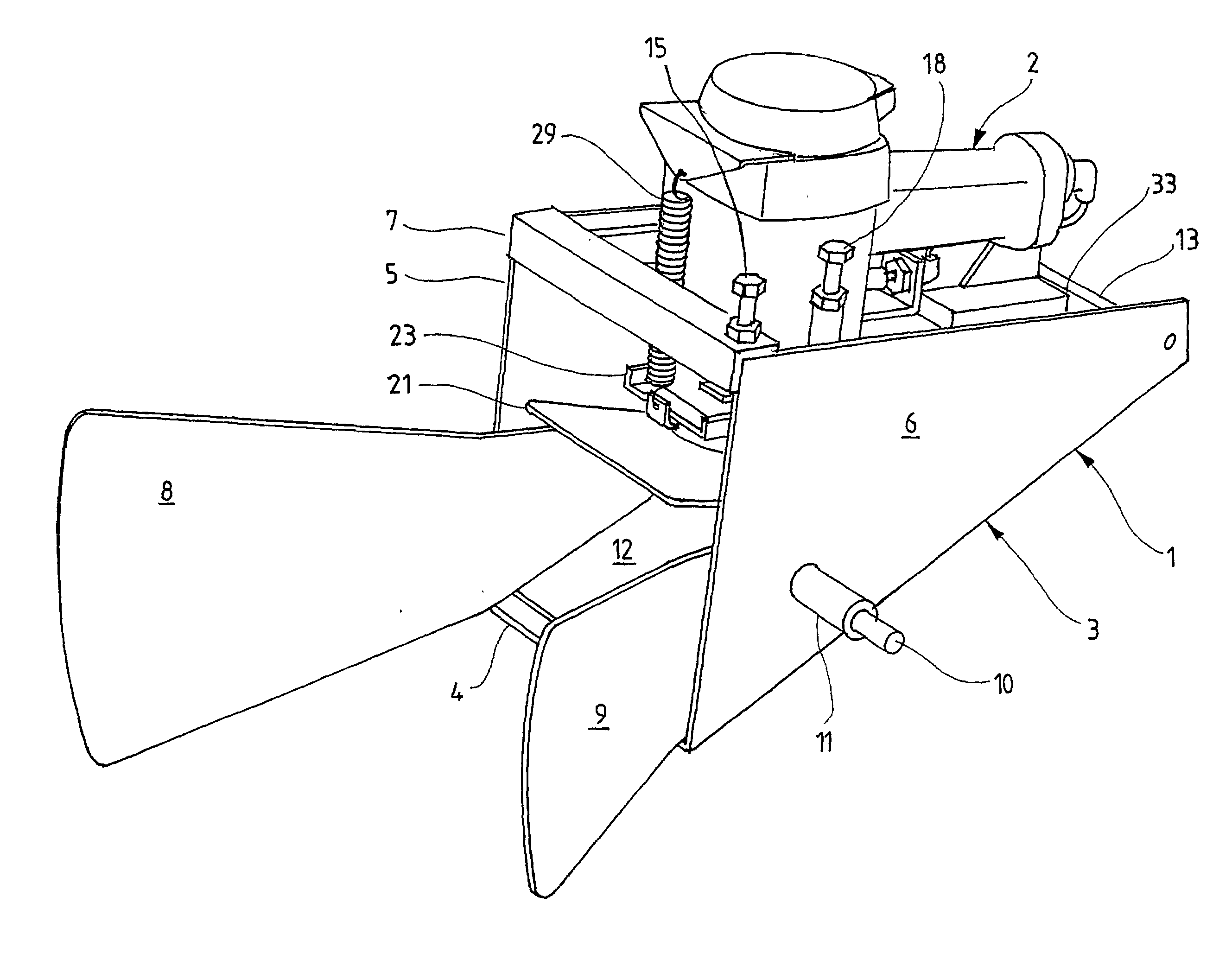

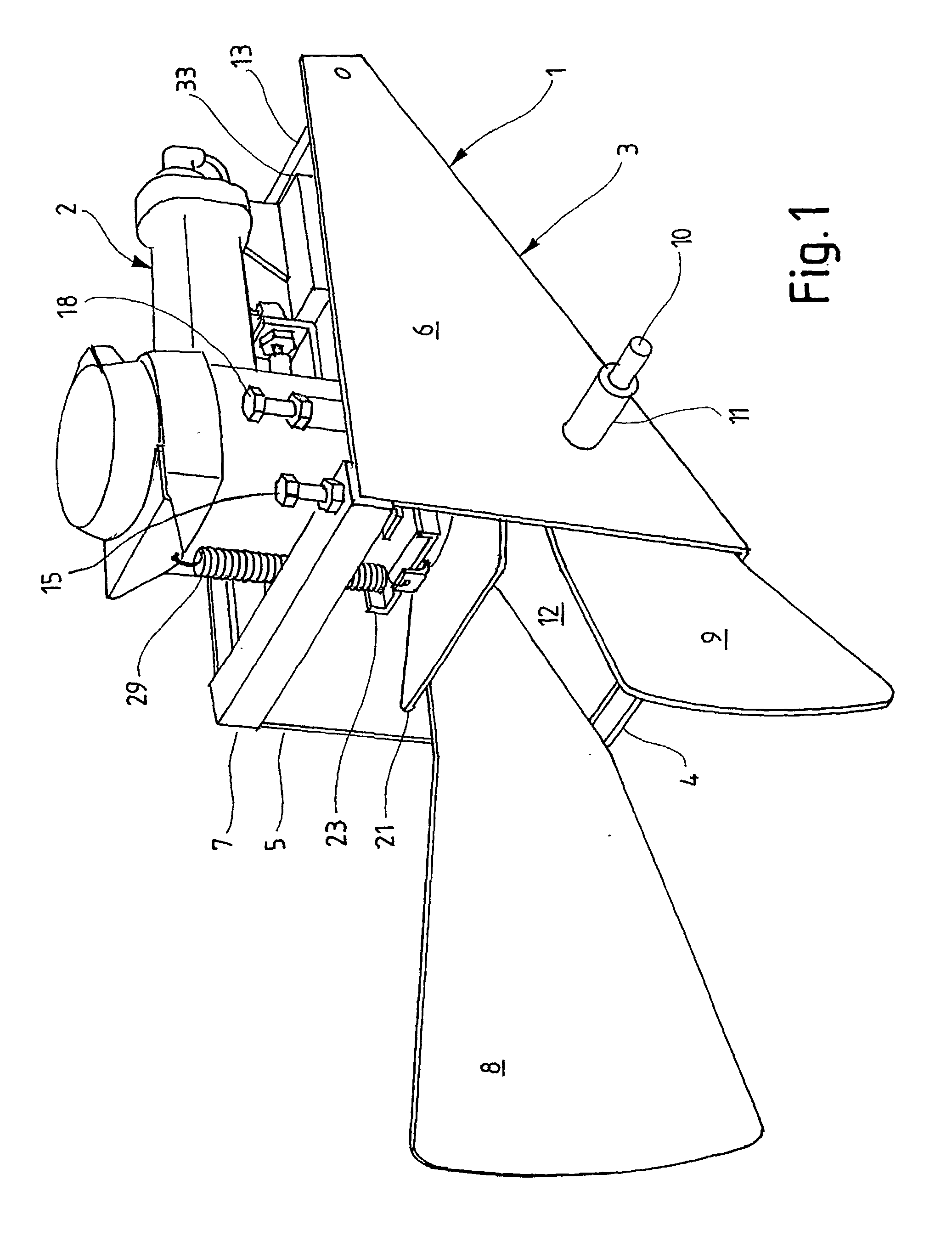

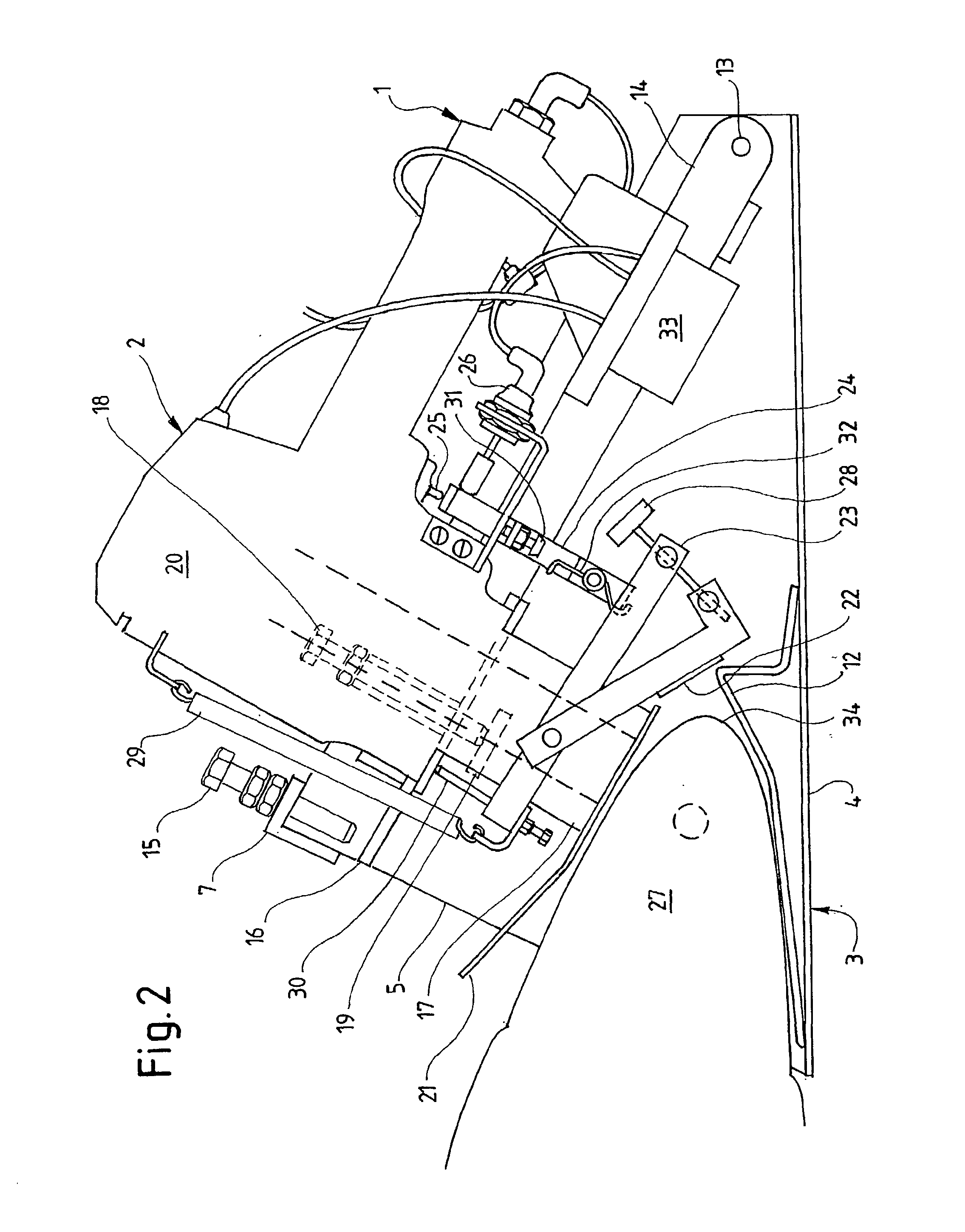

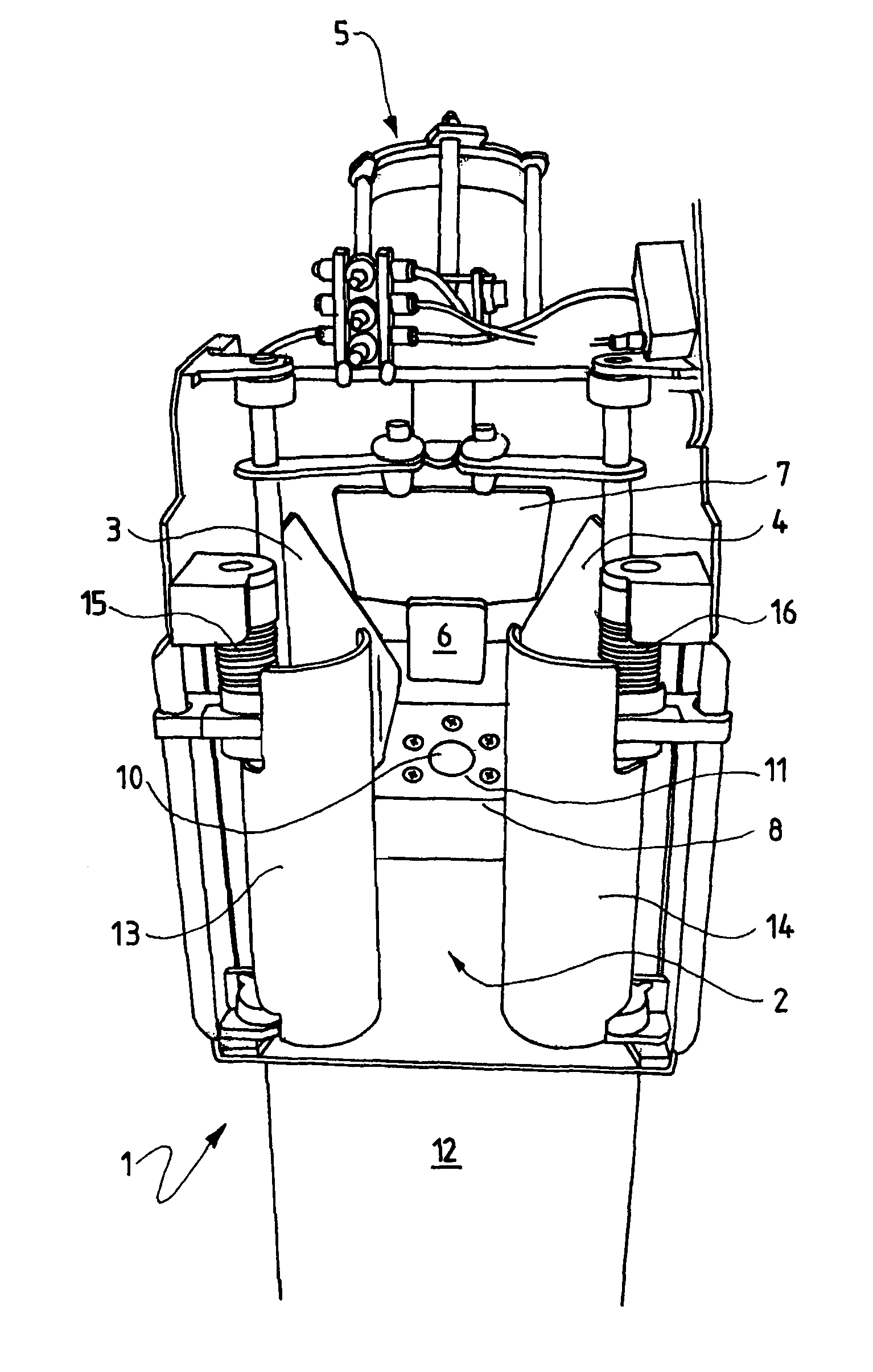

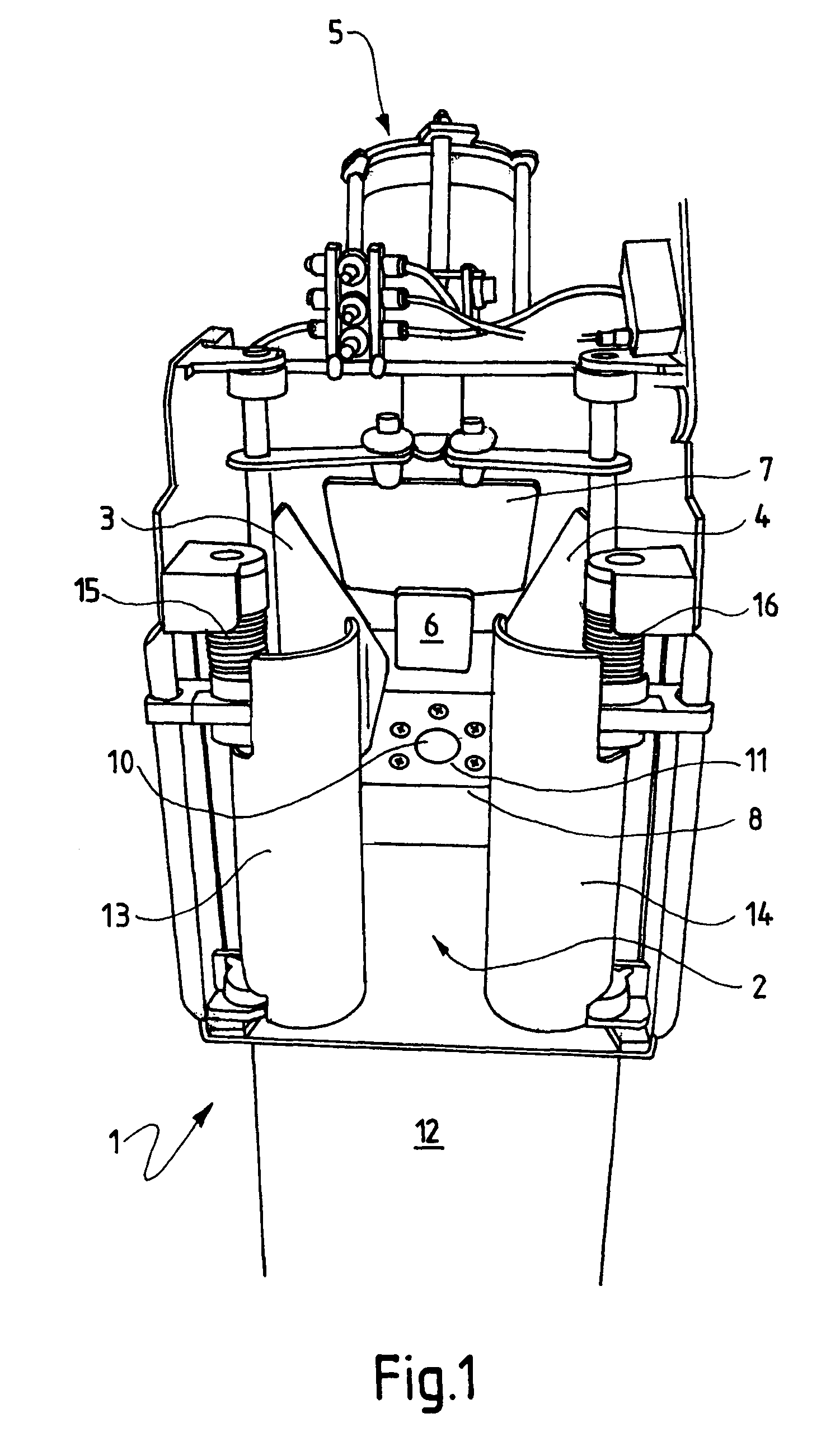

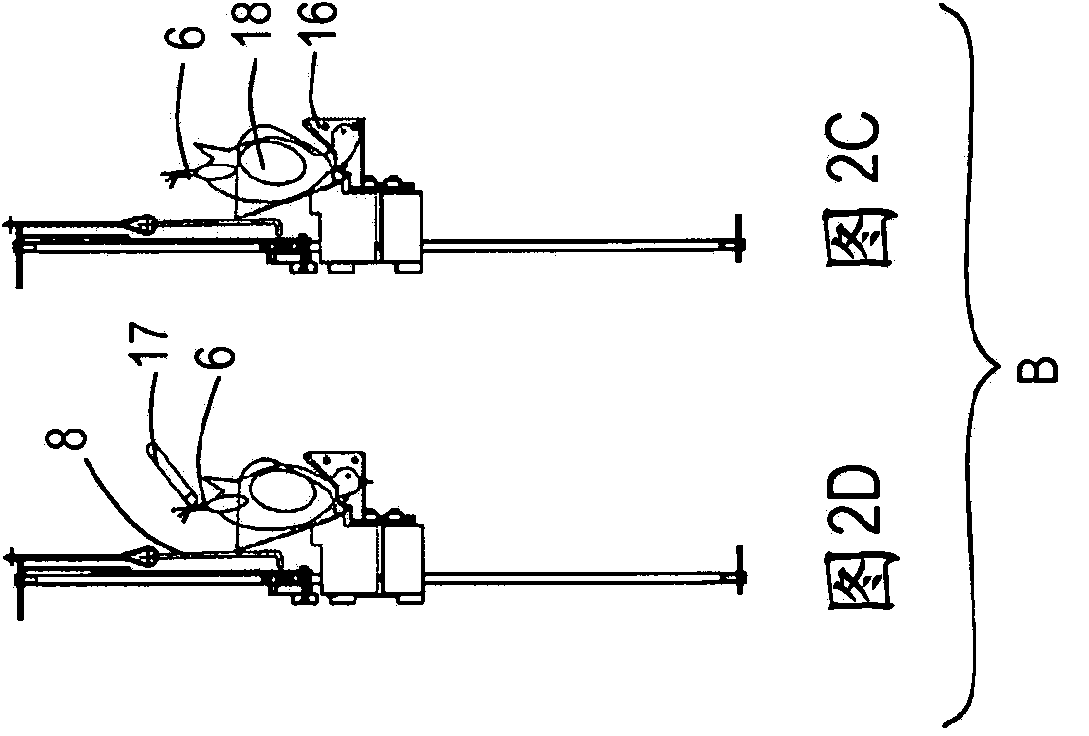

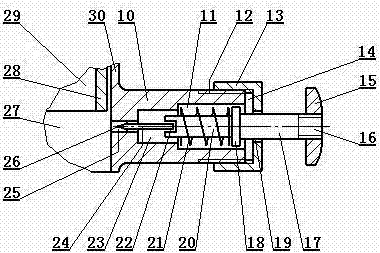

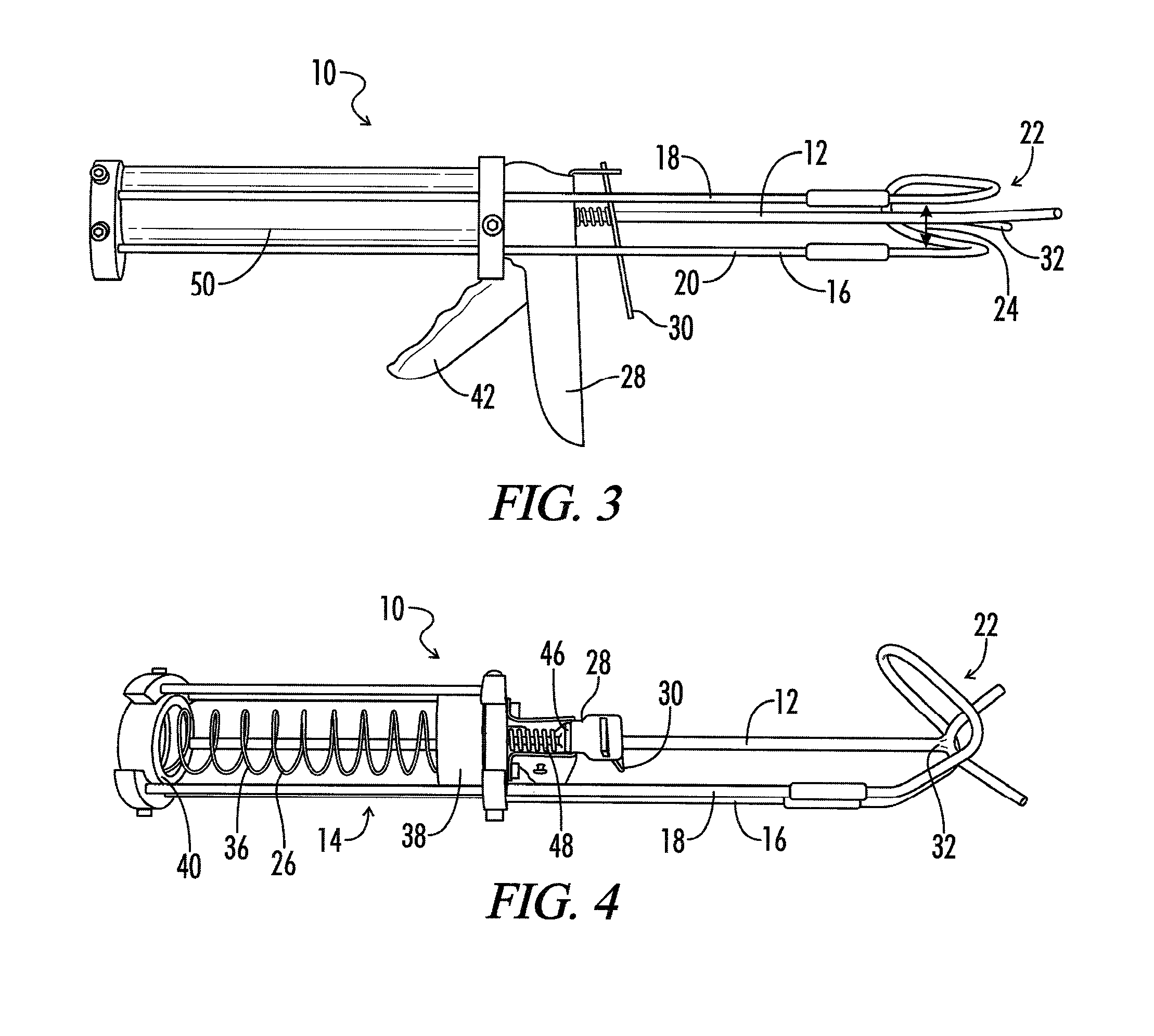

Stunning device for killing small animals or fish

InactiveUS6769976B2Rapid and repetitiveRapidly and efficiently stunnedBolt slaughtering/stunningPoultry/fish slaughtering/stunningSmall animalEngineering

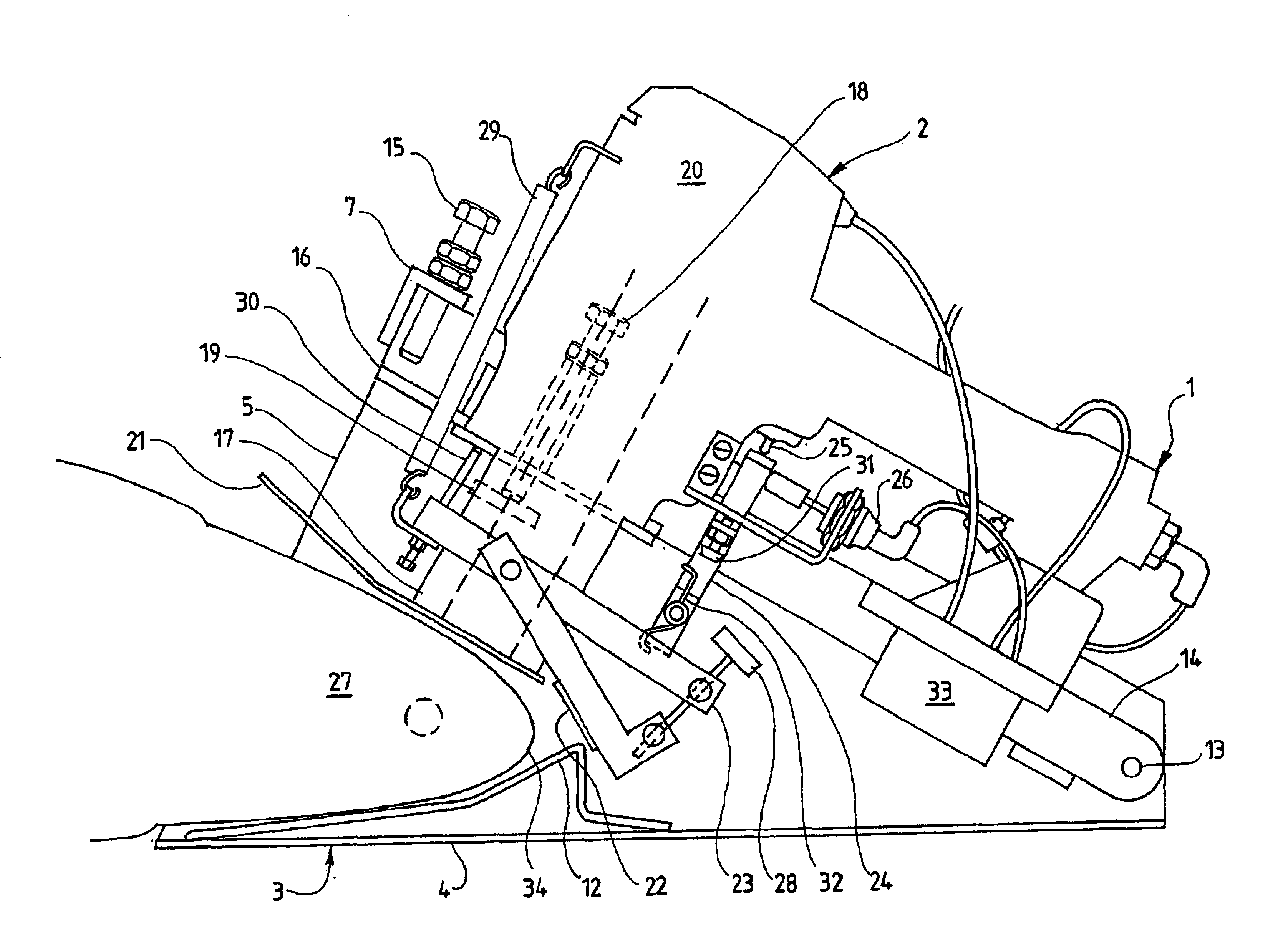

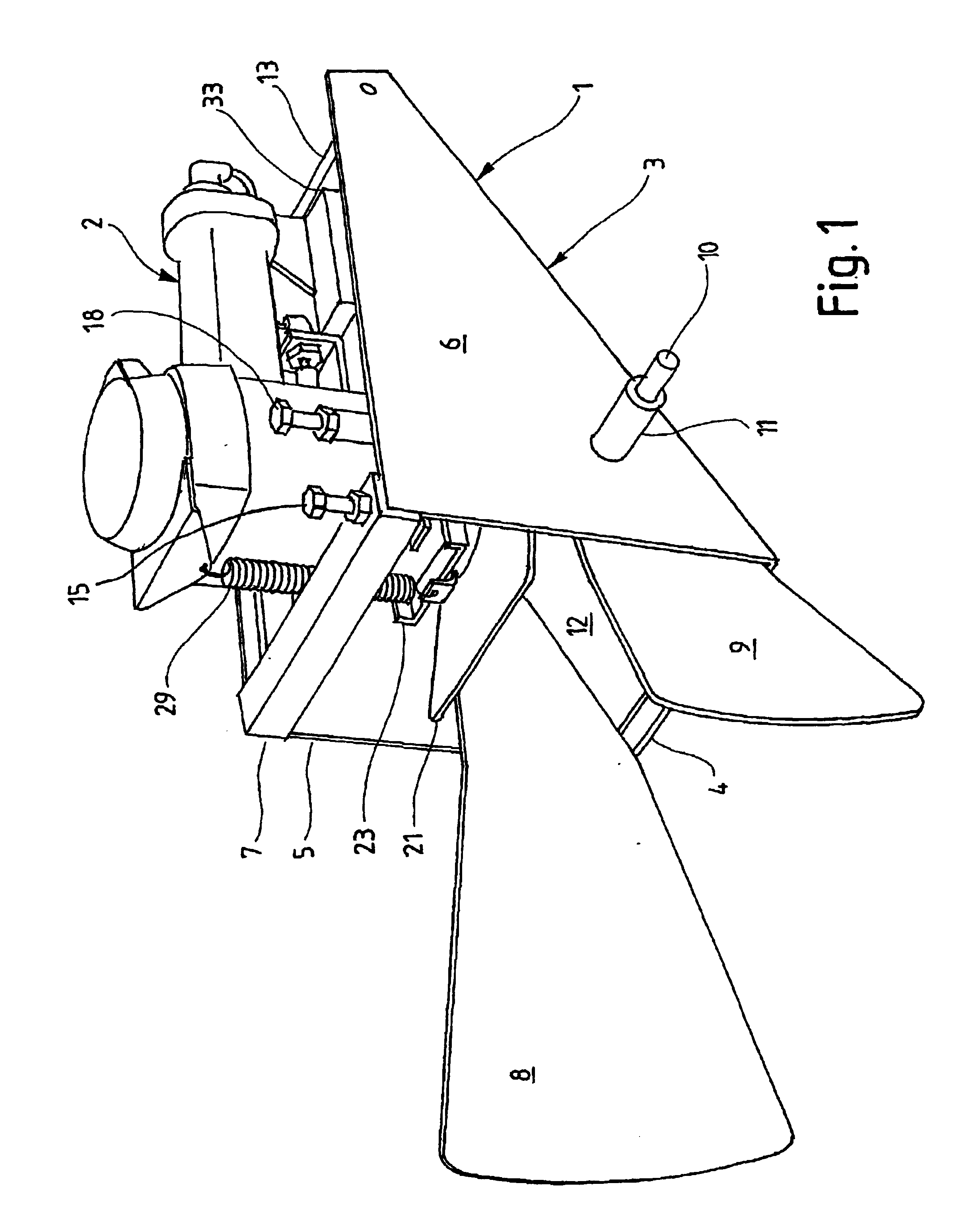

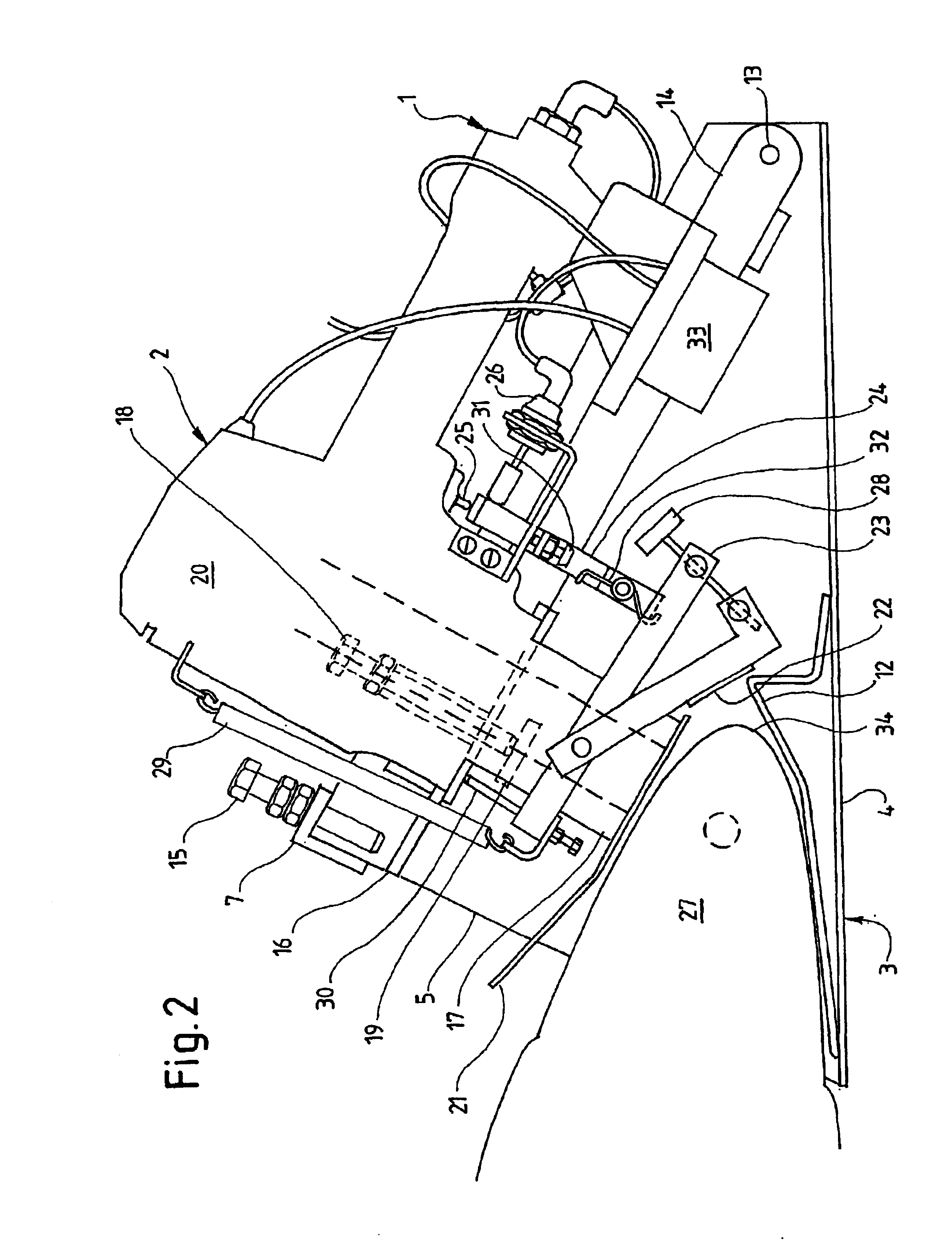

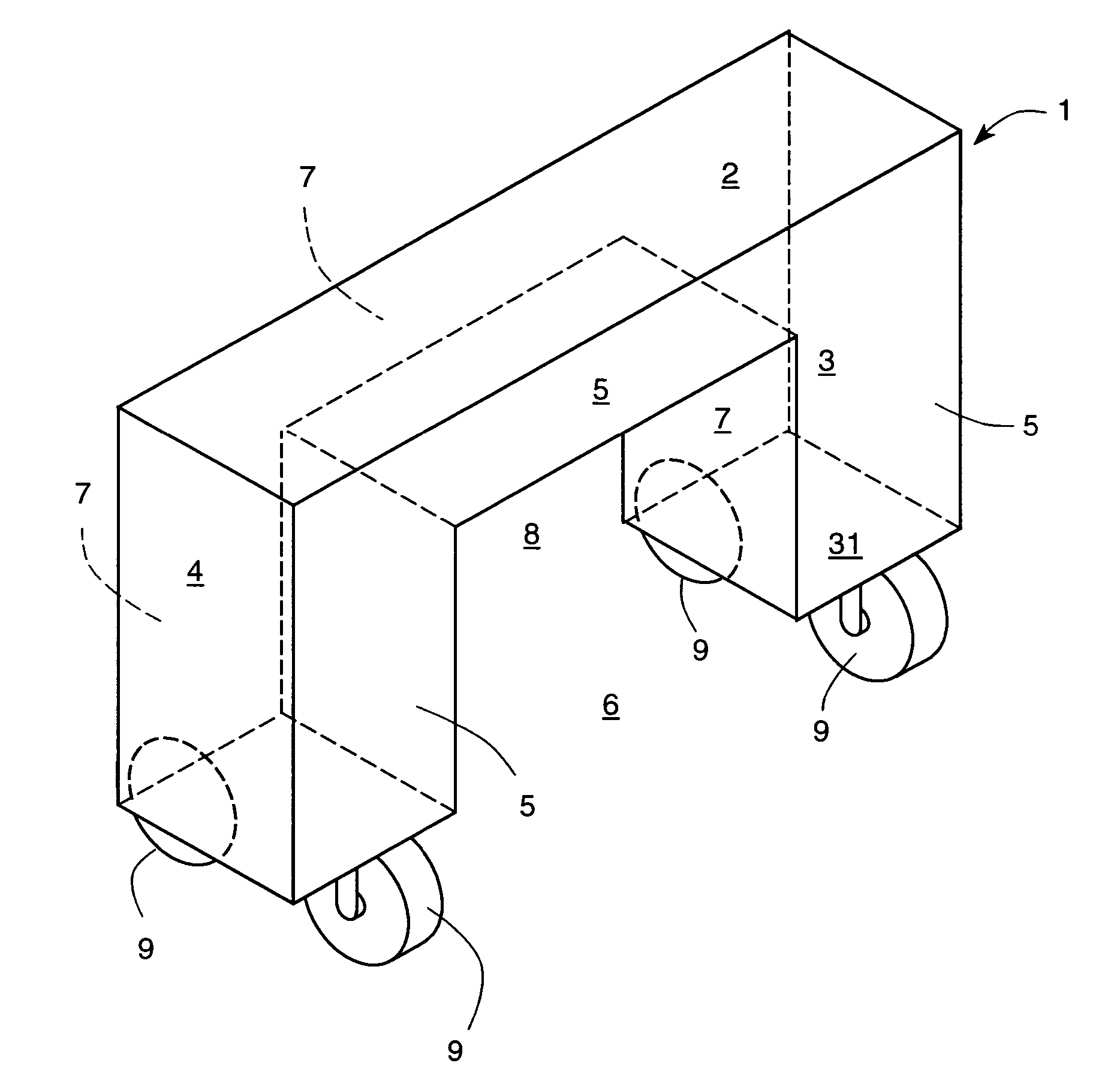

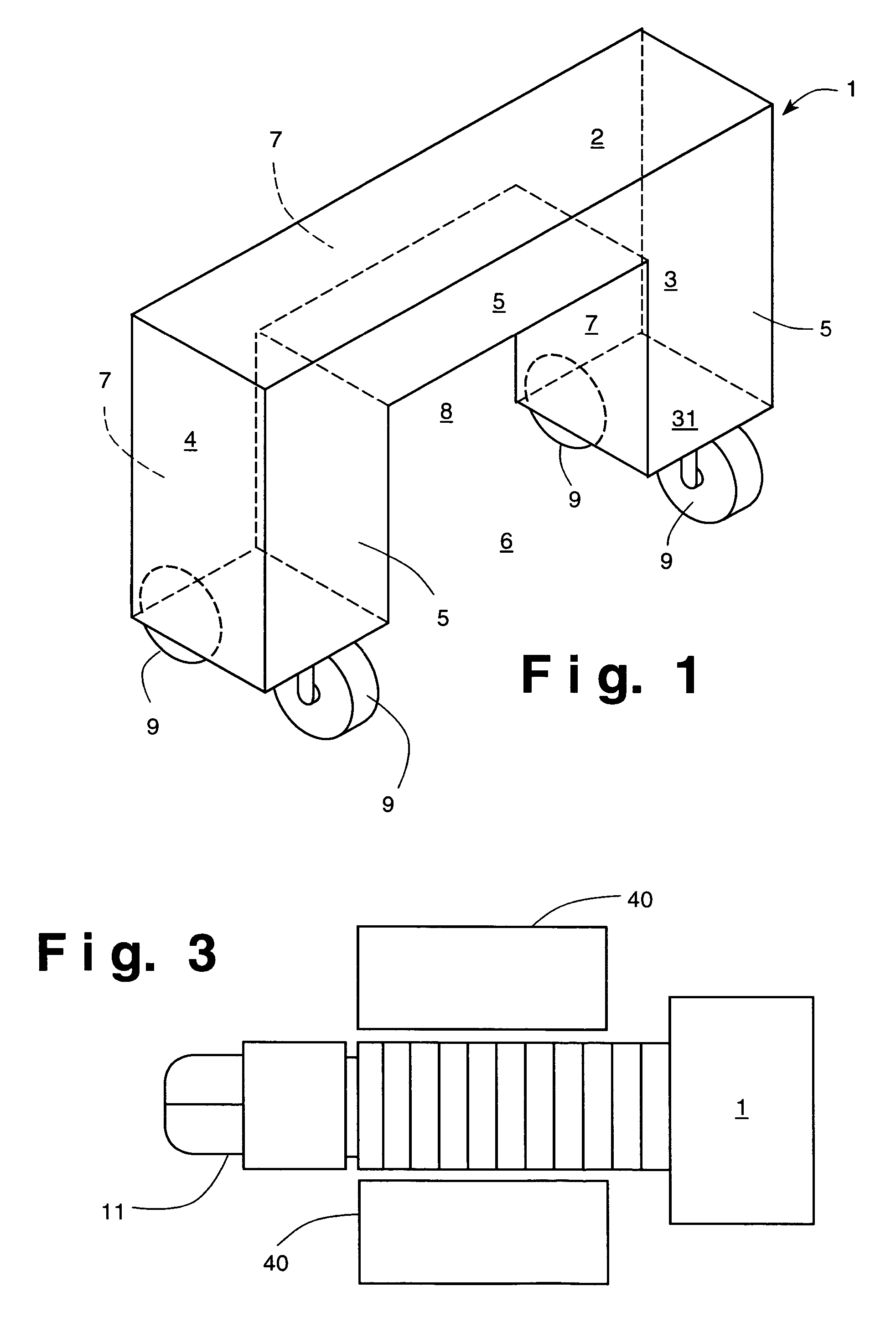

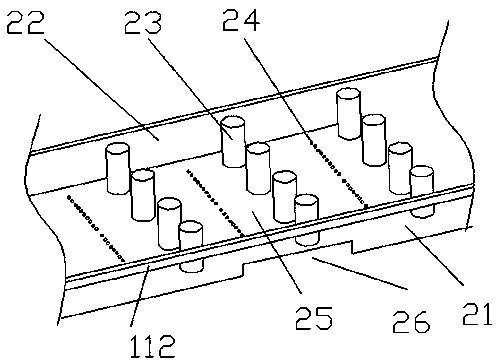

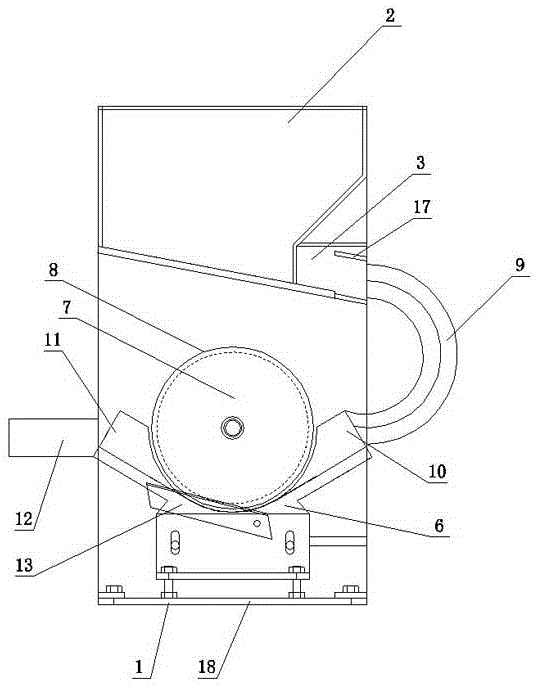

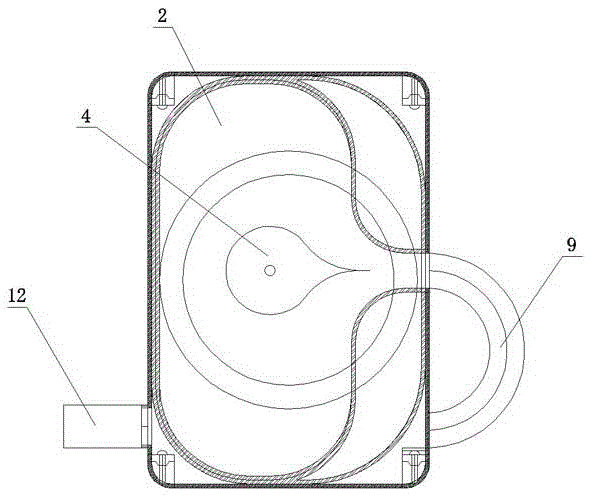

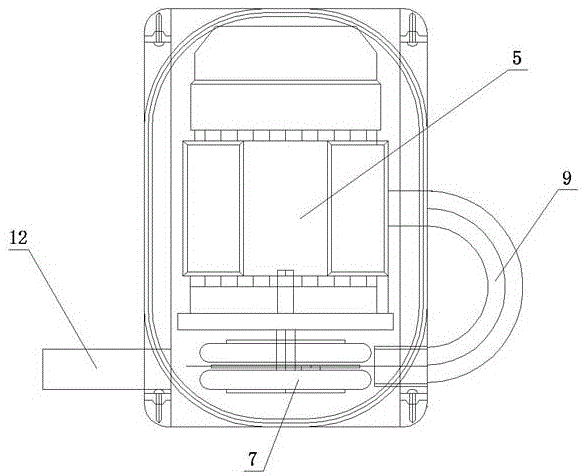

Stunning device (1) for small animals or fish of 2 kg to 7 kg weight comprises pneumatically powered piston assembly (2) which includes an extendible piston. Support (3) for piston assembly (2) includes base member (4) and multi-component trigger (22, 23, 24, 26). Piston assembly (2) is positioned to define a space between base member (4) and head plate (21) for receiving the head (27) of the animal. When the piston is activated by head (27) contacting plate (22), it extends and strikes head (27) just behind and / or between the eyes with sufficient force to kill the animal with a shock to the brain, but without affecting the external appearance of the animal or fish. The piston extends only once and then retracts, and trigger (22, 23, 24, 26) is reset by removing head (27) from device (1).

Owner:BASS RICHARD

Method for freezing edible marine animals

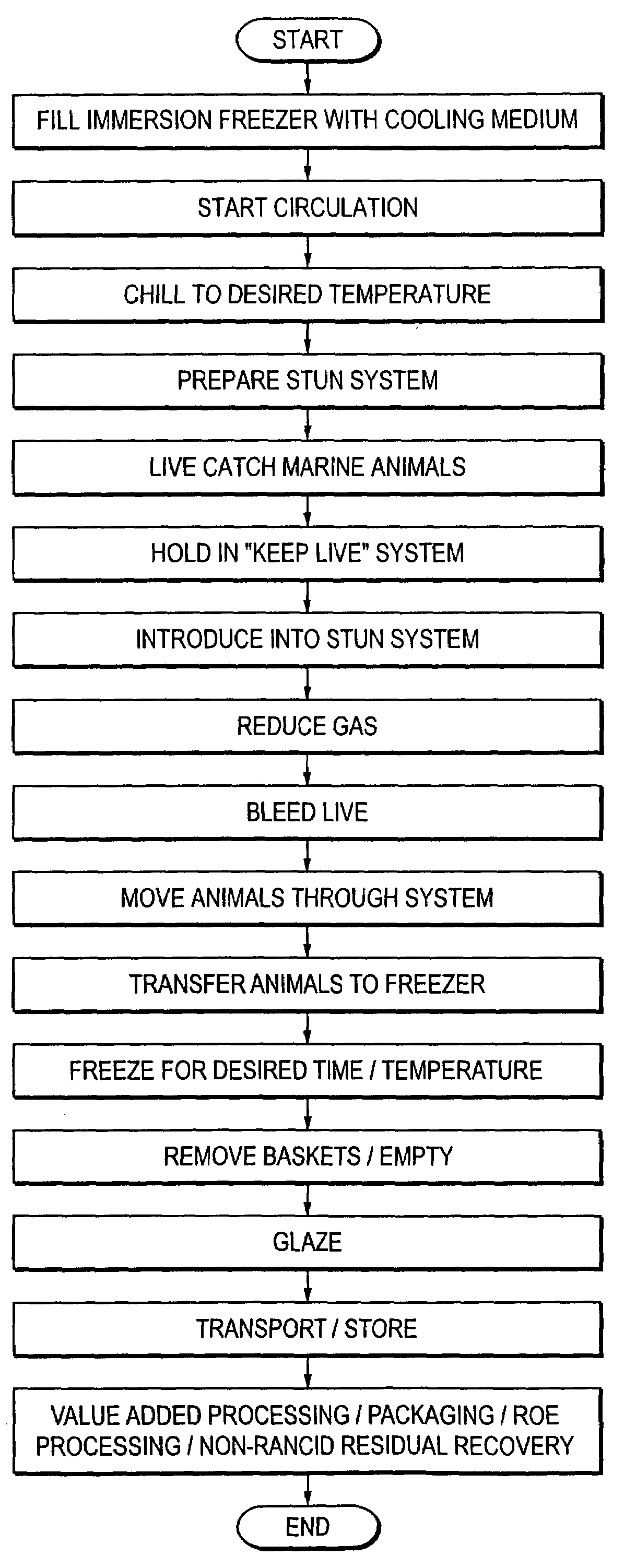

Various methods useful in connection with catching and freezing fish are disclosed. Also disclosed is an immersion freezer. In preferred embodiments, fish or other items to be frozen are immersed in a cooling medium. The cooling medium comprises an organic cooling agent, which preferably is a carbohydrate, sugar alcohol, glycoside, or non-toxic oil.

Owner:ALASKA OCEAN PROD CORP

Fish stunning apparatus

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

Method for decreasing spastic wing activity of poultry during slaughter

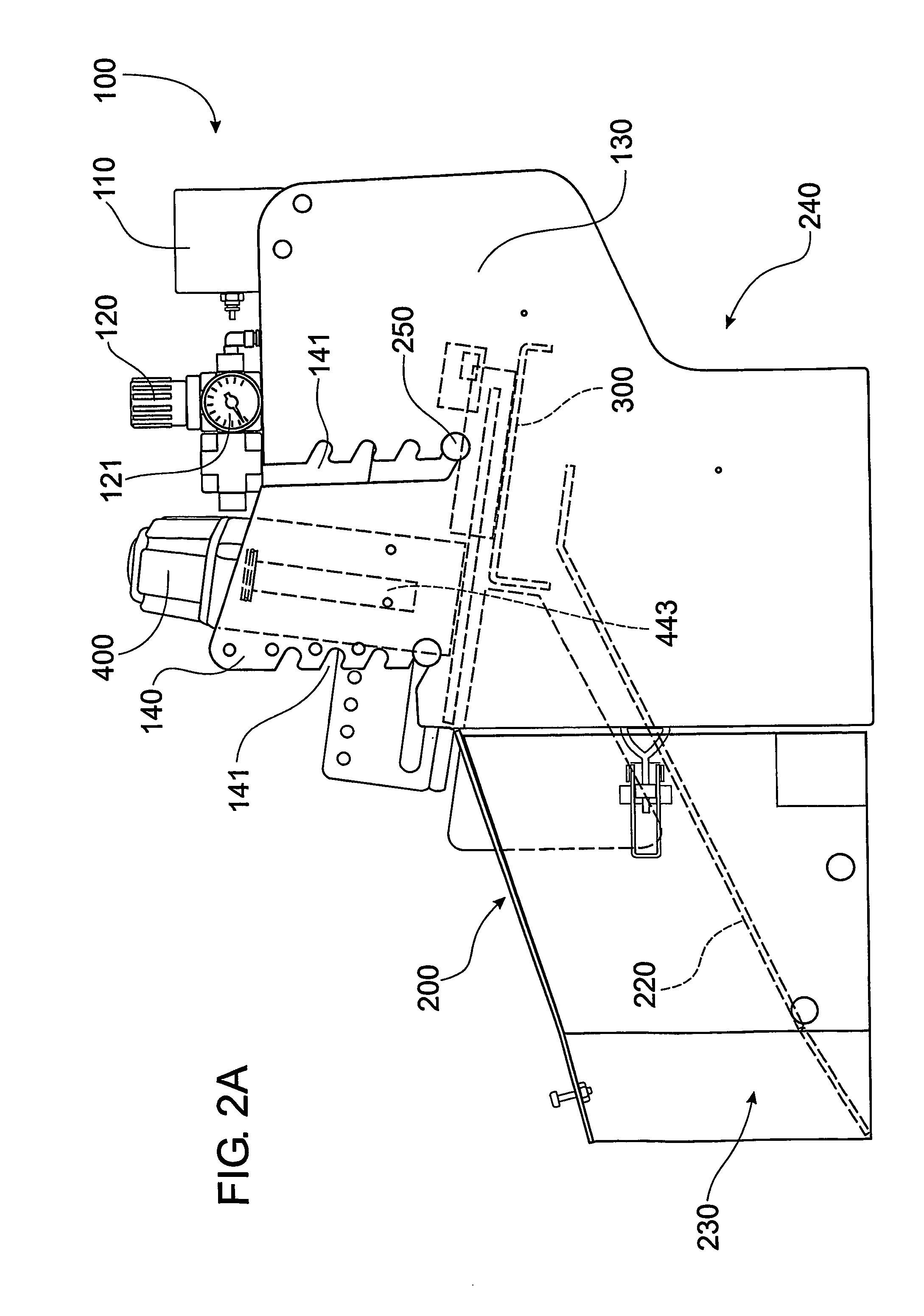

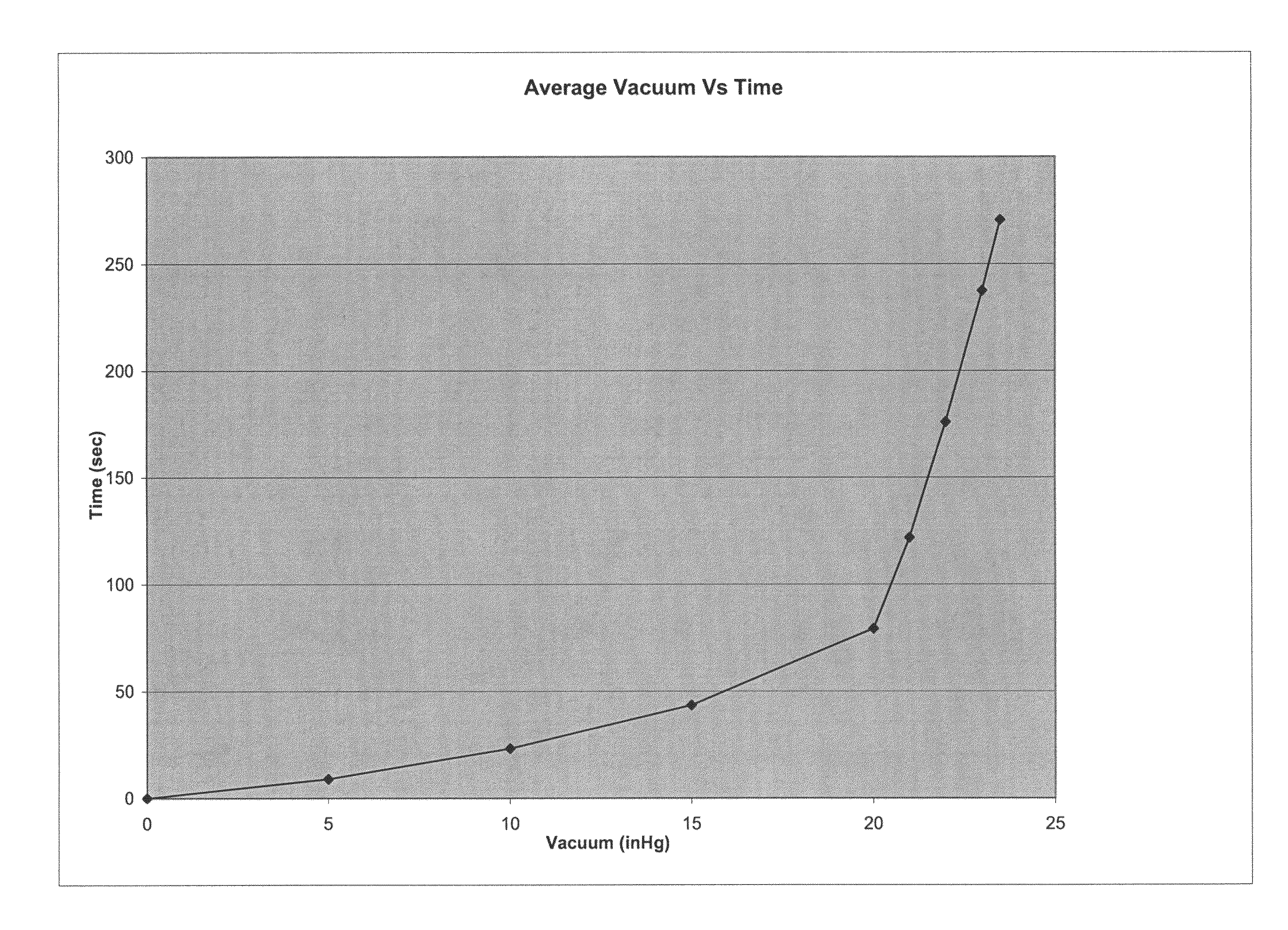

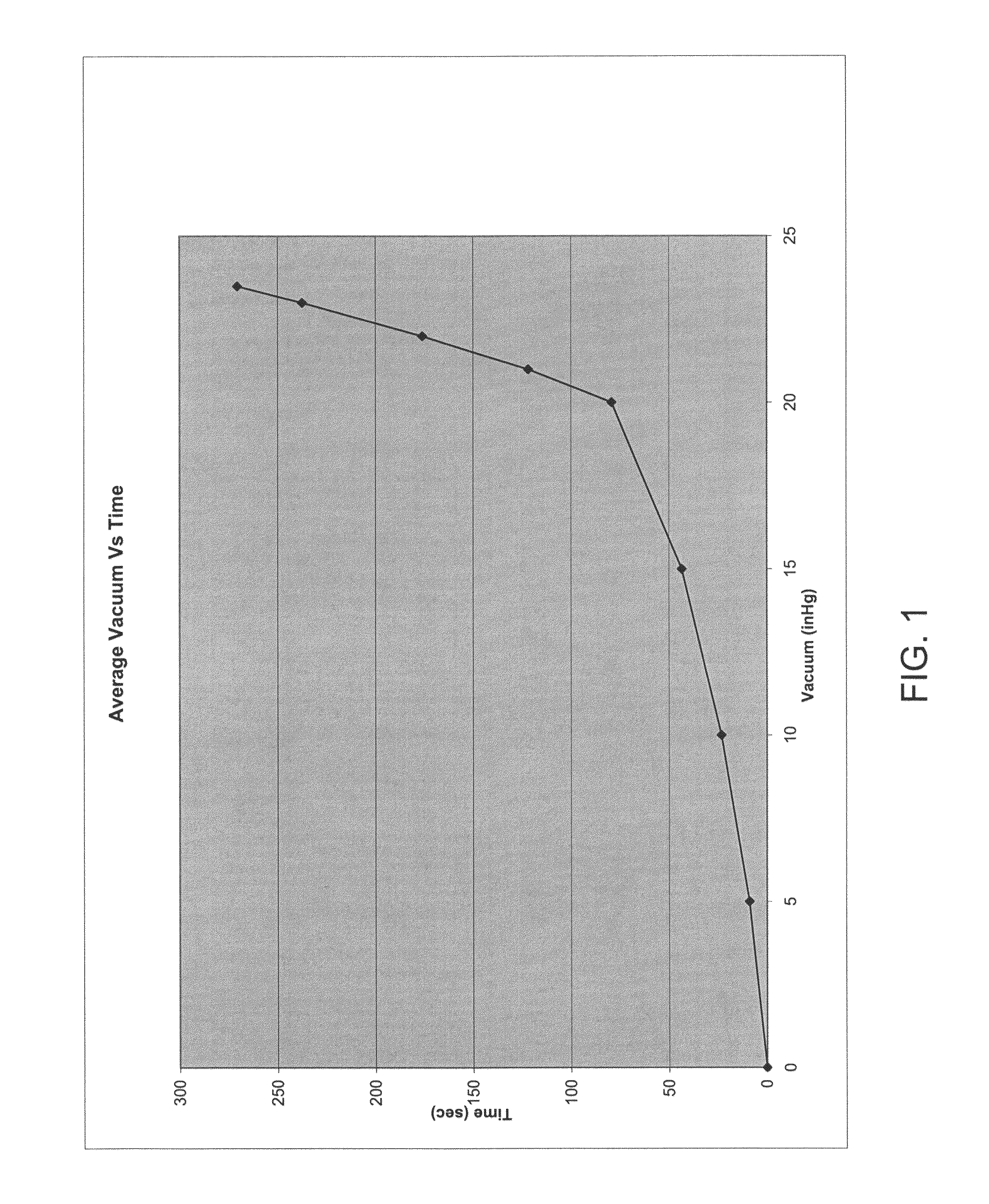

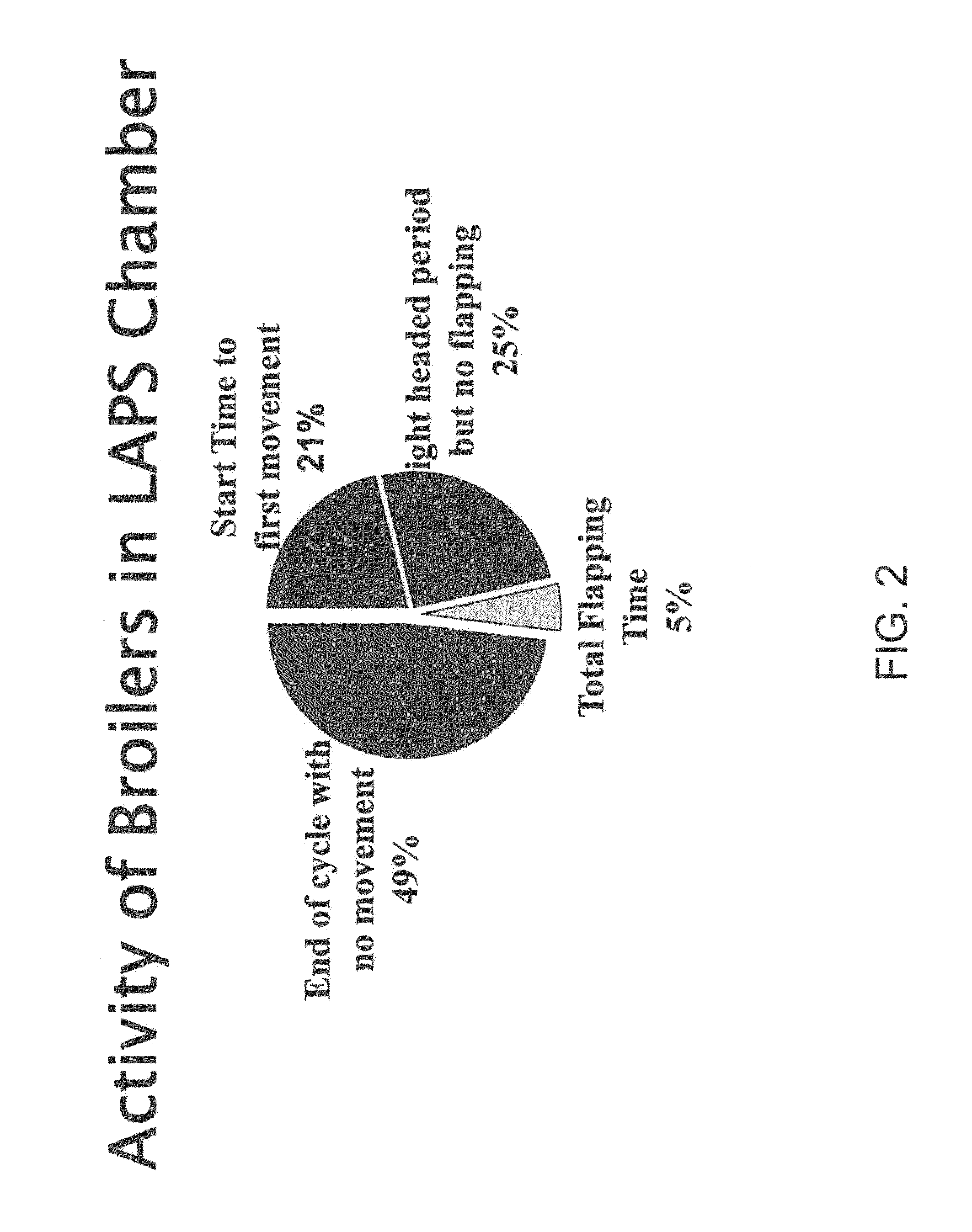

ActiveUS8113926B1Reduce the amount requiredReduced activityElectric current slaughtering/stunningBlood collection/stirring apparatusFowlAtmospheric pressure

The present disclosure generally relates to a method for humanely stunning and slaughtering poultry, and more particularly to a method for decreasing the spastic wing activity of poultry during slaughter. In particular, the birds are placed into a sealed chamber and the pressure in the chamber is reduced at a continuous rate to a target decompression pressure. The low atmospheric pressure slaughter is more humane than traditional slaughter techniques and results in less spastic wing activity.

Owner:CHEEK HOLLIS +1

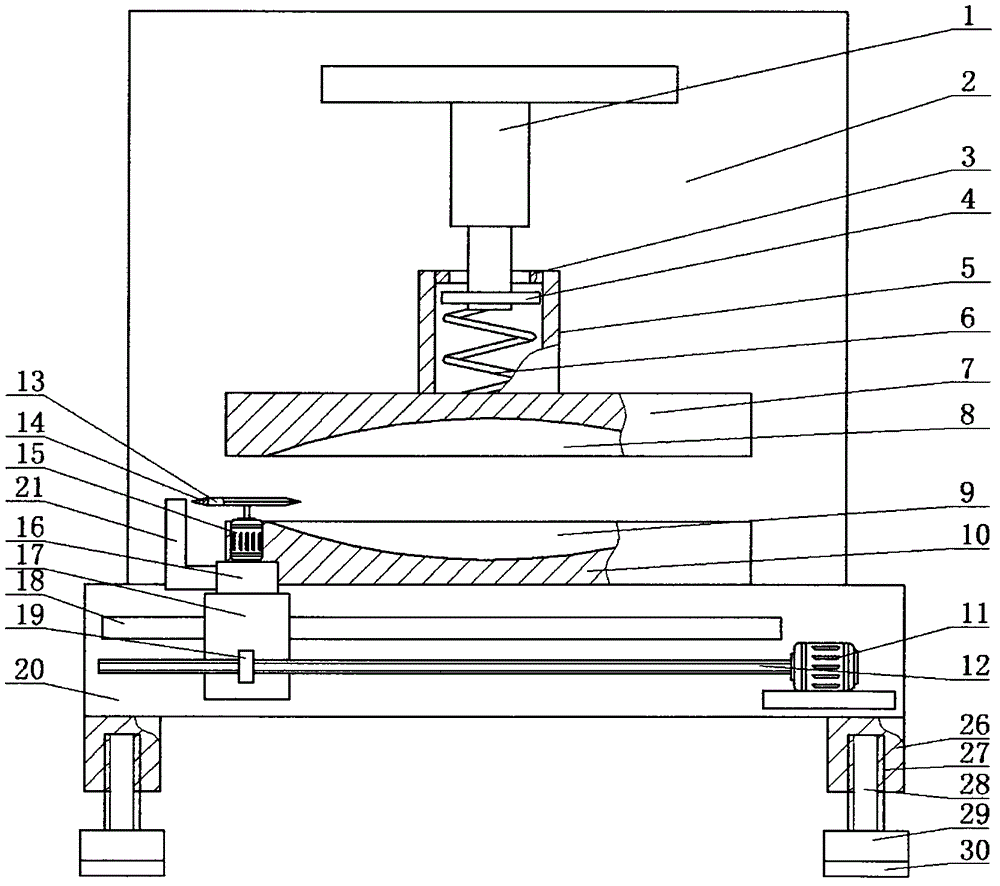

Efficient and fine live fish slaughtering device

InactiveCN104782731AAvoid scratchesPrevent crushingPoultry/fish slaughtering/stunningFish processingPush pullEngineering

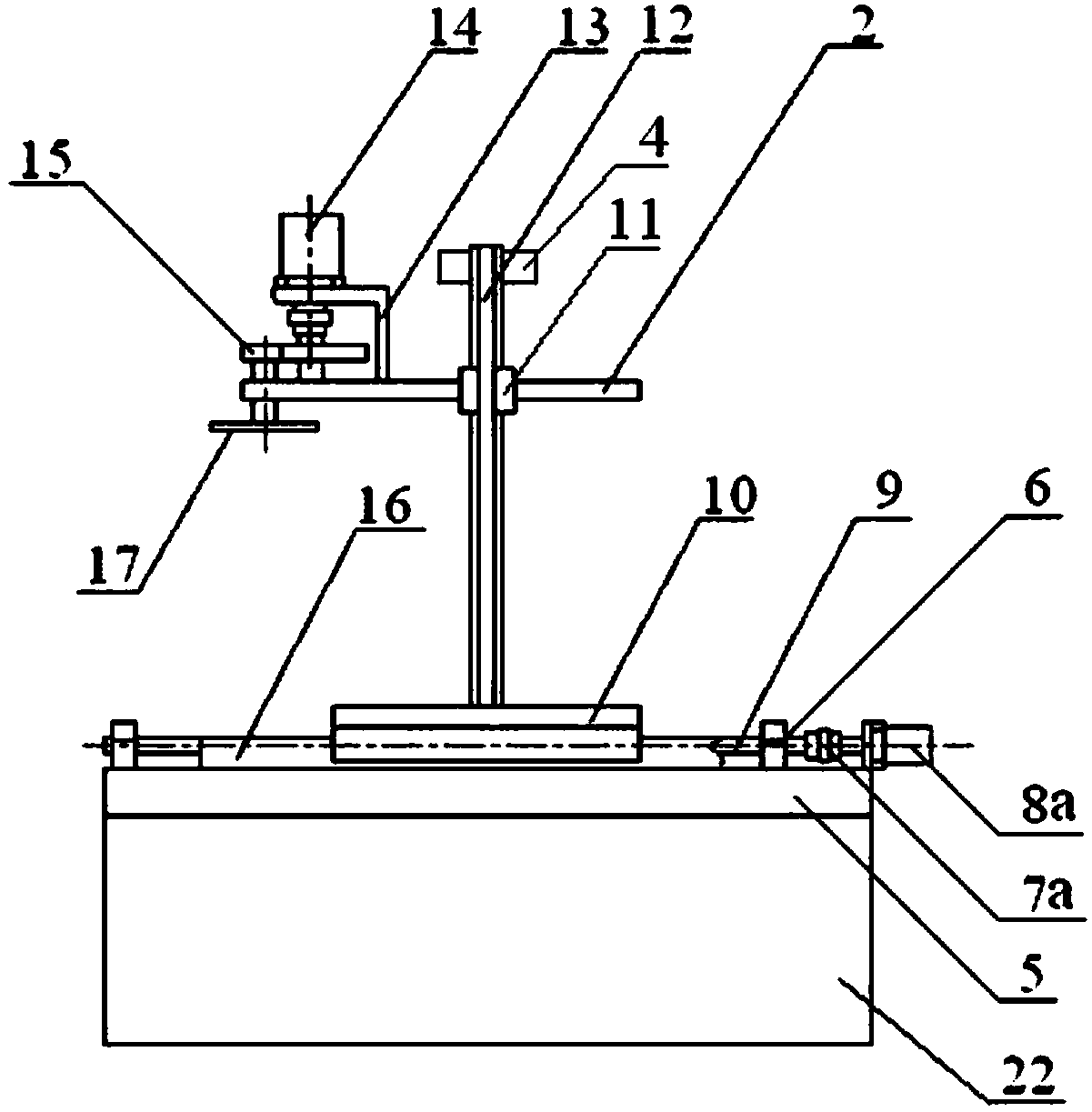

The invention discloses an efficient and fine live fish slaughtering device. The efficient and fine live fish slaughtering device comprises a base, a lower fixing plate and a support are installed on the upper portion of the base, the lower fixing plate is located on one side of the support, a push rod motor is installed on one side of the support, an upper fixing plate is installed on a push-pull rod of the push rod motor and located above the lower fixing plate, a fixing tube and a spring are installed on the upper portion of the upper fixing plate, the spring is located on the inner side of the fixing tube, and the lower end of the spring is connected with the upper fixing plate. The rotating motor can drive a cutter on a rotating disc to rotate at a high speed so that the cutter can rapidly cut off fish bones when touching the fish bones, and is prevented from scraping off fishes when touching the fish bones.

Owner:常熟市海格尔电器有限公司

Freezing method and apparatus

Various methods useful in connection with catching and freezing fish are disclosed. Also disclosed is an immersion freezer. In preferred embodiments, fish or other items to be frozen are immersed in a cooling medium. The cooling medium comprises an organic cooling agent, which preferably is a carbohydrate, sugar alcohol, glycoside, or non-toxic oil.

Owner:ALASKA OCEAN PROD CORP

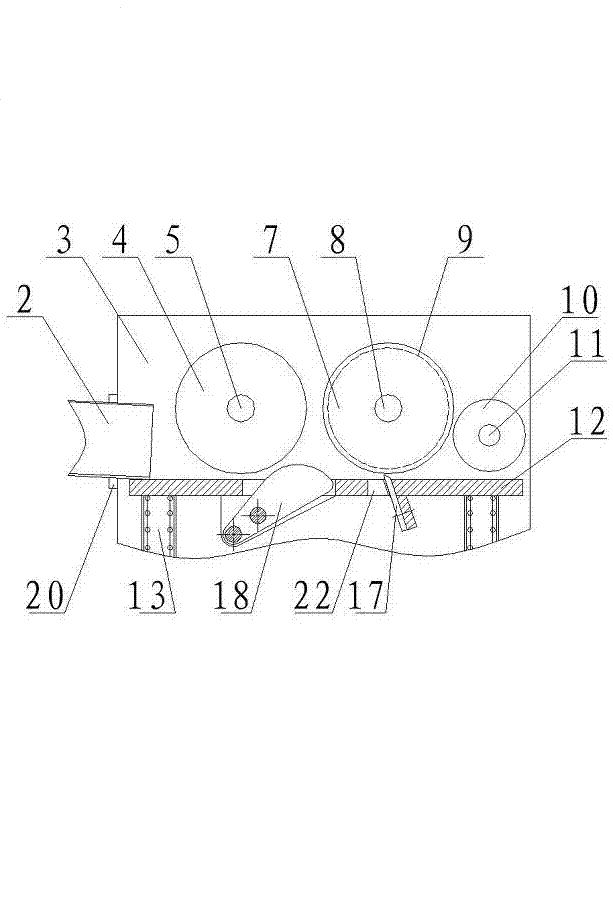

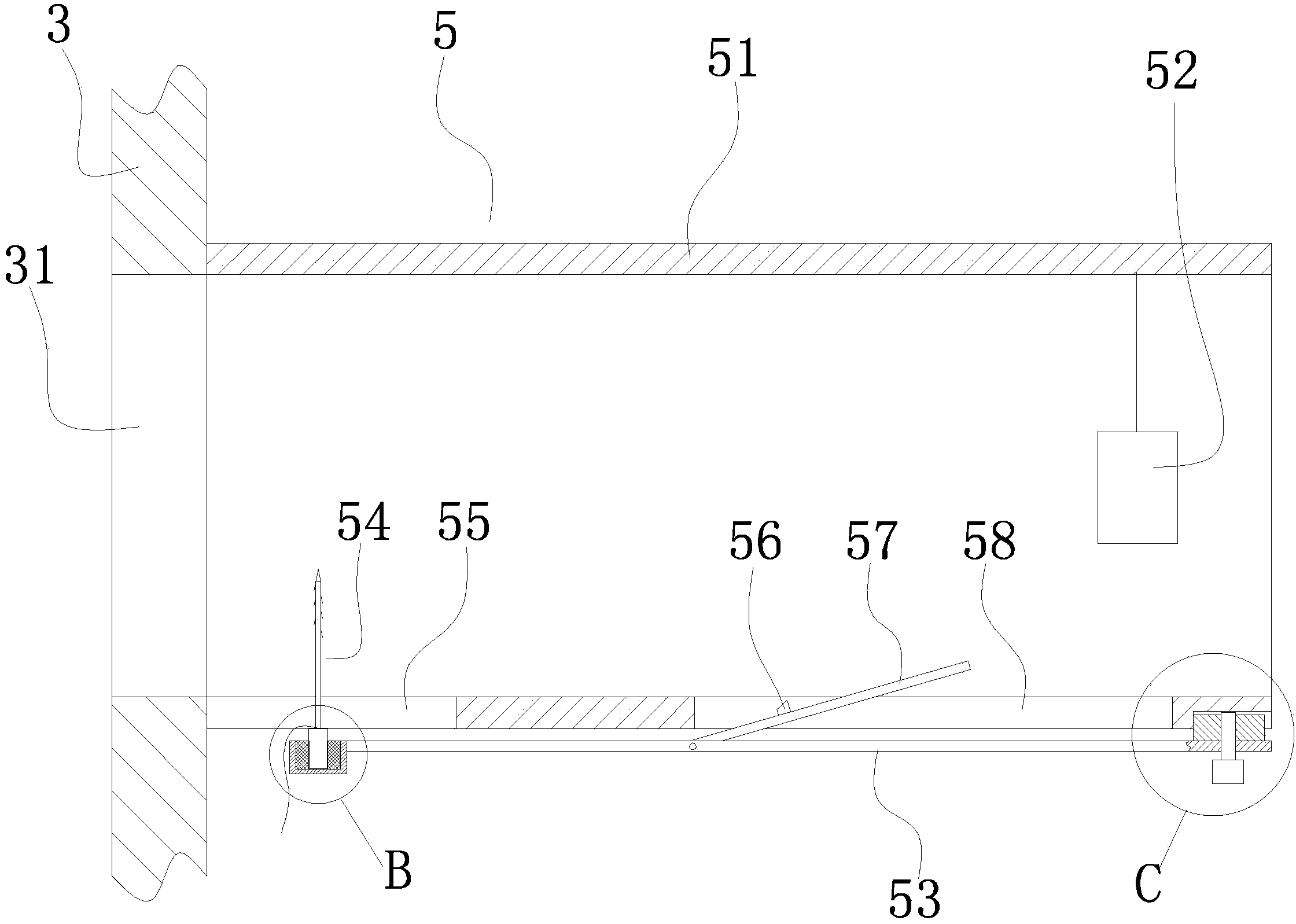

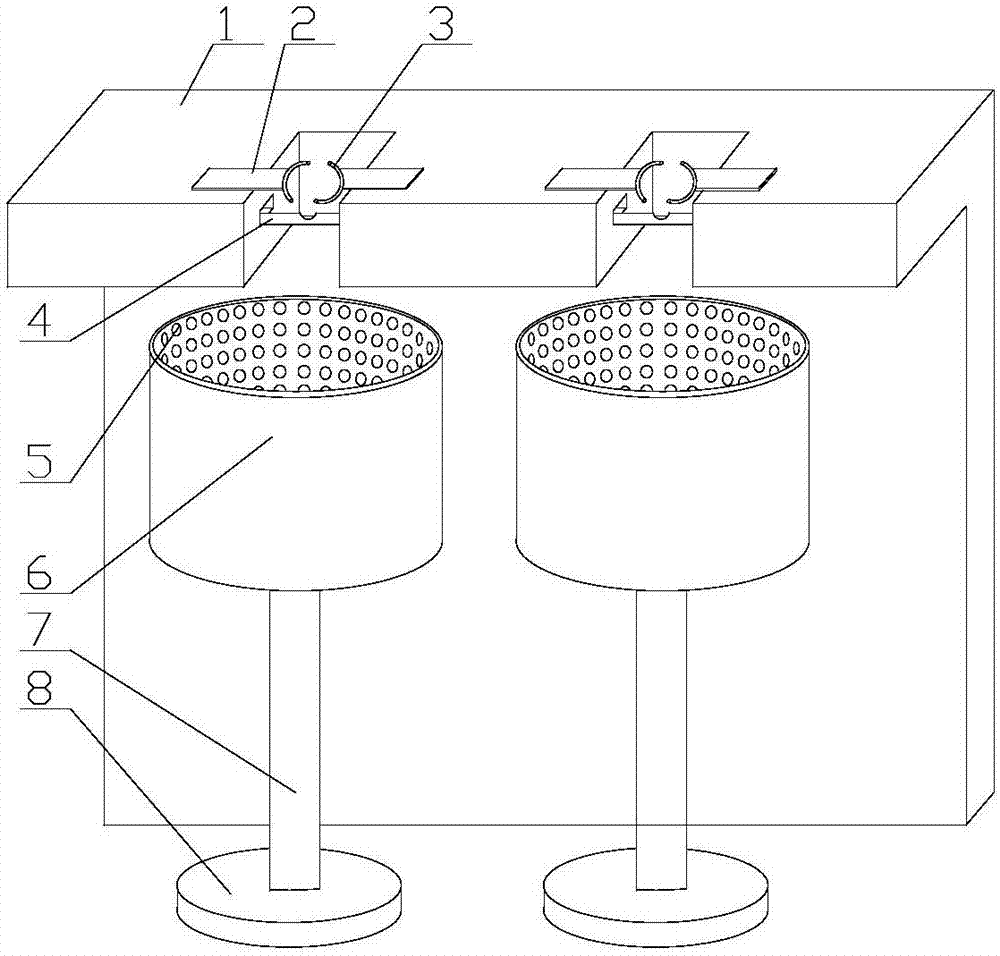

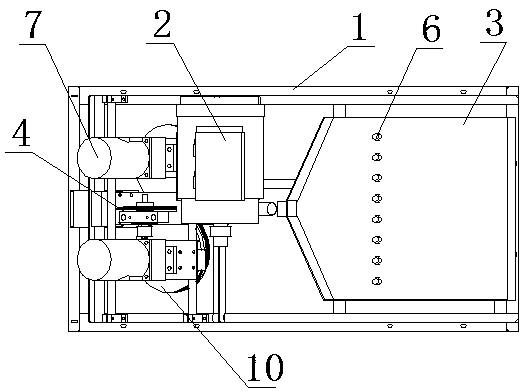

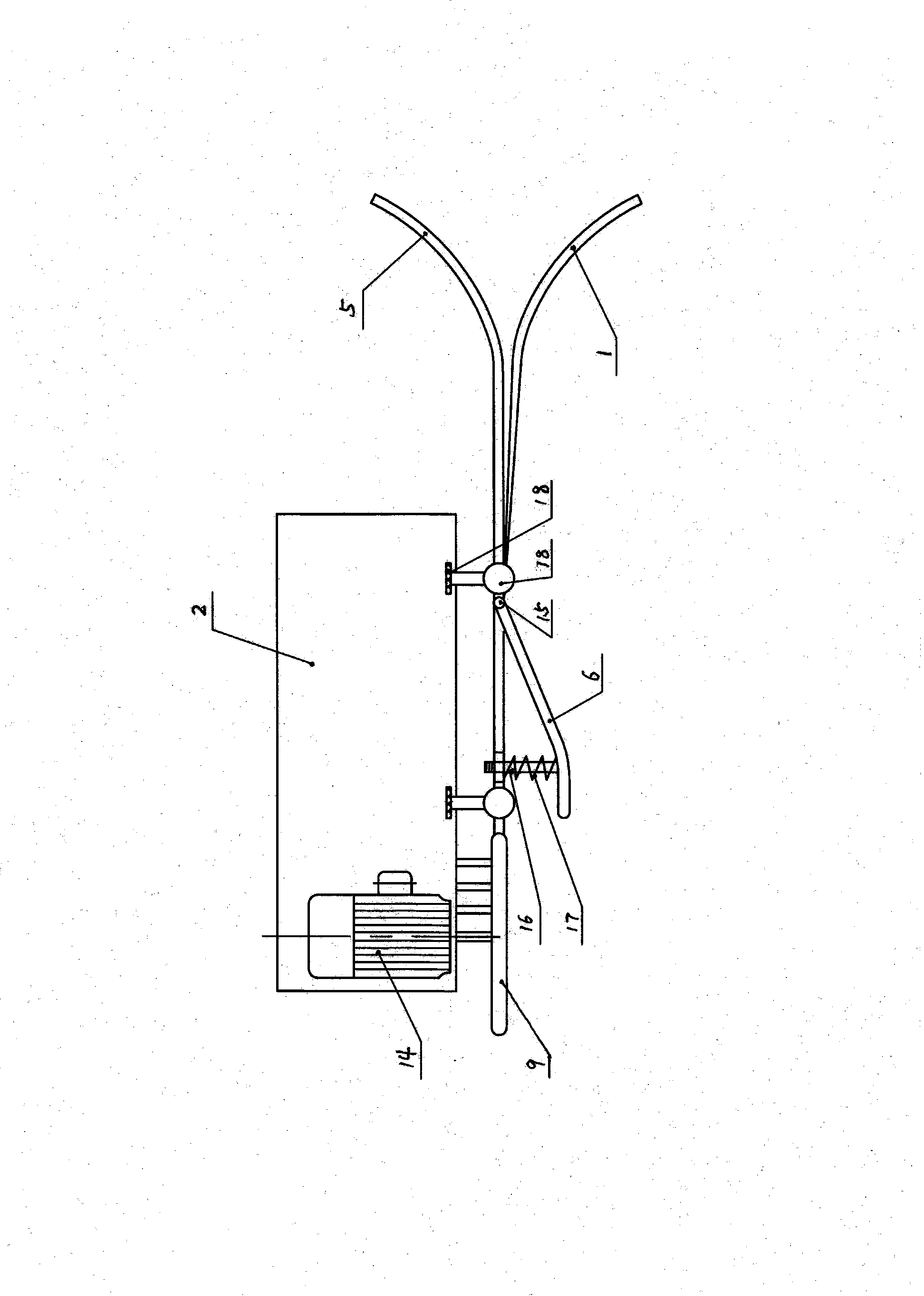

Full-automatic finless eel or loach processing equipment

ActiveCN105410143ASlaughter fastIncrease productionPoultry/fish slaughtering/stunningFinless eelBiochemical engineering

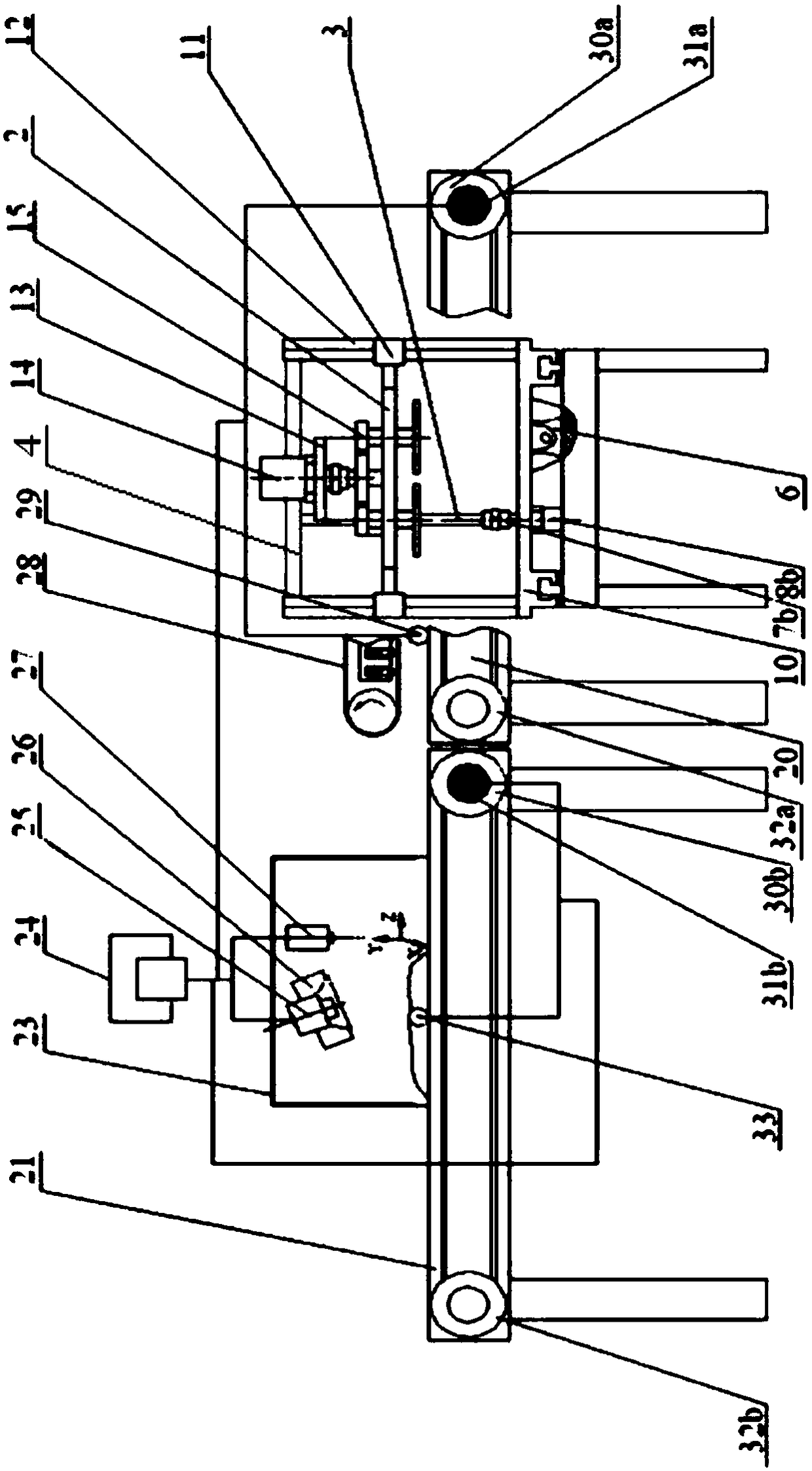

The invention relates to full-automatic finless eel or loach processing equipment and belongs to the field of aquatic product processing machinery. The equipment comprises a fixing rack, an adjustable rack, a feed barrel, a discharge barrel, a belly dissecting tool, a back dissecting tool and a knurling tool, a protective cover is arranged on the fixing rack, an upper fixed supporting plate and a lower fixed supporting plate are vertically arranged on the part, located inside the protective cover, of the fixing rack, a feed channel A is arranged between the upper fixed supporting plate and the lower fixed supporting plate, the feed barrel is installed on the part, located at the side of the feed channel A, of the fixing rack, and the feed barrel is communicated with the feed channel A. When the equipment works, finless eels or loaches are poured into the feed barrel and randomly grabbed by fluted discs, then the belly dissecting tool or the back dissecting tool can be selected through a tool rest for killing the finless eels or the loaches from the backs or the bellies, the equipment has the advantages of being high in killing speed and high in yield, the problems that existing killing devices are relatively complex in structure, low in work efficiency and poor in adaptability are solved, and the equipment is particularly applicable to killing and processing of the finless eels or the loaches.

Owner:JINGZHOU JICHUANG ELECTROMECHANICAL TECH CO LTD

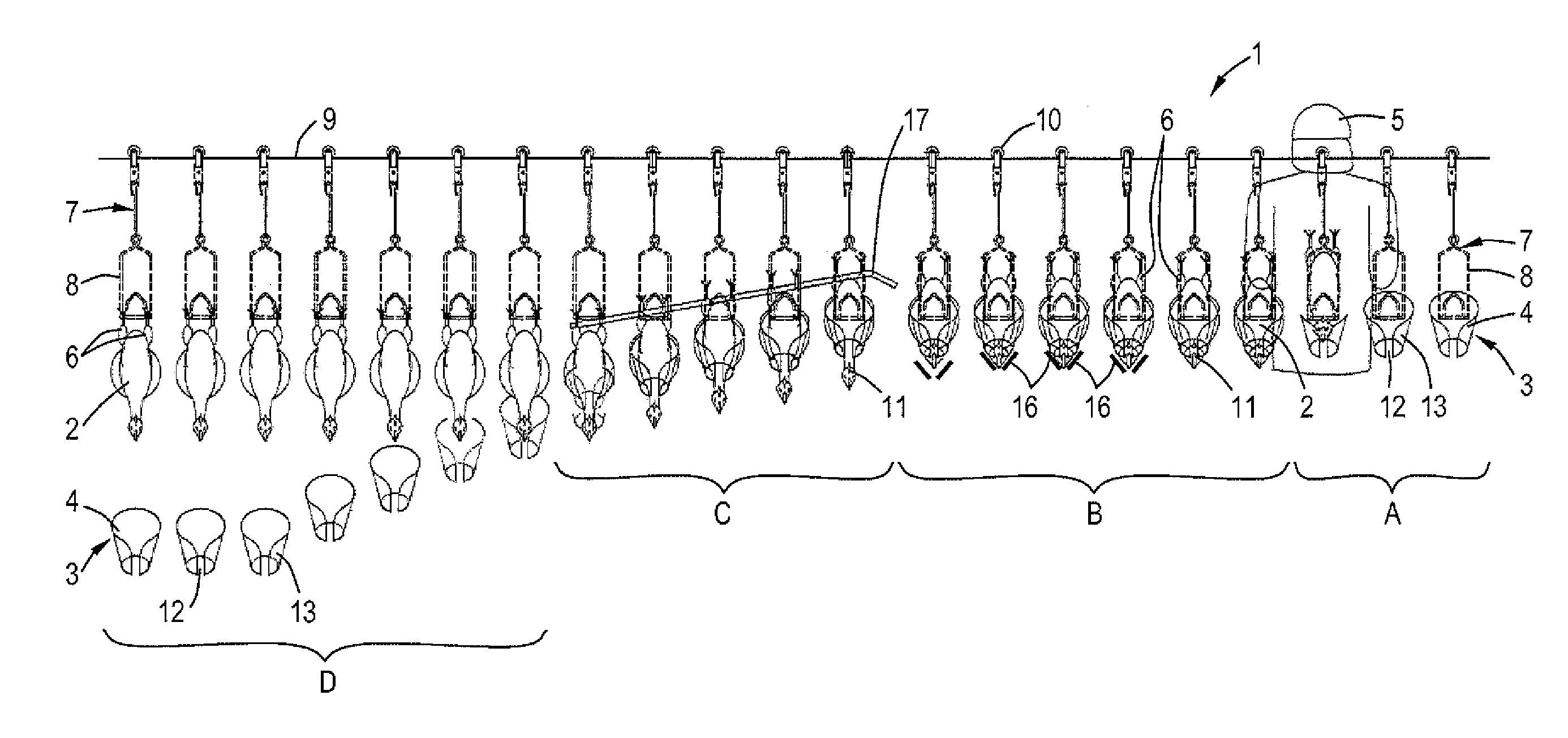

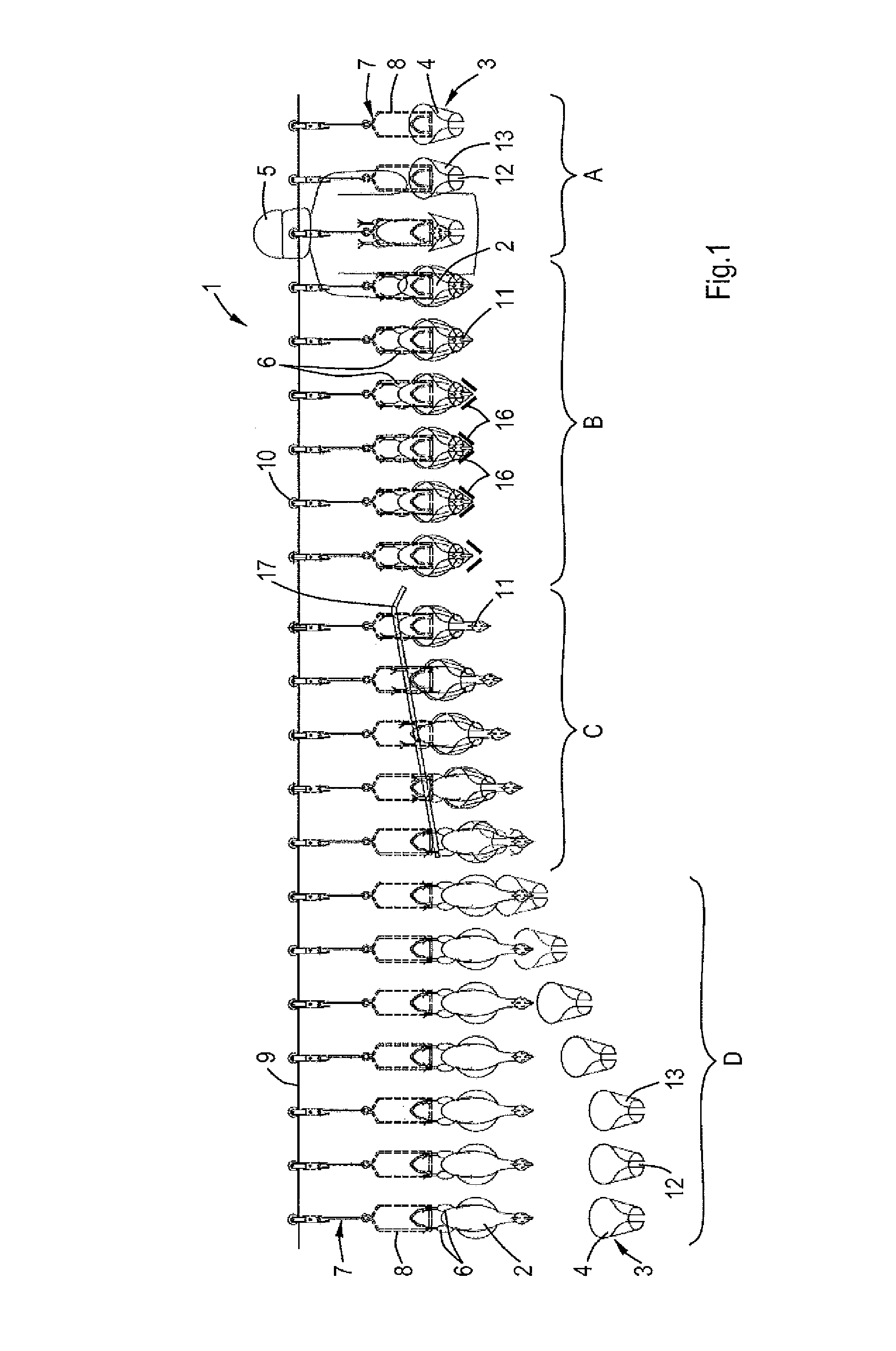

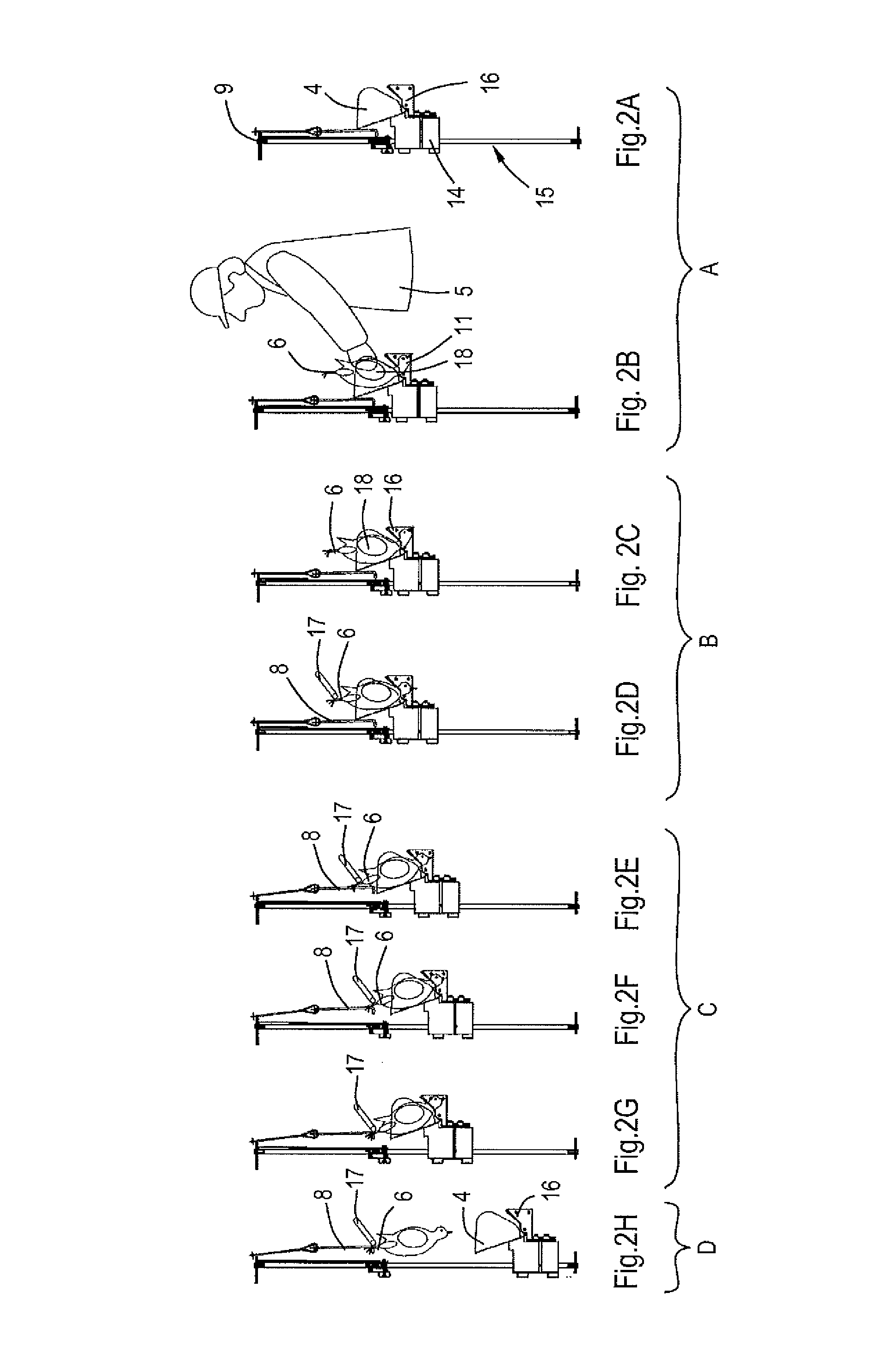

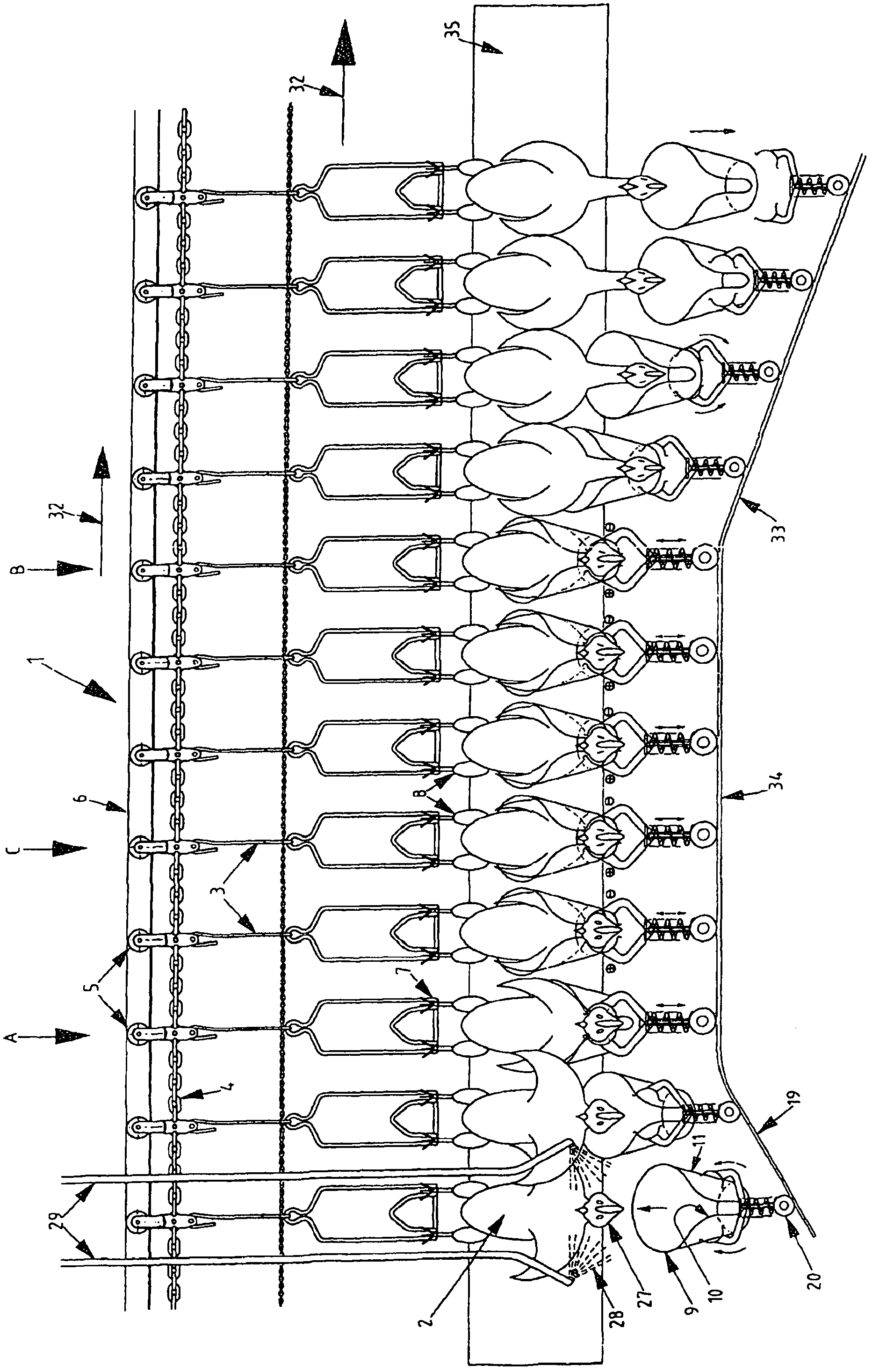

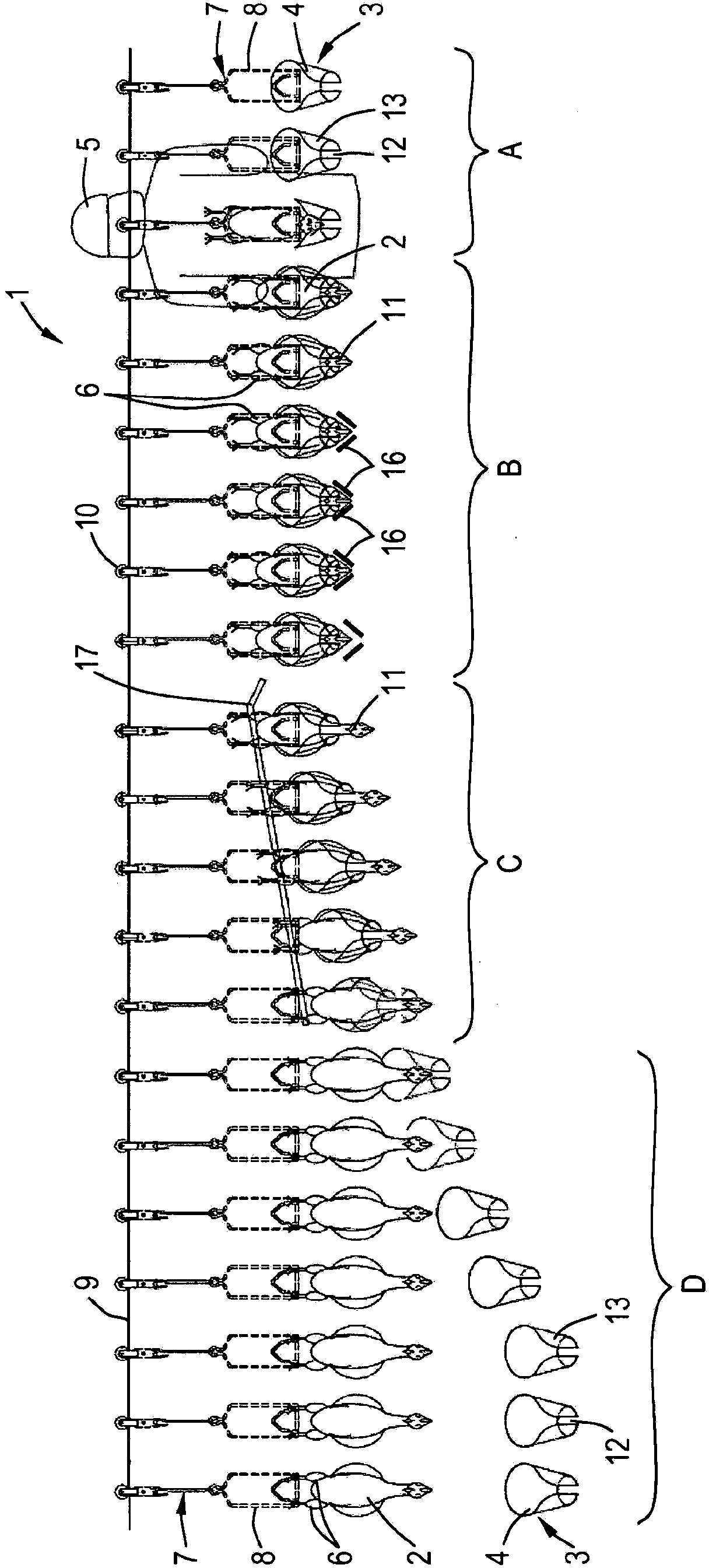

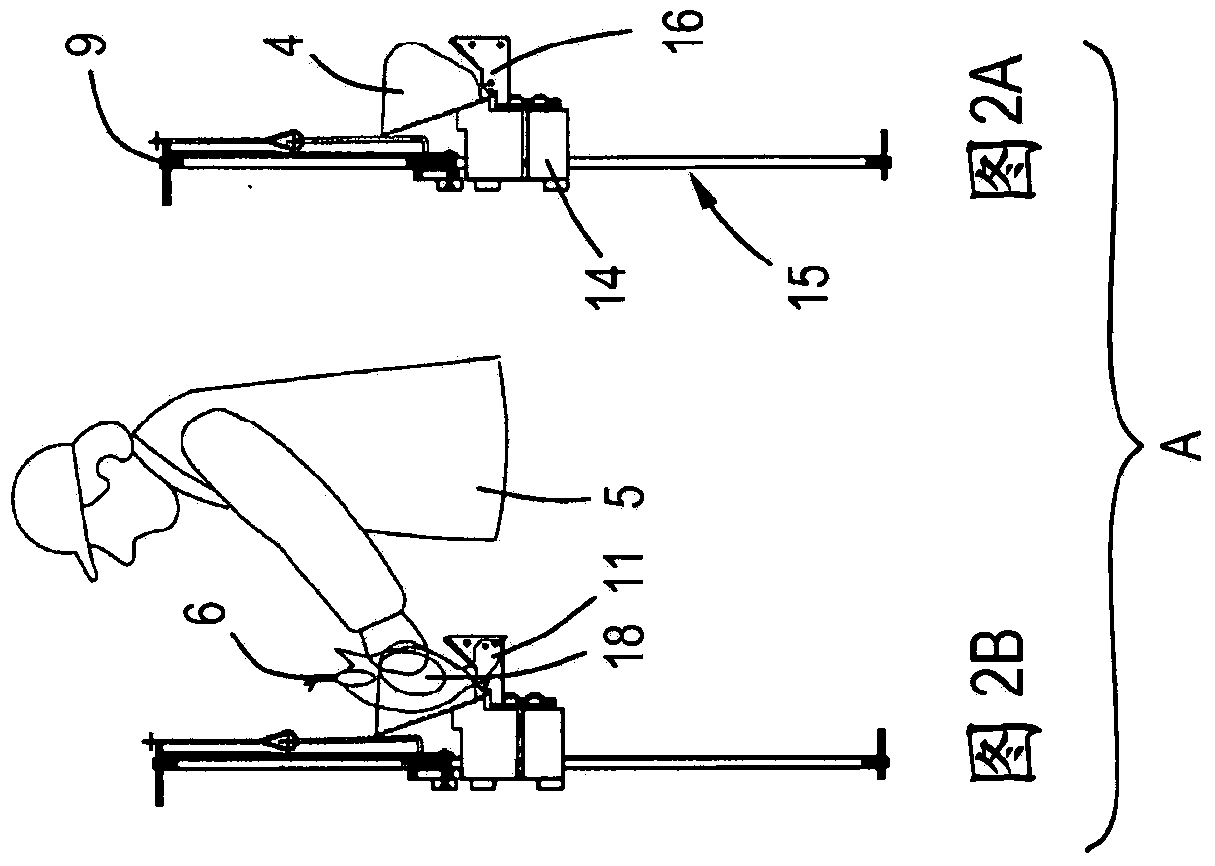

Method and installation for handling poultry

InactiveUS9179684B2Reduce stressFree from injuryPoultry/fish slaughtering/stunningSlaughterhouse arrangementsEngineering

The present invention relates to a method for handling poultry, such as chicken, turkey, geese, duck and quail, comprising the steps of (i) taking the poultry; (ii) placing the poultry in a confinement such that the poultry legs extend from the confinement; and (iii) coupling the poultry legs to a handling unit, and to an installation for handling poultry, such as chicken, turkey, duck and quail that takes the poultry and places the poultry in a confinement such that the poultry legs extend from the confinement; and the poultry legs are coupled to the handling unit.

Owner:TOPKIP

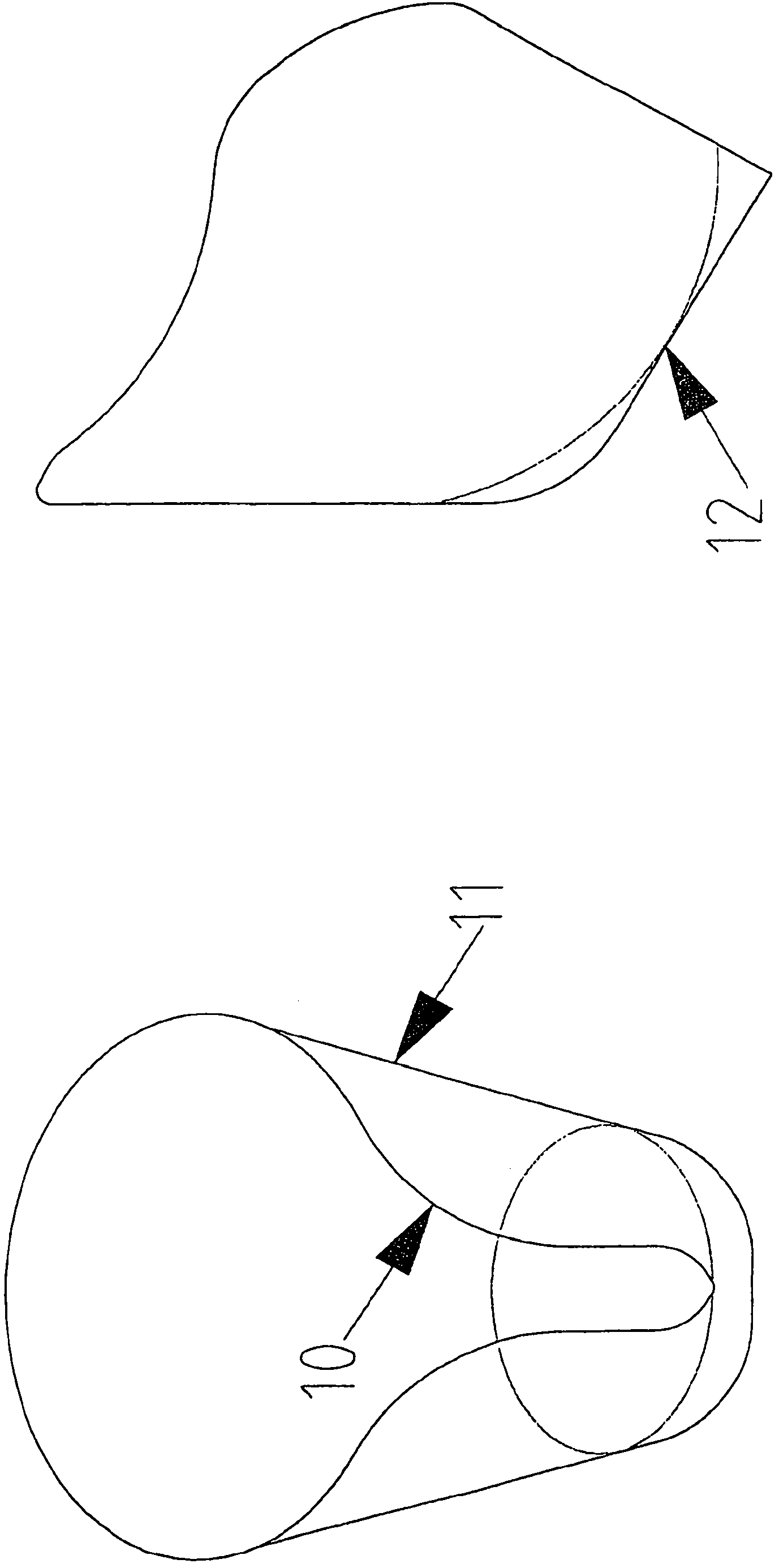

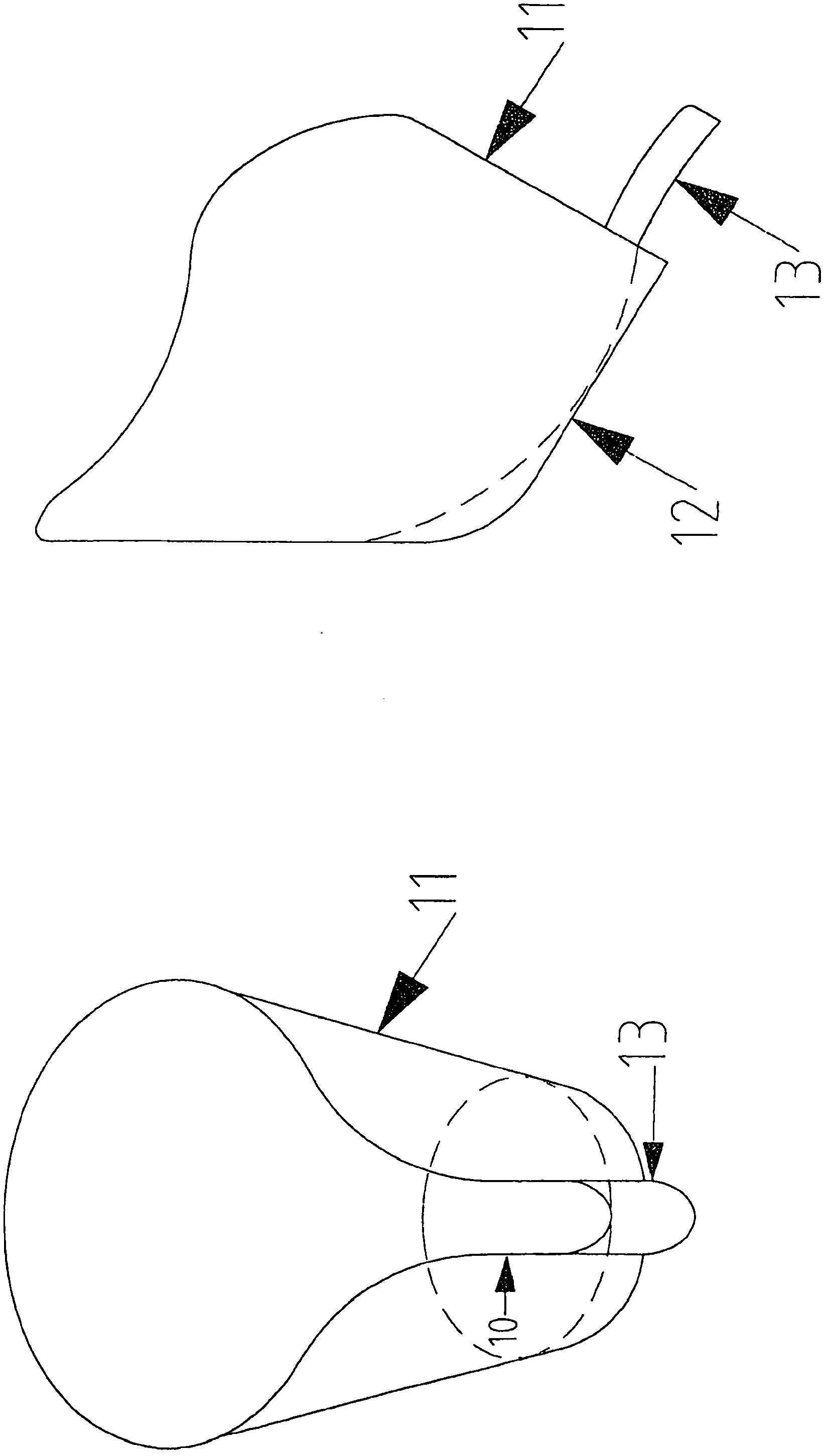

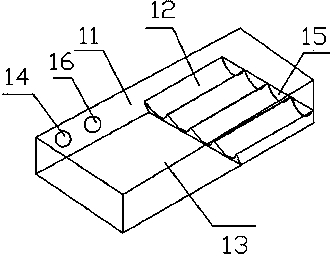

Combined tool for processing sea eel or finless eel

ActiveCN103976000AAffect online operationInhibit sheddingFish threading devicesPoultry/fish slaughtering/stunningLampreyFinless eel

The invention discloses a combined tool for processing sea eel or finless eel. The invention aims to provide a combined tool which is convenient and quick in operation, low in cost and fit for killing a small amount of sea eel or finless eel in the places, such as home, restaurants and hotels. The combined tool comprises a sea eel or finless eel automatic loading device, a shaping elastic sleeve and a cutter, wherein the sea eel or finless eel automatic loading device comprises a storage box with an opening at the upper end and a plurality of vertical insert plates which are arranged in the storage box and can be taken out of the storage box; a plurality of loaders are respectively arranged on the vertical insert plates; mesh enclosures are respectively arranged on one side of each of the vertical insert plates; the loaders on the same vertical insert plate are all located in the corresponding mesh enclosures; each of the loaders comprises an inducing sleeve, a pin, a dragging line, a trigger rod, a spring steel sheet and a bait bag; the spring steel sheet is arranged right under the inducing sleeve; the bait bag is arranged in the inducing sleeve; one end of the inducing sleeve is fixed on a side wall of each of the vertical insert plates; penetrating through holes are respectively arranged on the side walls of the vertical insert plates corresponding to the inducing sleeve.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

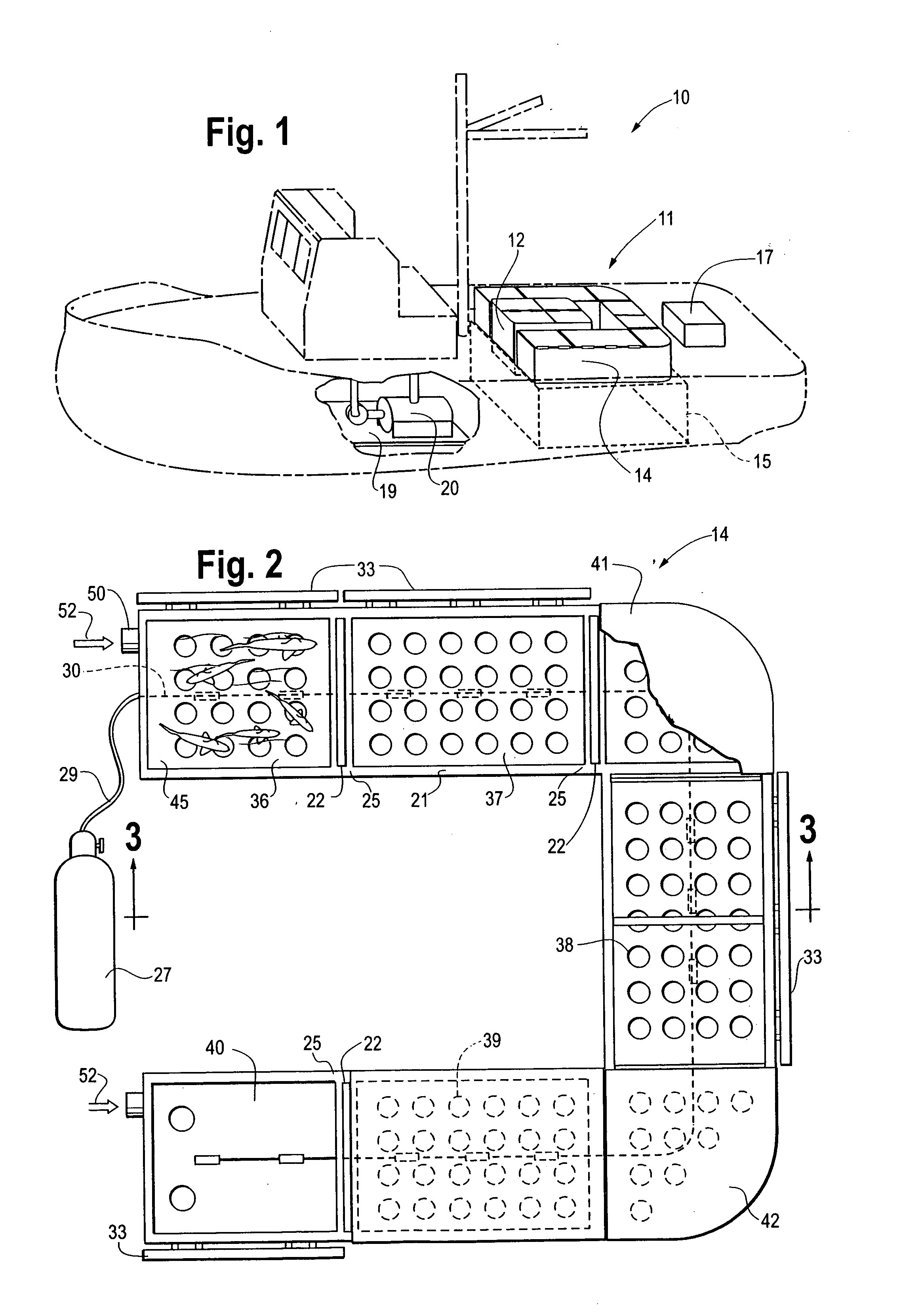

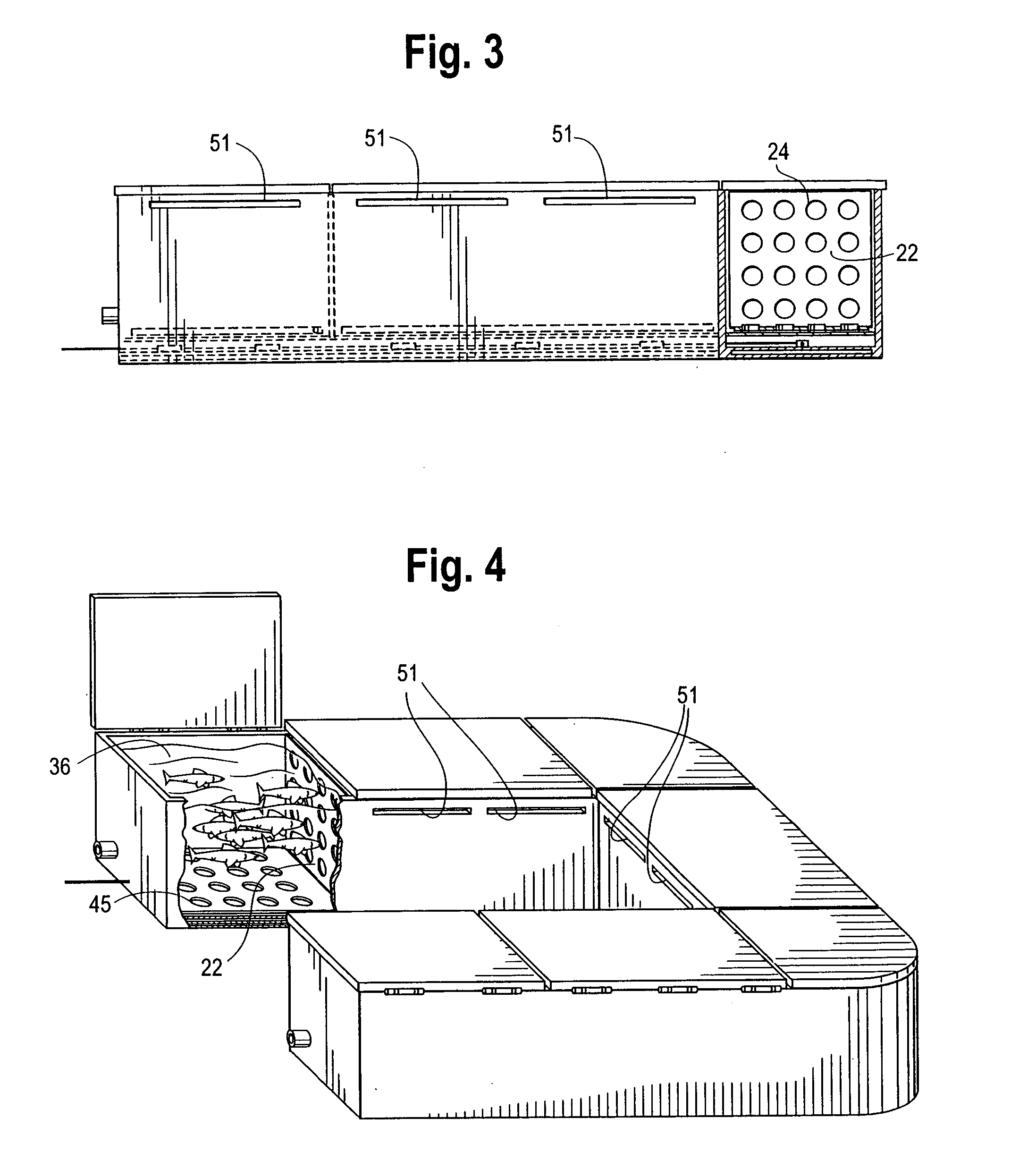

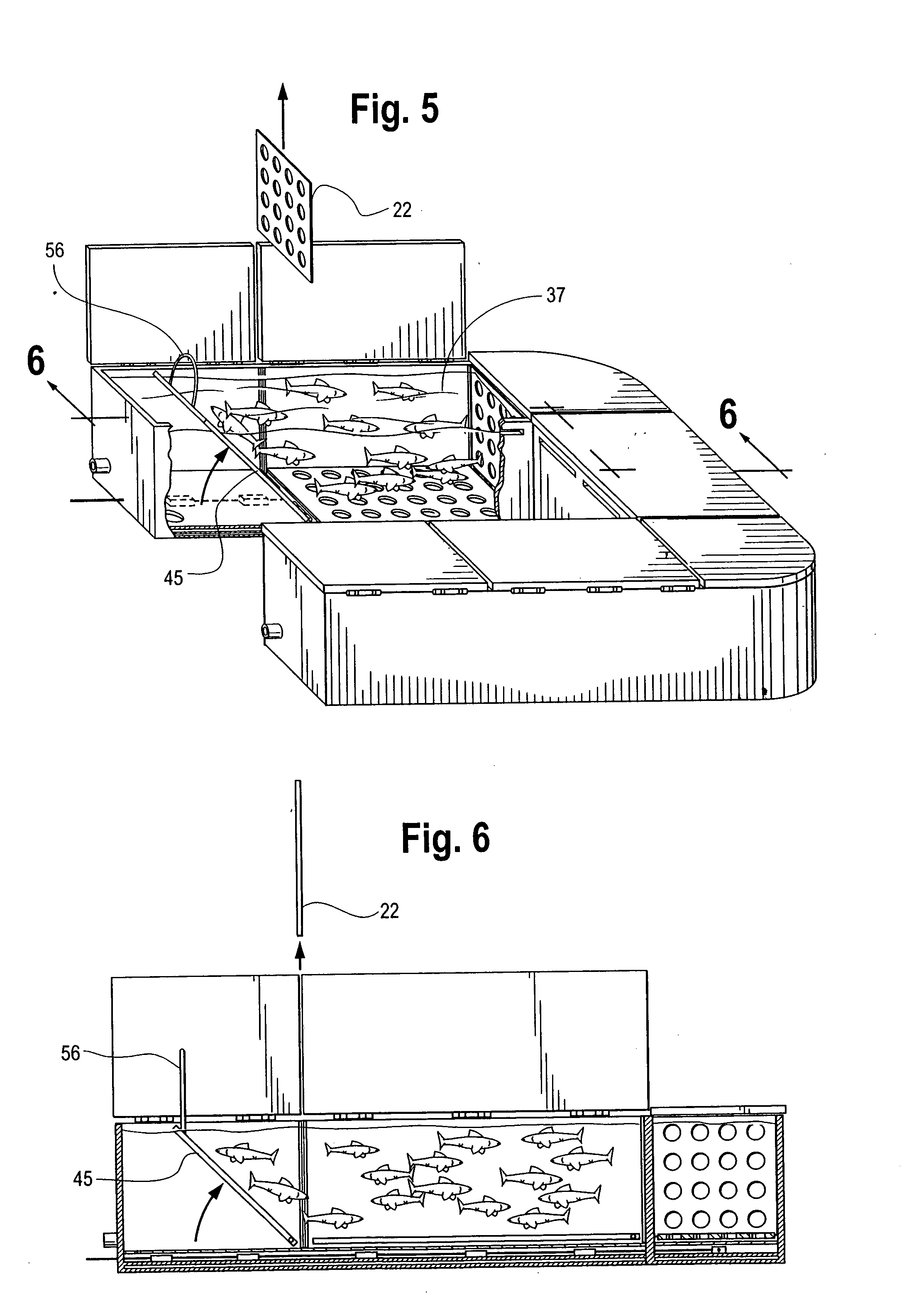

Procedure for electro-stunning and/or electro-sacrifice, for industrial application to marine inchthyological species in floating cages

InactiveUS6453596B1Acceleration in autolytical spoliationIncrease bacterial degradationElectric current slaughtering/stunningFishing netsElectricityEngineering

Procedure for electro-stunning and / or electro-sacrifice, for industrial application to marine ichthyological species in floating cages having a floating cage (12) with tuna fish (6) two divers are introduced, the hunter (1), who uses a rifle with a harpoon with a Teflon head and metallic tip (4), joined to equipment for transforming electric potential (3) on the boat (7) and also connected to a plate (5) submerged and the controller (2) that activates the equipment (3), which sends an electric stunning signal or a signal that kills the fish (6) to the two terminals of the plate (5) and tip (4), the fish is lifted from the water by the crane (10), and equipped with a collar or identifying plastic label (11), the rifle and the harpoon are recovered towards the boat (7).

Owner:GINES MENDEZ ESPANA

Method and installation for stunning poultry and the obtainable bleeded poultry

InactiveCN102480975AElectric current slaughtering/stunningPoultry/fish slaughtering/stunningBiologyMechanical engineering

The invention relates to a method and installation for stunning poultry, such as chicken, turkey, duck and quail, comprising the steps of : i) suspending the poultry with the poultry head down; ii) positioning the suspended poultry head; and iii) stunning the poultry via the suspended and positioned poultry head, and to obtainable debleeded poultry.

Owner:TOPKIP

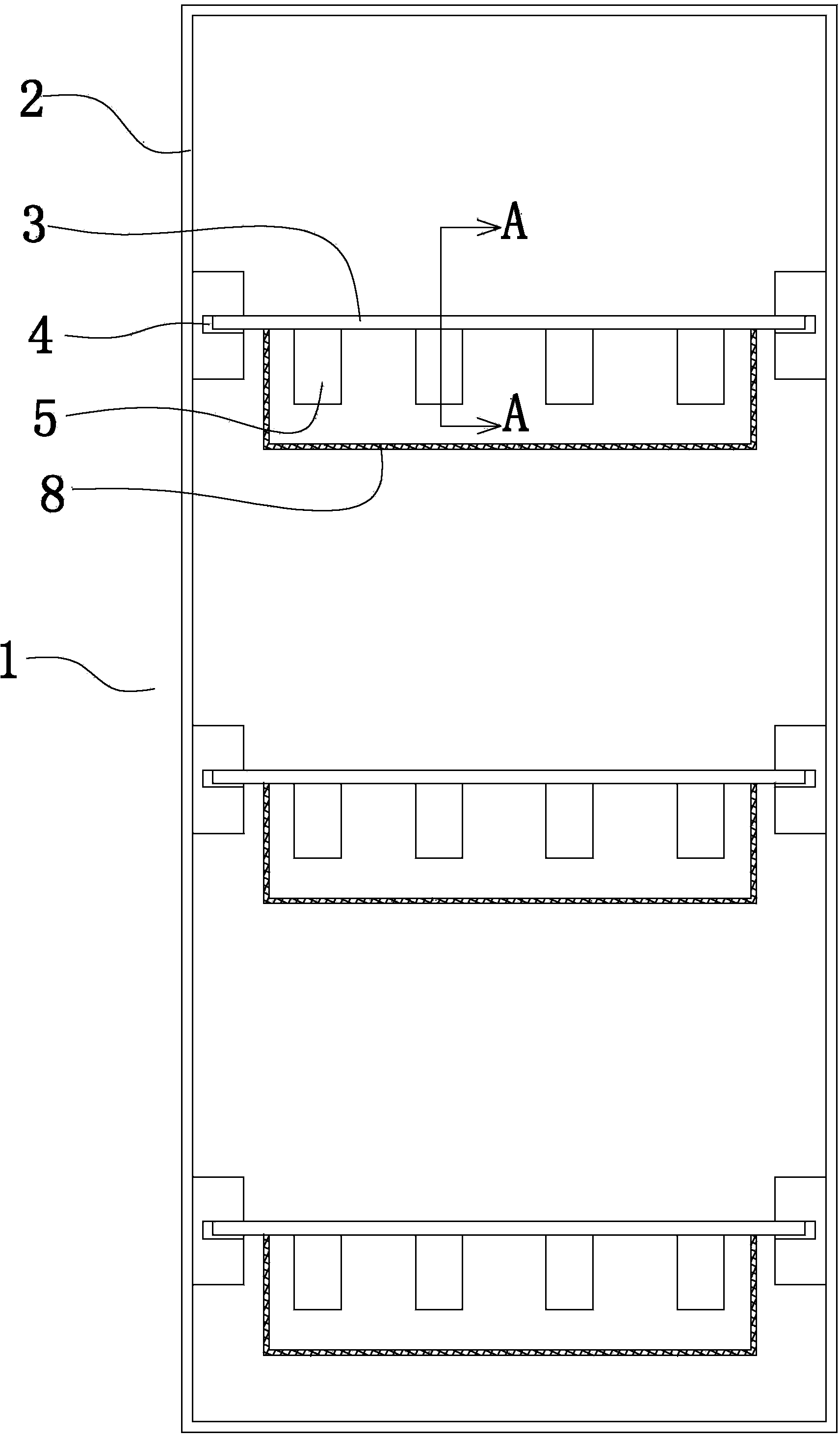

Cage device convenient for enabling chicken flocks to go out of cage and making preparations before slaughtering

ActiveCN105557554AReduced Chances of ContaminationSimple structureBiocideElectric current slaughtering/stunningEngineeringPollution

The invention provides a cage device convenient for enabling chicken flocks to go out of a cage and making preparations before slaughtering. The cage device comprises a frame, the cage and an egg conveying belt, wherein the cage adopts a cubic structure composed of a front side plate, a back side plate, a bottom plate, an upper side plate and two side plates; an air pipe is arranged at the lower part of a liquid inlet pipe on the corresponding side plate; the liquid inlet pipe is in threaded connection with a medicine pot; a collection conveying belt is arranged at the end part of the egg conveying belt; a corona device and a counter are arranged on the collection conveying belt; telescopic rods are arranged on two side walls of the corona device and driven by oil cylinders; enclasping plates are fixed at the end parts of the telescopic rods; the enclasping plates are arc-shaped plates and sponge layers are bonded in the enclasping plates; an infrared detection head is fixed on the upper wall of the corona device; the bottom of the corona device virtually presses the collection conveying belt; a rubber pipe is connected between the upper part and the bottom of the corona device in an insertion manner; a spring is connected to the exterior of the rubber pipe in a sleeving manner; and a corona head is fixed at the end part of the rubber pipe. The cage device is simple in structure and convenient to use, and has a chicken output effect; and chicken bodies and the empty cage are synchronously disinfected during chicken output, so that the probability of pathogenic bacterium pollution can be reduced and the preparations before slaughtering can be made.

Owner:HEILONGJIANG POLYTECHNIC

Anatomy device for soft-shelled turtle

InactiveCN103283805ADecompose at willReduce labor intensityPoultry/fish slaughtering/stunningEngineeringUltimate tensile strength

The invention discloses an anatomy device for a soft-shelled turtle. The anatomy device for the soft-shelled turtle comprises a workbench, pillars, an n-shaped frame and a live bearing, wherein the pillars are arranged on the bottom of the workbench, and the n-shaped frame and the live bearing are arranged on the top of the workbench. An expansion link is arranged in the n-shaped frame, a tray root which is perpendicular to and opposite to the expansion link is arranged on the top of the live beating, a rubber pad is arranged at the end, far away from the n-shaped frame, of the expansion link, a soft-shelled turtle placing tray is arranged at the end, far away from the live bearing, of the tray root, and a stopcock which controls the expansion link to stretch out and draw back is arranged on one side of the expansion link. By means of the anatomy device for the soft-shelled turtle, culling time of one single soft-shelled turtle is shortened and is within one minute, the culling efficiency of soft-shelled turtles is improved, the safety problem is solved, and the labor intensity of workers is reduced greatly. Further, the anatomy device for the soft-shelled turtle is simple in structure, convenient to use and suitable for popularization.

Owner:HUNAN XIANGHU AQUATIC PROD

Stunning device for killing small animals or fish

InactiveUS20030171085A1Rapidly and efficiently stunnedImprove fish qualityBolt slaughtering/stunningPoultry/fish slaughtering/stunningSmall animalEngineering

Stunning device (1) for small animals or fish of 2kg to 7kg weight comprises pneumatically powered piston assembly (2) which includes an extendible piston. Support (3) for piston assembly (2) includes base member (4) and multi-component trigger (22, 23, 24, 26). Piston assembly (2) is positioned to define a space between base member (4) and head plate (21) for receiving the head (27) of the animal. When the piston is activated by head (27) contacting plate (22), it extends and strikes head (27) just behind and / or between the eyes with sufficient force to kill the animal with a shock to the brain, but without affecting the external appearance of the animal or fish. The piston extends only once and then retracts, and trigger (22, 23, 24, 26) is reset by removing head (27) from device (1).

Owner:BASS RICHARD

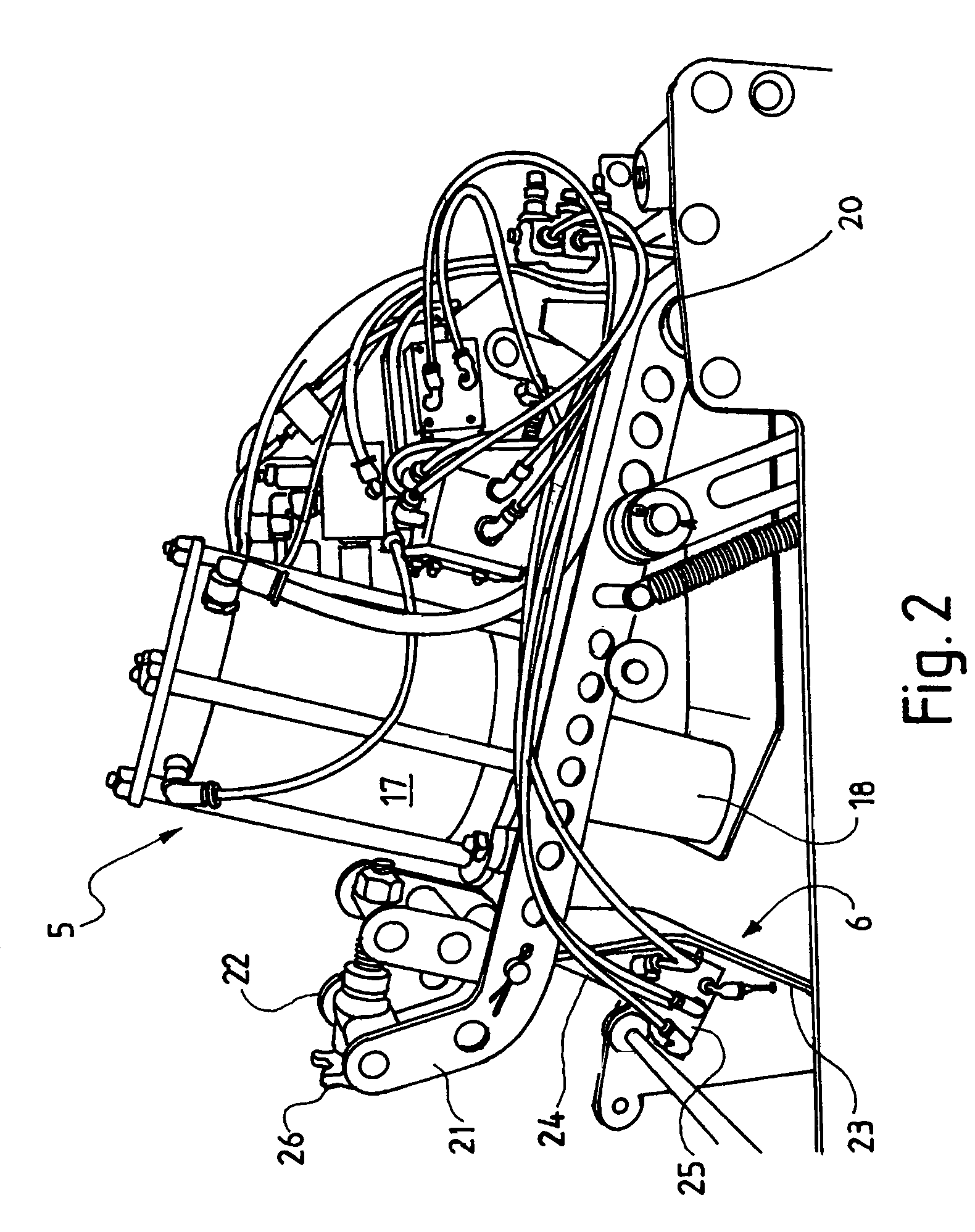

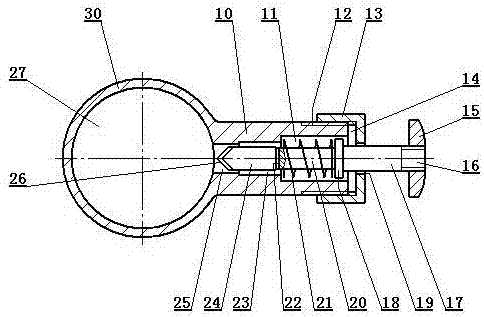

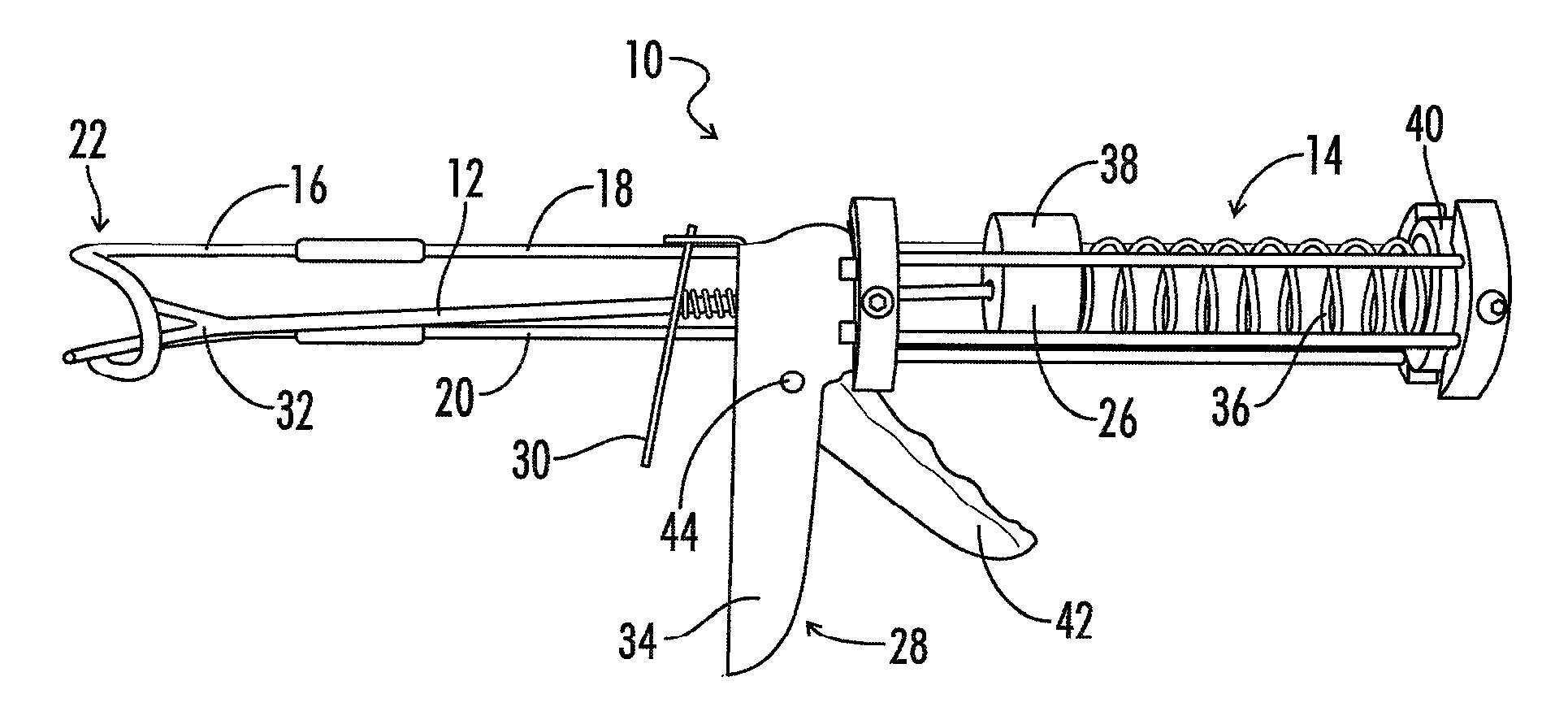

Fish processing device

InactiveUS7980925B2Easy to driveEasy to handlePoultry/fish slaughtering/stunningFish processingFish processingEngineering

A device for processing fish, the device comprising: an open channel through which a fish can pass; a fish processing means associated with the channel; a vertical guide plate pivotally mounted on each side of the channel, having a firing position and a retracted position; a mechanism for moving the fish processing means from a (“firing position”) to a position which allows passage of the fish through the channel after processing (“retracted position”); a mechanism for pivoting each guide plate between the firing and retracted positions (“guide plate pivot mechanism”); a trigger that when contacted by the head of the fish activates the fish processing means; and a mechanism for resetting the device after the processing of a fish, wherein the resetting mechanism is in communication with the trigger and wherein actuation of the mechanism by the trigger facilitates: activation of the fish processing means; movement of the fish processing means and guide plates from their respective firing positions to their respective retracted positions; return of the fish processing means and the vertical guide plates to their respective firing positions after they have attained their retracted positions; and priming of the at least one fish processing means.

Owner:RICHARD BASS PTY LTD

Method and installation for handling poultry

The present invention relates to a method for handling poultry, such as chicken, turkey, geese, duck and quail, comprising the steps of (i) taking the poultry; (ii) placing the poultry in a confinement such that the poultry legs extend from the confinement; and (iii) coupling the poultry legs to handling means, and to an installation for handling poultry, such as chicken, turkey, duck and quail, comprising means for taking the poultry and placing the poultry in a confinement such that the poultry legs extend from the confinement; and means for coupling the poultry legs to handling means.

Owner:TOPKIP

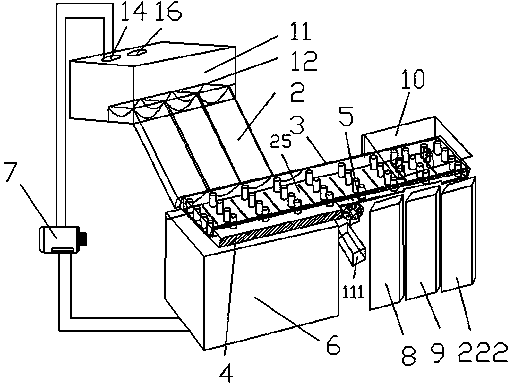

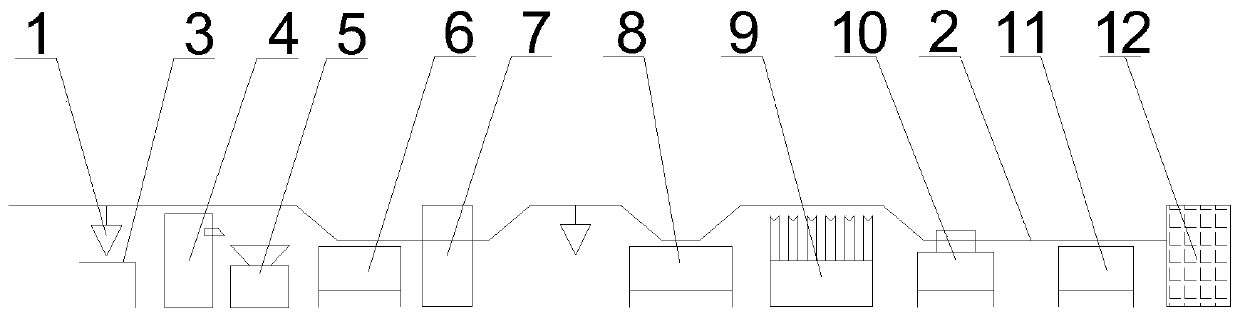

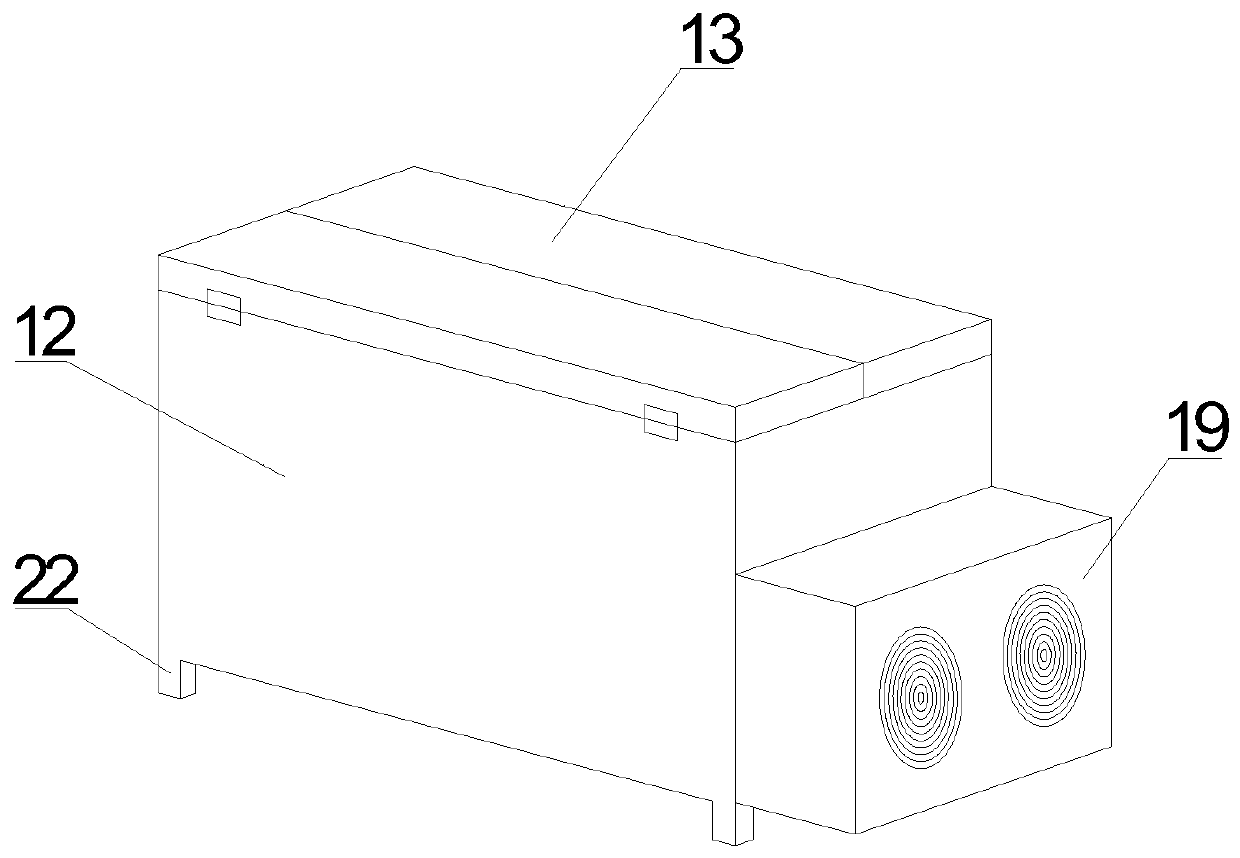

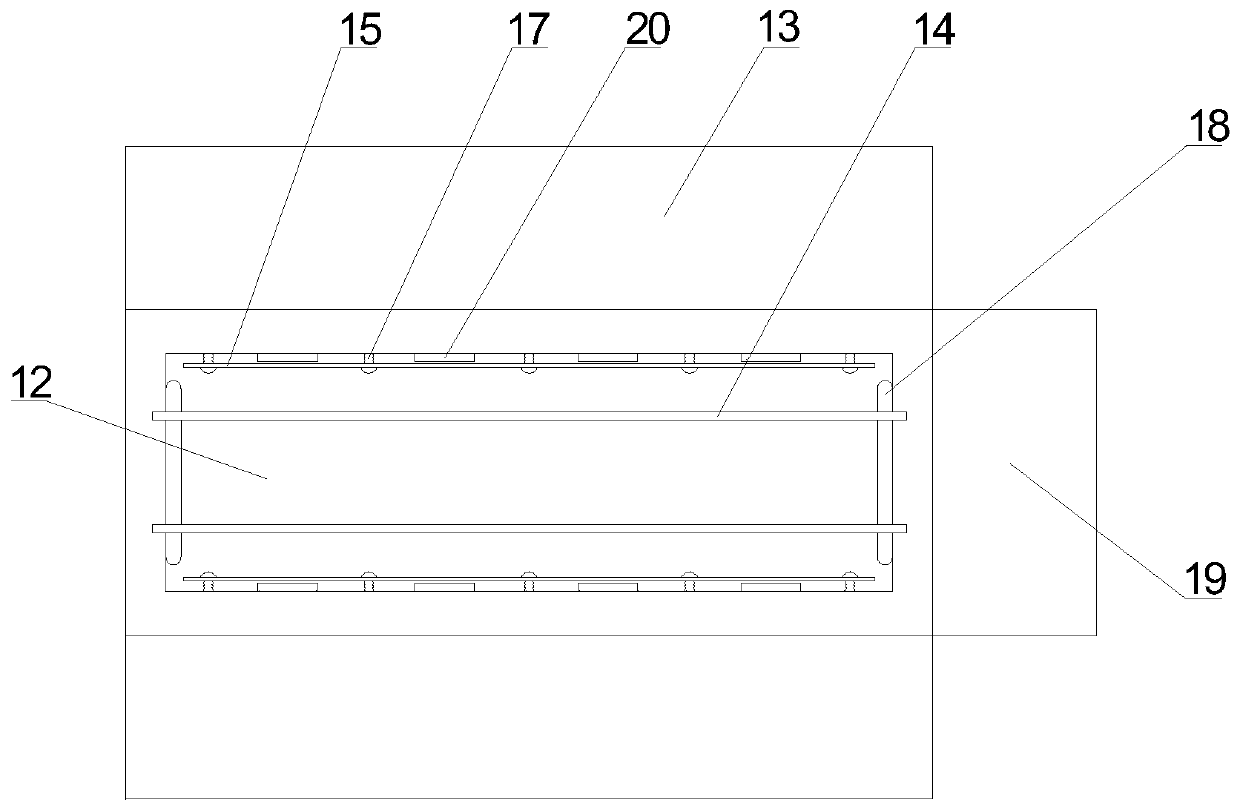

Intelligent feeding system of fish killing machine based on laser bar three-dimensional measurement

PendingCN108077374AHigh precisionImprove cutting effectFish work-tablesPoultry/fish slaughtering/stunningControl systemPrimary screening

The invention relates to an intelligent feeding system of a fish killing machine based on laser bar three-dimensional measurement. The intelligent feeding system comprises a laser bar three-dimensional measurement system and a fish killing mechanism. The intelligent feeding system is scientific and reasonable in design and high in degree of automation and can realize real-time adjustment of the position of a cutter according to the size of each fish in an assembly line so as to intelligently split a fish body, thereby avoiding the problems of incomplete cutting and over-cutting of the belly ofa traditional fish body, saving the material and saving the cost. The intelligent feeding system has no need of performing primary screening on fishes before the assembly line of the fish killing machine works and has no limit to the size of the fish body, so that the intelligent feeding system is higher in adaptability and lower in cost. By adopting an intelligent detection device and a controlsystem, the automation level of the whole assembly line of the fish killing machine is greatly improved, the production efficiency is effectively improved, and thus the intelligent feeding system is suitable for being widely popularized and used.

Owner:天津市宽达水产食品有限公司

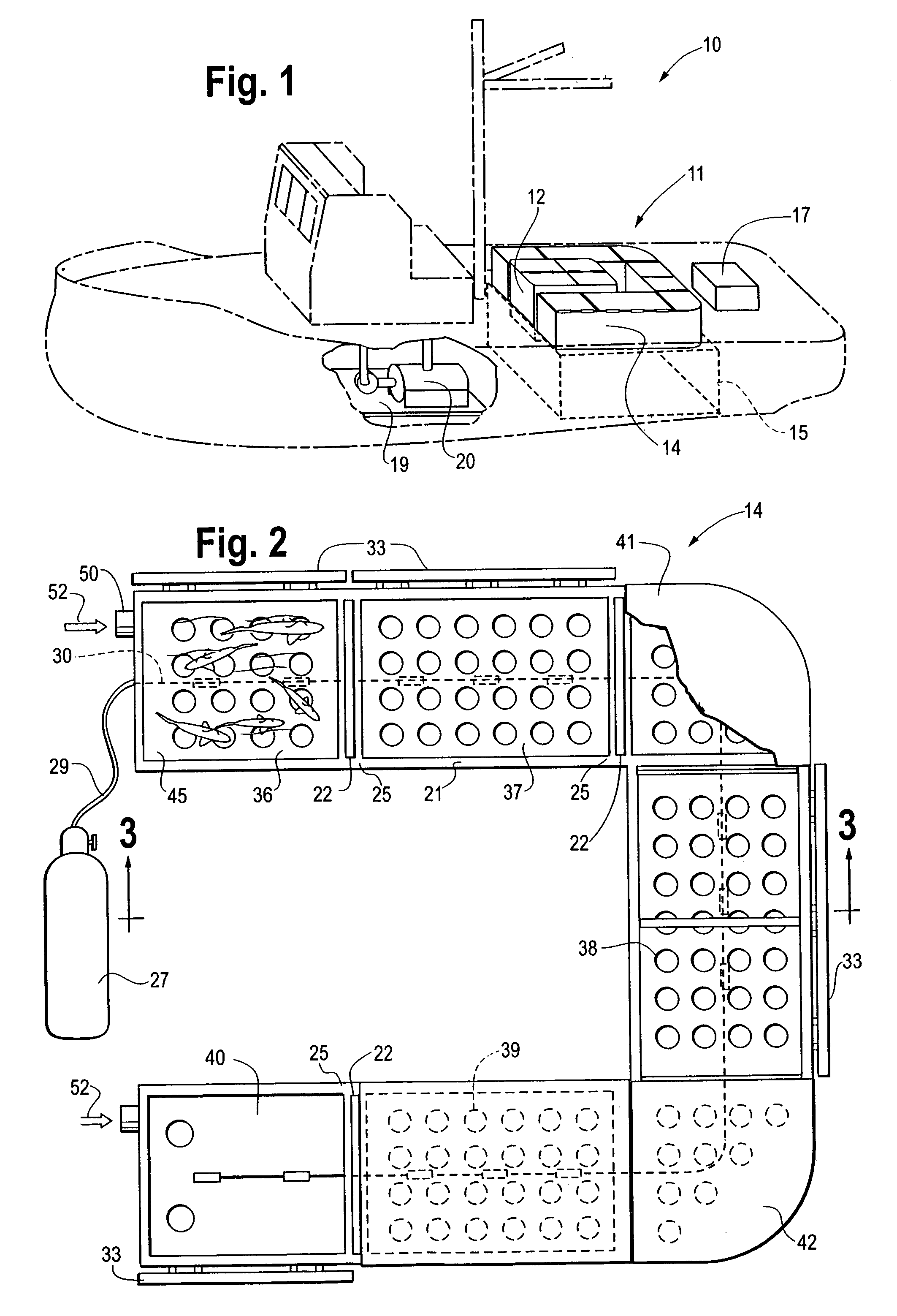

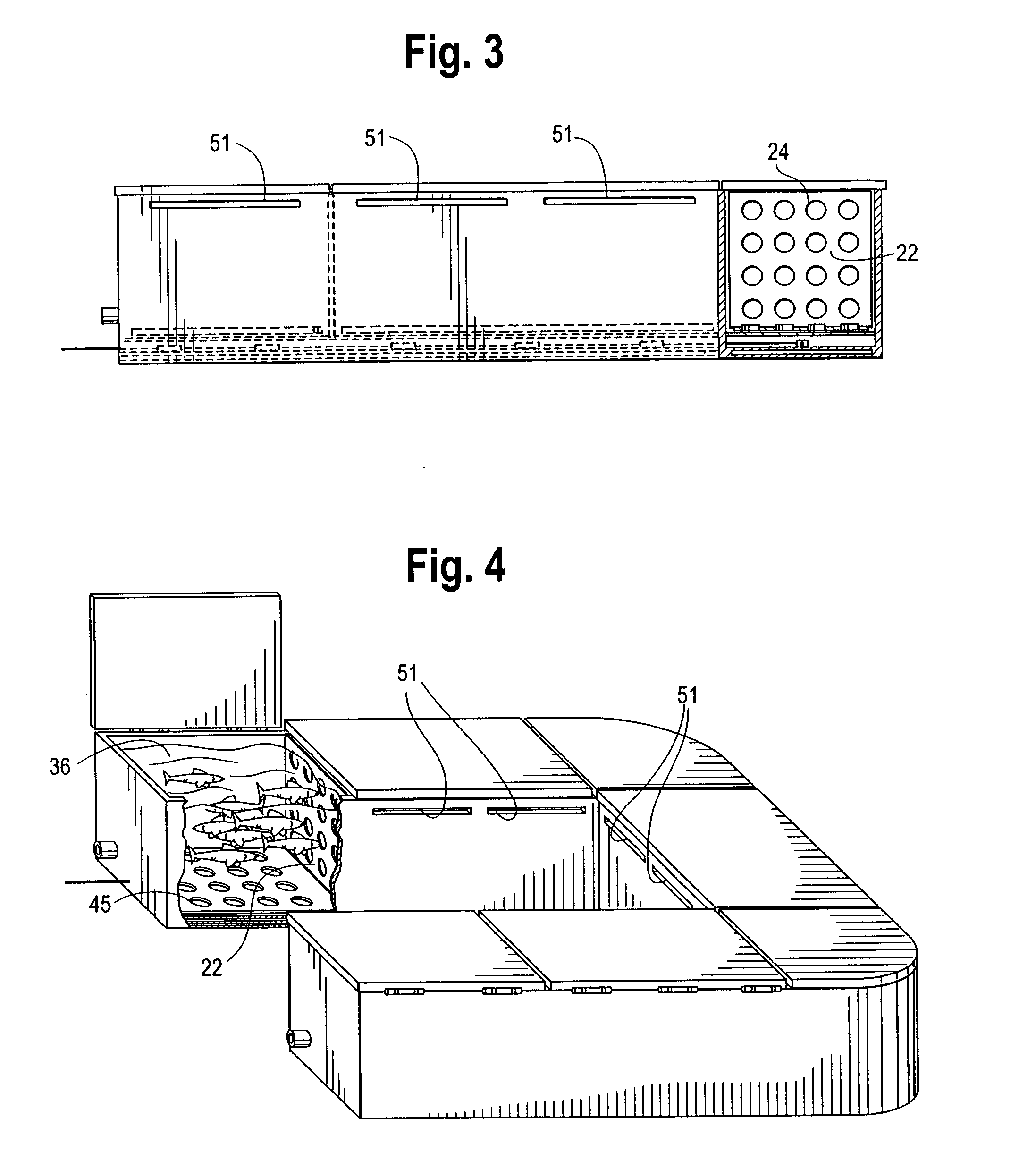

System and method for treating live cargo such as poultry with gas

ActiveUS20070026781A1Effective and efficient and treating operationEasy to adjustBlood collection/stirring apparatusGas slaughtering/stunningEngineeringAtmosphere

Animals such as poultry are stunned while still caged and on a vehicle or stationary platform prior to processing the animal by isolating the atmosphere surrounding the animal, adjusting the composition of the isolated atmosphere by introducing a gaseous mixture that brings the animal to the desired state, and evacuating or exhausting the gaseous mixture.

Owner:PRAXAIR TECH INC

Automatic slaughter tool for live poultry

ActiveCN107455431AImprove slaughter efficiencyReduce manual laborPoultry plucking mechanismsPoultry/fish slaughtering/stunningEngineering

Owner:常州仁财科技有限公司

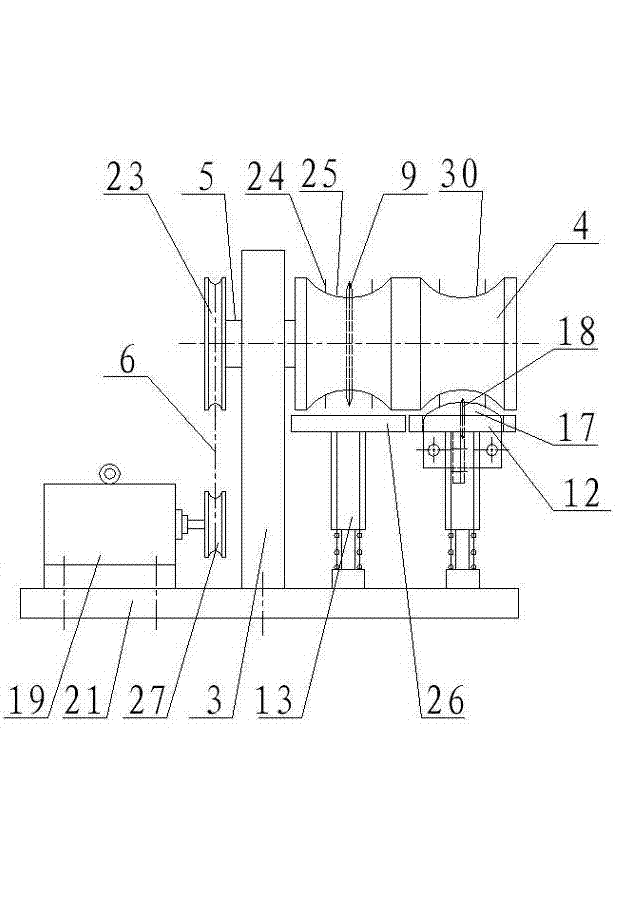

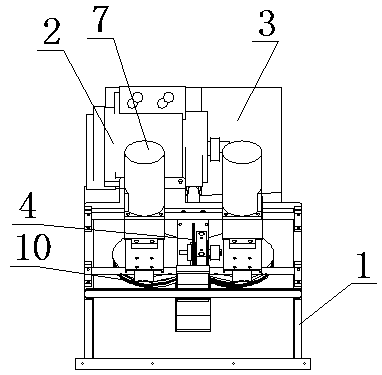

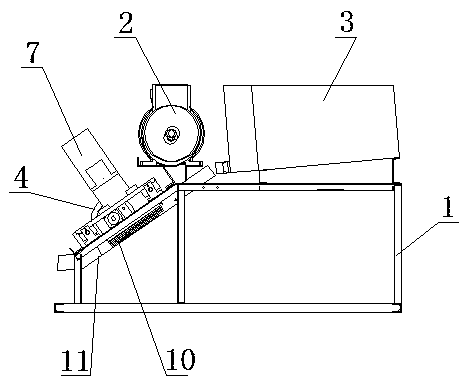

Swamp eel and loach deboning and killing machine

PendingCN109691491ASolve the manual completion of the eelSolve the problem of loach deboningPoultry/fish slaughtering/stunningFish filletingProduction lineWeatherfish

The invention relates to a swamp eel and loach deboning and killing machine, which belongs to the field of aquatic product processing machinery. The killing machine comprises a frame, a killing motor,a feed bin, and a killing deboning hobboing cutter; the feed bin is fixed at one end of the frame, the sliding rods are symmetrically arranged on the frame at the front end of the feed bin, and a conveying motor is fixed on the sliding rods through the symmetrically mounted mounting plates; conveying toothed discs are arranged on a transmission shaft of the conveying motor below the mounting plates; and a reserved gap is arranged between the conveying toothed discs. The killing machine has the characteristics of small size, convenient installation and commissioning, convenient use, high workefficiency, reliable work, low energy consumption, environmental protection and sanitation. The killing machine solves the problem that after killing the swamp eel and loach, deboning of the swamp eeland loach should be manually completed in the prior art. The single killing machine can kill 450-500 kilograms per hour, which is 30-40 times of artificial work efficiency. The killing machine can meet the requirements of households, restaurants, and the like, and can be produced into a processing line for the industrialization of swamp eel deep processing, which has broad market prospects.

Owner:JINGZHOU JICHUANG ELECTROMECHANICAL TECH CO LTD

An eel belly cutting device

InactiveCN104770454ASimple structureEasy to usePoultry/fish slaughtering/stunningSlaughtering tools/knivesAnguilliformesBiomedical engineering

The present invention discloses an eel belly cutting device, and comprises a hand-holding part and a cutter edge part. The device is characterized in that: a tapered cutter body is arranged within a half-circular bead flange; the hand-holding part is a finger fixing ring; and the finger fixing ring is arranged at the apex angle outside the bead flange part. Specifically, the cutter edge part is the tapered cutter body. Beneficial effects of the device are that the device is simple in structure, convenient to use and suitable for dissecting eels in various sizes.

Owner:方小玲

Loach killing machine

InactiveCN104054790ASolve technical problems that cannot be aligned downwardsRealize automatic slaughterAnimal stomach clearancePoultry/fish slaughtering/stunningWater resourcesEngineering

The invention relates to a loach killing machine. The loach killing machine comprises a workbench, a water tank, a sliding board, a conveying device, a baffle and a cutter. The water tank and the conveying device are arranged on the workbench. A bottom board of the water tank inclines upwards at 10 degrees to 20 degrees in the perpendicular direction. One connection end of the sliding board is connected with a water outlet of the water tank and the other connection end of the sliding board is connected with the conveying device. The cutter is arranged on the workbench and arranged adjacent to the baffle. The loach killing efficiency of the loach killing machine is high, and it is only required that loaches to be killed are placed in the water tank at a time, so that the loaches are automatically killed. The functions of killing, washing and the like are integrated and practicability is high. A water resource can be recycled, cost is saved, and the loach killing machine is environmentally friendly and economical.

Owner:杨荣建

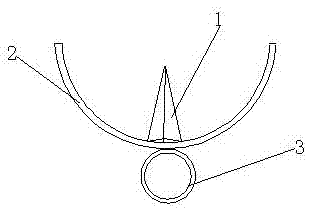

Eel slaughter machine

ActiveCN105454387ASmooth entryRapid slaughter processPoultry/fish slaughtering/stunningProduction lineAquatic product

The invention provides an eel slaughter machine. The eel slaughter machine comprises a rack, the upper portion of the rack is provided with a hopper, and a slaughter device is arranged under the hopper. The eel slaughter machine is characterized in that the side of the hopper is provided with a discharge port which is connected with a circle pipeline, the slaughter device is composed of a pressing wheel and a knife rest arranged at the bottom of the pressing wheel, the knife rest is provided with a circular arc groove corresponding to the pressing wheel, an outlet of the circle pipeline is connected with an inlet of the circular arc groove, and the upper portion of the circular arc groove is provided with a blade. The eel slaughter machine has the advantages of being simple in structure, wide in adaptation, capable of reducing labor intensity and saving labor and the like. According to the eel slaughter machine, through the circle pipeline, an eel can be sped up, the eel belly is made to face downwards, the body position change of the eel is prevented, and the eel successfully enters an eel pressing tank. The eel slaughter machine is small in size and wide in adaptive range and not only can meet the requirements of families and restaurants, but also can serve as a powerful tool of aquatic product processing enterprises for performing production line processing operation.

Owner:HUBEI JIALIANG MACHINERY

Slaughtering and processing device and slaughtering and processing method for chilled chicken

InactiveCN111418638AGreat tasteEnsure hygieneBlood collection/stirring apparatusPoultry/fish slaughtering/stunningBiotechnologyBrowning

The invention discloses a slaughtering and processing device and slaughtering and processing method for chilled chicken. The method comprises the following steps: manually fixing chicken on a hook ofa conveying device; sending the hung chicken into a stunning and killing device through the hook and the conveying device for welfare slaughtering, draining blood after slaughtering, and then performing soaking, scalding and unhairing, and sending the treated chicken into a first cleaning tank for cleaning; performing evisceration to remove internal organs after cleaning, and then performing cleaning again; and sending the chicken into a bone removing device to remove the head and feet after cleaning, sending the chicken into a cooling tank for pre-cooling, and sending the chicken into a low-temperature freezing box after per-cooling. The slaughtering and processing method is clean and rapid, ensures sanitation of slaughtering sites, reduces bacterial colony on the chicken, and avoids chicken taste deterioration caused by the huge change from the high temperature for unhairing to the freezing temperature, breeding of bacteria is prevented by a plasma electrostatic field, and the purpose of continuous insurance is achieved. Moreover, juice loss and surface browning are avoided, quality is ensured, the shelf life is prolonged, and the slaughtering and processing method has wide applicability in the field of chicken processing.

Owner:新疆帕戈郎食品有限公司

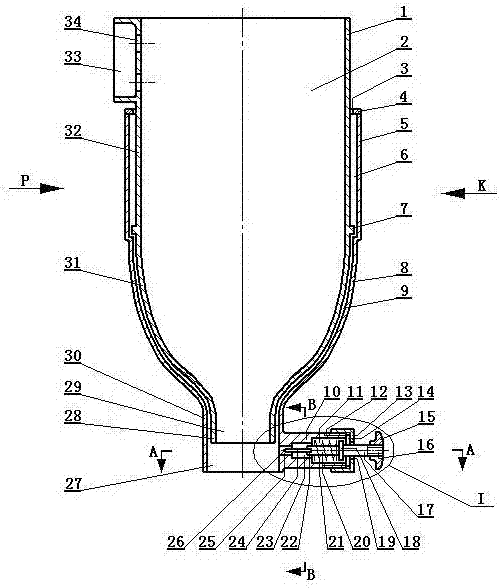

Chicken/duck slaughter device

InactiveCN107183131AFewer changes of laundryLess hassle with mopping floorsBlood collection/stirring apparatusPoultry/fish slaughtering/stunningShed bloodEngineering

The invention discloses a chicken / duck slaughtering device. The main features are: the outer end of the cylinder wall of the bottle-shaped fixed cylinder is equipped with a movable cylinder that can move up and down and rotate 360°, and the right end of the neck A of the integrated structure of the lower part of the movable cylinder is provided with a cylindrical cylinder with an integrated structure. The knife seat, the square guide hole at the left end of the knife seat is equipped with a blade that can move left and right to cut the chicken / duck neck when slaughtering chicken / duck. The transverse centerline of the knife seat and the vertical centerline of the cylinder neck A are perpendicular to each other. When slaughtering chickens / ducks, neither tightly grasp the two wings and the head of the chickens / ducks, nor cut the necks of the chickens / ducks with a kitchen knife. In the process of exhausting the blood, the trouble of struggling desperately and splashing the blood on the clothes and the floor of the slaughterer during the constant thumping can reduce the trouble of changing clothes and mopping the floor, and slaughtering chickens / ducks is easy and convenient.

Owner:詹秀云

Poultry euthanasia device

InactiveUS8932117B1Rapid deathSolve the lack of precisionSlaughtering animals fettering apparatusBolt slaughtering/stunningSpinal columnComputer science

Owner:KECK LLOYD +1

Automatic butchering and head cutting machine for poultry

ActiveCN103651718AGood separation effectConsistent positionPoultry/fish slaughtering/stunningPoultry processingCircular discReducer

The invention relates to equipment for carrying out butchering and head cutting on poultry, in particular to an automatic butchering and head cutting machine for poultry. The automatic butchering and head cutting machine mainly aims to solve the problem that the butchering and head cutting are manually carried out on the poultry with knives. The automatic butchering and head cutting machine comprises a machine body, a disc blade is arranged on a main motor shaft in the machine body, and a blade protection cover is arranged on a main motor. A transverse adjusting mechanism and a longitudinal adjusting mechanism of an upper adjusting mechanism and a lower adjusting mechanism are respectively provided with an adjusting handle, a threaded adjusting rod, a movable adjusting tube, a nut, a fixed tube and a blocking sheet, the fixed tube of the transverse adjusting mechanism is fixed to the machine body through a fixing supporting tube, the outer end of the movable adjusting tube of the transverse adjusting mechanism is connected with the fixed tube of the longitudinal adjusting mechanism, and the movable adjusting tube of the longitudinal adjusting mechanism is connected with an upper guide head guide rail. The movable adjusting tube of the lower adjusting mechanism is fixed to the machine body, and the fixed tube of the lower adjusting mechanism is connected with a lower guide head guide rail through a lower guide head guide rail fixing tube. A poultry head drive plate motor, a speed reducer, a poultry head drive plate, a stirring rod, a carcass blocking spring plate, a spring baffle, a screw rod and a spring are further arranged. The automatic butchering and head cutting machine has the advantage of being high in butchering and head cutting speed.

Owner:李传芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com