Combined tool for processing sea eel or finless eel

A combined tool and eel technology, applied in fish threading devices, poultry/fish slaughtering/stunning, etc., can solve the problems of low operation efficiency, poor safety, and high production cost, and achieve a solution that increases versatility and online efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

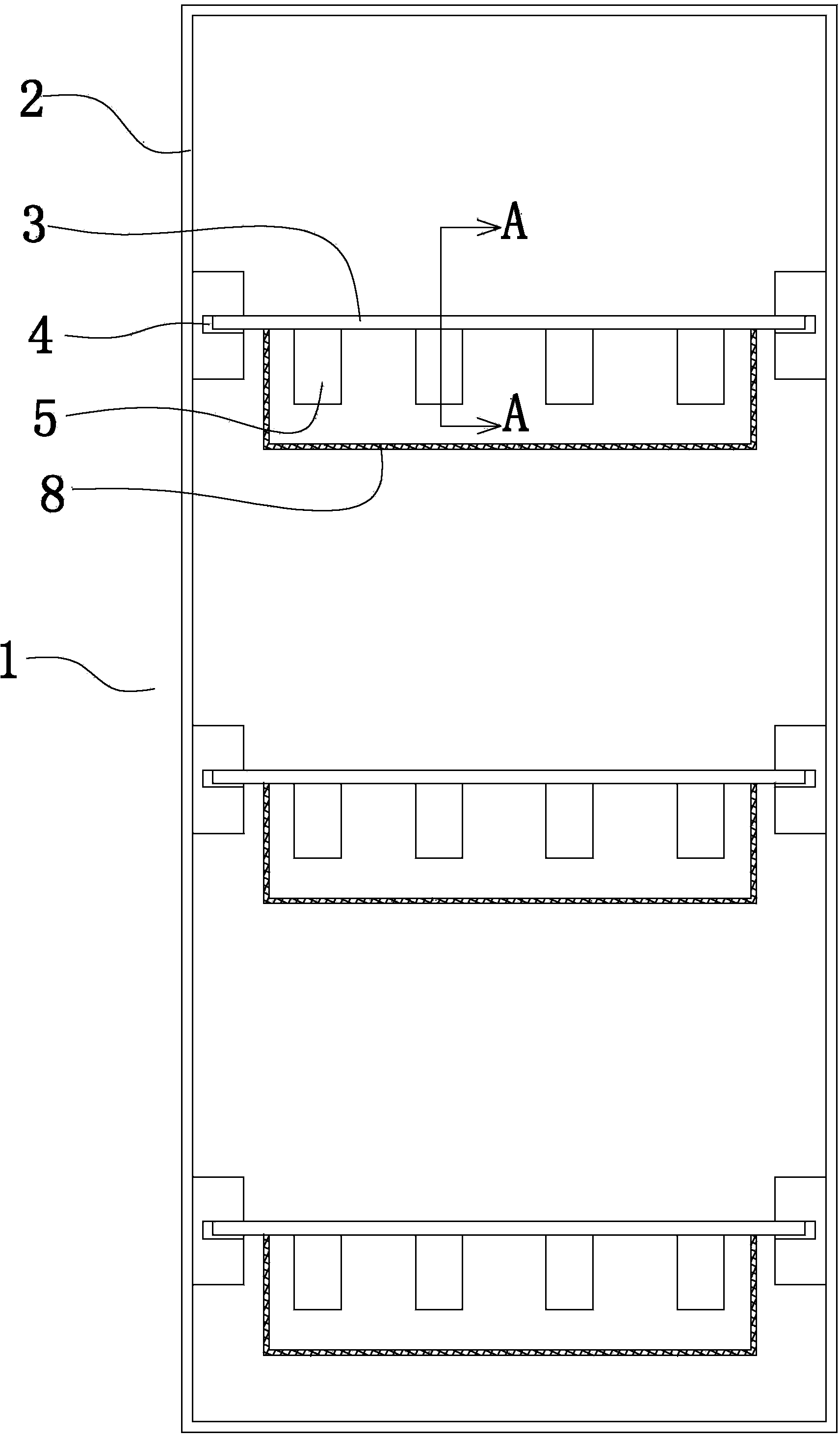

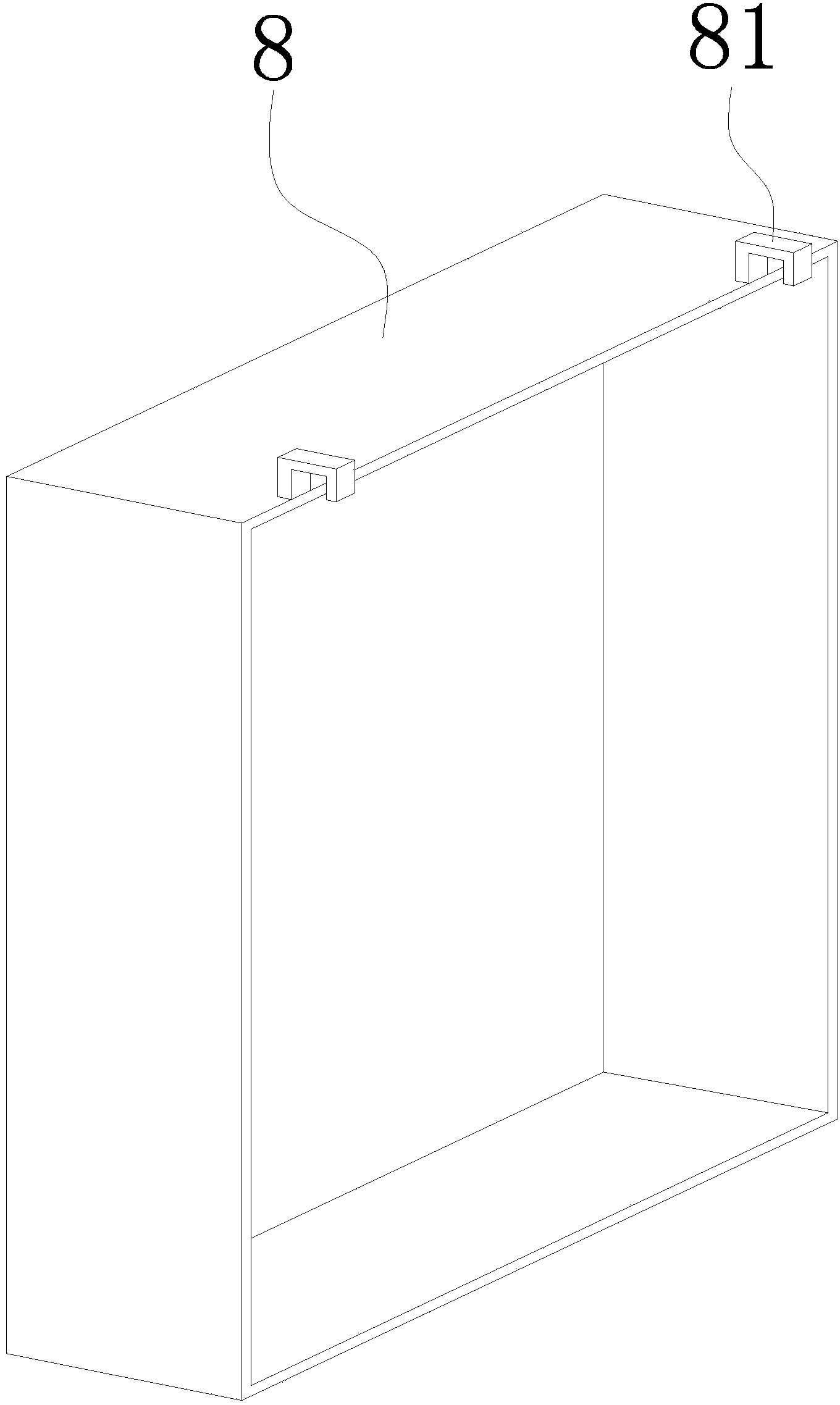

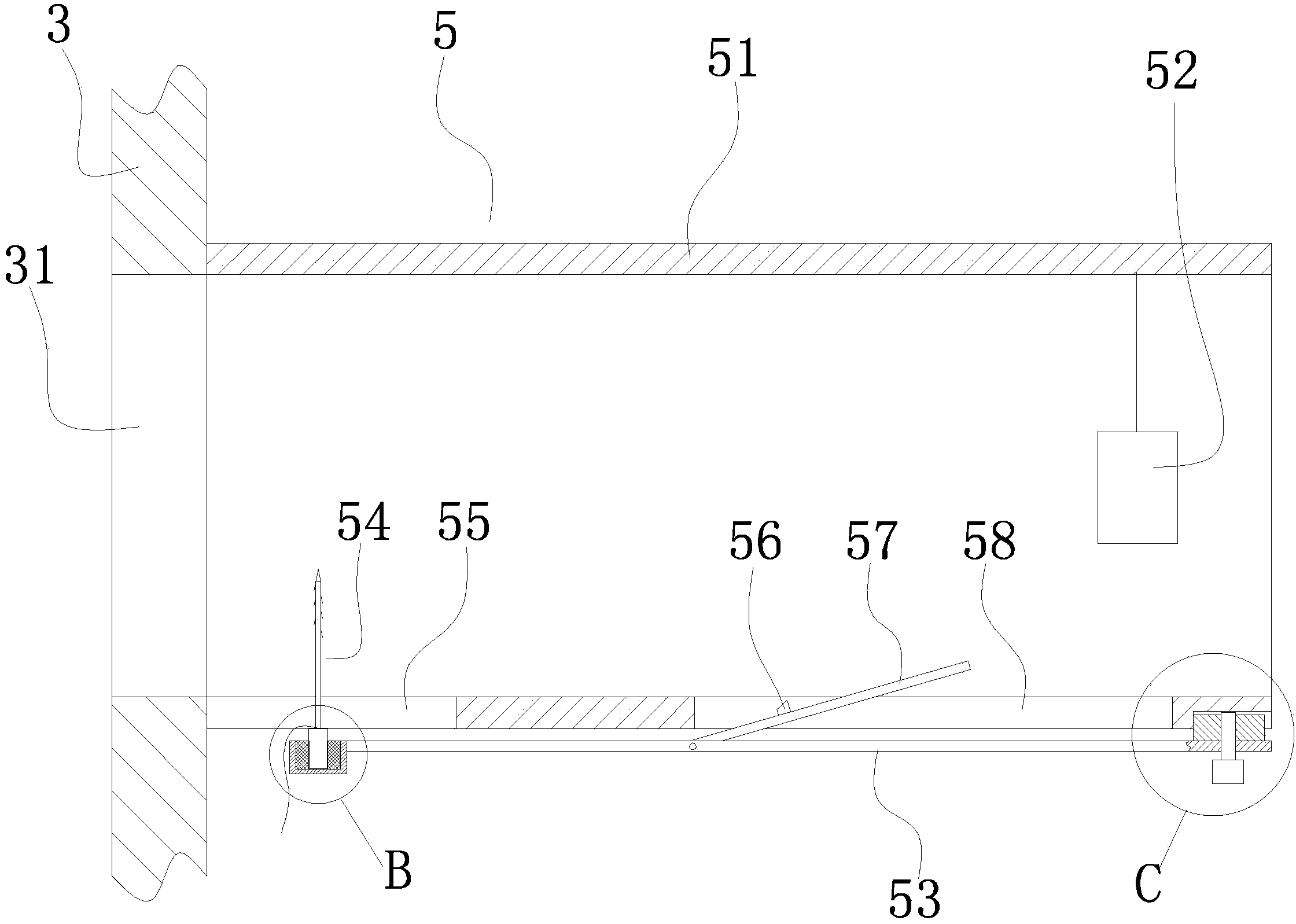

[0036] Such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a combined tool for processing eels or eels includes eel / eels automatic on-line device 1 , shaped elastic sleeve 6 and scalpel 7 . Both ends of the shaped elastic sleeve are open. The cross-section of the shaped elastic sleeve is circular. The side of the shaped elastic sleeve is provided with a gap 61 for the knife. The let-off notch extends axially along the shaped elastic sleeve and runs through both ends of the shaped elastic sleeve. The outer surface of the shaped elastic sleeve is provided with a winding column 63 and a handshake 62, and the winding column, the handshake position and the knife gap are located on opposite sides of the shaped elastic sleeve. The cutting knife can directly be made of existing blades, and the cutting knife in the present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com