Automatic butchering and head cutting machine for poultry

A head cutting machine, automatic technology, applied in the direction of poultry/fish slaughtering/stunning, slaughtering, poultry processing, etc., can solve the problems of poor separation effect, high production cost, easy to hurt workers, etc., and achieve good separation effect , Low production cost, fast cutting head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

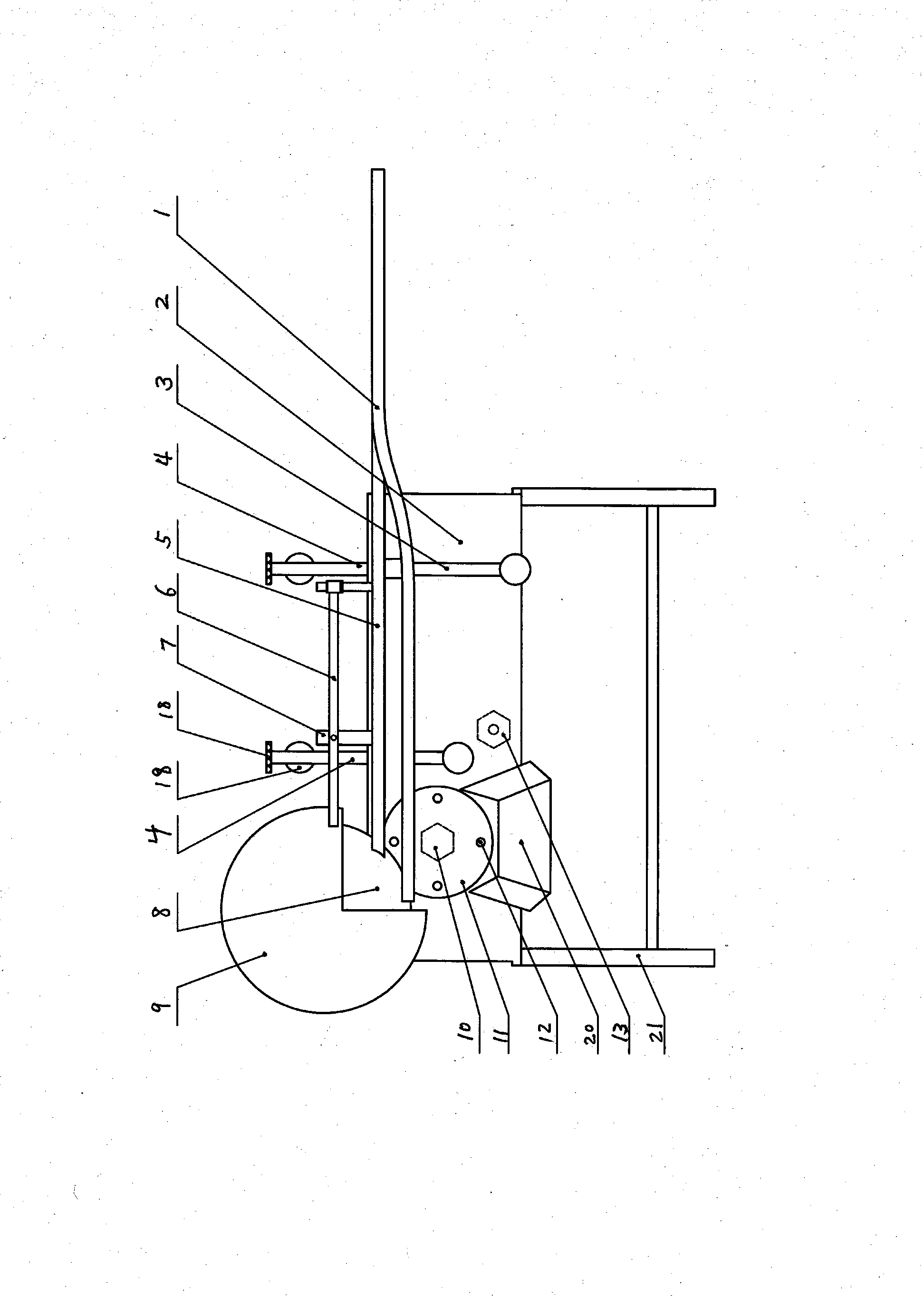

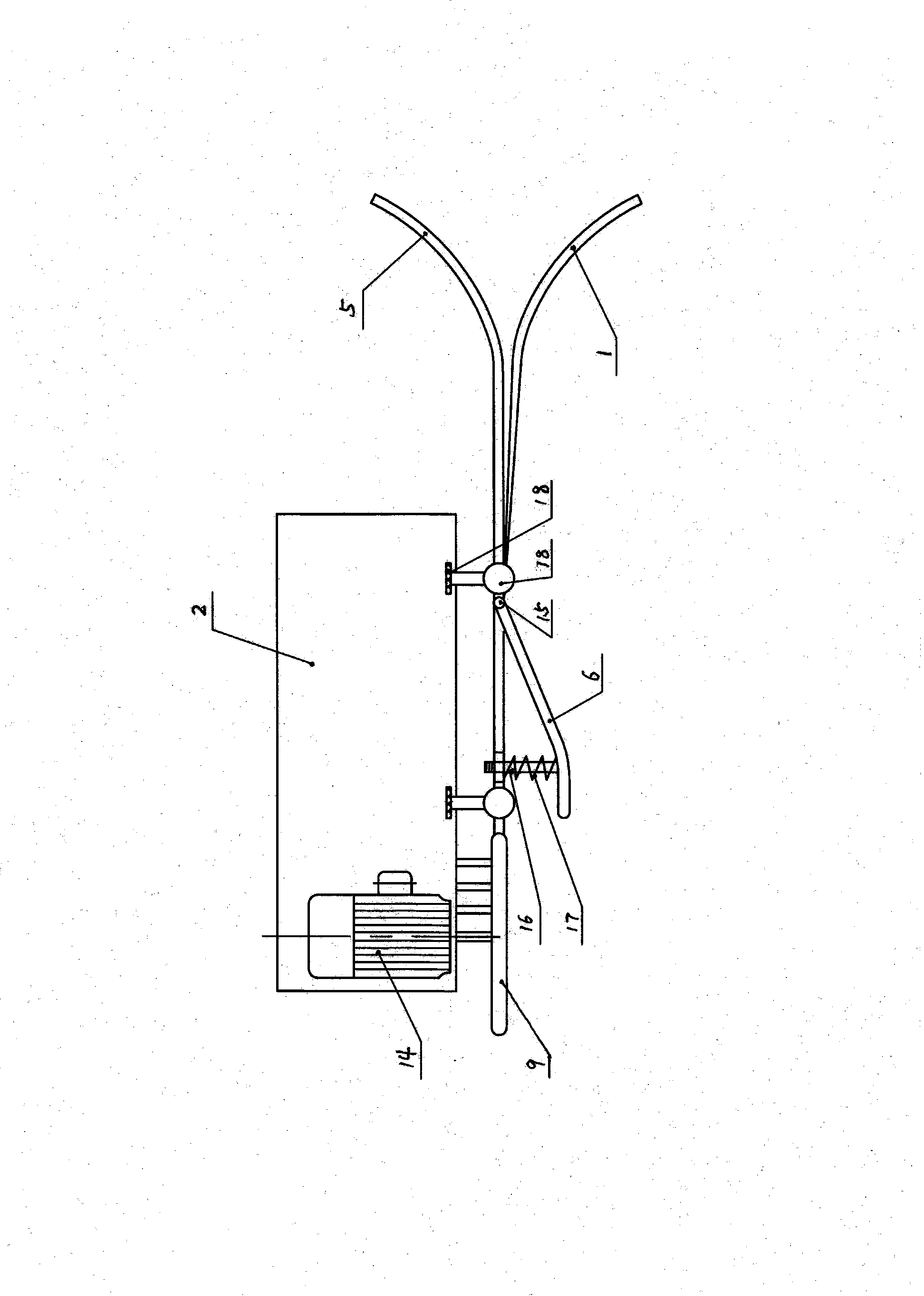

[0012] refer to figure 1 —3, it comprises body 2, and main motor 14 is equipped with in the rear portion of body, and disc blade 8 is housed on the main motor shaft, and disc blade is provided with blade guard 9, and blade guard is fixed on the main motor, also includes Two upper adjustment mechanisms 4, two lower adjustment mechanisms 3 and two guide rails made of steel pipes;

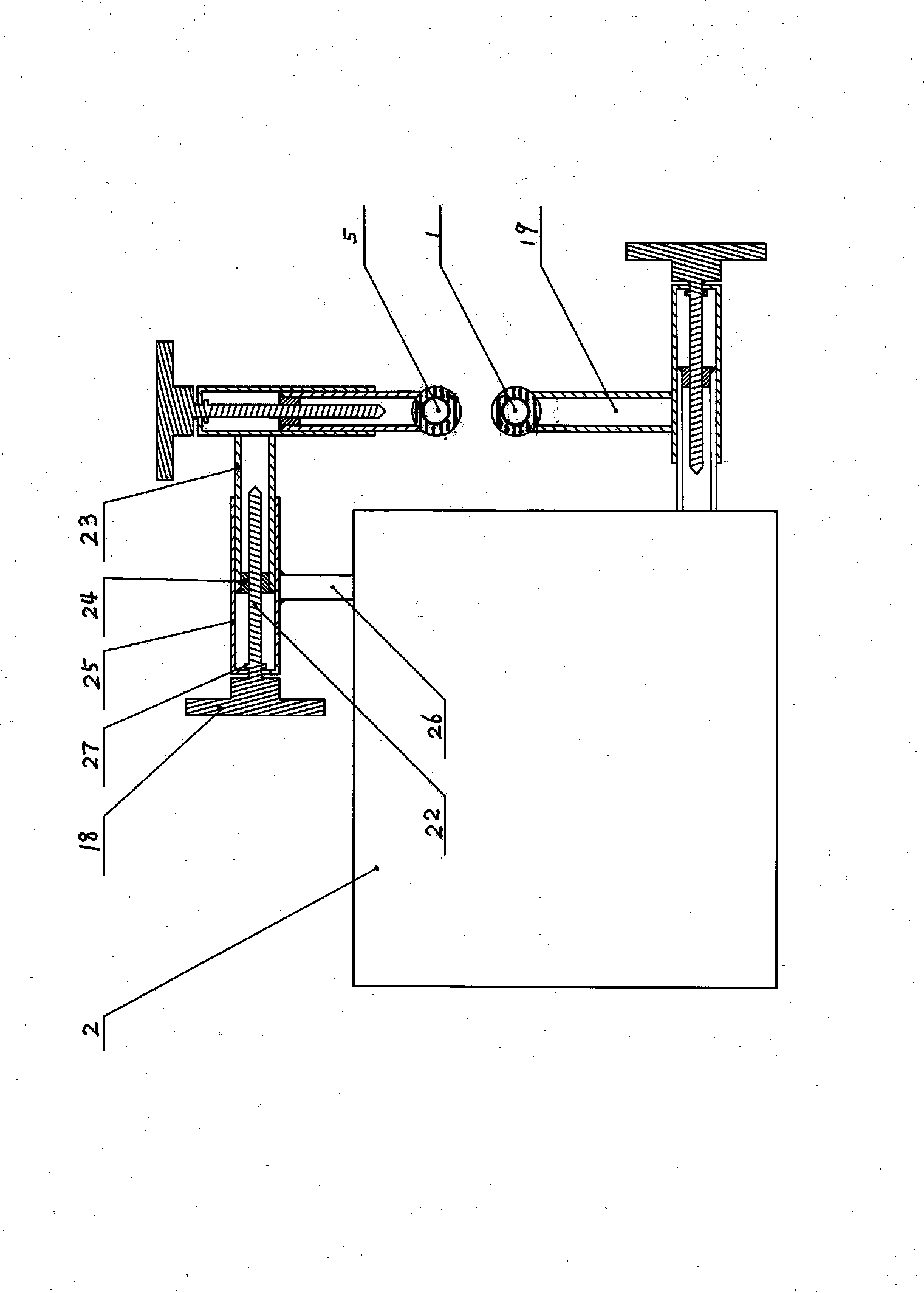

[0013] The upper adjustment mechanism is composed of a horizontal adjustment mechanism and a longitudinal adjustment mechanism. The structures of the horizontal adjustment mechanism, the longitudinal adjustment mechanism and the lower adjustment mechanism are all the same, and both include an adjustment handle 18, which is fixed with a threaded adjustment rod 22. There is a moving adjustment tube 23 on the outside of the rod, and a nut 24 is fixed inside the moving adjusting tube. The threaded adjusting rod is screwed with the nut in the moving adjusting tube. A fixed tube 25 is set on the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com